Forward multi-wing riveting double-impeller centrifugal ventilator for CRH train converter

A technology of centrifugal fans and converters, which is applied in the direction of non-variable pumps, machines/engines, liquid fuel engines, etc., can solve the problems of low safety and reliability, large space occupation, inconvenient installation, etc., and achieve simple structure Compact, strengthened support, reduce the effect of many welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

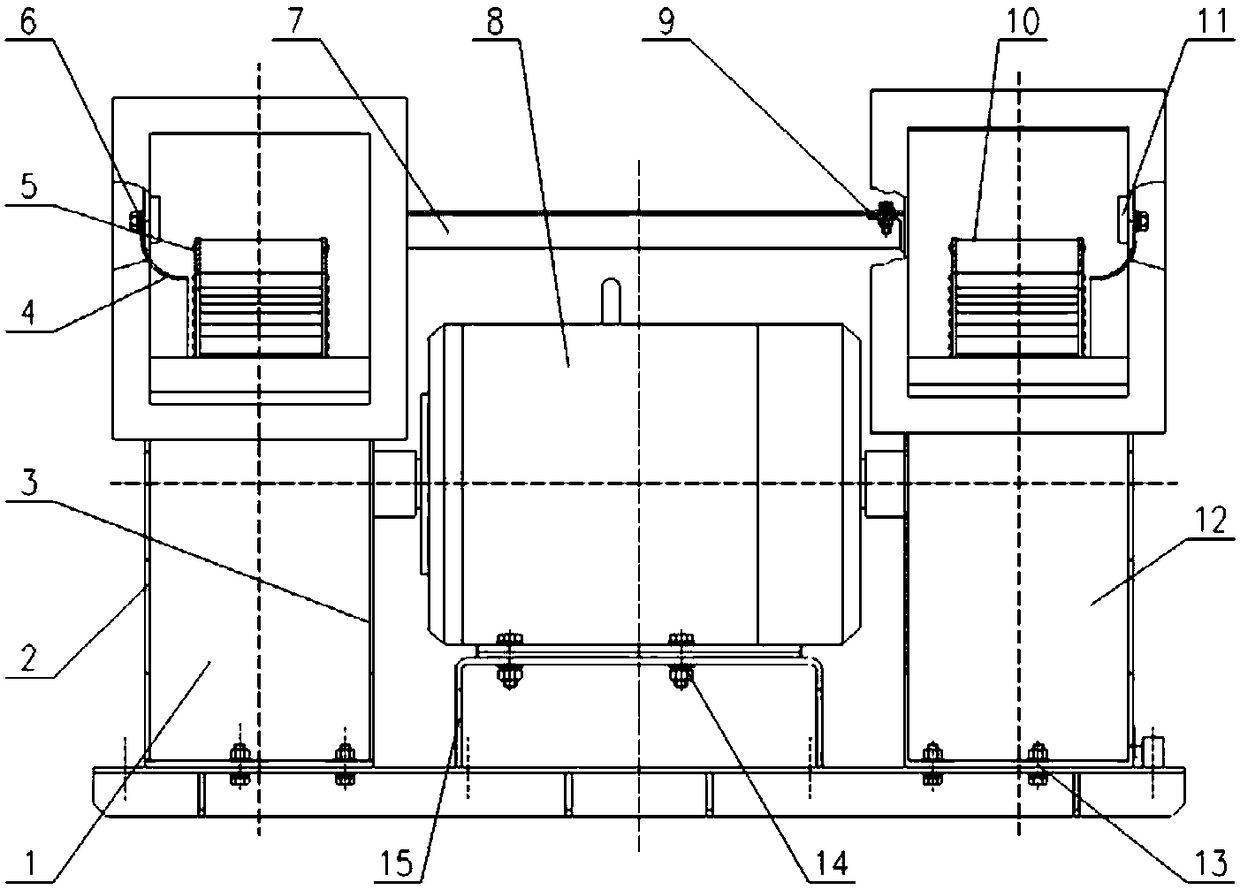

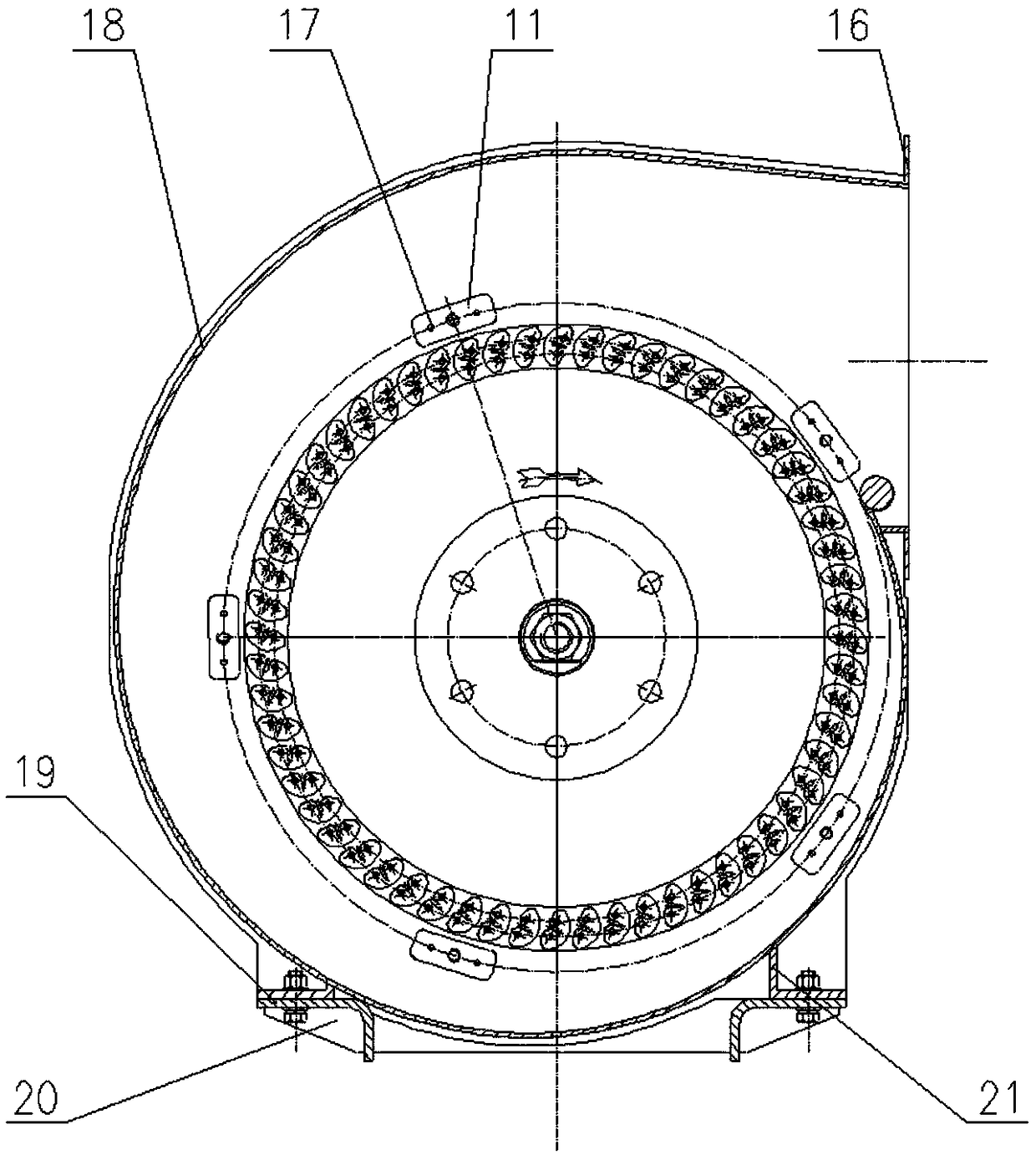

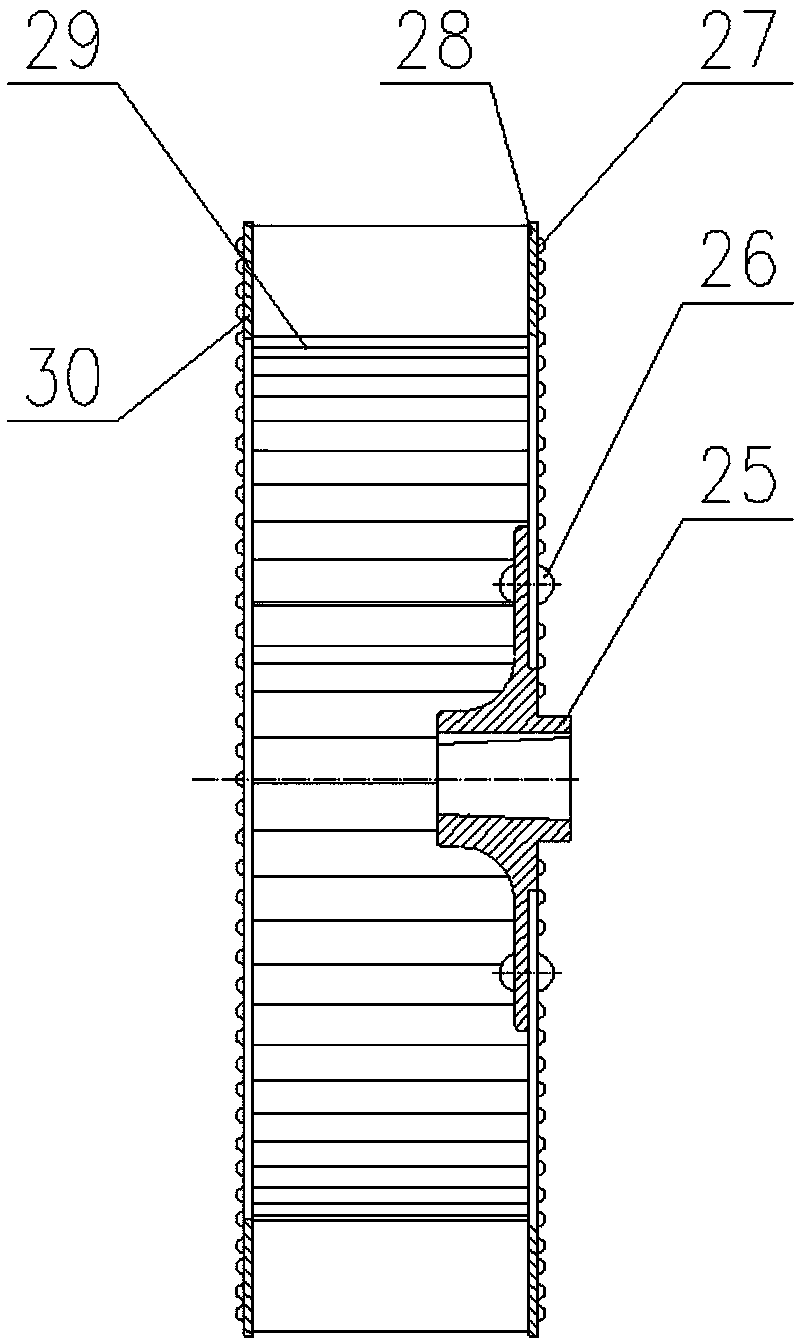

[0033] A forward multi-blade riveted double-impeller centrifugal fan for EMU converters, comprising: a left volute 1, a first side plate 2, a second side plate 3, an air inlet 4, a left impeller 5, and a first bolt 6 , connecting angle aluminum 7, three-phase asynchronous motor 8, second bolt 9, right impeller 10, installation block 11, right volute 12, third bolt 13, fourth bolt 14, mounting frame 15, air outlet 16, the first Three rivets 17, top plate 18, mounting frame base plate 19, mounting frame reinforcement plate 20, mounting angle plate 21, motor mounting base plate 22, motor mounting backing plate 23, reinforcing support plate 24, wheel core 25, first rivet 26, second Rivet 27, impeller rear disc 28, blade 29, impeller front disc 30; mounting frame 15 is welded by mounting frame base plate 19, mounting frame reinforcement plate 20, motor mounting base plate 22, motor mounting backing plate 23, and reinforcing support plate 24 Specifically, the mounting frame substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com