Flexible automatic packing production line for inflammables and explosives

A flammable, explosive, automatic packaging technology, applied in packaging, transportation packaging, packaging food, etc., can solve the problems of increasing the economic burden of enterprises, low work efficiency, troublesome operation of workers, etc., to facilitate automatic production, reduce safety hazards, The effect of simple packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now in conjunction with the following embodiments and accompanying drawings, the invention is described in detail.

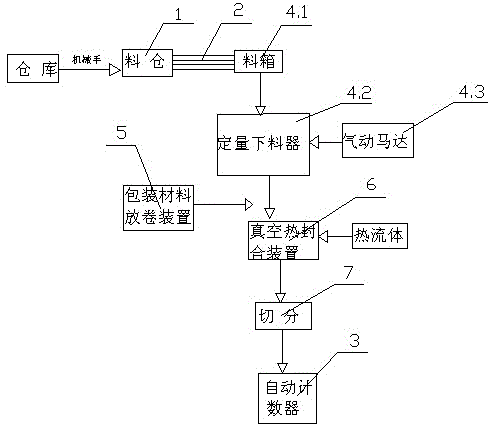

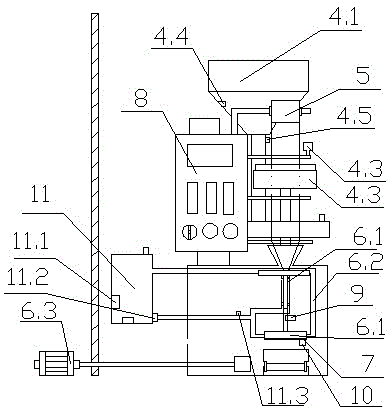

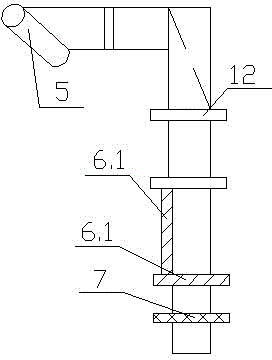

[0020] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Among them, the flexible automatic packaging production line for flammable and explosive materials, the entire packaging production line has a grounding anti-static device, and the silo 1 is connected to the automatic packaging machine and the automatic counter 3 in turn through the bucket lifting conveyor belt 2 . First, the raw materials are poured from the warehouse into the silo 1 through the manipulator. The silo 1 is equipped with a pneumatic valve 1.1, which controls the amount of material entering the material box 4.1 from the material silo 1. When the material in the material box 4.1 When the weight is less than the specified weight, the computer starts the silo 1 to discharge the material to the bucket elevator conveyor belt 2 quantitatively, and the bucket elevator conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com