Patents

Literature

31results about How to "Reduce large deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

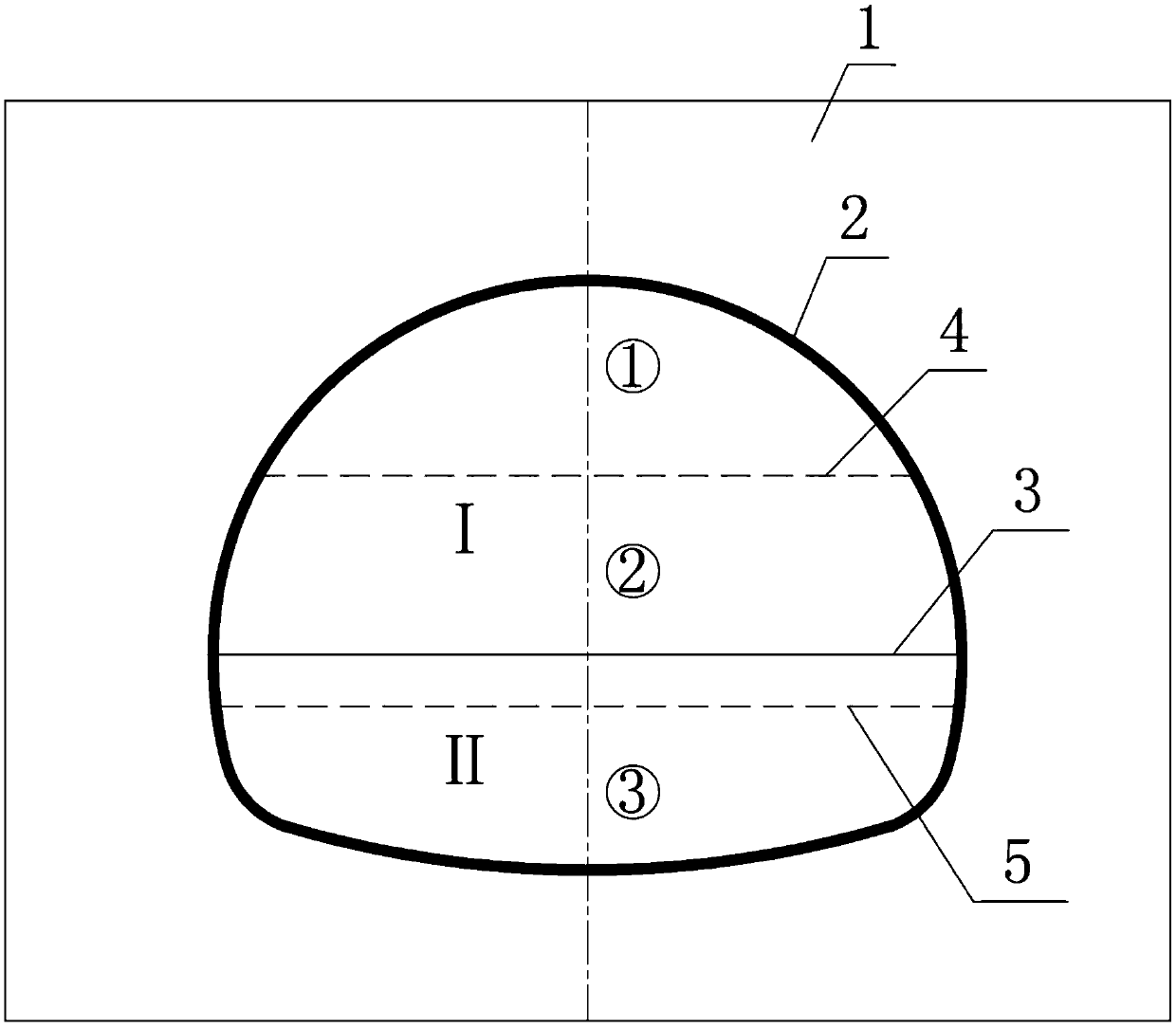

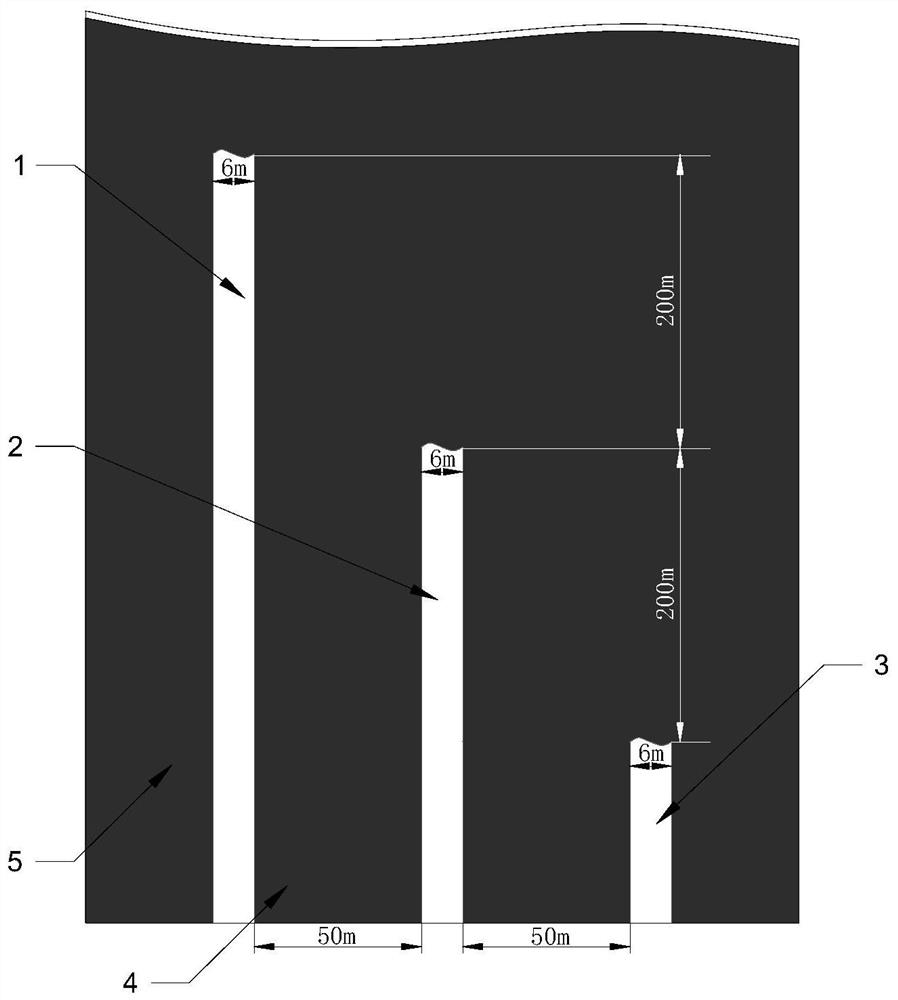

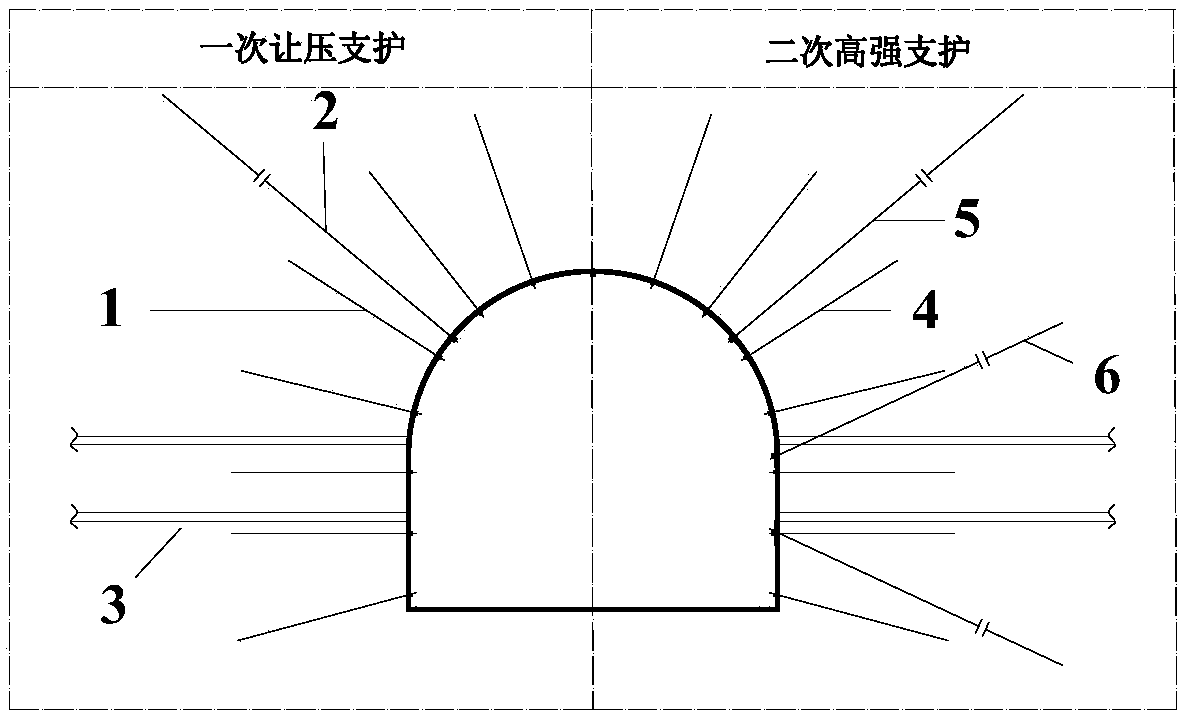

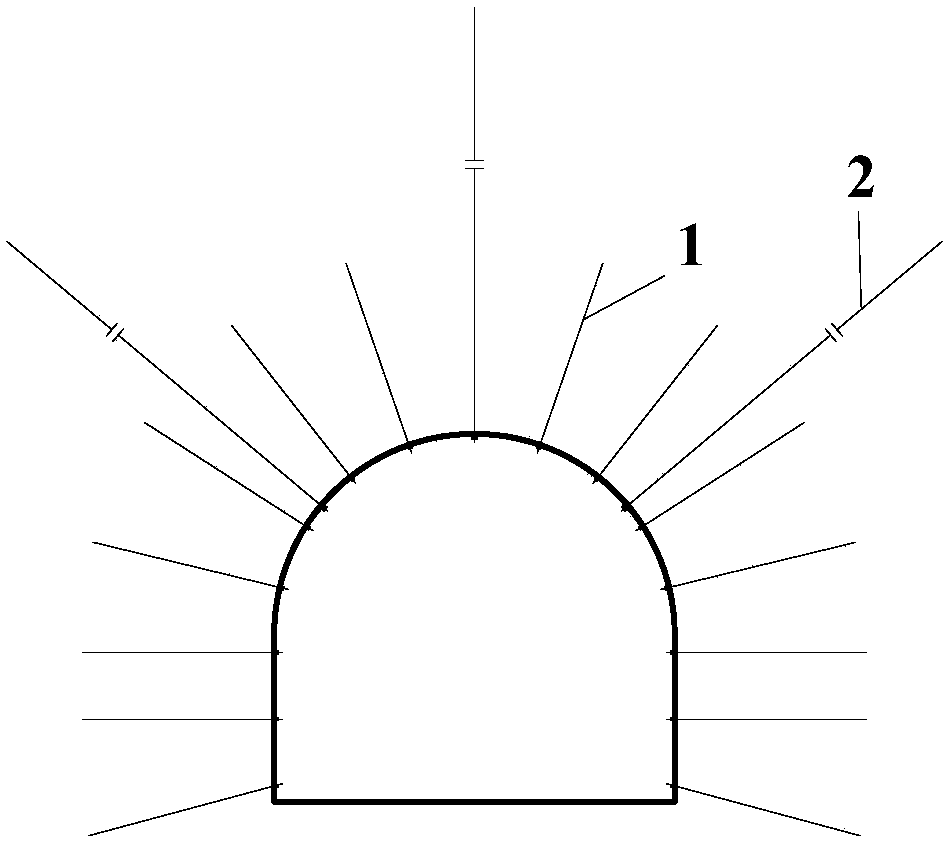

Pressure-relief support coordination control method for deep high-stress tunnel based on borehole pressure relief

ActiveCN106401645AAchieve long-term stabilityReduce repair rateMining devicesUnderground chambersLarge deformationHigh stress

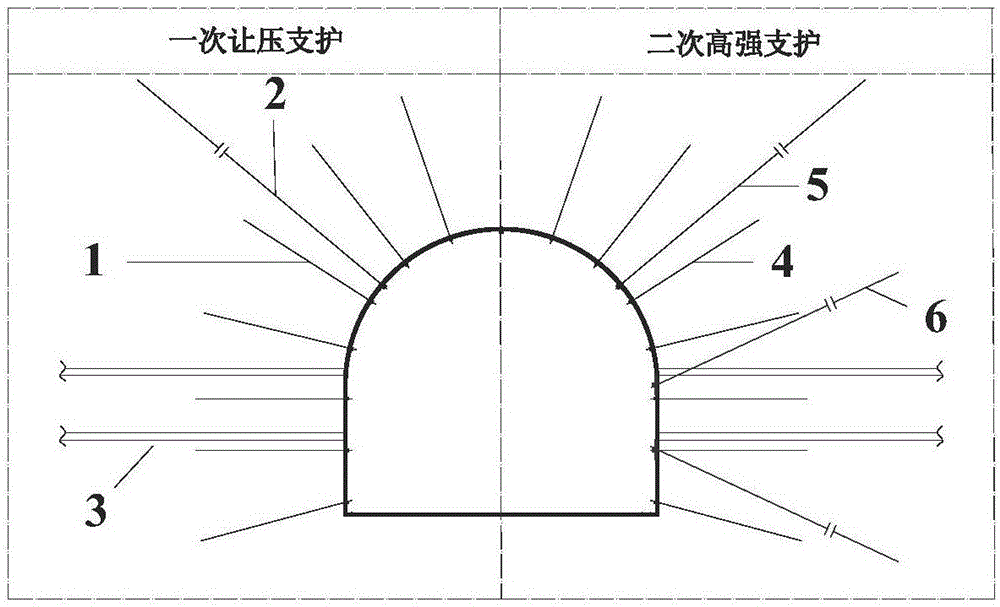

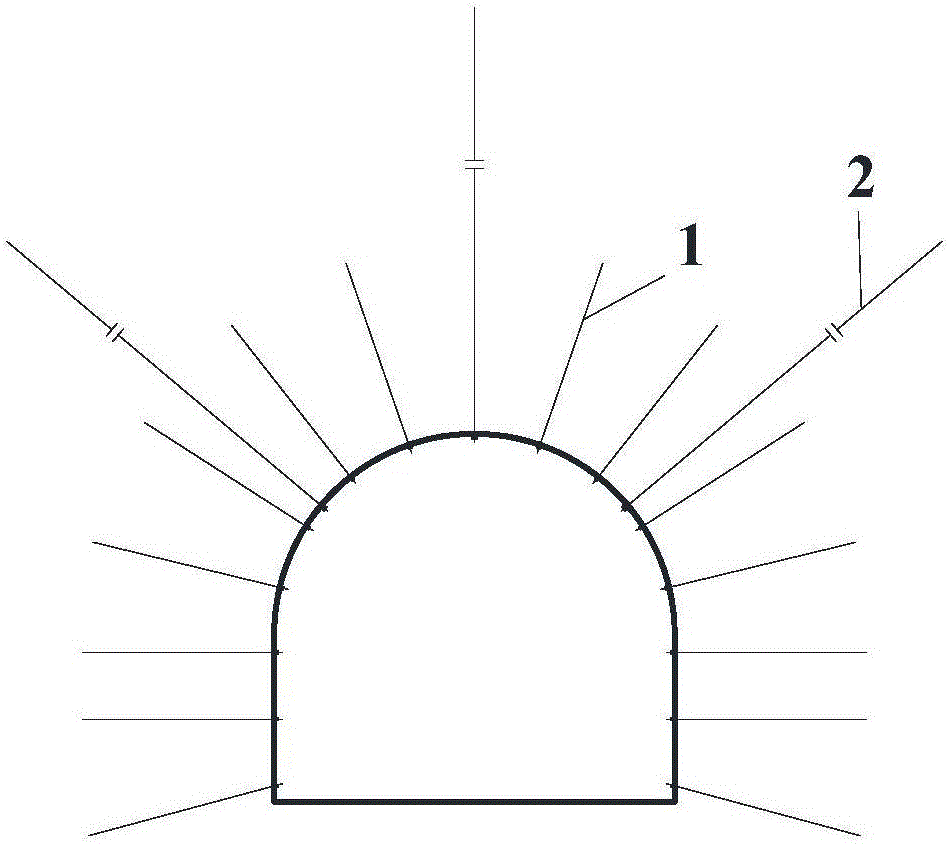

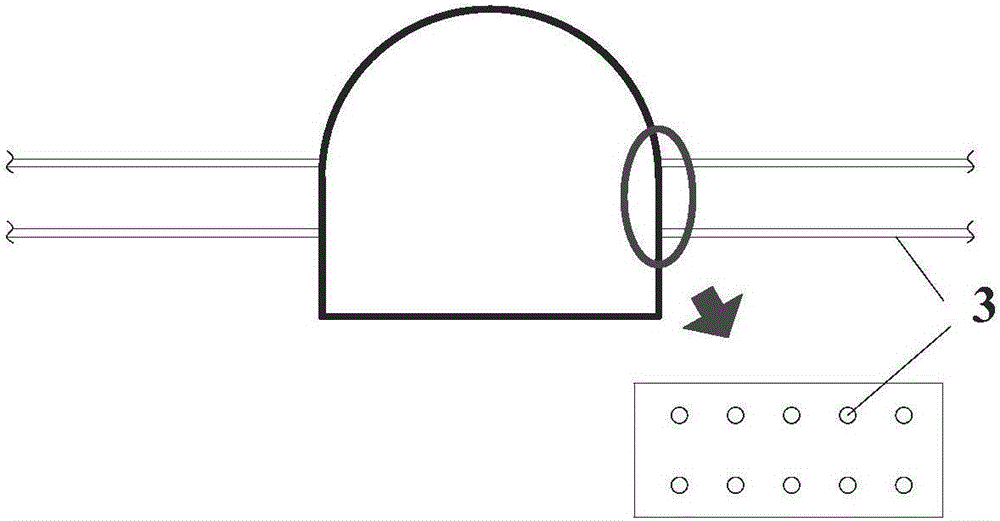

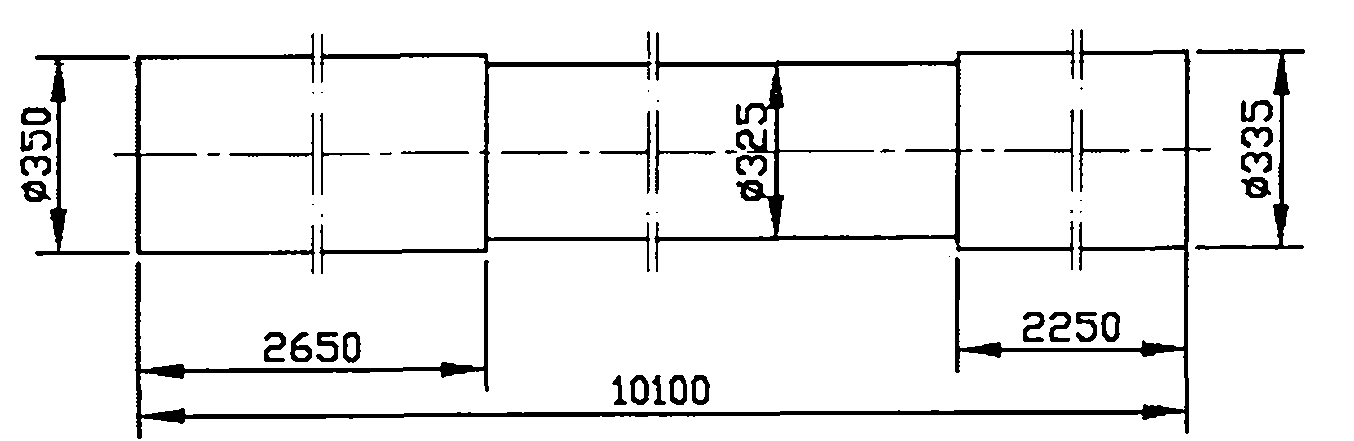

The invention discloses a pressure-relief support coordination control method for a deep high-stress tunnel based on borehole pressure relief. The method comprises three steps according to a time sequence, and the three steps are respectively a primary pressure relief support step, a borehole pressure relief step and a secondary high-strength anchor grouting support step. According to the pressure-relief support coordination control method for the deep high-stress tunnel based on borehole pressure relief, surrounding rock deformation in each stage is controlled by adopting different support and reinforcement methods according to difference of surrounding rock deformation ways in different stages after the tunnel is excavated, the support performances of surrounding rocks and supporting structures are fully played, and large deformation of the surrounding rocks of a deep high-stress tunnel is reduced, so the stability of the tunnel can be maintained for a long time. Meanwhile, the method disclosed by the invention is capable of effectively reducing the repair rate of the tunnel, alleviating the labor intensity of workers and lowering the comprehensive support cost of a mine.

Owner:HENAN POLYTECHNIC UNIV

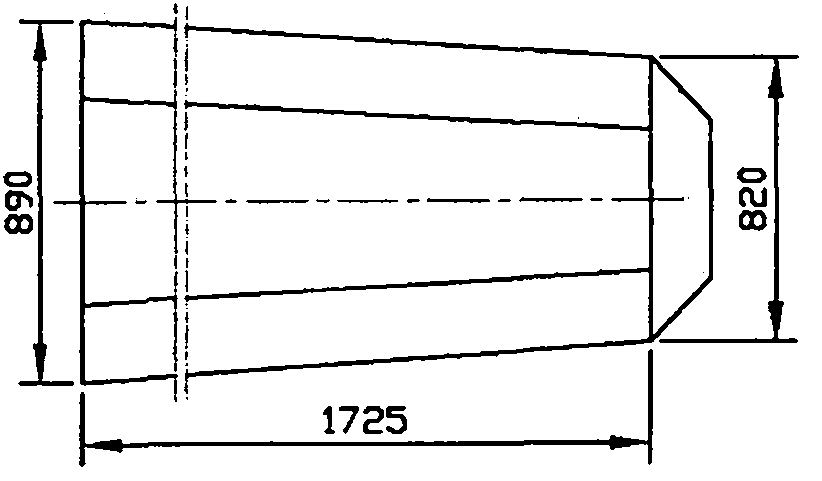

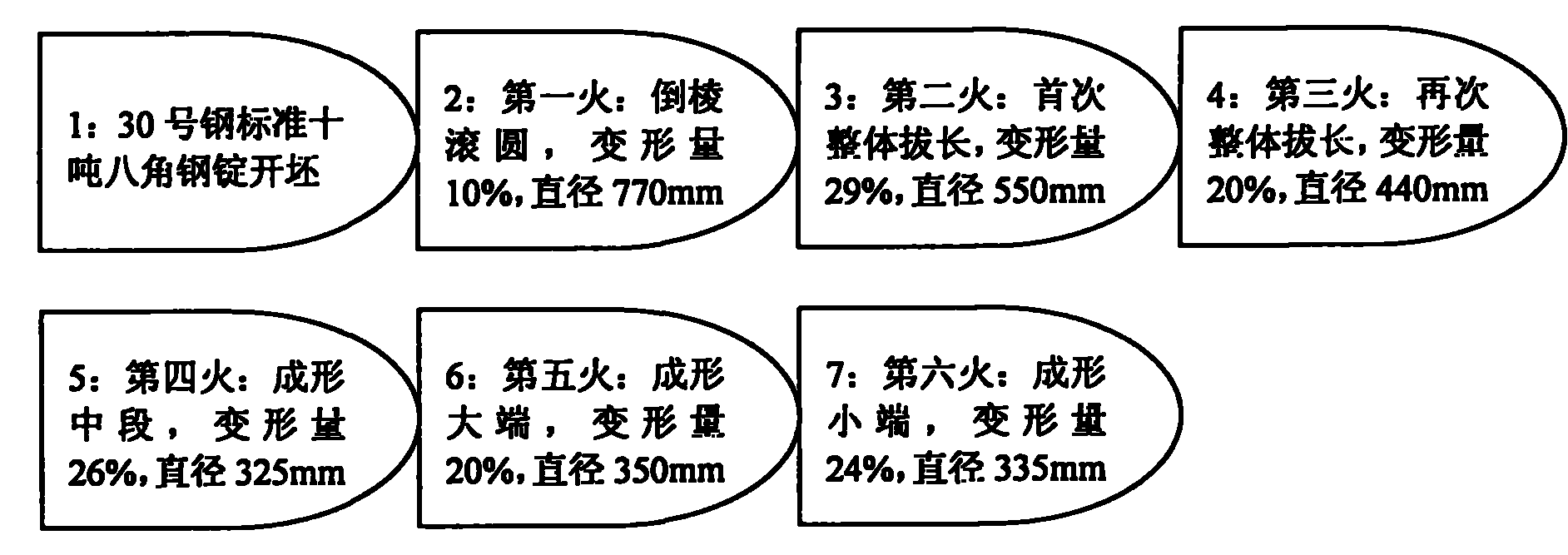

Method for forging large steel shaft forging

InactiveCN101920304AIncrease the amount of single deformationEliminate internal defectsEngine componentsSteel qualityCarbon steel

The invention discloses a method for forging a large steel shaft forging. The method comprises the following steps of: performing cogging, chamfered edge rounding, whole stretching for the first time, whole stretching again, section-by-section forging and the like on a medium carbon steel standard octagon ingot of which the carbon content is 0.3 to 0.4 percent. The step of whole stretching for the first time comprises the following steps of: heating a forged piece to a primary forging temperature; stretching on a forging hammer with a flat anvil; and reaching the deformation rate of 29 to 31 percent at the effective hole welding temperature of over 900 DEG C so as to overcome internal defects of the forged piece. The step of whole stretching again comprises the following steps of: heating the forged piece to the primary forging temperature; stretching on the forging hammer with the flat anvil; and reaching the deformation rate of 15 to 20 percent at the final forging temperature of 800 DEG C. And the single-time deformation rate of each section when the section-by-section forging is performed should not be less than 20 percent. The method of the invention effectively overcomes the internal defects of the material, reduces the material and working time waste, more reasonably distributes the deformation rate of each step, contributes to the reduction of the forging deforming force and realizes ideal material mechanical property.

Owner:SOUTH CHINA UNIV OF TECH

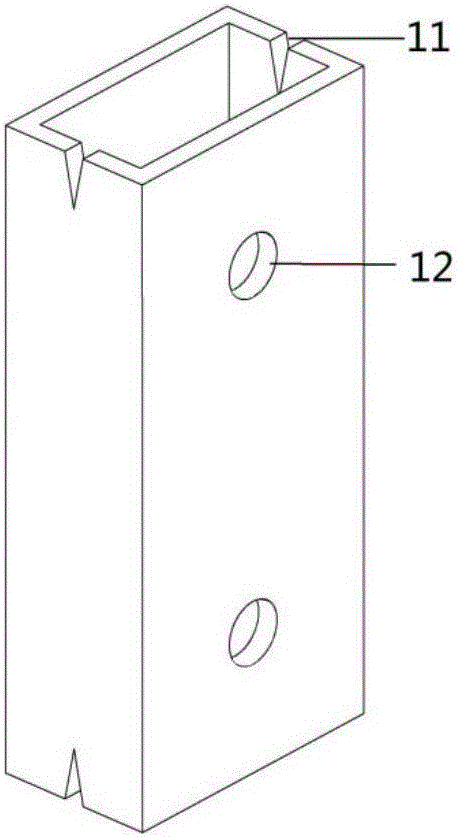

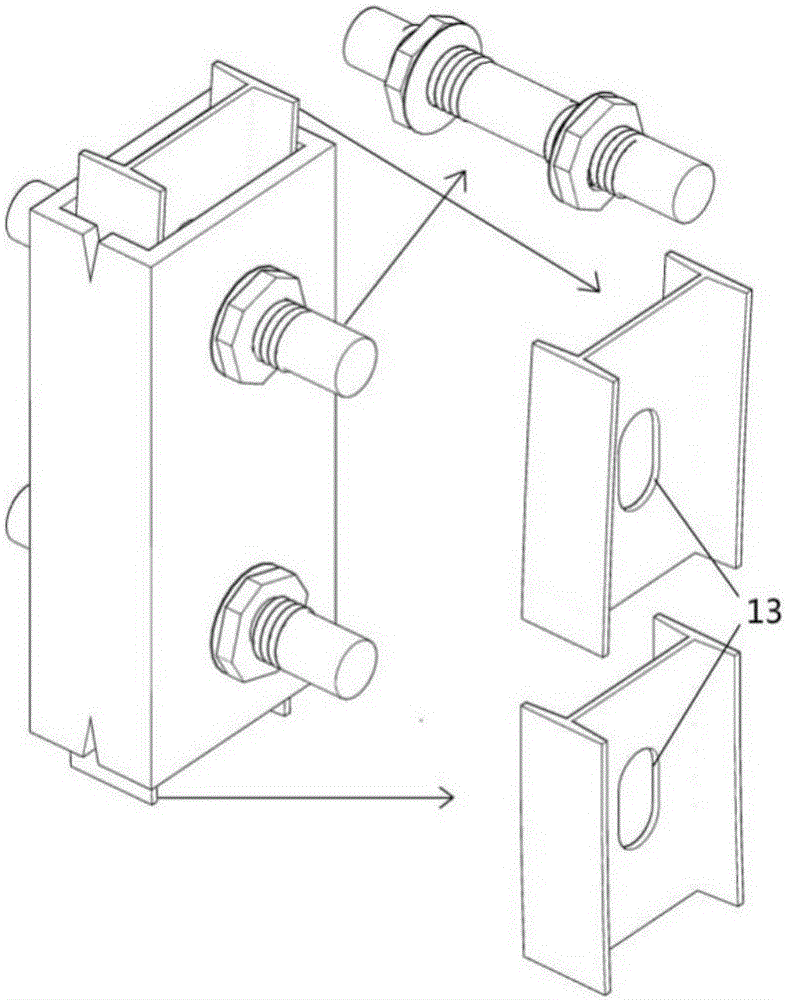

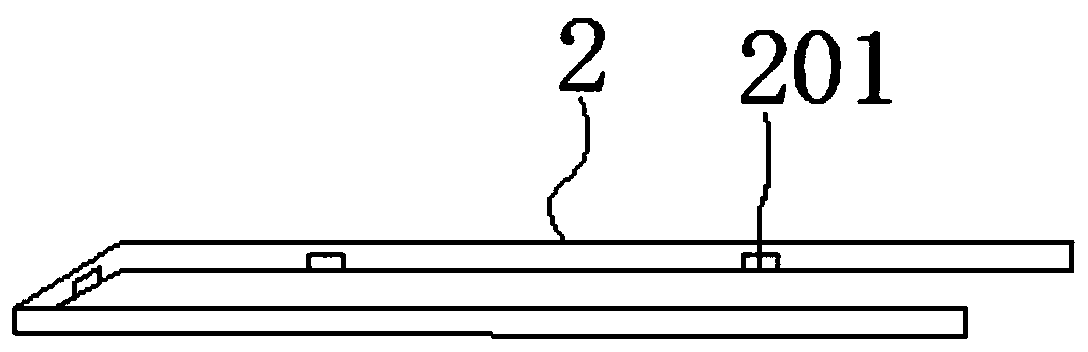

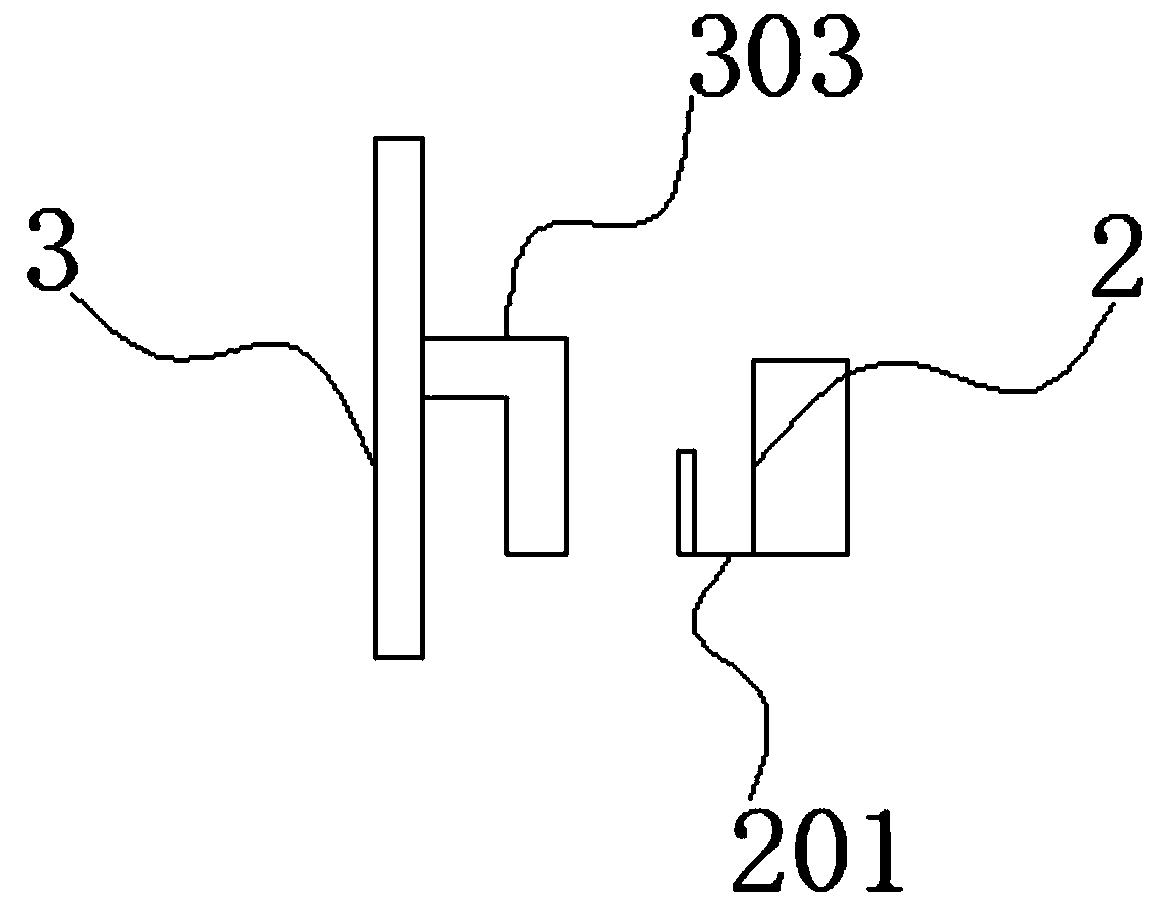

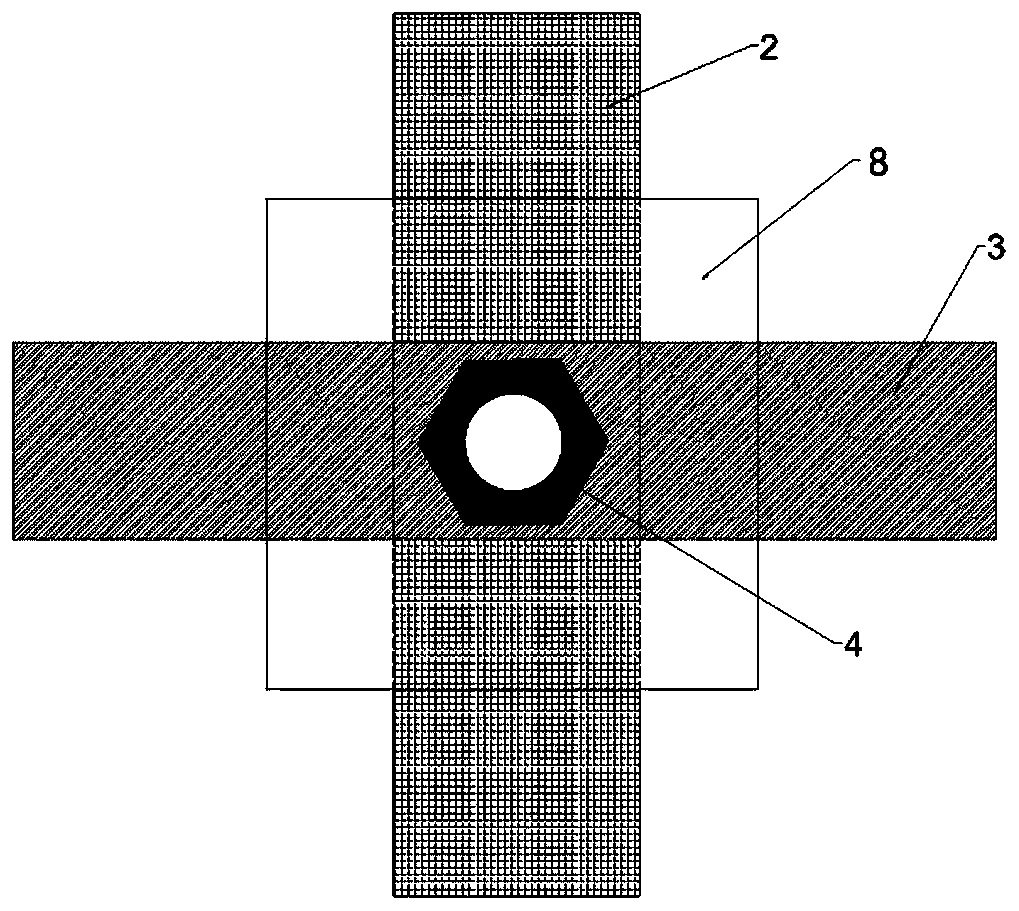

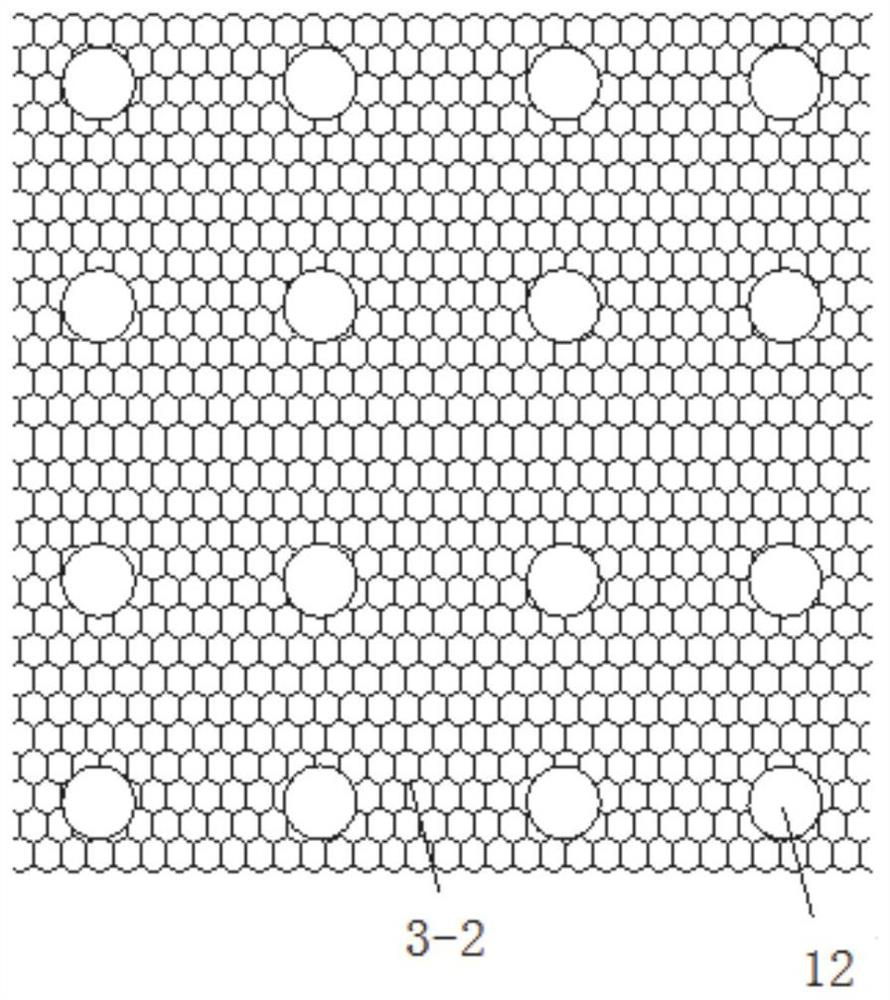

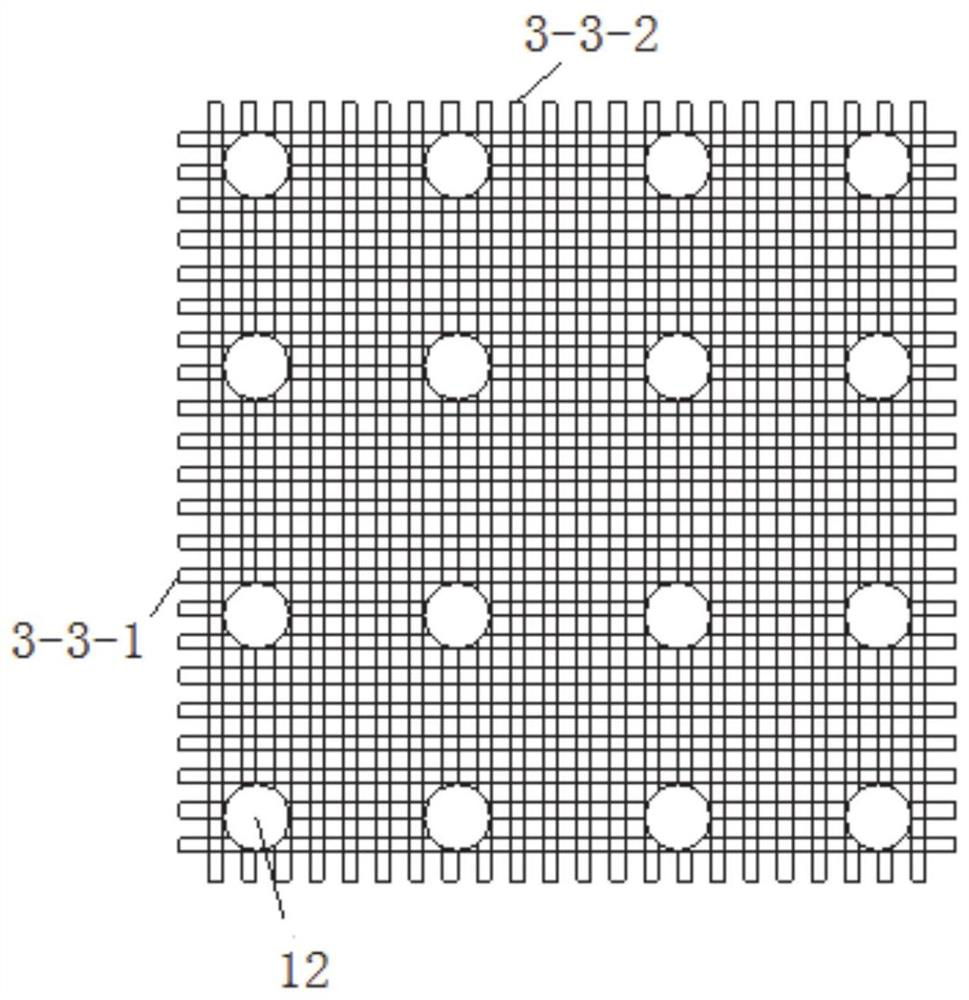

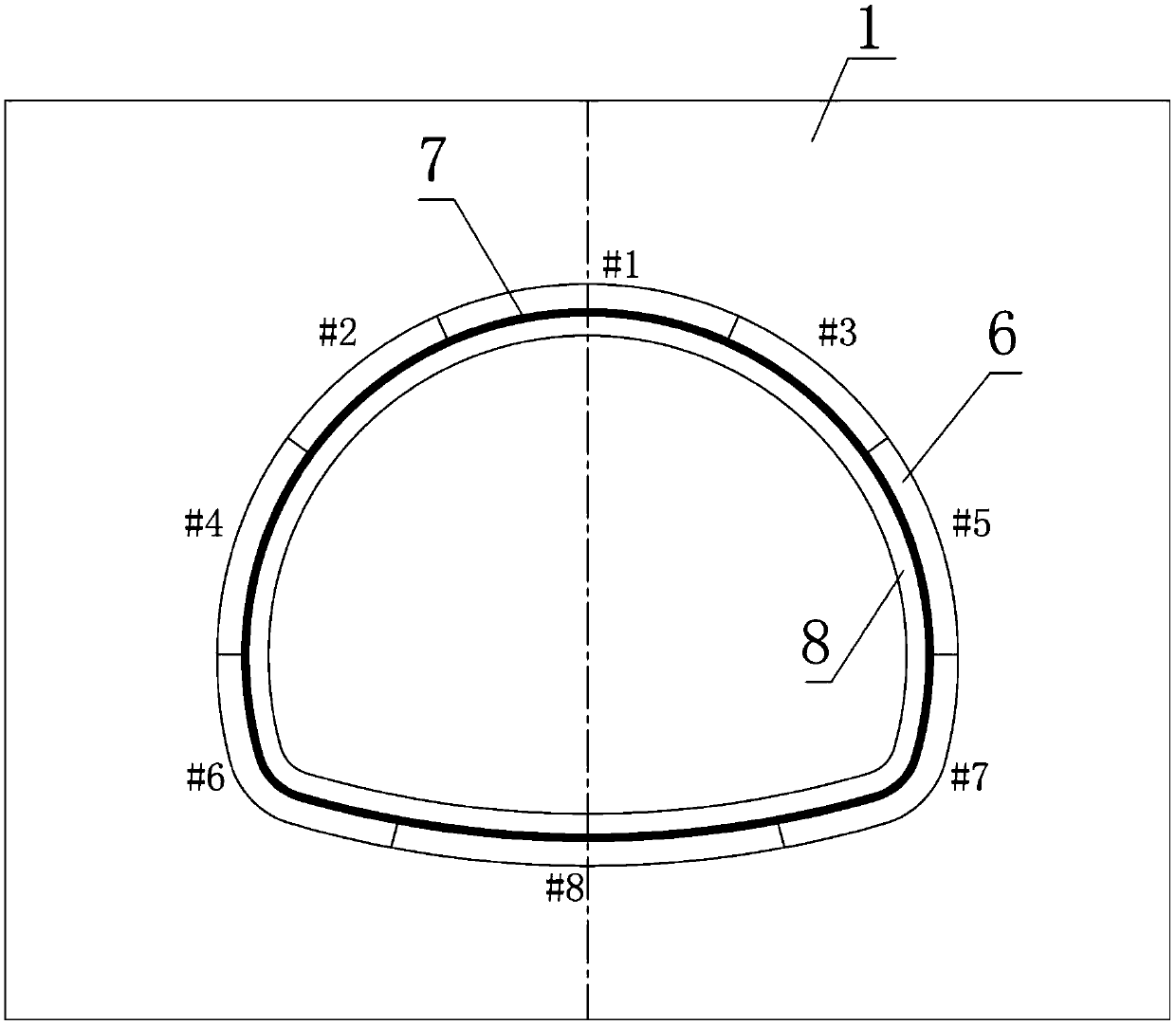

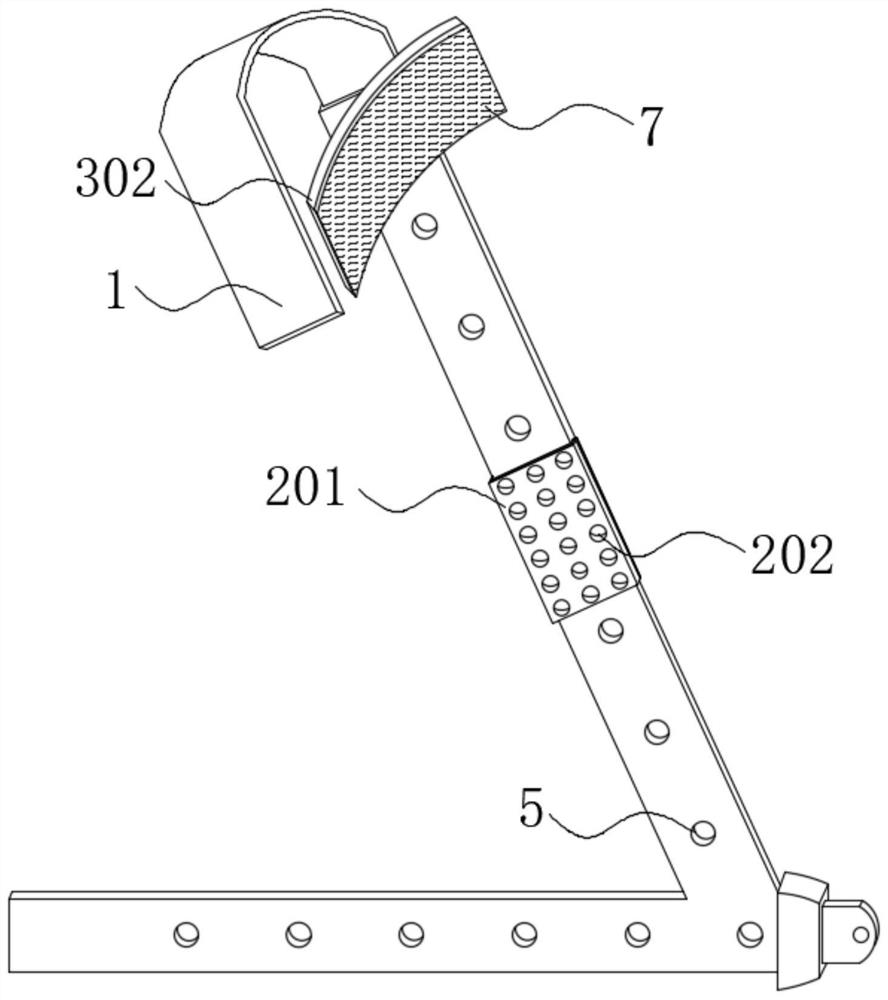

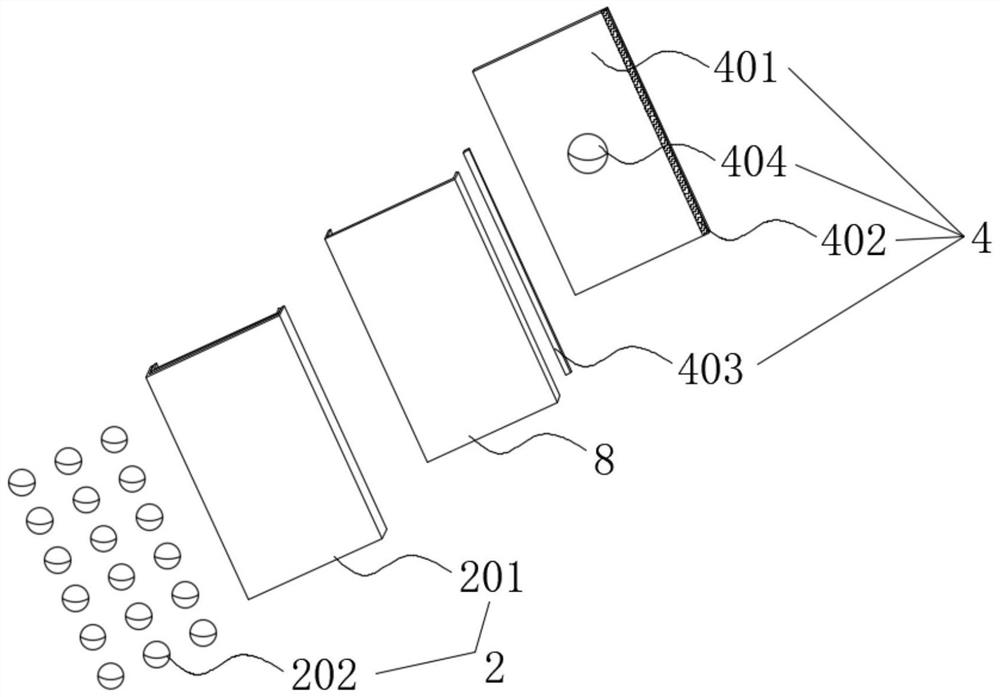

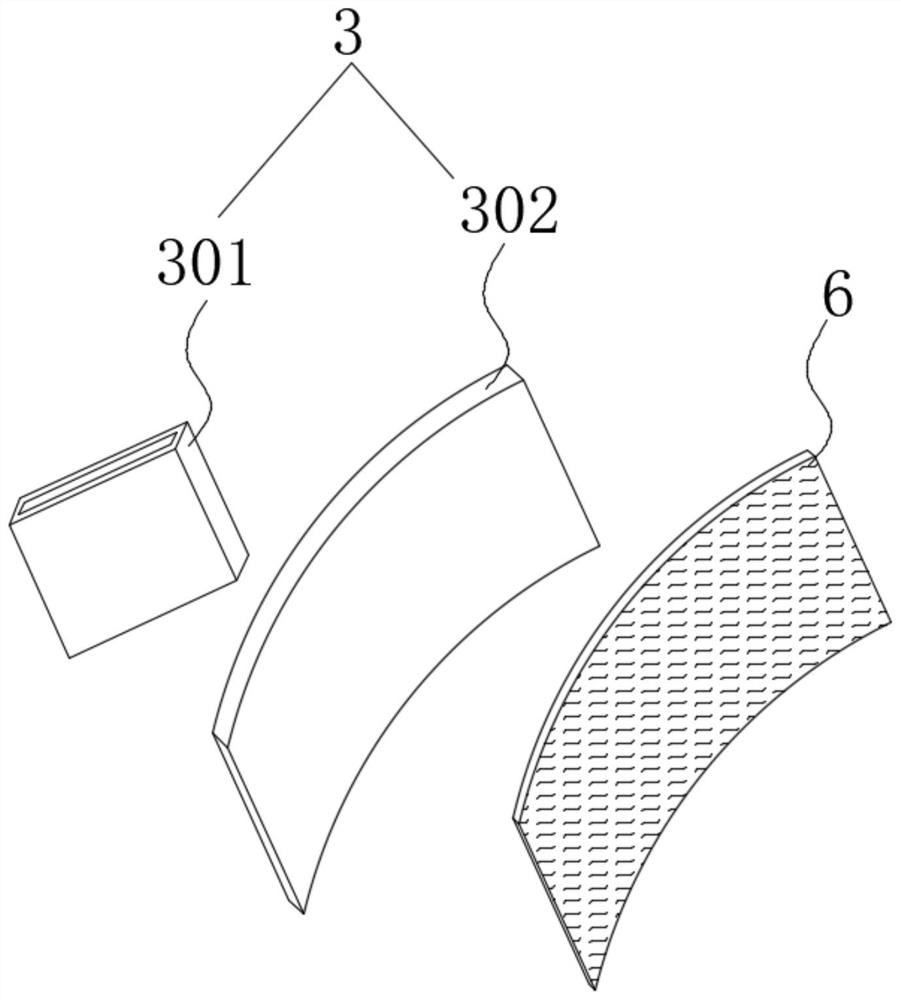

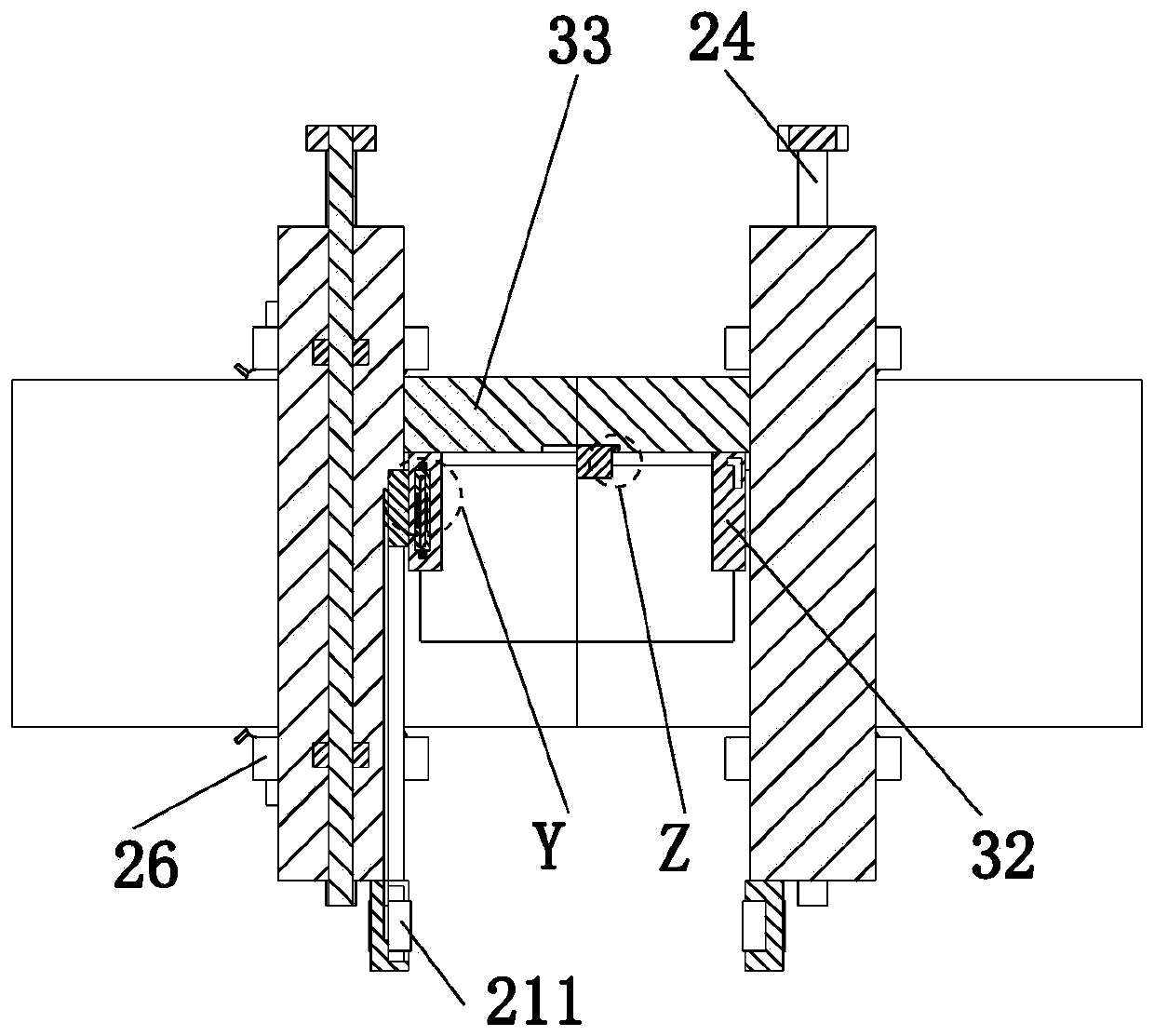

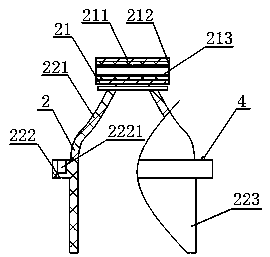

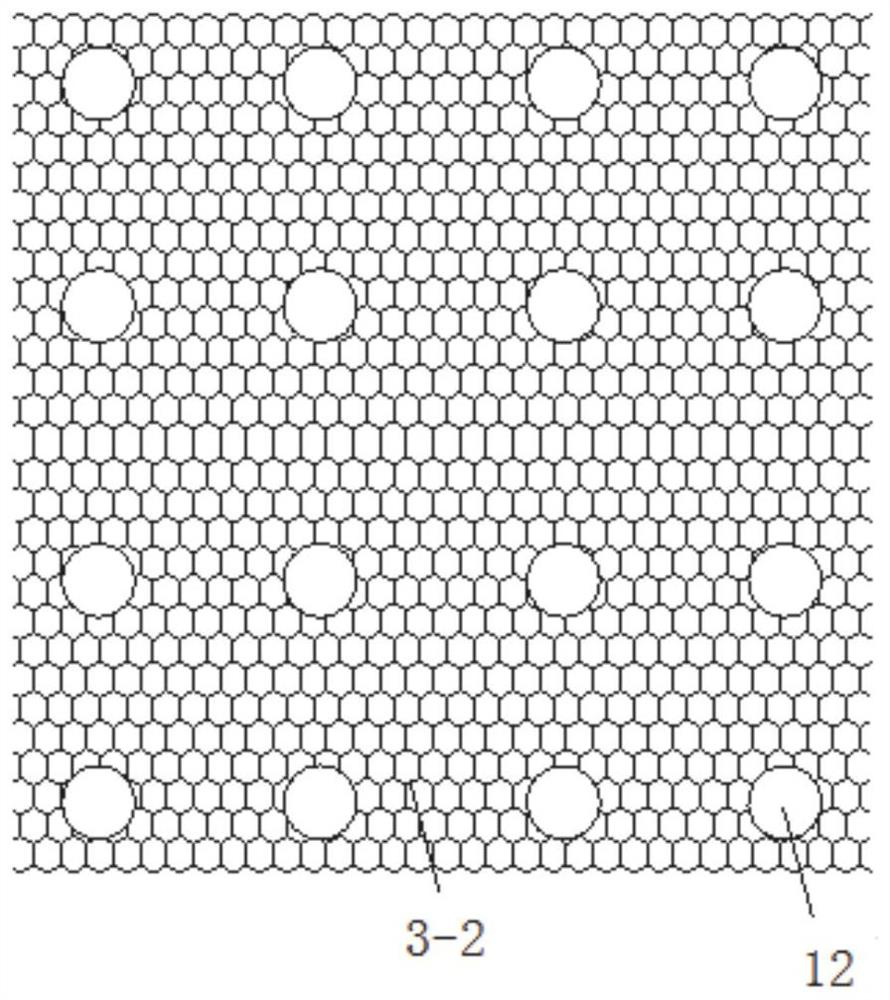

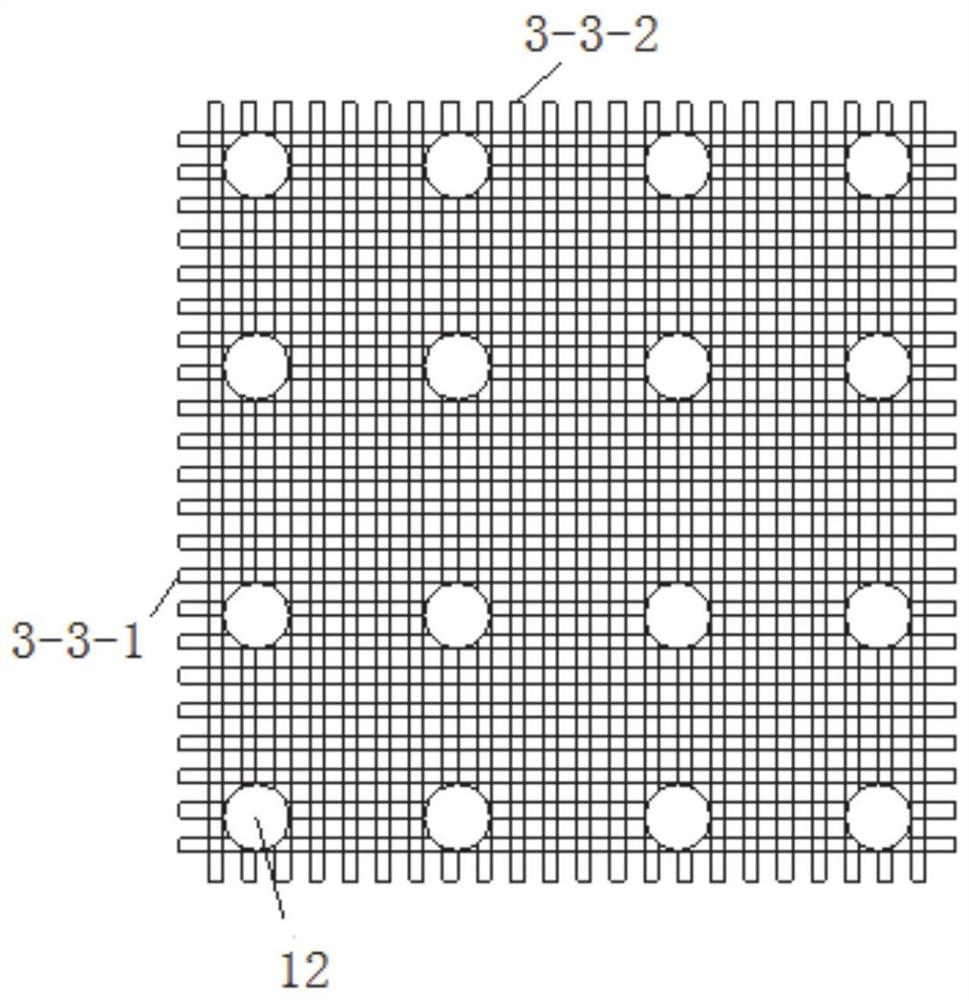

Support frame, support structure and construction method of support structure

ActiveCN105822329ADeformation weakeningReduce large deformationUnderground chambersTunnel liningLarge deformationTreatment costs

The invention relates to the technical field of tunnel construction, in particular relates to a support frame, a support structure and a construction method of the support structure, and provides a support frame which is formed by sequentially connecting a plurality of support segments in cycle, wherein hole grooves are formed in two ends of each support segment; adjacent support segments are connected through a first sleeve; the first sleeve is a hollow circumferential sleeve which is matched with the support segments in size; mounting holes are formed in two ends of the front wall surface and the rear wall surface of the first sleeve corresponding to the hole grooves; a second sleeve is a cross-shaped sleeve which comprises the circumferential sleeve similar to the first sleeve and two longitudinal sleeves which are symmetrically arranged at the centers of the front side wall and the rear side wall of the circumferential sleeve; energy-dissipation presplitting slots are formed in the middle parts of two ends of the left wall surface and the right wall surface of the circumferential sleeve. The support structure formed by combining the first sleeve and the second sleeve is reasonable in design and convenient to construct, and can effectively adapt to large deformation of a surrounding rock; the clearance-intrusion risk of the local large deformation of a tunnel is reduced; the overall stability of a primary lining support structure is improved; and the subsequent treatment cost of the engineering is reduced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

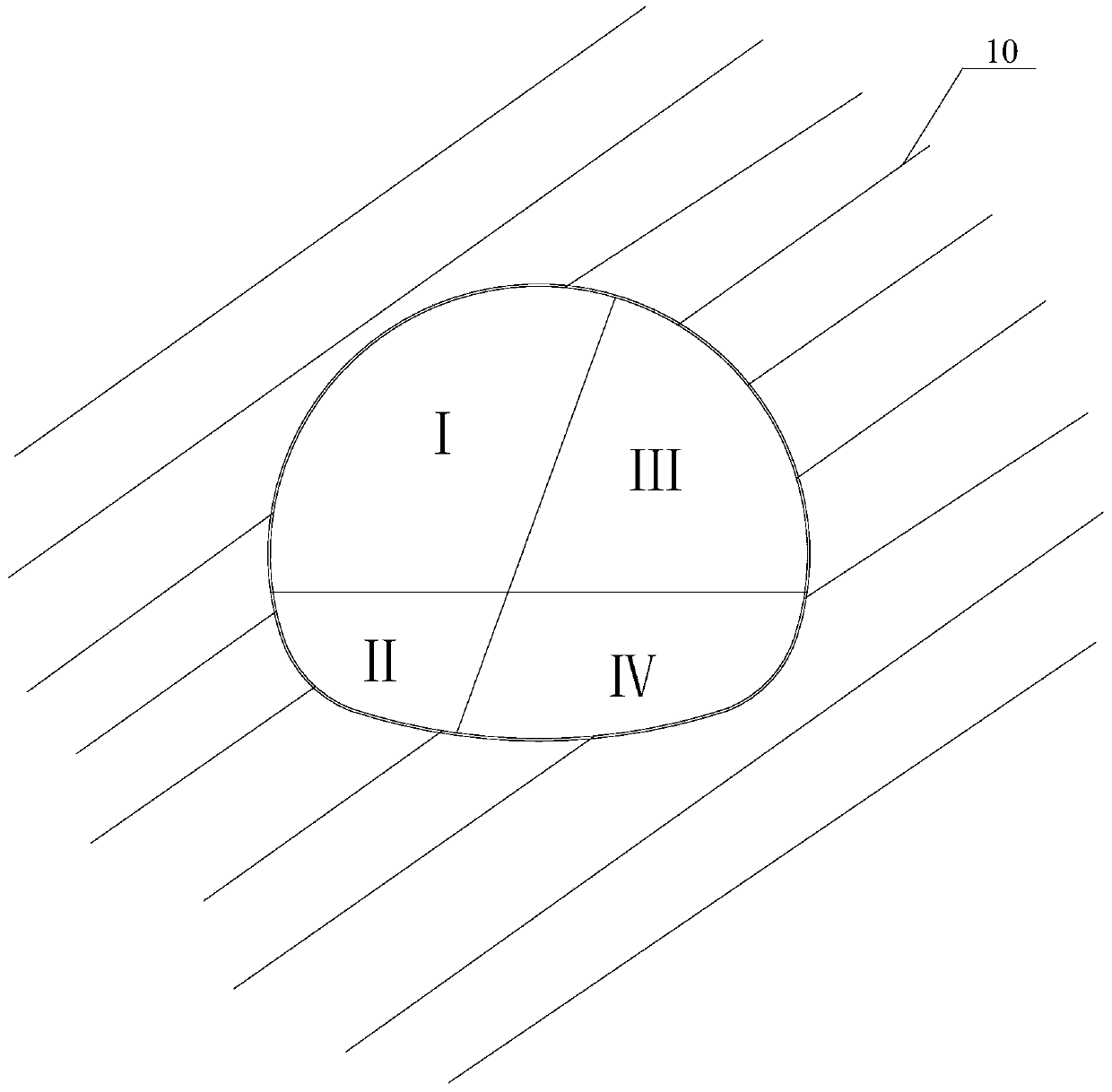

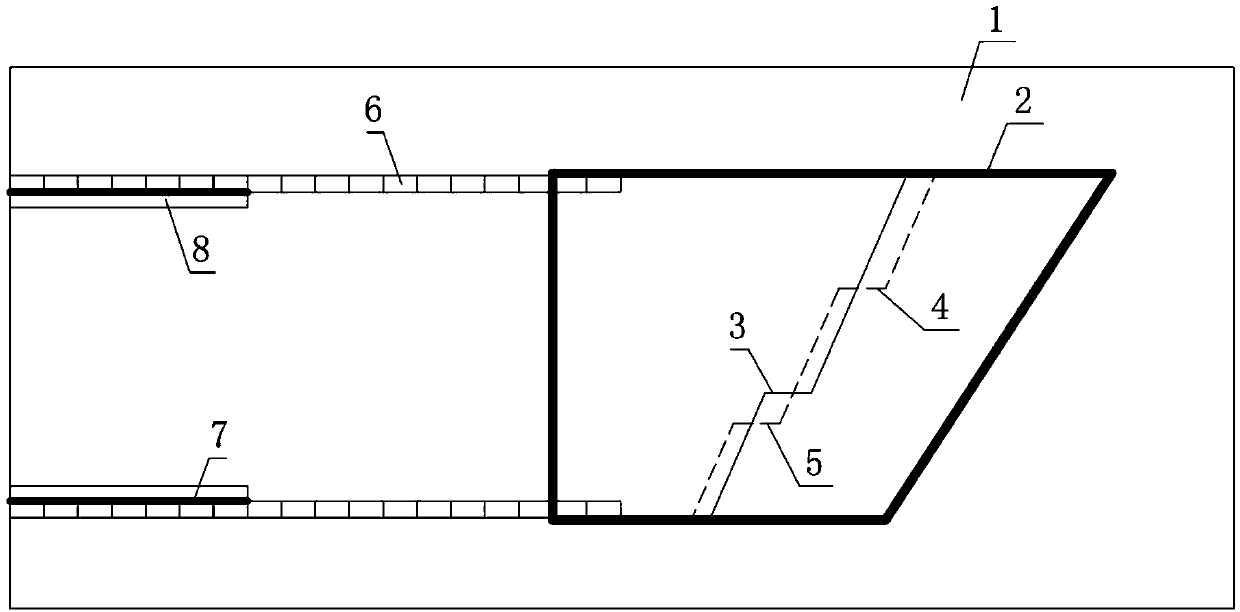

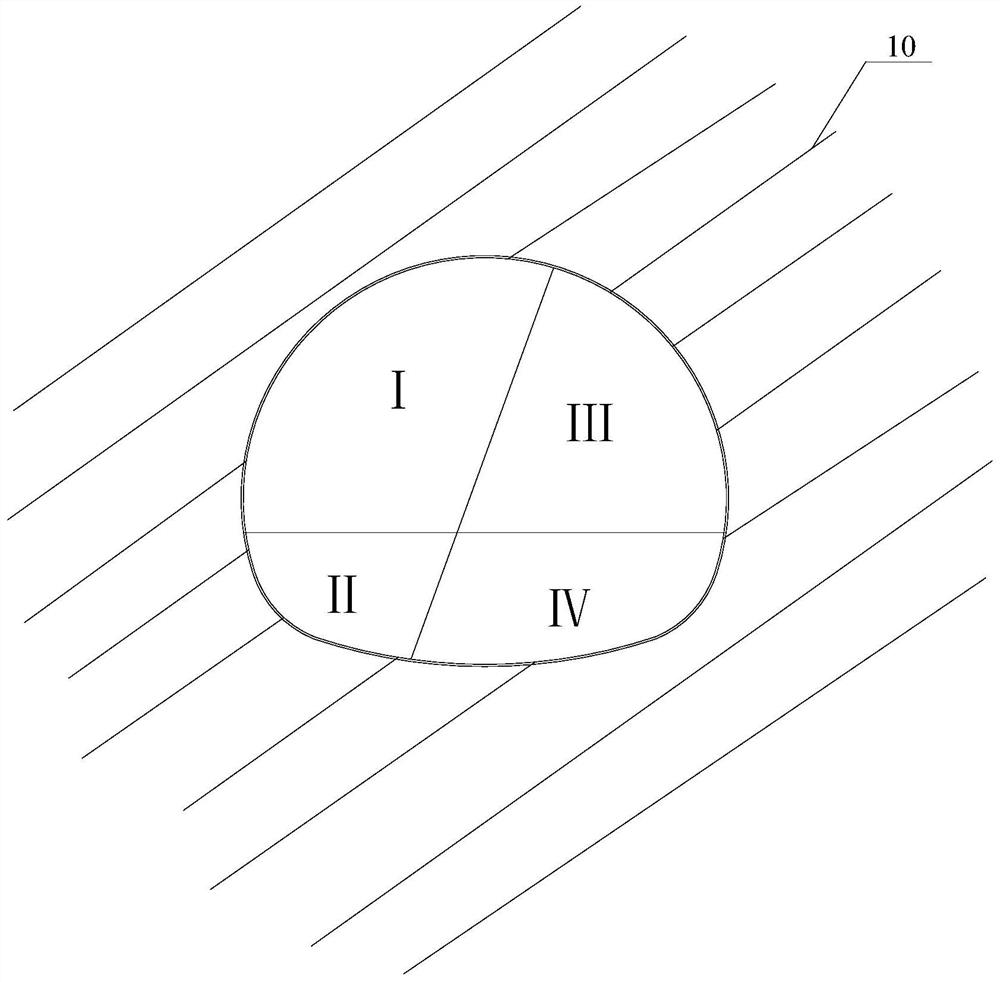

Construction method suitable for soft rock bedding tunnel

ActiveCN110080782AControl deformationImprove the stability of surrounding rockUnderground chambersTunnel liningTunnel constructionEngineering

The invention relates to the field of tunnel support, in particular to a construction method suitable for a soft rock bedding tunnel, which comprises the following steps: S1, excavating reverse-tilting upper step core soil, and constructing a first support system; S2, excavating core soil of the lower step of the reverse side, and constructing a second supporting system; S3, excavating upper stepcore soil along the inclined side, and constructing a third support system; S4, excavating core soil of the lower step along the inclined side, and constructing a fourth support system; and S5, disassembling the temporary support, and constructing a secondary lining. According to the construction method, reasonable excavation steps and supporting structures are adopted in a targeted mode accordingto the bias deformation characteristic of the bedding tunnel and the surrounding rock stability difference, deformation during tunnel construction can be effectively controlled, surrounding rock self-bearing is given to full play, the surrounding rock stability is improved, and therefore the construction risk and the engineering cost are reduced.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

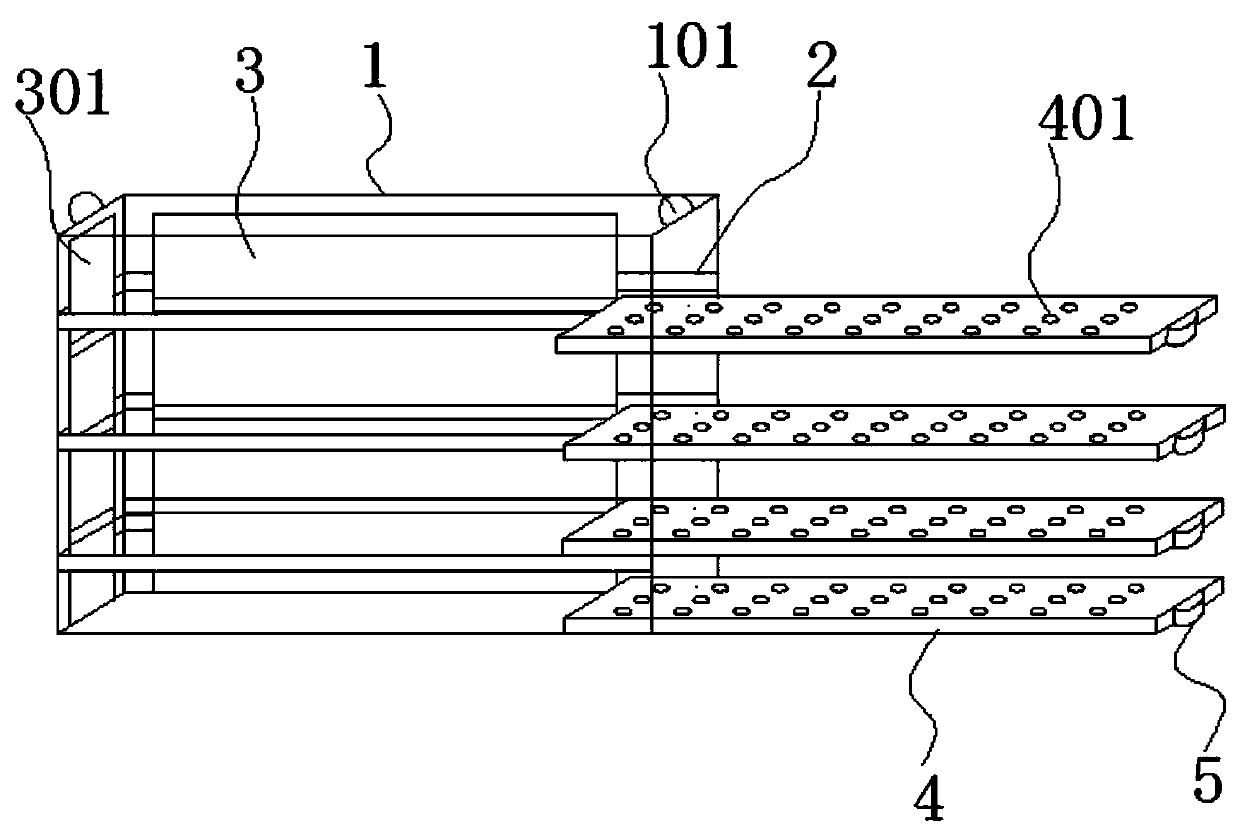

Combined type multifunctional quenching clamp

PendingCN110541063ASolve QuenchingImprove heat treatment productivityFurnace typesHeat treatment furnacesHardnessQuenching

The invention discloses a combined type multifunctional quenching clamp and belongs to the technical field of machine manufacturing vacuum heat treatment production operation. The combined type multifunctional quenching clamp comprises a main material frame and lifting rings. The lifting rings are welded to the two ends of the top of the main material frame correspondingly. C-shaped reinforcing ribs are welded to the surface of the side wall of the main material frame. Multiple C-shaped reinforcing ribs are arranged. Hook bases are arranged on the surfaces of side heads of the C-shaped reinforcing ribs correspondingly. According to the combined type multifunctional quenching clamp, workpieces are partitioned by means of through holes, multiple carrier plates carry out quenching treatment on the multiple workpieces, uniformity of workpiece heating is improved obviously, the uniformity of the quenching cooling process is improved, heat treatment hardness, strength, impact value and othermechanical performance of the workpieces reach the optimal level, the defects that when workpiece original furnace charging amount is large, quenching hardness is not uniform, soft points exist, andthe service life is short are effectively eliminated, the shaft workpieces are vertically clamped and fixed through through holes in the carrier plates, and thus the shaft workpieces can be fixed moreconveniently.

Owner:吴江华宏真空科技有限公司

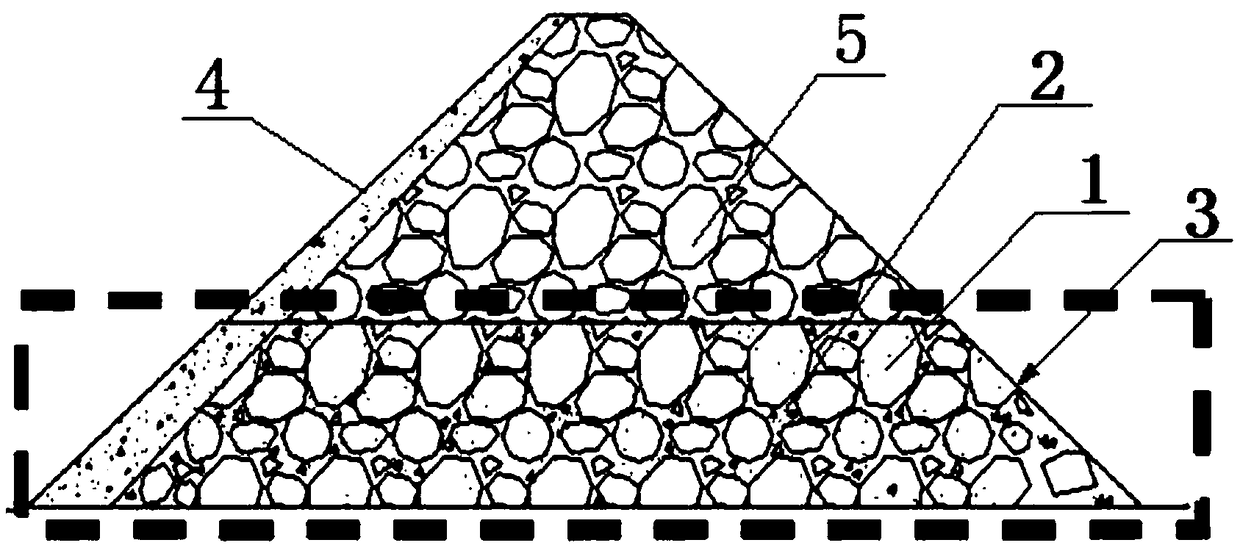

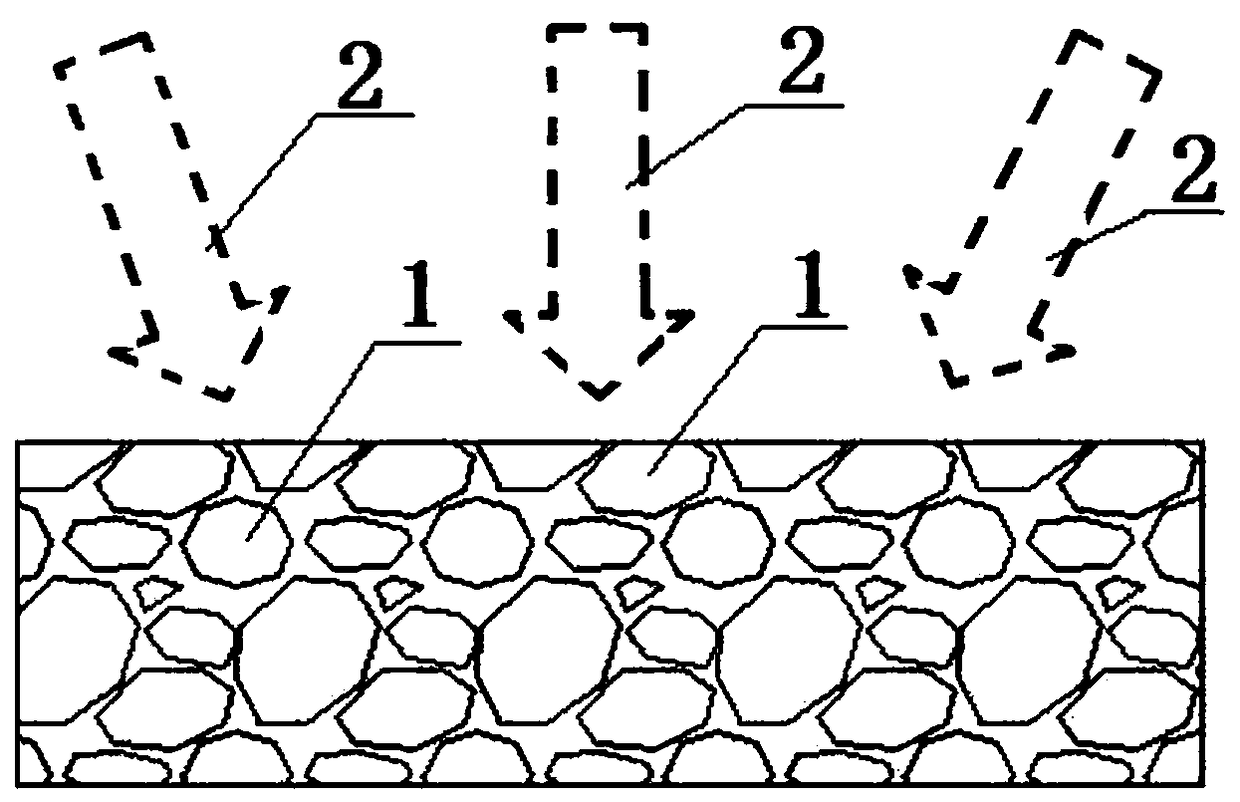

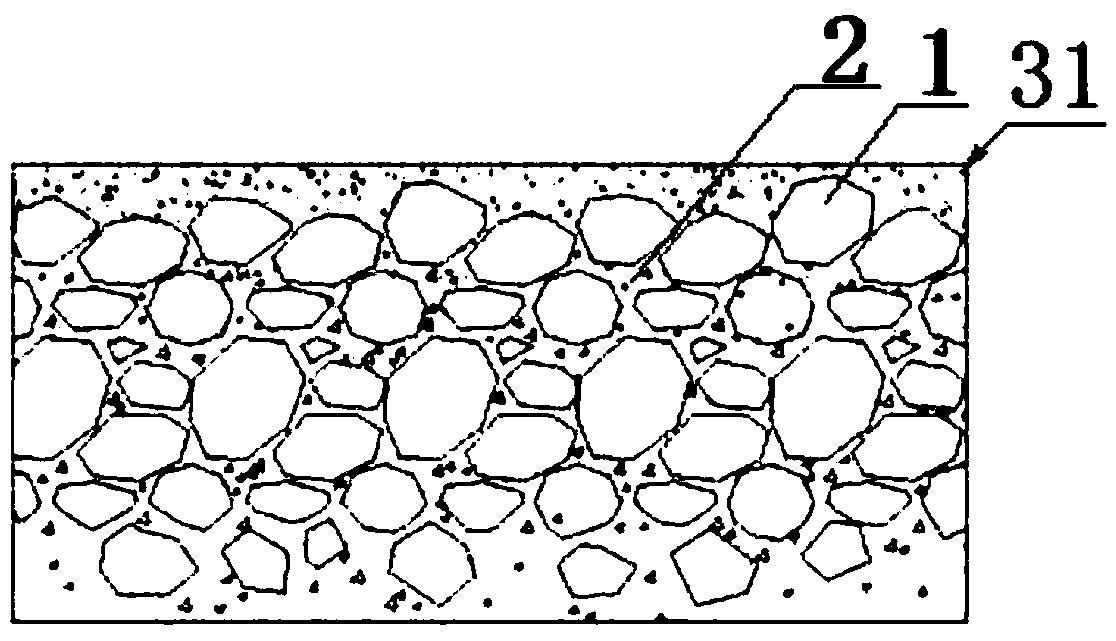

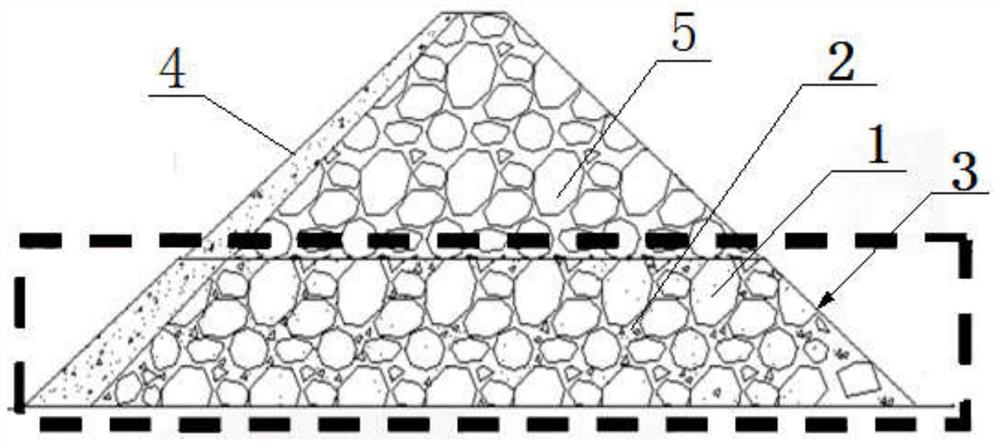

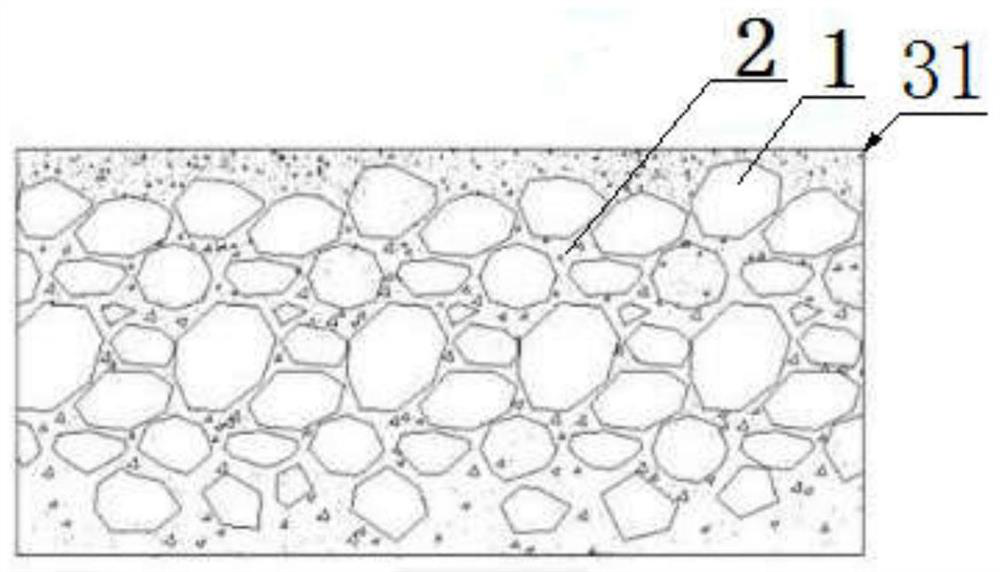

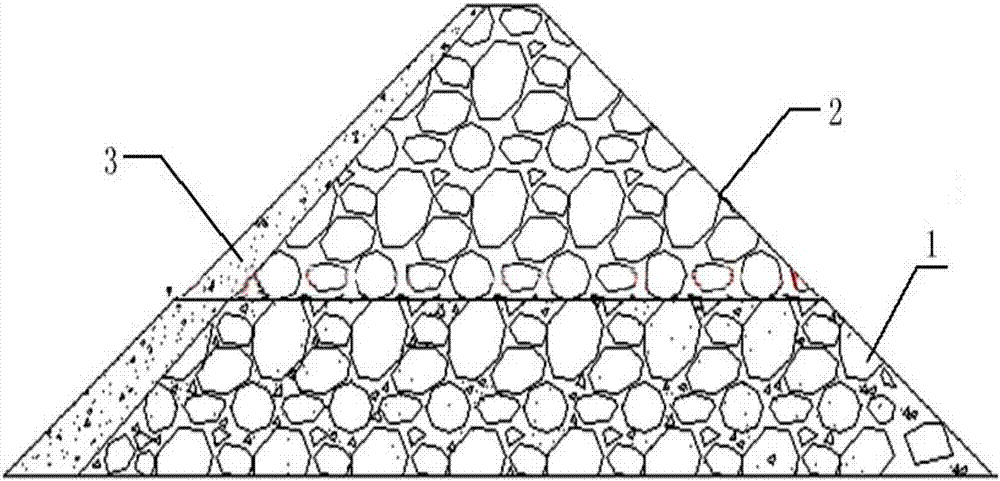

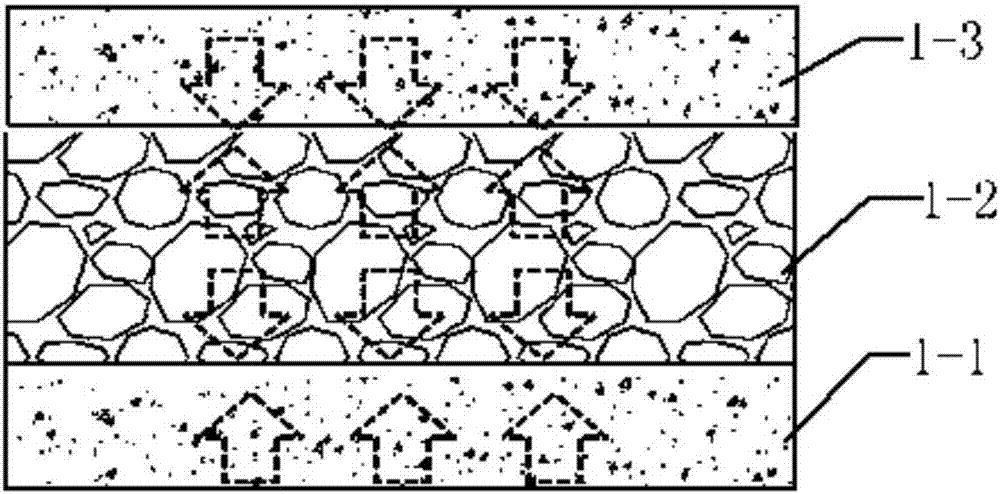

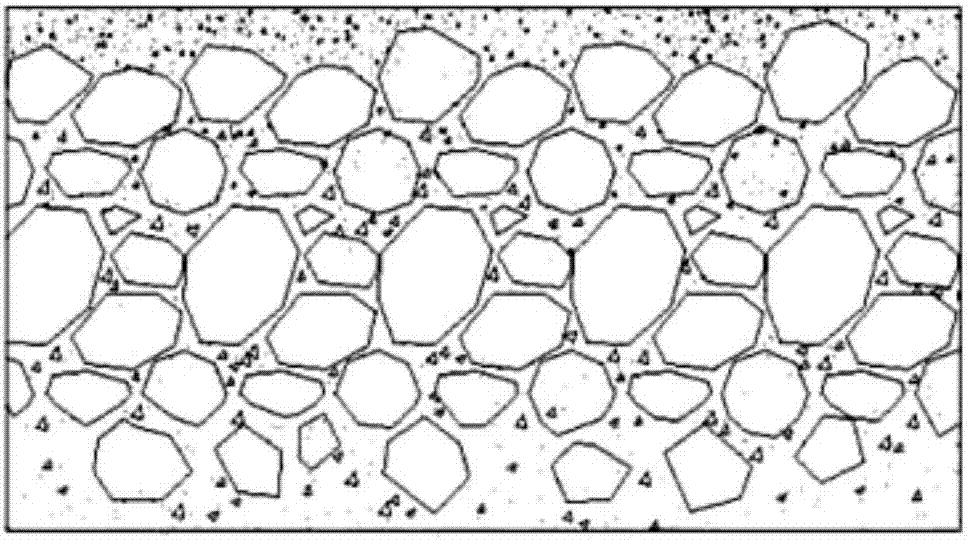

Roller-compacted concrete structure formed by pouring composite slurry into stone ballast and construction method of roller-compacted concrete structure

ActiveCN108643132ATake advantage ofEasy accessFoundation engineeringEarth-fill damsRoller-compacted concreteSlurry

The invention discloses a roller-compacted concrete structure formed by pouring composite slurry into stone ballast. The roller-compacted concrete structure consists of a plurality of composite-slurryroller-compacted concrete layers, wherein the composite-slurry roller-compacted concrete layers are formed by performing vibration rolling on the stone ballast and the composite slurry poured onto the surface of the stone ballast; the stone ballast is an excavated material with a particle diameter being greater than or equal to 5 mm; and the stone ballast is laid on a dam foundation in layers, the composite slurry is poured into the stone ballast laid in layers to fill gaps in the stone ballast randomly, and when the liquid level of the composite slurry gets close to the top surface of the stone ballast, rolling is performed on a storehouse surface through a vibrating roller to form a uniform, stable slurry-poured roller-compacted concrete structure. The roller-compacted concrete structure has the advantages of use of local materials, uniform and stable structure, excellent performance, fast construction and project cost saving. The invention also discloses a construction method of the roller-compacted concrete structure formed by pouring the composite slurry into the stone ballast.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

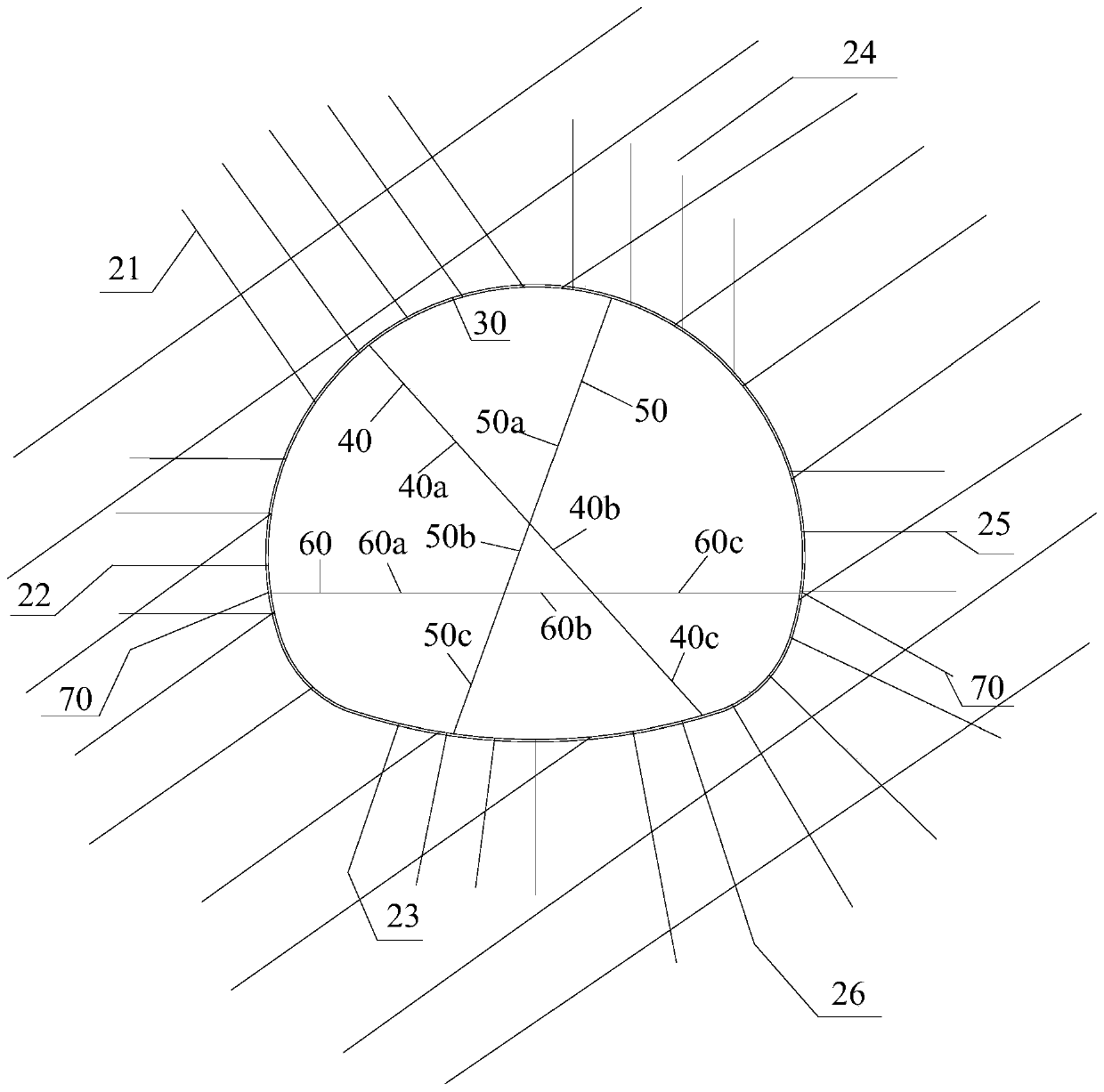

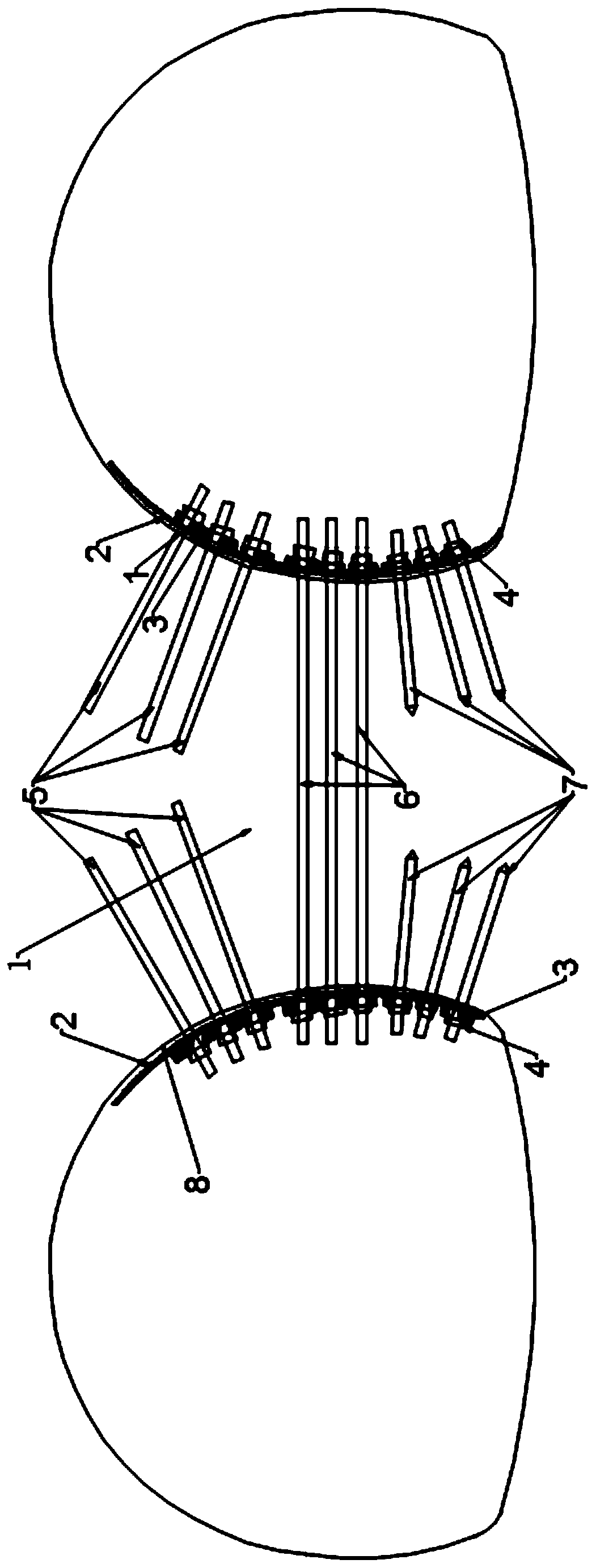

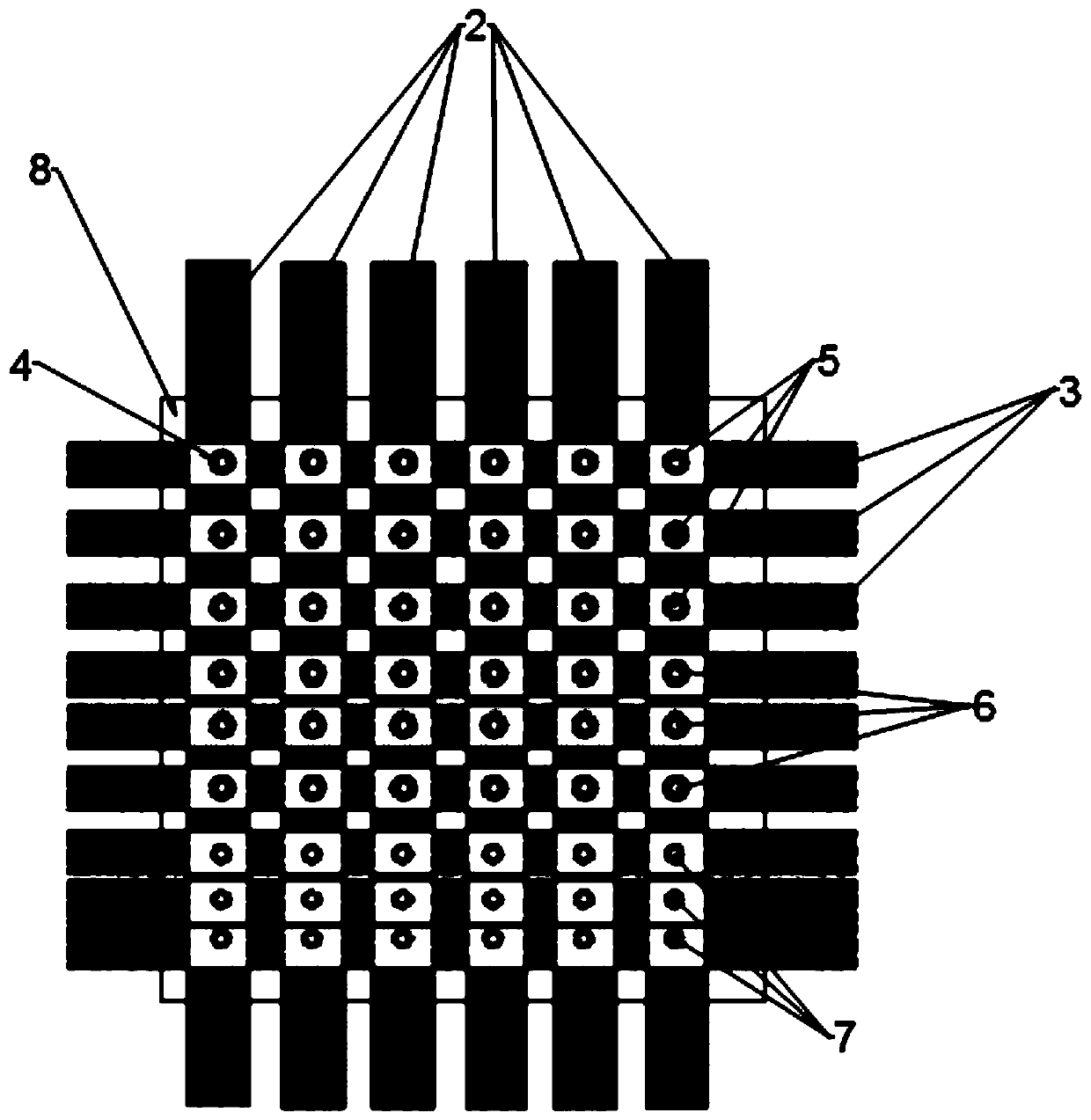

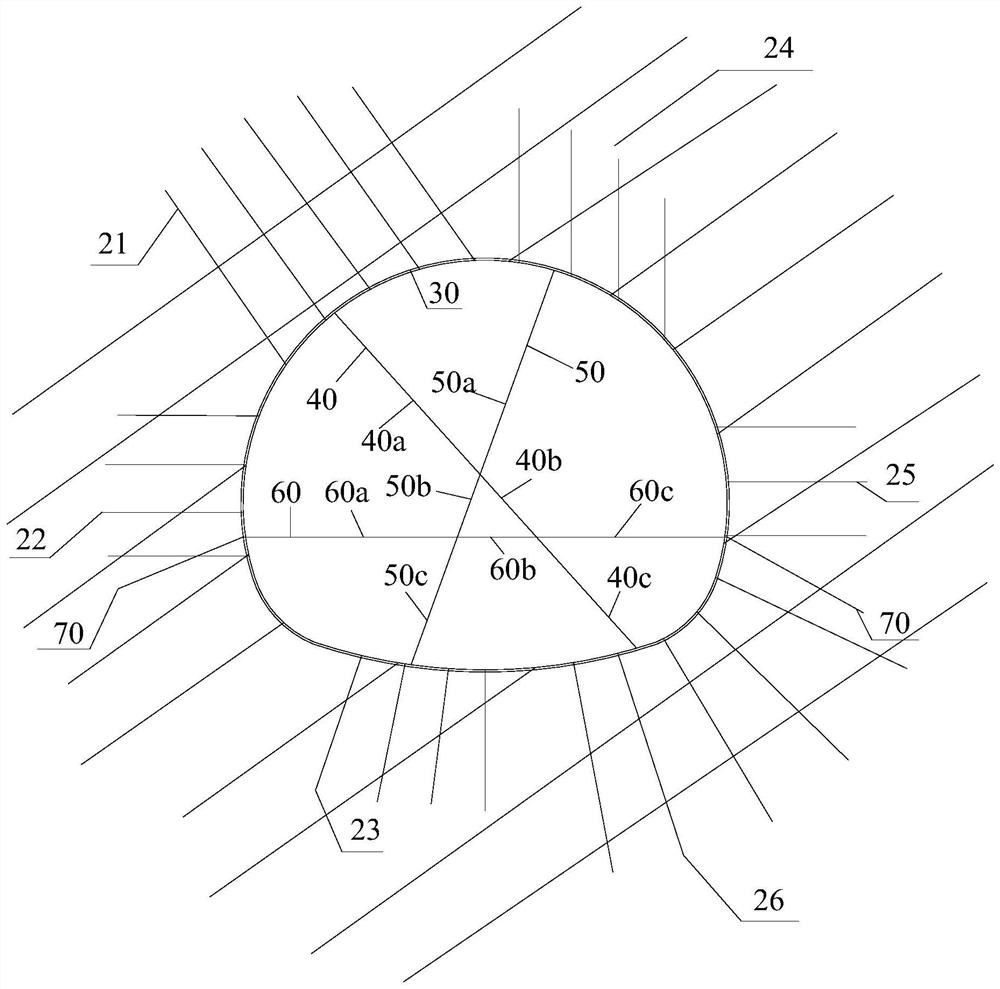

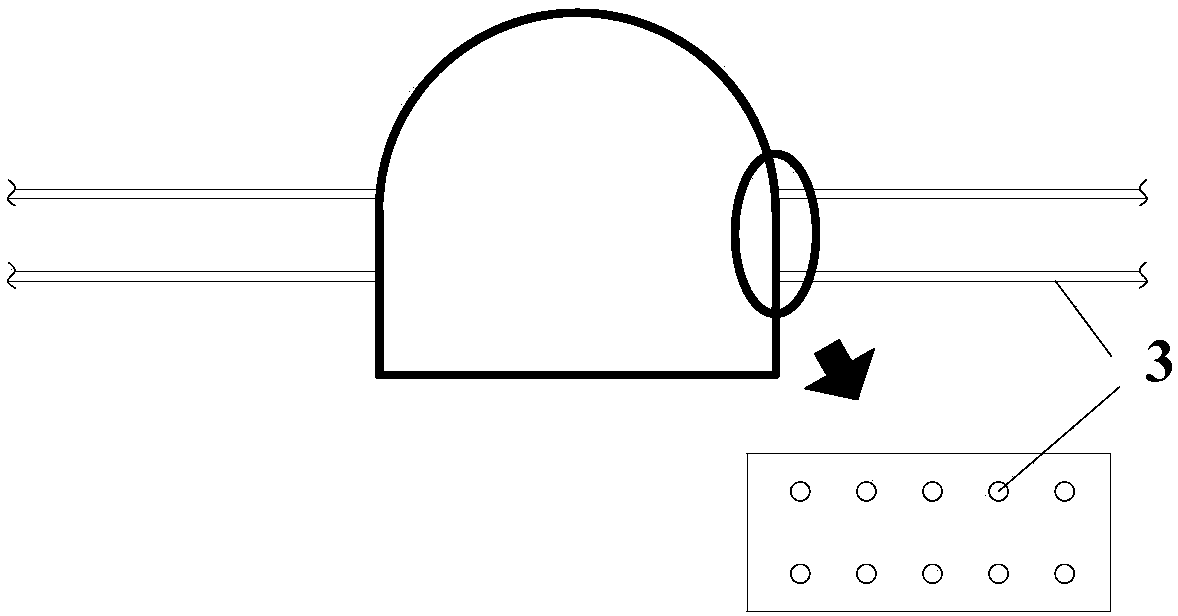

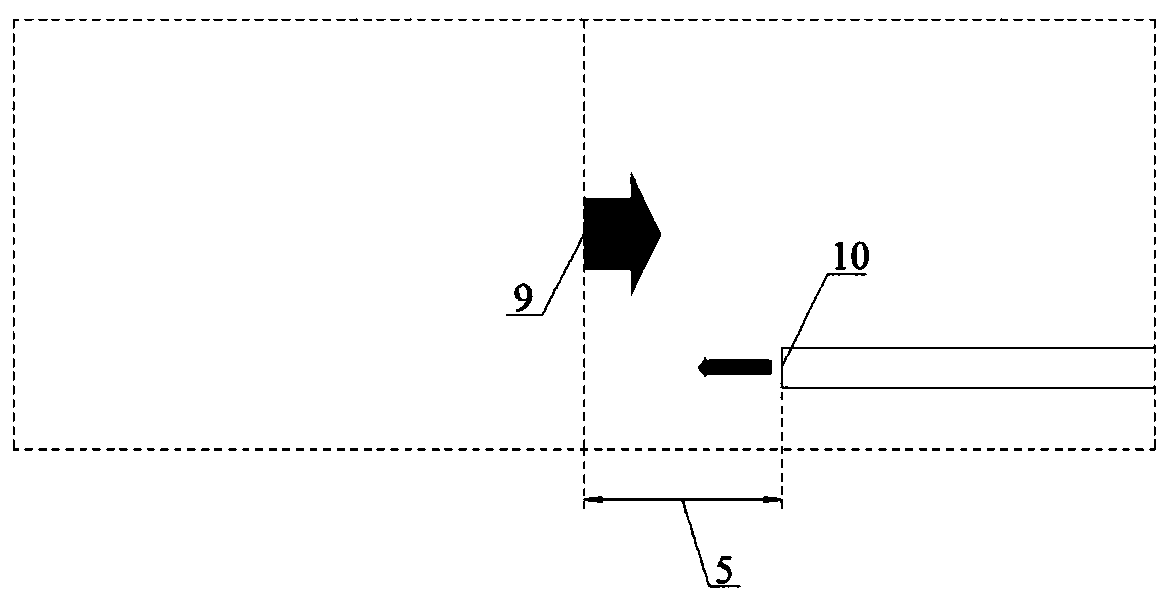

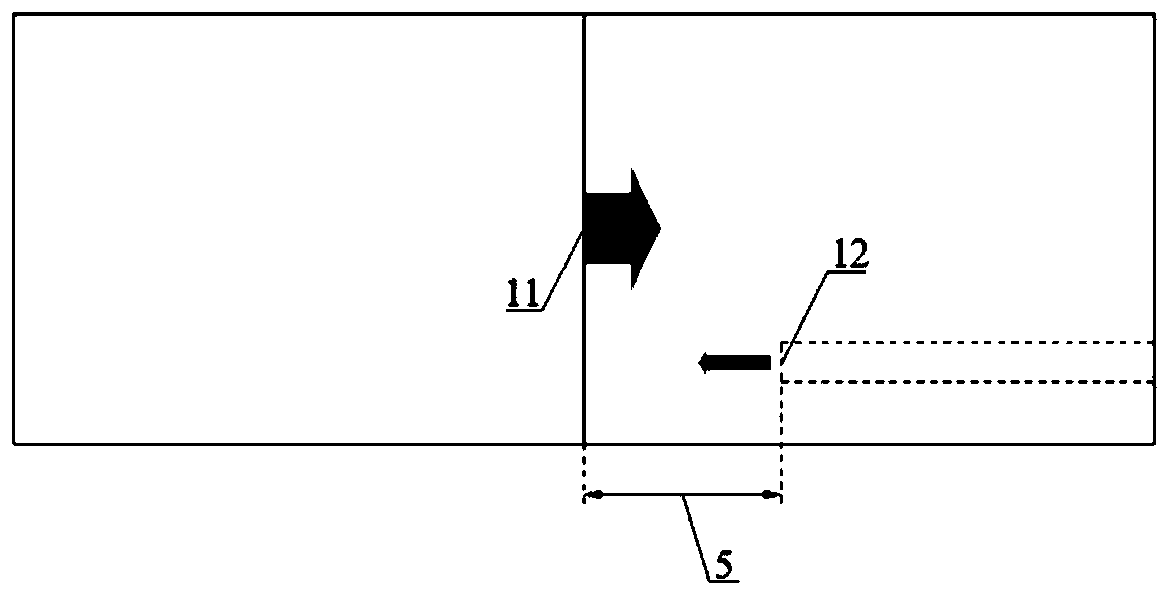

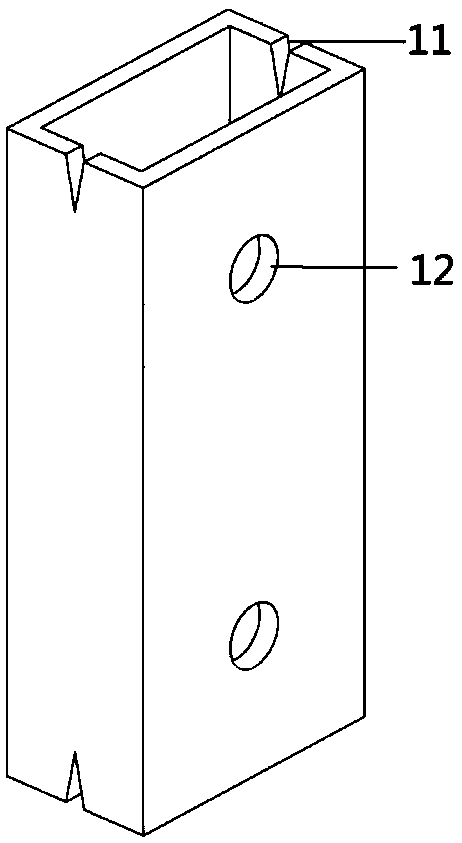

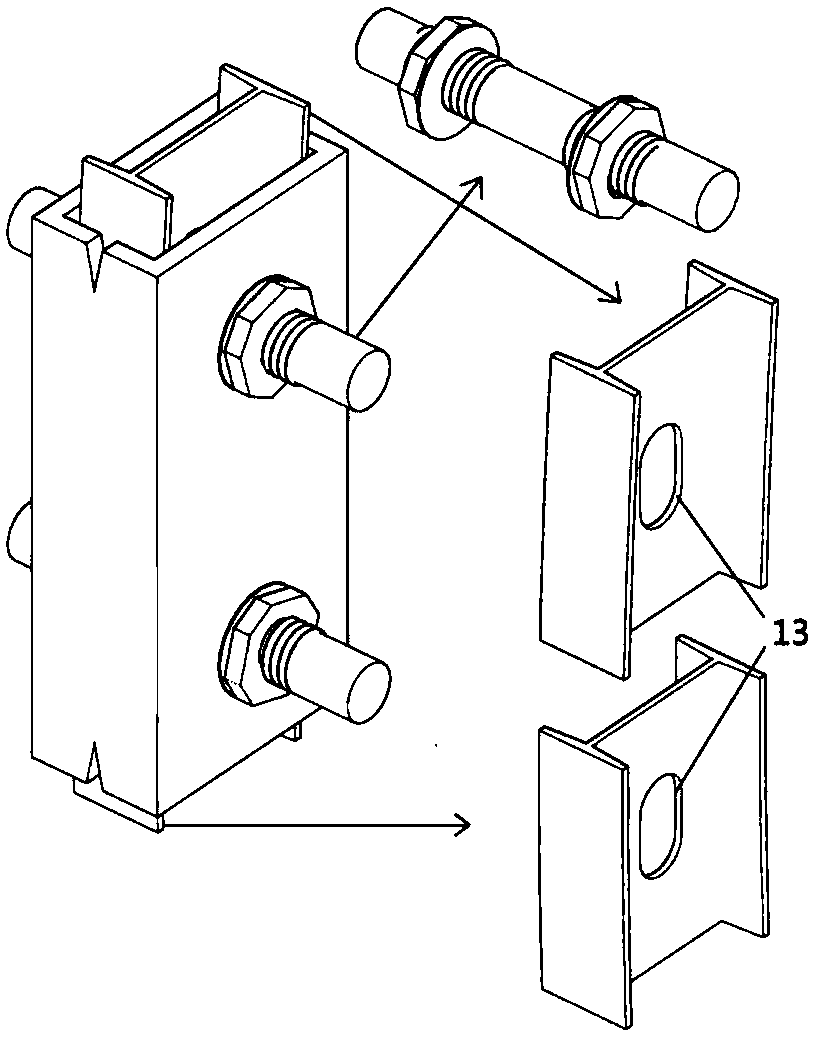

Integral support system and construction method of rock pillar in double-hole tunnel

InactiveCN109826644ATake full advantage of self-supporting capacityReduce economic costsUnderground chambersTunnel liningSupporting systemPre stress

Provided are an integral support system and a construction method of a rock pillar in a double-hole tunnel. Upper grouting bolts are anchored on left and right sides of the upper portion of the rock pillar in the tunnel, a horizontal pre-stress grouting bolt is horizontally anchored and penetrates through the middle of the rock pillar in the middle of the tunnel, lower grouting bolts are anchoredon the left and right sides of the lower portion of the rock pillar in the tunnel, the anchor heads of each bolt have appropriate exposed lengths, a plurality of mounting holes adapted to each bolt exposed end are formed in circumferential steel strips and longitudinal steel strips, a plurality of the circumferential steel strips are circumferentially arranged along the inner wall of the tunnel, the mounting holes on the circumferential steel strips respectively tightly sleeve the exposed ends of the corresponding upper grouting bolt, the horizontal pre-stress grouting bolt or the lower grouting bolt, a plurality of the longitudinal steel strips are arranged in the axial direction of the tunnel, the mounting holes of the longitudinal steel strips respectively tightly sleeve with the exposed ends of the corresponding bolts, and the exposed ends of the bolts are screwed with locking nuts. The construction method has simple construction process, is easy to operate, and especially has a significant effect on the support of a broken rock body.

Owner:NORTHEASTERN UNIV

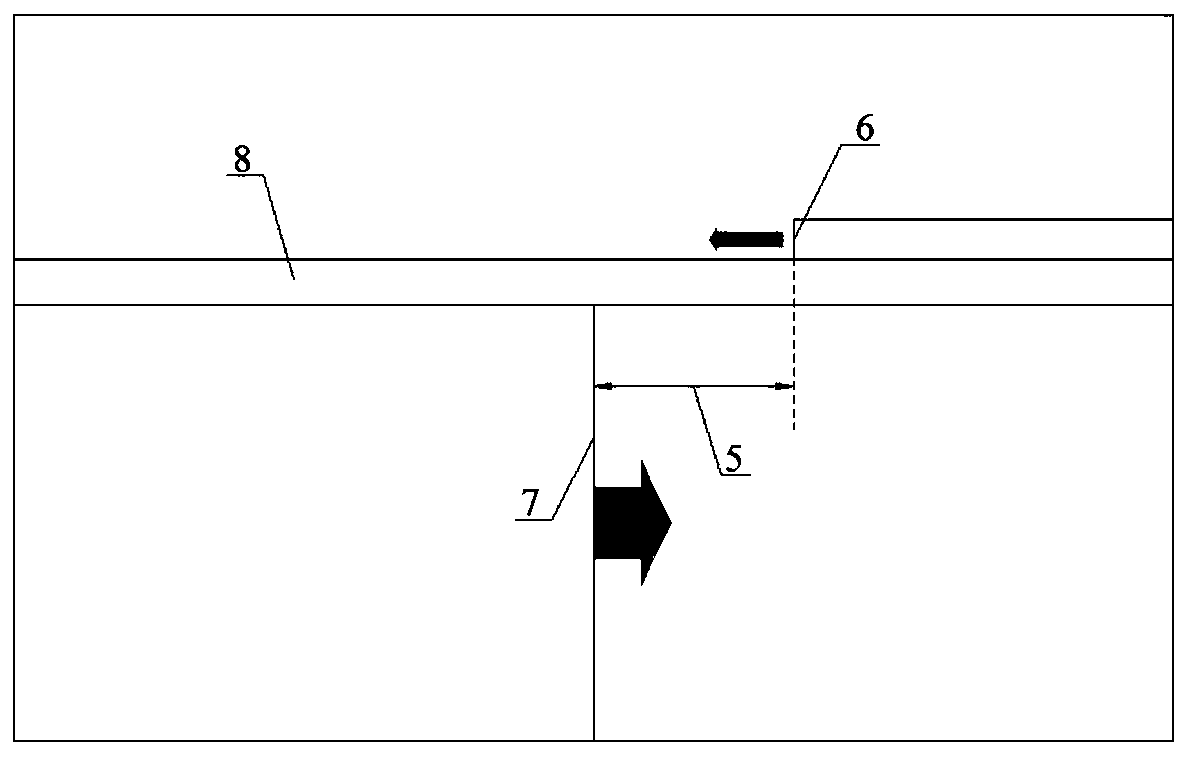

Mining-induced stress control methods for opposite stoping and tunnelling of close-range coal seams

InactiveCN110029994AReduce large deformationImprove support efficiencyUnderground chambersUnderground miningMining engineeringLarge deformation

The invention discloses a method for controlling roadway surrounding rock deformation under the condition of opposite stoping and tunnelling of close-range coal seams, and the method is used for the field of mining-induced stress control methods for opposite stoping and tunnelling of the close-range coal seams. The mining-induced stress control methods corresponding to three types of conditions include: the mining-induced stress control method for opposite stoping and tunnelling of the corresponding coal seam, the mining-induced stress control method for lower stoping and upper tunnelling of the adjacent coal seam, and the mining-induced stress control method for upper stoping and lower tunnelling of the adjacent coal seam. The technical problems of roadway large deformation, low roadway support efficiency and high support cost under the influences of stoping are effectively solved; and it can be seen that the roadway large deformation phenomenon is reduced by 70%, the support efficiency is improved by 20%, and compared with the prior art, the support cost is lowered to 60%.

Owner:CHINA UNIV OF MINING & TECH +1

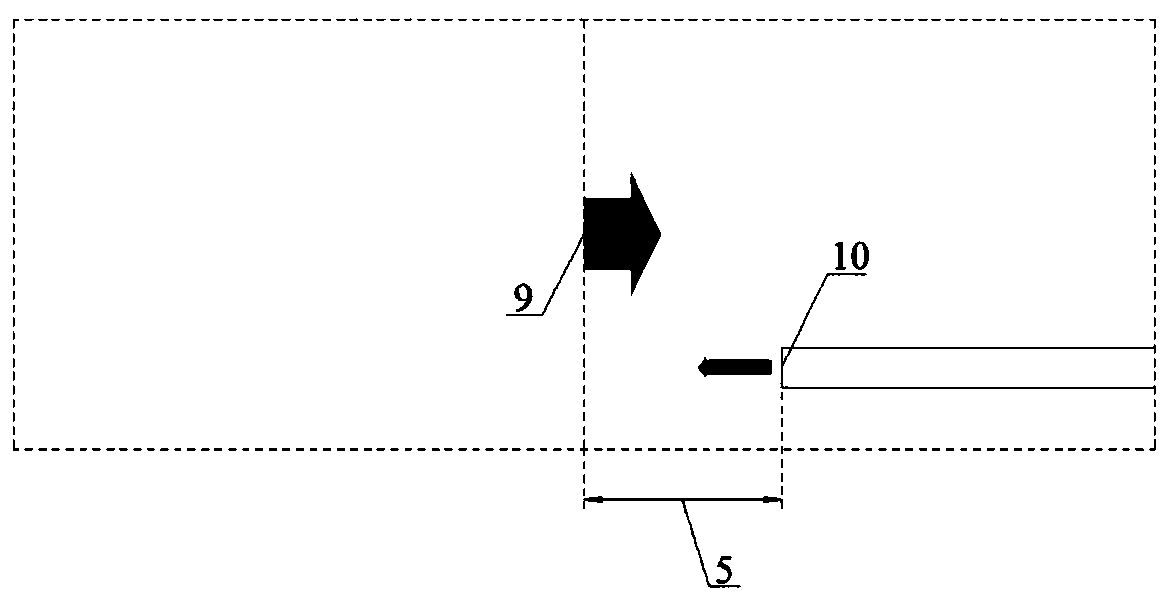

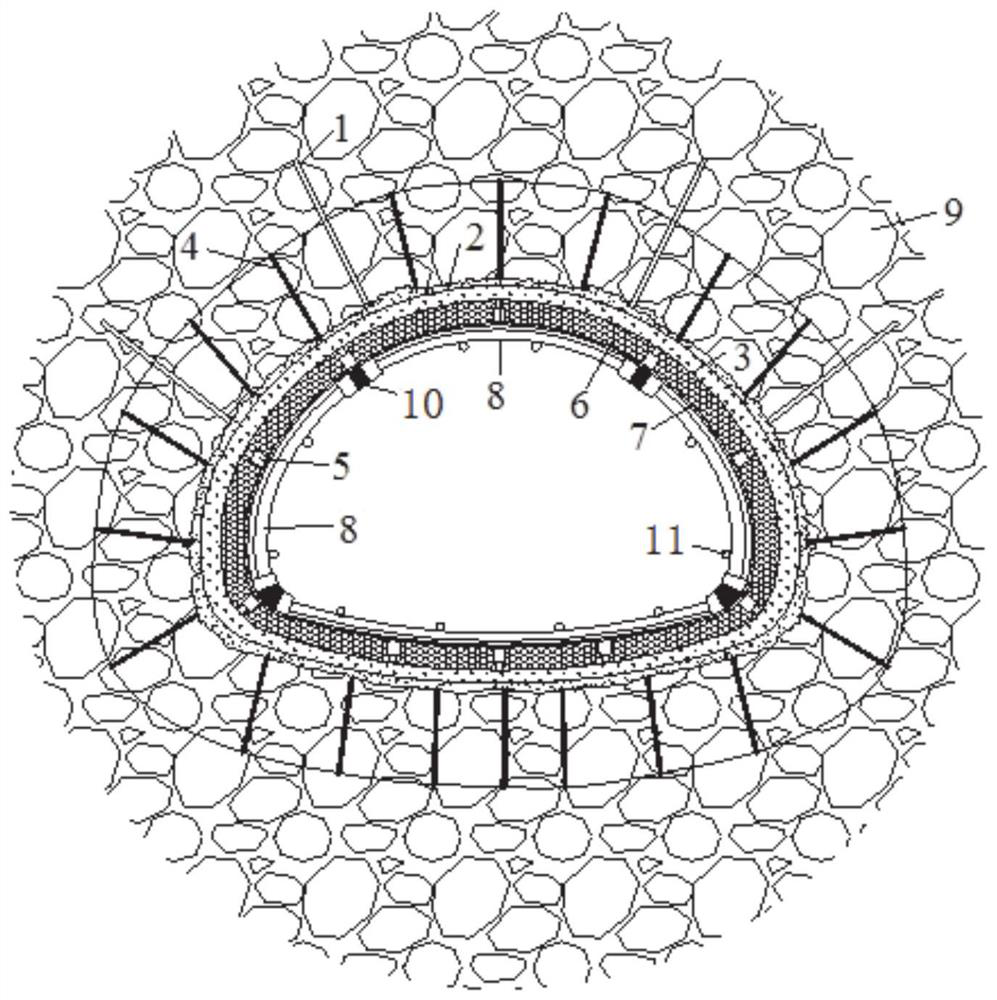

Traffic tunnel surrounding rock cooperative control system and construction method thereof

ActiveCN112647969ASmall overall deformationReduce large deformationUnderground chambersTunnel liningEnergy absorptionControl system

The invention relates to a traffic tunnel surrounding rock cooperative control system and a construction method thereof. The traffic tunnel surrounding rock cooperative control system comprises a quick-setting slurry layer, a flexible explosion-proof energy absorption layer, a rigid guard plate layer and a rigid arch frame which can be sequentially arranged from the inner wall of a tunnel to the inner space of the tunnel, and a plurality of telescopic pieces are arranged between the flexible explosion-proof energy absorption layer and the rigid guard plate layer; a gap between the flexible explosion-proof energy absorption layer and the rigid guard plate layer is filled with a flexible material; and the flexible explosion-proof energy absorption layer can be fixedly connected with surrounding rock through anchoring pieces, and the anchoring pieces can be inserted into the surrounding rock. Through a supporting structure, the problem of surrounding rock large deformation faced by a traffic tunnel can be effectively prevented and controlled.

Owner:SHANDONG UNIV +3

Micro-disturbance mechanical separate tunneling construction method for tunnel in weak surrounding rock

InactiveCN109594995AReduce disturbanceControl deformationUnderground chambersTunnel liningLarge deformationBuilding construction

The invention discloses a micro-disturbance mechanical separate tunneling construction method for a tunnel in weak surrounding rock. The method comprises the following steps: firstly, a shield is divided into multiple sub-shields from top to bottom, the multiple sub-shields are jacked gradually from bottom to top, and disturbance to the surrounding rock is reduced; then step separate excavation isperformed on a tunnel face, excavation disturbance is reduced as compared with overall excavation, surrounding rock deformation is controlled, tunnel deformation is prevented, and construction safetyis improved; secondly, the excavated tunnel is subjected to primary support with prefabricated members, and rapid sealing and primary support reinforcement are realized; finally, secondary lining isperformed on the primary support, and waterproof plates are arranged between the secondary lining and the primary support. The construction method is safe, efficient and economical, effectively controls large disturbance and large deformation of surrounding rock during excavation and reduces disaster losses of engineering construction.

Owner:CHANGAN UNIV

Comfortable automobile safety belt

PendingCN113954781APhenomena that facilitate the reduction of exposureReduce exposureBelt/harness contructionHot weatherDriver/operator

The invention discloses a comfortable automobile safety belt, and belongs to the field of automobile safety belts, the comfortable automobile safety belt comprises a safety belt main body, a contact assembly is arranged on the outer side of the safety belt main body, a neck protection part is arranged on the outer side of the safety belt main body, and a connecting assembly is arranged on the outer side of the contact assembly; the contact assembly comprises a U-shaped frame and a set of air bag balls, the air bag balls are filled with water sources, the U-shaped frame is slidably connected to the outer side of the safety belt body, and the air bag balls are fixedly connected to the front face of the U-shaped frame. According to the safety belt, the stuffiness phenomenon of the contact part of the safety belt and a driver in hot weather is reduced, comfort is improved, meanwhile, the contact phenomenon of the safety belt and the neck of the driver can be reduced, and comfort is improved.

Owner:常州方晟汽车部件有限公司

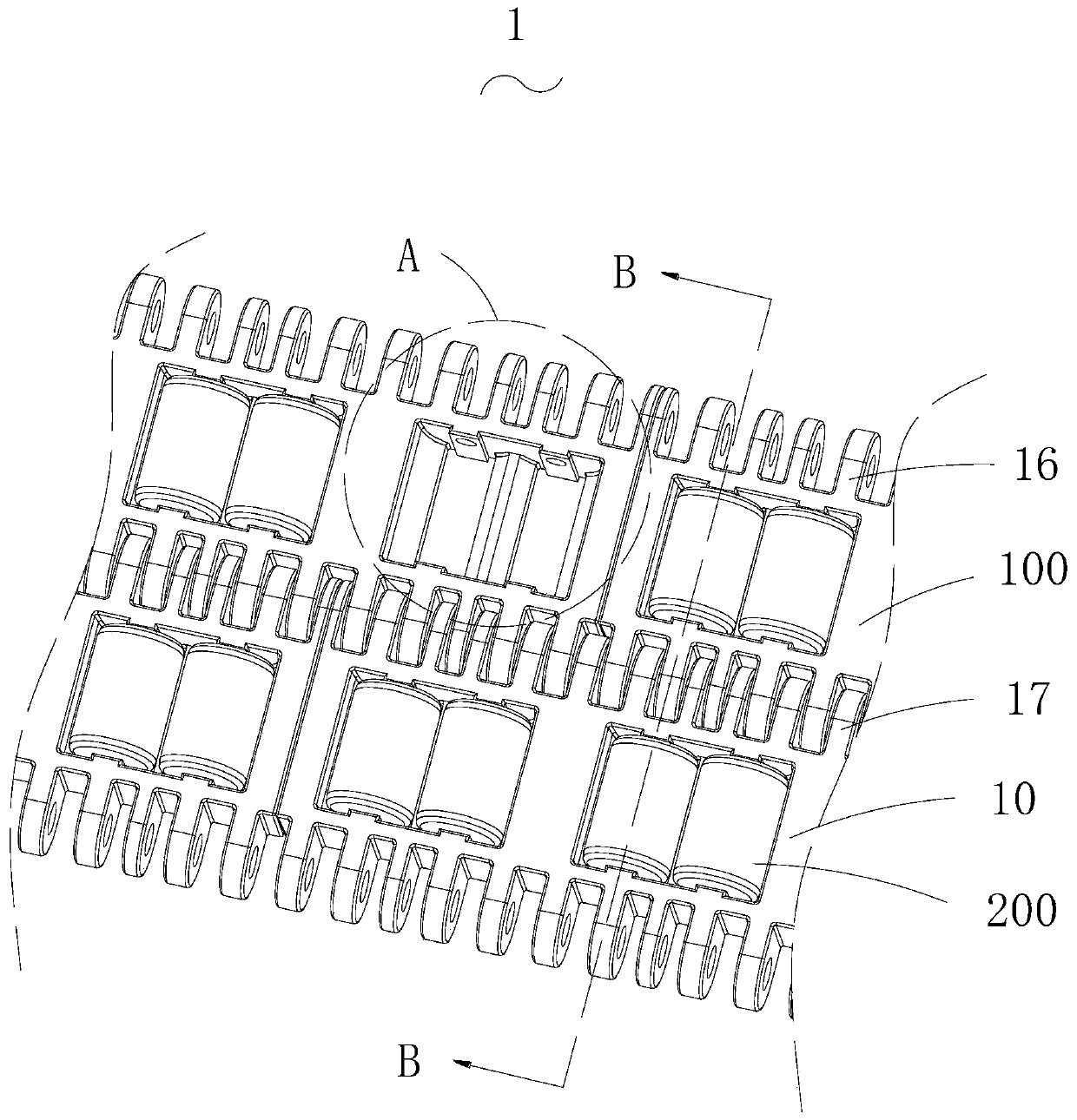

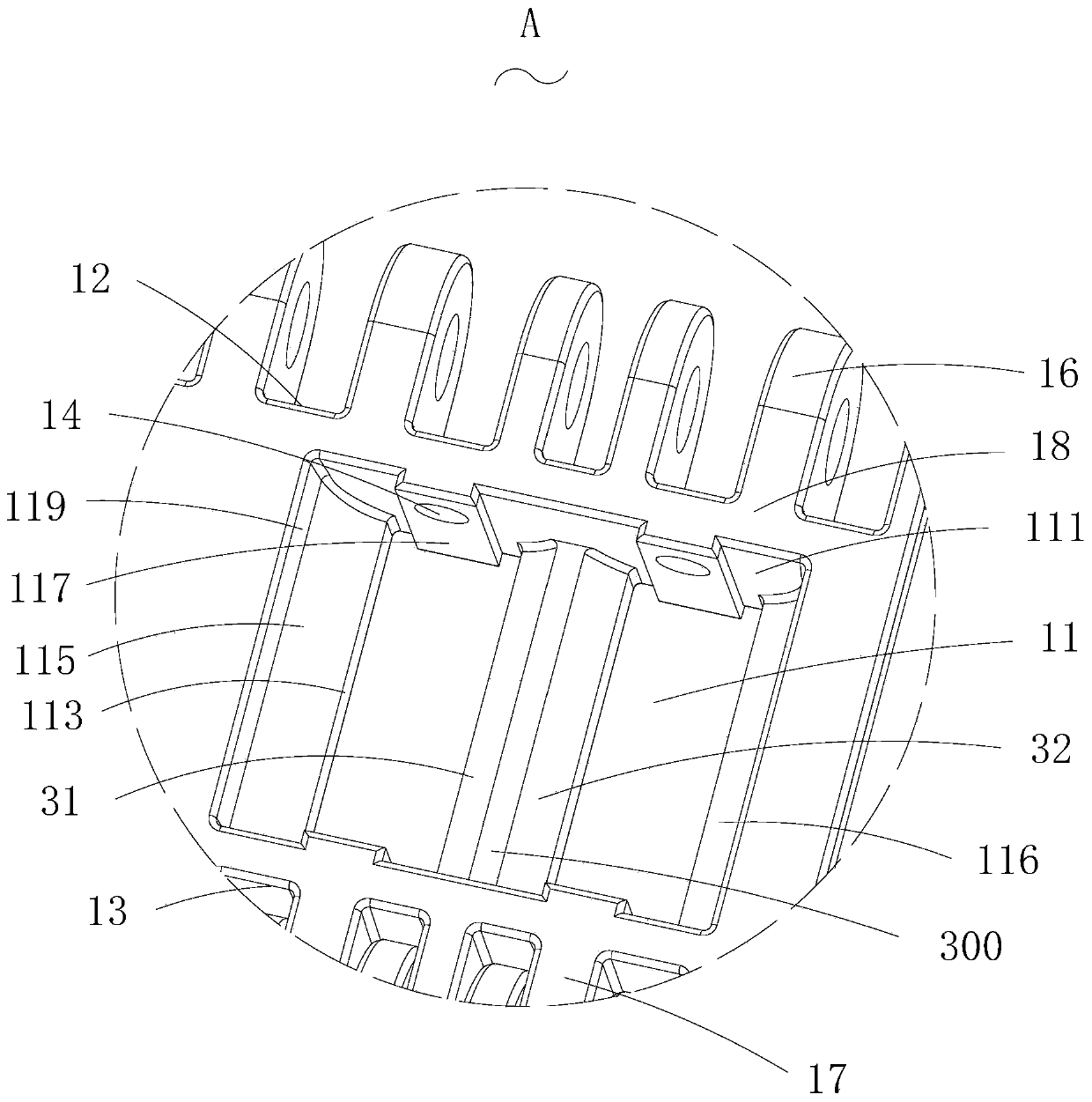

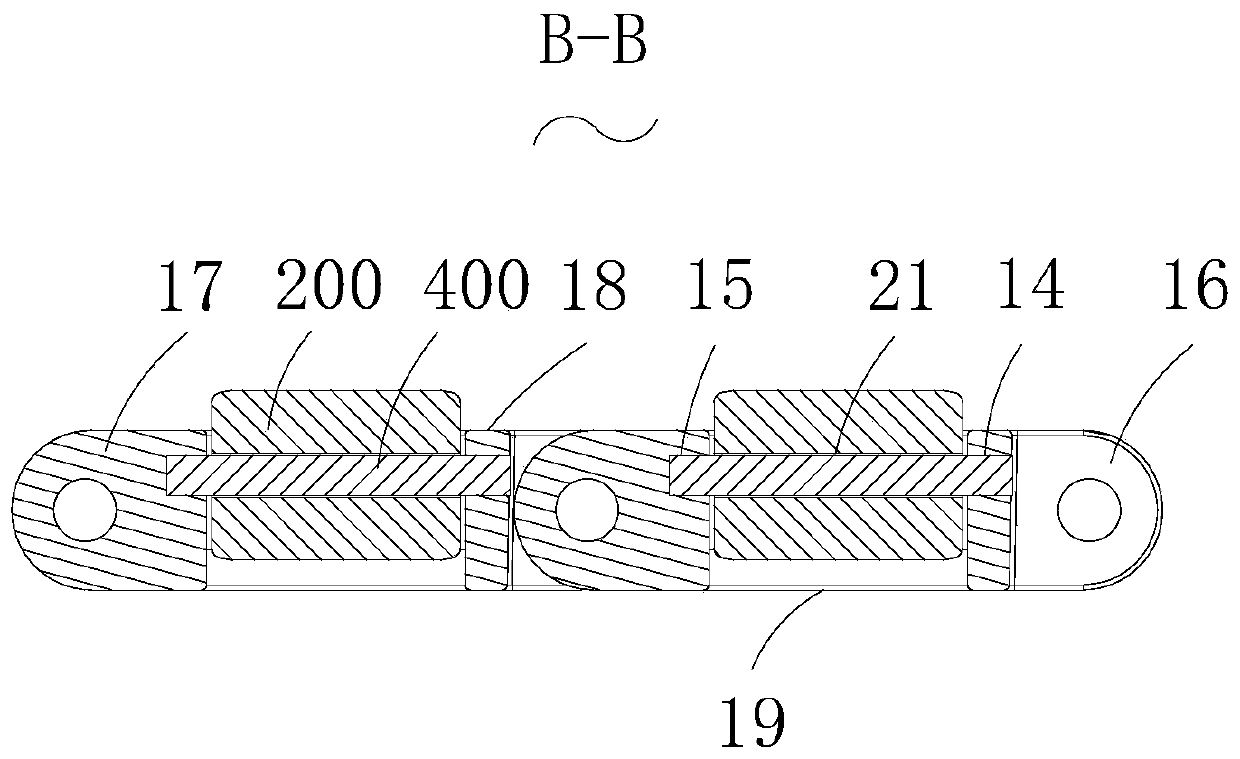

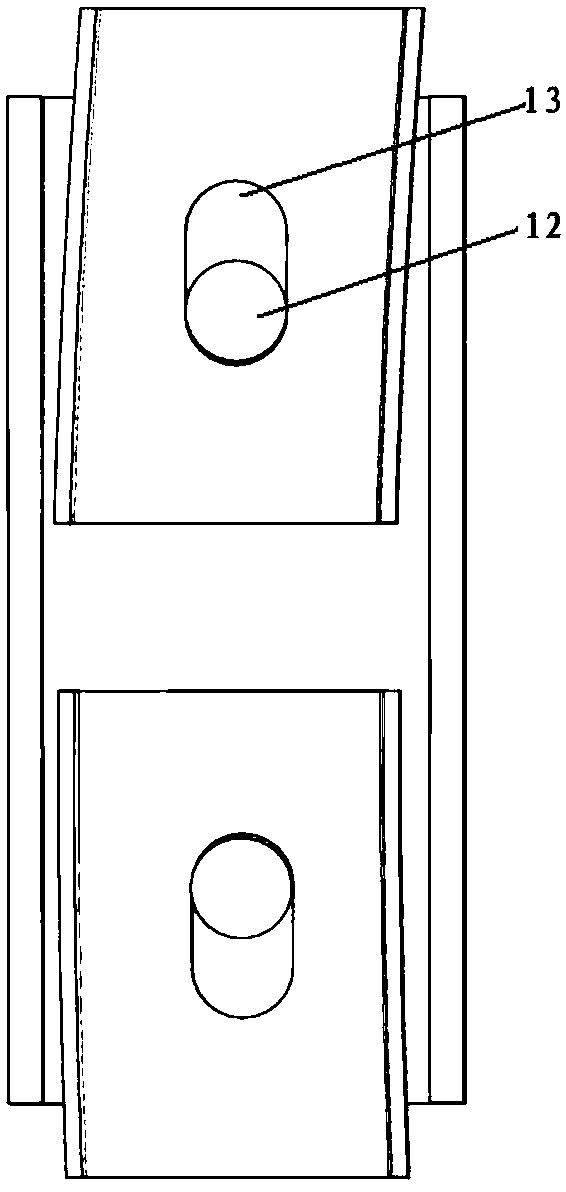

Transmission belt connecting piece and transmission belt module

InactiveCN111120575AAvoid direct floatingHigh compressive strengthConveyorsBelt fasteningsTransmission beltEngineering

The invention is applicable to the field of article conveying equipment, and discloses a transmission belt connecting piece and a transmission belt module. The transmission belt module comprises the transmission belt connecting piece, the transmission belt connecting piece comprises connecting piece bodies, rotating shafts connected to the connecting piece bodies and balls connected with rotatingshafts, a plurality of mounting grooves are formed in the connecting pieces in a penetrating mode, each mounting groove is provided with the plurality of balls, each mounting groove is provided with afirst groove surface, a second groove surface, a third groove surface and a fourth groove surface, first arc-shaped parts consistent with the balls are concavely arranged at the parts, facing away from the fourth groove surfaces, of the third groove surfaces, second arc-shaped parts consistent with the balls are arranged at the parts, facing away from the third groove surfaces, of the fourth groove surfaces, the plurality of balls are arranged between the first arc-shaped parts and the second arc-shaped parts, the first arc-shaped parts and the second arc-shaped parts can provide support force for the balls, and the balls are prevented from being directly suspended in the mounting grooves, so that the pressure resistance strength of the balls is enhanced, the situation of large deformation of the balls is reduced, and articles are smoothly conveyed favorably.

Owner:XINHAI IND BELTING

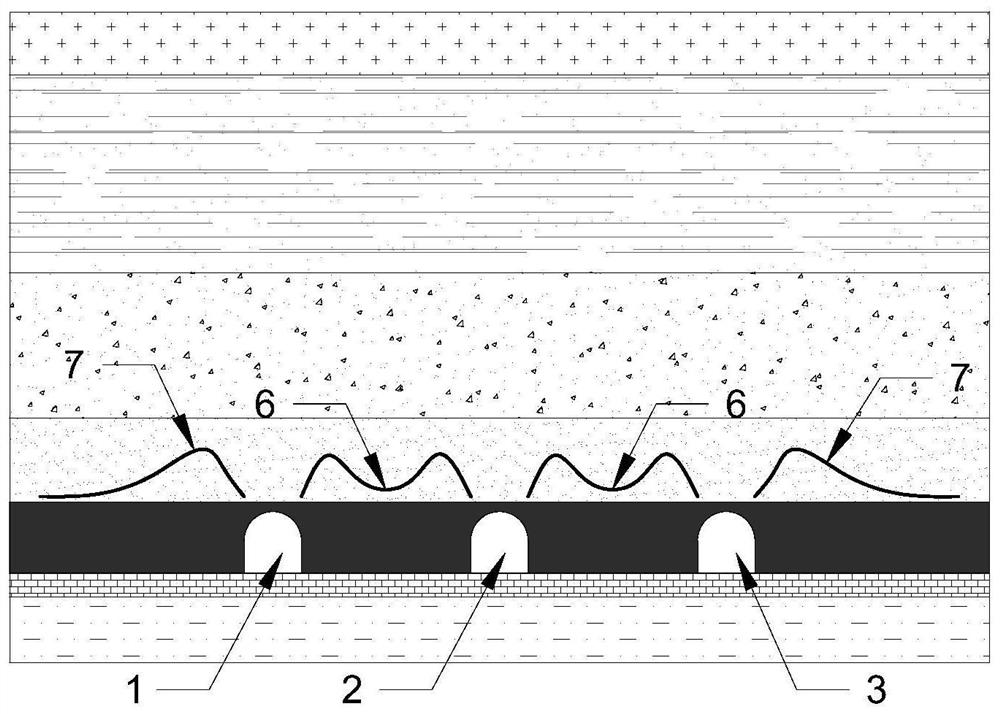

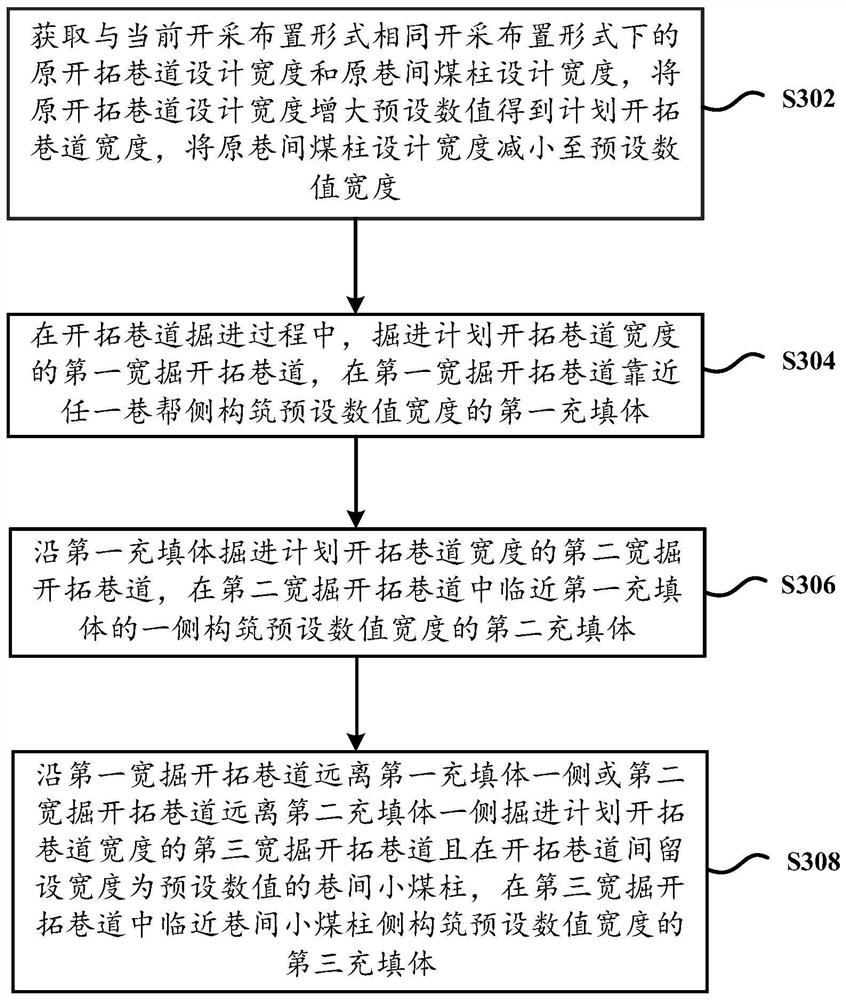

Anti-scour method for wide excavation and narrow roadway development in rock burst coal seam

ActiveCN111335895BIncrease widthReduce widthUnderground miningSurface miningStructural engineeringCoal pillar

The invention provides an anti-scour method for widening and narrowing roadway development in rock burst coal seams, which includes increasing the designed width of the original roadway design by increasing the preset value to obtain the planned width of the roadway, and reducing the designed width of the original coal pillar between roadways to the preset value. Sets the value width. The excavation plan develops the first wide excavation roadway with the width of the roadway, and constructs the first filling body with a preset numerical width on either side of the first wide excavation roadway. Excavating a roadway with the second widest width along the first filling body, and constructing a second filling body on the side adjacent to the first filling body in the second widening development roadway. Excavate along the first wide excavation roadway away from the side of the first filling body or the second wide excavation development roadway on the side away from the second filling body and excavate the third wide excavation roadway and leave a lane with a width of a preset value between the development roadways For small coal pillars, the third filling body is constructed on the side of the small coal pillars adjacent to the roadway in the third wide excavation roadway. Thereby reducing the supporting pressure of the coal pillars in the roadway developed by the rock burst coal seam.

Owner:CCTEG COAL MINING RES INST

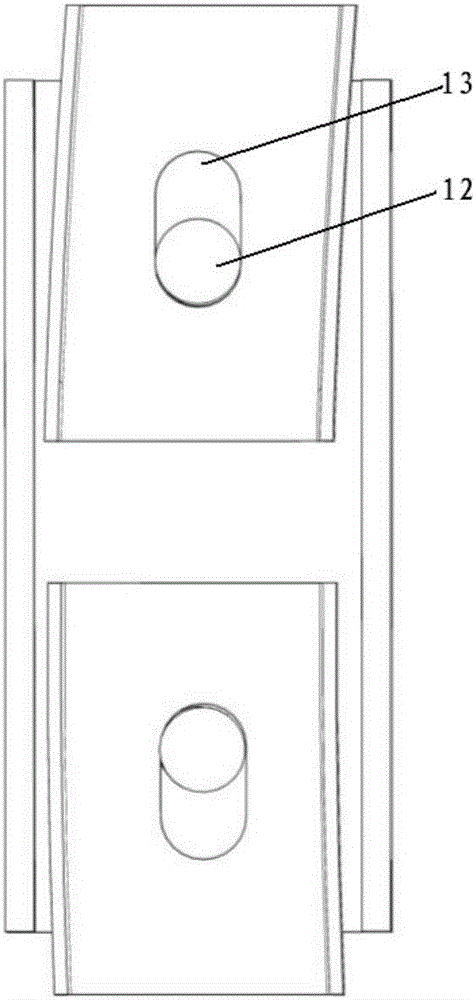

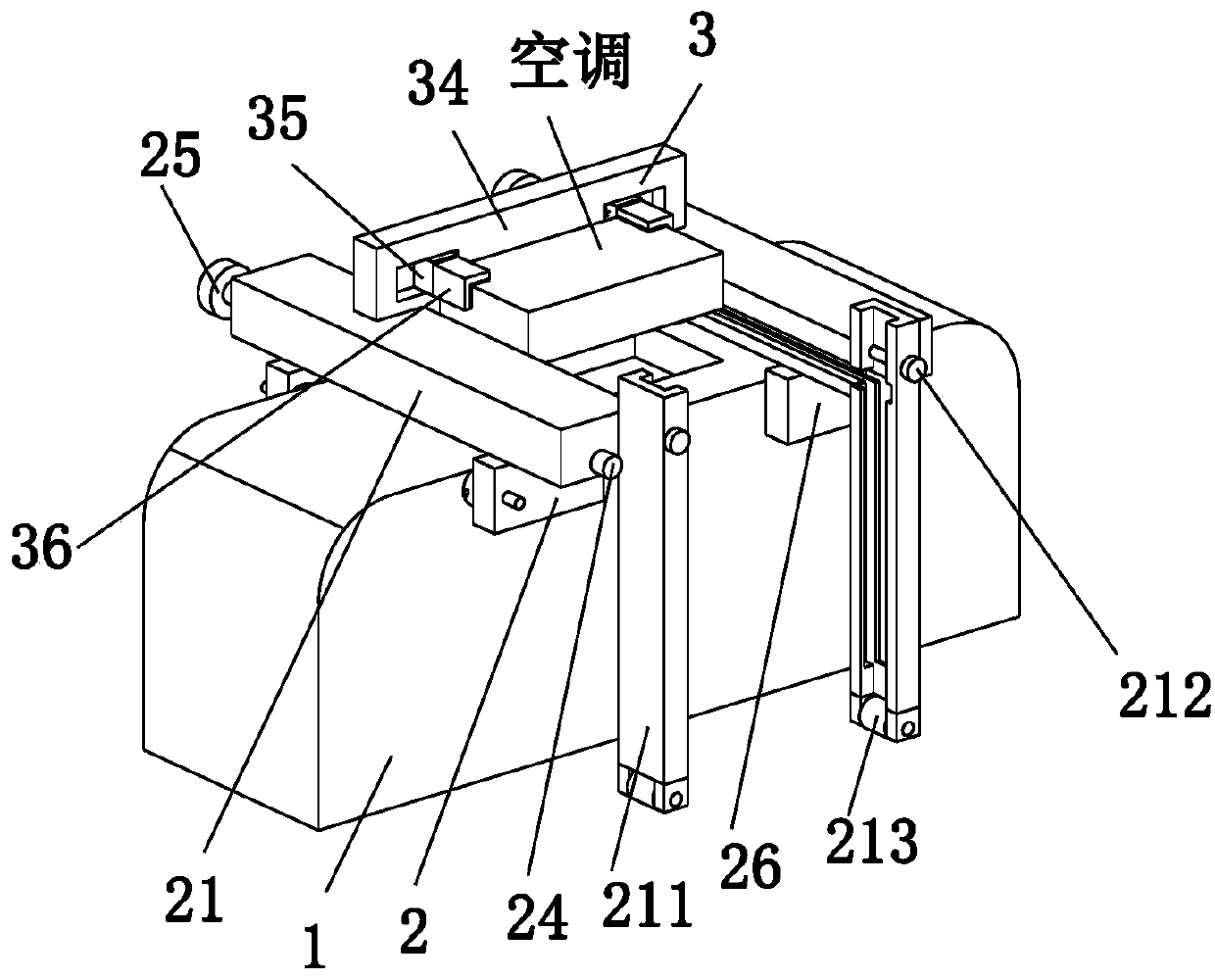

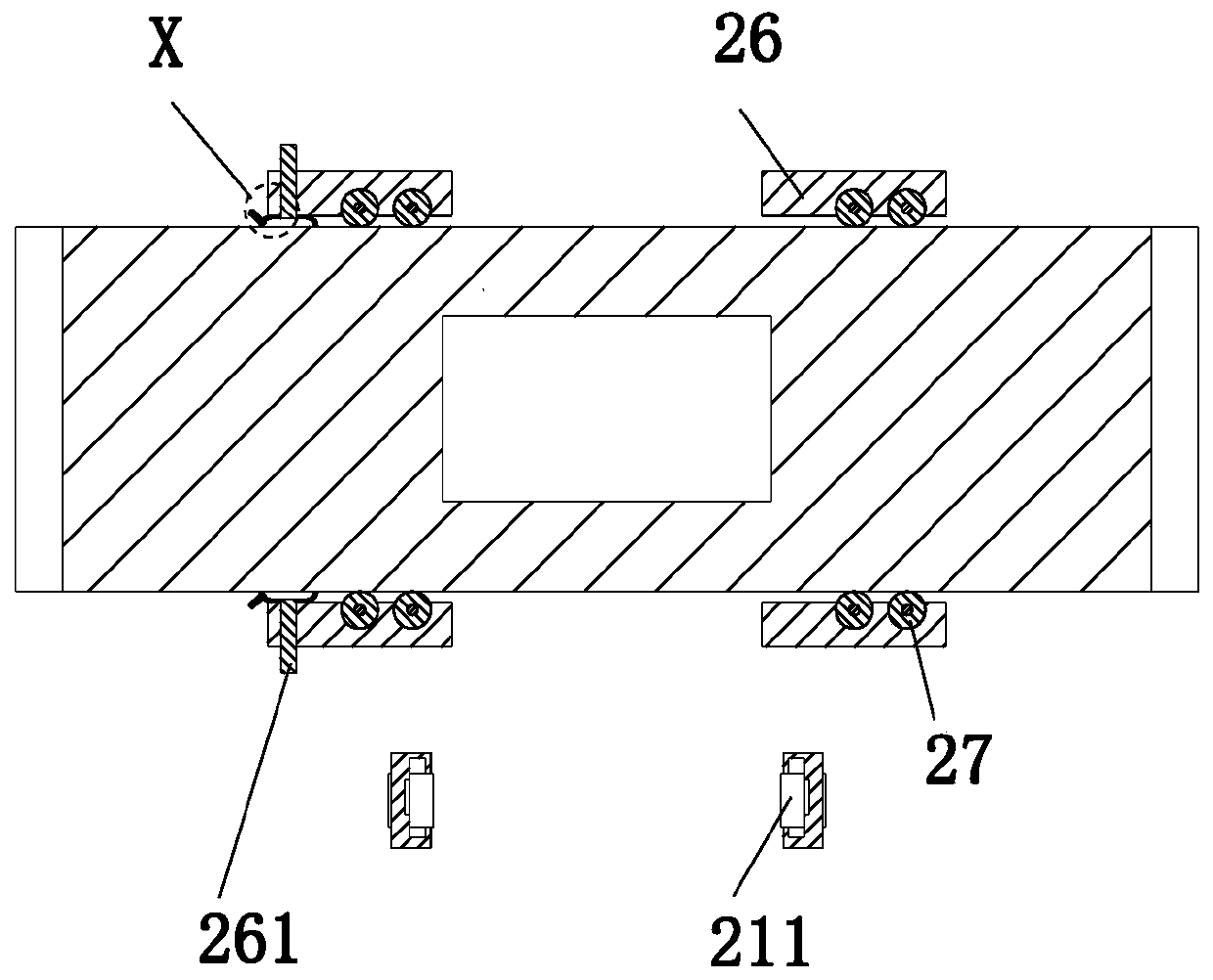

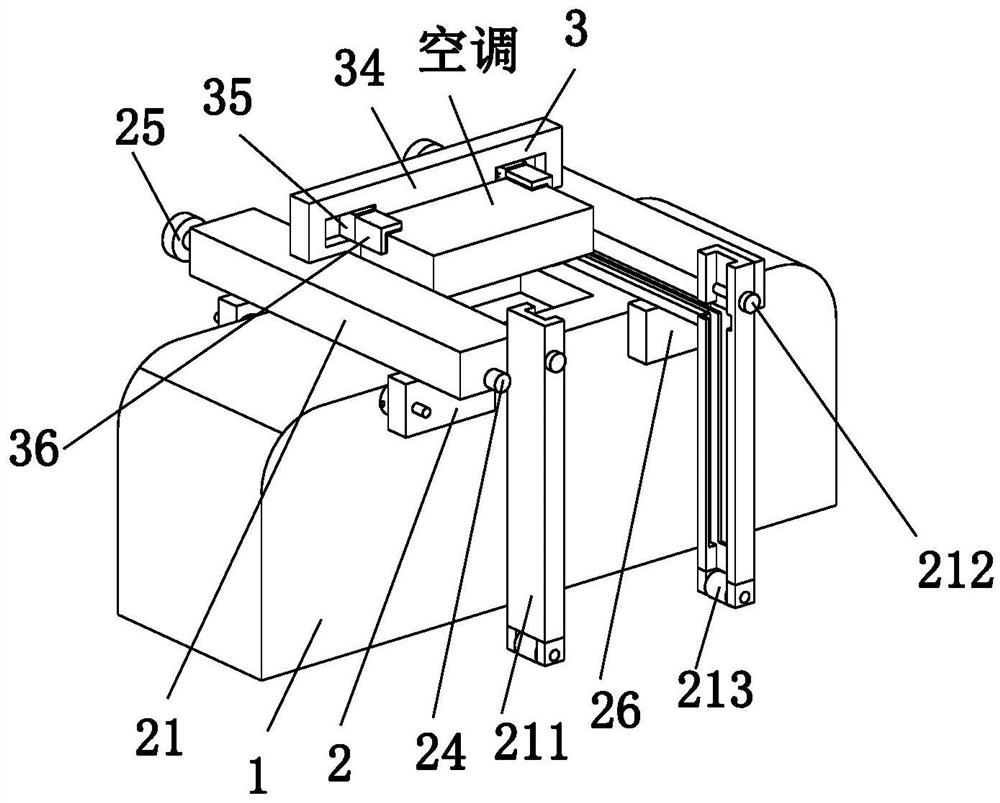

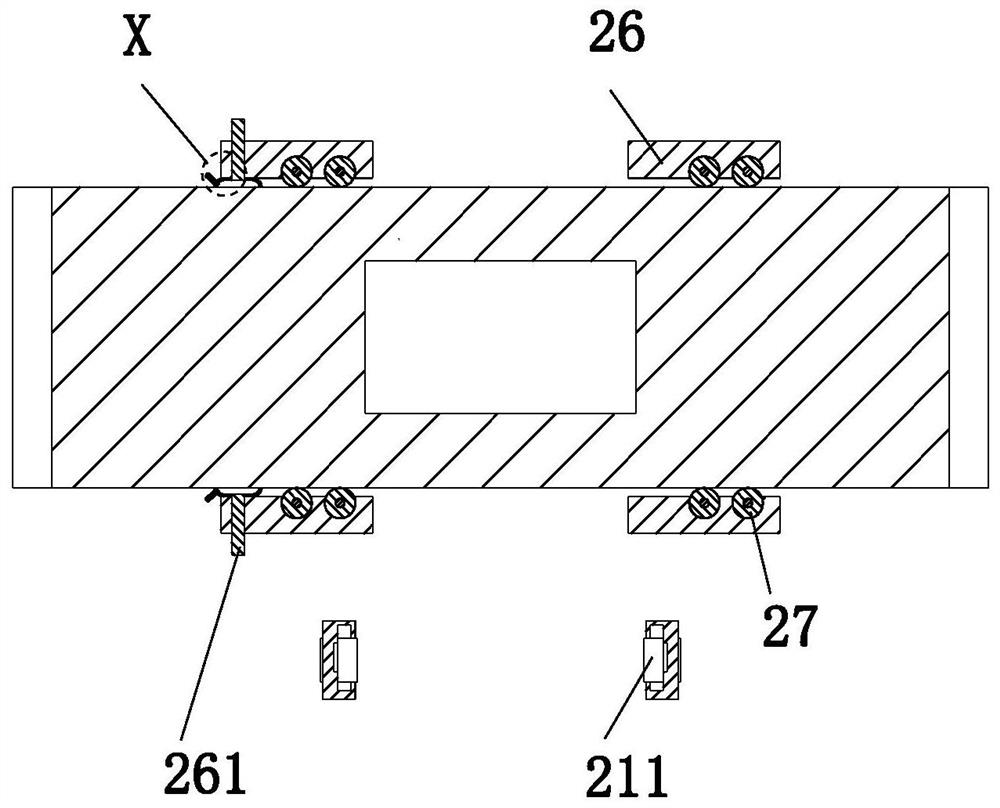

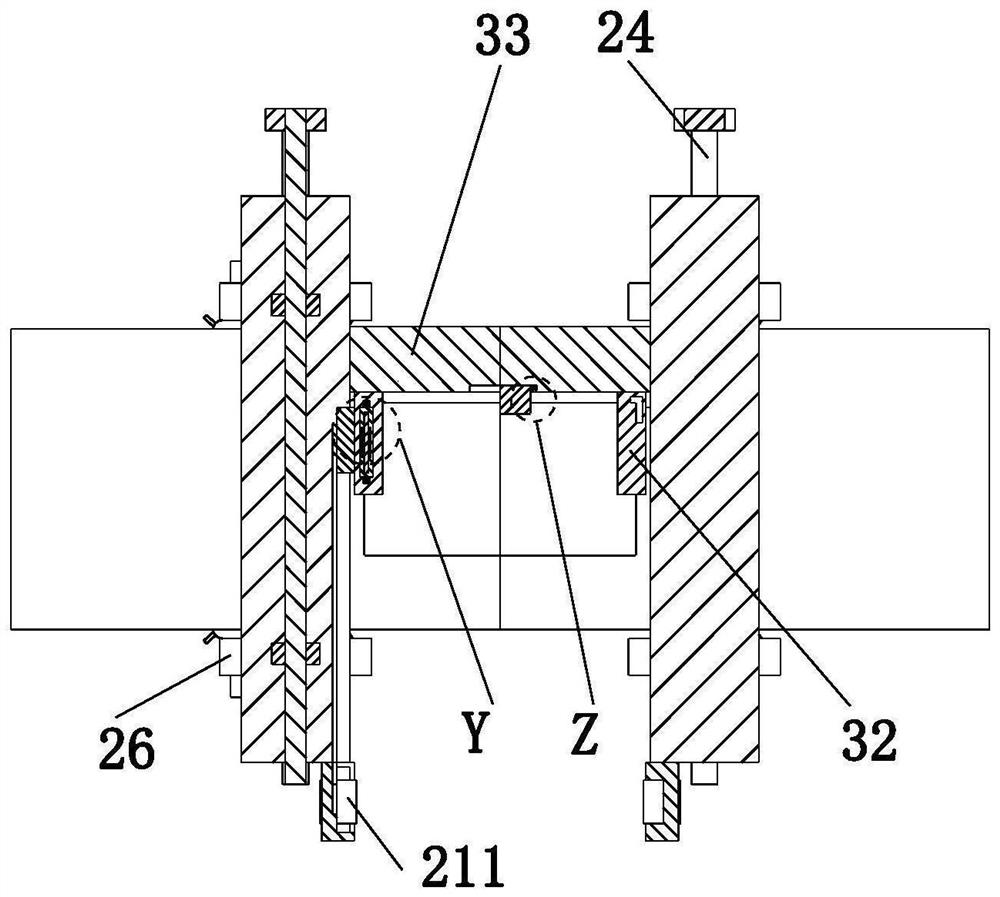

Railway vehicle air conditioner installation auxiliary positioning device

ActiveCN111409658AImprove the stabilityHigh precisionRailway heating/coolingMechanical engineeringElectrical and Electronics engineering

Owner:浙江硕维轨道股份有限公司

A construction method suitable for soft rock bedding tunnels

ActiveCN110080782BImprove stabilityGive full play to the carrying capacityUnderground chambersTunnel liningSupporting systemSupport system

The invention relates to the field of tunnel support, in particular to a construction method suitable for a soft rock bedding tunnel, which comprises the following steps: S1, excavating reverse-tilting upper step core soil, and constructing a first support system; S2, excavating core soil of the lower step of the reverse side, and constructing a second supporting system; S3, excavating upper stepcore soil along the inclined side, and constructing a third support system; S4, excavating core soil of the lower step along the inclined side, and constructing a fourth support system; and S5, disassembling the temporary support, and constructing a secondary lining. According to the construction method, reasonable excavation steps and supporting structures are adopted in a targeted mode accordingto the bias deformation characteristic of the bedding tunnel and the surrounding rock stability difference, deformation during tunnel construction can be effectively controlled, surrounding rock self-bearing is given to full play, the surrounding rock stability is improved, and therefore the construction risk and the engineering cost are reduced.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

A Coordinated Control Method of Pressure Relief Support in Deep High Stress Roadway Based on Drilling Pressure Relief

ActiveCN106401645BAchieve long-term stabilityReduce repair rateMining devicesUnderground chambersLarge deformationHigh stress

The invention discloses a pressure-relief support coordination control method for a deep high-stress tunnel based on borehole pressure relief. The method comprises three steps according to a time sequence, and the three steps are respectively a primary pressure relief support step, a borehole pressure relief step and a secondary high-strength anchor grouting support step. According to the pressure-relief support coordination control method for the deep high-stress tunnel based on borehole pressure relief, surrounding rock deformation in each stage is controlled by adopting different support and reinforcement methods according to difference of surrounding rock deformation ways in different stages after the tunnel is excavated, the support performances of surrounding rocks and supporting structures are fully played, and large deformation of the surrounding rocks of a deep high-stress tunnel is reduced, so the stability of the tunnel can be maintained for a long time. Meanwhile, the method disclosed by the invention is capable of effectively reducing the repair rate of the tunnel, alleviating the labor intensity of workers and lowering the comprehensive support cost of a mine.

Owner:HENAN POLYTECHNIC UNIV

Roller Compacted Concrete Structure and Construction Method of Injecting Composite Slurry into Gravel Material

ActiveCN108643132BTake advantage ofEasy accessFoundation engineeringEarth-fill damsRoller-compacted concreteStructural engineering

The invention discloses a roller compacted concrete structure in which composite slurry material is injected into gravel material. It is composed of multi-layer composite slurry roller compacted concrete layer. The composite slurry roller compacted concrete layer is formed by vibration rolling of gravel material and surface poured composite slurry. The gravel material is excavation material with a particle size greater than or equal to 5mm. The gravel material is piled up in layers on the dam foundation, and the composite slurry is poured on the layered gravel material and randomly filled with gravel material. When the liquid level of the composite slurry is close to the top surface of the gravel material, the surface of the storehouse is compacted by vibrating rollers. A grouted roller compacted concrete structure with a uniform and stable structure is formed. The invention has the advantages of local materials, uniform and stable structure, excellent performance, fast construction speed and saving engineering cost. The invention also discloses a construction method of the roller compacted concrete structure in which the composite slurry material is injected into the stone slag material.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

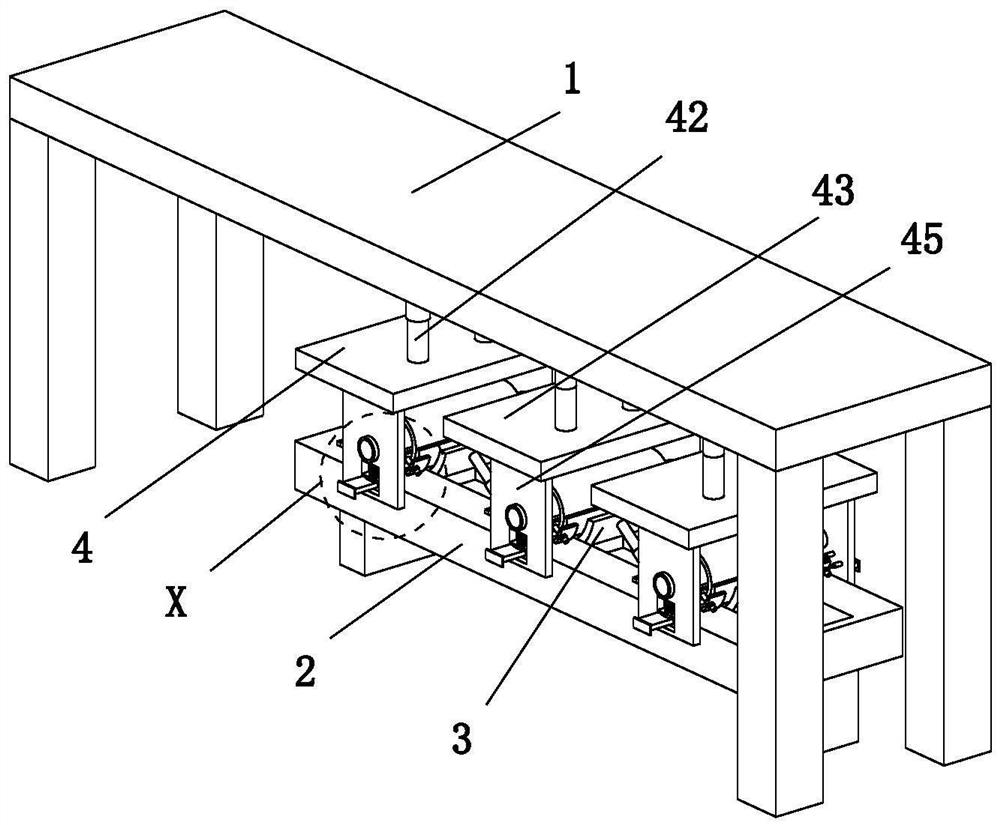

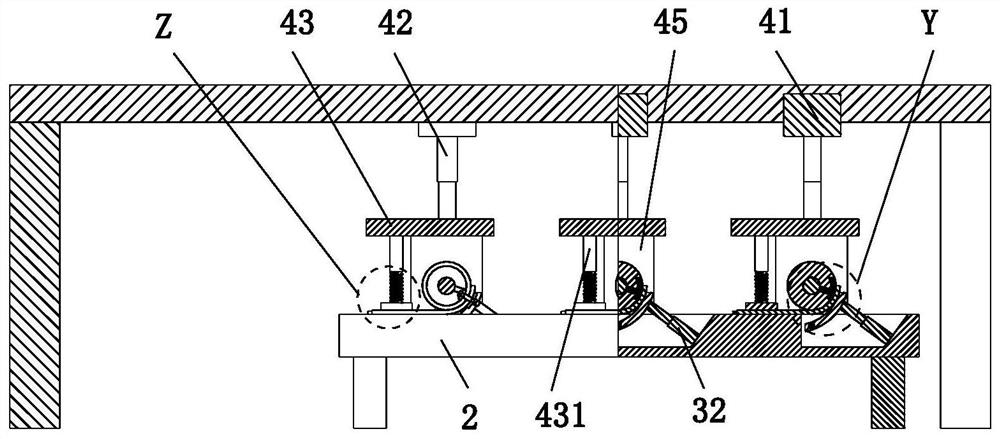

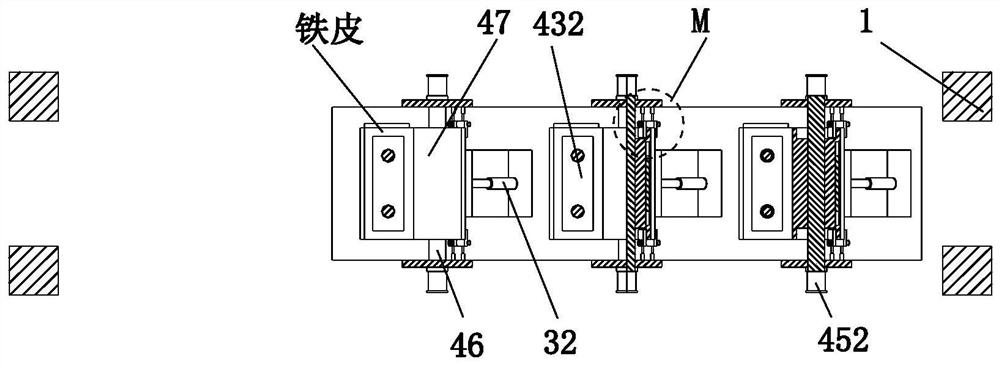

Method for manufacturing tea packaging cans

ActiveCN111229973BImprove the stabilityHigh forming precisionMetal-working feeding devicesPositioning devicesPackaging TankMechanical engineering

The invention relates to a manufacturing method of tea packaging cans, which uses a tea packaging can manufacturing device, which includes a gantry frame, a workbench, an auxiliary device and a side device, the lower part of the gantry frame There is a workbench on the side, the upper end of the workbench is equidistantly installed with an auxiliary device from left to right, the left side of the auxiliary device is provided with an edge device, and the lower end of the edge device and the upper end of the workbench are in a sliding fit , the upper end of the edge-lapping device is connected with the upper end of the gantry frame through a sliding fit. A method for manufacturing tea packaging cans according to the present invention. Improve the stability of the edge forming process, thereby improving the forming accuracy of the iron sheet tank body. The iron sheet pre-bending, integral reel edge forming and edge sealing treatment can be continuously operated on the same working line, which improves work efficiency.

Owner:安徽中联茶叶进出口有限公司

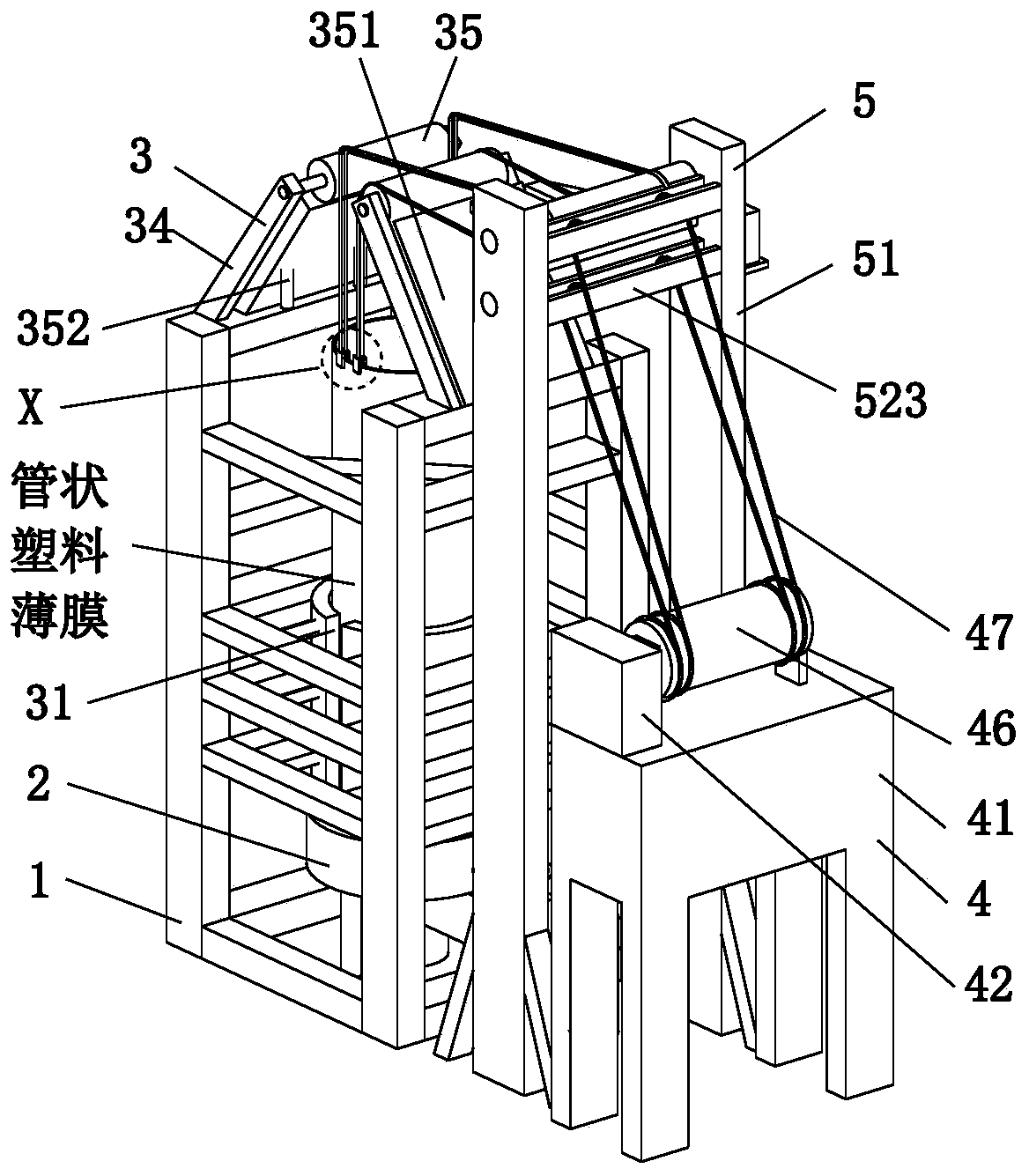

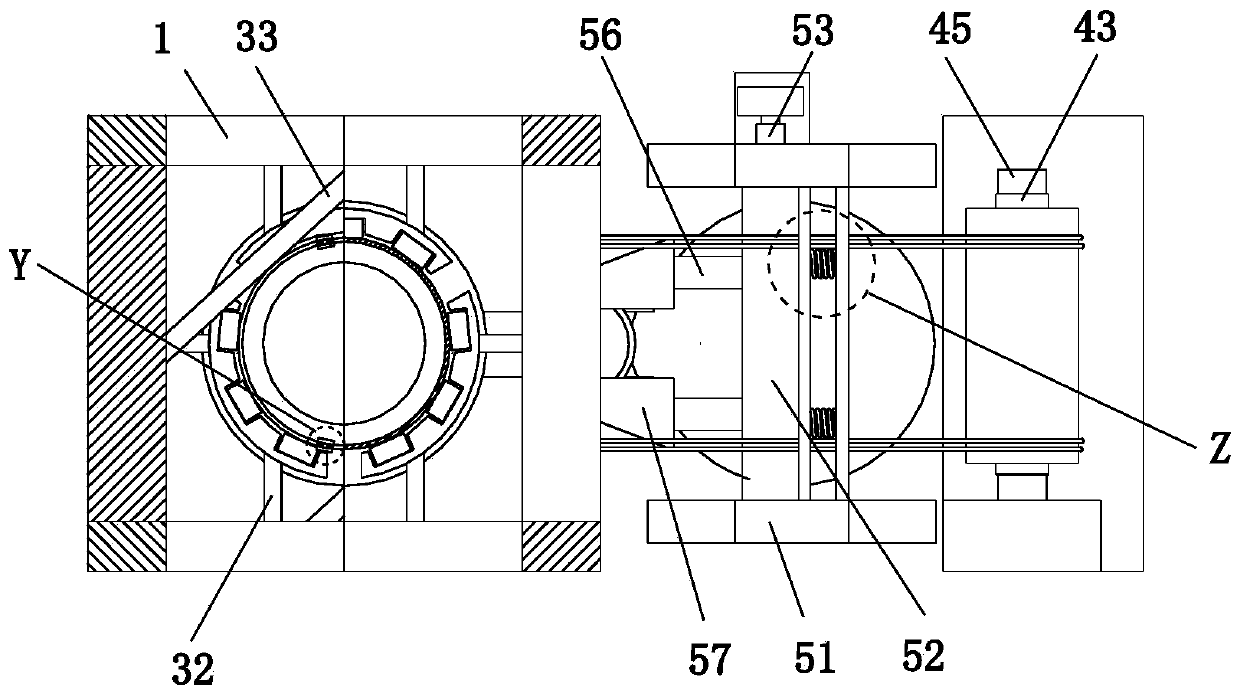

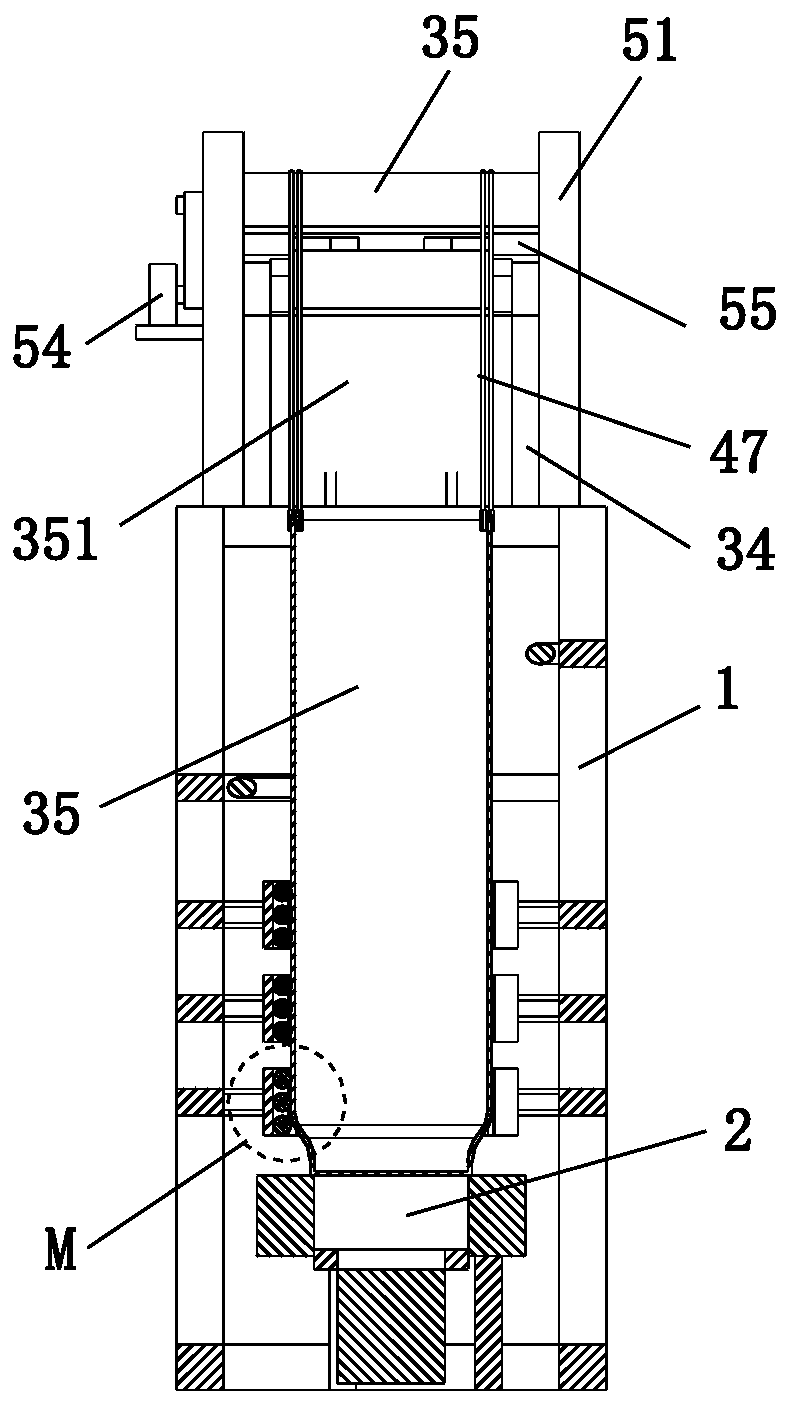

Blow molding preparing method for plastic film

The invention relates to a blow molding preparing method for a plastic film. A blow molding preparing device for the plastic film is used. The blow molding preparing device for the plastic film comprises a guide frame, an extruding machine, a guiding and fixing device, a traction device and a cutting device. The extruding machine is installed at the lower end of the interior of the guide frame. The guiding and fixing device is arranged above the extruding machine. The traction device is arranged on the right side of the guiding and fixing device. The cutting device is arranged between the traction device and the cutting device. By means of the blow molding preparing method for the plastic film, a multiple guiding and fixing design concept is adopted for conducting plastic film production,an adaptive guiding, clamping and fixing structure is adopted for the upper and the lower end of the initial-stage tubular plastic film, the forming size of the tubular plastic film and the completeness of the whole body of the plastic film are ensured, and the forming quality of the tubular plastic film is improved.

Owner:陈铭军

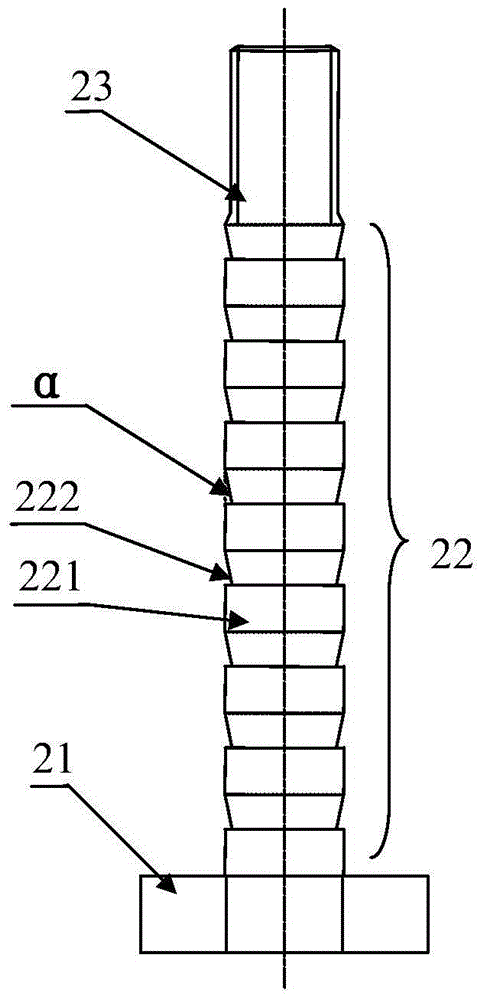

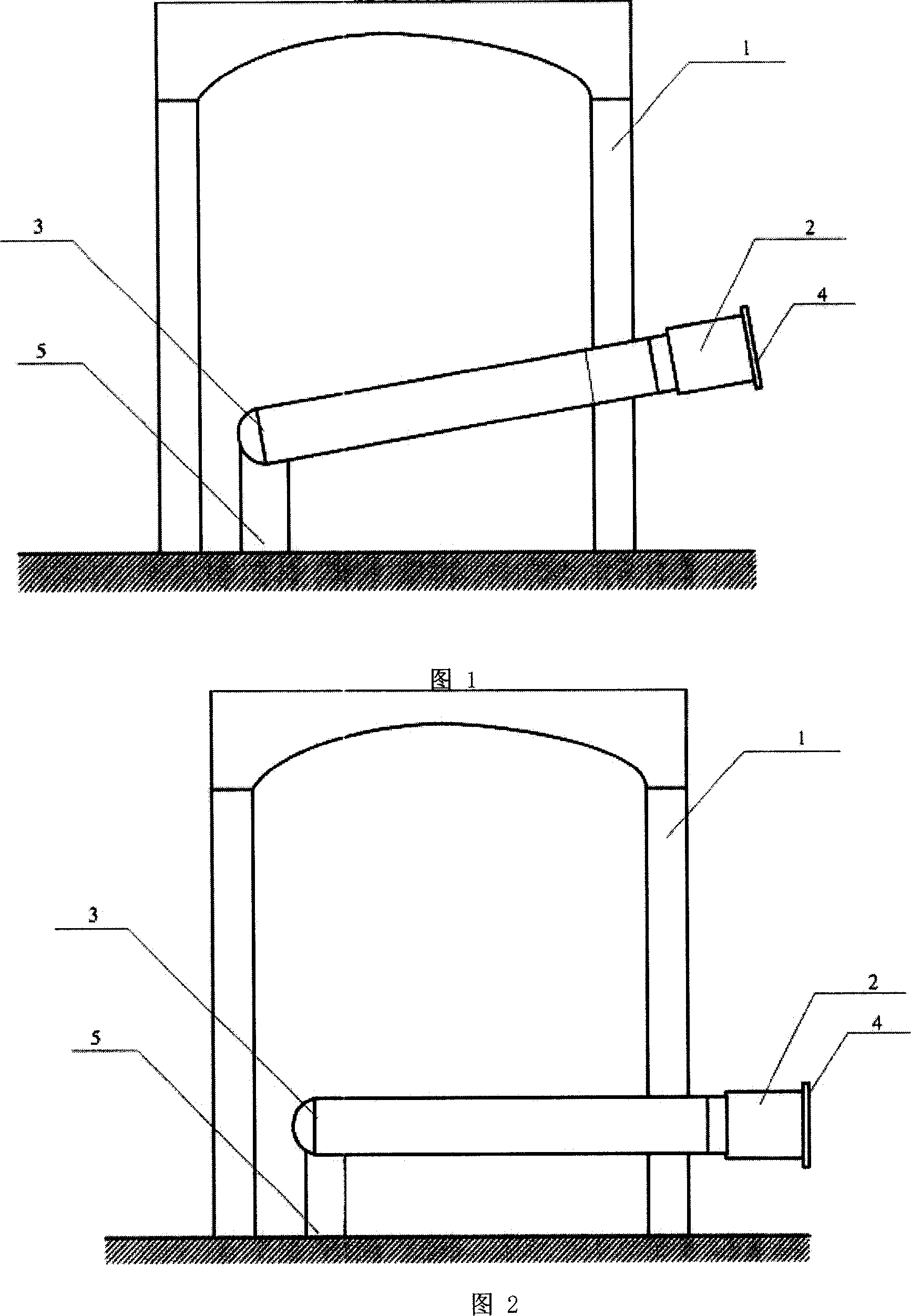

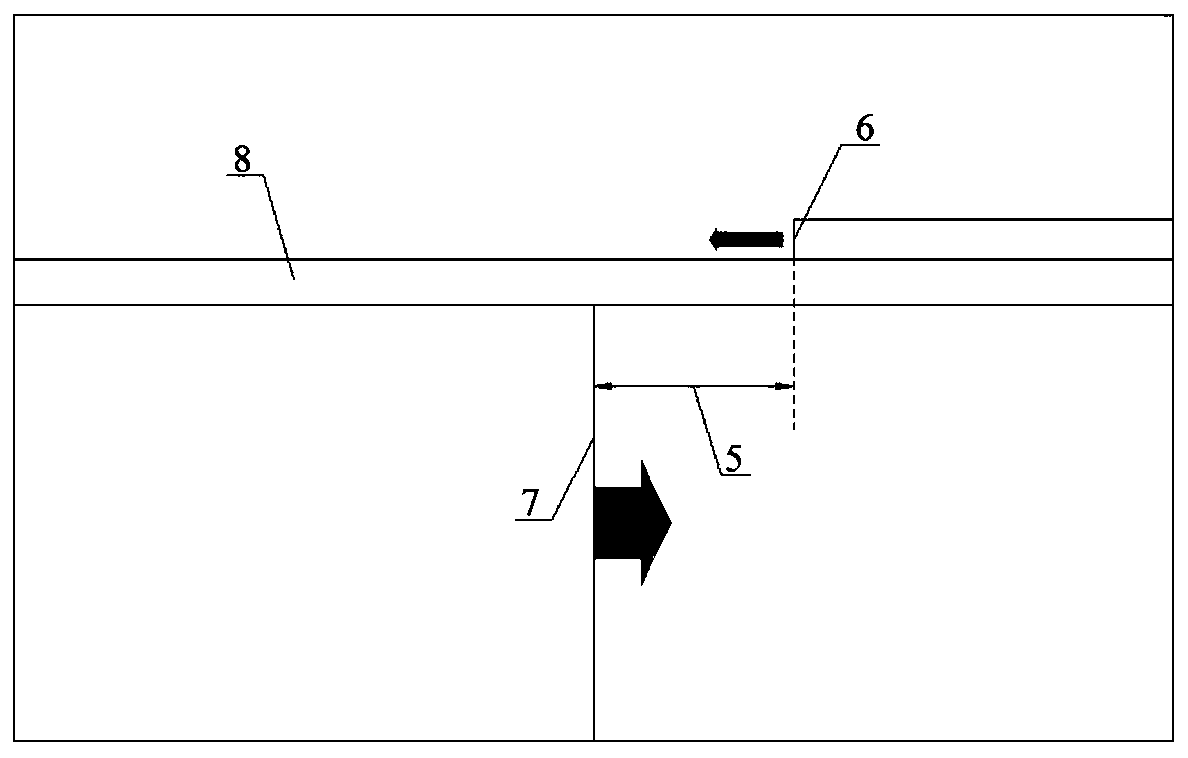

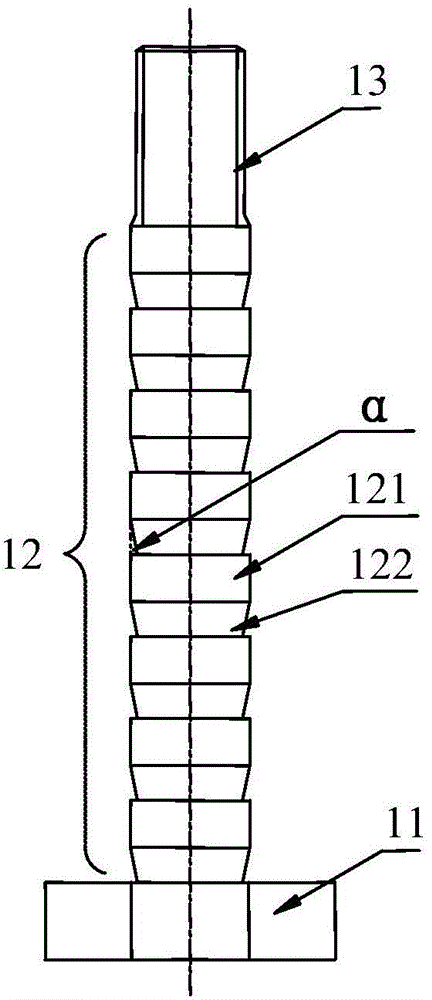

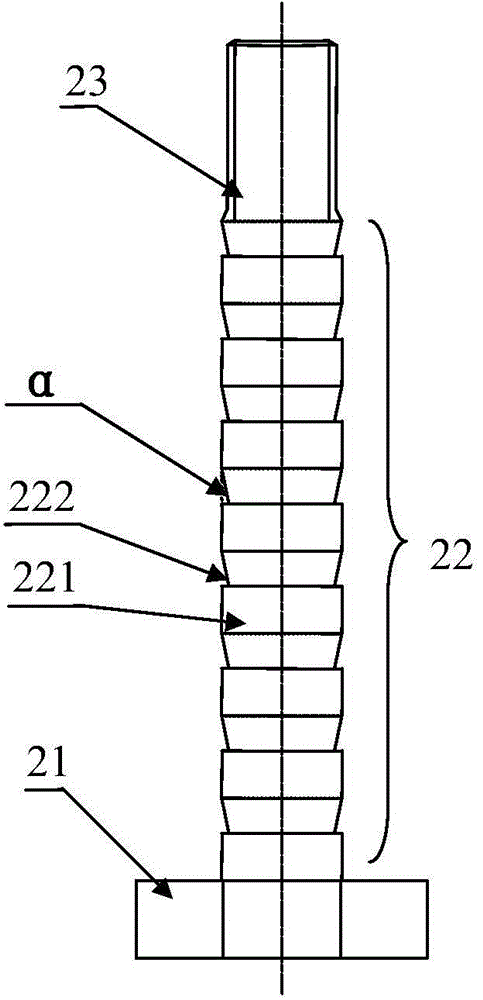

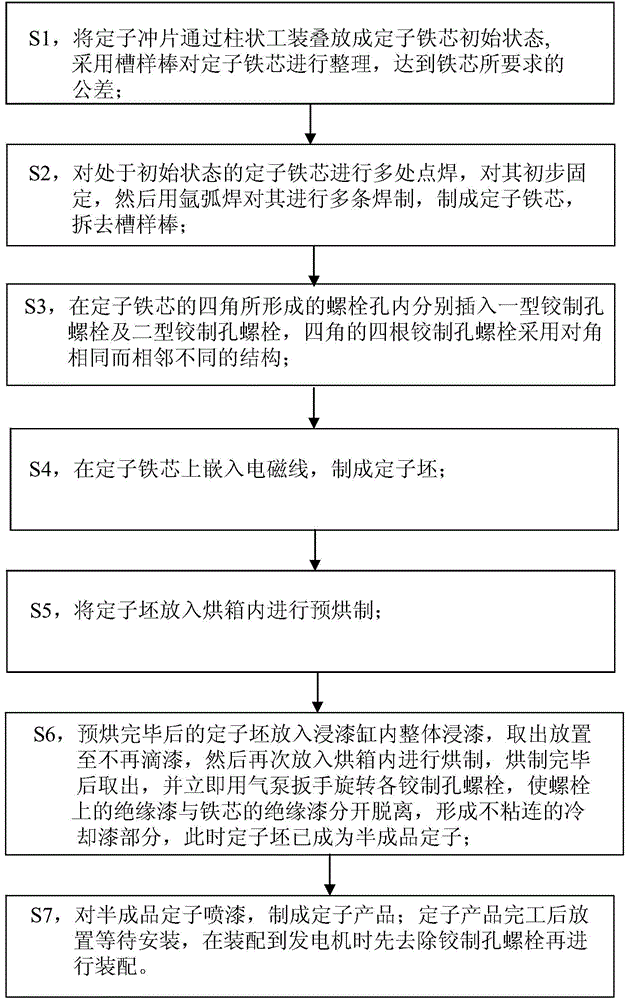

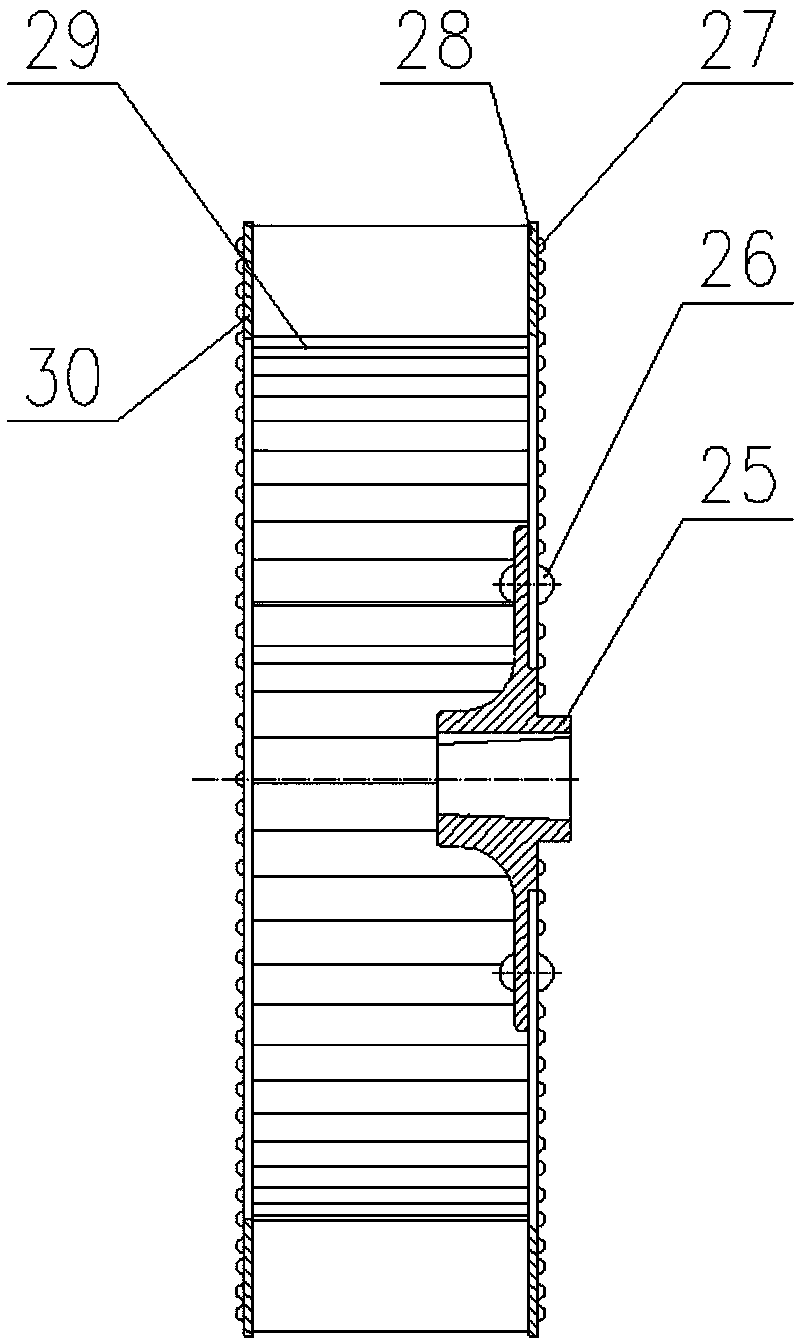

Stator bolt for eliminating stator deformation of exciter and method of using the same

ActiveCN104389881BReduce precision biasReduce correctionScrewsManufacturing stator/rotor bodiesEngineeringLarge deformation

The invention relates to stator bolts for eliminating exciter stator deformation and an application method of stator bolts, which relate to the technology of exciter stator manufacturing, and solve the problem that the existing stator is easy to deform. The stator bolts are reamed hole bolts, wherein a screw rod reamed shaft is formed by a plurality of subsections; the sections have the same structure and respectively comprise a reamed shaft section and a chamfering-shaped shaft section; each reamed shaft section is the shaft section matched with the dimension of an iron core bolt hole and makes contact with the stator iron core bolt hole; the diameter of the top part of each chamfering-shaped shaft section is matched with the diameter of the reamed shaft section, and each chamfering-shaped shaft section is inclined downwards according to a chamfer alpha so as to be in a turbination shape from the top part, is not in contact with the stator iron core bolt hole, and has the length smaller than the length of the reamed shaft section. According to the stator bolt for eliminating exciter stator deformation and the application method of the stator bolts, the traditional manufacturing manner of the exciter stator is improved, the four reamed hole bolts on four corners of the iron core of the stator adopt the structure with same opposite angles and different adjacent angles, the occurrence of the phenomenon of large deformation due to large clearance between the stator iron core and the bolt holes is reduced, the precision error after the stator iron core is finished is reduced, and the product quality is improved.

Owner:上海马拉松·革新电气有限公司

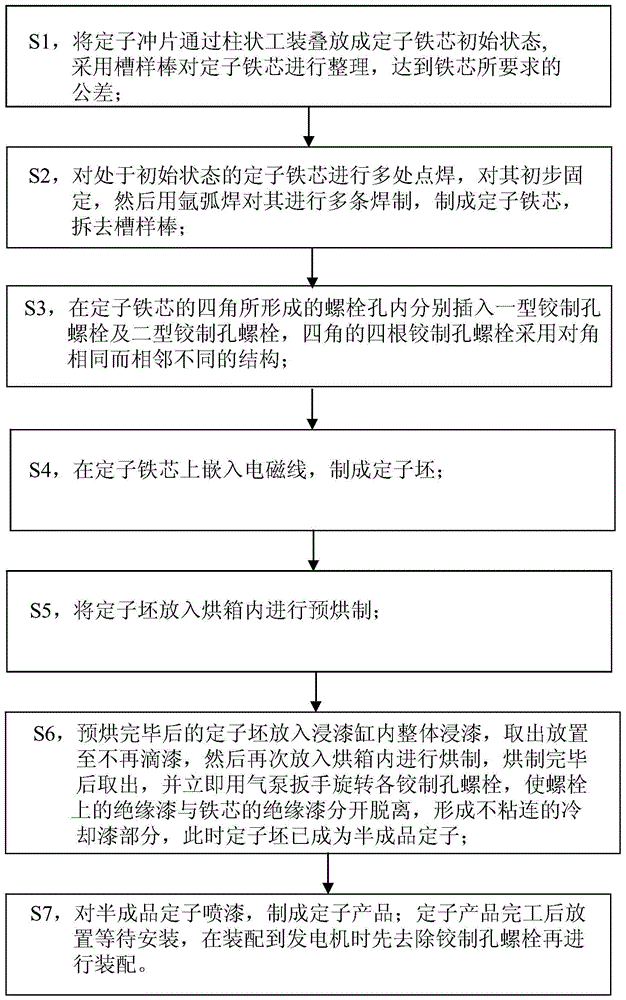

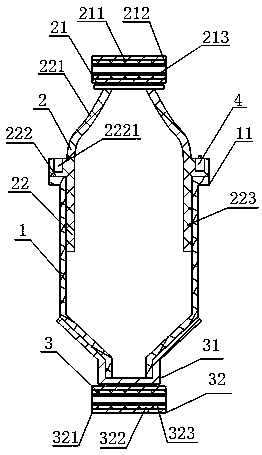

Reduction pot setup method in stove and reducing furnace constructed by the method

InactiveCN101113874AReduce large deformationExtended service lifeCrucible furnacesLarge deformationSmelting

The invention discloses a setting method of a metal vacuum-smelting reduction pot in a reduction furnace and a reduction furnace constructed by using the method. The sealing end of the reduction pot downwards and the material inlet of the reduction pot upwards are tipsily positioned in the reduction furnace. The sealing end of a reduction pot (3) is supported on a support saddle (5) arranged in a reduction furnace kiln body (1). The material inlet of the reduction pot (3) is supported on a position which is higher than the support saddle (5) on the reduction furnace kiln body (1). A crystallizer (2), which is connected with the material inlet of the reduction pot, is positioned outside the reduction furnace kiln body (1). The angle between the reduction pot (3) and a horizontal plane is 3-30 degrees. The invention solves the problems of inconvenience of adding materials of the existing reduction pot, small feeding amount, and great labor intensity when workers add materials, large deformation of the reduction pot and deficiency in energy utilization.

Owner:GUIZHOU SHIJI TIANYUAN MINING IND

A method for controlling dynamic stress in counter-mining and excavation of short-distance coal seams

InactiveCN110029994BReduce large deformationImprove support efficiencyUnderground chambersUnderground miningMining engineeringStructural engineering

Owner:CHINA UNIV OF MINING & TECH +1

A support frame, a support structure and a construction method for the support structure

ActiveCN105822329BDeformation weakeningReduce large deformationUnderground chambersTunnel liningEngineeringLarge deformation

The invention relates to the technical field of tunnel construction, in particular relates to a support frame, a support structure and a construction method of the support structure, and provides a support frame which is formed by sequentially connecting a plurality of support segments in cycle, wherein hole grooves are formed in two ends of each support segment; adjacent support segments are connected through a first sleeve; the first sleeve is a hollow circumferential sleeve which is matched with the support segments in size; mounting holes are formed in two ends of the front wall surface and the rear wall surface of the first sleeve corresponding to the hole grooves; a second sleeve is a cross-shaped sleeve which comprises the circumferential sleeve similar to the first sleeve and two longitudinal sleeves which are symmetrically arranged at the centers of the front side wall and the rear side wall of the circumferential sleeve; energy-dissipation presplitting slots are formed in the middle parts of two ends of the left wall surface and the right wall surface of the circumferential sleeve. The support structure formed by combining the first sleeve and the second sleeve is reasonable in design and convenient to construct, and can effectively adapt to large deformation of a surrounding rock; the clearance-intrusion risk of the local large deformation of a tunnel is reduced; the overall stability of a primary lining support structure is improved; and the subsequent treatment cost of the engineering is reduced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Shock-absorbing rubber air springs for vehicles

InactiveCN105179548BGuaranteed tightnessImprove shock absorptionSpringsGas based dampersAir springEngineering

Owner:GASTECH VEHICLE PARTS

Surrounding rock collaborative control system and construction method of traffic tunnel

ActiveCN112647969BSmall overall deformationReduce large deformationUnderground chambersTunnel liningInterior spaceControl system

The invention relates to a traffic tunnel surrounding rock collaborative control system and a construction method, comprising a quick-setting slurry layer that can be sequentially arranged along the inner wall of the tunnel to the direction of the inner space of the tunnel, a flexible explosion-proof energy-absorbing layer, a rigid guard plate layer and a steel arch frame, A plurality of telescopic parts are arranged between the flexible explosion-proof energy-absorbing layer and the rigid guard plate layer, and the gap between the flexible explosion-proof energy-absorbing layer and the rigid guard plate layer is filled with flexible materials; the flexible explosion-proof energy-absorbing layer can pass through anchors It is fixedly connected with the surrounding rock, and the anchor piece can be inserted into the surrounding rock. The support structure of the present invention can effectively prevent and control the large deformation of the surrounding rock faced by the traffic tunnel.

Owner:SHANDONG UNIV +3

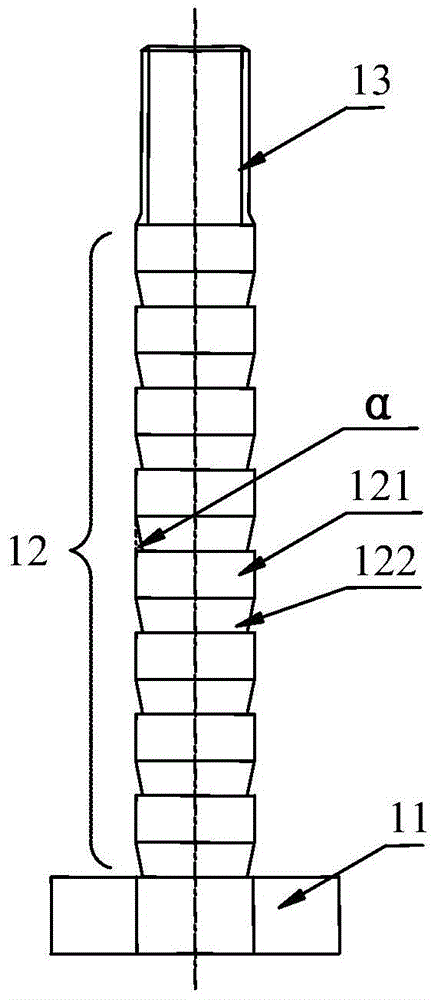

Stator bolts for eliminating exciter stator deformation and application method of stator bolts

ActiveCN104389881AReduce precision biasReduce correctionScrewsManufacturing stator/rotor bodiesEngineeringLarge deformation

The invention relates to stator bolts for eliminating exciter stator deformation and an application method of stator bolts, which relate to the technology of exciter stator manufacturing, and solve the problem that the existing stator is easy to deform. The stator bolts are reamed hole bolts, wherein a screw rod reamed shaft is formed by a plurality of subsections; the sections have the same structure and respectively comprise a reamed shaft section and a chamfering-shaped shaft section; each reamed shaft section is the shaft section matched with the dimension of an iron core bolt hole and makes contact with the stator iron core bolt hole; the diameter of the top part of each chamfering-shaped shaft section is matched with the diameter of the reamed shaft section, and each chamfering-shaped shaft section is inclined downwards according to a chamfer alpha so as to be in a turbination shape from the top part, is not in contact with the stator iron core bolt hole, and has the length smaller than the length of the reamed shaft section. According to the stator bolt for eliminating exciter stator deformation and the application method of the stator bolts, the traditional manufacturing manner of the exciter stator is improved, the four reamed hole bolts on four corners of the iron core of the stator adopt the structure with same opposite angles and different adjacent angles, the occurrence of the phenomenon of large deformation due to large clearance between the stator iron core and the bolt holes is reduced, the precision error after the stator iron core is finished is reduced, and the product quality is improved.

Owner:上海马拉松·革新电气有限公司

A kind of rail vehicle air conditioner installation auxiliary positioning device

ActiveCN111409658BImprove the stabilityHigh precisionRailway heating/coolingControl theoryMechanical engineering

Owner:浙江硕维轨道股份有限公司

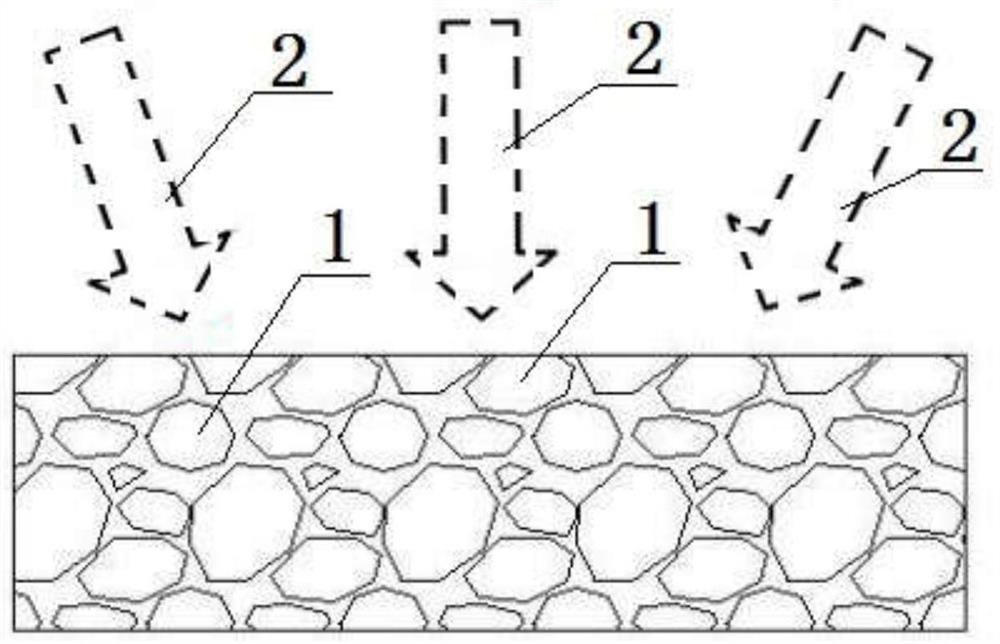

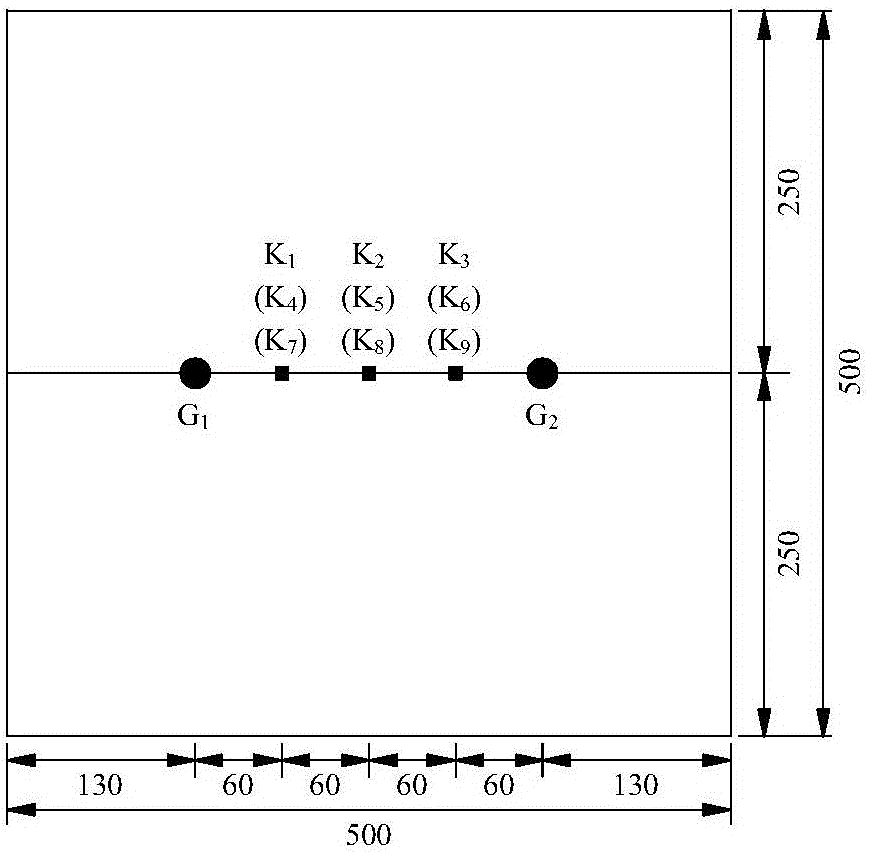

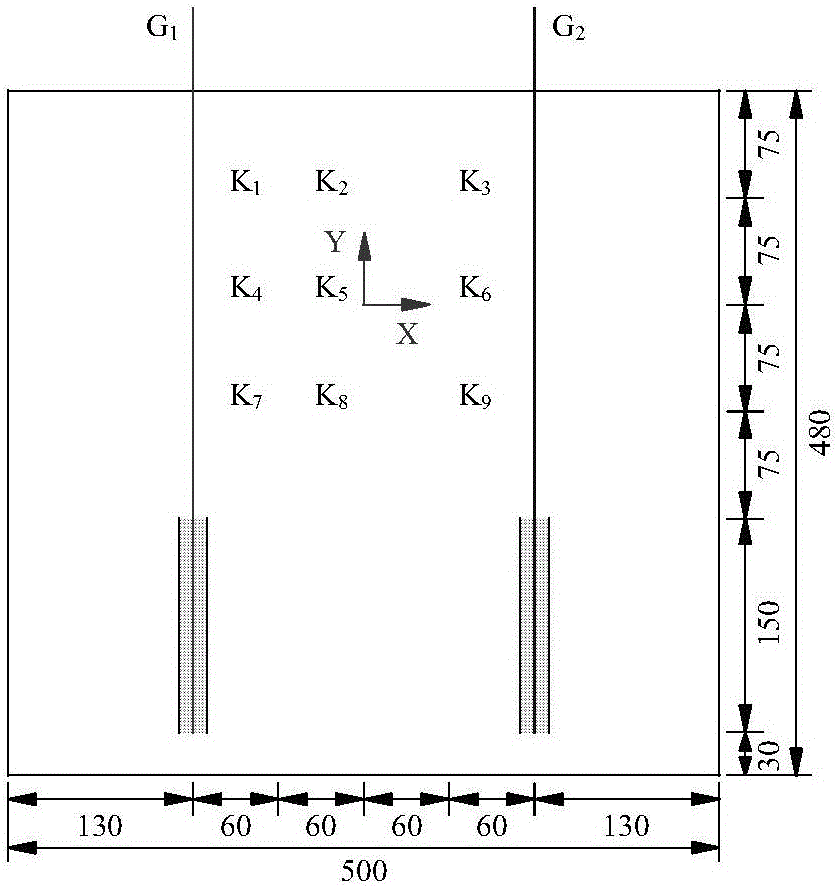

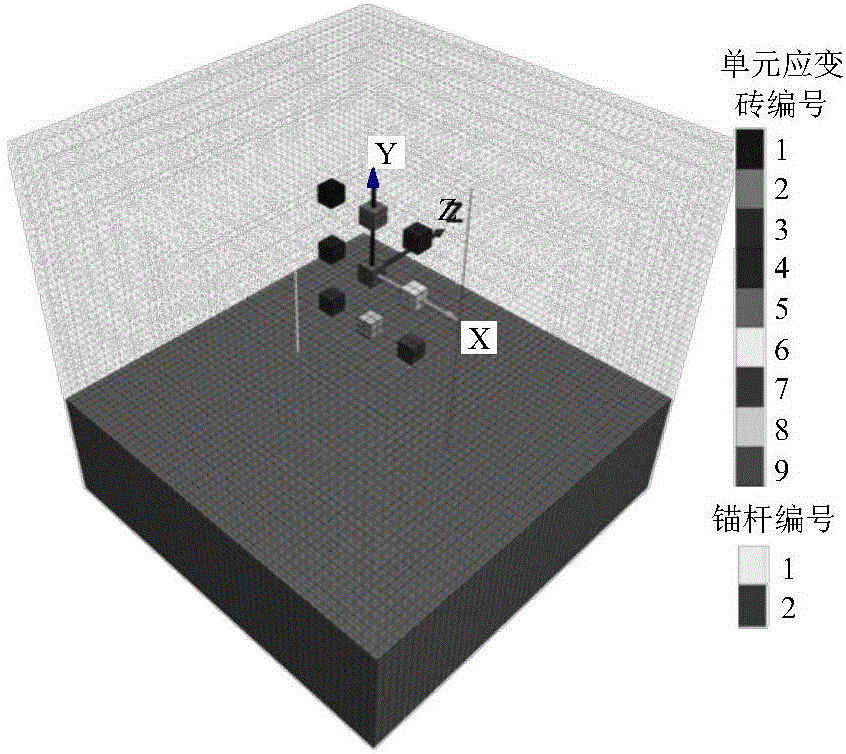

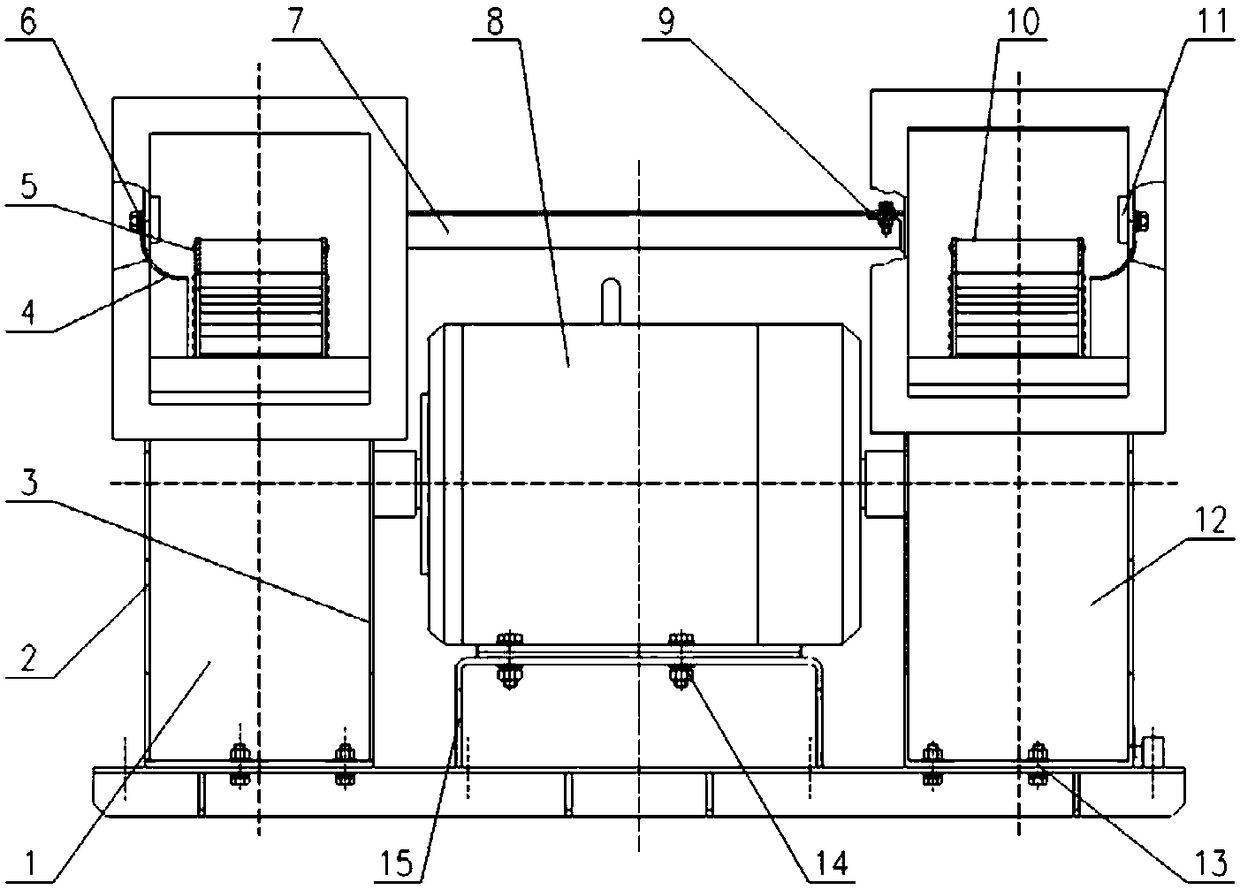

Detection method of cooperative effect generated in anchoring body under anchor pole cooperative reaction

InactiveCN106248262AReduce the impactCombined denseForce measurementApparatus for force/torque/work measurementEngineeringStressed state

The invention provides a detection method of a cooperative effect generated in anchoring body under an anchor pole cooperative reaction, belonging to a detection method of a cooperative effect generated under a cooperative reaction. The detection method comprises a step of selecting a model test piece material, making a model test piece, and determining the detection method of an anchoring body cooperative reaction under a pre-tightening force anchor pole effect through the model test piece, a step of detecting the shape, range and evolution rule of the anchoring body, a step of determining detection data, a step of establishing a corresponding relation between the cooperative reaction and tunnel surrounding rocks stability control through cooperative effect calculating, obtaining and evaluating the anchoring body cooperative effect, realizing a condition that the macroscopic function of a cooperative anchoring system is larger than the linear superpose sum of each sub system, and improving the stress state of a tunnel surrounding rocks anchoring structure. The detection method has the advantages that the bearing ability of the tunnel surrounding rocks anchoring structure can be substantially improved, the distribution shape, range and development evolution rule of the anchoring body cooperative effect are obtained, and the anchoring body intensity, rigidity, bearing ability, and anti-deformation ability are improved.

Owner:CHINA UNIV OF MINING & TECH

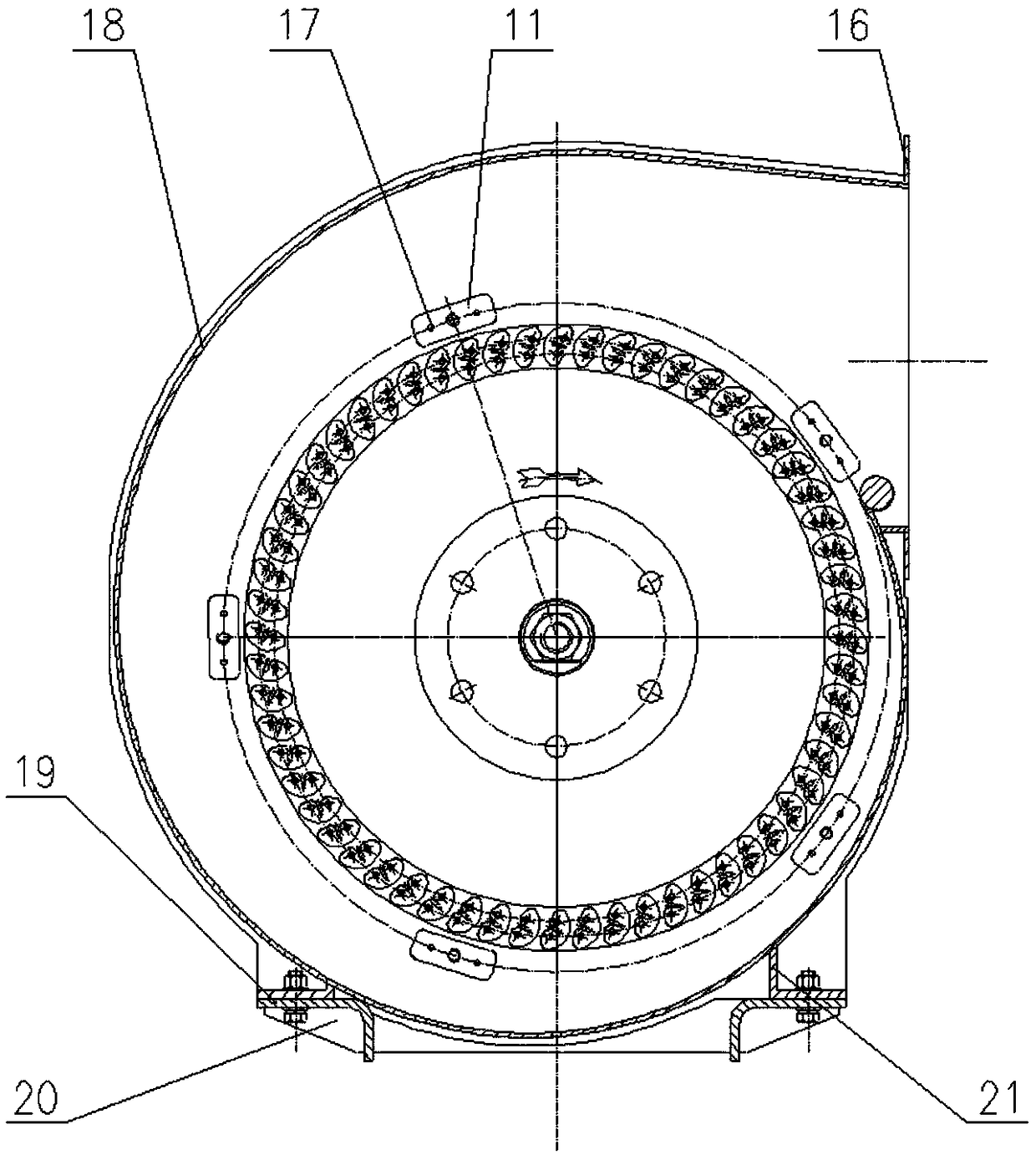

Forward multi-wing riveting double-impeller centrifugal ventilator for CRH train converter

PendingCN108953175AStable supportGuaranteed strength and rigidityPump componentsPump installationsImpellerLow noise

The invention provides a forward multi-wing riveting double-impeller centrifugal ventilator for a CRH train converter. The forward multi-wing riveting double-impeller centrifugal ventilator for the CRH train converter comprises a left volute, a left impeller, air inlets, a three-phase asynchronous motor, a right volute, a right impeller, a mounting frame and connecting angle aluminum; the left volute and the right volute are connected with the mounting frame by bolts through mounting holes at the bottoms, and are fixed through the connecting angle aluminum; the left impeller and the right impeller are fixed in the left and right volutes through shaft extenders on two sides of a motor; and the air inlets are fixed on the outer sides of the left volute and the right volute through mounting set blocks on first side plates. Through improvement of the forward multi-wing riveting double-impeller centrifugal ventilator for the CRH train converter, the advantages of high efficiency, low noise,simple and compact structure, less space, high reliability and convenience to install in the CRH train converter are achieved, and the problems and the defects in the background technology are effectively solved.

Owner:ZHUZHOU LINCE GRP +1

A super-high rockfill dam structure suitable for water conservancy and hydropower projects and its construction method

ActiveCN105780737BTake advantage ofBreak through limitationsEarth-fill damsRock-fill damsRoller-compacted concreteStructure of the Earth

The invention provides a super-high rockfill dam structure suitable for water conservancy and hydropower engineering and a construction method of the dam structure. According to a super-high rockfill dam, lower layer concrete with the slump constant ranging from 70 mm to 150 mm is cast on a treated dam foundation, before the lower layer concrete is initially set, dimension stone or cobbles with the particle diameter above 40 mm are selected for piling up middle-layer dimension stone, first-grading roller compacted concrete with the VC value ranging from 1 s to 5 s is cast on the middle-layer dimension stone, and finally, rolling is carried out until even bleeding appears in the surface; then, the steps are repeated, and a rolling dimension stone concrete base with the height ranging from 90 m to 110 m is formed; and a concrete panel of 200 m to 300 m is constructed on the base for piling up a dam body, and finally, a concrete seepage-proofing panel is casted on the upstream portion of the whole dam body. According to the structure, local excavated materials can be fully used, the aim that no abandoned materials exist is basically achieved, and the dam structure is energy-saving, environment-friendly, low in cost and good in whole performance, improves the work efficiency and shortens the construction period.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com