Surface treatment process for reducing roughness of electrolytic copper foil

An electrolytic copper foil and surface treatment technology, applied in metal material coating process, printed circuit components, etc., can solve the problems of increased glue thickness, insufficient surface roughness, and reduced MIT performance, so as to reduce the surface roughness. , Excellent resistance to normal temperature, good corrosion resistance and etching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

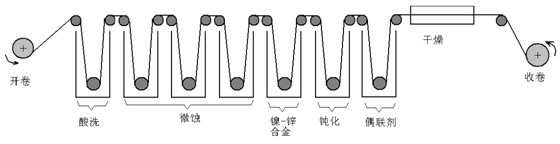

[0033] A surface treatment process for reducing the roughness of electrolytic copper foil in this embodiment, the process flow is:

[0034] LP wool foil—pickling—microetching—nickel plating—zinc alloy—passivation—silane coupling agent—drying—VLP copper foil.

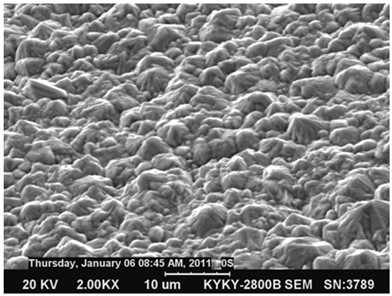

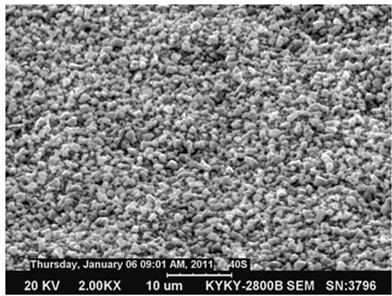

[0035] Using LP wool foil, the surface is first pickled to remove the oxide layer; then a micro-etching solution composed of hydrochloric acid-copper sulfate is sprayed on the rough surface of the copper foil, and the "peaks" are reacted into tiny nodular particles; A layer of nickel-zinc alloy, a layer of chromium-zinc alloy; finally, a layer of silane coupling agent is applied and then dried.

[0036] The specific process steps are as follows:

[0037] 1) Pickling: Dilute industrial pure concentrated sulfuric acid to dilute sulfuric acid with a concentration of 10% by volume, pump it into the pickling tank, put the copper foil into the pickling solution and soak for 3S;

[0038] The purpose of pickling is to remove t...

Embodiment 2

[0050] A surface treatment process for reducing the roughness of electrolytic copper foil, the specific treatment conditions are as follows:

[0051] 1) Pickling: Dilute industrial pure concentrated sulfuric acid to dilute sulfuric acid with a concentration of 12% by volume, pump it into the pickling tank, put the copper foil into the pickling solution and soak for 1S;

[0052] 2) Micro-etching: Dissolve copper sulfate pentahydrate in hot water (40°C), add industrially pure concentrated hydrochloric acid, mix well and etch the rough surface (crystal growth surface) sprayed on the copper foil; the specific process conditions are : CuSO 4 240 g / L, HCl 30g / L, temperature 40°C, time 25s;

[0053] 3) Nickel-zinc alloy plating: Dissolve nickel sulfate and zinc sulfate in water respectively and mix them, add industrially pure concentrated sulfuric acid, mix well and pump them into the nickel-zinc alloy plating tank for electroplating; the specific process conditions are: Zn 2+ 1....

Embodiment 3

[0058] A surface treatment process for reducing the roughness of electrolytic copper foil, the specific treatment conditions are as follows:

[0059] (1) Pickling: 15% sulfuric acid, time 1S;

[0060] (2) Microetching: CuSO 4 200 g / L, HCl 70g / L, temperature 35°C, time 40s;

[0061] (3) Nickel-zinc alloy: Zn 2+ 2.0 g / L, Ni 2+ 7 g / L, H 2 SO 4 150g / L, temperature 45℃, current density 6.7A / dm 2 , time 1S.

[0062] (4) Passivation: Cr 6+ 5g / L, Zn 2+ 0.2 g / L, K 4 P 2 o 7 80 g / L, 10.5, temperature is 32°C, current density is 6.8 A / dm 2 ; Processing time 3s.

[0063] (5) Silane coupling agent: KH560 5g / L, temperature 35°C, treatment time 1.5s.

[0064] (6) Drying: the temperature is 240°C, and the processing time is 5s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com