Patents

Literature

319 results about "Partial thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

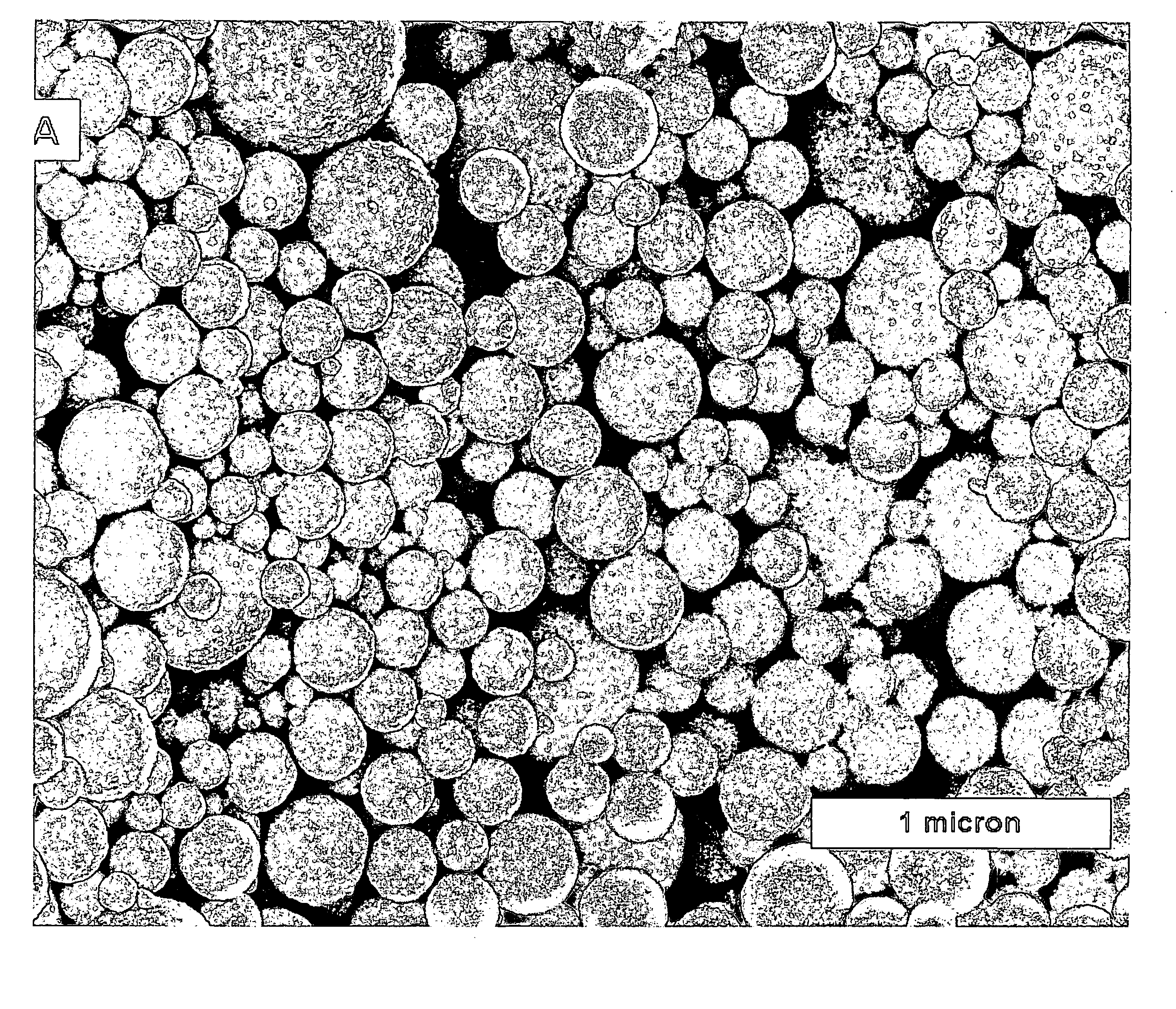

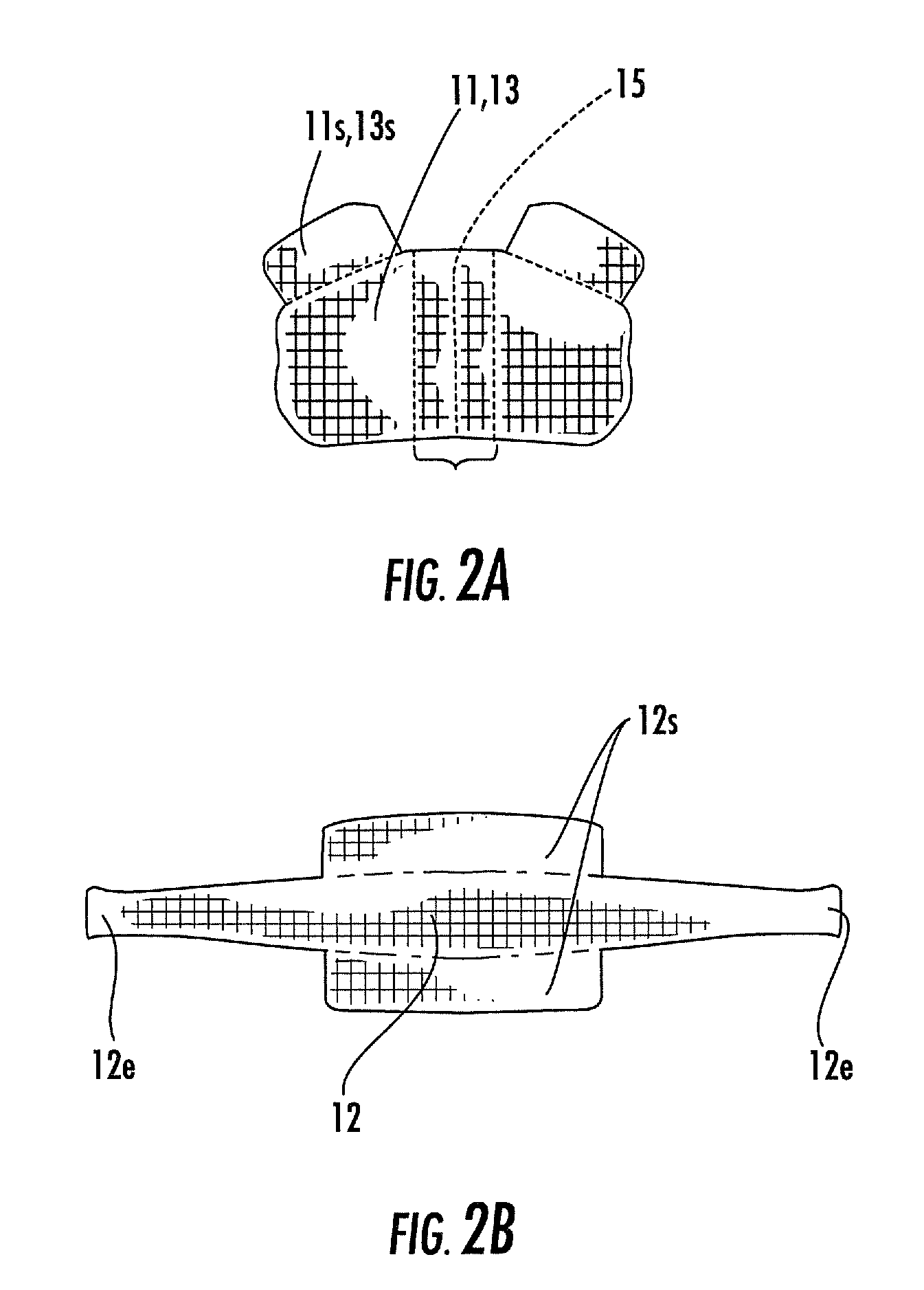

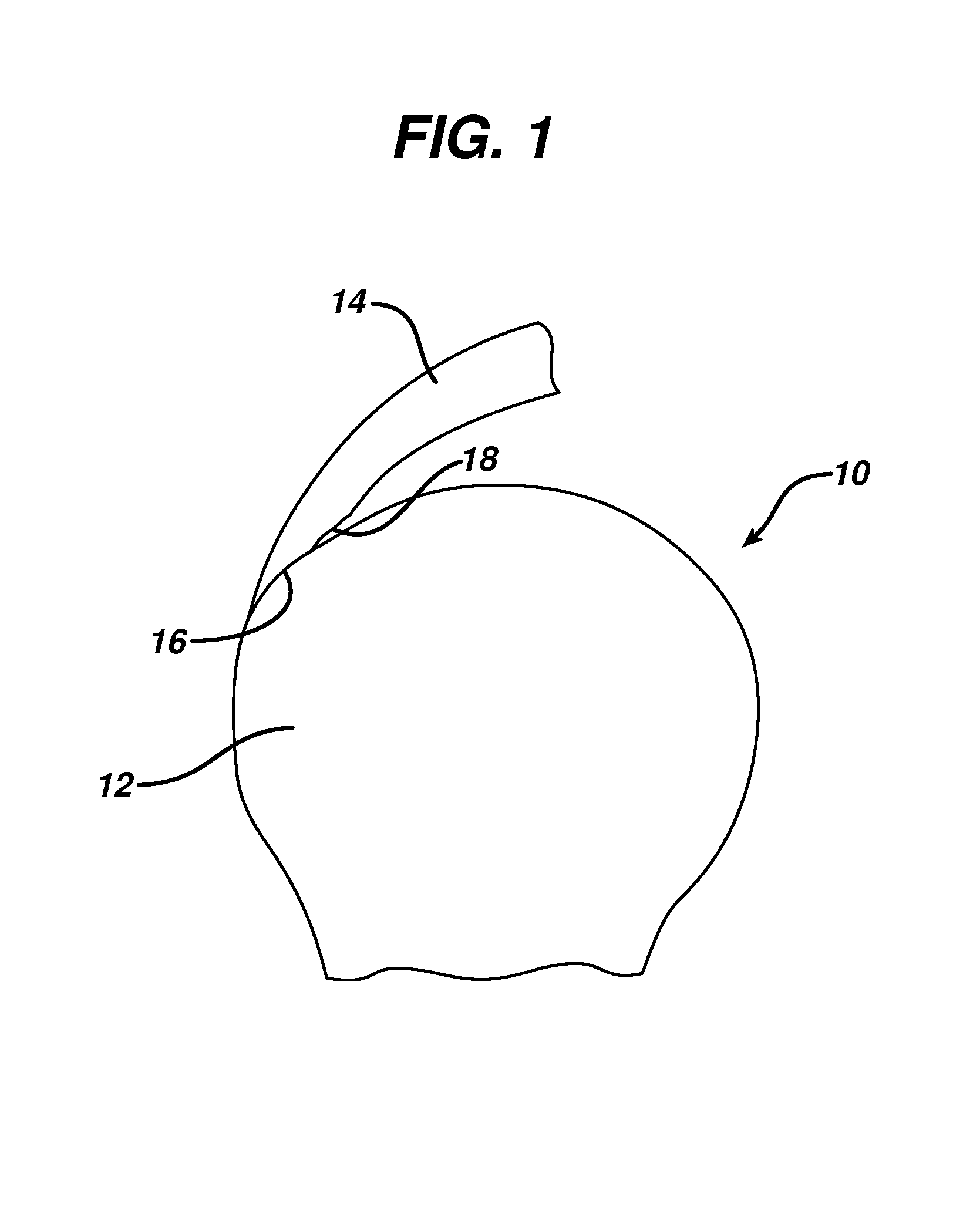

Tendon repair implant and method of arthroscopic implantation

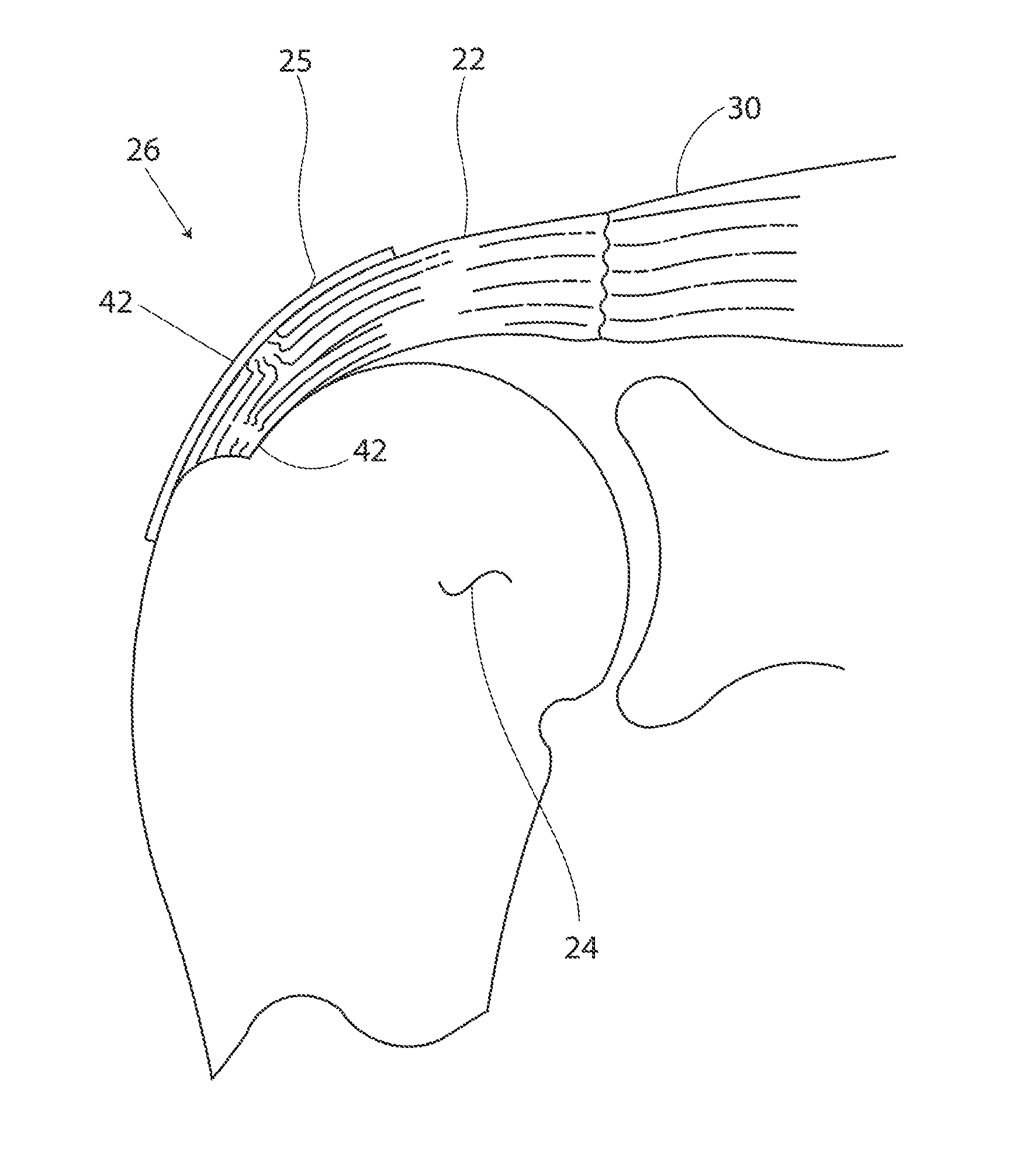

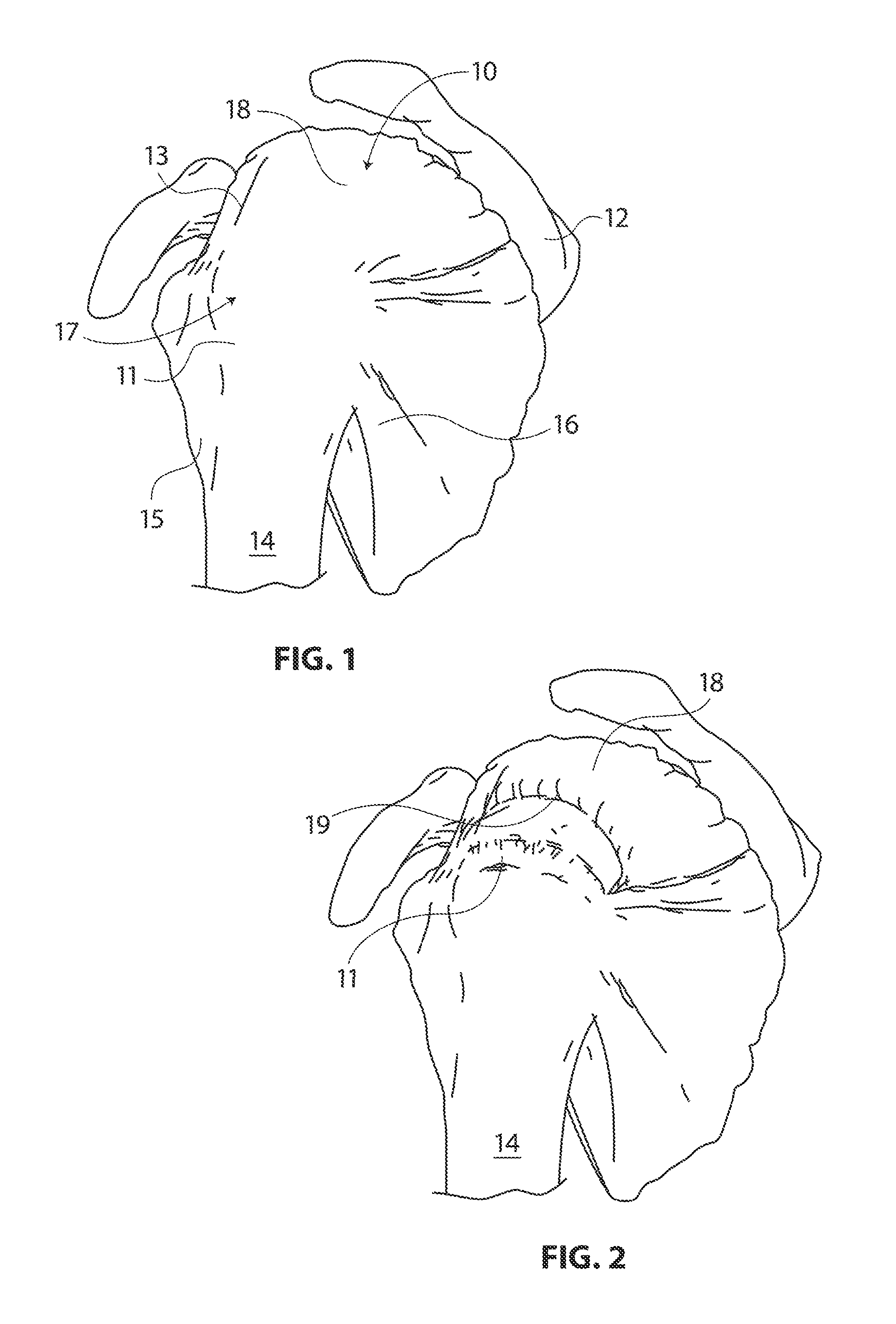

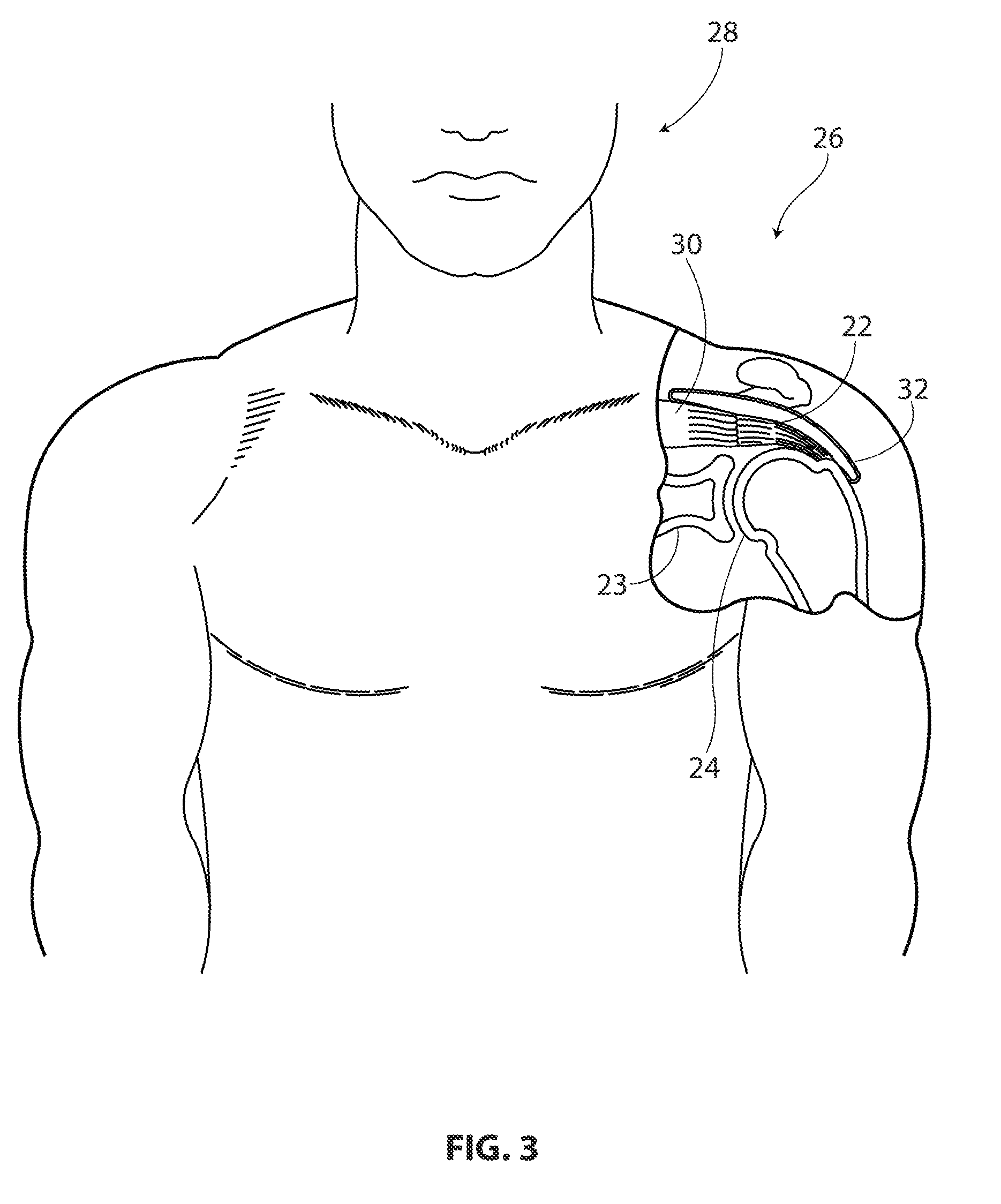

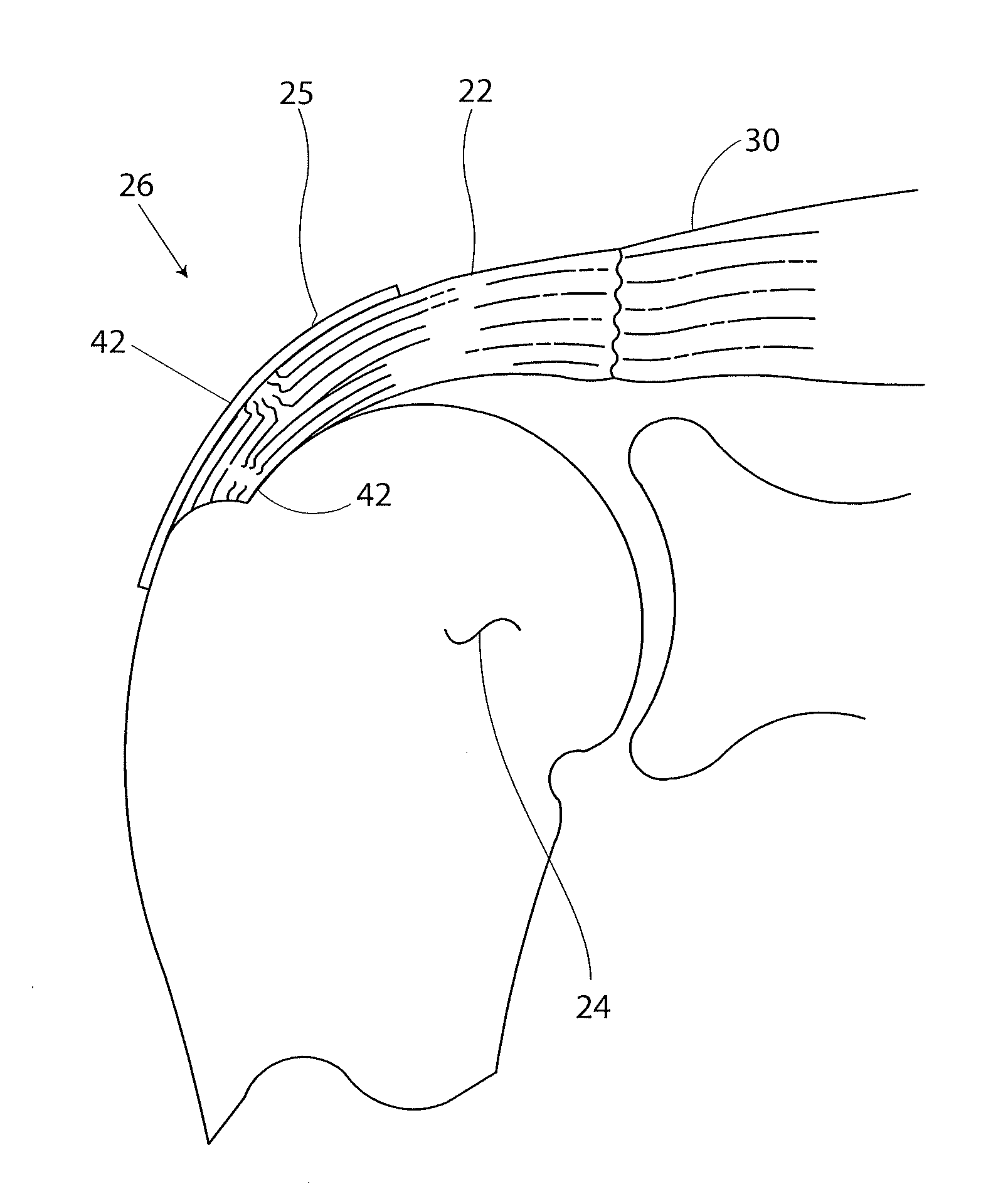

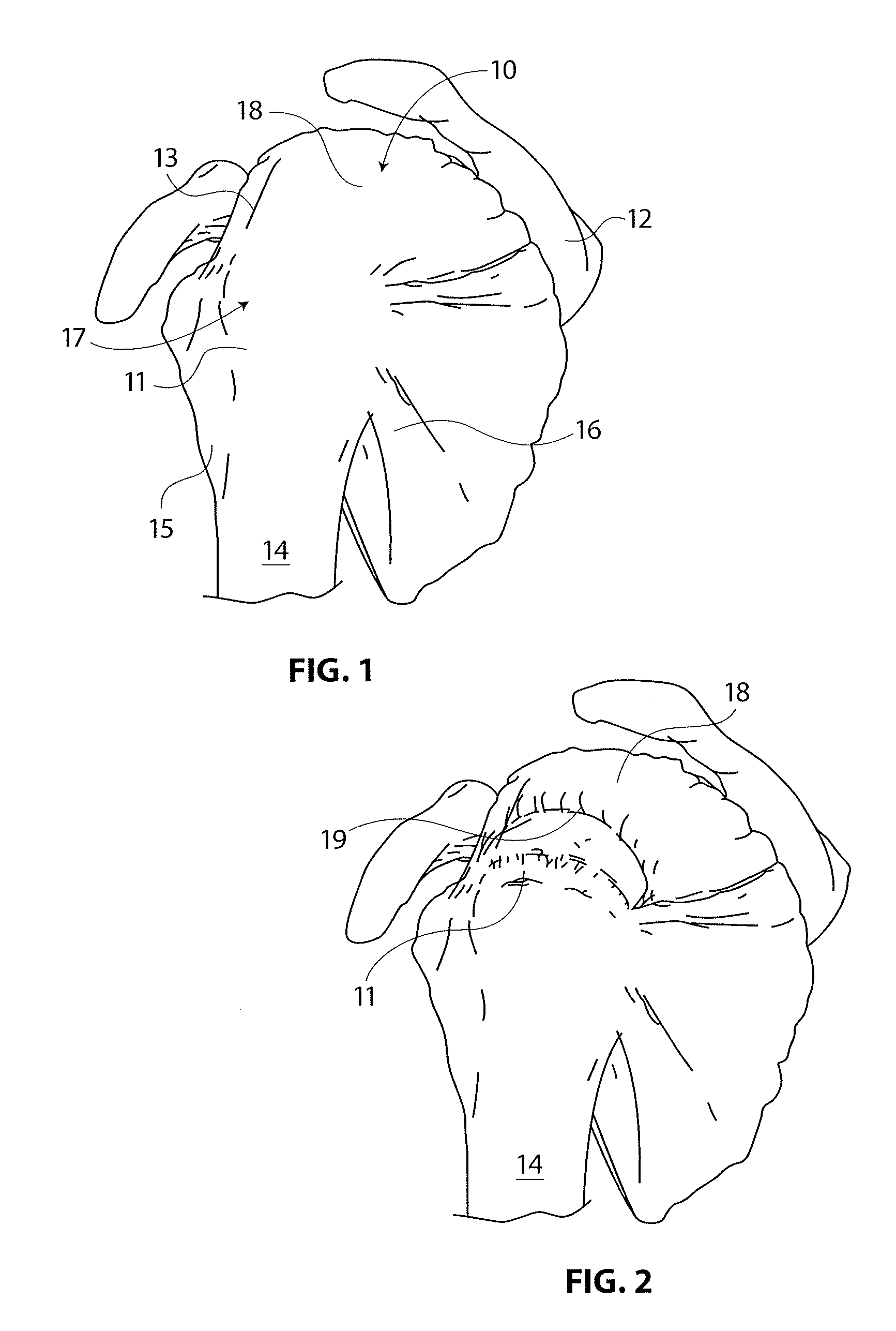

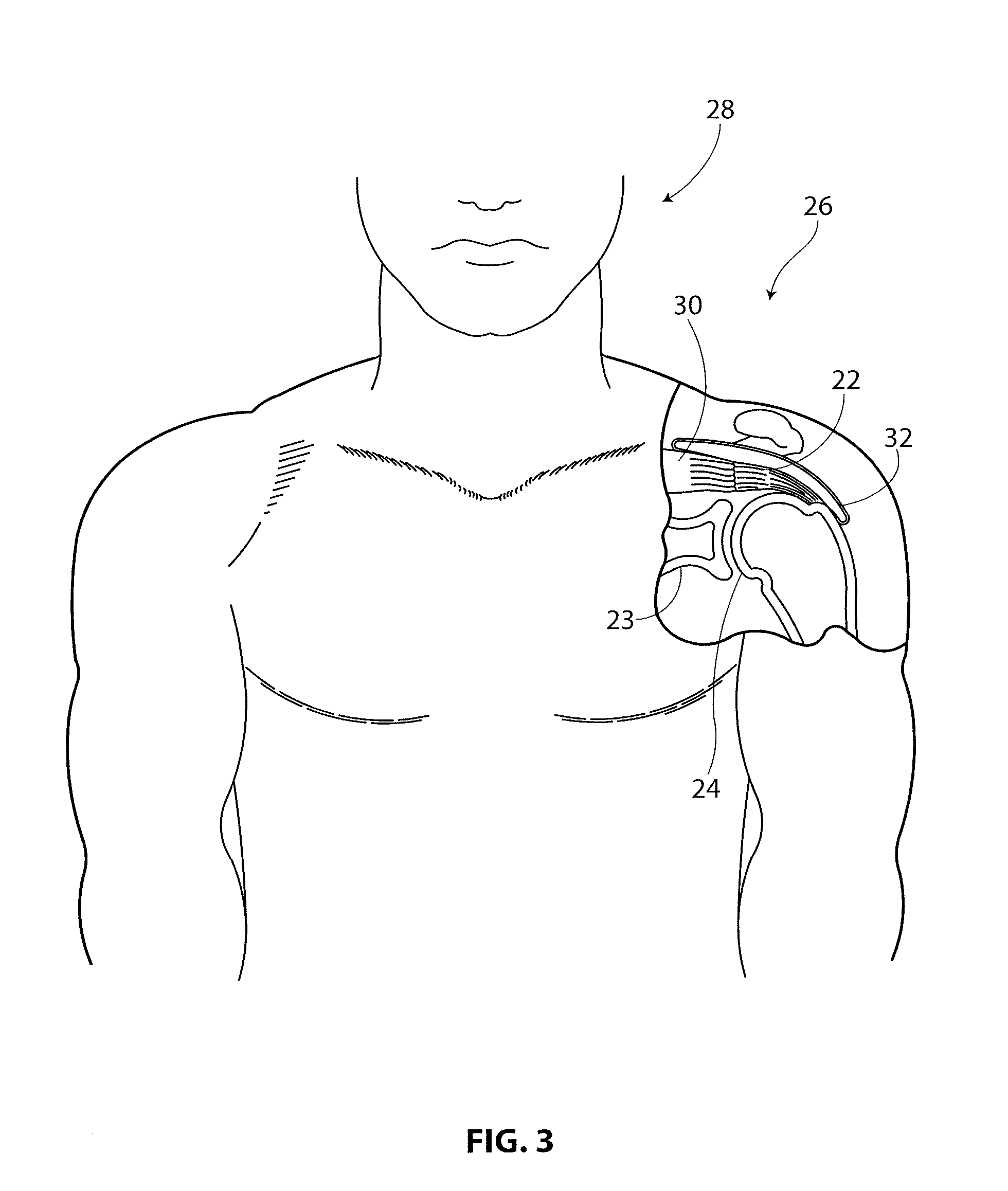

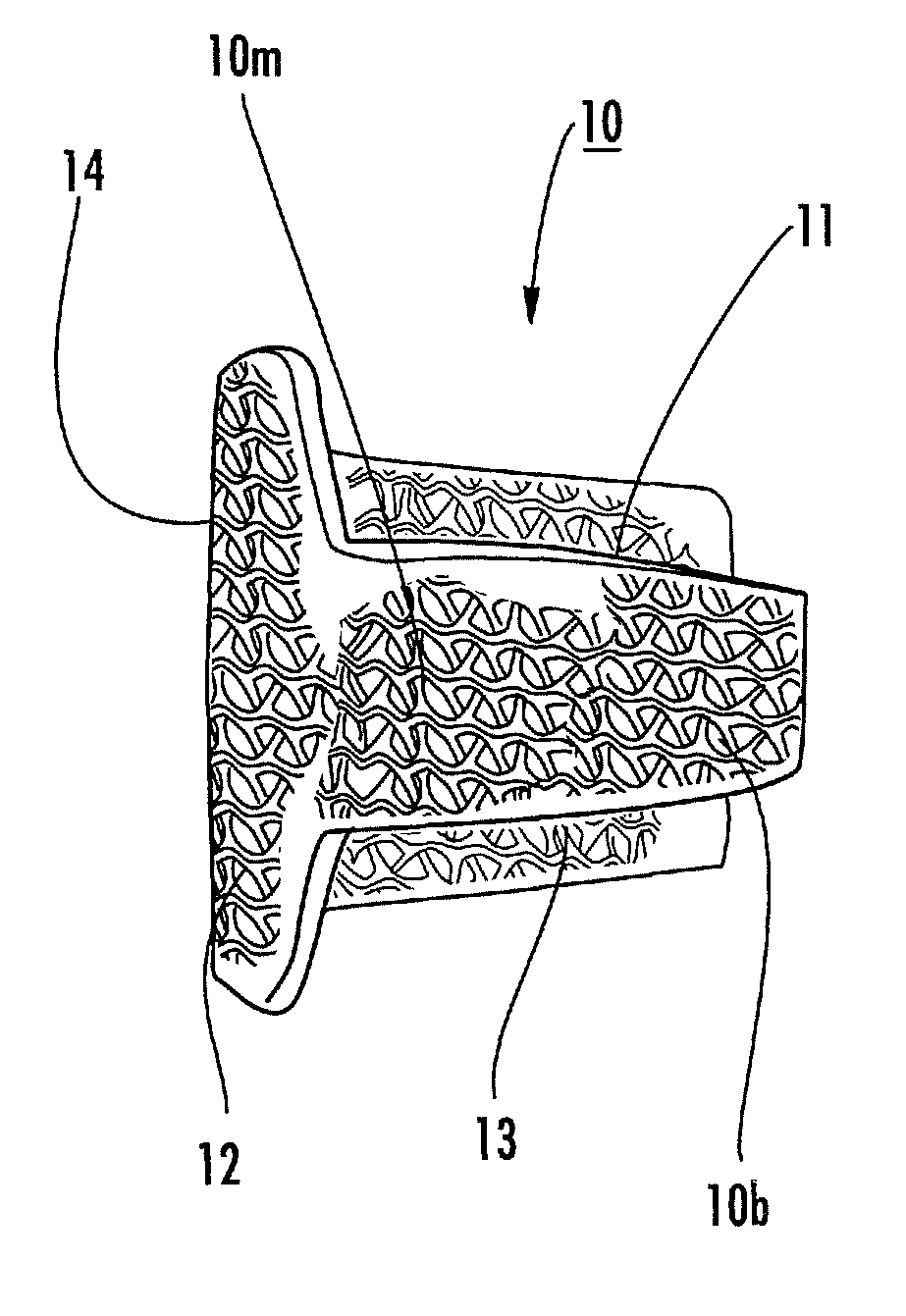

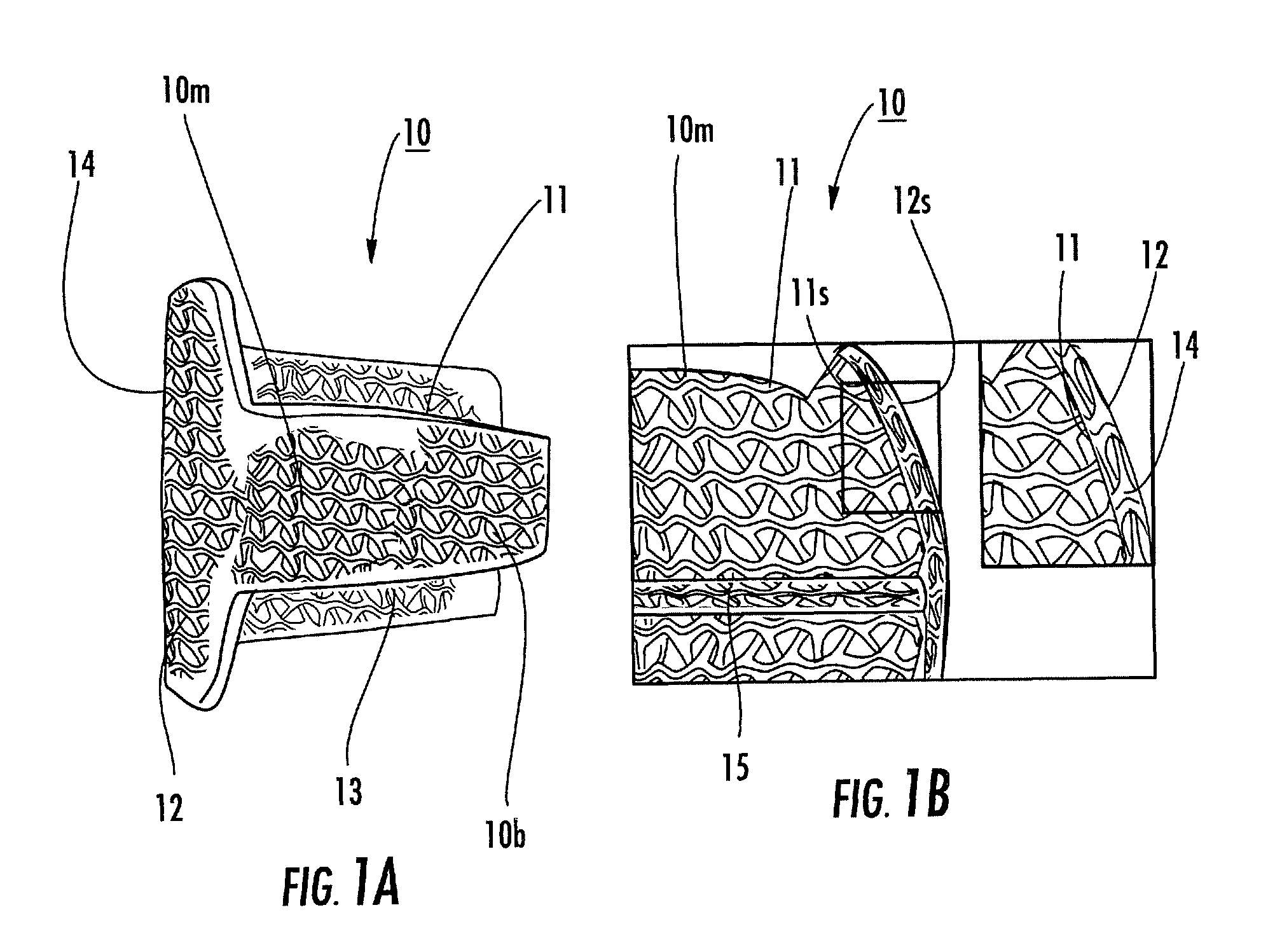

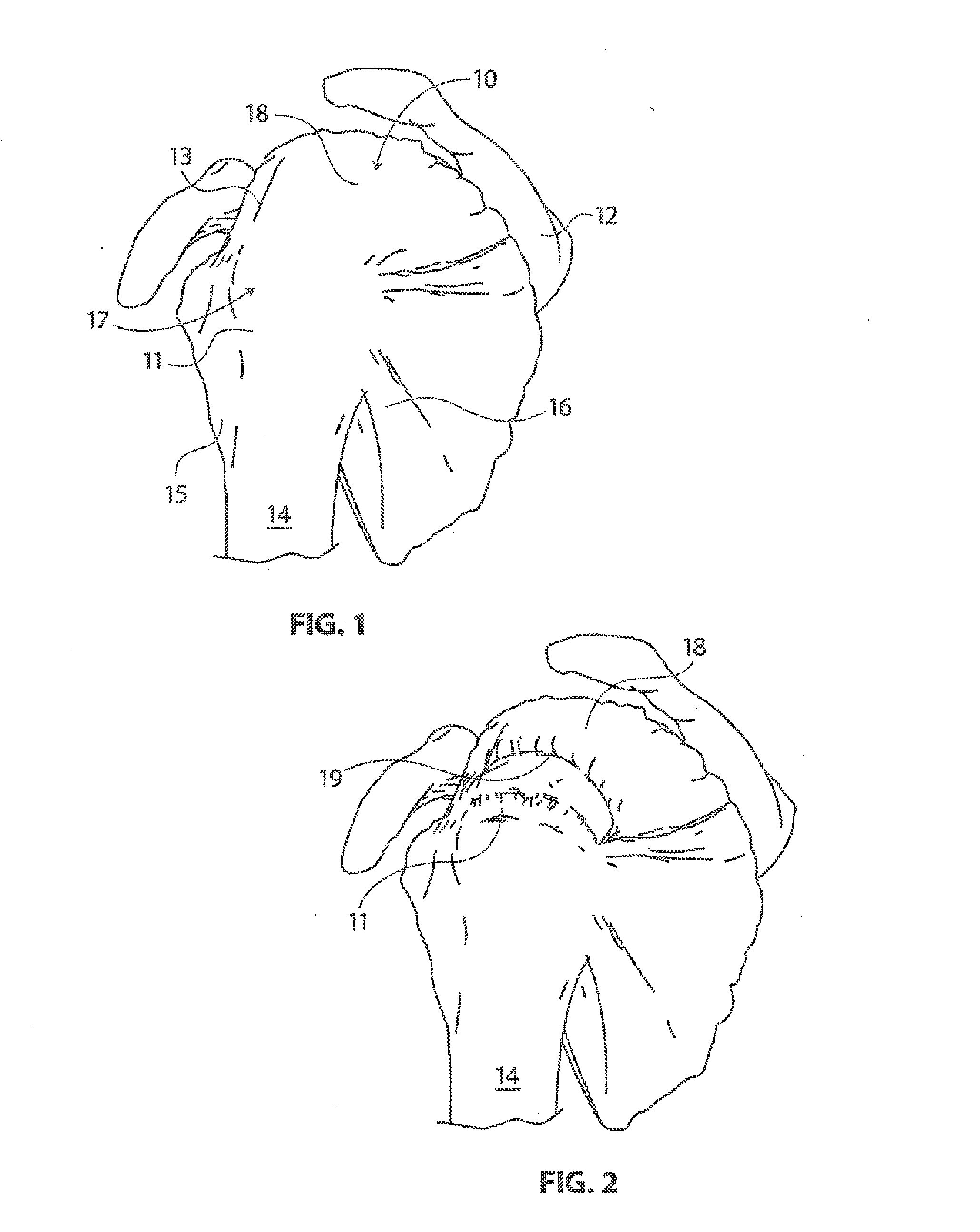

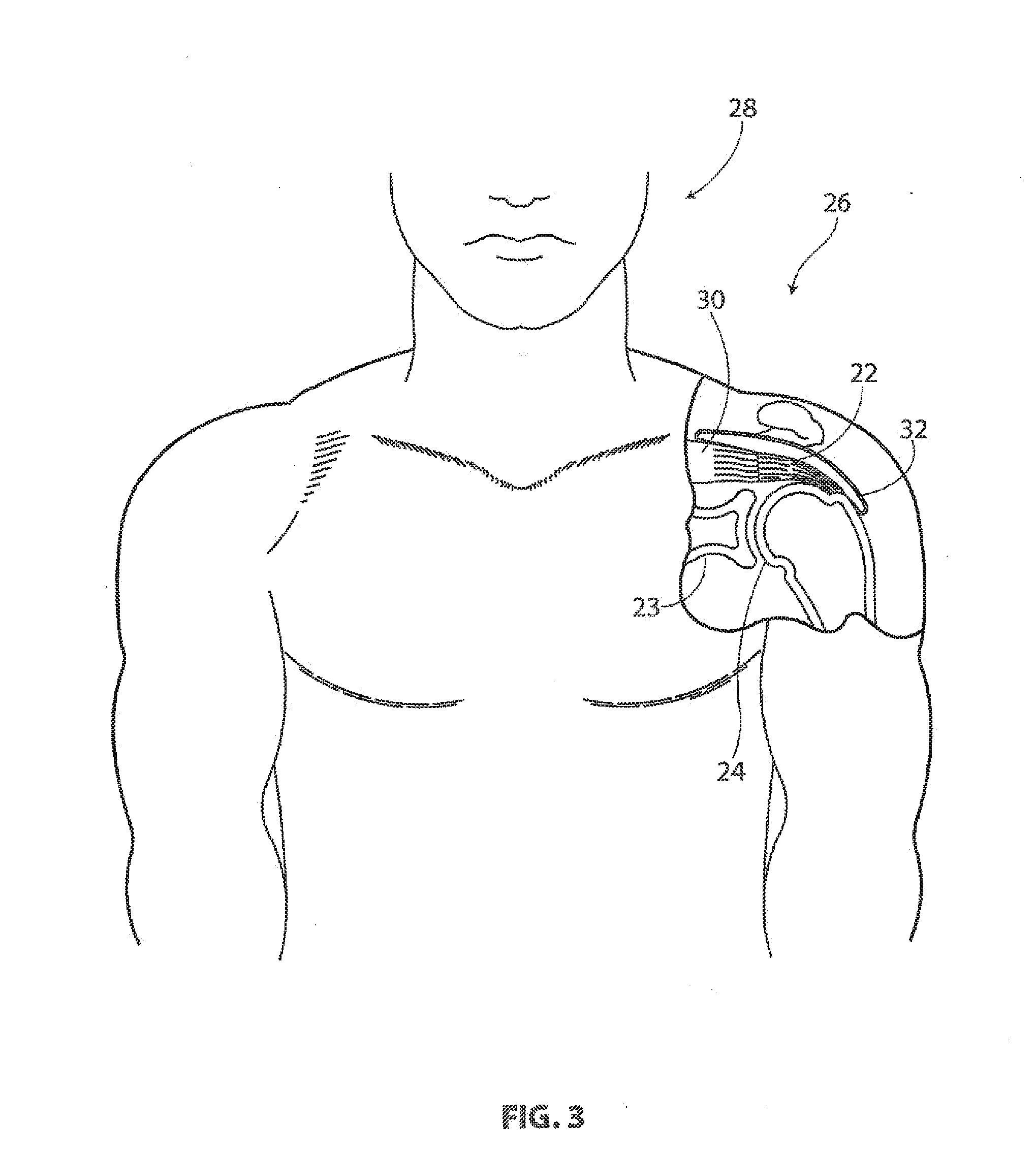

A tendon repair implant for treatment of a partial thickness tear in the supraspinatus tendon of the shoulder is provided. The implant may incorporate features of rapid deployment and fixation by arthroscopic means that compliment current procedures; tensile properties that result in desired sharing of anatomical load between the implant and native tendon during rehabilitation; selected porosity and longitudinal pathways for tissue in-growth; sufficient cyclic straining of the implant in the longitudinal direction to promote remodeling of new tissue to tendon-like tissue; and, may include a bioresorbable construction to provide transfer of additional load to new tendon-like tissue and native tendon over time.

Owner:ROTATION MEDICAL

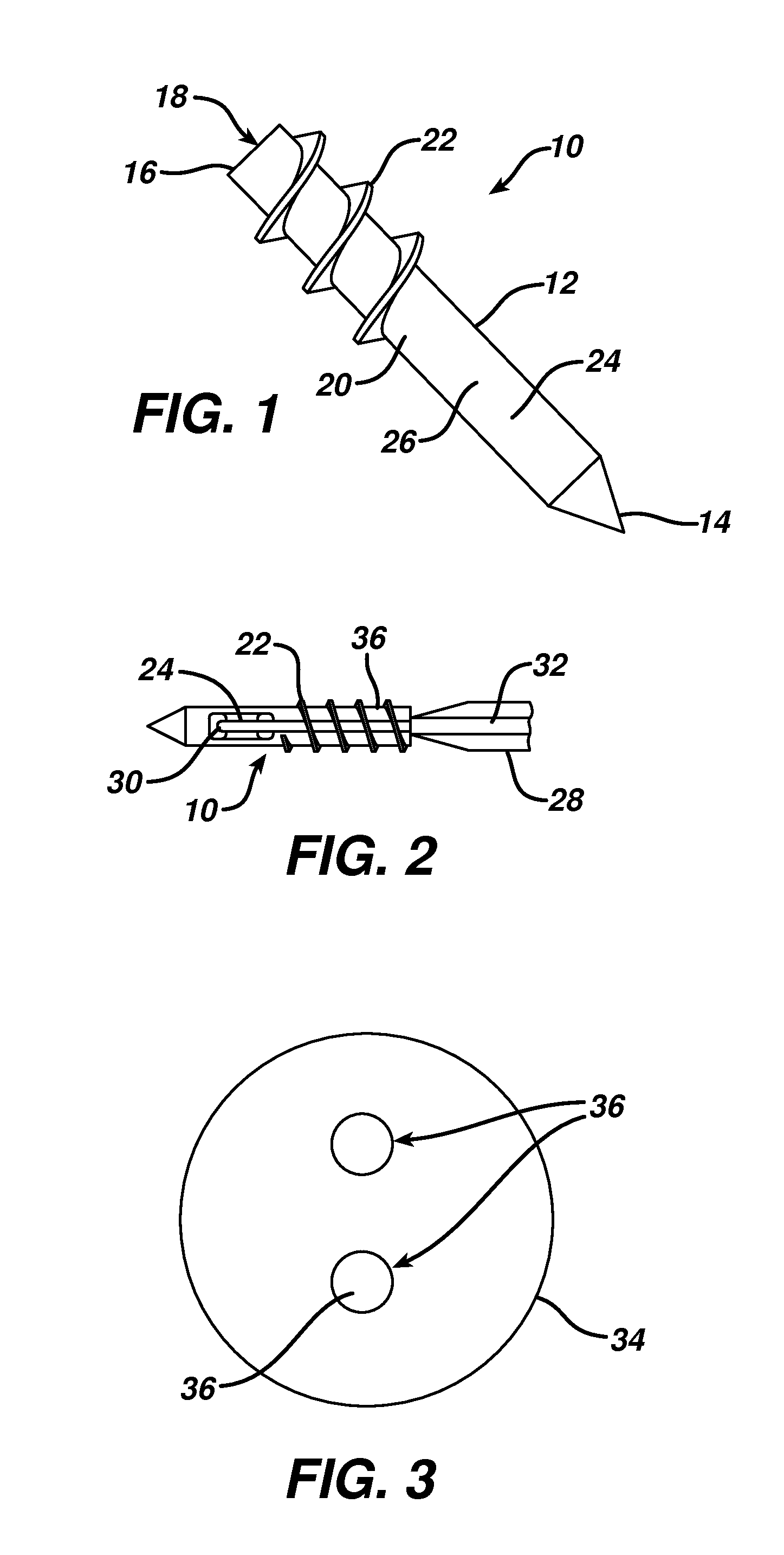

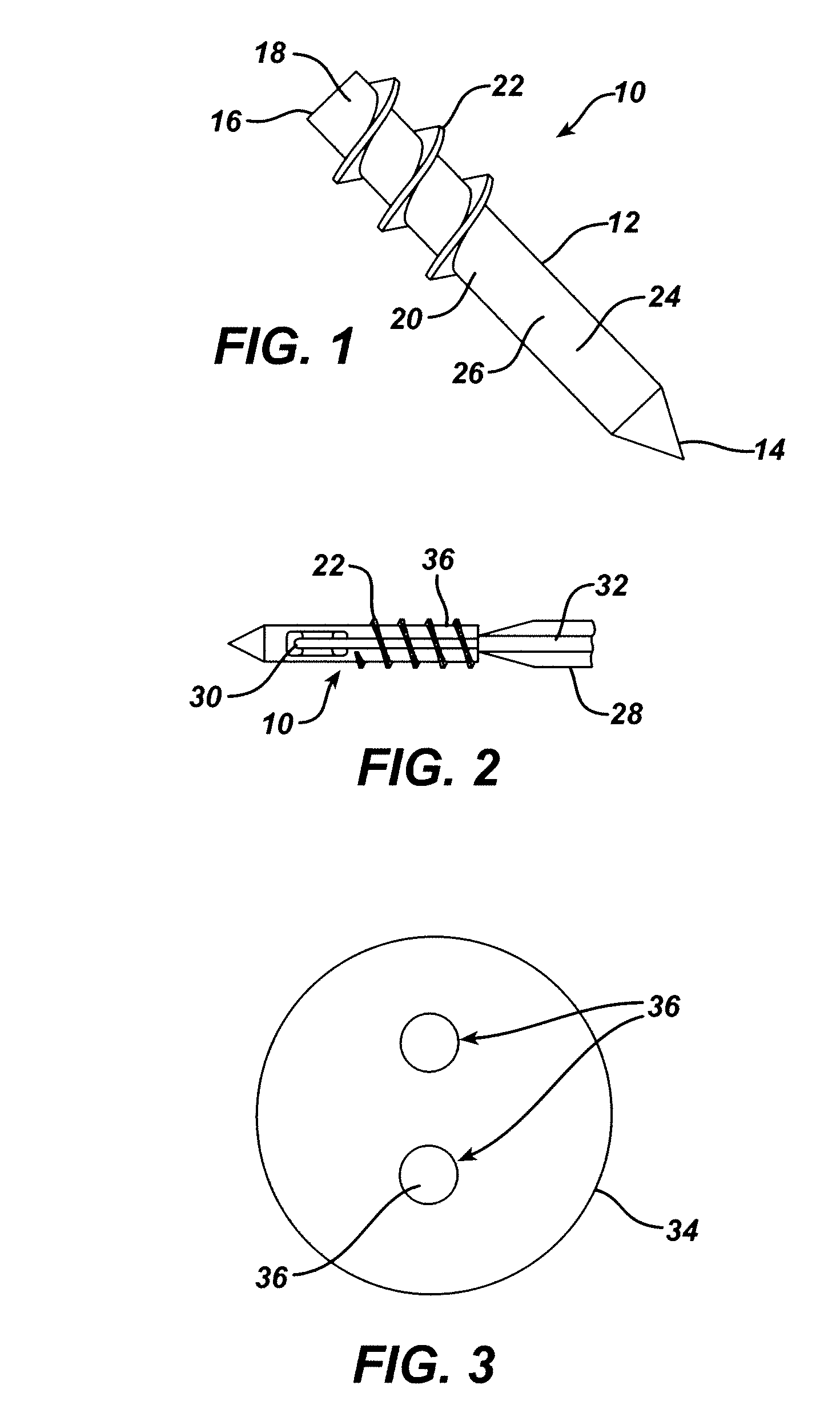

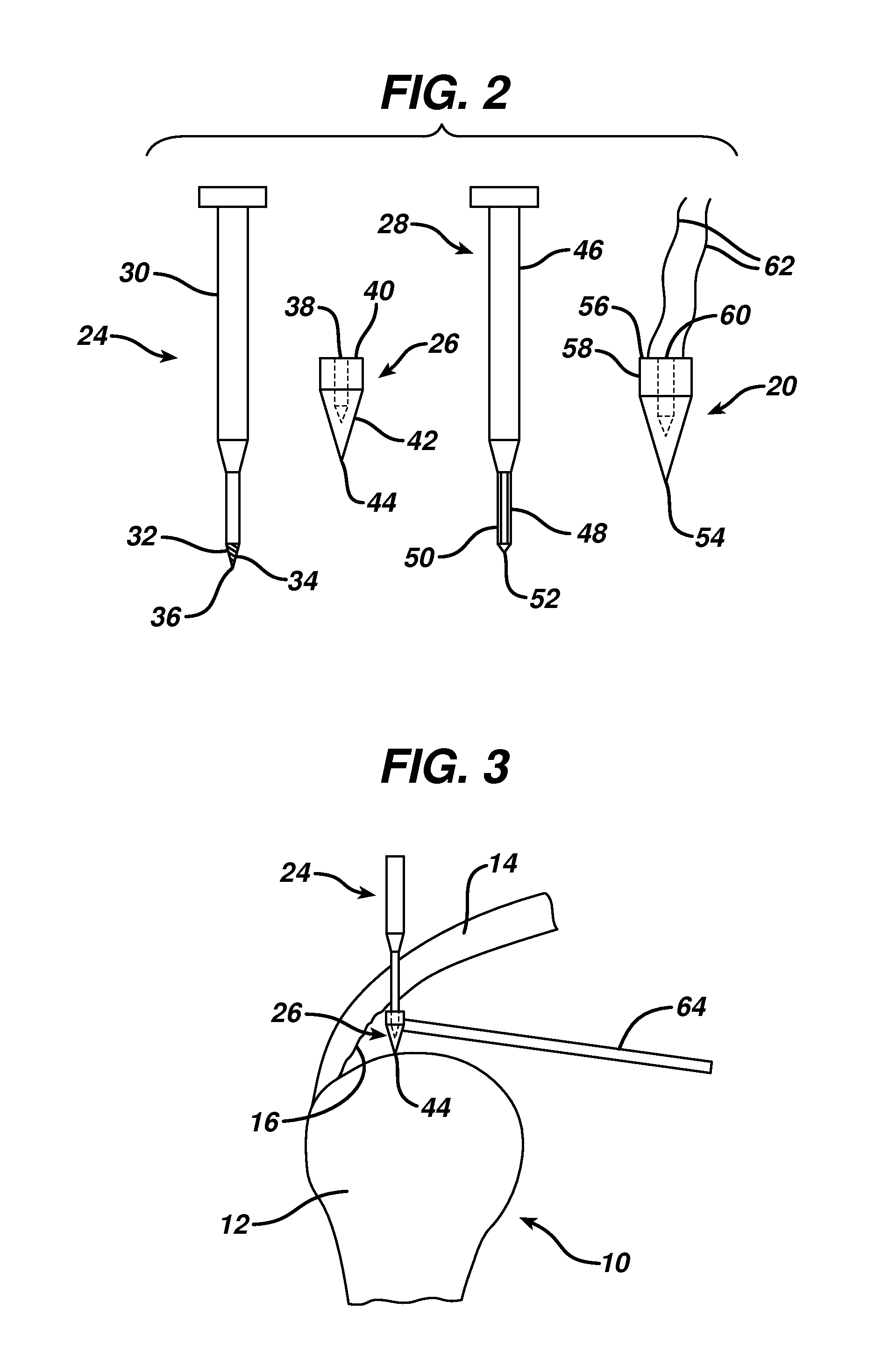

Partial thickness rotator cuff repair system and method

ActiveUS20110106154A1Easy to purchaseRelieve pressureSuture equipmentsLigamentsSuture anchorsRotator cuff

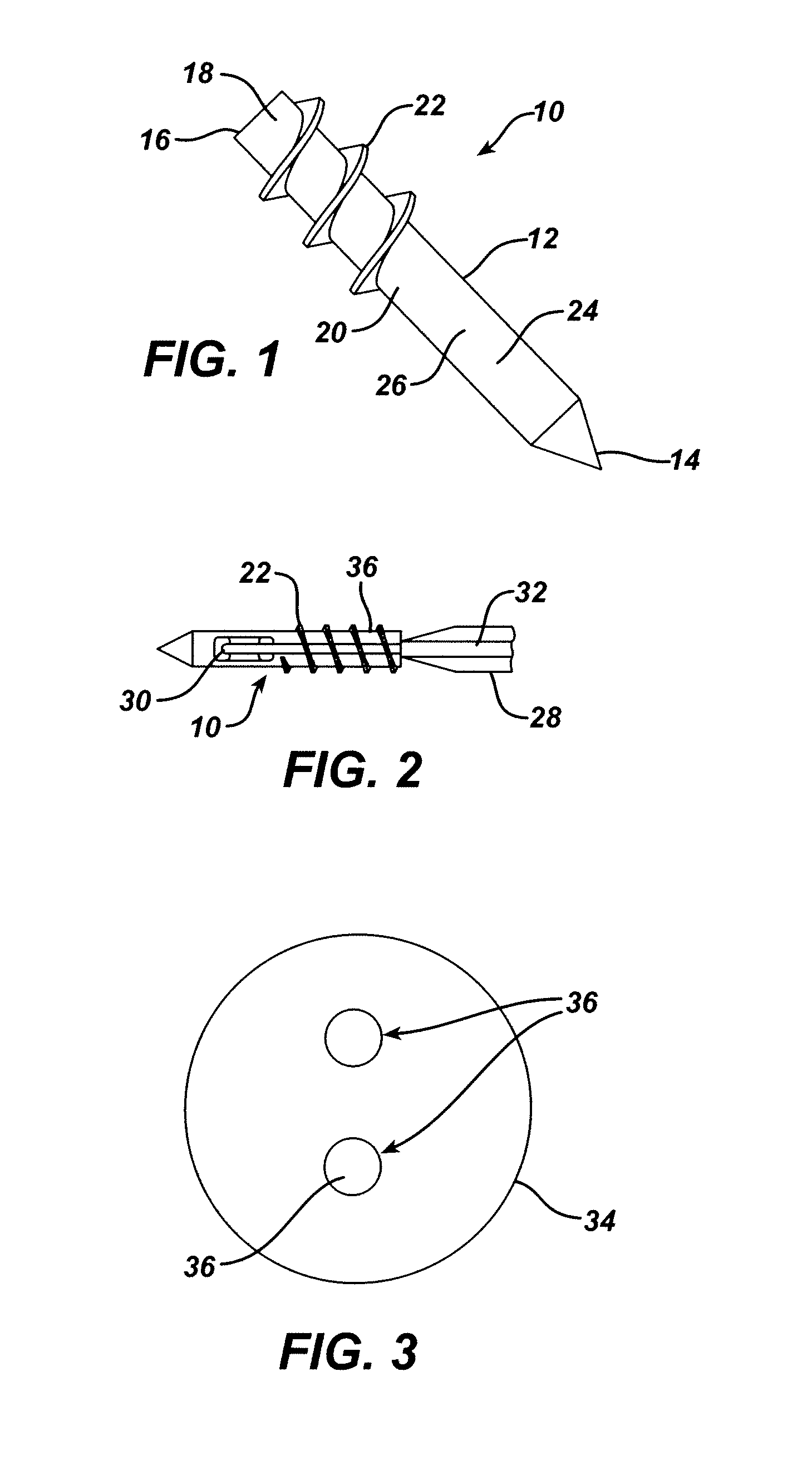

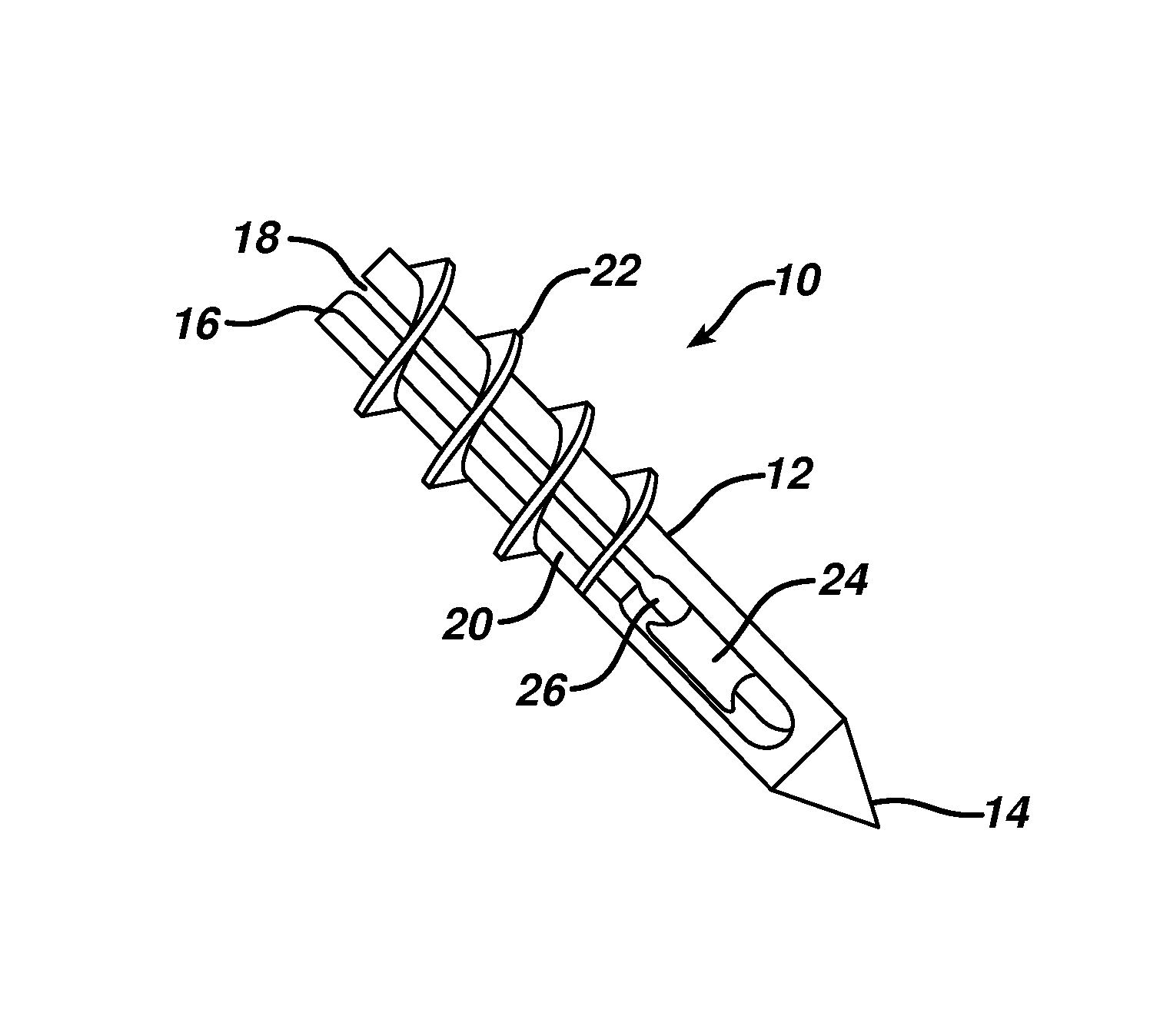

A suture anchor is disclosed which has an elongated body having a distal end, a proximal end and an exterior surface. An axially oriented bore extends into the body from the proximal end and a proximal portion of the bore has a plurality of abutment surfaces for engaging a tool. The bore includes one or more axially oriented suture passages leading to a suture attachment within the bore. A length of suture extends into the at least one suture passage from the body proximal end and extends to the suture attachment. A screw thread spirals about a portion of the exterior surface of the body adjacent the at least one suture passage. Between the bore and the exterior surface of the body the body has a wall thickness and wherein the suture passage comprises the area where the wall thickness goes to zero.

Owner:DEPUY SYNTHES PROD INC

Tendon repair implant and method of arthroscopic implantation

A tendon repair implant for treatment of a partial thickness tear in the supraspinatus tendon of the shoulder is provided. The implant may incorporate features of rapid deployment and fixation by arthroscopic means that compliment current procedures; tensile properties that result in desired sharing of anatomical load between the implant and native tendon during rehabilitation; selected porosity and longitudinal pathways for tissue in-growth; sufficient cyclic straining of the implant in the longitudinal direction to promote remodeling of new tissue to tendon-like tissue; and, may include a bioresorbable construction to provide transfer of additional load to new tendon-like tissue and native tendon over time.

Owner:ROTATION MEDICAL

Ink-jet printhead

Owner:BROTHER KOGYO KK

Partial thickness rotator cuff repair system and method

ActiveUS8672967B2Easy to purchaseRelieve pressureSuture equipmentsLigamentsSuture anchorsRotator cuff

A suture anchor is disclosed which has an elongated body having a distal end, a proximal end and an exterior surface. An axially oriented bore extends into the body from the proximal end and a proximal portion of the bore has a plurality of abutment surfaces for engaging a tool. The bore includes one or more axially oriented suture passages leading to a suture attachment within the bore. A length of suture extends into the at least one suture passage from the body proximal end and extends to the suture attachment. A screw thread spirals about a portion of the exterior surface of the body adjacent the at least one suture passage. Between the bore and the exterior surface of the body the body has a wall thickness and wherein the suture passage comprises the area where the wall thickness goes to zero.

Owner:DEPUY SYNTHES PROD INC

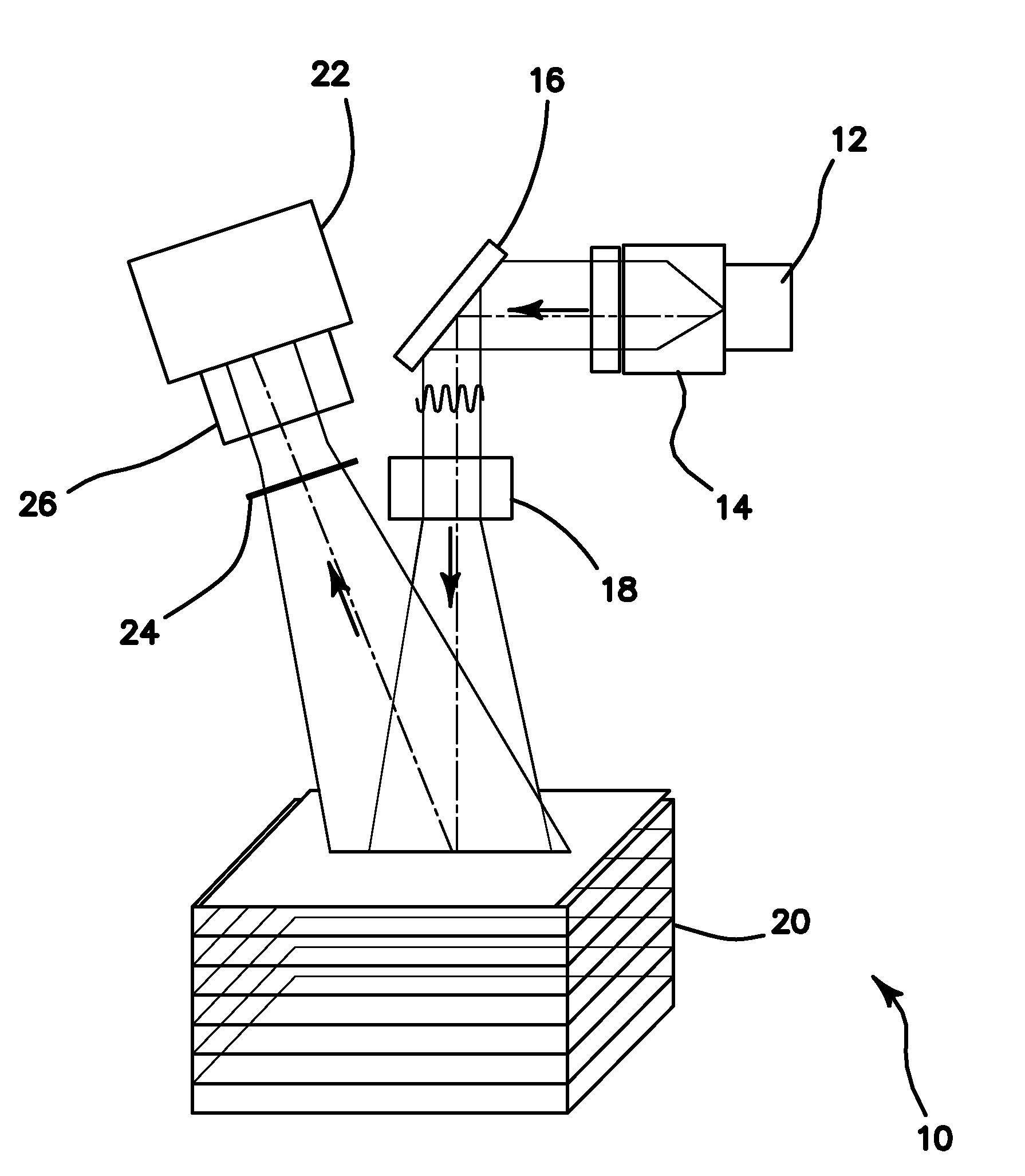

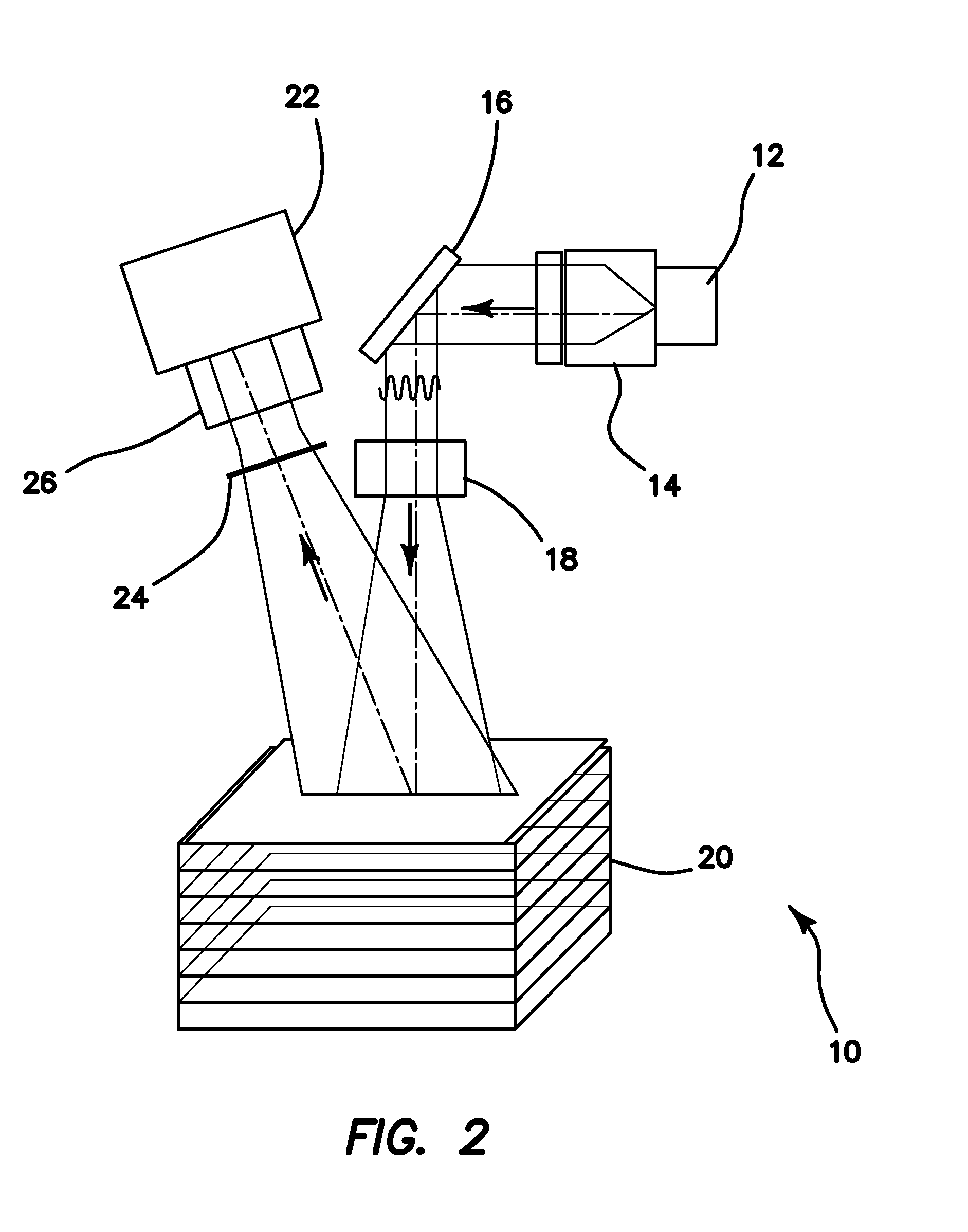

Method and apparatus for performing qualitative and quantitative analysis of burn extent and severity using spatially structured illumination

Frequent monitoring of early-stage burns is necessary for deciding optimal treatment and management. Superficial-partial thickness and deep-partial thickness burns, while visually similar, differ dramatically in terms of clinical treatment and are known to progress in severity over time. The disclosed method uses spatial frequency domain imaging (SFDI) far noninvasively mapping quantitative changes in chromophore and optical properties that may be an indicative of burn wound severity. A controlled protocol of graded burn severity is developed and applied to 17 rats. SFDI data is acquired at multiple near-infrared wavelengths over a course of 3 h. Burn severity is verified using hematoxylin and eosin histology. Changes in water concentration (edema), deoxygenated hemoglobin concentration, and optical scattering (tissue denaturation) are statistically significant measures, which are used to differentiate superficial partial-thickness burns from deep-partial thickness burns.

Owner:RGT UNIV OF CALIFORNIA

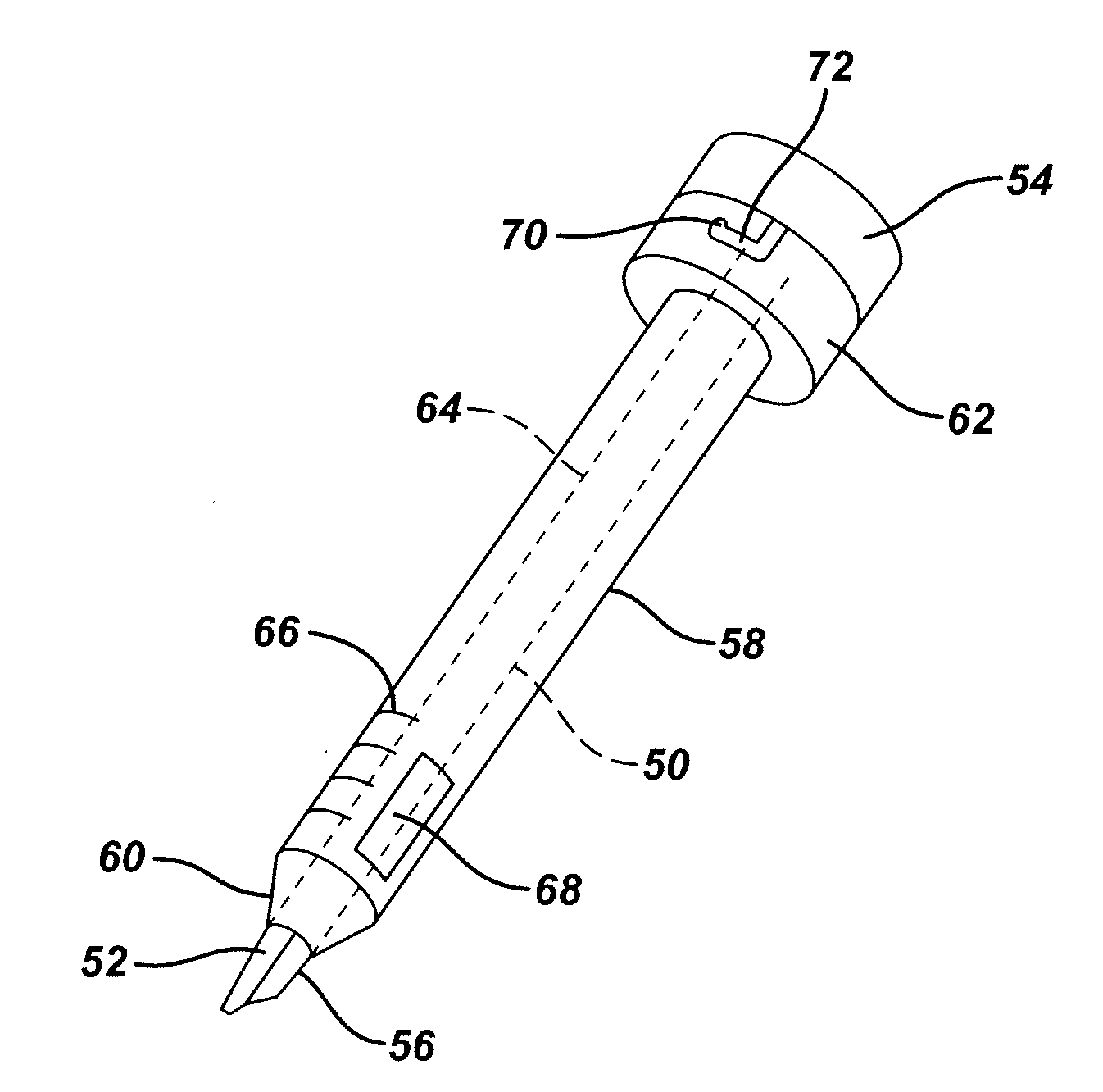

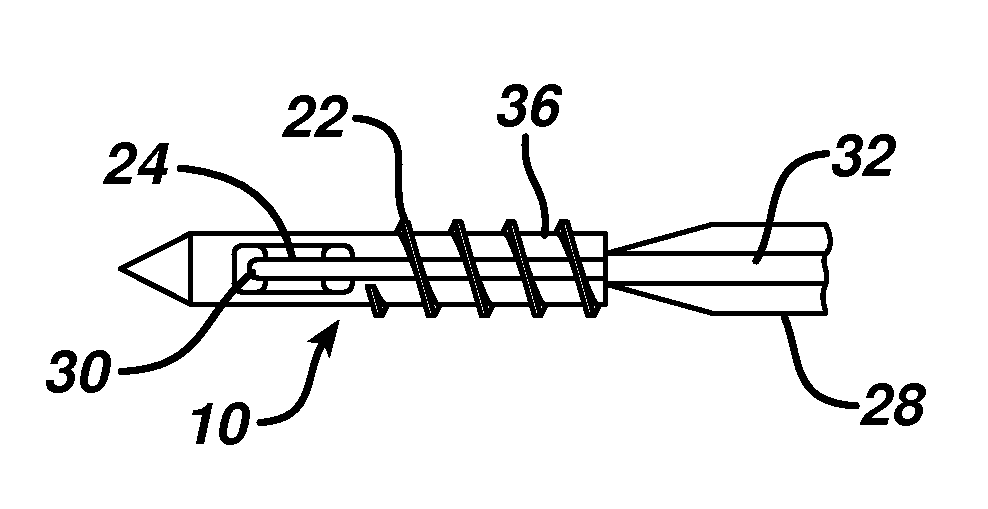

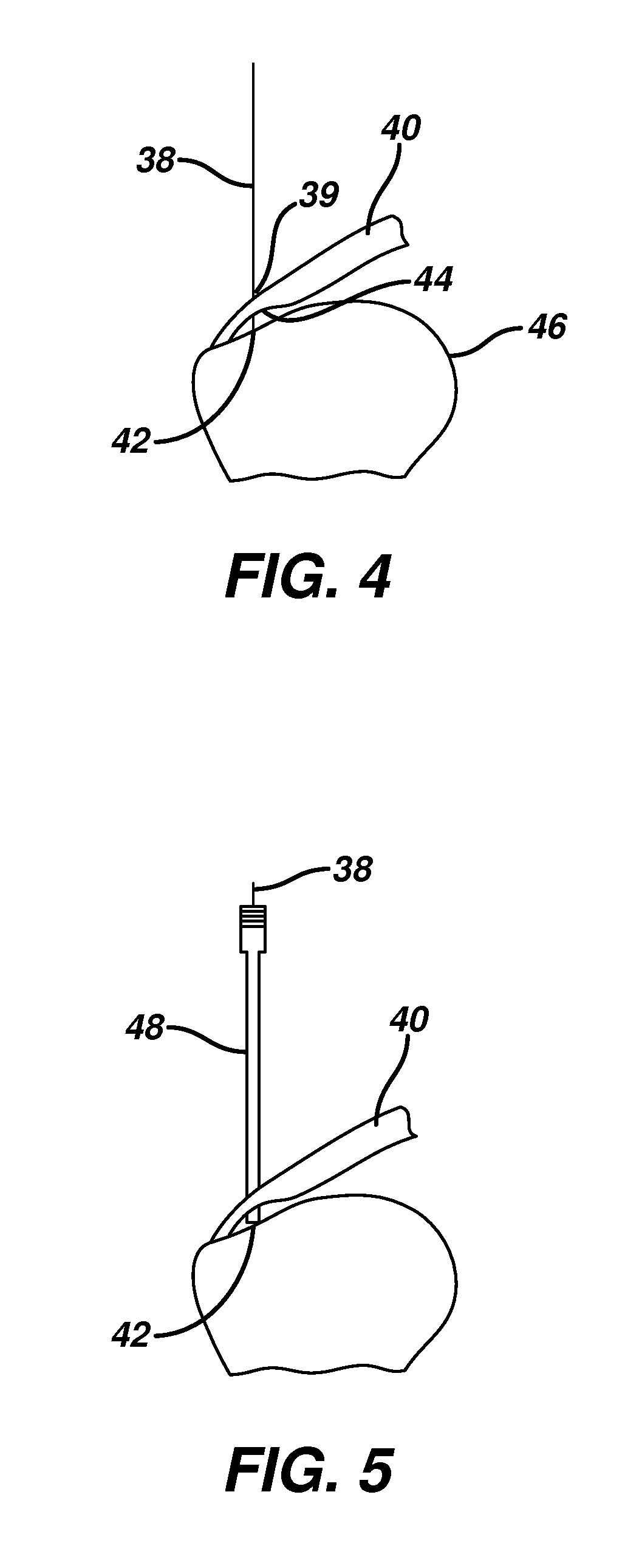

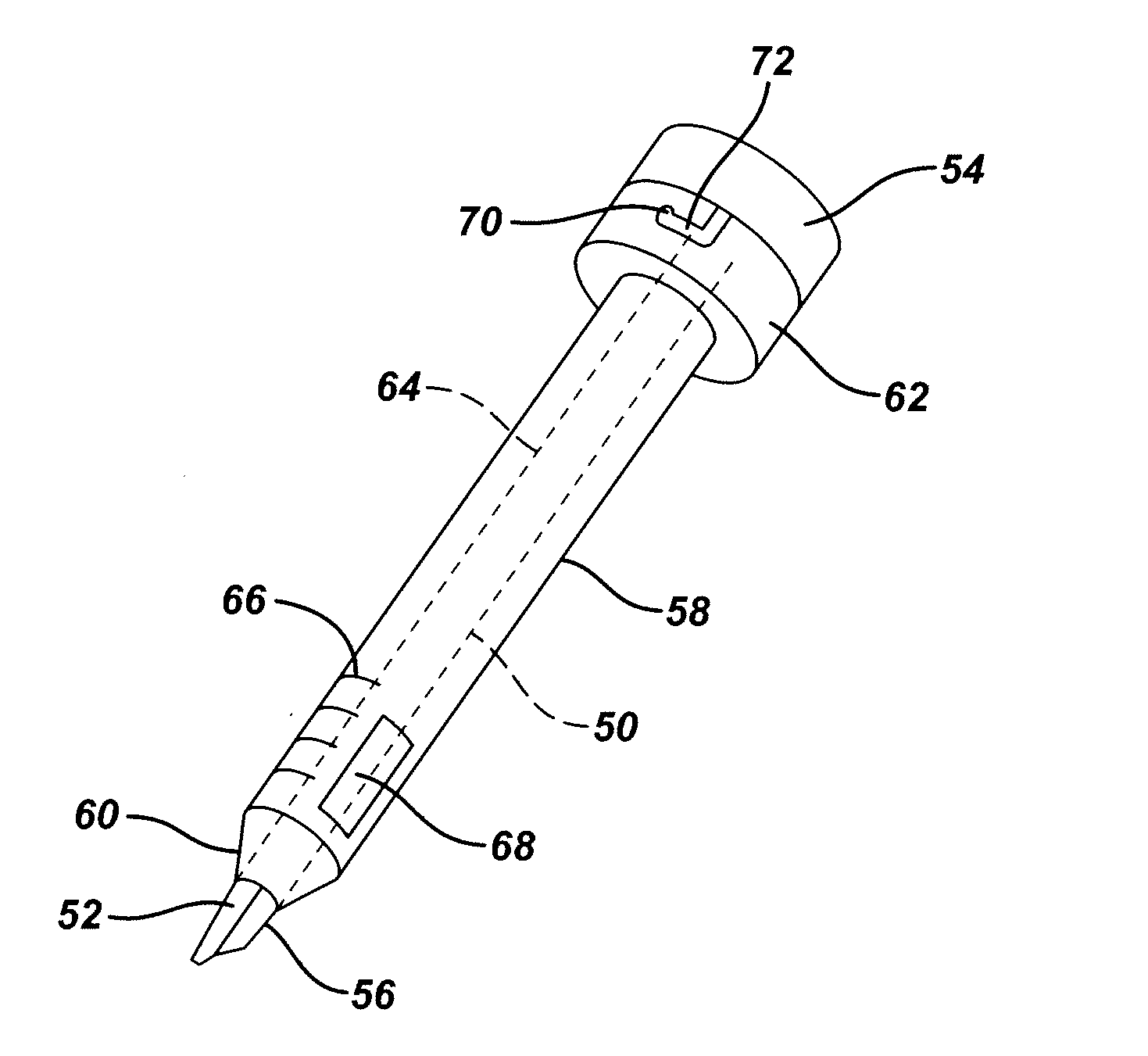

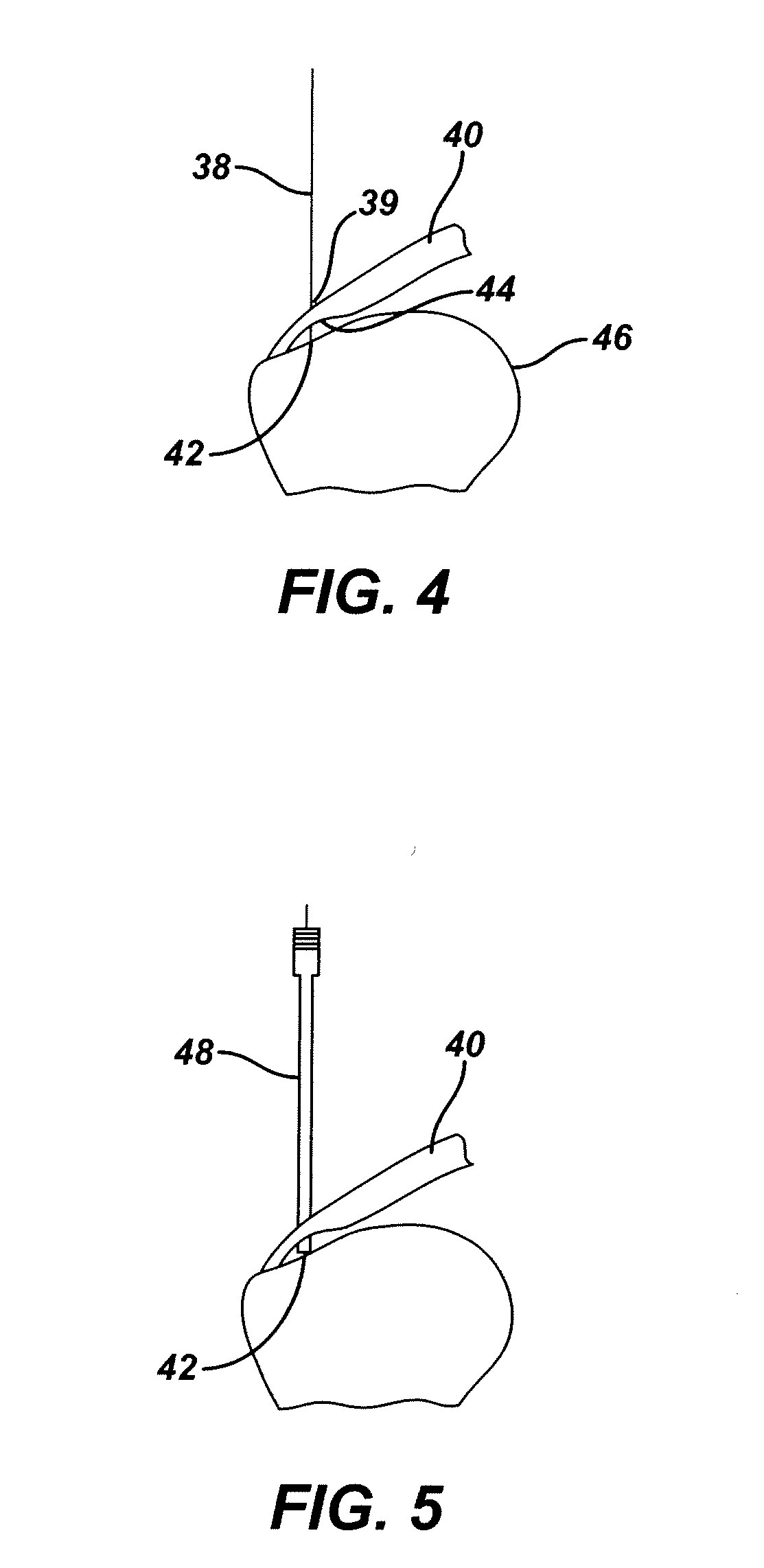

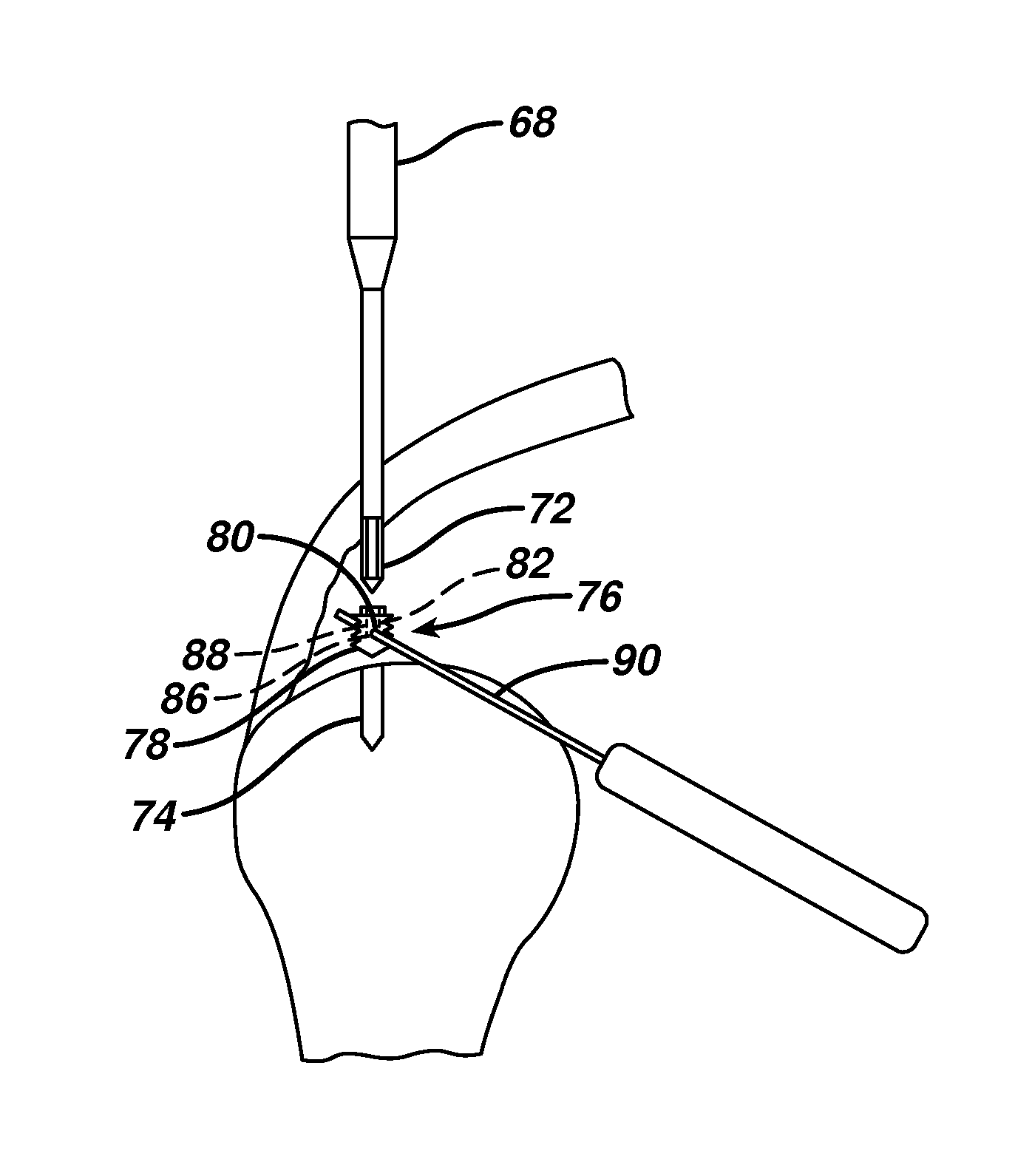

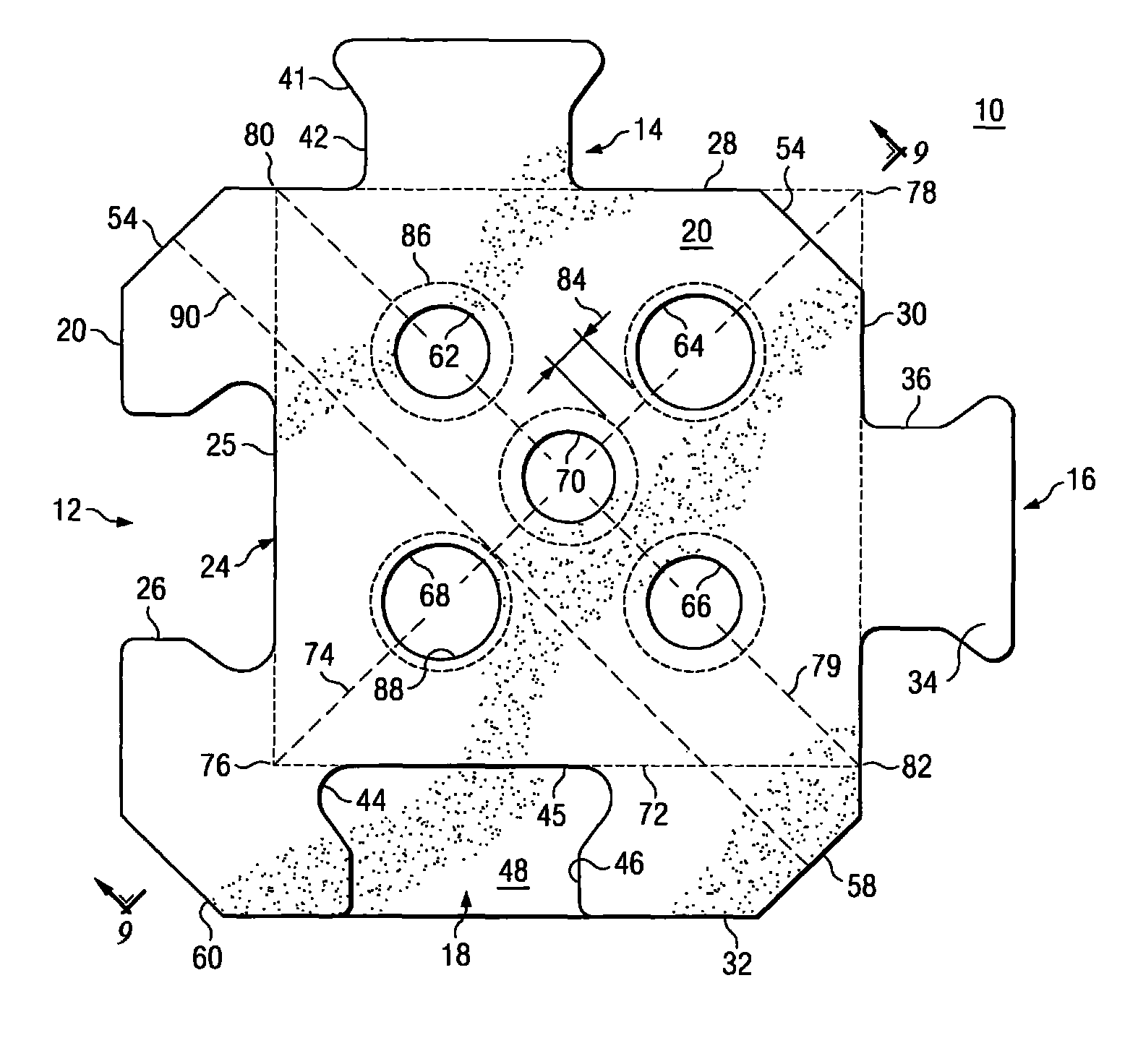

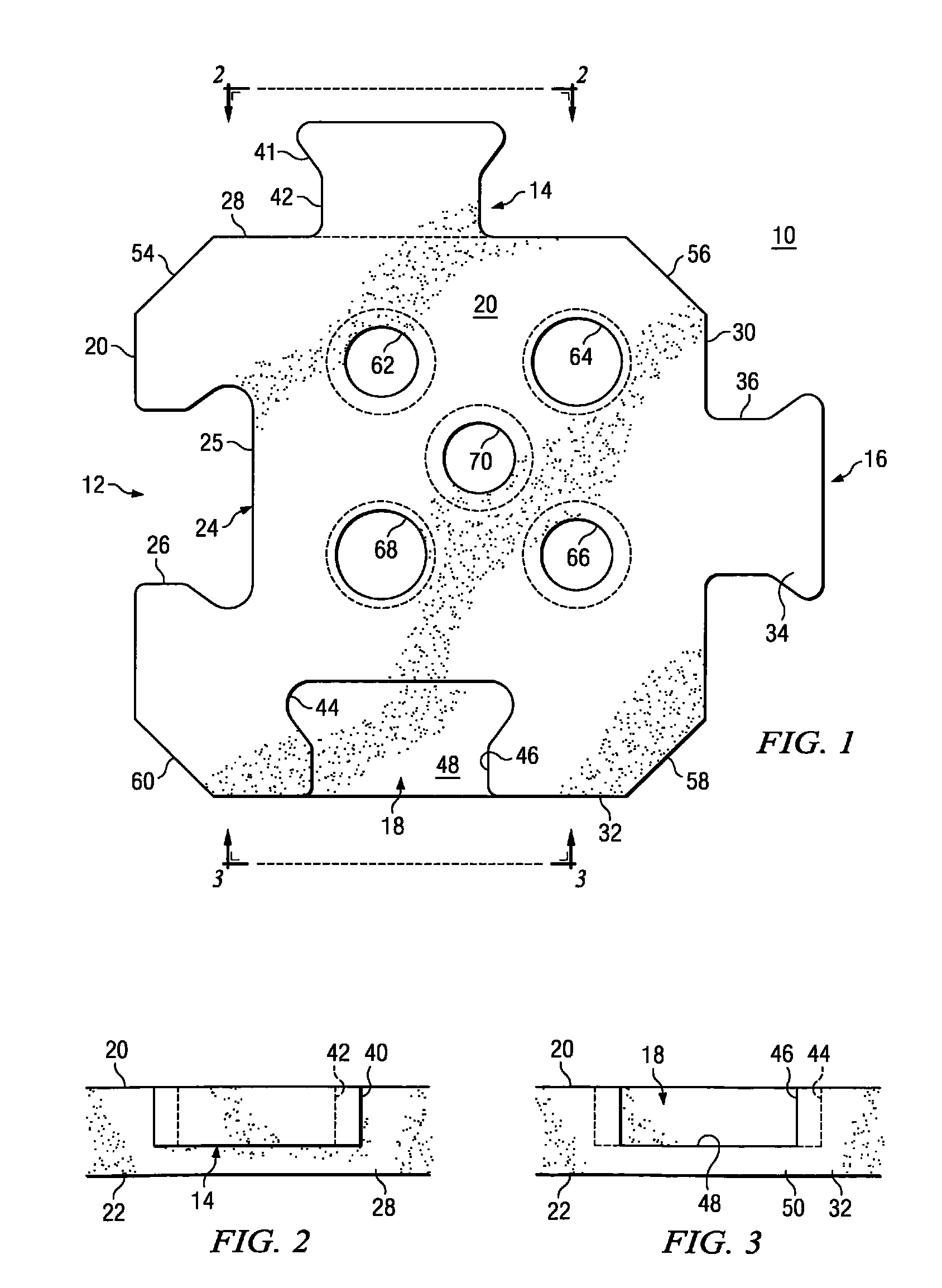

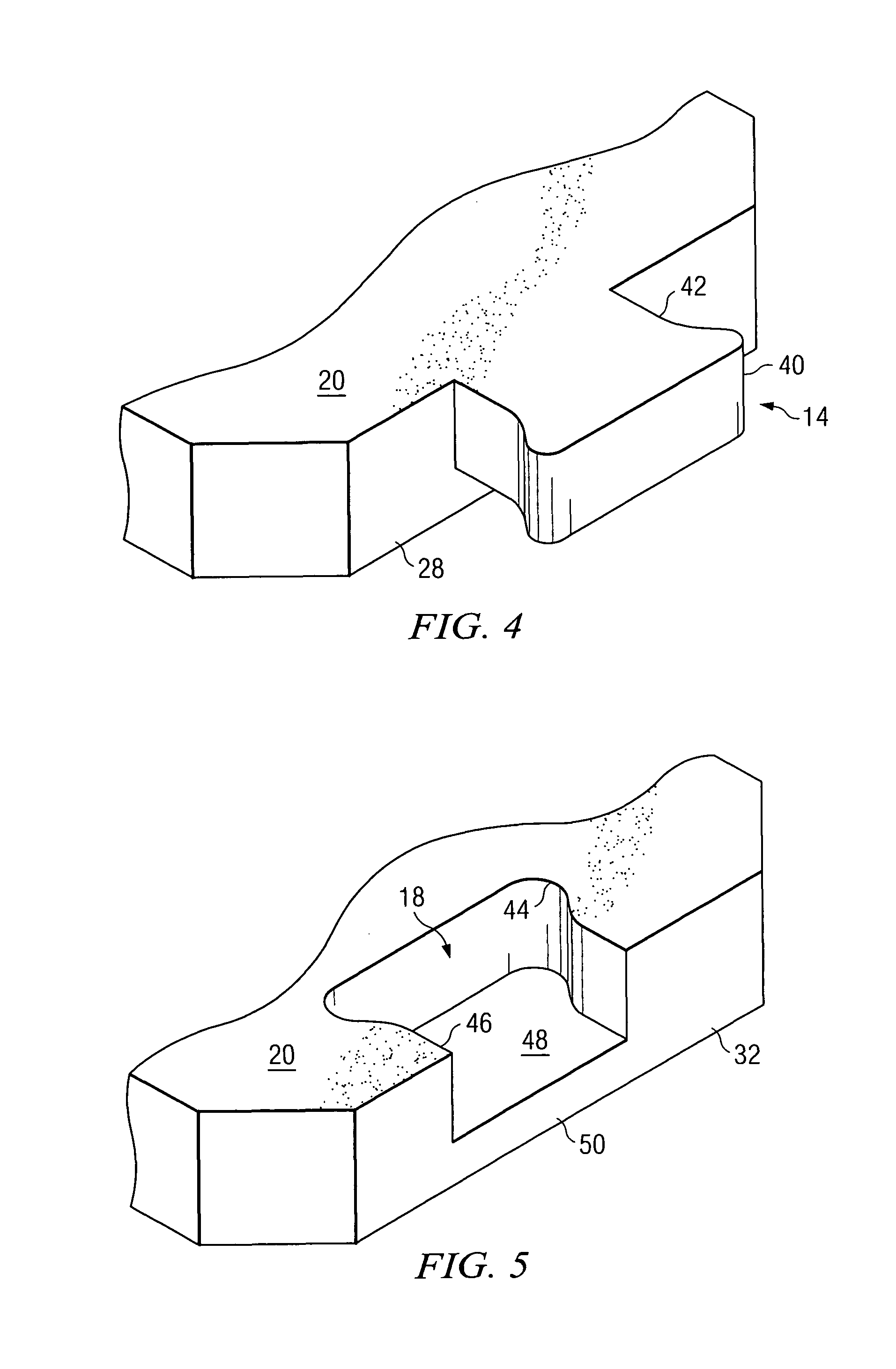

Cannula system and method for partial thickness rotator cuff repair

ActiveUS20120123473A1Expand accessIncrease surface areaSuture equipmentsLigamentsSuture anchorsDistal portion

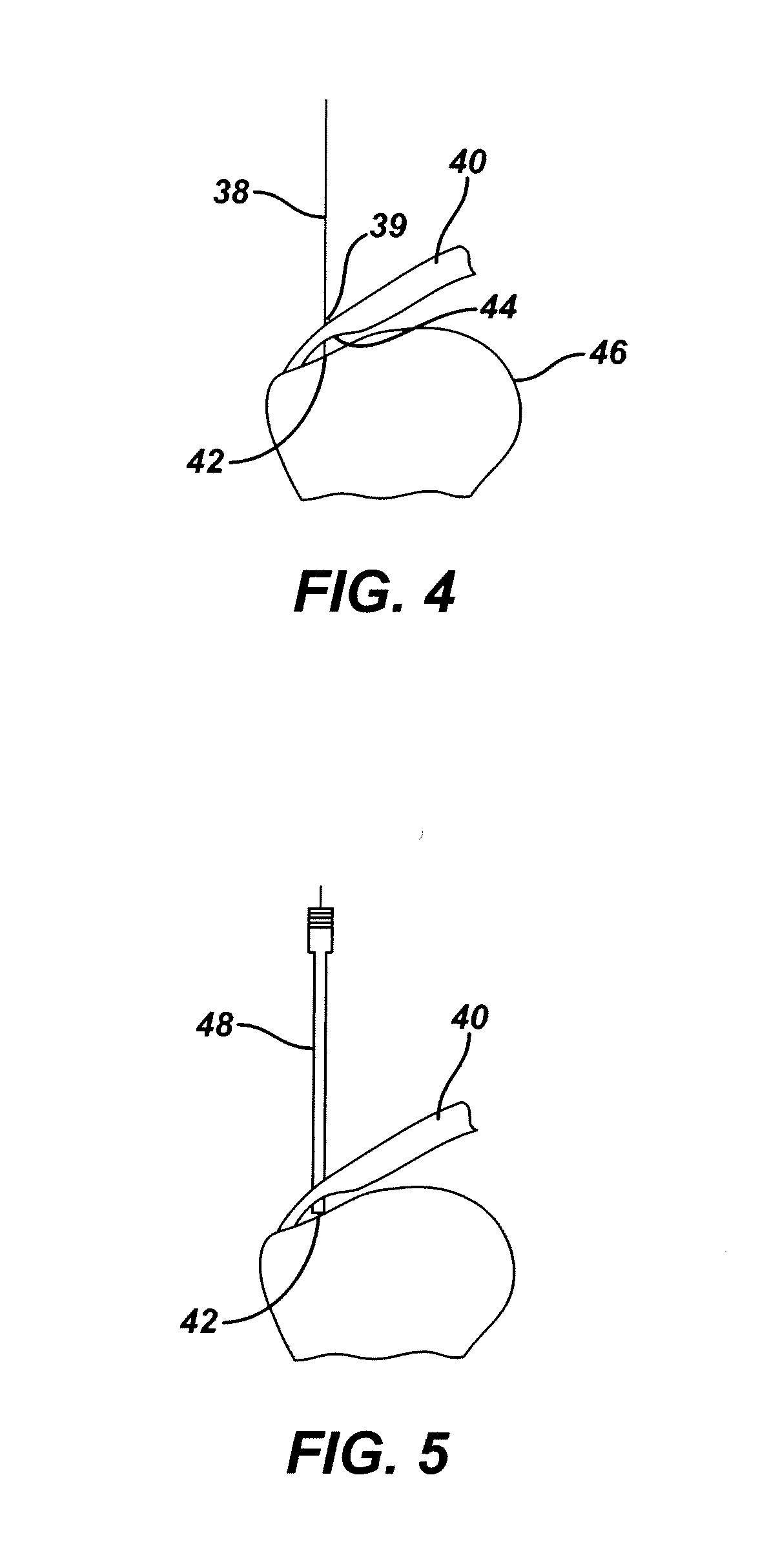

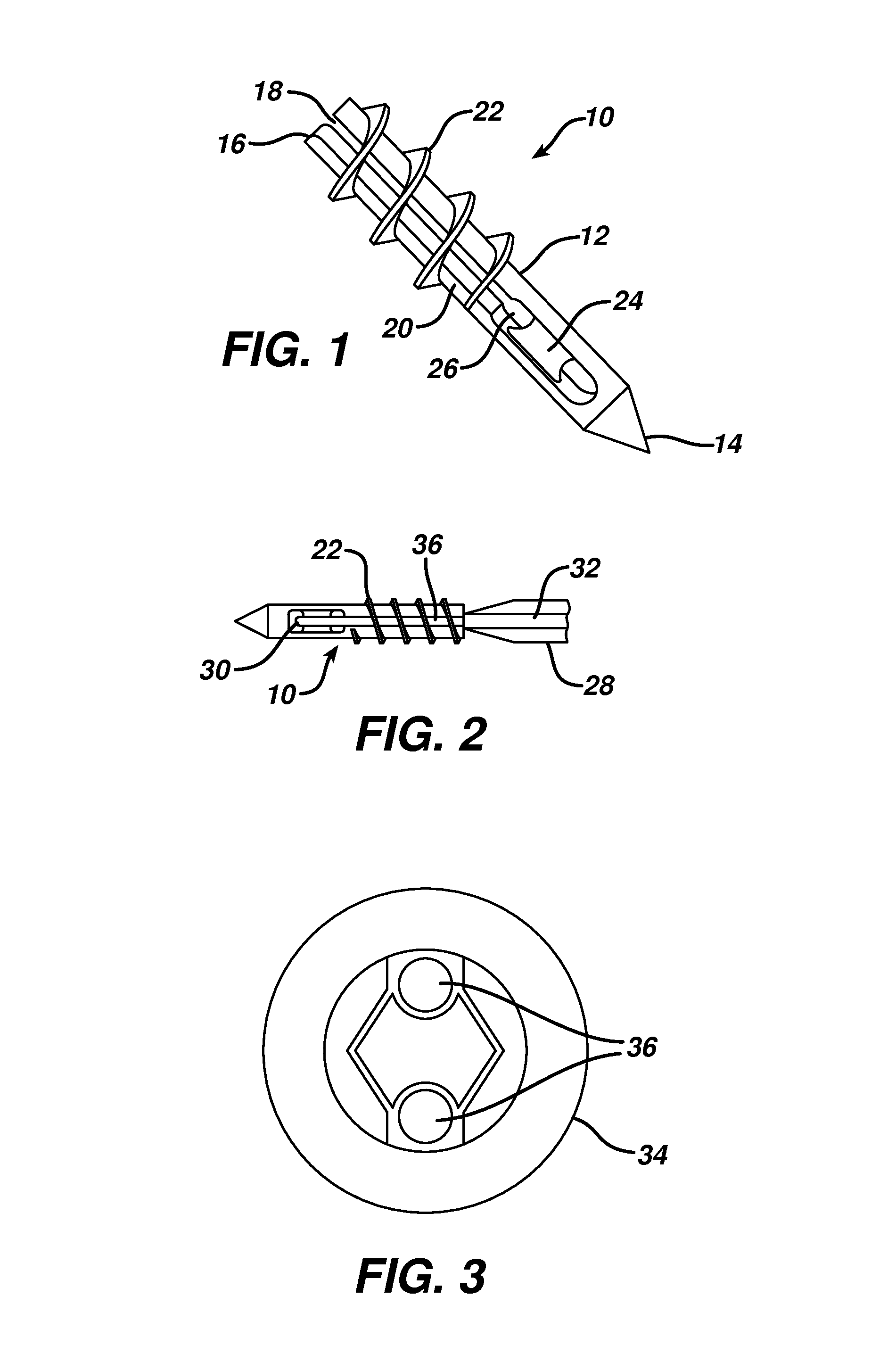

A trans-soft tissue anchor implantation system in one embodiment includes a positioning wire having a tissue penetrating distal tip, a cannula for passage through the soft tissue and a suture anchor. The cannula has an axial lumen therethrough sized to accommodate at least the positioning wire, a thin-walled distal portion and a tissue engaging feature, such as an arcuate groove, on at least a portion of an outer surface of the cannula proximal of and adjacent to the distal portion. Tissue, such as a tendon, expands into the groove allowing a surgeon to manipulate the tissue with the cannula.

Owner:DEPUY SYNTHES PROD INC

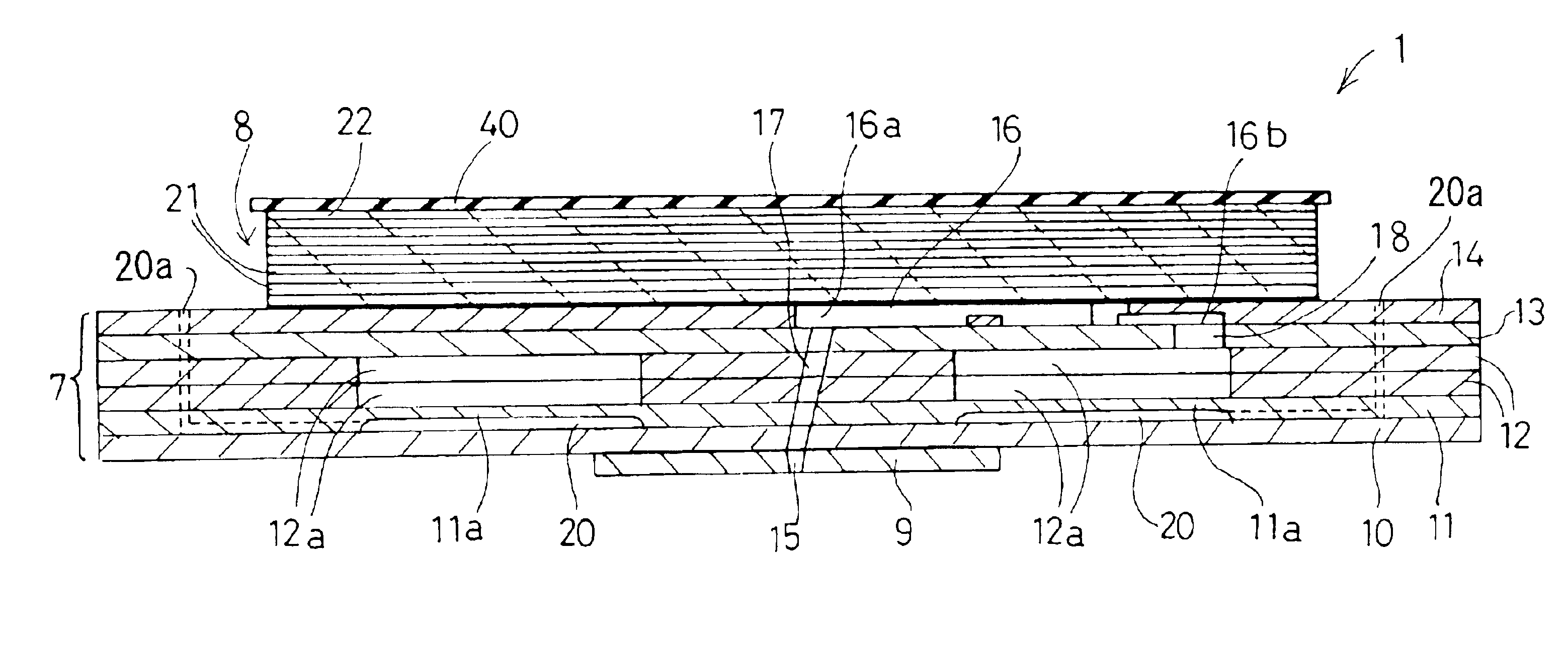

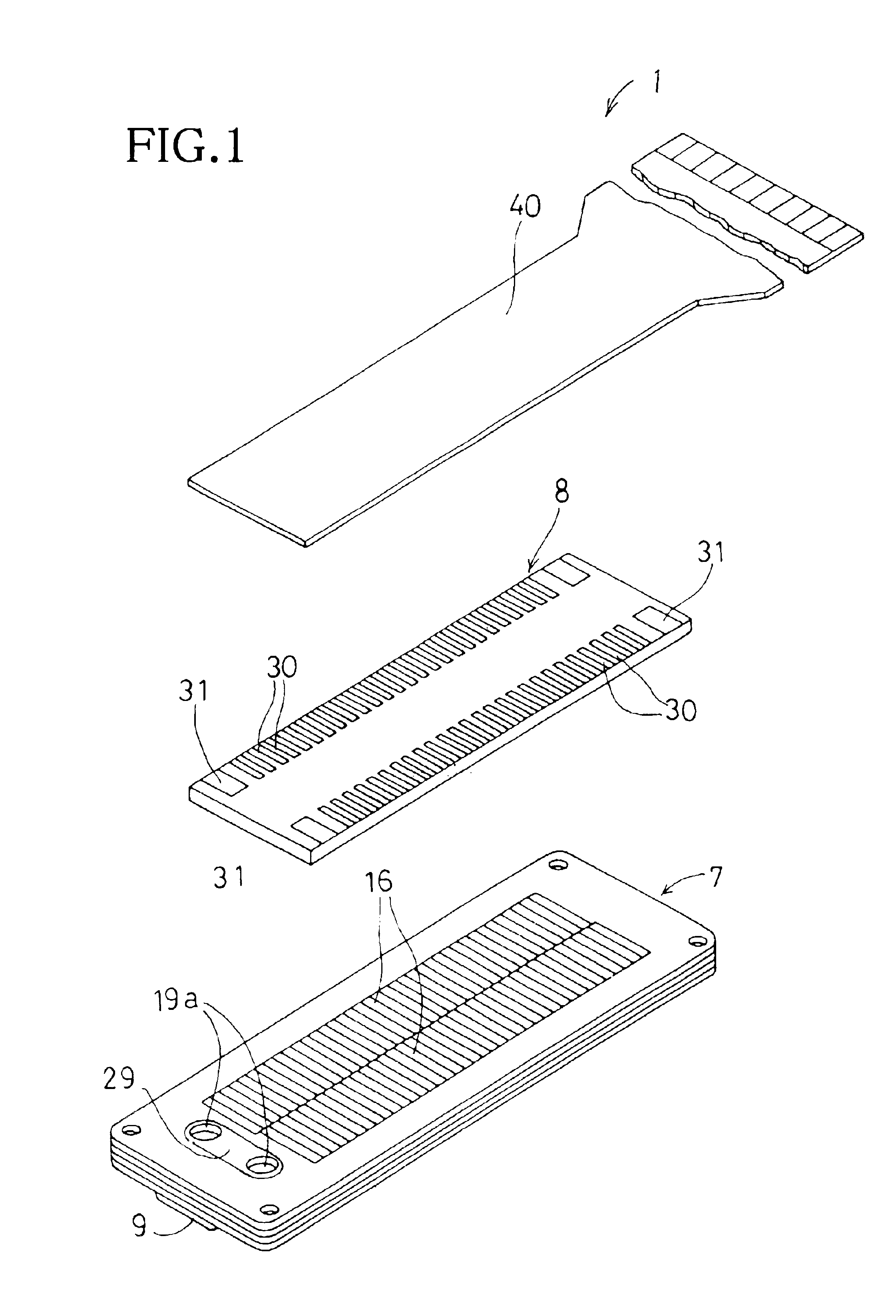

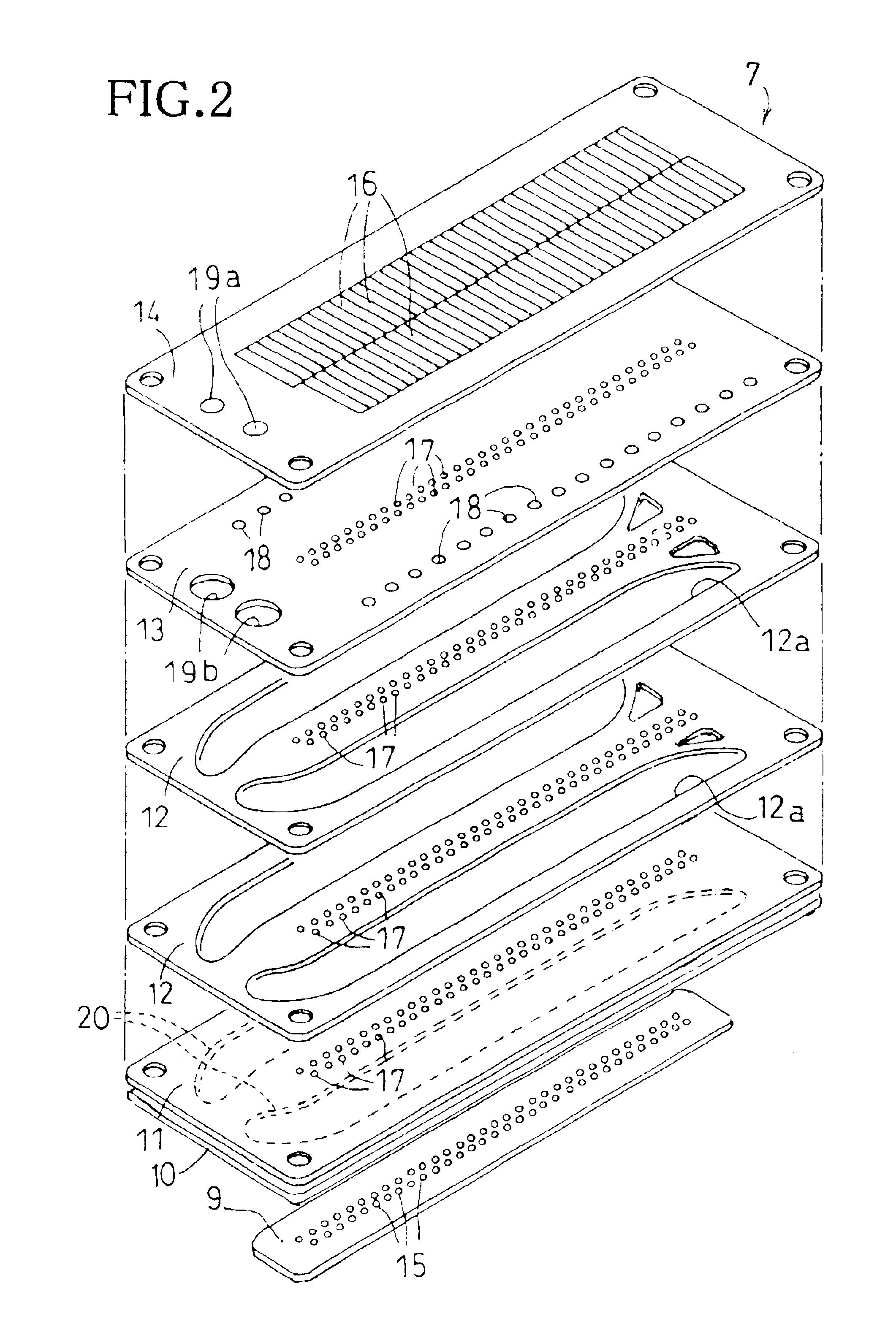

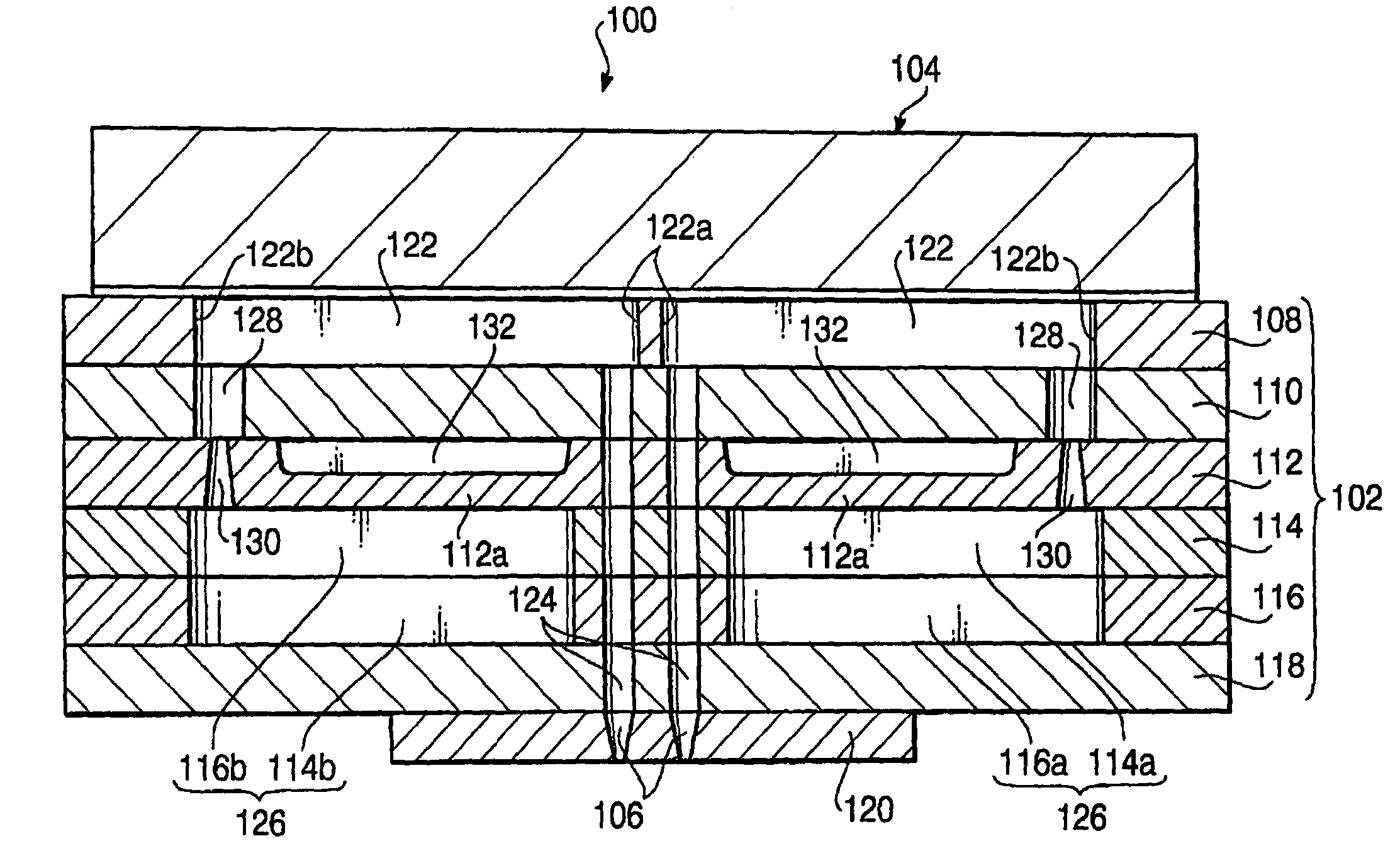

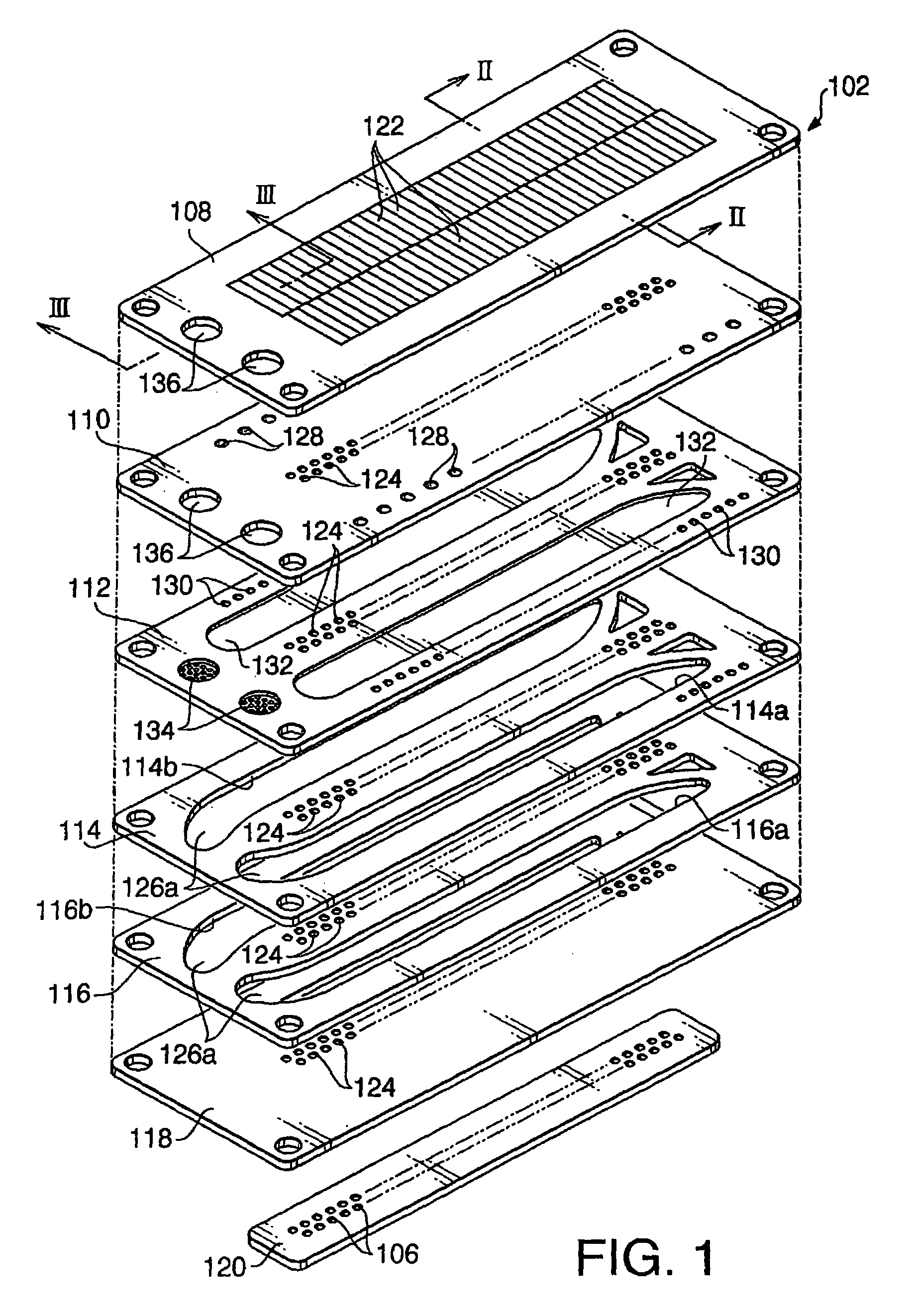

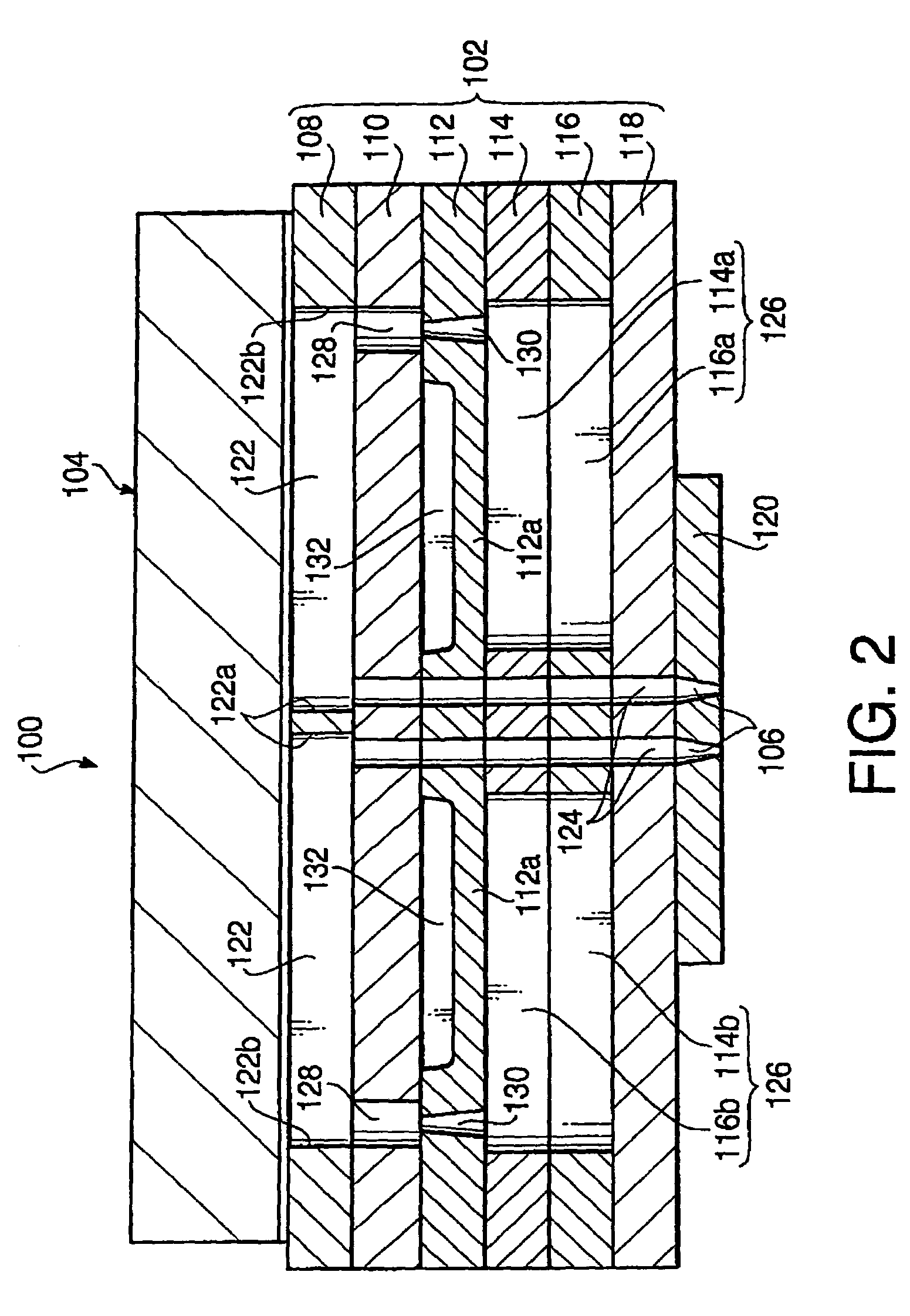

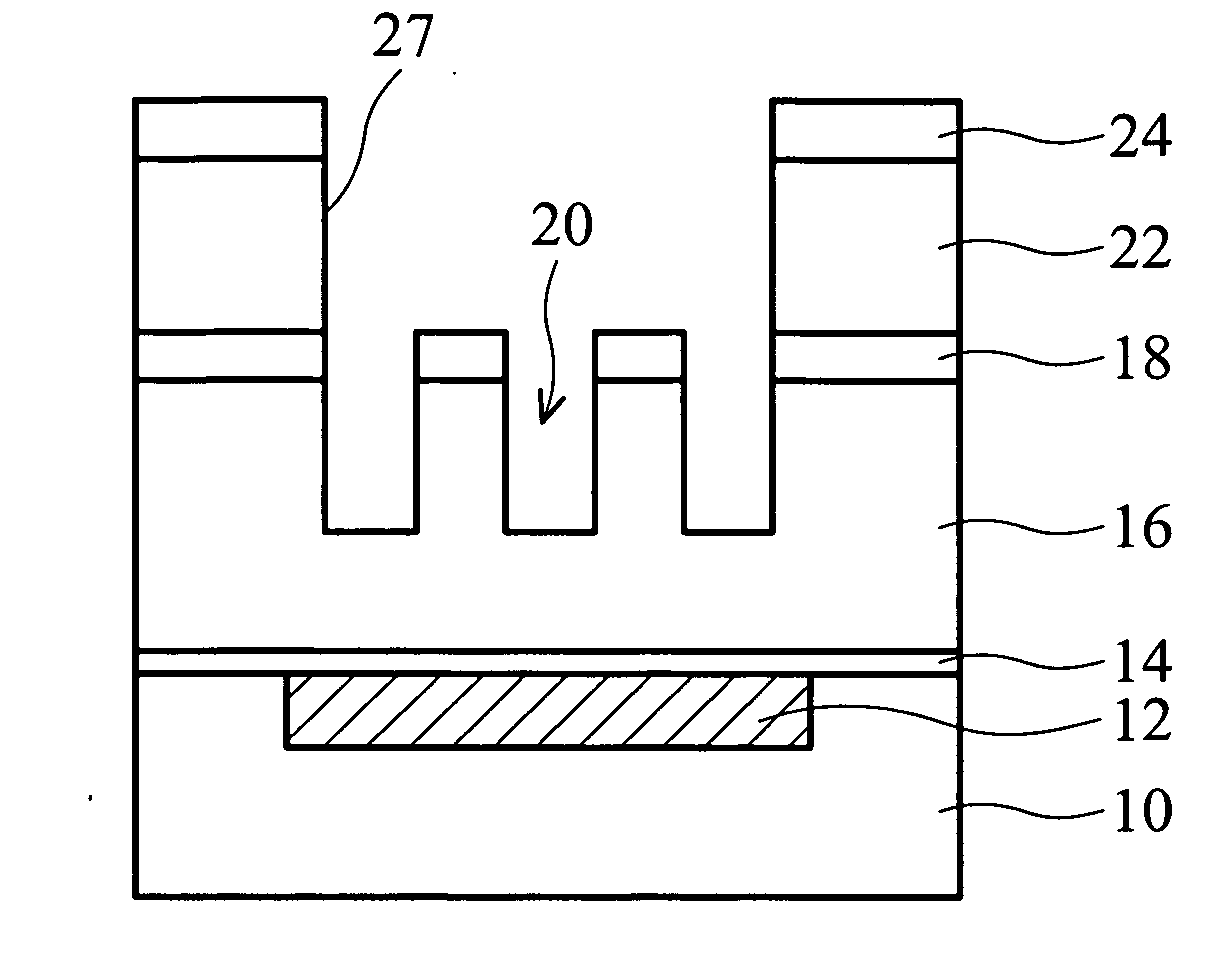

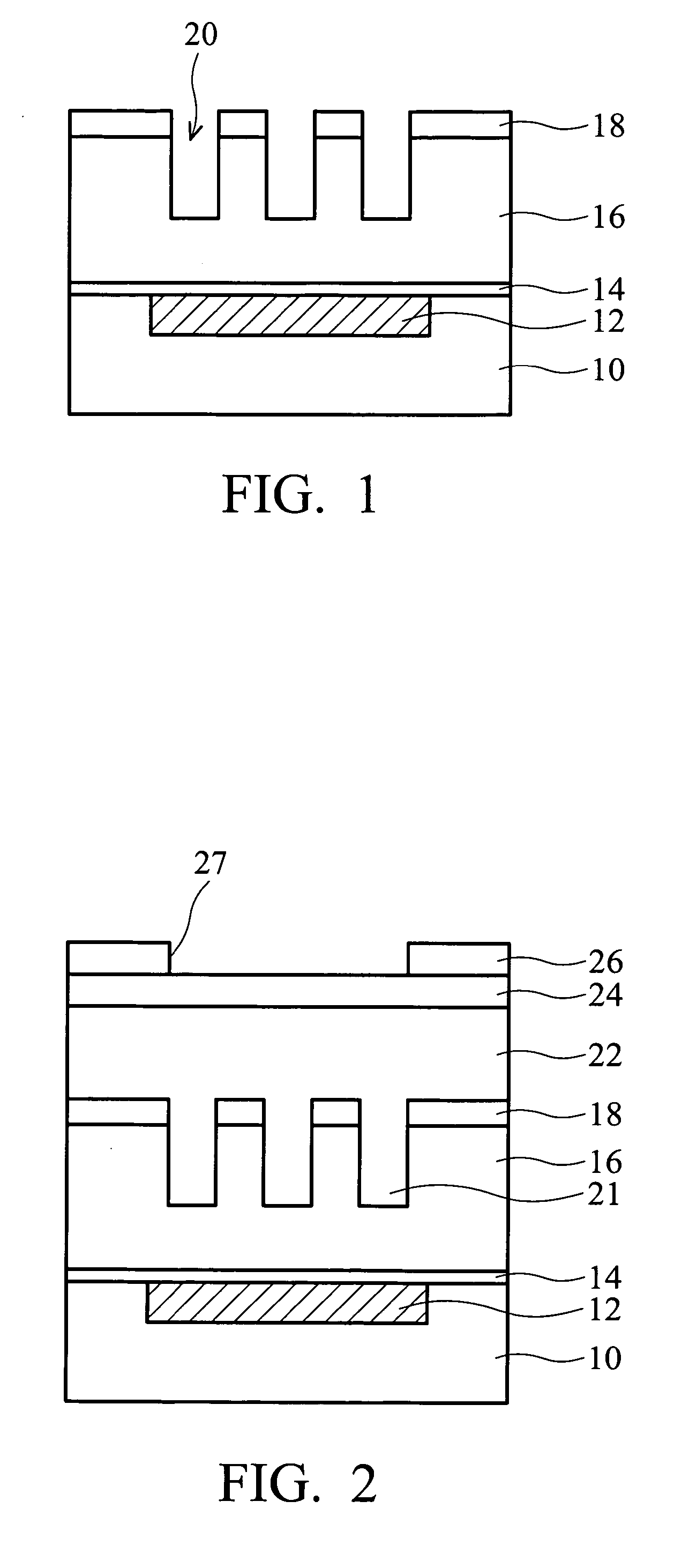

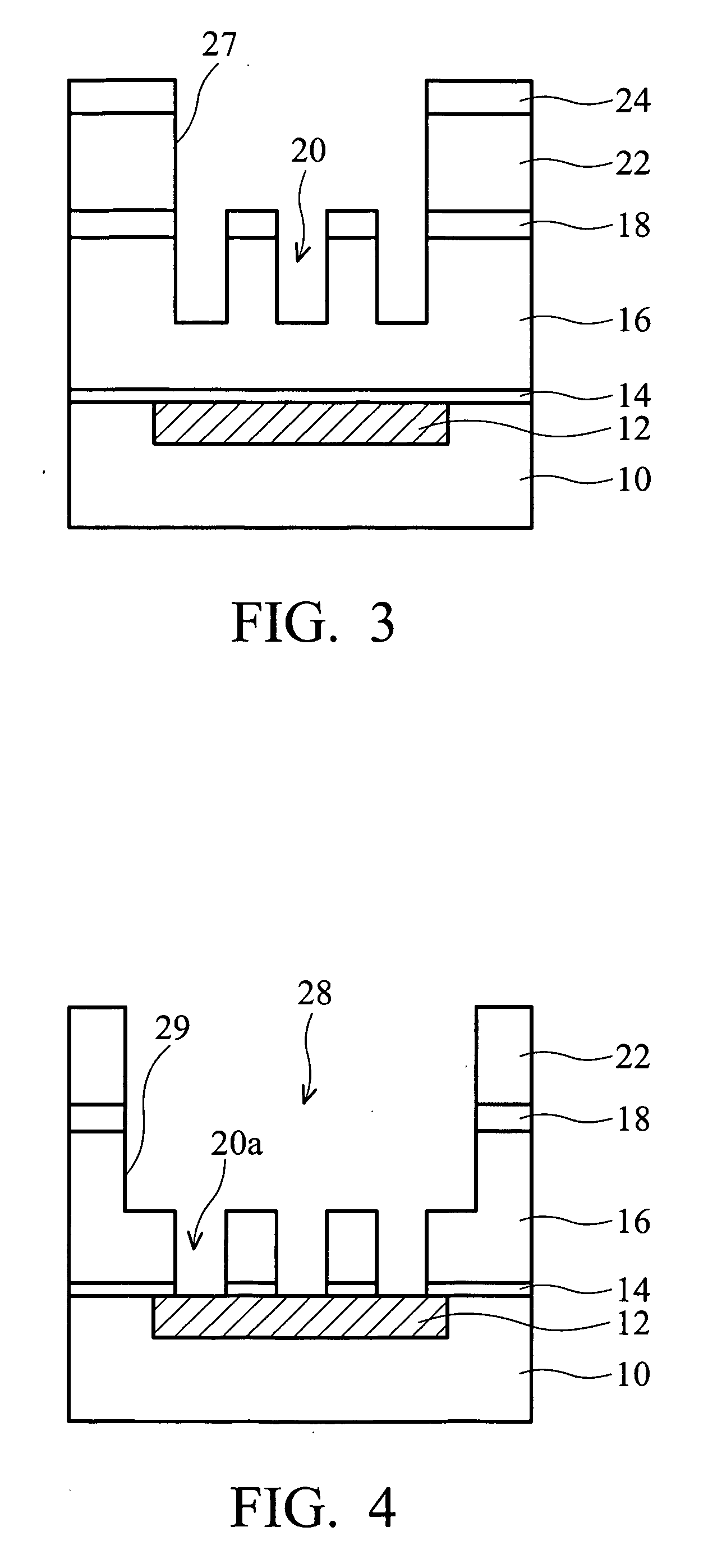

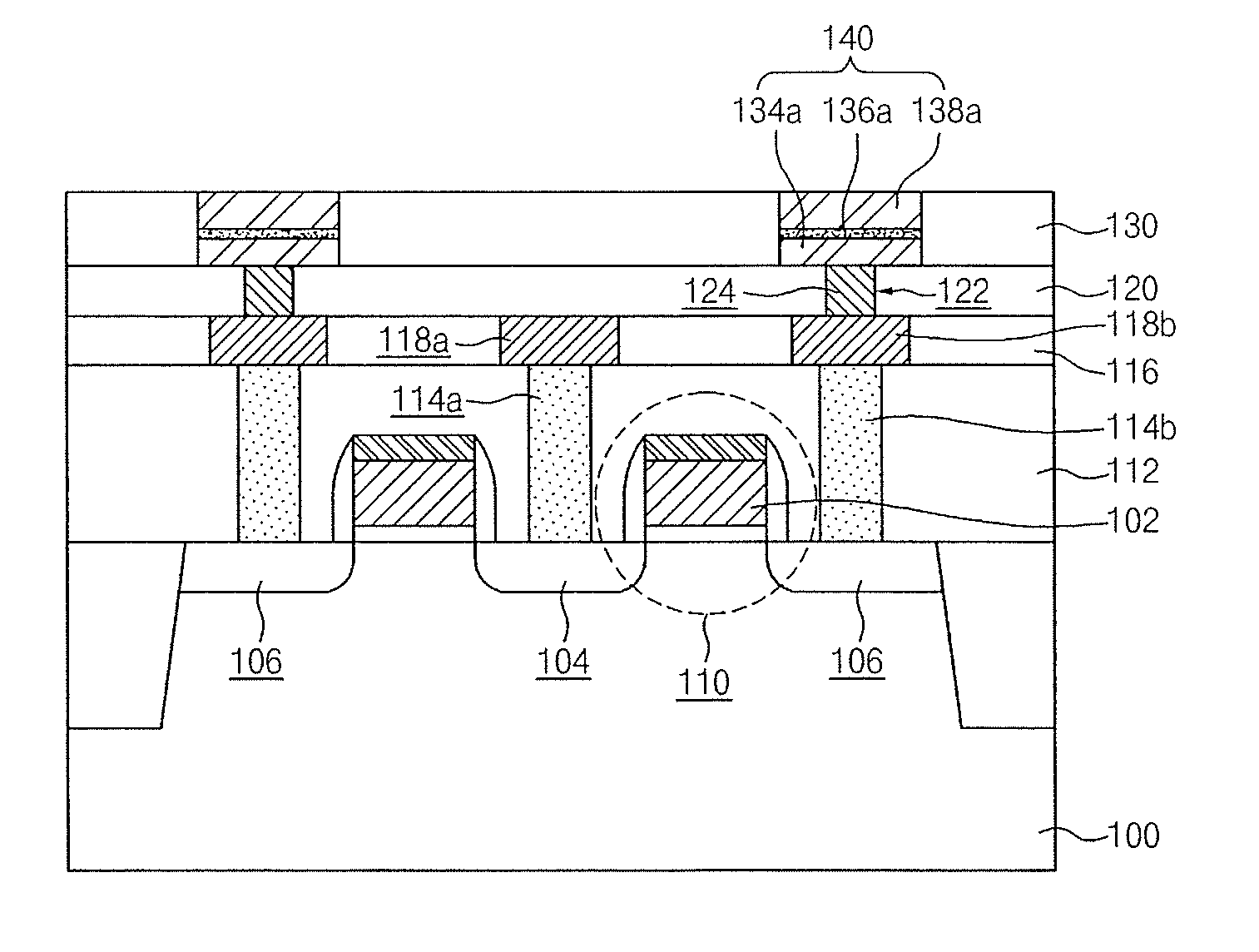

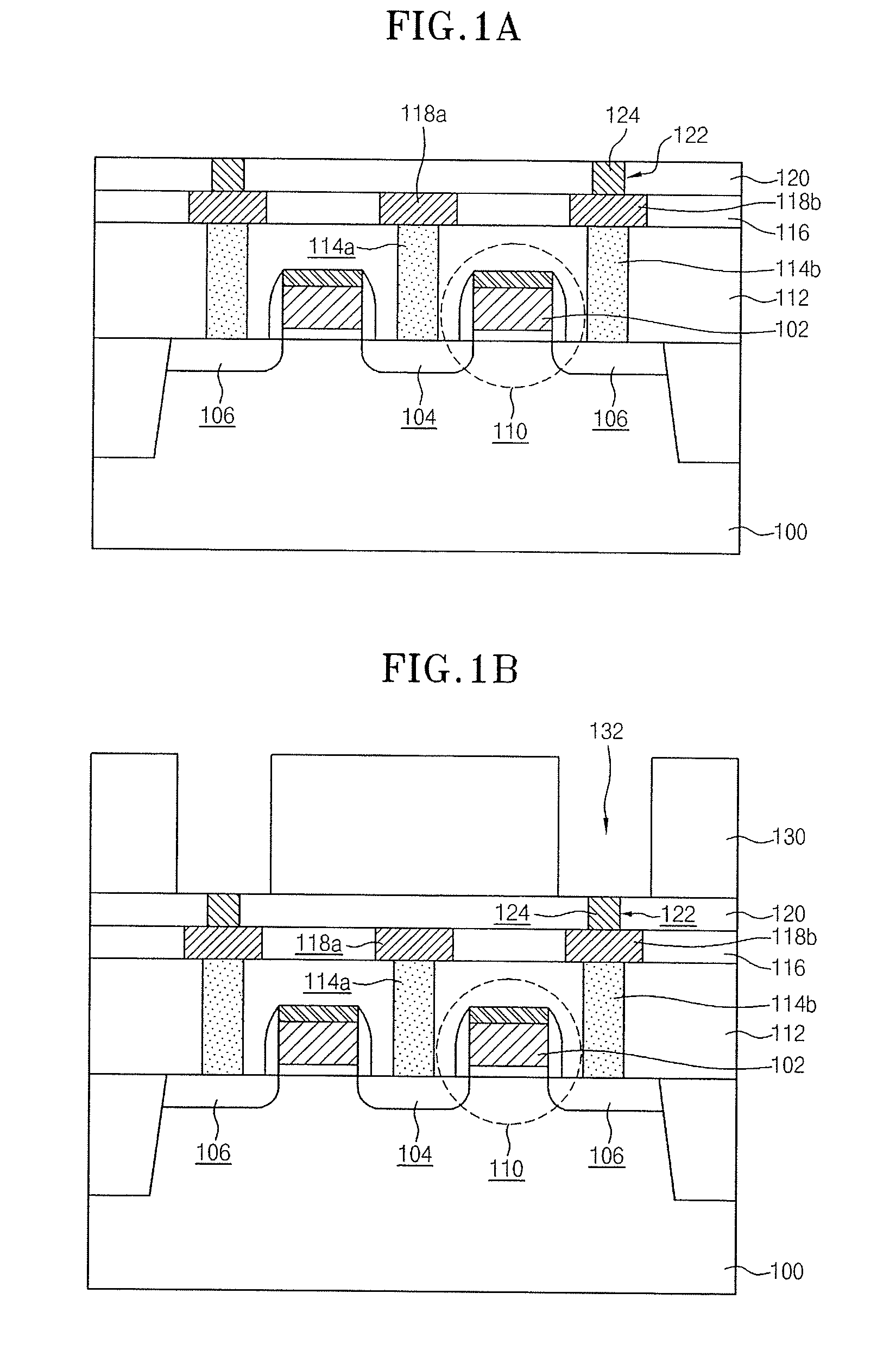

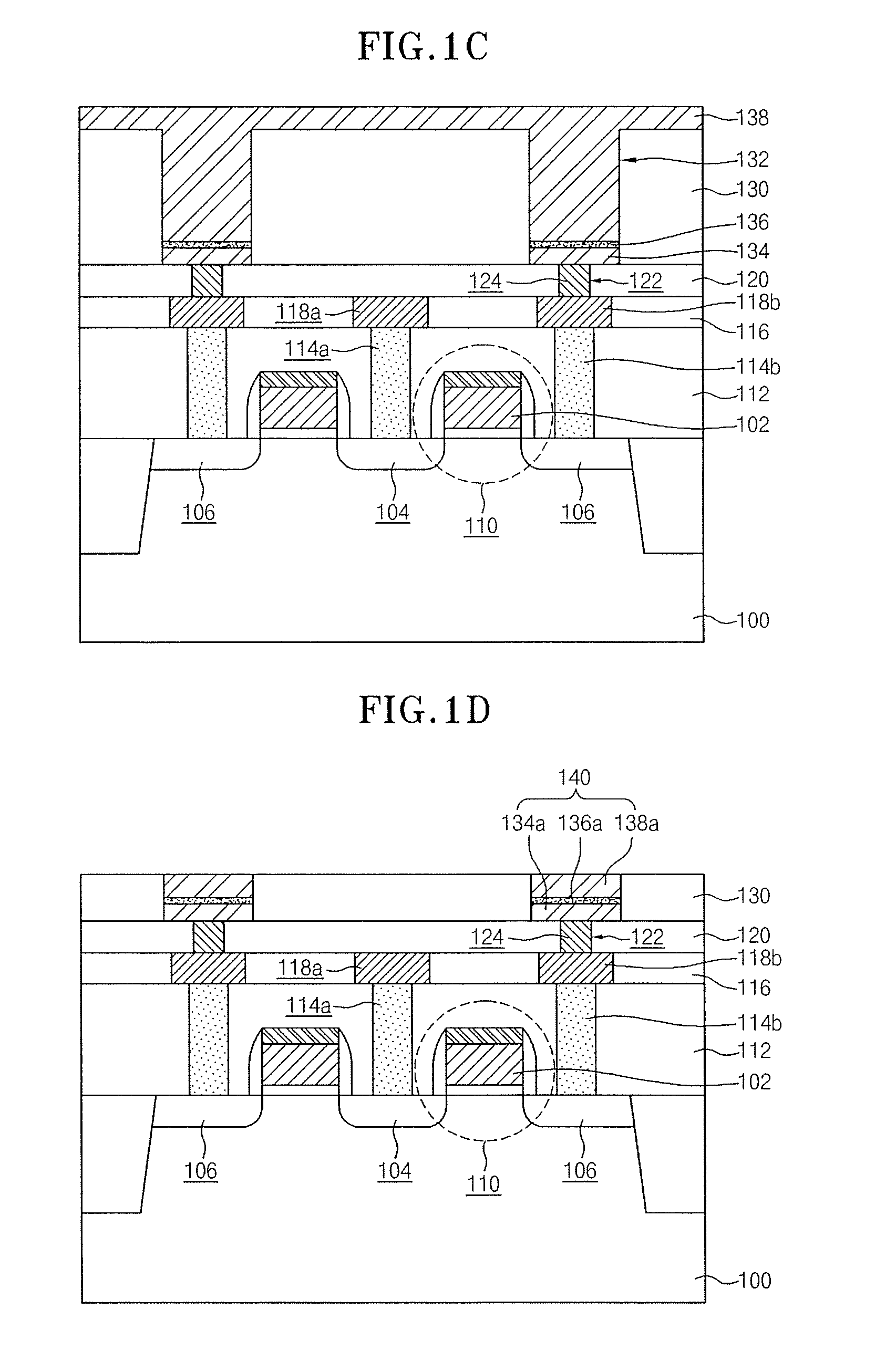

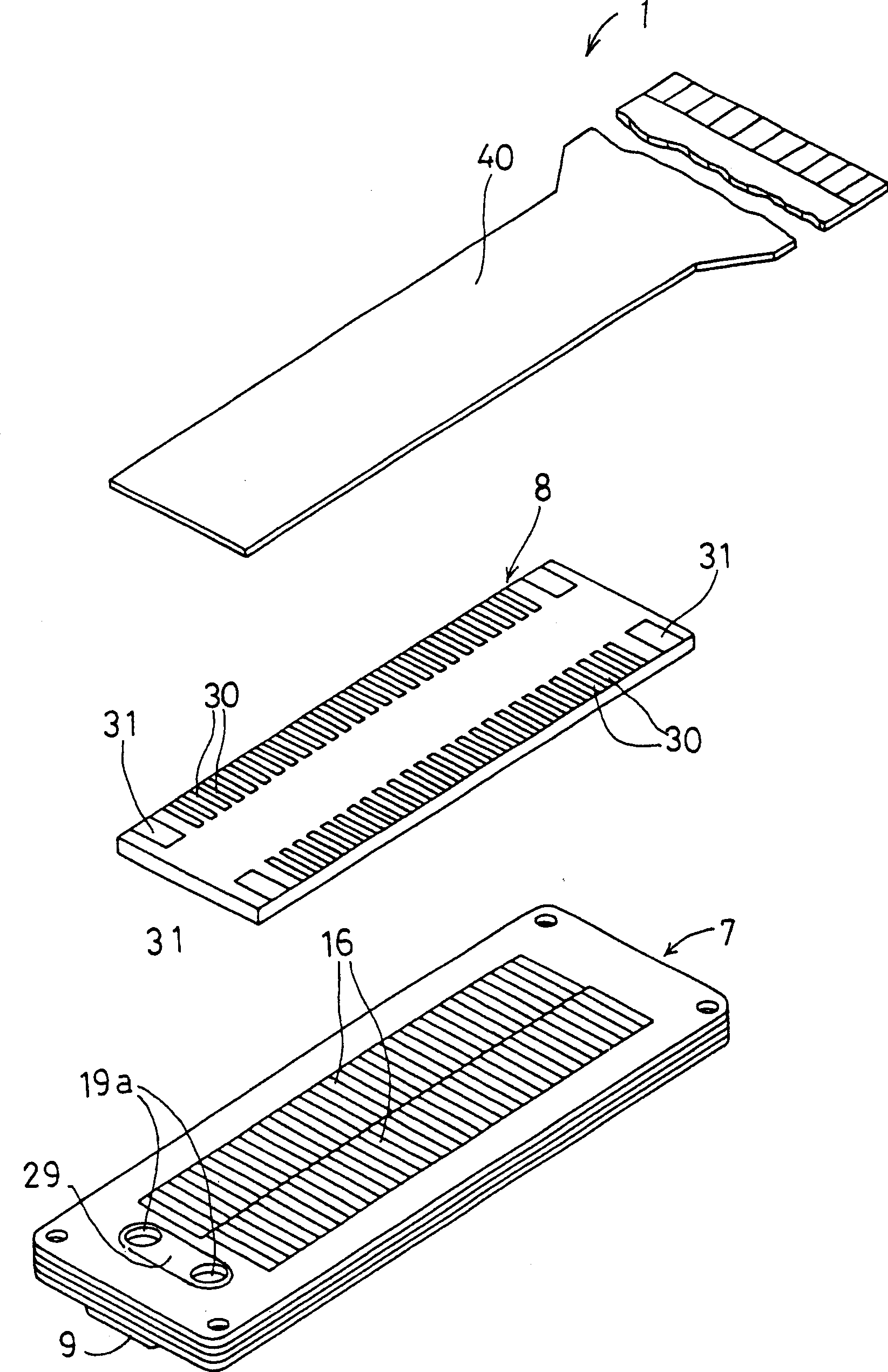

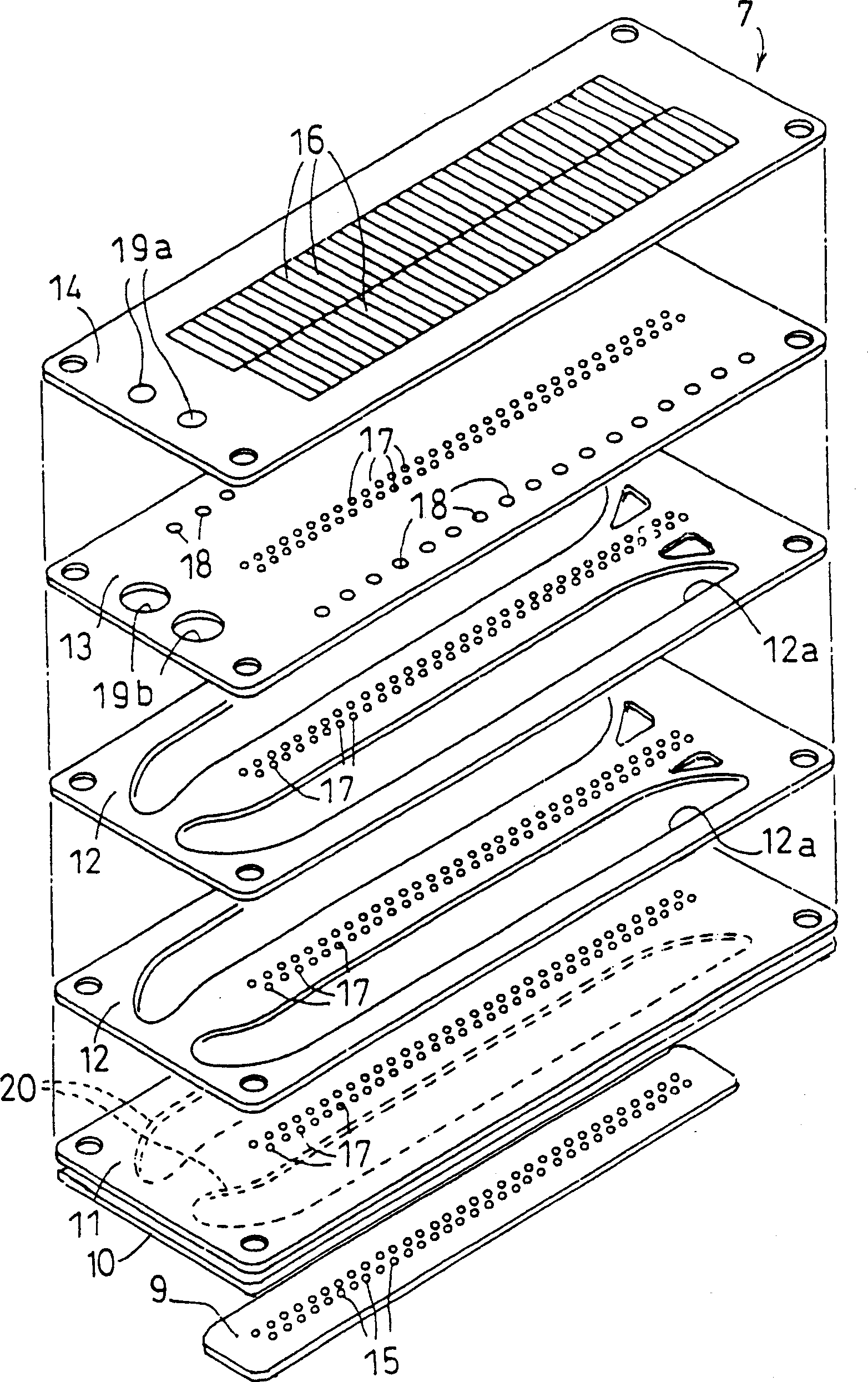

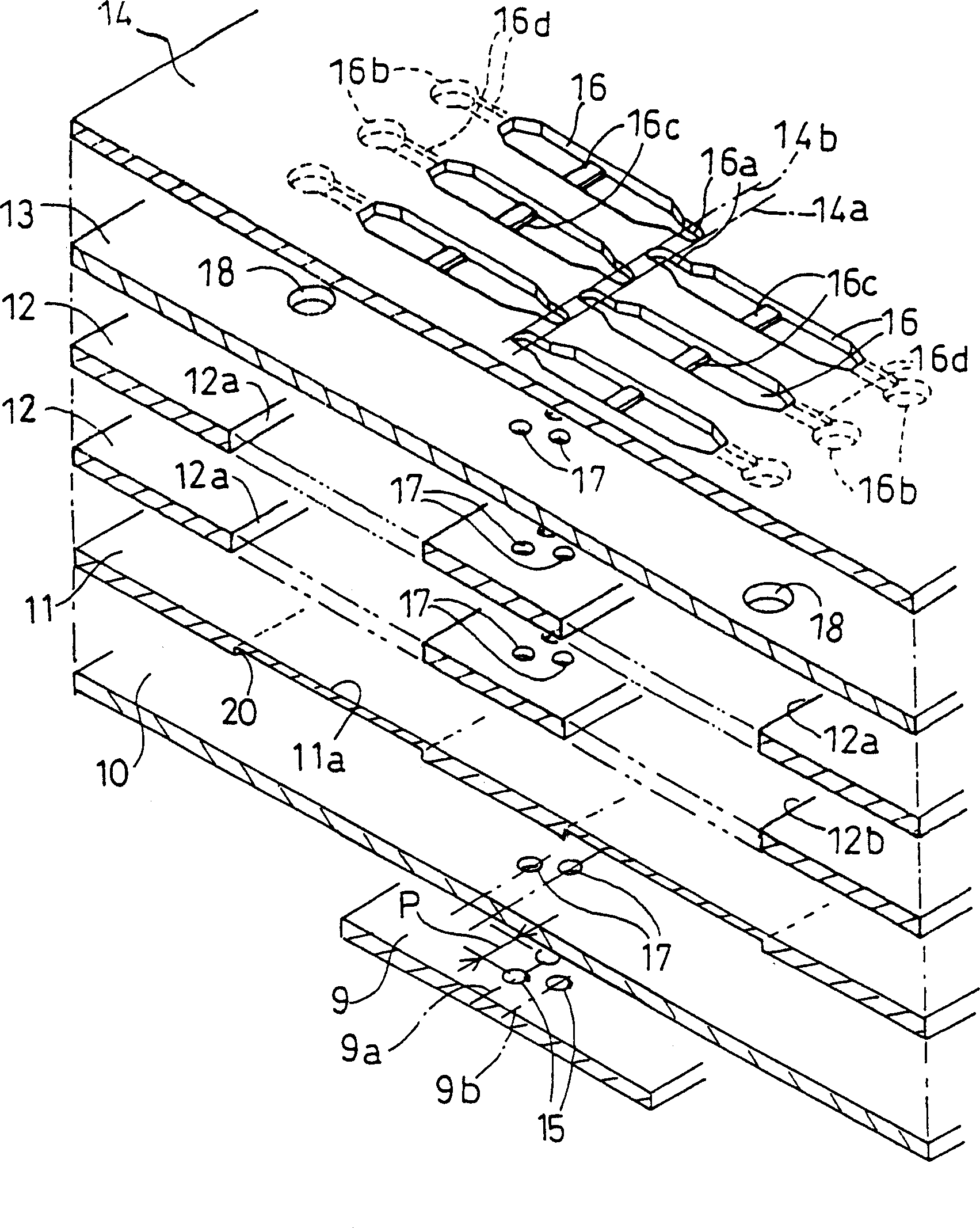

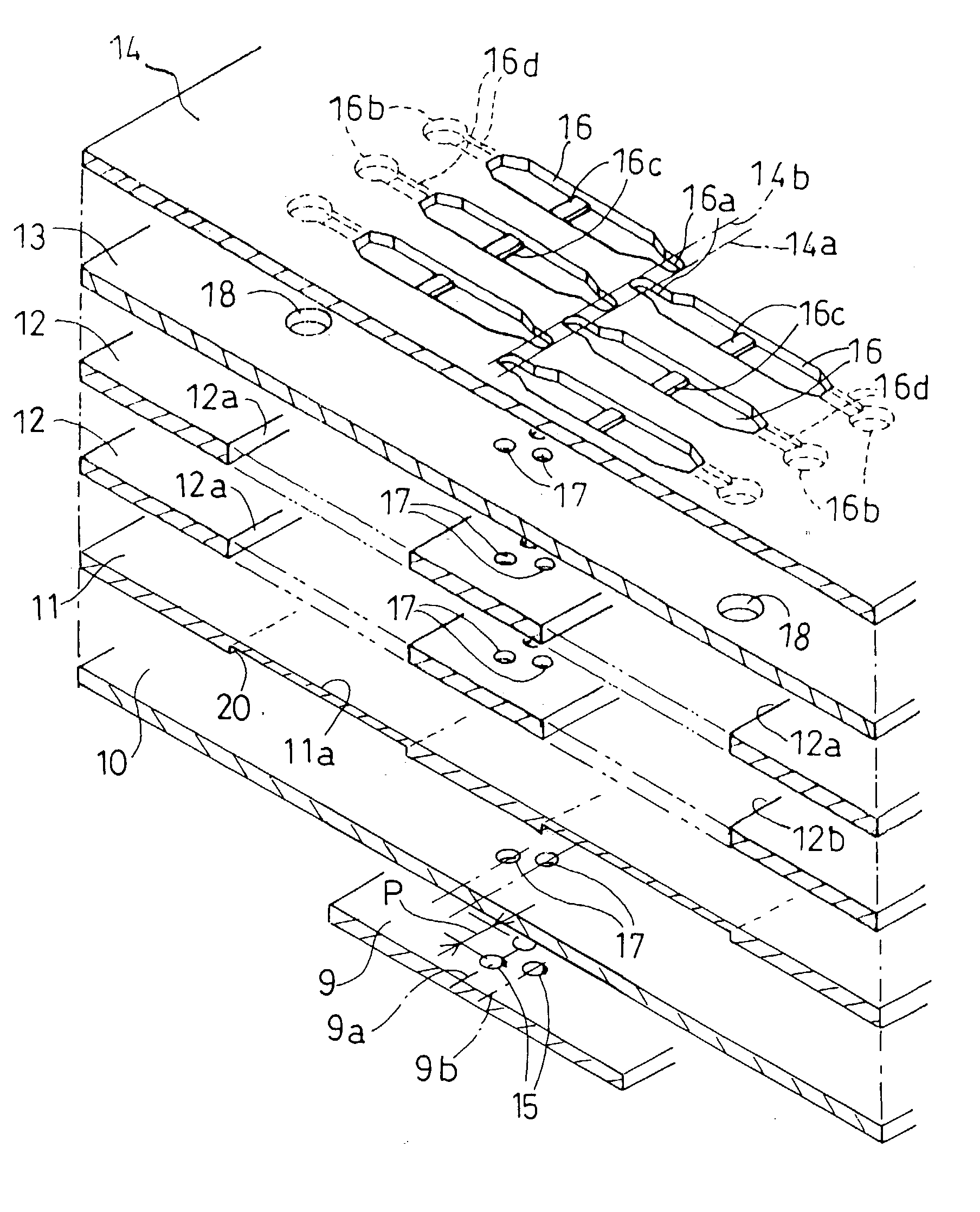

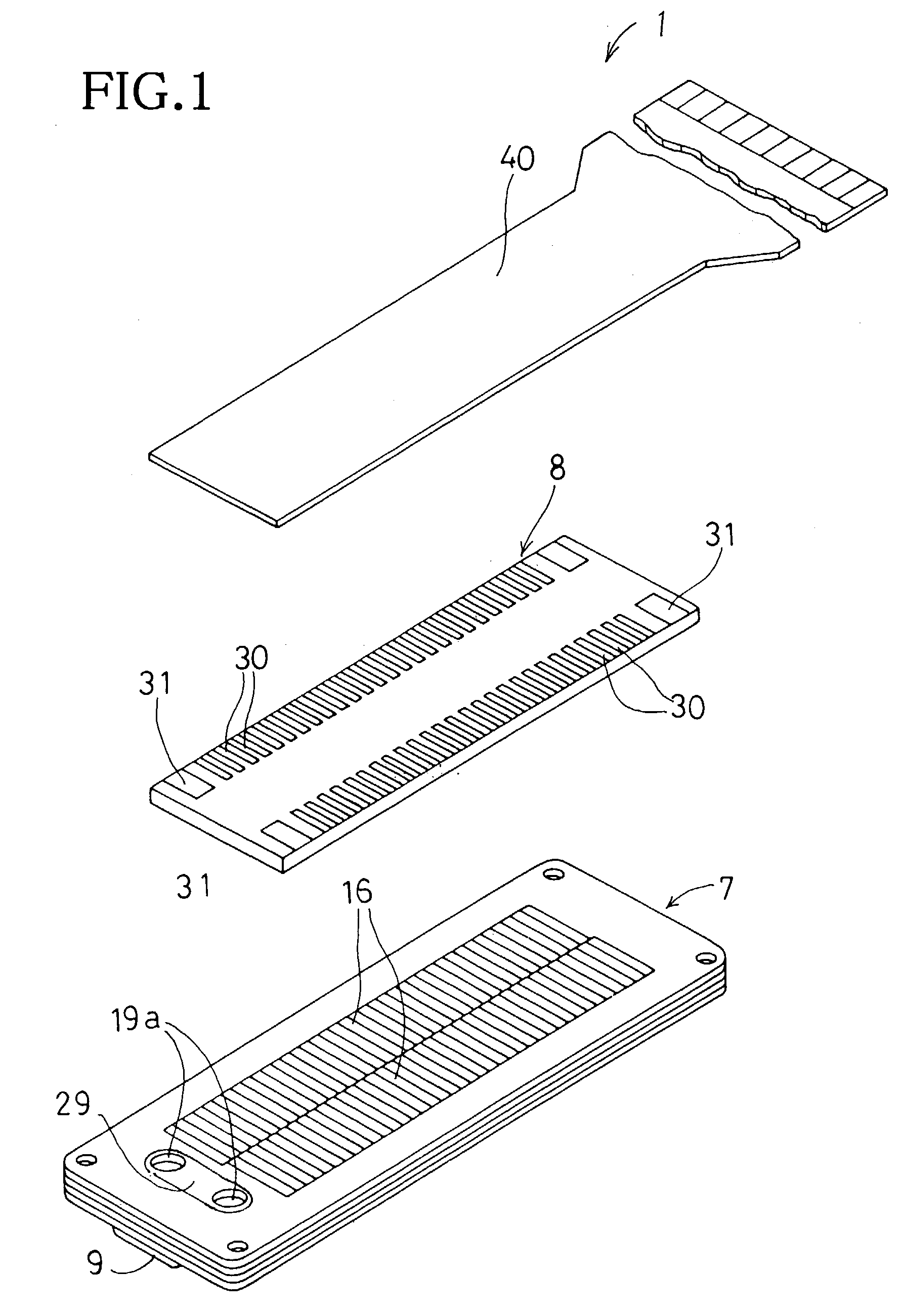

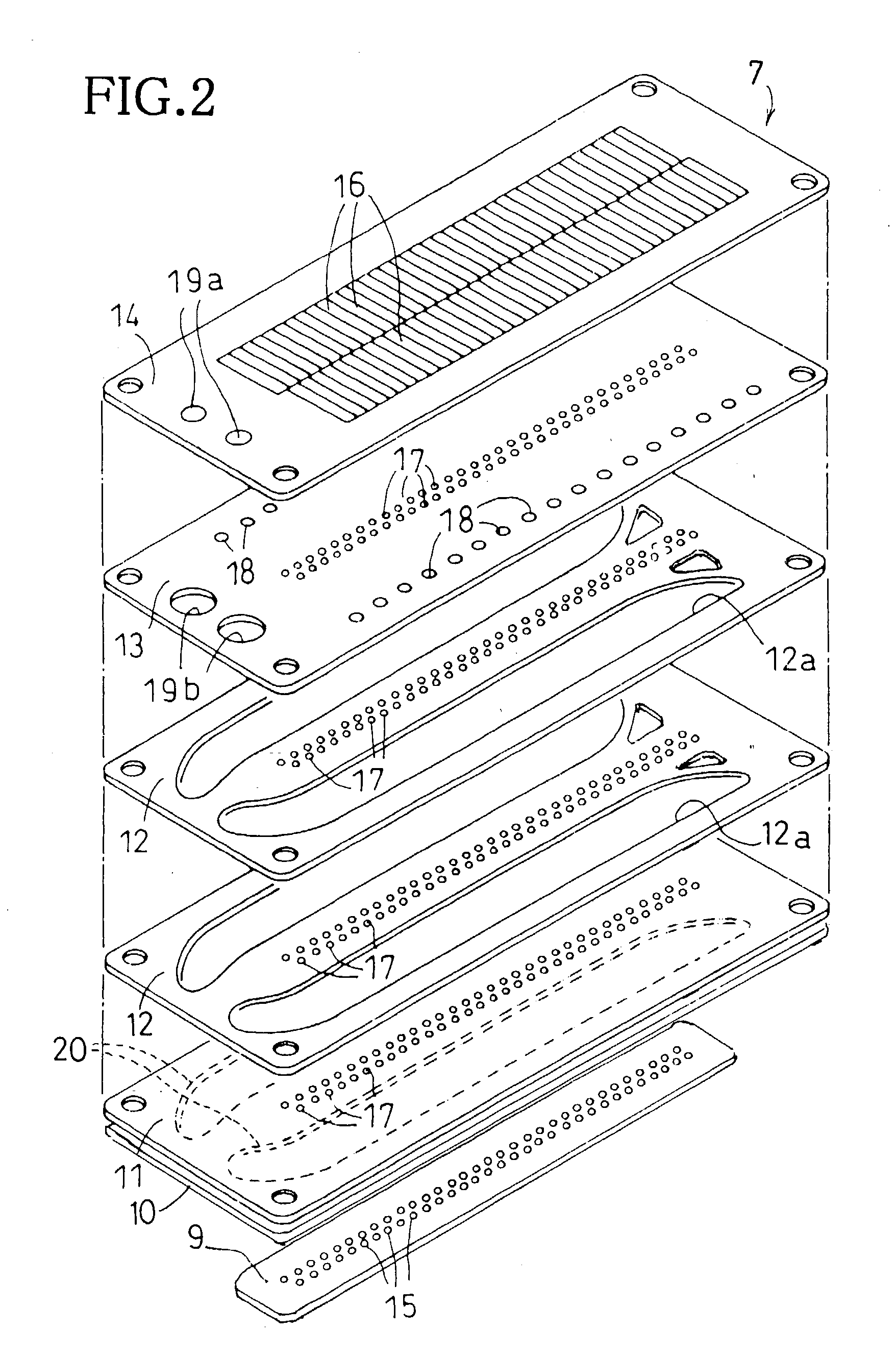

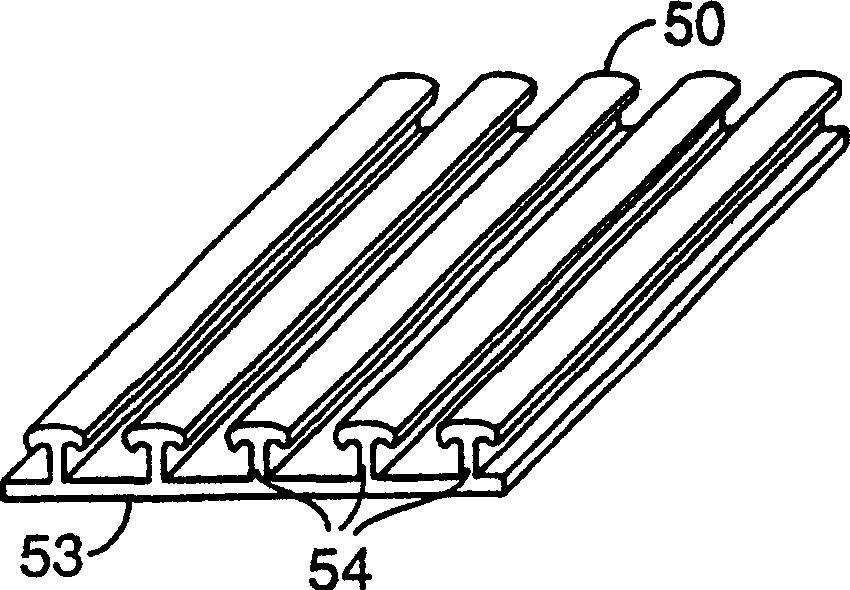

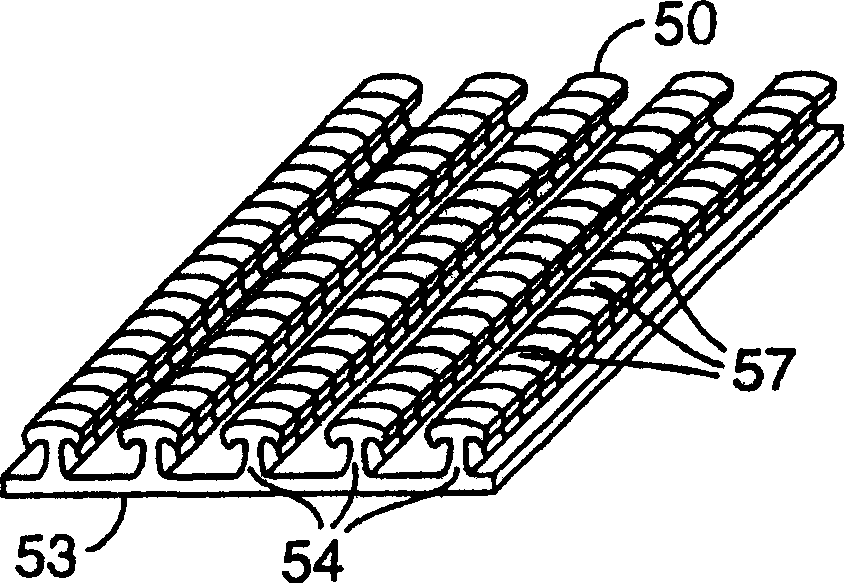

Ink-jet printhead

An ink-jet printhead includes a cavity unit and an actuator stacked together. The cavity unit is provided with a row of nozzle orifices and a row of pressure chambers communicating with the respective nozzle orifices. The actuator has a plurality of active portions for selectively actuating the respective pressure chambers to eject ink through the respective orifices. The cavity unit is a stack of plates including a cavity plate formed with the pressure chambers, a manifold plate formed with a manifold chamber and an intervenient plate interposed between the cavity plate and the manifold plate. The manifold chamber supplies ink from an external ink supply source to each of the pressure chambers. The intervenient plate is formed with a filter portion which filters ink provided from the external ink supplying source to the manifold chamber. The intervenient plate is formed with a damper wall facing the manifold chamber. The damper wall has a partial thickness of the intervenient plate.

Owner:BROTHER KOGYO KK

Dual cannula system and method for partial thickness rotator cuff repair

InactiveUS20110106013A1Minimize traumaMinimize removal and cutting and disturbanceSuture equipmentsCatheterSuture anchorsOuter Cannula

A method and system is provided for passing a suture anchor through a soft tissue and into a bone. The method includes the steps of locating a desired anchor receiving site on the bone; passing a locating wire through the soft tissue and into the bone at the anchor receiving site and passing over the locating wire an inner / outer cannula system which includes an inner cannula having a sharp distal tip, and an axial lumen therethrough sized to accommodate the positioning wire and an outer cannula having a distal end, and an axial lumen therethrough sized to accommodate the inner cannula and coaxially receiving the inner cannula, the distal end being tapered wherein to present a gradually increasing profile and wherein the distal tip of the inner cannula extends distally beyond the end of the distal end of the outer cannula. The sharp distal tip of the inner cannula passes through the soft tissue to create an opening therethrough and the tapered distal end of the outer cannula passes through the opening to expand the opening and minimize removal, cutting and disturbance of the tissue as it passes therethrough. The suture anchor passes through the outer cannula and is driven into the bone at the anchor site.

Owner:DEPUY MITEK INC

Method of depositing films on aluminum alloys and films made by the method

InactiveUS20060254922A1Enhanced nucleationSurface reaction electrolytic coatingLiquid/solution decomposition chemical coatingParticulatesMetallic materials

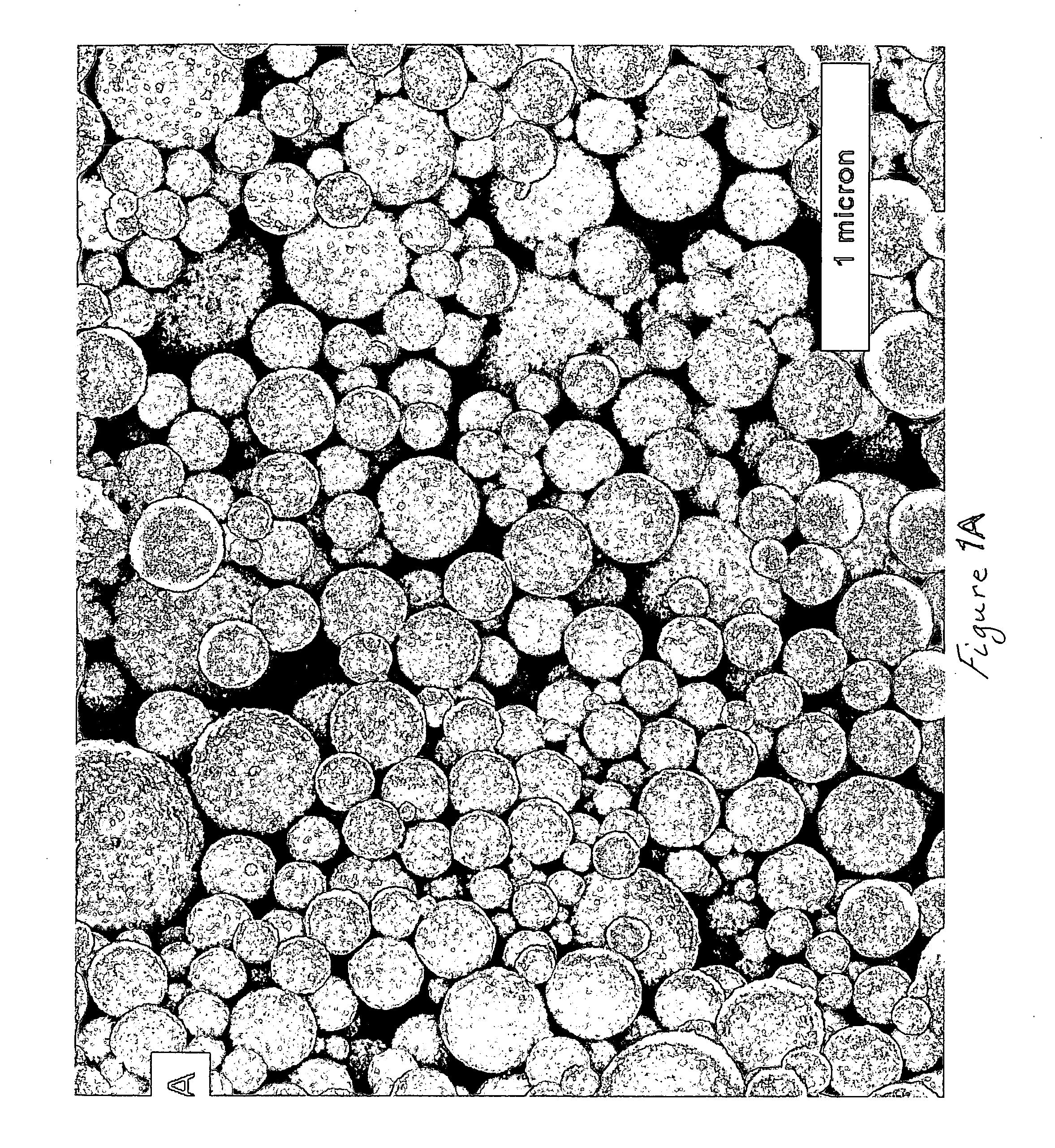

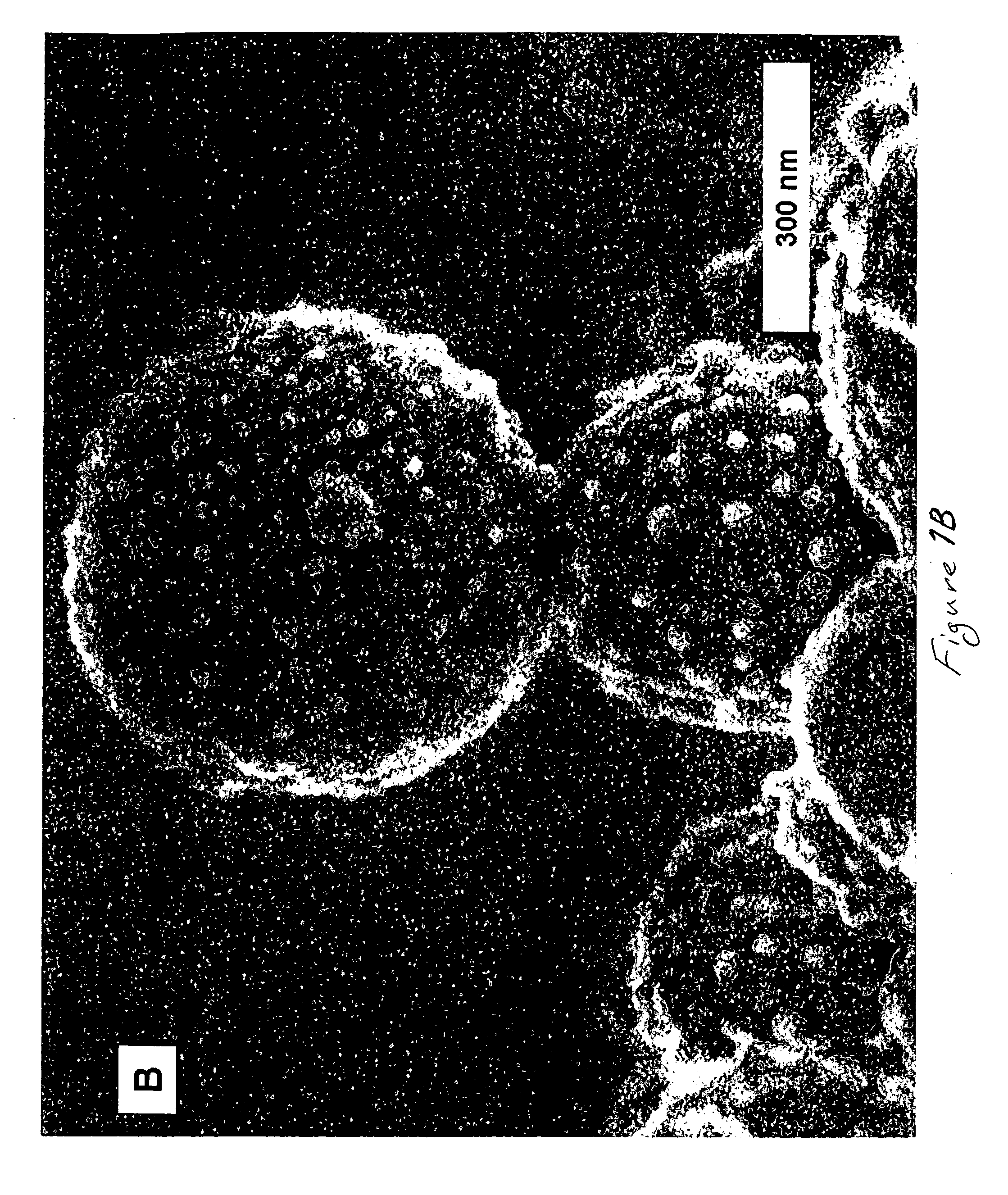

Method for depositing a metallic material on an aluminum alloy surface for galvanic displacement type deposition, electrodeposition or electroless deposition of a metallic film on the surface wherein the alloy surface is oxidized (e.g. anodized) to form aluminum oxide and the oxidized surface is etched to leave a partial thickness of a barier aluminum oxide on the alloy surface. The partial thickness of the barrier oxide is controlled by etching to form a porous, metallic particulate film for a thin barrier oxide, or a continuous metallic film for thicker barrier oxide. The metallic film then is electrodeposited or electroless deposited on the barrier film.

Owner:STC UNM

Methods and systems for forming implants with selectively exposed mesh for fixation and related implants

Owner:MIMEDX GROUP

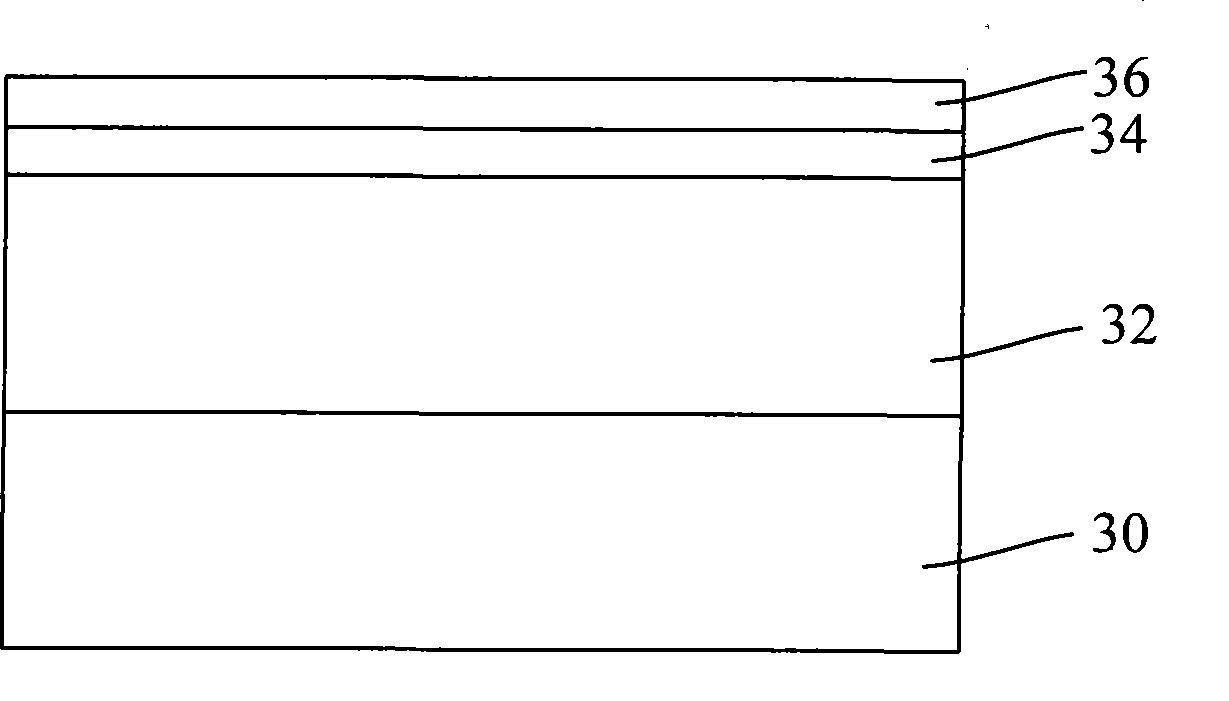

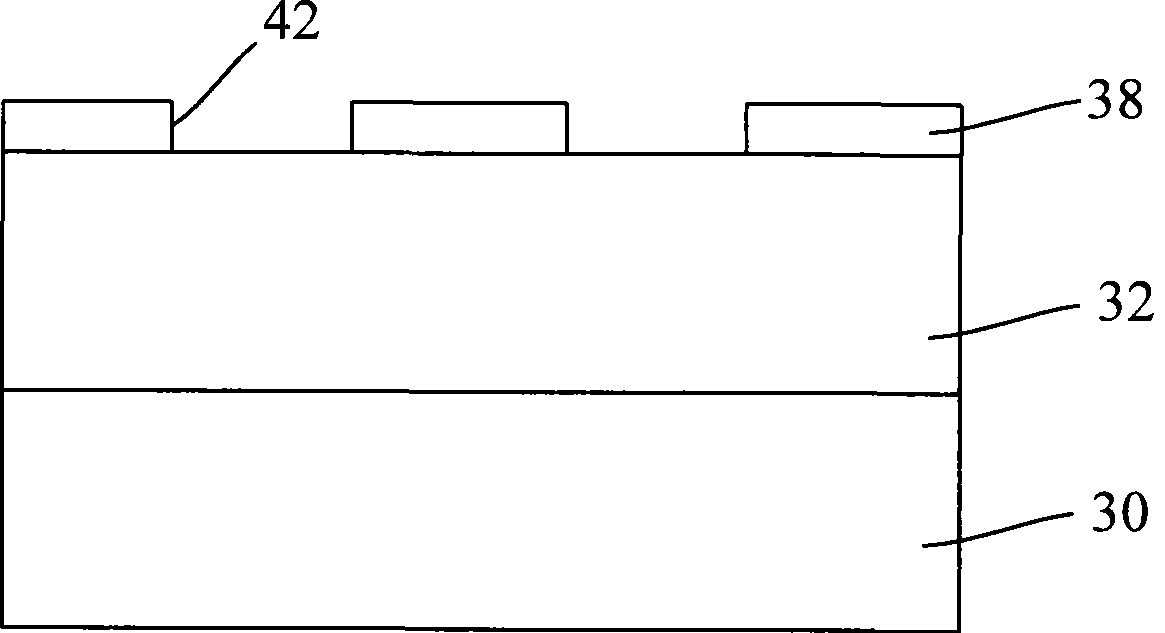

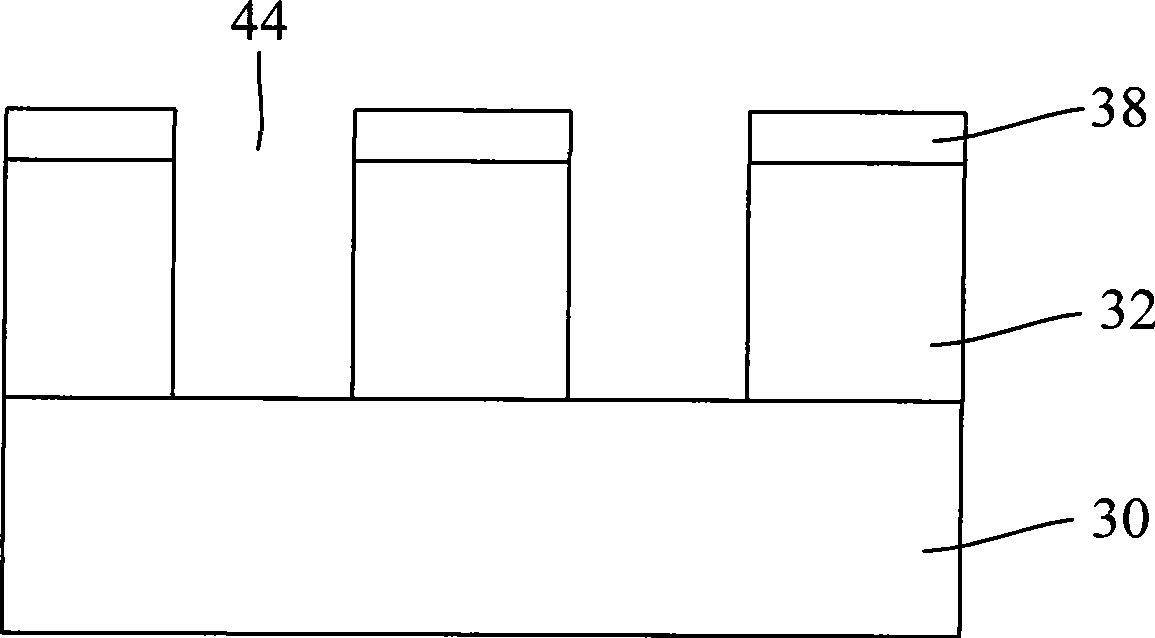

Partial-via-first dual-damascene process with tri-layer resist approach

InactiveUS20070134917A1Improved critical dimension controlAvoid ashing damageSemiconductor/solid-state device manufacturingResistEngineering

A partial-via-first dual-damascene method using a tri-layer resist method forms a first via hole through partial thickness of a dielectric layer, and forms a tri-layer resist structure on the dielectric layer to fill the first via hole with the bottom photoresist layer. A dry development process is performed to transfer a first opening on the top photoresist layer to the middle layer and the bottom photoresist layer, and expose the first via hole again, and remove the top photoresist layer. A dry etching process is then performed to form a second via hole under the first via hole and a trench over the second via hole. Finally a wet striping process is used to remove the remainder of the photoresist layer.

Owner:TAIWAN SEMICON MFG CO LTD

Method for manufacturing resistance RAM device

ActiveUS7833898B2Secure switching characteristicSmall sizeSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerEngineering

Manufacturing a resistance RAM device includes the steps of forming an insulation layer on a semiconductor substrate having a bottom electrode contact; etching the insulation layer to define a hole exposing the bottom electrode contact; depositing sequentially a bottom electrode material layer and a TMO material layer selectively within the hole; depositing a top electrode material layer within the hole and on the insulation layer in such a way as to completely fill the hole in which the bottom electrode material layer and the TMO material layer are formed; removing partial thicknesses of the top electrode material layer and the insulation layer to form a stack pattern comprising a bottom electrode, a TMO, and a top electrode.

Owner:SK HYNIX INC

Tendon repair implant and method of implantation

A tendon repair implant for treatment of a complete or partial thickness tear in the supraspinatus tendon of the shoulder is provided. The implant may incorporate features of rapid deployment and fixation by arthroscopic means that compliment current procedures; tensile properties that result in desired sharing of anatomical load between the implant and native tendon during rehabilitation; selected porosity and longitudinal pathways for tissue in-growth; sufficient cyclic straining of the implant in the longitudinal direction to promote remodeling of new tissue to tendon-like tissue; and, may include a bioresorbable construction to provide transfer of additional load to new tendon-like tissue and native tendon over time.

Owner:ROTATION MEDICAL

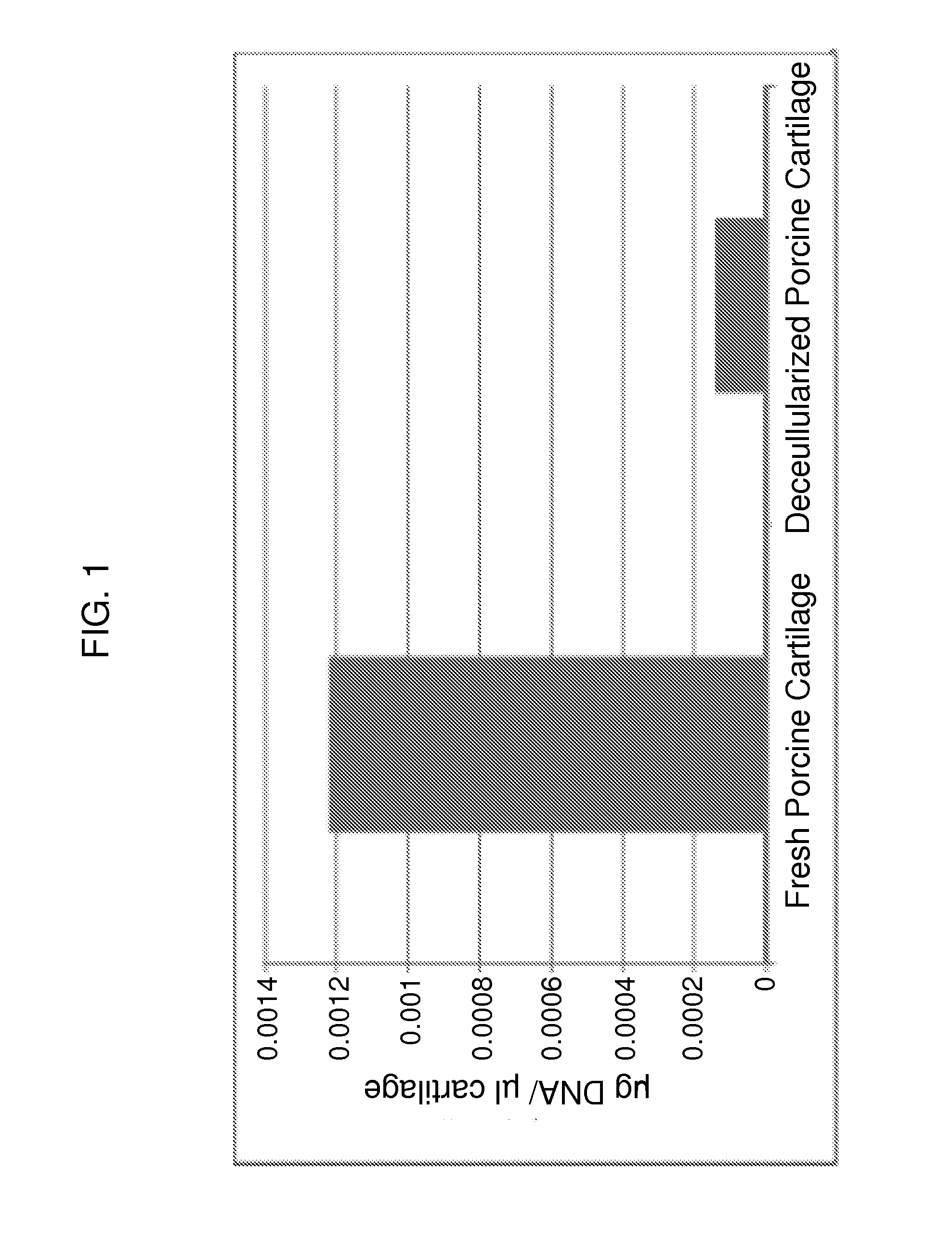

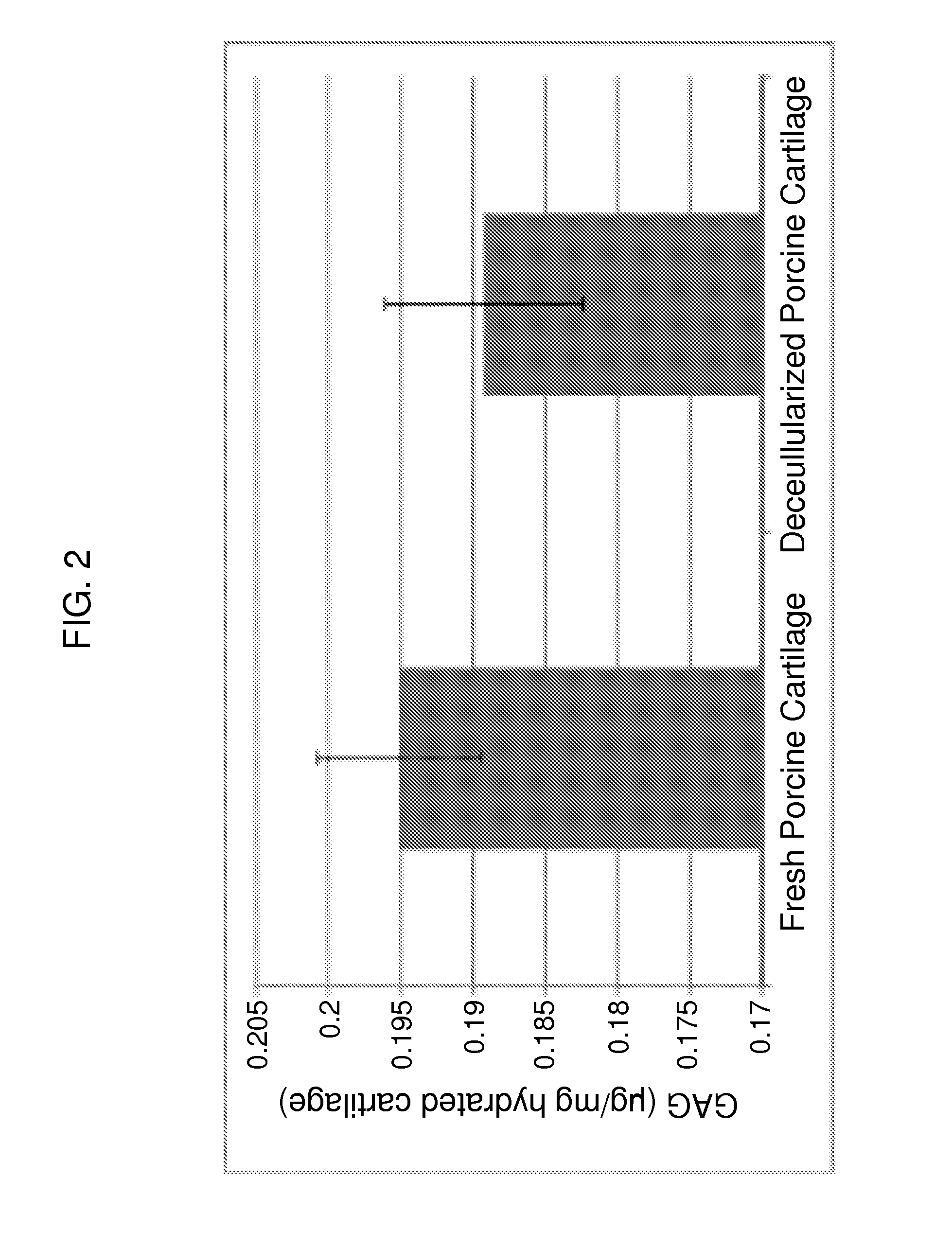

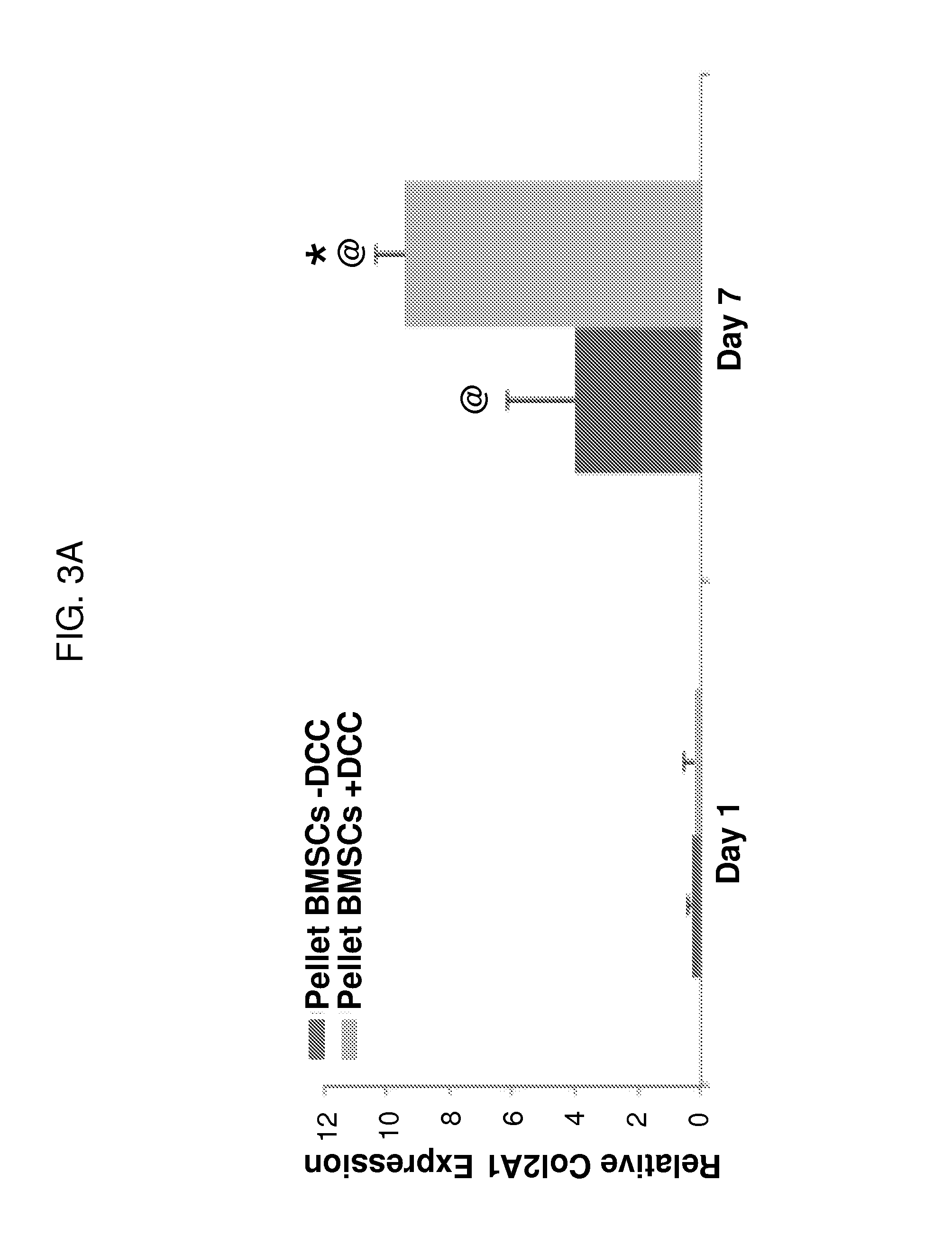

Decellularized hyaline cartilage powder for tissue scaffolds

ActiveUS20160235892A1Easy to disassembleImprove abilitiesUnknown materialsTissue regenerationMedicinePartial thickness

The present invention is related to compositions comprising decellularized cartilage tissue powder in the forms of paste, putty, hydrogel, and scaffolds, methods of making compositions, and methods of using these compositions for treating osteochondral defects and full- or partial-thickness cartilage defects.

Owner:UNIVERSITY OF KANSAS +1

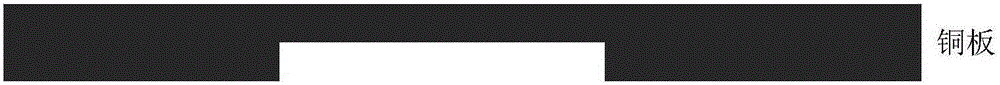

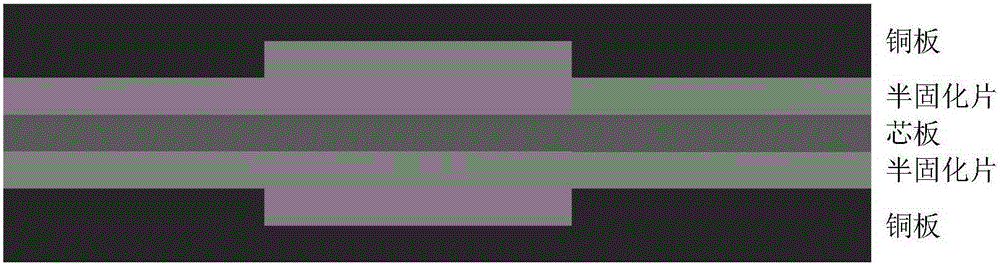

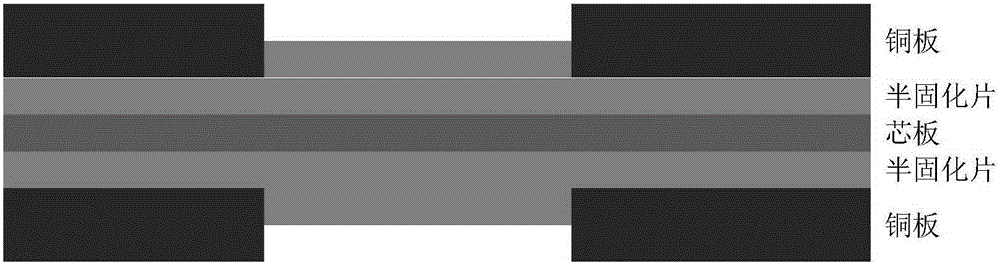

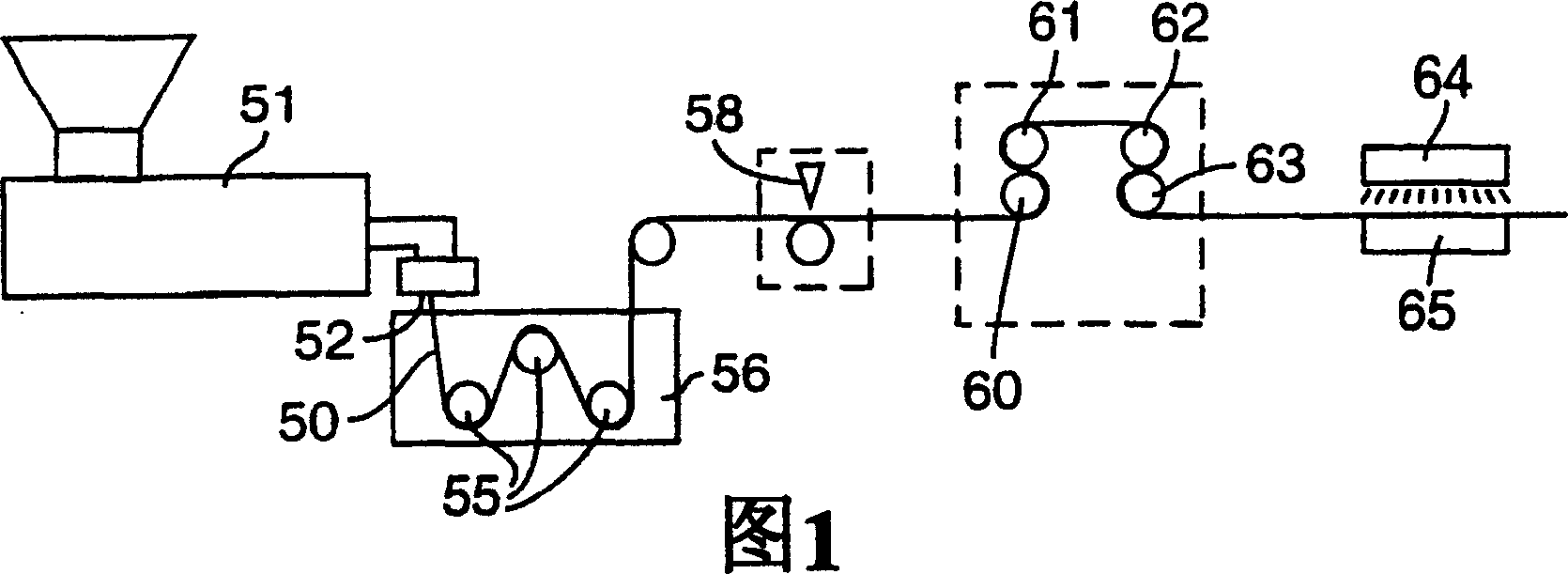

Ultra-thick copper circuit board and manufacturing method thereof

ActiveCN105188269AGuaranteed stabilityAvoid over erosionPrinted circuit aspectsConductive material chemical/electrolytical removalPrinting inkCopper

The invention relates to an ultra-thick copper circuit board and a manufacturing method thereof. The manufacturing method comprises the following steps: (1) etching partial thickness of a non-circuit-pattern area copper plate on one side of the copper plate by adopting an etching process to form a groove, and carrying out the lamination step on the side by virtue of a binding layer; (2) drilling, metalizing the hole, etching the rest thickness of the non-circuit-pattern area copper plate on the other side of the copper plate by adopting the etching process to obtain a circuit pattern; (3) carrying out the printing resistance soldering steps: printing resin onto the non-circuit-pattern area, drying, and then printing ink onto the entire circuit board; and (4) carrying out the subsequent procedures. By adopting the method, the copper plate of 80Z or more is realized, and the blank that a multilayer ultra-thick copper circuit board cannot be manufactured in the industry is filled; moreover, the manufacturing method is simple, the manufacturing method can be realized by adopting a circuit board conventional device, and the manufactured ultra-thick copper circuit board is good in yield and reliable in performance.

Owner:GCI SCI & TECH

Partial thickness rotator cuff repair system and method

Owner:DEPUY SYNTHES PROD INC

Ink jet printing head

A cavity unit of an ink-jet printhead is formed by laminating a base plate formed with pressure chambers , a spacer plate , a manifold plate, a damper plate , a cover plate , and a nozzle plate formed with nozzles . The manifold plate is formed with a manifold chamber that penetrates through the manifold plate. The damper plate is formed with a recess on a side facing away from the manifold chamber and a damper wall left on a side facing the manifold chamber to have a partial thickness of the damper plate. The damper plate is bonded to the manifold plate on an opposite side from the base plate such that the damper wall is positioned to face the manifold chamber. The cover plate is bonded to the manifold plate to seal the recess. Because the damper plate is relatively thick while the damper wall is thin enough to absorb a pressure wave in the manifold chamber generated upon ink ejection, the damper plate is easy to handle.

Owner:BROTHER KOGYO KK

Enzyme blocking skin protectant cream

InactiveUS6932976B2Reduced activityInhibit enzyme activityBiocideCosmetic preparationsSkin breakdownProtection Skin

The present inventions relate to novel skin protectant creams and the use of such creams to cleanse, treat, and protect skin. The skin protectant creams can be topically applied to protect skin from irritants, to block the action of irritants such as enzymes, and to treat skin that has been subject to irritants. The creams can be applied manually or incorporated into disposable applicators, such as wipers or swabs. The skin protectant creams of the present invention are particularly useful in the prevention of severe skin breakdown which can lead to partial thickness skin wounds.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Ink-jet printhead

A cavity unit of an ink-jet printhead is formed by laminating a base plate formed with pressure chambers, a spacer plate, a manifold plate, a damper plate, a cover plate, and a nozzle plate formed with nozzles. The manifold plate is formed with a manifold chamber that penetrates through the manifold plate. The damper plate is formed with a recess on a side facing away from the manifold chamber and a damper wall left on a side facing the manifold chamber to have a partial thickness of the damper plate. The damper plate is bonded to the manifold plate on an opposite side from the base plate such that the damper wall is positioned to face the manifold chamber. The cover plate is bonded to the manifold plate to seal the recess. Because the damper plate is relatively thick while the damper wall is thin enough to absorb a pressure wave in the manifold chamber generated upon ink ejection, the damper plate is easy to handle.

Owner:BROTHER KOGYO KK

Selectorized dumbbell weight with weight plates formed by a pair of welded weight subplates and method of manufacture thereof

Owner:POWERBLOCK HLDG

Compositions and methods for treating partial and full thickness wounds and injuries

InactiveUS20130108683A1Improve survival ratePromote tissue growthBiocidePeptide/protein ingredientsDamages tissuePartial thickness

The present invention provides compositions and methods for treating deep partial thickness or full thickness wounds or injuries. The present invention also provides compositions and methods for promoting healing and regeneration of impaired or damaged tissue at a site of such partial thickness or full thickness wounds or injuries, as well as promoting vascularization and angiogenesis in regenerating and / or supportive tissue at such sites.

Owner:BIOMIMETIC THERAPEUTICS INC

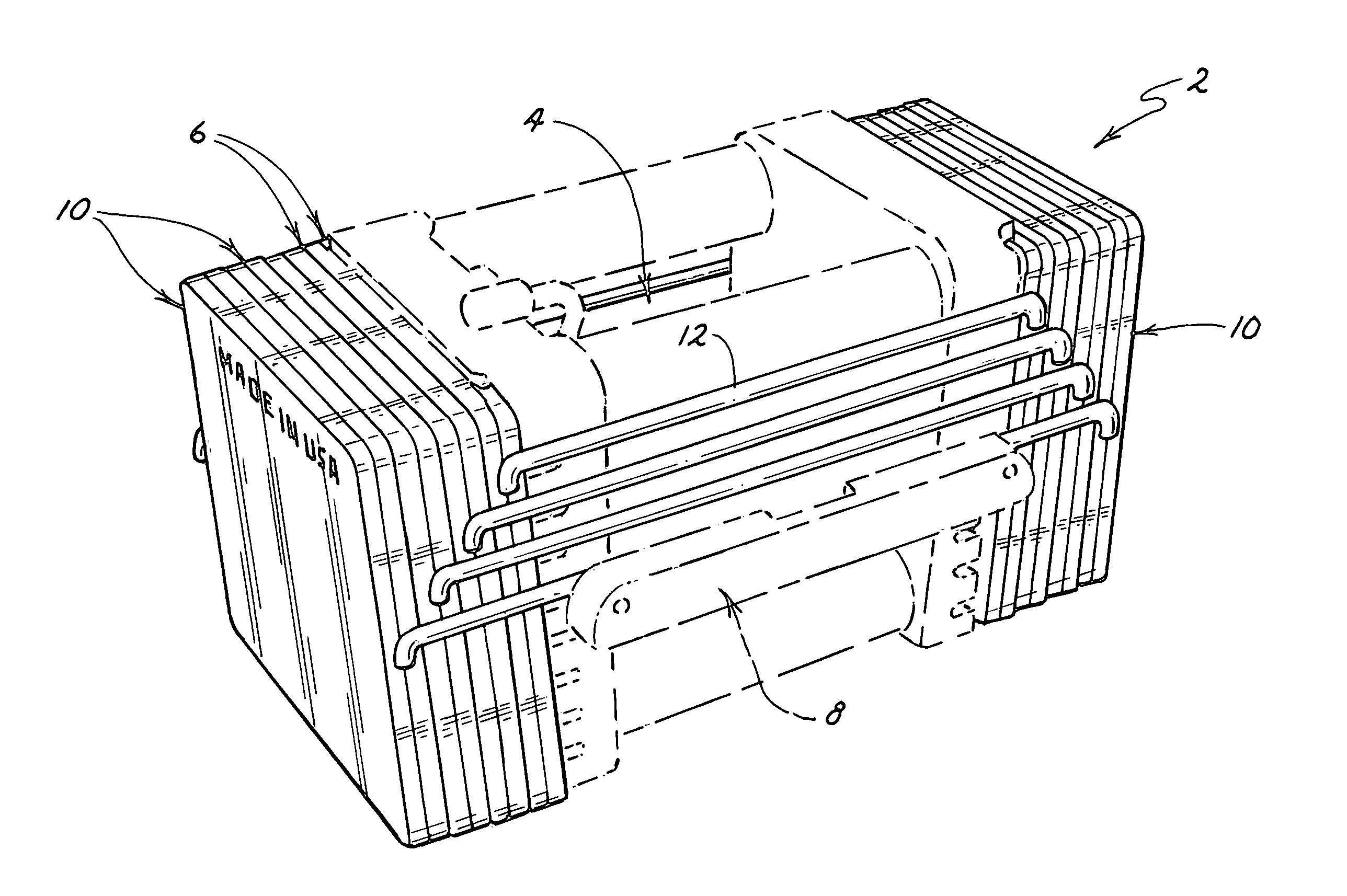

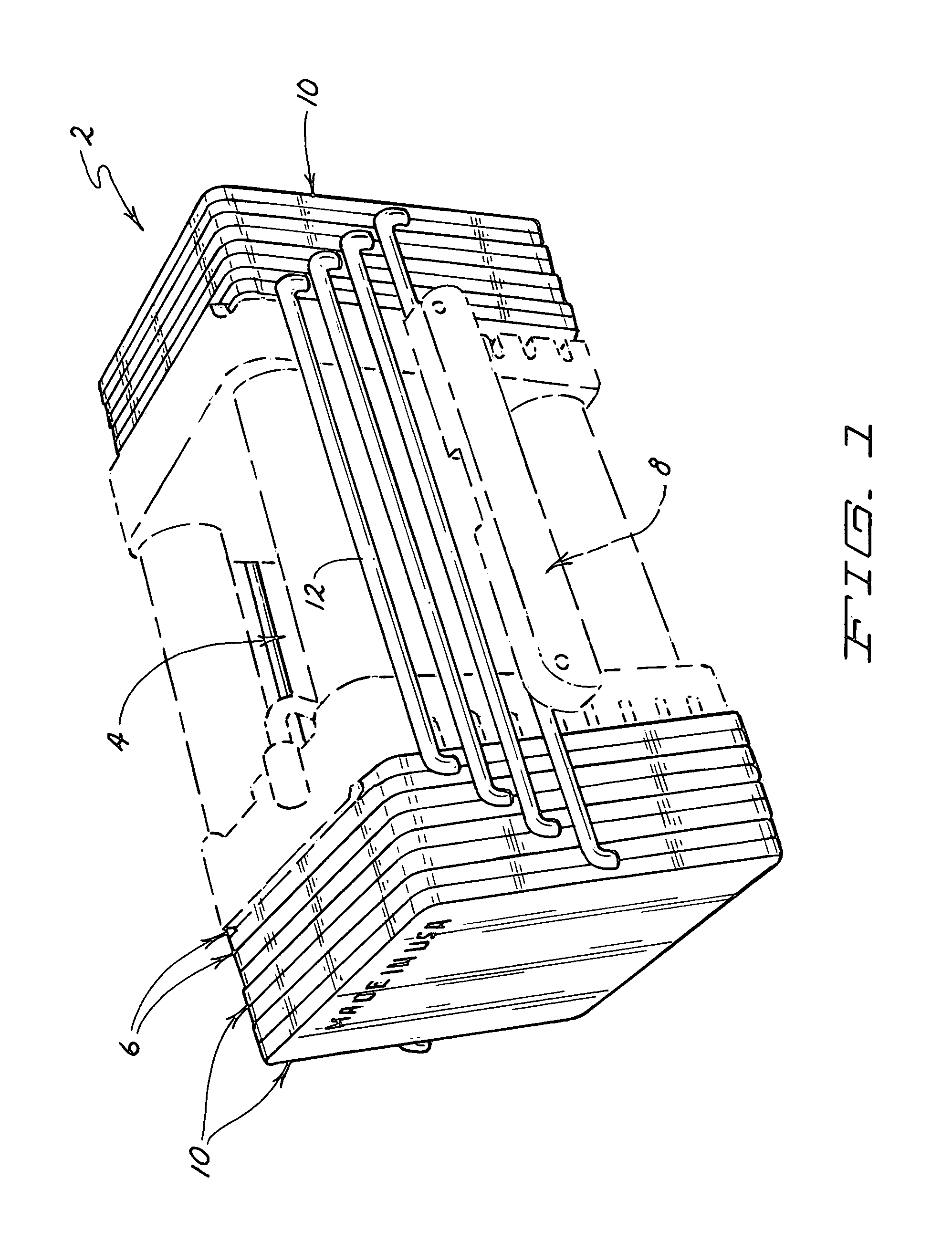

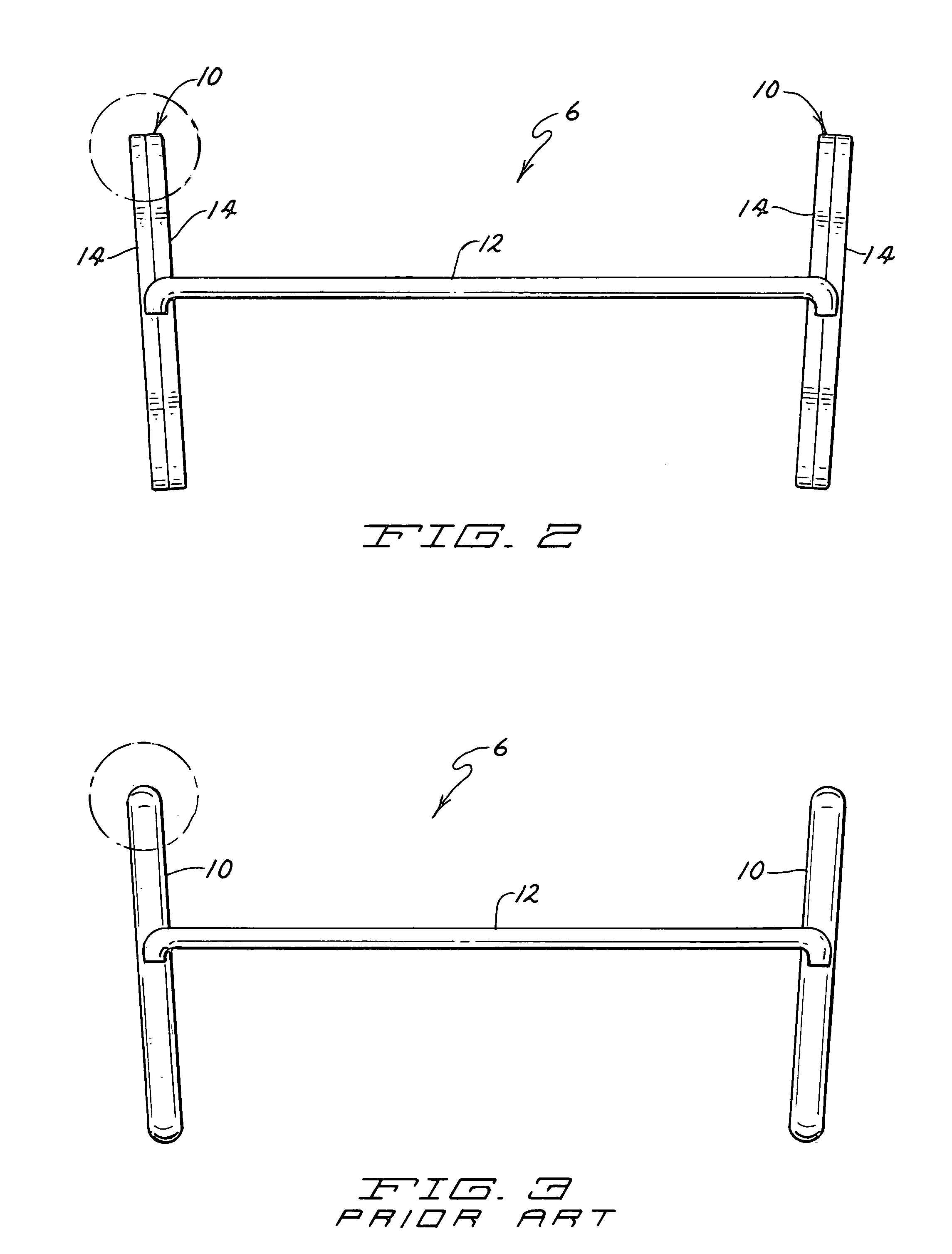

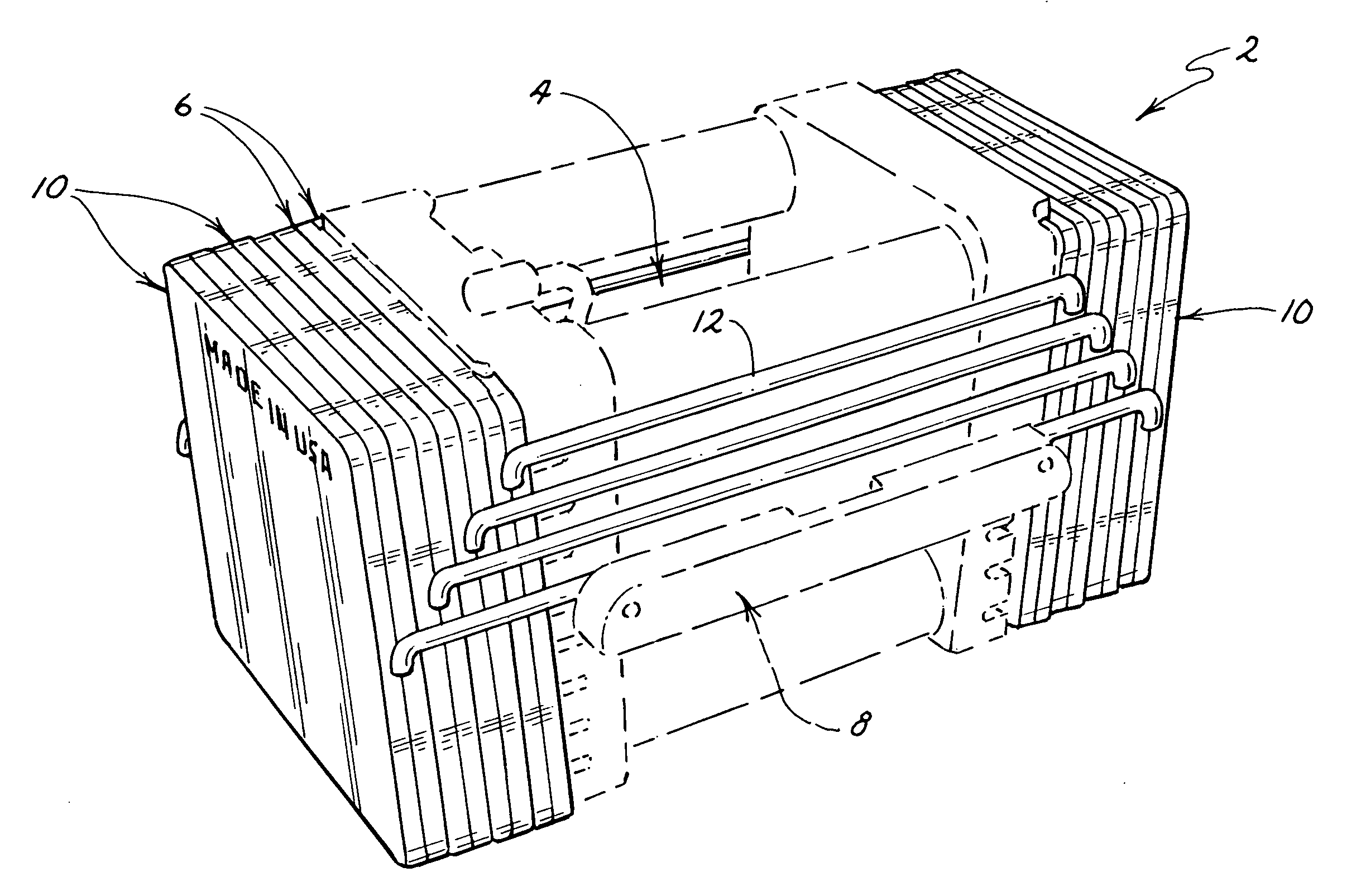

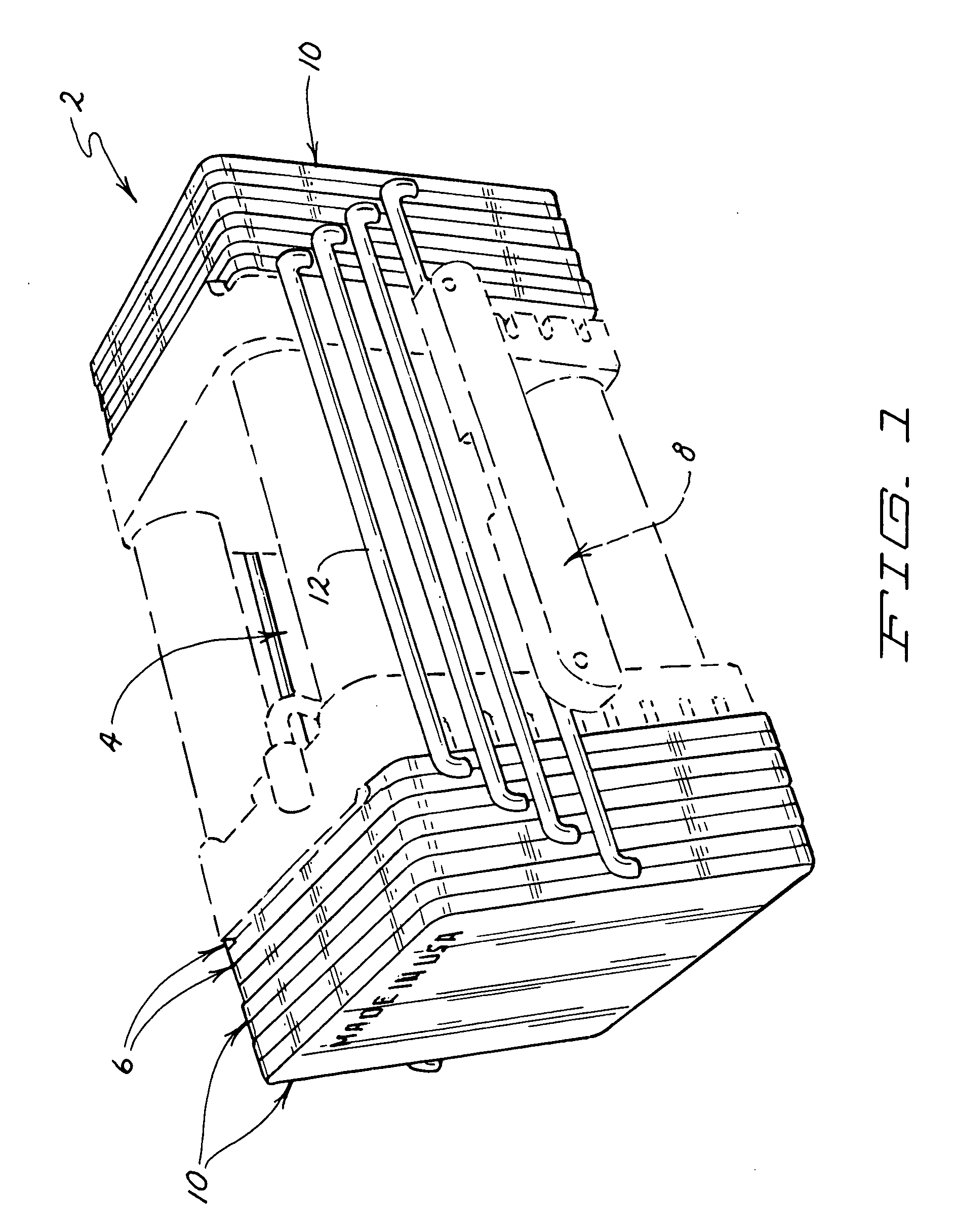

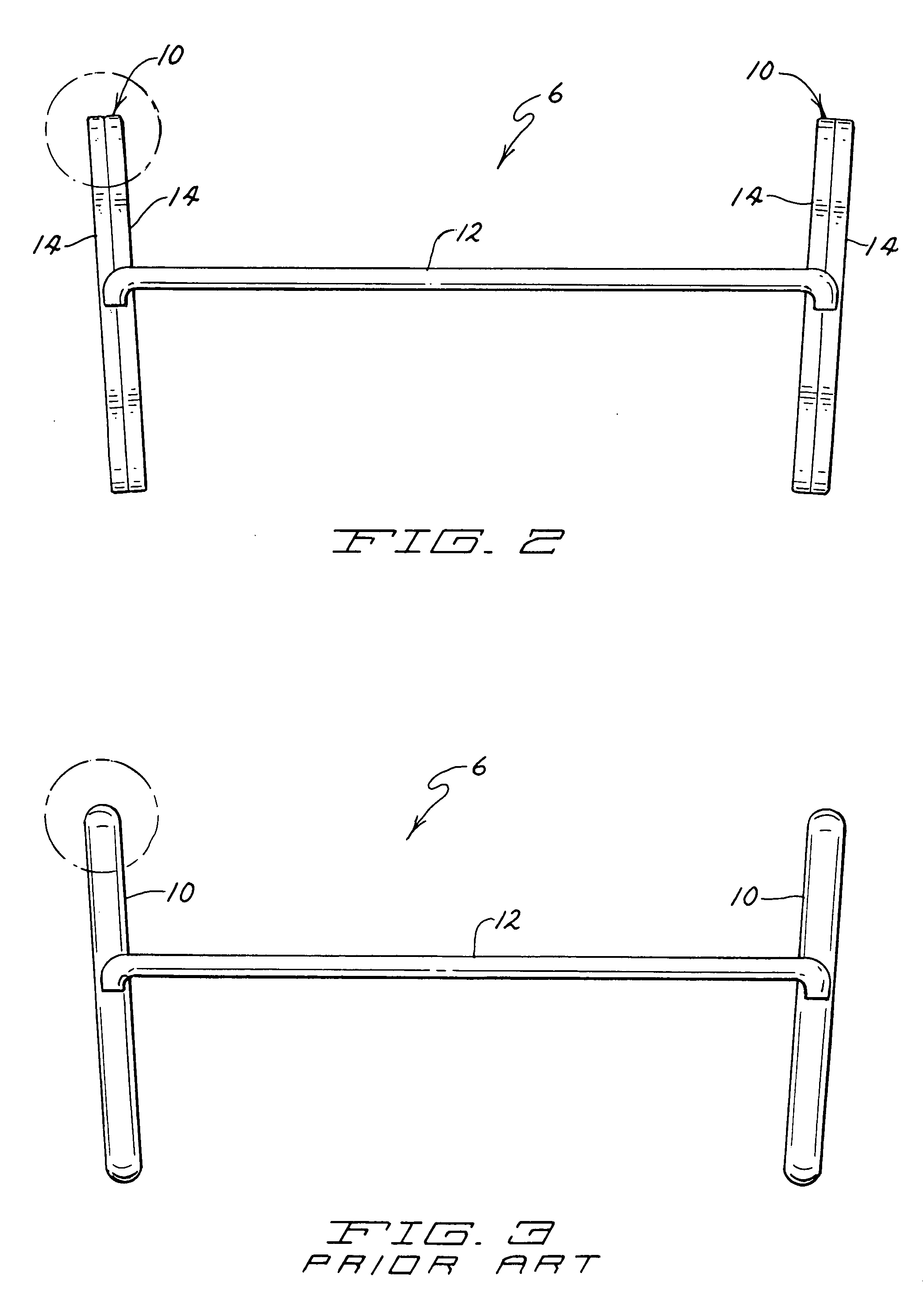

Selectorized dumbbell weight with weight plates formed by a pair of welded weight subplates and method of manufacture thereof

This invention relates to a selectorized dumbbell having a handle that can be dropped down between nested left and right stacks of weight plates. The weight plates can comprise individual weights or a pair of weight plates, one from each stack, can be connected together to form a single weight. A selector is provided to allow the user to select a desired number of weight plates from each stack and couple such weight plates to the handle to provide an adjustable weight dumbbell. Each weight plate comprises a pair of thinner or partial thickness weight subplates that are abutted and welded together, e.g. a ½″ weight plate is formed by a pair of ¼″ weight subplates. This substantially decreases the cost of manufacturing the selectorized dumbbell.

Owner:POWERBLOCK HLDG

Heat treated profile extruded hook

The present invention discloses a method of forming a unitary polymeric protrusion or fastener comprising a strong and flexible thin base and a plurality of spaced apart thin hook members protruding from the unitary base surface, the method Typically involves extruding thermoplastic resin through a die that is machined to form the base layer and spaced ridges, ribs or hook features protruding from above the base layer surface. When die forming spaced ridges or ribs, the cross-sectional shape of the hook member is formed by a template and the initial hook member thickness is formed by cutting the ridge transversely at spaced locations along its length to form the ridge The scattered cutting part. The base layer is then stretched longitudinally (in the ridge direction in the machine direction) to separate the ridge cuts, which are then formed into spaced hook members. These extruded or cut-ribbed hook parts are then heat treated to cause at least a partial thickness shrinkage of at least the hook head portion by 5% to 90%, preferably 30% to 90%.

Owner:3M INNOVATIVE PROPERTIES CO

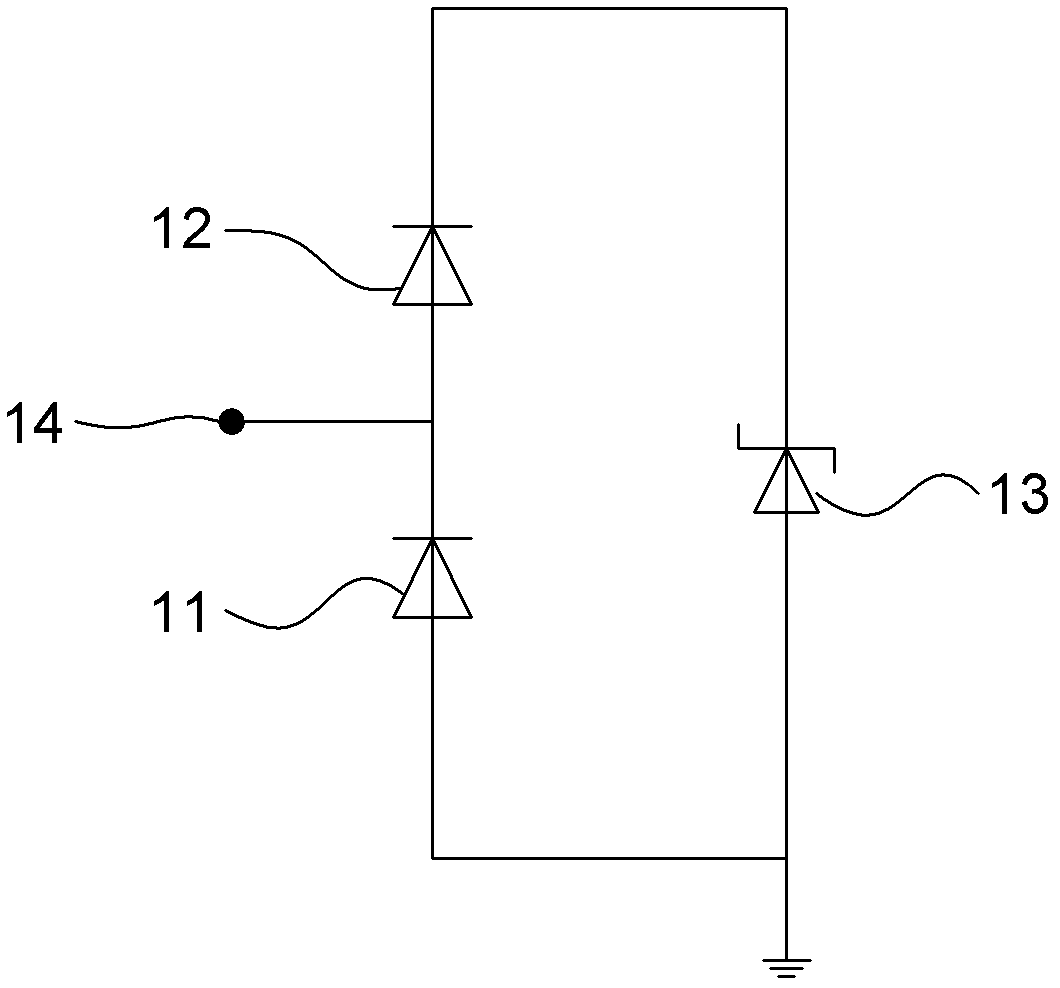

Manufacture method of Zener diode

ActiveCN102592995AReduce areaHighly integratedSemiconductor/solid-state device manufacturingDiffusion methodsInsulation layer

The invention discloses a manufacture method of a Zener diode. The manufacture method comprises the steps of: providing a substrate with an epitaxial layer; etching the epitaxial layer and partial thickness of substrate to form a first annular deep groove; forming an insulation layer on the epitaxial layer while forming a first deep groove filling; etching the epitaxial layer and partial thickness of substrate, forming at least one second deep groove in a region enclosed by the first deep groove; forming in situ doped polycrystalline silicon on the imaged insulation layer while forming a second groove filling; annealing the substrate to form a diffusion region, wherein the diffusion region and the substrate form a PN junction of the Zener diode; etching in situ doped polycrystalline silicon to form the imaged polycrystalline silicon to be used as a cathode of the Zener diode; and forming a metal layer on the back surface of the substrate, wherein the metal layer is used as an anode of the Zener diode. According to the invention, the deep groove process is used for replacing the traditional high-temperature diffusion method, thus the area of a device can be greatly reduced and the integrated level of the integrated circuit is improved.

Owner:ADVANCED SEMICON MFG CO LTD

Interlocking revetment block with array of vegetation holes

ActiveUS8123435B1Maximize hydraulic stabilityEasy to masterArtificial islandsConstruction materialVegetationEngineering

A concrete revetment block having interlocking arms and sockets and an array of vegetation holes. Two arms and two sockets are formed in the block to provide interlocking capabilities with neighbor blocks of a mat. One arm of the block is constructed with a partial thickness and one socket is constructed with a partial depth, thereby providing vertical interlocking capabilities with the neighbor blocks. An array of holes is formed through the block to allow vegetation to grow therethrough. Various holes are located in the block to allow easy grasping of the block by a workman for lifting the same. The holes are formed in the core square of the block, with respective diameters related to the thickness of the block to maximize the hydraulic stability of the block.

Owner:EROSION PREVENTION PRODS

Tungsten chemical mechanical polishing method and manufacture method of tungsten plug

InactiveCN101456153AReduce or eliminate open circuit problemsImprove stabilityPolishing machinesSemiconductor/solid-state device manufacturingSemiconductor structureSecondary stage

The invention relates to a method for tungsten chemico-mechanical grinding. The method comprises the following steps: providing a semiconductor structure provided with a medium layer, wherein the medium layer is provided with an opening, and the opening and the medium layer are provided with a metal barrier layer and a tungsten metal layer sequentially; performing the first stage of chemico-mechanical grinding to remove the tungsten metal layer of partial thickness on the medium layer; performing the second stage of the chemico-mechanical grinding to remove the remaining tungsten metal layer and the metal barrier layer on the medium layer; and performing the third stage of the chemico-mechanical grinding to remove the medium layer of partial thickness. The invention also provides a method for manufacturing a tungsten plug. The sunken defects can be reduced in the process of manufacturing the tungsten plug.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

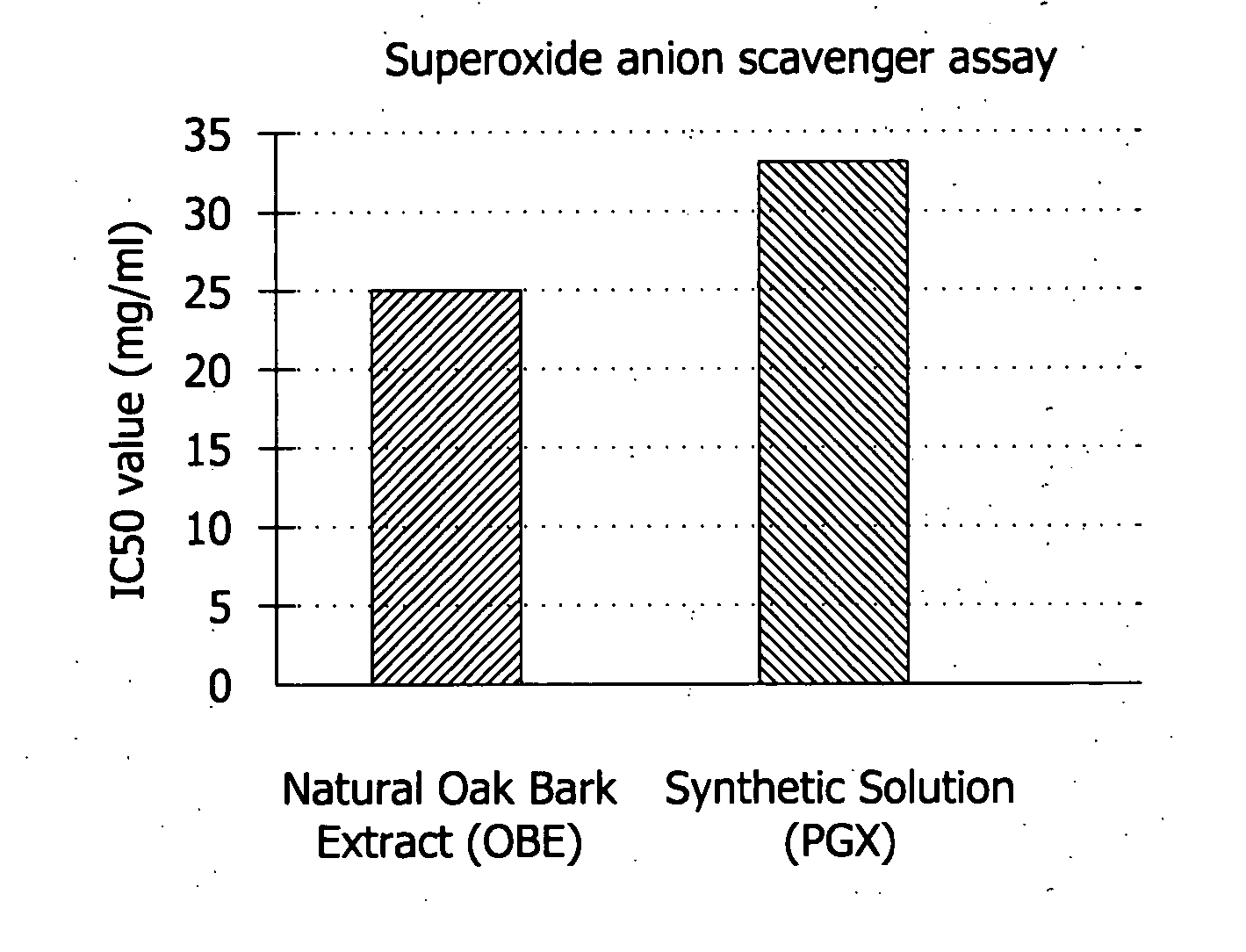

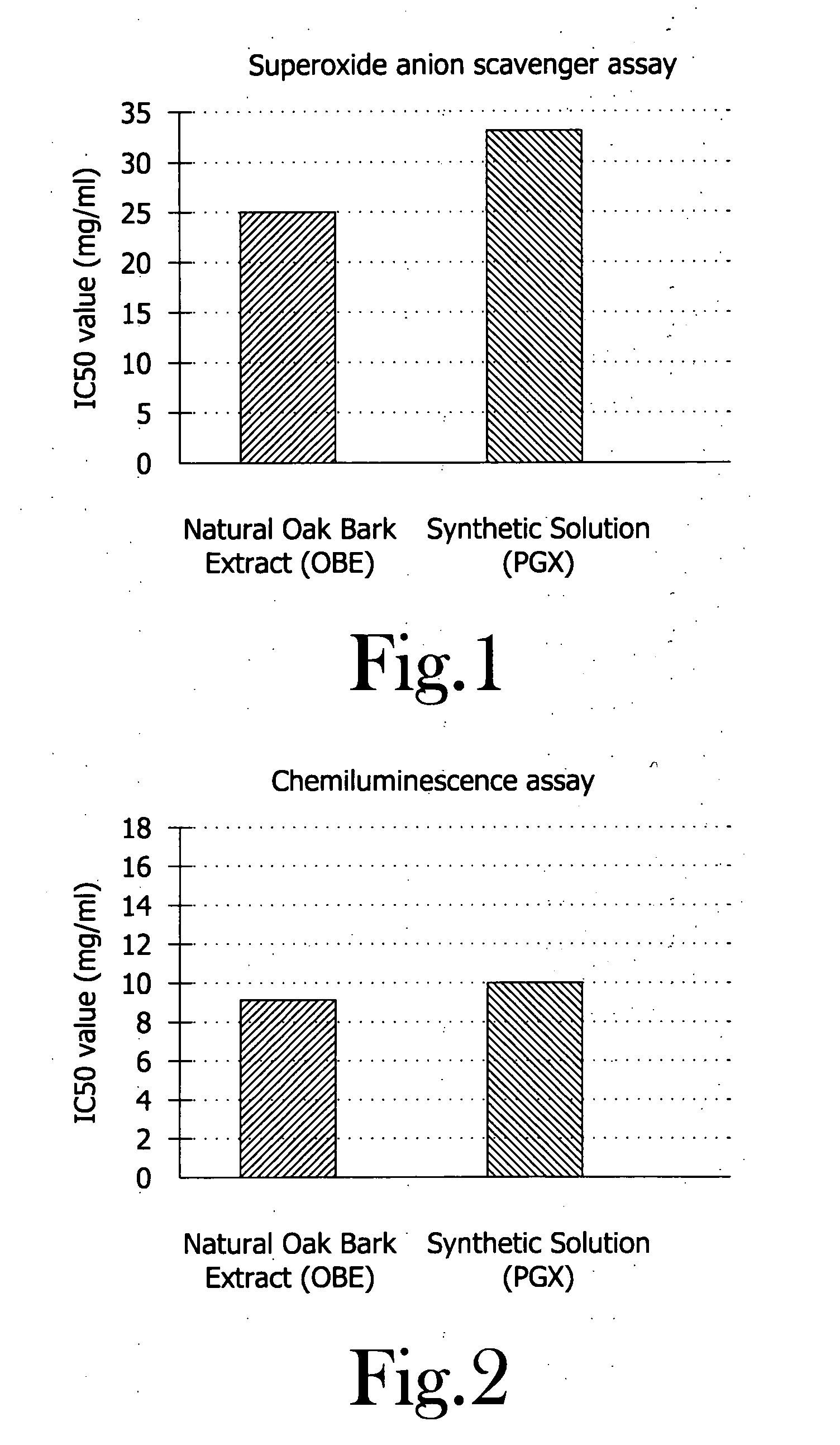

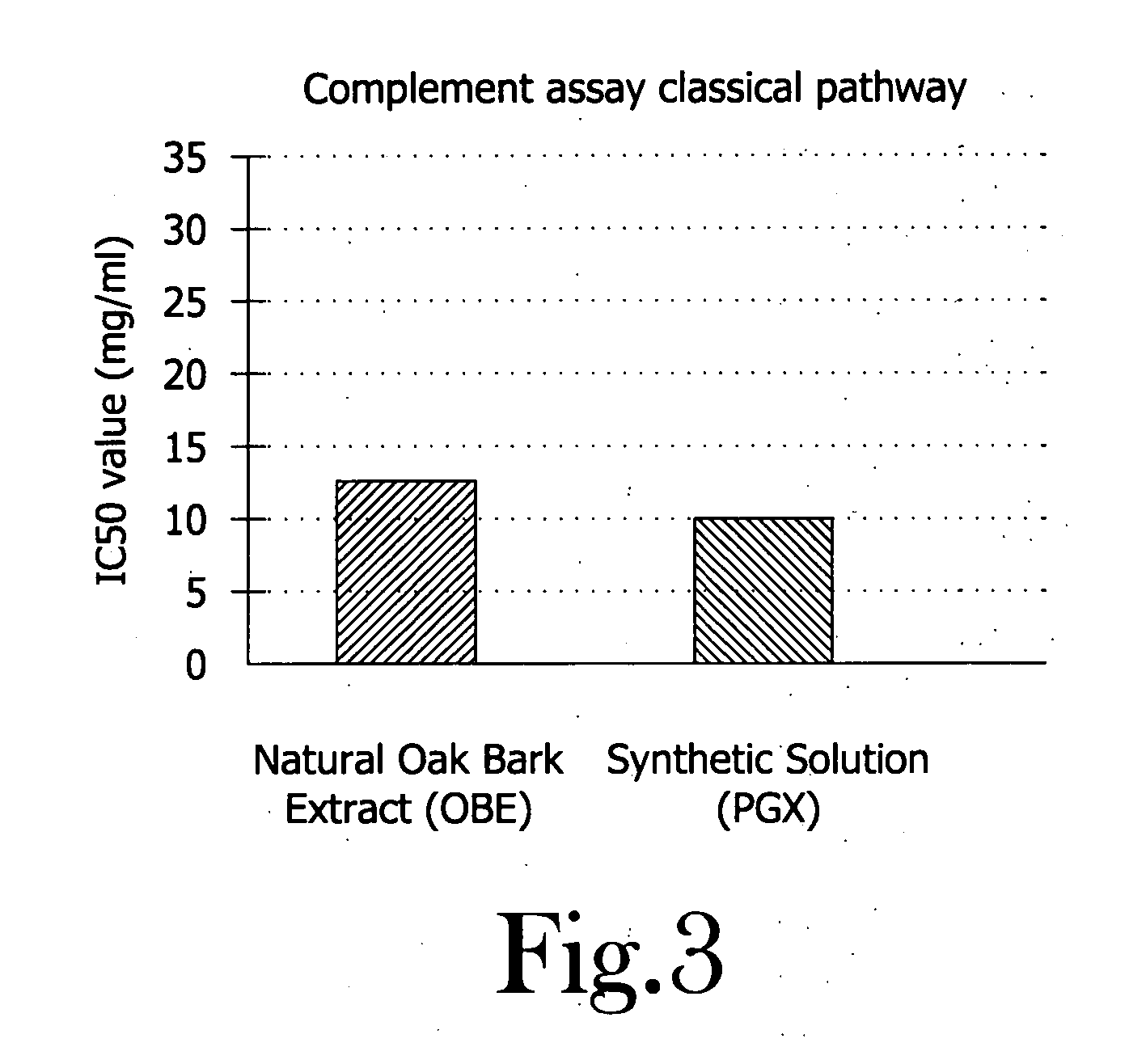

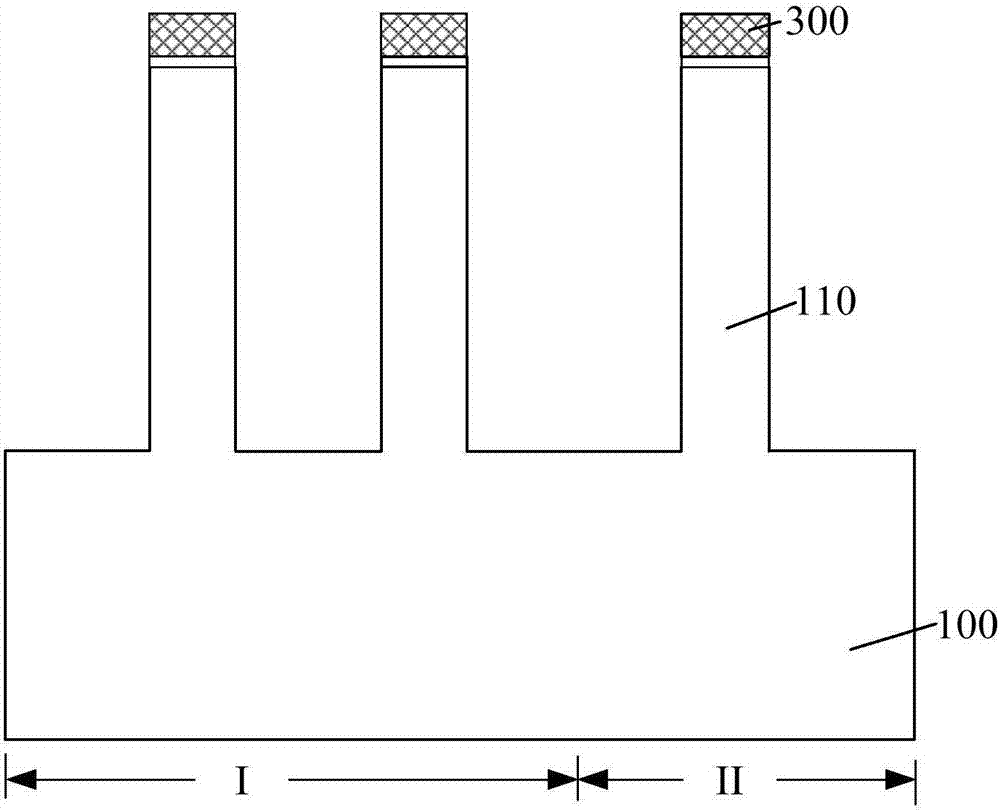

Reduction of reactive oxygen species in chronic wound management

InactiveUS20040170703A1Effective treatmentEffective in healingHeavy metal active ingredientsBiocideSuperoxideRubidium

Reactive oxygen species associated with a wound are modulated through treatment of the wound with a solution of metal ions selected from the group consisting of potassium ions, zinc ions, calcium ions and rubidium ions, at a pH of between about 5 and about 7. Preferably, citric acid is employed to adjust the pH of the solution. Application of the extract to a wound exhibiting superoxide anions has been found to be effective in the treatment of these wounds through the reduction of the level of superoxide anions. Moreover, treatment of partial thickness excision wounds as well as contact burn wounds with the present composition has been found to improve epithelialization of these wounds. In addition to the antioxidant activity of the present invention, treatment of the wound employing the present composition produces inhibitory effects on ROS production by human PMNs and on human complement activation, and therefore, is further beneficial in chronic wound management.

Owner:GREYSTONE MEDICAL GROUP

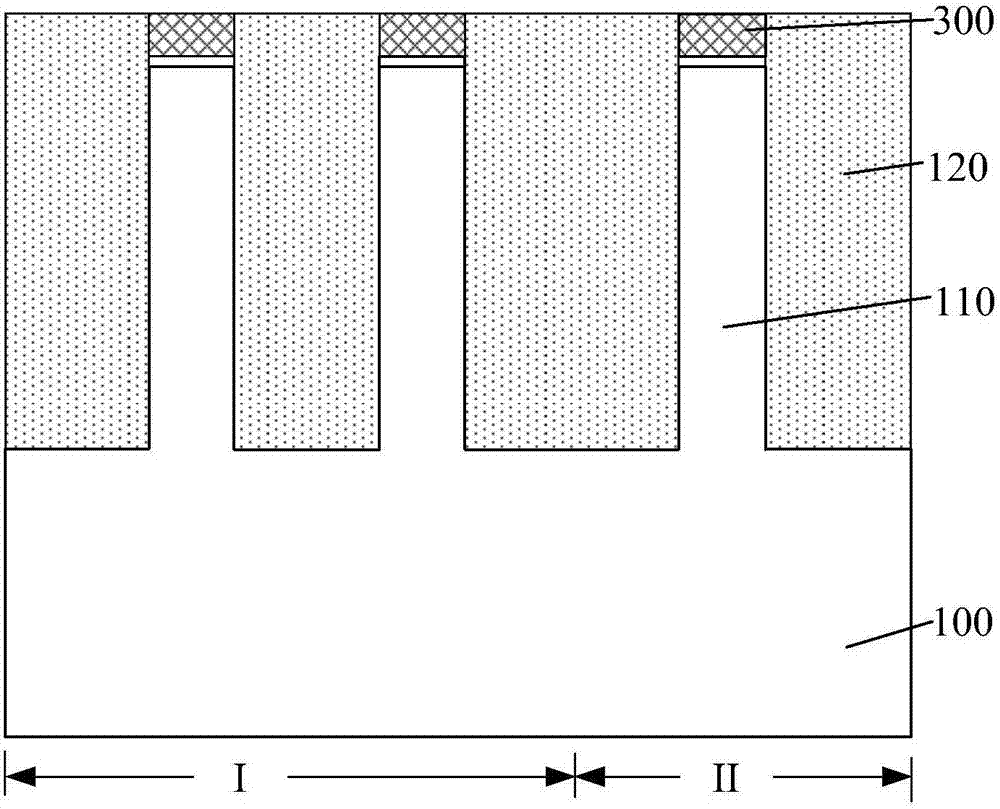

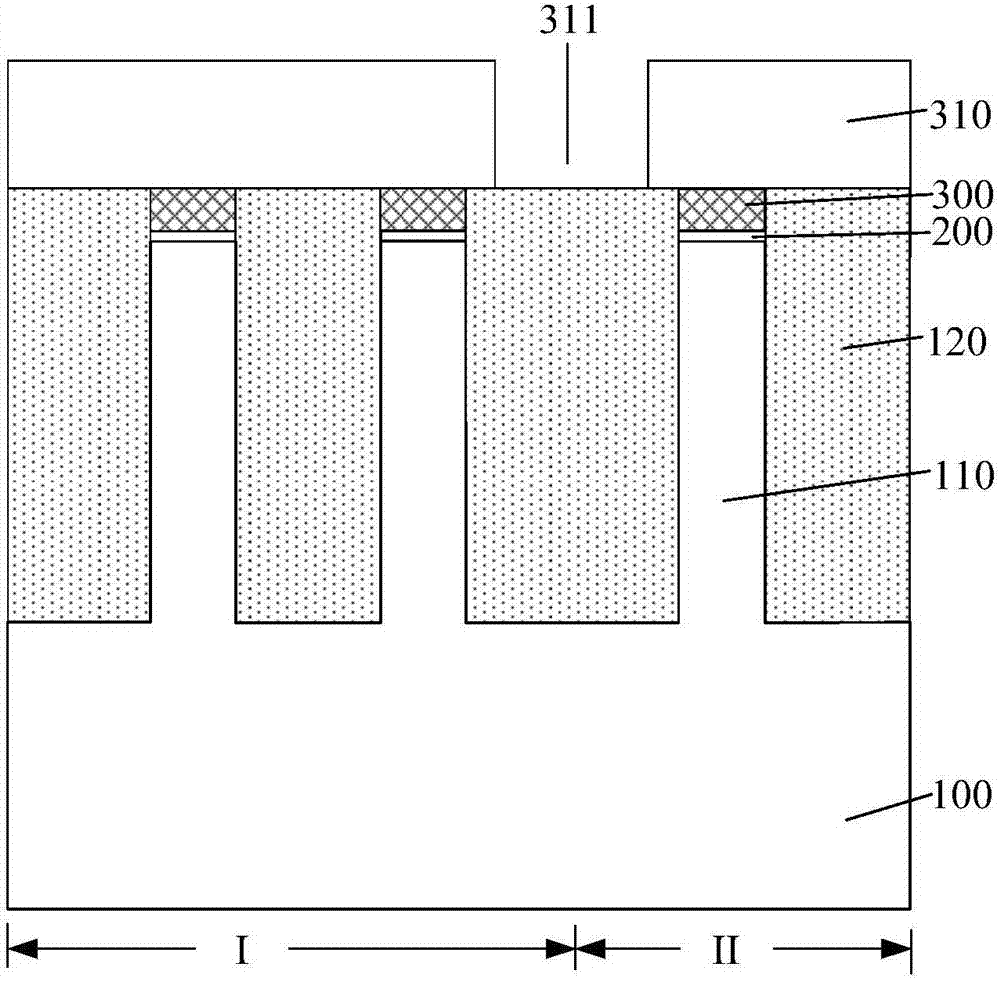

Semiconductor structure and manufacturing method thereof

ActiveCN107346759AAvoid lossImprove electrical performanceSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureIsolation layer

The invention provides a semiconductor structure and a manufacturing method thereof. The manufacturing method comprises the steps of: providing a base which comprises a substrate and fin portions protruding out of the substrate, wherein the substrate comprises a first region and a second region; forming a first initial isolating layer on the substrate; patterning the first initial isolating layer, and forming a first opening through which the substrate is exposed in a junction of the first region and the second region; forming a side wall protective layer which is made of a material different from that of the substrate and the fin portions on the side wall of the first opening; etching the substrate along the first opening, and forming a second opening in the substrate; forming a second initial isolating layer which fills up the second opening and the first opening; and removing a partial thickness of the second initial isolating layer, the side wall protective layer and the first initial isolating layer, so as to expose the fin portions. According to the semiconductor structure and the manufacturing method thereof, the first opening is formed in the first initial isolating layer at first, then the side wall protective layer is formed on the side wall of the first opening, and the substrate is etched along the first opening; and the side wall protective layer can protect the fin portions on two sides of the first opening, thereby preventing the fin portions from being damaged by the process of etching the substrate.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

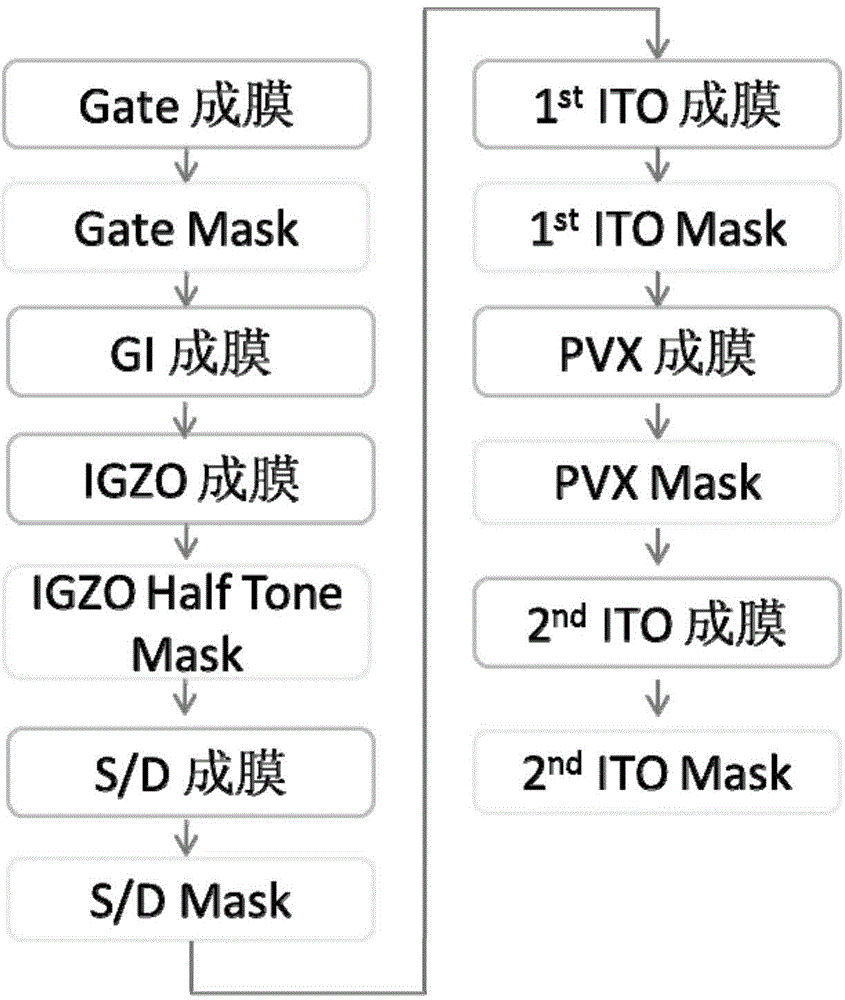

Array substrate manufacturing method

InactiveCN104091784AAvoid destructionFilm formationSolid-state devicesSemiconductor/solid-state device manufacturingActive layerPhotoresist

The invention discloses an array substrate manufacturing method. According to the method, in the active layer forming process, photoresist of partial thickness on the corresponding position of a channel region between the source drain electrodes above the active layer is reserved; then a source leakage metal layer is formed, and the source drain electrodes are further formed; finally the photoresist of partial thickness on the channel region between the source drain electrodes is stripped. According to the array substrate manufacturing method, when the semiconducting film is formed, partial photoresist is reserved on the TFT channel region through the semi-permeable mask process, damage to the metal oxide layer in the source leakage electrode etching process is avoided, the photoresist is stripped in the later stripping process, a traditional etching blocking layer can be replaced, the processes of film forming and masking for etching the blocking layer are omitted, production cost is reduced, the process is simplified, and product yield and product benefits are improved.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com