Patents

Literature

246 results about "Nickel zinc" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc Nickel Plating. Zinc-Nickel electroplating is an acid coating that is used in the protection of steel, cast iron, malleable iron, copper, and brass. Zinc-Nickel is recognized as an environmentally safe alternative to cadmium electroplating.

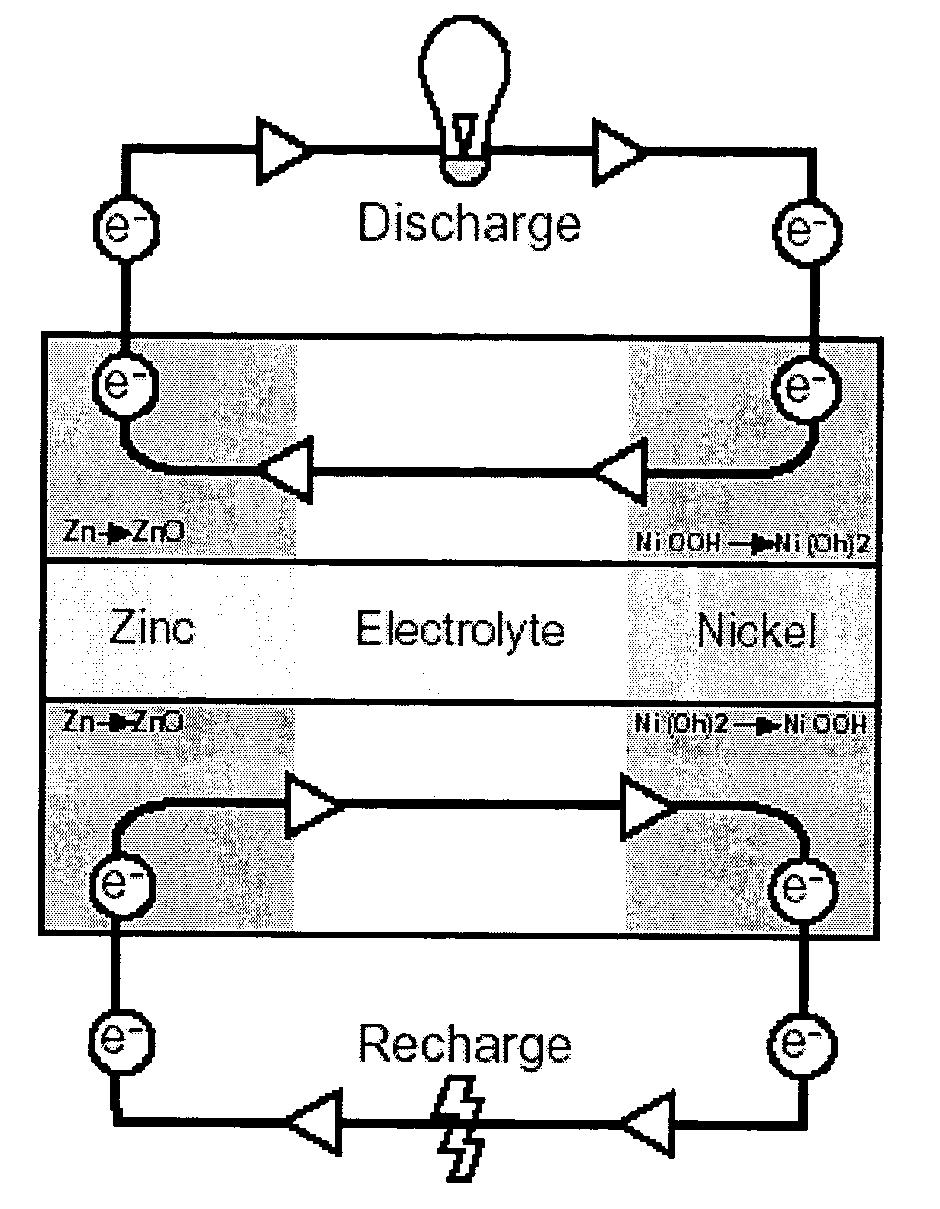

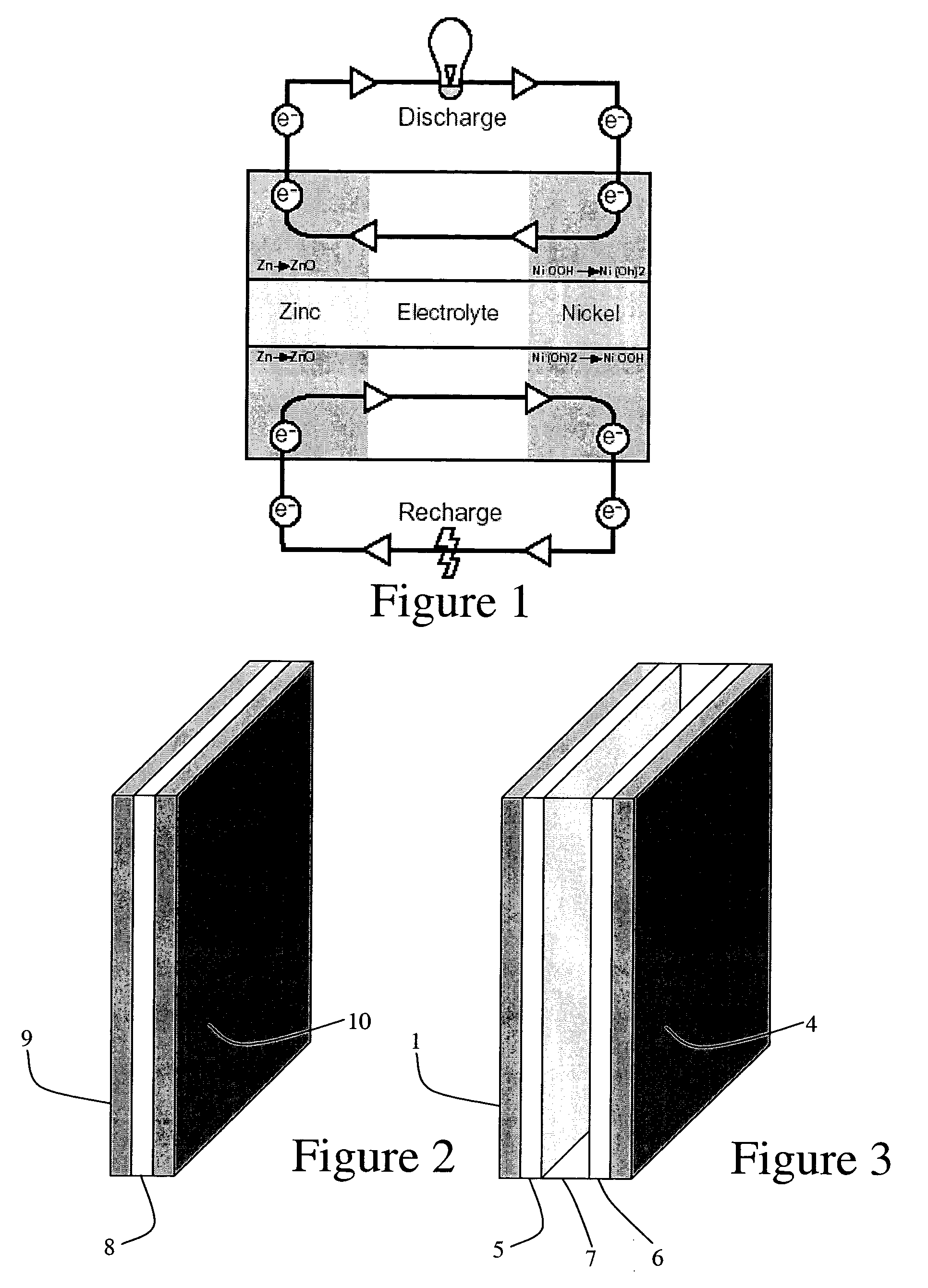

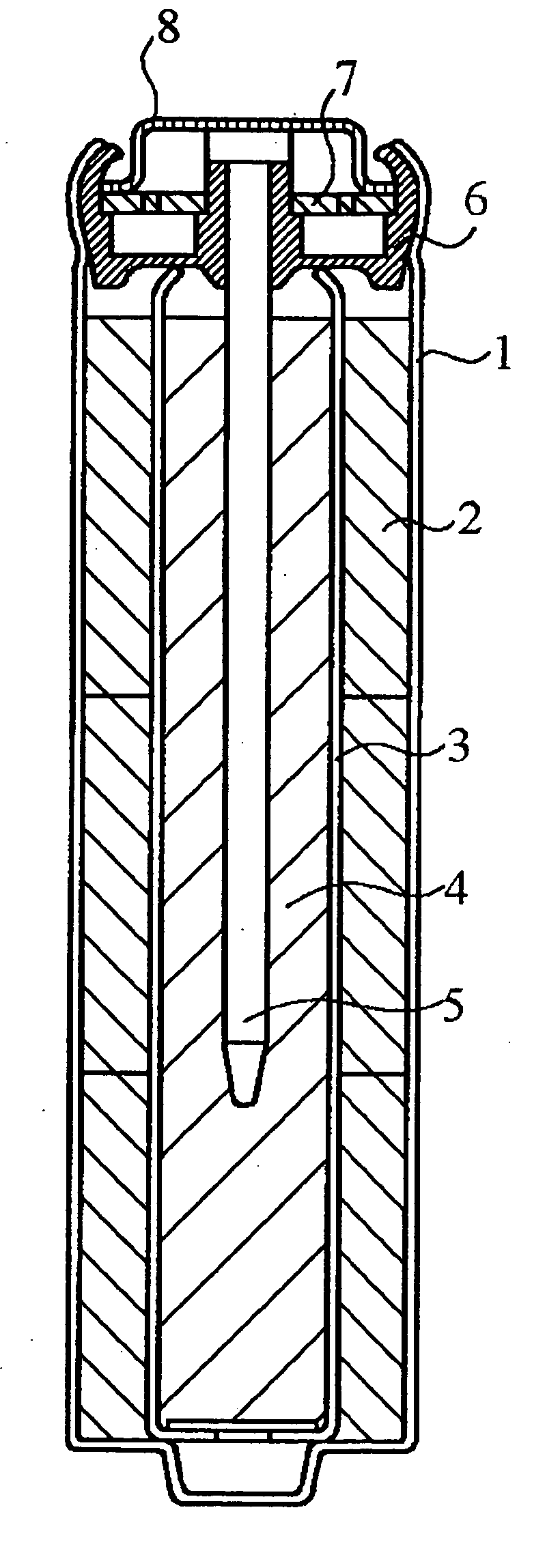

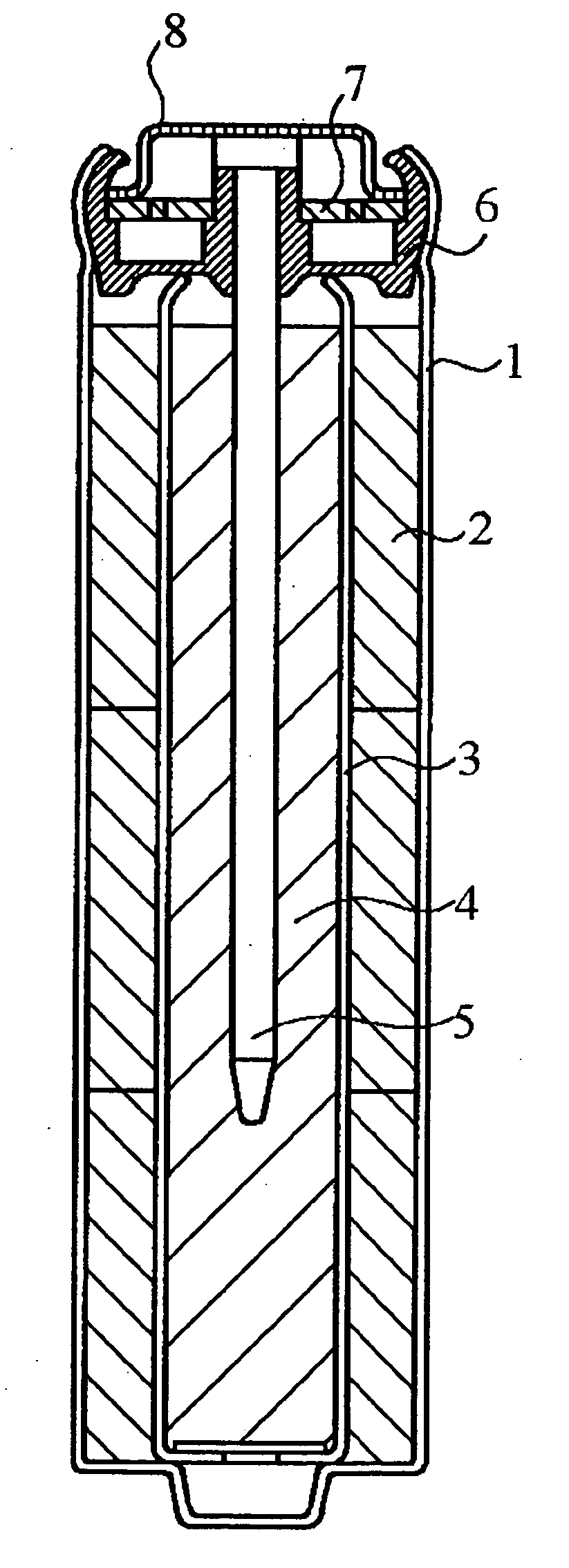

Nickel zinc battery design

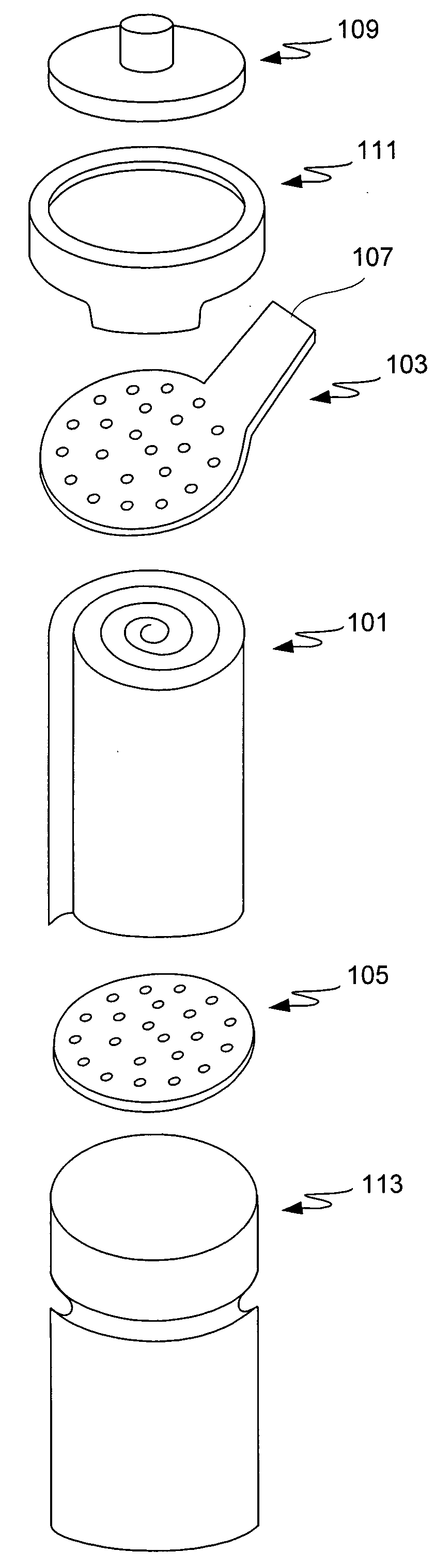

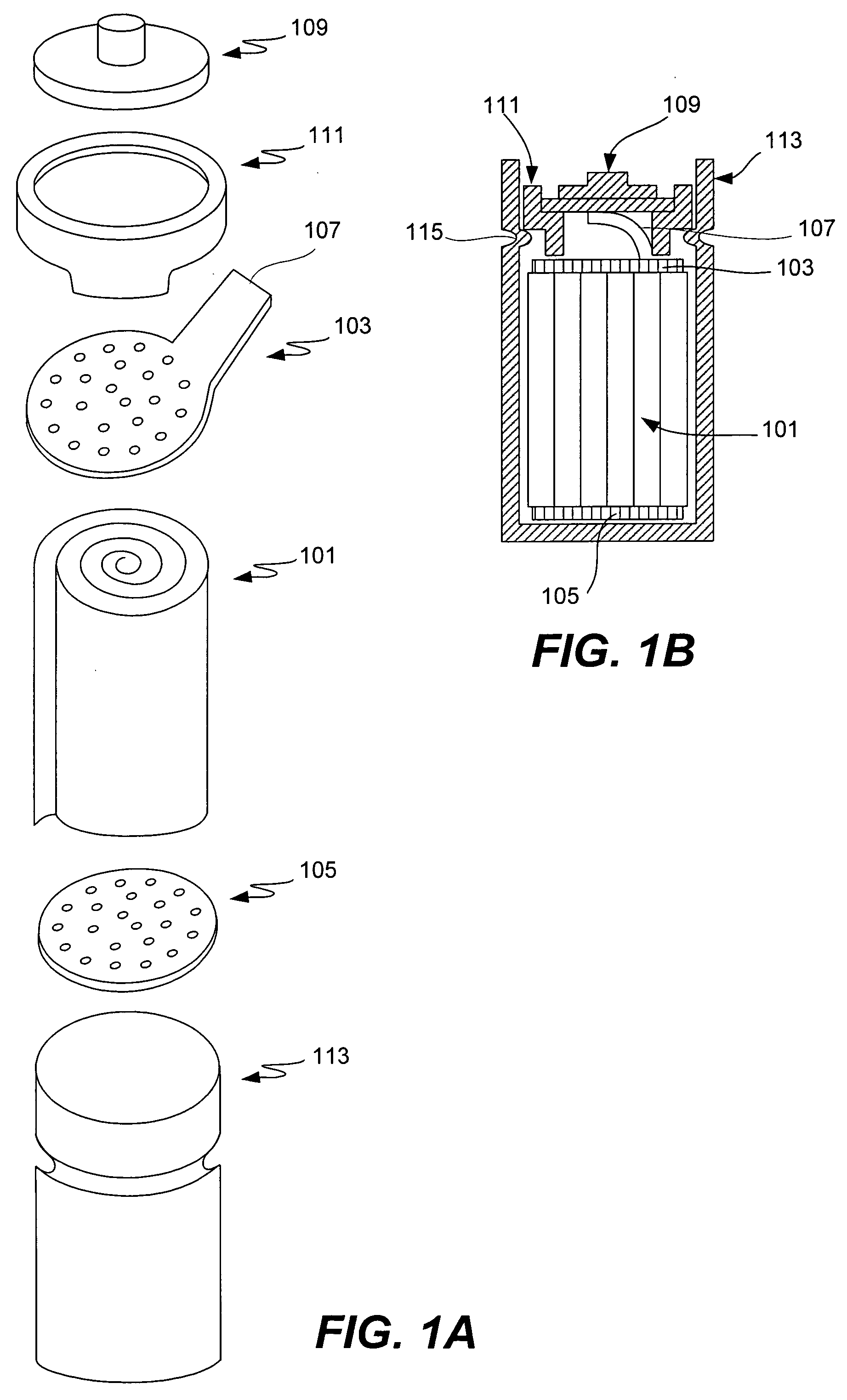

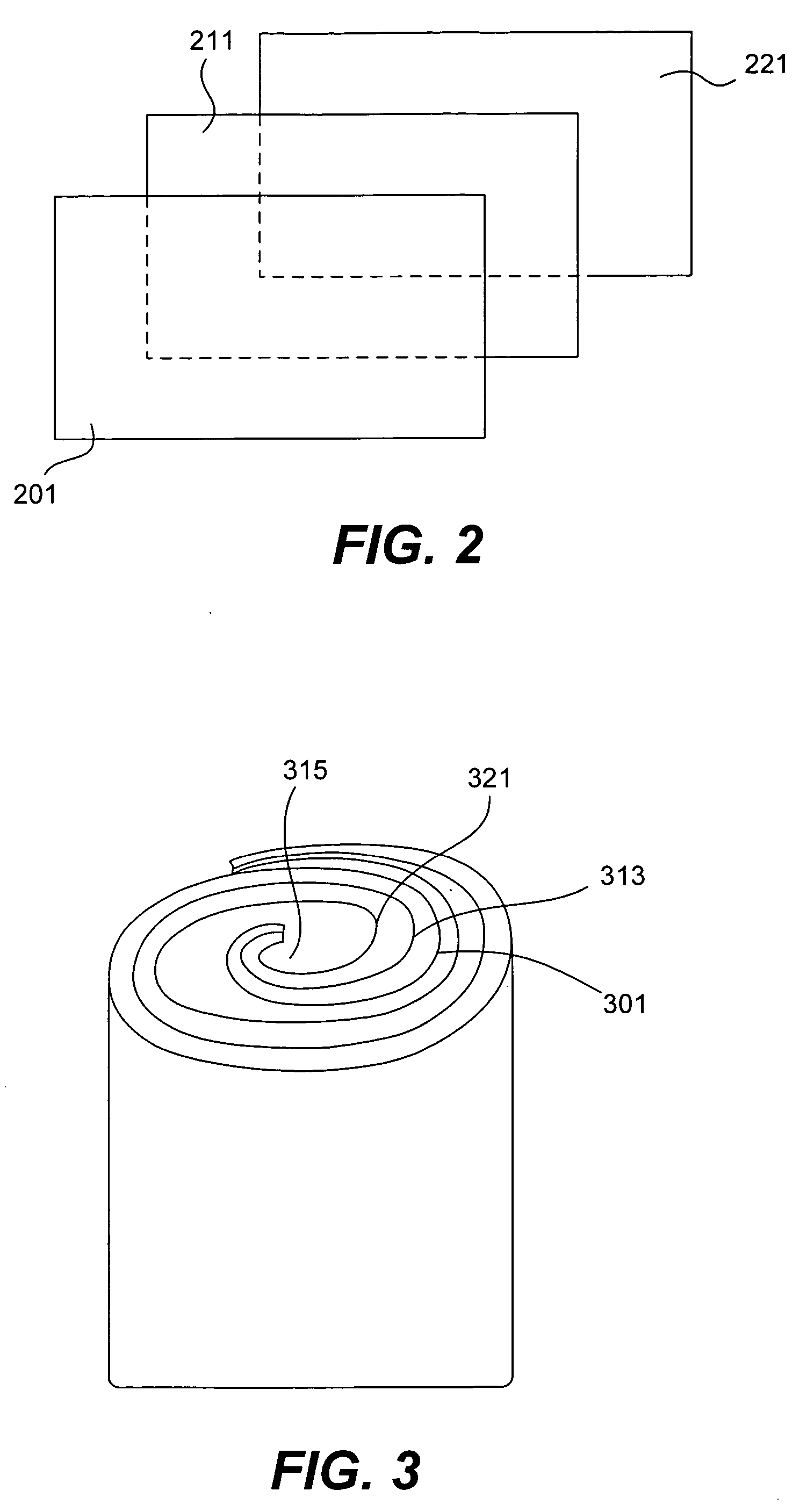

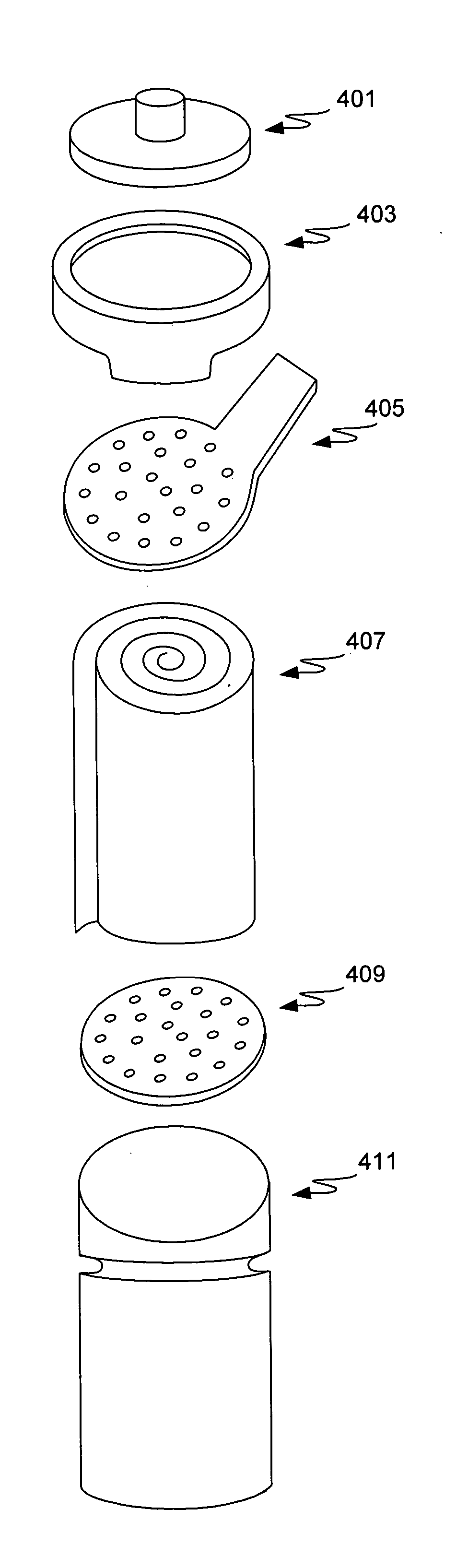

ActiveUS20060240317A1Resist buildupLower impedanceElectrode carriers/collectorsCell component detailsHydrogenElectrical polarity

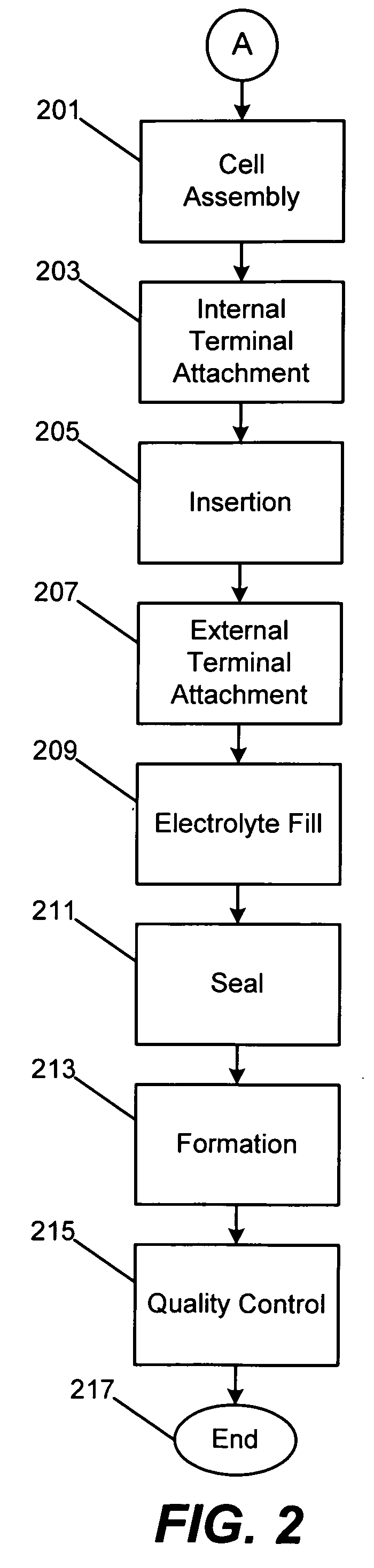

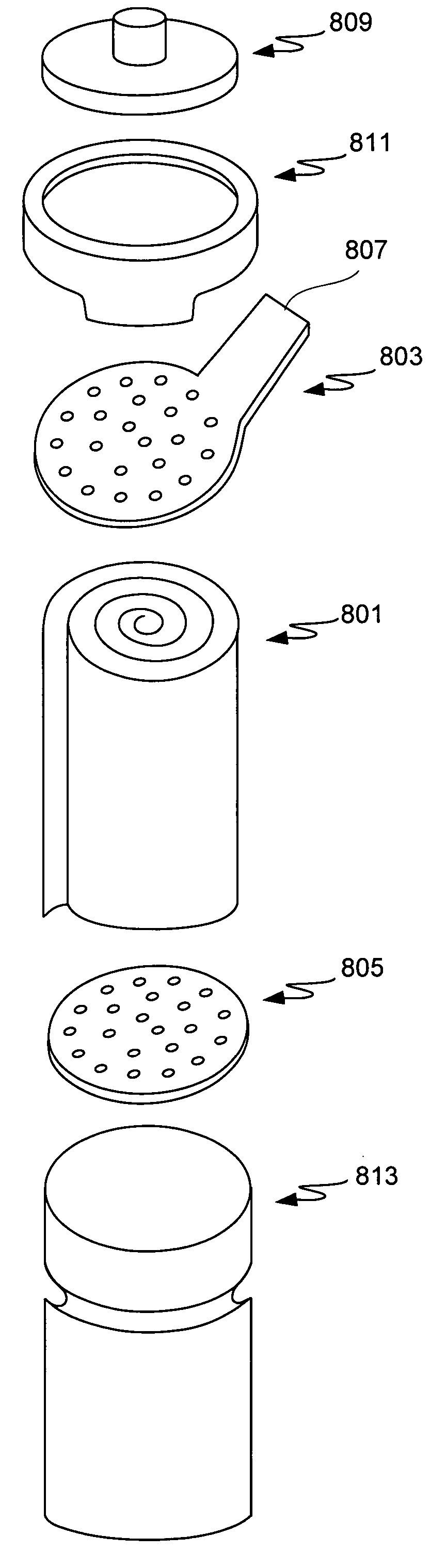

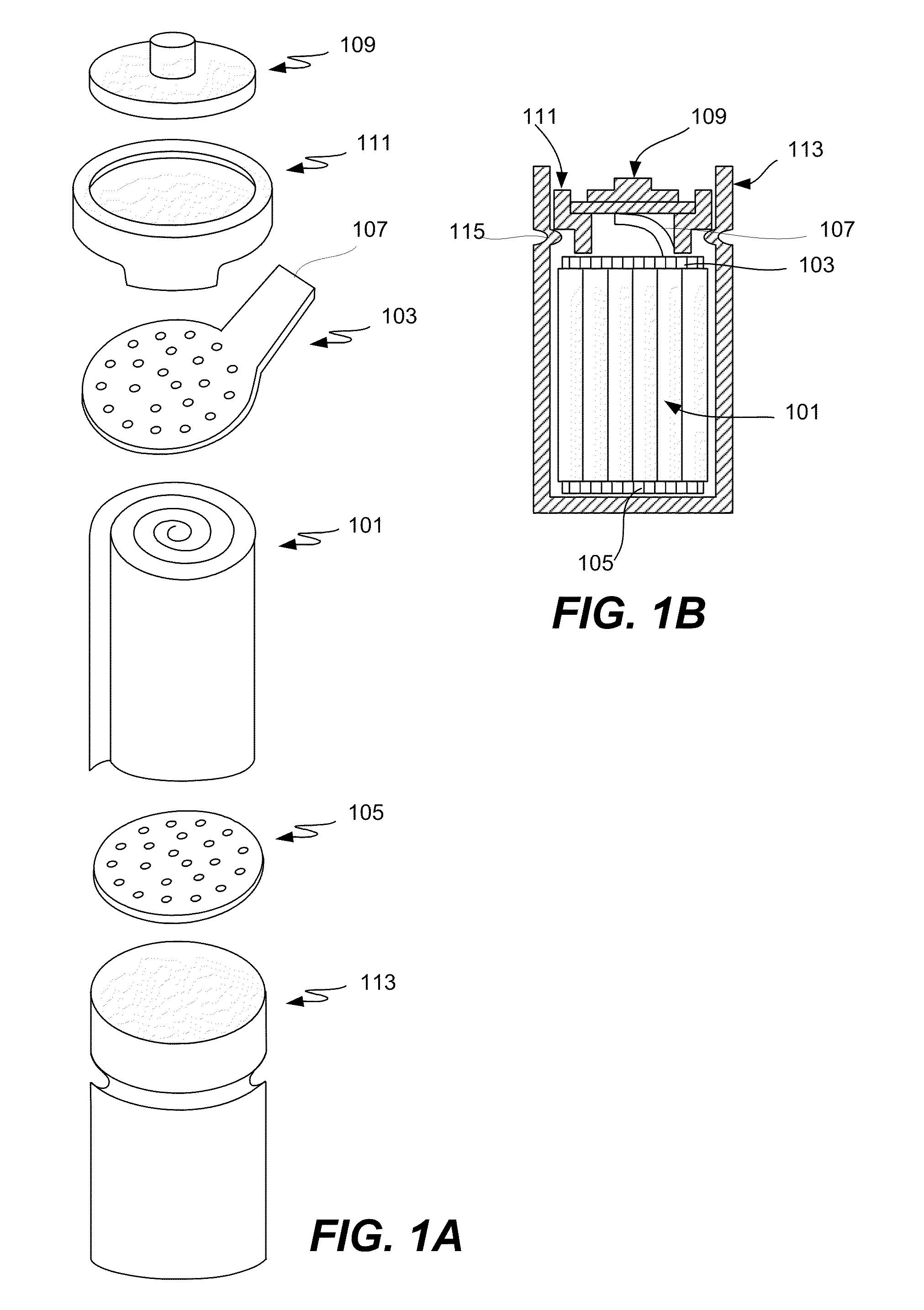

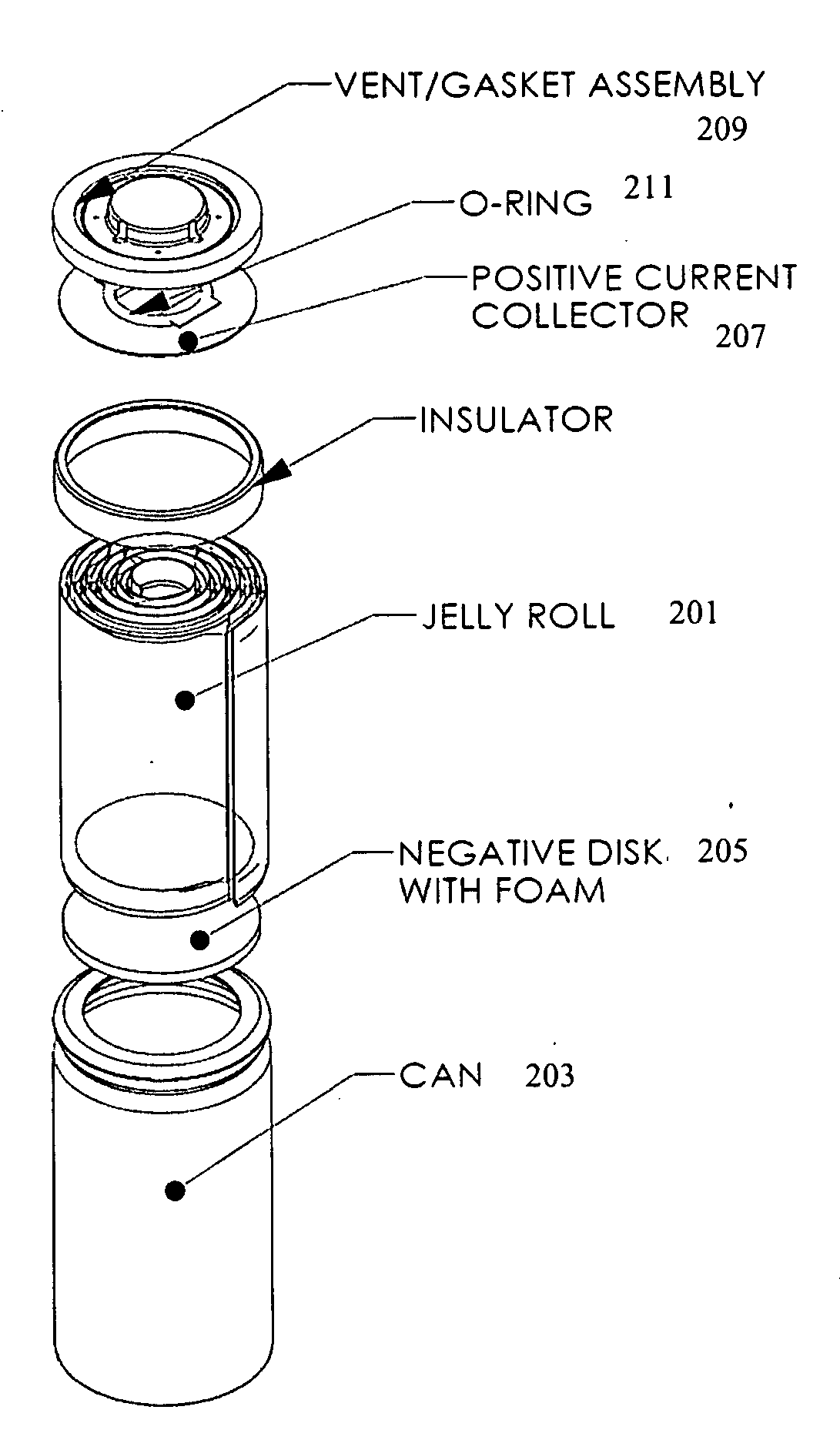

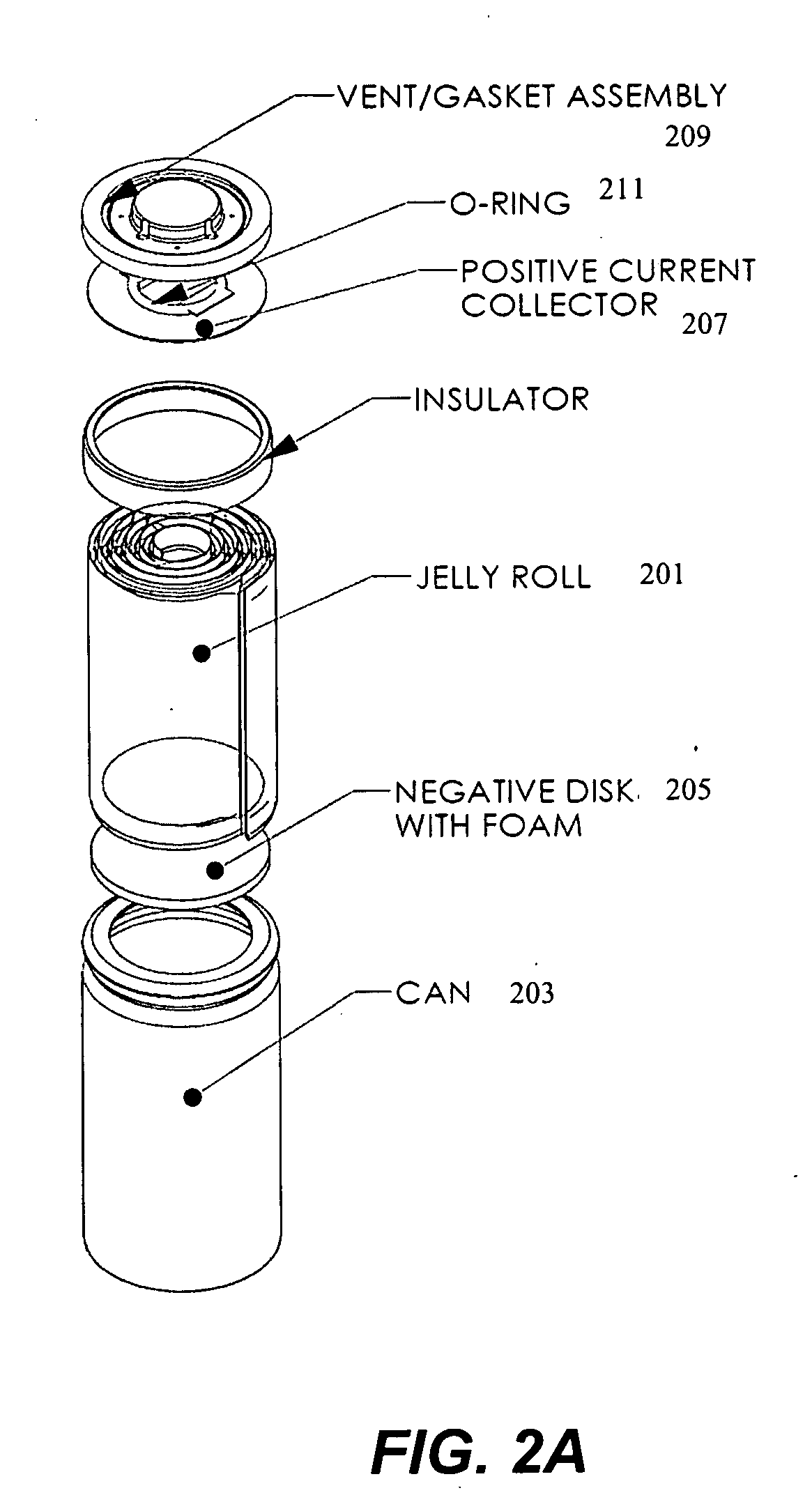

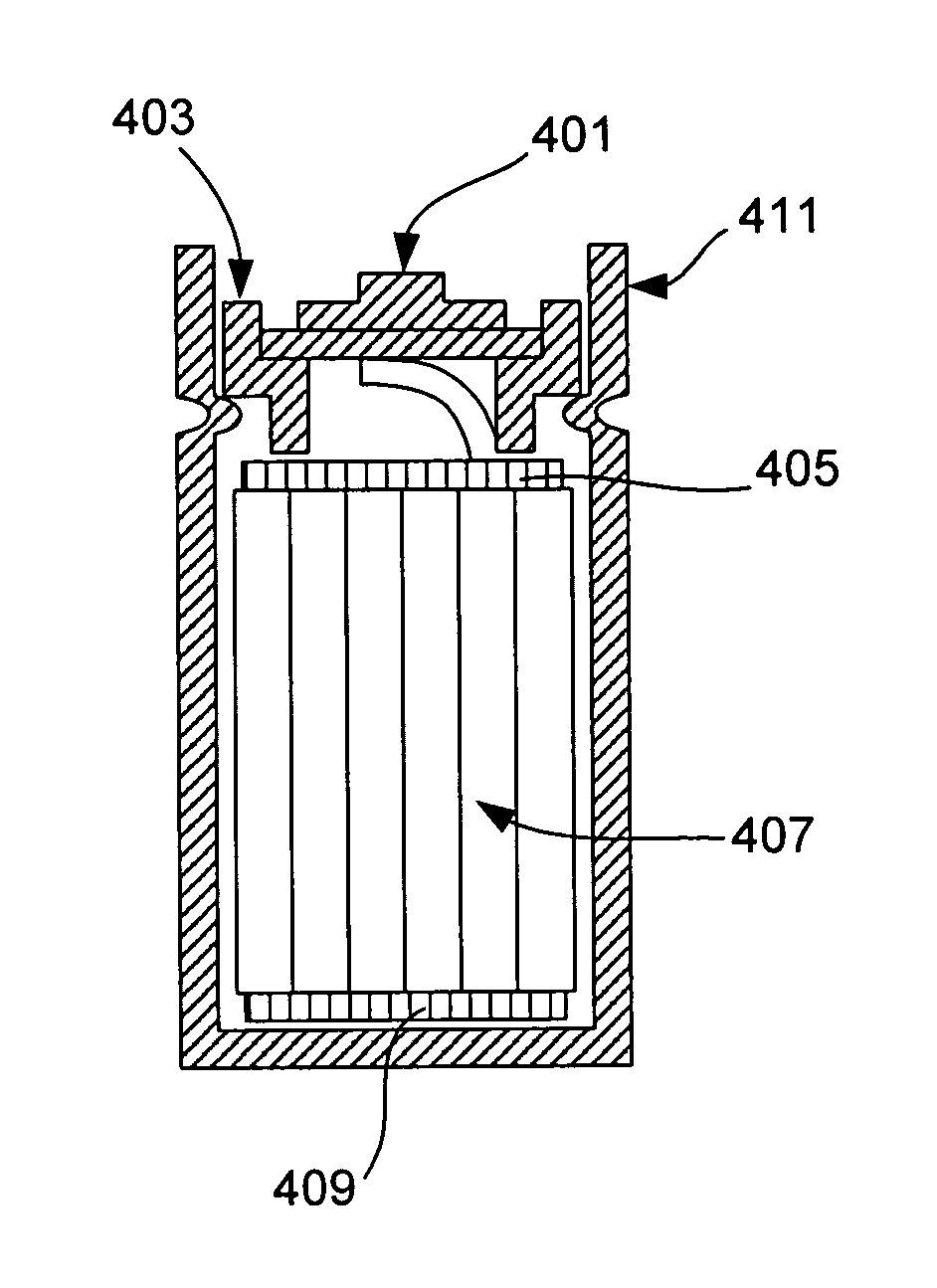

Nickel zinc cylindrical battery cell designs are described. The designs provided limit dendrite formation and prevent build up of hydrogen gas in the cell. The present invention also provides low-impedance cells required by rapid discharge applications. The cylindrical battery cells may have polarity opposite of that of conventional power cells, with a negative cap and positive can. The cylindrical cells may include a gel electrolyte reservoir.

Owner:ZINCFIVE POWER INC

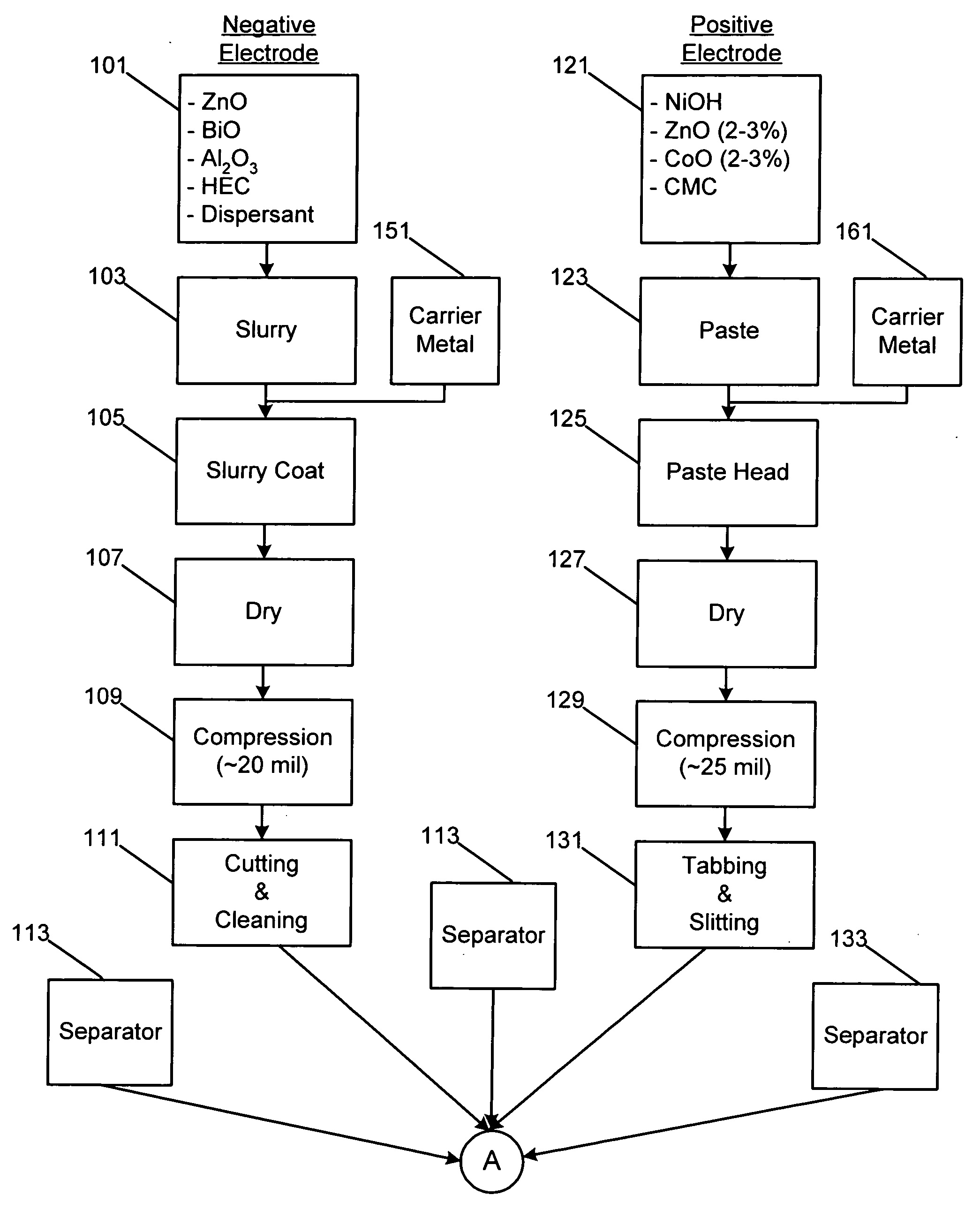

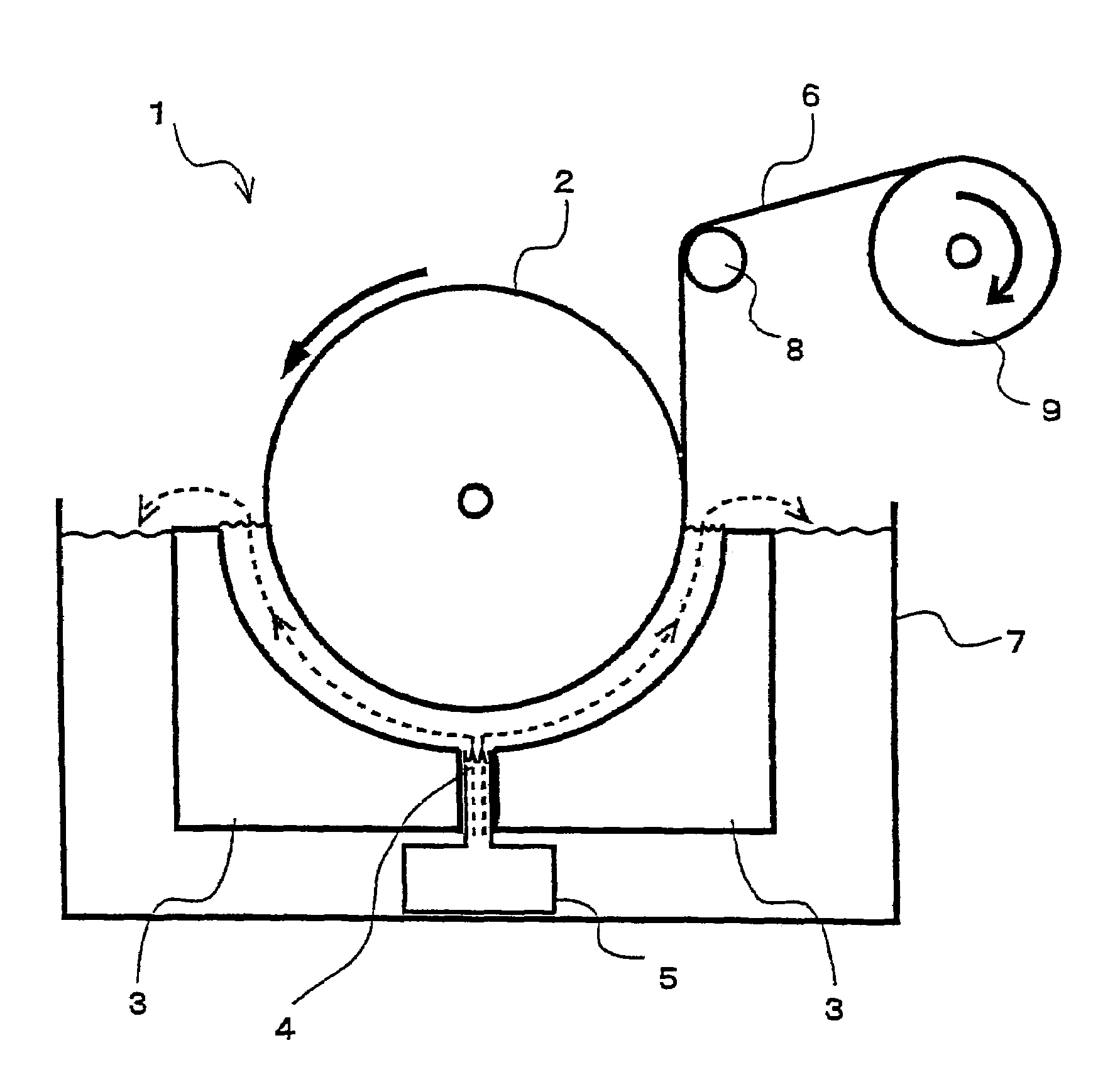

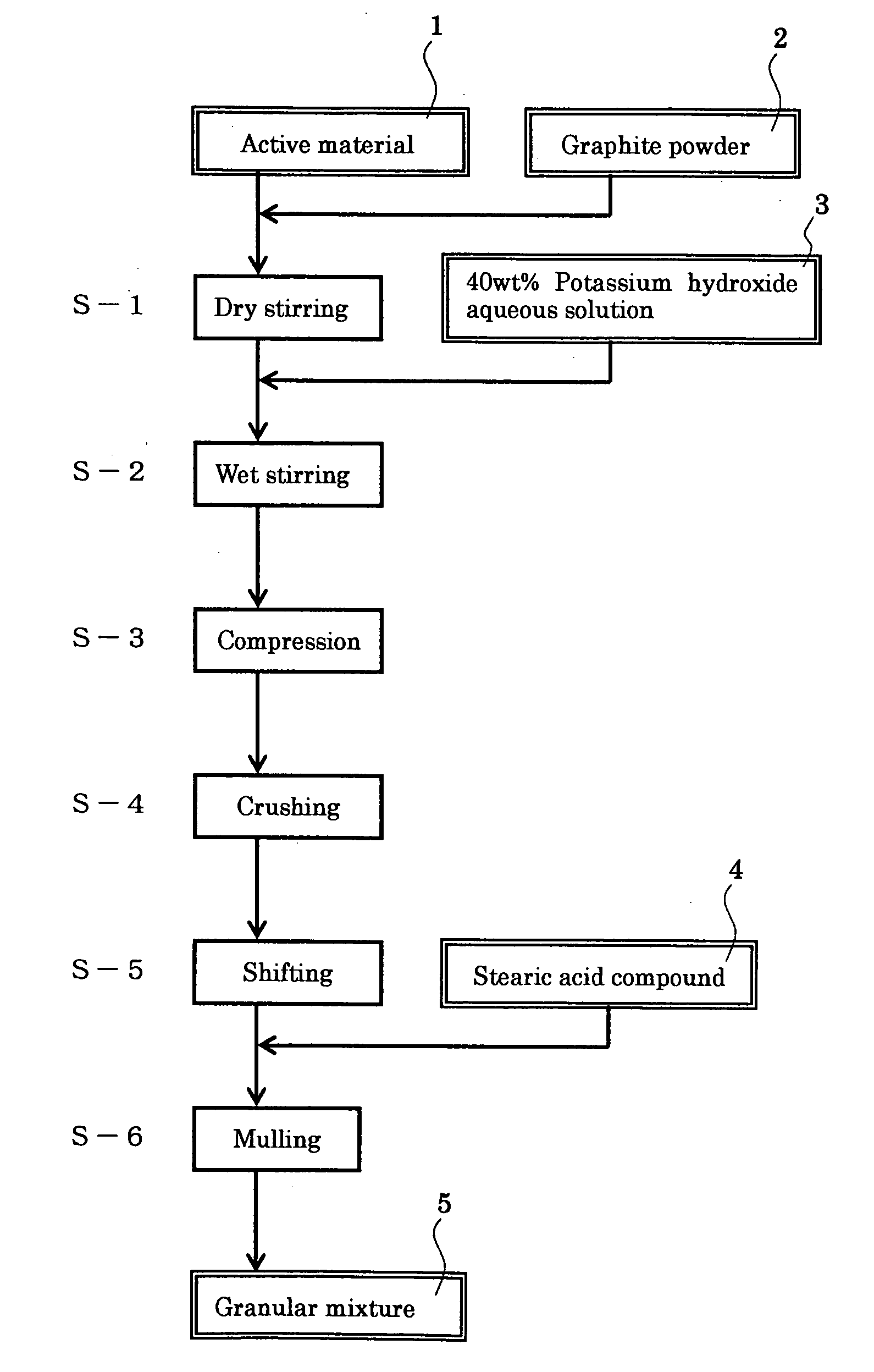

Method of manufacturing nickel zinc batteries

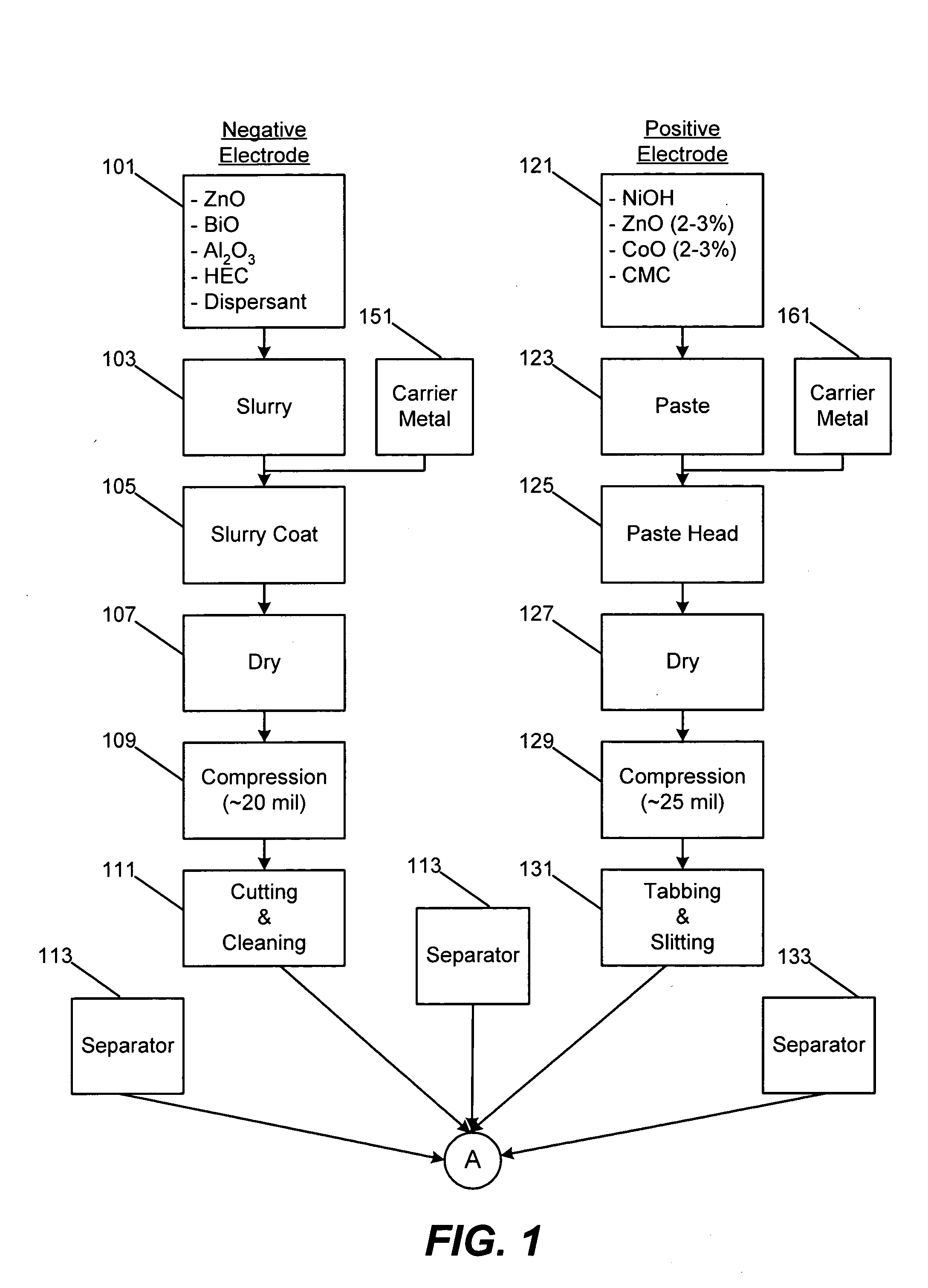

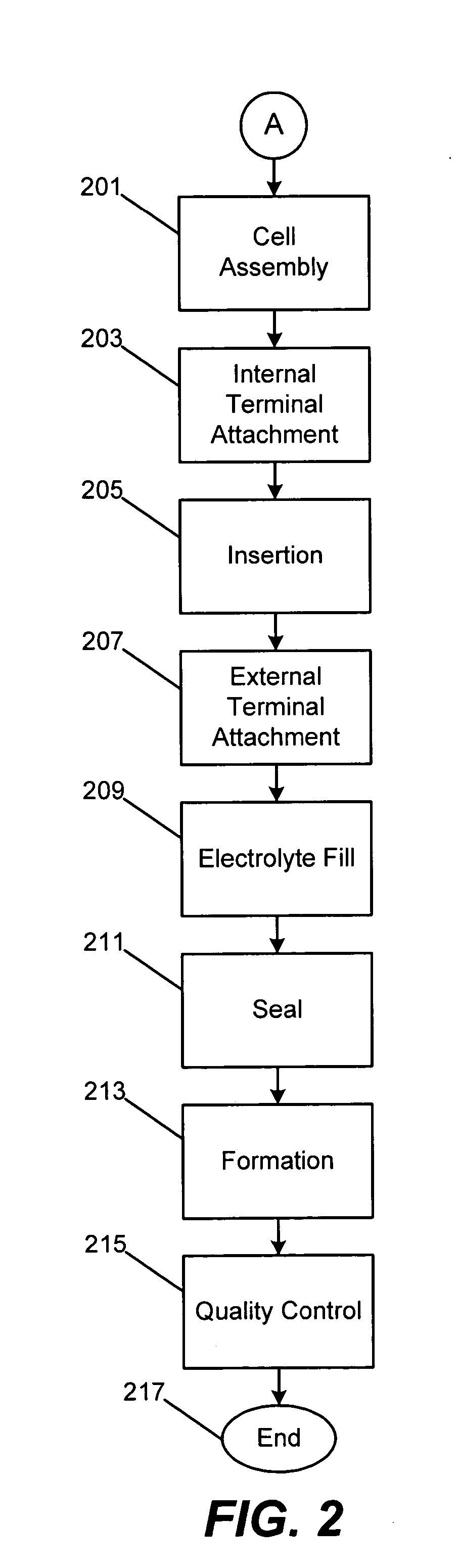

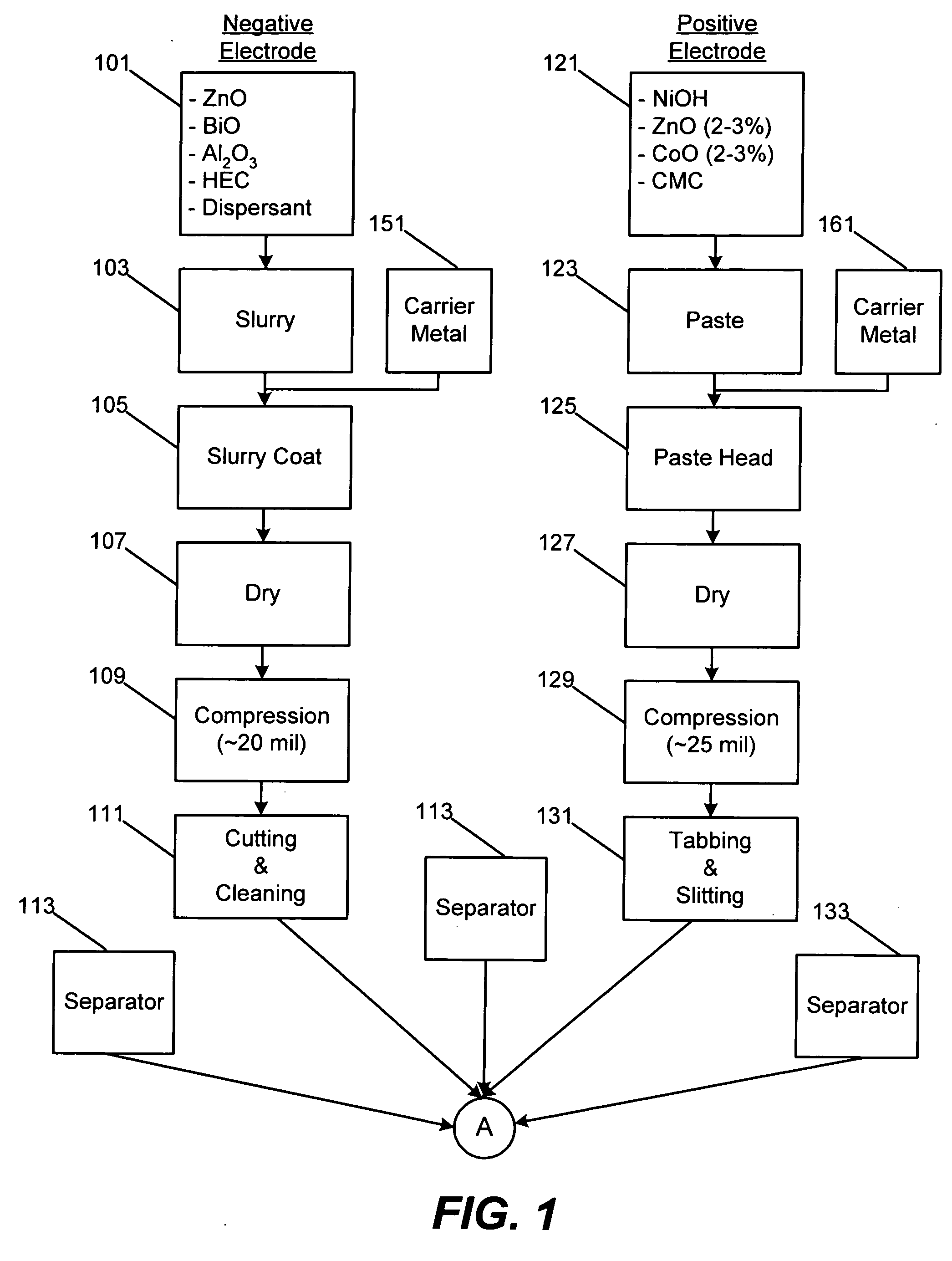

ActiveUS20050064292A1Improve efficiencyFinal product manufactureElectrode carriers/collectorsZinc compoundsSlurry

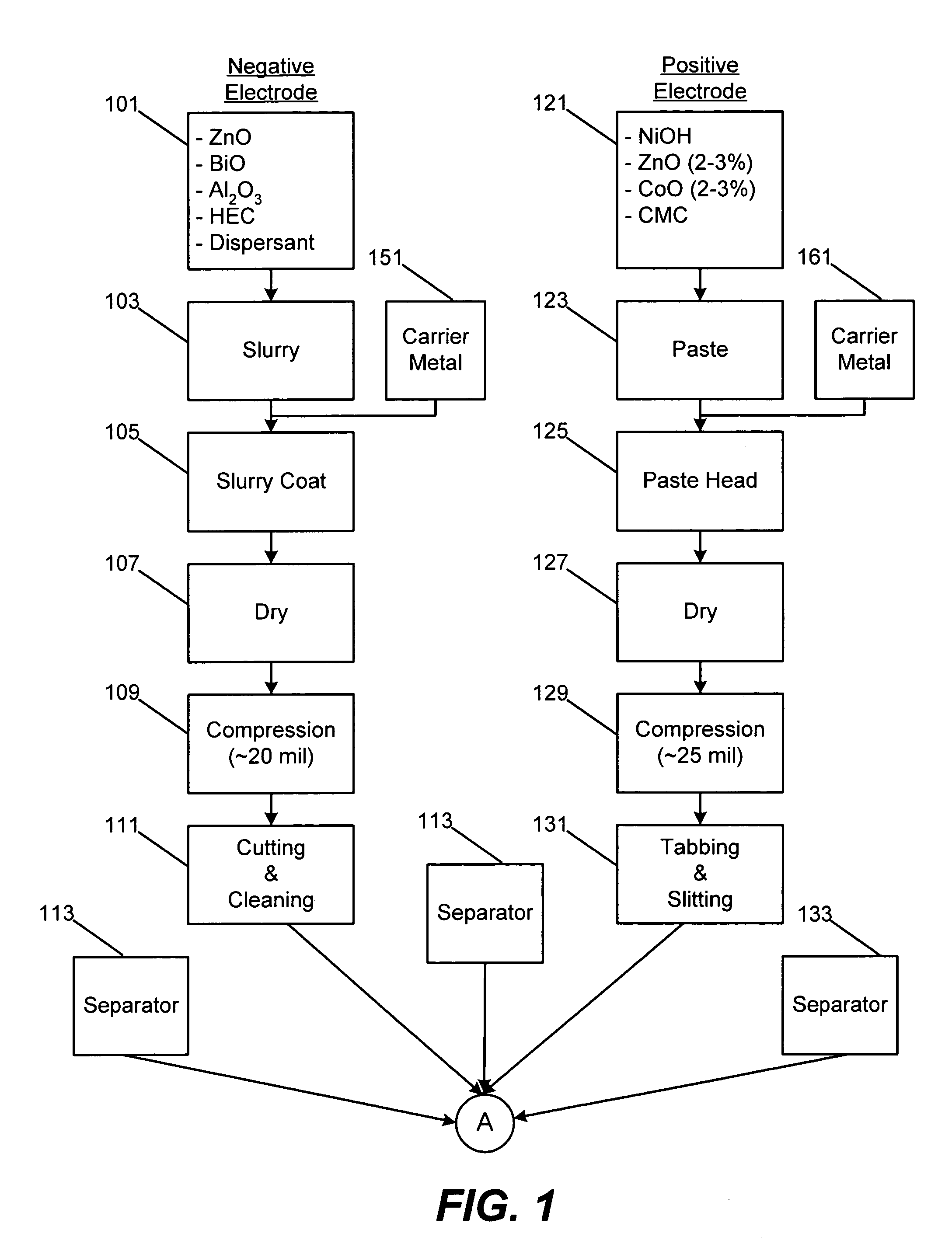

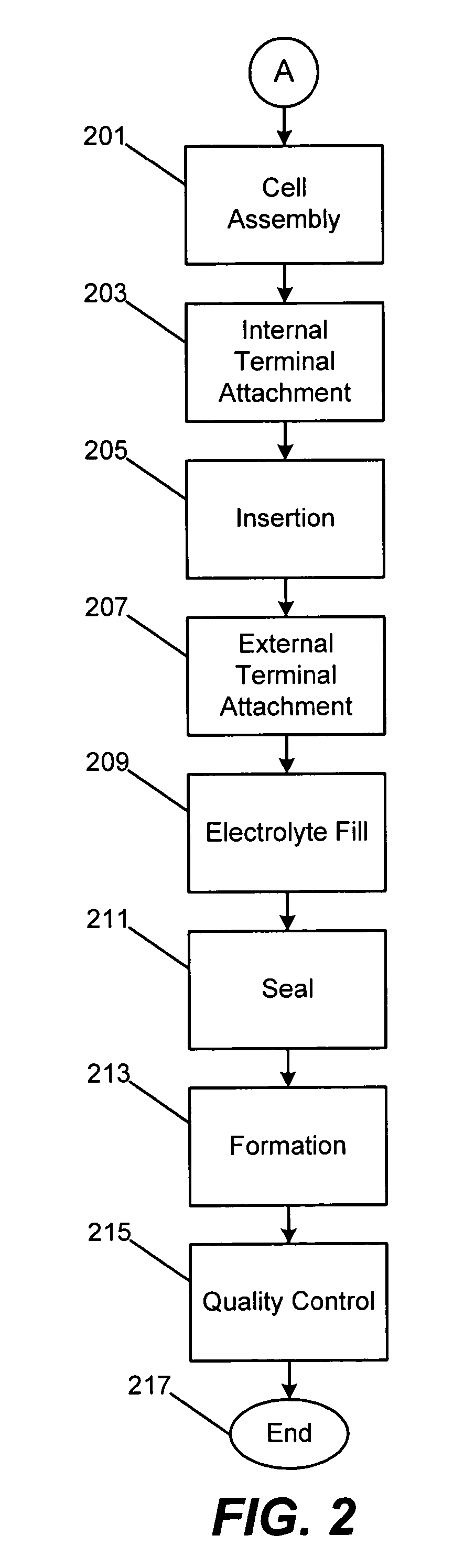

Methods of manufacturing a rechargeable power cell are described. Methods include providing a slurry or paste of negative electrode materials having low toxicity and including dispersants to prevent the agglomeration of particles that may adversely affect the performance of power cells. The methods utilize semi-permeable sheets to separate the electrodes and minimize formation of dendrites; and further provide electrode specific electrolyte to achieve efficient electrochemistry and to further discourage dendritic growth in the cell. The negative electrode materials may be comprised of zinc and zinc compounds. Zinc and zinc compounds are notably less toxic than the cadmium used in NiCad batteries. The described methods may utilize some production techniques employed in existing NiCad production lines. Thus, the methods described will find particular use in an already well-defined and mature manufacturing base.

Owner:ZINCFIVE POWER INC

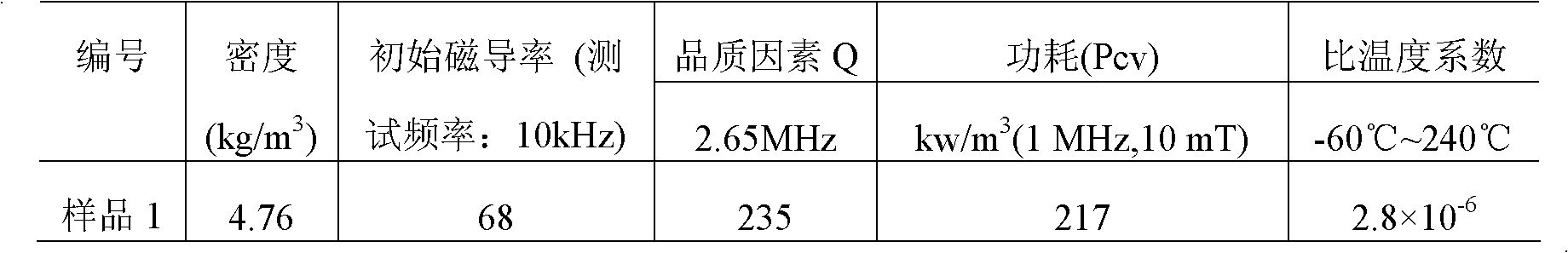

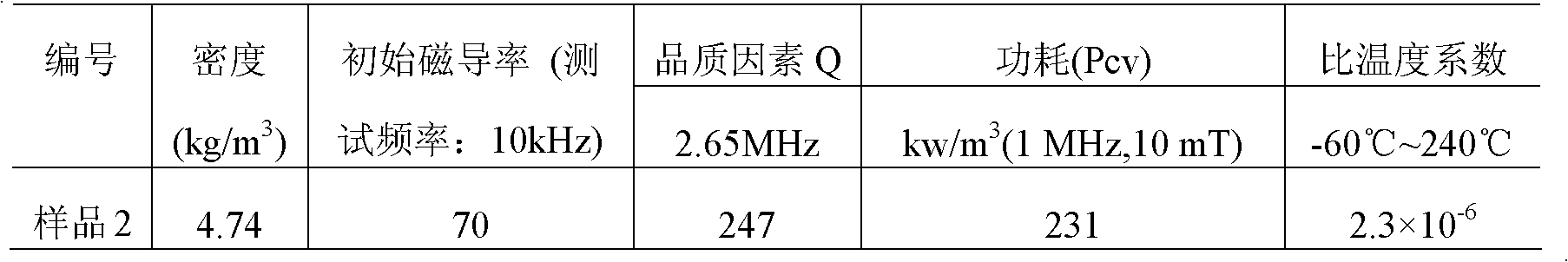

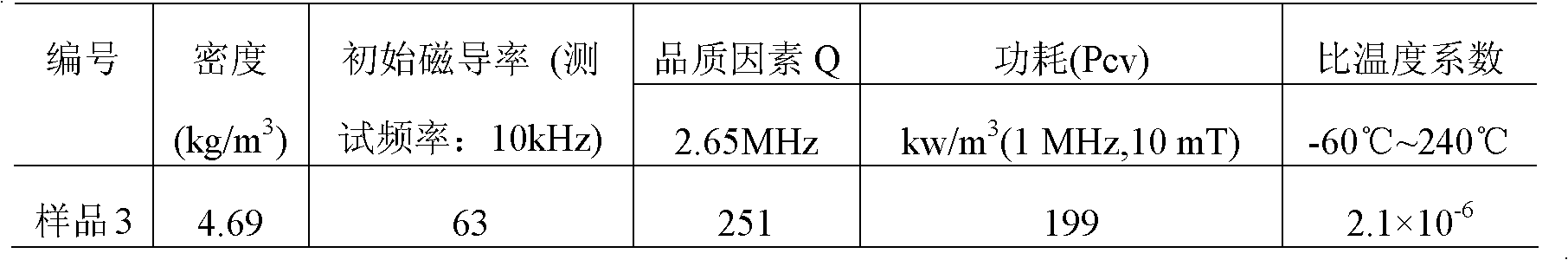

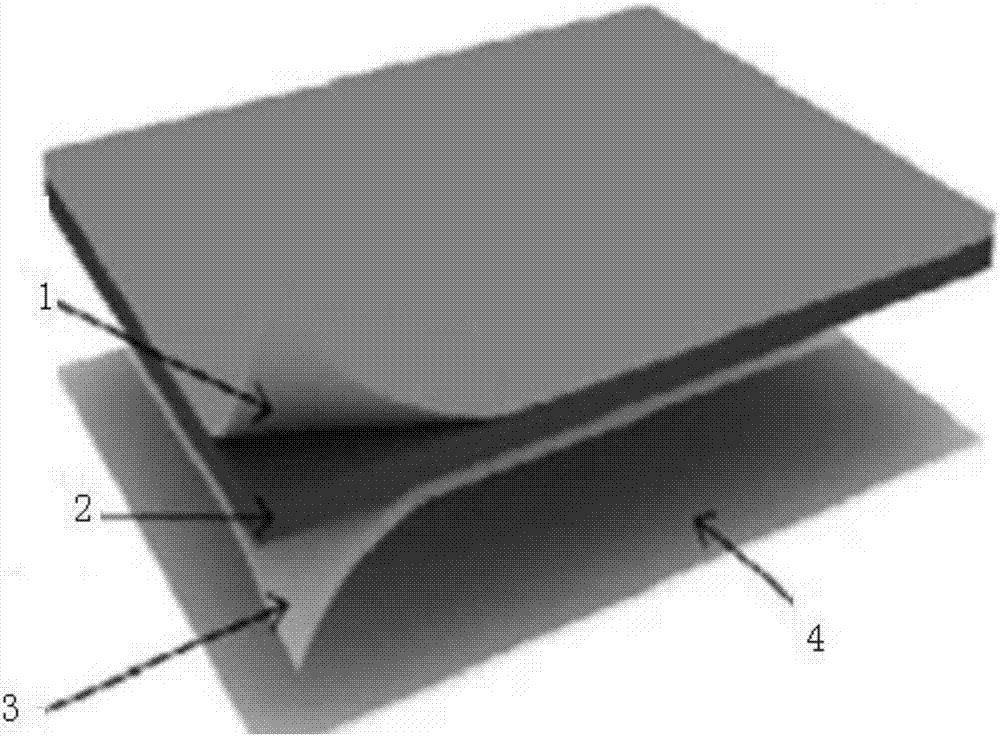

Nickel-zinc soft magnet ferrite material, inductor product and its producing method

InactiveCN1750182AIncrease inductanceImprove qualityInorganic material magnetismInductances/transformers/magnets manufactureSoft magnetInductor

This invention discloses a Ni-Zn soft magnetic ferrite material including a master composition: Fe2O3, NiO, CuO and ZnO, a first auxiliary composition: CO2O3 and / or MnO2, there is no oxide added with pb and Ge. This invention also discloses an inductor product with said material and a manufacturing method.

Owner:广东风华高新科技集团有限公司

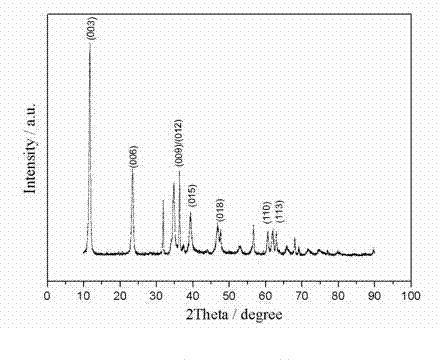

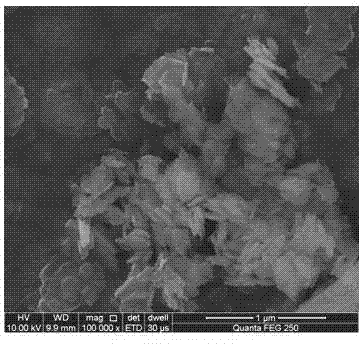

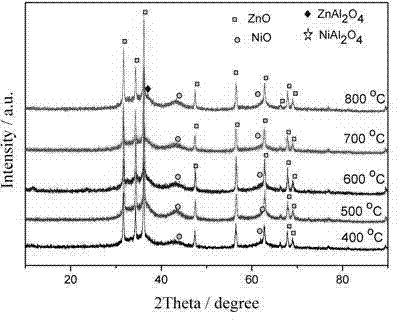

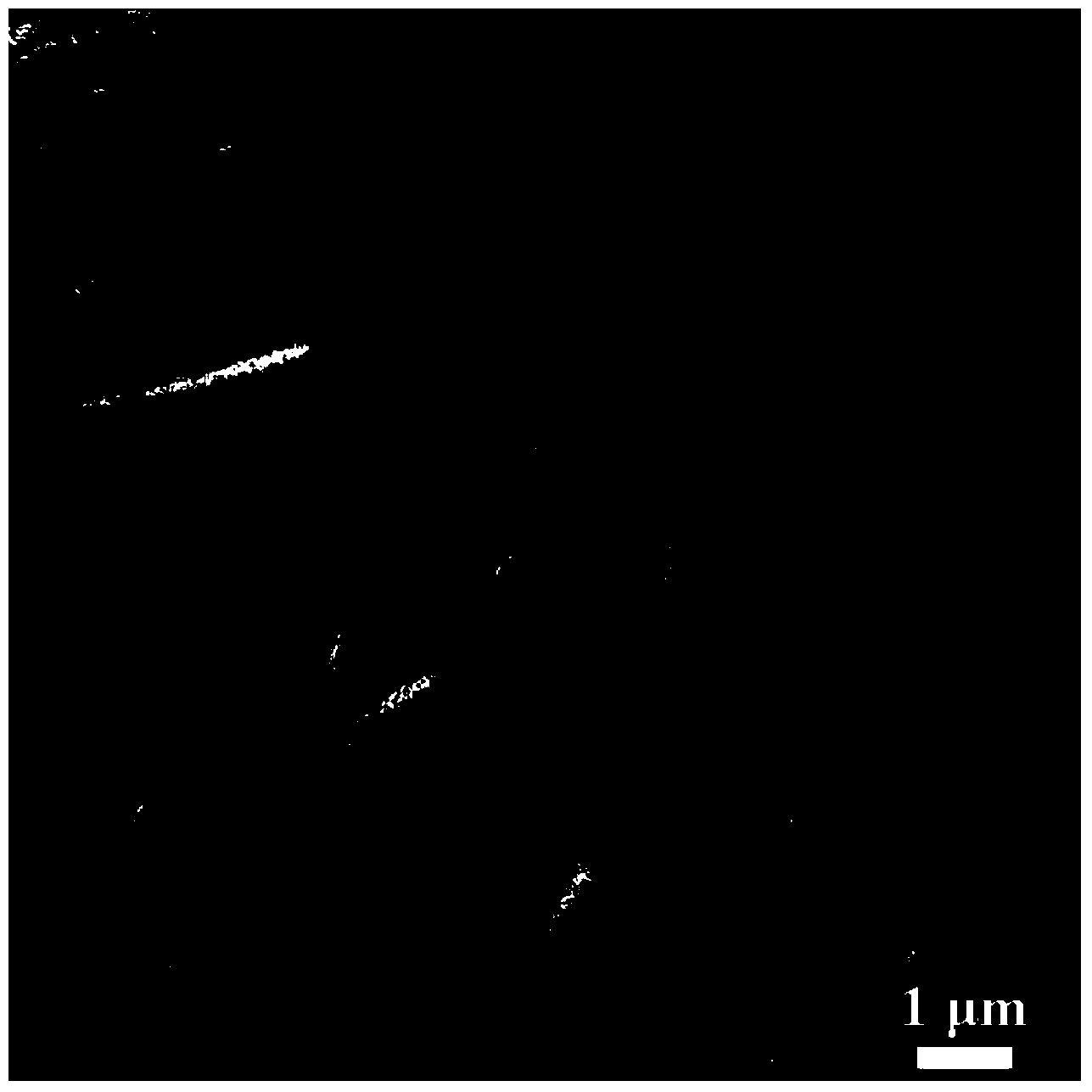

Preparation method for photocatalytic material with strong adsorption and high visible light degradation of performance

The invention discloses a gahnitem, zinc oxide and nickel zinc nano-composite photocatalytic material which has a high specific surface area and a mesoporous structure and is prepared by roasting at high temperature by taking ternary hydrotalcite as a precursor. The material is used for the adsorption and the degradation of organic pollutants. The photocatalytic material is prepared by taking zinc nitrate, nickel nitrate, aluminum nitrate, sodium carbonate, sodium hydroxide and the like as raw materials; preparing the raw materials into salt solutions and alkali solutions respectively; mixing the solutions by using a constant-flow pump at the temperature of 80 DEGC with magnetic stirring, transferring the mixed solution into a hydrothermal reaction kettle; performing hydrothermal treatment at 130 to 180 DEG C; performing suction filtration, washing and drying to the precursor; roasting the precursor in Muffle furnace for 2 to 6 hours at the temperature of 400 to 600 DEG C to obtain the product, wherein the specific surface area is greater than 150 m<2>.g<-1>. The photocatalyst disclosed by the invention has regular shape, large specific surface area, and super-high capacity for adsorbing and degrading organics, and can be reused; the raw materials for preparing the composite photocatalyst are abundant, the cost is low, and the process is simple.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Method of manufacturing nickel zinc batteries

InactiveUS20060207084A1Reduce reunionImprove efficiencyFinal product manufacturePrimary cellsZinc compoundsNickel cadmium

Methods of manufacturing a rechargeable power cell are described. Methods include providing a slurry, paste, or dry mixture of negative electrode materials having low toxicity and including dispersants to prevent the agglomeration of particles that may adversely affect the performance of power cells. The methods utilize semi-permeable sheets to separate the electrodes and minimize formation of dendrites; and further provide electrode specific electrolyte to achieve efficient electrochemistry and to further discourage dendritic growth in the cell. The negative electrode materials may be comprised of zinc and zinc compounds. Zinc and zinc compounds are notably less toxic than the cadmium used in nickel cadmium batteries. The described methods may utilize some production techniques employed in existing NiCad production lines. Thus, the methods described will find particular use in an already well-defined and mature manufacturing base.

Owner:POWERGENIX SYST

Electrolyte composition for nickel-zinc batteries

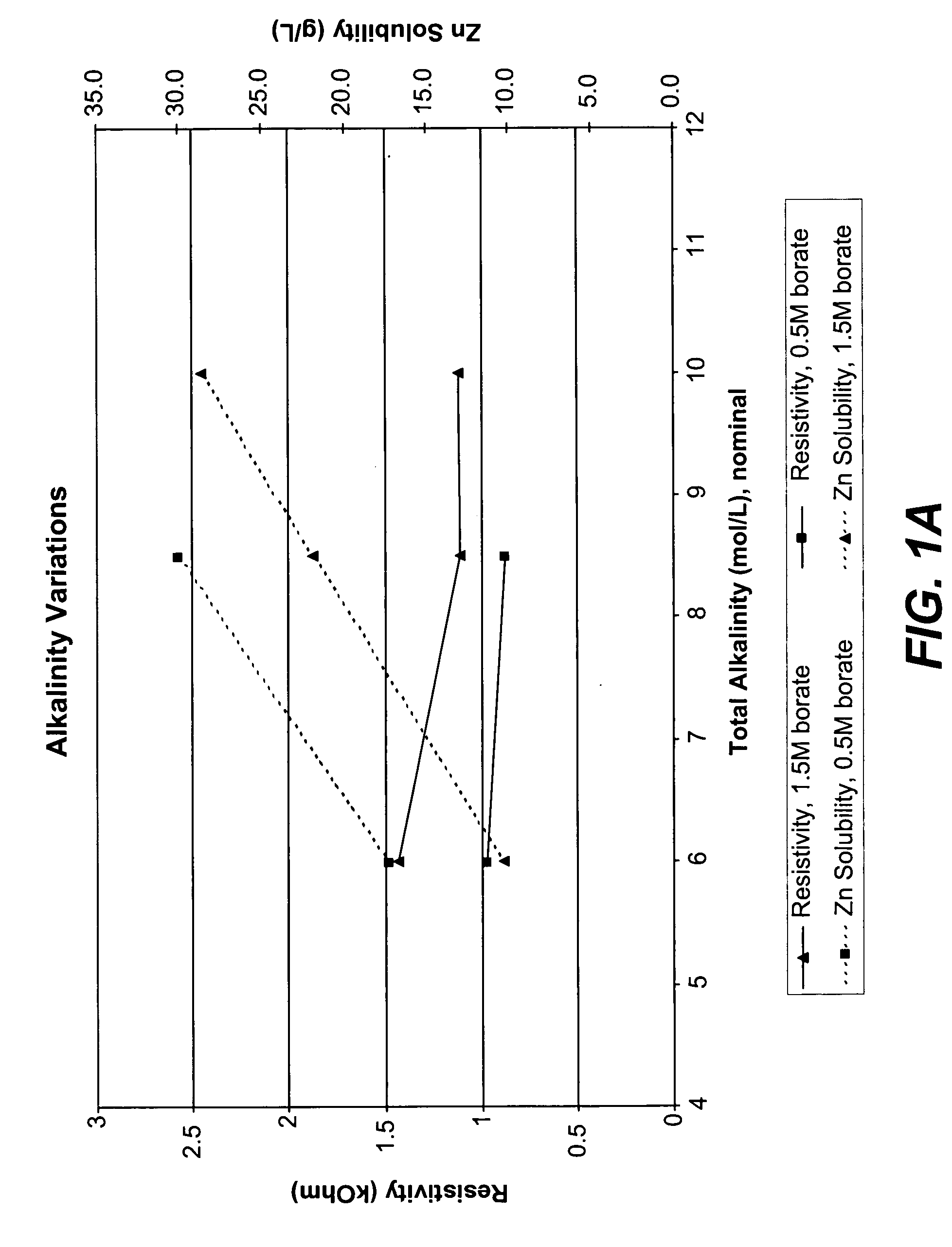

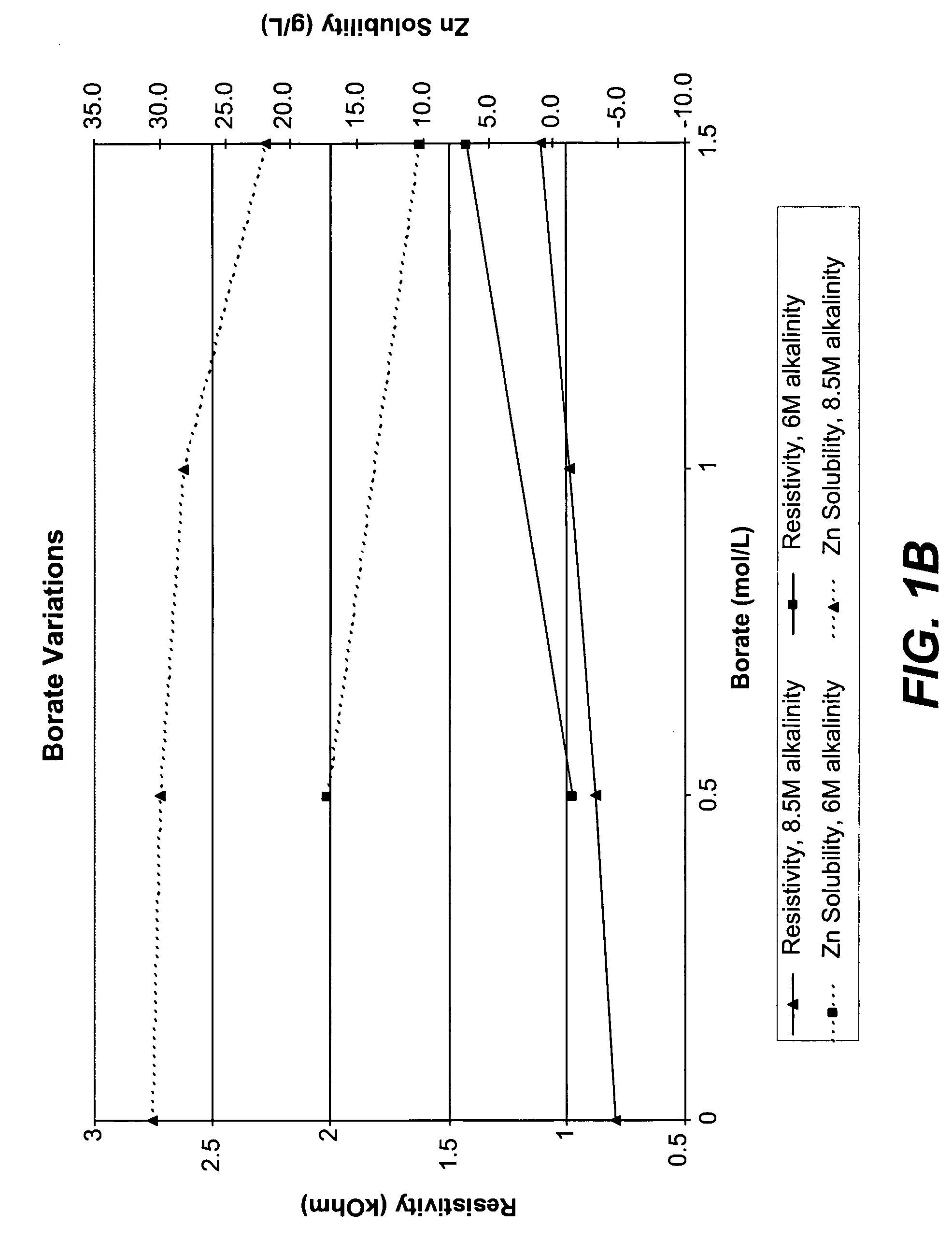

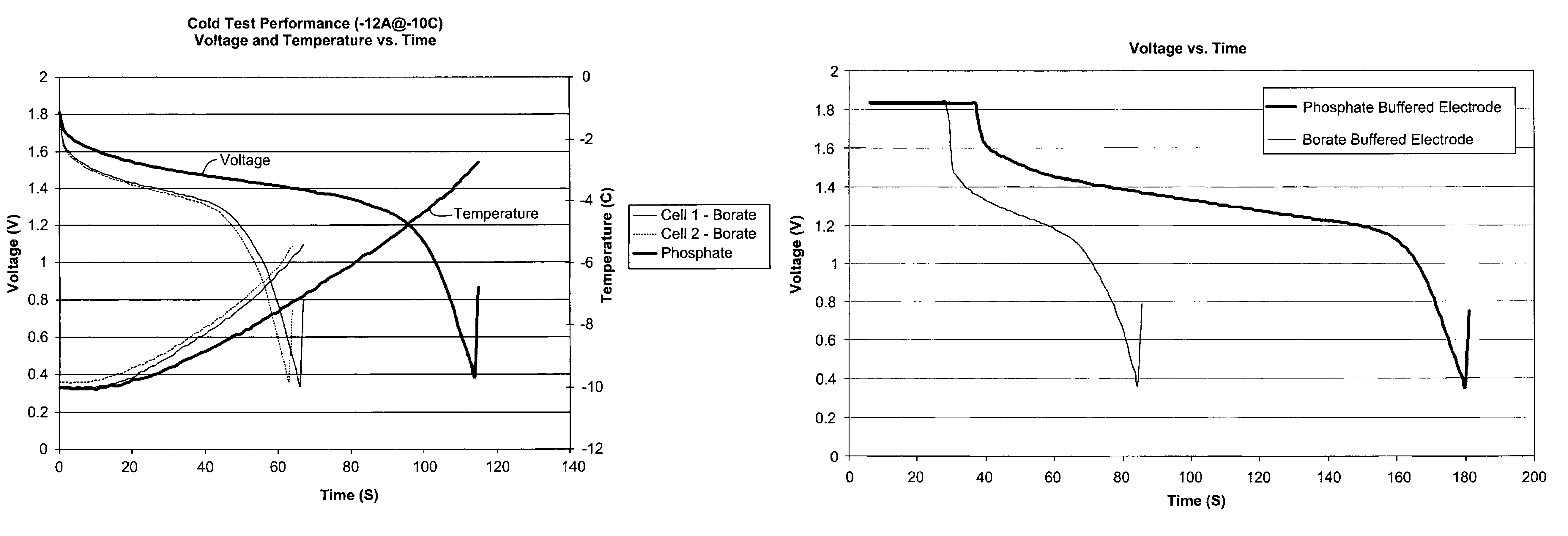

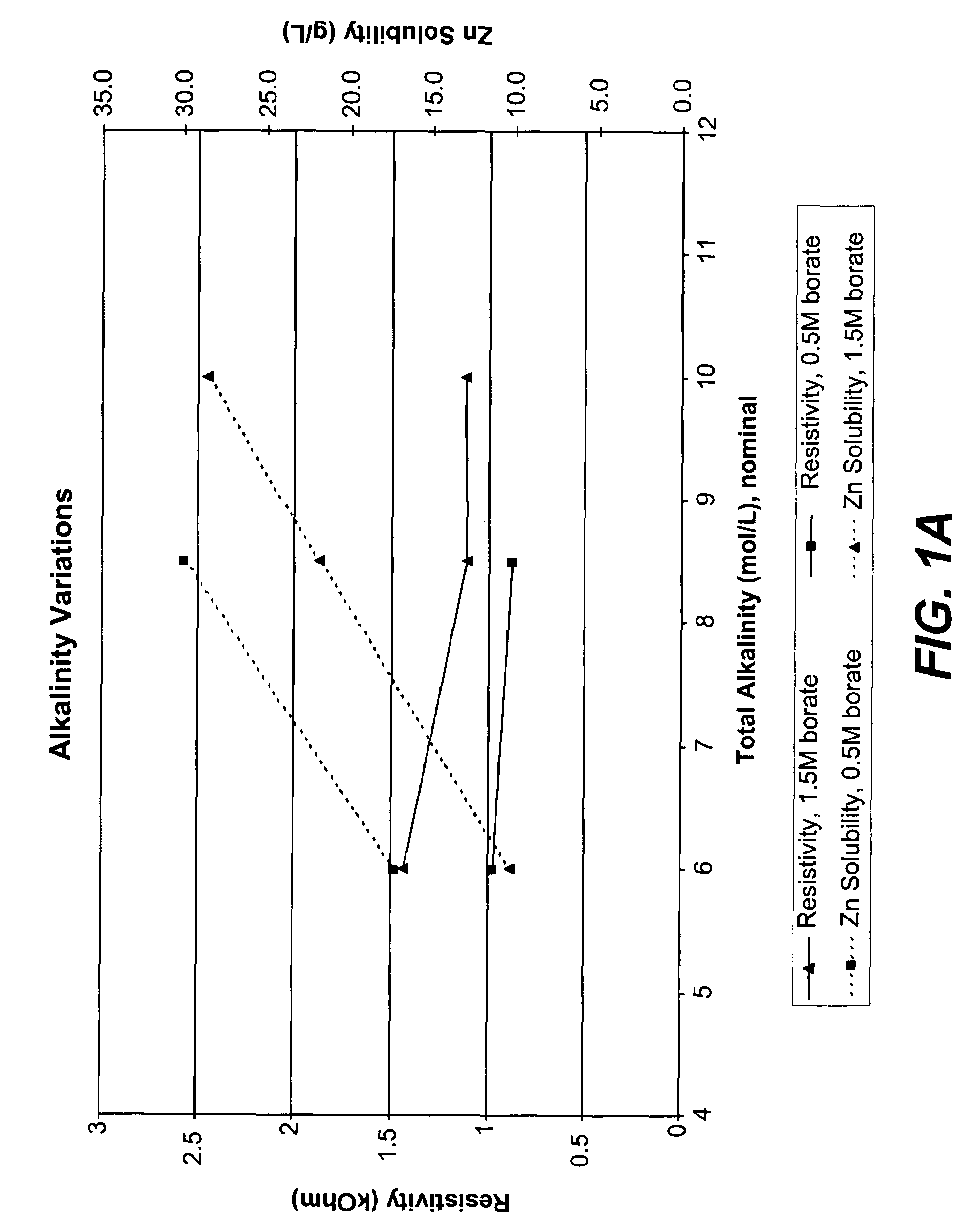

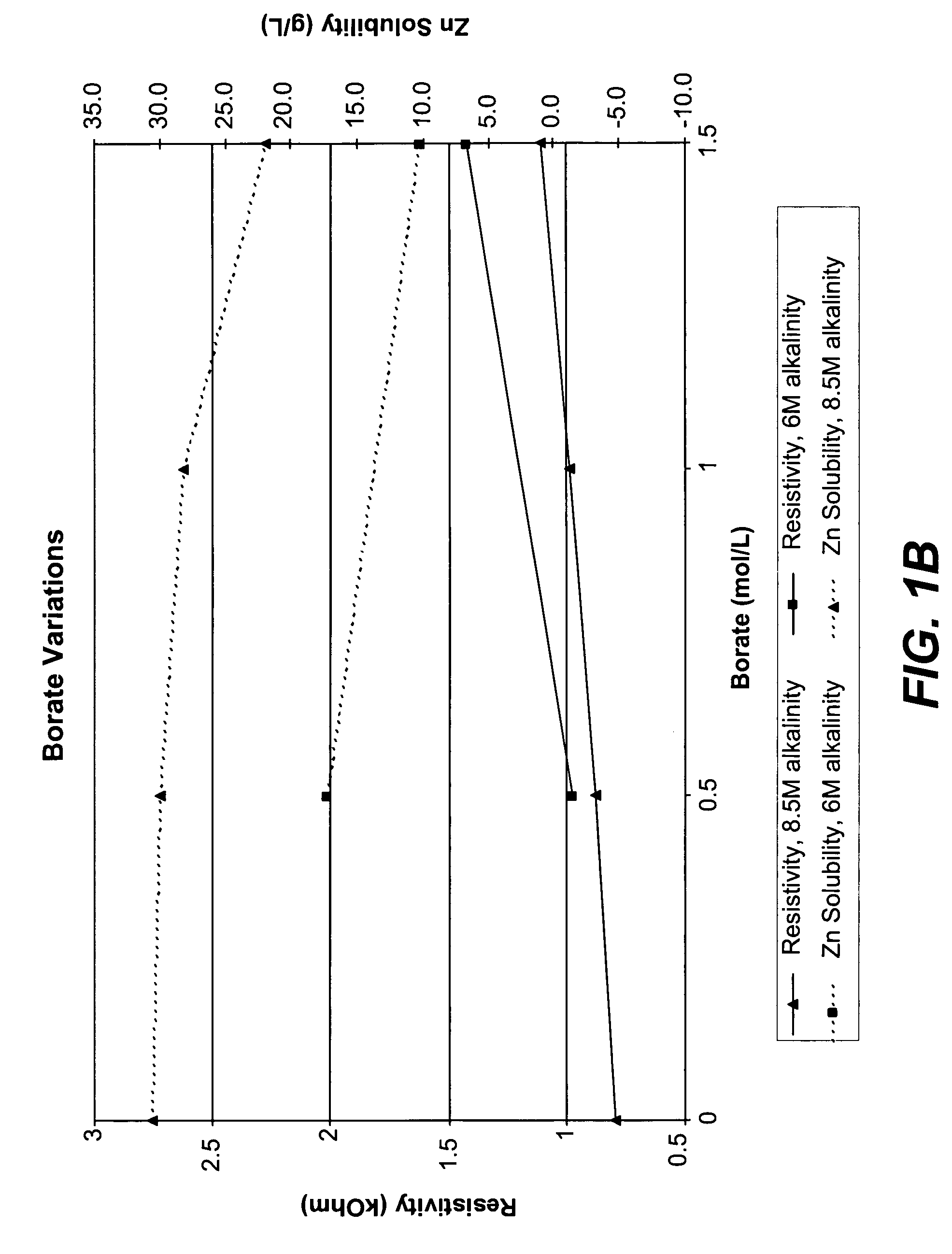

InactiveUS20060127761A1Minimize zinc corrosionFinal product manufactureElectrode carriers/collectorsHigh rateElectrolyte composition

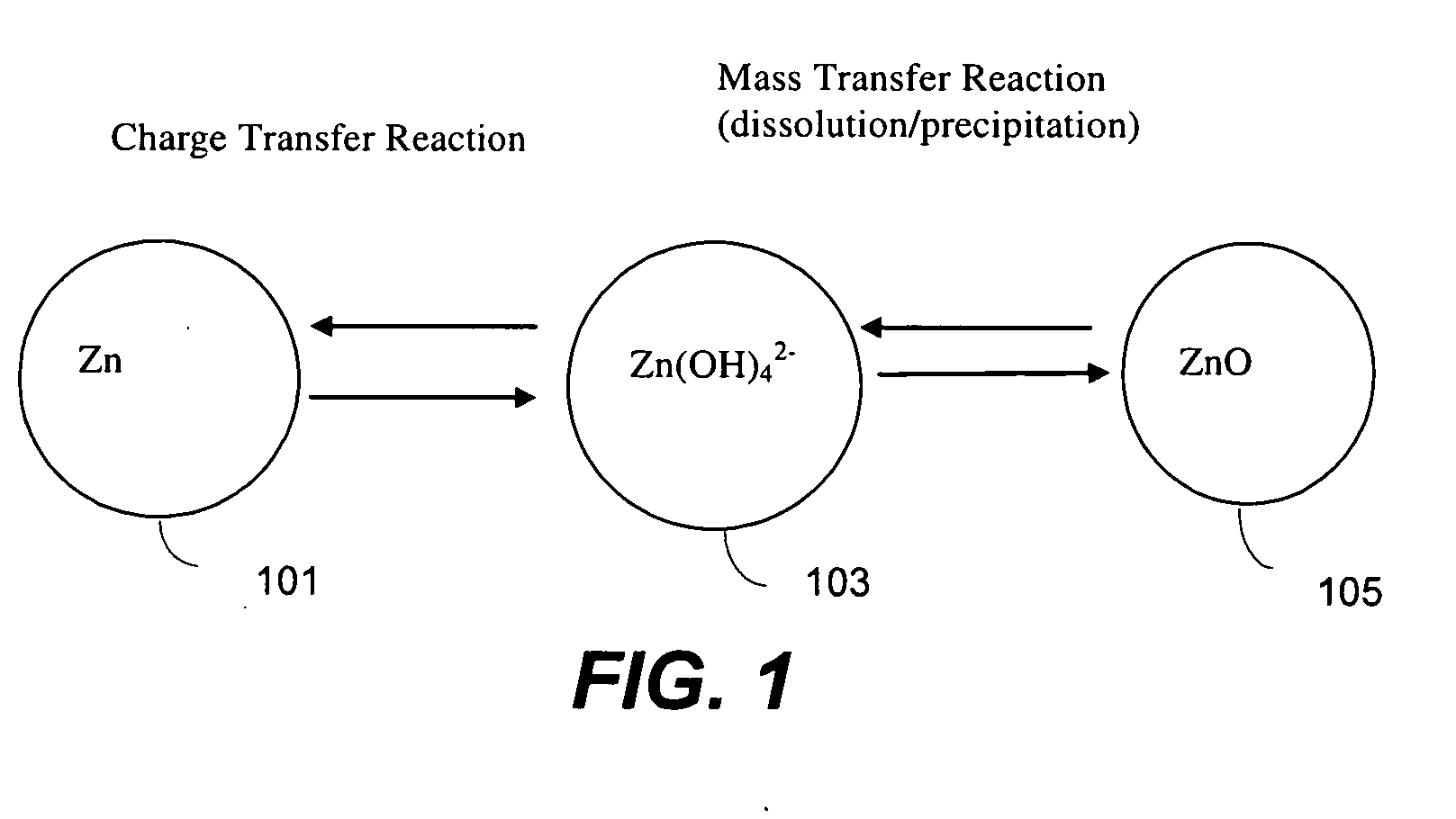

Electrodes and electrolytes for nickel-zinc secondary battery cells possess compositions that limit dendrite formation and other forms of material redistribution in the zinc electrode. In addition, the electrolytes may possess one or more of the following characteristics: good performance at low temperatures, long cycle life, low impedance and suitability for high rate applications.

Owner:ZINCFIVE POWER INC

Pasted zinc electrode for rechargeable nickel-zinc batteries

ActiveUS20100291439A1High viscositySimple working processFinal product manufacturePrimary cellsZinc metalSlurry

Active material for a negative electrode of a rechargeable zinc alkaline electrochemical cell is made with zinc metal particles coated with tin and / or lead. The zinc particles may be coated by adding lead and tin salts to a slurry containing zinc particles, a thickening agent and water. The remaining zinc electrode constituents such as zinc oxide (ZnO), bismuth oxide (Bi2O3), a dispersing agent, and a binding agent such as Teflon are then added. The resulting slurry / paste has a stable viscosity and is easy to work with during manufacture of the zinc electrode. Further, the zinc electrode is much less prone to gassing when cobalt is present in the electrolyte. Cells manufactured from electrodes produced in accordance with this invention exhibit much less hydrogen gassing, by as much as 60-80%, than conventional cells. The cycle life and shelf life of the cells is also enhanced, as the zinc conductive matrix remains intact and shelf discharge is reduced.

Owner:ZINCFIVE POWER INC

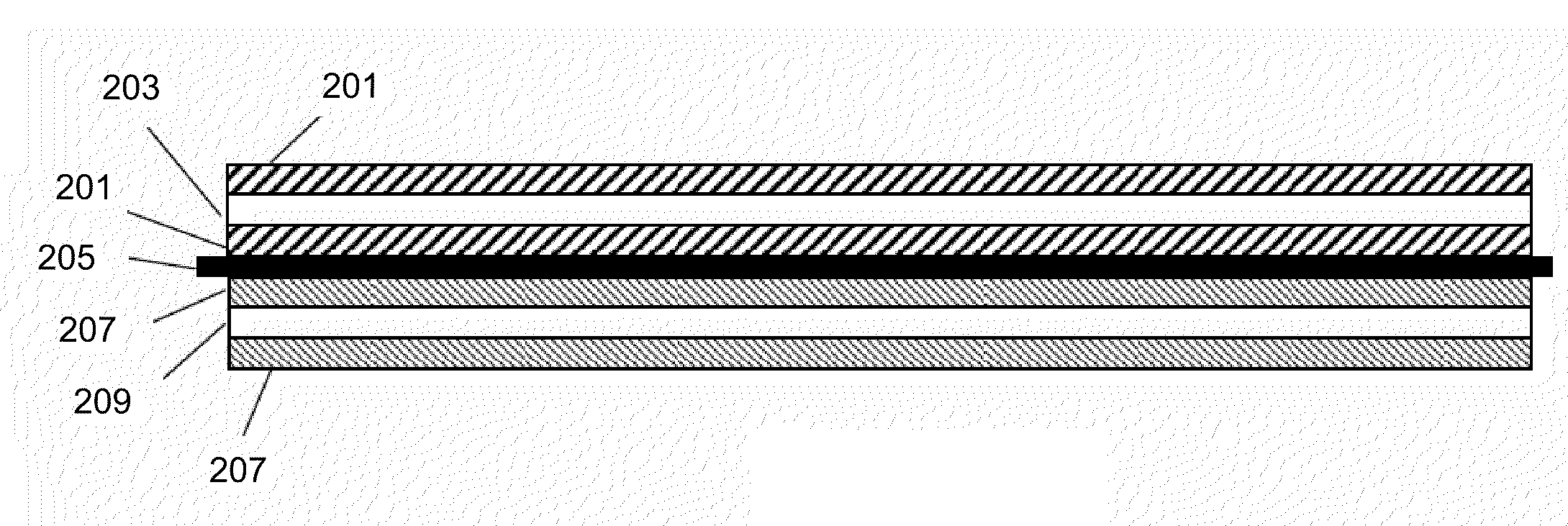

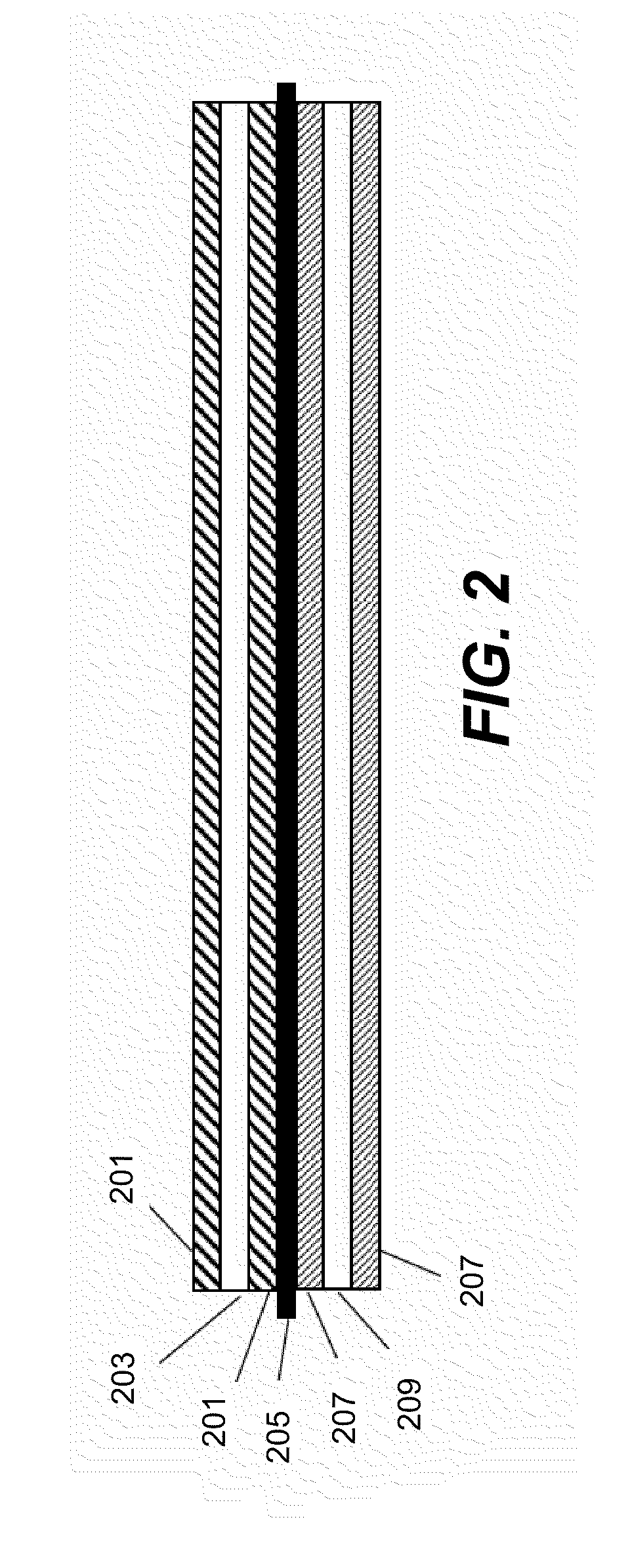

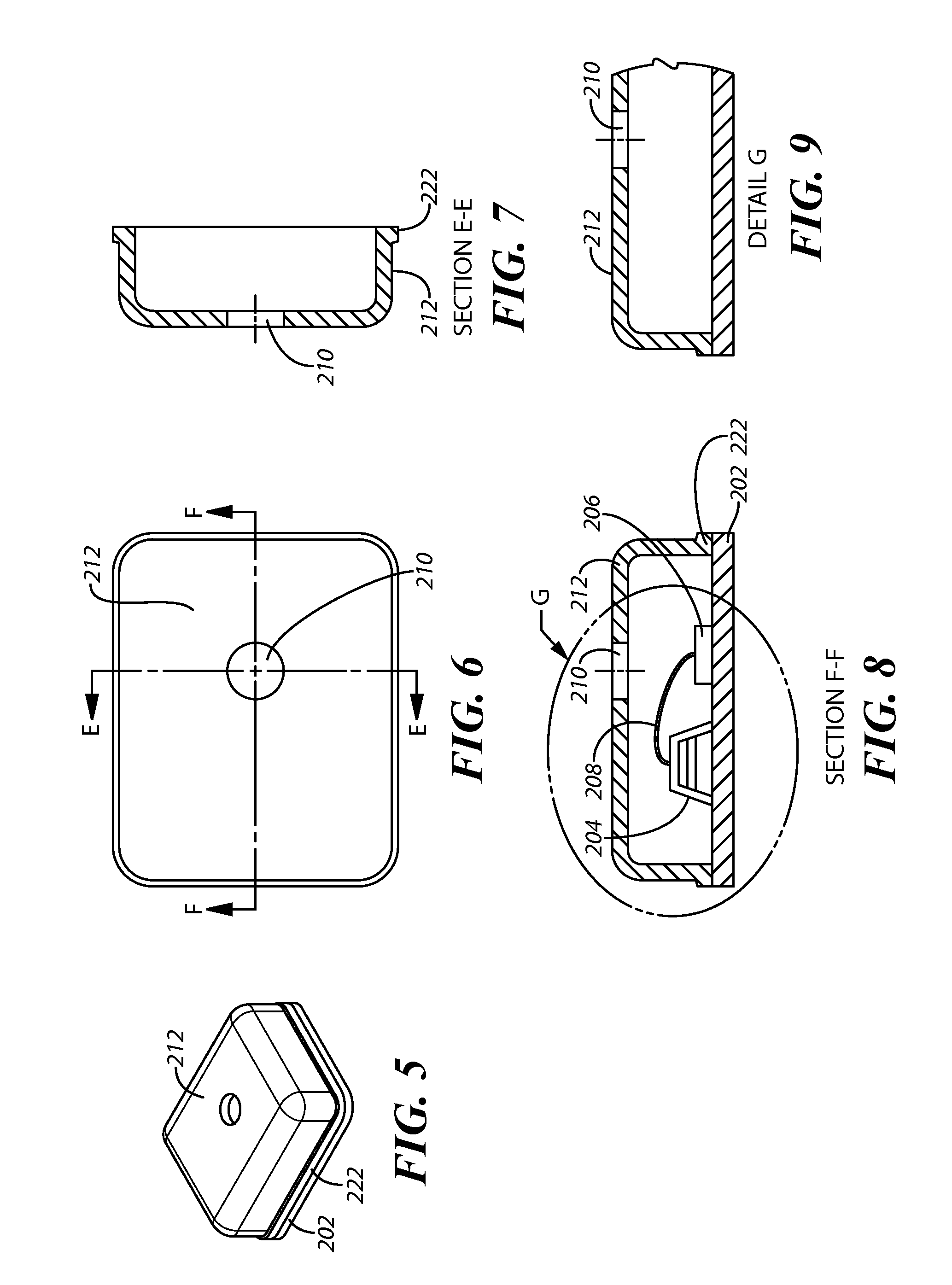

Cylindrical nickel-zinc cell with negative can

A nickel-zinc battery cell is formed with a negative can, a positive cap, and a jelly roll of electrochemically active positive and negative materials within. The inner surface of the can is protected with an anticorrosive material that may be coated or plated onto the can. Good electrical contact between the jelly roll and the cap is achieved through folding the nickel substrate over to contact a positive current collection disk.

Owner:ZINCFIVE POWER INC

Electrolyte composition for nickel-zinc batteries

InactiveUS7550230B2Minimize zinc corrosionFinal product manufactureWound/folded electrode electrodesHigh rateElectrolyte composition

Electrodes and electrolytes for nickel-zinc secondary battery cells possess compositions that limit dendrite formation and other forms of material redistribution in the zinc electrode. In addition, the electrolytes may possess one or more of the following characteristics: good performance at low temperatures, long cycle life, low impedance and suitability for high rate applications.

Owner:ZINCFIVE POWER INC

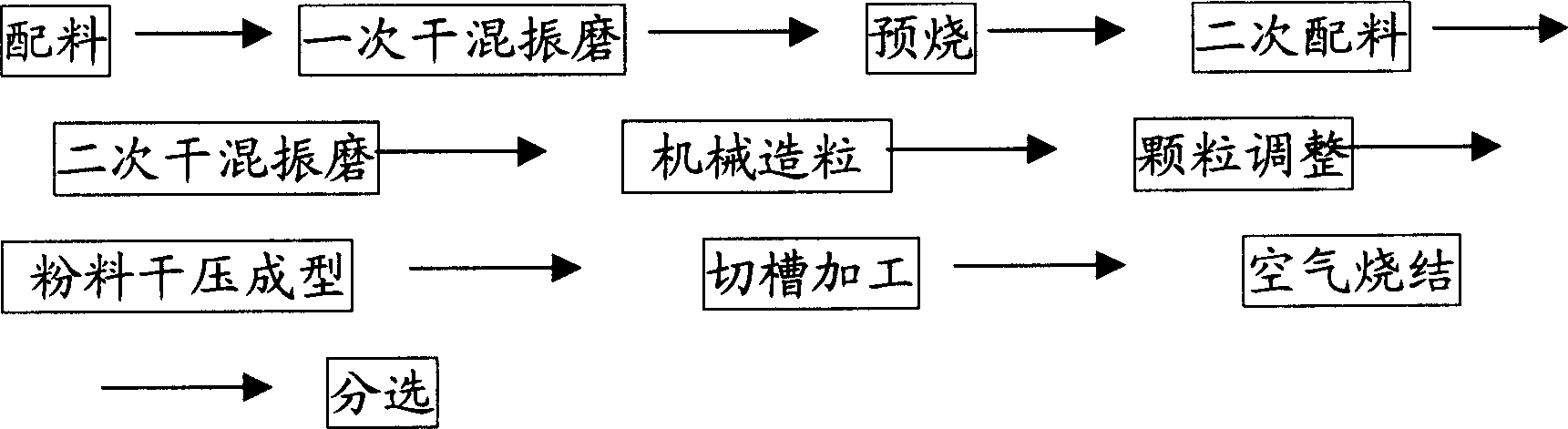

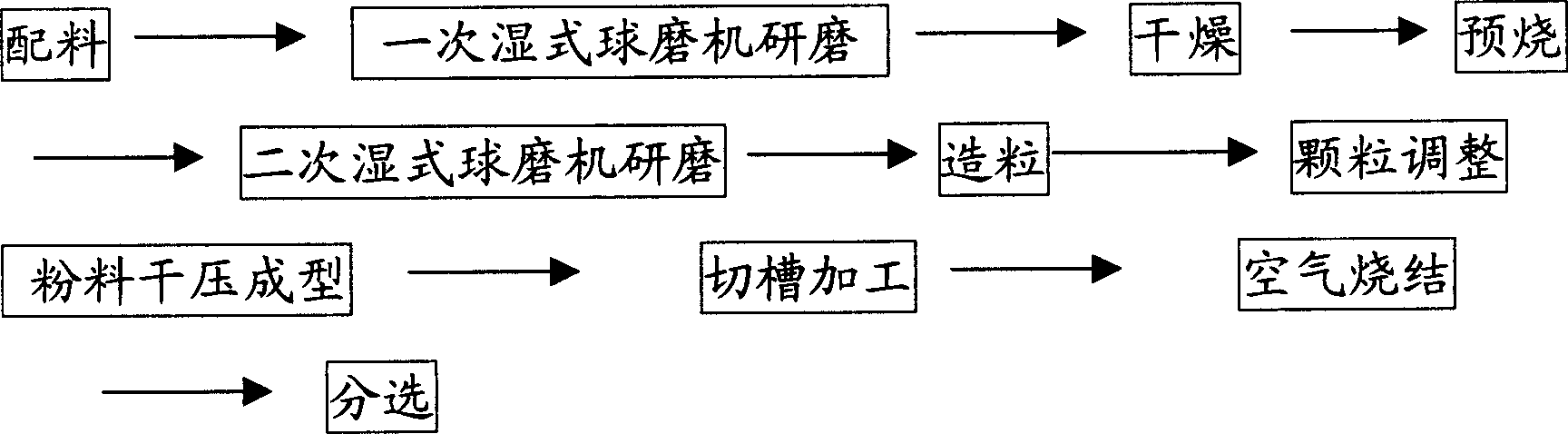

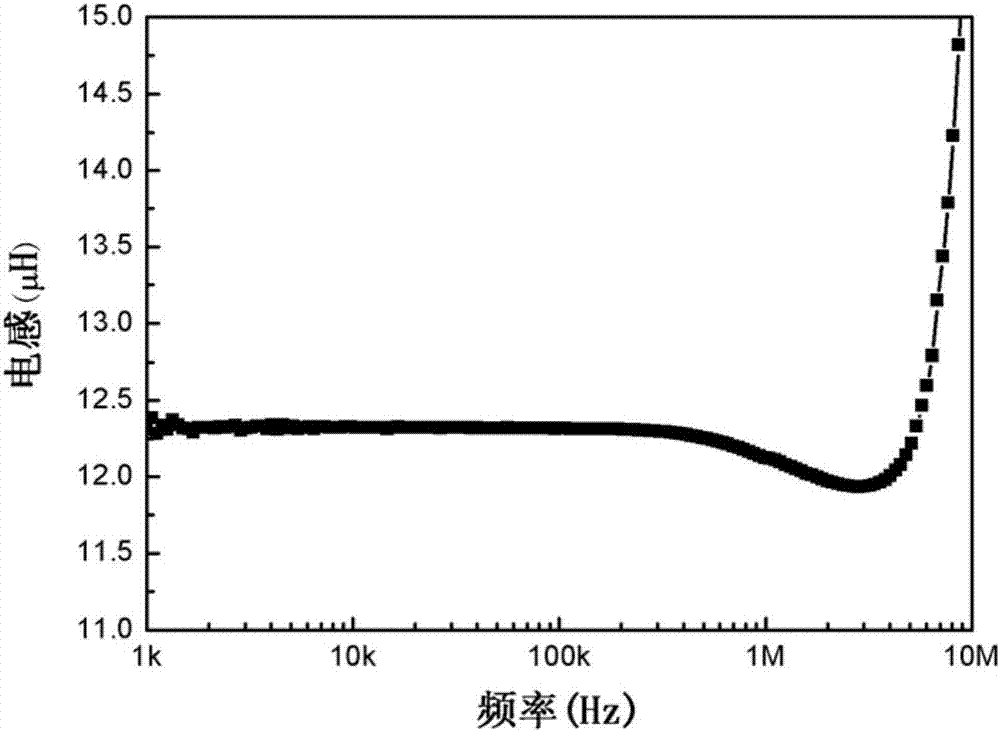

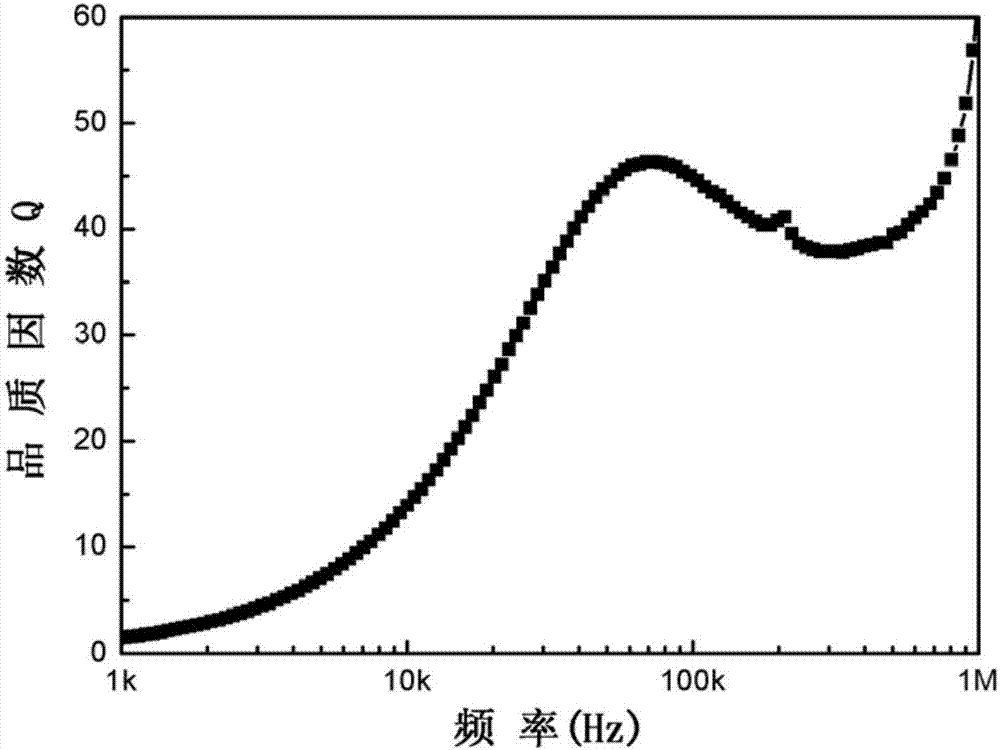

Ni-Zn soft magnetic ferrite material and preparation method thereof

The invention discloses a nickel-zinc soft magnetic ferrite material and a preparation method thereof. The material comprises the following compositions in mol percentage: 45 to 50 mol percent of ferric oxide Fe2O3, 20 to 26 mol percent of zinc oxide ZnO, 12 to 17 mol percent of nickel protoxide NiO, 5 to 10 mol percent of copper oxide CuO, and 3 to 10 mol percent of magnesium oxide MgO. The preparation method comprises the following steps: treating raw materials, proportioning, primary ball milling, drying, powdering or screening, preburning, secondary proportioning, secondary ball milling, secondary drying and secondary powdering or screening; the preburning condition is to carry out pre-synthesis in an air furnace at a temperature of between 900 and 980 DEG C, and the sintering temperature is between 1,050 and 1,100 DEG C. The nickel-zinc soft magnetic ferrite material has the characteristics of property of high Q, high frequency, high TC, high Bm and low cost.

Owner:广东肇庆微硕电子有限公司 +1

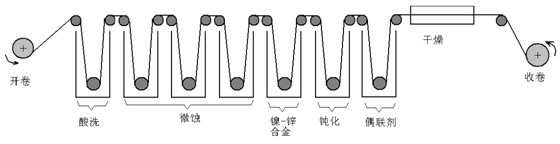

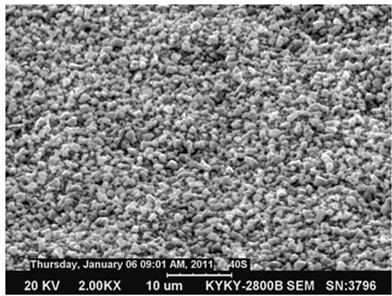

Surface treatment process for reducing roughness of electrolytic copper foil

ActiveCN102586831AReduce roughnessAccelerated corrosionPrinted circuit detailsMetallic material coating processesElectrolysisEtching

The invention relates to a surface treatment process for reducing roughness of an electrolytic copper foil, belonging to the technical field of electrolytic copper foil production processes. The surface treatment process comprises the following steps of: carrying out treatment steps of acid washing, micro etching, nickel-zinc alloy plating, passivating, coupling, drying and the like on the electrolytic copper foil with surface roughness (Rz) of 3-5 microns to form a VLP (Very Low Profile) copper foil, wherein the surface roughness (Rz) is reduced to 0.5-1.5 micron. The surface treatment process disclosed by the invention has the advantages that: the treated copper foil surface is reddish-brown and has excellent corrosion resistance, etching property and excellent normal-temperature and high-temperature oxidation resistance so as to be suitable for flexible copper-clad plates.

Owner:SHANDONG JINBAO ELECTRONICS

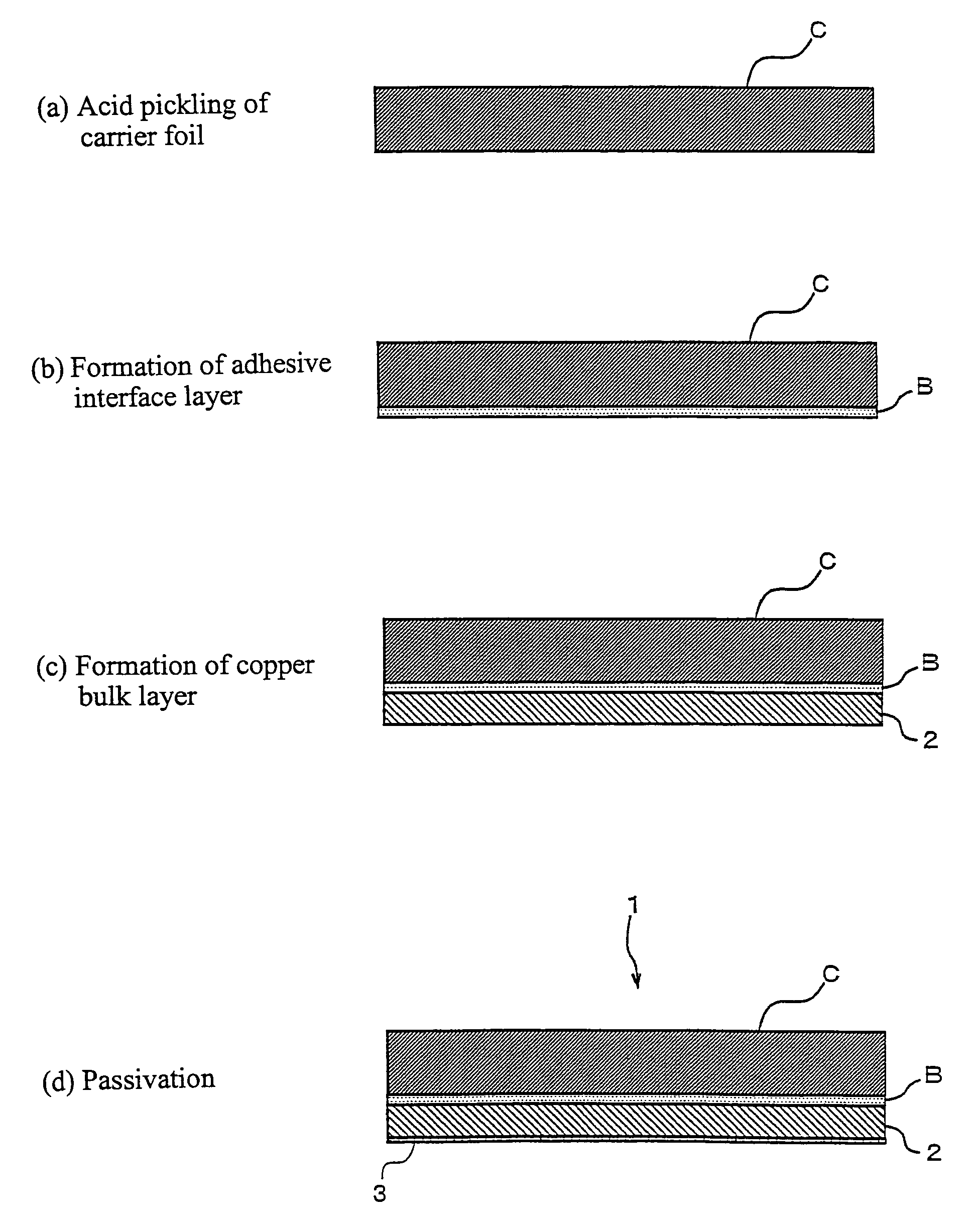

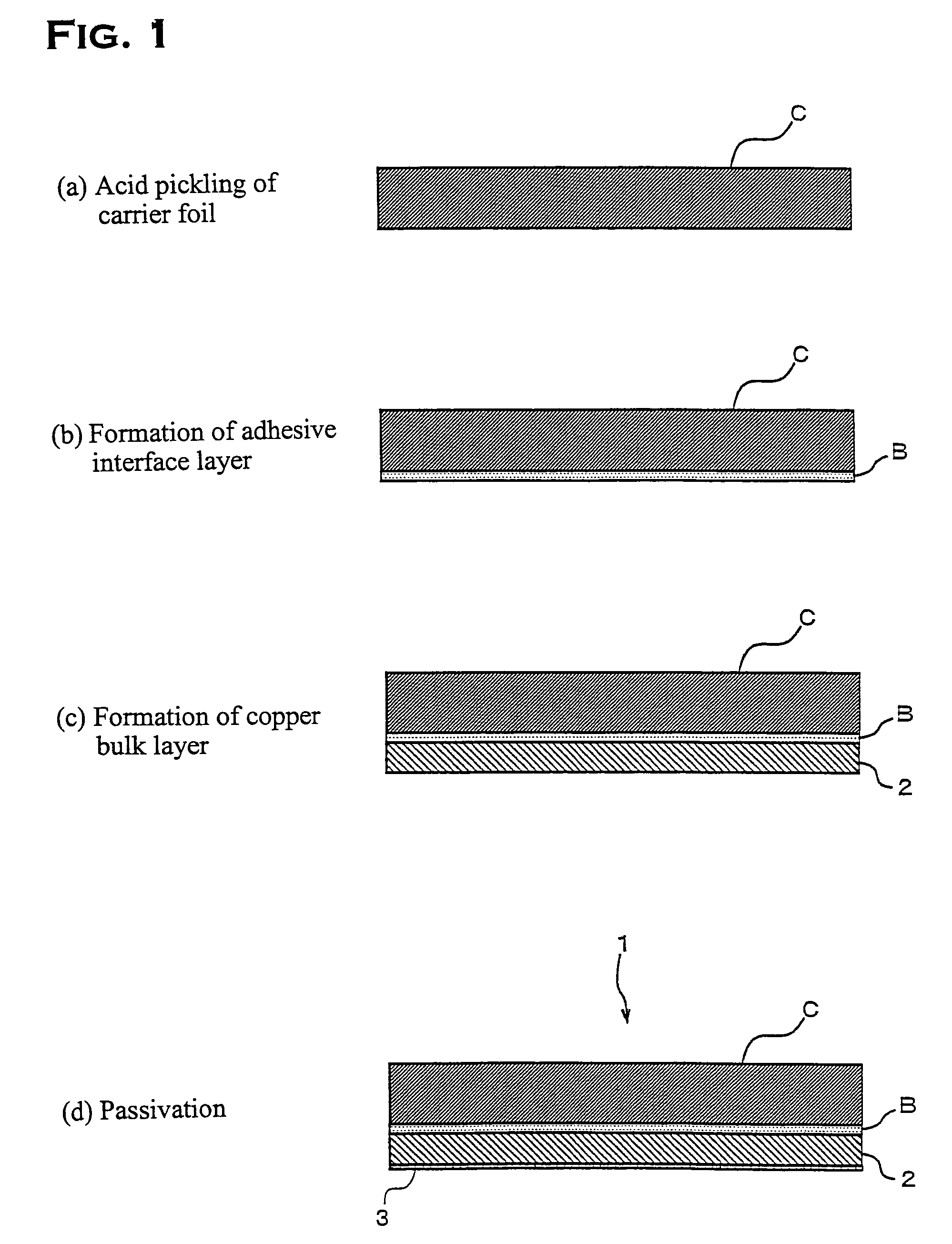

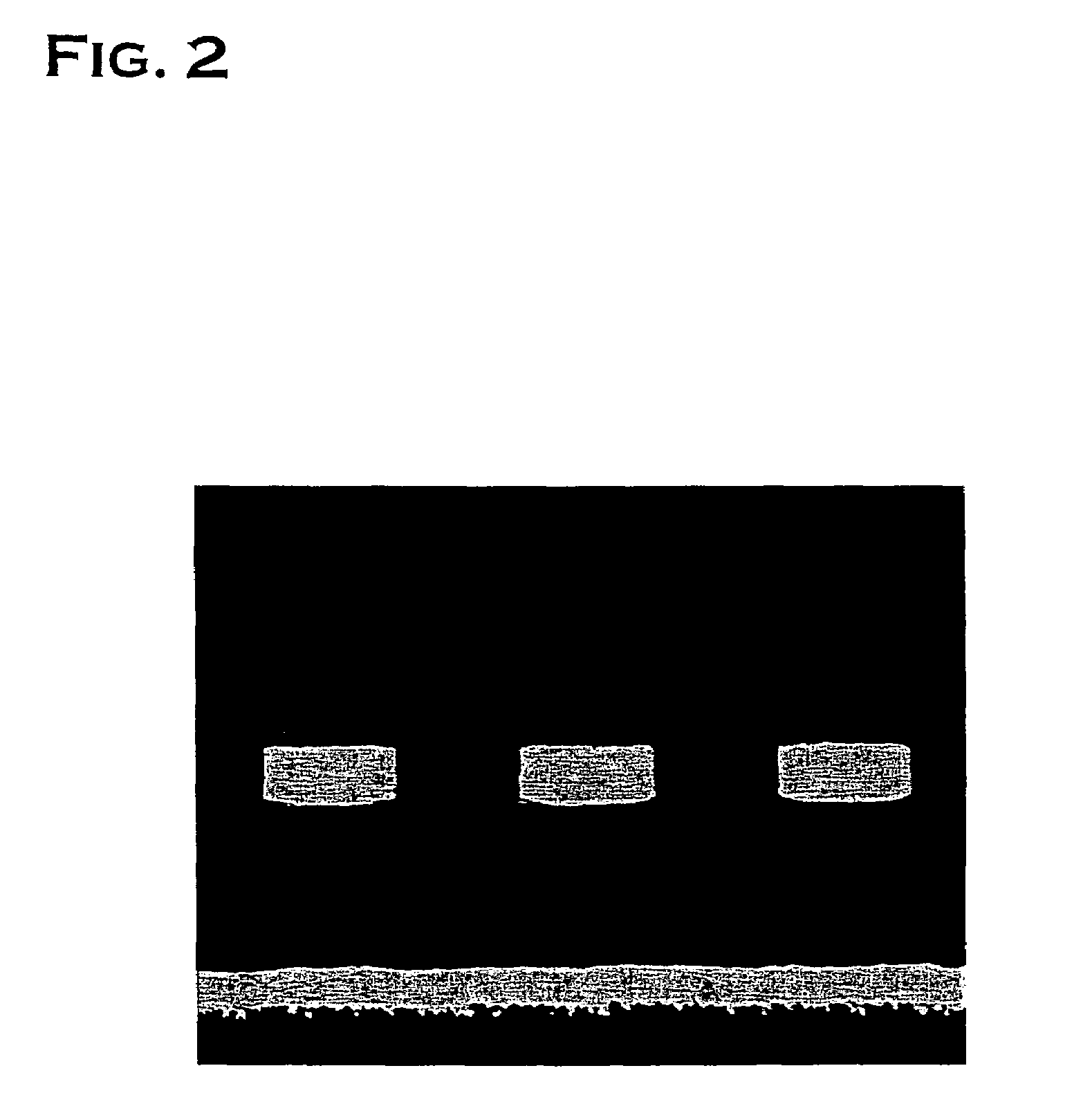

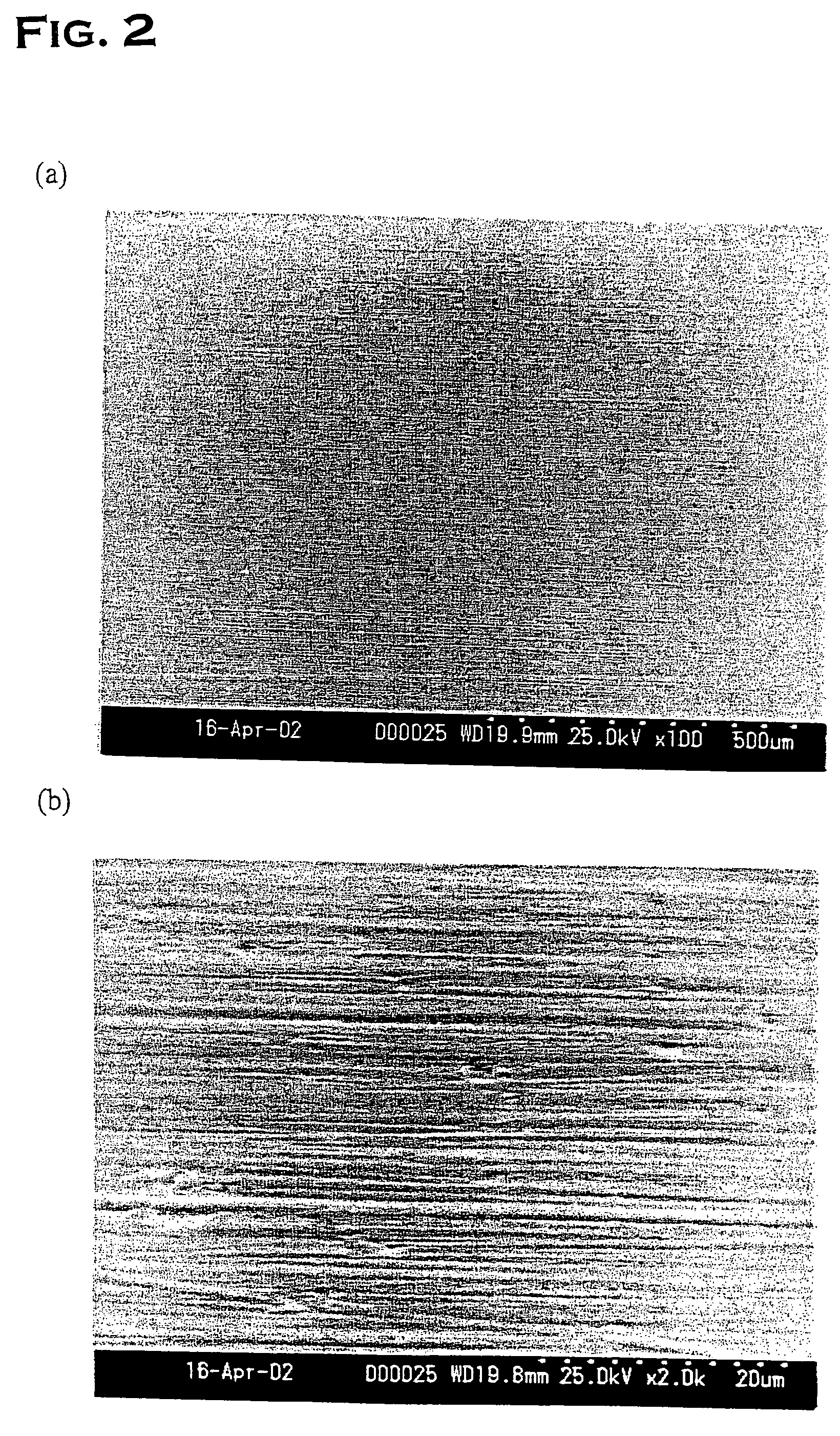

Electrodeposited copper foil with carrier foil

ActiveUS7691487B2Improve adhesion strengthGood chemical resistanceInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentInterface layerCopper foil

The present invention provides electrodeposited copper foil with a carrier foil which permits the formation of finer-pitch circuits and also enables the multilayer process to be easily performed to meet the requirements for recent printed wiring boards. According to the invention, there is provided electrodeposited copper foil with a carrier foil in which an adhesive interface layer is formed on a surface of the carrier foil and an electrodeposited copper foil layer is formed on the adhesive interface layer, which is characterized in that the electrodeposited copper foil layer is provided with a passivated layer formed without performing roughening treatment as nodular treatment and that a nickel-zinc alloy consisting essentially of 50 to 99% nickel by weight and 50 to 1% zinc by weight is adopted as the passivated layer.

Owner:MITSUI MINING & SMELTING CO LTD

Nickel zinc electrochemical cell incorporating dendrite blocking ionically conductive separator

A nickel-zinc electrochemical cell is disclosed using a polymer matrix separator. The polymer matrix separator includes a polymerization product of one or more monomers selected from the group of water-soluble, ethylenically-unsaturated acids and acid derivatives, and a crosslinking agent, and serves as a primary or supplemental source of electrolyte ionic species for the electrochemistry. Ionic species is contained as a solution phase within the polymer matrix membrane, allowing it to behave as a liquid electrolyte without the disadvantages. In secondary batteries (i.e., rechargeable), polymer matrix membranes are particularly useful as both an electrolyte reservoir and as a dendrite resistant separator between the charging electrode and the zinc electrode. The polymer matrix membrane protects the electrodes from corrosion and prevents zinc oxidation product from the zinc electrode to contaminate the electrolyte.

Owner:CHEN MUGUO +9

Flexible printed wiring board for chip-on flexibles

InactiveUS6984456B2More adhesiveReduce adhesionThermometers using material expansion/contactionPrinted circuit secondary treatmentElectrical resistance and conductanceChip on film

There is provided a flexible printed wiring board including an insulating layer having a high optical transmittance, a high adhesion strength and a high migration resistance, and suitable for a chip on film (hereafter referred to as COF). In a flexible printed wiring board for COF, having an insulating layer on which a conductive layer of an electrodeposited copper foil is laminated, and an optical transmittance of 50% or more of the insulating layer in the etched region when a circuit is formed by etching said conductive layer, electrodeposited copper foil was made to have a rust-proofing layer of a nickel-zinc alloy on the adhering surface to be adhered to the insulating layer; the surface roughness (Rz) of the adhering surface was made to be 0.05 to 1.5 μm, and the specular gloss was made to be 250 or more when the incident angle is 60°.

Owner:MITSUI MINING & SMELTING CO LTD

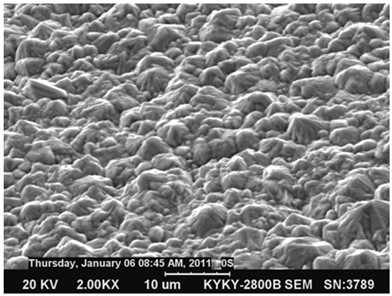

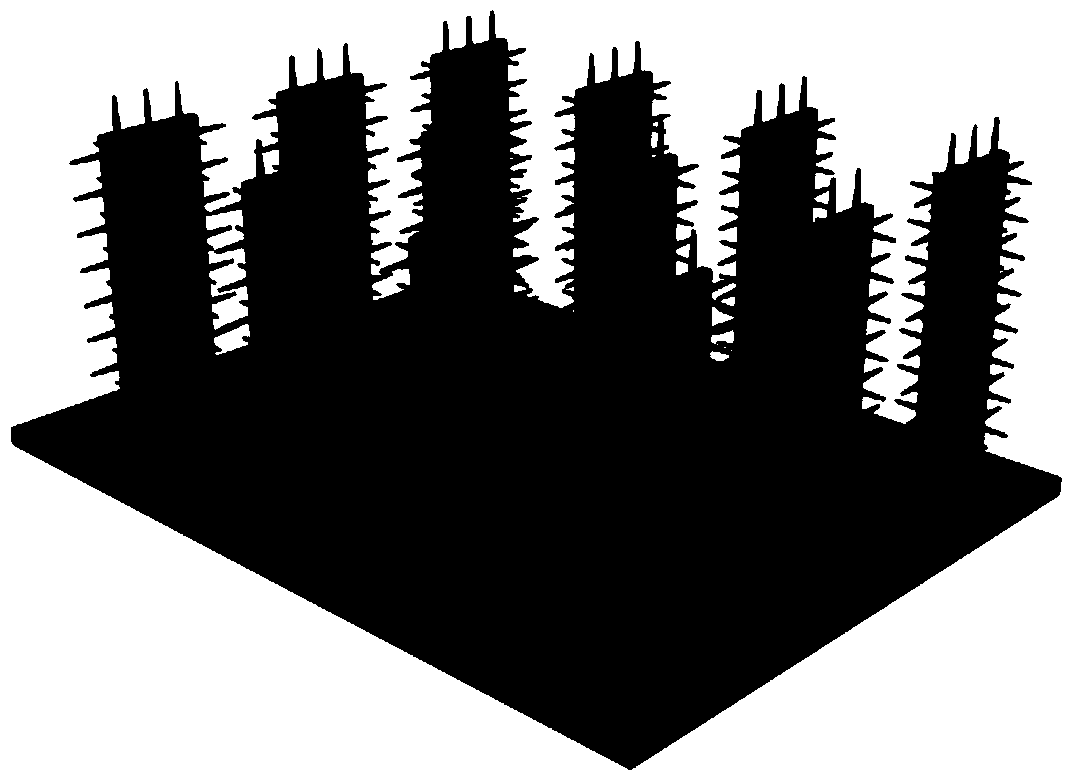

Material with surface multilevel nano micron structure, preparation method thereof and nickel-zinc cell containing the material in anode

ActiveCN104051728AImprove cycle performanceIncrease capacityMaterial nanotechnologyCell electrodesNanowireSynthesis methods

The invention discloses a material with surface multilevel nano micron structure. The material comprises: a porous conductive substrate, cobaltosic oxide primary rectangular micron sheet array growing on and perpendicular to the porous conductive substrate, and a plurality of villous nickel oxide secondary nanowires growing on the surface of each primary rectangular micron sheet. The invention also discloses a hydro-thermal synthesis method for preparing the material, and a cell containing the material in the anode, especially a nickel-zinc cell. The material has high specific surface area, can be used as the electrode material to improve the electrical contact performance of the electrode, thereby improving the overall electrical property of the electrode and cell containing the material.

Owner:BEIJING UNIV OF CHEM TECH

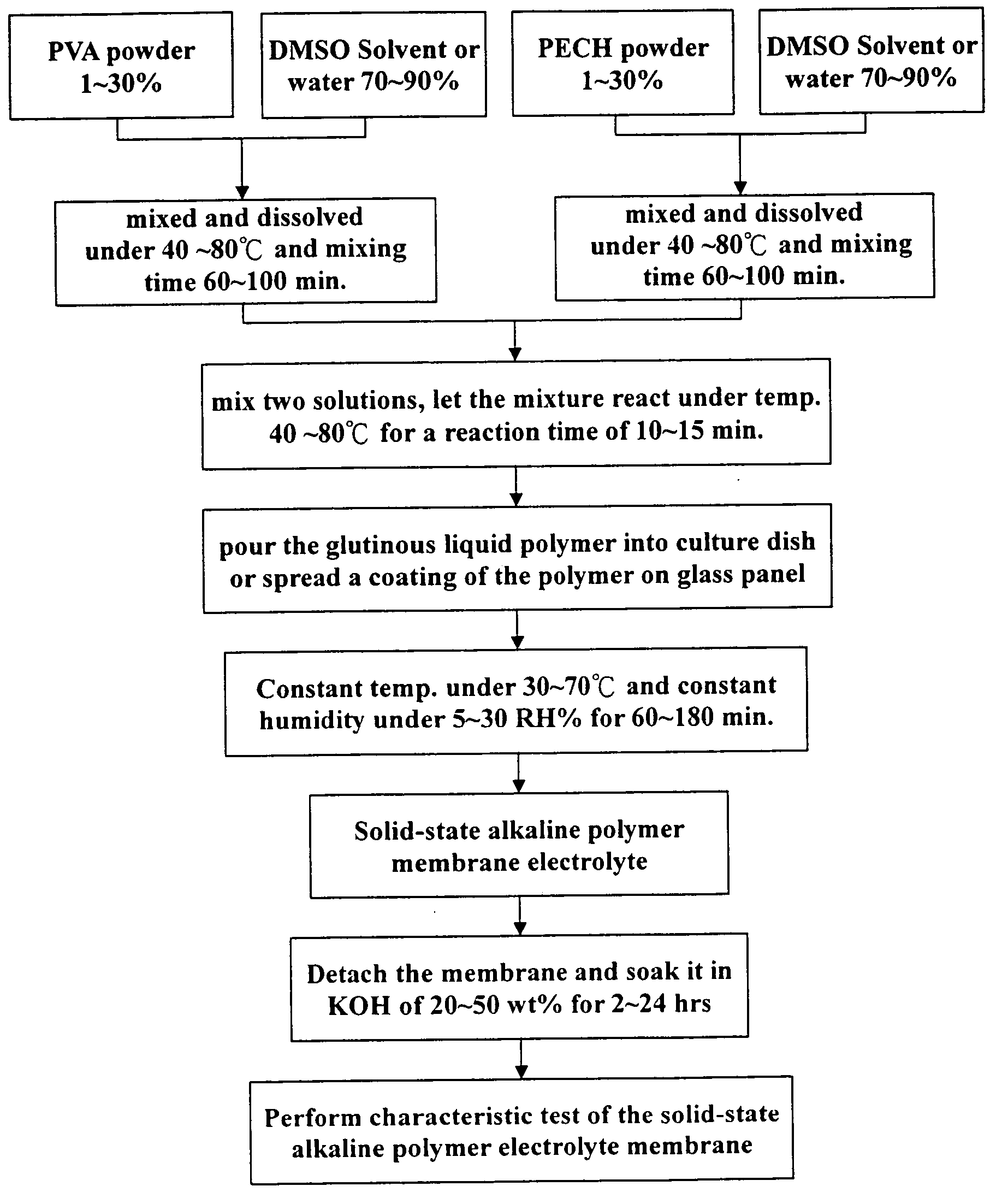

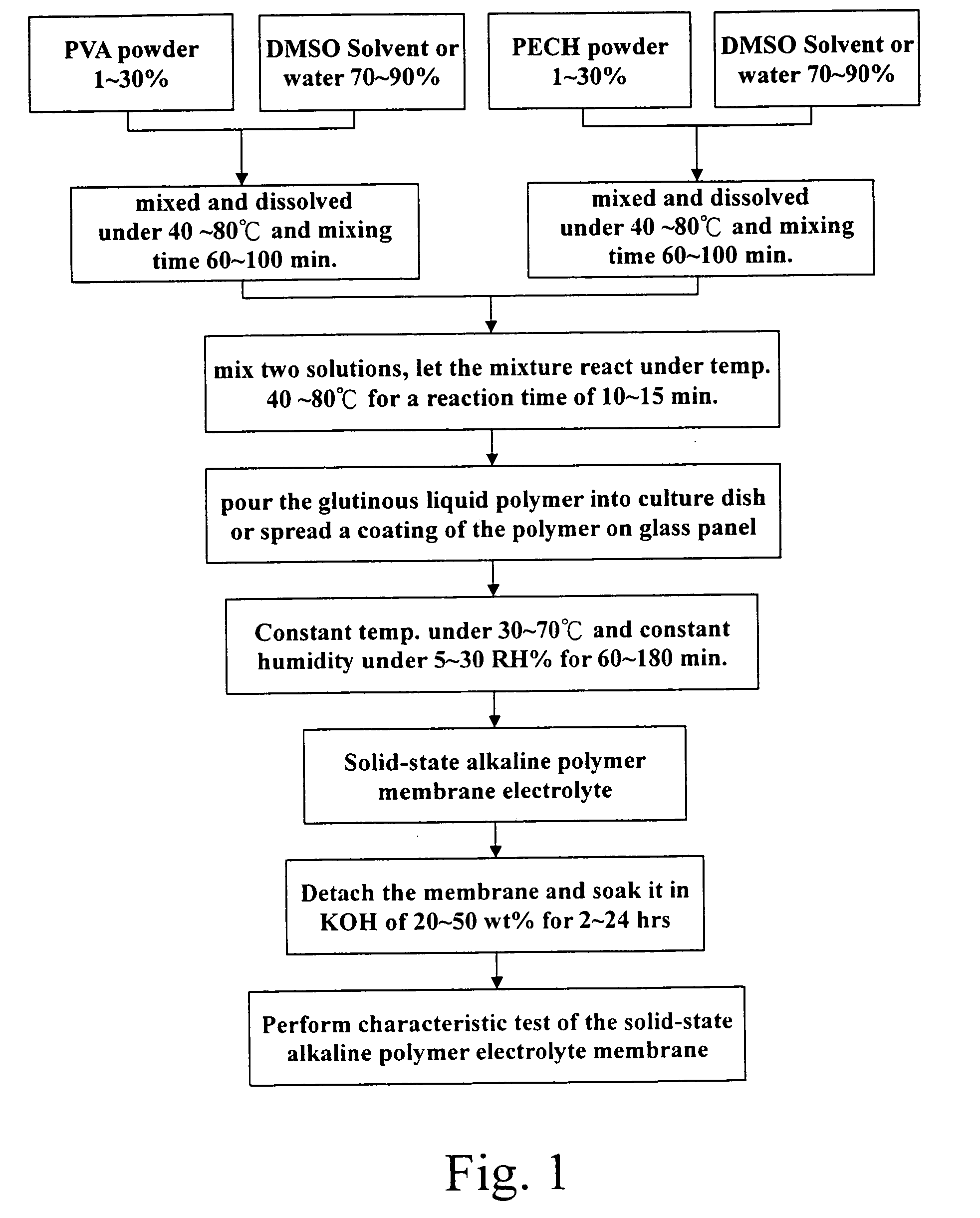

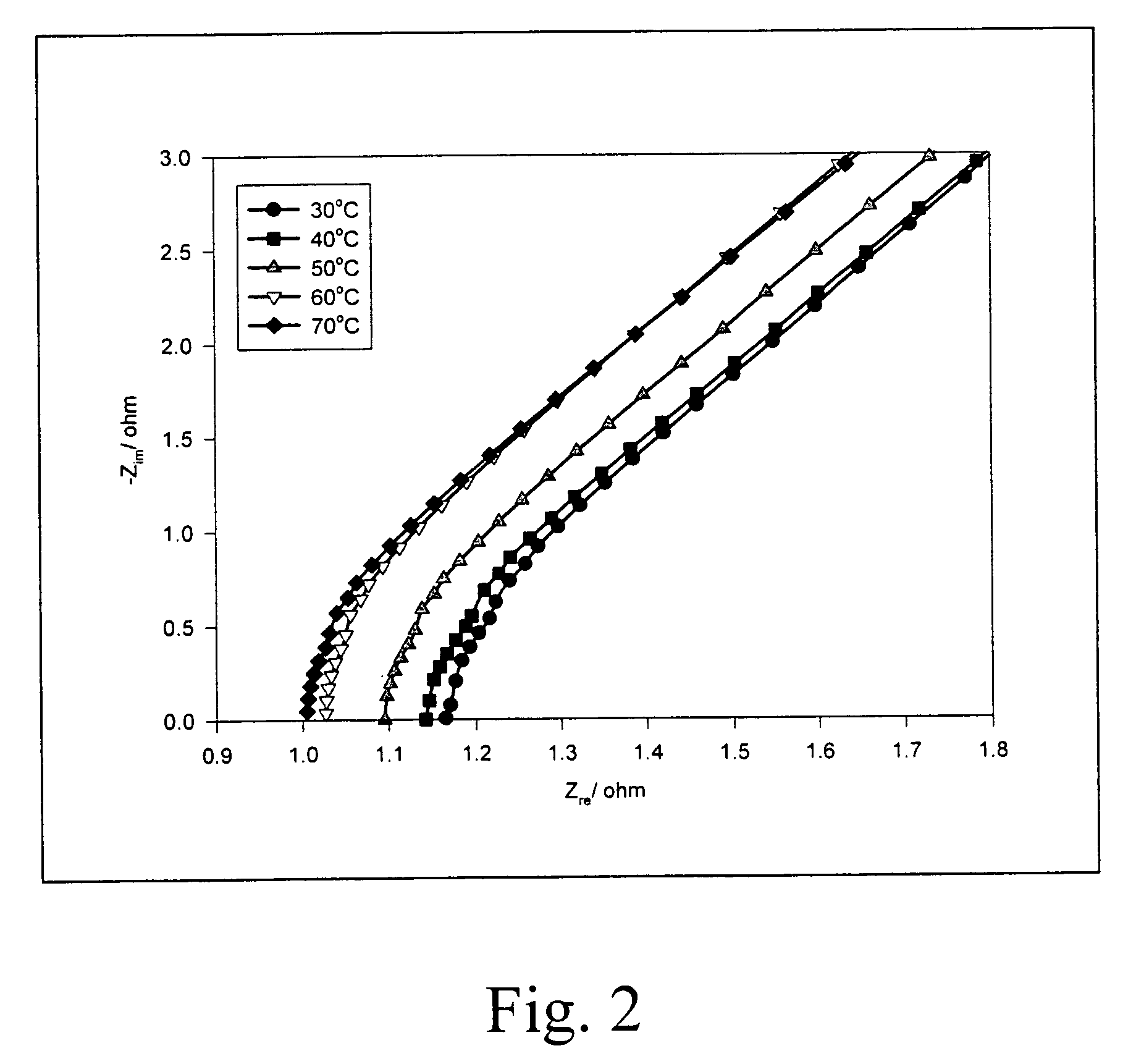

Alkaline polymer electrolyte membrane and its application

InactiveUS20050158632A1High mechanical strengthImprove electrochemical stabilityElectrolyte holding meansFuel and primary cellsNickel zincElectrochemistry

An alkaline polymer electrolyte membrane formed by mixing hydrophilic PVA, PECH and DMSO organic solvent possessing high mechanical strength and superior electrochemical stability, and with an ionic conductivity higher than 0.01 S / cm under normal temperature which may supersede the traditional PP / PE non-woven fabric separator and KOH electrolyte; in addition, the alkaline polymer electrolyte membrane shall be combined with a base material of glass fiber web, PE / PP porous film and Nylon porous film with thickness of 20 μm˜800 μm to obtain a composite solid-state alkaline polymer electrolyte membrane, which may be used as a separator membrane applicably inside a Zinc-air cell, a Nickel-hydrogen cell, a nickel-cadmium cell, a nickel-zinc cell, a fuel cell, a metal-air cell, a primary and secondary alkaline (Zn—MnO2) cells, and an alkaline capacitors.

Owner:NANYA PLASTICS CORP

NiZn (nickel zinc) ferrite material with high magnetic conductivity and high Curie temperature and preparation method thereof

The invention discloses a NiZn (nickel zinc) ferrite material with a high magnetic conductivity and a high Curie temperature, which belongs to the technical field of the preparation of ferrite materials. Components of the NiZn ferrite material with the high magnetic conductivity and the high Curie temperature comprise main materials and doping agents. The NiZn ferrite material with the high magnetic conductivity and the high Curie temperature is characterized in that: based on oxides, the main materials comprise: 48.5-49.9 mol% of Fe2O3, 31.0-34.0 mol% of ZnO, 4.0-8.0 mol% of CuO and the balance of NiO; and based on the oxides, by using the main materials are datum references, the doping agents in percentage by weight comprise: 0.001-0.30 wt% of MoO3, 0.001-0.20 wt% of V2O5, 0.01-0.40 wt%of Bi2O3, 0.001-0.05 wt% of Nb2O5 and 0.001-0.08 wt% of TiO2. Due to the high magnetic conductivity owned by the NiZn ferrite material with the high magnetic conductivity and the high Curie temperature, a low leakage coefficient can be obtained; the working frequency band of a device is widened beneficially; due to the high Curie temperature, the range of the working temperature of the device canbe widened; the working of the device in different environments is beneficial; due to high electrical resistivity, a wideband device can be prevented from generating an electronic fire striking problem in an MHz (megahertz) frequency range; and the reliability of a system and the device is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

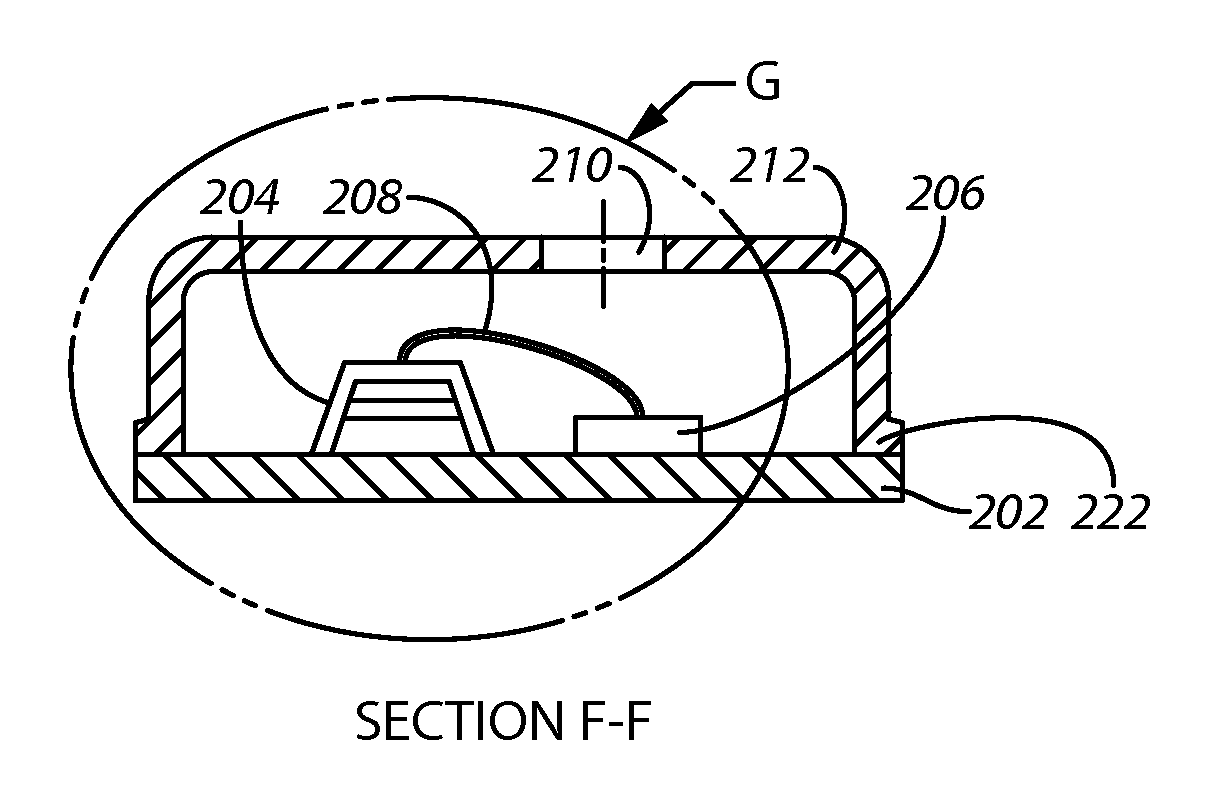

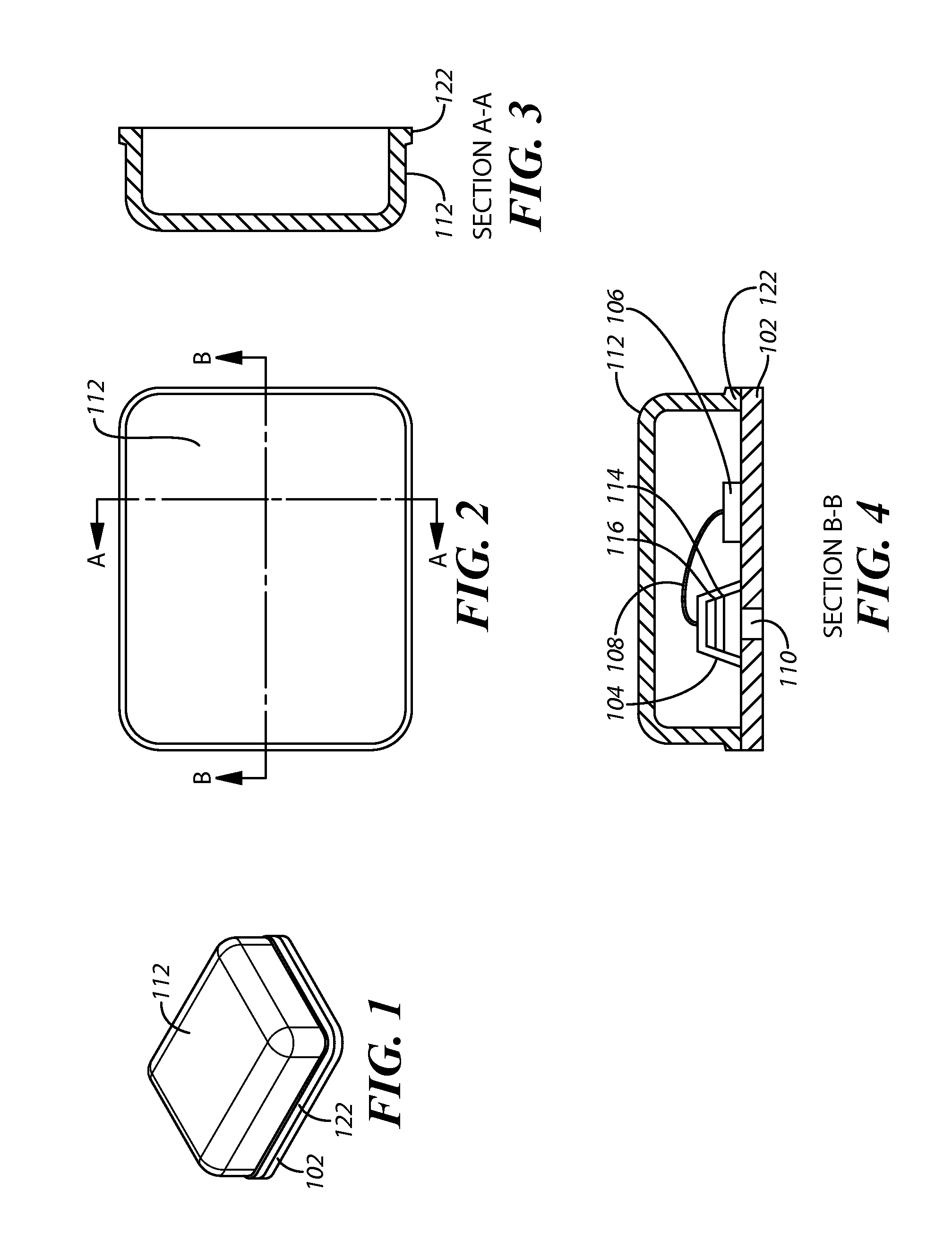

Cover for a MEMS microphone

A microphone assembly includes a base, a cover, and a microelectromechanical system (MEMS) die. The cover extends at least partially over and is coupled to the base. The cover and the base form a cavity. The MEMS die is coupled to the base and disposed within the cavity. At least a portion of the cover is constructed of a copper-nickel-zinc alloy that is effective in preventing solder from moving from a first portion of the cover to a second portion of the cover.

Owner:KNOWLES ELECTRONICS INC

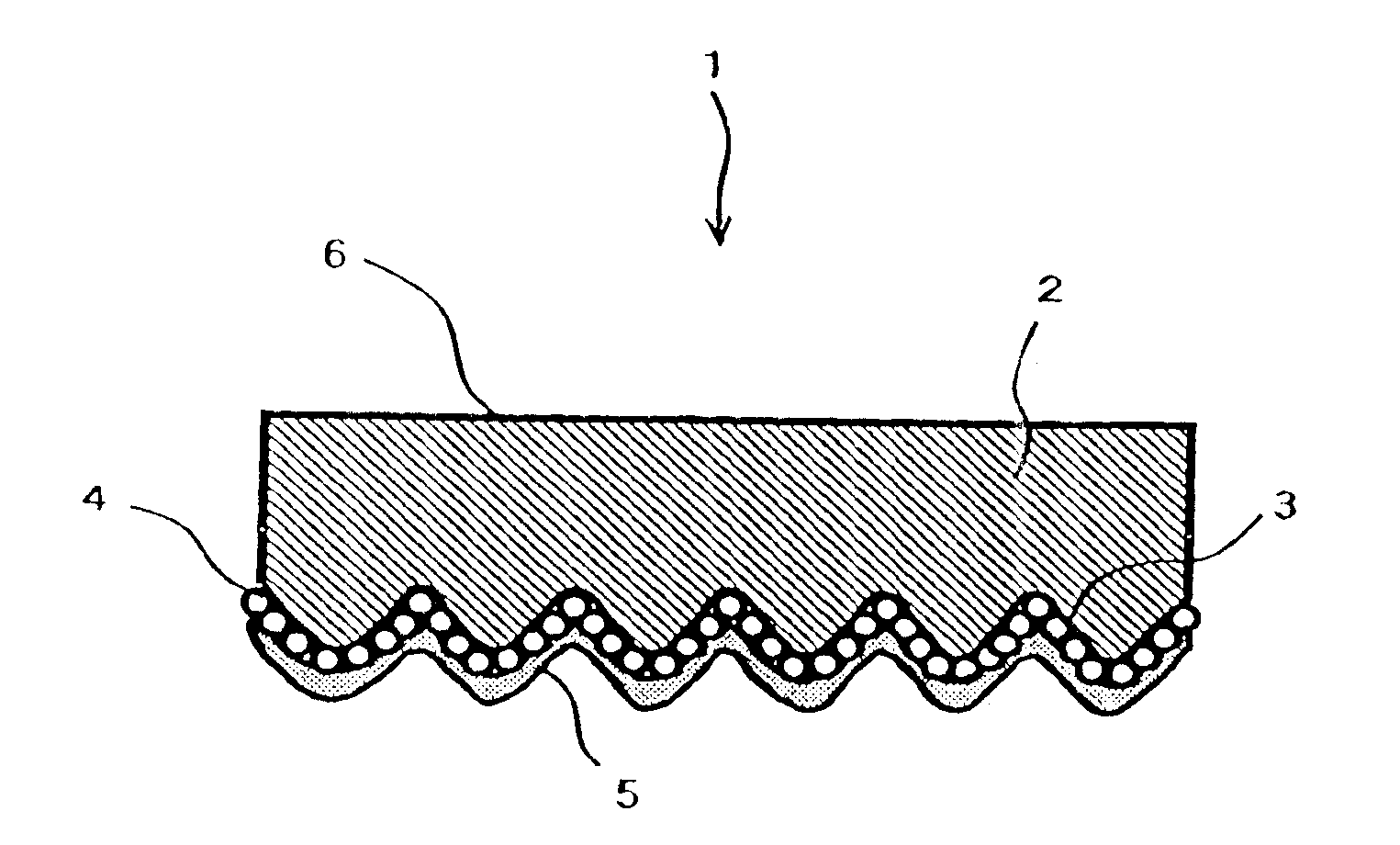

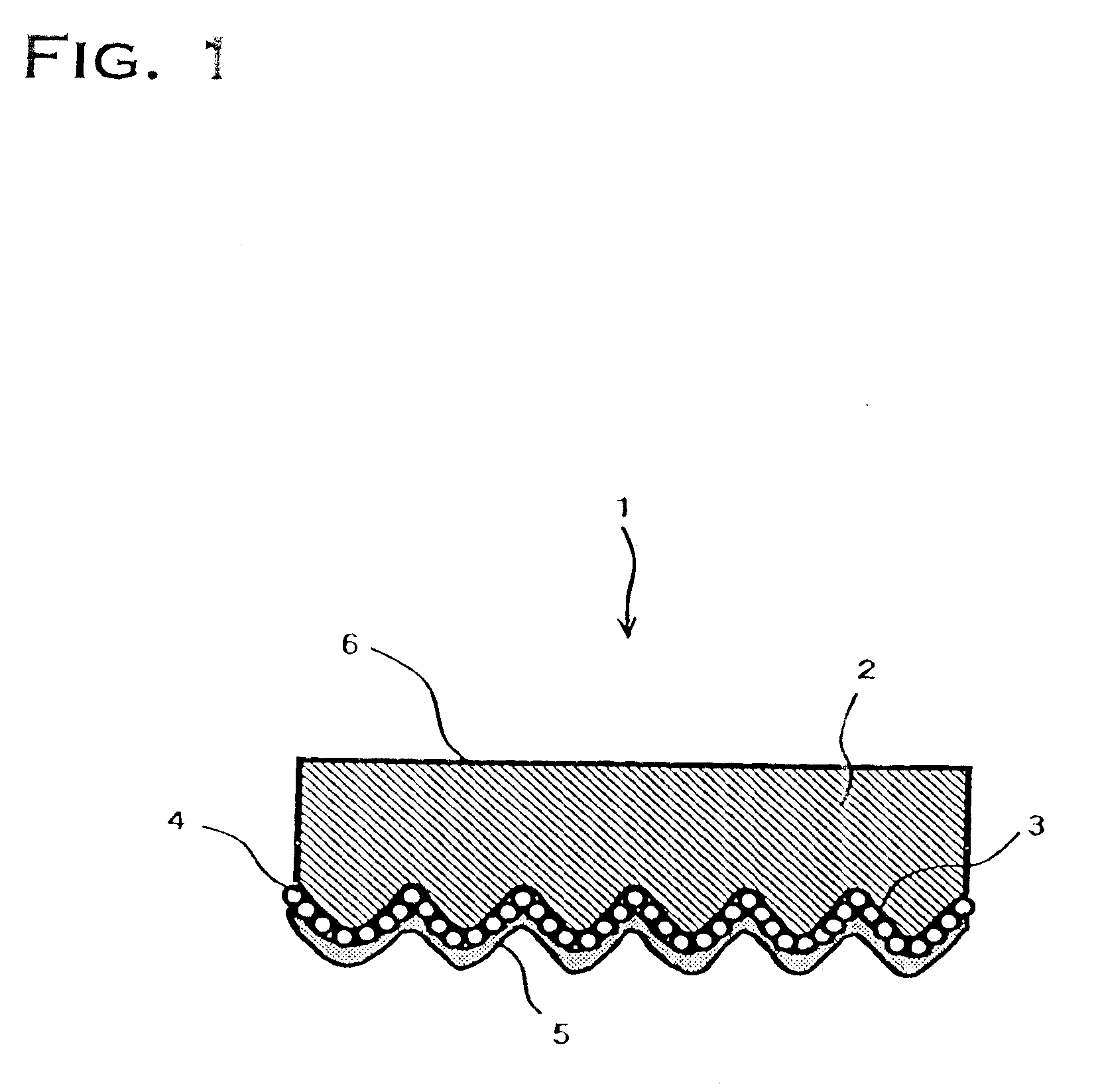

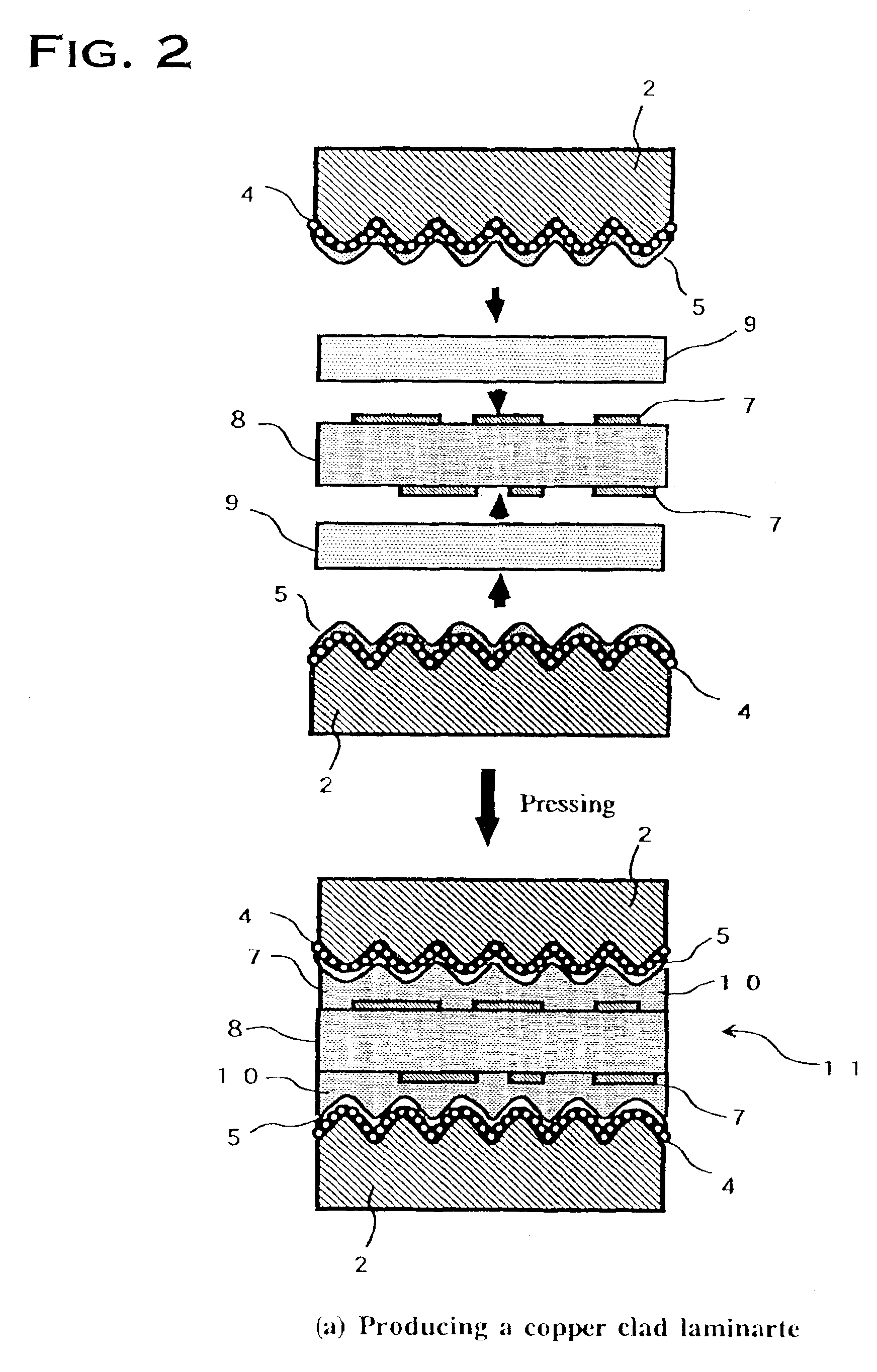

Copper foil for printed circuit board and copper clad laminate for printed circuit board

InactiveUS8142905B2High peel strengthEffectively preventing the circuit corrosion phenomenonAnodisationBaby linensCopper foilNickel zinc

Provided is a copper foil for a printed circuit board comprising a layer including nickel, zinc, a compound of nickel and that of zinc (hereinafter referred to a “nickel zinc layer”) on a roughened surface of a copper foil, and a chromate film layer on the nickel zinc layer, wherein the zinc add-on weight per unit area of the nickel zinc layer is 180 μg / dm2 or more and 3500 μg / dm2 or less, and the nickel weight ratio in the nickel zinc layer {nickel add-on weight / (nickel add-on weight+zinc add-on weight)} is 0.38 or more and 0.7 or less. This surface treatment technology of a copper foil is able to effectively prevent the circuit corrosion phenomenon in cases of laminating a copper foil on a resin base material and using a sulfuric acid hydrogen peroxide etching solution to perform soft etching to the circuit.

Owner:JX NIPPON MINING & METALS CORP

Method of manufacturing nickel zinc batteries

ActiveUS7833663B2Improve efficiencyFinal product manufactureElectrode carriers/collectorsZinc compoundsSlurry

Methods of manufacturing a rechargeable power cell are described. Methods include providing a slurry or paste of negative electrode materials having low toxicity and including dispersants to prevent the agglomeration of particles that may adversely affect the performance of power cells. The methods utilize semi-permeable sheets to separate the electrodes and minimize formation of dendrites; and further provide electrode specific electrolyte to achieve efficient electrochemistry and to further discourage dendritic growth in the cell. The negative electrode materials may be comprised of zinc and zinc compounds. Zinc and zinc compounds are notably less toxic than the cadmium used in NiCad batteries. The described methods may utilize some production techniques employed in existing NiCad production lines. Thus, the methods described will find particular use in an already well-defined and mature manufacturing base.

Owner:ZINCFIVE POWER INC

A kind of nickel-zinc-copper soft ferrite and preparation method thereof

InactiveCN102262950AHigh initial permeabilityHigh densityInorganic material magnetismInitial permeabilitySecondary component

The invention provides a nickel-zinc-copper soft ferrite and a preparation method thereof. The nickel-zinc-copper soft ferrite includes main components and auxiliary components, and the main components are iron oxide, nickelous oxide, zinc oxide, oxide Copper, characterized in that the content of the main components is as follows: iron oxide 65.05wt-66.35wt%; zinc oxide 20.66wt-22.20wt%; nickelous oxide 9.55wt-10.06wt%; copper oxide 2.91wt-3.17wt% ; The secondary component includes tungsten trioxide, and the content of the tungsten trioxide is 0.003wt-0.03wt%. The electromagnetic properties of the material in the invention reduce the loss performance of the product under the premise of maintaining high initial magnetic permeability and saturation magnetic flux density.

Owner:BYD CO LTD

Copper foil for printed-wiring board and copper-clad laminate using copper foil for printed-wiring board

InactiveUS6989199B2Reduced stabilityHigh absorptance for laser beamsInsulating substrate metal adhesion improvementThermometers using material expansion/contactionEtchingHeat resistance

The object is to provide a copper foil excellent in the property of selective etching between a resistor layer and a copper layer required in production of a printed-wiring board, and also excellent in UL heat resistance. For this purpose, a copper foil for printed-wiring board comprising a nodular treatment side on one side, wherein a nickel-zinc alloy layer is formed on the nodular treatment side is used for applications of printed-wiring boards. At the same time, a production method suitable for production of the copper foil is provided.

Owner:MITSUI MINING & SMELTING CO LTD

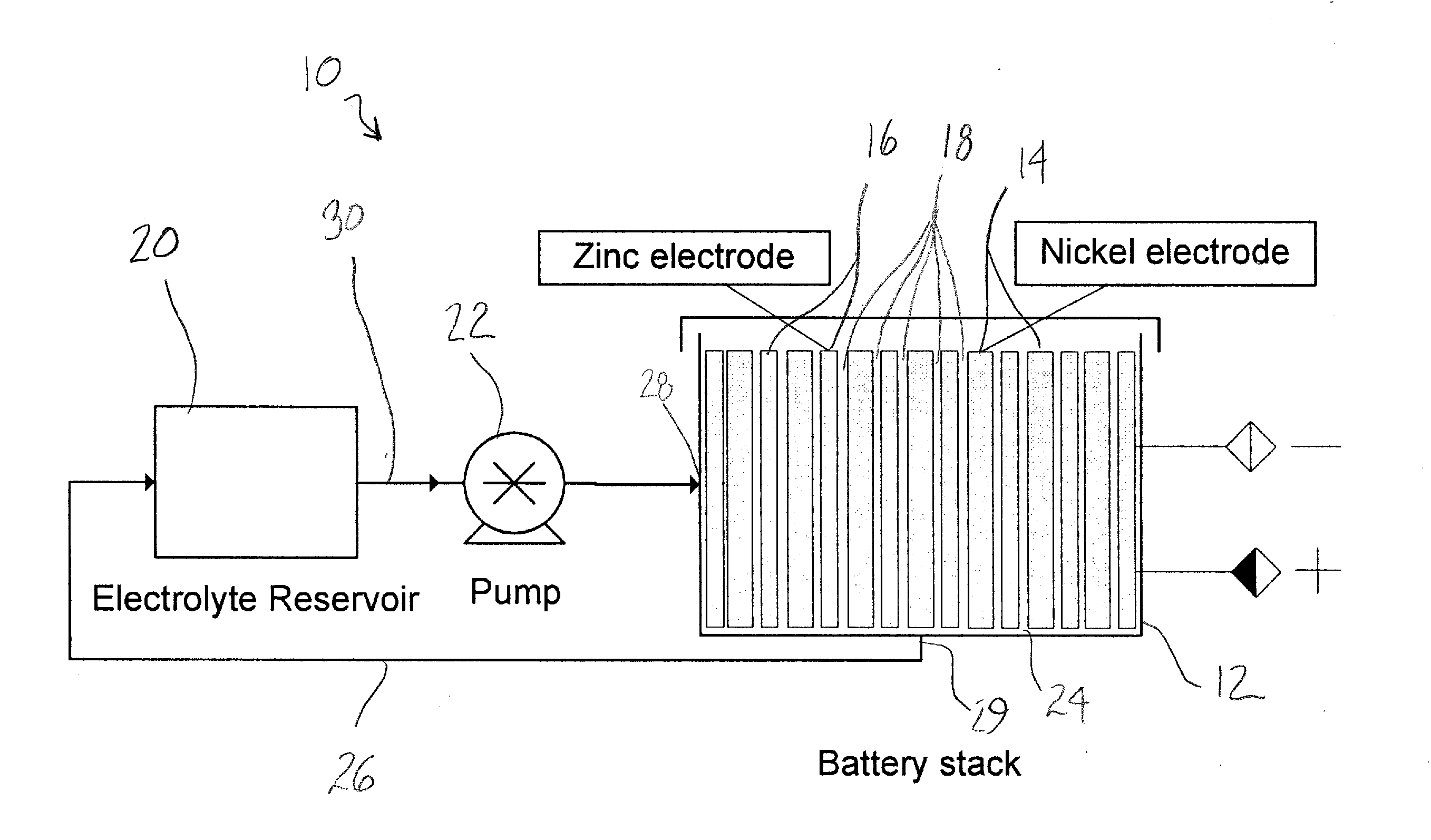

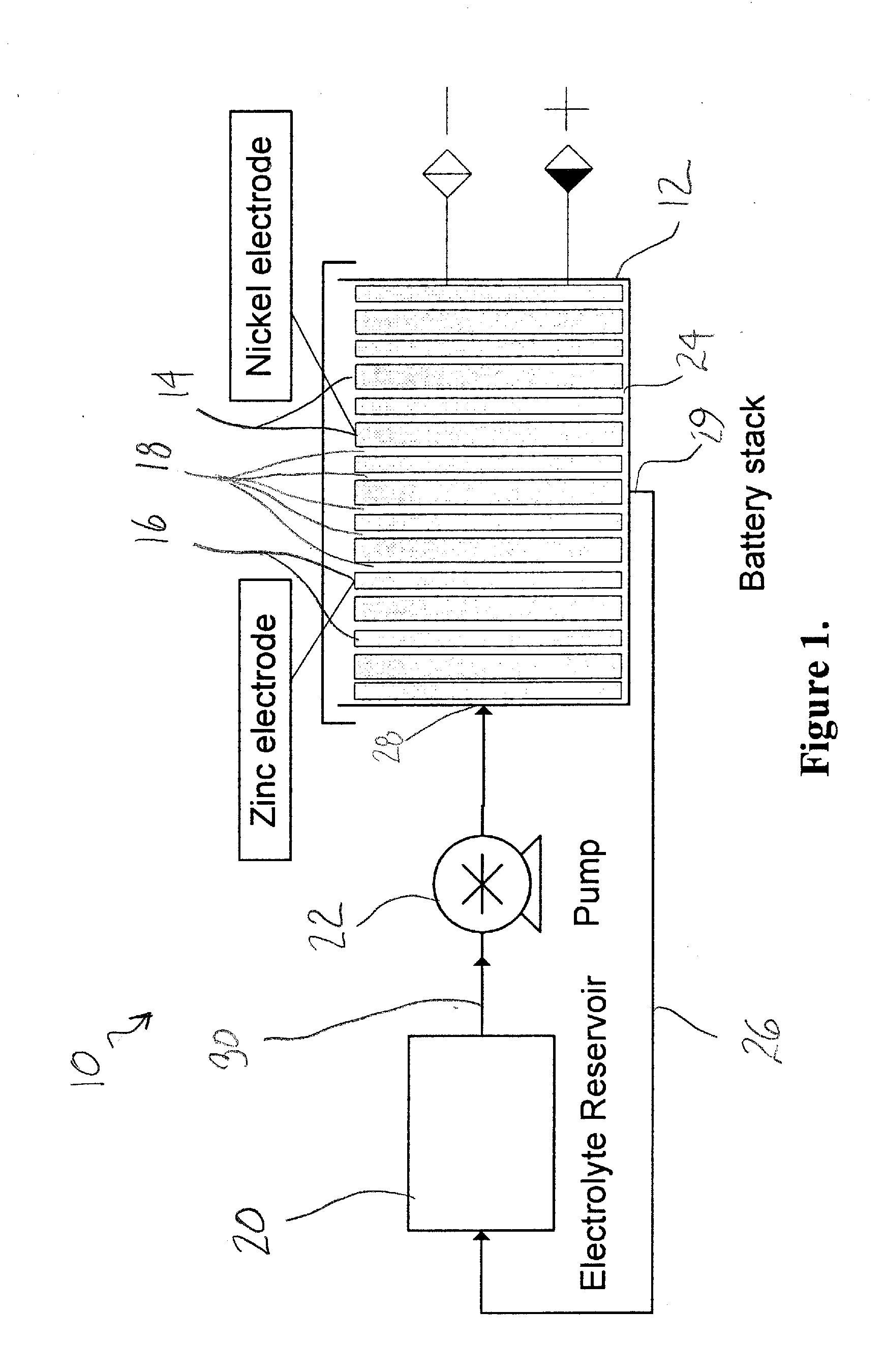

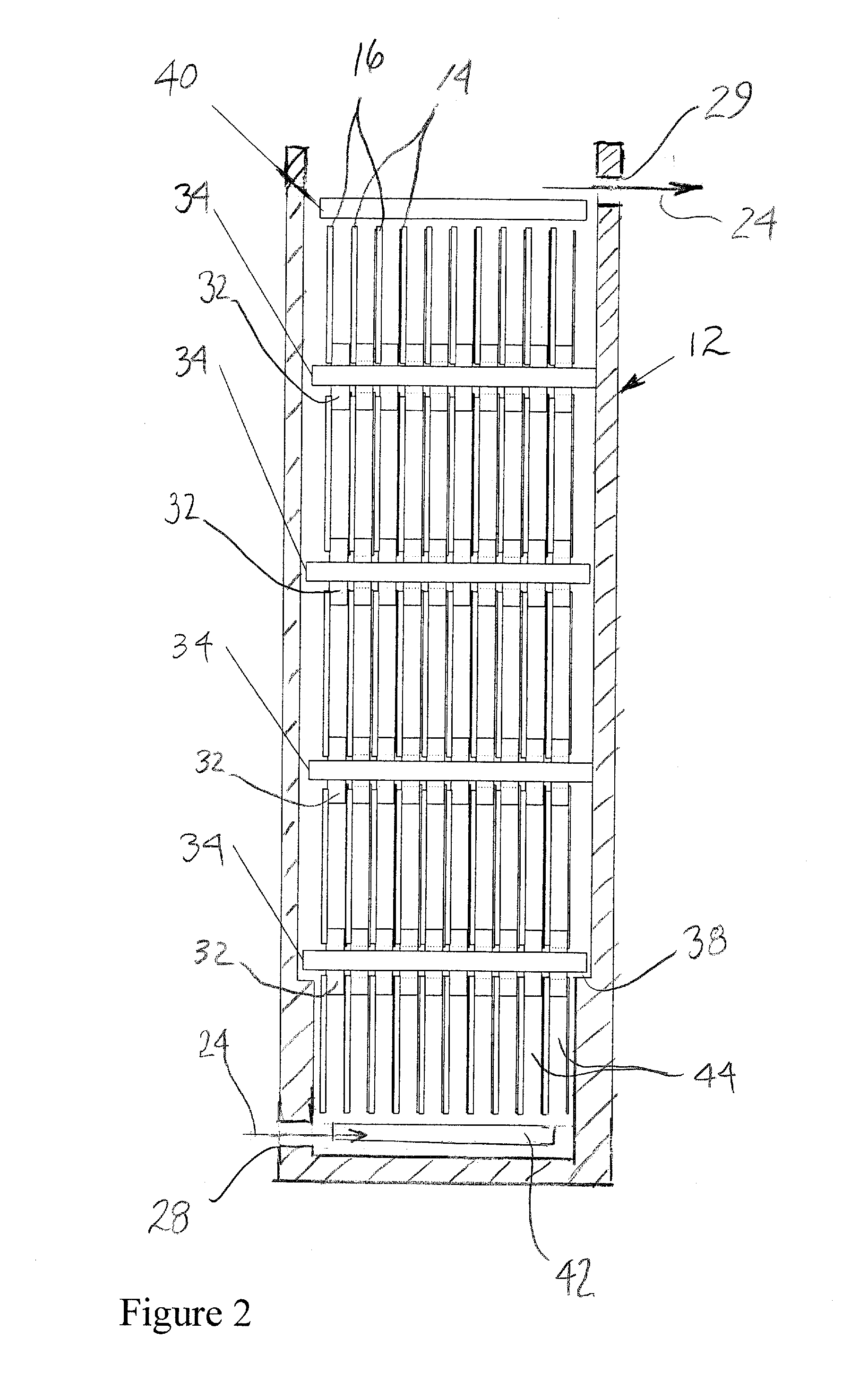

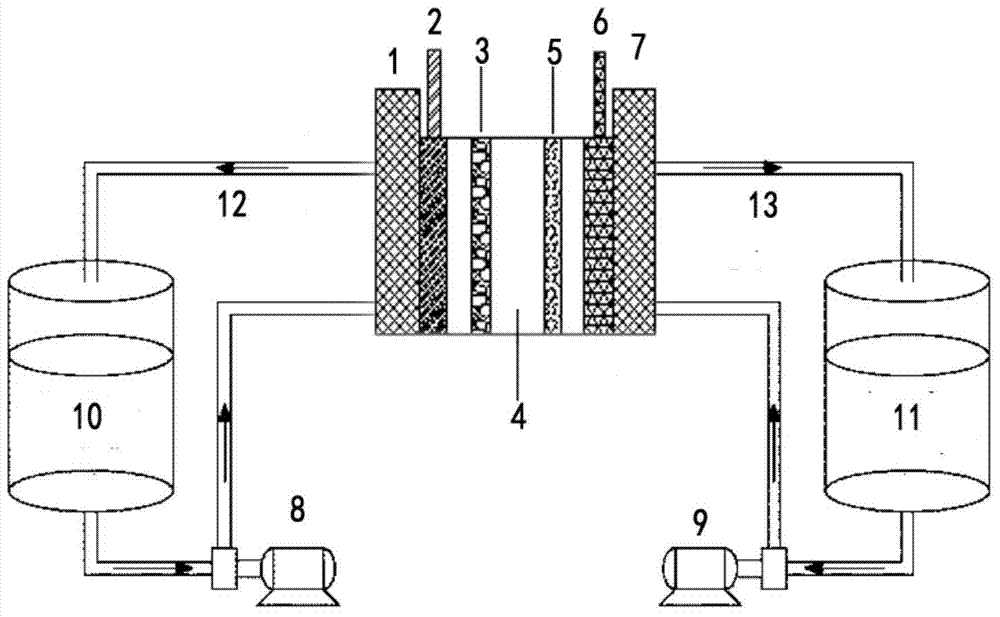

Nickel-Zinc Flow Battery

ActiveUS20130113431A1Improve cycle lifeEffective dissolutionElectrolyte moving arrangementsFinal product manufactureEngineeringNickel zinc

A nickel-zinc battery includes a battery housing, a nickel oxide positive electrode supported in the battery housing, a metal substrate negative electrode supported in the battery housing, a spacer disposed between the positive and negative electrodes, an electrolyte contained within the battery housing and a means for circulating electrolyte in fluid communication with the housing for circulating the electrolyte between the positive and negative electrodes. The electrolyte contains zinc and the metal substrate is adapted for deposition of the zinc during charging of the battery. The spacer maintains the positive electrode in a spaced relationship apart from the negative electrode.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

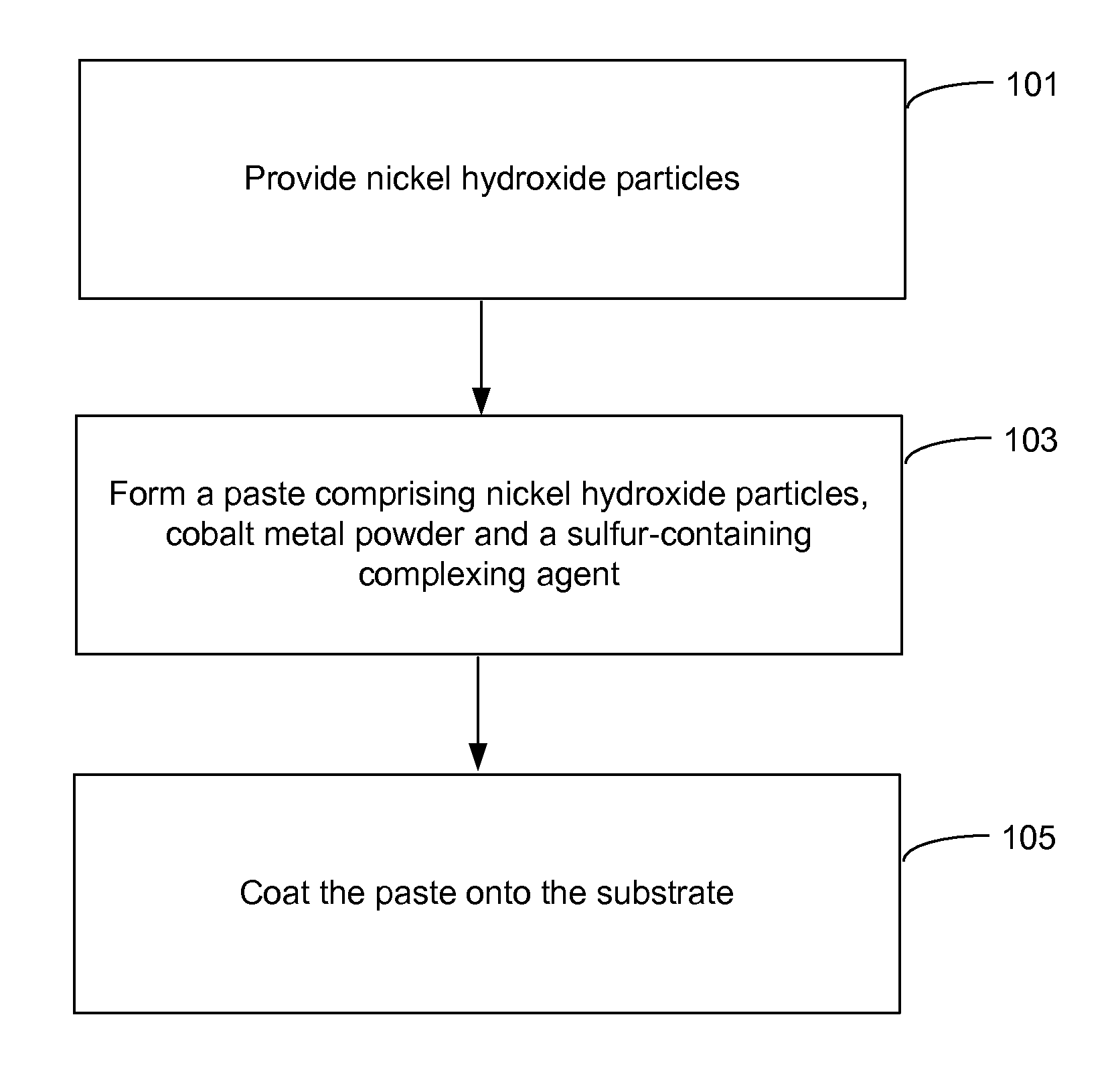

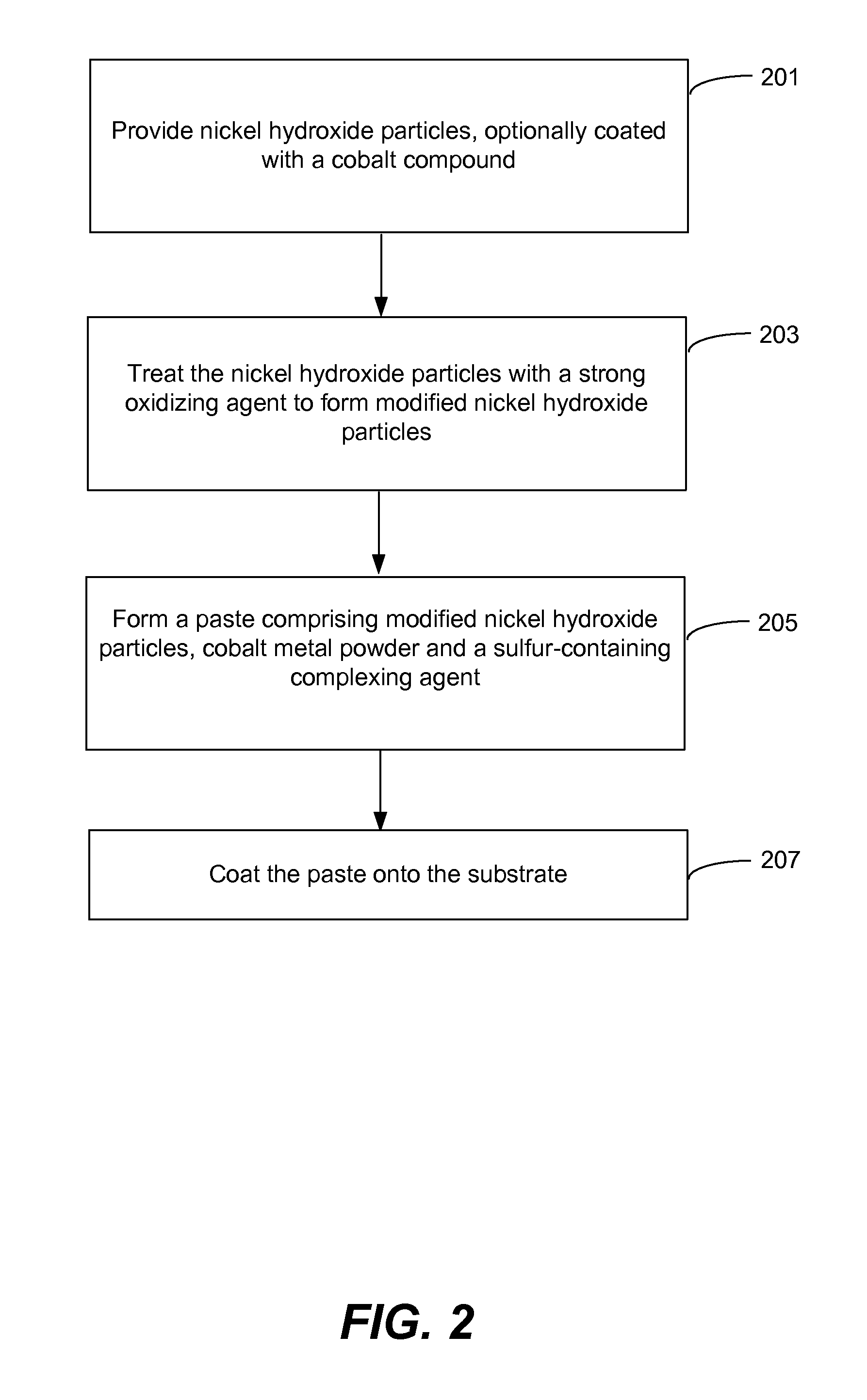

Pasted nickel hydroxide electrode and additives for rechargeable alkaline batteries

ActiveUS20140199591A1Prevent peelingMinimize migrationFinal product manufactureConductive materialNickel electrodeNickel zinc

A pasted positive nickel hydroxide electrode for use in battery cells (e.g., in nickel zinc cells, and nickel metal hydride cells) includes nickel hydroxide particles, a cobalt metal and / or cobalt compound and a sulfur-containing complexing agent capable of forming a complex with cobalt. The presence of the sulfur-containing complexing agent, such as dialkyldithiocarbamate (e.g., sodium diethyldithiocarbamate) improves lifetime and capacity utilization of the nickel electrode. The resulting pasted nickel hydroxide electrode includes a CoOOH conductive matrix after formation. The surface of the nickel hydroxide particles in the electrode is modified in some embodiments by providing a cobalt-containing coating onto the surface of the nickel hydroxide particles, followed by oxidation with a strong oxidizing agent. The complexing agent can be added before, after, or during the oxidation.

Owner:ZINCFIVE POWER INC

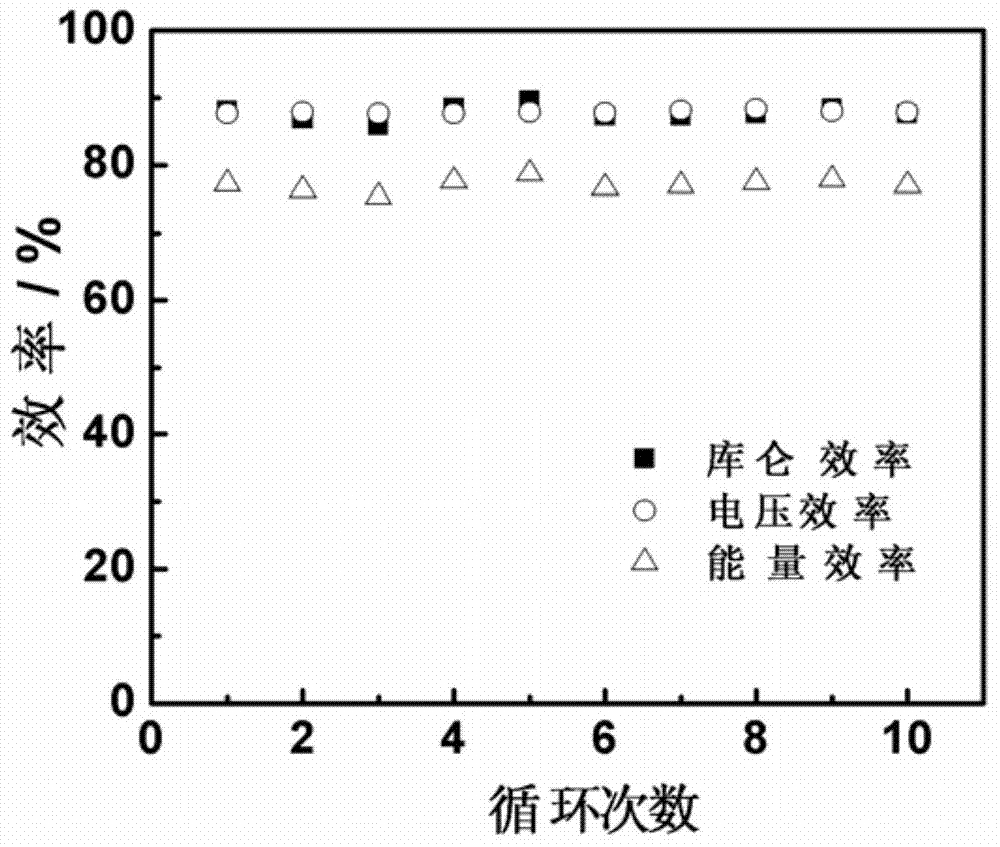

Zinc-nickel double-fluid flow battery

ActiveCN104716304ASolve the disadvantages of corrosionThere is no obvious attenuation in the charge-discharge cycle performanceAlkaline accumulator electrodesHigh concentrationAlkalinity

The invention relates to a zinc-nickel double-fluid flow battery. A single battery sequentially comprises a nickel electrode anode, a cation exchange membrane, an annular frame, an anion exchange membrane and a cathode that are superimposed in order. Both sides of the annular frame are respectively attached to the cation exchange membrane and the anion exchange membrane, two side opening ends of the annular frame are sealed by the cation exchange membrane and the anion exchange membrane, and the central cavity of the annular frame is enclosed into an electrolyte solution storage cavity. A third solution is loaded in the electrolyte solution storage cavity to conduct ions so as to form an ion conducting loop. Two different ion exchange diaphragms are used between the anode and cathode of the battery, by introducing the annular frame into the center, acidity and alkalinity of the electrolyte solutions at the anode and cathode are designed separately and independently, so that the anode electrolyte solution of the zinc-nickel fluid flow battery can use a low concentration alkali fluid, and the cathode electrolyte solution can use a zinc ion containing neutral aqueous solution, thus effectively solving the corrosion defect caused by the need of conventional nickel-zinc fluid flow batteries for a high concentration alkaline zincate aqueous solution.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

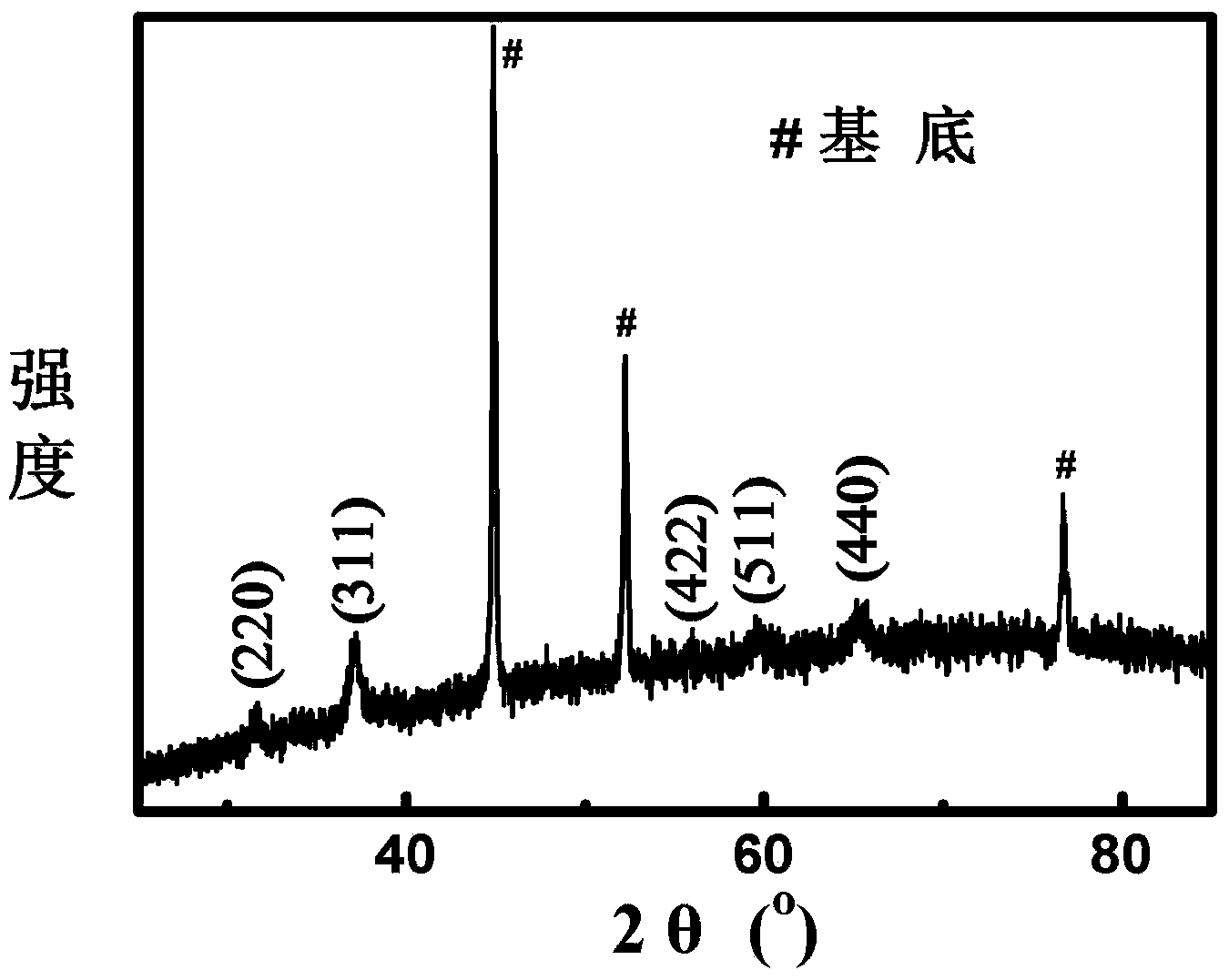

Special nickel-zinc ferrite material for integrated high frequency electrodeless discharge lamp inductive coupler and preparation method

The invention discloses a special nickel-zinc ferrite material for integrated high frequency electrodeless discharge lamp inductive coupler and a preparation method. The principal phase of the nickel-zinc ferrite material is spinel structure comprising Fe2O3, ZnO, NiO and Co2O3, wherein the composing and content are calculated in oxides comprising: Fe2O3 48mol%-56mol%, ZnO 15mol%-22mol%, NiO 20mol%-33mol%, Co2O3 0.001mol%-0.004. The invention can prepare a novel nickel-zinc soft magnetic ferrite with ultra wide temperature, high stability and low electromagnetic loss in high frequency and high current by using suitable formula and appropriate technological parameter, and the nickel-zinc ferrite material can do normal work in high temperature. The invention is contribute to reduce the electromagnetic loss and heat of the high frequency electronic discharge lamp inductive coupler, so as to guarantee the normal and stable work and is good for miniaturizing of device, therefore the material has very wide market prospect in novel electrodeless discharge lamp lighting system.

Owner:JIAXING LONG KINGS LIGHTING SCI & TECH

Enclosed nickel-zinc primary battery its anode and production methods for them

InactiveUS20040072070A1Gel electrodesSmall-sized cells cases/jacketsNickel oxide hydroxideZinc alloys

Owner:TOSHIBA BATTERY

Copper Foil for Printed Circuit Board and Copper Clad Laminate for Printed Circuit Board

InactiveUS20100261033A1Prevent deterioration in peel strengthImprove heat-resistant peel strengthAnodisationPrinted circuit secondary treatmentCopper foilNickel zinc

Provided is a copper foil for a printed circuit board comprising a layer including nickel, zinc, a compound of nickel and that of zinc (hereinafter referred to a “nickel zinc layer”) on a roughened surface of a copper foil, and a chromate film layer on the nickel zinc layer, wherein the zinc add-on weight per unit area of the nickel zinc layer is 180 μg / dm2 or more and 3500 μg / dm2 or less, and the nickel weight ratio in the nickel zinc layer {nickel add-on weight / (nickel add-on weight+zinc add-on weight)} is 0.38 or more and 0.7 or less. This surface treatment technology of a copper foil is able to effectively prevent the circuit corrosion phenomenon in cases of laminating a copper foil on a resin base material and using a sulfuric acid hydrogen peroxide etching solution to perform soft etching to the circuit.

Owner:JX NIPPON MINING& METALS CORP

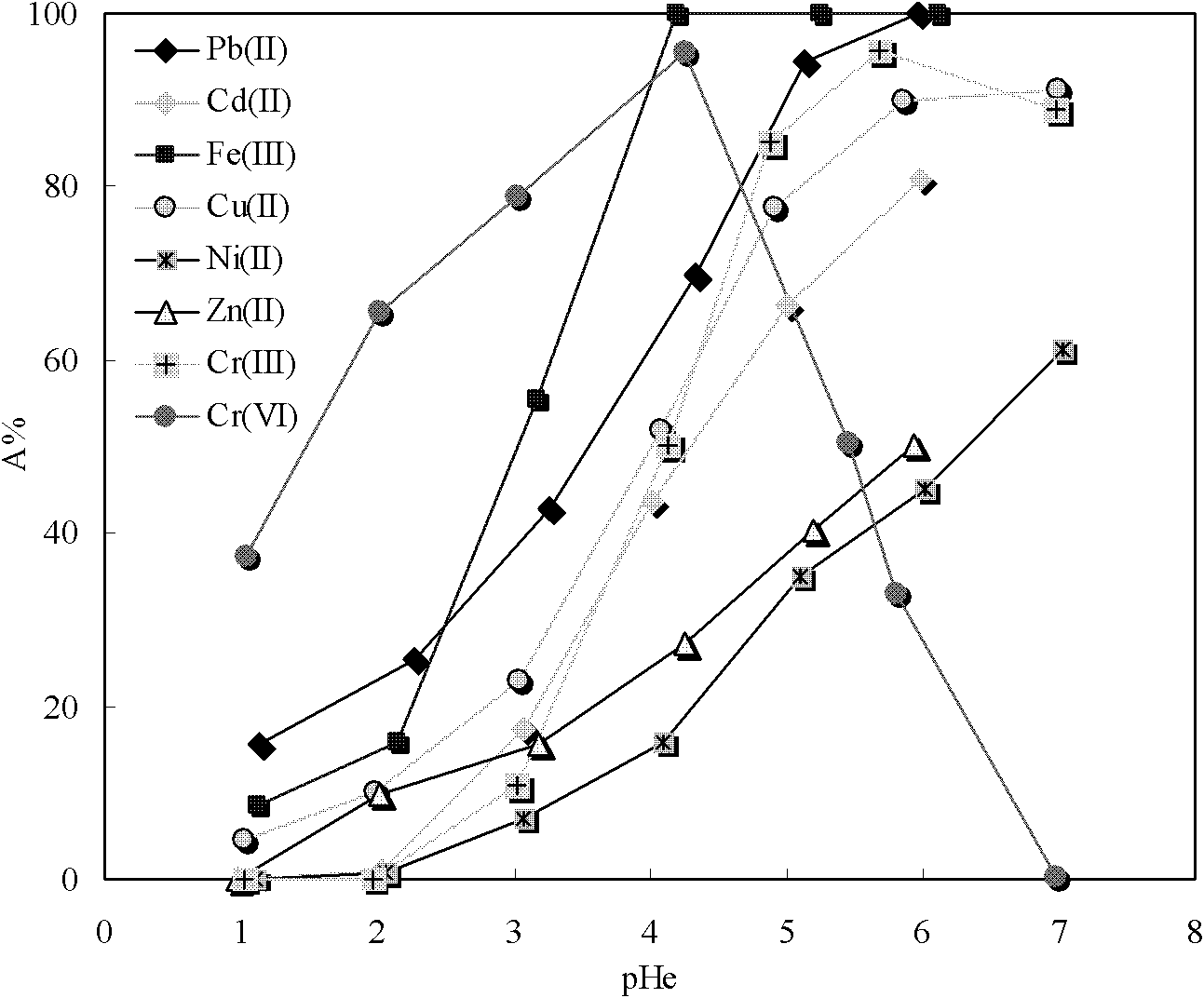

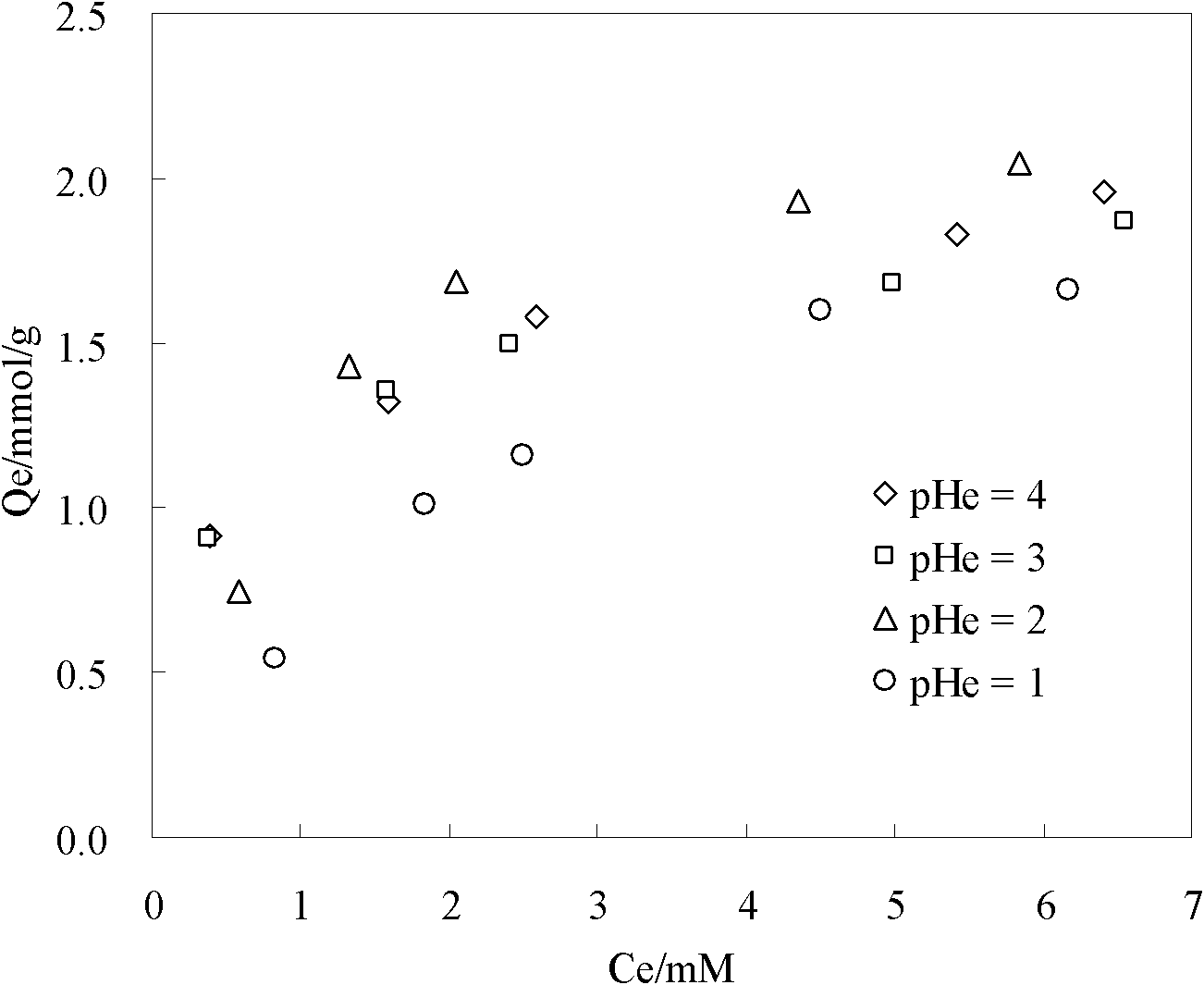

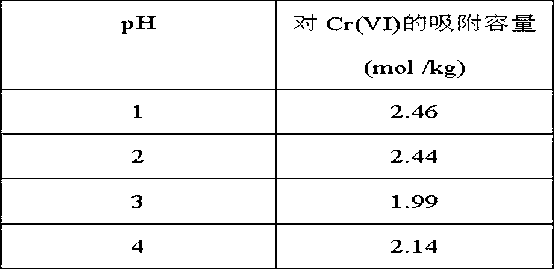

Method for absorbing and removing heavy metal and hexavalent chromium from waste liquid by using mangosteen slag

InactiveCN102935352AReasonable designEasy to operateOther chemical processesWater/sewage treatment by sorptionLiquid wasteSorbent

The invention relates to a method for absorbing and removing a heavy metal and hexavalent chromium from waste liquid by using mangosteen slag. The method comprises the following steps of washing a certain amount of mangosteen pericarp, mangosteen fruit stems or juice-squeezed solid residues, mixing the above solid residues and alkali and water according to a mass ratio of 1 : 0.05-0.2 : 0.5-2 with stirring; reacting for 0.5-48 hours; washing the solid product, drying in a vacuum oven at a temperature of 60-100 DEG C; smashing and screening to obtain an absorbent material; preparing a metal ion water solution containing lead cadmium copper iron nickel zinc and hexavalent chromium, wherein the concentration of the metal ion water solution is 0.1-10 mmol / L; and adding the absorbent material obtained from the step 3 according to a proportion of the weight of the absorbent to the volume of the solution being 0.25-20 g / L, wherein the absorbent cam absorb the hexavalent chromium ions and heavy metal ions in the water solution. The method has the beneficial effects of reasonable design, simple operation and significant effect, can not cause secondary pollutions after adsorption treatment, and is easy to popularize.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing ferrite magnetic sheet of wireless charger from waste soft-magnetic material

InactiveCN107216136ALow costImprove performanceInorganic material magnetismInductances/transformers/magnets manufactureManganeseSlurry

The invention specifically relates to a method for preparing a ferrite magnetic sheet of a wireless charger from a waste soft-magnetic material, belonging to the field of electromagnetic materials. The method comprises the following steps: (1) batching: subjecting reaction materials including (mass percentage) waste manganese-zinc magnetic cores (MnZnFeO3), waste nickel-zinc magnetic cores (NiZnFeO3), SiO2, Bi2O3, V2O5, CuO and ZnO2 to ball milling with water and then to sieving; (2) tape casting and slurrying: subjectintg powder, deionized water, PVA, PAA, PEG, PVB and latex to ball milling with a roller-type ball mill; (3) tape casting and molding: preparing a green body from tape-cast slurry on a tape casting machine; (4) adhesive discharging: subjecting the molded green body to adhesive discharging with an electric resistance furnace; (5) sintering: sintering the green body having undergone adhesive discharging in an elevator furnace in a reducing atmosphere; (6) film pasting; and (7) porcelain cracking. The method provided by the invention has the advantages of low cost, conservation of energy, environmental protection and excellent product performance.

Owner:重庆正峰电子技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com