NiZn (nickel zinc) ferrite material with high magnetic conductivity and high Curie temperature and preparation method thereof

A technology of ferrite material and high magnetic permeability, which is applied in the fields of high resistivity NiZn ferrite material and its preparation, high magnetic permeability, and high Curie temperature, can solve the problems of unfavorable cost and reduction, and achieve improvement Reliability, low leakage inductance coefficient, and the effect of avoiding electronic ignition problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

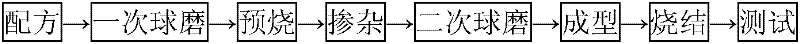

[0057] The main material of the NiZn ferrite material of the present invention is calculated as an oxide by mole percentage, and the dopant component is calculated by weight percentage as an oxide. High magnetic permeability of the present invention, high Curie temperature and high resistivity NiZn ferrite material and preparation method thereof, comprise the following steps:

[0058] 1) Recipe

[0059] Using 48.5~49.9mol% Fe 2 o 3 , 31.0-34.0mol% ZnO, 4.0-8.0mol% CuO, the balance being NiO;

[0060] 2) Ball milling once

[0061] Mix the above powders evenly in a ball mill for 1 to 3 hours;

[0062] 3) pre-burning

[0063] Dry the ball mill material obtained in step 2, and pre-fire it in a furnace at 800-1000°C for 1-3 hours;

[0064] 4) Doping

[0065] Add the following dopant to the powder obtained in step 3 by weight ratio: 0.001-0.30wt% MoO 3 , 0.001~0.20wt%V 2 o 5 , 0.01~0.40wt% Bi 2 o 3 , 0.001~0.05wt%Nb 2 o 5 , 0.001~0.08wt% nano-TiO 2 ;

[0066] 5) Seco...

Embodiment 1~8

[0079] Embodiments 1-8: A NiZn ferrite material with high magnetic permeability, high Curie temperature and high resistivity and its preparation method, comprising the following steps:

Embodiment 1~4

[0081] 1. Formula

[0082] Embodiment 1~4 master formula sees the following table:

[0083]

[0084] 2. One ball milling

[0085] Mix the above powders evenly in a ball mill for 2 hours;

[0086] 3. Pre-burning

[0087] Dry the ball mill material obtained in step 2, and pre-fire it in a furnace at 950°C for 2 hours;

[0088] 4. Doping

[0089] Add the following dopant by weight ratio to the powder obtained in step 3: 0.12wt% MoO 3 , 0.08wt%V 2 o 5 , 0.02wt% Bi 2 o 3 , 0.003wt% Nb 2 o 5 , 0.002wt% nano-TiO 2 ;

[0090] 5. Secondary ball milling

[0091] The powder obtained in step 4 was ball milled in a ball mill for 6 hours;

[0092] 6. Forming

[0093] Add 10wt% organic binder to the powder obtained in step 5 by weight, mix evenly, and after granulation, press the granular powder into a blank on a press;

[0094] 7. Sintering

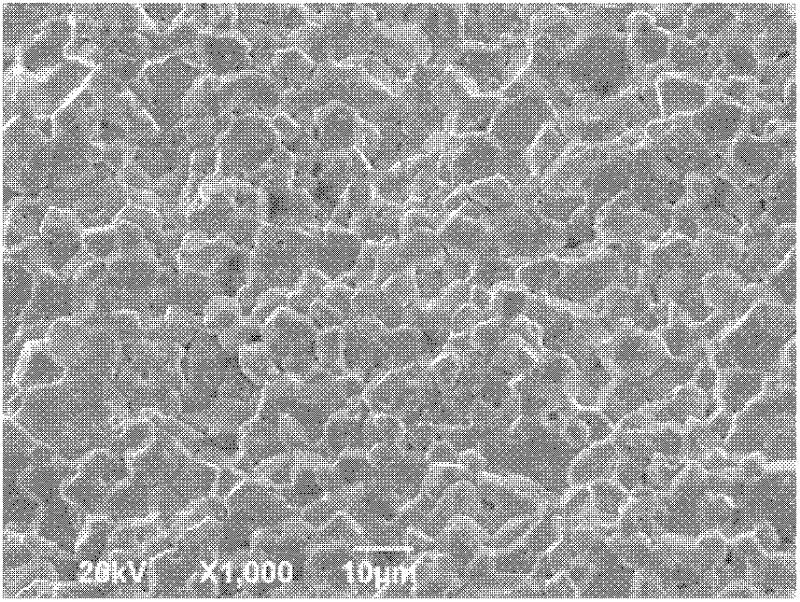

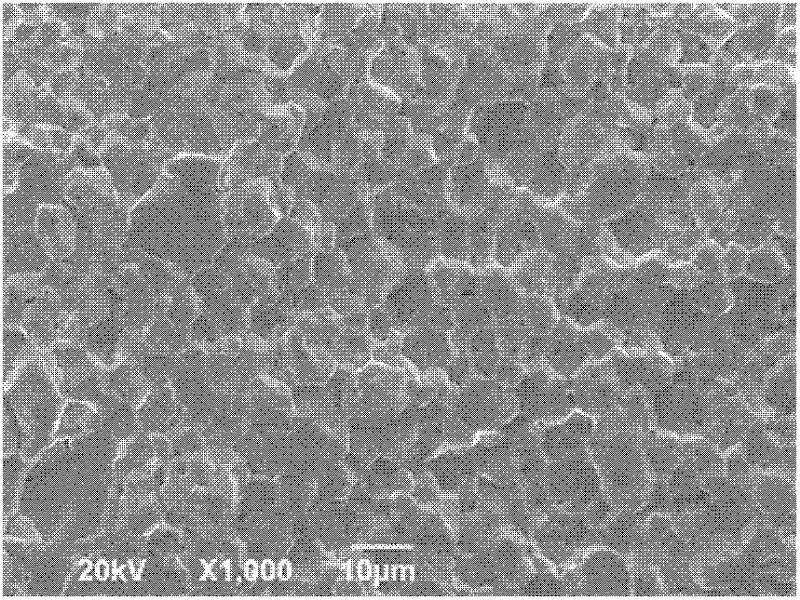

[0095] The blank obtained in step 6 was placed in a sintering furnace for sintering, and kept at 1080° C. for 3 hours.

[0096] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com