Welding apparatus with micropicture automatic-computing positioning system and operation mode

An automatic calculation and positioning system technology, applied in the direction of electrical program control, digital control, etc., can solve the problems of welding quality fluctuation, low work efficiency, and great influence, and achieve the effect of improving welding quality, high positioning accuracy and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

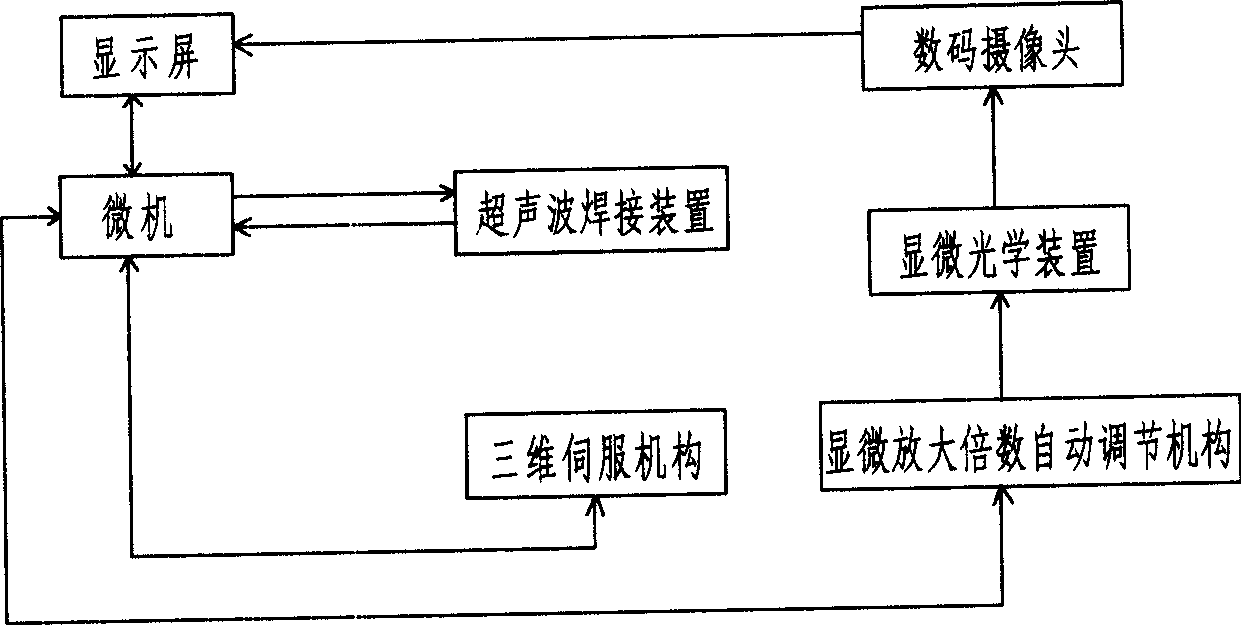

[0038] Embodiment 1 of the welding equipment with the microscopic image automatic calculation and positioning system is an automatic ultrasonic welding equipment, such as figure 1 As shown, it includes microscopic image automatic calculation and positioning system and ultrasonic welding device. The microcomputer and the digital camera on the eyepiece of the micro-optical device are respectively connected with the ultrasonic welding device, the precision three-dimensional servo mechanism, the micro-optic device and the digital camera. The microcomputer controls the ultrasonic welding device to complete the drawing wire and ultrasonic welding. The digital camera sends the image of the workpiece enlarged by the micro-optical device to the microcomputer. The three-dimensional servo motor in the precision three-dimensional servo mechanism drives the movement of the worktable according to the instructions of the microcomputer. The microscopic optical device can be equipped with a mi...

Embodiment 2

[0070] The existing ordinary manual ultrasonic welding machine can be refitted into automatic ultrasonic welding equipment by being equipped with the microscopic image automatic calculation and positioning system of the present invention, thereby obtaining low-cost automatic welding equipment.

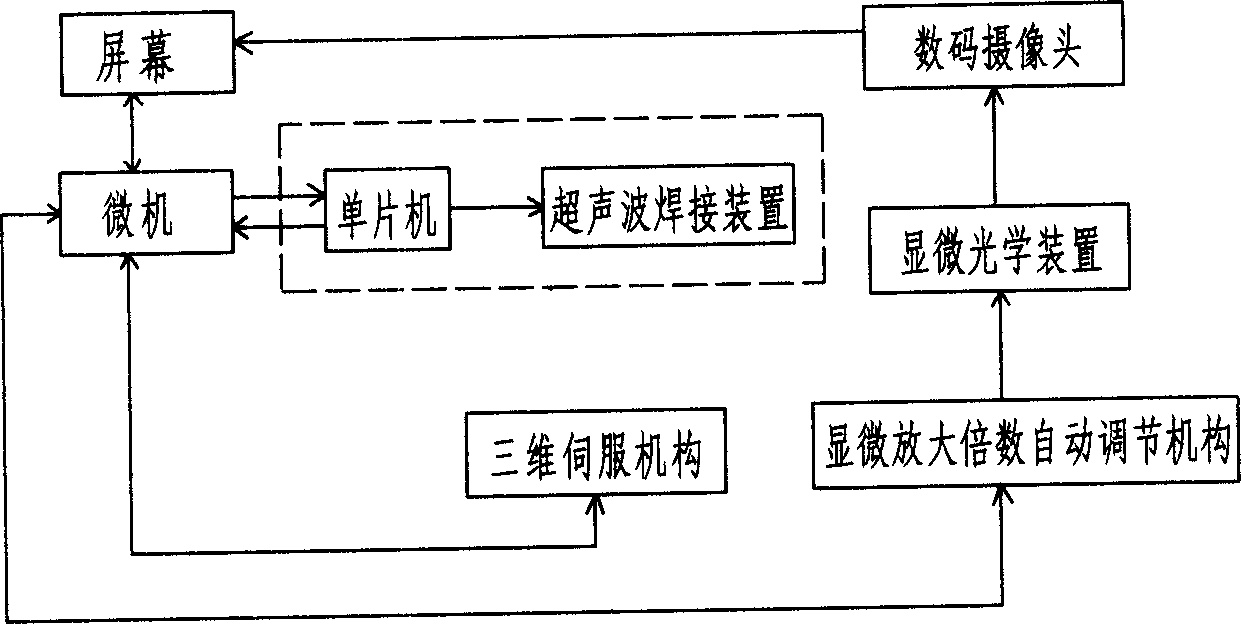

[0071] image 3 Shown is the embodiment 2 of welding equipment with microscopic image automatic calculation and positioning system of the present invention, including microscopic image automatic calculation and positioning system and manual ultrasonic welding machine. The manual ultrasonic welding machine is in the dotted line box, which is ultrasonic welding controlled by a single chip device. The single-chip microcomputer controls the ultrasonic welding device to complete the pulling wire and ultrasonic welding. The microscopic image automatic calculation and positioning system includes a precise three-dimensional servo mechanism, a microscopic optical device, a microcomputer with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com