Processing process of difficult-to-deform high temperature alloy GH141 cold-drawn material

A processing technology and superalloy technology, which is applied in the processing technology of hard-to-deform high-temperature alloy cold-drawn materials and the production field of GH141 alloy cold-drawn materials for fasteners. It can solve the problem of poor plasticity of alloy processing, which affects production efficiency and cannot find information And other issues

Inactive Publication Date: 2015-04-01

FUSHUN SPECIAL STEEL SHARES

View PDF6 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] GH141 alloy is a typical variety of hard-to-deform high-temperature alloy. Since the alloy contains a large amount of solid solution strengthening elements C, Mo, Cr, Co, etc., and contains more Al, Ti aging strengthening elements, the content of Al, Ti elements in the alloy and It reaches more than 4.7%, and its γ' phase Ni3 (Al, Ti) content reaches about 24%, which makes the alloy have poor processing plasticity and a narrow deformation temperature range. It is a very difficult to deform alloy, especially for cold deformation processing. If the bar is placed for a long time, it will easily cause stress cracks in the bar itself. At the same time, in the process of annealing and heat treatment, when it reaches 750 ° C ~ 910 ° C, a large amount of strengthening phase γ' phase will be precipitated, resulting in a larger structure. The superposition of the two stresses can easily cause transverse and longitudinal cracks on the surface of the bar, resulting in a large number of cold-drawn bars being rejected

In order to avoid stress cracks in the bar during production, softening and annealing treatment is required quickly after the bar is drawn, which seriously affects the production efficiency, and there are still surface cracks during the softening and annealing process, so the yield of the cold drawn material is extremely low, only in About 20% to 30%, at the same time, due to the need for multiple softening and annealing, the energy consumption is high and the production efficiency is low

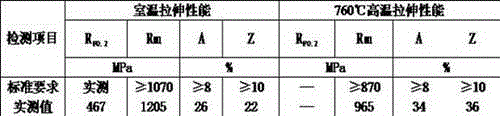

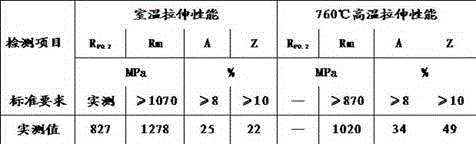

Moreover, in the standards for cold-drawn rods, the requirements for room temperature tensile and 760°C high-temperature tensile plasticity are both elongation after fracture ≥ 8%, and reduction of area ≥ 10%, which is difficult to meet.

Difficult-to-deform superalloys are usually used as important materials for military industry. Their production technology is strictly kept secret abroad, and relevant information cannot be found.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a processing process of a difficult-to-deform high temperature alloy GH141 cold-drawn material. On one hand, the structure of a cold-drawing blank and the ratio of cold drawing decrease section are controlled and the internal stress of a rod obtained after cold drawing is reduced by use of a special process; on the other hand, excellent usability is obtained by use of a reasonable thermal treatment process. The adopted technical scheme is as follows: 1, the internal structure of the cold-drawing blank is controlled; 2, softening annealing treatment is adopted; 3, a reasonable ratio of cold drawing decrease section is selected; 4, two different straightening processes are adopted after cold drawing; 5, a reasonable thermal treatment process is selected. The processing process of the difficult-to-deform high temperature alloy GH141 cold-drawn material has the advantages that the structure of the blank is controlled to be uniform, the grain is fine and the crack formation trend can be effectively reduced, the hardness of the cold-drawing blank is reduced by virtue of softening annealing, the internal stress of the rod obtained after cold drawing is reduced effectively by virtue of straightening, and due to the adopted reasonable heat treatment process, at a room temperature, the plastic percentage elongation after fracture of the cold-drawn rod is 25% and the percentage reduction of area is 22%, at 760 DEG C, the high temperature tensile plastic percentage elongation after fracture of the cold-drawn rod is 34% and the percentage reduction of area is 36%; in short, the difficult-to-deform high temperature alloy GH141 cold-drawn material is excellent in properties.

Description

technical field [0001] The invention belongs to the field of cold-drawn processing of metal materials, and discloses a process for processing hard-to-deform high-temperature alloy cold-drawn materials, which is mainly used for the production of GH141 alloy cold-drawn materials for fasteners. Background technique [0002] Difficult-to-deform superalloy cold-drawn materials are mostly used in key components of aerospace engines because of their excellent performance such as high temperature resistance, high strength, corrosion resistance, and oxidation resistance. Due to the high strength of this type of alloy, the internal stress increases sharply during cold working, and crack defects are prone to occur, especially the bar has high performance indicators, strict organizational requirements, and low yield. [0003] GH141 alloy is a precipitation hardening nickel-based superalloy developed on the basis of the American Rene′41 alloy composition and process, after optimizing and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22F1/00C21D8/06

Inventor 李宁张玉春李爱民田水仙张鹏王志刚纪肖杨晓利王树财王艾竹王明闫森于杰刘猛王洋洋李成龙管庆阳

Owner FUSHUN SPECIAL STEEL SHARES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com