Ultra-thick copper circuit board and manufacturing method thereof

A manufacturing method and circuit board technology, applied in printed circuit manufacturing, printed circuit, printed circuit, etc., can solve problems such as difficult performance guarantee and low product yield rate, and achieve reliable performance, simple manufacturing method, and improved yield rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of manufacturing method of the ultra-thick copper circuit board of present embodiment, comprises the following steps:

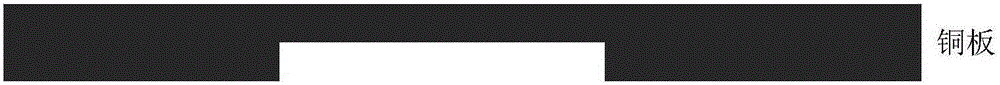

[0037] (1) The copper plate (thickness is 8OZ) is blanked, after drilling the positioning holes, the wet film printing operation is performed on the copper plate first, and after baking at 70-80°C for 20 minutes, the dry film is applied, and then the dry film is applied on the copper plate. On the first side, exposure and development expose the non-line pattern area, and the copper skin in the non-line pattern area of the copper plate is etched away by 50% of the total copper plate thickness by etching to form a groove. The partially etched copper plate is as follows figure 1 As shown, then the copper plate is stripped and etched for inspection;

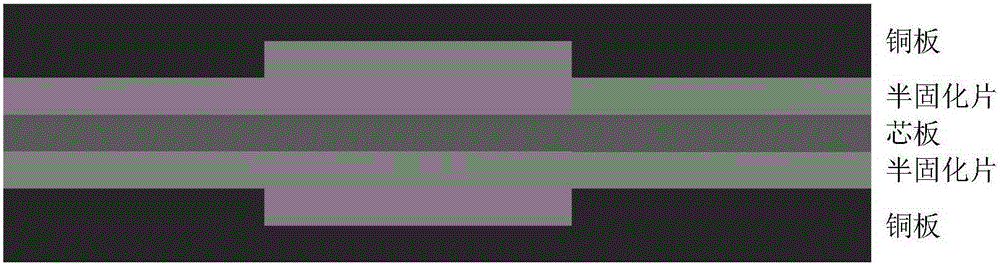

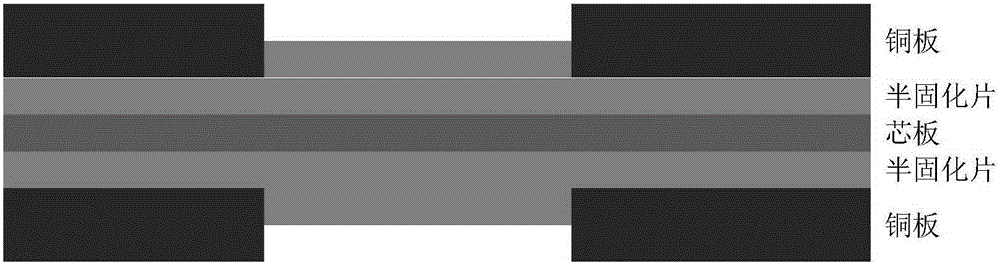

[0038] (2) Browning the core plate after blanking and the copper plate that step (1) obtains, filling epoxy resin powder in the groove of step (1) gained copper plate, the filling thickness of descri...

Embodiment 2

[0045] A kind of manufacturing method of the ultra-thick copper circuit board of present embodiment, comprises the following steps:

[0046] (1) The copper plate (thickness is 16OZ) is blanked, after drilling the positioning hole, the wet film printing operation is performed on the copper plate, and after baking at 70-80°C for 30 minutes, the dry film is applied, and then the copper plate is printed. On the first side, after exposure and development, the non-circuit pattern area is exposed, and the copper skin in the non-circuit pattern area of the copper plate is etched away by 40% of the total copper plate thickness by etching to form a groove, and then the copper plate is subjected to film removal and etching inspection;

[0047] (2) Carry out browning to the copper plate that core plate and step (1) obtain after blanking, fill in the epoxy resin powder in the groove of described copper plate in step (1), the filling thickness of described epoxy resin powder is 1 / 2 of the...

Embodiment 3

[0053] A kind of manufacturing method of the ultra-thick copper circuit board of present embodiment, comprises the following steps:

[0054] (1) The copper plate (thickness is 28OZ) is blanked, after drilling the positioning hole, the wet film printing operation is performed on the copper plate first, and after baking at 70-80°C for 40 minutes, the dry film is applied, and then the copper plate is printed. On the first side, after exposure and development, the non-circuit pattern area is exposed, and the copper skin in the non-circuit pattern area of the copper plate is etched away by 60% of the total copper plate thickness by etching to form a groove, and then the copper plate is subjected to film removal and etching inspection;

[0055] (2) Carry out browning to the copper plate that core plate and step (1) obtain after blanking, fill in the epoxy resin powder in the groove of described copper plate in step (1), the filling thickness of described epoxy resin powder is 1 / 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com