Capacitance type microphone with stress release membrane prepared at a low temperature and preparation method thereof

A capacitive microphone and its manufacturing method are applied to electrical components, electrostatic transducers, microphones, sensors, etc., and can solve the problems of high forming process temperature, difficulty in system integration, large size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Both the foregoing general description and the following detailed description are by way of example only, and are further explanation and illustration of the invention as claimed.

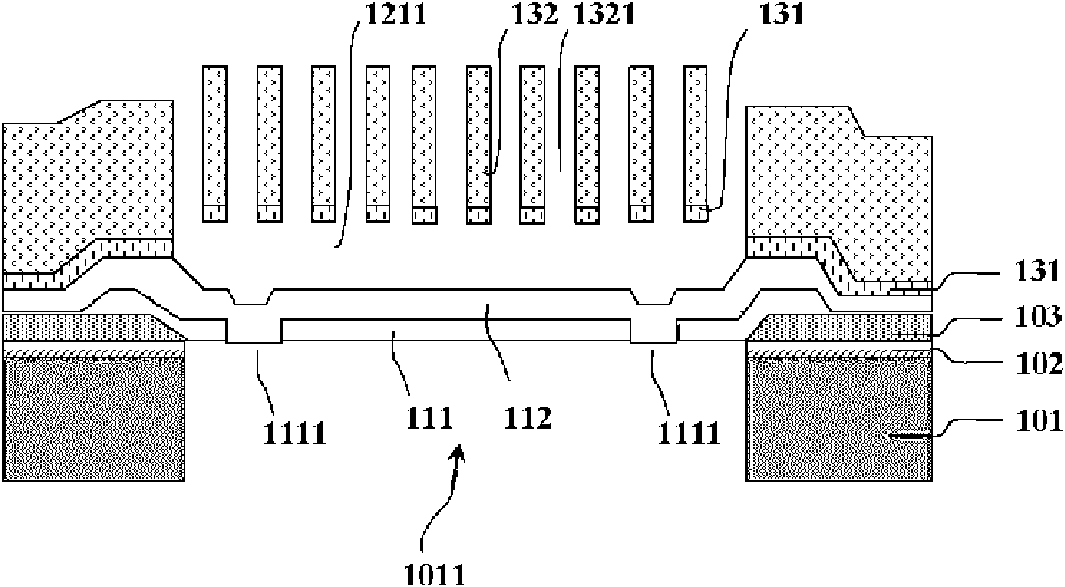

[0013] Figure 1A is a schematic cross-sectional structure diagram of the capacitive microphone of the present invention, wherein the microphone is based on a substrate 101 with a resonant cavity 1011 . Such as Figure 1A As shown, wherein, the microphone is arranged on the substrate 101 , and the resonant cavity 1011 is arranged on the substrate 101 . The substrate can be made of conductive, insulating or semiconducting materials. The pressure sensing diaphragm includes a conductive layer 111 and a sealing layer 112 . A rigid back plate is provided on the diaphragm, and the back plate is composed of a conductive layer 131 and a rigid structural layer 132 , both of which are provided with vent holes 1321 . An air gap 1211 is formed between the sealing layer 112 and the conductive layer 131...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com