Paint dipping device for windings of power transformer

A technology for power transformers and windings, which is applied to the device for coating liquid on the surface, coating, and coil manufacturing. The effect is good, the structure is simple, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

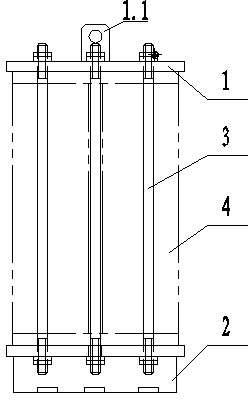

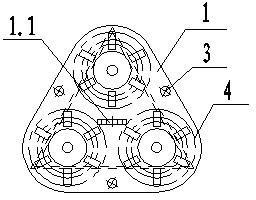

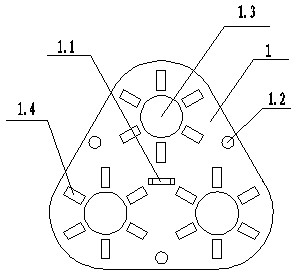

[0012] The technical content of the present invention will now be described in detail in conjunction with the accompanying drawings.

[0013] The present invention includes an upper platen 1, a lower platen 2 and three pull screws 3. ①The upper platen 1 is triangular in shape, the hanging plate 1.1 is placed in the middle of the upper platen 1, and the three upper platen pull screw holes 1.2 are opened on the upper platen 1 in a triangular shape. , 3 upper platen overflow paint holes 1.3 are triangularly opened on the upper platen 1, and each upper platen round overflow paint hole 1.3 is evenly opened with a plurality of upper platen square overflow paint holes 1.4; ②The lower platen 2 is triangular in shape, The triangular plate 2.1 is connected with the lower pressing plate 2, and each side of the triangular plate 2.1 is provided with a plurality of triangular plate overflow paint tanks 2.5, and the three lower pressing plate pull screw holes 2.2 are opened on the lower press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com