Patents

Literature

52results about How to "High welding consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

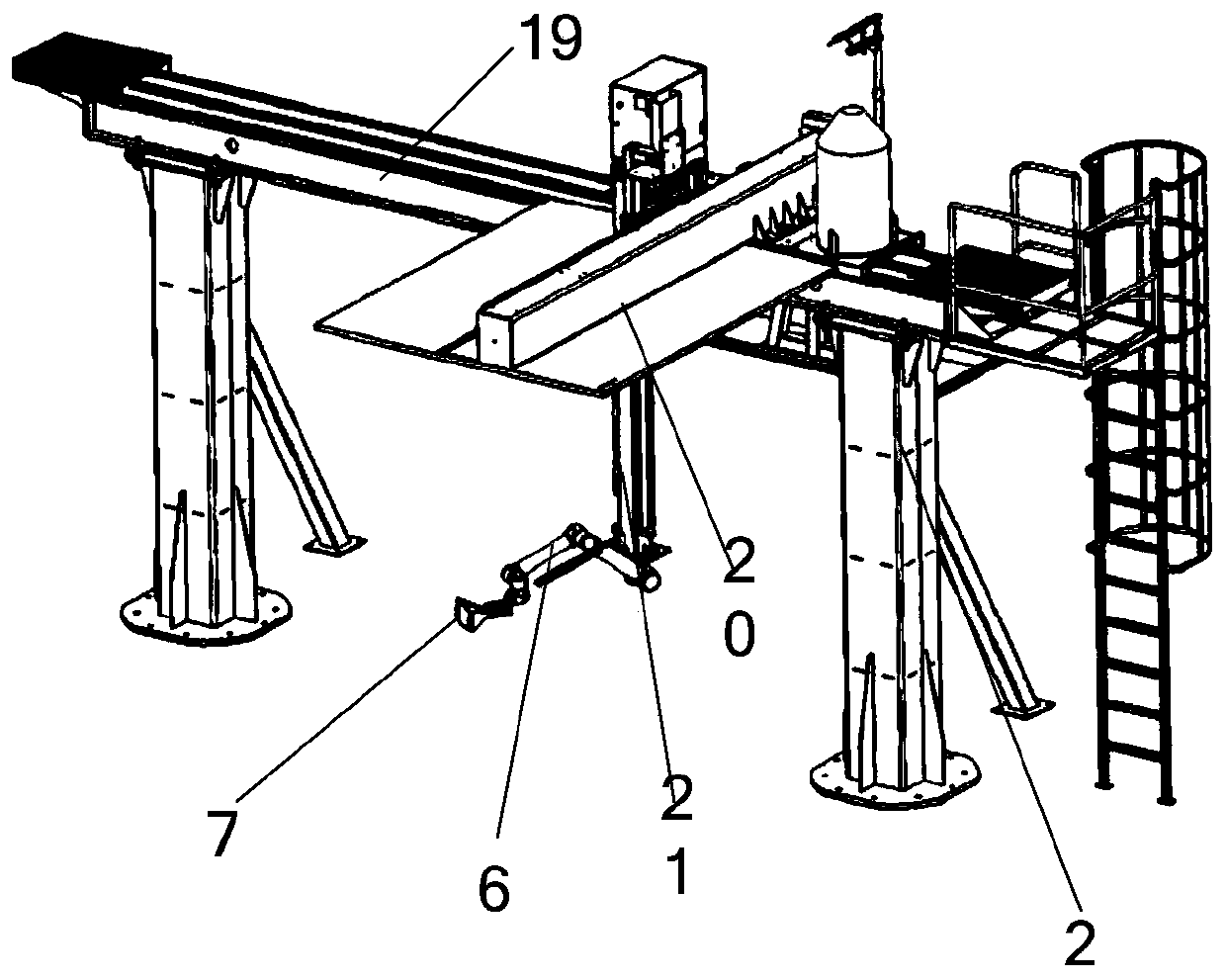

Flexible welding robot system and welding method thereof

ActiveCN110524581AAvoid harmAchieve high flexibilityProgramme-controlled manipulatorTotal factory controlImaging processingSimulation

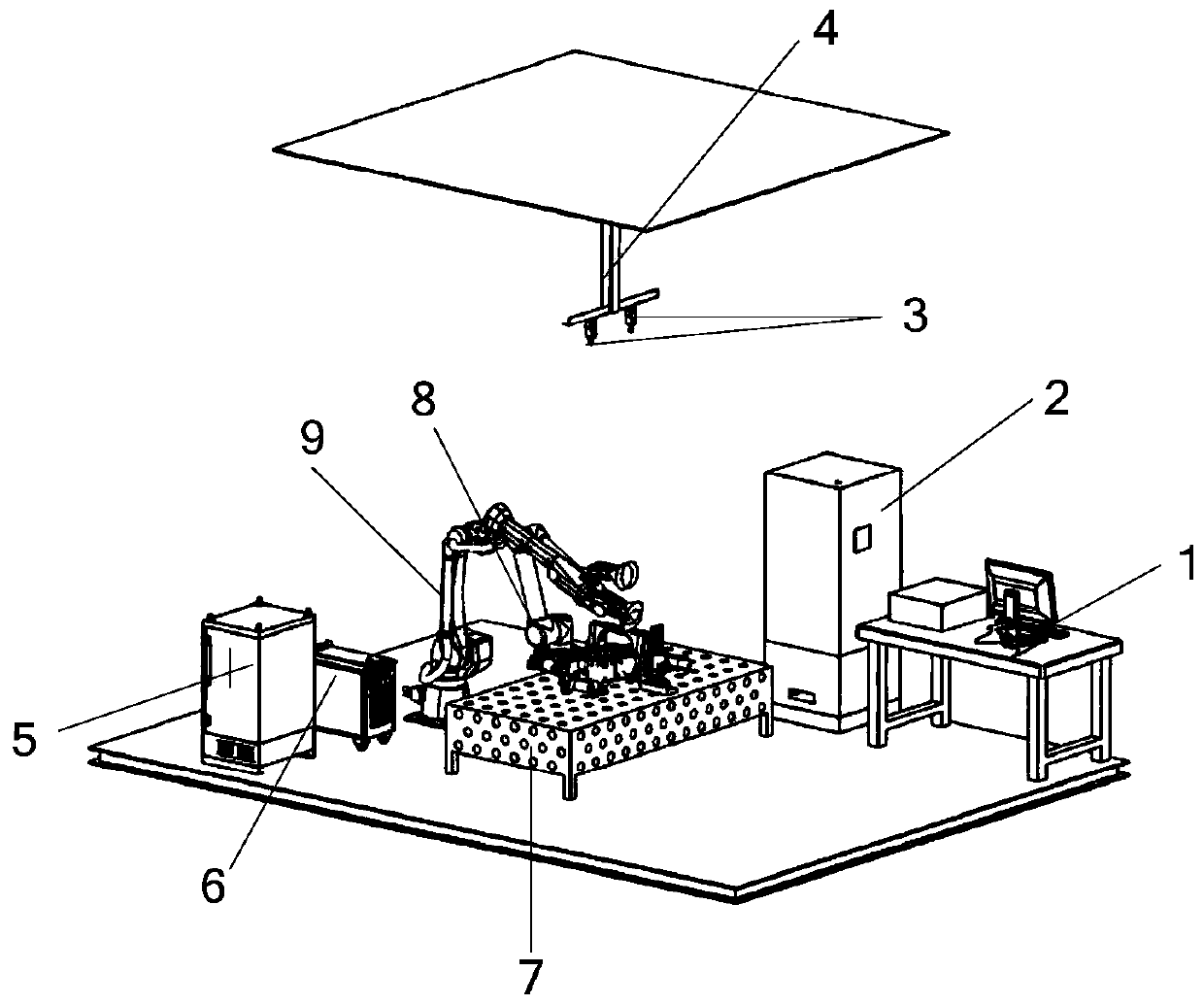

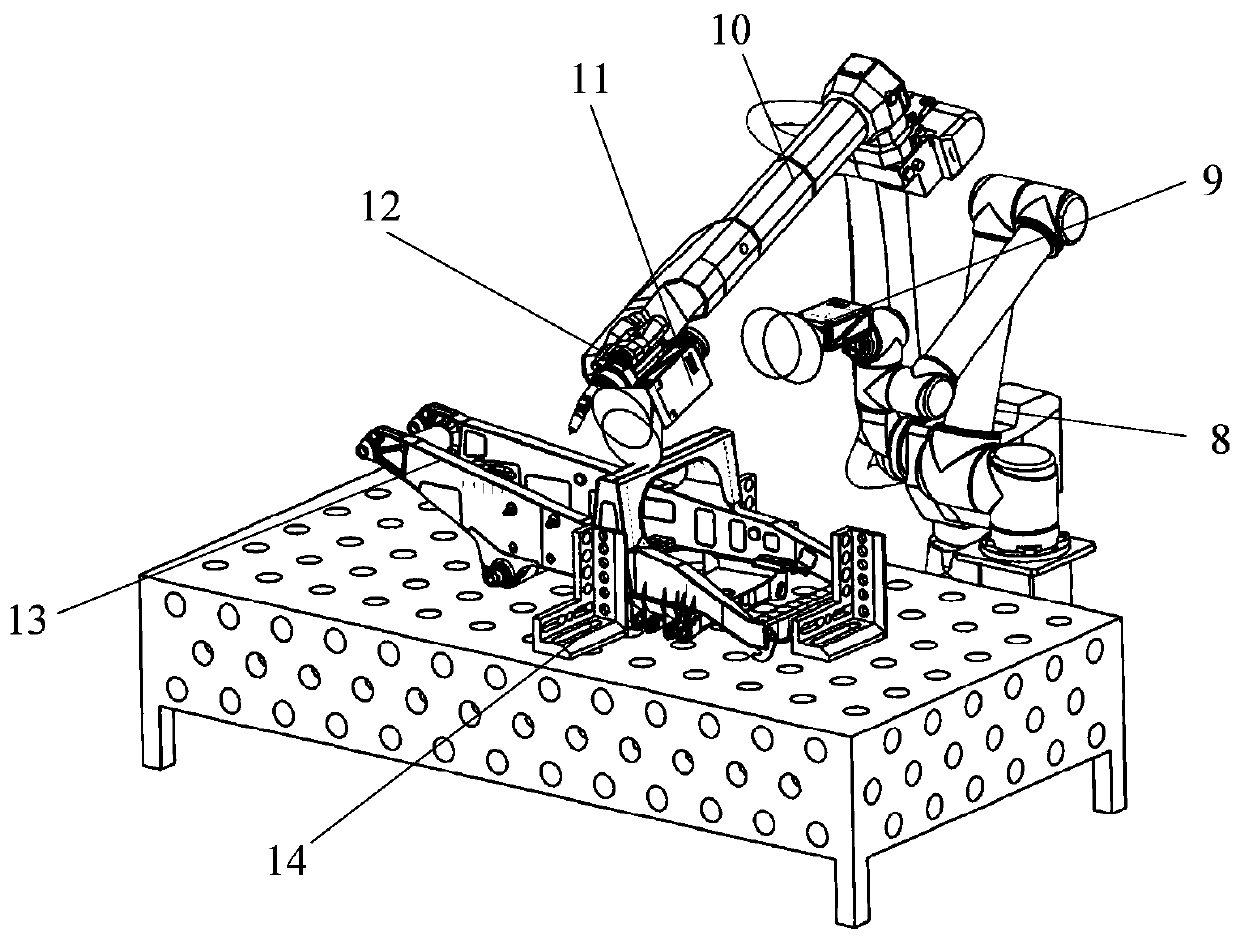

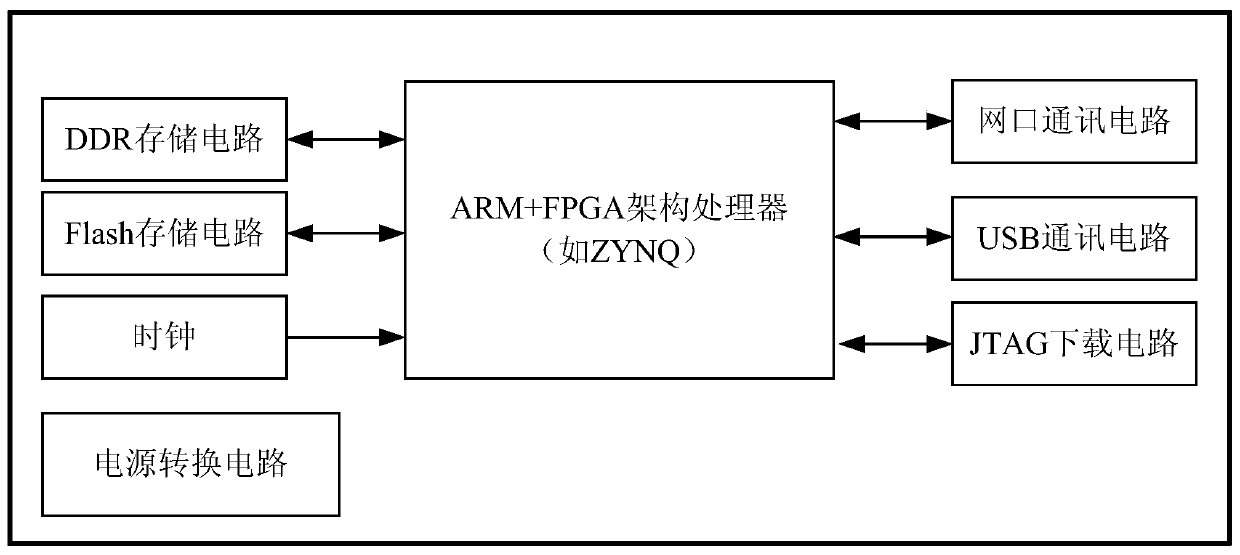

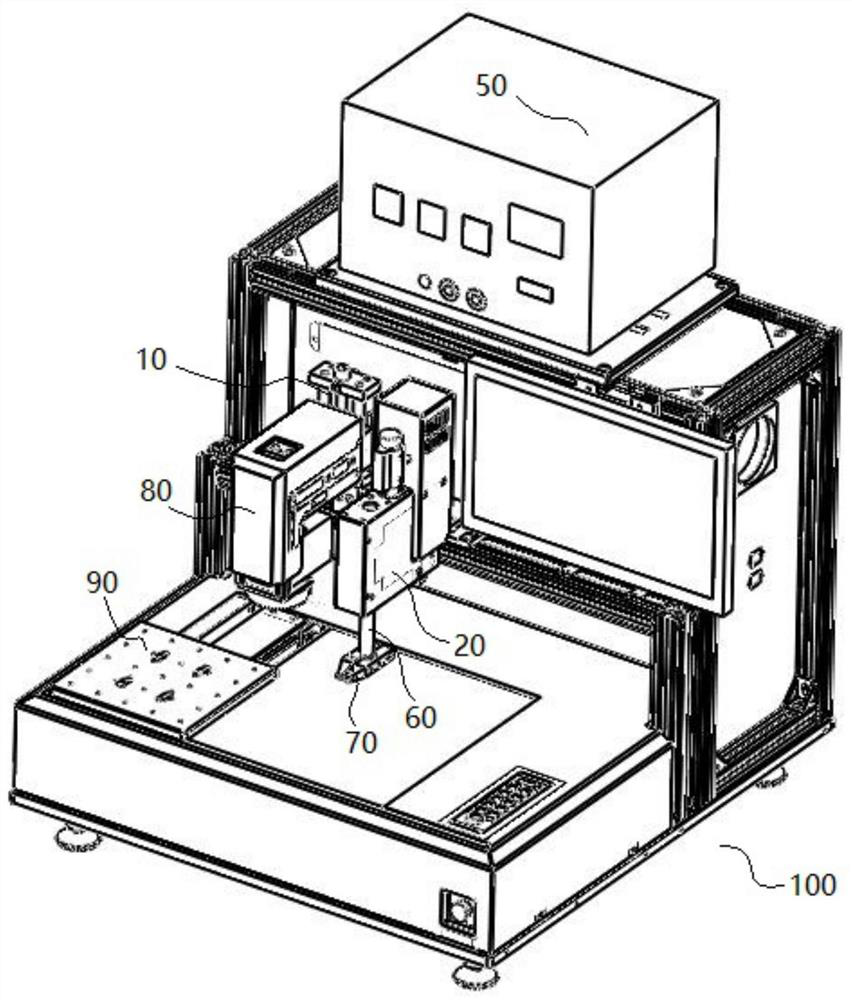

The invention discloses a flexible welding robot system and a welding method thereof. The welding method comprises the following steps: a global vision unit recognizes image information of a to-be-welded workpiece and locates the position of the to-be-welded workpiece; a flexible welding robot unit precisely recognizes the position of a to-be-welded workpiece through a precise positioning visual assembly, an image processing control machine solves a welding path, and the flexible welding robot conducts welding operation. A flexible detection robot unit recognizes the geometric dimension and quality of the appearance of a welded workpiece through a stereoscopic vision detection assembly, generates a welding quality report according to parameter information set by a user, and transmits a position with the welding deviation exceeding a threshold value and deviation value information to the flexible welding robot for repair welding. A master control unit executes image processing, data communication and motion control of the welding robot and the detection robot; and a workbench unit is used for quickly clamping different types of welding workpieces. The harm of welding operation to the body of a worker is avoided, and high flexibility and intelligence of the flexible welding robot system are achieved.

Owner:XIAN ZHONGKE PHOTOELECTRIC PRECISION ENG CO LTD

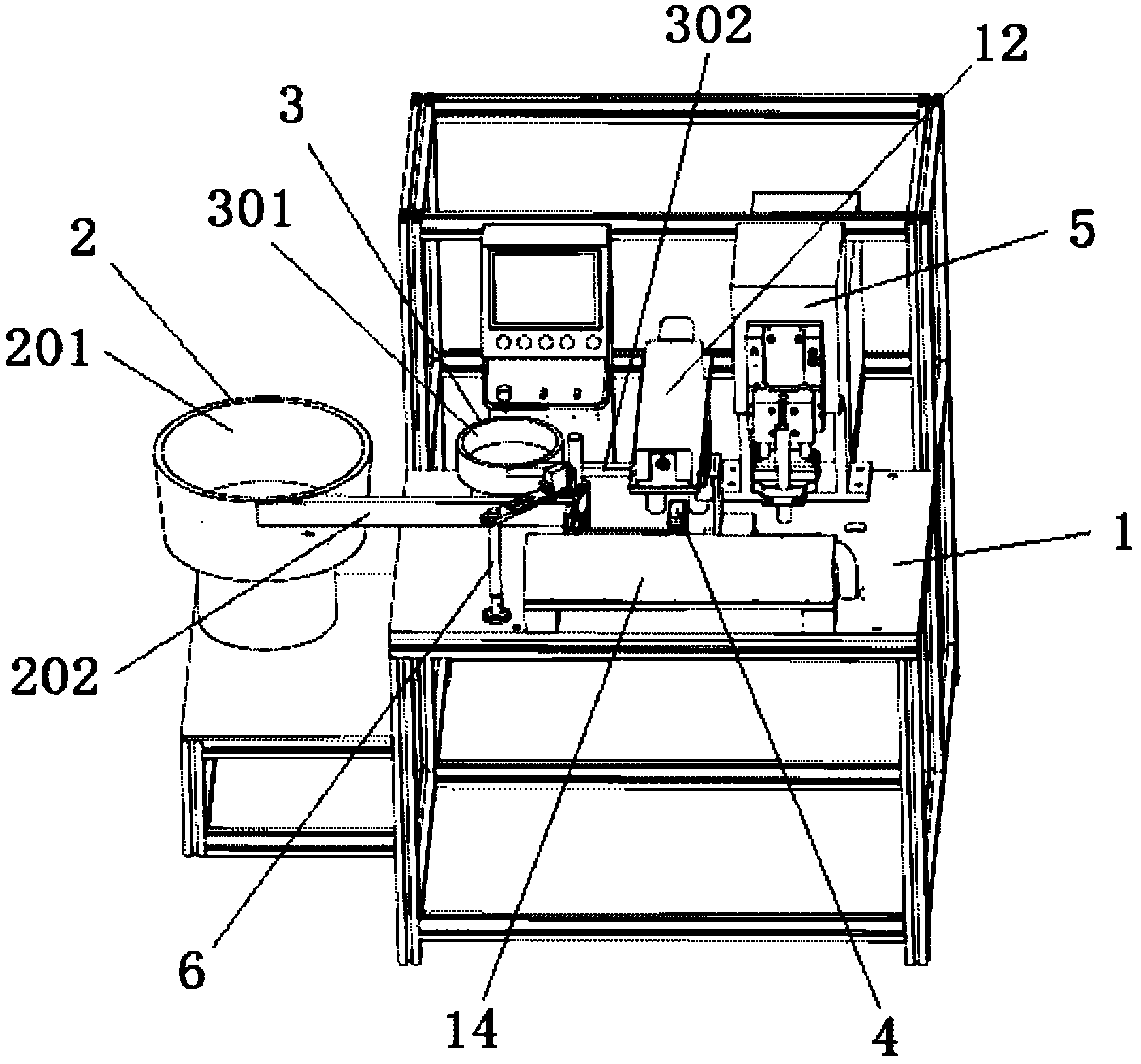

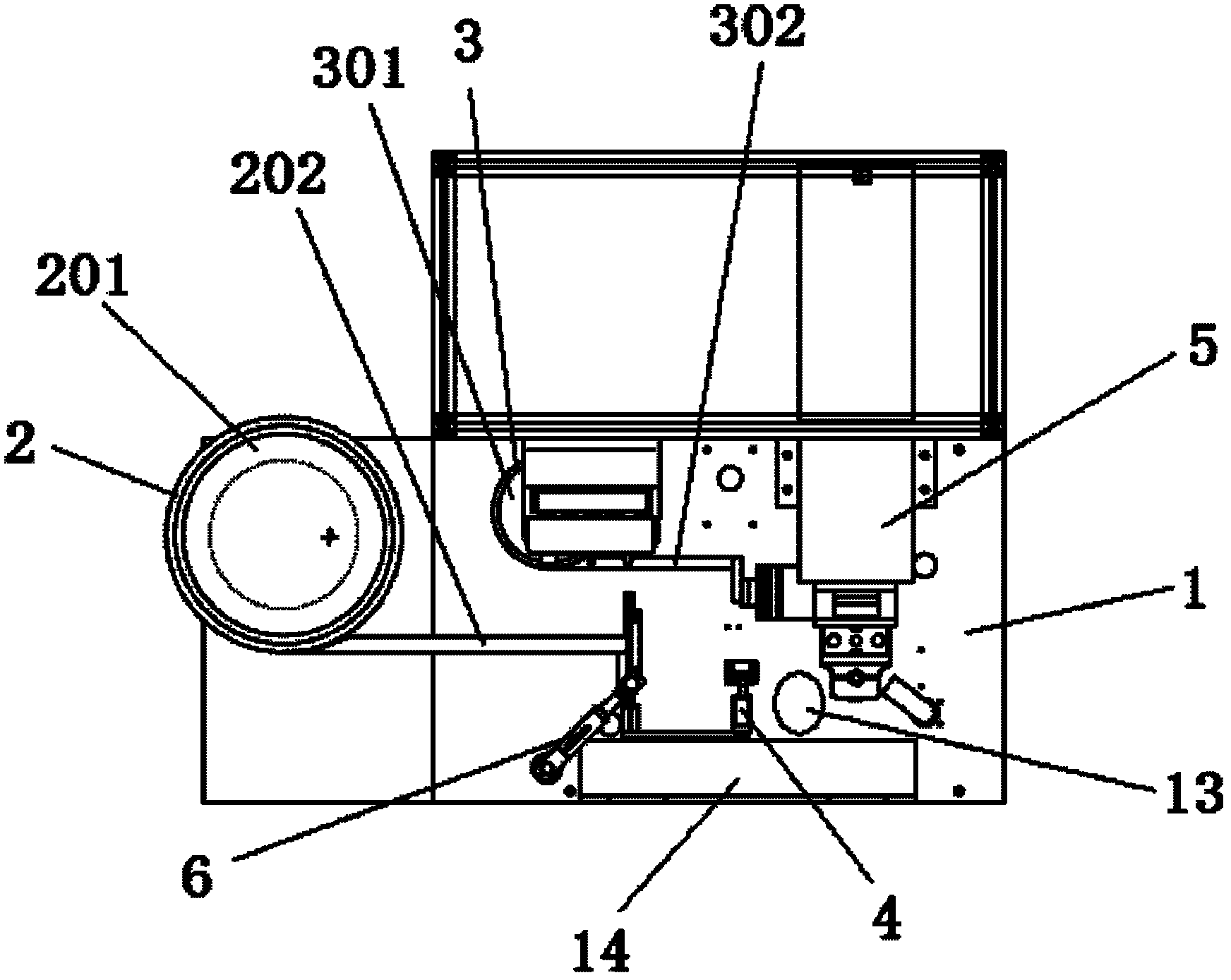

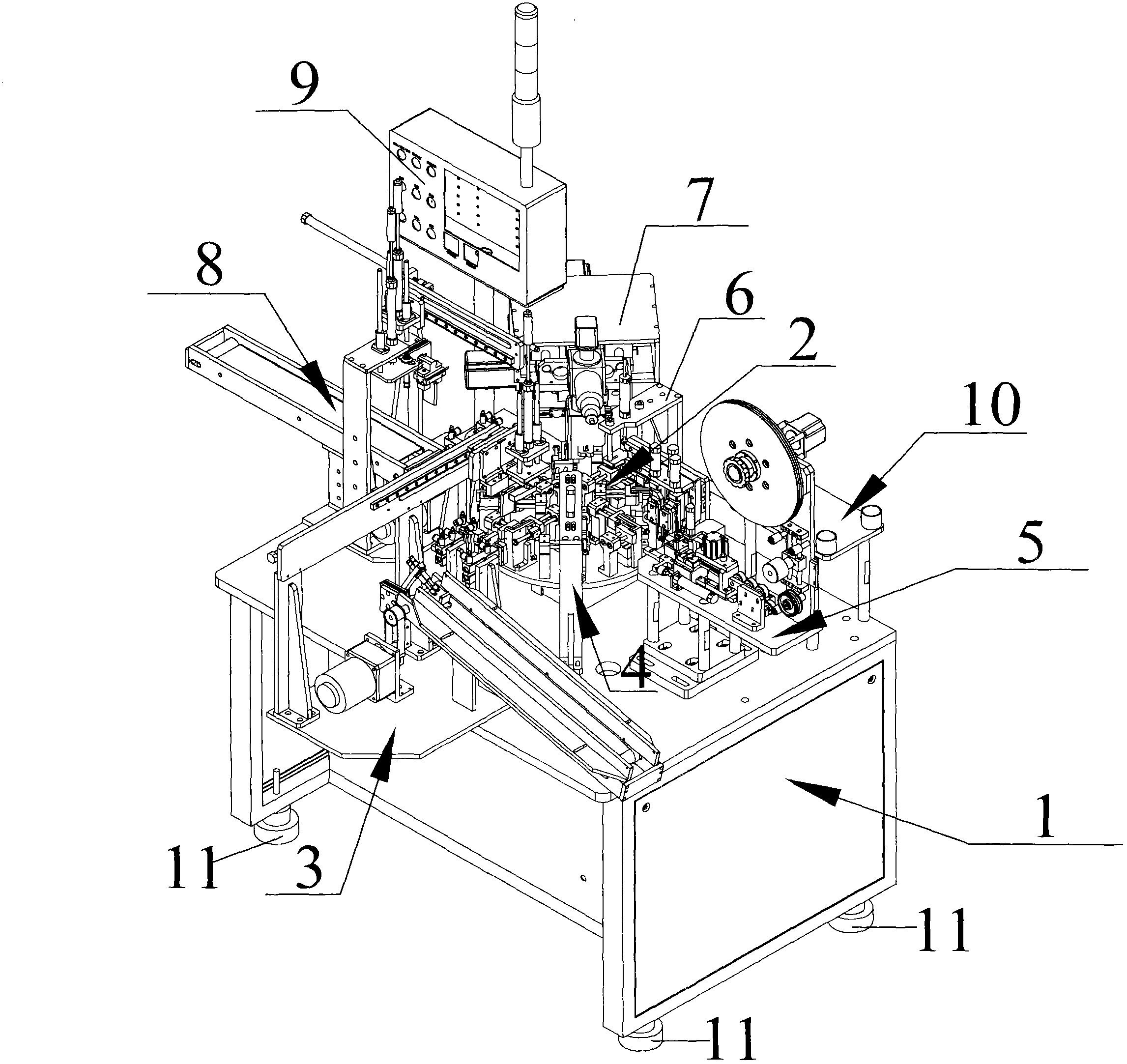

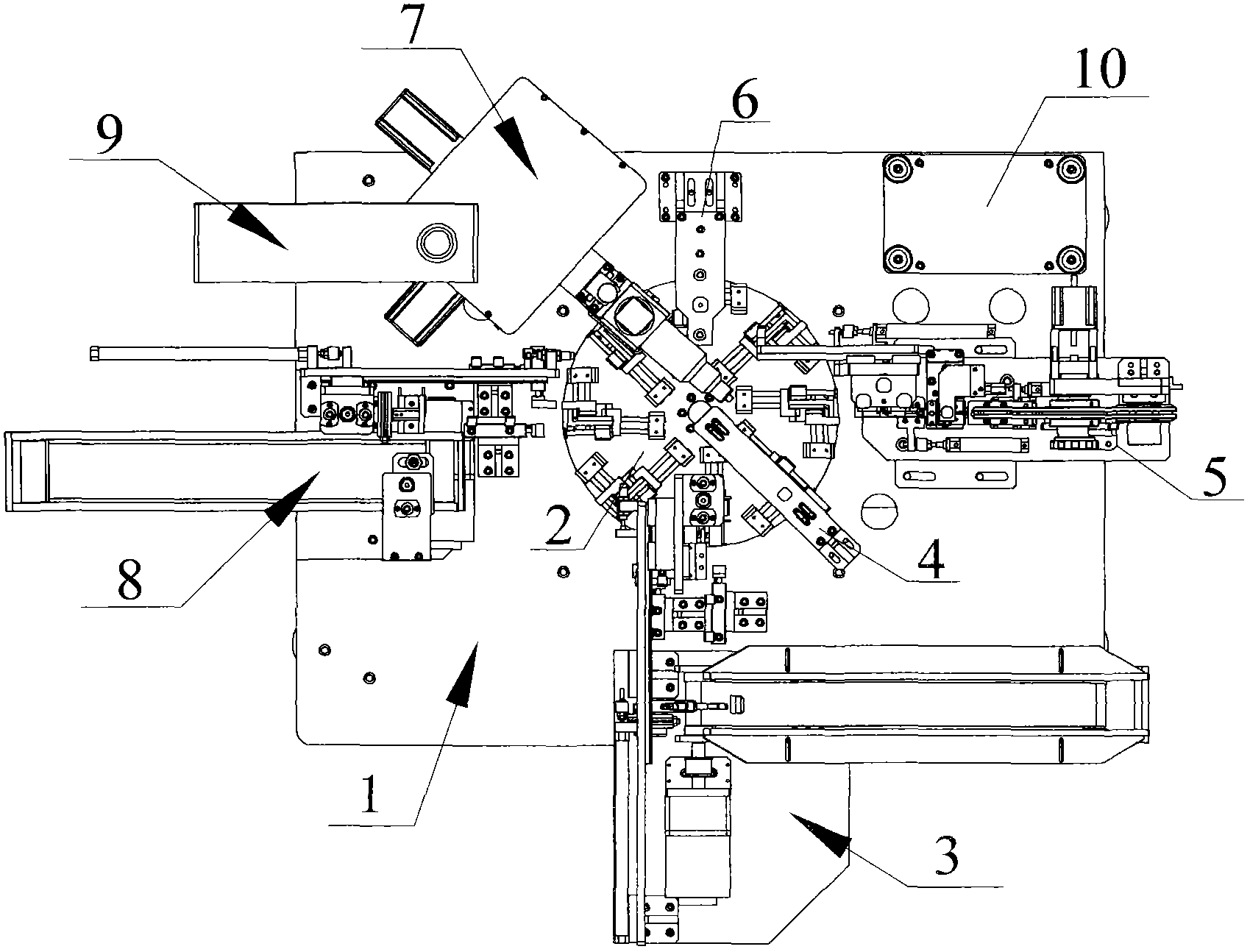

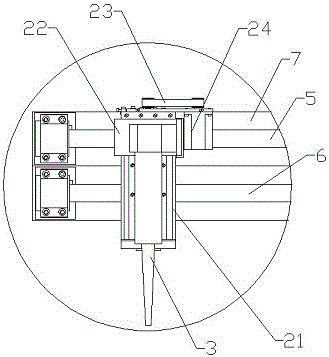

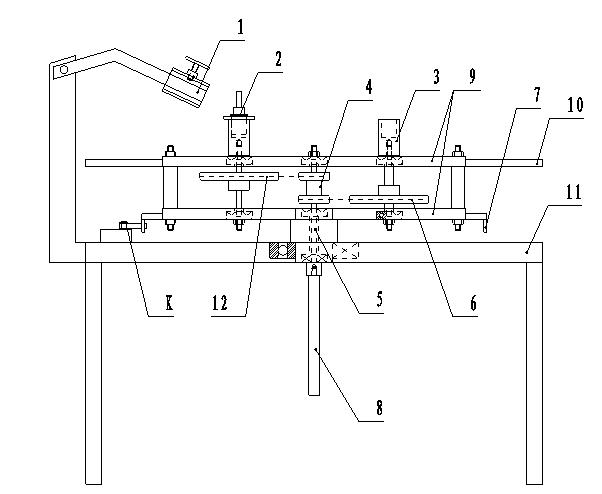

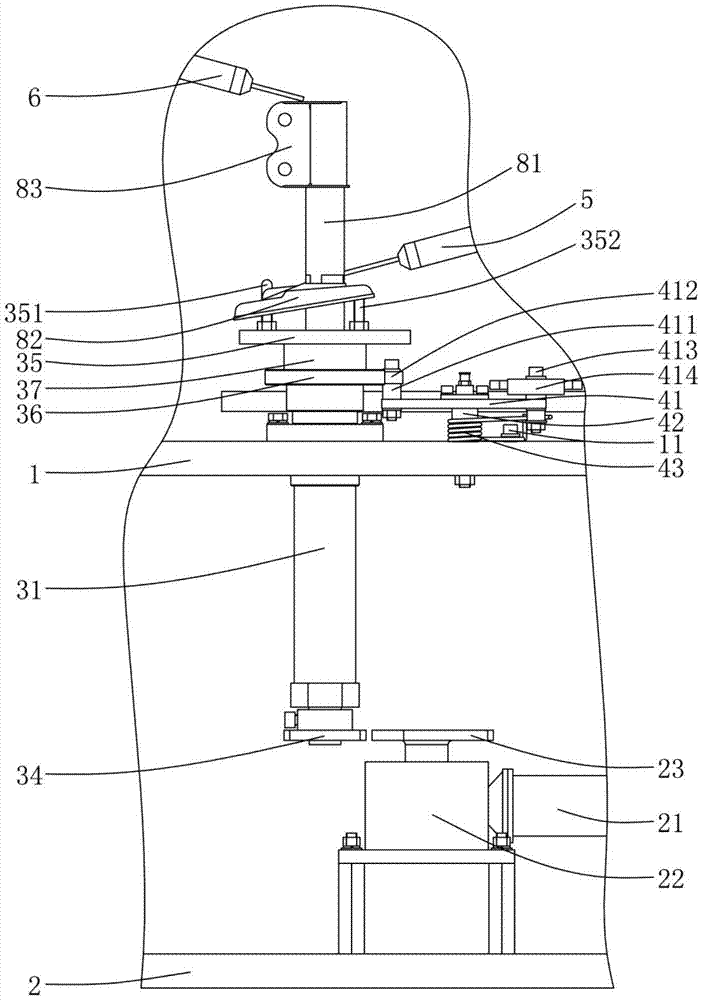

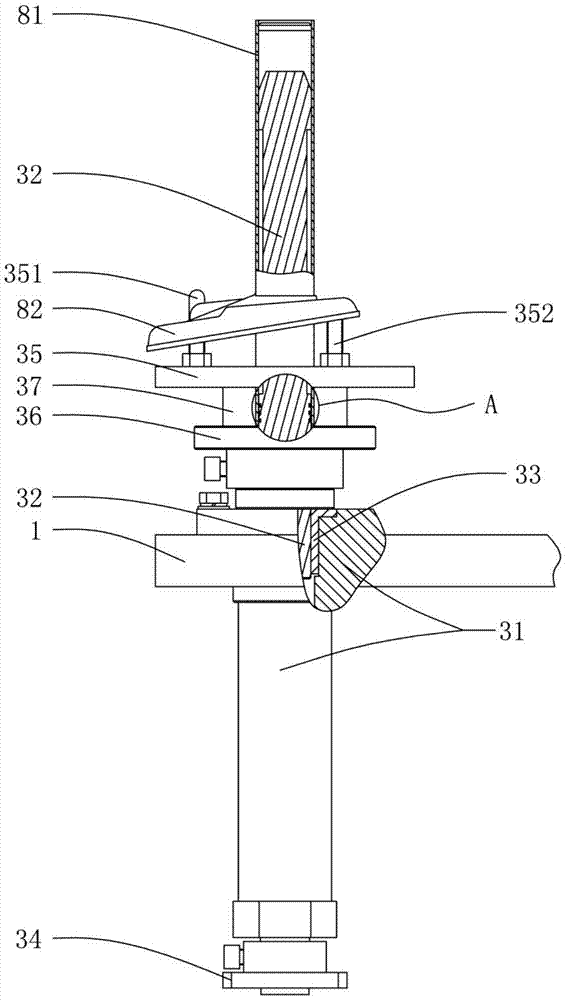

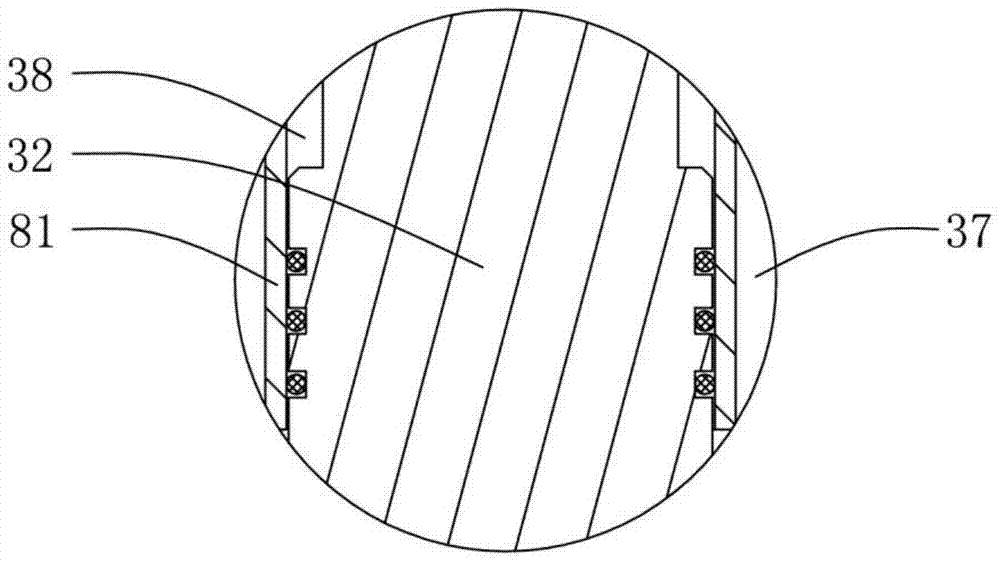

Static contact and silver point automatic welding device

ActiveCN102284813AHigh degree of automationNo manual operationWelding/cutting auxillary devicesAuxillary welding devicesSilverspotsSpot welding

The invention discloses a full-automatic welding device for a fixed contact and a silver point. The full-automatic welding device comprises a workbench and is characterized in that a fixed contact vibrating disc feeding device, a silver point vibrating disc feeding device, a transfer assembly table and an automatic spot-welding device are arranged on the workbench, wherein a fixed contact transfer device is arranged between the fixed contact vibrating disc feeding device and the transfer assembly table, an automatic spot-welding device is further arranged on an advancing route of the fixed contact transfer device, a sliver point transfer device is arranged between the silver point vibrating disc feeding device and the transfer assembly table and a fixed contact and silver point clamping and transferring device is arranged between the transfer assembly table and the automatic spot-welding device. The full-automatic welding device is high in degree of automation and can improve the production efficiency and the welding quality.

Owner:FORETECH ELEC APP JIANGSU CORP

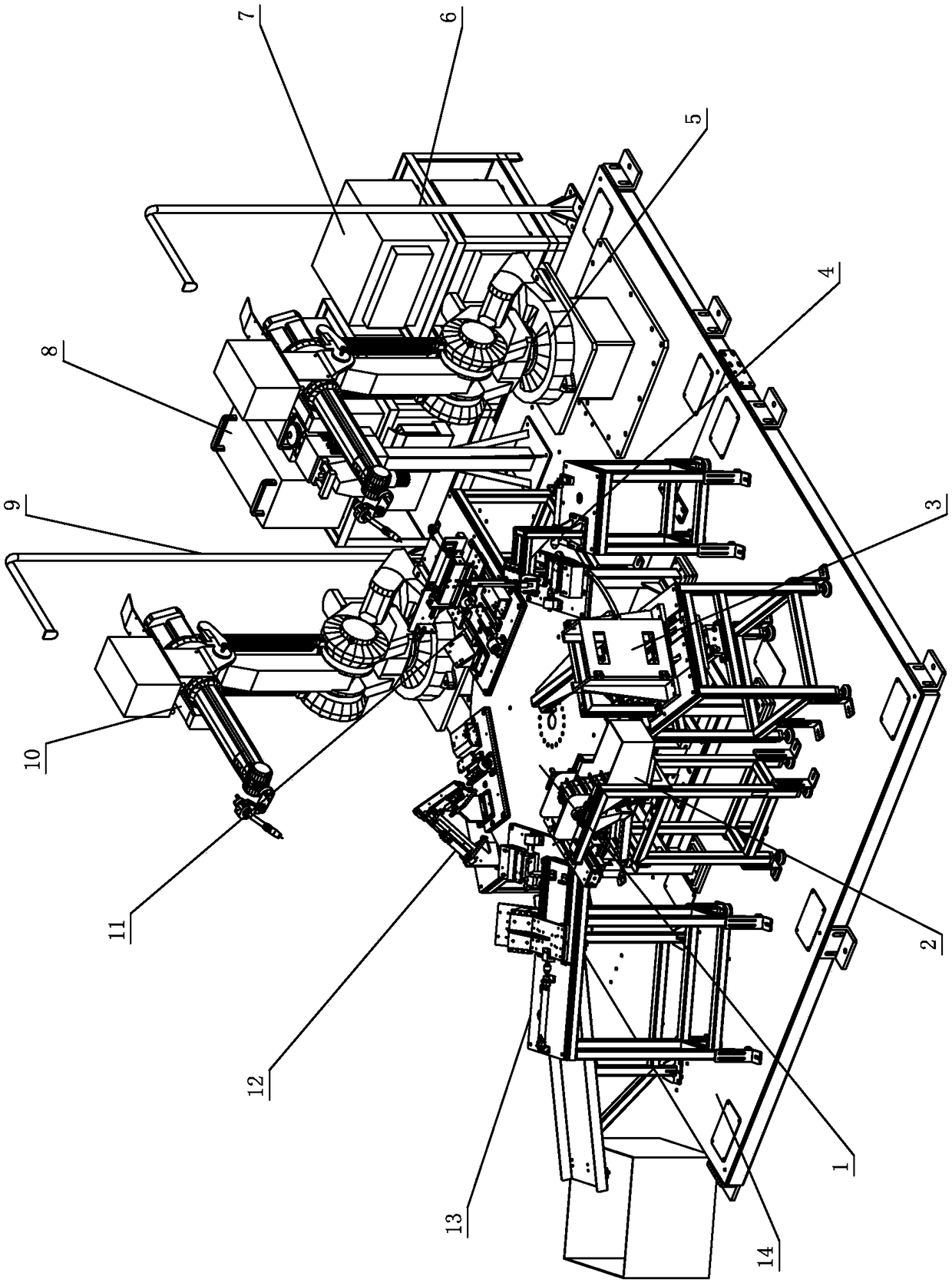

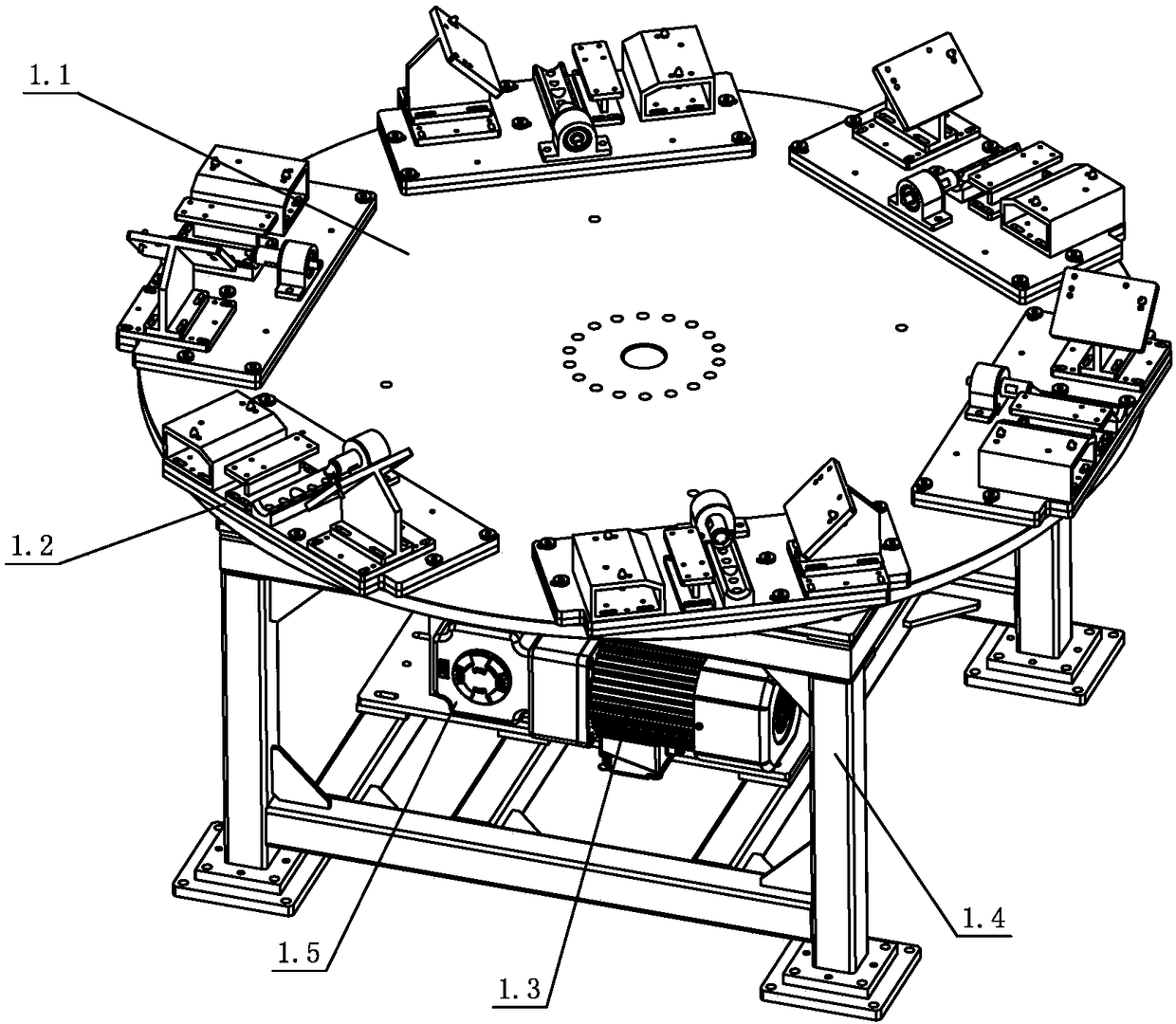

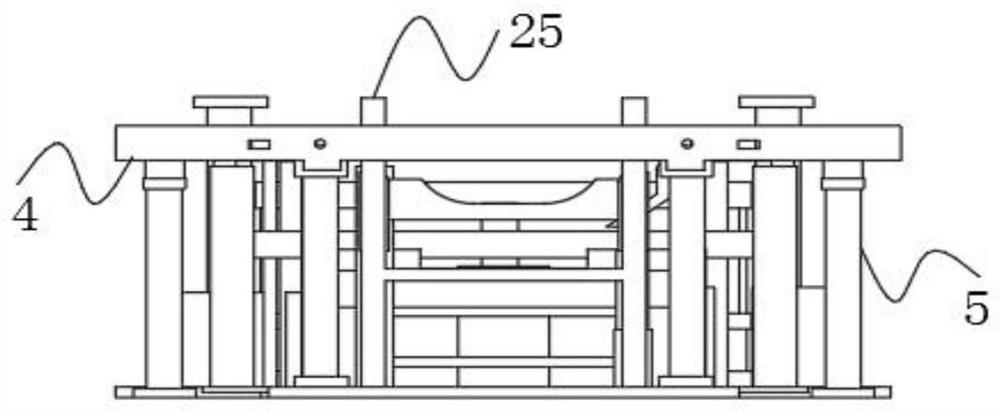

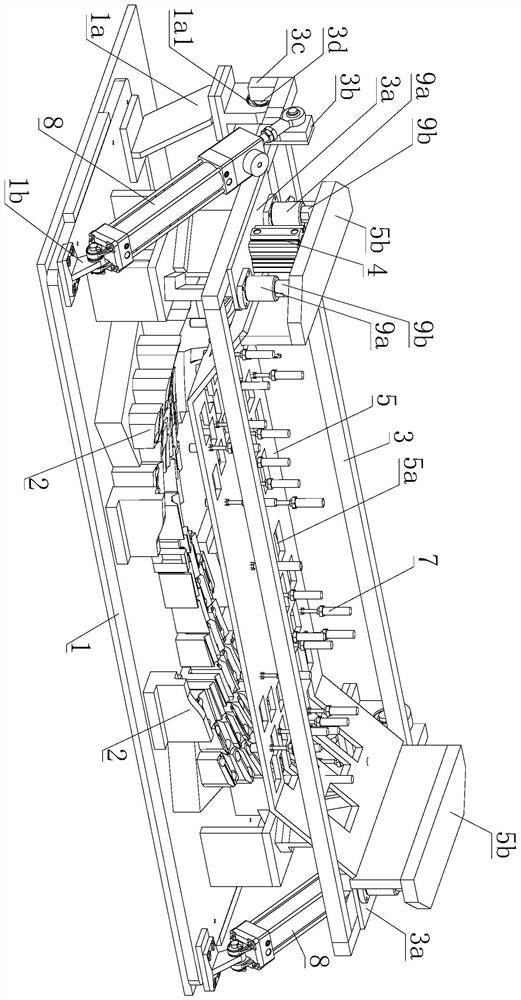

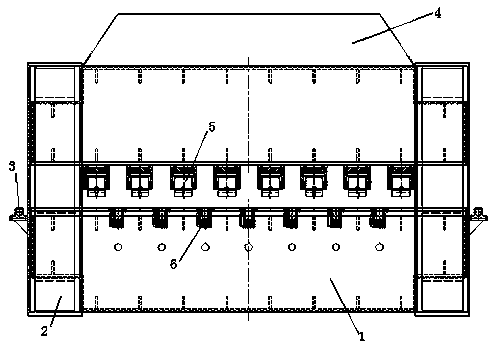

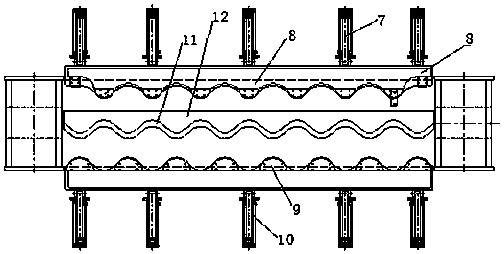

Automatic welding working station for automobile container hinge plate

PendingCN109108512AGuarantee welding qualityHigh welding consistencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPower component

An automatic welding working station for an automobile container hinge plate comprises a welding robot, a rotating disc feeding mechanism, a tube material loading mechanism and a hinge blank plate loading mechanism; the rotating disc feeding mechanism comprises a rotating disc and a welding positioning fixture; the welding positioning fixture rotates with the rotating disc step by step to a station corresponding to the tube material loading mechanism and / or the hinge blank plate loading mechanism; a tube material and a hinge blank plate which need to be welded are correspondingly placed on thewelding positioning fixture in a positioned manner; the tube material loading mechanism comprises a material discharging groove, a material loading guide groove and a material loading push block; tube materials roll to the material loading guide groove one by one; the material loading push block pushes the tube materials on the material loading guide groove to the welding positioning fixture; thehinge blank plate loading mechanism comprises a magnetic attracting plate and a transferring power component; the magnetic attracting plate attracts the hinge blank plate by using a magnetic attracting force; and the magnetic attracting plate moves the hinge blank plate to the welding positioning fixture. The automatic welding working station for the automobile container hinge plate has the characteristics of high automation degree, high welding efficiency, stable welding quality, good welding effect and low worker labor intensity.

Owner:GUANGDONG LXD ROBOTICS CO LTD

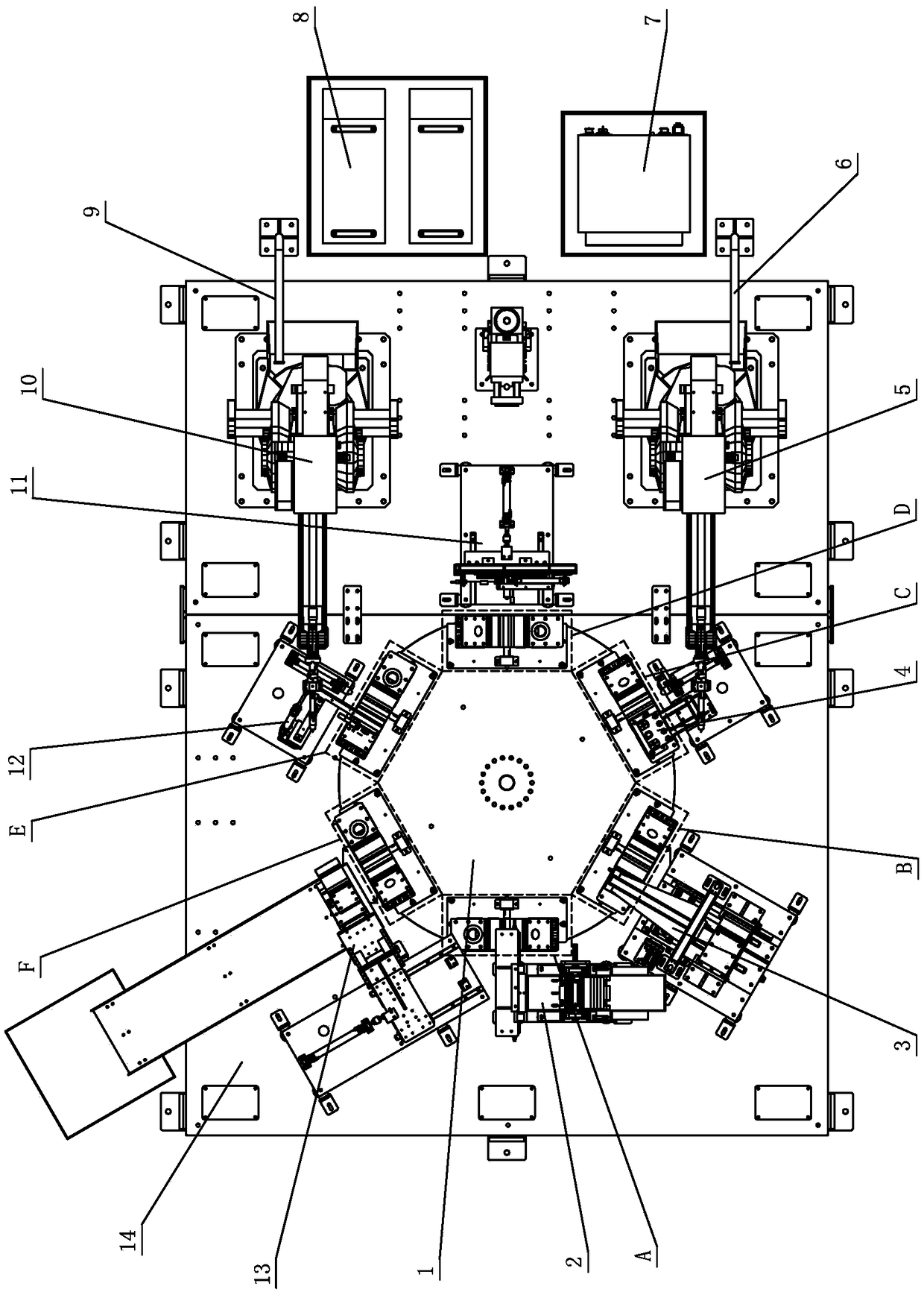

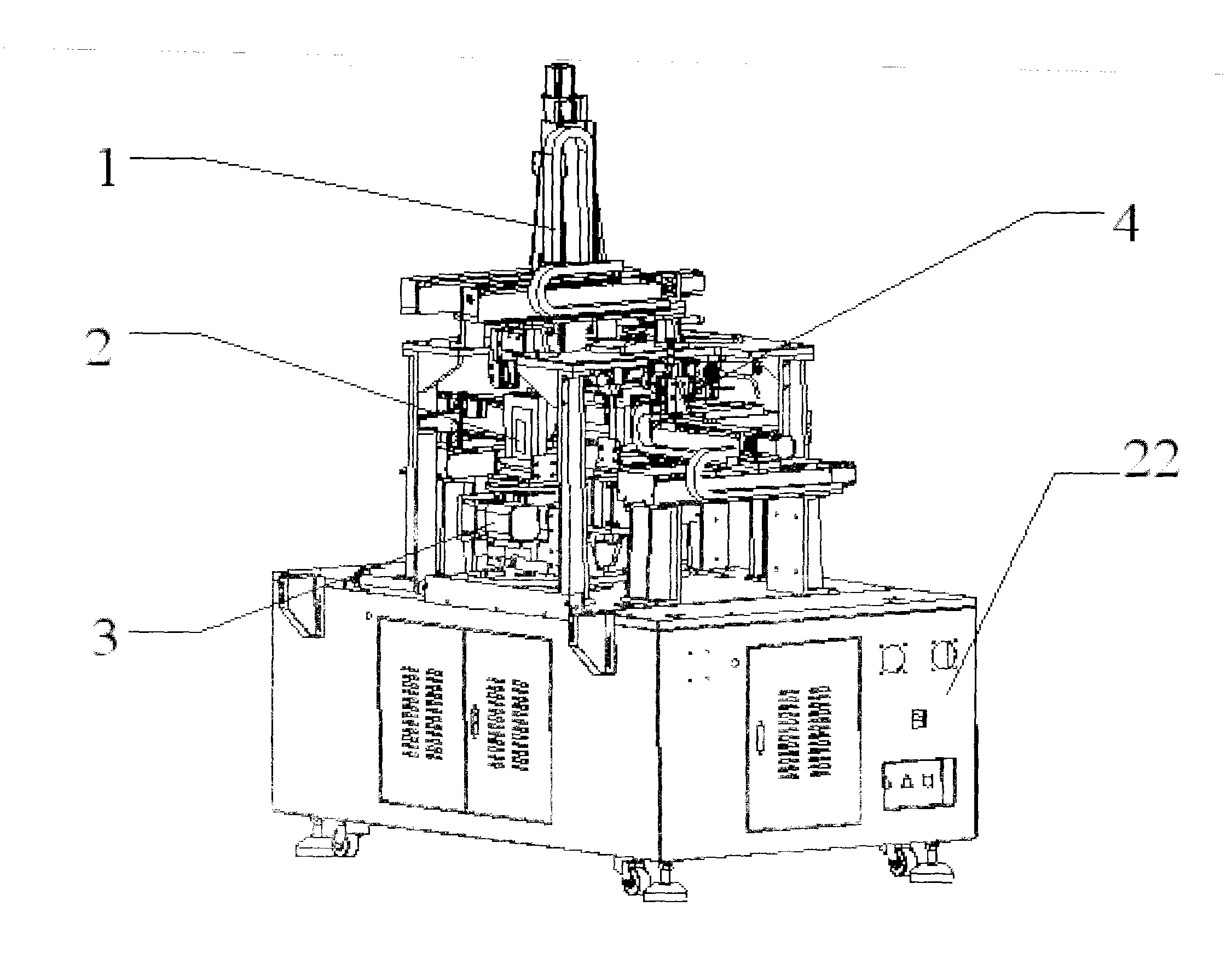

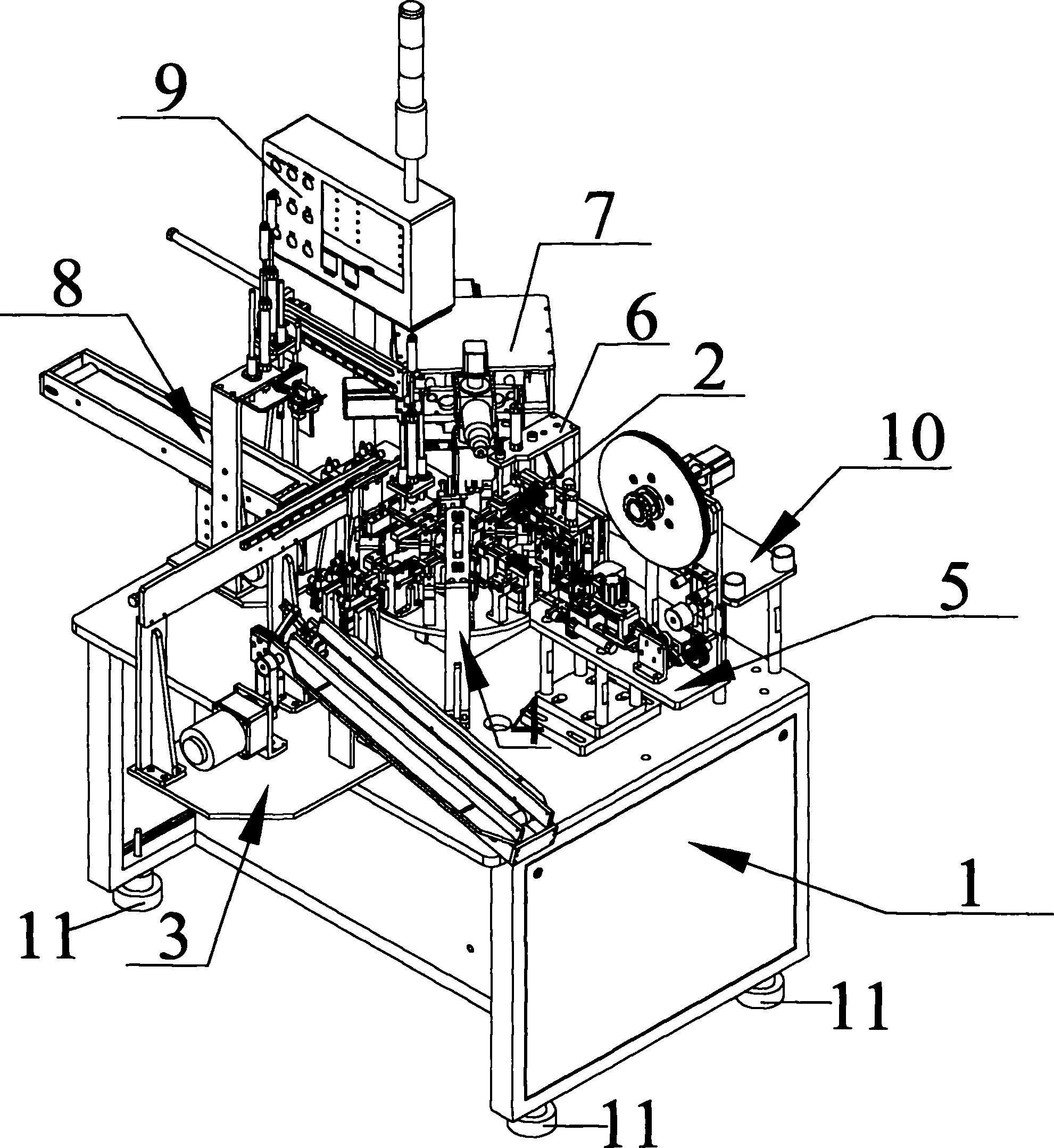

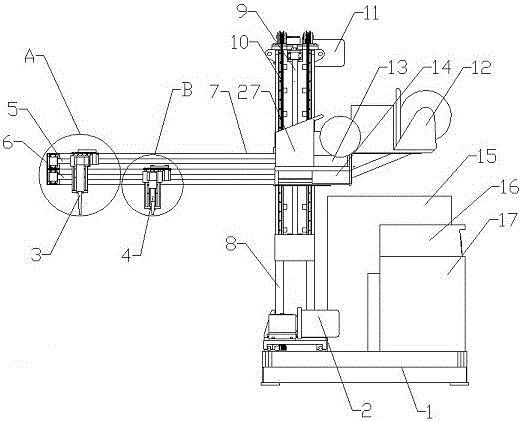

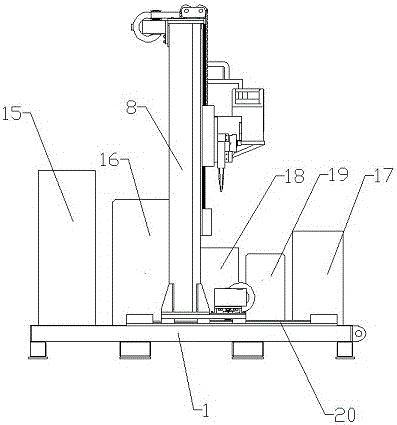

Full-automatic laser welding machine

ActiveCN102528285AWide range of applicationsBright futureLaser beam welding apparatusEngineeringManipulator

The invention belongs to the technical field of welding machines, and in particular relates to a full-automatic laser welding machine for a square workpiece. The laser welding machine comprises a support table, a clamp turntable arranged on the support table, a loading and unloading manipulator for transferring the workpiece to the clamp turntable and a positioning and welding unit for positioning and welding the workpiece on the clamp turntable, wherein both the loading and unloading manipulator and the positioning and welding unit are arranged on the support table. Compared with the prior art, the laser welding machine has the advantages that: the loading and unloading manipulator can automatically finish loading and unloading of the workpiece; the turntable clamp can ensure that the positioning and welding unit keeps the material in an abundant state all the time, so that the efficiency is improved; the workpiece is jointed with an upper pressing block under the action of a jacking cylinder through a correcting block in the positioning and welding unit and then welded, so that the assembly precision can be ensured, and the high welding quality is ensured; due to double laser heads, the welding efficiency can be ensured, and the high welding quality, the welding efficiency and the welding consistency are improved; and therefore, the laser welding machine has quite broad application range and prospect.

Owner:NINGDE AMPEREX TECH +1

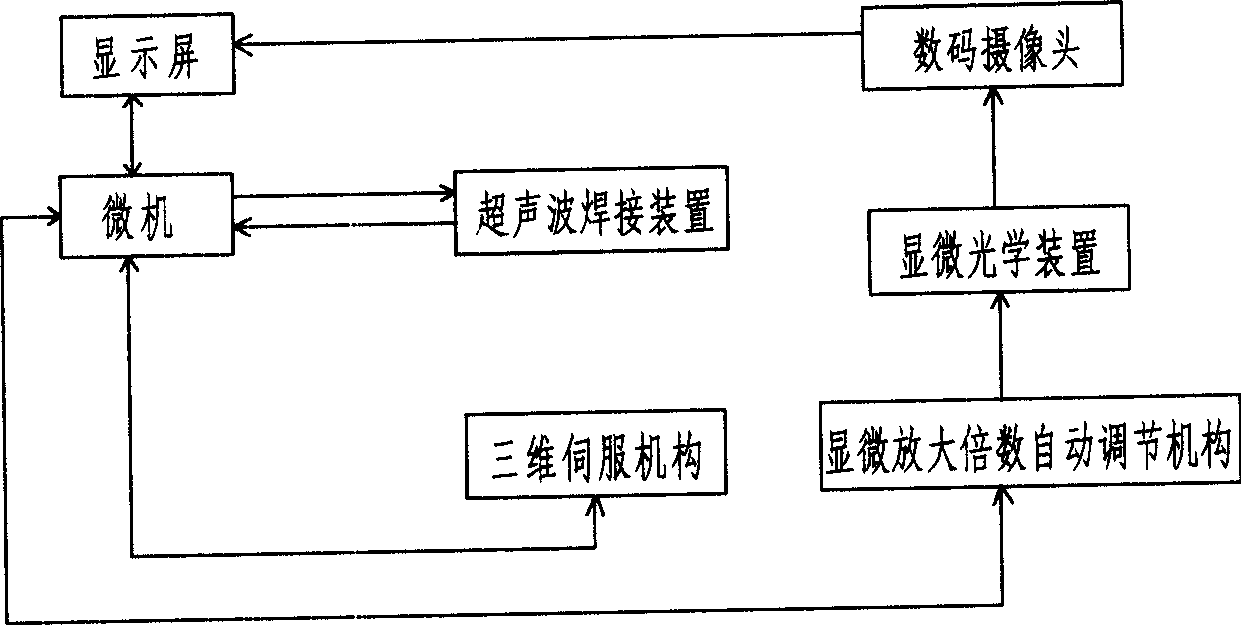

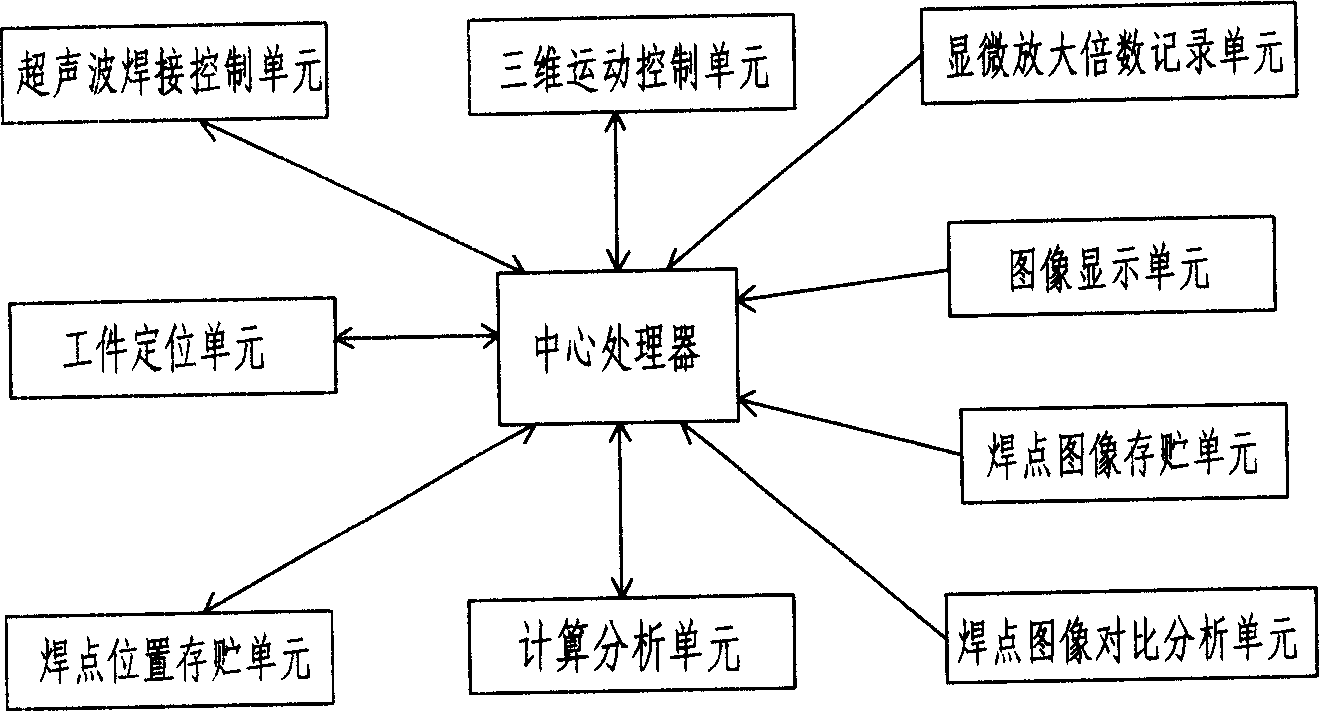

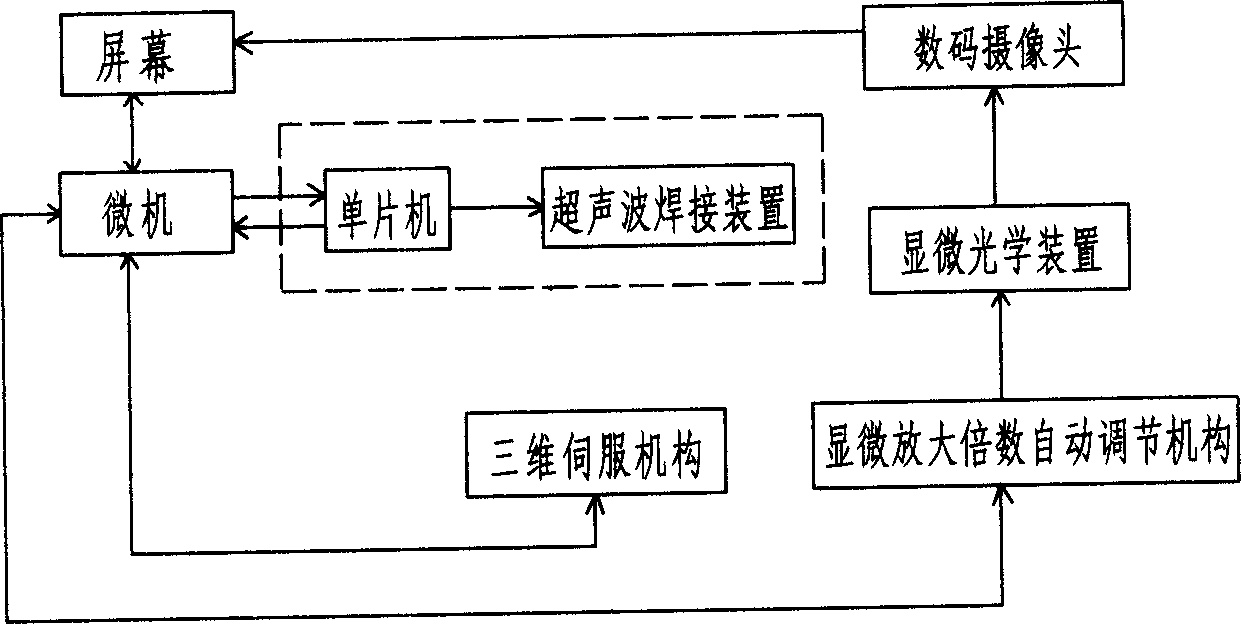

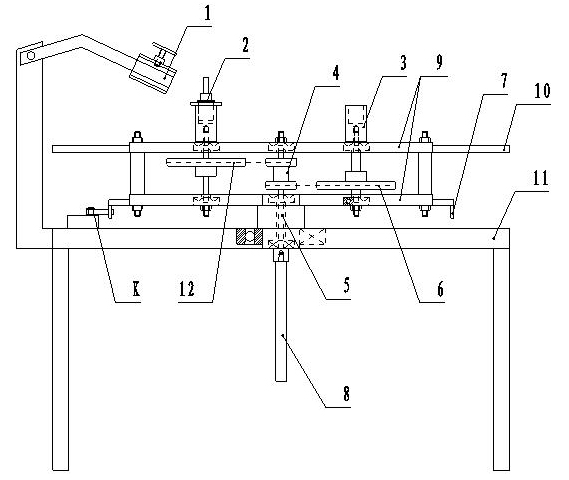

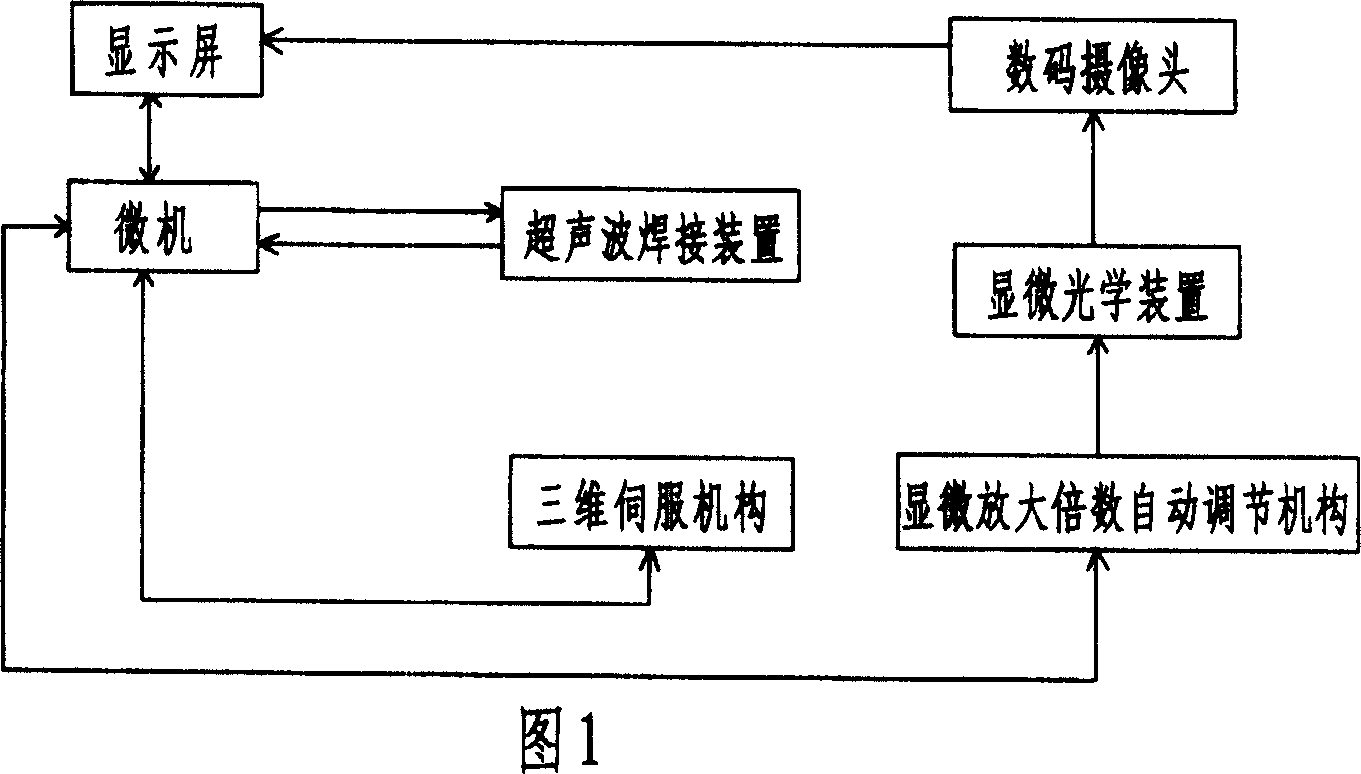

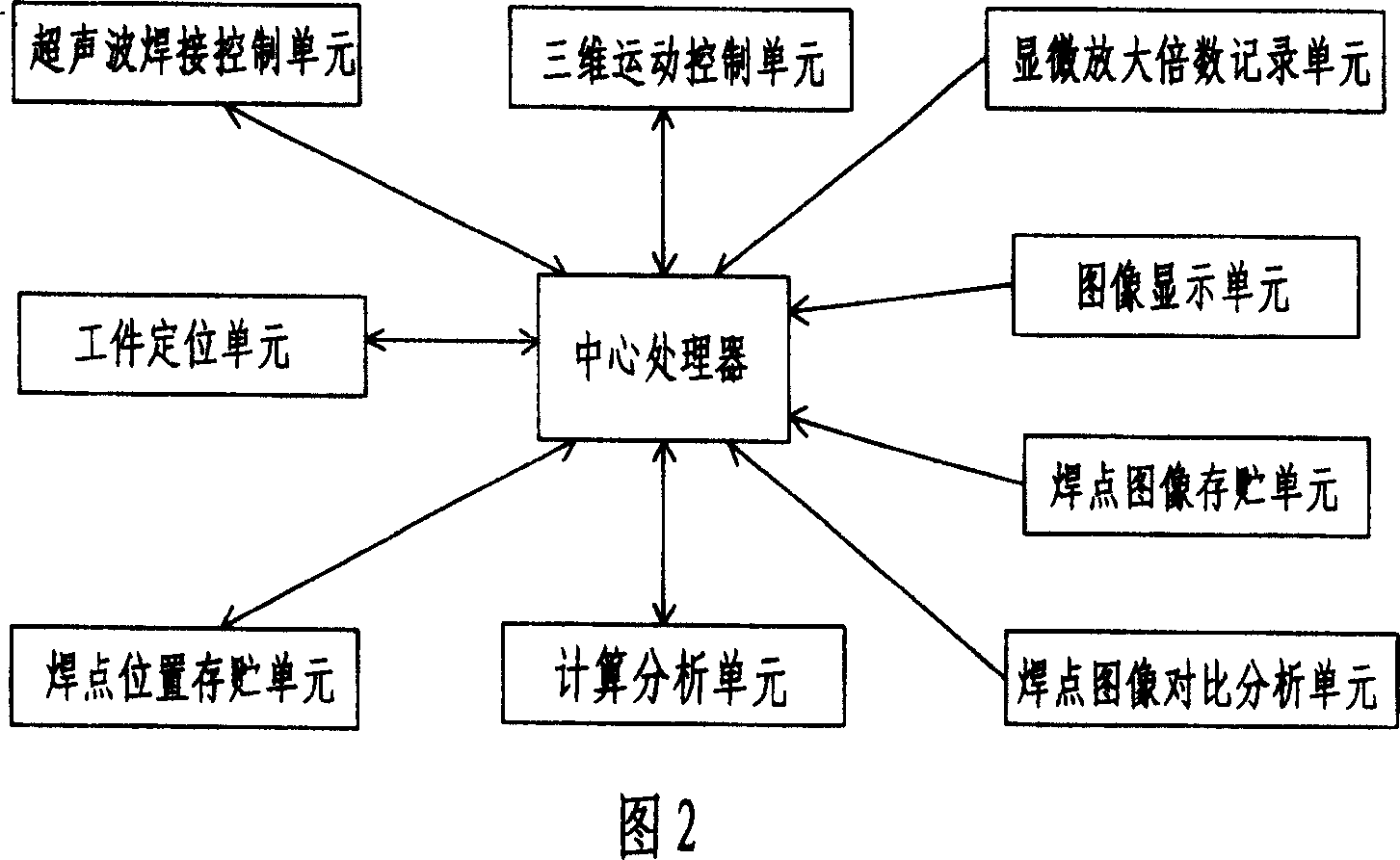

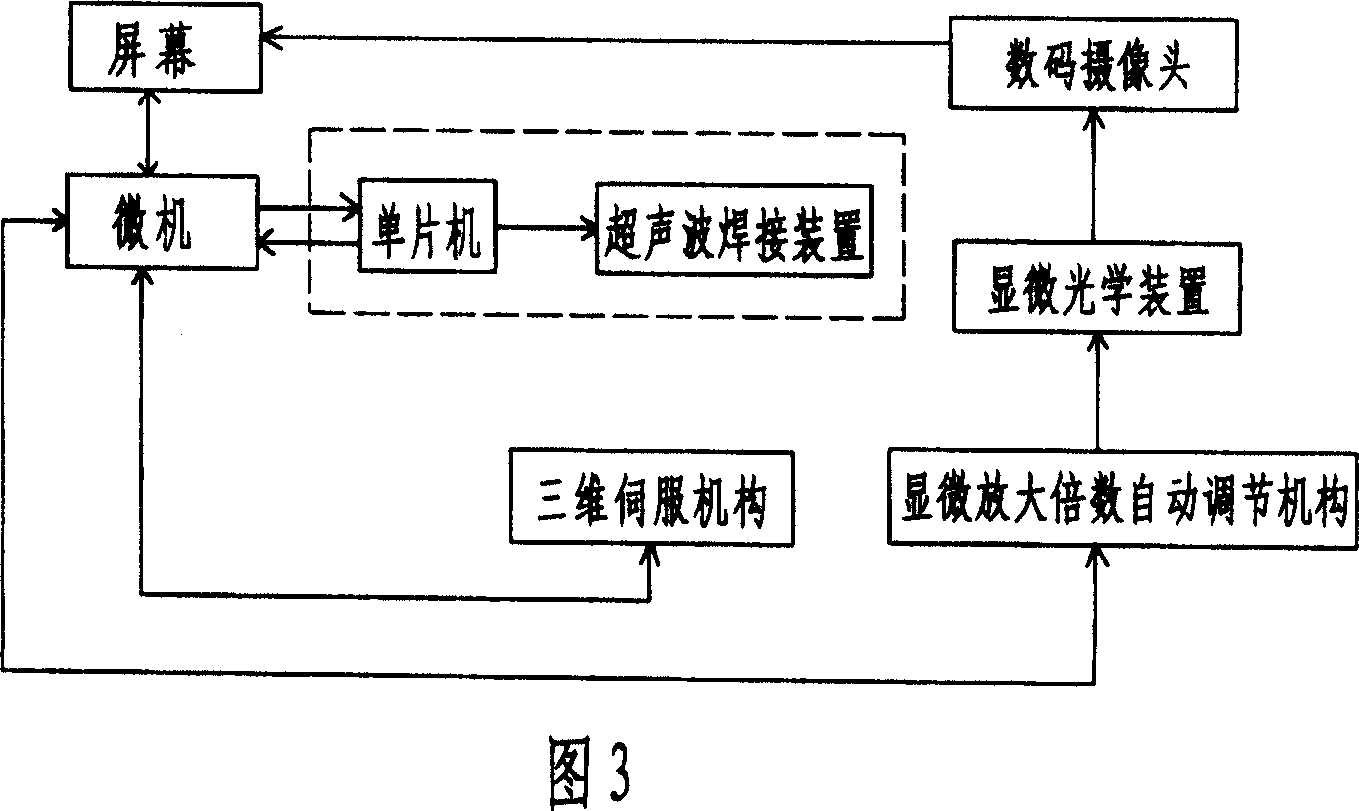

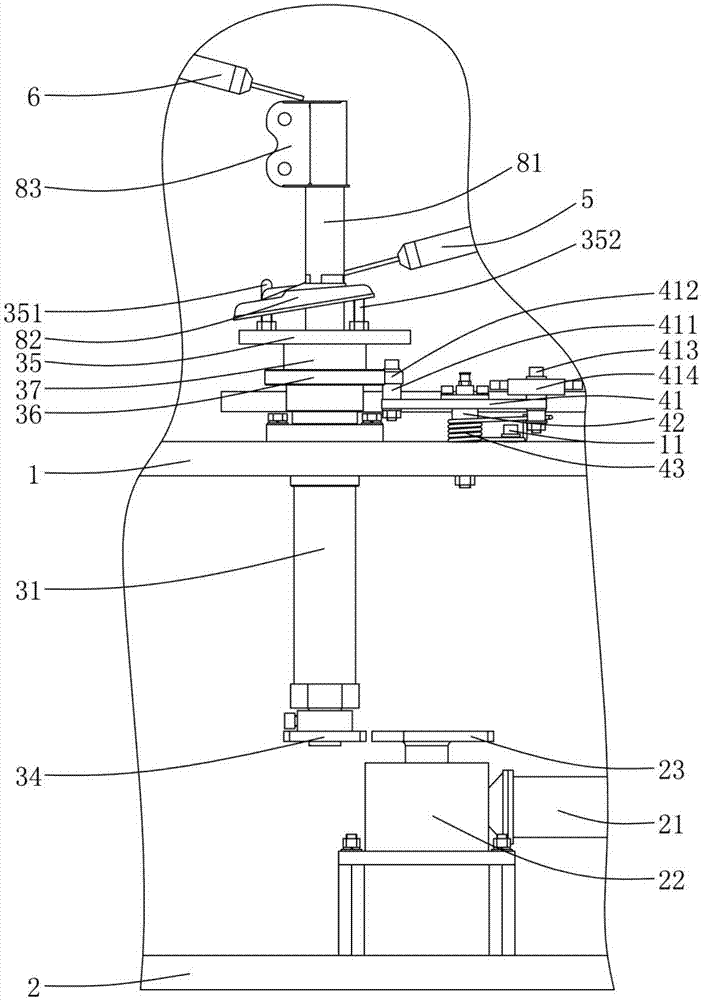

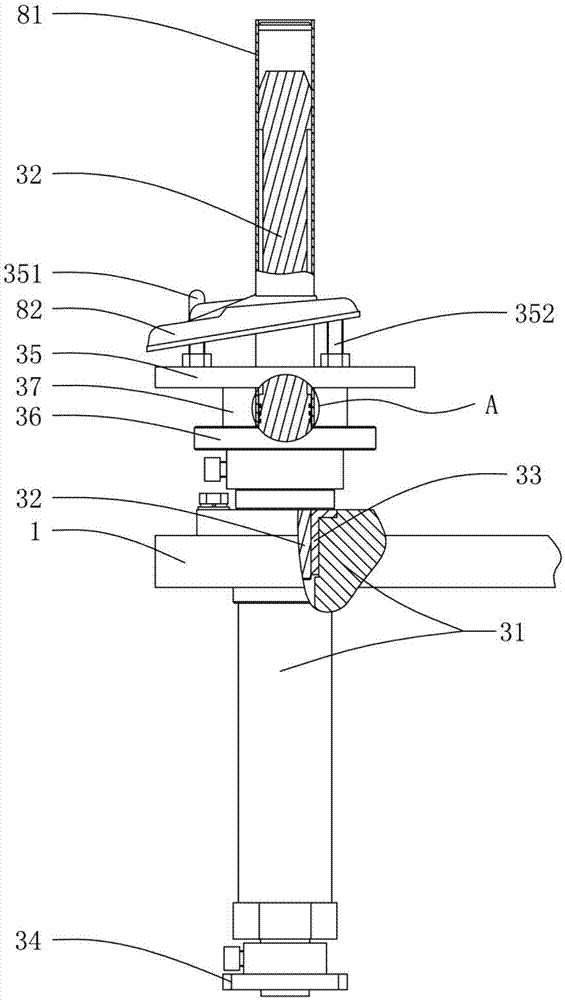

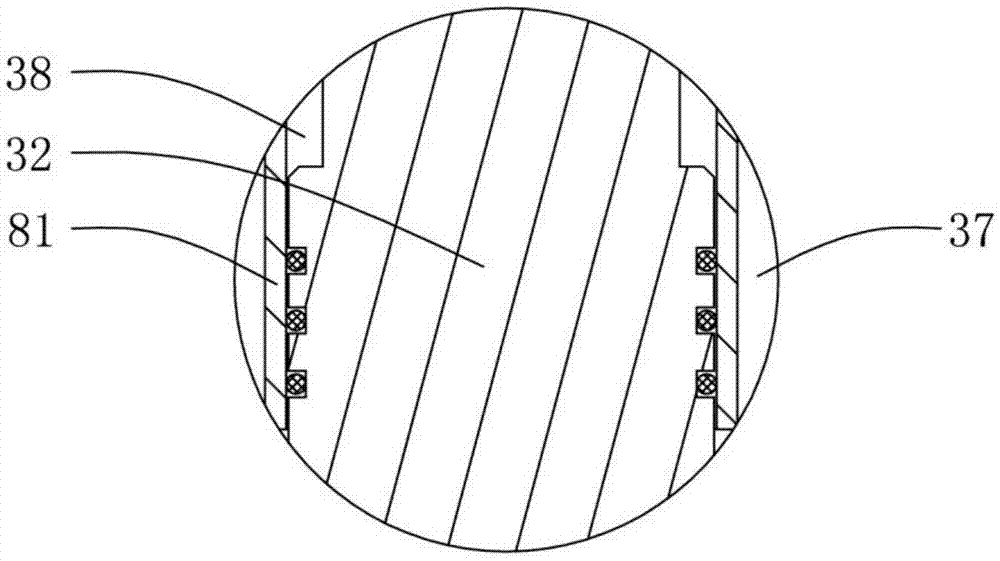

Welding apparatus with micropicture automatic-computing positioning system and operation mode

InactiveCN1710503APrecise positioningHigh positioning accuracyNumerical controlEngineeringMicrocomputer

The disclosed positioning system includes welding set, precision 3D servomechanism composed of 3D servomotor and worktable, micro optical unit, microcomputer, and digital pick-up head. The system possesses functions of automatic image recognition and microposition, and operational functions: determining position of welding spot by mouse click, automatic storing calculation, reaching to the designated position, and completing welding. It is possible to modify manual ultrasonic welding machine to automatic welding machine by using the invention. Comparing with manual welding machine, the system possesses advantages: lowering labors intensity, raised work efficiency to 4 - 6 times, high positioning precision (í‚0.005mm), good welding quality, and easy of use etc. Comparing with automatic ultrasonic welding machine, the system uses mouse to replace trackball so as to raise positioning precision, lower cost, and provide intuitive operation.

Owner:李光

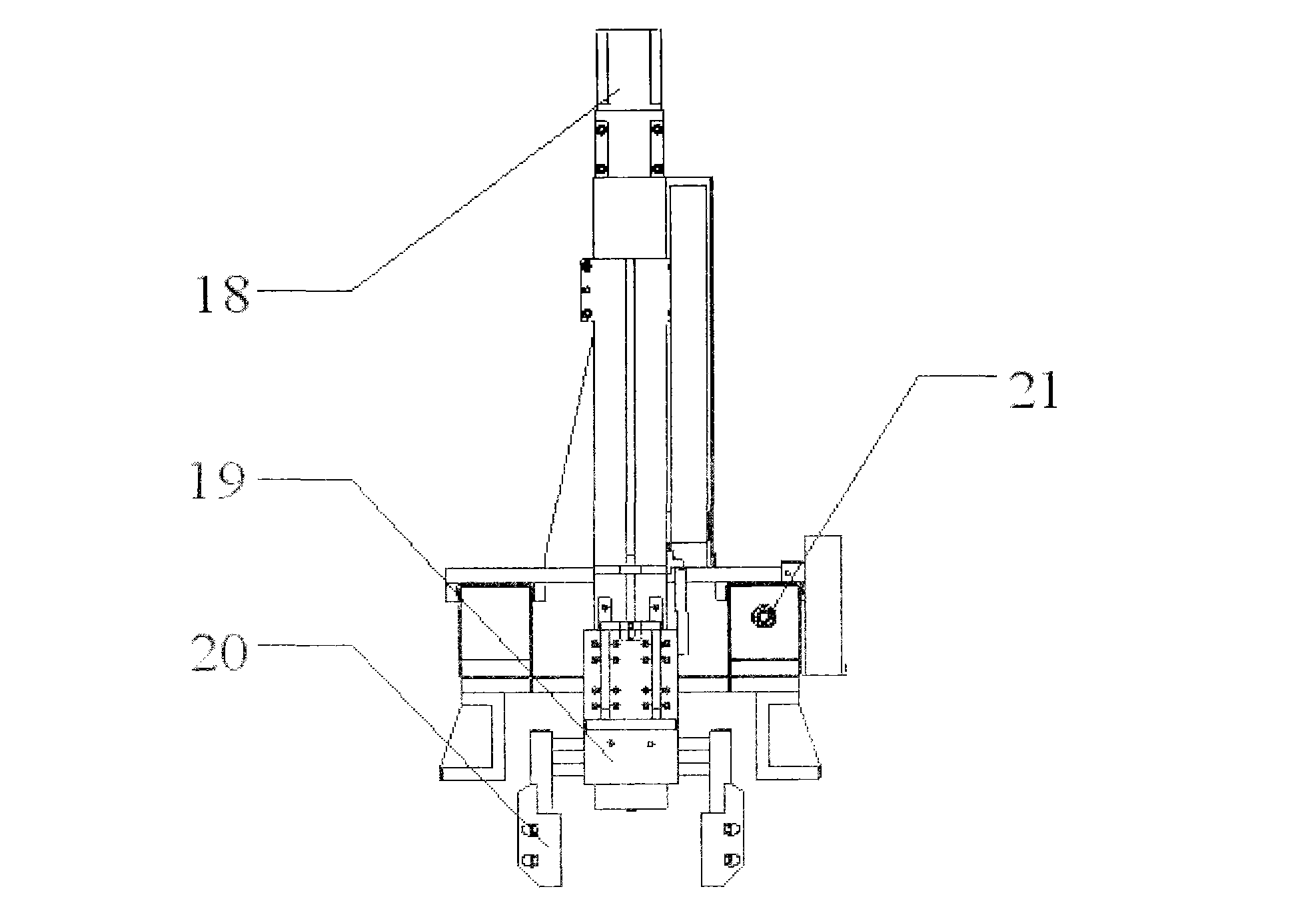

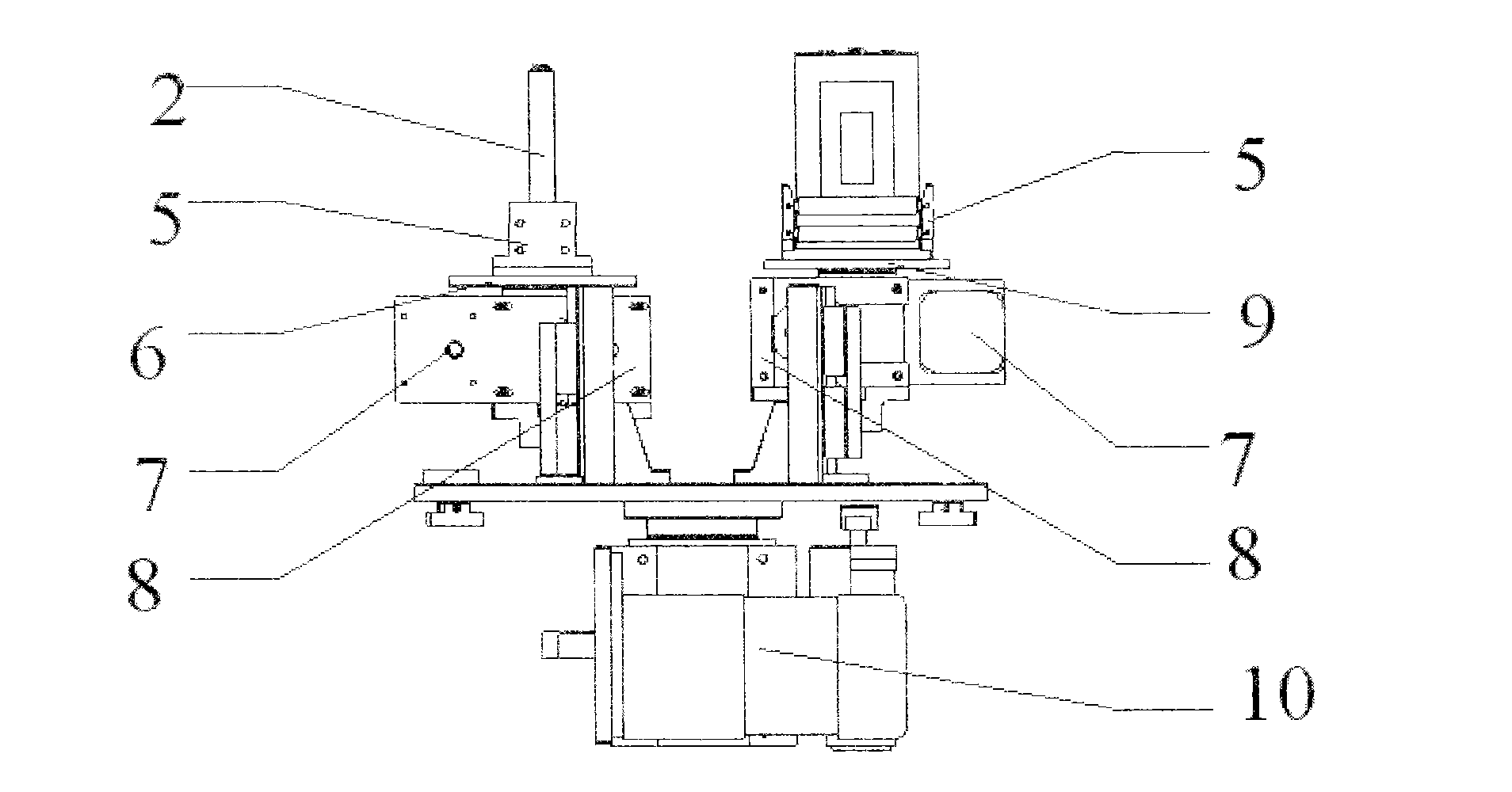

Full-automatic laser welder device and operation method

ActiveCN102689095AImprove compatibilityReduce the difficulty of debuggingLaser beam welding apparatusMechanical engineeringLaser

The invention belongs to the technical field of welding machines, and particularly relates to a full-automatic welder device and an operation method. The device comprises a cabinet, a turntable fixture, a feeding mechanism, a prepressing mechanism, a loading mechanism, a leveling mechanism, a welding mechanism, a discharging mechanism, a spot welder and a controller, wherein the turntable fixture is arranged on the cabinet, a workpiece is transferred onto the turntable fixture by the feeding mechanism, the prepressing mechanism is arranged on the cabinet, the loading mechanism is positioned on one side of the turntable fixture, the leveling mechanism is placed above the turntable fixture, the welding mechanism is arranged above the turntable fixture, the discharging mechanism is arranged on one side of the turntable fixture, the spot welder is disposed on one side of the loading mechanism, and the controller is arranged above the welding mechanism. The full-automatic welder device has the advantages that the device is high in compatibility, and is applicable to various types of products only by means of increasing or reducing assorted cushion blocks with proper heights, accordingly, fine adjustment is omitted, debugging difficulty is reduced, and type changing time is saved; and labor is saved, one person can operate multiple machines, and the quality of products, the qualified rate of the products, the consistency of the products and work efficiency are improved.

Owner:WUHAN YIFI LASER EQUIP CO LTD

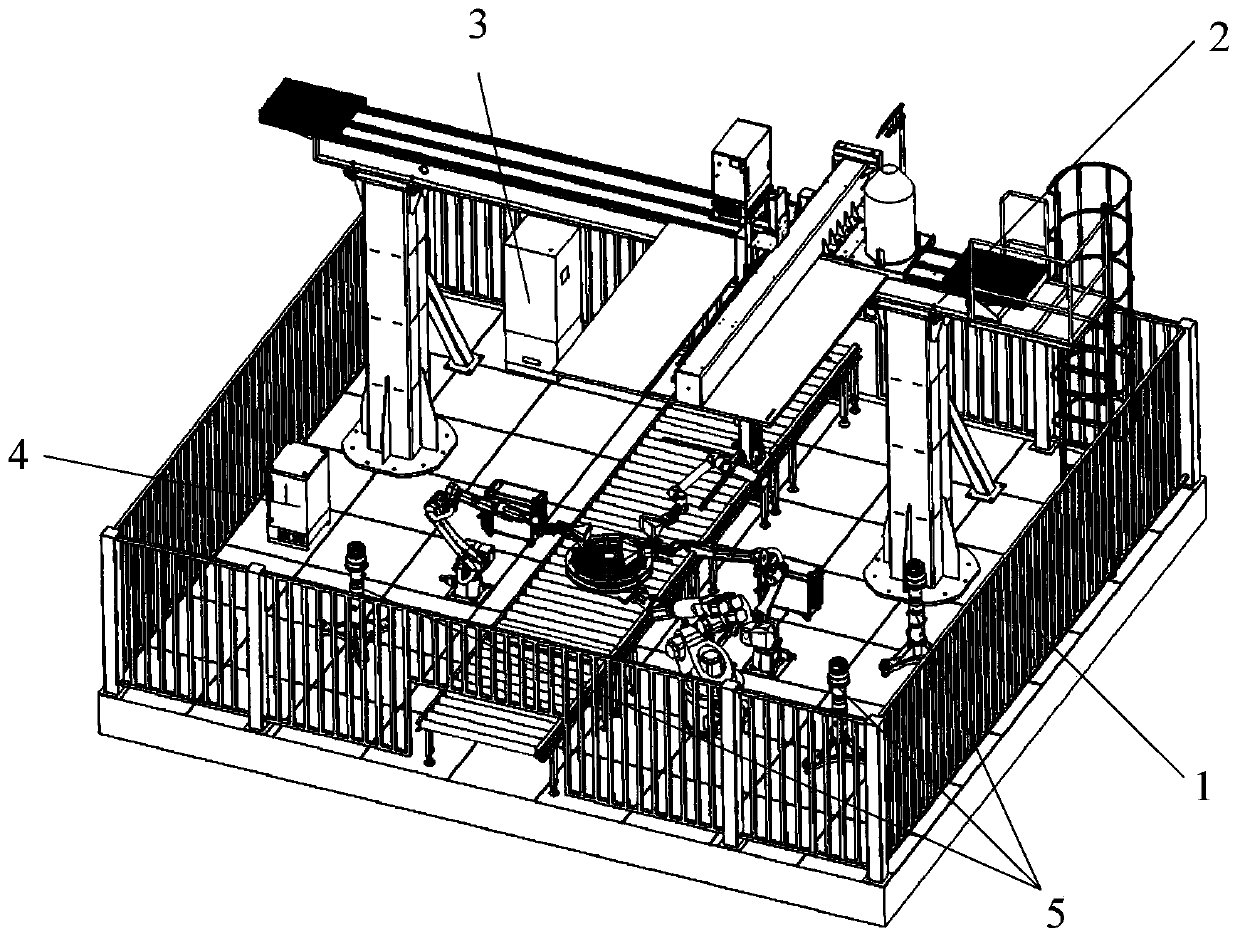

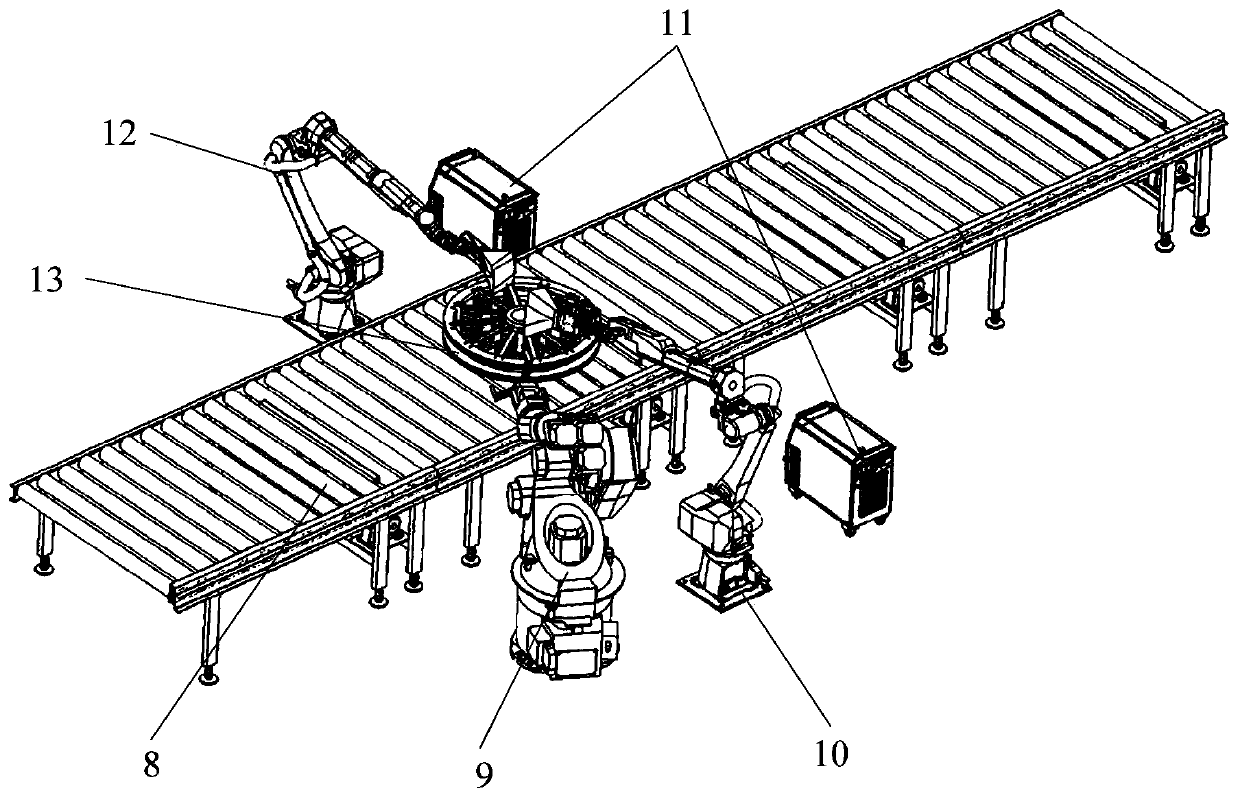

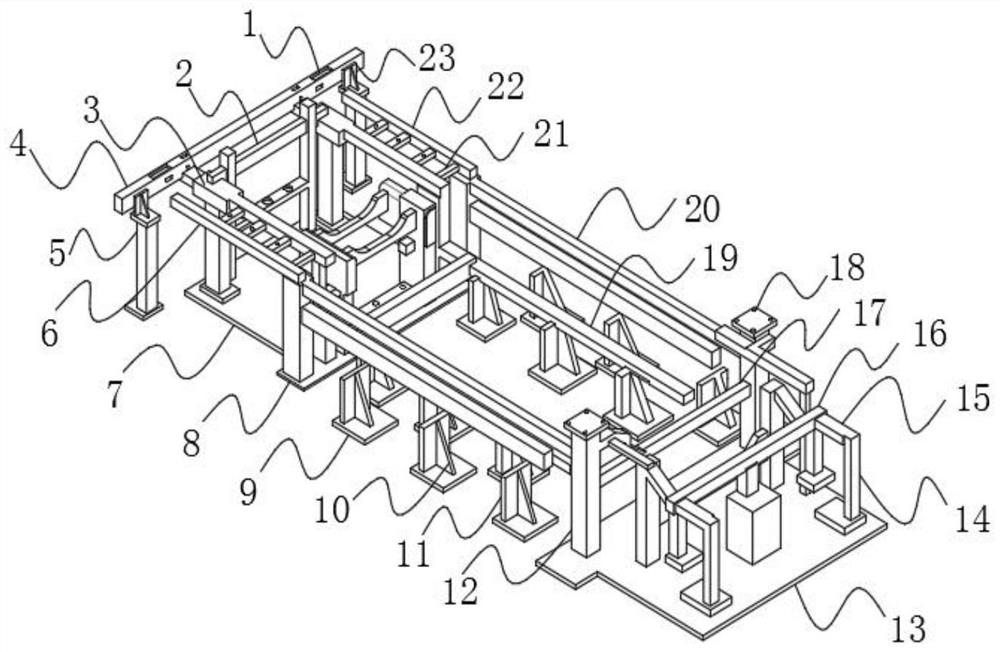

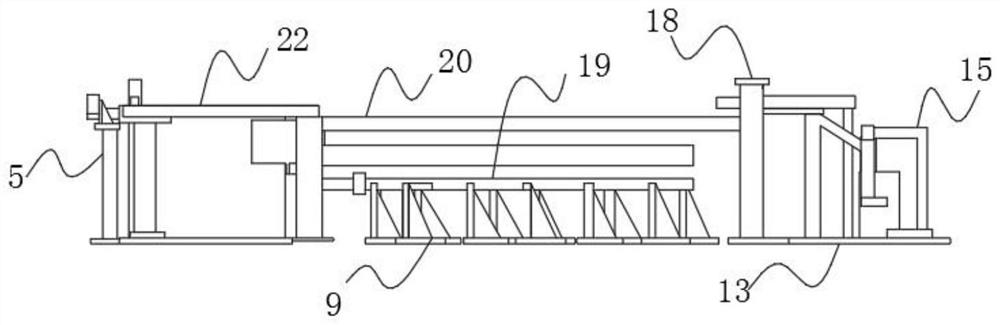

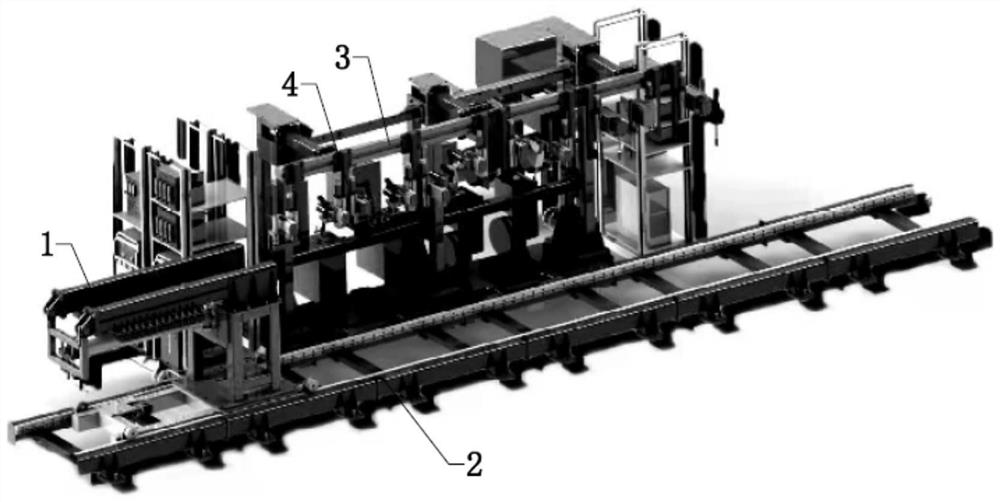

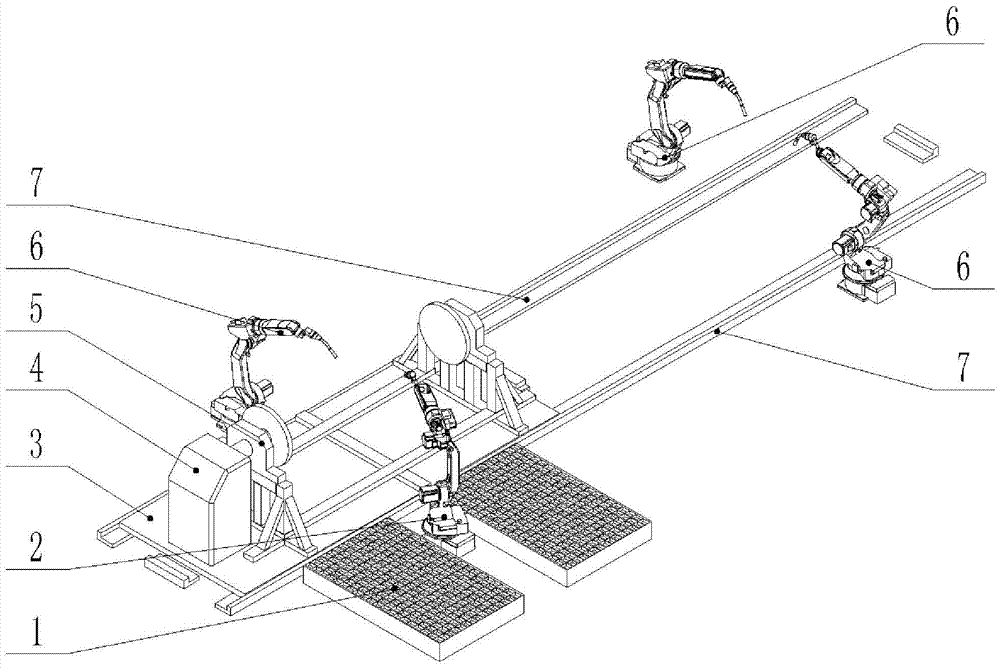

Flexible assembly welding robot workstation

ActiveCN110524582AImprove flexibilityHighly integratedProgramme-controlled manipulatorTotal factory controlEngineeringSpot welding

The invention discloses a flexible assembly welding robot workstation that comprises a global vision unit, a flexible welding robot group, a gantry truss detection unit, a master control unit and a conveying platform; the flexible welding robot group is arranged on the two sides of the conveying platform, welding workpieces are arranged on the conveying platform, the global vision unit is arrangedon the periphery of the flexible welding robot group, the gantry truss detection unit is arranged above the conveying platform, and the flexible welding robot group is controlled by the master control unit to conduct welding according to obtained image information. The high integration degree, high flexibility and high efficiency of the welding robot are achieved, the problems that manual assembly spot welding position deviation is large, and workpiece consistency is poor are solved, and the workpiece clamping and transferring frequency is effectively reduced. Multi-position assembly spot welding of workpieces is achieved, seamless connection of welding procedures is achieved, and the assembly precision, the welding consistency and the welding quality are improved.

Owner:XIAN ZHONGKE PHOTOELECTRIC PRECISION ENG CO LTD

Efficient double-welding-head combined welding device

InactiveCN105108285AGuarantee welding qualityImprove welding efficiency and welding consistencyArc welding apparatusDomestic vesselsEngineeringWelding

The invention discloses an efficient double-welding-head combined welding device. The welding device comprises two different welding device bodies which can be driven by an adjusting device to be adjusted in a multidirectional manner and carry out synchronous welding. By the adoption of the scheme, time for repeated transportation and clamping of workpieces and welding machines is saved. Synchronous automatic welding through two welding manners is achieved, the welding efficiency and the welding consistency are improved, and the labor intensity is reduced.

Owner:HIMILE MECHANICAL MFG

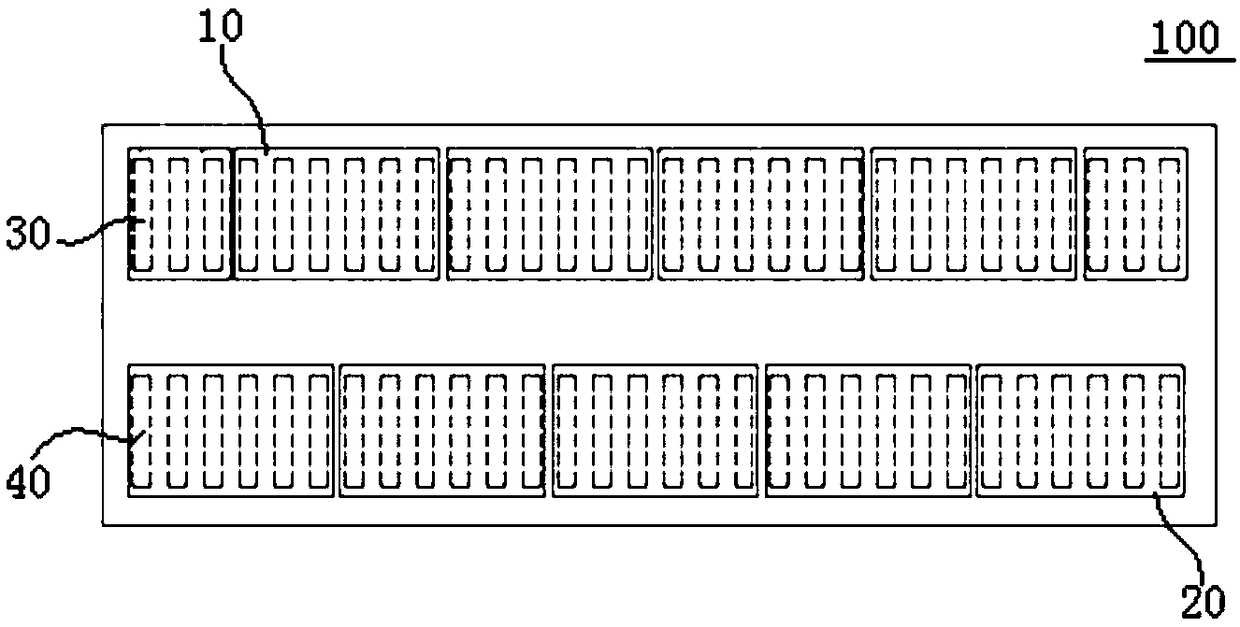

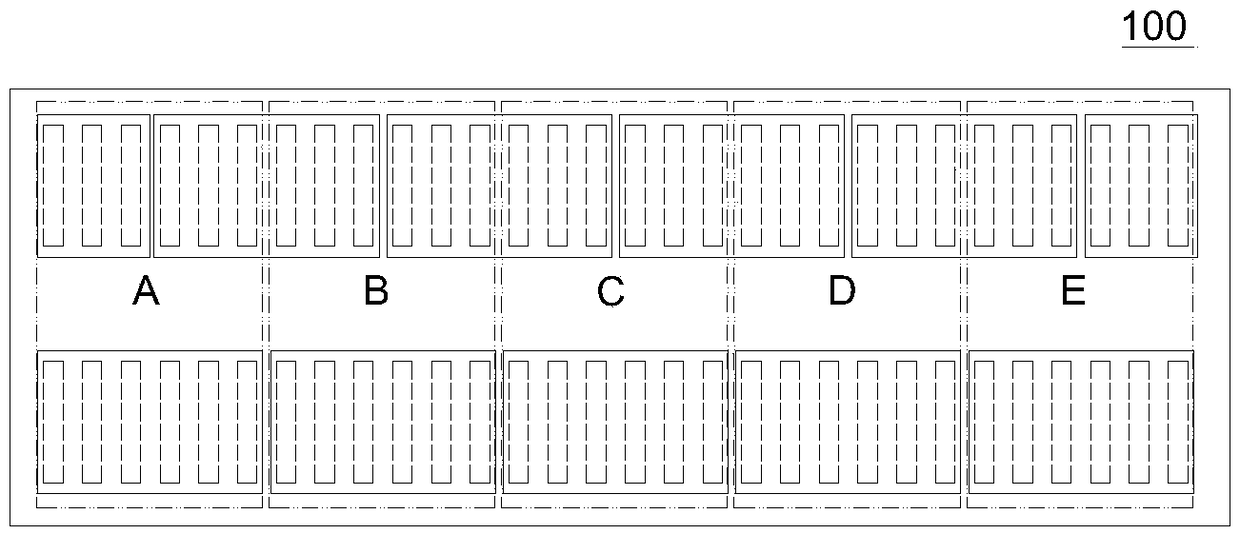

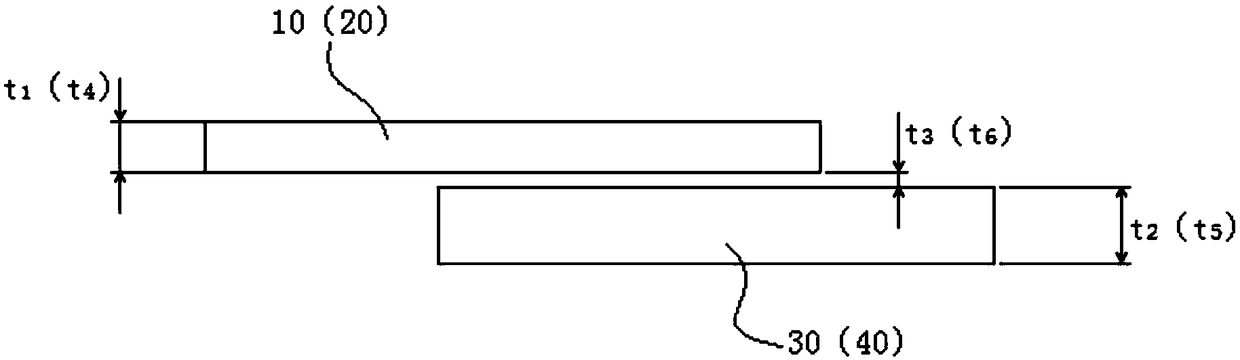

Welding method of battery module

InactiveCN109332894AHigh welding consistencyImprove stabilityWelding/soldering/cutting articlesMetal working apparatusElectrical batteryBusbar

The invention discloses a welding method of a battery module. The welding method comprises the following steps of: dividing first busbars connecting to first terminal posts of batteries and second busbars connected to second terminal posts of the batteries into a plurality of regions; and sequentially welding the first busbars in each region on the corresponding first terminal posts and welding the second busbars in each region on the corresponding second terminal posts until the first busbars in all the regions are welded on the corresponding first terminal posts and the second busbars in allthe regions are welded on the corresponding second terminal posts. Therefore, the welding efficiency is improved, the welding procedure is simplified, and the welding consistency and stability of theregion where the first busbars and the second busbars face each other are relatively high.

Owner:CH AUTO TECH CORP CO LTD

Automatic welding device of circular weld beads

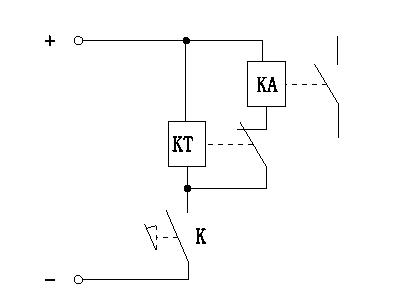

InactiveCN102000929AReduce labor intensityHigh welding consistencyWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftSprocket

The invention relates to an automatic welding device of circular weld beads, which is used for improving the welding quality and the welding efficiency of the circular weld beads and is characterized by comprising a machine frame, a vertical rotating shaft, a welding platform, a workpiece positioning seat, a carbon-dioxide protection welder and a control circuit, wherein the lower end of the vertical rotating shaft is rotatably connected with the machine frame, the upper end of the vertical rotating shaft is rotatably connected with the welding platform, the workpiece positioning seat is positioned on the welding platform and is rotatably connected with the welding platform, a welding torch of the carbon-dioxide protection welder is fixed on the machine frame through a welding torch support frame, and a wire feeding motor of the carbon-dioxide protection welder forms the driving relationship with the workpiece positioning seat sequentially through a transmission shaft, the vertical rotating shaft and chain wheels. The automatic welding device has simple structure, low cost, high welding efficiency and good weld bead quality, is convenient to operate and is particularly suitable for welding the circular weld beads on small members.

Owner:GREAT WALL MOTOR CO LTD

Welding apparatus with micropicture automatic-computing positioning system and operation mode

InactiveCN100351721CHigh precision of mechanical movementReduce mechanical transmissionComputer controlSimulator controlMicrocomputerUltrasonic welding

The disclosed positioning system includes welding set, precision 3D servomechanism composed of 3D servomotor and worktable, micro optical unit, microcomputer, and digital pick-up head. The system possesses functions of automatic image recognition and microposition, and operational functions: determining position of welding spot by mouse click, automatic storing calculation, reaching to the designated position, and completing welding. It is possible to modify manual ultrasonic welding machine to automatic welding machine by using the invention. Comparing with manual welding machine, the system possesses advantages: lowering labors intensity, raised work efficiency to 4-6 times, high positioning precision (+ / -0.005mm), good welding quality, and easy of use etc. Comparing with automatic ultrasonic welding machine, the system uses mouse to replace trackball so as to raise positioning precision, lower cost, and provide intuitive operation.

Owner:李光

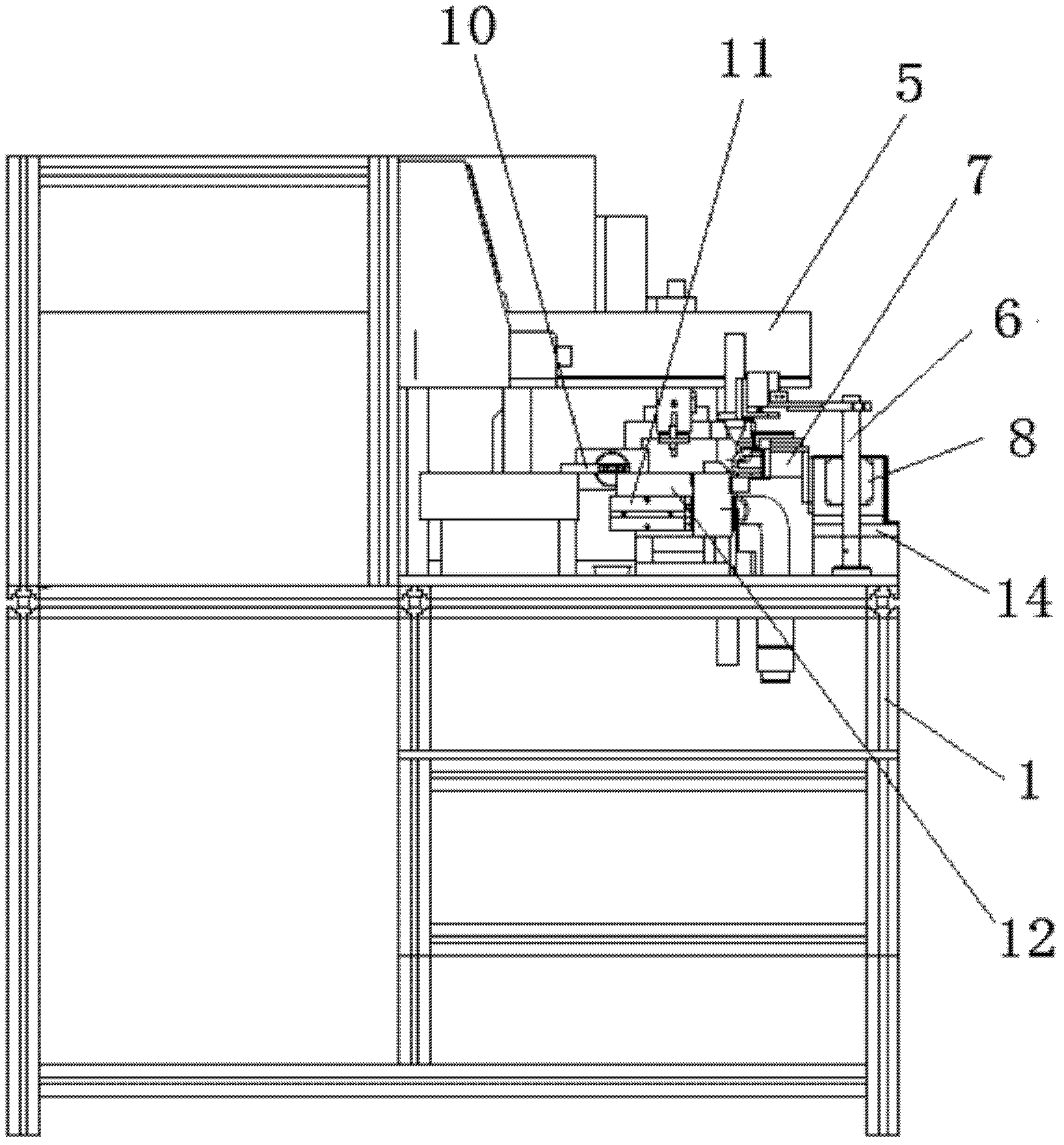

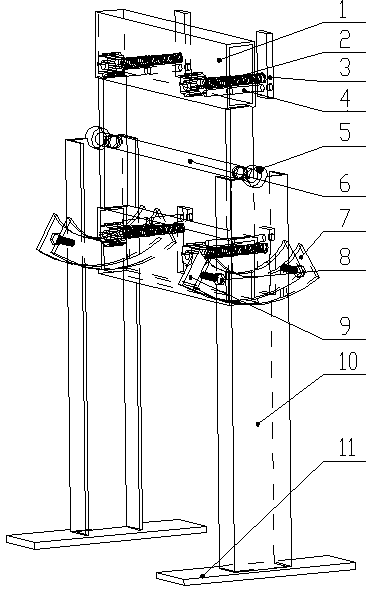

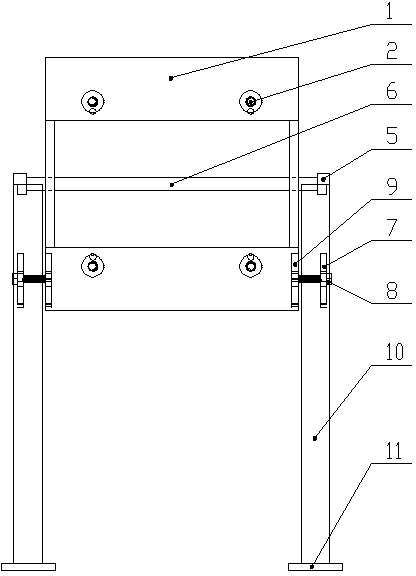

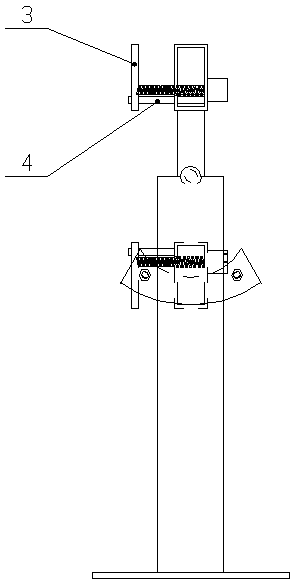

Welding mechanism of shock absorber welding machine

ActiveCN105436728AThe stop effect disappearsLess technology dependentWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRejection rate

The invention discloses a welding mechanism of a shock absorber welding machine. The welding mechanism comprises a first installation plate and a base, wherein a shock absorber installation and fixation mechanism, and a location device matched with the shock absorber installation and fixation mechanism are arranged on the first installation plate respectively; and a first welding gun used for welding a shock absorber spring disc, and a second welding gun used for welding a shock absorber support are arranged above the first installation plate respectively. The welding mechanism disclosed by the invention is simple and reasonable in structure, convenient to operate, low in manual labour intensity, low in the degree of dependence on the technology of an operator, and beneficial to improve the welding quality and consistency of products and reduce the rejection rate.

Owner:宁波力品格自动化科技有限公司

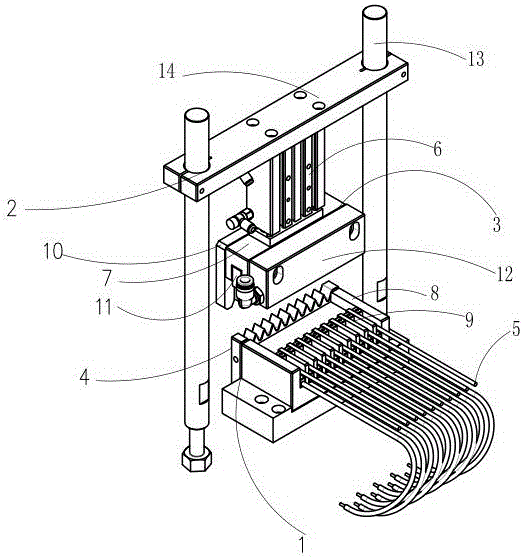

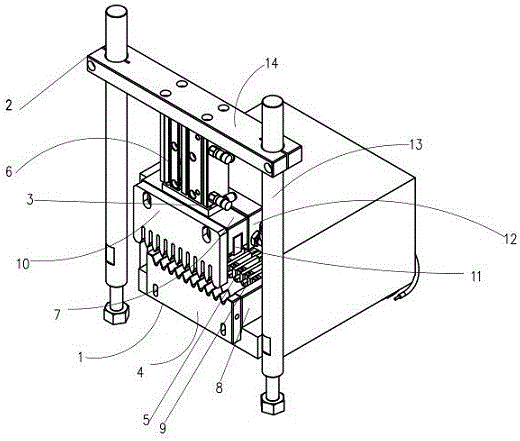

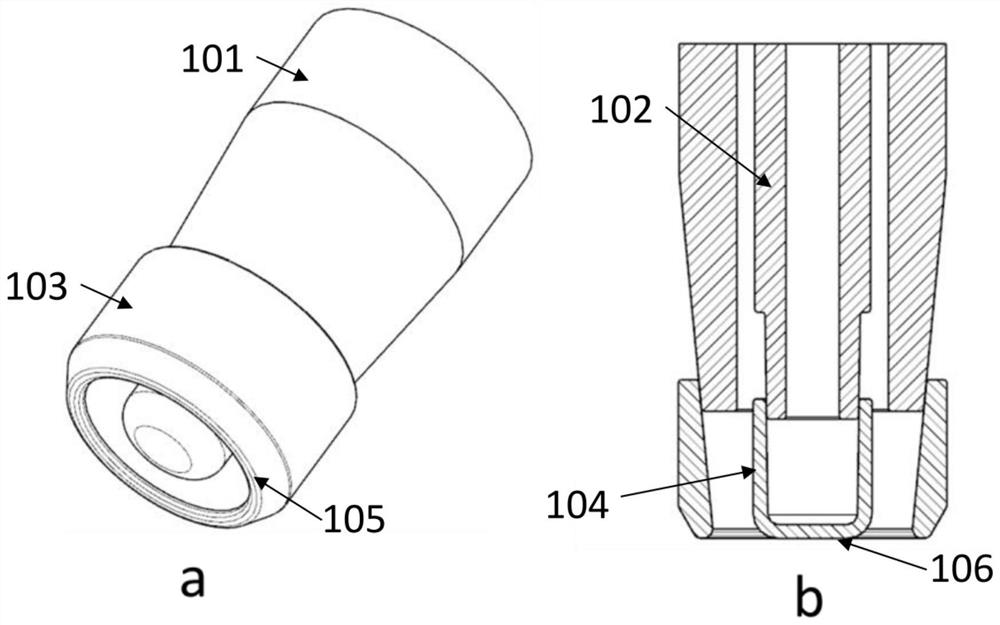

Welding device

InactiveCN106216866AImprove welding efficiencyHigh welding consistencyWelding apparatusEngineeringGrounding electrodes

The invention discloses a welding device. The welding device comprises a welding mechanism, a bracket, and a pressing mechanism fixed on the bracket; the welding mechanism includes a plate-shaped welding ground electrode and multiple welding electrode needles; multiple guide grooves are formed in one end, towards the pressing mechanism, of the welding ground electrode; the multiple welding electrode needles are arranged on one side of the welding ground electrode, and are opposite to sawtooth-shaped guide grooves one to one; and the pressing mechanism includes a driving device fixed on the bracket, and a fixed block fixed on the driving device and capable of moving up and down under driving of the driving device. The welding device realizes the function of synchronously welding multiple products, improves the welding efficiency, and prevents bad welding quality caused by nonuniform welding in joints of welded products.

Owner:惠州市益柏科技有限公司

Steel pipe welding device

InactiveCN105149805AImprove welding efficiency and welding accuracy and consistencySimple structureMetal working apparatusWelding apparatusSteel tubePipe welding

The invention provides a steel pipe welding device which comprises a welding portion and an adjusting portion. The welding portion comprises a containing seat, a fixed seat, a connection portion, a welding machine seat, fixing supports, heating plates and welding heads; the adjusting portion comprises a matching part, a rotating mechanical arm and a propulsive pipe; the containing seat is fixed on a machine tool body, at least one connection pipe is arranged on the containing seat, each connection pipe is internally provided with a connection circuit, the fixed seat is provided with a clamping portion, the welding machine seat is provided with at least four fixing backing plates, the lower portion of each fixing backing plate is provided with a long-strip-shaped fixing support, the heating plates are clamped on the corresponding fixing supports, and the bottom of each heating plate is provided with a welding head. According to the steel pipe welding device, the welding machine seat, the fixing supports, the heating plates and at least four welding heads of the welding portion are arranged again, the welding efficiency, the welding accuracy and the uniformity can be greatly promoted, and the welding portion is simple in structure, easy to manipulate and control and good in welding effect.

Owner:天津金立盛业有限公司

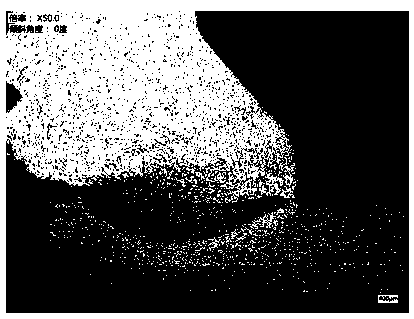

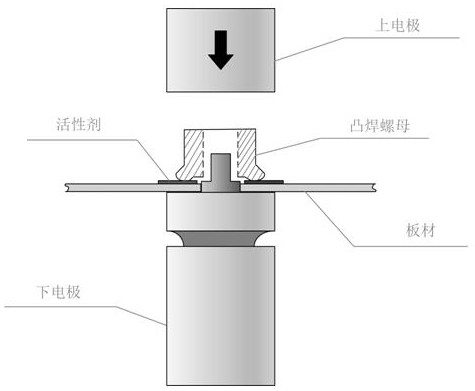

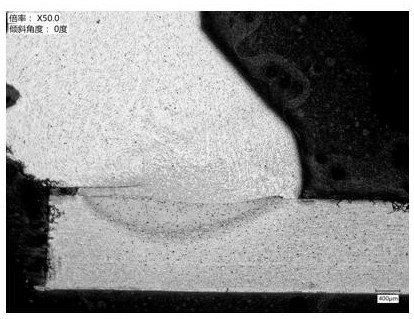

Aluminum alloy and steel optimized welding method based on magnetic control resistance spot welding

ActiveCN113843488ALow heat inputReduce severe thinningResistance welding apparatusSteel platesHigh resistivity

An aluminum alloy and steel optimized welding method based on magnetic control resistance spot welding comprises the steps that a steel plate and an aluminum alloy plate are arranged between an electrode and a controllable magnetic field, Joule heat is generated in the steel plate by applying welding current, and the temperature of the side, close to the steel plate, of the aluminum alloy plate is evenly increased through the blocking effect of a high-resistivity oxidation film between the steel plate and the aluminum alloy plate; and the side, close to the steel plate, of the aluminum alloy plate is molten to form molten aluminum alloy, the molten aluminum alloy flows and is stirred at a high speed under the action of Lorentz force generated by a magnetic field and current, aggregation of oxide film defects near an interface is inhibited, and thin and uniform intermetallic compounds are formed by heterogeneous materials on the two sides of the interface. By heating a steel side resistor, the heat input of the aluminum side is reduced, the thinning of the aluminum plate is reduced, the surface indentation of the aluminum plate is eliminated, and the thickness of an interface intermetallic compound layer is controlled; and lorentz force is generated through interaction of an external magnetic field and current, molten aluminum alloy is driven to flow at a high speed, the aluminum side nugget structure and defect distribution are improved, and the mechanical performance of a welded joint is improved. By avoiding direct contact between a copper electrode and an aluminum plate, electrode abrasion is reduced, and the performance, appearance quality and welding spot quality stability of an aluminum steel spot welding joint are improved.

Owner:SHANGHAI JIAO TONG UNIV

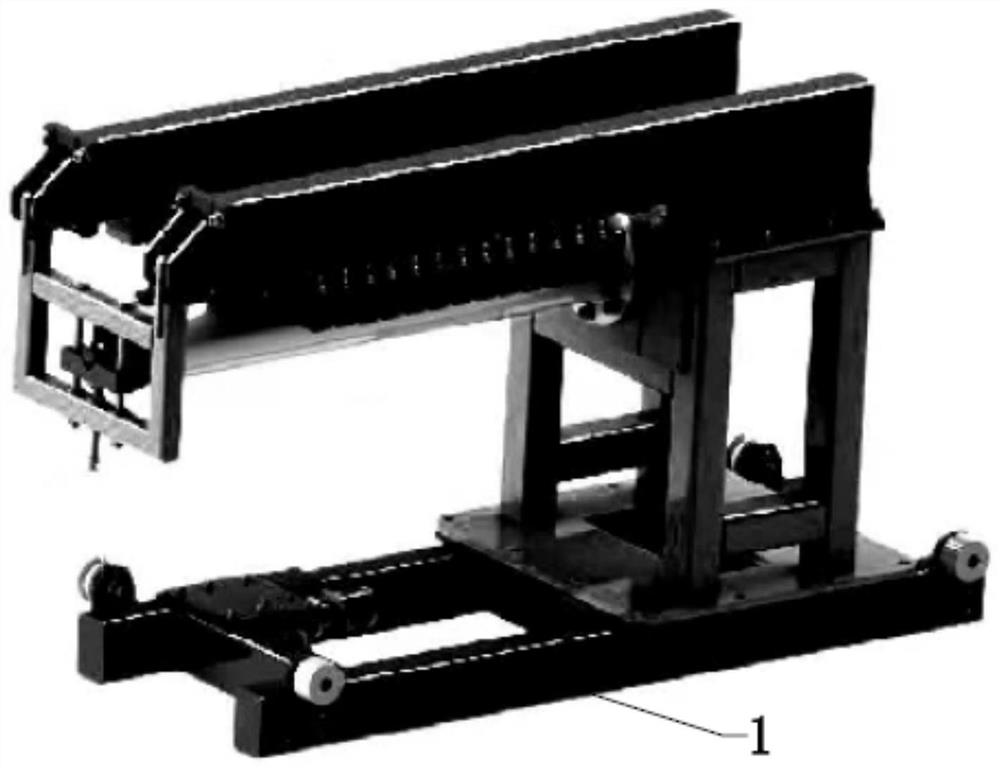

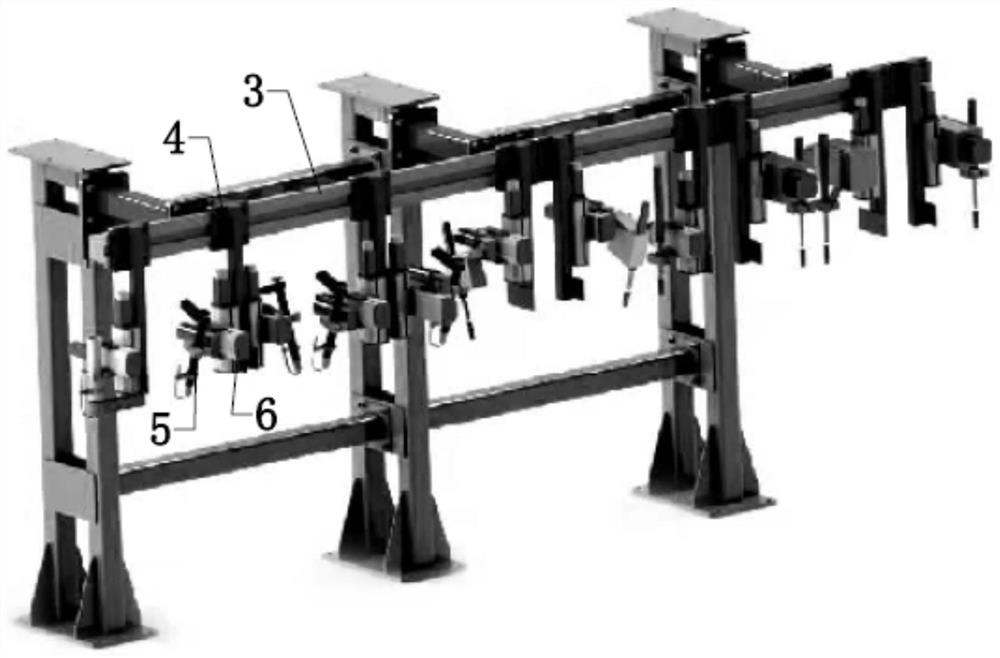

Splicing and welding tool of car body truss structure

InactiveCN111922591AHigh implementabilityHigh welding consistencyWelding/cutting auxillary devicesAuxillary welding devicesManufacturing engineeringSlide plate

The invention discloses a splicing and welding tool of a car body truss structure, and relates to the technical field of truss splicing tools. The splicing and welding tool comprises a car tail assembly tool, a chassis splicing tool and a car head assembly tool, wherein a car tail support column and a truss support column are arranged on the upper surface of the car tail assembly tool, a connecting column is arranged on one side surface of the car tail assembly tool, the chassis splicing tool is installed on one side surface of the connecting column, and a cross beam support frame is arrangedon the upper surface of the car head assembly tool. According to the splicing and welding tool, the sealing end of a car body is formed into a team, so that the implementation of the process is increased; a fixture structure is optimized, so that a fixture can meet the truss body welding technical requirements; a sliding plate is additionally installed so as to control and position key dimensions,so that the welding consistency is increased, and the quality problem caused by welding is reduced; and the fixture combination is diversified and modularized, so that the combined welding of all positions of the truss body is satisfied, the piece assembly time is shortened, and the welding quality of the truss body and the welding speed are obviously increased.

Owner:湖北瑞兴达特种装备科技股份有限公司

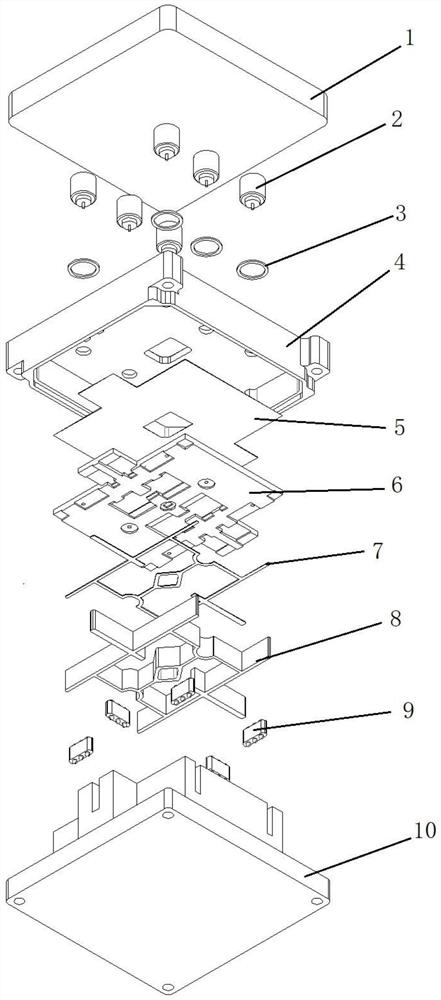

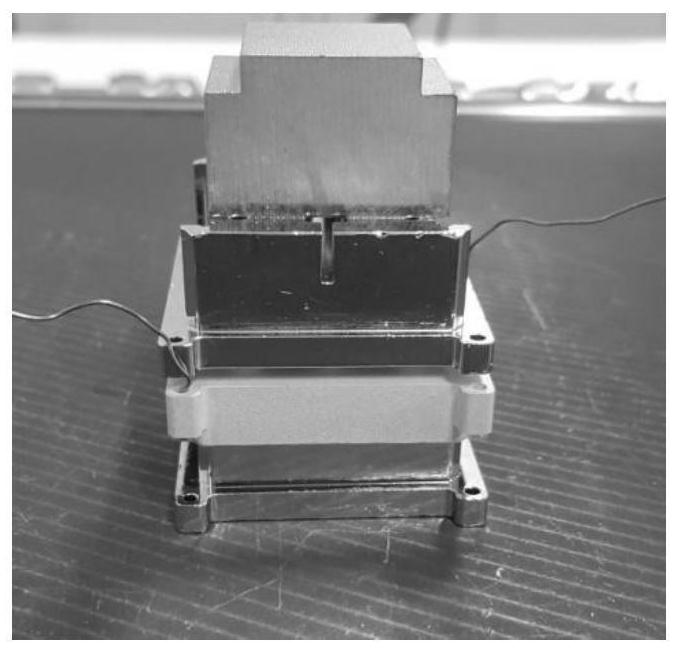

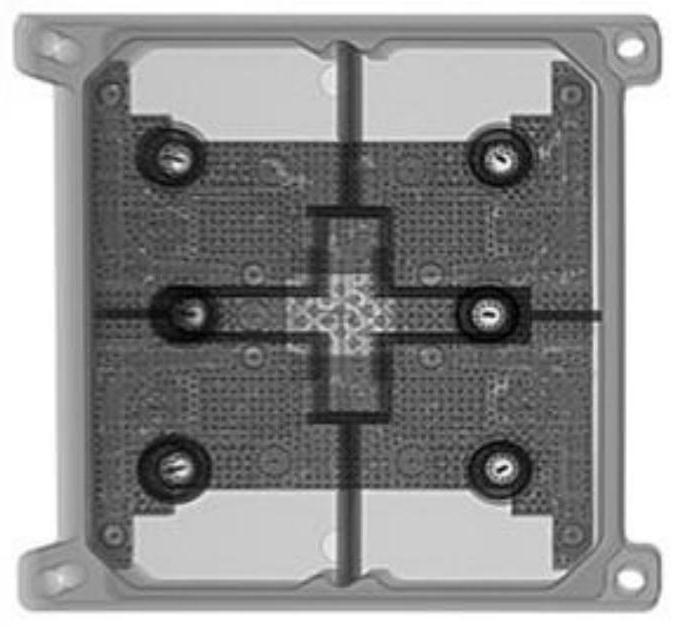

Double-sided laminated airtight brazing system and method in 3D microwave radio frequency module

InactiveCN112453617AWon't fall offAchieve airtight brazingSoldering auxillary devicesMicrowaveDielectric plate

The invention discloses a double-sided laminated airtight brazing system and method in a 3D microwave radio frequency module. The double-sided laminated airtight brazing system comprises an upper tool, a connector, a connector solder ring, a module tube shell, substrate solder, a substrate, surface layer device solder, a surface layer device, elastic tools and a lower tool. The connector and the connector solder ring are arranged between the upper tool and the module tube shell. The substrate solder, the substrate, the surface layer device solder, the surface layer device and the elastic toolsare arranged between the lower tool and the module tube shell. According to the double-sided laminated airtight brazing system and method in the 3D microwave radio frequency module, a double-sided one-time welding mode is adopted, the upper tool and the lower tool are used for clamping devices to be welded, one or more surface layer devices to be welded are limited on the welding face through oneor more elastic tools, and therefore the surface layer device is ensured not to fall off in the welding process, one-time laminated welding of one or more surface layer devices to be welded is achieved, and high welding penetration rate and airtight brazing can be guaranteed for microwave dielectric plates, surface layer devices and connectors of different shapes and types.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

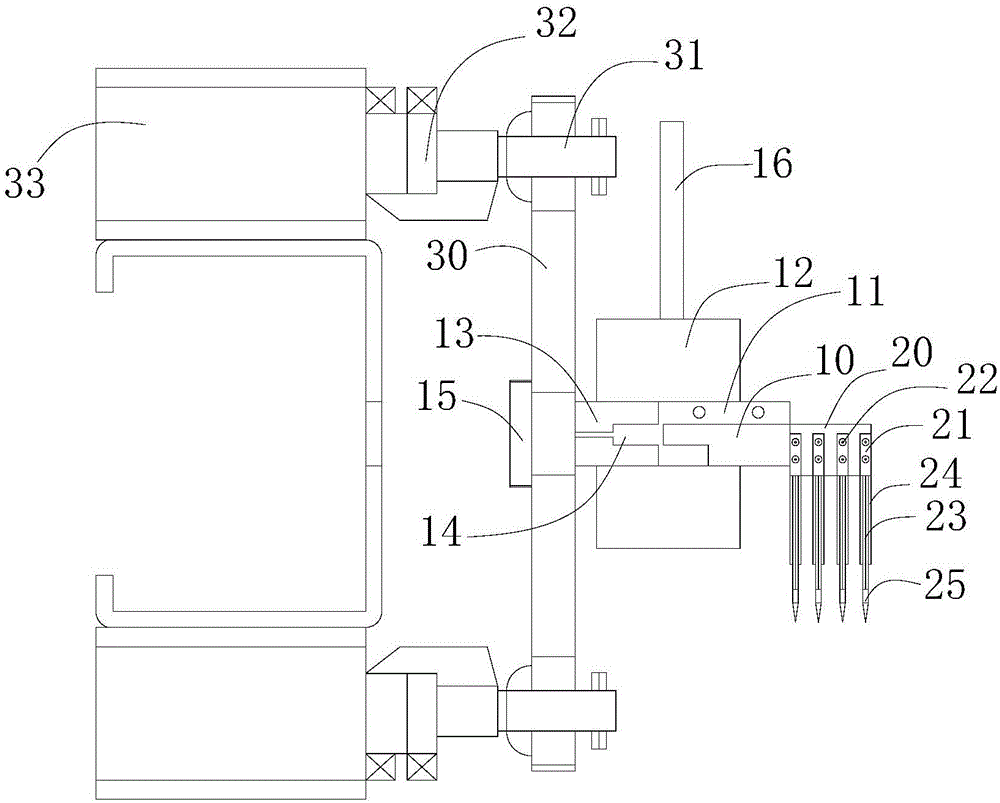

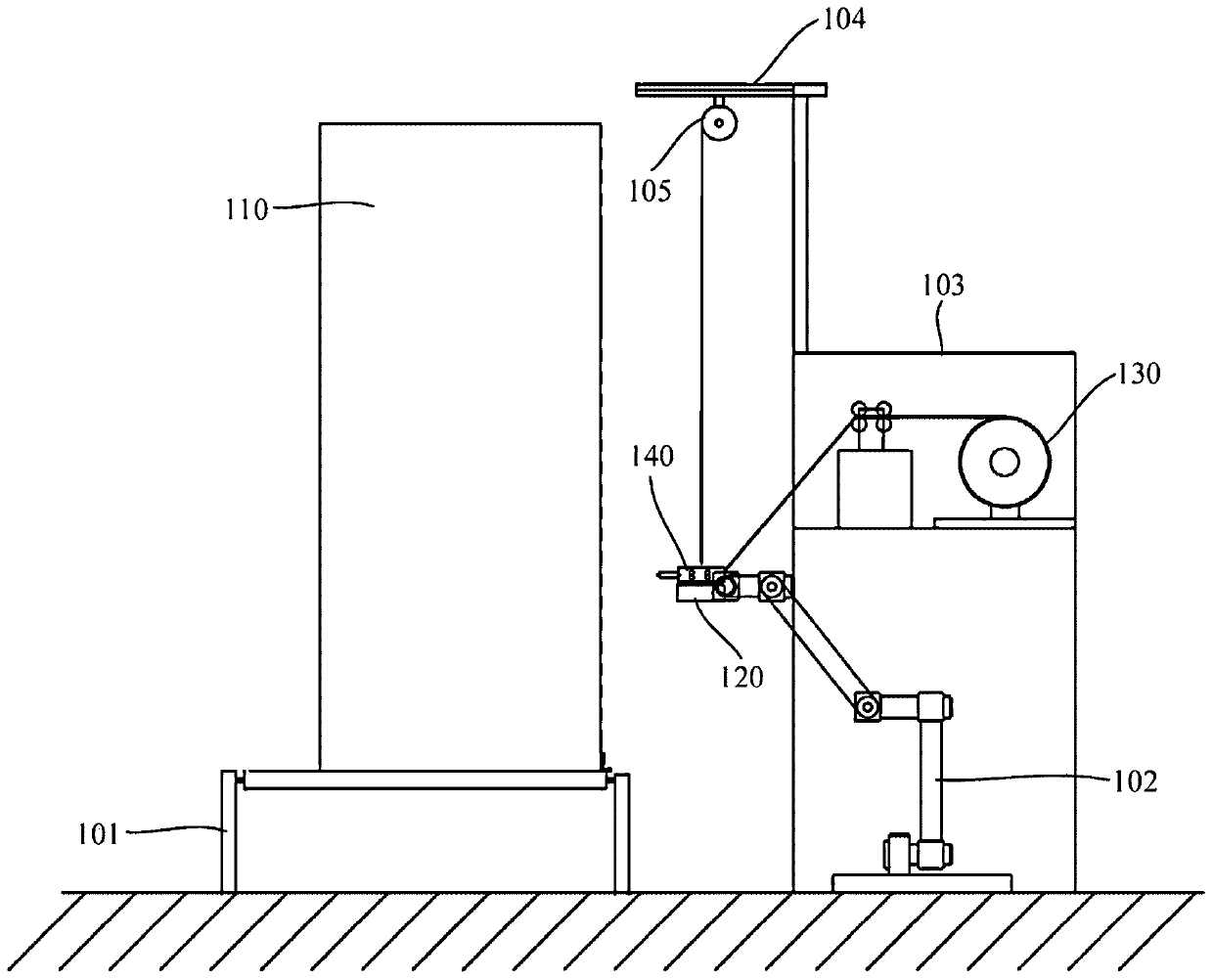

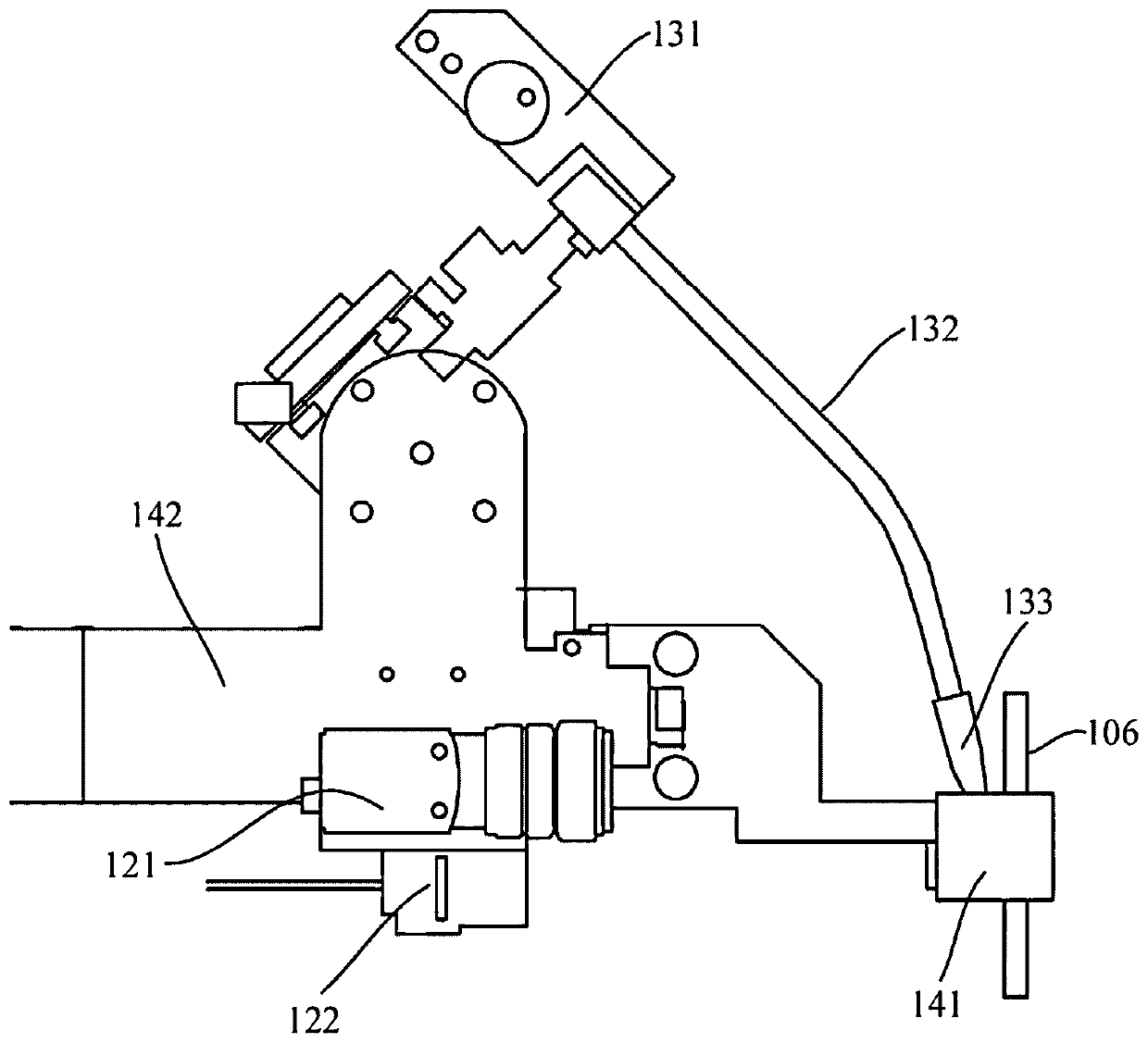

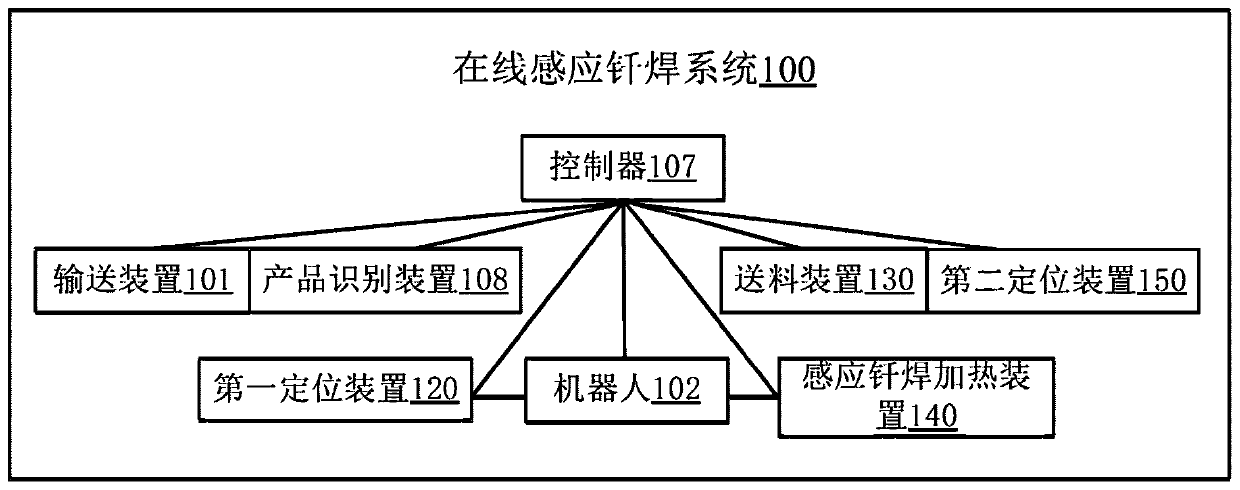

Online induction soldering system

PendingCN111151835AAchieve positioningAchieving identifiabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention provides an online induction soldering system. The online induction soldering system comprises a controller, a conveying device, a first positioning device, a robot, a feeding device andan induction soldering heating device, wherein the conveying device, the first positioning device, the robot, the feeding device and the induction soldering heating device are connected with the controller separately, and the first positioning device and the induction soldering heating device are both arranged on the robot; the first positioning device is configured to position a soldering pointof a to-be-treated product and determine the position of the soldering point; the robot is configured to move the first positioning device to a soldering station and move the induction soldering heating device to the position of the soldering point; the feeding device is configured to convey a soldering flux to the soldering point; and the induction soldering heating device is configured to perform induction heating soldering on the soldering point. According to the online induction soldering system, by additionally arranging the first positioning device, intelligent positioning and recognition of the position of the soldering point are realized; and by adjusting the position of the induction soldering heating device through the robot, intelligent induction heating of the soldering point is realized. Thus, intelligent induction soldering of the online to-be-treated product is realized, and the soldering efficiency and soldering consistency are improved.

Owner:HAIER SMART HOME CO LTD +1

Automatic welding tool for automobile grille decorating part

PendingCN113500340AConvenient and efficient lockingImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesWeld zone

The invention discloses an automatic welding tool for an automobile grille decorating part. The automatic welding tool comprises a base and an upper die surrounding frame, wherein profiling blocks are distributed on the upper side of the base, and the upper ends of the profiling blocks are configured to adapt to the outer contour of a grille and are used for positioning and supporting the grille; the upper die surrounding frame is located above the base, an upper die plate is installed in the upper die surrounding frame in a vertically movable mode through first air cylinders arranged at the two ends, pressing blocks are distributed on the lower side of the upper die plate, and the pressing blocks are connected with second air cylinders and are used for driving the corresponding pressing blocks to move up and down; and via holes are distributed in the upper die plate, and the via holes are configured at the positions corresponding to a decorating part welding area and are used for allowing welding heads to pass through. The automatic welding tool has the beneficial effects that the structure is simple, operation is facilitated, stability is high, automatic welding of the decorating part is facilitated, production efficiency is greatly improved, and production consistency and product quality can be guaranteed.

Owner:CHONGQING BALING AUTO PARTS

Welding equipment and welding method

ActiveCN114273832AImprove welding qualityHigh welding consistencyNuclear energy generationWelding/cutting auxillary devicesIndustrial engineeringSoldering gun

The invention discloses welding equipment. The welding equipment comprises a tool trolley, a guide part, a main frame and a welding suspension, the welding suspensions are arranged on the main frame, the number of the welding suspensions is at least three, mounting pieces for mounting and fixing welding guns are arranged on the welding suspensions, and the welding suspensions are linearly distributed; the tool trolley is used for placing a to-be-welded part and is arranged below the welding suspension; the tool trolley is matched with the guide part, and the guide part guides the tool trolley to move in the linear direction of the welding suspension. Compared with the prior art, the scheme has the advantages of stable welding quality, high welding consistency and high overall welding efficiency, and has high practicability.

Owner:CHINA-UKRAINE INST OF WELDING GUANGDONG ACAD OF SCI

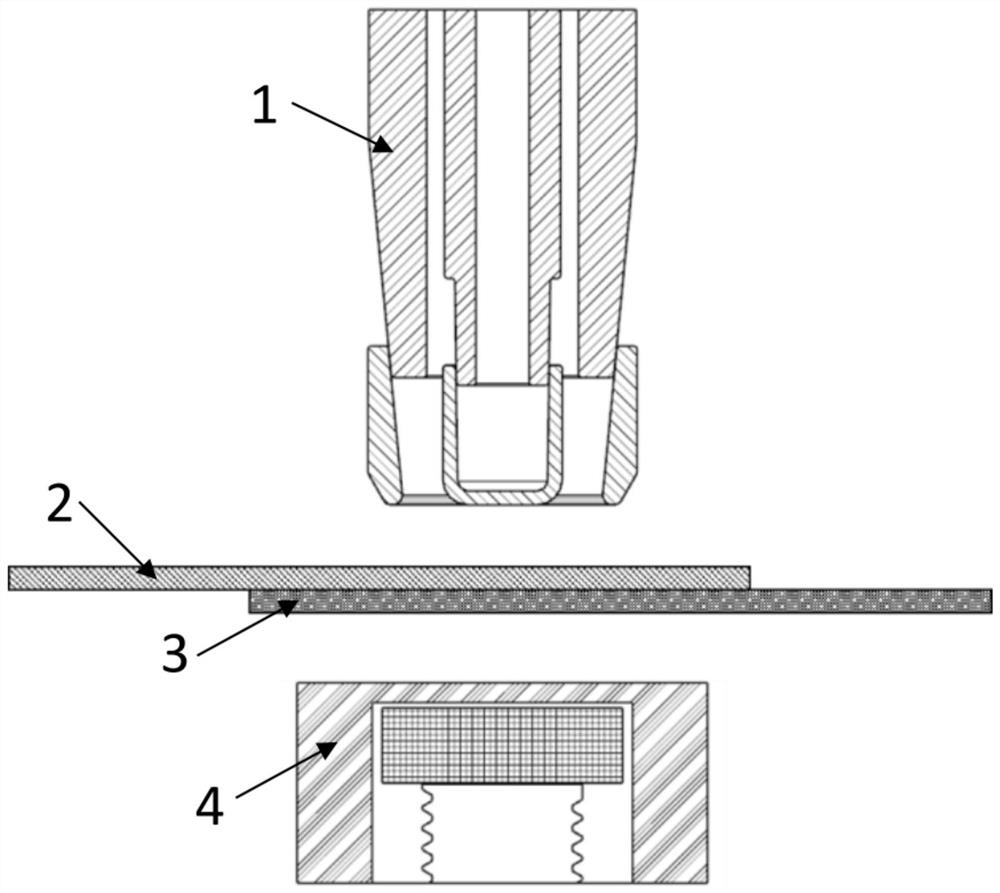

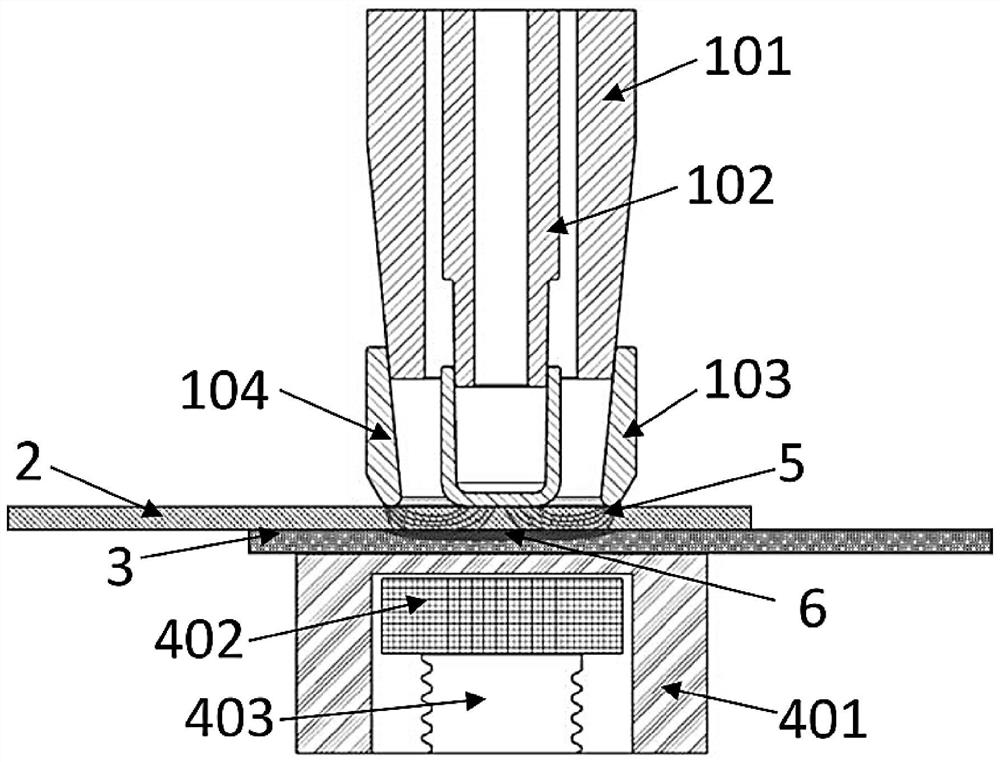

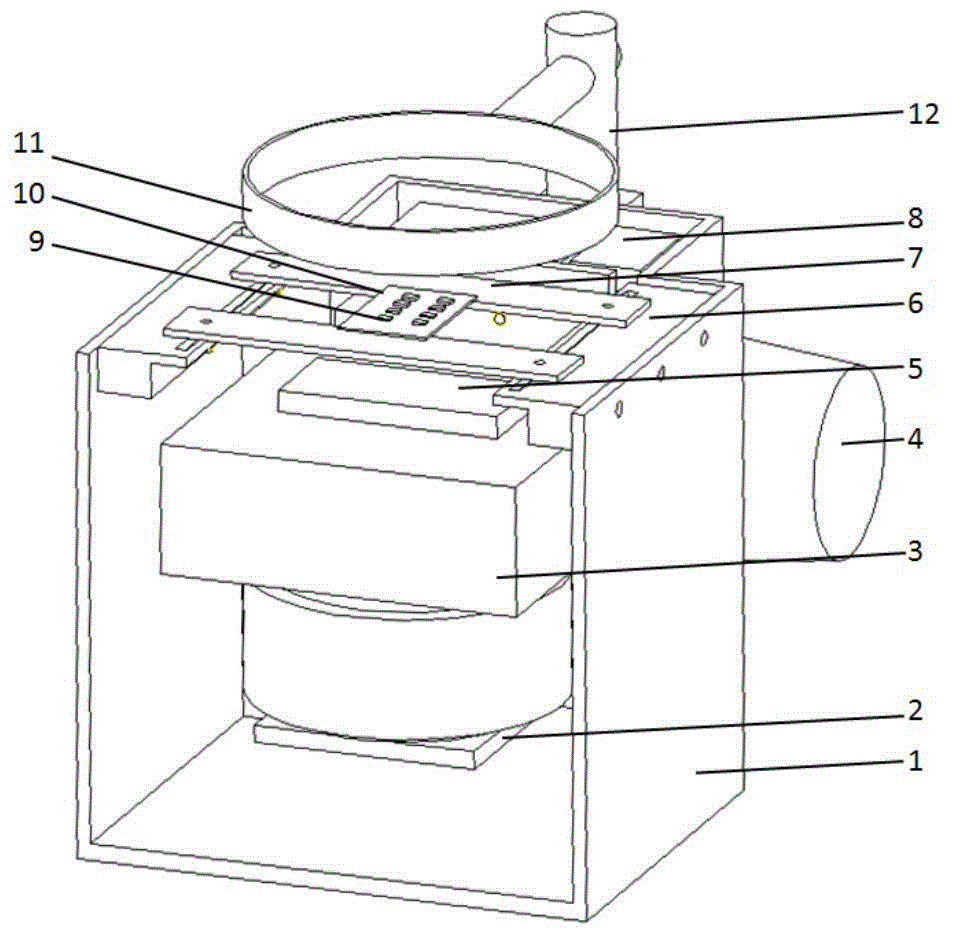

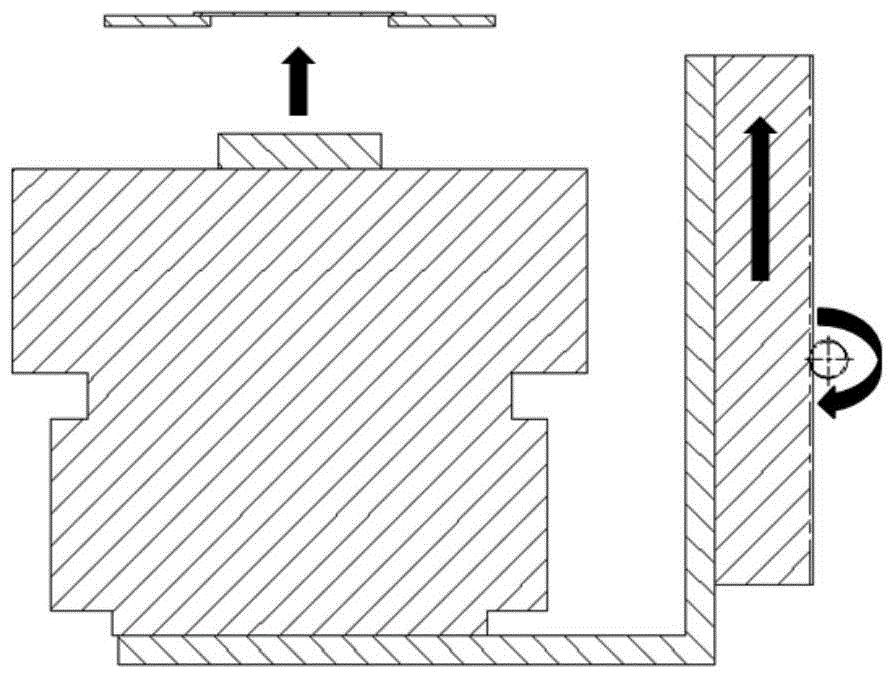

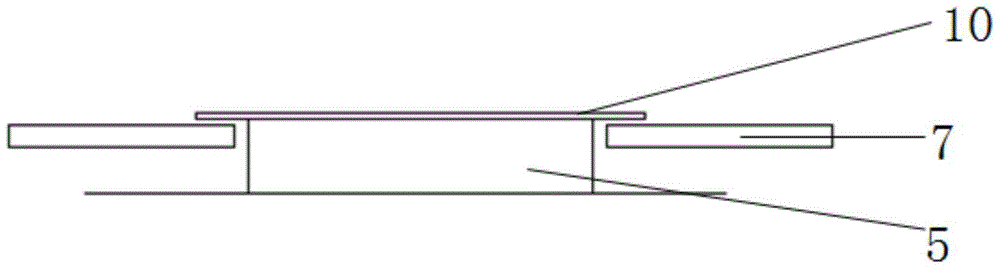

A new welding device and method for soldering components on ceramic substrates

InactiveCN104400174BGuaranteed stabilityGuaranteed reliabilityPrinted circuit assemblingSoldering auxillary devicesHeat transmissionOperability

The invention discloses a novel welding device and method for soldering components on a ceramic substrate. The device comprises a heating component, a lifting component and a bearing component; the heating component comprises a heating table; the heating table is connected with a power source through a wire, and the heating table transmits heat to the bottom of the substrate to be heated through a heat transmission block; the heating table is in contact with or is separated from the substrate to be heated through the lifting component; a gear transmission mechanism is embedded into the lifting component; a rotary knob can be rotated to enable the heating table to ascend and descend; the bearing component is arranged on the heat transmission block and comprises two bearing plates and two adjusting blocks; the adjusting blocks are arranged at the opposite positions of the plane on the upper portion of a shell; sliding grooves are formed in the adjusting blocks; the two ends of each bearing plate are placed on the sliding grooves in the adjusting blocks on the opposite positions respectively; and the distance between the bearing plates is adjustable. The device is simple in structure, good in operability, easy to produce and capable of being used for a long time, and the welding efficiency can be improved to be greatest extent.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

Rotary clamp equipment for manipulator

InactiveCN104924005AImprove quality and efficiencyImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesWork injuryFixed frame

The invention relates to rotary clamp equipment for a manipulator. The rotary clamp equipment comprises a fixing frame component, a rack, locking fixing plates, adjustment plates, locking bolts and foundations, wherein the locking fixing plates are weld on the rack; the locking bolts are mounted on the locking fixing plates in a threaded connection manner; the foundations are welded below the rack; the fixing frame component is mounted on the rack via bearings in a rotary manner; gripper jaws can clamp a workpiece by adjusting clamp bolts; the fixing frame component is rotated to an appropriate angle and then the locking bolts are locked ; and the equipment can be matched with the manipulator for operation at any angle. The rotary clamp equipment for the manipulator reduces labor intensity of a worker, improves product quality, and lowers labor cost as work to be accomplished by three persons originally can be accomplished only by one person at present; more appropriate gripper jaws can be replaced according to different workpiece shapes at the same time; the locking angle is adjusted by self weight and inertia of the workpiece; no electric energy is consumed; and the equipment is energy-saving, environmentally-friendly, safe and reliable and reduces work injuries.

Owner:天津鑫泰博弈科技有限公司

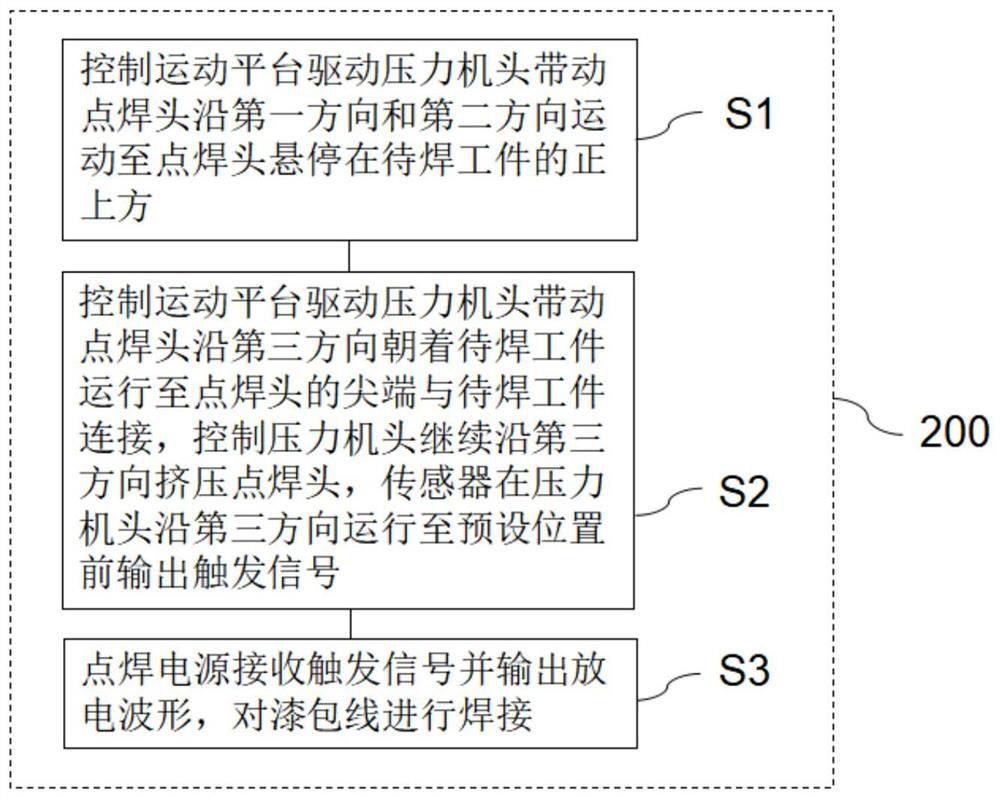

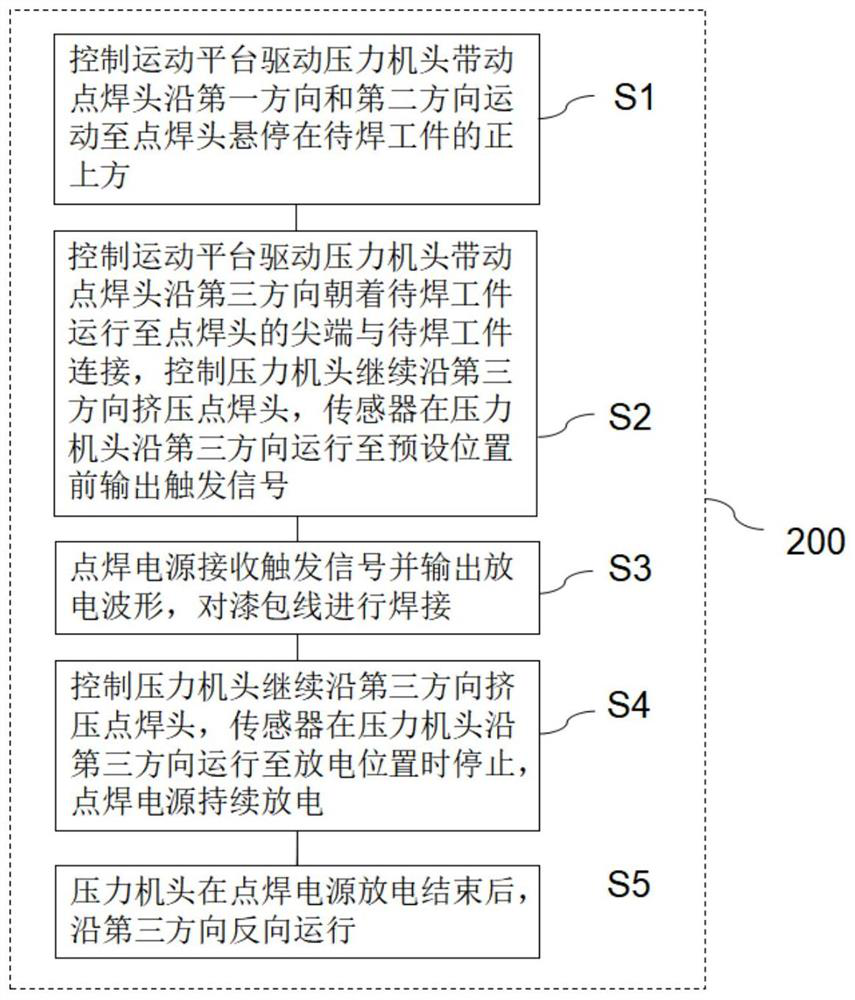

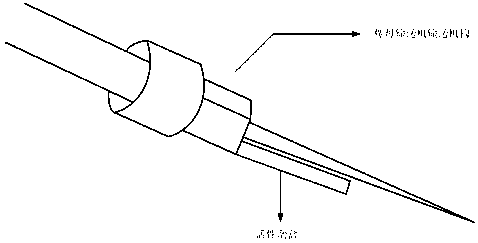

Stamping resistance welding welding system and its welding method

ActiveCN108723566BEasy to controlImprove welding accuracyResistance welding apparatusLacquerTin plating

The invention discloses a stamping resistance welding welding system and a welding method thereof. The stamping resistance welding welding system is used for welding workpieces to be welded in microelectronic assembly. The stamping resistance welding welding system includes: a motion platform; direction, the second direction and the third direction are movable, and any two of the first direction, the second direction and the third direction are perpendicular to each other; the spot welding head is set at the end of the press head adjacent to the workpiece to be welded; the sensor is at the When the press head moves to the preset position along the third direction, it outputs a trigger signal; the welding power source can receive the trigger signal and perform discharge, paint removal and welding on the enameled wire. Its welding method receives the sensor sensing signal and outputs the discharge trigger signal before the spot welding head moves to the set welding position, and realizes efficient paint removal and reliable welding by means of punching discharge. This stamping resistance welding welding system is suitable for welding magnet wire with small coils to tinned pads in microelectronics assembly.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

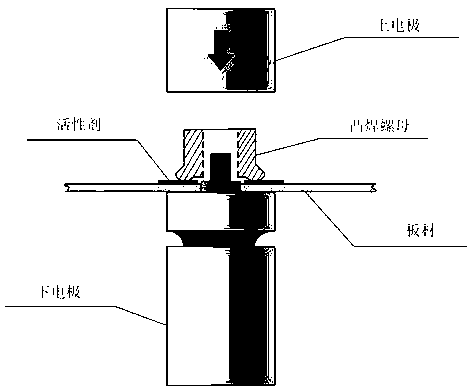

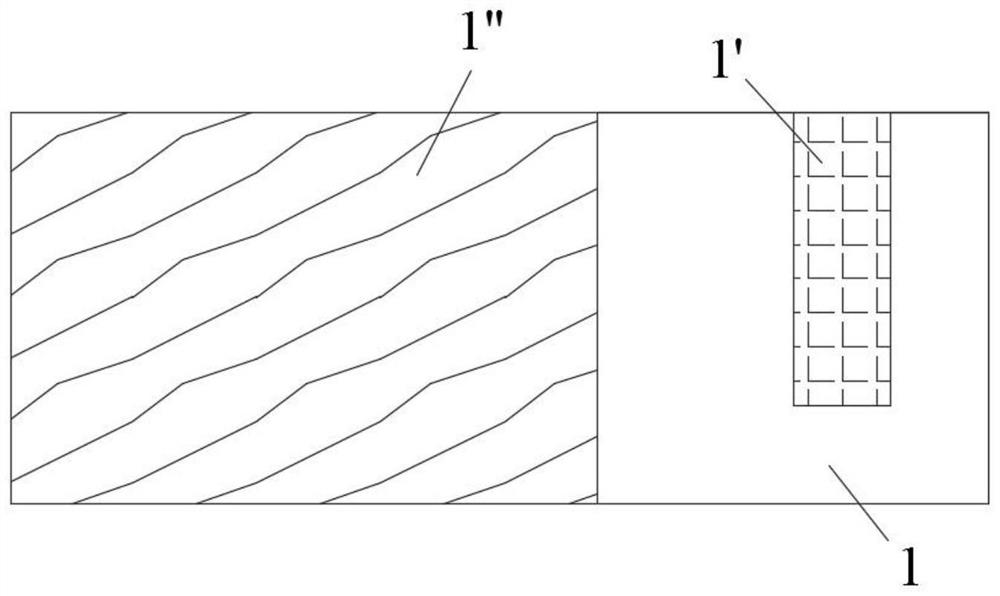

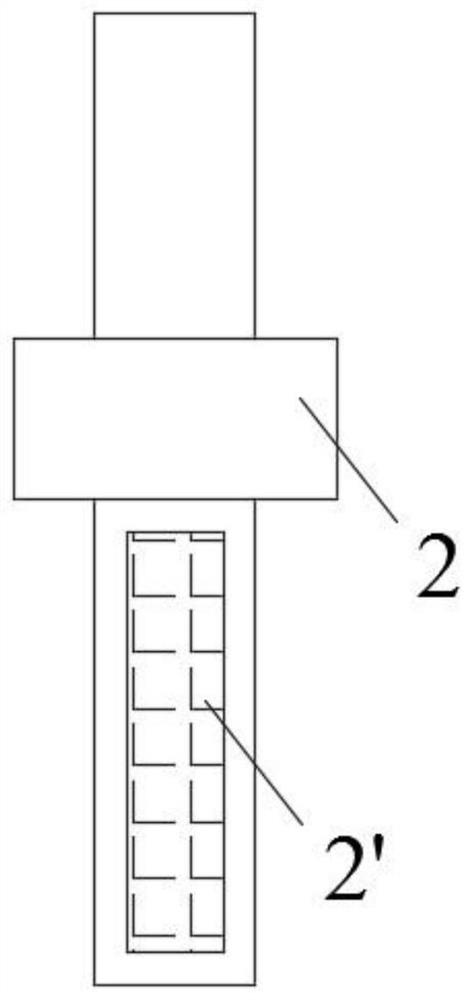

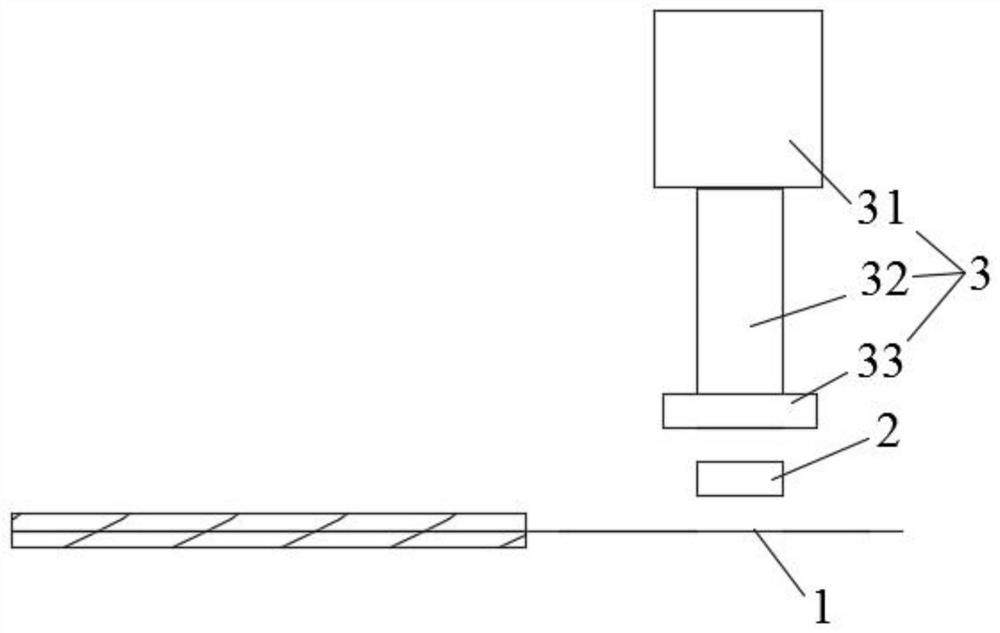

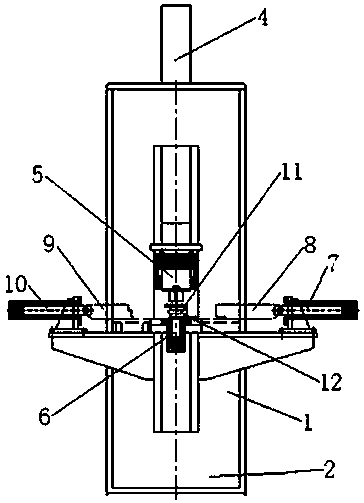

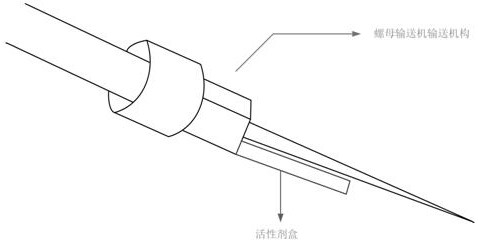

Auxiliary welding active agent and novel nut projection welding method for enhancing welding penetration

ActiveCN110666398ASmall currentShort welding timeWelding/cutting media/materialsSoldering mediaActive agentSoldering

The invention relates to an auxiliary welding active agent and a novel nut projection welding method for enhancing welding penetration. The auxiliary welding active agent comprises the following steps: 1) first, blending and forming the active agent by powder and a binder in a mass ratio of 1: (4-6), and then diluting the active agent by using acetone at a proportion of 1(1.5-3): 1, wherein the powder is prepared from the following components in percent by mass: 50-60% of carbon black, 4-10% of CaF2, 16-25% of TiO2 and 15-27% of Mn; 2) putting the prepared active agent in a special active agent box; 3) mounting the active agent box on a conveying structure of a nut conveyor; and 4) carrying out nut projection welding, wherein a nut passes the active agent box in a conveying process, so that the active agent is dipped in nut projection welding. The welding penetration can be improved greatly, the consistence of multi-emboss welding of the nut is improved, forming defects such as pseudosoldering and splashing are improved, and high-efficiency nut projection welding is achieved. The method reduces the probability of pseudo soldering greatly, cancels a repair welding step, improves the welding efficiency, reduces the energy consumption, saves the cost, and improves the welding quality of nut projection welding greatly.

Owner:XI'AN PETROLEUM UNIVERSITY

A new type of pole piece and tab welding process

ActiveCN111299798BHigh precisionGood welding performanceSecondary cellsCell component detailsEngineeringPole piece

The invention belongs to the technical field of lithium batteries, and in particular relates to a new welding process for pole pieces and tabs, comprising the following steps: S1, preparing the pole pieces and the pole tabs to be welded together; S2, first welding the metal parts of the pole pieces Clean the surface of the second welding surface of the metal part of the electrode and the metal part of the pole lug; S3, put the pole piece and the pole lug into the vacuum chamber of the vacuum cold pressing tool; S4, vacuum the vacuum chamber and keep it for a period of time; S5 . In the vacuum chamber, use a cold pressing tool to squeeze the surface-treated first welding surface and the second welding surface together; S6, fill the vacuum chamber with dry gas to complete the welding. The welding process has the characteristics of high precision, reliable welding effect and high welding consistency, which helps to solve the problems of poor consistency of welding procedures in the current industry, and at the same time can improve the energy density of the cell.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

Welding mechanism of a shock absorber welding machine

ActiveCN105436728BThe stop effect disappearsLess technology dependentWelding/cutting auxillary devicesAuxillary welding devicesRejection rateShock absorber

Owner:宁波力品格自动化科技有限公司

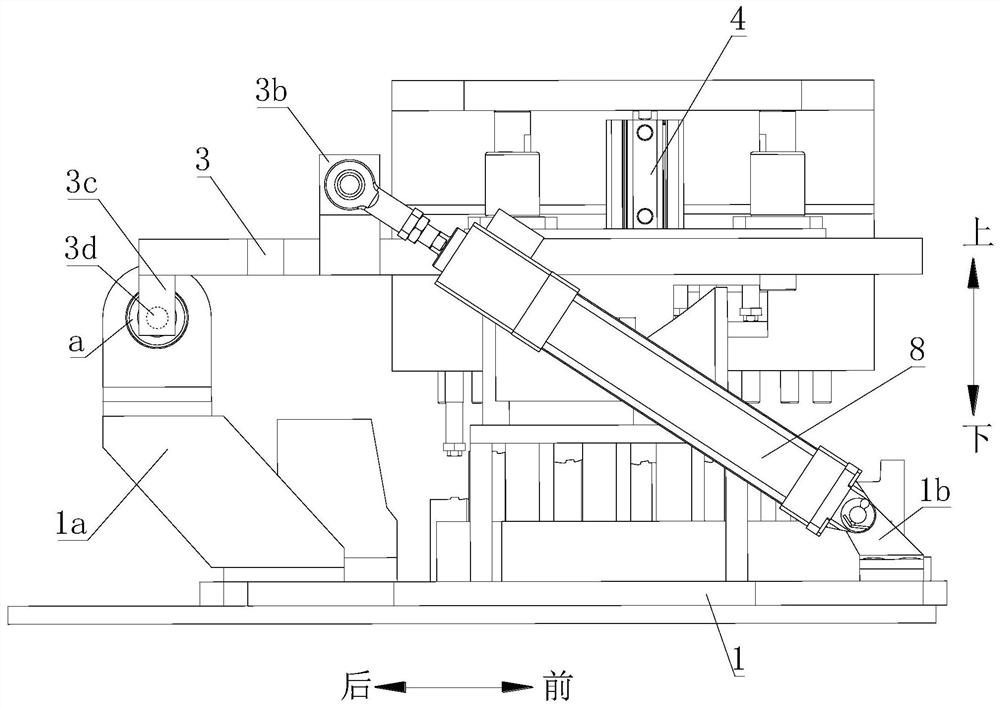

S-shaped steel positioning and shaping device

InactiveCN111001676ASimple structureEasy to useShaping toolsWelding/cutting auxillary devicesPhysicsEngineering

The invention relates to an S-shaped steel positioning and shaping device. The S-shaped steel positioning and shaping device comprises a workbench and oil cylinders, wherein a lower cross beam is arranged at the lower end of the workbench, the oil cylinders comprise positioning oil cylinders, clamping oil cylinders, pressing oil cylinders and shaping oil cylinders, the positioning oil cylinders are sequentially and fixedly arranged on one side of the top of the lower cross beam, the clamping oil cylinders are fixed to the other side of the top of the lower cross beam in parallel, the positioning oil cylinders, the clamping oil cylinders, the pressing oil cylinders and the shaping oil cylinders are installed at equal intervals, clamping molds, positioning molds, S-shaped steel and a transverse plate are placed on the workbench, the positioning oil cylinders are connected with the positioning molds, the clamping oil cylinders are connected with the clamping molds, the positioning molds and the clamping molds fix the S-shaped steel and the transverse plate from the two sides, the pressing oil cylinders press the top of the S-shaped steel and press the S-shaped steel and the transverseplate on the top of the lower cross beam, and the shaping oil cylinders are located at the bottom of the transverse plate. The S-shaped steel positioning and shaping device is simple in structure, convenient to use, accurate in positioning, high in welding precision, good in consistency, small in welding deformation and convenient to shape, the efficiency is improved, and the cost is reduced.

Owner:TAIZHOU HAILING HYDRAULIC MACHINERY

A kind of welding auxiliary activator and method for improving welding penetration nut projection welding

ActiveCN110666398BSmall currentShort welding timeWelding/cutting media/materialsSoldering mediaActive agentIndustrial engineering

A welding auxiliary activator and a nut projection welding method for improving welding penetration, 1) Firstly, powder and binder are mixed in a mass ratio of 1:4 to 6 to form an activator, and then acetone is used in a ratio of 1.5 to 3:1 Dilute the active agent, the powder includes the following components by mass percentage: carbon black 50% to 65%, CaF2 4% to 10%, TiO2 16% to 25%, Mn 15% to 27%; 2) will be made The active agent is placed in a special active agent box. 3) Install the active agent cartridge on the nut conveyor conveying structure. 4) Nut projection welding is carried out, and the nut passes through the active agent box during the conveying process, so that the nut bumps are dipped in the active agent. The invention can greatly increase the penetration depth of the weld nugget, improve the consistency of nut multi-bump welding, improve forming defects such as virtual welding and spatter, and realize high-efficiency nut projection welding. The method greatly reduces the probability of false welding, saves a repair welding process, improves welding efficiency, reduces energy consumption, saves costs, and greatly improves the welding quality of nut projection welding.

Owner:XI'AN PETROLEUM UNIVERSITY

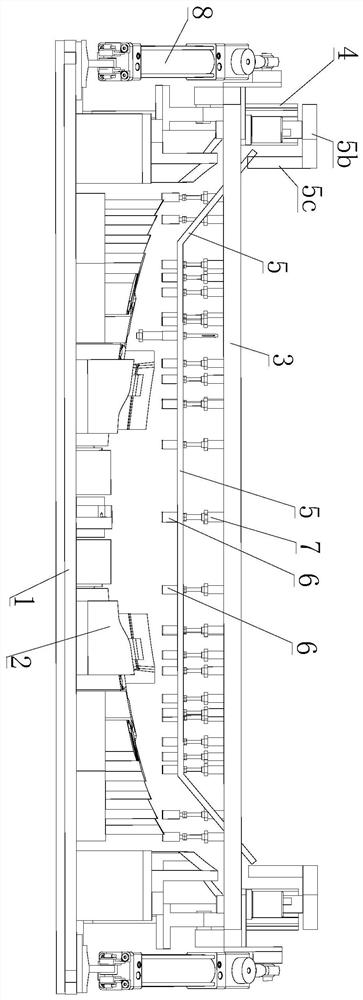

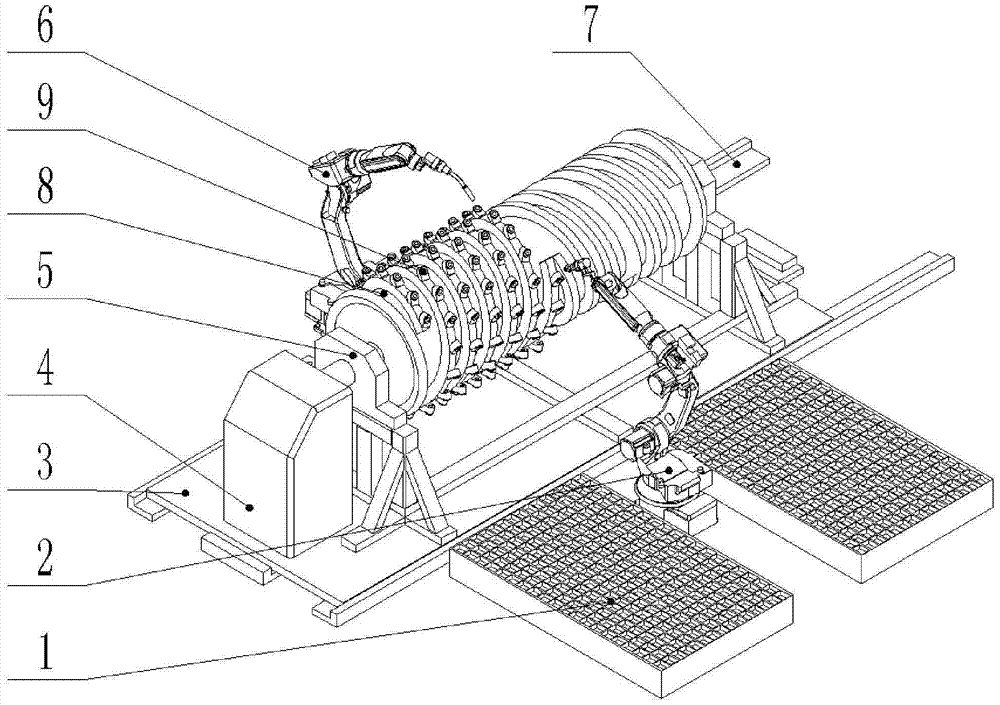

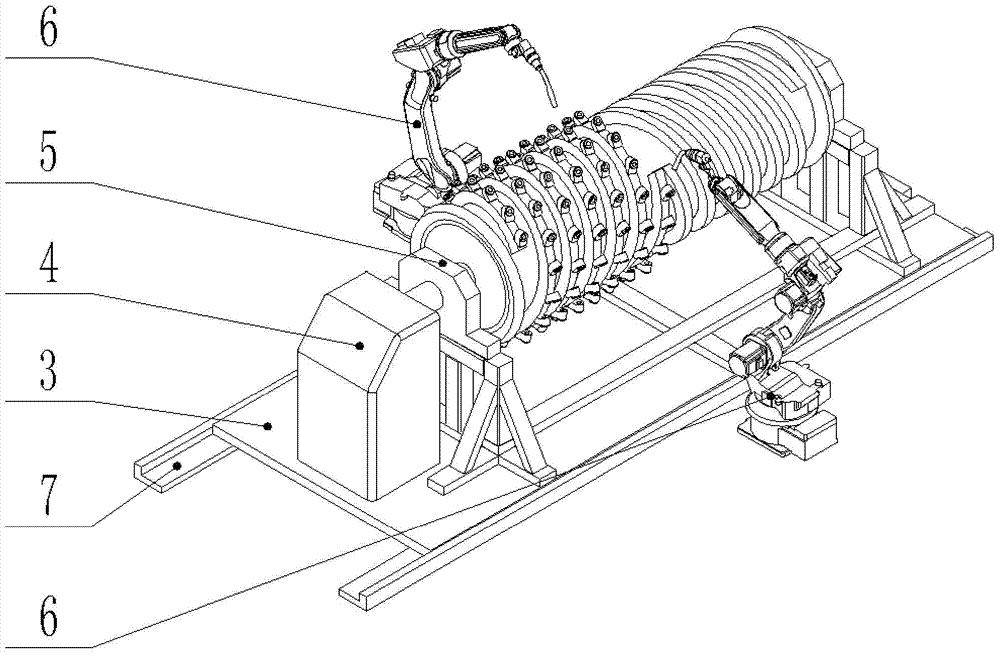

A double-station robot automatic welding production line for milling drum tool holders

ActiveCN105397356BHigh degree of automationReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesProduction linePavement maintenance

The invention relates to the technical field of pavement maintenance equipment, in particular to a double-station automatic welding production line of a milling drum knife holder robot; and the double-station automatic welding production line of the milling drum knife holder robot comprises a spot welding station, an all-welding station and a material transfer device. The spot welding station and the all-welding station are respectively arranged at the two ends of the material transfer device; and the material transfer device moves between the spot welding station and the all-welding station. The double-station automatic welding production line of the milling drum knife holder robot adopts a double-procedure welding process of spot welding and all welding to integrate a multi-robot collaborative manufacturing technology, so that the welding automation degree is largely increased, the welding quality and stability of a milling drum knife holder are effectively improved, the number of operators is reduced, and the adverse impact on environments and human bodies is eliminated.

Owner:SUZHOU HONGAN MACHINERY

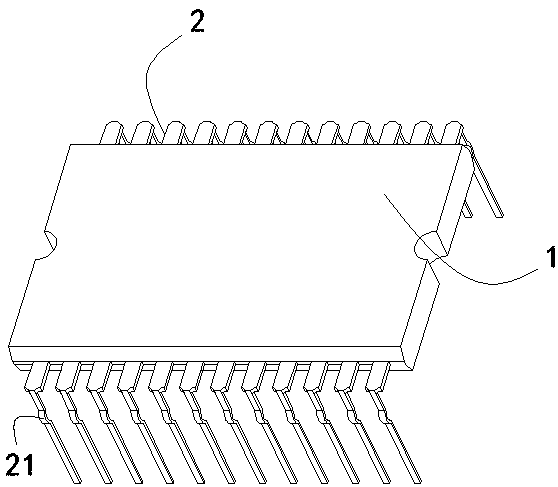

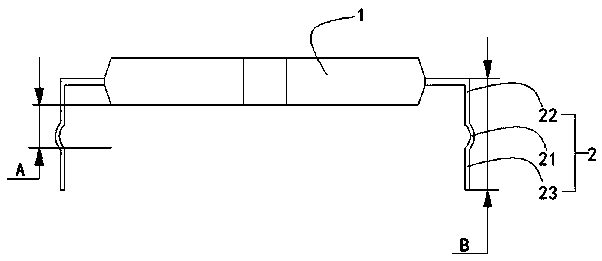

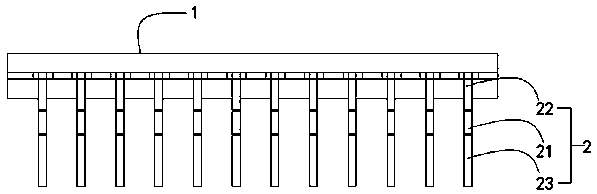

Power device and welding positioning method thereof

InactiveCN110948135AInstall height controlAvoid wear and tearPrinted circuit assemblingWorkpiece edge portionsProduction lineElectrical and Electronics engineering

The invention provides a power device which comprises a power device body, wherein two ends of the power device body are fixedly provided with a plurality of pins, and the pins are provided with limiting bulges used for limiting the installation height of the power device body. The power device can be directly inserted into a PCB for welding and fixing production, which not only eliminates the positioning height of an original gasket tool, but also improves the production efficiency and the quality consistency of the production line.

Owner:GREE ELECTRICHEFEI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com