A method for controlling dynamic stress in counter-mining and excavation of short-distance coal seams

A technology of mining stress and control method, which is applied in surface mining, mining equipment, underground mining, etc., can solve the problems of easy-to-drop anchor failure, tearing, and failure to protect the watch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

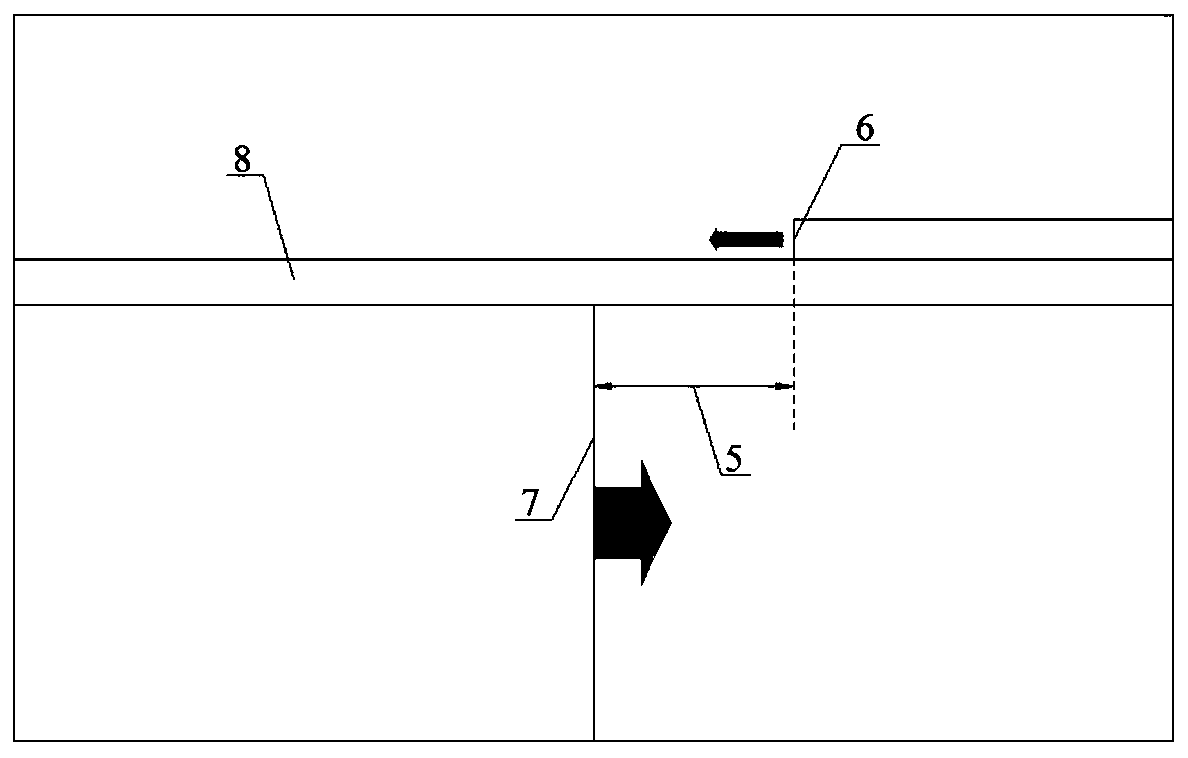

[0028] Such as figure 1 and Figure 4 As shown, the mining stress control method of this coal seam is: when the driving face 6 of the mining roadway in this coal seam meets the adjacent working face 7, that is, when the distance 5 between the working face and the driving face is 0m, the tunneling is stopped at this time. Continue the roadway excavation after the working face is 100m away from the excavation surface, and the support is carried out synchronously with the roadway excavation. The specific support measures are: use the anchor rod 1 and the anchor cable 3 to cooperate with the steel wire mesh 4 for support, and the steel wire mesh 4 covers the roof of the roadway With the two gangs, it is used to strengthen the support and prevent the two gangs of coal walls; the support is carried out synchronously with the roadway excavation, the anchor rod 1 is a twist-type resin anchor rod, Φ20×2000mm, and the distance between the anchor rods is L 1 The row spacing is 900mm, 5 ...

Embodiment 2

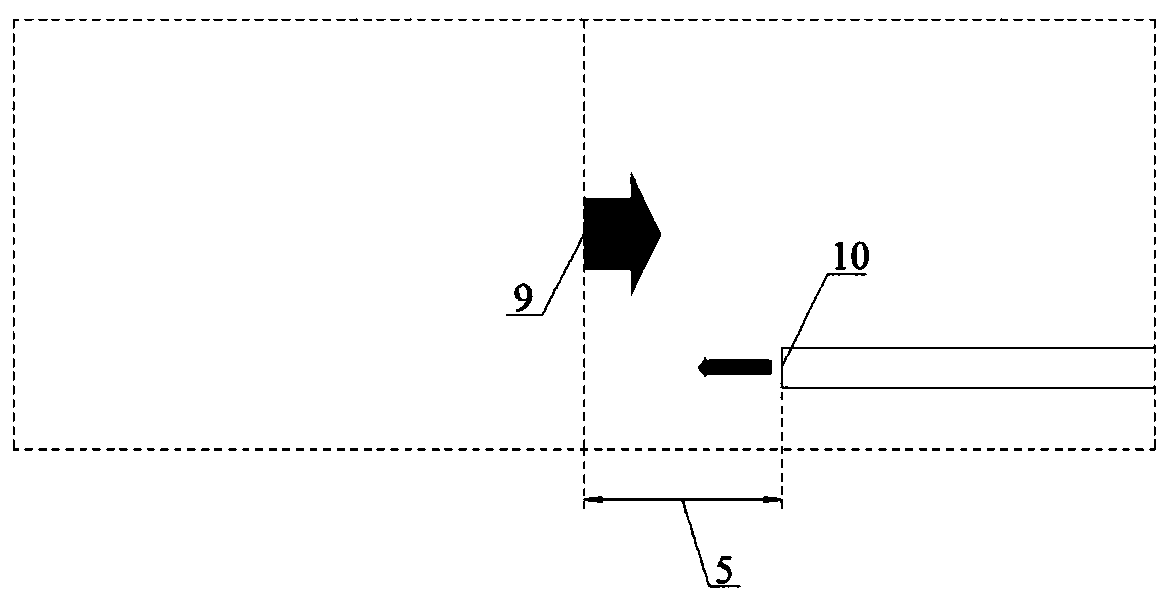

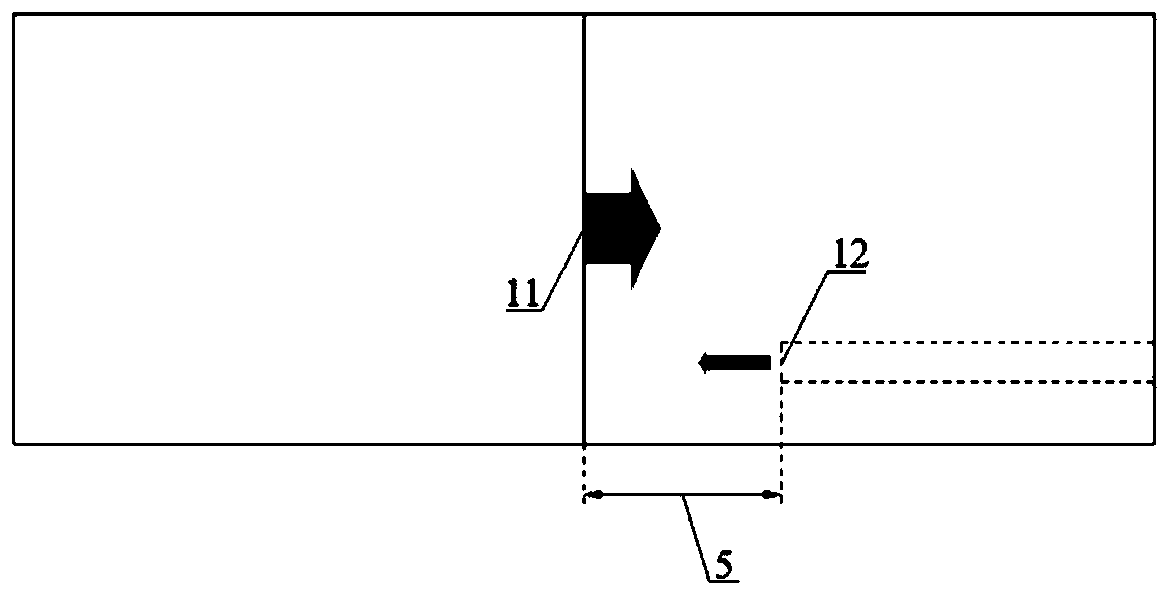

[0030] Such as figure 2 and Figure 5 As shown, the mining stress control method when adjacent coal seams are excavated and excavated: when adjacent coal seams are overlapped or staggered (the stagger distance is less than 10m) when mining; For the mining roadway of the coal seam working face, continue to excavate after the lower coal seam working face 9 is 70m away from the upper coal seam mining roadway excavation face 10, and the support is carried out synchronously with the roadway excavation. The specific support measures are: use the anchor rod 1 and the anchor cable 3 The steel wire mesh 4 is used for support, wherein the steel wire mesh 4 covers the roof and two sides of the roadway to strengthen the support and prevent the two sides of the coal wall; the support is carried out synchronously with the roadway excavation, and the bolt 1 is a twisted resin bolt , Φ20×2000mm, bolt 1 spacing L 2 The row spacing is 900mm, 5 in each row, the three in the middle are driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com