Low-cost and high-performance titanium alloy and preparation method thereof

A titanium alloy, high-performance technology, applied in the composition design and preparation of low-cost high-performance titanium alloy, can solve the problems of high price, increased alloy cost, and limited cost reduction, and achieve low raw material cost, uniform alloy composition, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

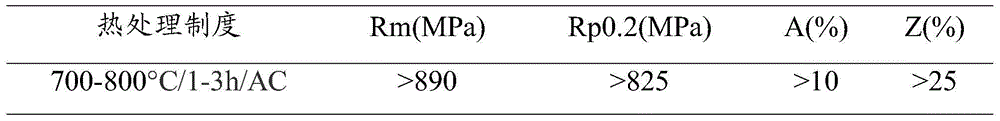

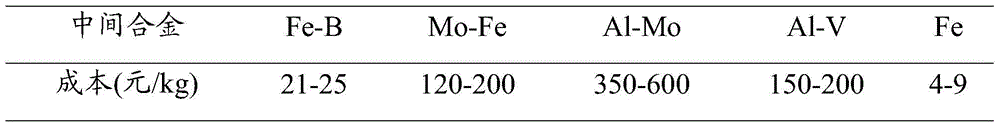

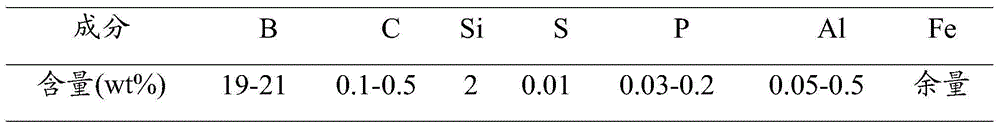

[0028] (1) The element ratio of the alloy composition design of the present invention is shown in Table 4, and the composition of the alloy is Ti-3Fe-0.3O-0.1B (mass percentage).

[0029] (2) Proportion the purchased sponge titanium, Fe-B master alloy, iron element, and titanium dioxide according to the ratio of 1 kg per ingot, and then put them into the water-cooled copper crucible of the cold crucible suspension melting furnace, and vacuumize the furnace body Introduce a certain amount of high-purity argon, and carry out the first melting of the alloy at 1600°C for 15 minutes.

[0030] (3) After the ingot is fully cooled, turn the ingot upside down and put it into a water-cooled copper crucible for re-melting to homogenize the alloy composition, and repeat this process for 3-4 times.

[0031] (4) Measure the phase transition temperature of the obtained alloy.

[0032] (5) The cast ingot is opened and forged at 20-100°C above the phase transition point to form a billet, and ...

Embodiment 2

[0041] (1) The element ratio of the alloy composition design of the present invention is shown in Table 6, and the composition of the alloy is Ti-1.5Fe-0.4O-0.2B (mass percentage).

[0042] (2) Proportion the purchased sponge titanium, Fe-B master alloy, iron element, and titanium dioxide according to the ratio of 1 kg per ingot, and then put them into the water-cooled copper crucible of the cold crucible suspension melting furnace, and vacuumize the furnace body Introduce a certain amount of high-purity argon, and carry out the first melting of the alloy at 1600°C for 15 minutes.

[0043] (3) After the ingot is fully cooled, turn the ingot upside down and put it into a water-cooled copper crucible for re-melting to homogenize the alloy composition, and repeat this process for 3-4 times.

[0044] (4) Measure the phase transition temperature of the obtained alloy.

[0045] (5) The cast ingot is opened and forged at 20-100°C above the phase transition point to form a billet, an...

Embodiment 3

[0054] (1) The element ratio of the alloy composition design of the present invention is shown in Table 8, and the composition of the alloy is Ti-3.5Fe-0.1O-0.25B (mass percentage).

[0055] (2) Proportion the purchased sponge titanium, Fe-B master alloy, iron element, and titanium dioxide according to the ratio of 1 kg per ingot, and then put them into the water-cooled copper crucible of the cold crucible suspension melting furnace, and vacuumize the furnace body Introduce a certain amount of high-purity argon, and carry out the first melting of the alloy at 1600°C for 15 minutes.

[0056] (3) After the ingot is fully cooled, turn the ingot upside down and put it into a water-cooled copper crucible for re-melting to homogenize the alloy composition, and repeat this process for 3-4 times.

[0057] (4) Measure the phase transition temperature of the obtained alloy.

[0058] (5) The cast ingot is opened and forged at 20-100°C above the phase transition point to form a billet, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature tensile strength | aaaaa | aaaaa |

| Room temperature tensile strength | aaaaa | aaaaa |

| Room temperature tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com