Capacitor microphone

A microphone and capacitor technology, applied in the field of capacitor microphones using semiconductor diaphragms, can solve the problems of inconsistent deformation of the central part of the diaphragm, vibration interference of diaphragm electrodes, uneven air gaps, etc., to achieve uniform gaps, increase bias, and improve sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

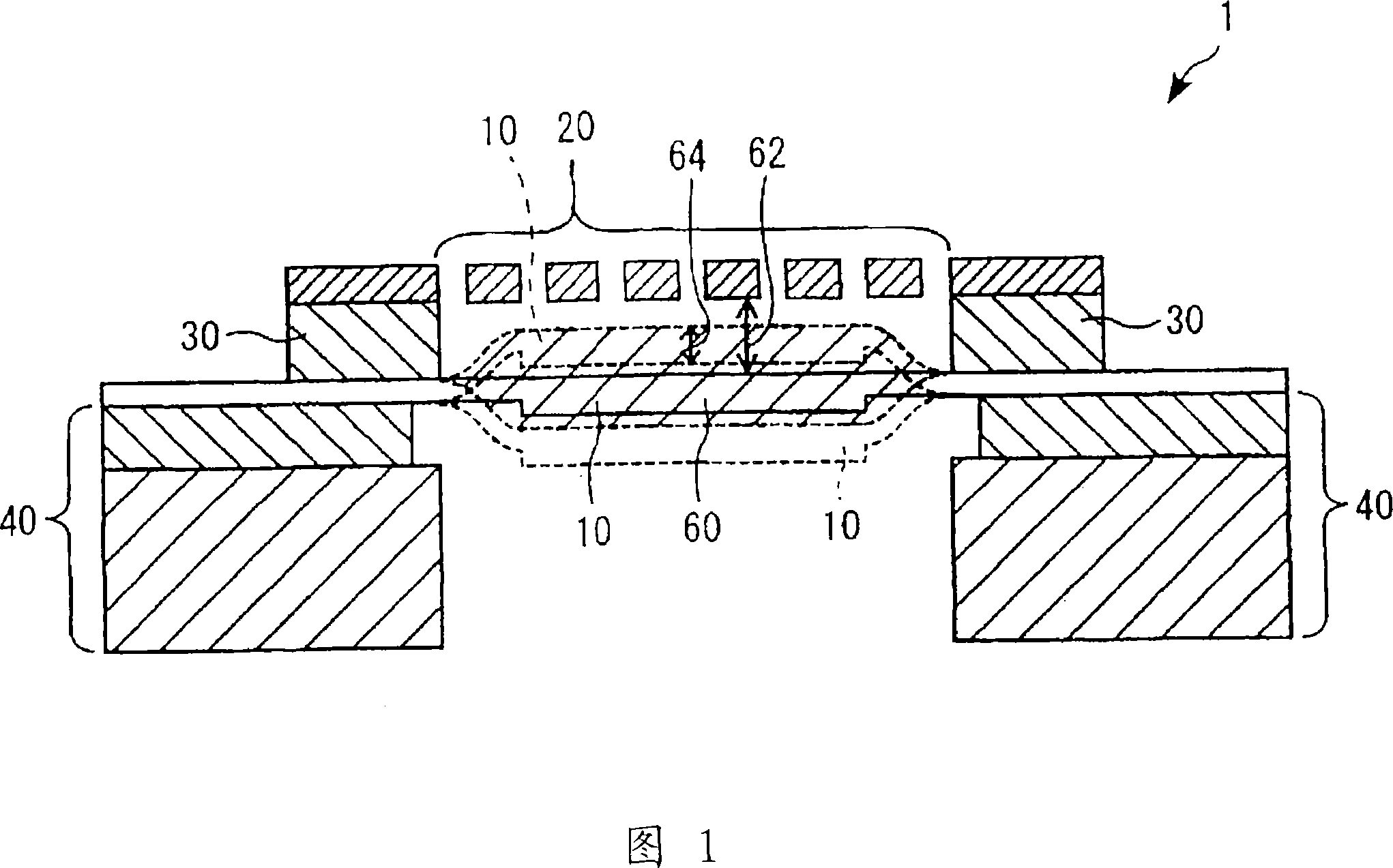

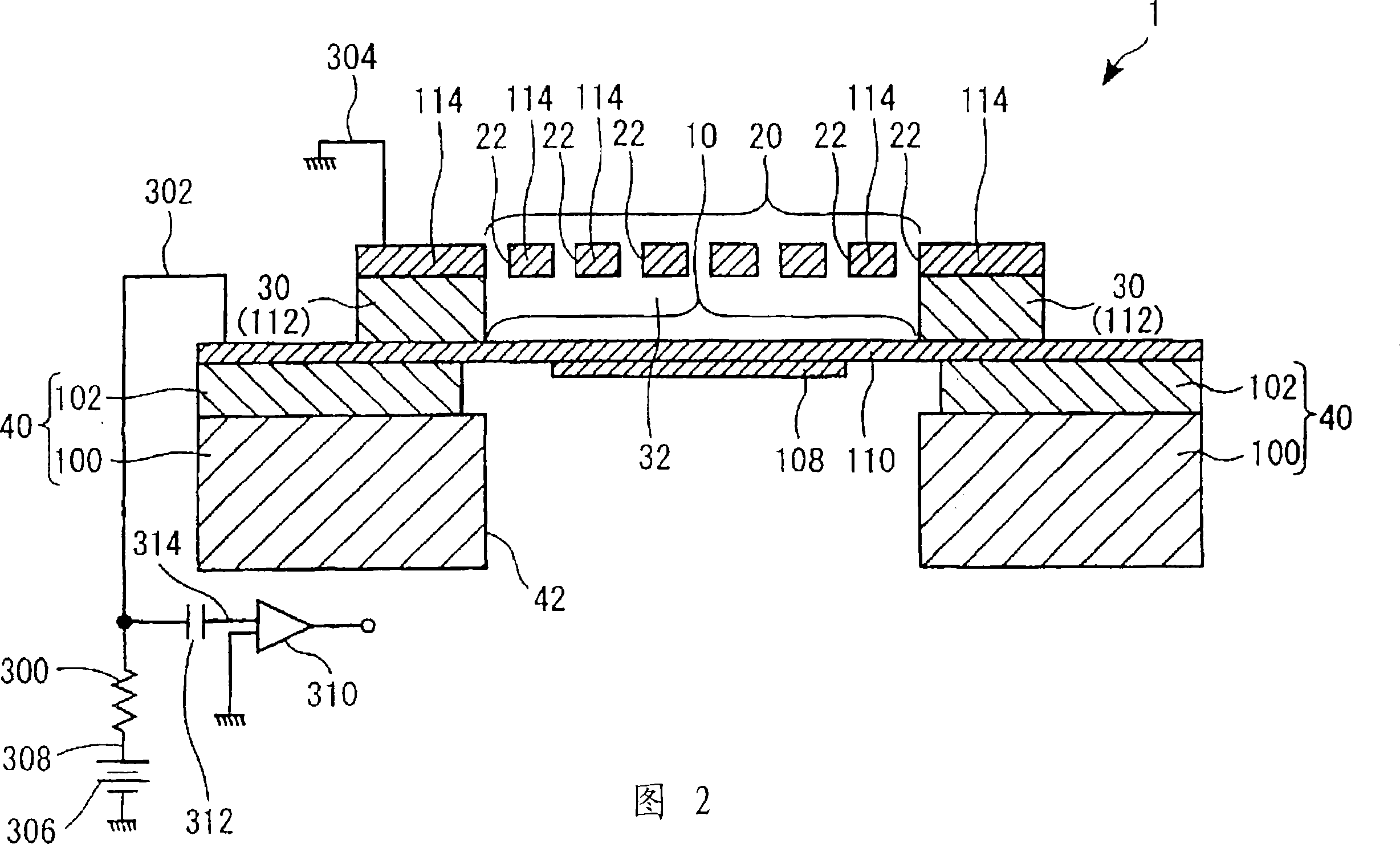

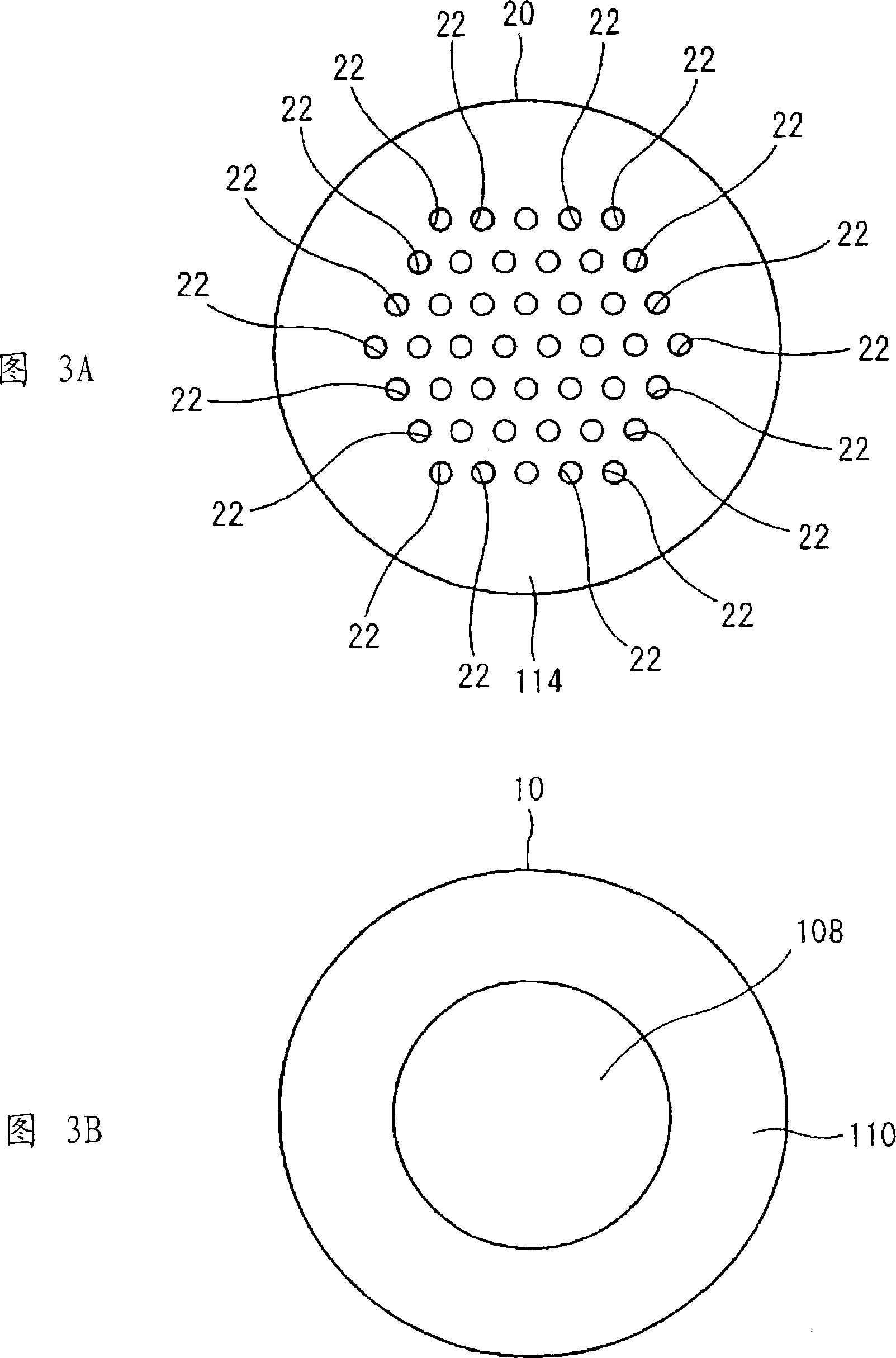

[0105] The general structure of the condenser microphone according to the first embodiment of the present invention will be described with reference to FIGS. 2 and 3A and 3B. 2 is a cross-sectional view schematically showing the structure of the condenser microphone 1; FIG. 3A is a top view of a back plate 20 included in the condenser microphone 1;

[0106] The condenser microphone 1 is called a "silicon microphone", which is produced using a semiconductor manufacturing process. As shown in FIG. 2, the condenser microphone 1 includes a sound sensing section and a detection section realized by a circuit.

[0107] (a) Structure of the sound sensing part

[0108] As shown in FIG. 2 , the acoustic sensing part of the capacitor sensor 1 includes the above-mentioned diaphragm 10 and back plate 20 , as well as a spacer 30 and a bottom 40 .

[0109] Separator 10 includes a designated portion (hereinafter referred to as non-fixed portion of conductive film 110 ) and insulating film 1...

no. 3 example

[0152] Next, a condenser microphone 3 in a third embodiment of the present invention will be described with reference to FIGS. 11A and 11B . Wherein, the central portion 14 of the diaphragm 11 has a double-layer structure including the conductive film 23 and the conductive film 110 . The conductive film 110 serves as a reinforcing film that reinforces the rigidity of the central portion 14 of the diaphragm 11 , and is formed to cover the entire central portion 14 . A plurality of proximal portions 15 are formed in the diaphragm 11 by using the conductive film 110, where they function as a bridge structure connecting the central portion 14 and the spacer 30 to each other. Each proximal portion 15 is bent and folded in a zigzag fashion to act as a spring. For this reason, the stiffness of the proximal portion 15 is significantly reduced compared to the stiffness of the central portion 14 , thereby ensuring that deformations of the diaphragm 11 that propagate the sound waves mus...

no. 4 example

[0155] 12A and 12B show a condenser microphone 4 according to a fourth embodiment of the present invention. The fourth embodiment is characterized in that a ring-shaped conductive film 24 is formed around the central portion 116 of the diaphragm 12, whereby the rigidity of the diaphragm 12 is increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com