Method for absorbing and removing heavy metal and hexavalent chromium from waste liquid by using mangosteen slag

A heavy metal, hexavalent chromium technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of long treatment time, limited treatment capacity, troublesome nutrient solution preparation, etc. To achieve the effect of reducing processing cost, shortening processing cycle and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

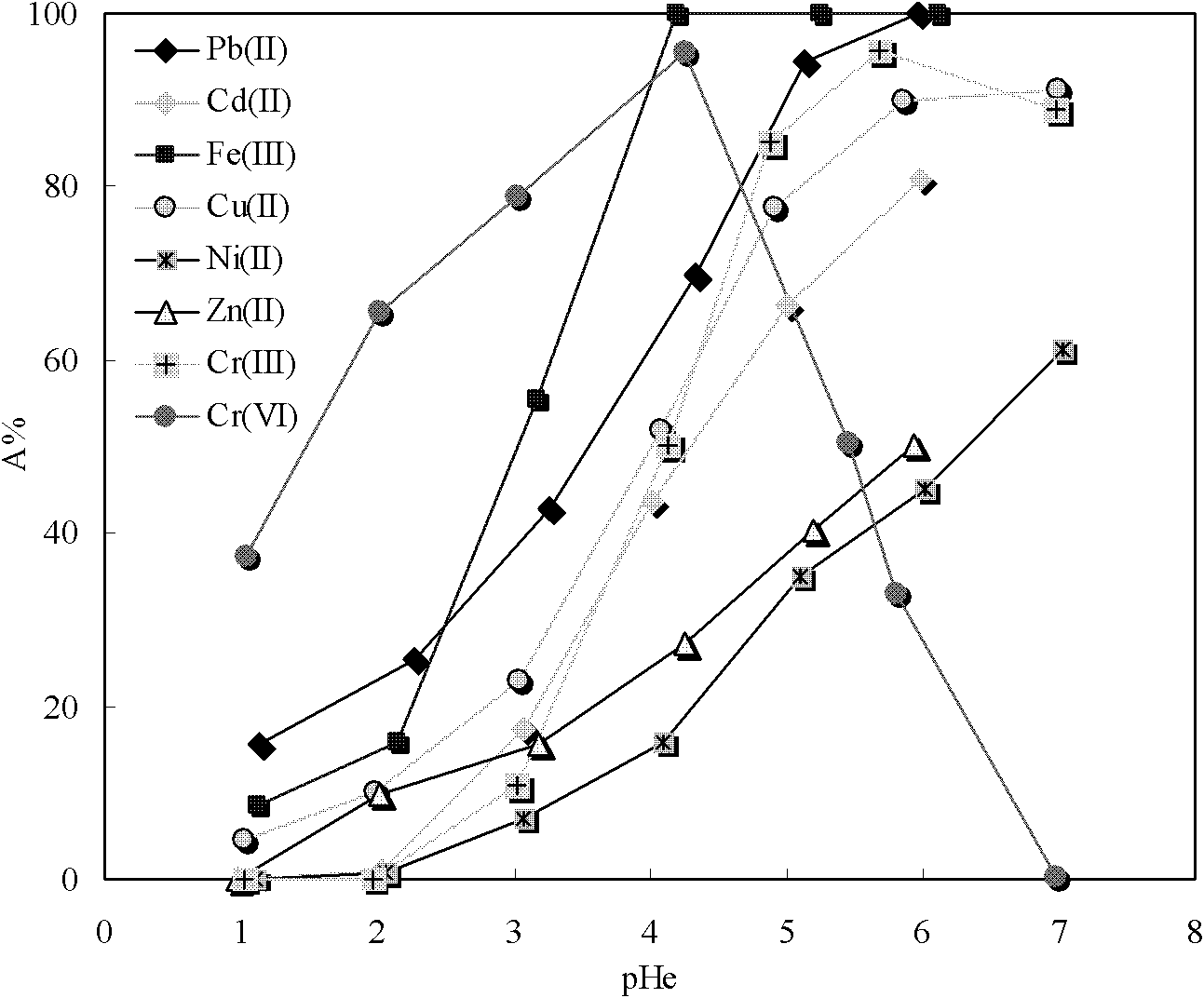

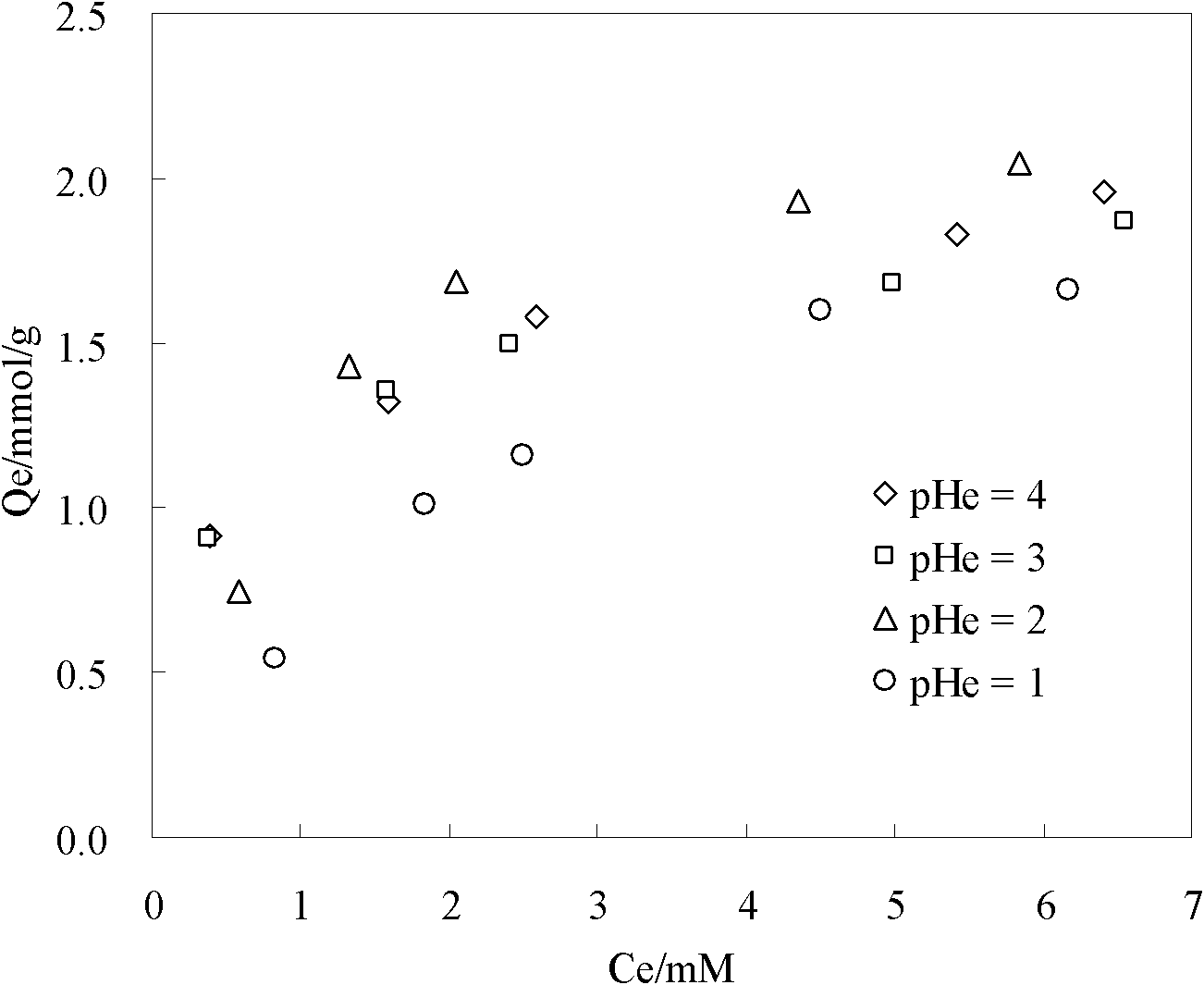

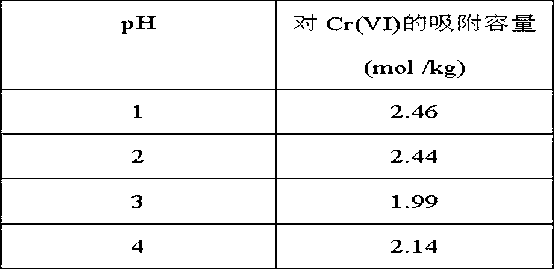

[0023] Embodiment 1: get 100 grams of mangosteen slag waste, cut into pieces no more than 1 cm in length, add 100 milliliters of water, add 5 grams of calcium hydroxide, add 10 grams of sodium hydroxide, make the pH value of the solution remain on 10 as far as possible, Stir for 12 hours, filter, wash the filter cake with water until neutral, then send it to an oven to dry at 60 o C After a total of 12 hours; crush and sieve the dried material, and collect particles below 40 mesh to be used as an adsorbent. Prepare an aqueous solution of metal ions containing lead, cadmium, copper, iron, nickel, zinc and hexavalent chromium with an initial concentration of 1 mmol per liter, mix it with the above adsorbent particles in a ratio of 1.6 g / l, and shake at room temperature for 24 Hours later, the adsorbent particles are removed by filtration, and the filtrate and the pre-adsorption solution are sent together for metal ion concentration analysis and detection. The analysis and detect...

Embodiment 2

[0025] Embodiment 2: get 100 grams of mangosteen slag waste, cut into pieces no more than 1 cm in size, add 60 milliliters of water, add 5 grams of calcium hydroxide and 1 gram of potassium carbonate, keep the pH value of the solution on more than 10 as far as possible, continue After keeping stirring for 2 hours, filter, wash the filter cake with water until neutral, and then send it into a vacuum oven at 70 o C Drying: crush and sieve the dried material, and collect particles below 40 mesh to be used as an adsorbent. Prepare an aqueous solution of metal ions containing lead, cadmium, copper, iron, nickel, zinc and hexavalent chromium with an initial concentration of 8 millimoles per liter, mix them with the above adsorbent particles at a ratio of 16 g / l, and shake at room temperature for 24 Hours later, the adsorbent particles are removed by filtration, and the filtrate and the solution before adsorption are sent together for metal ion concentration analysis and detection. T...

Embodiment 3

[0027] Embodiment 3: get 100 grams of mangosteen slag waste, cut into pieces no more than 1 cm in length, add 100 milliliters of water, add 5 grams of calcium carbonate, then add 5 grams of sodium carbonate, make the pH value of the solution remain on more than 10 as far as possible, After stirring for 8 hours, filter, wash the filter cake with water until neutral, then send it into a vacuum oven at 80 o C drying and drying; crush and sieve the dried material, and collect particles below 40 mesh to be used as an adsorbent. Prepare an aqueous solution of metal ions containing lead, cadmium, copper, iron, nickel, zinc and hexavalent chromium with an initial concentration of 5 mmol per liter, mix it with the above adsorbent particles at a ratio of 9 g / l, and shake at room temperature for 24 hours Finally, the adsorbent particles are removed by filtration, and the filtrate and the pre-adsorption solution are sent together for metal ion concentration analysis and detection. The ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com