Dustproof heat dissipation device for UV LED power supply

A heat dissipation device and power supply technology, applied in the direction of measuring devices, data processing power supply, digital processing power distribution, etc., can solve the problems of insufficient heat dissipation, reduced heat dissipation performance, short circuit or damage of electronic components, etc., to achieve fast installation and cleaning , Satisfy the protective ability and improve the effect of dustproof ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

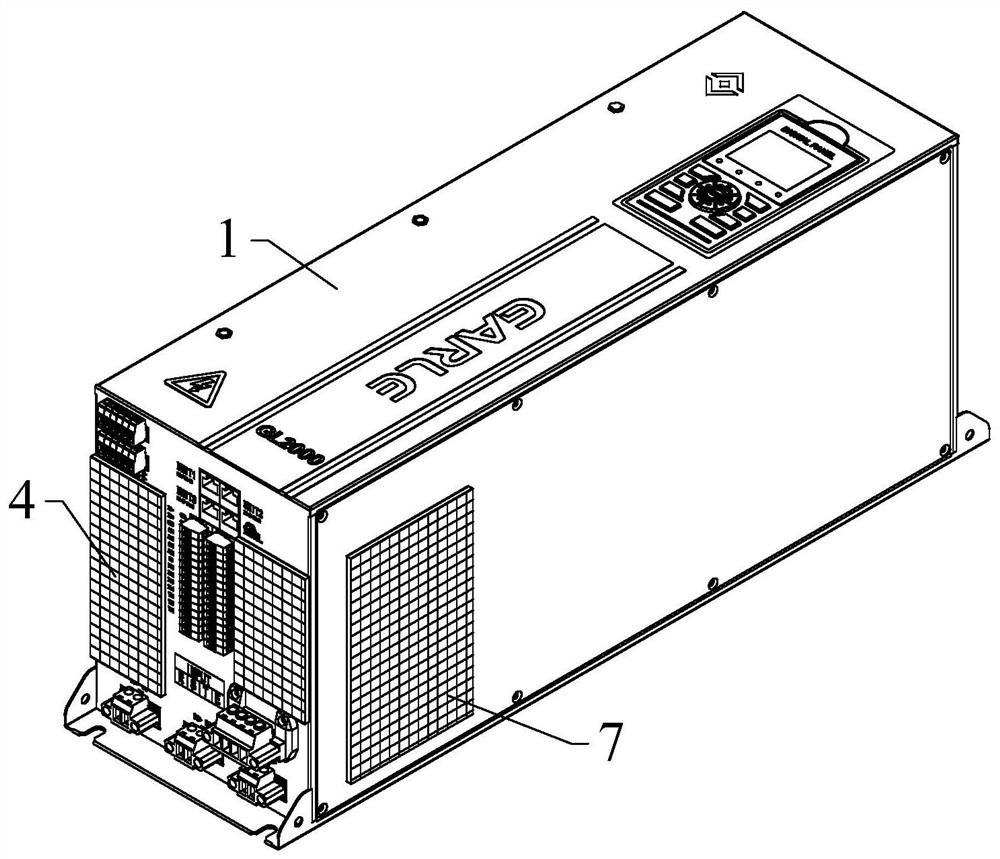

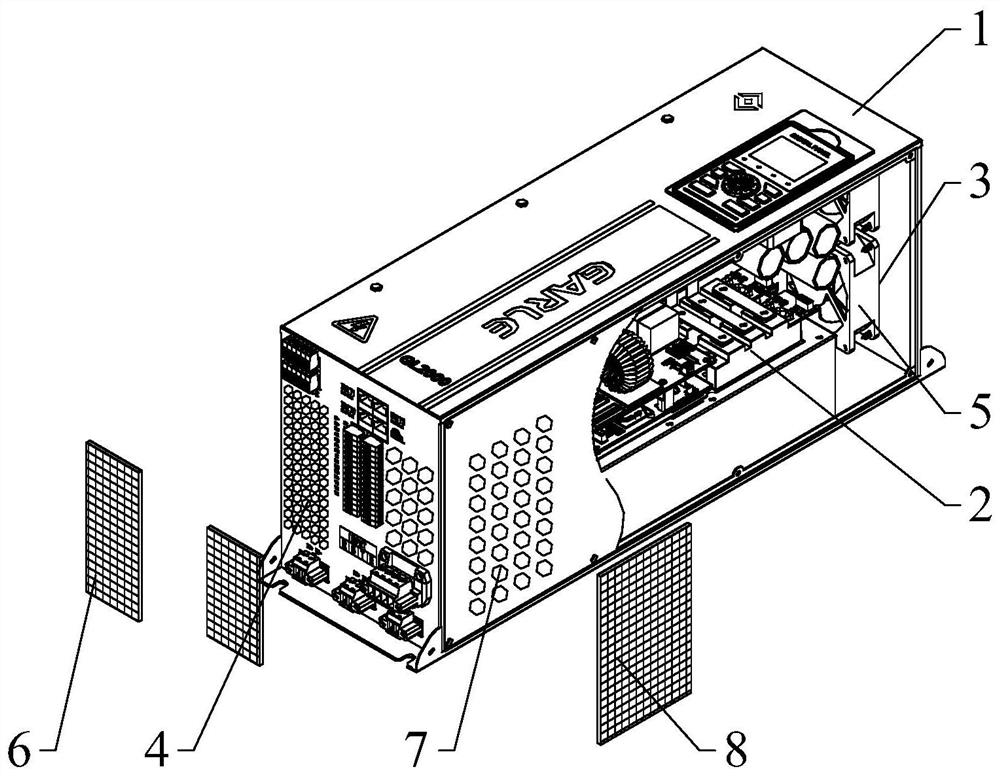

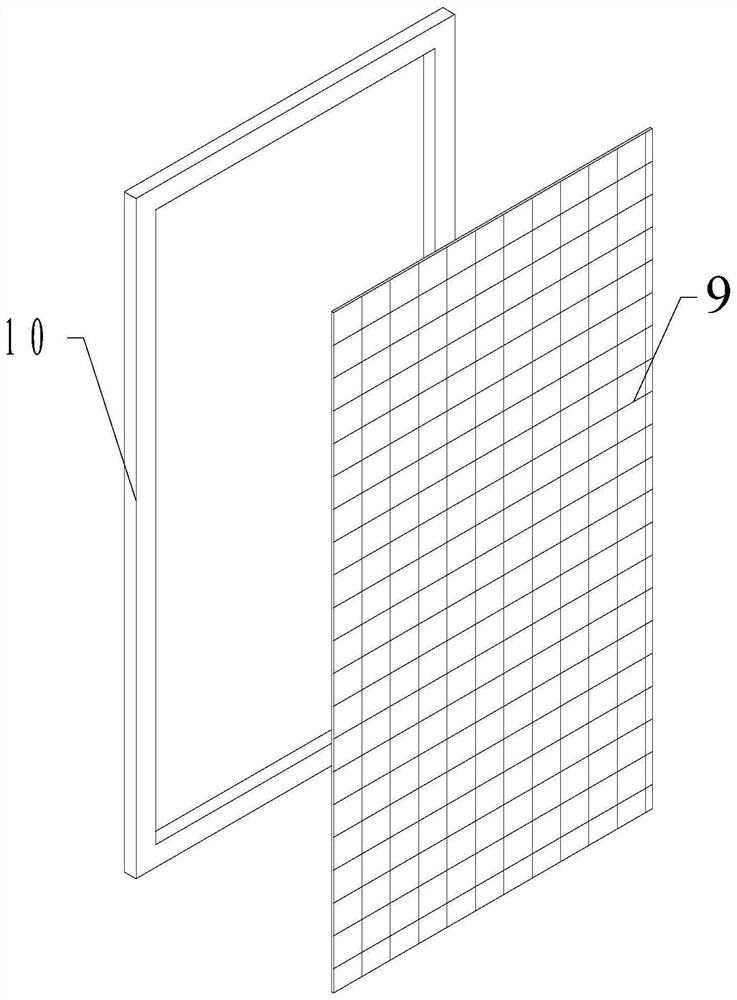

[0023] See Figure 1 to 3 As shown in the figure, the present invention provides a dust-proof heat dissipation apparatus for the UV LED power source, including the chassis housing 1, and the inside of the chassis casing 1 is provided with an electronic component 2, and the right end of the chassis housing 1 is provided. The wind hole 3, the left end of the chassis casing 1 is provided with a first inlet air hole 3, and the first inlet air hole 4 is formed into a heat dissipation airway, and the heat dissipation wind is independent cooling. The road is convenient for air to circulate in the chassis housing 1, and the inside of the chassis housing 1 will cool heat.

[0024] The inner side of the outlet 3 is provided with a heat dissipation fan 5, and the heat dissipation fan 5 is exhausted inside the chassis housing 1, and the heat of the electronic component 2 can be used according to different power, and the fan of different air volume is replaced, and the heat dissipation of diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com