Patents

Literature

81 results about "Packing procedure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

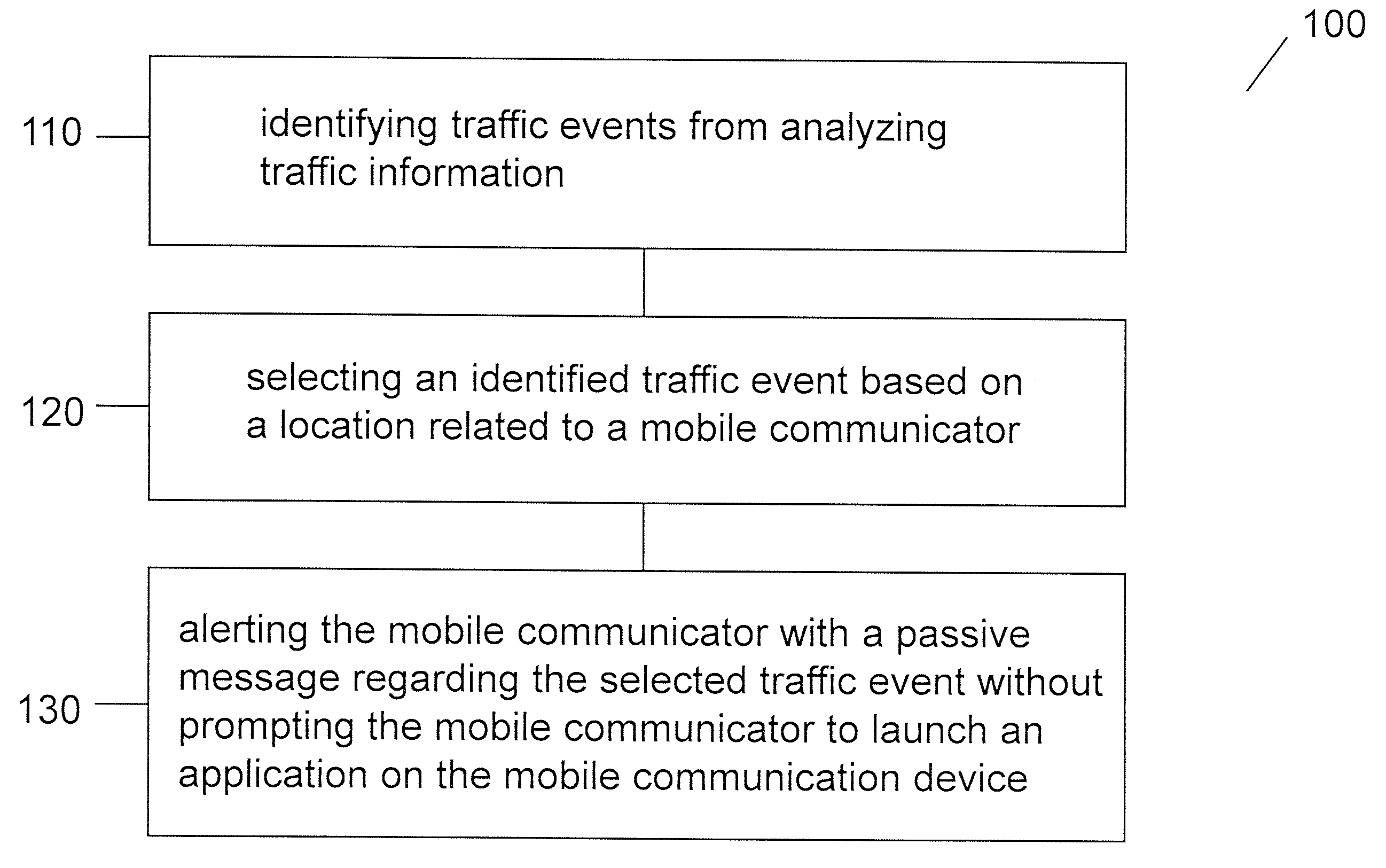

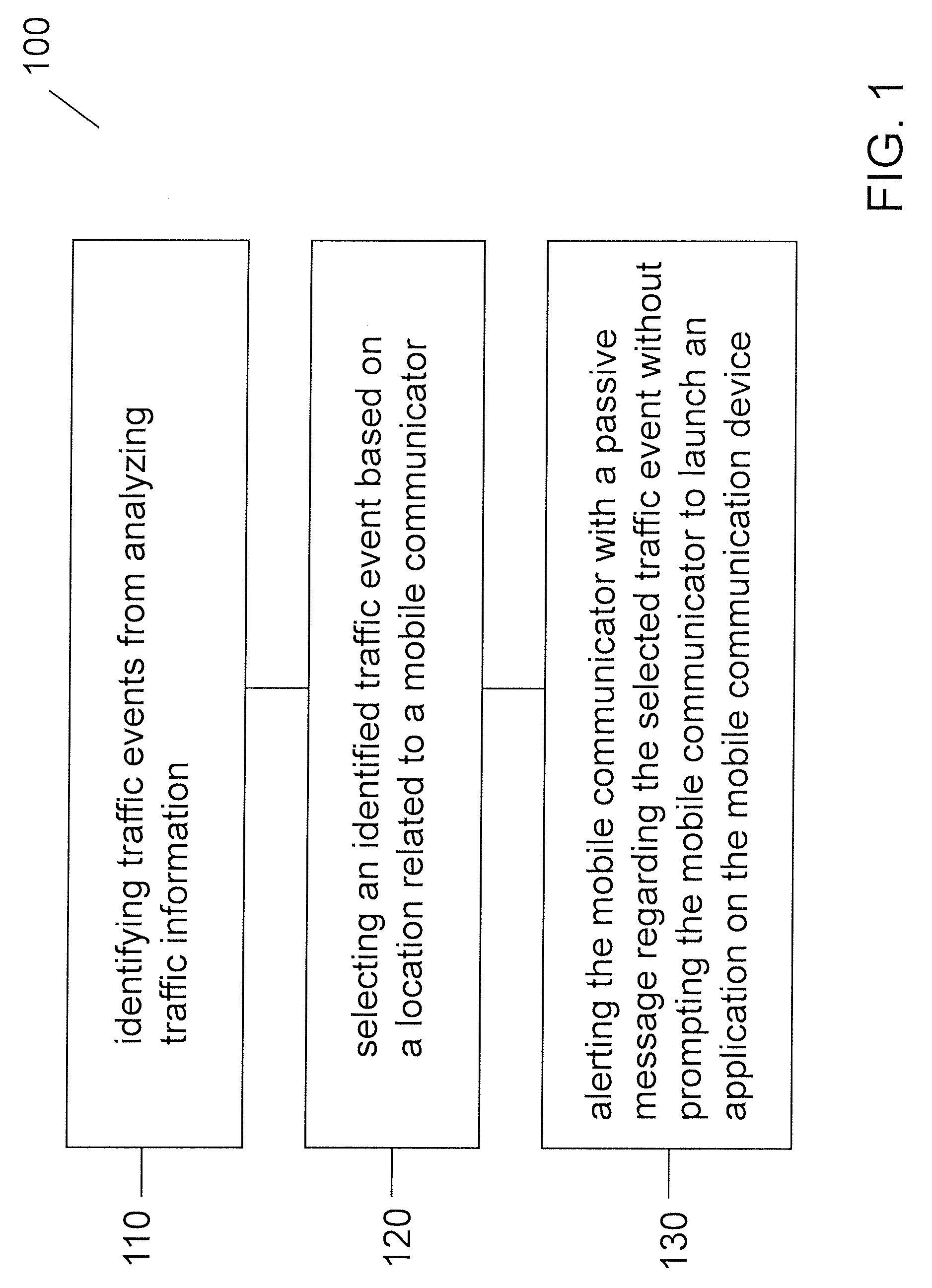

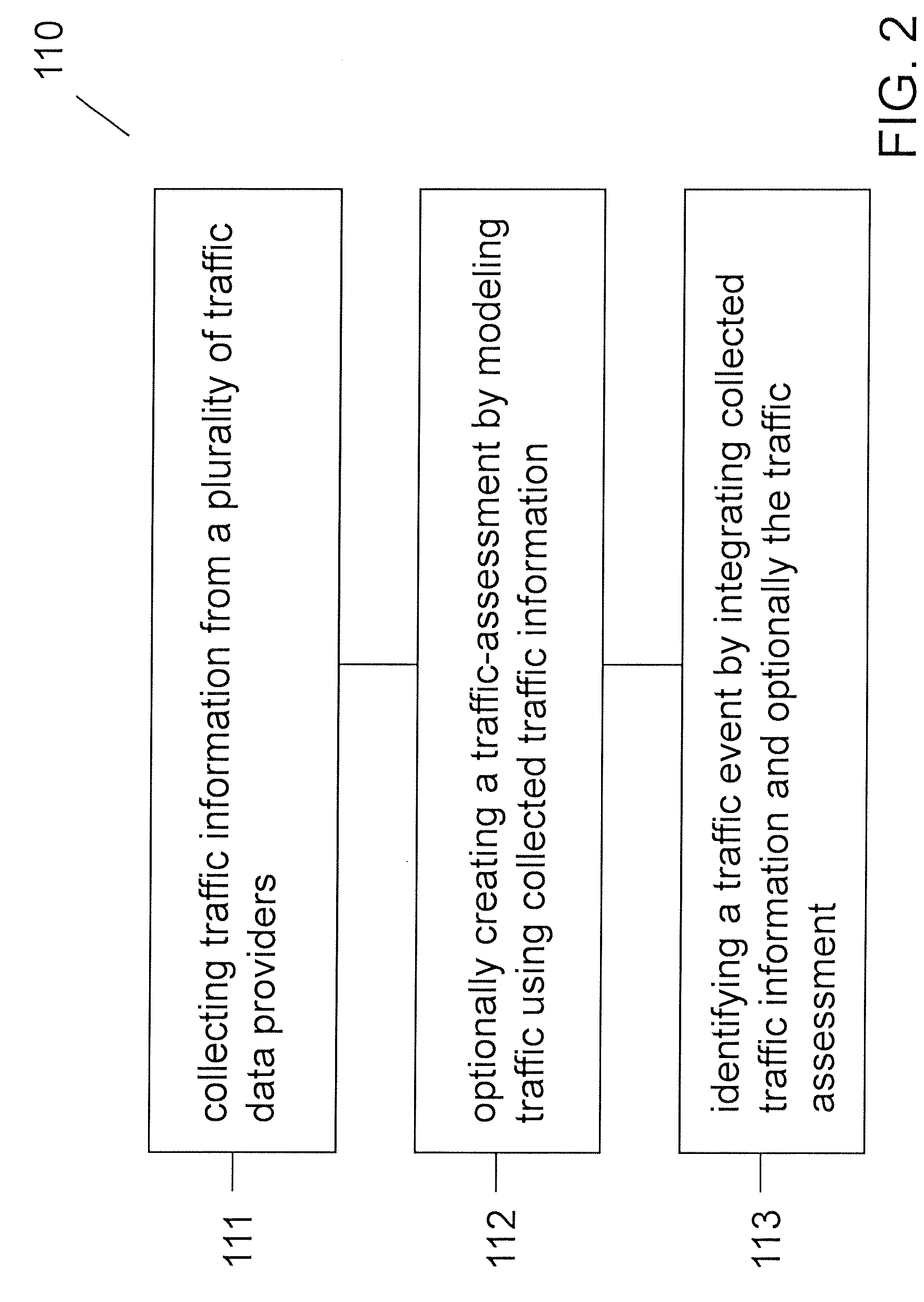

Mobile alerting network

ActiveUS20090176511A1Sufficient operationService provisioningLocation information based serviceSensor arrayOn board

A Mobile Alert Network service includes identifying an Alert Area related to an Event Location, identifying a group of subscribers in the Alert Area, and broadcasting an Alert Message to the identified subscribers in a push-to-talk-equivalent environment. The Alert Messages can alert the subscribers about the cause of the alert, offer message related choices, and offer event related choices, such as promotion information or offers. The MAN Service may include an Alert Information Service, a Subscriber Selector, and a Broadcast Module to generate an Alert Message. The event related choices may be generated based on campaigns by Promotional Agents. A wrapper can be downloaded to manage Alert Messages, a mailbox, and to update on board applications. A on-board logger can provide a detailed account of the operations of the handset and its user. A Sensor Array can be used to determine the location of users, based on the self-identification information, broadcast by the cell phones.

Owner:GLOBAL TRAFFIC NETWORK INC

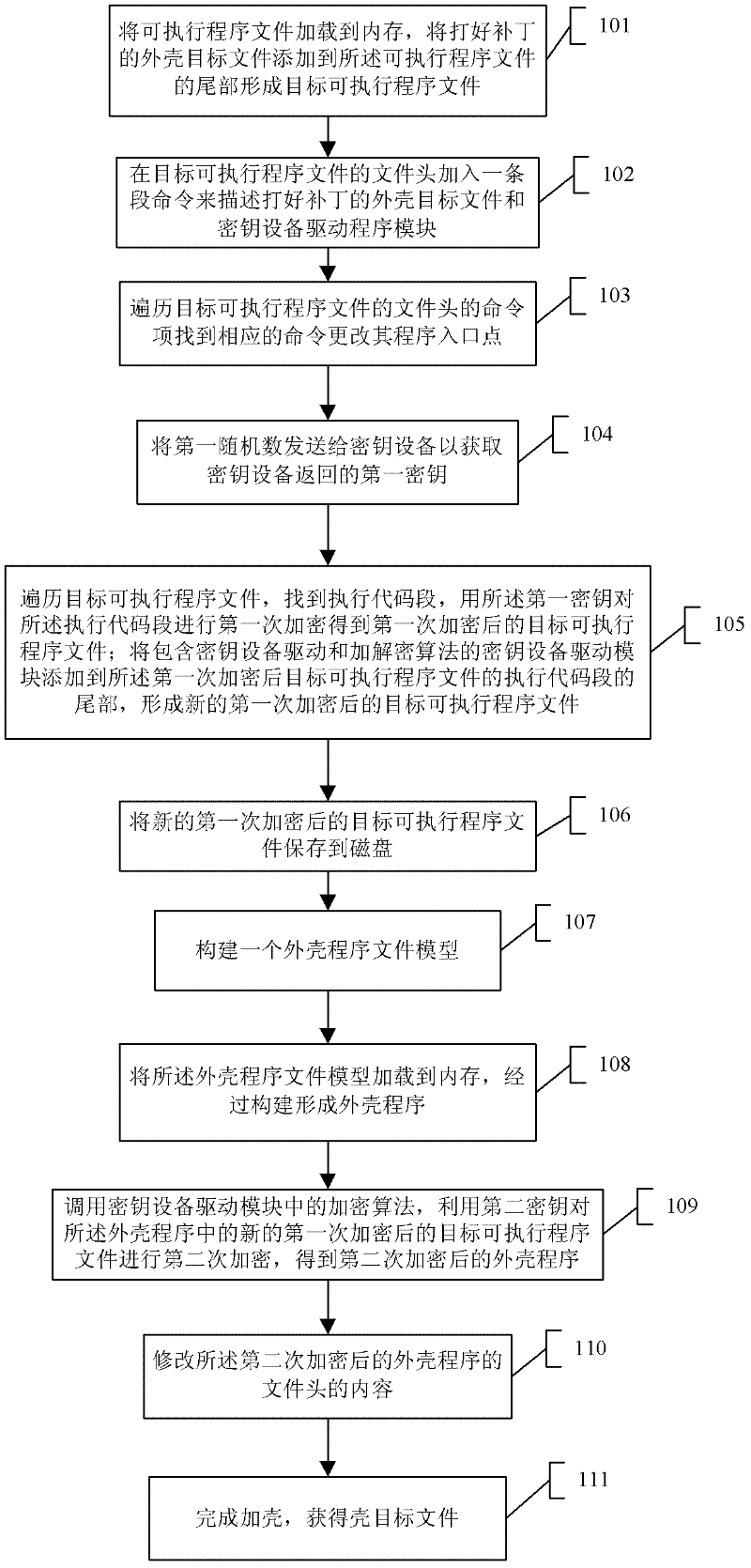

Protecting method for packing executable program

ActiveCN102609666AImprove securityIncrease the difficultyPlatform integrity maintainanceProgram/content distribution protectionPacking procedureComputer software

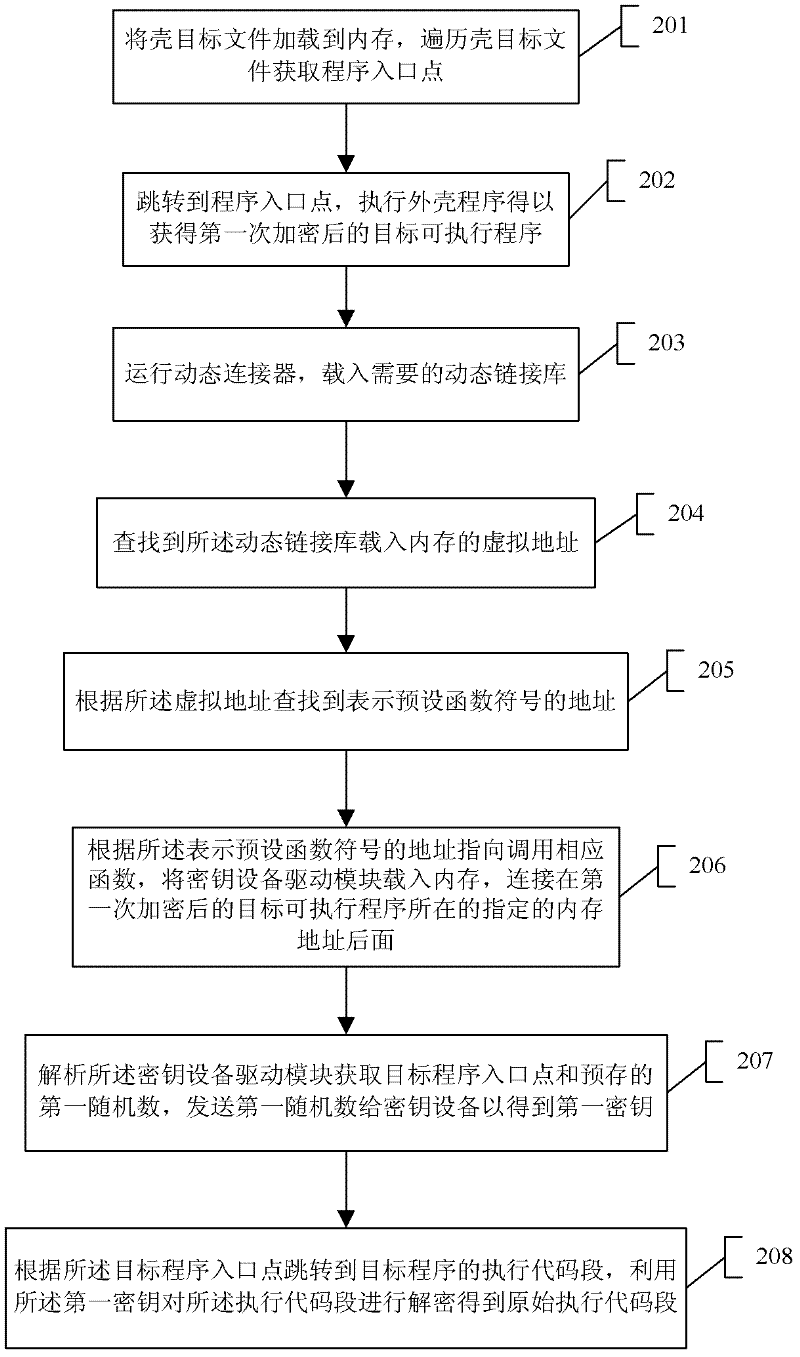

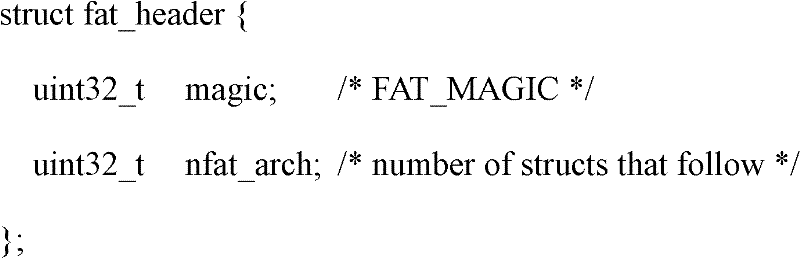

The invention discloses a protecting method for packing an executable program, belonging to the technical field of computer software program protection, wherein the method comprises the following steps: firstly, adding a shell target file with fixed patches to the tail part of an executable program file so as to form a target executable program file; modifying a file head correspondingly; processing a first encryption to an executed code section; adding a key equipment drive program module to the tail part of the file which is encrypted at the first time so as to form a new target executable program file which is encrypted at the first time; constructing a shell program; processing a secondary encryption to the new target executable program file of the shell program which is encrypted at the first time; modifying the file head correspondingly; and completing a packing procedure, and storing the current shell program. According to the invention, the problems that packing-protected software is cracked by an attacker easily and distorted illegally in the prior art are effectively solved.

Owner:FEITIAN TECHNOLOGIES

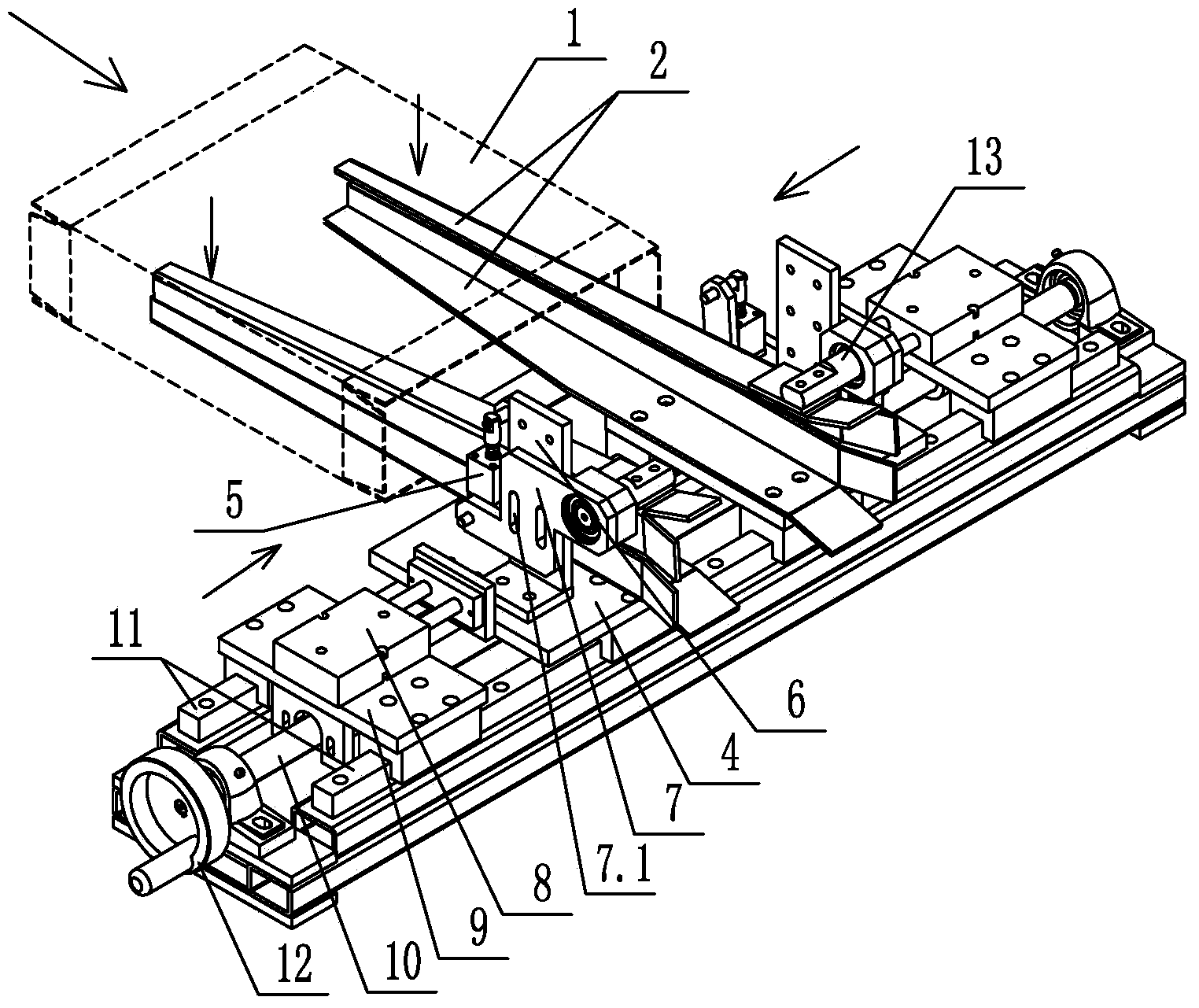

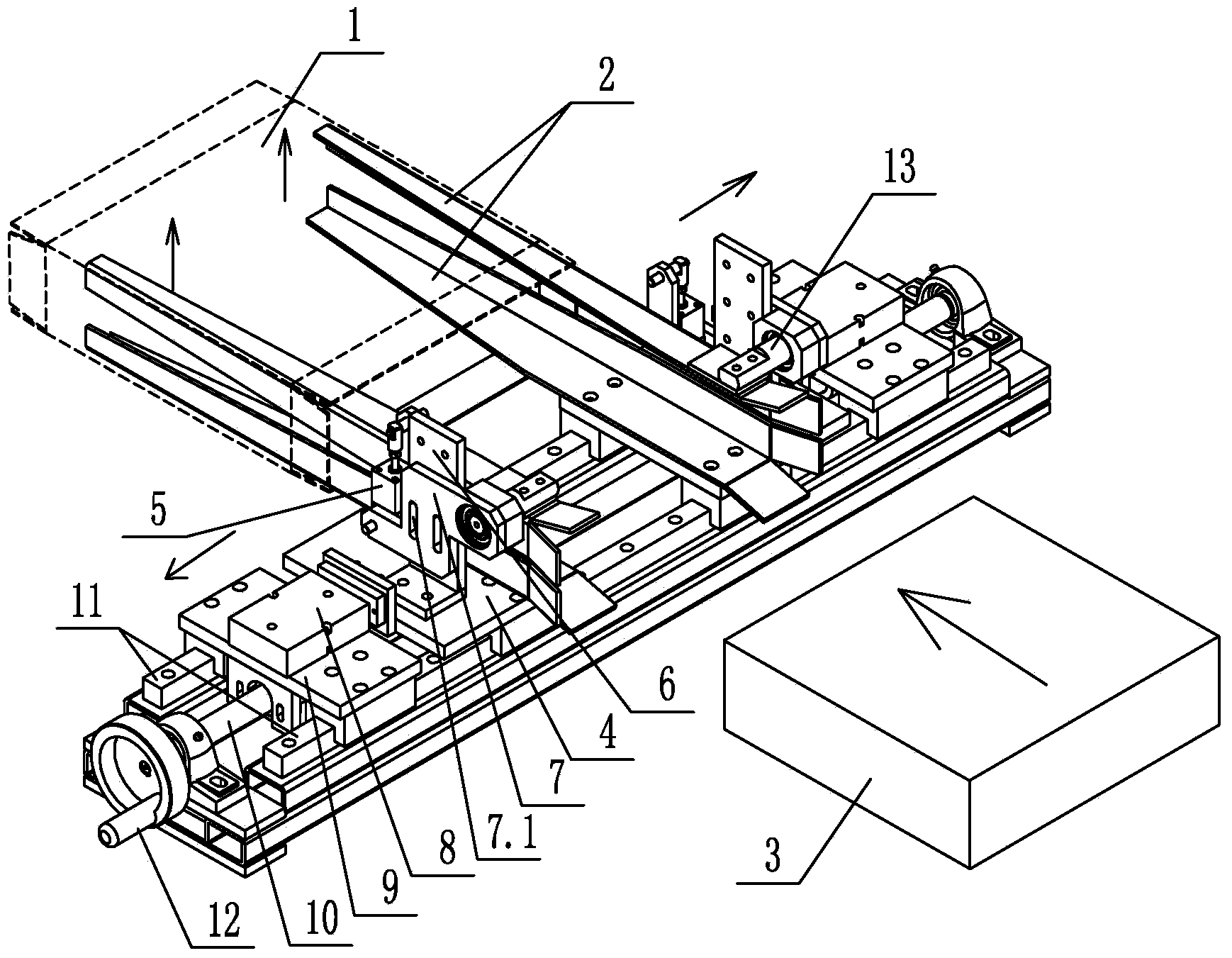

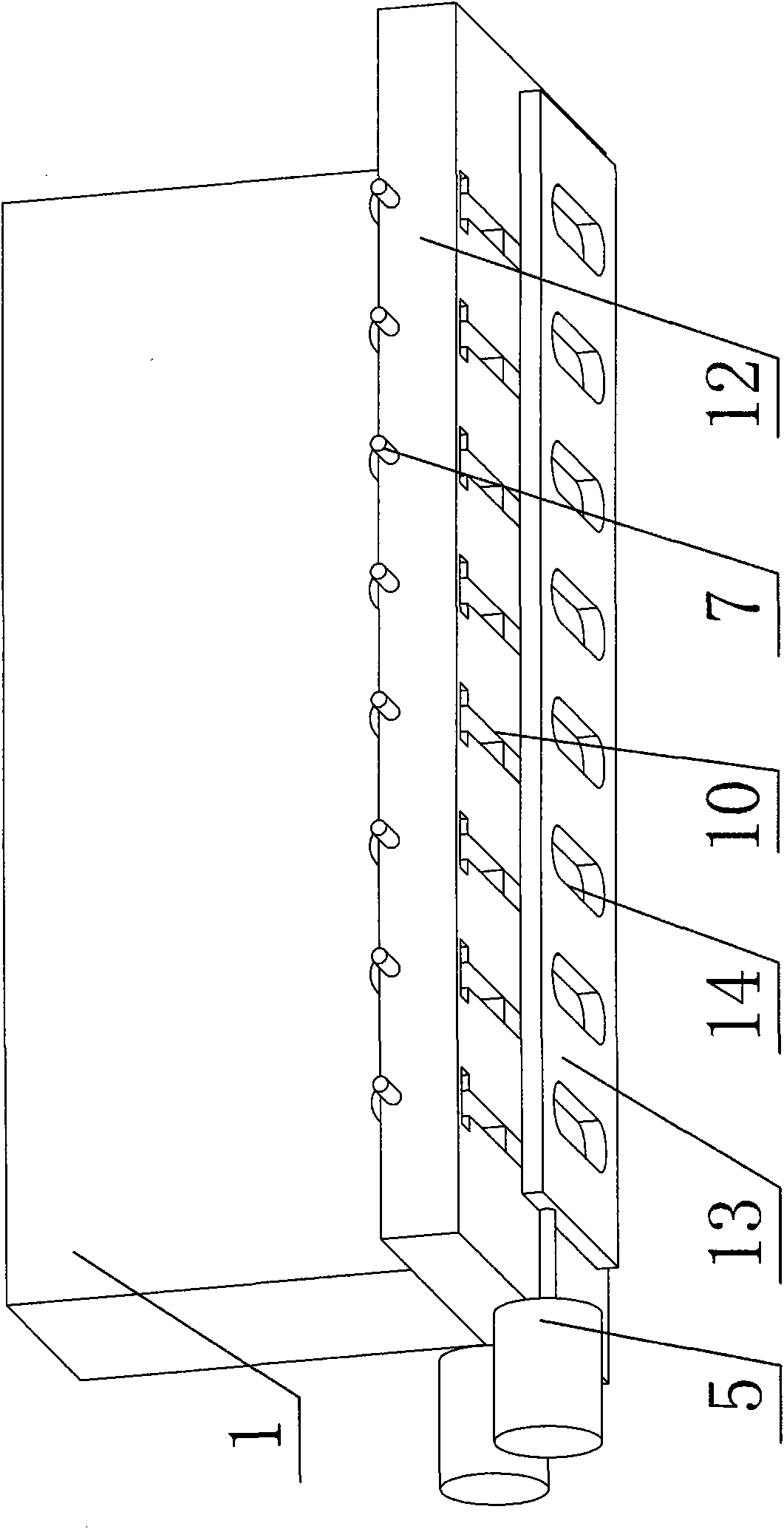

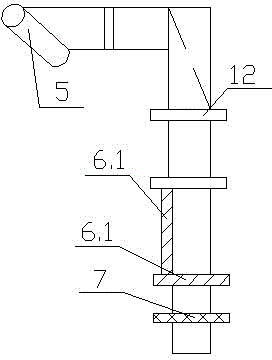

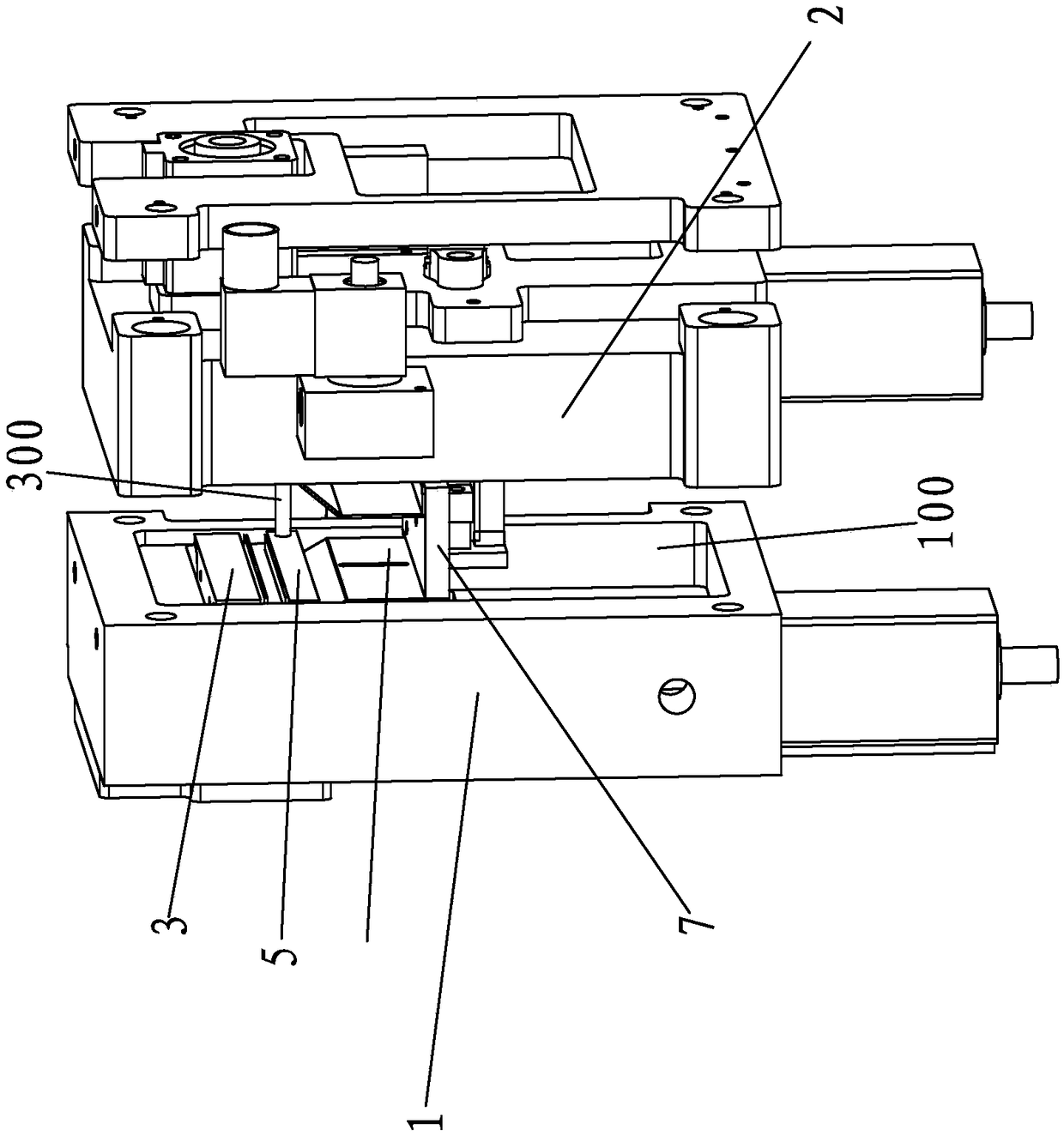

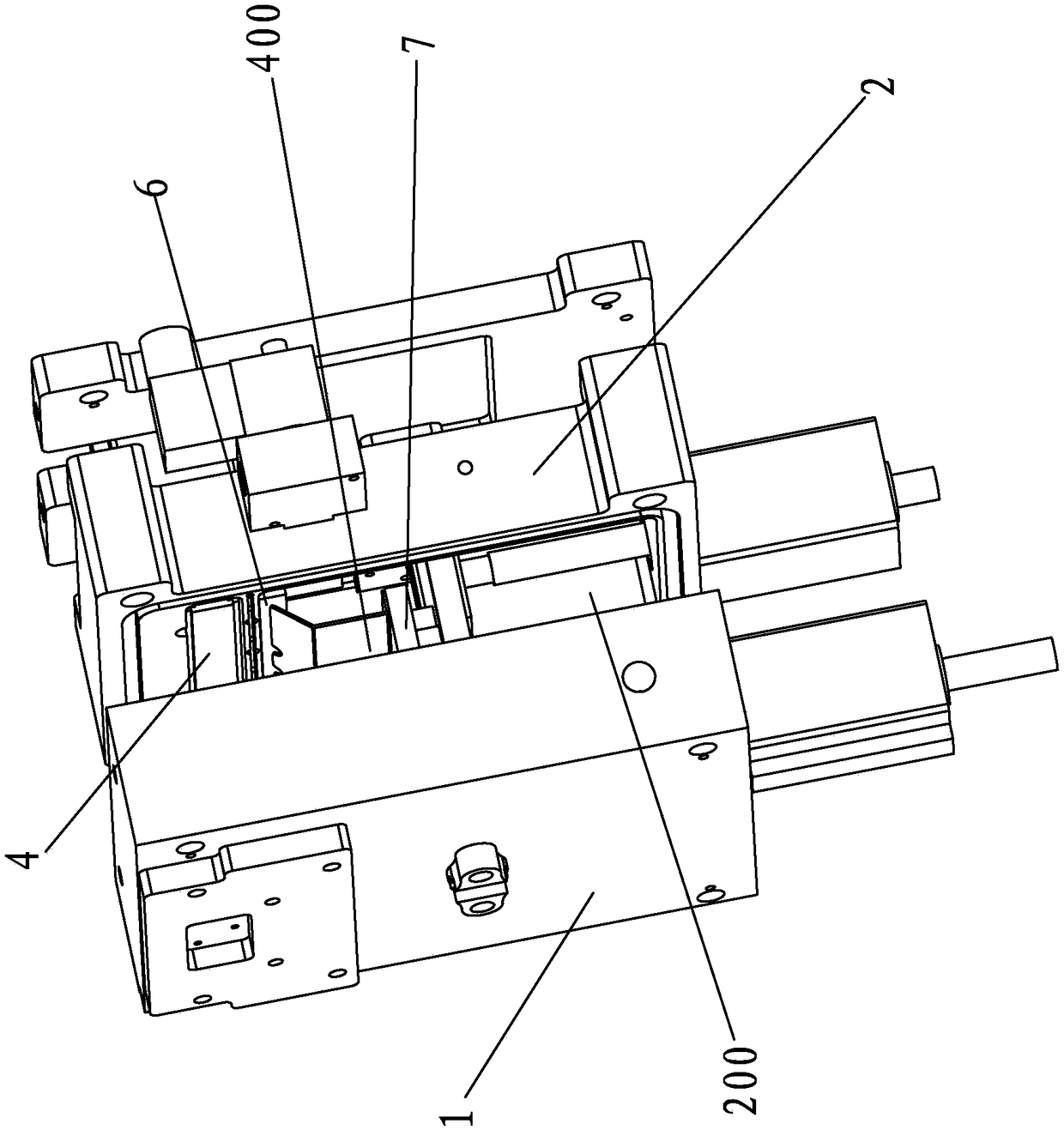

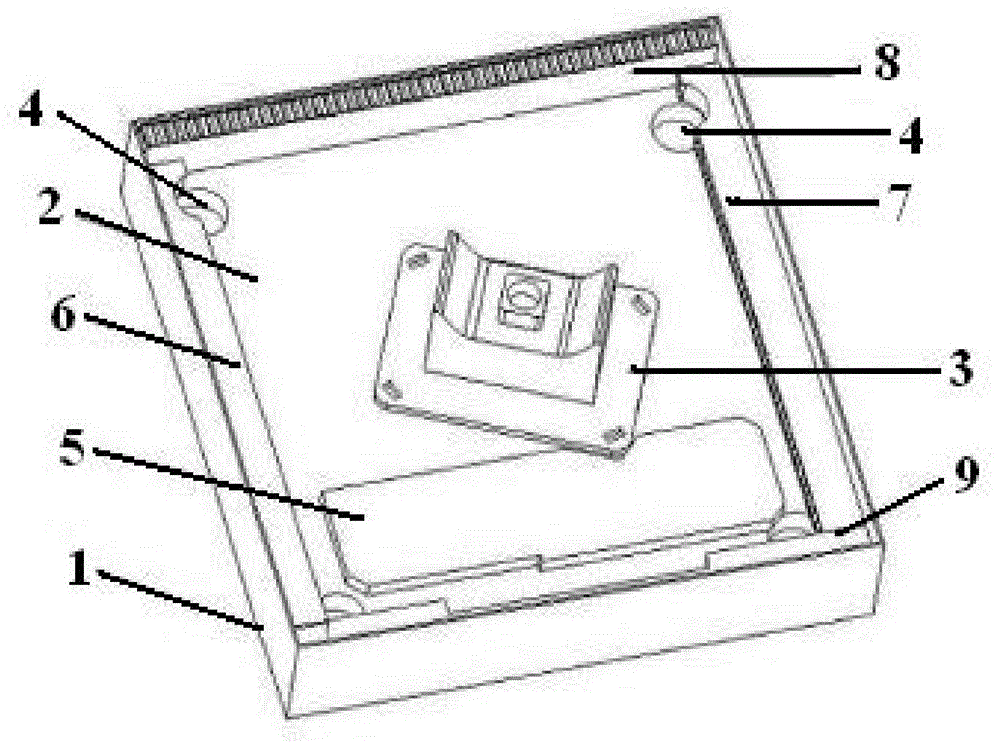

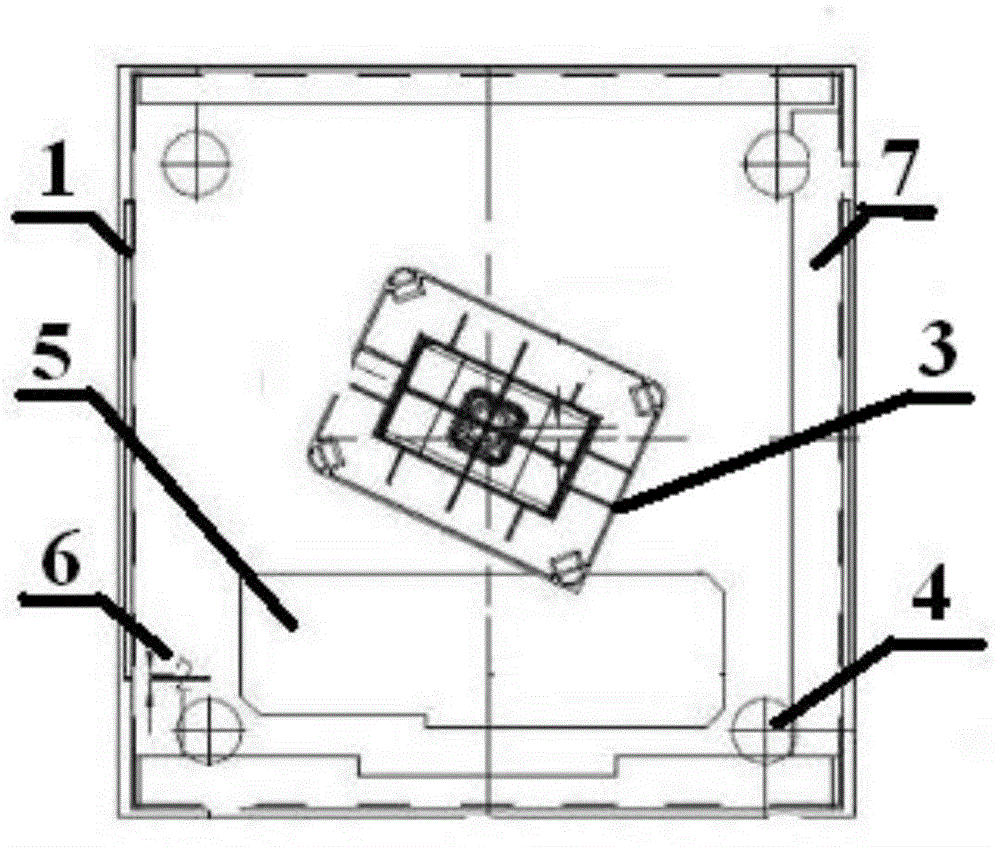

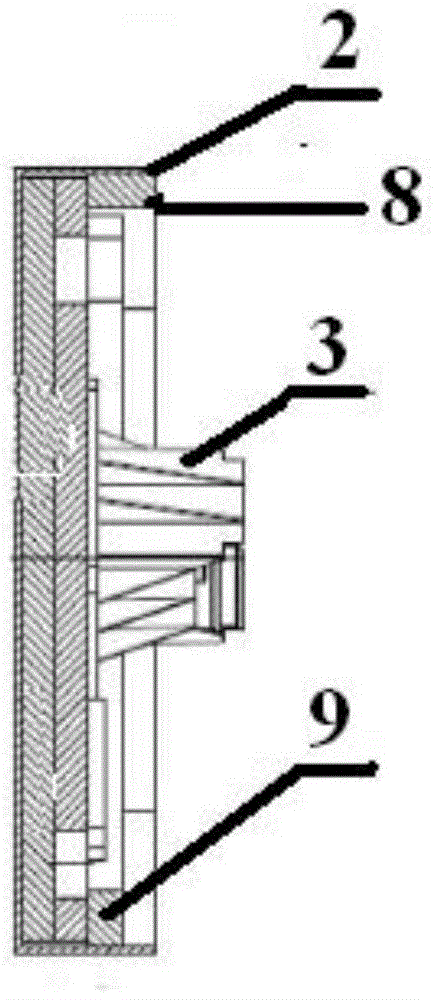

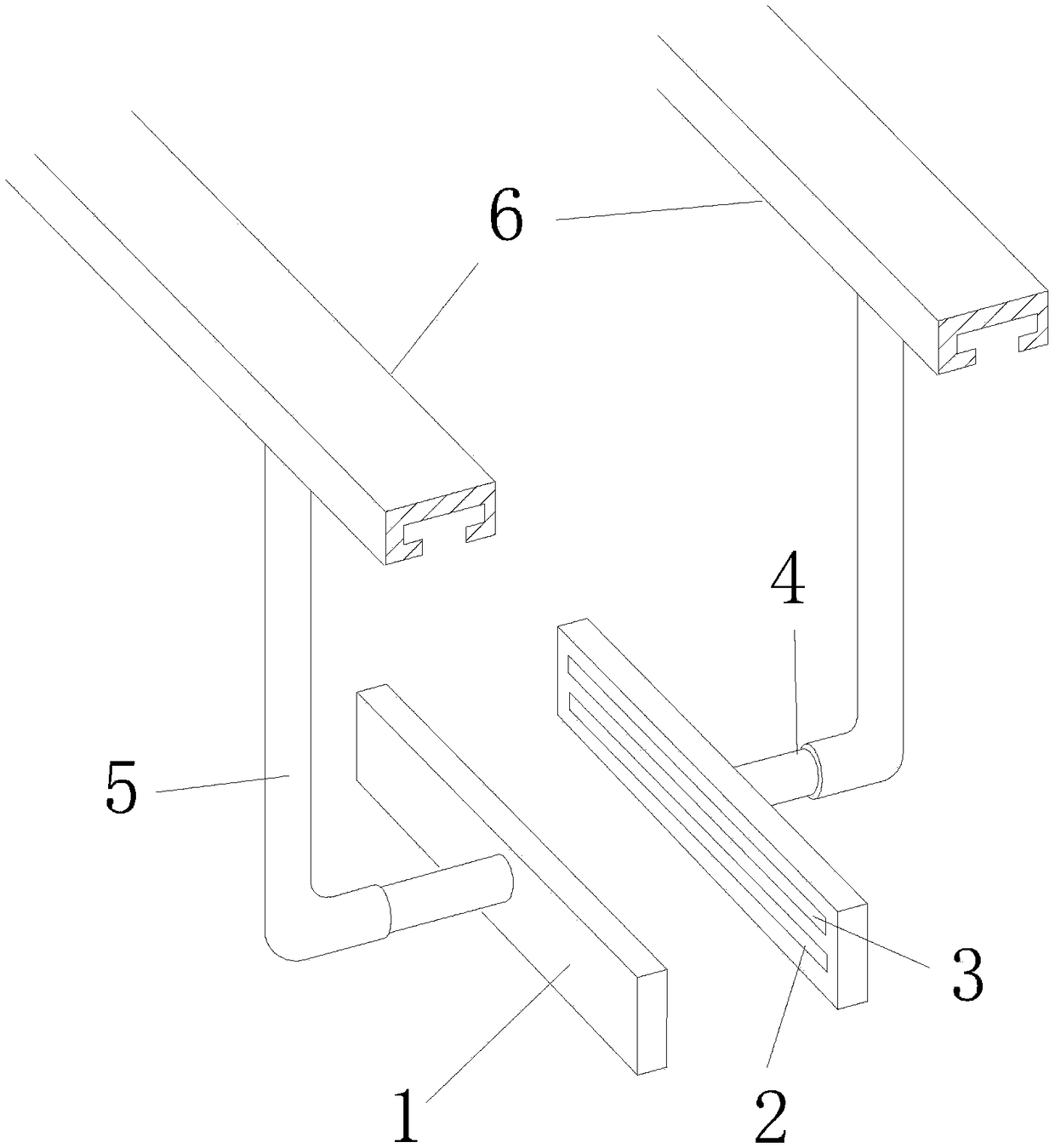

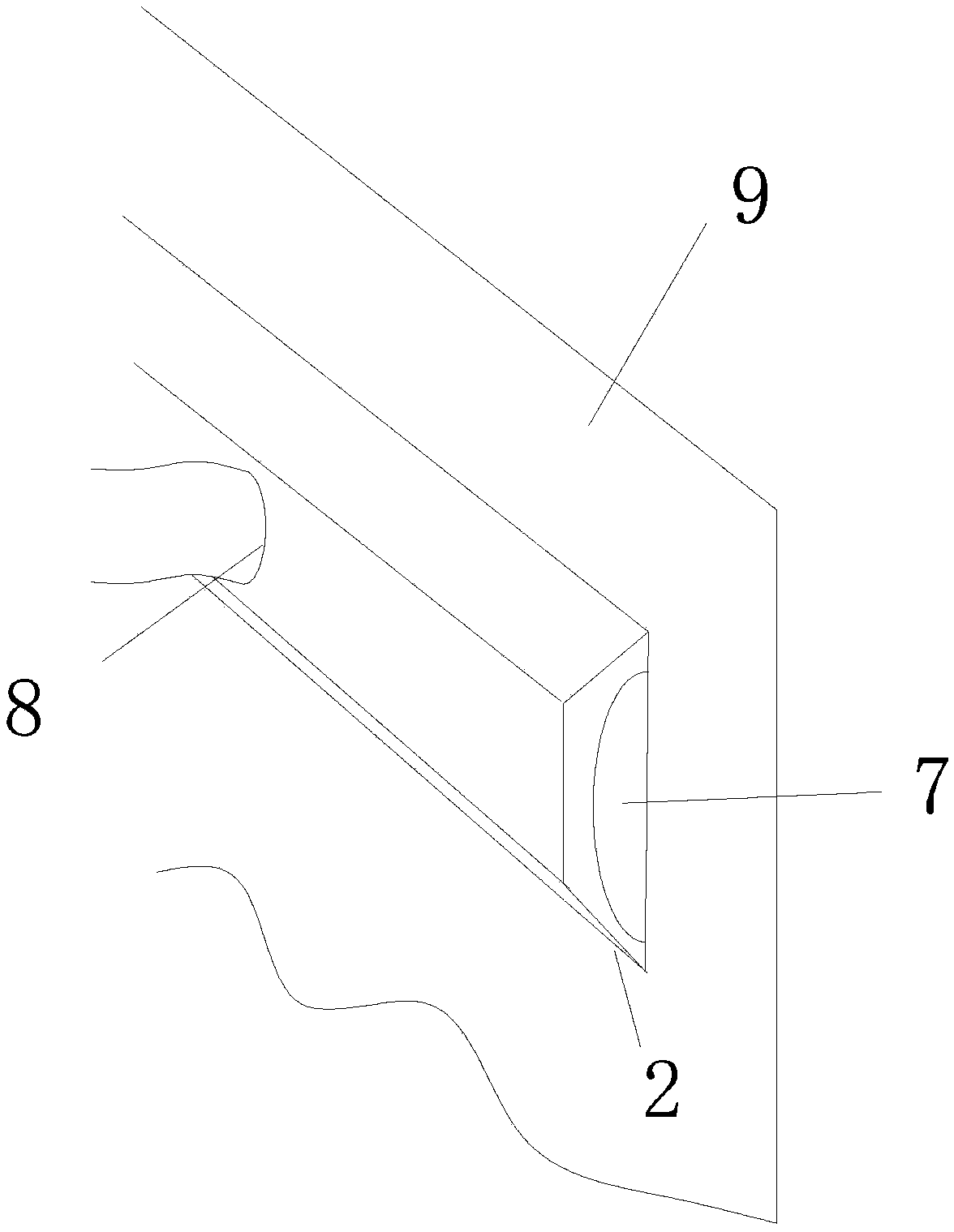

Case packing mechanism enabling paper box to be opened in stretching mode

The invention discloses a case packing mechanism enabling a paper box to be opened in a stretching mode. The case packing mechanism is characterized by comprising four angle-shaped supporting guiding boards, the angle-shaped supporting guiding boards can be inserted into a paper box barrel and correspond to the four corners of the paper box barrel to enable the paper box barrel to be opened in a stretching mode. The upper supporting guiding board and the lower supporting guiding board at the same side are provided with a clamping seat mechanism capable of driving the upper supporting guiding board and the lower supporting guiding board to be opened and closed, and when the four angle-shaped supporting guiding boards are opened in a stretching mode in parallel, a channel for objects to be contained to pass is defined. According to the case packing mechanism, due to the fact that the four angle-shaped supporting guiding boards are used for enabling the paper box to be opened in a stretching mode and fixing the paper box, and then the channel defined when the four angle-shaped supporting guiding boards are opened in a stretching mode in parallel is used for guiding the objects to be contained in, and the objects to be contained are pushed in the paper box. The case packing mechanism can directly pack finished bricks very conveniently for the wall and floor tile industry, the case packing speed is fast, procedures are easy, the most trouble packing procedures are removed, and the production efficiency is greatly improved.

Owner:FOSHAN RUIBO CERAMICS ELECTRICAL & MECHANICAL

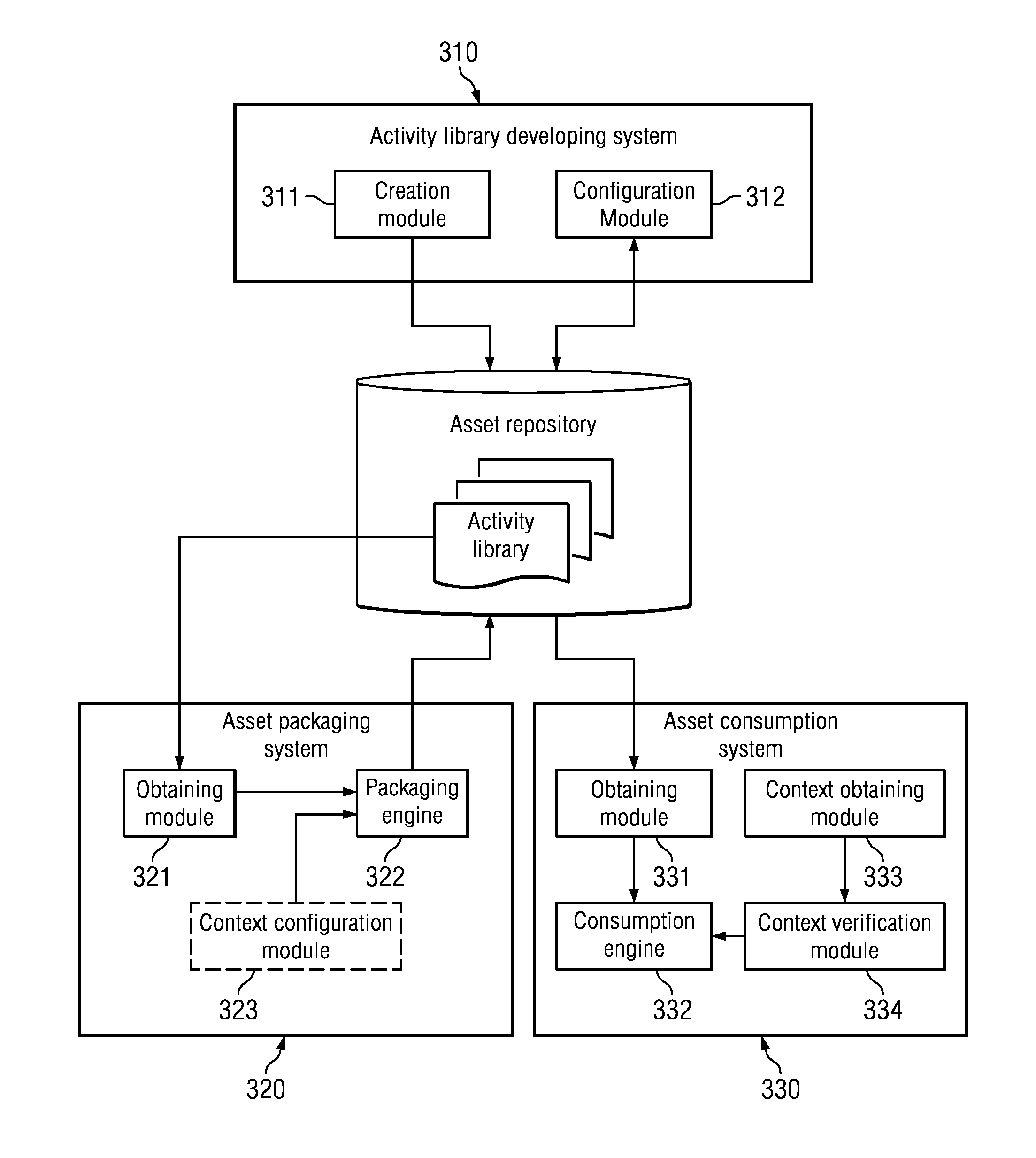

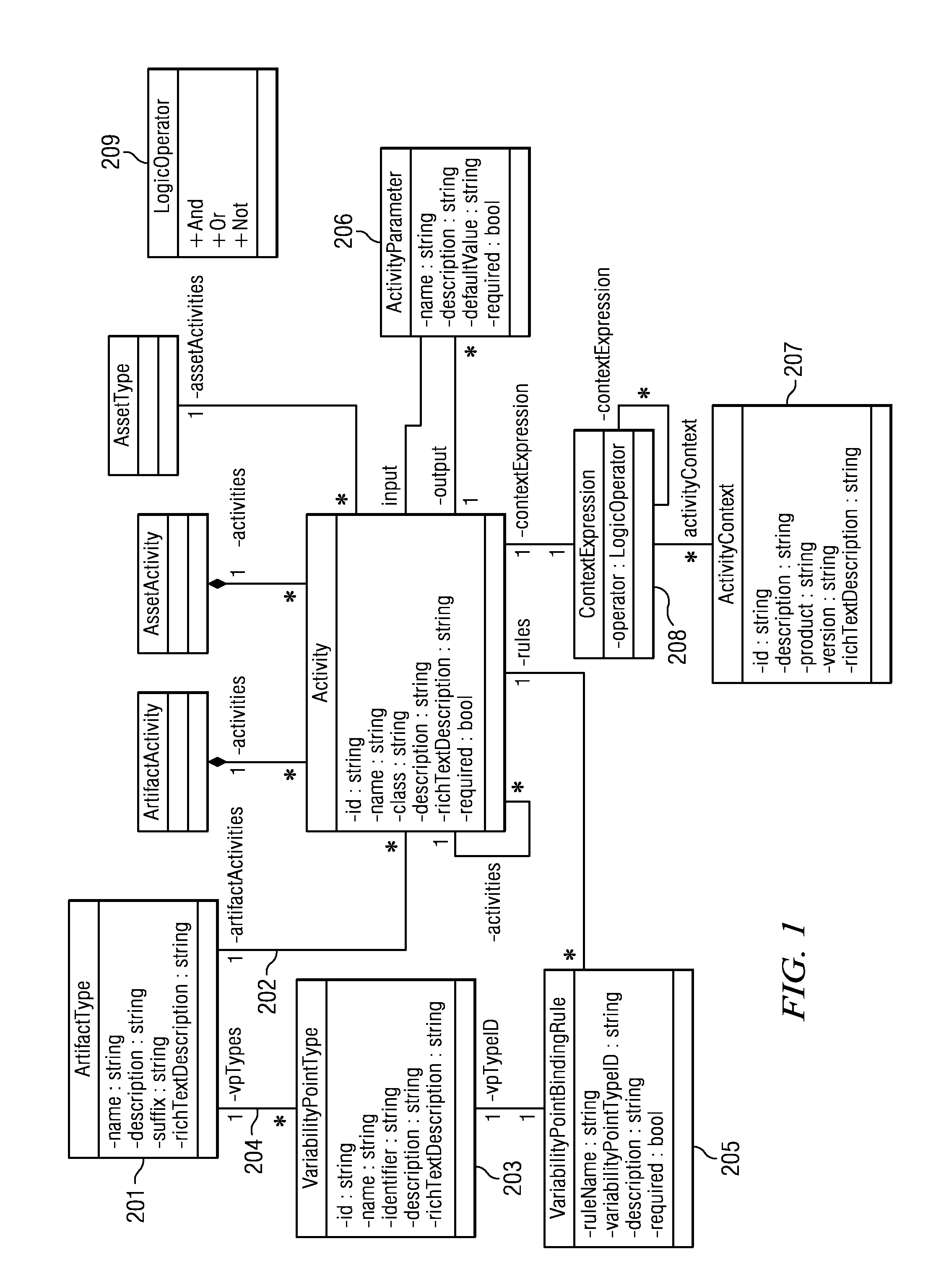

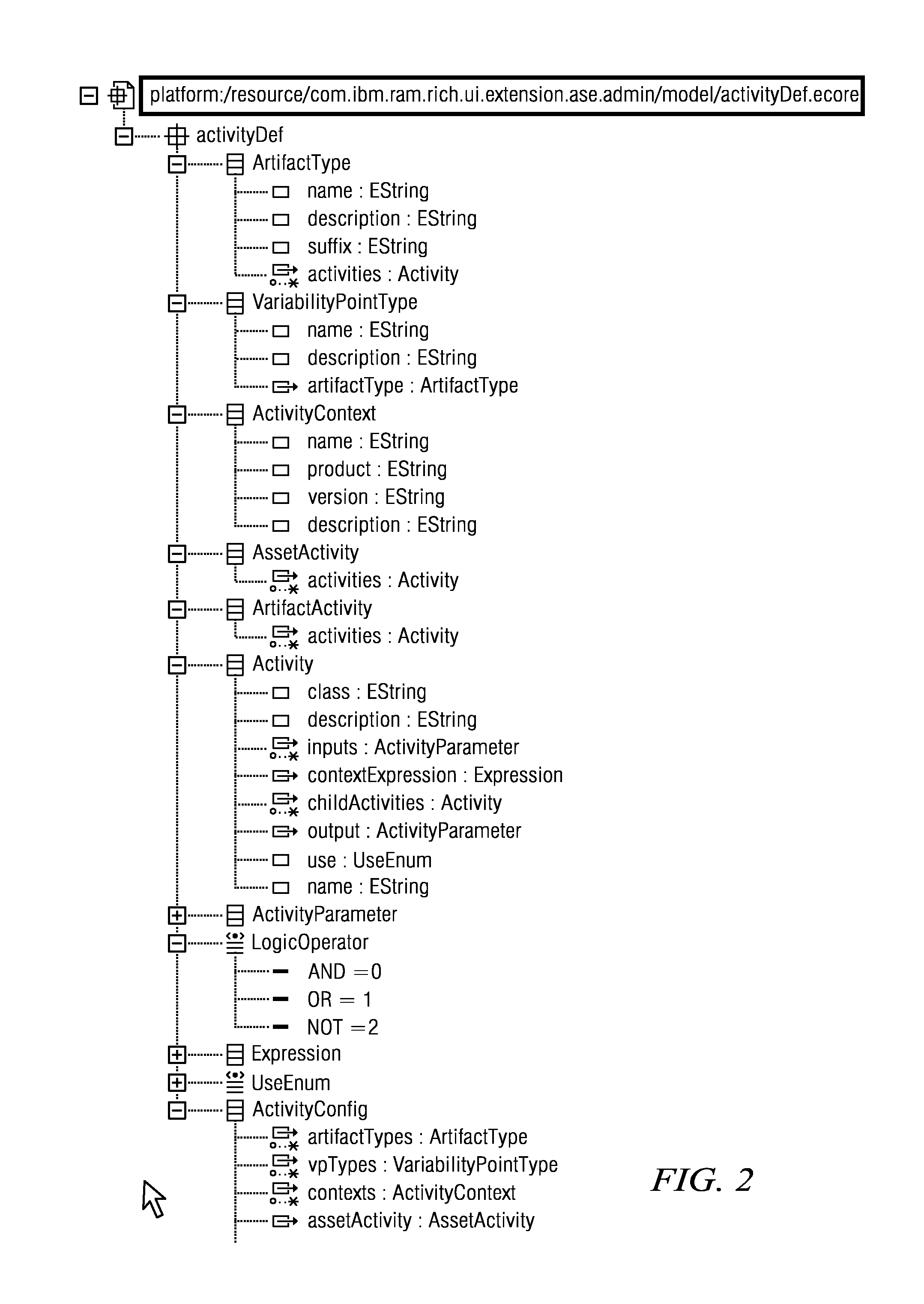

Software Asset Packaging and Consumption Method and System

A reusable asset packaging and consumption method and system that support consumption activities and variability point instances associated with asset types or artifact types. Generic consumption activities and variability point types for different asset types or artifact types and developed and stored in a repository. When an asset packager packages an asset, a needed activity is selected from the activities associated with the type of the asset. The activity, a variability point instance bound with the activity, and the context constraints, together with the artifacts is packaged into the asset package, where the asset package is then stored in a repository. During consumption, the asset consumer obtains the asset package, verifies the context, and executes the activity packaged in the asset, while specifying variability point values for the bound variability instance.

Owner:IBM CORP

Shading glue film production method

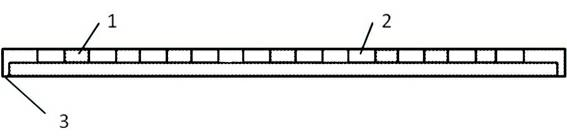

InactiveCN101187748AEasy to tear offQuick pasteLamination ancillary operationsLaminationAdhesivePacking procedure

The invention relates to a process for preparation of a shading glue film, which provides a process for preparation that centralized light can be assuredly projected on a shading glue film of an outer frame of a display screen, when in use, the invention has more convenient employment, easy pasting and easy tearing, and no remaining trace, which can be attached for a long term. The process for preparation of the shading glue film of the invention firstly has a fist time pasting, and materials such as a separating type film membrane, a double-sided adhesive, and an auxiliary separating type film membrane are respectively arranged on each feeding shaft and are fixed, and then a separating type surface of the separating type film membrane is pasted with the double-sided adhesive, and then the separating type surface of the separating type film membrane and the double-sided adhesive which are pasted are stamped in one time to start a waste discharging procedure, and remainder of an inner frame is torn, products of waste material which is torn are cut off to get a bale packing procedure through a trimming machine and a photoinduction after a second time pasting, a second time stamping, a second time waster discharging procedure. The shading glue film of the invention is convenient for assembling staffs to tear off the shading glue film of the outer frame which is accurately pasted on the periphery of the display screen, and assembling work can be effectively simplified and working efficiency can be improved.

Owner:东莞市三贤汽车配件有限公司

Shutter-style multiple row synchronous metering device

The invention relates to a metering device of packing machine, concretely a shutter-style multiple row synchronous metering device used in multiple row simultaneity metering and packing. It includes hopper with scraping flitch, metering plate and closing plate set in sequence under the hopper, the hopper and scraping flitch are jointed as one body. The aforementioned scraping flitch, metering plate and closing plate are all with elongated slot of equal-width and equal-distance, one side of the scraping flitch and closing plate is respectively connected with air cylinder, a slide mechanism is set in the elongated slot of the metering plate. Compared to the present technology, the invention has simple structure, can implement multiple row synchronous metering during the packing procedure, the metering scope is great and can fix on the amount of the materials by adjusting the slide position for the invention employs regulable link slide block structure in the metering plate, evades the extrusion and damnification from the machine itself to the materials for the integrated structure and bulk movement of the hopper and scraping flitch, diminishes the fine material content of the materials, also evades material pollution and improves quality of the materials.

Owner:唐山大松包装机械制造有限公司

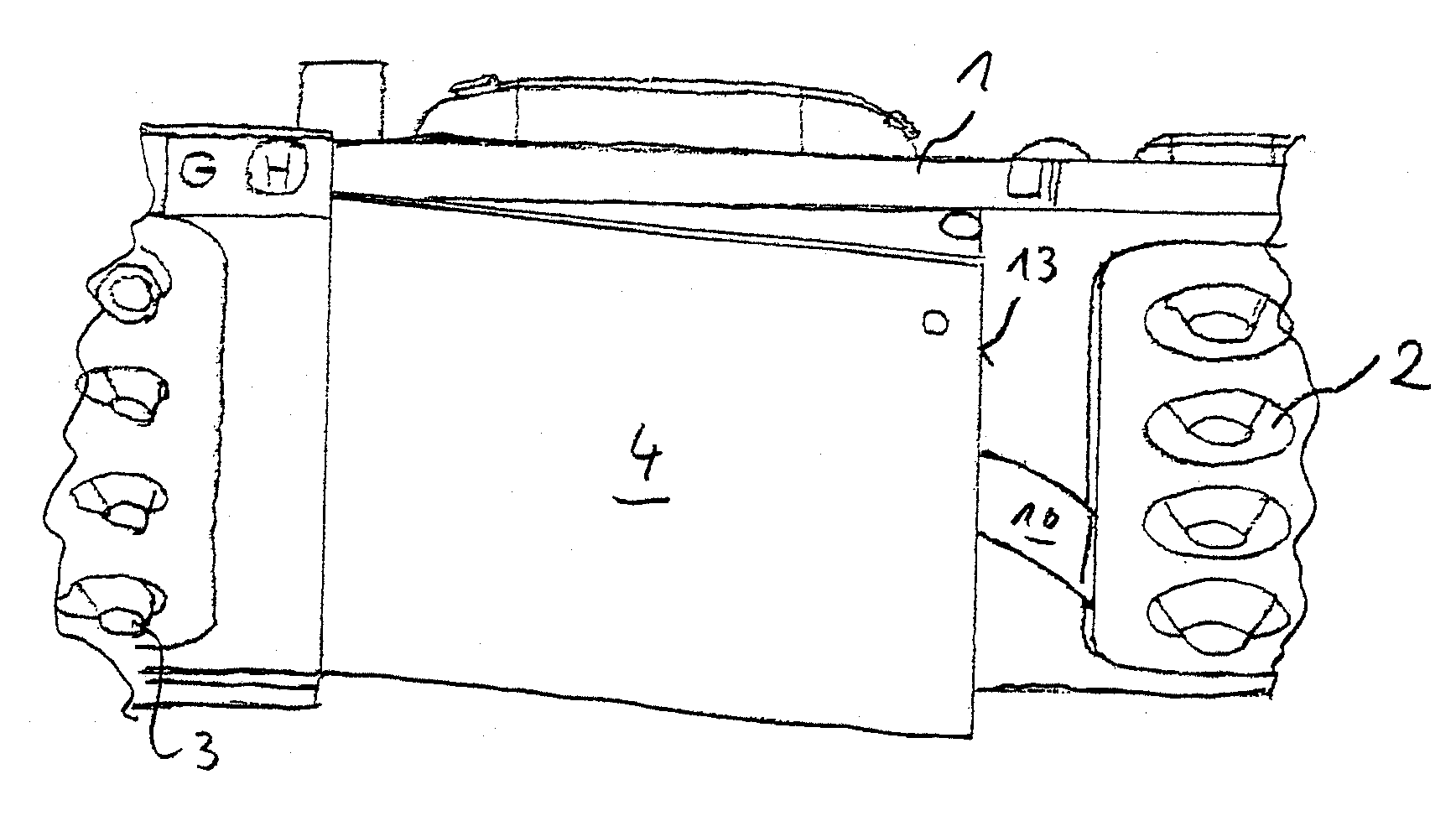

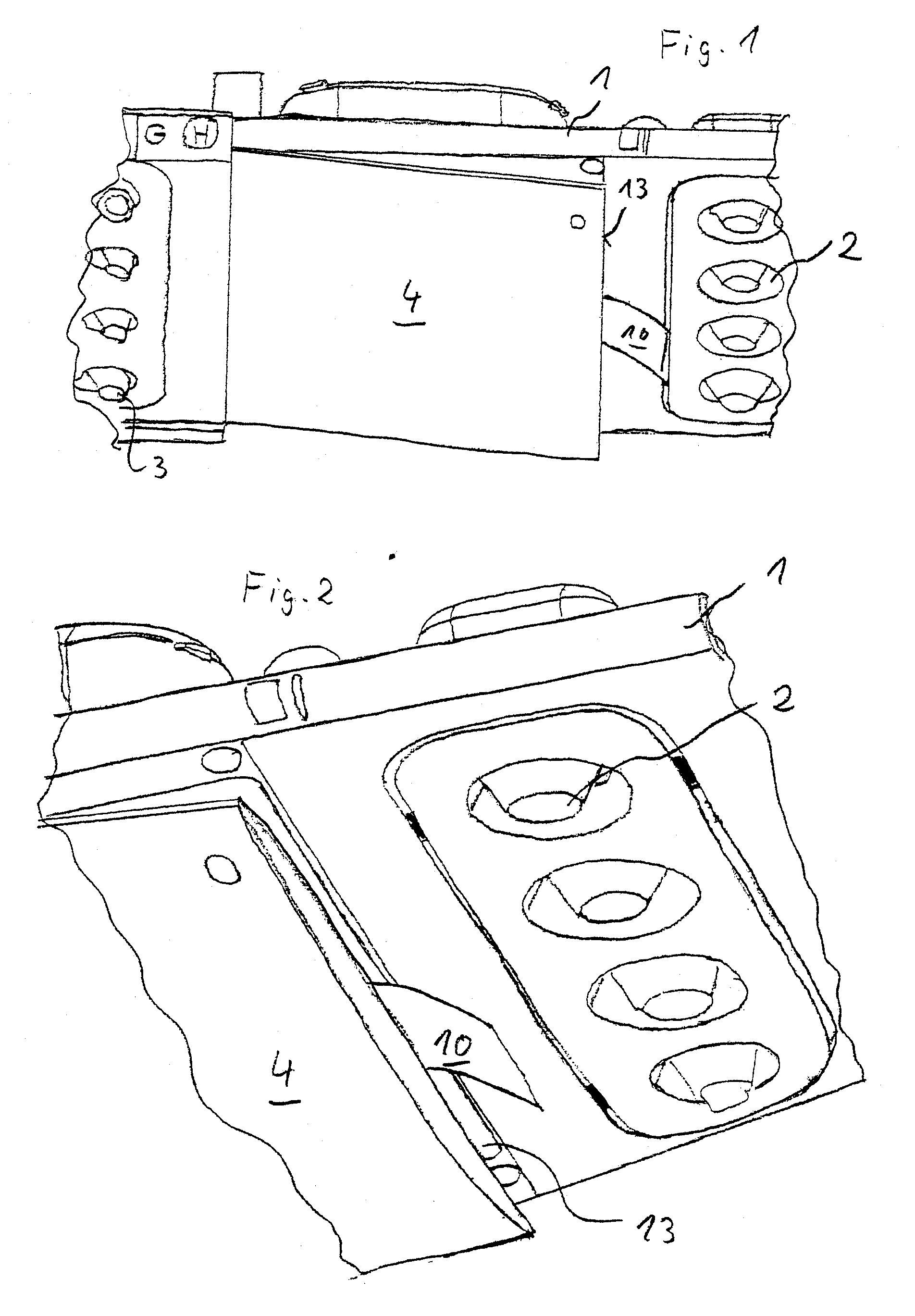

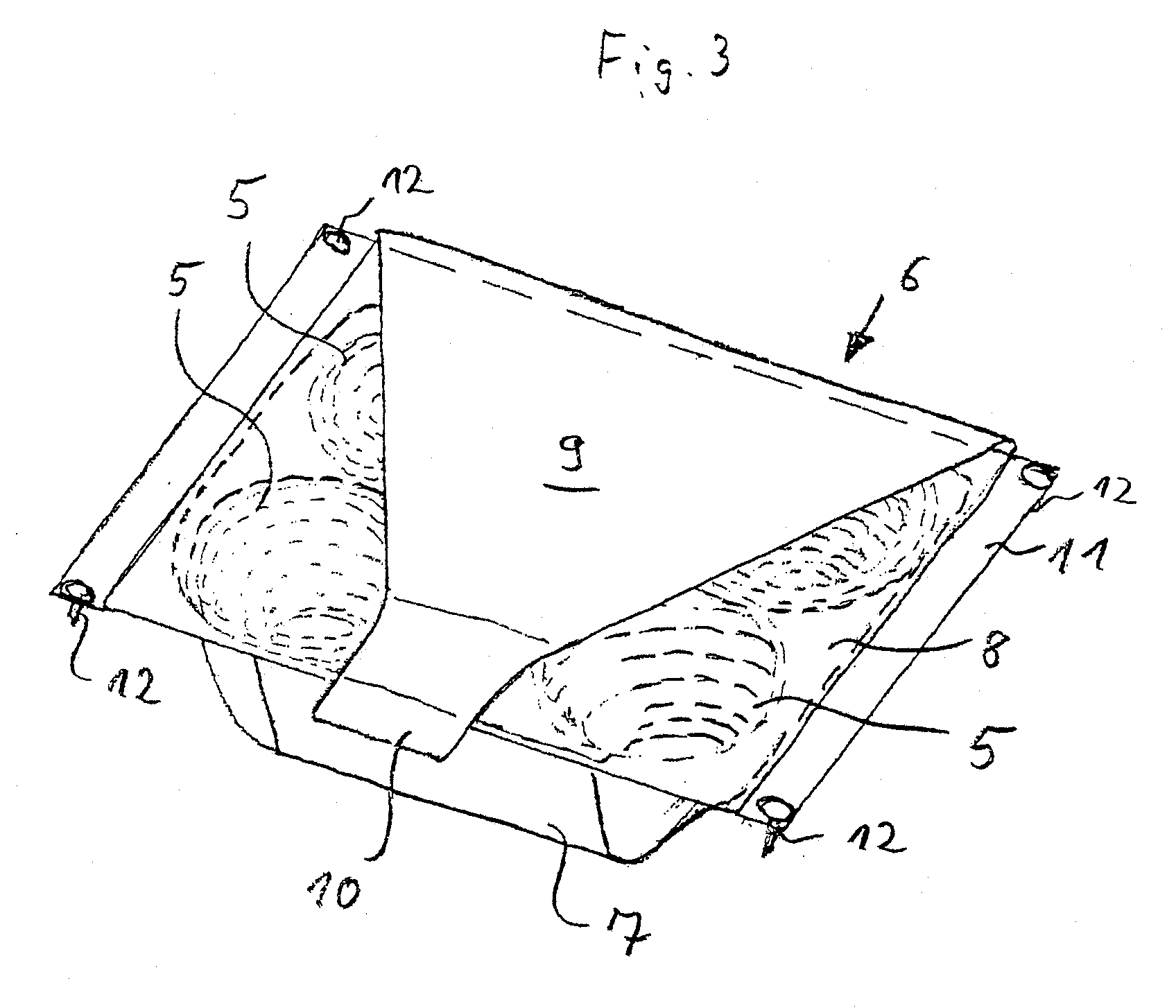

Method for equipping a personal service unit with passenger oxygen masks

ActiveUS20070066132A1Less complicatedGood reproducibilityRespiratorsAir-treatment apparatus arrangementsTelecommunicationsPacking procedure

A method for equipping a personal service unit with passenger oxygen masks includes arranging one or more passenger oxygen masks in an intermediate container ready for use, and then attaching the intermediate container together with the masks located therein within the personal service unit. In this manner, the comparatively lengthy packaging procedure which is difficult to carry out in overhead work, may be effected in a simplified and reproducible manner outside the aircraft.

Owner:BE AEROSPACE SYST

Production technology of brine-free arecanut

The invention belongs to the technical field of food processing, and particularly relates to a production technology of brine-free arecanut. The production technology does not include removing kernels, spot marinating, cooling slices, brine production procedures during processing, and comprises the following steps: dried arecanuts poaching, fermenting liquid preparation, fermenting, baking, seeds pressing, slicing, and packing procedures. A fermenting liquid 1 and a fermenting liquid 2 are respectively adopted for fermenting during fermenting, the fermenting liquid 1 is food-grade Ca(OH)2 glycerin solution, and the fermenting liquid 2 is an aqueous solution of a sweetener, a cooling agent and flavors and fragrances. The produced arecanuts have good condition, and uniform flavor without mouth firing, the production technology is simple, the mechanical degree is high, and the shelf life of the product is long.

Owner:湖南品上王食品集团股份有限公司

Packing machine, sealing device and packing method

InactiveCN104843241ANo manual operationAvoid the problem of unstable packaging qualityWrappers shrinkageWrapper twisting/gatheringPacking procedureEngineering

The invention is applicable to the technical field of a packing device, and provides a packing machine, a sealing device and a packing method. The packing machine comprises a blowing frame used for placing a double-layered thermal shrinkage film, a front conveying device for conveying the double-layered thermal shrinkage film, and a film separating part used for folding the double-layered thermal shrinkage film into two layers of thermal shrinkage films at intervals, a sealing device for cutting and sealing the two layers of thermal shrinkage films, a back conveying device used for conveying the packed thermal shrinkage films and a shrinkage furnace for thermally shrinking the thermal shrinkage films which are arranged in order. The sealing device comprises a cross sealing unit and a side sealing unit; the cross and side sealing units include an upper cutter, a lower cutter, and a driving mechanism for driving the upper and lower cutters to press to each other; a heating part is arranged on the upper cutter or the lower cutter; the upper and lower cutters of the cross and side sealing units are moved at the same time to cut and seal the thermal shrinkage films. The packing machine can automatically realize feeding, cutting and sealing, thermal shrinkage, and other packing procedures without manual operation; besides, the packing machine avoids unstable packing quality and improves the packing efficiency.

Owner:YEE FOO PACKAGING SHENZHEN CO LTD

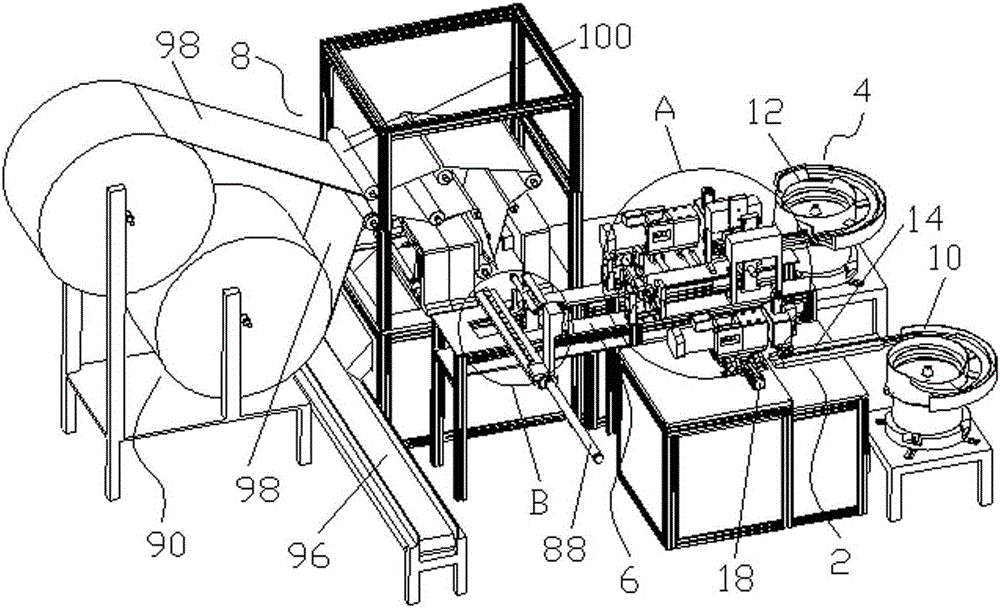

Flexible automatic packing production line for inflammables and explosives

ActiveCN102717922ASolve the short circuitSolve the arcWrapping material feeding apparatusWrapper twisting/gatheringProduction lineHuman–machine interface

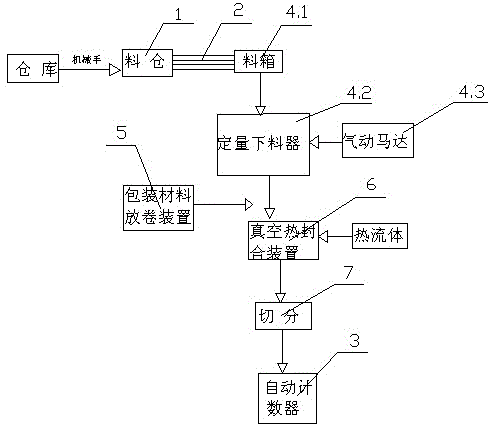

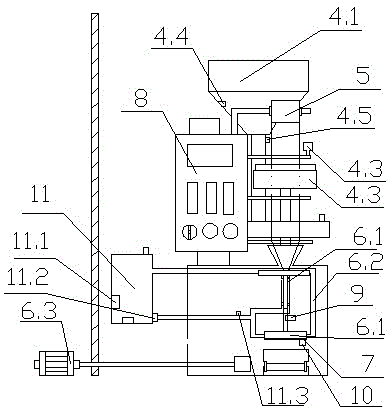

The invention discloses a flexible automatic packing production line for inflammables and explosives. The flexible automatic packing production line comprises a storage bin, an automatic packing machine and an automatic counter, wherein the storage bin is connected with the automatic packing machine and an automatic counter in sequence through a bucket type elevating conveying belt; and the automatic packing machine comprises a quantitative blanking device, a packing material uncoiling device, a vacuum heat sealing device, a cutting device, a PLC (Programmable Logic Controller) and a human-machine interface. The flexible automatic packing production line has the advantages that a pneumatic motor is adopted for controlling quantitative blanking, so that the phenomena of electric arcs, electric sparks and short circuit generated by the conventional electric motor are avoided, and existing potential safety hazards are reduced; a heater in a thermal fluid heat exchange way is adopted, so that the phenomena of short circuit, electric arcs, electric sparks and the like caused by heating with the conventional electric heating pipe are avoided, high safety coefficient is achieved; the PLC is used for setting the bag length, so that the troubles of replacement of a gear and adjustment of the bag length are eliminated; through computer tracking, accurate material filling is ensured; and the packing production line is adopted, so that the packing procedure becomes easy, and automatic production is convenient.

Owner:柳真

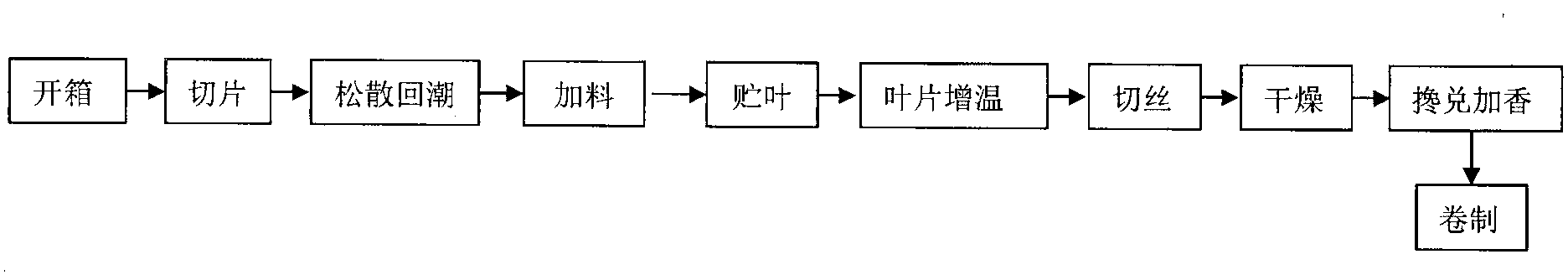

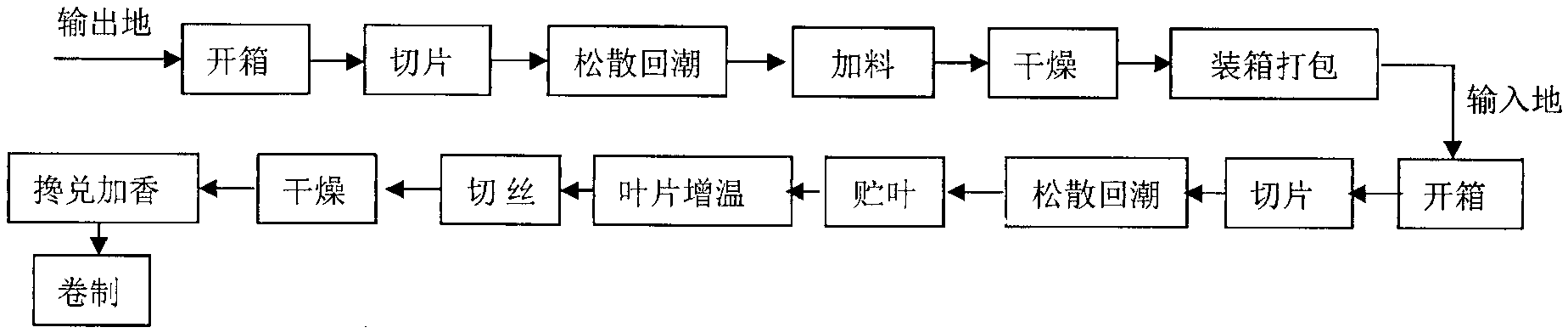

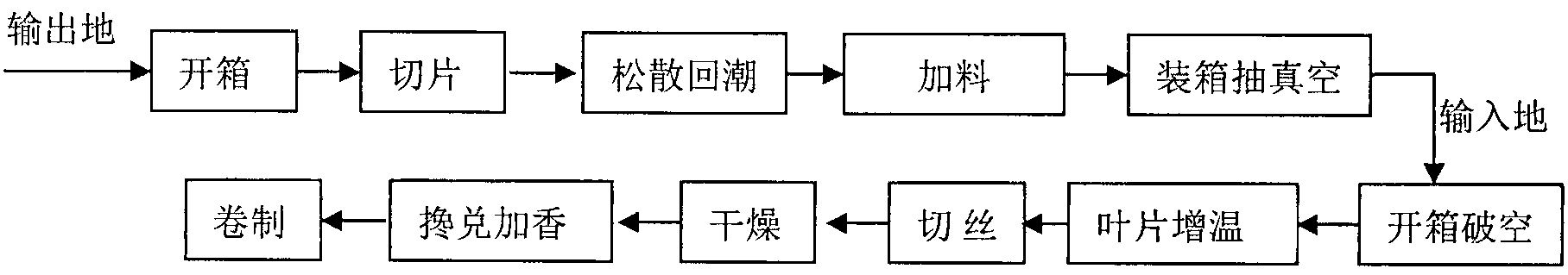

Processing technique for non-locally making smoked sheet into cut tobacco after feeding

The invention discloses a processing technique for non-locally making a smoked sheet into cut tobacco after feeding, and the processing technique comprises the following steps that an output brand raw material is unpacked, sliced, loosened, moisturized and fed in in an output place; the fed raw material is directly packed, vacuumized and sent to an input place, and is unpacked or broken in the input place; the material is directly fed through turning over the pack, enters a smoked sheet heating procedure before slicing, and is sliced; and the making is completed after drying, mixing and adding fragrance. The processing technique for non-locally making the smoked sheet into cut tobacco after feeding has the main characteristics that (1) the tobacco leave raw material is vacuum and anaerobic when being transported, biochemical reaction difficult occurs in the tobacco leaves, so that the inherent color of the cured tobacco raw material can be effectively maintained; (2) compared with a traditional non-local cut tobacco making technical process, the technical process reduces drying and packing procedures after feeding in the output place as well as the unpacking, slicing, loosening and moisturizing procedures in the input place, the process is simplified, the energy consumption is reduced, and the chips are reduced; and (3) compared with a local production technical process, the tobacco leaves experience the same heating process, so that the consistency in the sensory quality of output brand cigarette is ensured, and meanwhile the cigarette prescription, feeding and other cigarette product core technologies are protected.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

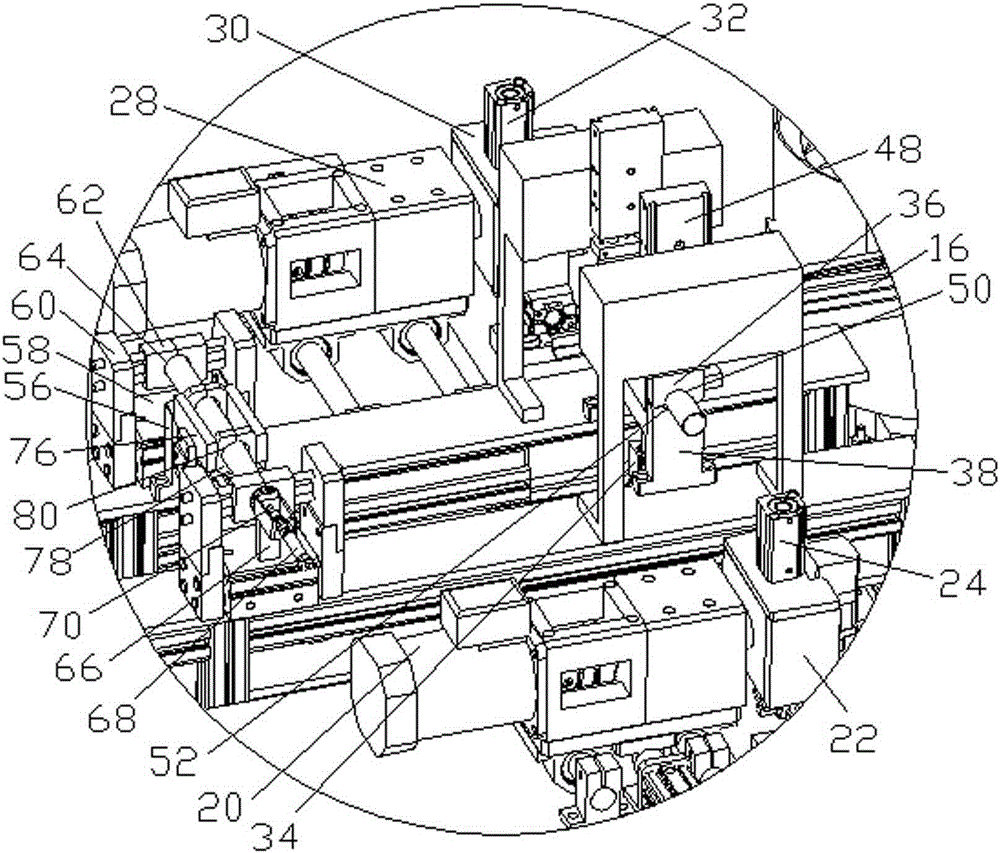

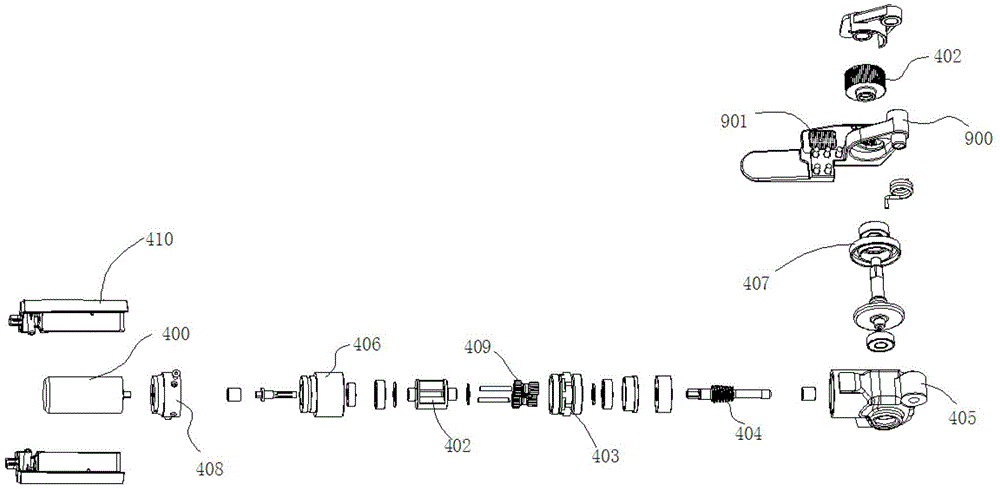

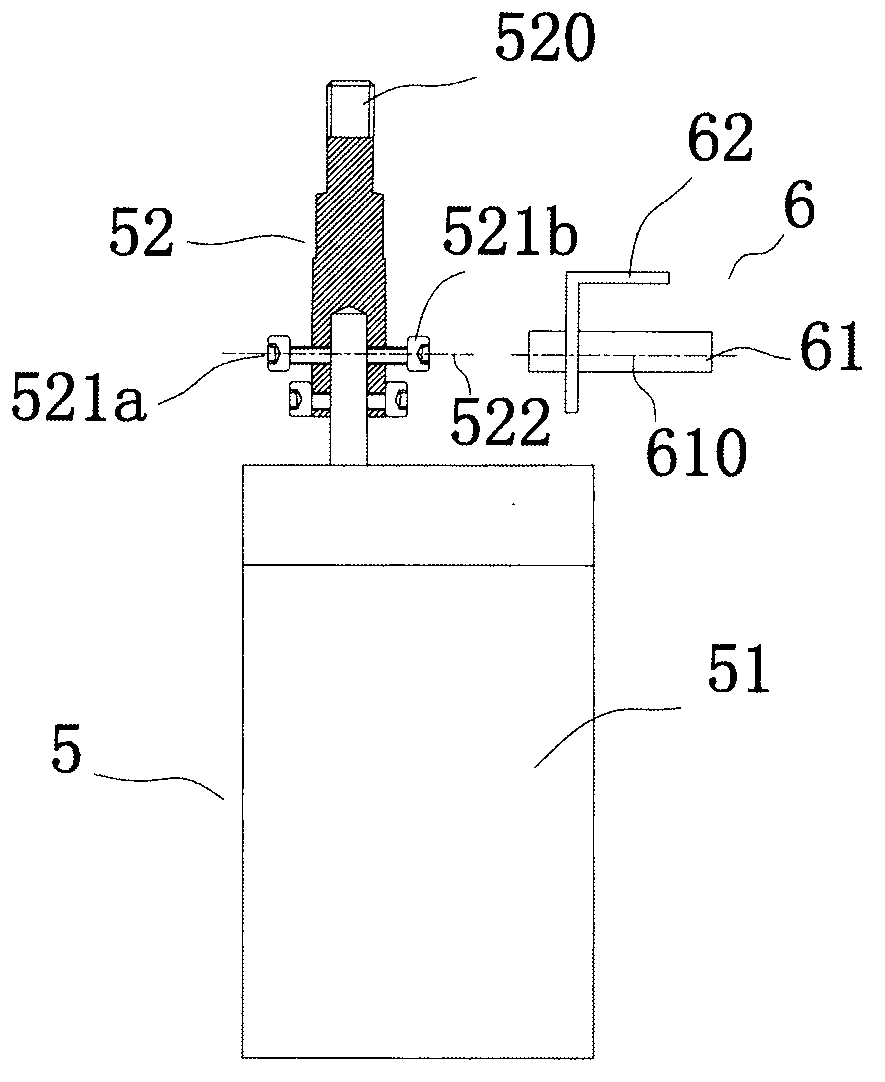

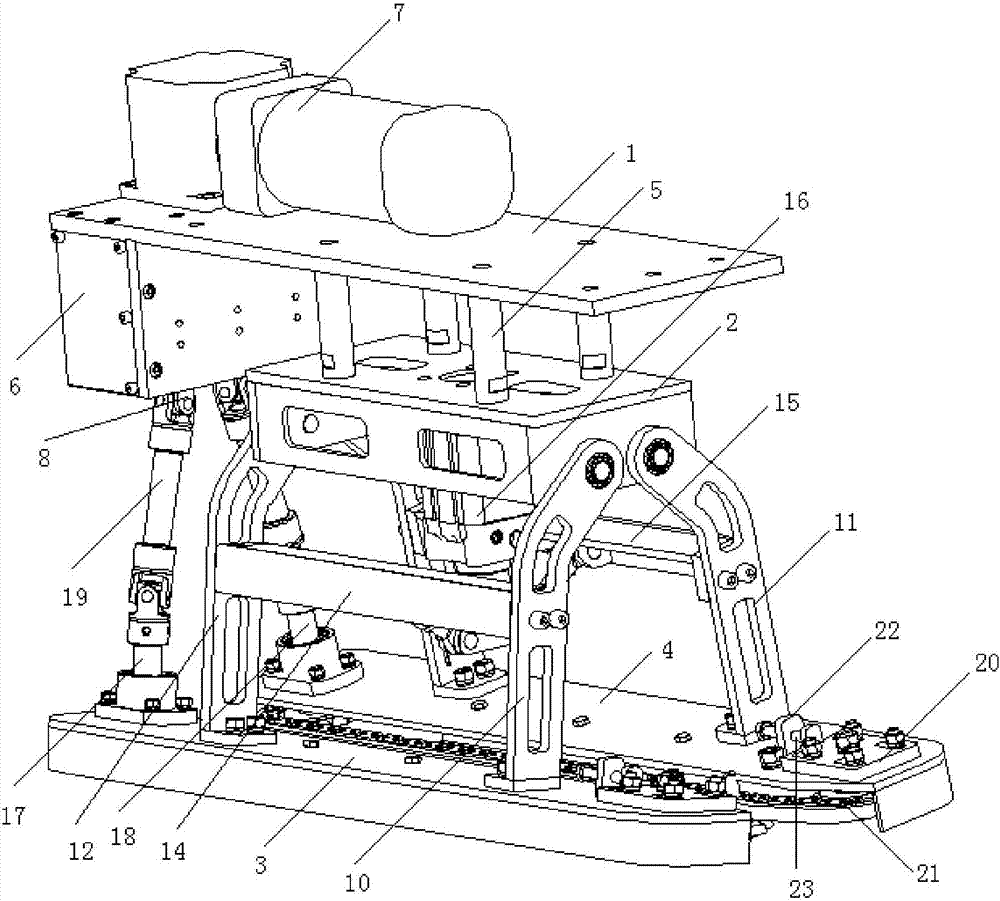

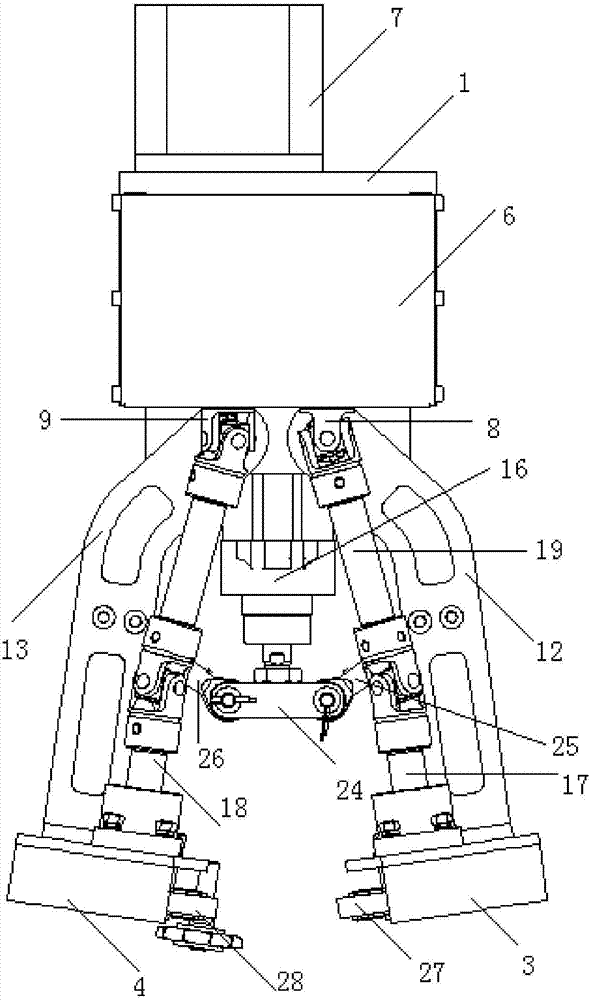

Toner cartridge ink cylinder component assembler for printer

ActiveCN105196051AIncrease productivityGuaranteed assembly accuracyAssembly machinesPacking procedureEngineering

The invention relates to a toner cartridge ink cylinder component assembler for a printer The toner cartridge ink cylinder component assembler comprises a first assembling device, a second assembling device, a transfer device part of which is arranged between the first assembling device and the second assembling device and a packing device arranged outside the transfer device; the assembler is also provided with a first vibration disc and a second vibration disc, wherein a first rail is arranged between the first vibration disc and the first assembling device, and a second rail is arranged between the second vibration disc and the second assembling device. Large ends and small ends can be assembled at the same time, production efficiency is improved, charging of the small ends and large ends is recognized by adopting a CCD (charge coupled device) mechanism, thus ensuring assembling precision; the transfer carrying adopts three manipulators for charging and discharging, and the second manipulator comprises a clasping manipulator to ensure a precise direction of a workpiece in a stamping procedure; the stamping procedure and detection procedure are integrated to reduce work stations; the packing procedure adopts a manner of sealing three sides plus pre-sealing the next, and sealing and charging can be favorably performed at the same time.

Owner:JIANGSU BVM INTELLIGENT TECH

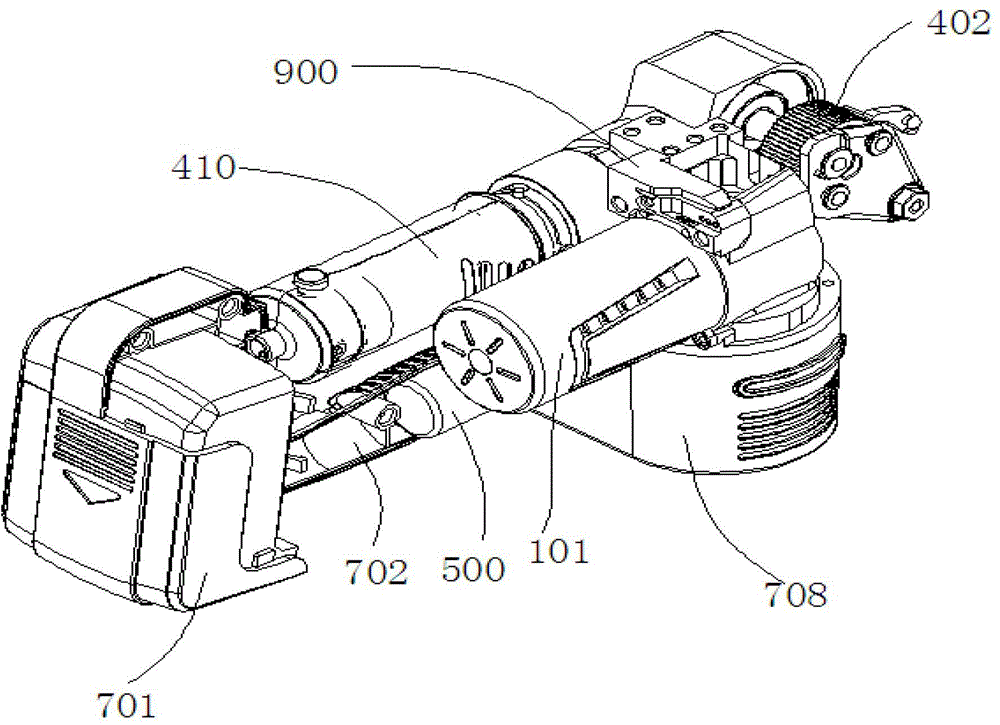

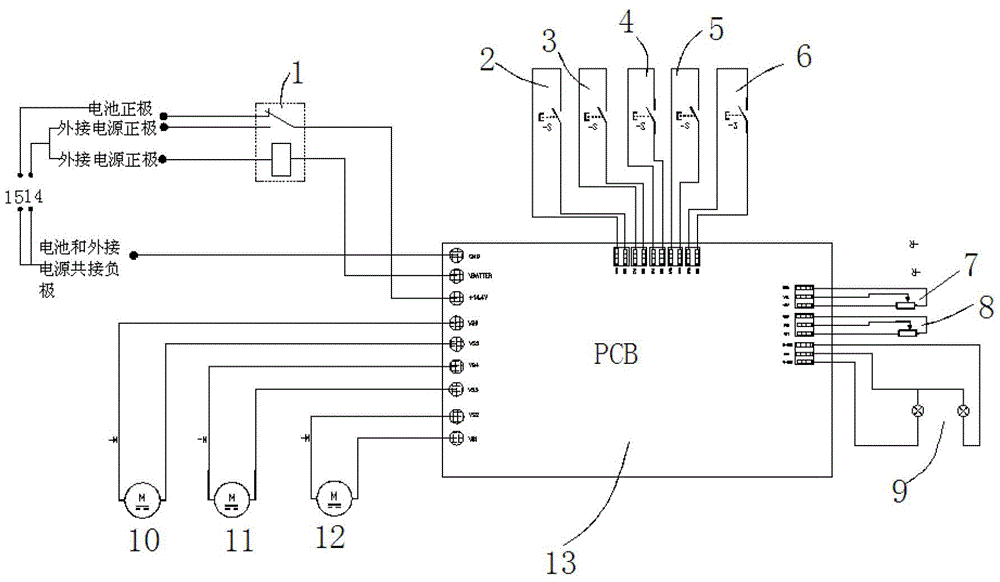

Electric packing machine

ActiveCN102910308ACompact structureImprove compactnessBinding material applicationBundling machine detailsPolyethylene terephthalateBand shape

The invention relates to an electric packing machine comprising a battery, a body, a handle, a tensioning device, a band cutting device, a fusion welding device and an electric control board, wherein a relay is arranged on the electric control board, a corresponding tensioning motor, a band cutting motor and a fusion welding motor coordinate with the electric control board to control the operation, a jack module is connected between the battery and the electric control board in parallel, and a rewinding switch module and a potentiometer knob module are arranged on the electric control board to control the fusion welding and the tensioning band; according to the invention, the brand new tensioning device, the band cutting device and the fusion welding device are used for realizing the packing procedures of band-shaped wires such as PET (polyethylene terephthalate) bands and PP (Propene Polymer) bands, so that the electric packing machine has the advantages of compact structure, strong structure compactness and strong packing firmness, and the like, and meanwhile, a power supply is designed to double power supplies of battery and jack so as to selectively utilize the power supply of the packing machine under different environments.

Owner:浙江维派包装设备有限公司

Vacuum packaged liquid food and out-phase interface deoxygen system engnieering

ActiveCN1724313AGuaranteed qualityPackaging by pressurising/gasifyingPackaging under vacuum/special atmosphereProcess equipmentPacking procedure

A zero-oxygen packed liquid food features that its producing and packing procedure, a heterophase interface oxygen-expelling system is used for expelling all oxygen-contained air from liquid food and packing container. The heterophase interface oxygen-expelling system and its zero-oxygen liquid storage, zero-oxygen pouring machine and zero-oxygen packing container are also disclosed.

Owner:张建华

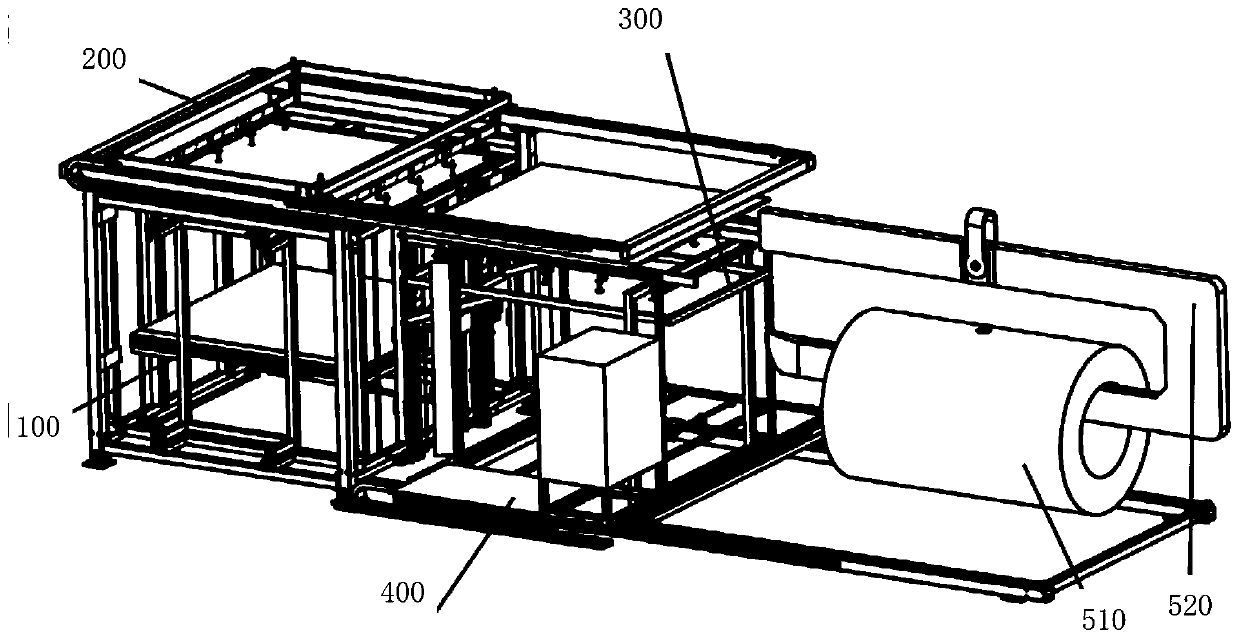

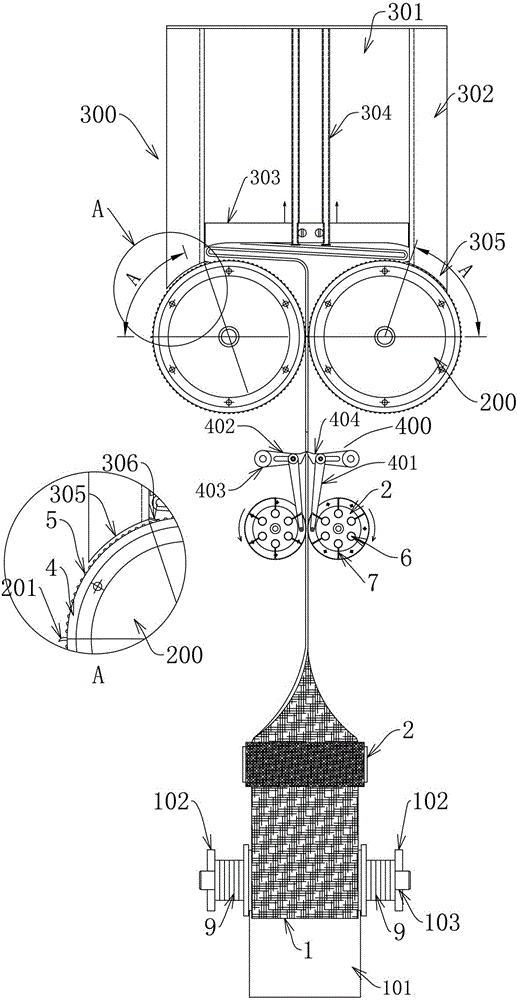

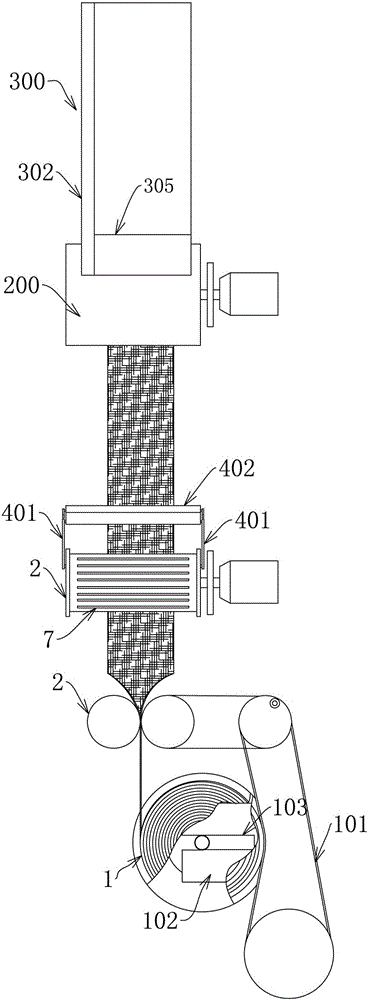

Coil automatic packing equipment and method

ActiveCN110077639AReduce manpower consumptionAvoid the unsafe factors of manual operationWrapping material feeding apparatusWrapper twisting/gatheringPacking procedureEngineering

The invention relates to coil automatic packing equipment and method. The equipment comprises a corrugated paper winding part, an inner bag sleeving part and an outer bag sleeving part; the corrugatedpaper winding part is mounted in a first packing procedure position; the inner bag sleeving part and the outer bag sleeving part are mounted in a second packing procedure position and a third packingprocedure position, and the two positions can be exchanged; the arrangement positions of the three procedure positions are matched with the coil transfer direction; the corrugated paper winding partstores corrugated papers through a caching shelf; a conveying unit sucks the corrugated papers from the caching shelf to convey above an emptying unit, and opens the corrugated papers as a door shape;the emptying unit conveys the corrugated papers to a binding unit; the binding unit conveys the corrugated papers to a corresponding coil position for fixed binding of the corrugated papers; the inner bag sleeving part is used for feeding inner bag packing materials into a coil inner cavity for fixed binding; and the outer bag sleeving part is used for sleeving outer bag packing materials on theouter surface of a coil for fixed binding. The equipment improves the coil packing efficiency, and can achieve unmanned packing.

Owner:湖南严格智能技术有限公司 +1

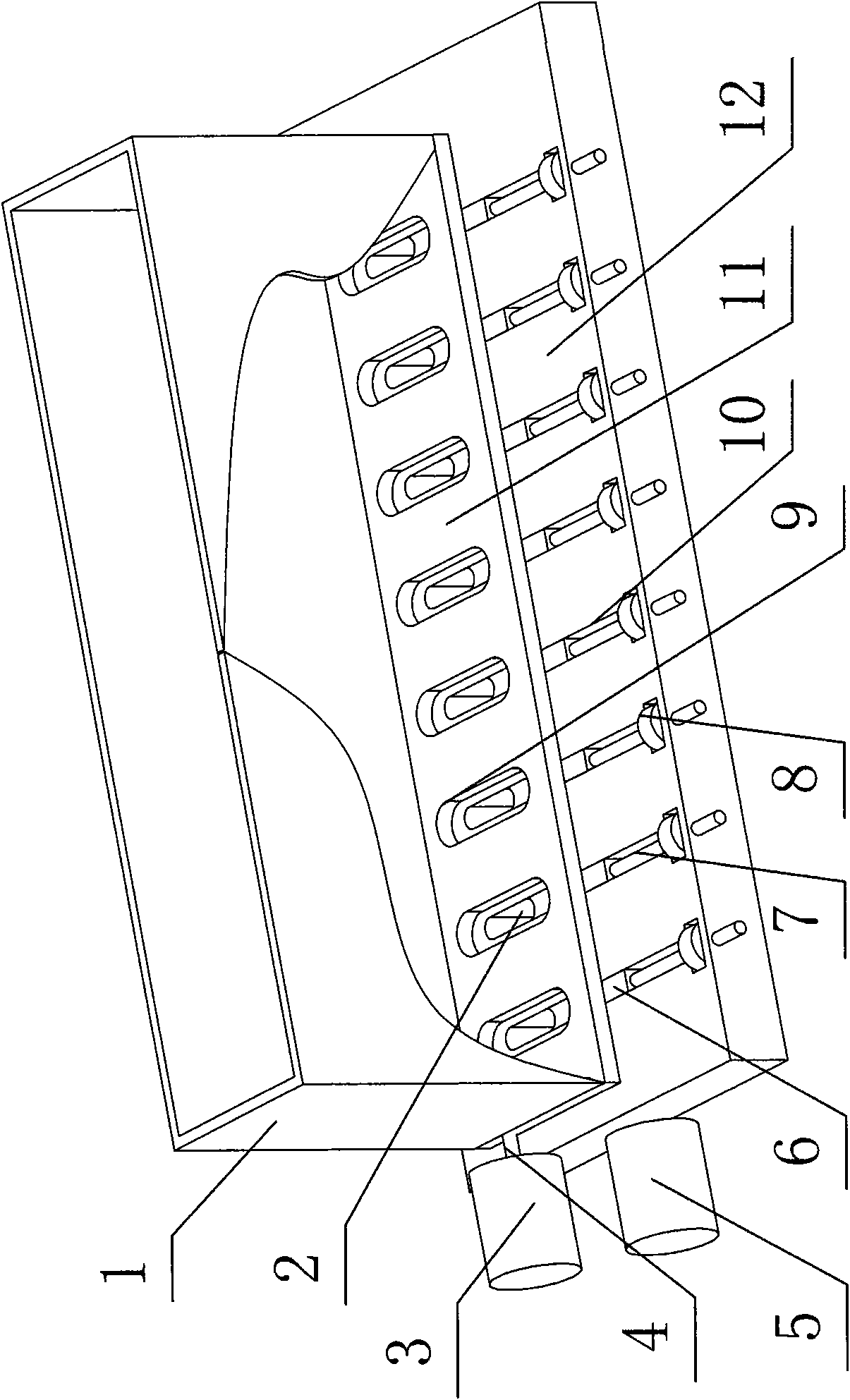

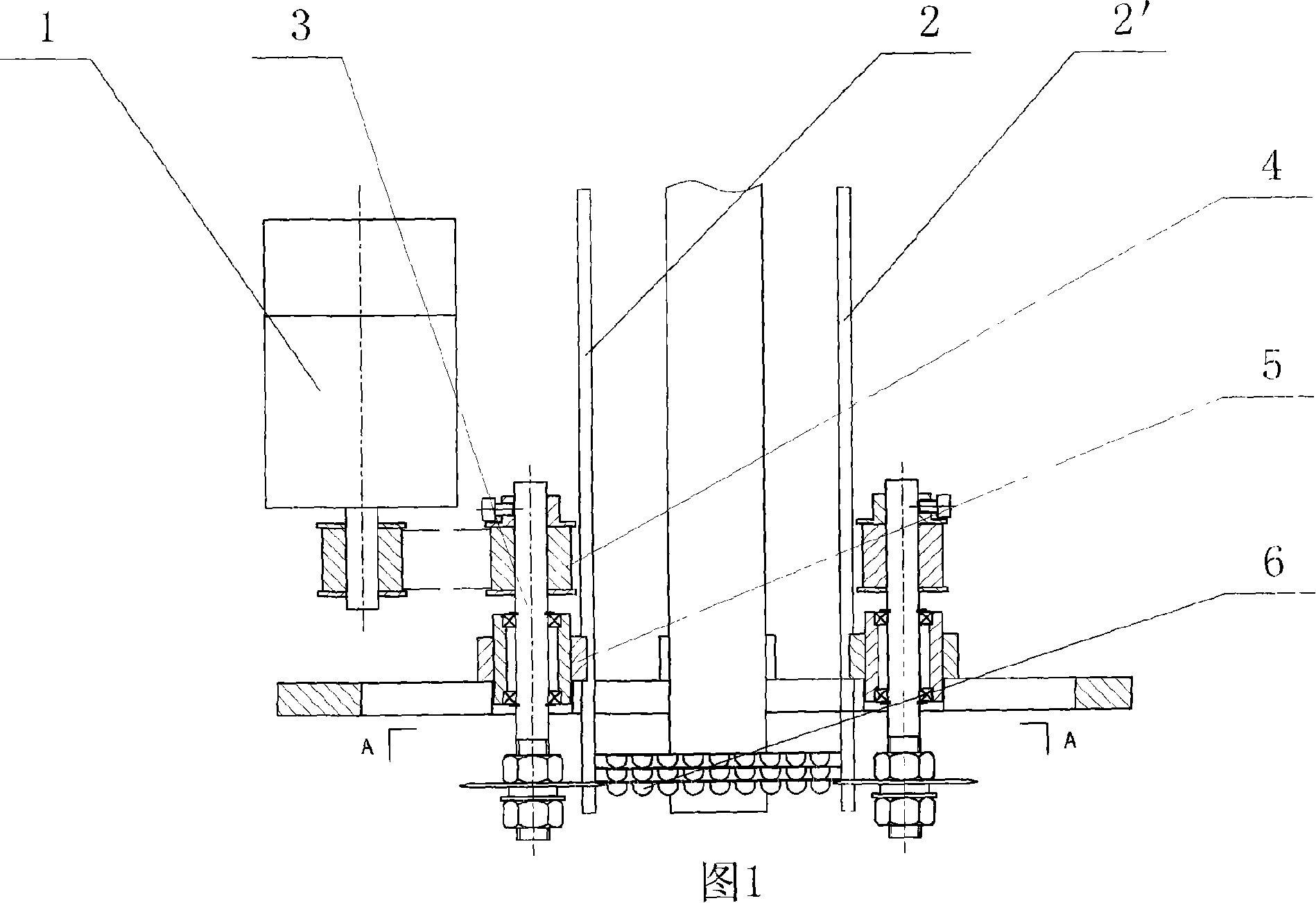

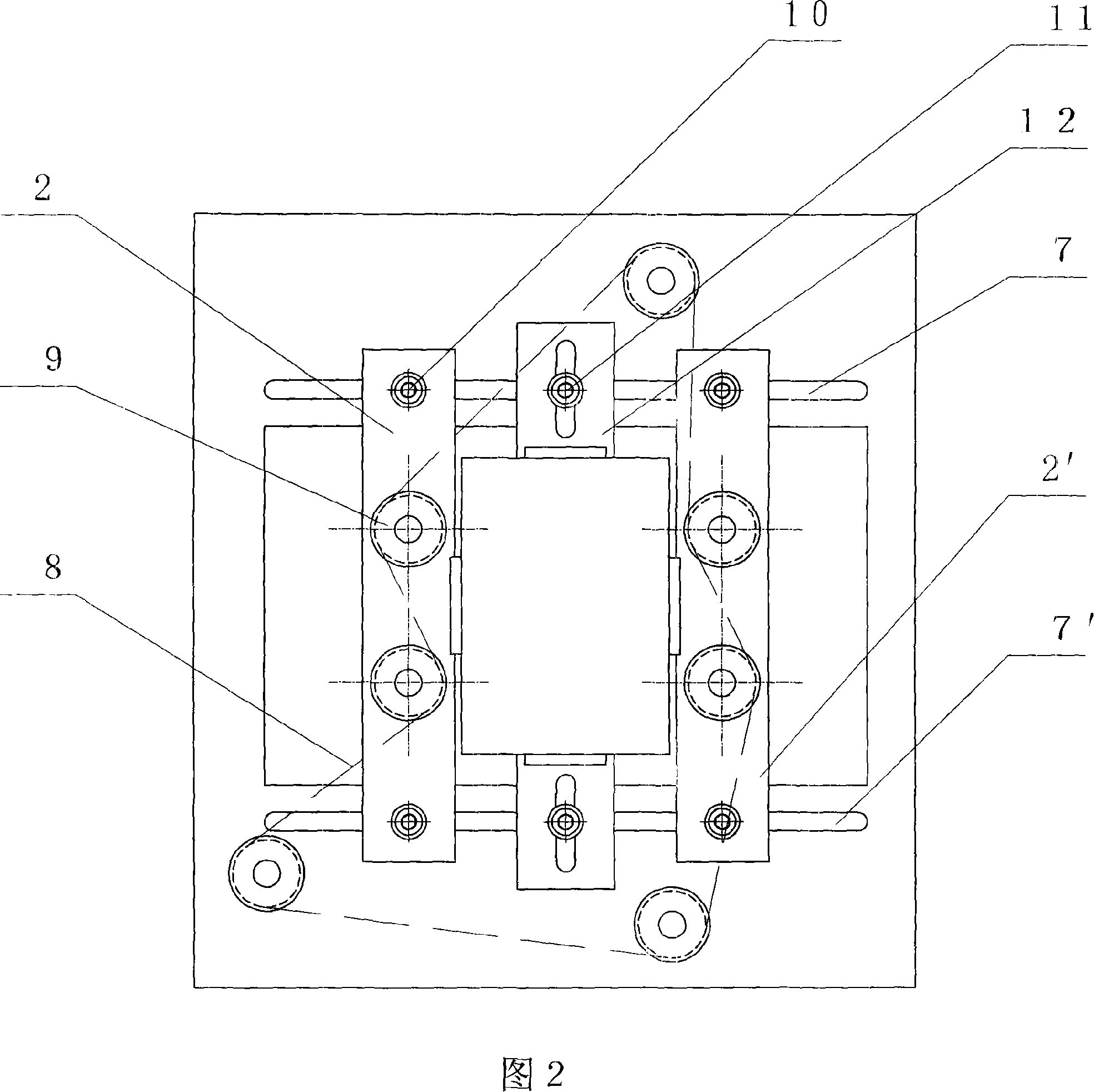

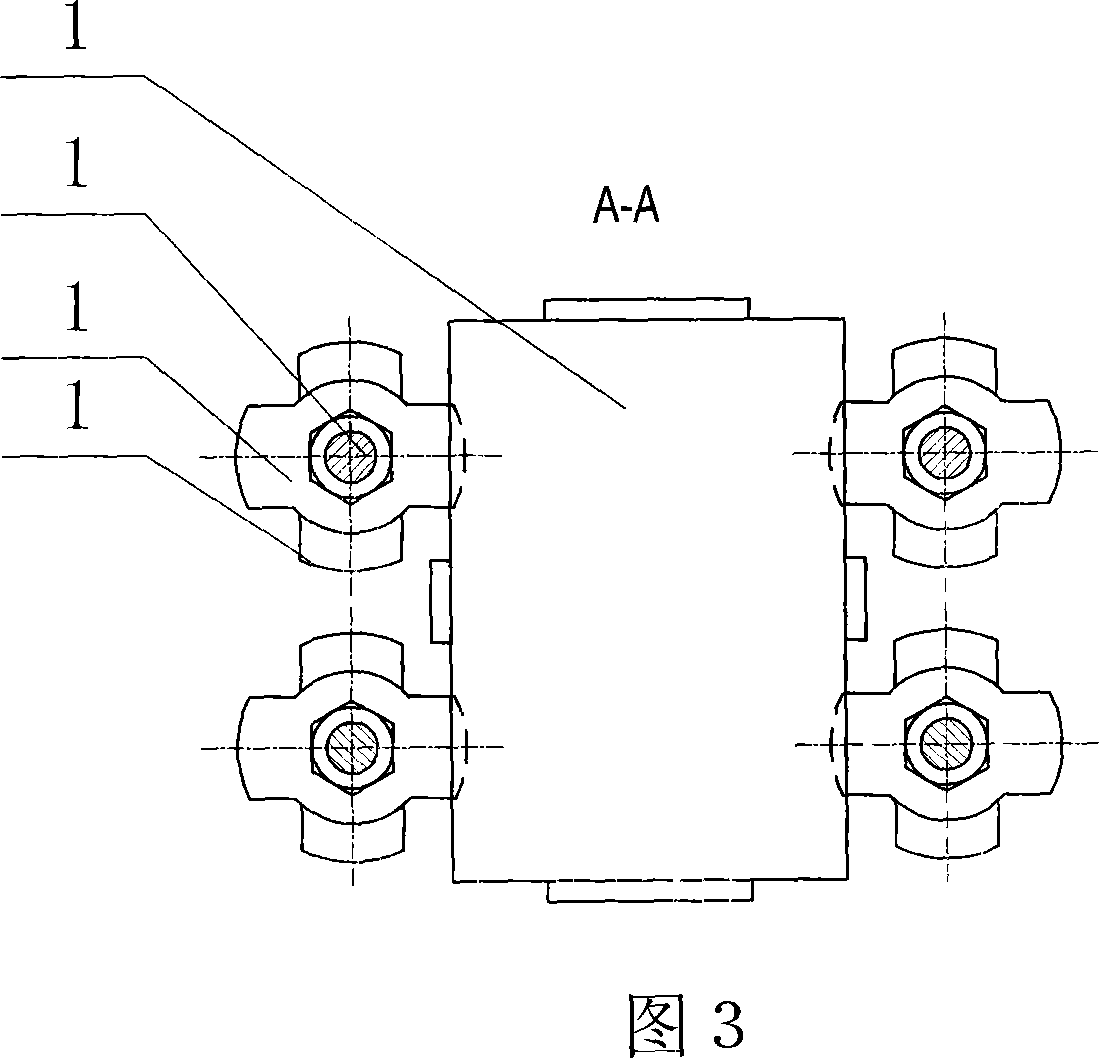

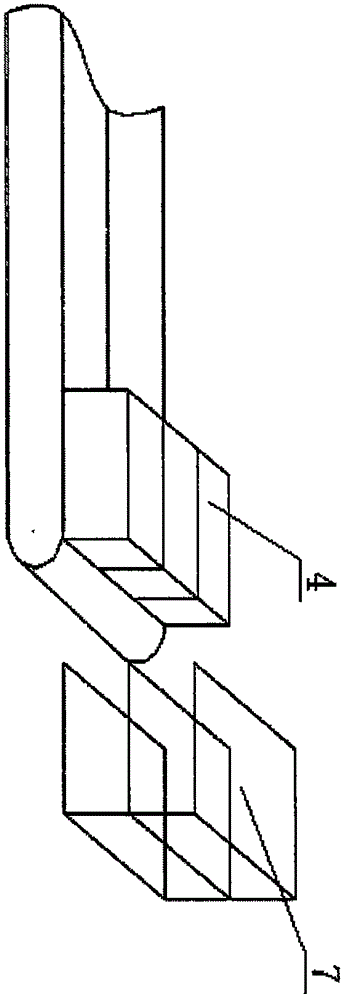

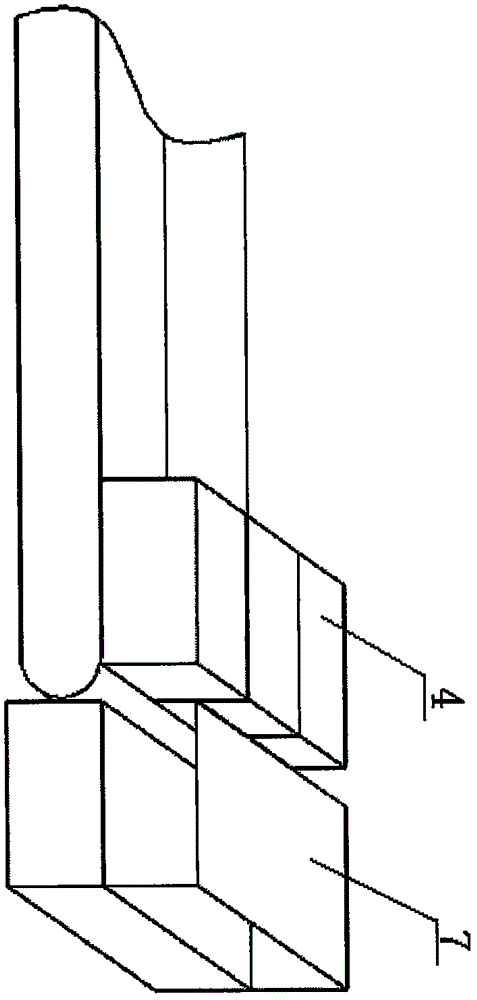

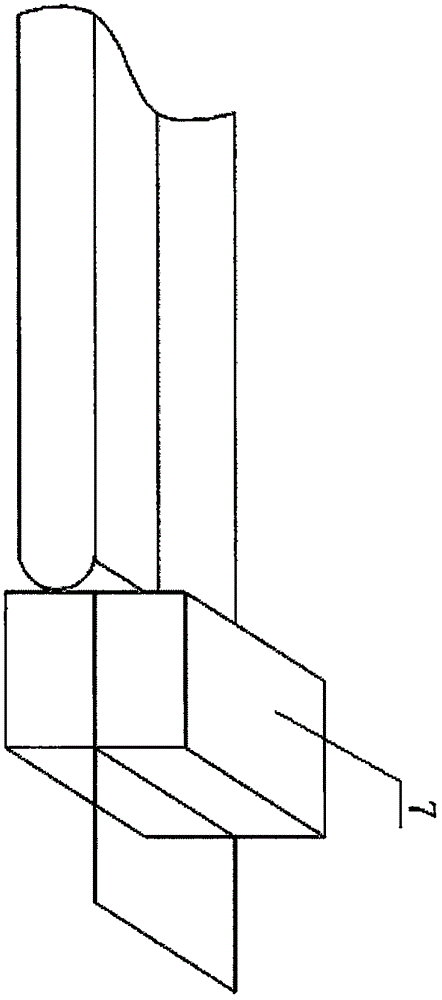

Medicine plate baiting mechanism of box packing machine

InactiveCN101108659AMeet the requirements of unmanned operationEasy to adjustPackagingElectric machineryPacking procedure

The invention discloses a medicine discharging mechanism of a box packing machine, which is characterized in that the medicine discharging mechanism comprises a motor (1) and a material warehouse. The material warehouse consists of top and bottom, left and right adjustable plates; at least an upper baffle (4) and a lower baffle (5) are mounted on the left and right adjustable plates (2, 2'); the upper baffle and the lower baffle are fixed on the same rotating shaft (3) and are arranged in a shape of cross; the rotating shaft is drive jointed with the motor and linked through a driving band, and the rotating shaft and the motor rotate synchronously. The invention realizes the discharging speed of the upper baffle and the lower baffle through controlling the rotating speed of the motor based on the requirement of the medicine box packing, increases the working efficiency, provides the reliable box packing procedure for the whole process linkage of the medicine with simple structure and convenient operation.

Owner:ZHEJIANG HUALIAN PHARM MASCH CO LTD

Antibacterial and mite-suppression bed core for babies and method for manufacturing antibacterial and mite-suppression bed core

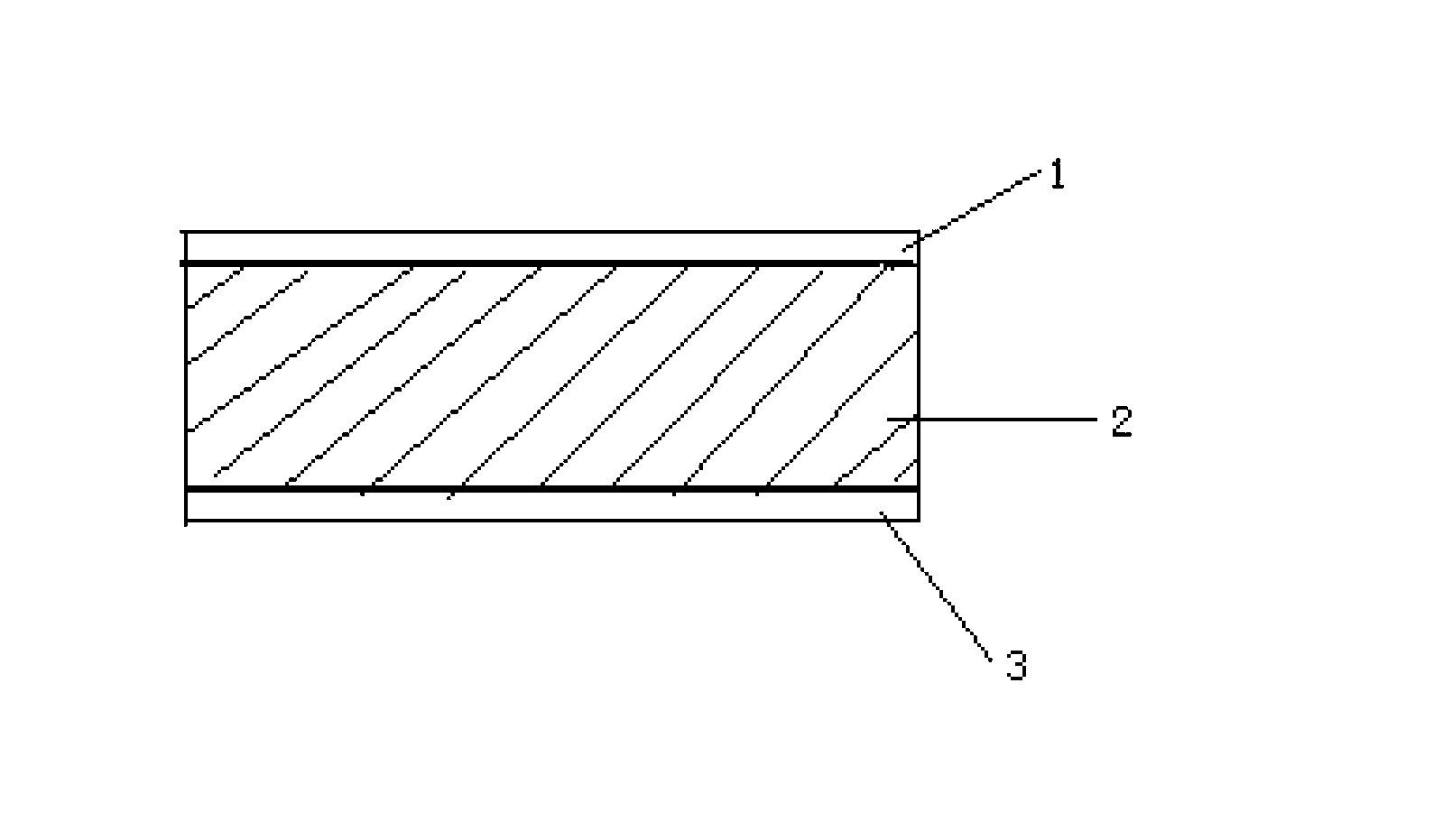

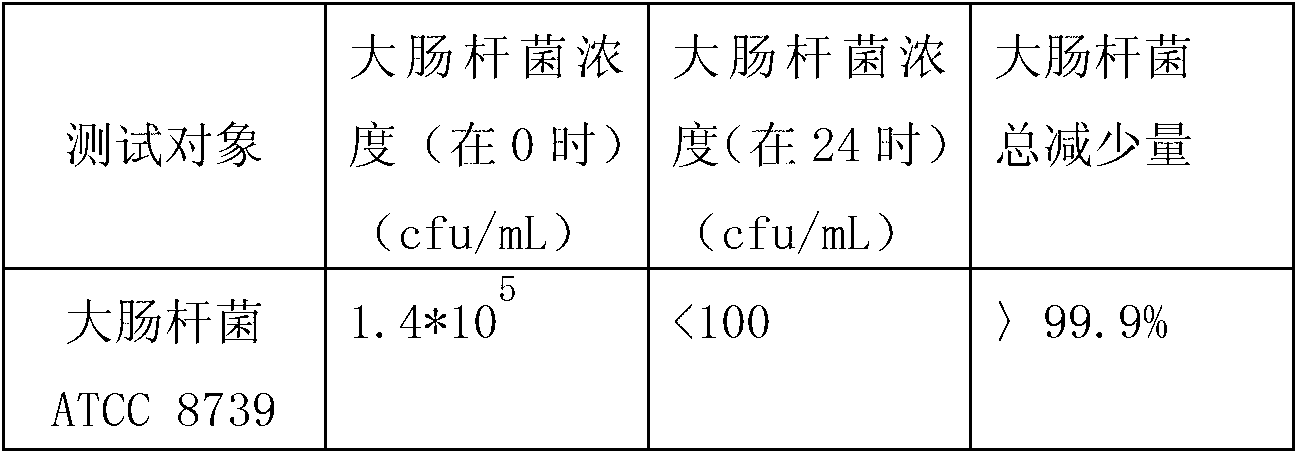

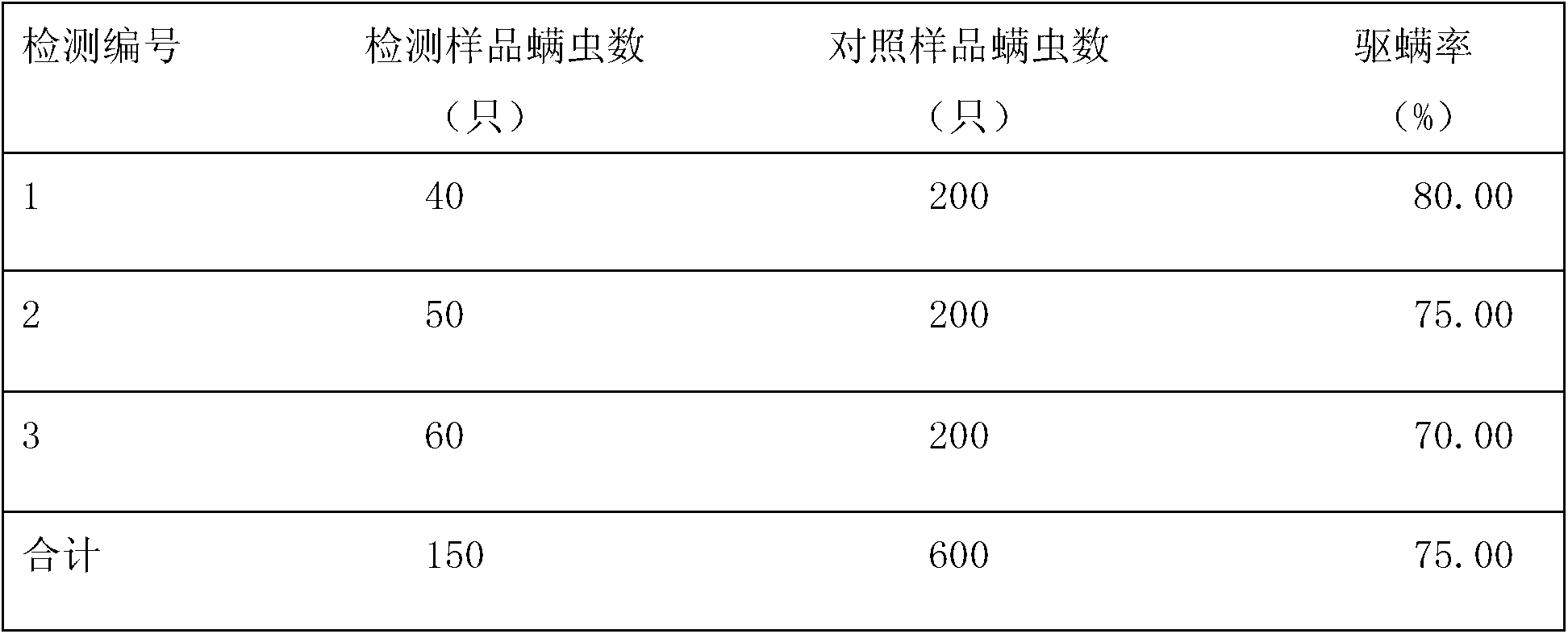

InactiveCN103054400ANot easy to layerNot easy to be environmentally friendlyStuffed mattressesSpring mattressesSurface layerUltraviolet

The invention discloses an antibacterial and mite-suppression bed core for babies. The antibacterial and mite-suppression bed core comprises at least one middle layer and surface layers, the surface layers are arranged on upper surfaces or lower surfaces of the middle layers, each surface layer is a non-woven layer comprising, by weight, from 15% to 40% of fibers with low melting points and from 60% to 85% of hemp fibers, and each middle layer comprises, by weight, from 60% to 85% of natural bamboo fibers and from 15% to 40% of fibers with low melting points. The invention further discloses a method for manufacturing the antibacterial and mite-suppression bed core for the babies. The method includes steps of respectively manufacturing the various layers including the upper and lower surface layers and the middle layers; sequentially laying the upper and lower surface layers and the middle layers; and performing oven drying, cold rolling, cooling, cutting and inspection and packing procedures to manufacture the antibacterial and mite-suppression bed core. The antibacterial performance, the healthcare performance, ultraviolet resistance, moisture absorption and removal properties and an environmental protection property of the antibacterial and mite-suppression bed core for the babies are greatly improved as compared with an existing mattress.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

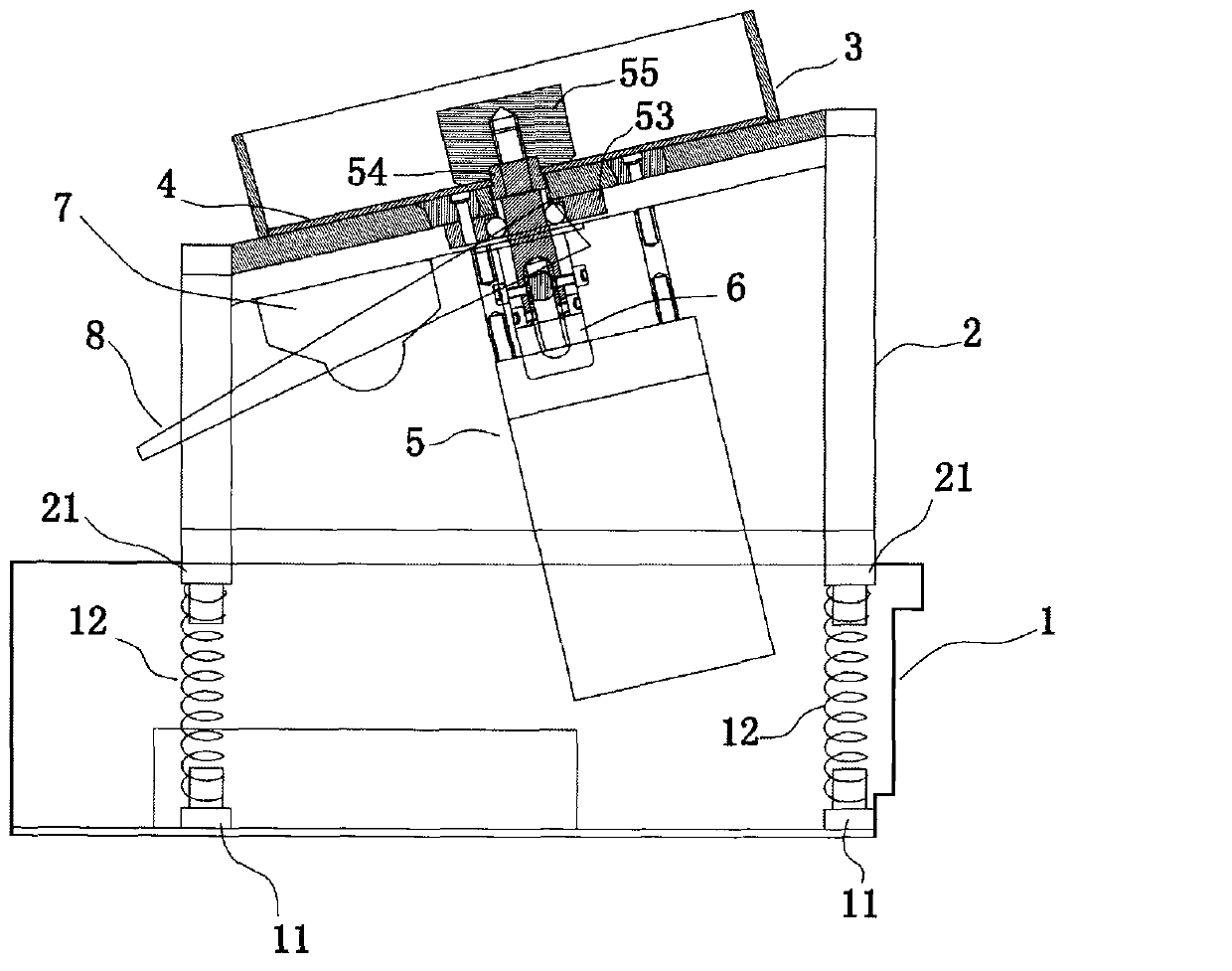

Abdominal pad folding machine

ActiveCN106743964AStable storageSolve the problem of output speed changeFolding thin materialsPacking procedureAbdominal pad

The invention provides an abdominal pad folding machine, solves the problems of disadvantageous subsequent packing procedures caused by disordered gauze easily generated by entering the gauze in an emptying table after passing through a folding roller and machine damage caused by easy winding of the gauze into the folding roller in a traditional folding machine, and solves the problems of difficult provision of stable gauze conveying linear velocity along with diameter change of a gauze roll and complex folding roller mechanism and high use cost caused by excessive dependence on the folding roller in fixed-length cutting of the gauze. The abdominal pad folding machine comprises a frame, an upper winding mechanism and a roller pair, and further comprises the emptying table with a baffle plate, and an intermittent rotating mechanism relatively fixed to the baffle plate; the intermittent rotating mechanism is driven to drive the baffle plate to intermittently move; the upper winding mechanism includes a conveying belt tightly contacted with the lower end of the gauze roll to form friction matching; and the gauze roll is always kept at the same linear velocity with the conveying belt. The abdominal pad folding machine further comprises two flying shear mechanisms positioned between the roller pair and the folding roller. The abdominal pad folding machine is mainly used for folding and fixed-length cutting of the gauze, and is reliable and stable in performance.

Owner:XINXIANG HUAXI MEDICAL SANITARY MATERIALS

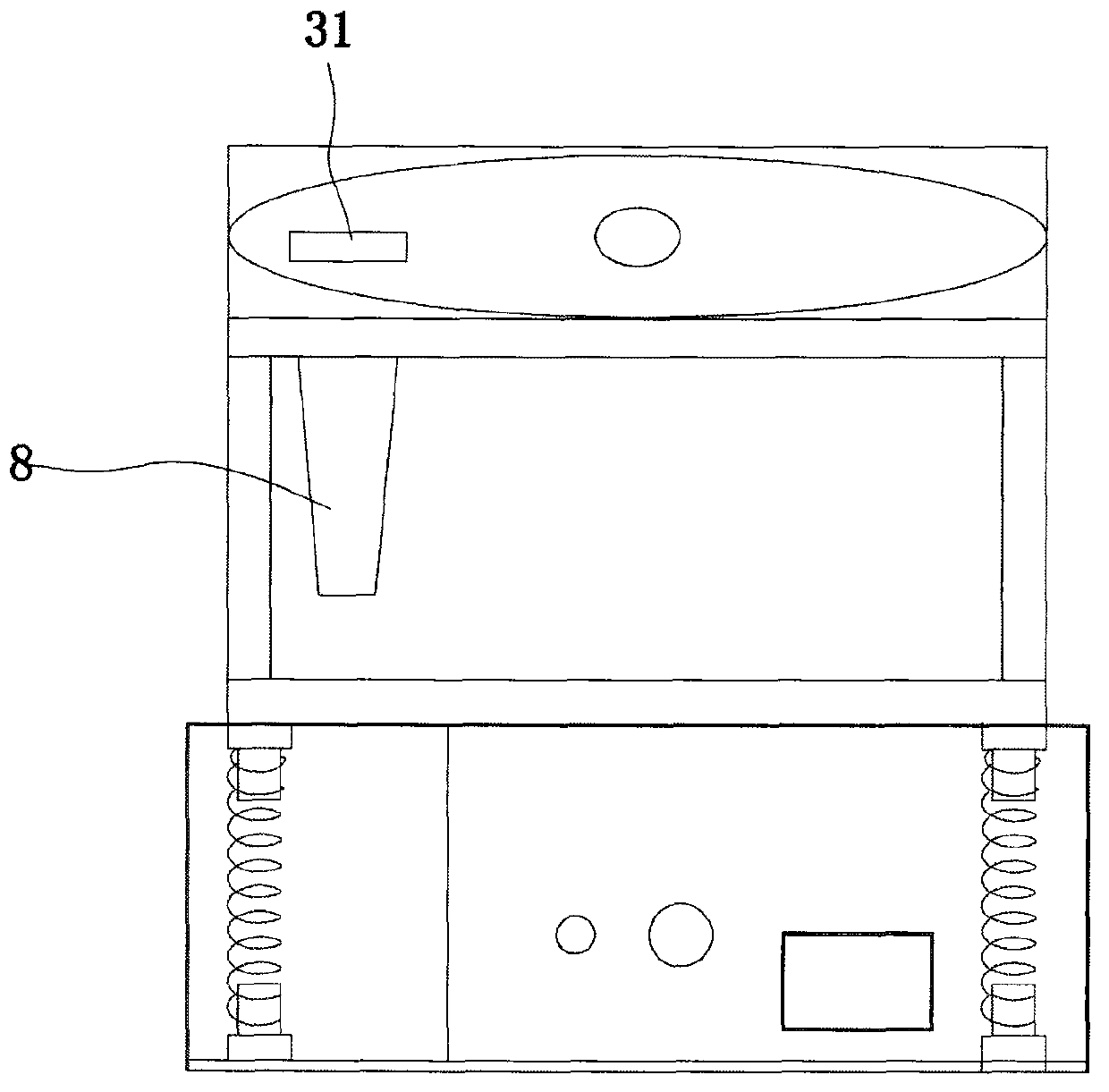

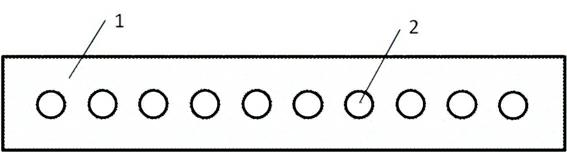

Tablet counting packing machine with counting accuracy and high packing efficiency

InactiveCN103129784AAccurate countImprove packaging efficiencyPackaging automatic controlElectric machineryPacking procedure

The invention discloses a tablet counting packing machine with counting accuracy and high packing efficiency. The tablet counting packing machine comprises a base, a shell, a tablet storage plate and a table counting plate; a control circuit is arranged in the base, the shell is positioned at the upper end of the base, the top surface of the shell is oblique, the tablet storage plate is fixed onto the oblique surface of the shell, the tablet counting plate is arranged inside the tablet storage plate, is provided with tablet holes and is connected with a rotation driving device, the rotation driving device comprises structures such as a power-off brake motor and a connecting spindle, and two screws are horizontally arranged at one end, which is close to the power-off brake motor, of the connecting spindle; a metal proximity detector is fixed to the lower end surface of the tablet storage plate by a detector fixing device, and the central axis of the metal proximity detector and central axes of the two screws on the connecting spindle are positioned on the same plane; and the base is connected with the shell by springs, and a vibration motor is fixed to the lower end surface of the tablet storage plate. The tablet counting packing machine has the advantages that owing to a spring connecting structure, tablets can smoothly fall into the tablet holes of the tablet counting plate, the metal proximity detector controls the power-off brake motor to rotate by a half circle so as to complete a tablet counting and packing procedure at one step, and the tablet counting packing machine is accurate in counting and high in packing efficiency.

Owner:冯国桦

Die cutting process for food packing box

InactiveCN104802451ASimple processImprove yieldBox making operationsPaper-makingPaper tapePacking procedure

The invention discloses a die cutting process for a food packing box, and relates to the field of die cutting processes of packing products. The process comprises seven major steps of inspecting a device; preparing a printing product; arranging a die cutting cutter; feeding paper; starting to test die cutting; regulating pressure; performing die cutting; the printing product is processed by humidity regulating or shaping; the moisture content of the printing product is regulated to be adapt to the temperature and humidity in a workshop; small die cutting pressure can lead to difficult modifying, and large die cutting pressure can lead to reduction of a steel cutter deformation precision, and the edge is obtunded; in case of large-area modifying, a part with corresponding size can be cut on a piece paper and clung to the rear surface of cushion paper to be used as a cushion other; in case of fine modifying, a modifying paper tape is used for modifying in the corresponding line on the cutter die cushion paper; the excessive leftovers of the product subjected to die cutting are removed. The process is simple and reasonable and high in yield, and the production cost can be reduced while the production efficiency can be increased.

Owner:ANHUI JIAXIN PACKAGING & PRINTING

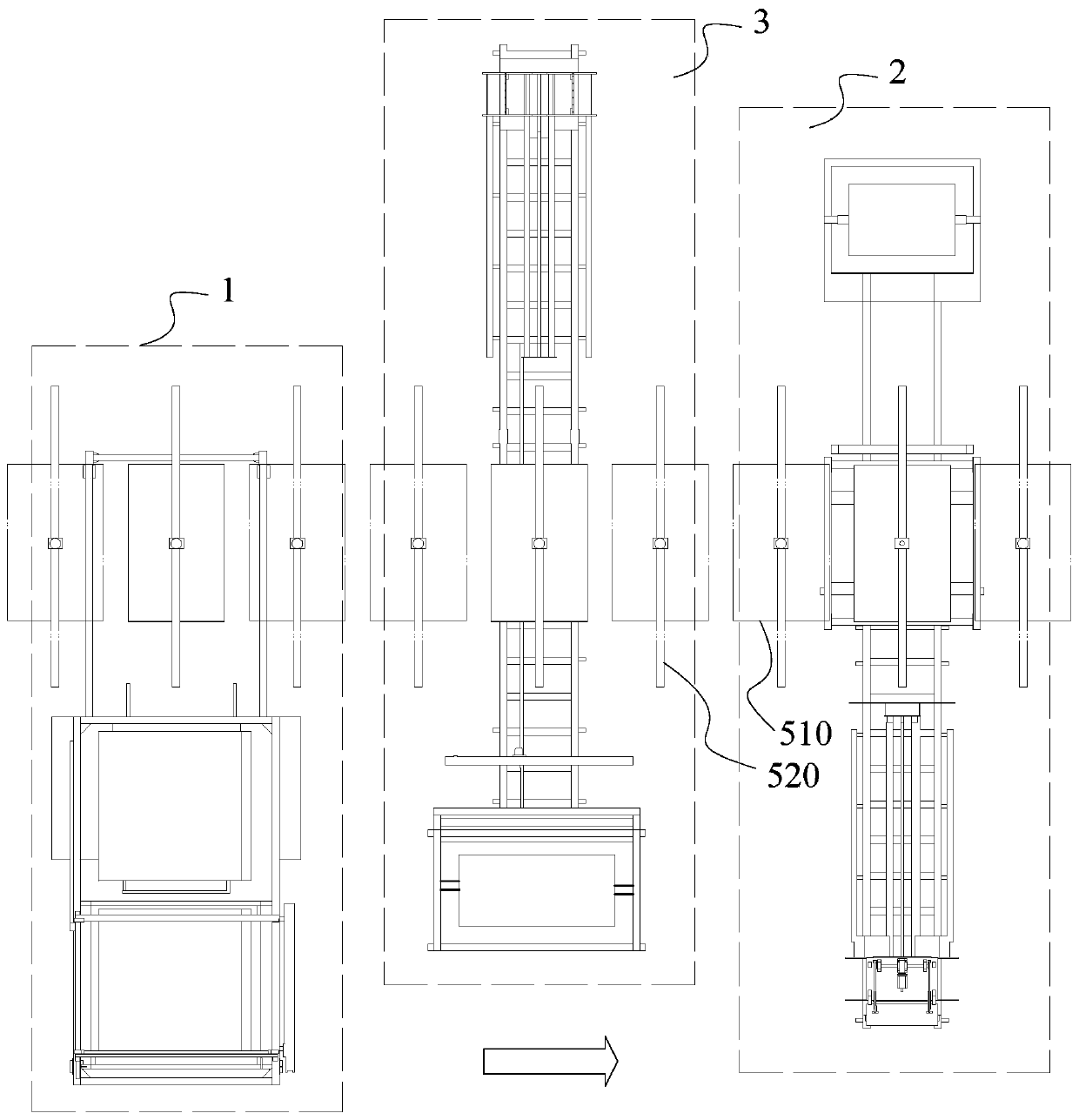

Tea leaf packing process

ActiveCN108382672APreservation effectImprove freshnessPackaging by pressurising/gasifyingPacking procedureEngineering

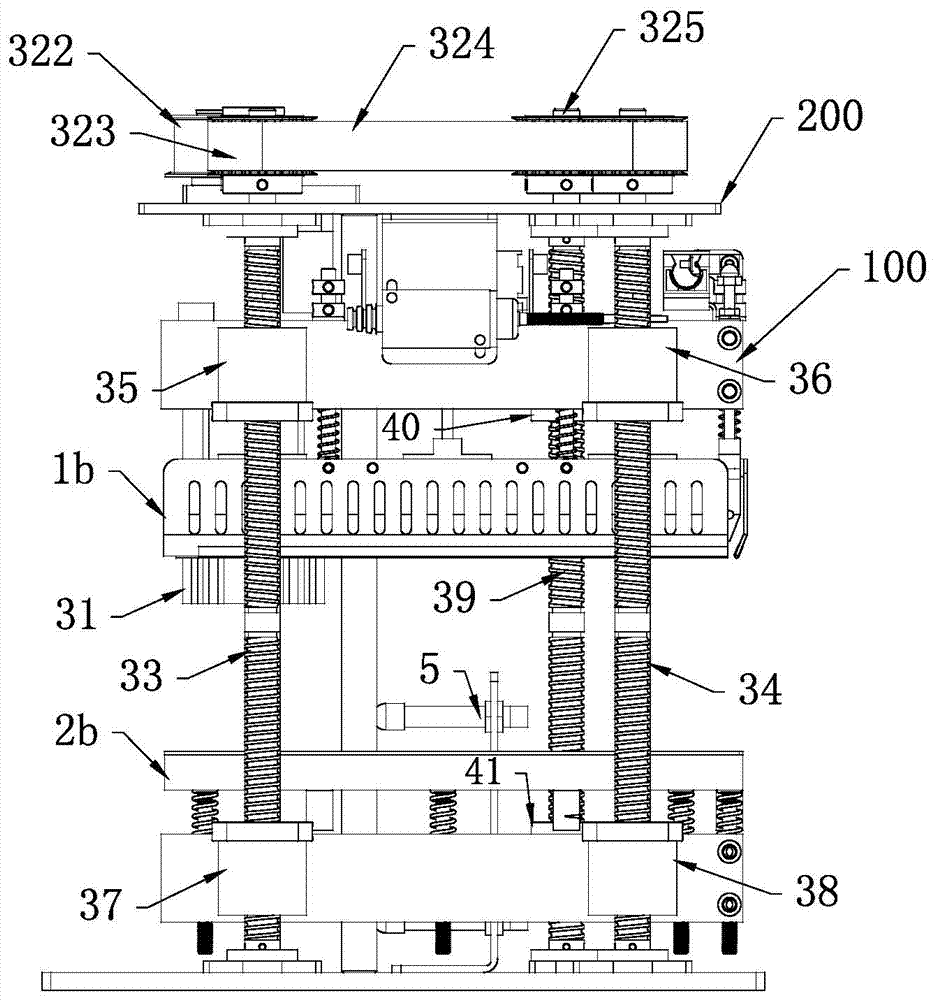

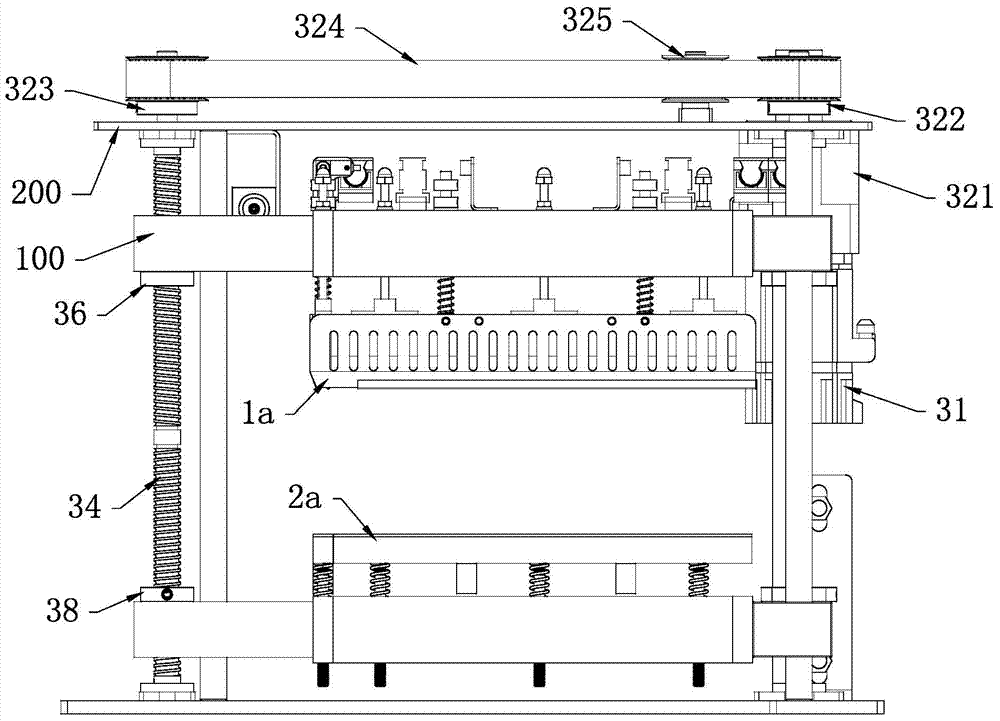

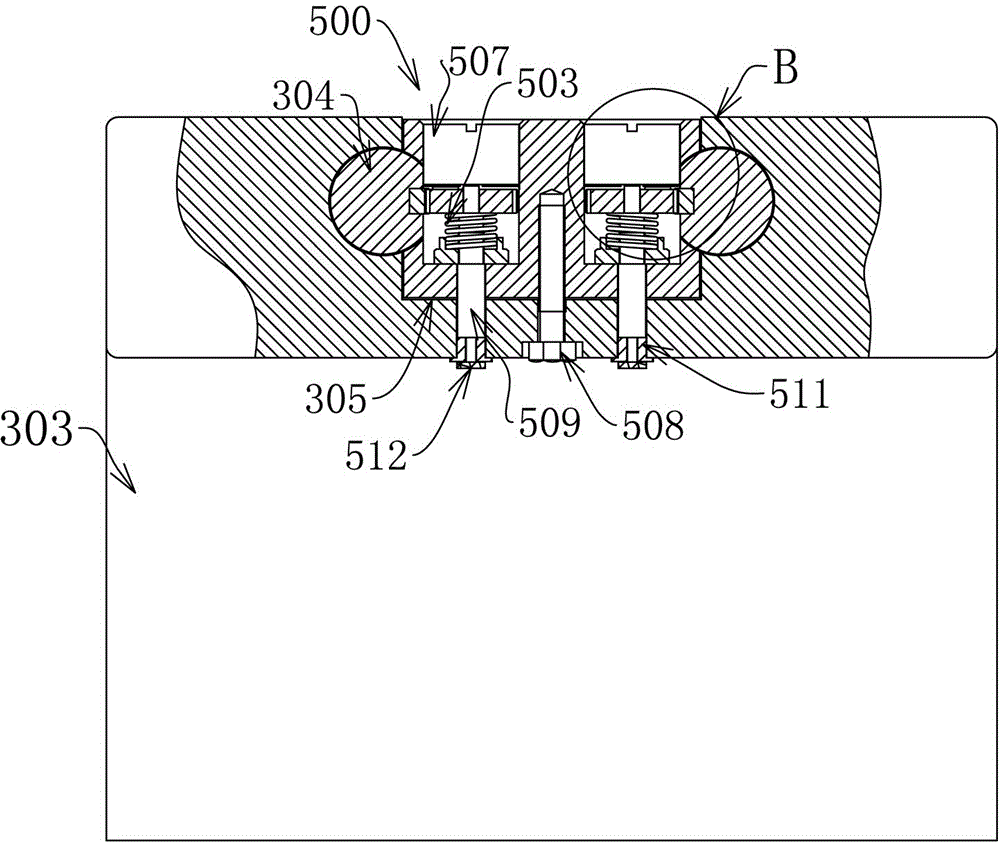

The invention discloses a tea leaf packing process. The tea leaf packing process includes a pre-treatment procedure and a packing procedure. The packing procedure is implemented through the followingsteps that (1) packing bags fall; (2) die closing is performed, and the tea leaf packing bags on a shaping cavity are completely contained in an airtight cavity; (3) primary vacuumizing is performed on the airtight cavity of the step (2); (4) sealing is performed, specifically, hot-pressing sealing is performed on the primarily vacuumized packing bags in the airtight cavity; (5) secondary vacuumizing on the airtight cavity is started; (6) primary vacuum breaking is performed on the airtight cavity; (7) upper shaping treatment is performed in the airtight cavity; (8) lower shaping treatment isperformed in the airtight cavity; (9) tertiary vacuumizing is performed on the airtight cavity; (10) secondary vacuum breaking is performed on the airtight cavity; and (11) die opening is performed, shaped packing bags on the shaping cavity are taken out, and then tea leaf packing is finished. Compared with the prior art, by means of the tea leaf packing process, the fresh-keeping effect of tea leaves in the bags is good, no tea leaf piece residue exists, six-side shaping is achieved, and therefore the advantages of good packing and shaping effects, attractive packing and many procedures are achieved.

Owner:安溪县钱盛自动化设备有限公司

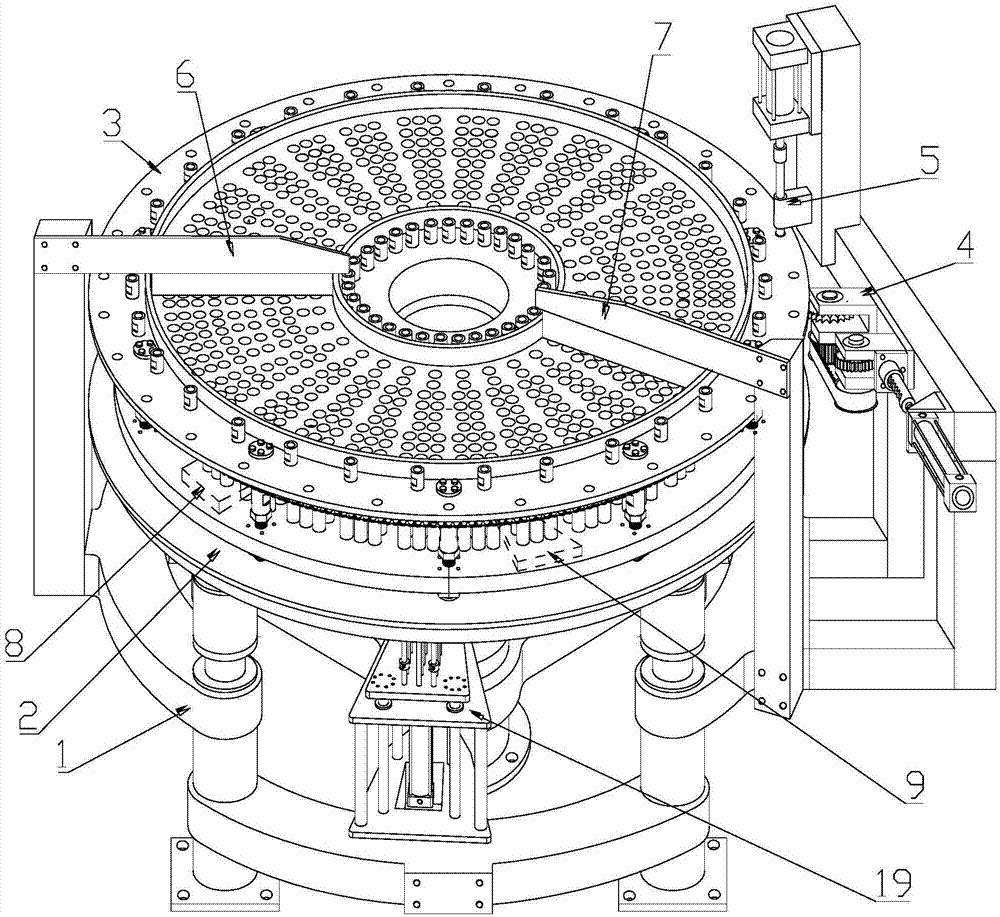

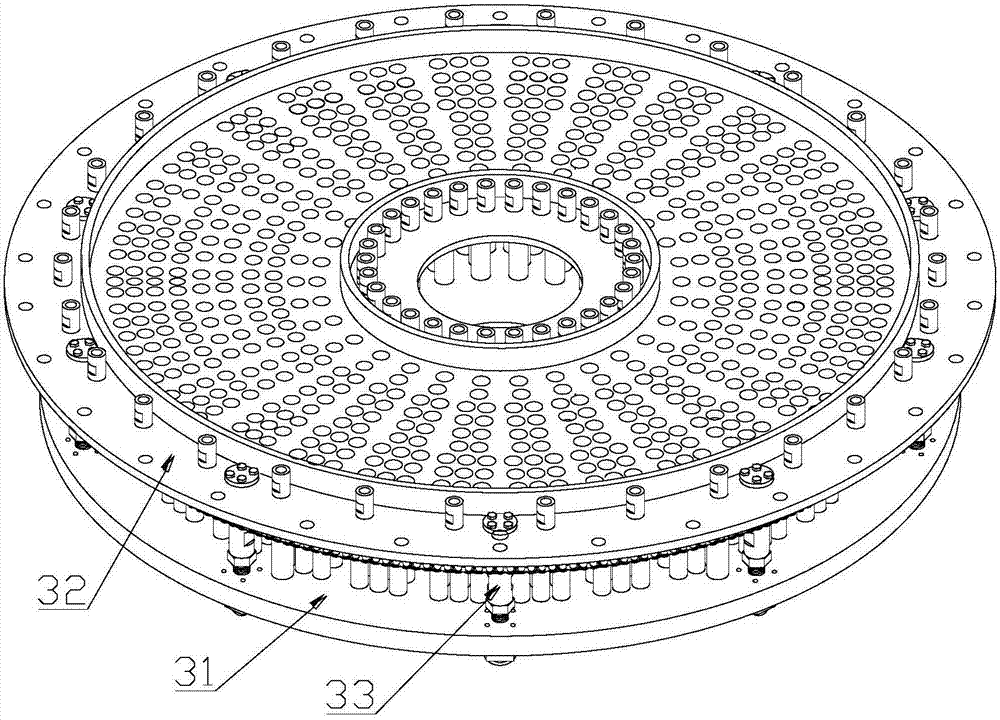

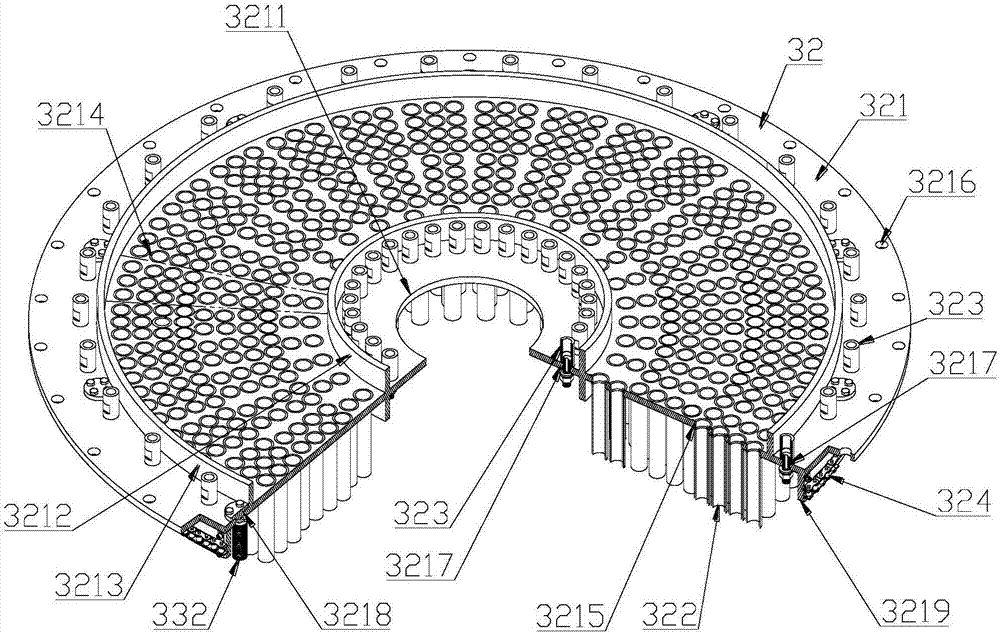

Indexing turntable multi-station vibration worktable for powder explosive small cartridge charger

ActiveCN106931841ASimplify transfer between processesSmall operating areaAmmunition storagePacking procedureHoneycomb

The invention discloses an indexing turntable multi-station vibration worktable for a powder explosive small cartridge charger. The worktable comprises a base, a vibration disc and an indexing rotary worktable. The indexing rotary worktable is provided with vertical packing cylinder channel fan-shaped areas distributed in a honeycomb form and with bottoms; the indexing rotary worktable intermittently rotates in the clockwise direction; and at each time of rotation, the unitized packing cylinder channels in each fan-shaped area are transposed from the fan-shaped area to an adjacent fan-shaped area. When small cartridge plastic packing cylinders rotate to multiple fan-shaped areas of a filling area, the packing cylinders are gradually and fully filled with powder explosives and the powder explosives are compacted by vibration through vibration of the vibration disc for reaching the standard; when the explosive-charged small cartridge plastic packing cylinders rotate to a capping area and stop, a capping and ejecting mechanism jacks up the packing cylinders fully filled with the powder explosives for capping; and when the capped small cartridge plastic packing cylinders rotate to an ejecting area and stop, a cartridge ejecting mechanism ejects the capped packing cylinders from the packing cylinder channels. The worktable improves the operation safety, the reliability and the working efficiency in explosive cartridge filling and packing procedures.

Owner:HEFEI P M ONE MACHINERY CO LTD

Cache-on-board (COB) technology-based integrated light emitting diode (LED) packing method

InactiveCN102437271ALower working temperatureFlexible thickness controlSemiconductor devicesCooking & bakingHeat resistance

The invention relates to a cashe-on-board (COB) technology-based integrated light emitting diode (LED) packing method, which comprises the following steps that: 1. thickness of a mould and diameter of a reserved hole are adjusted; 2. the reserved hole on the mould is aligned to an LED chip which is well fixed on an aluminum circuit board, and the mould covers the aluminum circuit board; 3. after fluorescent glue is sprayed on the aluminum circuit board, the aluminum circuit board is baked, then the mould is removed after the baking so as to obtain an LED packing unit. The method has followinng beneficial effects that: the shape, position, thickness and quantity of the fluorescent flue can be adjusted by adjusting the thickness of a silicone board and the diameter of the reserved hole, so the LED integrated packing procedures can be simplified, the heat resistance and the working temperature of the LED chip can be reduced, the shape, position, thickness and quantity of the fluorescent glue can be flexible to control, the light emitting efficiency and the consistency, stability and service life of the product can be improved, the packing efficiency also can be improved, the waste can be reduced, and the product cost can be reduced. The baking temperature is set as 140 to 160 DEG C, so the packing effect is better.

Owner:秦会斌 +6

Automatic cake packing device and application method

InactiveCN108792025ASolve the problem of only one boxing processImprove protectionPackagingElectric machineryPacking procedure

The invention discloses an automatic cake packing device and an application method, and relates to the technical field of automatic packing. The automatic cake packing device comprises a supporting frame; a first motor penetrates through and is fixedly connected with one side of the supporting frame; the end of an output shaft of the first motor is fixedly connected with a first gear; the first gear is engaged with a second gear; the inner surface of the second gear is fixedly connected with a first rotating shaft; the first rotating shaft penetrates through the supporting frame and is rotationally connected with the supporting frame; the circumferential side surface of the first rotating shaft is fixedly connected with a first transmission roller; the circumferential side surface of the first transmission roller is in transmission connection with a first conveying belt; one side of the supporting frame is rotationally connected with a second transmission roller through a second rotating shaft; and the circumferential side surface of the second transmission roller is in transmission connection with the inner surface of the first conveying belt. Through structures of the first conveying belt and a second conveying belt, the problems that a cake box shakes due to human factors and cakes are damaged in the transporting process due to the fact that an existing cake packing machinesimply carries out one step of packing procedure are solved.

Owner:宿松县京味食品有限公司

Automatic discharging and receiving machine for injection molding machine

ActiveCN104176316AReduce investmentReduce manual involvementPackaging automatic controlSolenoid valvePacking procedure

An automatic discharging and receiving machine for an injection molding machine comprises a frame consisting of an upper layer, an intermediate layer and a lower layer, wherein the upper layer is provided with a receiving hopper, a hot-melting sealing machine and a film cutting machine and further provided with a bearing device for bearing charging baskets and a basket withdraw device for pushing the charging baskets to move; the intermediate layer is provided with a positioning device for lifting the charging baskets; a basket supply device for pushing the charging baskets to move is further arranged at the lower part of the intermediate layer; the lower layer is provided with a descending cylinder and a lifting cylinder; a hot-melting electric cabinet is arranged at the bottom of the lower layer. The automatic discharging and receiving machine can realize continually automatic basket replacement and material receiving, and the maximal quantity of replaced baskets can be up to 9; when one basket is full, a PLC gives a command to control a corresponding solenoid valve and a corresponding cylinder mechanism to automatically send out the full charging basket, and then an empty charging basket is automatically fed in, so that the whole material receiving and replacing process needs no manual intervention; meanwhile, the full charging basket can be automatically sealed and packed, so that follow-up sealing and packing procedures are eliminated, the labor intensity of workers is lowered, and the operational efficiency is improved.

Owner:SICHUAN RUITENG ELECTRONICS

Full-automatic bag-clamping supporting machine

InactiveCN107187662AAdjustable speedFully automatedWrapper twisting/gatheringPackaging automatic controlPacking procedureEngineering

The invention discloses a fully automatic bag clamping and supporting machine, which includes a mounting plate, a cylinder seat, a left chain seat, and a right chain seat. A support rod is fixedly connected between the mounting plate and the cylinder seat, and a gear box is installed on the mounting plate. The input shaft of the gearbox is connected with the geared motor. The gearbox has two left output shafts and right output shafts that turn in opposite directions. Arm, rear right swing arm, front left swing arm, rear left swing arm lower ends are respectively fixedly connected to the front and rear parts of the left chain seat, front right swing arm, rear right swing arm lower ends are fixedly connected to the front and rear parts of the right chain seat respectively. At the rear, the present invention is widely used in automatic bagging and packaging processes in the fields of chemical industry, grain, food, pharmaceuticals, etc. The mechanical structure is simple, stable and reliable, and it can well keep the shape of the packaging bag vertically flat, thereby eliminating the need for manual assistance Work, to achieve packaging automation.

Owner:HEFEI KEZHENG AUTOMATION ENG

Composite corrugated paperboard buffering cushion base

InactiveCN105460406AStable stateAchieve the role of fixed flat-screen TVContainers to prevent mechanical damageCardboardSocial benefits

The invention provides a composite corrugated paperboard buffering cushion base. The composite corrugated paperboard buffering cushion base comprises a cushion framework and a buffering body, wherein the cushion framework is formed by folding a corrugated paperboard, and the buffering body is bonded to the cushion framework and formed by bonding honeycomb paperboards; a groove is formed in the middle of the buffering body; the cushion base further comprises a plastic supporting piece fixed to the groove of the buffering body; insertion ports are preformed in the periphery of the buffering cushion base; the buffering cushion base is connected with an edge cushion through the insertion ports; a positioning corrugated board is fixed to the buffering body. The composite corrugated paperboard buffering cushion base is novel in design, and adopted materials are environmentally friendly and economical; on the premise of completely guaranteeing transport safety of flat panel televisions, the cyclic utilization rate of the materials is increased, the packing difficulty is lowered, the packing procedures are simplified, and enterprise cost is lowered; economic benefits and social benefits are obvious.

Owner:MACROSCOPIC CENTURY TIANJIN CO LTD

Multifunctional food package transportation device

InactiveCN109018527AEasy to openIncrease the degree of unmannedPackaging by pressurising/gasifyingWrapper twisting/gatheringABSORPTION BASEPacking procedure

The invention discloses a multifunctional food package transportation device. The device comprises an absorption base; a vacuum absorption port is formed in the lower part of the front surface of theabsorption base; a hot sealing device is arranged above the vacuum absorption port; the back surface of the absorption base is connected with the front end of an extension rod; the back end of the extension rod is connected with a right-angled lifting rod; and the upper end of the right-angled lifting rod is connected with a slide rail. A vacuum absorption cabin is formed in the vacuum absorptionport; and an air extracting port is formed in the back of the vacuum absorption cavity. The device can use the vacuum absorption port for absorbing packing bags to achieve a transportation purpose; through coaction of the extension rod and the vacuum absorption port, openings in the packing bags can be conveniently kept opened to achieve smooth filling; and after filling, through coaction of the extension rod, the vacuum absorption port and the hot sealing device, the food packing bags are directly sealed to finish packing procedures. The device greatly simplifies the transportation, filling and hot sealing process of food packages, is higher in unmanned degree of the packing procedures, and greatly improves the production efficiency.

Owner:东台世恒机械科技有限公司

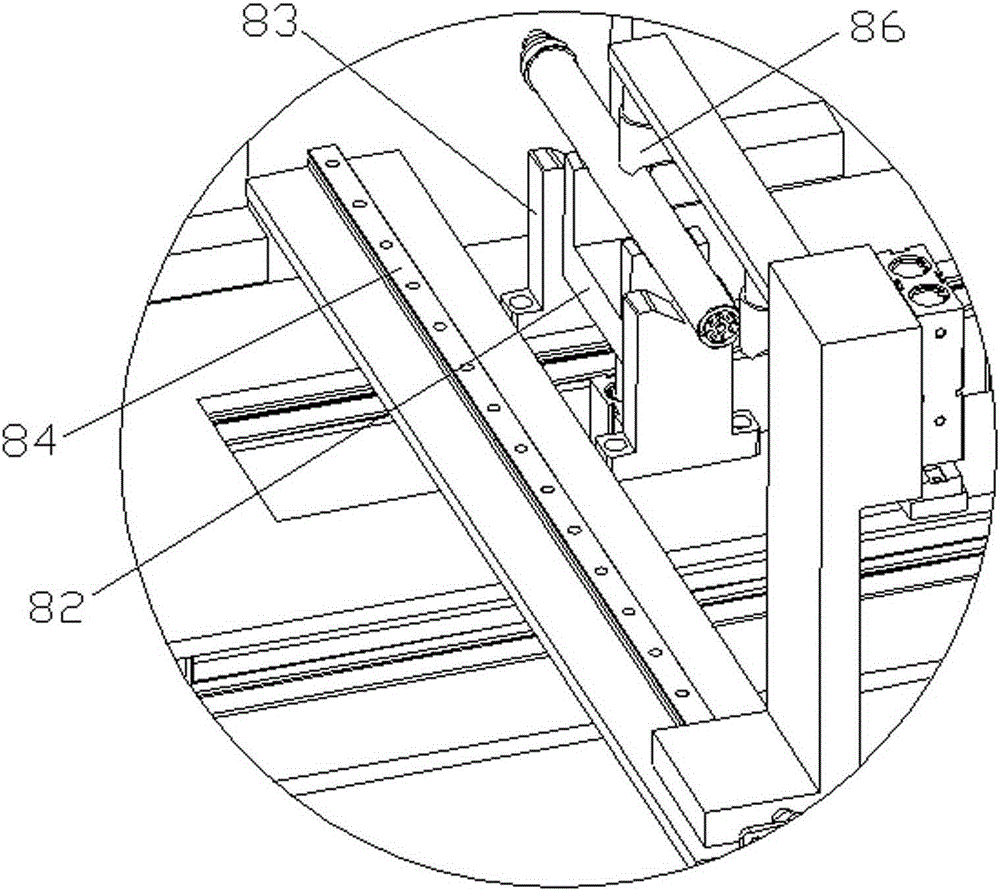

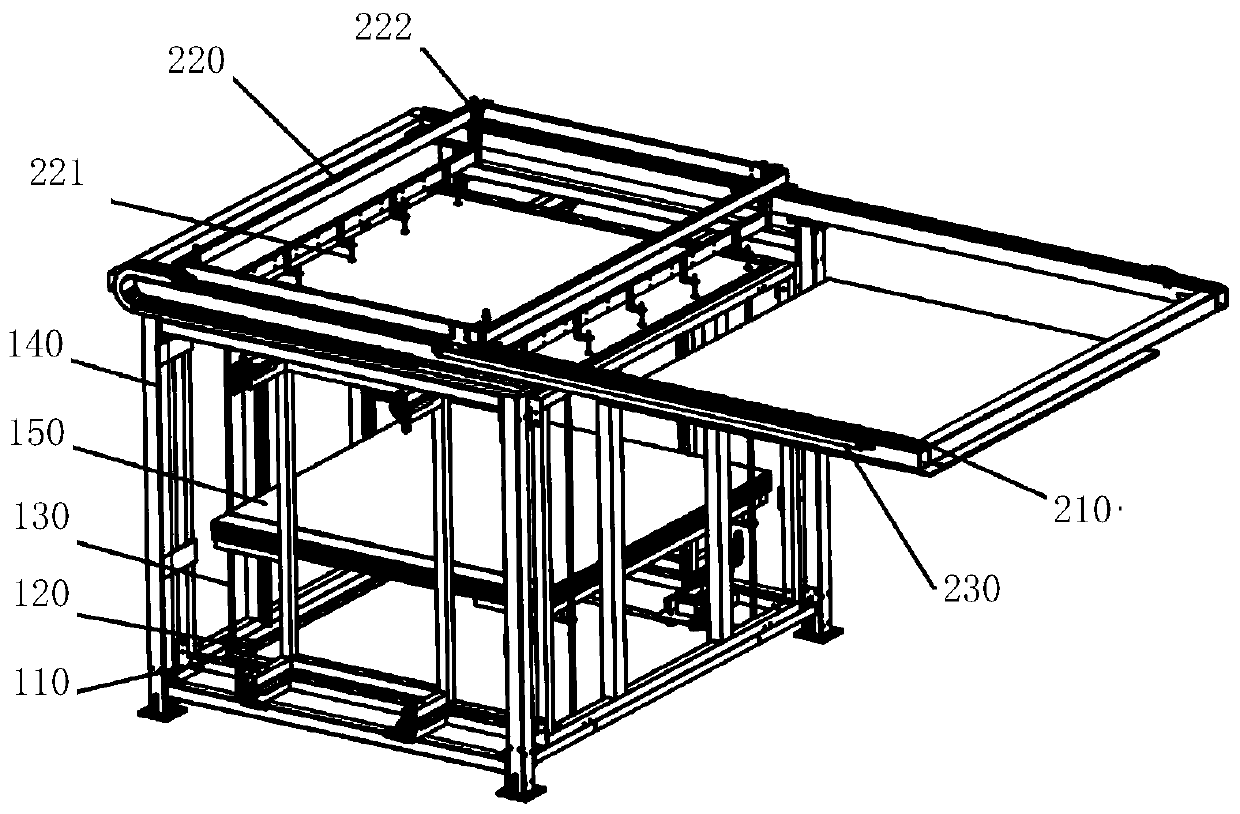

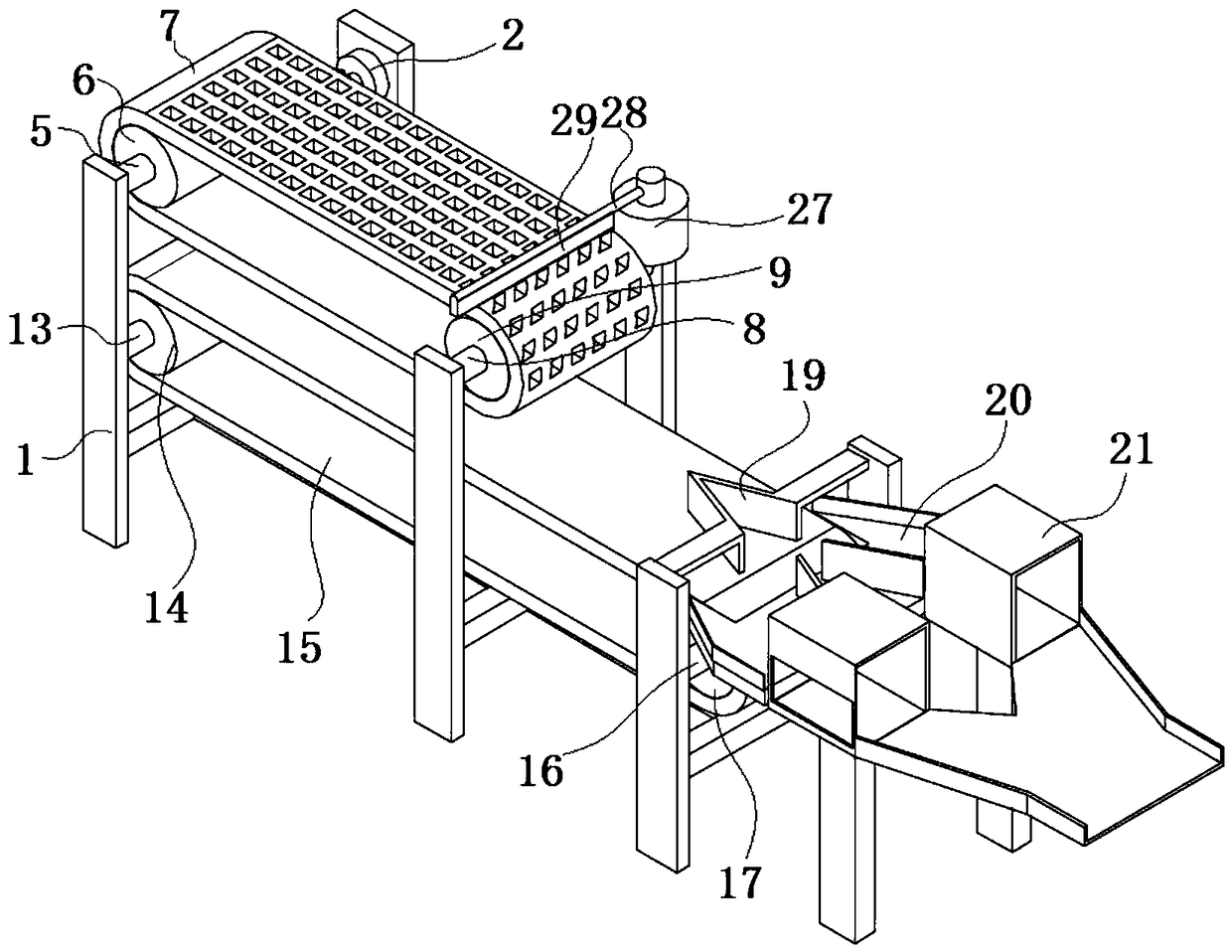

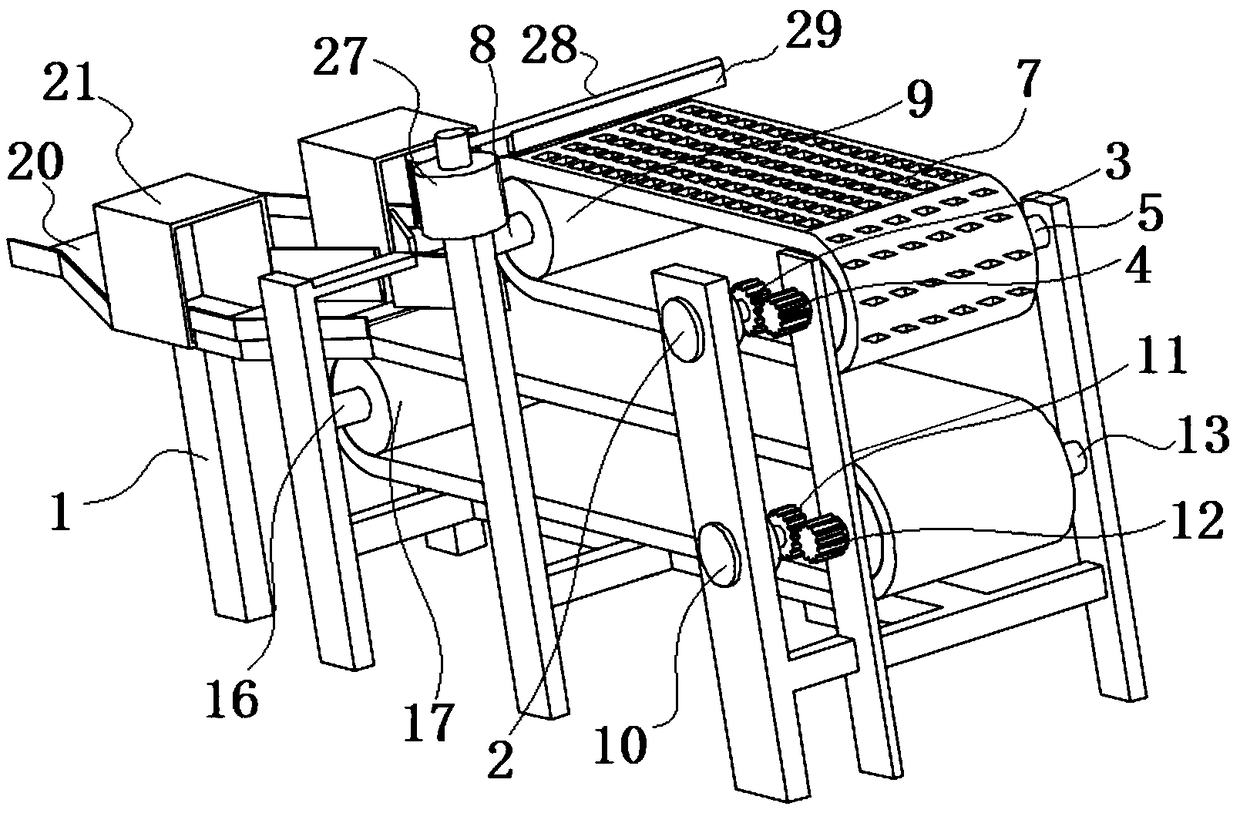

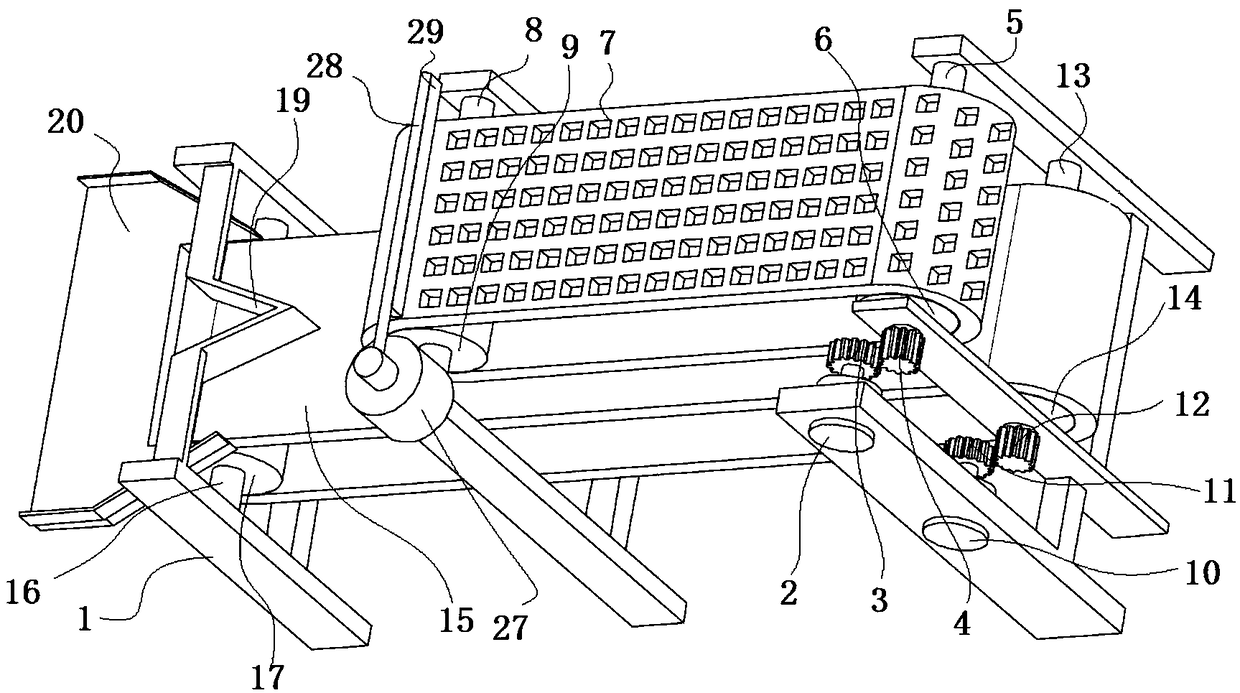

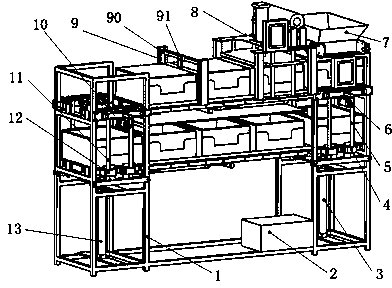

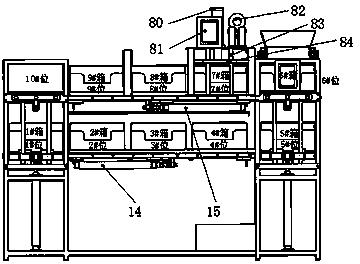

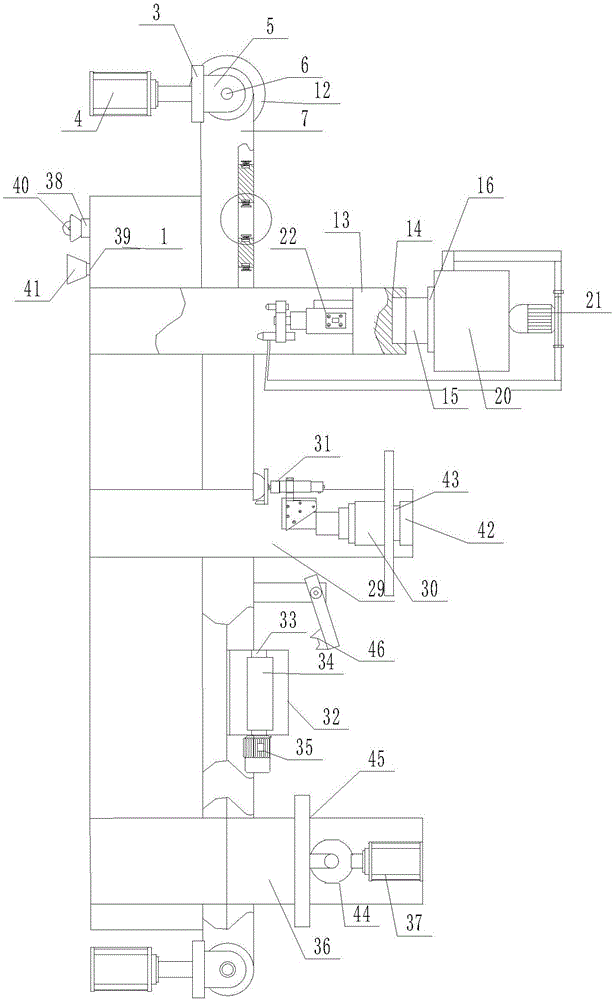

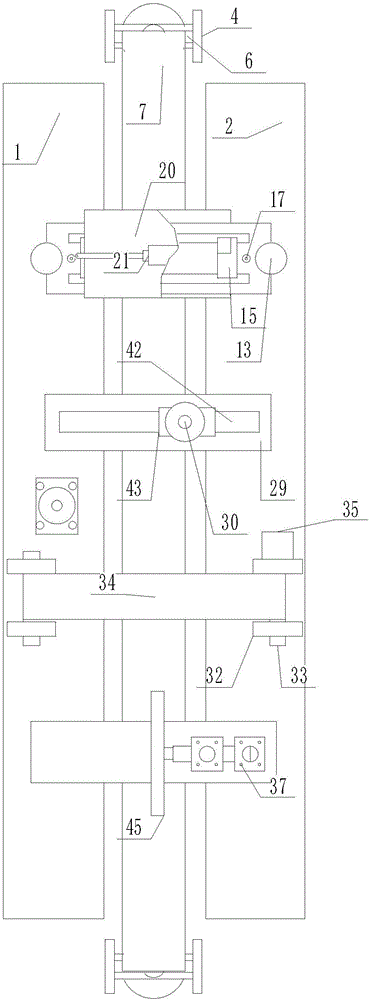

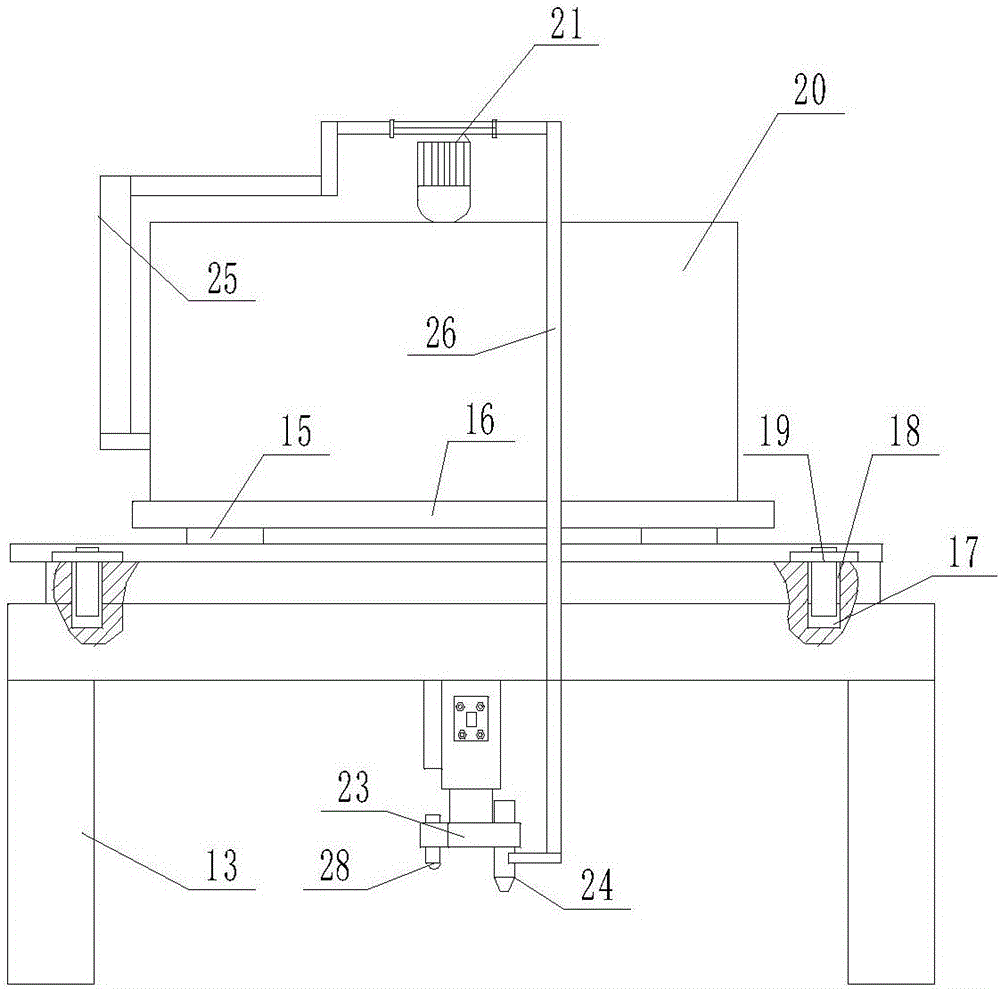

Automatic line design for ballast packing box packing procedure

The invention discloses an automatic line design for a ballast packing box packing procedure. The design comprises a worktable, a conveying belt and a support frame arranged on the worktable, a guide device and a pushing device mounted on the worktable, a moving device mounted on the support frame, and a clamping device connected with the moving device, wherein multiple packing boxes are put on the conveying belt. The automatic line design for the ballast packing box packing procedure is designed and optimized by contacting with problems in a traditional scheme and combining with actual conditions; the guide device is arranged at the front end of a production line of the procedure for tightly moving one batch of three packing boxes to an appointed position; the transverse and longitudinal movements of wide air jaws are finished through a rodless cylinder; the clamping of one batch of three packing boxes is finished through the wide air jaws; the position of a cylinder stopping working satisfies the requirements of the procedure; and after cartons are manually covered, the last pushing step is finished by a box pushing cylinder, so that the operation is more convenient and intelligent.

Owner:XIAN UNIV OF SCI & TECH

Batch packaging release device for box-packed cosmetics

ActiveCN106742424AReduce manufacturing costPackaging machinesProgrammable logic controllerPacking procedure

The invention discloses a batch packaging release device for box-packed cosmetics. The batch packaging release device comprises a first machine and a second machine, moving mechanisms are fixed on the lower surfaces of the first machine and the second machine, the inner portions of the first machine and the second machine are of hollow structures, the outer portions of the first machine and the second machine are of rectangular structures, a conveying mechanism is arranged between the first machine and the second machine, a raw material pouring mechanism, a sealing mechanism and a box cover conveying mechanism are arranged on the first machine and the second machine and positioned above the conveying mechanism, and a label printing mechanism is arranged on the first machine. The batch packaging release device has the advantages that the device integrates a plurality of packaging processes, one worker can finish integral operations, the device is provided with a PLC (programmable logic controller), complete automation and intellectualization of the device can be achieved after programming is performed by a mechanical engineer, and the production cost of companies is reduced.

Owner:GUANGDONG MARUBI BIOLOGICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com