Patents

Literature

312results about How to "Increase layout space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

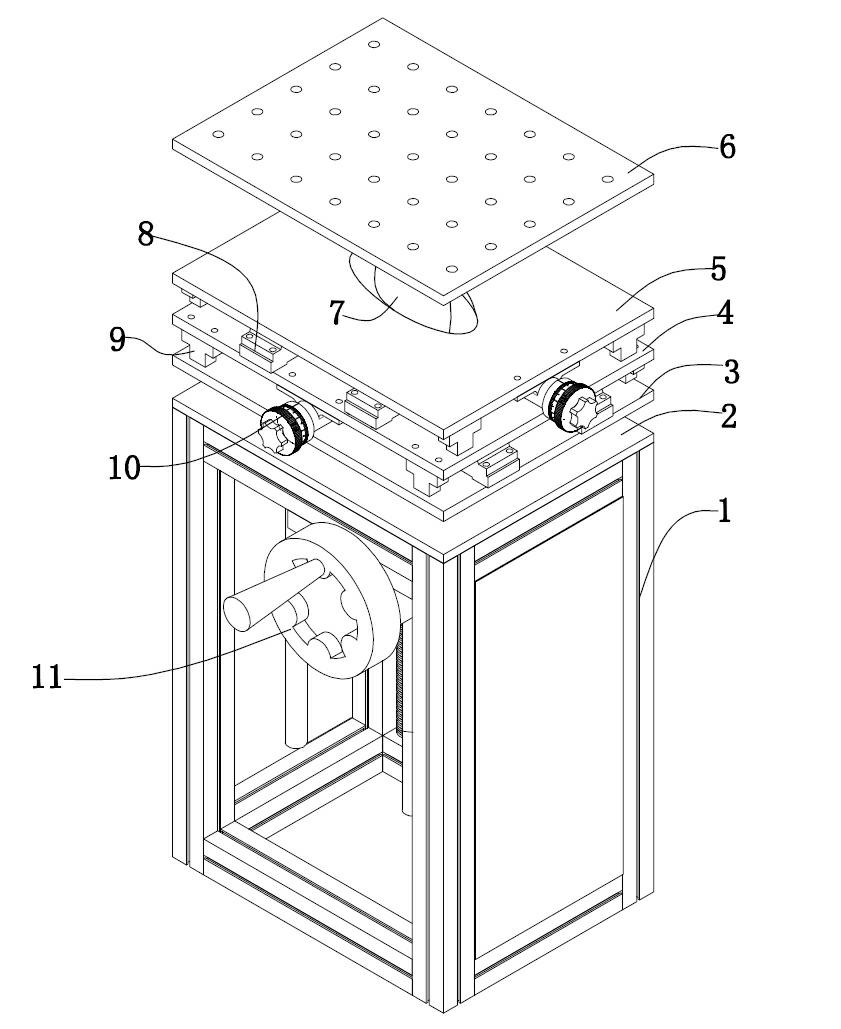

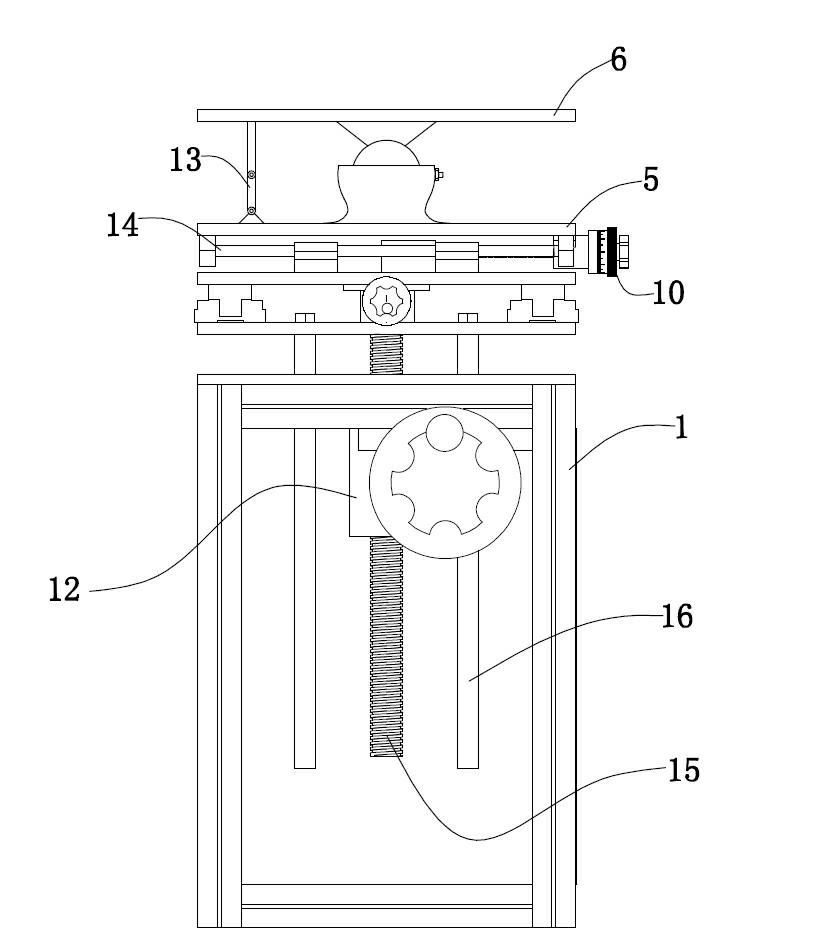

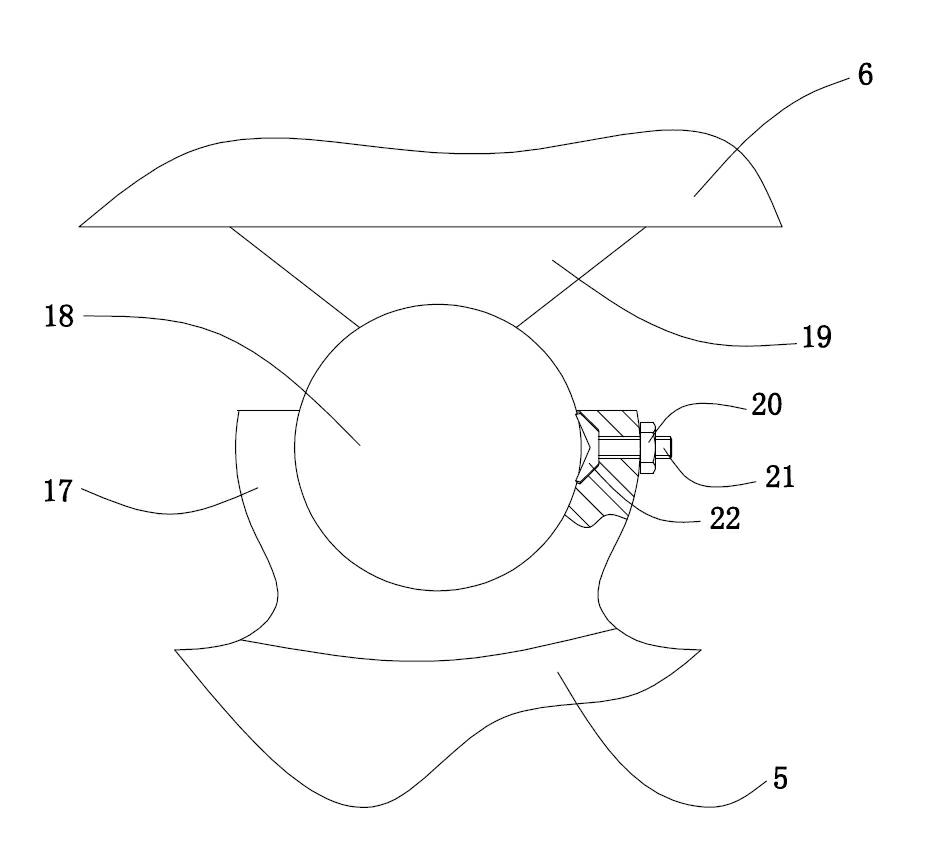

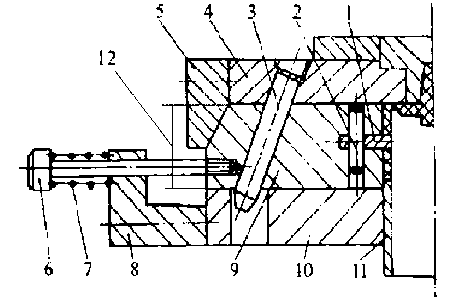

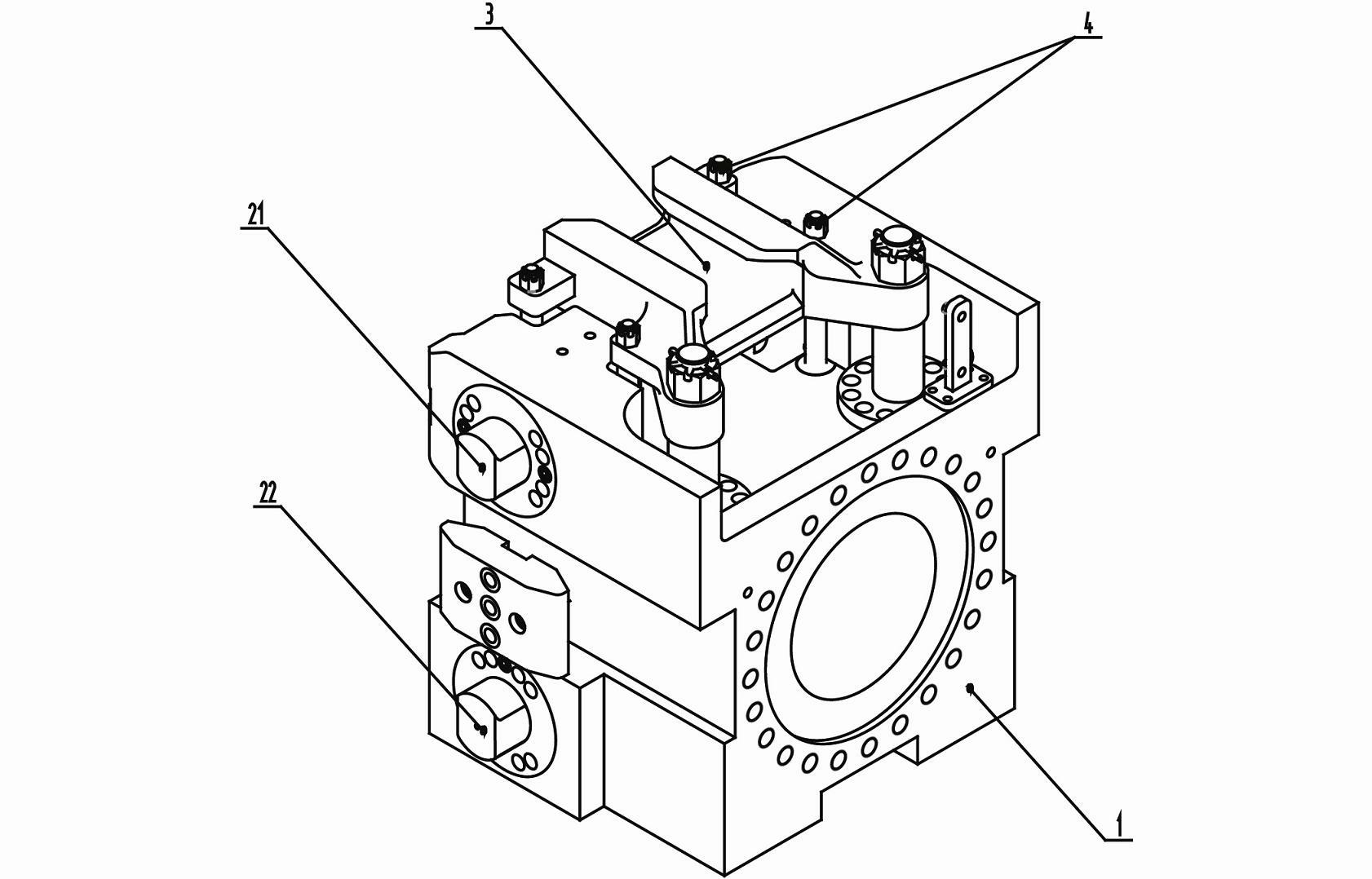

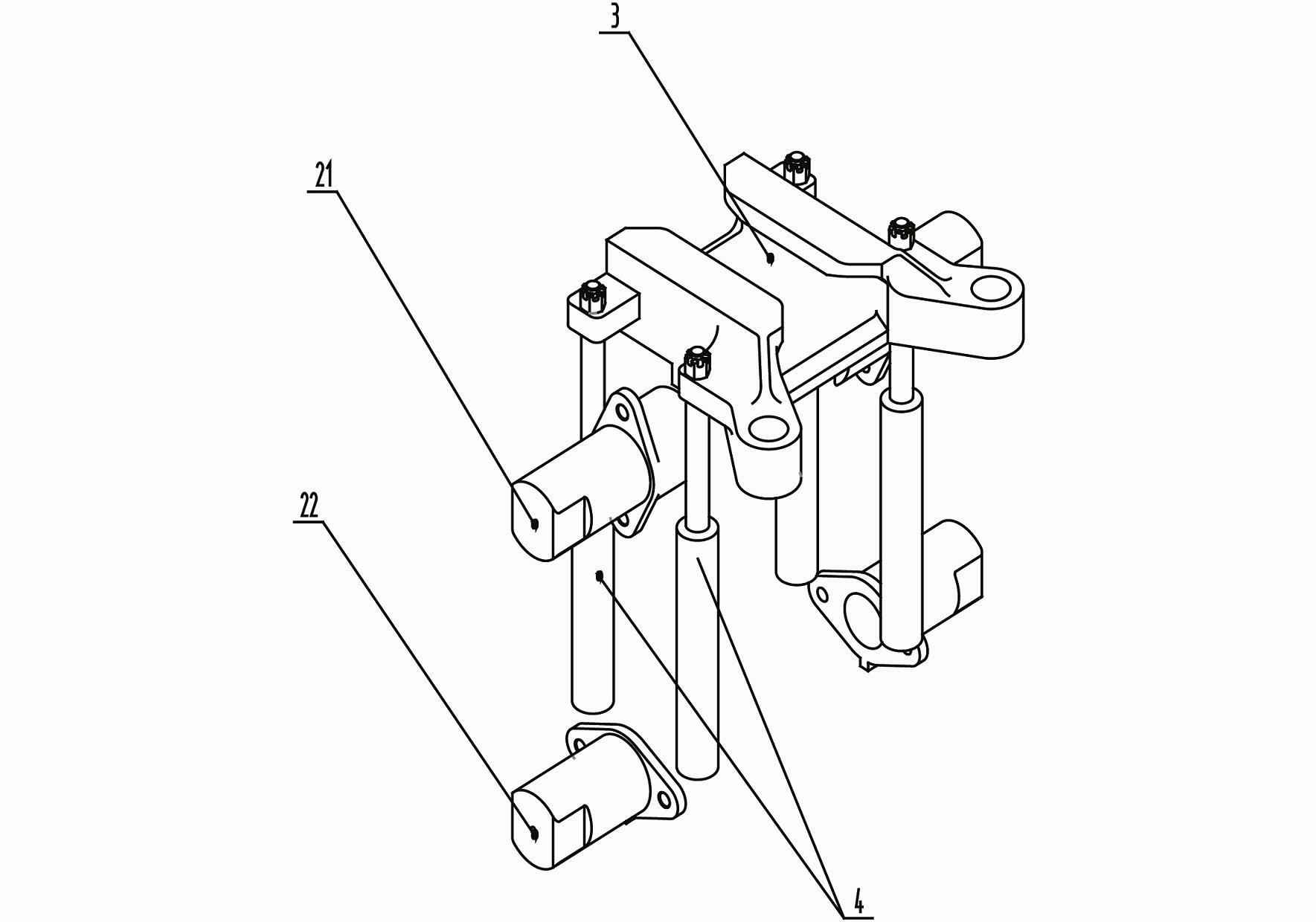

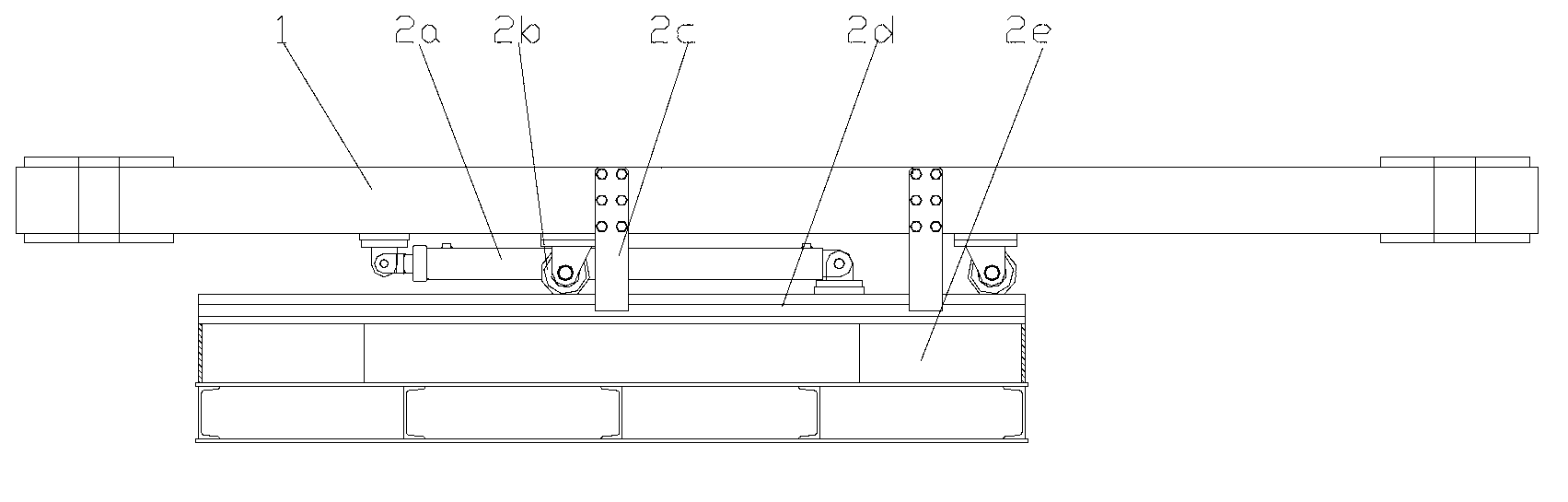

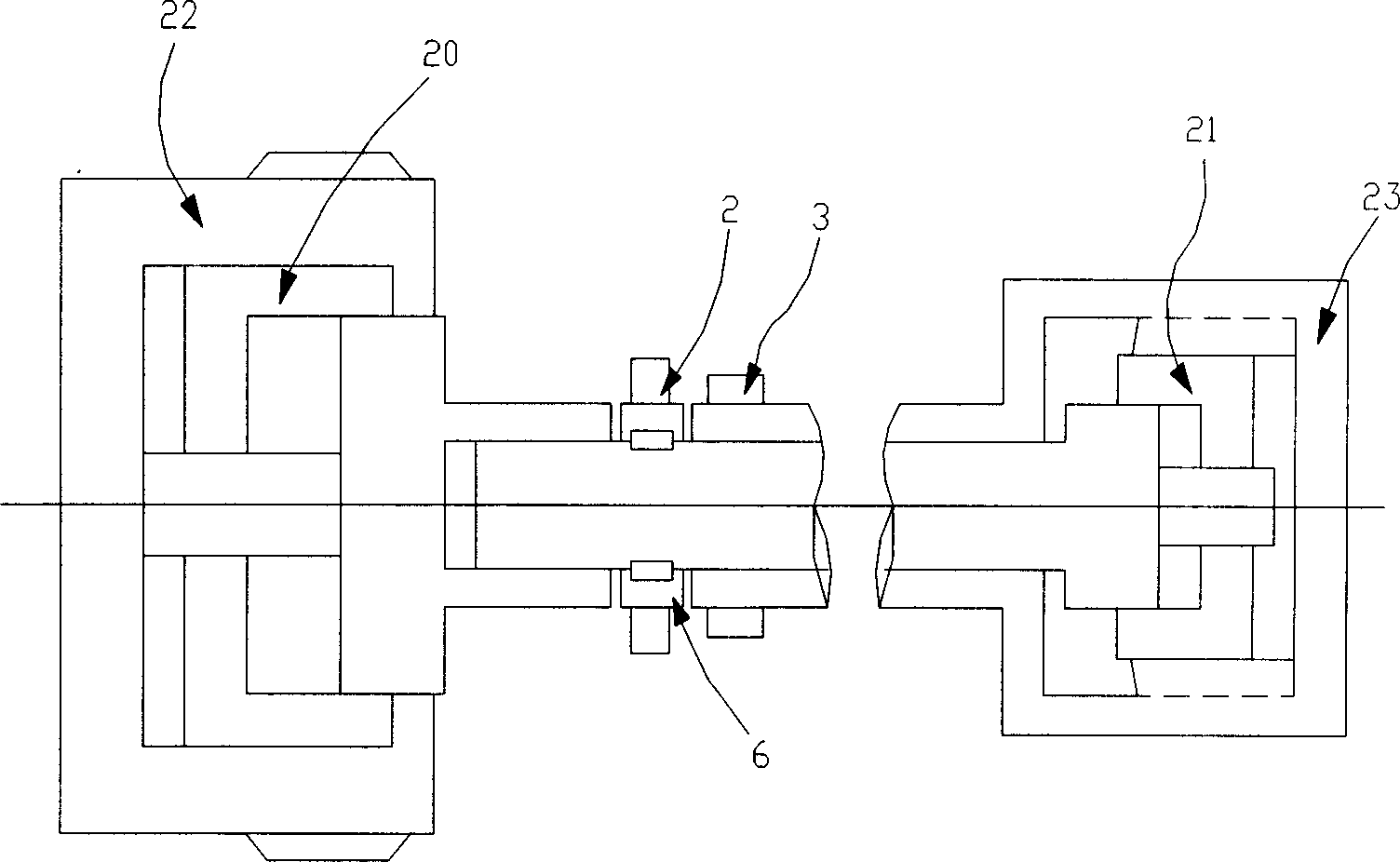

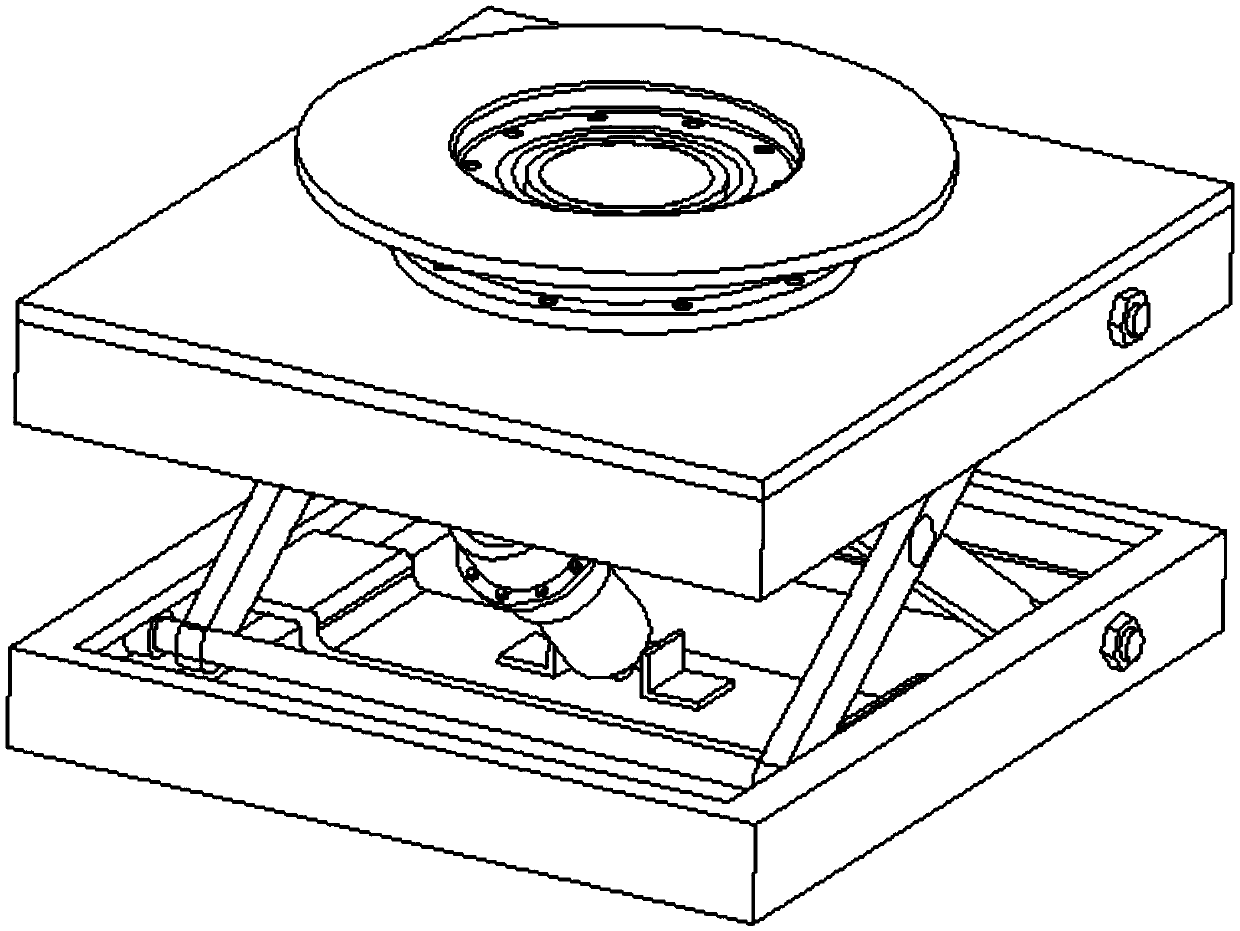

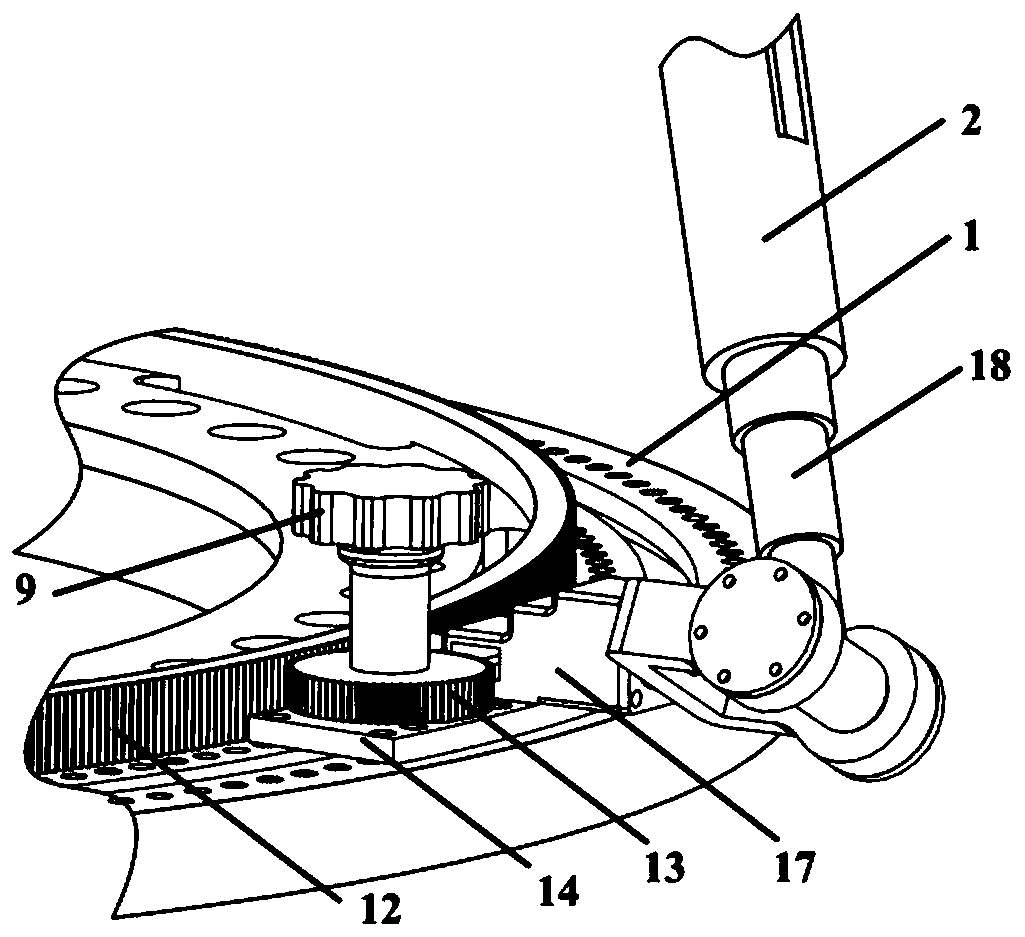

Workbench with multiple degrees of freedom

InactiveCN102211330ANo interferenceIncrease layout spaceWork benchesLarge fixed membersLocking mechanismEngineering

The invention relates to a workbench with multiple degrees of freedom, which can move and rotate in multiple directions and is beneficial to overcoming of the disadvantage that the workbench in the prior art is of a fixed structure and can not move. The workbench comprises an elevator mechanism, a moving mechanism on a horizontal plane and a multi-angle rotating mechanism, wherein the elevator mechanism and the moving mechanism are of a lead screw moving mechanism, and the multi-angle rotating mechanism comprises a universal connection device and a locking mechanism. The moving mechanism can drive the workbench to move on the horizontal plane and ensure that the workbench can reach any positions on the horizontal plane within an effective range, and an X-directional moving mechanism and a Y-directional moving mechanism can operate independently or in a combined manner; the multi-angle rotating mechanism drives the surface of the workbench to incline; and the mechanisms are mutually combined to complete position change of the workbench surface.

Owner:许晓华

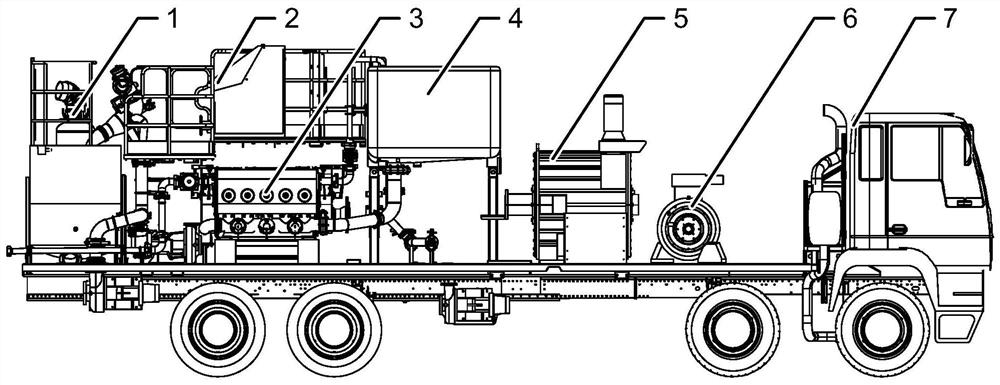

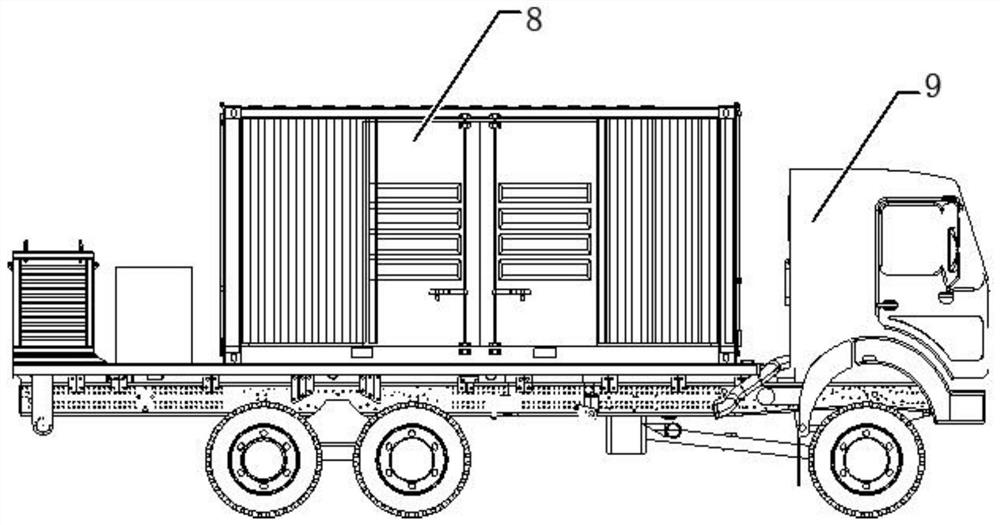

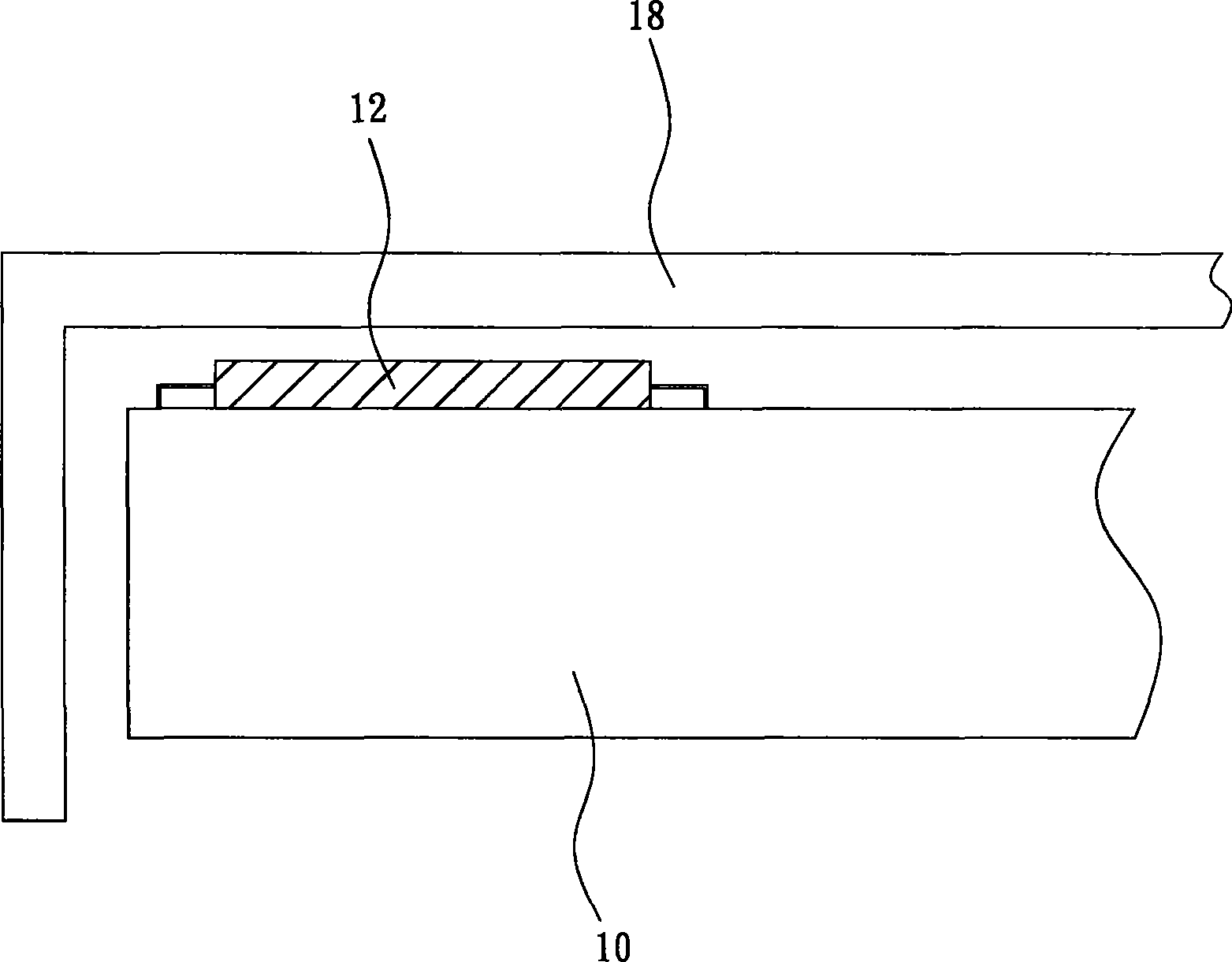

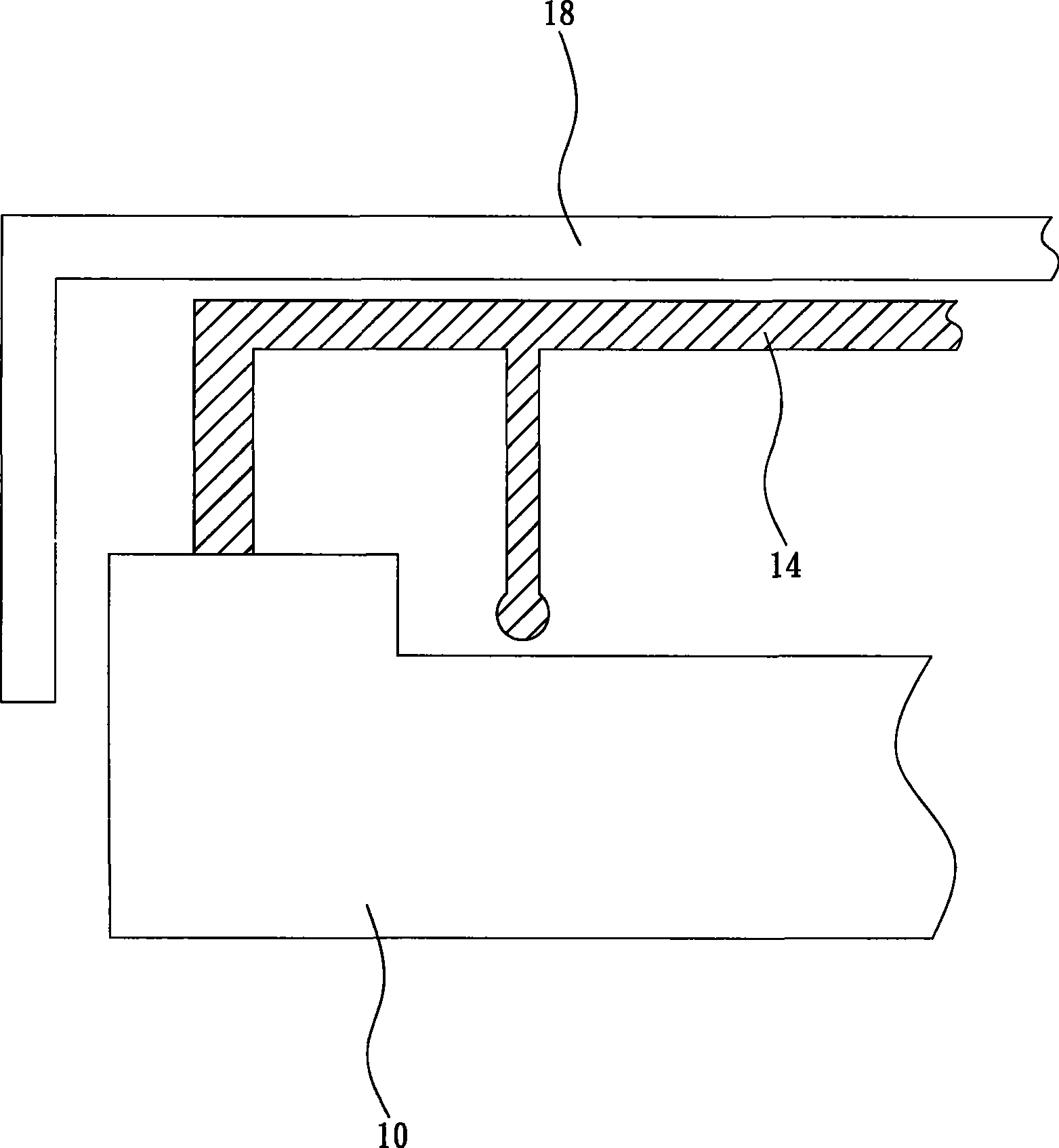

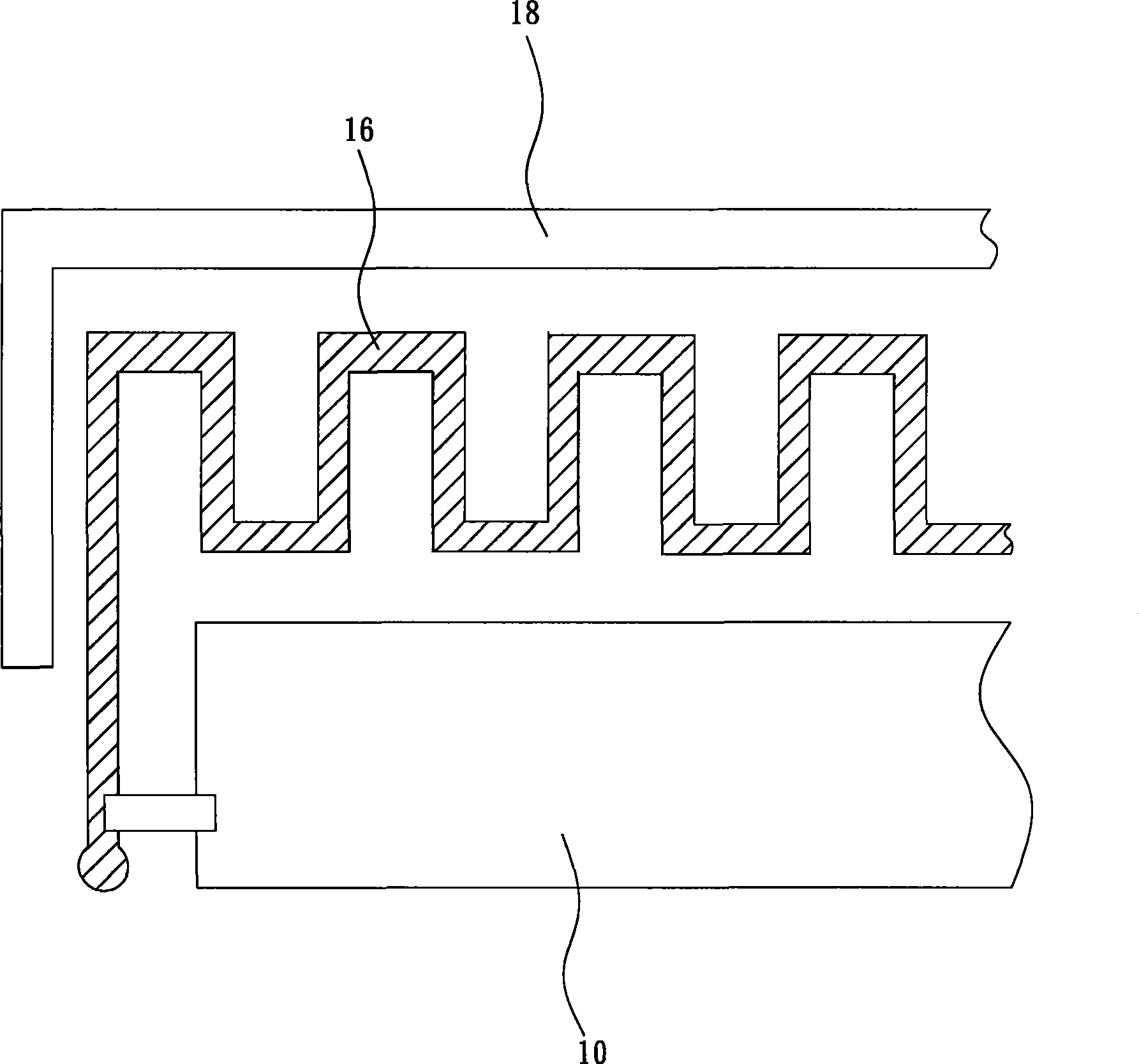

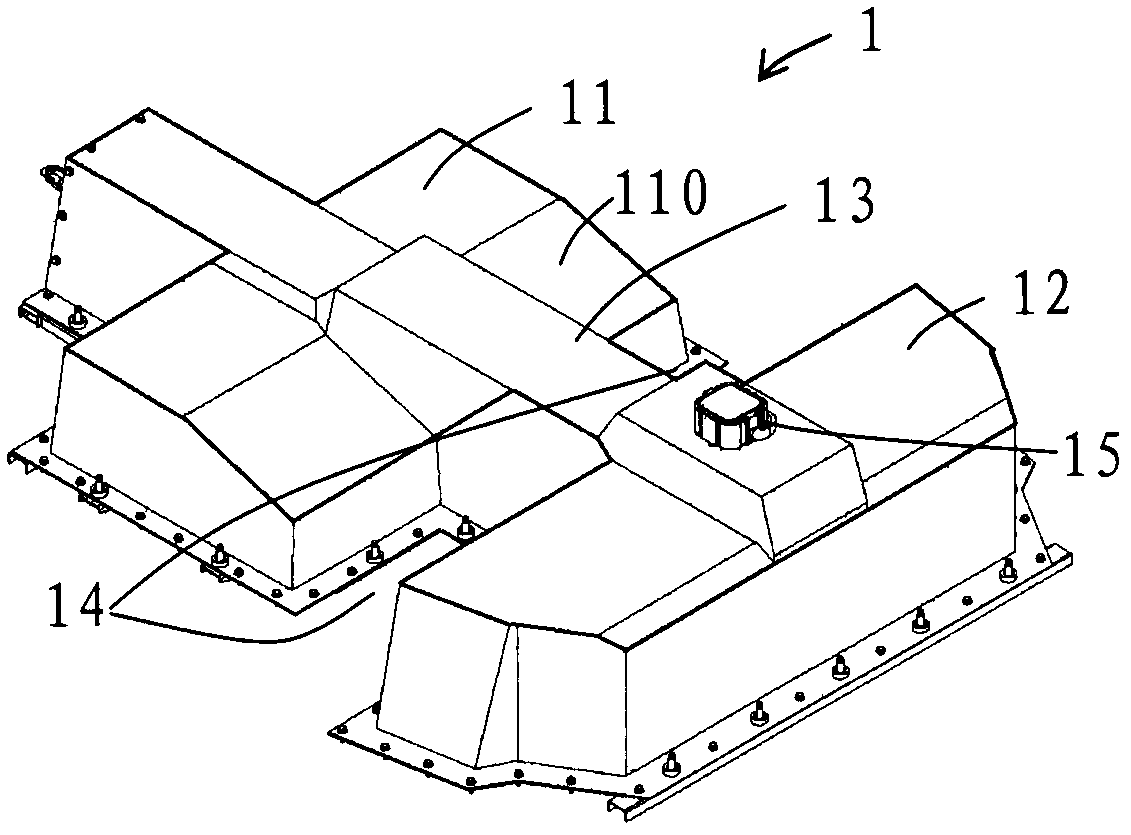

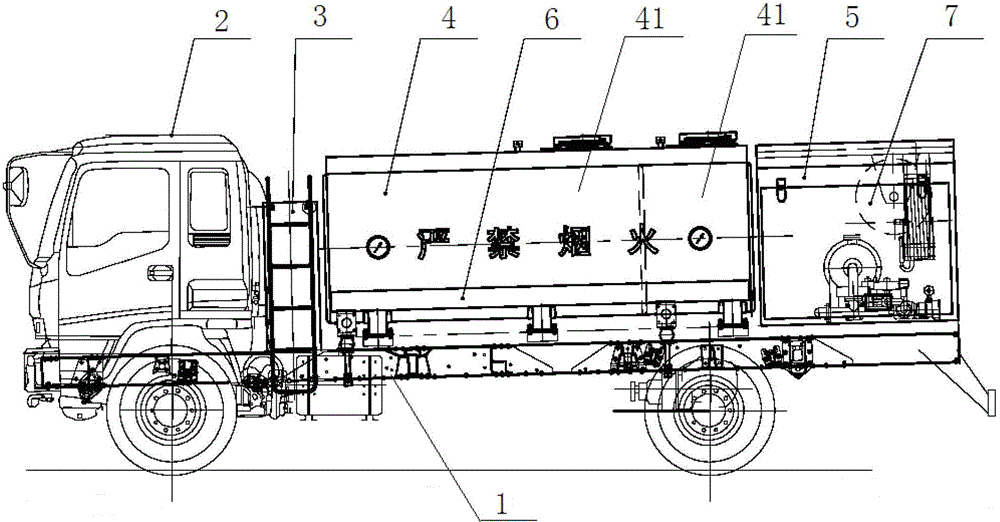

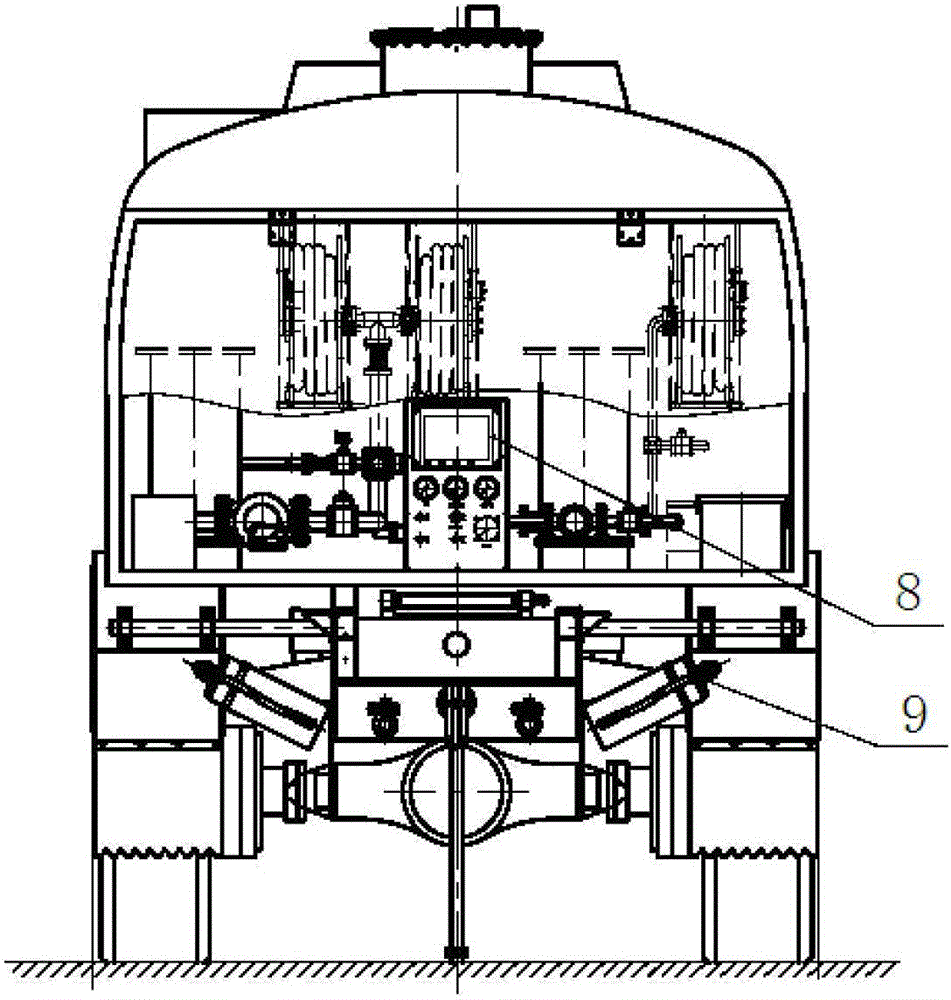

Electrically-driven ultra-large-displacement well cementation equipment

PendingCN111677476AIncrease layout spaceReduce dependenceDischarging apparatusPumpsConvertersFrequency changer

The invention discloses electrically-driven ultra-large-displacement well cementation equipment. The electrically-driven ultra-large-displacement well cementation equipment comprises a first loading body and a second loading body; an auxiliary motor, a main motor, a clear water module, a pumping module, a control module, a hydraulic module and a mixing module are fixedly loaded on the first loading body; and a frequency converter module is fixedly loaded on the second loading body. The electrically-driven ultra-large-displacement well cementation equipment has the beneficial effects that the main motor is adopted to drive a plunger pump, torque converters are reduced, the layout space of the whole vehicle is increased, the auxiliary motor is adopted to drive a whole vehicle hydraulic system, and the number of driving motors is reduced; the frequency converter module and the well cementation equipment are loaded separately, the loading requirement is lowered, the structure is simpler, the occupied space is reduced, one frequency converter module can supply power to all the modules on the multiple first loading bodies at the same time, and use is flexible; and the main motor, the auxiliary motor and the hydraulic heat dissipation device are intensively distributed on the front portion of the first loading body, wiring is simple, connection is convenient, heat dissipation of equipment is intensively achieved, scalding accidents of workers in the operation process are avoided, and operation safety is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

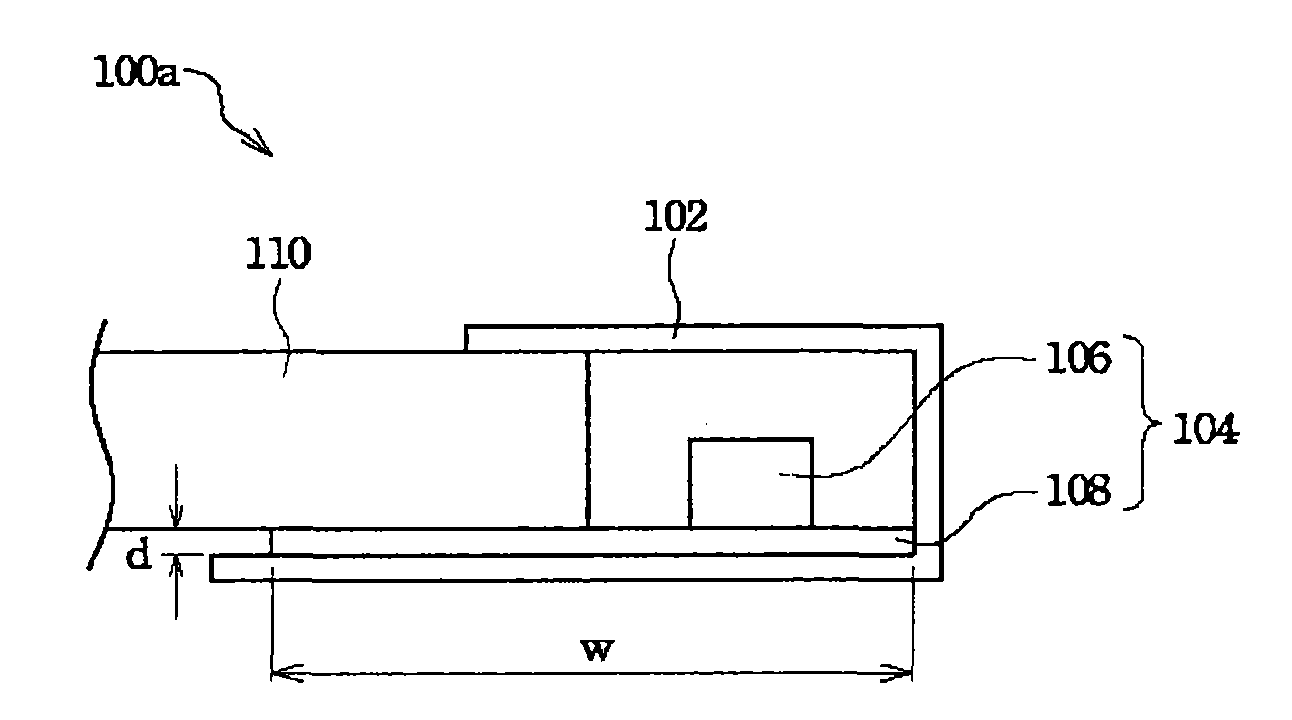

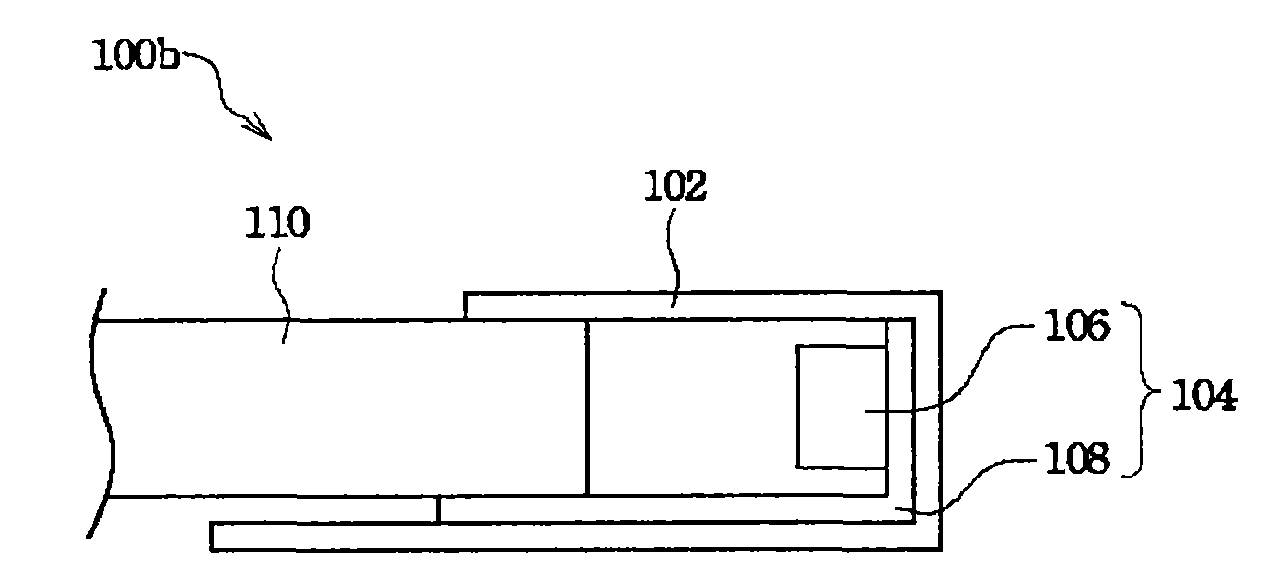

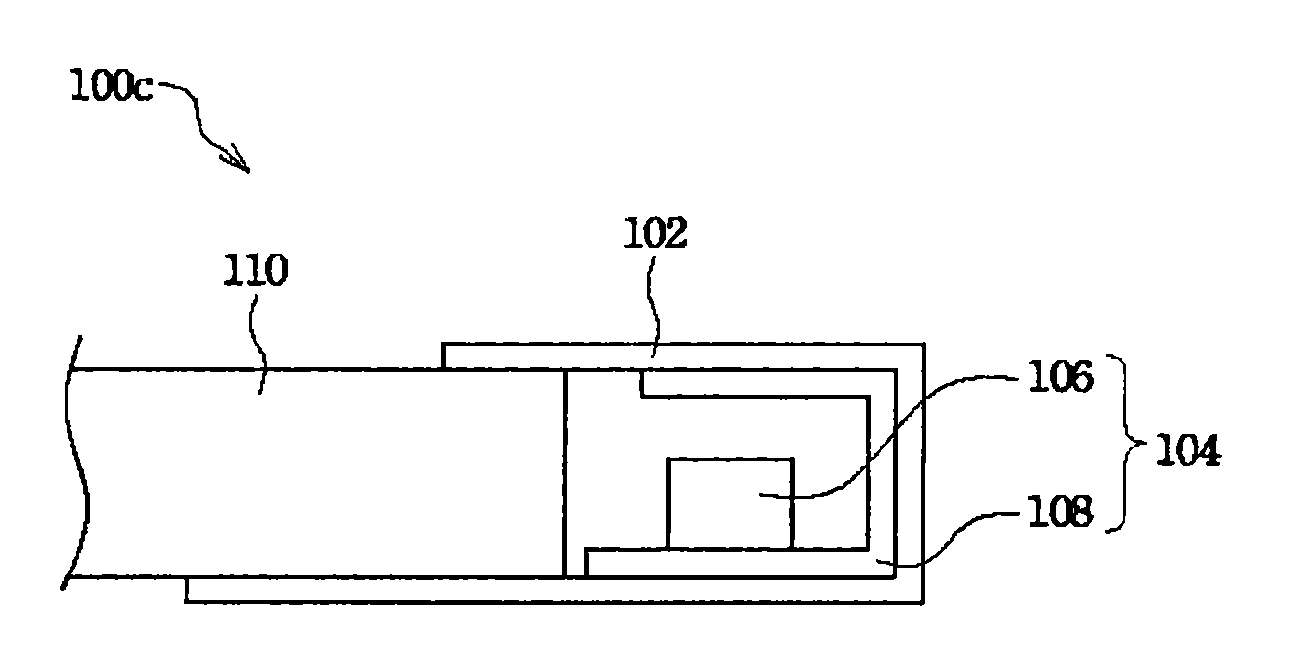

Radio communication device

InactiveCN101431175AImprove functionalityEnhance the ability to send and receive signalsAntenna supports/mountingsRadiating elements structural formsProtection layerCommunication device

A wireless communication device comprises a shell body and an antenna unit. The antenna unit is arranged on the outer surface or the inner surface of the shell body, a protective layer can be selectively covered on the outer surface of the antenna unit, and the protective layer can cover part of the surface of the shell body. Therefore, the antenna which is not arranged on a circuit board can not only save the circuit layout area on the circuit board, but also use the saved layout area as other purposes, and the antenna unit is formed at the shell body, thereby enhancing the effectiveness of transceiving signals of the wireless communication device.

Owner:DELTA ELECTRONICS INC

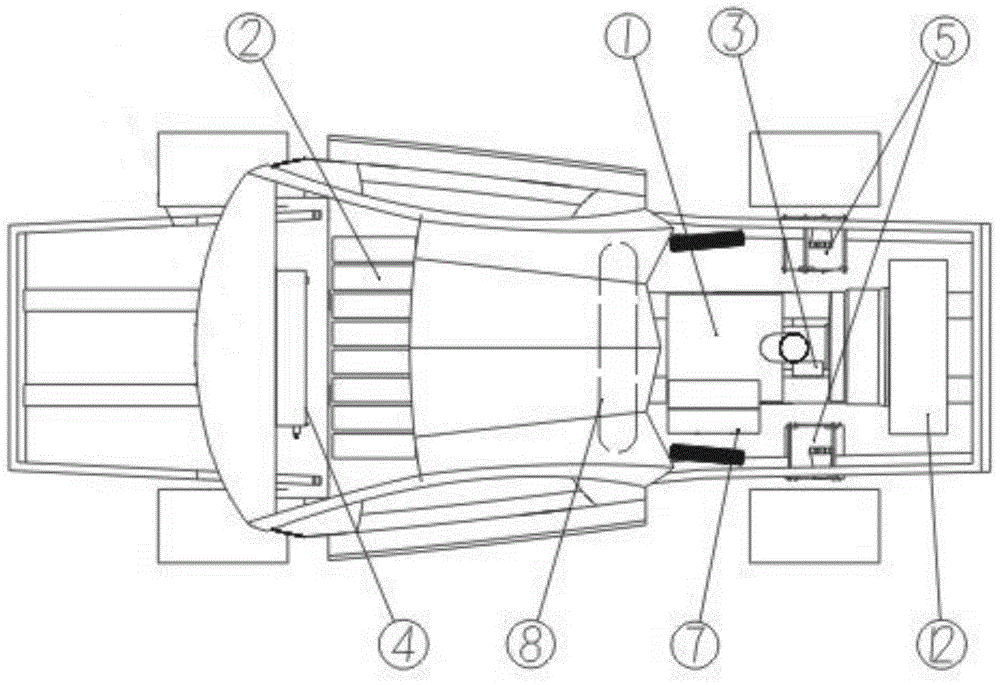

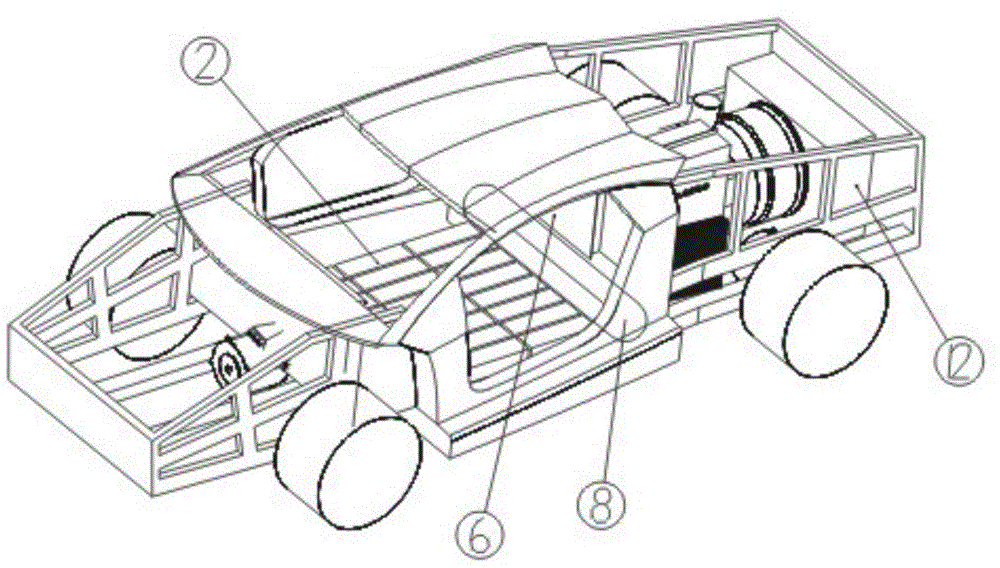

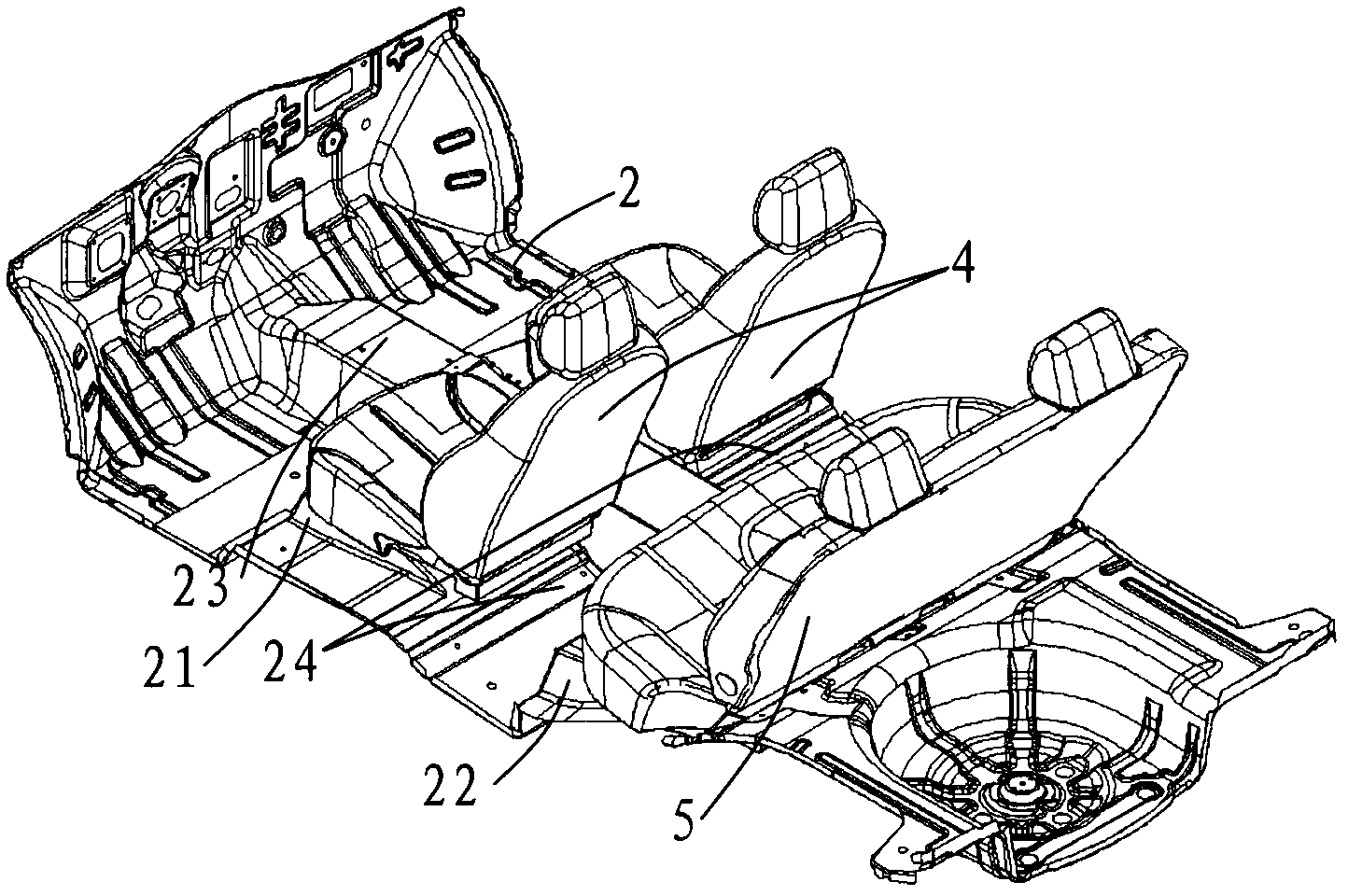

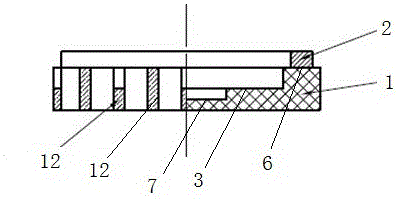

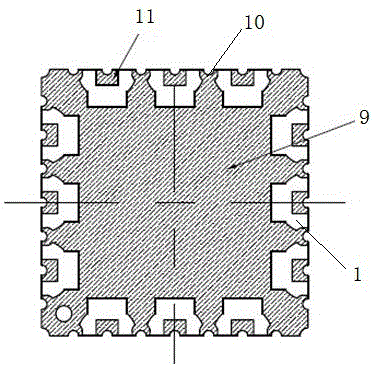

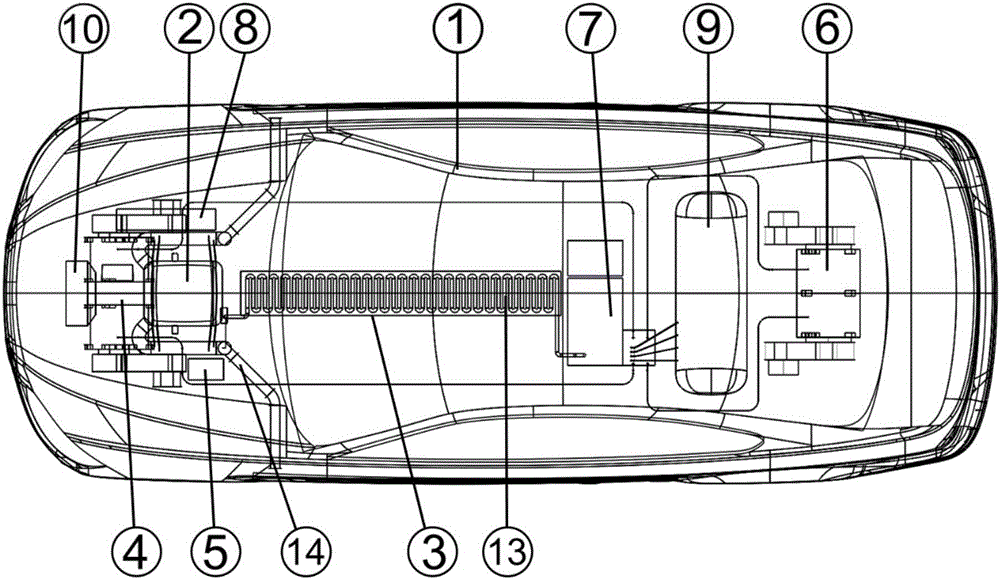

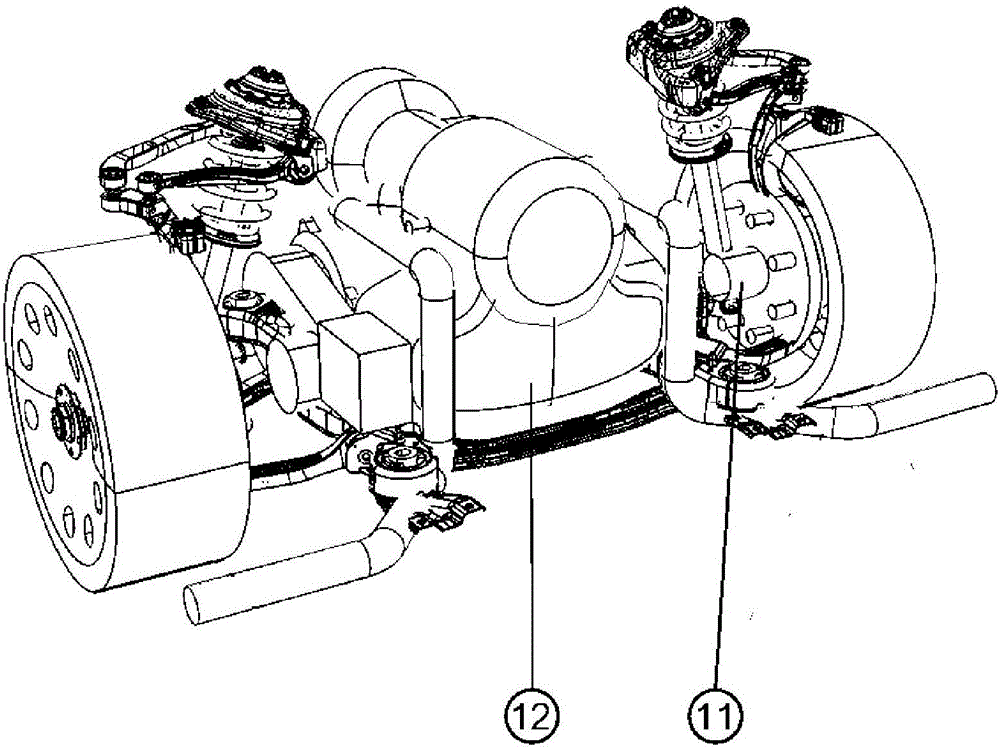

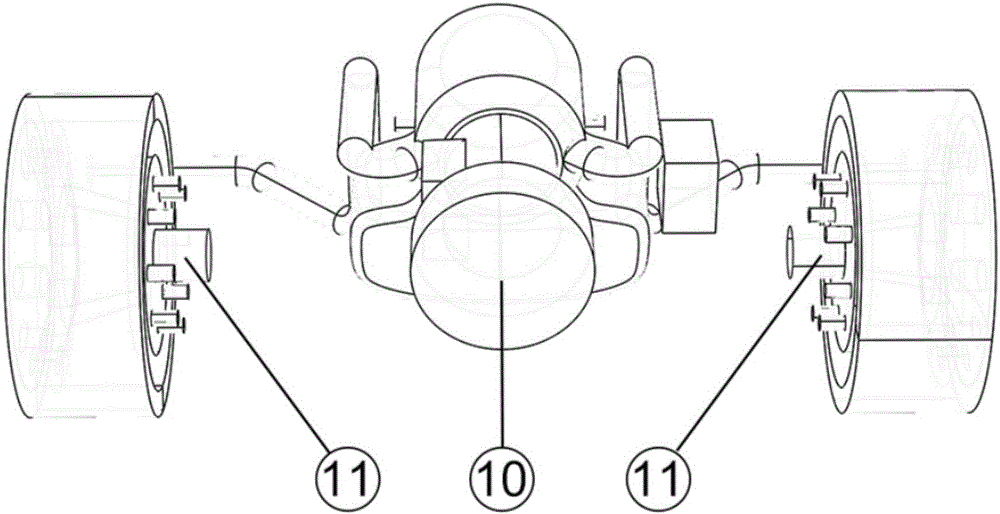

Mid-engine incremental stroke electric vehicle

ActiveCN104802629ASimple structureAvoid pollutionHybrid vehiclesSpeed controllerVehicle frameElectric machine

The invention provides a mid-engine incremental stroke electric vehicle. The electric vehicle comprises a vehicle body, a turbo shaft engine (1), a battery pack (2), a generator (3), a whole vehicle controller (4), a driving motor (5), a gas controller (6), a battery controller (7), a gas holder (8) and a gas inlet tank (12), and is characterized in that the vehicle body comprises a vehicle main body, wherein the bottom structure of the vehicle main body forms a vehicle frame; the turbo shaft engine (1) is distributed between a front axle and a rear axle and is close to the vehicle frame of the rear axle; the axis of the output shaft of the turbo shaft engine (1) is positioned on the symmetry planes of the vehicle body; the air inlet of the turbo shaft engine (1) faces towards the tail of the vehicle; the gas inlet tank (12) is communicated with the air inlet of the turbo shaft engine (1); the gas inlet tank (12) is communicated with a gas inlet grille on a vehicle covering piece. The electric vehicle has the characteristics of high energy conversion efficiency, good operating performance, long driving mileage and high vehicle body structural strength.

Owner:刘慕华

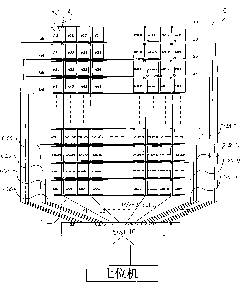

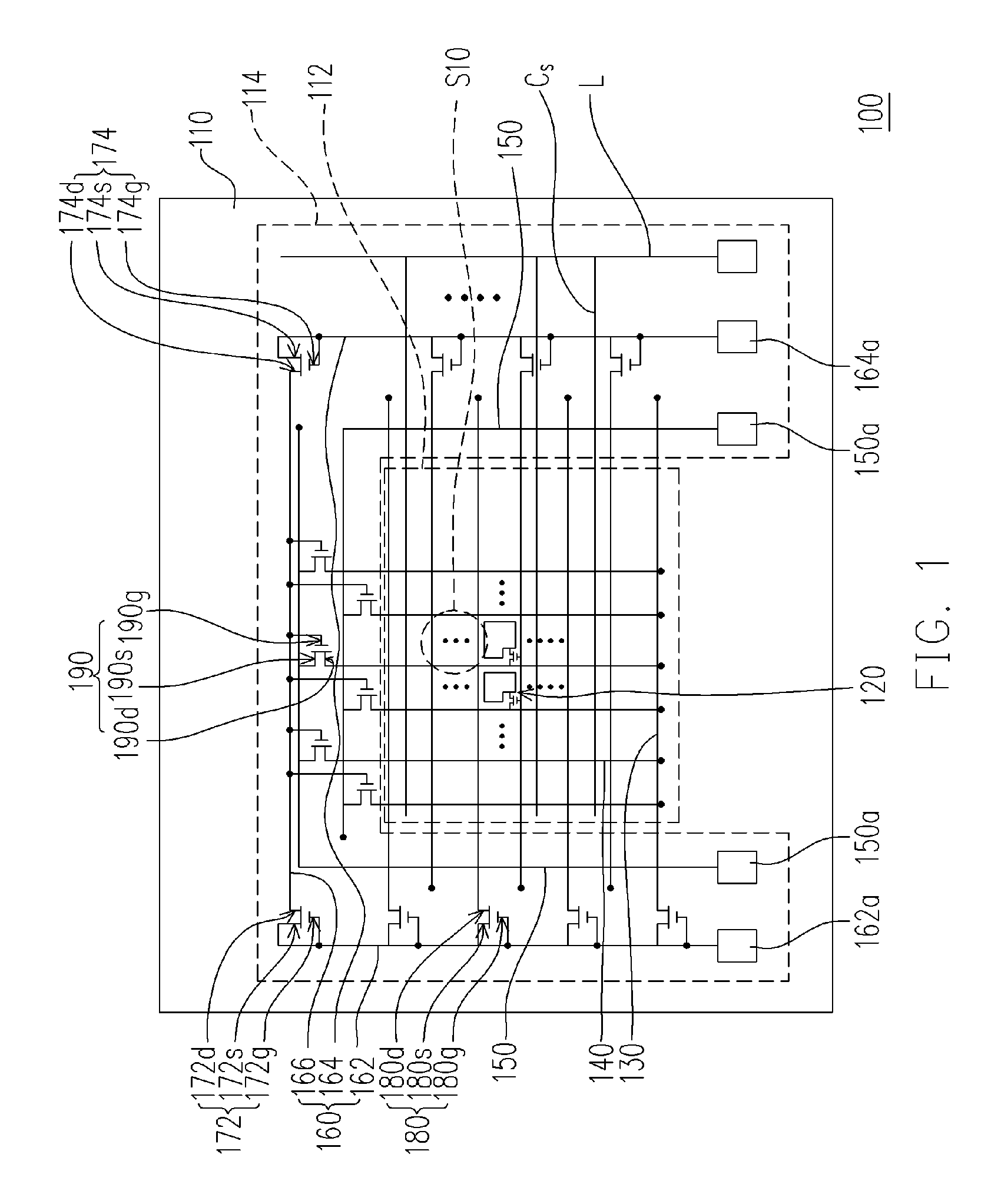

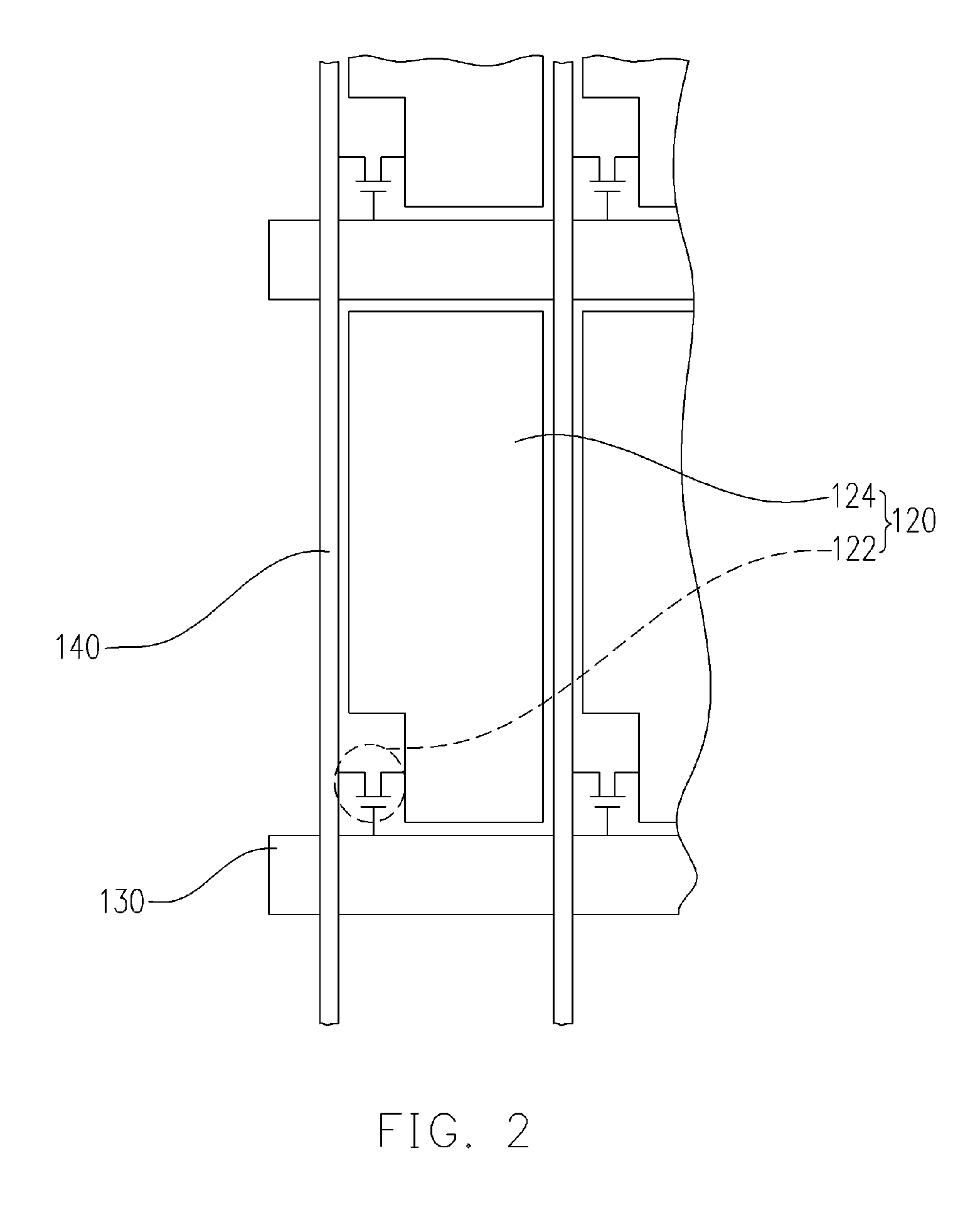

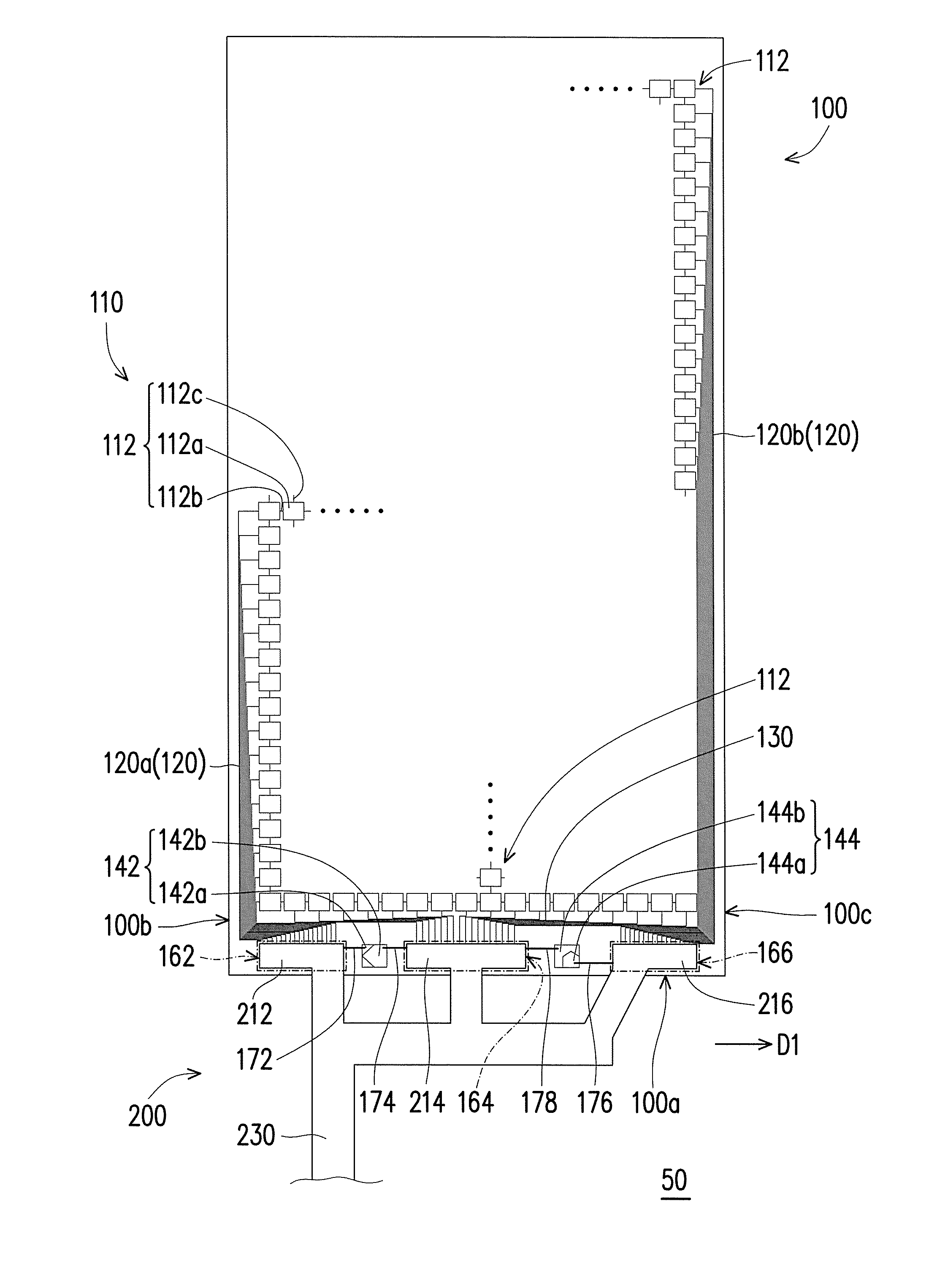

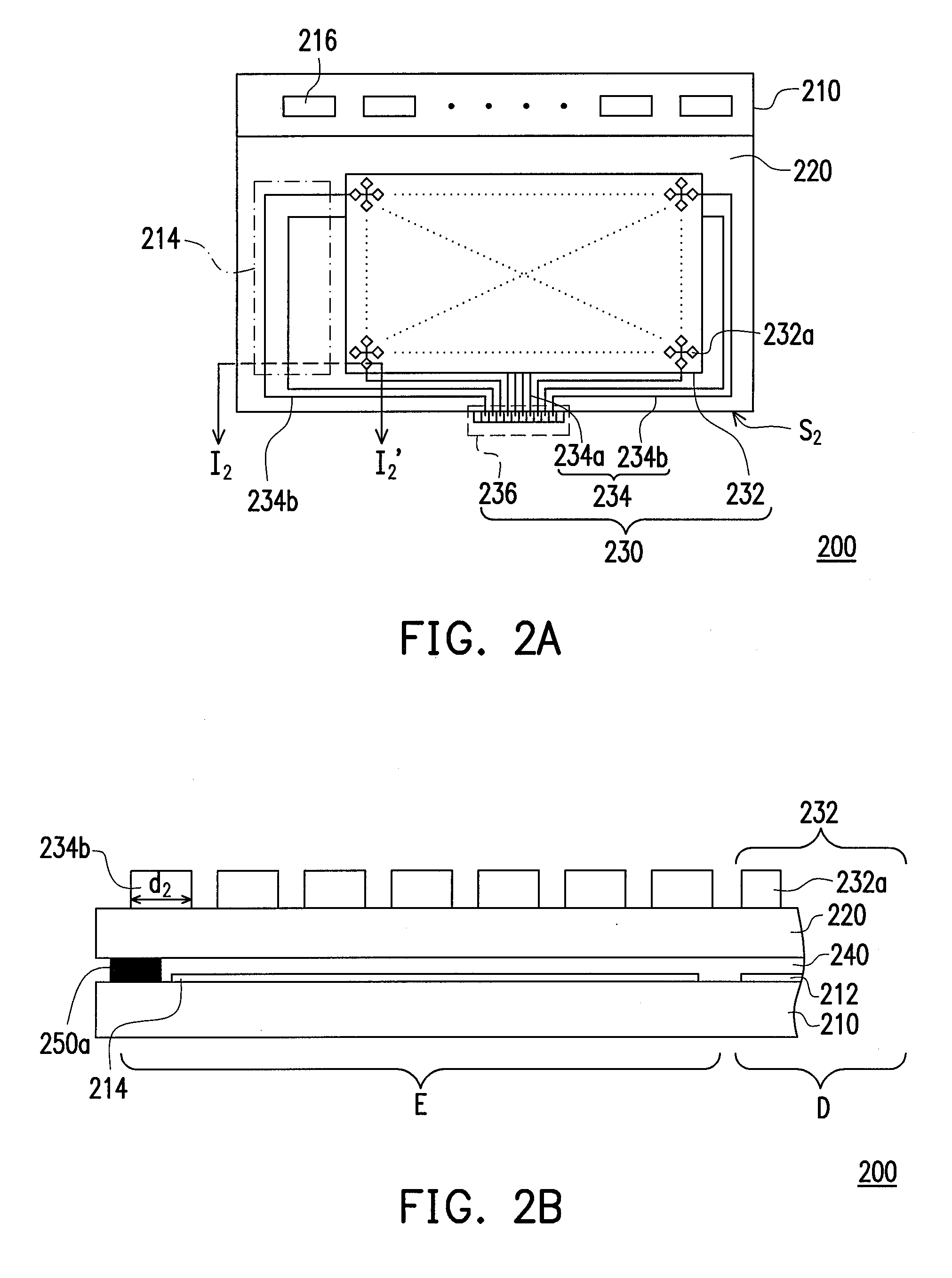

Active display device and driving method thereof

InactiveCN101826300AReduce in quantityLow costStatic indicating devicesDisplay deviceElectrical polarity

An active display device comprises a sub-pixel array and a sub-pixel array driving circuit; all of the sub-pixels of the same column in the sub-pixel array are connected with the same data line, each data line is connected with and located between two adjacent columns of sub-pixels, two columns of sub-pixels are arranged between two adjacent data lines; each line of sub-pixels correspond to two scanning lines, the sub-pixels of odd-numbered columns in the same line are connected to one of the scanning lines, the sub-pixels of even-numbered columns in the same line are connected to the other one of the scanning lines, and the sub-pixels connected with each data line are disposed in the same line. When driving, the sub-pixels of odd-numbered columns in the same line are controlled by one scanning line, and the sub-pixels of even-numbered columns in the same line are controlled by the other scanning line. The number of the scanning lines is decreased by half compared with the traditional organic display device, the column inversion and the point inversion of the polarity of the sub-pixel array can be realized, and thereby improving the process yield, reducing the cost and improving the display effect while realizing the high fining.

Owner:SHANTOU GOWORLD DISPLAY (PLANT II) CO LTD

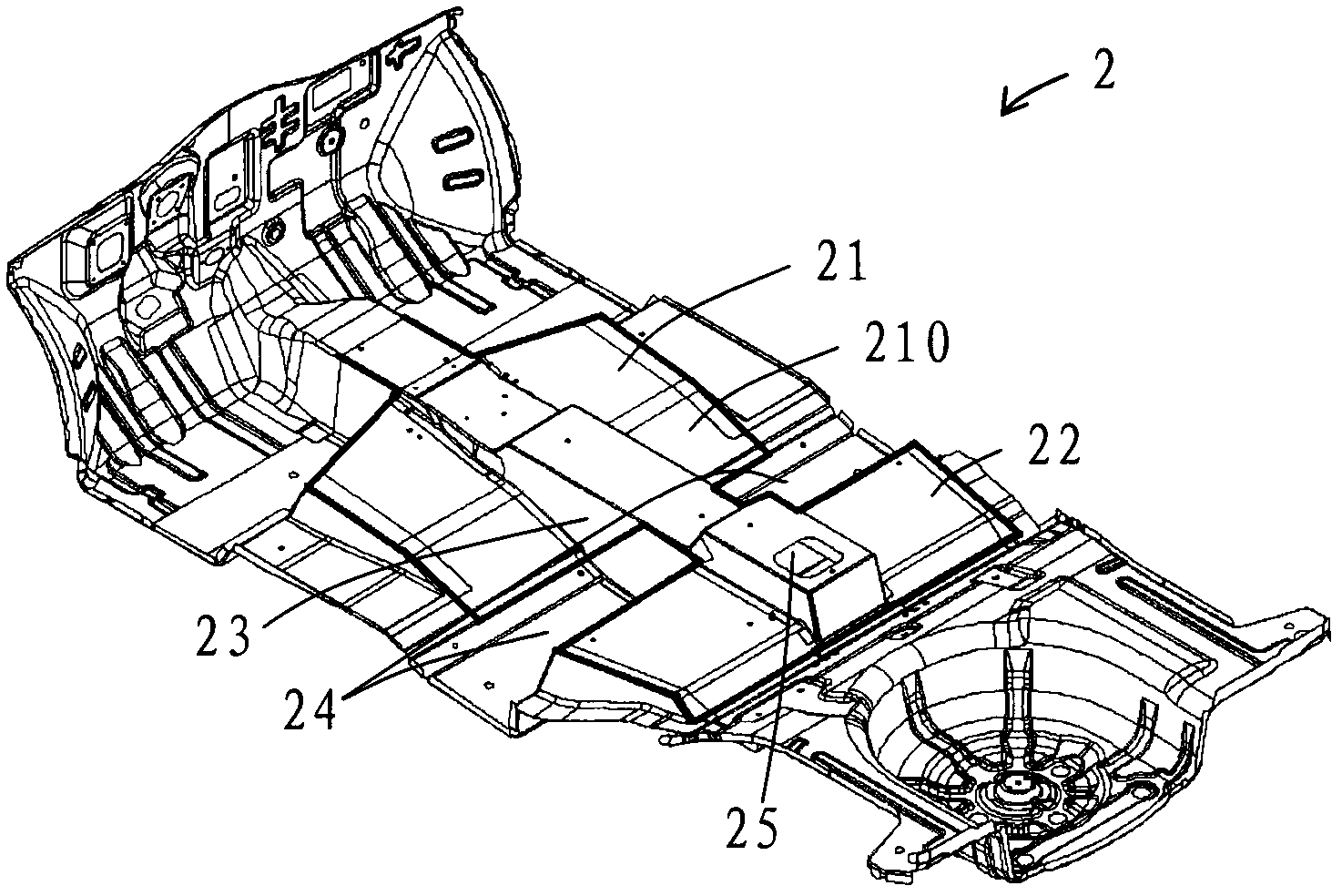

Battery box for vehicle, vehicle body component and automobile

ActiveCN102938450AOptimize layoutIncrease in sizeElectric propulsion mountingSuperstructure subunitsEngineeringFloor covering

The invention discloses a battery box for a vehicle, a vehicle body component and an automobile. The battery box for the vehicle comprises a first battery accommodation part having a first battery space for accommodating the battery, a second battery accommodation part which is apart from the first battery accommodation part and has a second battery space for accommodating the battery, and a third battery accommodation part which is connected with the first battery accommodation part and the second battery accommodation part, wherein a space between boxes for accommodating feet of a passenger is formed at the two sides of the third battery accommodation part between the first battery accommodation part and the second battery accommodation part; and the third battery accommodation part has a third battery space which is communicated with the first second battery space and the second battery space. The vehicle body component comprises a floor covering member which is provided with an accommodation part for accommodating the battery box for the vehicle, wherein the accommodation part is below the space of the passenger; and a floor beam structure which is fixed on the lower portion of the floor covering member and forms the boundary for accommodating the battery box for the vehicle. Therefore, requirements for relatively high range and safe reliability can be met.

Owner:SAIC GENERAL MOTORS +1

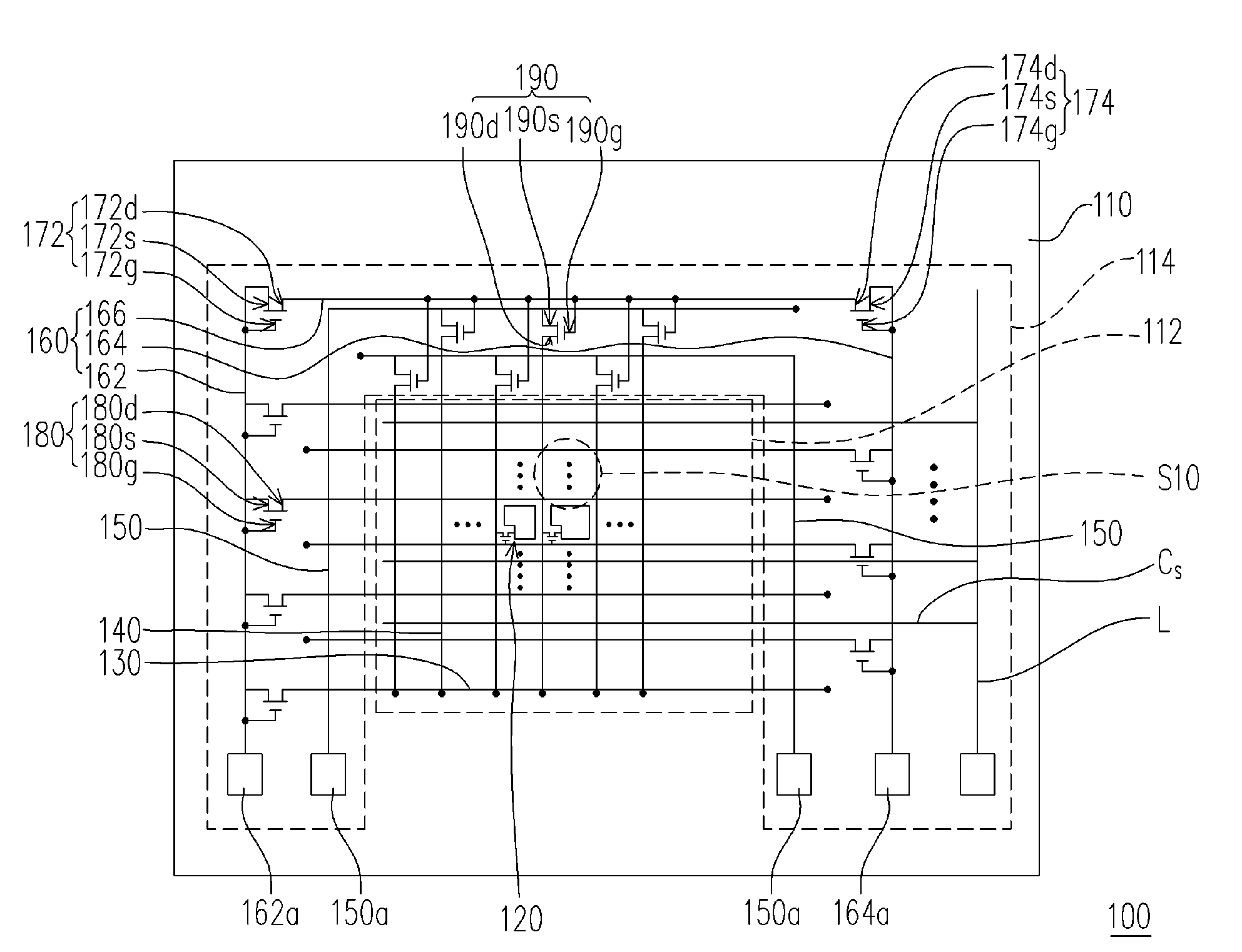

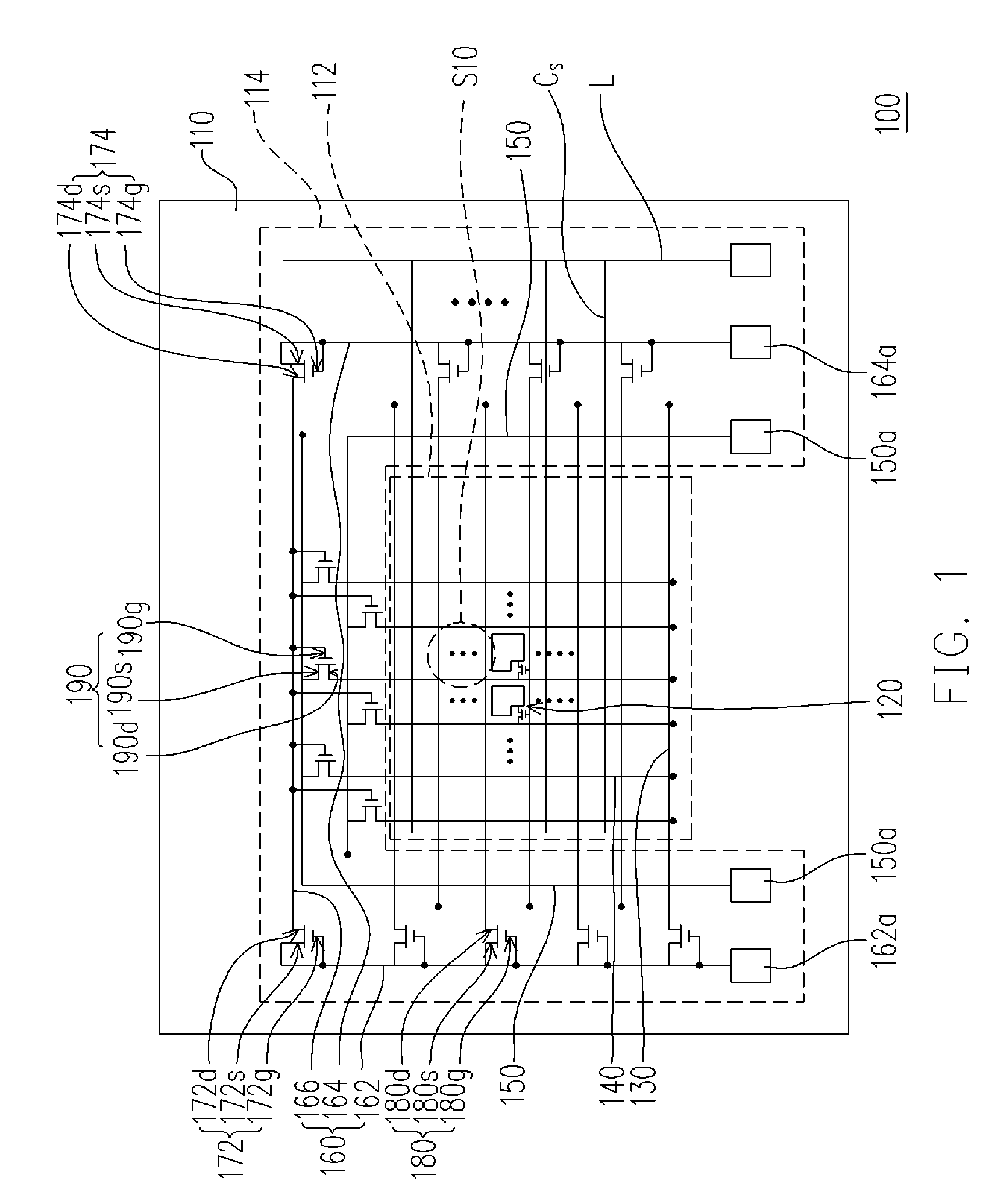

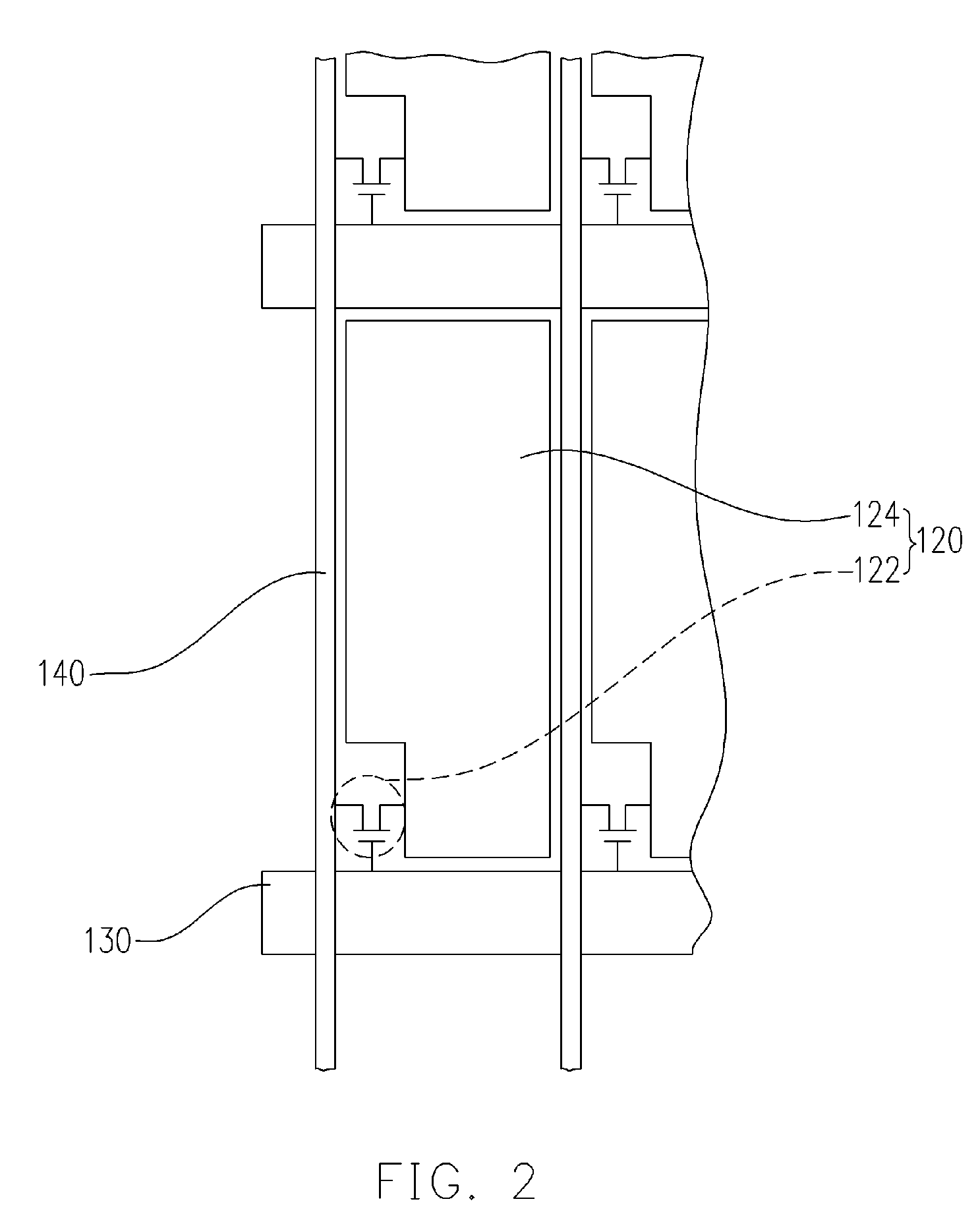

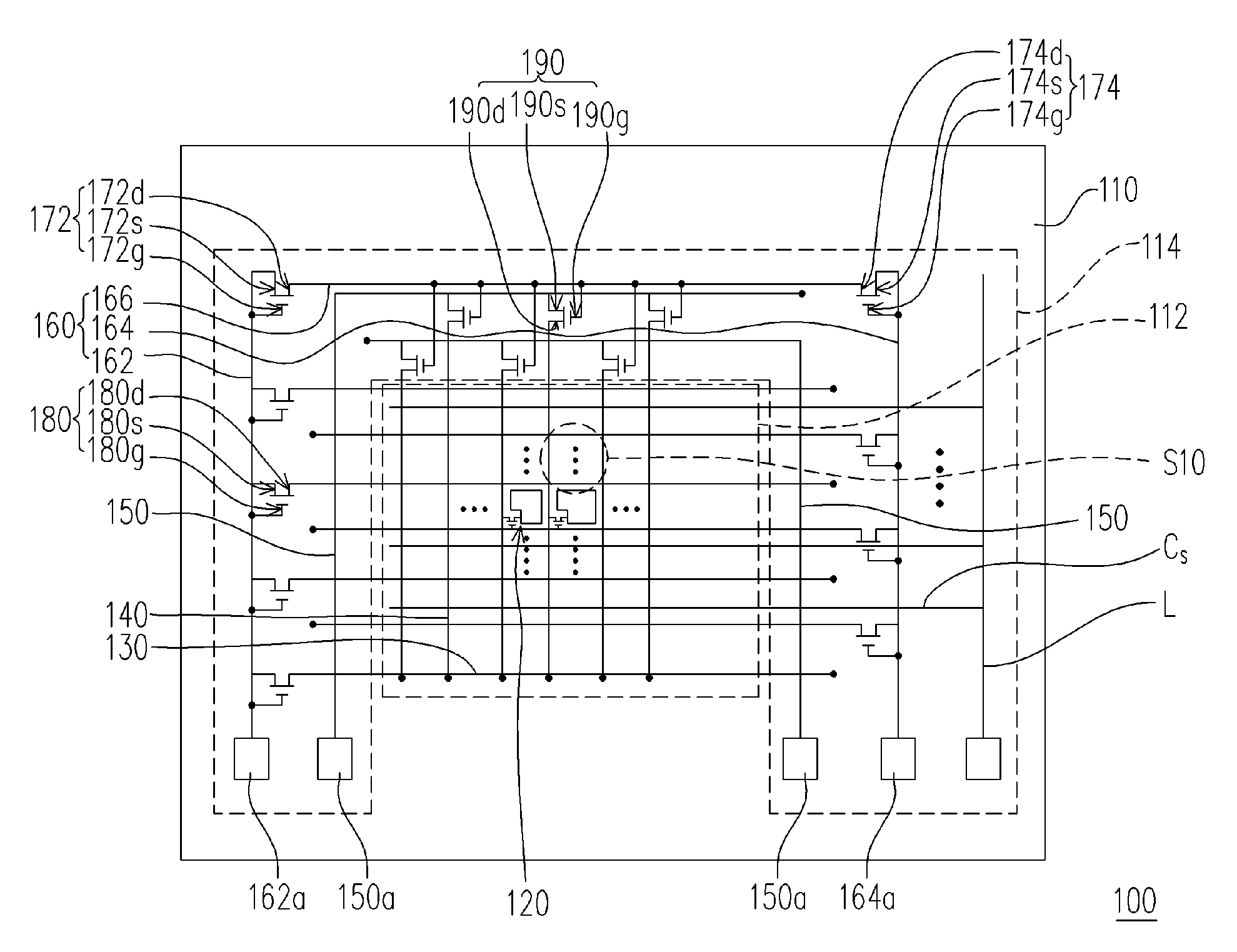

Active device array substrate, liquid crystal display panel and examining methods thereof

InactiveUS7298165B2Optimize layoutReduce in quantityNon-linear opticsIndividual semiconductor device testingLiquid-crystal displayScan line

Pixel units are disposed in a display region of a substrate, and scan lines and data lines are used to control the pixel units. Inner short ring includes a first segment, a second segment and a connecting segment connecting both segments. The gates and sources of the first and second active device connect with the first and second segments respectively, and the drains connect with the connecting segment. The gates and sources of part of the third active devices connect with the first segment, and the drains connect with the odd scan lines. The gates and sources of other third active devices connect with the second segment, and the drains connect with the even scan lines. The gates of the fourth active devices connect with connecting lines, and the sources connect with data testing lines, and the drains connect with the odd and even data lines respectively.

Owner:CHUNGHWA PICTURE TUBES LTD

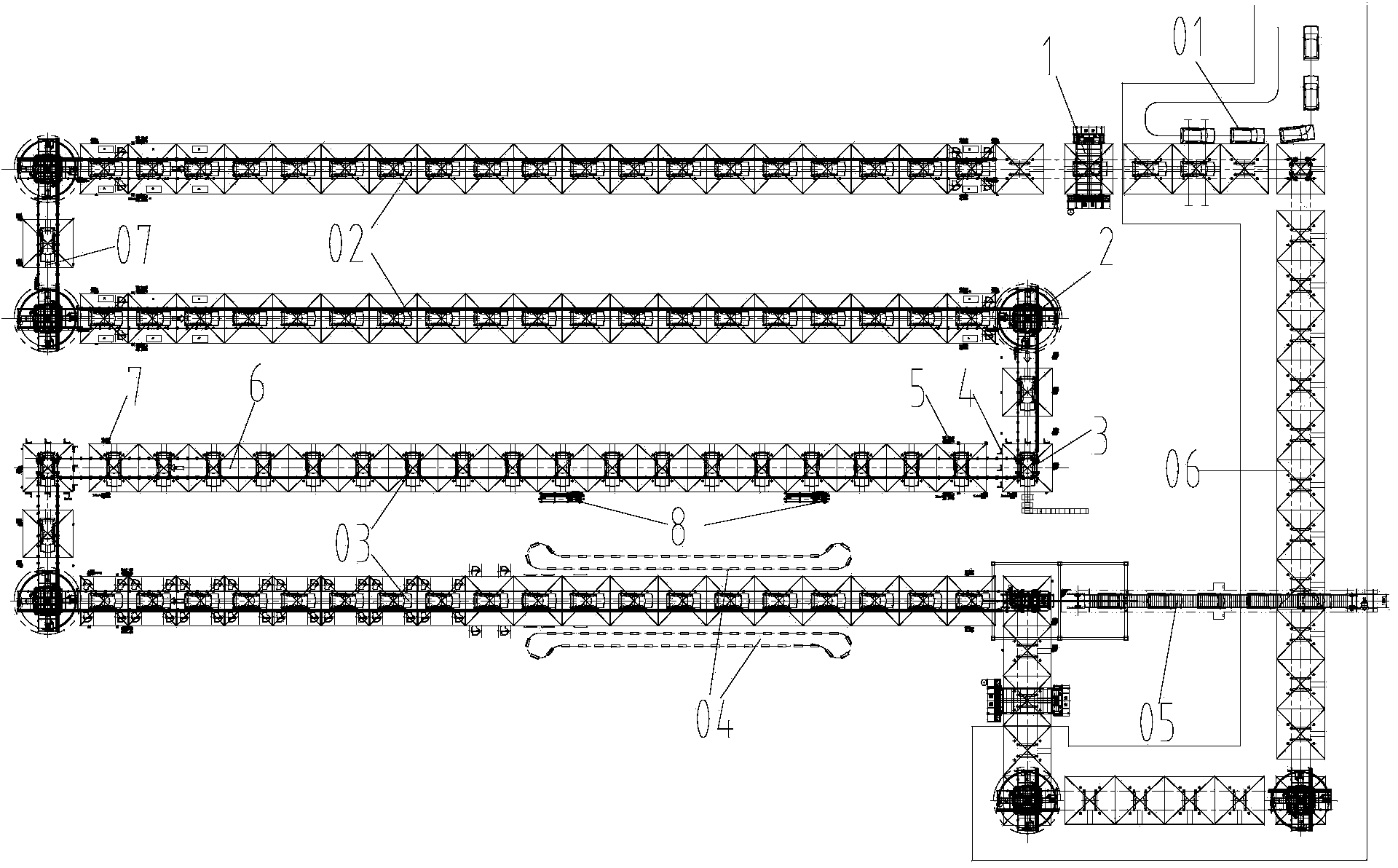

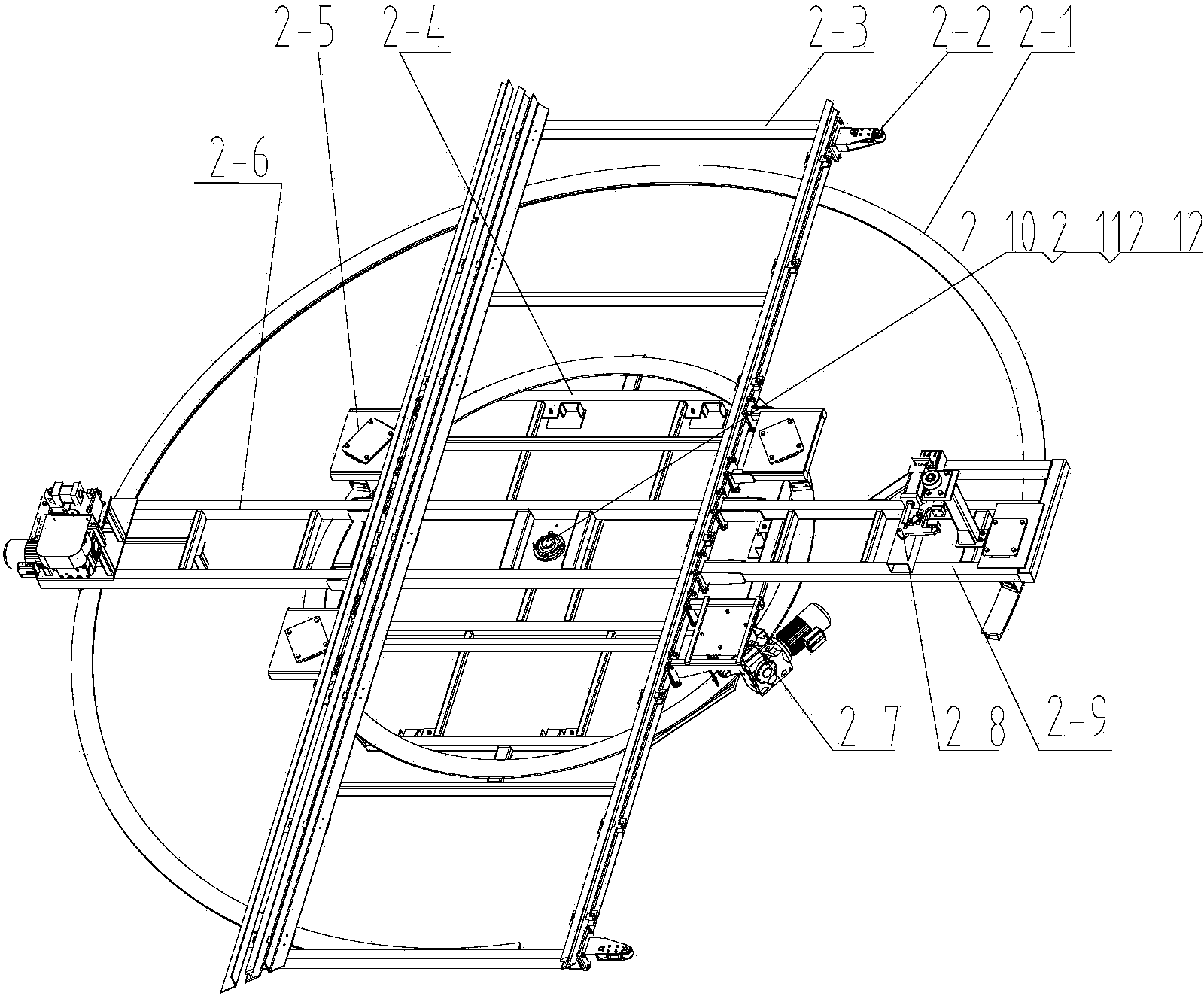

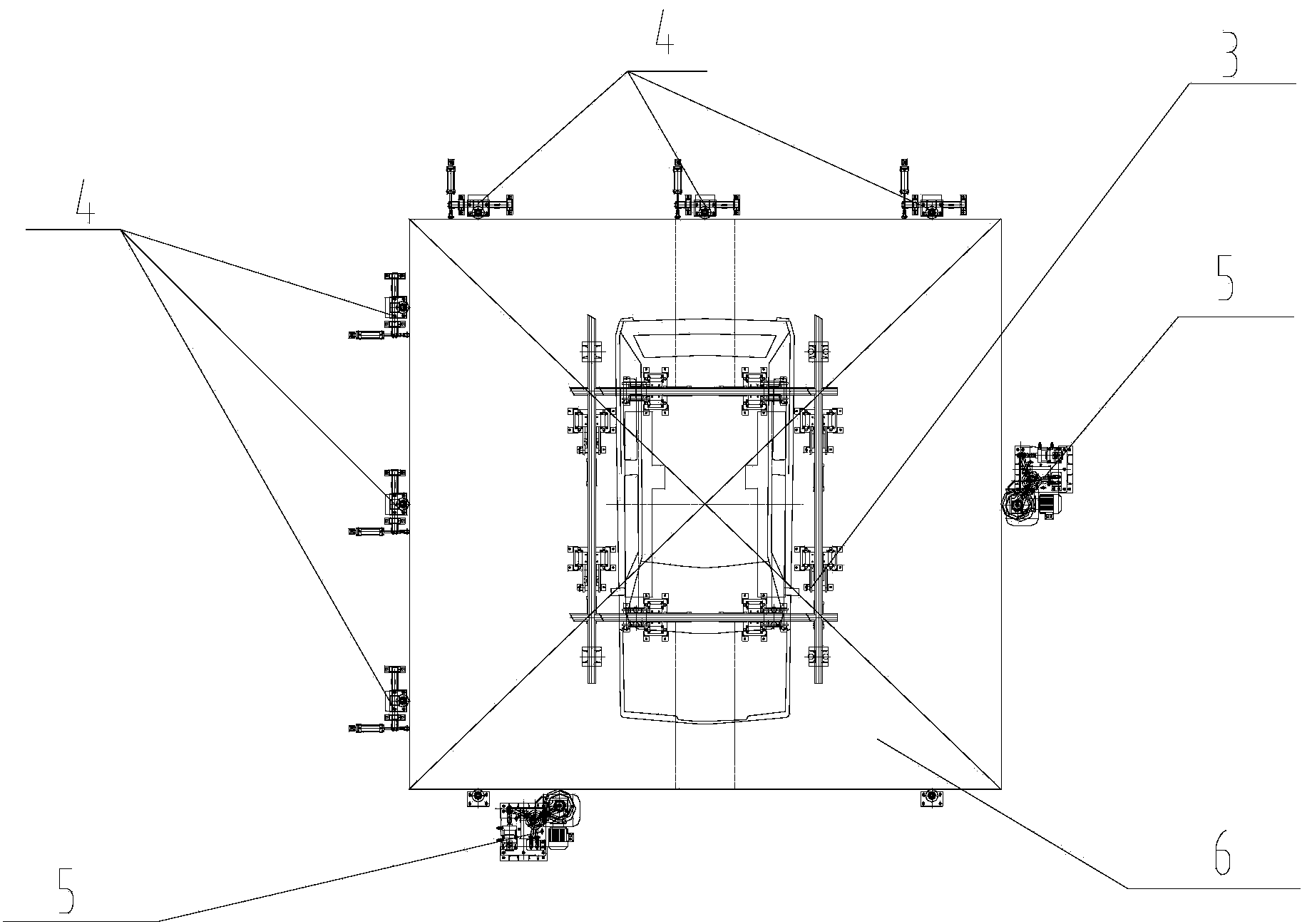

Automobile assembly sliding plate conveying line

InactiveCN104044872AIncrease productivityOptimize space layoutConveyor partsMechanical conveyorsEngineeringSlide plate

The invention discloses an automobile assembly sliding plate conveying line. A track system of the conveying line comprises trim lines and chassis lines. Line turning portions are arranged inside the trim lines, chassis lines and / or the connecting positions of the ending ends of the trim lines and the starting ends of the chassis lines, steering devices are arranged at the ends of the line turning portions, and a transition track is arranged between every two adjacent steering devices. The ending ends of the chassis lines and the starting ends of the trim lines are connected through sliding plate recovery lines, and then a sliding plate can cyclically move in a whole line. A sliding plate body is provided with a lifting table and workpiece storage mechanisms, the workpiece storage mechanisms are used for storing workpieces needing to be stored in disassembly station sections of the trim lines, and the lifting table is used for lifting workpieces in lifting station sections of the chassis lines. The chassis lines are provided with following power supply systems respectively in an ascending station section and a descending station section of the lifting table, and the following power supply systems can provide electric power correspondingly when the lifting table ascends and descends. The technical performance of a sliding plate conveying system can be improved at least in the aspect of assembly accuracy or work efficiency or manufacturing cost, and application prospects are good.

Owner:QUZHOU WOSI ELECTRONICS TECH

Active device array substrate, liquid crystal display panel and examining methods thereof

InactiveUS20070170948A1Optimize layoutReduce in quantityNon-linear opticsIndividual semiconductor device testingLiquid-crystal displayActive devices

Pixel units are disposed in a display region of a substrate, and scan lines and data lines are used to control the pixel units. Inner short ring includes a first segment, a second segment and a connecting segment connecting both segments. The gates and sources of the first and second active device connect with the first and second segments respectively, and the drains connect with the connecting segment. The gates and sources of part of the third active devices connect with the first segment, and the drains connect with the odd scan lines. The gates and sources of other third active devices connect with the second segment, and the drains connect with the even scan lines. The gates of the fourth active devices connect with connecting lines, and the sources connect with data testing lines, and the drains connect with the odd and even data lines respectively.

Owner:CHUNGHWA PICTURE TUBES LTD

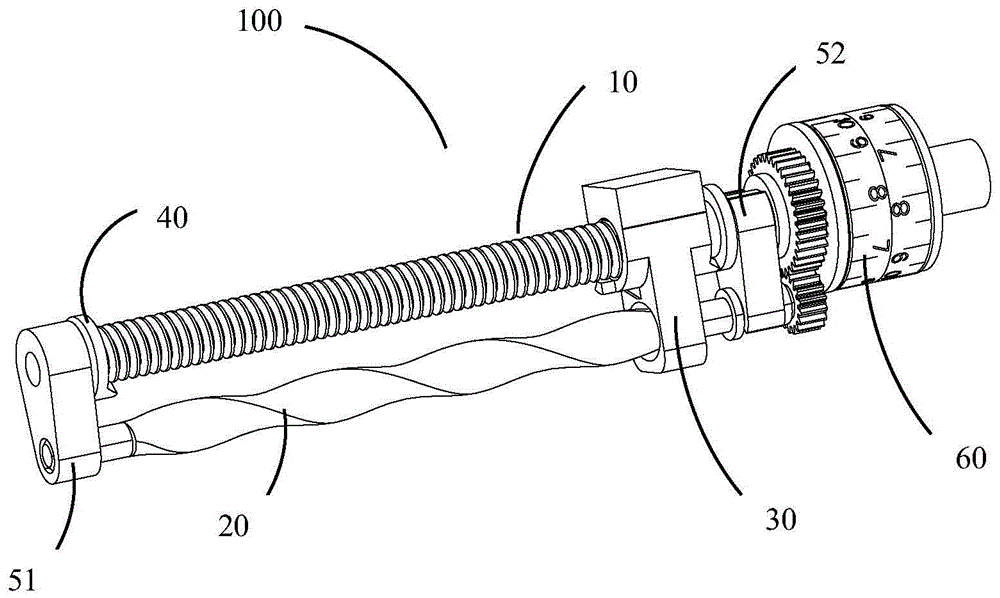

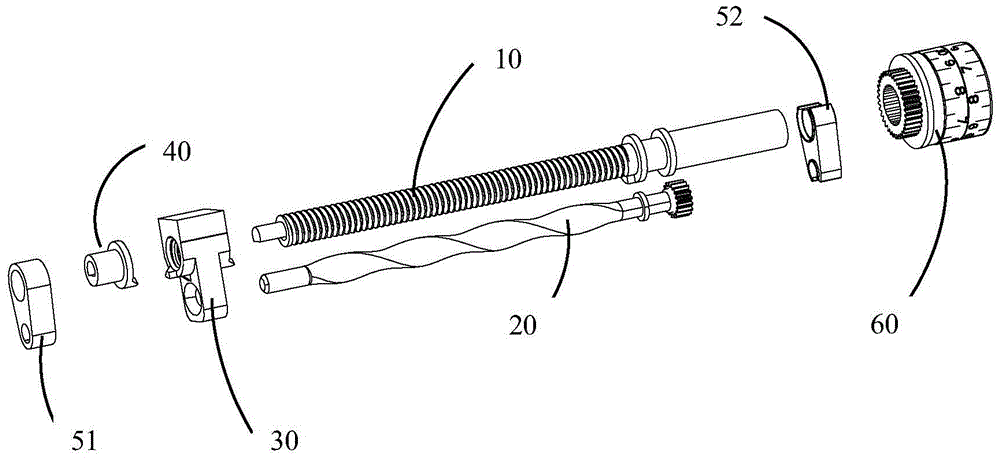

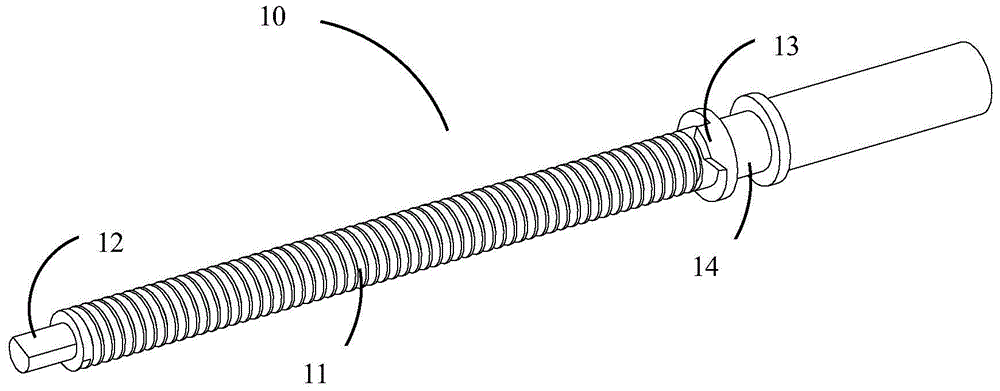

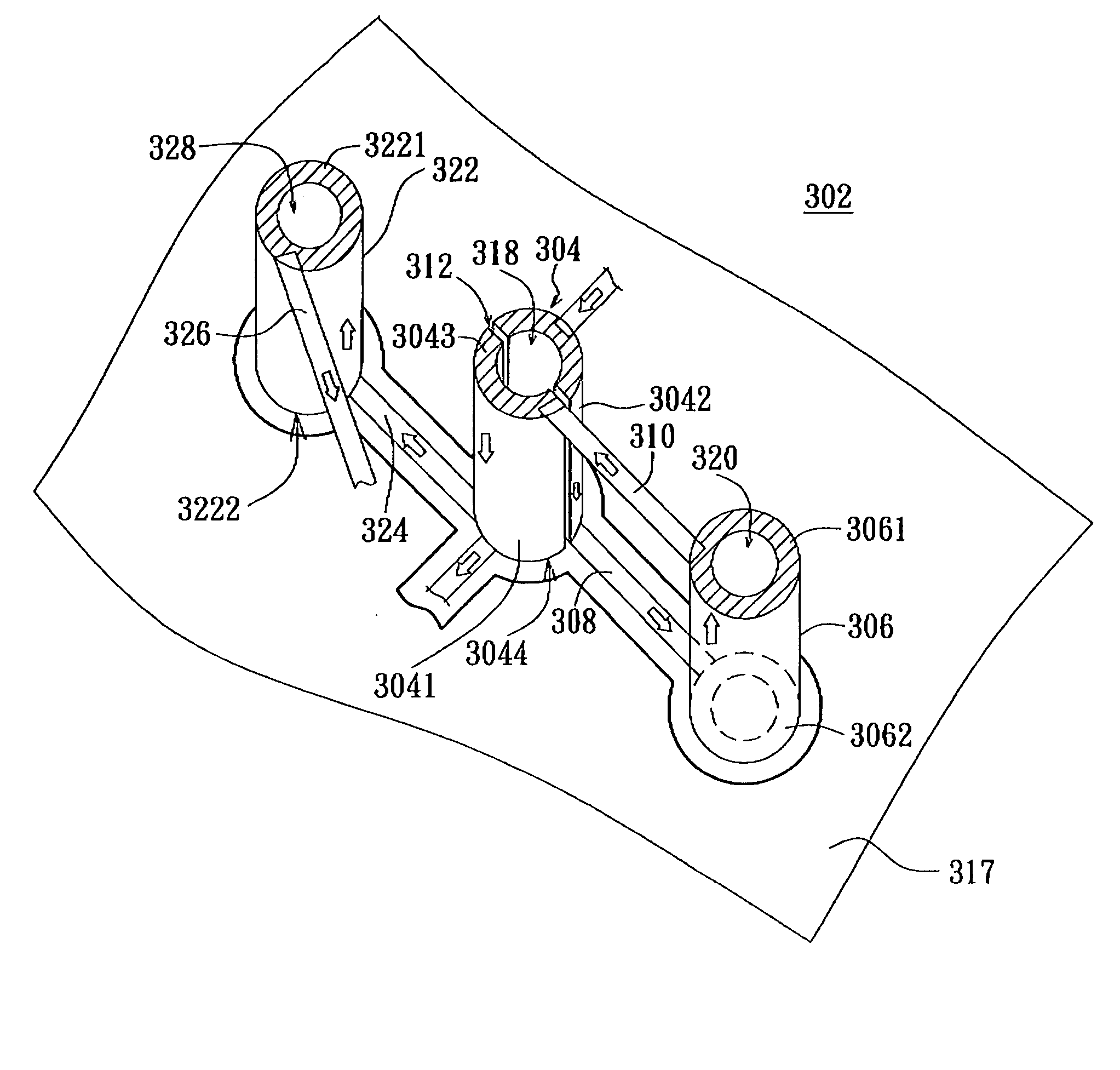

Regulating device for rotating scale of tunable antenna

The invention discloses a regulating device for a rotating scale of a tunable antenna. The regulating device comprises a threaded rod, a drive rod, a drive slide block, a check block, a support block and a gear drive mechanism, wherein the device is mounted on a fixing plate in the antenna, the threaded rod and the drive rod are axially parallel, the drive slide block is connected with the threaded rod and the drive rod through a screw mechanism, the check block is fixed on the threaded rod and keeps synchronous rotation with the threaded rod, a support piece supports the threaded rod and the drive rod at the two ends, and the gear drive mechanism is sleeved with the threaded rod, keeps axially concentric with the threaded rod, and drives a scale ring to rotate through gear mesh drive, so as to indicate the electric downtilt of the antenna. According to the regulating device for the rotating scale of the tunable antenna, the scale of the antenna is changed from linear stretching to circumferential rotating, so that the risk of clamping a linear scale is avoided, the spaces of an end face and a plane of the antenna are saved, the structure is compact, and the functions of regulating the electric downtilt and indicating the angle of the tunable antenna are realized.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

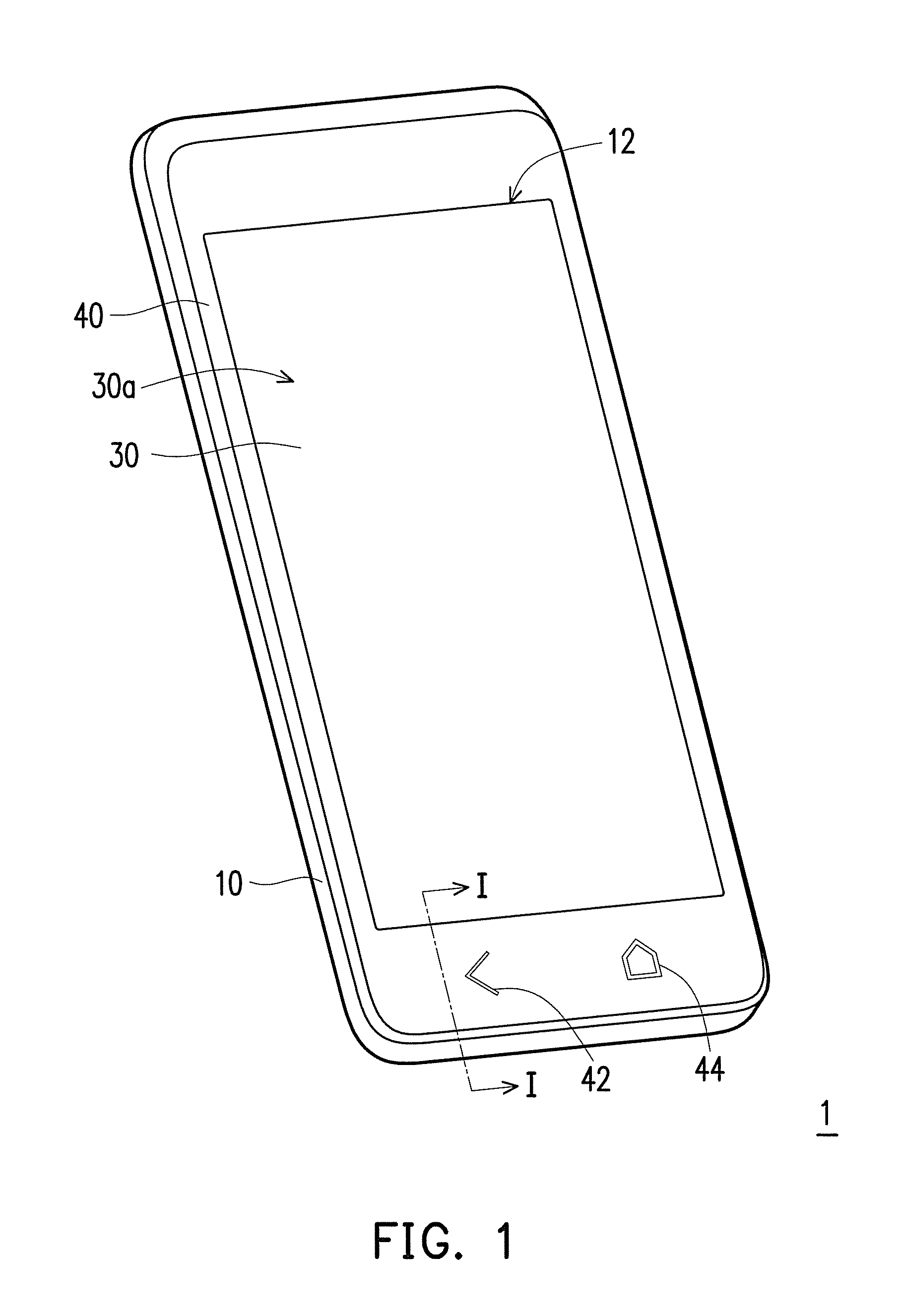

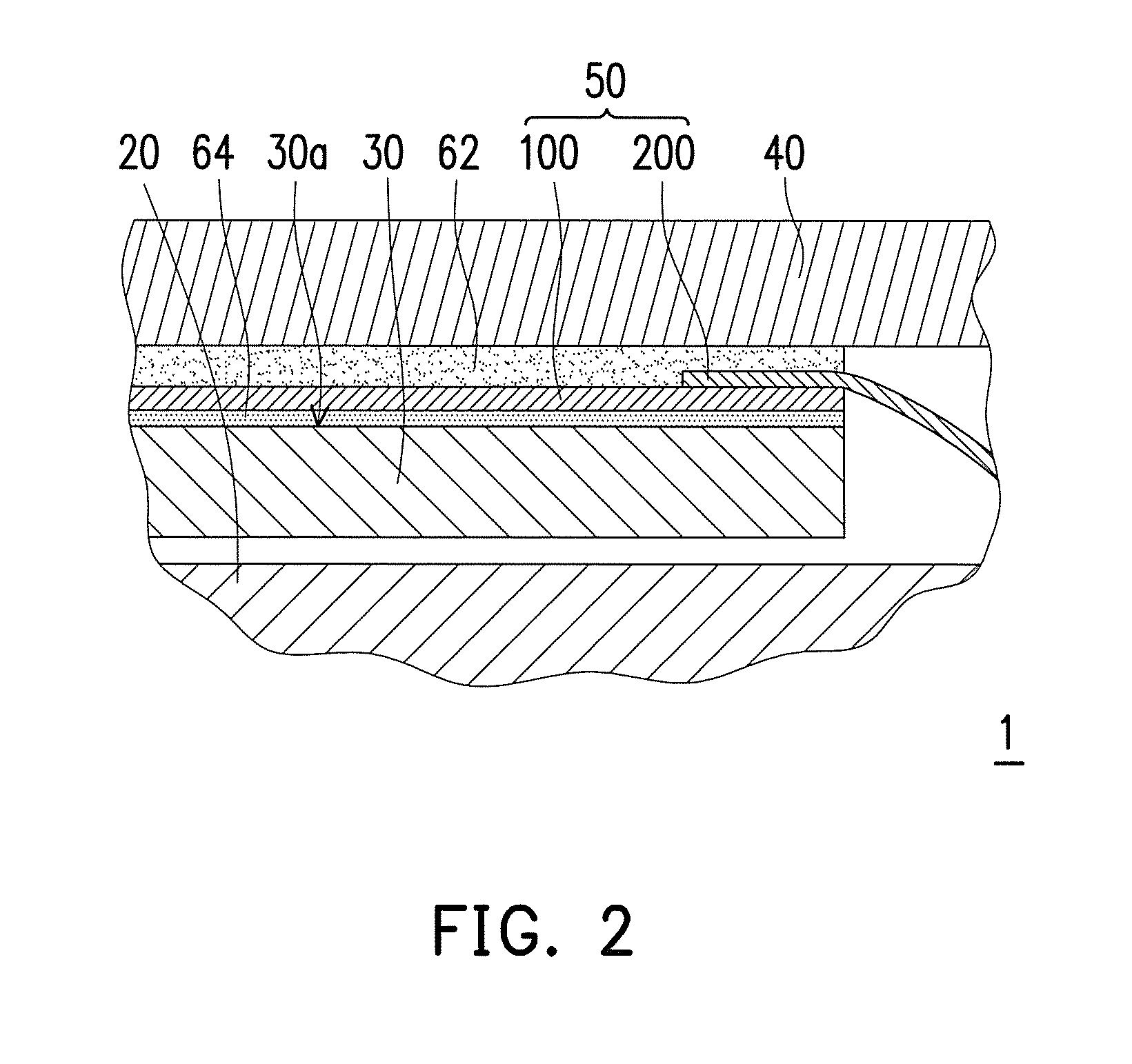

Touch panel assembly and electronic apparatus

InactiveUS20140218629A1Small sizeReduce manufacturing costNon-linear opticsInput/output processes for data processingFlexible circuitsTouch panel

A touch panel assembly includes a touch panel and a flexible circuit board. The touch panel includes a sensing array having sensing units, first connection lines, second connection lines, at least one input element, and pads. The first and second connection lines are outside the sensing array and electrically connected to the sensing units respectively. The input element is outside the sensing array and close to a side of the touch panel. The pads are in a bonding region of the touch panel and electrically connected to the first and second connection lines respectively. The bonding region is close to the side of the touch panel and is arranged along with the input element in parallel to the side of the touch panel. The flexible circuit board has a connecting portion extended and attached to the bonding region. Terminals of the connecting portion are electrically connected to the pads respectively.

Owner:HTC CORP

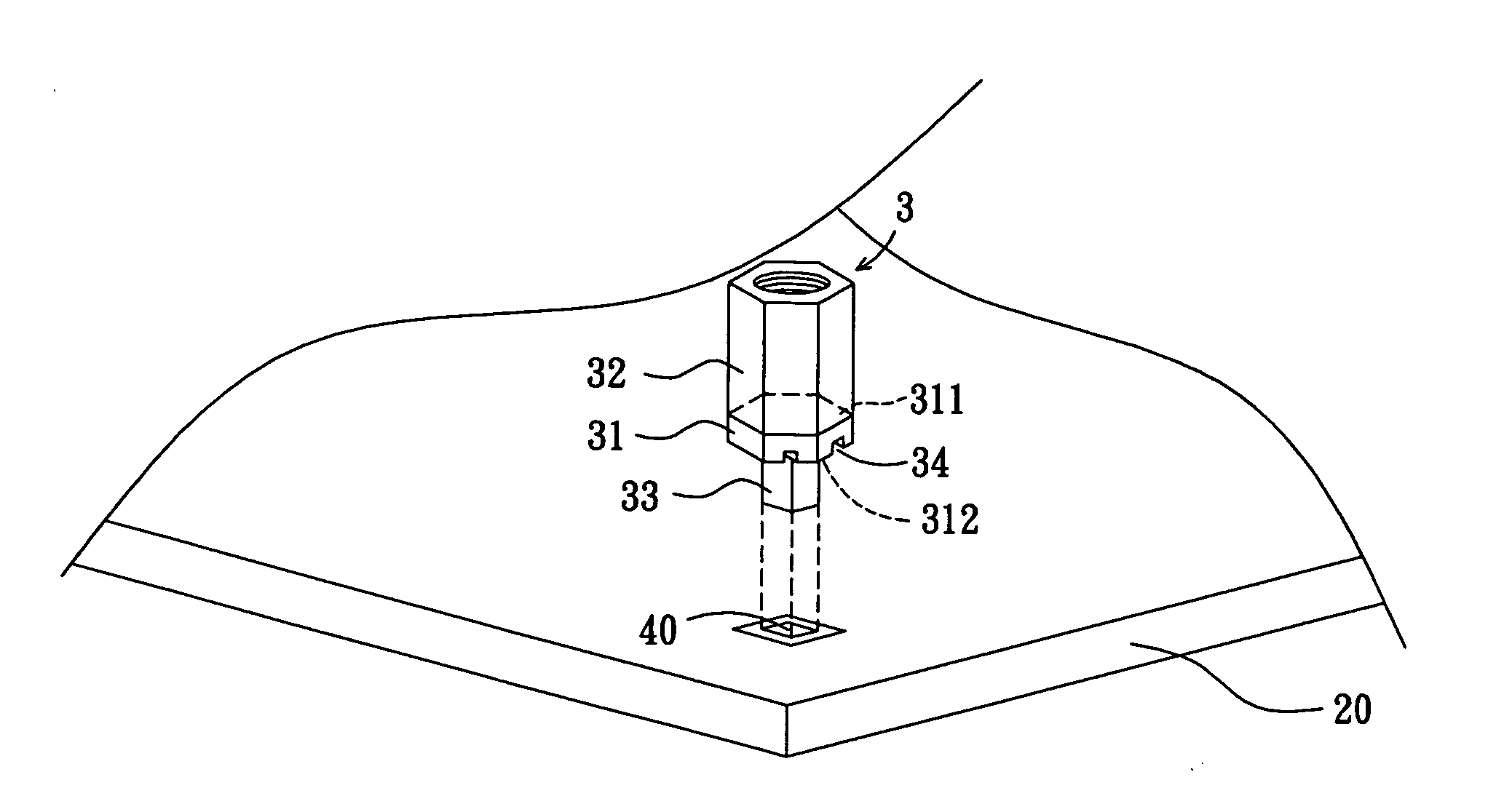

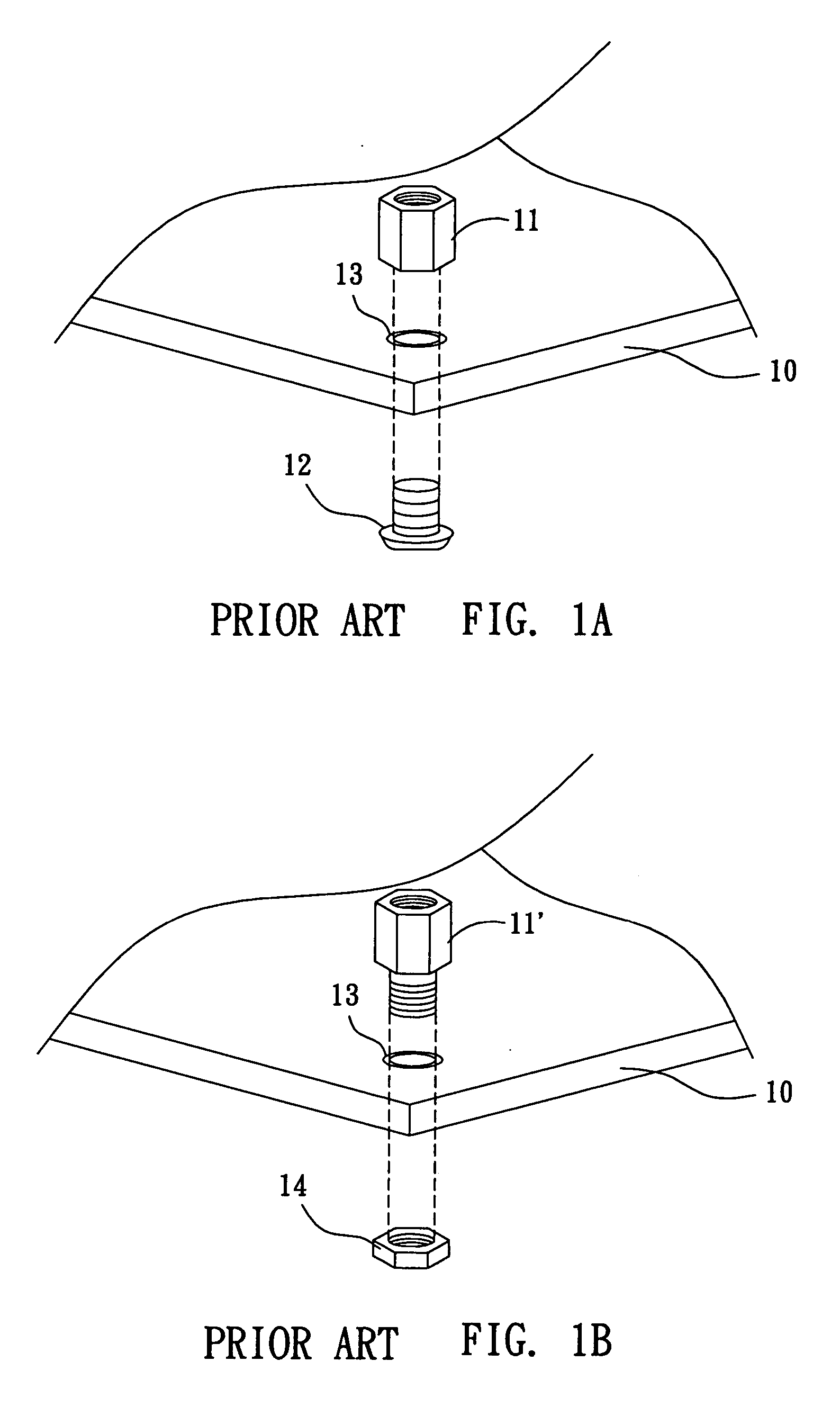

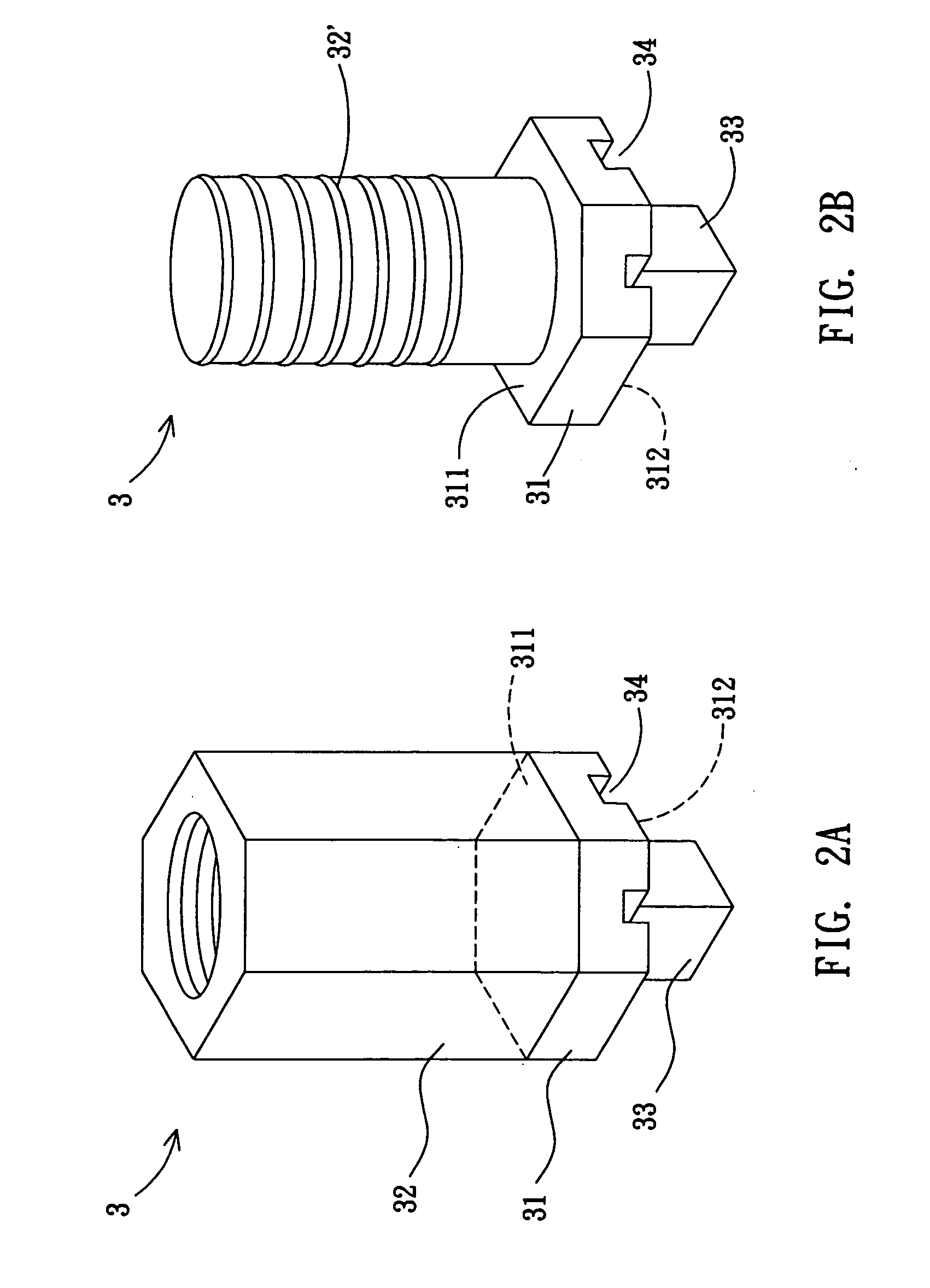

Main board and fixing component thereof

InactiveUS20060040529A1Reduce extra spaceIncrease layout spaceFinal product manufacturePrinted circuit aspectsEngineeringElectrical and Electronics engineering

Owner:VIA TECH INC

Core-pulling and demoulding combination device

The invention declares a core-pulling and demoulding combination device, which comprises a fixed template and a movable template forming a cavity, wherein a slide block, an inclined guide post, a lateral mold core, a positioning mechanism and an ejector rod are arranged in the cavity; the lateral mold core is hinged to the slide block; the ejector rod and the inclined guide post are fixed in the cavity; the positioning mechanism comprises a compression spring and a bolt; the inclined guide post is fixed on the fixed template; the lateral mold core is hinged to the slide block through a pin; during mold opening, the fixed template move upwards, the inclined guide post drives the slide block to move to the left in a guide sliding chute in the movable template, so as to complete the core-pulling action; in order to guarantee that during mold closing, the inclined guide post can accurately enter into an inclined hole in the slide block to facilitate reset of the slide block, a positioning device is arranged on the mechanism; and with the bolt and the compression spring, the slide block is propped against a spacing stop block for positioning when withdrawn. During the whole process, the demoulding and core-pulling are good in processing property, the cost is low, and therefore, the device provided by the invention is suitable for medium and small sized injection moulded pieces.

Owner:AIMBON (CHENGDU) ELECTRIC APPLICANCE CO LTD

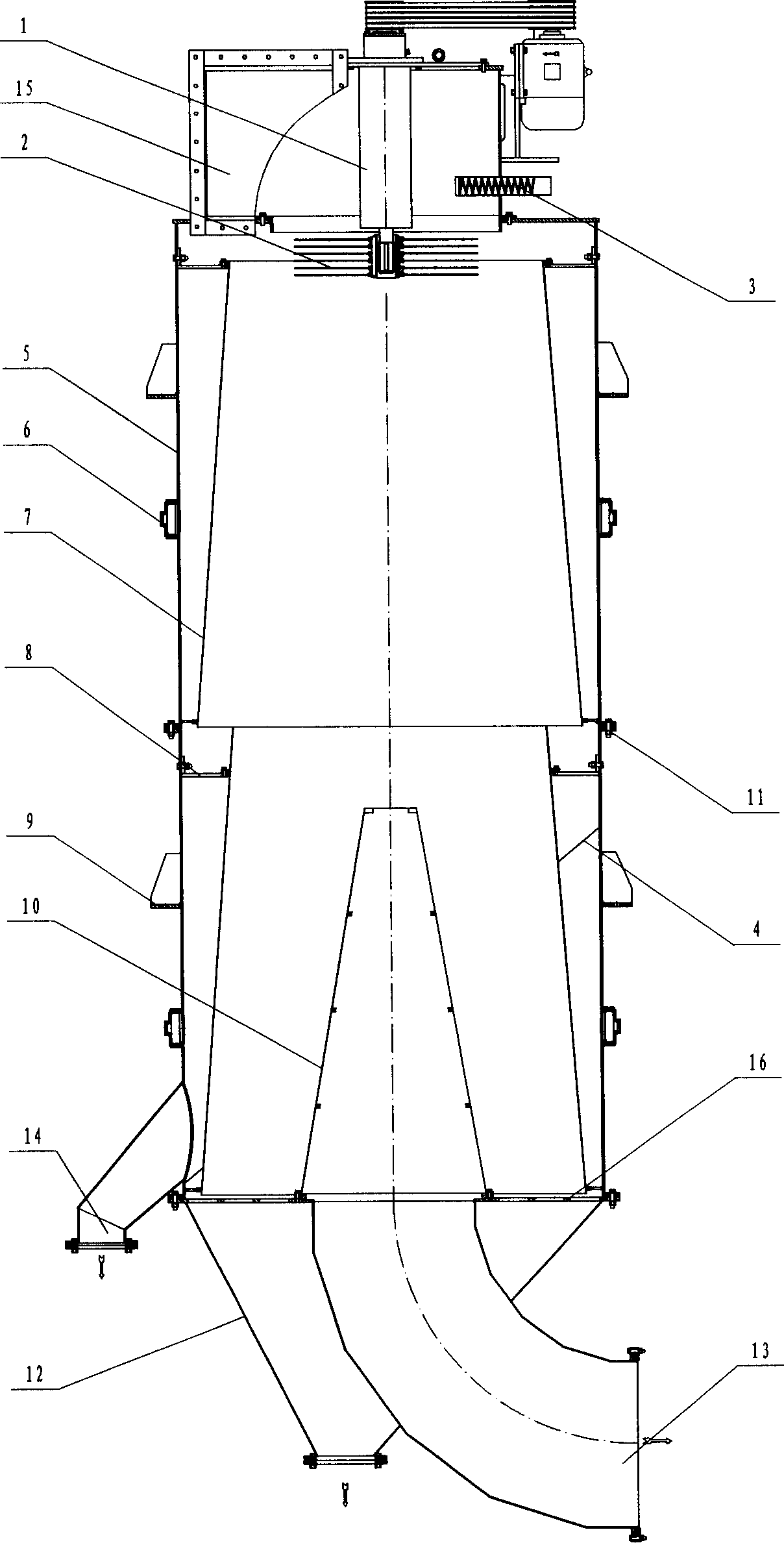

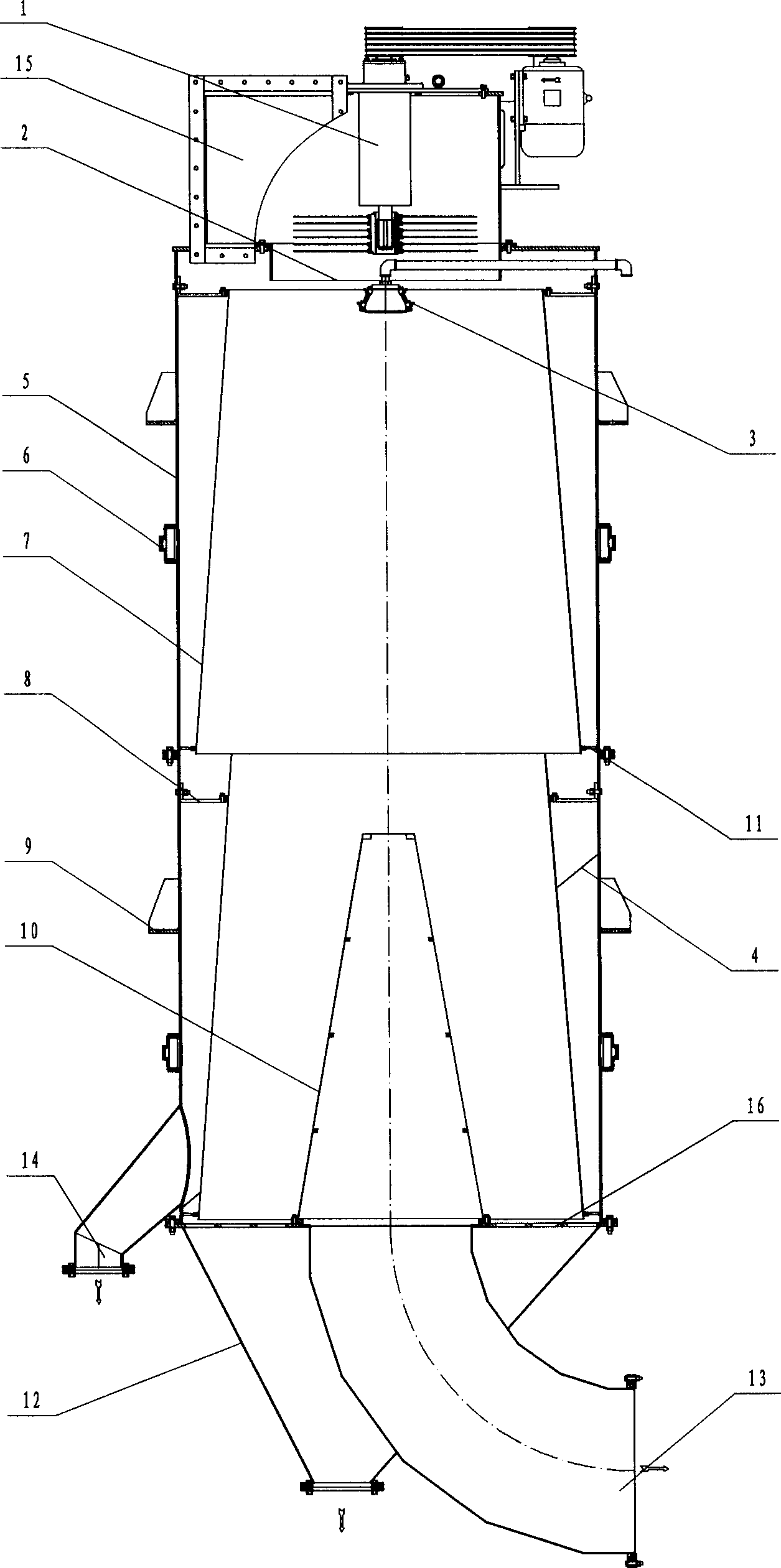

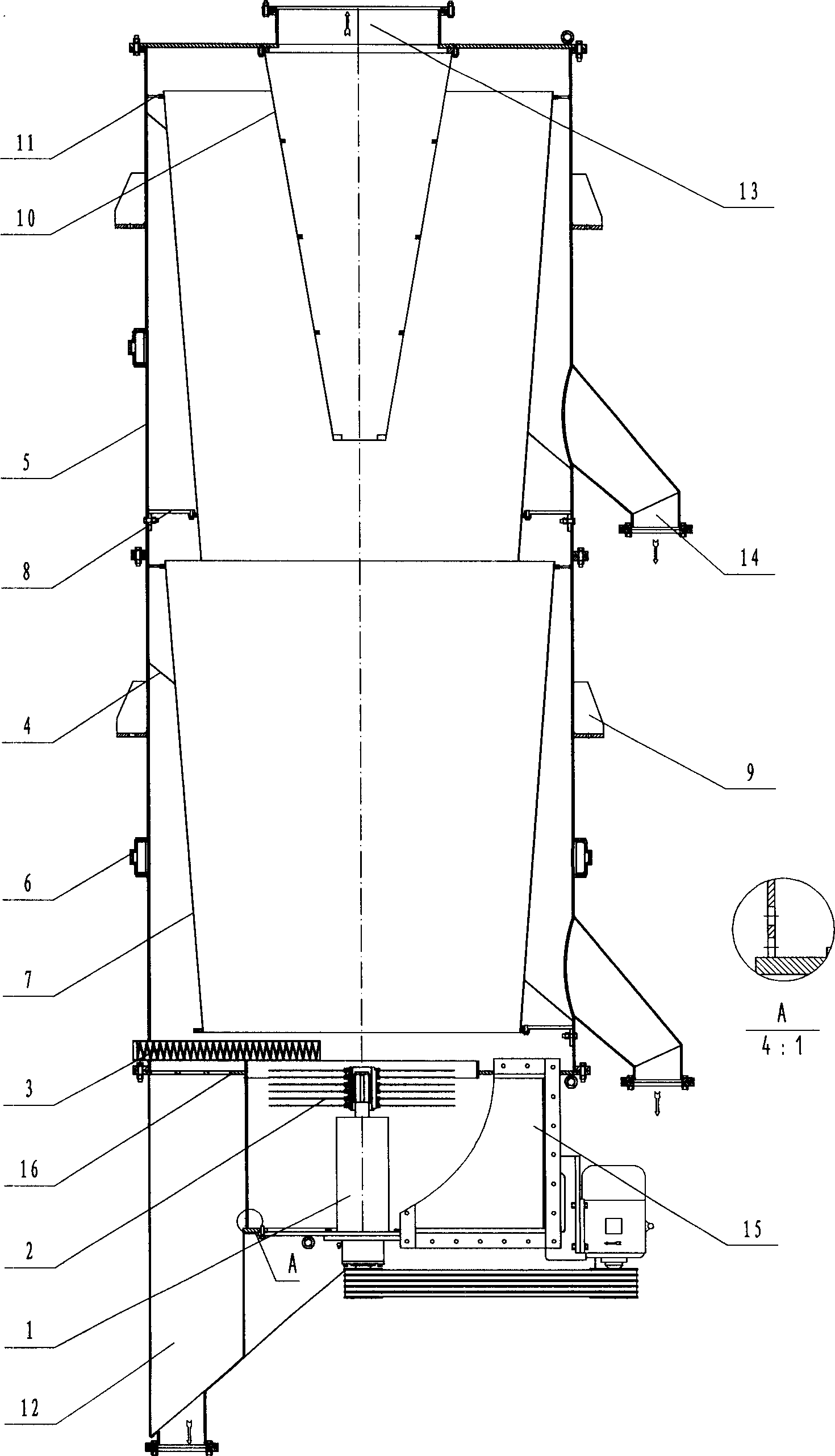

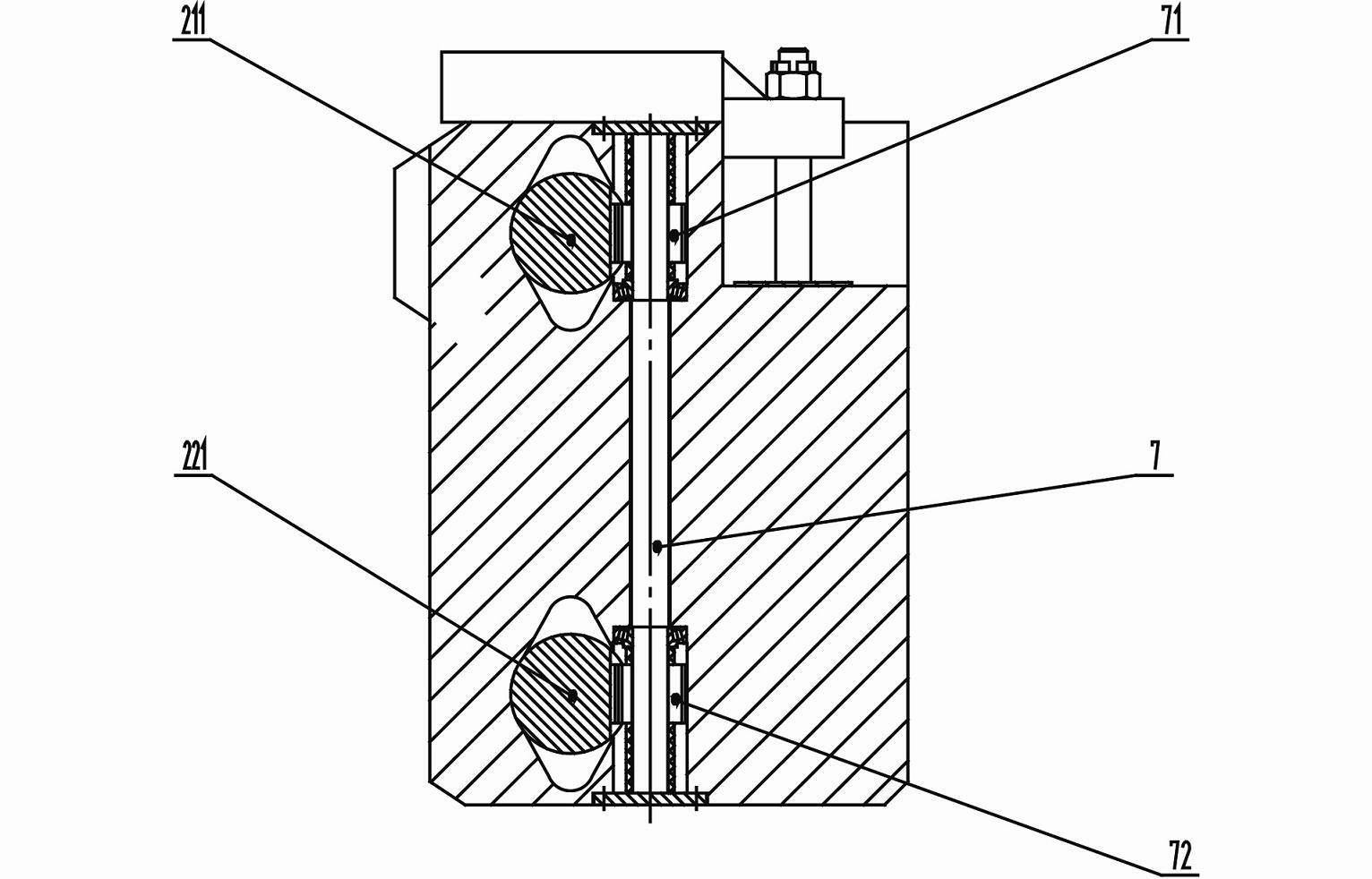

Drying separator

InactiveCN1419098ALarge three-dimensional space rangeIncrease profitDrying solid materials with heatDispersed particle separationThermal energyEngineering

The present invention relates to a drying separation equipment, containing tower body, driving device, start-rotating needle wheel, granule sorting device, separating needle wheel and air power separator. It is characterized by that it mainly utilizes the rotor of start-rotating needle wheel to disperse material and start rotational flow, and utilizes the rotational flow to enhance heat condution of material and gas flow, and can force the dried material to make regular centrifugal movement to clean tower wall and eliminate sticky wall phenomenon. The sorting device can be used for collecting the products with different grain sizes or cooling, and the separating needle wheel can raise separation effect. Said invention can implement air flow circularting drying and can raise utilization rate of heat energy.

Owner:高根树

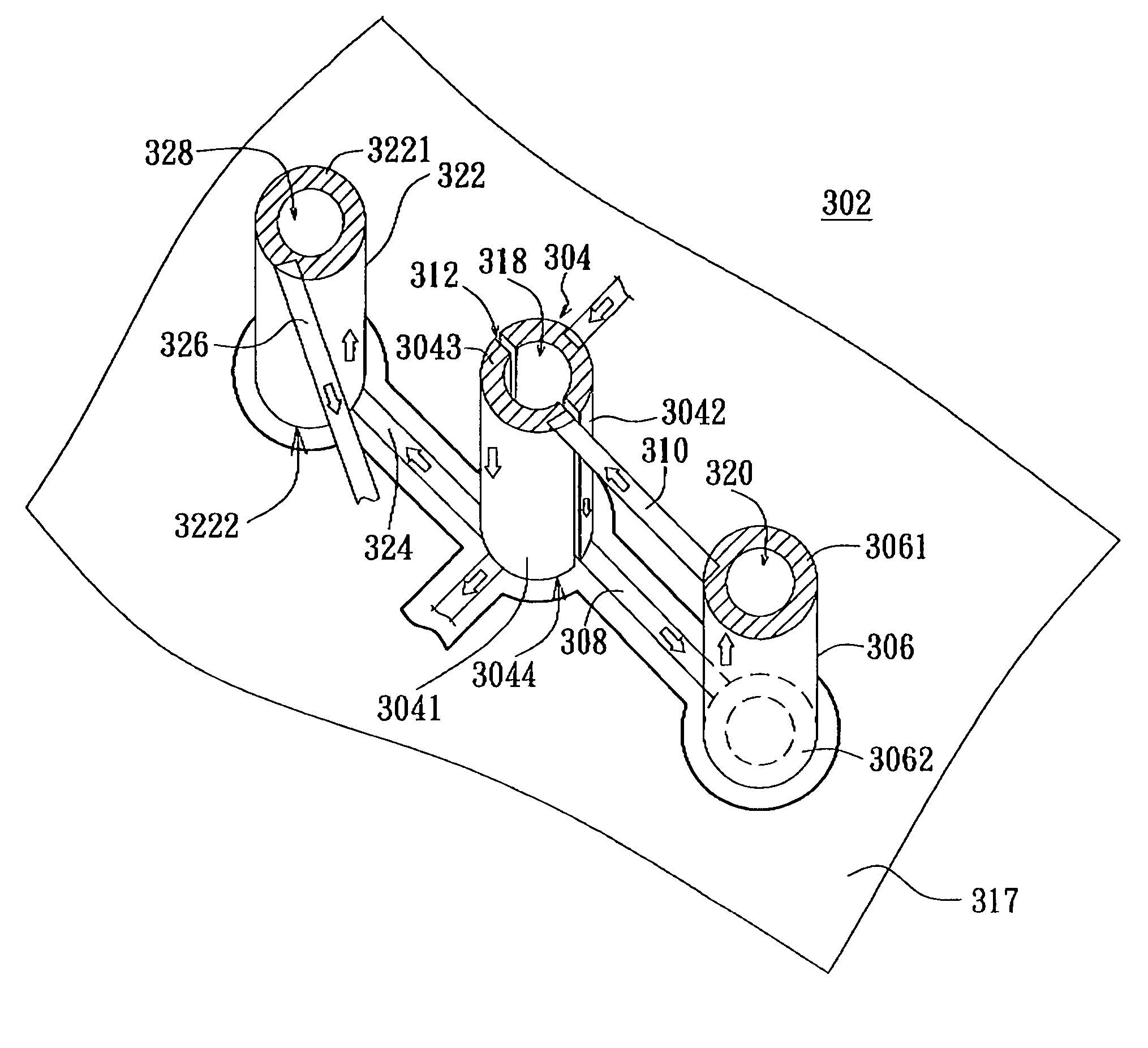

Safety pin interlocking device for crane, single cylinder safety pin type telescopic arm and crane

InactiveCN102153023ALower the altitudeIncrease the itineraryCranesStructural engineeringMechanical engineering

The invention discloses a safety pin interlocking device for a crane, a single cylinder safety pin type telescopic arm and a crane. The safety pin interlocking device for the crane comprises a pin pull device dovetail groove and a mechanical lock which is fixedly connected with the dovetail groove; the motion path of the dovetail groove is perpendicular to an axis of a cylinder pin; meanwhile, the motion path of an upper cylinder pin is intersected with the motion path of the dovetail groove, and the motion path of a lower cylinder pin is intersected with the motion path of the mechanical lock; when the arm pin moves to the unlocking position, an arm pin pulling oil cylinder drives the dovetail groove to lock the upper cylinder pin, and meanwhile, the dovetail groove drives the mechanicallock to lock the lower cylinder pin; and when the cylinder pin moves to the unlocking position, the upper cylinder pin locks the dovetail groove by a cylinder pin body, and meanwhile, the lower cylinder pin locks the mechanical lock by the cylinder pin body, thereby the arm pin is directly and indirectly locked. The single cylinder safety pin type telescopic arm and telescopic arm type crane provided by the invention comprise the safety pin interlocking device.

Owner:DALIAN UNIV OF TECH +2

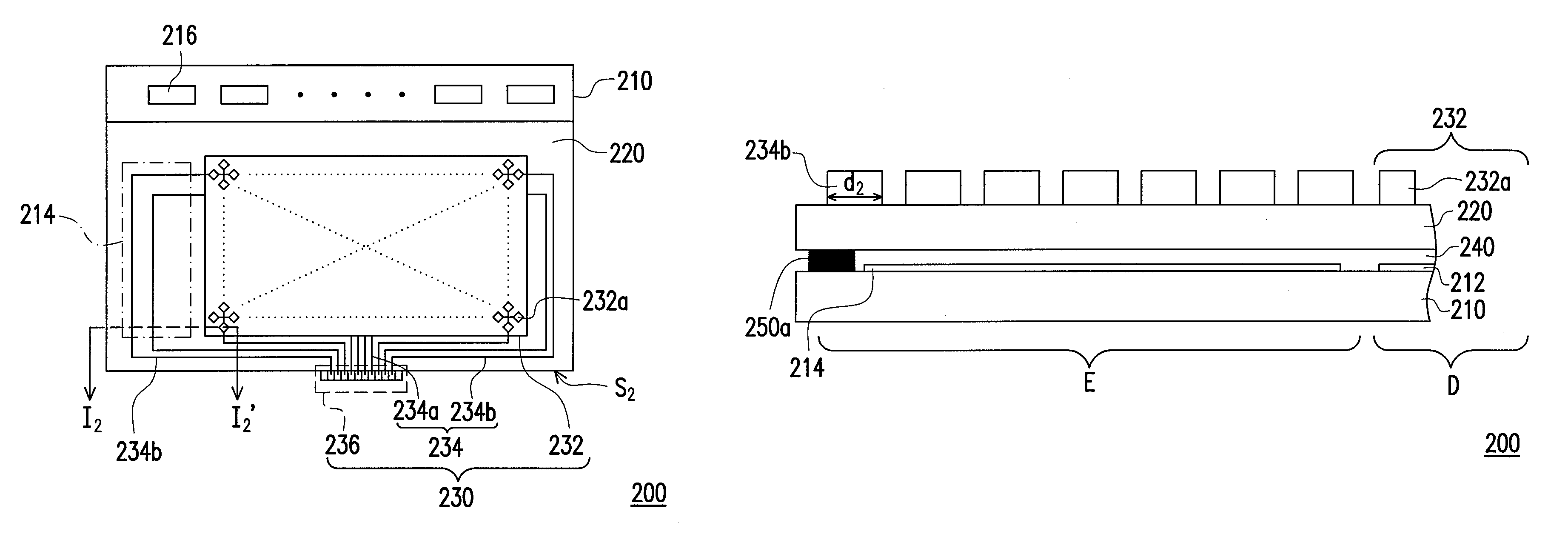

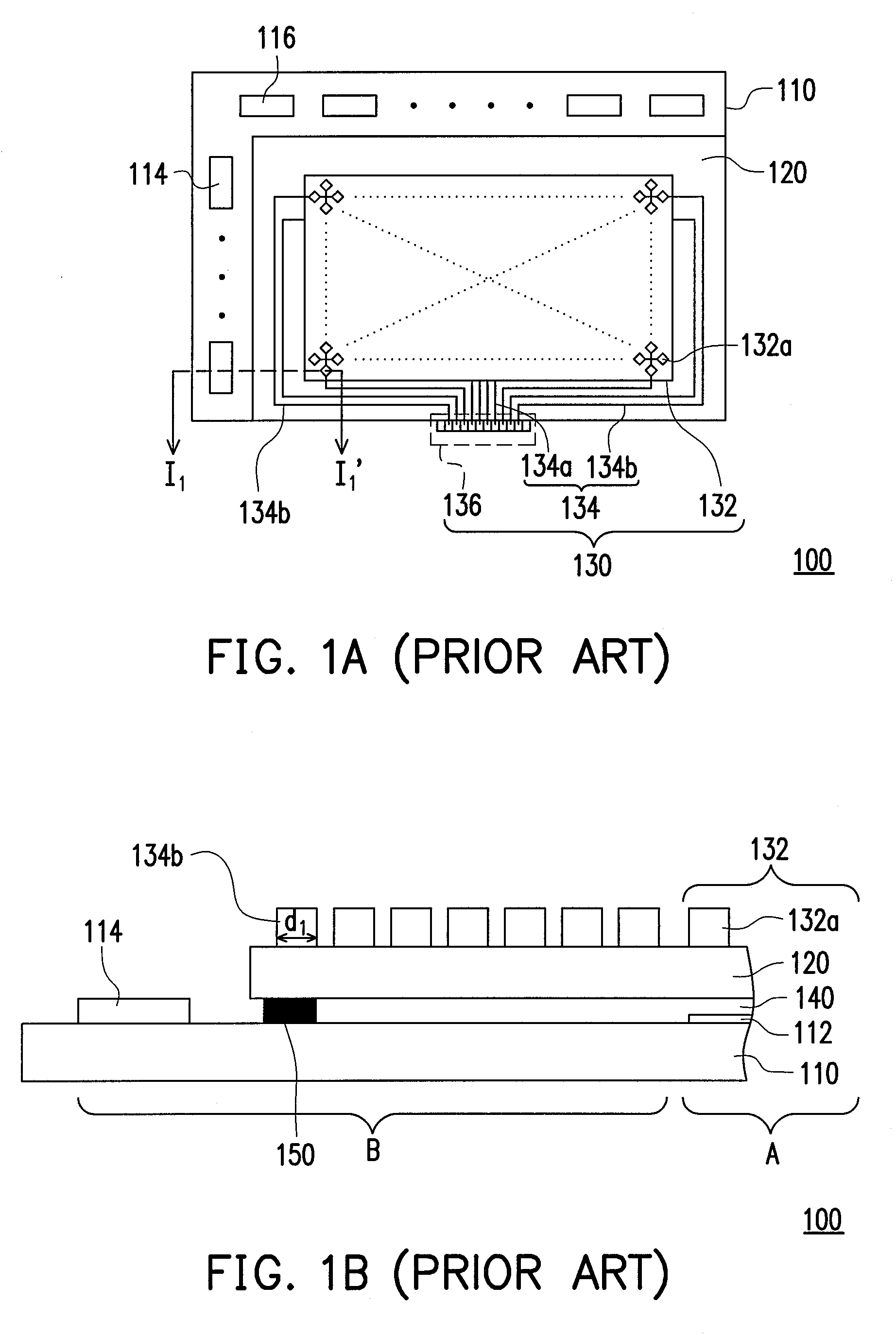

Touch panel display

ActiveUS8421760B2Increase layout spaceReduce widthCathode-ray tube indicatorsInput/output processes for data processingEngineeringTouch panel

Owner:AU OPTRONICS CORP

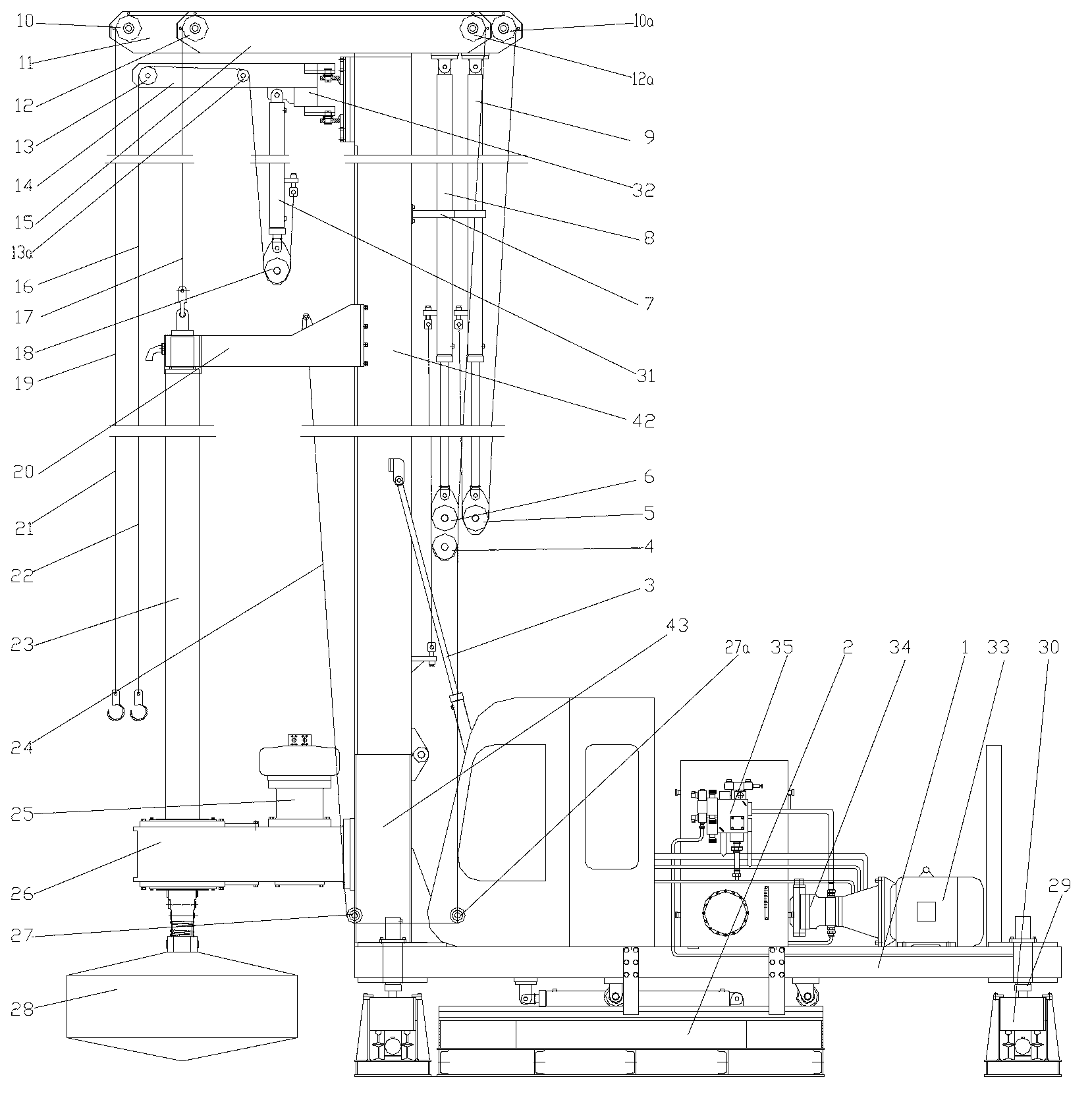

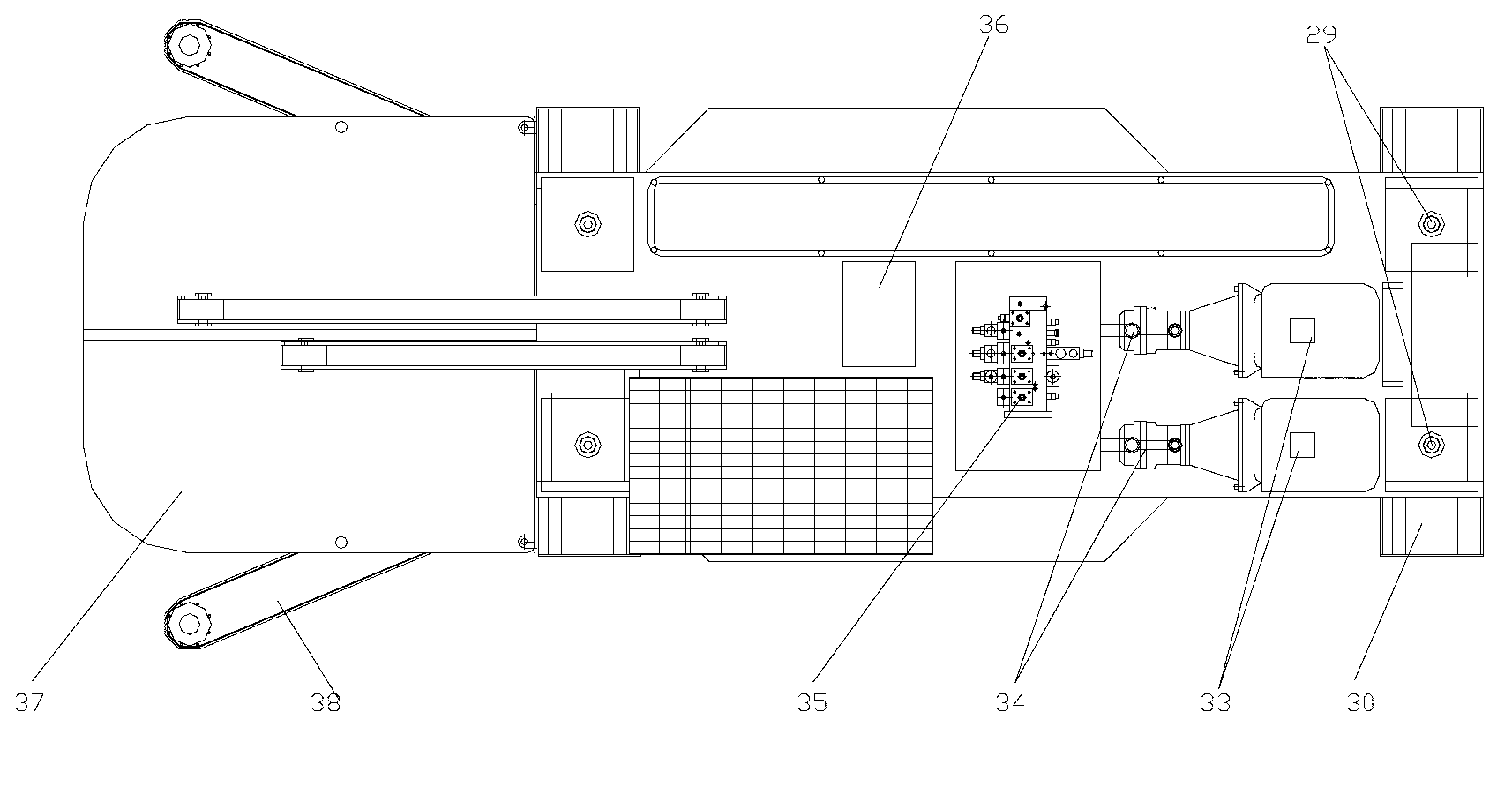

Hydraulic engineering driller

InactiveCN103225479AFlexible layoutOptimize equipment layout spaceConstructionsRotary drillingDrill bitPower transmission

The invention discloses a hydraulic engineering driller which adopts a drilling hydraulic cylinder and a hydraulic motor driven drilling bit component for drilling; a drilling stroke is controlled by the drilling hydraulic cylinder through a pulley block; the drilling hydraulic cylinder is laid out relatively flexibly; the equipment layout space is optimized; the drilling component has a greater ascent and descent space fundamentally; the drilling stroke is prolonged; the drilling movement frequency is reduced, so that the drilling construction efficiency is improved; in addition, due to the optimization, the equipment layout space can be made full use of, so that the driller is compact in structure; with the adoption of a hydraulic driving structure and electrohydraulic control, a stepless speed regulation function is realized, and the driller can meet the drilling requirements of different stratums; a power head is driven by a hydraulic motor and can be combined with mechanical speed reduction, the power transmission reliability is improved further, and the adjustable scope of torque variation is wider; and when the equipment is in use, the labor intensity is reduced, the use cost and labor cost are saved, and the driller can be used for engineering pile hole construction and meets the technological requirements.

Owner:CHONGQING HAIBEN HYDRAULIC MACHINERY MFG

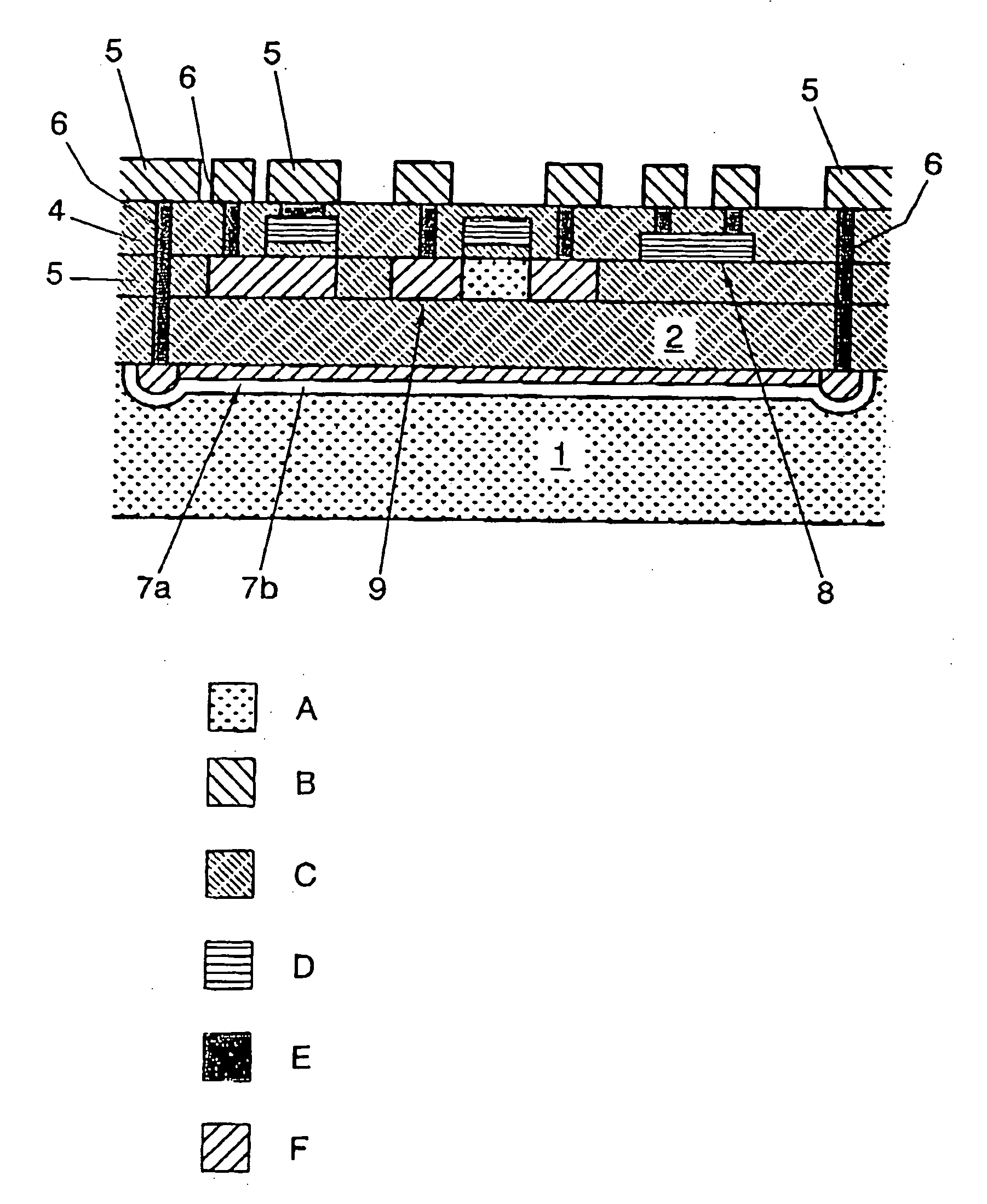

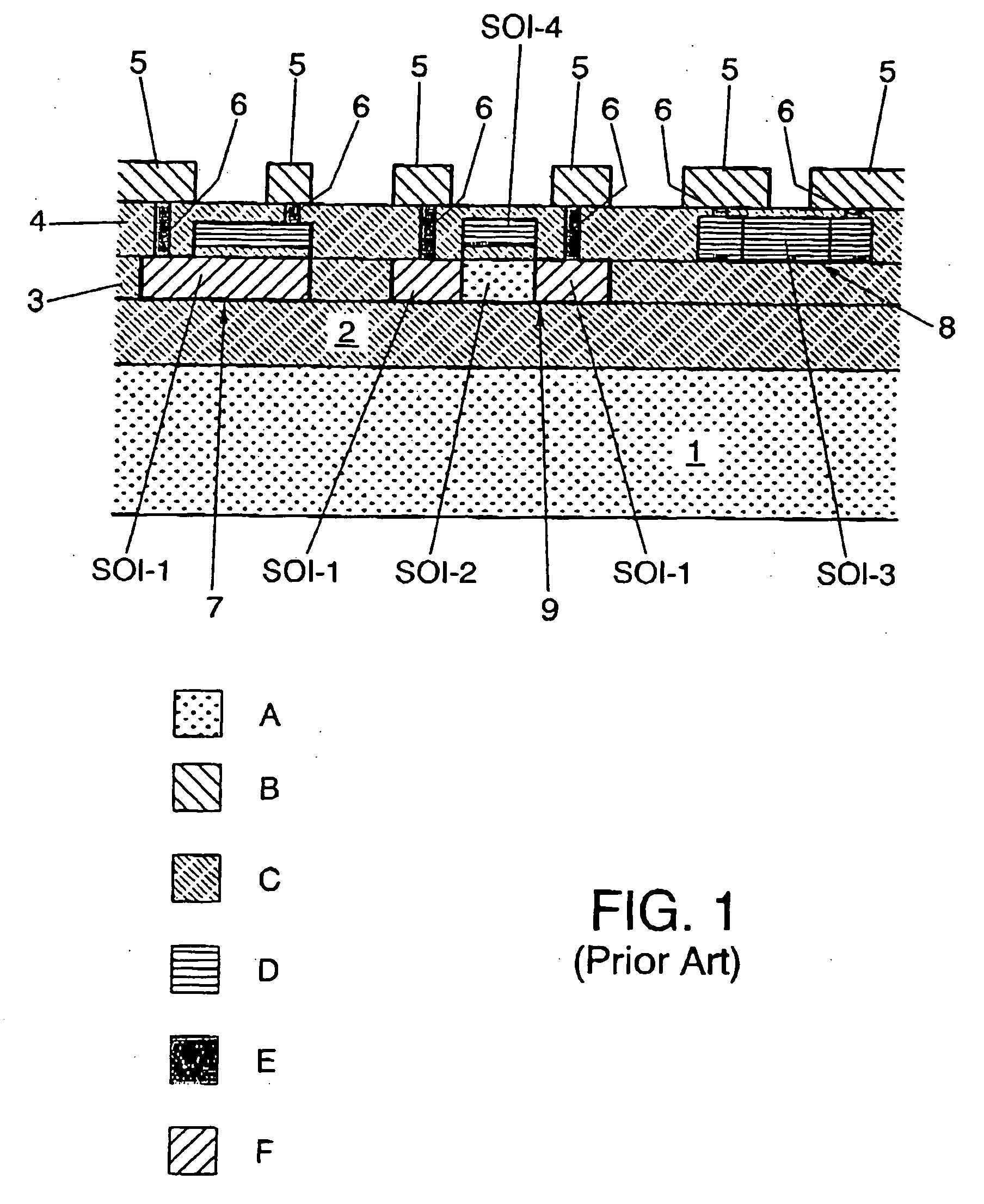

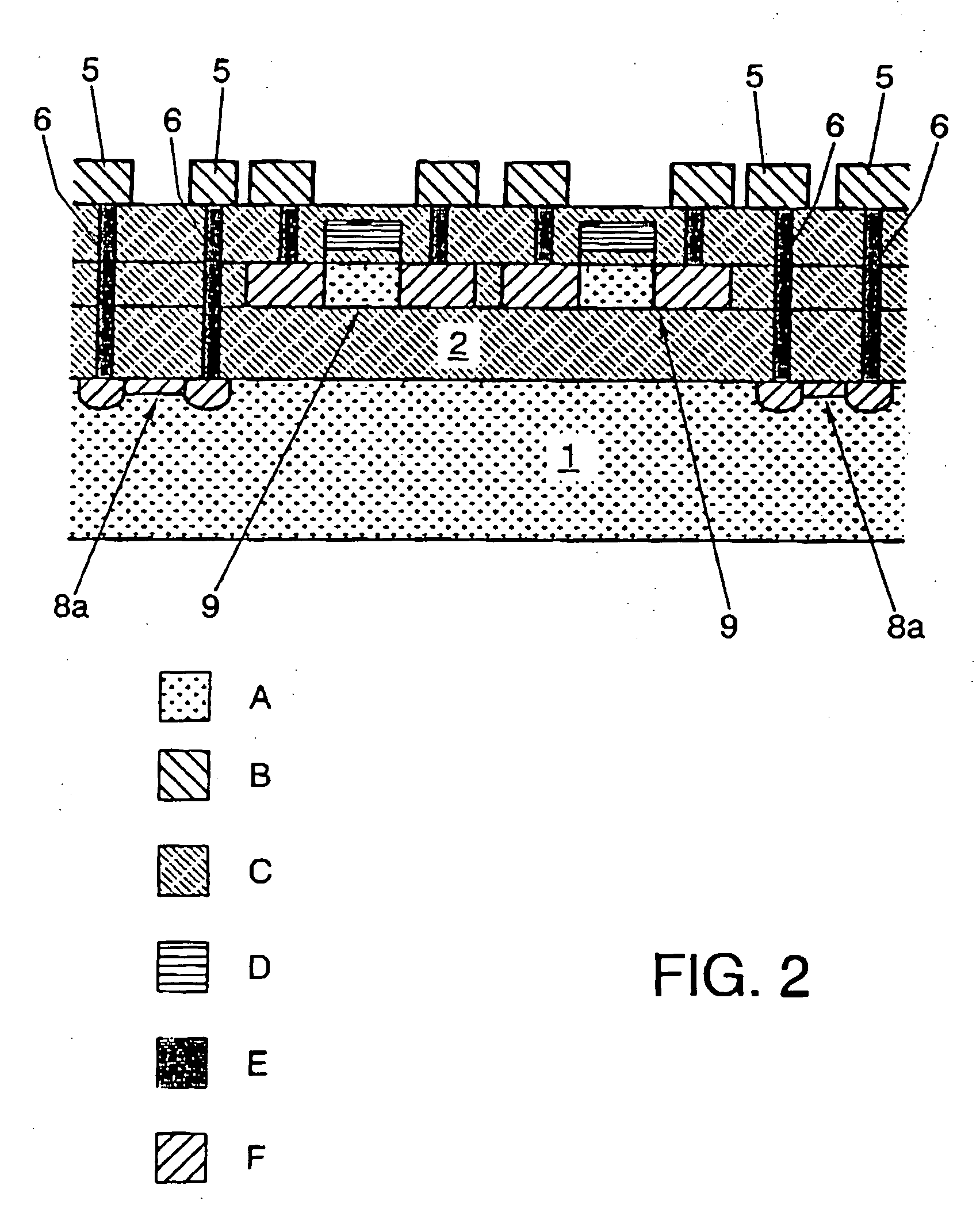

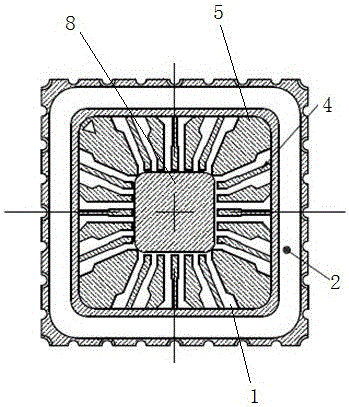

Semiconductor device comprising an integrated circuit

InactiveUS20060273395A1Increase in sizeImprove layout efficiencySolid-state devicesSemiconductor/solid-state device manufacturingBuried oxideIntegrated circuit

A semiconductor device with a plurality of passive components (7,7a,8,8a) comprising a bottom substrate (1), a buried oxide layer (2) on a portion of the top surface of the bottom substrate (1), an dielectric intermediate insulating layer (3) on a portion of the buried oxide layer (2), a dielectric top insulating layer (4), and at least one implanted passive component (7a,8a) of a semiconductor material implanted under the buried oxide layer (2) within the top surface portion of the bottom substrate (1), the implanted semiconductor material having a material polarity being opposite to the bottom substrate polarity. When the implanted passive component (7a) is an AC decoupling capacitor (7a), the bottom and side portions of the implanted semiconductor material are surrounded by a depletion layer (7b) of a semiconductor material implanted between said bottom substrate (1) and said implanted semiconductor material.

Owner:SEIKO EPSON CORP

High-frequency and high-speed ceramic leadless shell for parallel seam welding

ActiveCN105977215AIncrease layout spaceImprove flatnessSemiconductor/solid-state device detailsSolid-state devicesMetallurgyRadio frequency signal

The invention discloses a high-frequency and high-speed ceramic leadless shell for parallel seam welding, and relates to the technical field of semiconductor packaging devices. The shell comprises a ceramic part, a sealing ring and a metal cover plate, wherein a back grounding metal pattern is arranged on the back of the ceramic part, a plurality of grounding terminals protruding outwards are arranged on the back grounding metal pattern, radio-frequency signal transmission pads are arranged between the grounding terminals, a front grounding metal pattern is connected with the back grounding metal pattern via an internal or external metallic interconnection hole, a front grounding wire is connected with the back grounding metal pattern via an internal or external metallic interconnection hole, and radio-frequency signal transmission wires are connected with the radio-frequency signal transmission pads via separate external or external and internal combined metallic interconnection holes. The shell is low in echo loss and insertion loss and good in flatness in band, does not have resonance points, can realize a parallel seam welding sealing mode, reduces the difficulty and the cost of a sealing process, guarantees high reliability and high air tightness, and is favorable for batch application.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Engine camshaft

This invention relates to motor distribution structure and to provides one motor cam axle, which comprises axle part and the gas in cam axle and drainage cam axle fixed and is characterized by connecting gas in cam axle and drainage axle in same axle to move relatively. This invention can get best distribution phase angle under load of motor change to improve motor property and enlarge distribution space and to release motor weight and also it makes the motor power output smooth with less consumption power to release whole system quality to improve the motor total property.

Owner:CHERY AUTOMOBILE CO LTD

Backlight module, assembly method thereof and liquid crystal display using backlight module

InactiveCN101630091AIncrease layout spaceReduce difficultyLighting support devicesElectric circuit arrangementsLiquid-crystal displayLight guide

The invention discloses a backlight module, an assembly method thereof and a liquid crystal display using the backlight module. The backlight module at least comprises: a light guide panel; a shell which clamps the light guide panel and forms an accommodating space with the light guide panel; at least one light emitting diode light bar arranged in the accommodating space and provides at least onelight beam that enters the light guide panel. The light emitting diode light bar at least comprises a flexible circuit board and a plurality of light emitting diodes; and the flexible circuit board at least comprises a first part and at least two second parts, wherein the light emitting diodes are arranged on the first part of the flexible circuit board and the second parts are overlapped with each other. The difficulties in the assembly of the backlight module can be reduced.

Owner:INNOLUX CORP

Dual-fuel transport refueling method and transport refueling truck

InactiveCN102717744AAvoid explosionReal-time detection and display of liquid level heightTank vehiclesLarge containersFuel tankEngineering

The invention relates to a dual-fuel transport refueling method and a transport refueling truck. The dual-fuel transport refueling method comprises the following steps of: 1) preparing a fuel transport refueling truck, retrofitting a chassis of the fuel transport refueling truck by using an automotive chassis, and arranging a power takeoff, wherein the inside of an oil tank of the fuel transport refueling truck is divided into front and rear independent closed compartments through a partition plate, two kinds of oils are simultaneously filled in the two closed compartments, and a plurality of refueling guns are arranged at oil channel outlets of the two closed compartments; 2) determining oil of a vehicle which is required to be refueled, and parking the vehicle which is required to be refueled within the working range of the refueling guns of the corresponding closed compartment; 3) taking out one refueling gun which corresponds to the oil, and inserting into an oil tank of the vehicle which is required to be refueled; 4) starting an engine, wherein the engine of the automotive chassis drives an oil pump to work through the power takeoff so as to fill fuel in the closed compartment into the oil tank of the vehicle which is required to be refueled by using the refueling gun; and 5) after the operation is finished, shutting down the engine, and placing the refueling gun at the original position. The transport refueling truck can simultaneously fill two different kinds of fuels, has high motility and safety, and can refuel fire fighting vehicles at any time.

Owner:XINXING HEAVY IND HUBEI 3611 MECHANICAL

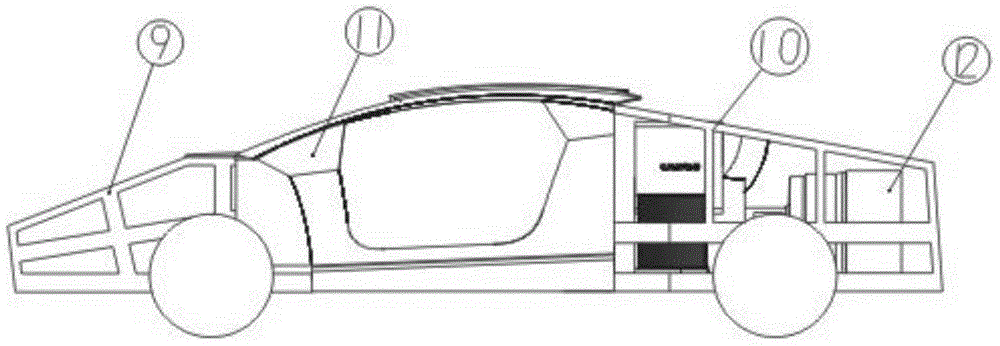

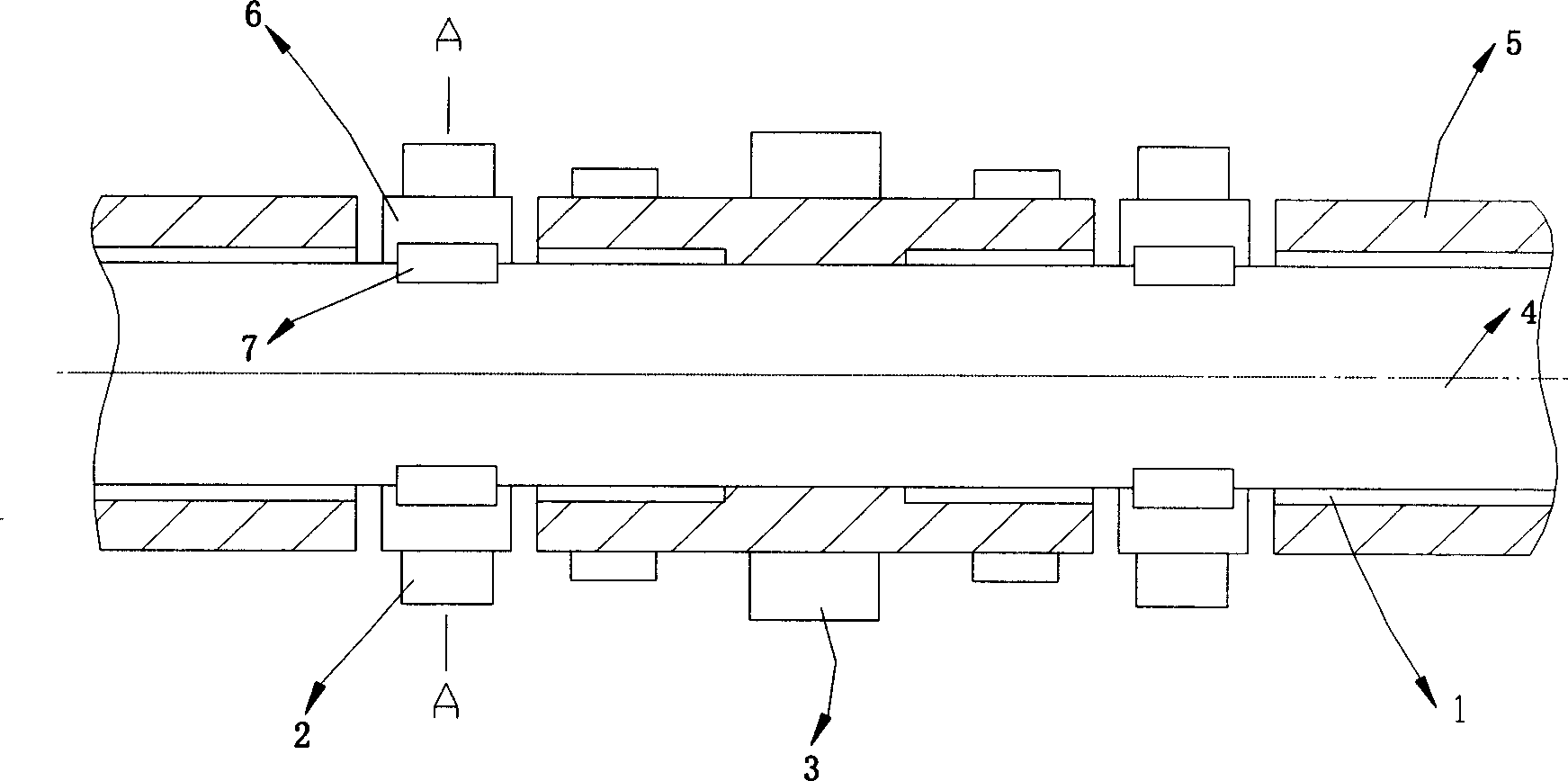

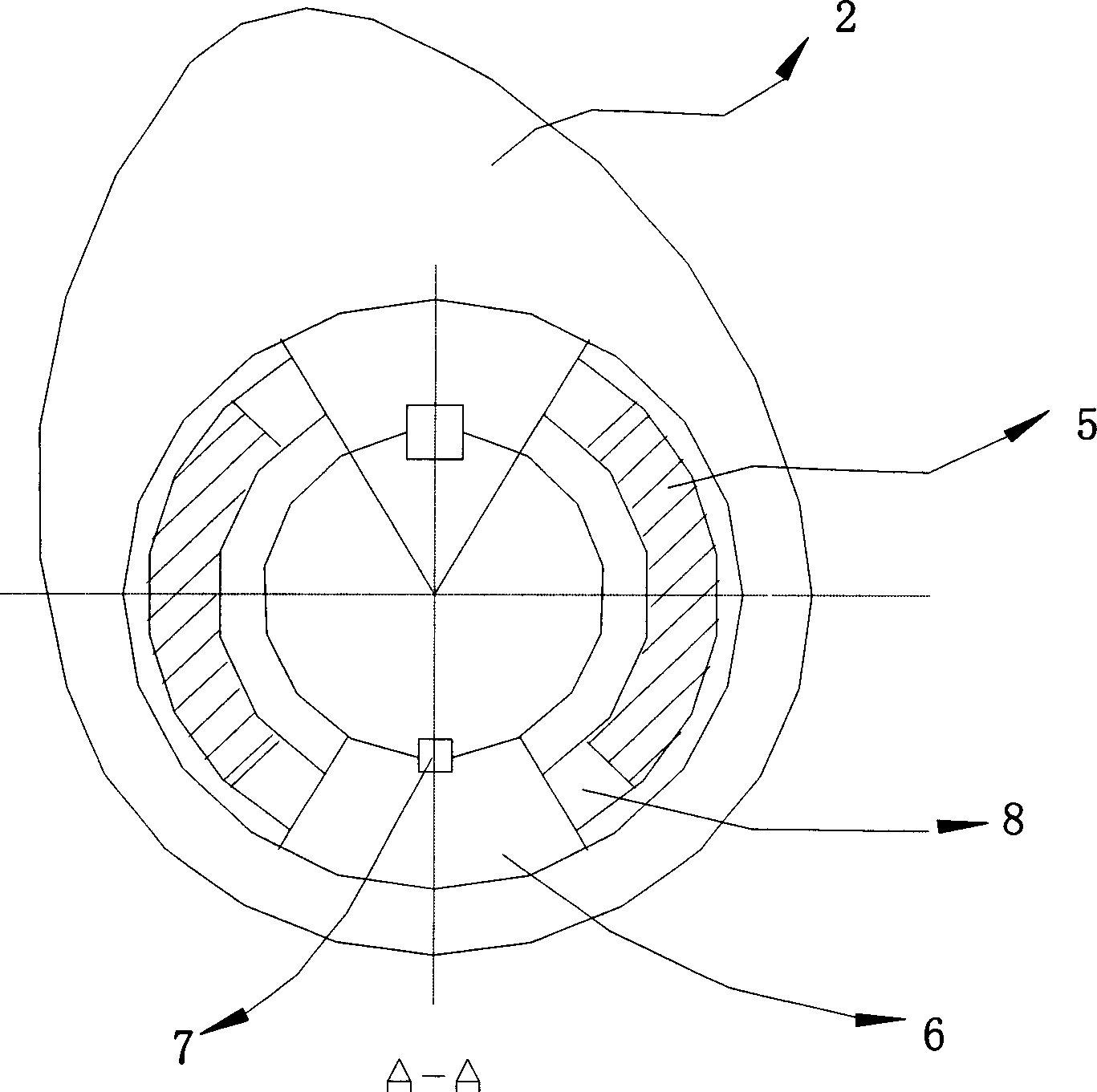

Extend range type electric passenger vehicle with engine arranged at front position

ActiveCN105774512AImprove power densitySmooth runningHybrid vehiclesGas turbine plantsVehicle frameDrive motor

The invention provides an extend range type electric passenger vehicle with an engine arranged at the front position. The extend range type electric passenger vehicle comprises the turbine shaft engine (2), a battery pack (3), an electric generator (4), a drive motor (6), a storage tank (9) and a split type heat regenerator (12). The extend range type electric passenger vehicle is characterized in that the turbine shaft engine (2) is arranged and installed on an automobile frame above a front axle; the axis of an output shaft of the turbine shaft engine (2) is located on a symmetry plane of an automobile body; the split type heat regenerator (12) is located below the turbine shaft engine (2); and exhaust gas exhausted out of the turbine shaft engine (2) is adopted by the split type heat regenerator (12) for preheating inflow gas of the turbine shaft engine (2). By the adoption of the extend range type electric passenger vehicle, a gas turbine is adopted as a power source and arranged at the position on the symmetry center line above the automobile front axle, an output shaft of the gas turbine is longitudinally arranged, and the extend range type electric passenger vehicle has the beneficial effects that the energy conversion efficiency is high, a front wheel, a rear wheel, a left wheel and a right wheel bear weight in a balanced manner, the operation performance is good, and the running mileage is large.

Owner:刘慕华

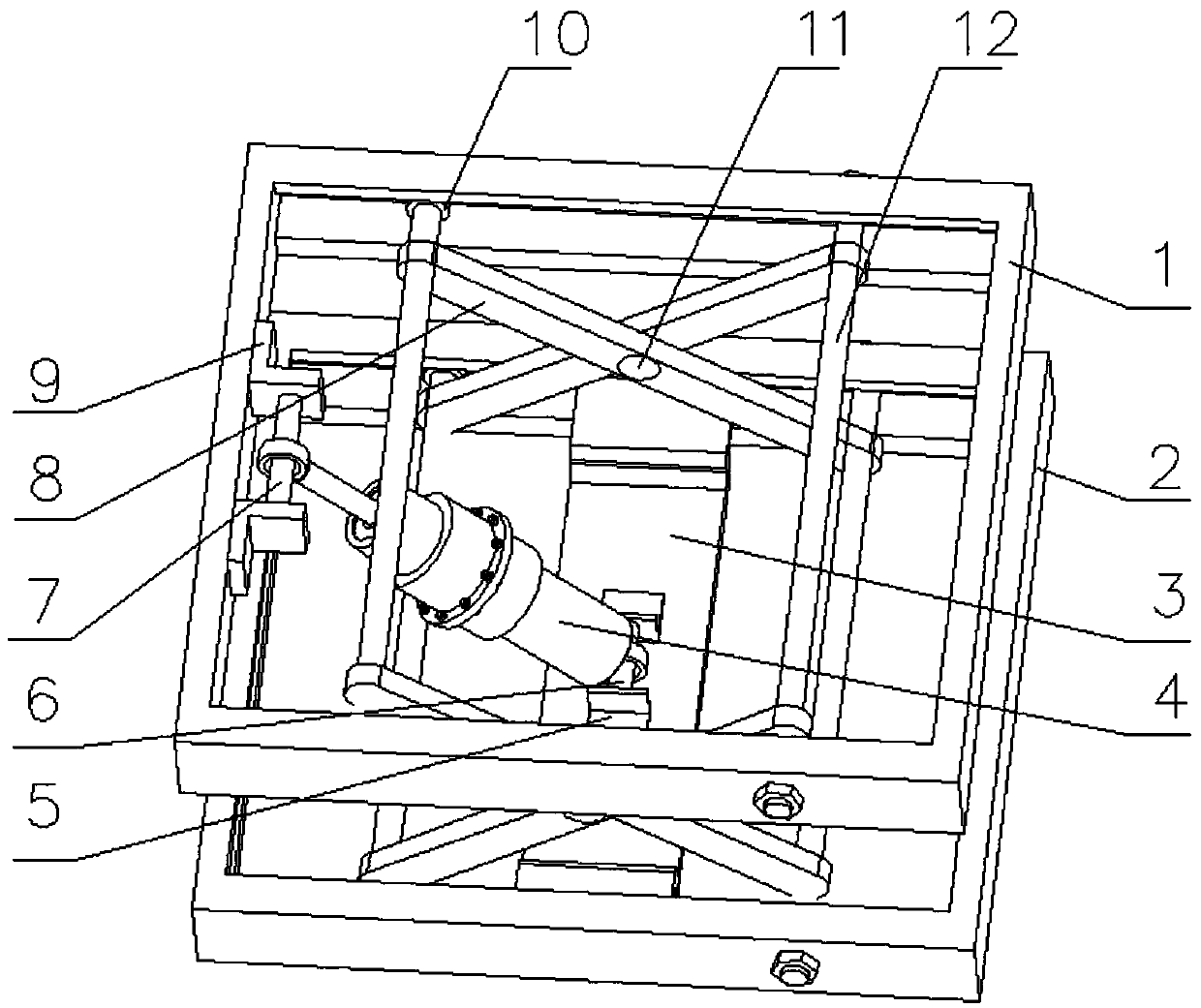

Low-frequency three-dimensional vibration-isolating mining dump vehicle seat based on magnetic negative-stiffness spring design

InactiveCN105546026ATo achieve the effect of vibration isolation in the horizontal directionIncrease the isolation dimensionNon-rotating vibration suppressionVertical vibrationFixed frame

The invention discloses a low-frequency three-dimensional vibration-isolating vehicle seat based on a magnetic negative-stiffness spring design, and aims to solve the problem that a common car seat cannot isolate low-frequency vibrations in a horizontal direction. The low-frequency three-dimensional vibration-isolating vehicle seat comprises a vertical vibration-isolating part and a horizontal vibration-isolating part, wherein the vertical vibration-isolating part comprises a shear type suspension and a zero-stiffness magnetic damper; the shear type suspension comprises a hinged type link mechanism which is connected between a shear type suspension upper part and a shear type suspension lower part; the two ends of the zero-stiffness magnetic damper are separately positioned on the shear type suspension upper part and the shear type suspension lower part; the horizontal vibration-isolating part comprises an upper plate, a rubber damping spring seat, a primary magnet set, an outer magnet set and a seat fixing frame; when the seat bears the vibrations in the horizontal direction, a seat plate connecting plate horizontally vibrates, so that a rubber damping spring horizontally vibrates while a magnet on a bottom plate vibrates relatively; by virtue of the acting force of the rubber spring and a magnetic negative-stiffness spring to the upper plate, the upper plate is kept to have relatively small vibration displacement, and therefore, vibrations in the horizontal direction are isolated.

Owner:JILIN UNIV

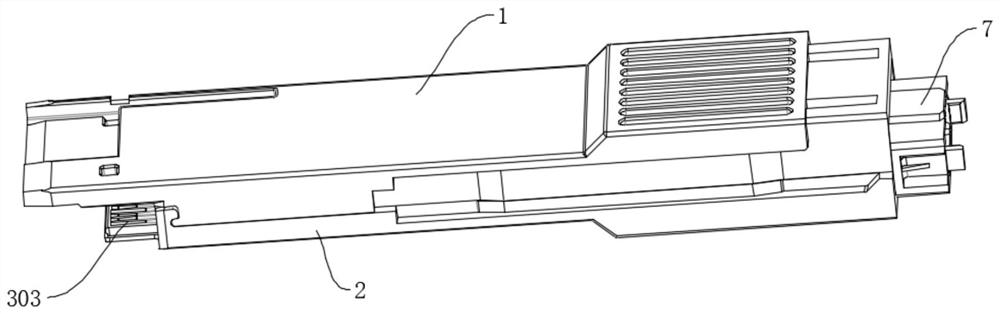

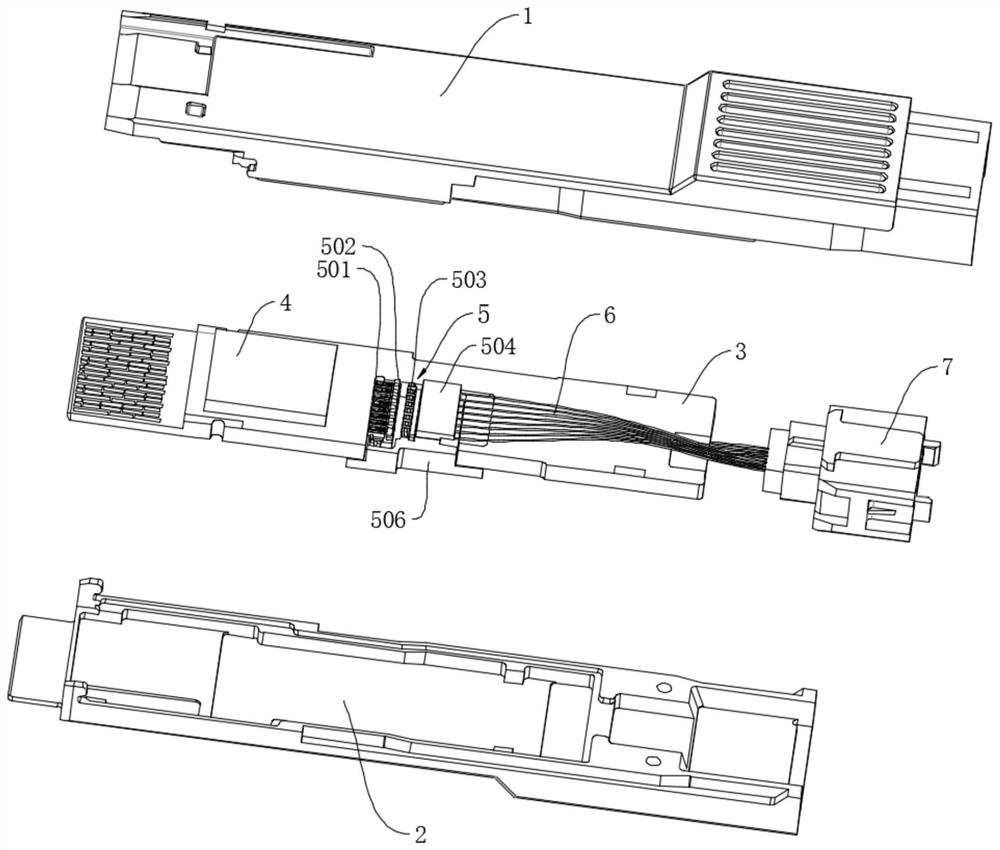

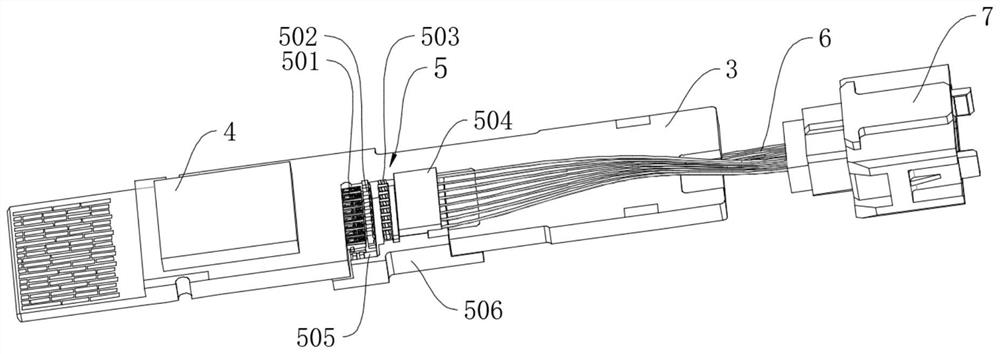

800G optical module

PendingCN112711108AHigh strengthIncrease wiring spaceCoupling light guidesOptical ModuleHemt circuits

The invention provides an 800G optical module, which is simple and reliable in structure, increases the layout space, avoids the over-compact arrangement of optical chips or circuits and greatly reduces the crosstalk between signals. The optical module comprises a main heat dissipation shell and an auxiliary heat dissipation shell which can be spliced into a whole, wherein an accommodating cavity is formed between the main heat dissipation shell and the auxiliary heat dissipation shell. An accommodating cavity is formed in the main heat dissipation shell, a PCB is arranged in the accommodating cavity, a control chip is arranged on the PCB, and the LED lamp is characterized in that the PCB comprises an electric port part and a thickening part, the electric port is formed in the electric port part, a transmitting end is arranged on one side, close to the main heat dissipation shell, of the thickening part of the PCB, and the transmitting end is connected to an optical port after being connected with an optical fiber. A receiving end is arranged on one side, close to the auxiliary heat dissipation shell, of the thickened part of the PCB, and the receiving end is connected to the optical port after being connected with an optical fiber.

Owner:HENGTONG ROCKLEY TECHNOLOGY CO LTD

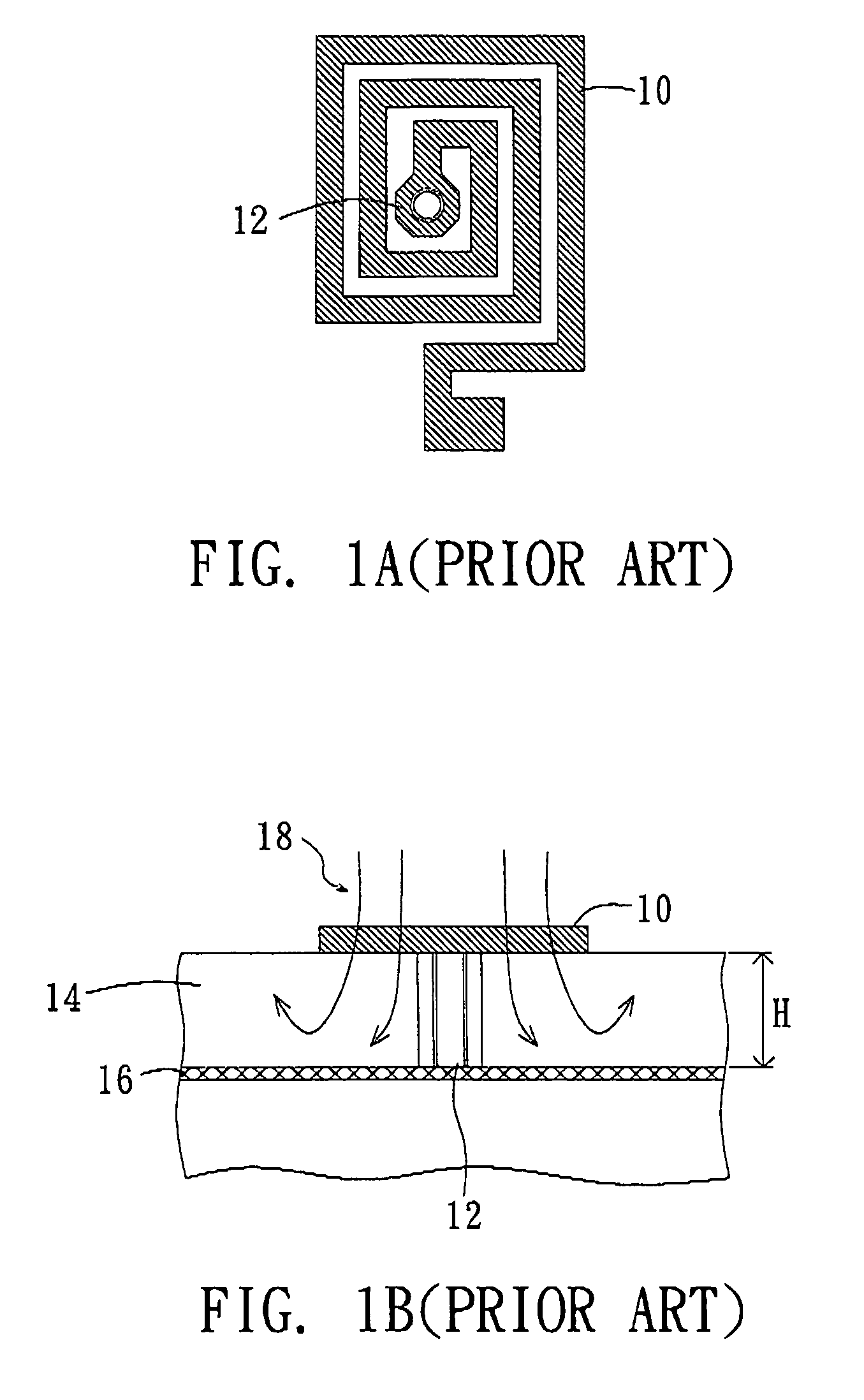

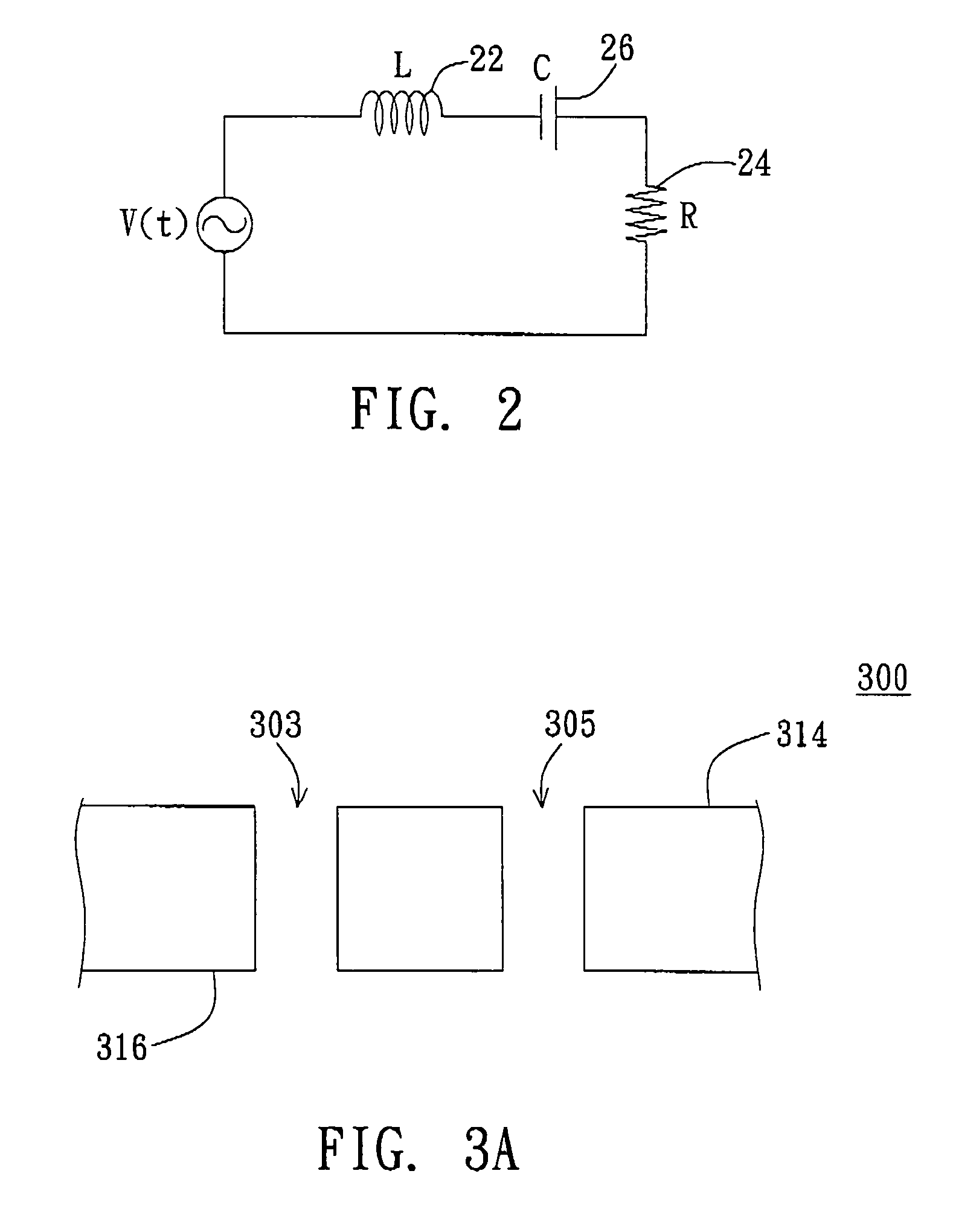

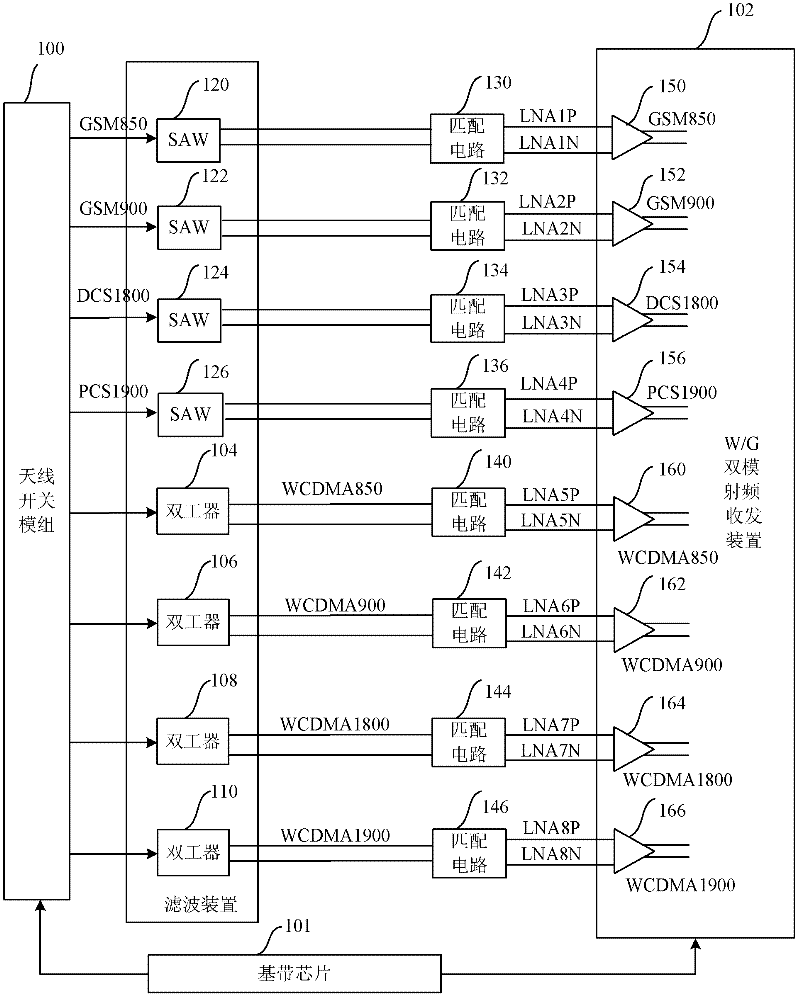

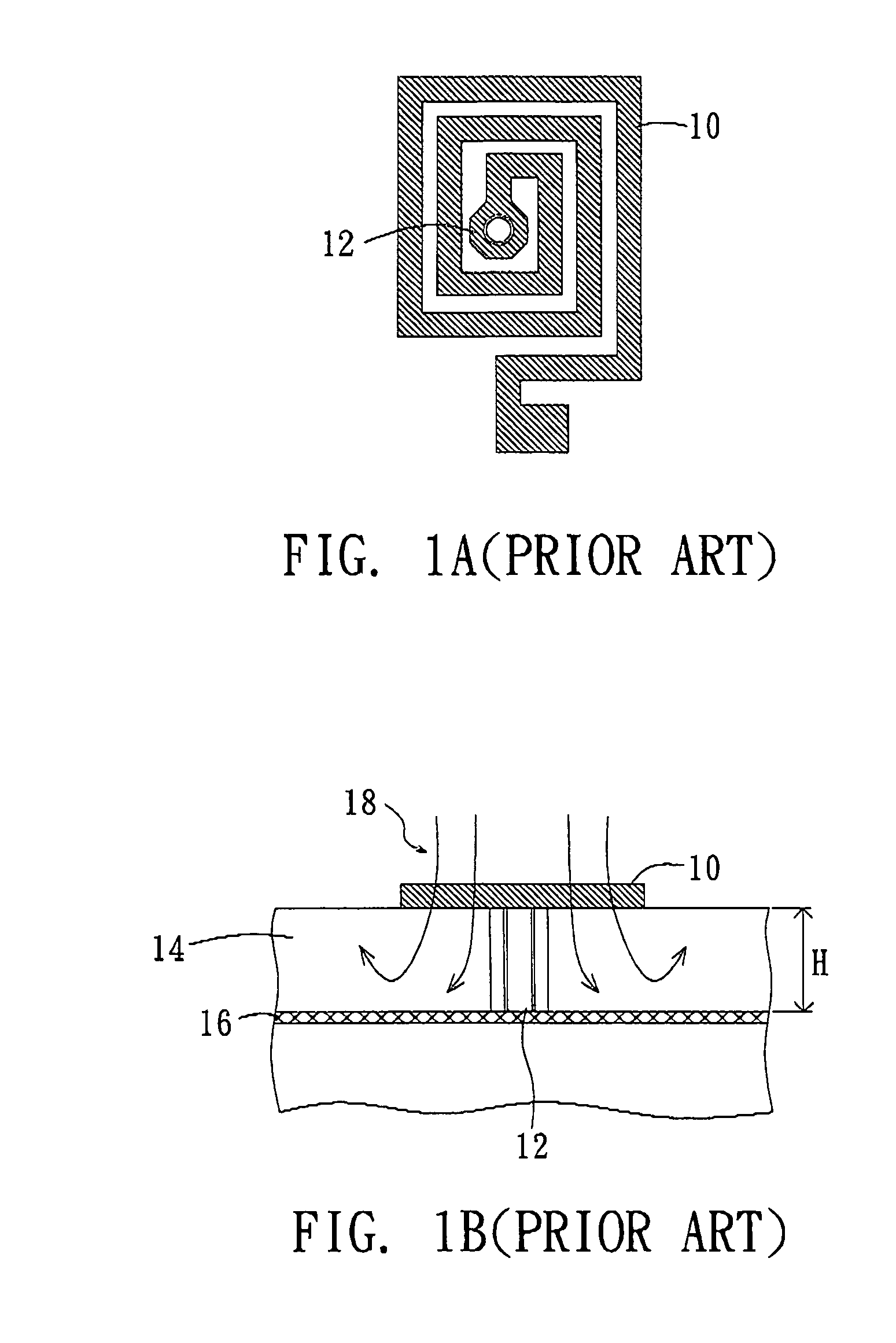

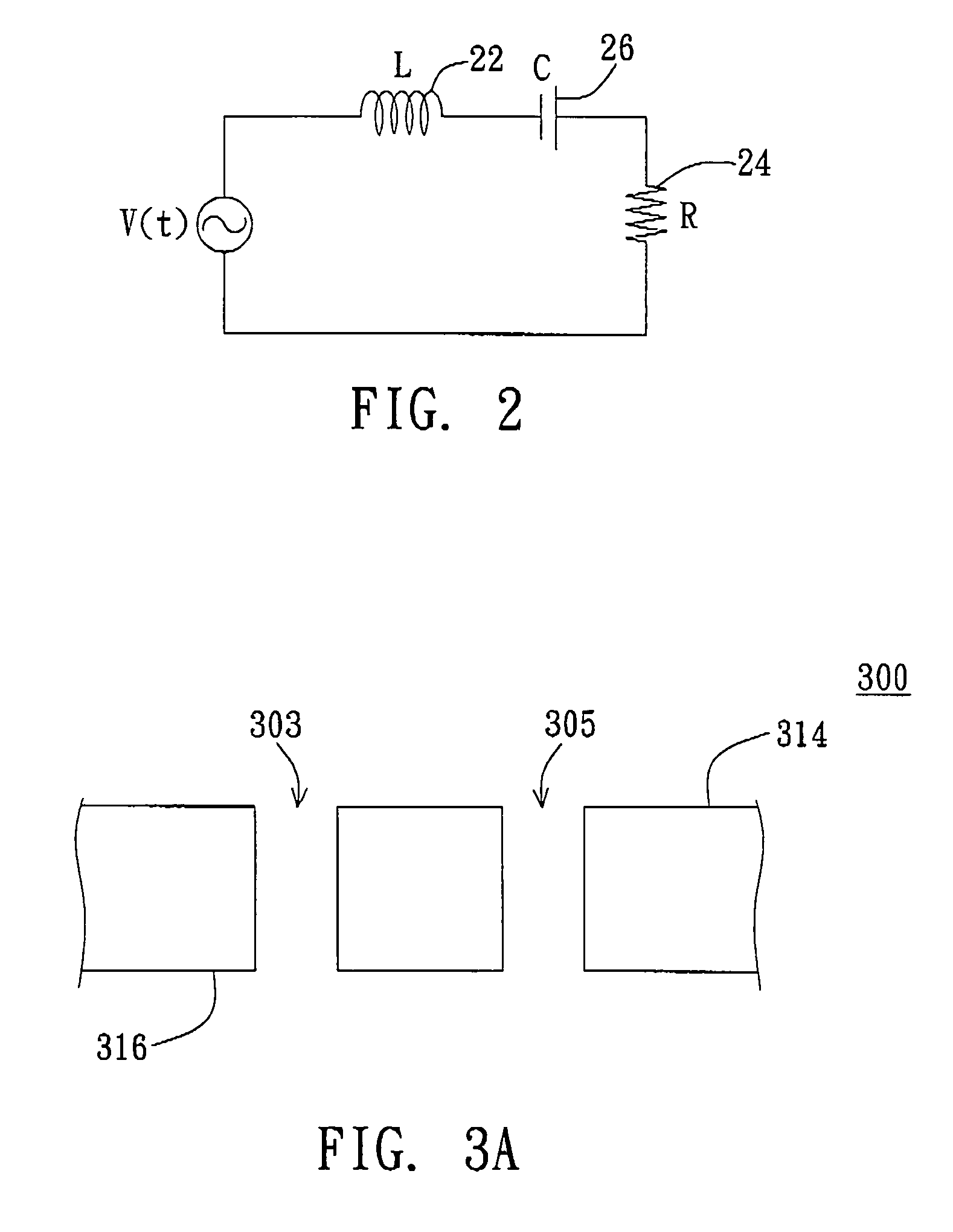

Circuit substrate

ActiveUS7145428B2Increase layout spaceLarge inductance valueSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsEngineeringInductor

A circuit substrate includes an inductor element and a reference plane. The inductor element includes a first conductive column, a second conductive column, a first trace, and a second trace. The first and second conductive columns penetrate the circuit substrate from a first surface to a corresponding second surface. The first conductive includes a left conductive column and a right conductive column. The second conductive column is adjacent to one side of the first conductive column. The first trace electrically connects a first lower portion of the left conductive column and a second lower portion of the second conductive column. The second trace electrically connects a first upper portion of the right conductive column and a second upper portion of the second conductive column. The reference plane is disposed on the second surface. Accordingly, the magnetic line of force produced by the inductor element is parallel to the reference plane.

Owner:ADVANCED SEMICON ENG INC

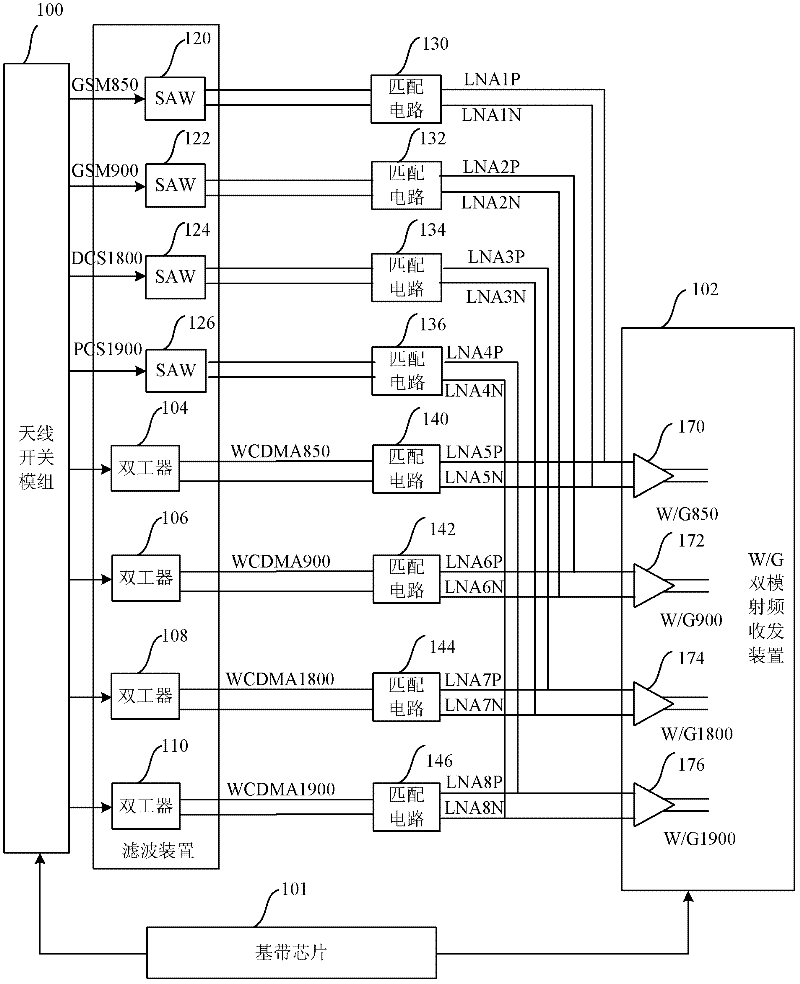

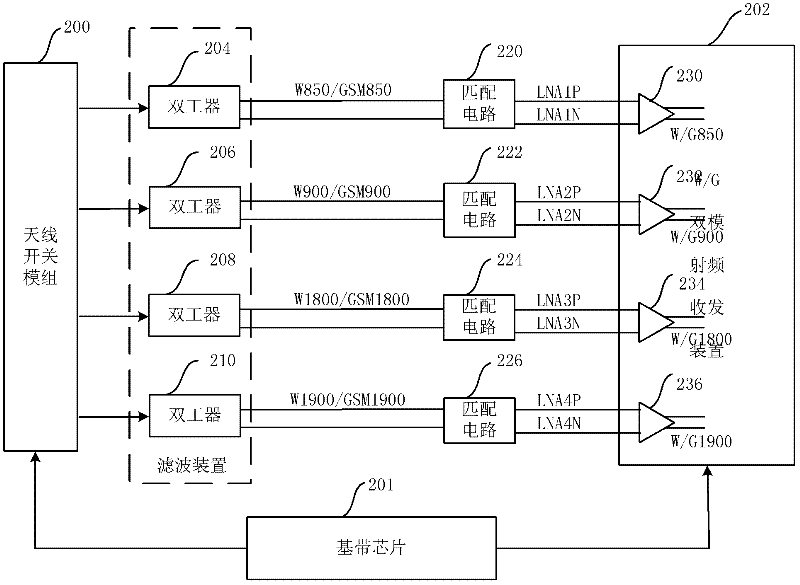

Dual-mode radio frequency transceiver, filtering device and dual-mode terminal

InactiveCN102404881AReduce in quantityHighly integratedTransmissionWireless communicationTransceiverDual mode

The invention provides a dual-mode radio frequency transceiver, a filtering device and a dual-mode terminal. A multi-mode radio frequency transceiver at least comprises an LNA (Low-Noise Amplifier), wherein the LNA is provided for the same frequency band of a first mode signal and a second mode signal, is used for receiving signals of corresponding frequency bands of the first mode signal and the second mode signal in a time division multiplexing manner and outputting the received signal after amplification. As the LNA is a multiplexing LNA, the number of LNAs in the dual-mode radio frequency transceiver is reduced, so that the dual-mode radio frequency transceiver can be integrated to a larger extent, and layout space is increased; and therefore, a multi-mode terminal including the dual-mode radio frequency transceiver has higher integration, and the miniaturization of the terminal is more beneficial to being realized.

Owner:ZTE CORP

Circuit substrate

ActiveUS20050152184A1Increase layout spaceLarge inductance valueSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsEngineeringInductor

A circuit substrate includes an inductor element and a reference plane. The inductor element includes a first conductive column, a second conductive column, a first trace, and a second trace. The first and second conductive columns penetrate the circuit substrate from a first surface to a corresponding second surface. The first conductive includes a left conductive column and a right conductive column. The second conductive column is adjacent to one side of the first conductive column. The first trace electrically connects a first lower portion of the left conductive column and a second lower portion of the second conductive column. The second trace electrically connects a first upper portion of the right conductive column and a second upper portion of the second conductive column. The reference plane is disposed on the second surface. Accordingly, the magnetic line of force produced by the inductor element is parallel to the reference plane.

Owner:ADVANCED SEMICON ENG INC

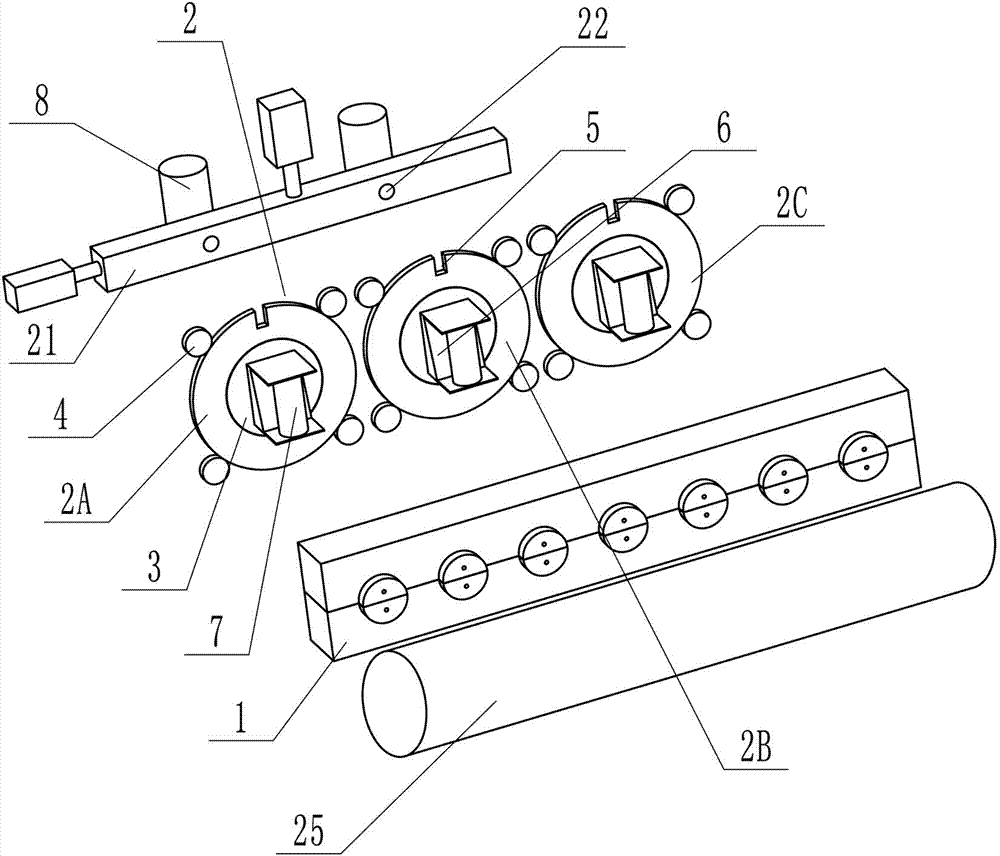

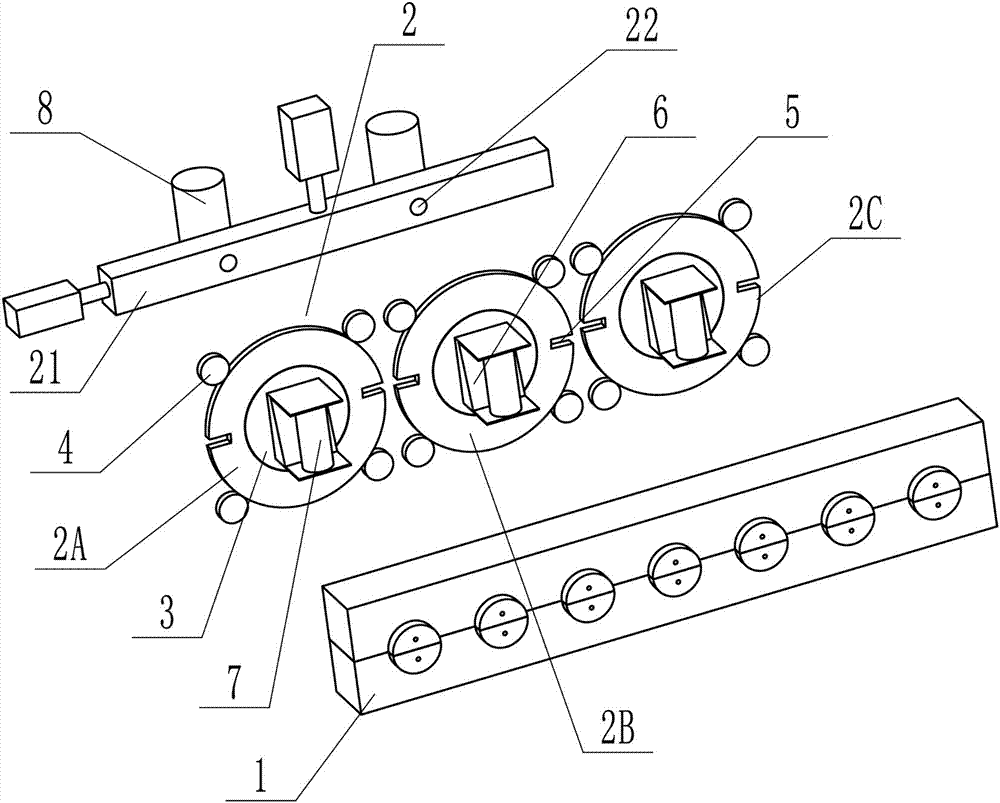

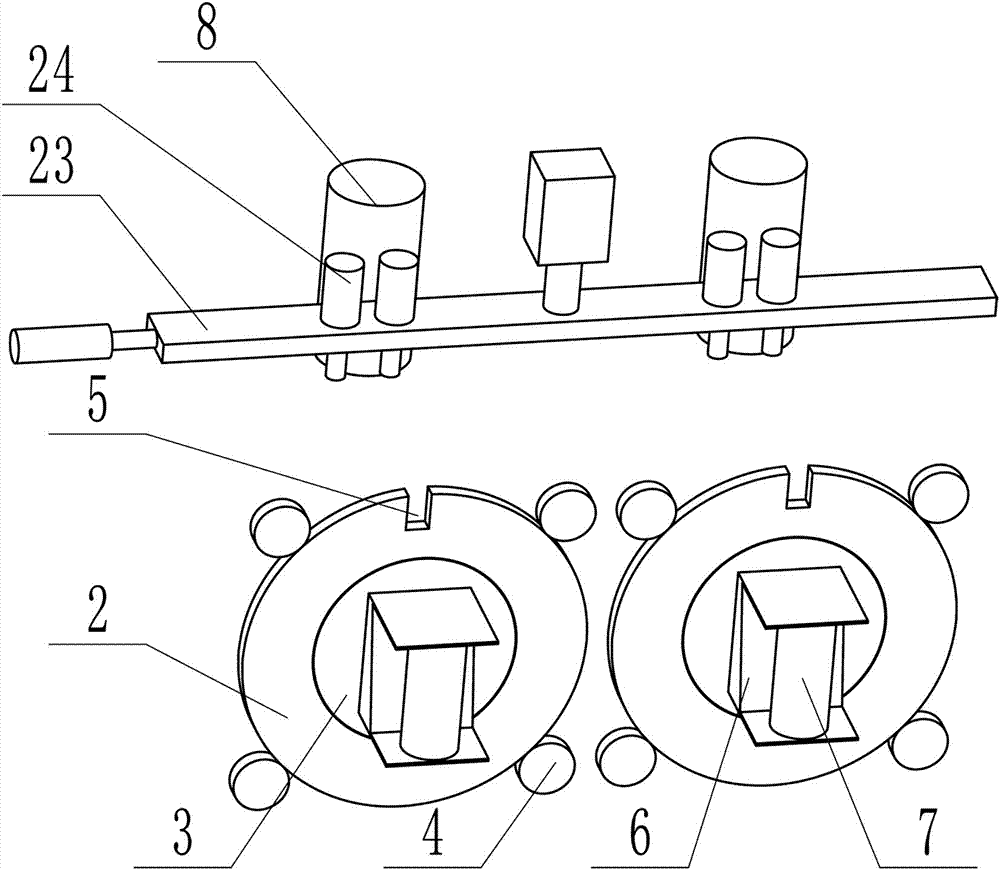

Mesh weaving structure of hexagonal wire mesh weaving machine

InactiveCN107138656APrevent falling outSmall structureWire networkBraidEngineeringMechanical engineering

The invention relates to a mesh weaving structure of a hexagonal wire mesh weaving machine. The mesh weaving structure comprises a wire twisting device, first wire feeding devices, rotating devices, a wire poking device and second wire feeding devices; the first wire feeding devices are arranged behind the wire twisting device and used for feeding wires to the wire twisting device, the rotating devices are arranged between the first wire feeding devices and the wire twisting device and used for enabling the mesh wires to rotate, the wire poking device is arranged between the rotating devices and the first wire feeding devices and used for poking the mesh wires from one gear disc to a gear disc located at the adjacent position of the gear disc, and the second wire feeding devices are used for feeding the wires to the wire twisting device. According to the mesh weaving structure of the hexagonal wire mesh weaving machine, the gear discs used for enabling the mesh wires to rotate are arranged behind the wire twisting device, therefore, the condition that the mesh wires located behind the wire twisting device are woven when weaving is conducted can be effectively prevented, it is guaranteed that the weaving work is smoothly conducted, a spring-shaped mesh wire structure is omitted, and the labor intensity of workers is greatly reduced; meanwhile, the using time of the first wire feeding devices is long, therefore, frequent replacement is not needed, and the working efficiency is improved.

Owner:定州市精锐机械科技有限公司

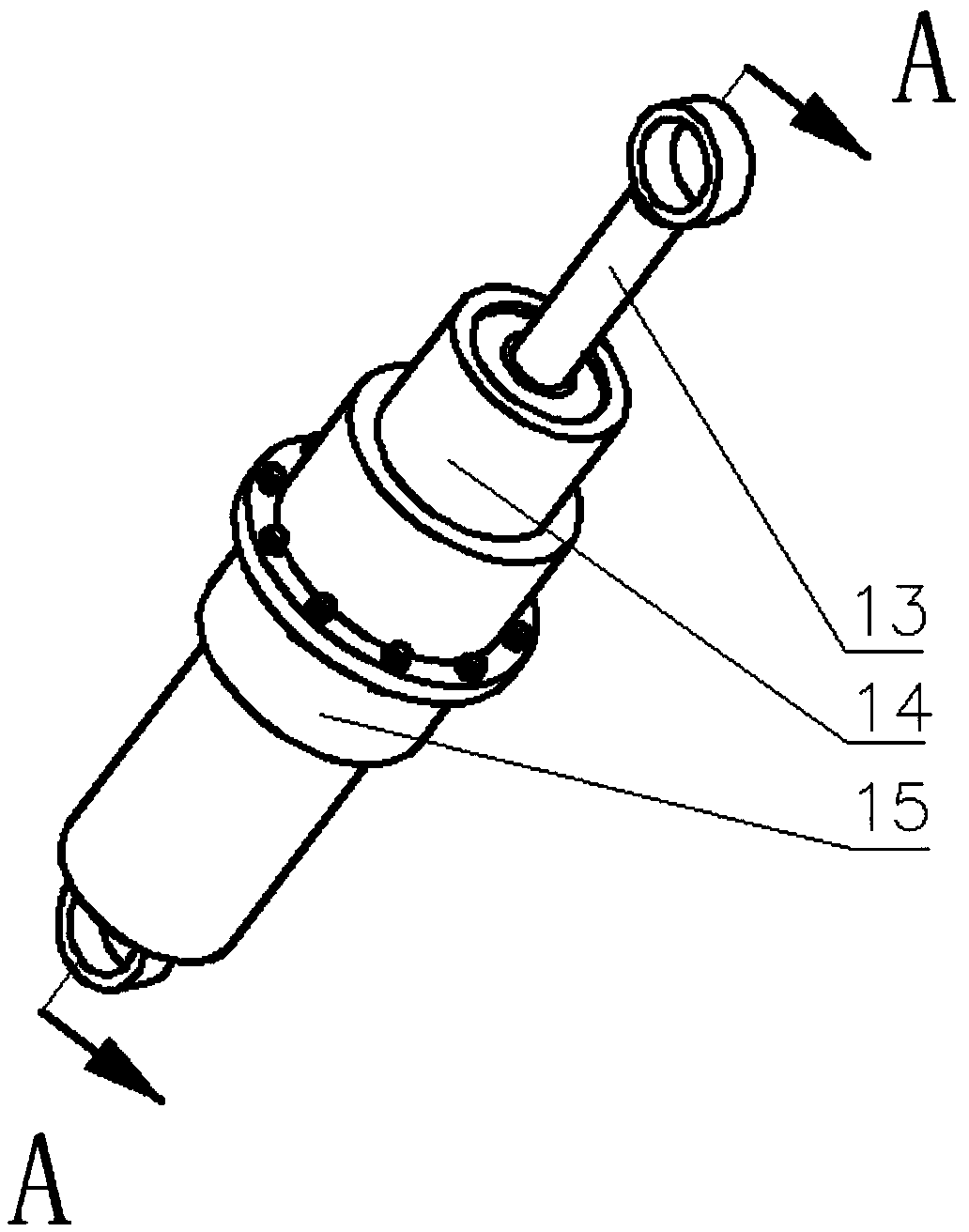

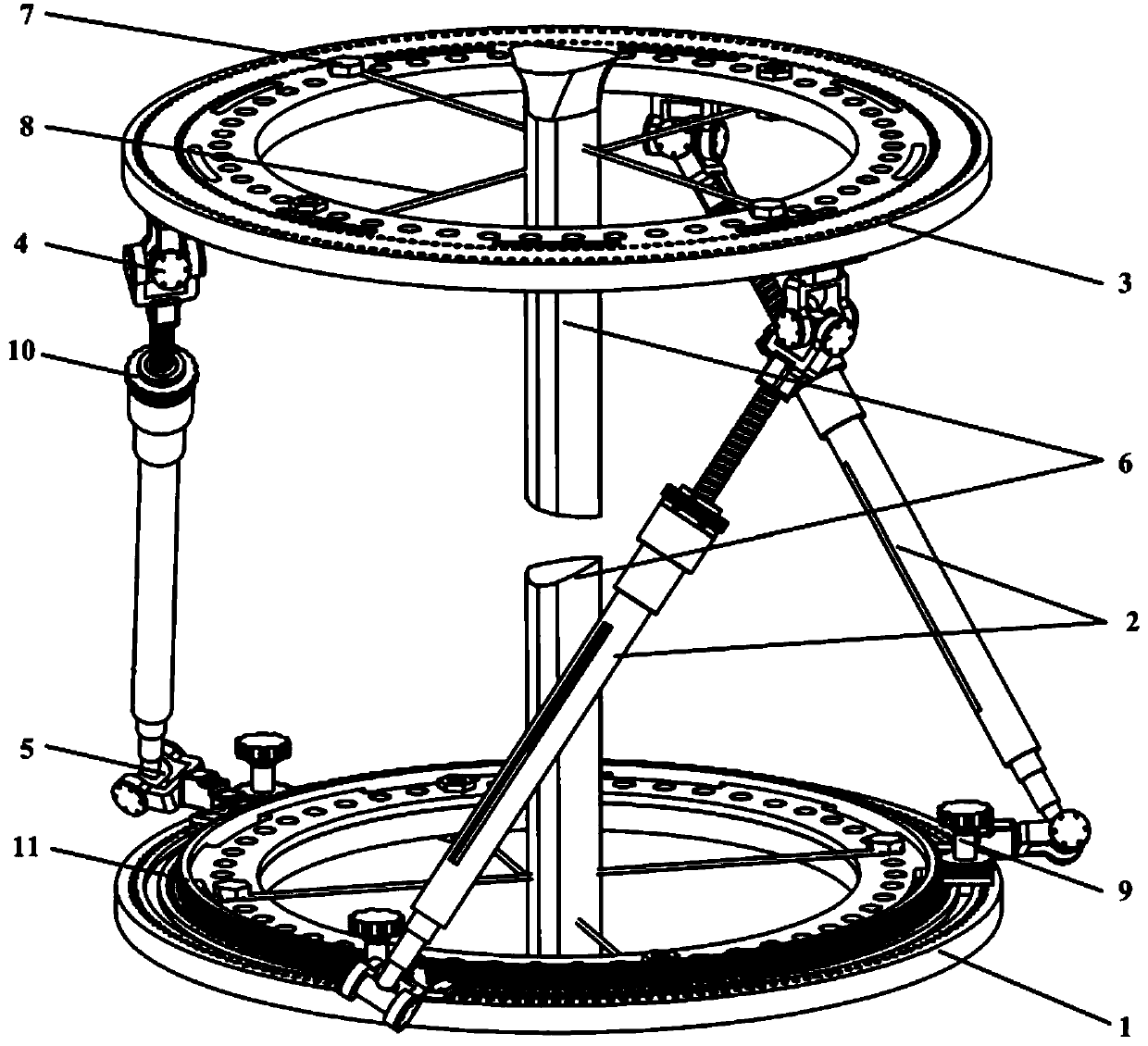

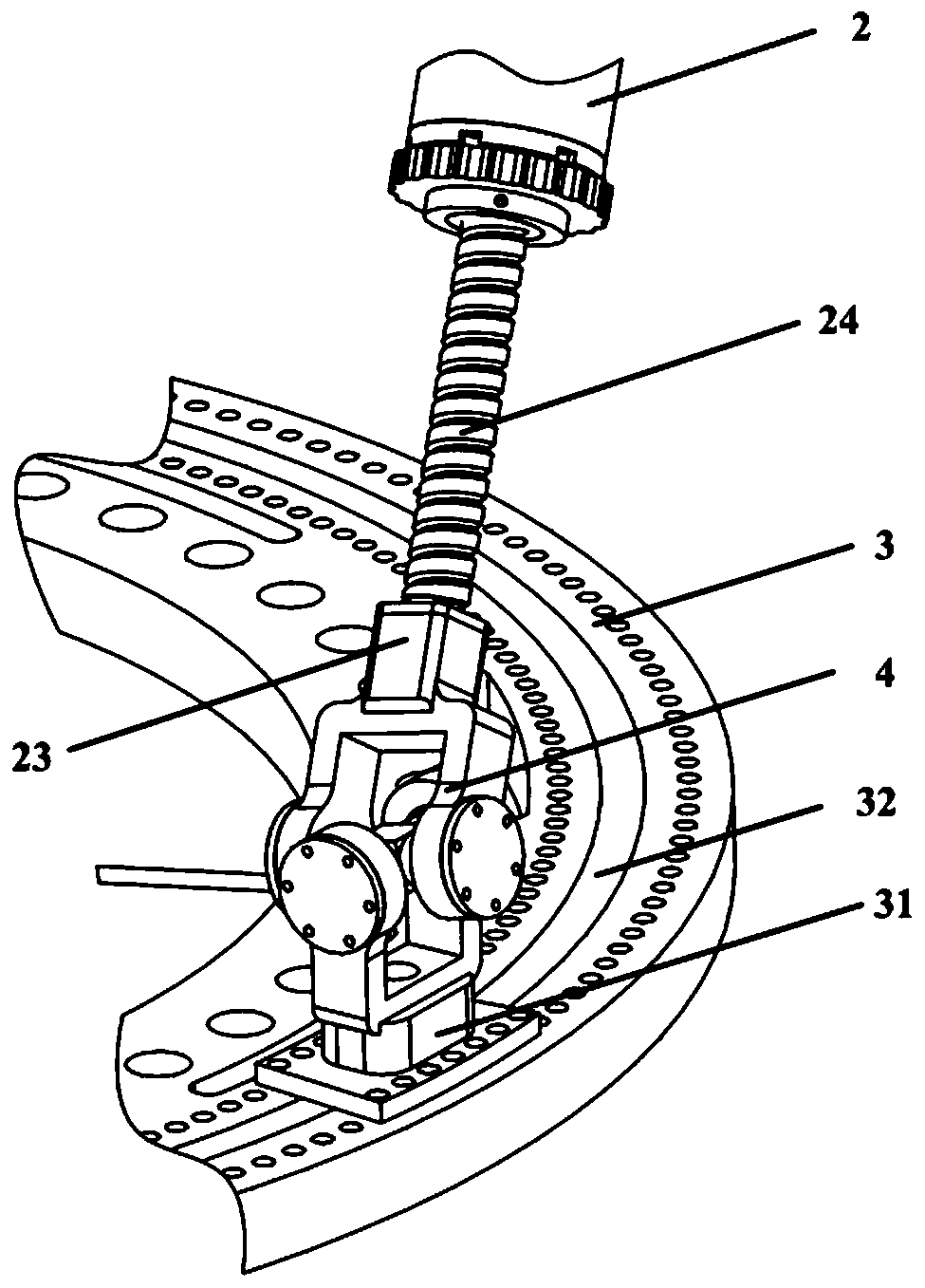

Three-branched chain parallel external fixation device adopting annular adjustment

ActiveCN109745107ALarge working spaceReduce collisionExternal osteosynthesisEngineeringBone deformity

The invention relates to a three-branched chain parallel external fixation device adopting annular adjustment. The three-branched chain parallel external fixation device comprises a near end ring, a far end ring, a hook joint, a spherical hinge, telescopic branched chains, annular guide rails, adjusting hand wheels, adjusting knobs, kirschner wires and a locking wire chucks. Through kirschner wires, the near end ring and the far end ring of the external fixation device are perpendicularly and rigidly fixed to a deformable bone separately, the annular guide rails are arranged on the near end ring and the far end ring respectively, the adjusting hand wheels are connected with sliding blocks on the annular guide rails, the adjusting knobs are installed on the telescopic branched chains, through the adjusting hand wheels and the adjusting knobs, the sliding blocks move around the annular guide rails, meanwhile, the telescopic branched chains extend or retract, and therefore the three-branched parallel external fixation device realizes 6-DOF movement and can correct any spatial three-dimensional bone deformity. The three-branched chain design is adopted, the annular guide rails are arranged, a 3-PUPS parallel structure is formed, and the three-branched chain parallel external fixation device has the advantages of being simple in structure, large in work space and flexible to operate, being provided with a few movement chains, and not being interfered easily.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com