Patents

Literature

74results about How to "Solve the heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

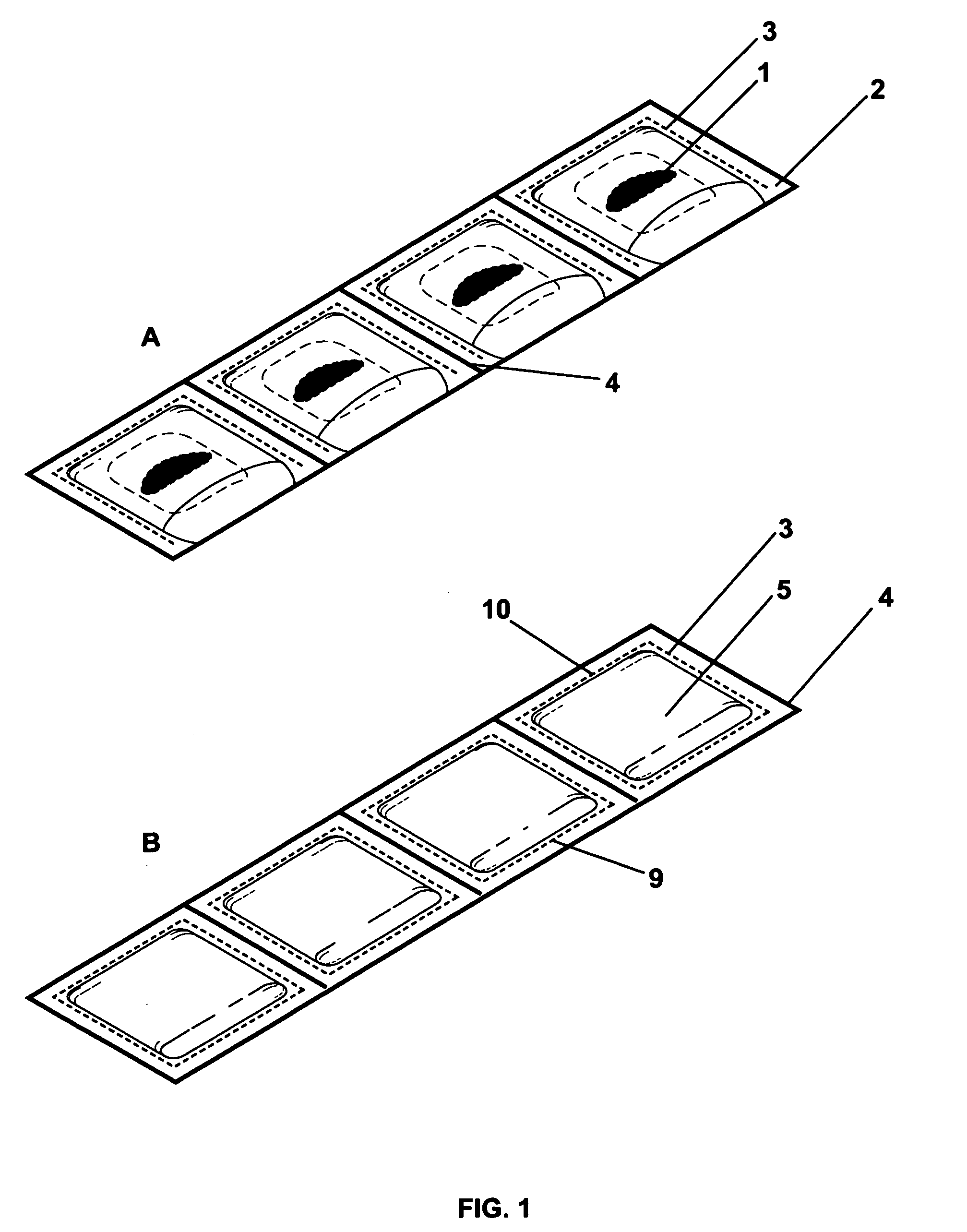

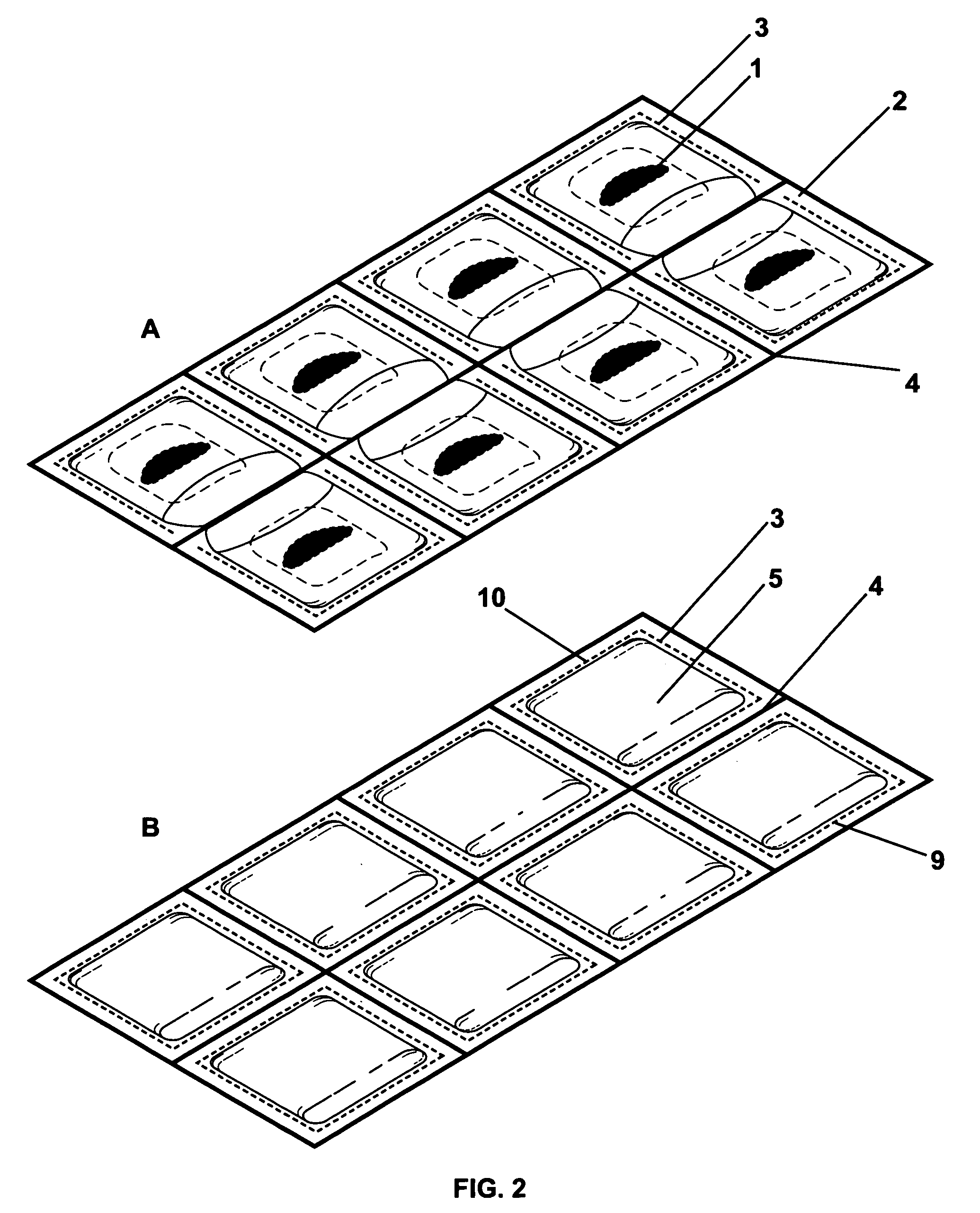

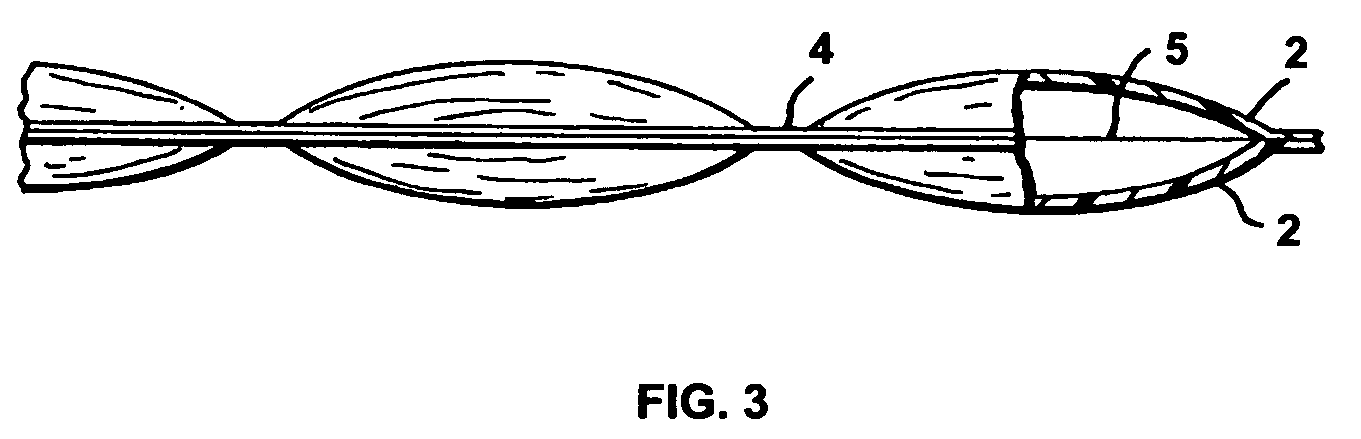

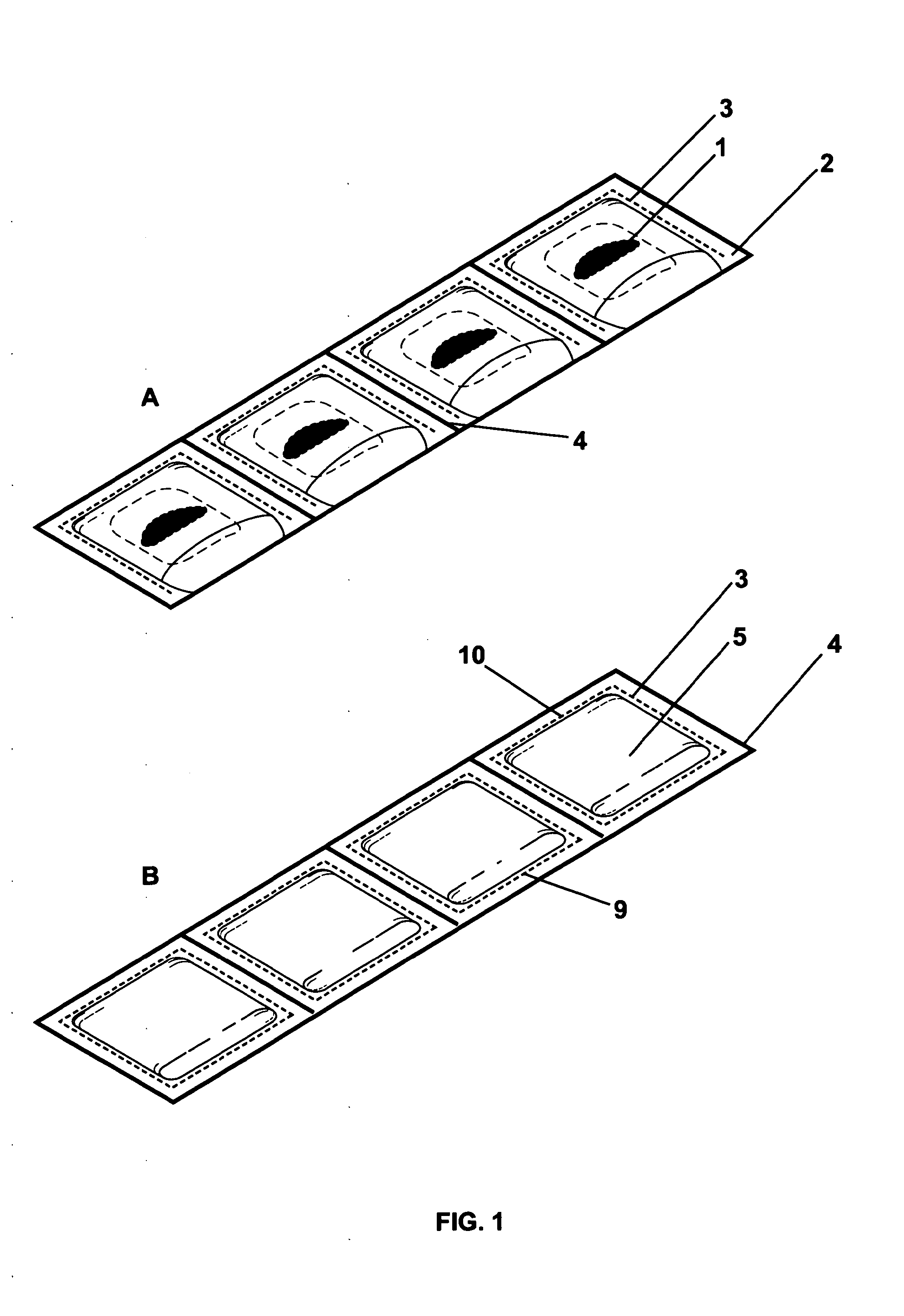

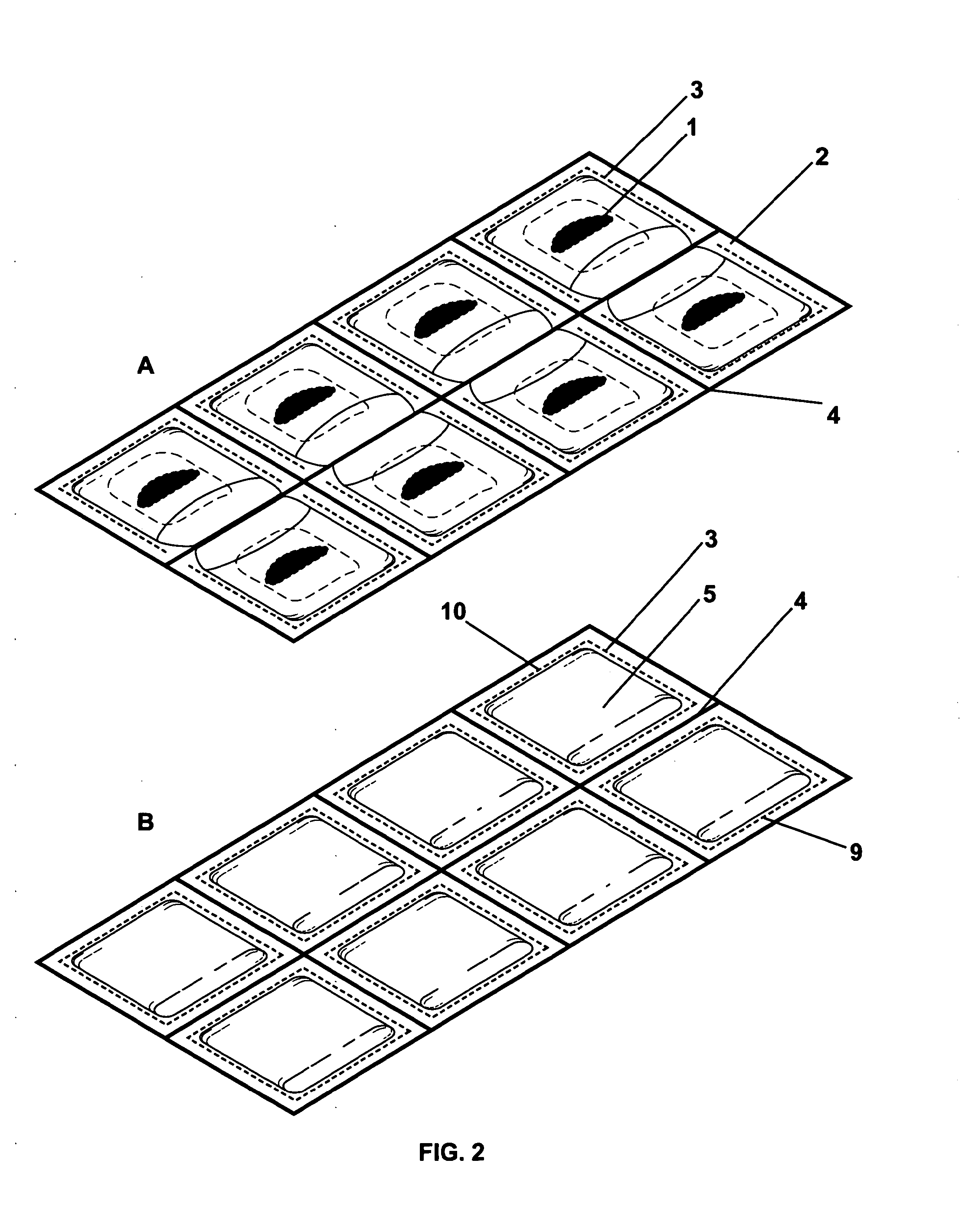

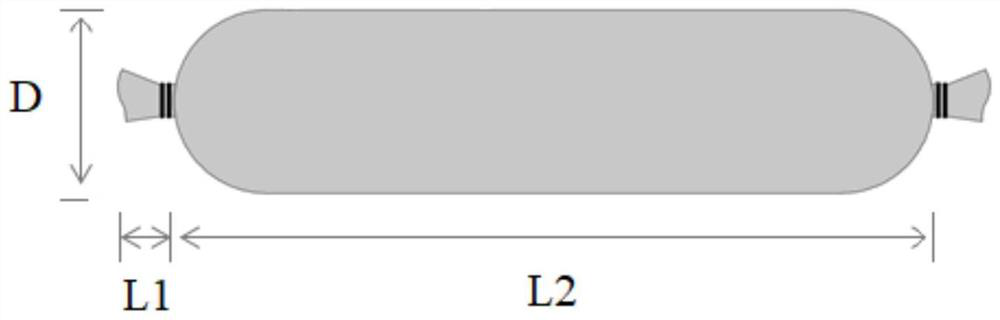

Sealed, edible film strip packets and methods of making and using them

The invention provides, in one aspect, a method of making a confectionery packet or sachet formed with an edible film and enclosing a center composition. The packet or sachet can be designed to be placed in the mouth, where the film dissolves and the center composition is released. In preferred embodiments, the center composition comprises a sugar alcohol, such as xylitol, that creates a cooling sensation. Many other flavors and / or colors or sensates can also be used in the center composition, and some embodiments include breath-freshening, anti-bacterial, nutriceutical, or pharmaceutical compositions in the center composition. The invention also comprises the edible packets or sachets, especially those composed of film with a desired retained water level suitable for producing a self-sealing film and / or an edible film packet that is stable at room temperature for at least six to twelve months.

Owner:CARROLL THOMAS J +5

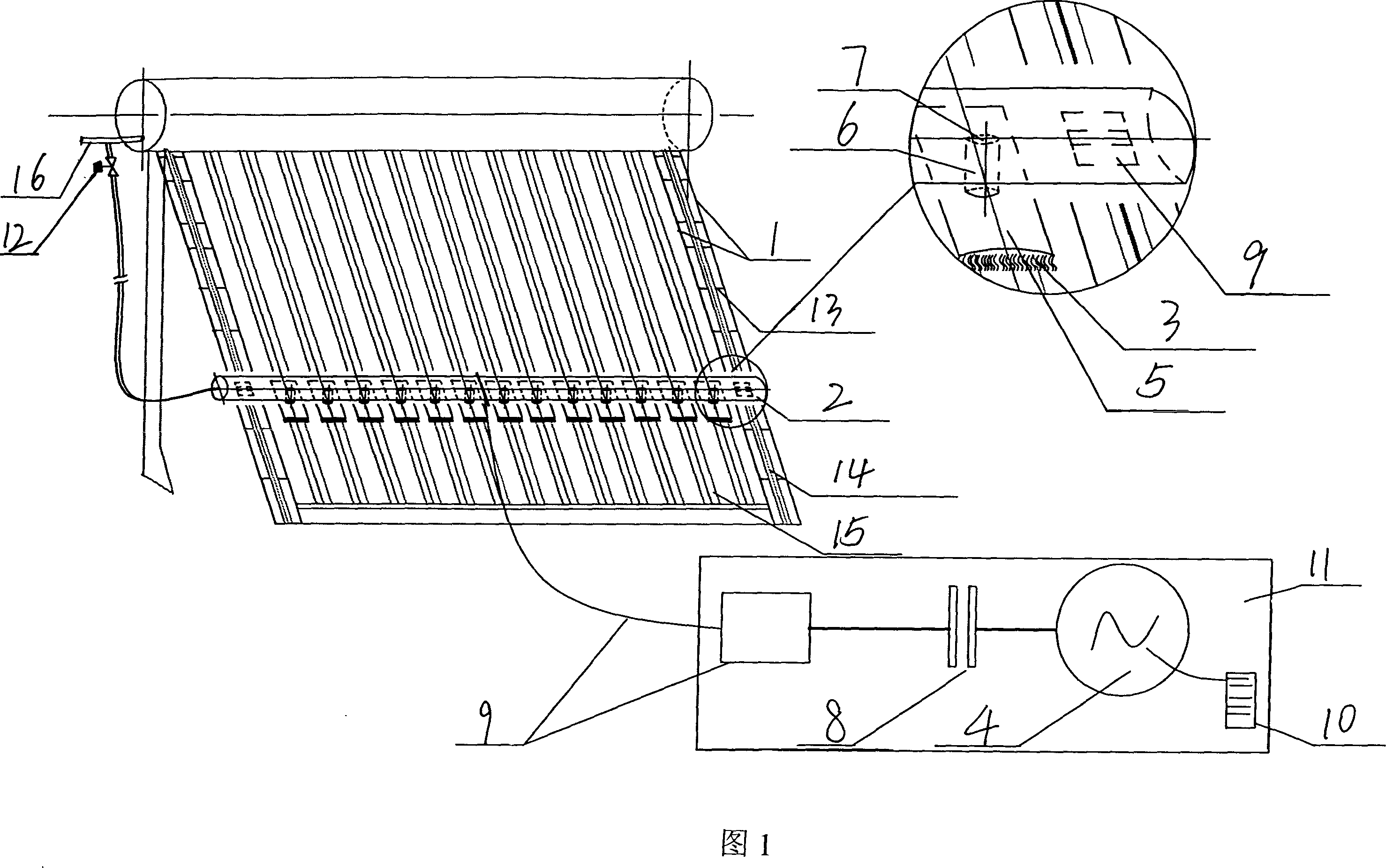

Solar vacuum tube heat-collector superficial dust automatic cleaning device

InactiveCN1970175ASolve the heatEasy to cleanSolar heating energySolar heat devicesCollector deviceEngineering

The automatic cleaning device for the accumulated dust on the surface of the solar vacuum tube heat accumulator comprises the track on the heat accumulator along its surface, sliding bar moving up and down on the said surface along the track, with soft wiping block on the slide bar connecting with the solar vacuum tube, and drive moving device moving up and down along the solar heat accumulator surface driven by the electric motor reacting with the said surface on the slide bar with good solution for the heating issue due to accumulated dust on the vacuum tube surface, with simple structure, safe, reliable and good dust eliminating effect.

Owner:ZHONGYUAN ENGINEERING COLLEGE

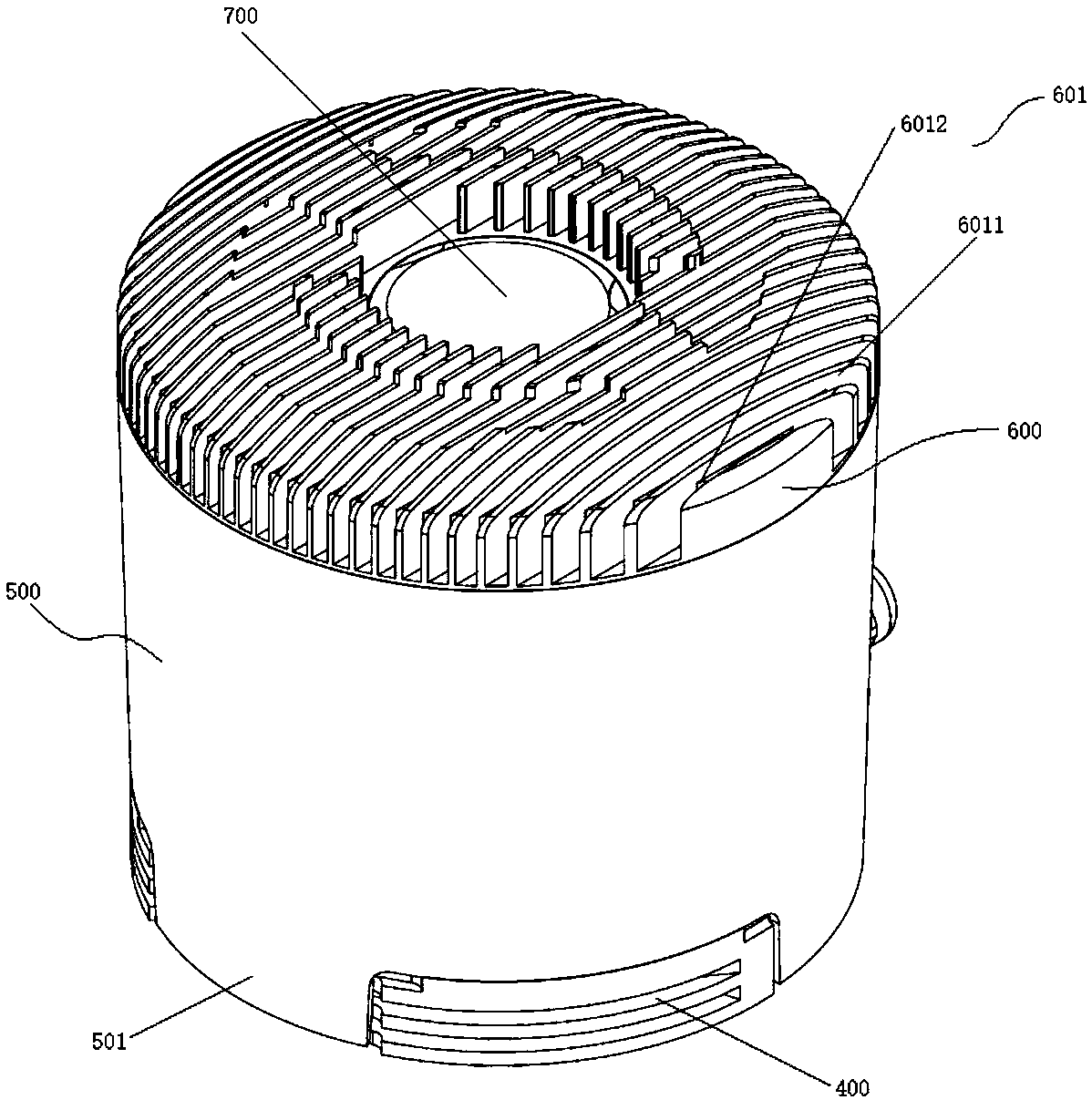

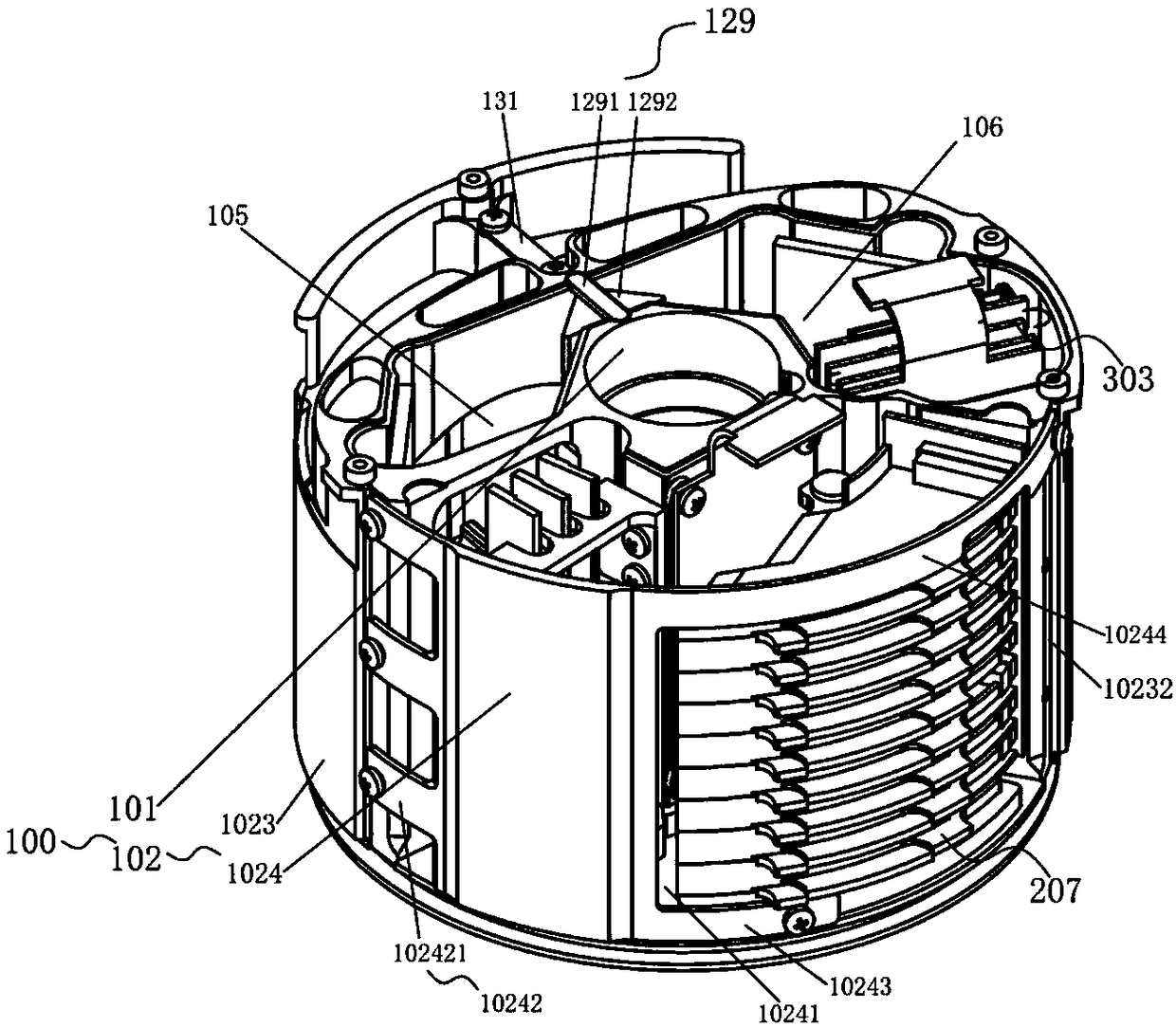

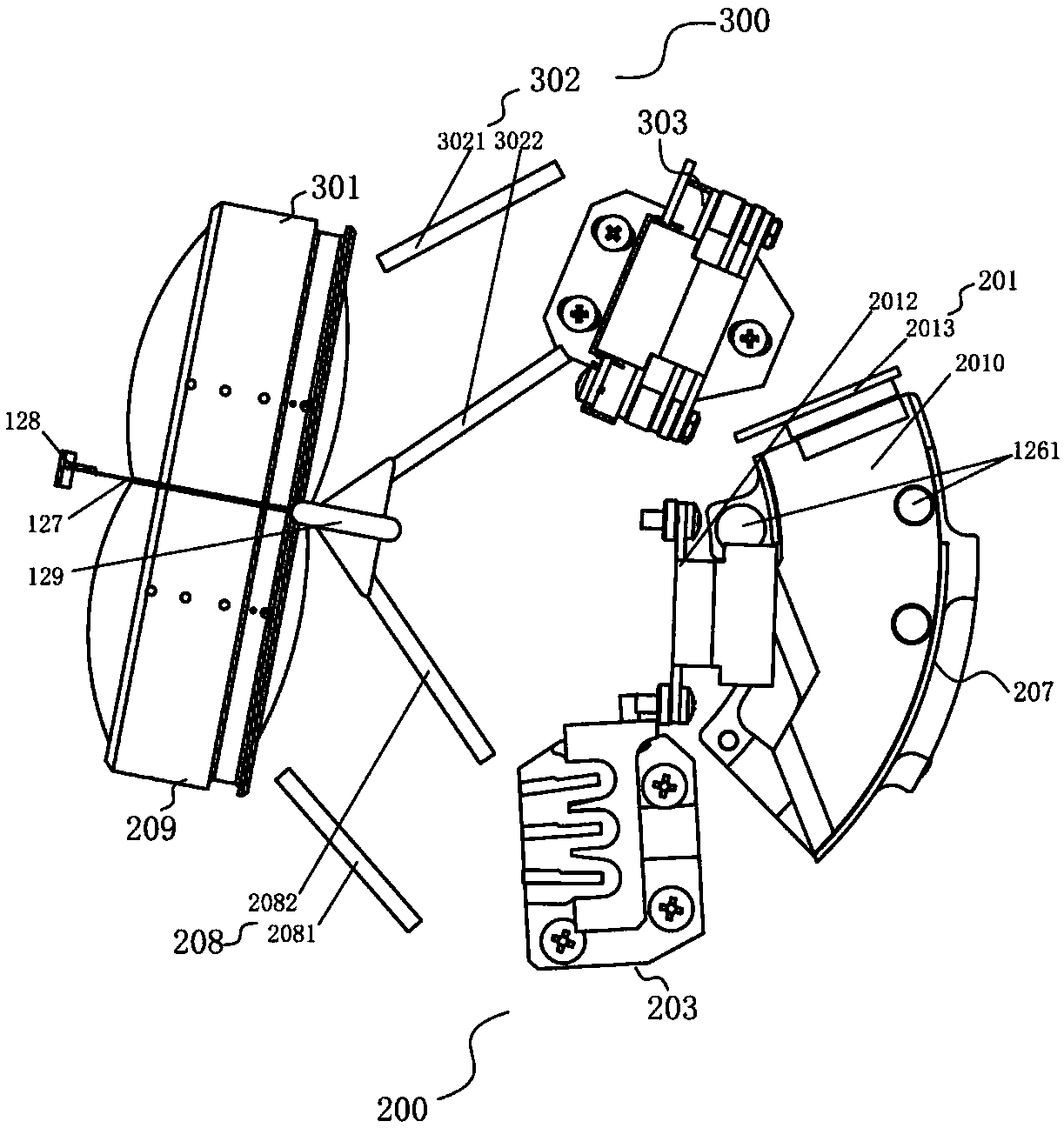

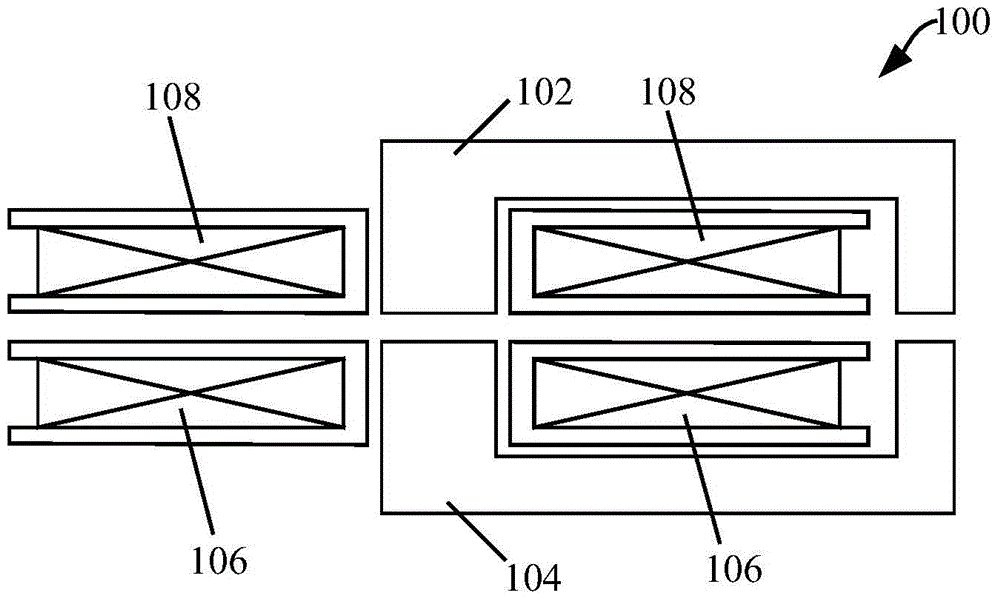

Laser radar

PendingCN108761471AEasy to achieve high wiring harnessSolve the cooling problemElectromagnetic wave reradiationRadarLight beam

The invention provides a laser radar. The laser radar comprises a rotor, a laser emitting system and a receiving system; the rotor is provided with an emitting cabin and a receiving cabin which are separated from each other; the laser emitting system is arranged in the emitting cabin; the receiving system is arranged in the receiving cabin; the laser emitting system comprises an emitting circuit group, a first number of outgoing optical fibers, and an optical fiber fixing device; the emitting circuit group includes a second number of laser light sources; laser beams emitted by the laser lightsources are coupled to the outgoing optical fibers; the optical fiber fixing device comprises an optical fiber fixing plate; the optical fiber fixing plate has a first side surface and a second side surface; optical fiber fixing grooves are formed in the first side surface and / or the second side surface; and the optical fiber fixing grooves are used for fixing the outgoing optical fibers. According to the laser radar of the invention, an arbitrary number of optical fibers can be fixed by means of the combination of the optical fiber fixing device and the optical fiber coupling technology, so that the high wiring harness of the laser radar can be realized; the arrangement of the laser is more flexible; and the heat dissipation parts of a heat sink component and a top cover can be used in amatched manner, so that the heat dissipation problem of the laser radar can be solved.

Owner:HESAI TECH CO LTD

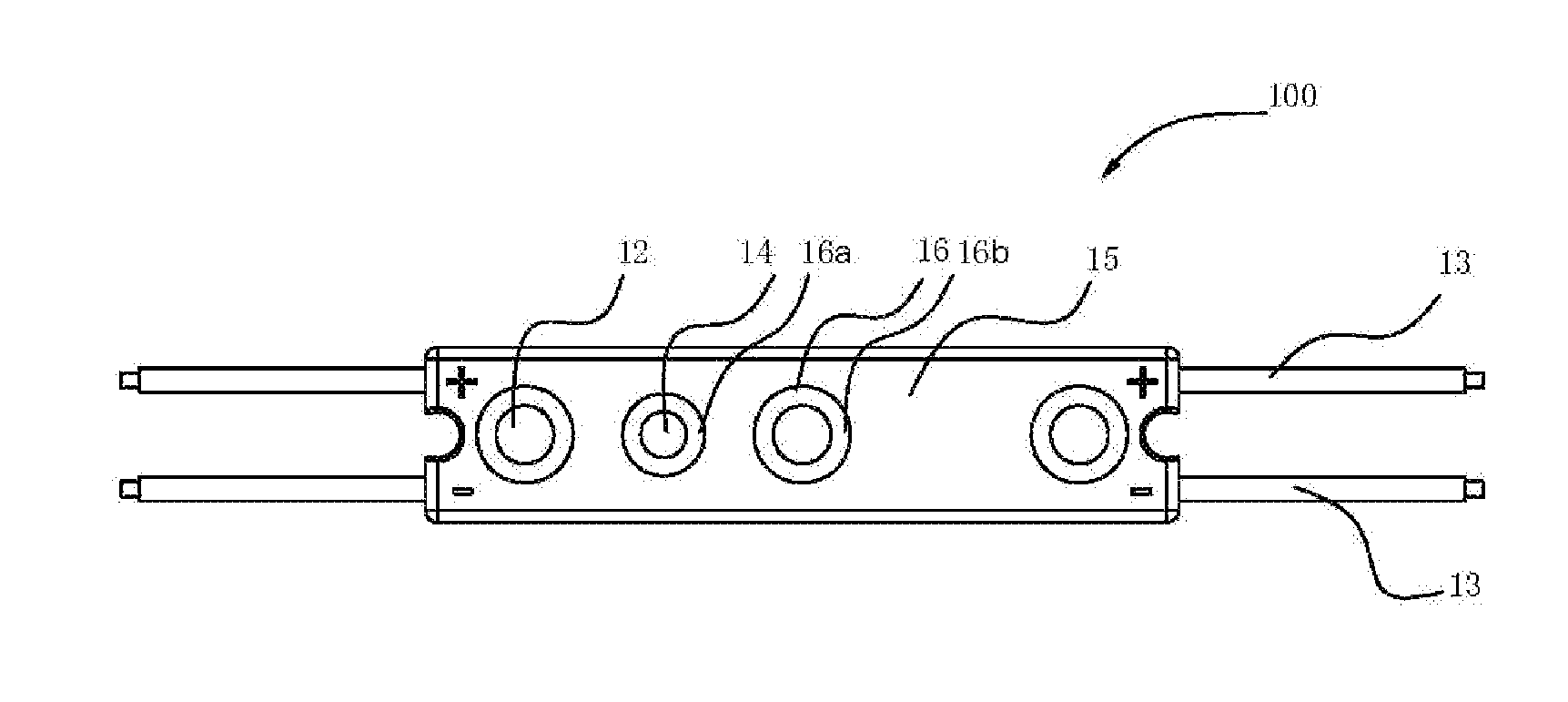

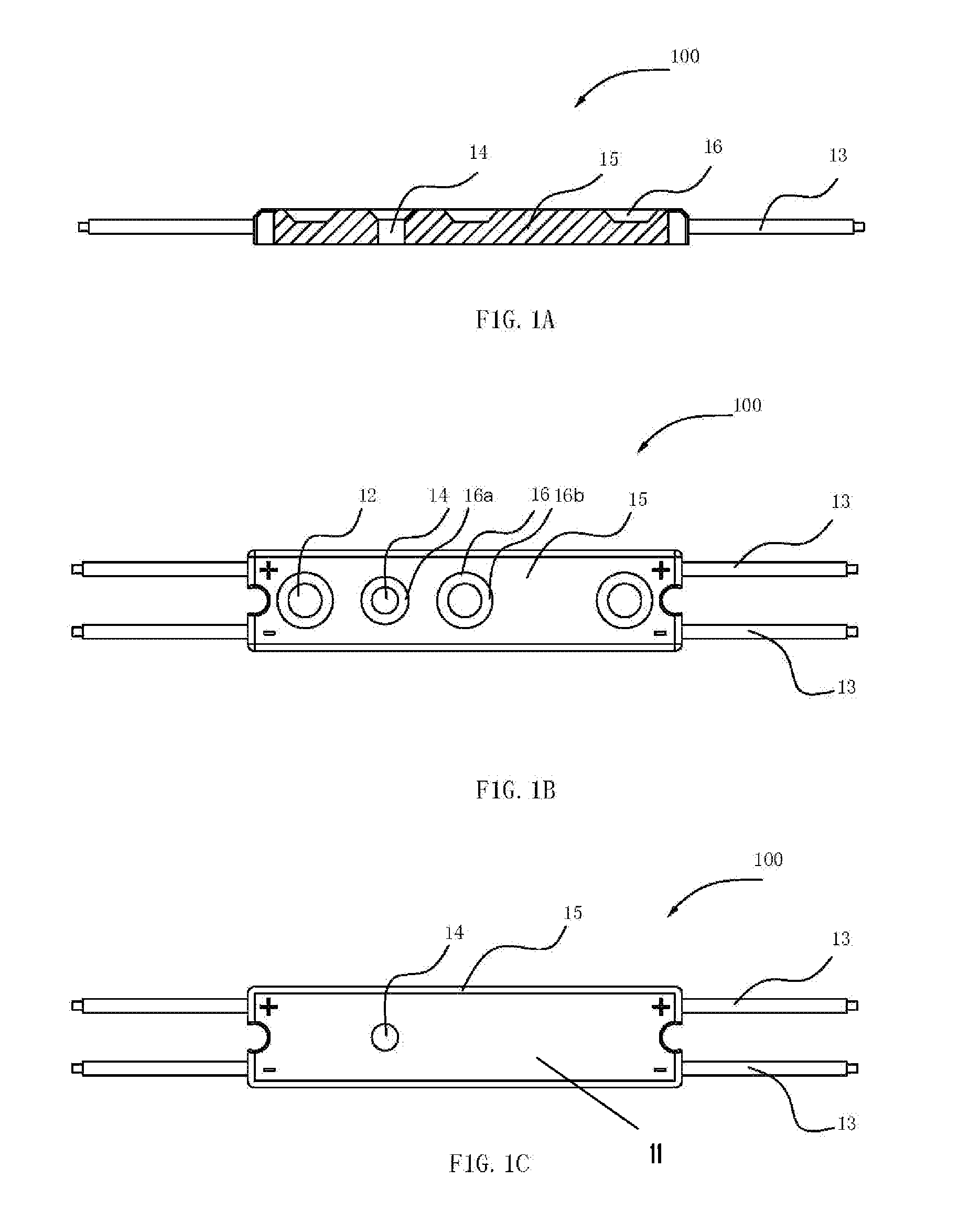

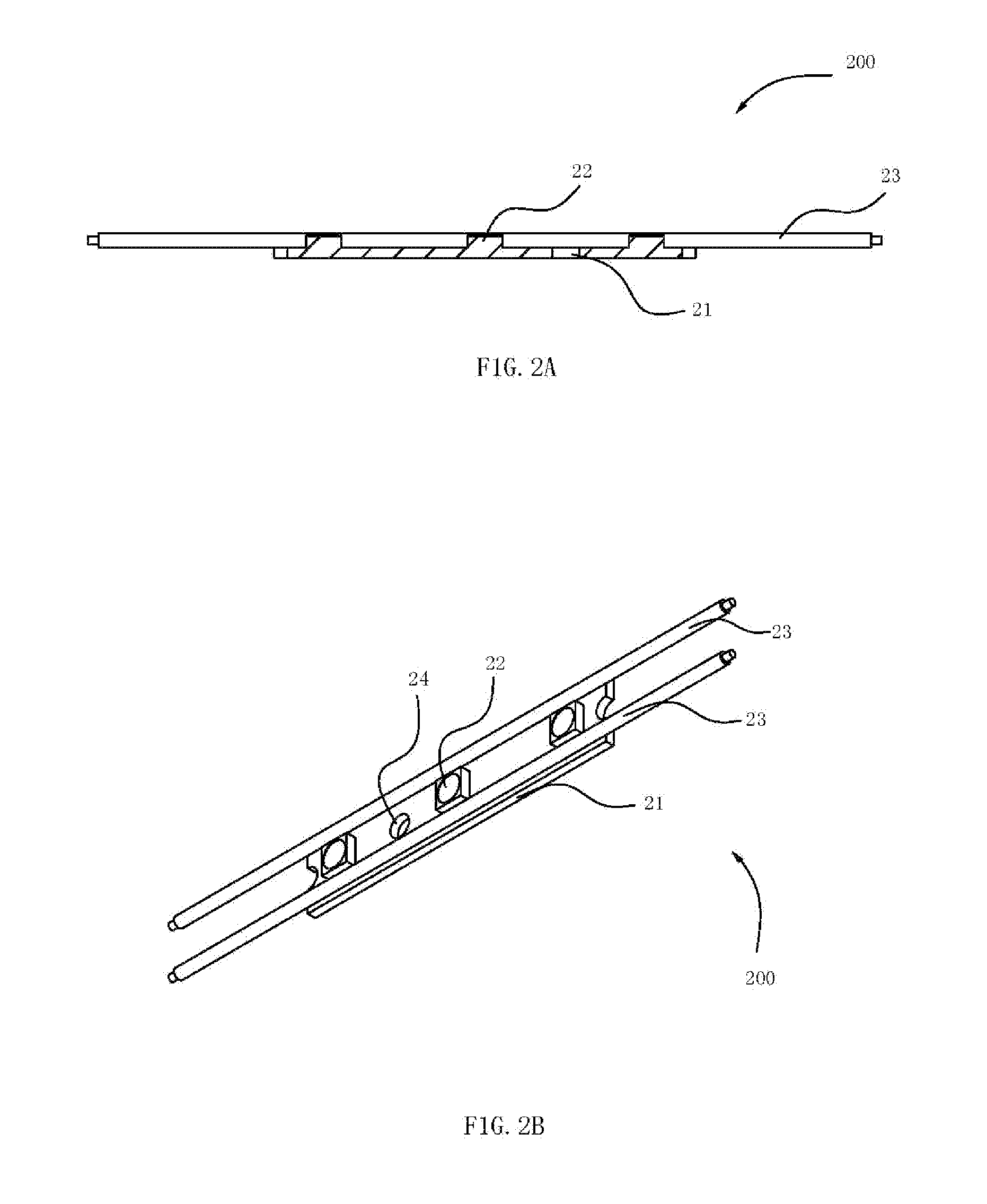

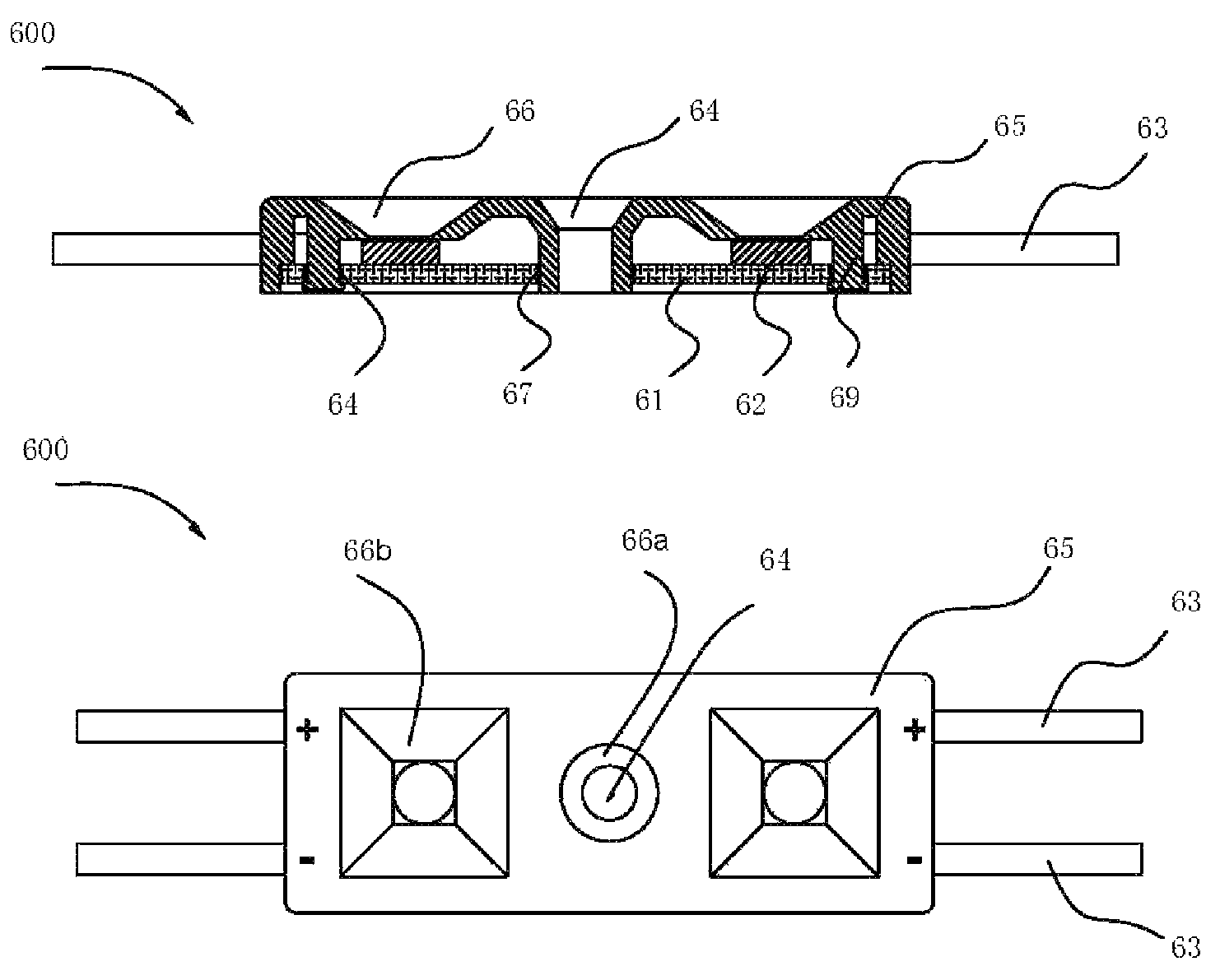

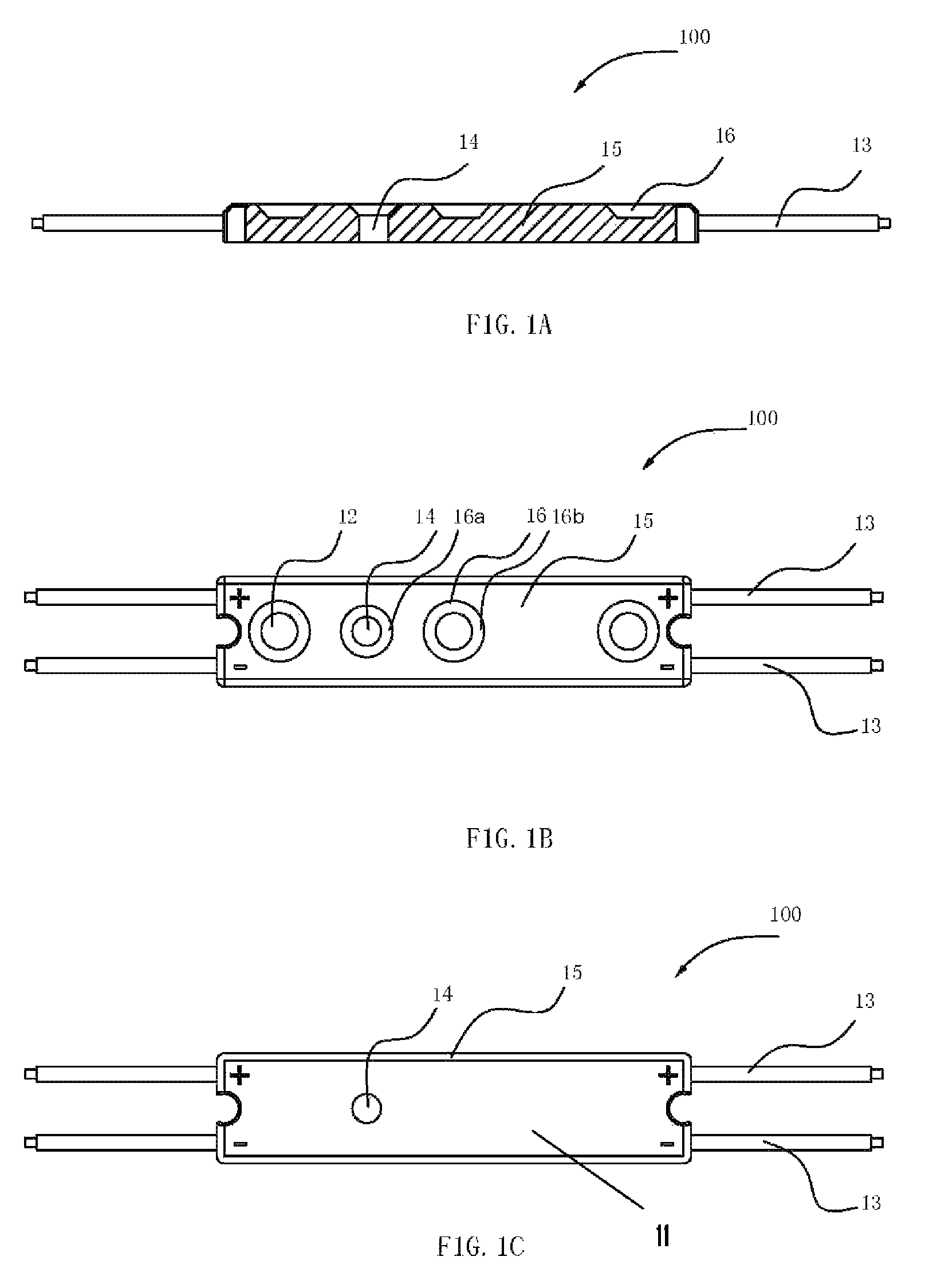

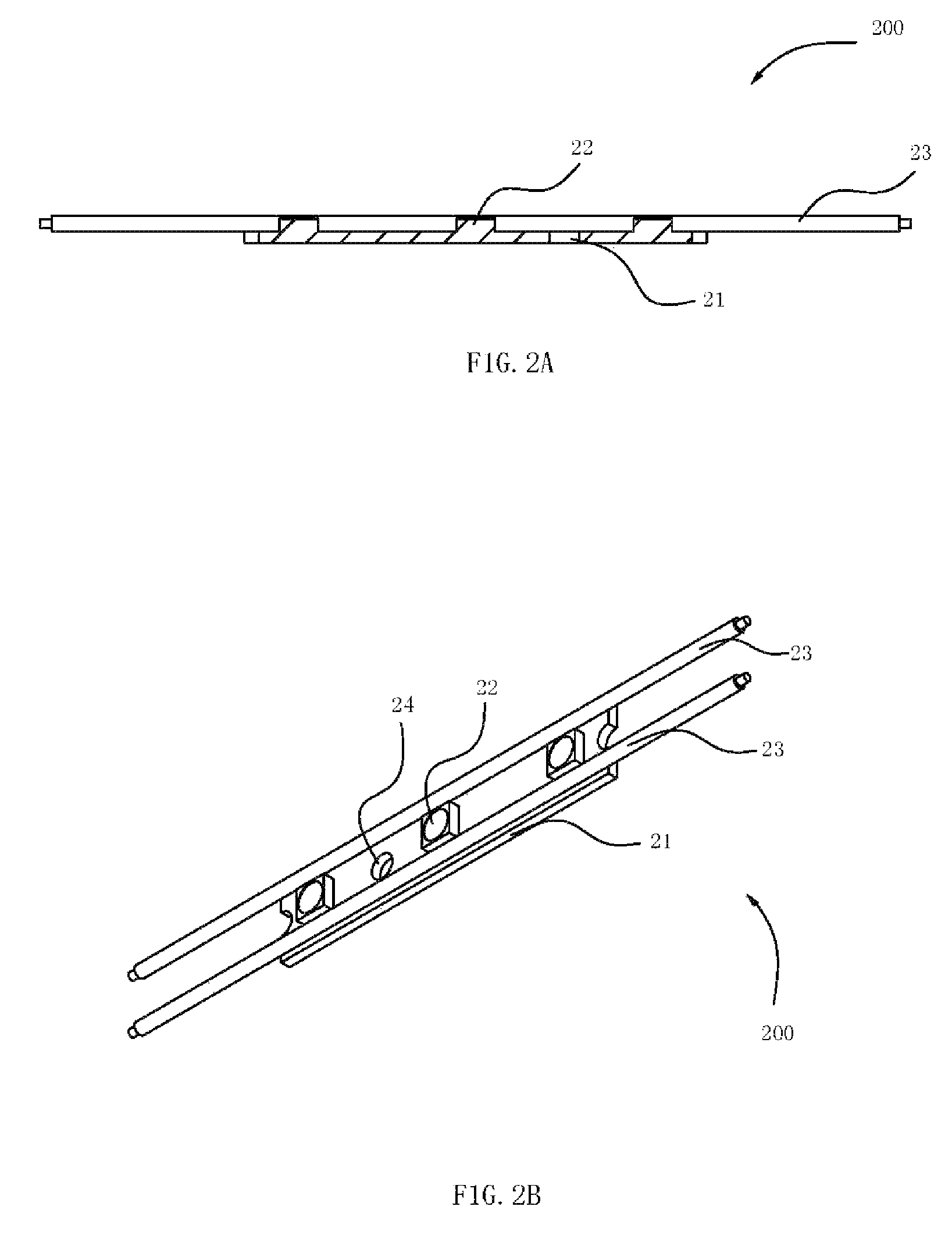

Light emitting diode light source modules

InactiveUS20120002407A1Increase usageLow manufacturing costPoint-like light sourceVehicle interior lightingMetal substrateEngineering

The present invention provides a highly-protective, heat dissipating LED light source module that may be waterproof or non-waterproof. In an embodiment, the present invention provides an LED light source module comprising: a waterproof housing comprising a metal substrate and a plastic cover integrally disposed on one or more surfaces of the metal substrate; and at least one light emitting diode, electronic component, and power line disposed on and operably connected with the metal substrate and encapsulated thereon by the plastic cover. In other embodiments are provided LED light source modules comprising: a circuit board with at least two through holes disposed at selected positions; at least one light emitting diode, electronic component, and power line disposed on the circuit board and operably connected therewith; and a plastic cover comprising at least two pins disposed and shaped for interconnection with corresponding through holes of the circuit board. The simple LED light source models disclosed may be efficiently and inexpensively produced and are capable of withstanding the harsh environments in which they are sometimes used.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD +1

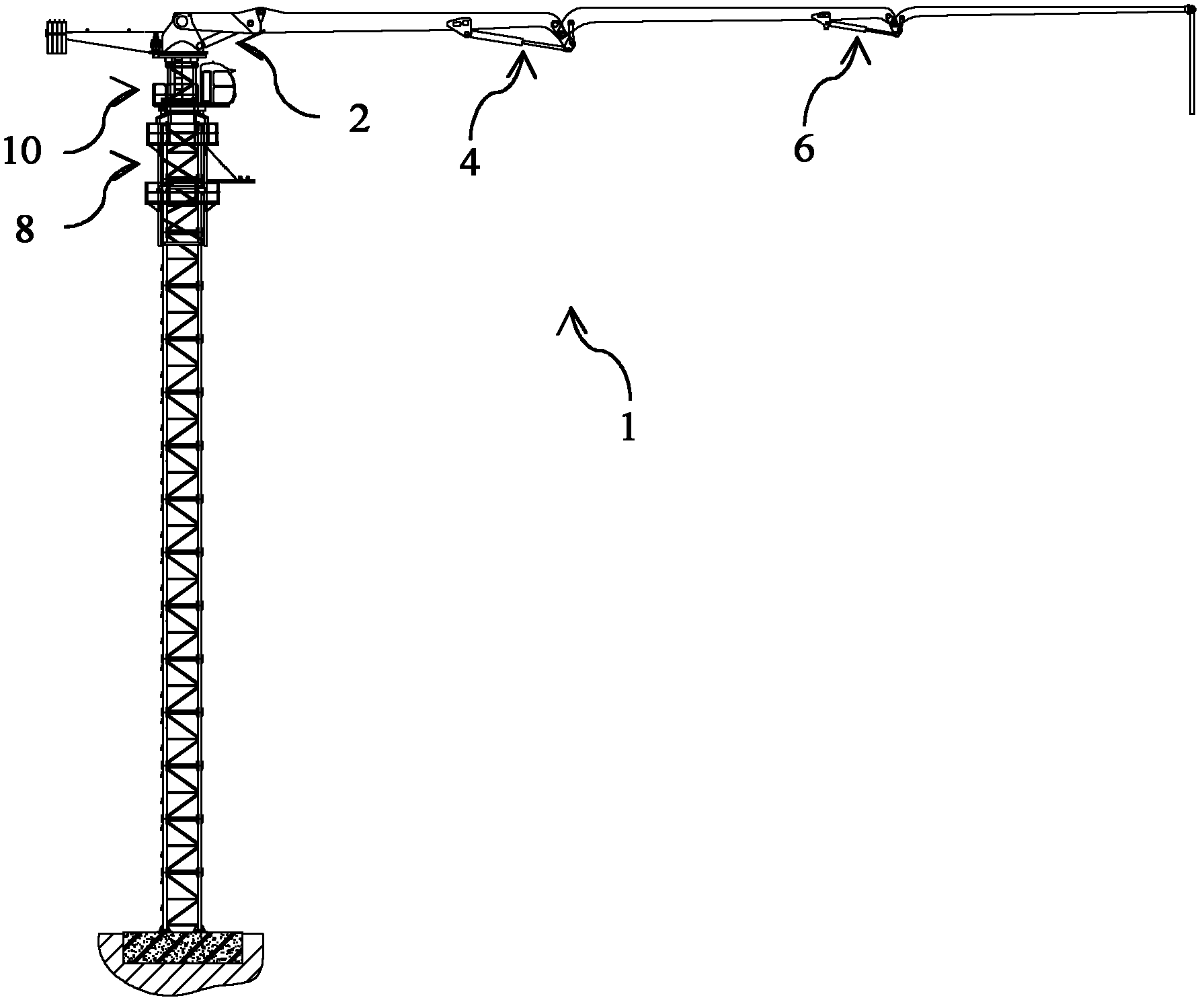

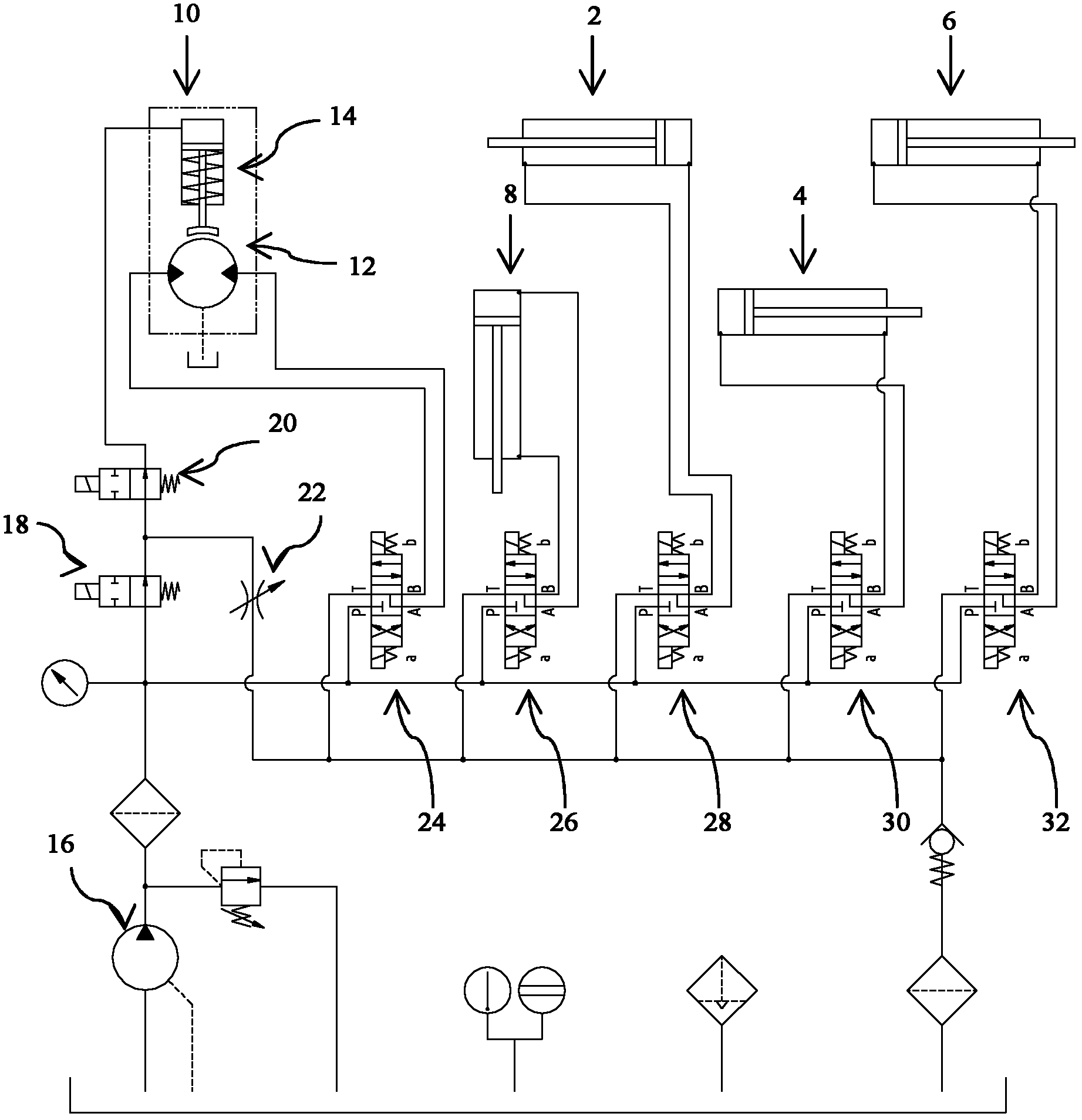

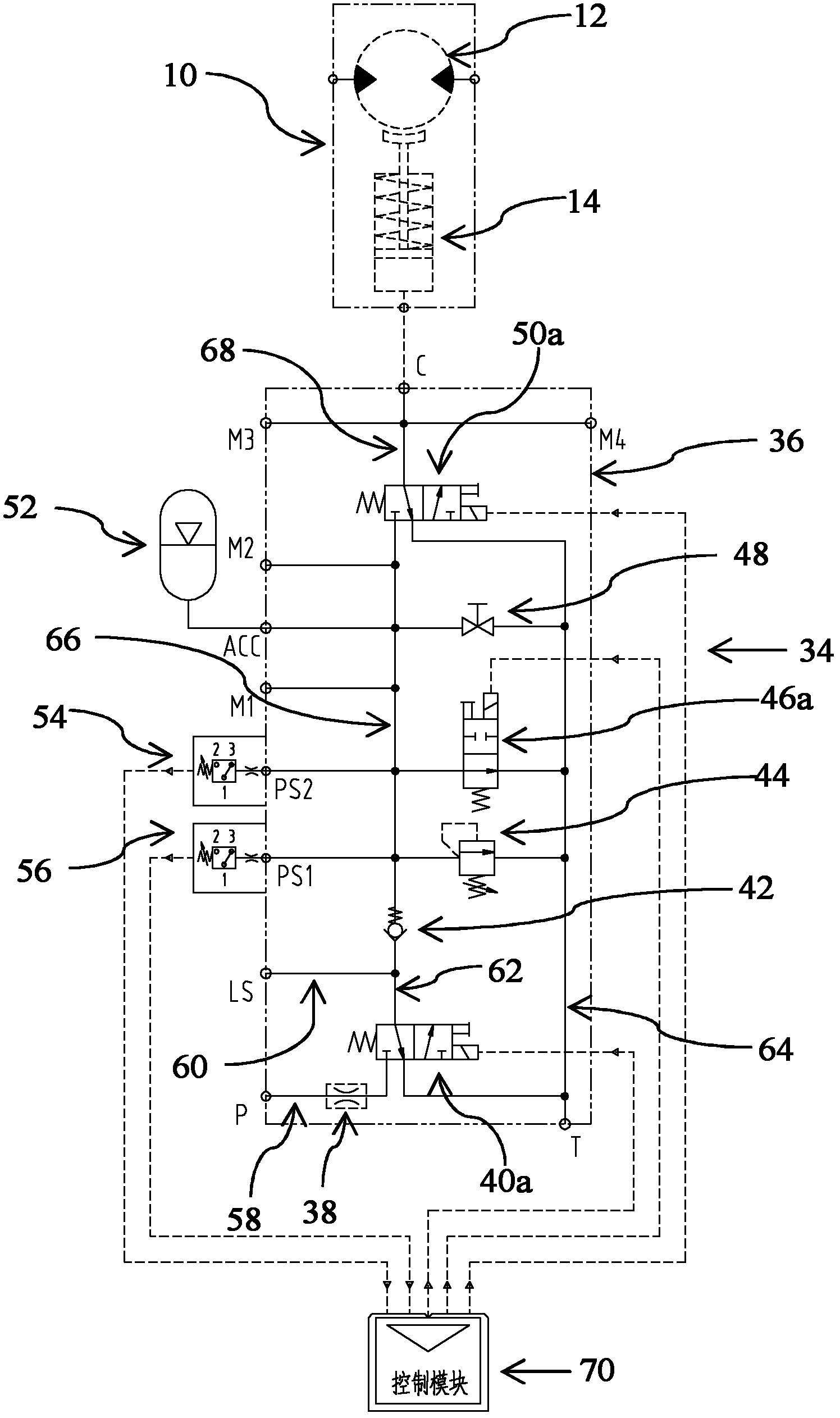

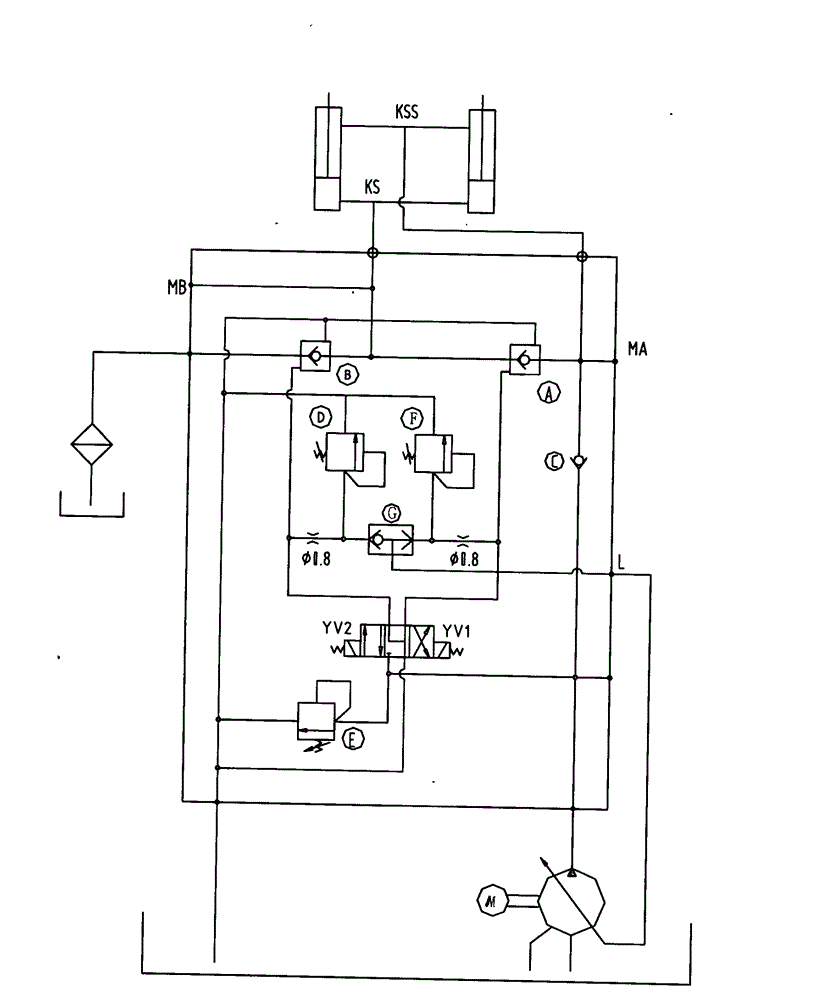

Braking valve bank, hydraulic system having same and concrete spreader

ActiveCN102425580ASolve the heatReliable brakingServomotor componentsServomotorsTowerPetroleum engineering

The invention discloses a braking valve bank, which comprises an energy accumulator, a pressure detector, a liquid charging valve, a one-way valve and a working valve, wherein the energy accumulator is used for storing oil; the pressure detector is used for detecting the pressure of the oil in the energy accumulator; the liquid charging valve is arranged on a liquid charging oil path of the energy accumulator, and is used for charging liquid into the energy accumulator; the one-way valve is used for locking the oil in the liquid charging oil path and preventing the oil from reflowing; the working valve is arranged on a working oil path of the energy accumulator, and is used for controlling the oil of the energy accumulator to be released; and two independent oil paths, i.e.,, the charging oil path of the energy accumulator and the working oil path of a brake. The invention further discloses a hydraulic system having the braking valve bank and a typical operation machine, i.e., a tower type concrete spreader having the hydraulic system. The braking valve bank can be applied to braking, clamping, pressure keeping, and the like.

Owner:ZOOMLION HEAVY IND CO LTD

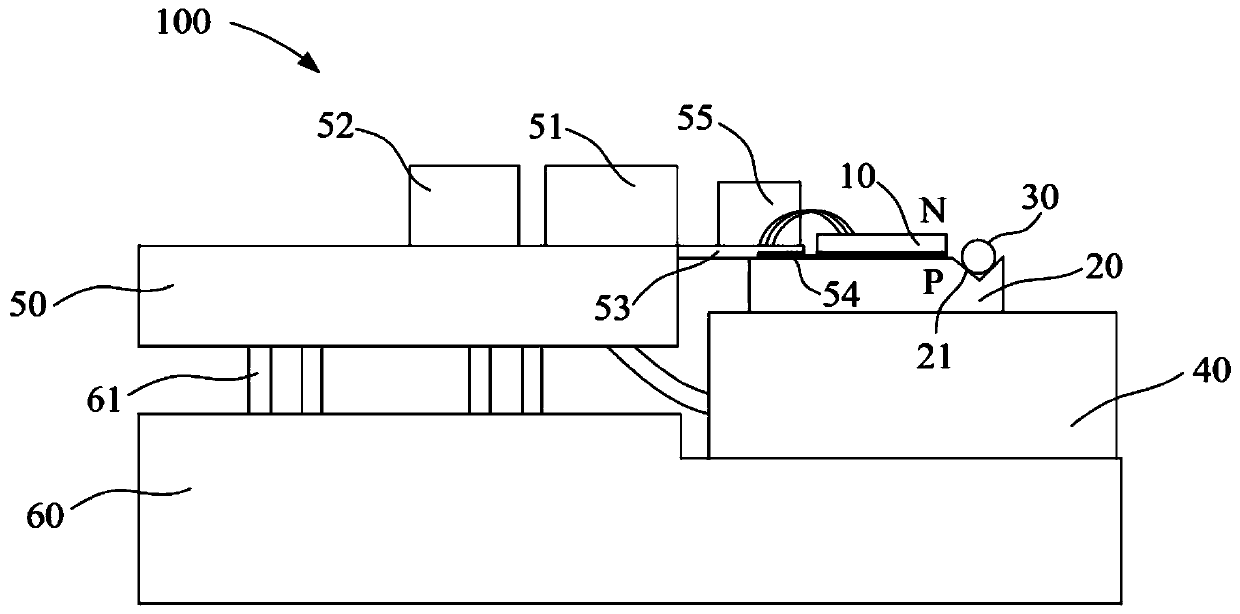

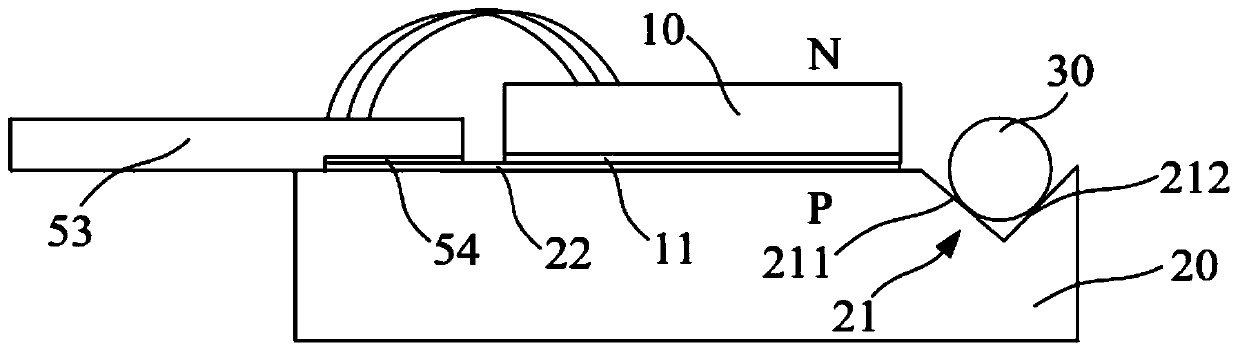

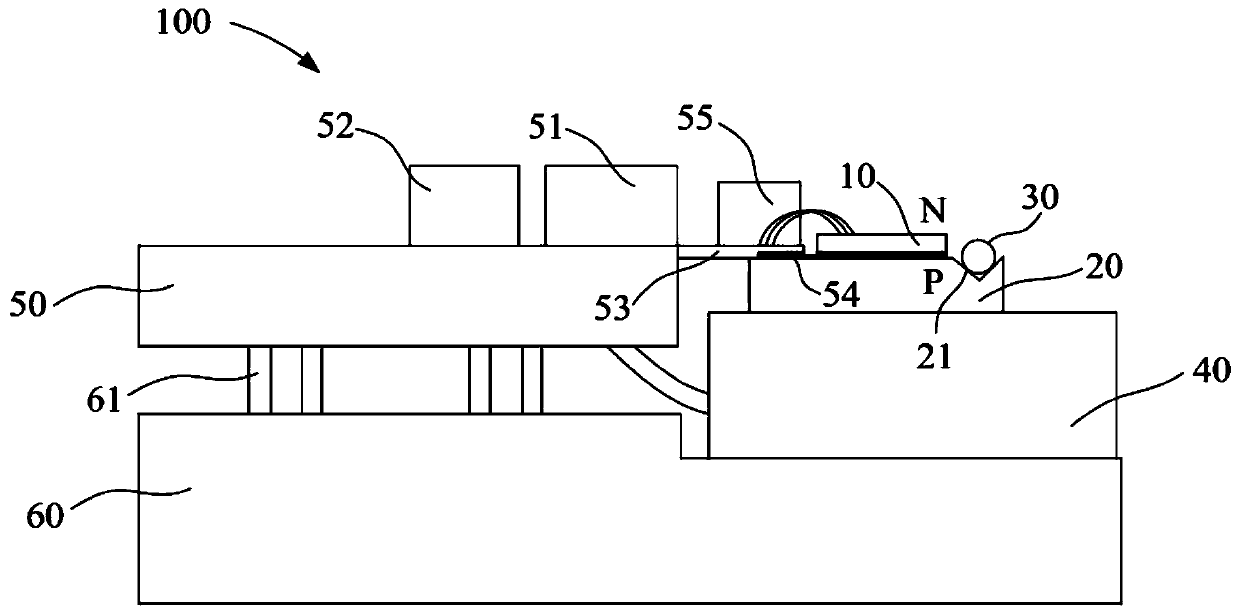

Laser emitting device for laser radar, and laser radar

ActiveCN109917353ASolve the heatSolve the problem that heat is difficult to be exportedElectromagnetic wave reradiationRadarOptoelectronics

The invention provides a laser emitting device for a laser radar. The laser emitting device comprises a laser source used for emitting a laser beam and including an N pole and a P pole; and a heat sink component used for dissipating the heat of the laser source. The laser source is disposed on the heat sink component, and the P pole of the laser source is soldered to the heat sink component. The invention also provides a laser radar comprising a rotor, wherein the laser emitting device is disposed in an emitting bin of the rotor. According to the laser emitting device of the invention, the laser source is inverted on the heat sink component, and the heat sink component dissipates a large amount of heat generated by the laser source during operation, thereby effectively solving the problemthe laser source generates a large amount of heat and the heat is difficult to be exported, so that the laser source can be prevented from being damaged by excessively high temperature.

Owner:HESAI TECH CO LTD

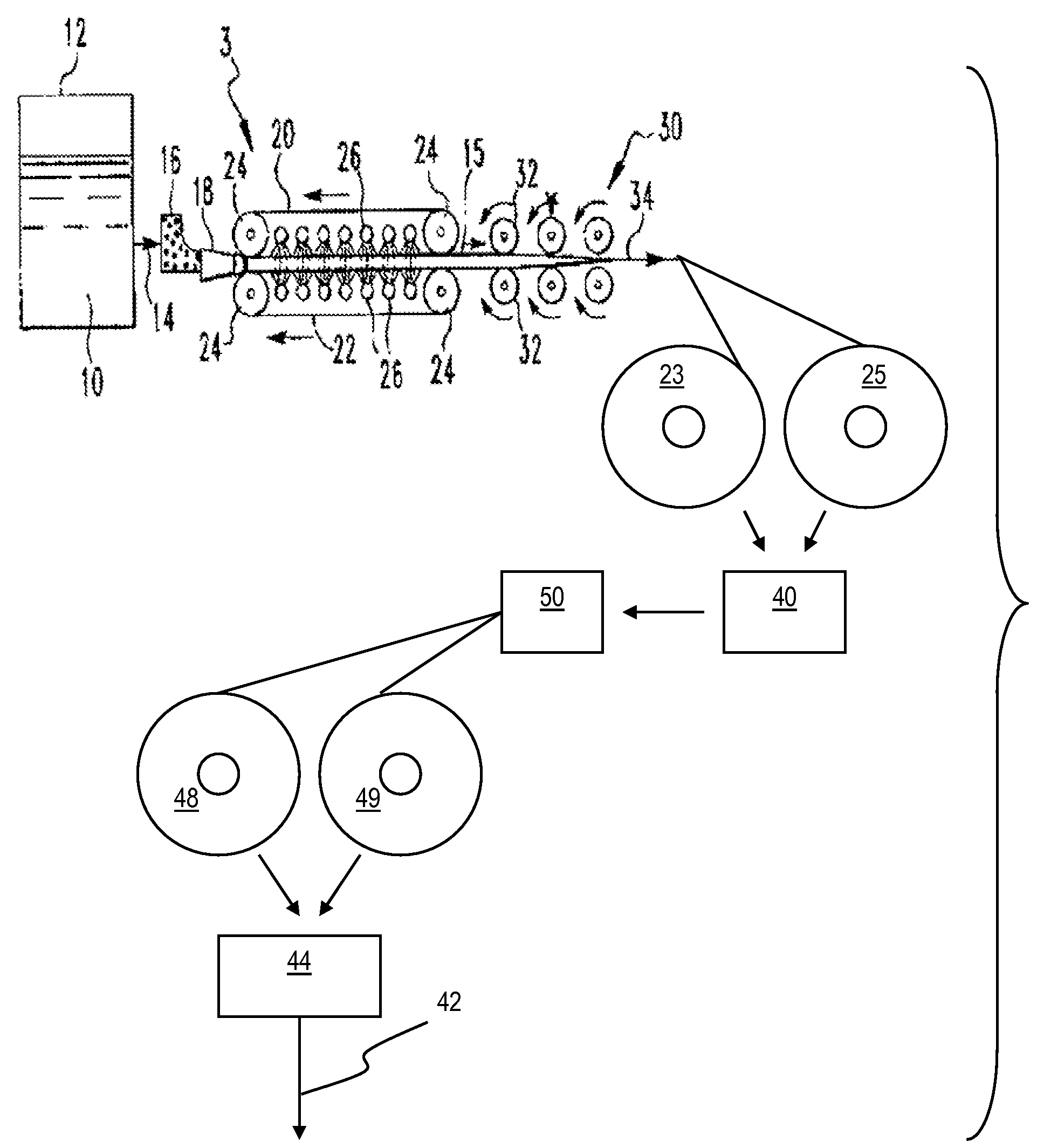

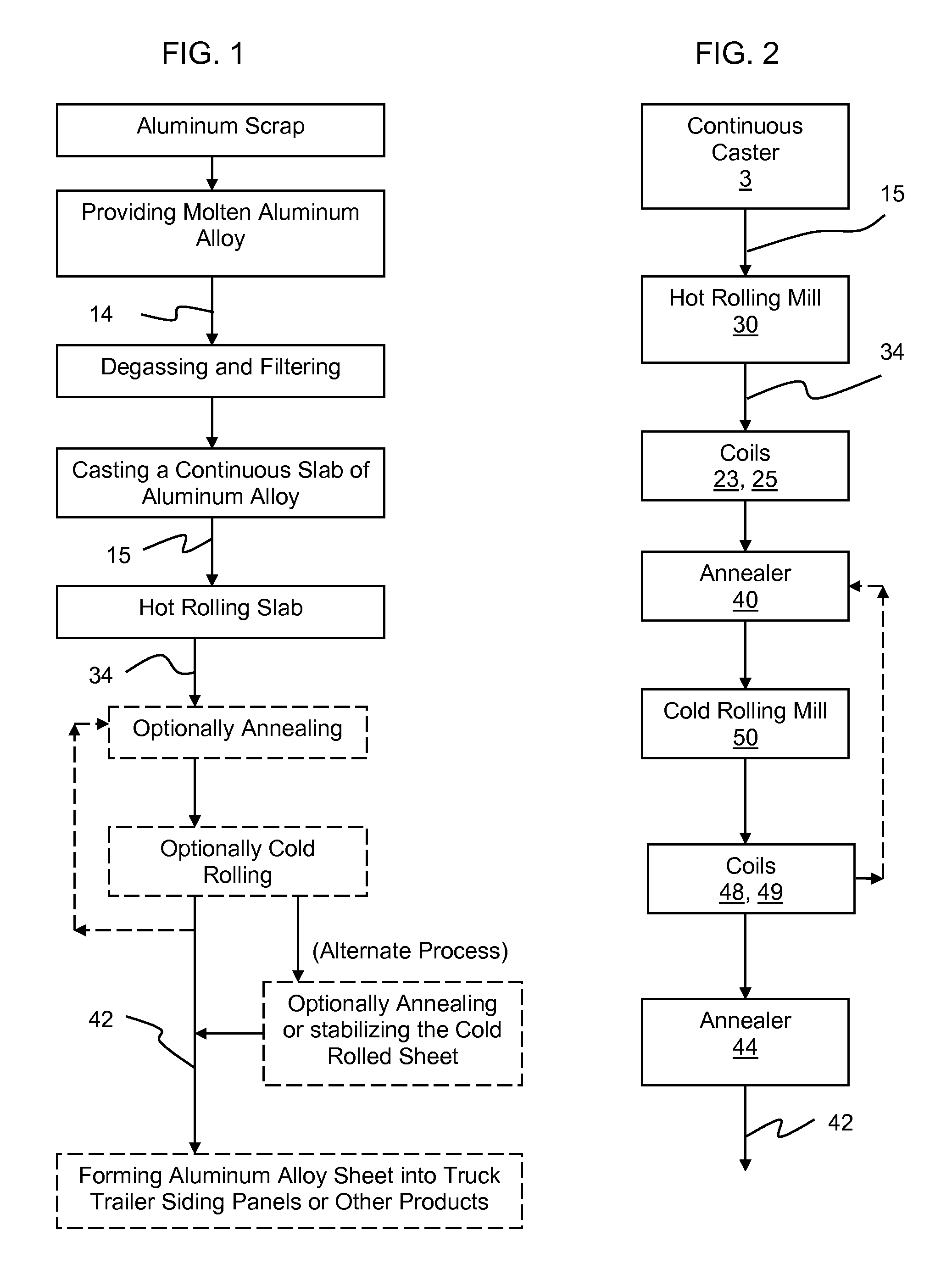

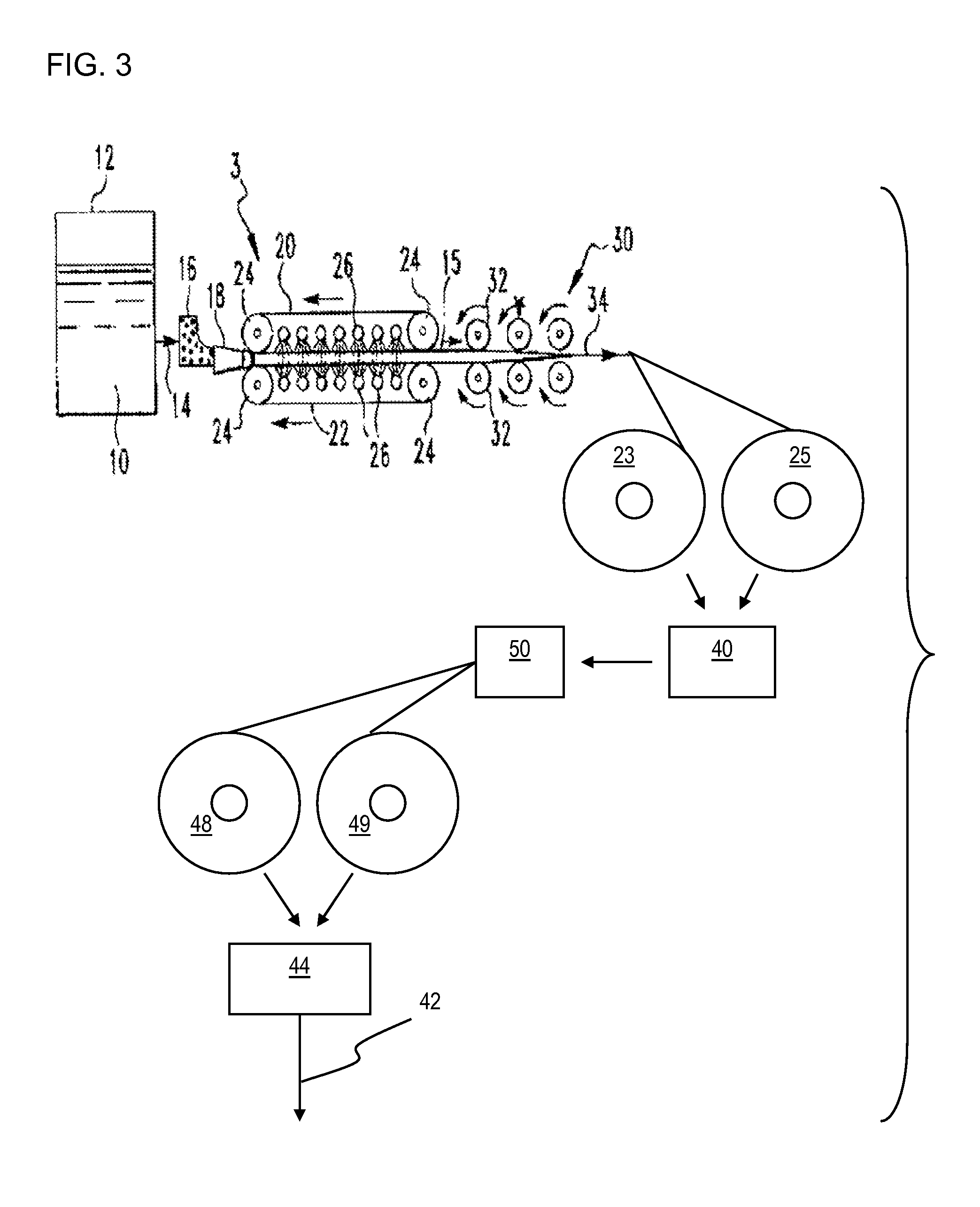

Method for making high strength aluminum alloy sheet and products made by same

Disclosed is a method for producing a non-heat-treatable high strength aluminum sheet from aluminum scraps using a continuous caster. The method includes providing a molten aluminum non-heat-treatable alloy including Si about 0.7% max., Fe about 0.8% max., Cu about 0.3% max., Mn about 0.5-1.2%, Mg about 1.3-2.8%, Zn about 0.20% max., Cr about 0.2% max., Zr about 0.30% max., Sr about 0.30 max., the remainder aluminum, incidental elements and impurities; and continuously casting the molten aluminum alloy into a slab and rolling the slab into a sheet product with high strength and reasonable formability. Typically, the sheet product is used for the products, such as truck trailer siding panel or electrical conduits for the building industry.

Owner:COMMONWEALTH INDS

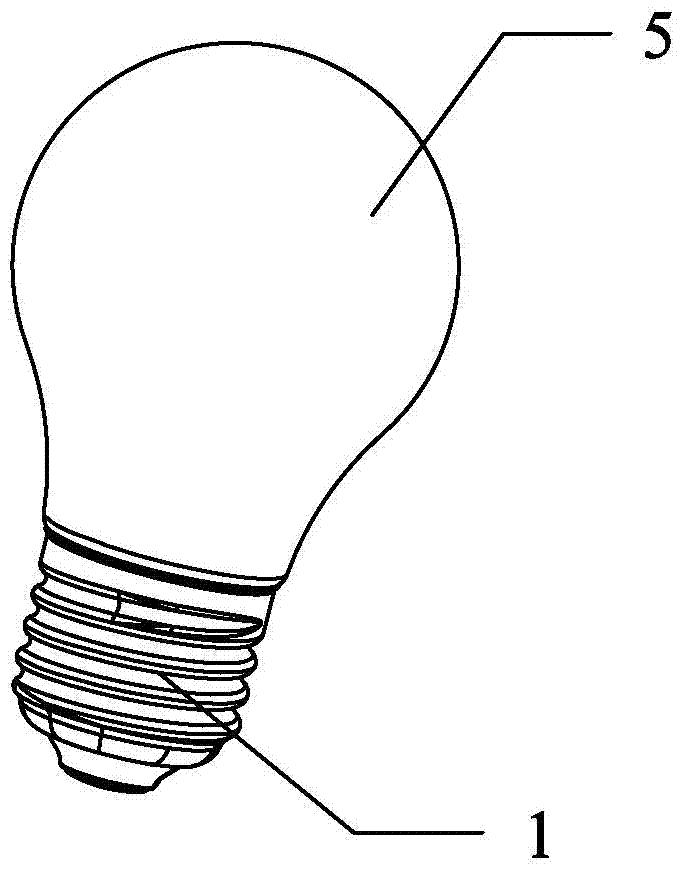

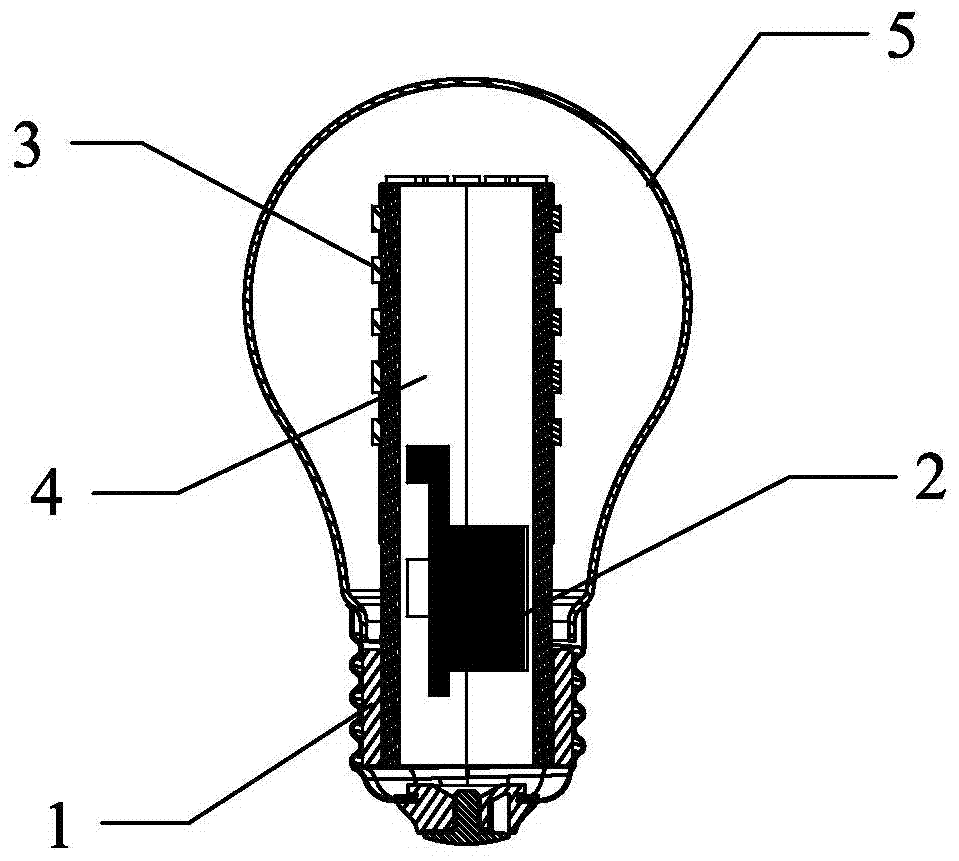

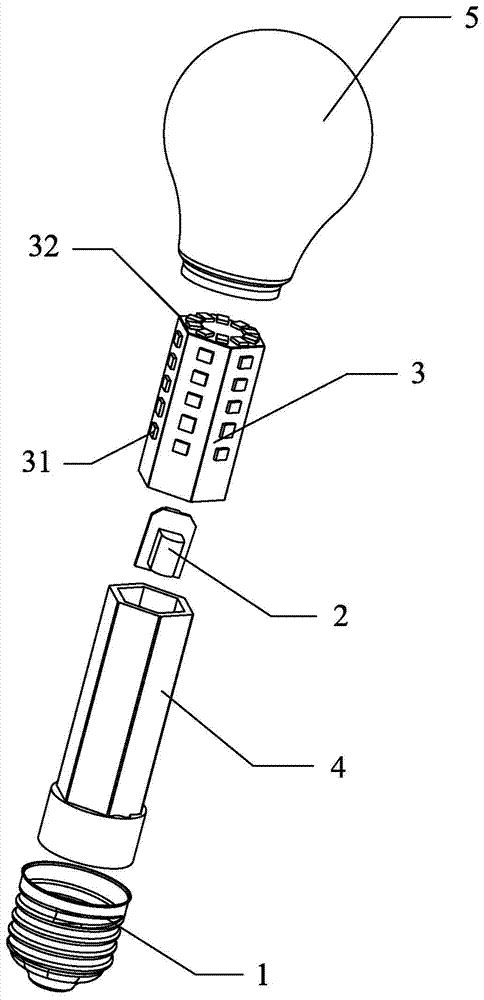

LED lamp bulb

InactiveCN103499043AExtended service lifeIncrease surface areaPoint-like light sourceLighting heating/cooling arrangementsEngineeringLED lamp

The invention discloses an LED lamp bulb which comprises a lamp holder, an LED power source, an LED light source, a heat conduction device and a lamp cover. The heat conduction device is mounted in the lamp holder in an interference fit mode, the LED light source is mounted on the heat conduction device, the LED power source is electrically connected with the LED light source and the lamp holder respectively, and the lamp cover is fixedly connected to the lamp holder. The LED lamp bulb has the advantages of being simple and safe in structure, good in heat radiating effect, large in light-emitting area, good in illumination effect and the like.

Owner:GUANGDONG BENBON ELECTRICAL

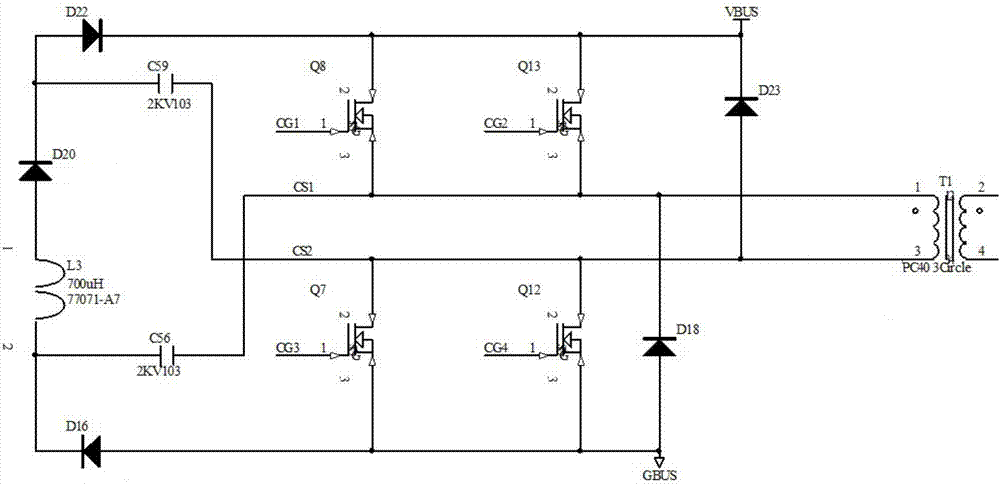

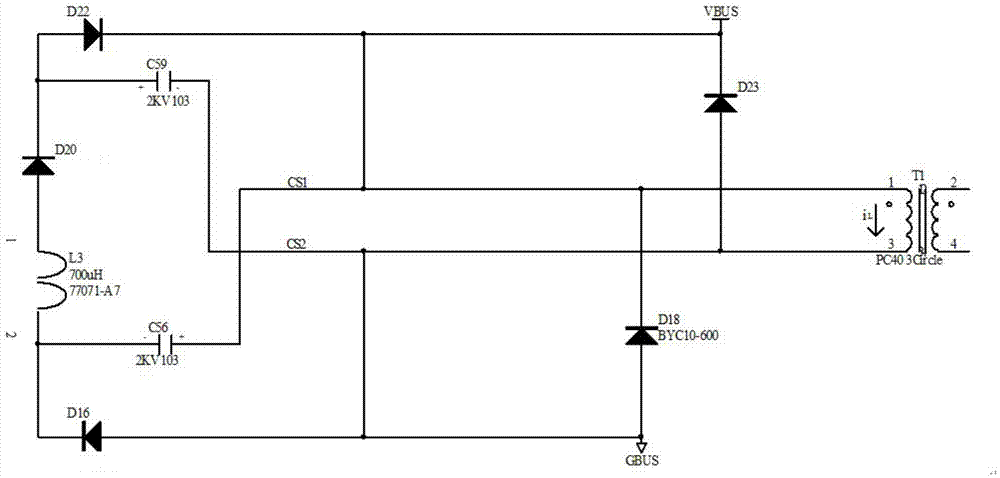

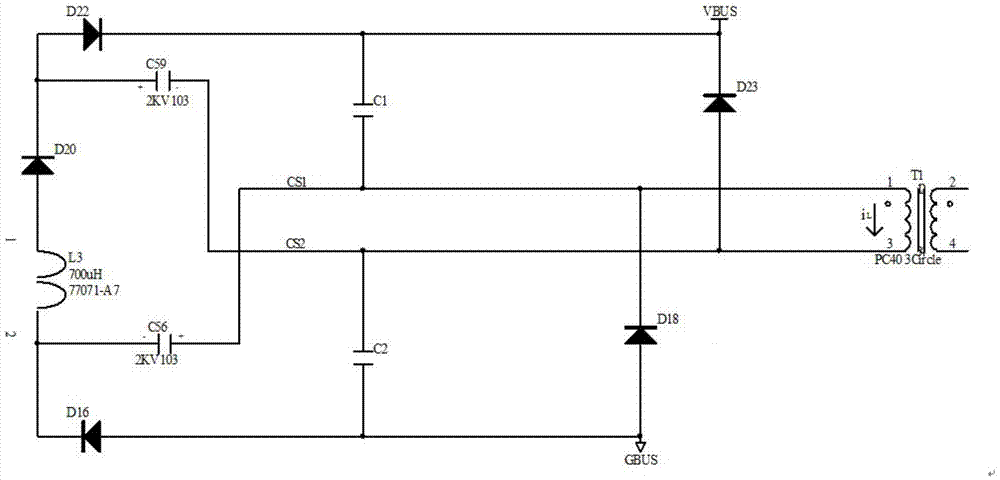

Absorption circuit for absorbing spike voltage of two-transistor forward converter

InactiveCN104518653AGuaranteed uptimeAvoid the disadvantage of large lossEfficient power electronics conversionPower conversion systemsElectrical resistance and conductanceVoltage spike

The invention relates to the field of switching power supplies, in particular to an absorption circuit for absorbing spike voltage of a two-transistor forward converter. A resistor is replaced by an iron-silicon-aluminum magnet ring to serve as an absorption loop in a switching power supply, the technical problems that during absorption of the spike voltage by means of resistance-capacitance in the prior art, heat generation is high, energy loss is high and energy efficiency is low are solved, voltage spikes generated by reverse restoration of diodes can be effectively suppressed, reliable running of the circuit is guaranteed, the defect that the conventional RCD buffering absorption network is high in loss is avoided, RC absorption is fully replaced, heat generation is low, safety is higher, energy efficiency is high, and the absorption circuit is widely applicable to power supply products.

Owner:武汉瑞莱富科技有限公司

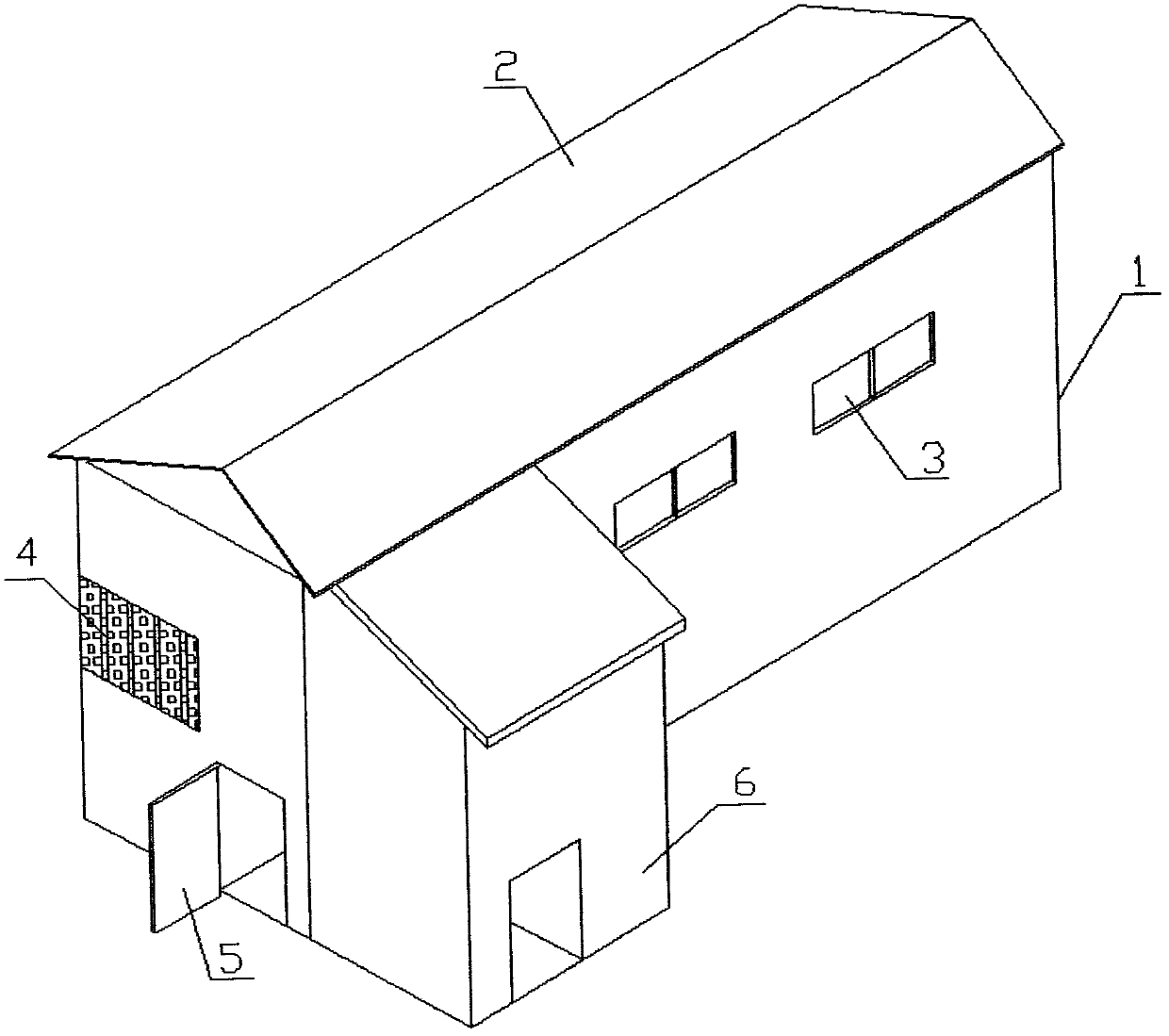

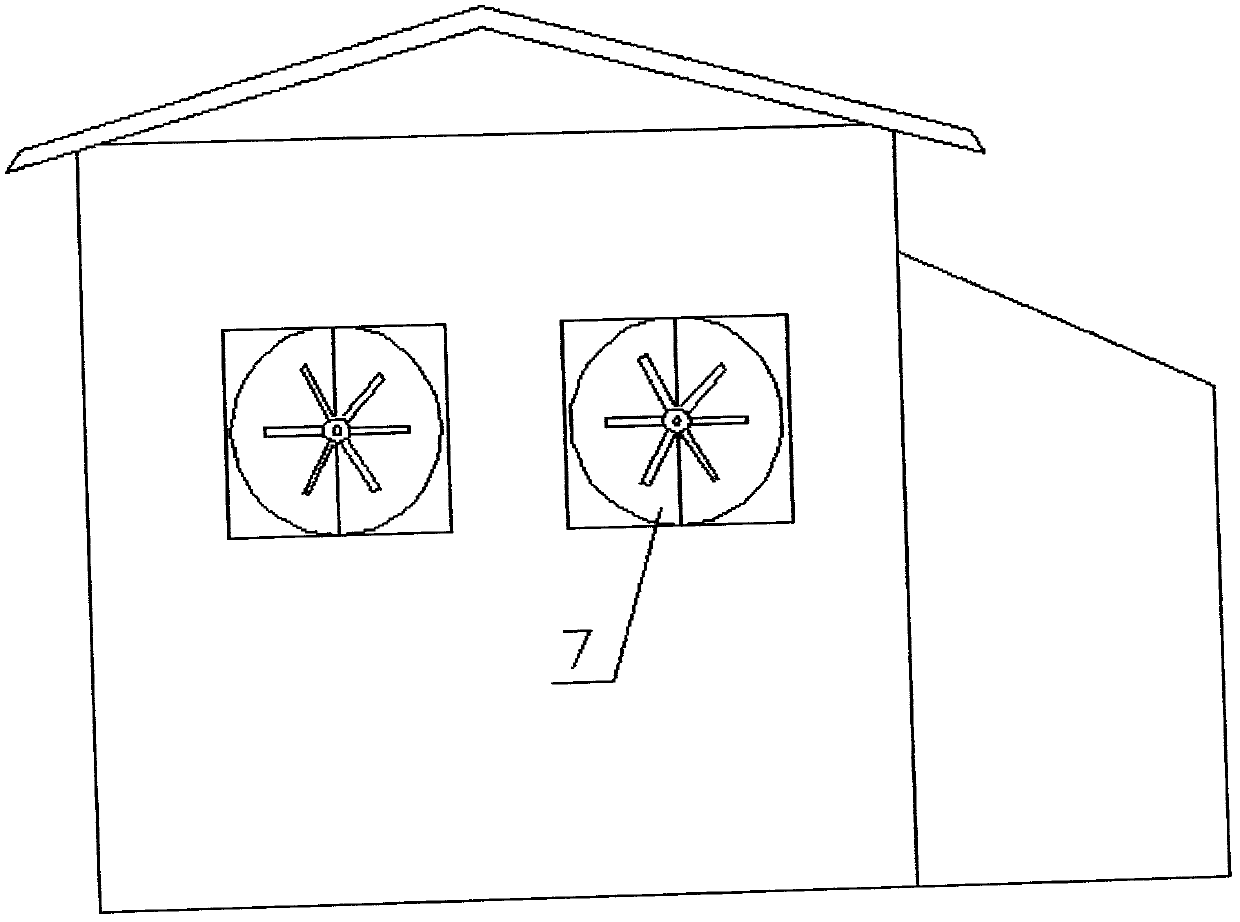

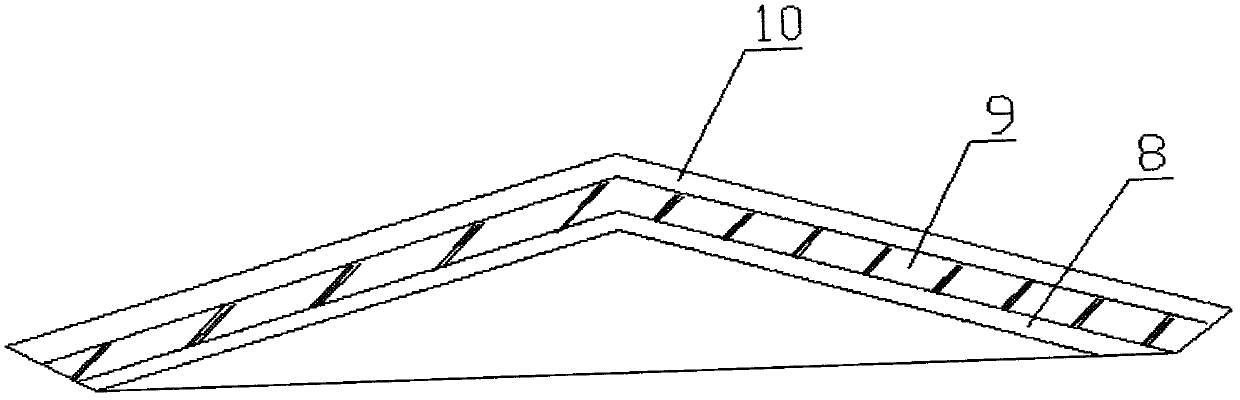

Energy-saving environment-friendly pig house

InactiveCN102599067ASolve the problem that pigs are afraid of heatSolve the heatAnimal housingThermal insulationOutdoor temperature

An energy-saving environment-friendly pig house relates to the technical field of pig breeding and comprises a rectangular enclosed wall and a roof at the top of the wall. The lateral side of the wall is provided with a window. A door is arranged at the front of the wall. The energy-saving environment-friendly pig house is characterized in that a through hole is reserved at the front of the wall and on one side of the door, a wet curtain is installed in the through hole and connected with a groundwater pipe, a suction fan is installed at the rear of the wall, and a heating house is disposed on one side of the wall and connected with the pig house through a heating passage inside the heating house. When outdoor temperature is high, the temperature of the pig house can be kept within a proper range by means of the thermal-insulation pig house and the exhaust ventilation wet curtain, and the problem that pigs are unable to stand high heat is solved effectively. When the outdoor temperature is low in winter, an underground flame path is used for heating, the house is warm inside, and a comfortable environment at the proper temperature is provided for pigs. Using the thermal-insulation exhaust ventilation pig house can solve a plurality of problems in raising pigs.

Owner:蒋洪福

Light emitting diode light source modules

InactiveUS9303861B2Produced inexpensively and efficientlySimple structurePoint-like light sourceVehicle interior lightingComputer moduleInterconnection

The present invention provides a highly-protective, heat dissipating LED light source module that may be waterproof or non-waterproof. In an embodiment, the present invention provides an LED light source module comprising: a waterproof housing comprising a metal substrate and a plastic cover integrally disposed on one or more surfaces of the metal substrate; and at least one light emitting diode, electronic component, and power line disposed on and operably connected with the metal substrate and encapsulated thereon by the plastic cover. In other embodiments are provided LED light source modules comprising: a circuit board with at least two through holes disposed at selected positions; at least one light emitting diode, electronic component, and power line disposed on the circuit board and operably connected therewith; and a plastic cover comprising at least two pins disposed and shaped for interconnection with corresponding through holes of the circuit board. The simple LED light source models disclosed may be efficiently and inexpensively produced and are capable of withstanding the harsh environments in which they are sometimes used.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD +1

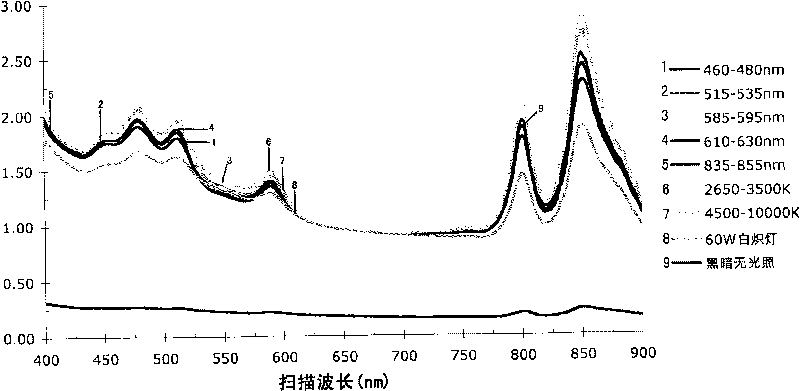

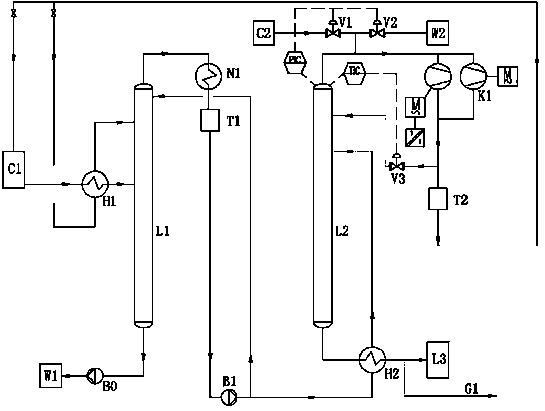

Bio-hydrogen production method by photosynthetic bacteria

InactiveCN101760480AImprove conversion efficiencySolve the heatMicroorganism based processesFermentationLight energyBiology

The invention relates to a bio-hydrogen production method by photosynthetic bacteria, which comprises the following step: (1) under an anaerobic condition, an organic acid is used as a fermentation substrate, the photosynthetic bacteria are fermented and cultured under one or a plurality of light sources with the wavelengths selected from the ranges of 400-500nm, 510-550nm, 575-600nm, 600-640nm and 780-880nm or the white light corresponding color temperature range of 2650-10000K, and the light intensity is 3000-7000Lux, so mixed gas is generated; and (2) hydrogen is separated from the generated mixed gas. With a proper light source, the invention can provide adequate light energy for hydrogen production by fermenting the photosynthetic bacteria, greatly increases the efficiency of energy conversion, and avoids the energy consumption steps of temperature reduction and the like on the whole fermentation system.

Owner:SHANGHAI INST OF BIOLOGICAL SCI CHINESE ACAD OF SCI

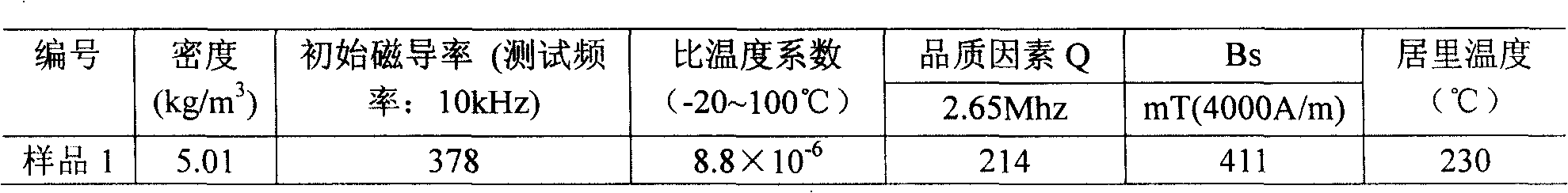

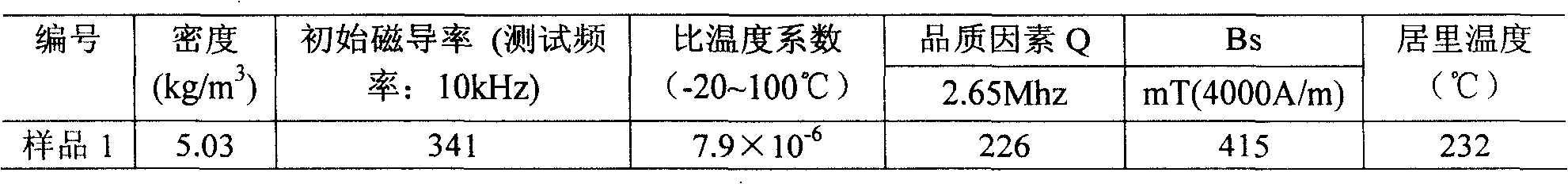

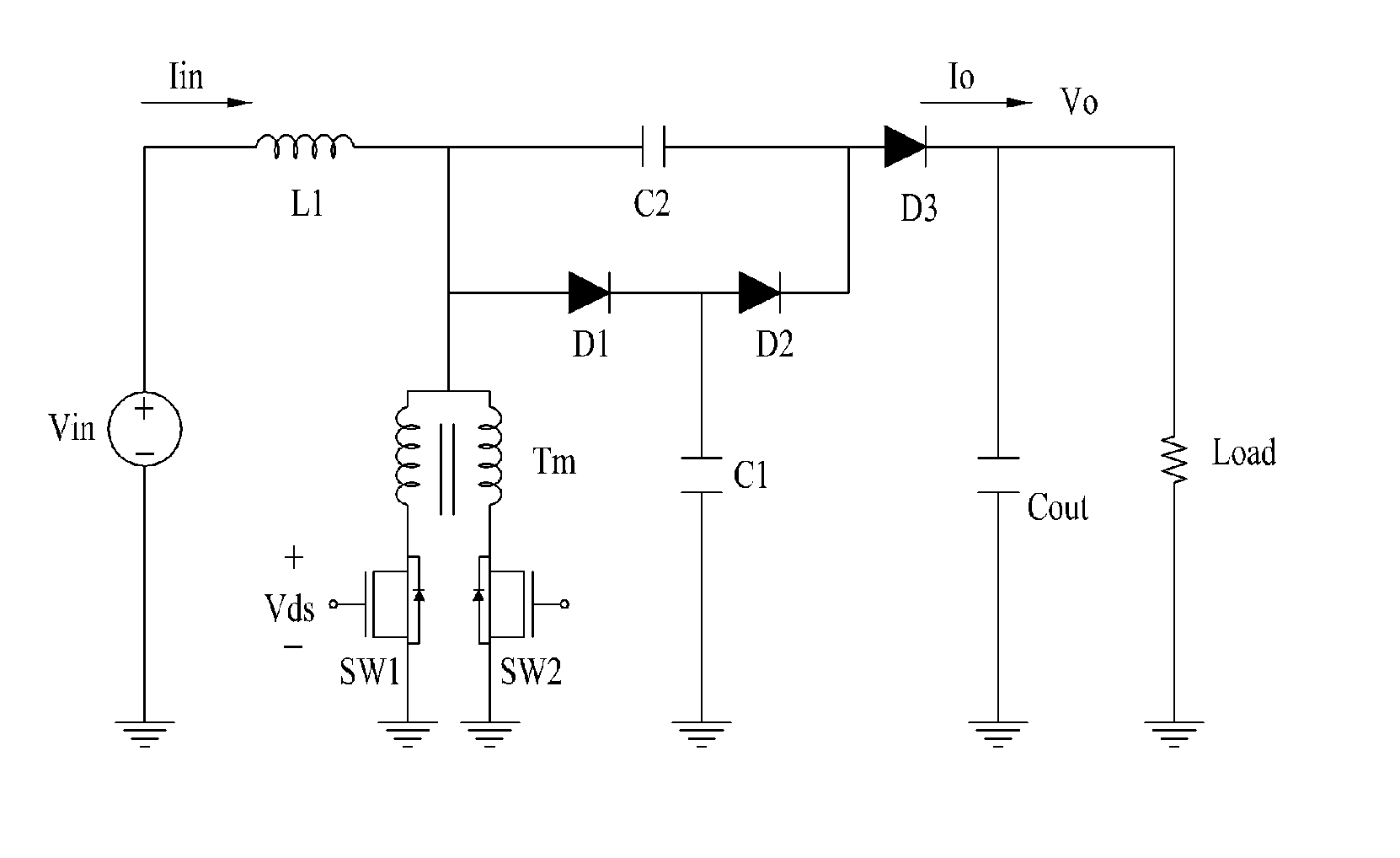

Nickel-zinc-ferrite material used for high-frequency non-polar lamp power coupler and preparation method thereof

InactiveCN101259998ASolve efficiency problemsSolve the heatElectric lighting sourcesElectric discharge lampsTemperature coefficientHigh resistivity

The invention discloses a nickel zinc ferrite material used in a high-frequency electrodeless lamp power coupler and a preparation method, wherein the main phase of the nickel zinc ferrite material is a spinel structure which comprises Fe2O3, ZnO, CuO, NiO and CoO, is characterized in that: the content of each composition is as follows as calculated according to oxide: Fe2O3 is 45 to 49 mol percent; ZnO is 23 to 31 mol percent; CuO is 2.5 to 4.8 mol percent; NiO is 14 to 25 mol percent; and CoO is 0.5 to 1.2 mol percent. The nickel zinc ferrite material, which has higher resistivity, has extremely low electromagnetic loss under high-temperature heavy current and particularly under 2.5 MHz to 3 MHz high frequency; meanwhile, the quality factor Q of the nickel zinc ferrite material is more than 200 all the time; therefore, the nickel zinc ferrite material effectively solves the problems that a high-frequency electrodeless lamp power coupler has low efficiency and high heat productivity. Moreover, the nickel zinc ferrite material also has excellent temperature stability, and the initial permeability of the material is always kept between 300 and 400 under a broad temperature range ranging from minus 20 DEG C to plus 100 DEG C; meanwhile, the specific temperature coefficient of the material is less than 9.0x10<-6>, which is propitious to maintain the operating stability of a power coupler.

Owner:TONGXIANG TELIYOU ELECTRONICS SCI & TECH

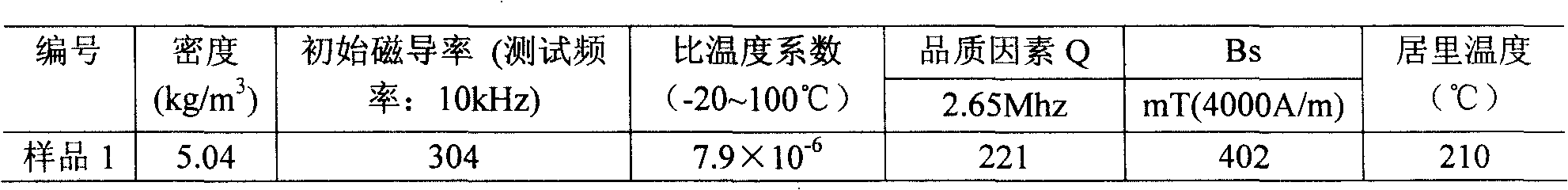

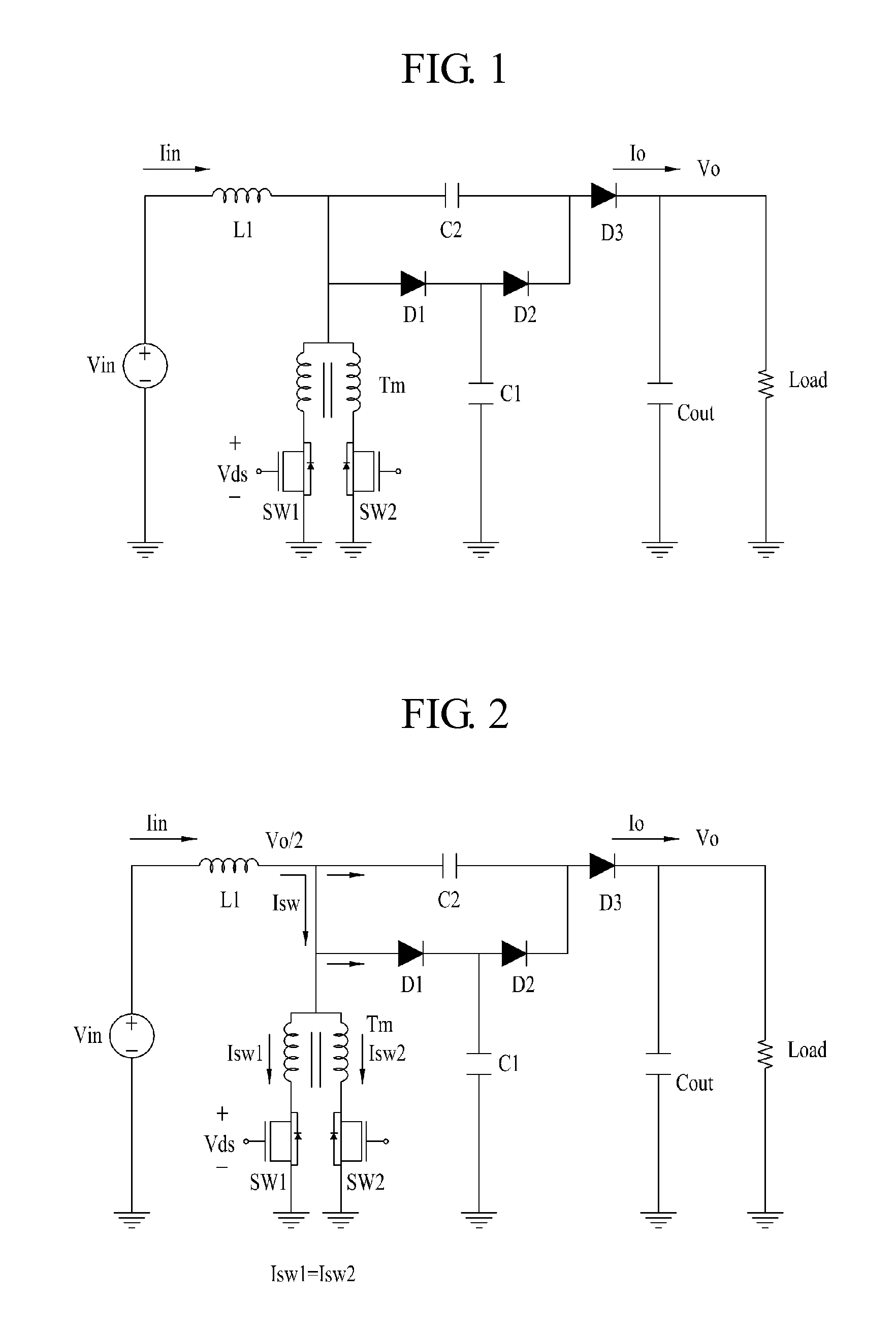

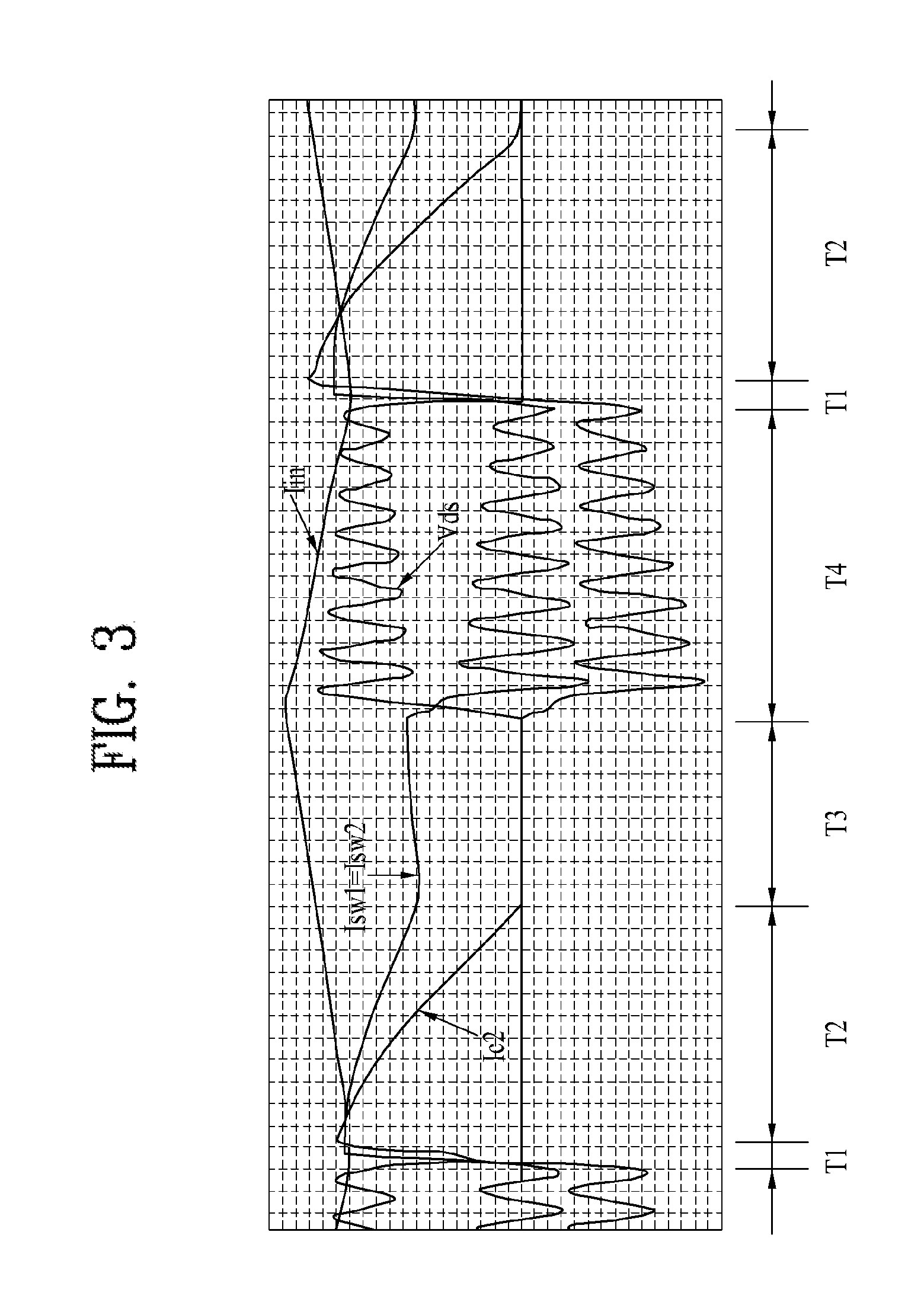

Dc-dc boost converter circuit and method for driving the same

ActiveUS20110309817A1Reduce power lossImprove circuit efficiencyEfficient power electronics conversionApparatus without intermediate ac conversionSoft switchingTransformer

Disclosed herein are a DC-DC boost converter circuit, which is capable of preventing power loss and stabilizing switching elements by implementing soft switching and improving efficiency by adding a charge pumping function, and a method for driving the same. The DC-DC boost converter circuit, in which an inductor and an output diode are connected in series and an output capacitor and a load are connected to an output port of the output diode in parallel, includes an output stabilization circuit in which first and second switching elements, a transformer, a plurality of boost capacitors, and a plurality of diodes are connected in series / parallel between the inductor and the output diode.

Owner:POSTECH ACAD IND FOUND

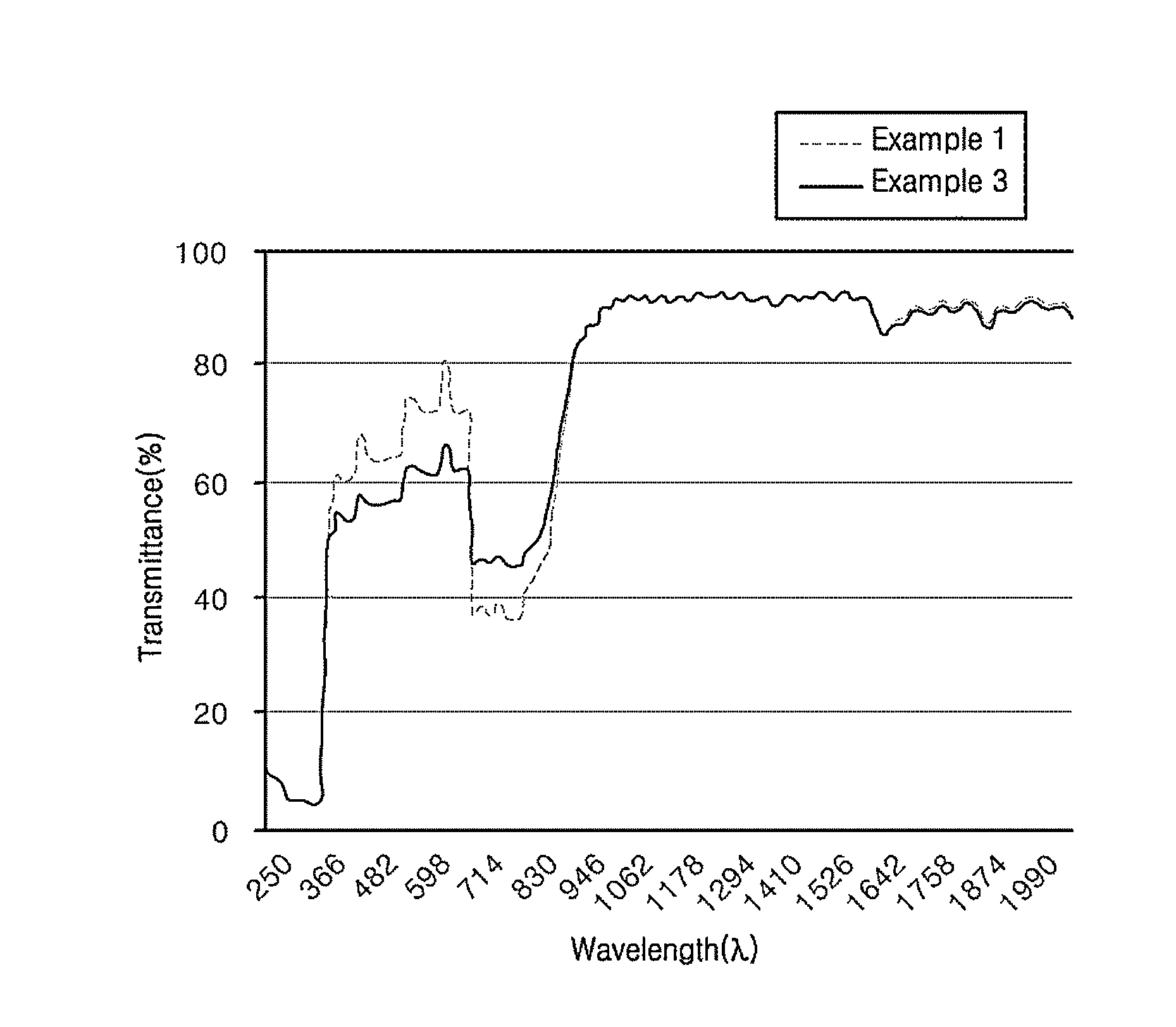

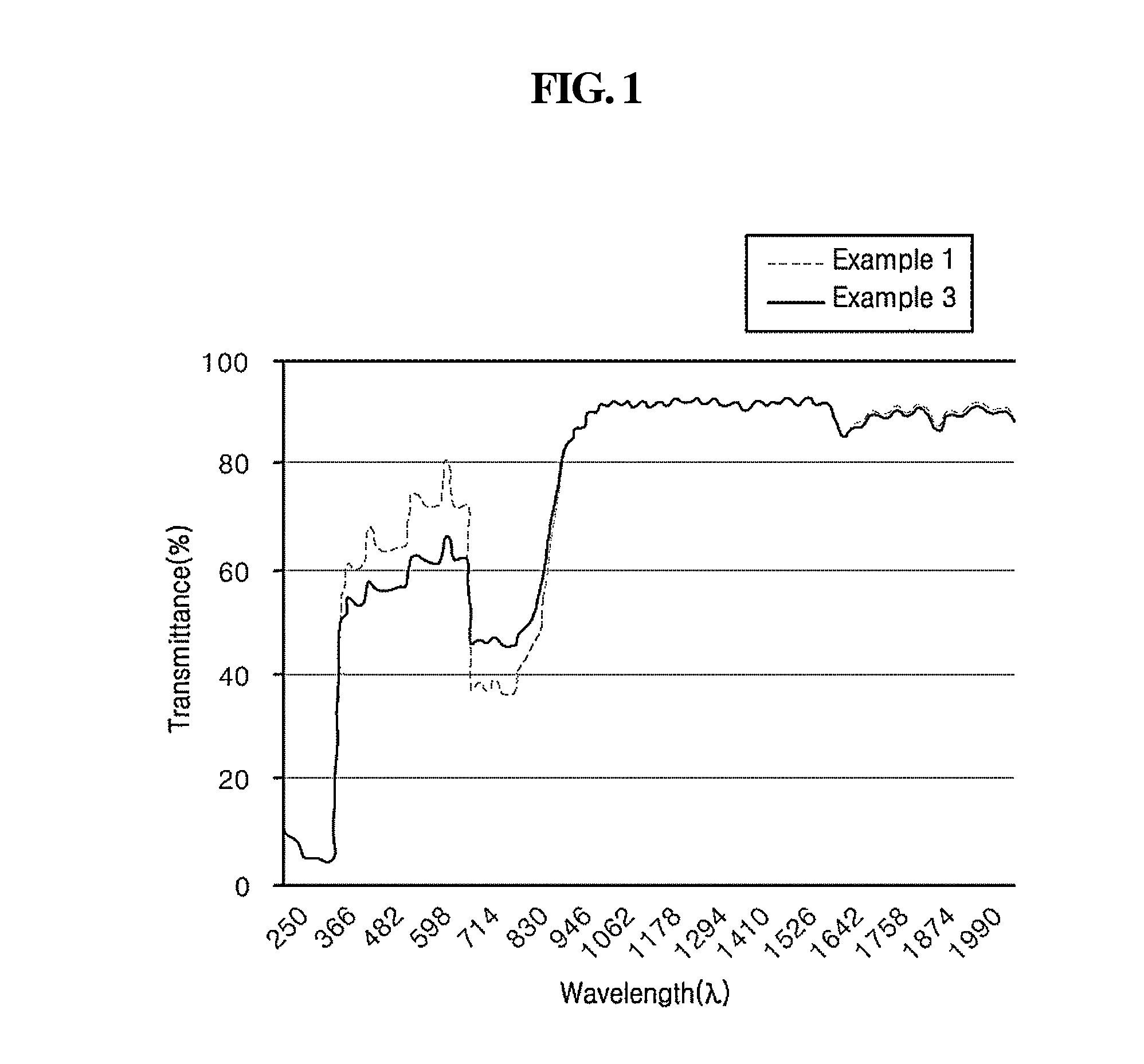

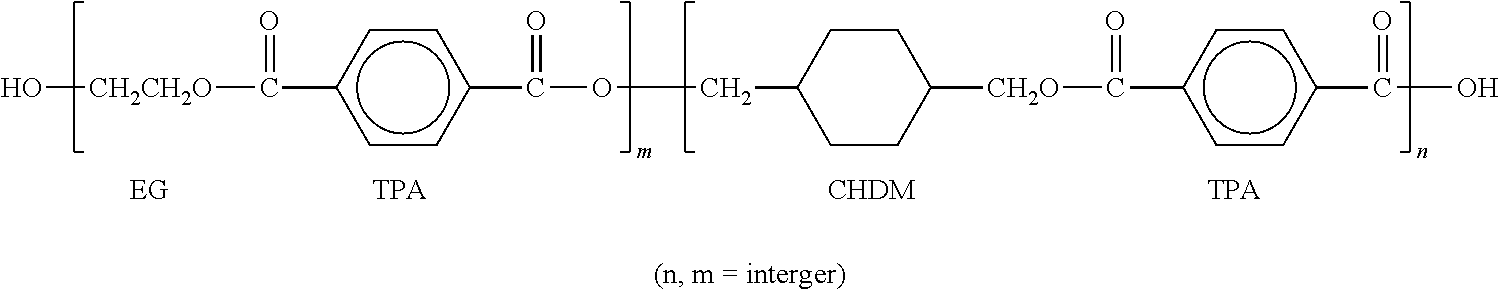

Multilayer optical film having high heat resistance and method for manufacturing the same

InactiveUS20150002935A1Improve heat resistanceImprove featuresLamination ancillary operationsSynthetic resin layered productsPolyesterPolyethylene terephthalate glycol

The present invention provides a multilayer optical film having a structure in which a first resin layer and a second resin layer are alternately laminated, wherein the first resin layer comprises a crystalline naphthalene dicarboxylic-acid polyester and the second resin layer comprises polyethylene terephthalate glycol (PETG).Also, the present invention provides a method for manufacturing a multilayer optical film comprising (a) melting extrusion a first resin comprising a crystalline naphthalene dicarboxylic-acid polyester and a second resin comprising PETG respectively and then alternately laminating the first resin and the second resin; and (b) elongating the laminated sheet in step (a) and then thermosetting them.

Owner:LG HAUSYS LTD

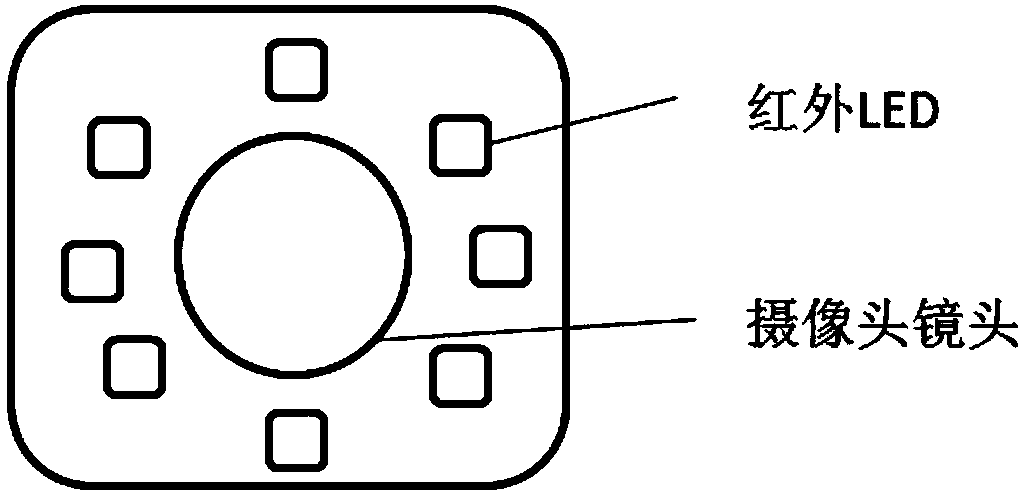

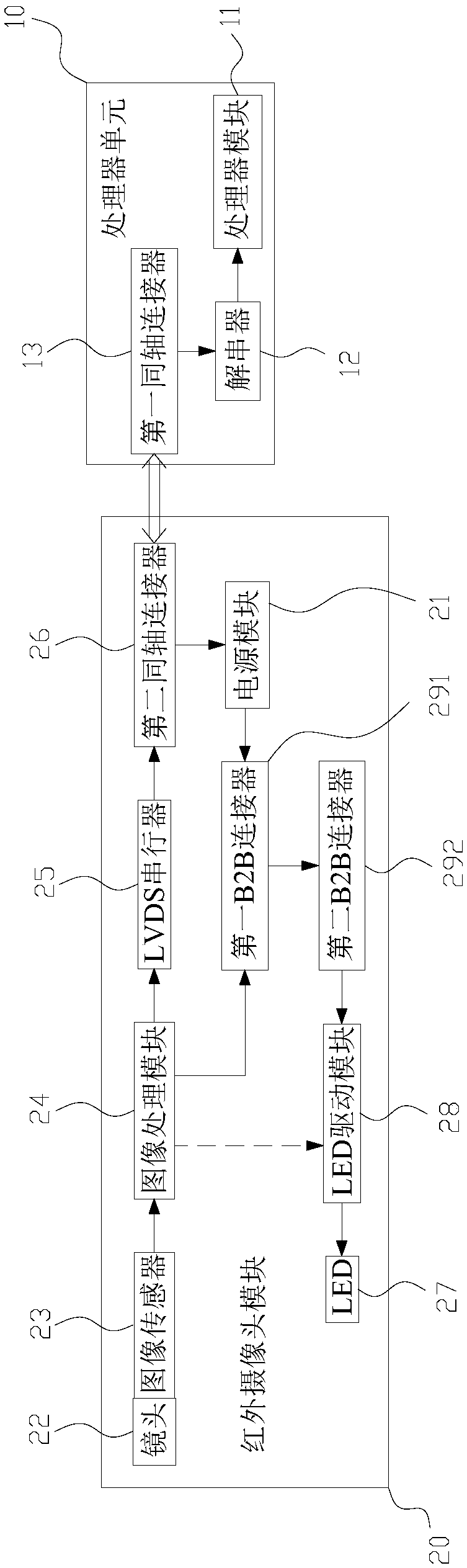

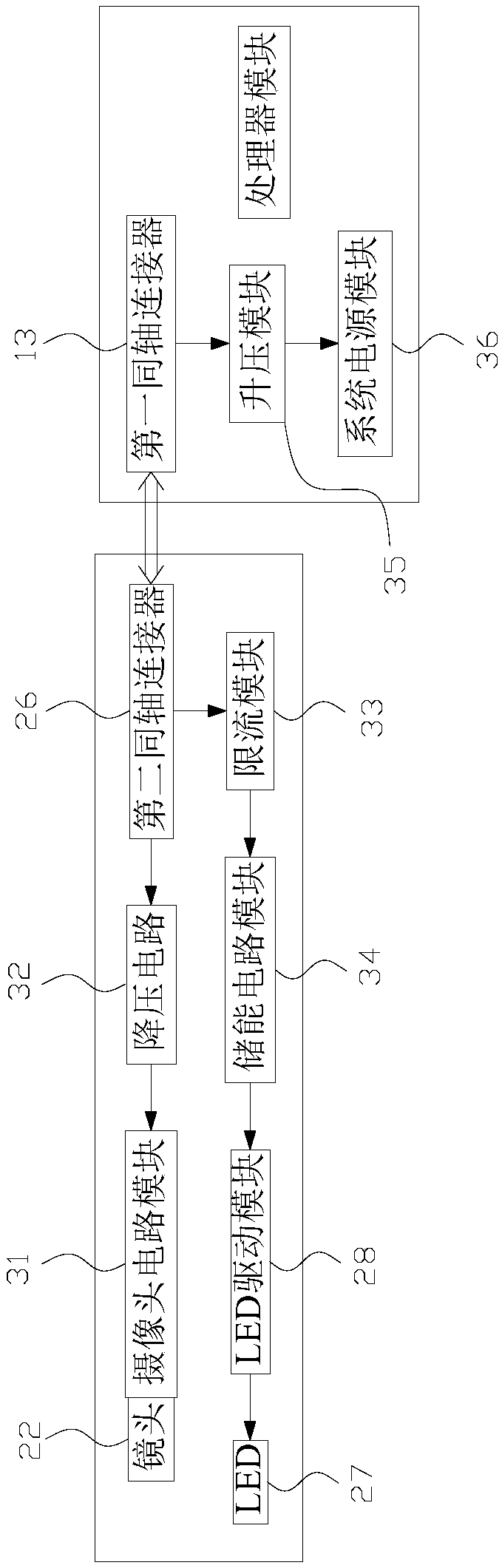

A driver monitoring infrared camera device and image brightness control method

InactiveCN109005320AReduce image gainReduce wiring harnessTelevision system detailsColor television detailsImaging processingComputer module

The invention relates to the technical field of a vehicle-mounted camera, in particular to a driver monitoring infrared camera device and an image brightness control method, comprising a processor unit and an infrared camera module. The infrared camera module comprises a power module, a lens, an image sensor, an image processing module, an LVDS serializer and a second coaxial connector connected in sequence, and an LED, an LED driving module, a second B2B connector and a first B2B connector connected in sequence. The second coaxial connector and the first B2B connector are powered by the powersupply module; The image processing module is respectively connected with the LED driving module and the first B2B connector. The second coaxial connector is connected to a first coaxial connector ofthe processor unit. The invention aims to provide a driver monitoring infrared camera device, which solves the technical problems that the existing infrared camera device has many wire harnesses, theinstallation position is difficult to confirm, the infrared LED module generates heat and the camera size is large.

Owner:HUIZHOU DESAY SV AUTOMOTIVE

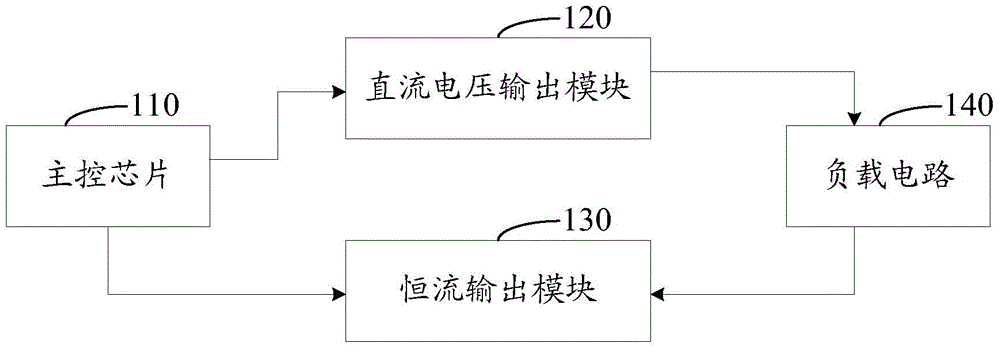

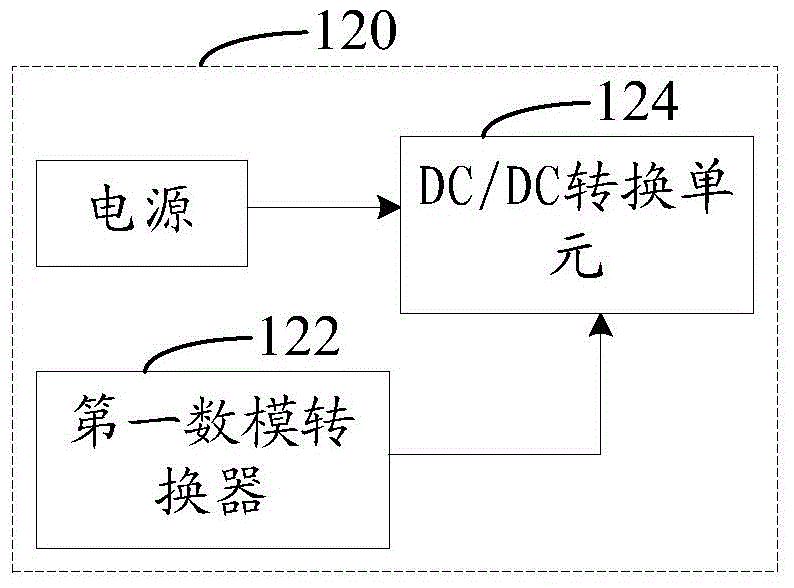

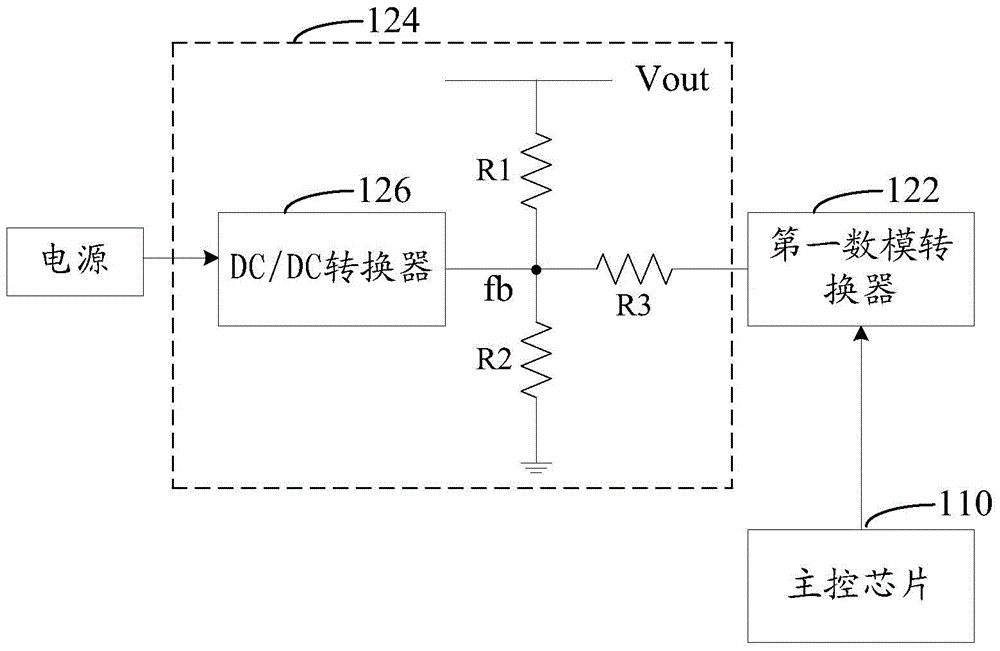

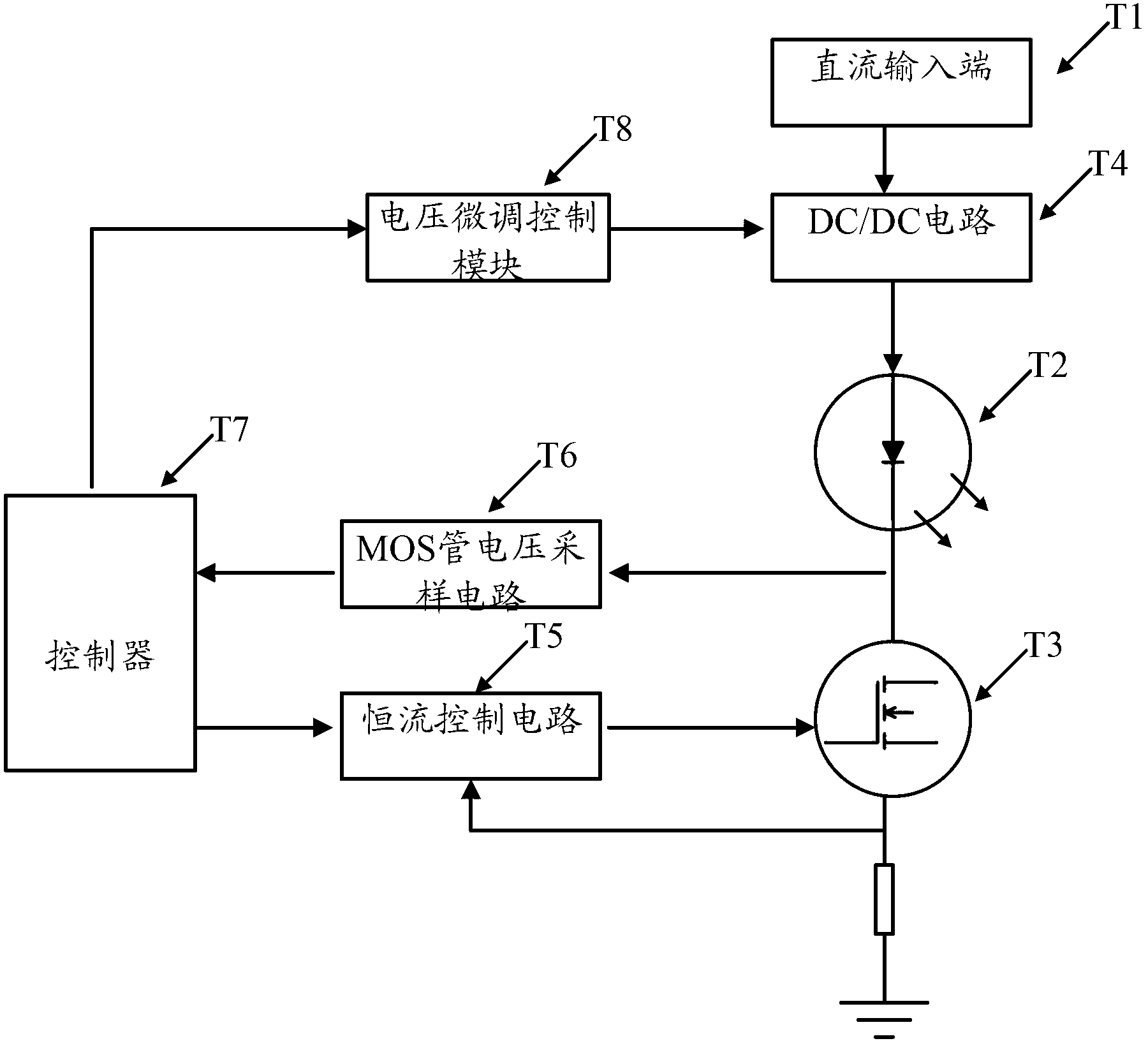

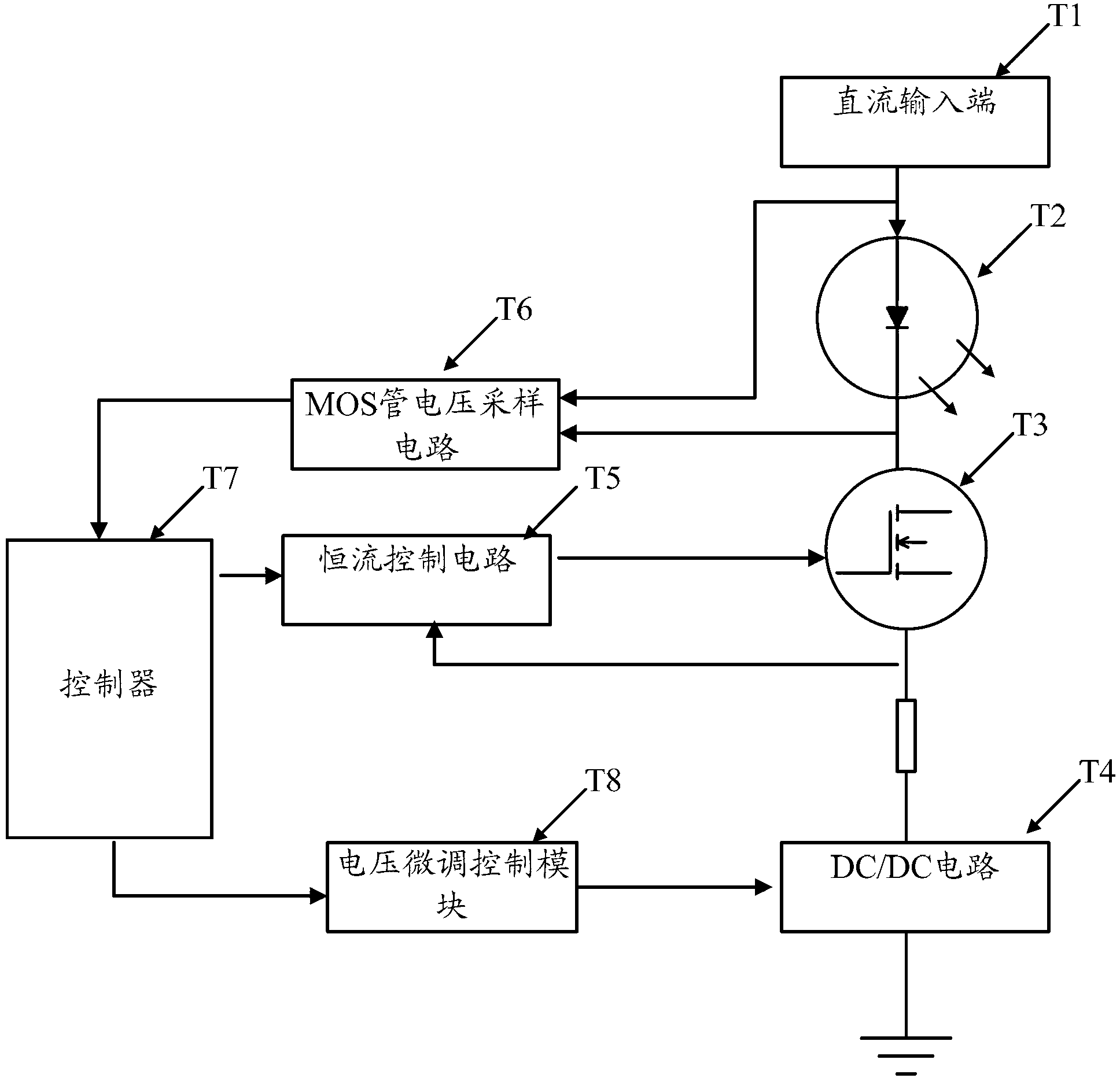

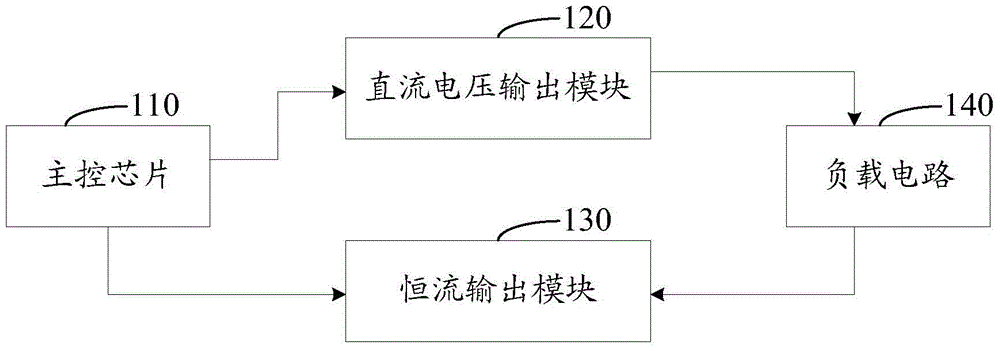

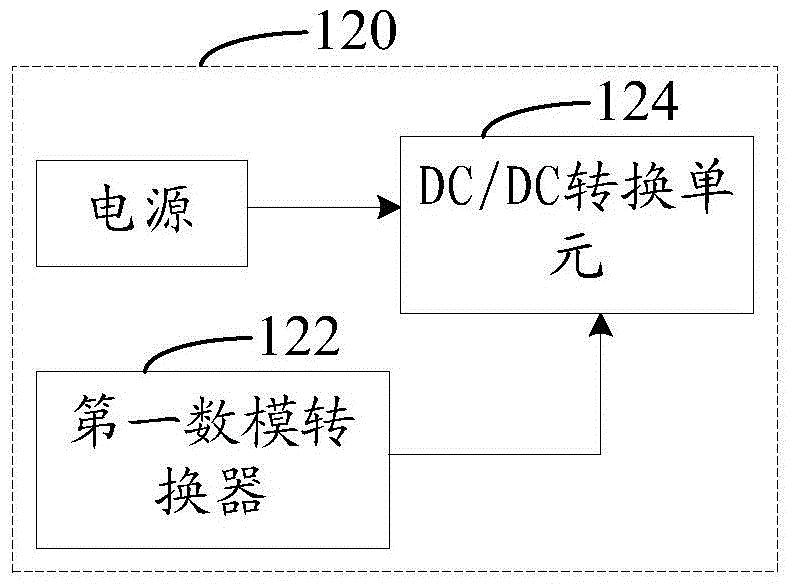

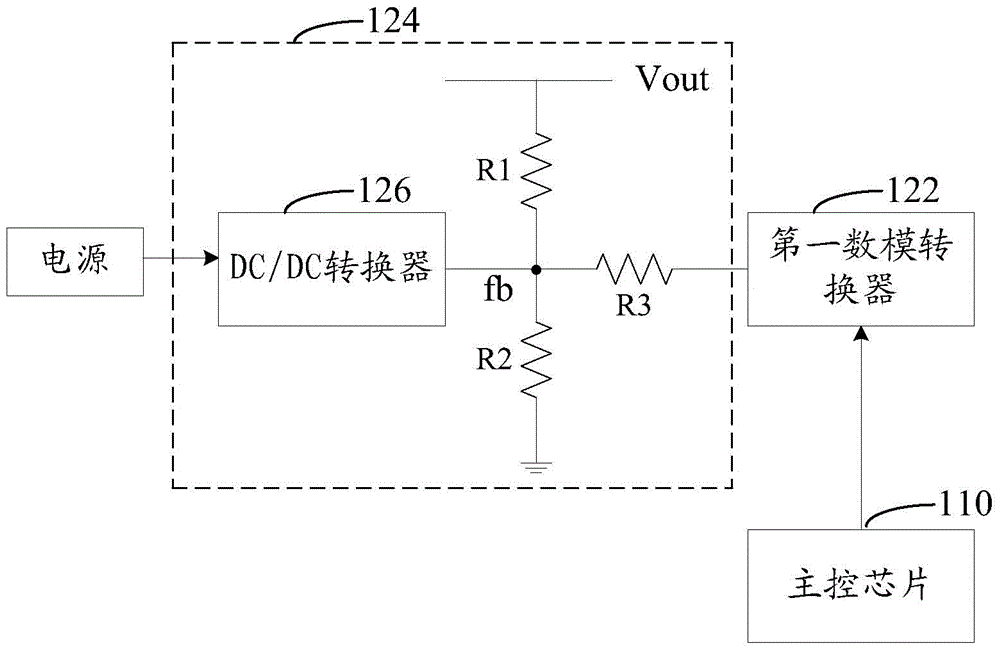

Power supply circuit for constant current source

ActiveCN104699158ASmall pressure dropSolve the heatElectric variable regulationLoad circuitDc voltage

The invention discloses a power supply circuit for a constant current source. The power supply circuit comprises a main control chip, a direct voltage outputting module and a constant current outputting module, wherein the main control chip is connected with the direct voltage outputting module and the constant current outputting module respectively to be used for outputting a control instruction according to power supply voltage needed by a load circuit so as to regulate the output voltage of the direct voltage outputting module; the direct voltage outputting module is used for supplying a variable direct voltage for the load circuit; the constant current outputting module is used for outputting a constant electric current to the load circuit. The power supply circuit disclosed by the invention can reduce the calorific value and enlarge the scope of the output current.

Owner:SHENZHEN COMEN MEDICAL INSTR

Transformer

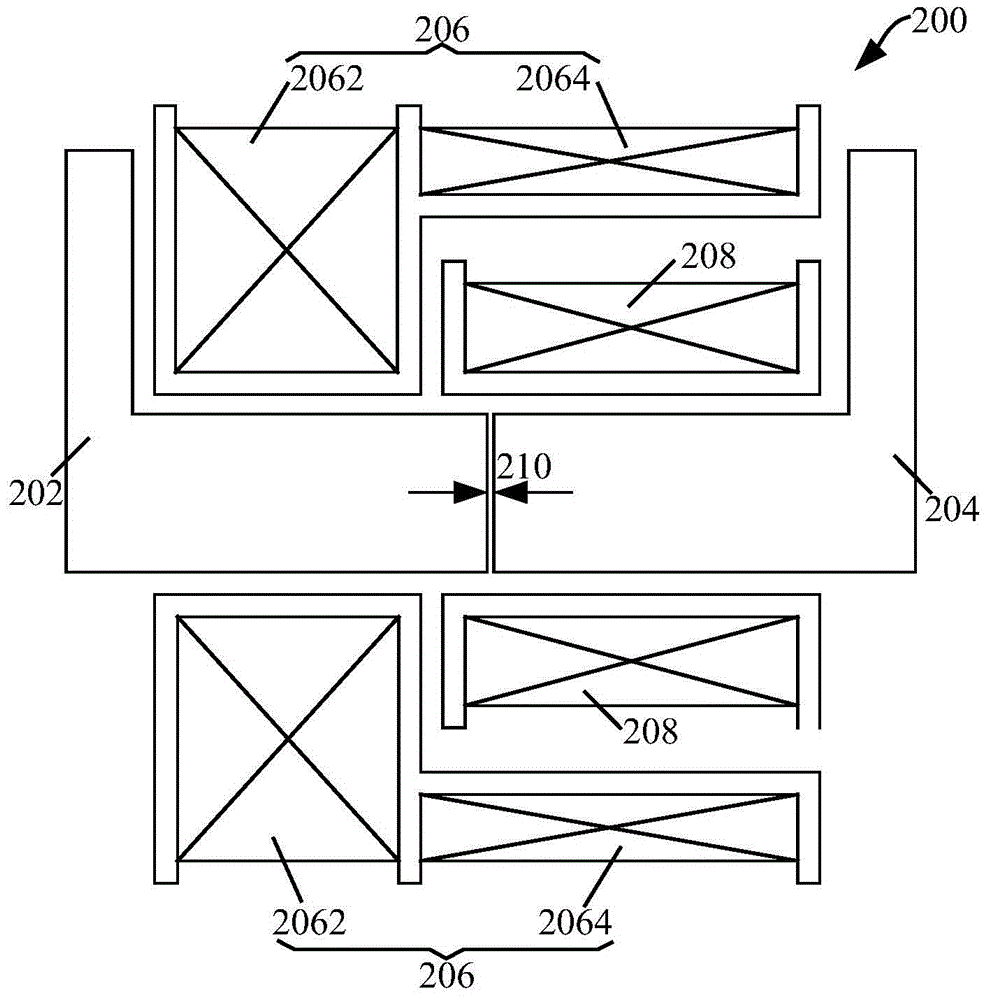

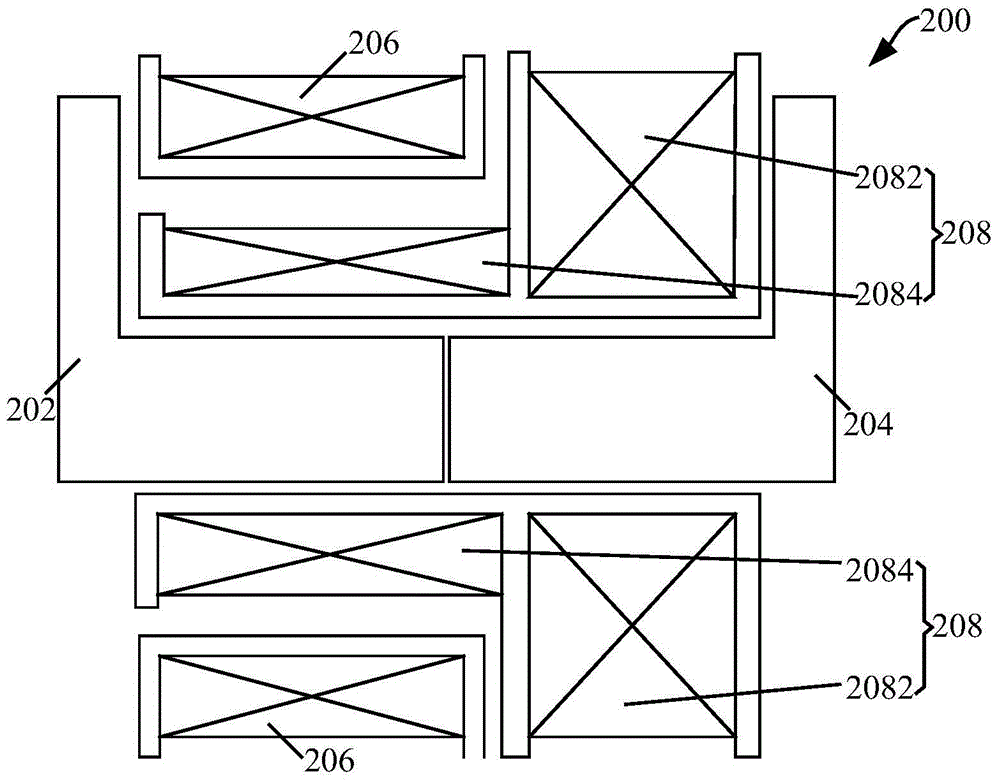

ActiveCN103985525AGood anti-satisfactionImprove abilitiesTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerElectrical and Electronics engineering

The invention provides a transformer, which comprises a magnetic core assembly, a primary winding and a secondary winding, wherein the primary winding and the secondary winding are wound on the magnetic core assembly and are matched with the magnetic core assembly to be used, the primary winding comprises a first winding and a second winding, the first winding is coupled with the secondary winding in the axial direction, the second winding is coupled with the secondary winding in the radial direction, and / or the secondary winding comprises a third winding and a fourth winding, wherein the third winding is coupled with the primary winding in the axial direction, the fourth winding is coupled with the primary winding in the radial direction. Through the technical scheme of the transformer, the primary winding and the secondary winding in the transformer can be coupled in both the axial direction and the radial direction, in addition, the production cost of the transformer is reduced, and the heat radiation effect of the transformer is optimized.

Owner:MIDEA GRP CO LTD +1

LED (Light-Emitting Diode) constant-current source

InactiveCN102938961AReduce power consumptionSolve heat dissipation difficultiesElectric light circuit arrangementComputer moduleEngineering

The embodiment of the invention discloses an LED (Light-Emitting Diode) constant-current source which is used for solving the problem that heat of an LED lamp T2 is difficult to radiate. The LED constant-current source provided by the embodiment of the invention comprises a direct-current input end T1, the LED lamp T2, an MOS (Metal Oxide Semiconductor) tube T3, a DC (Direct-Current) / DC circuit T4, a constant-current control circuit T5, a controller T7 and a voltage fine turning control module T8, wherein the direct-current input end T1 is connected with the LED lamp T2; the LED lamp T2, the MOS tube T3 and the DC / DC circuit T4 are sequentially connected; the MOS tube T3 is connected with one end of the DC / DC circuit T4; the other end of the DC / DC circuit T4 is grounded; the controller T7 is connected with the MOS tube T3 through the constant-current control circuit T5; and the voltage fine turning control module T8 is connected with the DC / DC circuit T4. With the adoption of the LED constant-current source provided by the invention, the problem that the heat of the LED lamp T2 is difficult to radiate can be effectively solved.

Owner:GUANGDONG VTRON TECH CO LTD

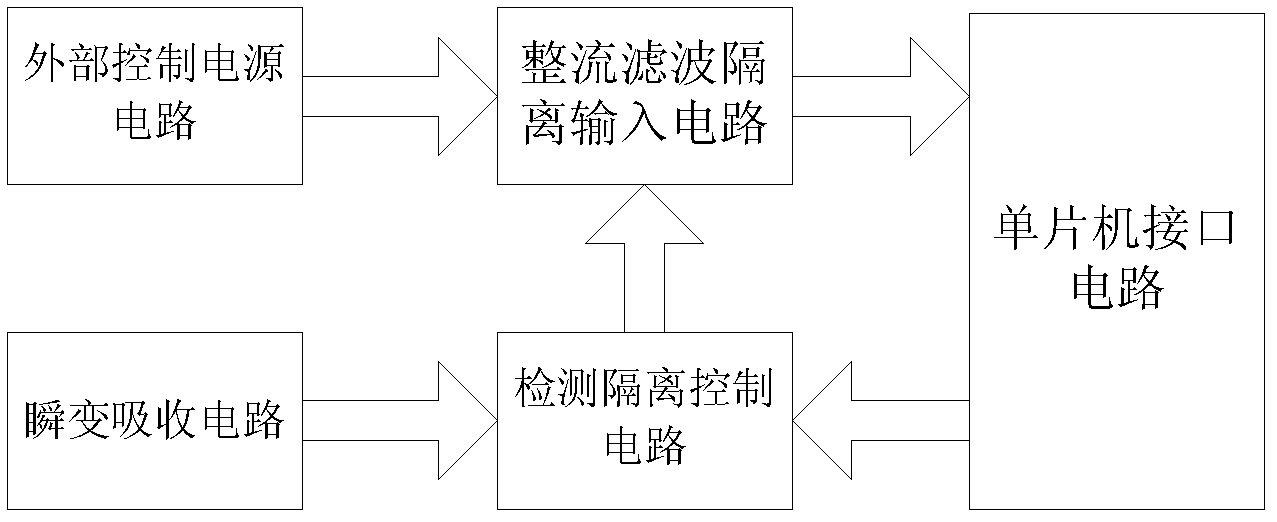

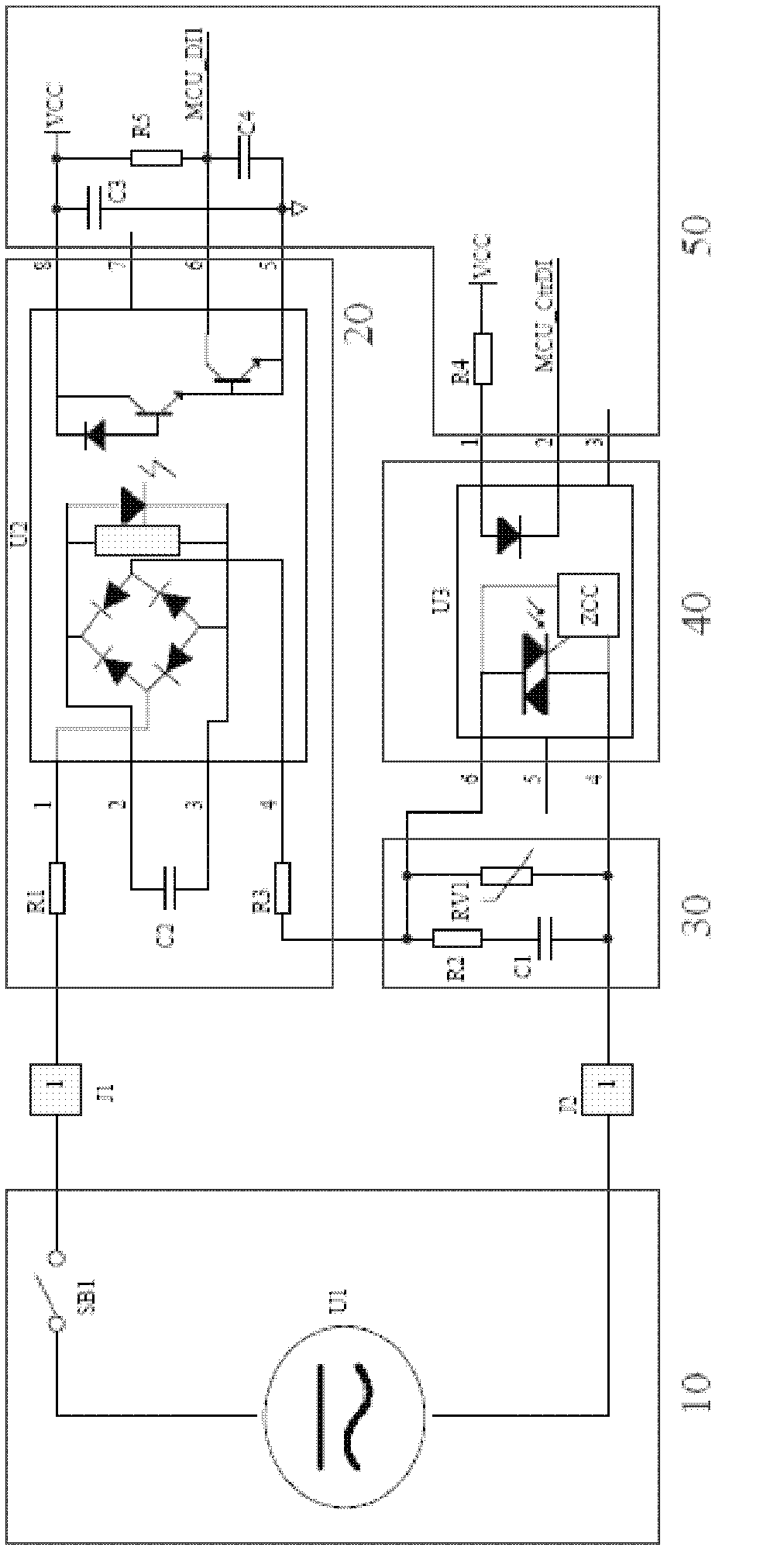

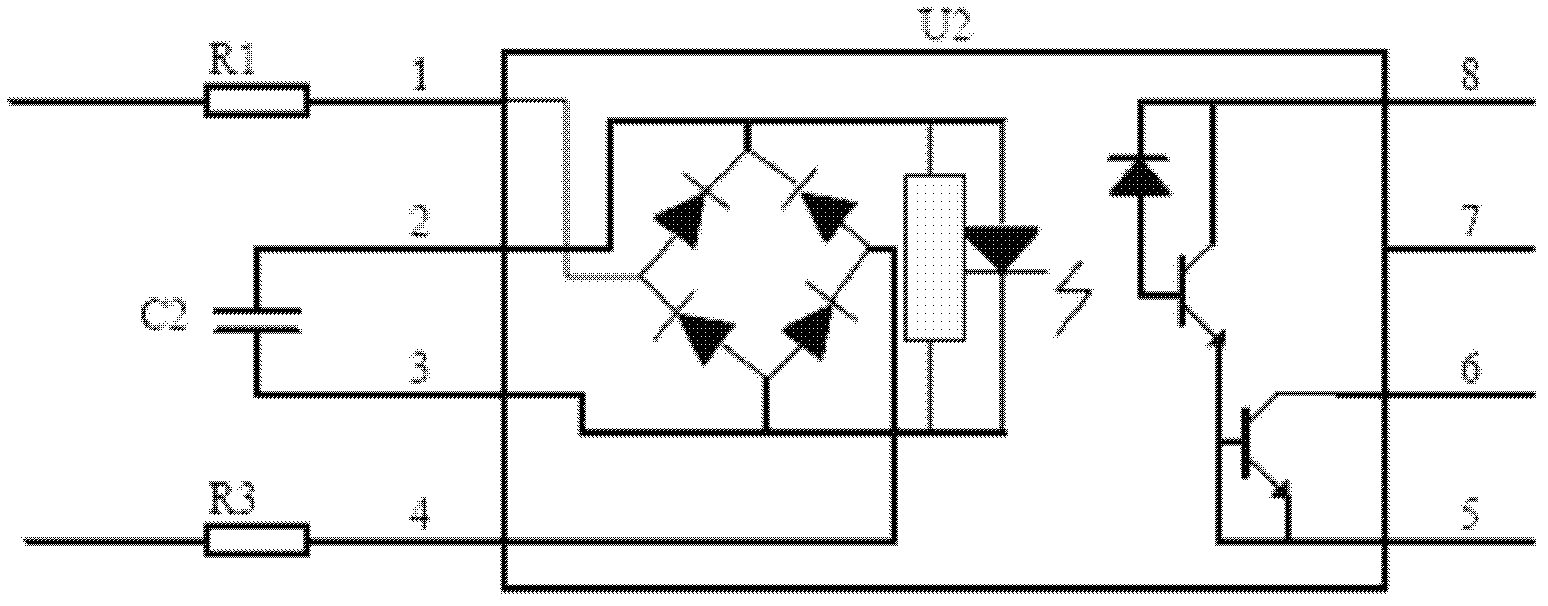

AC and DC digital input circuit

ActiveCN102508453AEasy to handleGuaranteed uptimeProgramme controlComputer controlMicrocontrollerAutomatic control

The invention discloses an AC and DC digital input circuit. The circuit comprises an external control power supply circuit, a rectifying and filtering isolation input circuit, a detection isolation control circuit, a transient absorption circuit and a singlechip interface circuit. The circuit of the invention can realize AC and DC digital input signal acquisition without changing a hardware circuit structure; and the circuit is simple, reliable and low in cost. The circuit has higher practicability in the field of electrical engineering, particularly, in a power equipment protection device and an industrial automatic control situation.

Owner:JIANGSU SFERE ELECTRIC

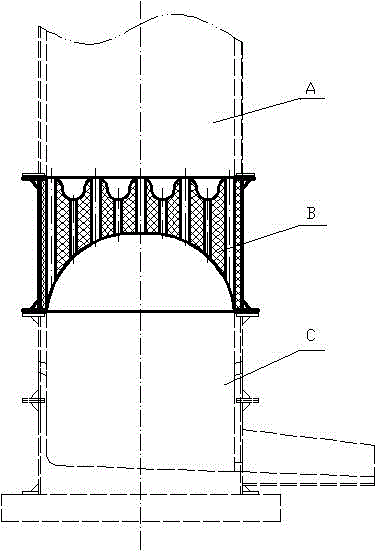

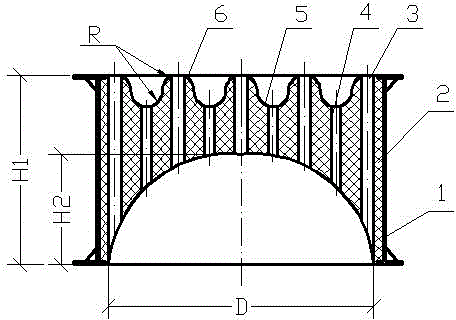

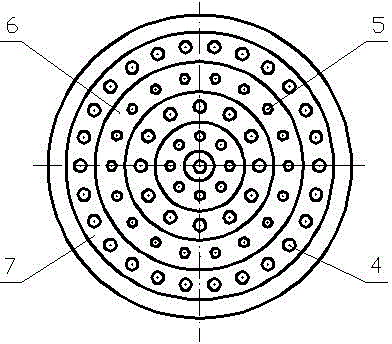

Integral cellular fire-resistant hearth for fuel gas cupola furnace

The invention relates to an integral cellular fire-resistant hearth for a fuel gas cupola furnace. According to the hearth, the high-temperature fire-resistant castable integral forming and normal-temperature hardening burn-free technology is adopted, by means of the cellular runner structure, the structural design of an annular round boss and a groove, and optimization of the bottom arch-shaped structure, fuel gas, molten iron and slag are ascended and descended through respective runways, direction contact between the fuel gas and the molten iron is reduced, and the burning loss of an alloy element is reduced. The fire-resistant hearth can effectively replace a water-cooling grate bar and a fire-resistant ball in the modern fuel gas cupola furnace, a large amount of water resources can be saved, the energy consumption can be reduced by 10-15%, the operation safety is improved, and the tapping temperature is increased.

Owner:李明弟

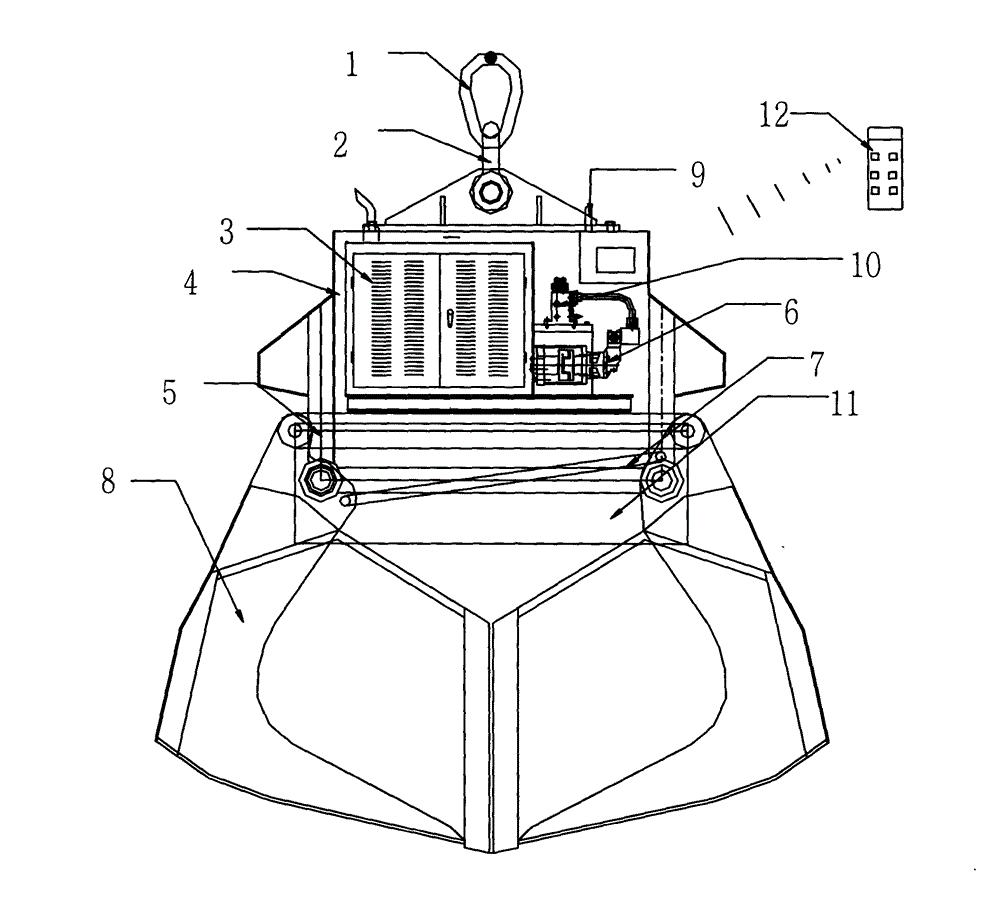

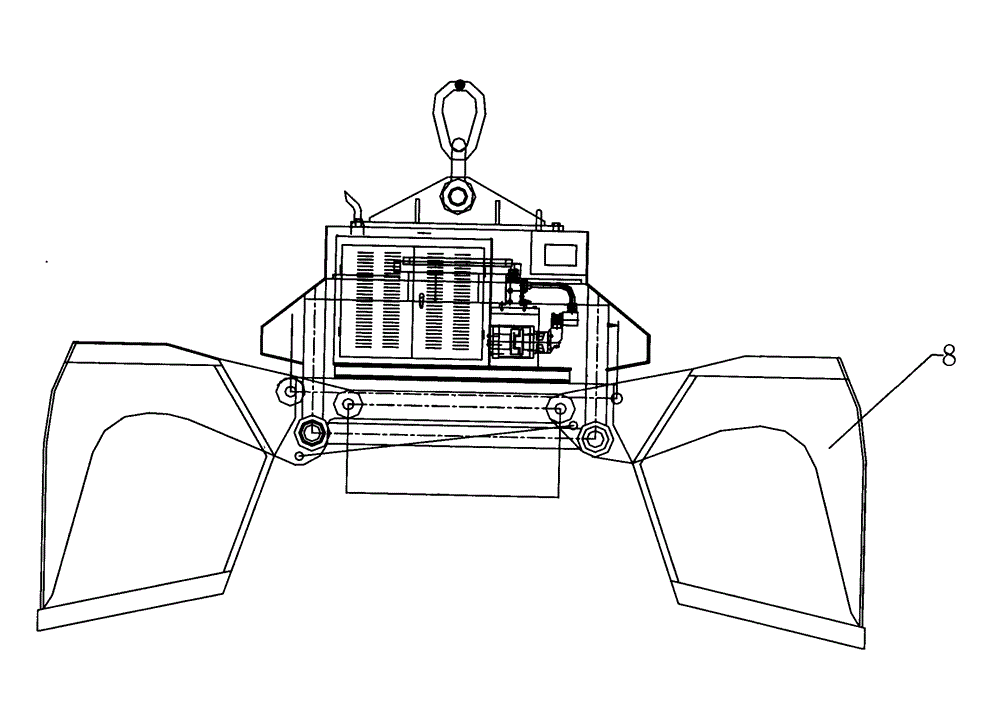

Hydraulic grab driven by diesel through wireless remote control

InactiveCN103145033AExtend working lifeSolve the heatLoad-engaging elementsSolenoid valveRemote control

The invention relates to a hydraulic grab driven by a diesel through wireless remote control. The hydraulic grab comprises a hoisting ring, a shackle, an outer shell, a through girder, two bucket bodies, a hydraulic device and a wireless remote control device, wherein the hydraulic device is provided with a hydraulic pump, an oil cylinder, and a control valve block system, the oil cylinder is connected with the hydraulic pump by a solenoid valve and is driven by the hydraulic pump through power provided by the diesel connected with the hydraulic pump, and two ends of a connecting rod are respectively connected at the inner side edges of the two bucket bodies through pin rolls so as to play a position limiting and protecting role in closing and opening of the grab. The grab can be remotely controlled to grab cargoes or when no power is available, the oil cylinder can be driven to close or open the grab to grab the cargoes, and the hydraulic grab is applicable to poor working environments, can work regardless of high frequency service conditions, is long in work service life, improves the efficiency of enterprises, overcomes potential safety hazards of the production and is convenient to operate.

Owner:SHANGHAI GUANBO MACHINERY EQUIP

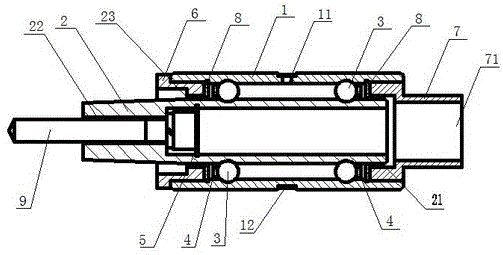

Drawing leather roller sleeve bearing

InactiveCN106015319ASolve the heatImprove axial clearance accuracyRolling contact bearingsTextile treatmentEngineeringMechanical engineering

Owner:CHENGDU KECHUANG JIASI TECH

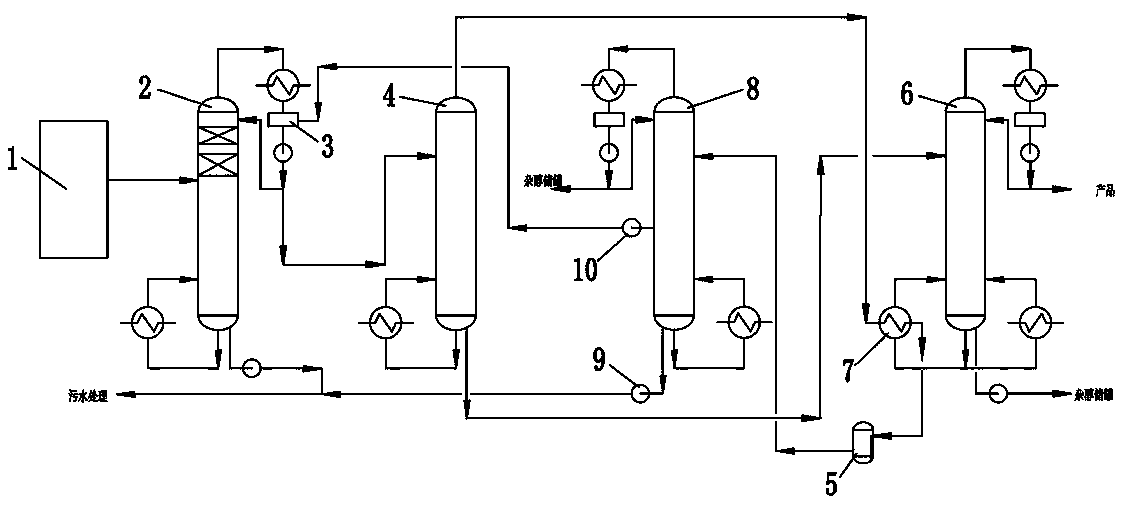

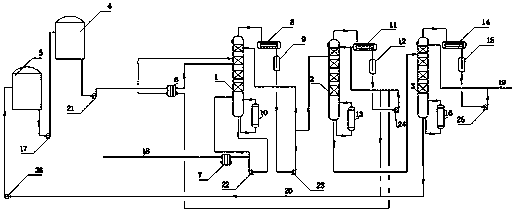

THF rectification equipment for PBT production

PendingCN110975316AHigh yieldTake advantage ofEnergy recuperation in distillationFractional distillationReboilerWastewater

The invention relates to THF rectification equipment for PBT production, which includes a first rectification column, a second rectification column, a third rectification column and a fourth rectification column. The first rectification column is connected to a THF wastewater device. A top outlet of the first rectification column is connected to the middle upper part of the second rectification column. A gas phase outlet of the second rectification column is connected to an auxiliary reboiler shell inlet of the third rectification column. An auxiliary reboiler shell outlet of the third rectification column is connected to a recovery liquid tank and the middle upper part of the fourth rectification column in order. A side-draw outlet of the fourth rectification column is connected to a reflux tank of the first column through a side-draw pump, and a bottom product of the fourth rectification column is combined with the product of the first rectification column and then conveyed to a sewage treatment system. The bottom of the second rectification column is connected to the third rectification column through a pipeline, a heavy component is discharged from the bottom of the third rectification column and a THF product is produced from the column top. The equipment can effectively improve the THF yield, reduce energy consumption and effectively save the operation cost.

Owner:查都(海南)科技有限公司

Sealed, Edible Film Packets and Methods of Making and Using Them

Owner:THE HERSHEY COMPANY

Itching-relieving liniment

InactiveCN105435033AAnti-inflammatorySolve the heatPharmaceutical delivery mechanismDermatological disorderPreservative freeSide effect

The invention discloses an itching-relieving liniment. The itching-relieving liniment is prepared from common cnidium fruits, radix sophorae flavescentis, radix stemonae, amur corktree bark and rhizoma atractylodis. All the Chinese herbs are taken at the same weight part and soaked with ethyl alcohol to prepare the itching-relieving liniment. The itching-relieving liniment is free of hormonal side effects, does not contain preservatives and has an ideal itching relieving effect.

Owner:管遵信 +1

Constant current source power supply circuit

ActiveCN104699158BSmall pressure dropSolve the heatElectric variable regulationLoad circuitPower flow

Owner:SHENZHEN COMEN MEDICAL INSTR

Modified glass fiber cloth, preparation method of modified glass fiber cloth, solid ammonia storage device and automobile

PendingCN113930962AHigh thermal conductivityImprove adhesionExhaust apparatusFibre treatmentGlass fiberAmmonia storage

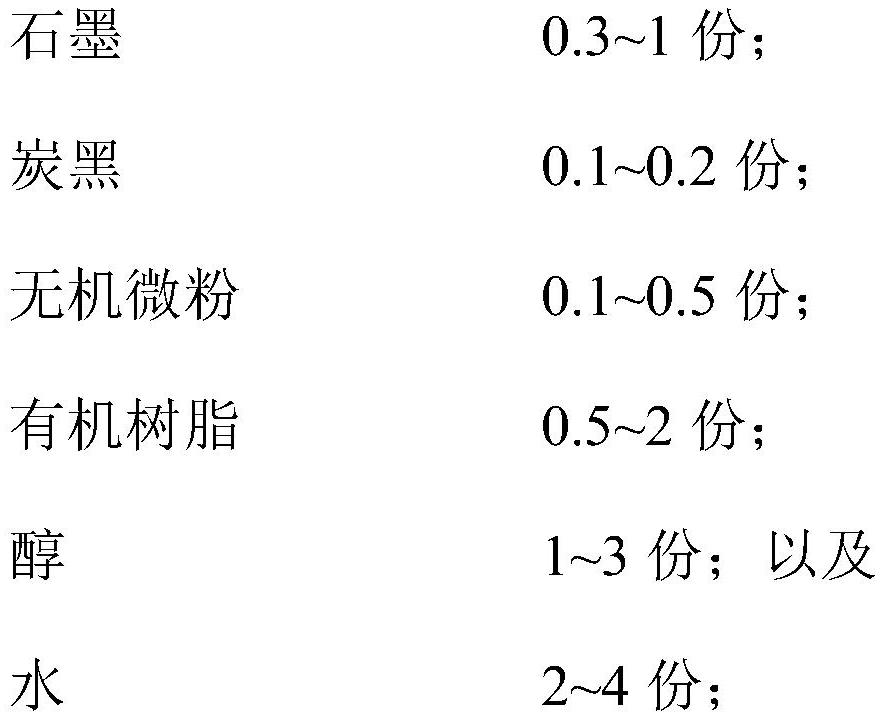

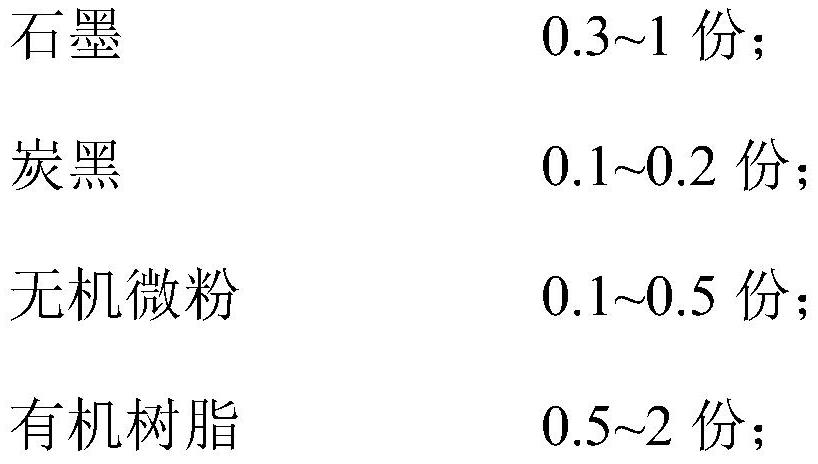

The invention relates to a preparation method of modified glass fiber cloth. The method comprises the following steps of placing glass fiber base cloth in a suspension liquid for dipping and pulling, and then carrying out heat treatment, wherein the suspension liquid is prepared from the following components in parts by mass of 0.3 to 1 part of graphite, 0.1 to 0.2 part of carbon black, 0.1 to 0.5 part of inorganic micro powder, 0.5 to 2 parts of organic resin, 1 to 3 parts of alcohol and 2 to 4 parts of water; the inorganic micro powder is selected from at least one of aluminum oxide micro powder and magnesium oxide micro powder; and the organic resin is phenolic resin. The modified glass fiber cloth prepared by the preparation method has better heat-conducting property.

Owner:FAW JIEFANG AUTOMOTIVE CO

Largngopharyngitis treating medicine composition and its prepn

InactiveCN1973871AExcellent clinical effectEffective in treating pharyngitisUnknown materialsRespiratory disorderAlcoholMedicine

The medicine composition for treating laryngopharyngitis is prepared with rehmannia root 5-100 weight portions, date coating 3-100 weight portions, and tortoise plastron 5-200 weight portions. The preparation process includes the steps of decoction, filtering, concentrating the filtrate to obtain paste of density 1.00-1.15, dissolving the paste in alcohol, filtering, concentrating the filtrate to obtain dense paste of density 1.20-1.50 while recovering alcohol, and drying to obtain the medicine composition. The medicine composition is used in treating laryngopharyngitis, and has high safety, low cost, high effective component content and high stability.

Owner:胡丹

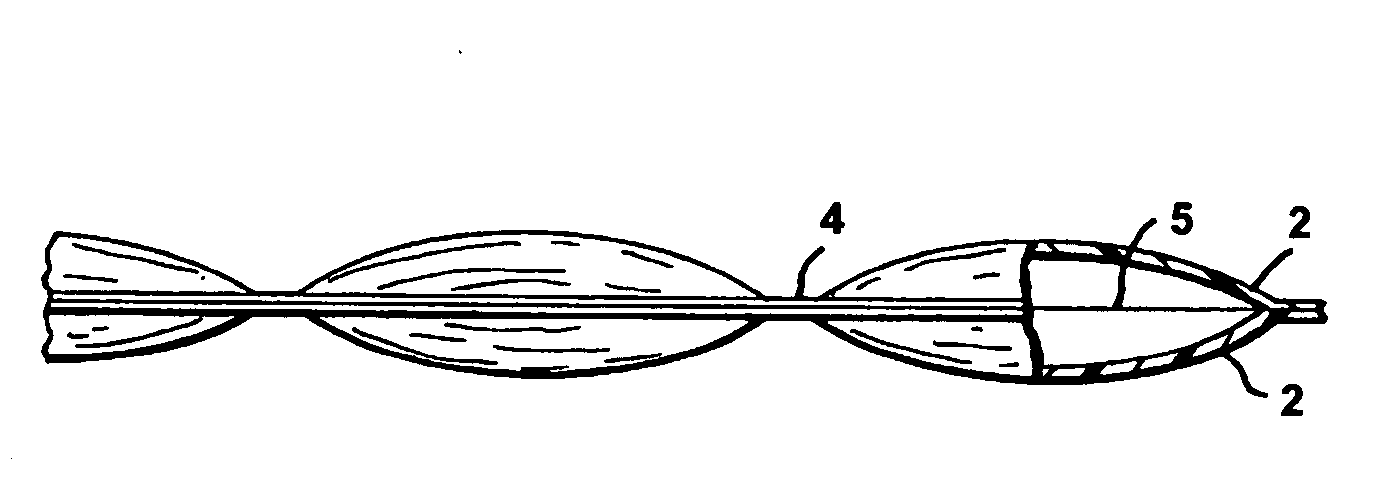

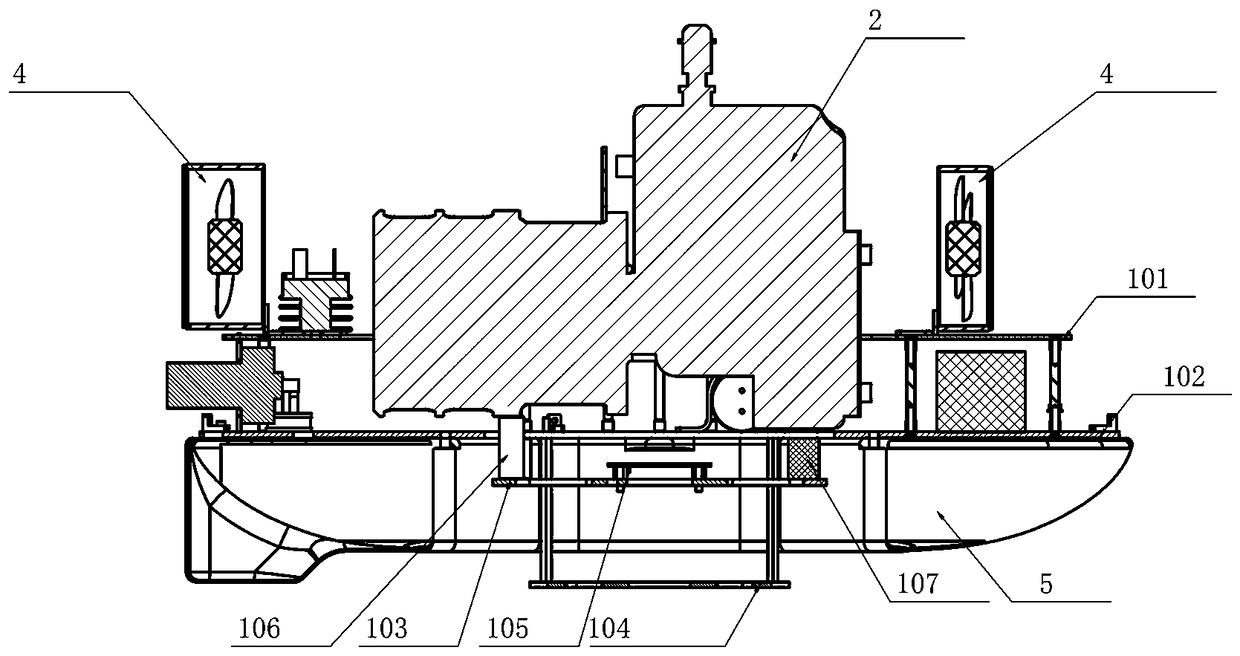

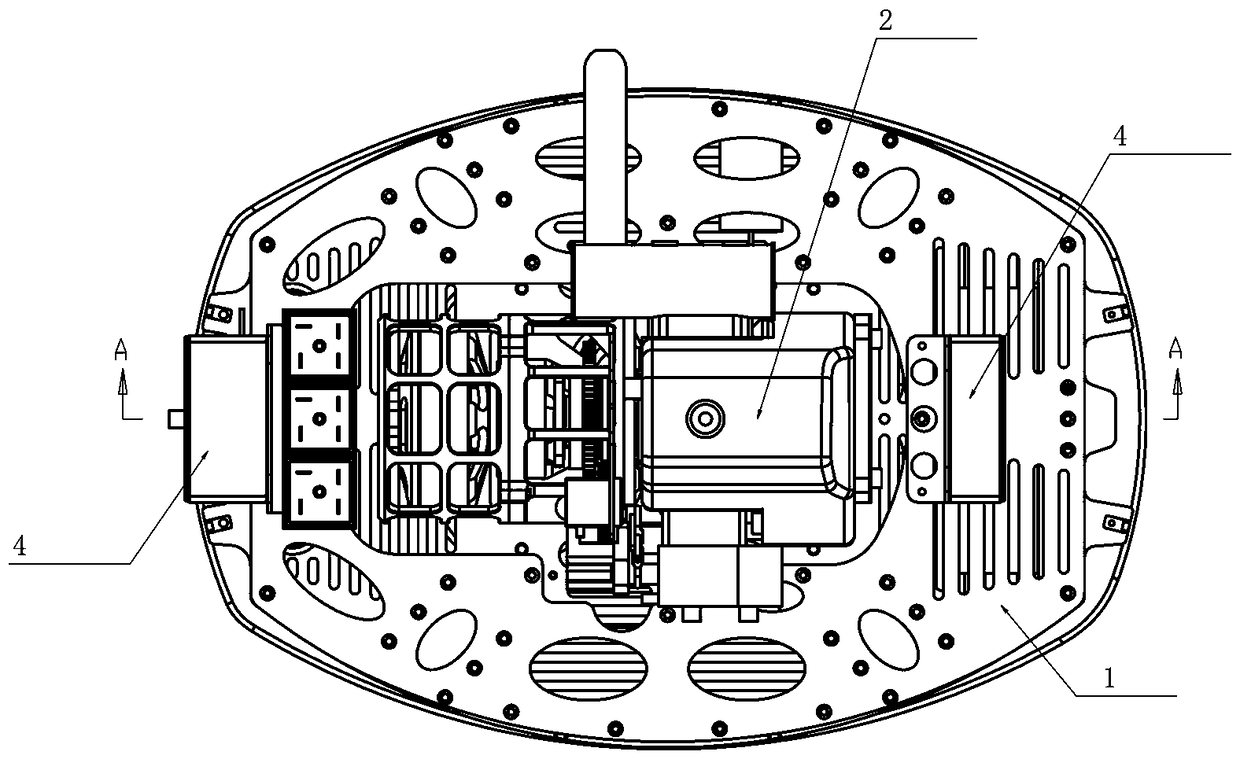

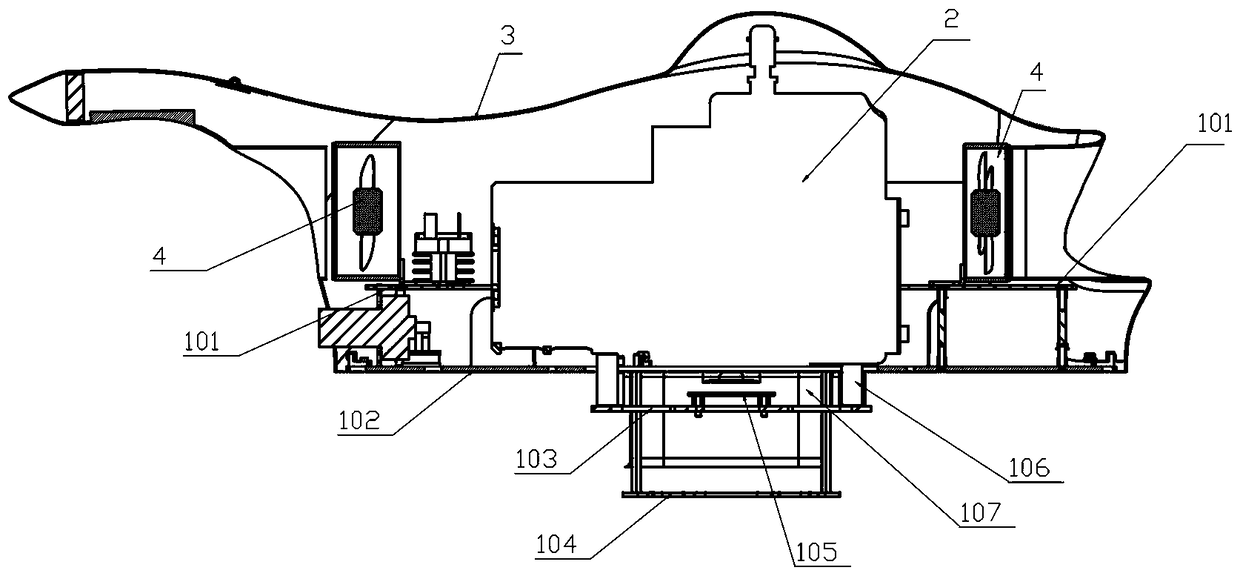

Rotor unmanned aerial vehicle

PendingCN108341064AGood aerodynamic shapeSolve the heatPower plant fuel tanksPower plant constructionUncrewed vehicleEngineering

The invention discloses a rotor unmanned aerial vehicle. The rotor unmanned aerial vehicle comprises an equipment platform and a power generation device; the equipment platform comprises an upper plate and a lower plate which are arranged in sequence from the top to bottom; the upper plate is connected with the lower plate through a connecting column; an opening is formed in the center of the upper plate; and the power generation device is placed in the opening. The rotor unmanned aerial vehicle has the advantages that larger loading capacity of the rotor unmanned aerial vehicle can be guaranteed, and meanwhile, the load balance of the rotor unmanned aerial vehicle can also be guaranteed, good vibration reducing performance and heat radiation performance of the rotor unmanned aerial vehicle can be guaranteed, and so on.

Owner:中科灵动航空科技成都有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com