Patents

Literature

51 results about "Jelly roll" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

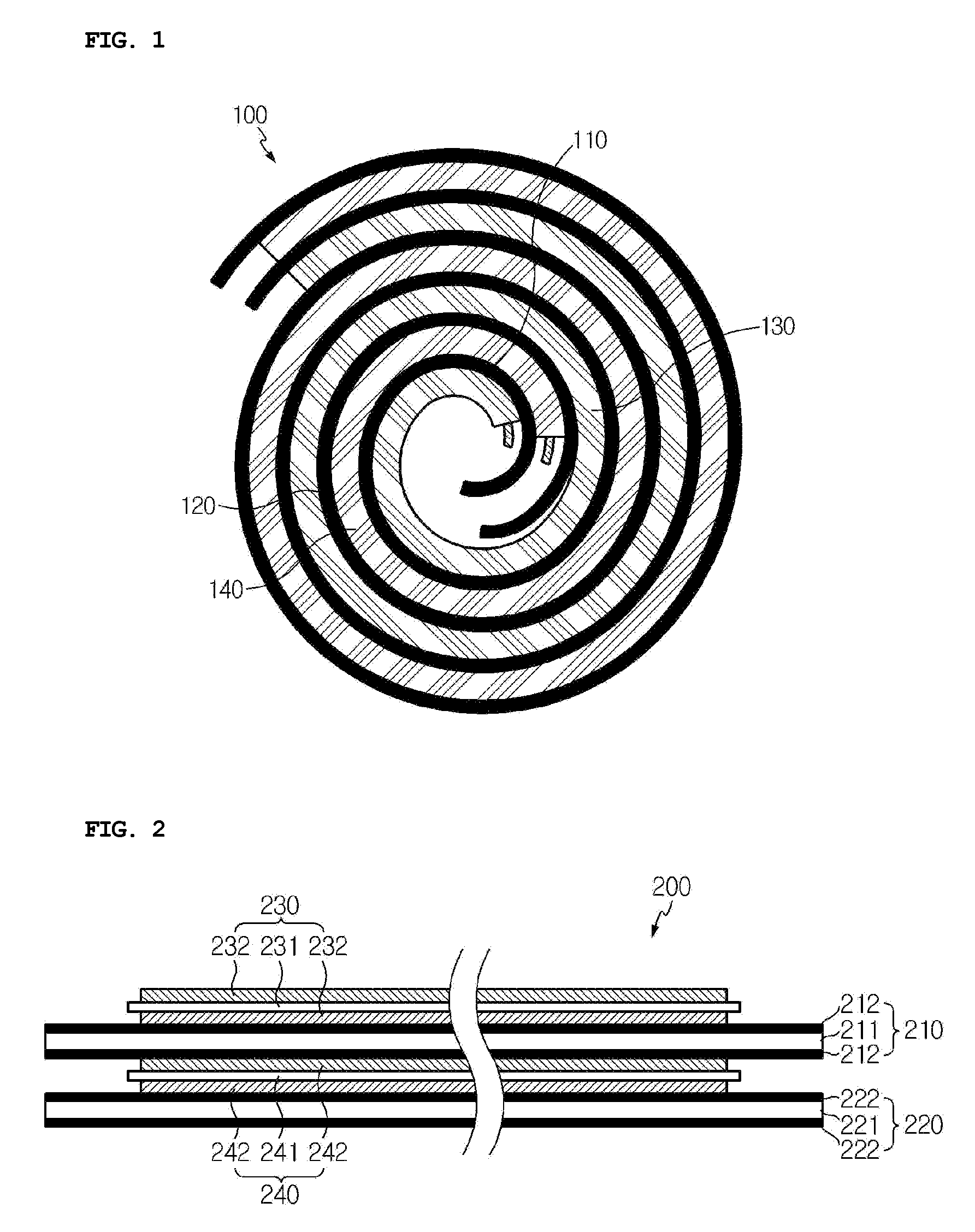

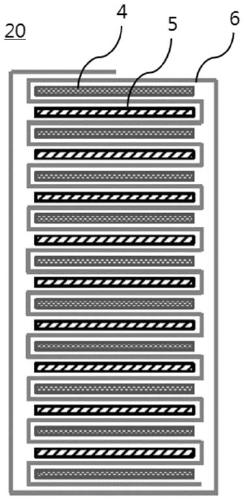

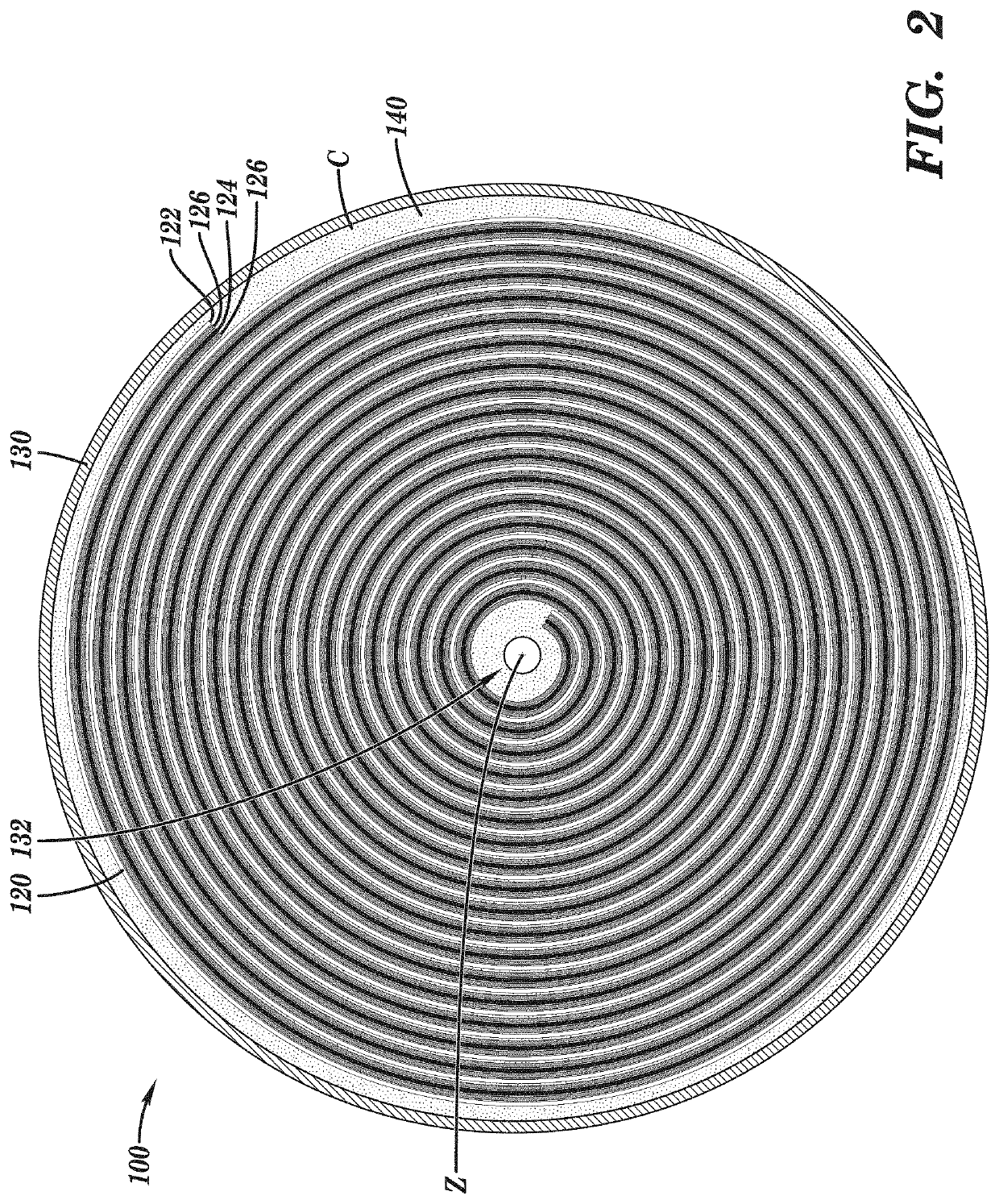

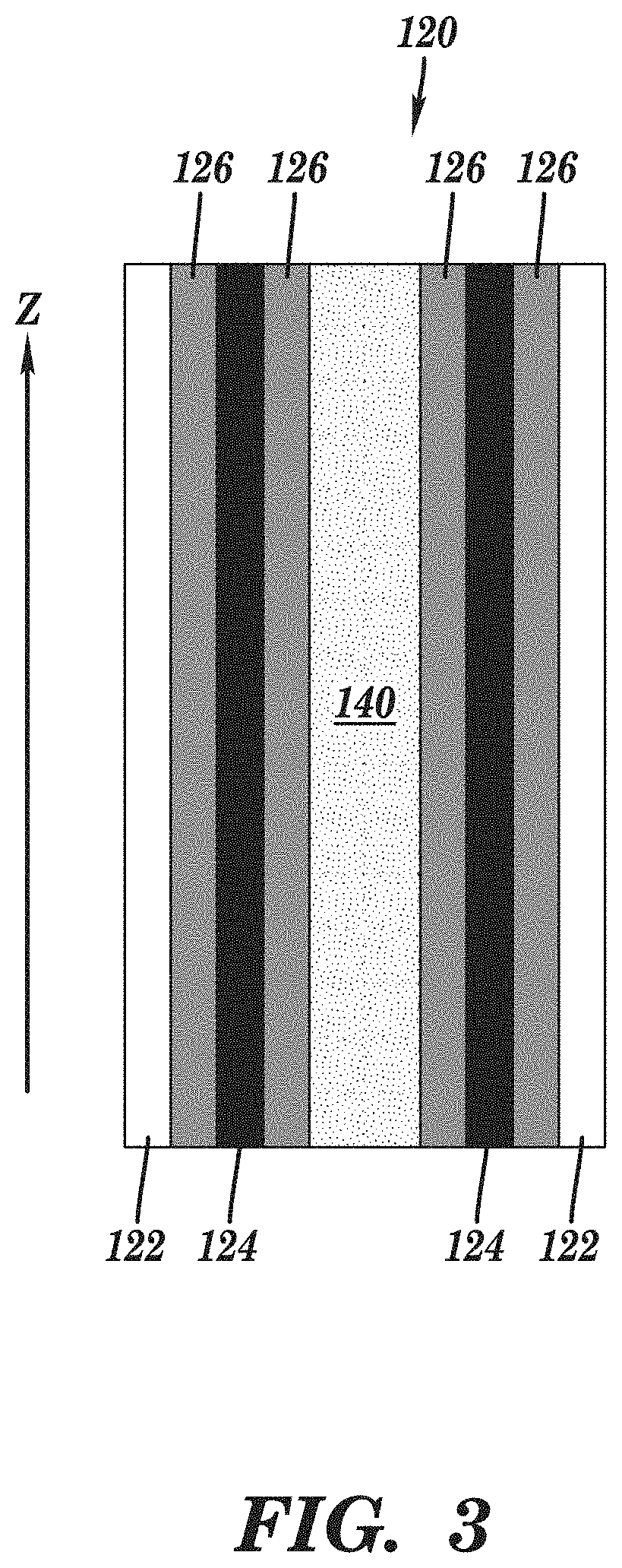

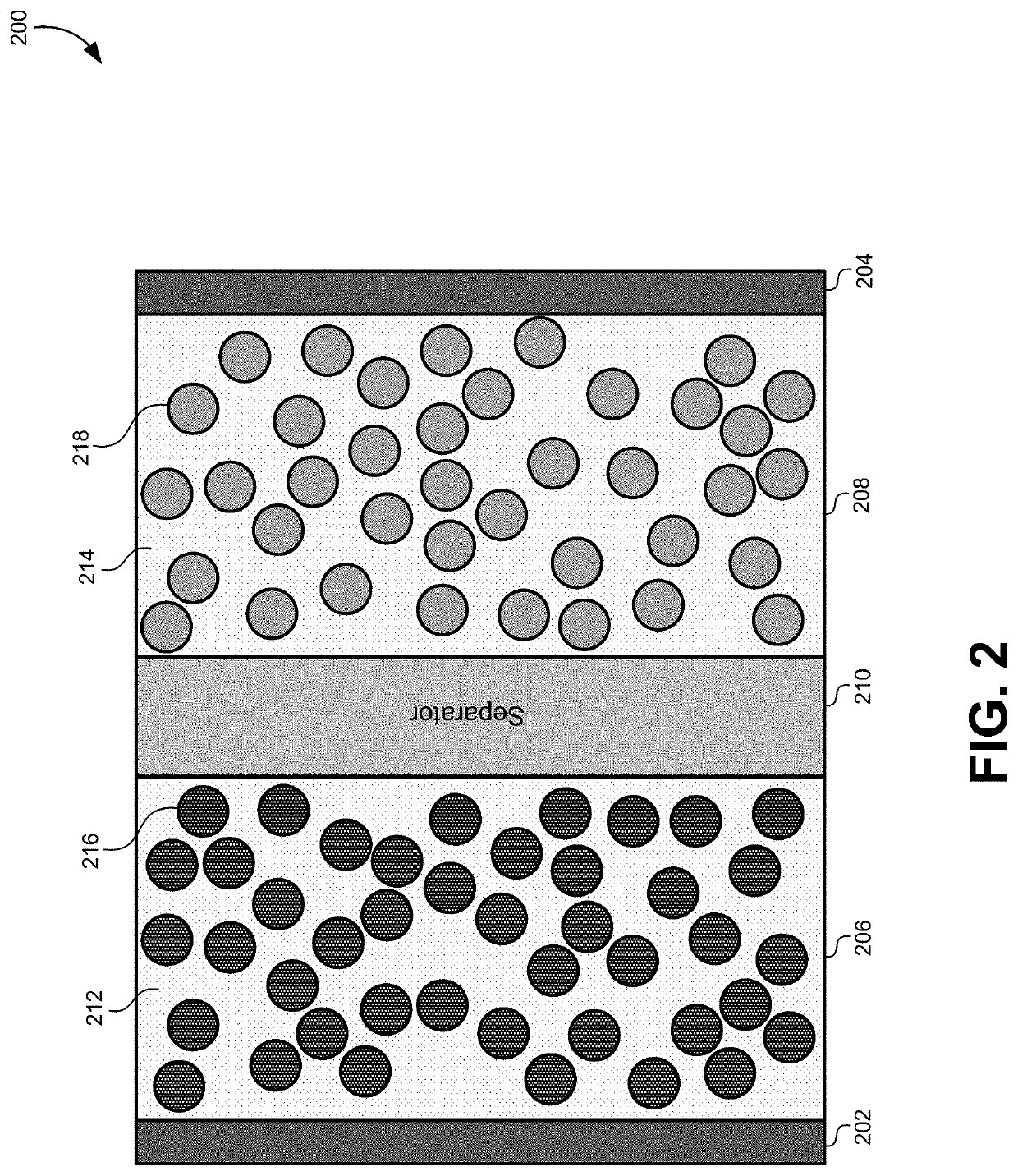

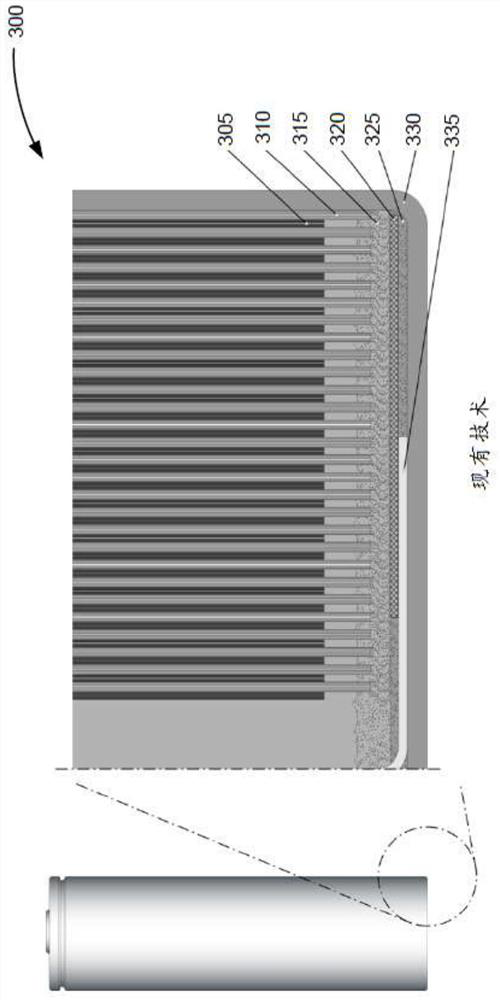

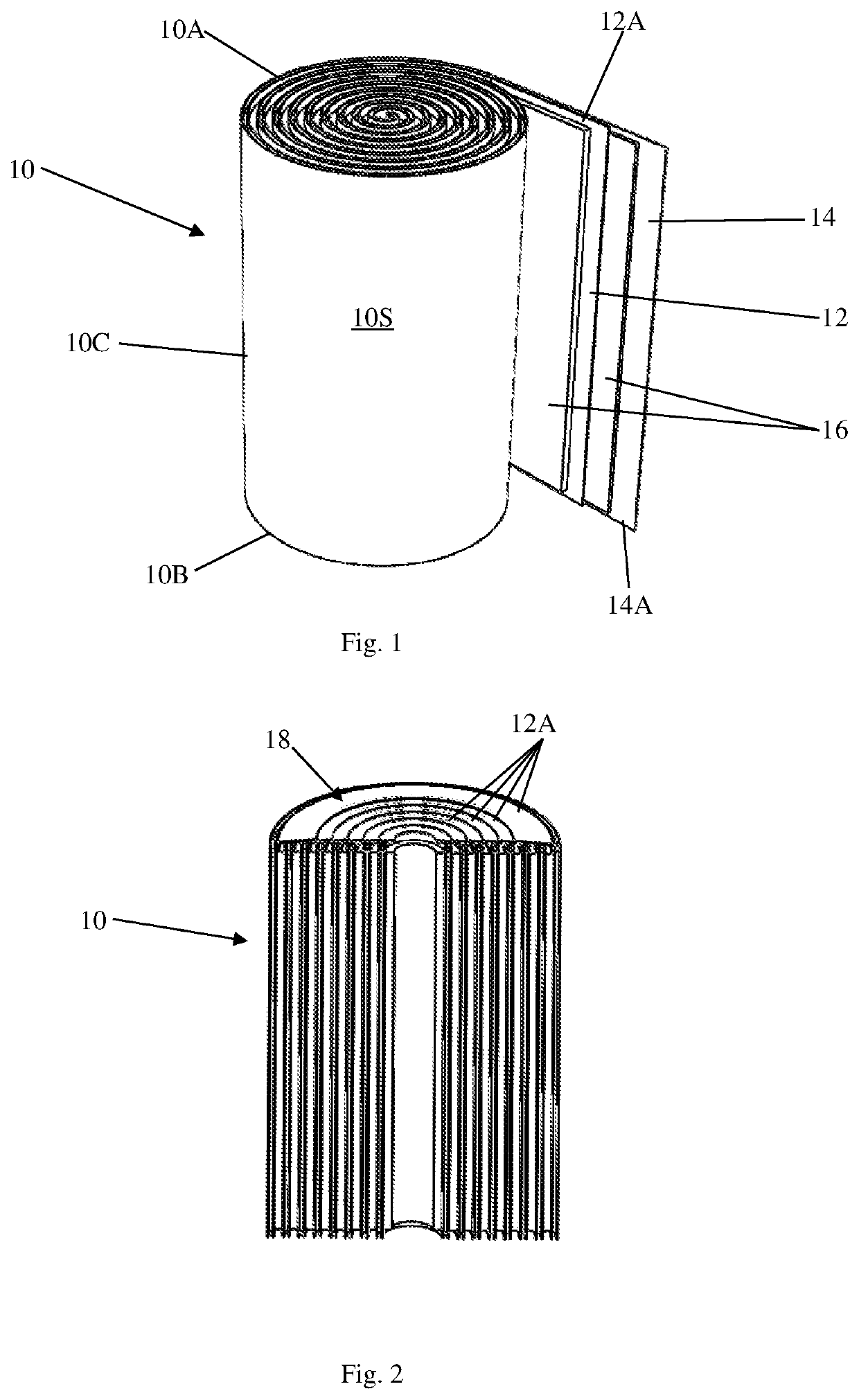

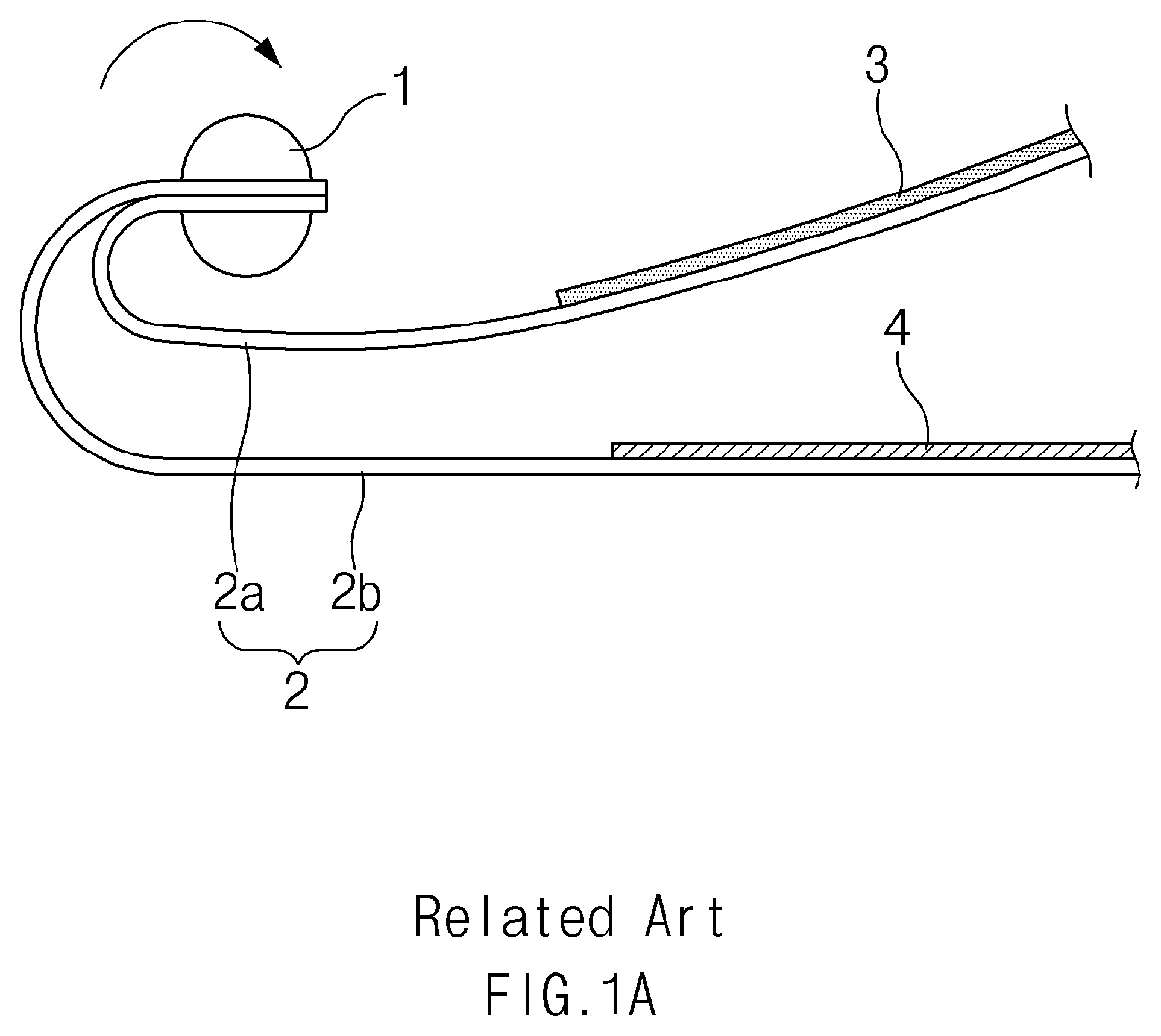

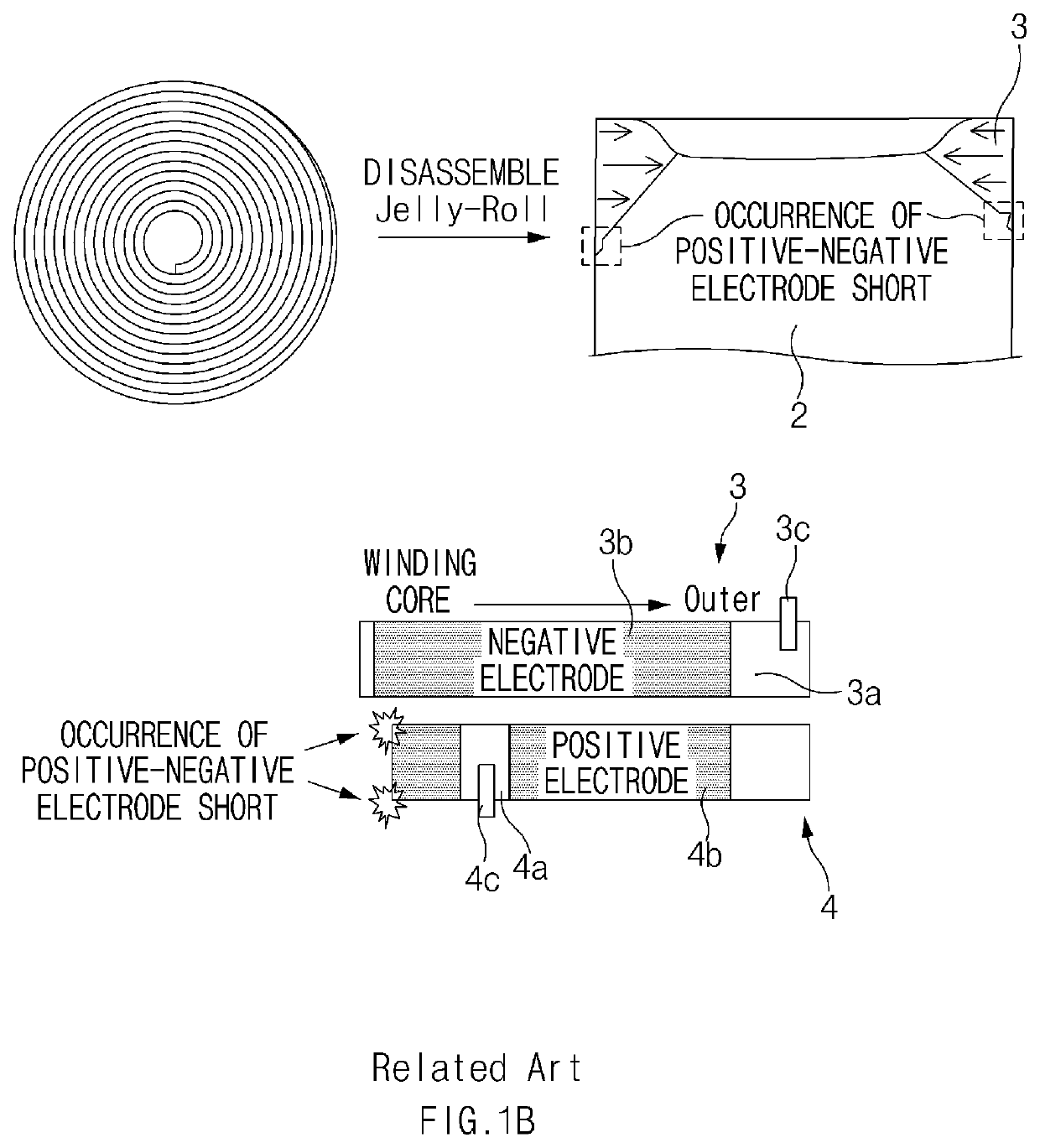

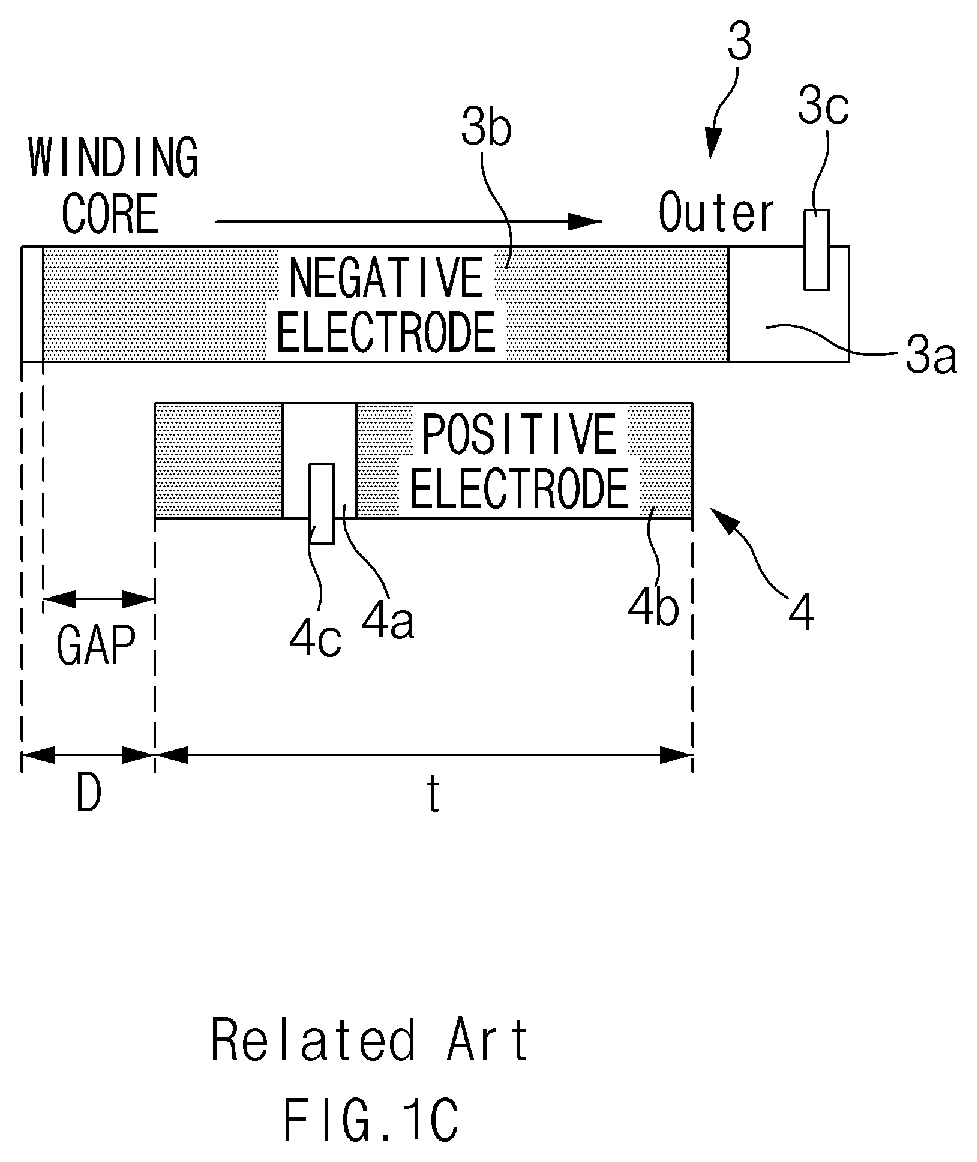

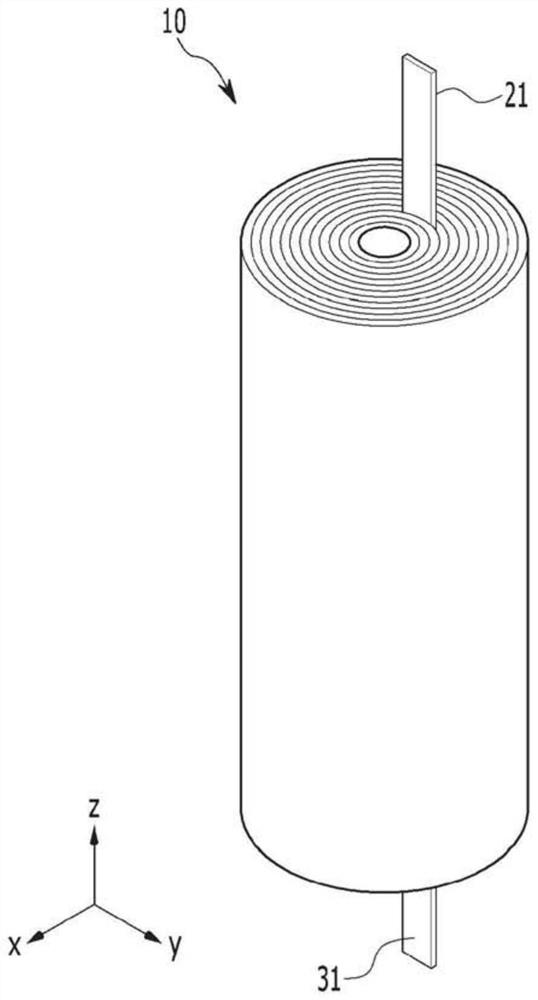

The jelly roll or Swiss roll design is the design used in the majority of cylindrical rechargeable batteries, including nickel-cadmium (NiCd), nickel-metal hydride (NiMH) and lithium-ion (Li-ion). In this design, an insulating sheet is laid down, then a thin layer of an anode material is laid down, a separator layer is applied, and a cathode material is layered on top. This sandwich is then rolled up and inserted into a hollow cylinder casing. The battery is sealed, metal contacts are attached, and an optional button top is applied if the battery is intended to replace an AAA/AA/C/D alkaline battery. A label with the brand name is then applied, or a blank protective label, often green (NiMh) or blue (NiCd), for a generic or OEM battery.

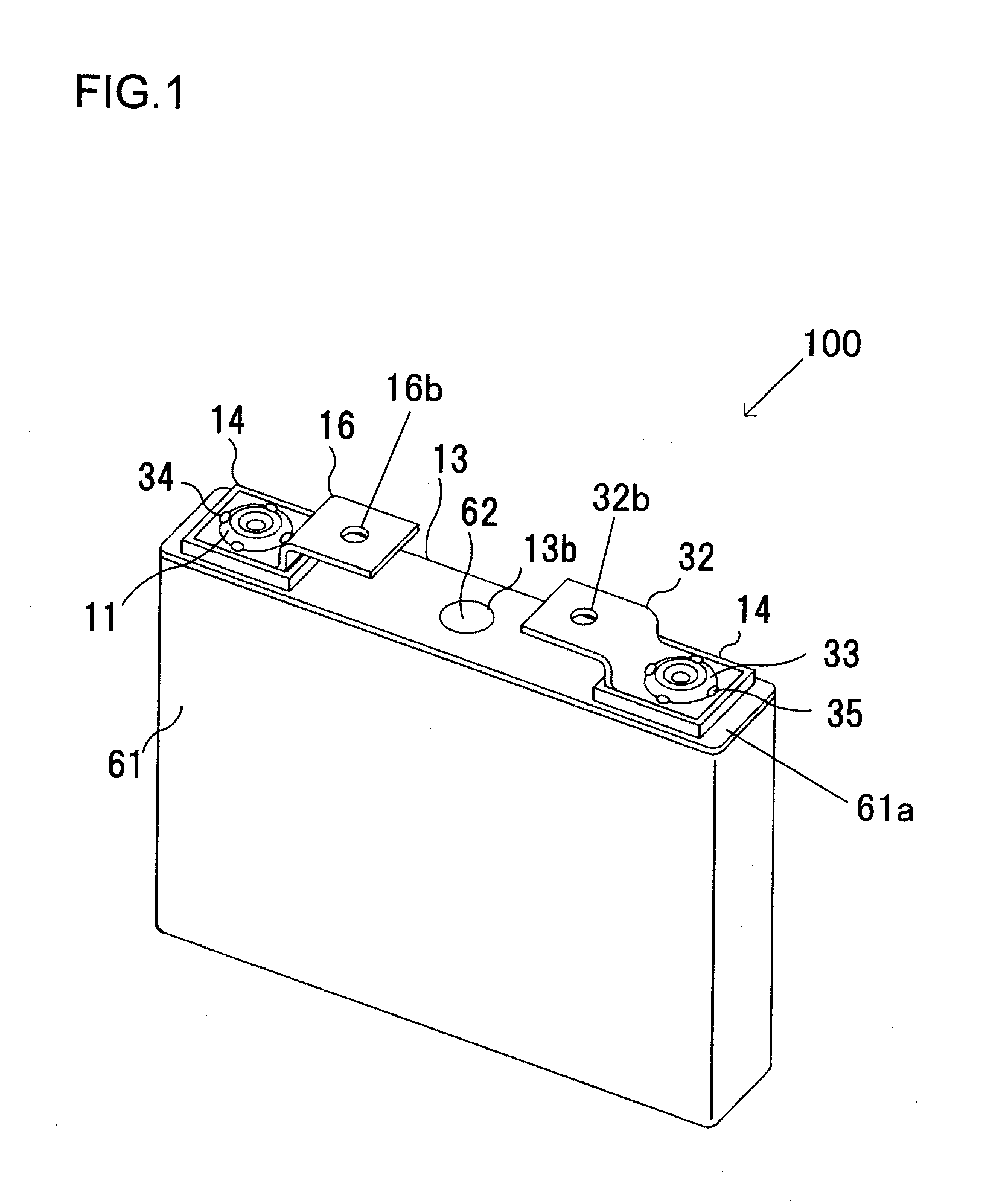

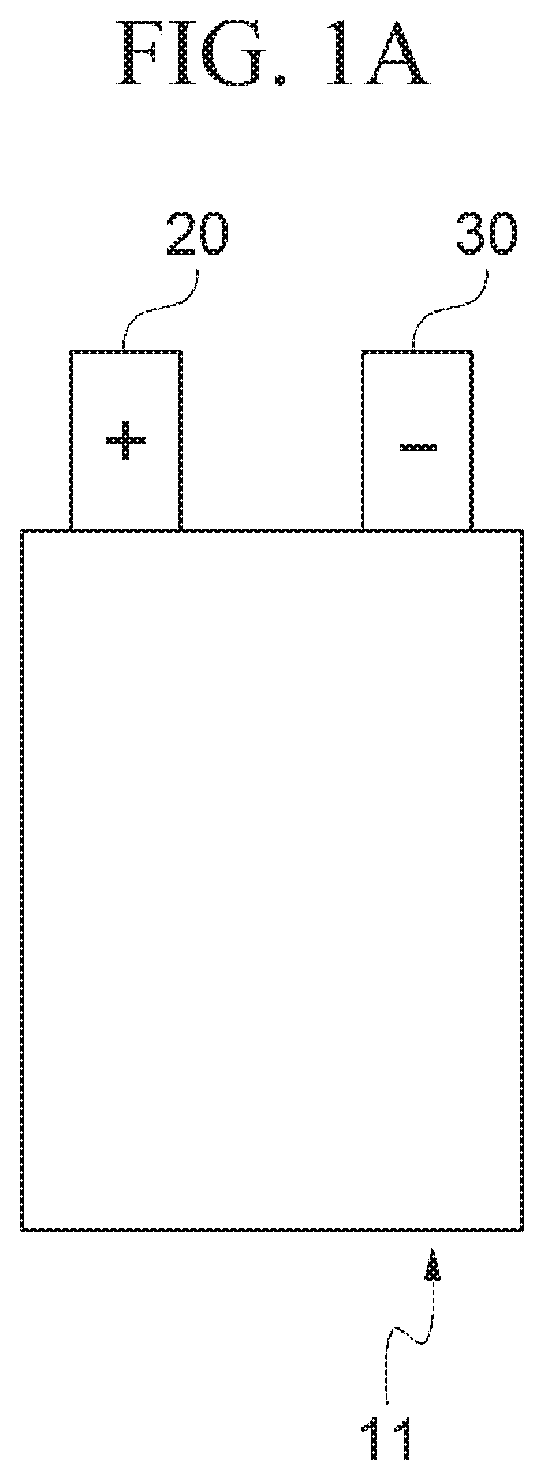

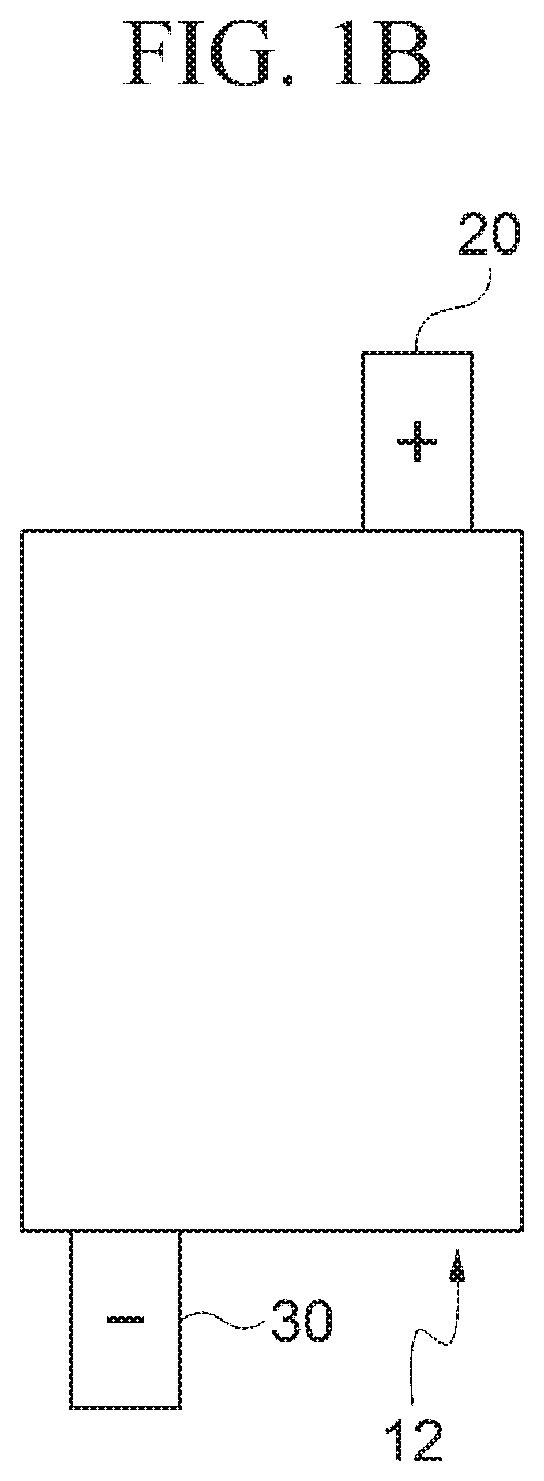

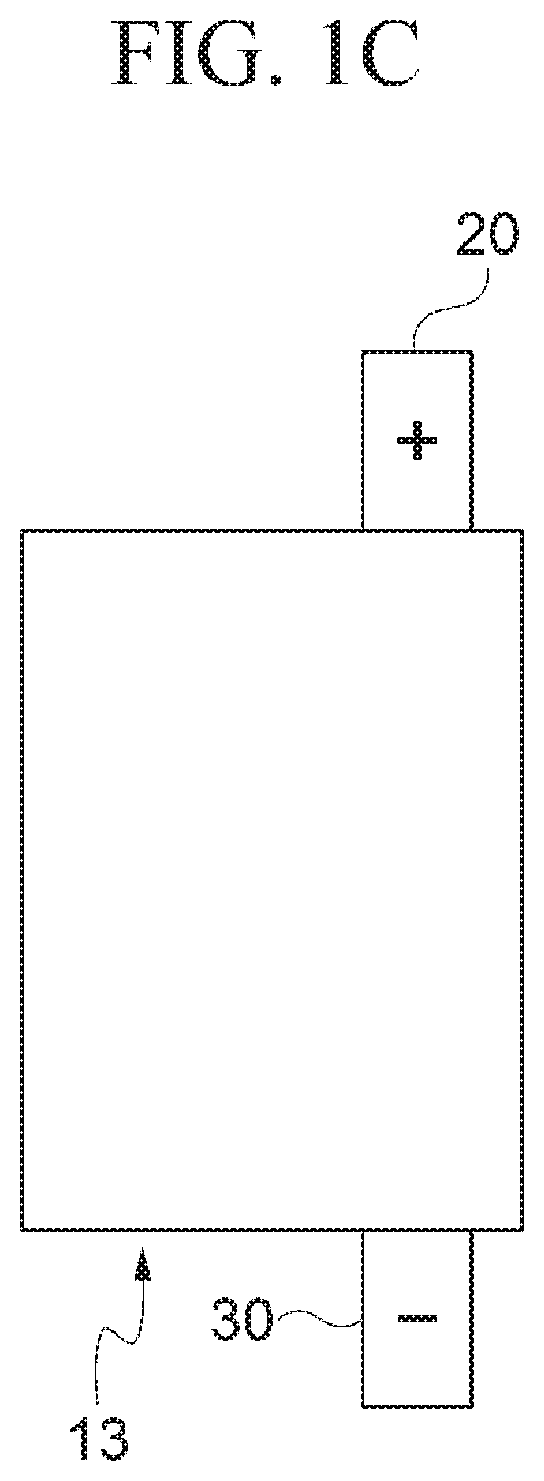

Batteries with variable terrace positions

InactiveUS20120177953A1Facilitates efficient use of spaceElectrode carriers/collectorsCells structural combinationEngineeringMechanical engineering

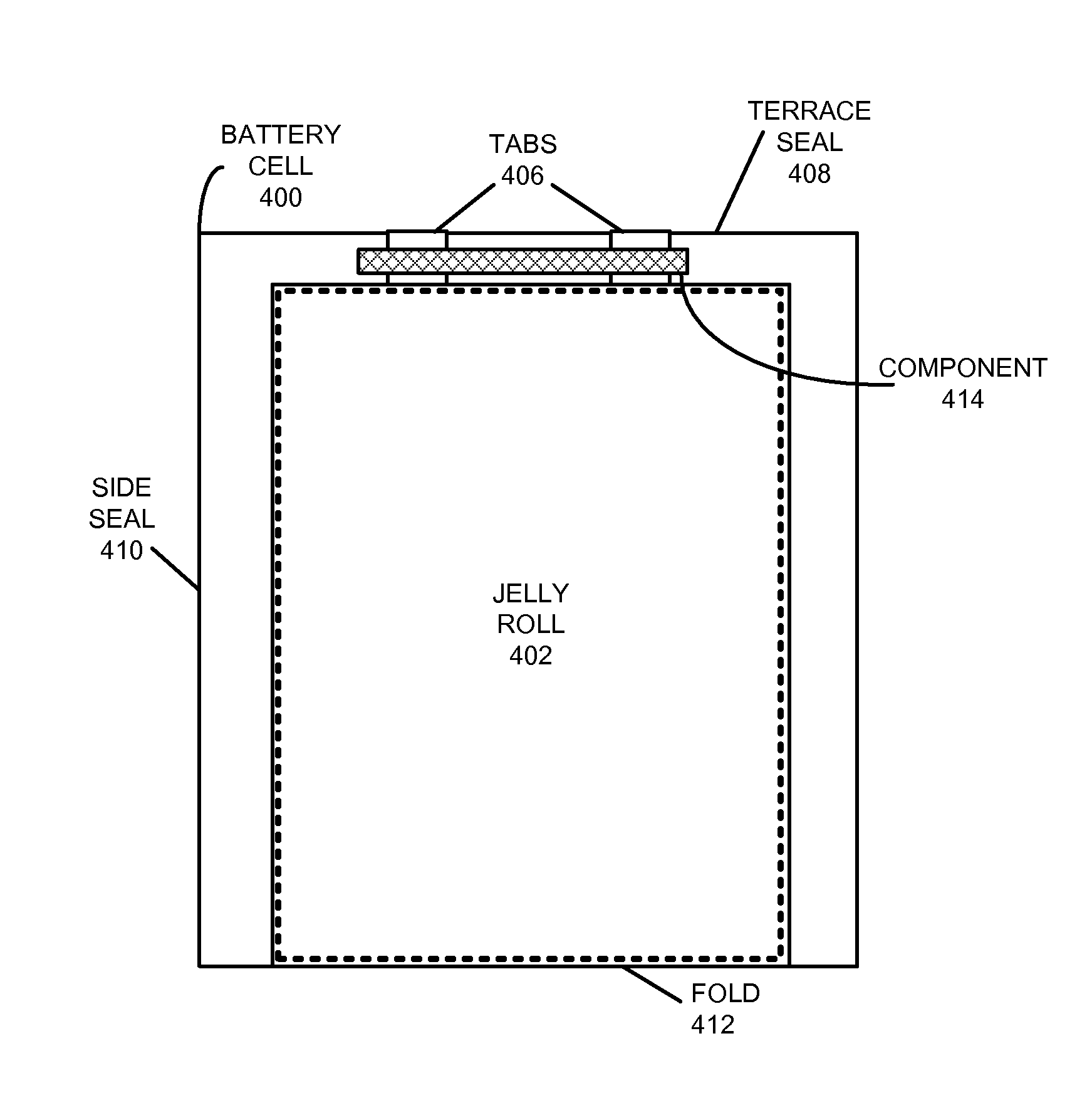

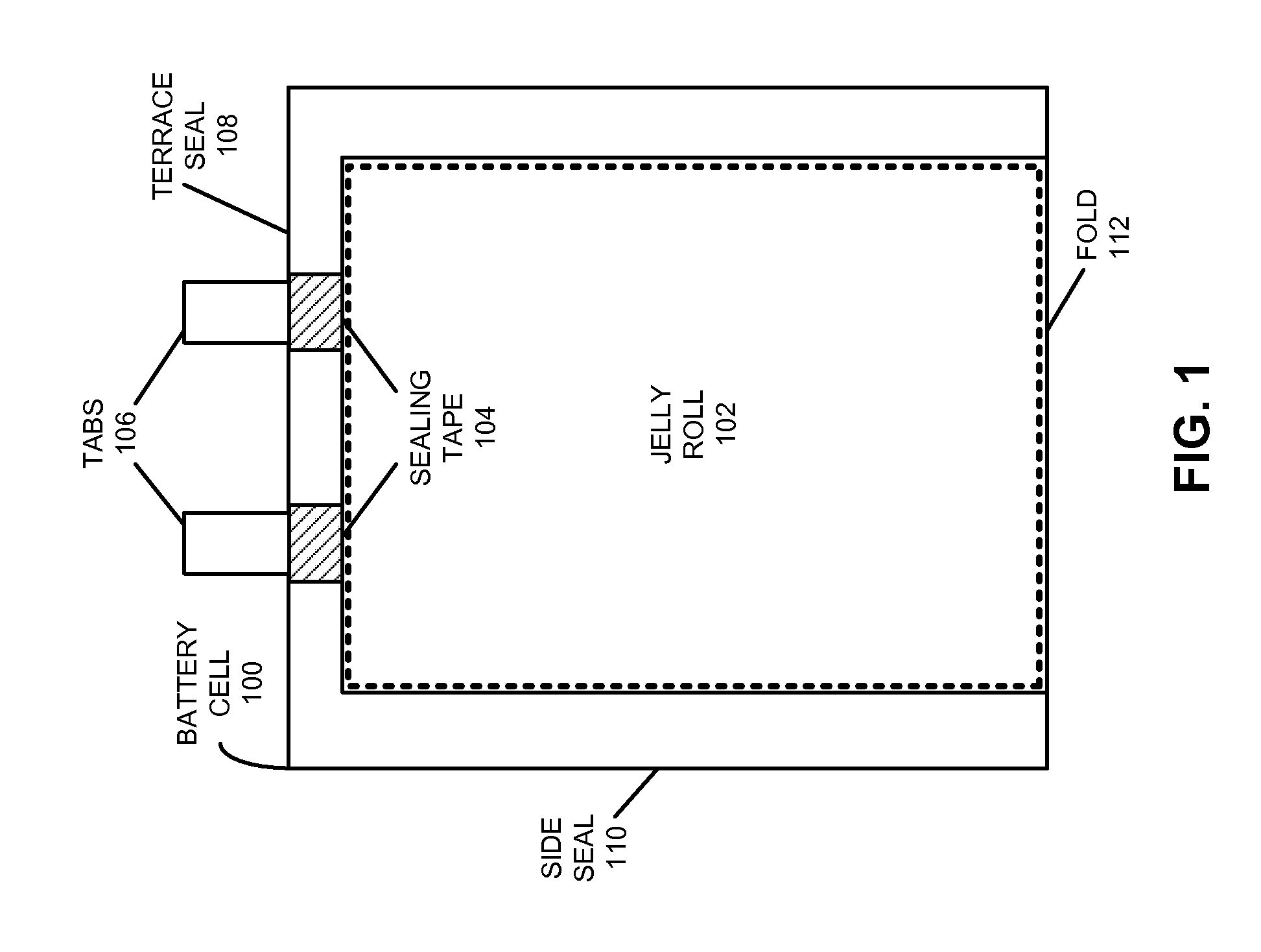

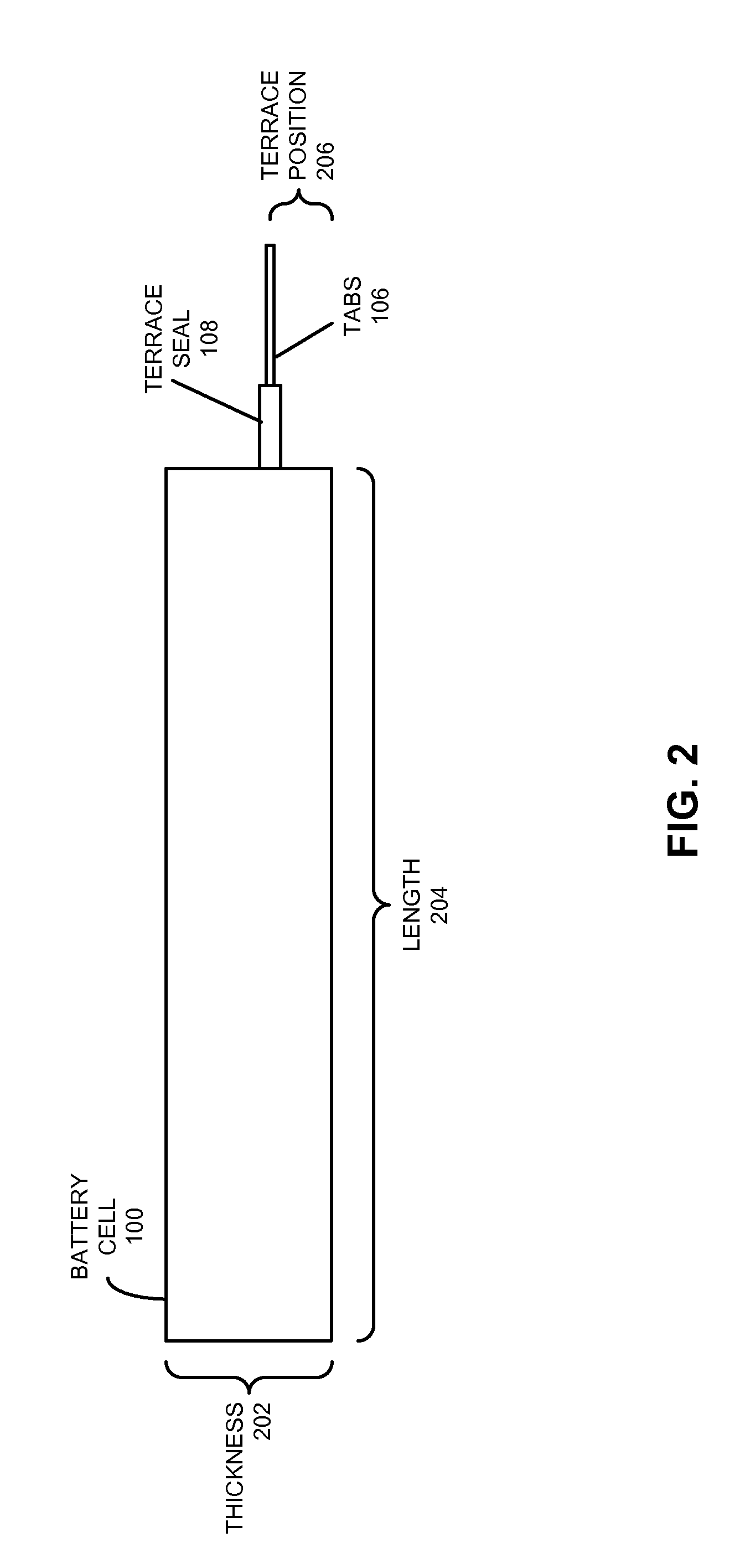

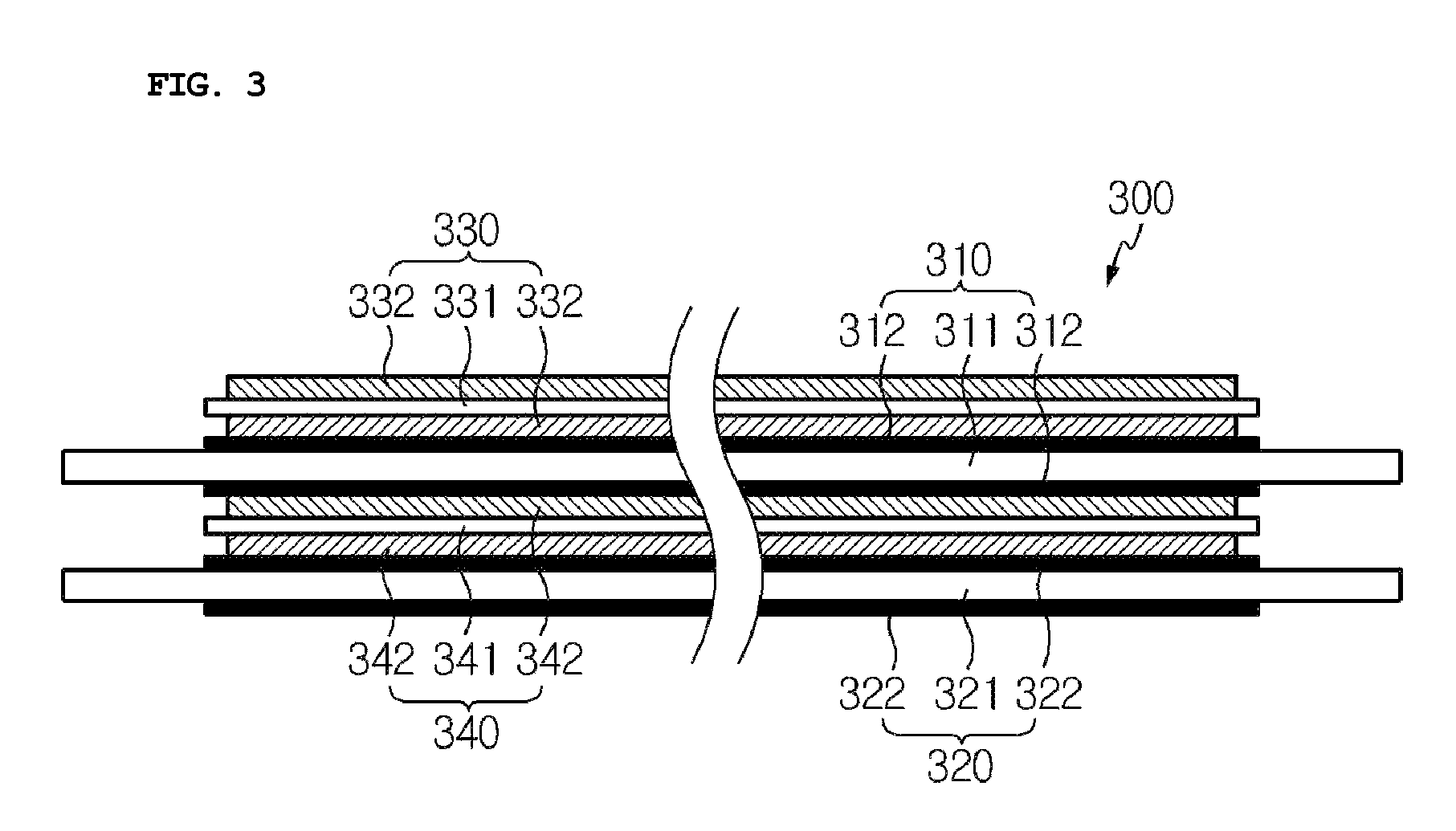

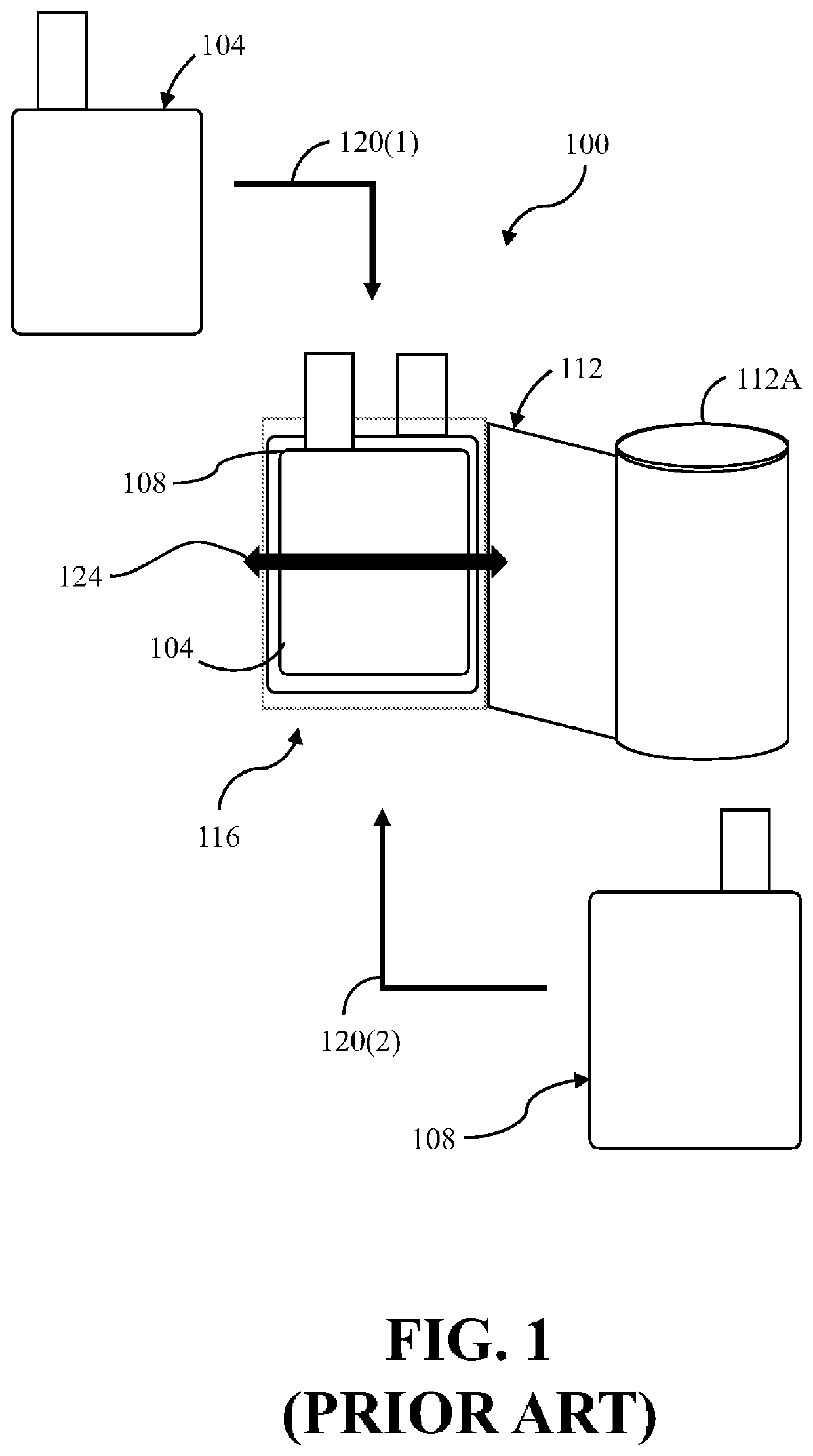

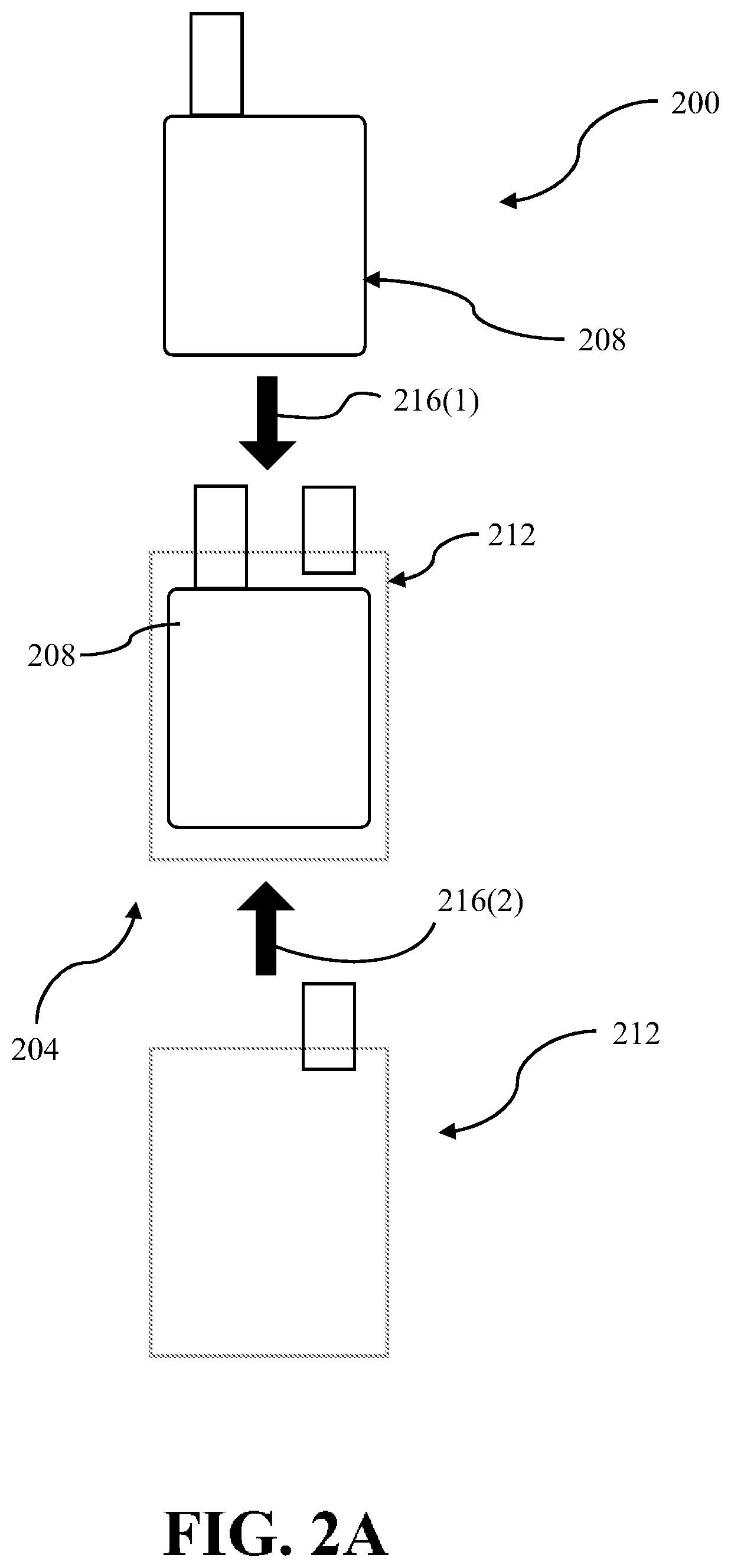

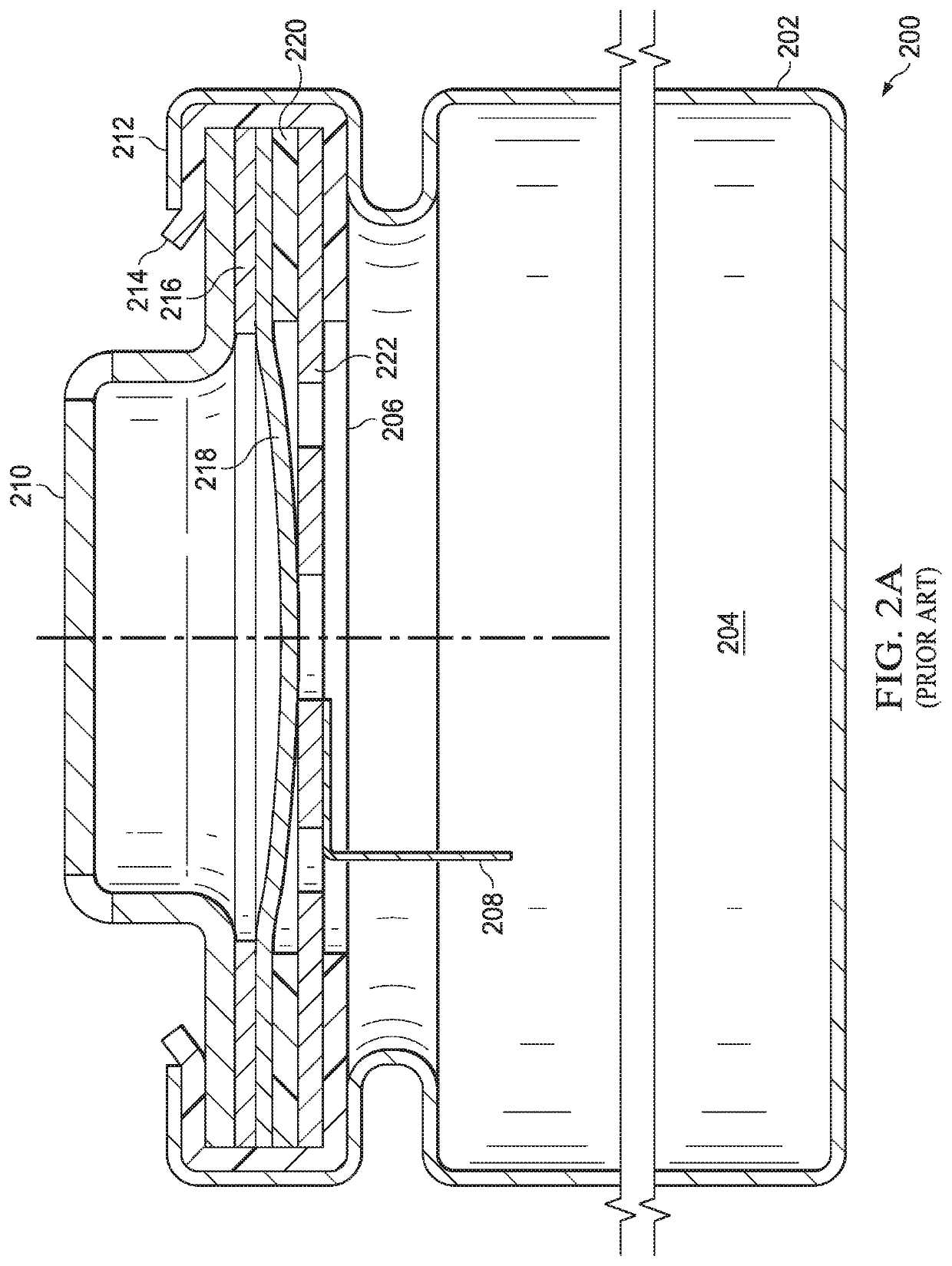

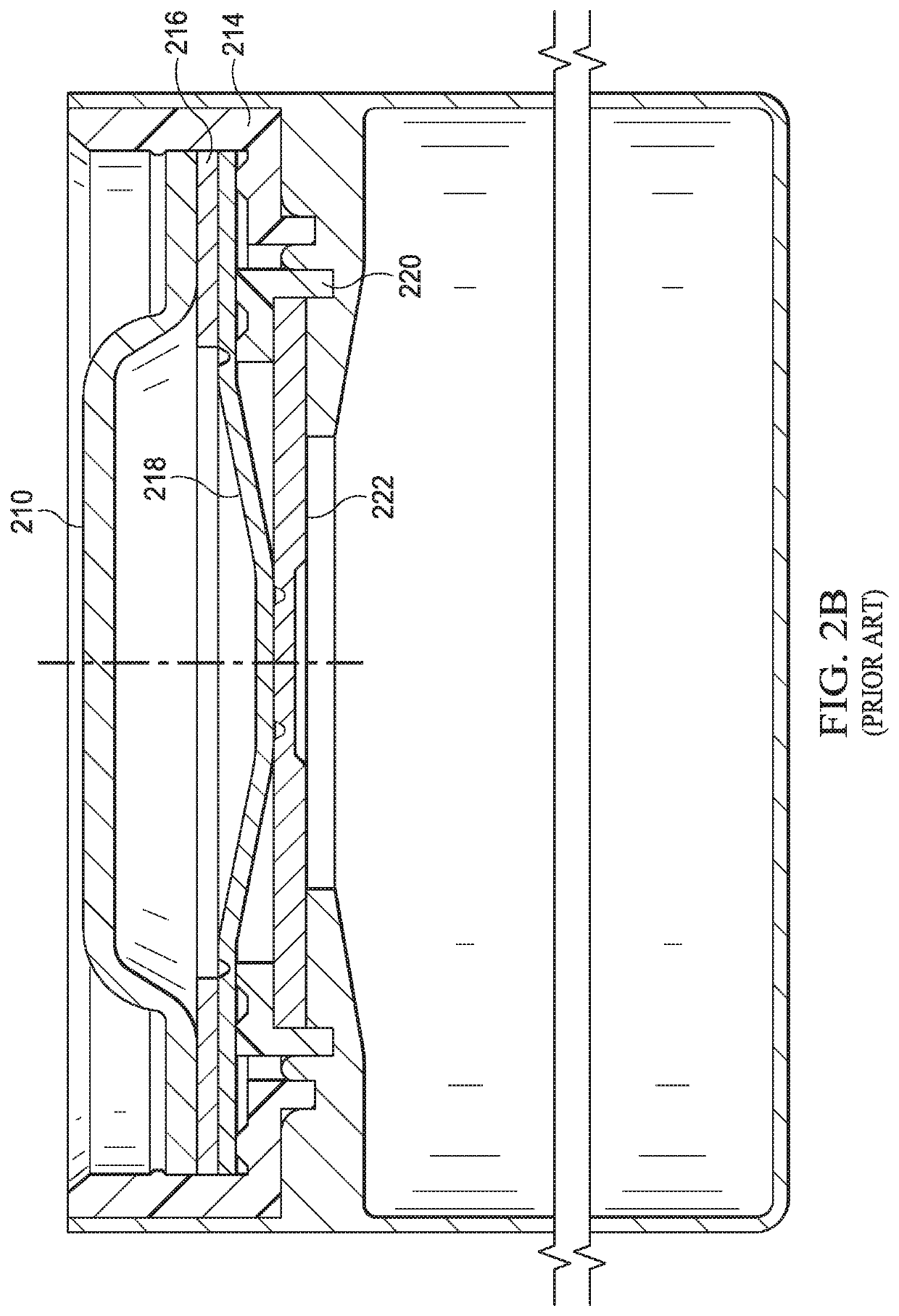

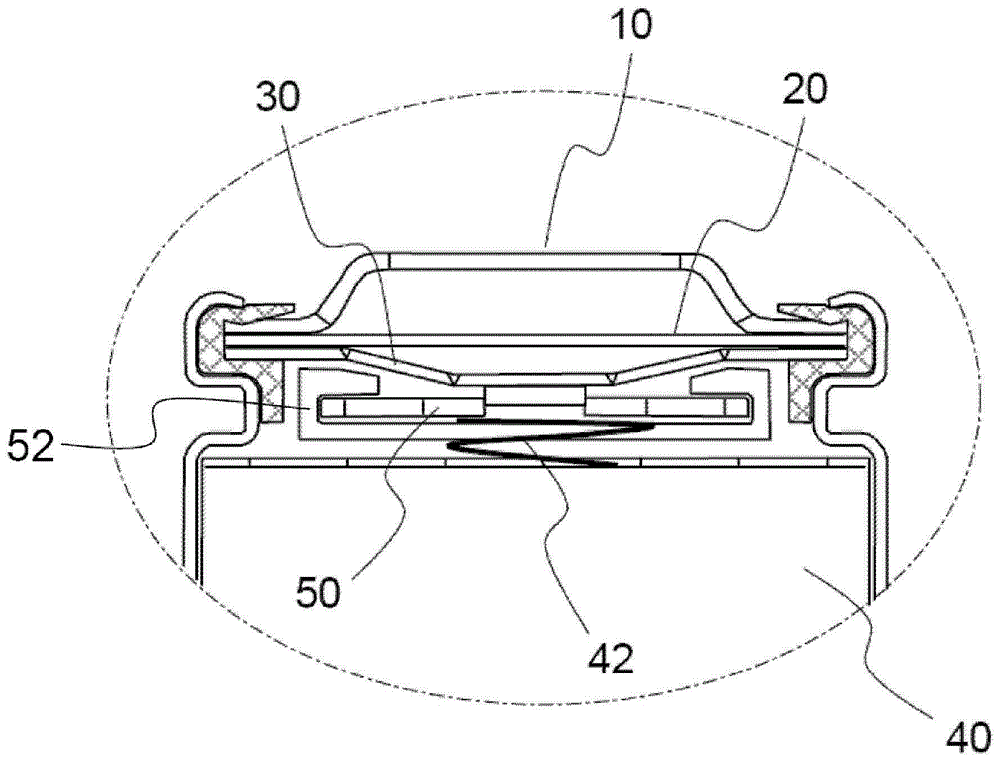

The disclosed embodiments provide a battery cell. The battery cell includes a jelly roll enclosed in a pouch, wherein the jelly roll includes layers which are wound together, including a cathode with an active coating, a separator, and an anode with an active coating. To create the pouch, a first cup and a second cup are formed in a flexible sheet of pouch material based on a terrace position in the battery cell that facilitates efficient use of space within a portable electronic device. The second cup is folded over the first cup, and a terrace seal is formed at the terrace position by sealing the jelly roll in the pouch along a rim of the first and second cups.

Owner:APPLE INC

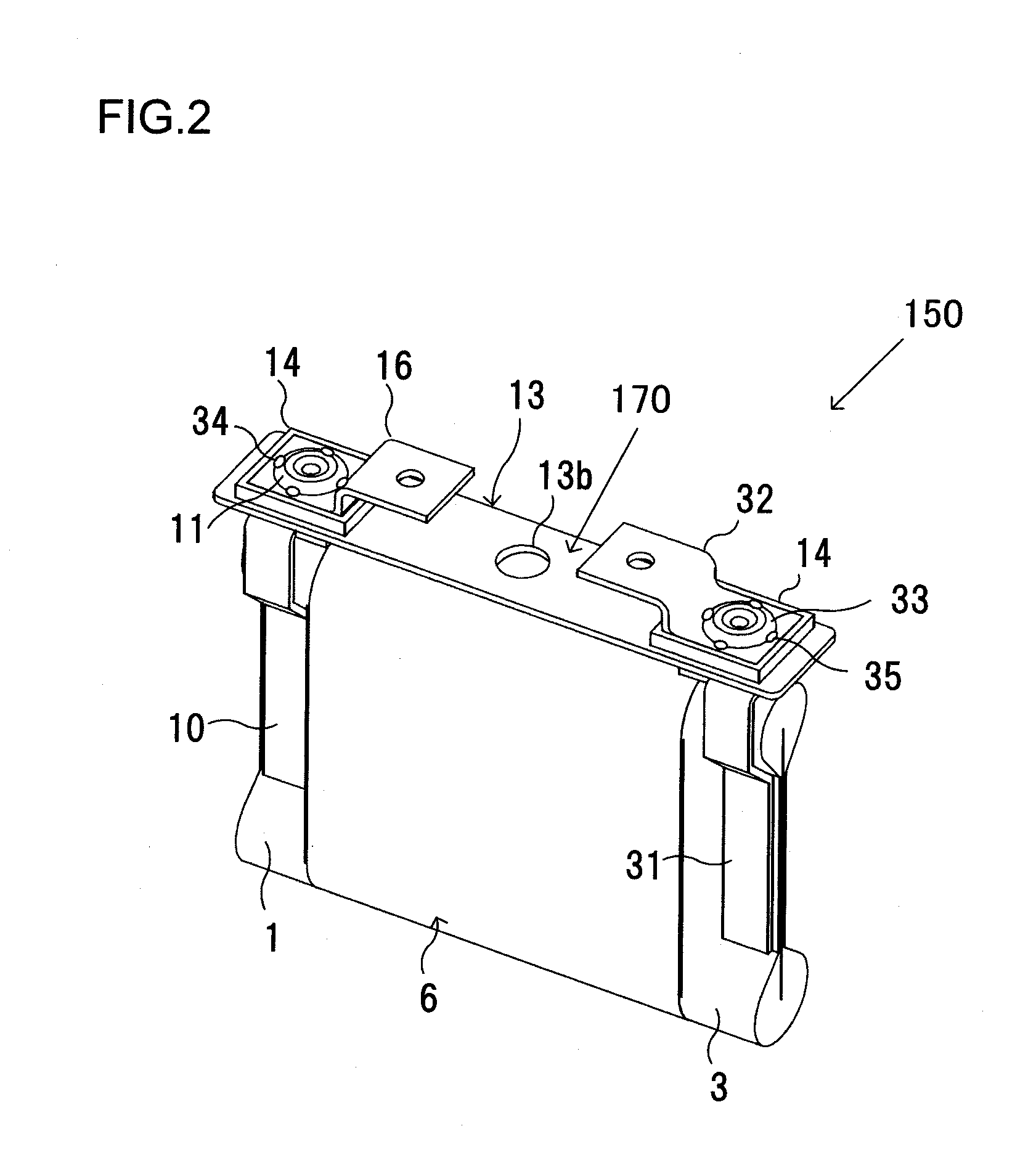

Secondary battery and fabrication method thereof

InactiveUS20120058374A1Minimize wettabilityAvoid it happening againFinal product manufactureSmall-sized cells cases/jacketsElectrical batteryEngineering

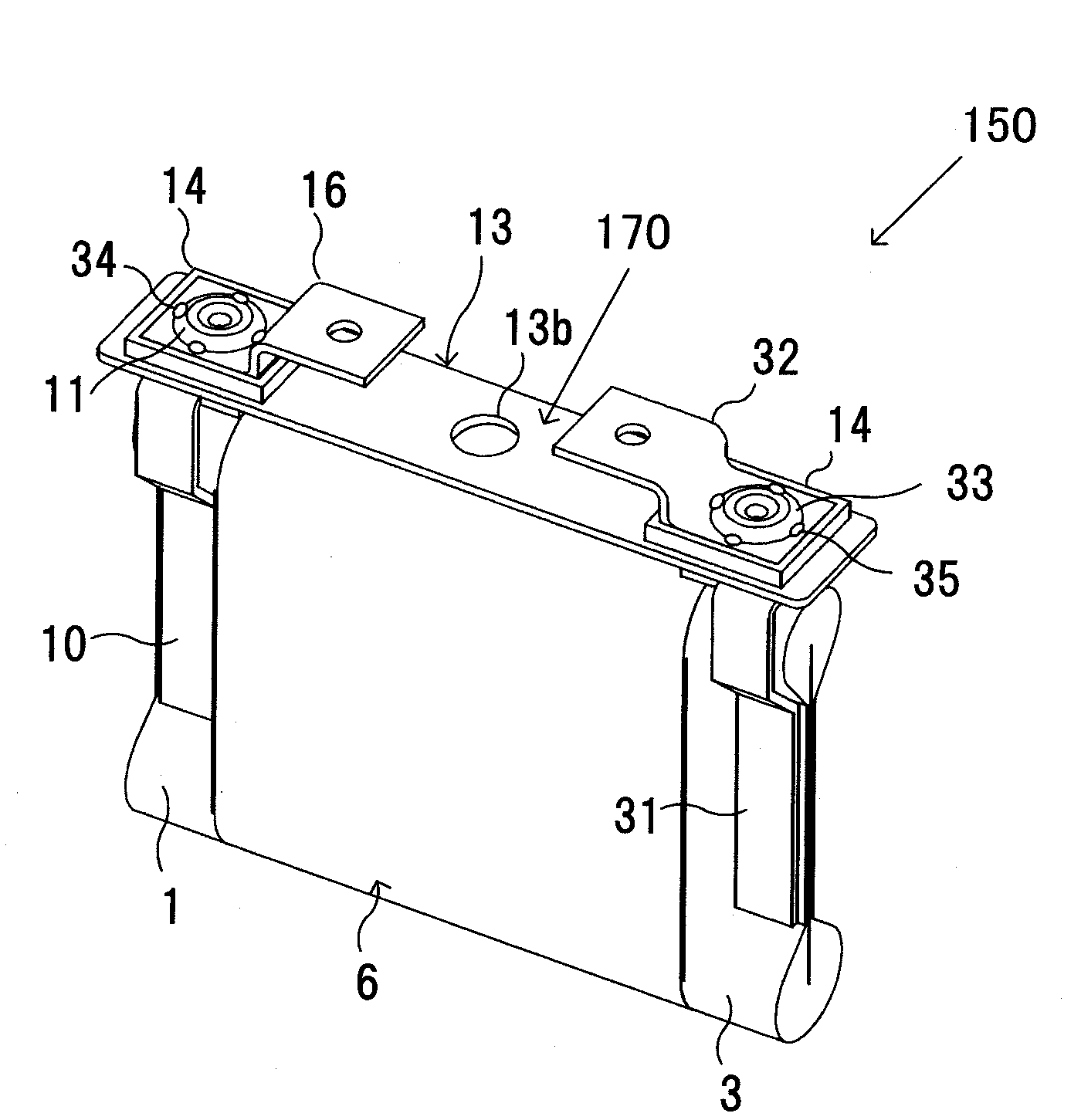

A secondary battery includes: a jelly roll that includes a positive and a negative electrode wound via a separator; a case; a lid; and electrically conductive input / output members, wherein: the electrically conductive input / output members include, at least; a positive and a negative electrode current collector plate with one end thereof connected to the positive and the negative electrode respectively; a positive and a negative electrode external conductive member with one end thereof connected to another end of the positive and the negative electrode current collector plate respectively and another end thereof extending to an outer side of the lid; the one end of the positive and the negative electrode external conductive member are respectively swage-fused to the other end of the positive and the negative electrode current collector plate; and an oxide layer is formed at a surface of each swage-fused area.

Owner:HITACHI AUTOMOTIVE SYST LTD

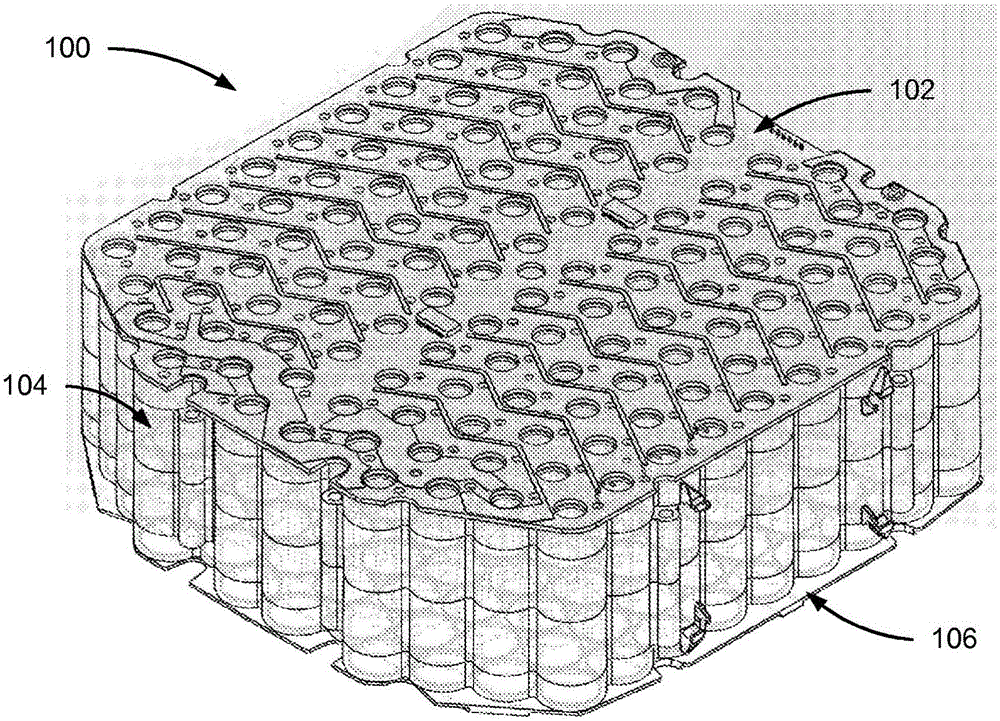

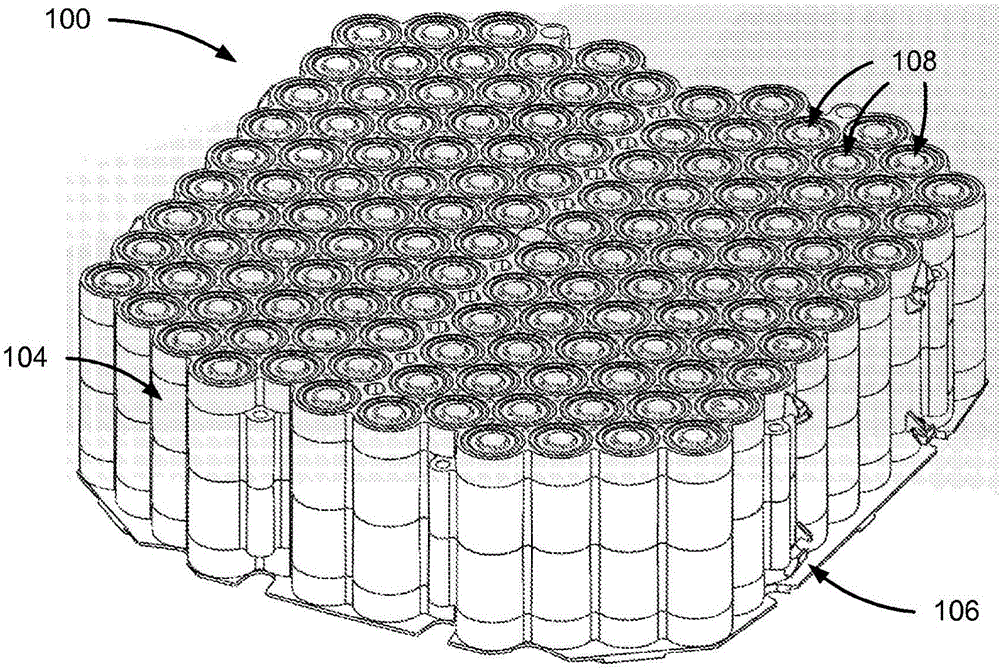

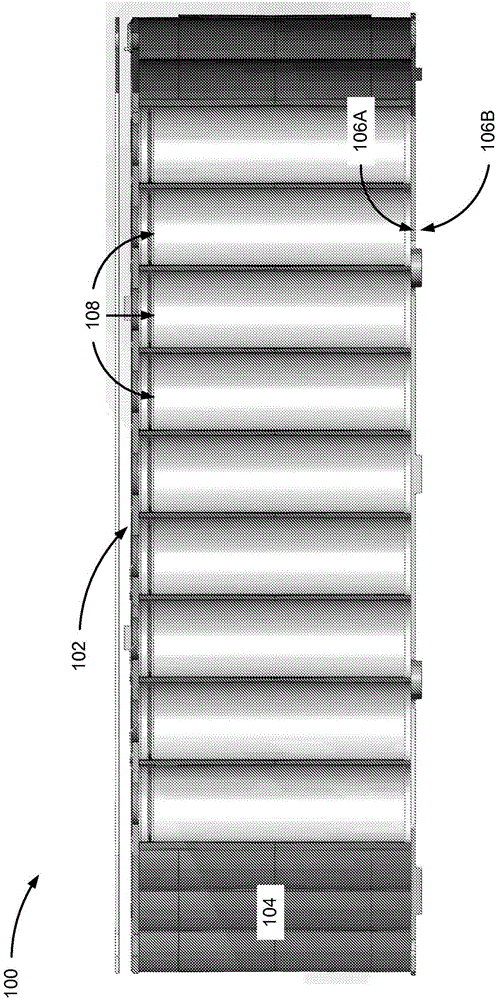

Battery housing

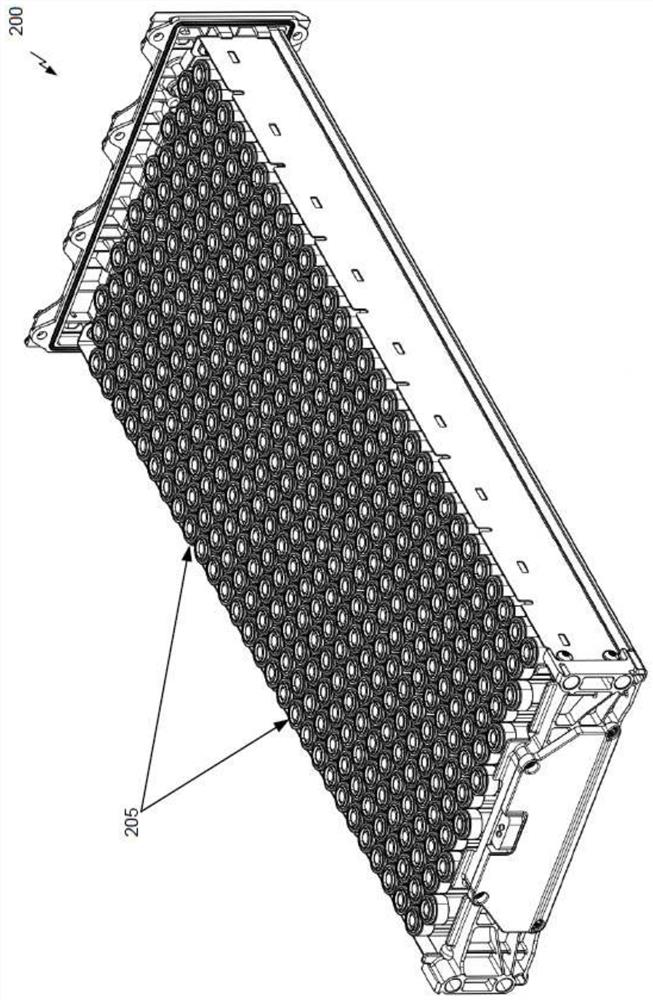

InactiveCN104995758AHigh thermal conductivityImprove heat transfer performanceBattery isolationSecondary cellsThermodynamicsBattery cell

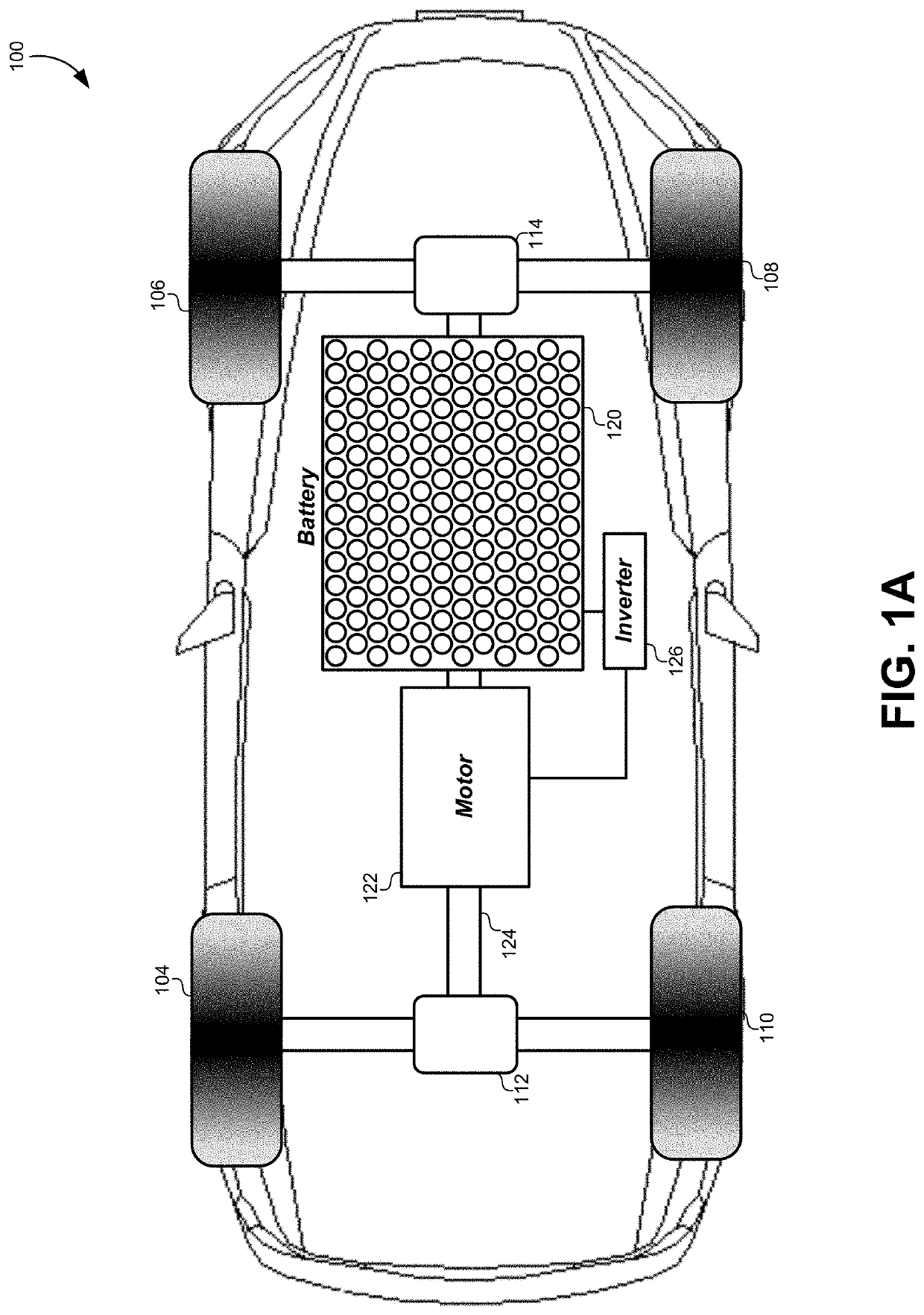

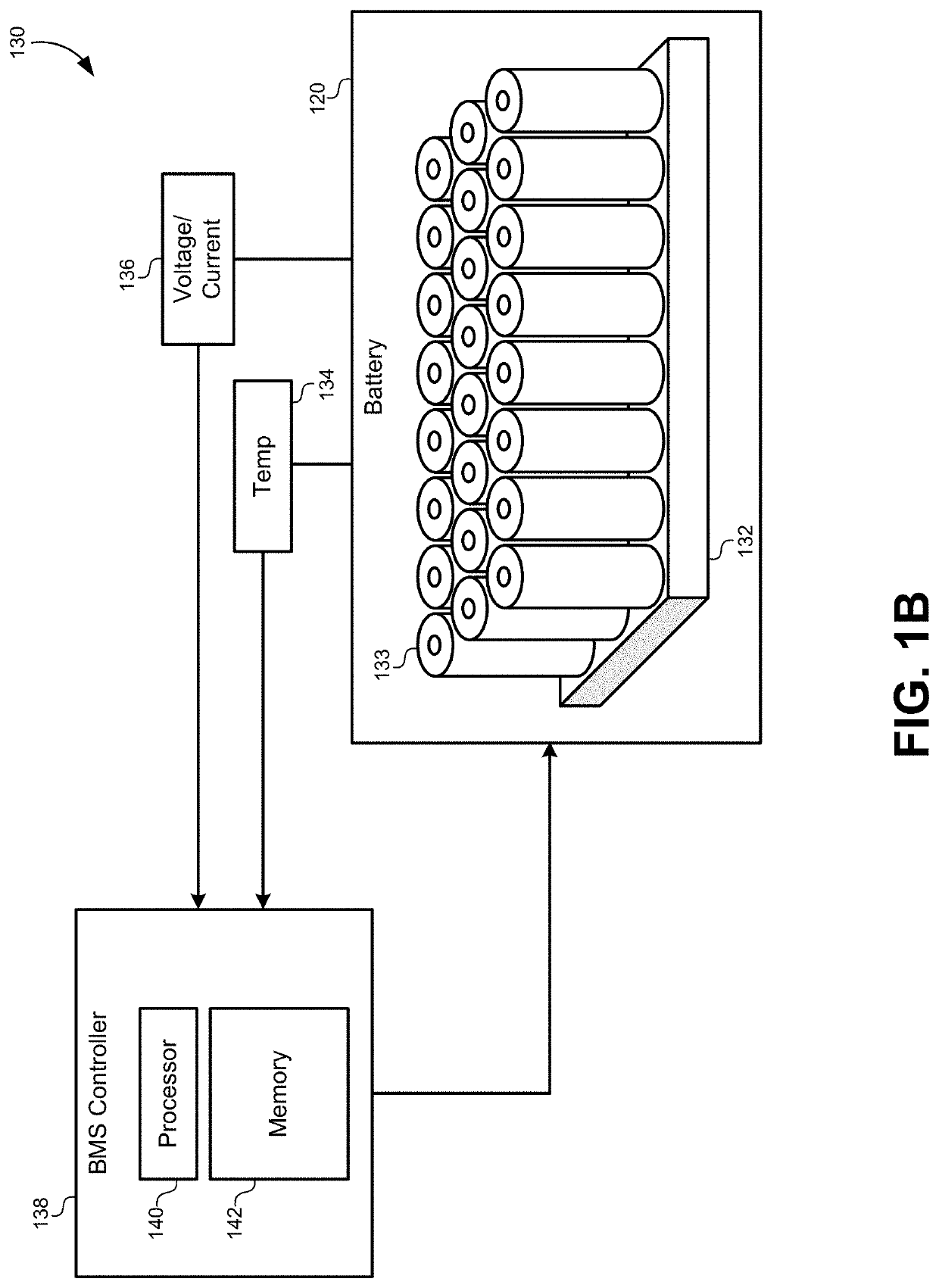

A battery housing includes a heat spreader, a thermal interface that contacts a surface of the heat spreader, and a battery frame that is configured to hold a plurality of battery cells. When a battery cell is inserted into the battery frame, the thermal interface contacts the cell at the same end as the cell's negative terminal. As a result, the thermal interface allows heat to be transferred between the battery cell and the heat spreader. It is advantageous to make a thermal connection at the end with the negative terminal because the internal jelly roll structure of the battery cell causes the cell to have a higher thermal conductivity at its negative terminal.

Owner:FASTER FASTER

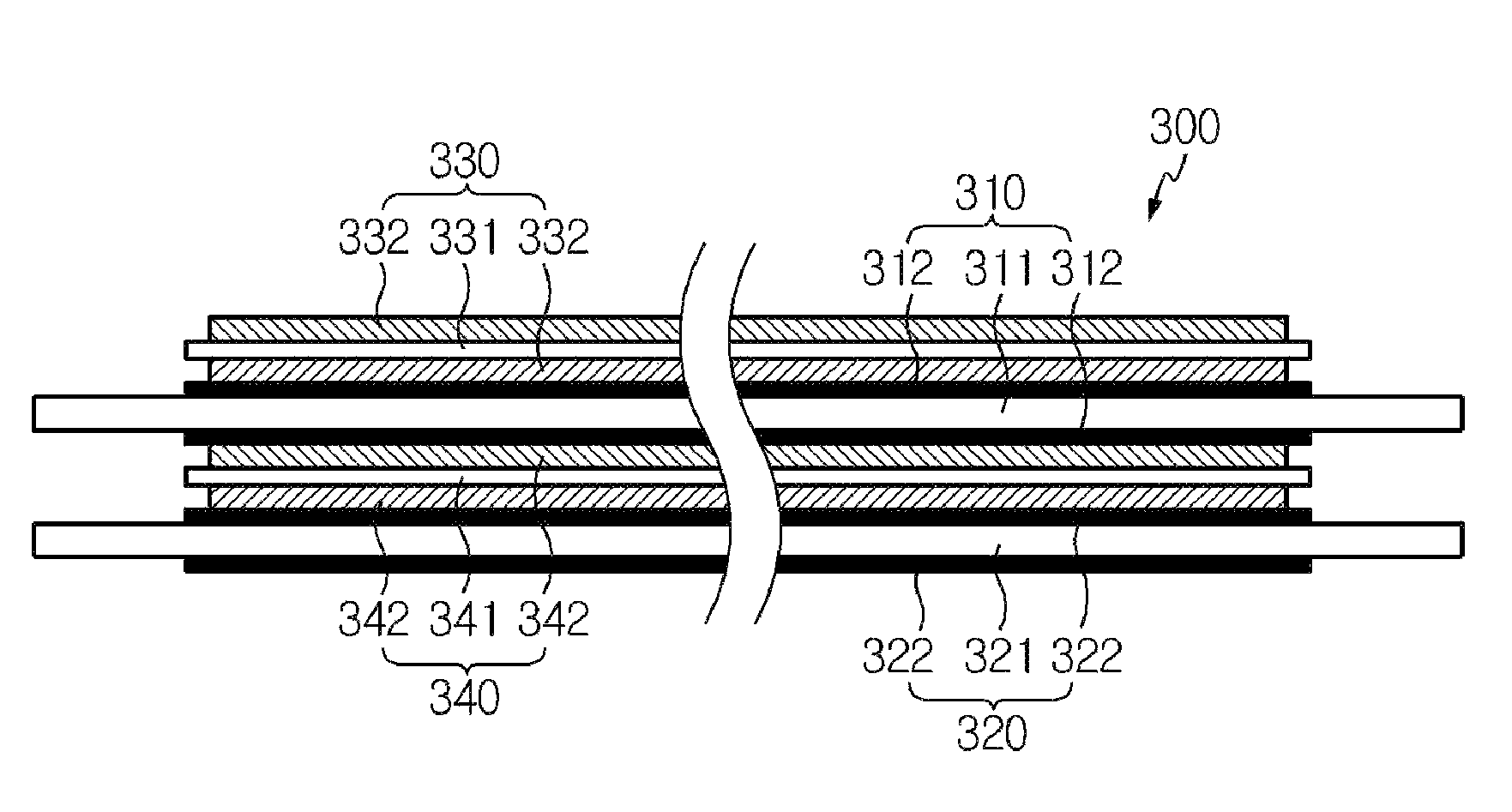

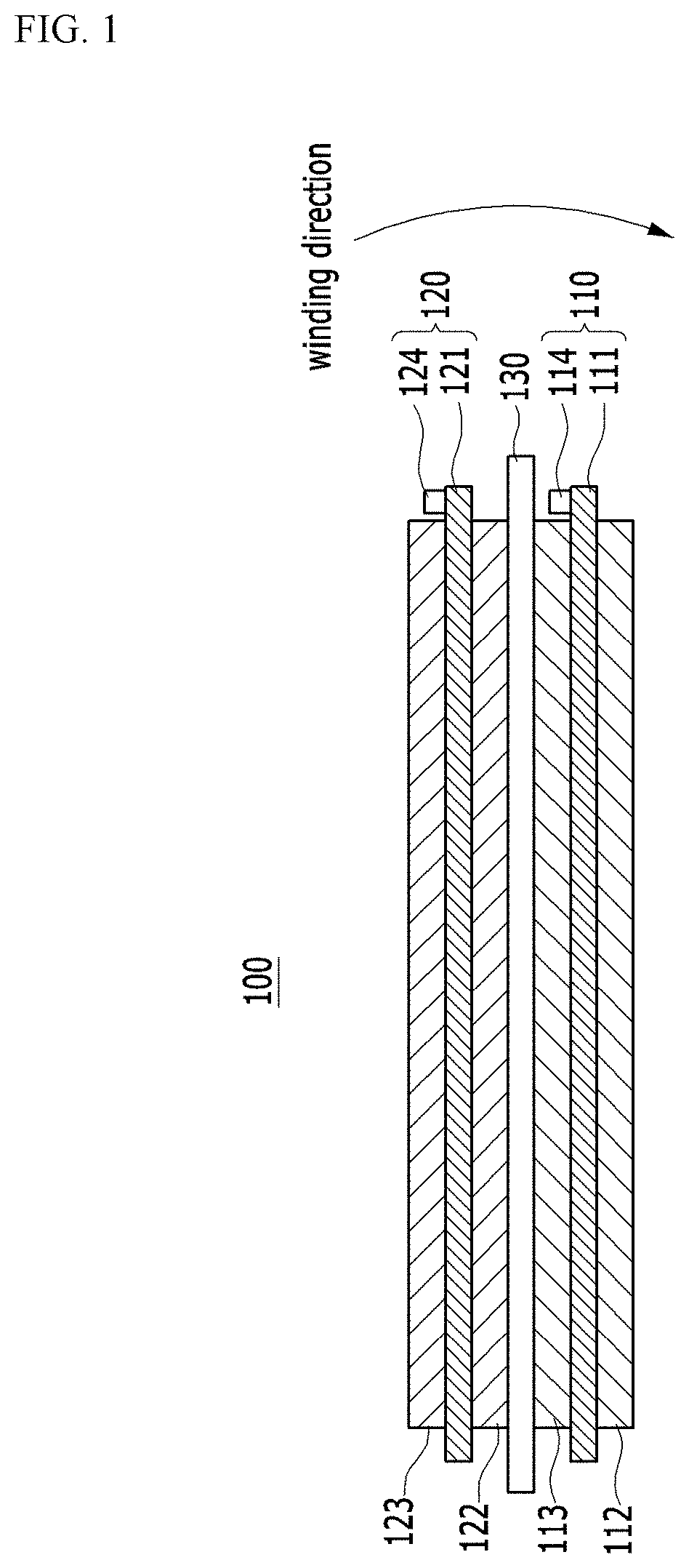

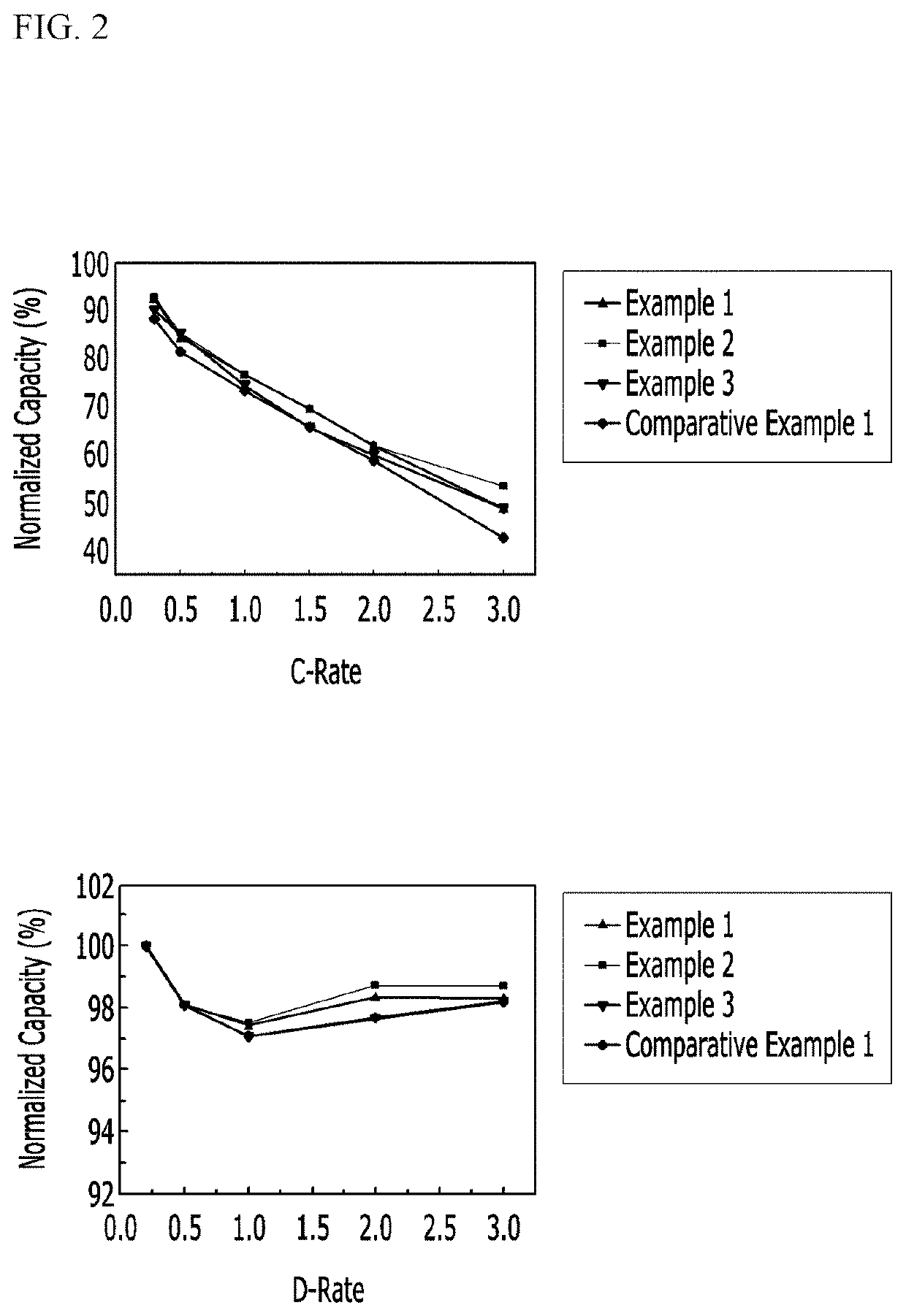

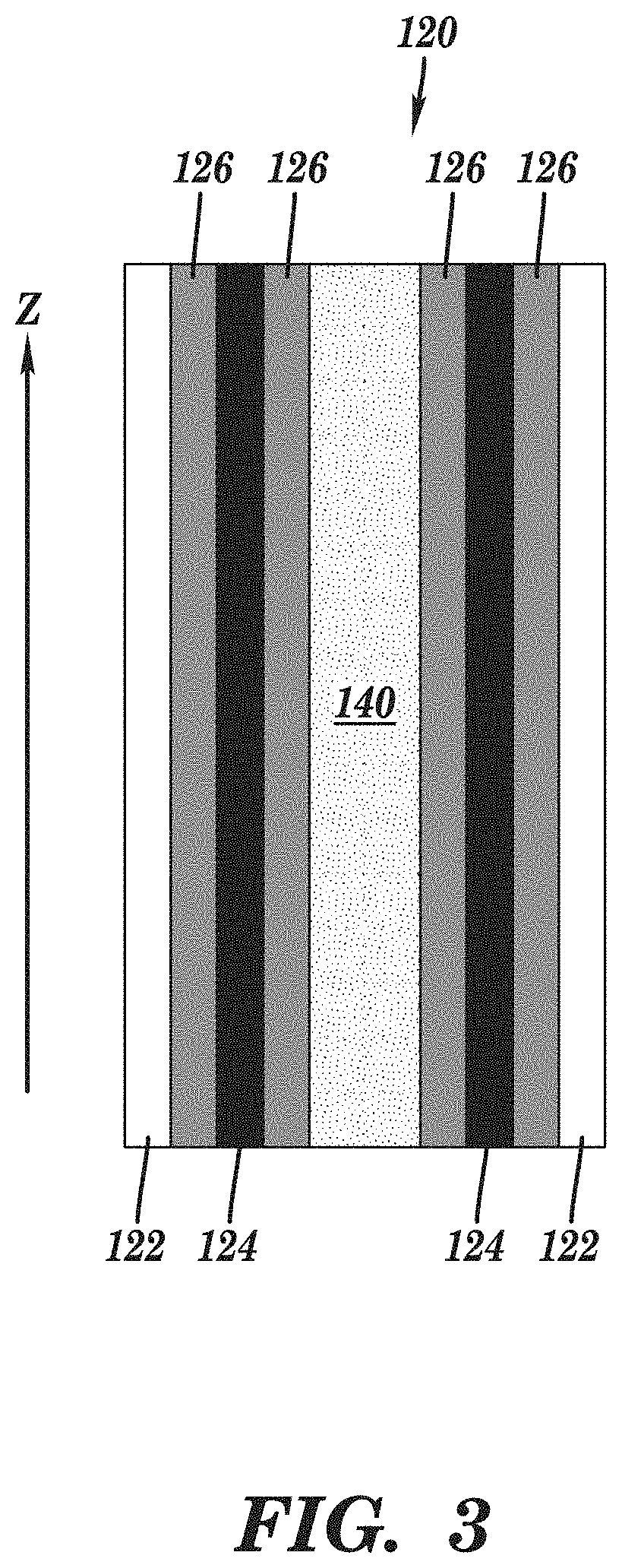

Jelly-roll type electrode assembly pattern-coated with active material and secondary battery including the same

ActiveUS20140004399A1Improve rapid charging propertyLower internal resistanceCell electrodesFinal product manufactureOptoelectronicsAnode

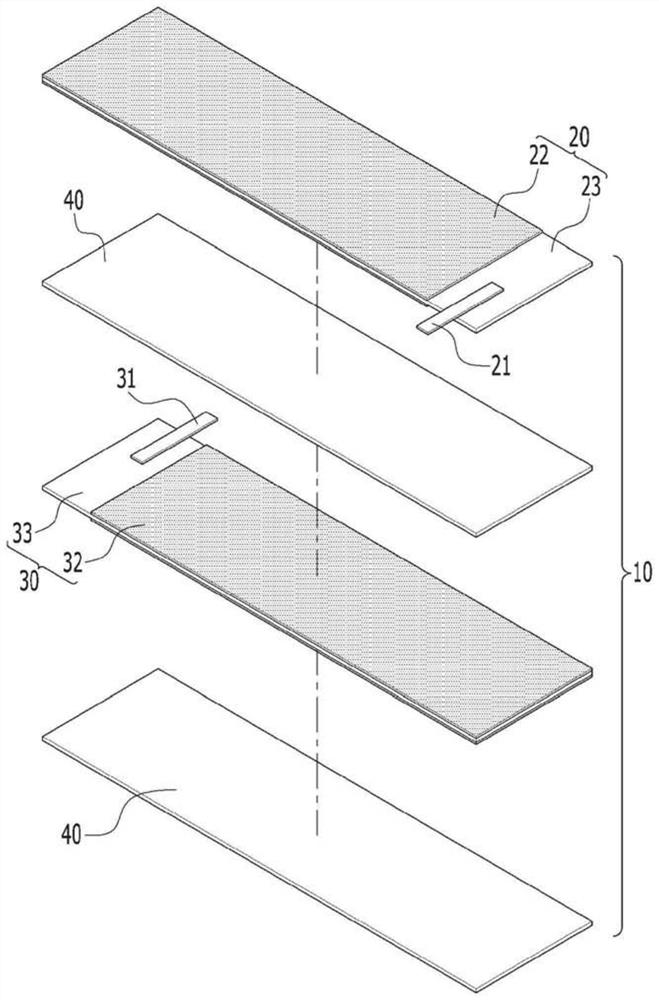

Provided is a jelly-roll type electrode assembly pattern-coated with active materials manufactured by winding and compressing a separator and an anode and a cathode arranged on both sides of the separator. The anode includes anode flat coated portion coated with an anode active material and anode curved uncoated portion not coated with the anode active material, which are alternately formed. The cathode includes a cathode flat coated portion coated with a cathode active material and a cathode curved uncoated portion not coated with the cathode active material, which are alternately formed.

Owner:LG ENERGY SOLUTION LTD +1

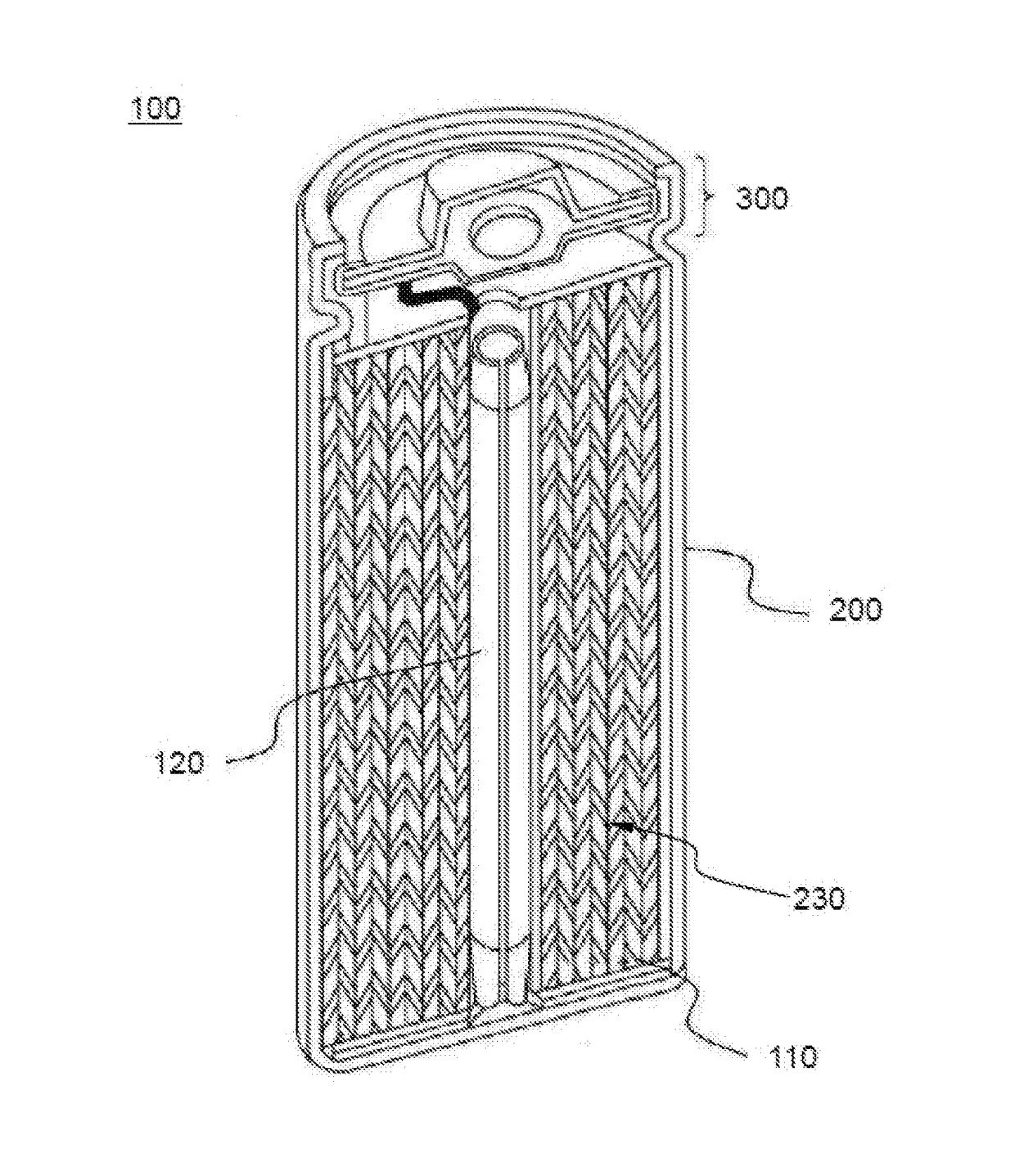

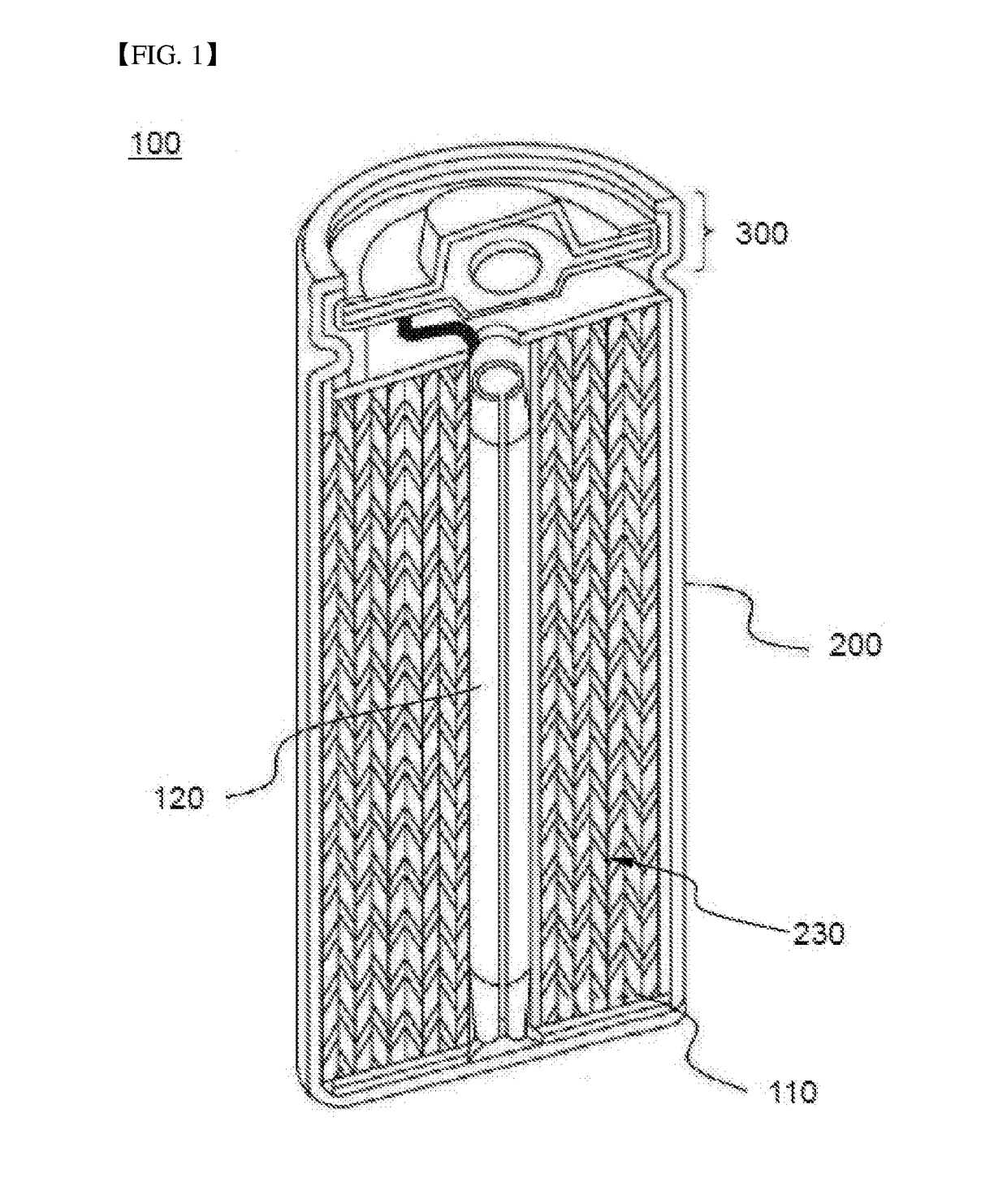

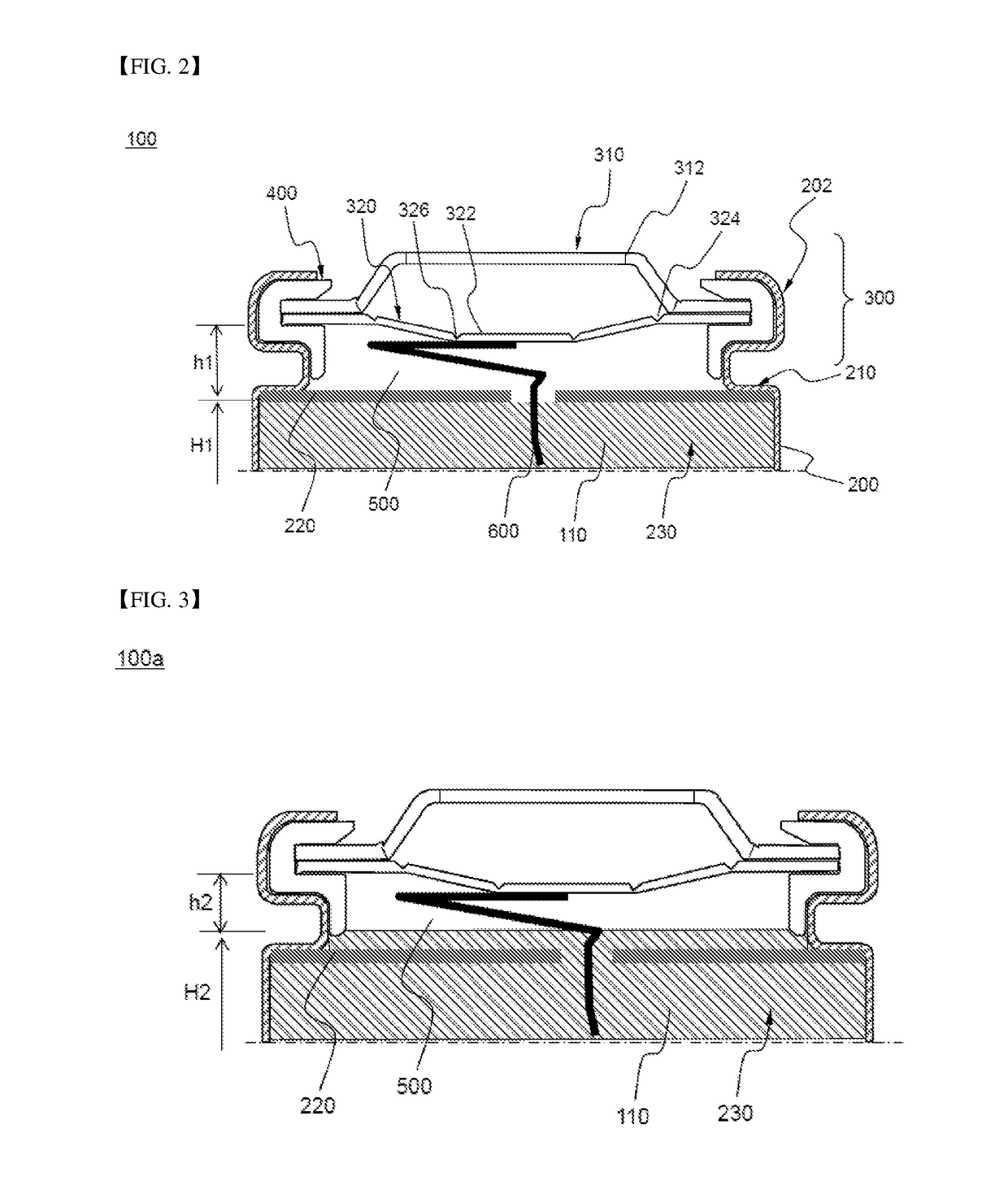

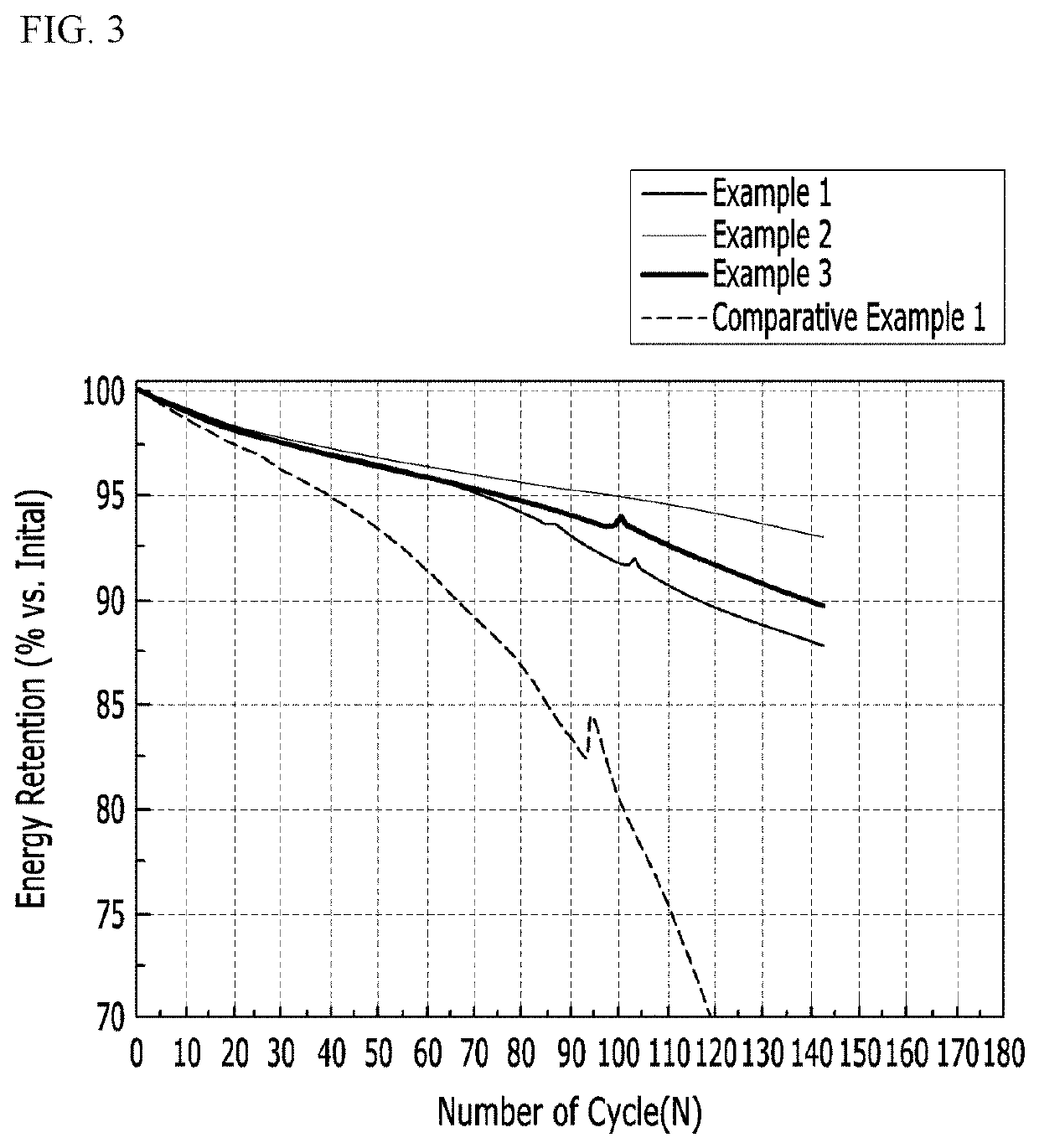

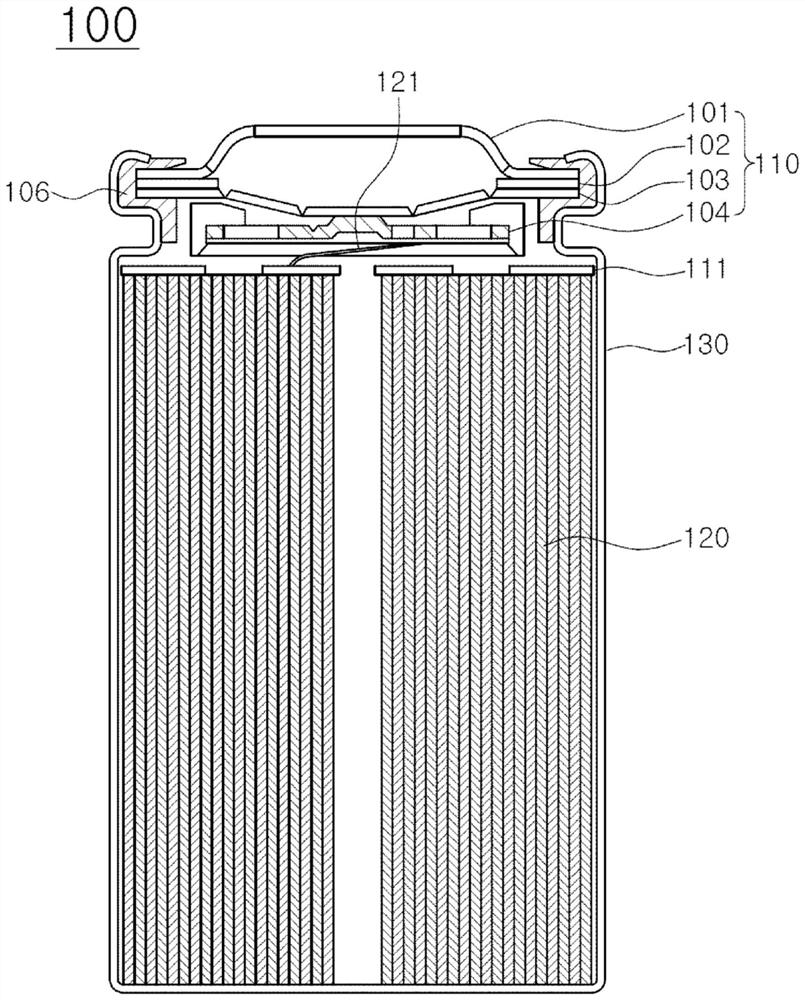

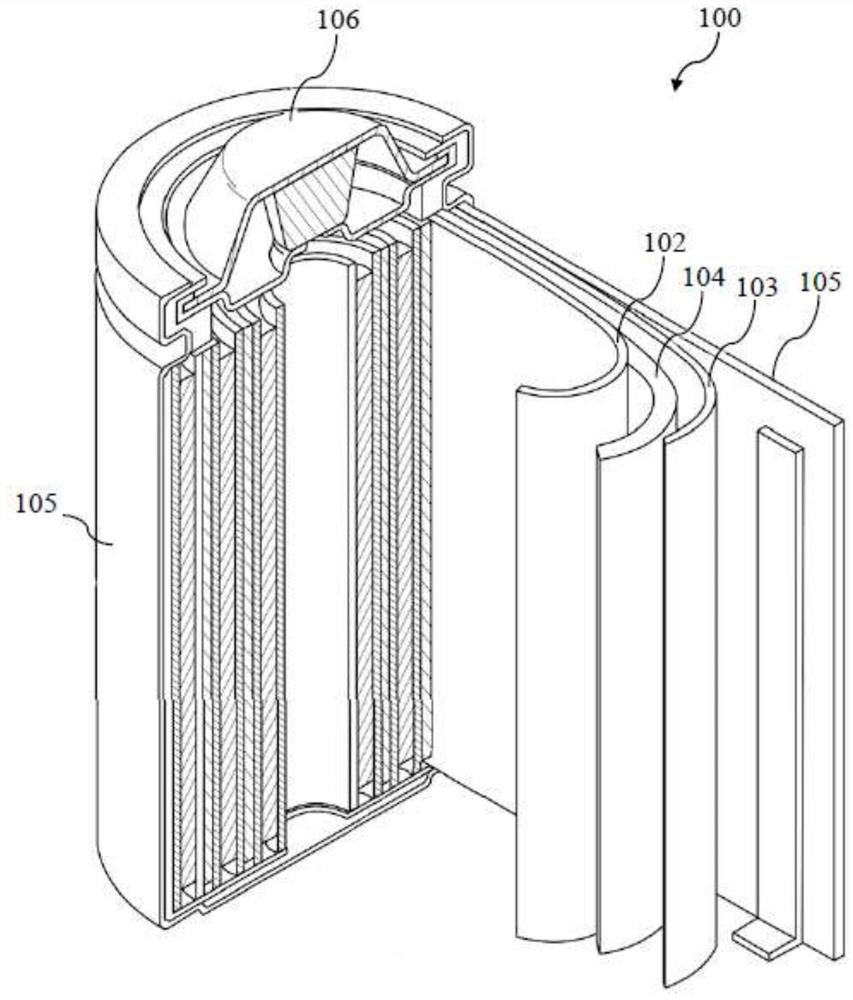

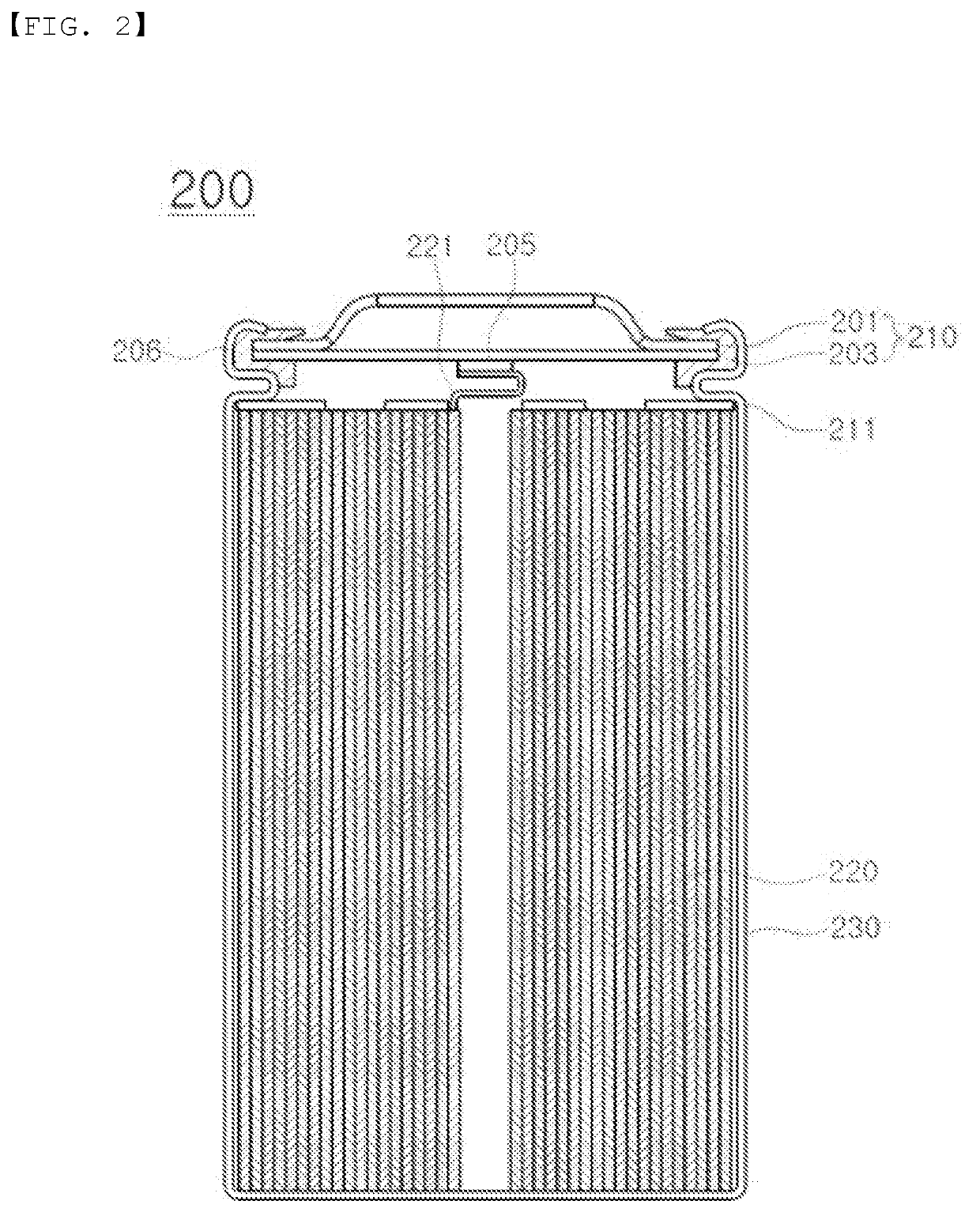

Cylindrical battery including pressurizing part and method of manufacturing the same

ActiveUS20170294641A1Improve life characteristicsReduce capacityFinal product manufactureCell electrodesElectrical batteryOxide

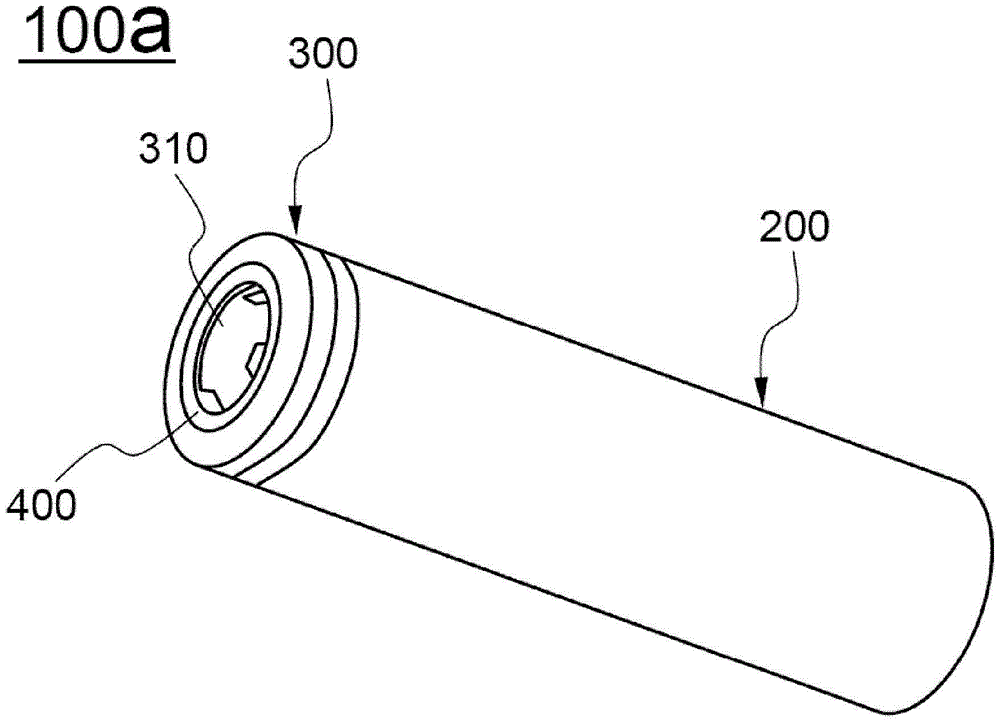

Disclosed herein is a cylindrical battery including an electrode assembly (jelly roll) including a positive electrode, a separator, and a negative electrode, a cylindrical container including a receiving part for receiving the electrode assembly together with an electrolytic solution, a cap assembly mounted to an open upper end of the cylindrical container, a safety vent mounted in the cap assembly, and a pressurization part located between the safety vent and the receiving part, the pressurization part communicating with the receiving part, the pressurization part being configured to apply a predetermined pressure, which is generated by gas, to the receiving part, wherein the positive electrode includes a lithium composite transition metal oxide represented by Formula 1 in the specification as a positive electrode active material.

Owner:LG ENERGY SOLUTION LTD

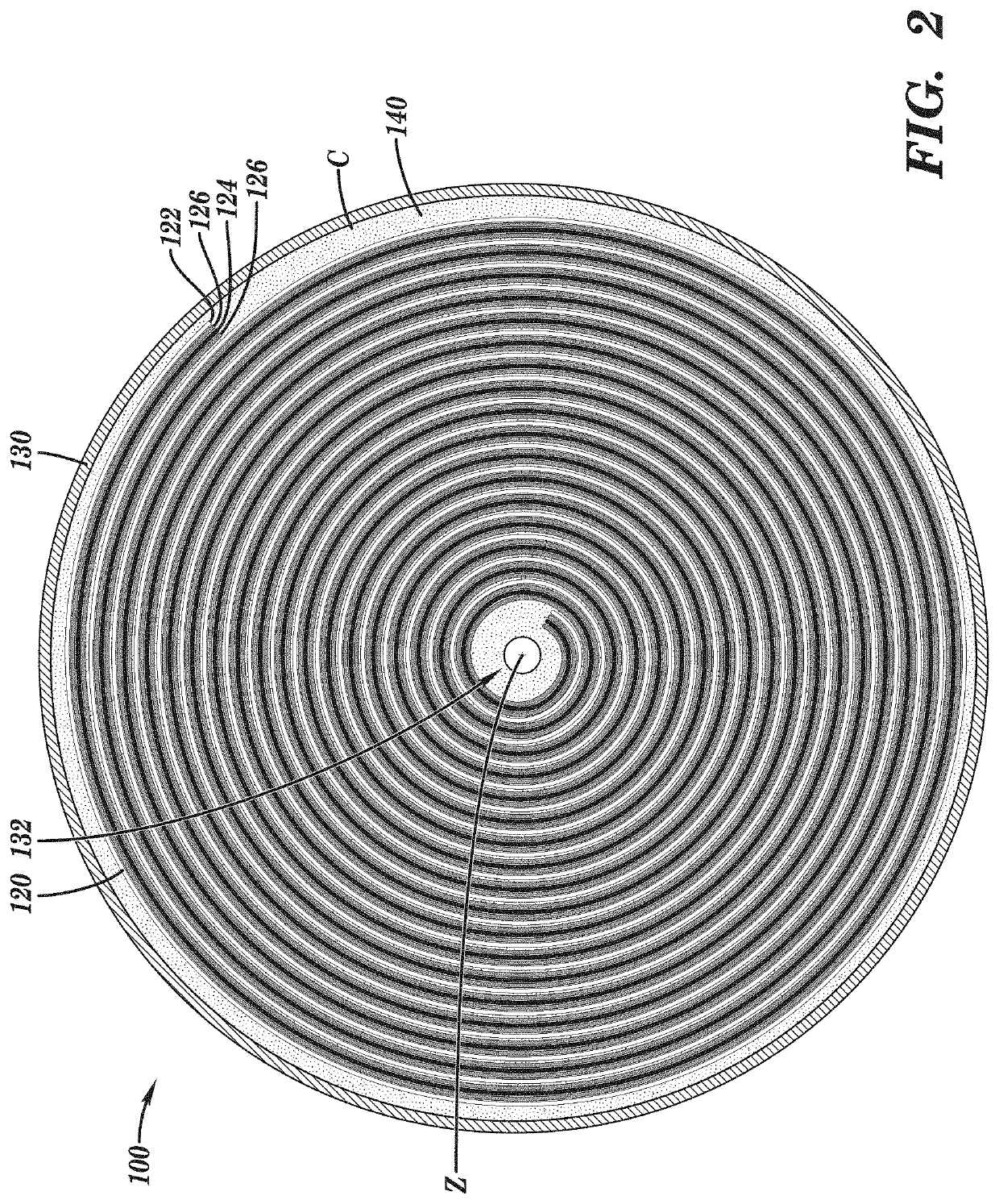

Electrode assembly and method for constructing the same

ActiveUS9178201B2Improve heat resistanceImprove thermal stabilityFinal product manufactureWound/folded electrode electrodesPorous coatingPorous substrate

A jelly-roll type electrode assembly is disclosed. The jelly-roll type electrode assembly includes an anode, a cathode, and separators interposed between the anode and the cathode and having a greater length than width. Each of the separators is longer than the anode and the cathode. Each of the separators has a porous substrate and porous coating layers formed on both surfaces of the porous substrate. The porous coating layers include a mixture of inorganic particles and a binder polymer. The porous coating layers are formed only in areas where the separators are in contact with the anode and the cathode. The porous coating layers enhance the heat resistance of the separators. Due to the enhanced heat resistance, the separators can prevent the performance of a battery from deteriorating. In addition, the porous coating layers can be prevented from being separated from the separators during battery assembly processing.

Owner:LG ENERGY SOLUTION LTD

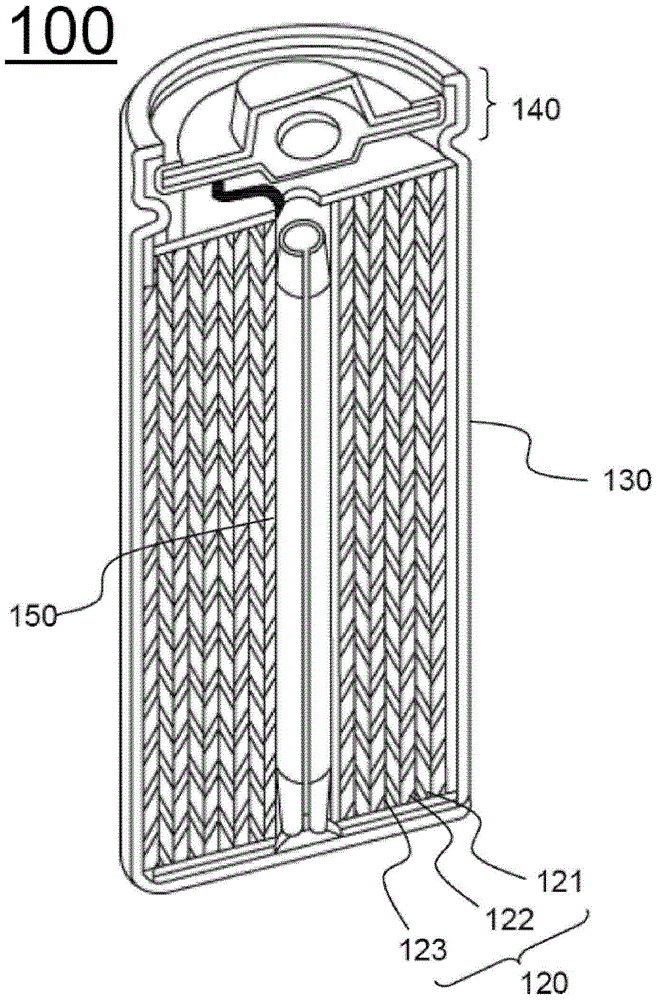

Strip-shaped electrode used for cylindrical jelly roll and lithium secondary battery comprising same

ActiveCN110462885AAvoid crackingReduce thicknessFinal product manufactureWound/folded electrode electrodesBattery cellMaterials science

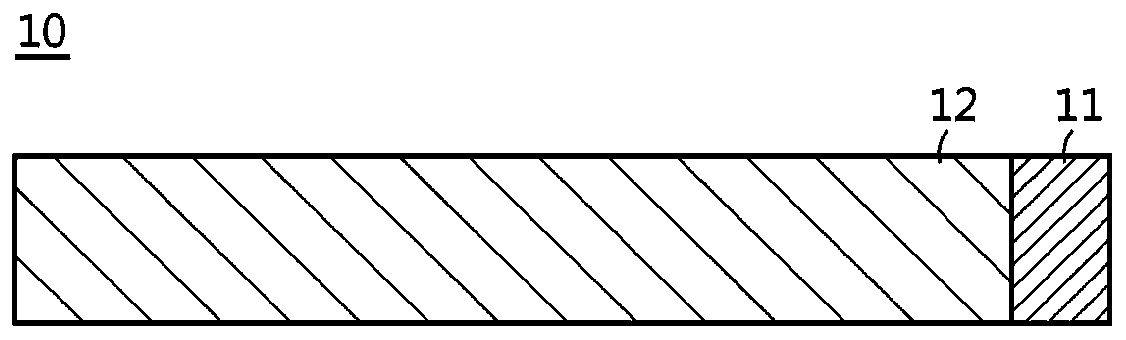

The present invention relates to a strip-shaped electrode used for a cylindrical jelly roll in which a strip-shaped electrode assembly is wound in a cylindrical shape such that a hollow space is formed at a core part thereof, and a lithium secondary battery comprising the same, the strip-shaped electrode comprising: a strip-shaped electrode current collector; a first electrode active material layer formed on at least one surface of the strip-shaped electrode current collector; and a second electrode active material layer formed on the first electrode active material layer, wherein the second electrode active material layer is formed to be shorter than the first electrode active material layer such that the first electrode active material layer has one lengthwise side surface, a part of which is exposed to the outside.

Owner:LG ENERGY SOLUTION LTD

Method for manufacturing jellyroll-type electrode assembly and method for manufacturing jellyroll-type polymer secondary battery

ActiveCN104247126AImprove design flexibilityEasy to removeSolid electrolytesElectrode manufacturing processesElectrical batteryElectrical connection

The present invention relates to a method for manufacturing a jellyroll-type electrode assembly, and provides a method for manufacturing an electrode assembly comprising: a notching step for forming a plurality of electrode units by notching each unidirectionally long cathode and anode into a predetermined size and shape, and notching the electrode units so as to be electrically connected to one another by a connecting unit on both ends of the electrode units; a stacking step for forming a unit cell by stacking the cathodes and anodes on one another with a separation film being a boundary; and a winding step for winding the unit cell, by bending the connecting unit so that the electrode units having the cathodes and anodes lie on top of one another. Furthermore, the present invention provides a method for manufacturing a secondary battery using the obtained electrode assembly. In manufacturing the jellyroll-type electrode assembly and polymer secondary battery, the simplification of the production process of which is easy according to the present invention, it is possible to manufacture a jellyroll-type electrode assembly and polymer secondary battery having excellent design flexibility. Furthermore, the purpose of the present invention is to provide an efficient method for processing a separation film used for manufacturing an electrode assembly so as to conform to the shape of the electrode assembly.

Owner:LG ENERGY SOLUTION LTD

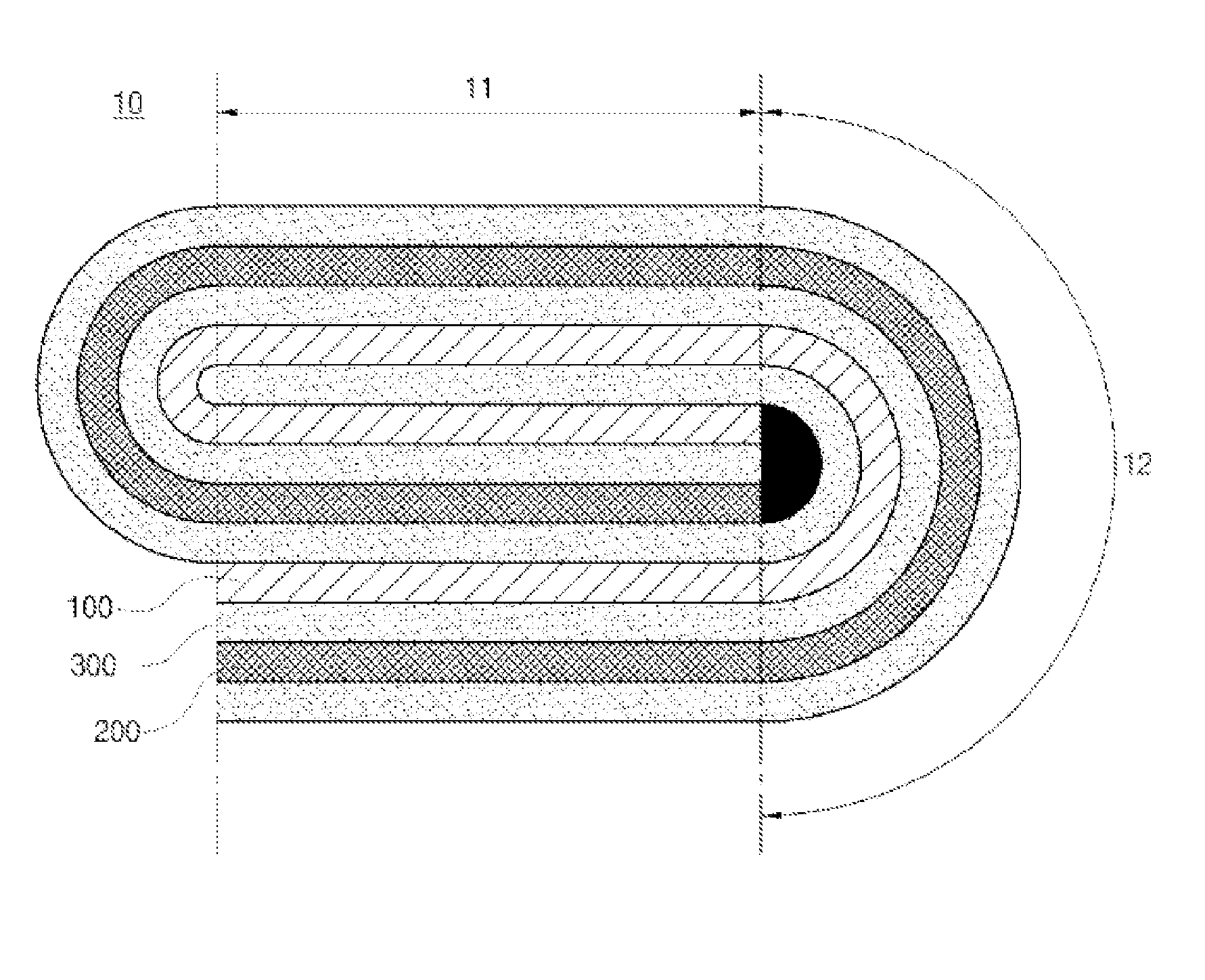

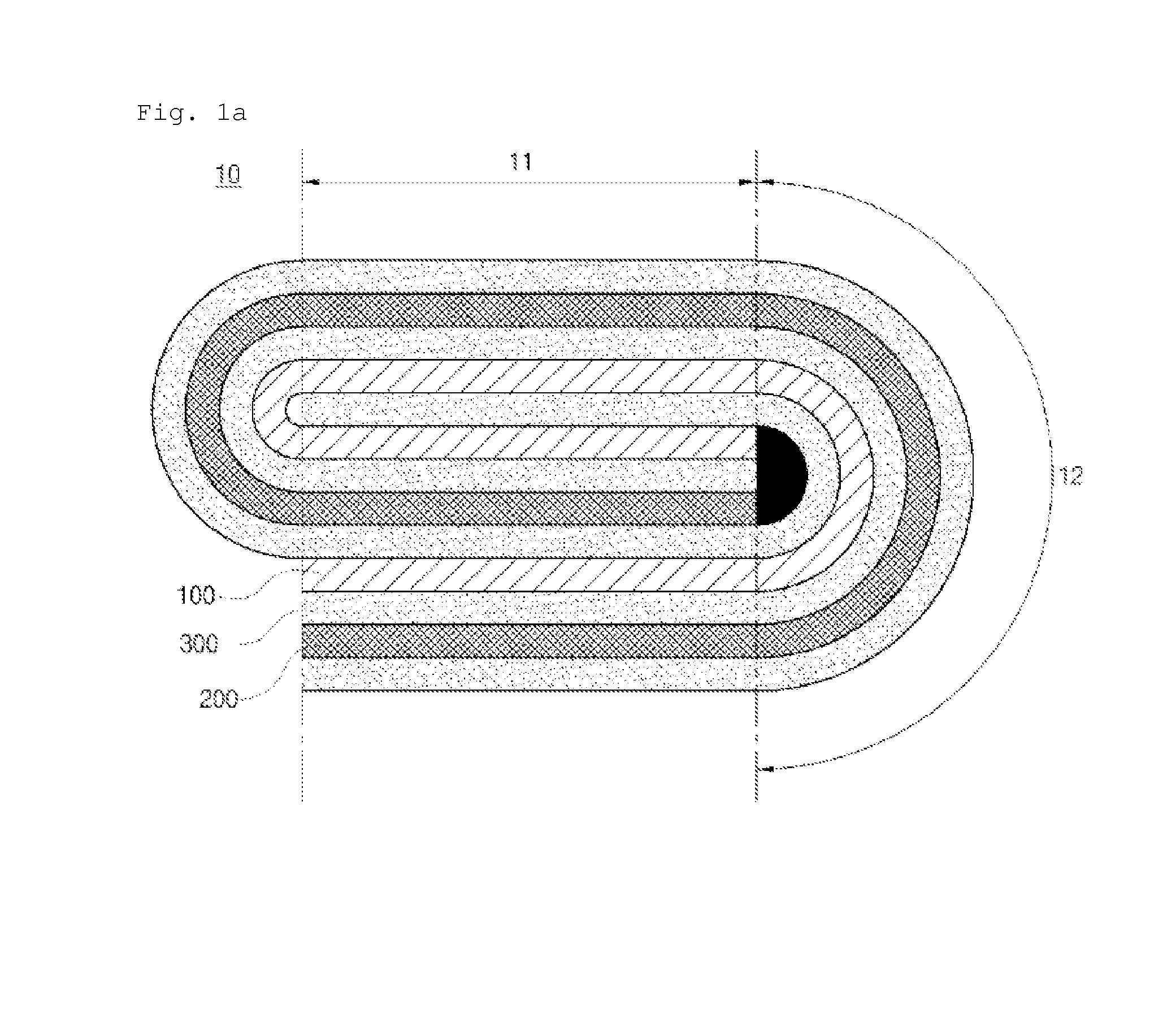

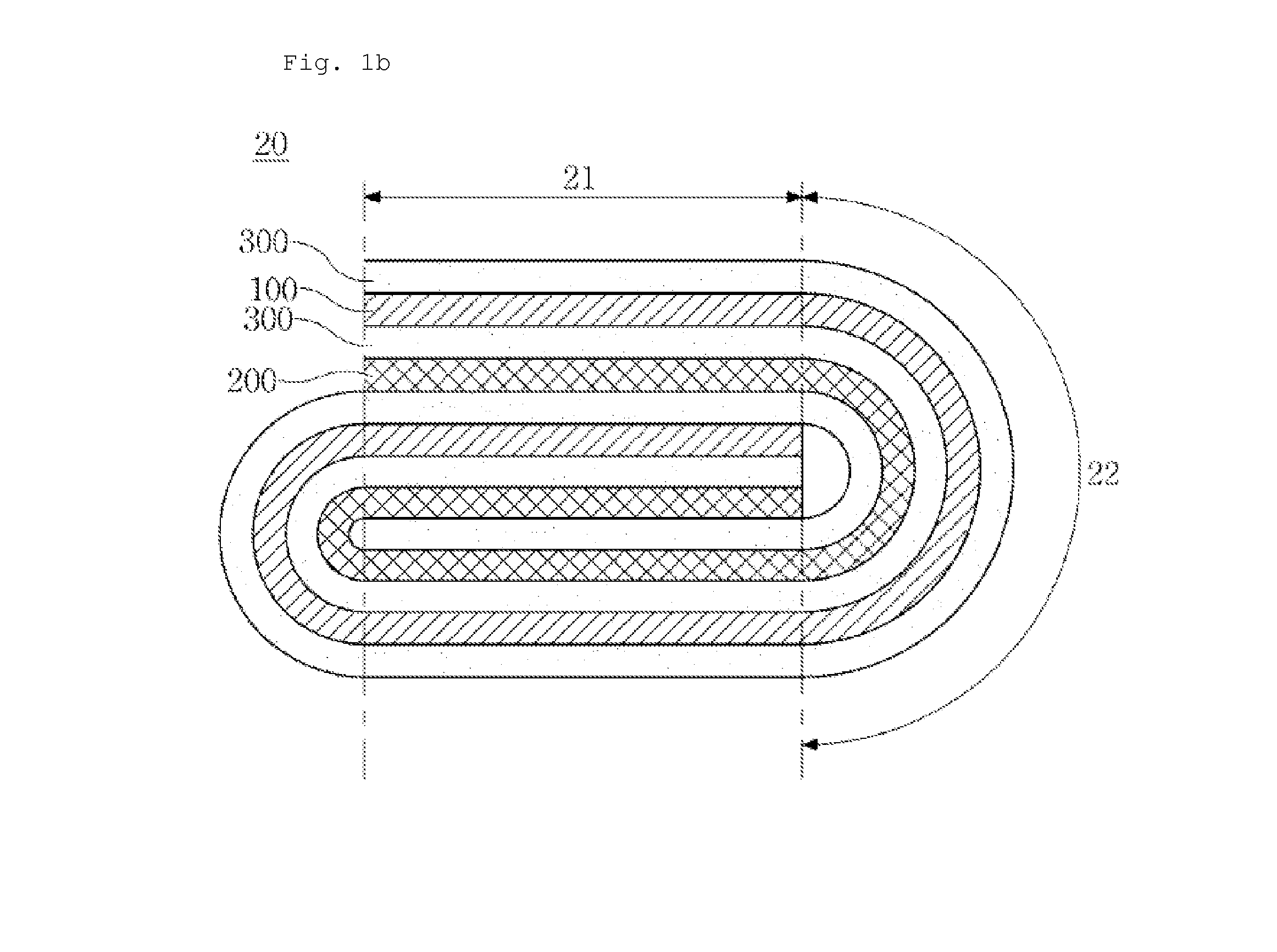

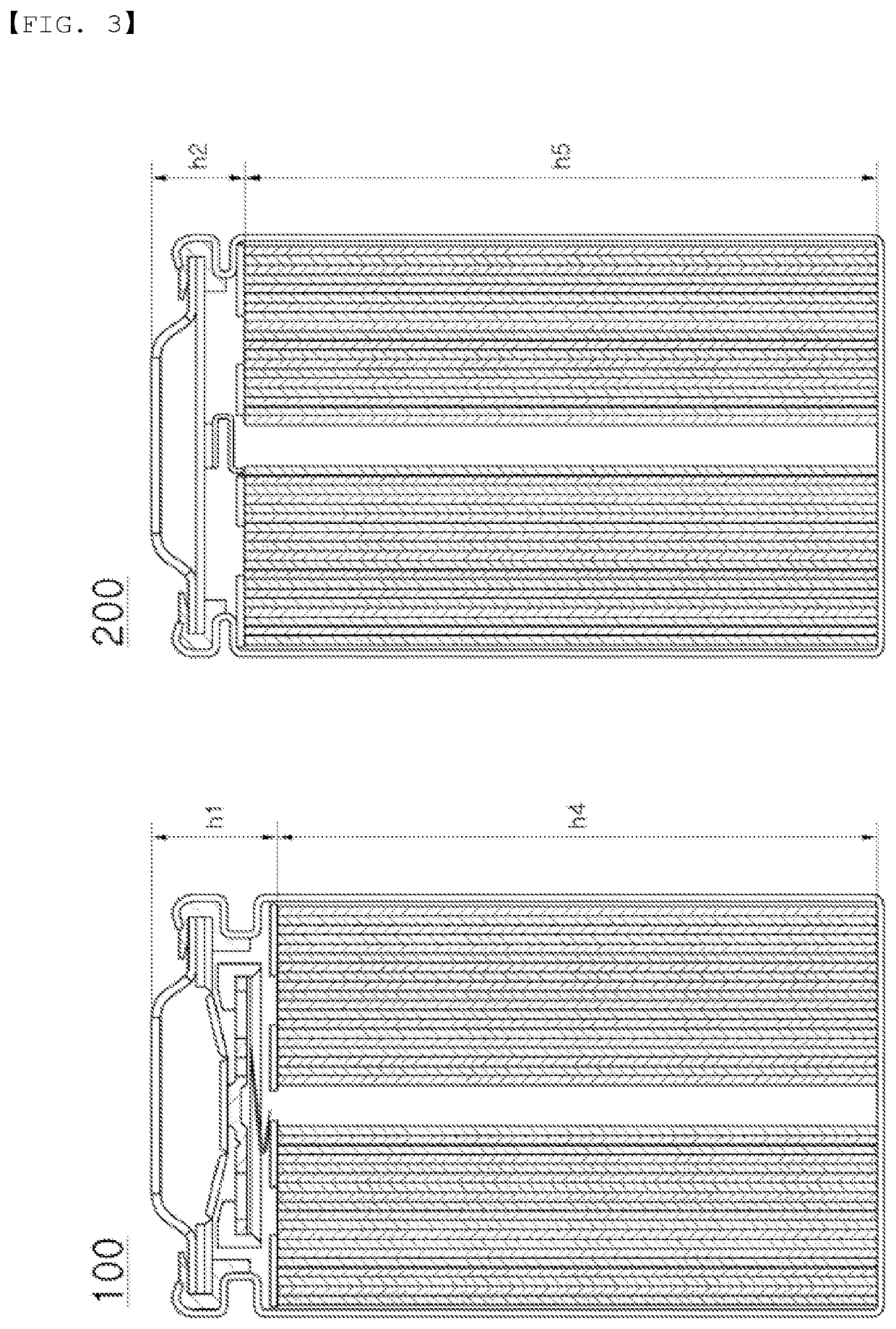

2 stack type jelly roll for secondary battery and battery cell having the same and battery pack having the same and making method of the same

PendingCN111435754ALarge-sized flat cells/batteriesFinal product manufactureBattery cellBattery pack

The present invention relates to a stack type jelly roll for a secondary battery including a cathode, an anode, and a separator. More particularly, the present invention relates to a stack type jellyroll for a secondary battery having a hybrid form of a winding stack manner and a zigzag type stack manner, and a method of manufacturing the same.

Owner:SK ON CO LTD

Anode Subassemblies for Lithium-Metal Batteries, Lithium-Metal Batteries Made Therewith, and Related Methods

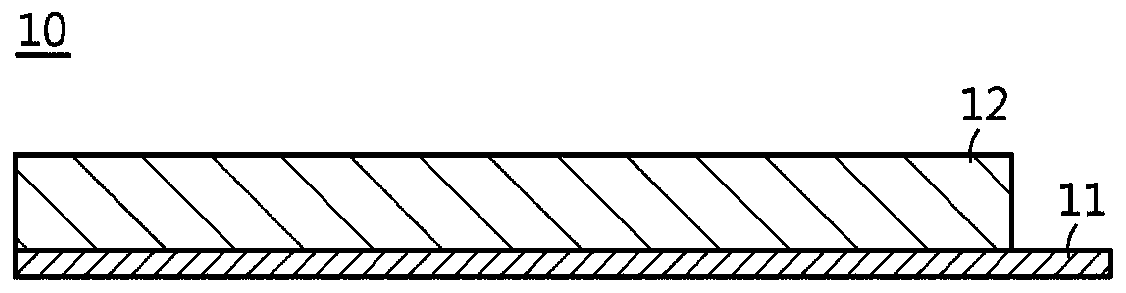

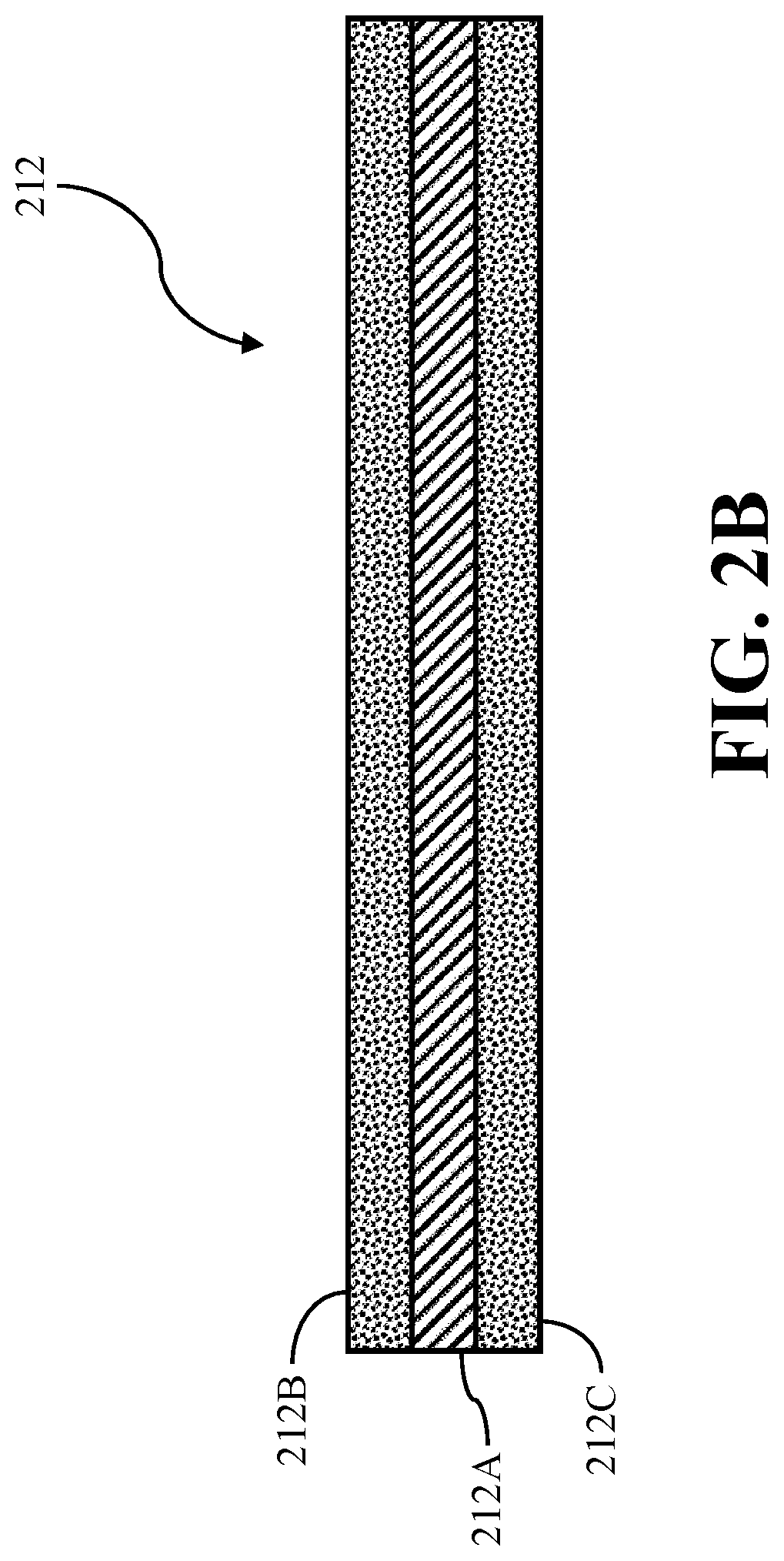

Anode subassembly sheets that include a lithium-metal layer sandwiched between a pair of separator layers to ease handling of the lithium metal to promote fast and efficient stacked-jellyroll assembly. In some embodiments, the separator layers are pressure laminated to the lithium-metal layer without any bonding agent. In some embodiments, a stacked jellyroll is made by alternatingly stacking anode subassembly sheets with cathode sheets. In some embodiments, a functional coating beneficial to the lithium-metal layer is provided to one or more separator layers prior to laminating the separator(s) to the lithium metal layer. Lithium-metal batteries made using stacked jellyrolls made in accordance with aspects of the disclosure are also described.

Owner:SES HLDG PTE LTD

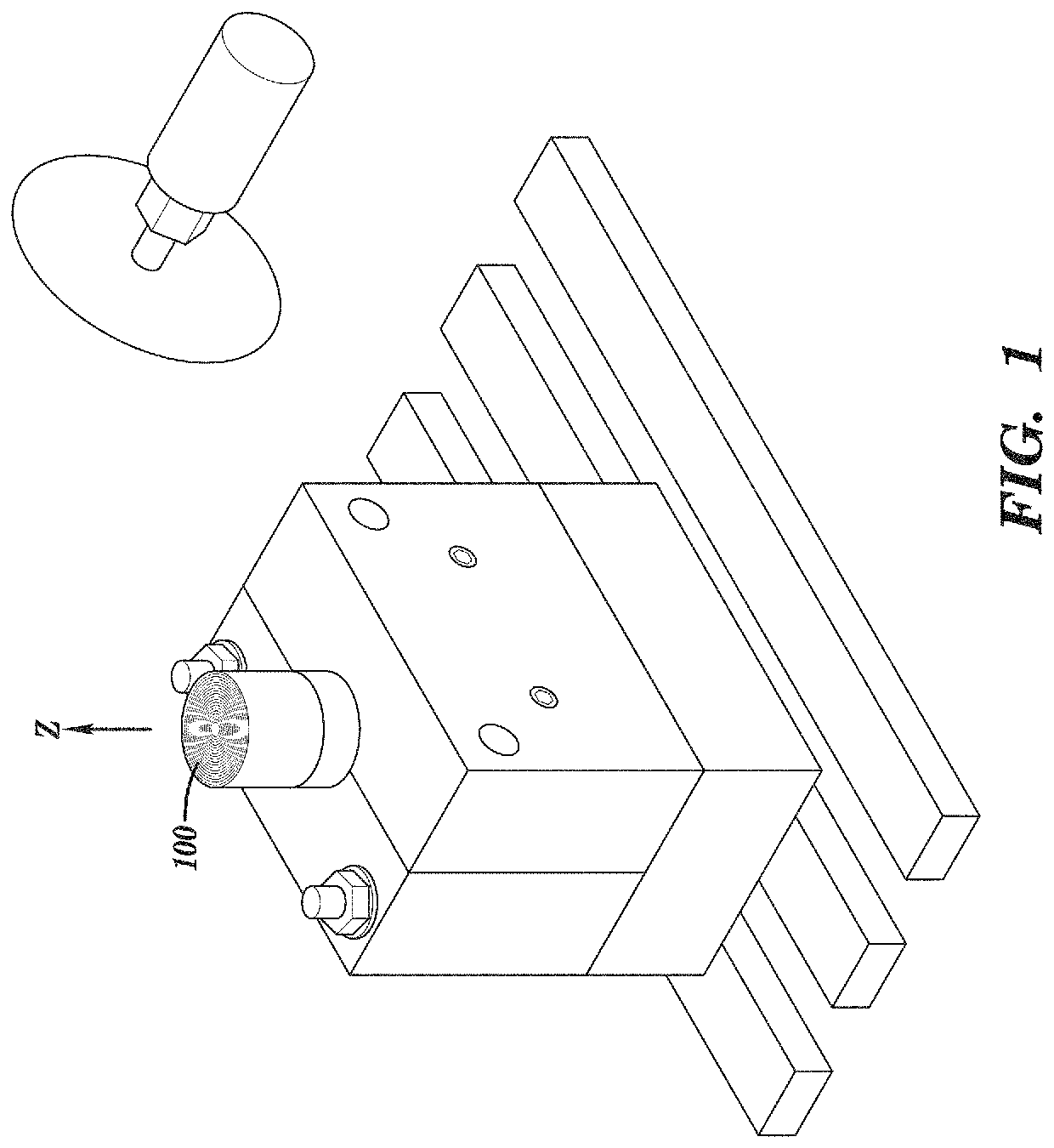

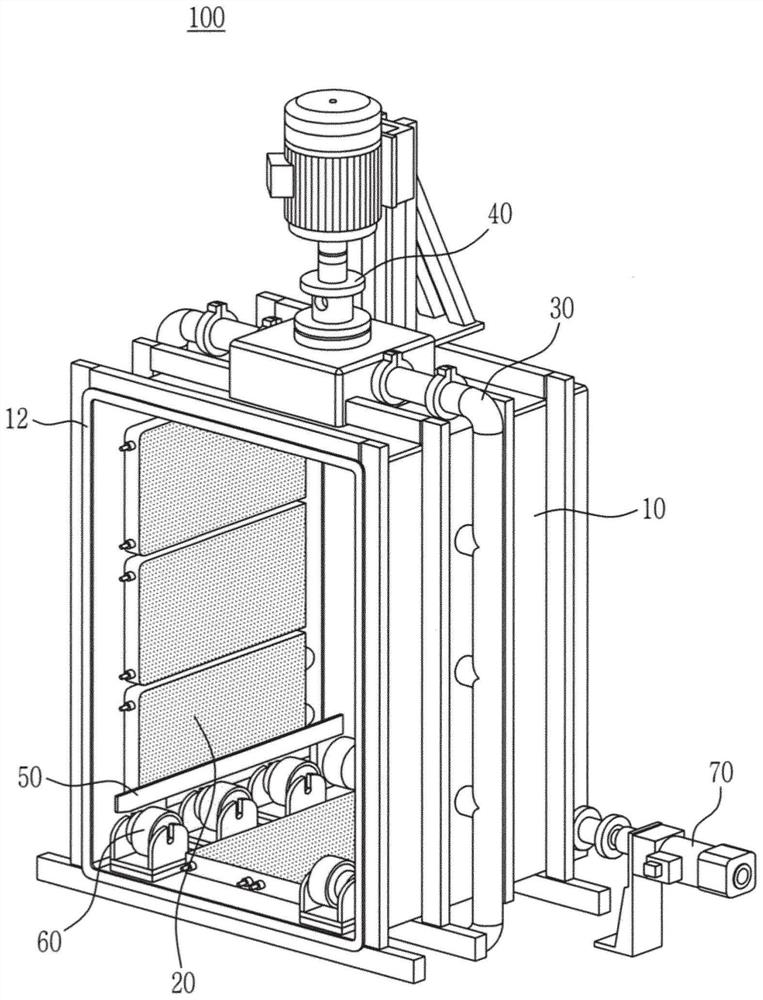

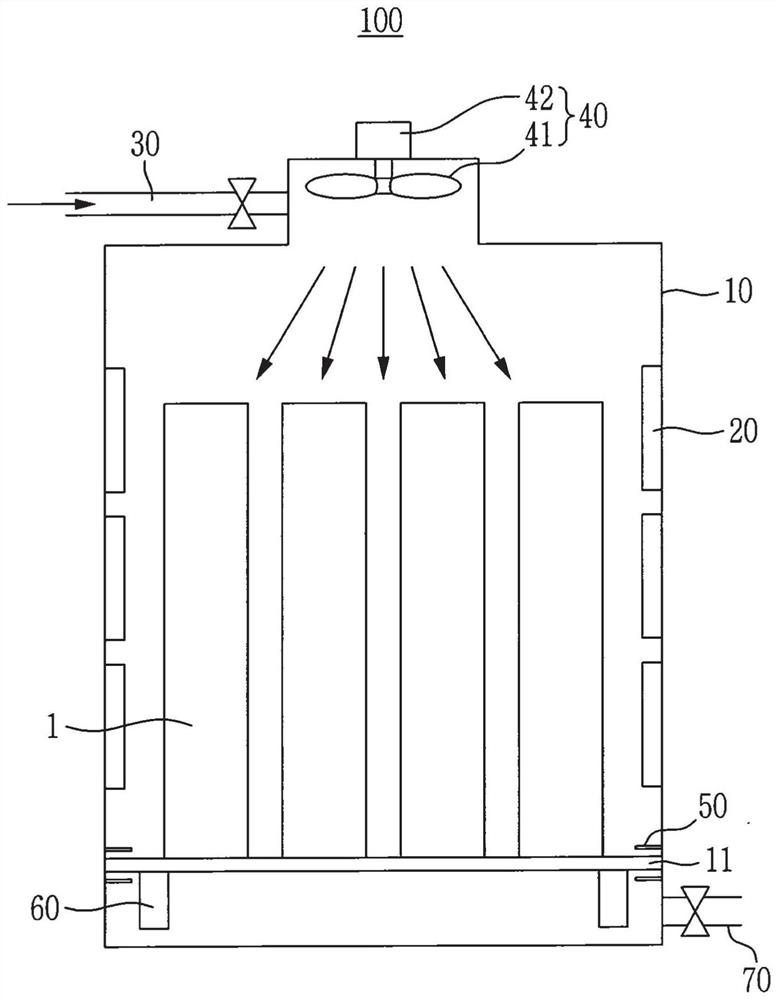

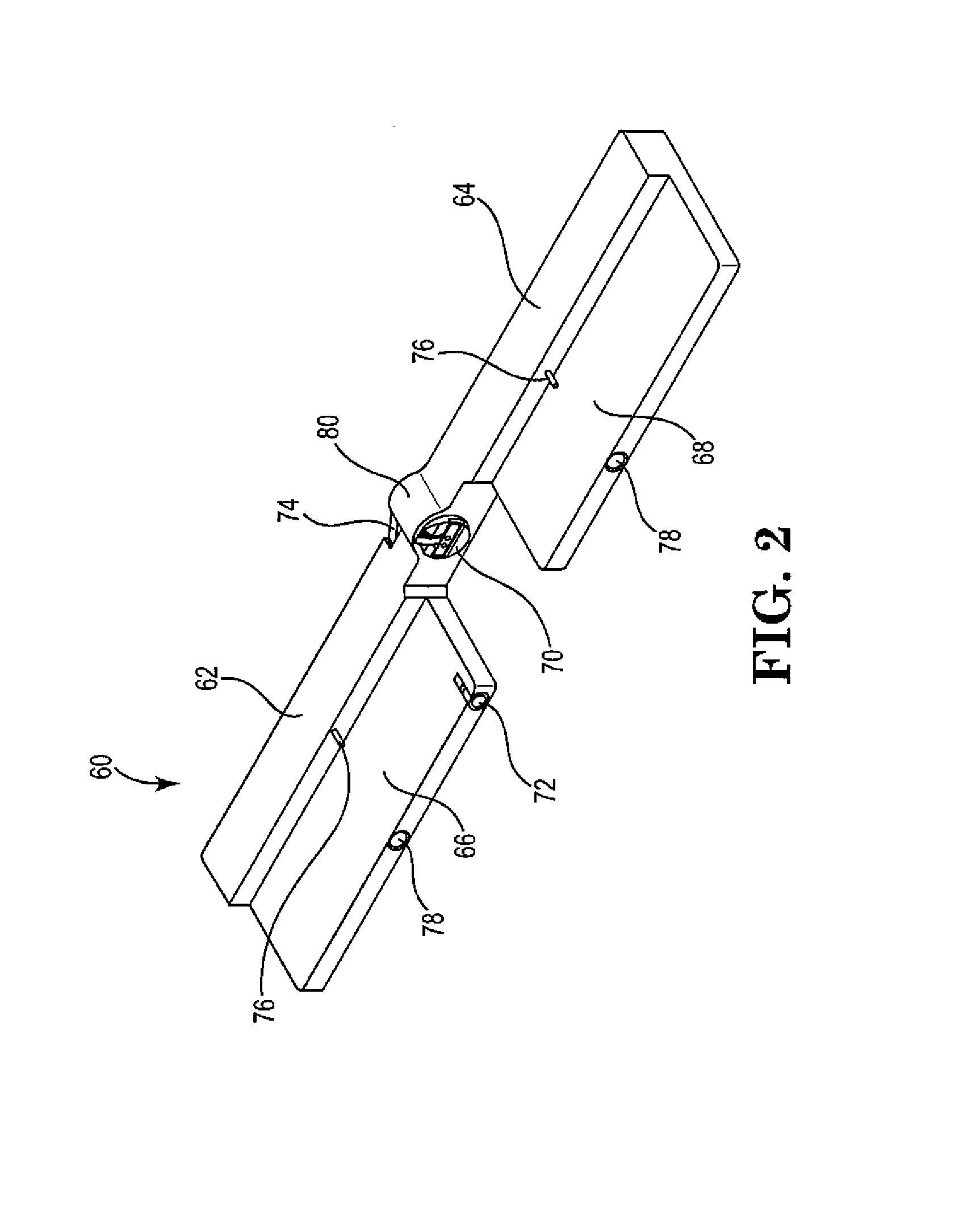

Apparatus and Method for Evaluating Electrode Embrittlement

ActiveUS20200225134A1Electrode brittlenessConvenient and accurateMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesEngineeringMechanical engineering

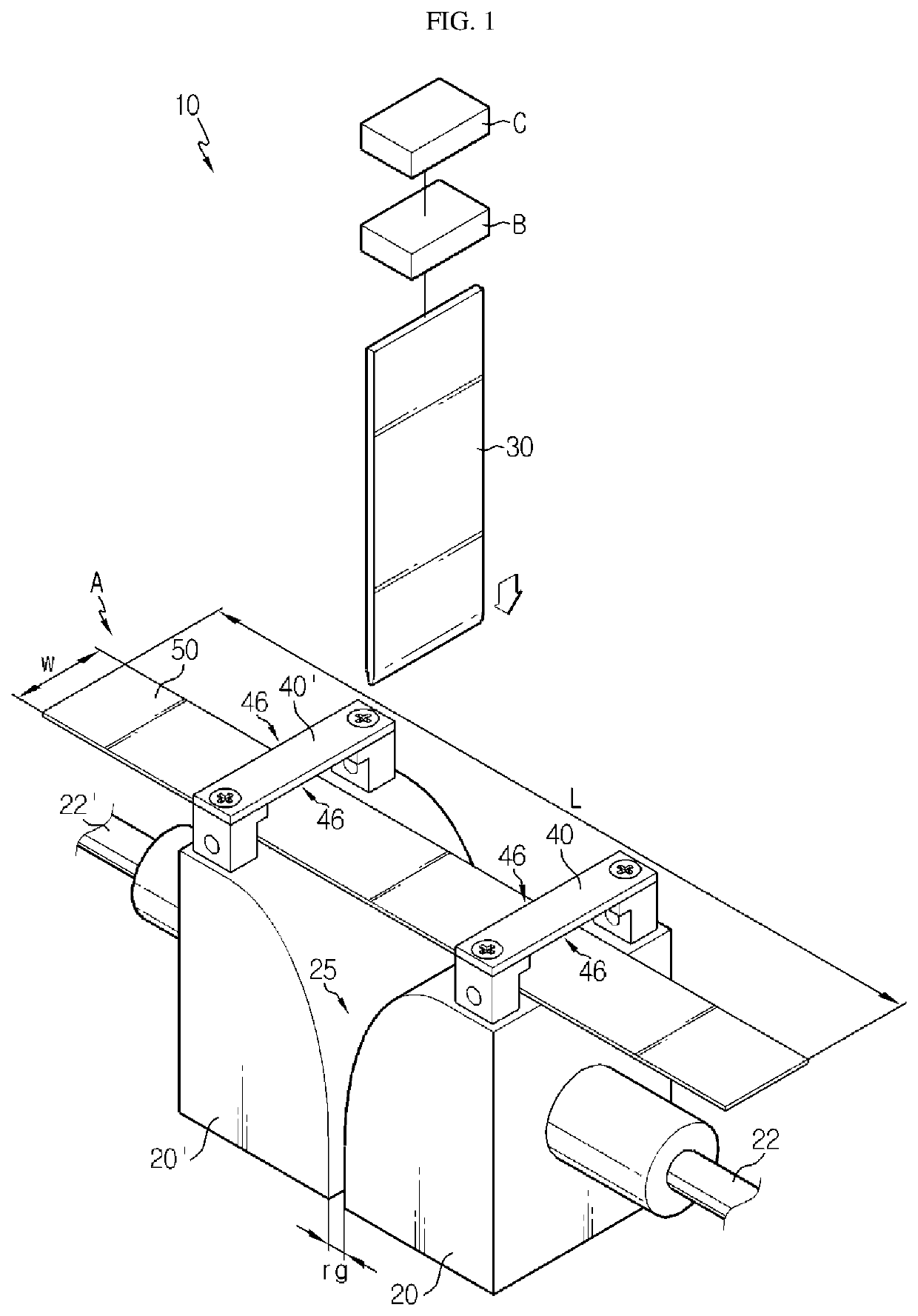

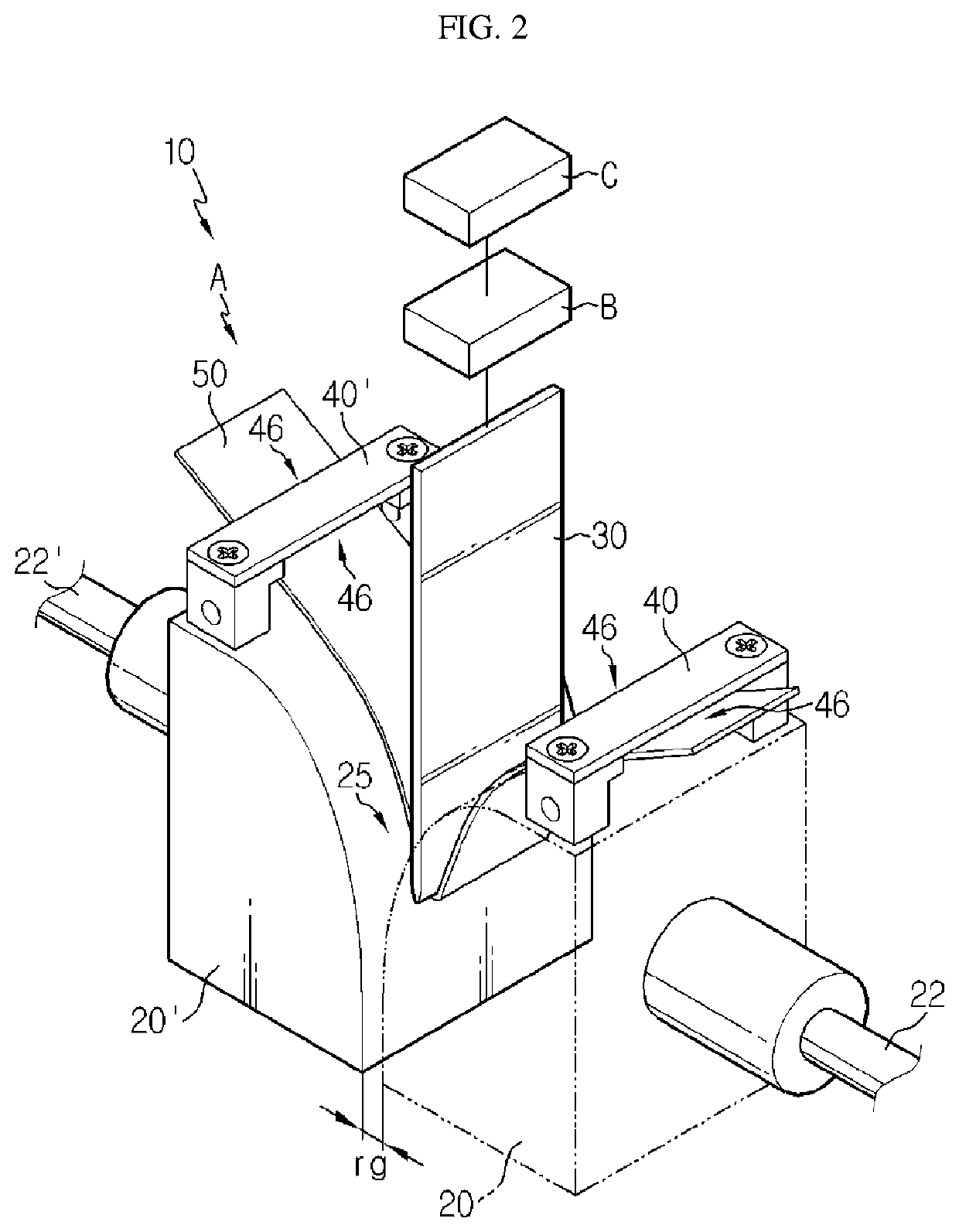

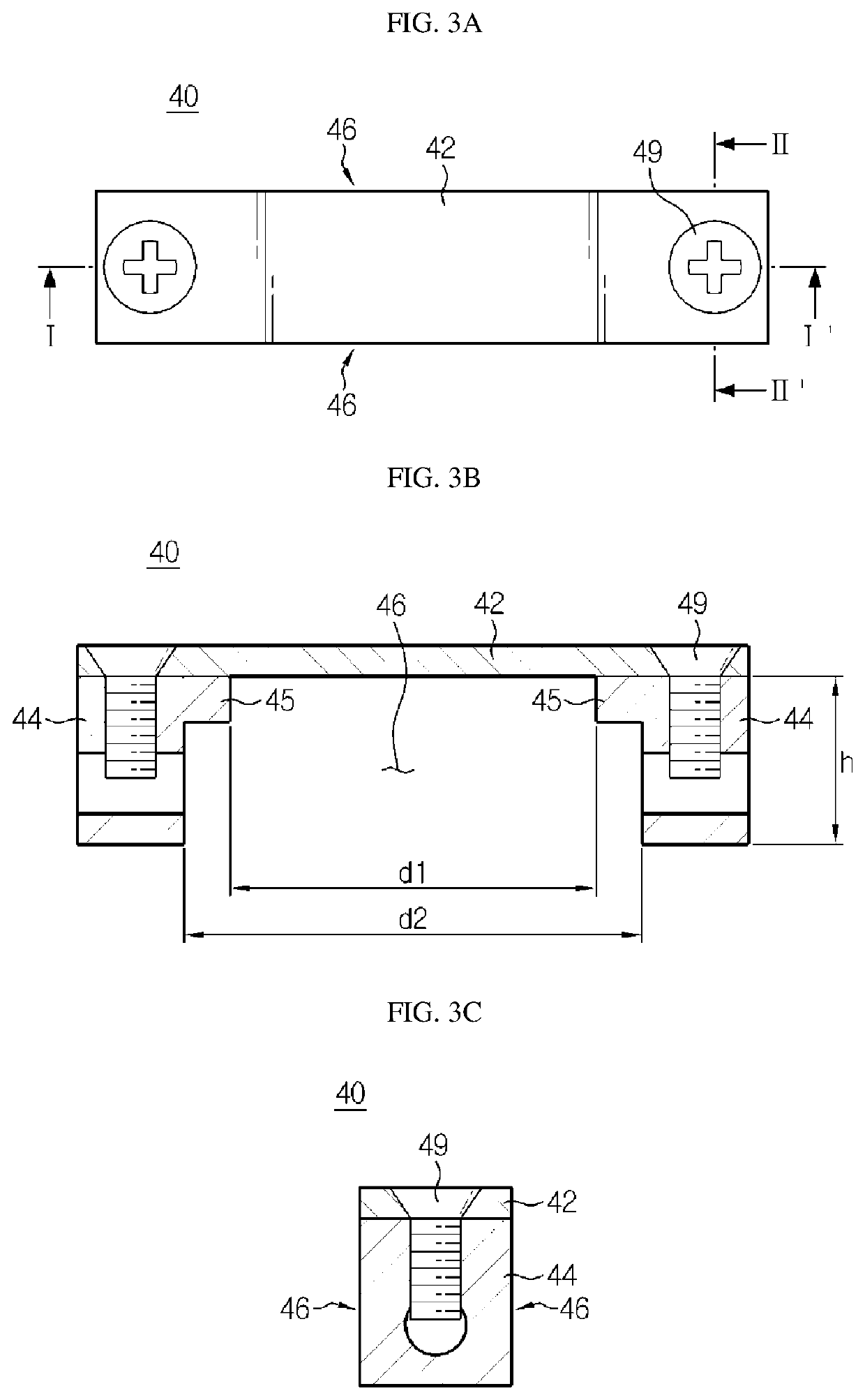

Apparatus and methods of evaluating brittleness by measuring force applied to an electrode specimen by simulating a wound state of a jelly-roll type electrode assembly are disclosed herein. In an embodiment, a brittleness evaluation apparatus includes a jig unit, a driving unit, and a measurement analyzing unit. The jig unit includes two jigs, a groove formed between the jigs, a pressing plate, and guides. The jigs facing each other and have top surfaces formed in a horizontal plane and configured to receive a specimen arranged on the top surfaces along a length direction extending between and along the top surfaces. The pressing plate is arranged perpendicular to the length direction and configured to cause the specimen to bend by descending into the groove. The guides are located on each of the top surfaces of the jigs and configured to prevent distortion of the specimen during descent of the pressing plate.

Owner:LG ENERGY SOLUTION LTD

Jelly-roll type electrode assembly having anode in which anode mixtures containing active material with different composition are formed on both sides of electrode current collector, secondary battery comprising the same, and device comprising secondary battery

PendingUS20210359288A1High outputIncrease capacityFinal product manufactureWound/folded electrode electrodesElectrical batteryAnalytical chemistry

The present disclosure relates to a jelly-roll type electrode assembly in which a long sheet-type cathode and a long sheet-type anode are wound in a state where a separator is interposed between the cathode and the anode, wherein the anode is configured such that an anode mixture is formed on both sides of an anode current collector, and the anode current collector is configured such that when winding to form an electrode assembly, if a side that winds inward is referred to a first side and a side that winds outward is referred to a second side, an active material of a first anode mixture coated on the first side contains 70 wt % or more artificial graphite as an active material based on the total weight of the active material, and an active material of a second anode mixture coated on the second side contains 70 wt % or more natural graphite as an active material based on the total weight of the active material.

Owner:LG ENERGY SOLUTION LTD

Electrode assembly with projecting tab for battery and methods of forming same

ActiveUS20200099037A1Assembling battery machinesFinal product manufactureElectrical batteryElectrical connection

Embodiments of the disclosure provide an electrode assembly including: a jelly roll electrode having a plurality of electrode sheets, the plurality of electrode sheets including an anode sheet, a cathode sheet, and a separator separating the anode sheet from the cathode sheet, an electrolyte disposed between the anode sheet and the cathode sheet of the jelly roll electrode, and a tab projecting from an axial end of the plurality of electrode sheets, the tab including a subsection of the plurality of electrode sheets contacting each other at an axial end of the jelly roll electrode; and a first conductive tab coupled to the tab of the electrode assembly, wherein the first conductive tab is configured to electrically couple the electrode assembly to a battery terminal.

Owner:CUSTOM ELECTRONICS

Battery cell design with a non-invasive lithium reference lead

A battery cell providing a non-invasive reference lead includes a cap positioned at a top of the battery cell, where the cap includes an anode section and a cathode section separated by an insulator section. The battery cell also includes a jelly roll comprising an anode lead and a cathode lead extending from a top of the jelly roll. The anode lead of the jelly roll is electrically coupled to the anode section of the cap, and the cathode lead of the jelly roll is electrically coupled to the cathode section of the cap. The battery cell further includes a lithium sleeve providing a reference lead for the battery cell. The lithium sleeve and the cap enclose the jelly roll.

Owner:CHONGQING JINKANG POWERTRAIN NEW ENERGY CO LTD

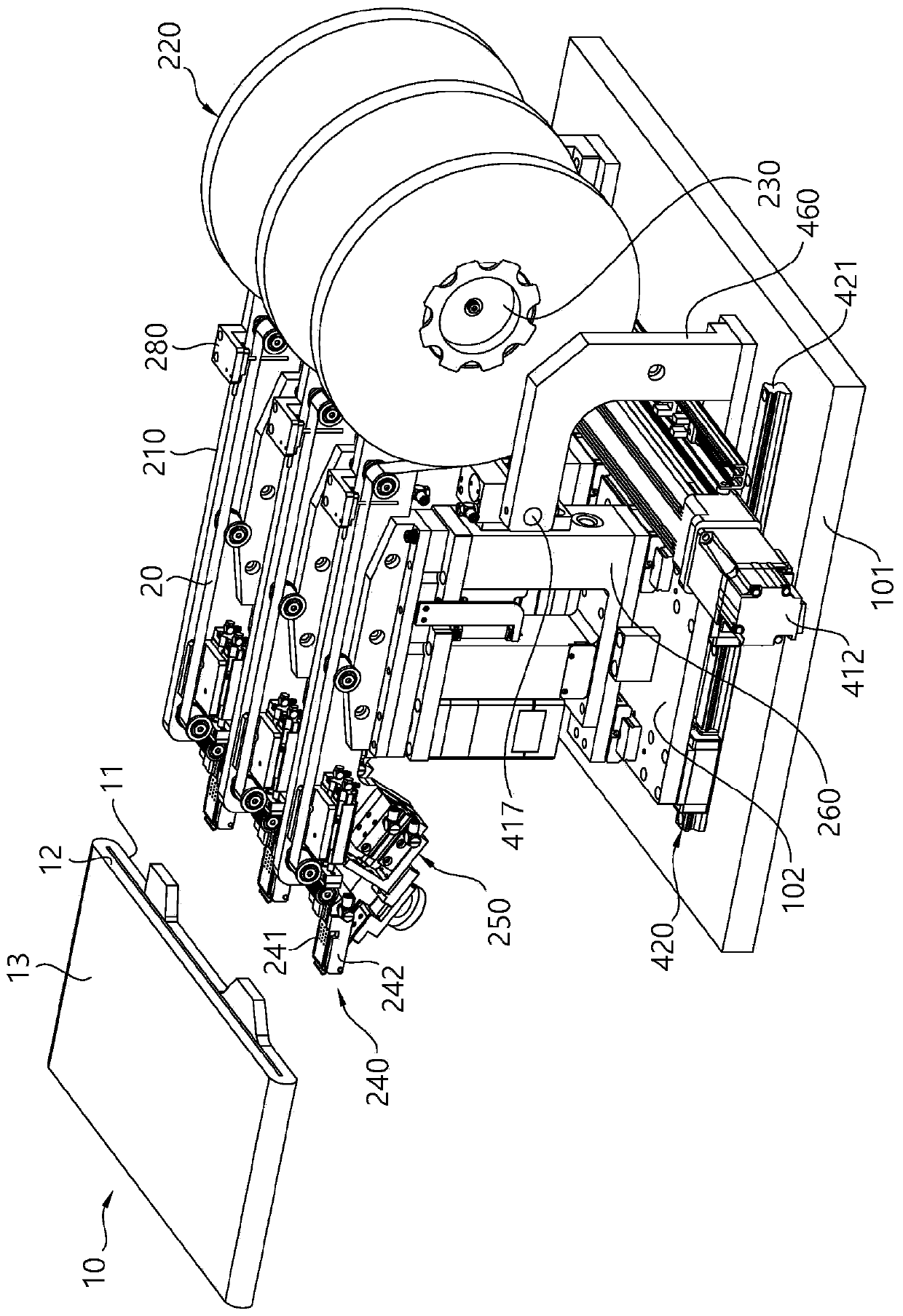

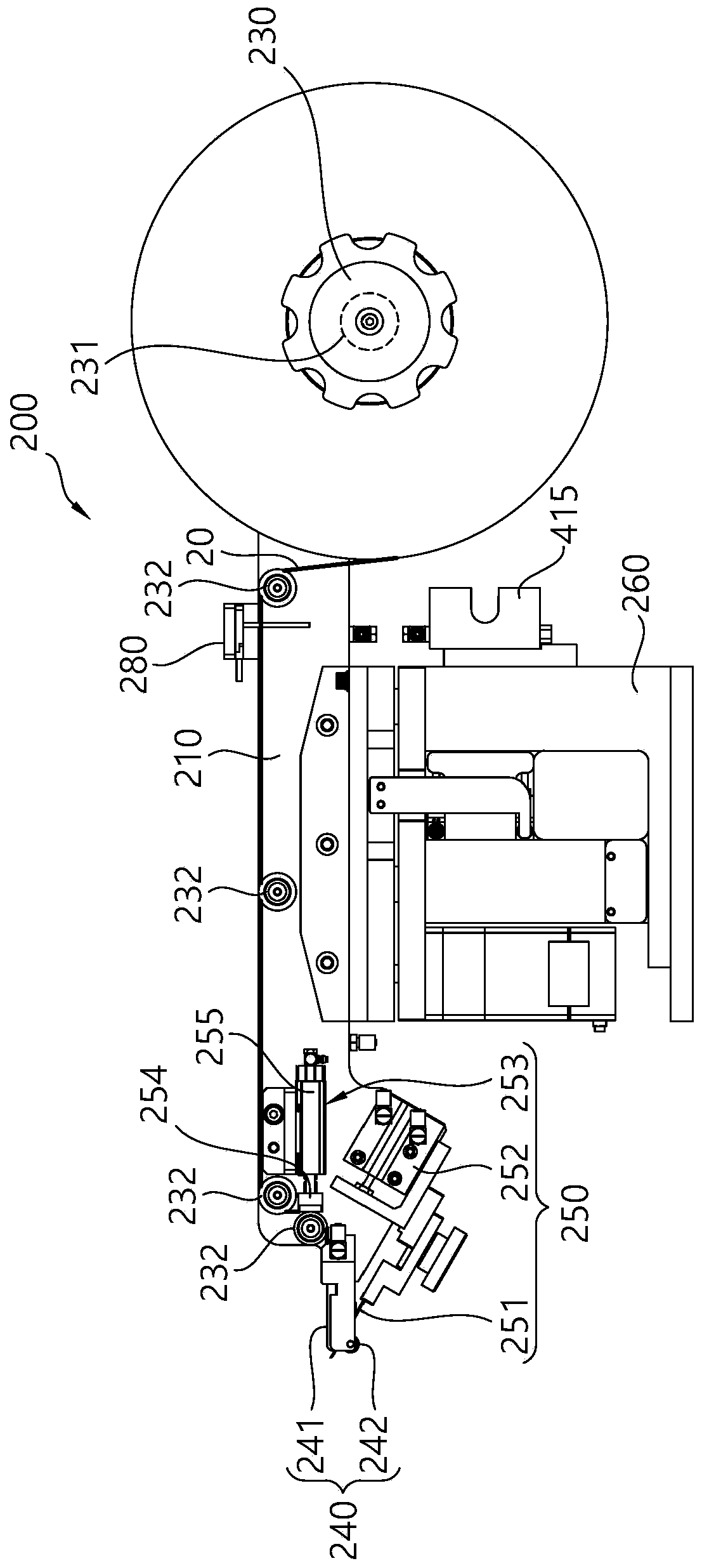

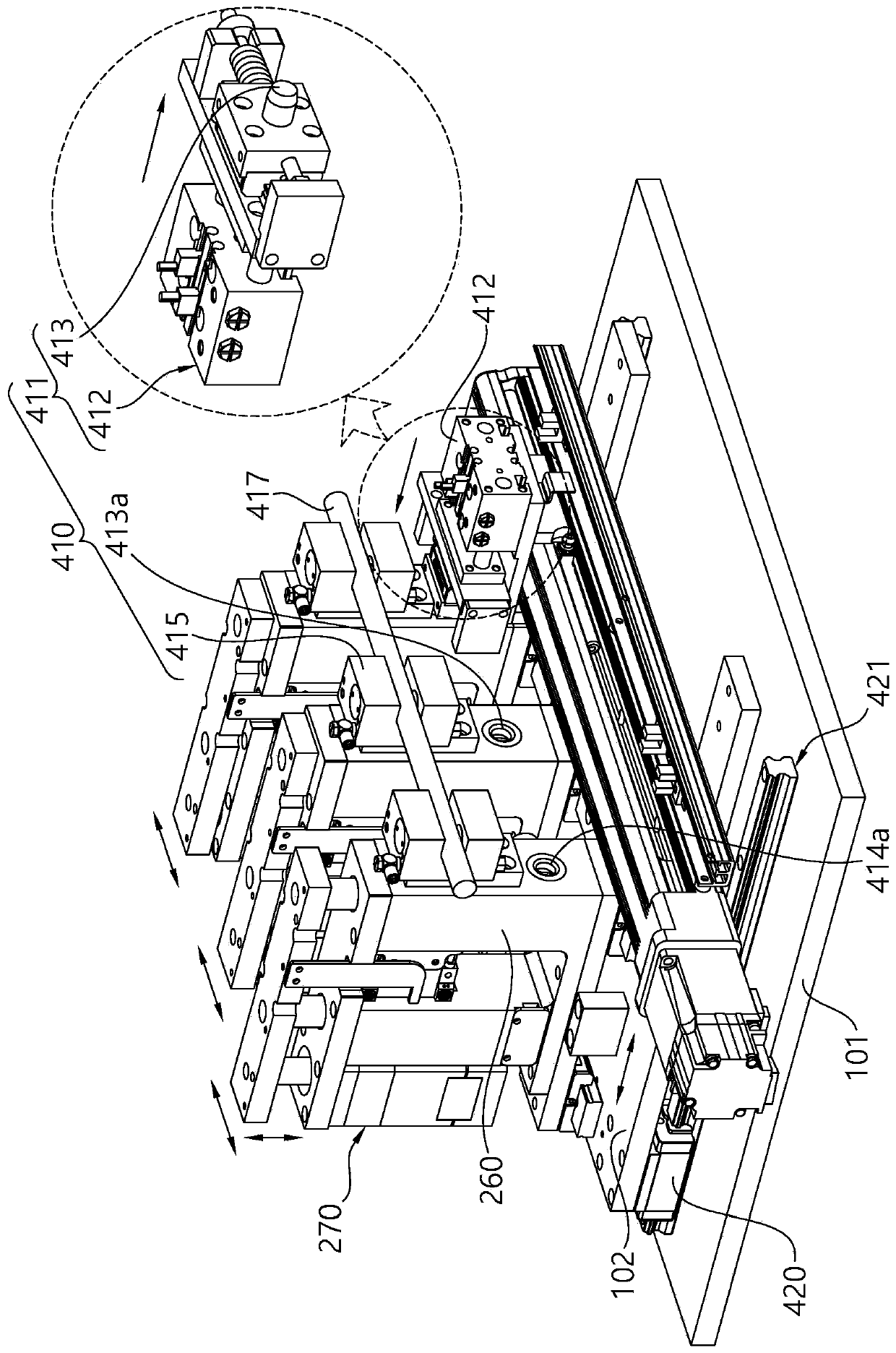

Tape attaching apparatus for jelly roll of secondary battery and tape attaching method using same

ActiveCN111483865AAvoid damageImprove productivityAssembling battery machinesFinal product manufactureAdhesive beltEngineering

The present invention relates to a tape attaching apparatus for a jelly roll of a secondary battery and a tape attaching method using the same, the apparatus comprising: a first base; a plurality of attaching units capable of moving back and forth on the first base toward the winding core; and a control unit that controls the operation of the plurality of attaching units, each attaching unit including: a tape roll placement unit that is capable of detaching and attaching an adhesive tape roll, wherein the tape roll is formed by winding a tape in a roll shape; a head that temporarily fixes thedistal end side of the tape unwound from the tape reel and presses and adheres the tape to the jelly roll; a lifting means for lifting the head; and the cutting part is used for cutting the adhesive tape on one side of the head part when the adhesive tape is adhered to the roll core. According to the present invention, tension is provided while attaching is carried out, the tape can be firmly adhered while the jelly roll is pressed, and the tape can be firmly adhered while taking into account the partial thickness difference of the jelly roll, thereby preventing the jelly roll from being damaged and enabling the tape to be firmly adhered.

Owner:주식회사이노렉스

Cylindrical secondary battery including adhesive portion including gas generating material

PendingCN111615766ASmall structureIncreasing the thicknessFinal product manufactureCylindrical casing cells/batteryEngineeringConductive materials

Owner:LG ENERGY SOLUTION LTD

Interface between jelly roll area of a battery cell and cell can

InactiveCN113169427AFinal product manufactureSmall-sized cells cases/jacketsElectrical connectionEngineering

An embodiment is directed to a cylindrical battery cell, comprising a cell can, a jelly roll area of anode electrode, separator, and cathode electrode foils arranged in a middle section of the cell can. The anode electrode foils, the cathode electrode foils, or both extend out of the jelly roll area into an electrolyte area of the cell can. In one embodiment, some of the extended electrode foils are in direct contact with an end (e.g., top or bottom) of the cell can. In another embodiment, the extended electrode foils contact a plurality of connection taps that are thermally and electrically connected to an end (e.g., top or bottom) of the cell can. In another embodiment, the extended electrode foils are bent and stacked so as to function as a foil-integrated connection tap that is thermally and electrically connected to an end (e.g., top or bottom) of the cell can.

Owner:TIVENI MERGECO INC

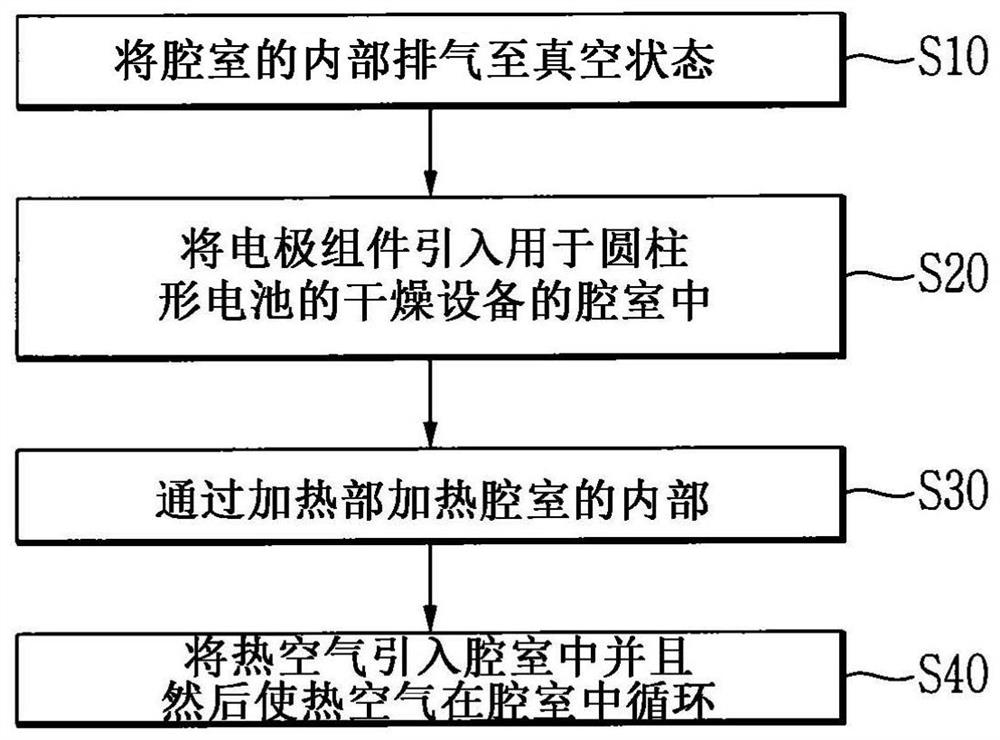

Method for manufacturing cylindrical battery and drying apparatus for performing same

PendingCN112534615ADrying solid materials with heatElectrode thermal treatmentAir cycleElectrical battery

Owner:LG ENERGY SOLUTION LTD

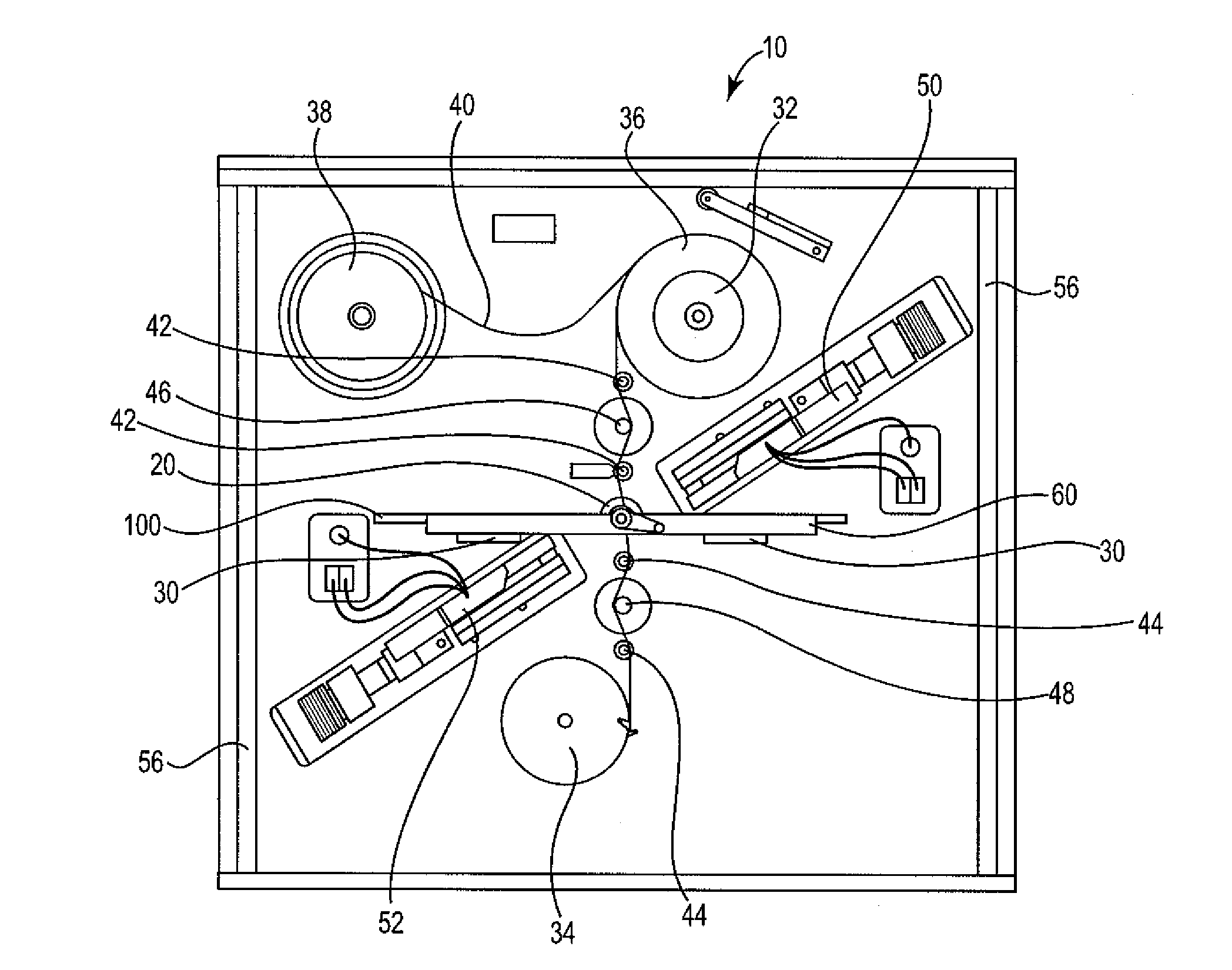

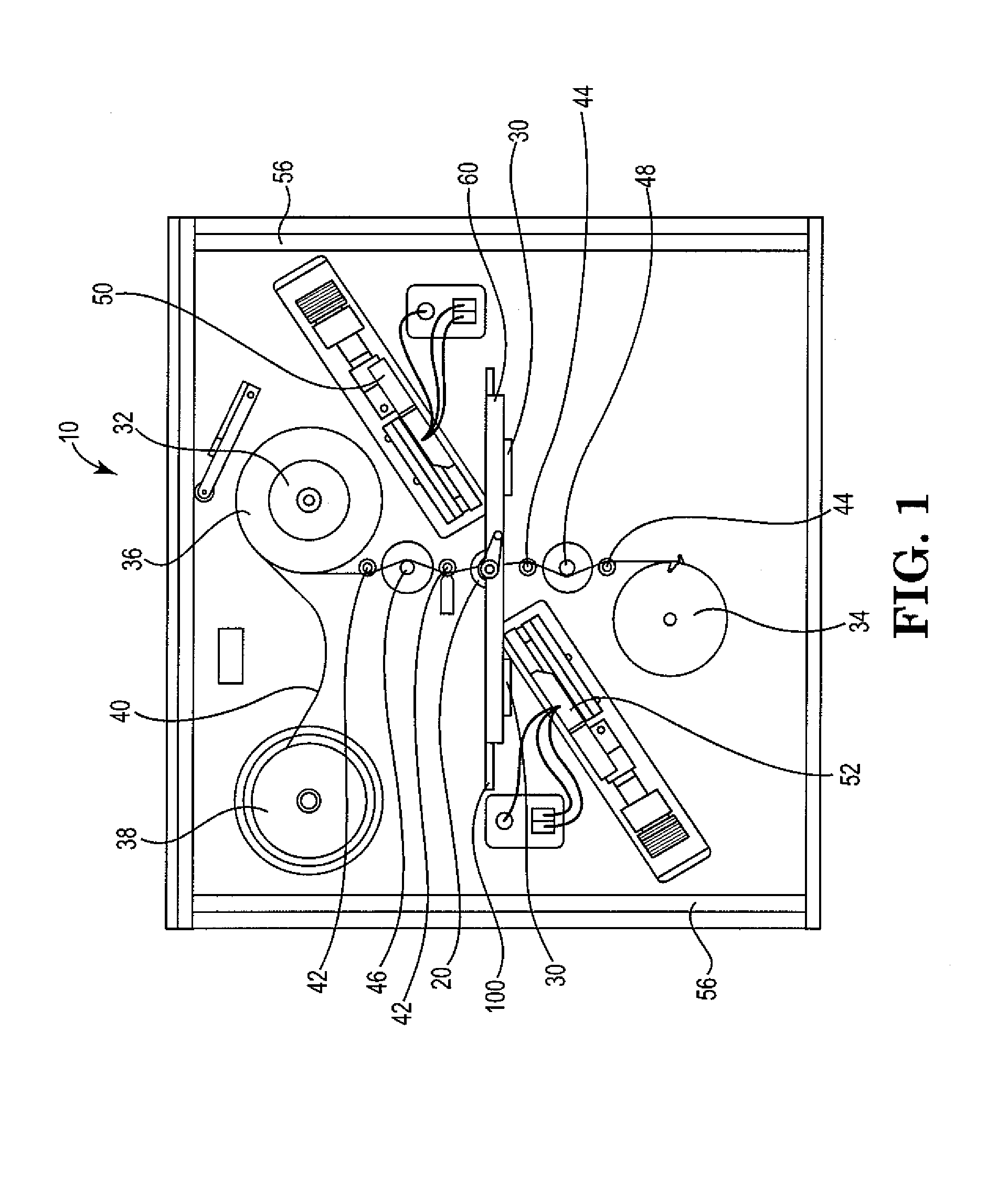

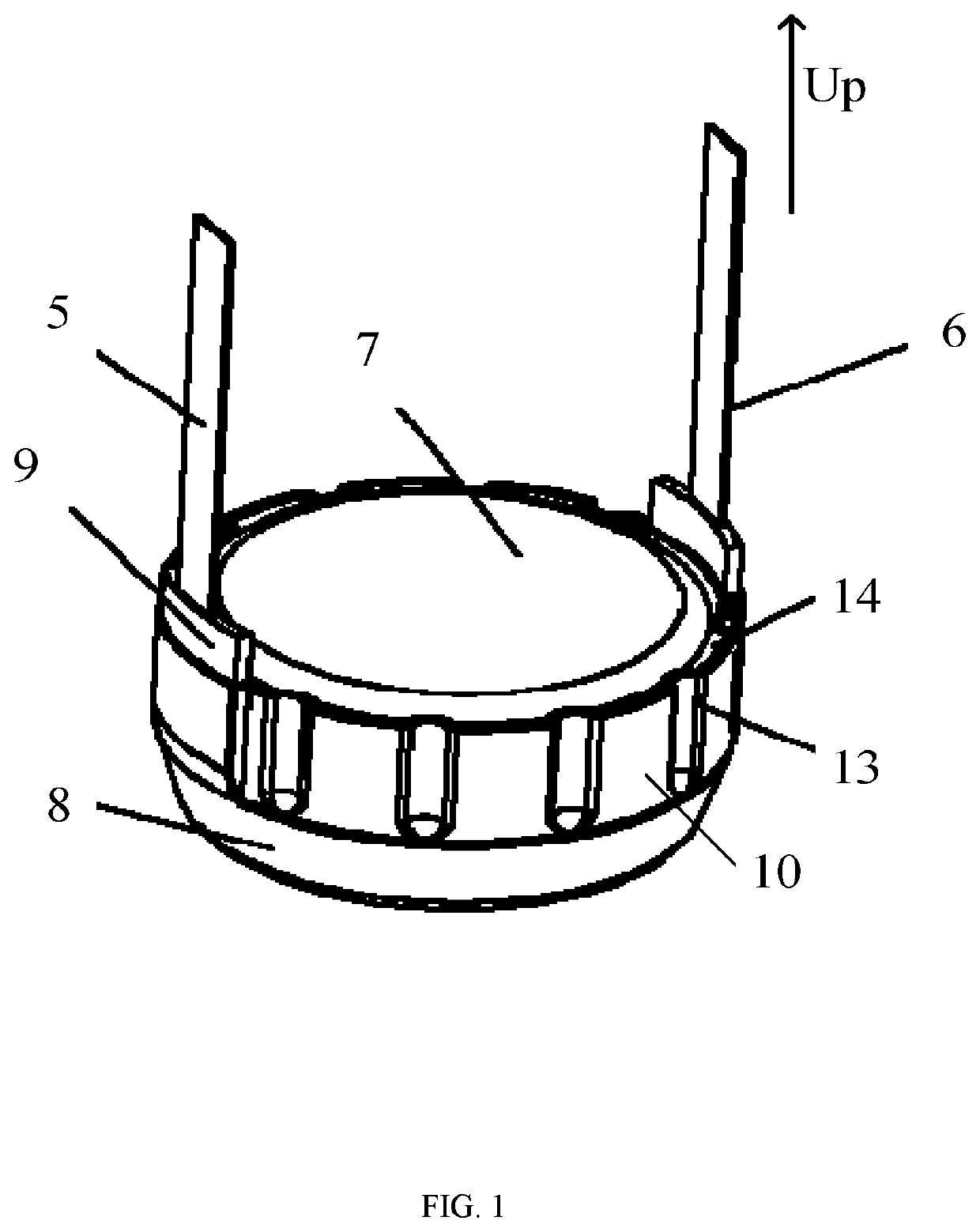

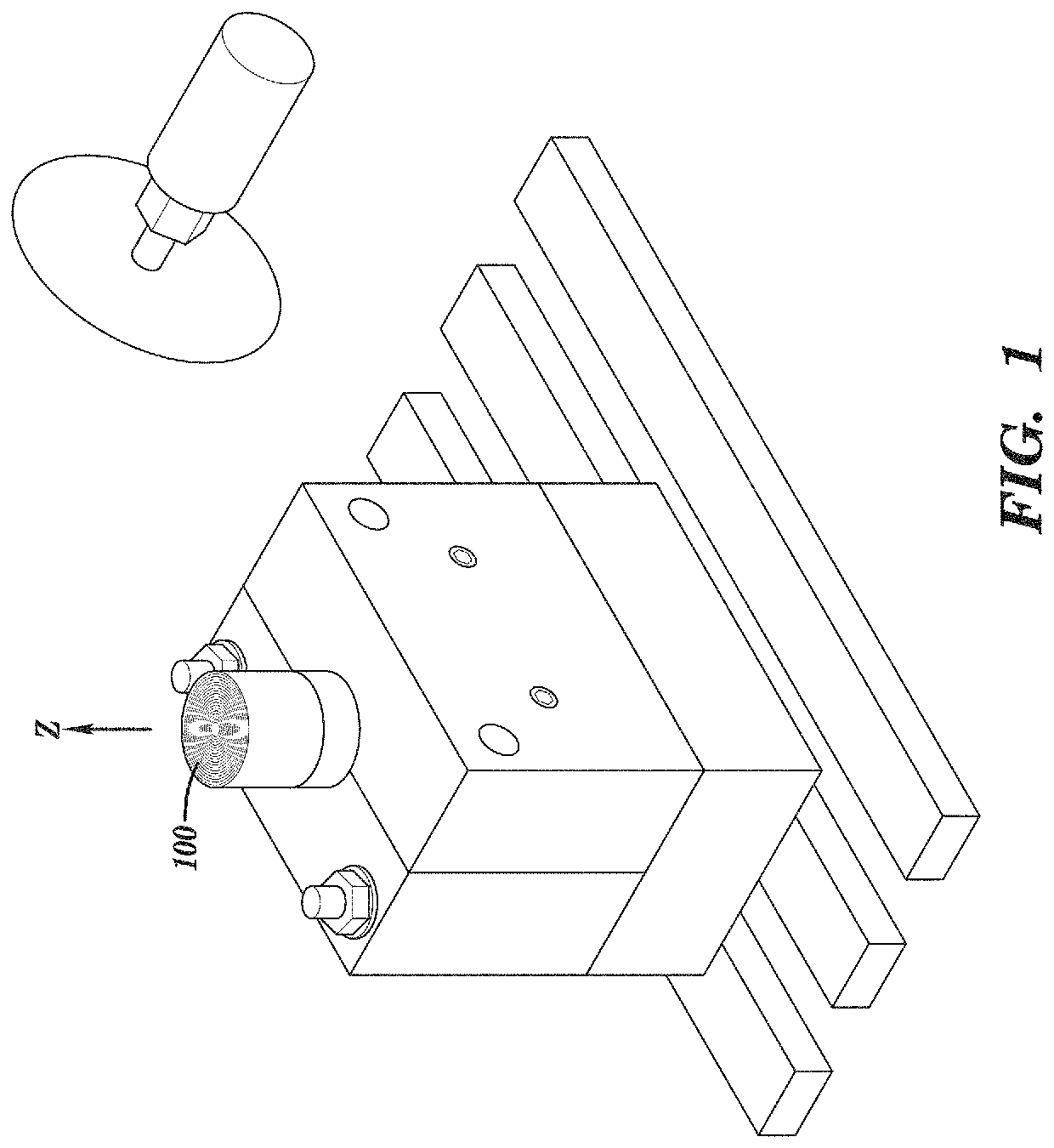

Coiling device for making an electrode assembly and methods of use

ActiveUS8832914B2Contact member manufacturingAssembling battery machinesEngineeringMechanical engineering

A system for the automated coiling of a jelly roll electrode assembly for controlled assembly and tensioning of jelly roll assembly is provided. The system includes: a shuttle, and a mandrel to which electrodes are welded; a base, mateable with the shuttle and on which the battery head assembly is mounted for welding to the mandrel; and a coiling device. The coiling device has an upper spool, a lower spool, holding a separator strip and a platform between the two holding the base. The separator strip is threaded through a passage in the mandrel separating positive and negative portions. Rotating the mandrel coils the positive electrode, the separator strip and the negative electrode to coil around the mandrel. The coiling device may include a feedback loop braking one or both spools and allowing the coiling tension to be programmed to a desired level.

Owner:MEDTRONIC INC

Battery

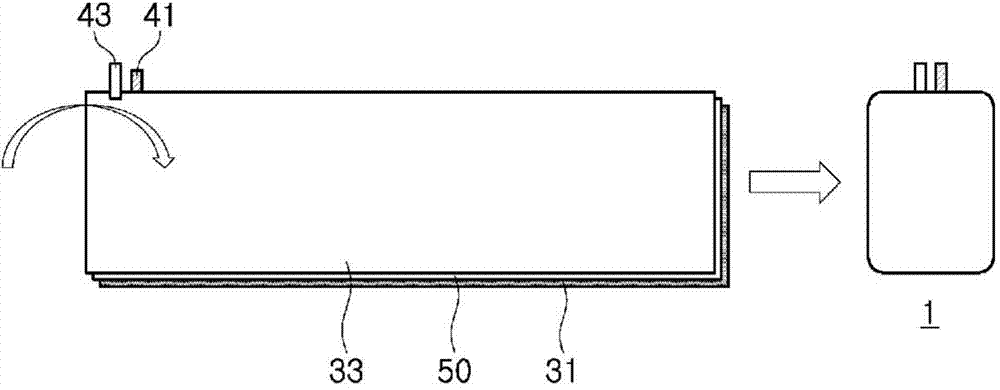

ActiveUS11482762B2Final product manufactureSmall-sized cells cases/jacketsEngineeringElectrochemistry

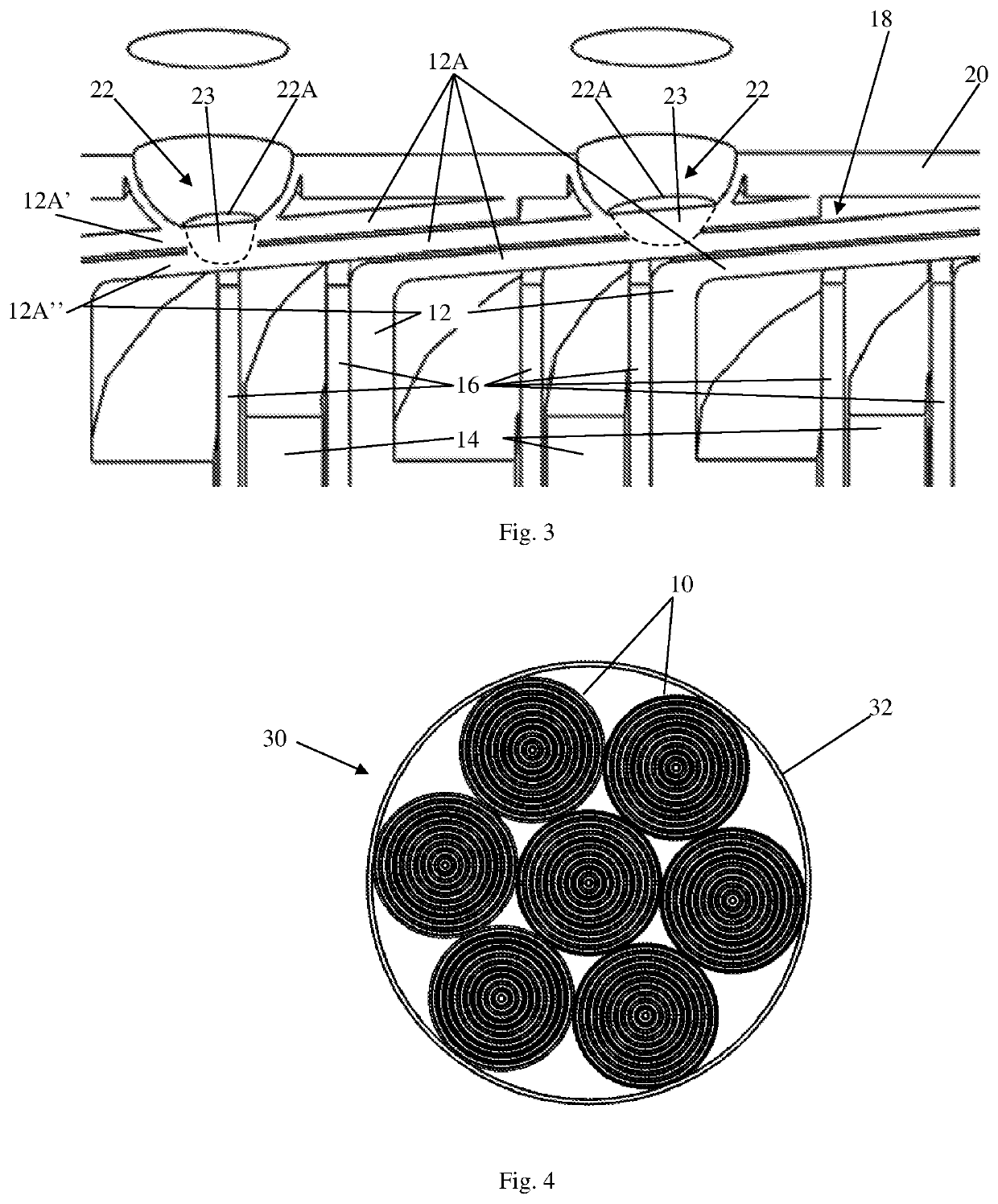

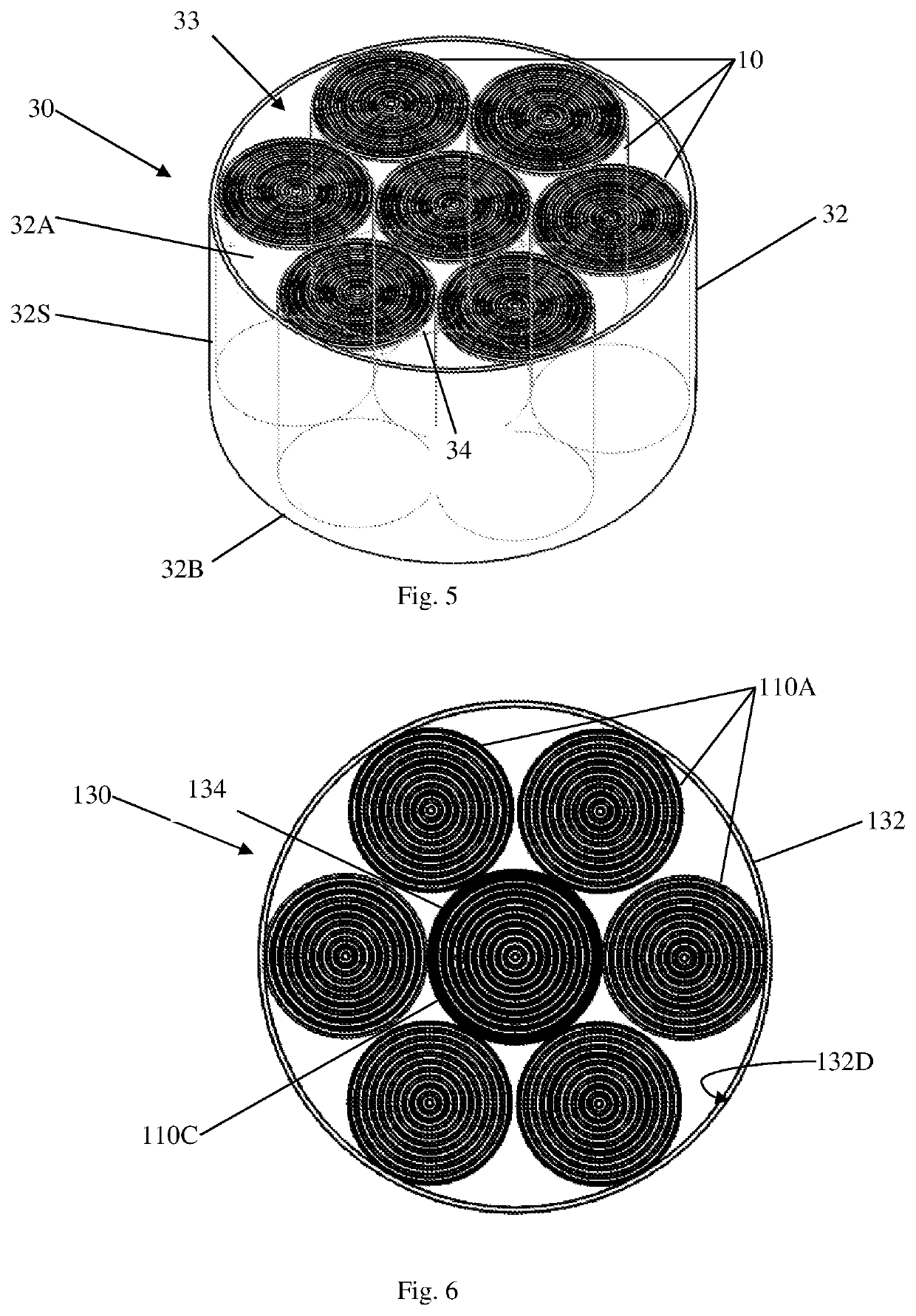

A battery (30) is disclosed which comprises: a housing (32) containing an electrolyte solution; a plurality of jelly roll electrode assemblies (10) arranged substantially in parallel with each other in contact with the electrolyte solution within the housing (32) thereby forming a single electrochemical system of the battery (30), each jelly roll electrode assembly (10) having a first end (10A) and an opposing second end (10B); and a current collector plate (20); wherein the current collector plate (20) is arranged to be shared among and in direct physical and electrical contact with the first ends (10A) of the plurality of jelly roll electrode assemblies (10).

Owner:GP TECH & INNOVATION LTD

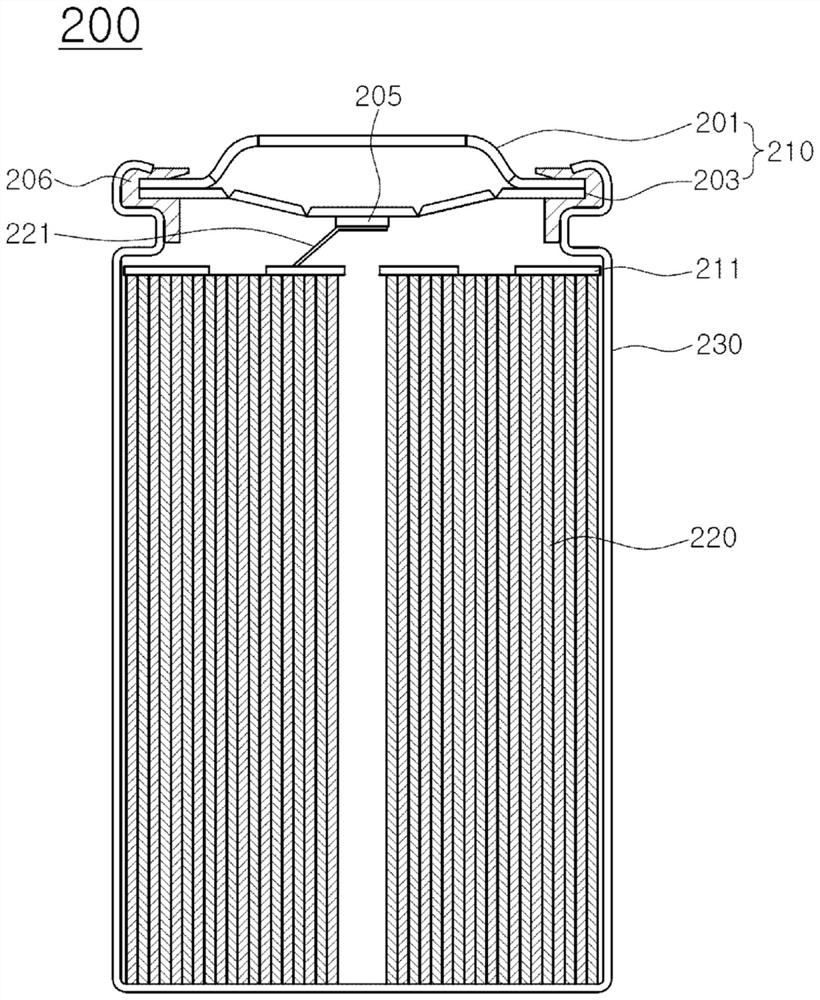

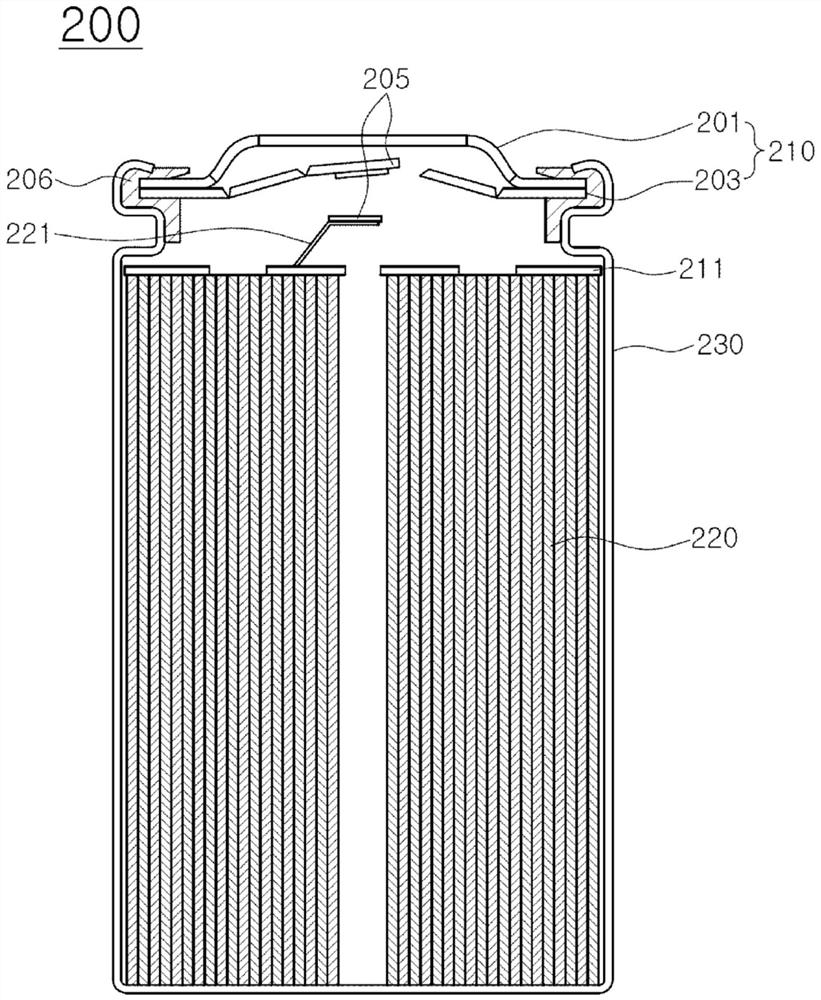

Battery cell having welded battery cap

ActiveUS11495854B2Low profileMinimize damageFinal product manufactureSmall-sized cells cases/jacketsElectrical connectionEngineering

A battery includes a can, a jelly roll contained in the can, a top insulator contained in the can adjacent to and above the jelly roll, and a battery cap. The battery cap is welded to an inner surface of the can adjacent to and above the top insulator and includes an outer conductive ring, an insulator ring, and a conductive top plate, wherein the outer conductive ring, the insulator ring, and the conductive top plate are crimped together. The battery cap further includes a conductive rupture plate electrically connected to the conductive top plate and a cathode electrically connected to the conductive rupture plate and extending into the jelly roll. The battery may further include an opening in a central portion of the conductive top plate and a central portion of the conductive rupture plate cover welded upon the opening in the central portion of the conductive top plate.

Owner:TESLA INC

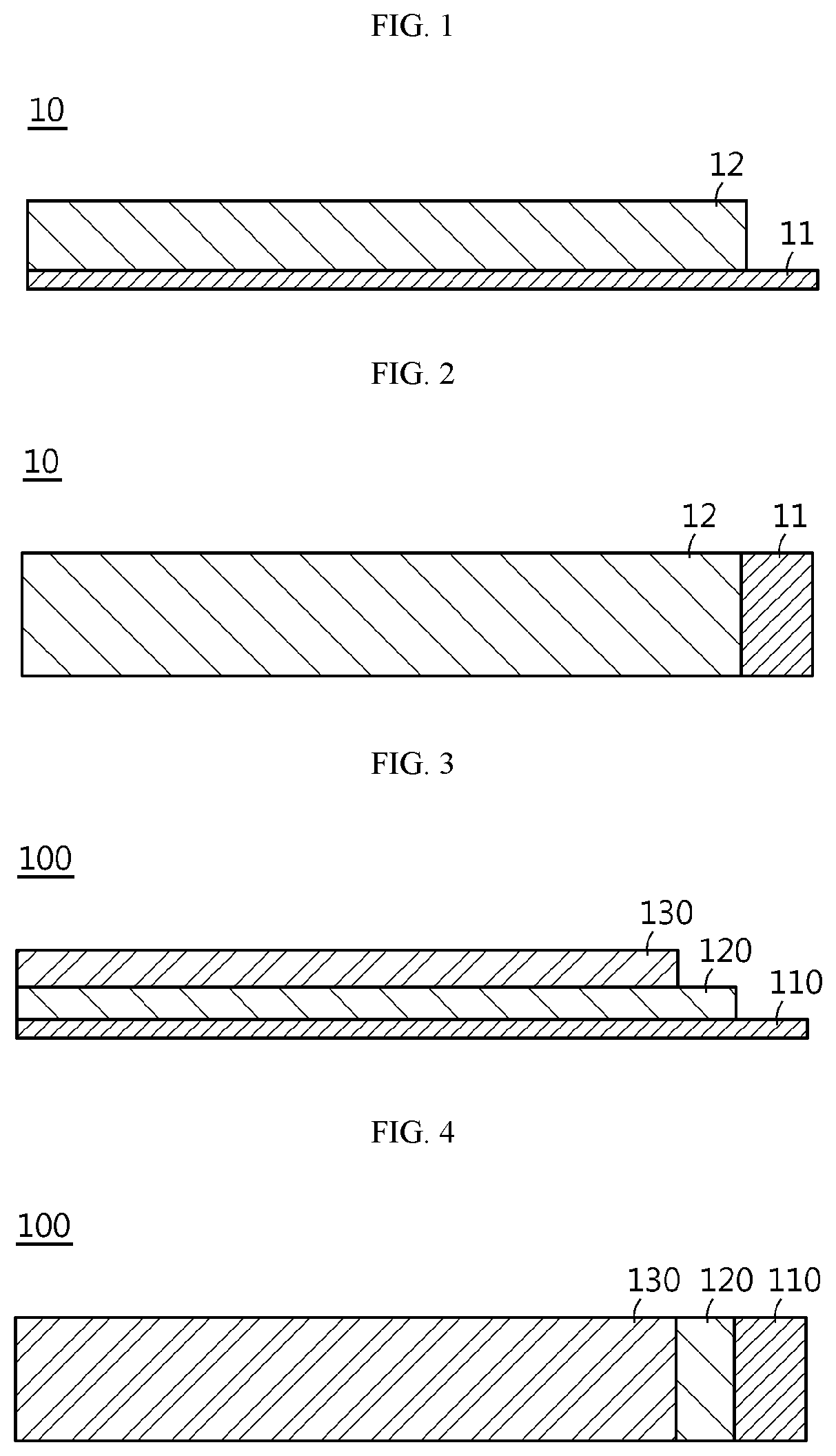

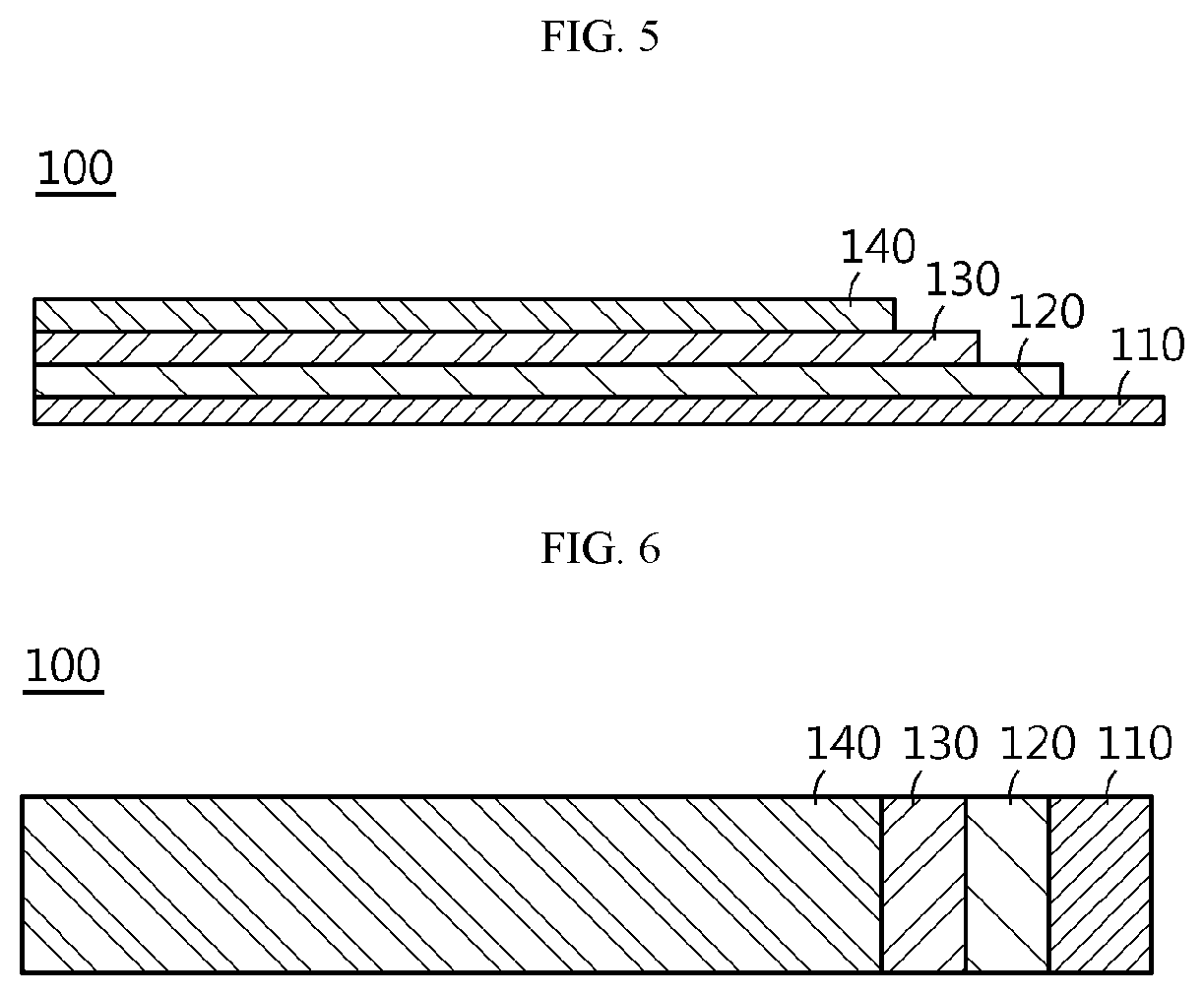

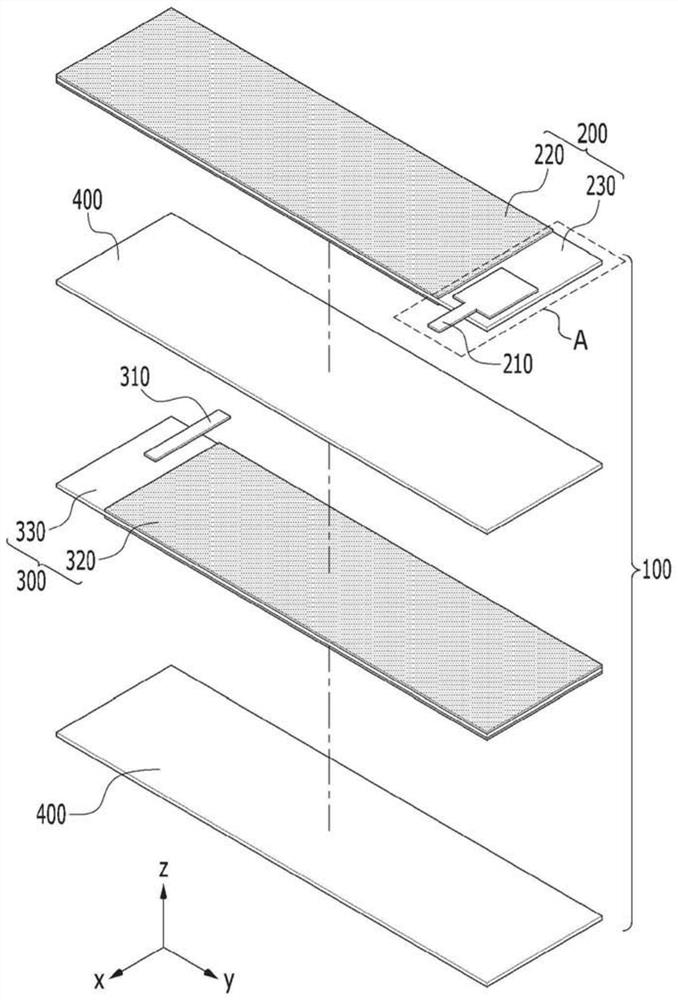

Electrode assembly and method for manufacturing same

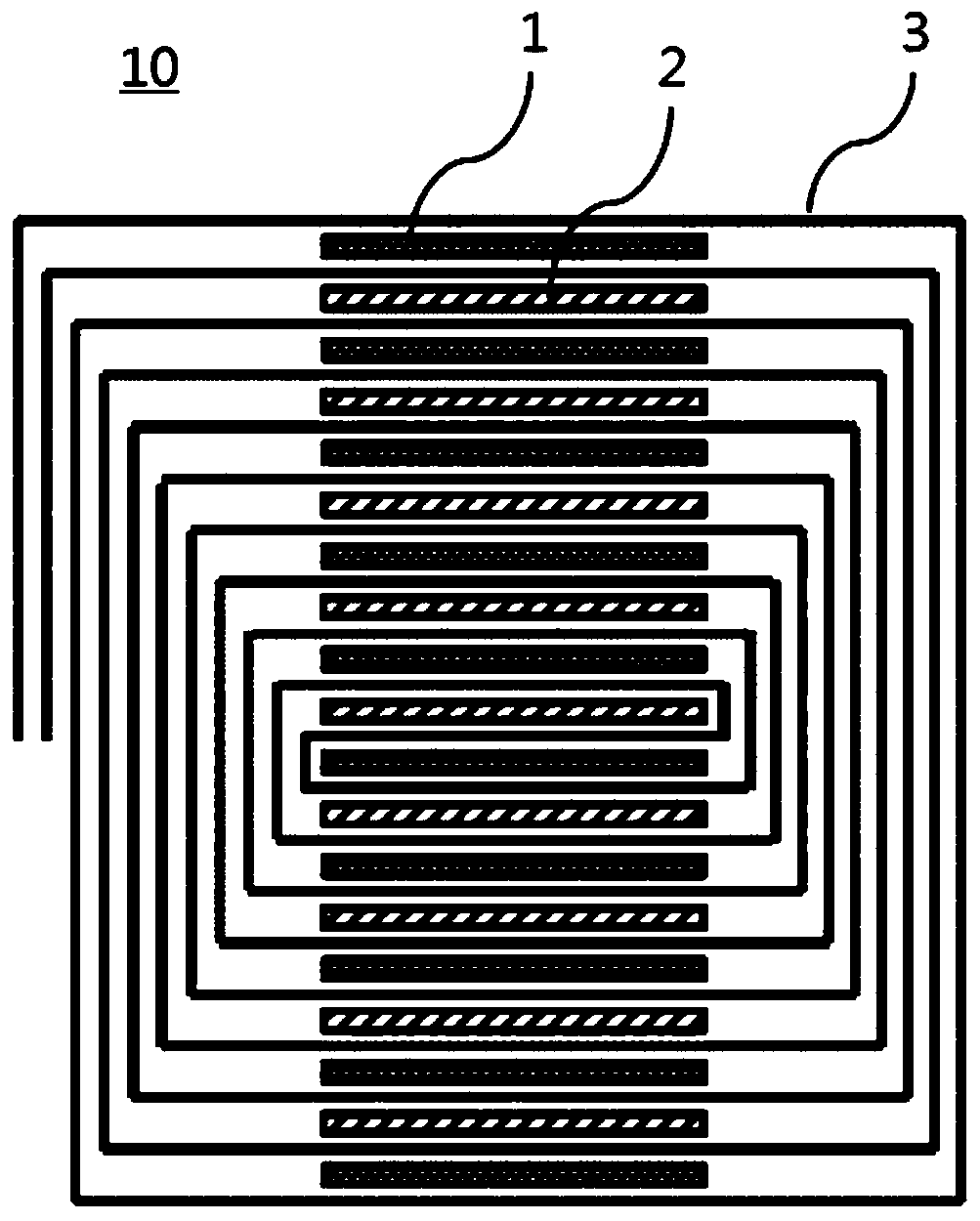

PendingUS20220344697A1Shorten the lengthImprove the immunityFinal product manufactureWound/folded electrode electrodesEngineeringMaterials science

A jelly-roll type electrode assembly including a negative electrode, a first separator, a positive electrode, and a second separator that are wound together is provided. The negative electrode includes a negative electrode active material on a surface of a negative electrode collector and which has, on a first end thereof, a first negative electrode collector-exposed portion that is not coated with the negative electrode active material to expose the surface of the negative electrode collector. The negative electrode is wound together with the first separator such that the first negative electrode collector-exposed portion is disposed in a central region where the winding starts, and a negative electrode tab is coupled to the first negative electrode collector-exposed portion.

Owner:LG ENERGY SOLUTION LTD

Strip-shaped electrode used for cylindrical jelly roll and lithium secondary battery comprising same

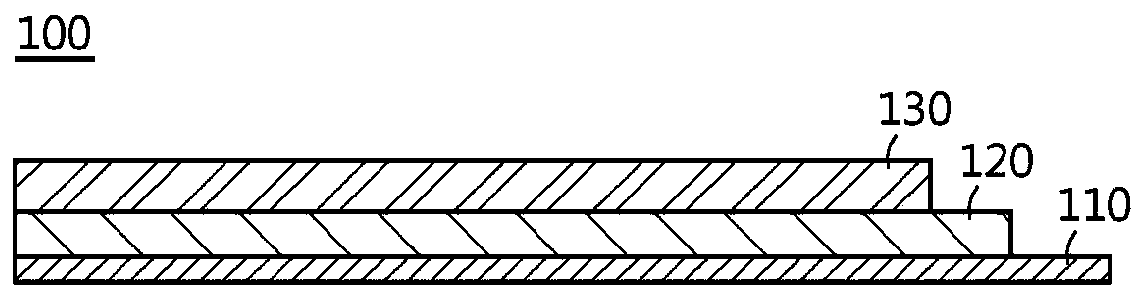

ActiveUS20200067071A1Reduce loading amountReduce press rateFinal product manufactureWound/folded electrode electrodesEngineeringBattery cell

The present disclosure relates to a strip-like electrode for use in a cylindrical jelly roll which includes a strip-like electrode assembly wound cylindrically to form a hollow cavity at the core portion thereof, and a lithium secondary battery including the same. The strip-like electrode includes: a strip-like electrode current collector; a first electrode active material layer formed on at least one surface of the strip-like electrode current collector; and a second electrode active material layer formed on the first electrode active material layer, wherein the second electrode active material layer is formed to have a length smaller than the length of the first electrode active material layer so that a part of one longitudinal surface of the first electrode active material layer can be exposed to the outside.

Owner:LG ENERGY SOLUTION LTD

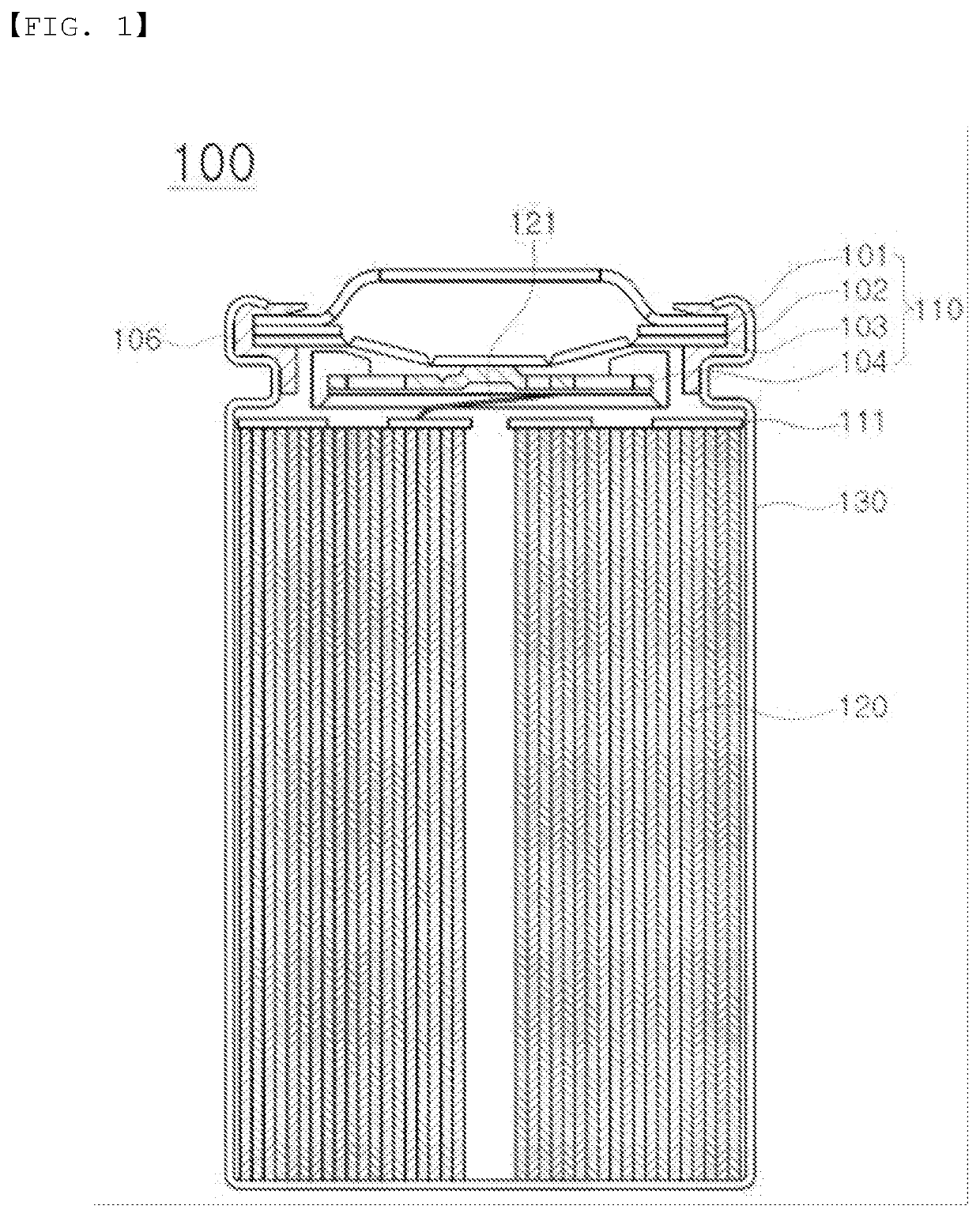

Cap assembly with novel structure and cylindrical battery using same

ActiveCN103548175BAvoid fireImprove securityCylindrical casing cells/batteryFire rescueElectrical batteryStructural engineering

The present invention relates to a cap assembly to be mounted on the open upper end of a cylindrical container in a battery structure in which an electrode assembly (gel roll) of an anode / separator / cathode structure is covered Built in a cylindrical container. The cap assembly includes: a scored safety vent secured so that the safety vent can be ruptured by high pressure gas from the battery; a protruding upper end cap attached along the outer surface of the safety vent; mounted on the upper end cap a liner on an outer surface of the battery; and a fire extinguishing member comprising a fire extinguishing component for preventing fire of the battery, at least a portion of which is mounted at an interface between the upper end cap and the liner.

Owner:LG ENERGY SOLUTION LTD

Secondary battery and device including the same

PendingCN114766069AAvoid deformationEasy dischargeFinal product manufactureWound/folded electrode electrodesElectrical batteryJelly roll

A secondary battery according to one embodiment of the present invention comprises: a jelly-roll-type electrode assembly in which a first electrode sheet, a second electrode sheet, and a separator provided between the first electrode sheet and the second electrode sheet are wound together; and a first electrode tab coupled to the uncoated portion of the first electrode tab and disposed at a central portion of the jelly-roll-type electrode assembly, in which the first electrode tab includes a coupling portion coupled to the uncoated portion and an extension portion extending outwardly from the coupling portion, a width of the coupling portion is wider than a width of the extension portion, and the coupling portion is wound at a center portion of the jelly-roll-type electrode assembly by 3 / 4 turns or more and one turn or less.

Owner:LG ENERGY SOLUTION LTD

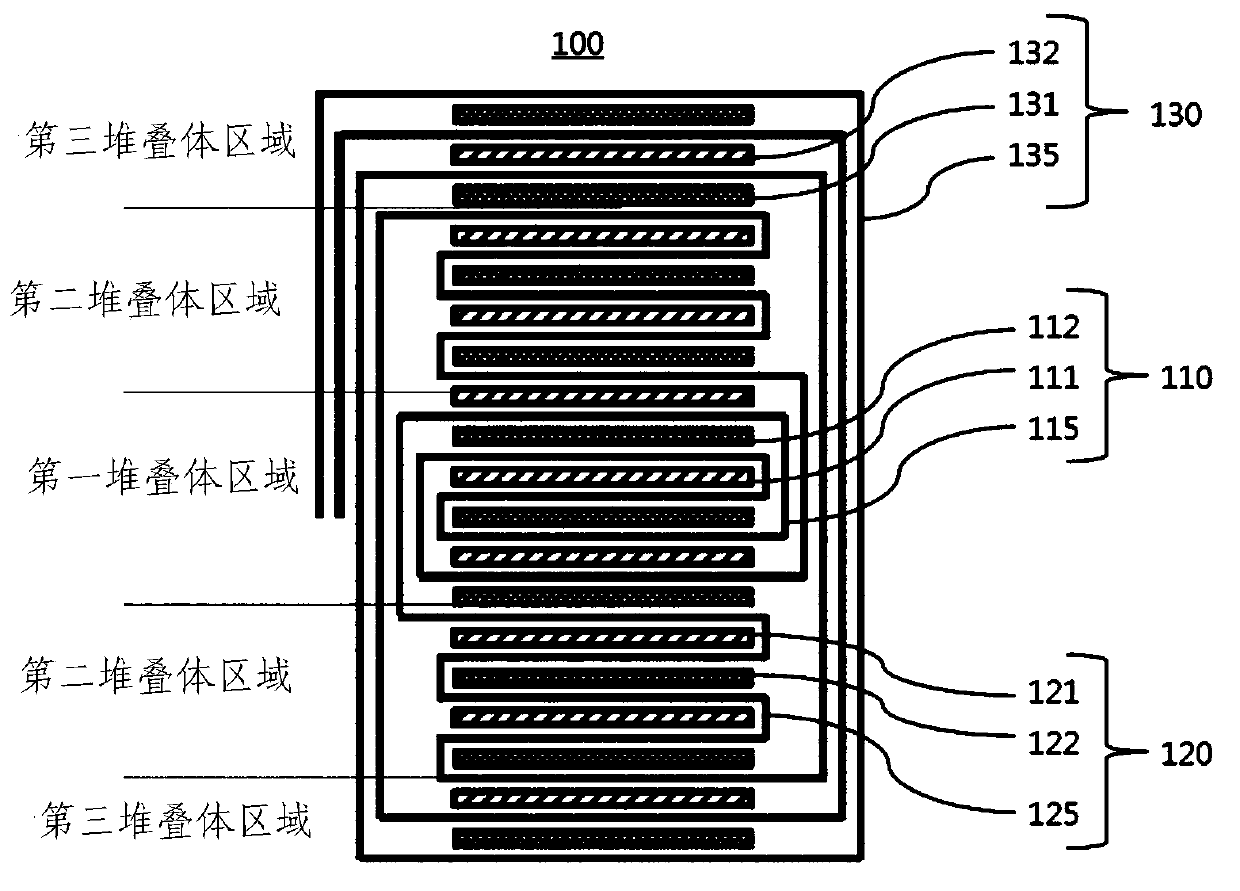

High voltage battery cell

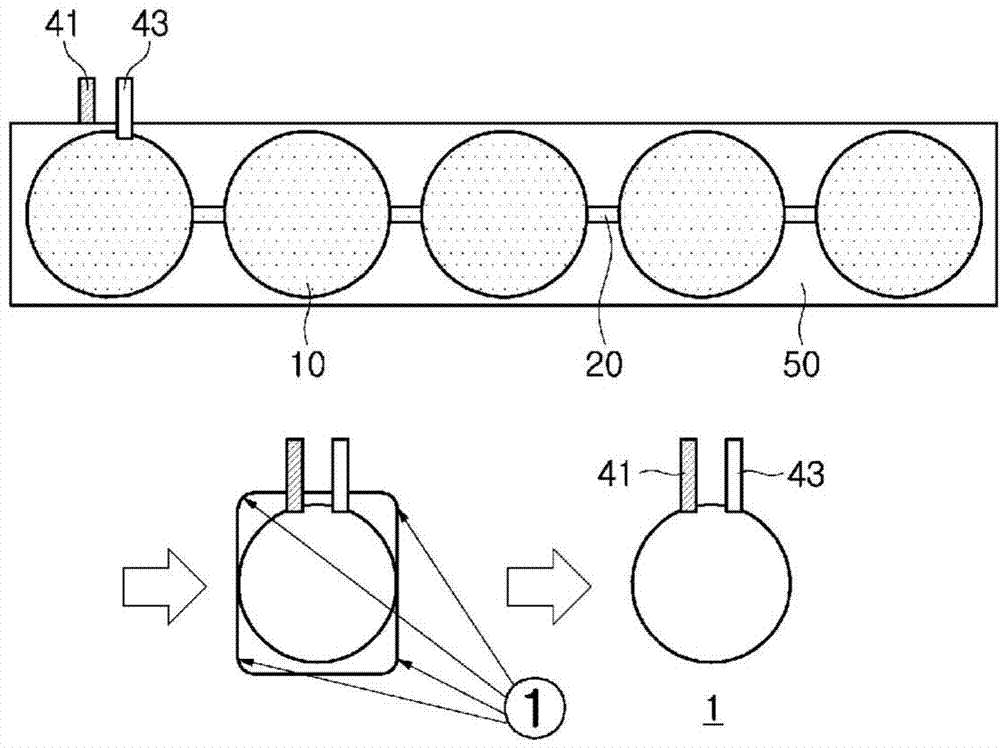

ActiveUS20200014072A1Final product manufactureWound/folded electrode electrodesHigh voltage batteryEngineering

The present invention provides a high voltage battery cell, and specifically a high voltage battery cell including a jelly roll in which three different types of jelly roll units are stacked freely and connected in series. According to embodiments of the present invention, there is provided a high voltage battery cell which is capable of implementing various cell structures while having a high voltage, and is relatively resistant to an external impact than other typical secondary cells.

Owner:SK ON CO LTD

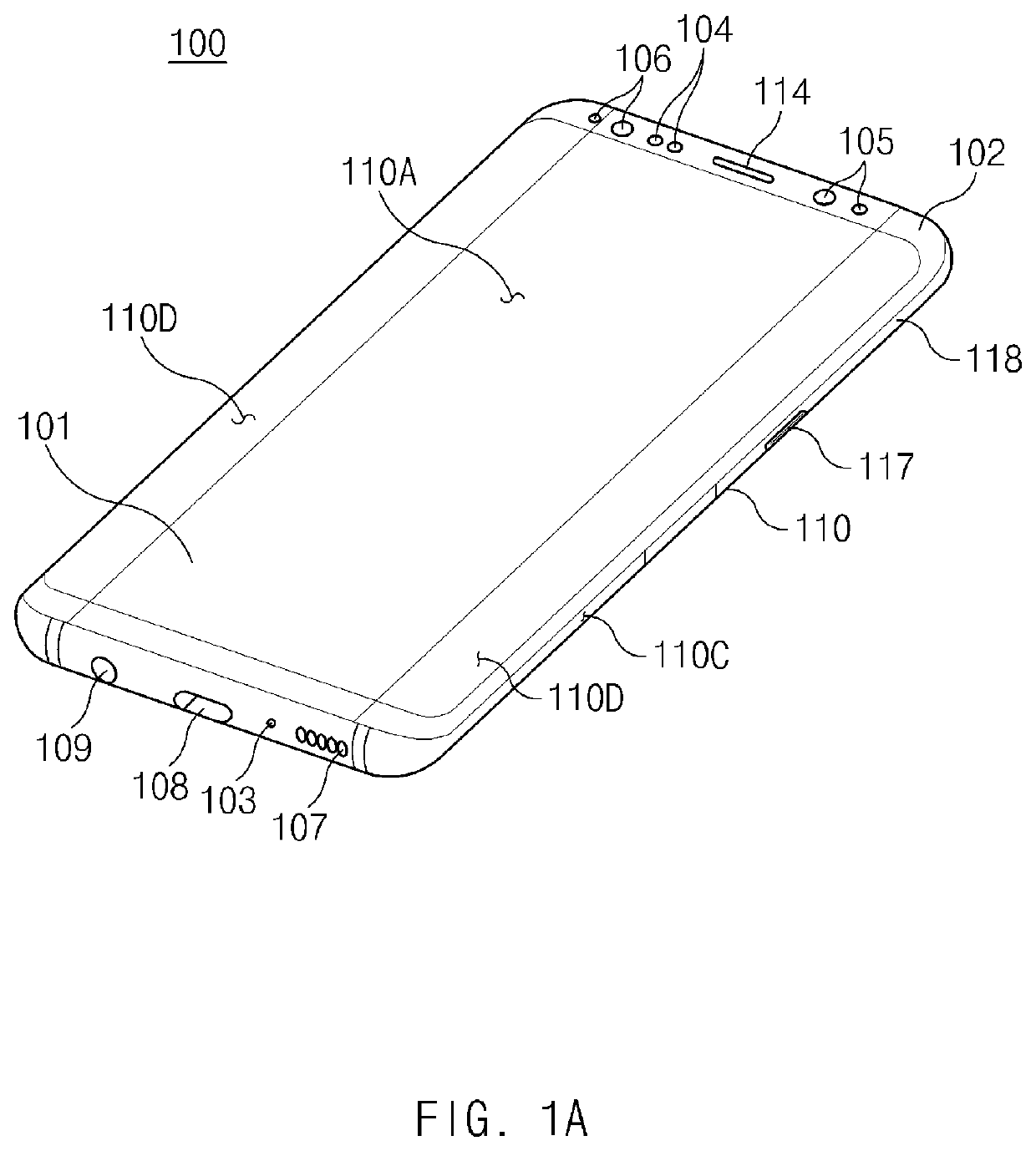

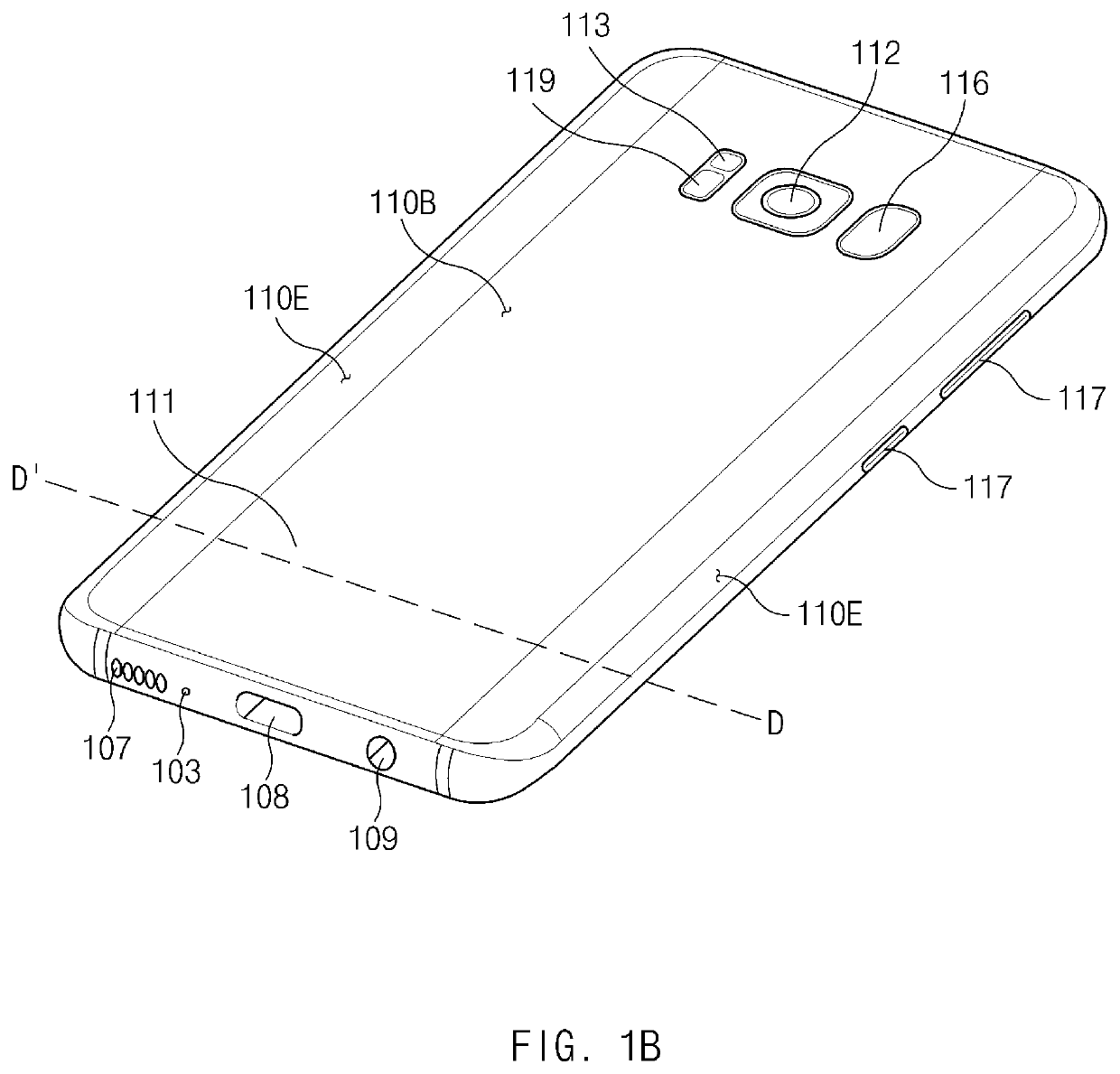

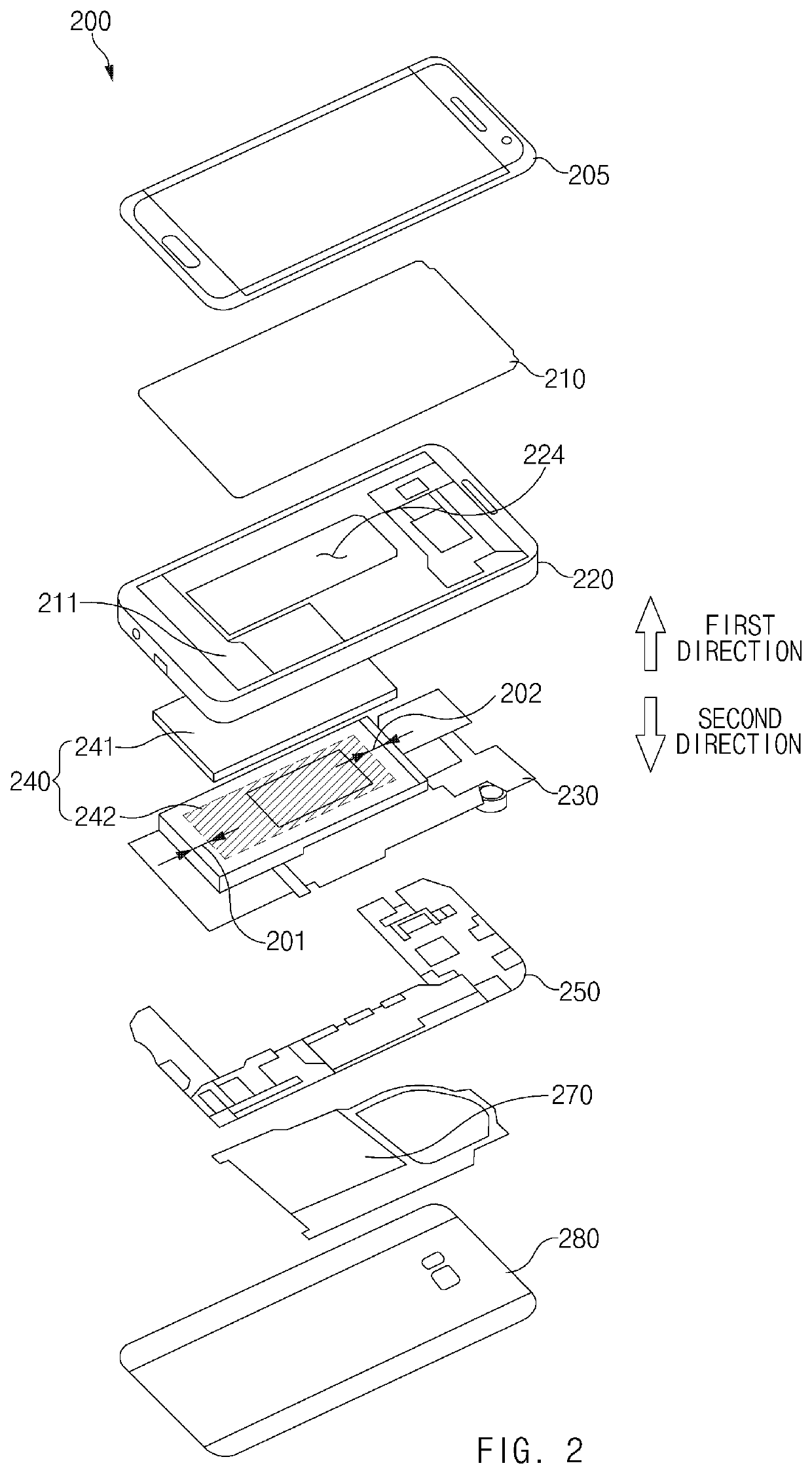

Electronic device including battery structure

ActiveUS11127983B2Reduce distortionLow heat generationFinal product manufactureSmall-sized cells cases/jacketsAdhesive beltDisplay device

In one embodiment of the disclosure an electronic device comprising: a display; a first plate having opposing first and second faces, wherein the display is disposed on the first face; a second plate coupled to the second face of the first plate, at least one adhesive layer including a first adhesive layer adhering to the second face of the first plate, a jelly-roll, a roll fixing tape disposed on one region of the jelly-roll, a pouch containing the jelly-roll and the roll fixing tape, wherein the at least one adhesive layer including the first adhesive layer is disposed between and attached to one face of the pouch, and wherein one end of the first adhesive layer and one end of the roll fixing tape face are in the same direction while the first adhesive layer and the roll fixing tape vertically surround the one face of the pouch.

Owner:SAMSUNG ELECTRONICS CO LTD

Pouch packaged lithium-ion battery with tooth-shaped sealing edge

ActiveUS20220216542A1InhibitionIncrease energy densityFinal product manufactureSmall-sized cells cases/jacketsThin film cathodesEngineering

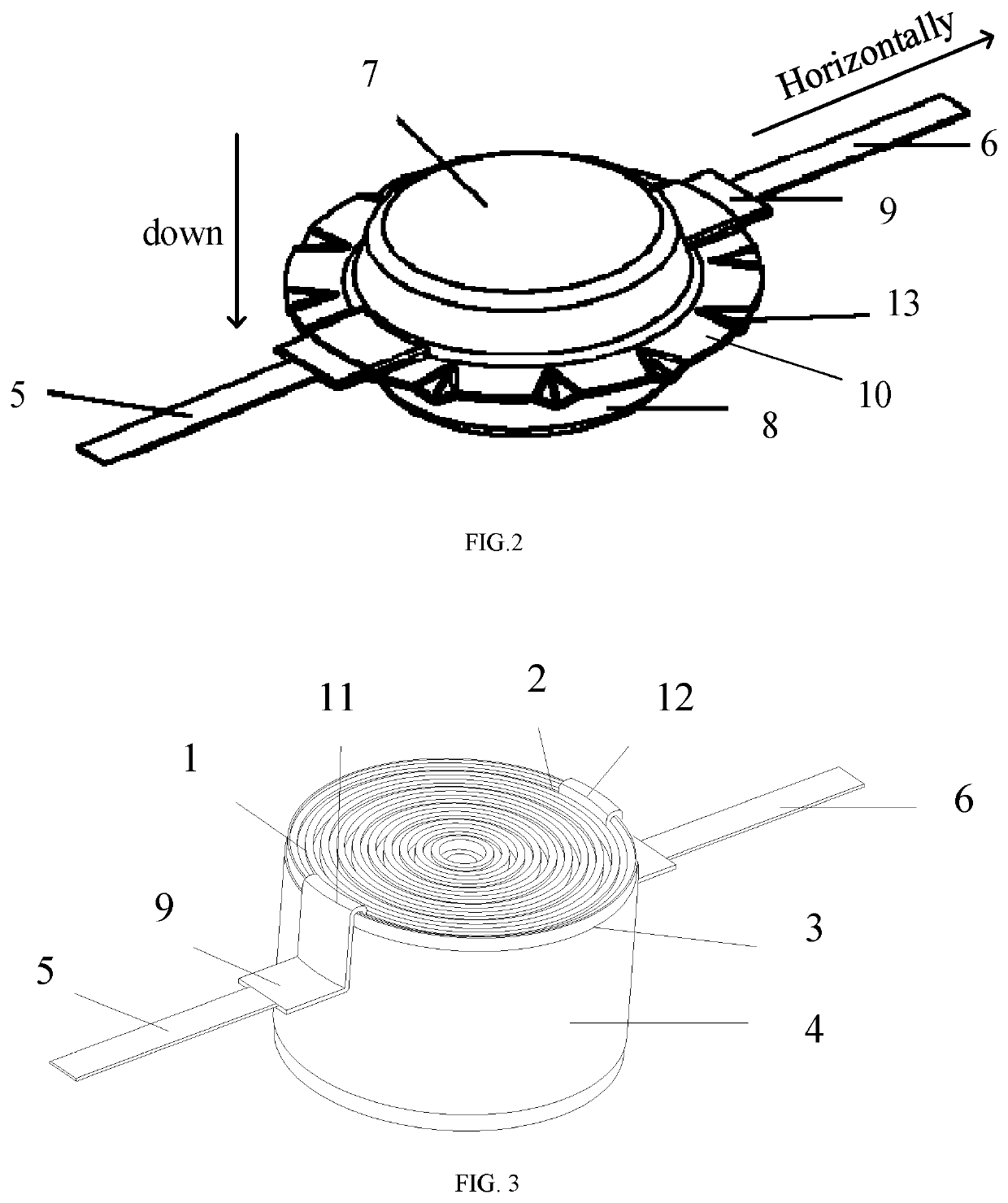

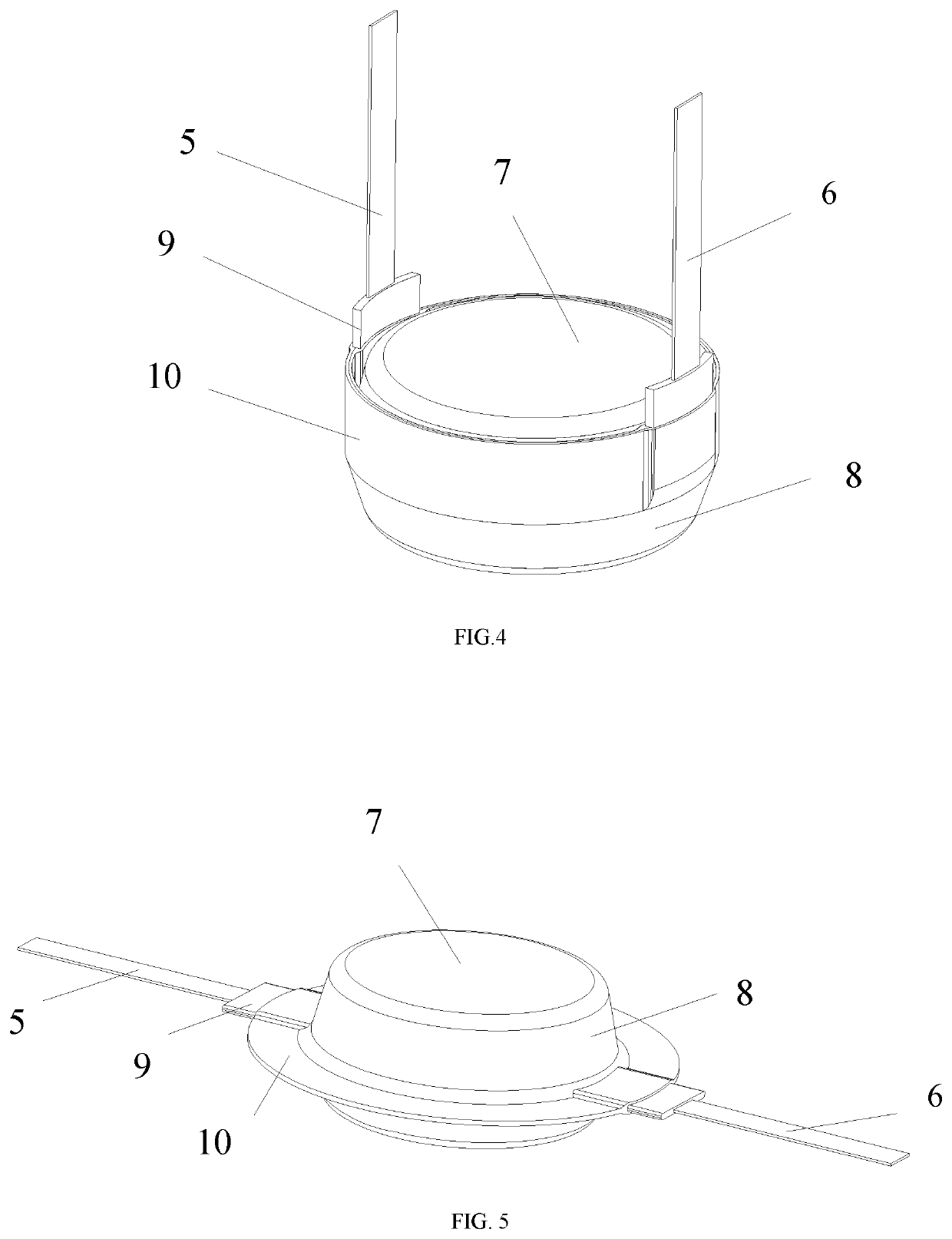

A pouch packaged lithium-ion battery with a tooth-shaped sealing edge, including a main body, which includes an aluminum-plastic film arranged with a jelly roll disposed therein. The jelly roll includes a cathode, an anode and a film separating the two. The cathode, the film and the anode are winded and overlaid. A cathode tab and an anode tab are respectively arranged on both sides of the jelly roll. A middle part of the aluminum-plastic film extends toward an outside of the lithium-ion battery to form a sealing edge. The cathode tab and the anode tab extend horizontally and penetrate the sealing edge. A joint between the cathode / anode and the sealing edge is covered with a tab sealant. The sealing edge, the cathode tab and the anode tab are bent to attach to a surface of the main body. The surface of the sealing edge is arranged with tooth-shaped grooves.

Owner:GUANGDONG VDL NEW ENERGY CO LTD

Cylindrical secondary battery configured to prevent overcharge thereof

ActiveUS20210074987A1Avoid assemblyAvoid shakingFinal product manufactureSmall-sized cells cases/jacketsStructural engineeringConductive materials

A cylindrical secondary battery configured to have a structure to which an adhesion unit, including an adhesive material, a conductive material, and PTC particles, is provided. The adhesion unit is configured to couple a cap assembly, which functions as a positive electrode terminal of the cylindrical secondary battery, and a positive electrode tab of a jelly-roll type electrode assembly to each other.

Owner:LG ENERGY SOLUTION LTD

Electrode assembly with projecting tab for battery and methods of forming same

Embodiments of the disclosure provide an electrode assembly including: a jelly roll electrode having a plurality of electrode sheets, the plurality of electrode sheets including an anode sheet, a cathode sheet, and a separator separating the anode sheet from the cathode sheet, an electrolyte disposed between the anode sheet and the cathode sheet of the jelly roll electrode, and a tab projecting from an axial end of the plurality of electrode sheets, the tab including a subsection of the plurality of electrode sheets contacting each other at an axial end of the jelly roll electrode; and a first conductive tab coupled to the tab of the electrode assembly, wherein the first conductive tab is configured to electrically couple the electrode assembly to a battery terminal.

Owner:CUSTOM ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com