Patents

Literature

79 results about "Vibrating electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scanning Vibrating Electrode Technique (SVET), also known as Vibrating Probe within the field of biology, is a Scanning Probe Microscopy (SPM) technique which visualizes electrochemical processes at a sample. It was originally introduced in 1974 by Jaffe and Nuccitelli to investigate the electrical current densities near living cells.

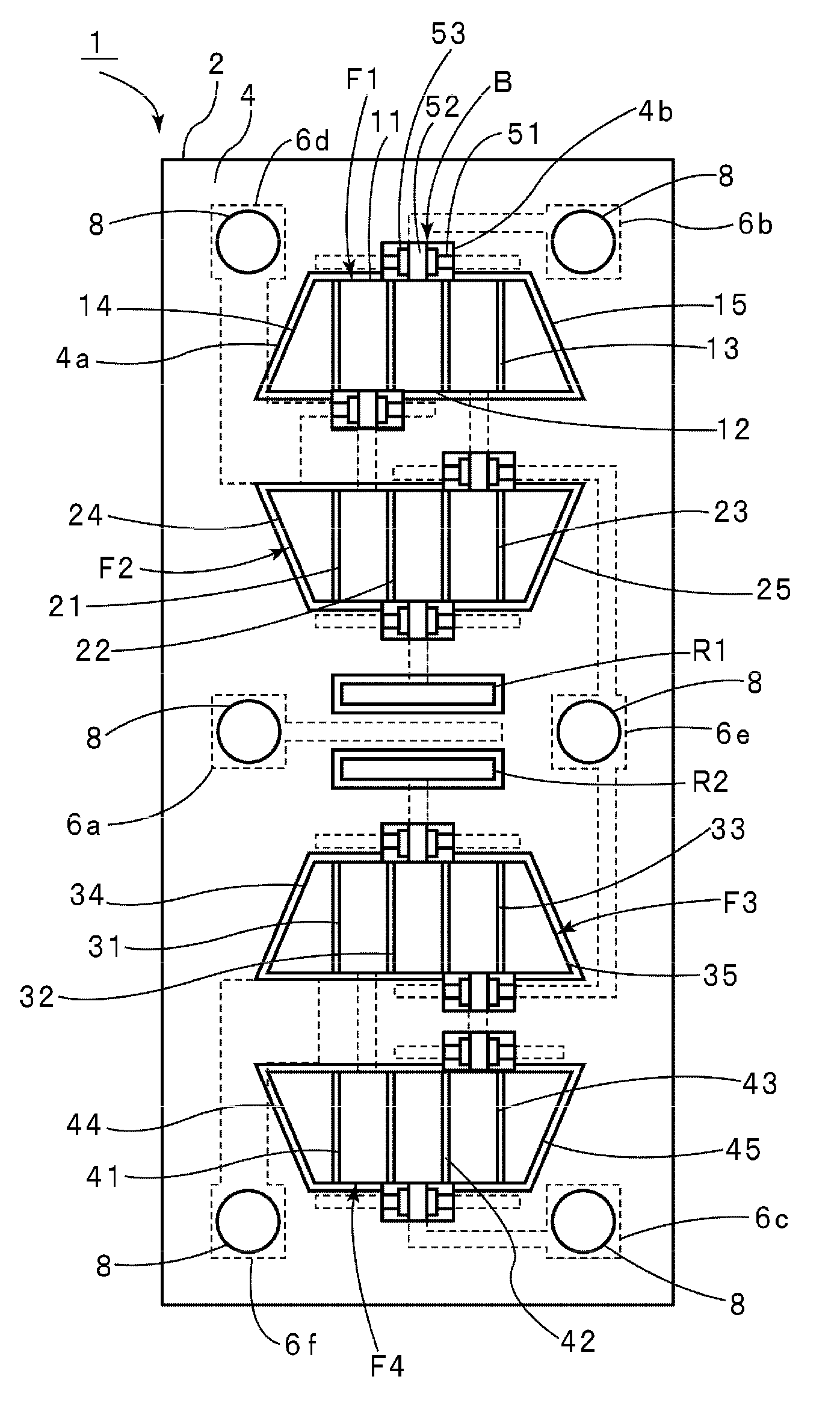

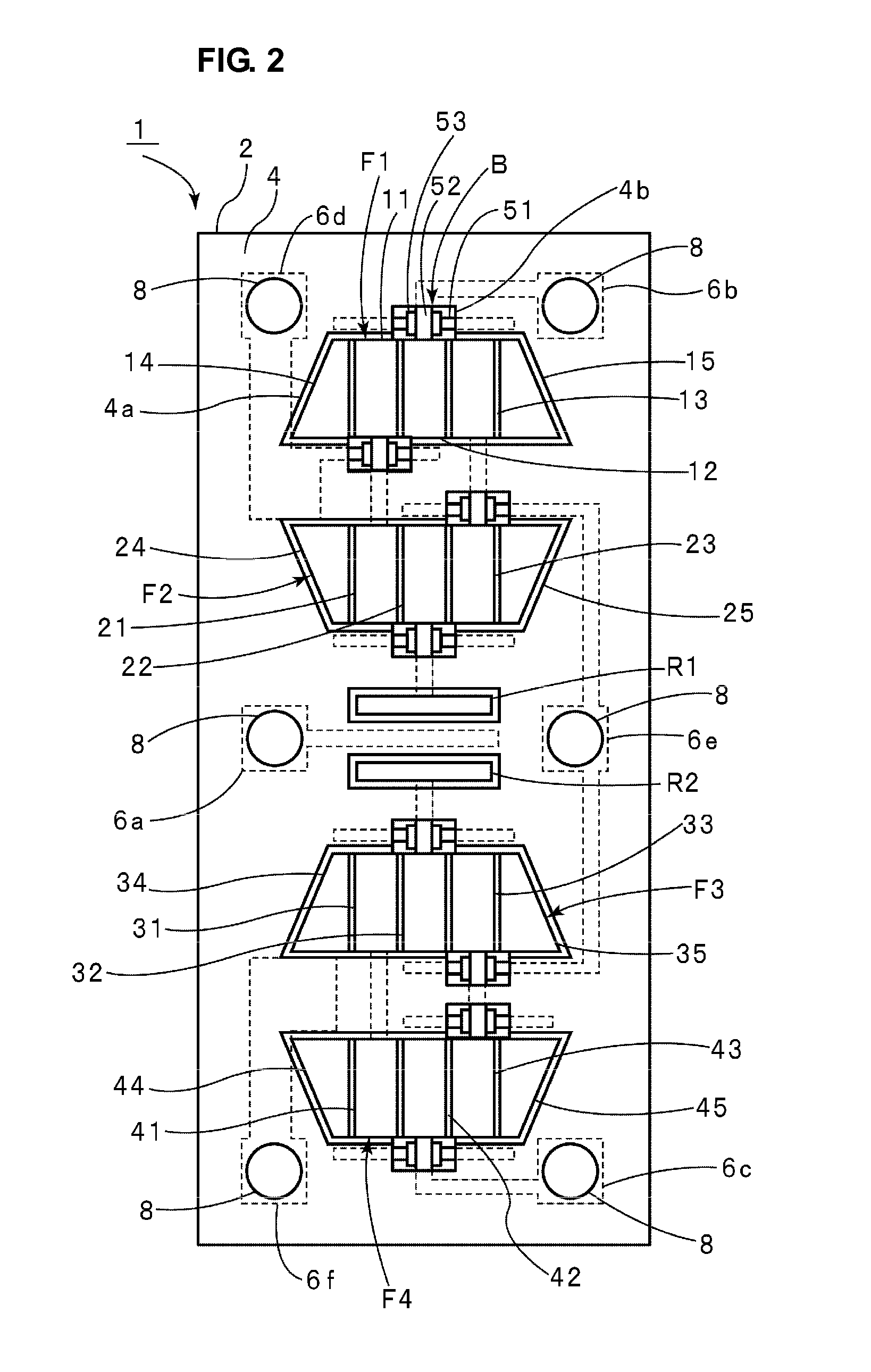

Capacitor microphone

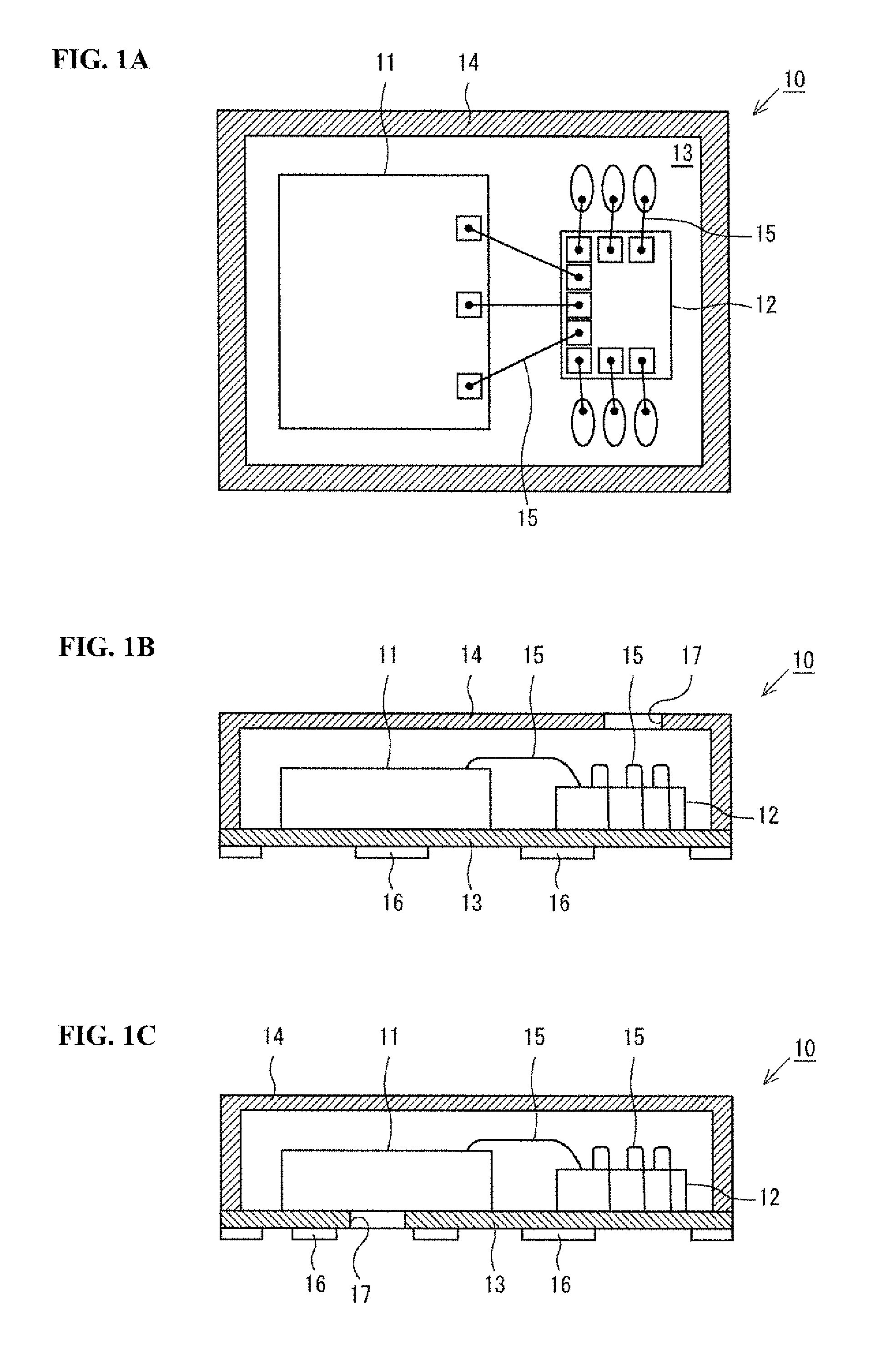

InactiveUS20070058825A1Uniform stress distributionDegree of improvementPiezoelectric/electrostrictive microphonesSemiconductor electrostatic transducersCapacitanceEngineering

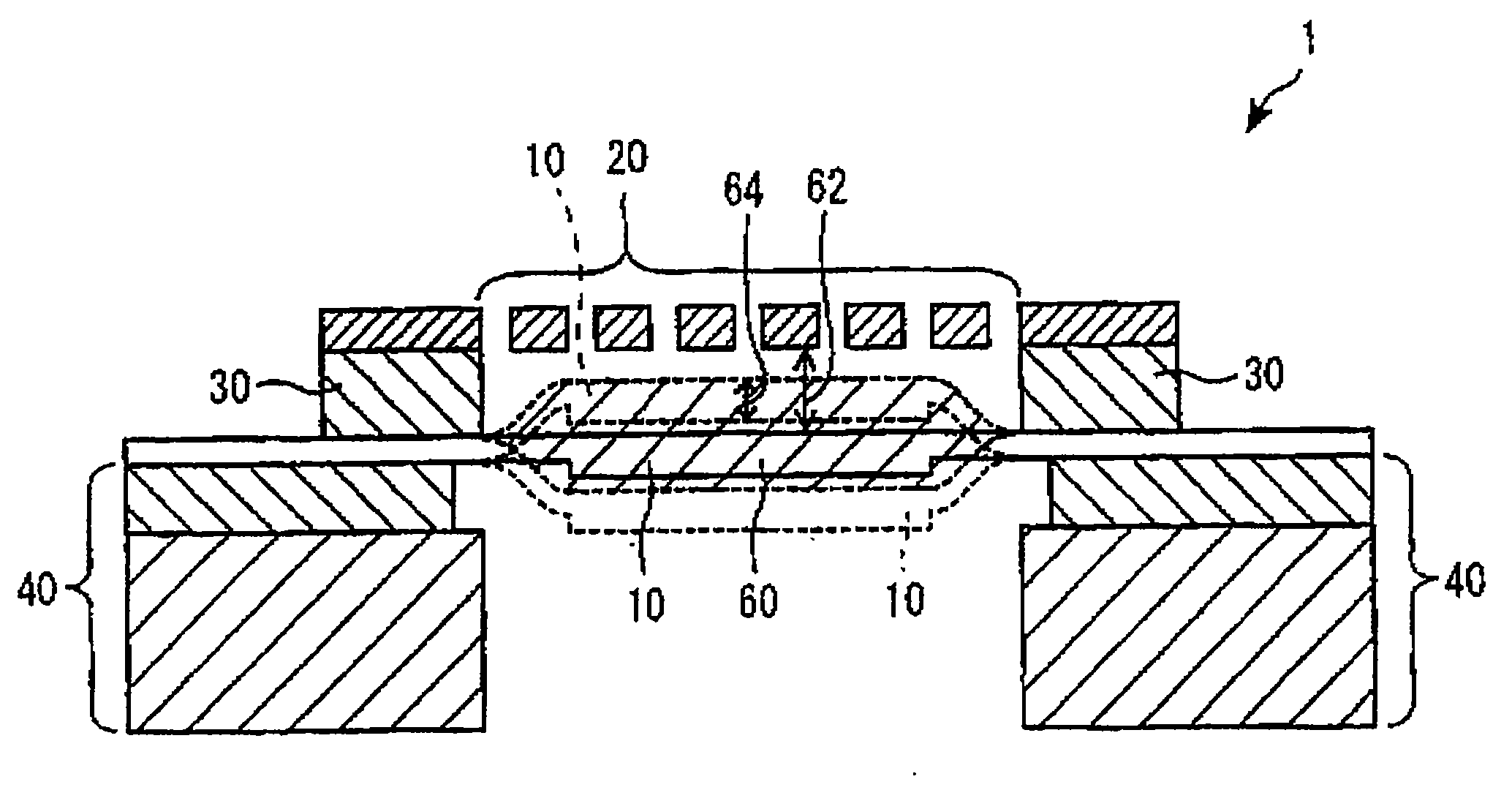

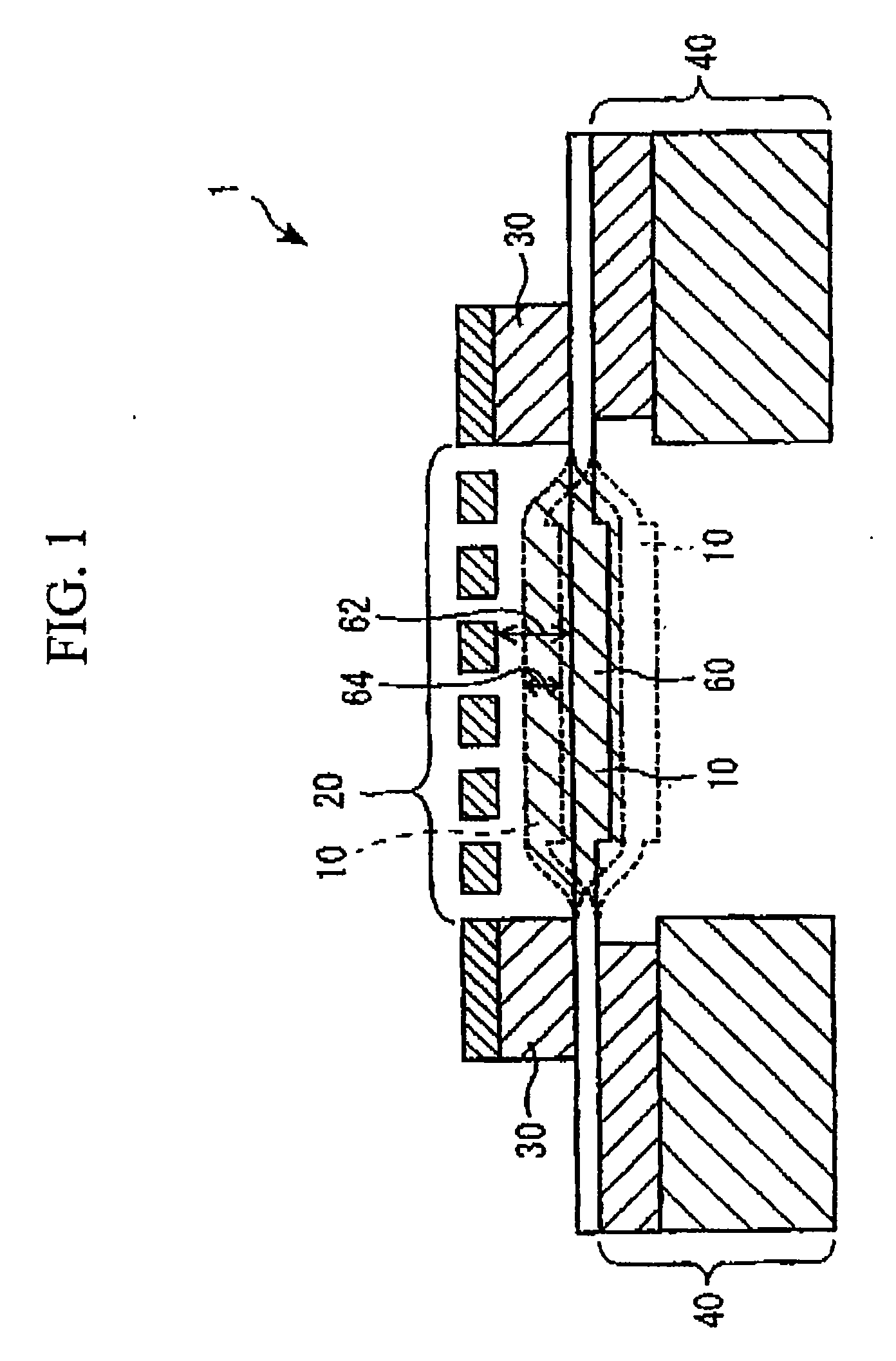

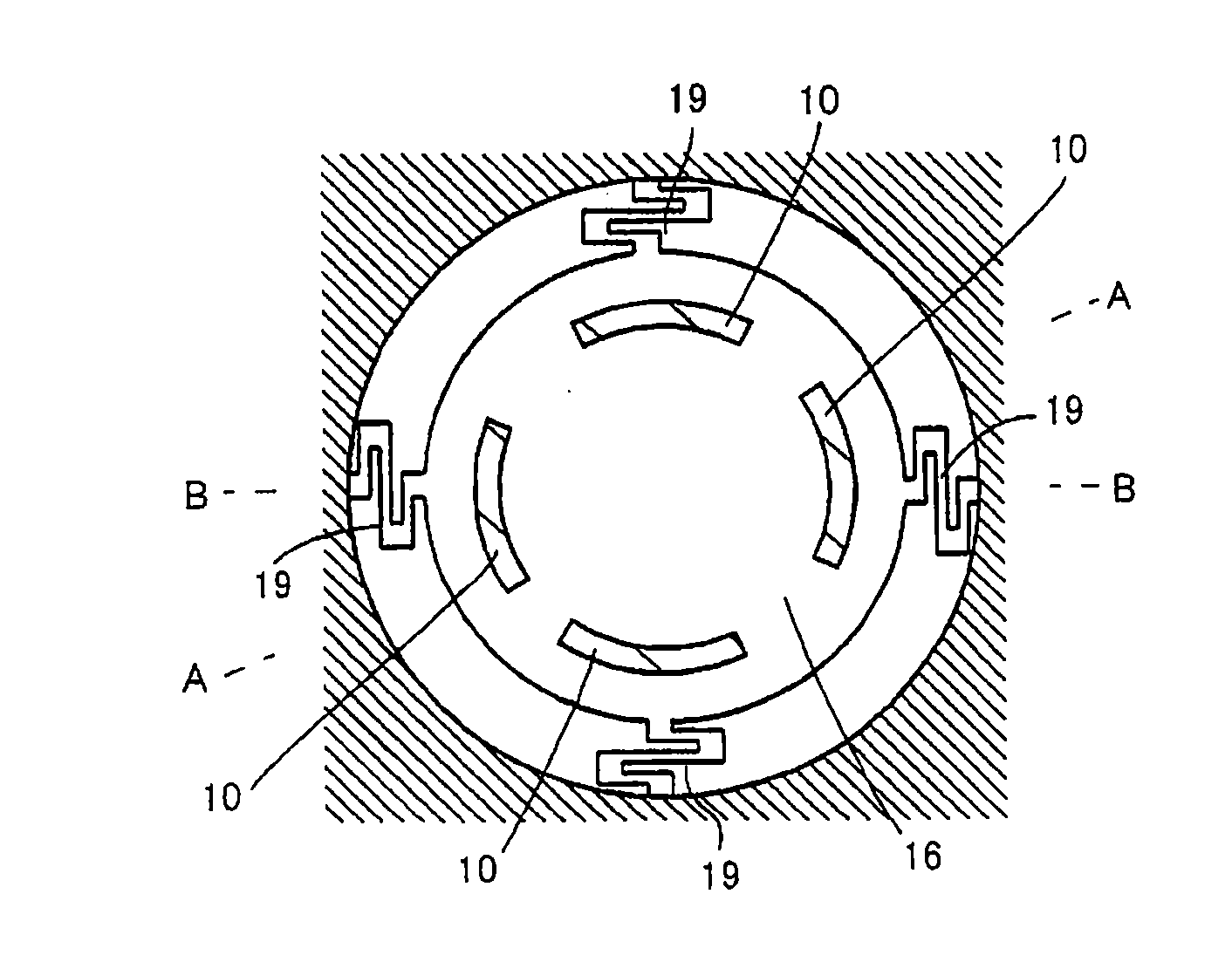

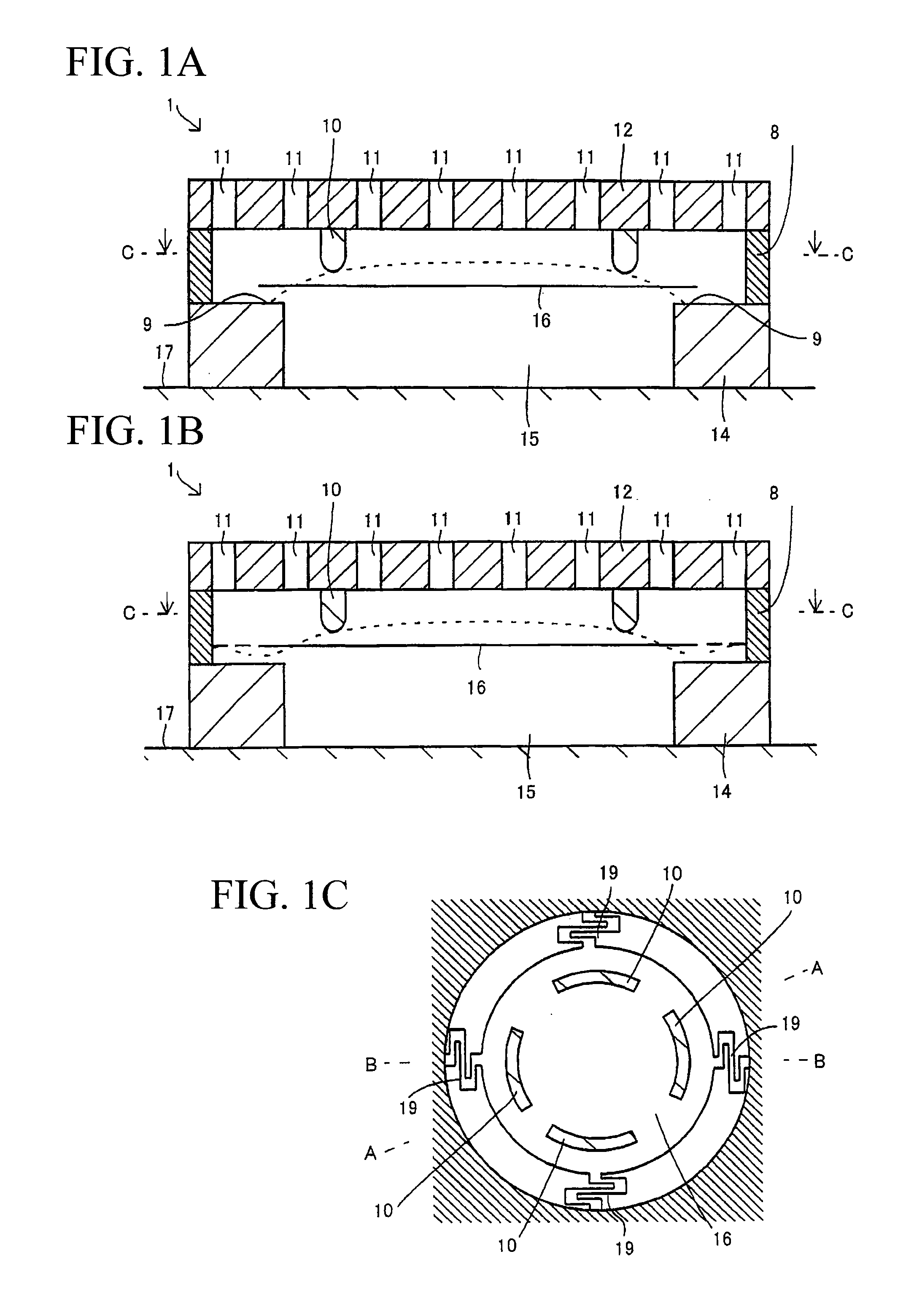

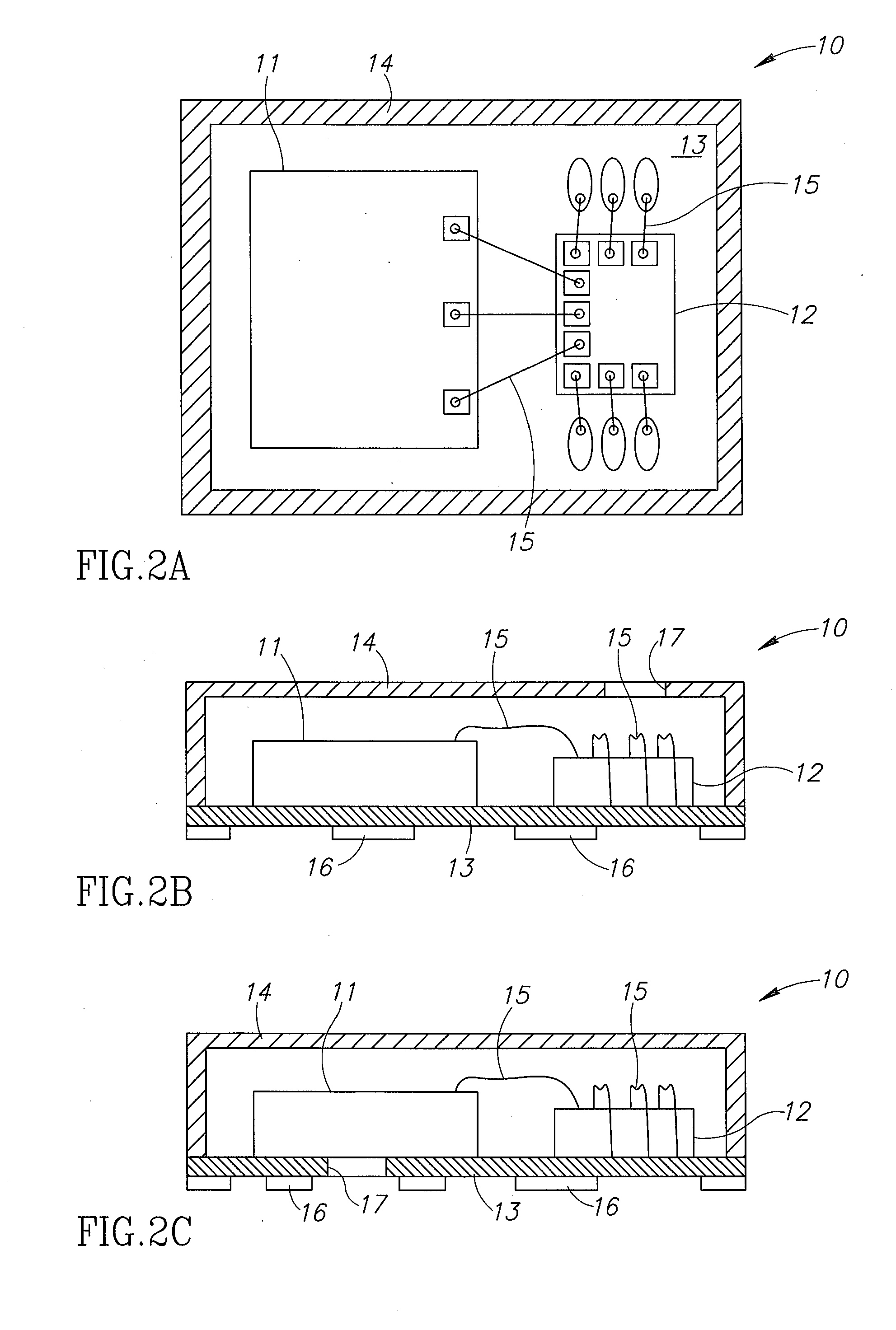

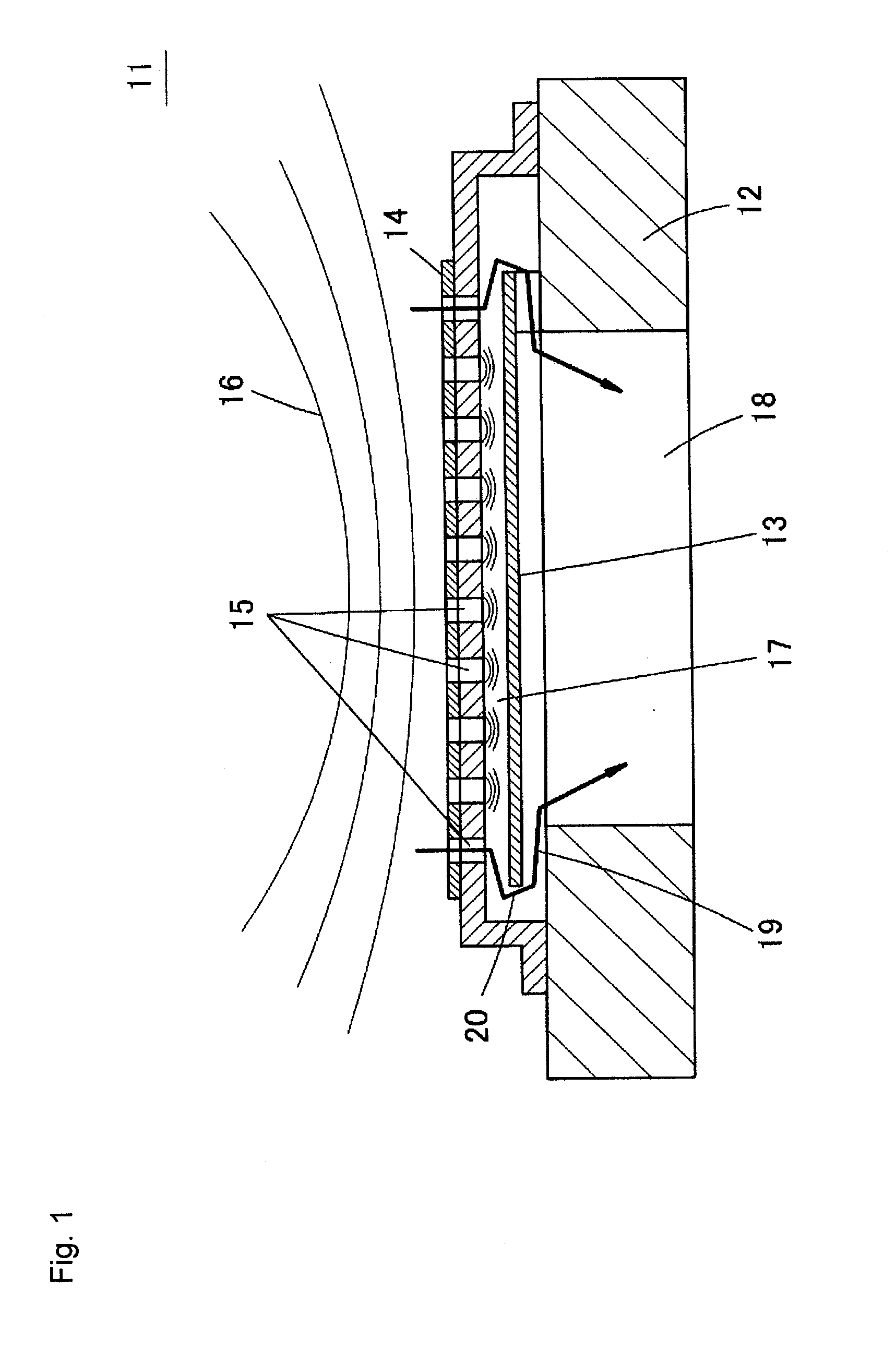

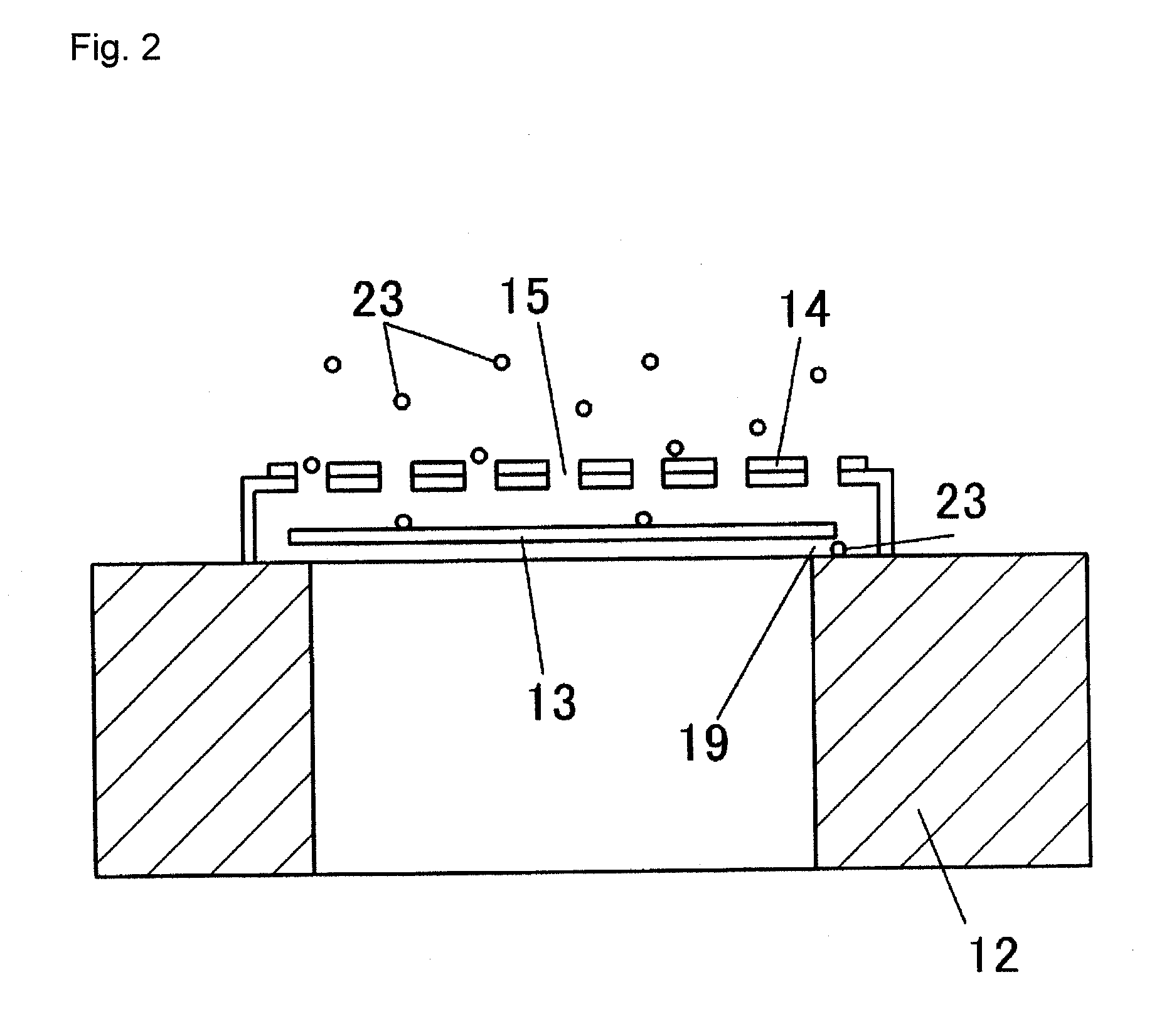

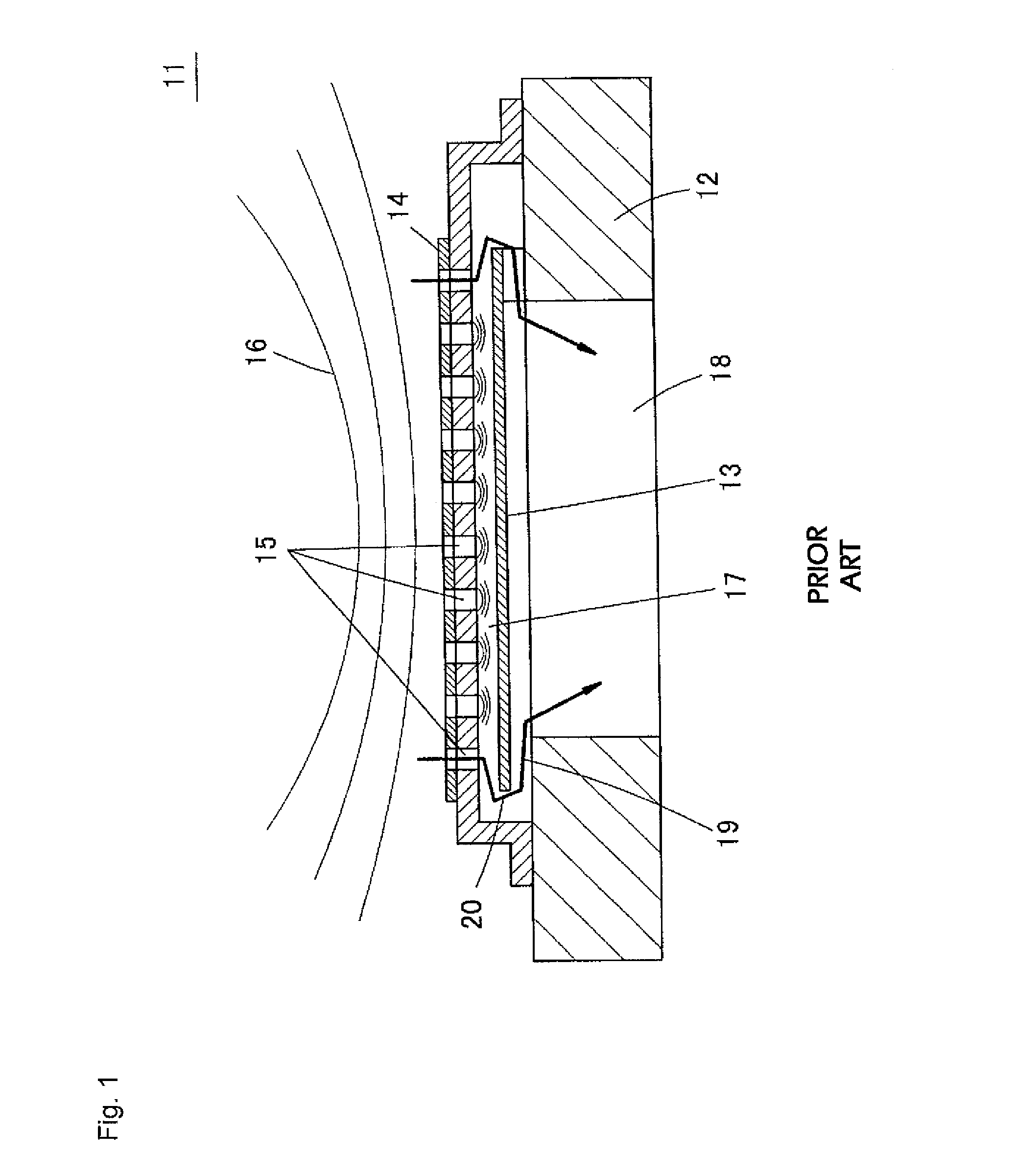

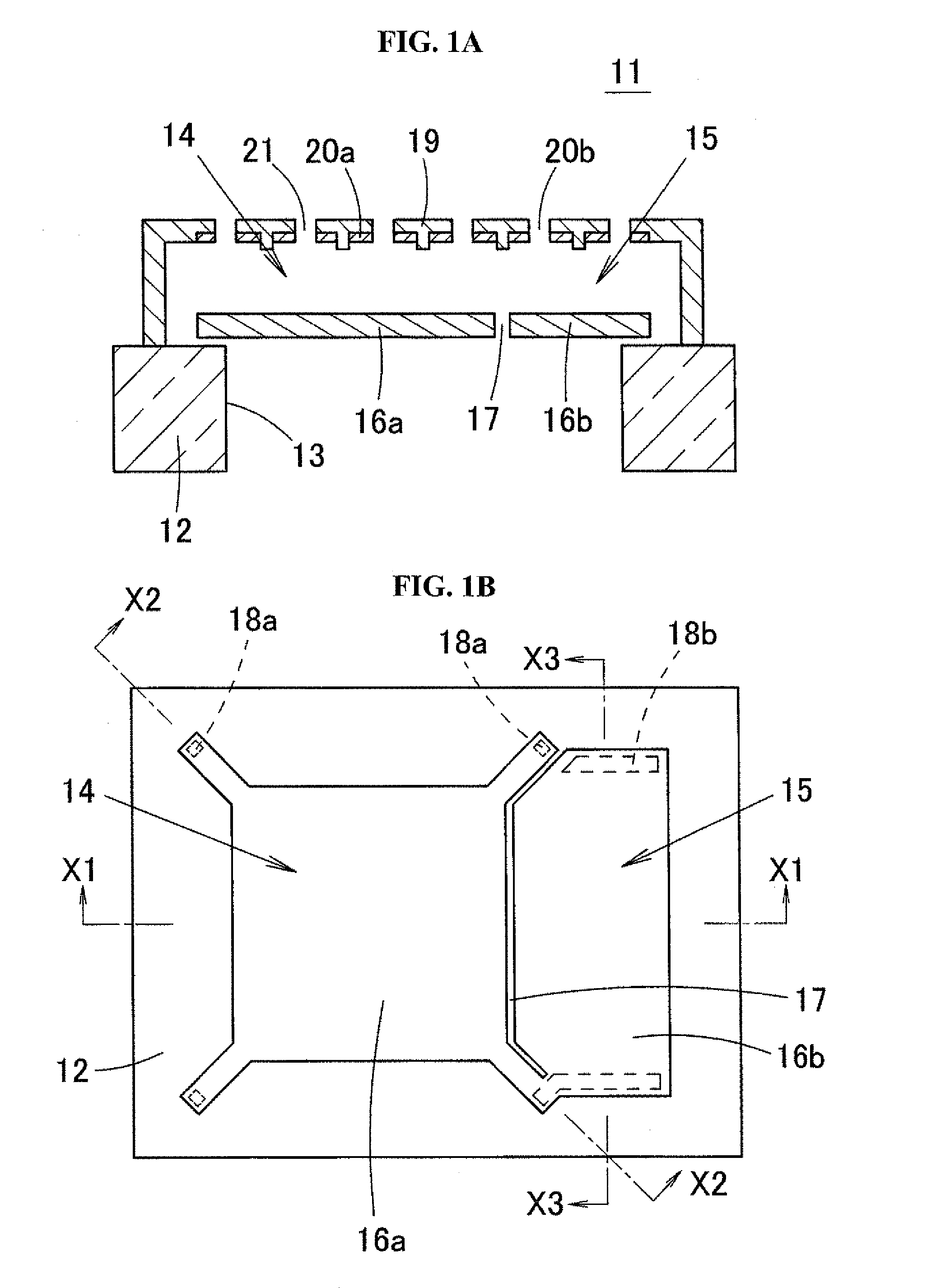

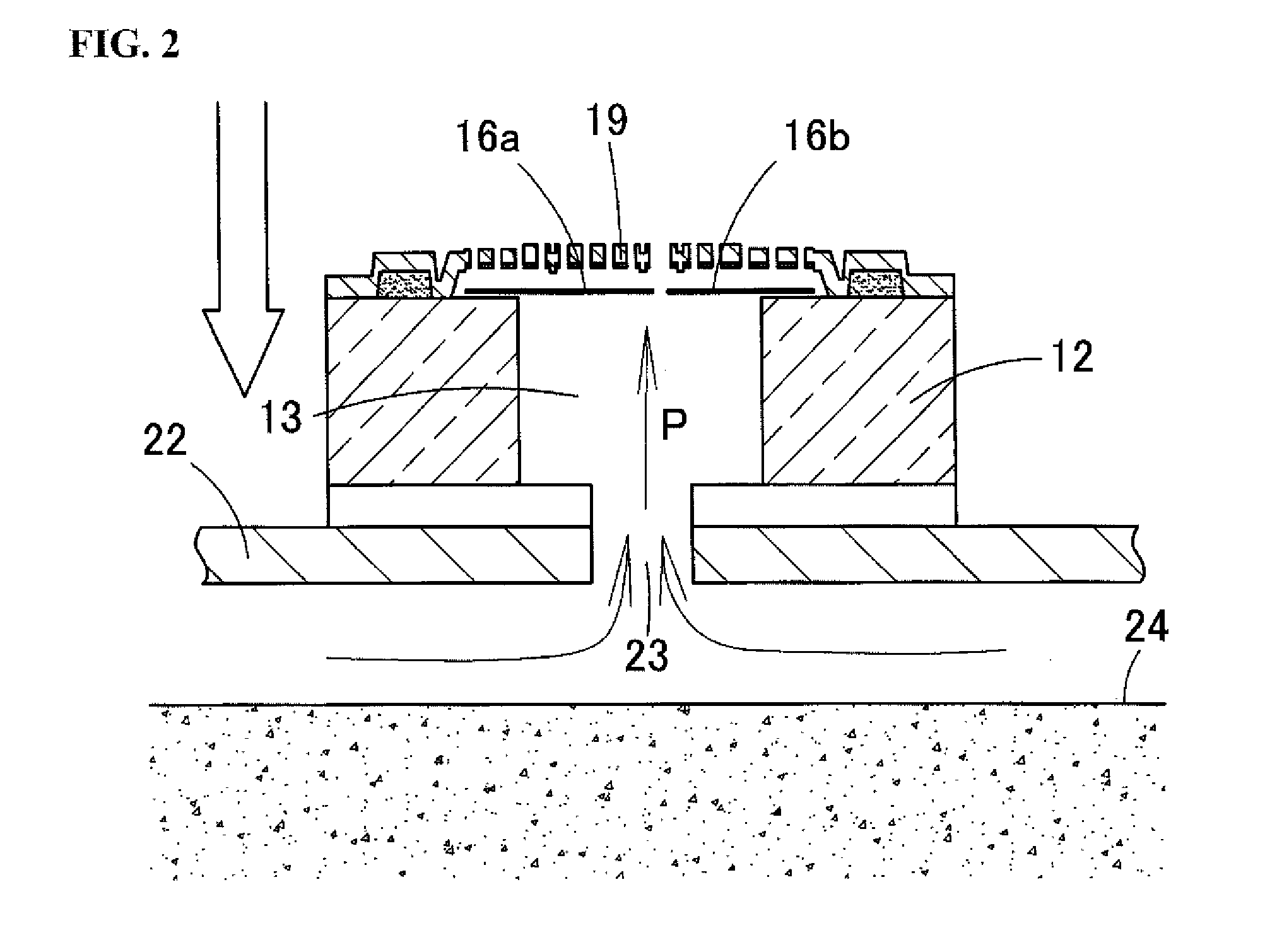

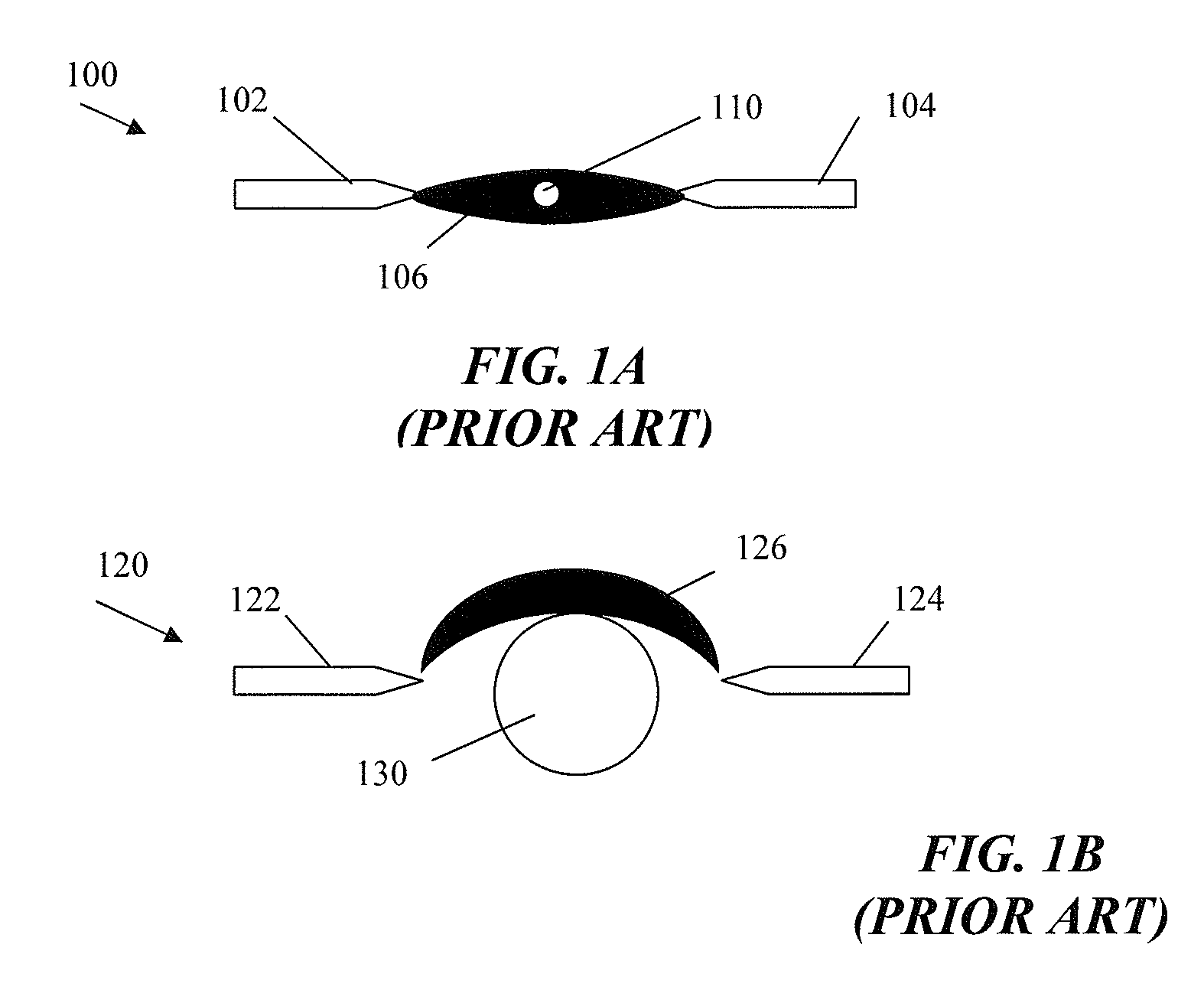

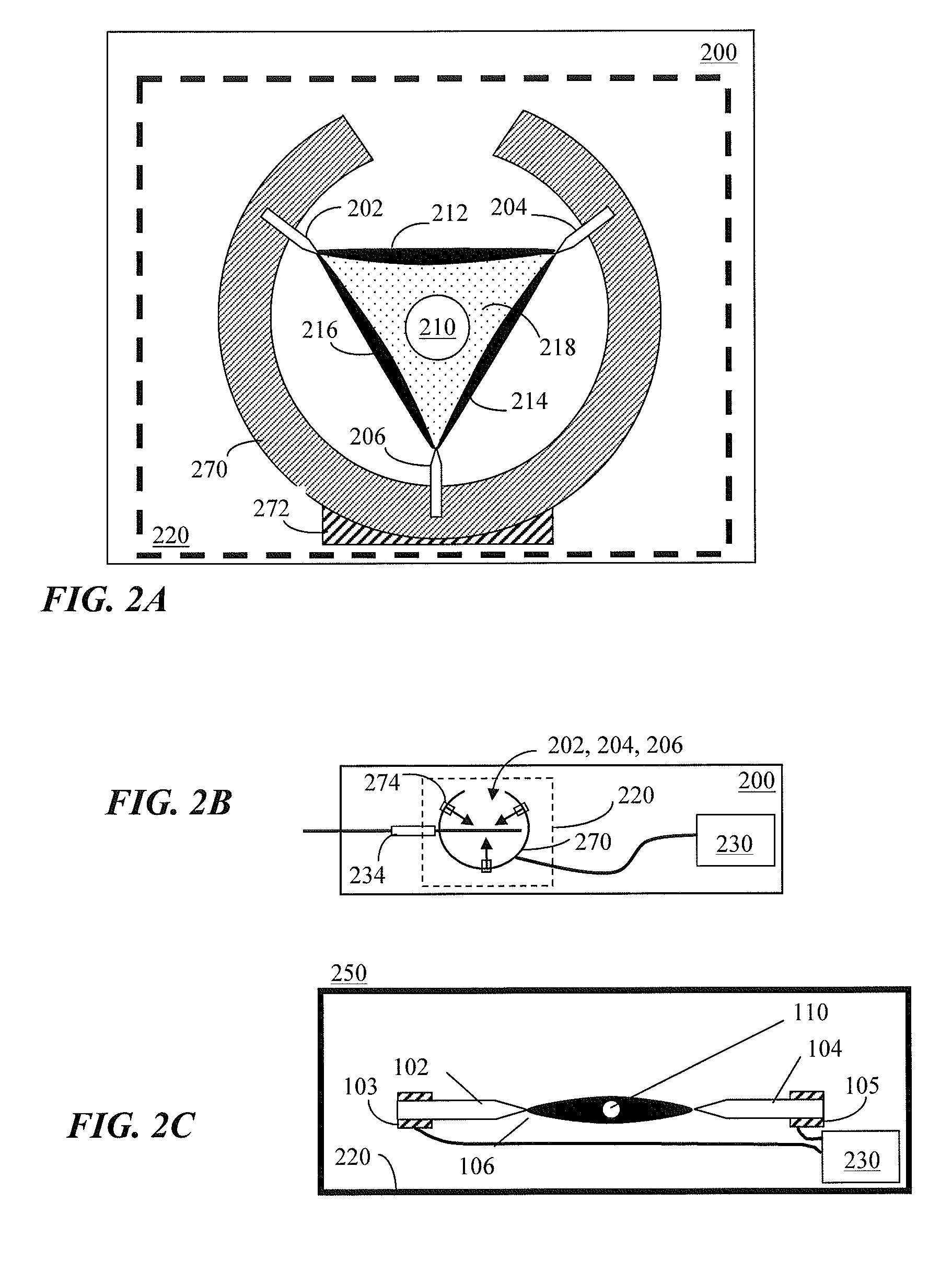

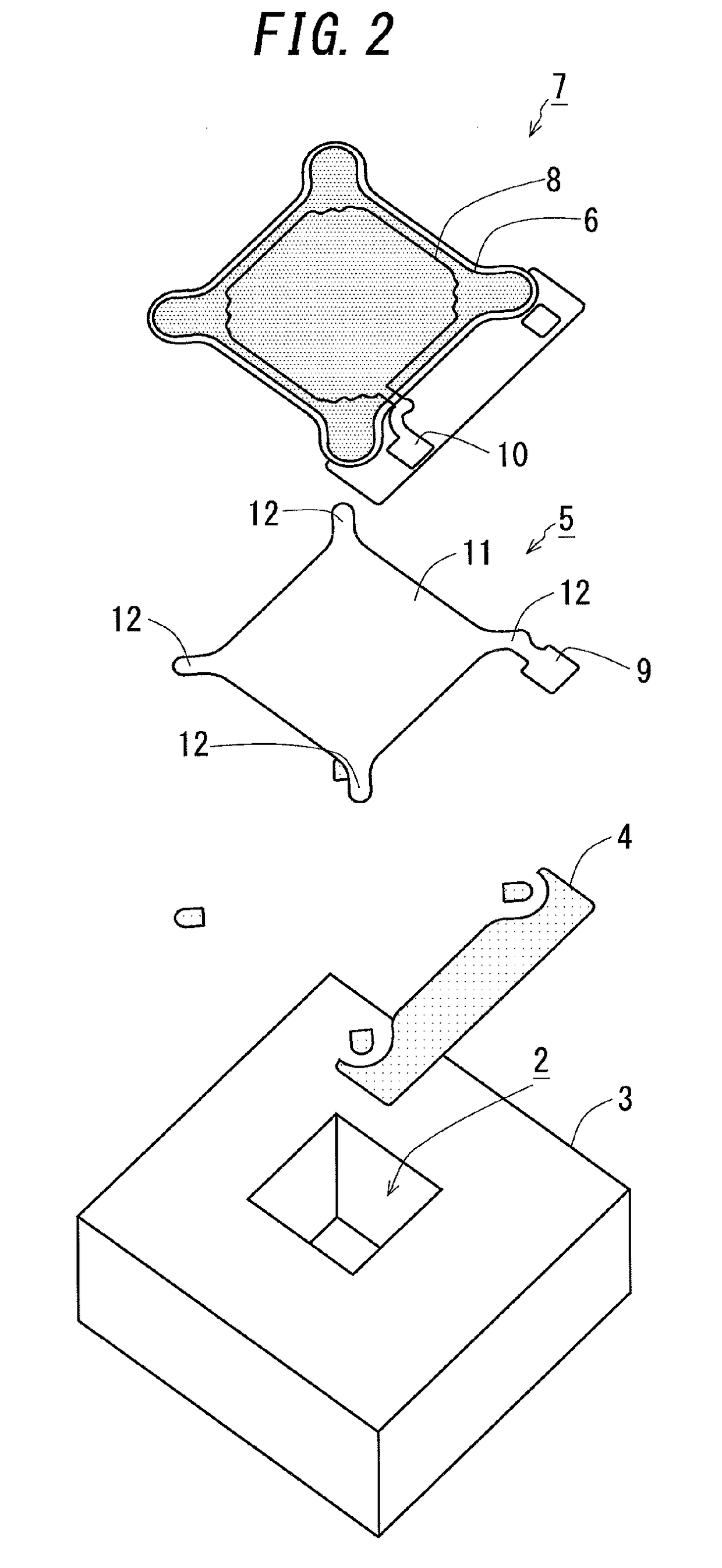

A capacitor microphone is constituted by a plate having a fixed electrode, a diaphragm including a center portion and at least one near-end portion that is fixed to the outer periphery, in which the center portion having a vibrating electrode, which is positioned relative to the fixed electrode and which vibrates in response to sound waves, is increased in rigidity in comparison with the near-end portion; and a spacer that is fixed to the plate and the near-end portion of the diaphragm and that has an air gap formed between the plate and the diaphragm. Alternatively, a diaphragm electrode is horizontally supported by extension arms extended from a circular plate thereof and is vertically held in a hanging state being apart from a fixed electrode with a controlled distance therebetween.

Owner:YAMAHA CORP

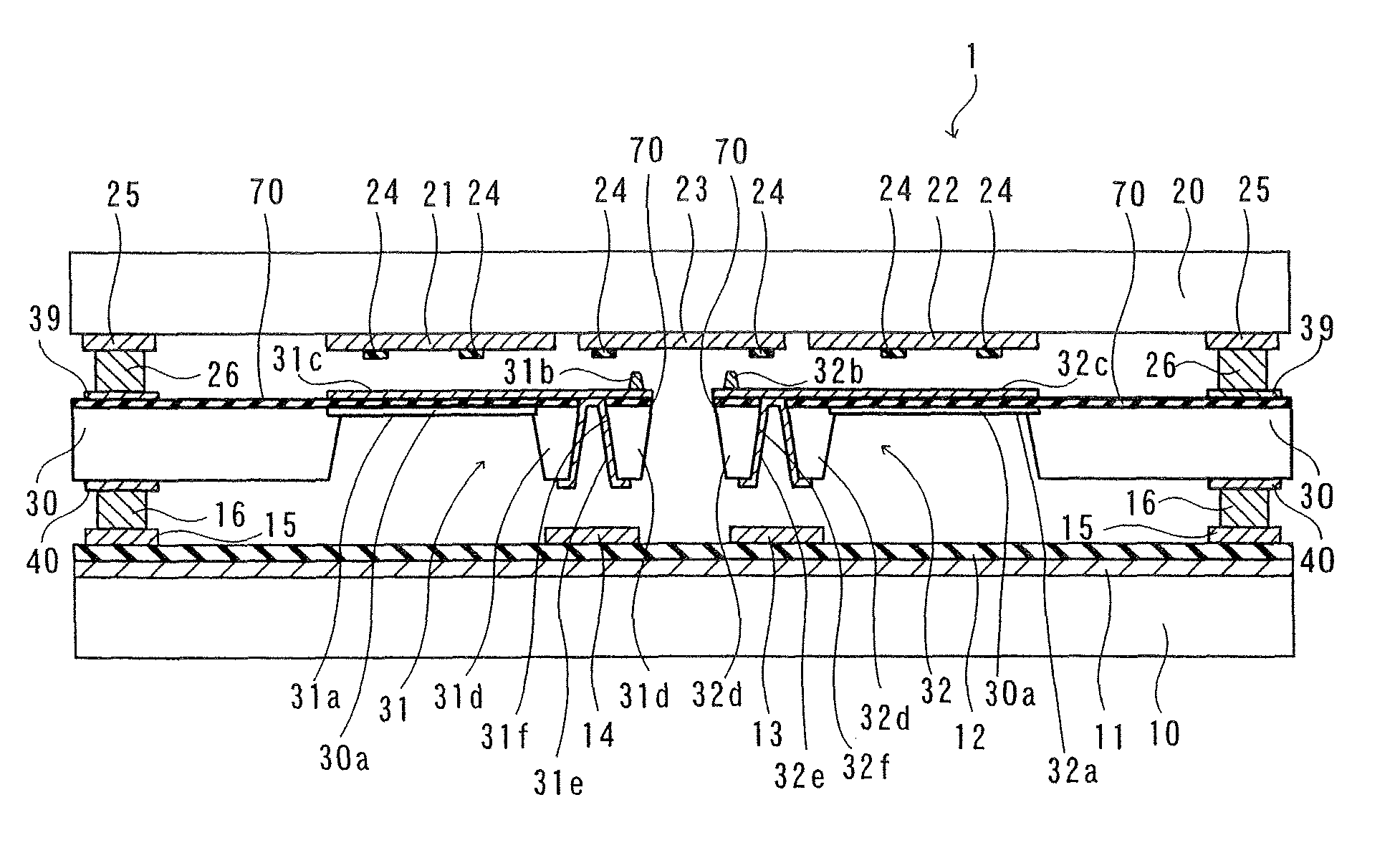

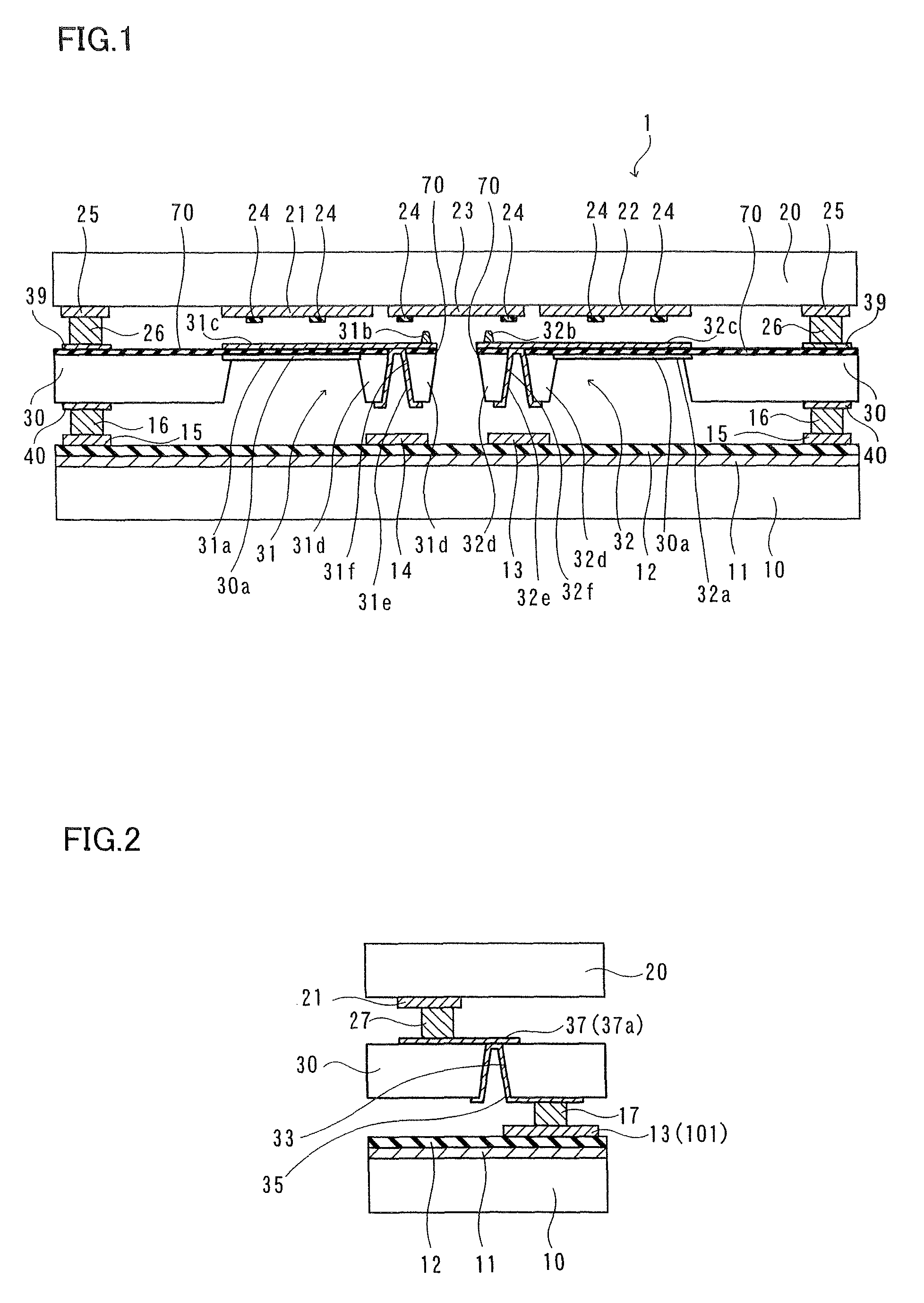

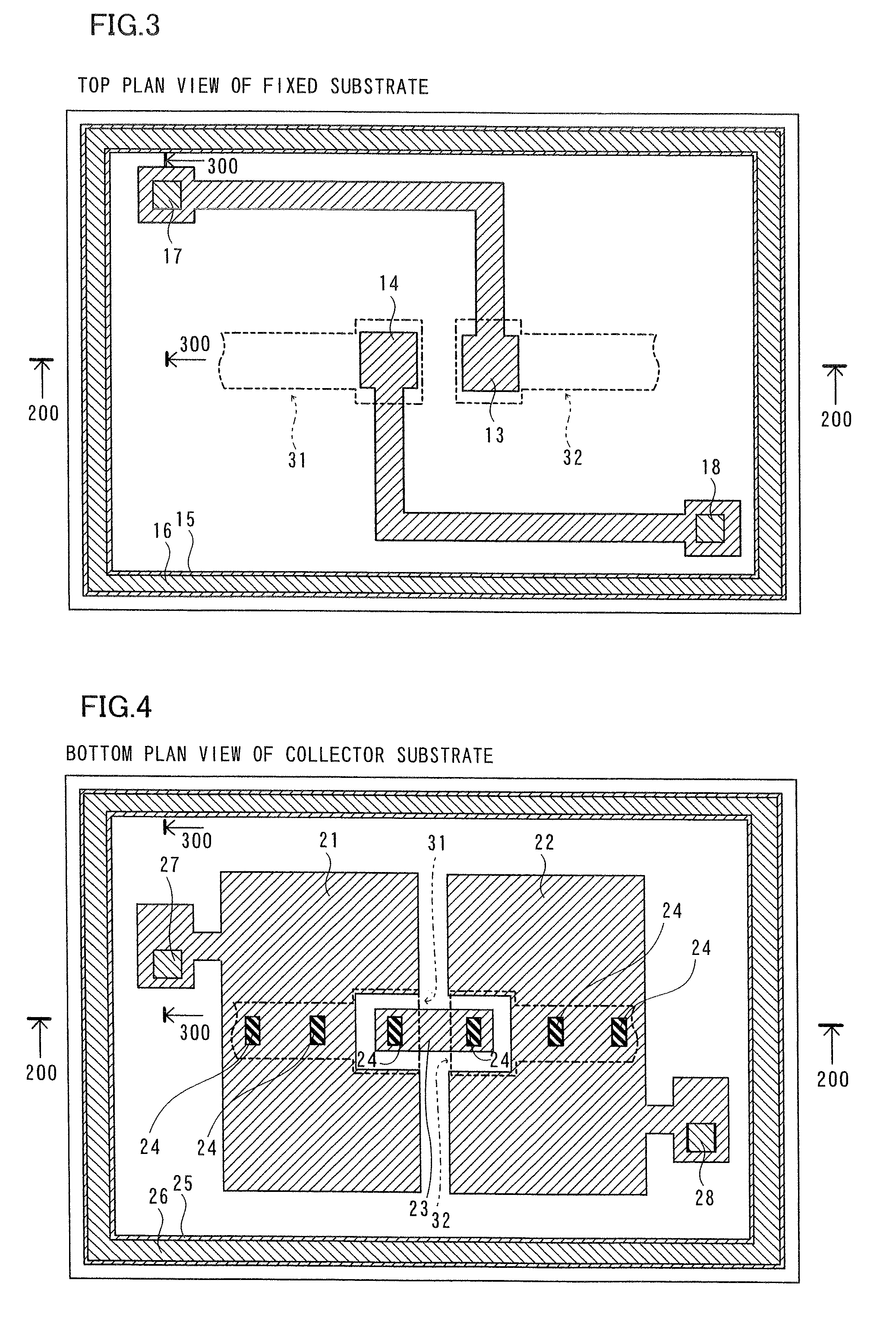

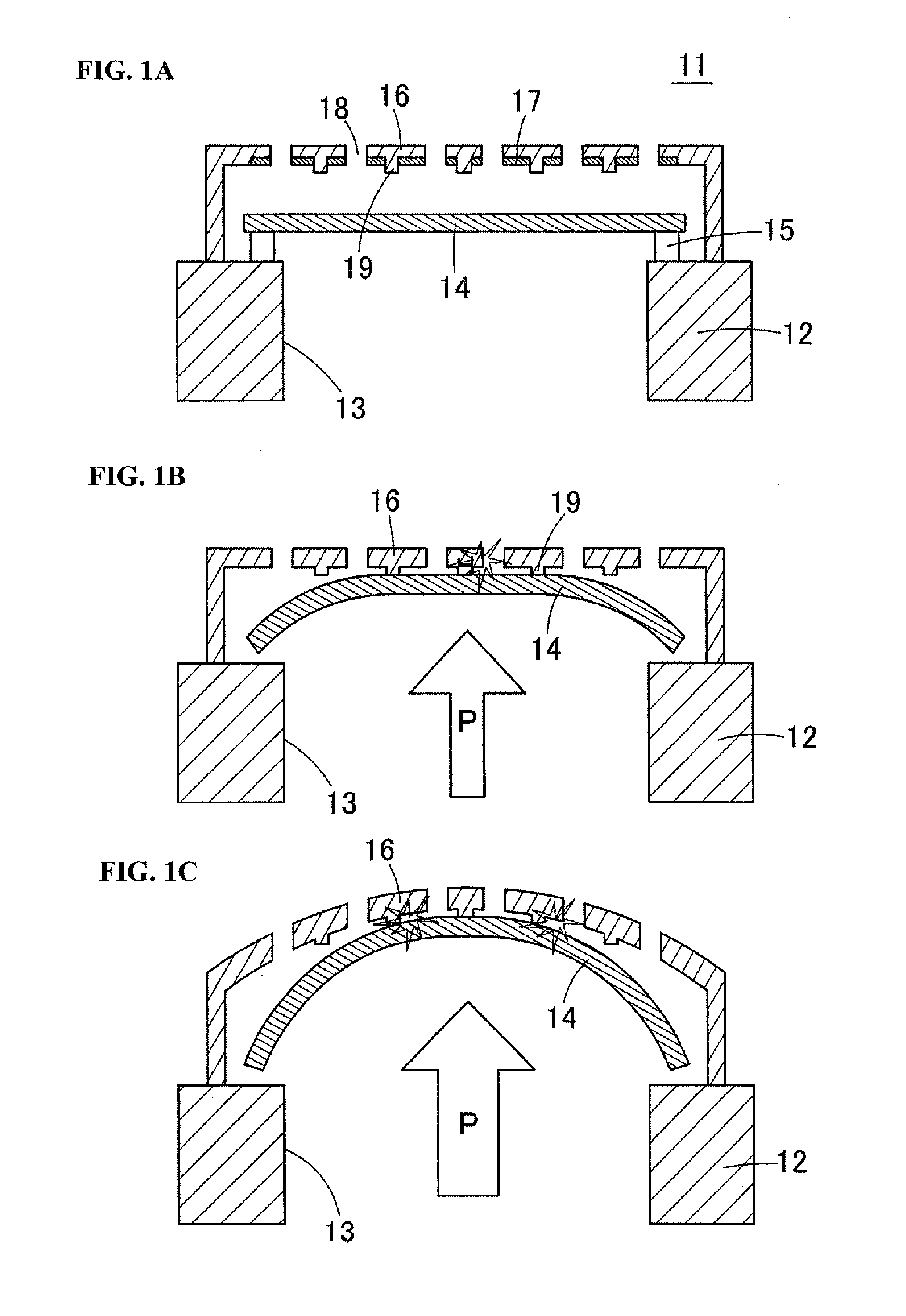

Electrostatic pressure transducer and manufacturing method therefor

InactiveUS20080123876A1Improve stabilityReduce displacementSemiconductor electrostatic transducersDeaf-aid setsTransducerEngineering

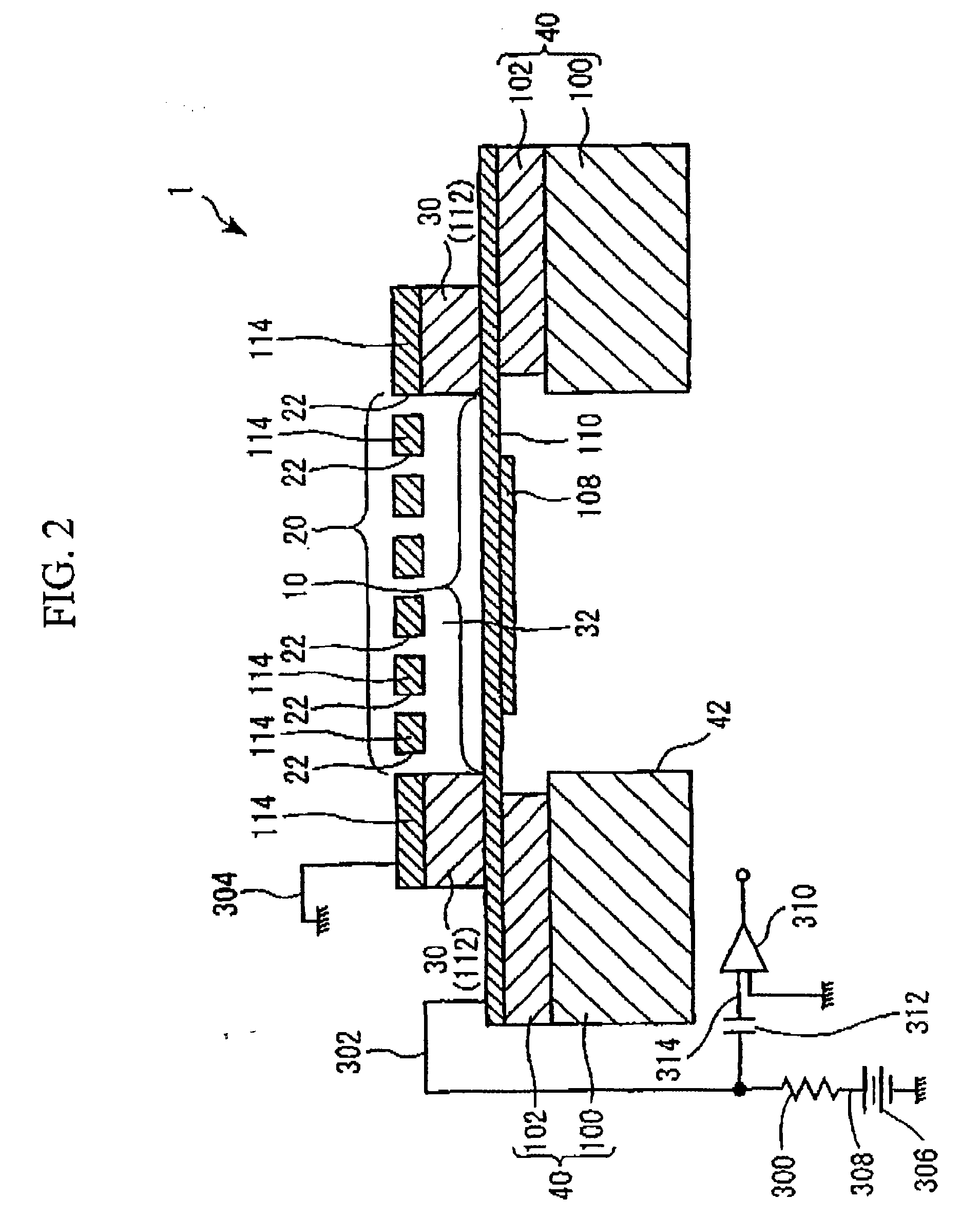

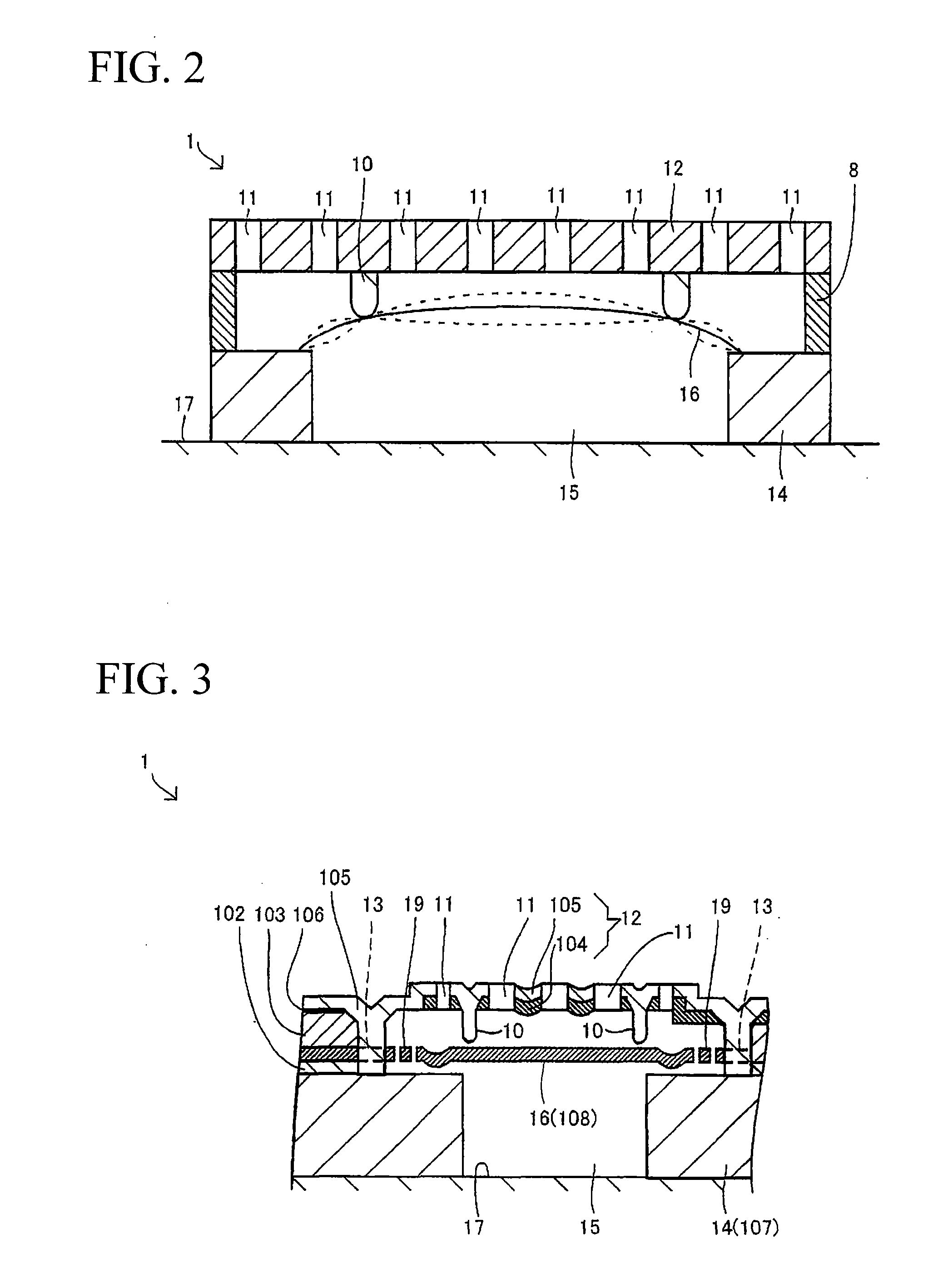

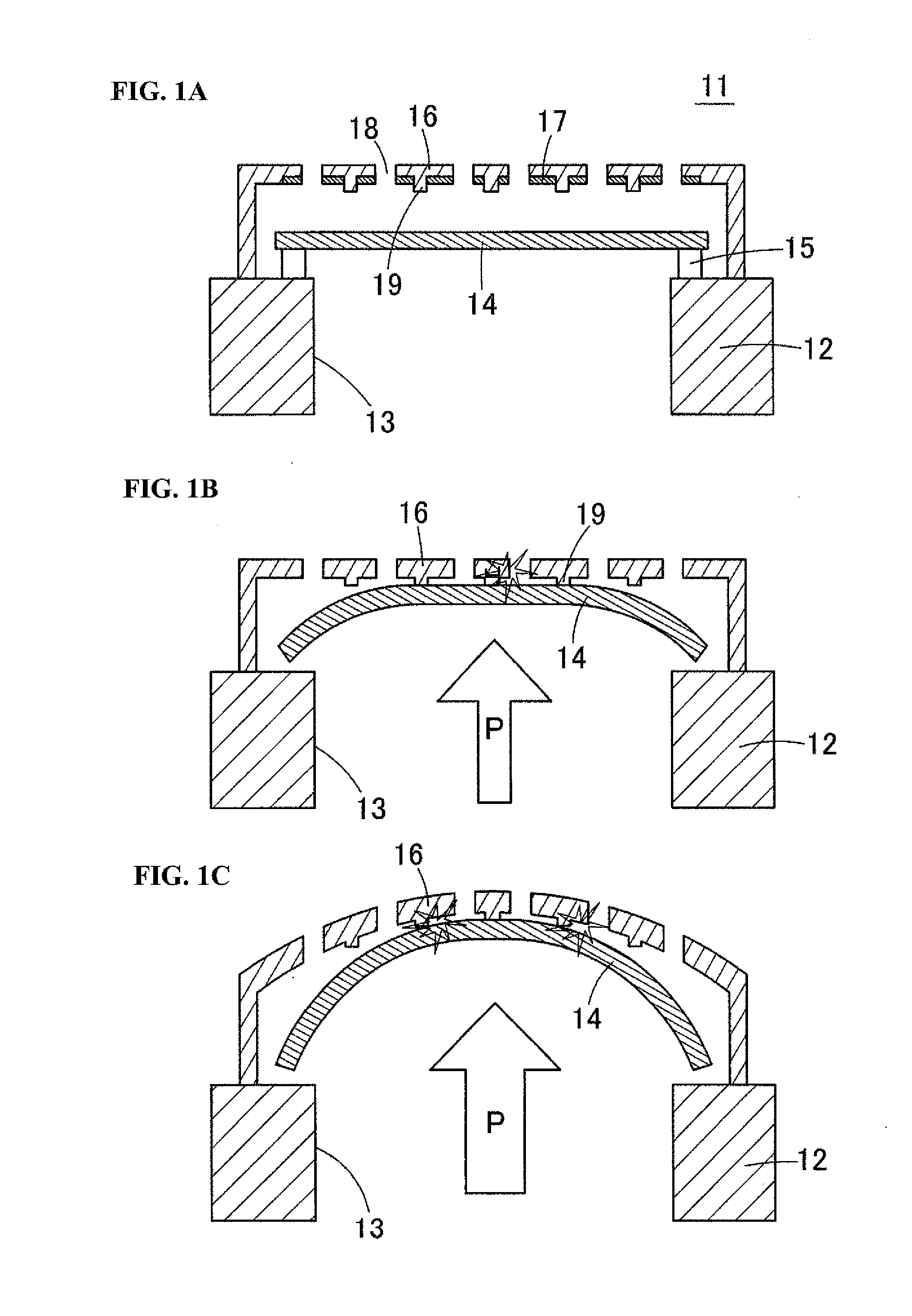

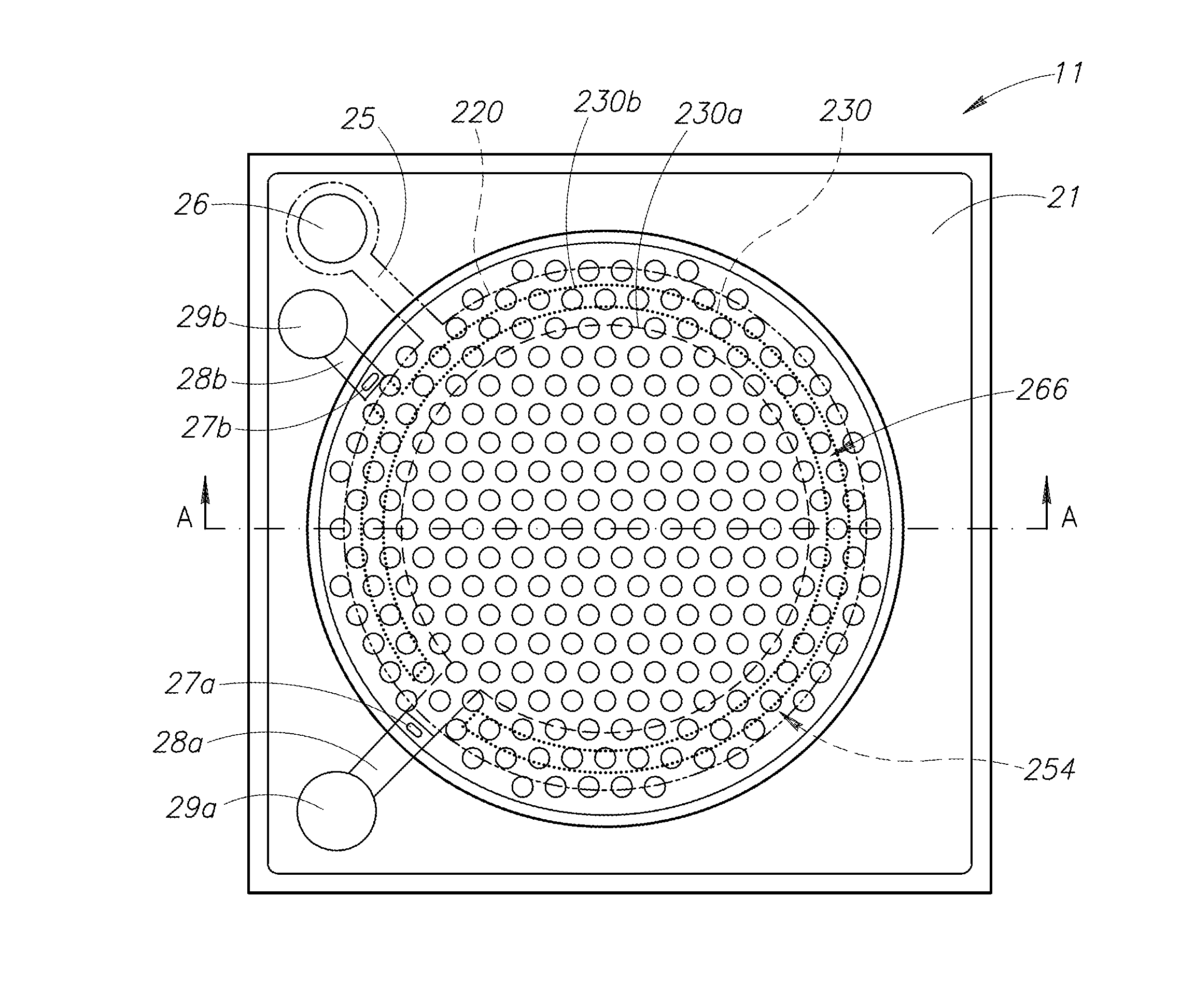

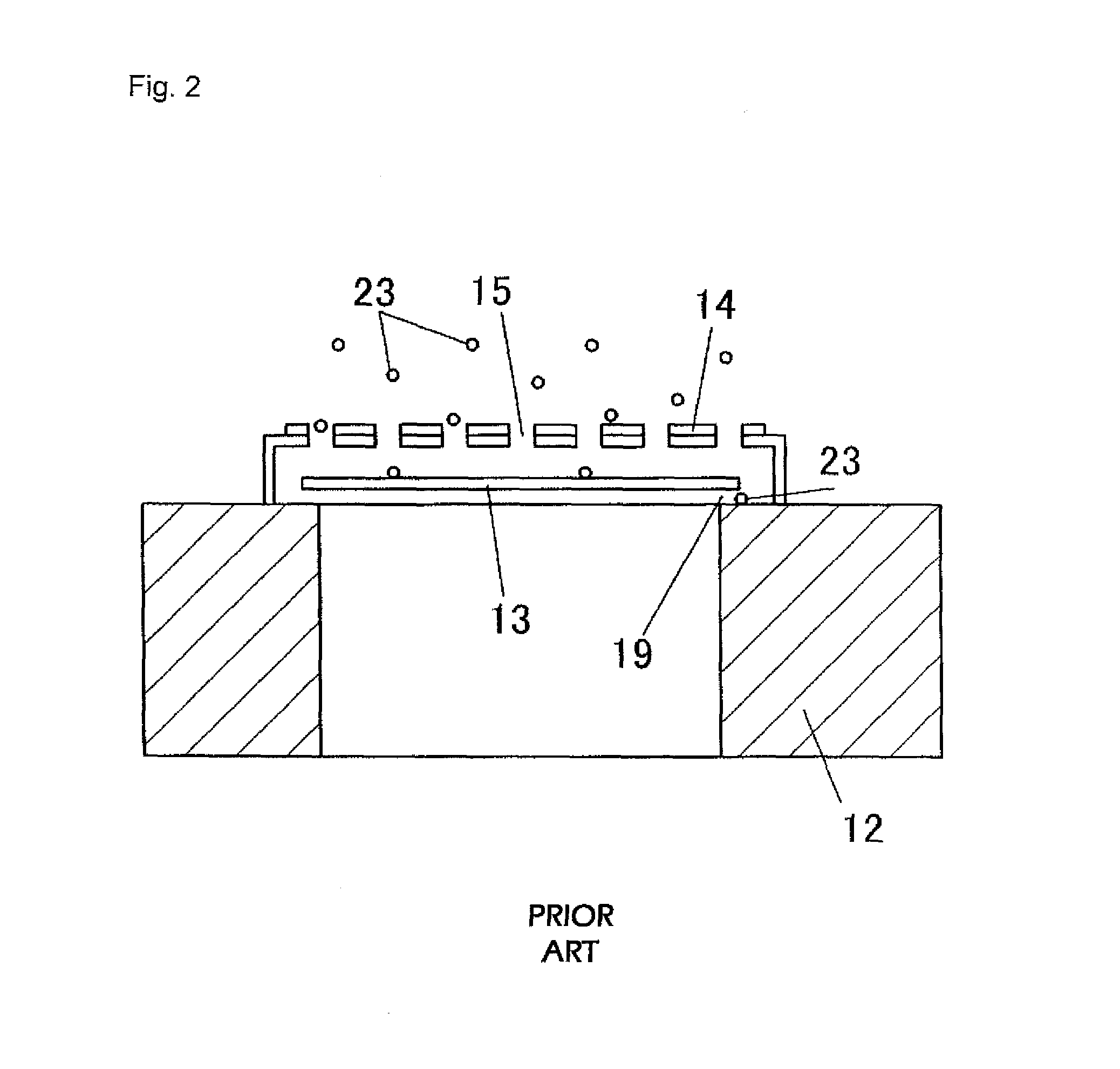

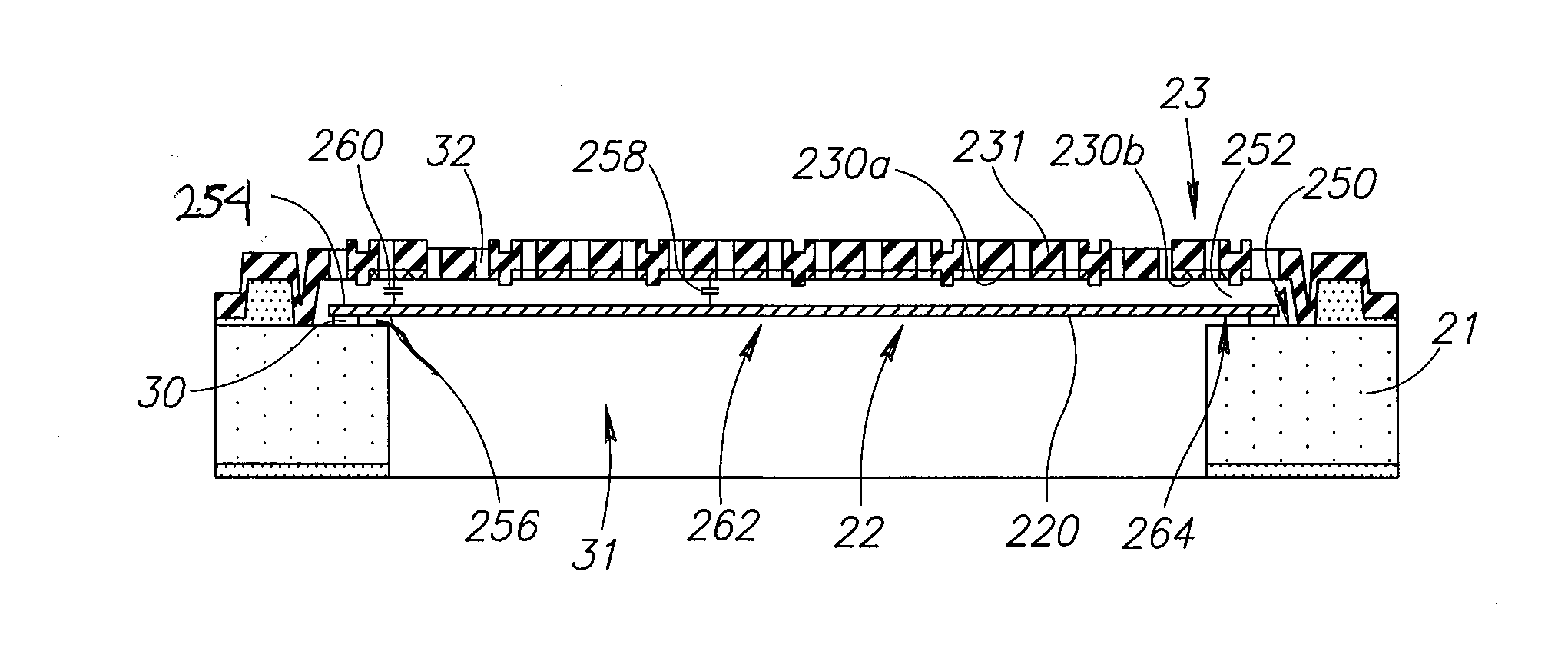

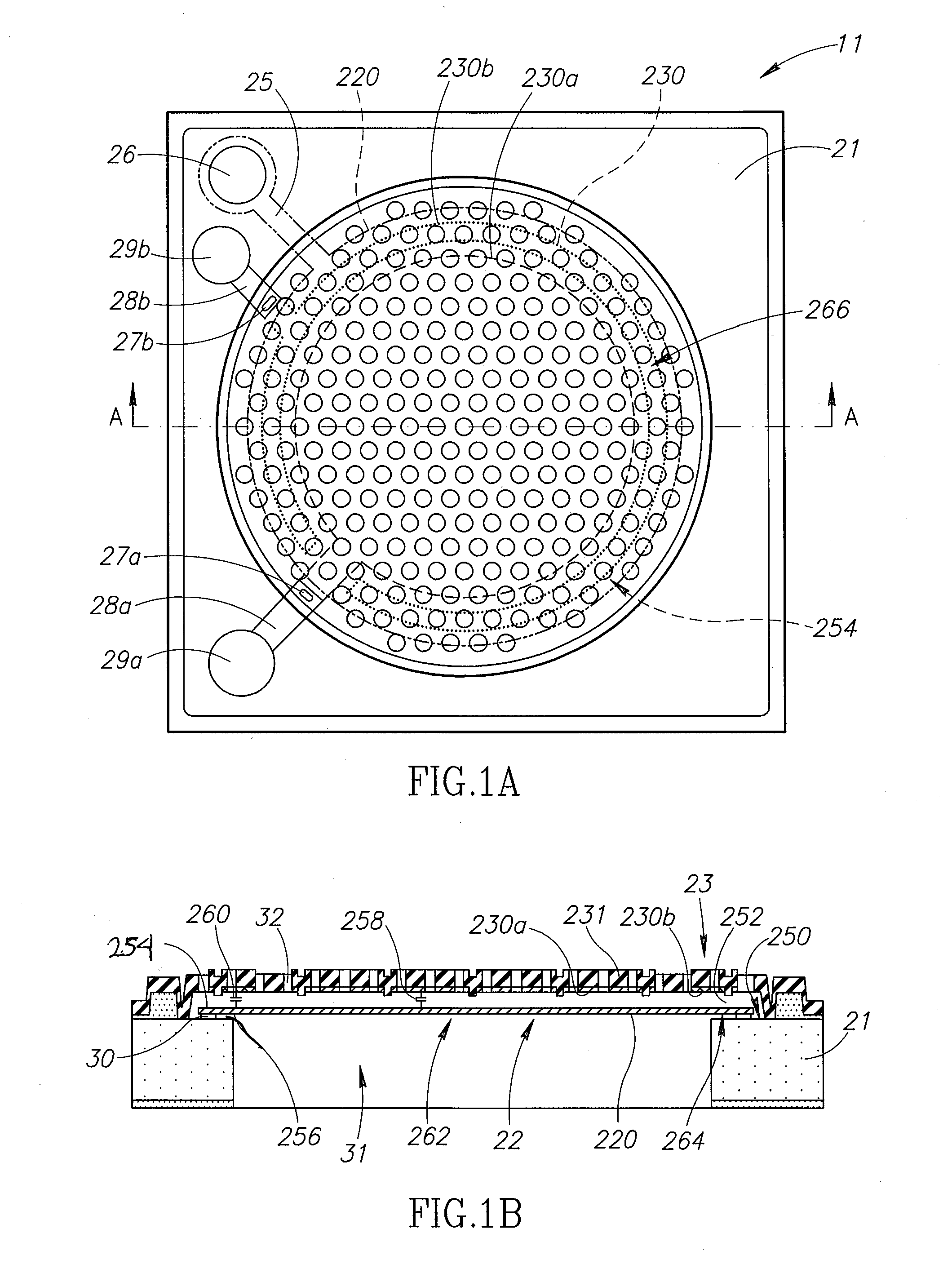

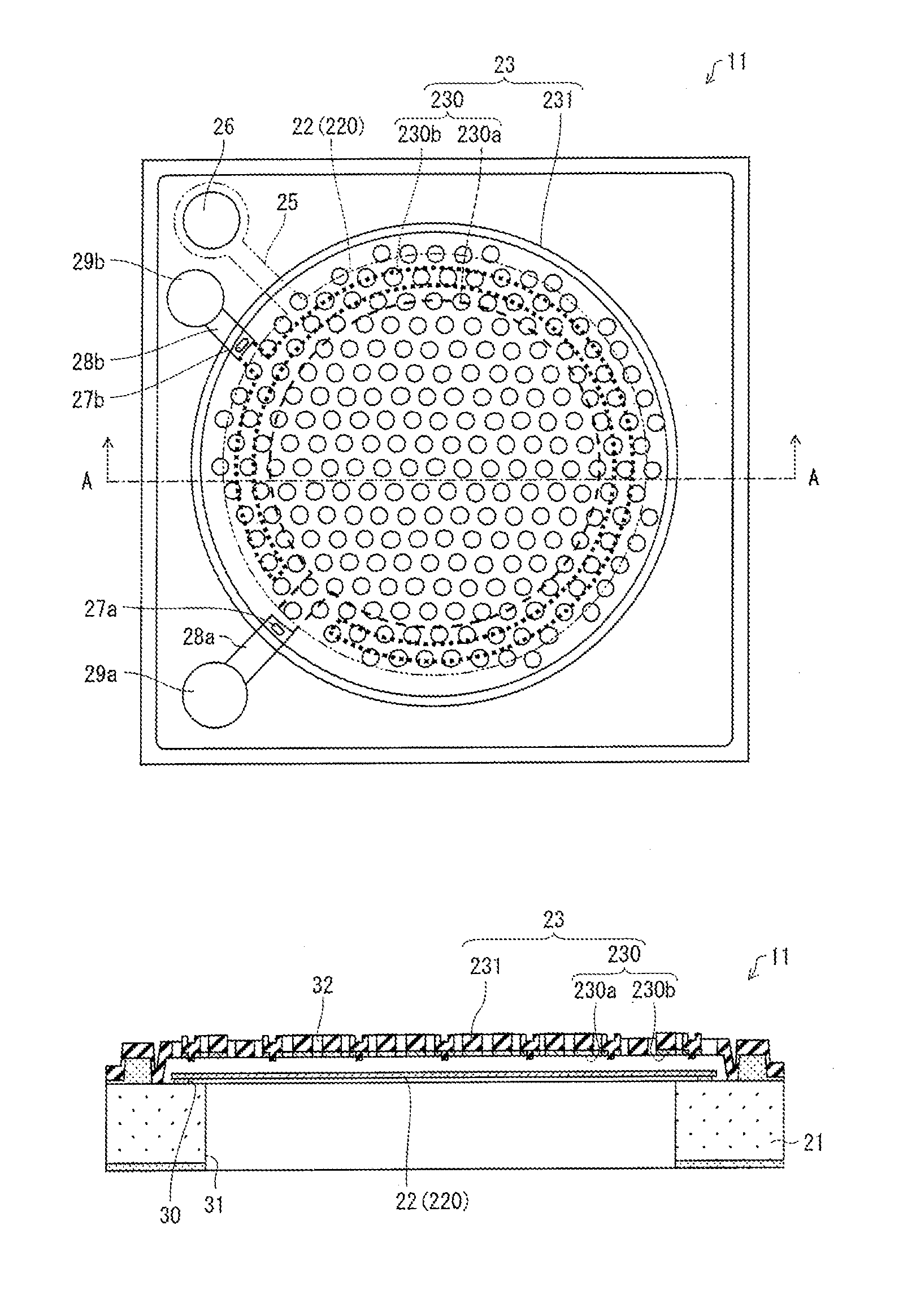

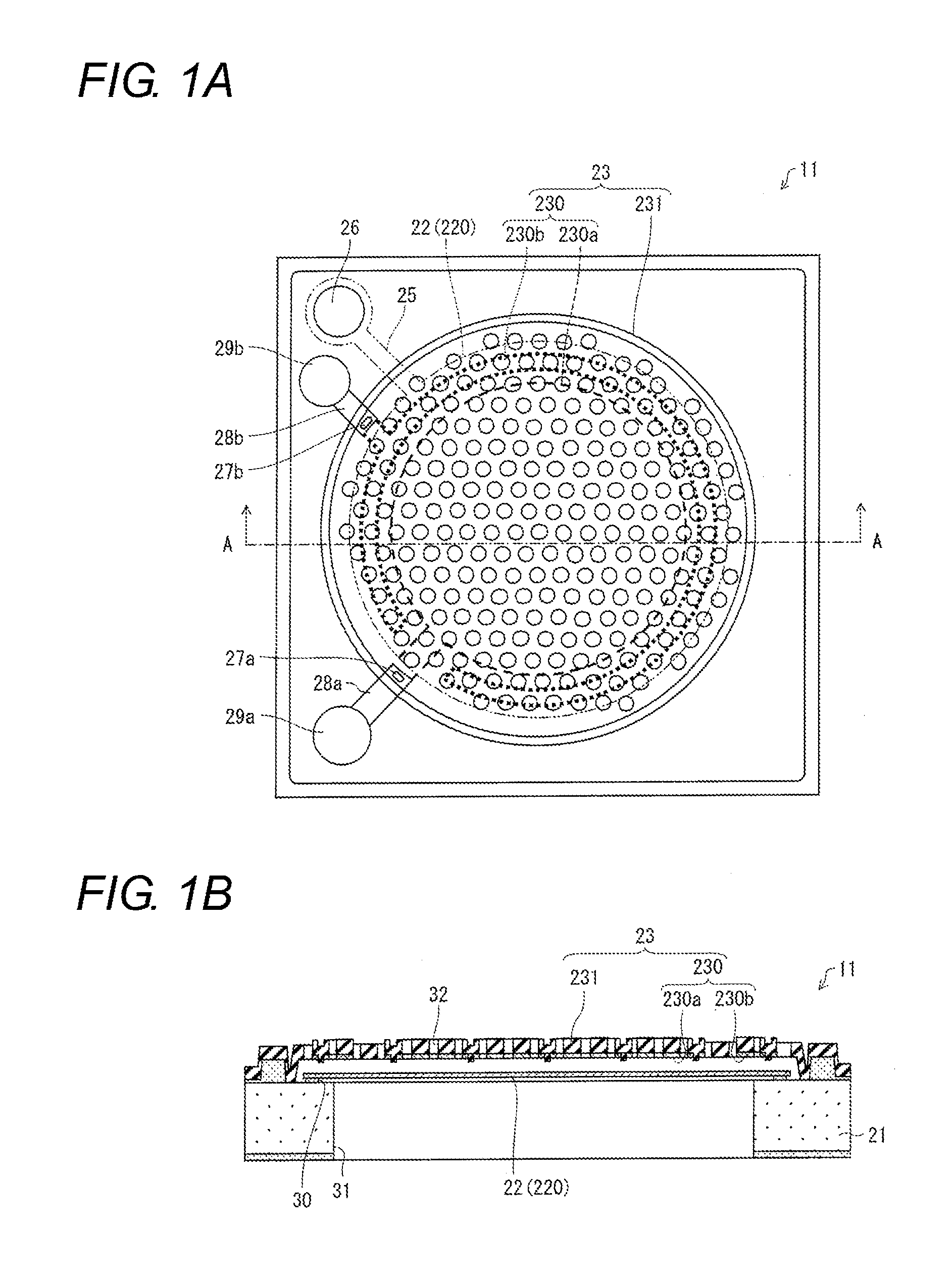

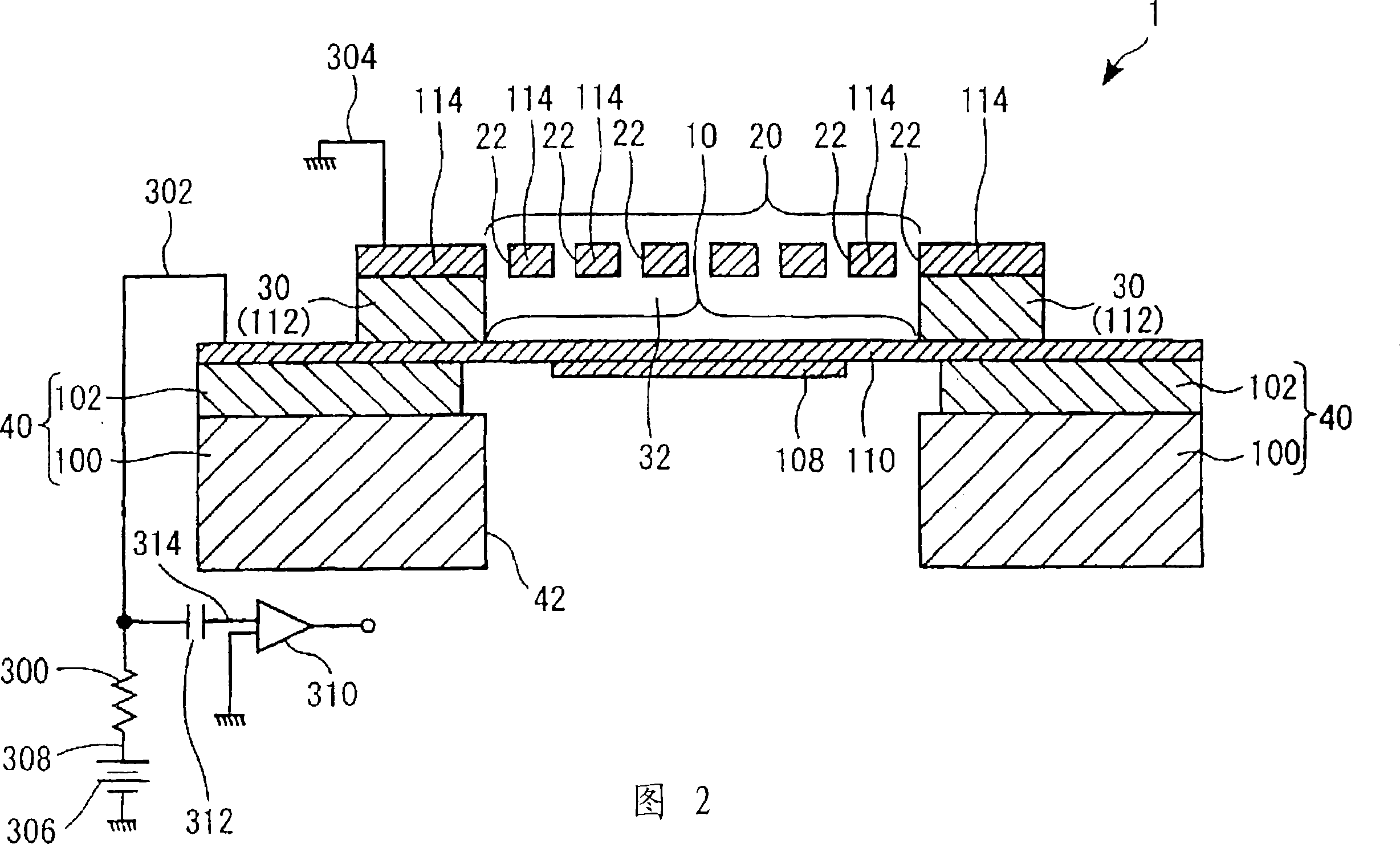

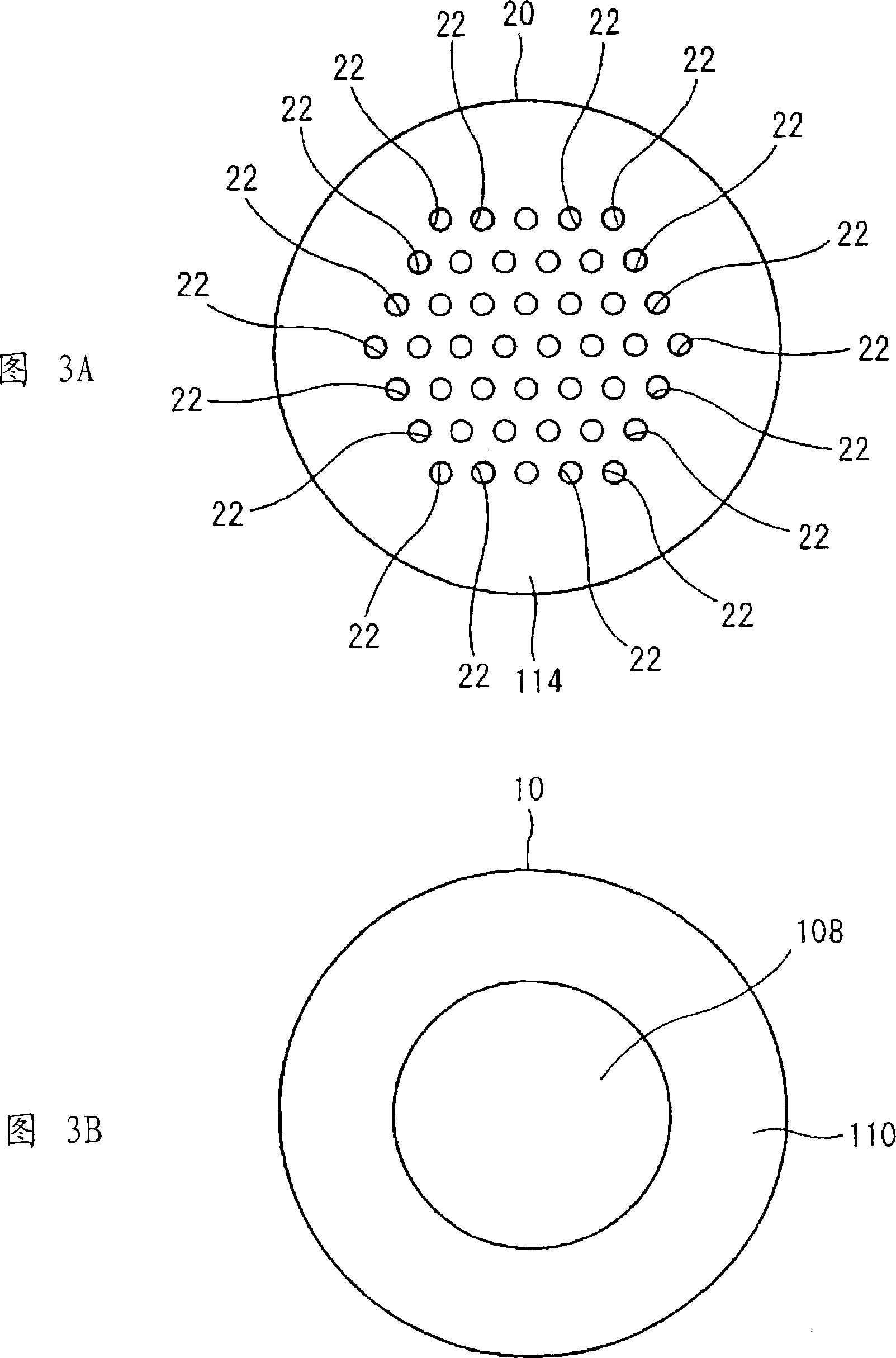

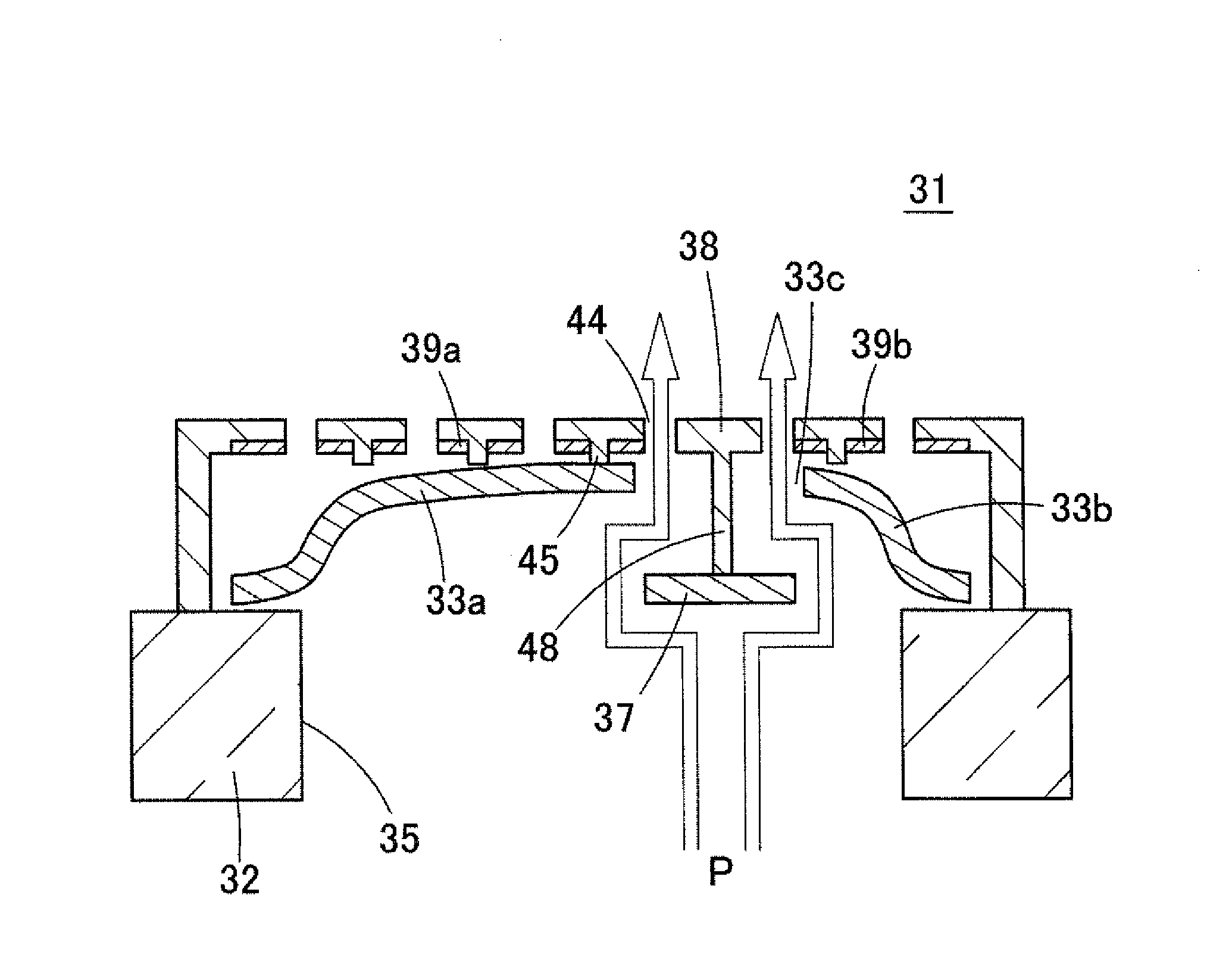

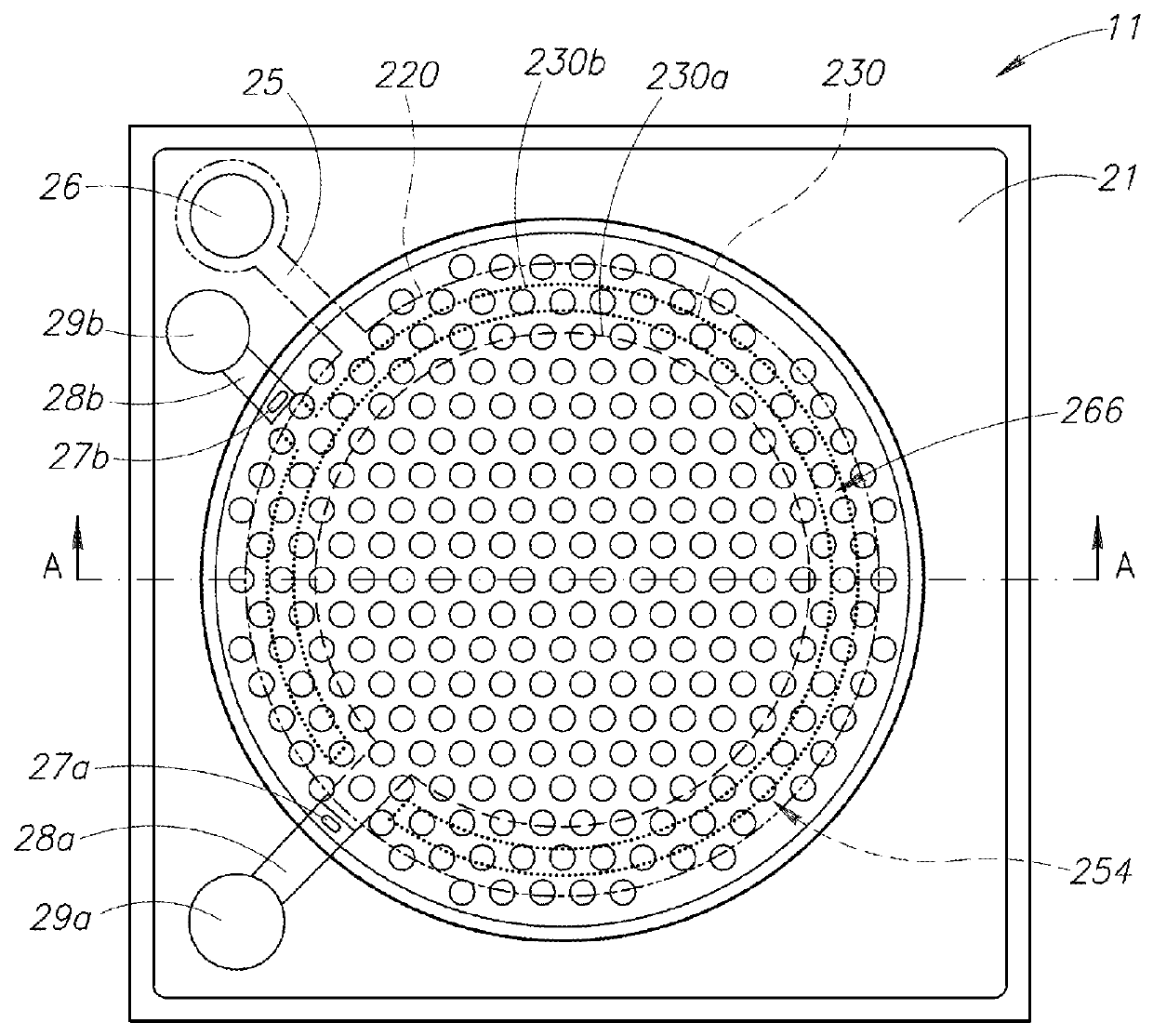

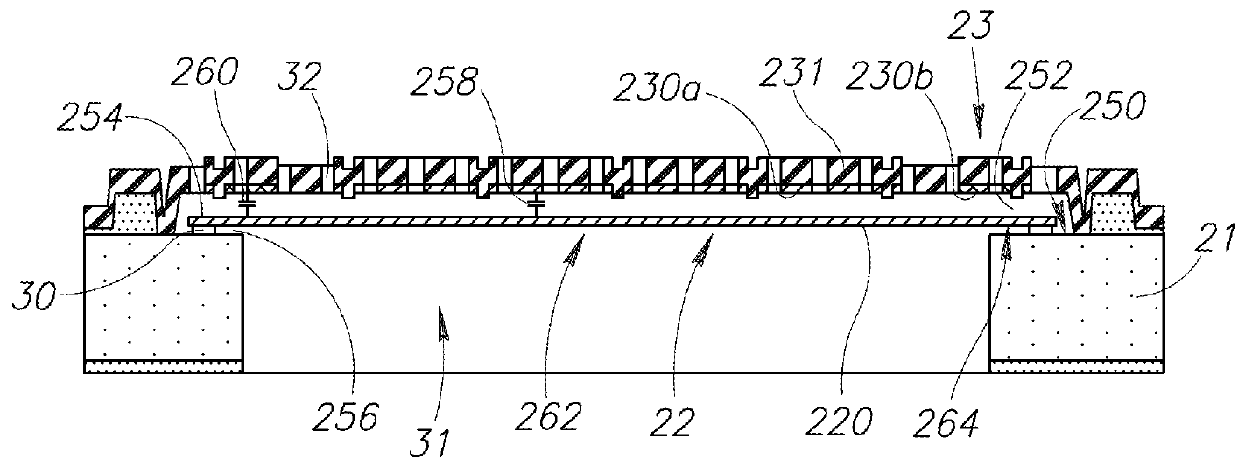

An electrostatic pressure transducer (e.g., a condenser microphone) includes a plate having a plurality of holes and forming a fixed electrode, a diaphragm forming a vibrating electrode, at lease one spacer that is positioned between the plate and the diaphragm in the ring-shaped internal area internally of the peripheral end of the diaphragm, and a stopper plate having an opening, which is positioned opposite to the plate with respect to the diaphragm. The diaphragm vibrates relative to the plate in such a way that, due to electrostatic attraction, the internal portion thereof moves close to the plate while the external portion thereof moves opposite to the plate, wherein the peripheral end thereof partially comes in contact with the opening edge of the stopper plate. Thus, it is possible to realize flat frequency characteristics while improving the sensitivity in low-frequency ranges.

Owner:YAMAHA CORP

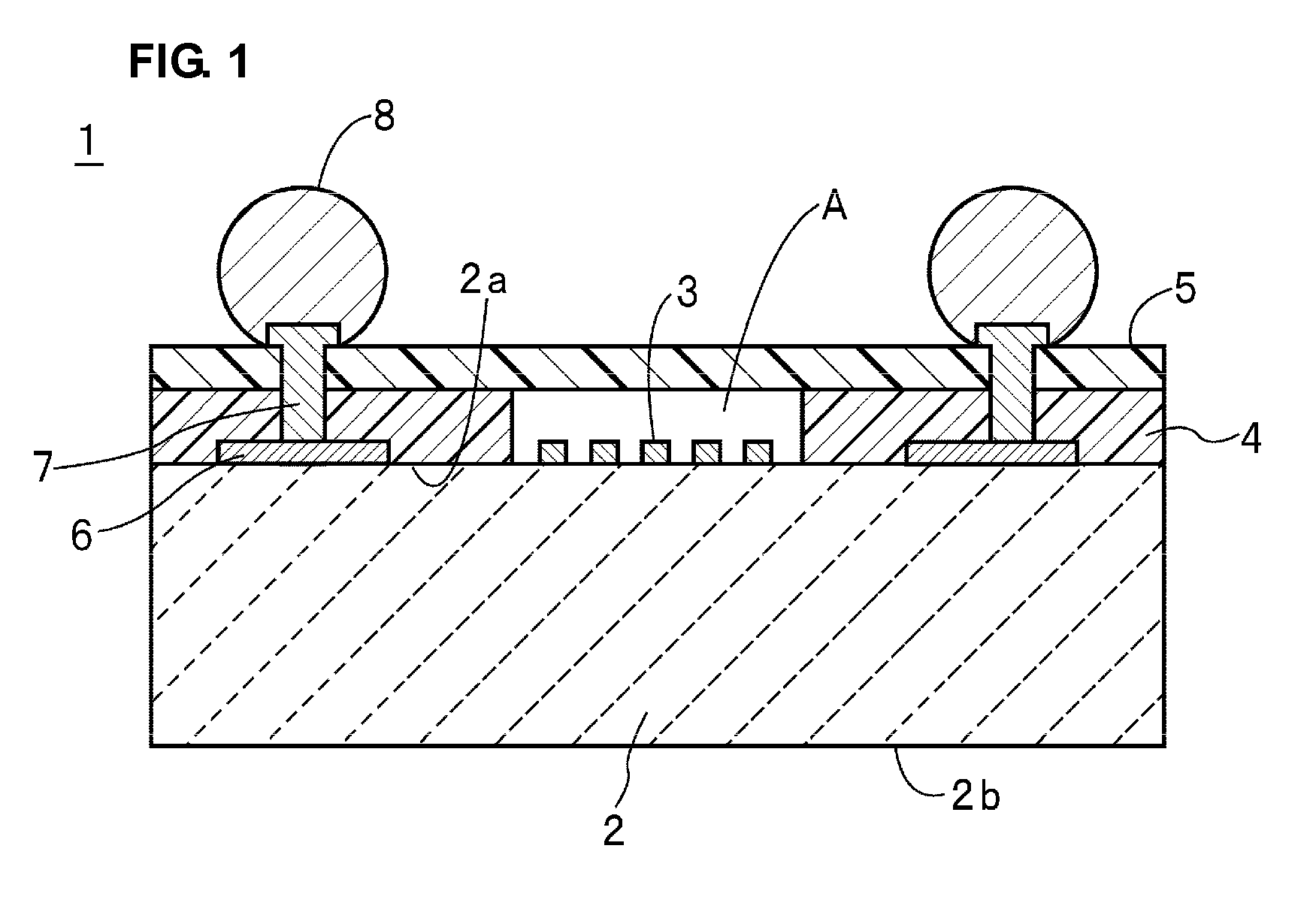

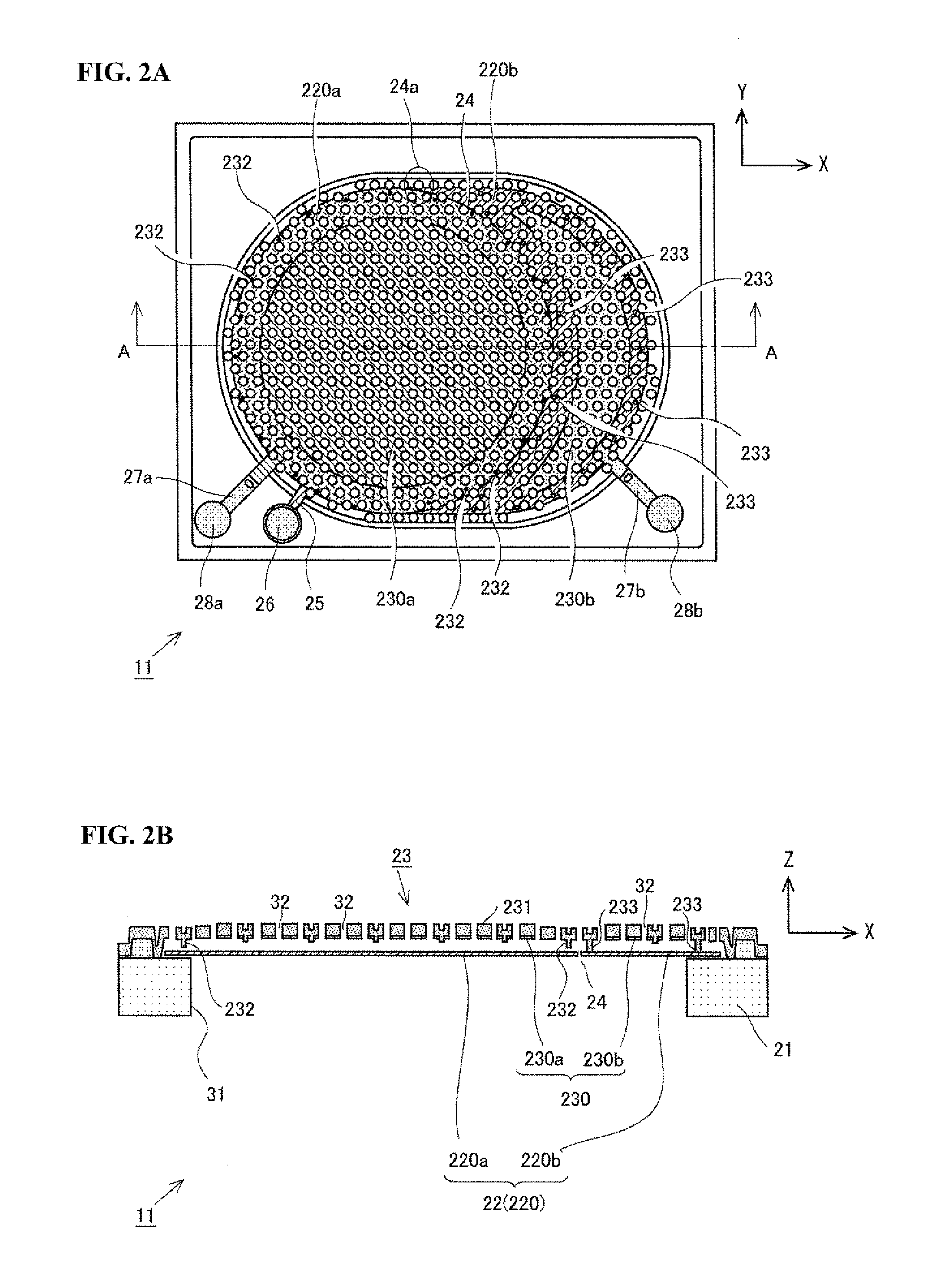

Acoustic transducer and microphone

ActiveUS20150078592A1Avoid damageAvoid stress concentrationSemiconductor electrostatic transducersSolid-state devicesTransducerEngineering

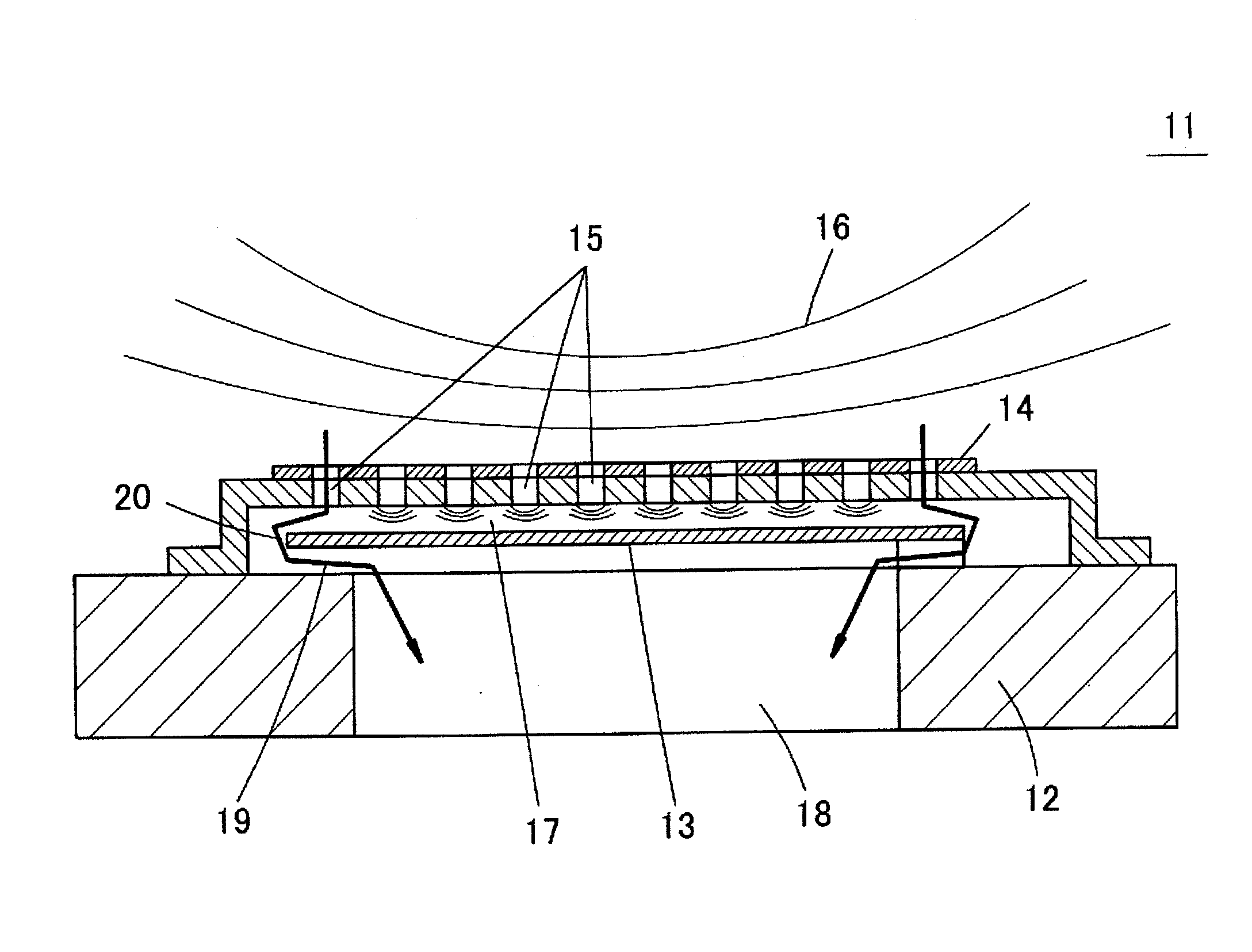

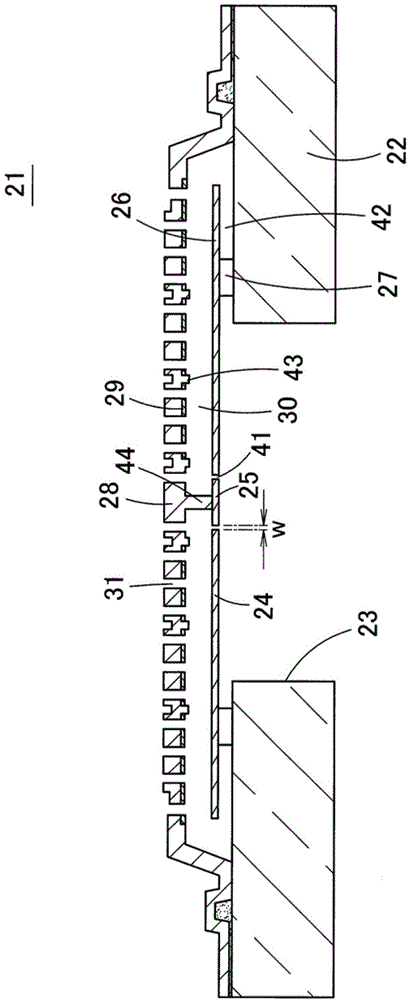

An acoustic transducer has a substrate having a cavity, a vibrating electrode plate disposed above the substrate and having a void portion that allows pressure to escape, a fixed electrode plate disposed above the substrate opposite the vibrating electrode plate, and a leak pressure regulation portion that hinders leakage of air pressure by passing through the void portion when the vibrating electrode plate is not undergoing deformation, and that becomes separated from the void portion and allows pressure to escape by passing through the void portion when the vibrating electrode plate undergoes deformation from being subjected to pressure.

Owner:MMI SEMICON CO LTD

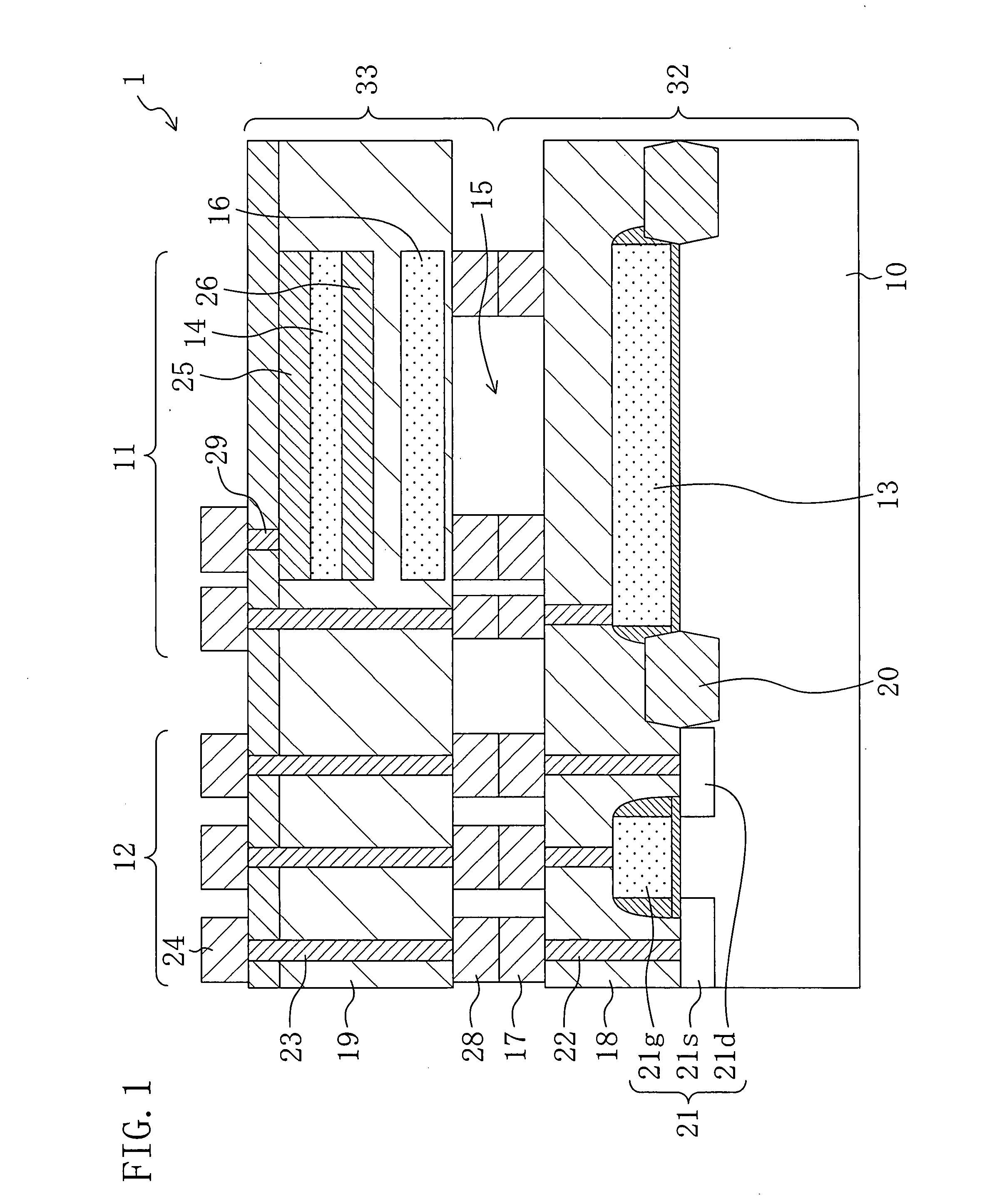

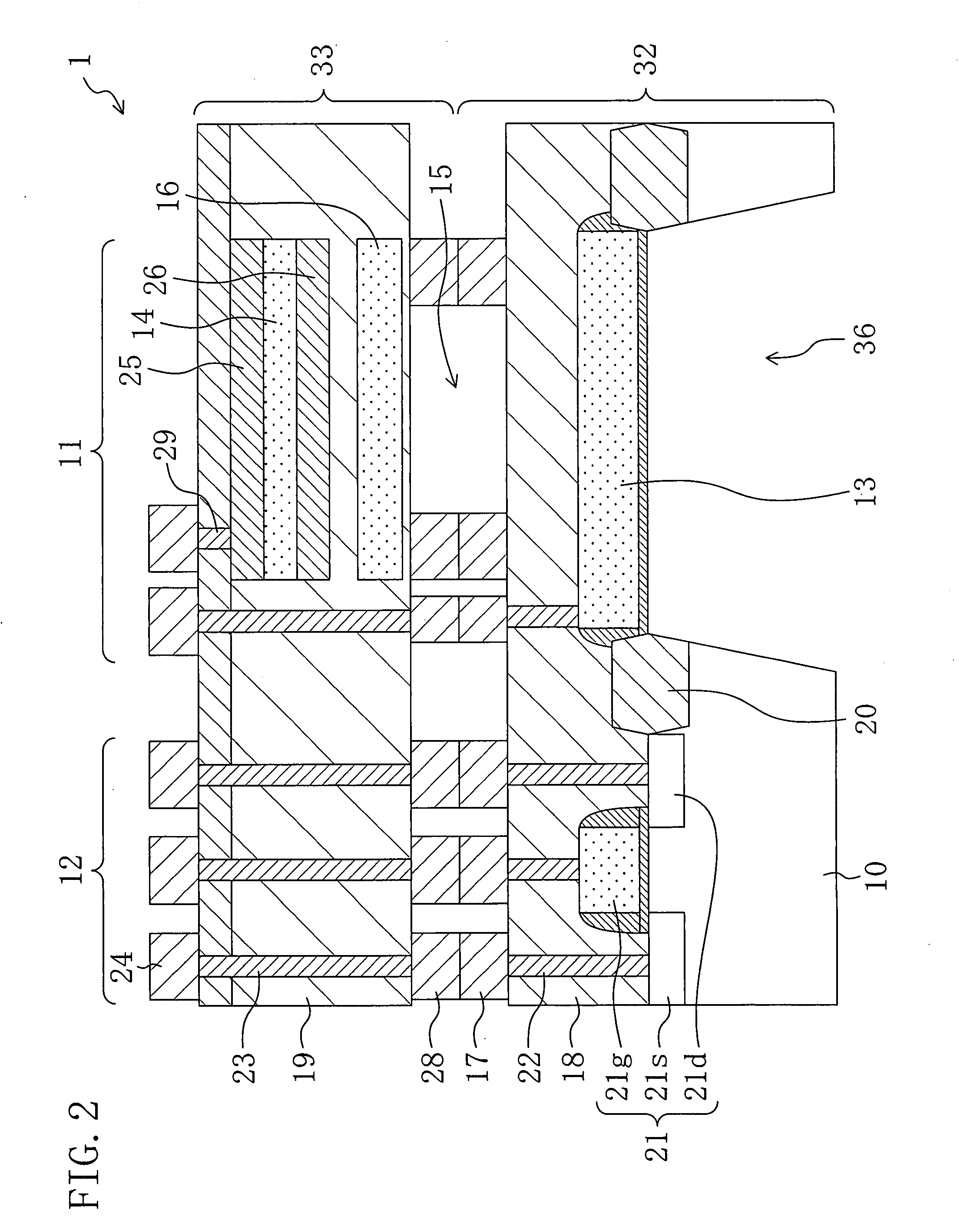

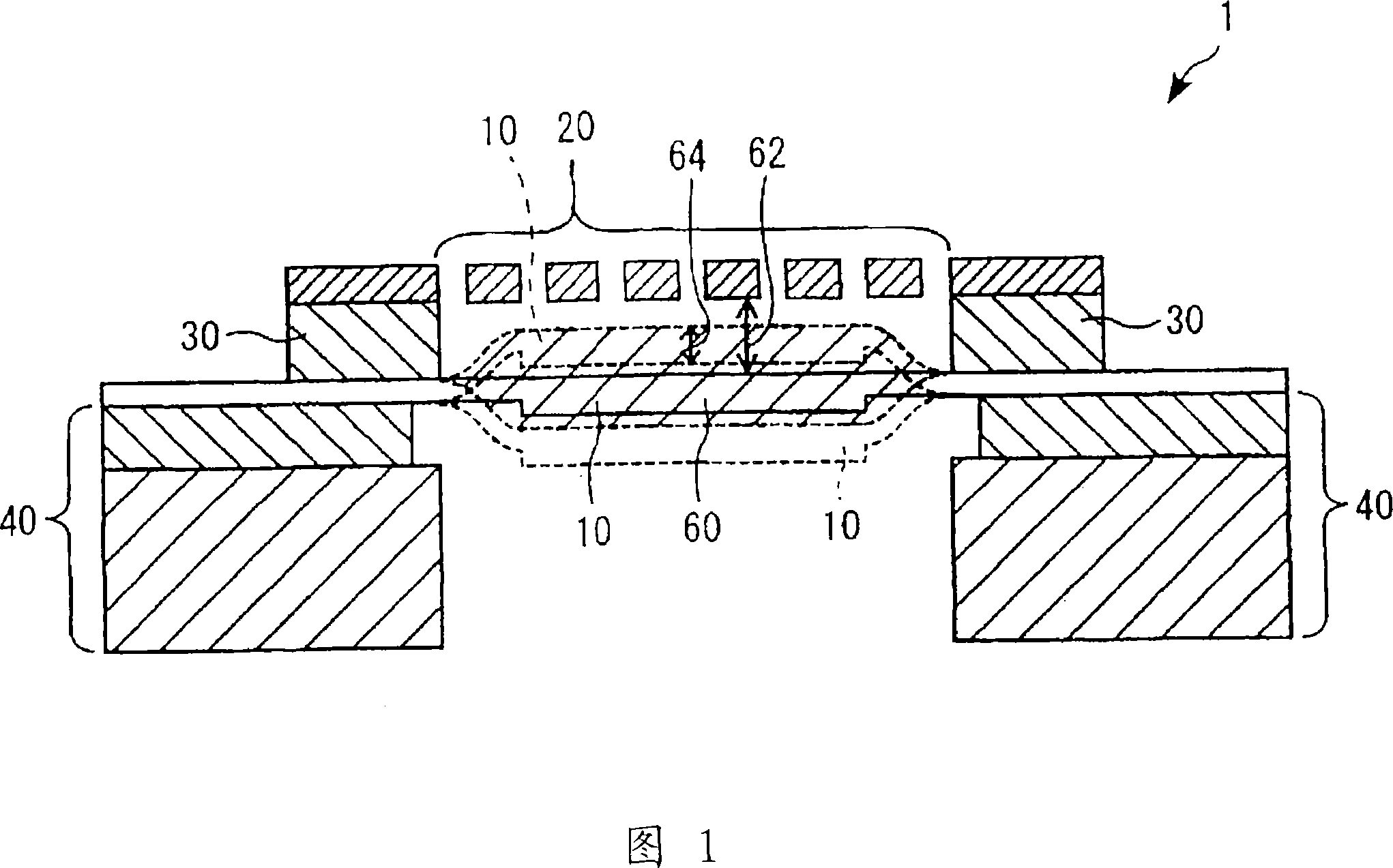

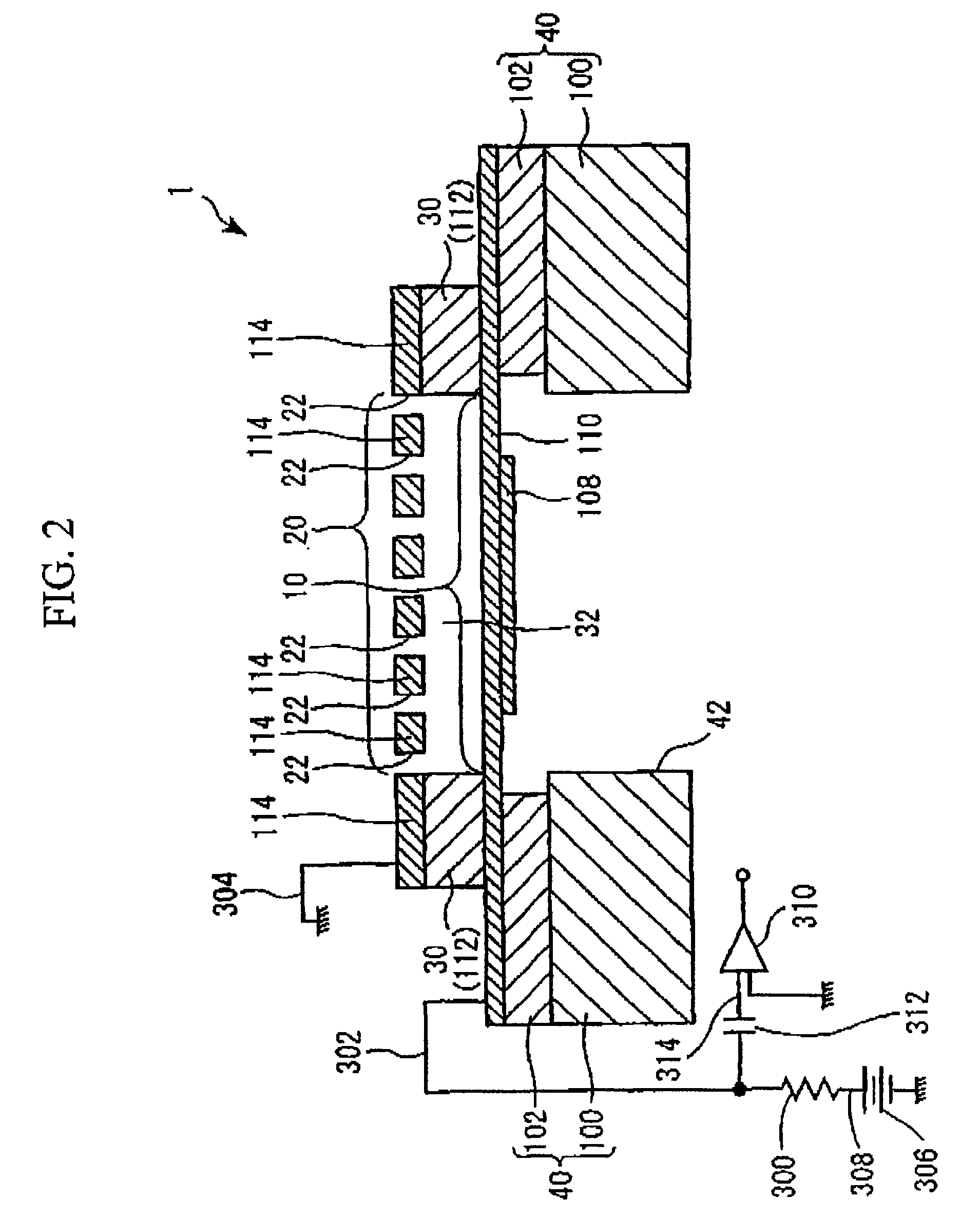

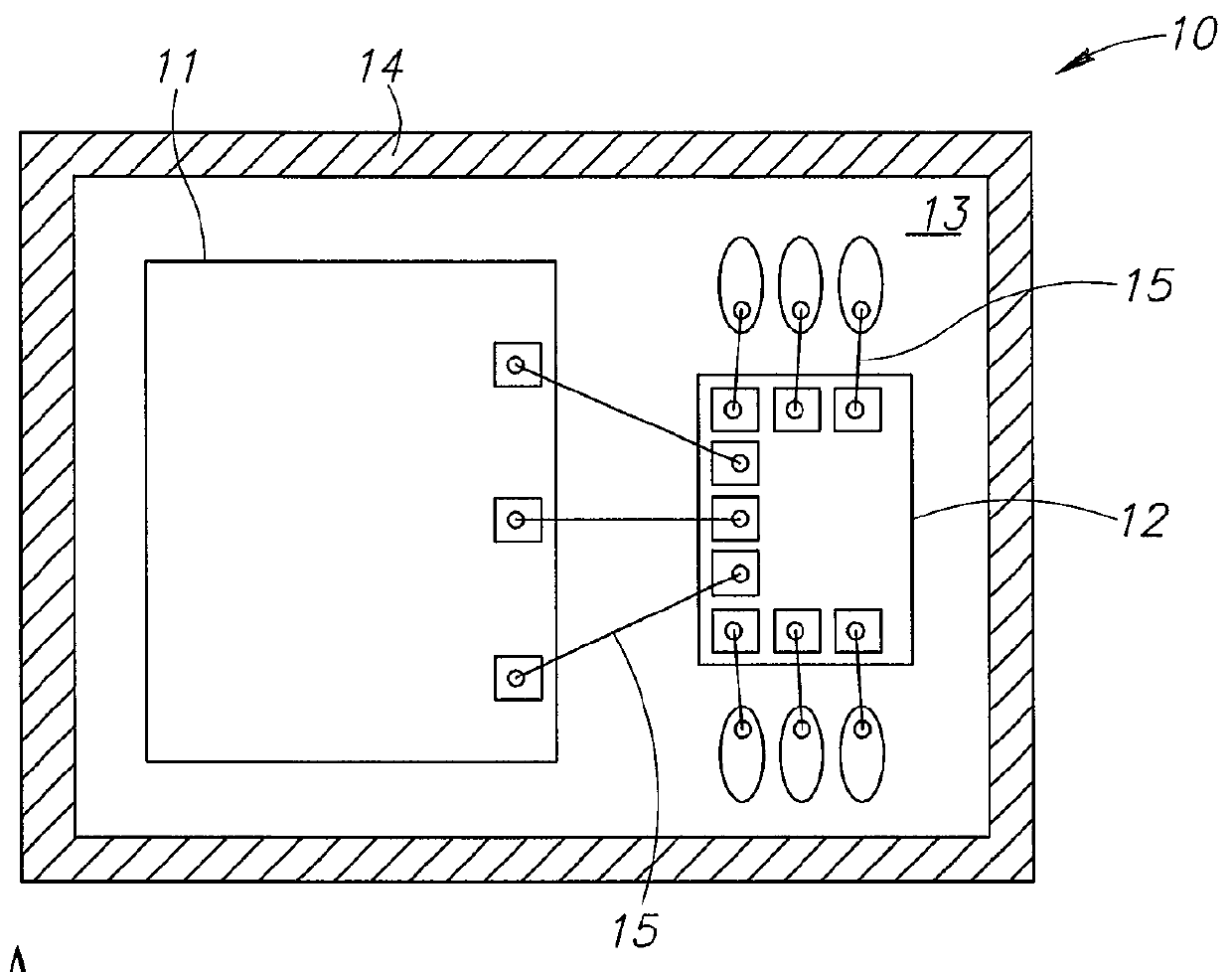

Electro-mechanical transducer, an electro-mechanical converter, and manufacturing methods of the same

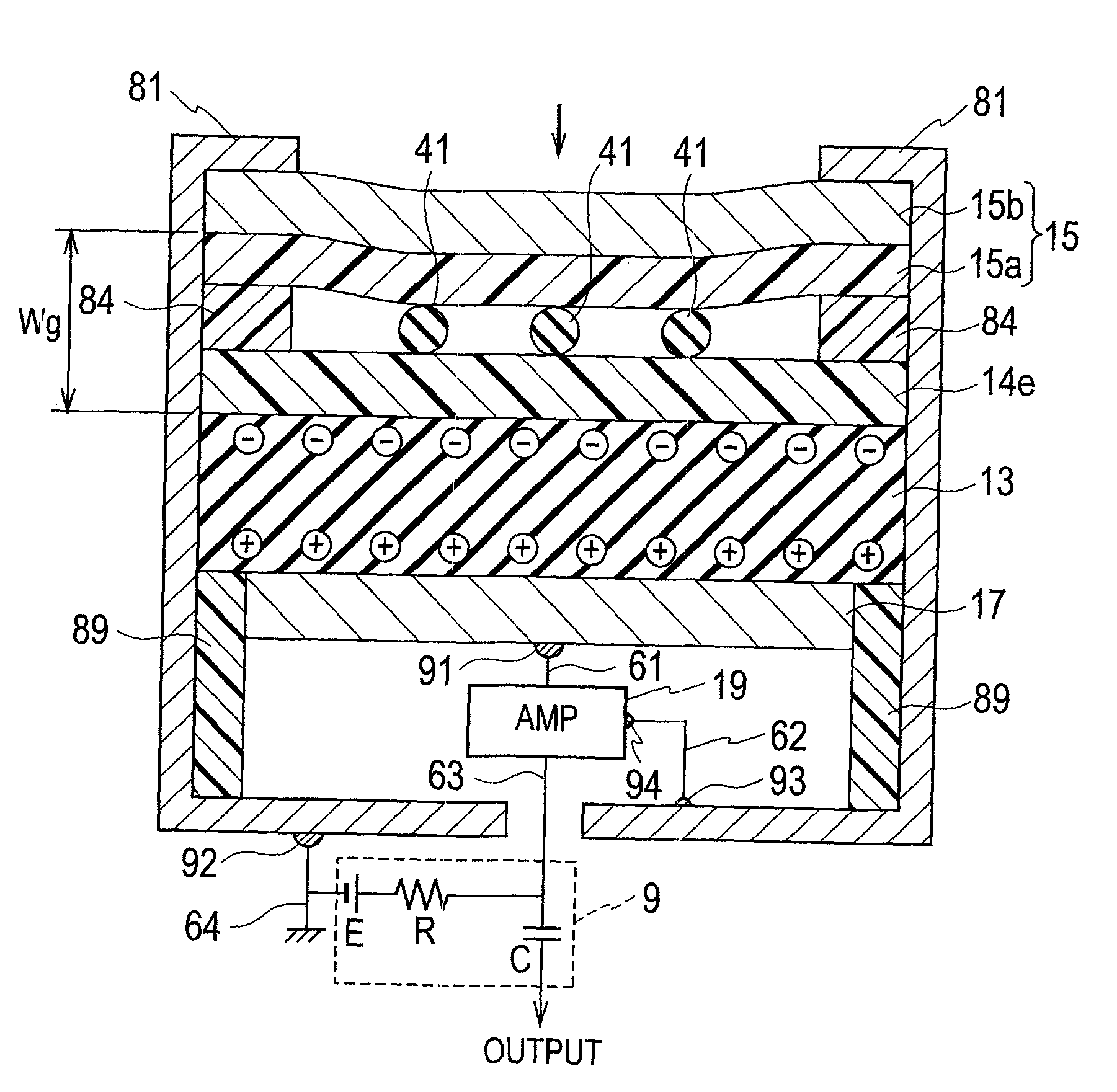

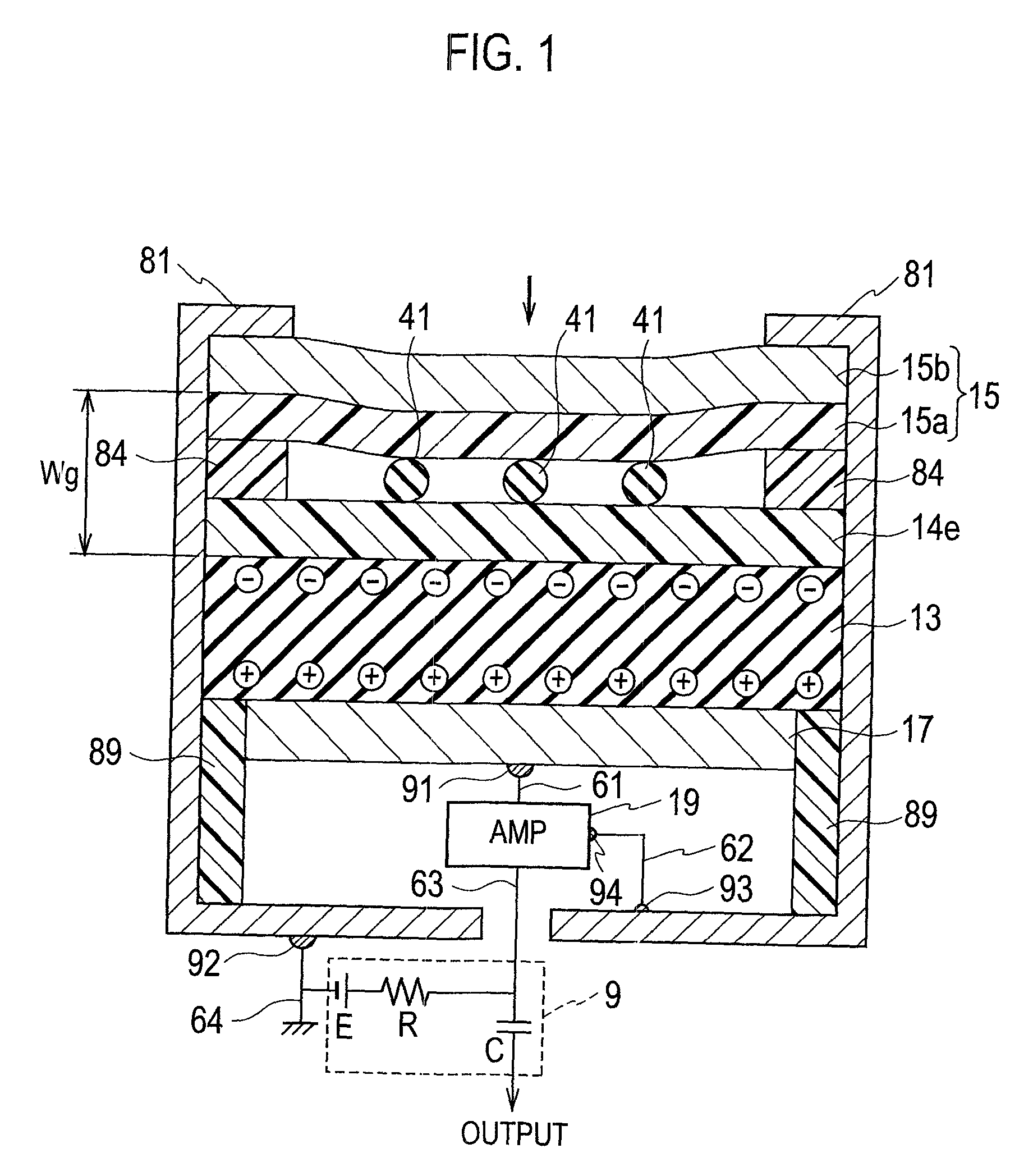

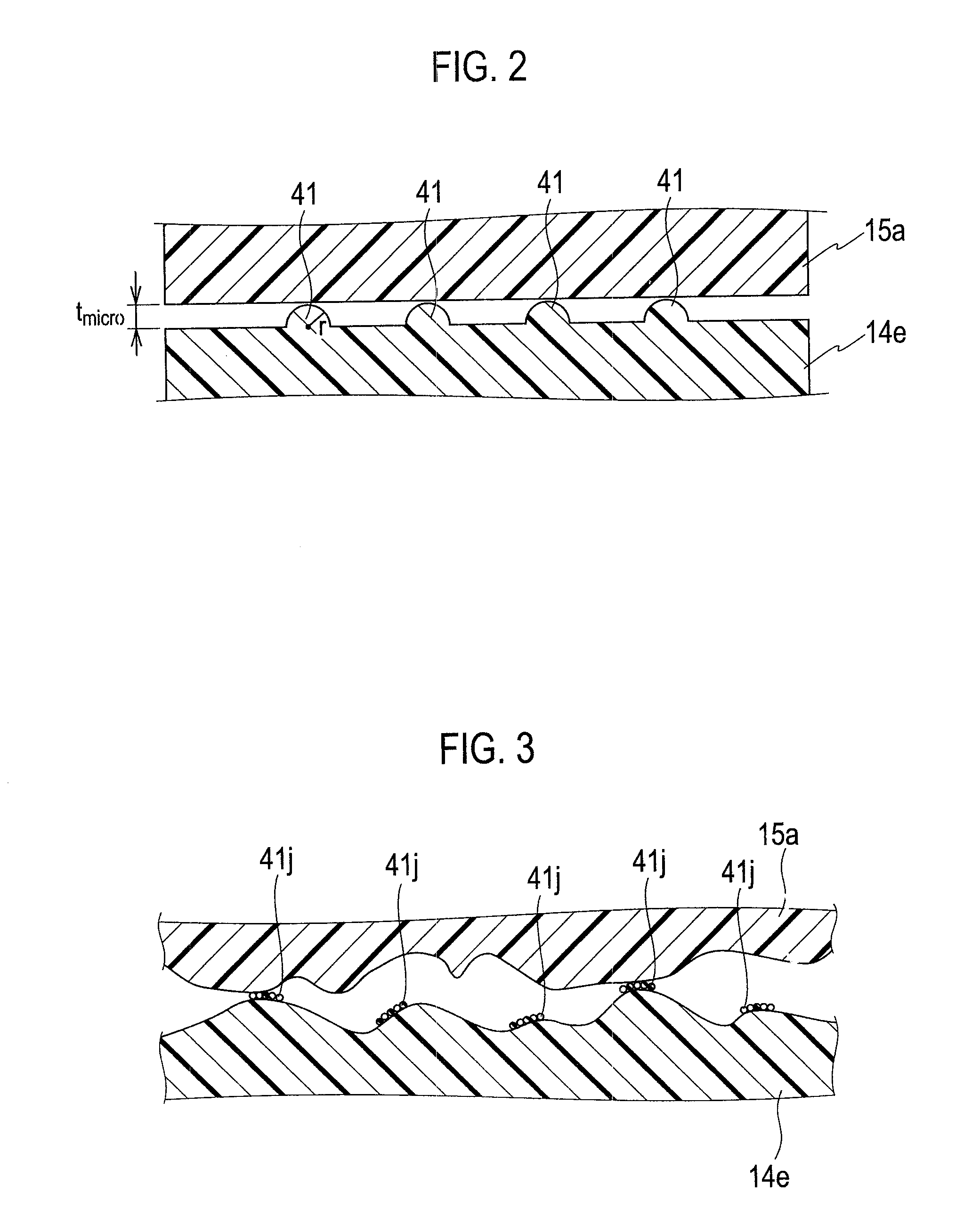

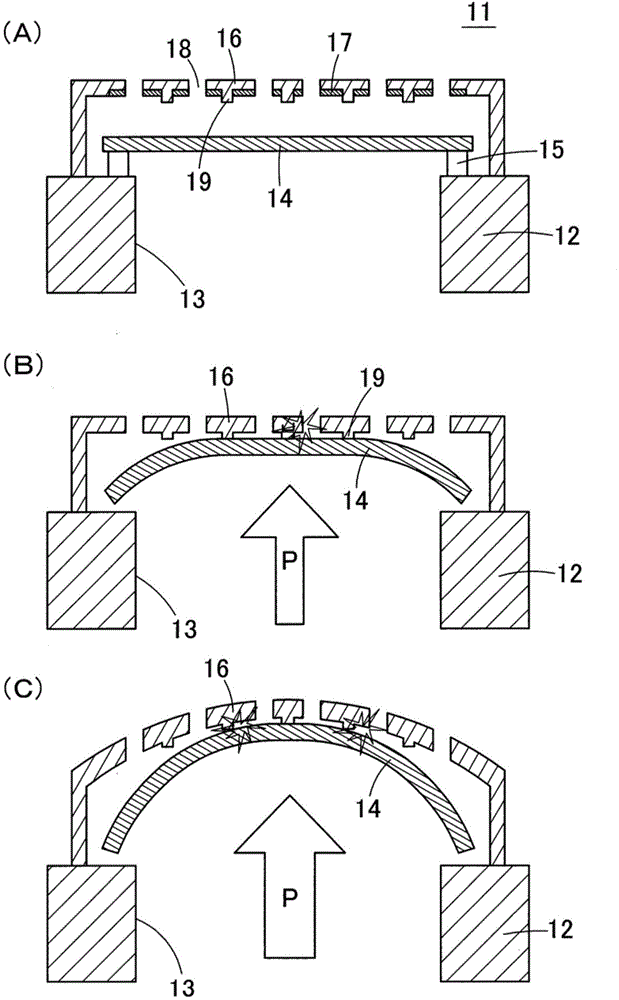

InactiveUS20110108838A1Increase freedomStrong sound pressurePiezoelectric/electrostrictive microphonesSemiconductor electrostatic transducersMicrometerTransducer

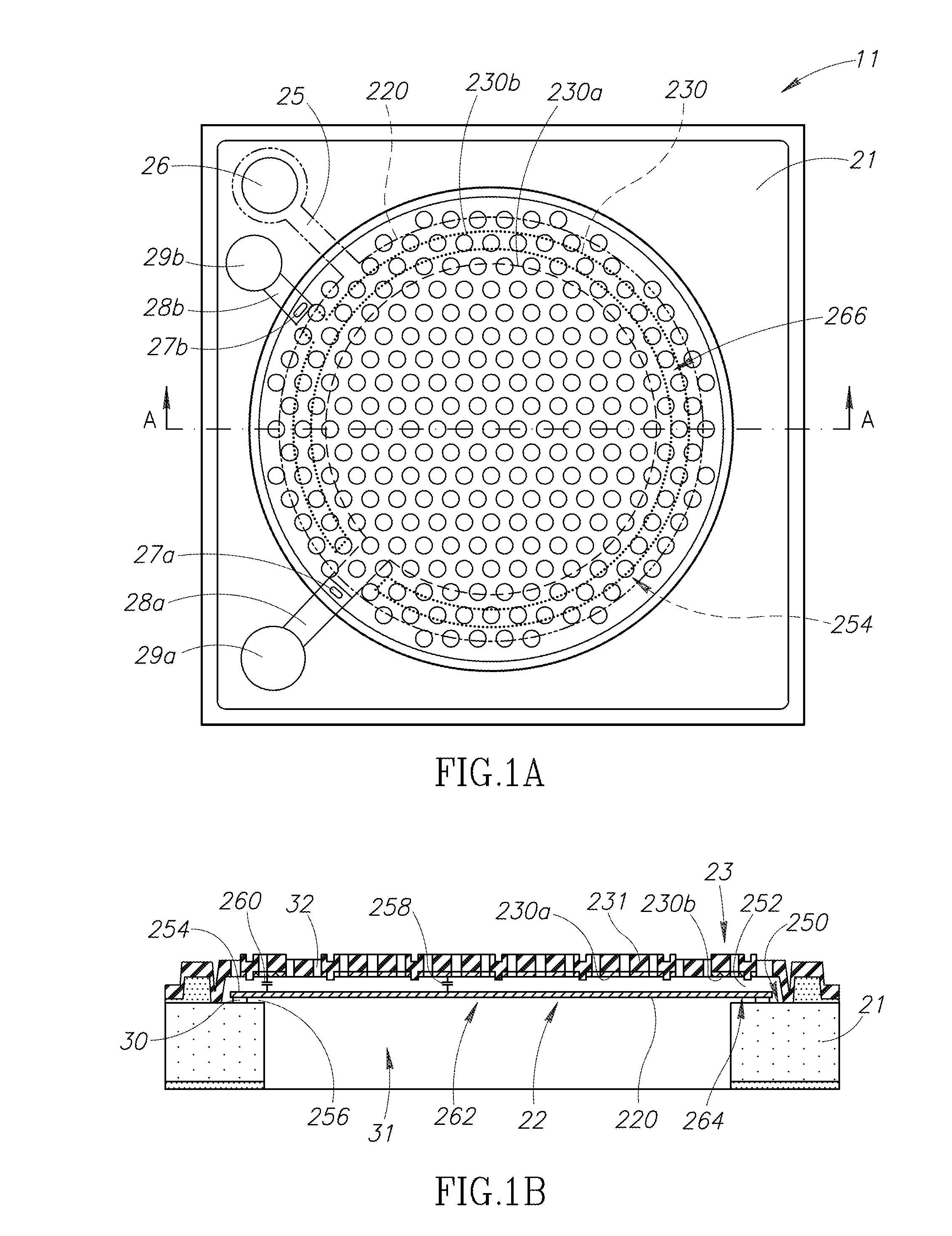

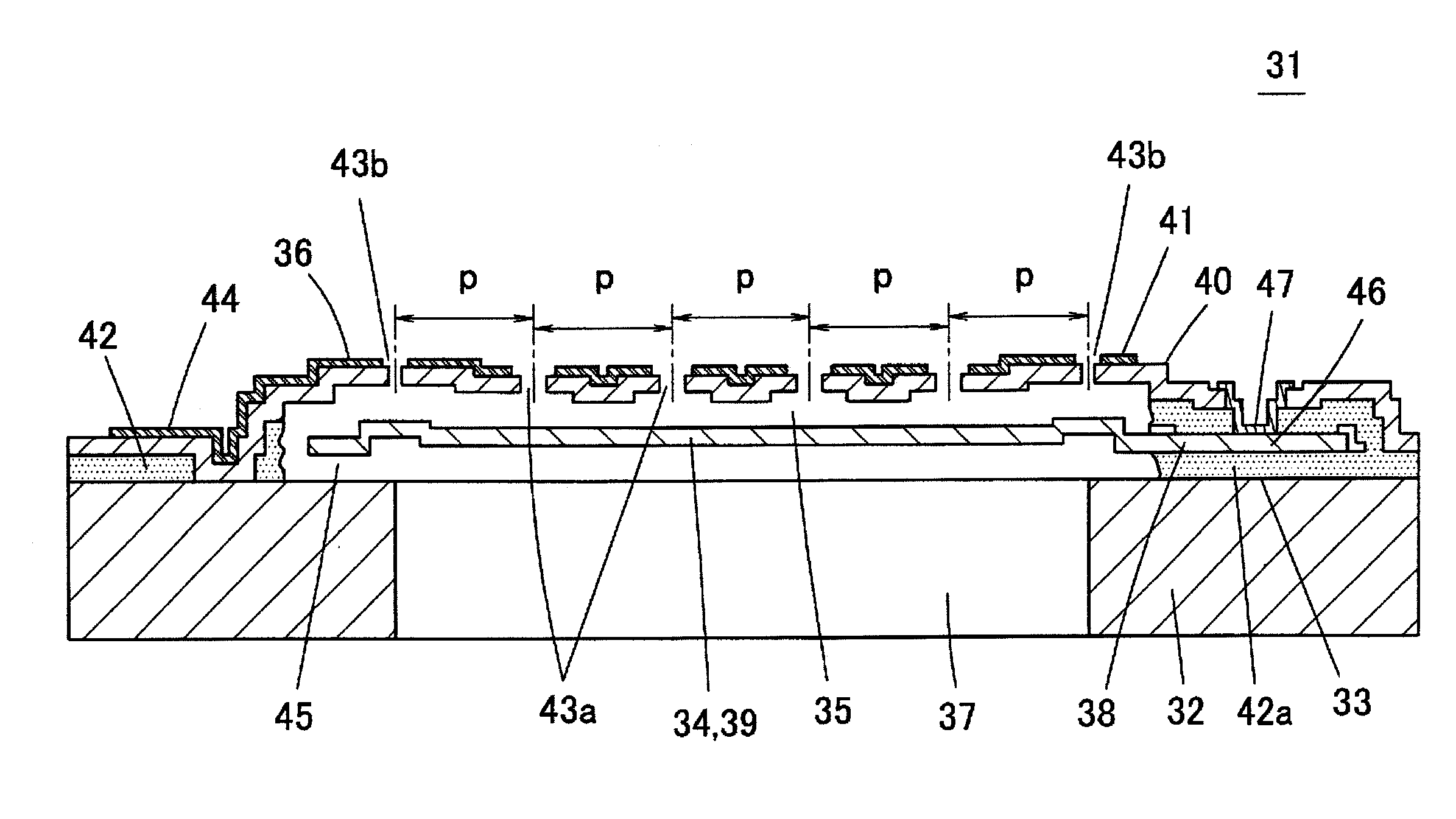

An electro-mechanical transducer contains a vibrating electrode (15b), a vibrating-electrode-insulating film (15a) disposed at a bottom surface of the vibrating electrode (15b), an electret layer (13) facing to the vibrating electrode (15b), an electret-insulating layer (14e) joined to a top surface of the electret layer (13), and a back electrode 17 in contact with a bottom surface of the electret layer (13). A microgap between ten nanometers and 100 micrometers is established between the vibrating-electrode-insulating film (15a) and electret-insulating layer (14e). A central line average roughness Ra of the vibrating electrode (15b), including a bending, is 1 / 10 or less of a gap width measured between the bottom surface of the vibrating electrode (15b) and the top surface of the electret layer (13).

Owner:SAITAMA UNIVERSITY

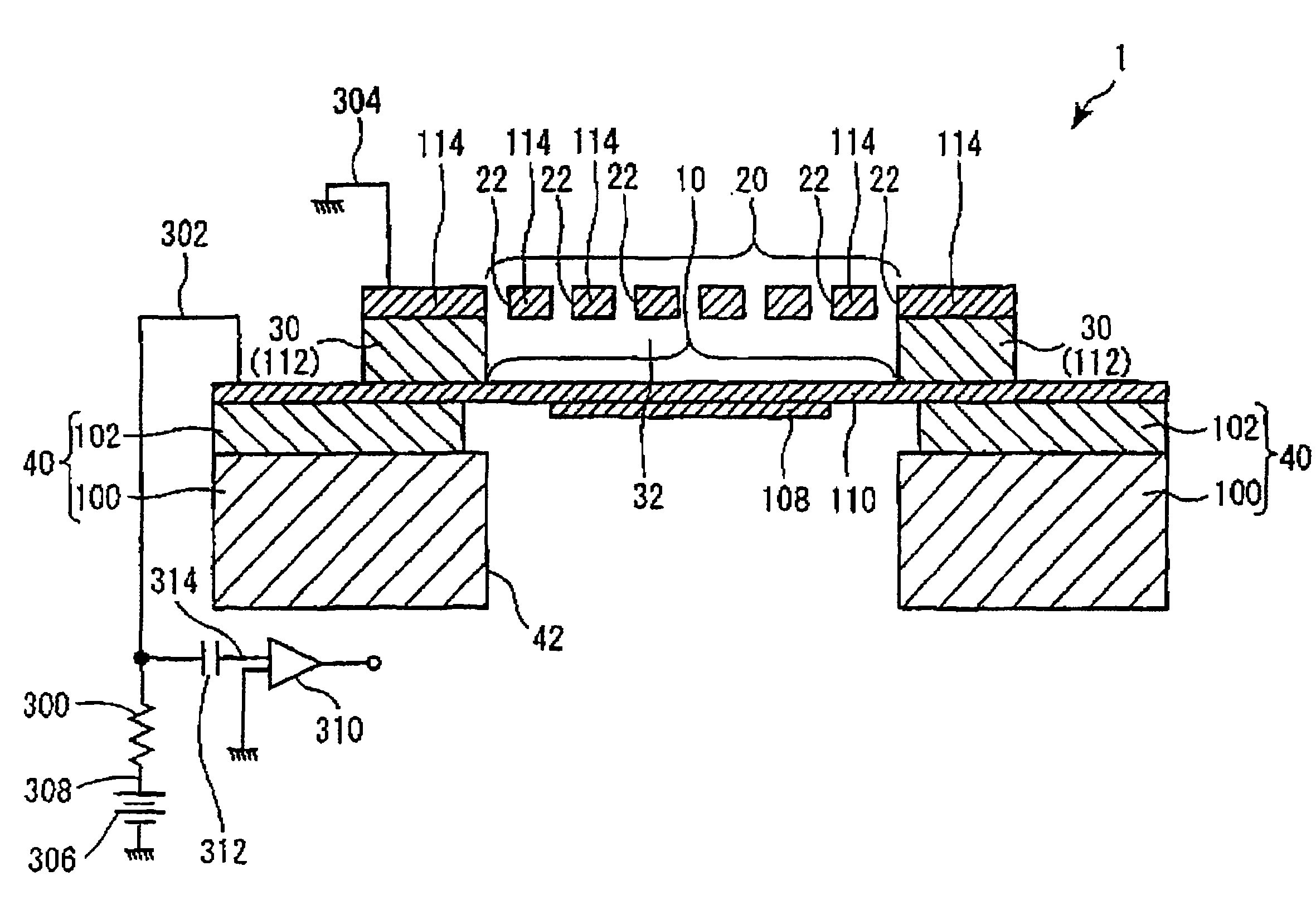

Acoustic transducer and interface circuit

ActiveUS20140010374A1Reduce variationSemiconductor electrostatic transducersSolid-state devicesCapacitanceDigital interface

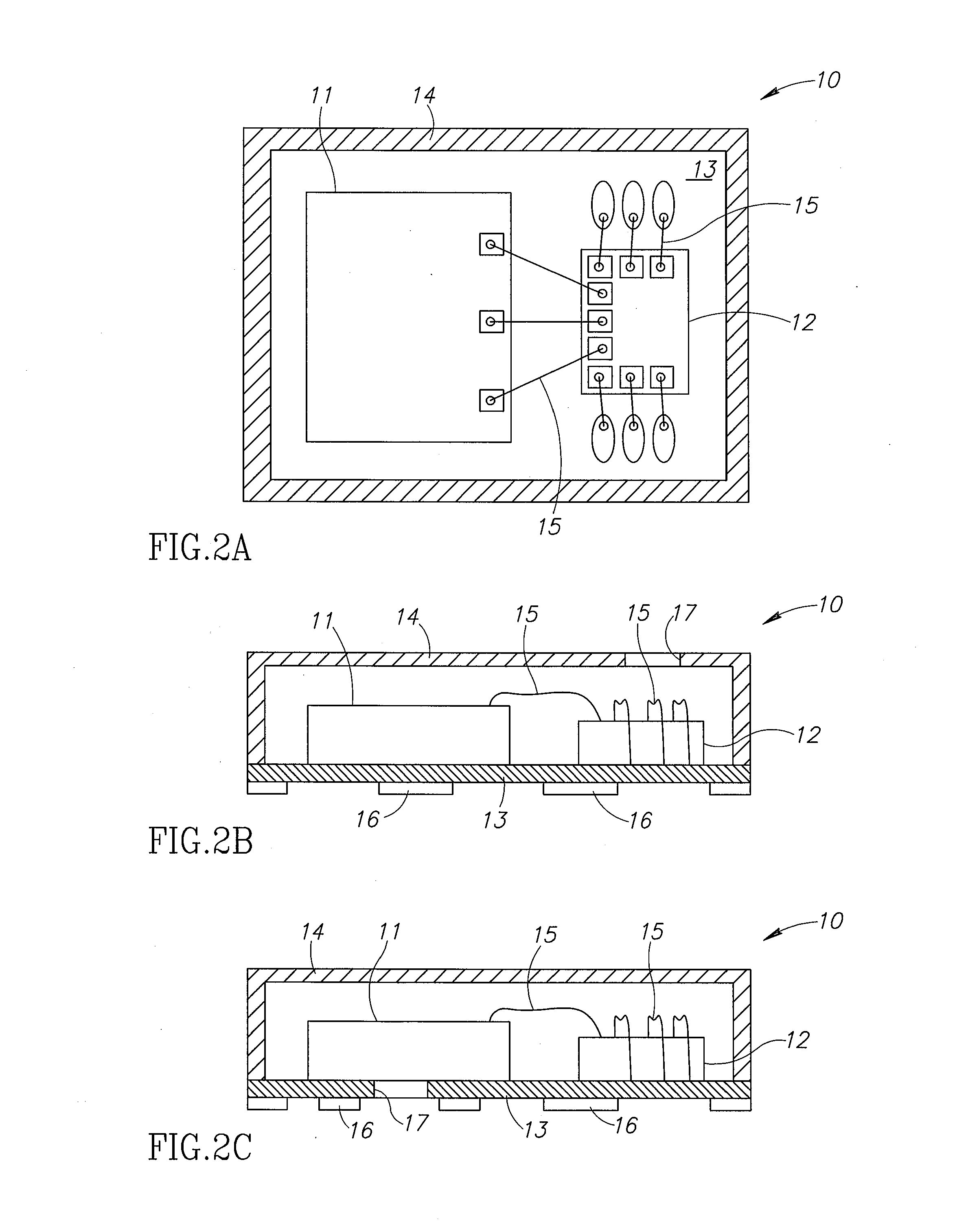

The present disclosure is directed to an acoustic transducer configured to detect a sound wave according to changes in capacitances between a vibrating electrode and a fixed electrode. At least one of the vibrating electrode and the fixed electrode being divided into a plurality of divided electrodes, and the plurality of divided electrodes outputting electrical signals. The disclosure includes a digital interface circuit coupled to the divided electrodes. The circuit includes a recombination stage, which supplies a mixed signal by combining the first digital processed signal and the second digital processed signal with a respective weight that is a function of a first level value of the first processed signal. An output stage is included, which supplies, selectively and alternatively, a first processed signal, a second processed signal, or a mixed signal.

Owner:ORMON CORP +1

Electrostatic capacitive vibrating sensor

ActiveUS20100212432A1Reduce sound resistanceLow dust-proof propertyVibration measurement in solidsMicrophonesVibrating electrodeAcoustics

An electrostatic capacitive vibration sensor has a substrate, a through-hole, a vibrating electrode plate, and a fixed electrode plate opposite the vibrating electrode plate. The fixed electrode plate is subjected to vibration to perform membrane oscillation. Pluralities of acoustic holes are made in the fixed electrode plate. The vibrating and fixed electrode plate are disposed on a surface side of the substrate such that an opening on the surface side of the through-hole is covered. A lower surface of an outer peripheral portion of the vibrating electrode plate is partially fixed to the substrate. A vent hole that communicates a surface side and a rear surface side of the vibrating electrode plate is made between the surface of the substrate and the lower surface of the vibrating electrode plate. In addition, the acoustic hole has a smaller opening area except at the outer peripheral portion.

Owner:MMI SEMICON CO LTD

Electrostatic capacitive vibrating sensor

ActiveUS8327711B2Reduce sound resistanceLow dust-proof propertyVibration measurement in solidsMicrophonesVibrating electrodeAcoustics

An electrostatic capacitive vibration sensor has a substrate, a through-hole, a vibrating electrode plate, and a fixed electrode plate opposite the vibrating electrode plate. The fixed electrode plate is subjected to vibration to perform membrane oscillation. Pluralities of acoustic holes are made in the fixed electrode plate. The vibrating and fixed electrode plate are disposed on a surface side of the substrate such that an opening on the surface side of the through-hole is covered. A lower surface of an outer peripheral portion of the vibrating electrode plate is partially fixed to the substrate. A vent hole that communicates a surface side and a rear surface side of the vibrating electrode plate is made between the surface of the substrate and the lower surface of the vibrating electrode plate. In addition, the acoustic hole has a smaller opening area except at the outer peripheral portion.

Owner:MMI SEMICON CO LTD

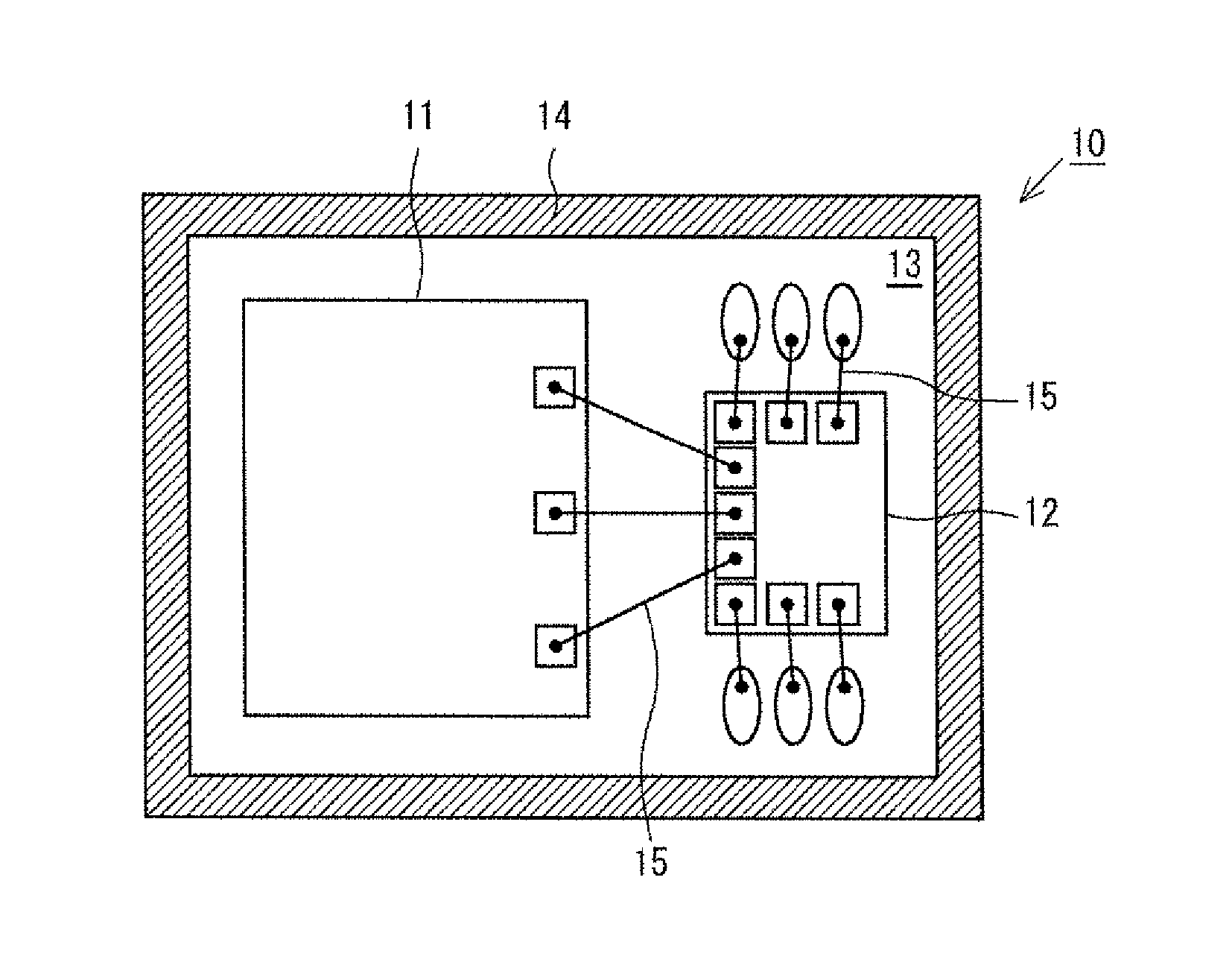

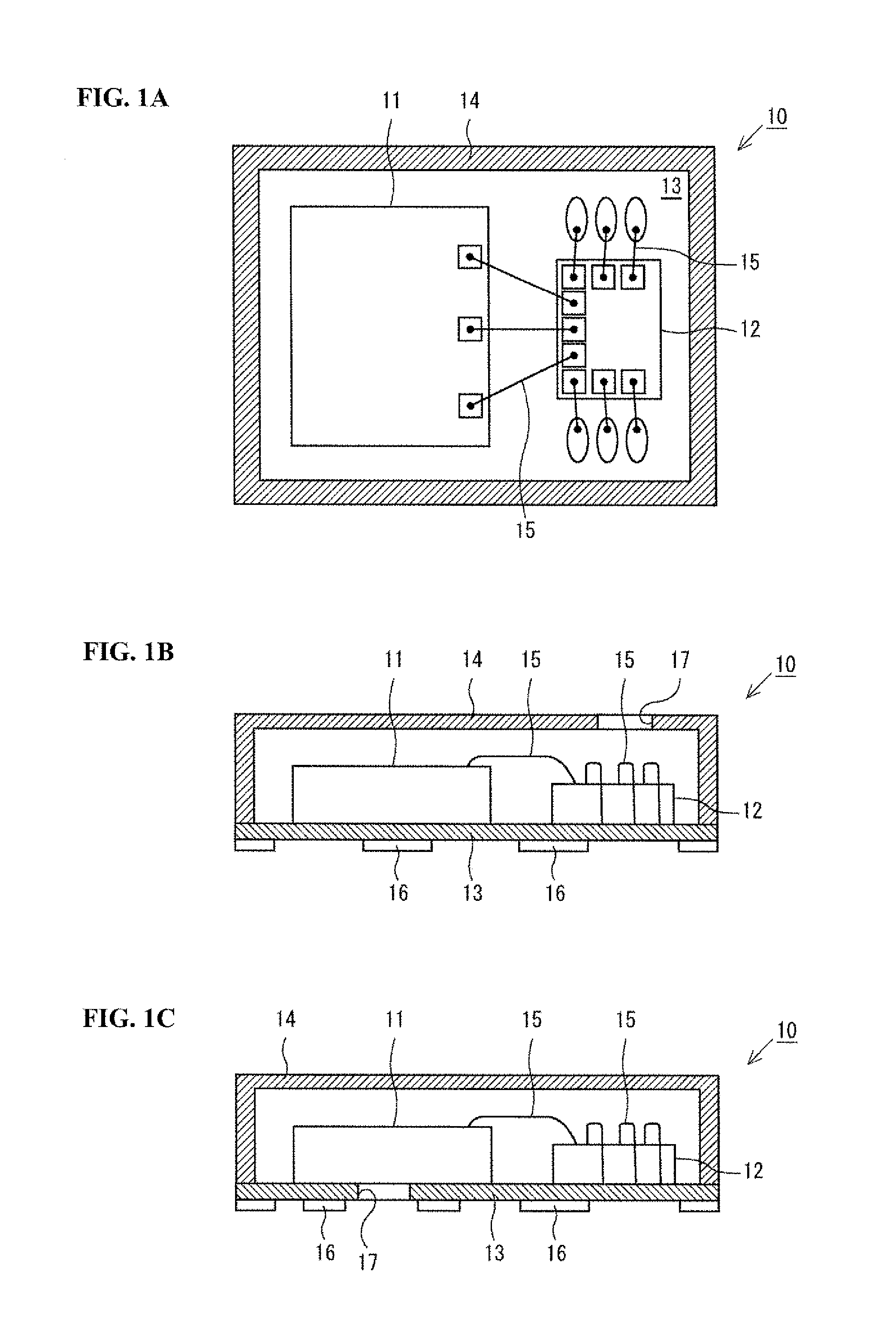

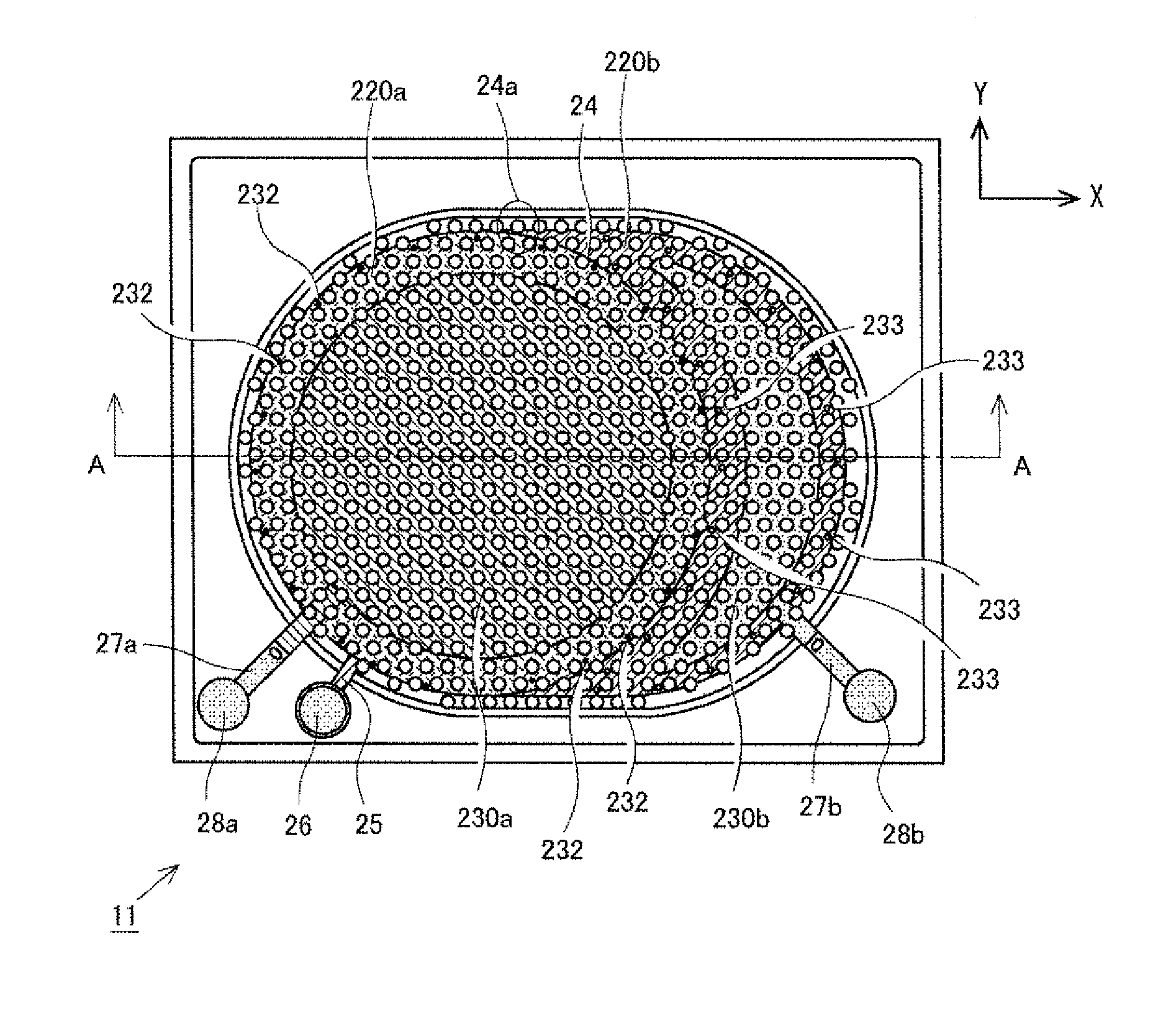

Capacitance sensor, acoustic sensor, and microphone

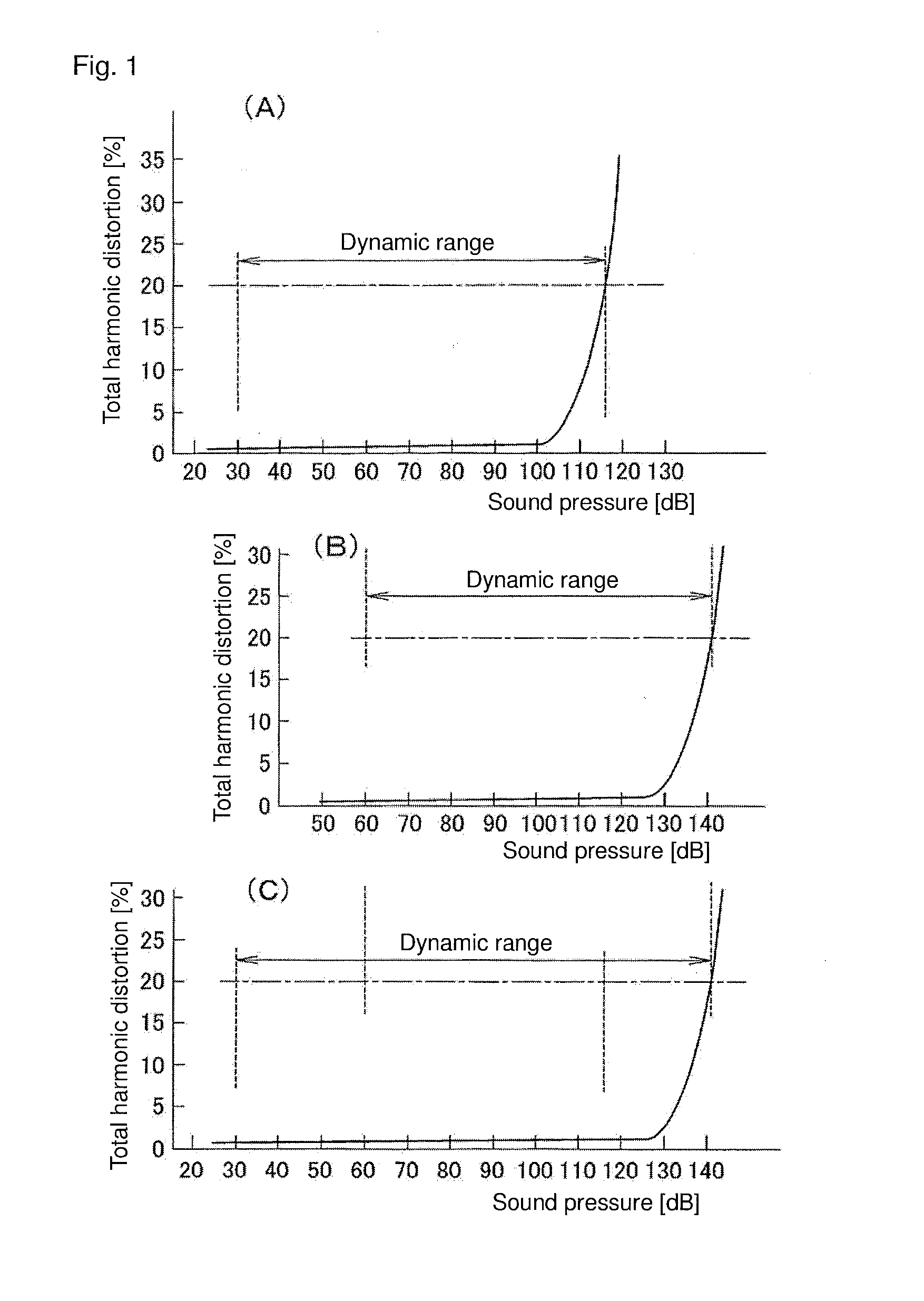

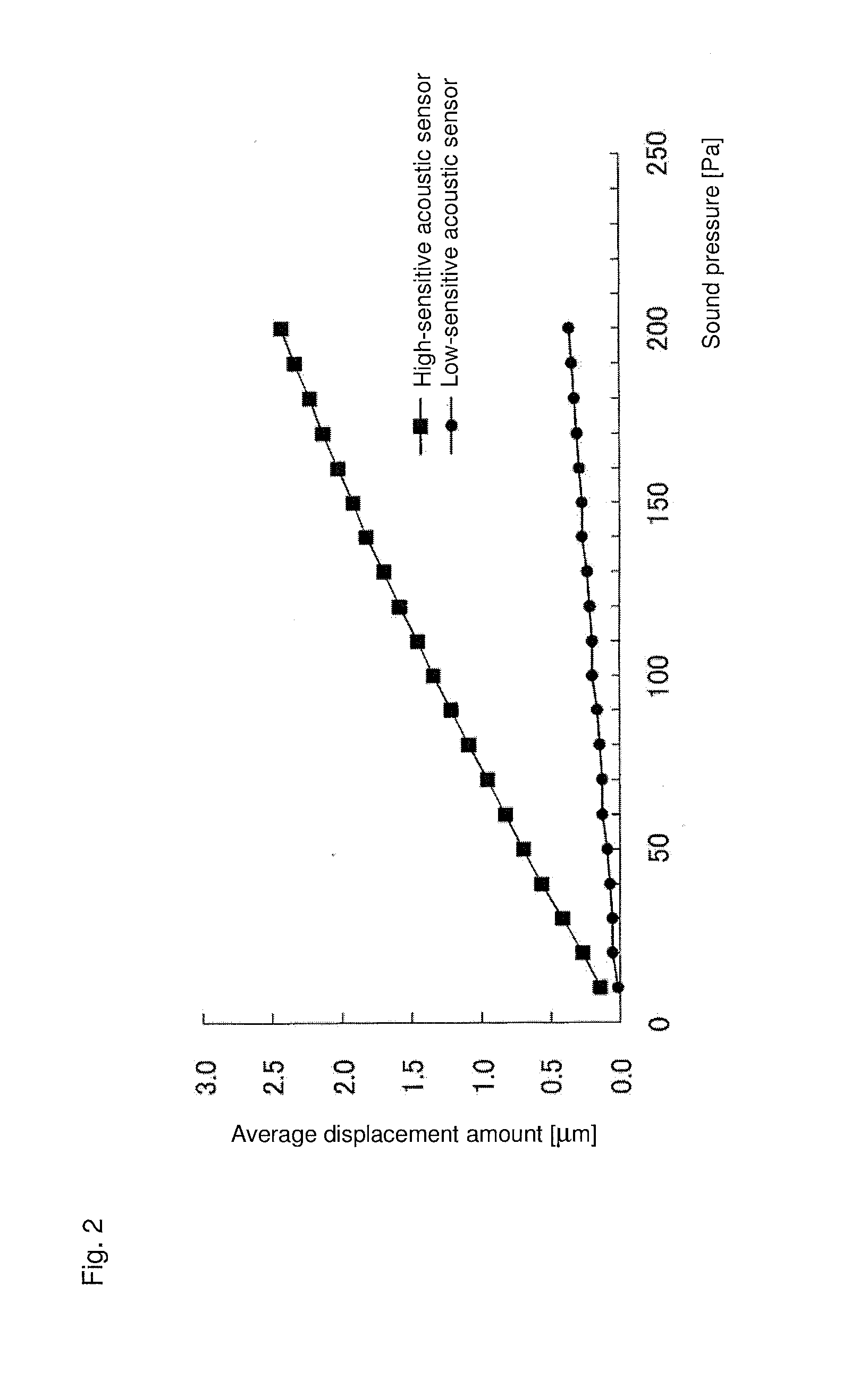

ActiveUS20150104048A1Increase independenceWide dynamic rangeVibration measurement in solidsVibration measurement in fluidEngineeringCapacitance transducer

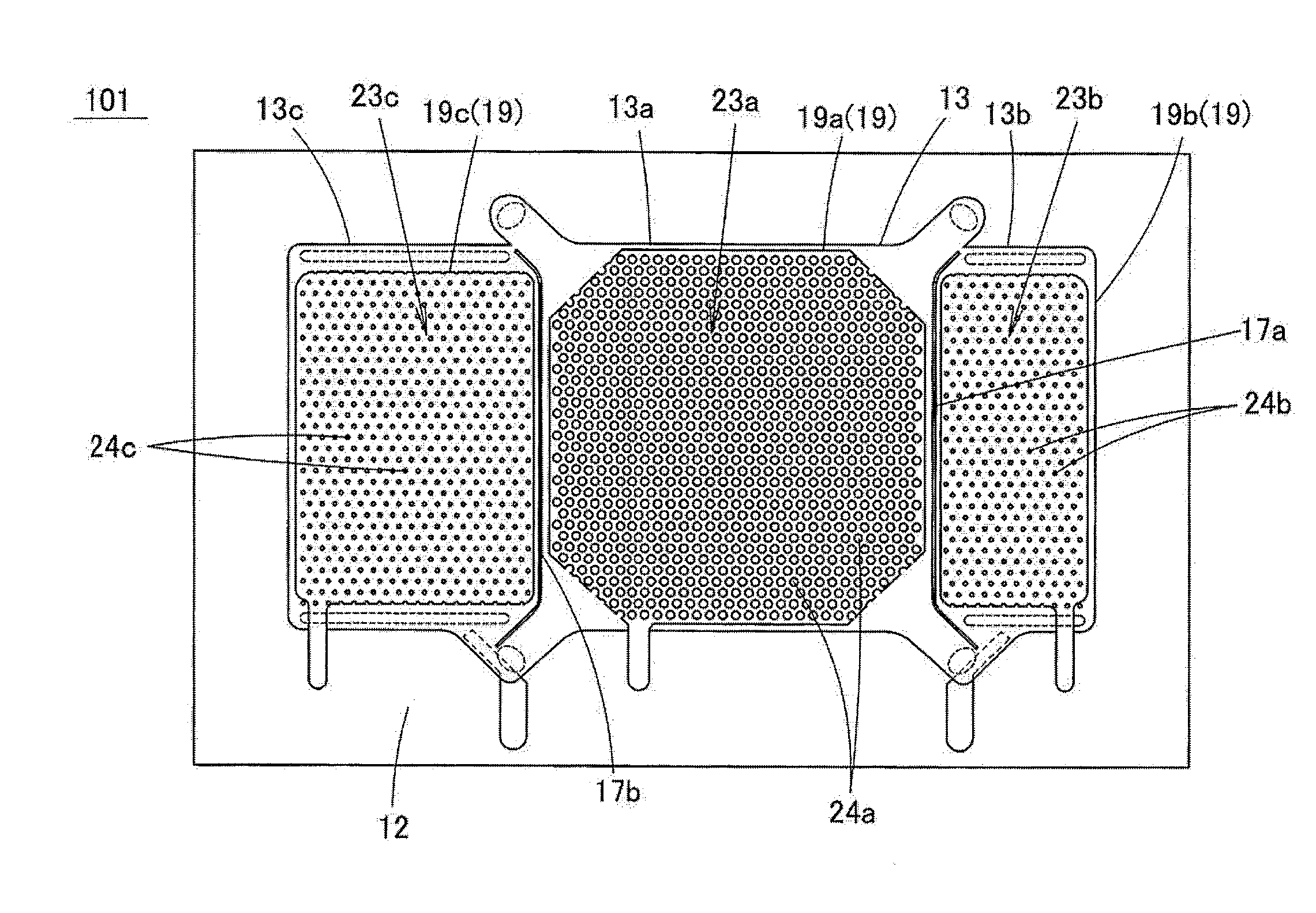

A capacitance sensor has a substrate, a vibration electrode plate formed over an upper side of the substrate, a back plate formed over the upper side of the substrate to cover the vibration electrode plate, and a fixed electrode plate arranged on the back plate facing the vibration electrode plate. At least one of the vibration electrode plate and the fixed electrode plate is divided into a plurality of regions. A sensing unit configured by the vibration electrode plate and the fixed electrode plate is formed in each of the divided regions. The plurality of sensing units output a plurality of signals having different sensitivities. At least some sensing units of the sensing units have vibration electrode plates having areas different from the areas of the vibration electrode plates in the other sensing units.

Owner:MMI SEMICON CO LTD

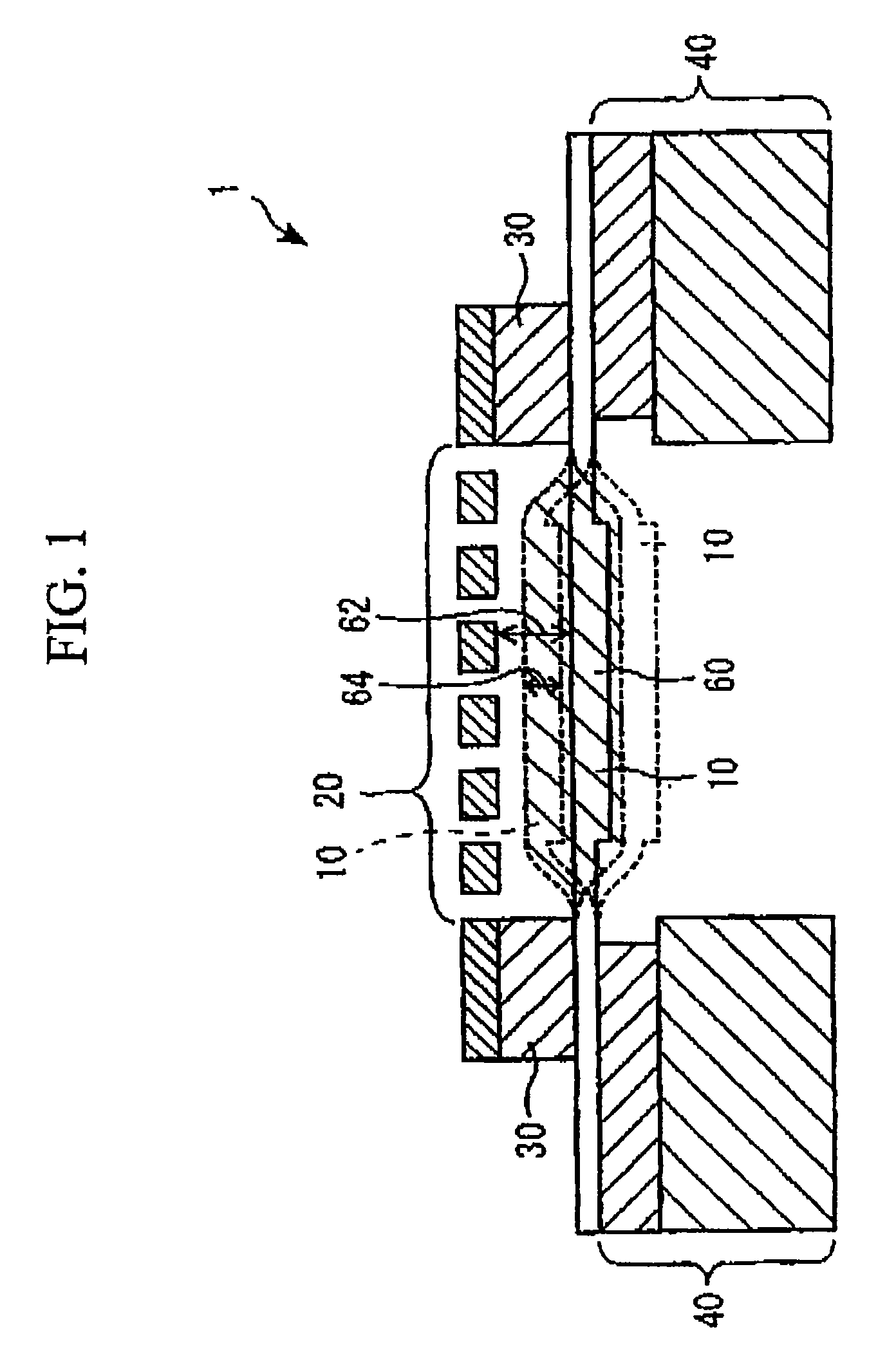

Acoustic transducer

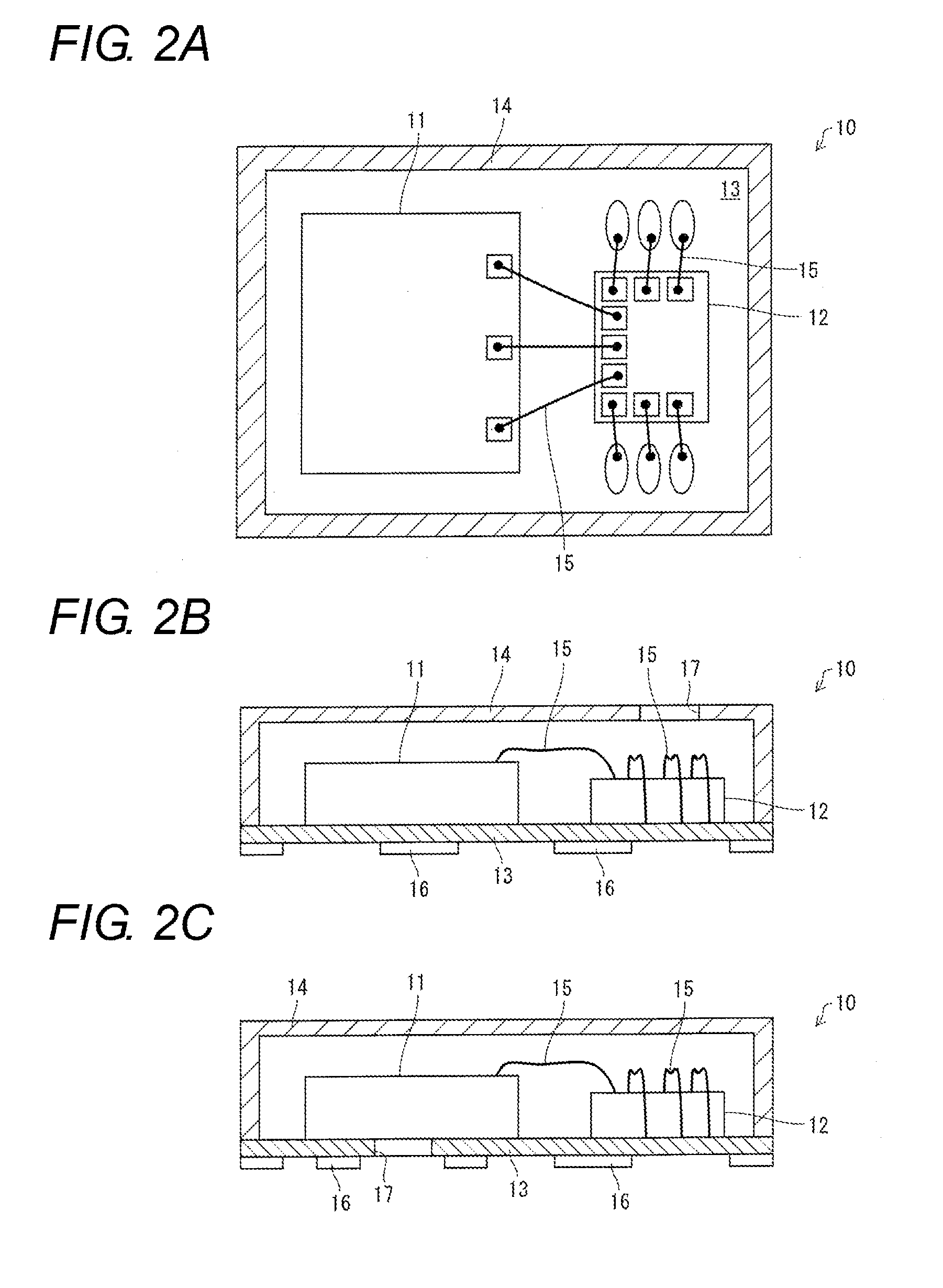

Provided is an acoustic transducer including: a semiconductor substrate; a vibrating membrane provided above the semiconductor substrate, including a vibrating electrode; and a fixed membrane provided above the semiconductor substrate, including a fixed electrode, the acoustic transducer detecting a sound wave according to changes in capacitances between the vibrating electrode and the fixed electrode, converting the sound wave into electrical signals, and outputting the electrical signals. At least one of the vibrating electrode and the fixed electrode is divided into a plurality of divided electrodes, and the plurality of divided electrodes outputting the electrical signals.

Owner:ORMON CORP +1

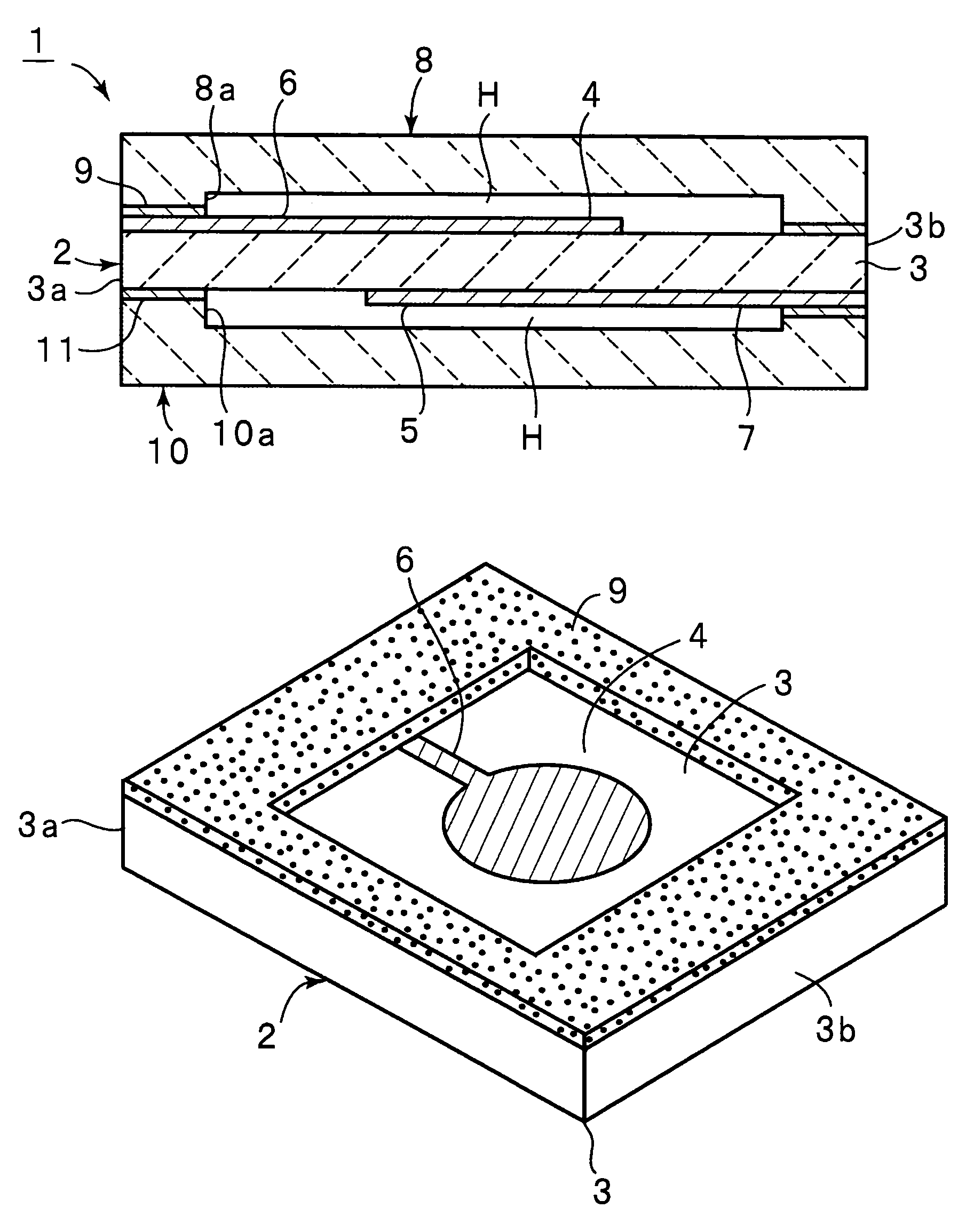

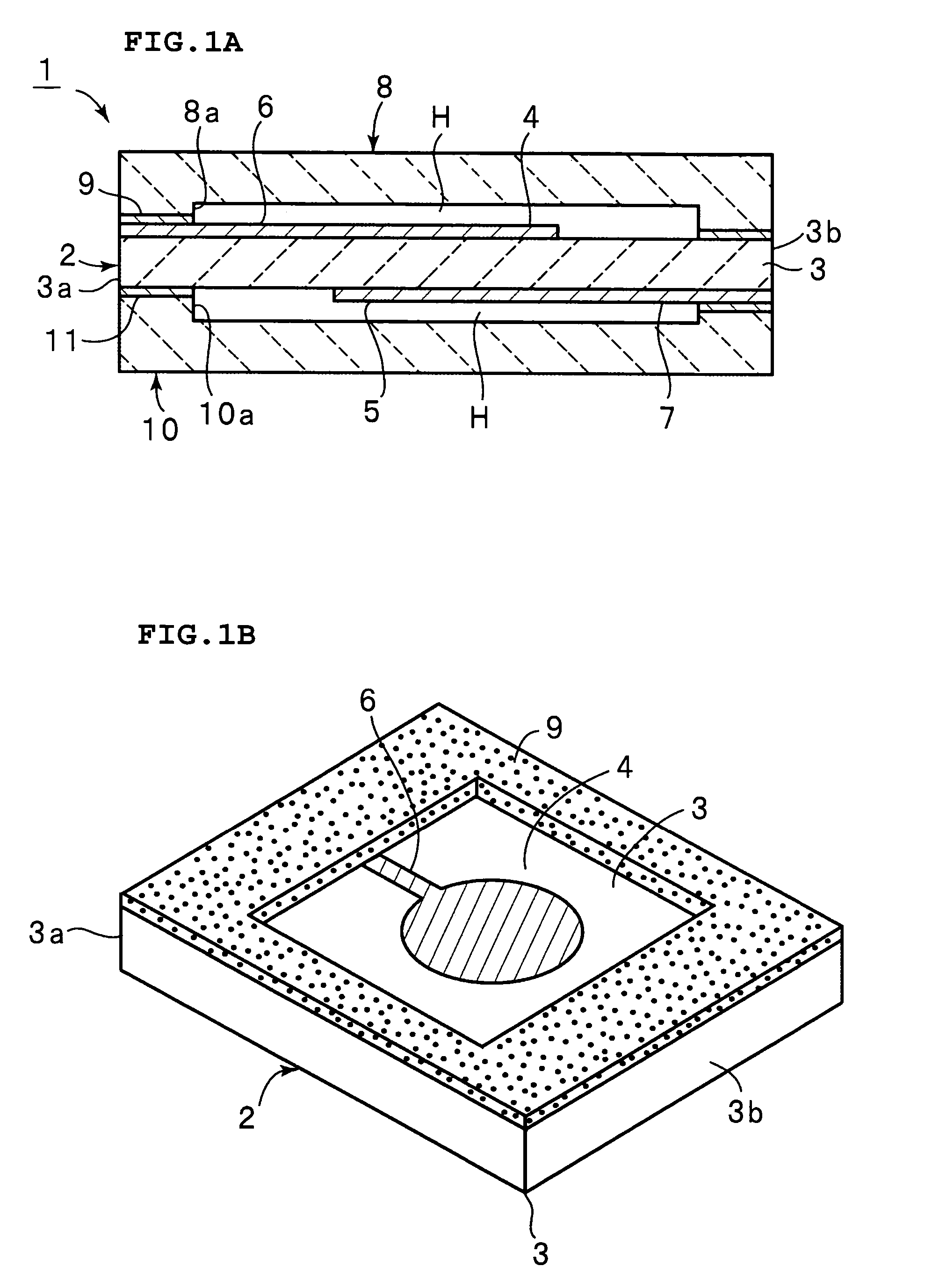

Method for fabricating condenser microphone and condenser microphone

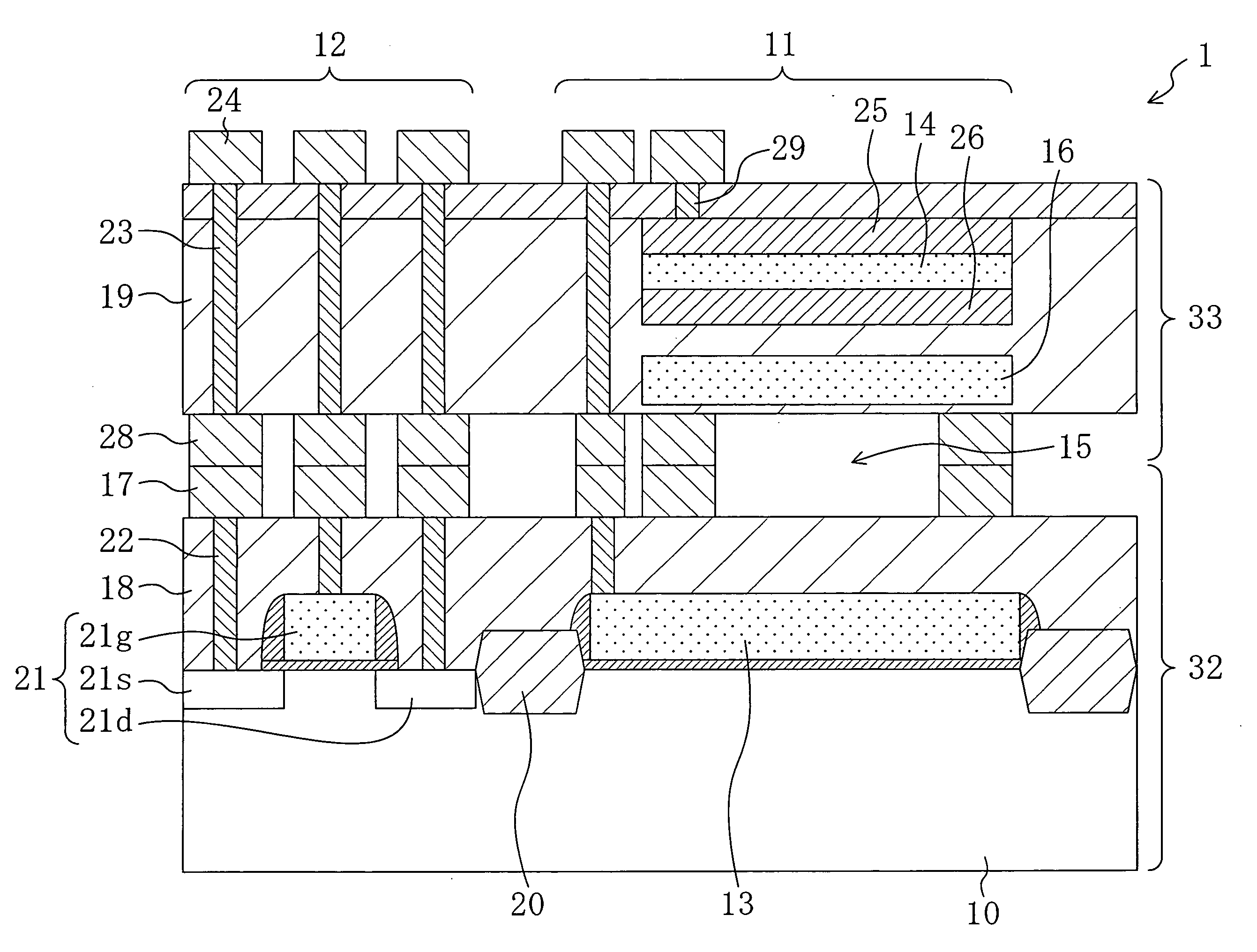

ActiveUS20070272992A1Improve vibration resistanceReduce parasitic capacitanceTransistorSemiconductor/solid-state device detailsDielectricSemiconductor chip

A first semiconductor chip includes a fixed electrode formed on a first semiconductor substrate and a plurality of first metal spacers formed on a first interlayer dielectric. A second semiconductor chip includes a vibrating electrode formed on a second semiconductor substrate and a plurality of second metal spacers formed on a second interlayer dielectric. The first and second semiconductor chips are metallically bonded to each other using the first and second metal spacers. An air gap is formed in a region of the condenser microphone located between the first semiconductor chip and the second semiconductor chip except bonded regions of the first and second metal spacers.

Owner:PANASONIC CORP

Piezoelectric resonator component

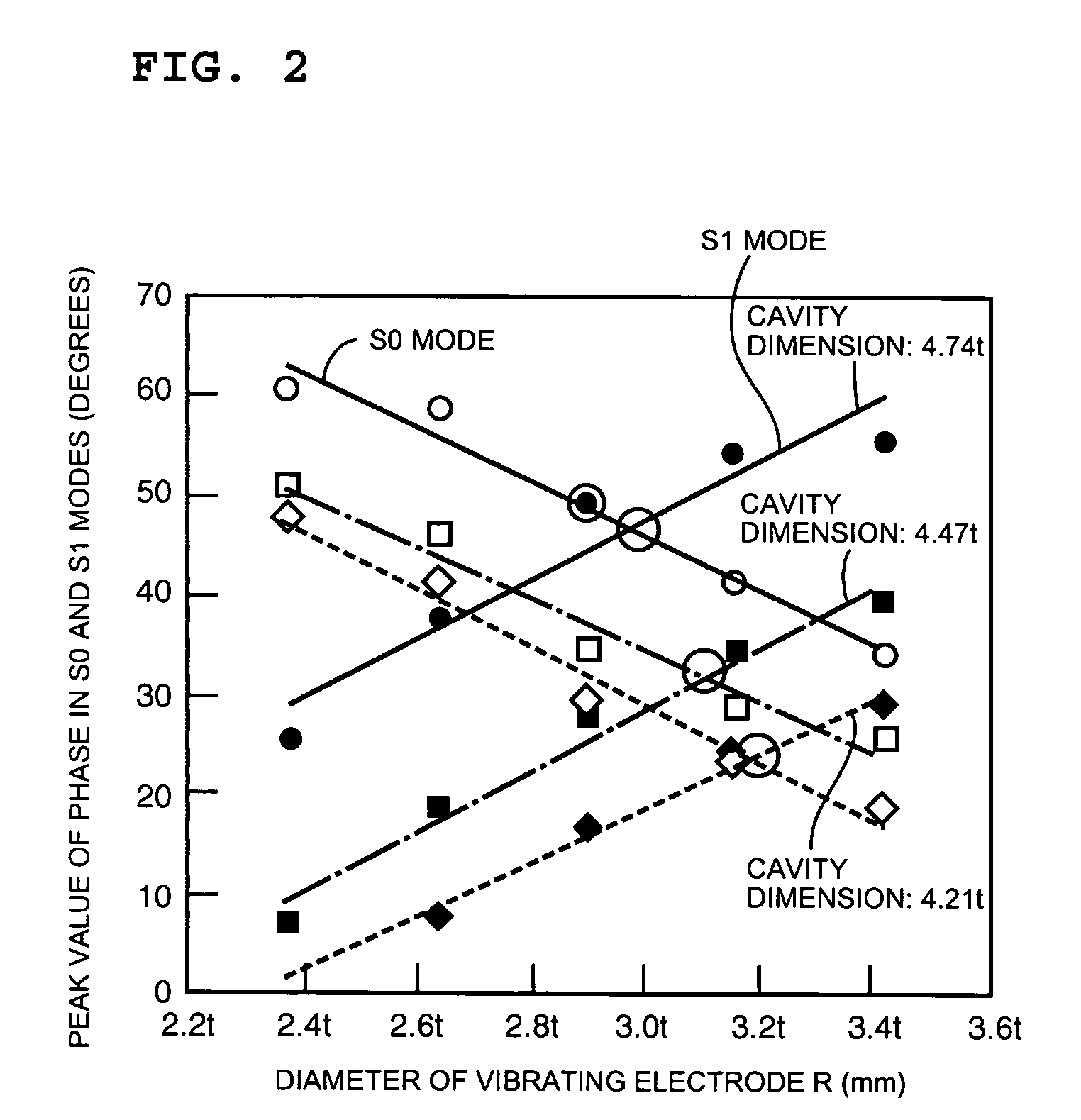

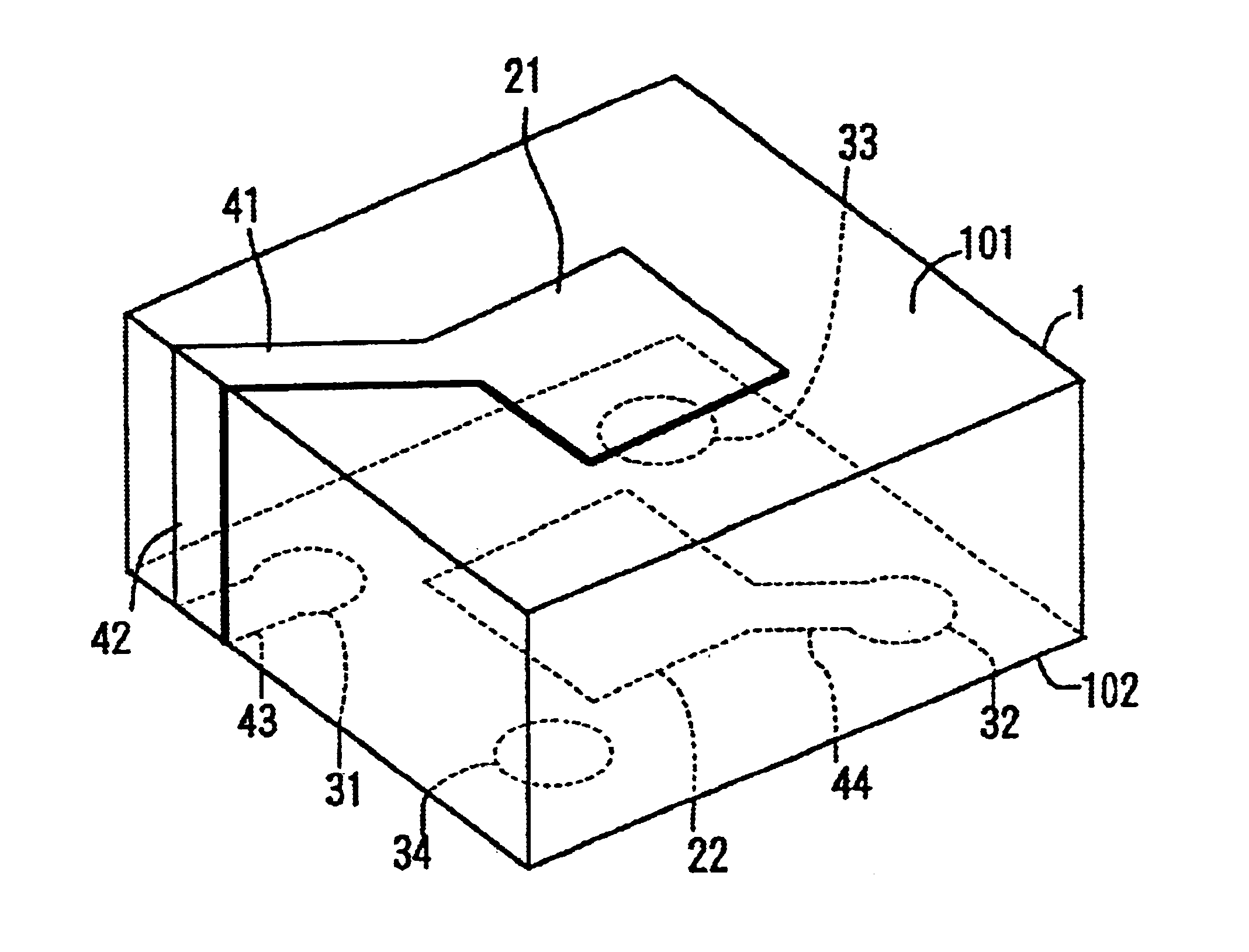

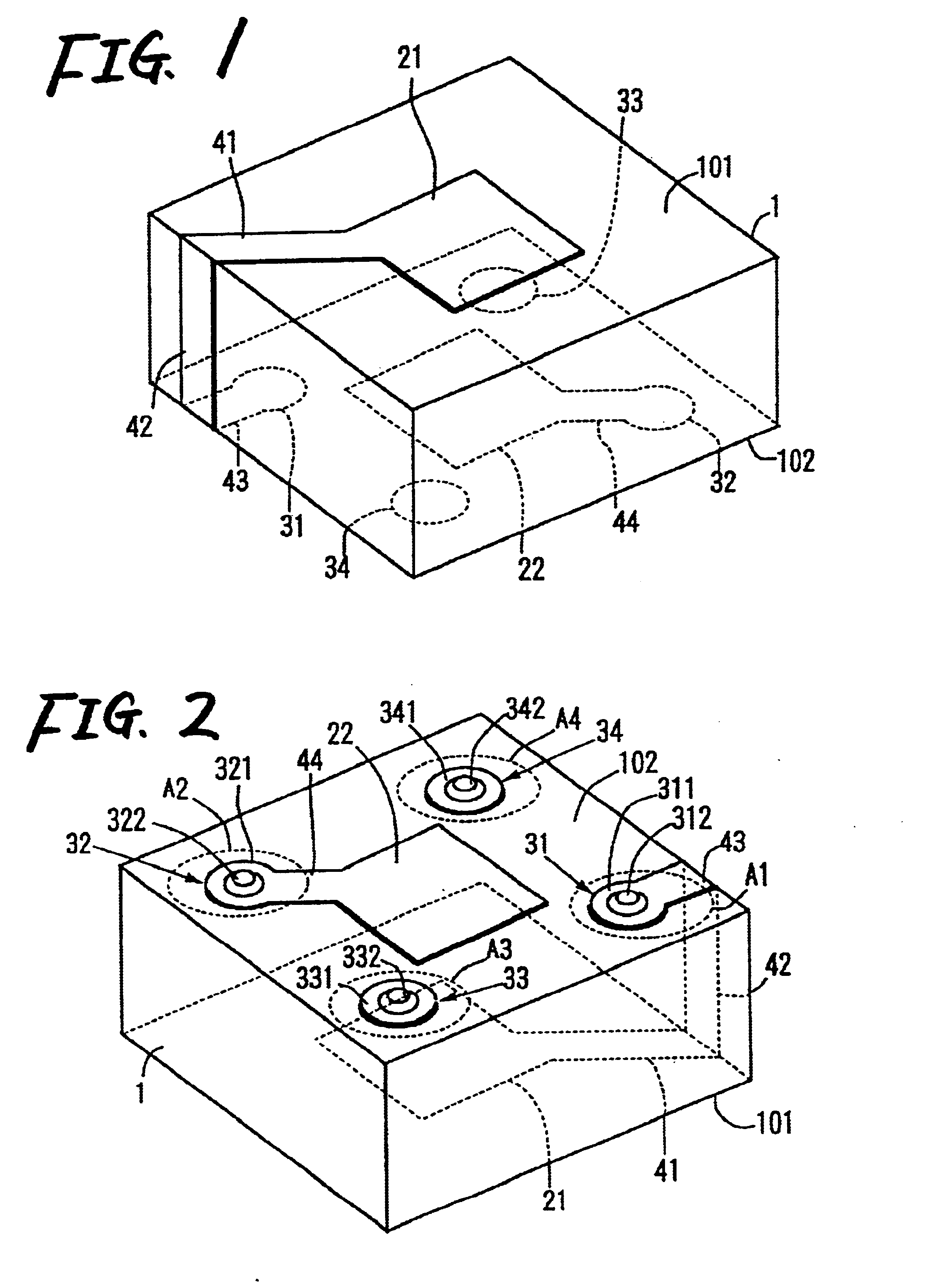

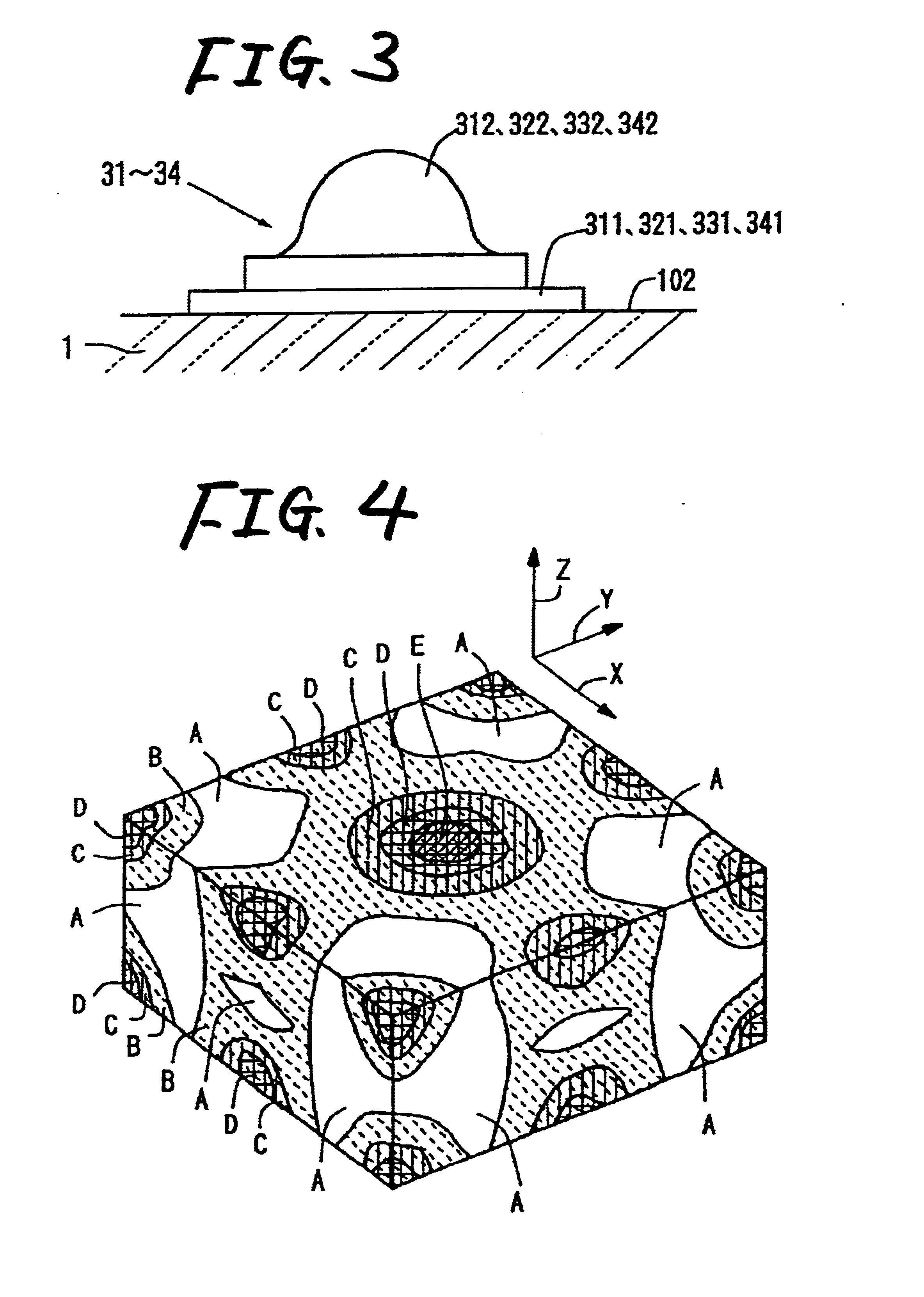

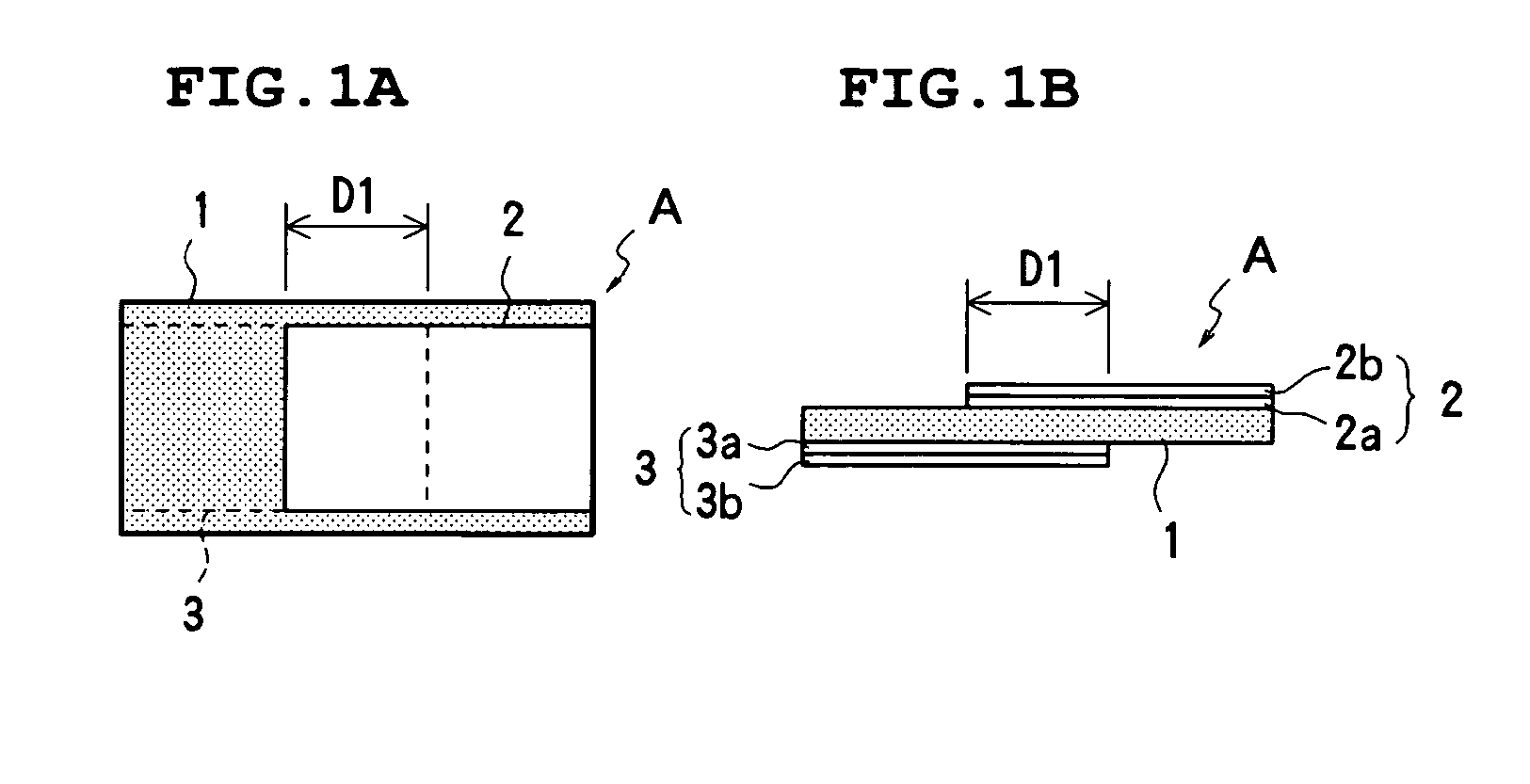

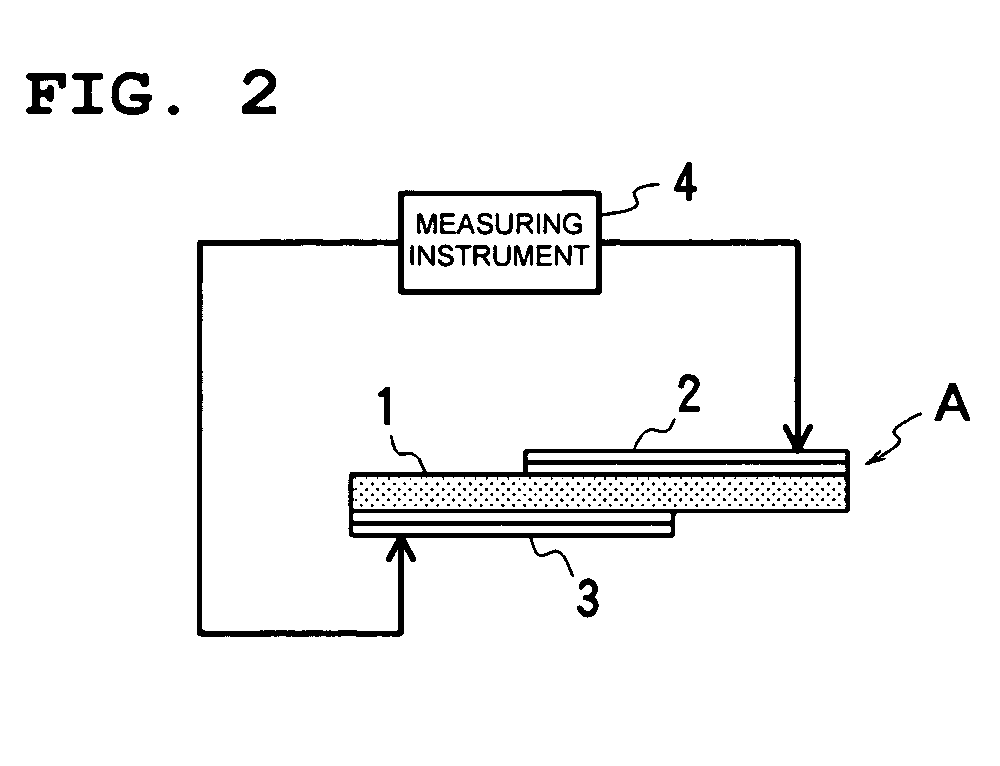

ActiveUS6987347B2Simplify manufacturing stepsReduce manufacturing costPiezoelectric/electrostriction/magnetostriction machinesImpedence networksLongitudinal vibrationPeak value

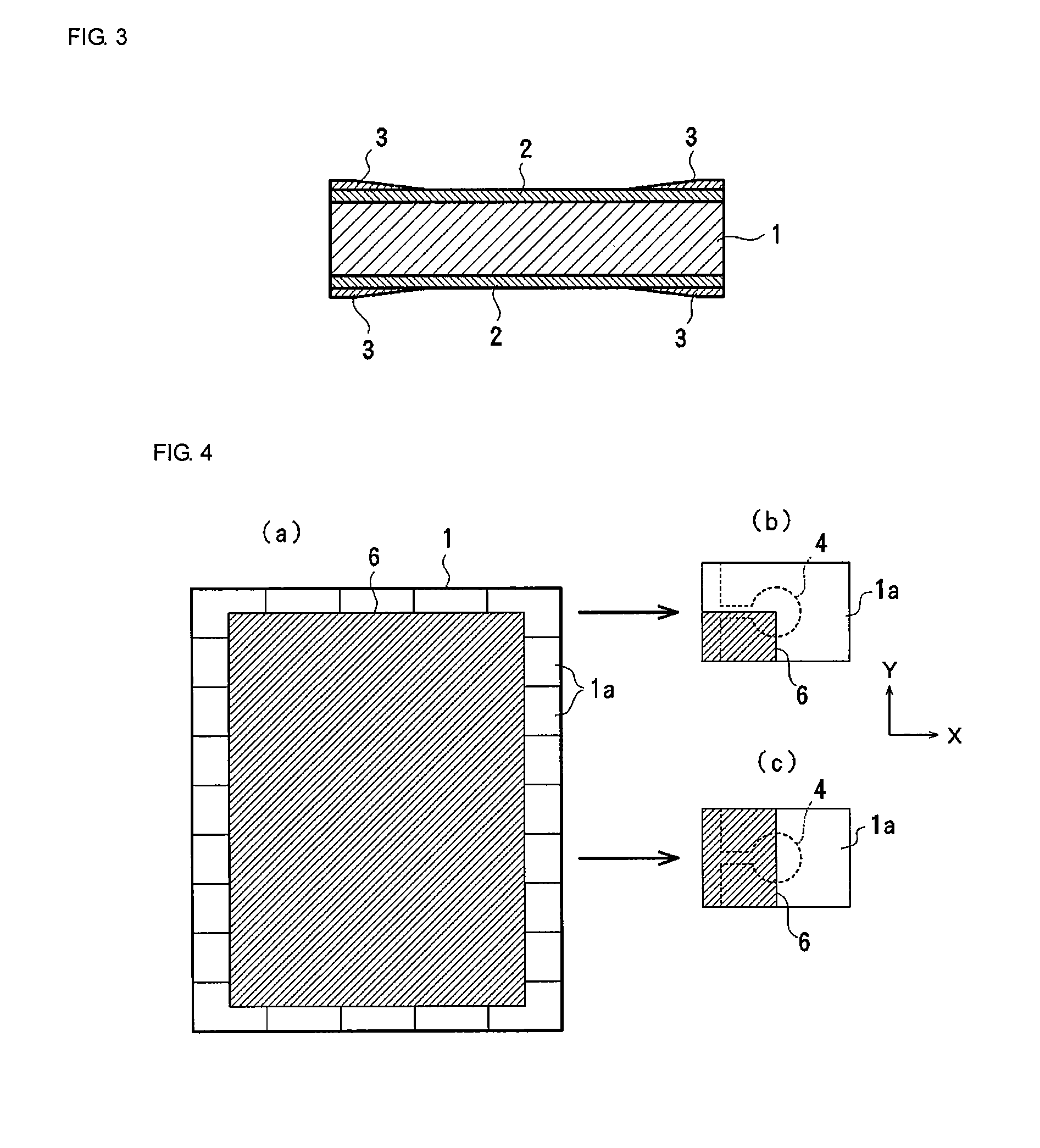

A piezoelectric resonator component includes an energy-trapped piezoelectric resonator utilizing a third order harmonic wave of thickness longitudinal vibration and including a piezoelectric substrate having first and second major surfaces and polarized in a direction of thickness between the first and second major surfaces, and first and second vibrating electrodes opposed to each other with the piezoelectric substrate interposed therebetween, and first and second casing substrates respectively laminated on the first and second major surfaces of the piezoelectric resonator so that cavities are arranged so as not to interfere with vibration of a vibration section where the first and second vibrating electrodes face each other through the piezoelectric substrate. The first and second vibrating electrodes are dimensioned so that the difference between the peak values of the phases of S0 and S1 modes of the fundamental wave of the thickness longitudinal vibration falls within a range of about ±5 degrees.

Owner:MURATA MFG CO LTD

Sound transducer and microphone using same

Provided is an acoustic transducer including: a semiconductor substrate; a vibrating membrane, provided above the semiconductor substrate, including a vibrating electrode; and a fixed membrane, provided above the semiconductor substrate, including a fixed electrode, the acoustic transducer detecting a sound wave according to changes in capacitances between the vibrating electrode and the fixed electrode, converting the sound wave into electrical signals, and outputting the electrical signals. At least one of the vibrating electrode and the fixed electrode is divided into a plurality of divided electrodes, and the plurality of divided electrodes outputting the electrical signals.

Owner:ORMON CORP +1

Surface acoustic wave device

ActiveUS20100327694A1Reduce materialSimple manufacturing processPiezoelectric/electrostriction/magnetostriction machinesImpedence networksSurface acoustic wave sensorEngineering

A highly reliable surface acoustic wave device includes wiring lines that do not easily rupture at a three-dimensional wiring portion. The surface acoustic wave device includes a plurality of surface acoustic wave elements located on a piezoelectric substrate, a supporting member arranged on the piezoelectric substrate so as to enclose vibrating portions including electrodes such as IDT electrodes, and a cover member stacked so as to cover openings of the supporting member and to define hollow spaces facing vibrating electrodes. Furthermore, a three-dimensional wiring portion at which a first wiring line and a second wiring line are stacked with an insulating layer interposed therebetween is provided on the piezoelectric substrate. The three-dimensional wiring portion is enclosed by the supporting member, and thereby disposed inside a space enclosed by the piezoelectric substrate, the supporting member, and the cover member.

Owner:MURATA MFG CO LTD

Capacitor microphone

InactiveCN101189910ASmooth vibration without disturbanceSmooth vibrationElectrostatic transducer microphonesEngineeringSound wave

A capacitor microphone is constituted by a plate having a fixed electrode, a diaphragm including a center portion and at least one near-end portion that is fixed to the outer periphery, in which the center portion having a vibrating electrode, which is positioned relative to the fixed electrode and which vibrates in response to sound waves, is increased in rigidity in comparison with the near-end portion; and a spacer that is fixed to the plate and the near-end portion of the diaphragm and that has an air gap formed between the plate and the diaphragm. Alternatively, a diaphragm electrode is horizontally supported by extension arms extended from a circular plate thereof and is vertically held in a hanging state being apart from a fixed electrode with a controlled distance therebetween.

Owner:YAMAHA CORP

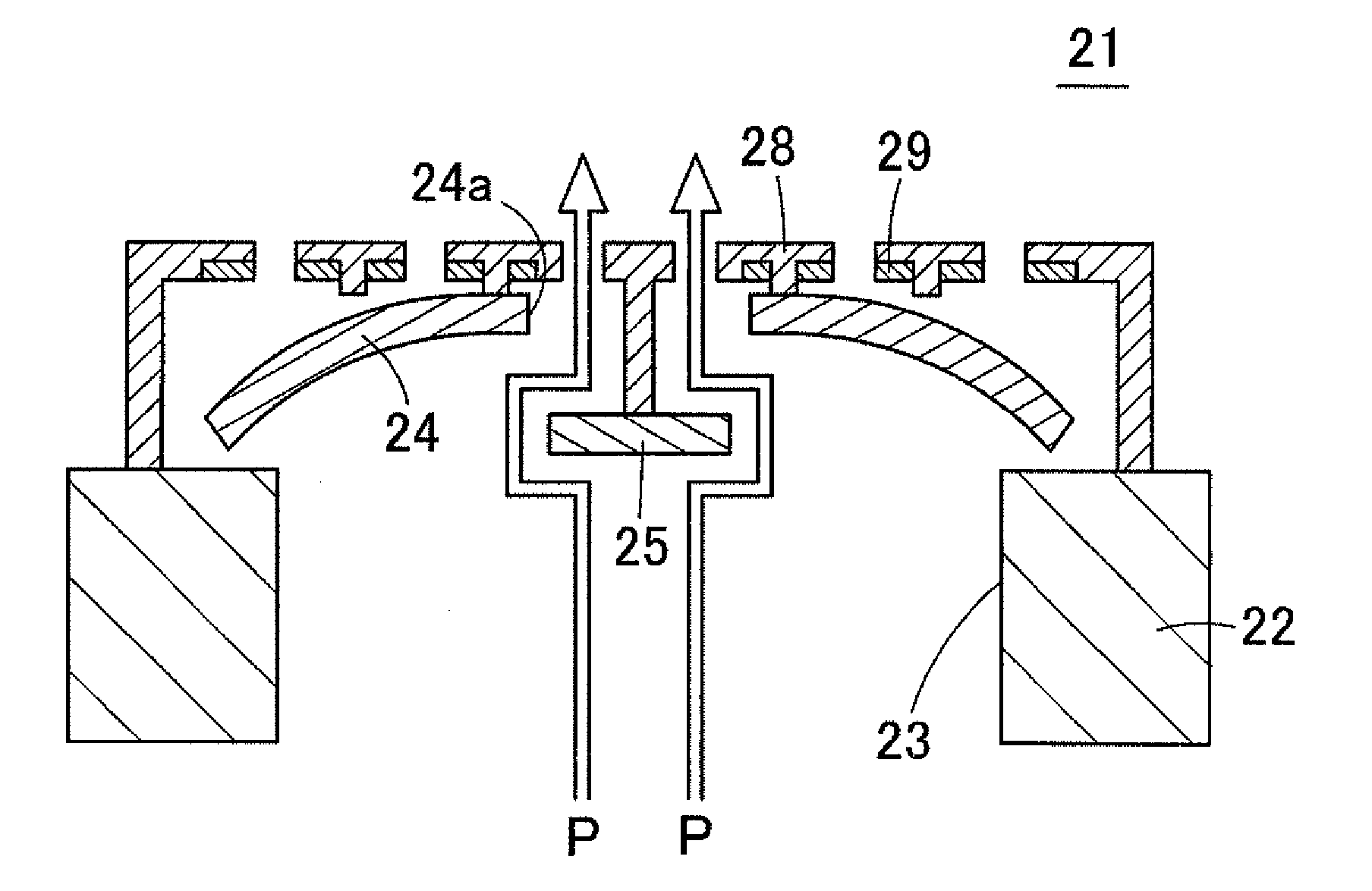

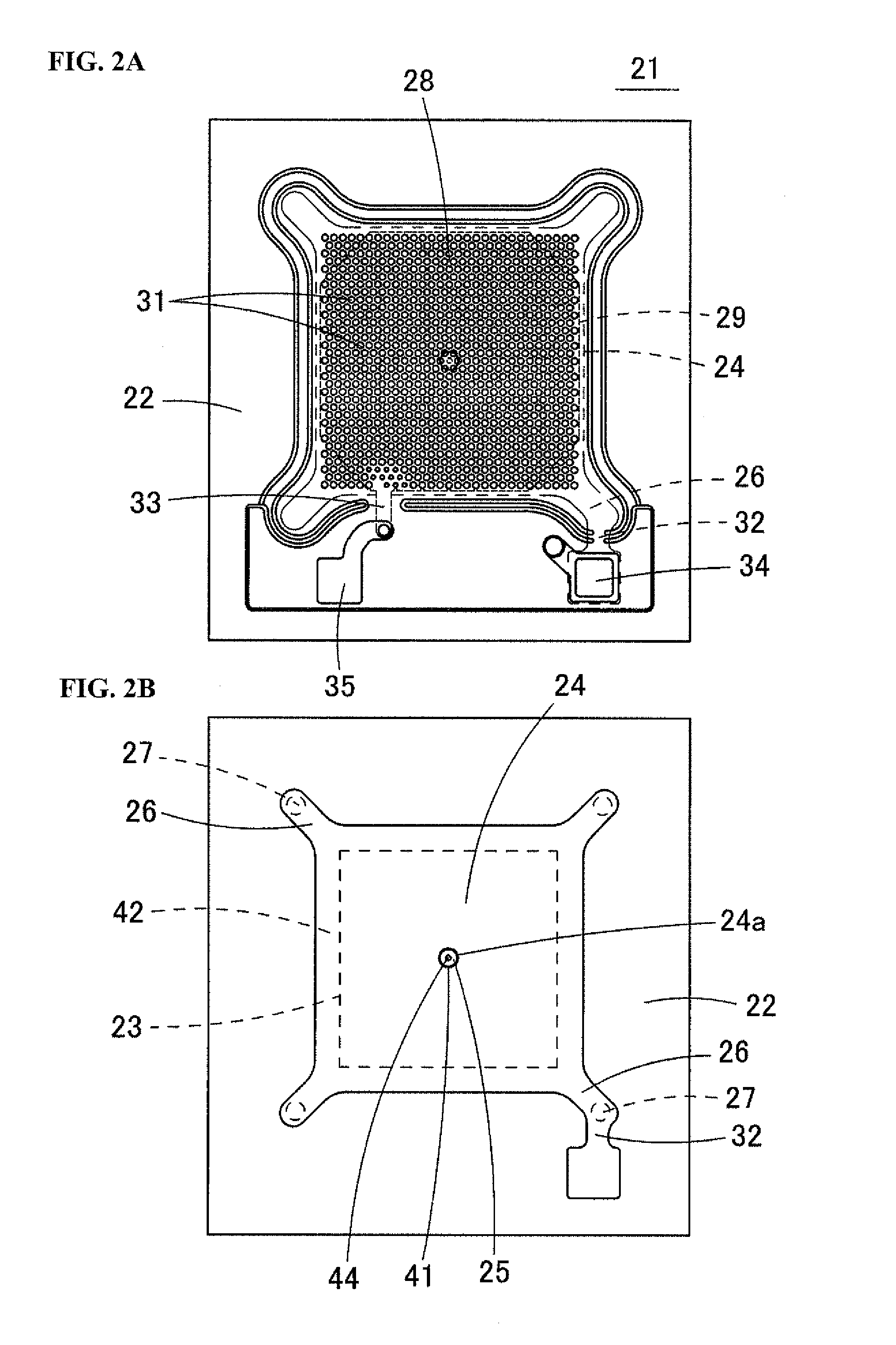

Acoustic transducer and microphone

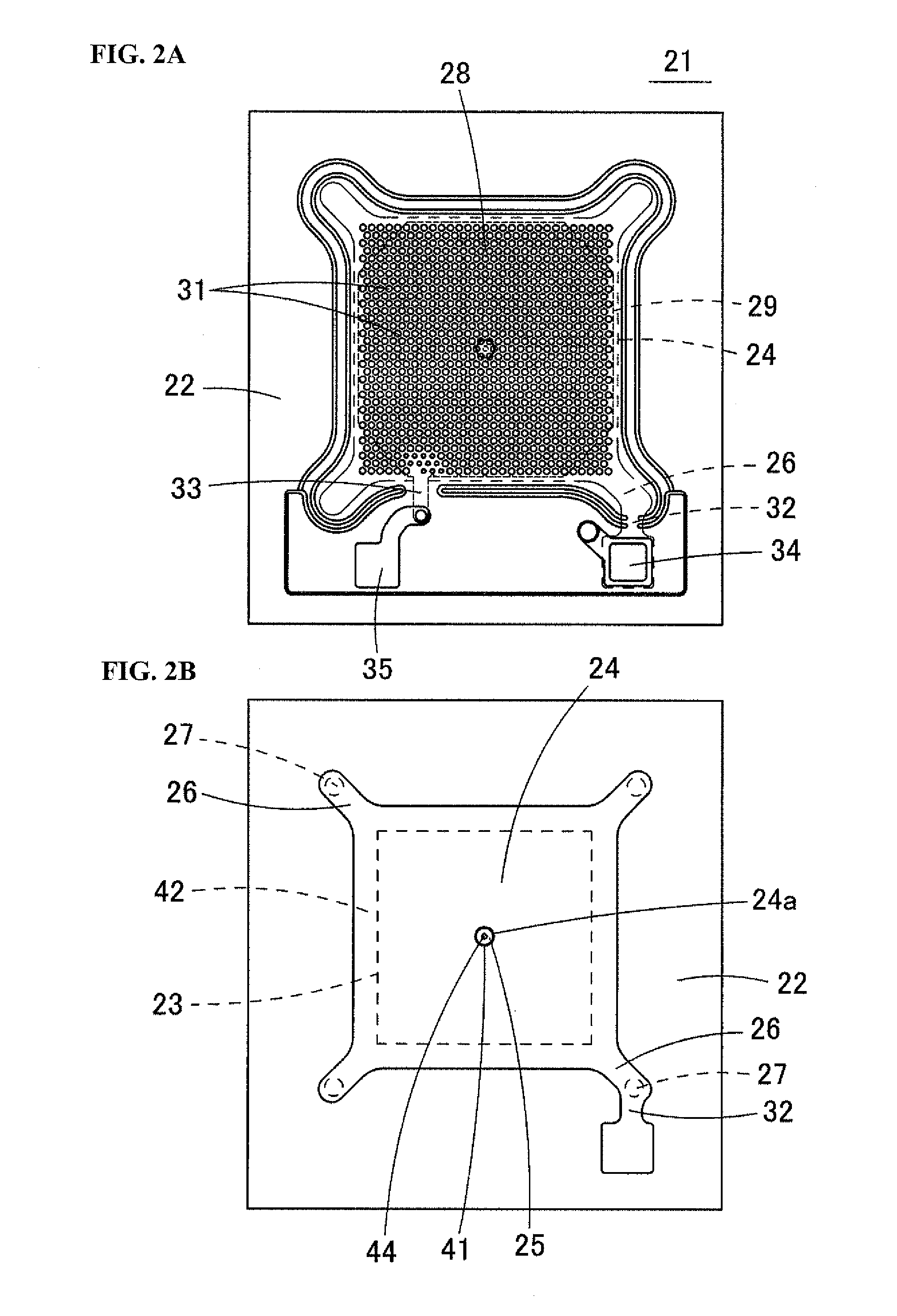

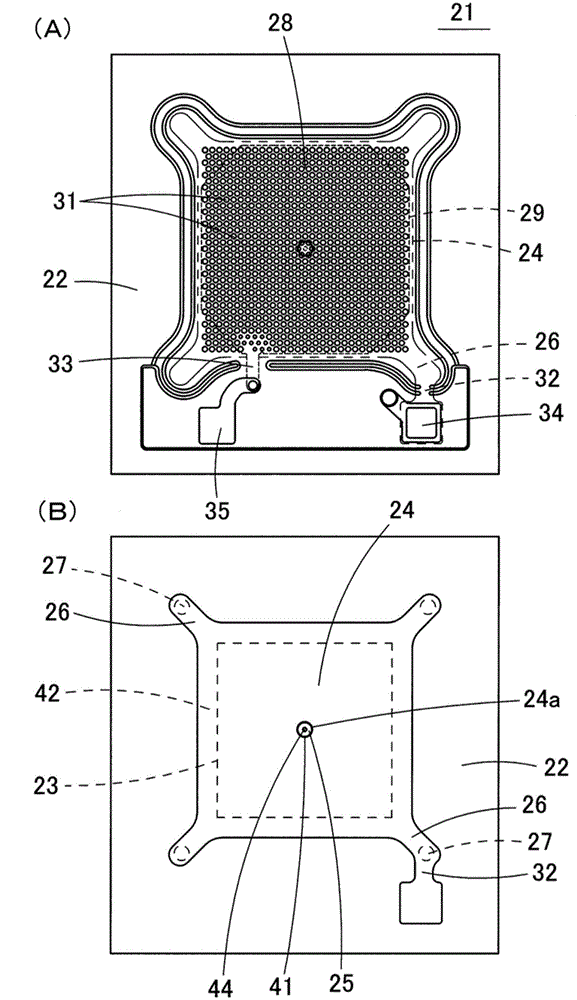

ActiveCN104469578ASemiconductor electrostatic transducersSolid-state devicesVibrating membraneStress concentration

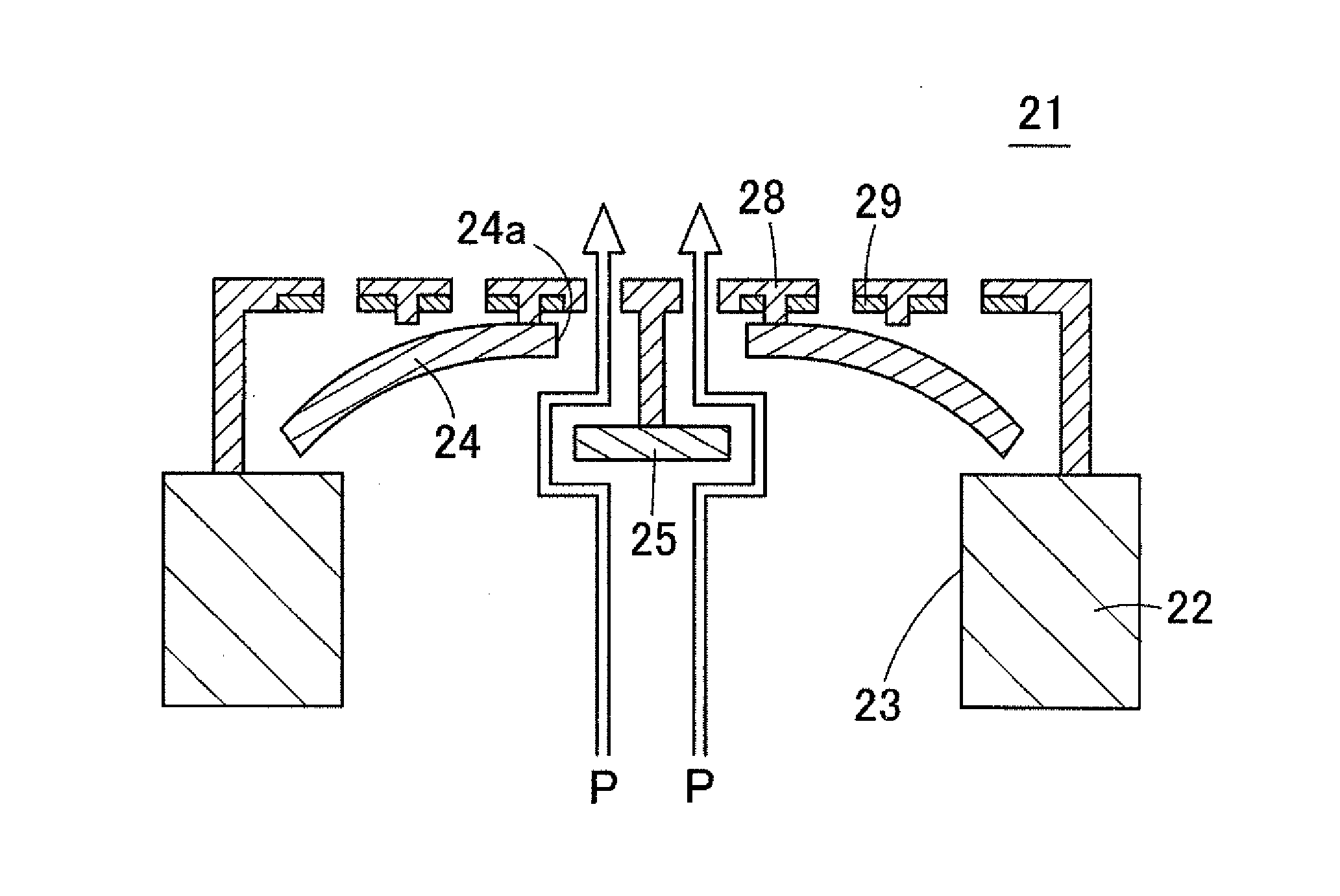

The invention provides an acoustic transducer and a microphone. By keeping the frequency characteristics, a vibrating electrode plate, to which high air pressured is applied, is prevented from displacement (deformation), and an electrostatic volumetric type acoustic transducer and the like are prevented from stress concentration or electrode plates are prevented from being damaged. A substrate (22) has a cavity (23) that penetrates up and down. A vibrating membrane (24) is arranged on the substrate (22) to cover the top opening of the cavity (23). A dome-shaped backboard (28) is arranged on the substrate (22) to cover the vibrating membrane (24). A fixed electrode plate (29), opposite to the vibrating membrane (24), is disposed below the backboard (28). The backboard (28) and the fixed electrode plate (29) are equipped with multiple acoustic holes (31). An opening (24a) is disposed in the center of the vibrating membrane (24), and an adjusting portion (25) is configured in the opening (24a). The adjusting portion (25) is supported by a supporting portion (44) that extends downwards under the backboard (28).

Owner:MMI SEMICON CO LTD

Acoustic transducer and microphone

ActiveUS9549263B2Avoid deformationPrevent leakageSemiconductor electrostatic transducersSolid-state devicesTransducerVibrating electrode

An acoustic transducer has a substrate having a cavity, a vibrating electrode plate disposed above the substrate and having a void portion that allows pressure to escape, a fixed electrode plate disposed above the substrate opposite the vibrating electrode plate, a plurality of sensing portions configured by the vibrating electrode plate and the fixed electrode plate, at least one of the vibrating electrode plate and the fixed electrode plate being divided into a plurality of regions, and a sensing portion being configured by the vibrating electrode plate and the fixed electrode plate in each of the divided regions, and a leak pressure regulation portion that hinders leakage of air pressure passing through the void portion when the vibrating electrode plate is not undergoing deformation.

Owner:MMI SEMICON CO LTD

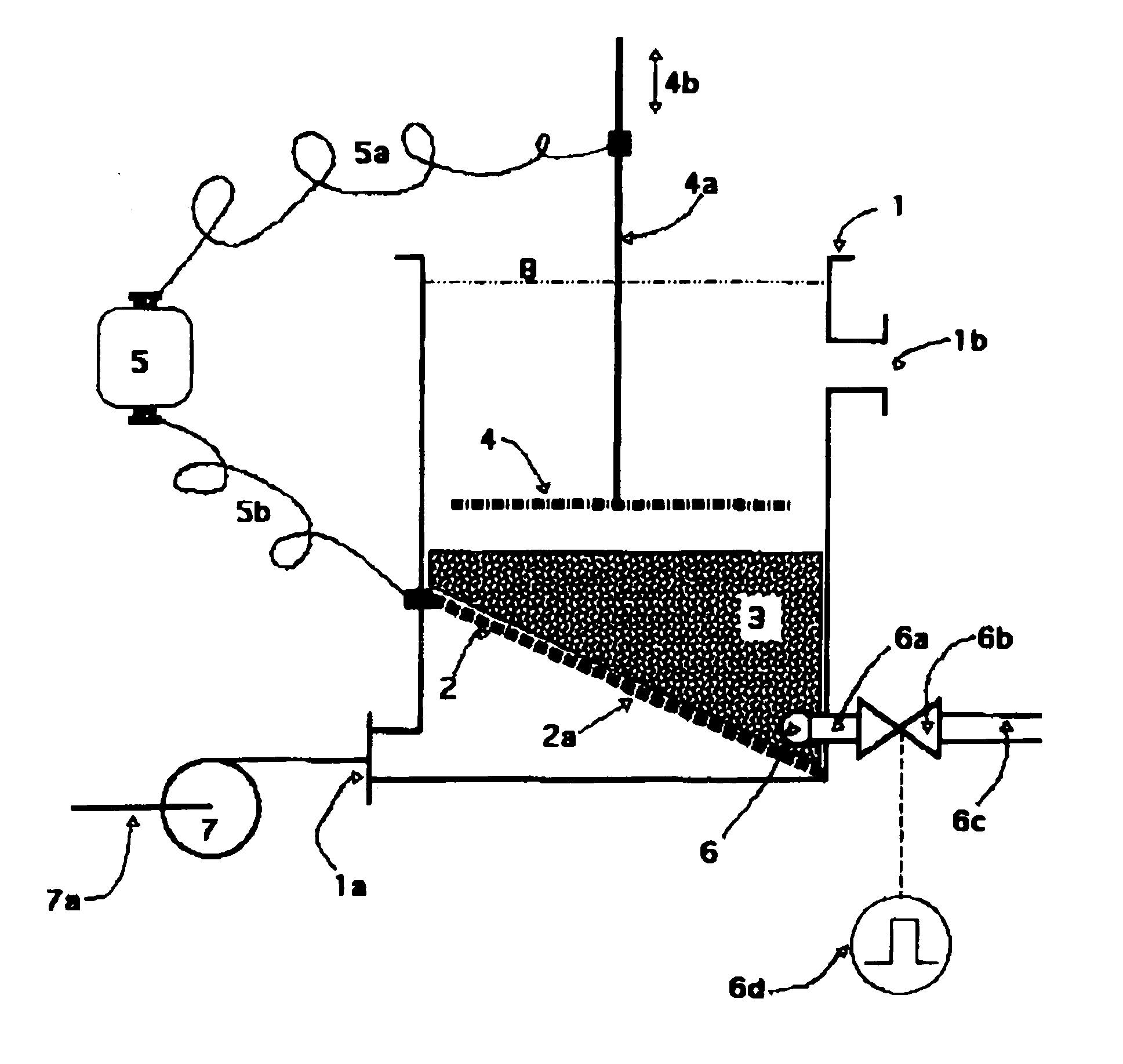

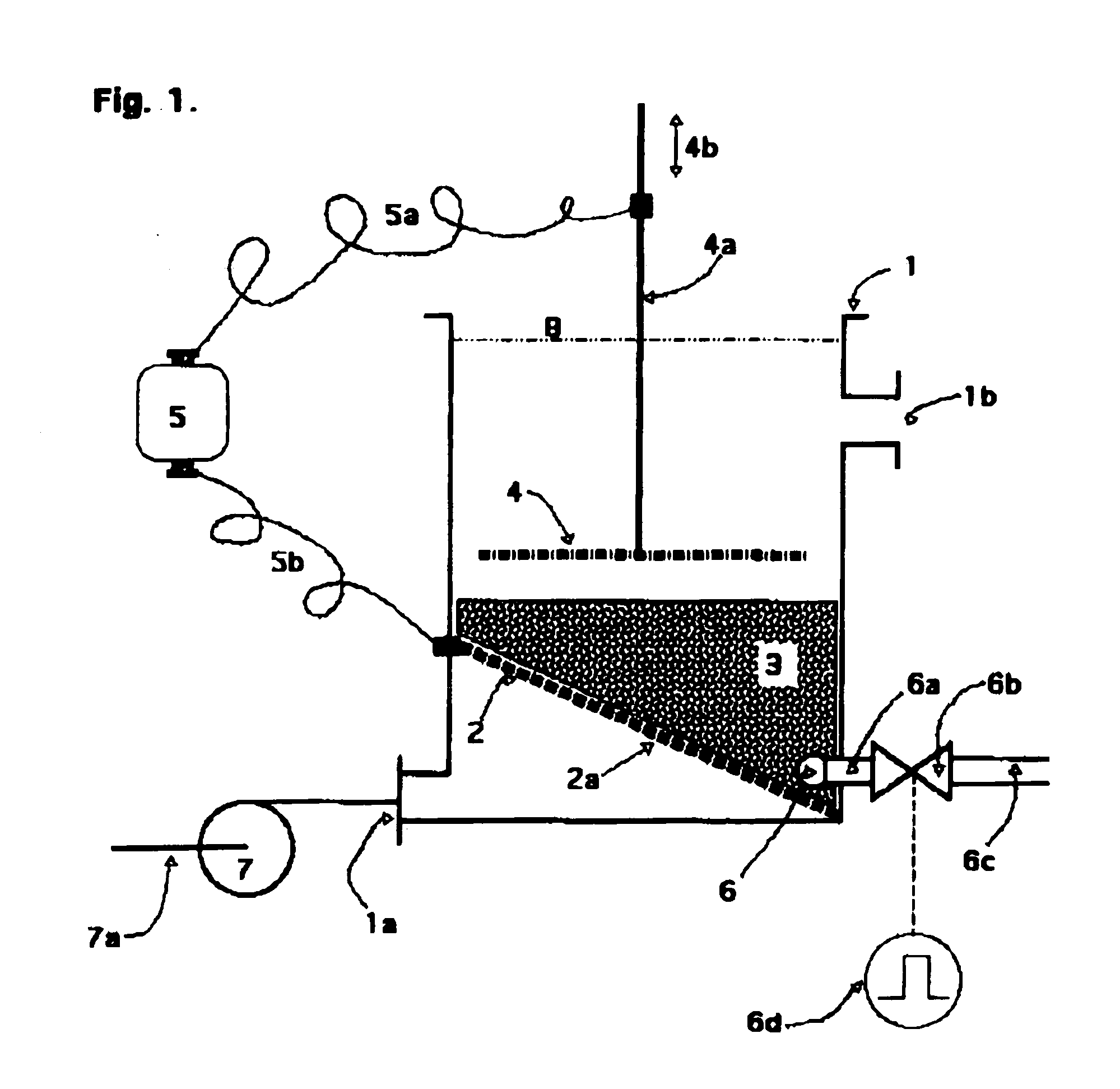

Moving electrode electroflocculation process

InactiveUS20100326841A1Minimize build-upMinimal energy requirementCellsWater/sewage treatment apparatusElectricityFluidized bed

The present invention provides a high volume, foul-resistant electrolytic process for treating contaminated water comprising at least one upflow electroflocculation cell consisting of (i) a lower (or “bottom”) electrode (3) in form of a porous, non-fluidized bed of loose iron or aluminium granules kept in periodic motion by pulsed gas injections and (ii) an upper (or “top”) vibrating electrode (4) made of an iron or aluminium grid mesh or ribmesh. A voltage potential between the upper (4) and lower (3) electrode causes ions to be released from the moving electrodes. These ions oxydise and / or render insoluble contaminants in the ascending flow of wastewater and create easy filterable insoluble contaminants resulting in substantially cleansed water. Such moving electrodes electroflocculation cells are useful at municipal water works and commercial and industrial applications were large amounts of raw water have to be processed.

Owner:JULIUS BLUM GMBH

Capacitor microphone

InactiveUS8059842B2High sensitivityPiezoelectric/electrostrictive microphonesSemiconductor electrostatic transducersCapacitanceEngineering

A capacitor microphone is constituted by a plate having a fixed electrode, a diaphragm including a center portion and at least one near-end portion that is fixed to the outer periphery, in which the center portion having a vibrating electrode, which is positioned relative to the fixed electrode and which vibrates in response to sound waves, is increased in rigidity in comparison with the near-end portion; and a spacer that is fixed to the plate and the near-end portion of the diaphragm and that has an air gap formed between the plate and the diaphragm. Alternatively, a diaphragm electrode is horizontally supported by extension arms extended from a circular plate thereof and is vertically held in a hanging state being apart from a fixed electrode with a controlled distance therebetween.

Owner:YAMAHA CORP

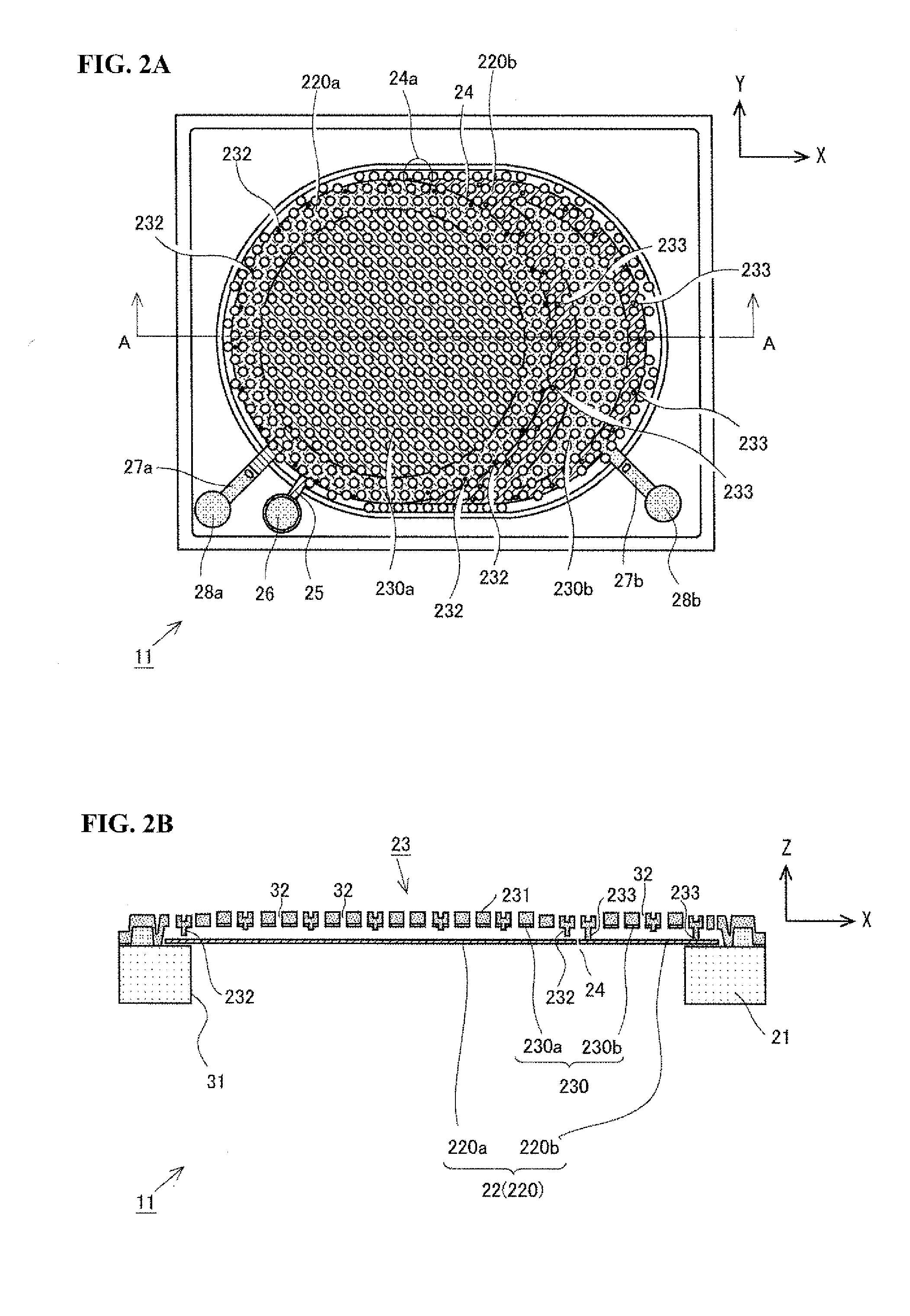

Acoustic transducer and microphone

ActiveUS20150078591A1Improve acoustic propertiesWide dynamic rangeTransducer detailsSemiconductor electrostatic transducersCapacitanceTransducer

An acoustic transducer has a vibrating film and a fixed film formed above an opening portion of a substrate, and at least a first sensing portion and a second sensing portion that detect sound waves using change in capacitance between a vibrating electrode provided in the vibrating film and a fixed electrode provided in the fixed film, convert the sound waves into electrical signals, and output the electrical signals. In the first sensing portion and the second sensing portion, the fixed film is used in common, and the vibrating electrode is divided into a first sensing region and a second sensing region that respectively correspond to the first sensing portion and the second sensing portion. In the first sensing portion, a protrusion portion that protrudes toward the vibrating electrode is provided on a region of the fixed film that opposes the first sensing region.

Owner:MMI SEMICON CO LTD

Piezoelectric resonator, piezoelectric resonator component and method of making the same

InactiveUS6903489B2Minimized suppression of vibration energyFirm supportImpedence networksPiezoelectric/electrostriction/magnetostriction machinesVibrating electrodePiezoelectric resonators

A first vibrating electrode is provided on a first side of a piezoelectric substrate perpendicular to the thickness direction. A second vibrating electrode is provided on a second side opposite to the first side to face the first vibrating electrode. A first pad and a second pad are respectively formed on a side of the piezoelectric substrate perpendicular to the thickness direction in area having a small vibration displacement. The first pad and the second pad are electrically connected to the first vibrating electrode and the second vibrating electrode.

Owner:TDK CORPARATION

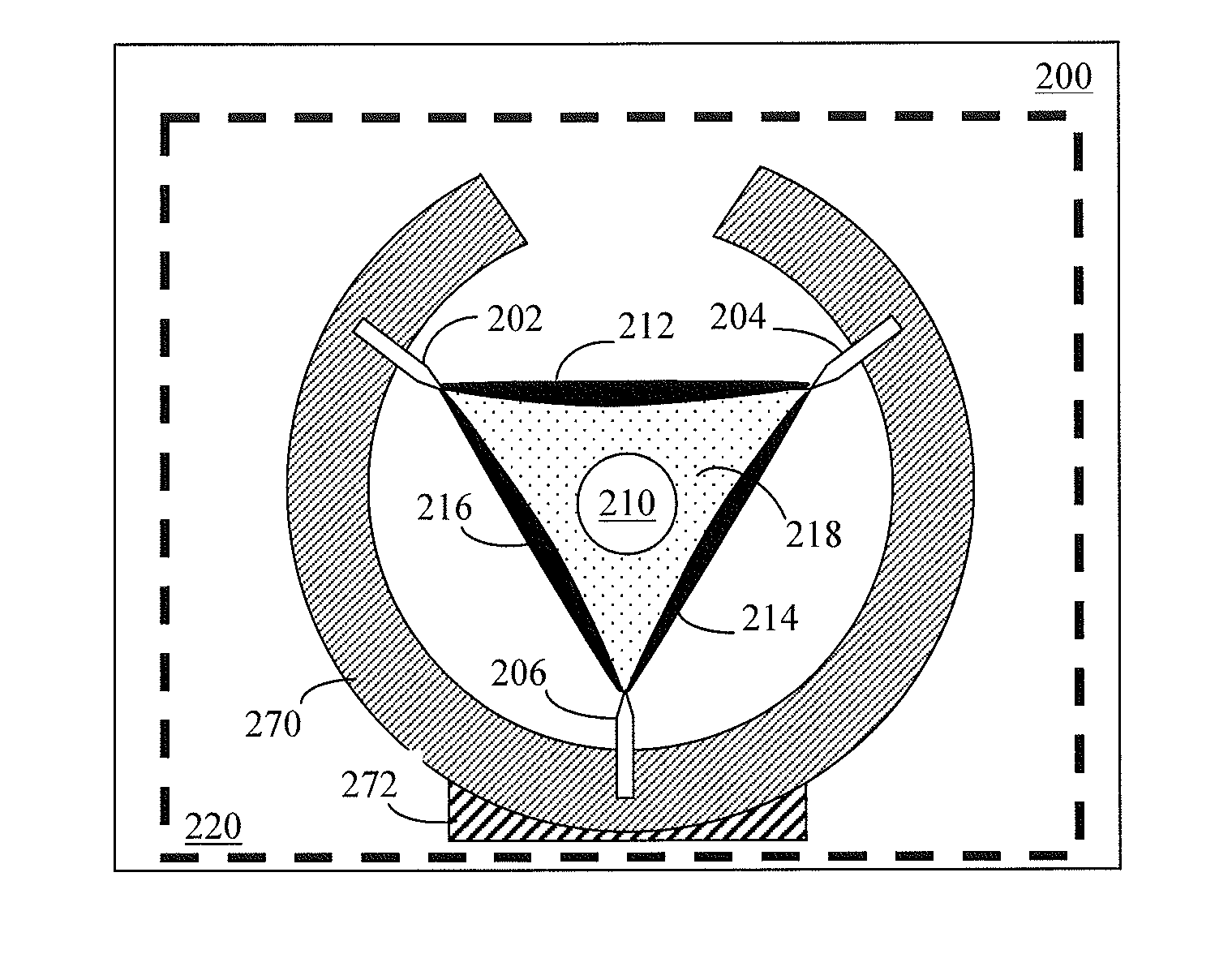

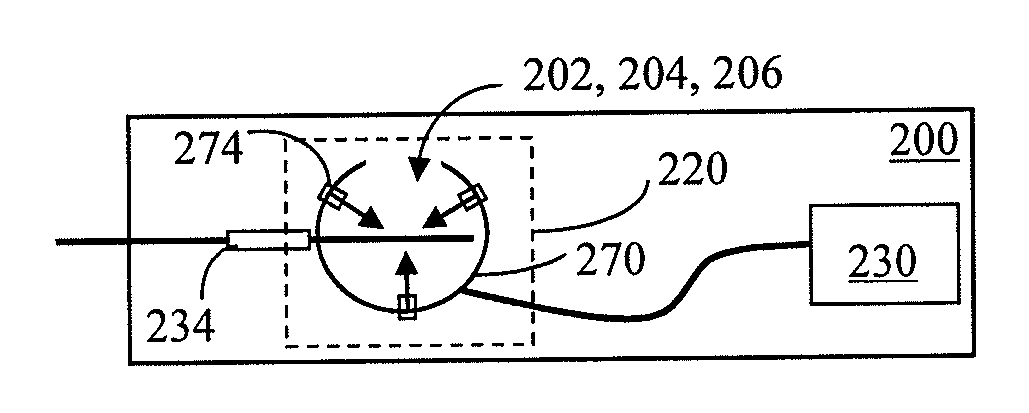

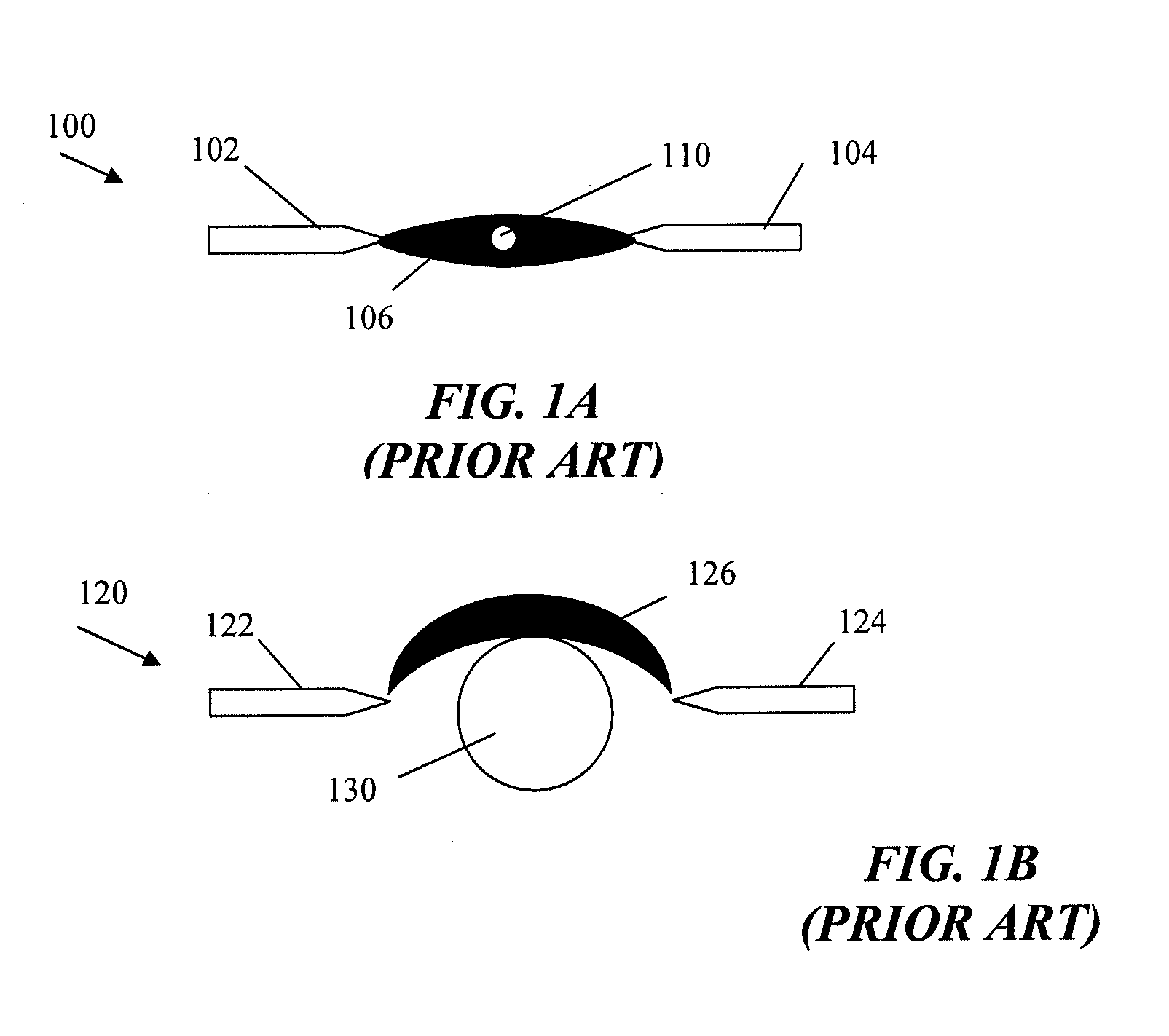

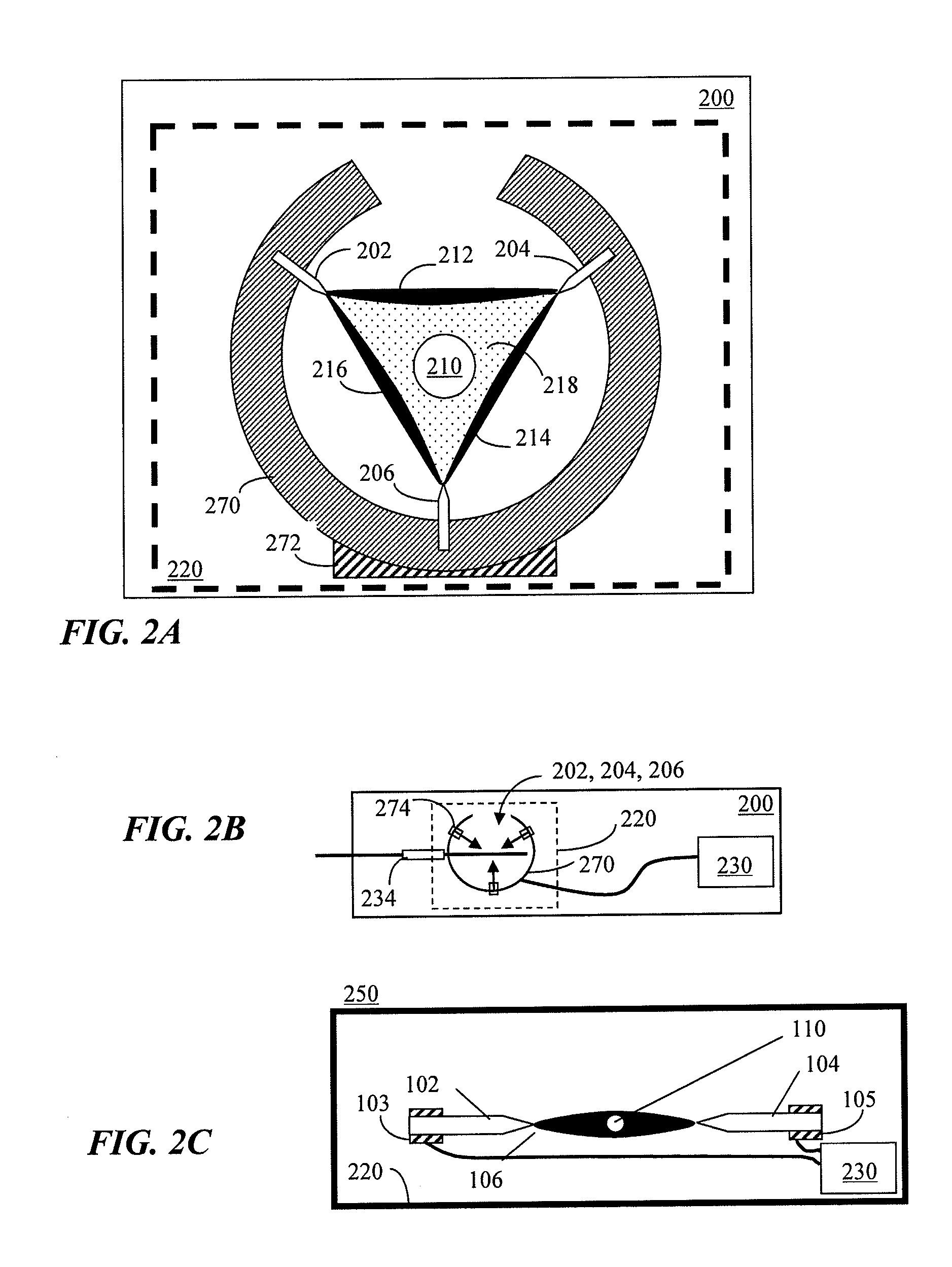

Multi-electrode system with vibrating electrodes

InactiveUS7985029B2Improve stabilityEnhanced isothermic rangeGlass furnace apparatusRotary drum furnacesFiberVibrating electrode

Owner:3SAE TECH

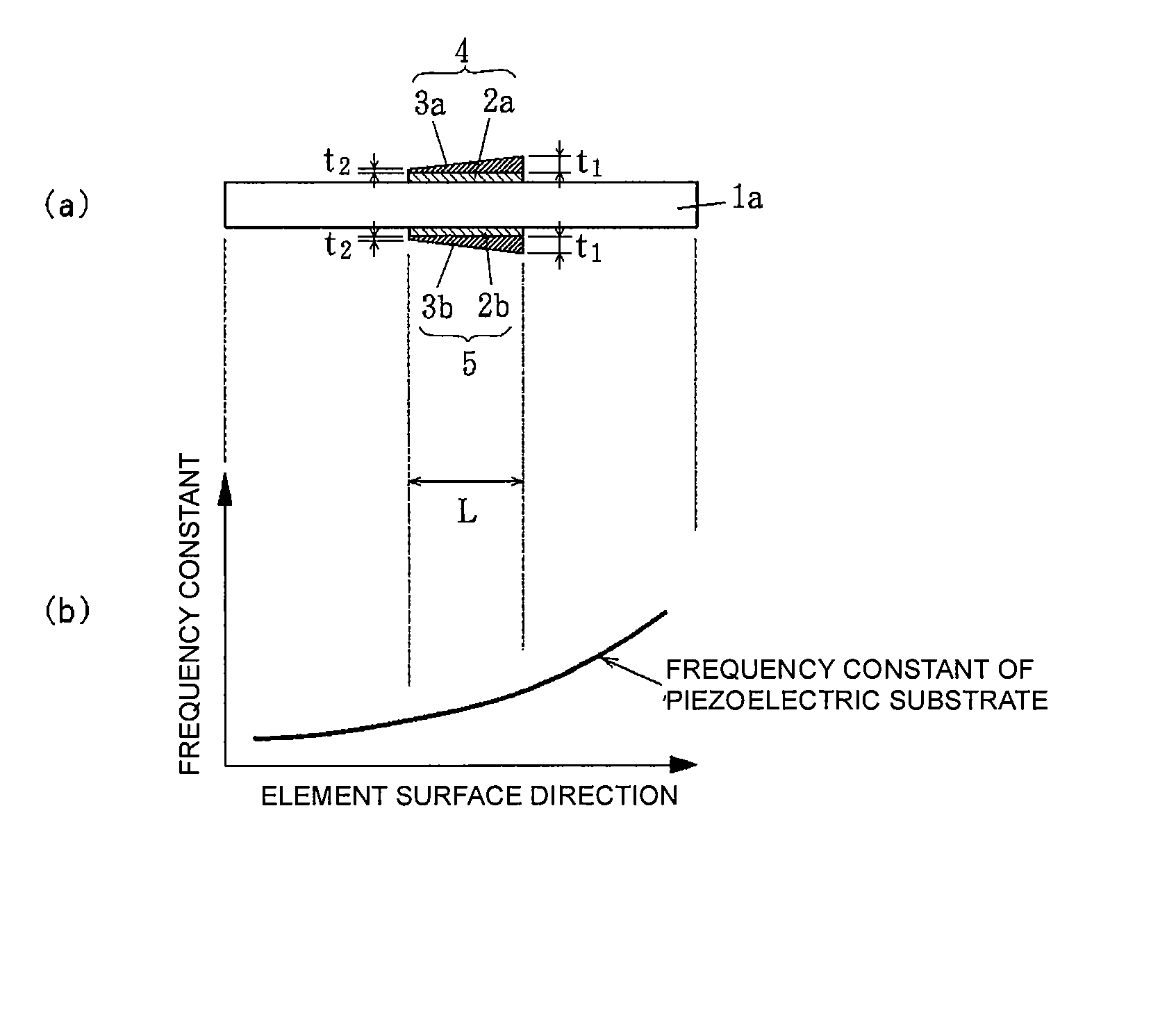

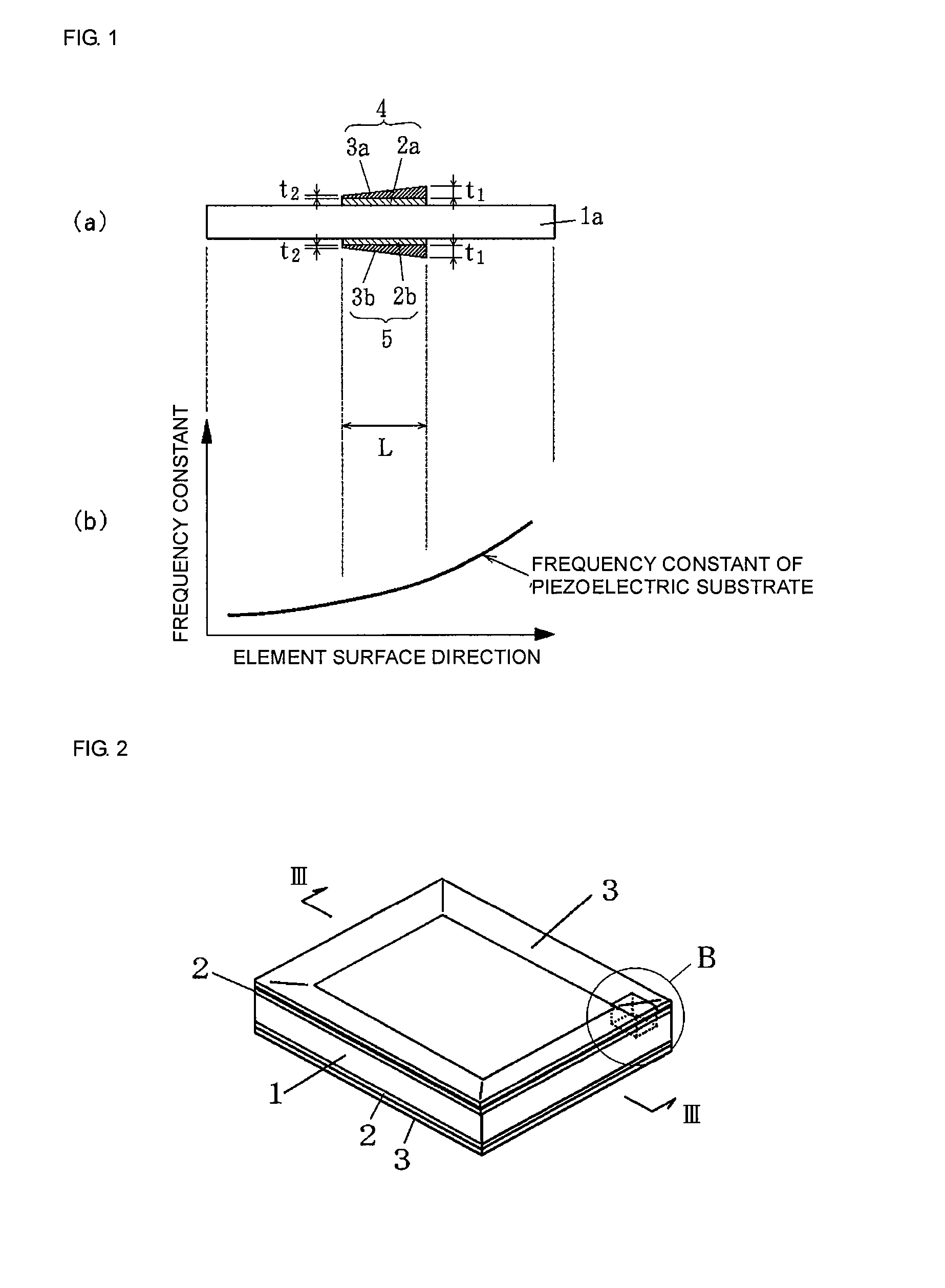

Piezoelectric Resonator and Method for Producing the Same

InactiveUS20080048527A1Accurate resonant frequencyReduce variationPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksVibrating electrodePiezoelectric resonators

To reduce frequency variations caused by a change in frequency constant and suppress unnecessary vibrations in the case where the frequency constant of a piezoelectric substrate has a gradient. A piezoelectric resonator has vibrating electrodes 4 and 5 facing each other, which are formed on two major surfaces of a piezoelectric substrate 1a, and trapped vibrations are generated between the two vibrating electrodes. The piezoelectric substrate 1a has a constant thickness. The frequency constant of the piezoelectric substrate 1a has a gradient in a surface direction. The vibrating electrodes 4 and 5 are formed to have a gradient thickness so that the thickness gradually increases as the frequency constant of the piezoelectric substrate increases. By forming the vibrating electrodes to have a gradient thickness, unnecessary in-band vibrations are suppressed, and frequency variations are reduced.

Owner:MURATA MFG CO LTD

Acoustic transducer and interface circuit

ActiveUS9380380B2Reduce variationSemiconductor electrostatic transducersElectrets selectrostatic transducerCapacitanceDigital interface

The present disclosure is directed to an acoustic transducer configured to detect a sound wave according to changes in capacitances between a vibrating electrode and a fixed electrode. At least one of the vibrating electrode and the fixed electrode being divided into a plurality of divided electrodes, and the plurality of divided electrodes outputting electrical signals. The disclosure includes a digital interface circuit coupled to the divided electrodes. The circuit includes a recombination stage, which supplies a mixed signal by combining the first digital processed signal and the second digital processed signal with a respective weight that is a function of a first level value of the first processed signal. An output stage is included, which supplies, selectively and alternatively, a first processed signal, a second processed signal, or a mixed signal.

Owner:ORMON CORP +1

Electrostatic induction generator

Owner:SANYO ELECTRIC CO LTD

Acoustic transducer and microphone

ActiveUS9374644B2Suppress internal stressImprove acoustic propertiesSemiconductor electrostatic transducersElectrostatic transducer microphonesCapacitanceTransducer

An acoustic transducer has a vibrating film and a fixed film formed above an opening portion of a substrate, and at least a first sensing portion and a second sensing portion that detect sound waves using change in capacitance between a vibrating electrode provided in the vibrating film and a fixed electrode provided in the fixed film, convert the sound waves into electrical signals, and output the electrical signals. In the first sensing portion and the second sensing portion, the fixed film is used in common, and the vibrating electrode is divided into a first sensing region and a second sensing region that respectively correspond to the first sensing portion and the second sensing portion. In the first sensing portion, a protrusion portion that protrudes toward the vibrating electrode is provided on a region of the fixed film that opposes the first sensing region.

Owner:MMI SEMICON CO LTD

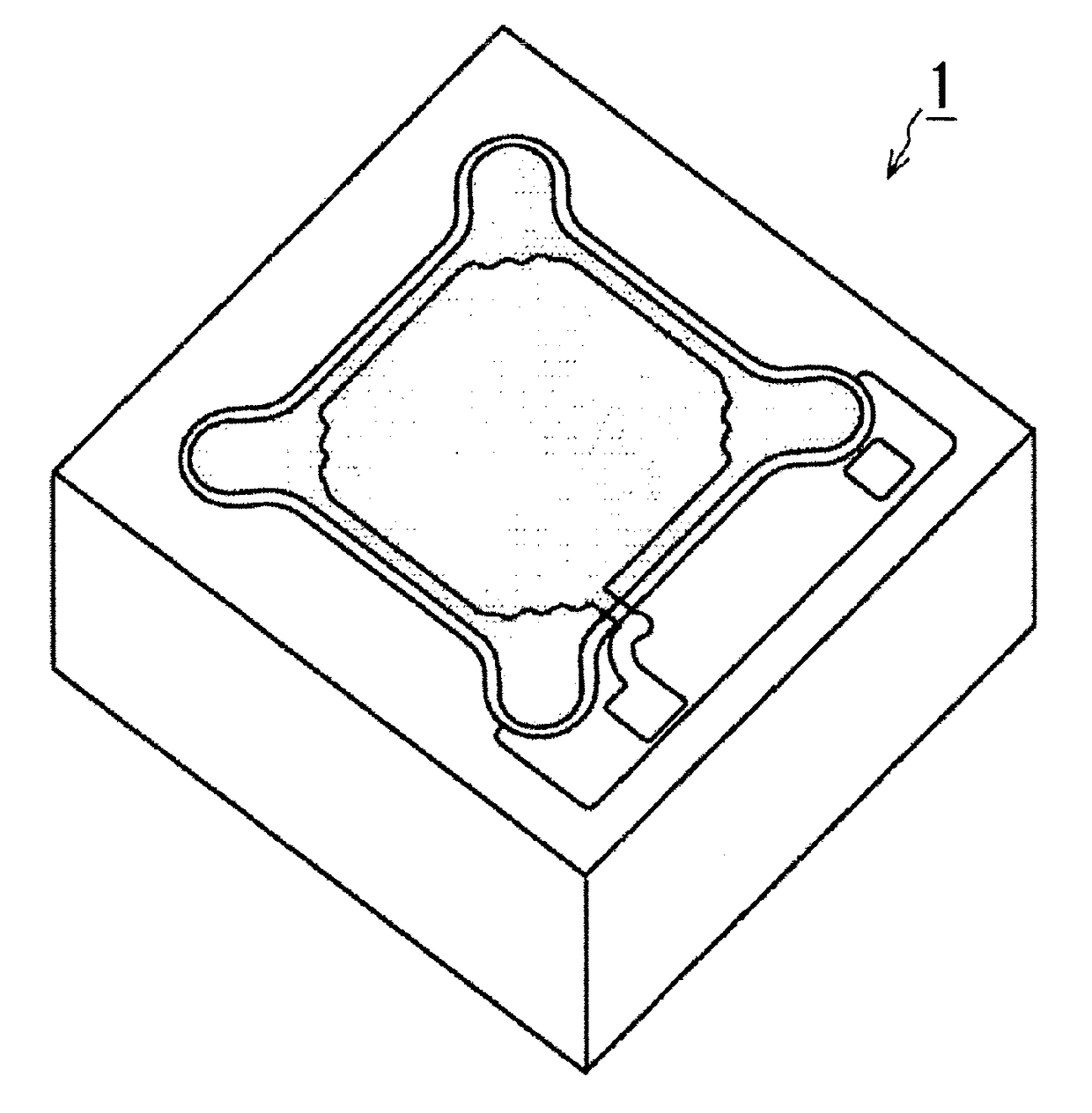

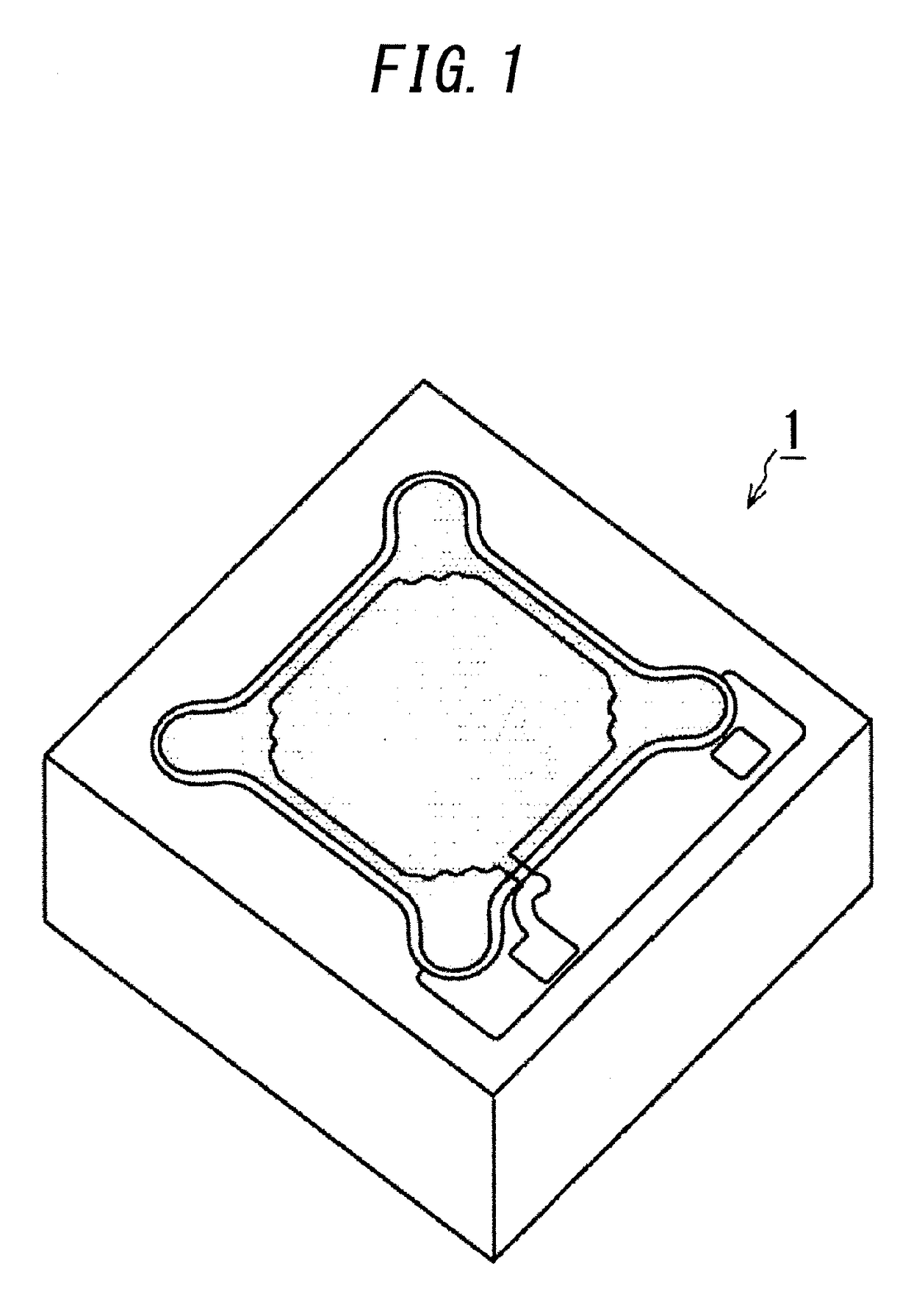

Capacitance type transducer and acoustic sensor

ActiveUS20170289702A1Prevent excessive deformationImprove frequency characteristicsDecorative surface effectsSemiconductor electrostatic transducersCapacitanceTransducer

A capacitance type transducer has a substrate with an opening on a surface thereof, a back plate arranged to oppose the opening of the substrate, and a vibrating electrode film arranged to oppose the back plate across a gap between the vibrating electrode film and the back plate. The capacitance type transducer converts a displacement of the vibrating electrode film into a change in capacitance between the vibrating electrode film and the back plate. The capacitance type transducer has a pressure releasing flow channel which is an air flow channel formed by a gap between a part of the vibrating electrode film and a protruding portion integrally provided on the back plate.

Owner:MMI SEMICON CO LTD

Multi-electrode system with vibrating electrodes

ActiveUS20110277511A1Improve stabilityEnhanced isothermic rangeGlass making apparatusRotary drum furnacesFiberVibrating electrode

A multi-electrode system includes a fiber holder that holds at least one optical fiber, a plurality of electrodes arranged to generate a heated field to heat the at least one optical fiber, and a vibration mechanism that causes at least one of the electrodes from the plurality of electrodes to vibrate. The electrodes can be disposed in at least a partial vacuum. The system can be used for processing many types of fibers, such processing including, as examples, stripping, splicing, annealing, tapering, and so on. Corresponding fiber processing methods are also provided.

Owner:3SAE TECH

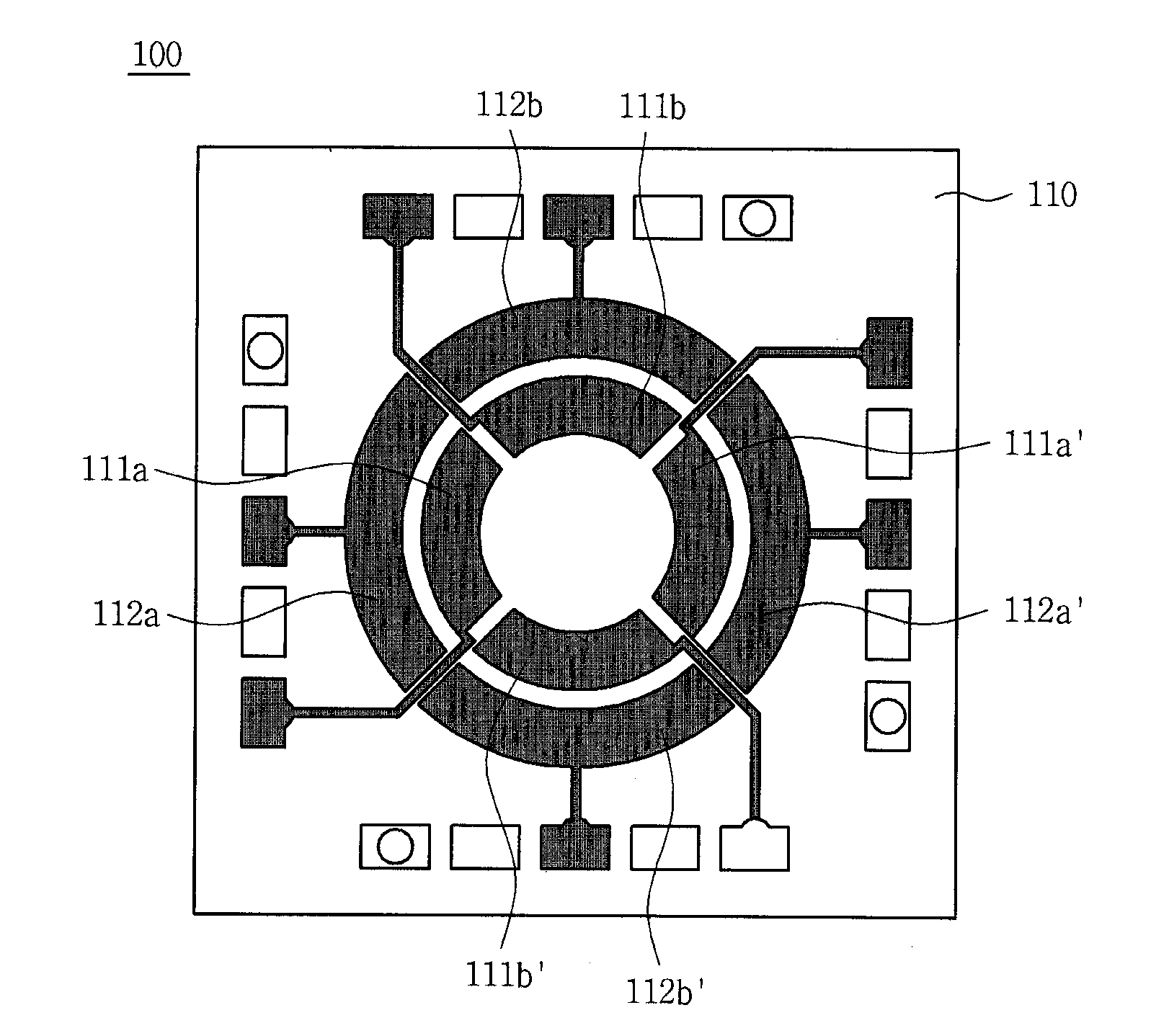

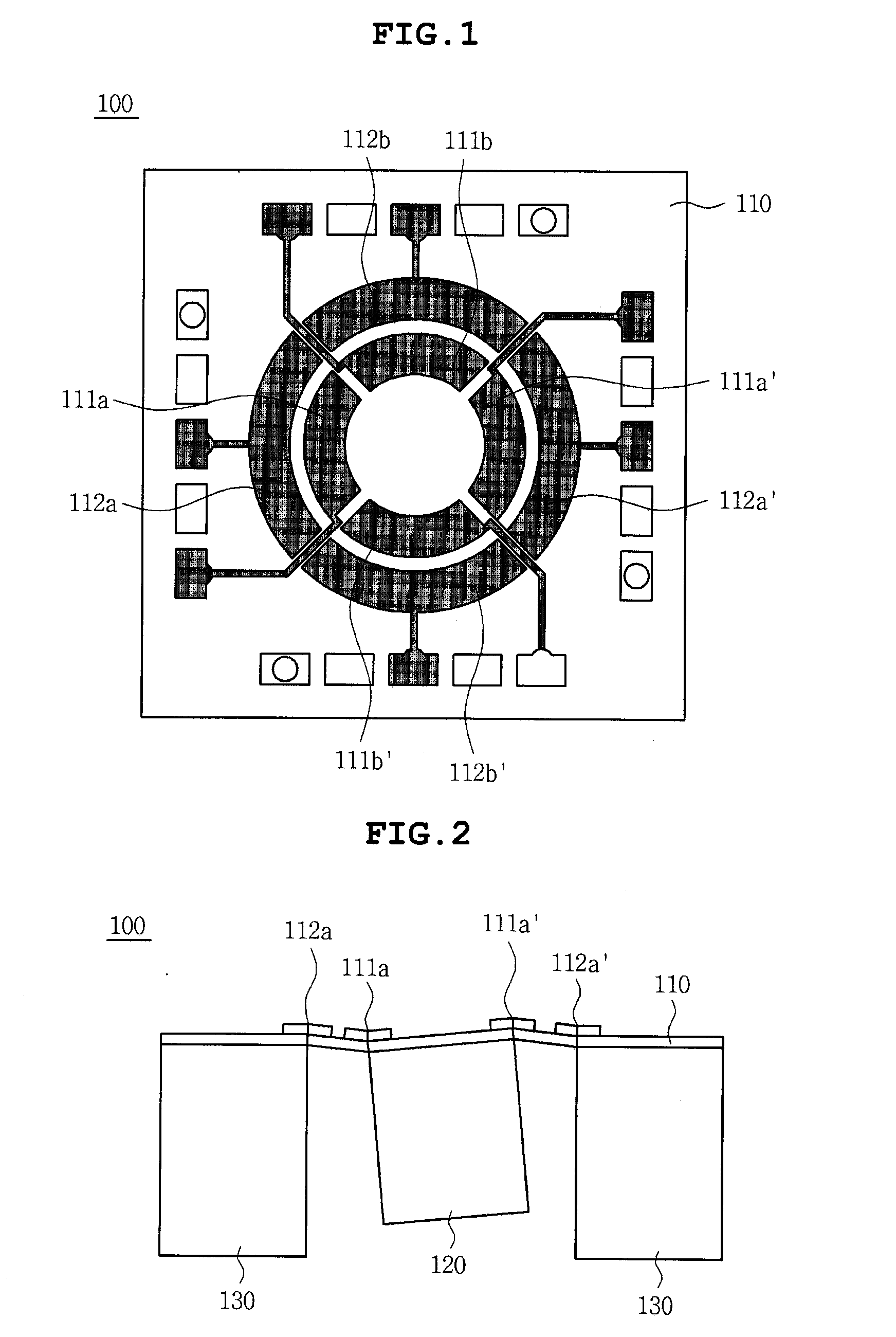

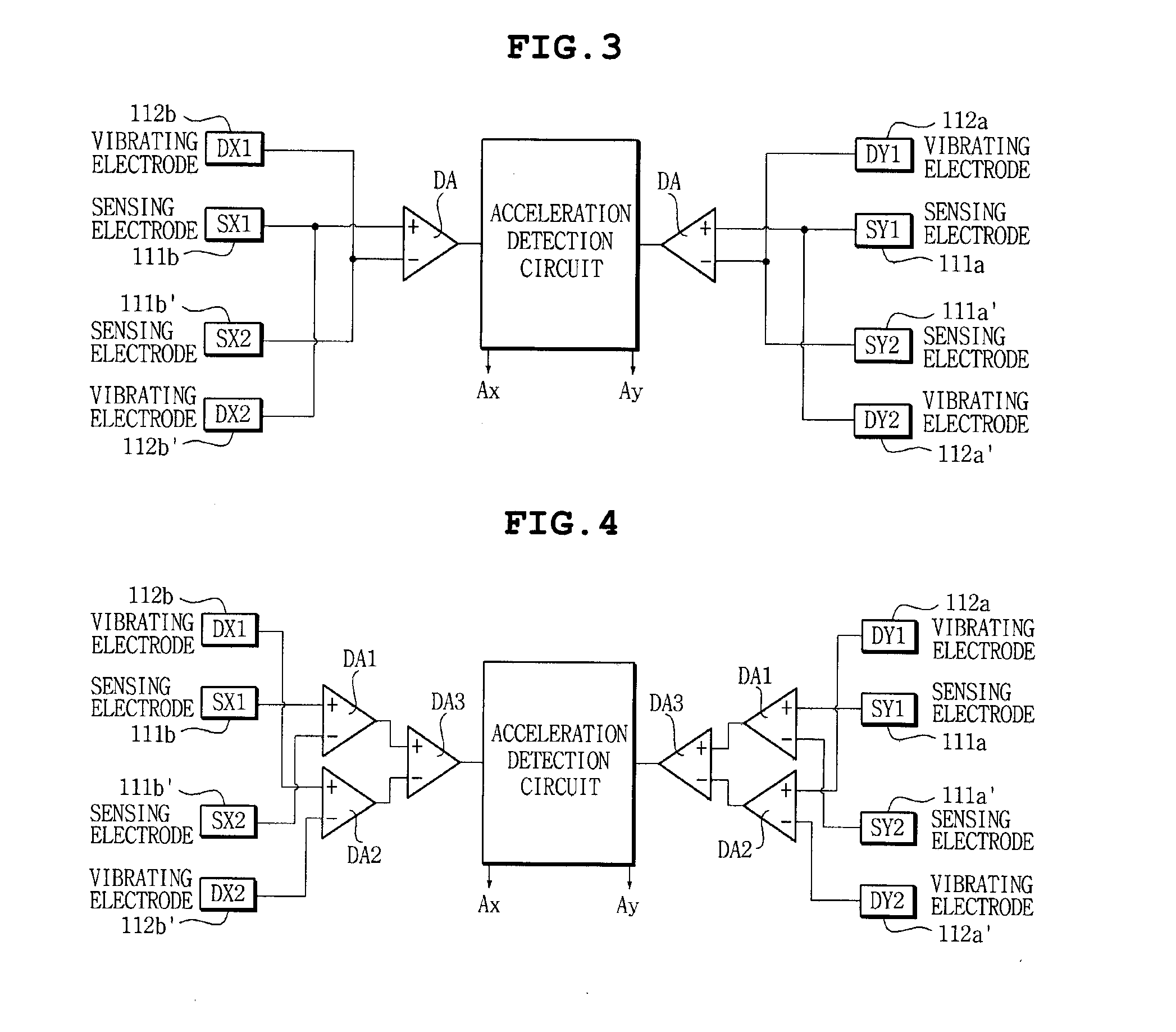

Inertial sensor

InactiveUS20120227488A1High sensitivityAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsAngular velocityDifferential amplifier

Disclosed herein is an inertial sensor including: a driving body displaceably supported on a flexible substrate part in a floating state; a displacement detection unit having a sensing electrode detecting displacement of the driving body; a vibrating part having a vibrating electrode vibrating the driving body; a differential amplifier connected to the sensing electrode and the vibrating electrode, and a circuit unit connected to the differential amplifier to calculate acceleration and angular velocity, wherein the acceleration is calculated by using the sensing electrode and the vibrating electrode.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

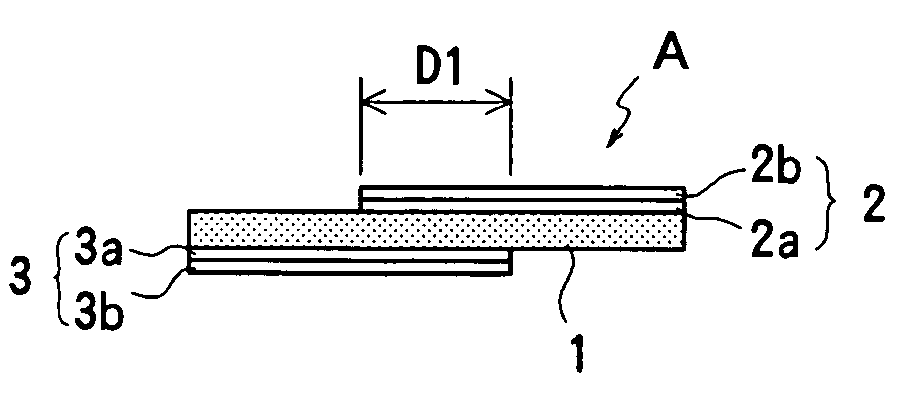

Method for manufacturing piezoelectric resonator

ActiveUS20060048358A1Easy to adjustImprove frequency measurement accuracyPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyVibrating electrodePiezoelectric resonators

A method of manufacturing a piezoelectric resonator includes forming first electrodes larger than vibrating electrodes in an area D1 including the vibrating electrodes on obverse and reverse surfaces of a piezoelectric substrate, and measuring the resonant frequency fr1 of a resonator including the first electrodes. The thickness of a metallic thin film required for frequency adjustment is determined based on the measured resonant frequency. Then, second electrodes formed of the metallic thin film having the determined thickness are formed in an area D2 including at least the vibrating electrodes of the piezoelectric substrate. By removing unnecessary portions of the first and second electrodes, a pattern of the resulting vibrating electrodes is formed. Thus, high-accuracy frequency adjustment can be achieved without the need for complicated positioning.

Owner:MURATA MFG CO LTD

Acoustic transducer and microphone

ActiveUS9544697B2Avoid deformationPrevent leakageSemiconductor electrostatic transducersSolid-state devicesTransducerEngineering

An acoustic transducer has a substrate having a cavity, a vibrating electrode plate disposed above the substrate and having a void portion that allows pressure to escape, a fixed electrode plate disposed above the substrate opposite the vibrating electrode plate, and a leak pressure regulation portion that hinders leakage of air pressure by passing through the void portion when the vibrating electrode plate is not undergoing deformation, and that becomes separated from the void portion and allows pressure to escape by passing through the void portion when the vibrating electrode plate undergoes deformation from being subjected to pressure.

Owner:MMI SEMICON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com