Patents

Literature

117results about How to "Improve dipping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

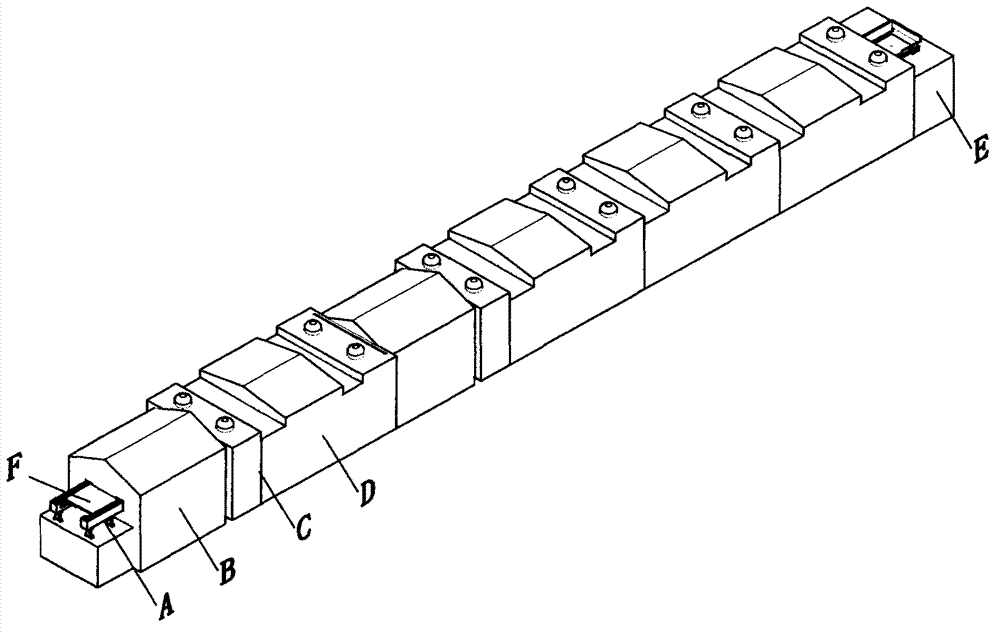

Paint immersing method of stator of outdoor open-type motor

ActiveCN101707423AIncrease the amount of remnantsImprove the dipping effectManufacturing dynamo-electric machinesChemistryLacquer

The invention provides a paint immersing method of a stator outdoor of an open-type motor, which is characterized by comprising the steps of: firstly, potting the end part of one end of the stator subject to primary vacuum paint immersion (VPI) with a potting adhesive, and then overturning, wherein a semi-closed surface is formed at the end part of the potting adhesive and immersion paint on the surface of the stator; and secondly, carrying out secondary paint immersion, wherein since the potting adhesive at the lower end exists, the immersion paint can not be lost because of the gravity during the secondary paint immersion, which not only can obviously increase the remain amount of paint in a stator slot and remarkably enhancing the paint immersion effect, and can lead the motor to operate more safely and reliably. The invention has broader application range, and is especially suitable for the outdoor open-type motor.

Owner:XINJIANG GOLDWIND SCI & TECH +1

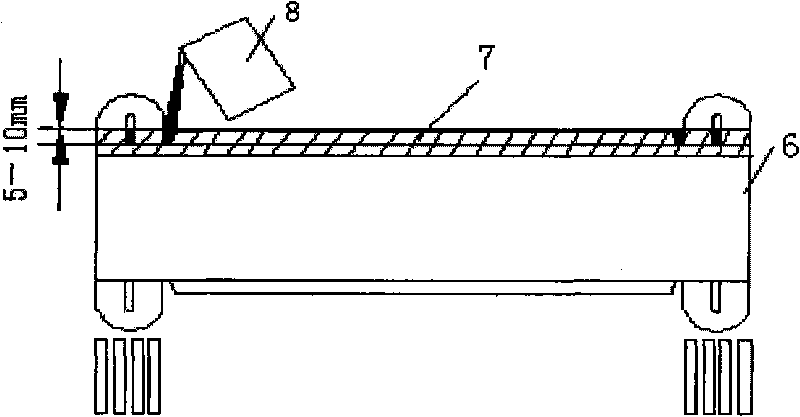

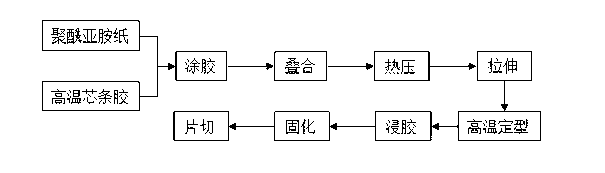

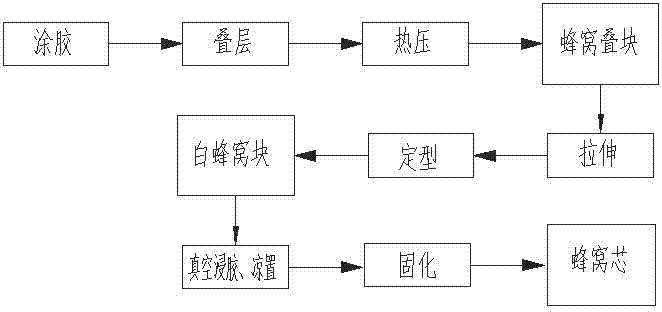

Preparation method of polyimide paper honeycomb core

ActiveCN103264530AExtended service lifeImprove heat resistancePaper/cardboard articlesSynthetic cellulose/non-cellulose material pulp/paperHeat resistanceHoneycomb

The invention relates to a preparation method of a polyimide paper honeycomb core. The method includes the following steps: (1) raw material paper is glued, laminated and hot-pressed, and a honeycomb stacked block is manufactured; (2) the honeycomb stacked block is molded at high temperature after being pulled, and a white honeycomb block is manufactured; (3) gum dipping is carried on the white honeycomb block, and the white honeycomb block is solidified; (4) a honeycomb after the gum dipping and solidification is sliced. The method is characterized in that the raw material paper is polyimide paper. Due to the fact that the polyimide paper is made of polyimide fibers, good characteristics of the polyimide fibers are inherited. Therefore, the prepared polyimide paper honeycomb core has better heat-resistant performance, dielectric performance, smoke and fire toxicity and mechanical performance compared with an aramid fiber paper honeycomb core in the prior art, the water absorption rate is low, the application field is widened, and service life of the honeycomb is prolonged in special environments. Production equipment of the aramid fiber paper honeycomb core in the prior art can be used, novel instruments and devices do not need to be added, process procedures are basically unchanged, operation is convenient, and equipment cost is not increased.

Owner:ARAMICORE COMPOSITE

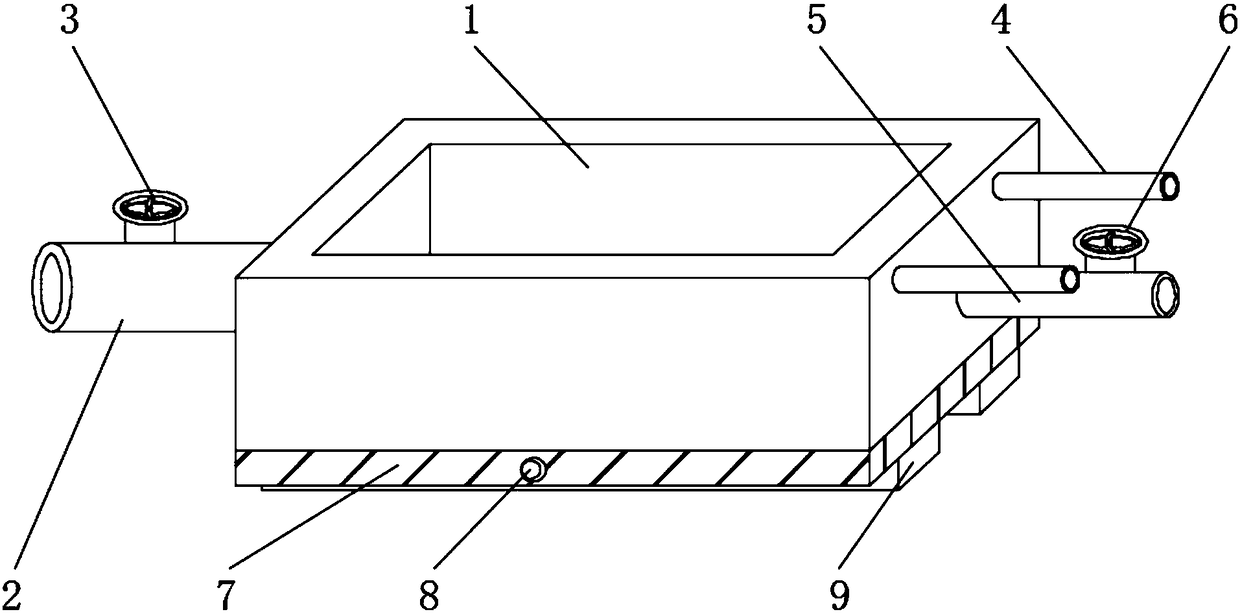

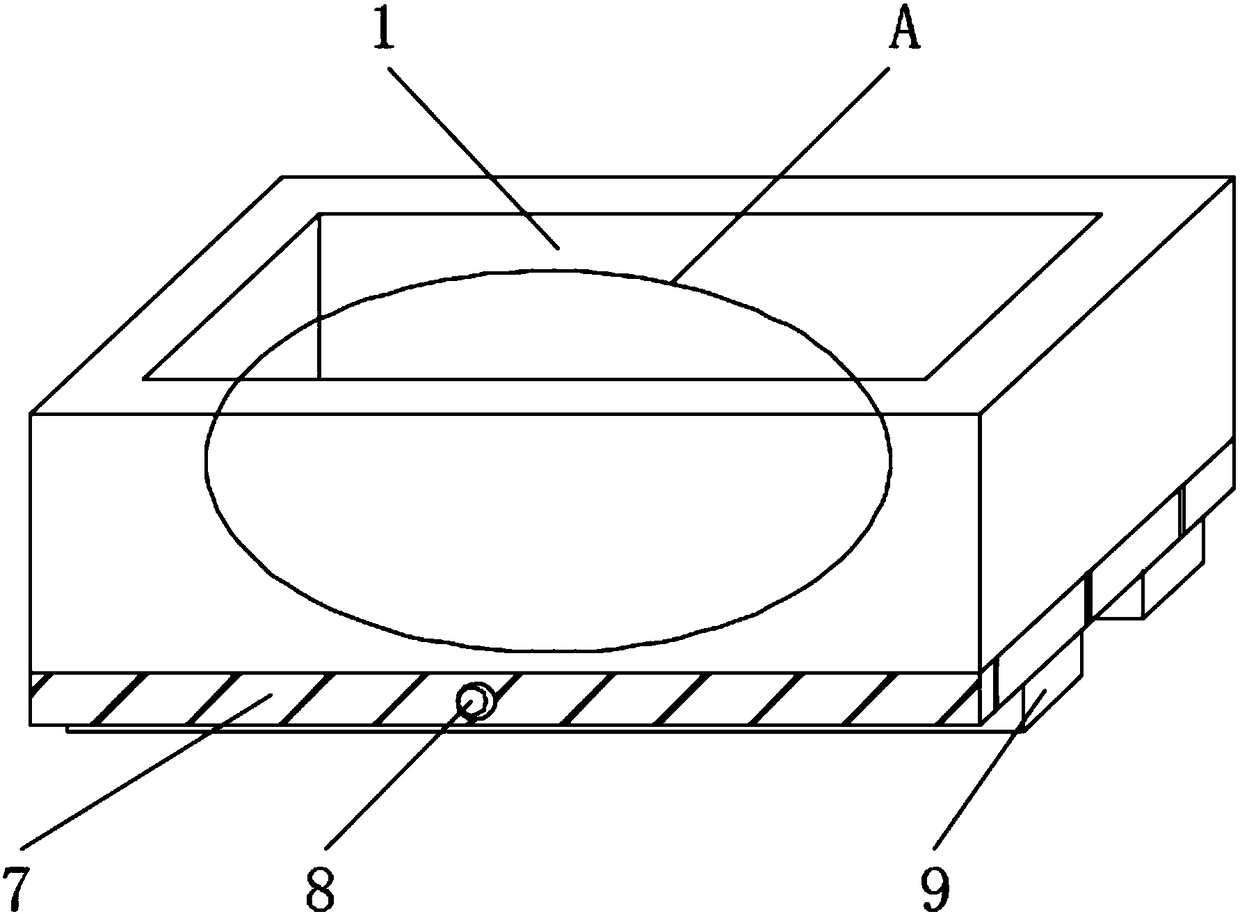

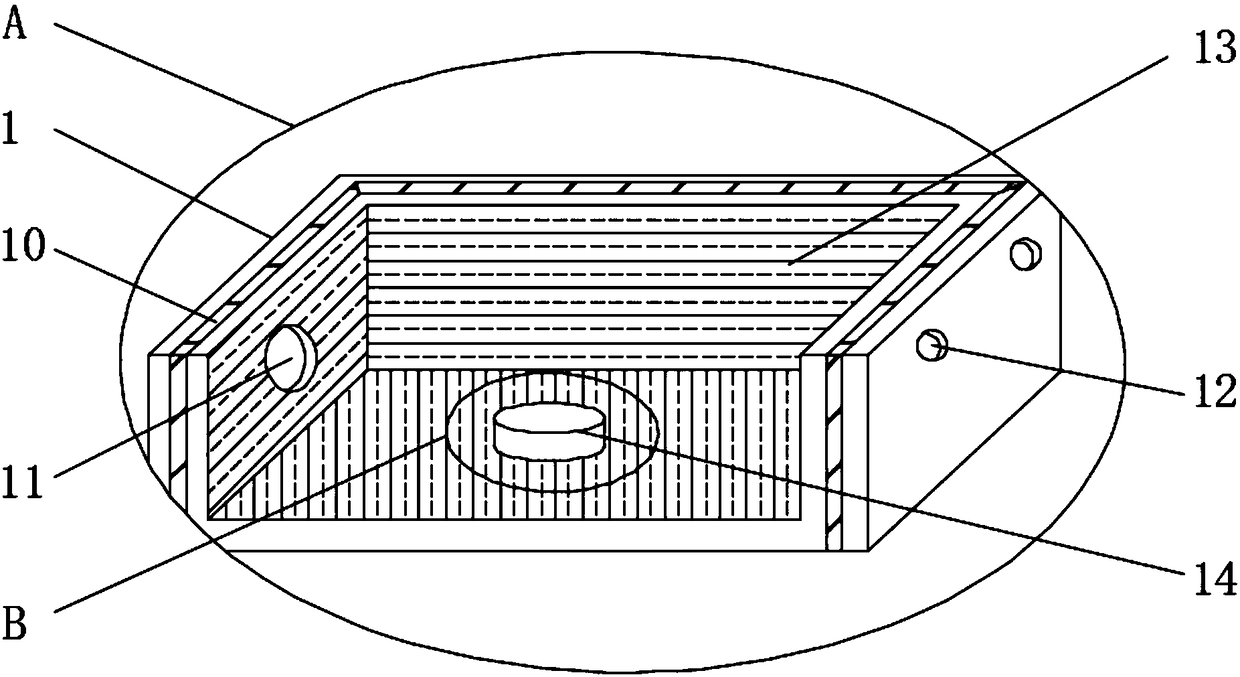

Flexible ultrasonic glue dipping device

The invention discloses a flexible ultrasonic glue dipping device. The flexible ultrasonic glue dipping device comprises a tank body, wherein the tank body is provided with an inner concave chamber for containing liquid resin, is of a two-layer structure and comprises an inner tank body and an outer tank body; a space for storing cycling medium is formed between the inner tank body and the outer tank body; the outer tank body is respectively provided with a liquid inlet and a liquid outlet which are respectively communicated with the space; and the outer wall of the outer tank body is provided with a flexible ultrasonic device with adjustable parameters such as frequency and power. The flexible ultrasonic glue dipping device disclosed by the invention has the advantages that ultrasonic waves produced by the ultrasonic device act on fiber and the liquid resin uniformly by means of the cycling medium to realize glue dipping, and after the glue dipping procedure is finished, when a glue dipping tank is cleaned, the ultrasonic waves also act on sewage in the tank body, therefore, for the glue dipping and cleaning processes, a physical means is adopted in the flexible ultrasonic glue dipping device, and on the basis of realizing glue dipping, the cleaning effect is improved, the cleaning process is simplified, and the influence on the reuse effect of the glue dipping tank is avoided.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

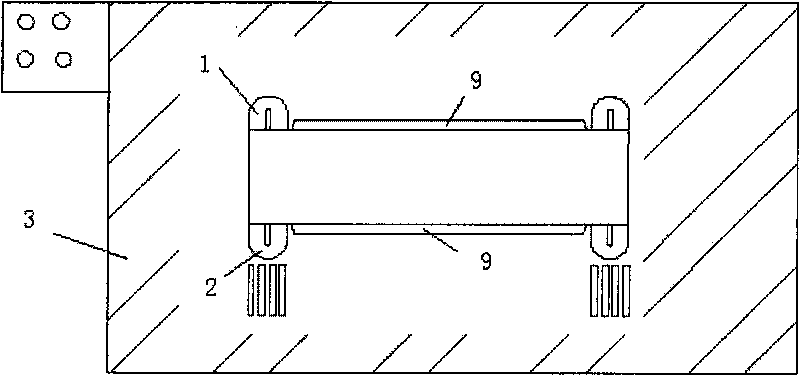

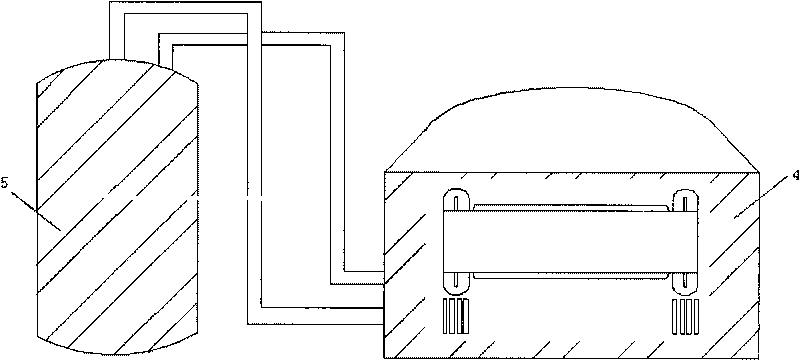

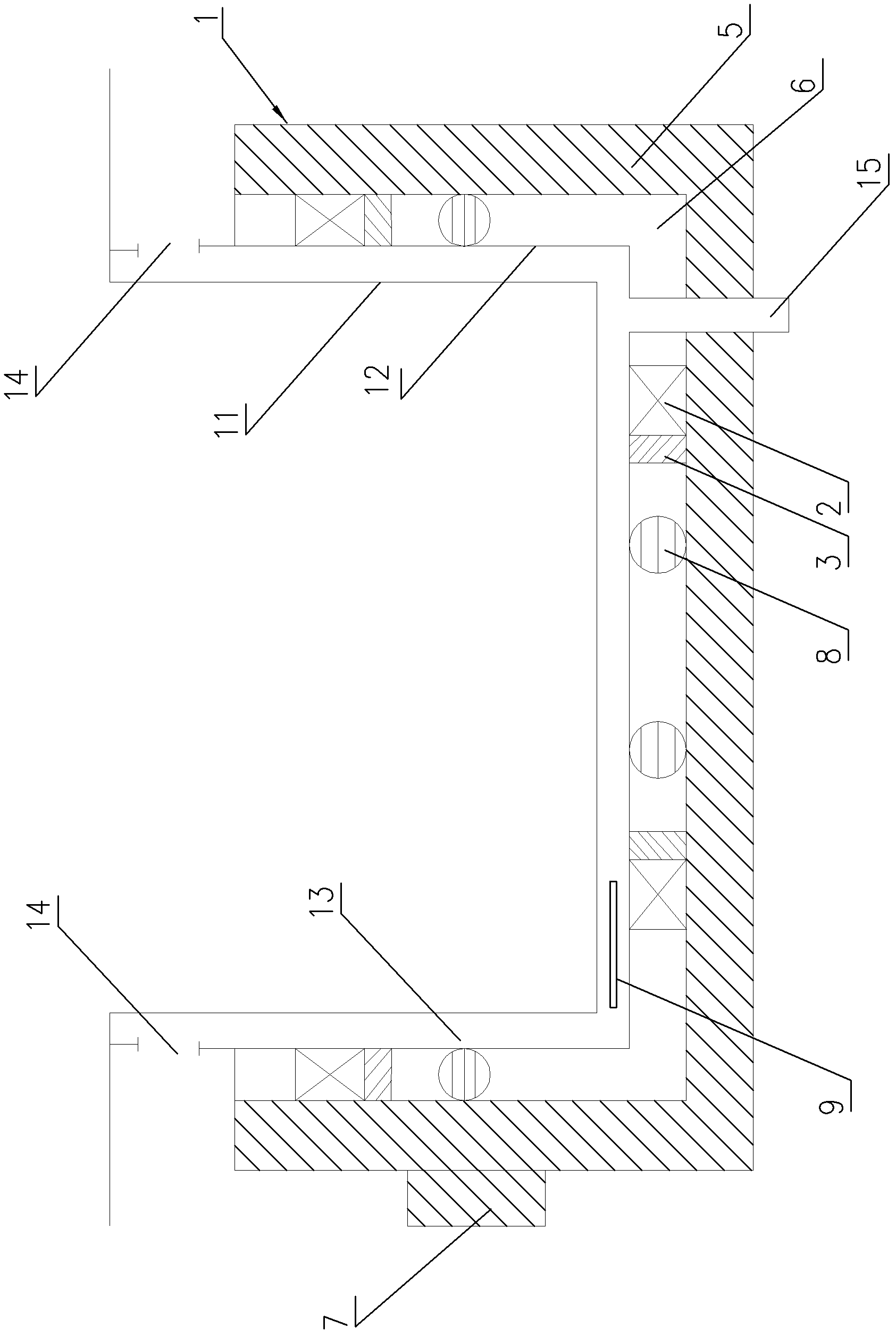

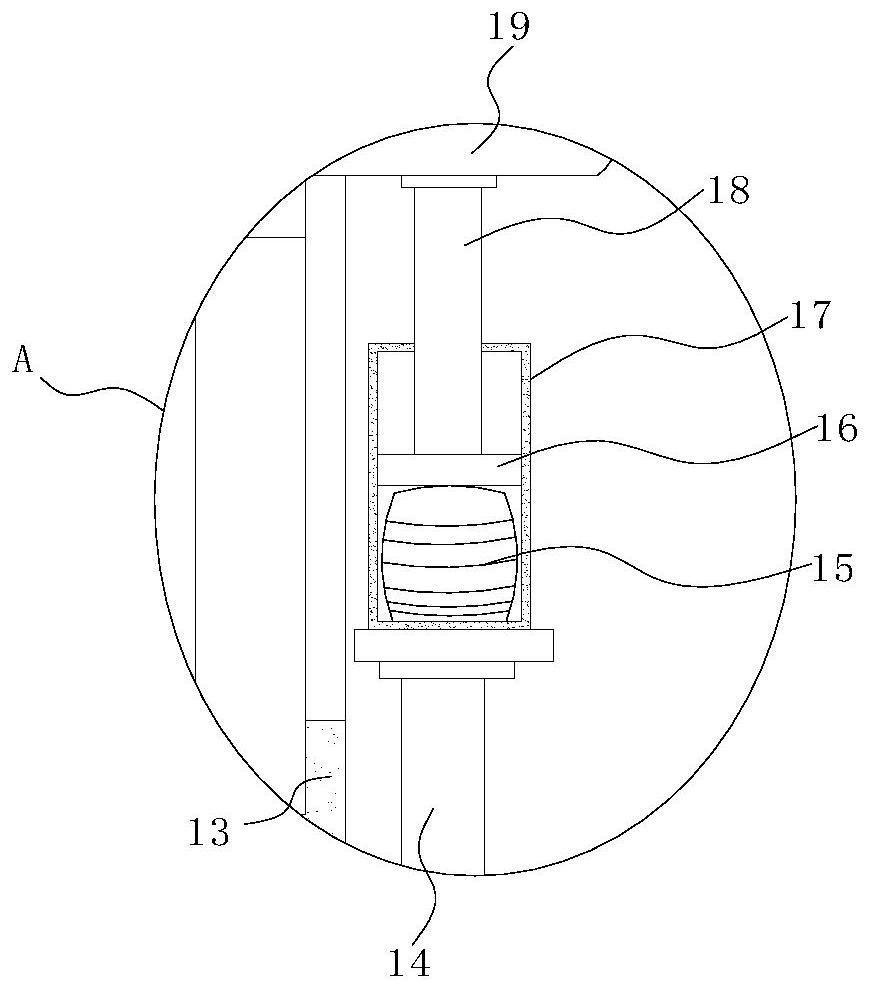

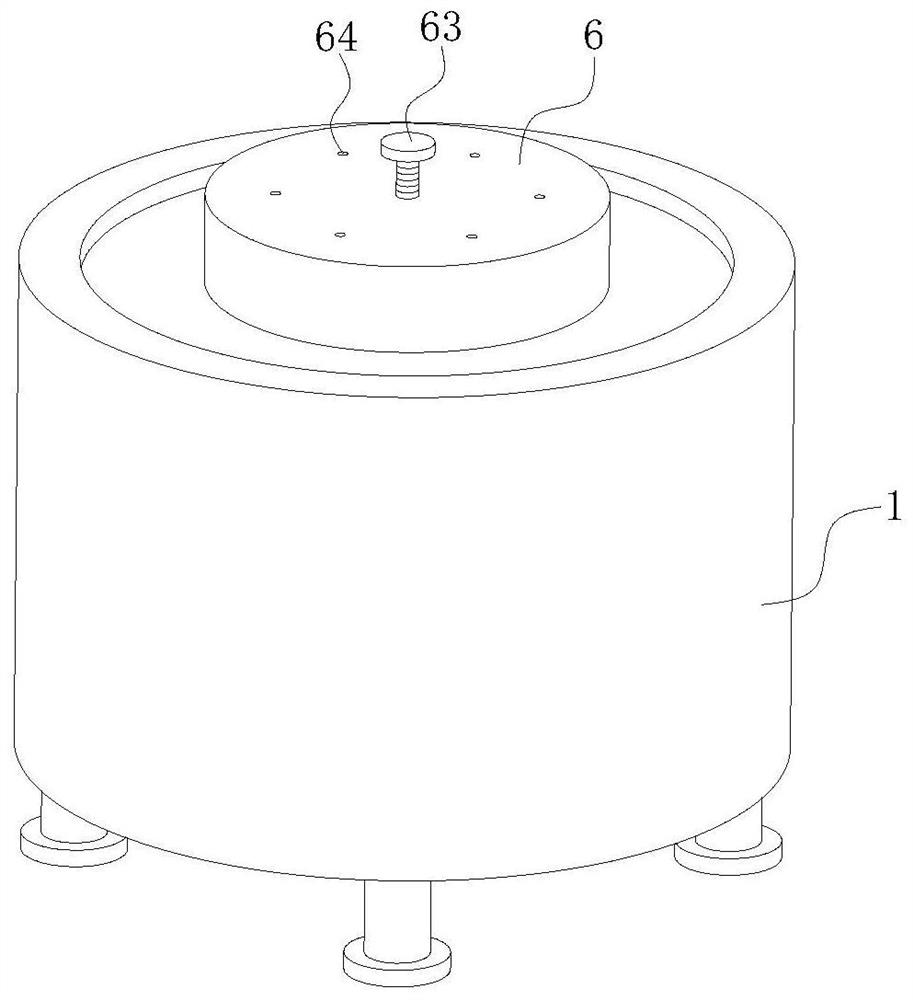

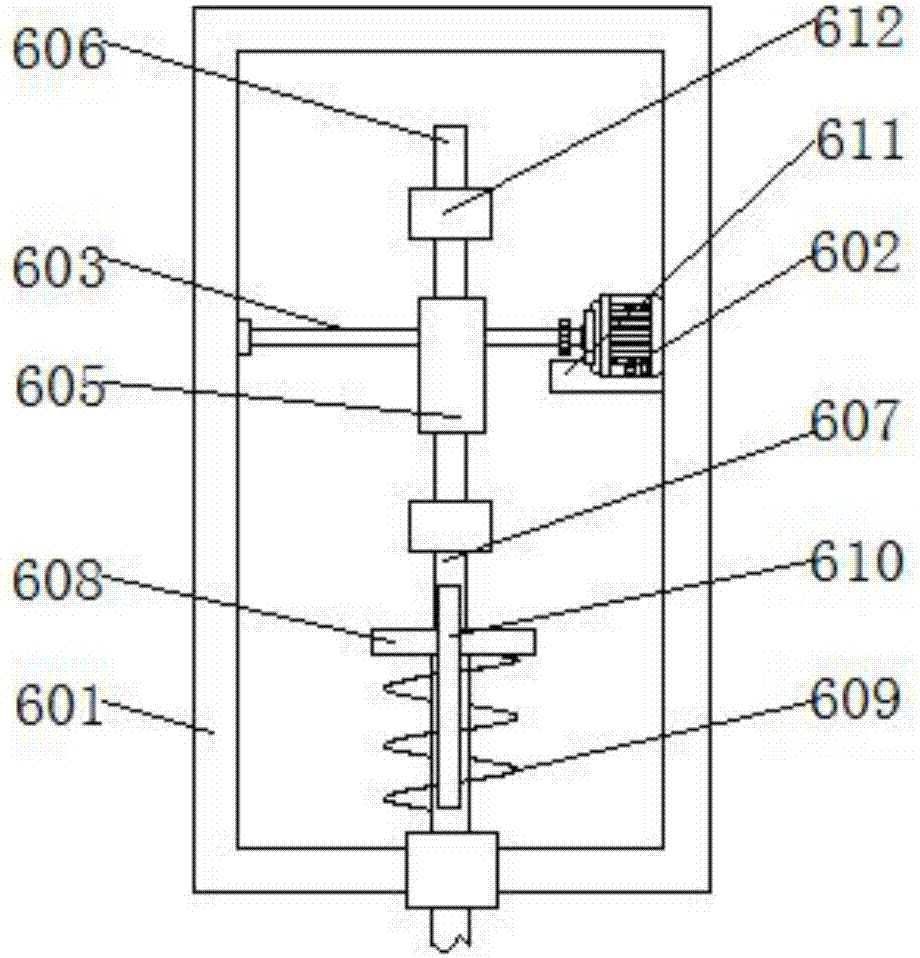

Vacuum pressure varnished product design device

InactiveCN107961946AImprove work efficiencyEasy to viewLiquid surface applicatorsCoatingsVacuum pressureEngineering

The invention discloses a vacuum pressure varnished product design device. The vacuum pressure varnished product design device comprises a barrel. The barrel is a hollow cylinder. An opening of the barrel faces upwards. A fixing base is fixed to the middle of the inner bottom face of the barrel. An electric heating piece and a temperature sensor are fixed to the left side of the inner bottom faceof the barrel. A barometric sensor and a humidity sensor are fixed to the upper end of the inner wall of the barrel. A PLC is fixed to the upper end of the outer side face of the barrel. A liquid inlet of the upper end of the outer side face of the barrel communicates with a liquid outlet of an external liquid storage barrel through a liquid inlet pipe. An operator checks conditions in the barrelthrough a transparent observation window and checks the ongoing process of a varnishing technique conveniently, so that the working efficiency of varnishing technique design by the operator is improved; the varnishing effect of a to-be-varnished workpiece is improved through an ultrasonic vibrating rod; and through coordinate application of the temperature sensor and the electric heating piece, the temperature of paint liquid in the barrel is constant, and the varnishing effect of the to-be-varnished workpiece is ensured.

Owner:SHANDONG UNIV OF TECH

Online cleaning equipment for chips

ActiveCN102806212AEfficient removalSatisfy high quality and high efficiencyCleaning using liquidsSlide plateEngineering

Owner:铜陵太阳岛农业科技有限公司

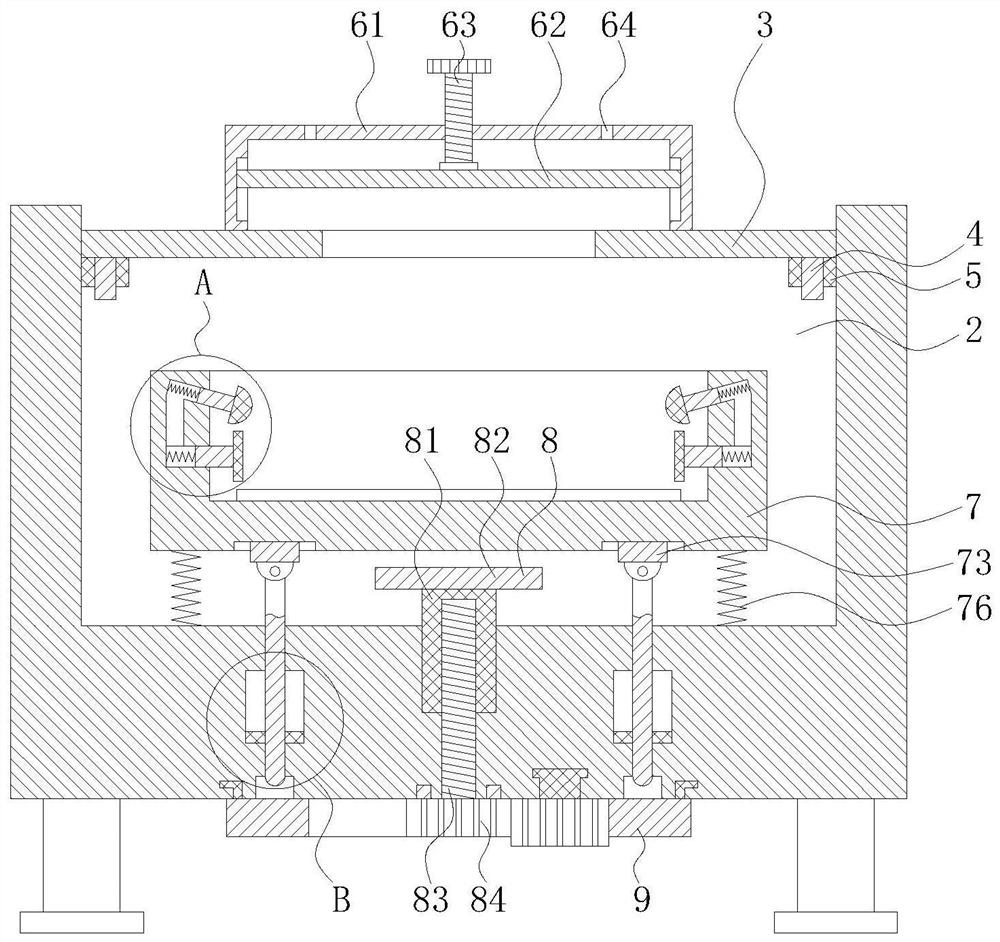

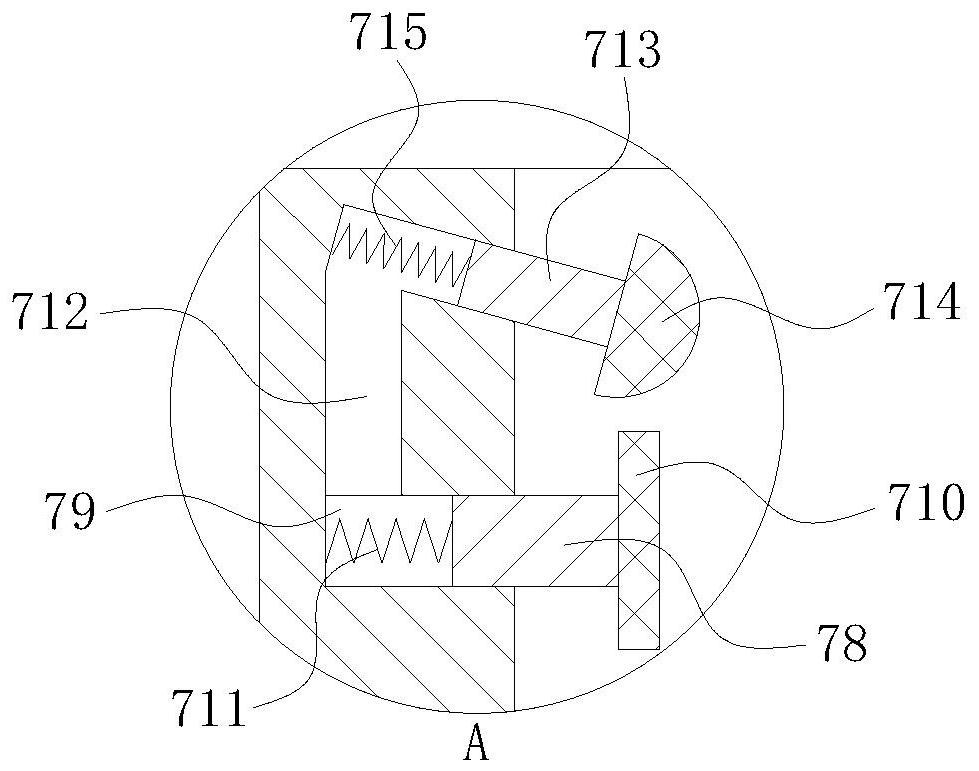

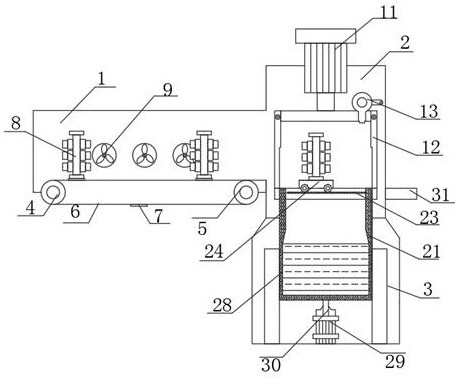

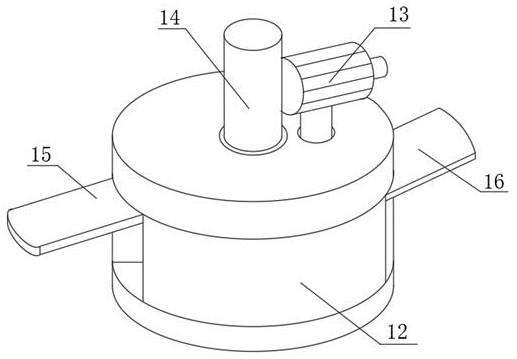

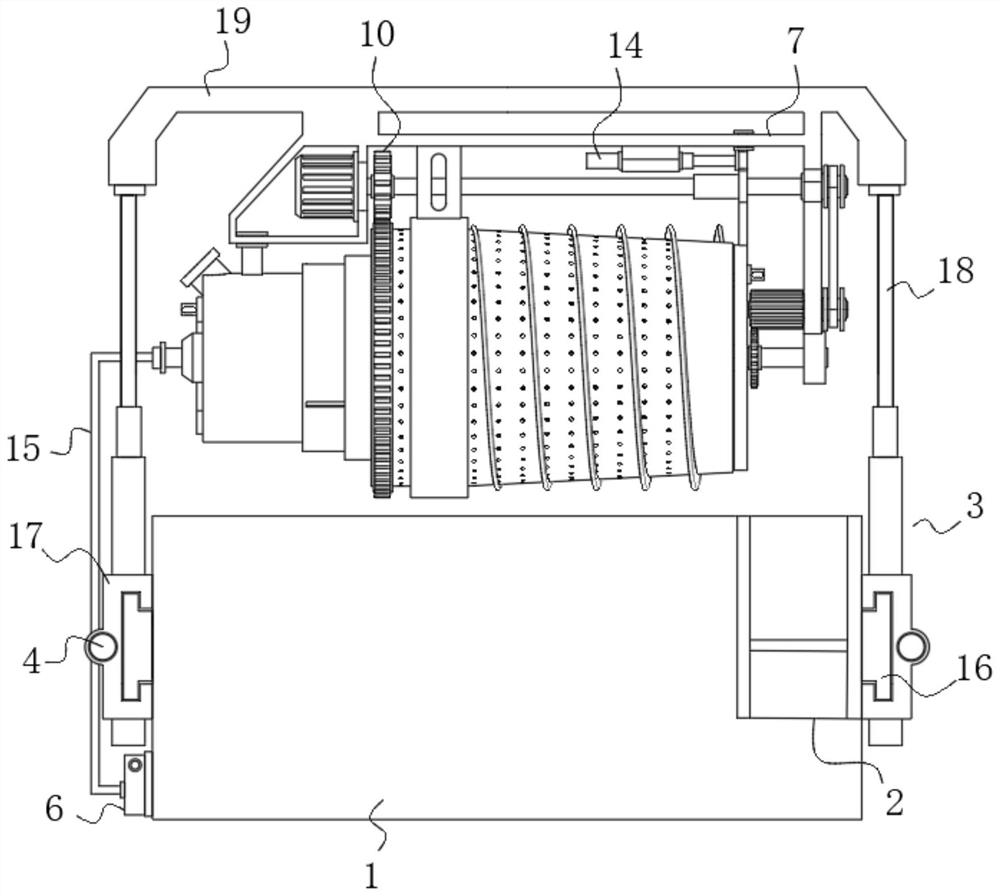

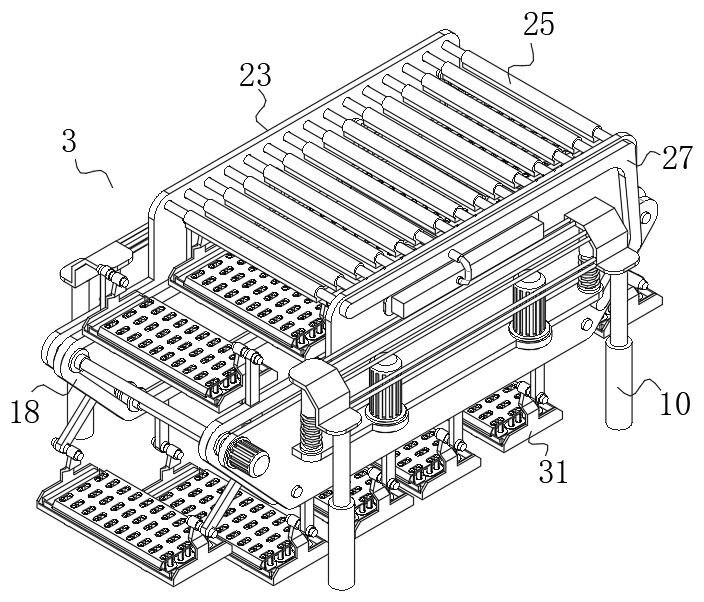

Accessory paint dipping device for conveying mechanical equipment manufacturing

InactiveCN112090681AImprove dipping effectImprove the quality of workPretreated surfacesCoatingsLiquid storage tankEngineering

The invention discloses an accessory paint dipping device for conveying mechanical equipment manufacturing, and relates to the technical field of mechanical equipment manufacturing. The accessory paint dipping device for conveying mechanical equipment manufacturing comprises a bottom plate, wherein a first side support and a second side support are fixedly arranged at the top of the bottom plate through bolts; sliding grooves are formed in the first side support and the second side support; a first sliding block is arranged in the sliding groove of the first side support in a sliding mode; a second sliding block is arranged in the sliding groove of the second side support in a sliding mode; a liquid storage tank is fixed to the top of the bottom plate; a liquid discharging pipe which is incommunication with the interior of the liquid storage tank is arranged on the outer surface of the front side of the liquid storage tank; connecting plates are respectively and fixedly connected to the adjacent sides of the first sliding block and the second sliding block; and vertical plates are respectively fixed to the free ends of the two groups of connecting plates; and a metal net cage is fixedly arranged between the vertical plates. When the accessory paint dipping device performs paint dipping operation on mechanical accessories, the accessory paint dipping device has a relatively good paint dipping effect, meanwhile can reduce the unnecessary waste, and facilitates the reduction of production cost, and therefore, the paint dipping device is suitable for being used.

Owner:湖州吴兴双德输送机械有限公司

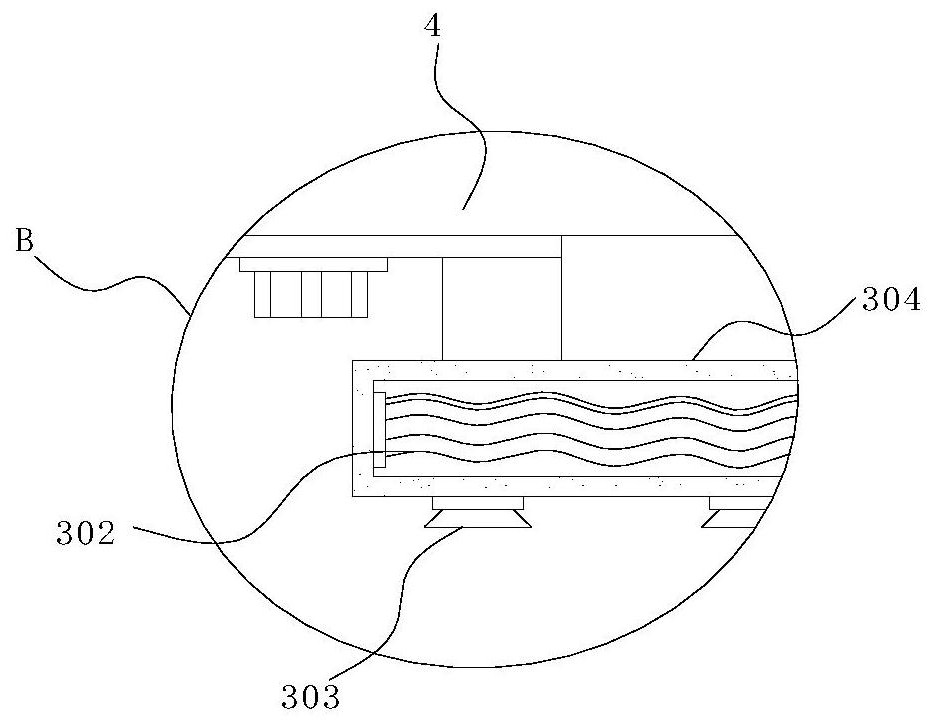

Honeycomb preparation process

InactiveCN103879122AImprove performanceImprove uniformityLiquid surface applicatorsLaminationHoneycombCapillary action

The invention relates to a honeycomb preparation process which comprises the following steps: (1) gluing a base material, laminating and performing hot-pressing, and preparing a honeycomb laminating block; (2) drawing the honeycomb laminating block, performing high-temperature setting, and preparing a white honeycomb block; (3) impregnating the white honeycomb block in impregnating equipment filled with impregnating liquid at least one time; airing once in a matched mode after impregnation each time, and curing; and (4) slicing the honeycomb subjected to the impregnating and the curing. The method is characterized in that the impregnation in the step (3) is vacuum impregnation, the used impregnating equipment is vacuum impregnating equipment, and the airing step is performed in the vacuum impregnating equipment. According to the honeycomb preparation process, a traditional normal-pressure impregnation is modified into the vacuum impregnation, comprehensive effects in three aspects of a wetting mechanism, a capillary phenomenon and an adsorption effect are utilized, the impregnation speed is increased, the impregnation uniformity is improved, the process is simple and easy to operate, the production efficiency can be greatly improved, the production cost is reduced, and the honeycomb with the excellent comprehensive performance is obtained.

Owner:ARAMICORE COMPOSITE

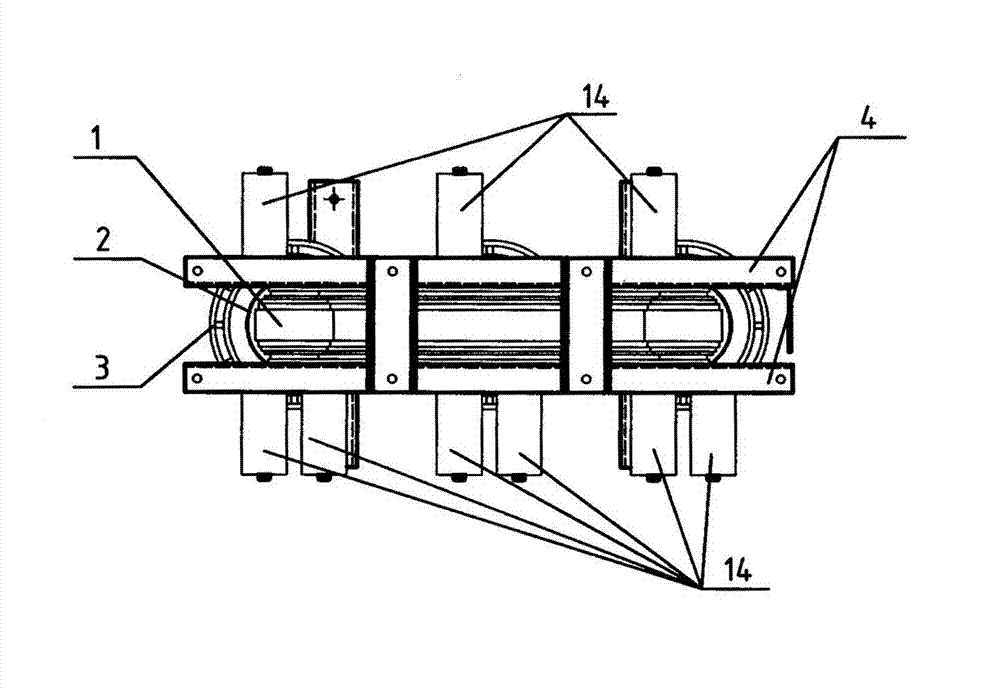

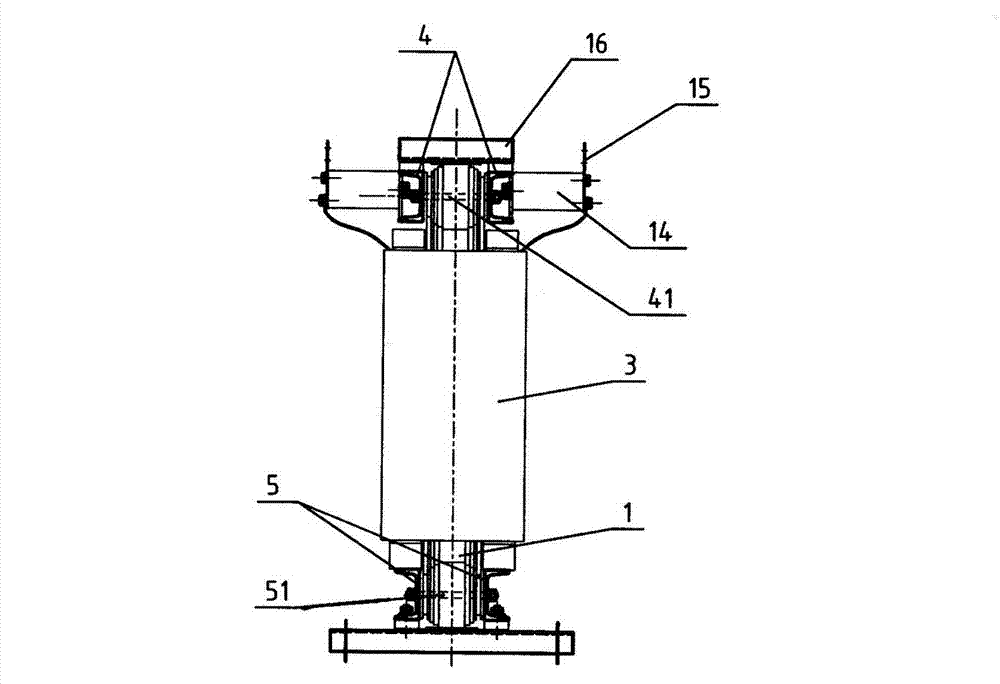

Dry type iron-core starting reactor for cold water medium-pressure unit of air conditioner

InactiveCN102903488AHigh dielectric strengthPrevent creepage phenomenonDynamo-electric motors/converters startersTransformers/inductances coils/windings/connectionsGlass fiberPressure units

The invention discloses a dry type iron-core starting reactor for a cold water medium-pressure unit of an air conditioner, belonging to the field of starting devices of motors. An insulation cylinder is arranged between an iron core and a coil, a first supporting rod is arranged between the iron core and the insulation cylinder, an upper cushion block and a lower cushion block are arranged on the upper end and the lower end of the coil, a pair of upper clamp pieces is arranged above the upper cushion block and is connected through a first piercing screw rod, a pair of lower clamp pieces is arranged below the lower cushion block and is connected through a second piercing screw rod, a drawing screw rod is connected between the pair of upper clamp pieces and the pair of lower clamp pieces, a compression nail is arranged on the pair of upper clamp pieces, a glass fiber cylinder is arranged on the inner side layer of the coil, a second supporting rod is arranged between the glass fiber cylinder and the insulating cylinder, the outer side of the glass fiber cylinder is provided with an epoxy glass laminated sheet, an insulation supporting strip is arranged between the epoxy glass laminated sheet and the glass fiber cylinder, the outer side of the epoxy glass laminated sheet is wound with a winding and a compression ring, a wire outgoing end rind is arranged between the winding and the compression ring, and the outer side layer of the winding is externally provided with an insulating layer. The dry type iron-core starting reactor has the advantages of being reduced in size, saving the cost and preventing creepage phenomena on the surface of the coil.

Owner:常熟市森源电气科技有限公司

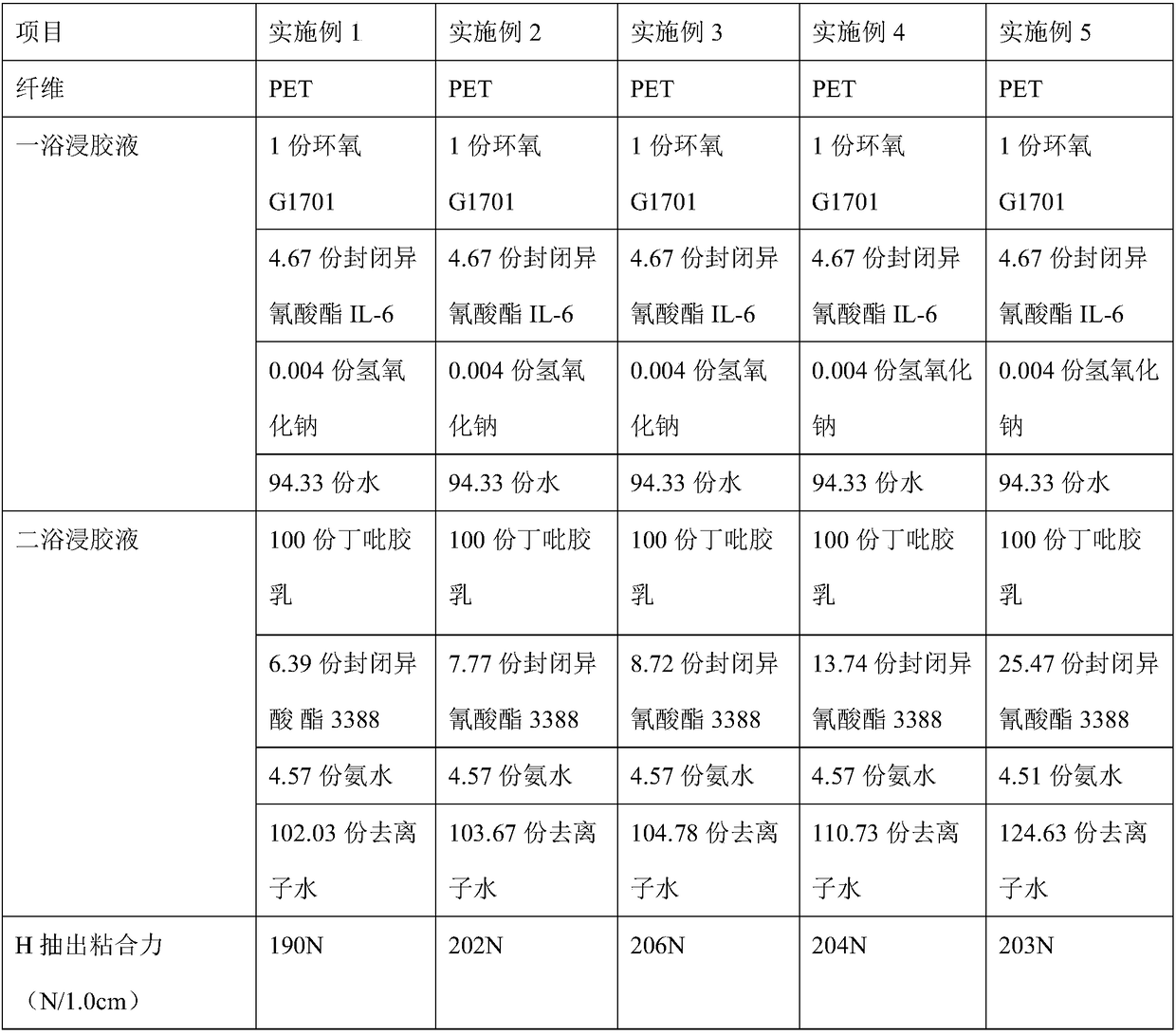

Environment-friendly fiber framework material impregnation liquid, preparation method thereof and application of liquid

The invention discloses environment-friendly fiber framework material impregnation liquid, a preparation method thereof and an application of the liquid. The liquid comprises, by weight, 70-120 partsof rubber latex, 5-50 parts of blocked isocyanate, 0.5-5 parts of ammonium hydroxide and the rest water, and the total solids content of the impregnation liquid is 8%-30%. The prepared impregnation liquid does not contain hazardous substances such as resorcinol and formaldehyde and cannot pollute environments and effectively reduces occupational hazard. The impregnation liquid is simple and convenient in preparation process step, impregnation processes are easily operated, impregnated fiber and rubber has excellent bonding effect, and the impregnation effect of the liquid is better than that of traditional RFL (resorcinol and formaldehyde latex).

Owner:PERFORMANCE FIBERS KAIPING COMPANY

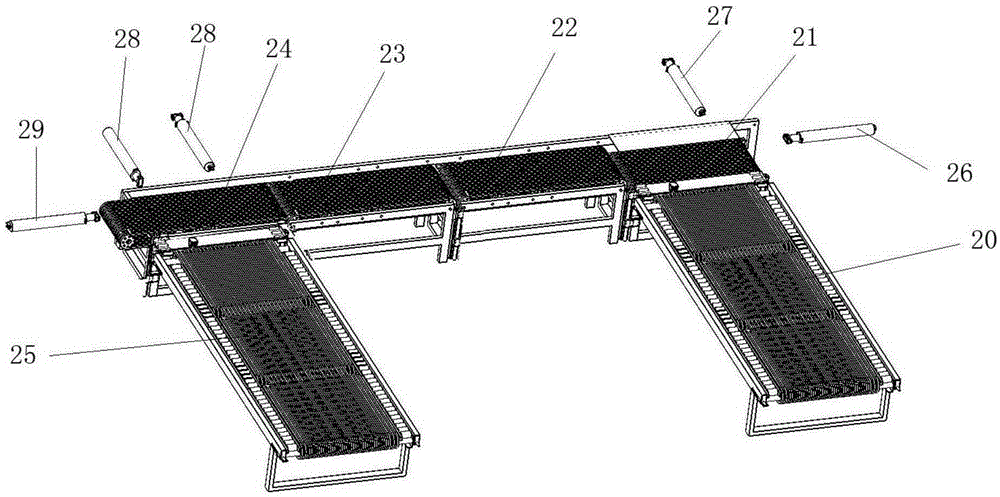

Omnidirectional cleaning production line and cleaning method

ActiveCN105414096ARealize automatic cleaningPrevent rustDrying gas arrangementsCleaning using liquidsProduction lineCleaning methods

The invention discloses an omnidirectional cleaning production line and a cleaning method. A first immersion cleaning device can carry out immersion cleaning on a valve with a cleaning fluid; a spray washing device can wash the valve in six mutually perpendicular directions; a second immersion cleaning device carries out the immersion cleaning with clear water to remove the cleaning fluid; an air-heating drying device allows the clear water to be evaporated, and the valve is dried and prevented from being rusted; and a control device realizes the effect of automatic running of movements above. Therefore, the cleaning effect is good and the cleaning efficiency is high when the omnidirectional cleaning production line for the large valve is used to clean the valve.

Owner:青岛高通超越轨道科技有限公司

Large valve cleaning production line

ActiveCN105537174ARealize automatic cleaningPrevent rustCleaning using liquidsProduction lineEngineering

The invention discloses a large valve cleaning production line and a cleaning method. A valve is fixed by a bearing device, and is conveniently transported; a transmission device and a pushing-extracting device achieve effects of transmission and guide, so that the bearing device along with the valve passes through a first soaking device, a spraying flushing device, a second soaking device and an air-heating drying device in sequence, so that automatic cleaning of the valve is realized. Besides, the first soaking device can be used for soaking the valve by use of a cleanout fluid; the spraying flushing device can flush the valve in six directions which are perpendicular to one another by use of the cleanout fluid; the second soaking device is used for soaking the valve by use of clear water to remove the cleanout fluid; and finally, the clear water is evaporated by virtue of the air-heating drying device, so that the valve is dried to prevent corrosion; and a control device realizes automatic operation of the actions. The large valve cleaning production line is good in cleaning effect and is high in cleaning efficiency while used for cleaning the valve.

Owner:盐城大丰新阳机械厂

Method for preparing marine polyester cable

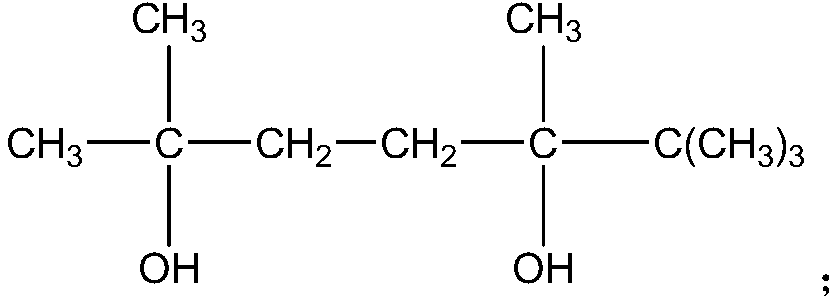

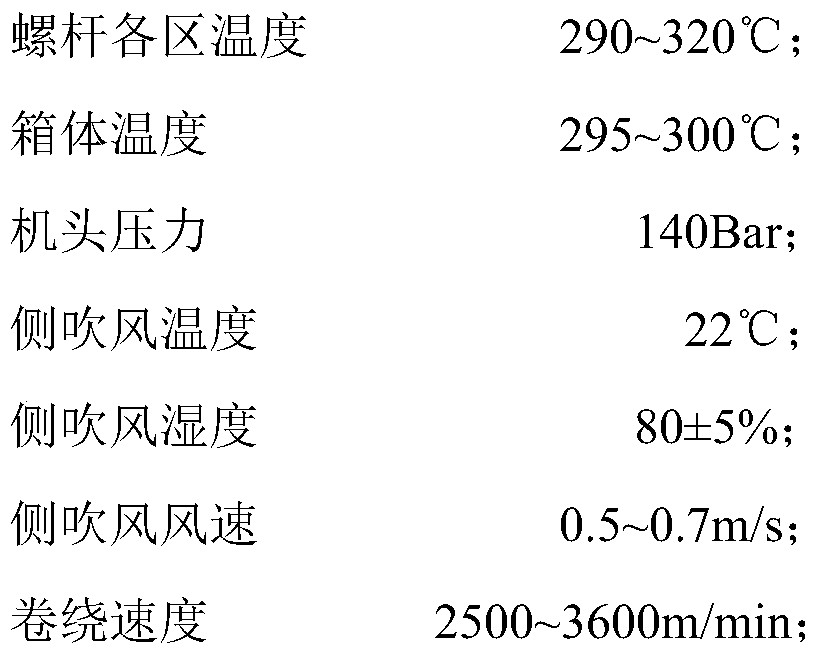

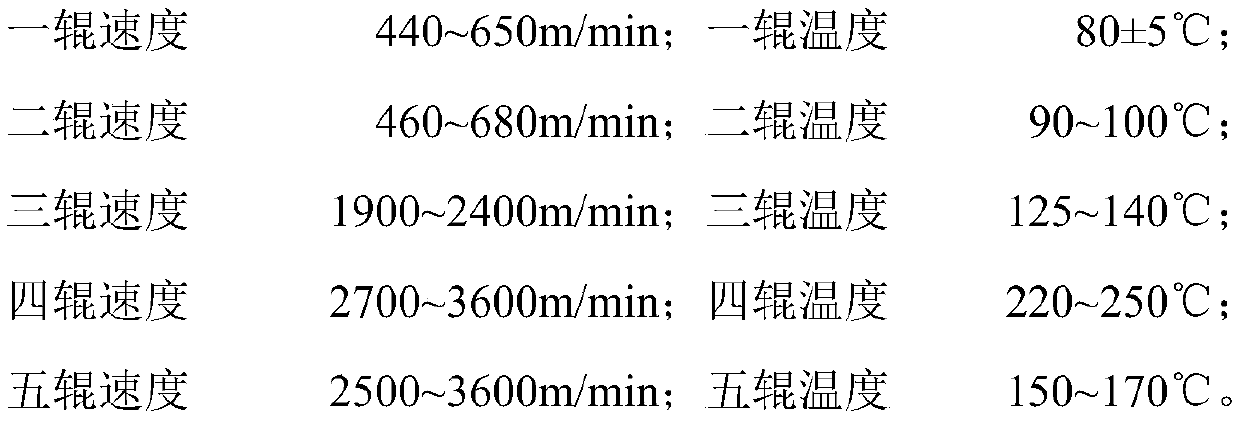

ActiveCN109735935AImprove dipping effectHigh breaking strengthArtificial filament heat treatmentMelt spinning methodsSolid phasesDisiloxane

The invention relates to a marine polyester cable and a preparation method thereof. The marine polyester cable is prepared by the following steps: twisting modified polyester industrial yarns, and performing impregnation treatment on the woven rope, thereby obtaining the marine polyester cable. The modified polyester industrial yarns are prepared by performing solid phase polycondensation tackifying on modified polyester melt and performing spinning; the preparation method of the modified polyester before solid phase polycondensation tackifying comprises the following steps: uniformly mixing terephthalic acid, ethylene glycol, dihydric alcohol containing silicon on the main chain, 2,5,6,6-tetramethyl-2,5-heptandiol and metal oxide doped modified Sb2O3 powder, and sequentially carrying outan esterification reaction and a polycondensation reaction; the dihydric alcohol containing silicon on the main chain comprises dimethyl silicone diol, dimethyl diphenyl disiloxane diol or tetramethyldisiloxane diol; and the prepared marine polyester cable has the linear density of 1200+ / -3ktex and the breaking strength of more than or equal to 480kN. The method disclosed by the invention is simple in process, and the prepared marine polyester cable is high in breaking strength and high in quality.

Owner:JIANGSU HENGLI CHEM FIBER

Recombined bamboo timber processing technology

InactiveCN107498666AReduce transshipment costsSimple processWood treatment detailsCane mechanical workingCarbonizationEngineering

The invention discloses a recombined bamboo timber processing technology. The recombined bamboo timber processing technology comprises the following steps that a bamboo is sawed off, specifically, the bamboo is sawed off by utilizing a cut-off machine, and the number of the bamboo sections obtained by once sawing through the cut-off machine is greater than two; bamboo ties are prepared, specifically, the multiple bamboo sections are conveyed to different bamboo tying machines correspondingly, and the bamboo sections are defibered by utilizing the bamboo tying machines to obtain the bamboo ties; sterilization and carbonization are conducted, specifically, the bamboo ties are conveyed to a drying and sterilizing carbon drying machine, carbonized, and then taken out; primary drying is conducted, specifically, the bamboo ties are conveyed to a reciprocating type drying line to be subjected to drying for the first time; gumming is conducted, specifically, the dried bamboo ties are conveyed to a gumming line to be subjected to gumming, and after gumming is completed, the bamboo ties are subjected to drying for the second time; quantitative mat formation is conducted, specifically, after the secondary drying is completed, the bamboo ties are conveyed to a forming machine to be subjected to quantitative mat formation; and compression moulding is conducted, specifically, the bamboo ties which are subjected to mat formation are conveyed to a loader through a base plate, and the bamboo ties on the loader are conveyed to a pressing machine through the base plate to be subjected to compression moulding.

Owner:蒋红卫

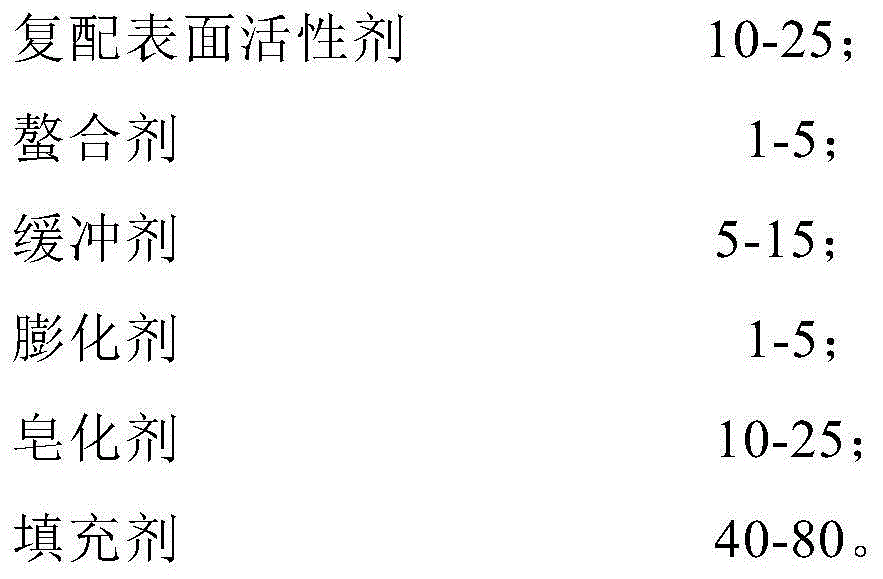

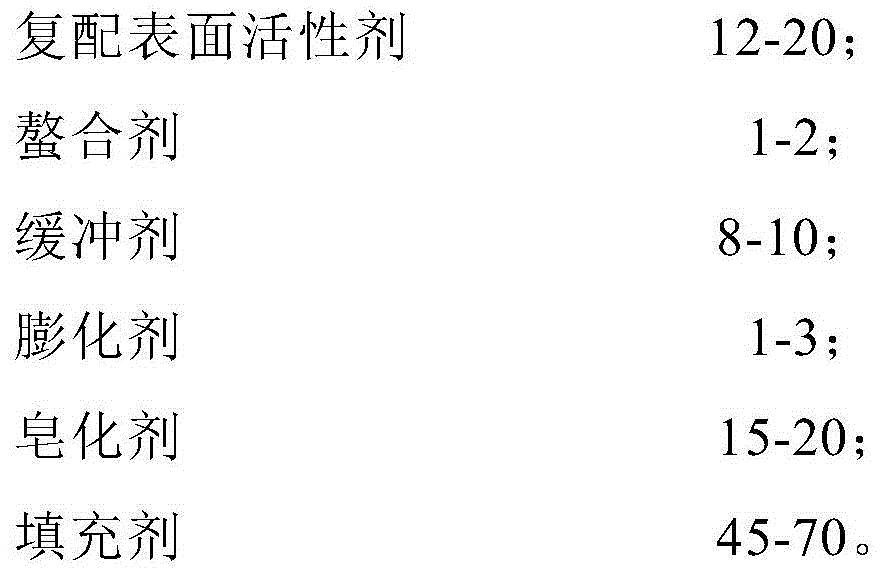

Reusing treatment immersion cleaning agent for PET bottle flake

InactiveCN104560419ANo yellowing when baked at high temperatureImprove permeabilityOrganic detergent compounding agentsAnionic surface-active compoundsCleansing AgentsBottle

The invention relates to a reusing treatment immersion cleaning agent for a PET bottle flake. The reusing treatment immersion cleaning agent is prepared from the following raw materials in parts by weight: 10-25 parts of a compound surfactant, 1-5 parts of a chelating agent, 5-15 parts of a buffering agent, 1-5 parts of an expanding agent, 10-25 parts of a saponifier and 40-80 parts of a filler. Compared with the prior art, by adopting the surfactant compounded by surfactants with the emulsion dispersion property and the seepage property, the reusing treatment immersion cleaning agent has the strengthened seepage property and is capable of easily seeping into capillary pores of the bottle flake to remove pollutants. As for removing pollutants in the capillary pores with hard surfaces, the mechanical force is useless, and sufficient seepage time is needed, so that the formula needs to be operated in a static impregnation mode. When being used, the impregnation time of the PET bottle flake is generally 8-15 minutes, and the impregnation time of an oil bottle flake which is severely polluted is 20-35 minutes.

Owner:CITY RECYCLING

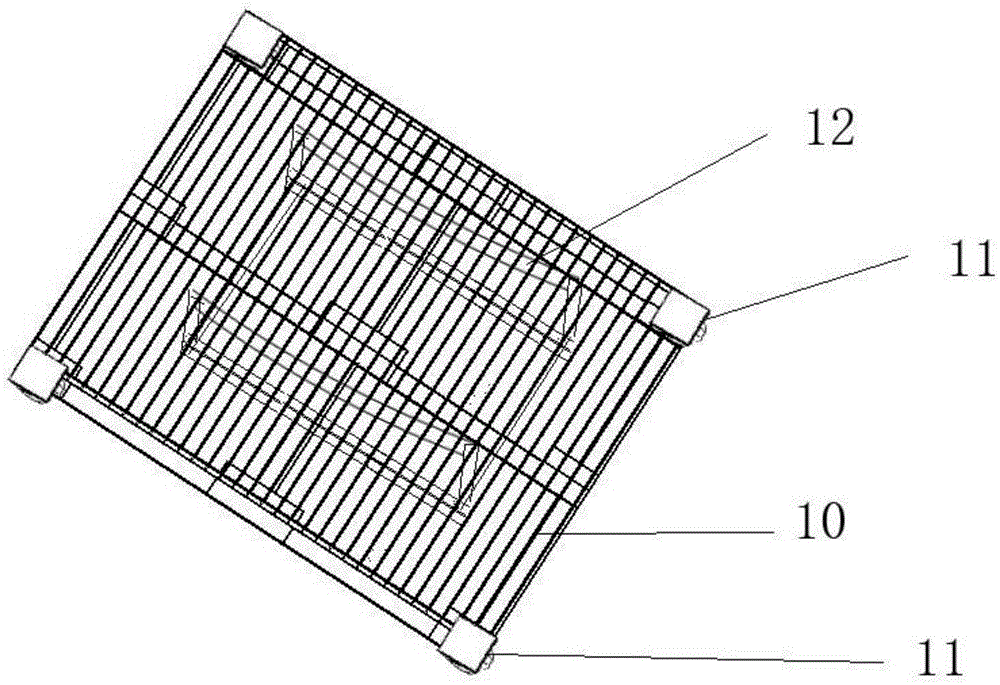

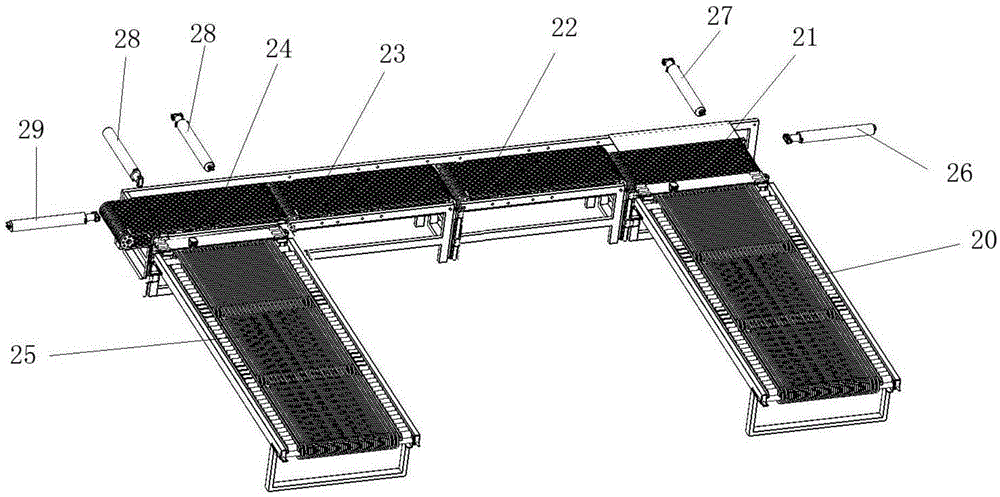

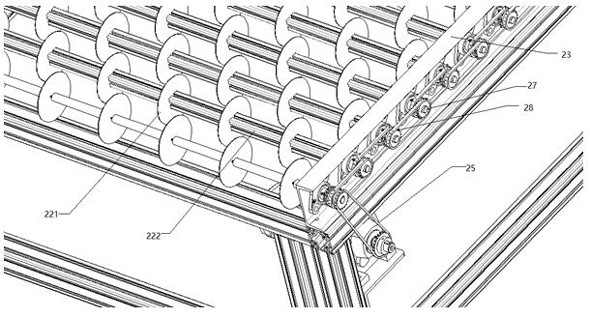

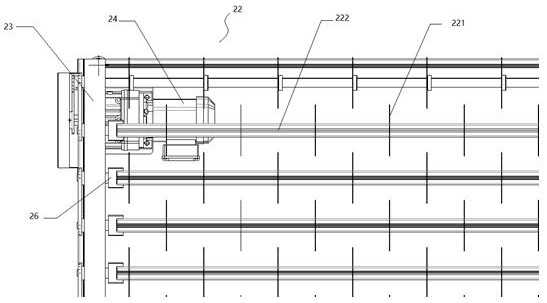

Glue dipping and conveying system for fiberglass mesh cloth

PendingCN112221834AIncrease the itineraryIncrease dipping timeLiquid surface applicatorsCoatingsFiberglass meshGlass fiber

The invention relates to a glue dipping and conveying system for fiberglass mesh cloth. The glue dipping and conveying system is characterized in that the glue dipping and conveying system comprises aglue dipping module and a conveying module; the output end of the glue dipping mechanism is connected to the output end of the conveying mechanism; tension rollers are arranged on a roller set frame,and the fiberglass mesh cloth between the two tension rollers can be tensioned by eccentric adjustment of the tension rollers, so that the situation that a glue film is formed in case of a large voiddensity, and impregnation cannot be achieved is avoided; an adjustment roller is arranged to prolong the glue dipping time of the fiberglass mesh cloth, so that the glue dipping effect is improved; asquare hole is formed in the center of a wheel disk to be matched with a rotating roller with a square section, so that a notch is avoided during long-term squeezing of a round hole; and the end of arotating roller unit is connected to positioning U-steel through a positioning block so that the wheel disk can be disassembled and replaced directly in the positioning U-steel conveniently, and thewheel disk replacement efficiency is improved.

Owner:南通拓普新型建材有限公司

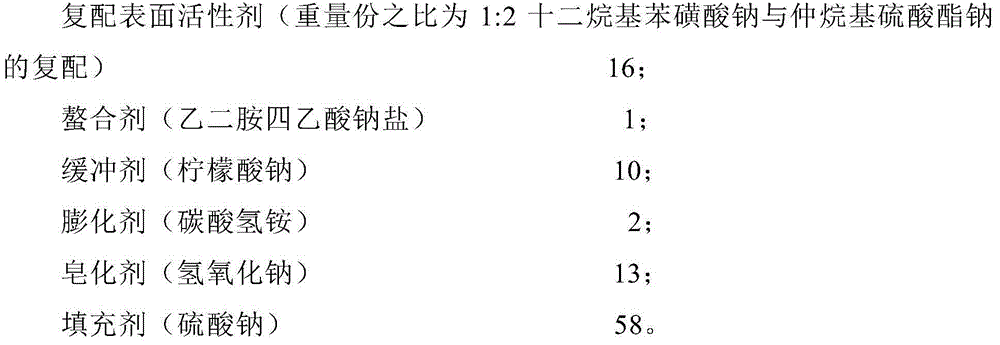

Building wall surface painting device

InactiveCN111593868AEasy to dipImprove dipping effectBuilding constructionsStructural engineeringMechanical engineering

The invention discloses a building wall surface painting device, and relates to the technical field of building decoration. The building wall surface painting device comprises a base, a connecting assembly is fixed to the base, a painting assembly is movably connected to the connecting assembly, and a material collecting box is arranged below the painting assembly; a material preparing assembly isfurther arranged on the base, and the material preparing assembly communicates with the material collecting box; and a handheld spraying assembly is arranged on the connecting assembly, and a limiting adjusting assembly is further arranged on the base. According to the building wall surface painting device, the painting assembly is arranged so that a wall surface can be painted; the material collecting box is arranged below the painting assembly so that painting coating can be conveniently dipped, dipping in a coating barrel is not needed, and the painting efficiency is improved; and the limiting adjusting assembly can be integrally limited at the current position, meanwhile, painting of the wall surface cannot be influenced, and the painting effect is improved.

Owner:袁池保

Method for improving overall performance of decorative base paper

InactiveCN102251432ALight weightIncrease bulkInorganic compound additionKaolin clayMaterials science

The invention relates to a method for improving the overall performance of decorative base paper, belonging to the technical field of paper making. In the method, the ratio of calcined kaolin is increased, and the ratio of titanium dioxide is reduced. The formula of white decorative base paper comprises the raw materials of calcined kaolin, titanium dioxide and paper pulp; the formula of light-colored decorative base paper comprises the raw materials of calcined kaolin, titanium dioxide, iron oxide yellow, iron oxide red and paper pulp; and the formula of dark-colored decorative base paper comprises the raw materials of calcined kaolin, titanium dioxide, iron oxide yellow, iron oxide red and paper pulp. The calcined kaolin used in the invention is in a porous unformed microgranular structure and has a smaller volume weight in comparison with the titanium dioxide. Thus, for the decorative base paper made from the calcined kaolin, the loose depth, air permeability, paper penetrability and gum dipping performance are obviously improved, the printing applicability is enhanced, the consumption of the titanium dioxide is reduced, and the production cost is lowered.

Owner:德州泰鼎新材料科技有限公司

Medical instrument cleaning and drying equipment for surgical operation

InactiveCN112893253AEasy dischargeEasy to cleanDrying machines with progressive movementsCleaning using liquidsSurgical operationApparatus instruments

The invention relates to the technical field of medical instrument cleaning equipment, and provides medical instrument cleaning and drying equipment for surgical operation. The equipment aims to solve the problems that a common medical instrument cleaning machine for surgical operation is low in cleaning efficiency, cannot quickly clean medical instruments, is high in energy consumption and poor in cleaning effect, and meanwhile does not have a drying function. The medical instrument cleaning and drying equipment for surgical operation comprises a lower machine box and an upper machine box which are vertically and integrally communicated, a conveying mechanism used for conveying the medical instruments is arranged in an inner cavity of the lower machine box, and an instrument inlet and an instrument outlet are formed in the two sides, corresponding to the input end and the output end of the conveying mechanism, of the upper machine box correspondingly. Immersion cleaning cavities, spraying cavities and drying cavities are sequentially formed in the inner cavity of the lower machine box and the inner cavity of the upper machine box in the moving direction of the conveying mechanism, the spraying cavities and the drying cavities are separated through vertically-arranged partition plates, and mixed immersion cleaning mechanisms and spraying cleaning mechanisms are arranged in the immersion cleaning cavities and the spraying cavities correspondingly. The medical instrument cleaning and drying equipment for surgical operation is particularly suitable for cleaning surgical medical instruments, and has high social use value and application prospects.

Owner:丁亚宁

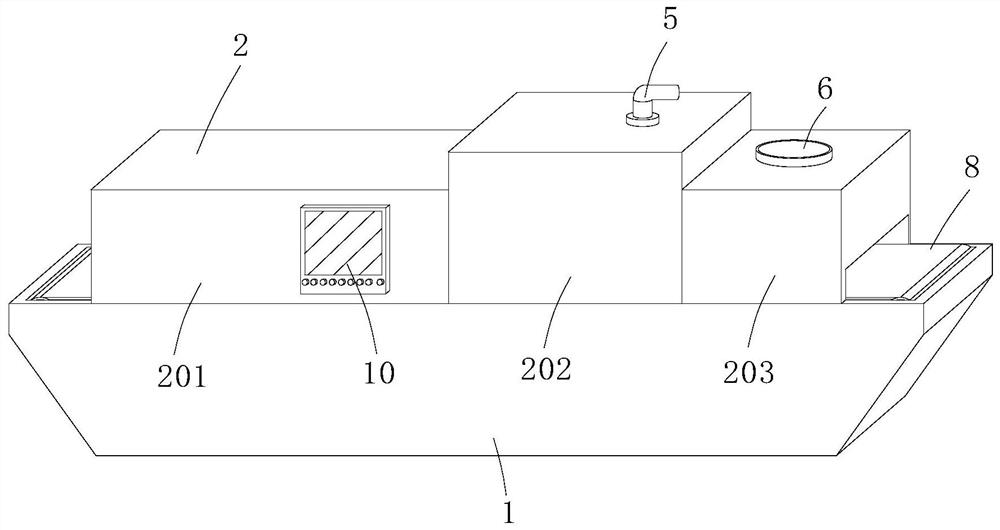

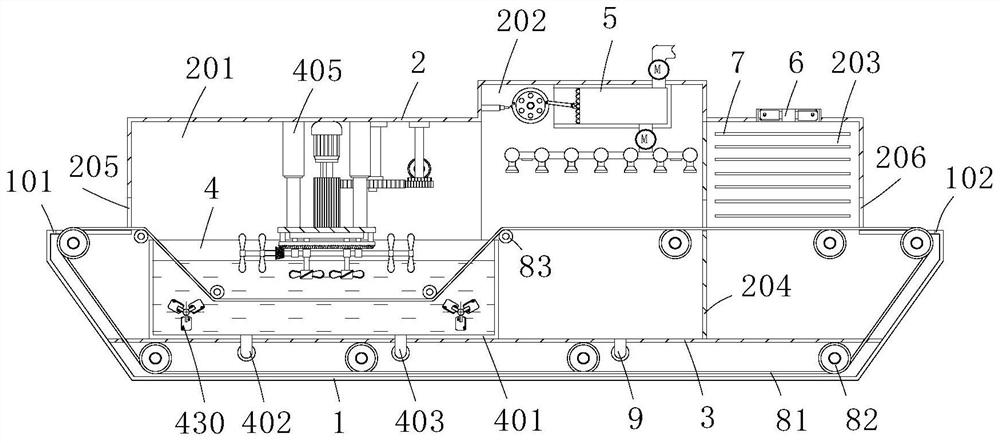

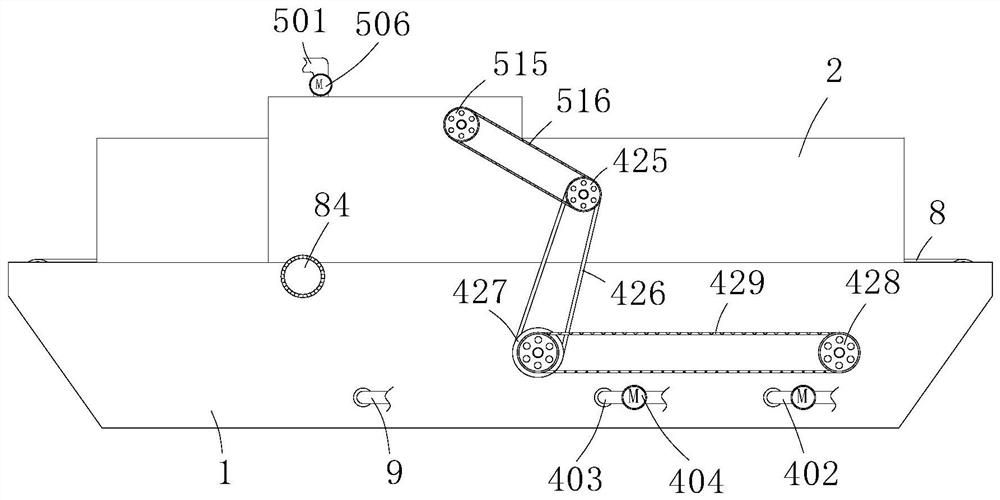

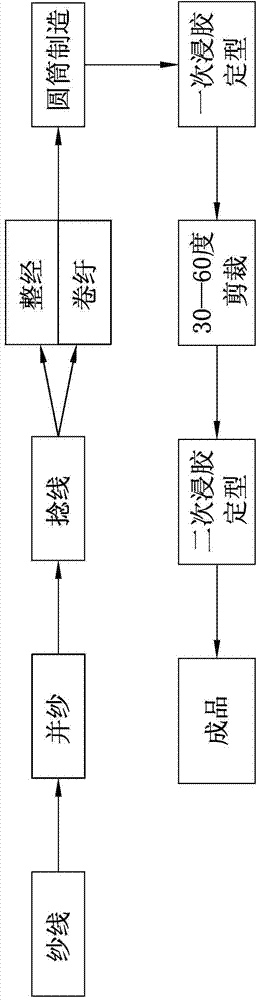

Production technology for impregnated interwoven fabric

InactiveCN103806278AOutstanding and Beneficial Technical EffectsEasy to cutFibre treatmentWoven fabricsTextile technologyPolyvinyl alcohol

The invention belongs to the technical field of textile, and relates to a production technology for impregnated interwoven fabric. The production technology comprises the steps of doubling yarns, twisting yarns, warping and carrying out pirn winding to produce a cylindrical cloth through a cylindrical weaving machine, performing one-time impregnation and setting, shearing strip-shaped fabric according to a 45-degree included angle formed with the edge of the cylindrical cloth, performing secondary impregnation on the shorn strip-shaped fabric, and then carrying out stretching and setting to form an impregnated wide-angled cloth product in which the warp yarns and weft yarns form included angles of 20-40 degrees or wide angles of 140-160 degrees, wherein the formula used in the primary impregnation comprises the following active ingredients in parts by weight: 0.5-2 parts of polyvinyl alcohol and 98-99.5 parts of water; the formula used in the secondary impregnation comprises the following active ingredients in parts by weight: 5+ / -0.1 parts of natural latex, 20+ / -0.1 parts of butadiene-vinyl pyridine latex, 10+ / -0.1 parts of water, and 15+ / -0.1 parts of 6.5% RLF solution. The production technology has the advantages that the shearing accuracy is high after the primary impregnation, the utilization rate of the fabric is high, latex is evenly distributed in the fabric and firmly bonded after primary and secondary impregnations, and the production technology is applicable to production of fabric wrapping layers of a triangular belt or a toothed belt.

Owner:ZHEJIANG GUOLI TECH

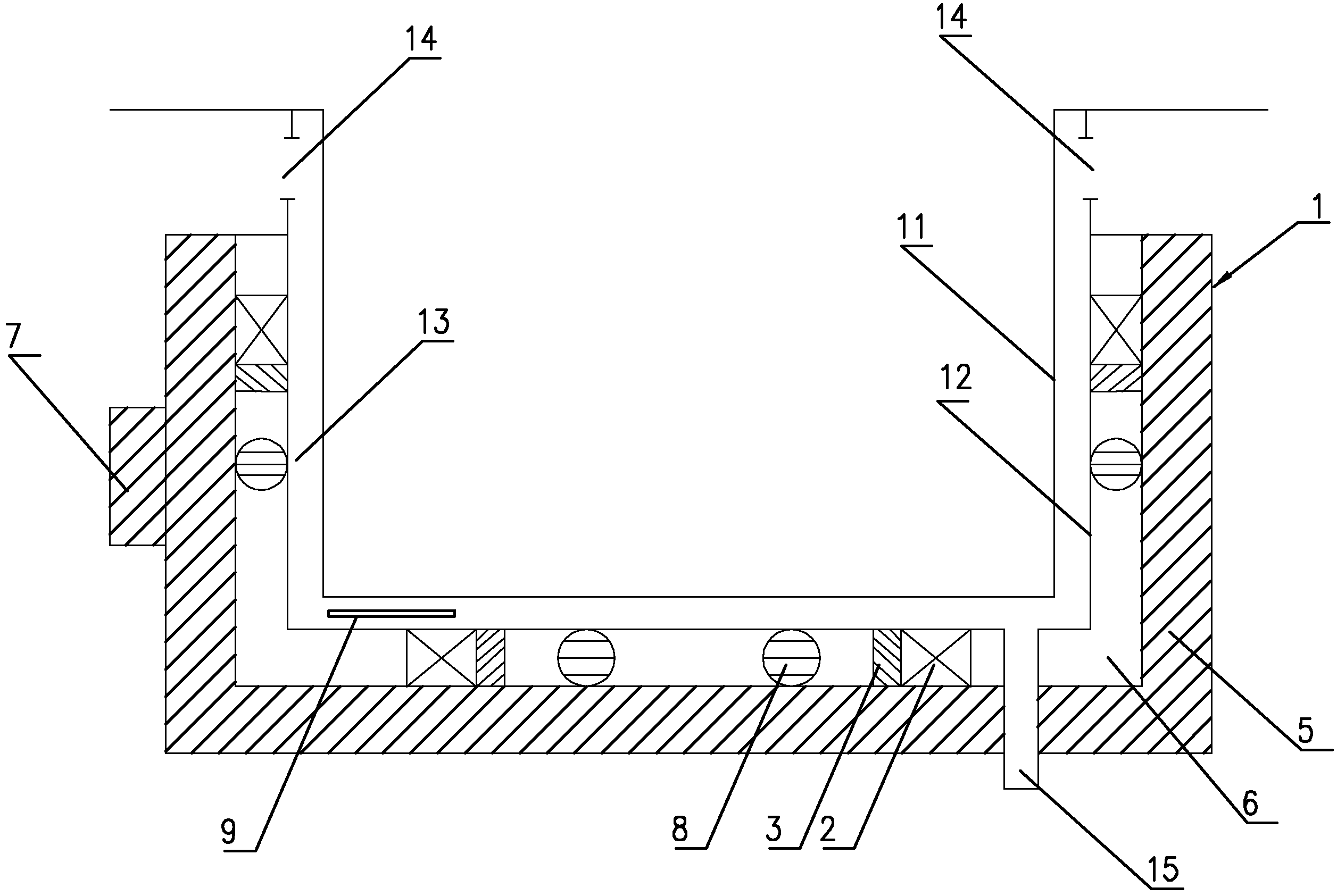

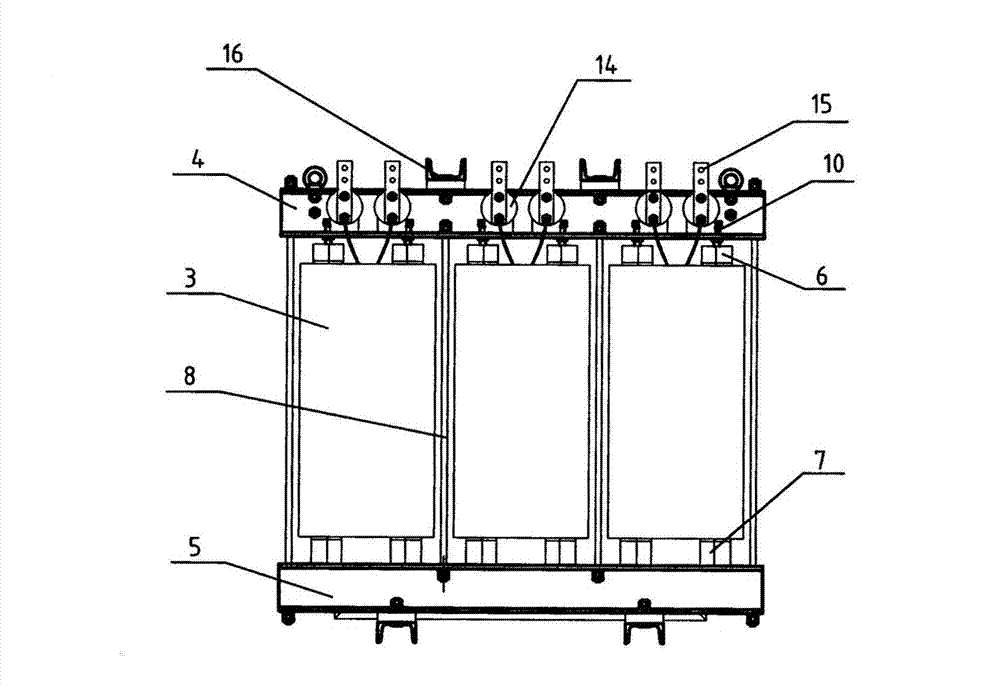

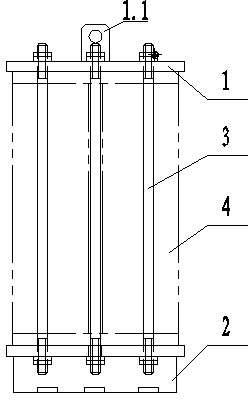

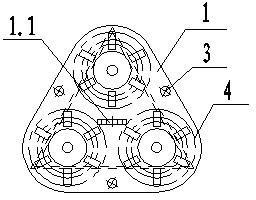

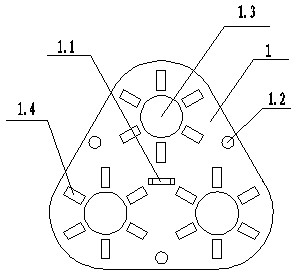

Paint dipping device for windings of power transformer

ActiveCN102683002AEven by forceTake advantage ofLiquid surface applicatorsCoatingsElectricityTransformer

A paint dipping device for windings of a power transformer consists of an upper pressing plate, a lower pressing plate and three pull screws, wherein three groups of round paint spilling holes and square paint spilling holes are formed on the upper pressing plate, as well as the lower pressing plate. The paint dipping device overcomes the shortcoming that a traditional single or single group of winding has to be fixed by a steel plate for paint dipping and vacuum drying, has a reasonable structure, is uniform in winding stress and good in paint dipping effect and can complete paint dipping ofthree windings of one power transformer at one time. By adopting the paint dipping device provided by the invention, a plurality of windings can be subjected to vacuum drying in each tank, so that the electricity-saving and insulating paint utilization effects are remarkable, the operating efficiency is high and the cost is lowered.

Owner:常德国力变压器有限公司

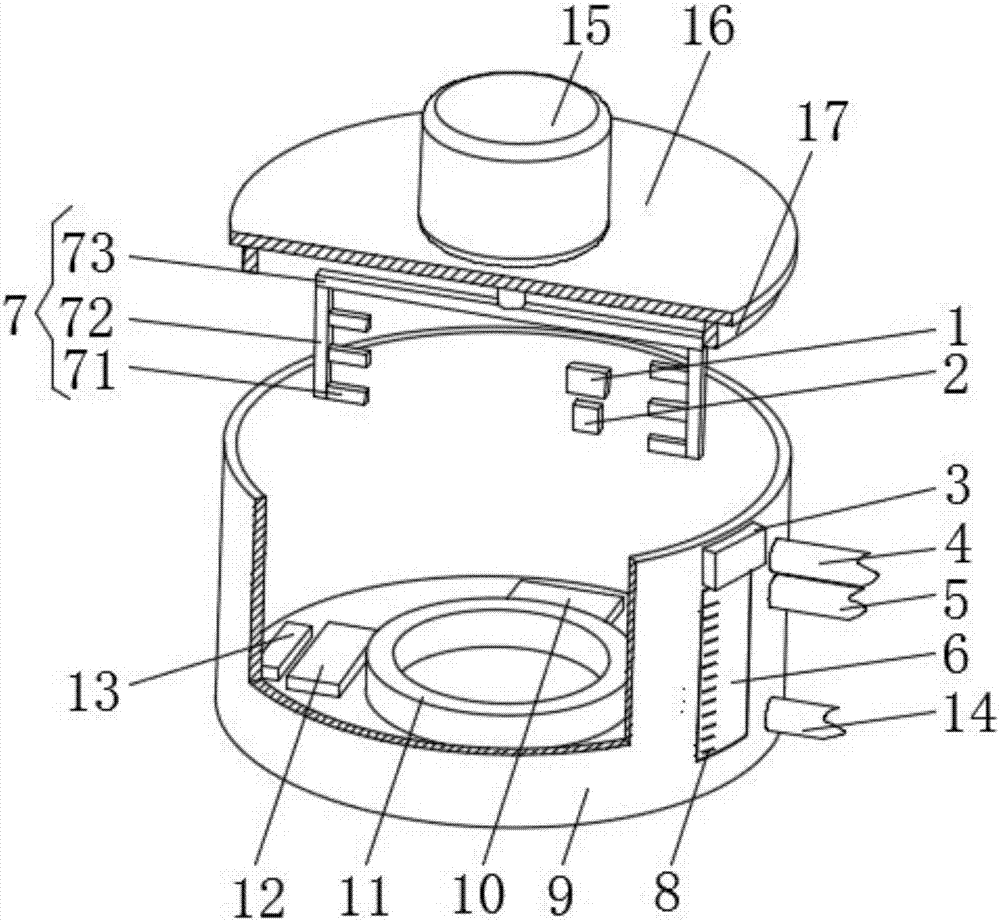

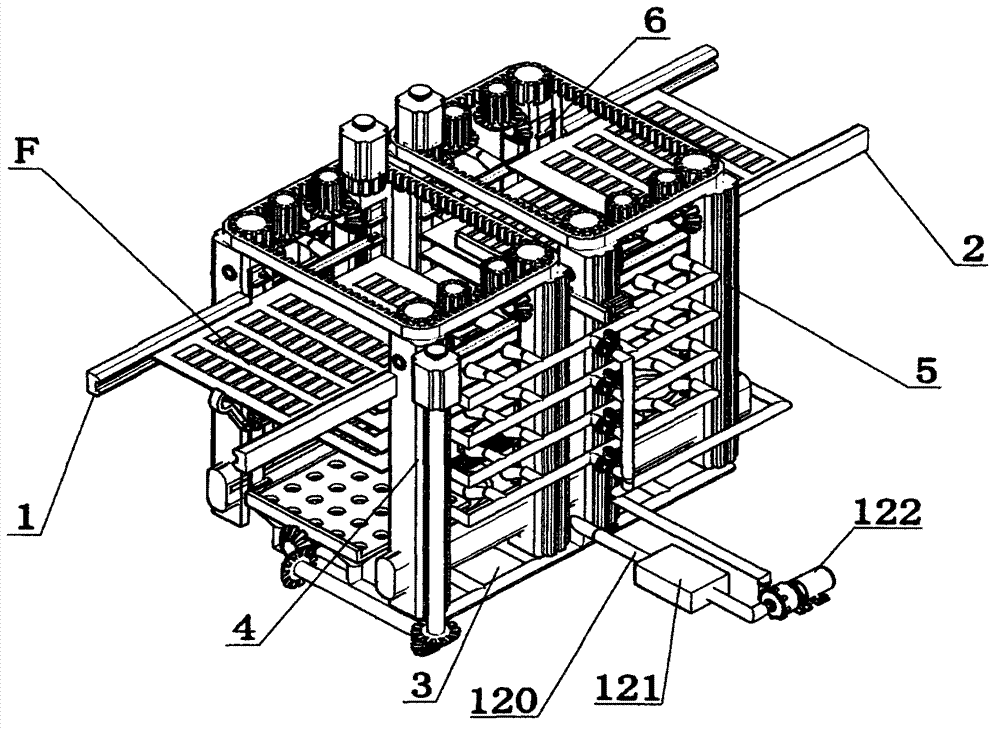

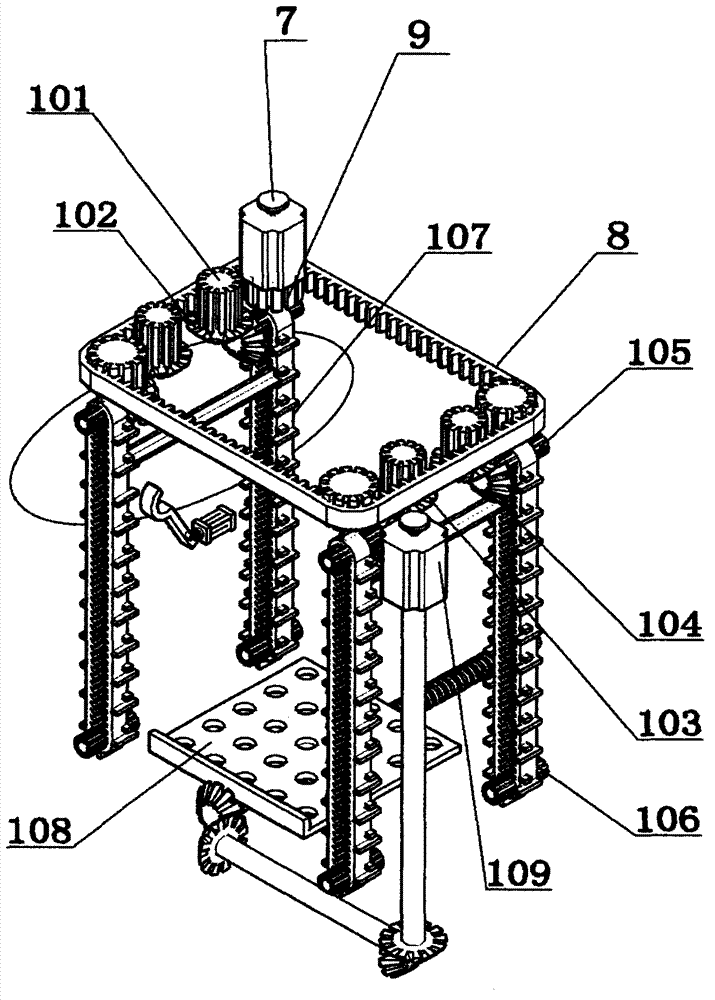

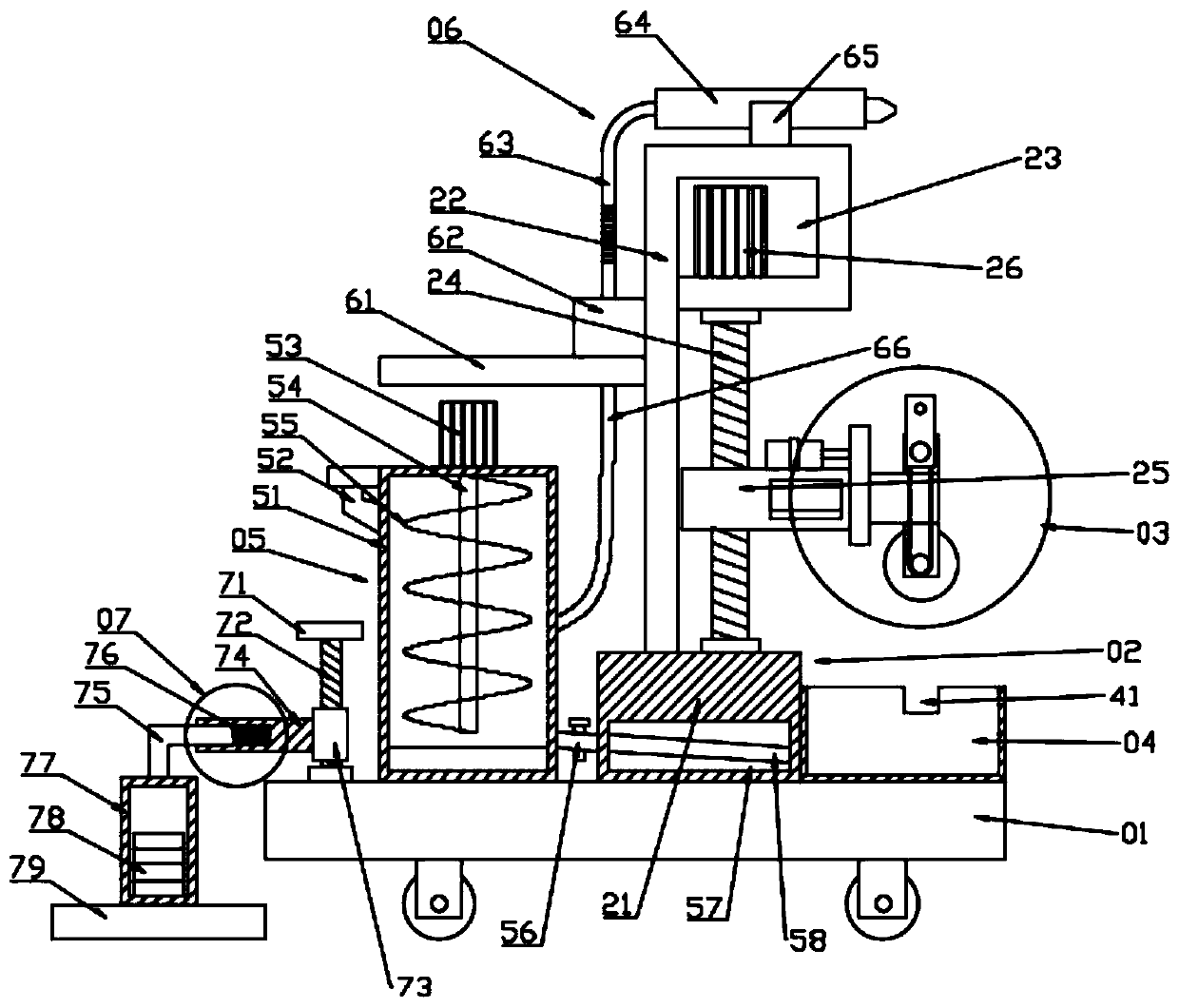

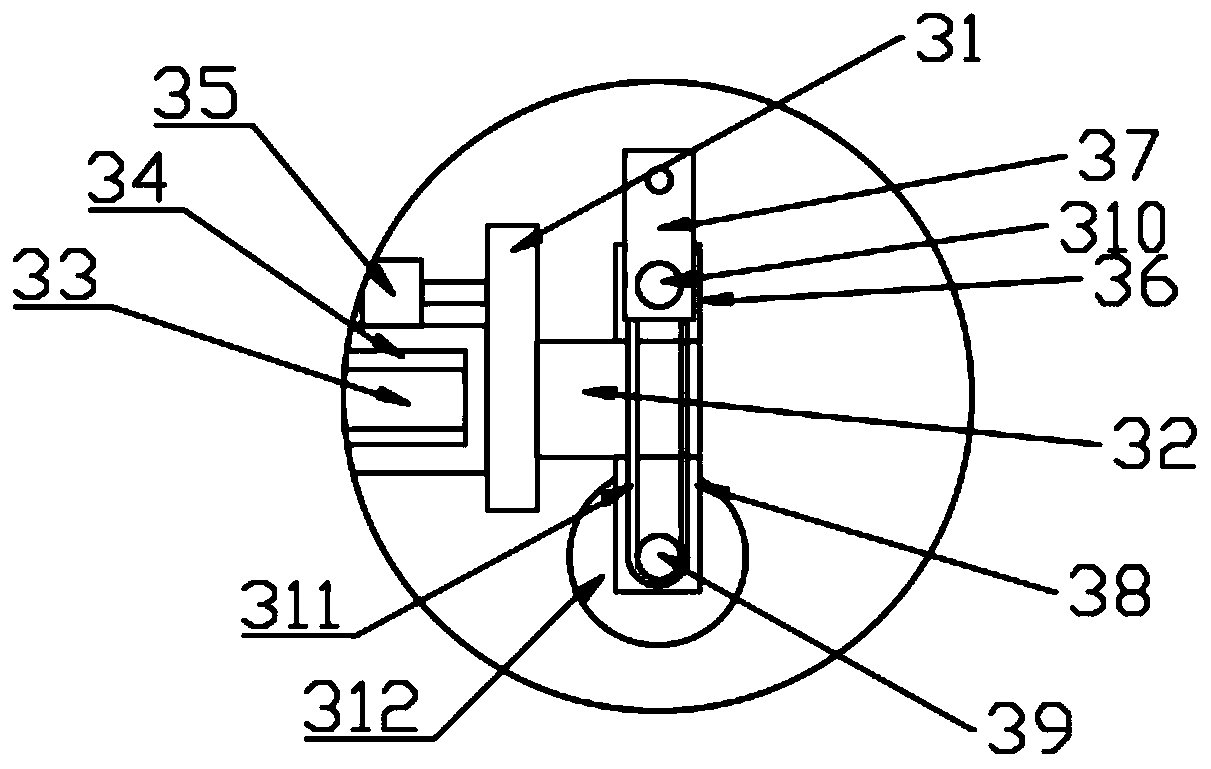

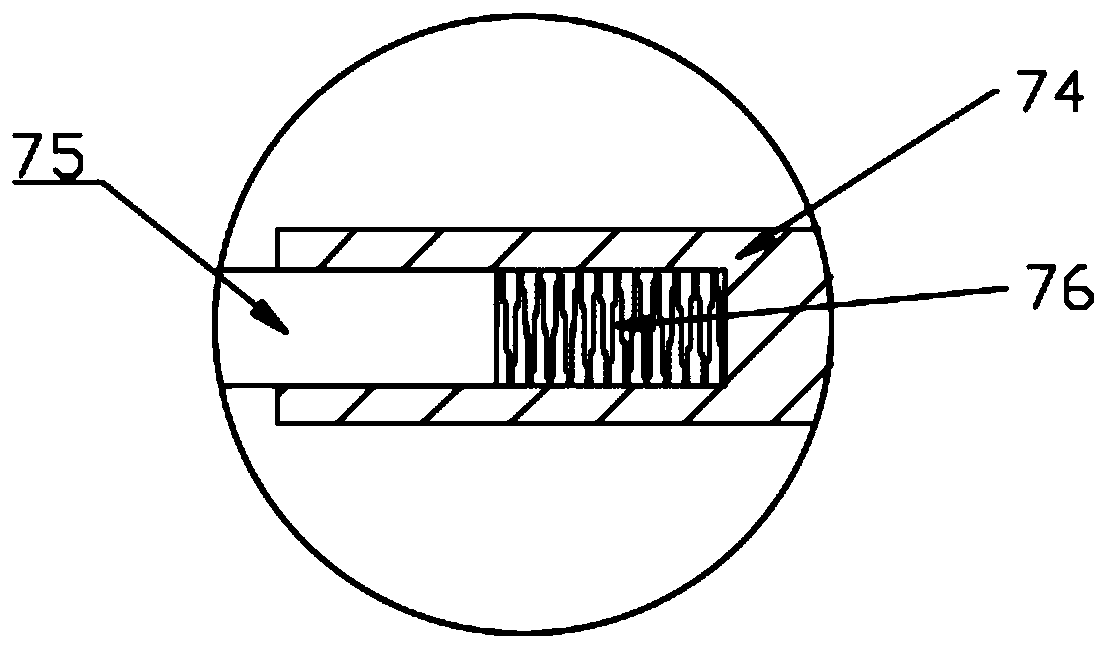

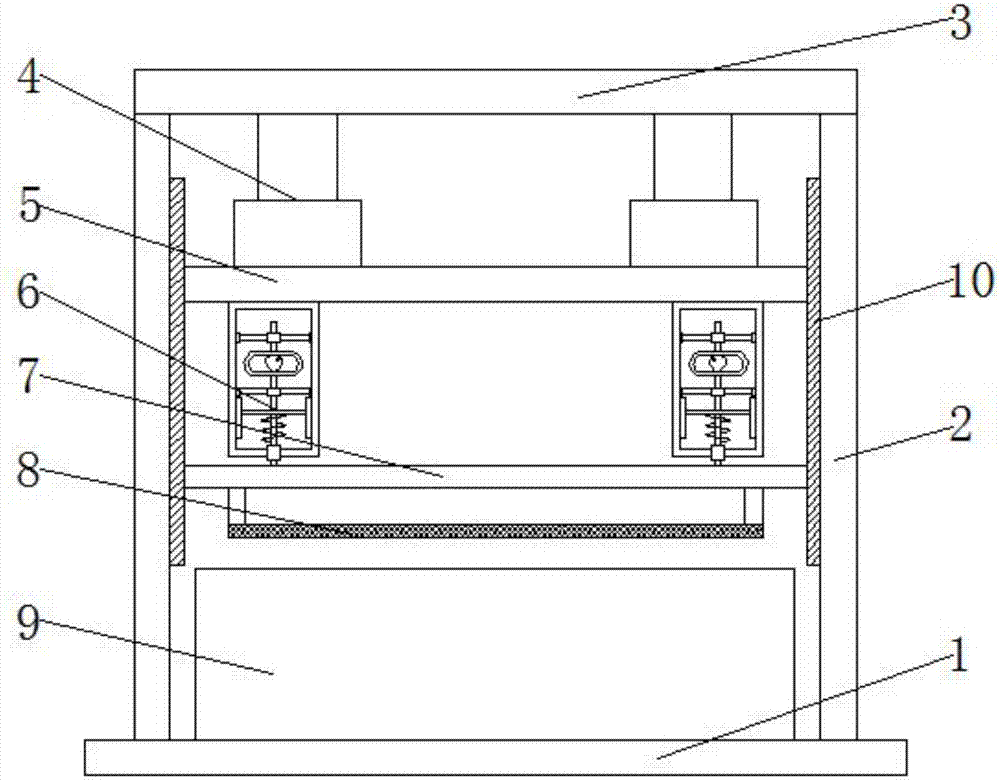

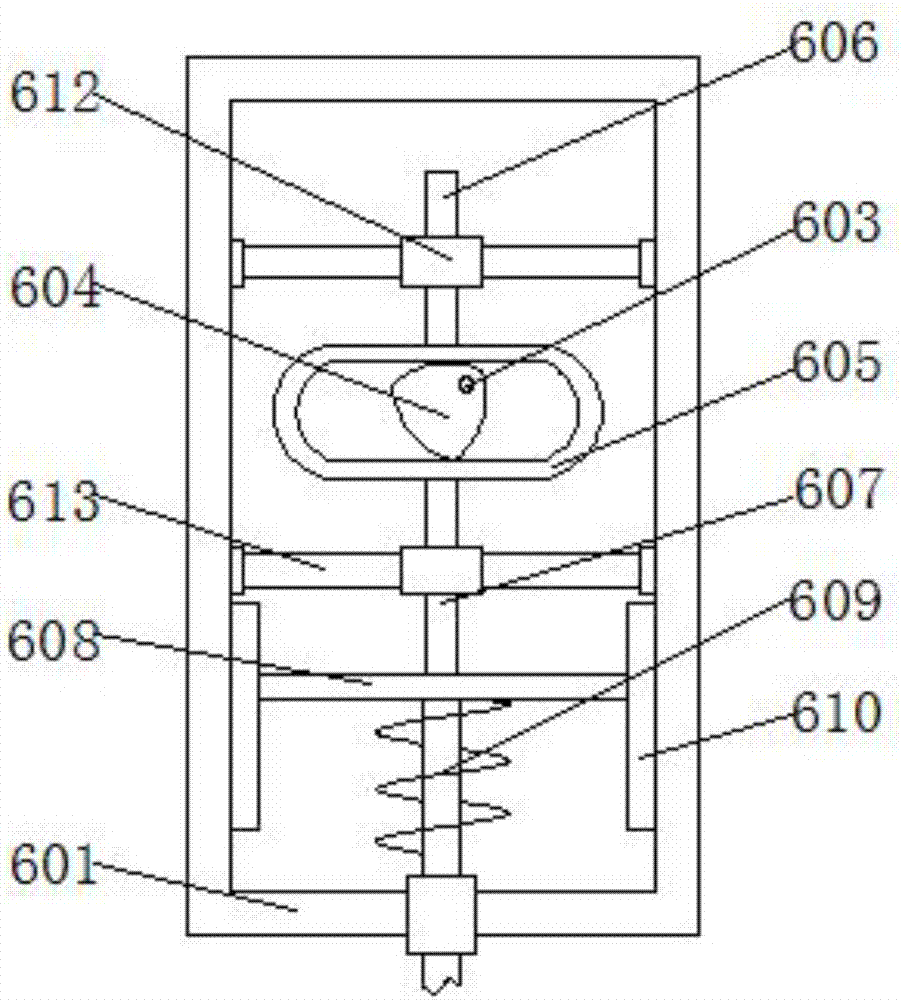

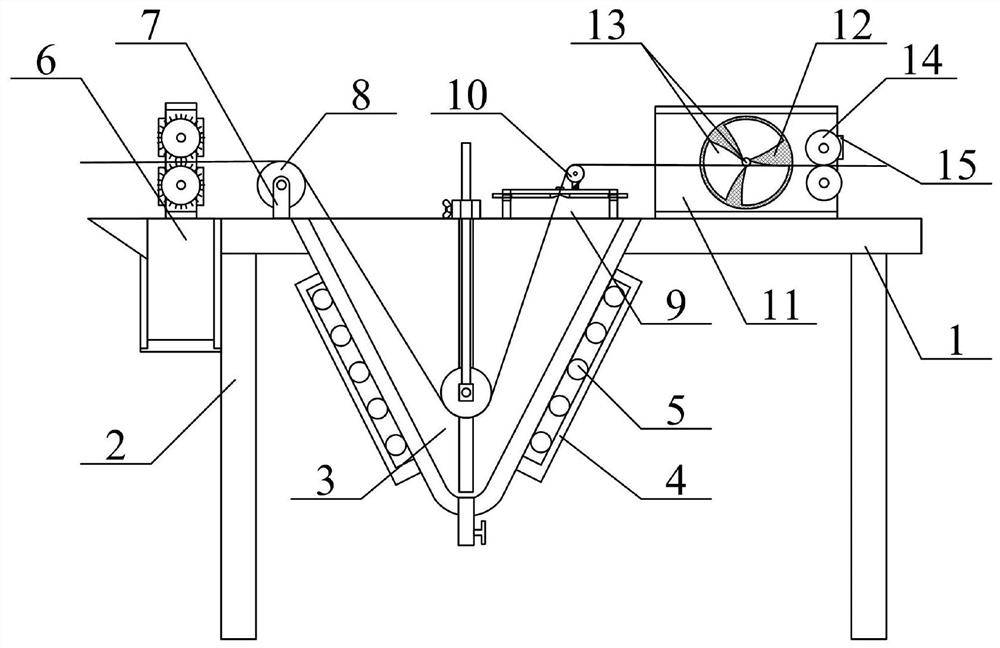

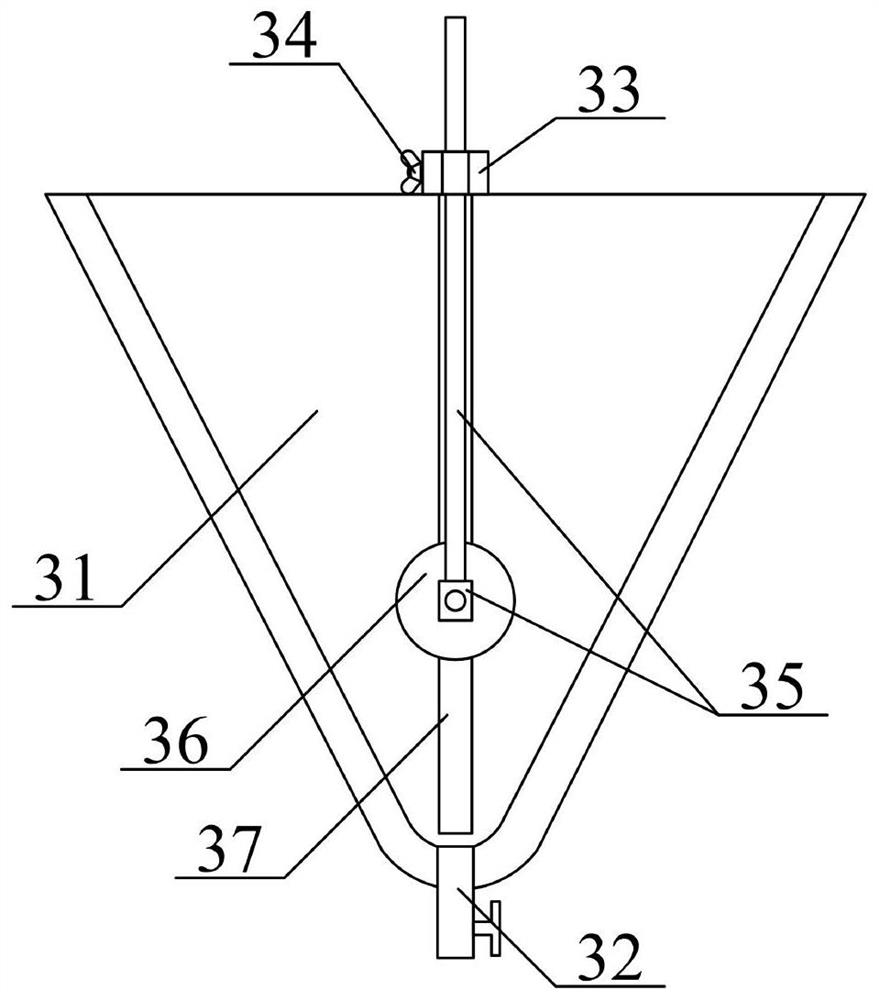

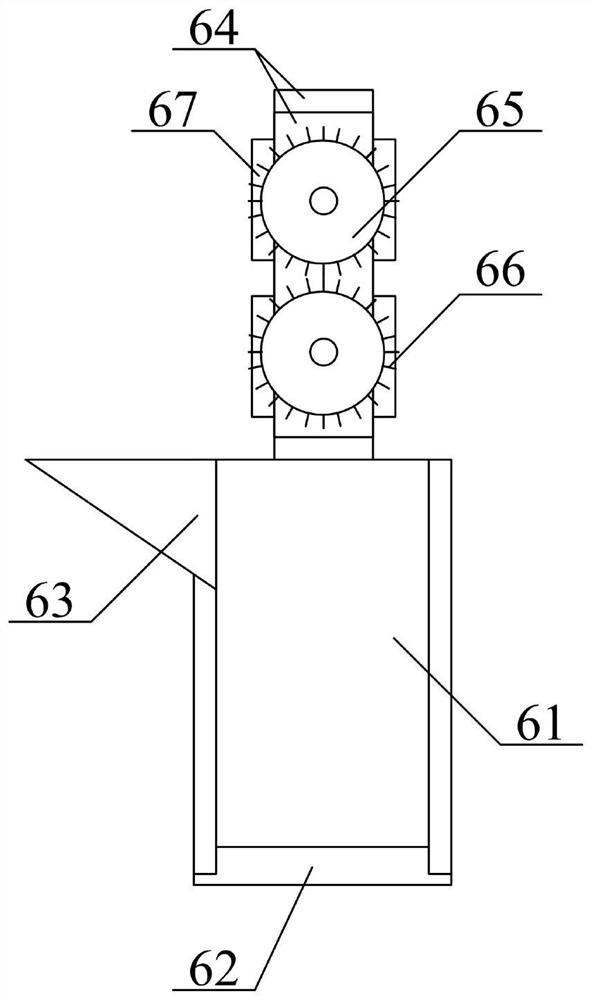

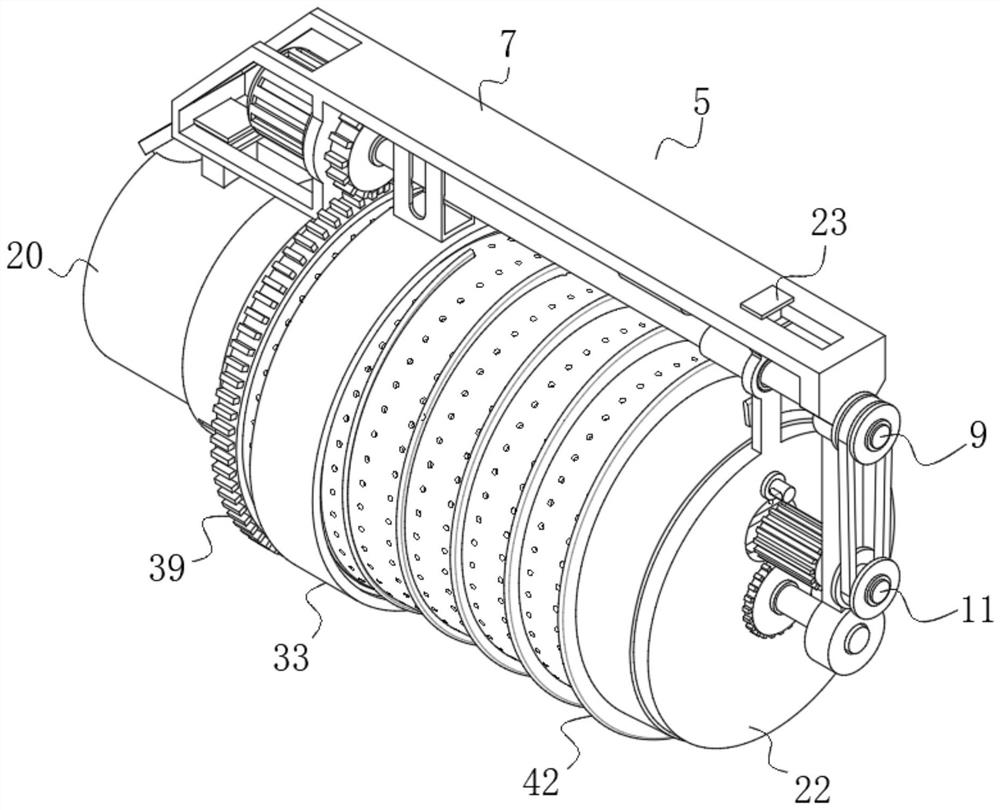

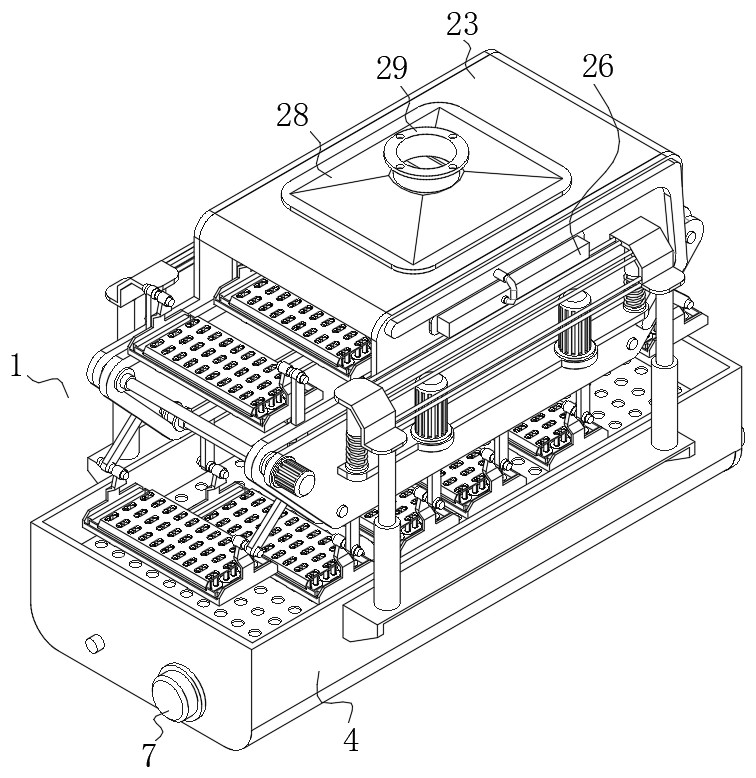

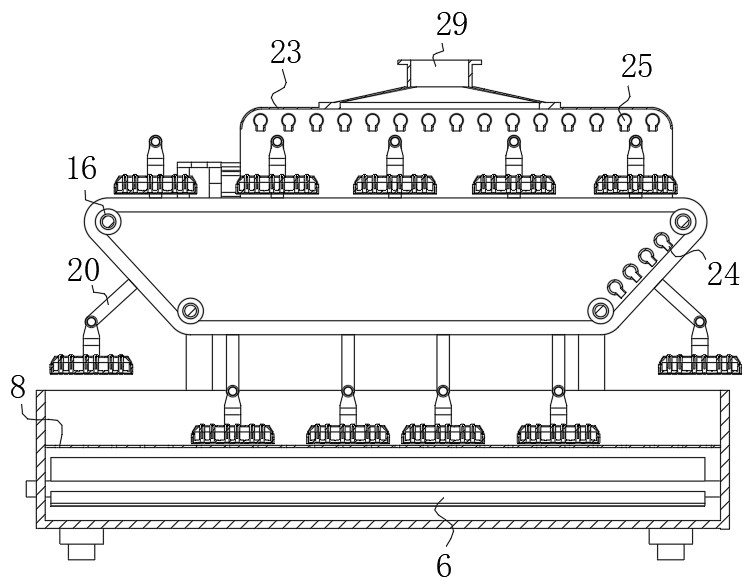

Dipping paint processing equipment and dipping paint processing method for motor stator of electric vehicle

InactiveCN113162346AInfluence of varnish effectImprove dipping effectElectric machinesManufacturing dynamo-electric machinesElectric machineElectric vehicle

The invention belongs to the technical field of electric automobile accessories and particularly relates to electric automobile motor stator paint dipping processing equipment and a paint dipping processing method. The electric automobile motor stator paint dipping processing method comprises the following steps that firstly, pretreatment is conducted, specifically, a motor stator is pre-dried, and then redundant impurities on the surface of the motor stator are removed; and step 2, paint dipping is as follows, the paint dipping cavity is filled with paint, then the pretreated motor stator is placed in the square groove, and after a cover plate is covered, air in the paint dipping cavity is pressurized through a pressurizing mechanism. The square frame and the motor stator move up and down under the action of the lifting mechanism, and meanwhile, the motor stator rolls back and forth in the square groove under the action of the swinging mechanism; and step 3, drying is as follows, a surface of the motor stator subjected to paint dipping treatment is carried out so as to cure the paint on the surface of the motor stator. According to the method, paint can permeate into gaps of the winding, so the paint dipping effect is improved; and moreover, curing of the upper paint is avoided, and the paint dipping effect is further improved.

Owner:武汉华胜天辰科技有限公司

Paint dipping device for computer fittings

ActiveCN107350122ASolve low work efficiencyImprove work efficiencyLiquid surface applicatorsCoatingsLacquerSlide plate

The invention discloses a paint dipping device for computer fittings. The paint dipping device comprises a base, wherein fixed plates are fixedly connected at the two sides of the top of the base; the tops of the fixed plates are fixedly connected with a supporting plate; electric telescopic poles are fixedly connected at the two sides of the bottom of the supporting plate; the bottom ends of the electric telescopic poles are fixedly connected with a slide plate; the two sides of the bottom of the slide plate are fixedly connected with transmission devices; the bottoms of the transmission devices are fixedly connected with a placing plate; the bottom of the placing plate is fixedly connected with a placing screen board; the bottom of the base is fixedly connected with a paint tank; the paint tank is positioned below the placing screen board; each transmission device comprises a housing; and the right side of the inner cavity of the housing is fixedly connected with a motor. The invention relates to the technical field of computers. The paint dipping device for the computer fittings solves the problem that working efficiency for the conventional paint dipping device for the computer fittings is too low, improves paint dipping effect, meets using effects of a user, and improves working efficiency of a worker.

Owner:徐州迅达网络科技有限公司

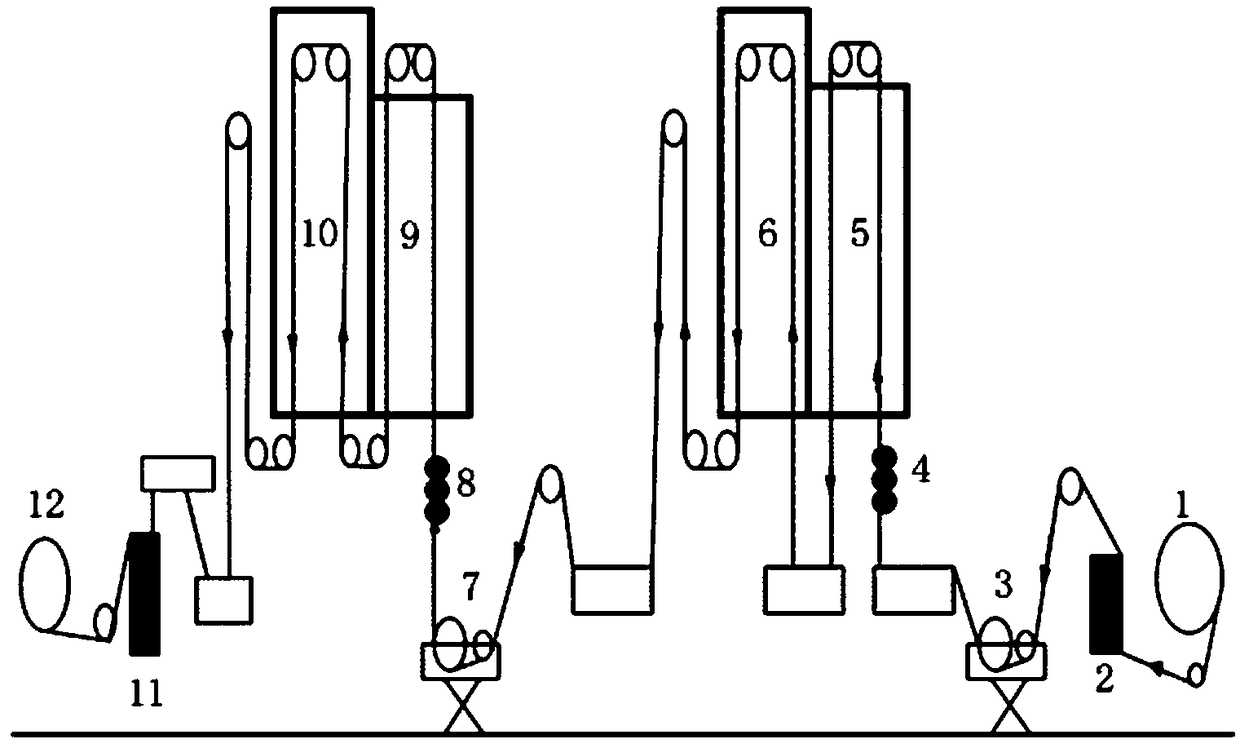

Station setting method for varnishing, drying and packing sucker rods

The invention discloses a station setting method for varnishing, drying and packing sucker rods, which is mainly used for a one-by-one varnishing procedure, a continuous drying procedure and a bundling packing procedure of the sucker rods for an oilfield. The three procedures are developed to form fifteen stations including batch feeding, single-rod turnover i, single-rod conveying, single-rod turnover ii, shifting by the aid of a shifting wheel, continuous varnishing, single-rod pre-hanging, single-rod hanging, chain conveying, continuous drying, single-rod discharging placement, single-layer placement, transfer, drop bundling and outward whole-bundle lifting, and the fifteen stations are mutually connected to realize the three procedures, so that the sucker rod varnishing effect is ideal, drying speed is fast, and the sucker rods can be bundled and packed after being dried. The station setting method has the advantages of station setting reasonableness, short anticorrosion paint film forming cycle, safety and reliability in use of a flow production line, economical production environment, environmental protection, high production efficiency, high automation degree and the like, the varnishing quality of the sucker rods can be ensured particularly at low temperature in winter, and anticorrosion paint films are even and smooth.

Owner:洛阳水星天成石油设备有限公司

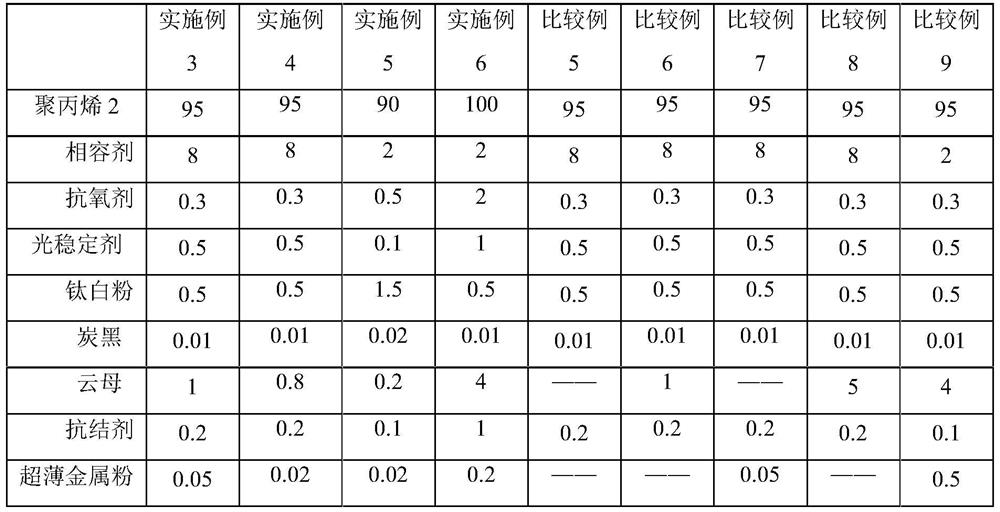

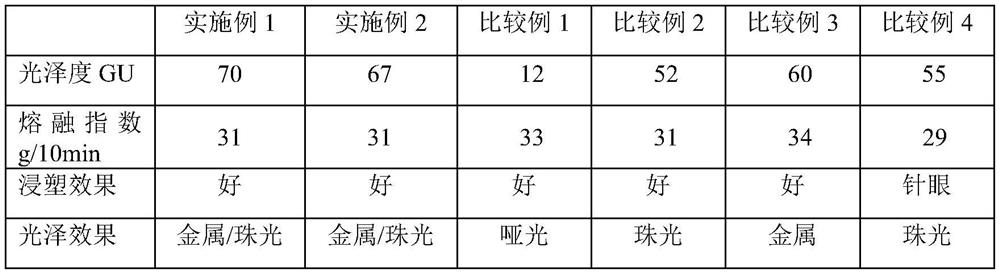

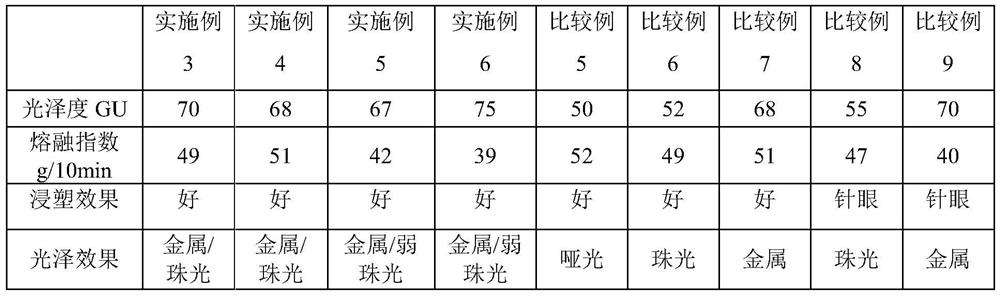

High-gloss polypropylene-based powder coating as well as preparation method and application thereof

The invention discloses a high-gloss polypropylene-based powder coating as well as a preparation method and application thereof. The polypropylene-based powder coating is prepared from the following components in parts by mass: 90-100 parts of polypropylene resin, 2-8 parts of a compatilizer, 0.5-2 parts of an antioxidant, 0.1-1 part of a light stabilizer, 0.01-2 parts of toner, 0.2-4 parts of mica powder, 0.01-0.2 part of ultrathin metal powder and 0.1-1 part of an anti-caking agent. The ratio of the width to the thickness of the ultrathin metal powder is larger than 100. According to the invention, in order to improve the surface gloss of plastic dipping and rubber coating of the polypropylene powder, through the combined action of the ultrathin metal powder and the mica powder, the glossiness of the polypropylene-based powder coating is improved without reducing the plastic dipping manufacturability of the polypropylene-based powder coating, and the polypropylene-based powder coating with high gloss and good plastic dipping effect is prepared.

Owner:会通新材料(上海)有限公司

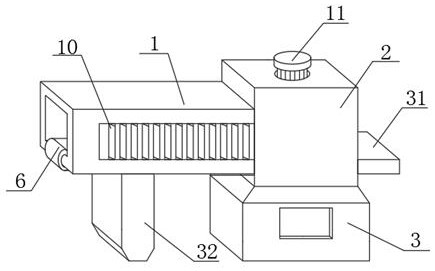

Efficient gum dipping device for raw cloth processing

InactiveCN112742673AEasy to installEasy to cleanSpraying apparatusPretreated surfacesAdhesive glueElectric machinery

The invention provides an efficient gum dipping device for raw cloth processing. The device comprises a workbench, supporting legs, a gum dipping frame structure, protective shells, an electric heating pipe, a sundry collecting frame structure, a supporting frame, a roller, a uniform gum scraping frame structure, an end cover mounting frame structure, an air drying box, a dustproof net, a fan, a driving roller and a driving motor; the supporting legs are connected to the four corners of the lower part of the workbench through bolts respectively; the gum dipping frame structure is mounted on the left side of the interior of the workbench; and the protective shells are arranged on the left side and the right side of the gum dipping frame structure correspondingly. The device has the beneficial effects that through arrangement of a mounting pipe, a mounting bolt and a supporting rod, the mounting bolt is loosened, the supporting rod is moved upwards, the supporting rod is tightly attached to the lower part of the mounting pipe, and then raw cloth winds around the lower part of the gum dipping roller, so that a worker can conveniently mount the raw cloth before gum dipping, and the worker does not need to manually enter gum to mount the raw cloth.

Owner:滨州市沾化区凯棣化工有限公司

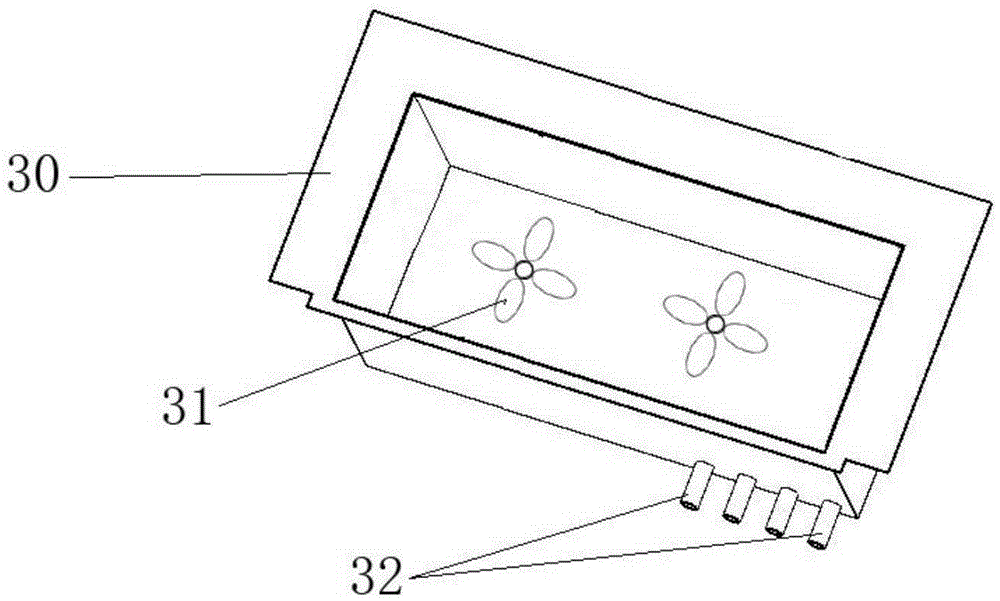

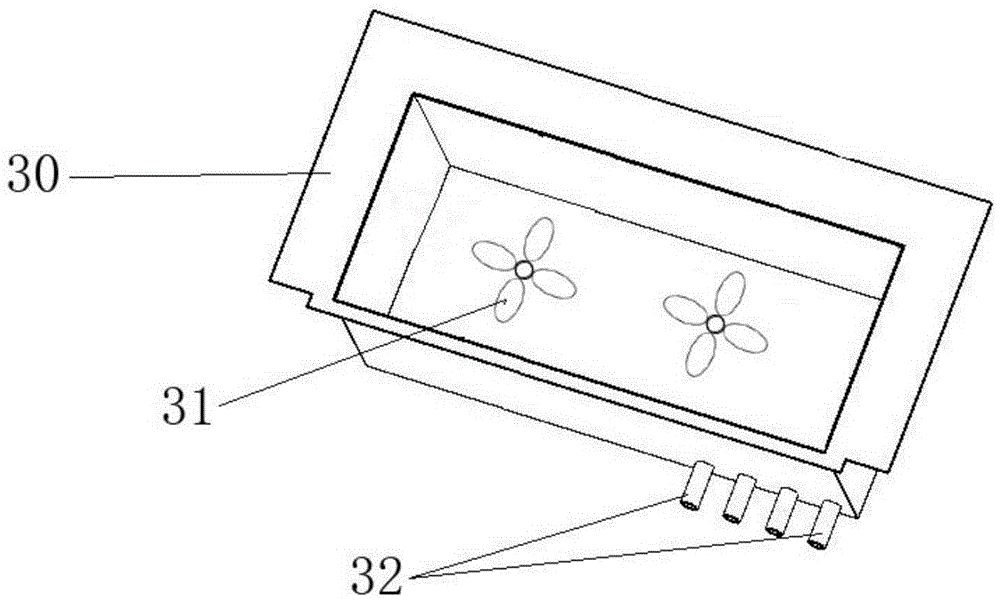

Lost foam slurry dipping device for new energy foundry

The invention discloses a lost foam slurry dipping device for a new energy foundry. The lost foam slurry dipping device comprises a dust removal box channel, an upper working box and a lower working box; a driven wheel, a driving wheel and a belt are arranged at the bottom of the dust removal box channel; the driven wheel and the driving wheel are connected through the belt; a containing plate is fixed to the belt; a tree set mold frame is arranged on the containing plate; three sets of ash removal fans are arranged on one side face of the dust removal box channel at equal intervals; and a shutter is installed on the other side face of the dust removal box channel. According to the lost foam slurry dipping device for the new energy foundry, a slurry dipping device is designed and matched with the movement of a slurry lifting barrel from bottom to top, slurry is slowly pressed into the slurry dipping device, the tree set mold frame is submerged by the slurry, passive slurry dipping is achieved in this way, the impact acting force is small, and damage and breakage of the tree set mold frame are avoided; and then a rotating motor is started, the whole slurry dipping device is driven to rotate, the tree set mold frame makes uniform contact with the slurry, the slurry dipping effect is remarkably improved, the lost foam slurry dipping device is suitable for different working conditions, and better application prospects are brought.

Owner:含山县承力铸造厂

Self-adhesive tape gum dipping and drying system

PendingCN111871715AIncrease the itineraryIncrease dipping timeLiquid surface applicatorsCoatingsGlass fiberAdhesive

The invention relates to a self-adhesive tape gum dipping and drying system. The system is characterized by comprising a gum dipping module and a drying module; the drying module is arranged at the output end of the gum dipping module; tensioning rollers are arranged on a roller set frame, and when self-adhesive tape is wound around the tensioning rollers of the roller set frame, the glass fiber self-adhesive tape between the two tensioning rollers is tensioned through eccentric adjustment of the tensioning rollers, so that tension is formed on the surface of the self-adhesive tape; the problem that a sizing material film is formed and cannot be soaked under the condition that the gap density of the self-adhesive tape is large is solved; besides, by arranging adjusting rollers, the strokeof the self-adhesive tape between the adjusting rollers is increased, the gum dipping time of the self-adhesive tape is prolonged, and the gum dipping effect is improved; and secondary glue brushing is executed at the side edge of a drying tower body, the glass fiber self-adhesive tape subjected to primary glue dipping and drying is brushed with adhesive sticker again, meanwhile, the glass fiber self-adhesive tape is turned into the drying tower body to be subjected to secondary drying, extra drying equipment does not need to be additionally arranged, the using field is saved, and the structure is simpler.

Owner:南通拓普新型建材有限公司

Roll immersion equipment for rotor machining and machining method thereof

PendingCN114481275AImprove dipping effectIncrease speedElectrolysis componentsCleaning using liquidsEngineeringMachining

The invention discloses roll-dipping equipment for rotor machining and a machining method of the roll-dipping equipment, and relates to the technical field of barrel-plating equipment. The device comprises a tank body, a cleaning tank and a barrel plating tank which are isolated from each other are sequentially formed in the tank body from front to back, a discharging hopper is fixedly installed on the end face of the tank body, a supporting mechanism is fixedly installed on the peripheral side face of the tank body, and two symmetrical driving parts are installed between the opposite surfaces of the tank body and the supporting mechanism; and a roll dipping mechanism is fixedly installed on the bottom face of the supporting mechanism, two pump bodies are installed on the side face of the tank body, and one ends of water inlets of the two pump bodies communicate with the cleaning tank and the barrel plating tank correspondingly. Through the design of the roll dipping mechanism, the device can efficiently complete the roll dipping operation of rotor parts, the device can also realize the pretreatment of rotors in an automatic mode during the roll dipping operation, and through the realization of the pretreatment function, the multifunctionality and the automation degree of the device are effectively improved.

Owner:重庆宝迪科技有限公司

Leakage-proof gum dipping tank for glove processing

InactiveCN108080212AImprove dipping effectExtended service lifeLiquid surface applicatorsRotary stirring mixersBiochemical engineeringSteel plates

The invention discloses a leakage-proof gum dipping tank for glove processing. The leakage-proof gum dipping tank comprises a gum dipping tank body and a gum dipping tank power base, wherein a gum liquid inlet pipe is fixedly arranged on one end of the gum dipping tank body; overflow pipes are parallelly and fixedly arranged above the other end of the gum dipping tank body; a gum liquid outlet pipe is arranged at one end, which is close to the gum dipping tank body, under the middle part between the adjacent overflow pipes; installation guide rails are movably arranged on the lower end of thegum dipping tank power base; reinforced steel plate placement cavities are fixedly arranged at two sides of the inner part of the gum dipping tank body. The leakage-proof gum dipping tank for the glove processing, disclosed by the invention, is provided with the overflow pipes, the reinforced steel plate placement cavities and stirring blades, so that leakage of the gum dipping tank during use canbe prevented, the gum dipping tank can be reinforced, and the weather fastness of the gum dipping tank body is increased; meanwhile, a gum dipping effect of gloves can be increased, the leakage-proofgum dipping tank is applicable to different working situations, and a better using prospect is brought.

Owner:浙江倬瑜服饰有限公司

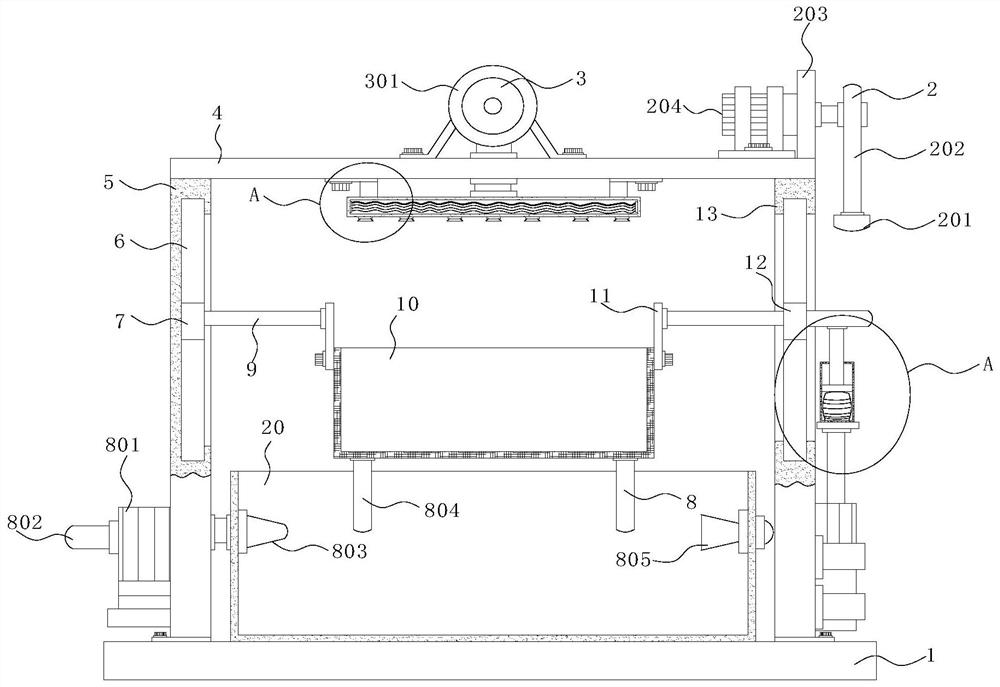

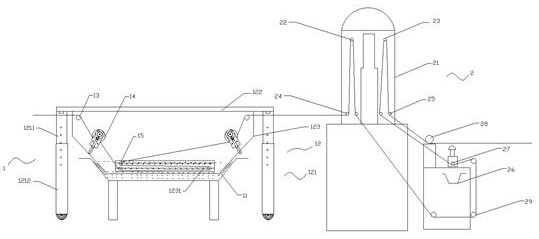

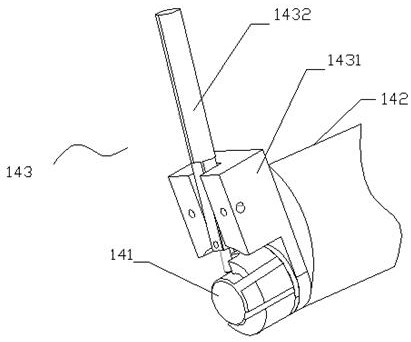

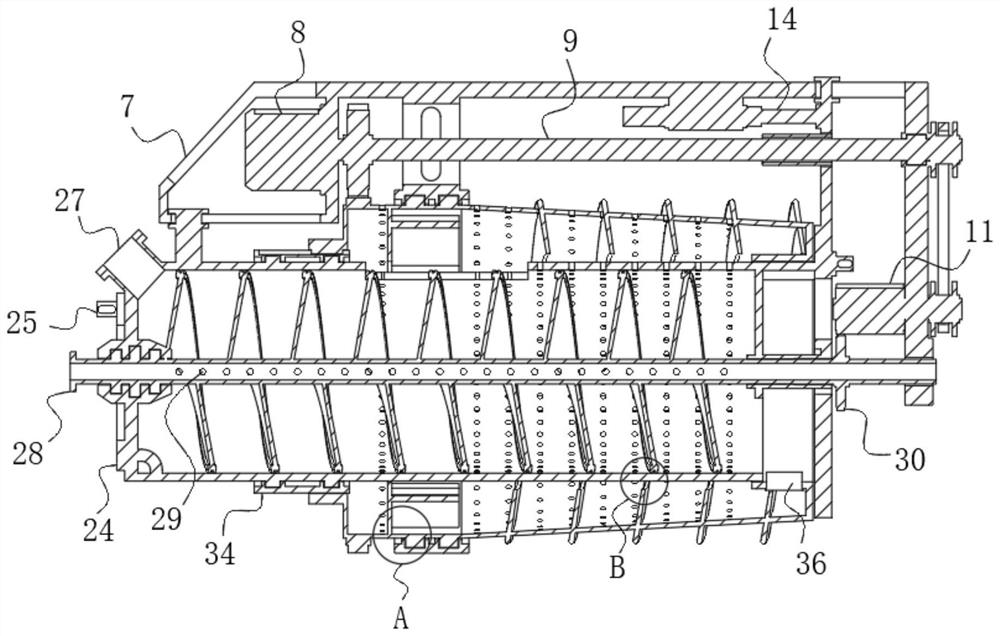

Typesetting and paint dipping equipment and typesetting and paint dipping method for choking coil

InactiveCN112489993AImprove processing efficiencyImprove the dipping effectCoils manufactureElectric machineryStructural engineering

The invention discloses typesetting and paint dipping equipment for a choking coil, and belongs to the technical field of choking coil processing. The equipment comprises an equipment body, wherein the equipment body comprises a paint storage mechanism and a feeding mechanism which are connected in sequence; the paint storage mechanism comprises a paint storage box, two rotating shafts which are symmetrically arranged and connected through a belt are rotationally connected between the inner surfaces of the paint storage box, the circumferential side faces of the two rotating shafts are each fixedly connected with a set of stirring blades distributed in a circumferential array, the end face of the paint storage box is fixedly connected with an auxiliary motor, and one end of an output shaftof the auxiliary motor is fixedly connected with one rotating shaft. Through the design of the paint storage mechanism and the feeding mechanism, the device can integrally complete paint dipping anddrying operation of the choking coil in an automatic mode, during paint dipping operation, two guide foot parts of the choking coil can be effectively subjected to anti-dipping protection, and throughintegrated completion of the operation, the machining efficiency and the paint dipping effect of the device are effectively improved.

Owner:南京荧河谷科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com