Patents

Literature

777 results about "Vibrating membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

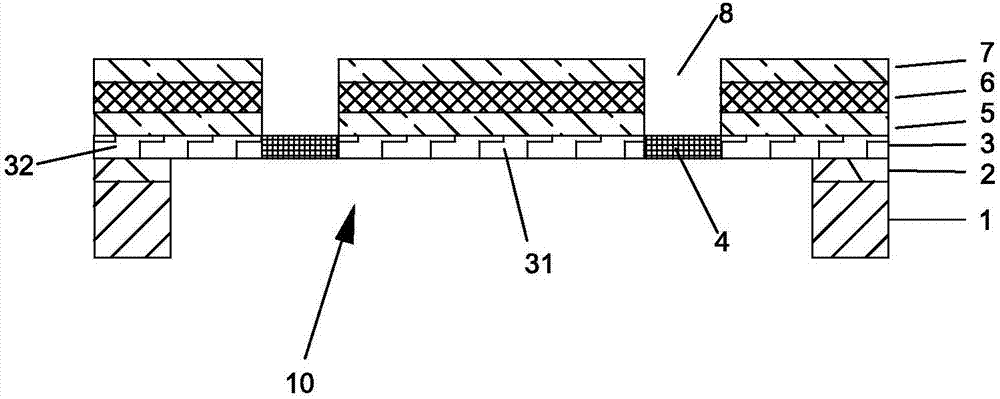

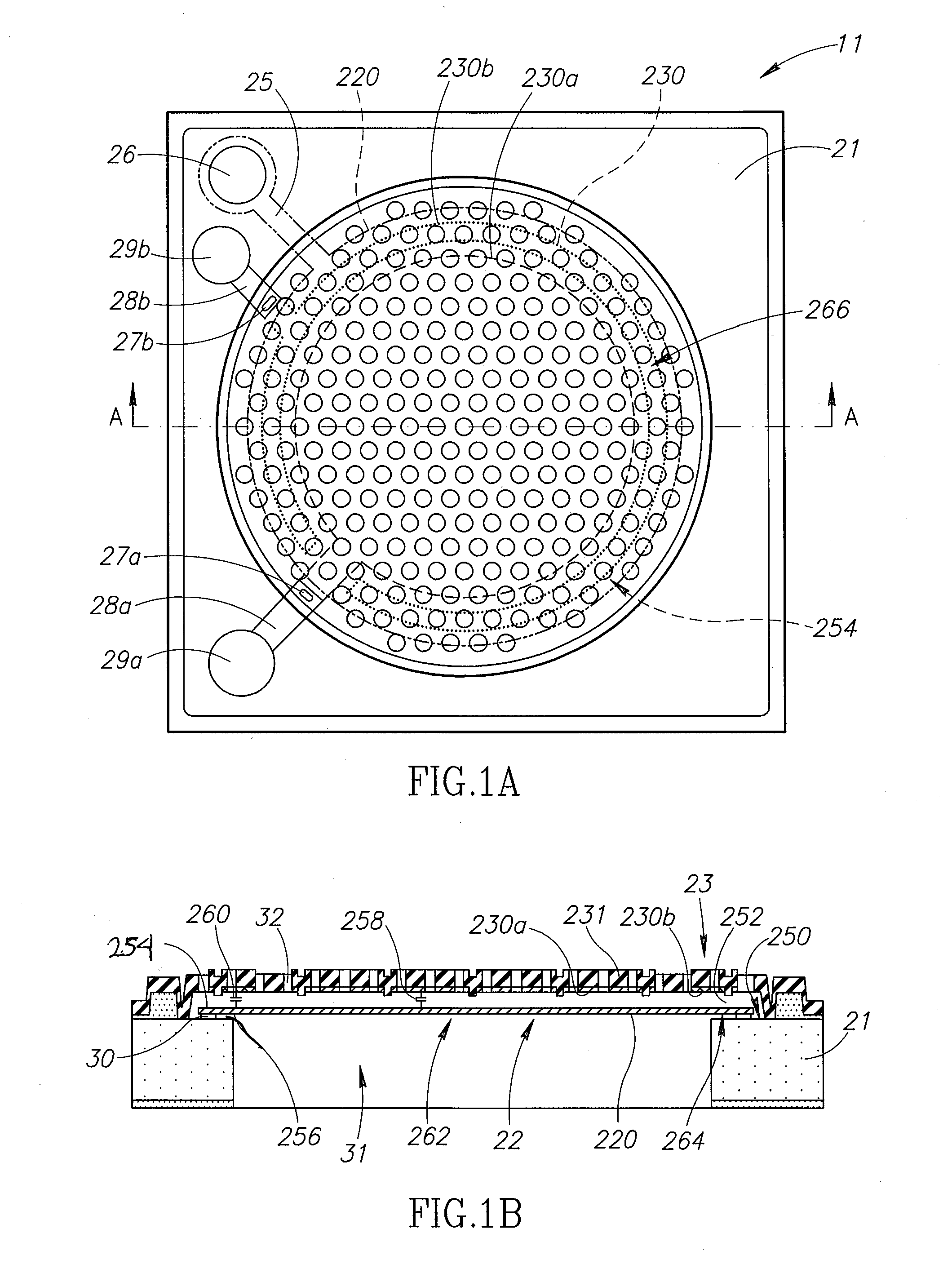

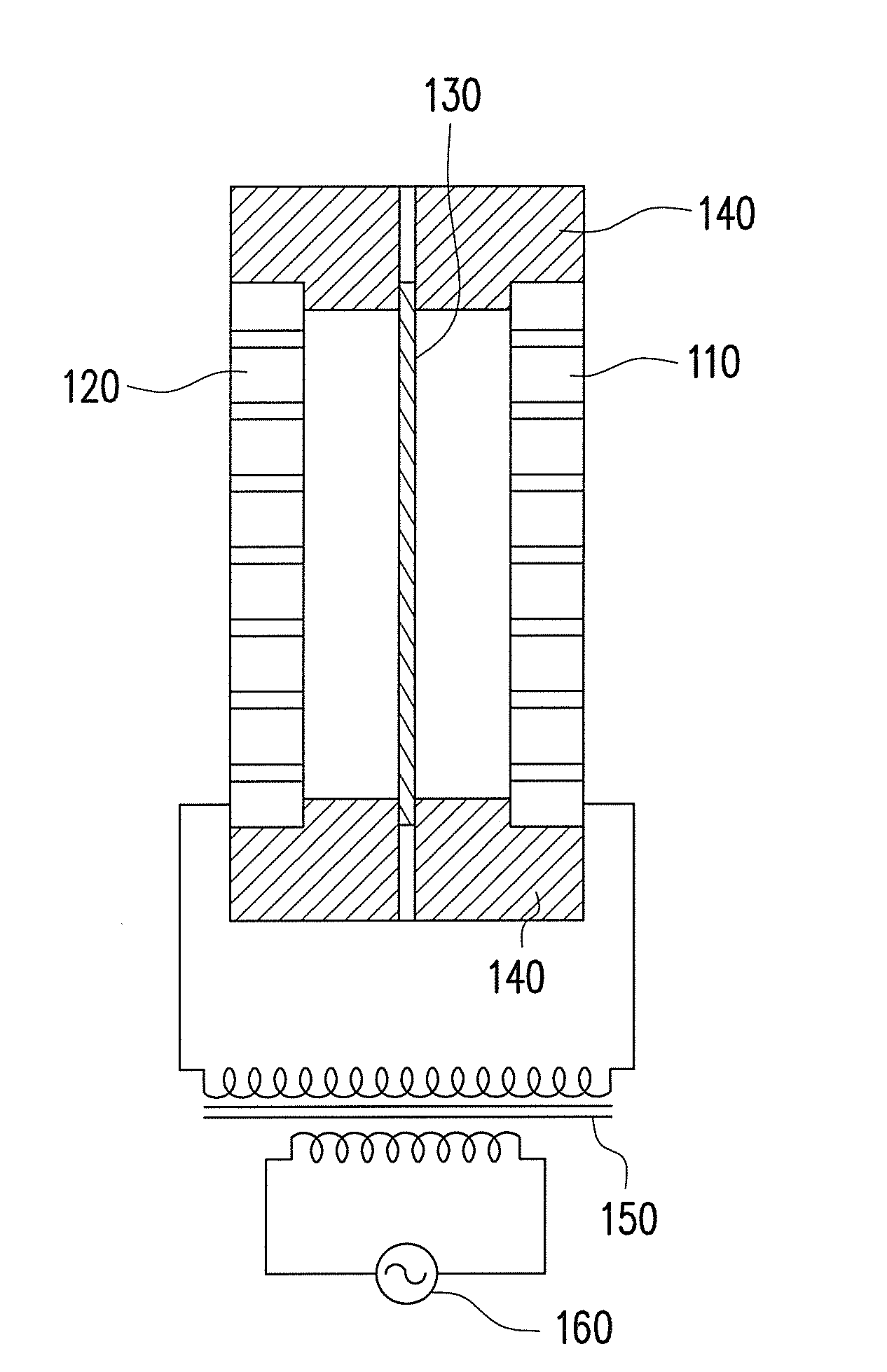

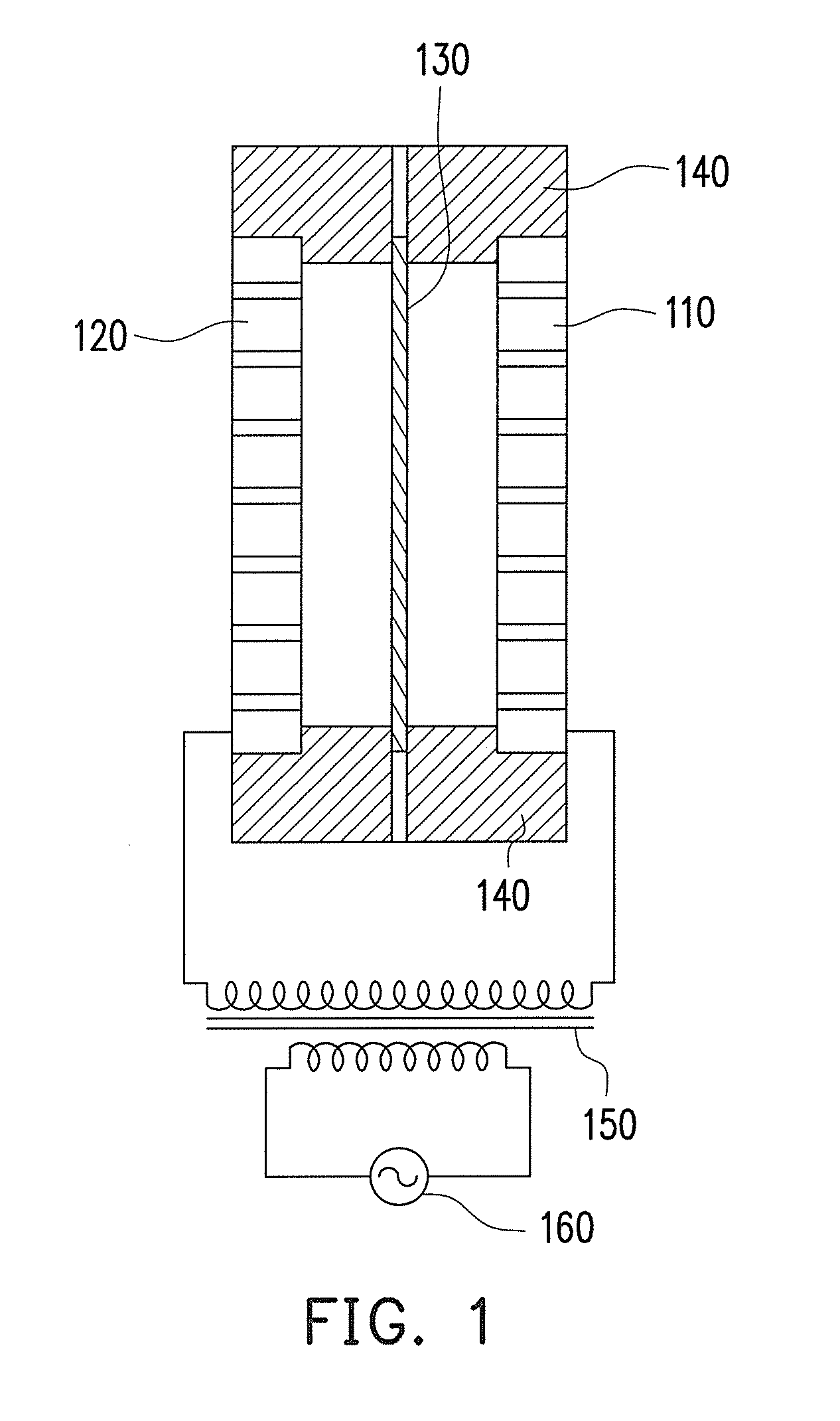

Lighting device

ActiveUS20100096967A1Excessive coolingLess energy inputPoint-like light sourceElectric discharge tubesVibrating membraneEffect light

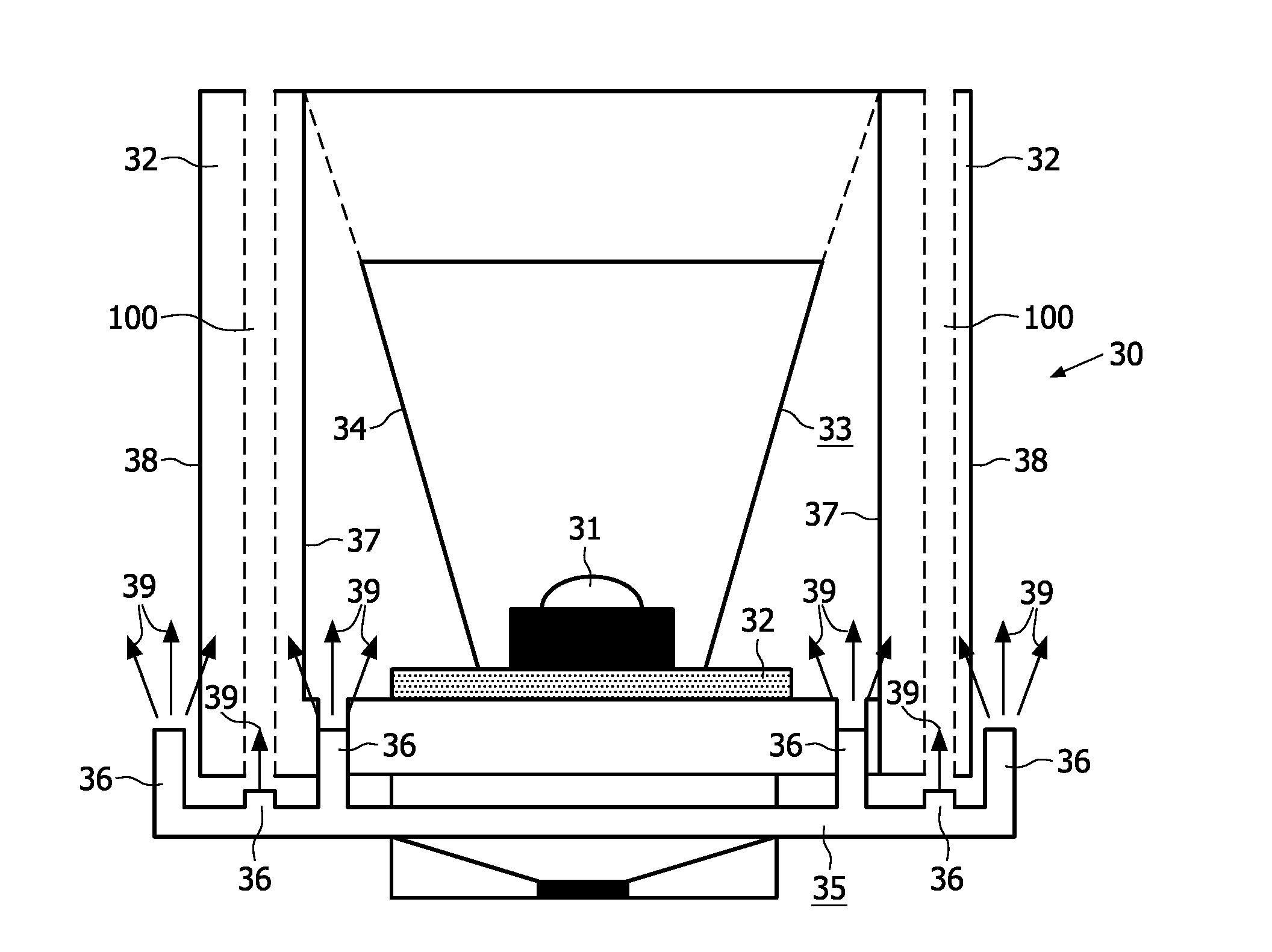

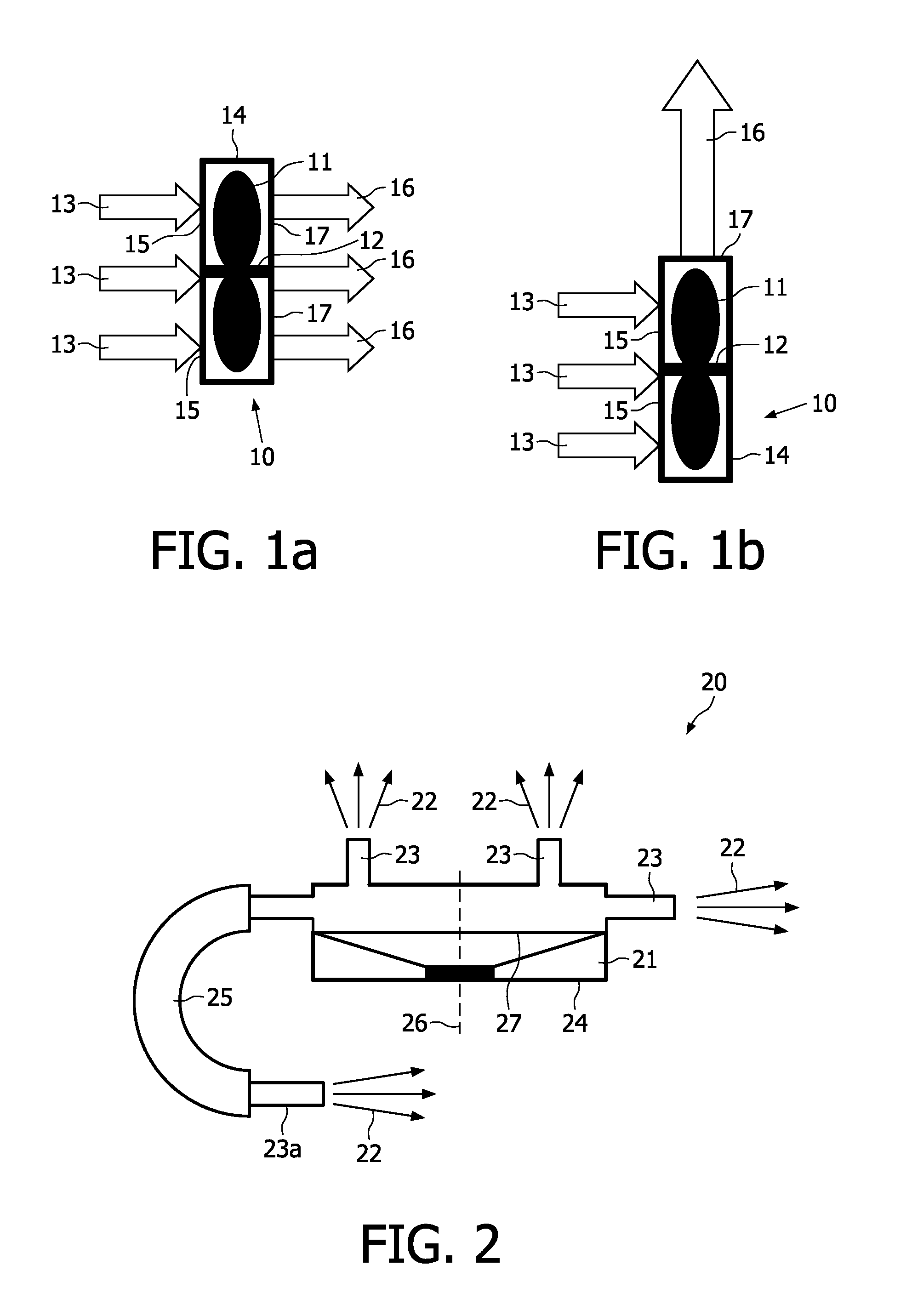

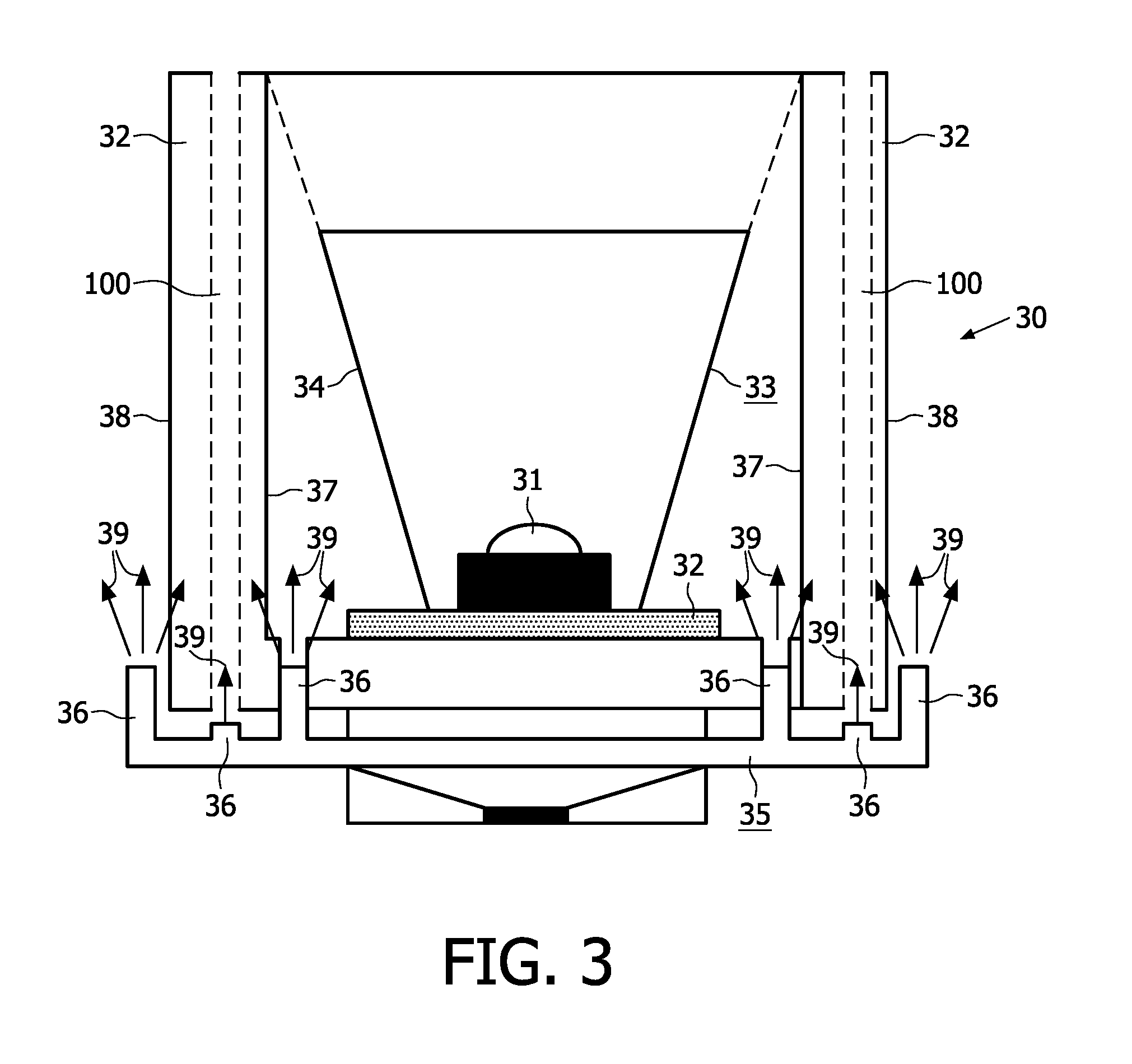

The invention relates to a lighting device comprising a light source (31) which is mounted on a heat sink (32) having an outer contour (34). Furthermore, it comprises a cooling device (35) for dynamically cooling the light source via cooling of the heat sink by means of a fluid flowing alongside the contour of the heat sink, the cooling device having one or a plurality of cooling openings (36, 43). The cooling device is a vibrating membrane cooling system for generating a sequence of fluid pulses (39). The cooling openings are arranged alongside the heat sink. The light source comprises optical means (33) for collimating and directing light originating from the light source during operation, while the contour of the heat sink has a shape similar to that of the optical means.

Owner:SIGNIFY HLDG BV

Liquid preparation containing tobramycin

The application describes a sterile aqueous inhalation solution containing the active agent tobramycin. The preparation has a high content of active agent (about 80 to 120 mg / ml of tobramycin) and contains an acidic adjuvant, but contains only a low concentration of sodium chloride (at most about 2 mg / ml). It can be injected or administered as an aerosol, for example with conventional nebuliser. It is particularly suitable for application in combination with a modern vibrating membrane nebuliser and allows the administration of a therapeutic single does in markedly less than 10 minutes.

Owner:PARI PHARMA GMBH

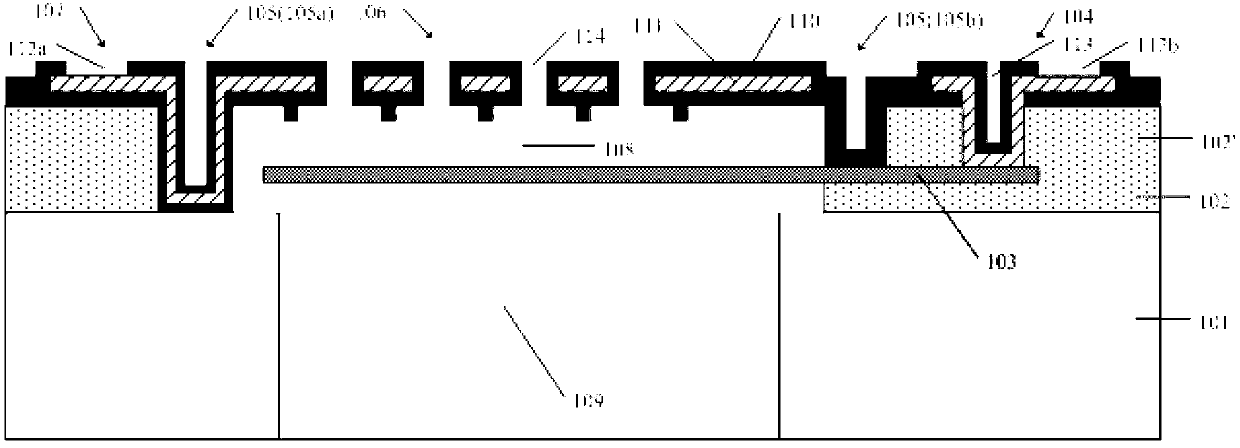

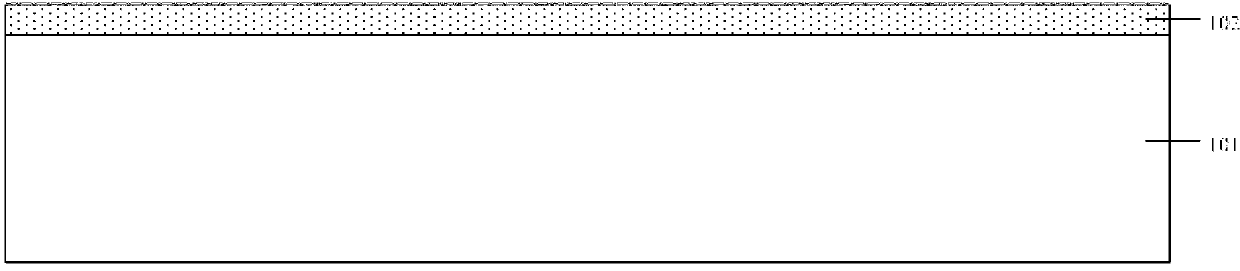

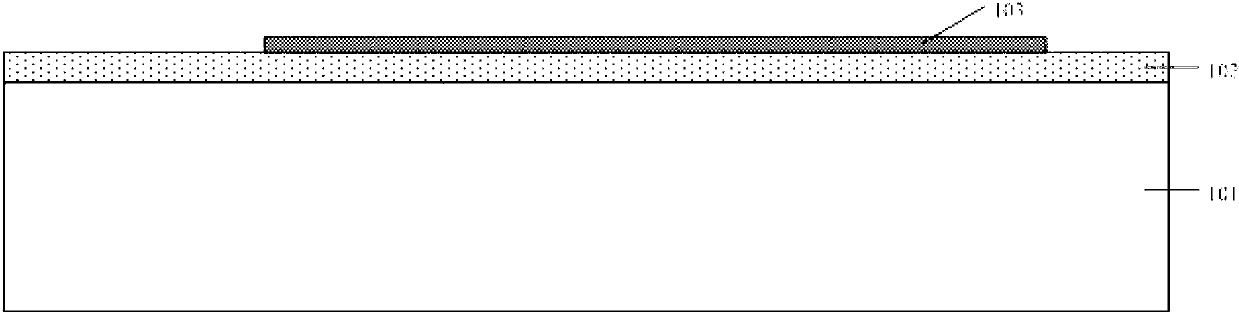

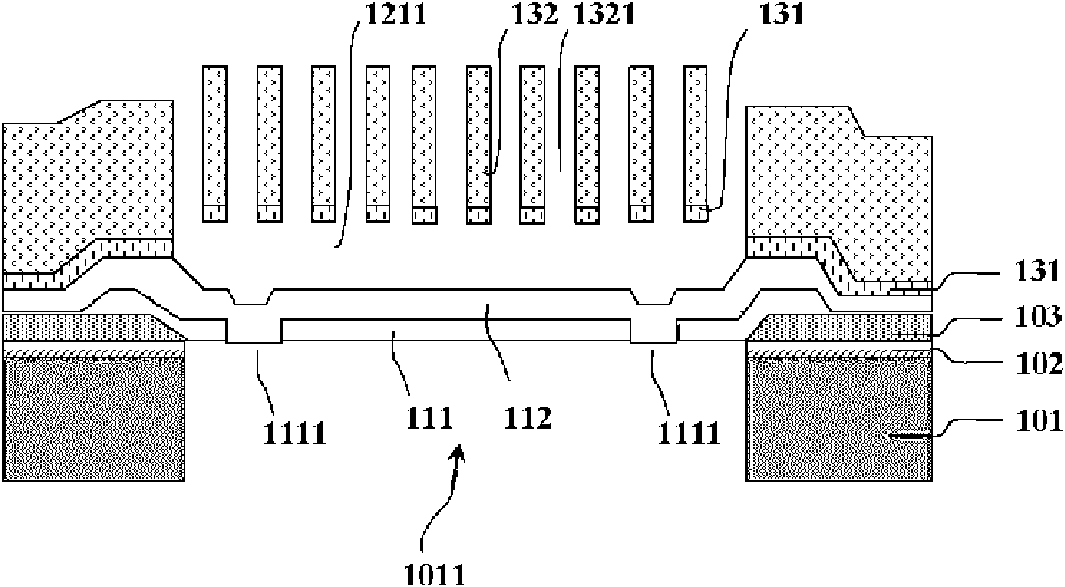

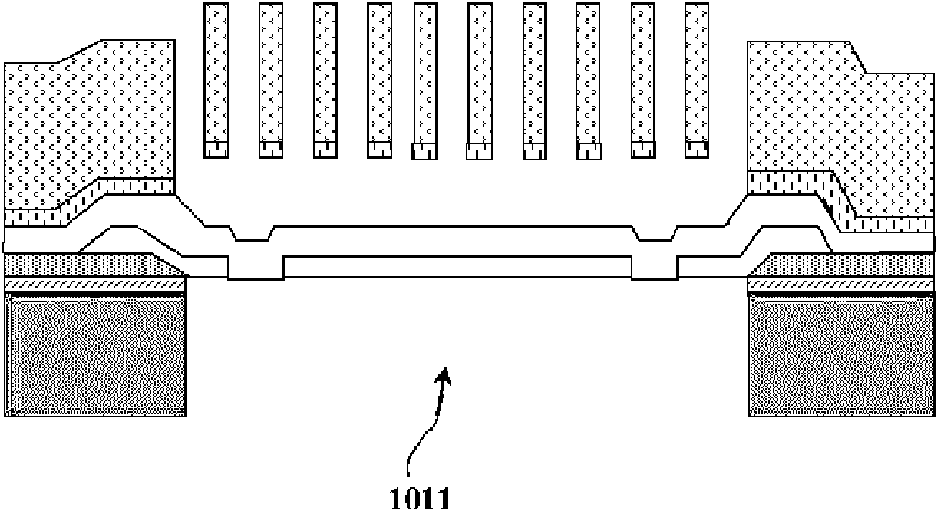

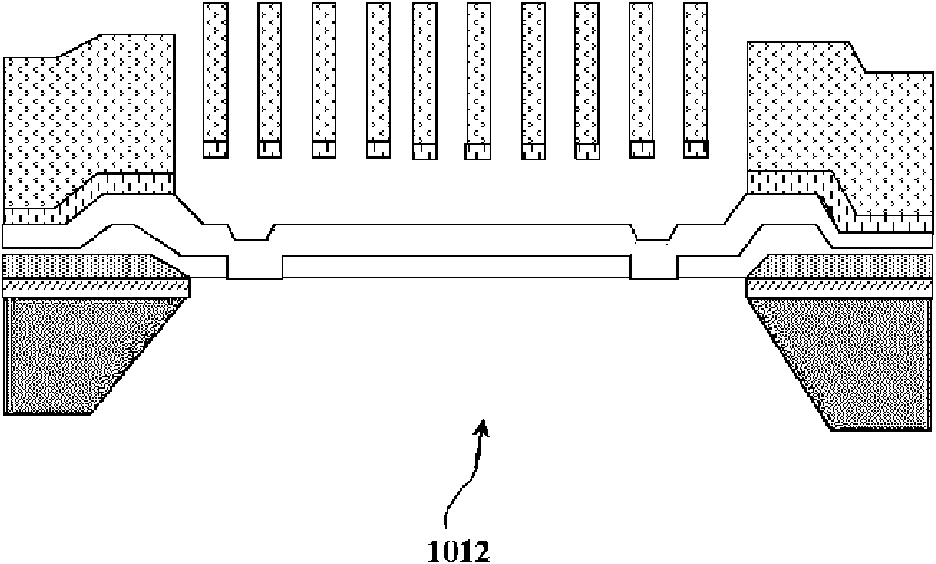

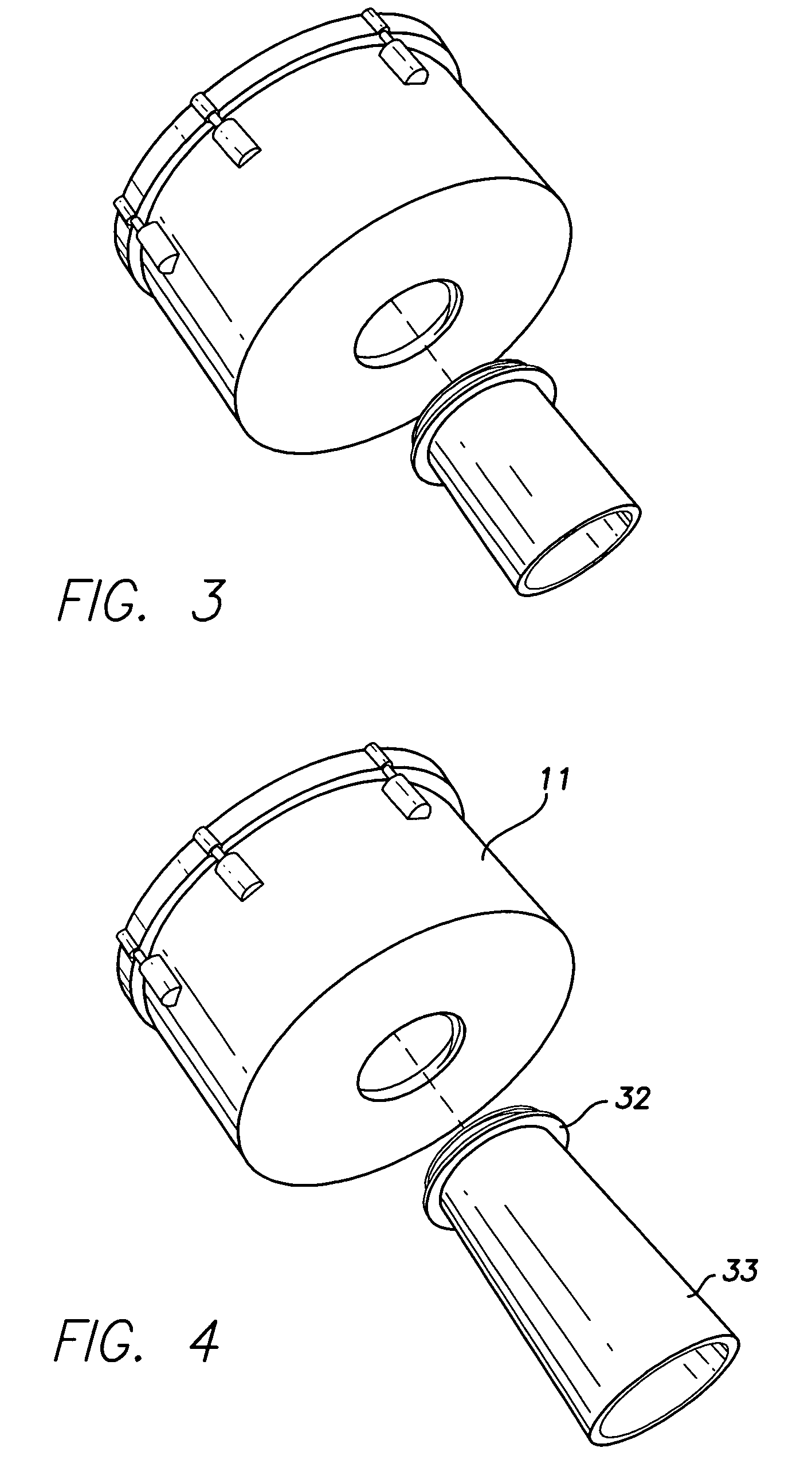

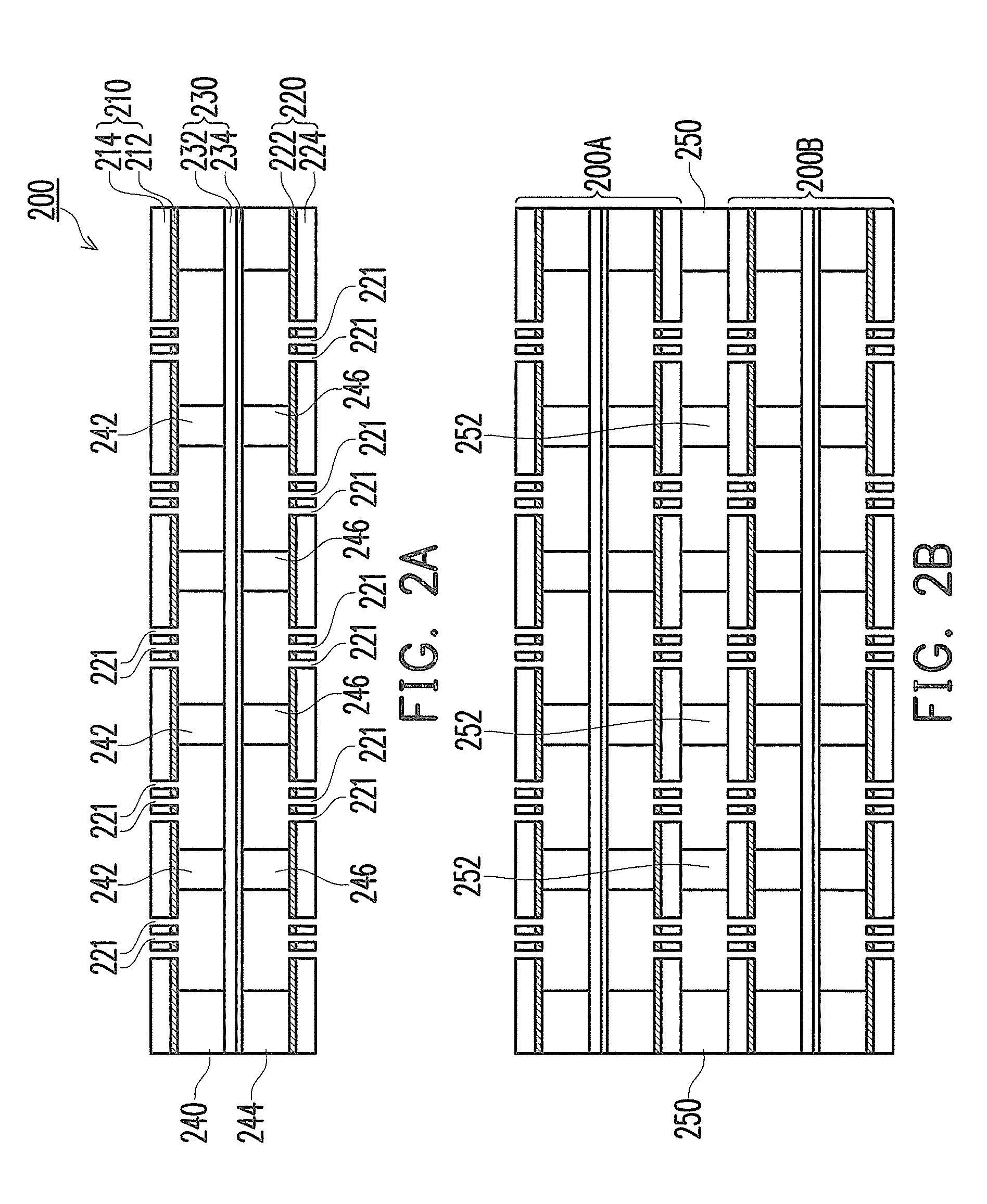

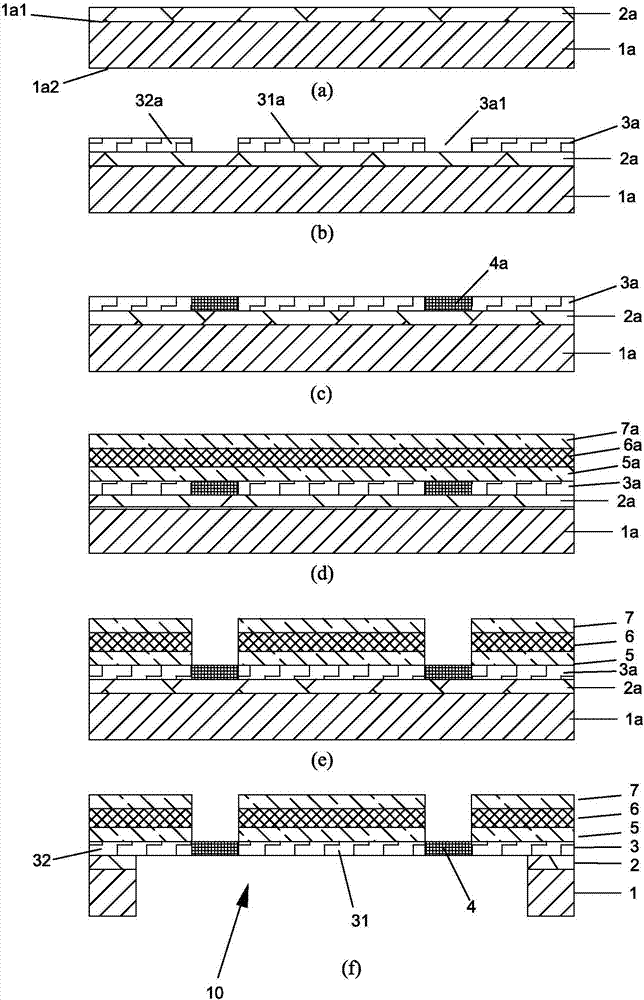

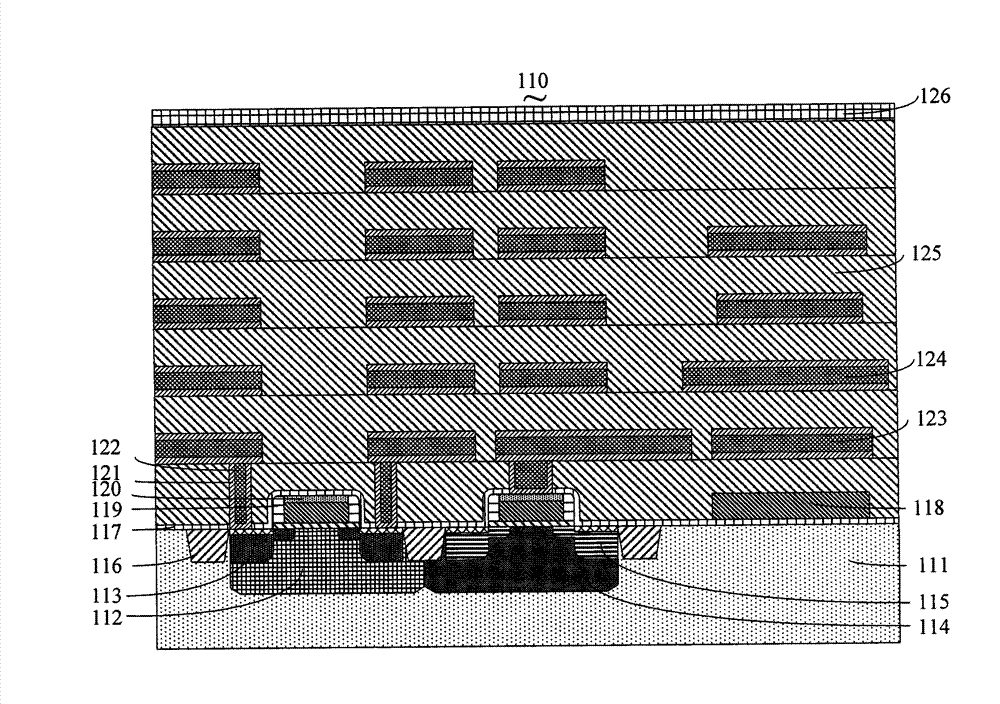

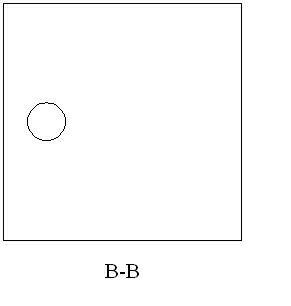

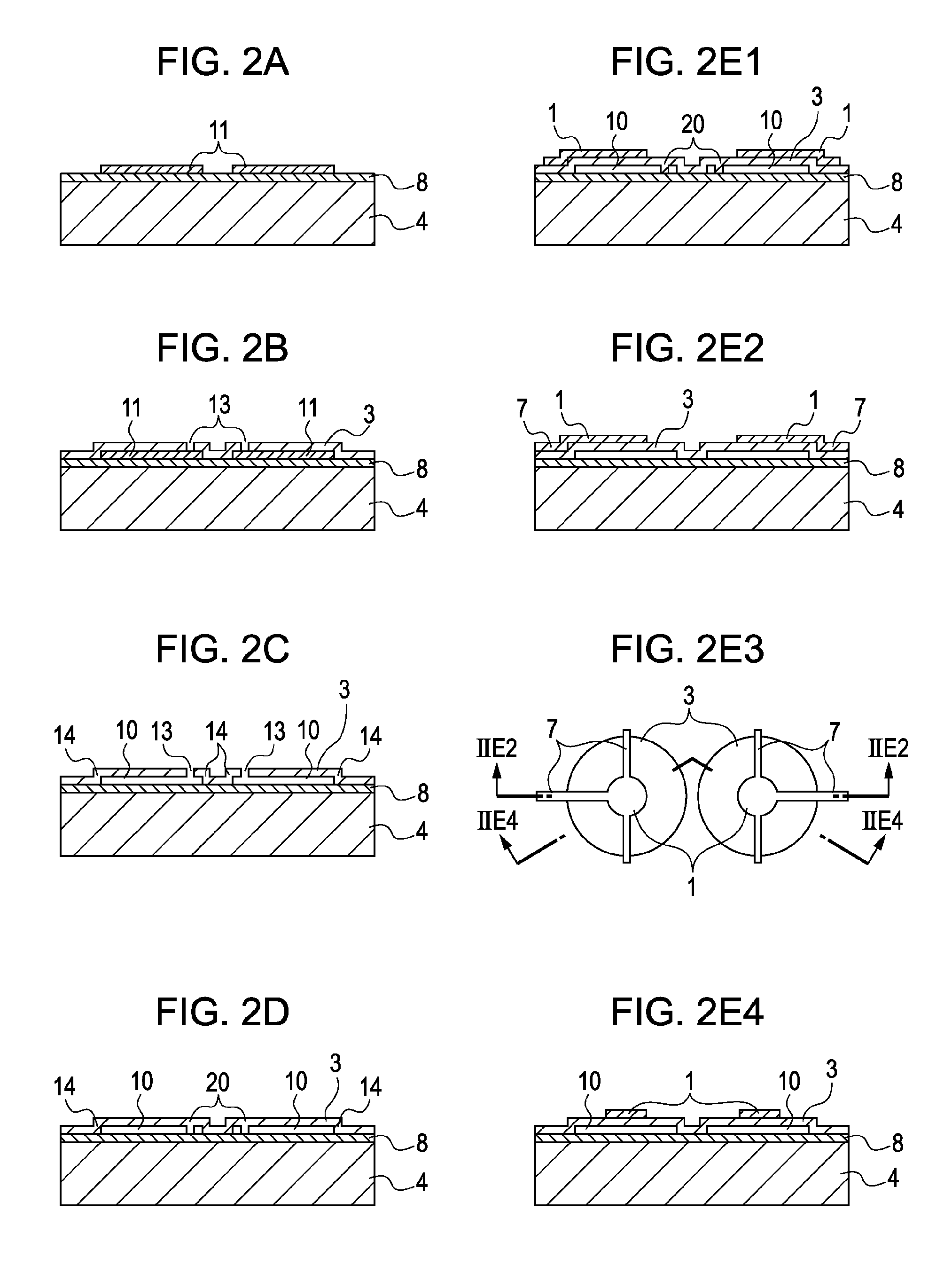

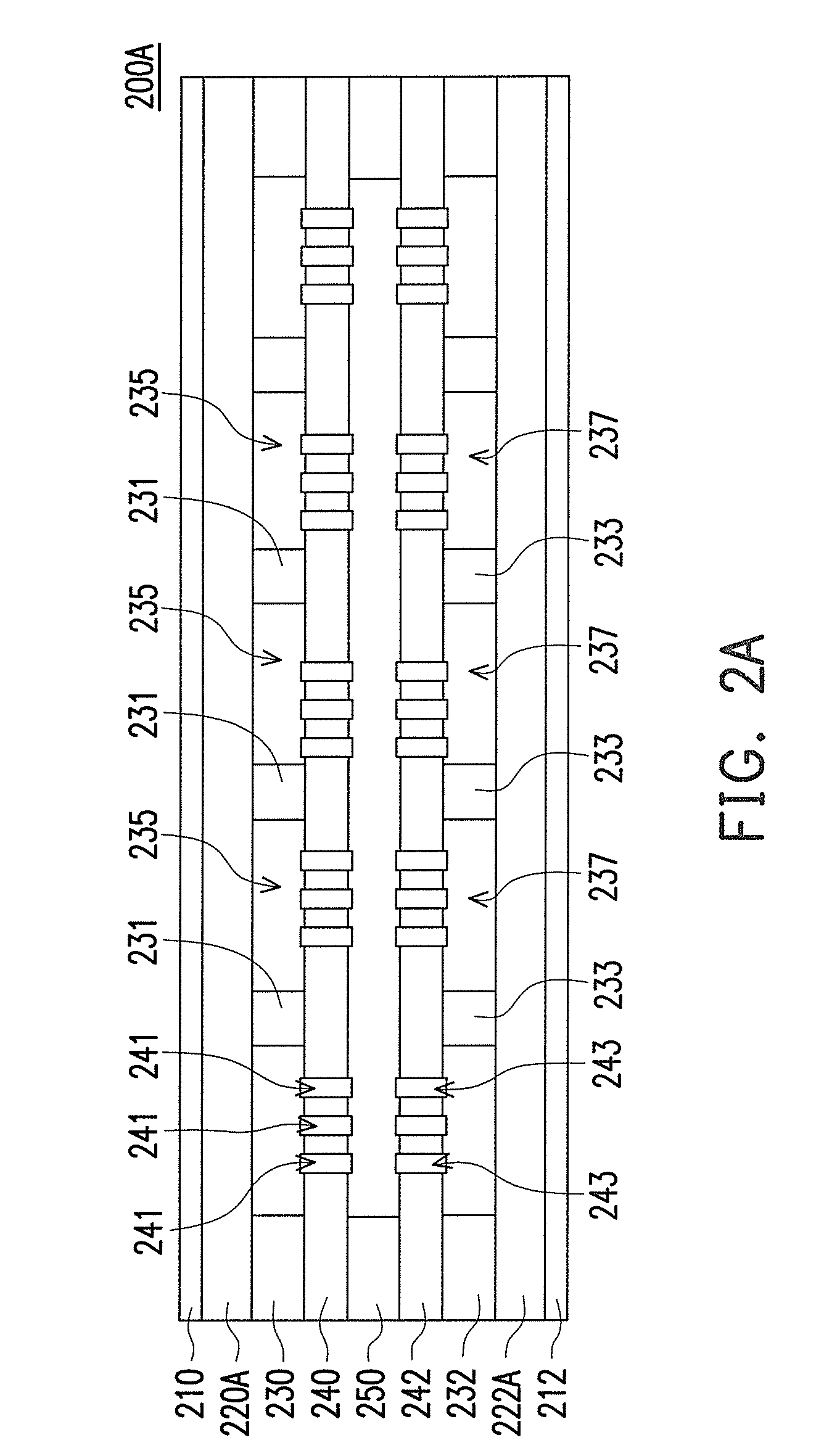

MEMS (micro electro mechanical system) microphone structure and manufacturing method of MEMS microphone structure

ActiveCN103281661AAvoiding Shedding DefectsNot easy to damageSemiconductor electrostatic transducersElectrostatic transducer microphonesVibrating membraneMems microphone

The invention discloses an MEMS (micro electro mechanical system) microphone structure, which comprises a semiconductor substrate, a first dielectric layer, a lower electrode vibrating membrane and an upper electrode structure, wherein the semiconductor substrate is provided with a cavity, the first dielectric layer is provided with a through hole communicated with the cavity, the lower electrode vibrating membrane is positioned above the through hole, in addition, at least one part of the lower electrode vibrating membrane is in contact with the upper surface of the first dielectric layer, the lower electrode vibrating membrane is led out from a lower electrode connecting part, the upper electrode structure is provided with an insulating layer and comprises an annular support structure, a backboard and an upper electrode connecting part, the backboard is provided with a plurality of through holes, at least one part of the annular support structure downwards extends to the lower electrode vibrating membrane, the rest parts of the annular support structure downwards extend to the substrate, the backboard is hung above the lower electrode vibrating membrane through the annular support structure, in addition, an air gap is formed between the backboard and the lower electrode vibrating membrane, and an upper electrode is embedded in the insulating layer of the backboard and is led out from the upper electrode connecting part. The MEMS microphone structure has the advantage that the damage or the falling of the upper electrode and the vibrating membrane in the release process can be avoided.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

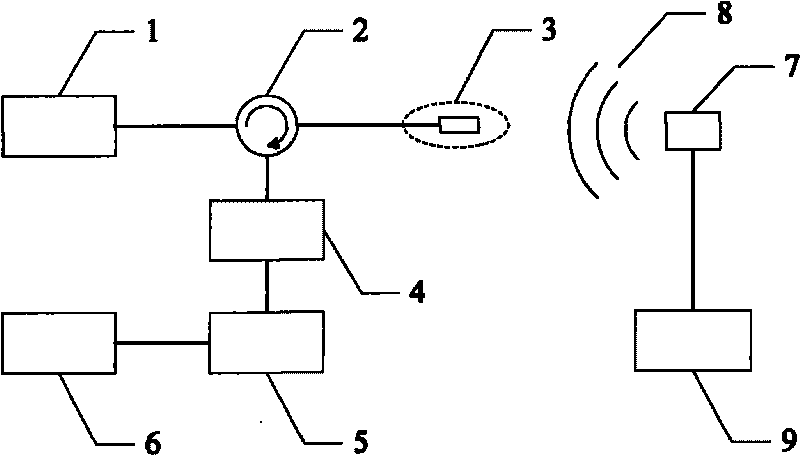

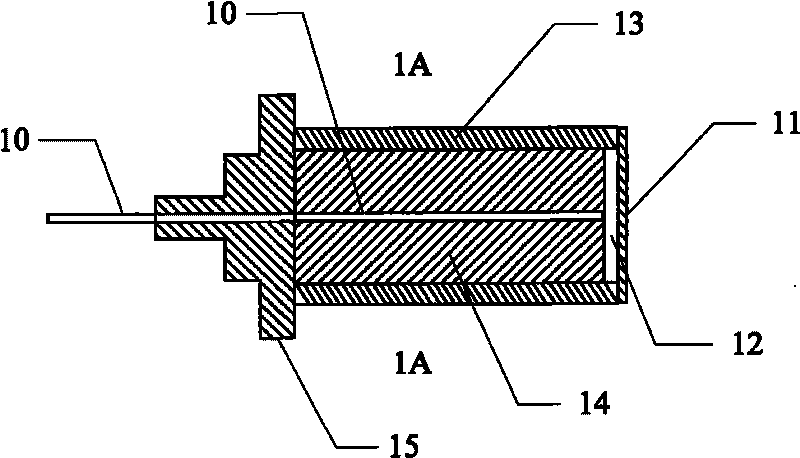

Optical fiber extrinsic Fabry-Perot interference ultrasonic sensing and detection device

InactiveCN101762318AImprove stabilityEasy to packTesting dielectric strengthSubsonic/sonic/ultrasonic wave measurementVibrating membraneUltrasound - action

The invention discloses an optical fiber extrinsic Fabry-Perot interference ultrasonic sensing and detection device, comprising a 1550nm light source, a 1550nm optical circulator, an optical fiber Fabry-Perot ultrasonic sensor, a photoelectric transition module, a signal amplification module, an oscillograph, a piezoelectric transducer and a signal generator. The basic structure of the optical fiber Fabry-Perot ultrasonic sensor is composed of a single mode optical fiber, a quartz vibrating membrane, an outer ceramic bushing, an inner ceramic bushing and a metal base. The light emitted by the 1550nm light source reaches the optical fiber Fabry-Perot ultrasonic sensor through the optical circulator, when ultrasonic wave acts on the ultrasonic sensor, as the light reflected by the optical fiber Fabry-Perot ultrasonic sensor is modulated by the ultrasonic signal, the reflected light reaches the photoelectric conversion module by the circulator and then is converted into an electric signal, and the ultrasonic signal can be observed by the oscillograph after amplification. The invention has simple structure, easy manufacture, low cost and high sensitivity, strong practicability, easy encapsulation and is convenient for mass production, and can be applied to related fields of industrial detection, power system safety and the like.

Owner:SHANGHAI UNIV

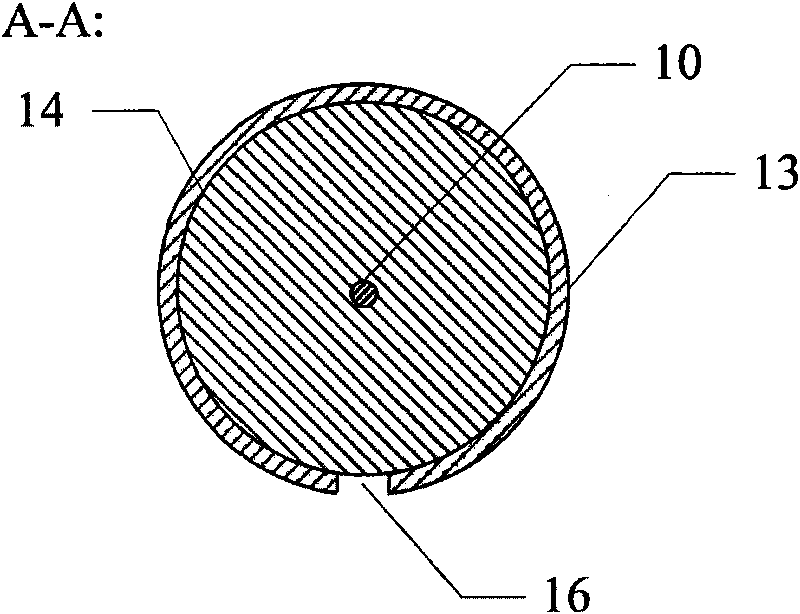

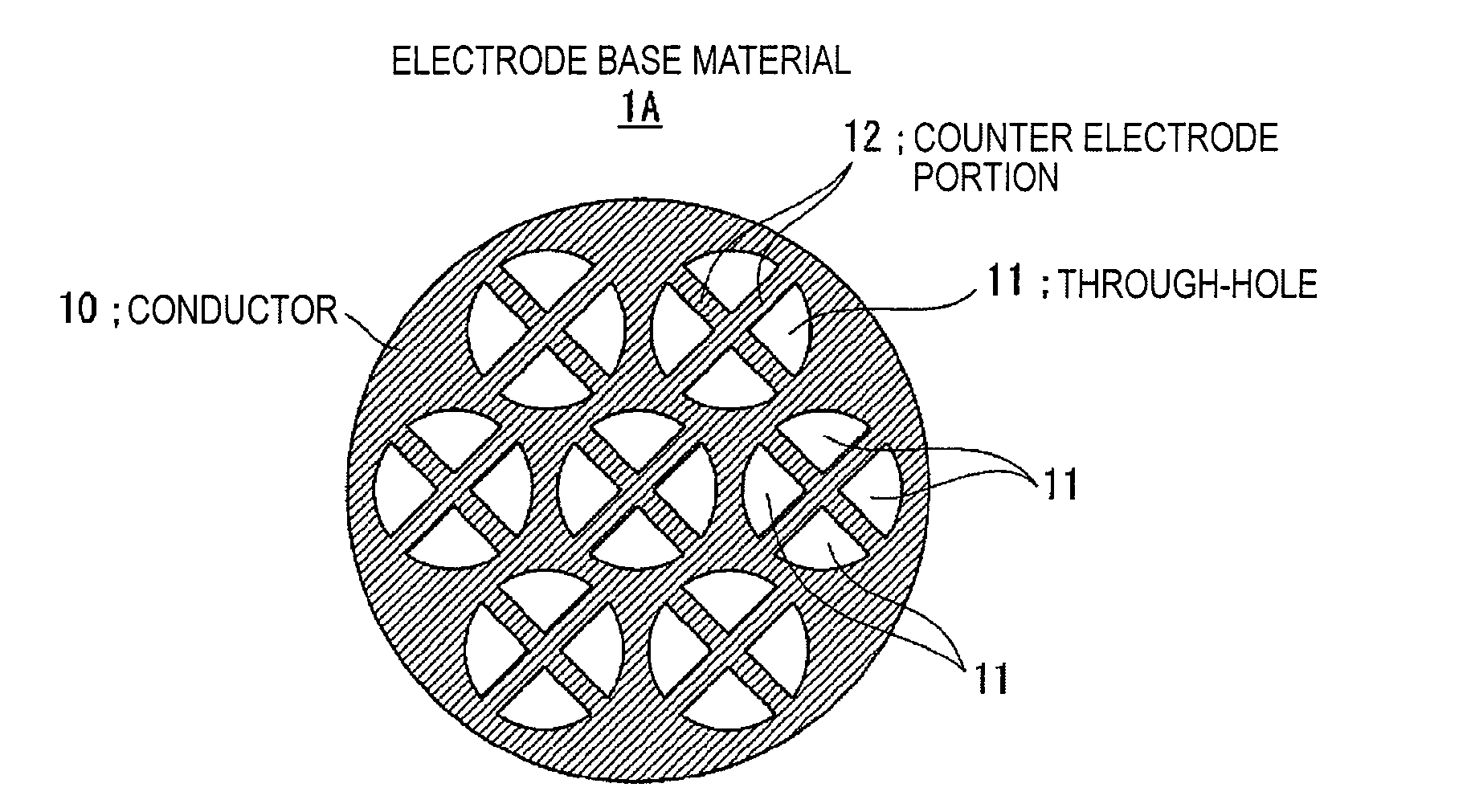

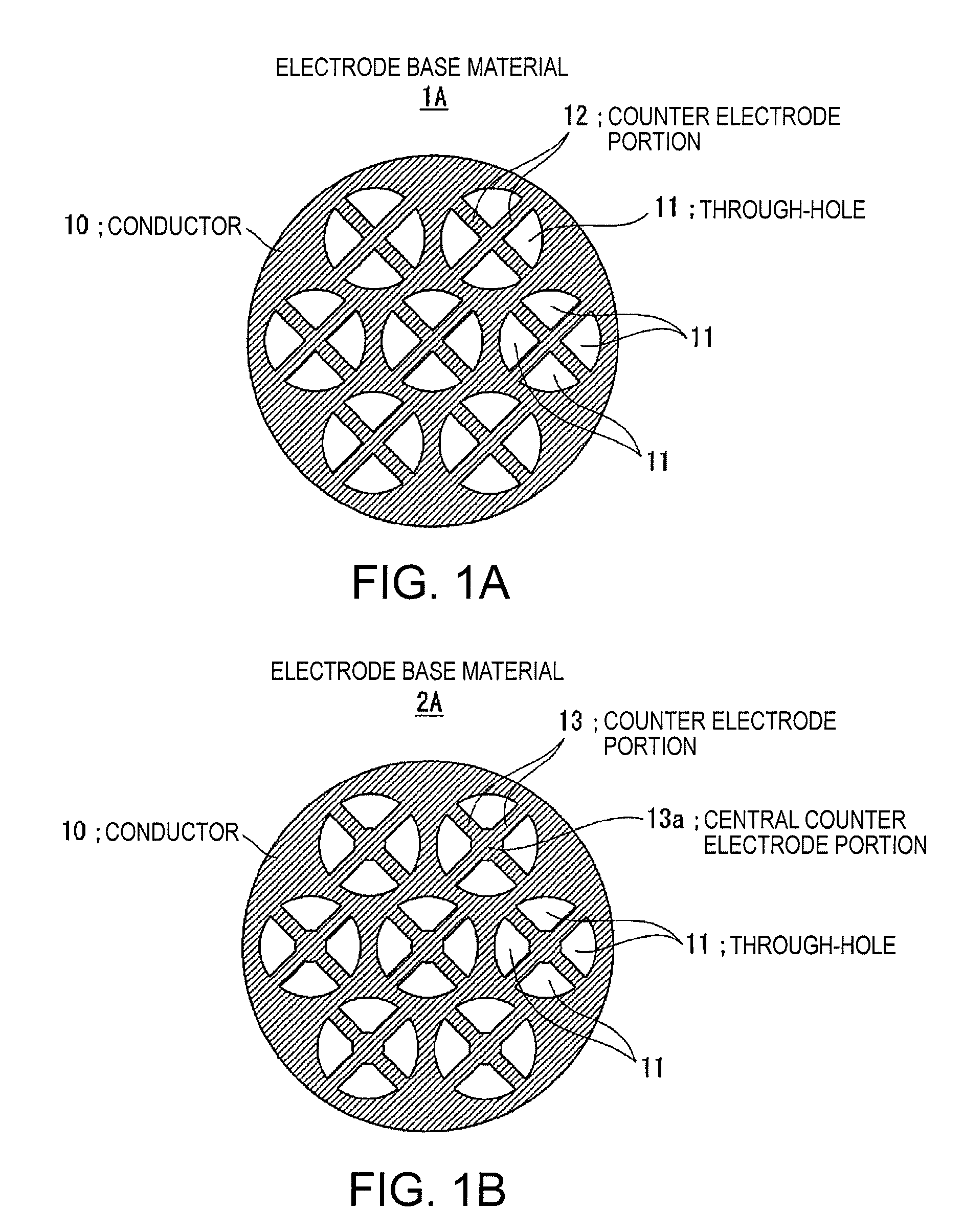

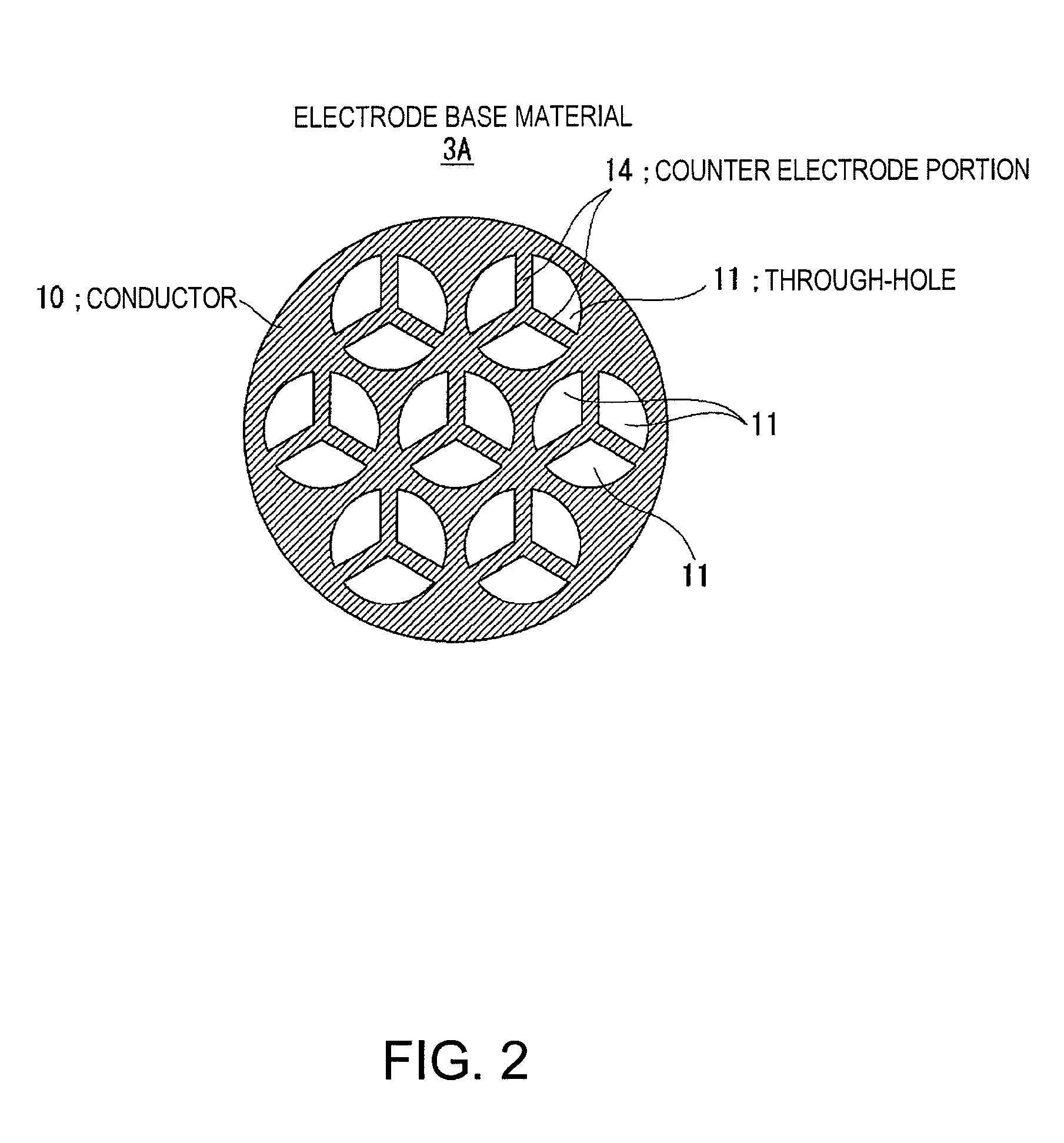

Electrostatic ultrasonic transducer, method of manufacturing electrostatic ultrasonic transducer, ultrasonic speaker, method of reproducing sound signal, and super-directivity sound system, and display device

InactiveUS20070195976A1Increase the output sound pressureEfficiently displacedElectrostatic transducersTransducer casings/cabinets/supportsVibrating membraneSignal wave

An electrostatic ultrasonic transducer includes a first electrode that has through-holes, a second electrode that has through-holes, and a vibrating membrane that is disposed such that the through-holes of the first electrode and the through-holes of the second electrode form a pair, interposed between a pair of electrodes composed of the first electrode and the second electrode, and having a conductive layer applied with a direct current bias voltage. The first electrode and the second electrode each have counter electrode portions that are formed in the through-holes to face the vibrating membrane, and a modulated wave, which is obtained by modulating a carrier wave in an ultrasonic frequency band with a signal wave in an audible frequency band, is applied between the pair of electrodes.

Owner:SEIKO EPSON CORP

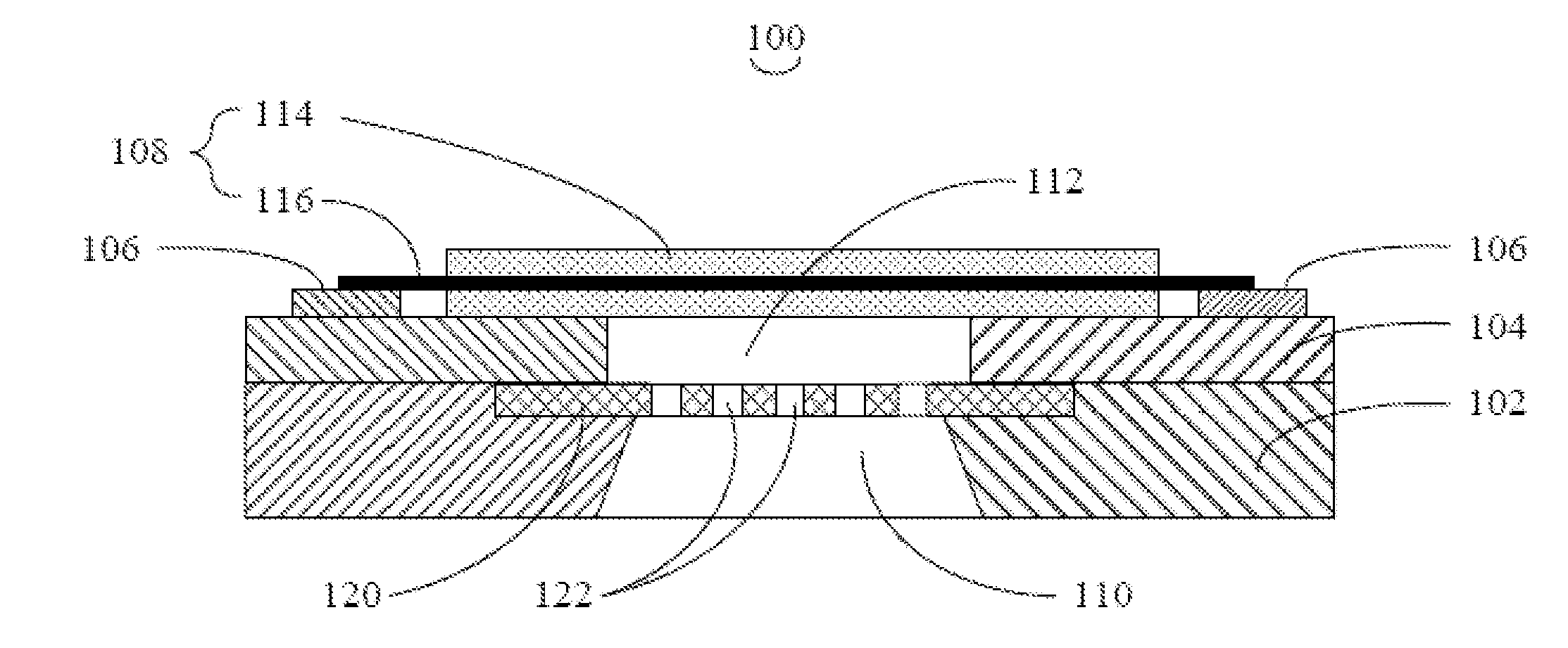

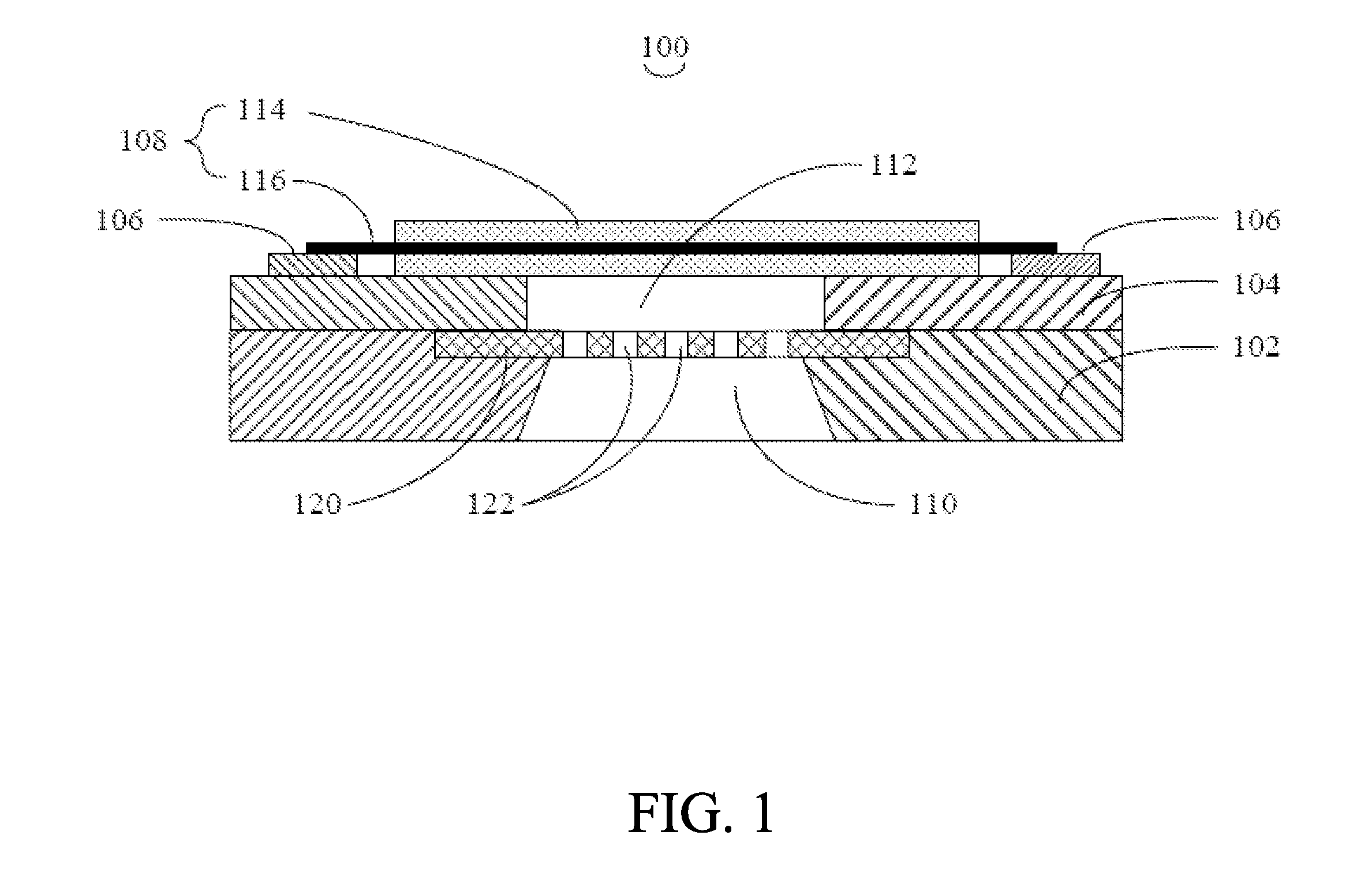

Capacitance type microphone with stress release membrane prepared at a low temperature and preparation method thereof

InactiveCN101572850AHigh sensitivityReduce parasitic capacitanceElectrostatic transducer microphonesResonant cavityParasitic capacitance

A capacitance type microphone with a stress release membrane prepared at a low temperature and a preparation method thereof. The capacitance type microphone includes a substrate having at least a resonant cavity; a septum, arranged on the top of the resonant cavity and connected with the substrate for implementing a mechanical vibration when being excitated by an acoustic pressure wave; a back board, arranged on the top of the septum and having a plurality of perforations; an air gap is provided the back board and the septum; a capacitor is composed of the septum, the air gap and the back board. The method includes steps: forming the resonant cavity on the substrate; forming the septum on the top of the resonant cavity, wherein the septum is connected with the substrate; setting the back board on the top of the septum, wherein the back board has a plurality of perforations; forming the air gap between the back board and the septum. The invention is a MEMS capacitance type microphone processed by a completely low-temperature technique. It is capable of being used as a post IC circuit processing technique being compatible thereof. The structure of the vibration diaphragm of the capacitance type microphone is a stress-releasing structure, and is capable of reducing a parasitic capacitance. Comparing with the traditional initial stress release membrane, the invention improves the sensitivity of the microphone more effectively.

Owner:王文 +1

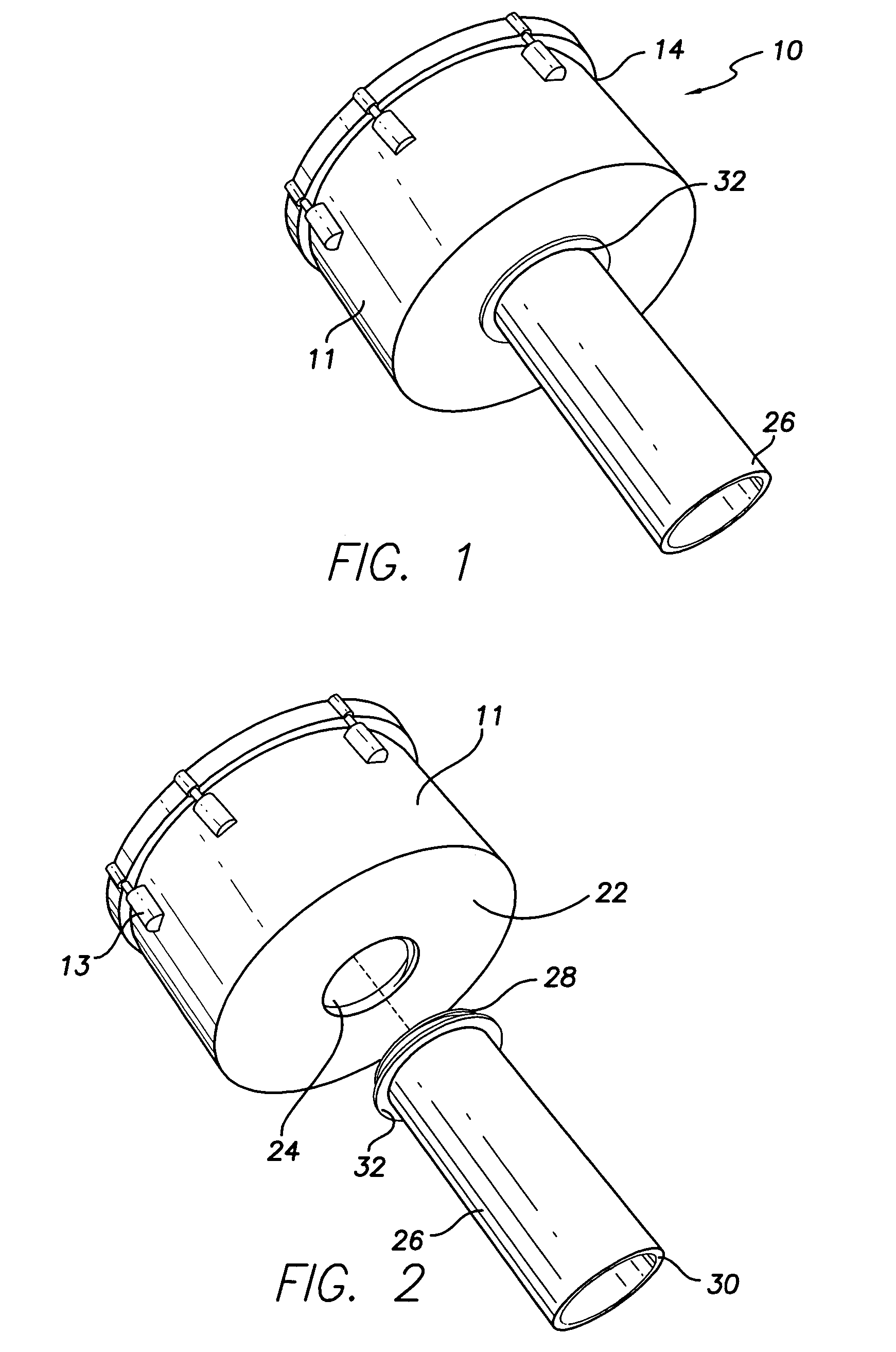

Pitch modulator drum

A drum with a vibrating membrane for producing sounds in a range of low to high resonant frequencies including a drum shell with a first open end and a second open end, a drumhead, including a vibrating membrane, covering said first open end, a cover with a threaded opening extending across and secured to said second end, and a resonant member having a first end and a second end, with the first end having a threaded means for detachable coupling with the threaded opening in the cap in airtight relation to enhance and manipulate the low resonant frequencies independent of the high resonant frequencies upon the striking of the membrane.

Owner:REMO INC

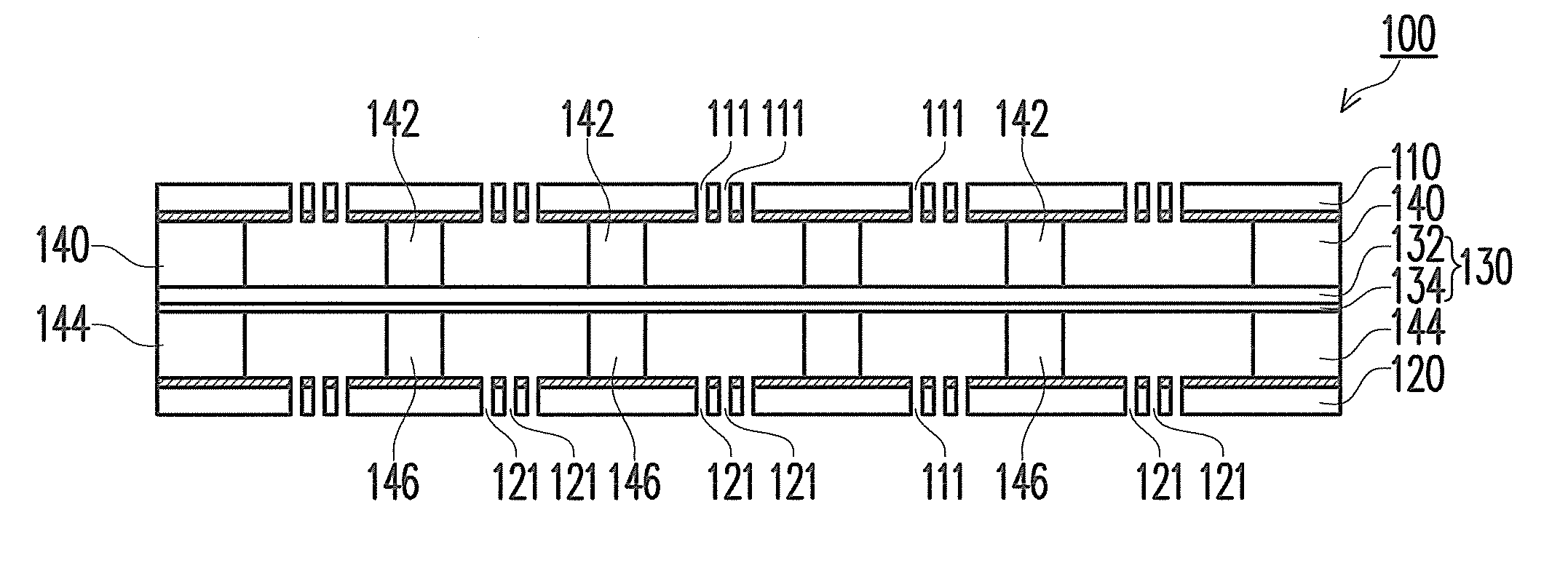

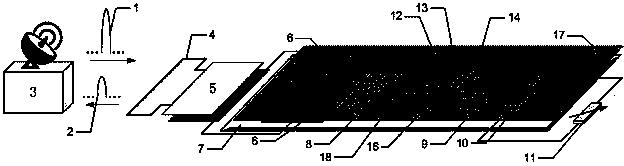

Flat speaker unit and speaker device therewith

ActiveUS20110255721A1Simple structureTransducer detailsElectrets selectrostatic transducerVibrating membraneEngineering

A flat speaker unit is provided herein. The flat speaker unit includes a first porous electrode, a second porous electrode, and a vibrating membrane with an electret layer disposed there between. In one embodiment, a plurality of supporting members may be configured between the vibrating membrane and the first porous electrode, or between the vibrating membrane and the second porous electrode. In one embodiment, a flat speaker device is provided with at least two flat speaker unit stacked together. By electrically connecting two ends of a signal source respectively to the first and second porous electrodes, or, in another embodiment, electrically connecting one end of the signal source to both of the first and second porous electrodes and connecting another end of the signal source to the vibrating membrane, a sound with low THD is generated accordingly from the flat speaker unit.

Owner:IND TECH RES INST

Micro-electro-mechanical pressure sensor

ActiveUS20090013792A1Fluid pressure measurement by electric/magnetic elementsElectricityVibrating membrane

The present micro-electro-mechanical pressure sensor includes a substrate, a dielectric isolation layer, at least two electrodes, and a vibrating membrane. The substrate includes an acoustic cavity. The dielectric isolation layer is formed on the substrate, and the dielectric isolation layer includes a through hole corresponding to the acoustic cavity. The at least two electrodes are separately formed on the dielectric isolation layer. The vibrating membrane covers the through hole, and the vibrating membrane includes at least one carbon nanotube structure with two opposite ends. The two opposite ends of the carbon nanotube are respectively connected to at least a given one of the at least two electrodes.

Owner:TSINGHUA UNIV +1

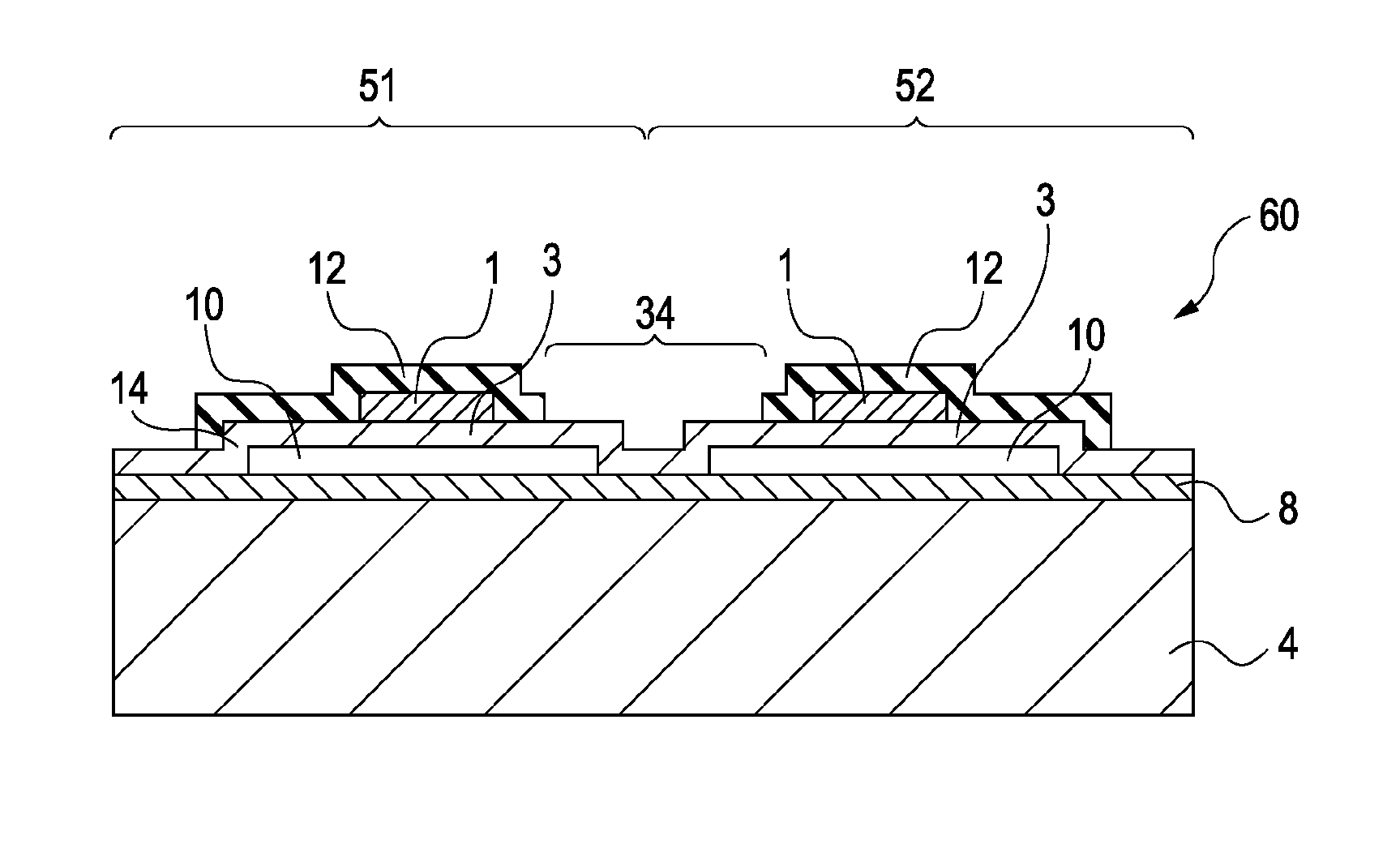

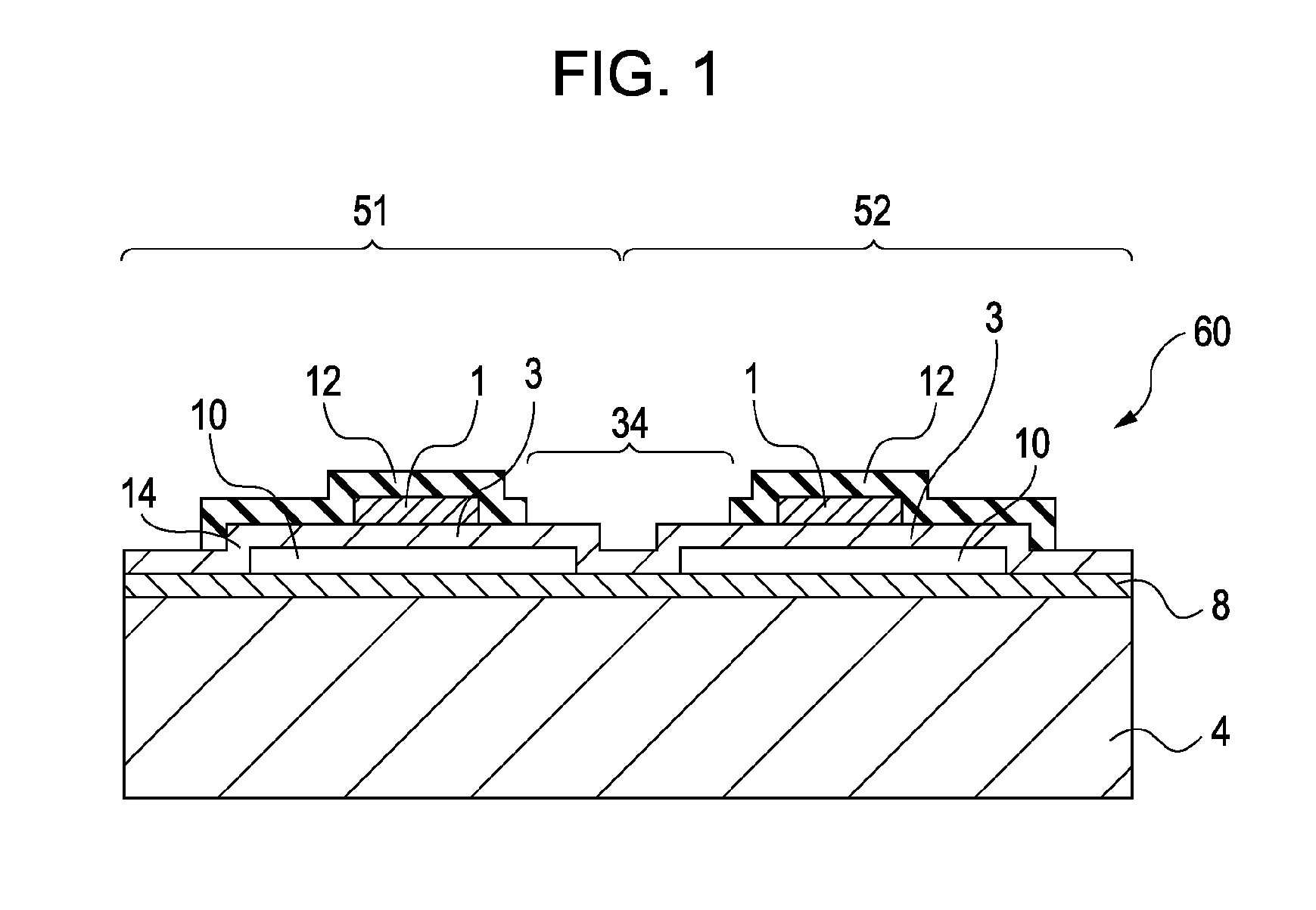

Capacitive electromechanical transducer

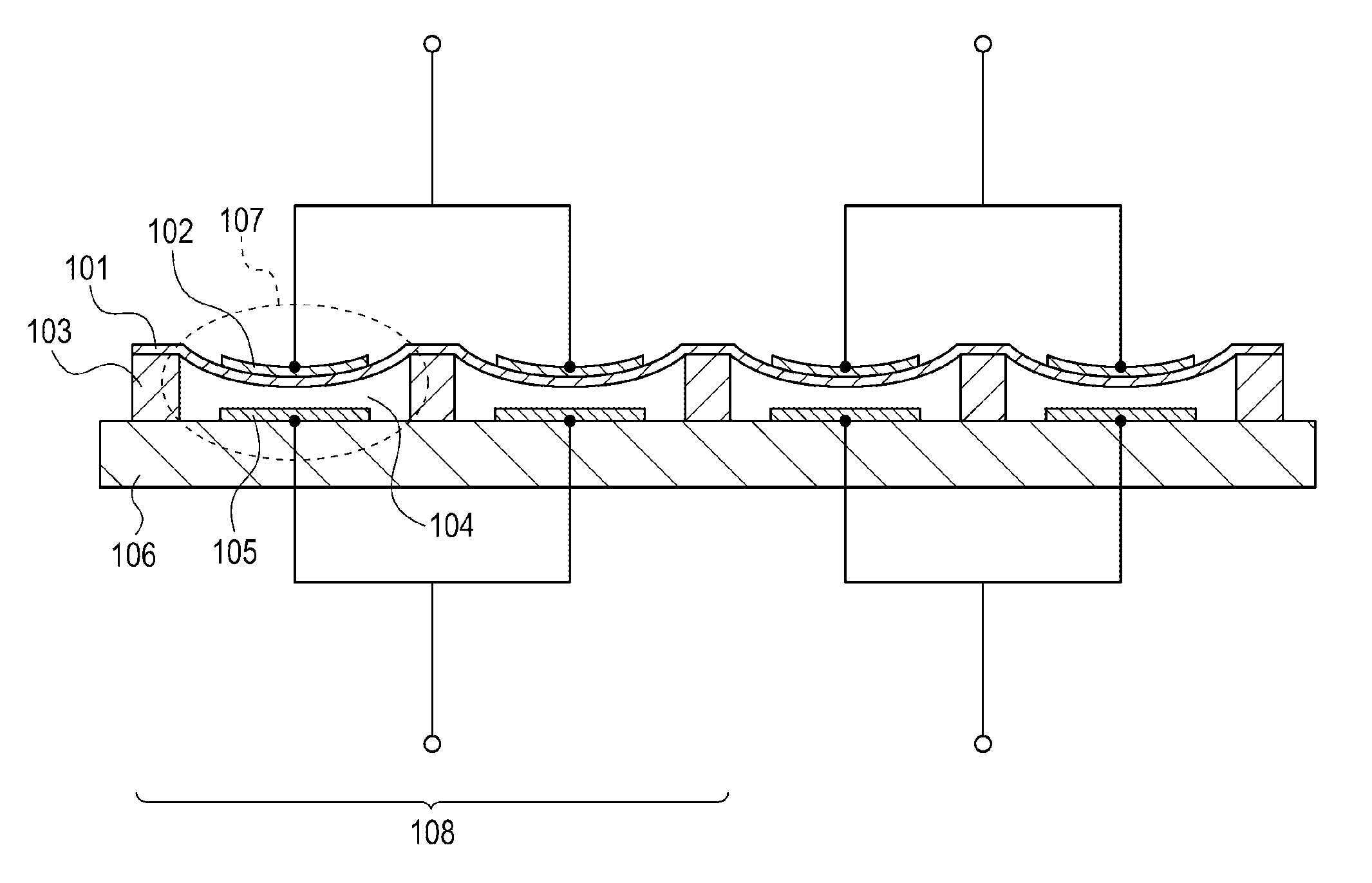

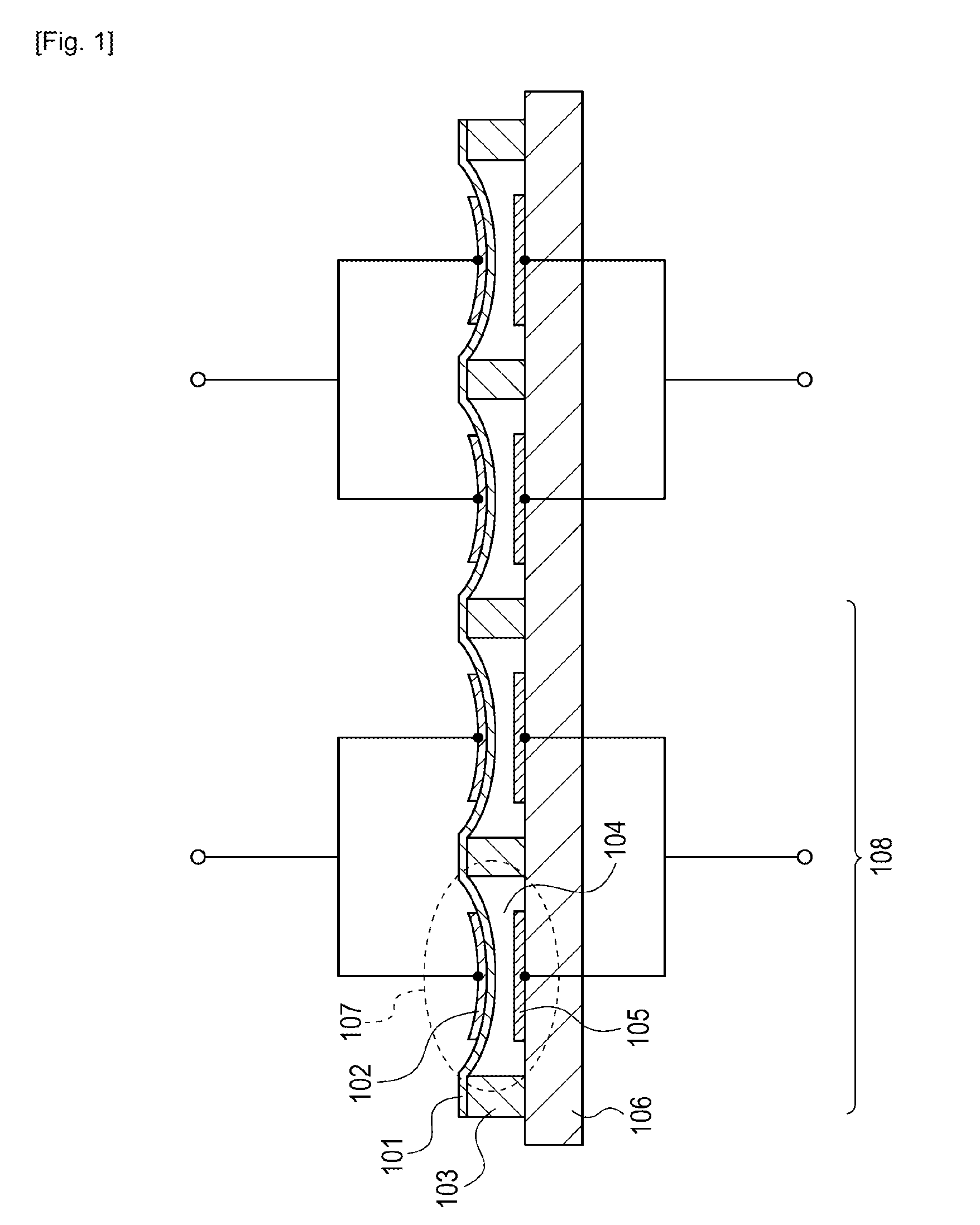

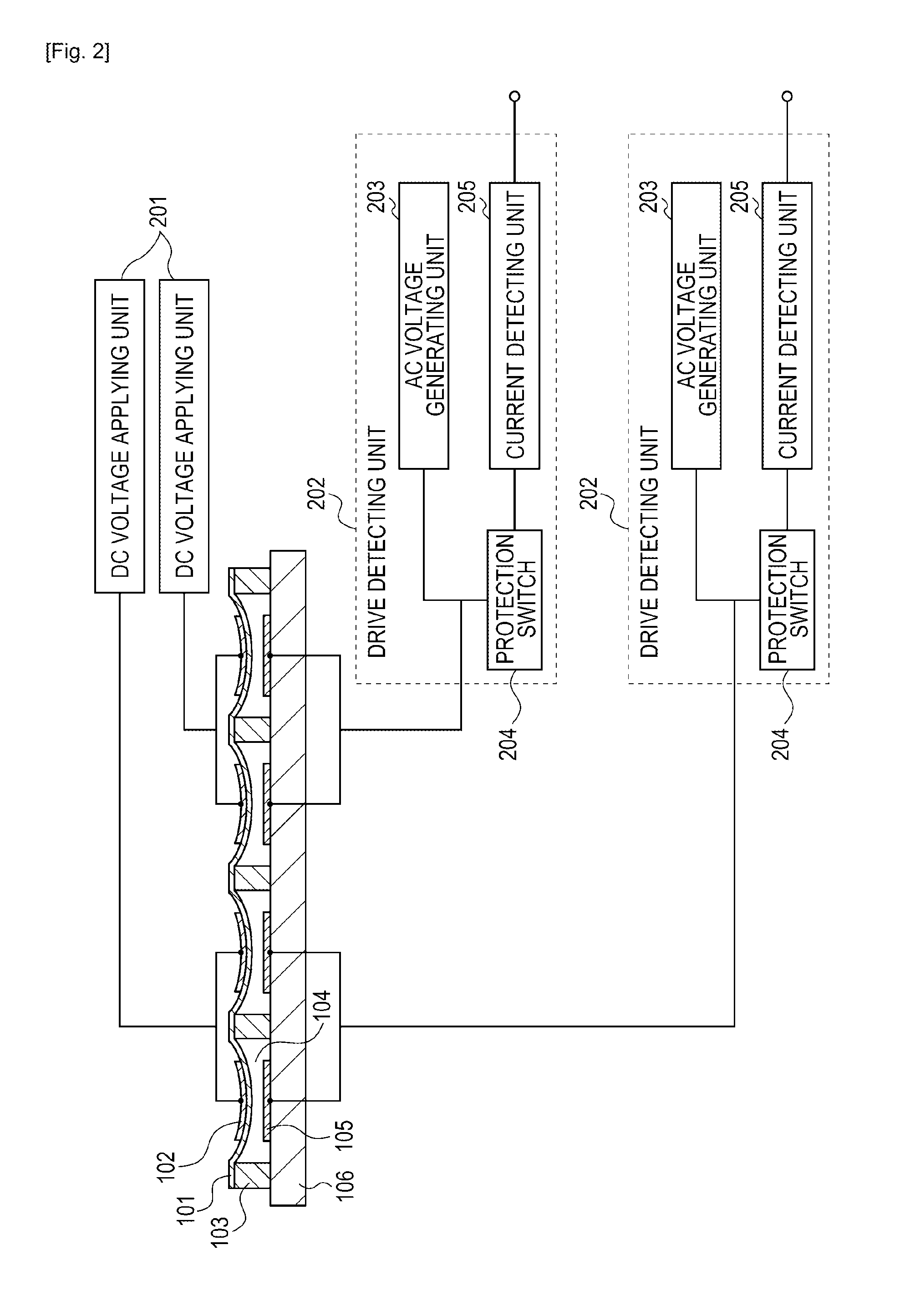

ActiveUS20120086307A1Improve featuresEfficient receptionMechanical vibrations separationElectrostatic motorsVibrating membraneEngineering

The present invention relates to an electromechanical transducer capable of arbitrarily varying the amount of deflection of a vibrating membrane for every element.The electromechanical transducer includes a plurality of elements including at least one cell that includes a first electrode and a second electrode opposed to the first electrode with a gap sandwiched therebetween and a direct-current voltage applying unit configured to be provided for each element and to separately apply a direct-current voltage to the first electrodes in each element. The first electrodes and the second electrodes are electrically separated for every element.

Owner:CANON KK

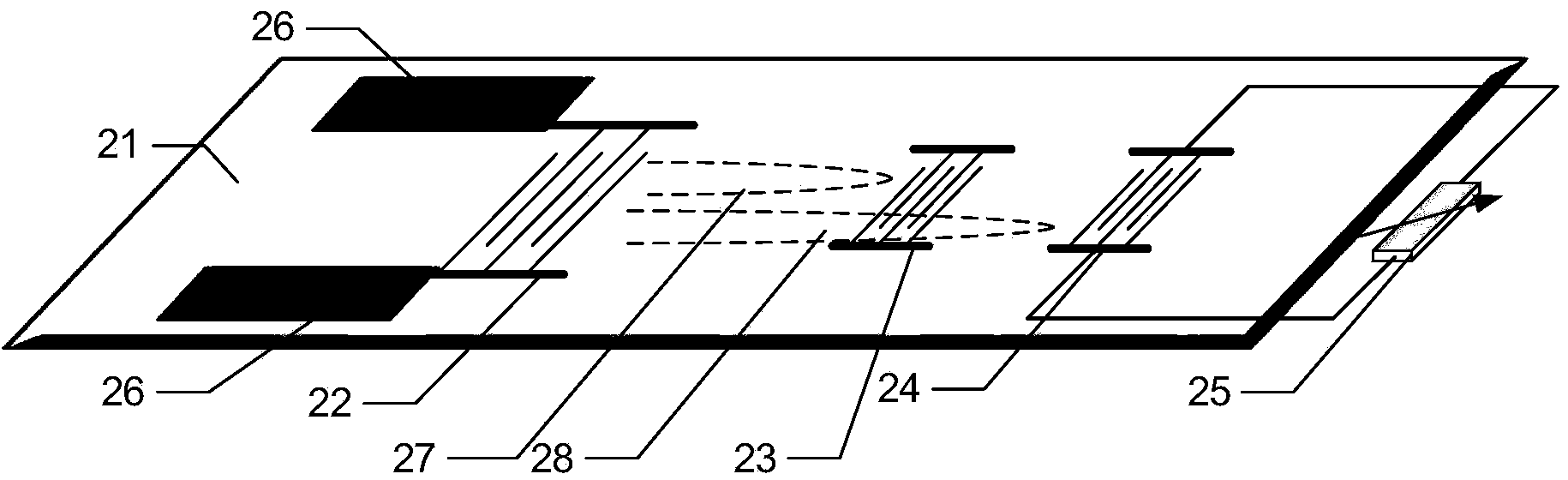

Piezoelectric ultrasonic transducer and manufacturing method thereof

ActiveCN107511318AIncreased sound pressure outputReduce the modulus of elasticityMechanical vibrations separationVibrating membraneUltrasonic sensor

The invention provides a piezoelectric ultrasonic transducer and a manufacturing method thereof. The piezoelectric ultrasonic transducer comprises a base, a vibrating membrane, a first electrode, a piezoelectric membrane and a second electrode, wherein the center of the base is provided with a cavity; the vibrating membrane is fixed to the base; the first electrode, the piezoelectric membrane and the second electrode are sequentially deposited on the vibrating membrane along a direction from the base to the vibrating membrane; the piezoelectric ultrasonic transducer is characterized in that the vibrating membrane comprises a first vibrating membrane and a second vibrating membrane, wherein the first vibrating membrane is positioned at the center; the second vibrating membrane is positioned at the outer side of the first vibrating membrane; the first vibrating membrane and the second vibrating membrane are arranged in a spaced manner and are connected with each other through an elastic structure layer; and the piezoelectric ultrasonic transducer is also provided with a through hole at a position corresponding to the elastic structure layer, wherein the through hole penetrates through the second electrode, the piezoelectric membrane and the first electrode. The piezoelectric ultrasonic transducer provided by the invention can improve output of sound pressure.

Owner:AAC TECH PTE LTD

Acoustic transducer

Provided is an acoustic transducer including: a semiconductor substrate; a vibrating membrane provided above the semiconductor substrate, including a vibrating electrode; and a fixed membrane provided above the semiconductor substrate, including a fixed electrode, the acoustic transducer detecting a sound wave according to changes in capacitances between the vibrating electrode and the fixed electrode, converting the sound wave into electrical signals, and outputting the electrical signals. At least one of the vibrating electrode and the fixed electrode is divided into a plurality of divided electrodes, and the plurality of divided electrodes outputting the electrical signals.

Owner:ORMON CORP +1

Generator collecting acoustic energy and sound sensor

ActiveCN104836473AImprove utilization efficiencyReduce sound energy lossTransducer detailsFriction generatorsVibrating membraneElectricity

The invention provides a generator capable of collecting acoustic energy, which combines a Helmholtz acoustic resonance cavity and a triboelectric nanometer generating component. The triboelectric nanometer generating component with thin membrane structures is arranged on the outer wall or at the opening position of the Helmholtz acoustic resonance cavity. Sound passes through the acoustic resonance cavity to allow an electrode layer and a frictional layer of the triboelectric nanometer generating component to mutually contact and separate and to generate electric energy on two electrode layers. The generator does not need to be provided with a vibrating membrane, and can reduce unnecessary acoustic energy loss, and efficiently convert sound energy into electric energy; the generate can be used as a sound sensor which does not need a power supply, and is a self-driven passive sound sensor.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

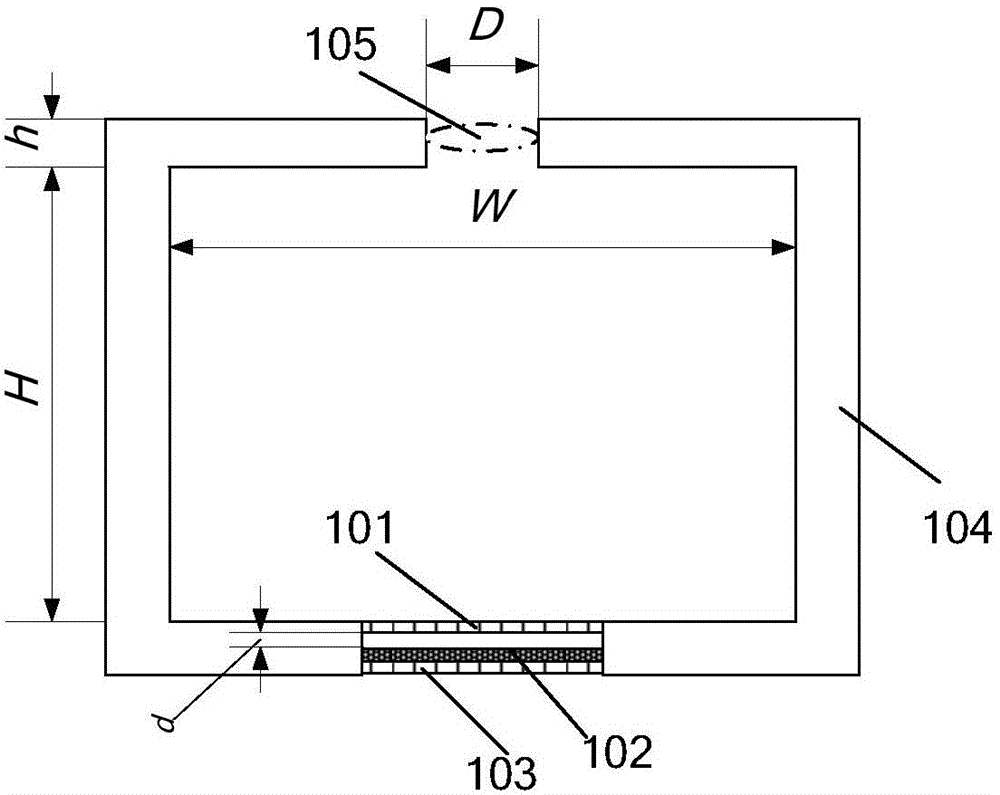

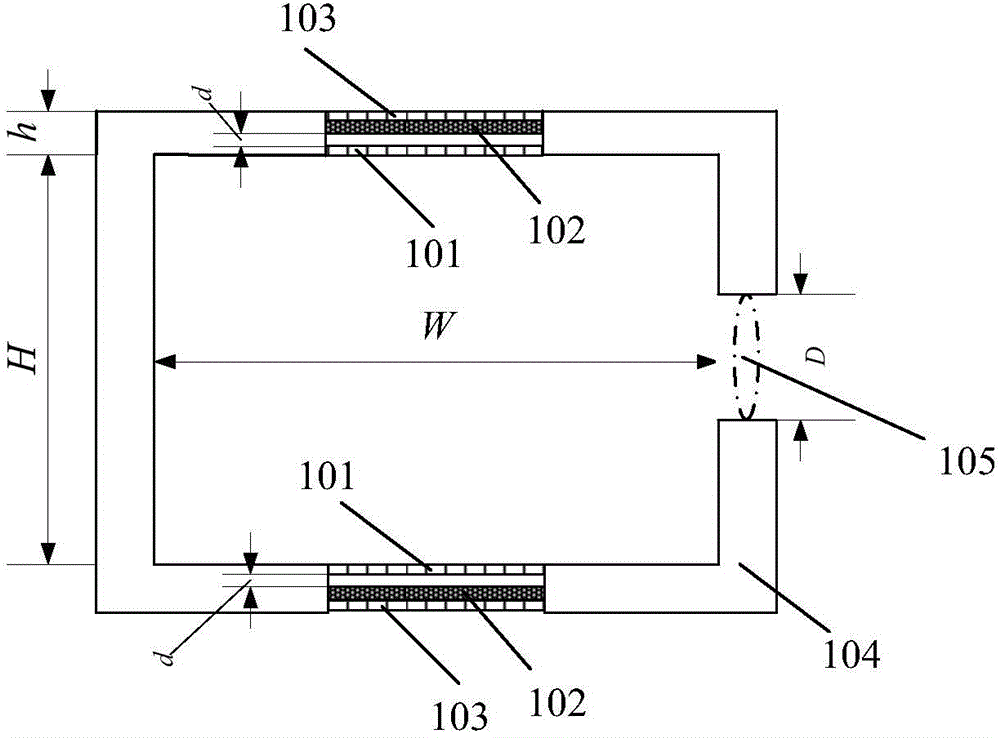

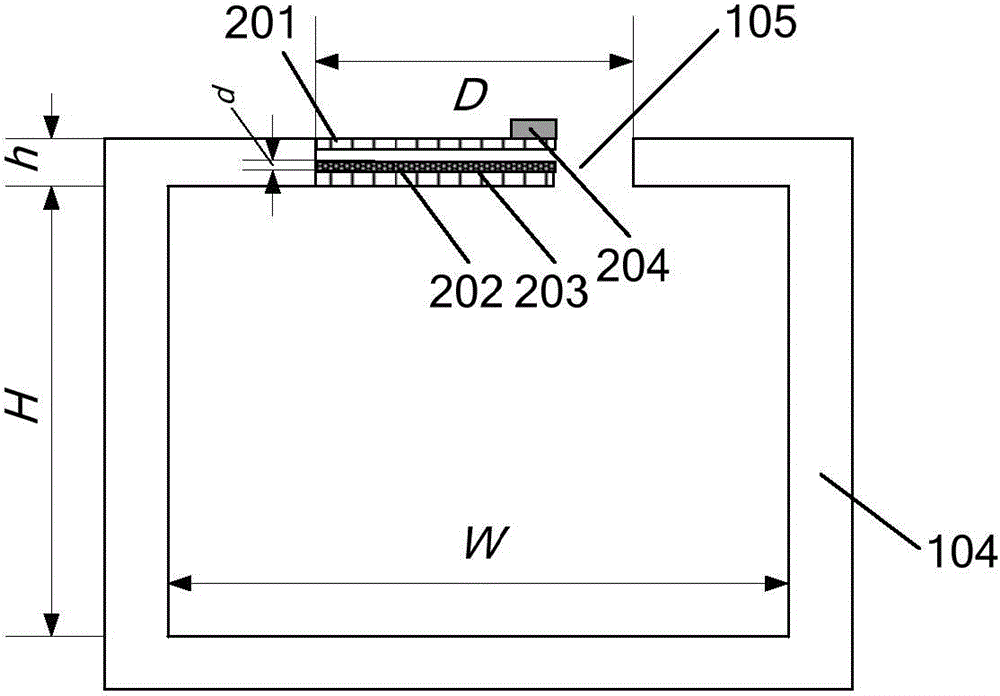

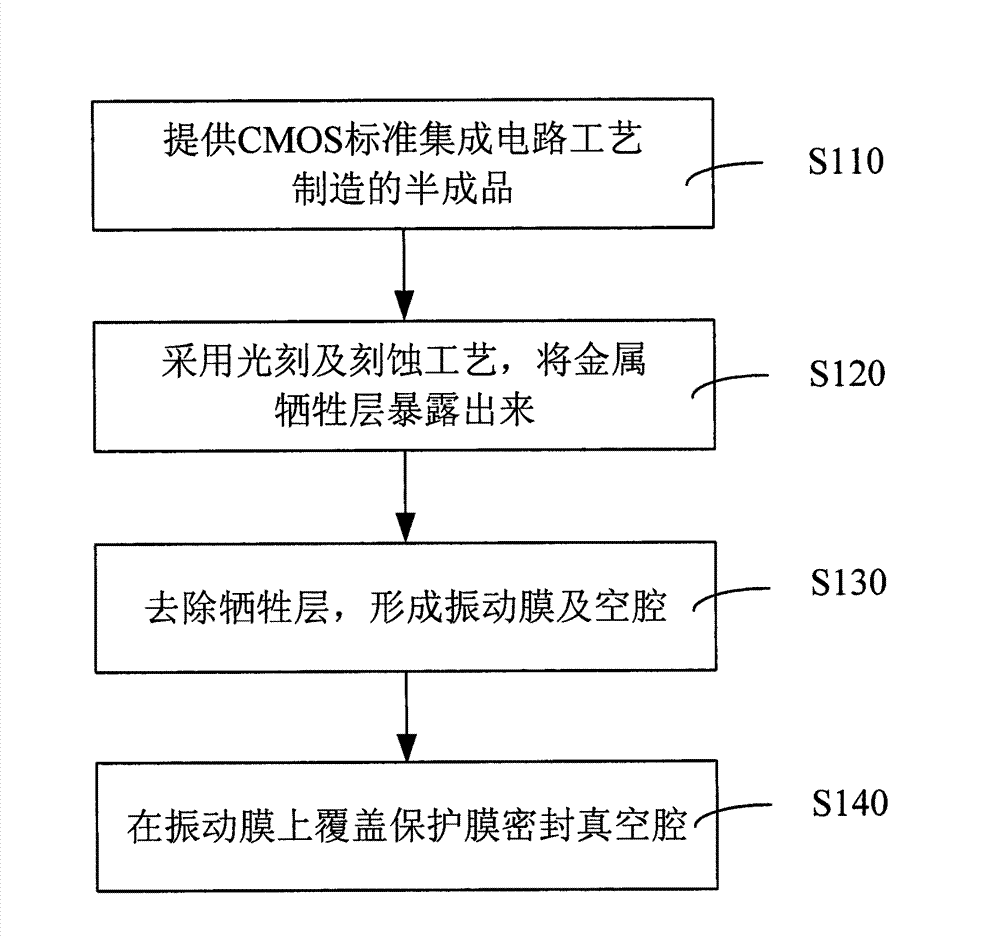

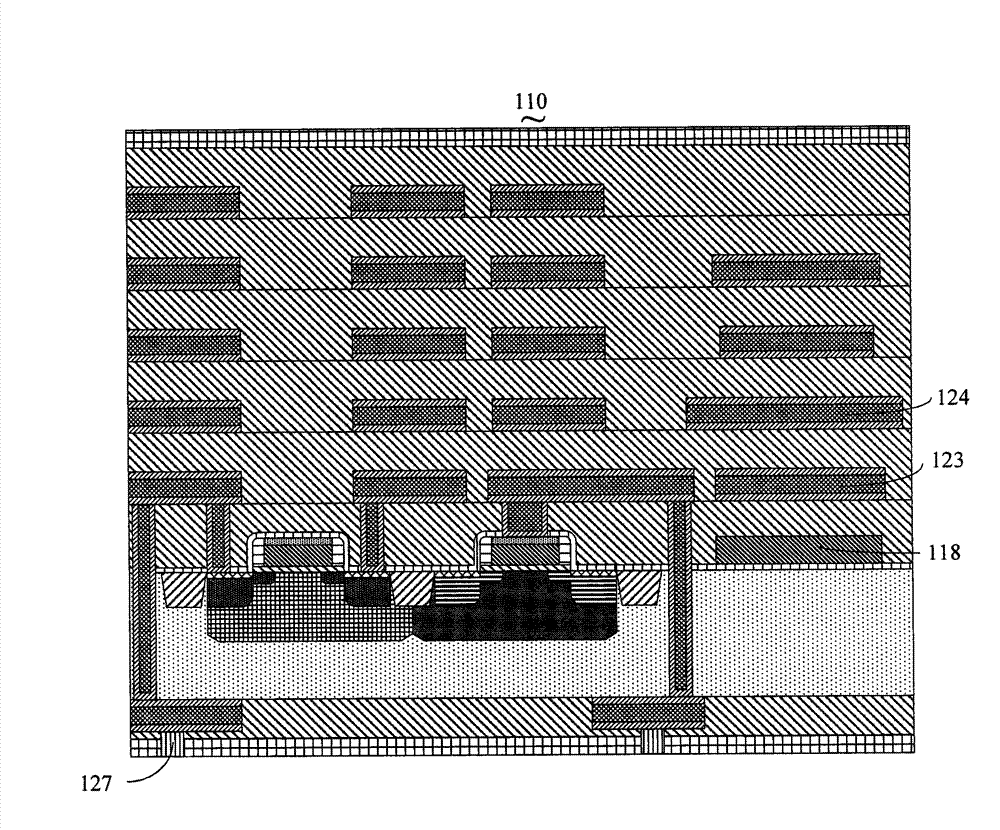

Absolute pressure transducer chip and production method thereof

ActiveCN102967407AImprove compatibilityImprove reliabilityDecorative surface effectsChemical vapor deposition coatingVibrating membraneMetallic materials

The invention relates to an absolute pressure transducer chip which comprises an absolute pressure transducer integrated on a complementary metal-oxide-semiconductor transistor (CMOS) chip. The absolute pressure transducer comprises a pressure sensitive unit, the pressure sensitive unit comprises a field-effect tube and a vibrating membrane, the field-effect tube comprises a floating gate, the vibrating membrane is provided with polycrystalline silicon or metal materials serving as grids in inserting mode and is used for inducing absolute pressure change, the floating gate is embedded in a dielectric layer of the CMOS chip, and a cavity is formed on the vibrating membrane and sealed. In the absolute pressure transducer chip, a sacrificial layer and the electric conductive vibrating membrane are manufactured on a metal electric conductive layer of an integrated circuit formed by aid of the CMOS standard manufacture process, and finally a pressure transducer micro-unit is manufactured, the existing CMOS process is not changed, and the absolute pressure transducer chip is good in compatibility. In addition, the invention further relates to a production method of the absolute pressure transducer chip.

Owner:SHENZHEN INST OF ADVANCED TECH

Noise power-generating device and noise power-generating equipment consisting of same

InactiveCN103219862ASave energyImprove efficiencyDynamo-electric machinesHelmholtz resonatorMagnetic poles

The invention provides a noise power-generating device and noise power-generating equipment consisting of the same. The noise power-generating device comprises a sound wave collecting pipe, wherein one end of the sound wave collecting pipe is opened; an air-isolating and sound-transmitting thin film is sealed at the opening of the sound wave collecting pipe; a trumpet-shaped inlet is also formed at the opening of the sound wave collecting pipe; a sound-isolating plate is arranged outside the sound wave collecting pipe 4; one end of the sound-isolating plate is connected with the trumpet-shaped inlet 1; the other end of the sound-isolating plate is connected with the closed end of the sound wave collecting pipe 4; the sound-isolating plate and the outer wall of the side surface of the sound wave collecting pipe form a cavity; a plurality of columns of acoustical-electrical converting units which are uniformly arranged along the axial direction are arranged on the side surface of the sound wave collecting pipe; each of the acoustical-electrical converting unit comprises a helmholtz resonator with a resonating cavity and an acoustical-electrical converter connected with the helmholtz resonator; the acoustical-electrical converter comprises a vibrating film arranged in the cavity in the tail end of the resonating cavity and connected with a coil through a connecting rod; a coil is sleeved on a magnetic pole; and the magnetic pole is arranged on the sound-isolating plate. The coil is connected with an output bus through a current-collecting wire, so that the mechanical energy of noise is converted into electric energy.

Owner:XI AN JIAOTONG UNIV

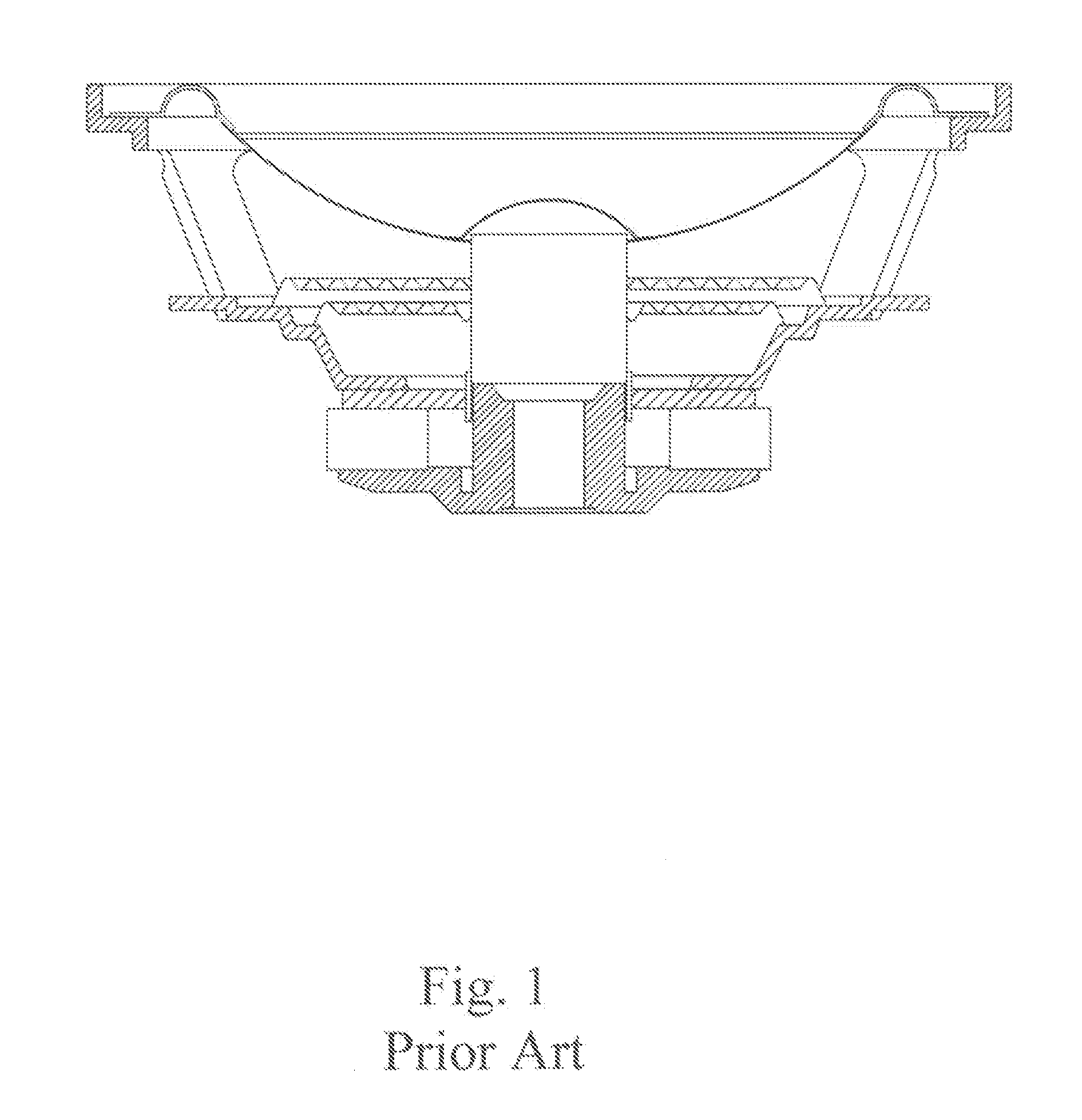

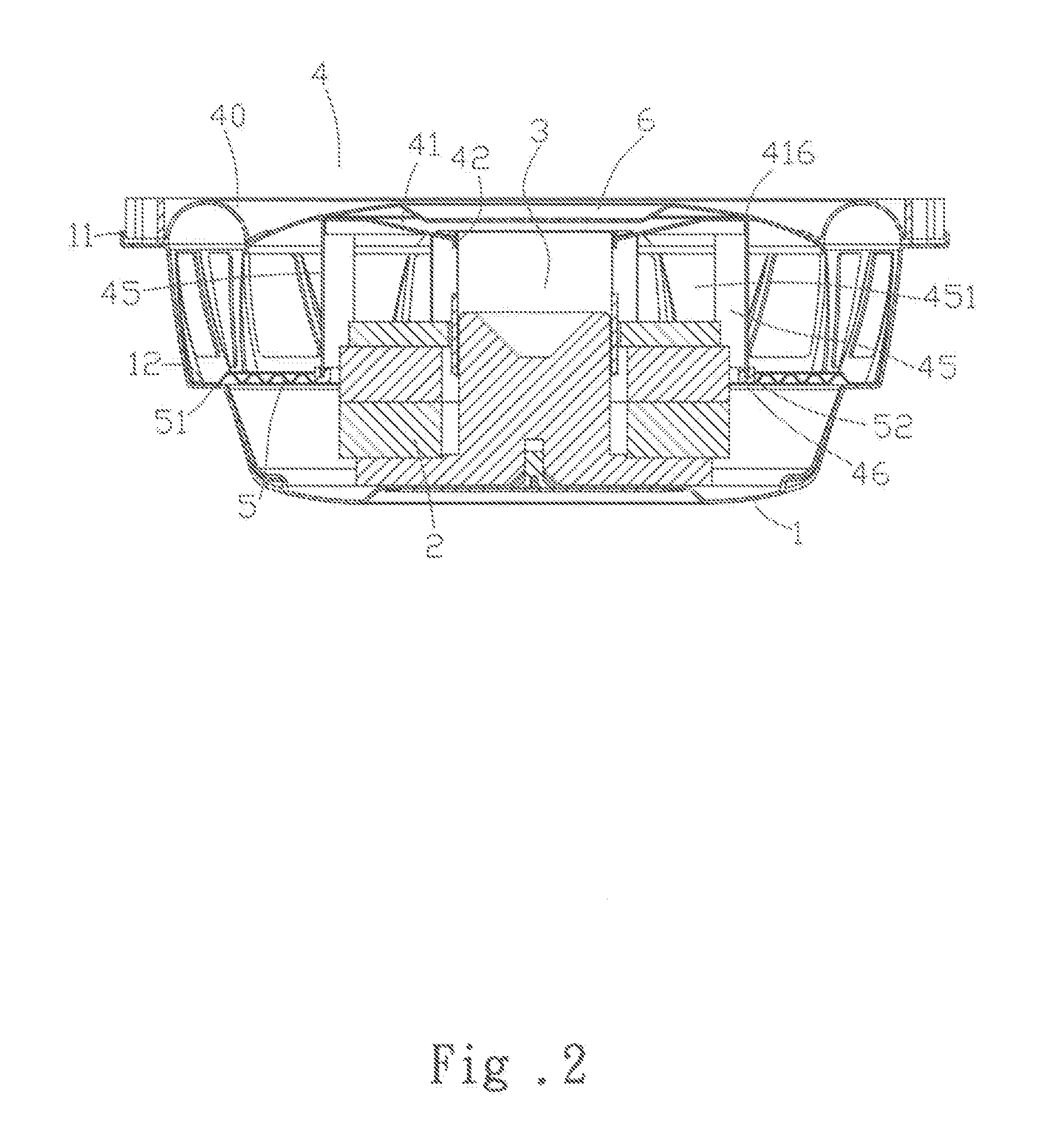

Earphone via drumhead

InactiveUS20100254562A1InhibitionBone conduction transducer hearing devicesHearing impaired stereophonic signal reproductionVibrating membraneDrumhead

A bowl-shaped cover (1) with a hole at the bottom replaces the cover with a sound hole of the conventional earphone, thus creating a constant space. The earphone sound vibrates the cover (1) by beating the inside of the cover (1) and then the vibration is transmitted to a rubber drumhead (vibrating membrane) (2) which is attached onto the cover (1). The rubber drumhead (vibrating membrane) (2) of the earphone works as a soft earmuff and makes wearing feel soft and comfortable. The present invention relates to the earphone that converts sound into vibration and also isolates sound.

Owner:KOO YOUN YOUNG

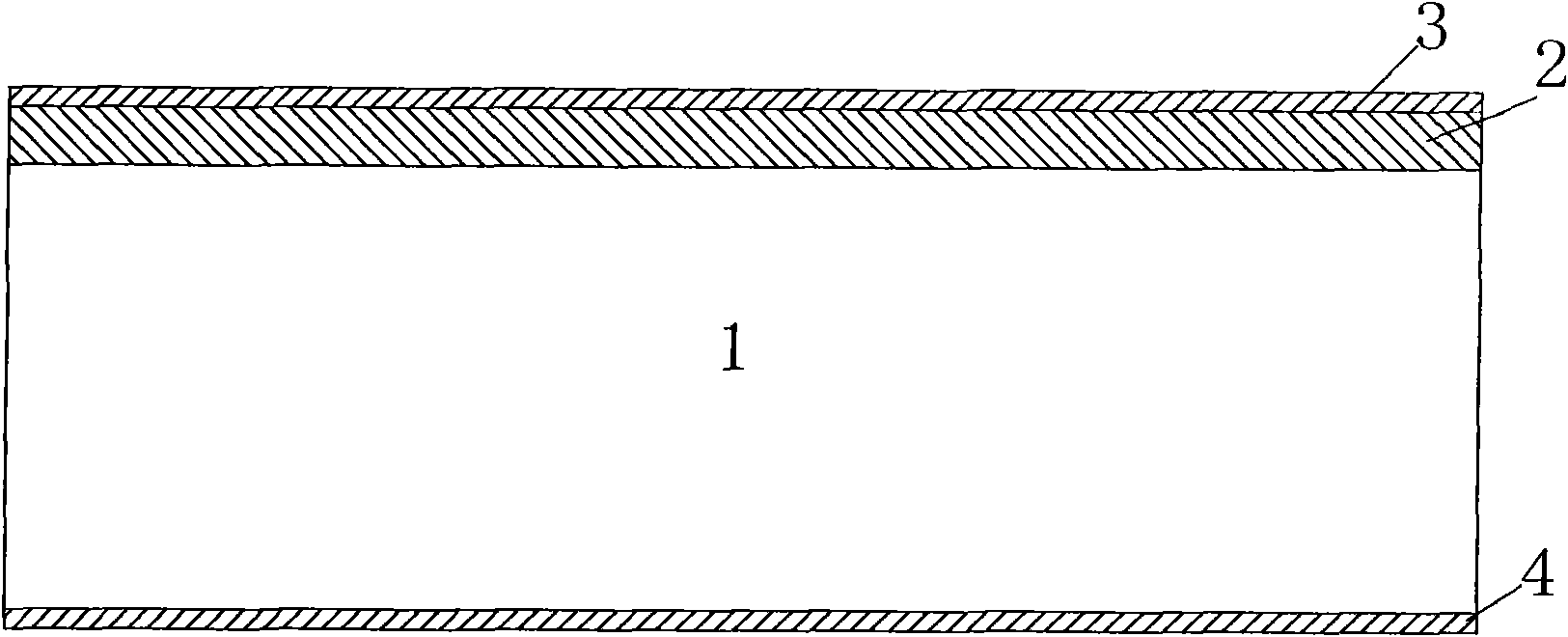

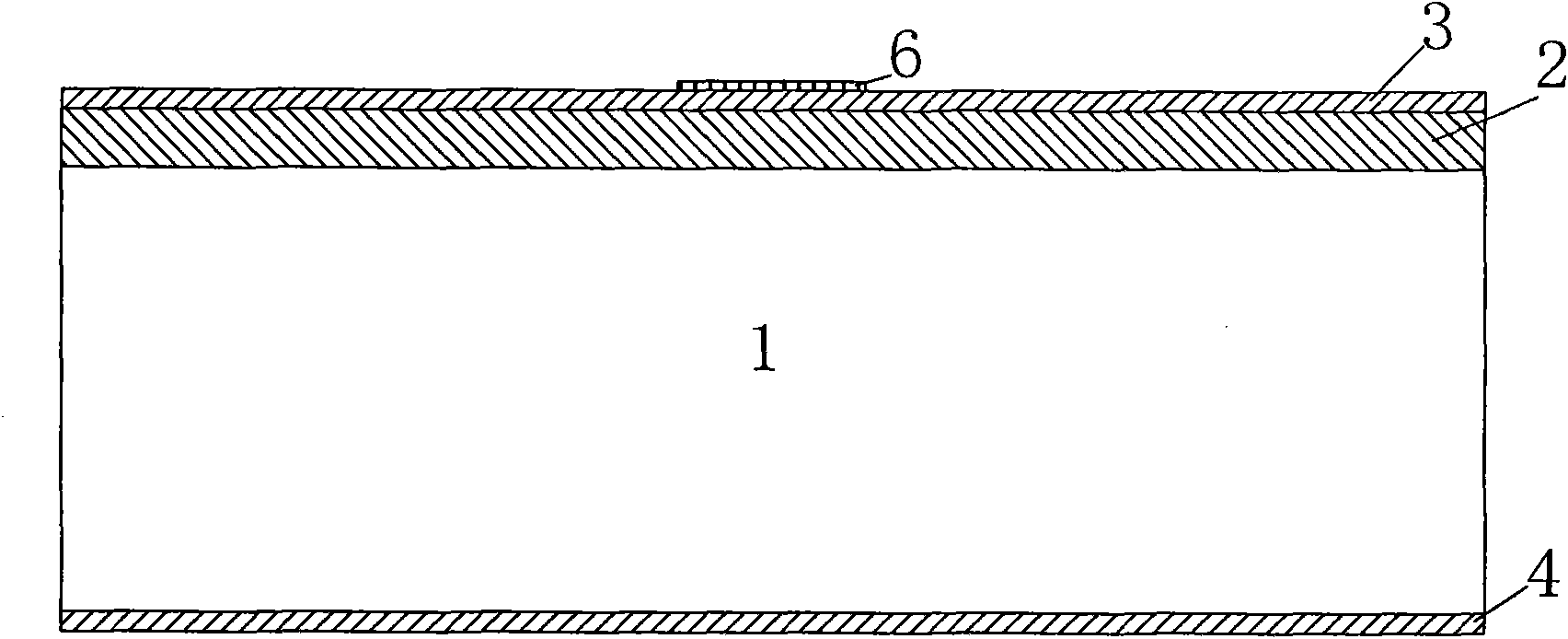

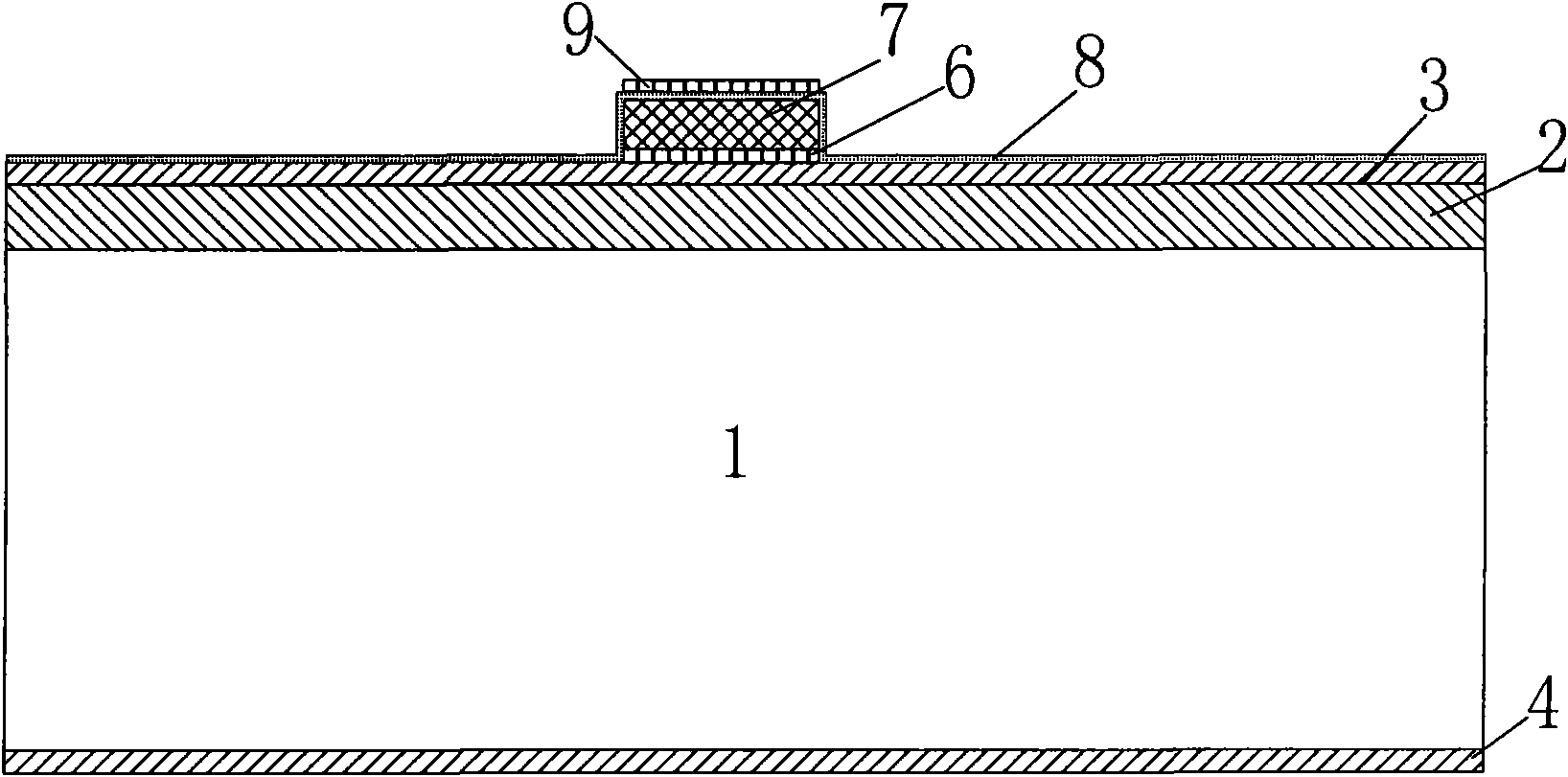

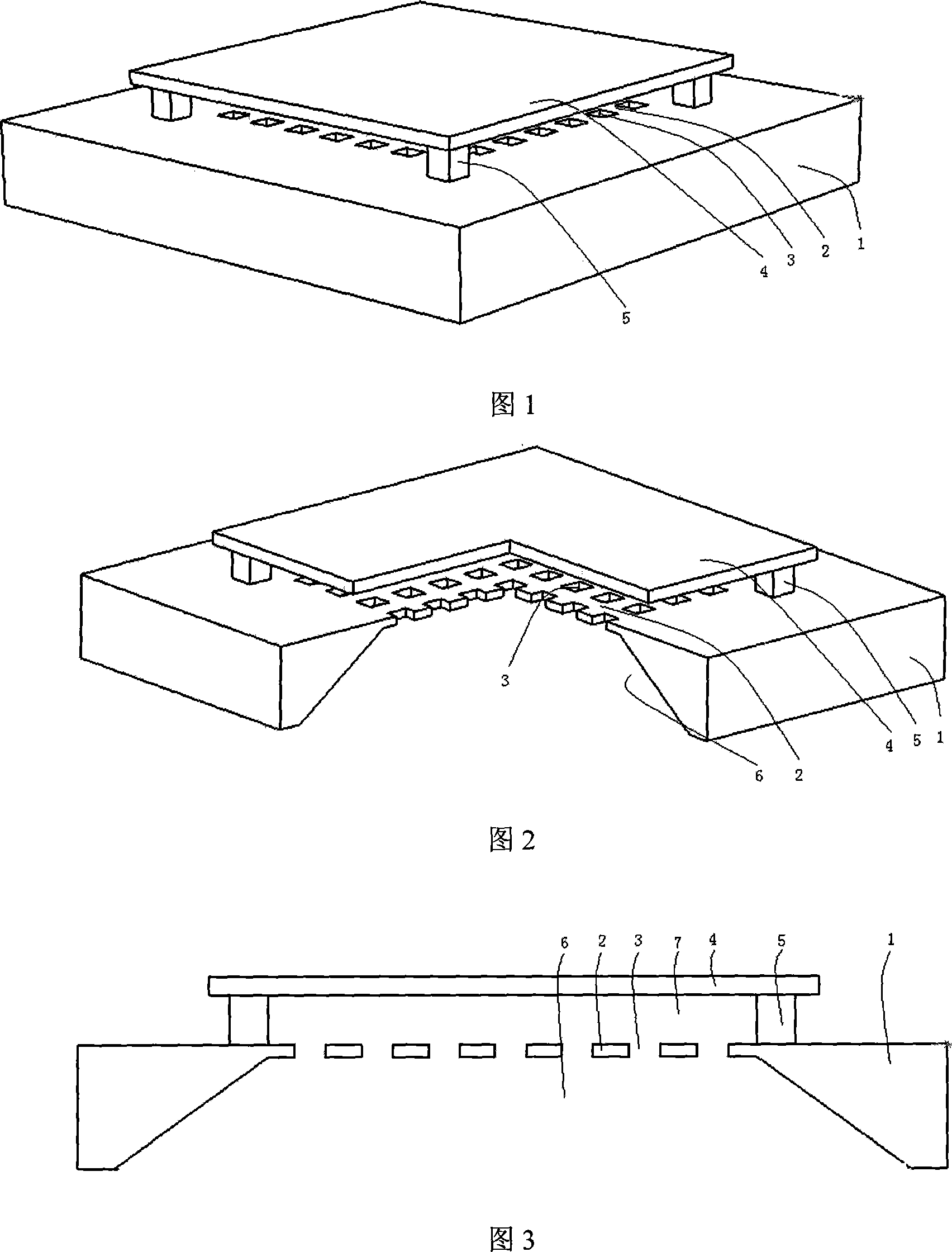

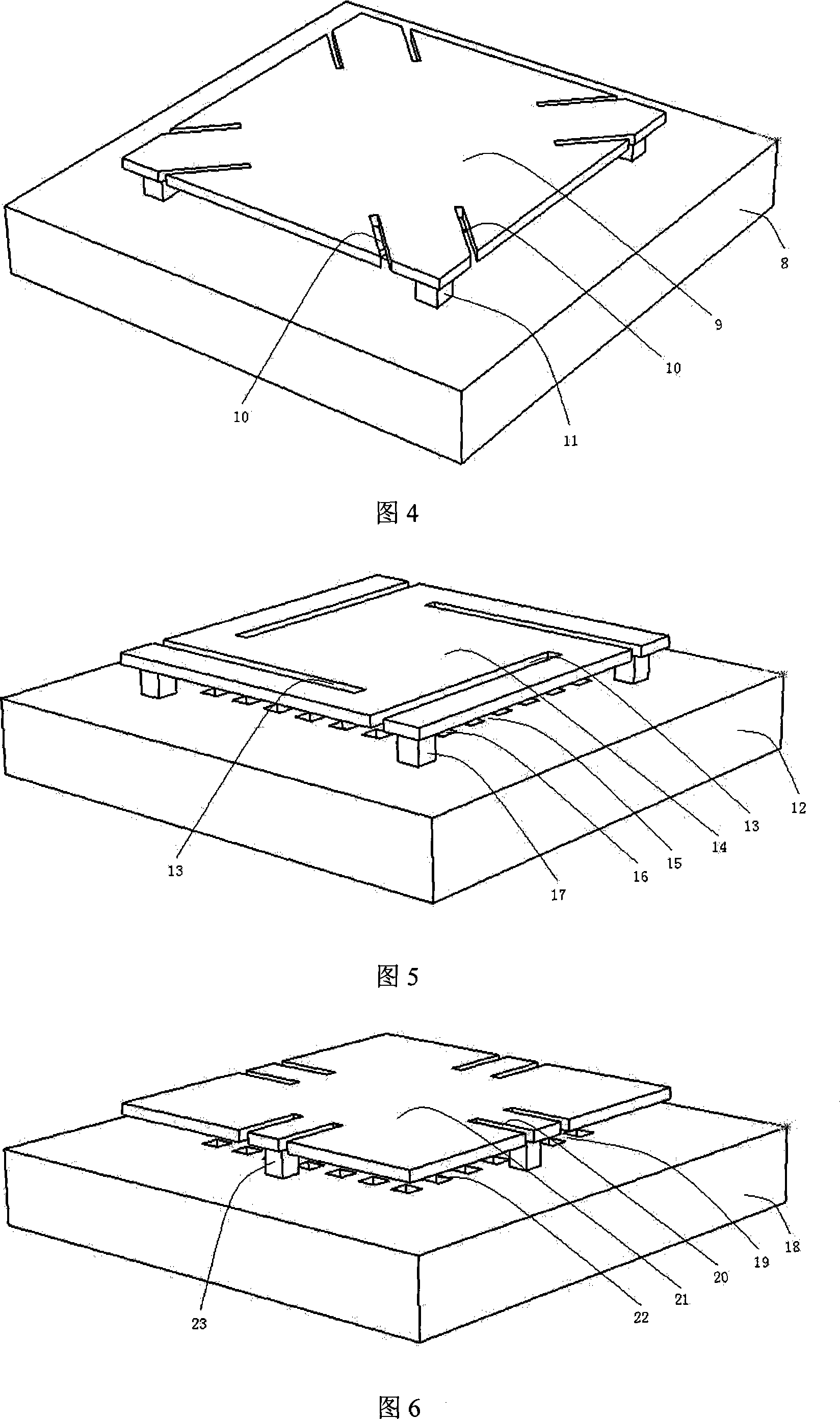

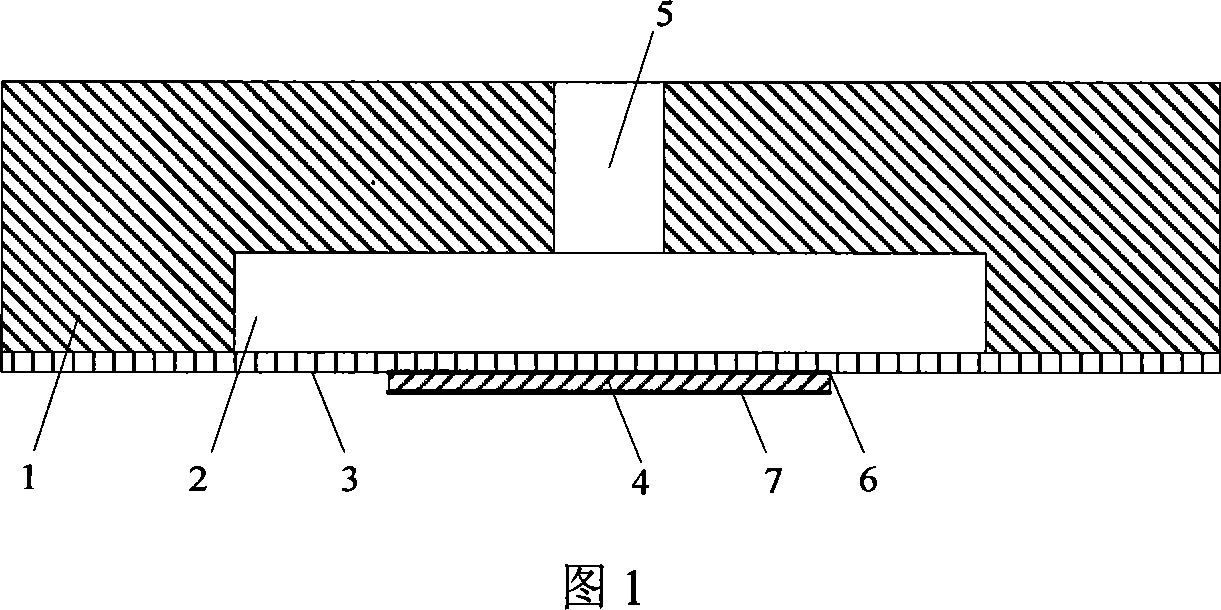

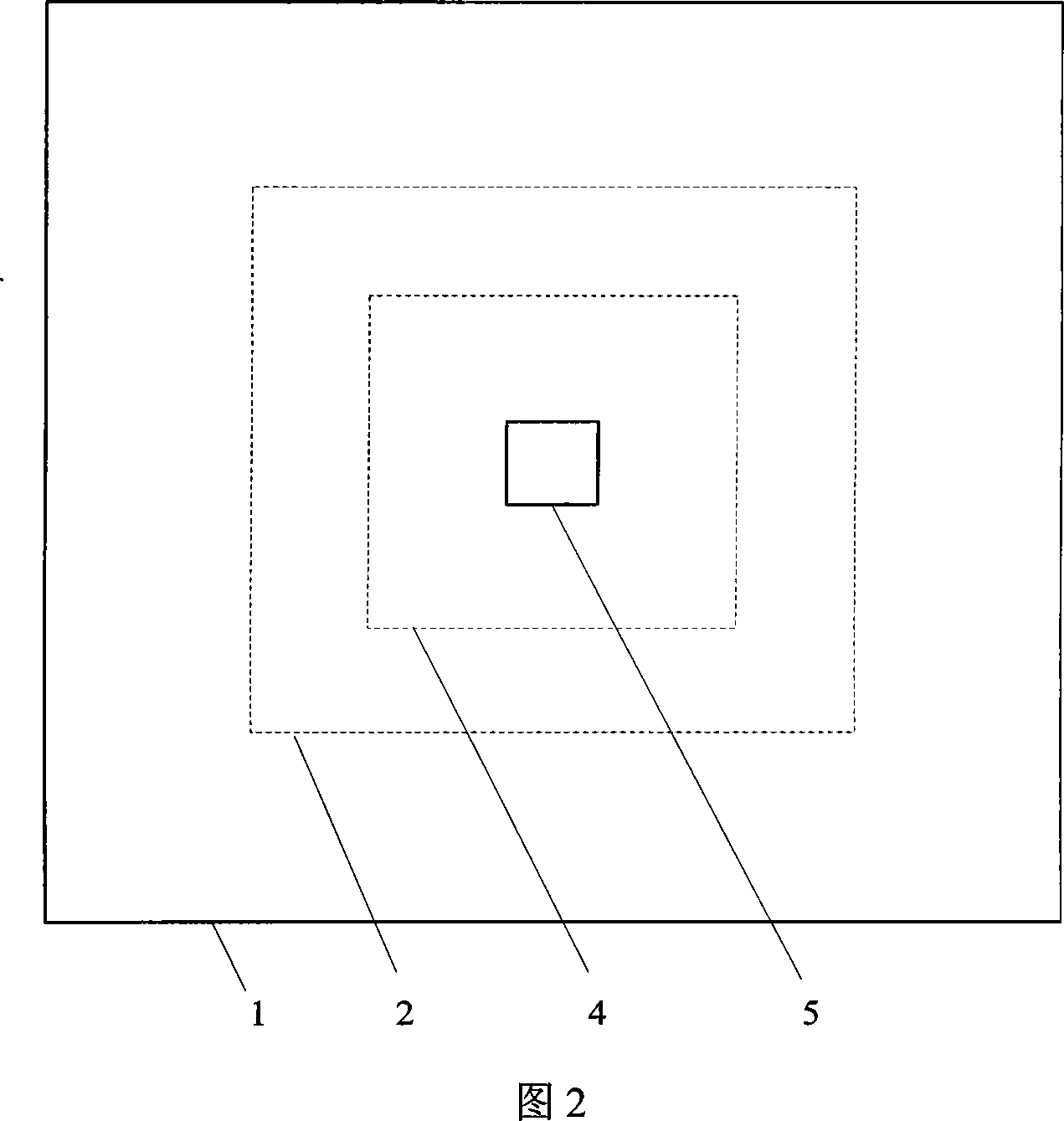

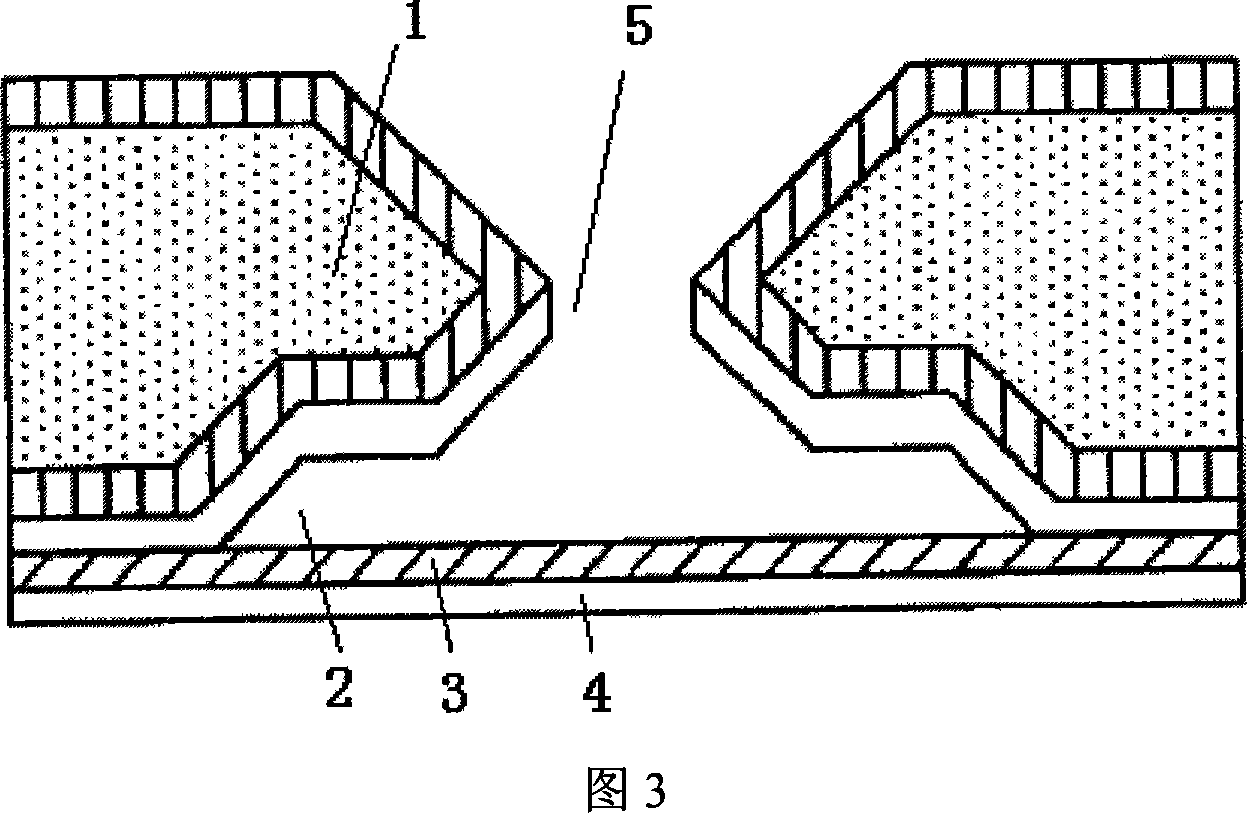

Soft support bridge type silicon micro-piezoelectric ultrasonic transducer chip and prepration method thereof

InactiveCN101645484AHigh sensitivityGood process compatibilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionVertical projectionUltrasonic sensor

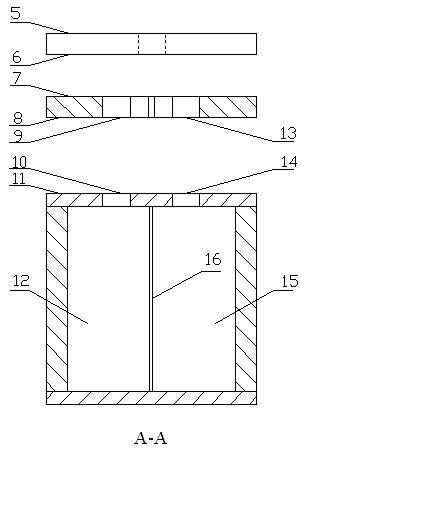

The invention relates to a soft support bridge type silicon micro-piezoelectric ultrasonic transducer chip which comprises a silicon substrate with a square conical hole which is small at the top andbig at the bottom in the center; a silicon layer and a first oxidation layer are sequentially covered on the front surface of the silicon substrate, and a second oxidation layer is covered on the backsurface; the corresponding silicon layer and the first oxidation layer above the square hole of the front surface of the silicon substrate constitute a square vibration membrane, one pair of oppositesides of the square vibration membrane respectively etch a vertical narrow slot, and the vertical projection of each narrow slot is positioned on the inner side of the hole edge above the front surface of the silicon substrate; a lower electrode, a piezoelectric membrane and an upper electrode are sequentially deposited on the square vibration membrane; a polyimide membrane is deposited on various parts on the front surface of the silicon substrate; and the square vibration membrane which is etched with the vertical narrow slots and the polyimide membrane commonly constitute a soft support anti-sound leakage bridge type vibration membrane. The anti-sound leakage bridge type structure is used on the vibration membrane of the transducer; in order to avoid sound leakage through the narrow slots, the soft polyimide membrane is deposited on the narrow slots, which has little effect on vibration of the vibration membrane and can still keep high sensitivity.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Condenser miniature silicon microphone and preparative method

InactiveCN101022685AReduce areaImprove design flexibilityElectrets selectrostatic transducerElectrostatic transducer microphonesCapacitanceEngineering

A micro-silicon microphone of capacity type is prepared using back electrode plate with conduction function as one electrode of capacity and using vibration membrane with conduction function as another electrode of capacity, using multiple insulation support to support vibration membrane, firm-jointing said supports with vibration membrane and back electrode plate and arranging narrow groove on said vibration membrane for making vibration membrane be not sensitive on residual stress.

Owner:MEMSENSING MICROSYST SUZHOU CHINA

Amazing Member and Atomizer Including the Same

ActiveUS20110284656A1Extended Diffusion AngleSatisfactory atomization characteristicLighting and heating apparatusUltrasonic humidifiersVibrating membraneEngineering

Owner:MURATA MFG CO LTD

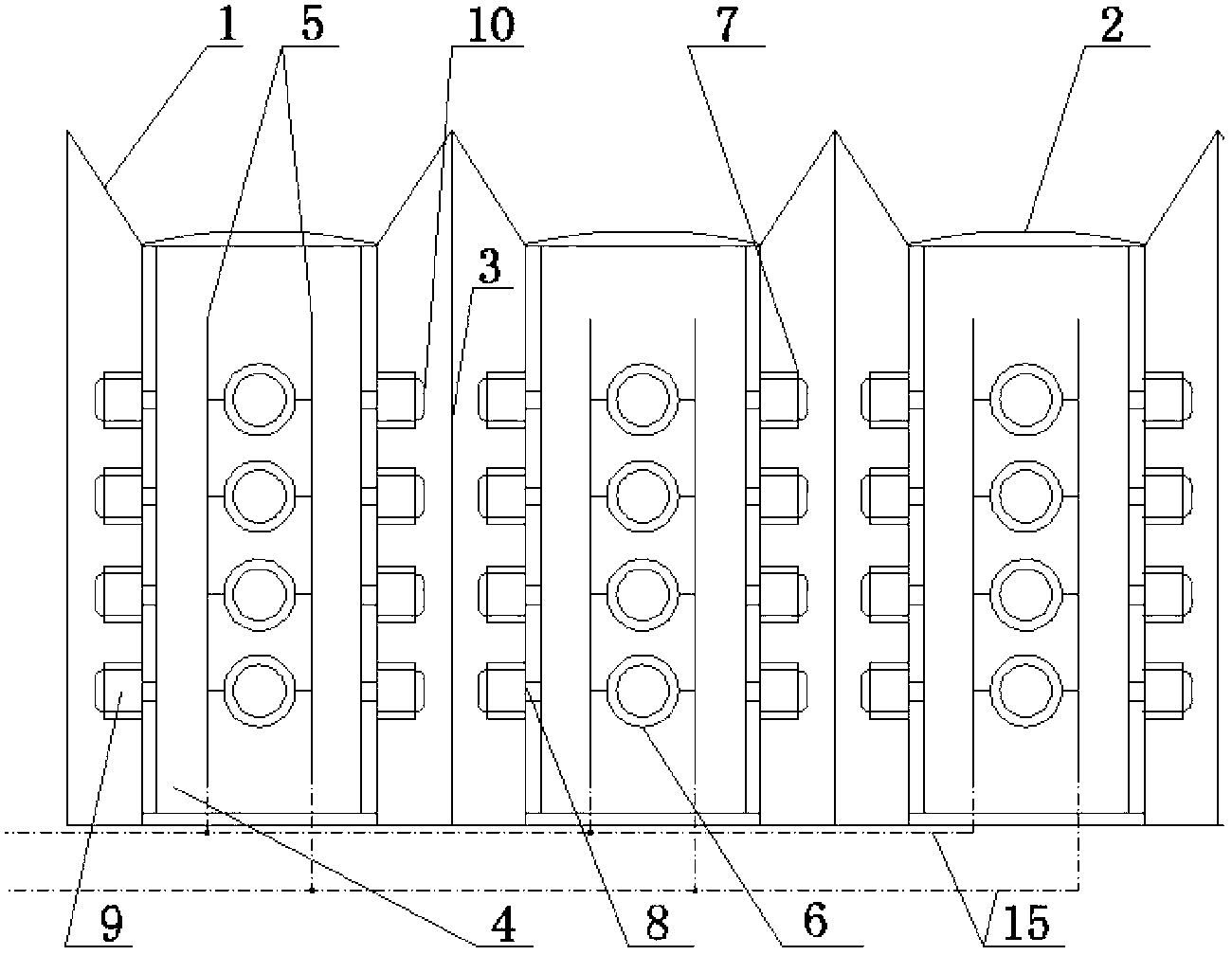

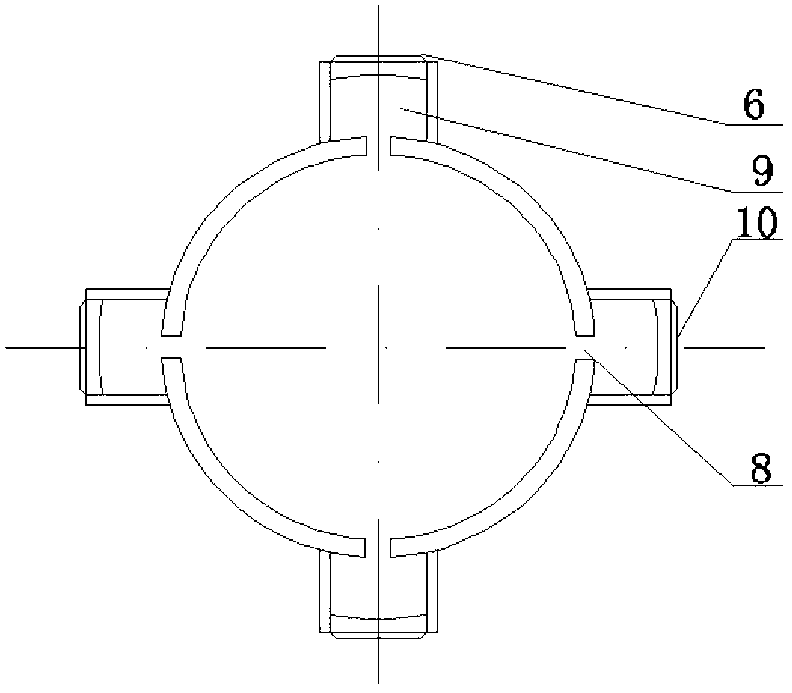

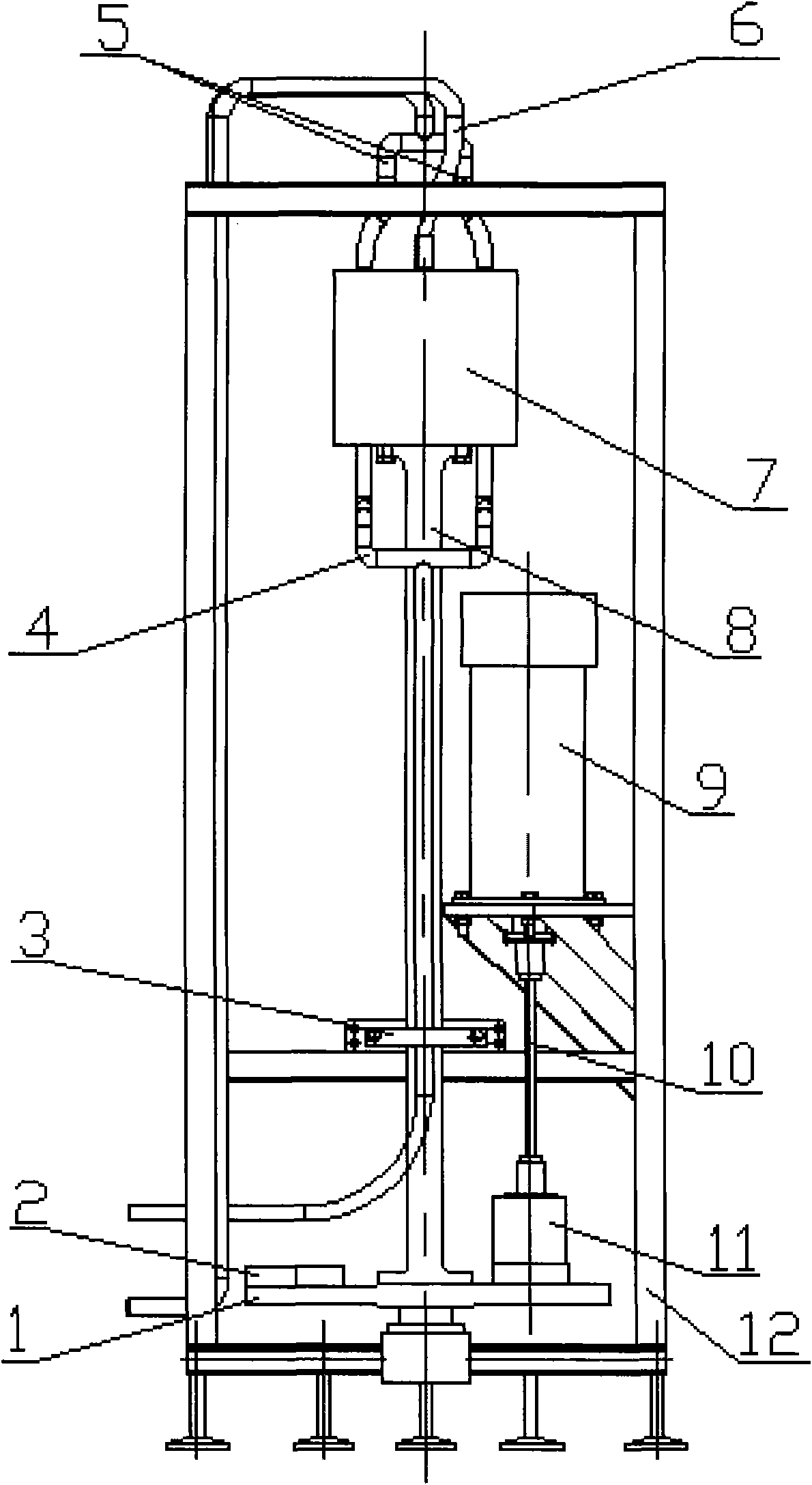

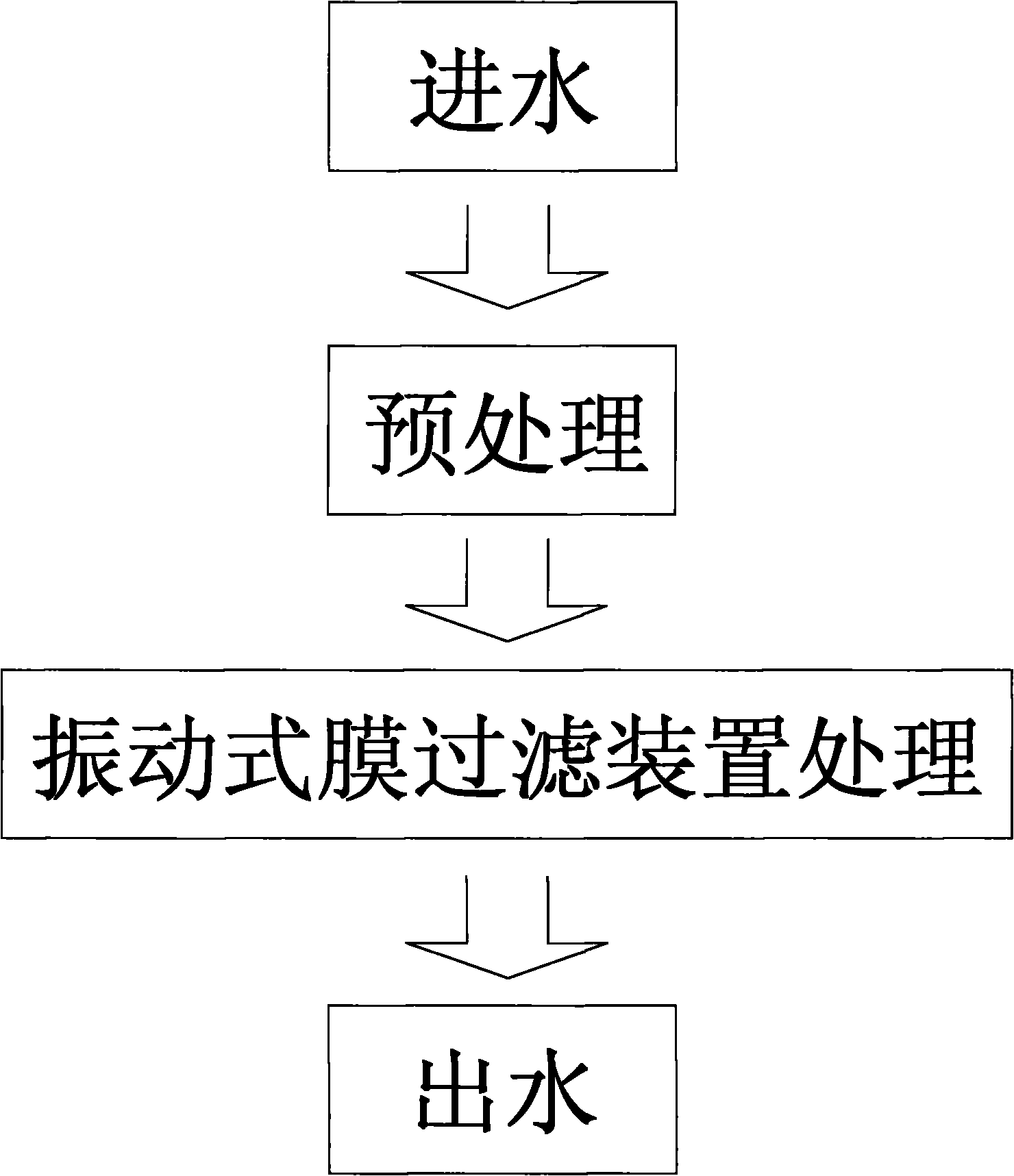

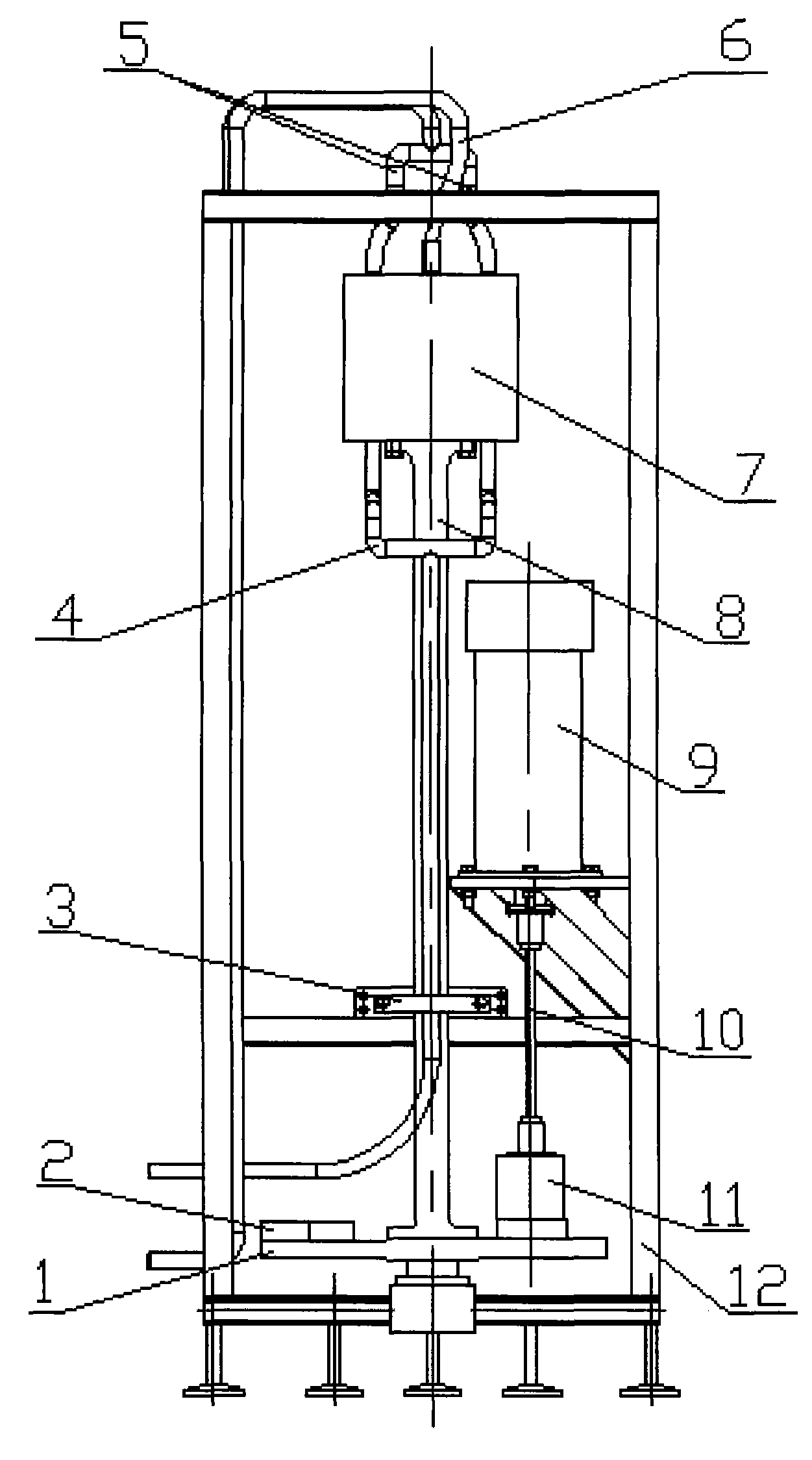

Vibrating membrane filtration device and industrial wastewater treatment method applying the same

InactiveCN101805043AAvoid cloggingStable fluxUltrafiltrationWater/sewage treatment bu osmosis/dialysisVibrating membraneIndustrial waste water

The invention discloses a vibrating membrane filtration device which comprises a vibration generation device fixedly connected with a support, a membrane component and a vibration transmission device used for connecting the vibration generation device and the membrane component; the vibration generation device is a motor; the vibration transmission device comprises a bottom plate, a counterweight, an elastic spindle, a transmission shaft and an eccentric block; one end of the elastic spindle is fixedly connected with the center of the bottom plate, and the other end thereof is fixedly connected with the membrane component; the counterweight and the eccentric block are respectively and fixedly connected with both ends of the center of the bottom plate; the rotating shaft of the motor is connected with the eccentric block through the transmission shaft; and the membrane component is provided with a concentrated water pipe, a water inlet pipe and a water outlet pipe, and a filter membrane is arranged in the membrane component. The invention can effectively prevent the filter membrane from being blocked, maintains stable water flux, effectively solves the technical difficult problems of low membrane flux and membrane blockage of wastewater during the filtration process so that a membrane separation technology can be better applied in an industrial wastewater treatment method, thereby not only improving the water treatment efficiency, but also reducing the water treatment cost.

Owner:SUZHOU LIBIRUITE ENVIRONMENTAL PROTECTION TECH

Speaker diaphragm supporting structure

InactiveUS20160127832A1Improve structural strengthPrecise alignmentTransducer detailsLoudspeakersVibrating membraneEngineering

A speaker diaphragm supporting structure includes a basket defining a flared front opening and an internal shoulder portion, and having annular magnet mounted to a rear side thereof; a voice coil located in the annular magnet; a diaphragm including a soft suspended flange for fixing to the flared front opening of the basket, a rigid vibrating membrane having a centered voice coil fixing hole for gluing to around the voice coil, a plurality of supporting legs integrally formed on a rear side thereof and a fixing ring portion glued to rear ends of the supporting legs; and a flexible suspension member having an outer circumferential edge set on the internal shoulder portion of the basket and an inner circumferential edge glued to the fixing ring portion, so that the suspension member is held to around an outer side of the annular magnet.

Owner:MEILOON INDAL

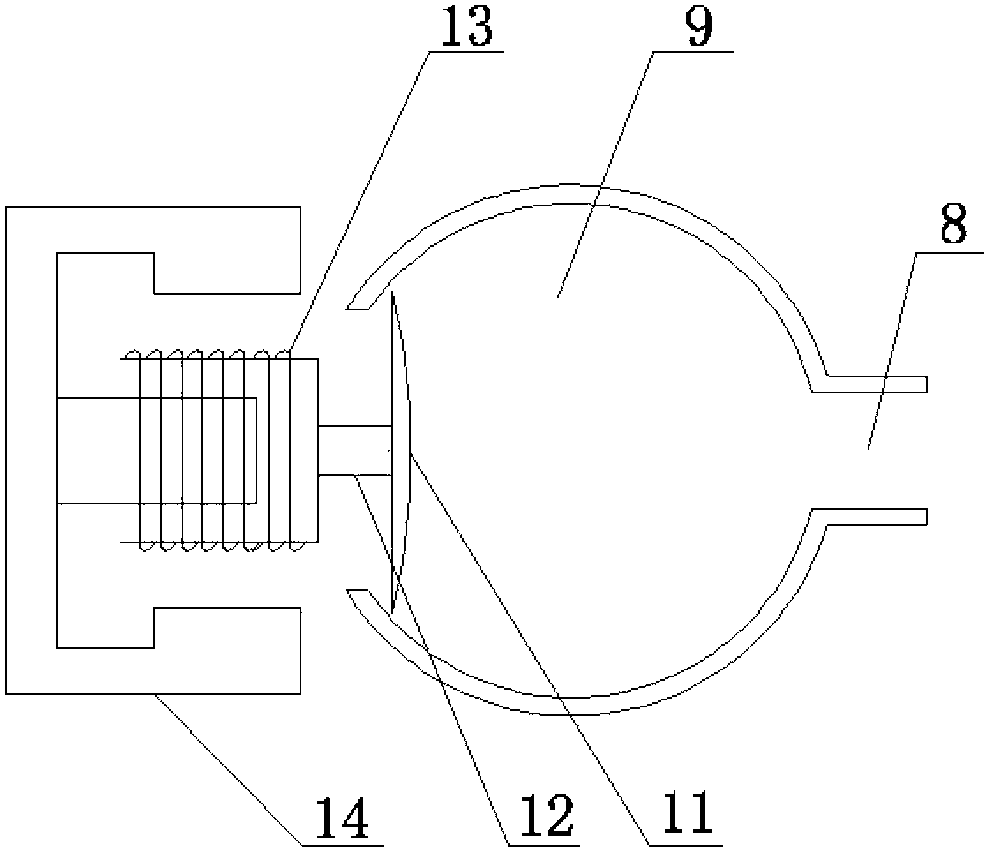

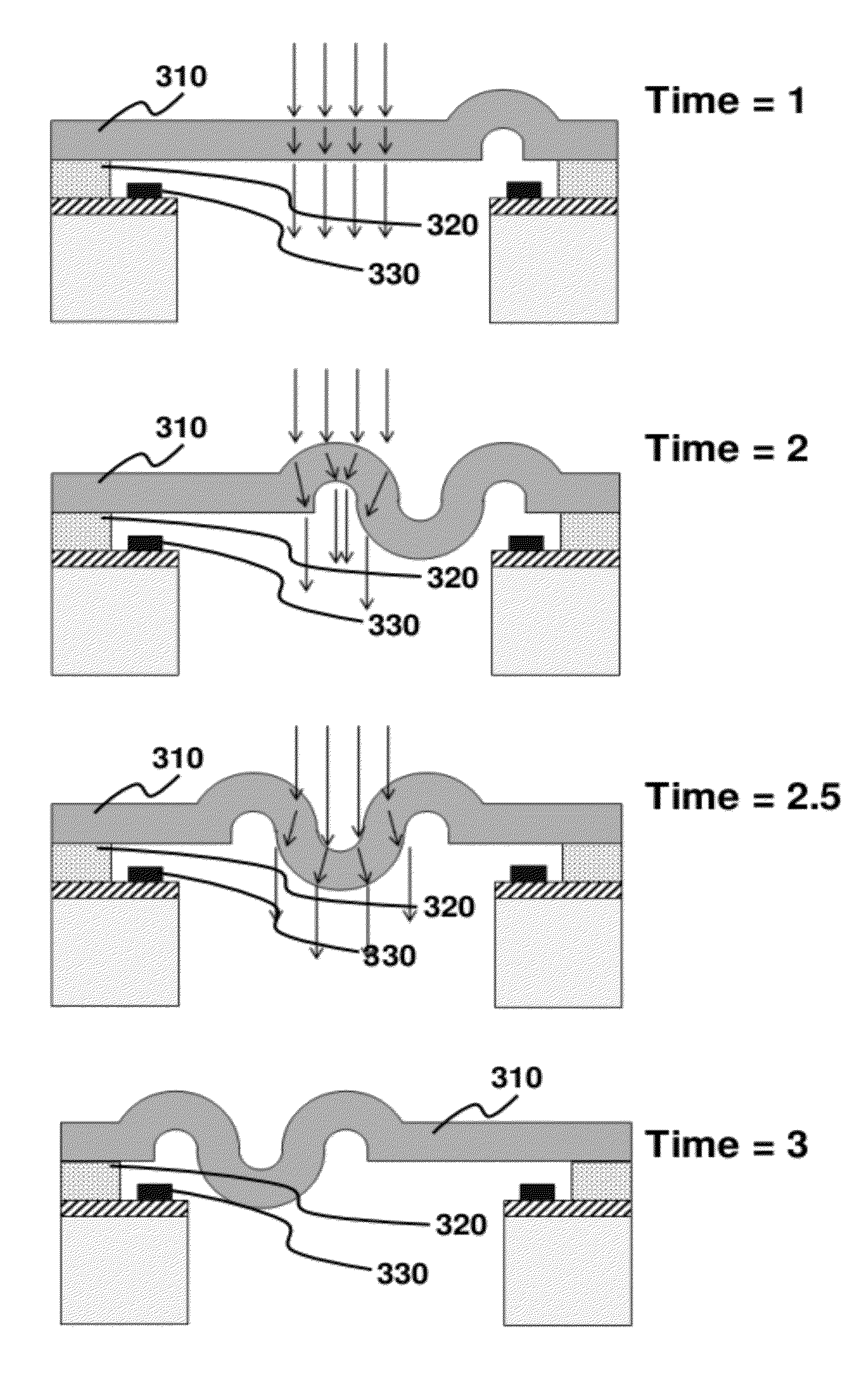

Piezoelectric combining jet device and its making process

InactiveCN101066542AImprove reliabilityImprove consistencyLiquid spraying apparatusVibrating membraneEngineering

The piezoelectric combining jet device includes a silicon base, a cavity, a jet, a vibrating membrane and a piezoelectric actuator. It features the piezoelectric actuator comprising piezoelectric material, and one upper electrode and one lower electrode adhered separately to the upper and lower surfaces of the piezoelectric material. The piezoelectric combining jet device is made through an electrochemical etching process, which includes preparing a porous silicon layer, releasing porous silicon to form cavity, inducing coupled plasma etching to form the jet, low pressure chemical vapor depositing the vibrating silicon diaphragm, and sol-gel process to prepare the piezoelectric film. The piezoelectric combining jet device with cavity, jet, vibrating silicon diaphragm and piezoelectric film prepared on the identical silicon base has high reliability and consistency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

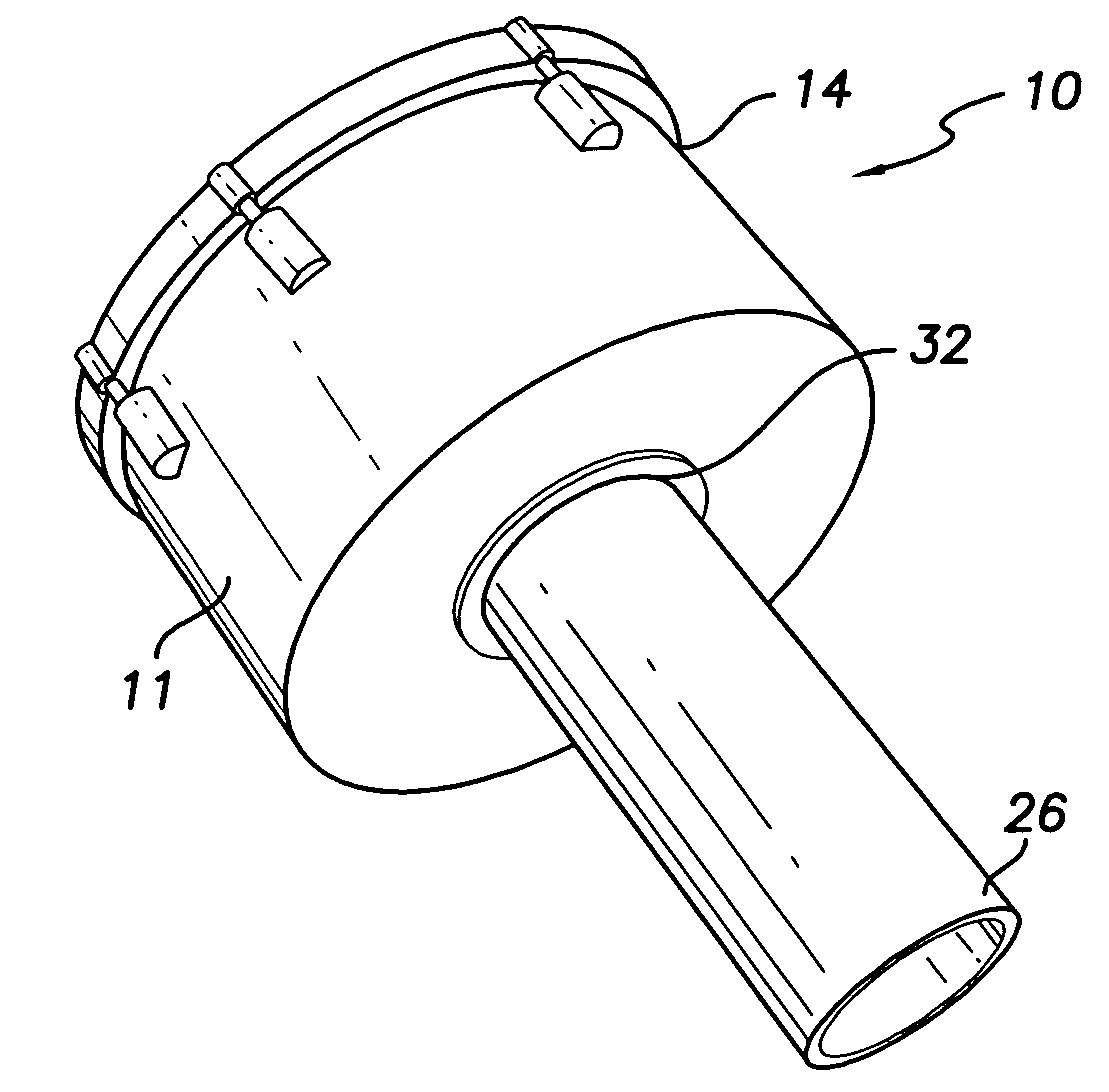

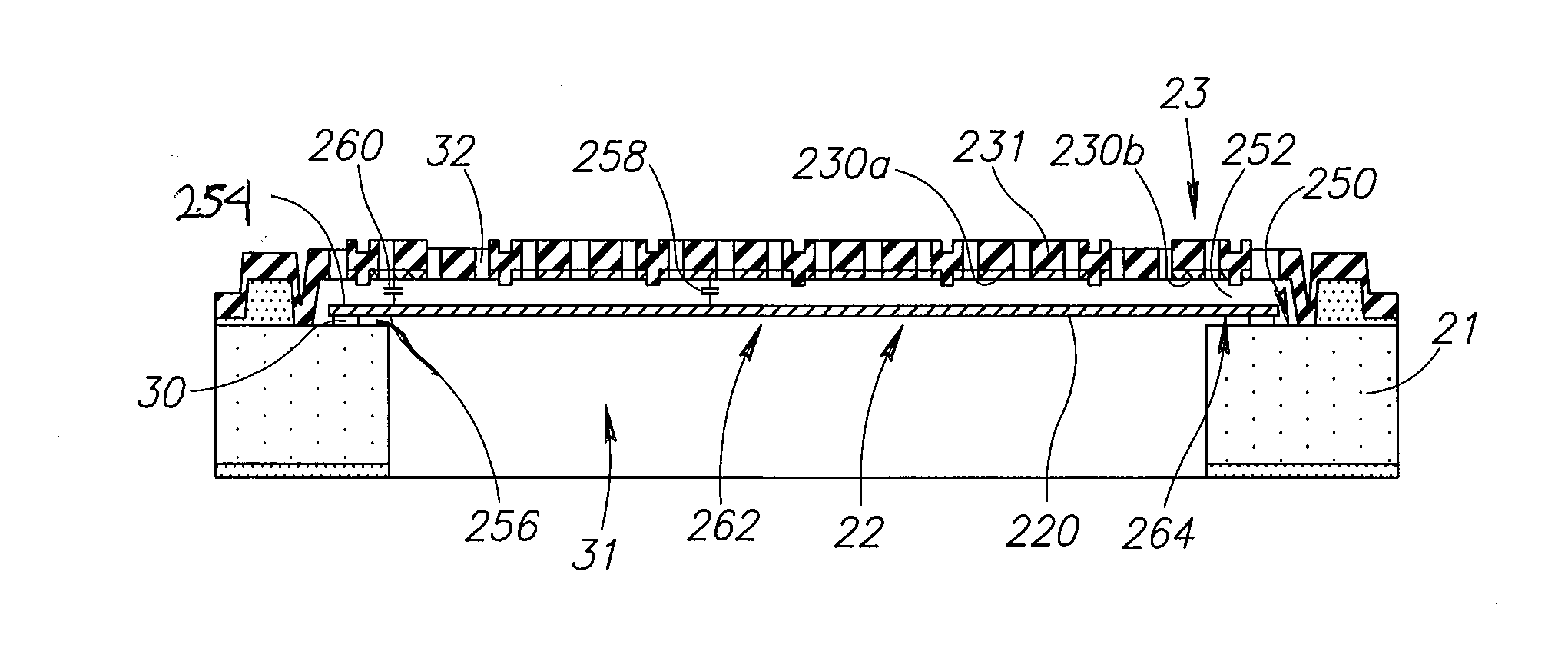

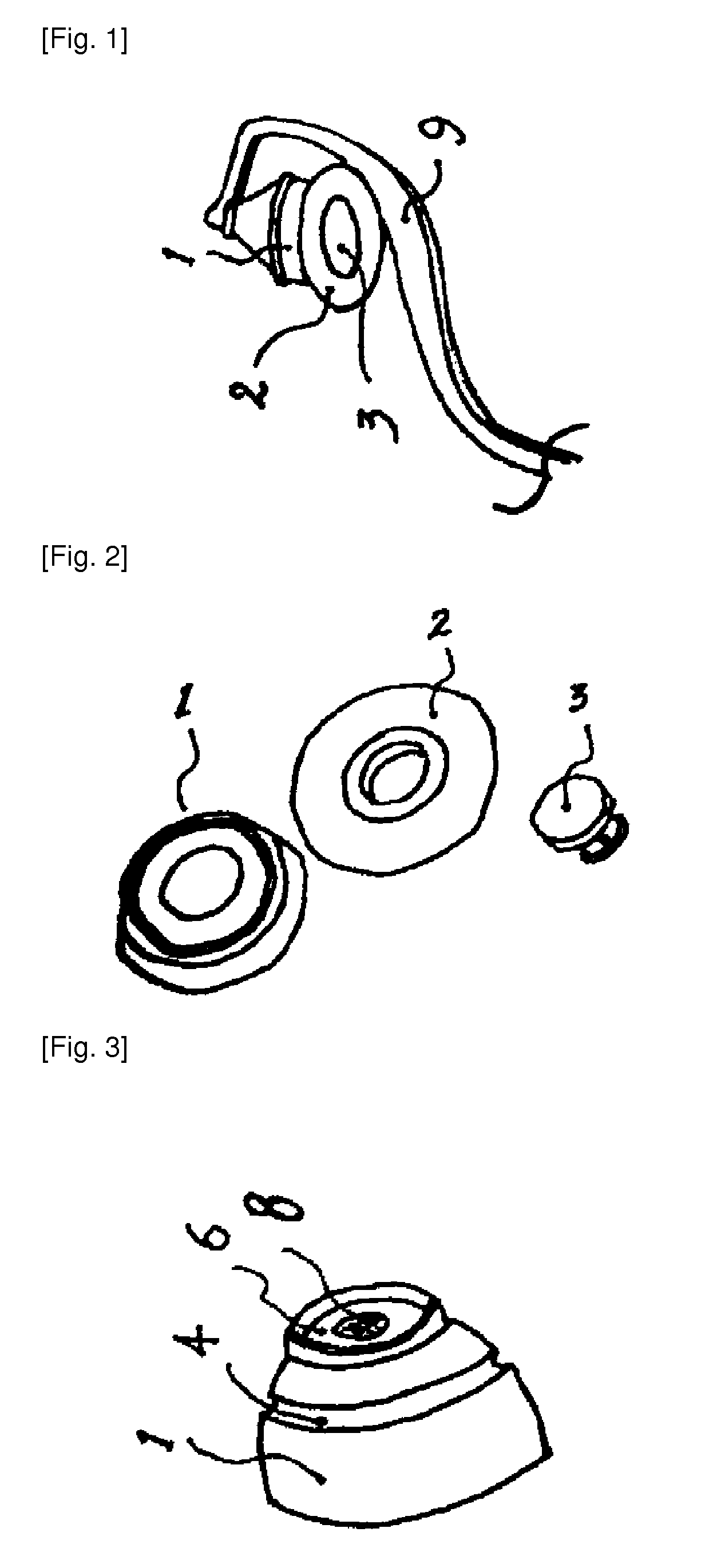

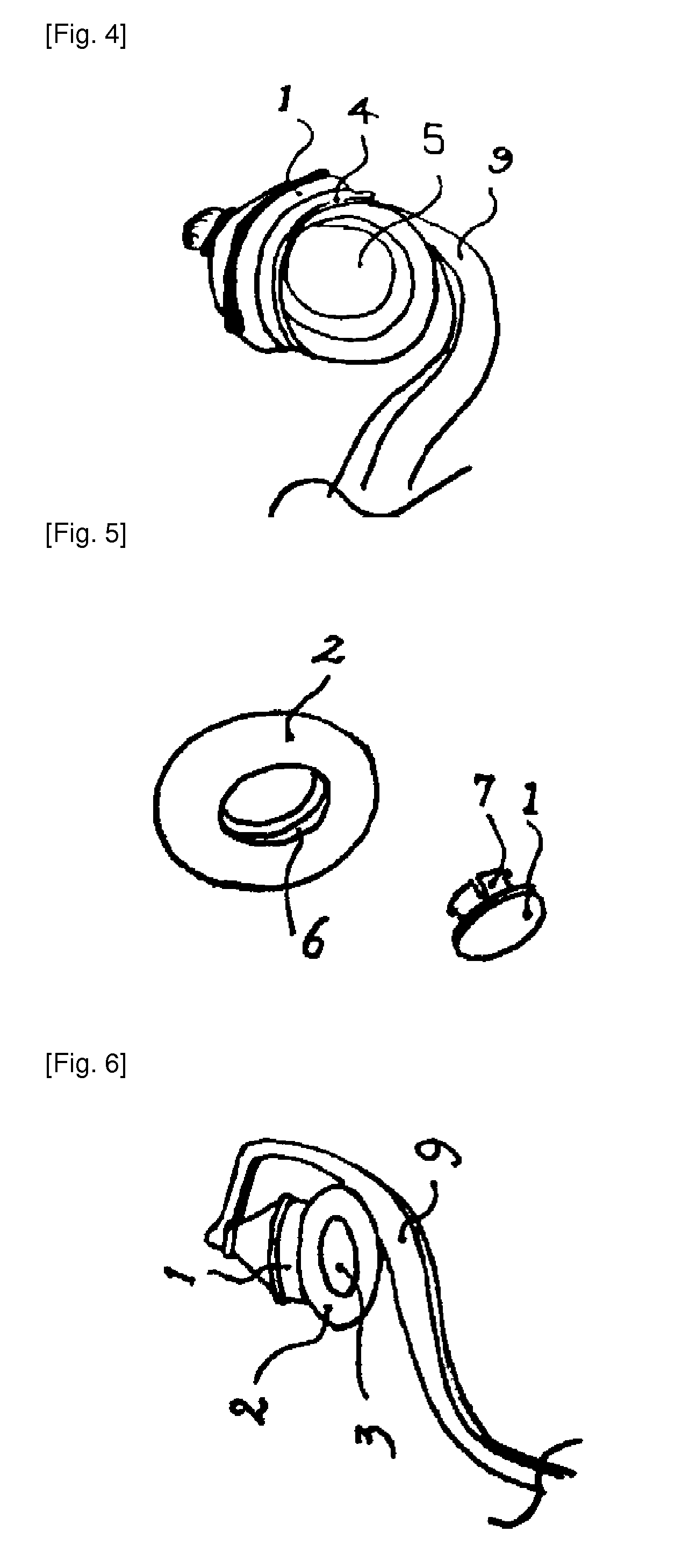

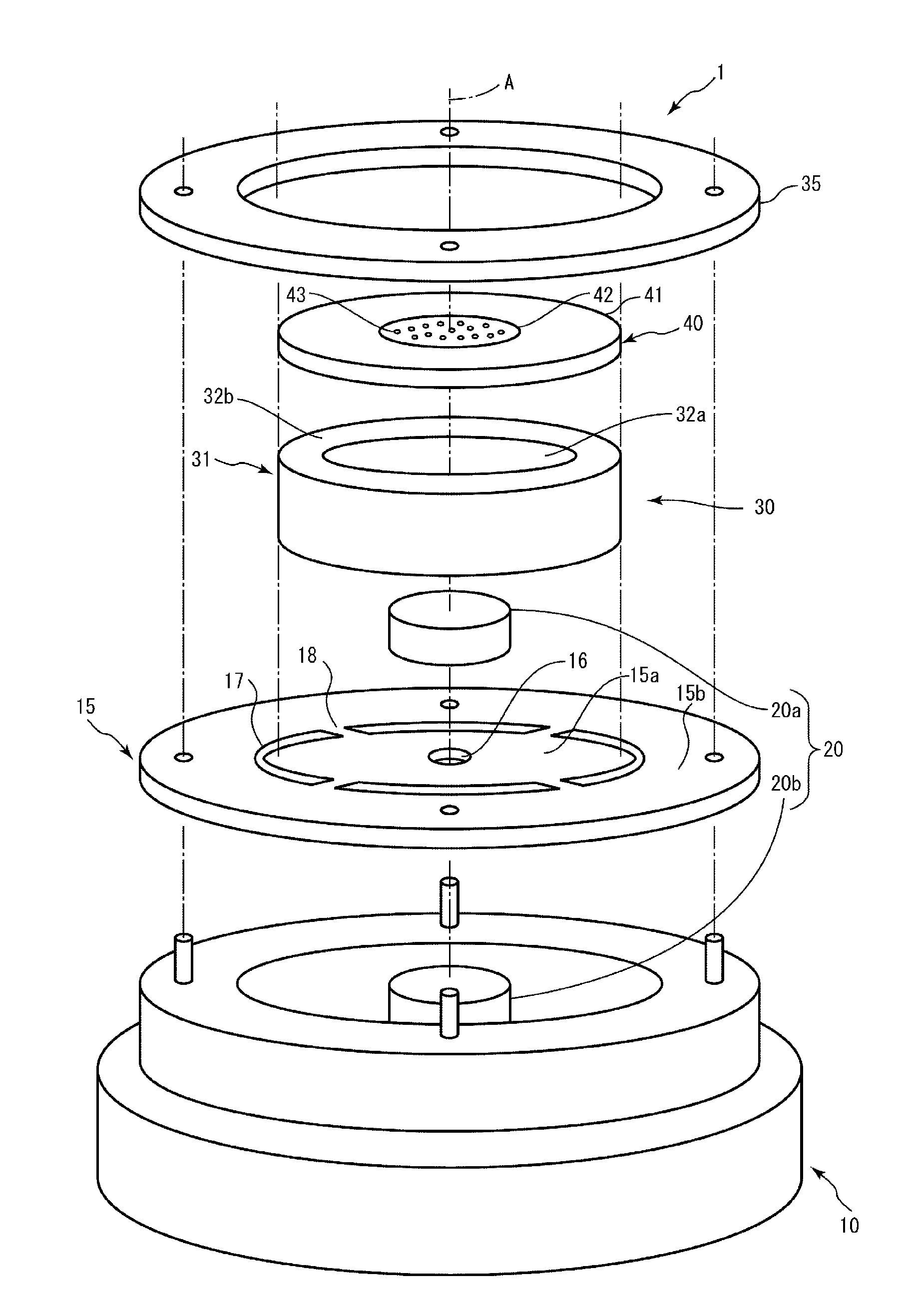

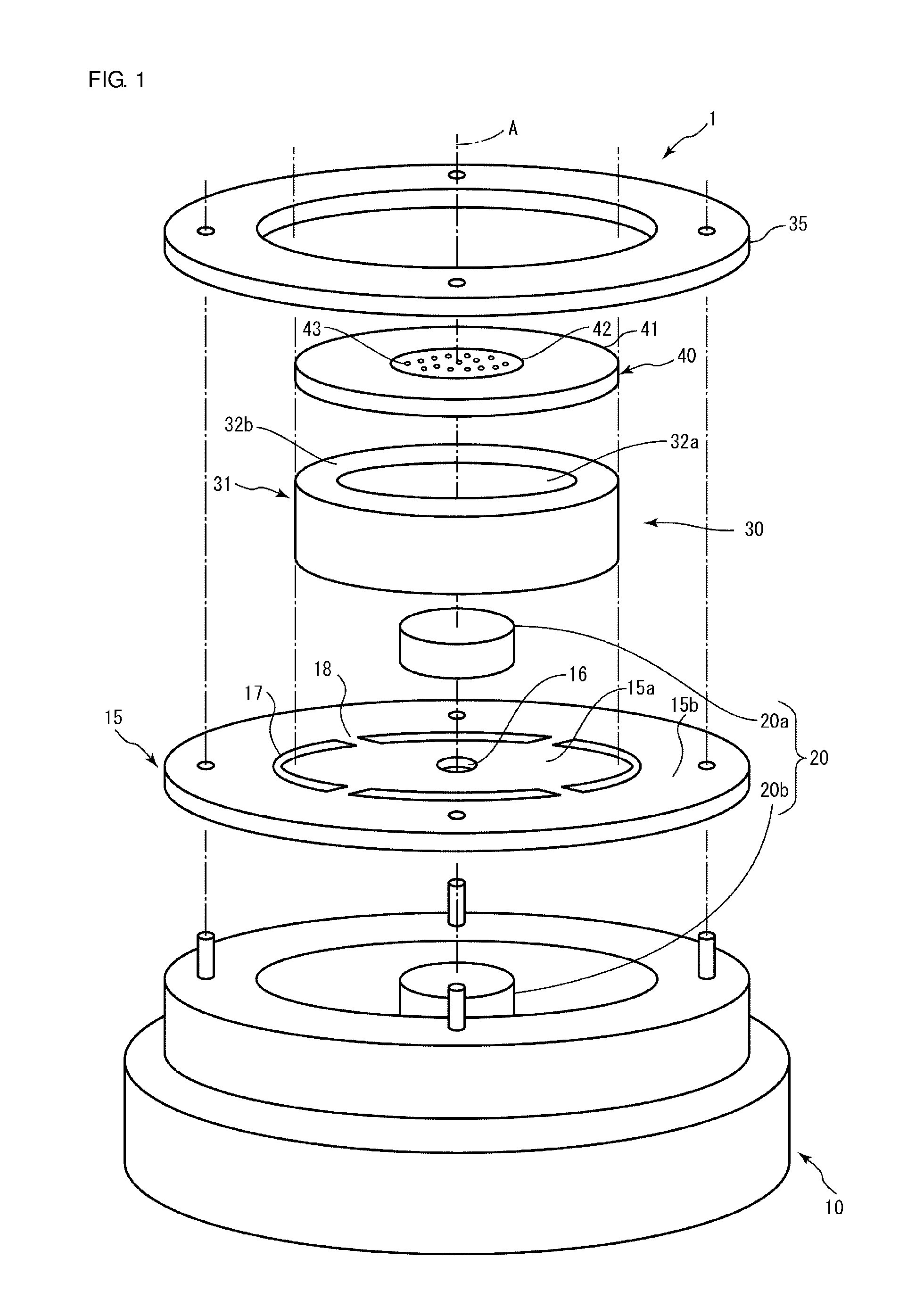

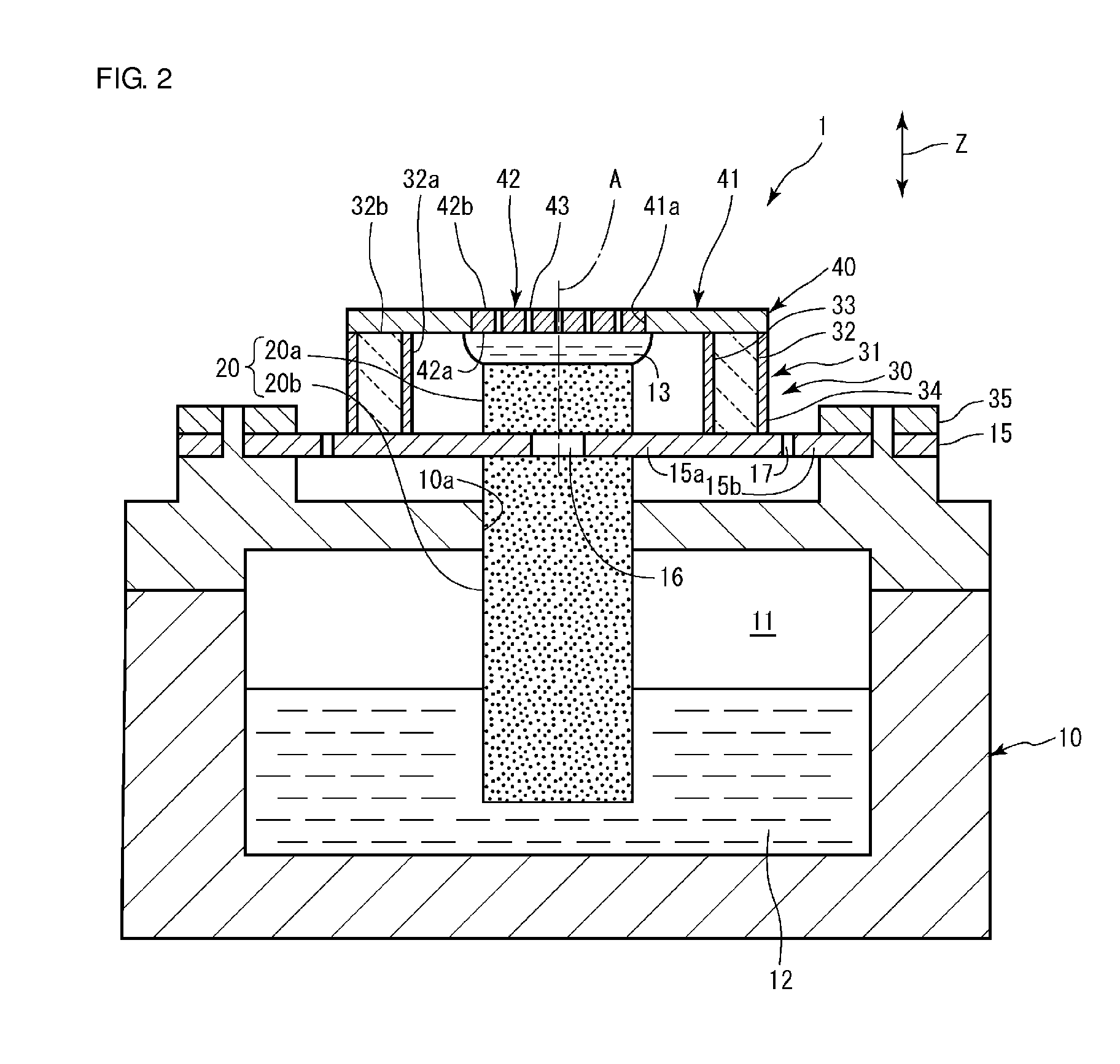

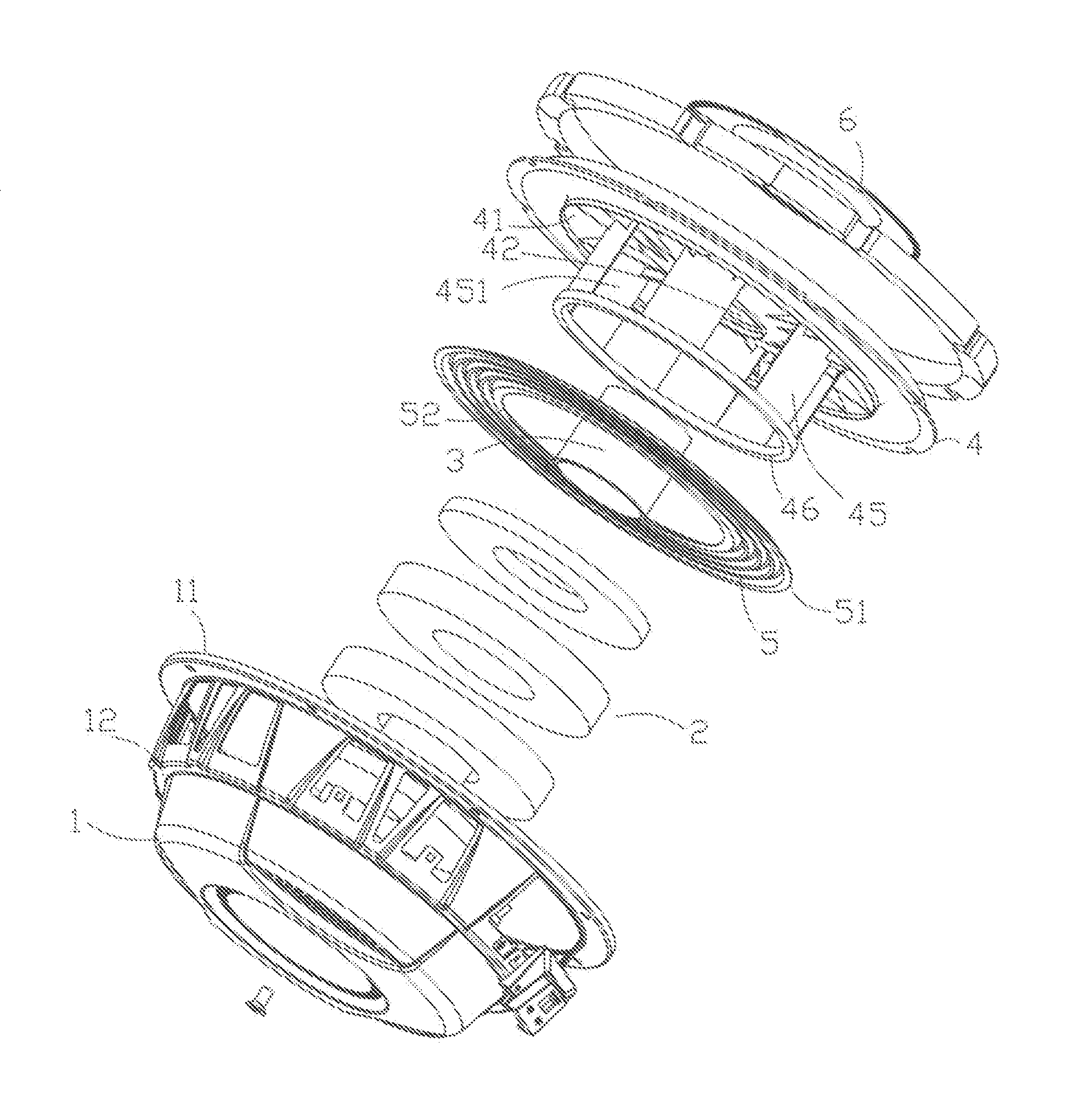

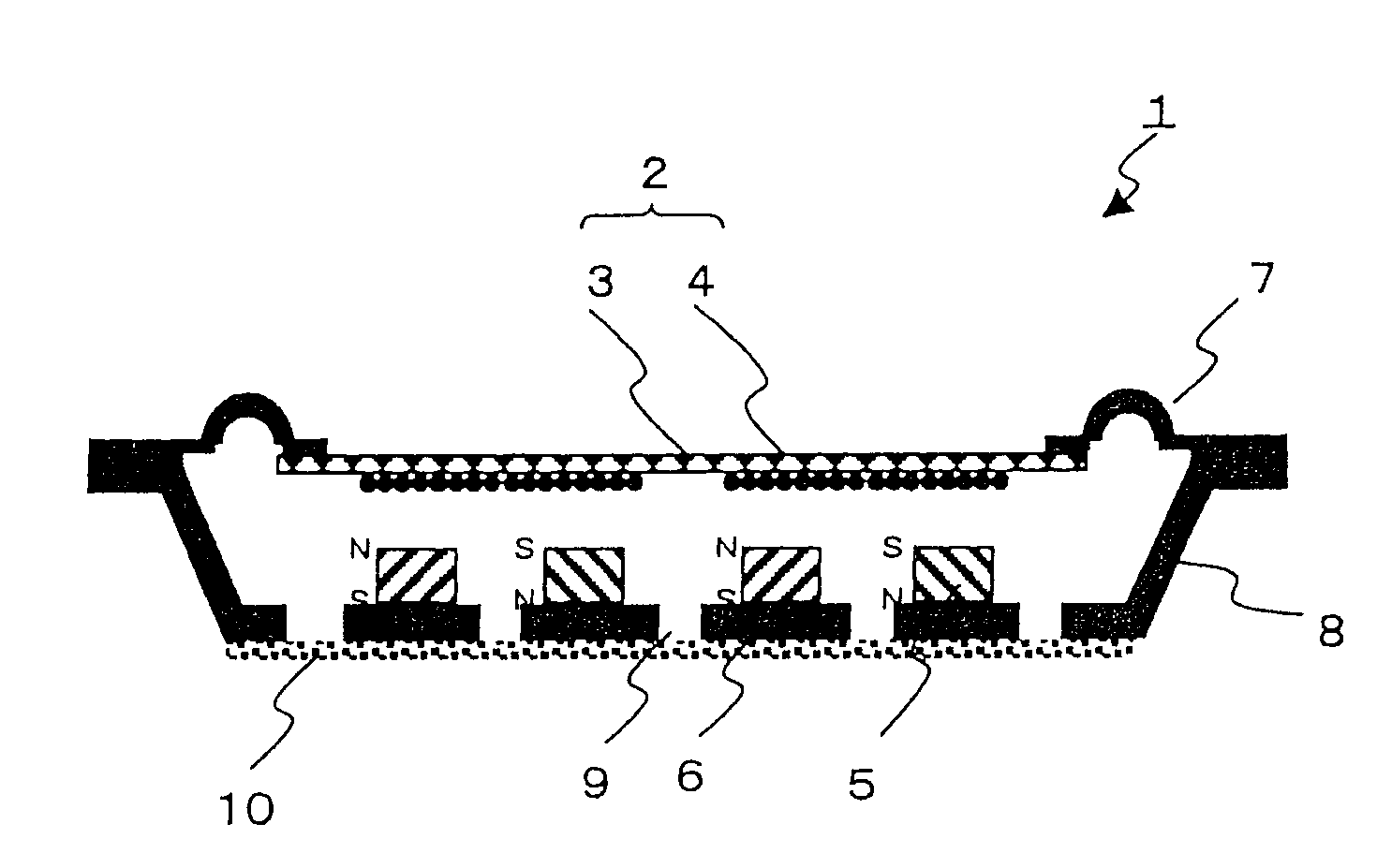

Atomizing member and atomizer equipped with same

ActiveCN102307674AImprove vibration efficiencyImprove atomization efficiencyLighting and heating apparatusUltrasonic humidifiersVibrating membraneNebulizer

Disclosed is an atomizing member having high atomization efficiency, which uses a piezoelectric vibrator and can reduce power consumption; further disclosed is an atomizer using the same. An atomizing member (30) is equipped with a piezoelectric vibrator (31) and a vibrating membrane (40). The piezoelectric vibrator (31) has a cylindrical piezoelectric body (32), a first electrode (33) formed on the inner circumferential face of the piezoelectric body (32), and a second electrode (34) formed on the outer circumferential face of the piezoelectric body (32). The piezoelectric vibrator (31) produces cylindrical breathing vibration. The vibrating membrane (40) is provided at the aperture on one side in the axial direction of the piezoelectric body (32) to cover the aperture. Through-holes (43) are formed in the center of the vibrating membrane (40).

Owner:MURATA MFG CO LTD

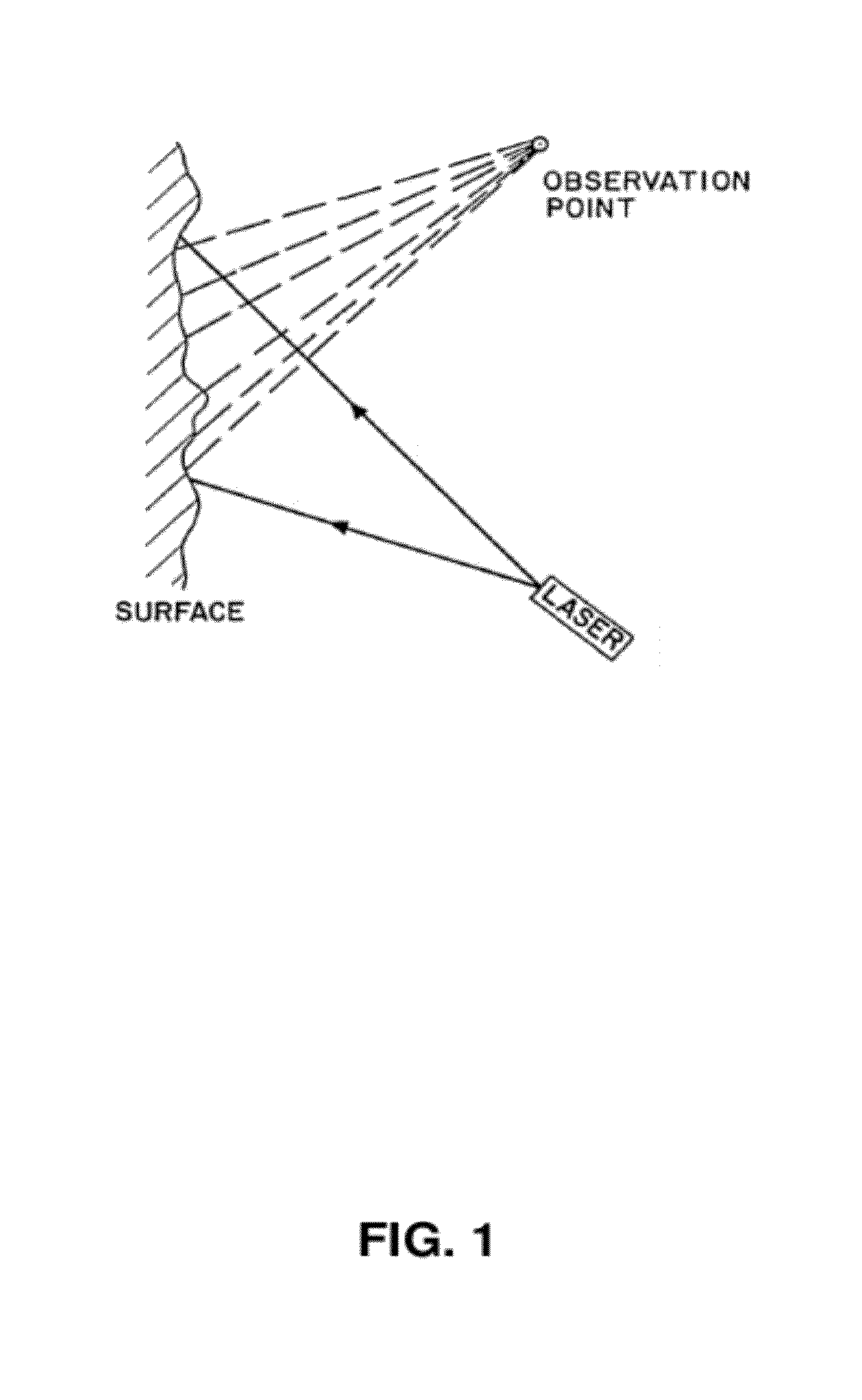

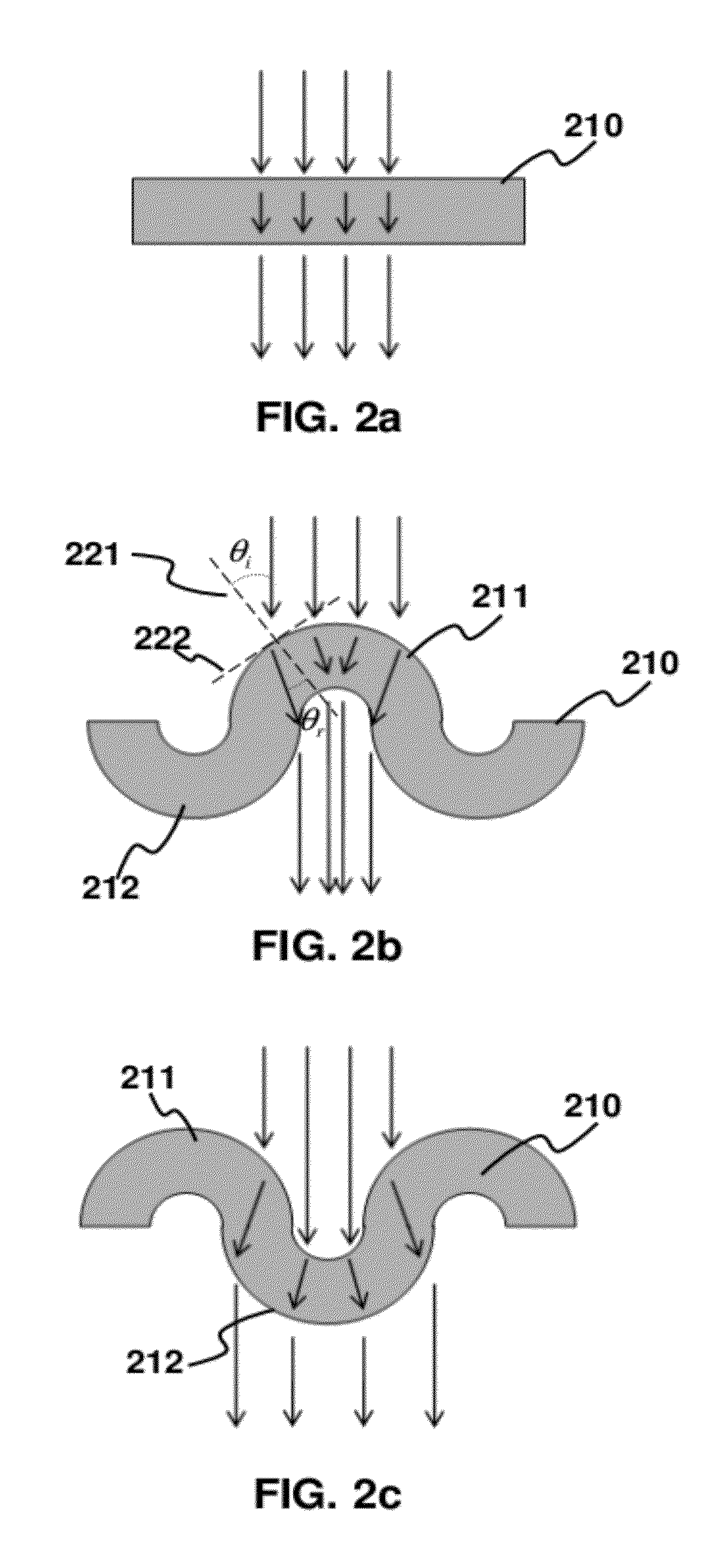

Device for reducing speckle effect in a display system

InactiveUS20120206784A1Suppress speckle noiseSimple optical systemOptical elementsVibrating membraneLaser scanning

The present invention relates to a method and apparatus for speckle noise reduction in laser scanning projection display. In particular, a MEMS device with a vibrating membrane through which light rays are refracted with temporally varying angles is provided for reducing the effect of speckling.

Owner:HONG KONG APPLIED SCI & TECH RES INST

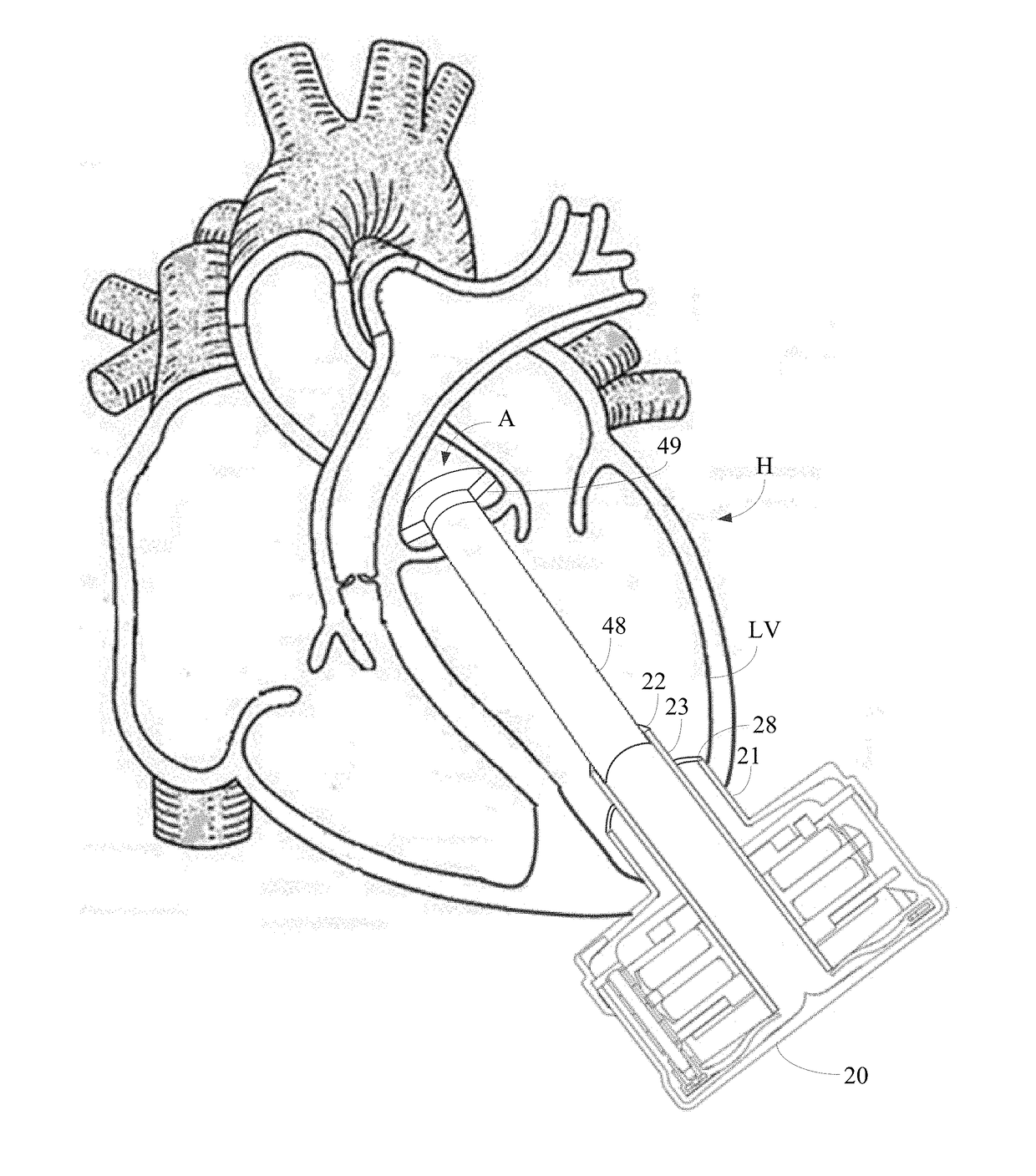

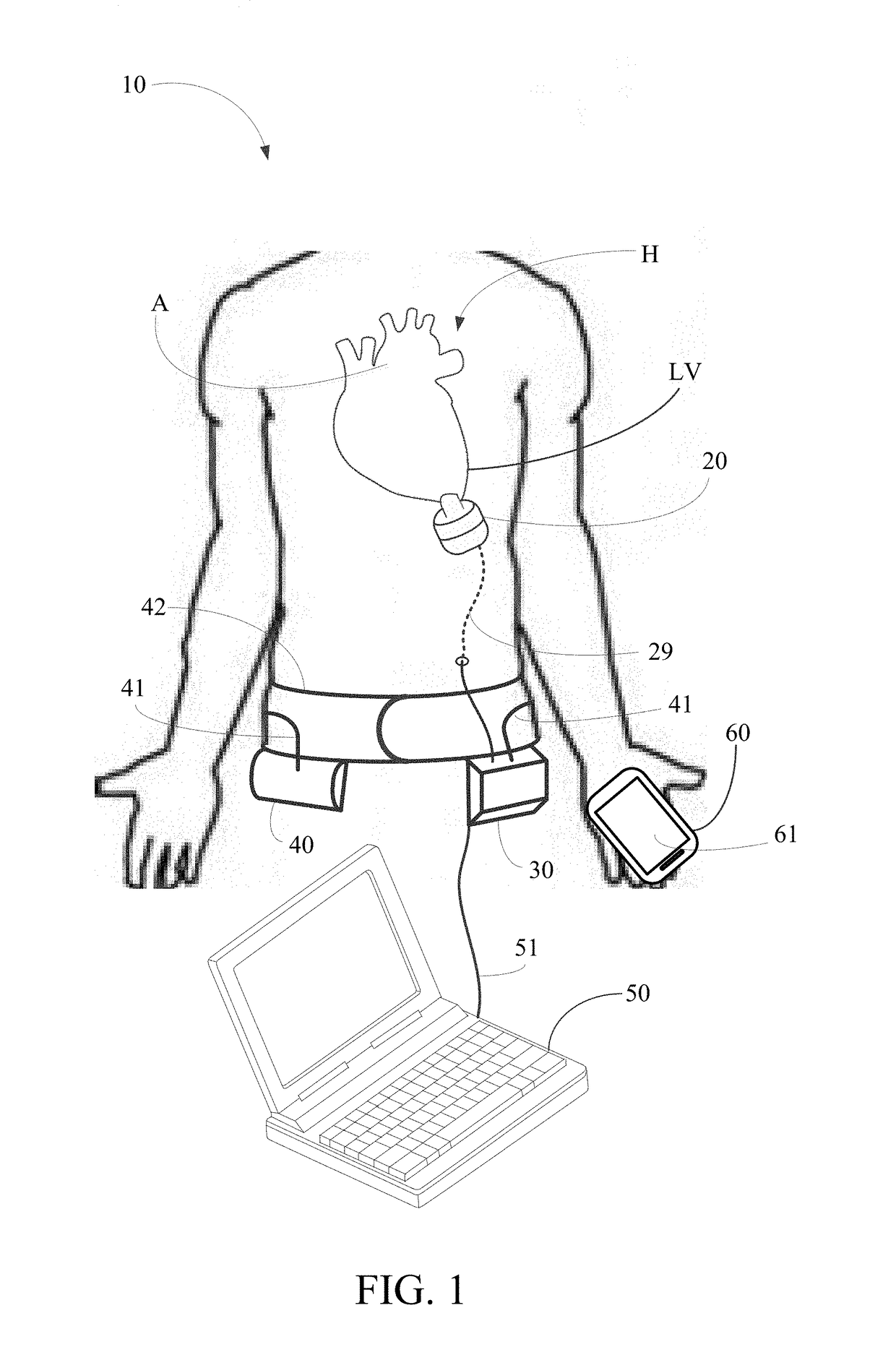

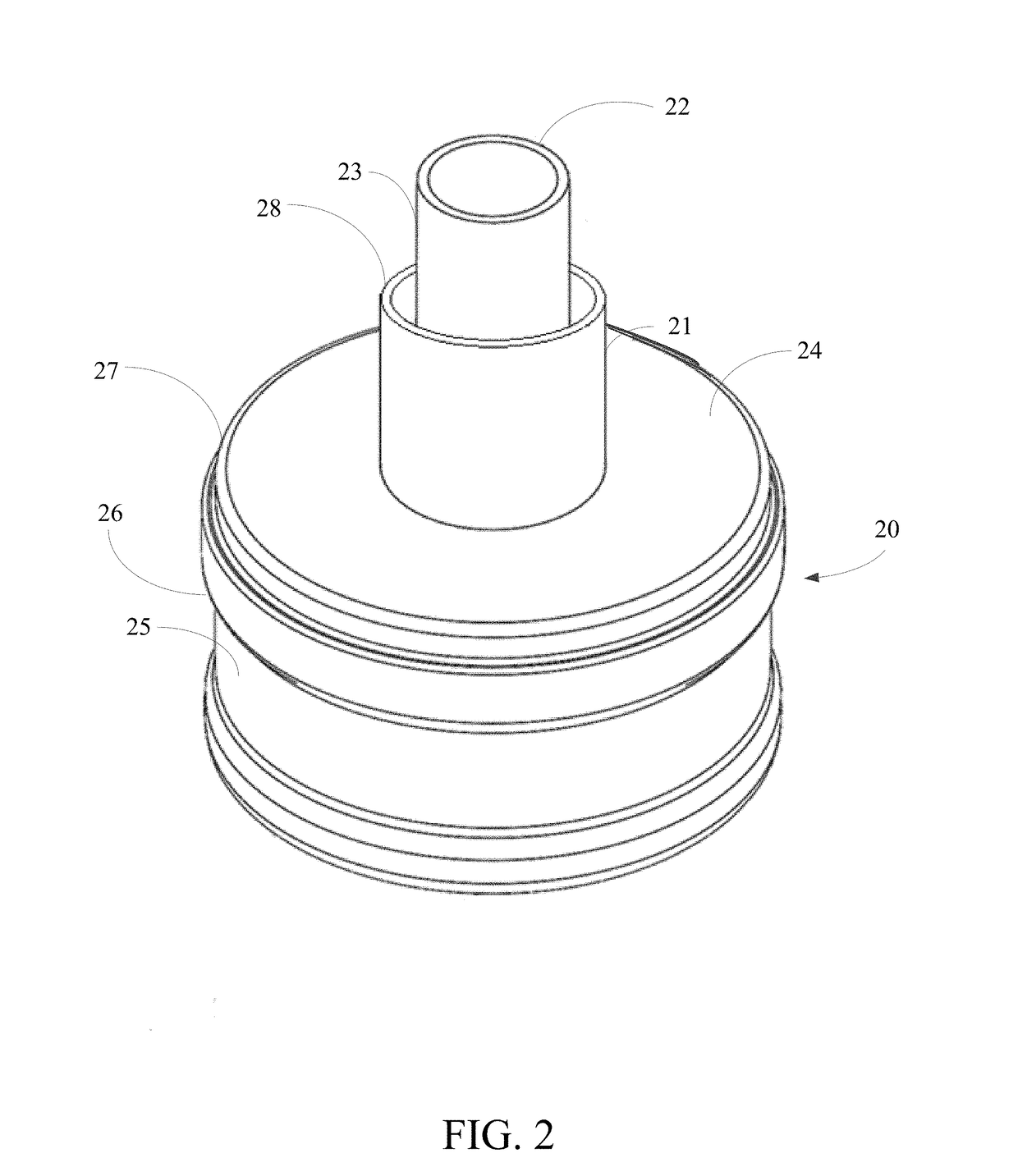

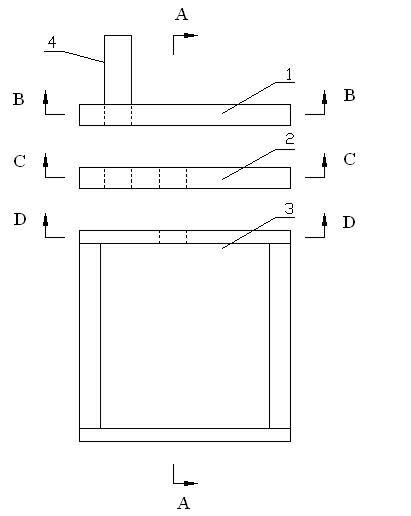

Implantable pump system having a coaxial ventricular cannula

ActiveUS20170290967A1Reduce hemolysisReducing platelet activationStentsHeart valvesVibrating membraneHemolysis

An implantable cardiovascular blood pump system is provided, suitable for use as a left ventricular assist device (LVAD) system, having an implantable cardiovascular pump, an extracorporeal battery and a controller coupled to the implantable pump, and a programmer selectively periodically coupled to the controller to configure and adjust operating parameters of the implantable cardiovascular pump. The implantable cardiovascular blood pump includes a coaxial inflow cannula and outflow cannula in fluid communication with one another and with a pumping mechanism. The pumping mechanism may be a vibrating membrane pump which may include a flexible membrane coupled to an electromagnetic actuator assembly that causes wavelike undulations to propagate along the flexible membrane to propel blood through the implantable cardiovascular pump. The implantable cardiovascular pump may be programmed to operate at frequencies and duty cycles that mimic physiologic flow rates and pulsatility while avoiding thrombus formation, hemolysis and / or platelet activation.

Owner:CORWAVE SA

Variable frequency and jet flow oscillator

ActiveCN102135122AWorking frequency adjustmentStable and reliable working frequencyFluid-pressure actuator componentsVibrating membraneJet flow

The invention discloses a variable frequency and jet flow oscillator which is used for controlling the high-frequency switching of jet flow in different pipelines. The upper end face of a single-film double-cavity vibration exciter is in parallel fit with the lower surface of an oscillation jet flow component, and the upper surface of the oscillation jet flow component is in parallel fit with thelower surface of a cover plate; the upper surface of the cover plate is provided with an inlet passage; an oscillation jet flow component cusp is arranged between a first outlet passage and a second outlet passage on the oscillation jet flow component; a vibrating membrane vertical to the upper end face in the single-film double-cavity vibration exciter; the single-film double-cavity vibration exciter is divided into a first cavity and a second cavity through the vibrating membrane; the first cavity is provided with a first cavity inlet; the second cavity is provided with a second cavity outlet; and the first cavity outlet, and the second cavity outlet are connected with a first control port and a second control port of the oscillation jet flow component respectively. The working frequency of the jet flow oscillator is actively controlled by changing the excitation frequency of the oscillator and the adjusted working frequency is stable and reliable.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Electromechanical transducer and method for manufacturing the same

InactiveUS20100123366A1Sufficient massSolve the lack of rigidityMicrophonesLoudspeakersVibrating membraneElectromechanical transducer

An electromechanical transducer of the present invention includes a first electrode, a vibrating membrane formed above the first electrode through a gap, a second electrode formed on the vibrating membrane, and an insulating protective layer formed on a surface of the second electrode side. A region where the protective layer is not formed is present on at least part of a surface of the vibrating membrane.

Owner:CANON KK

Surface acoustic wave electric current sensor

InactiveCN103954823AImprove temperature stabilityHigh detection sensitivityCurrent/voltage measurementVibrating membraneElectricity

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI +1

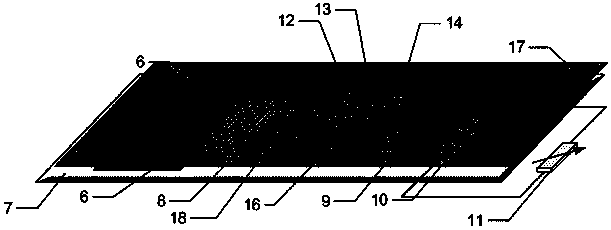

Flat speaker unit and speaker device therewith

A reliable flat speaker unit and a speaker device with the same are provided herein. A conductive electrode of a vibrating membrane of the speaker unit is disposed on both utmost sides of the speaker unit to isolate the speaker unit from environmental moisture, which can significantly improve the reliance of the speaker device. A barrier layer can optionally be disposed on the external side of the conductive electrode to further isolating the speaker unit from moisture, which can improve the reliance and the lifetime of the speaker device. In an embodiment, at least a getter is disposed inside the flat speaker unit to absorb moisture therein. The speaker unit at least includes a electret vibrating membrane with a conductive electrode, a plurality of supporting members, and a electrode structure with a plurality of holes.

Owner:IND TECH RES INST

Flat speaker

InactiveUS7912239B2Avoid collisionAvoid easy disconnectionTransducer detailsVibrating membraneEngineering

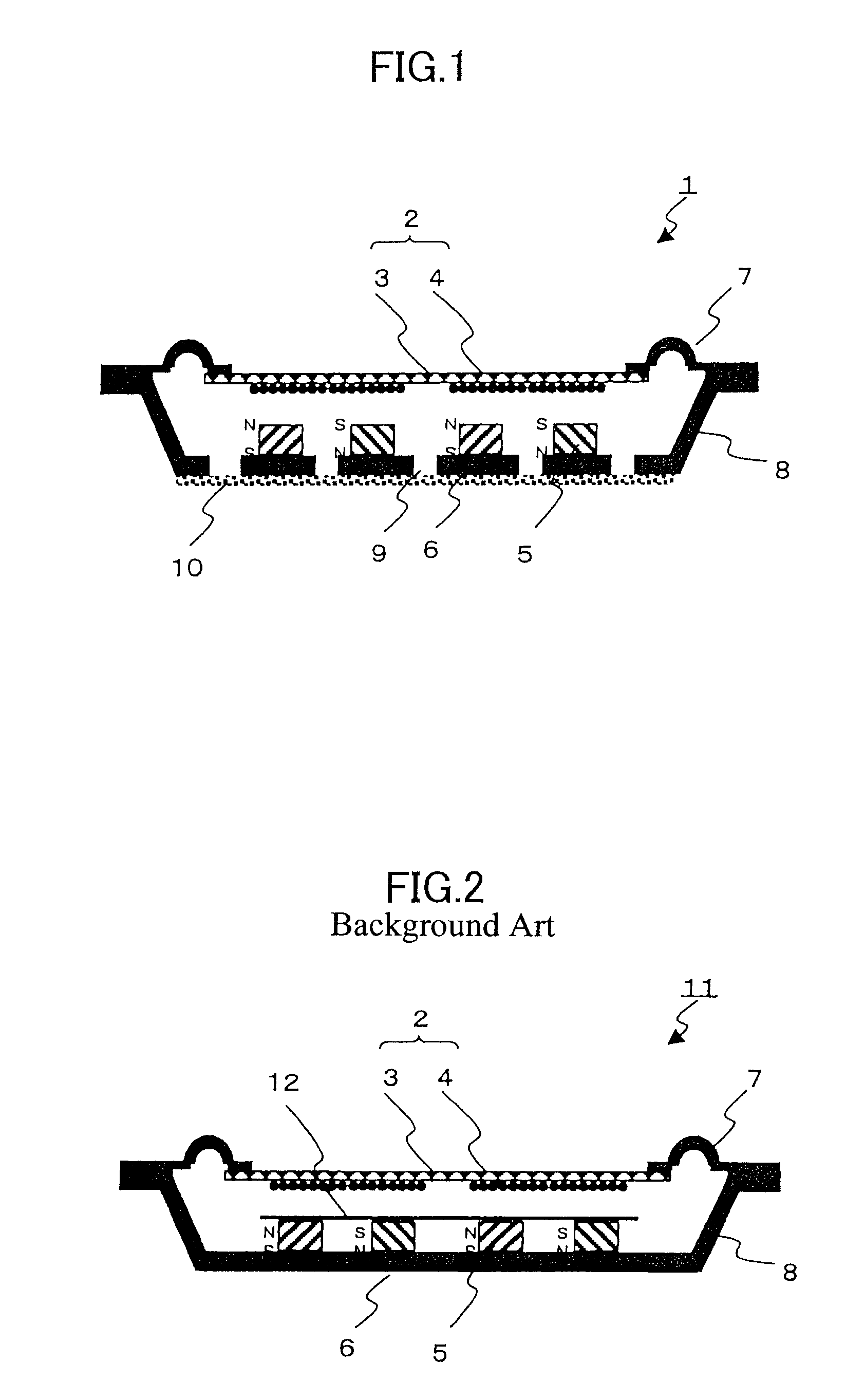

A flat speaker comprising a vibrating plate including a spiral voice coil, a lead portion extracted from the vice coil and reinforced by the reinforcing member, and an electric supply line; an edge portion supporting the vibrating plate; and a yoke, supporting the edge portion, on which the permanent magnet arranged to face the voice coil. The flat speaker 1 of the invention includes a vibrating membrane 2 of an insulating base film 3 with a spiral or meandering voice coil 4 formed on one or both faces thereof, a permanent magnet 5 arranged on corresponding location facing the voice coil 4; and a yoke 6 on which the permanent magnet 5 is arranged. The vibrating membrane 2 is avoided from hitting the permanent magnet by providing a perforated sheet on the back face of the yoke to control acoustic resistance.

Owner:FURUKAWA ELECTRIC CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com