Nickel-zinc-ferrite material used for high-frequency non-polar lamp power coupler and preparation method thereof

A power coupler, nickel-zinc ferrite technology, applied in discharge lamps, lighting devices, light sources, etc., can solve the problems of large heat generation and low efficiency of high-frequency induction lamp power couplers, achieve low electromagnetic loss, improve Effects of electromagnetic loss characteristics, good temperature stability characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

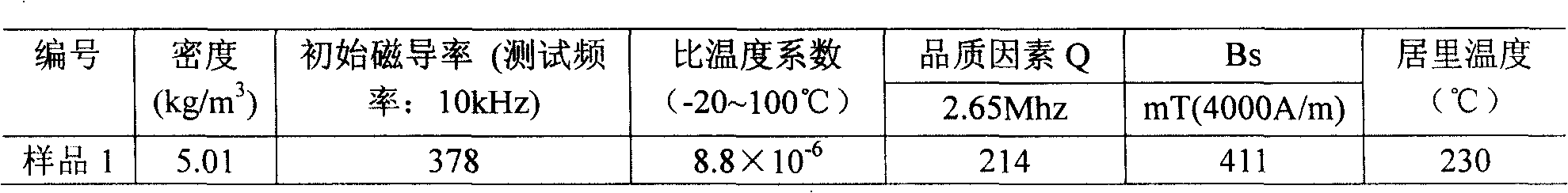

Embodiment 1

[0026] 1) Selection of raw materials: the nickel-zinc ferrite material used in the high-frequency electrodeless lamp power coupler provided in this embodiment, the main composition is selected from industrially pure Fe 2 o 3 , ZnO, CuO, NiO and CoO.

[0027] 2) Composition design and weighing: according to Fe 2 o 3 49 mol%, ZnO 23 mol%, CuO 2.5 mol%, NiO 25 mol%, and CoO 0.5 mol%.

[0028]3) Mixing of raw materials: Put the weighed raw materials into a sand mill, add deionized water, the weight of deionized water is 1.2 times of the total weight of raw materials, and the ball milling time is 3 hours.

[0029] 4) Pre-burning: Dry the raw materials that have been ball-milled once, and put them into an electric furnace for pre-burning. The pre-burning temperature is 950°C, and the pre-burning time is 1.5 hours. After pre-burning, it is cooled with the furnace. After pre-burning, XRD phase analysis was carried out on the pre-fired material, and it was confirmed that only spine...

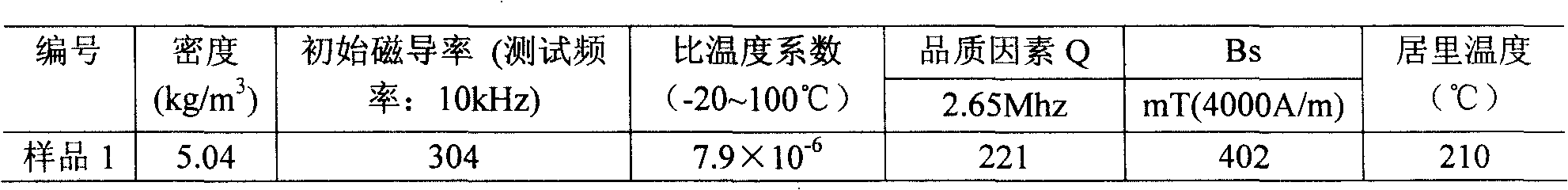

Embodiment 2

[0037] 1) Selection of raw materials: a kind of nickel-zinc ferrite material used for high-frequency electrodeless lamp power coupler provided by the present invention, the main composition selects industrially pure Fe 2 o 3 , ZnO, CuO, NiO and CoO.

[0038] 2) Composition design and weighing: according to Fe 2 o 3 49 mol%, ZnO 31 mol%, CuO 4.8 mol%, NiO 14 mol%, and CoO 1.2 mol%.

[0039] 3) Mixing of raw materials: Put the weighed raw materials into a sand mill, add deionized water, the weight of deionized water is 1.2 times of the total weight of raw materials, and the ball milling time is 1.5 hours.

[0040] 4) Pre-burning: Dry the raw materials that have been ball-milled once, and put them into an electric furnace for pre-burning. The pre-burning temperature is 950°C, and the pre-burning time is 1.5 hours. After pre-burning, it is cooled with the furnace. After pre-burning, XRD phase analysis was carried out on the pre-fired material, and it was confirmed that only sp...

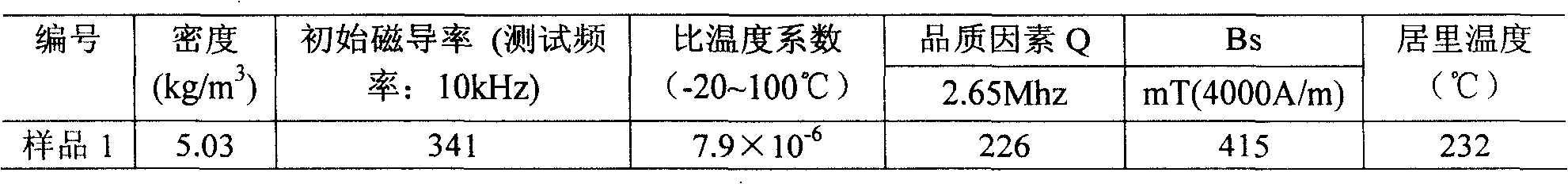

Embodiment 3

[0048] 1) Selection of raw materials: a kind of nickel-zinc ferrite material used for high-frequency electrodeless lamp power coupler provided by the present invention, the main composition selects industrially pure Fe 2 o 3 , ZnO, CuO, NiO and CoO.

[0049] 2) Composition design and weighing: according to Fe 2 o 3 45 mol%, ZnO 27 mol%, CuO 4 mol%, NiO 23 mol%, and CoO 1.0 mol%.

[0050] 3) Mixing of raw materials: Put the weighed raw materials into a sand mill, add deionized water, the weight of deionized water is 1.2 times of the total weight of raw materials, and the ball milling time is 3 hours.

[0051] 4) Pre-burning: Dry the raw materials that have been ball-milled once, and put them into an electric furnace for pre-burning. The pre-burning temperature is 800°C, and the pre-burning time is 3.5 hours. After pre-burning, it is cooled with the furnace. After pre-burning, XRD phase analysis was carried out on the pre-fired material, and it was confirmed that only spinel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Saturation flux density | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com