Method for manufacturing cylindrical battery and drying apparatus for performing same

A technology for cylindrical batteries and drying equipment, applied in the direction of cylindrical shell batteries/batteries, electrode manufacturing, secondary batteries, etc., can solve the problems of large loss of time, cost and equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

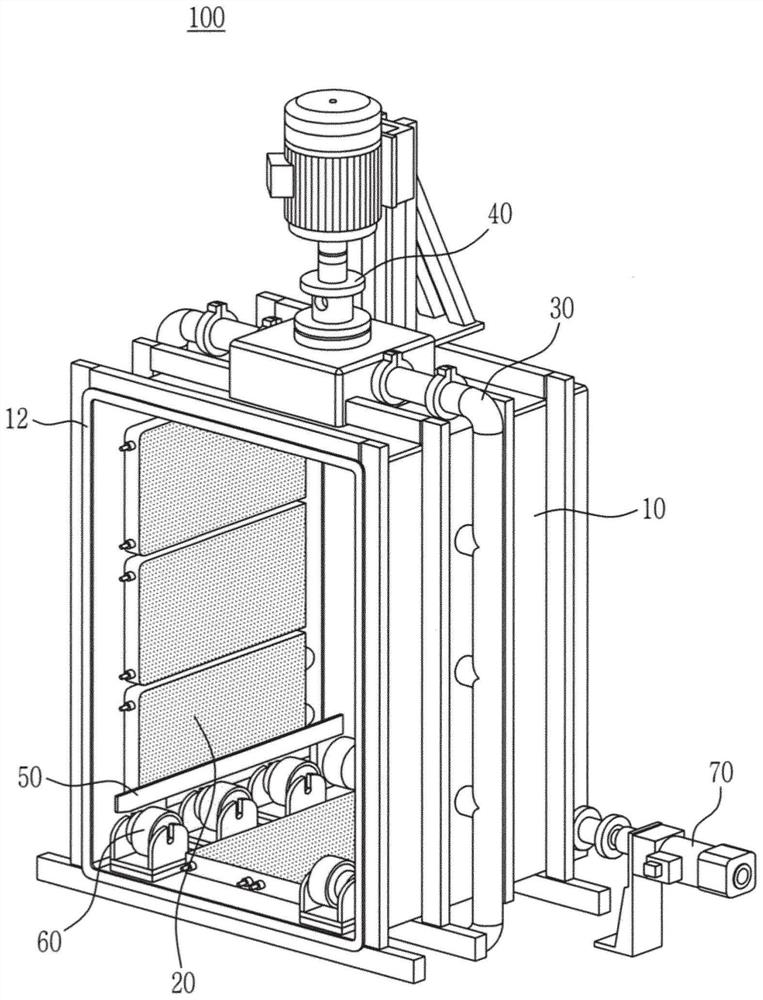

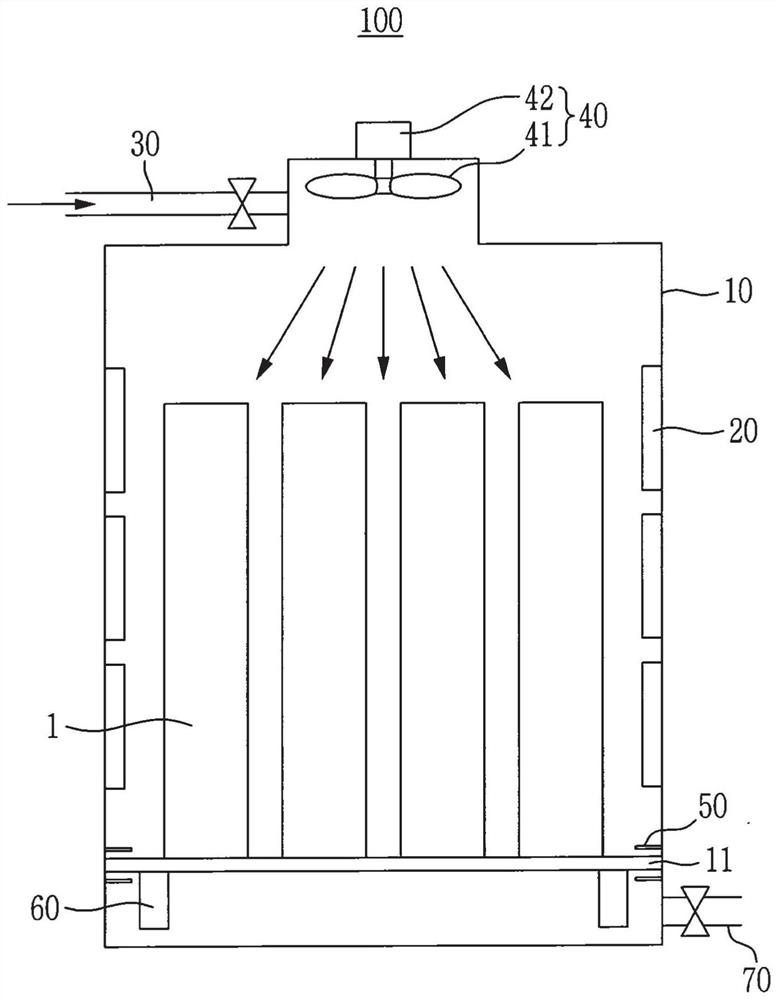

[0060] The positive electrode plate, the negative electrode plate, and the separator interposed between the positive electrode plate and the negative electrode plate were spirally wound to manufacture the electrode assembly 1 having a jelly-roll structure. The initial moisture concentration of the fabricated electrode assembly 1 was 174 ppm in the positive electrode and 337 ppm in the negative electrode.

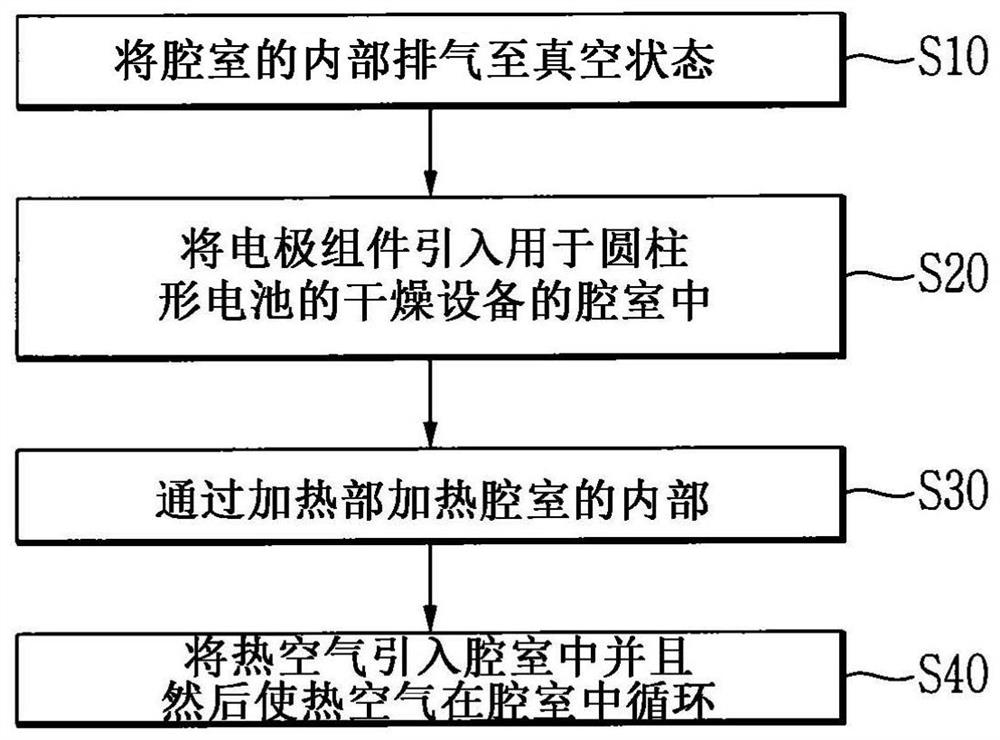

[0061] Subsequently, after the electrode assembly 1 was accommodated in the chamber 10, drying of the electrode assembly 1 was performed while introducing hot air. In this case, the temperature inside the chamber 10 was raised to 85° C. by the heating portion 20 , and then, the temperature of the supplied hot air was 85° C., and the hot air was supplied for 30 minutes. In this example, measure and Figure 4 shows the change in the amount of moisture in the electrode according to the drying time. Figure 4 (a) shows the change in the amount of moisture in the positive elect...

example 2

[0066] The positive electrode plate, the negative electrode plate, and the separator interposed between the positive electrode plate and the negative electrode plate were spirally wound to manufacture the electrode assembly 1 having a jelly roll structure, and the moisture concentration of the negative electrode was measured. The electrode assembly 1 with an initial negative electrode moisture concentration of 487 ppm was dried under a vacuum of −100 kPa and a temperature of 100° C. for 15 minutes, and then N was introduced when 15 minutes had elapsed. 2 , and the fan 41 was operated at a speed of 30 Hz in a state where the nitrogen gas pressure was 50 kPa, so that additional drying was performed for 15 minutes while the nitrogen gas was circulated. After the drying was completed, the water concentration in the negative electrode was measured to be 257.8 ppm.

example 3

[0068] The positive electrode plate, the negative electrode plate, and the separator interposed between the positive electrode plate and the negative electrode plate were spirally wound to manufacture the electrode assembly 1 having a jelly roll structure, and the moisture concentration of the negative electrode was measured. Electrode assembly 1 with an initial negative electrode moisture concentration of 487 ppm was dried under a vacuum of −100 kPa and a temperature of 100° C. for 27 minutes, and then N was introduced when 27 minutes had elapsed. 2 , and the fan 41 was operated at a speed of 30 Hz in a state where the nitrogen gas pressure was 50 kPa, so that additional drying was performed for 3 minutes while the nitrogen gas was circulated. After the drying was completed, the water concentration in the negative electrode was measured to be 284.9 ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com