Battery housing

A battery casing and battery technology, applied in the field of cooling systems, can solve the problems of increasing the number of potential failure points in the connection system, increasing the overall cost of the battery casing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Overview of the battery case

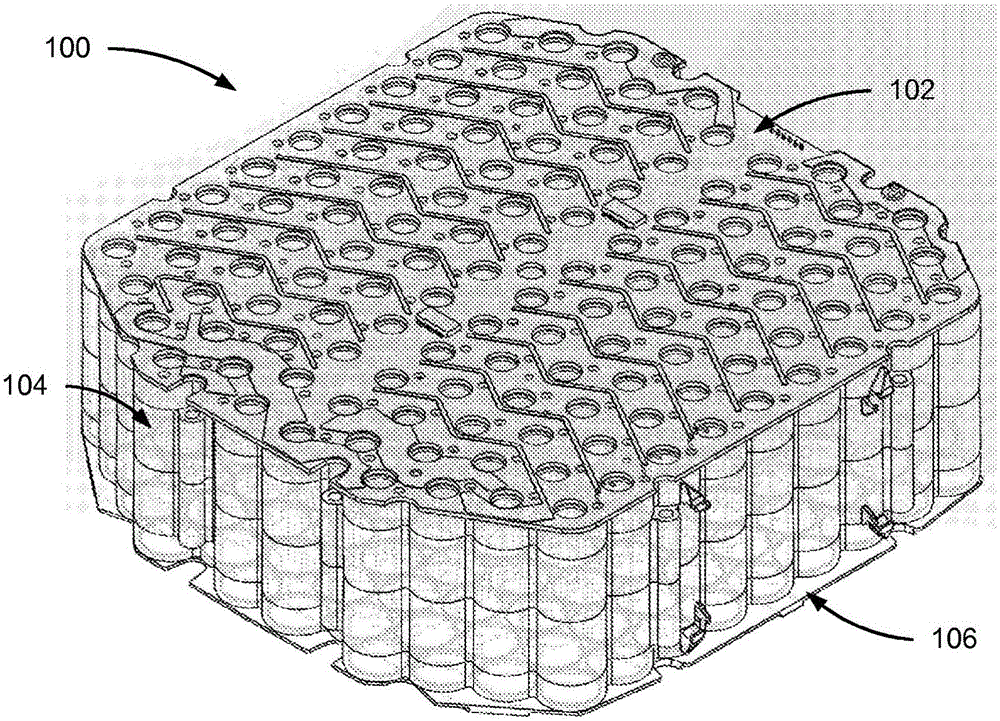

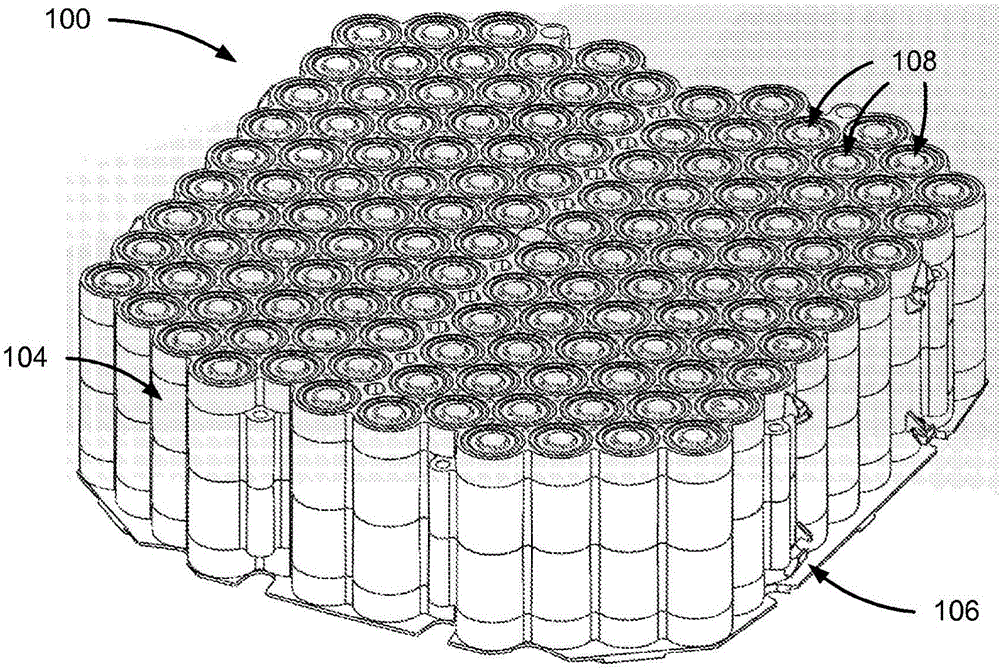

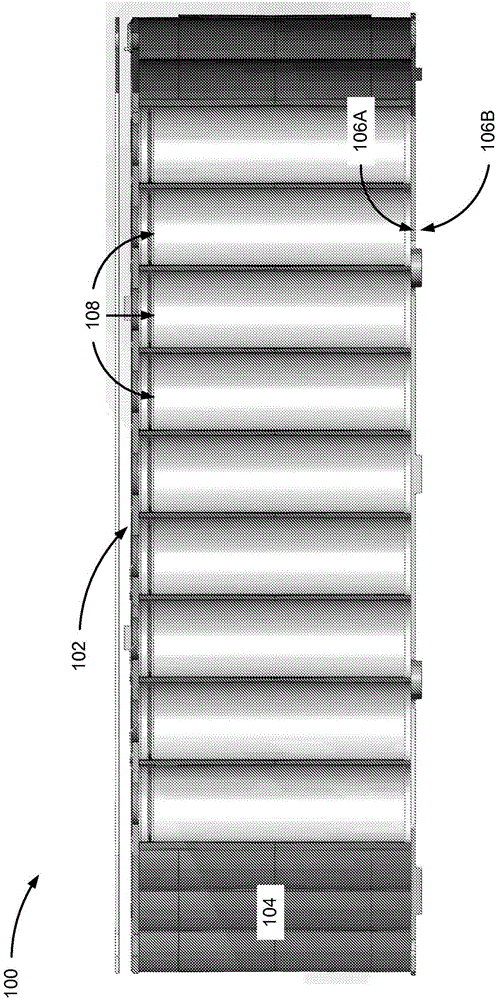

[0020] Figure 1A is a perspective view of a battery case 100 according to one embodiment. The battery housing 100 includes a circuit board 102 , a frame structure 104 and a heat sink 106 . Figure 1B is a perspective view of the battery case 100 with the circuit board 102 removed. like Figure 1B As shown, frame structure 104 contains compartments for battery cells 108 . Figure 1C is a side cross-sectional view of the battery housing 100 showing the battery cells 108 inside the frame structure 104 .

[0021] The circuit board 102 contains circuitry for electrically connecting the battery cells 108 . In one embodiment, the circuit board 102 connects the battery cells 108 in a parallel-series configuration. In a parallel-series configuration, the battery cells 108 may be divided into groups of cells, where the cells in each group are connected in parallel, and the groups are connected in series. In other embodiments, the circuit boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com