Ink jet printing head

An inkjet print head and nozzle technology, applied in printing and other directions, can solve the problems of not allowing the formation of a buffer cavity and reducing the rigidity of the print head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

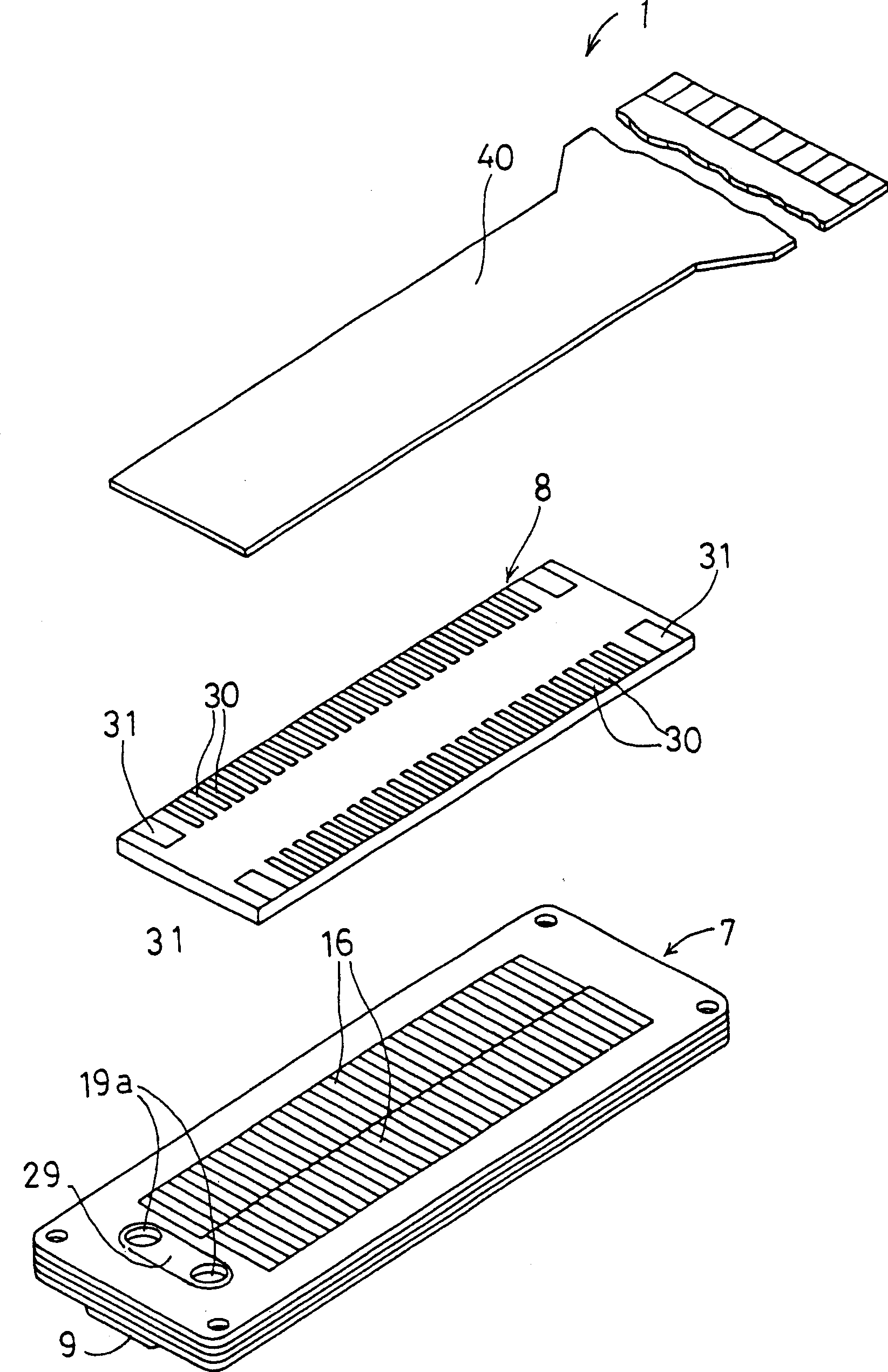

[0017] will refer to Figures 1 to 4 An inkjet printhead 1 according to an embodiment of the present invention is explained. In this inkjet print head 1, a flexible flat cable 40 is bonded to the upper surface of a sheet-shaped piezoelectric actuator 8 to be connected with an external device, and the piezoelectric actuator 8 is bonded to a cavity unit 7 . Ink is ejected from nozzles opening on the lower surface of the chamber unit 7 .

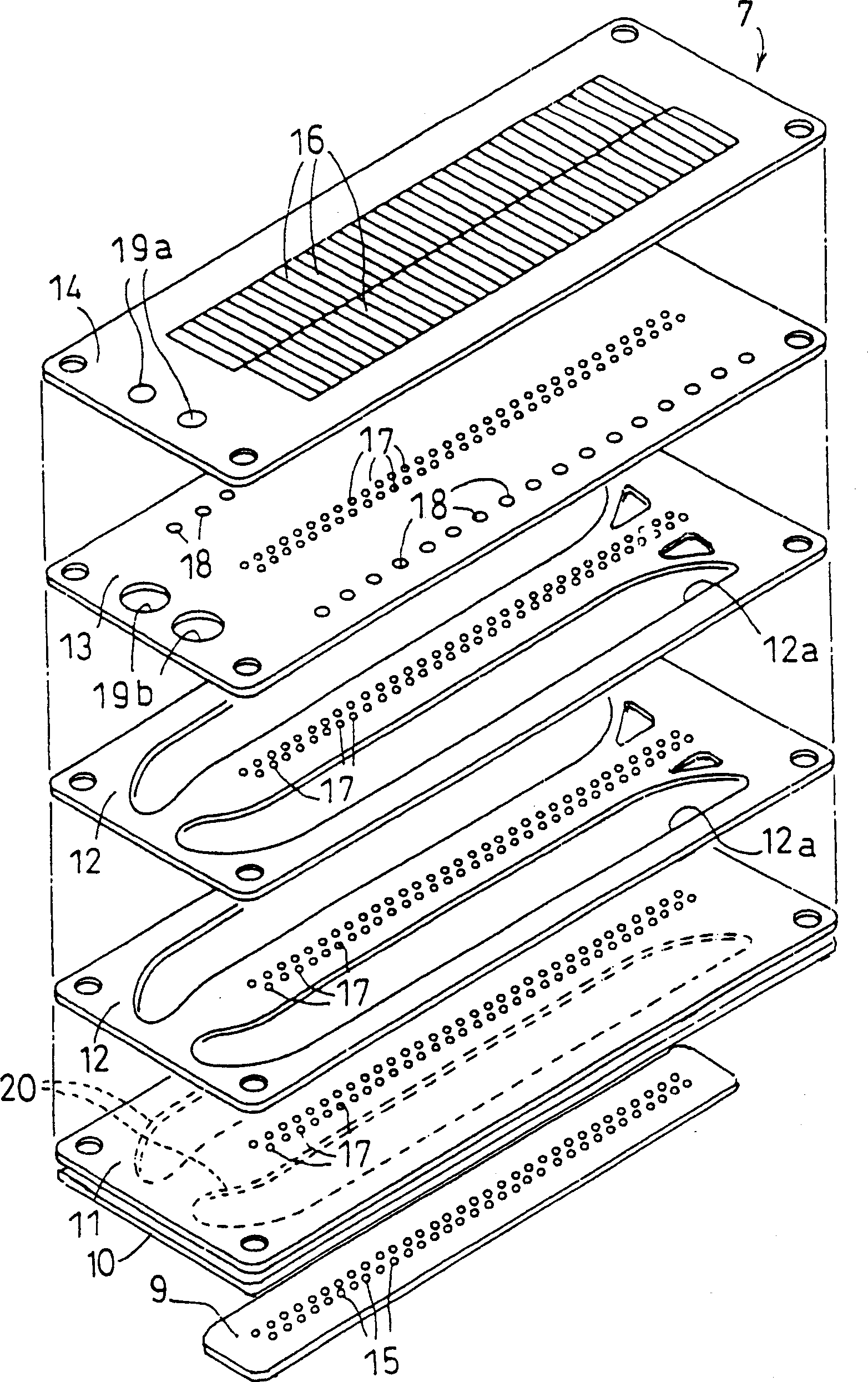

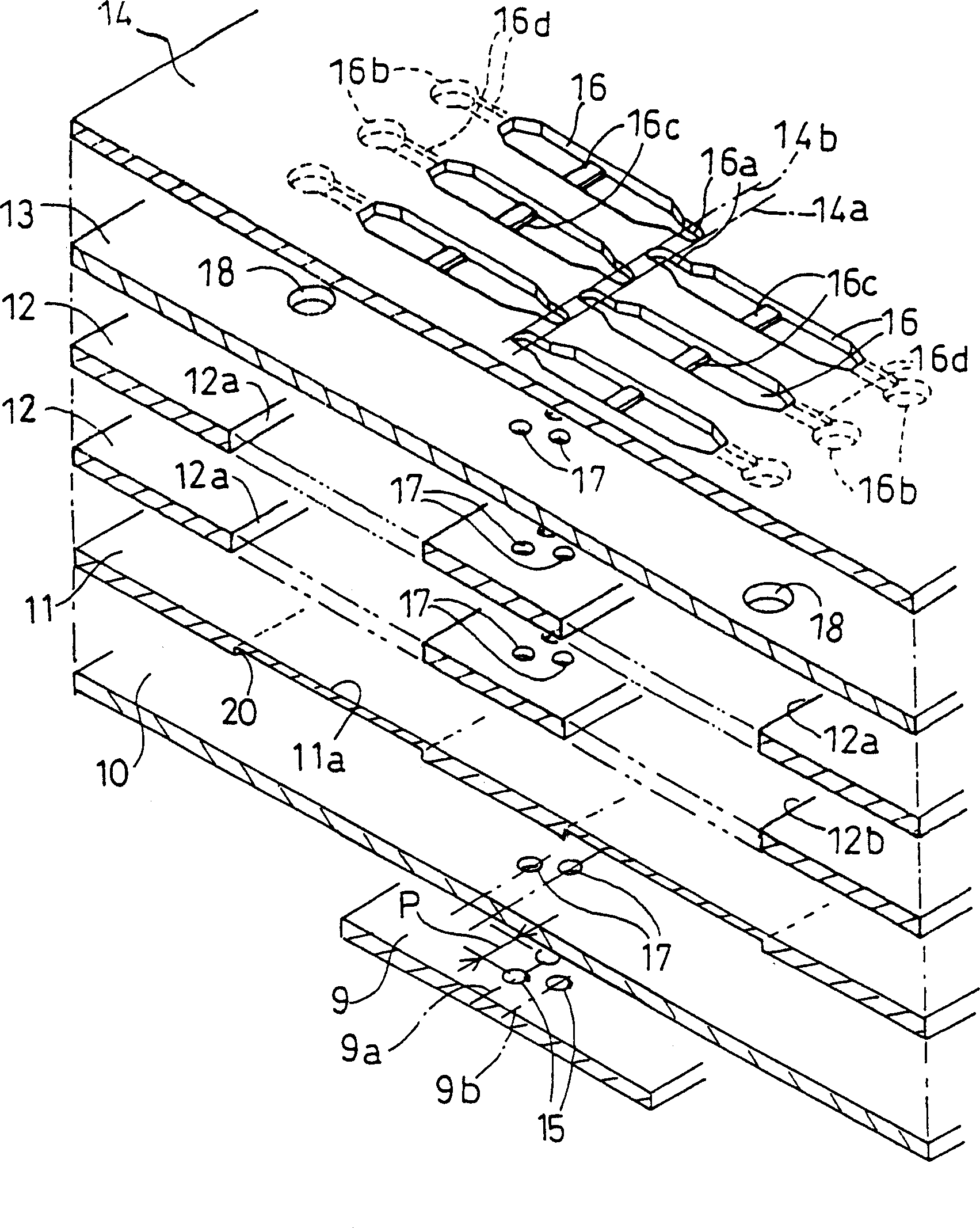

[0018] will refer to figure 2 and image 3 The structure of the chamber unit 7 will be described. The cavity unit 7 is formed by laminating and bonding seven layers of sheets, namely a nozzle plate 9, a cover plate 10, a buffer plate 11, two manifold plates 12, 12, a partition plate 13, and a base plate 14. form. In this embodiment, each layer of plates 10, 11, 12, 12, 13, 14, except the nozzle plate 9, is made of 42% nickel steel and has a thickness of about 50-150 microns. Openings and grooves are formed in these plates as ink channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com