Piezoelectric combining jet device and its making process

A jet and piezoelectric technology, applied in the field of synthetic jet production, can solve the problems of low reliability and consistency, and achieve the effect of improving reliability and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

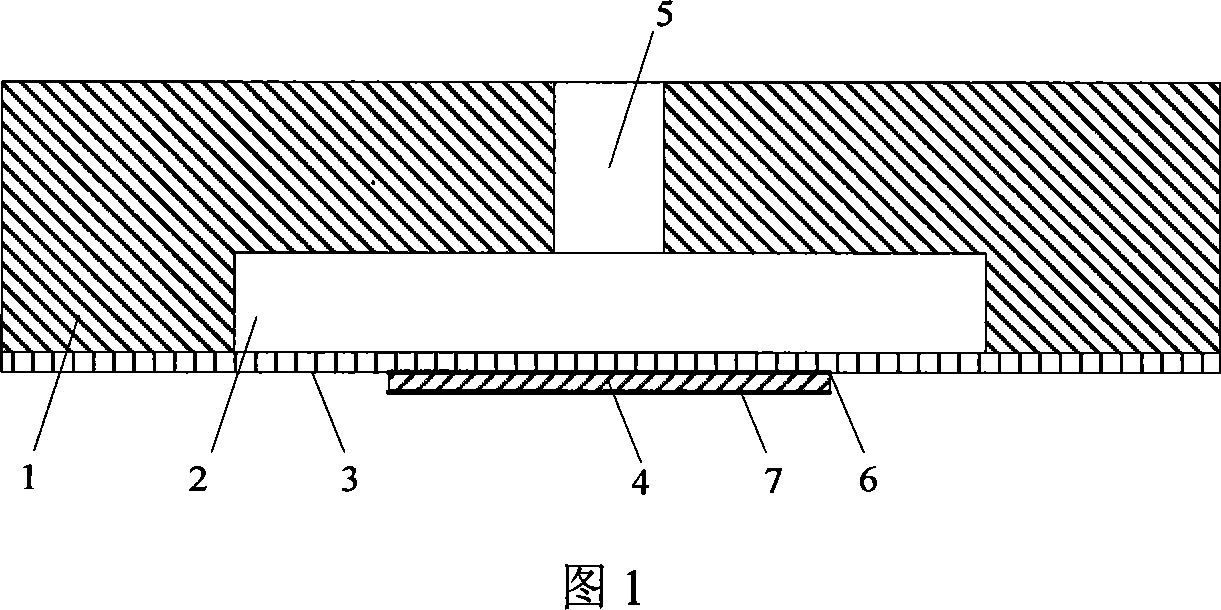

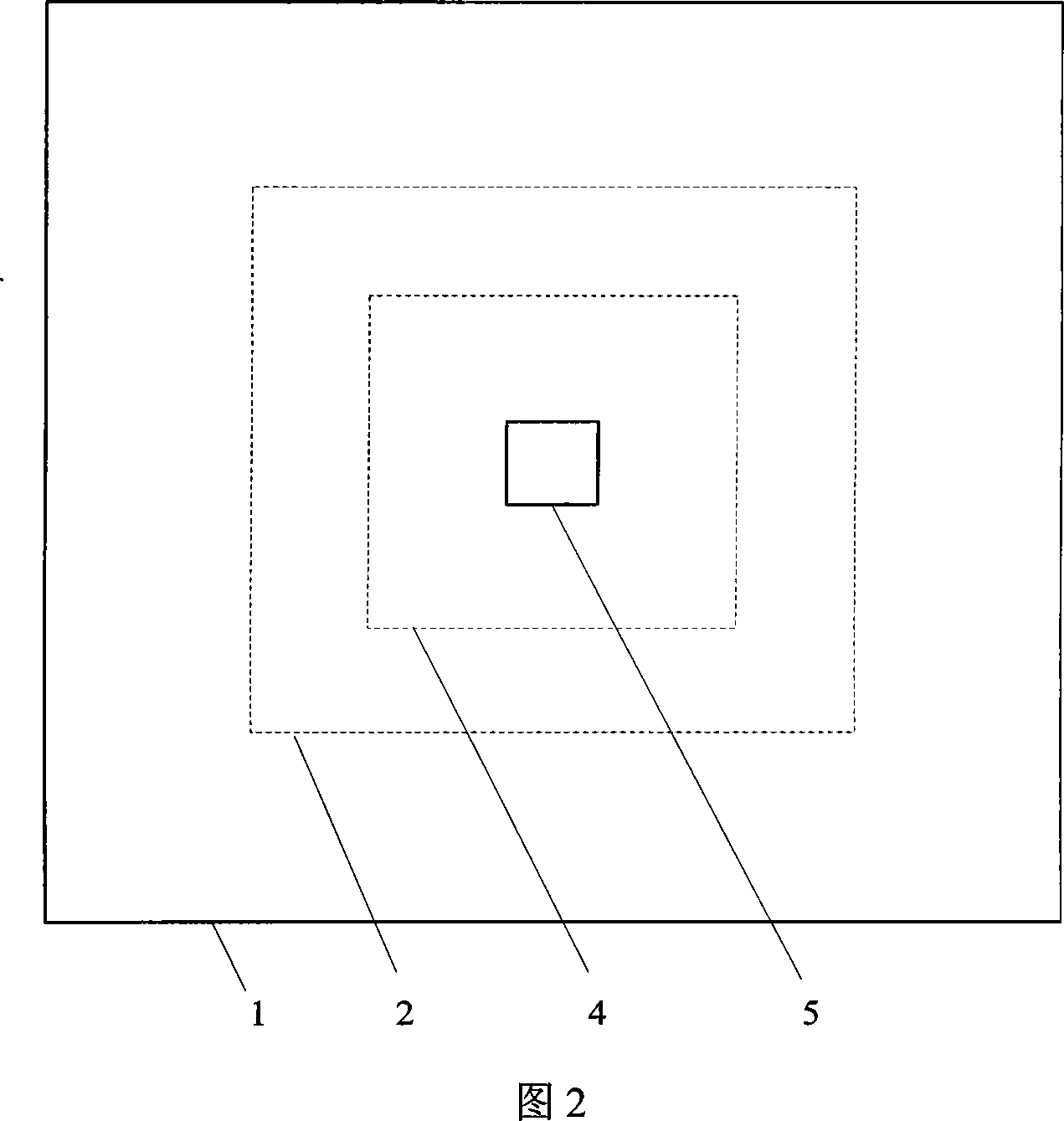

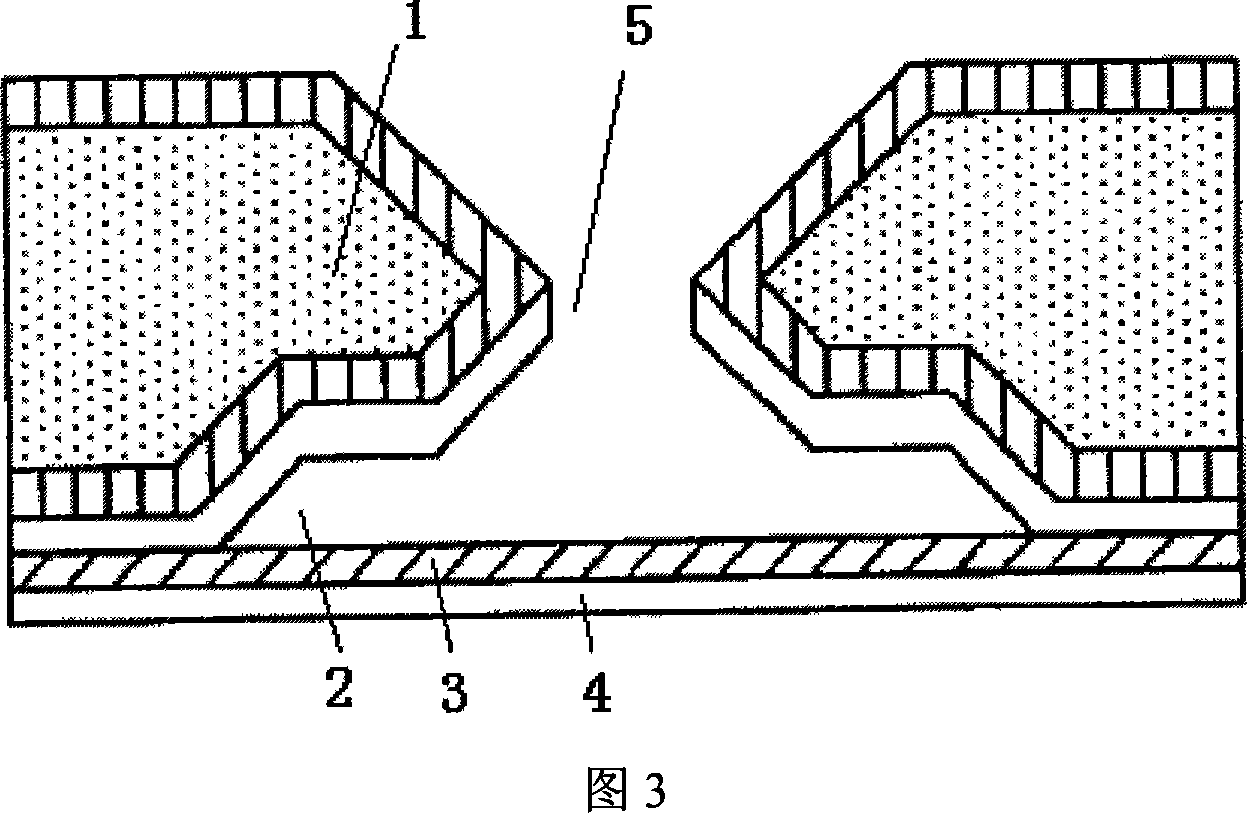

[0016] Refer to Figure 1 and Figure 2. The present invention includes a silicon substrate 1 , a cavity 2 , a spout 5 , a vibrating membrane 3 , a piezoelectric actuator 4 , an upper electrode 6 and a lower electrode 7 . Below the silicon substrate 1 is a cavity 2 with a square cross-section. Located above the cavity 2 and connected to the cavity 2 is a nozzle 5 with a square cross-section. The cavity 2 and the nozzle 5 run through the silicon substrate 1, and the nozzle 5 is connected to the cavity. 2 and the external flow field. The vibrating diaphragm 3 is made of polysilicon material, located on the lower surface of the silicon substrate 1 , and forms a suspended film below the cavity 2 . The piezoelectric actuator 4 is composed of a PZT piezoelectric ceramic material, and an upper electrode 6 and a lower electrode 7 attached to its upper and lower surfaces, and is located in the center of the lower surface of the vibrating diaphragm 3 . Wherein, the cross-sectional shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com