Patents

Literature

246 results about "Linear scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A linear scale, also called a bar scale, scale bar, graphic scale, or graphical scale, is a means of visually showing the scale of a map, nautical chart, engineering drawing, or architectural drawing.

System and method for generating message notification objects on dynamically scaled timeline

InactiveUS20050268237A1Preserving spaceData processing applicationsMultiple digital computer combinationsEmail addressPassword

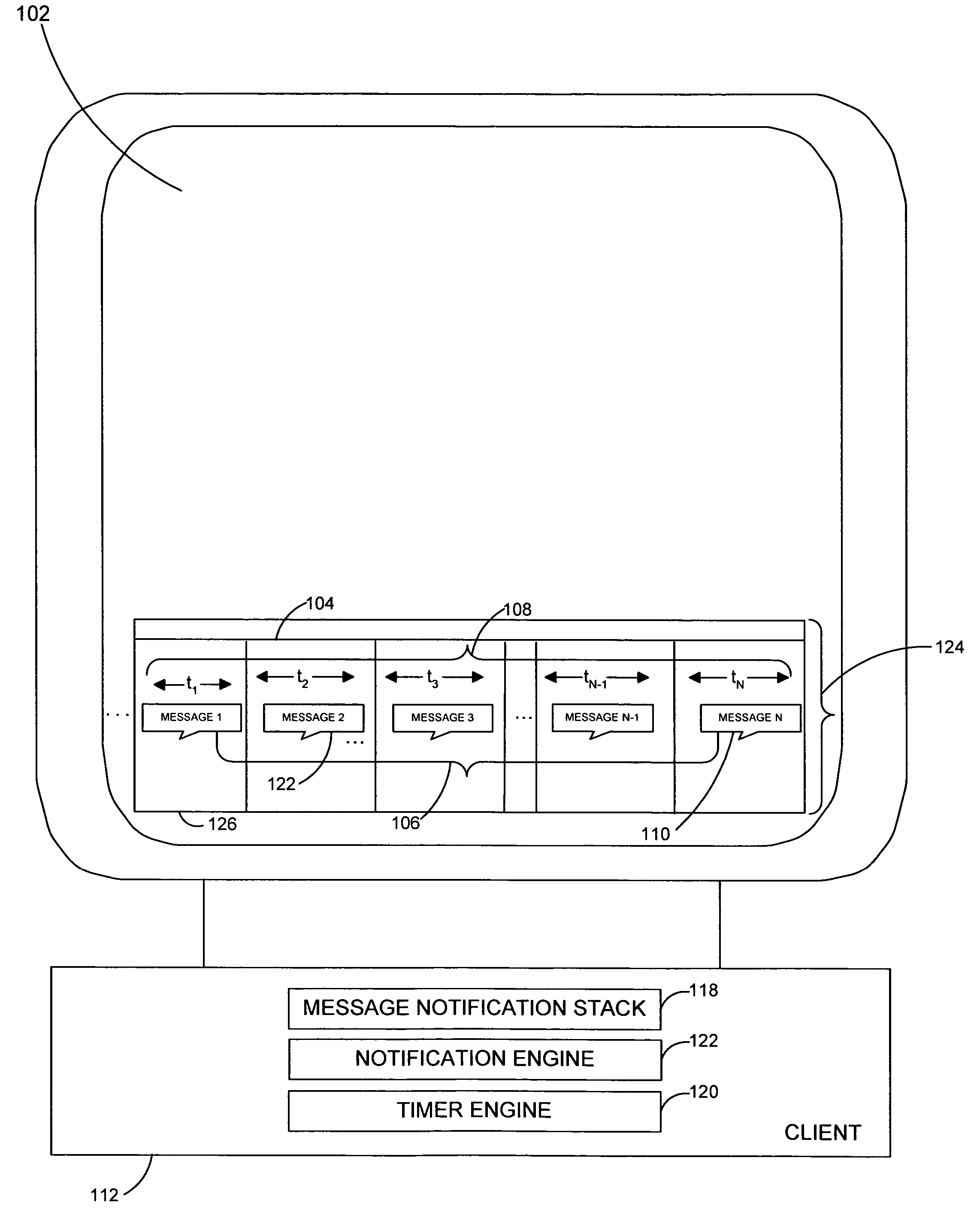

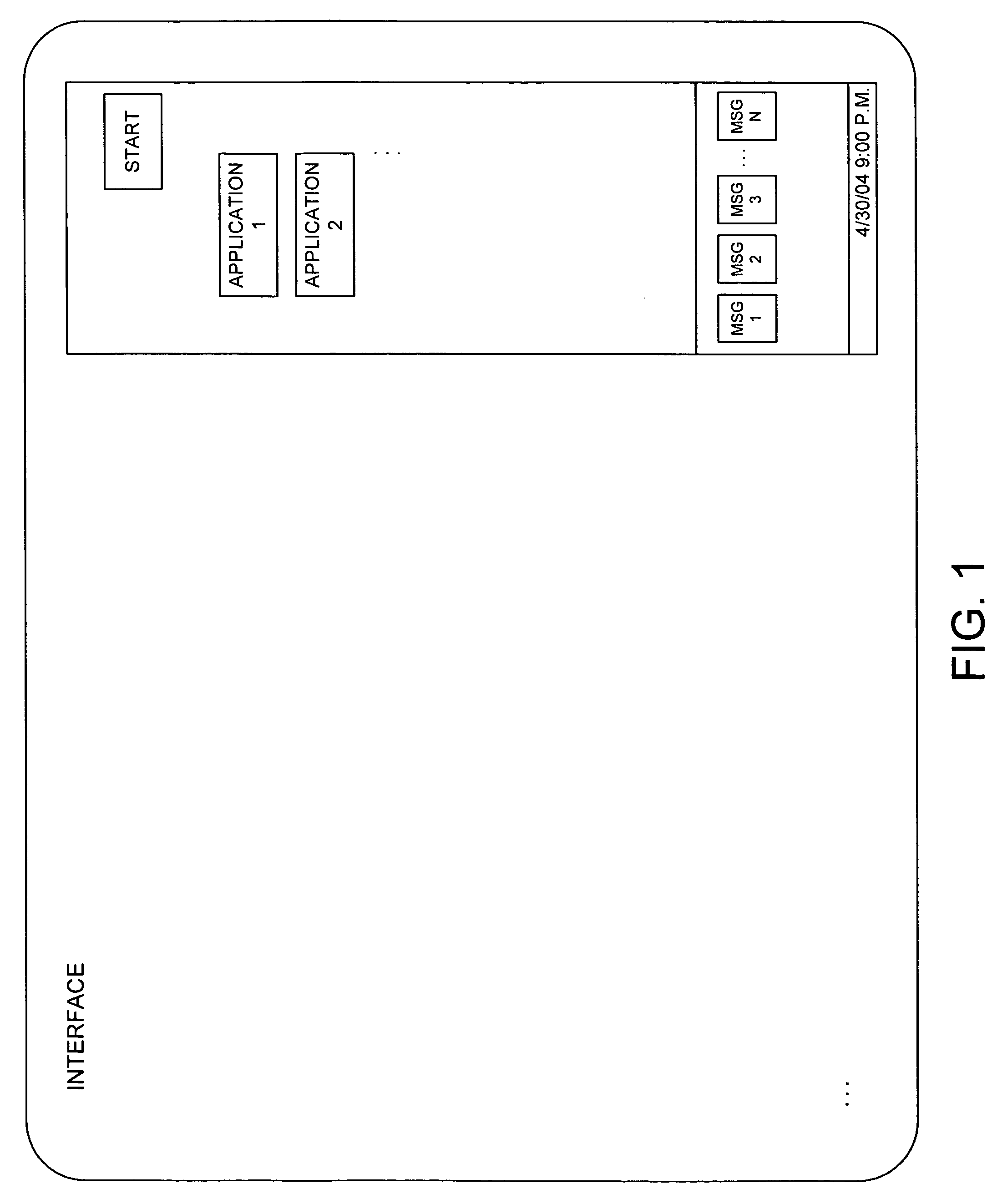

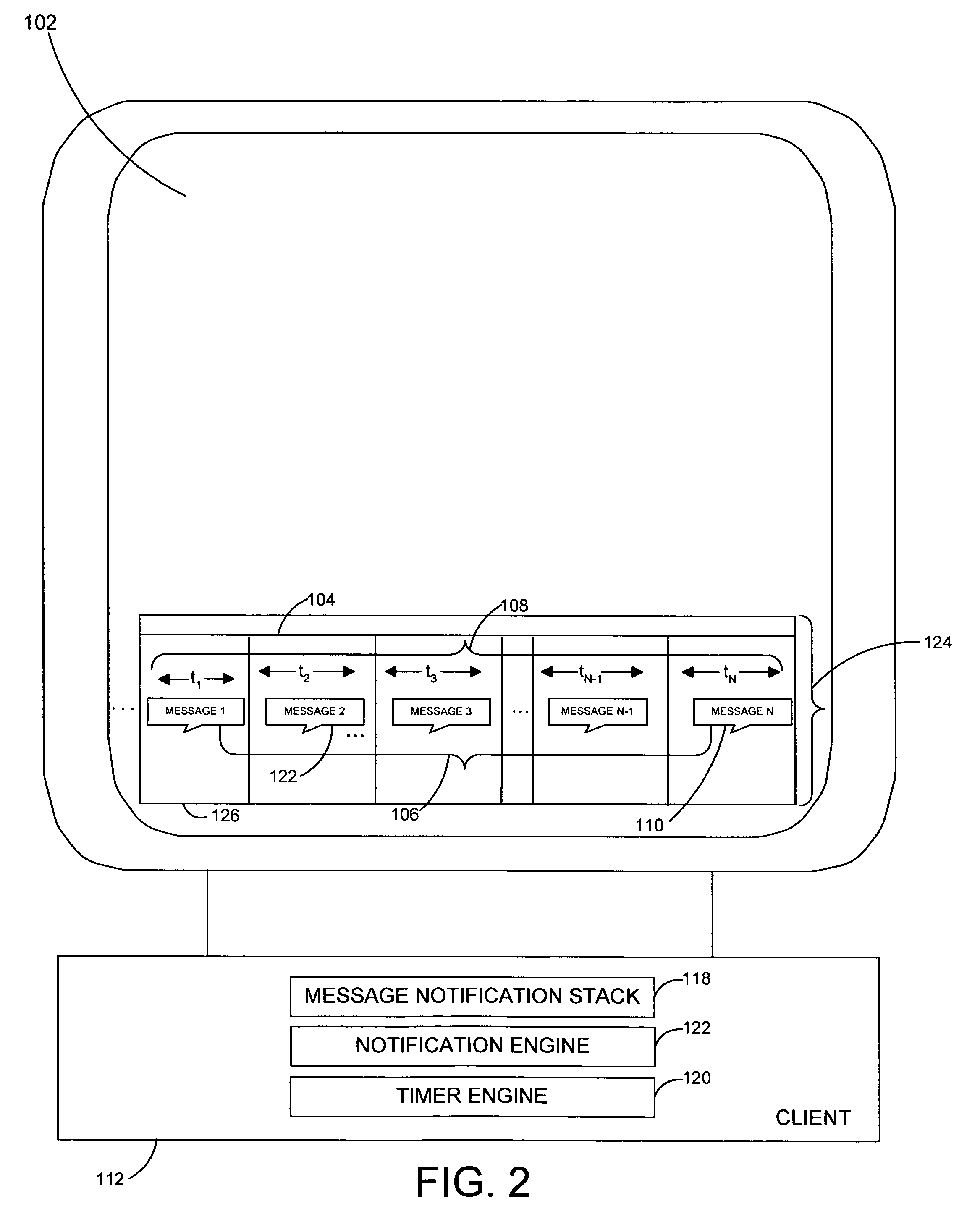

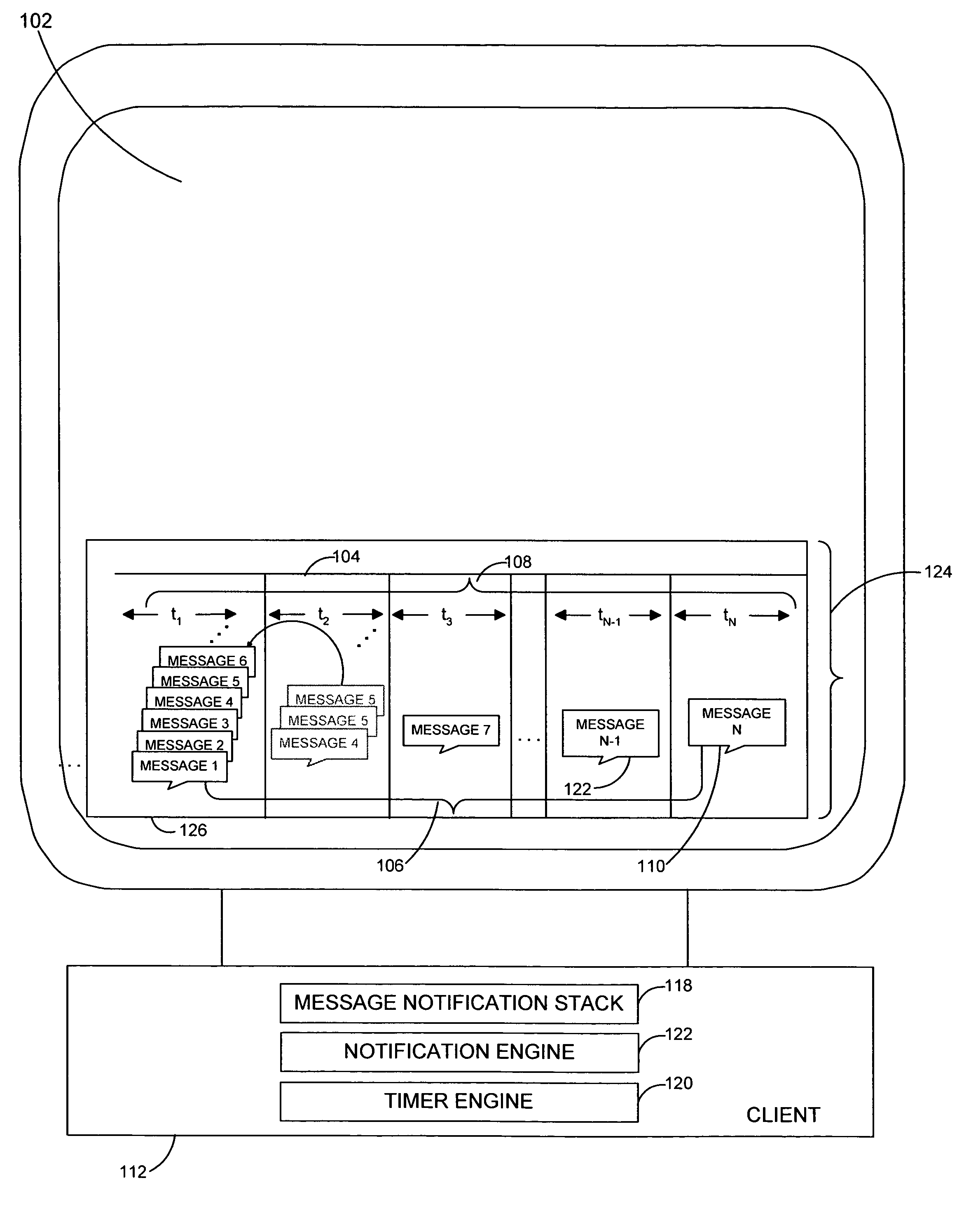

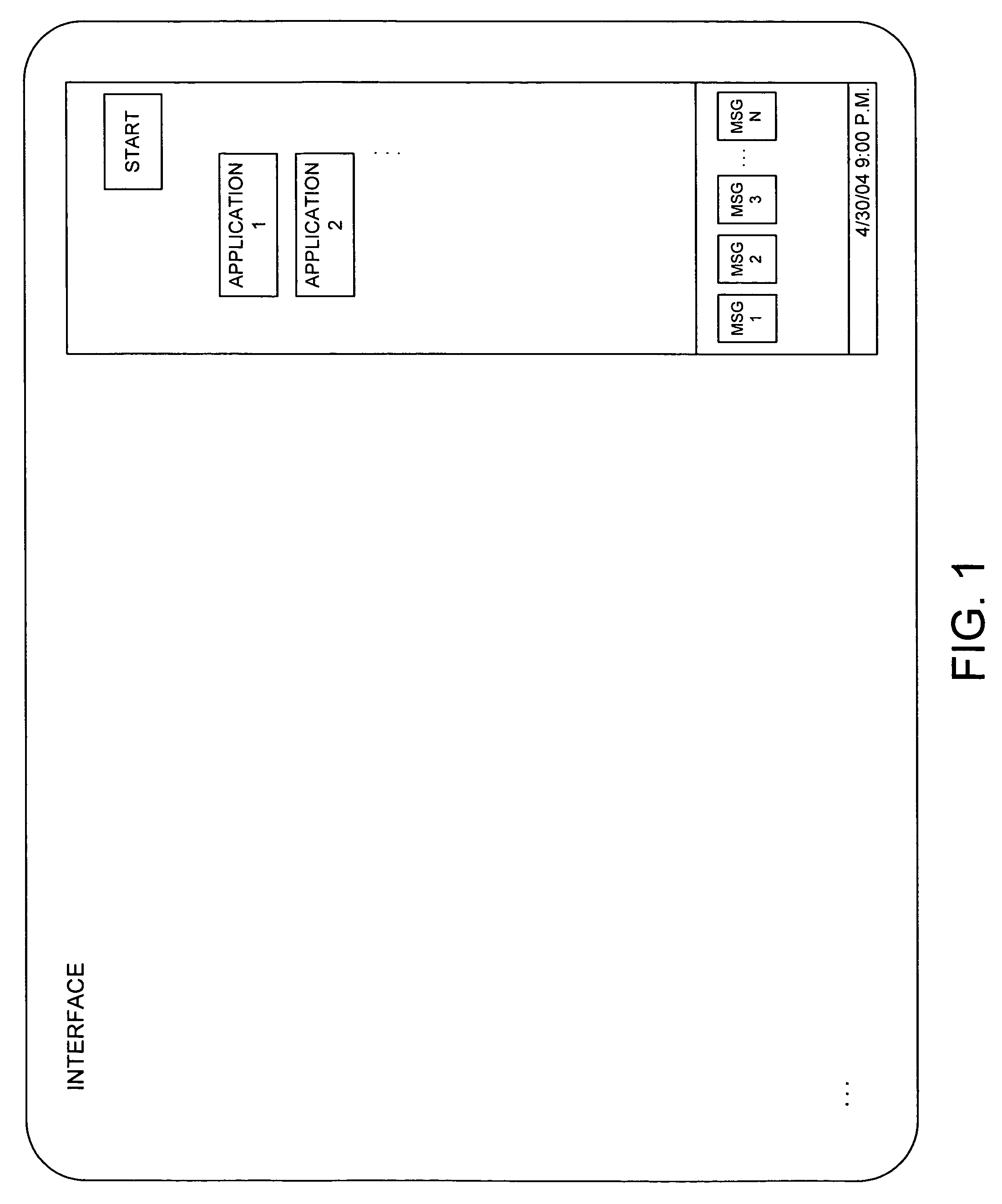

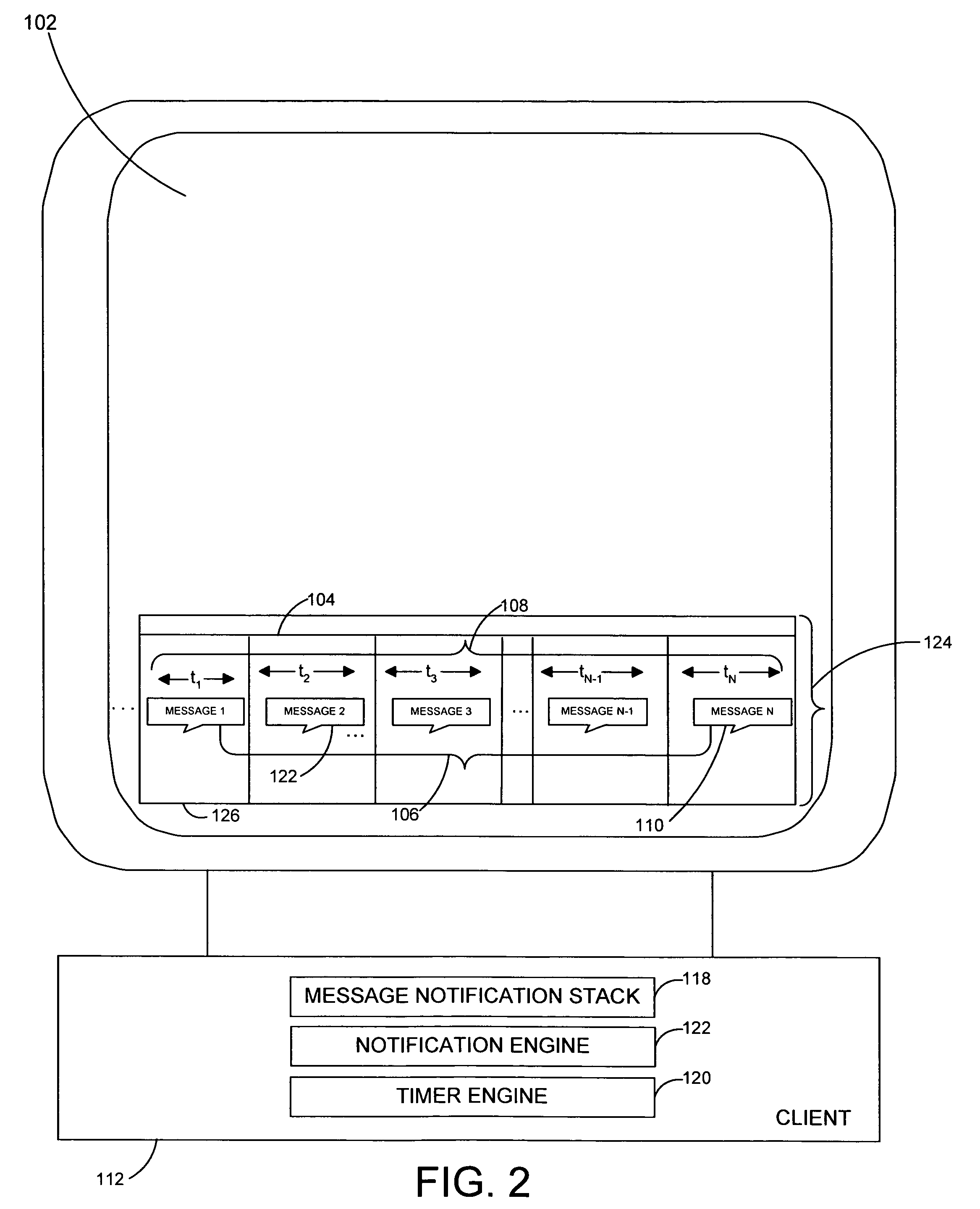

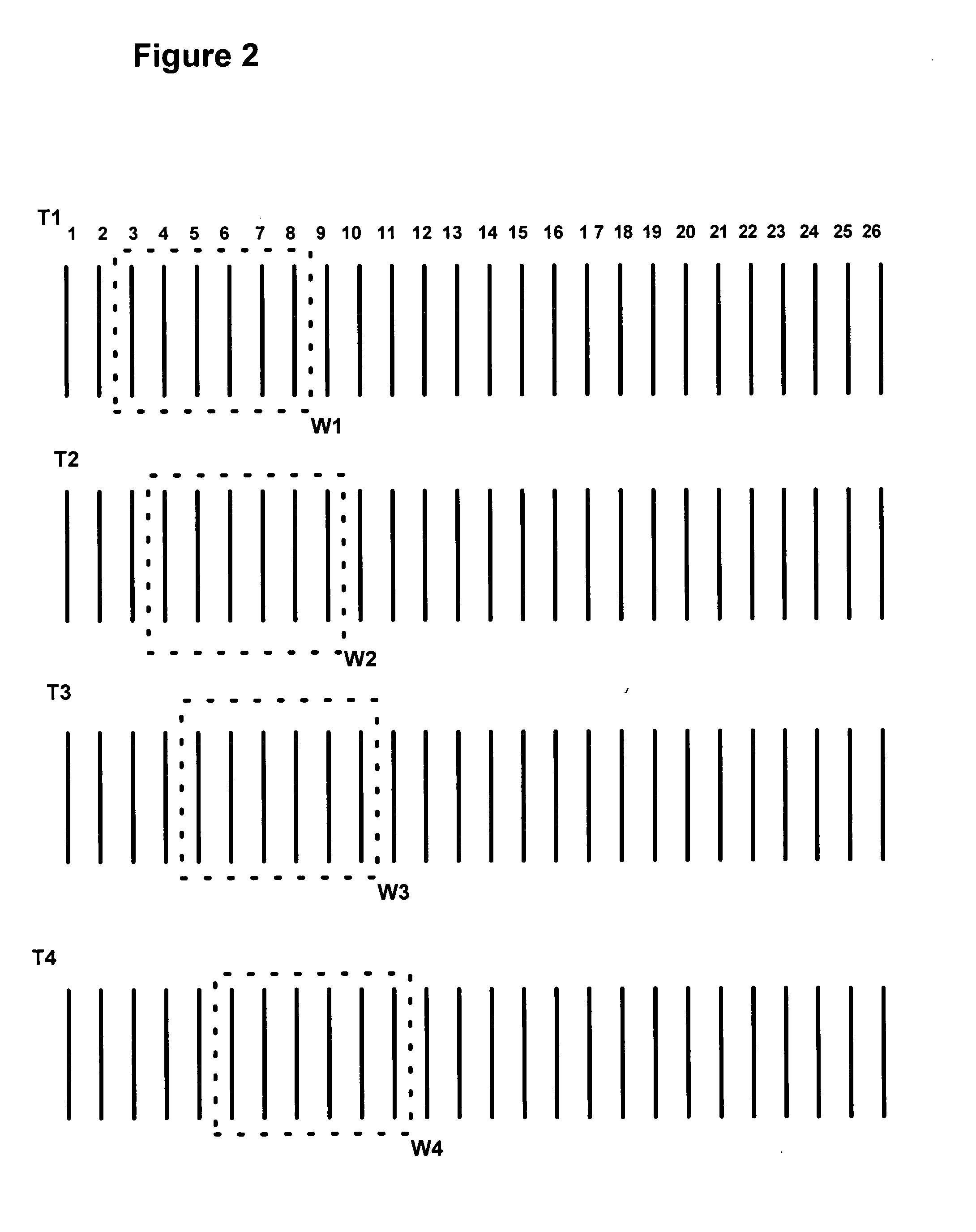

A system and related techniques to collect and manage a set of incoming message notification objects, such as instant message notifications, email notifications, download notifications, transaction notifications and others and present those objects to the user an icon, tile or other representation on a dynamically scaled timeline. According to embodiments, the dynamically scaled timeline may present the most recently received object farthest to the right on a notifications bar or facility, and slide objects to the left to represent that passage of time as those objects age. Instead of presenting those objects on a linear scale, according to the invention the time intervals in which the objects may be presented may be scaled to cause the oldest message objects to be presented on a relatively compressed dimension. The most recently received messages in contrast may be presented on wider intervals, to permit the user to perceive the differences in arrival of those items more clearly. According to embodiments, when more than one message object slides to an overlapping point with another, those objects may be stacked into a cascading message stack. When two or more stacks touch, they may be merged into a single stack. According to embodiments of the invention in another regard, when the user hovers over a given message object a popup box may appear which displays attributes of that object, such as message or other notification type, the date and time which the object was received, the source of the underlying message or other data. In further embodiments, one or more of the message notification objects may be clickable or otherwise reactivatable to reveal actions, dialogs, inputs or other interactions which were presented at the time the message was originally received, such as a query box to input a password or a selection for an email address.

Owner:MICROSOFT TECH LICENSING LLC

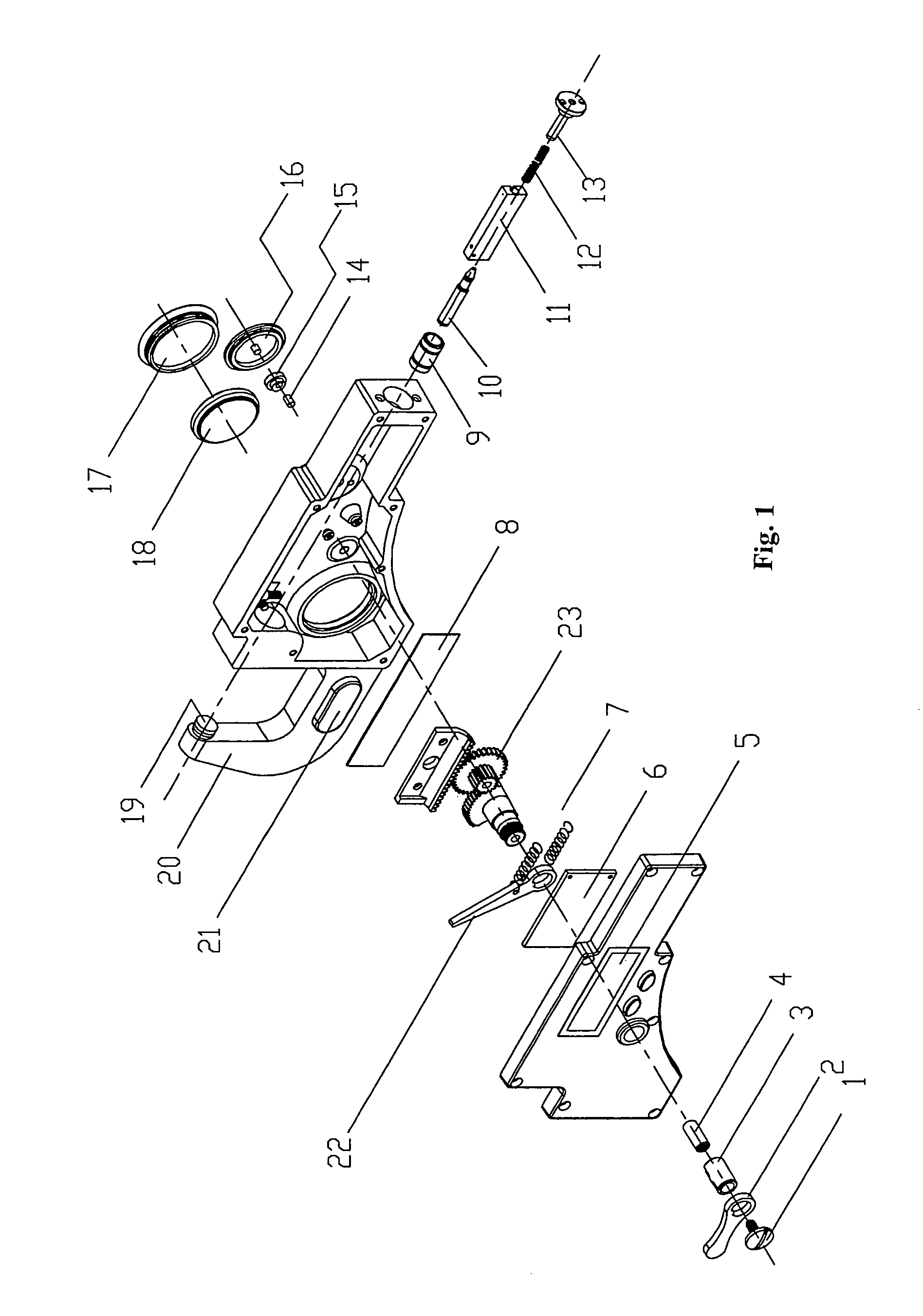

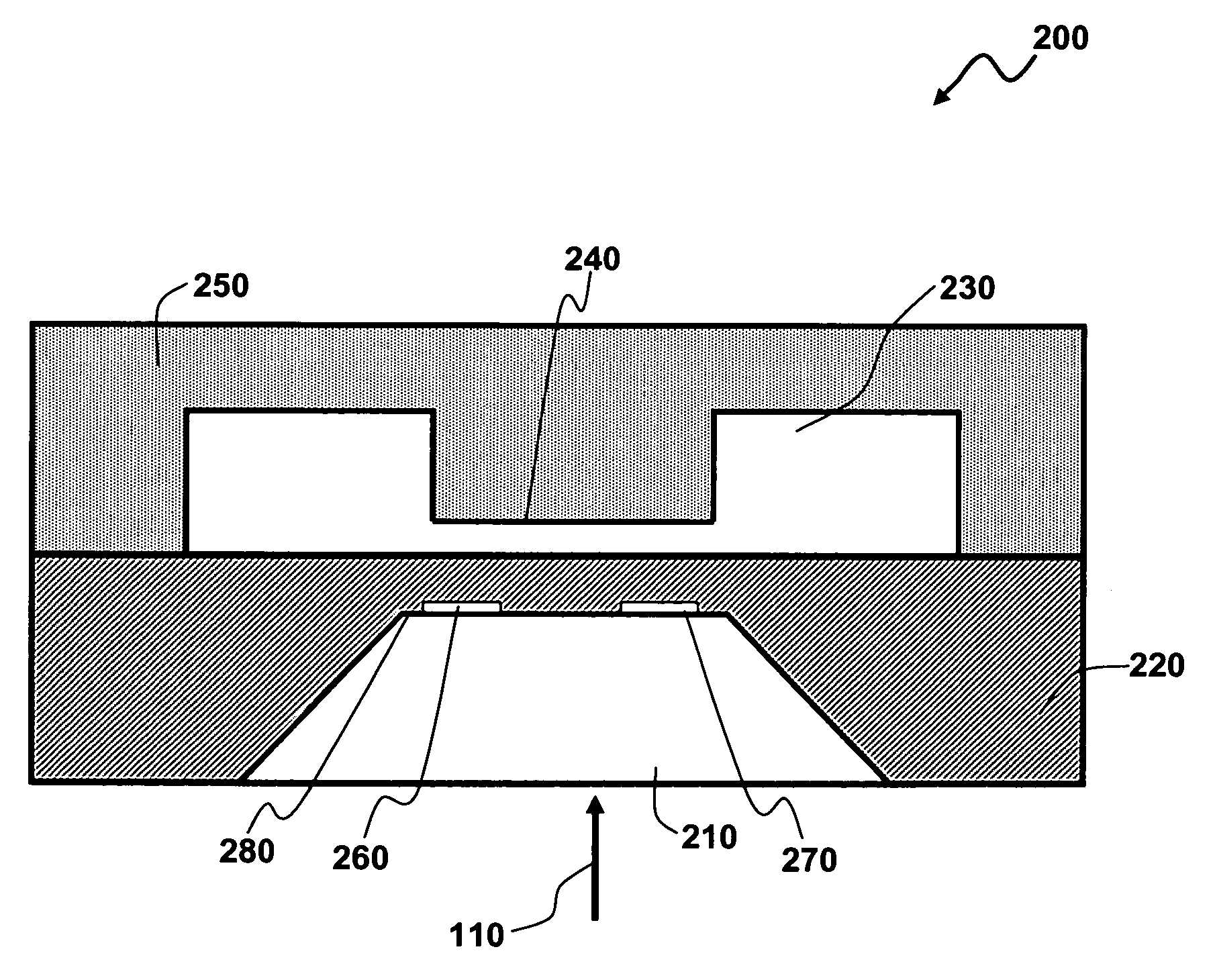

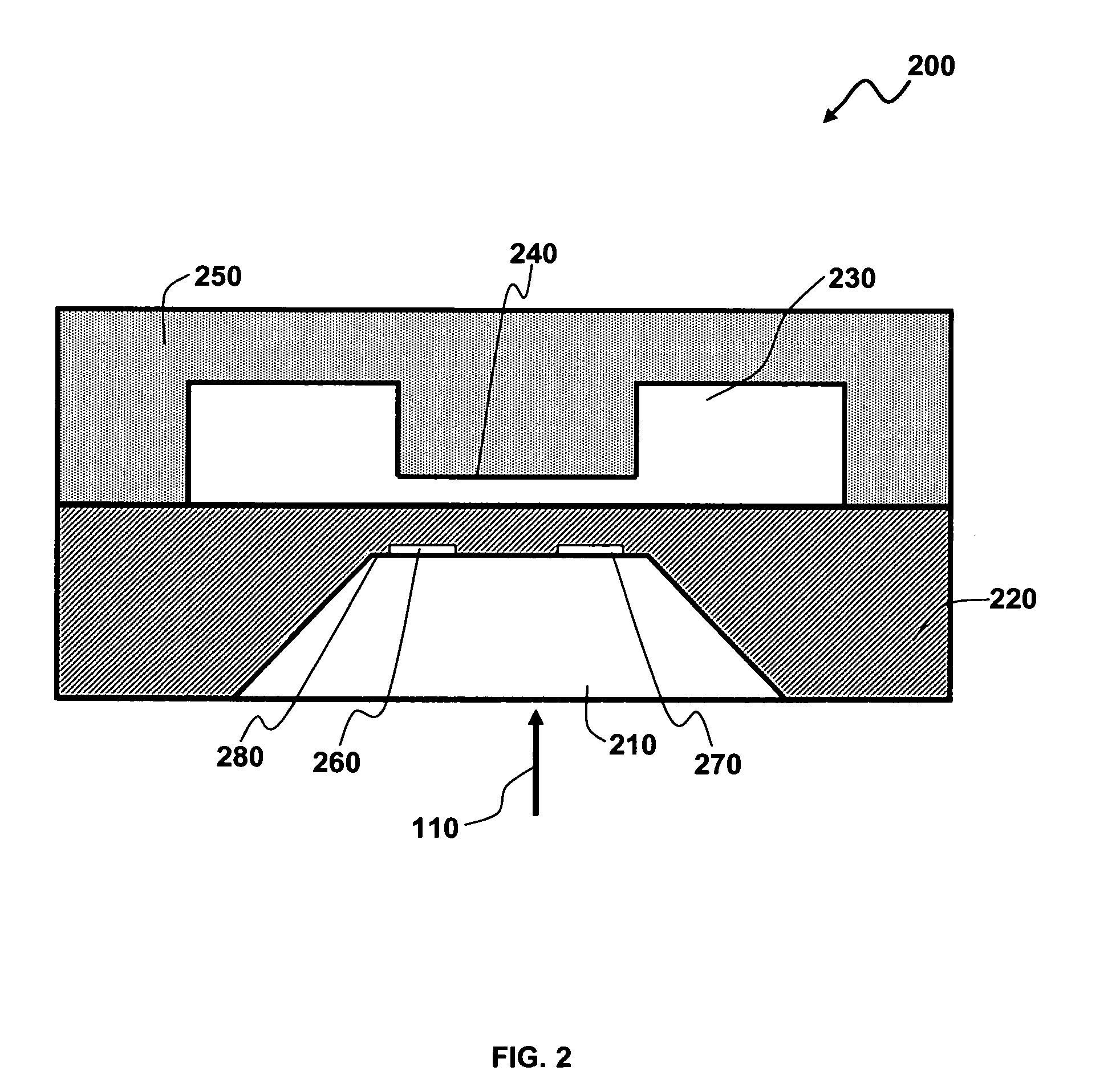

Dual span absolute pressure sense die

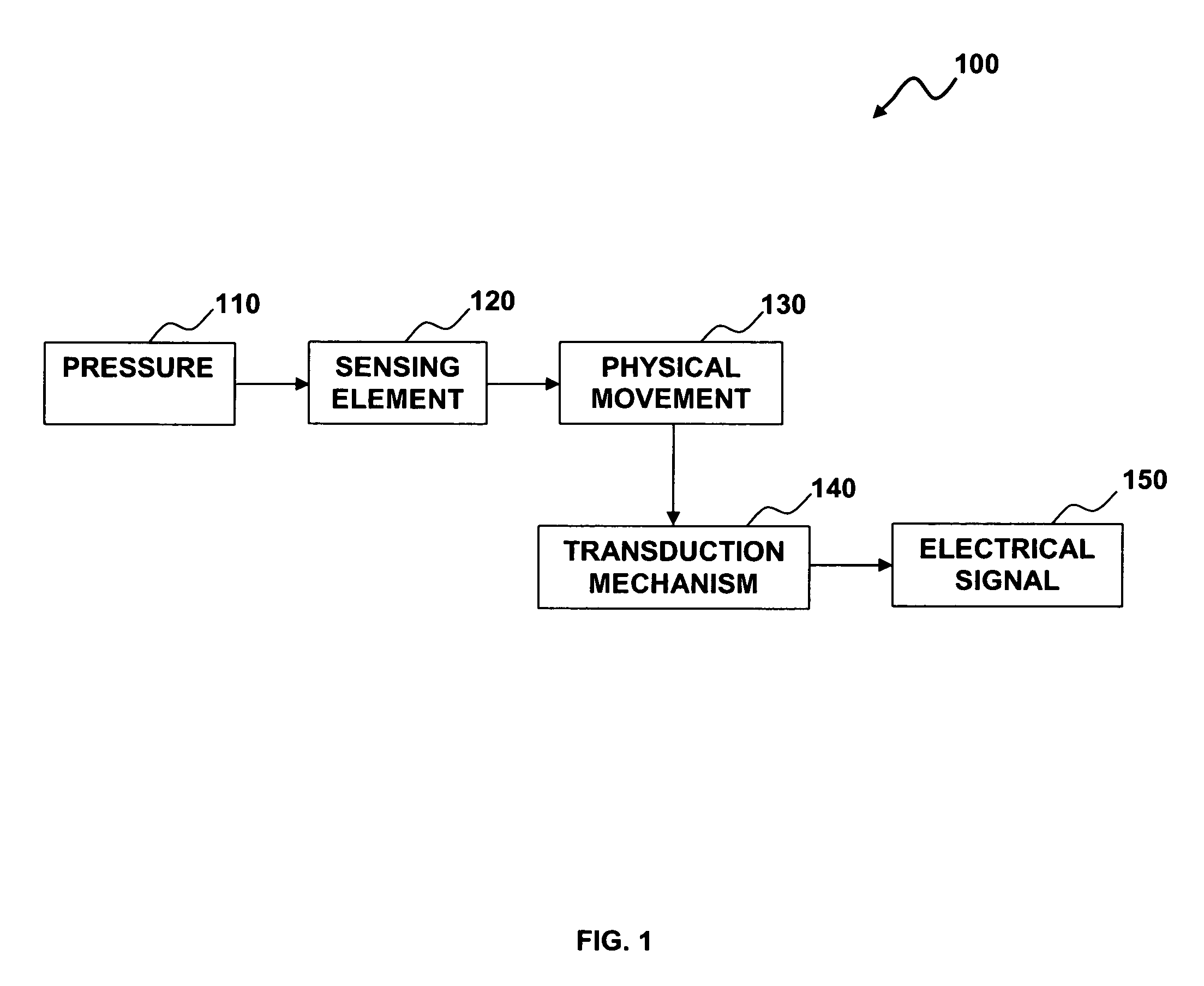

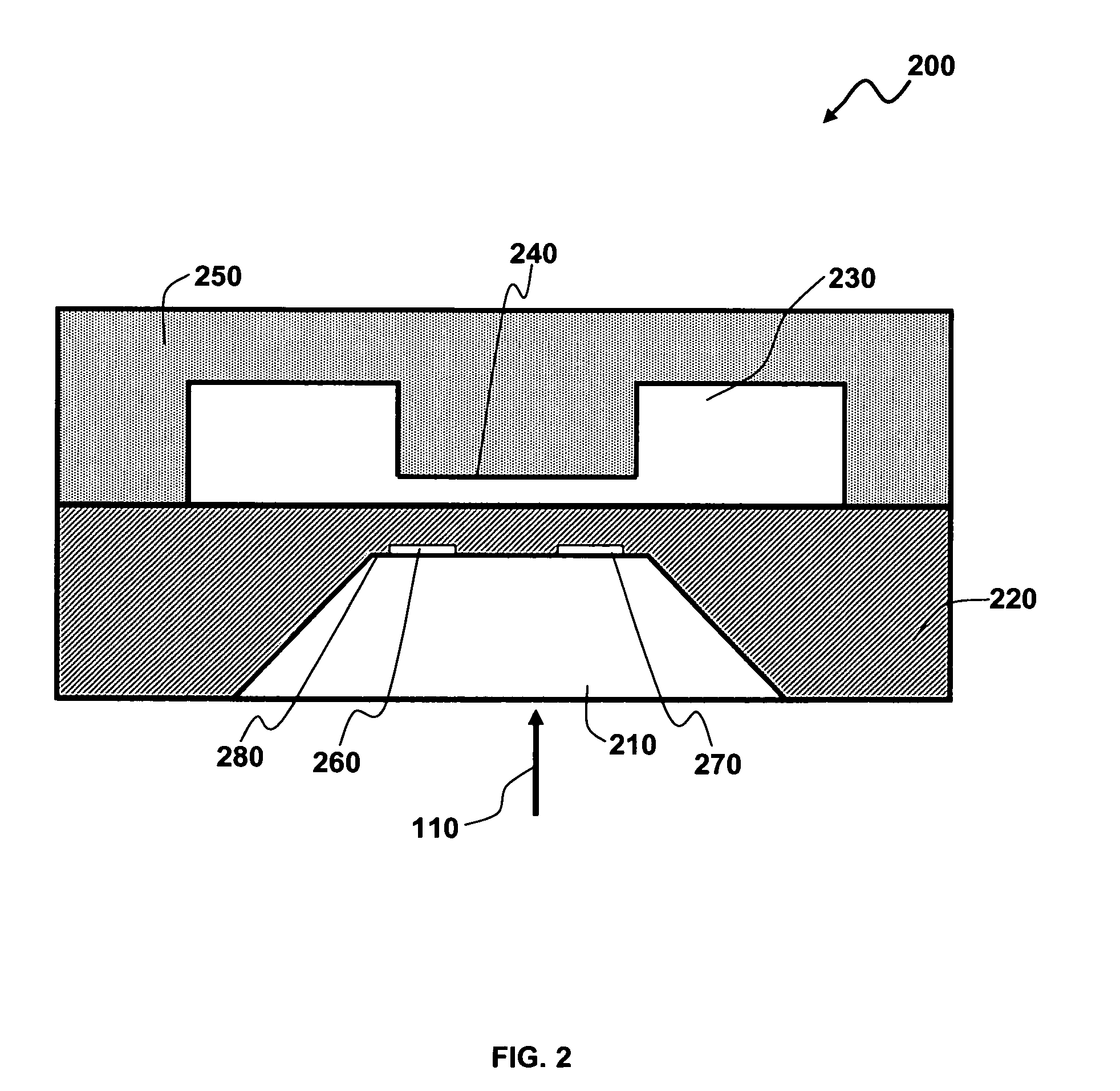

InactiveUS7503221B2Accurate measurementSmall voltageFluid pressure measurement using ohmic-resistance variationMultiple fluid pressure valves simultaneous measurementPressure senseHigh pressure

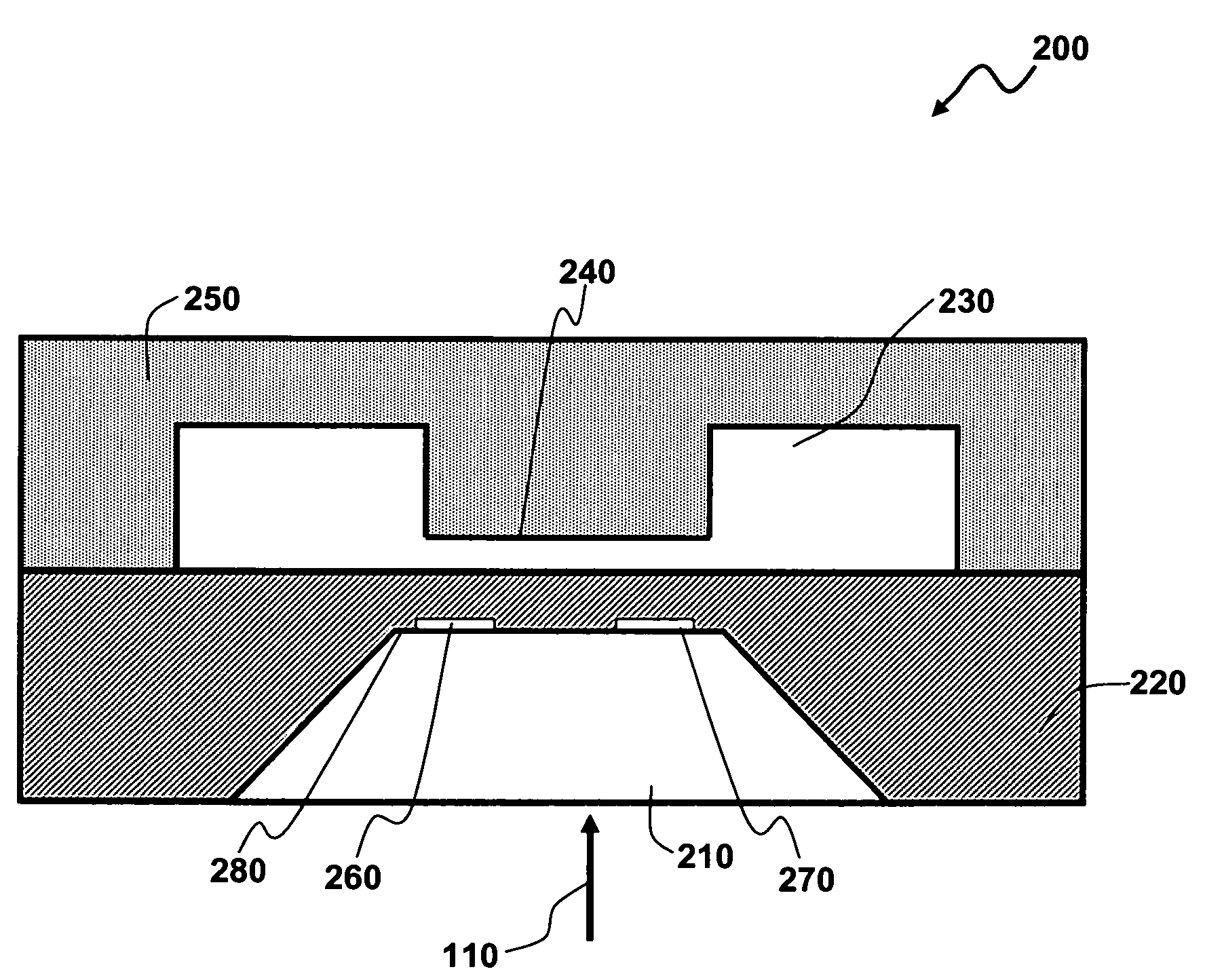

An absolute pressure sensor includes a sense die with a reference chamber on a top side thereof. The reference chamber comprises a precisely fabricated beam that limits the travel of a diaphragm. The beam can be positioned in a cap or cover member of the sense die, thereby allowing the sense die diaphragm to move freely for a particular distance. Over this distance, the sense die will have one sensitivity. When the sense die is pressurized to a certain point, the diaphragm moves until it contacts the beam member in the cap or cover. When the diaphragm hits the beam, the sensitivity of the sense die changes, thereby allowing a smaller voltage out for the greater pressure in. Such an arrangement permits the sensor to provide a function that accurately measures low pressure and measures a higher pressure without utilizing a linear scale.

Owner:HONEYWELL INT INC

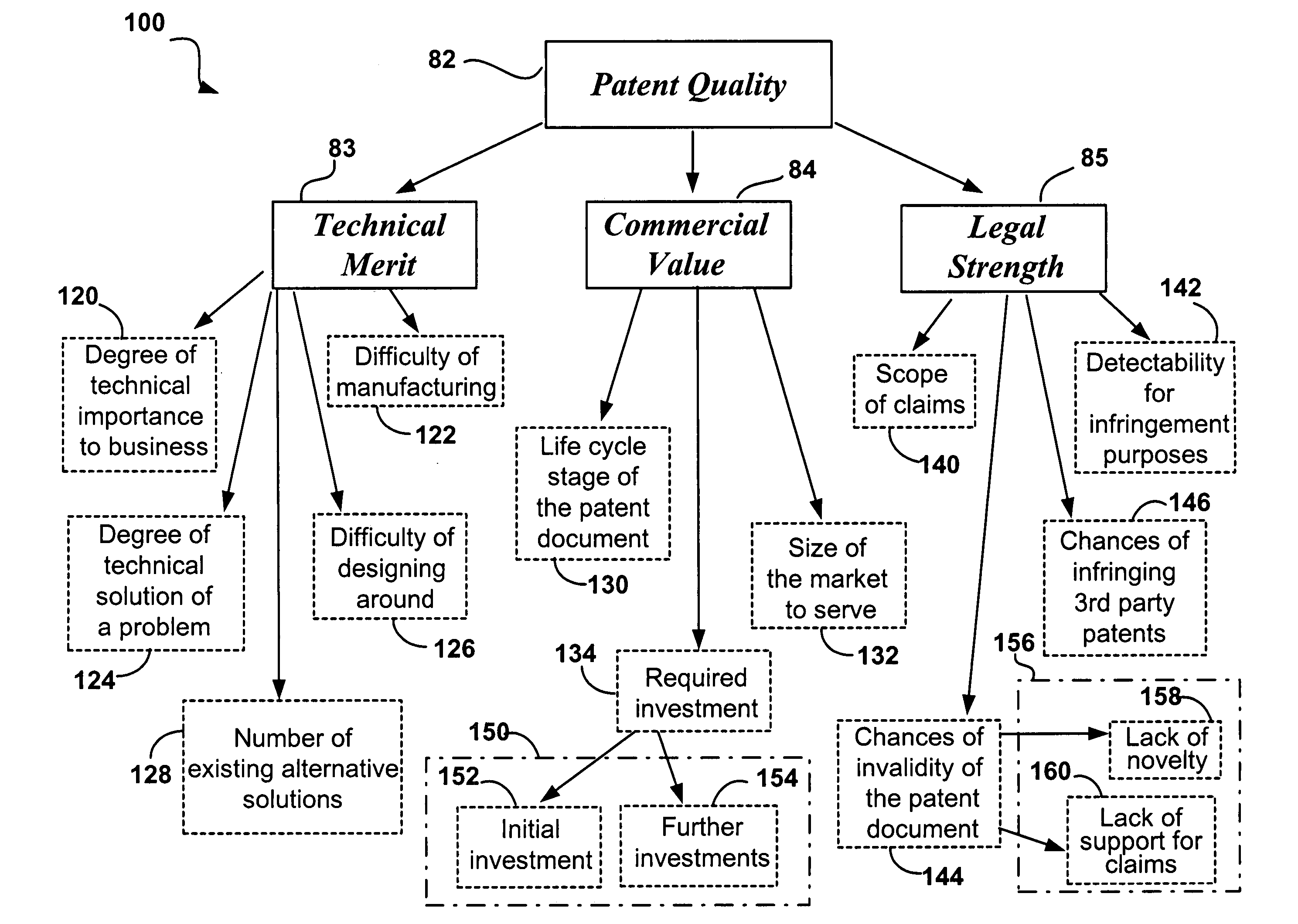

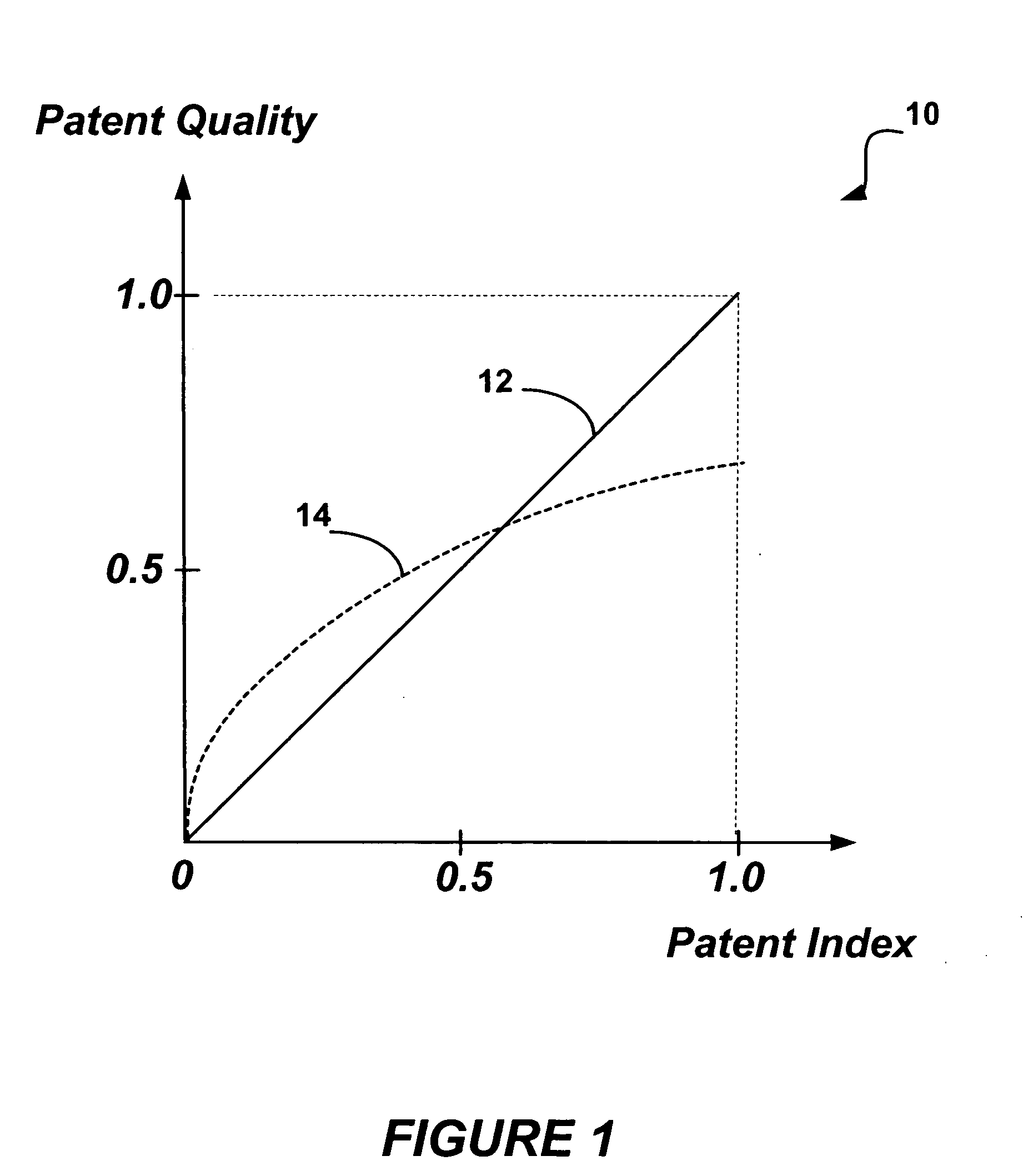

System and methods for patent evaluation

ActiveUS20060036635A1Avoid problemsConsistent resultData processing applicationsDigital data processing detailsArtificial Intelligence SystemUser interface

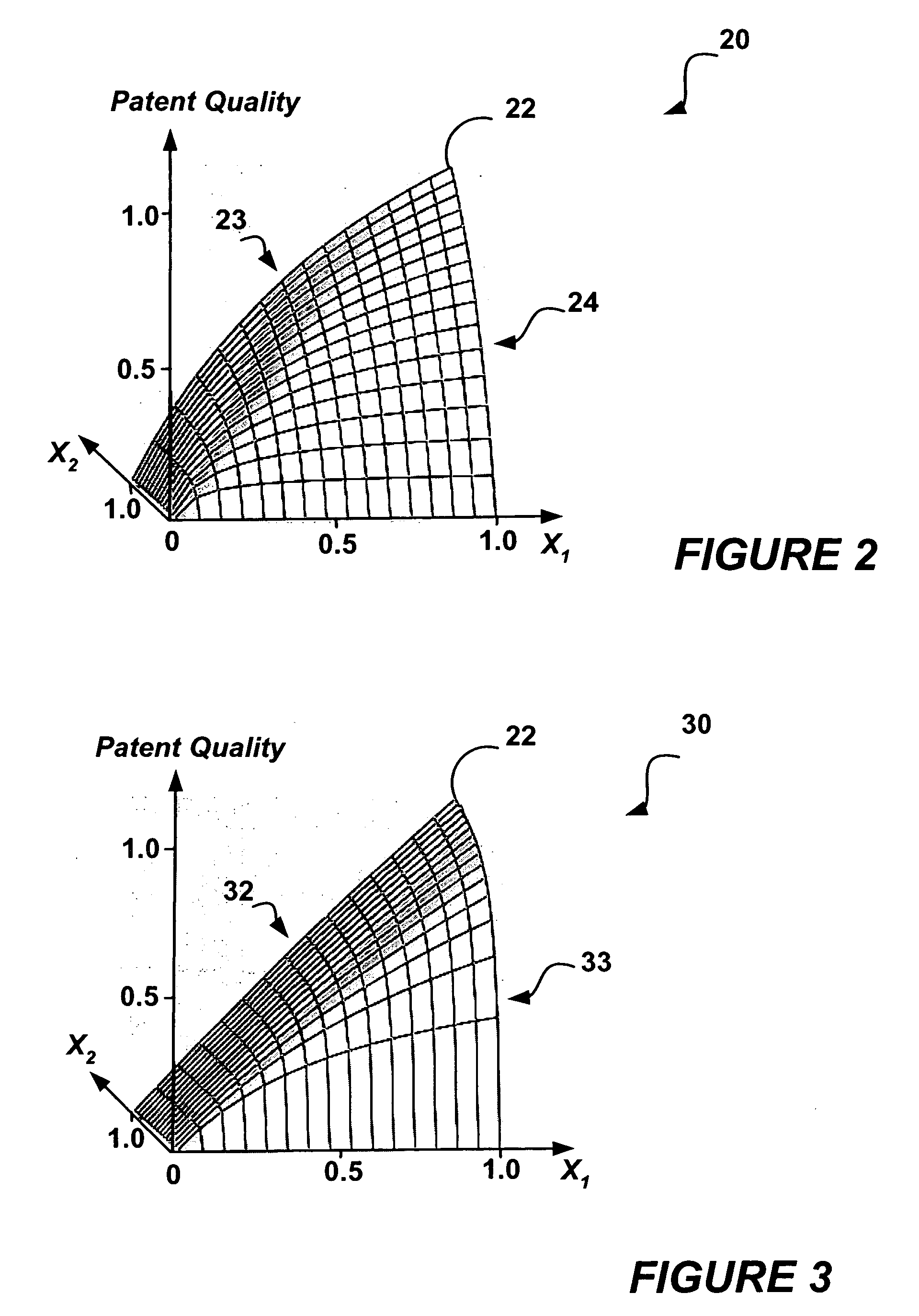

A system, methods, computer program product, a web site and an Artificial Intelligence system for evaluating a patent document have been provided. According to the methods for patent evaluation of the embodiments of the invention, the patent document is characterized by a number of patent indices arranged into a hierarchy, each index reflecting a different aspect of the patent document. The indices are combined into a Patent Quality index, which is an integral characteristic of the patent document, according to a non-linear scale, which preferably satisfies certain predetermined rules derived from the best practices of qualified experts. In one of the embodiments, a bias associated with an expert, influencing the evaluation of a patent has been taken into account. A corresponding method for determining a monetary value of the patent document is also described. The system for patent evaluation comprises a Patent Quality and Monetary Value processing unit for implementing one of the methods, and respective input and output data means, including a friendly graphical user interface. The system is implemented to be accessible via a network. A corresponding web site having a link, causing a computer program associated with the web site, which performs one of the methods, to execute and to display the results of the execution on a screen, is described. An Artificial Intelligence (AI) system for analyzing and interpreting patent indices and a Visualization unit for color-coded visualization of the results of evaluation are also provided.

Owner:WILLIAMS ALLAN

System and method for generating message notification objects on dynamically scaled timeline

InactiveUS7353466B2Data processing applicationsMultiple digital computer combinationsTime lineWorld Wide Web

A system and related techniques to collect and manage a set of incoming message notification objects, such as instant message notifications, email notifications, download notifications, transaction notifications and others and present those objects to the user with an icon, tile or other representation on a dynamically scaled timeline. According to embodiments, the dynamically scaled timeline may present the most recently received object farthest to the right on a notifications bar or facility and slide objects to the left to represent passage of time as those objects age. Instead of presenting those objects on a linear scale, according to the invention, the time intervals in which objects may be presented may be scaled to cause the oldest message objects to be presented on a relatively compressed dimension. The most recently received messages may be presented on wider intervals, to permit the user to perceive differences in arrival of items more clearly.

Owner:MICROSOFT TECH LICENSING LLC

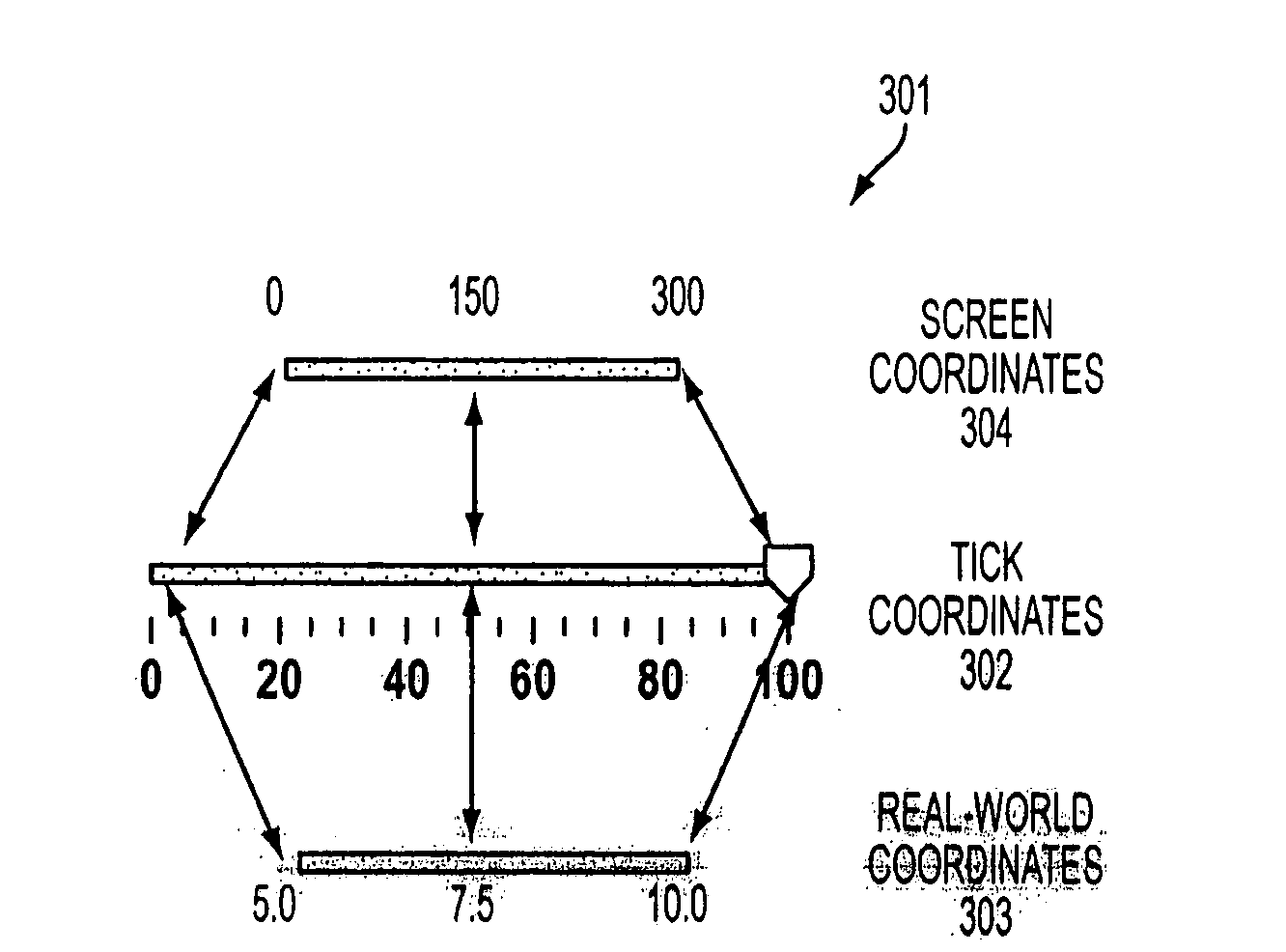

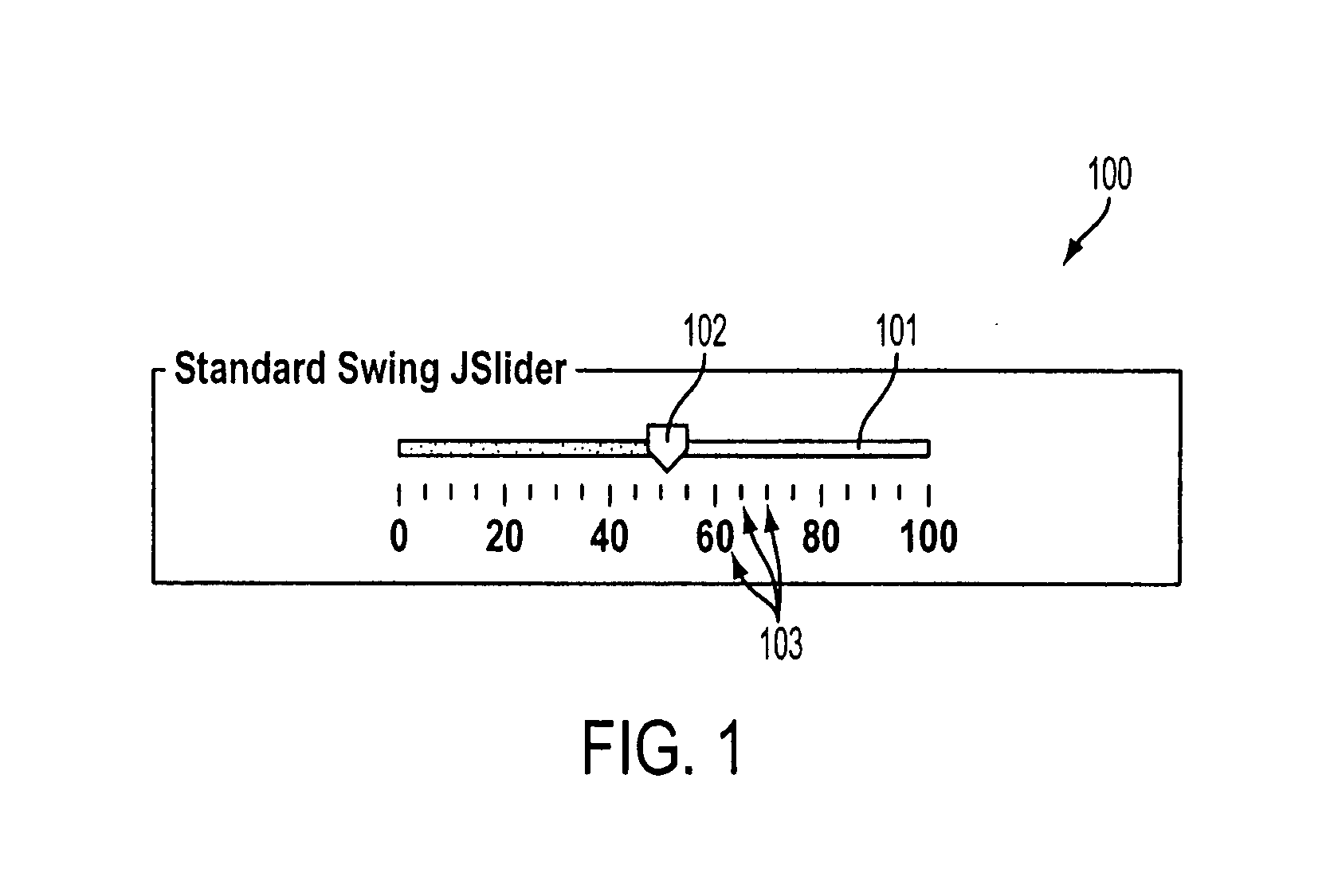

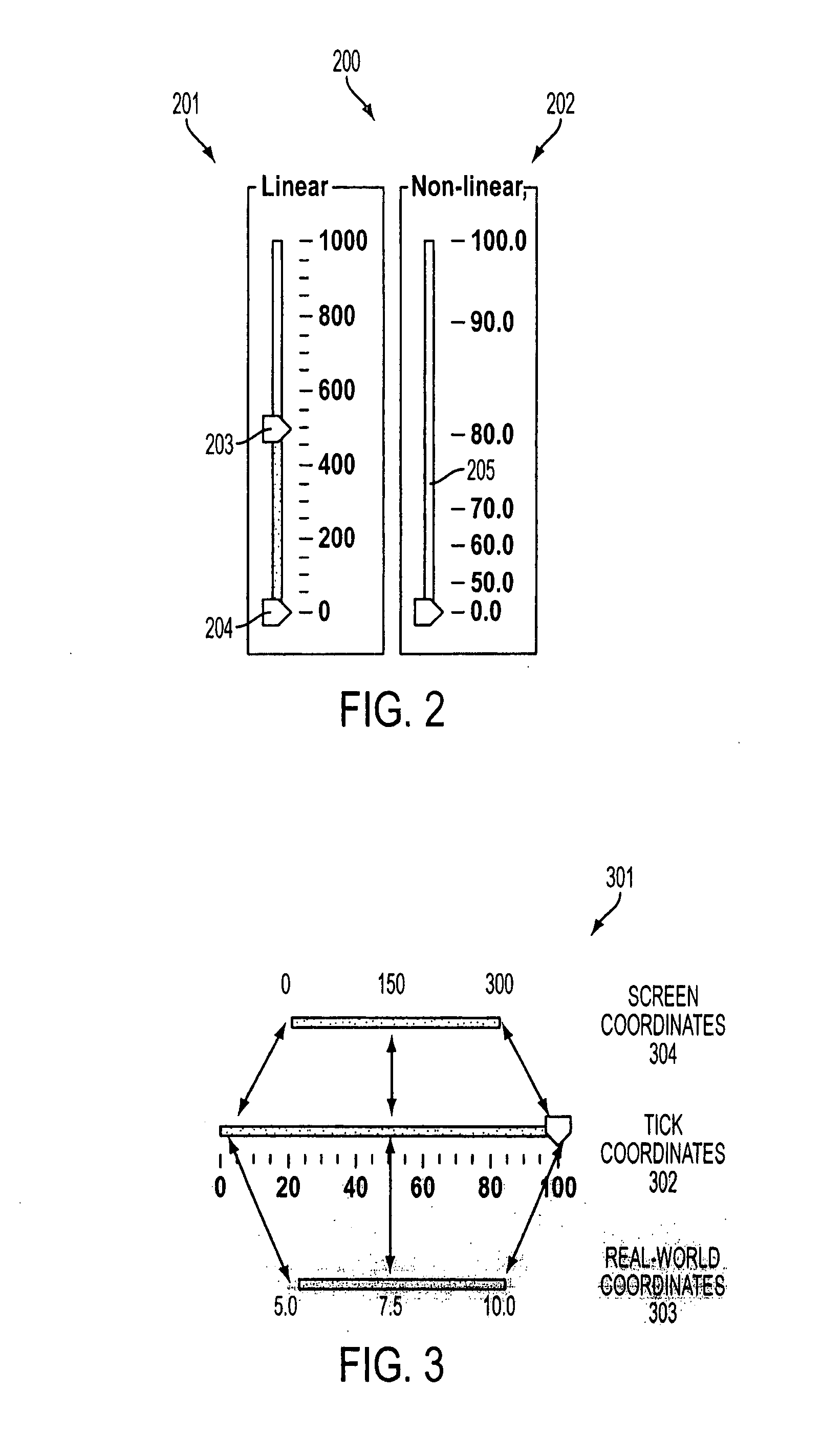

Method and apparatus for choosing ranges from a multi-range slider

InactiveUS20080184167A1Simple processSave spaceInput/output processes for data processingComputer scienceUser interface

A multi-range slider that simplifies the process for a user to pick multiple value ranges for various applications and saves a user's display area by providing multiple value selectors arranged in a single, possibly non-linear scale. The multi-range slider has the ability to display massive amounts of data and information in an easily viewable, condensed and manageable format in the context of a larger display such that the slider does not obscure or clutter the user interface. The multi-range slider allows the user to select ranged values as well as single values. The multi-range slider provides multiple range selectors for the user to pick multiple ranges. The scale of the multi-range slider may be linear or non-linear.

Owner:MAPINFO

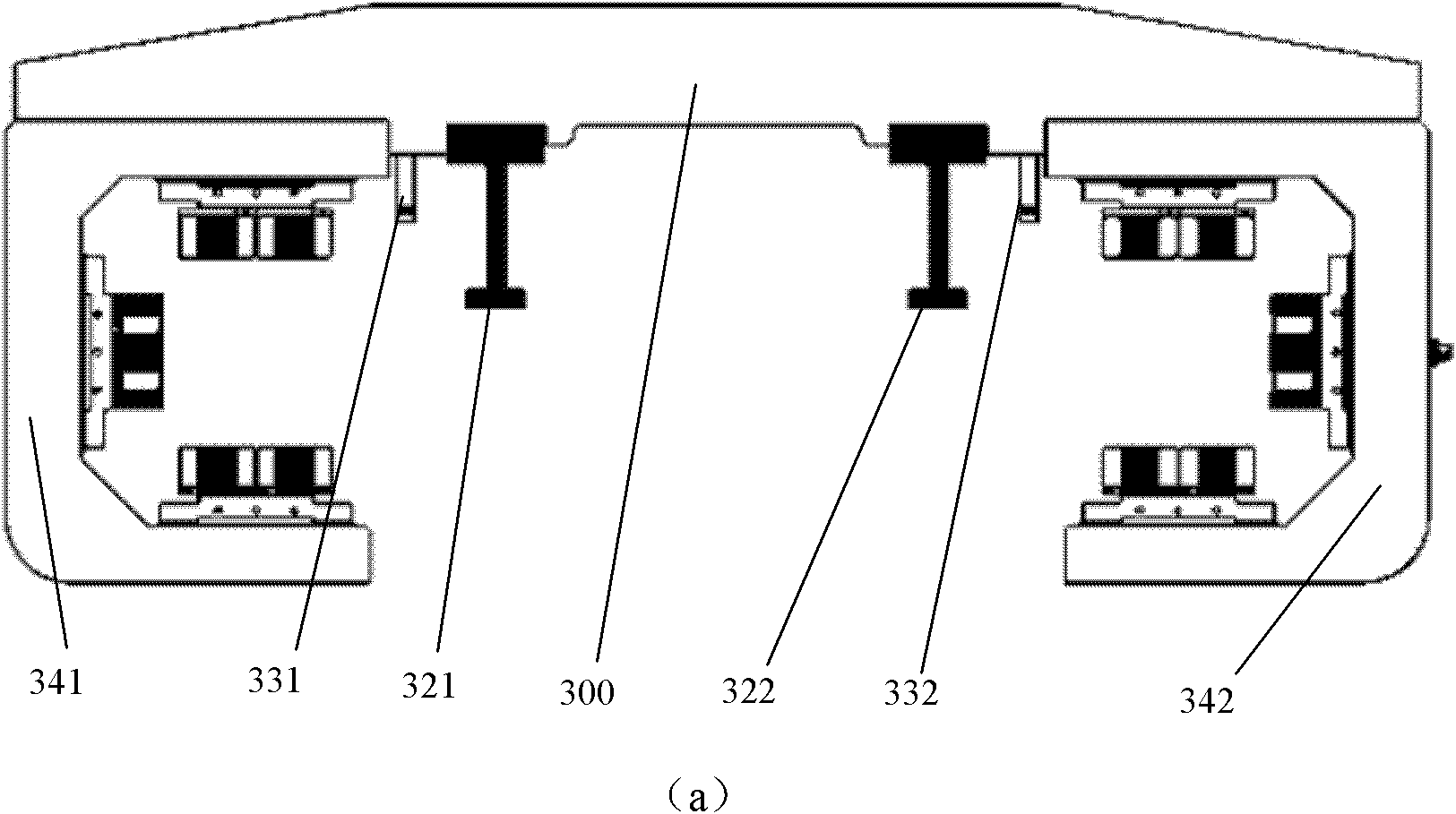

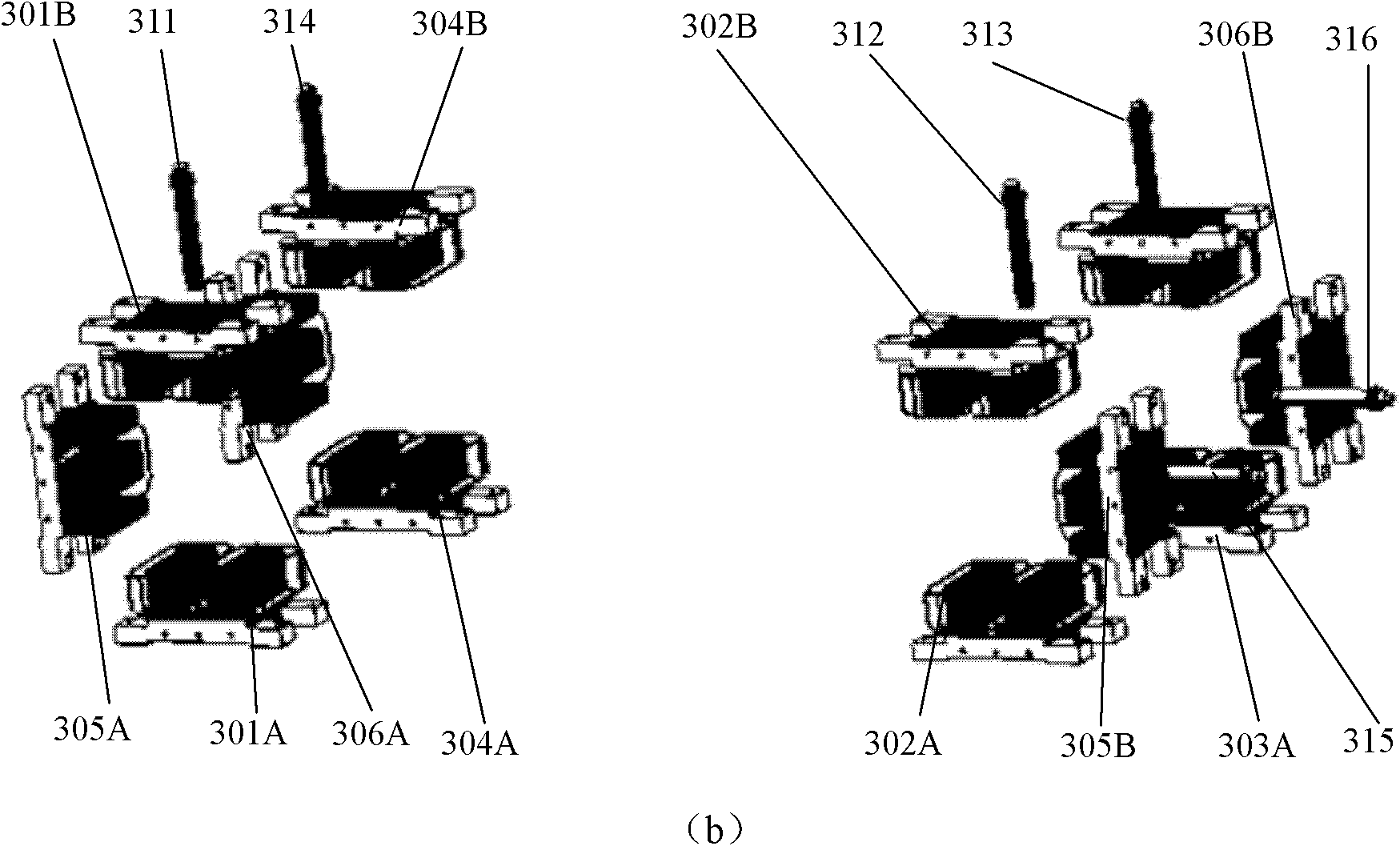

Mask aligner mask platform adopting magnetic suspension technology

InactiveCN101900952AReduce large deformationNo contactPhotomechanical exposure apparatusMicrolithography exposure apparatusGas phaseEngineering

The invention provides a mask aligner mask platform adopting the magnetic suspension technology. The mask aligner mask platform mainly comprises a precision slideway, a base, a suspension and the like, wherein the inside of the suspension is provided with an electromagnet which combines with a vortex displacement sensor to realize that the suspension is suspended above the slideway stably; the stator of a linear electric motor is fixed on the base, the rotor of the linear electric motor is fixed on the suspension; and the slideway surface is provided with a linear scale which combines with a linear scale reading-head arranged on the suspension to realize the precise and linear positioning motion of the suspension. The magnetic suspension mask aligner mask platform provided by the invention utilizes electromagnetic attraction and electromagnetic linear drive to ensure that the mask aligner mask platform can perform precise and fast reciprocating linear positioning motion, realize the functions of ultra-clean, high-speed, long-distance and precise positioning motion and the like which can not be realized by using the traditional scheme using a rotary servo motor for drive, a precision ball lead screw for transmission and a slideguide for support, and have higher suspension stiffness and better load-bearing characteristic than the gas phase suspension mask aligner mask platform.

Owner:CENT SOUTH UNIV

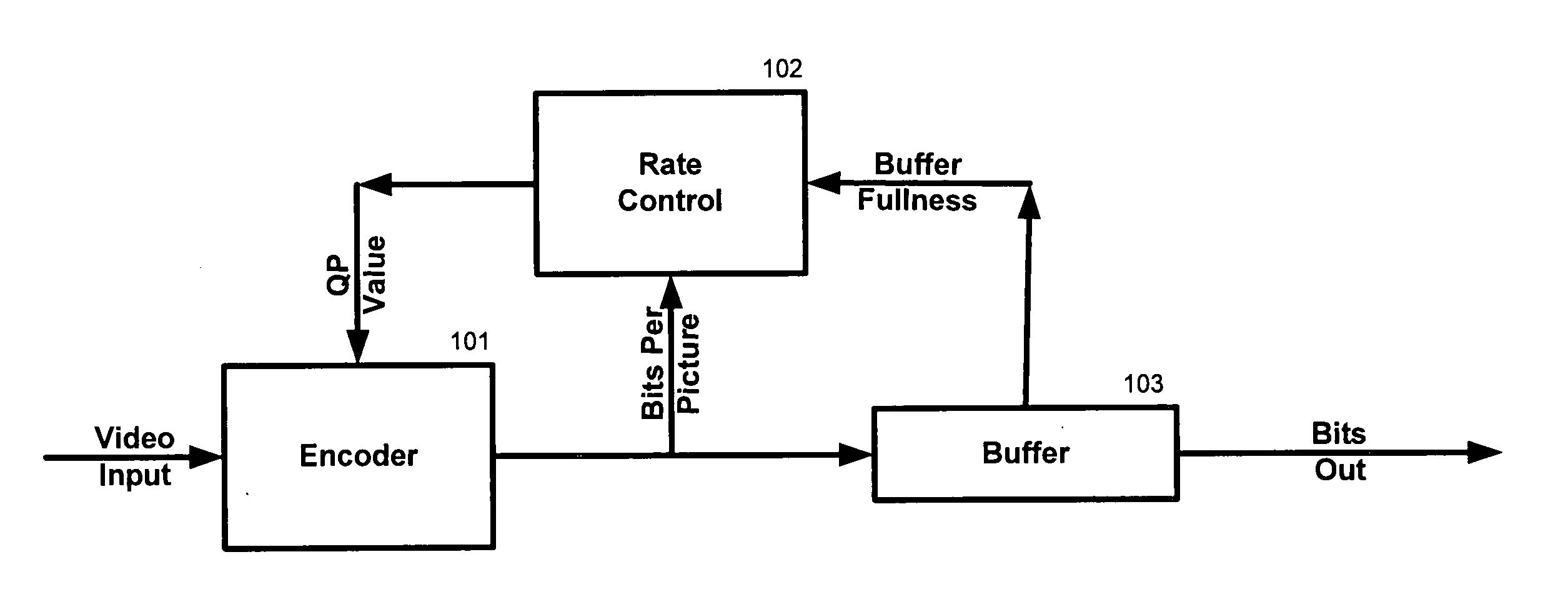

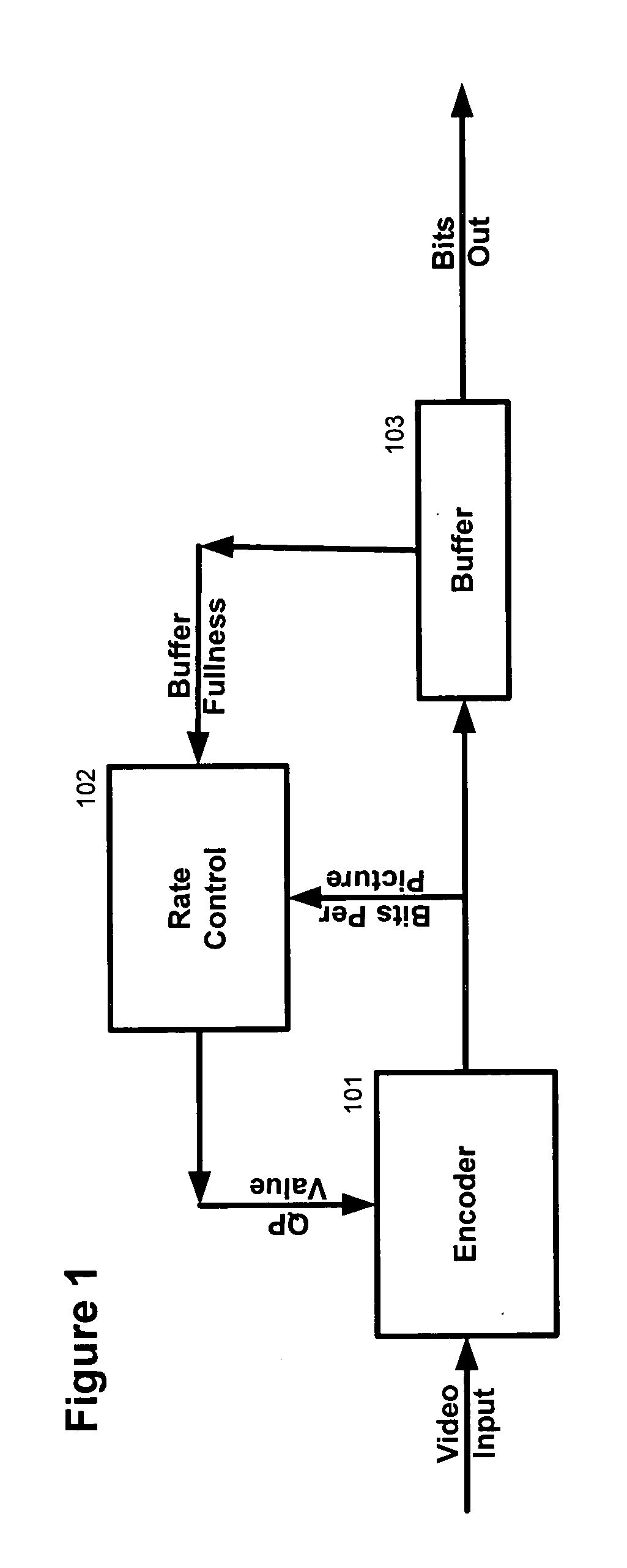

Picture layer rate control for video encoding

InactiveUS20070177665A1Color television with pulse code modulationColor television with bandwidth reductionScale modelComputation complexity

A one-pass picture-layer rate control (RC) method and system for controlling a video encoder: The bit allocation and determination of quantization parameter (QP) in this rate control method and system are based on a Rate-Quantization (R-Q) scale model. The R-Q model is a linear one, wherein the number of bits per picture is in reverse ratio of quantization scale for that picture. A conversion of exponential-based QP to linear-scaled QP is taken in the calculation of complexity model and determination of QP. The conversion is integer-based and is consistent with the quantization array defined in the H.264 standard.

Owner:SHARP KK

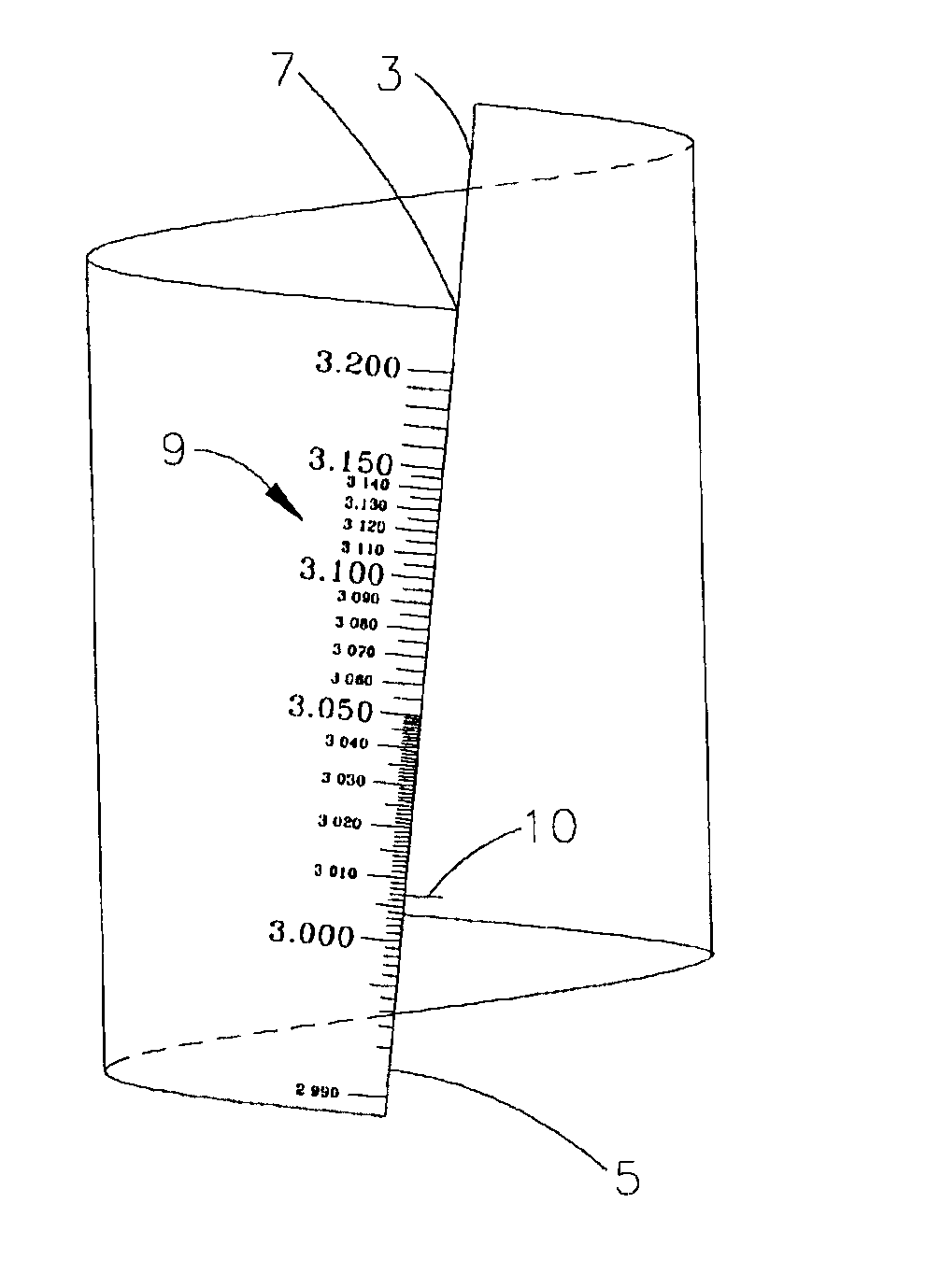

Helically formed cylinder of varying length and diameter

InactiveUS6904941B2Learn how to use it quicklyFast formingSleeve/socket jointsFluid pressure sealed jointsVernier scaleEngineering

A variable diameter cylinder made from a sheet having first and second edges that are opposite to each other and that slideably connect with each other to form a helical joint of a cylinder such that sliding the edges of the sheet along the joint varies a diameter and length of the cylinder. When marked with a scale, the cylinder acts as a measuring device that is both highly accurate and easy to use. A helical-based scale can be used alone, or a linear scale can be used in combination with a Vernier scale.

Owner:HOWARD DAVID W

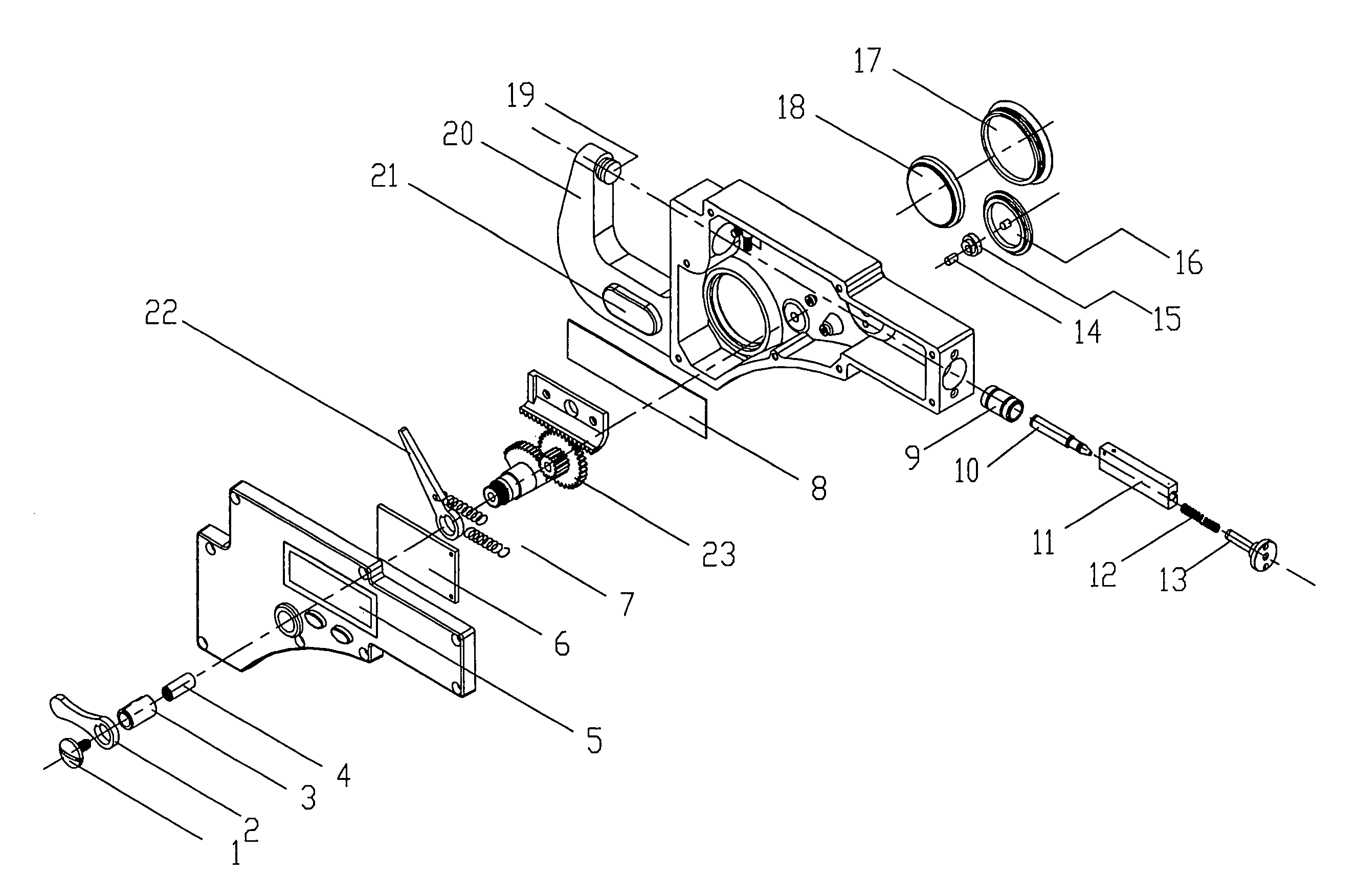

High-speed measuring electronic digital outside micrometer

ActiveUS8091251B1Without loss of accuracyFaster and precise travelMicrometersMechanical measuring arrangementsLinear motionMicrometer

A high-speed measuring electronic digital outside micrometer allowing a user to make measurements quickly and effectively compared to conventional electronic outside micrometers with rotary thread spindles, which have limited measuring speed. This high-speed measuring electronic digital outside micrometer features: a linear motion digital sensor, a linear scale digital sensor, a linear motion digital sensor base, a digital display unit, an electronic processing unit, a micrometer body, a linear spindle, a linear spindle movement unit, a spindle control unit, a micrometer anvil, and retractable springs. In a stationary position, the measuring surface of the micrometer anvil and the linear spindle are in contact to the other. By operating the spindle control unit, it will create distance between the micrometer anvil and the linear spindle measuring surface. This distance is a measurable distance of the micrometer. By set free of the spindle control unit, the retractable springs will re-set the micrometer to its stationary position.

Owner:ZHANG YANCHEN +1

Dual span absolute pressure sense die

InactiveUS20080105057A1Small voltageHigh pressureFluid pressure measurement using ohmic-resistance variationMultiple fluid pressure valves simultaneous measurementPressure senseEngineering

An absolute pressure sensor includes a sense die with a reference chamber on a top side thereof. The reference chamber comprises a precisely fabricated beam that limits the travel of a diaphragm. The beam can be positioned in a cap or cover member of the sense die, thereby allowing the sense die diaphragm to move freely for a particular distance. Over this distance, the sense die will have one sensitivity. When the sense die is pressurized to a certain point, the diaphragm moves until it contacts the beam member in the cap or cover. When the diaphragm hits the beam, the sensitivity of the sense die changes, thereby allowing a smaller voltage out for the greater pressure in. Such an arrangement permits the sensor to provide a function that accurately measures low pressure and measures a higher pressure without utilizing a linear scale.

Owner:HONEYWELL INT INC

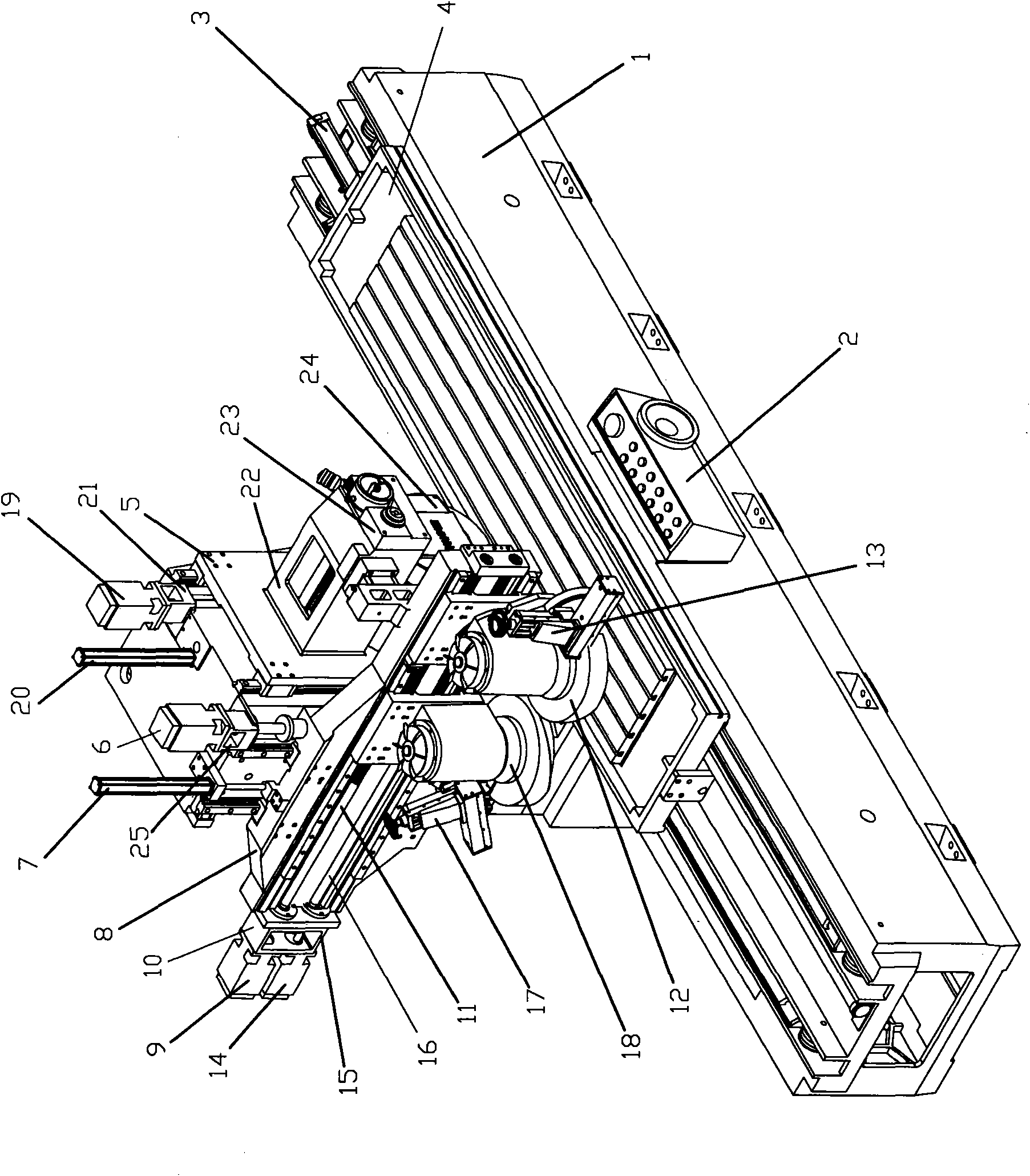

Numerically controlled multi-functional surface grinding machine

InactiveCN101559575AIncrease productivityGood value for moneyGrinding drivesGrinding headsReciprocating motionClosed loop

The invention relates to the field of grinding machine used for mechanical processing, in particular to a numerically controlled multi-functional surface grinding machine which comprises an upright post, a vertical grinding wheel head mechanism, a horizontal grinding wheel head mechanism, an operation box, a worktable mechanism and a base; both the vertical grinding wheel head mechanism and the horizontal grinding wheel head mechanism are arranged on the upright post; and the upright post, the operation box and the table mechanism are all arranged on the base. Compared with the prior art, the invention adopts the matched use of the vertical grinding wheel head mechanism and the horizontal grinding wheel head mechanism which are linked with the reciprocating motion of a worktable and form fully closed loop control by being matched with the information of related position of the feedback of a precise linear scale, and realizes the grinding of planes, curved surfaces or guide surfaces and the like after one-time clamping of the workpiece, thus having higher production efficiency and higher cost performance.

Owner:洪清德

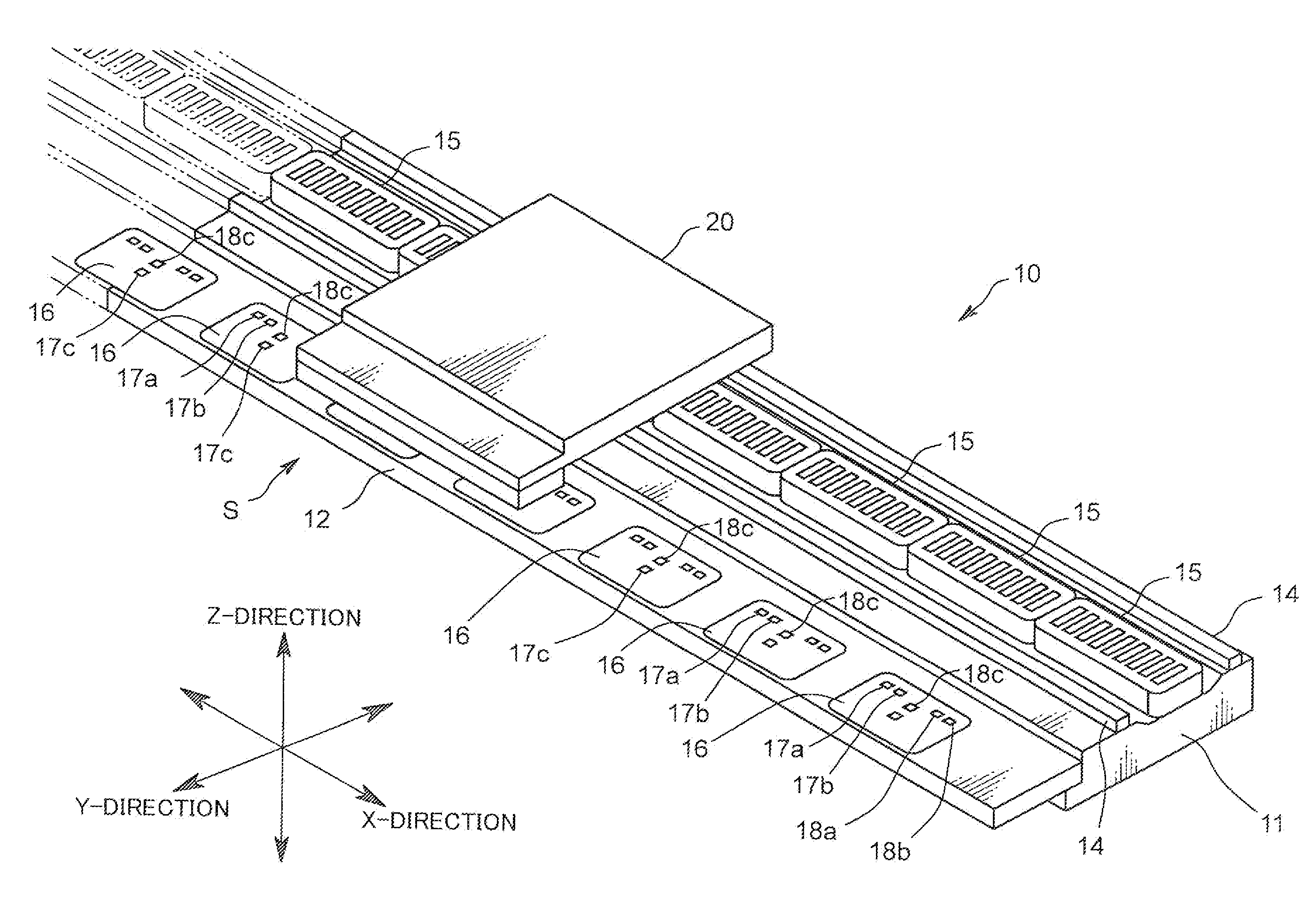

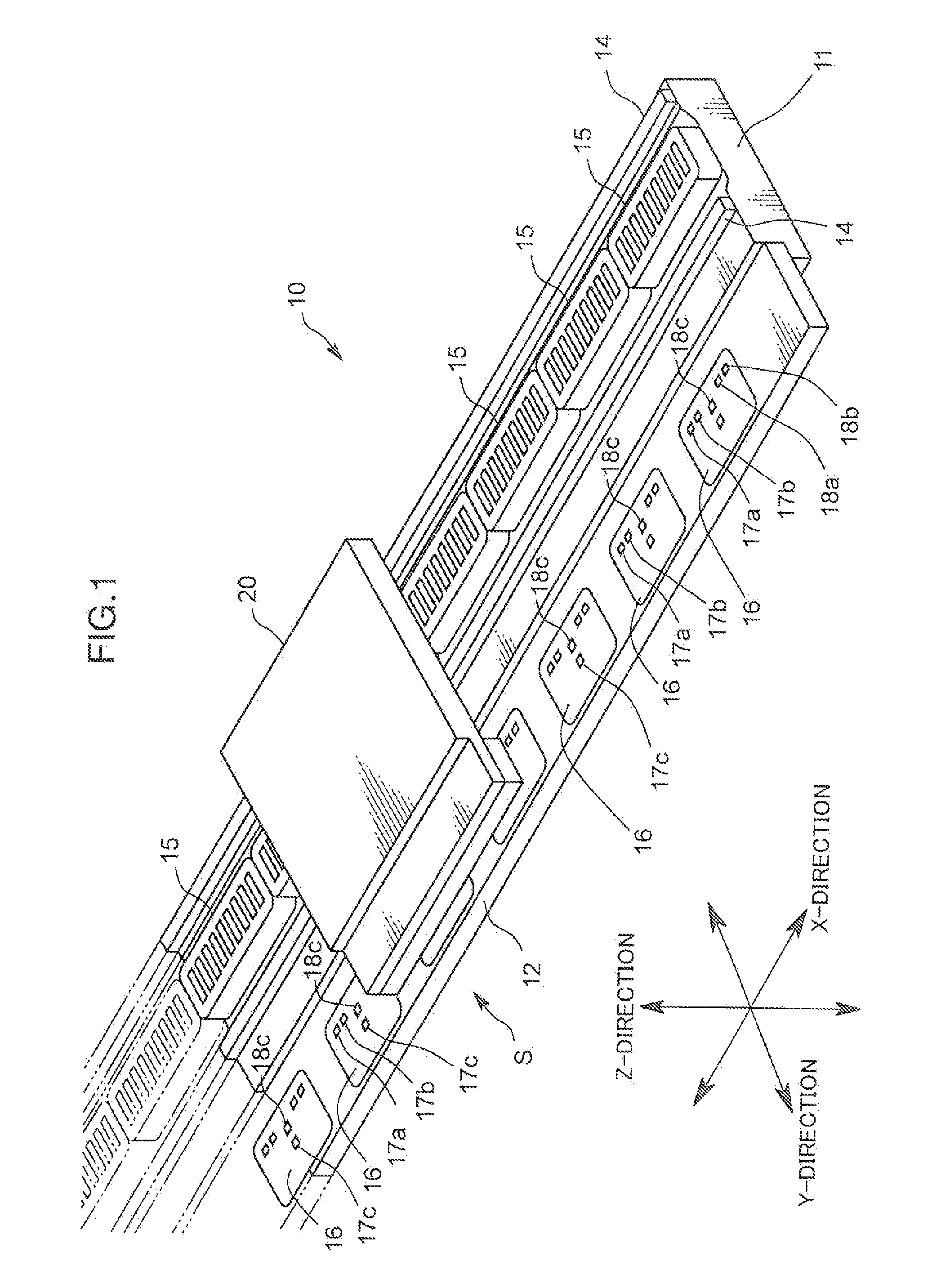

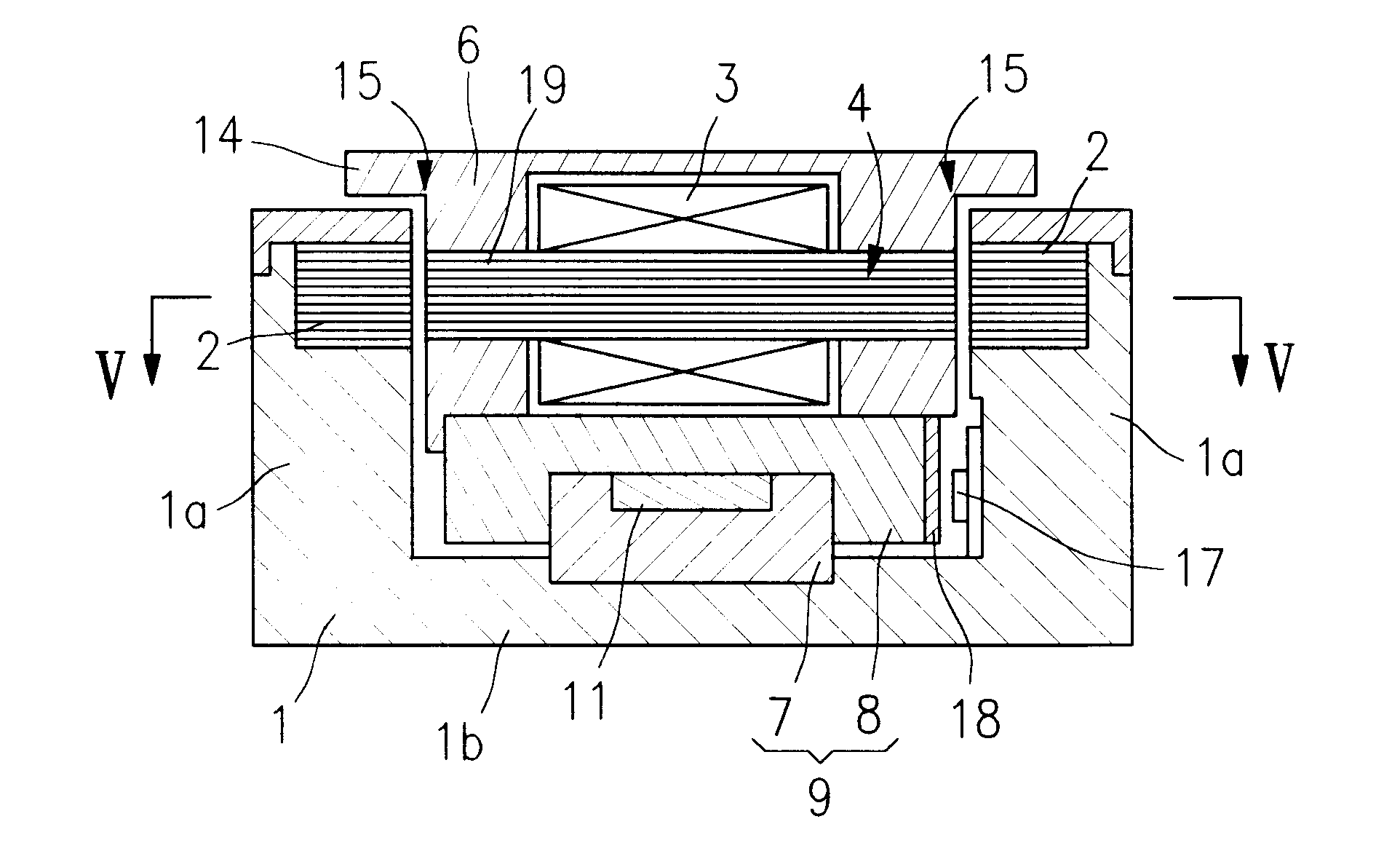

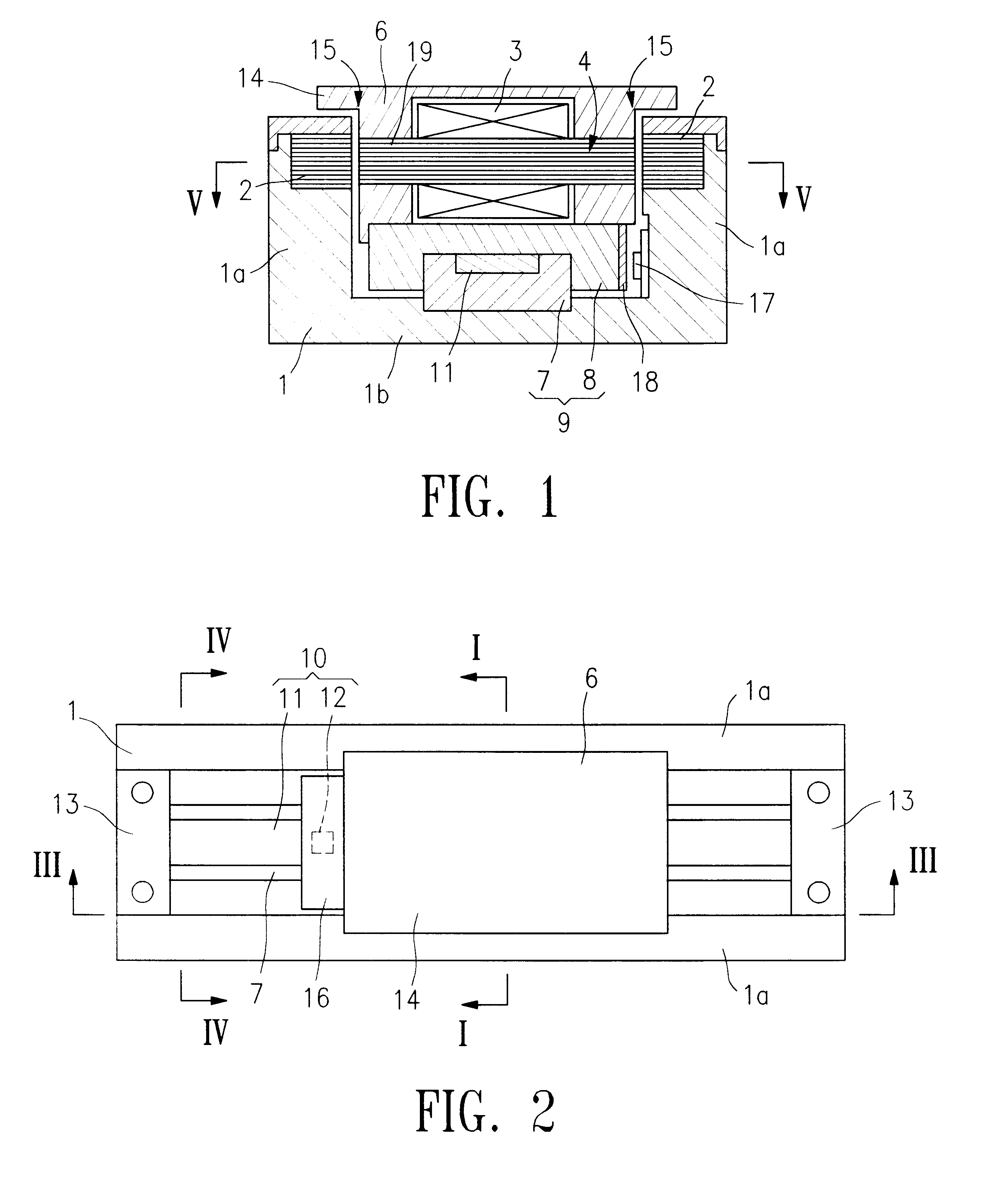

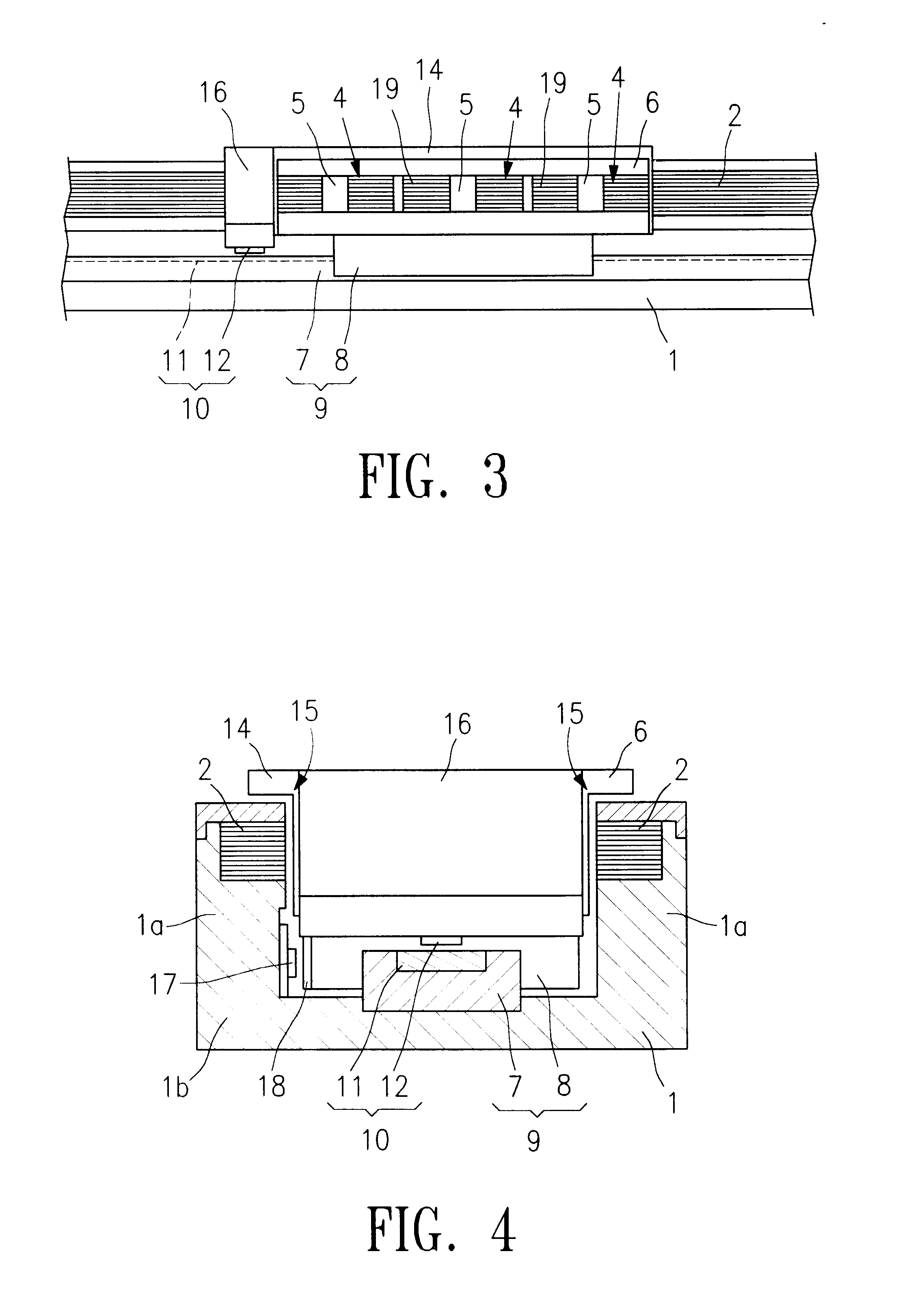

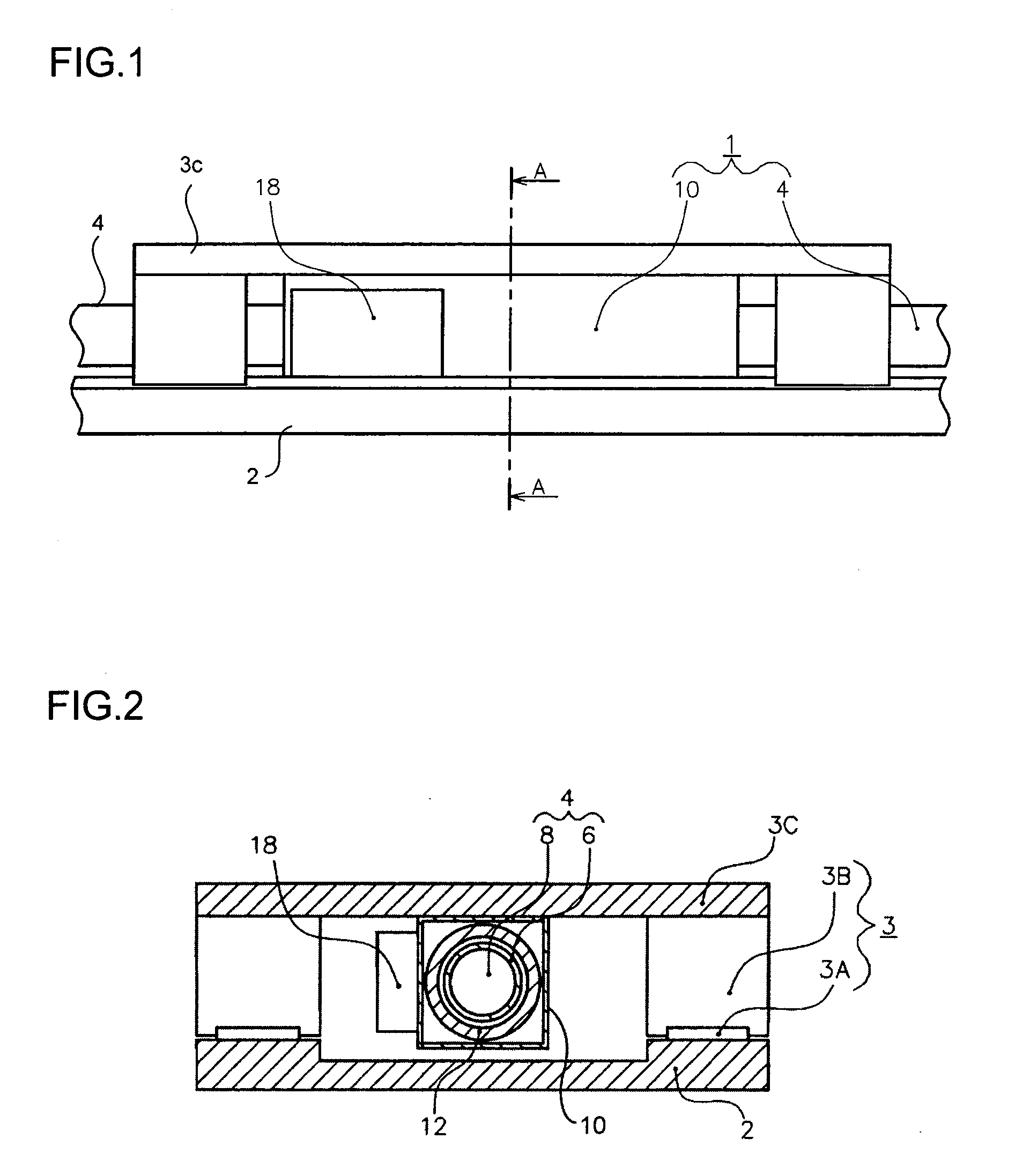

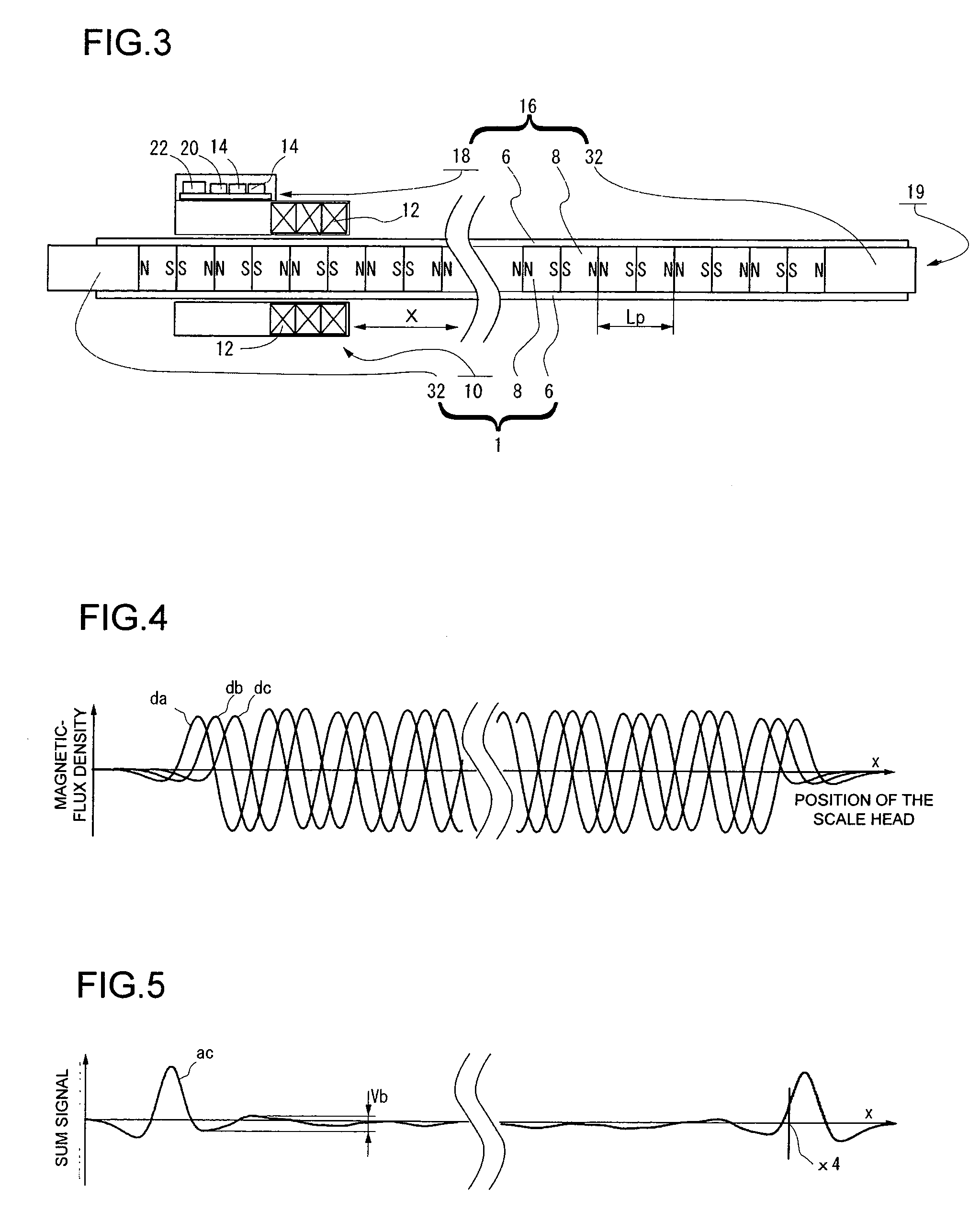

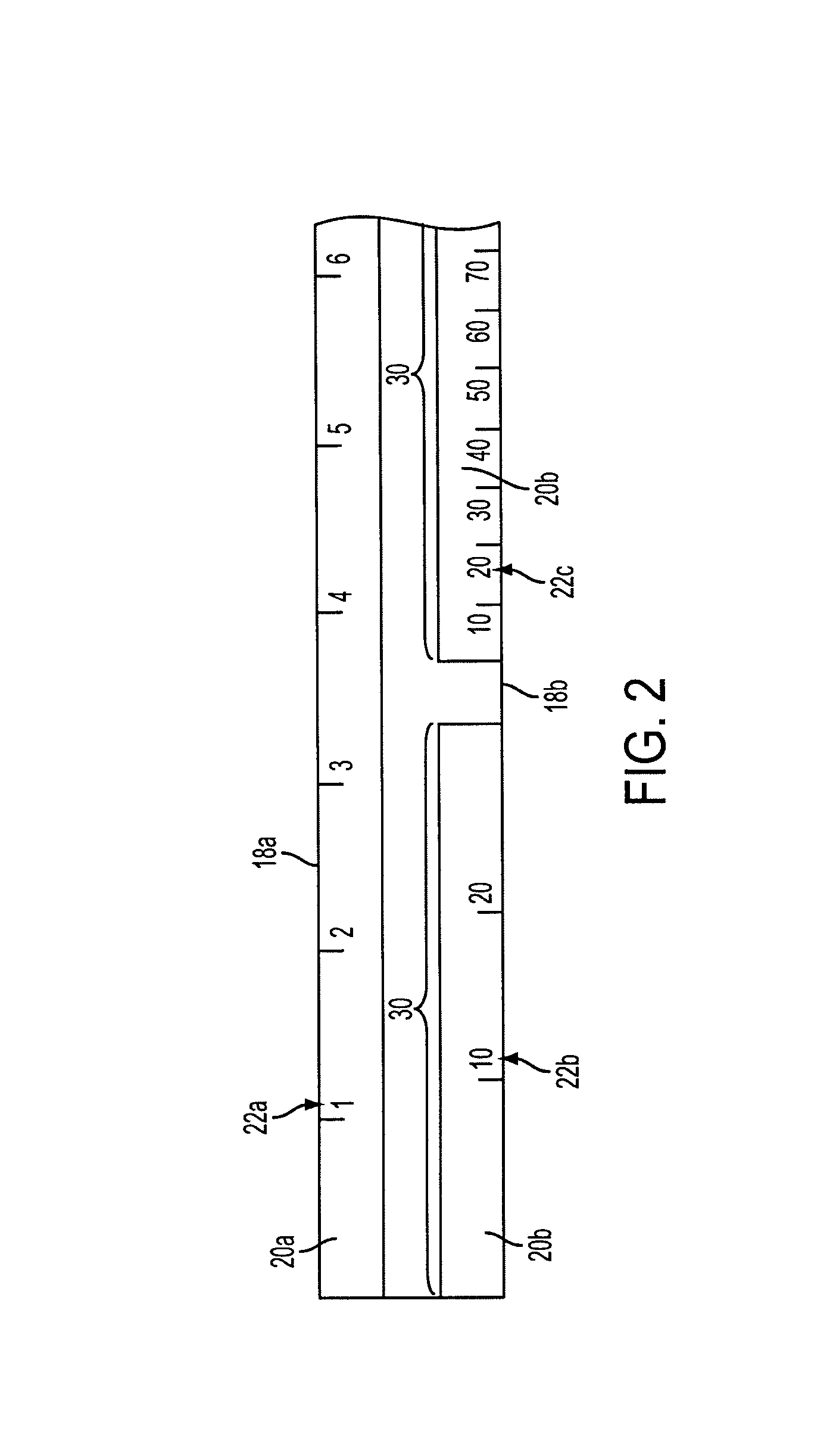

Linear scale, linear motor, and linear motor controller

ActiveUS20110109252A1Continuous detectionDC motor speed/torque controlAC motor controlWave shapeLeg length

Disclosed is a linear scale for obtaining a distance from a reference point. A scale detection mechanism is adapted to output waveform signals of the same phase. Also the scale detection mechanism corresponds to a magnetic flux density generated by magnetic bodies of a scale element. The scale detection mechanism may be sensors. The sensors are arranged at even intervals corresponding to a scale length of the scale element. The sensors are adapted to output sine-wave signals having the same phase to continuously detect the scale element in a movement direction of the scale element. The scale element has opposite ends each has the same polarity and configured such that an output voltage of the single sensor detecting the end of the scale element is reduced to one-half of an output voltage of the single sensor detecting the remaining portion of the scale element.

Owner:YAMAHA MOTOR CO LTD

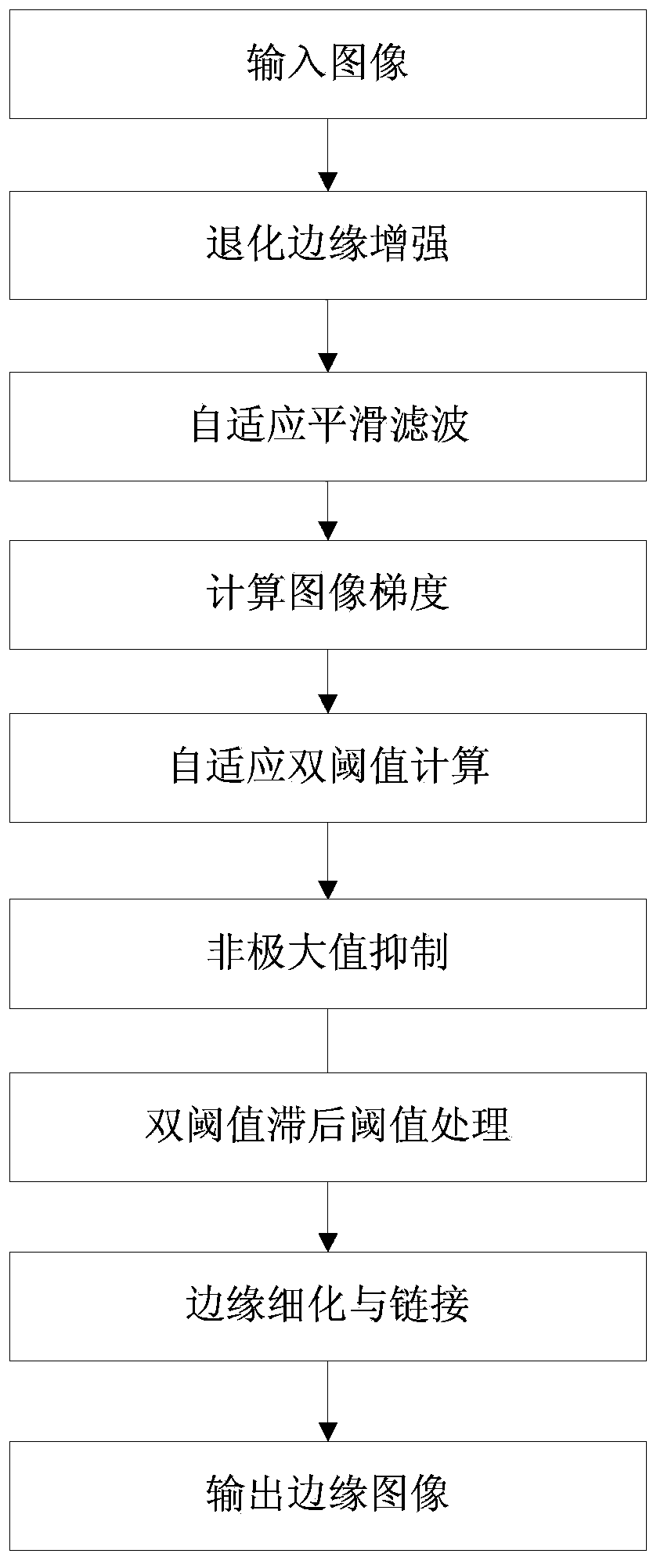

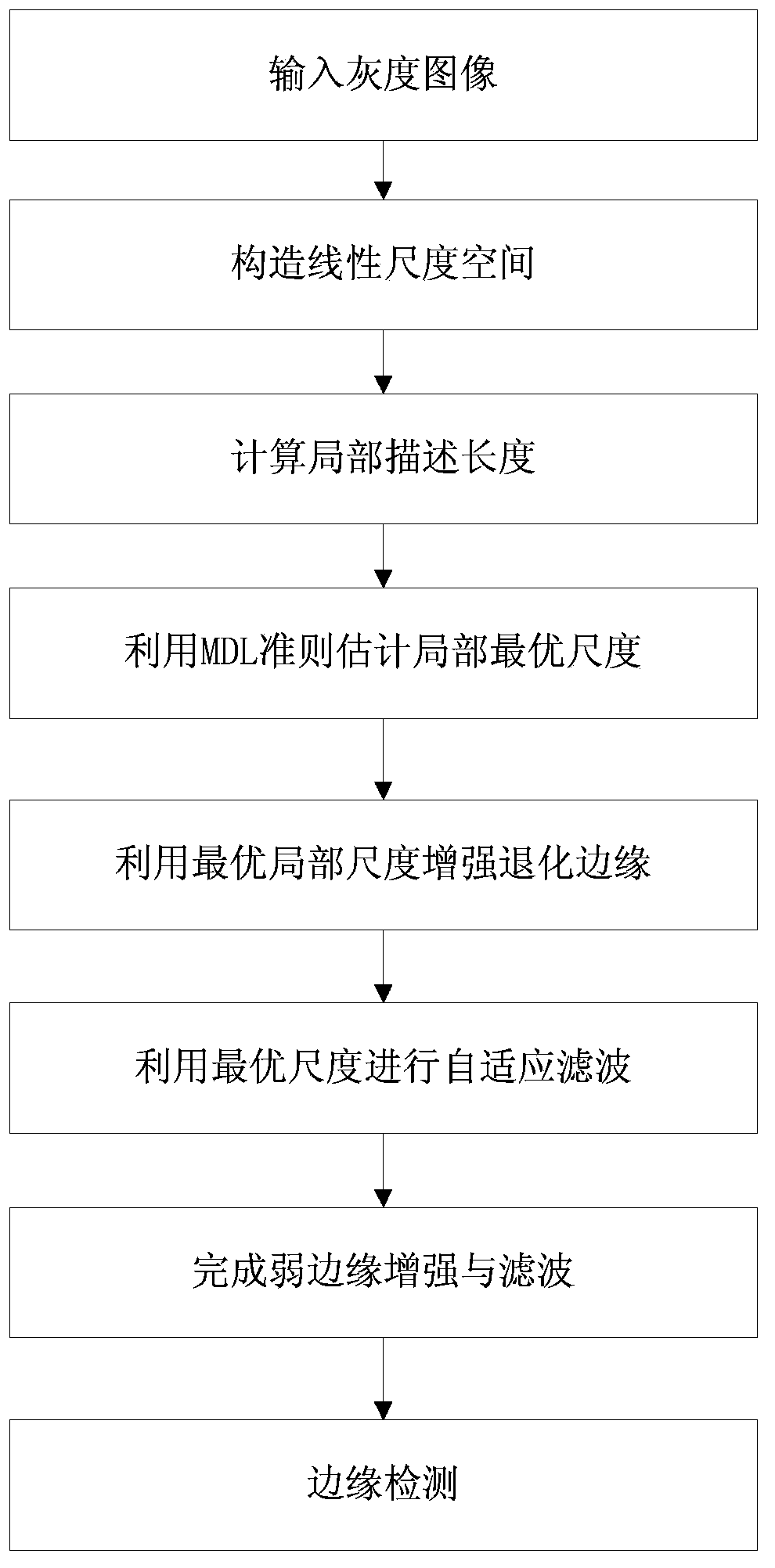

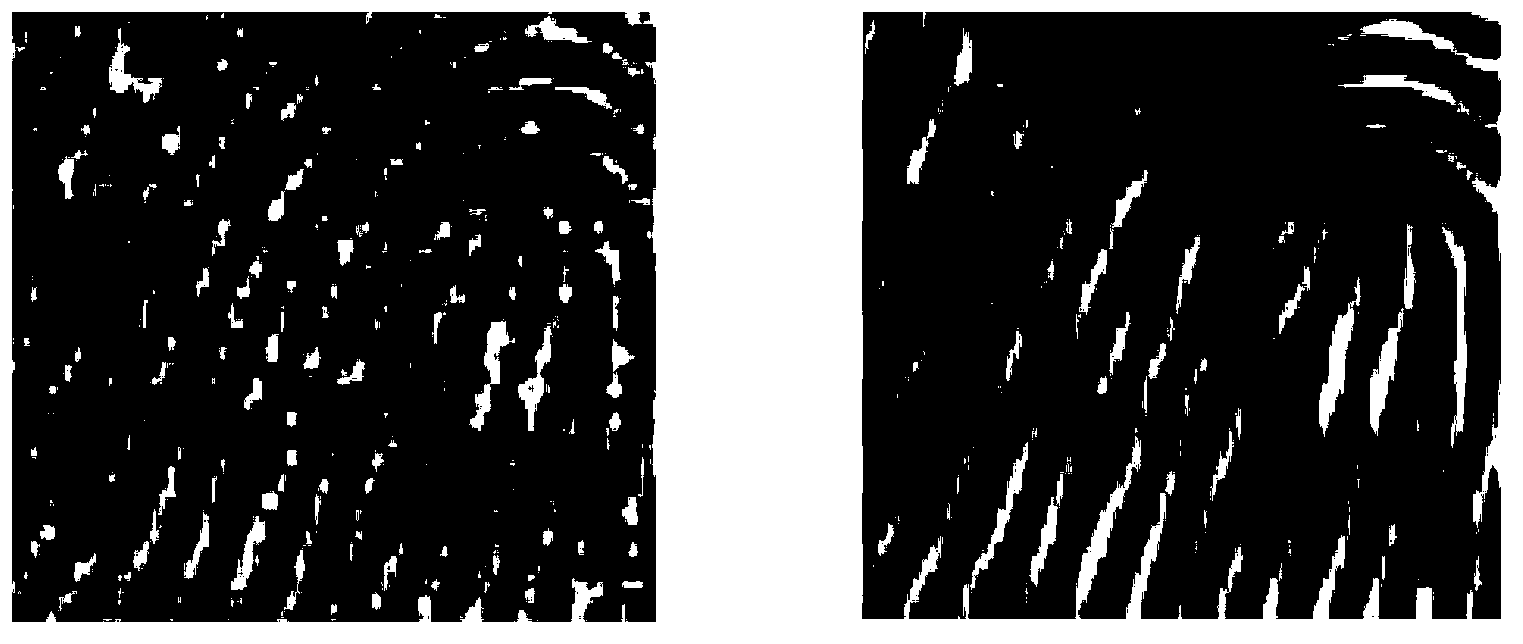

Multi-scale image weak edge detection method based on minimum description length

ActiveCN103440644AImprove stabilityGood filter smoothing effectImage enhancementImage analysisScale spaceSelf adaptive

The invention discloses a self-adaptive multi-scale image weak edge detection method based on the minimum description length (MDL) principle. The self-adaptive multi-scale image weak edge detection method based on the minimum description length principle comprises the steps that firstly, a linear scale space is constructed by means of multi-scale Gaussian smoothing, then the local description length of an image is calculated and the optimum local smoothness scale is determined by means of the minimum description length principle, and finally edge detection is carried out on the image treated with local smoothing to obtain all edges of the weak edge image. The self-adaptive multi-scale image weak edge detection method based on the minimum description length principle has the advantages that common noise can be filtered effectively, a real weak edge can be extracted, and the phenomena of edge fracture, edge deviation, false edge responses and the like can be avoided; in addition, the algorithm used in the method is a non-iterative filter method, the computing speed is greatly improved, and the stability of the algorithm is greatly improved.

Owner:SUN YAT SEN UNIV

Linear motor

InactiveUS6441515B1Easy to manageAccurate detectionStructural associationPropulsion systemsEngineeringLinear encoder

A linear motor includes a frame linearly extending in a longitudinal direction and having a channel-shaped cross section. The frame has sidewalls and a bottom wall that define a channel. A core is disposed on each of the side walls of the frame. An armature-side block is disposed in the channel of the frame. The armature-side block has a plurality of armatures, each of the armatures having two end surfaces at positions opposing to the cores provided on the side walls of the frame. One linear guide is disposed between the frame and the armature-side block. The linear guide has a rail fixed to the bottom wall of the frame and a slide block fixed to the armature-side block, such that one of the frame and the armature-side block is linearly movable relative to the other. A linear encoder having a linear scale and a sensor spaced a distance from the linear scale are disposed within the channel of the frame.

Owner:SANKYO SEIKI MFG CO LTD

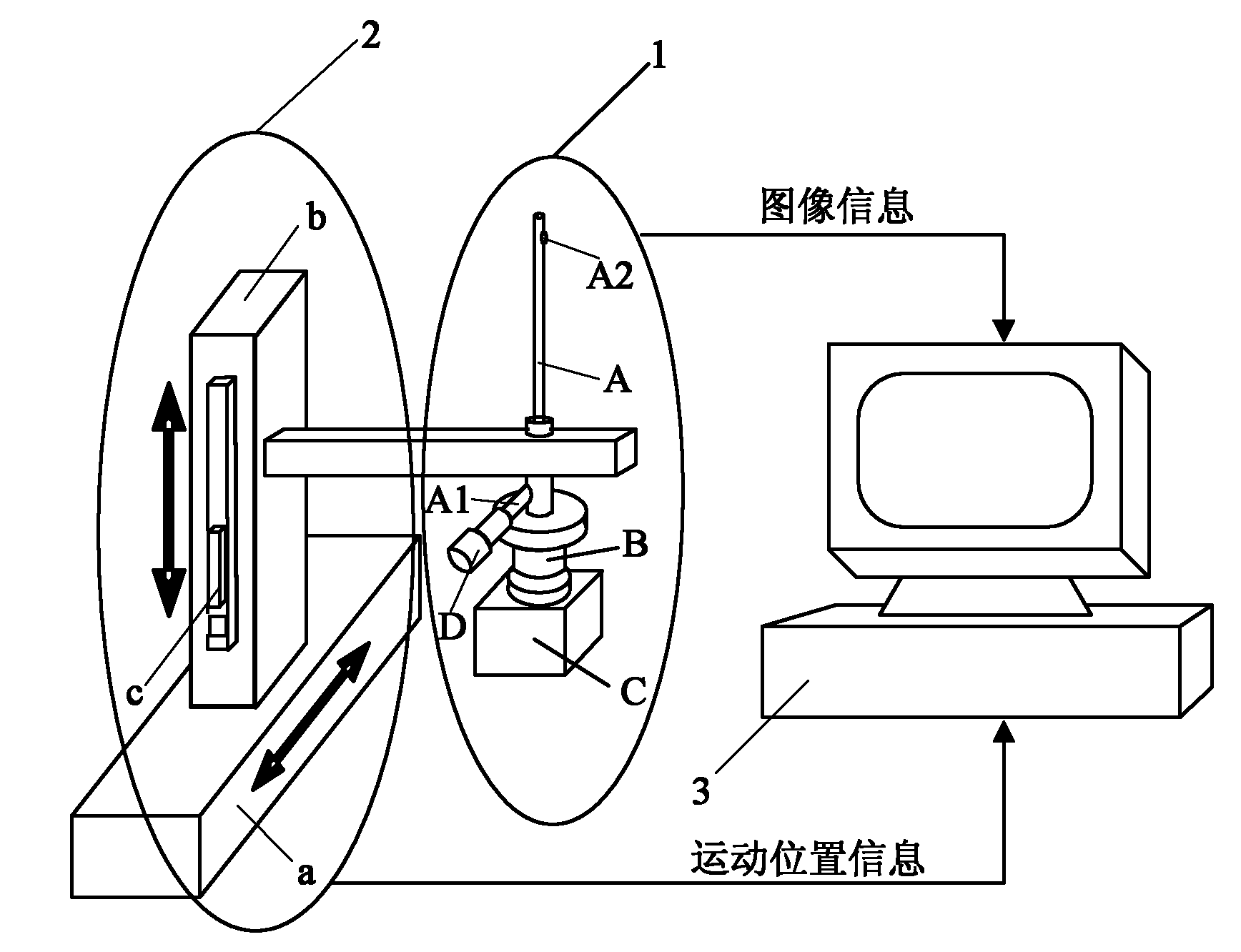

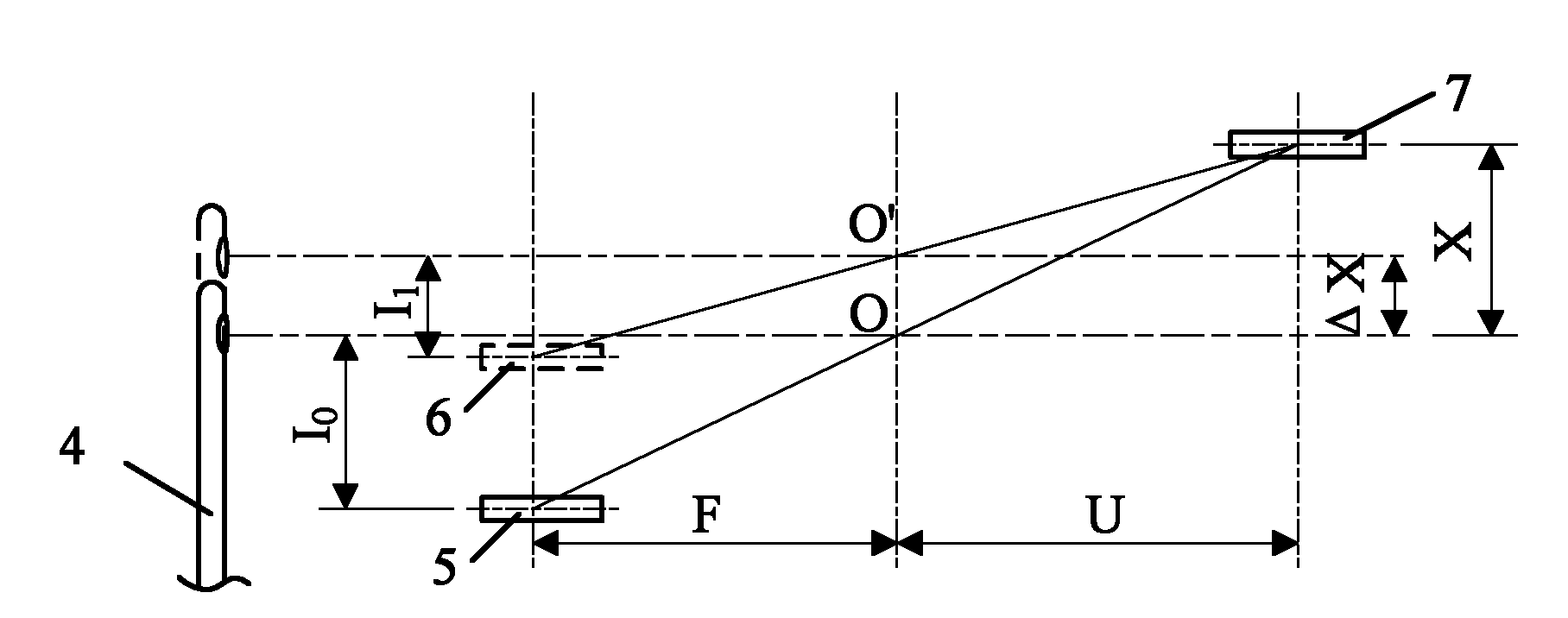

Assembly measuring device and method of tiny parts in narrow space based on industrial fiberscope

InactiveCN101852589AIncrease useRealize integrated lighting observationUsing optical meansLinear motionFiberscope

The invention discloses assembly measuring device and method of tiny parts in a narrow space based on an industrial fiberscope, used for the on line measurement on tiny parts in a narrow space. The assembly measuring device comprises a fiberscope detection device, a precise linear motion platform and a computer, wherein the fiberscope detection device acquires assembled image information and transmits the assembled image information to the computer; the precise linear motion platform is used for moving the fiberscope detection device; and the motion information of a precise linear guide rail is controlled by computer programming. In the measuring method, the fiberscope carries out measurement on two different positions in the measuring direction, and then the computer processes and computes by combining with image information measured twice with motion position information, thereby measuring the information for assembling the tiny parts. By adopting the industrial fiberscope and a light source interface thereof, the invention realizes the integrated illumination observation in the narrow space. The information on the motion trail of the fiberscope can be precisely obtained in real time by adopting the precise motion guide rail additionally provided with a linear scale to drive the fiberscope to move.

Owner:DALIAN UNIV OF TECH

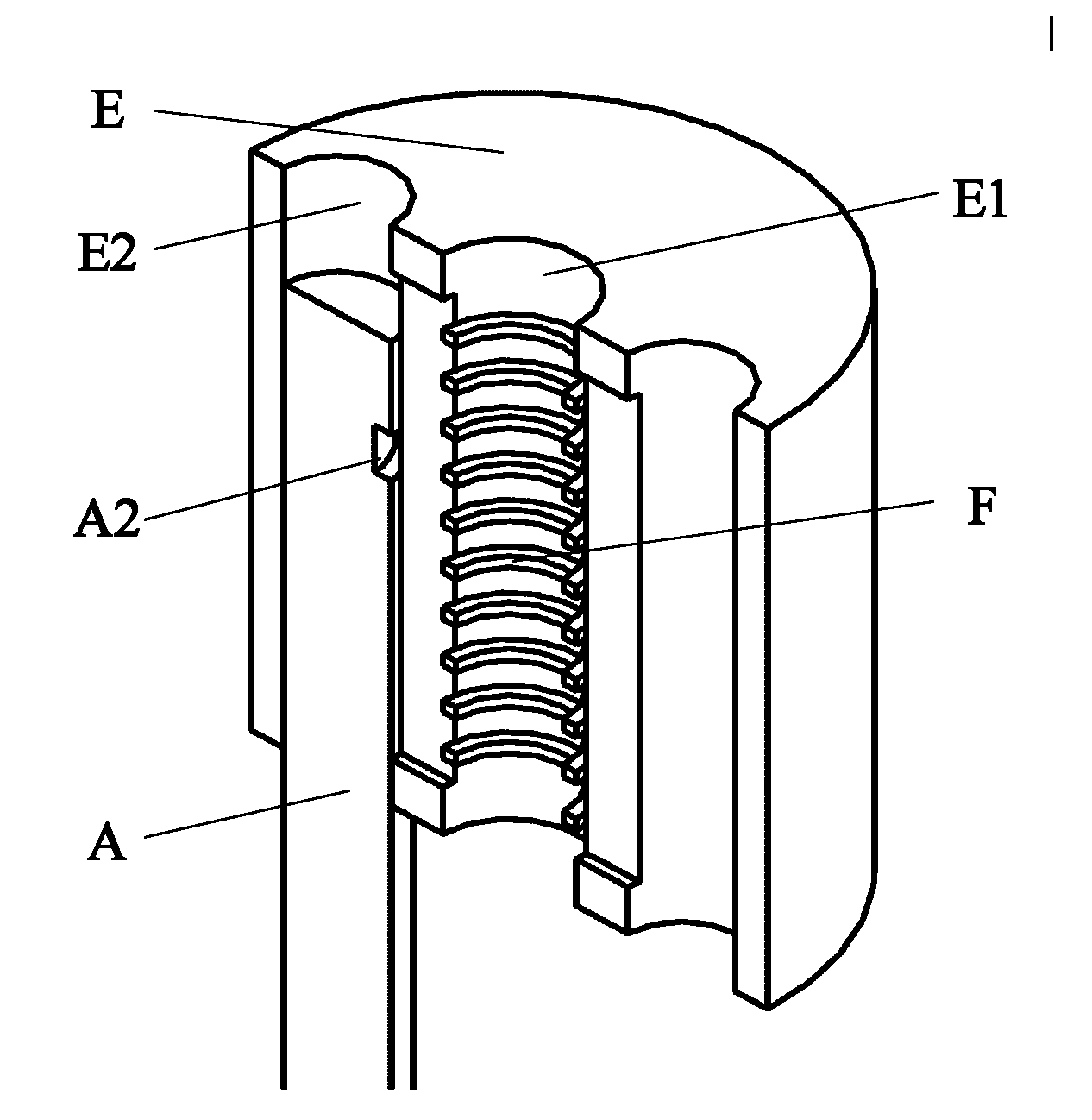

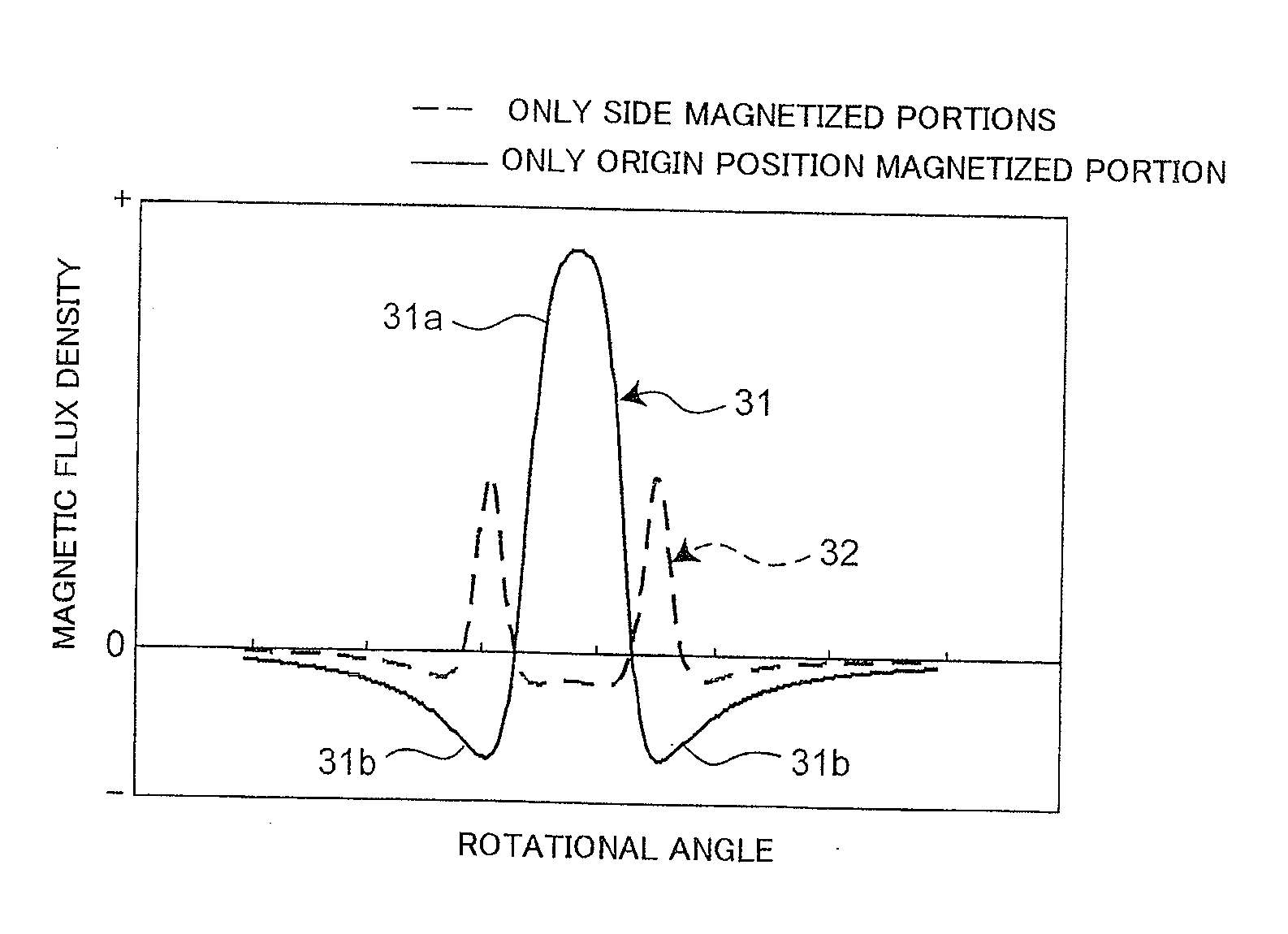

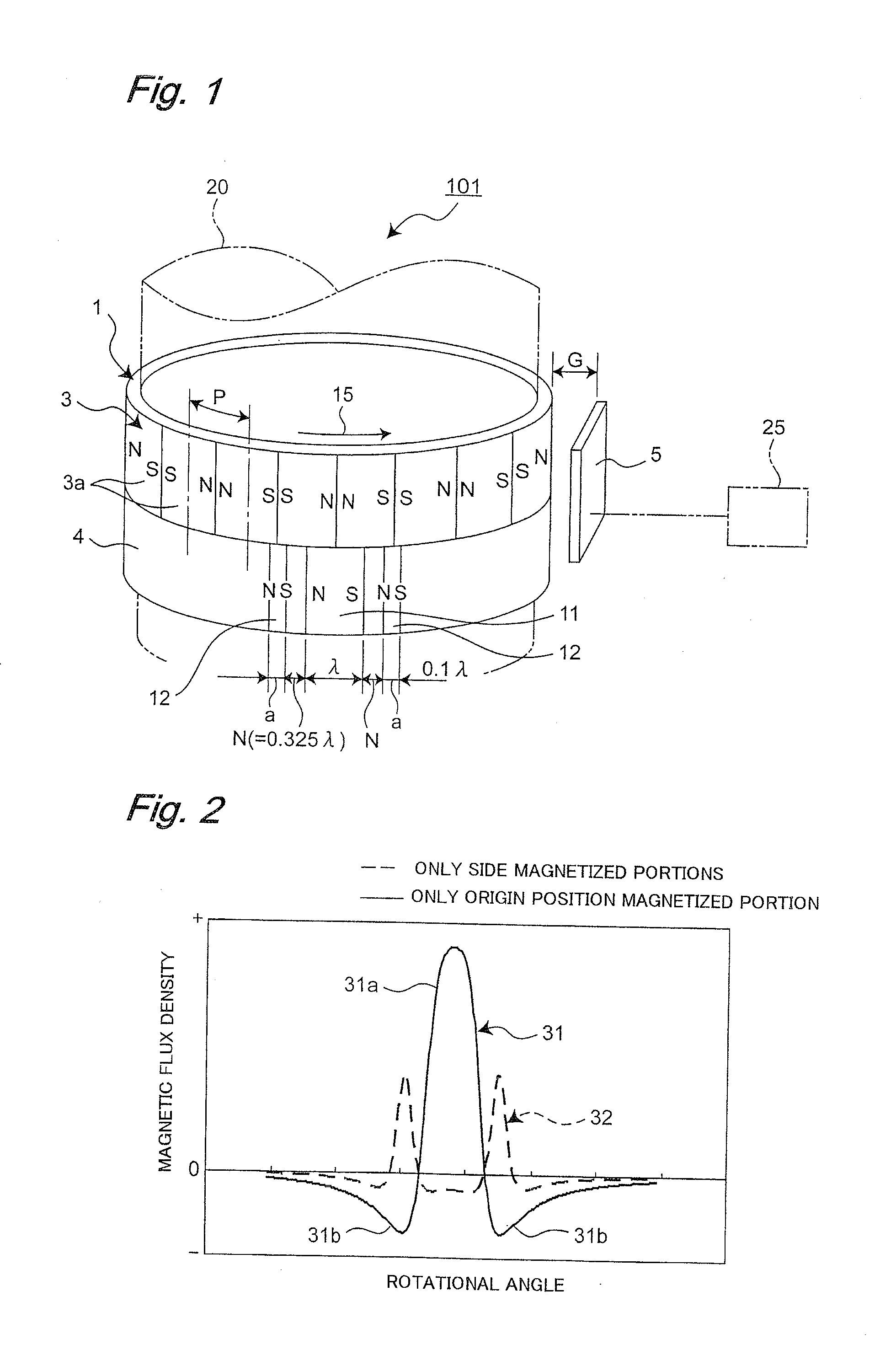

Origin position signal detector

InactiveUS20110291646A1Improve detection stabilityReduce false detectionMagnetic measurementsUsing electrical meansMagnetizationSignal detector

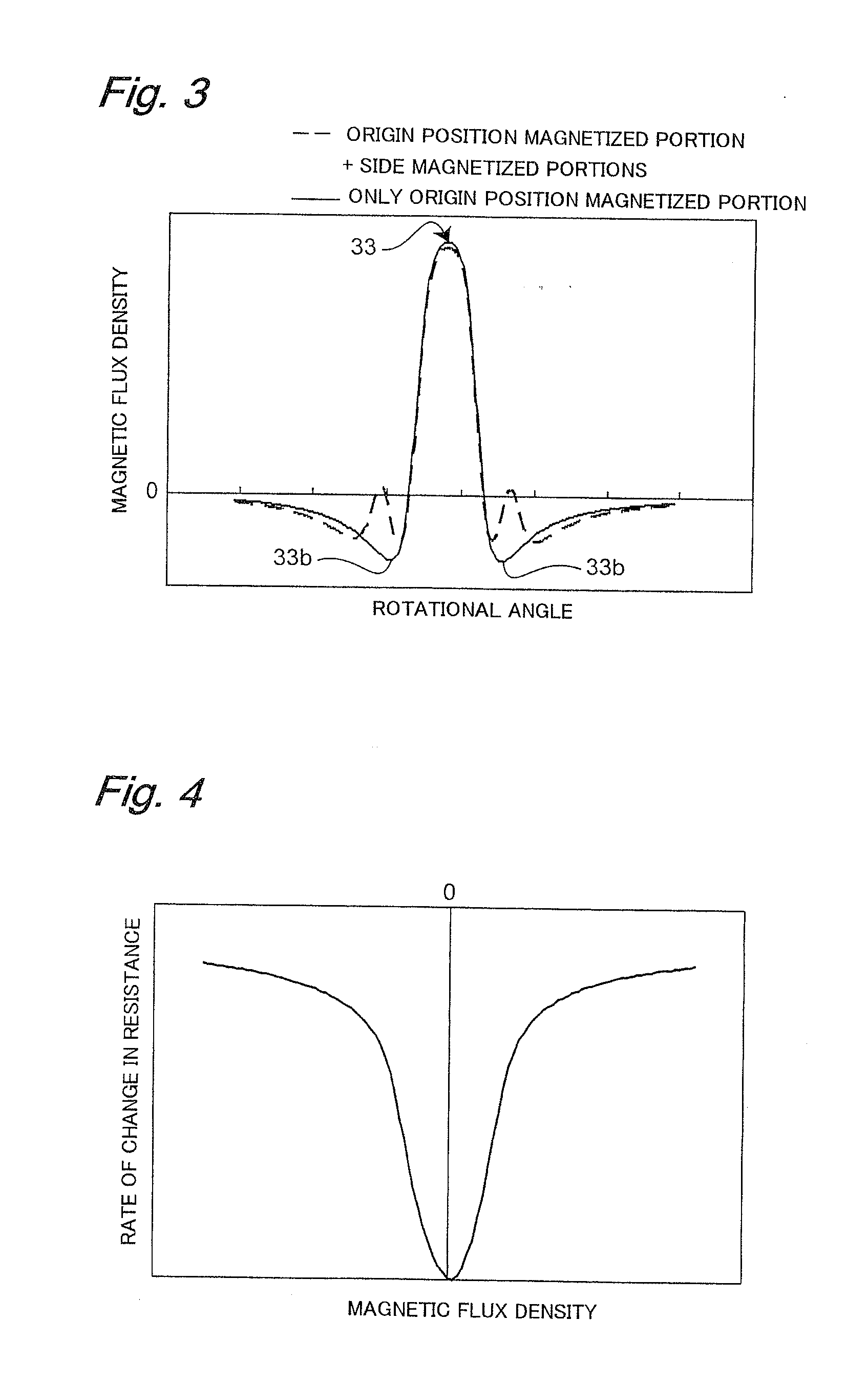

An origin position signal detector comprising: a rotary or linear scale (1) which includes an incremental track (3) magnetized at equal intervals and an origin position detection track (4) for detecting an origin position, and a magnetic sensor (5) which detects magnetic fields from the scale. The origin position detection track includes an origin position magnetized portion (11) and side magnetized portions (12) provided on both sides of the origin position magnetized portion (11) and magnetized with magnetization in the same direction at one or more positions as the origin position magnetized portion (11).

Owner:MITSUBISHI ELECTRIC CORP

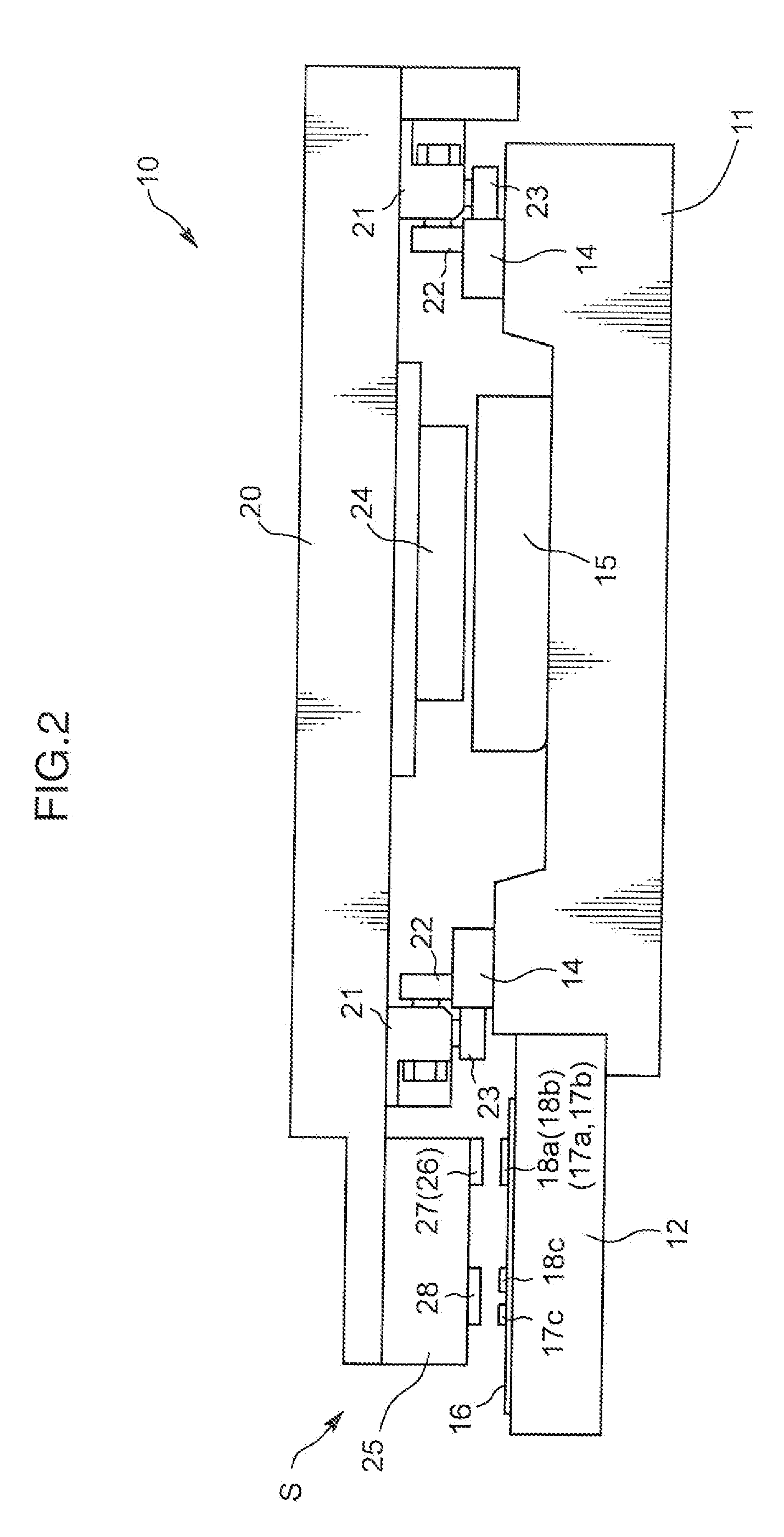

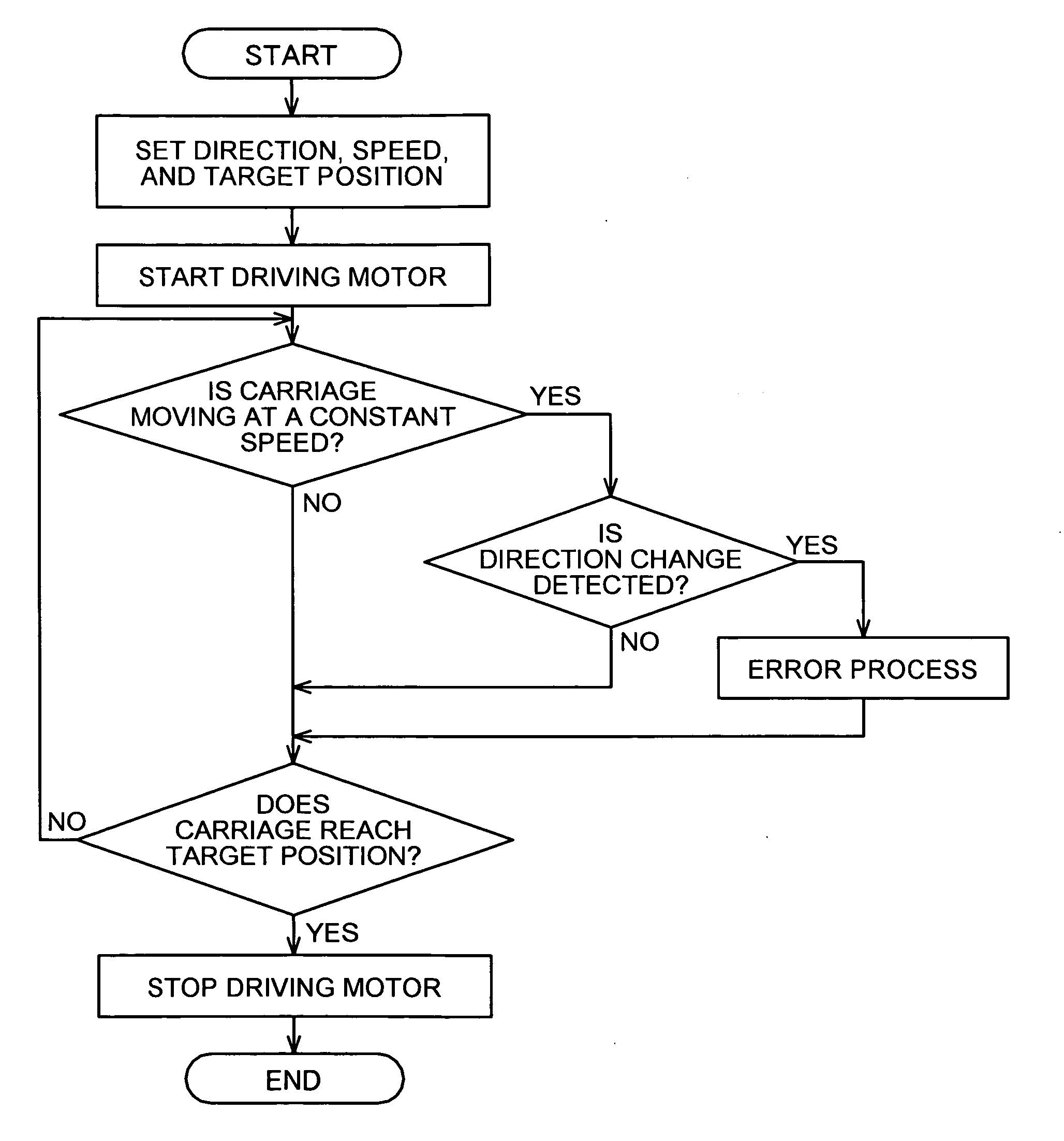

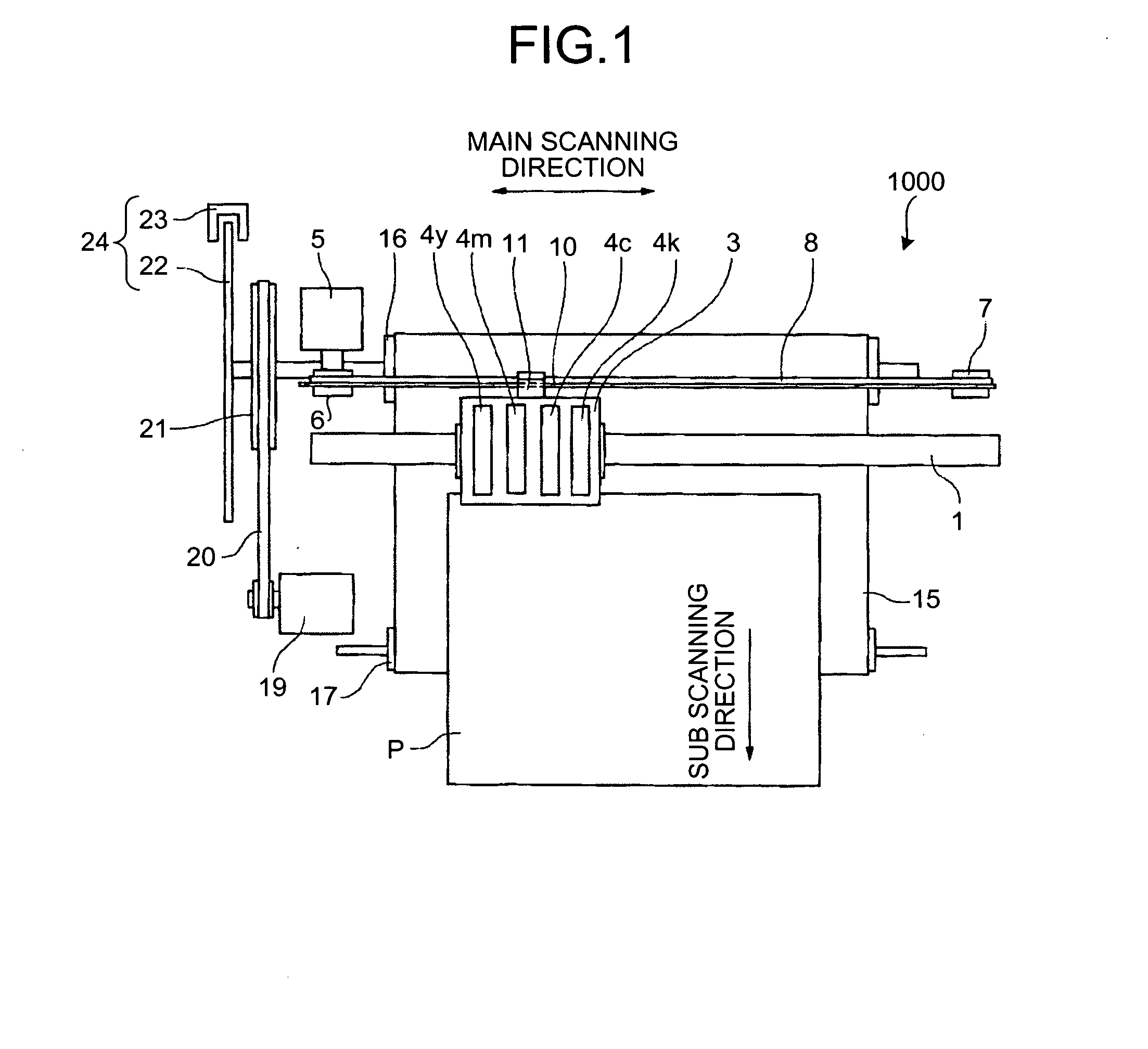

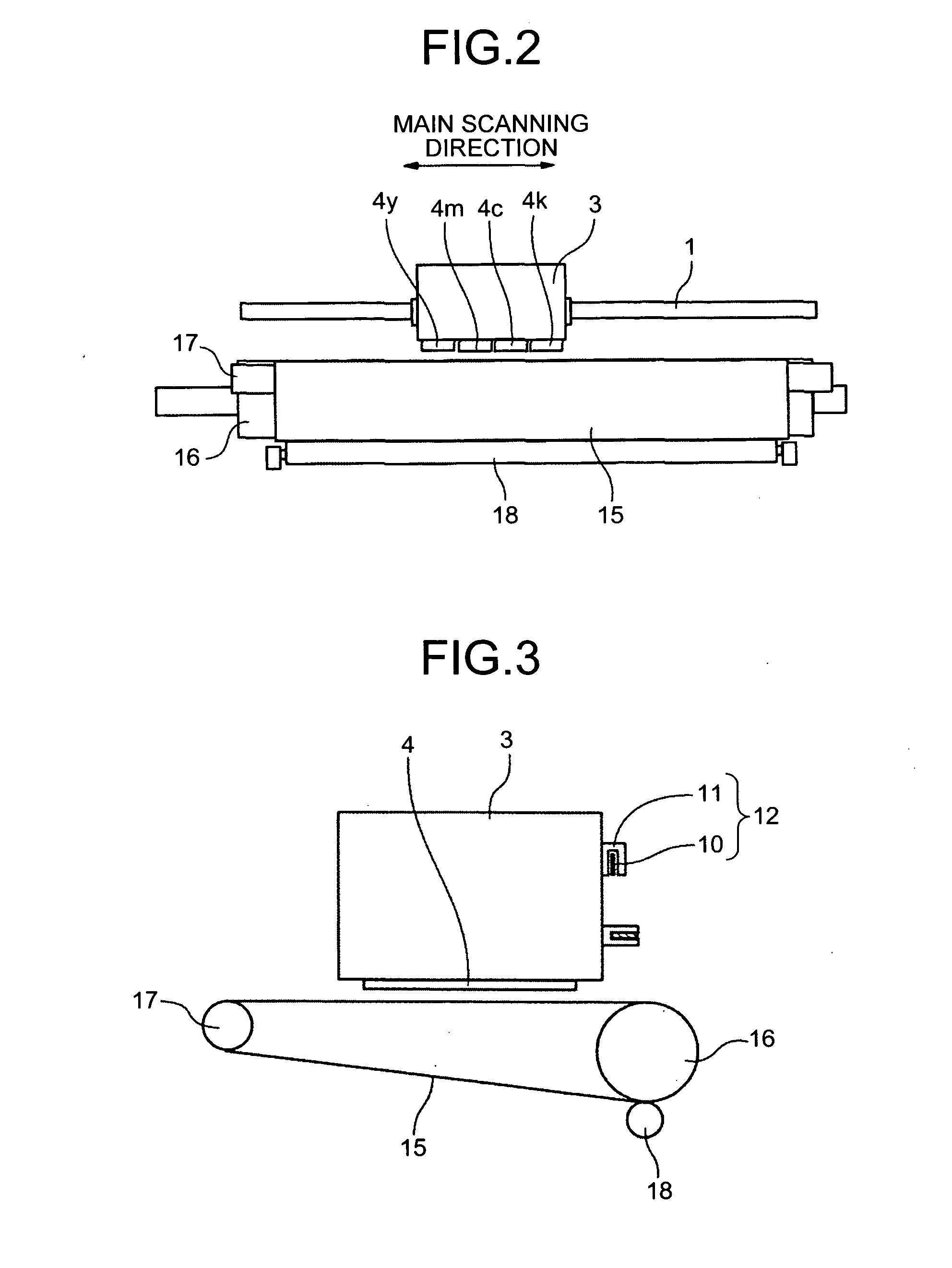

Image forming apparatus

InactiveUS20080225070A1Solve problemsSpacing mechanismsOther printing apparatusImage formationEngineering

In an image forming apparatus, a control unit determines that dirt is present on the linear scale when a detecting unit detects a change in a moving direction of a moving member while the moving member is moving at a constant speed.

Owner:RICOH KK

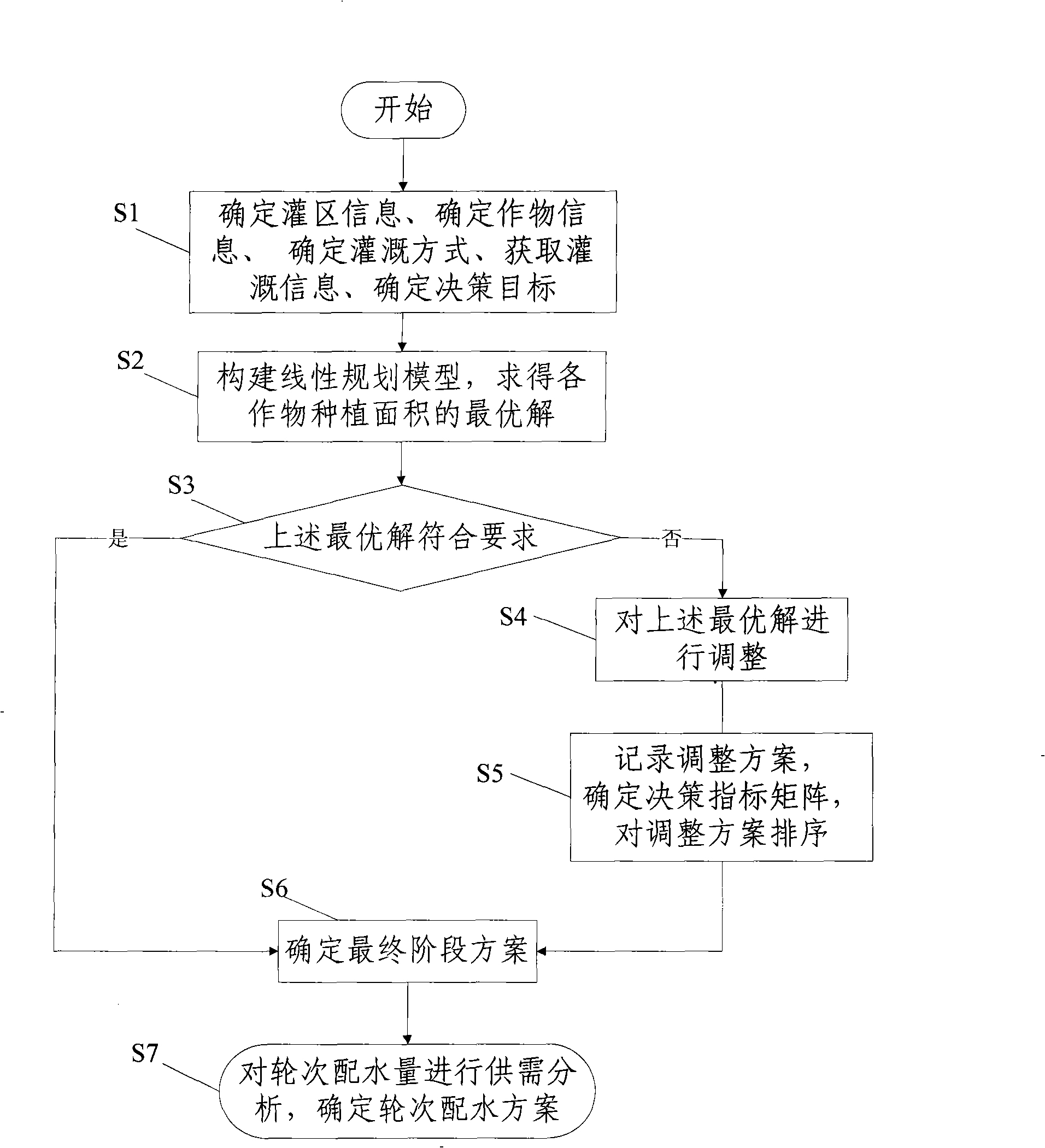

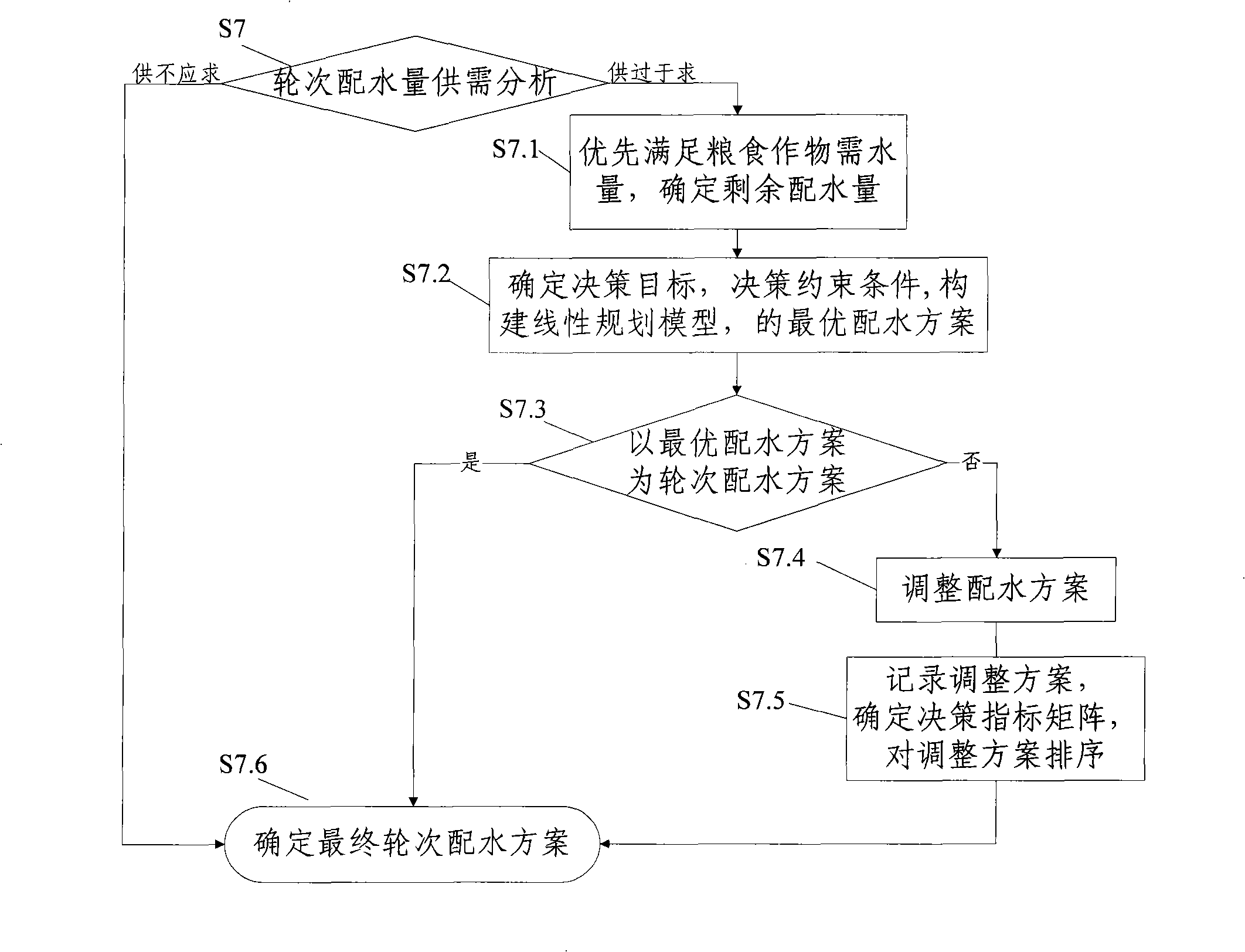

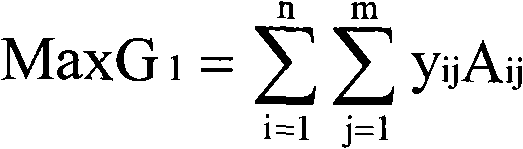

Determination method of irrigation district water delivery project

The invention relates to a determination method of a water distribution scheme in an irrigation area. The method is characterized in that by determining the information of the irrigation area and crops, a crop irrigation mode is determined, the irrigation information in the irrigation mode is acquired, and a decision objective of a stage water distribution scheme in the irrigation area is determined; by constructing a linear planning model, an optimal solution of crop planting area in the irrigation mode is obtained; by exchanging the optimal solution with the decision maker, an adjustment scheme is acquired for figuring out a decision index matrix, and the adjustment scheme is sorted by calculations such as linear scale transformation, linear weighting, and the like; and finally, the stage water distribution scheme and a shift water distribution scheme in the irrigation area are determined. The determination method adopts advanced irrigating theories and technologies, perfects the decision process of irrigation water management, and improves the efficiency of the irrigation water management.

Owner:CHINA AGRI UNIV

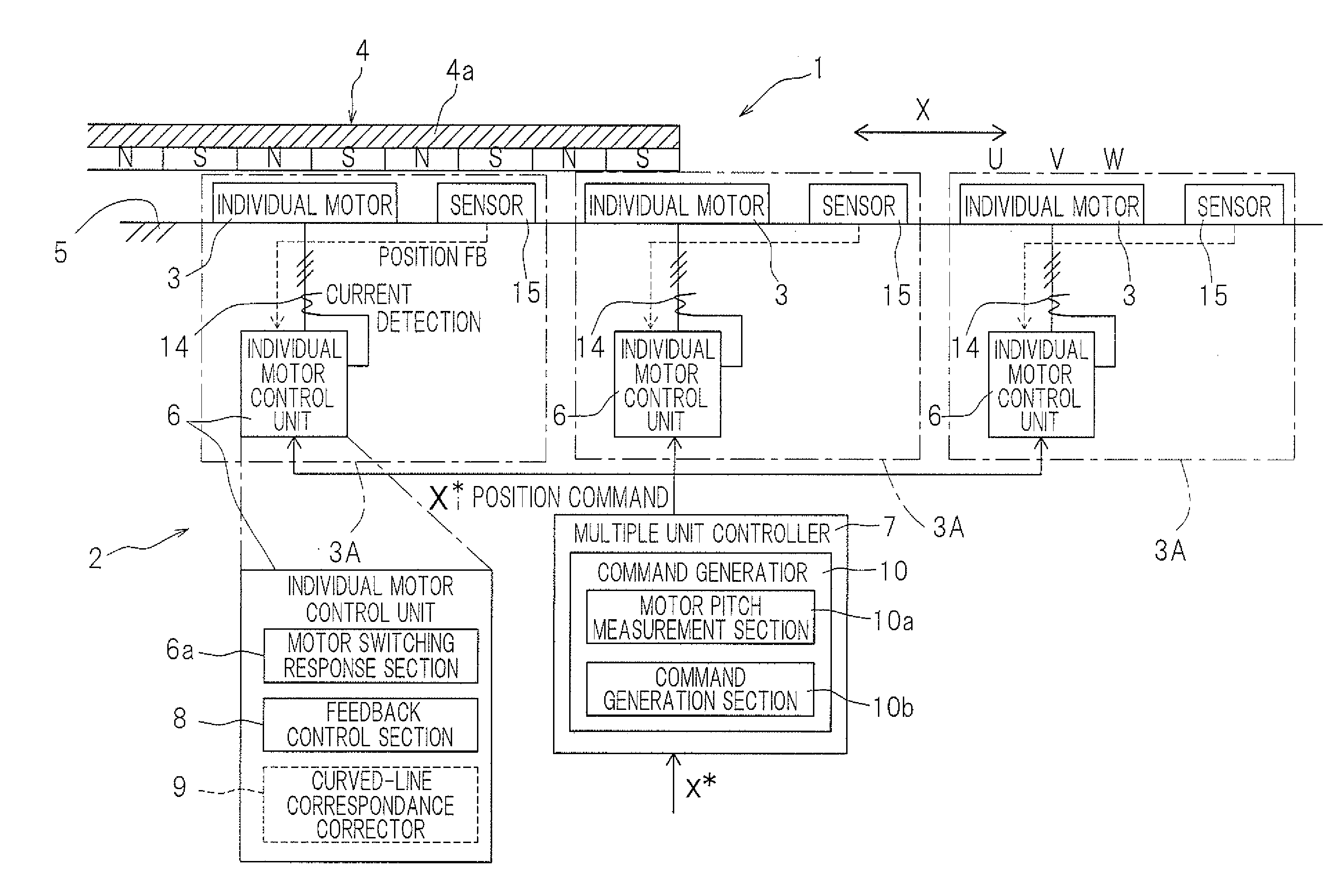

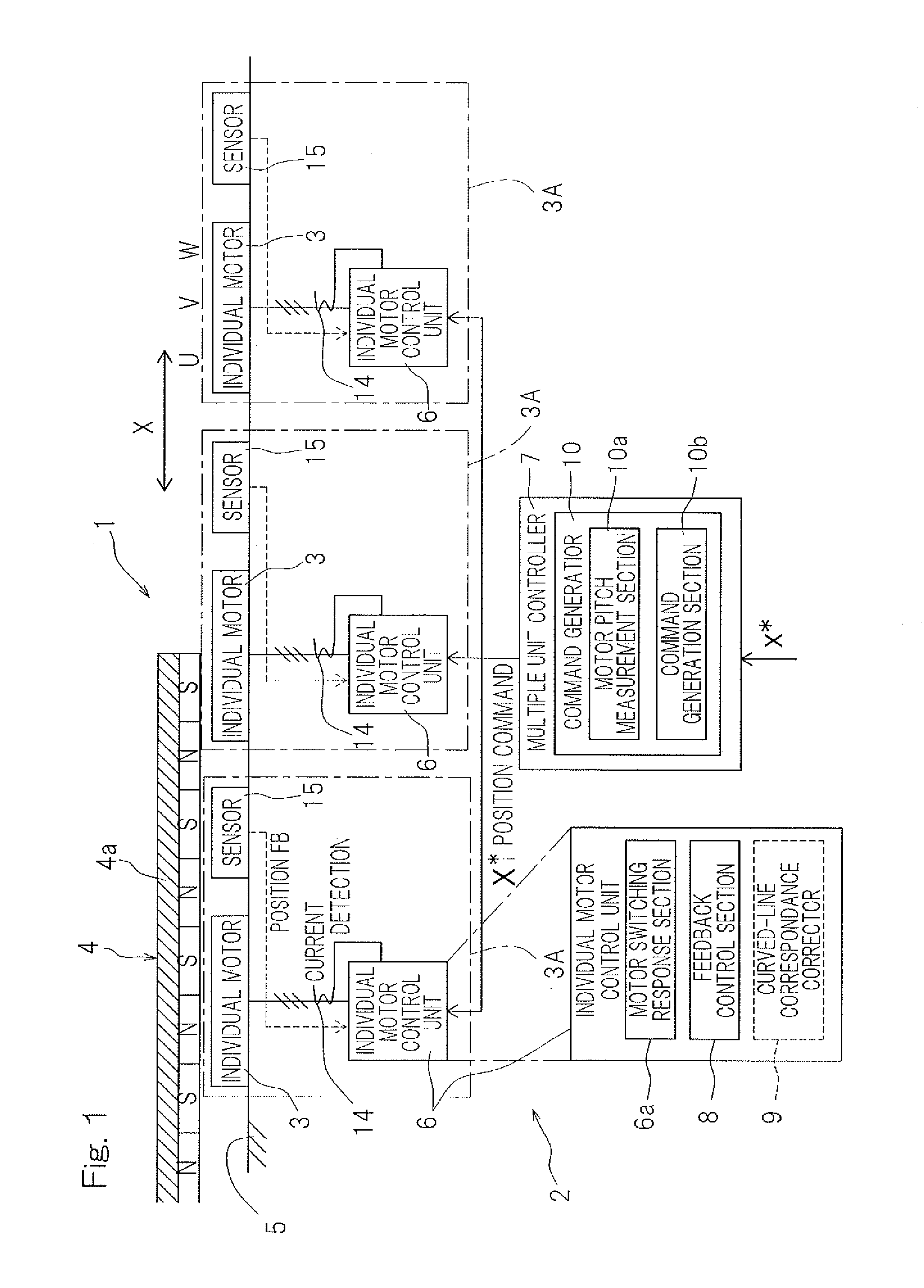

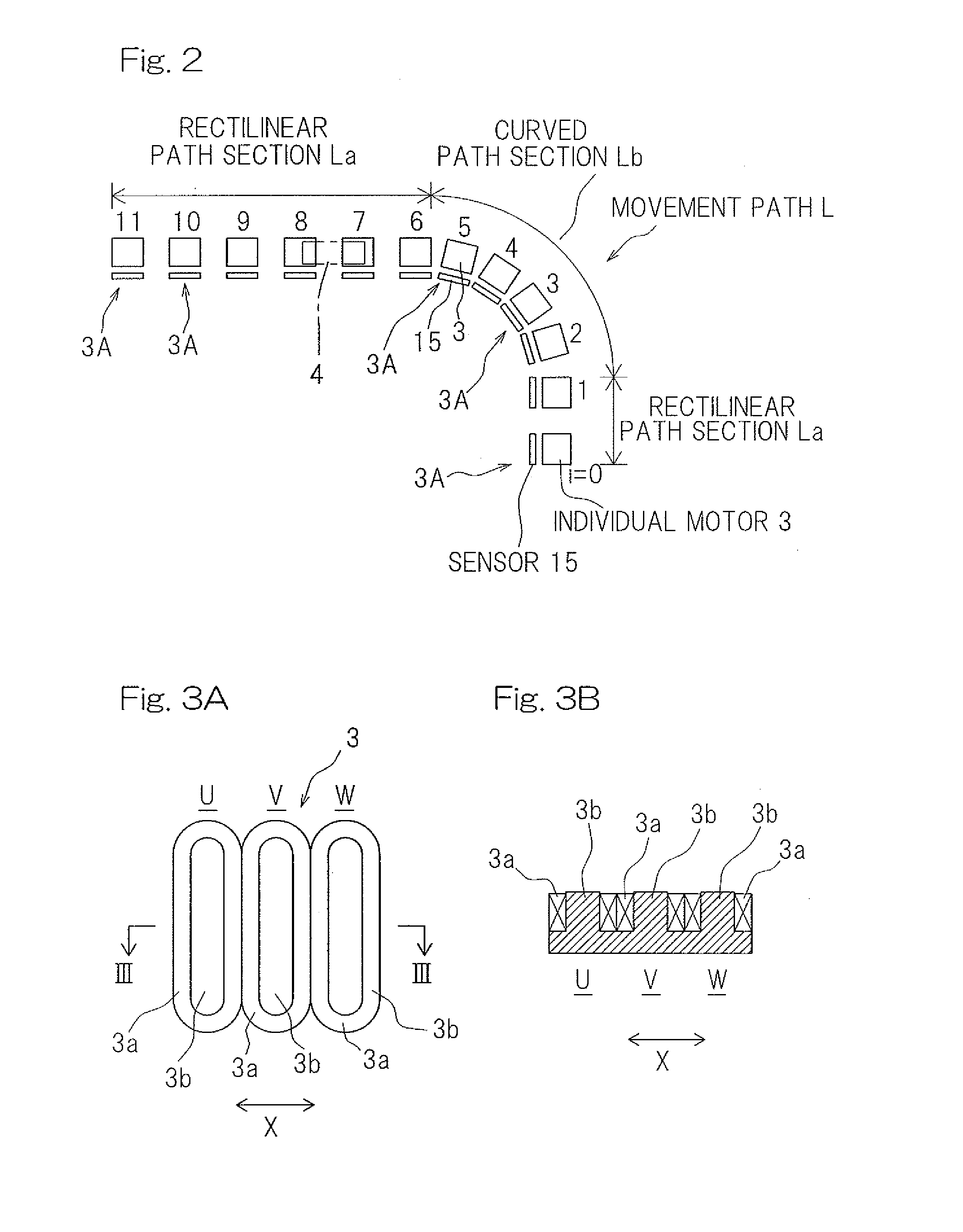

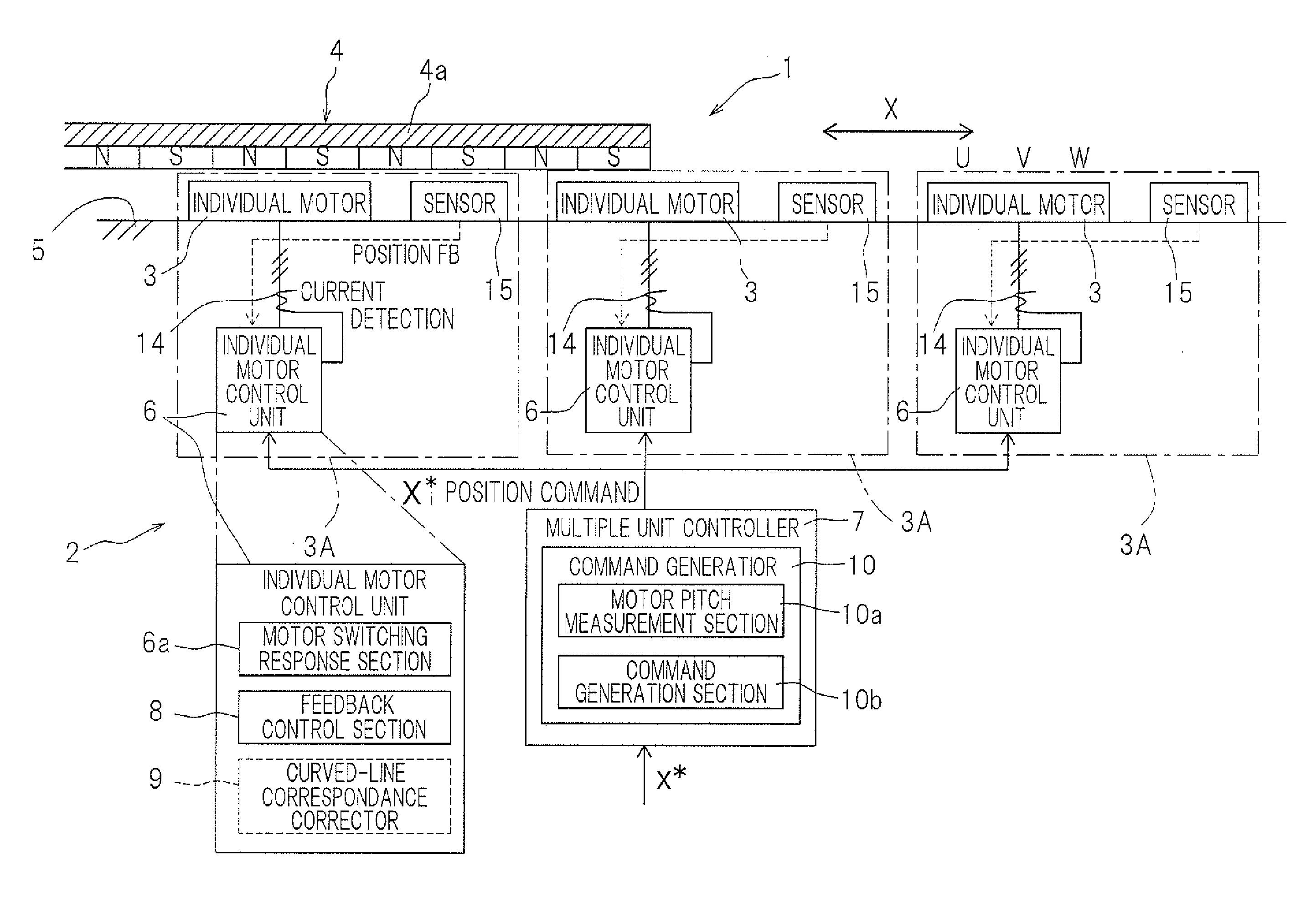

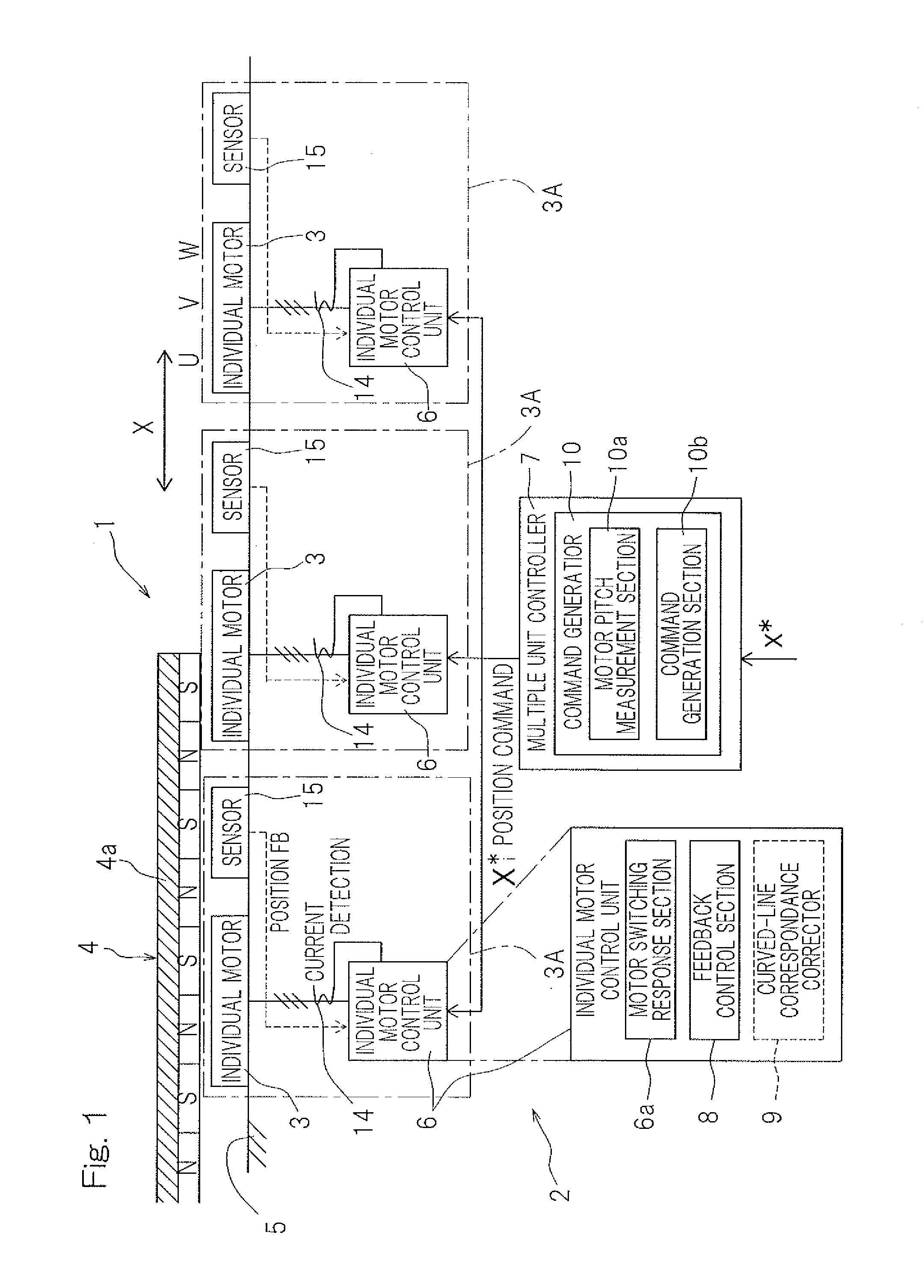

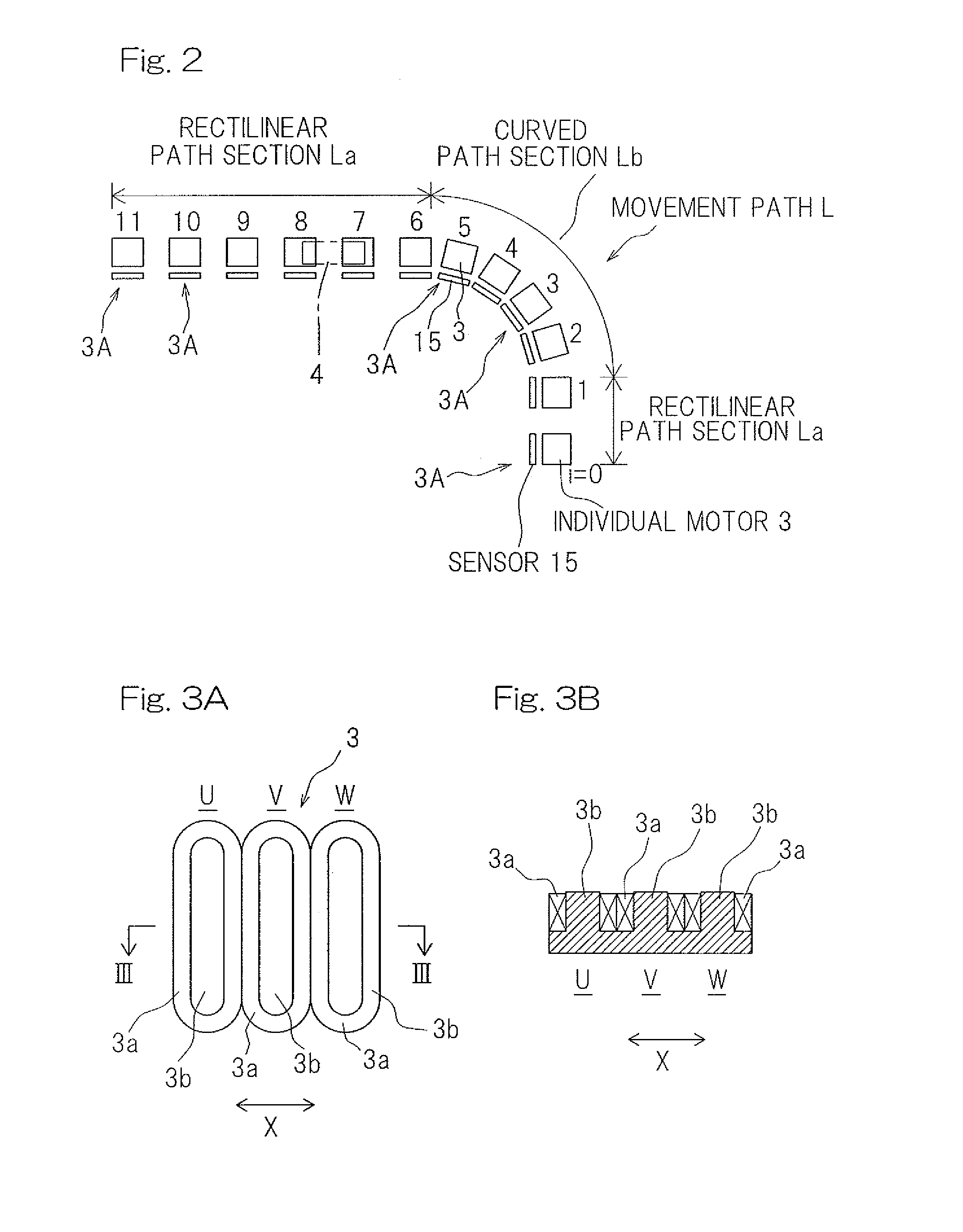

Discontinuous linear motor system

ActiveUS20130229134A1Simple power supplyLow costMotor/generator/converter stoppersDC motor speed/torque controlEngineeringMotor function

A linear motor system includes a discontinuous linear motor and motor control device. The discontinuous linear motor includes a mover and a plurality of individual motors spaced from each other along a movement path of the mover. Each of the individual motors functions as an armature on a primary side of one independent linear motor. A sensor, arranged to act as a linear scale, is disposed for each individual motor and detects a position of the mover. The motor control device includes a plurality of individual motor control units and a multiple unit controller to comprehensively control the individual motor control units. The individual motor control units control the individual motors disposed in curved path sections, and each of the individual motor control units includes a curved-line correspondence corrector to correct a detection value obtained from the sensor according to a relationship between a curved line of the path and a position of the sensor.

Owner:MURATA MASCH LTD

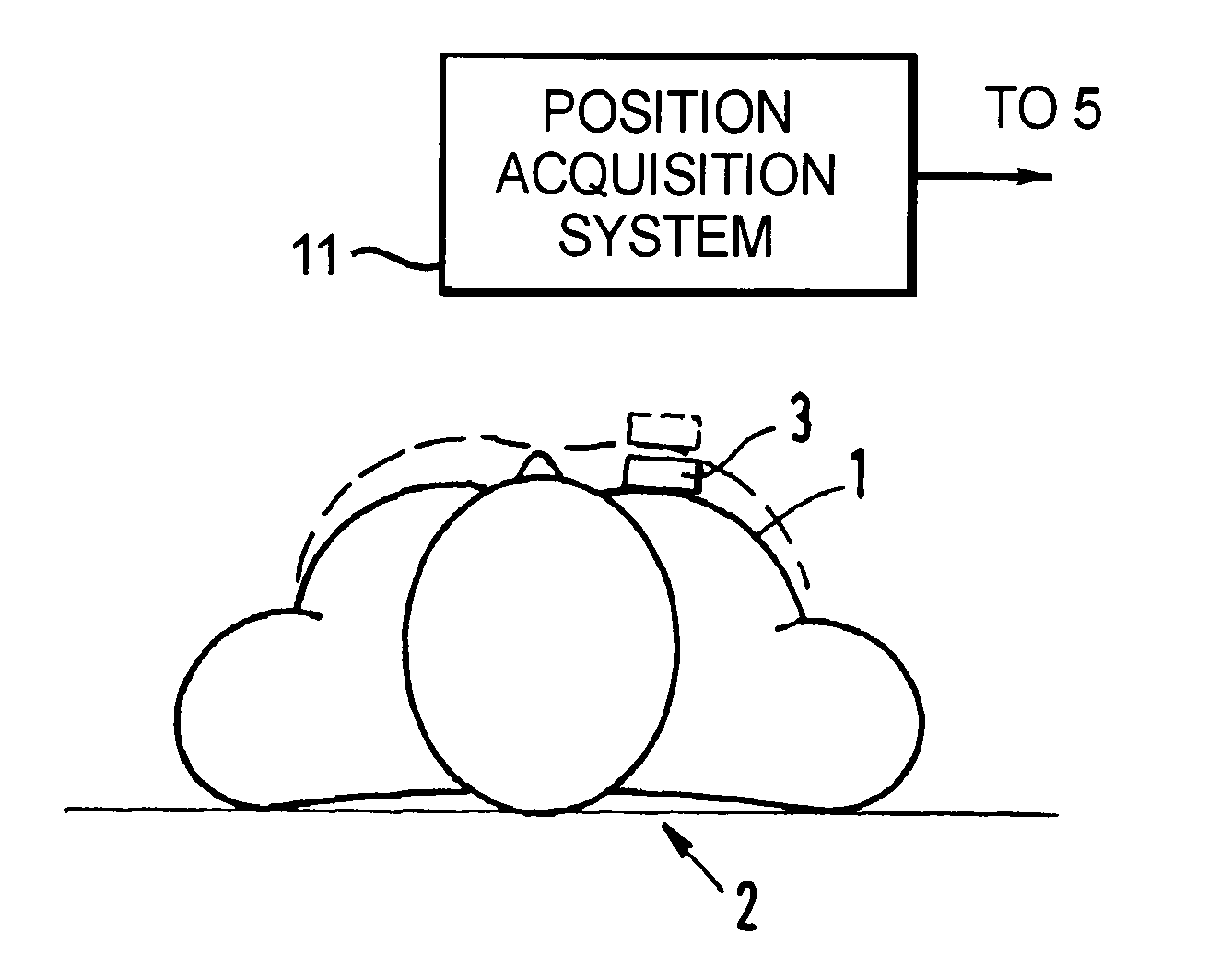

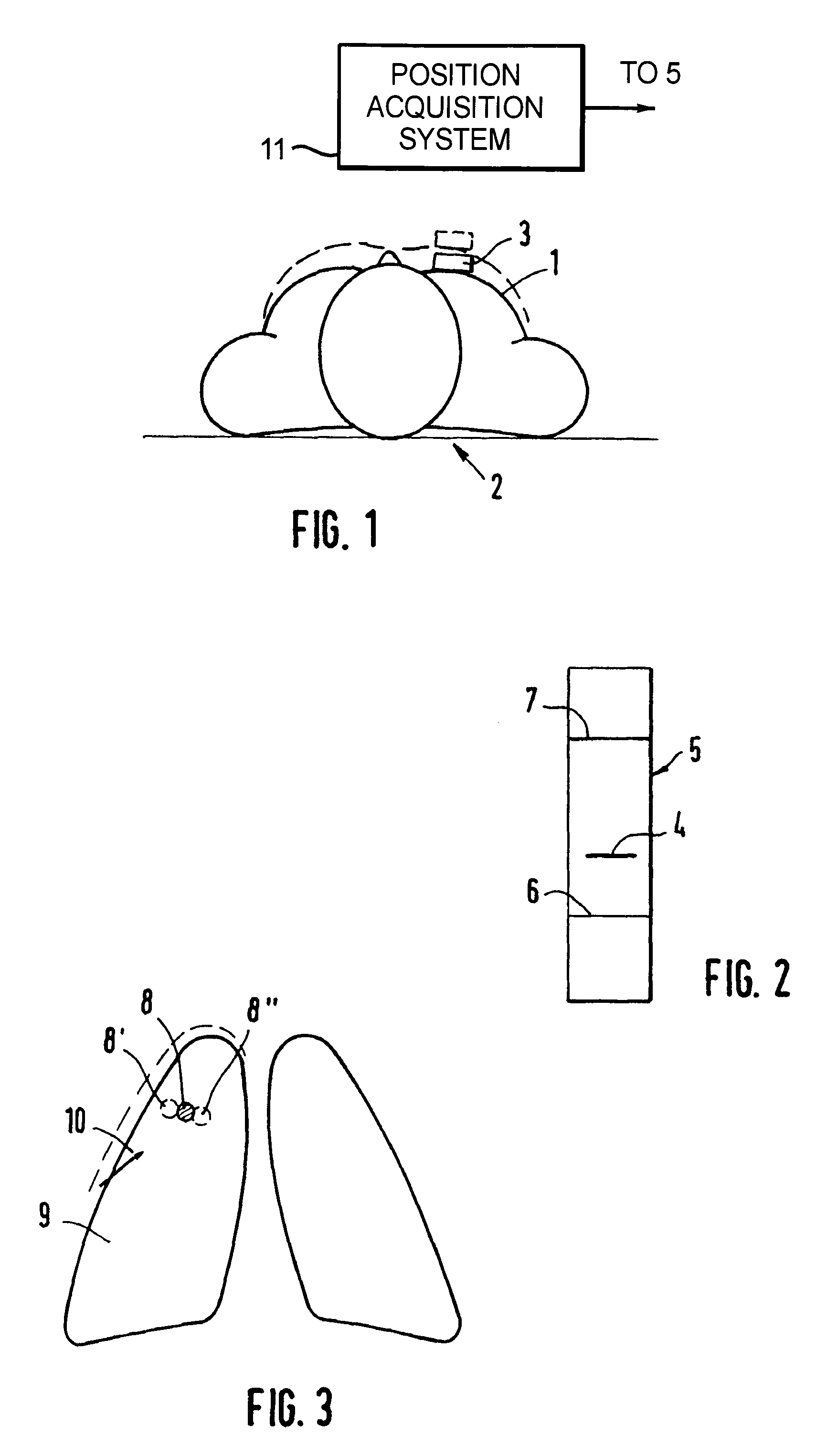

Method for respiration-dependent triggering of a medical image exposure

In a method for respiration-dependent triggering of a data acquisition event in an imaging procedure, a navigation system is employed in order to reproduce the position of a body part moving due to respiration on a scale, particularly a linear scale. Triggering for the exposure of an image ensues at prescribed positions of a pointer relative to the scale, i.e. at prescribed scale values.

Owner:SIEMENS AG

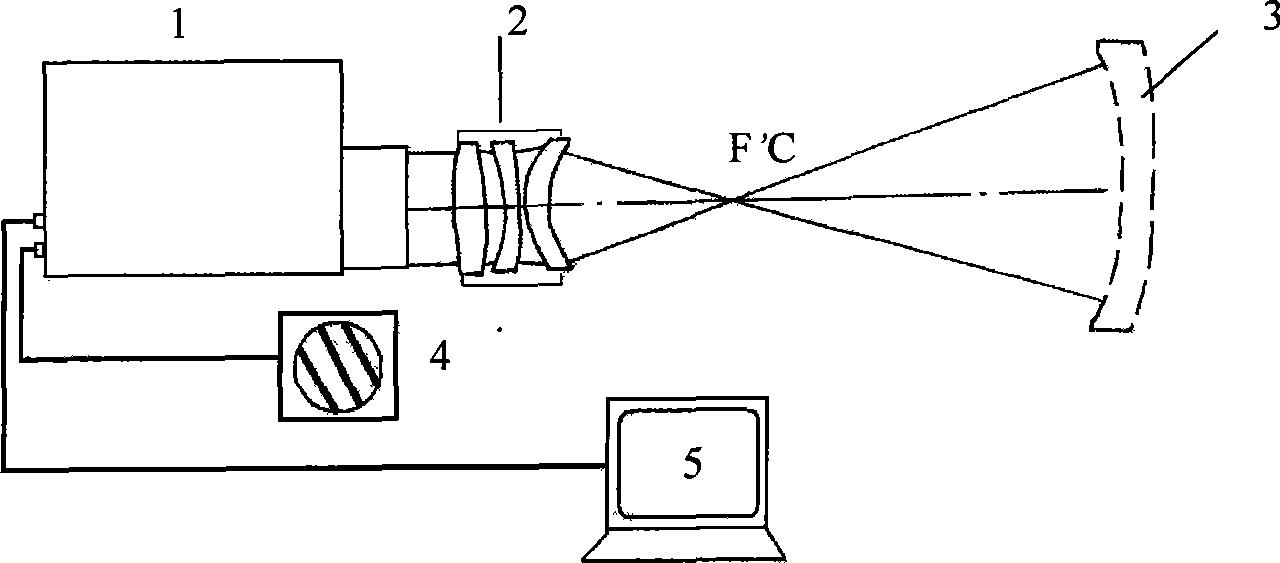

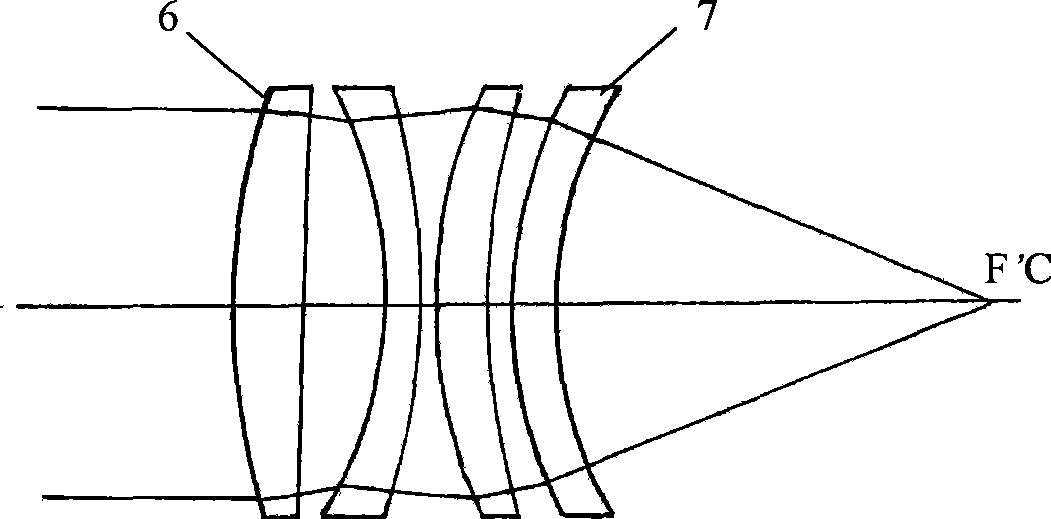

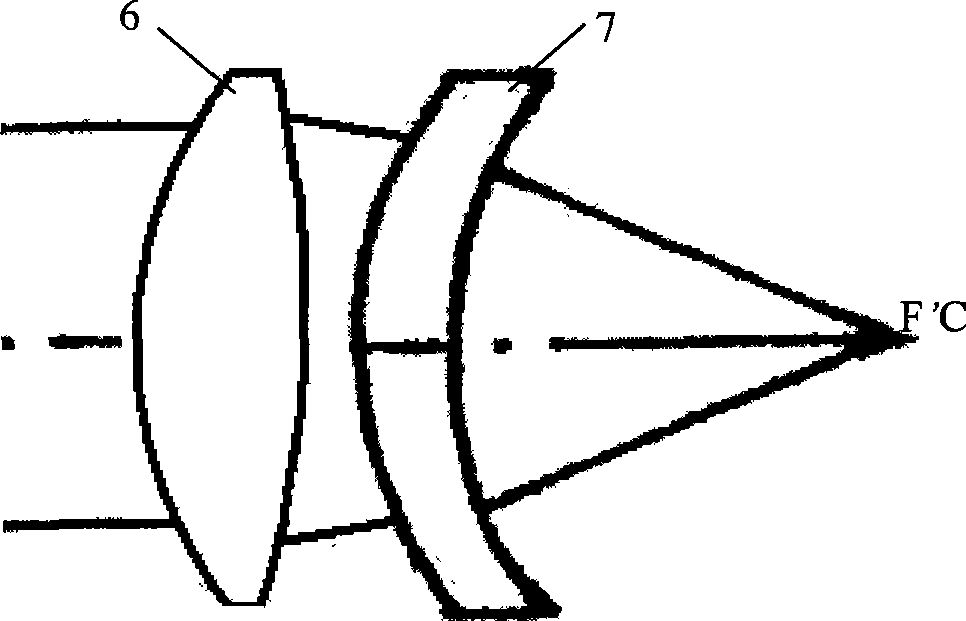

Optical transmission spherical surface detector

InactiveCN101545760AOvercoming spherical templateOvercome the disadvantage of one-to-one correspondence of radiiUsing optical meansCoatingsSurface finishOptical processing

The invention discloses an optical transmission spherical surface detector for inspecting the surface shape quality of lens convex-concave spherical surfaces, which is characterized by adopting a spherical surface non-contact interference method to obtain a standard spherical wave of which the curve radius changes continuously in certain range by a standard transmission spherical surface instrument consists of a group of positive lenses so as to achieve the detection of the convex-concave spherical surfaces with different curve radiuses, wherein the relative aperture detection coverage of a detected piece can reach F / 0.75 to 11. The optical transmission spherical surface detector has the characteristics of multiple functions, no damage to the surface finishment of a detected spherical surface and high test precision, and overcomes the disadvantage of contact measurement of the prior spherical surface sample plate; and if the optical transmission spherical surface detector is used together with a length-measuring linear scale, a length-measuring interferometer, and the like, the curve radiuses of the spherical surfaces can be measured precisely. The optical transmission spherical surface detector can be extensively applied to the optical manufacturing industry to inspect the surface shape quality of various lens convex-concave spherical surfaces.

Owner:NANJING UNIV OF SCI & TECH

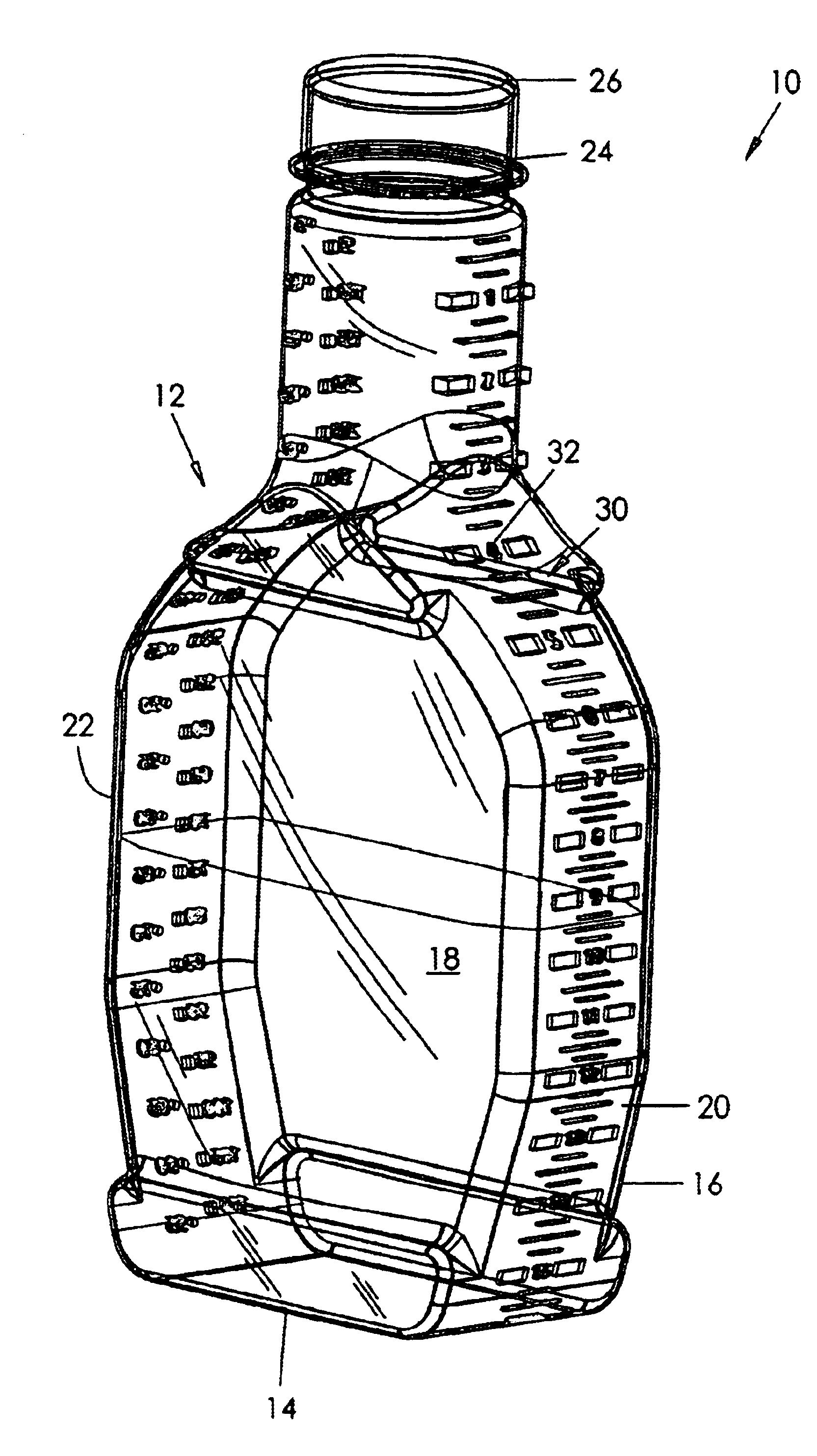

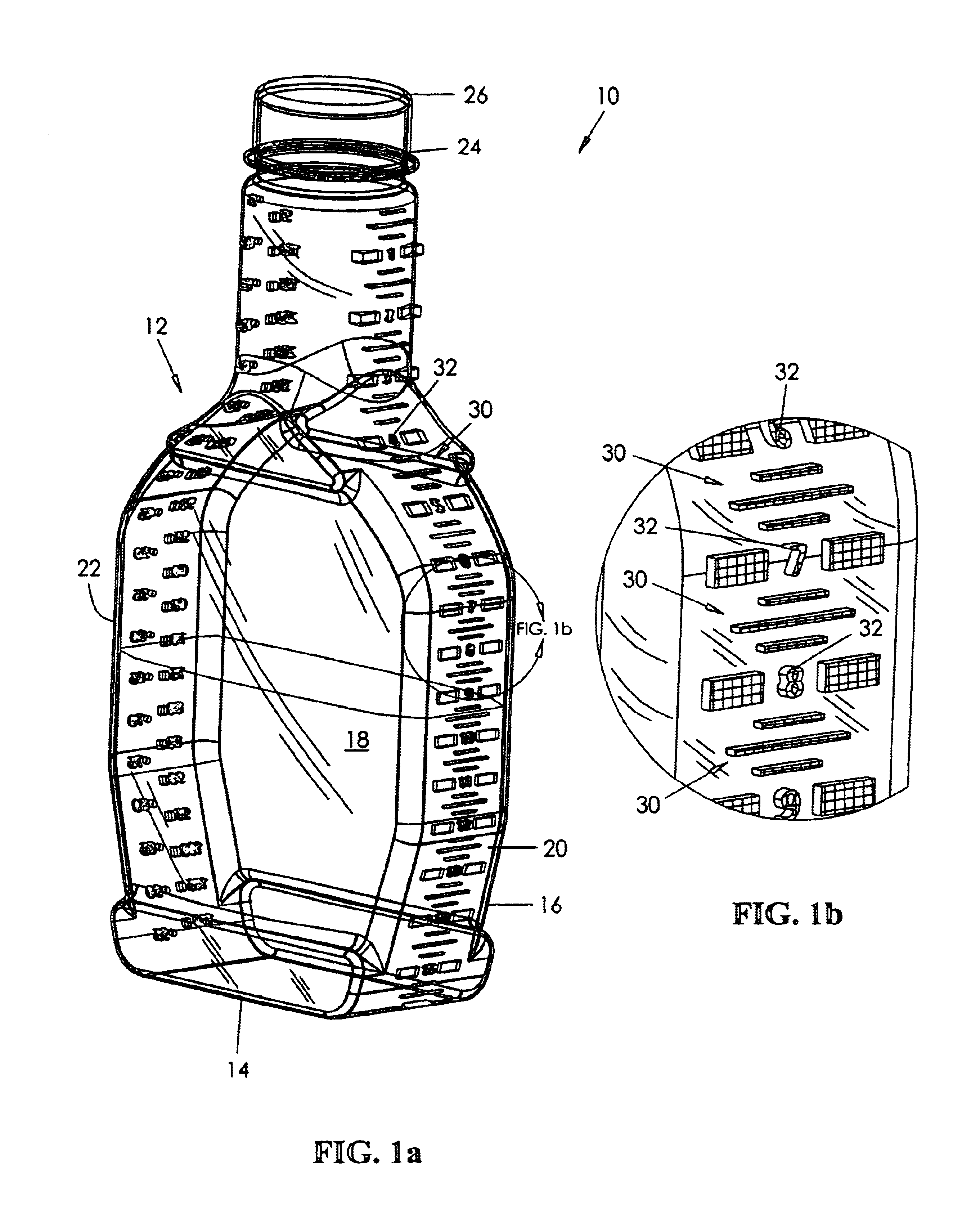

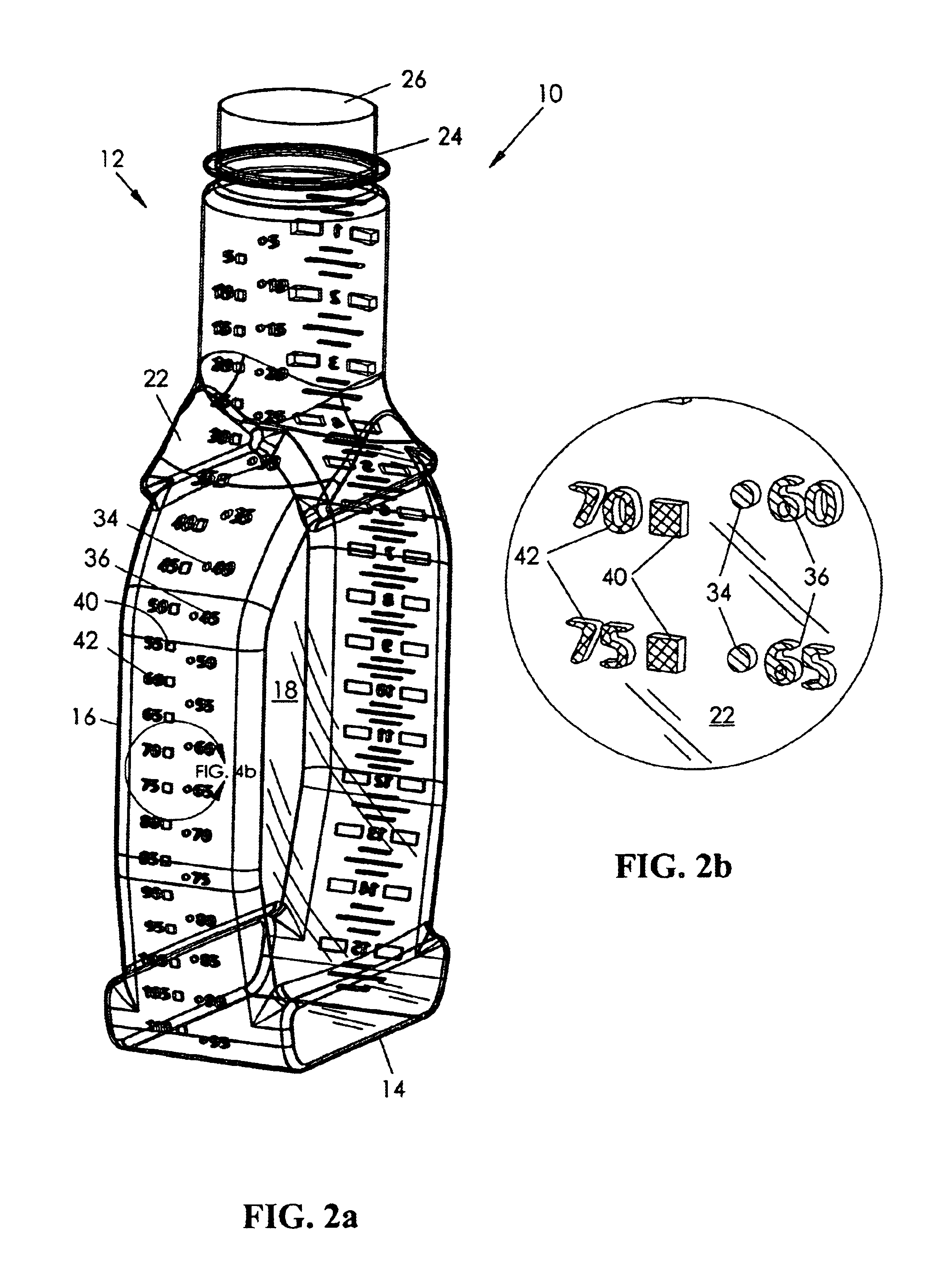

Container for monitoring consumption of selected chemical compounds of a liquid

InactiveUS6837376B2Improve discriminationFast and accurate correlationStampsCapsChemical compoundProcess engineering

A container for monitoring consumption of a volume of liquid or selected chemical compounds thereof includes a container body having a construction defining an open top. A first set of linear scale indicia is positioned on a container side wall along with a corresponding first set of graduated numeric indicia for indicating an amount of liquid consumption. Second sets of corresponding linear scale and graduated numeric indicia are positioned on another side of the container body for indicating consumption of a preselected chemical compound of the liquid. Thus, a user is able to visually determine the relationship between consumption of a particular volume of the liquid and consumption of an amount of a preselected chemical compound thereof. This enables a user to modify consumption habits if desired. The container may include a third set of indicia, the second and third sets being distinguished by different shape and color components.

Owner:PAULI DONNA KAY

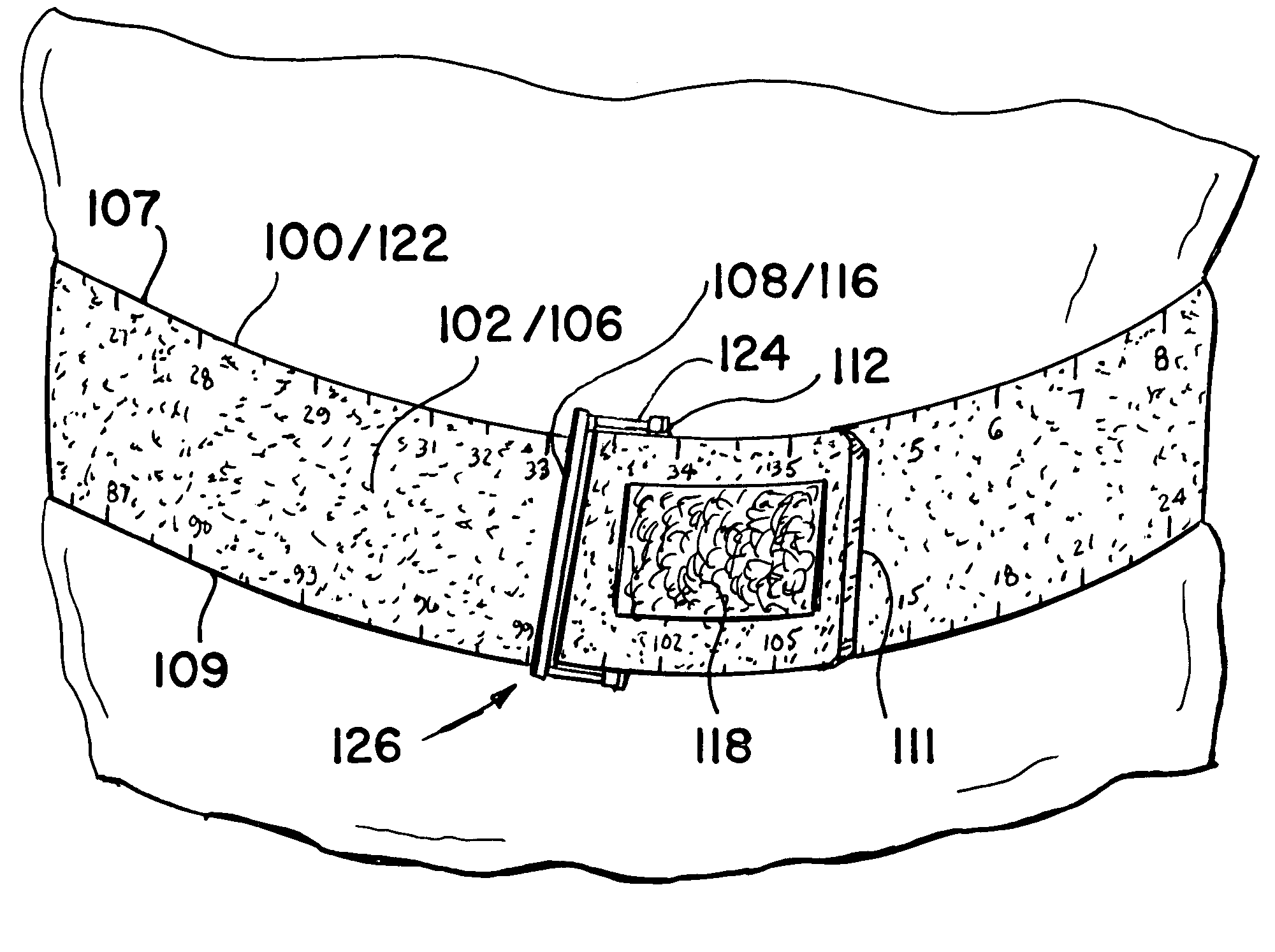

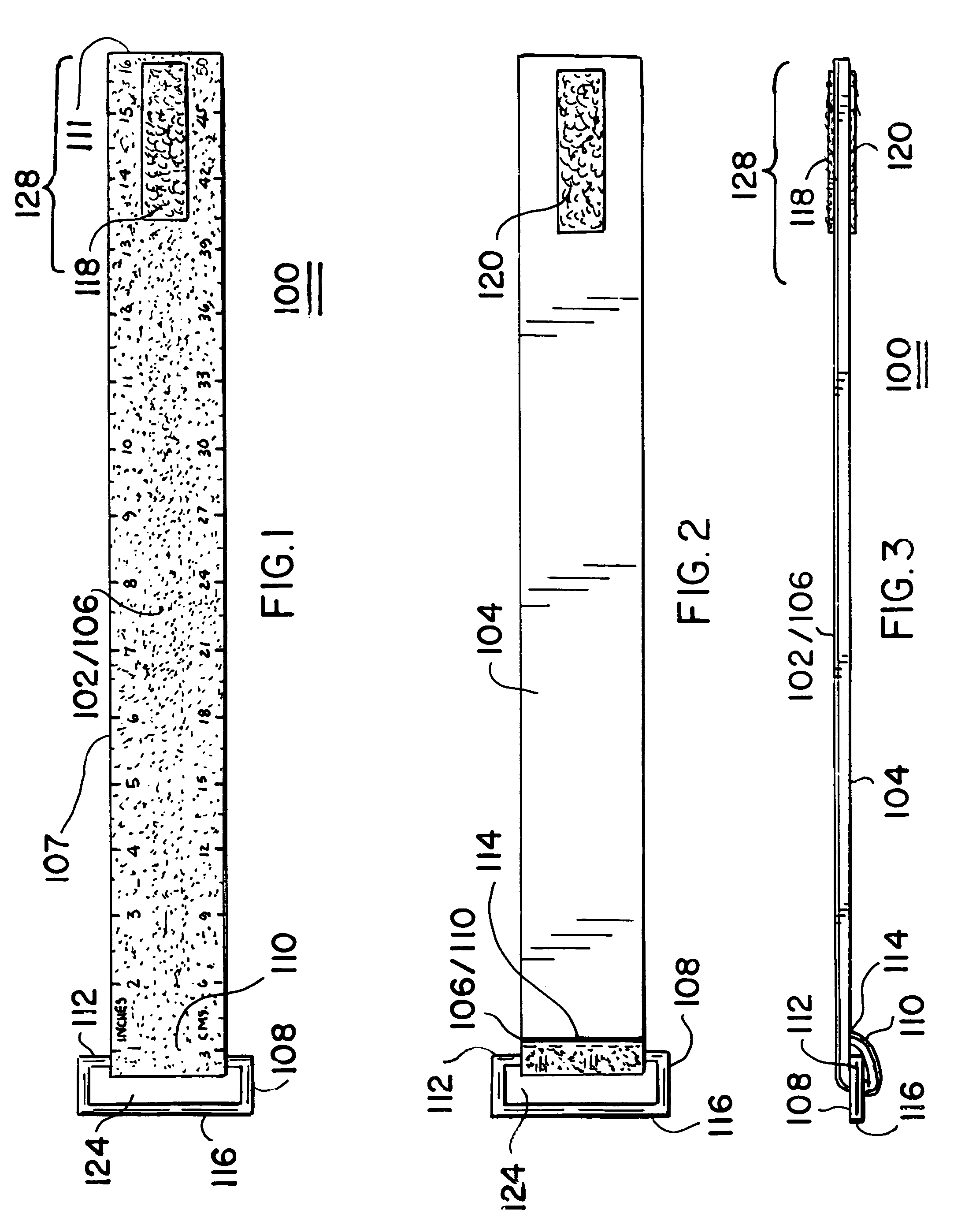

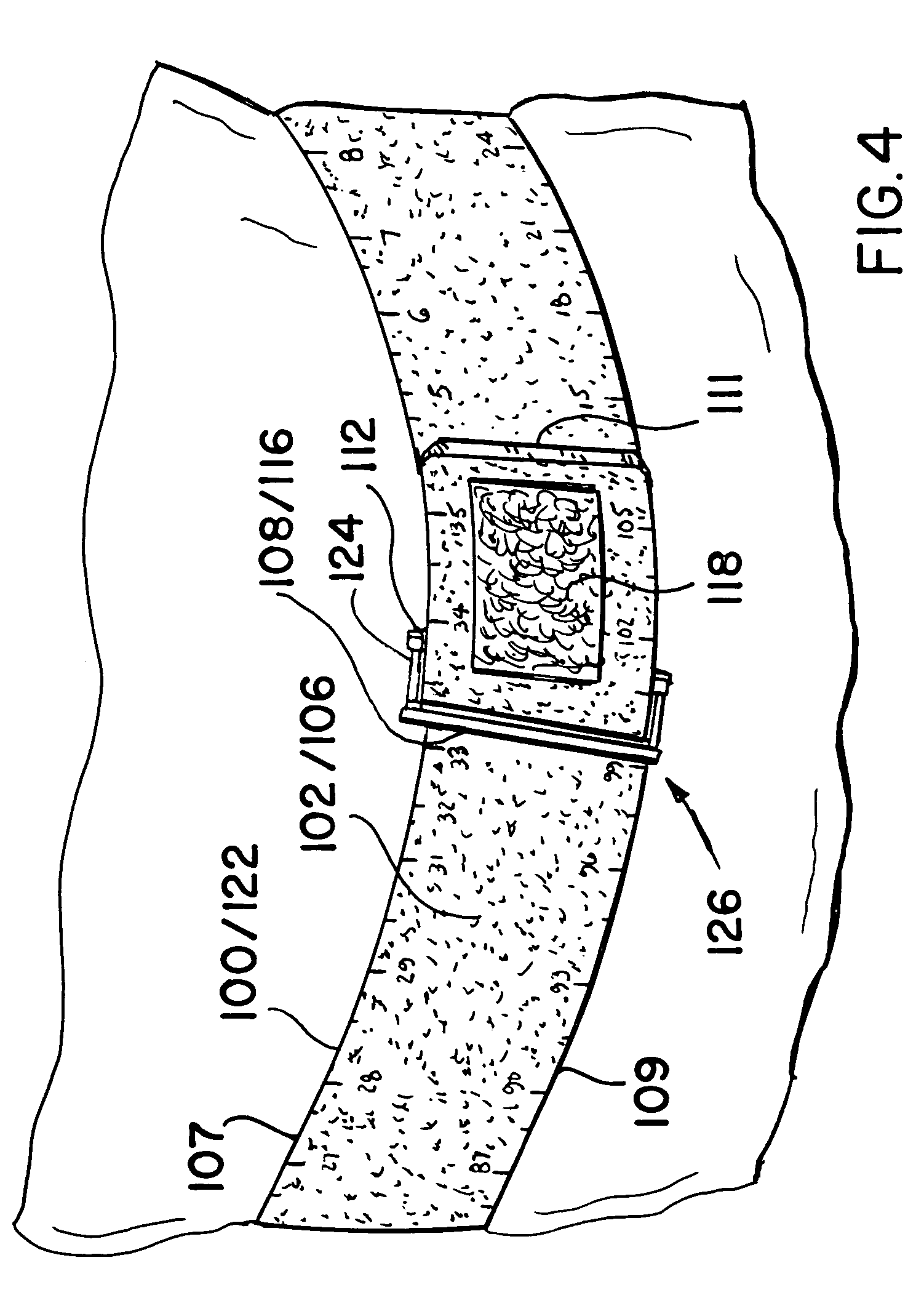

Belt or band-like exercise result measurement article with selectable display aspect

A band-like exercise result measurement article with selectable display aspect includes a planar strip of a flexible material having first and second ends, an elastic inner surface and an outer surface of a loop material, the outer surface having, along its length, at least one linear scale imprinted upon it. The article also includes a buckle, a first segment of a hook material affixed to the inner surface near the second end and a second segment of a hook material affixed to the outer surface of the strip near its second end. When the first hook segment is fastened to the outer surface through the buckle, the article displays a measurement of scale. When the second hook segment is fastened to the outer surface through the buckle, the measurement is precluded from display.

Owner:GAUNA SILVINA MARCELA

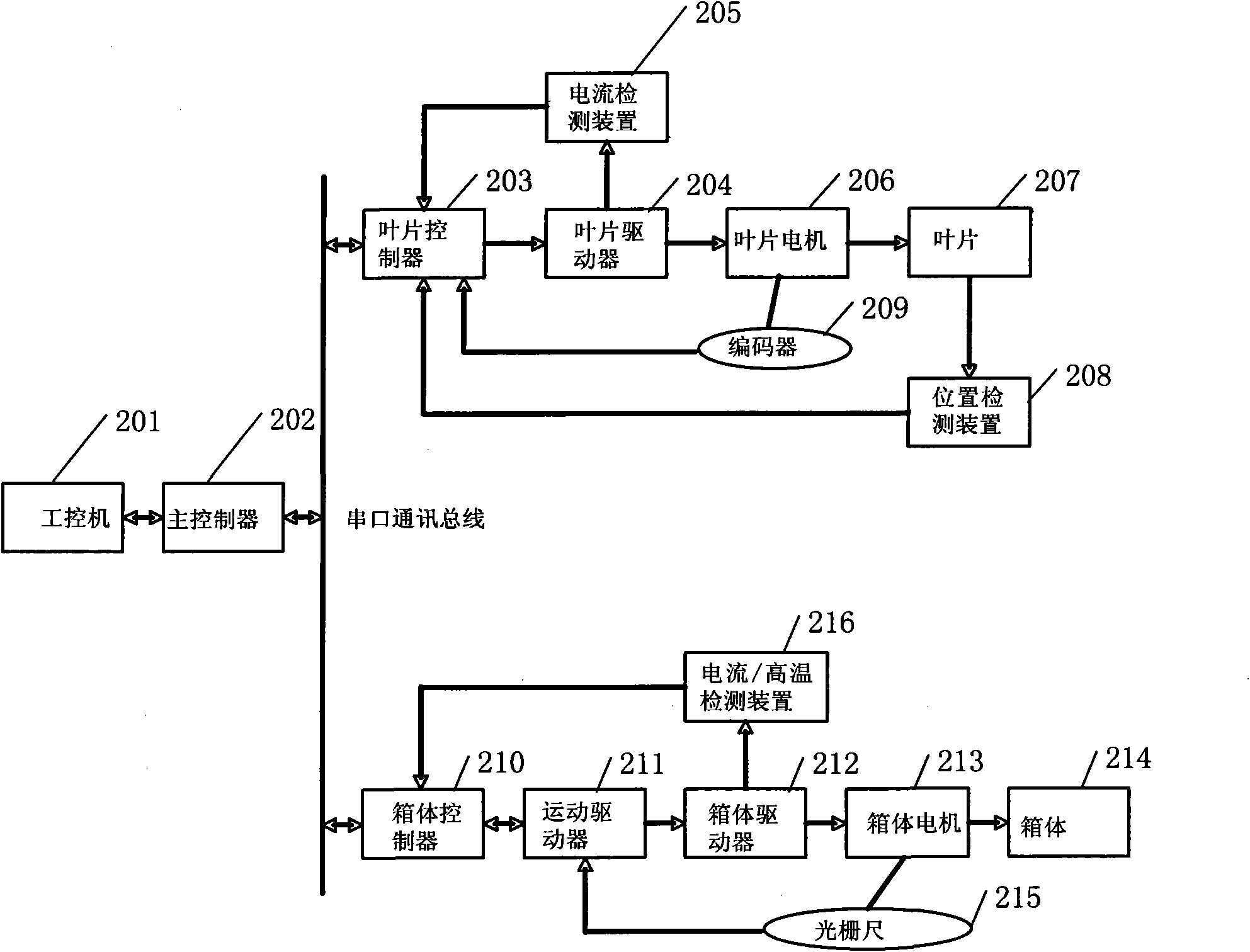

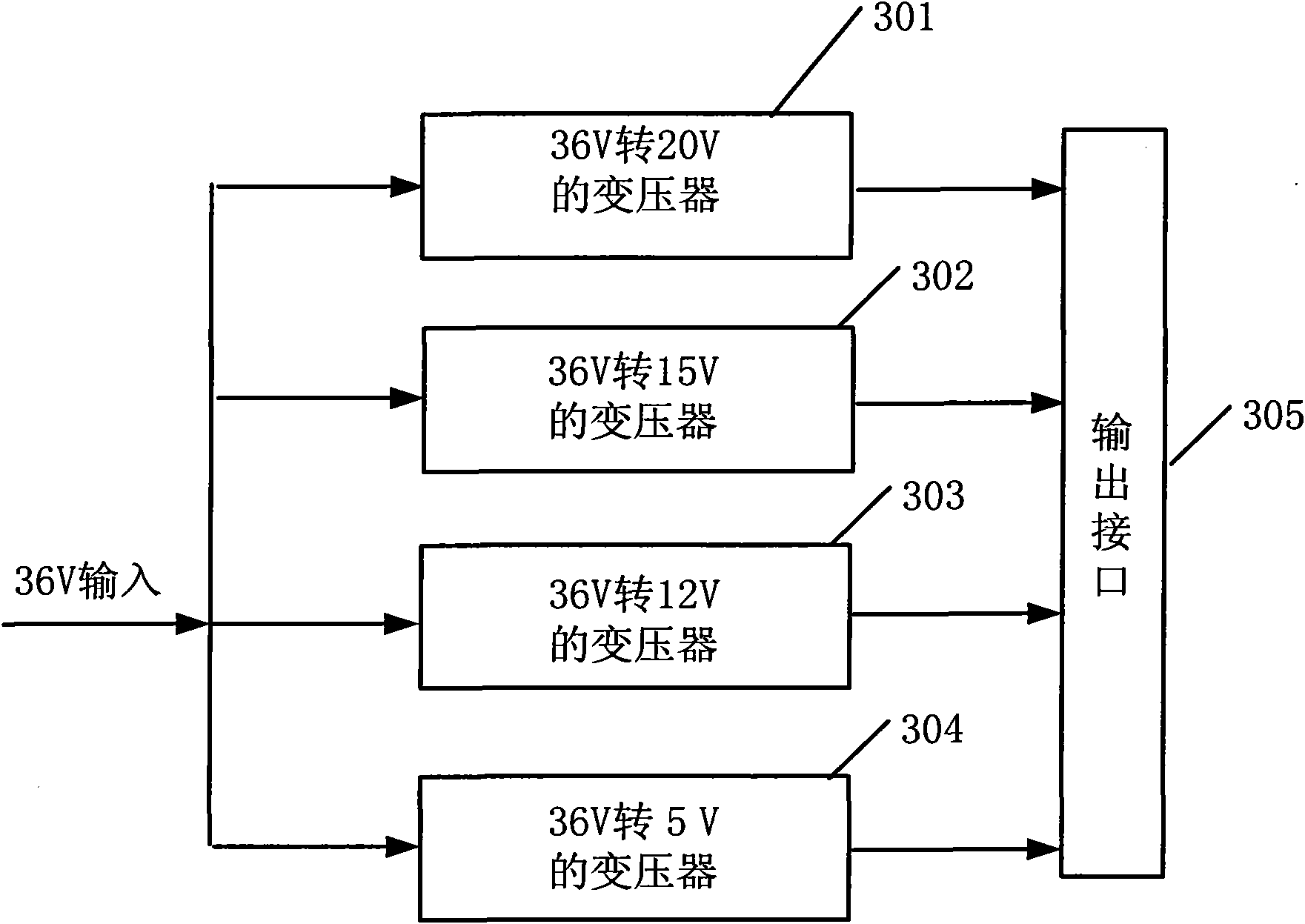

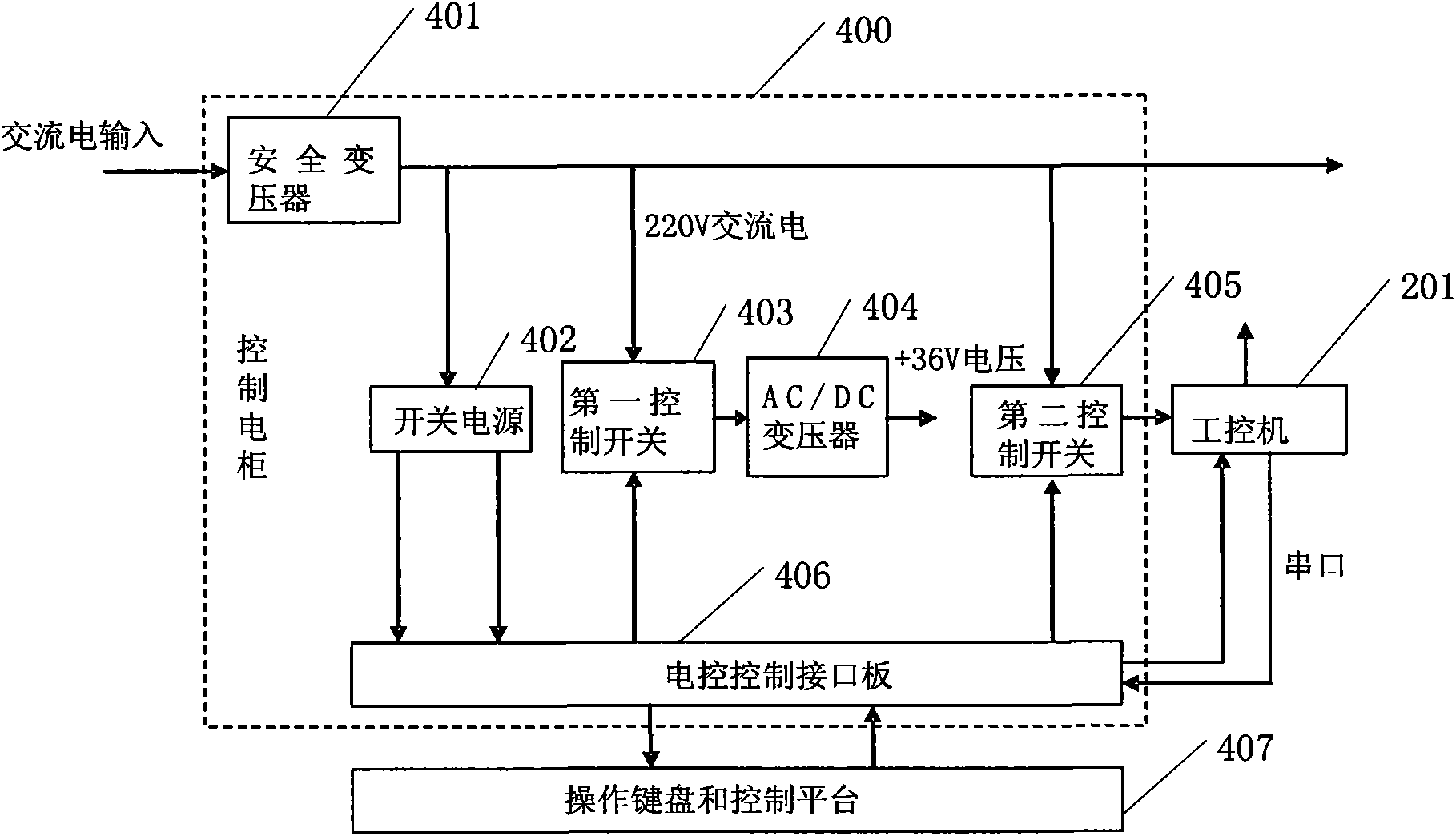

Multi-leaf collimator control system

ActiveCN102117051AHigh running precisionThe control process is stable and reliableProgramme controlComputer controlControl systemClosed loop feedback

The invention relates to a multi-leaf collimator control system, comprising an industrial control computer, and a main controller connected with the industrial control computer, wherein the main controller is connected with a blade and cabinet controller which controls and connects with a blade and cabinet driver; the blade and cabinet driver is in driving connection with a blade and cabinet motor which is in transmission connection with a blade and a cabinet body; the blade and the cabinet body are provided with position detectors which are connected with the blade and cabinet controller to form a feedback loop; and the driver is connected with the blade and cabinet controller by a current detector to form a feedback loop. The multi-leaf collimator control system is controlled by the industrial control computer, realizes the closed-loop feedback adjustment by using an encoder or a linear scale, and improves running precision of the blade and the cabinet body; moreover, the control process is stable, reliable, convenient and rapid.

Owner:SHEN ZHEN HYPER TECH SHENZHEN

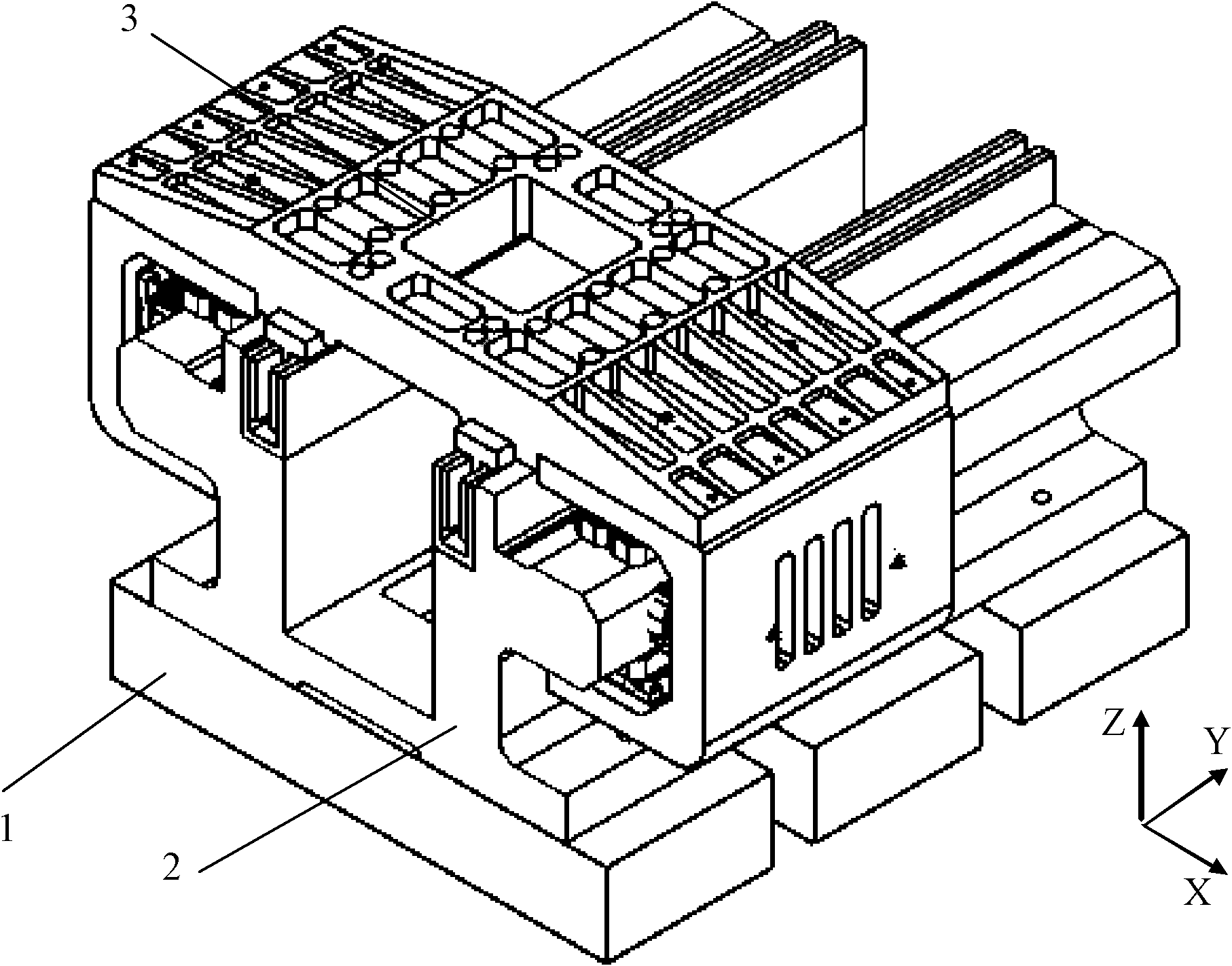

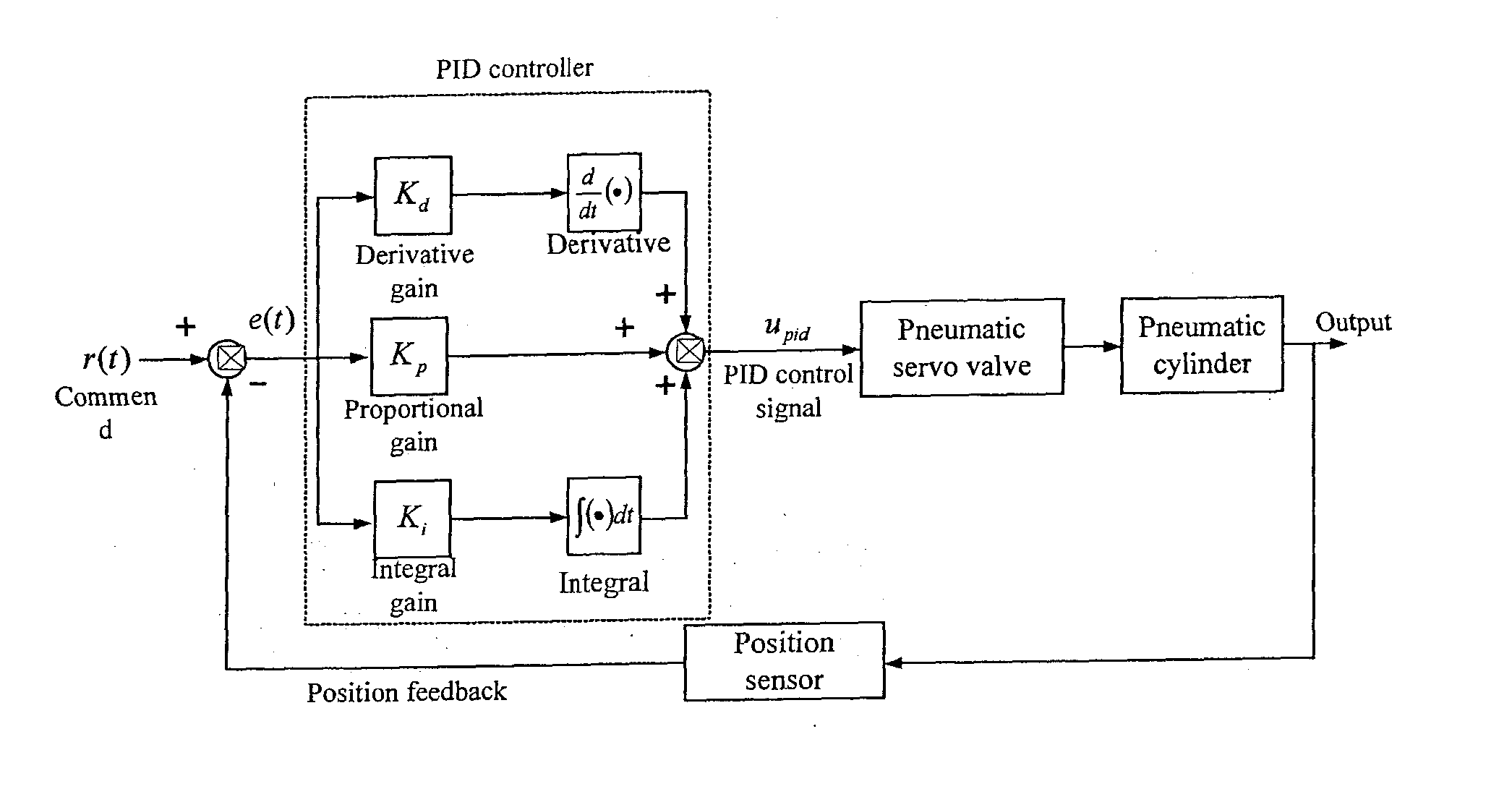

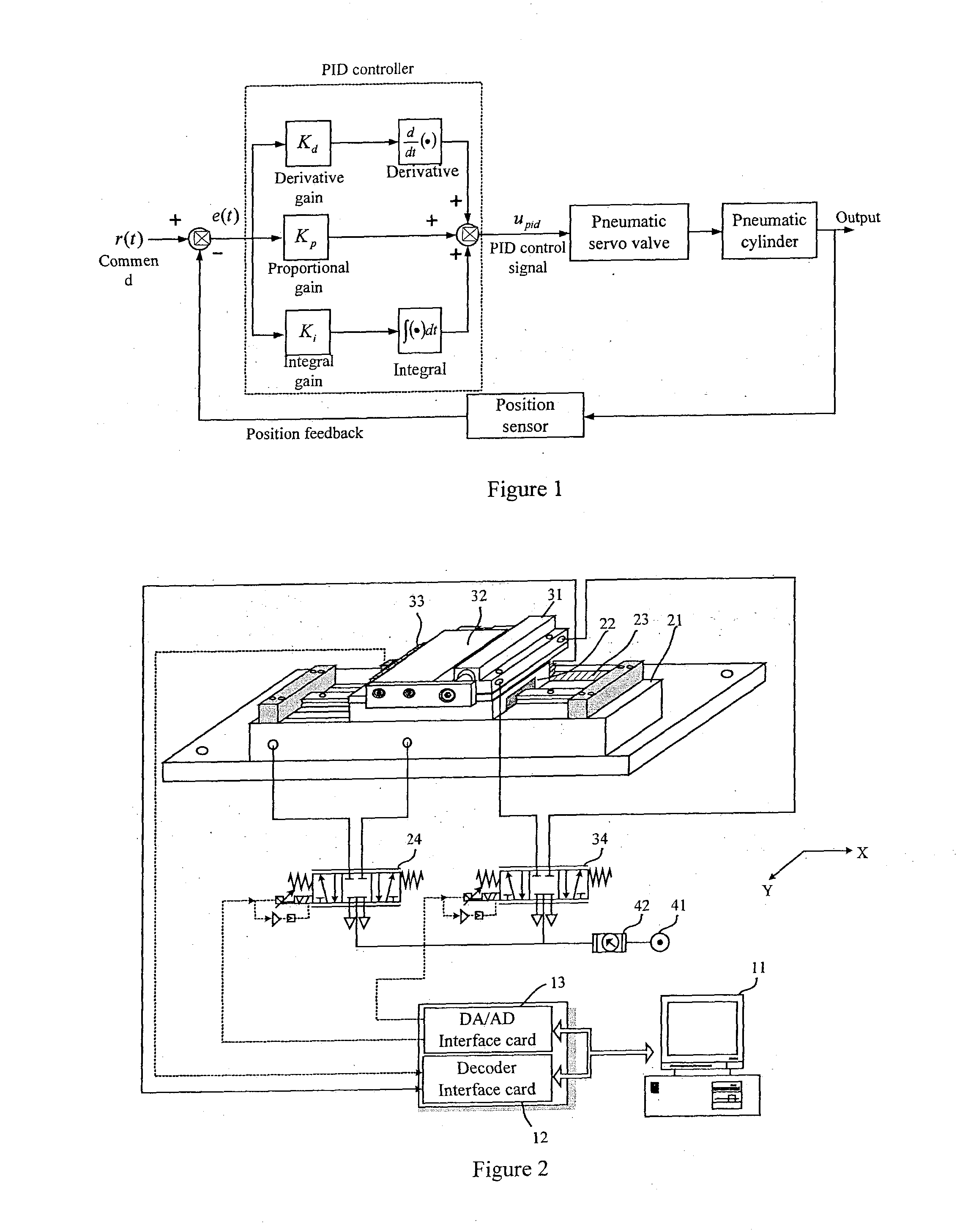

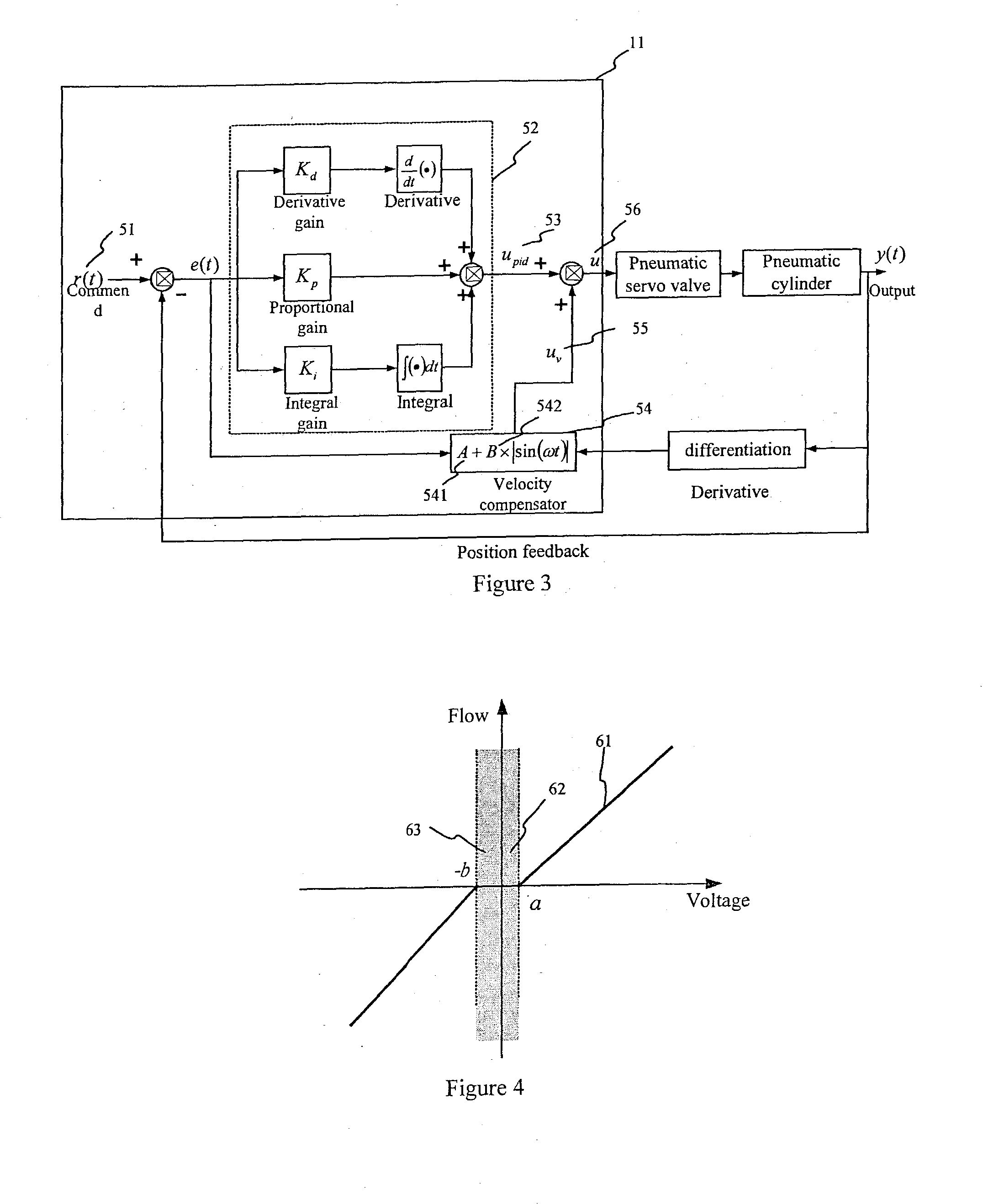

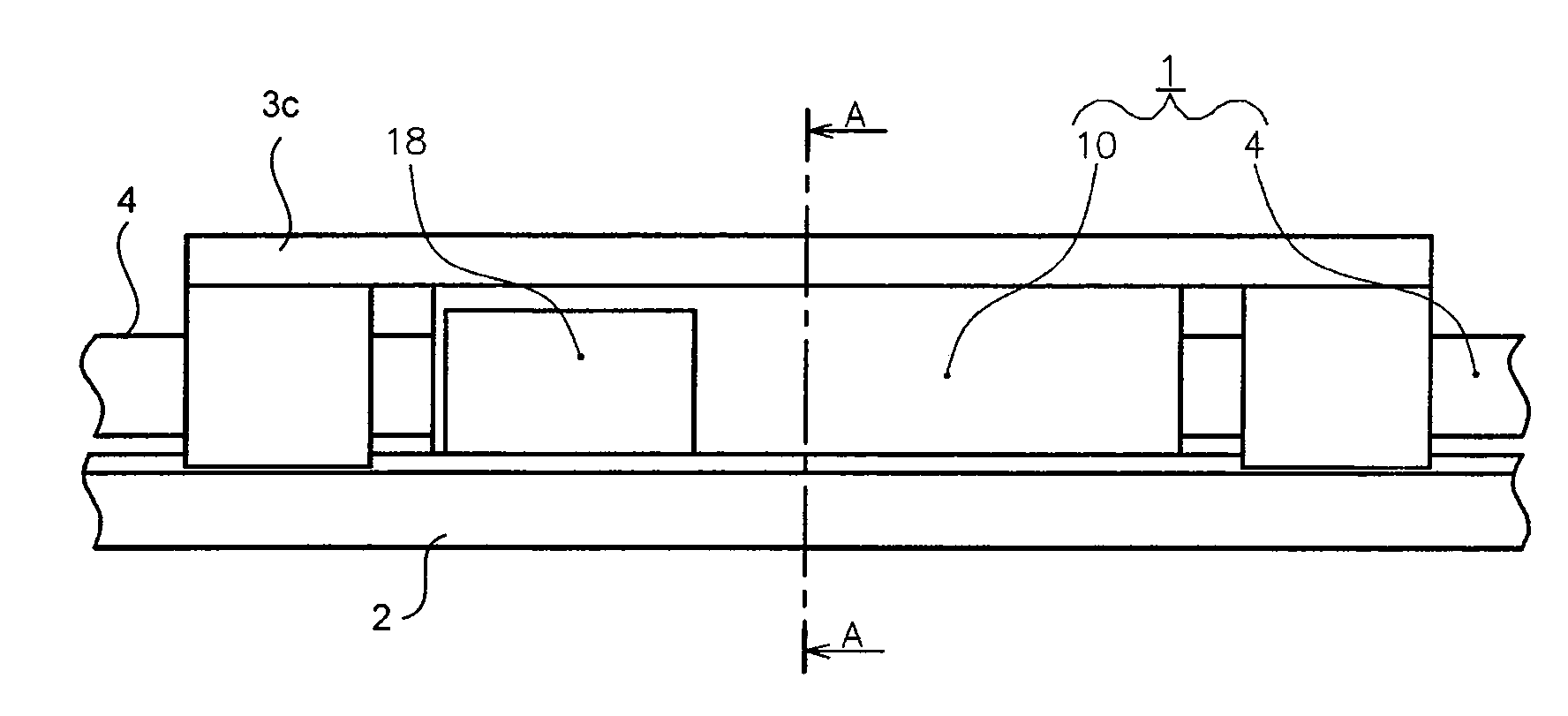

Design and control method of a micro-nanometer precision servo pneumatic X-Y positioning table

InactiveUS20050004689A1Precise positioningComputer controlSimulator controlControl signalFriction force

A micro-nanometer precision servo pneumatic X-Y positioning table comprises by two slide air cylinders and drives the two slide air cylinders by the servo control rule to make the pneumatic table to get the purpose of X-Y two degrees of freedom precision positioning. However, the pneumatic servo system is a high time-variant and nonlinear system and the nonlinear friction force; causes the stick-slip phenomenon of the servo pneumatic system. Therefore the. micro-nanometer precision servo pneumatic X-Y positioning table in accordance with the present invention has a new velocity feedback compensation method to overcome the nonlinear friction force and the stick-slip phenomenon. The new method is to add a velocity compensation signal, which periodic frequency is larger than the system's natural frequency into the control signals. The method is to put the velocity compensation signal directly into the servo valve control signals. By this method; it is able to avoid the complex control rules and the calculation of the feedback compensation and to get higher precision positioning. The positioning precision of the micro-nanometer servo pneumatic X-Y positioning table is about the resolution of the linear scale (ex. in this case 20 nanometer, is the resolution of the used optical linear scale; if the resolution is 10 nanometer the precision can be also 10 nanometer) not only for long stroke but also for micro-step command.

Owner:SHIH MING CHANG +1

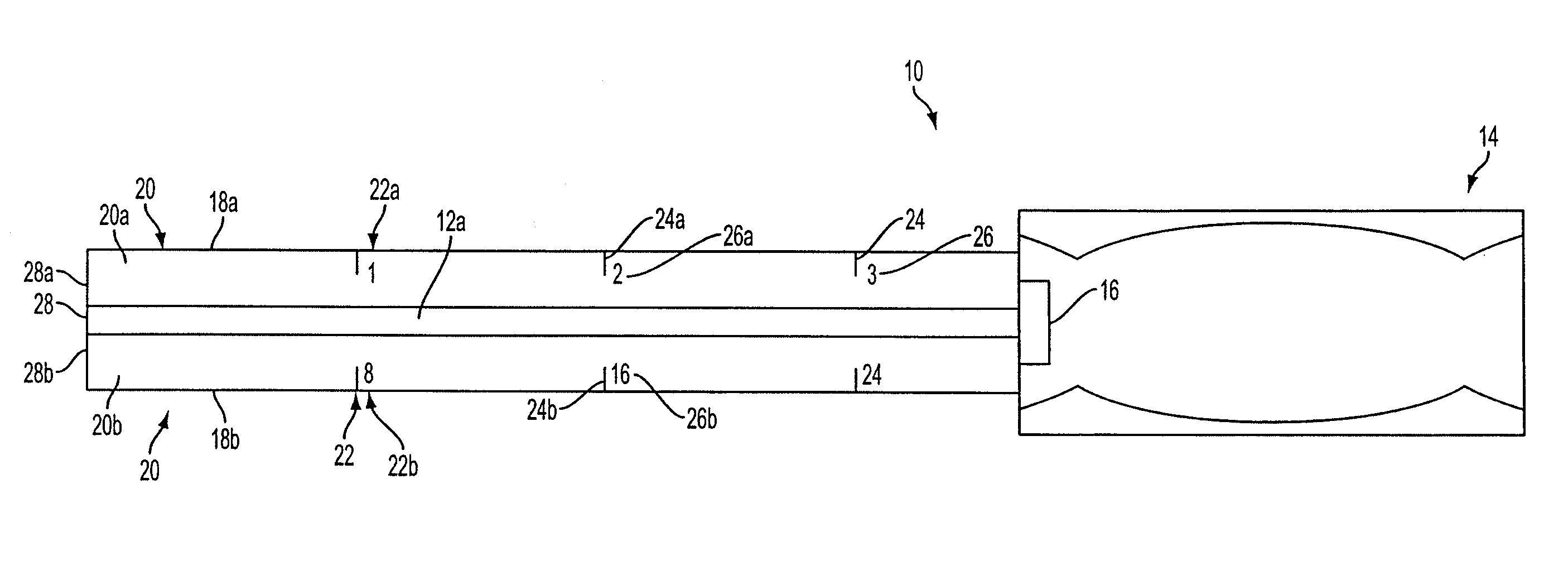

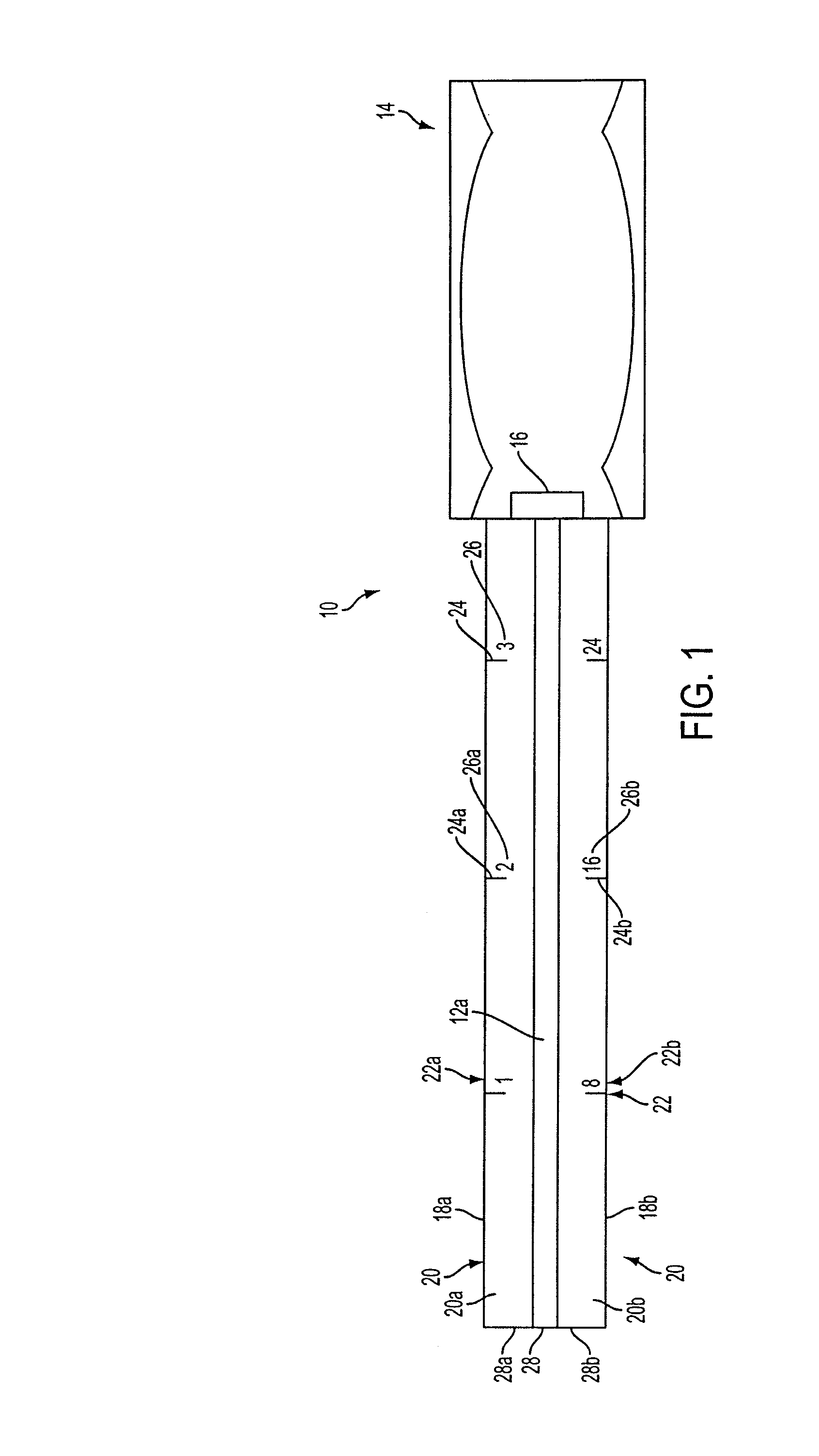

Linear Motor

InactiveUS20080265690A1Effective magnetic flux densityEnhancing the motor thrustElectric signal transmission systemsMotor/generator/converter stoppersMotor driveElectric machine

A position-data converter and a motor-drive control device are connected. The position-data converter receives two-phase, sine-wave analog signals da and db from two first magnetic detectors, respectively, and converts these signals da and db to position data. On receiving a positioning instruction, the motor-drive control device calculates the value of current, from the current position signal generated by the position-data converter. The permanent magnets incorporated in a linear motor are used as components of a linear scale, as well.

Owner:WAKO GIKEN

Measuring device

A measuring device, such as a ruler, tape measure, etc. includes a first edge having a first set of indicia corresponding to a first linear scale, and a second edge having a second set of indicia corresponding to a second linear scale. The first linear scale may be actual, while the second linear scale may be non-actual, such as a linear scale employed on an engineering or architectural drawing. The indicia of the second linear scale are spaced apart and labeled with numerical values that correspond to the scaled distance between the indicia, and therefore provide an indication of the actual length of an object upon measurement of the length of a corresponding feature on a drawing drawn to scale.

Owner:J & A DEV ASSOCS

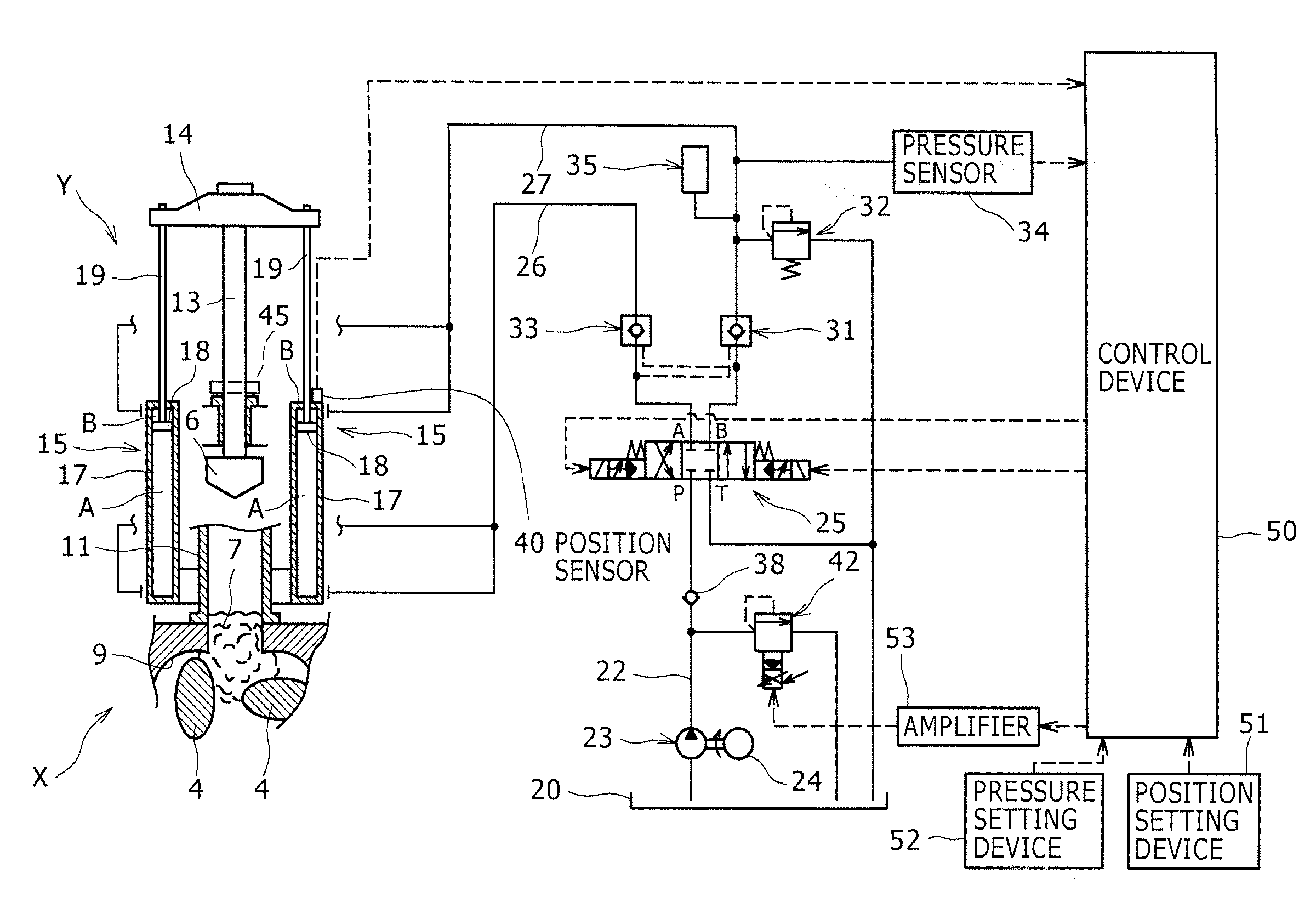

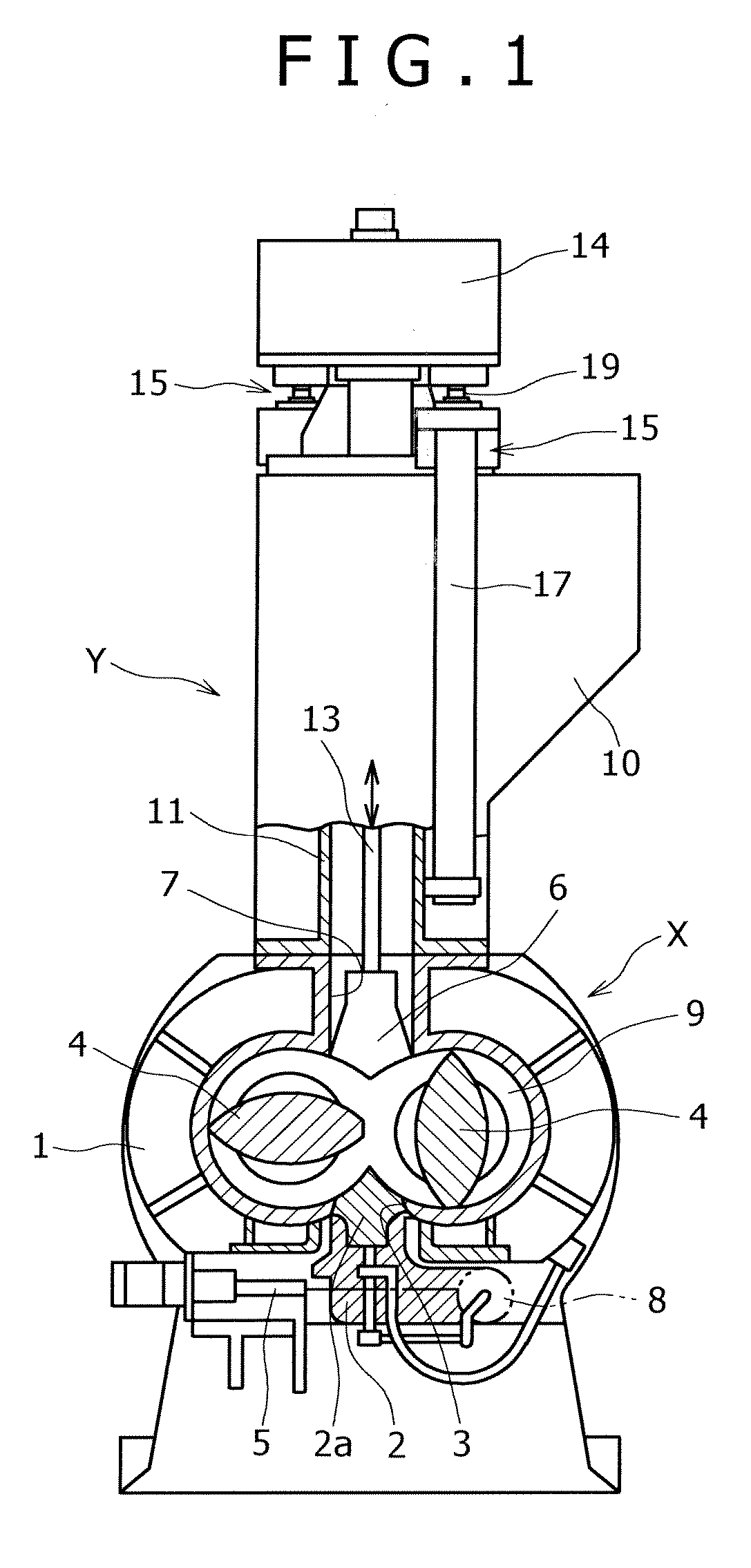

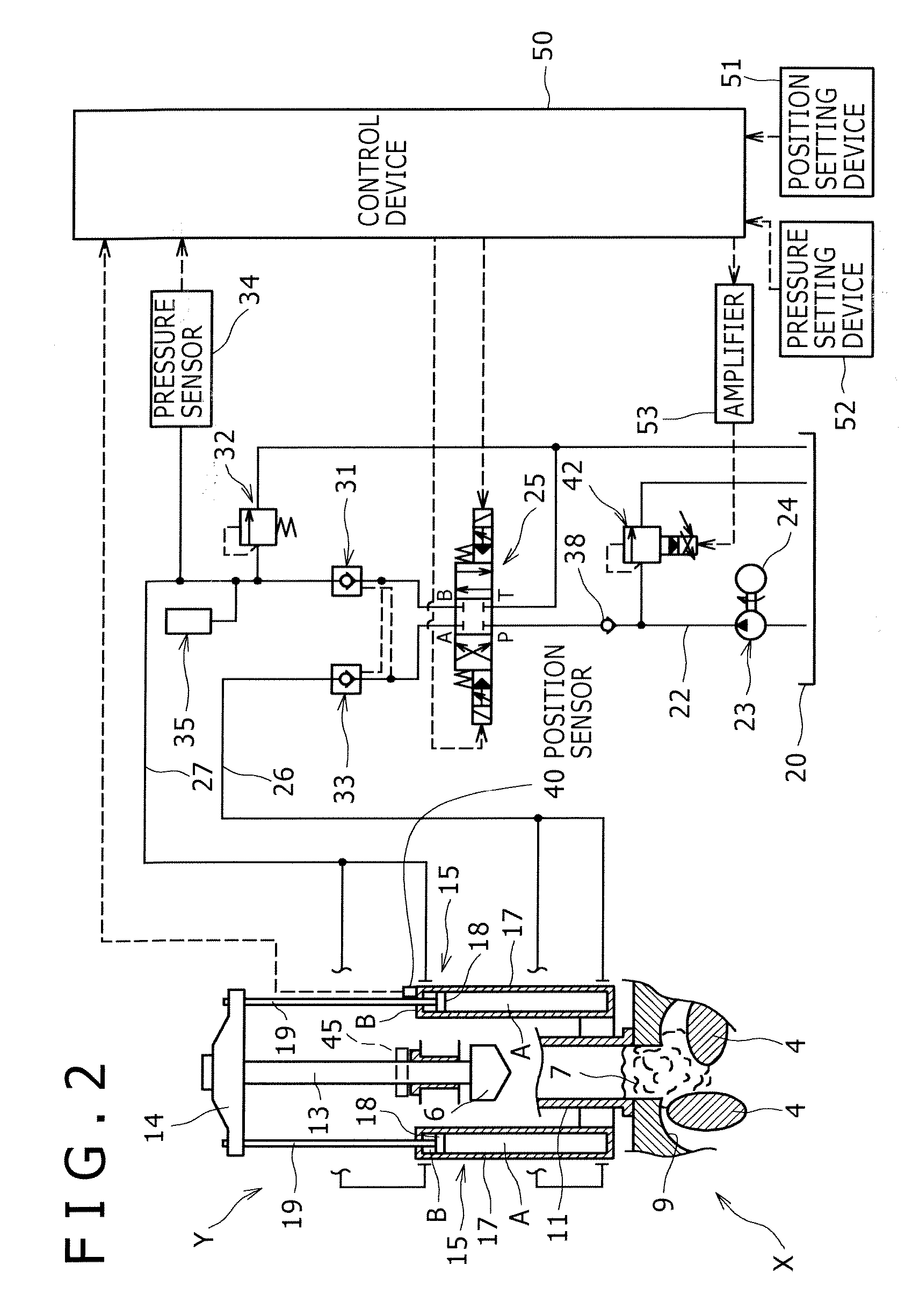

Batch mixer

ActiveUS20070025176A1Improve accuracyLow costTransportation and packagingRotary stirring mixersHydraulic cylinderSolenoid valve

A batch mixer, which includes a floating weight that is freely elevatable by hydraulic cylinders in a hopper which is provided for a mixer main body in a communicated state and into which mixing materials are charged, includes: a linear scale capable of continuously detecting the elevating / lowering position of a floating weight; a position setting device that sets the elevated position of the floating weight; and a control device that controls the elevating / lowering position of the floating weight based on the positional detection signal of the linear scale and the set value of the position setting device. The control device sends a stop signal to a direction switching solenoid valve to stop the action of the hydraulic cylinders when the positional detection signal matches the positional set value. With such a constitution, the stop position of the floating weight can be changed without requiring a complicated work.

Owner:KOBE STEEL LTD

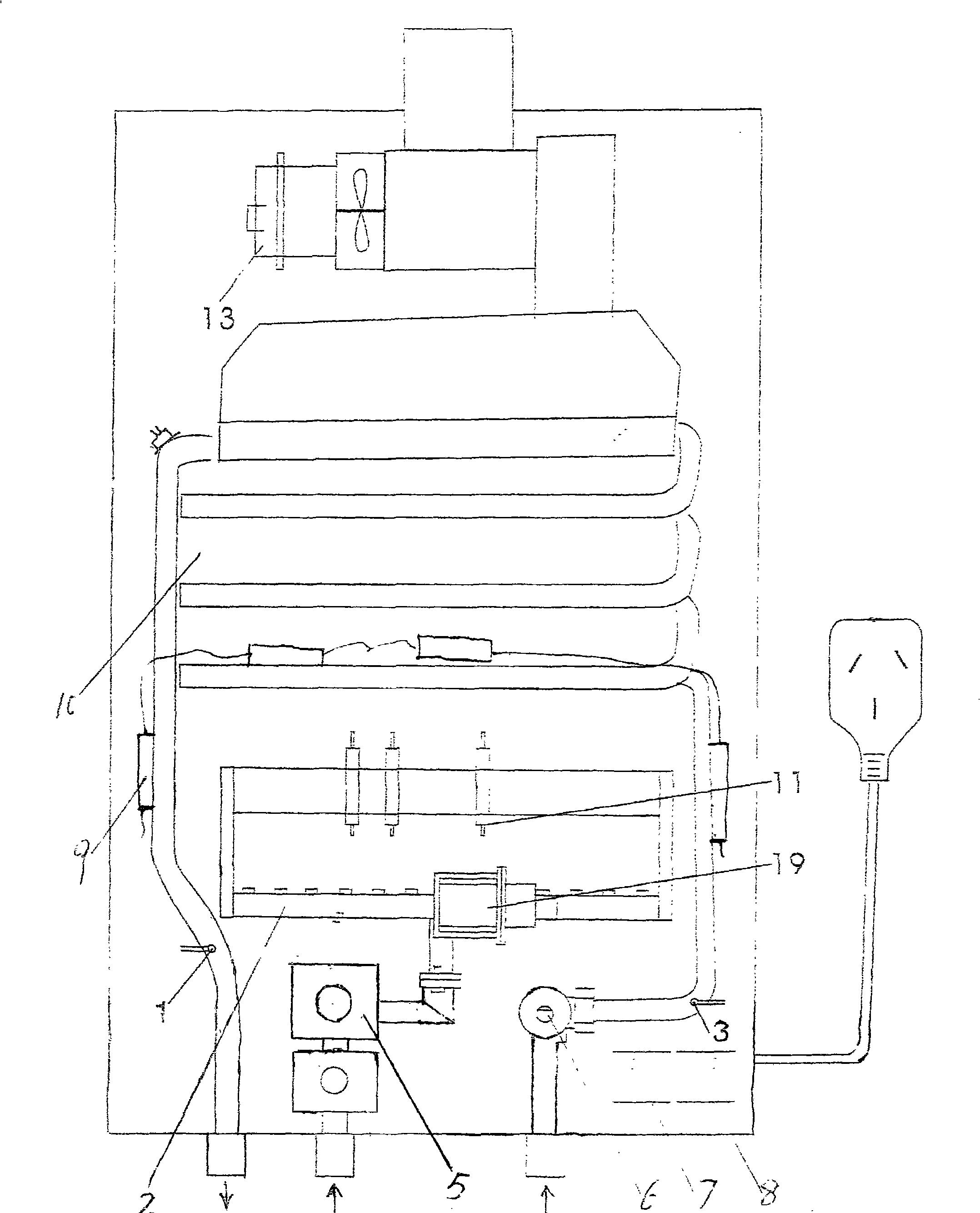

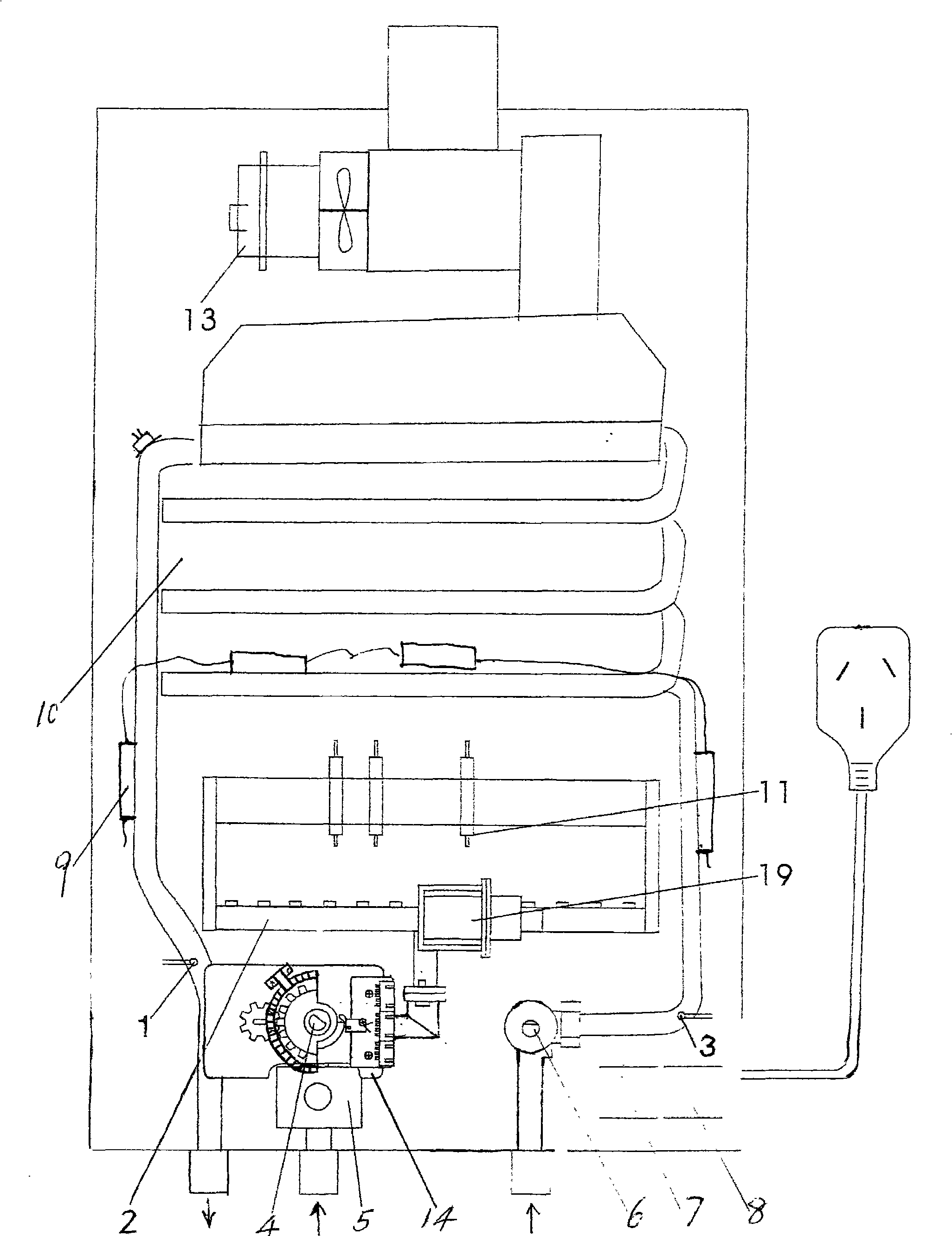

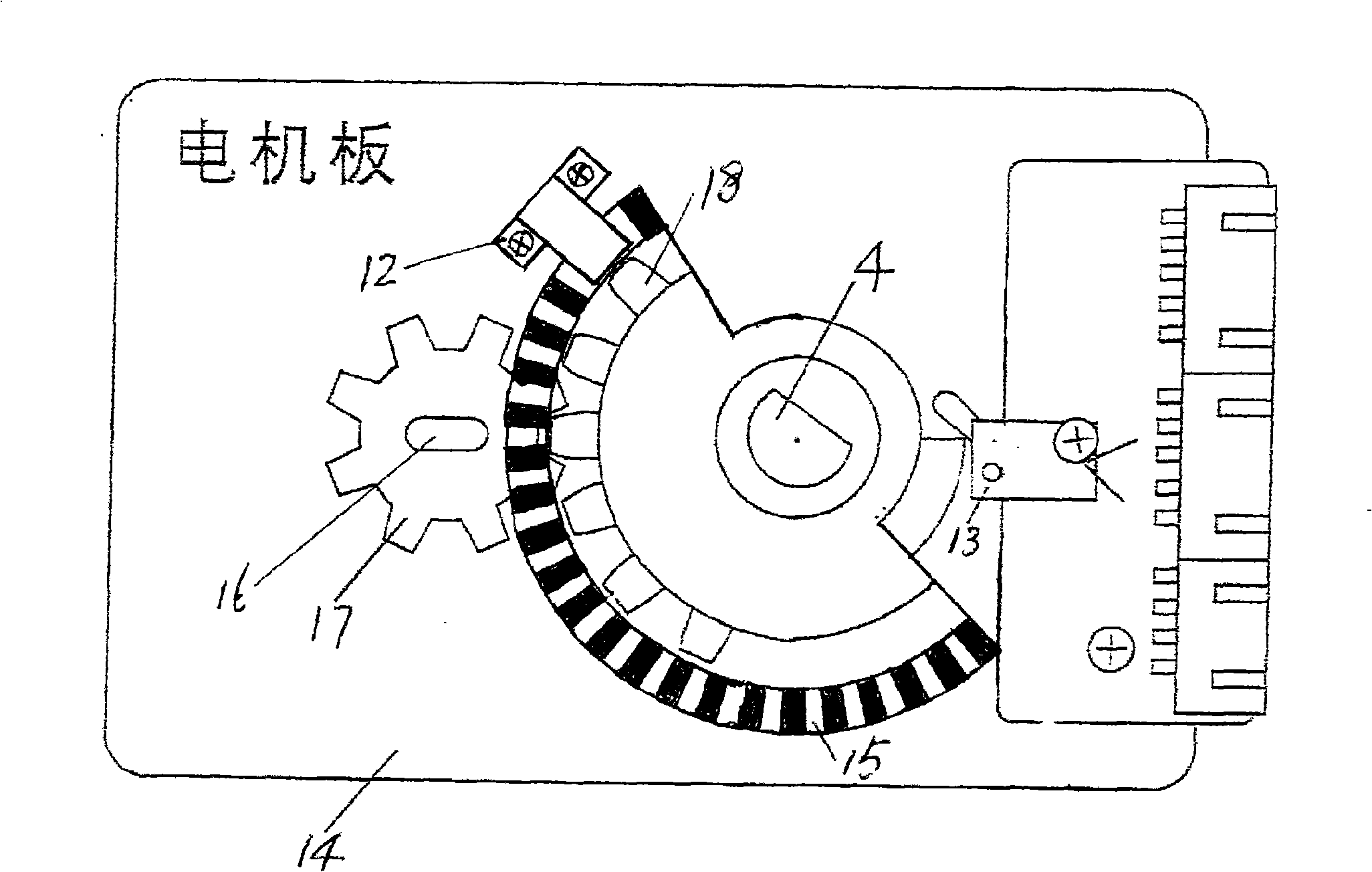

Dynamoelectric proportion valve automatic subsection antifreeze constant temp gas water heater

Owner:朱殿臣

Discontinuous linear motor system

ActiveUS8796959B2Simple power supplyLow costMotor/generator/converter stoppersDC motor speed/torque controlElectric machineMotor control

A linear motor system includes a discontinuous linear motor and motor control device. The discontinuous linear motor includes a mover and a plurality of individual motors spaced from each other along a movement path of the mover. Each of the individual motors functions as an armature on a primary side of one independent linear motor. A sensor, arranged to act as a linear scale, is disposed for each individual motor and detects a position of the mover. The motor control device includes a plurality of individual motor control units and a multiple unit controller to comprehensively control the individual motor control units. The individual motor control units control the individual motors disposed in curved path sections, and each of the individual motor control units includes a curved-line correspondence corrector to correct a detection value obtained from the sensor according to a relationship between a curved line of the path and a position of the sensor.

Owner:MURATA MASCH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com