Patents

Literature

34results about How to "Reduce mechanical transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

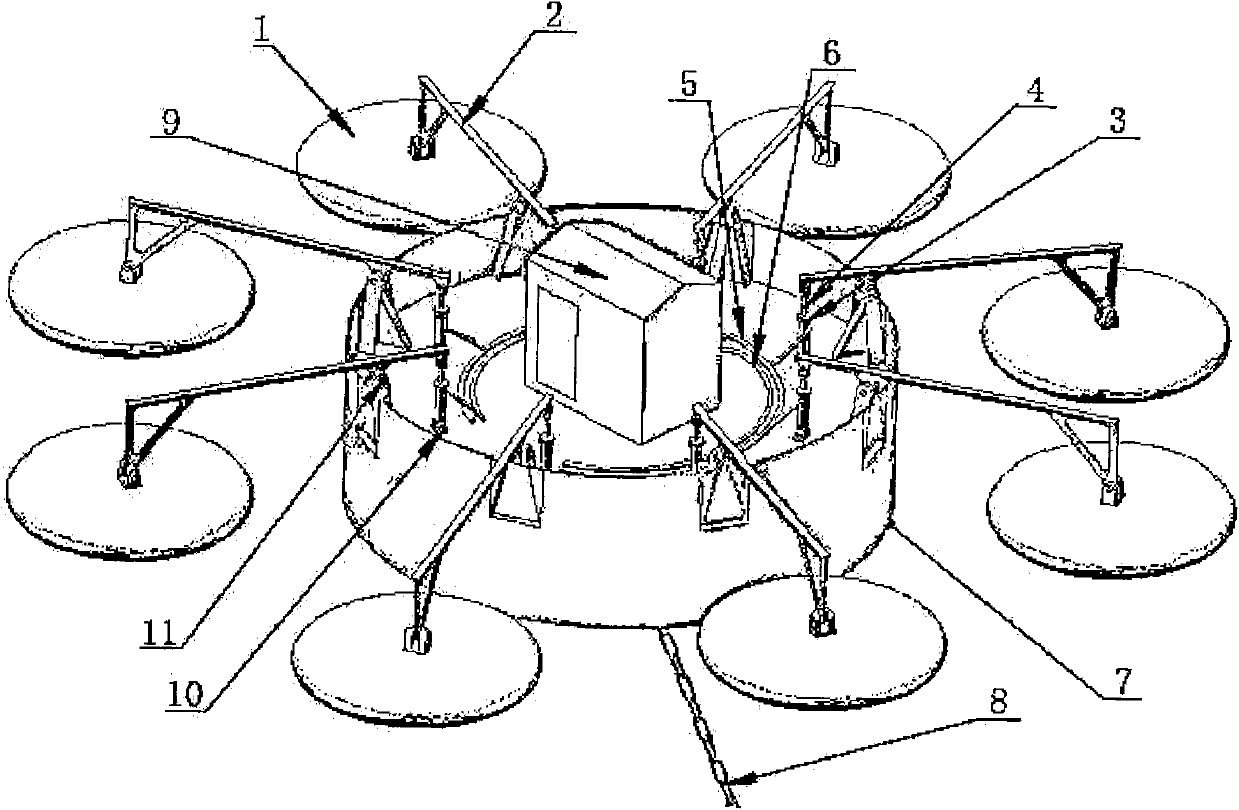

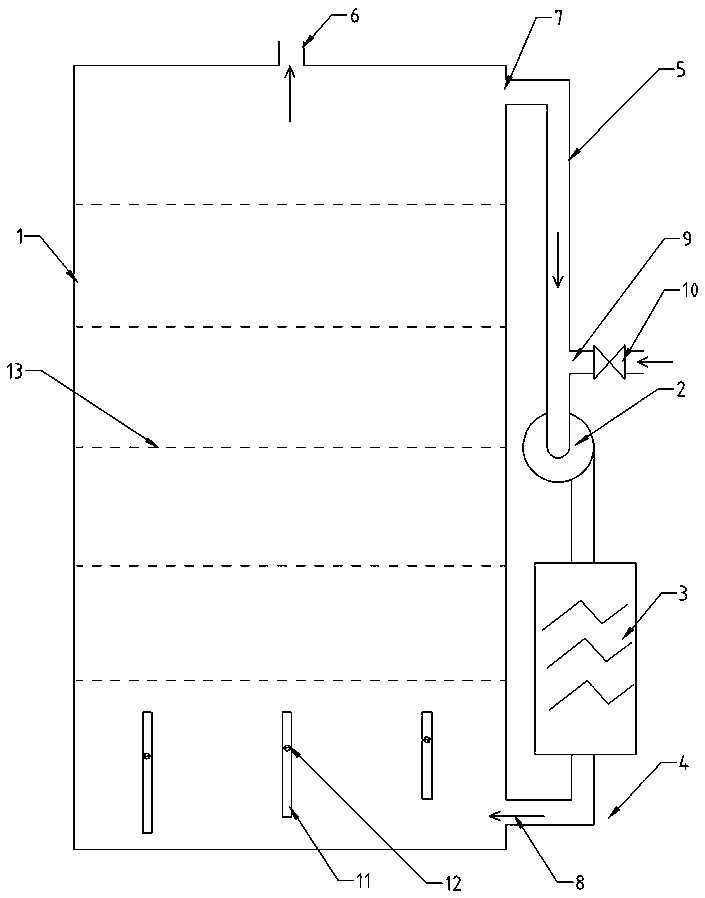

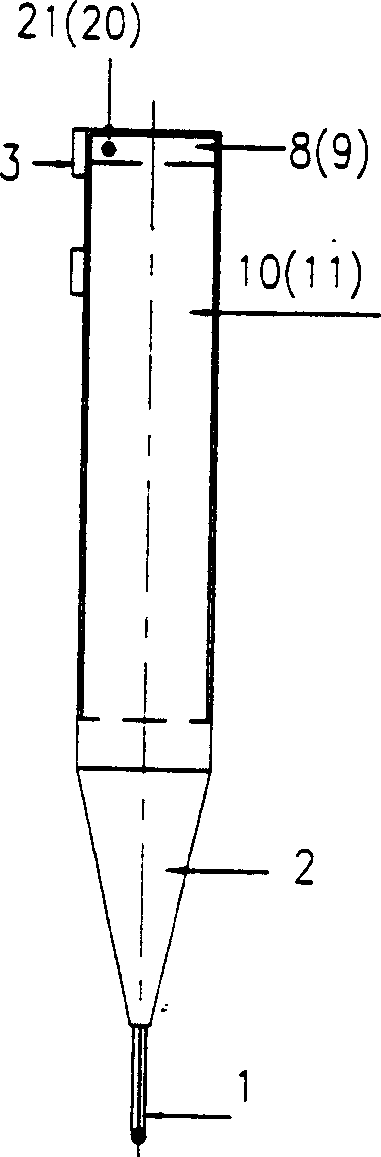

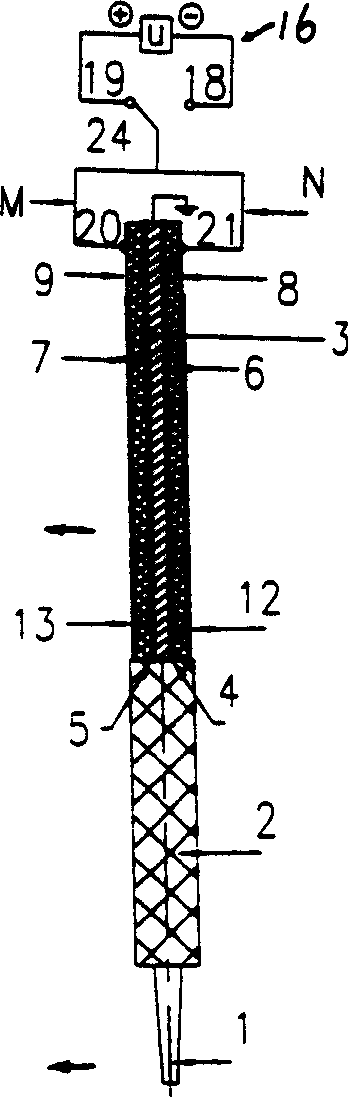

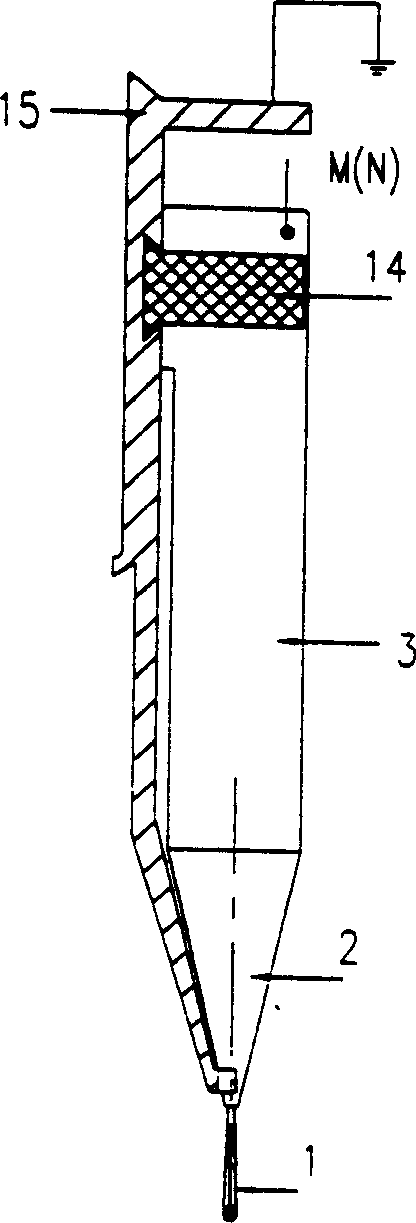

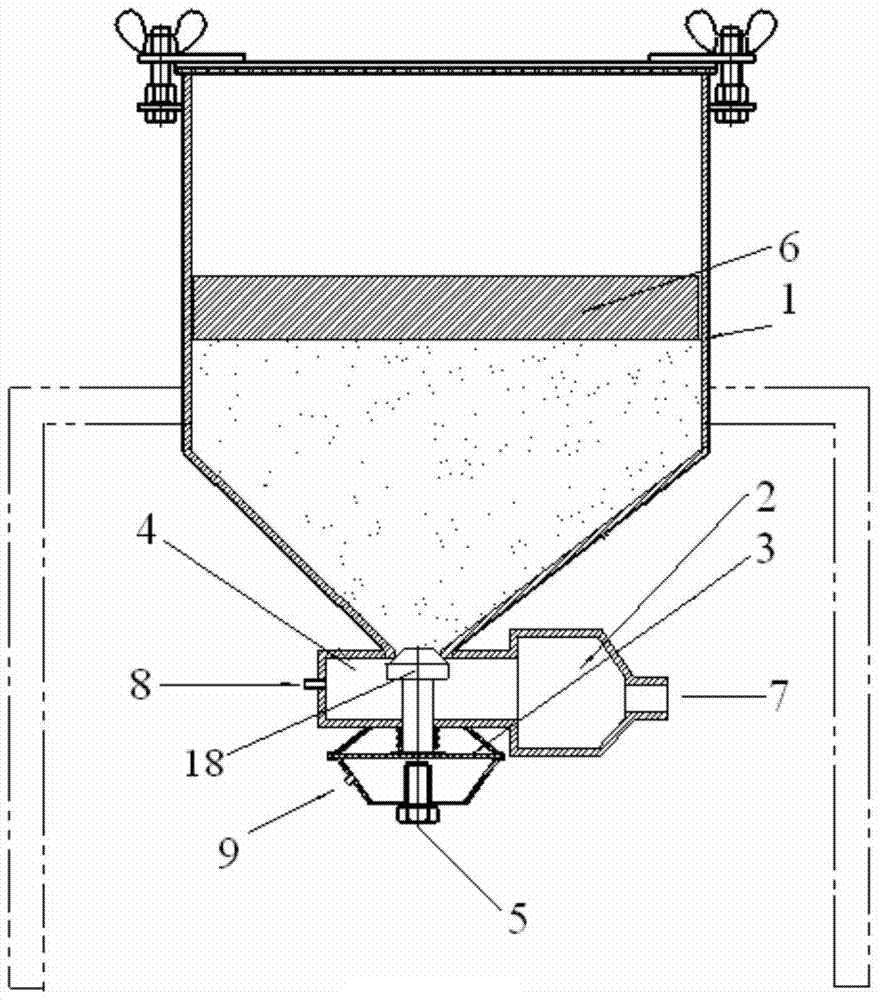

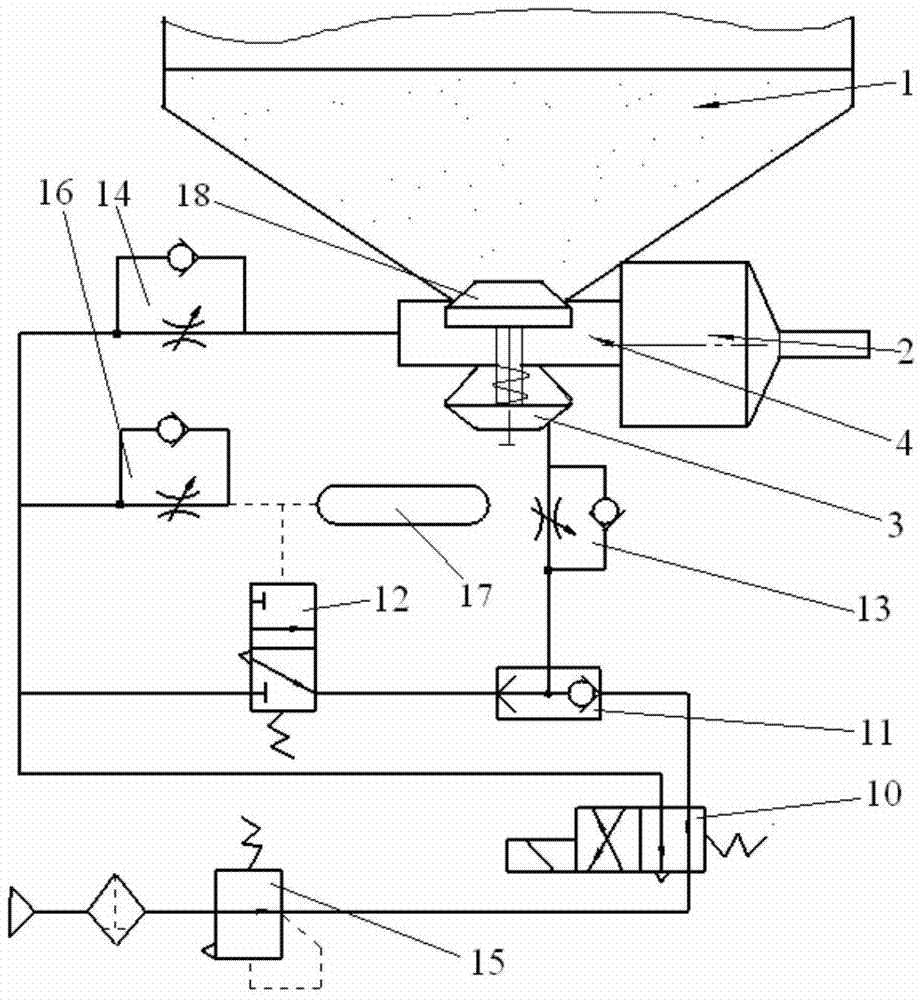

A floating type wave power generation system

InactiveCN102022248AEfficient captureControllable outputMachines/enginesEngine componentsWave power generationMechanical energy

A floating type wave power generation system is characterized in that the system consists of eight sets of lever-type floating bodies and a hydraulic energy accumulation converter with the hydraulic pump function. On a floating workbench 7, eight sets of levers 2 and a floating body 1 are connected through supporting hinge bearers 10 and 11; in this way, the highly undulating displacement caused by waves can be converted to relatively lesser displacement of a piston rod 4, and the minor force that the floating body bears can be converted through the lever to the major force on the piston rod. The piston rod drives a hydraulic tank 3 to switch and transmit the hydraulic energy through a connecting oil pipe5, a high-pressure oil pipe6, a hydraulic oil tank and four no-return valves of each set to a hydraulic motor in a hydraulic power generation control chamber 9; in this way the generator is driven to work. The present system can absorb, convert and accumulate the intermittent unstable wave energy in a highly effective way and can buffer the destructive effect of waves. The floating platform can be suitable to different marine space by adjusting the length of an anchor chain 8. And in various sea conditions, kinetic energy and potential energy possessed by waves in the sea surface can be converted and accumulated as hydraulic mechanical energy by utilization of the wave drop; thus the generator is driven to unremittingly provide electric power.

Owner:杨超

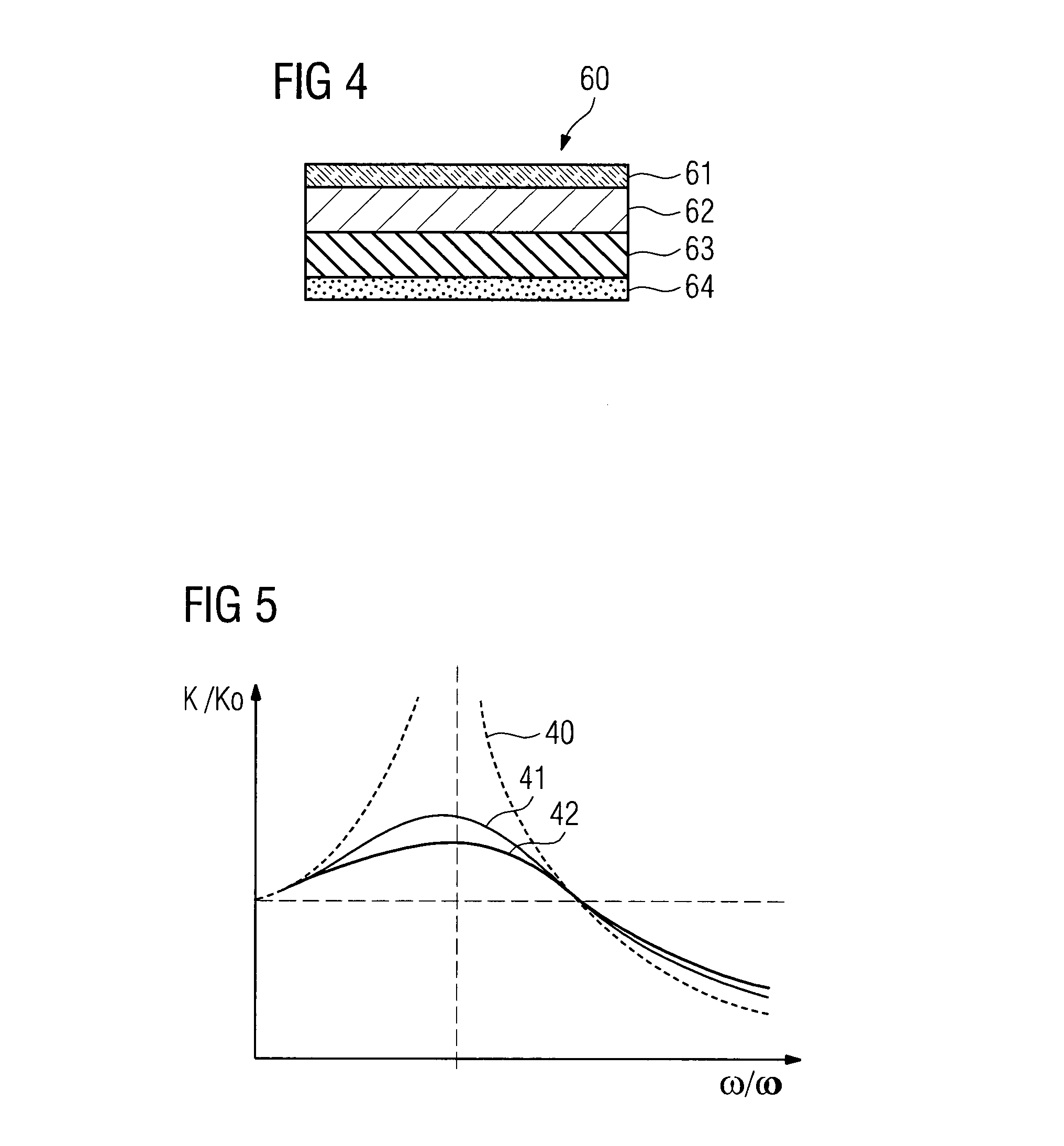

Copolymers as additives in thermoplastic elastomer gels

InactiveUS6133354AGood damping propertiesPrevent surfacePlastic/resin/waxes insulatorsFilm/foil adhesivesElastomerImide

The present invention teaches a method for enabling the formation of a high damping composition. The method includes mixing a centipede polymer, i.e., a poly(disubstituted ethylene-co-maleimide) polymer, and plasticizers or extenders within a non-vulcanized thermoplastic elastomer to form a relatively high damping gel composition.

Owner:BRIDGESTONE CORP

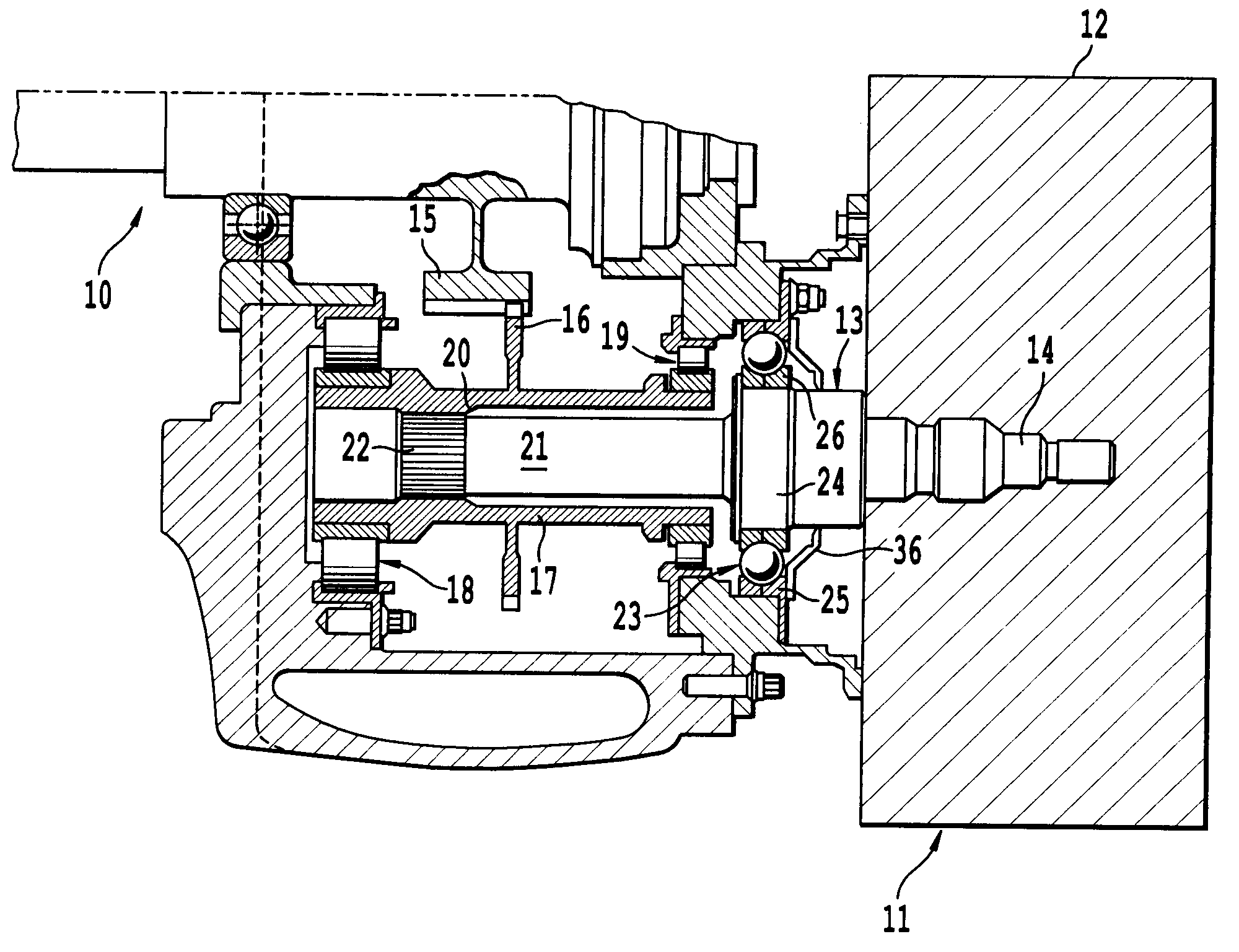

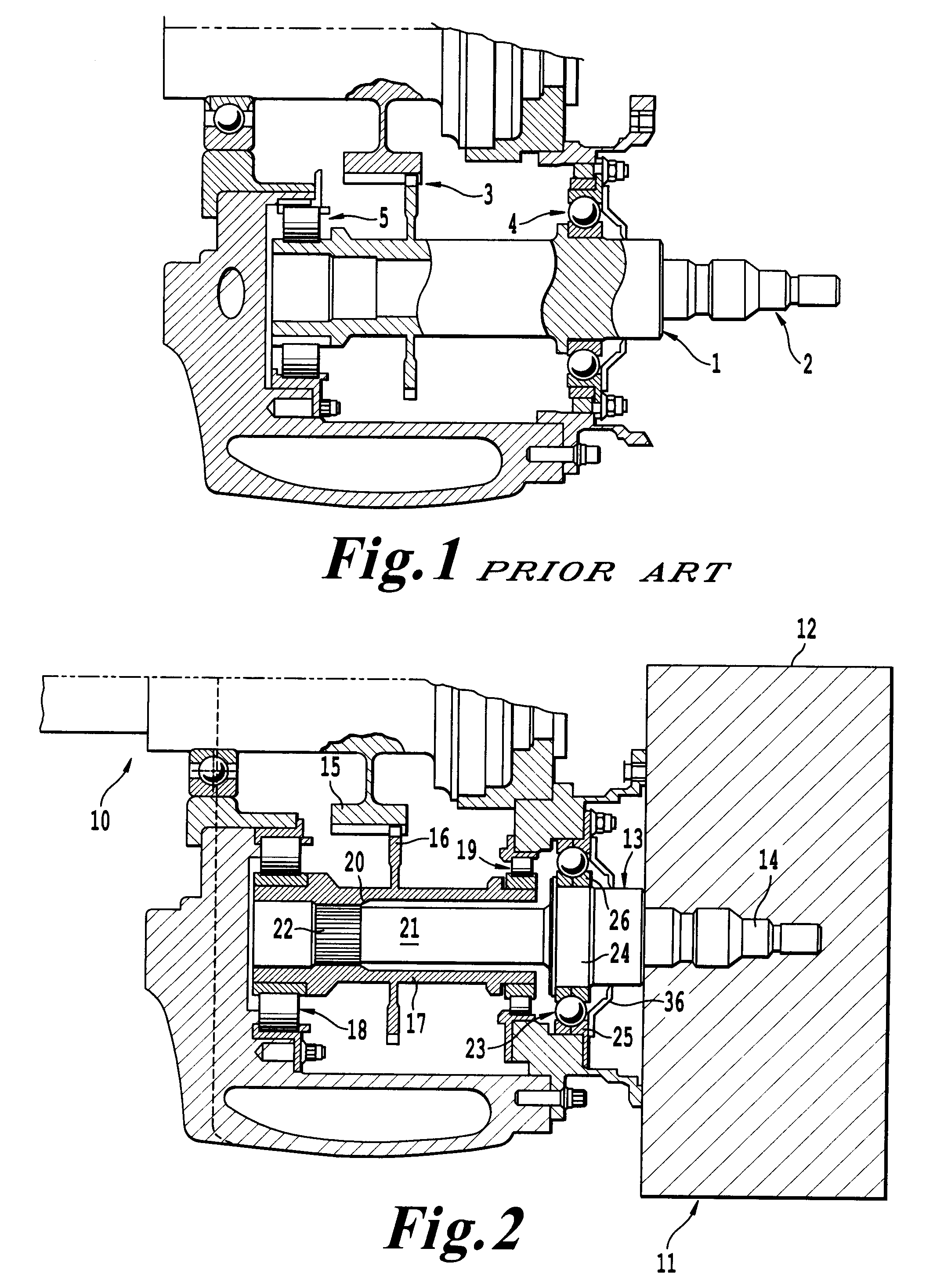

Device for driving the rotor of turbine engine auxiliary

ActiveUS20080053257A1Reduce transmissionReduce mechanical transmissionEngine fuctionsGas turbine plantsMechanical loadRotational coupling

The device for driving the rotor of an auxiliary (11) of the invention is mounted on a turbine engine auxiliaries support (10) which comprises means (15) for driving the rotor shaft (13). It comprises a tubular shaft (17) driven by one of said means (15) and supported by a first bearing (18) and a second bearing (19) which are secured to the auxiliaries support (10), the rotor shaft (13) being coaxial with the tubular shaft (17) and a rotational-coupling means being formed between the rotor shaft (13) and the tubular shaft (17).By virtue of the invention, mechanical loads of the auxiliary (11) are transmitted to a lesser extent to the rotor shaft support bearings (18, 19) and to the auxiliaries support gear train.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

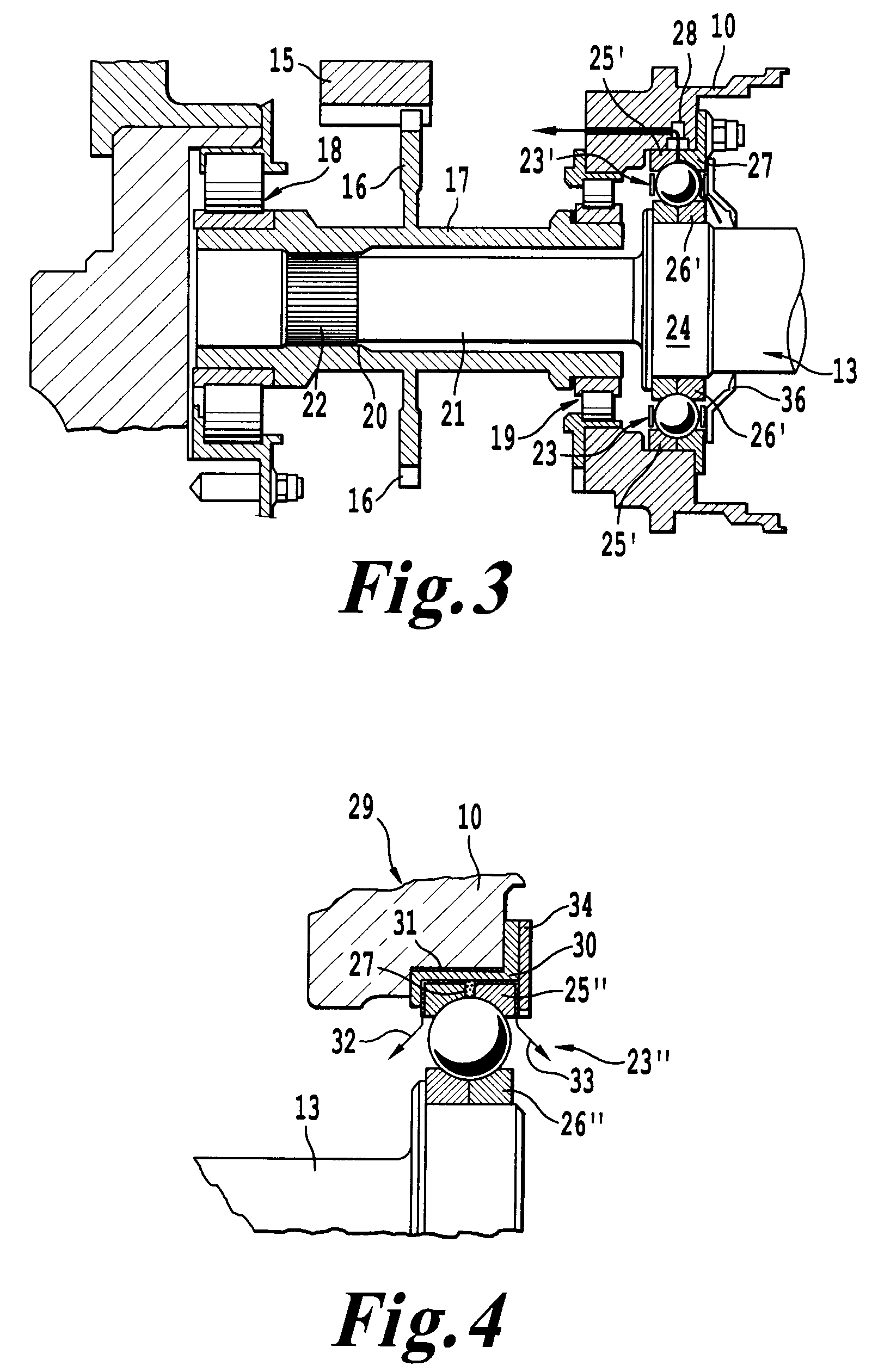

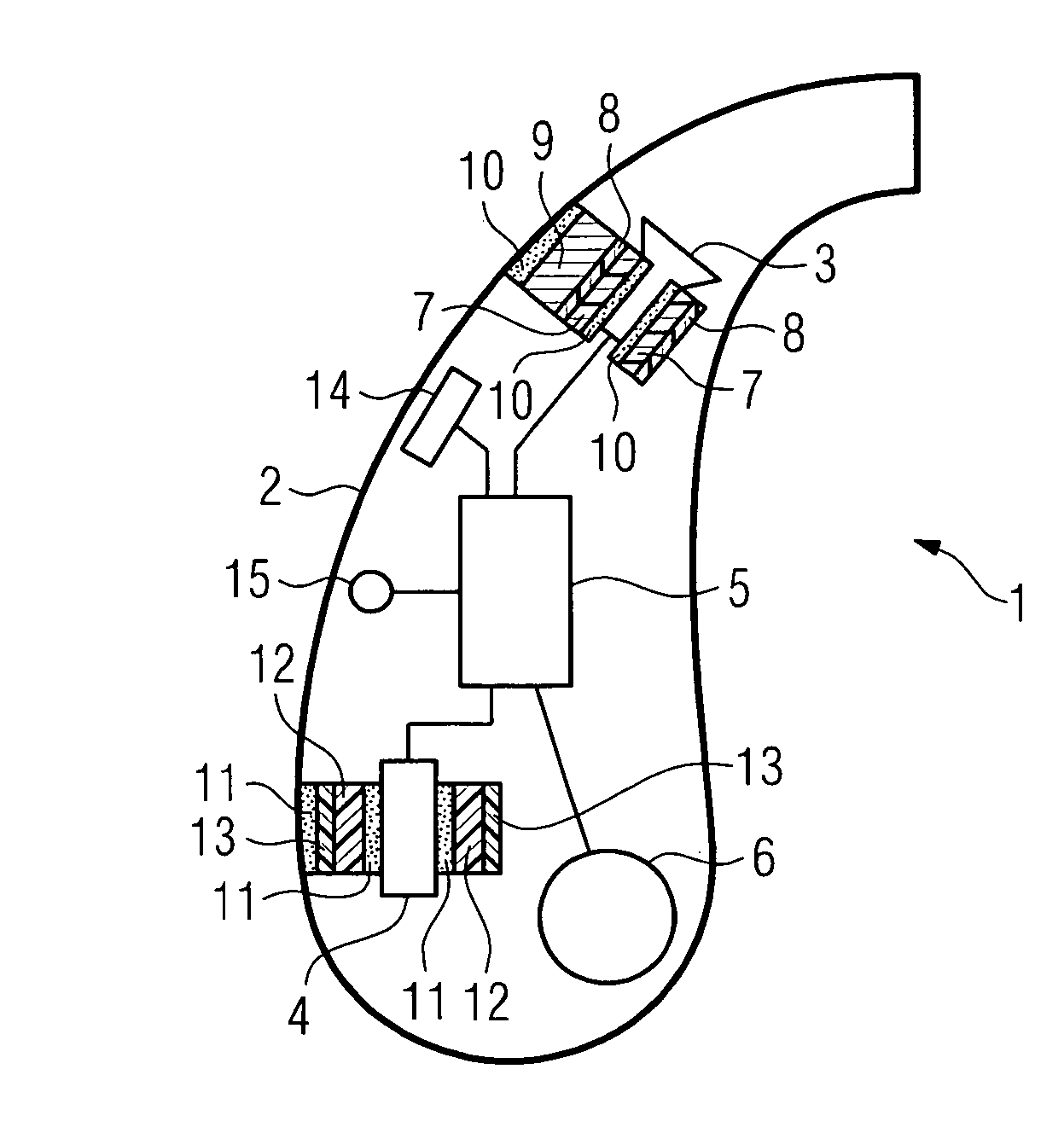

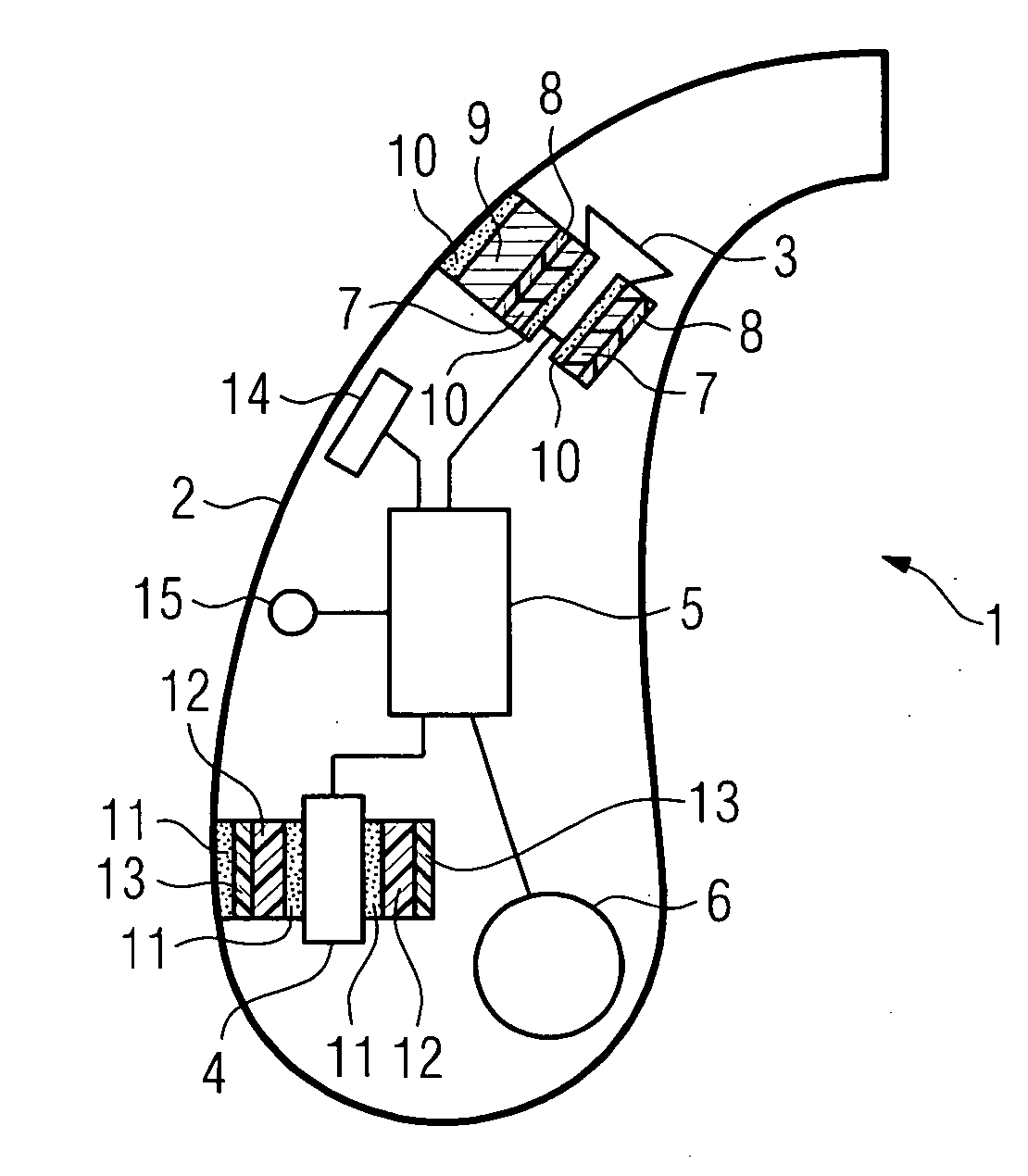

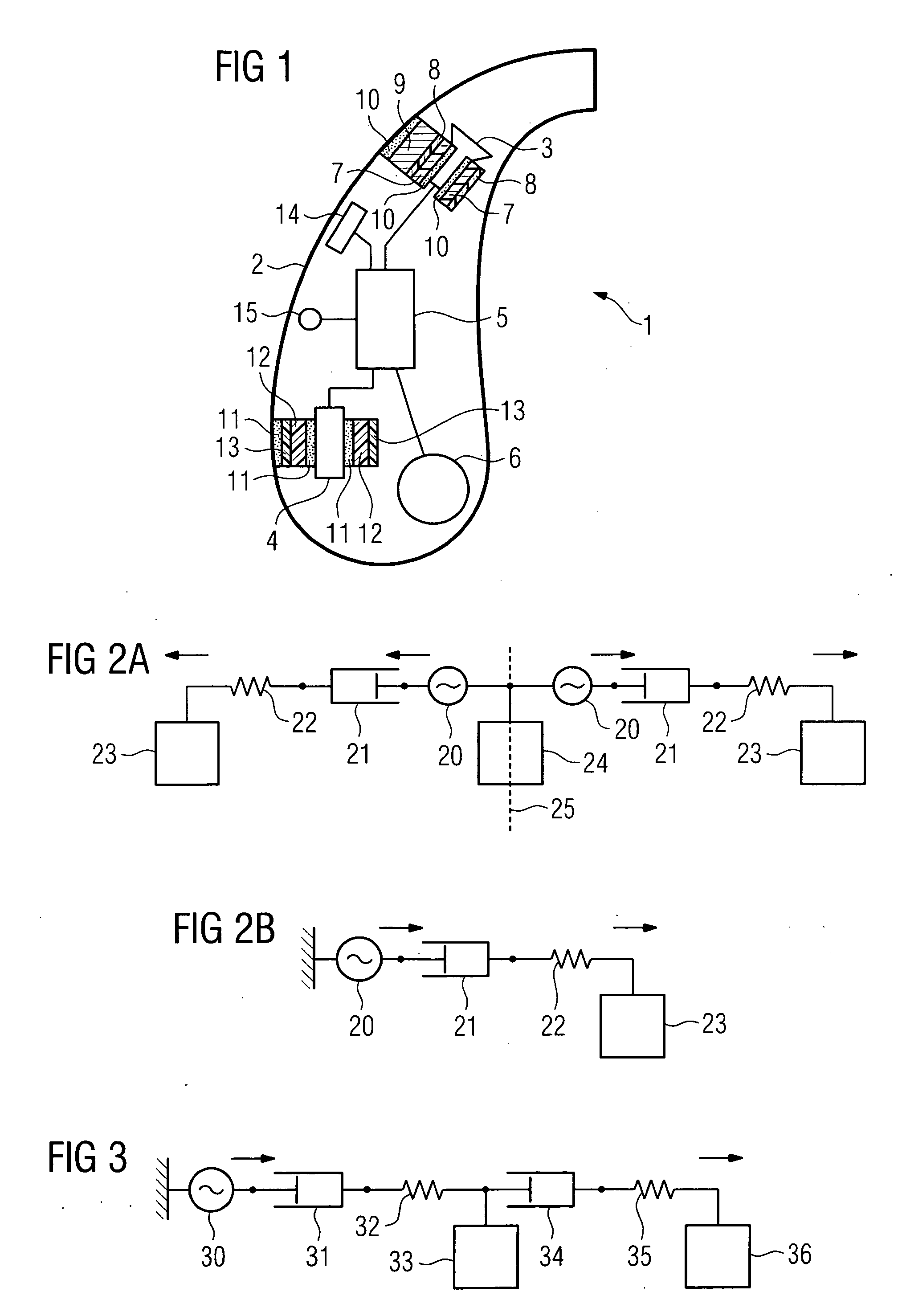

Hearing aid with an attenuation element

ActiveUS8259975B2Reduce riskPrevent solid-borne sound transmissionDeaf-aid setsUltrasound attenuationEngineering

Owner:SIVANTOS PTE LTD

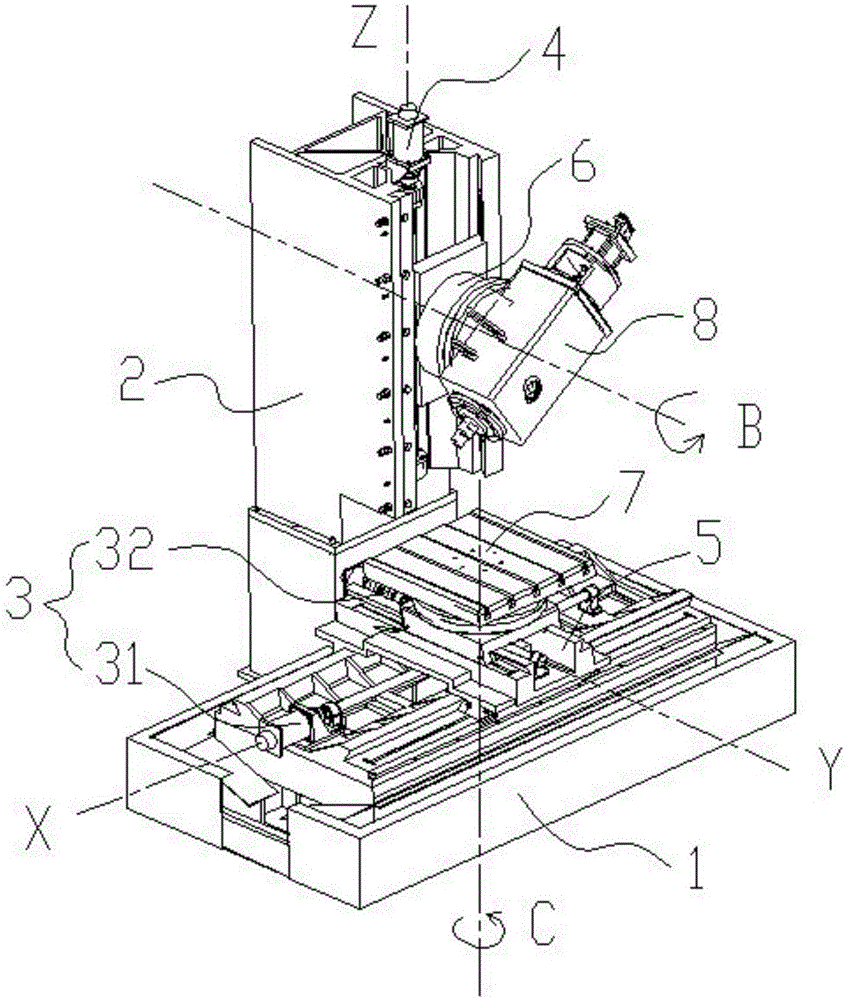

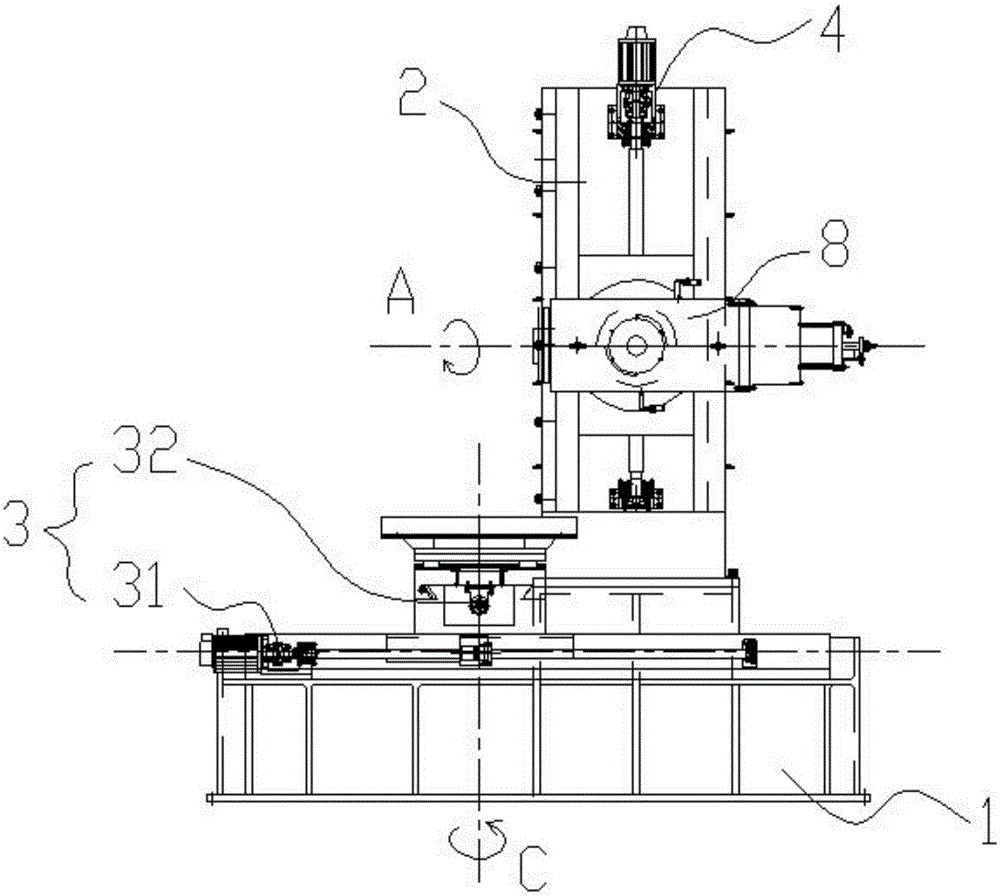

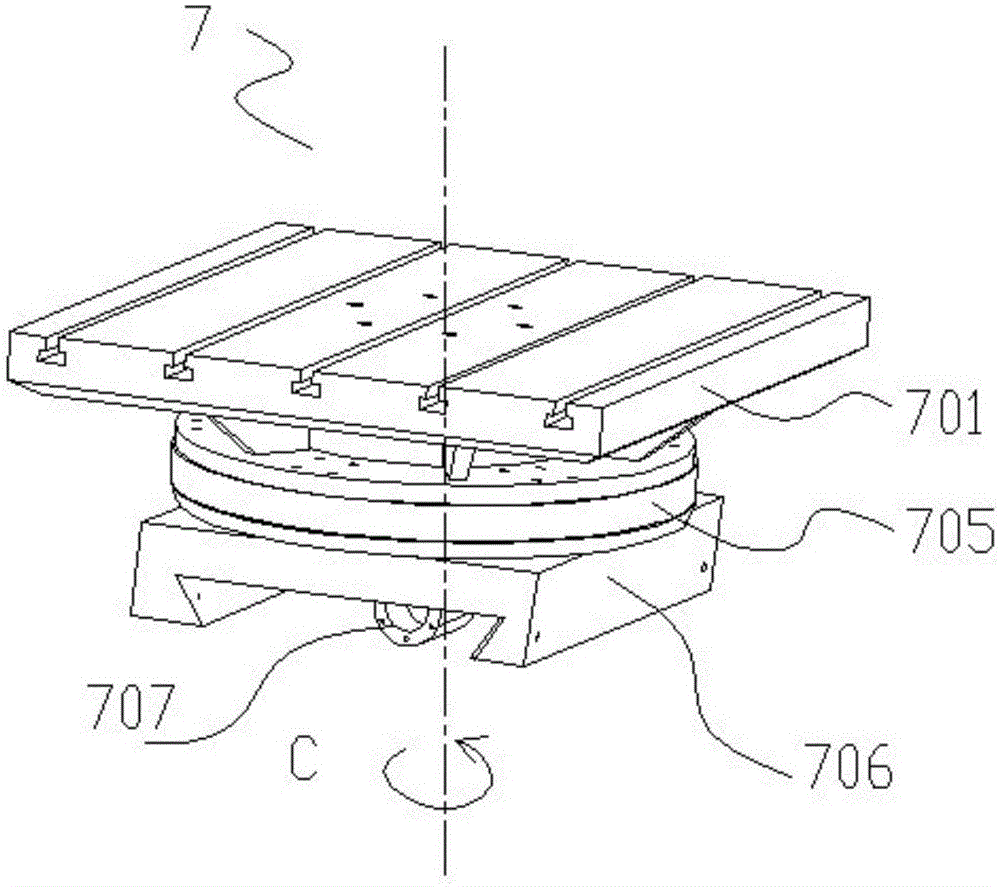

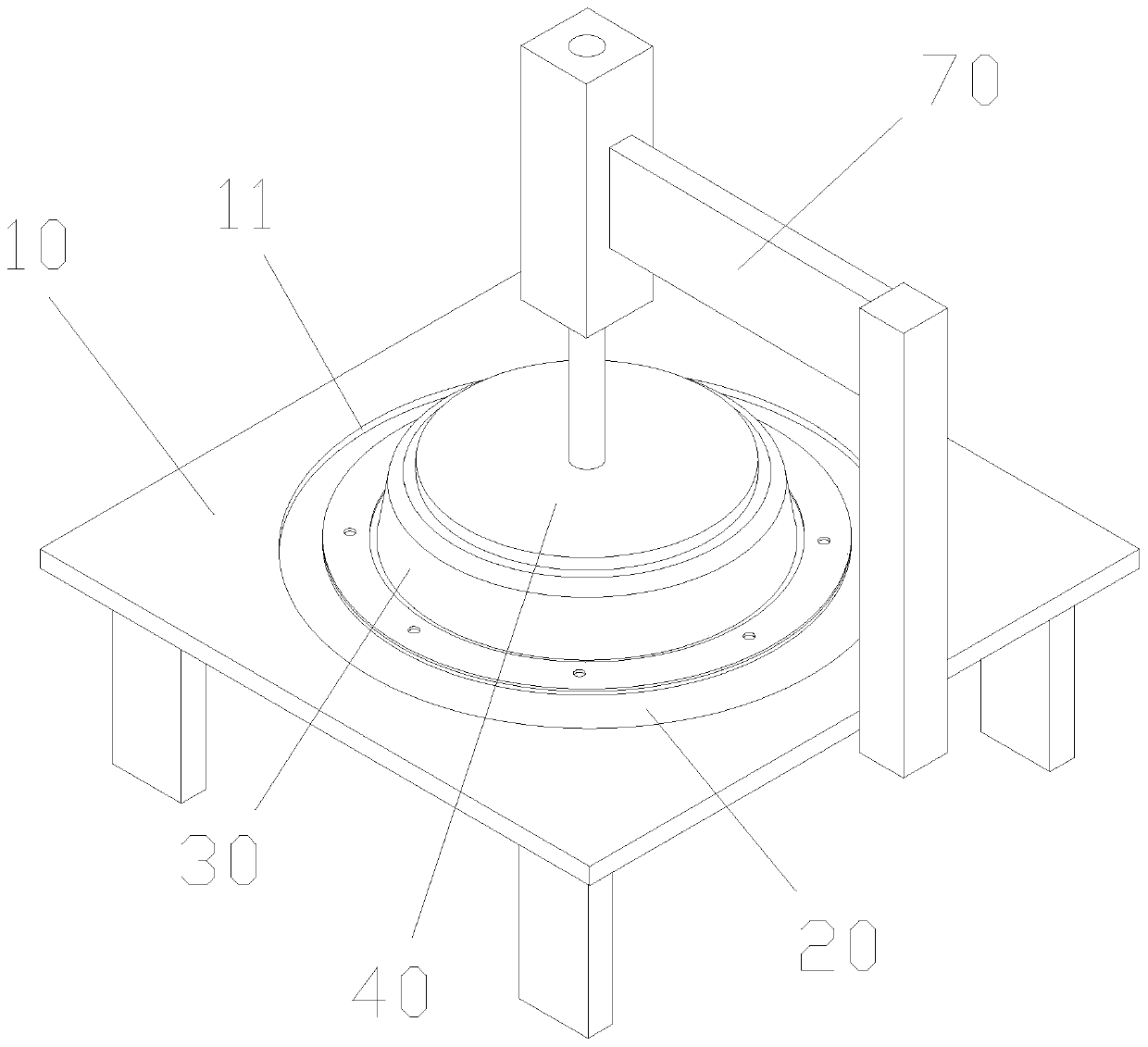

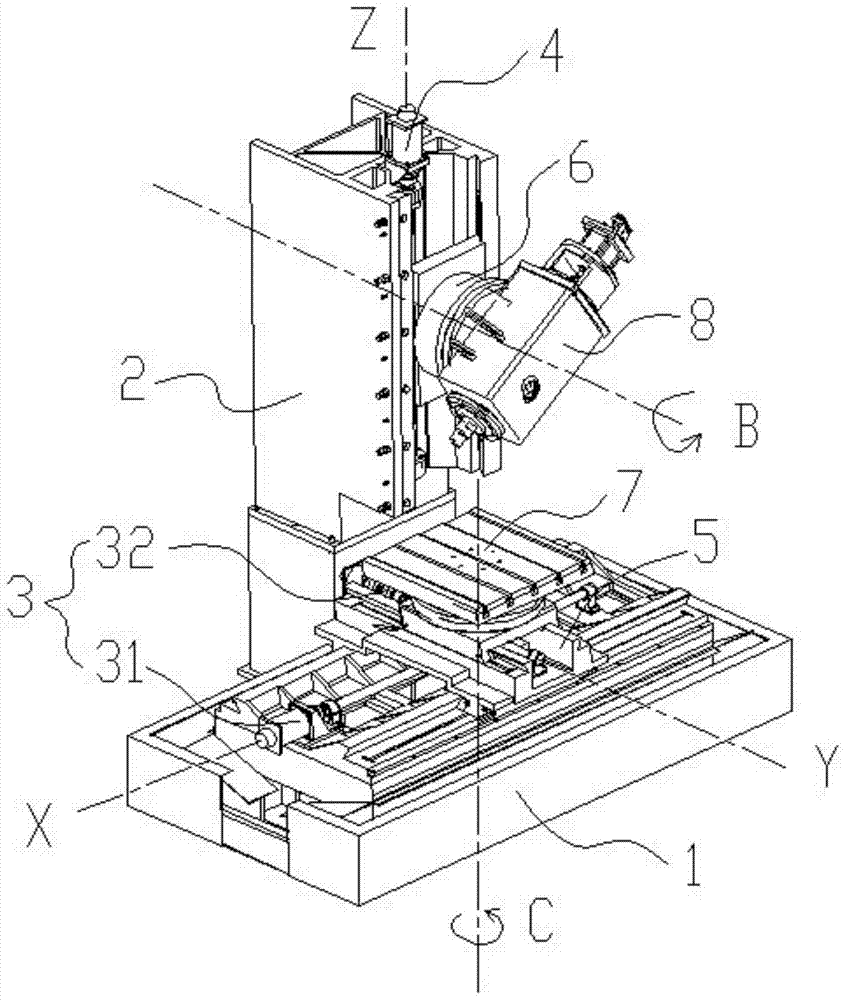

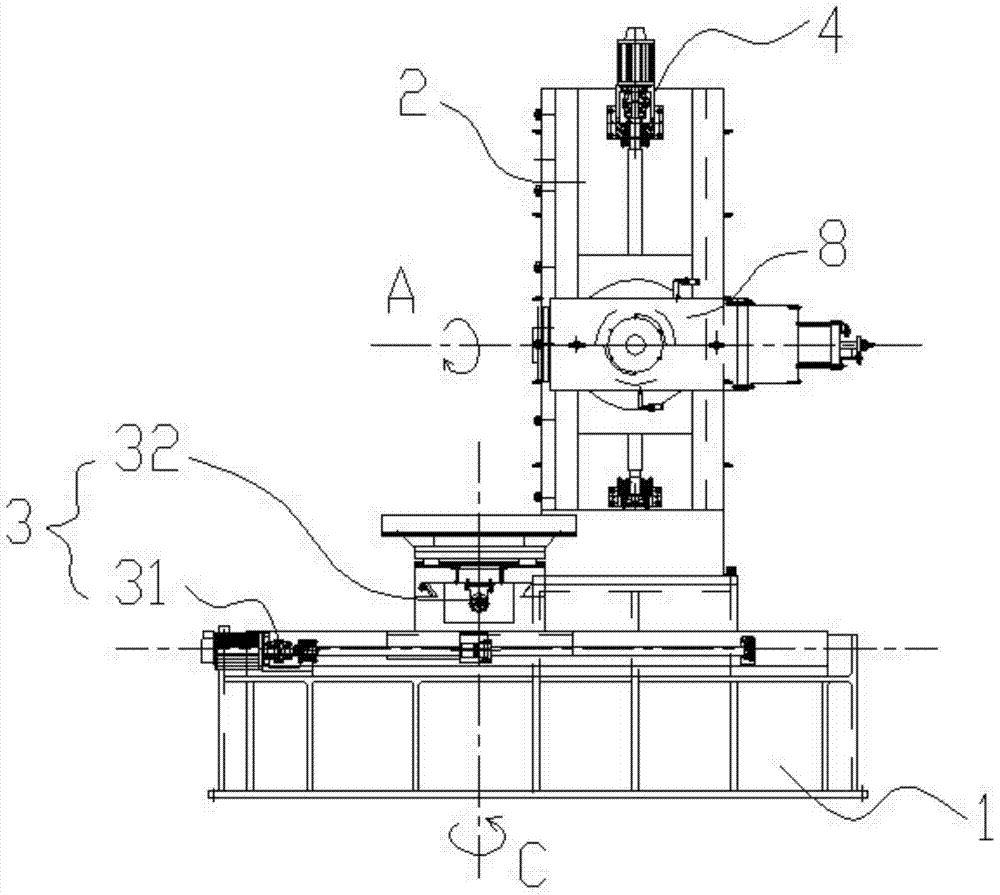

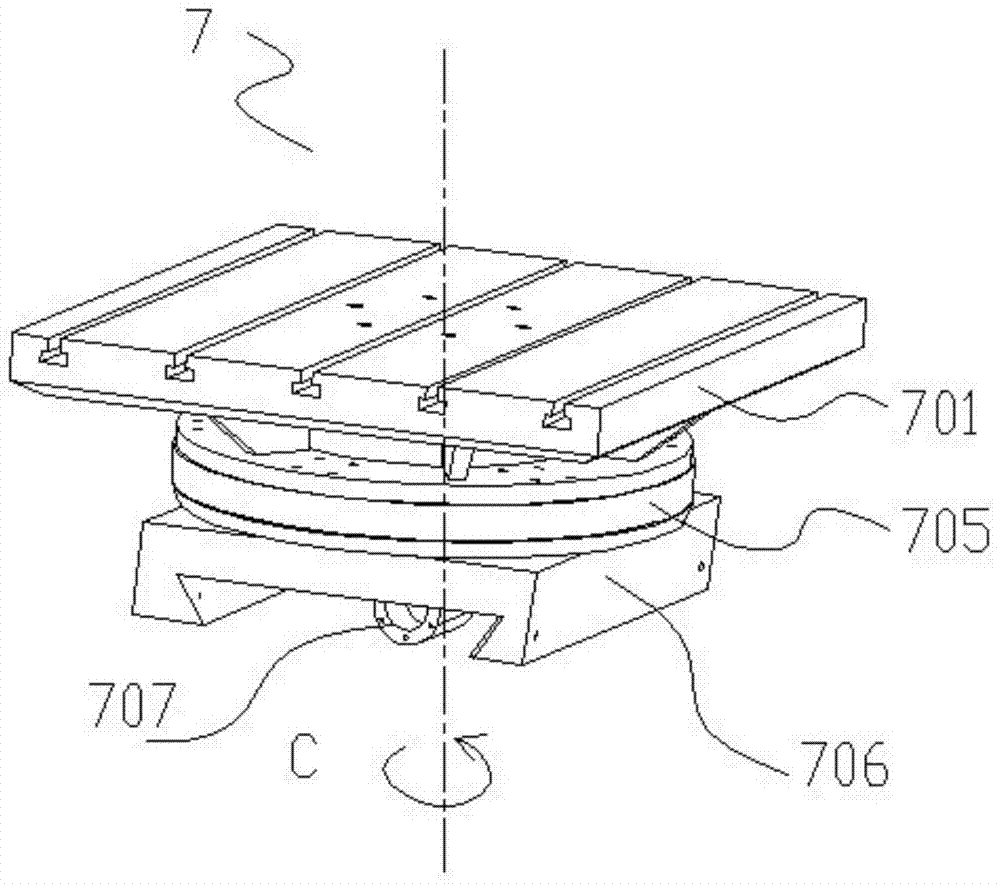

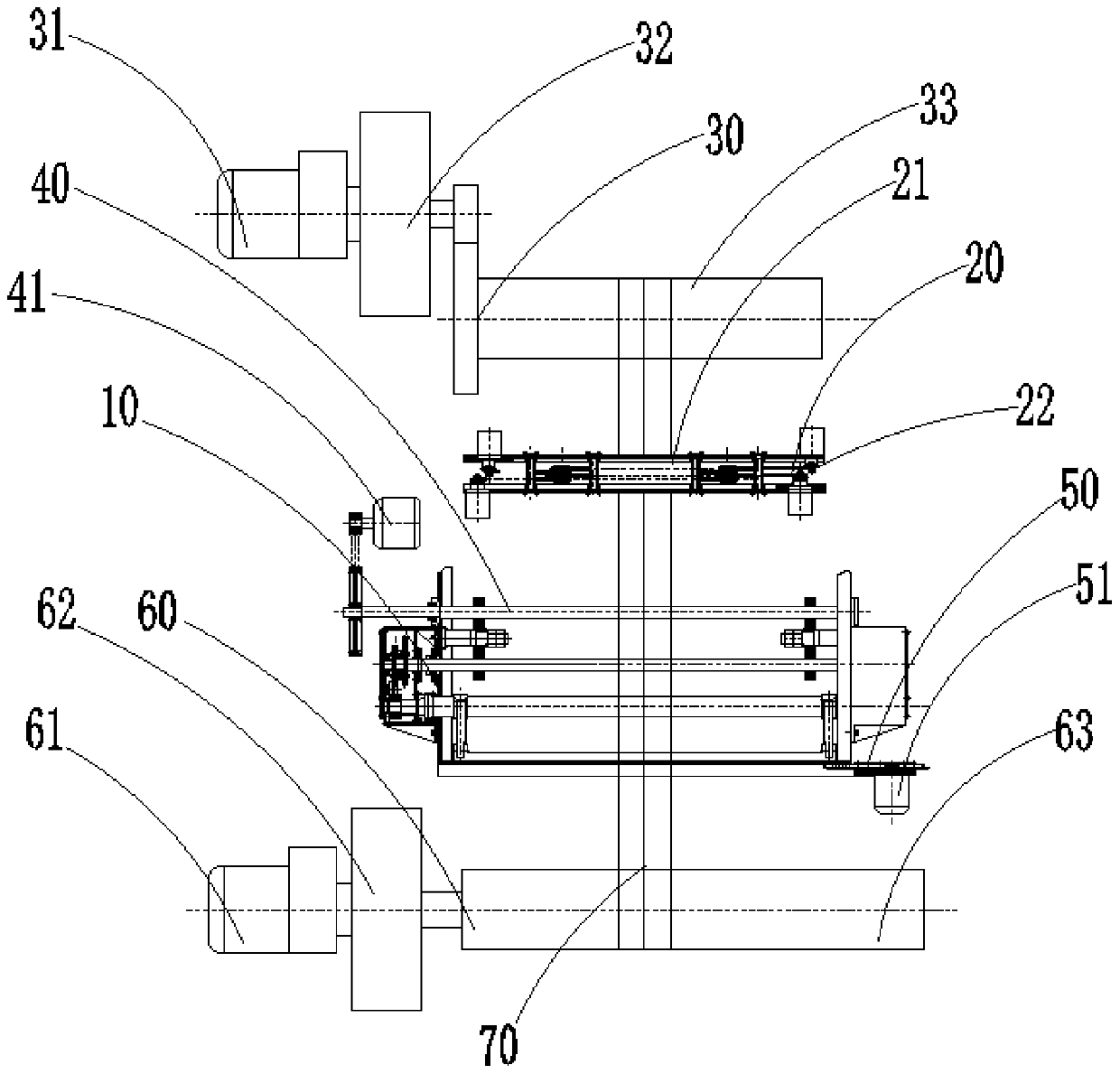

Novel single-spindle pentahedron machining CNC milling machine

ActiveCN105108214AReduce manufacturing costReduce processing costsPrecision positioning equipmentMilling machinesEngineeringPentahedron

The invention discloses a novel single-spindle pentahedron machining CNC milling machine, belongs to the field of numerically-controlled machine tools and relates to pentahedron machining tools. The novel single-spindle pentahedron machining CNC milling machine comprises a lathe bed, a stand column, a horizontal feeding system and a vertical feeding system. The vertical feeding system is connected with a spindle in a 360-degree rotating mode through a spindle indexing device. The horizontal feeding system is connected with a workbench indexing device in a 360-degree rotating mode. According to the novel single-spindle pentahedron machining CNC milling machine, a single-spindle pentahedron can be machined; meanwhile, machining transmission precision and indexing accuracy are improved, the machining range is widened, machining efficiency is improved and the machining cost is lowered.

Owner:邓力凡

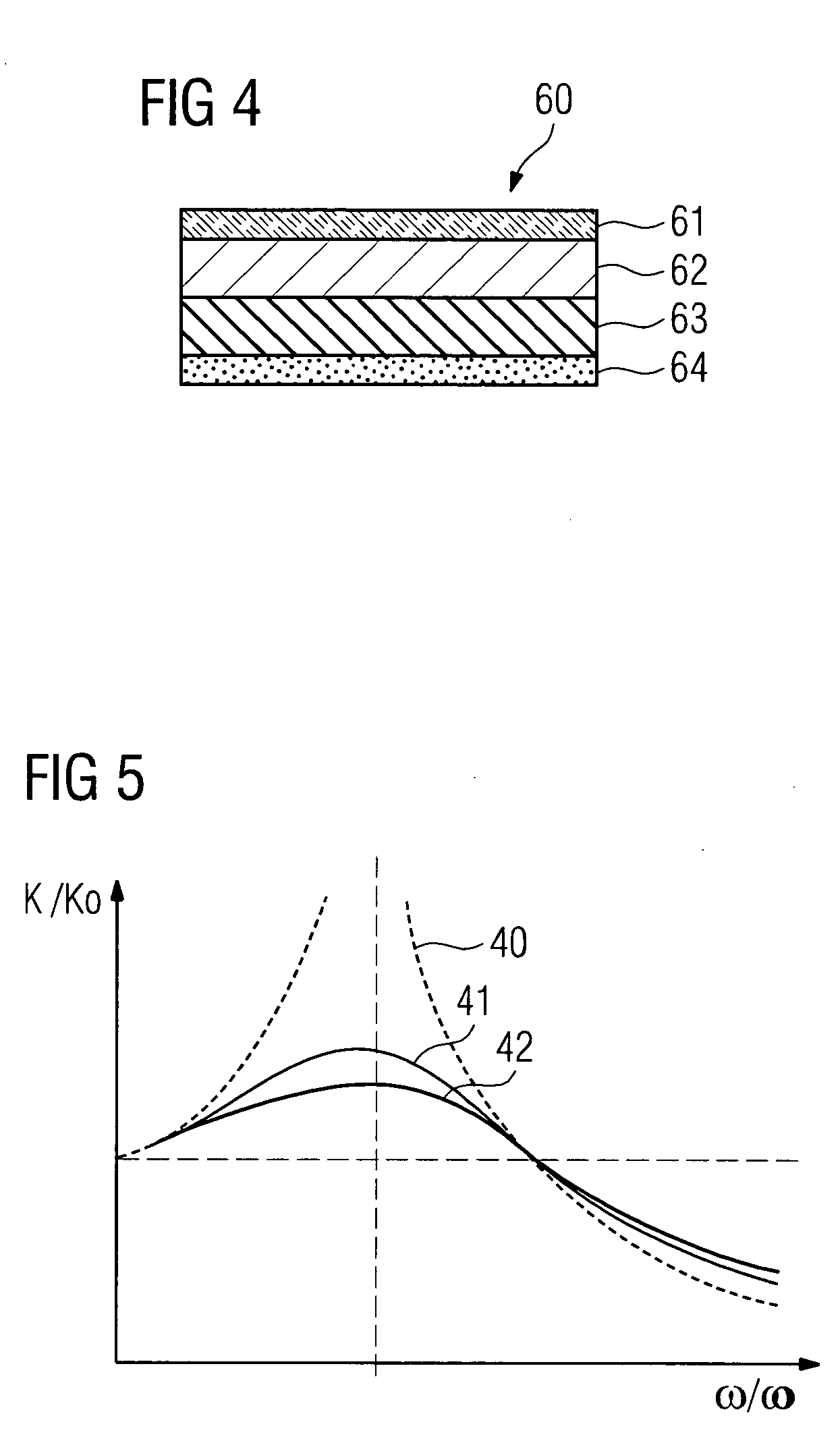

Hearing aid with an attenuation element

ActiveUS20100054513A1Improve the attenuation effectReducing overall hearing aid volumeDeaf-aid setsUltrasound attenuationEngineering

A shielding element and a decoupling element are integrated into a combined attenuation element. The shielding element may be a shielding foil, preferably made of copper. The attenuation element may include a flexible backing foil, preferably a plastic backing foil which supports the shielding foil. It may also include an adhesive layer with which the electronic component is affixed to a housing. The physical properties of all elements of the attenuation element are attuned to one another such that it simultaneously attenuates both electromagnetic alternating fields as well as mechanical oscillations.

Owner:SIVANTOS PTE LTD

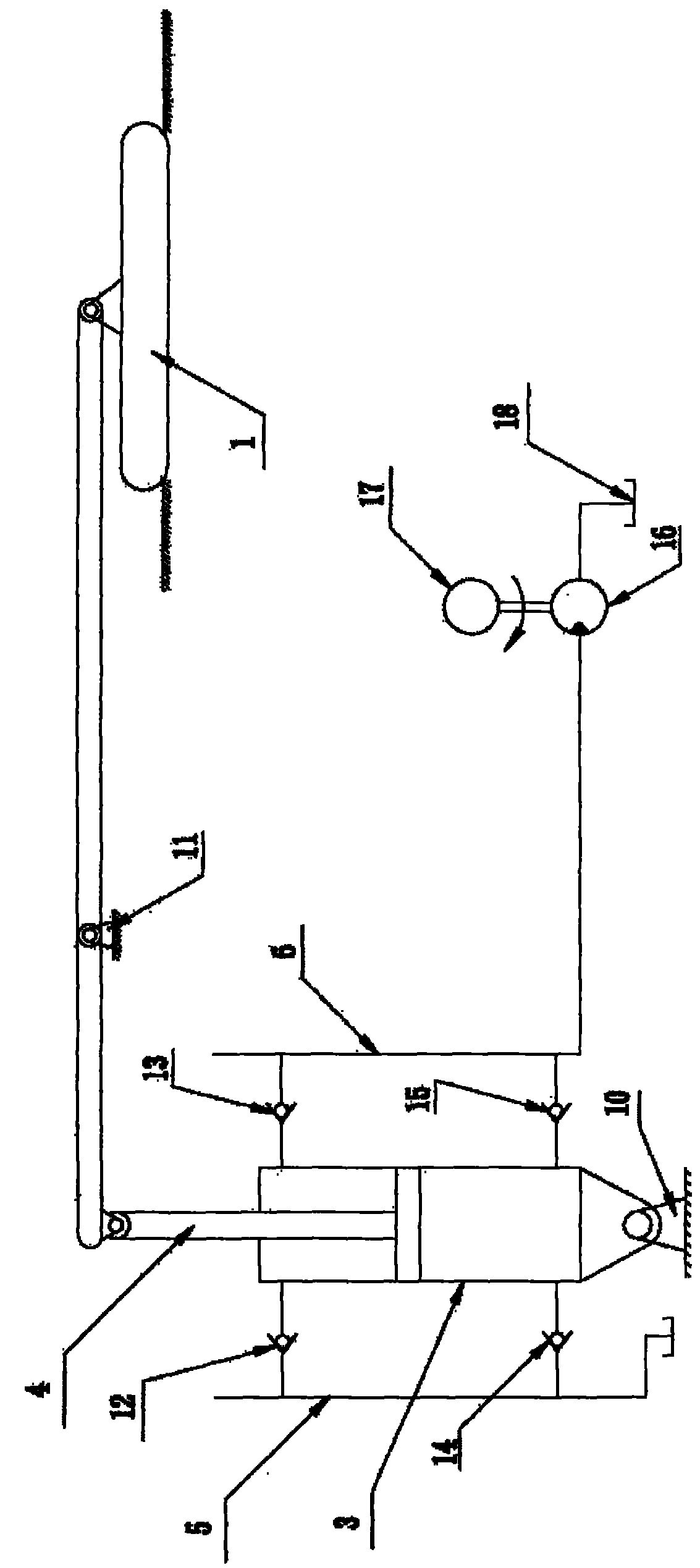

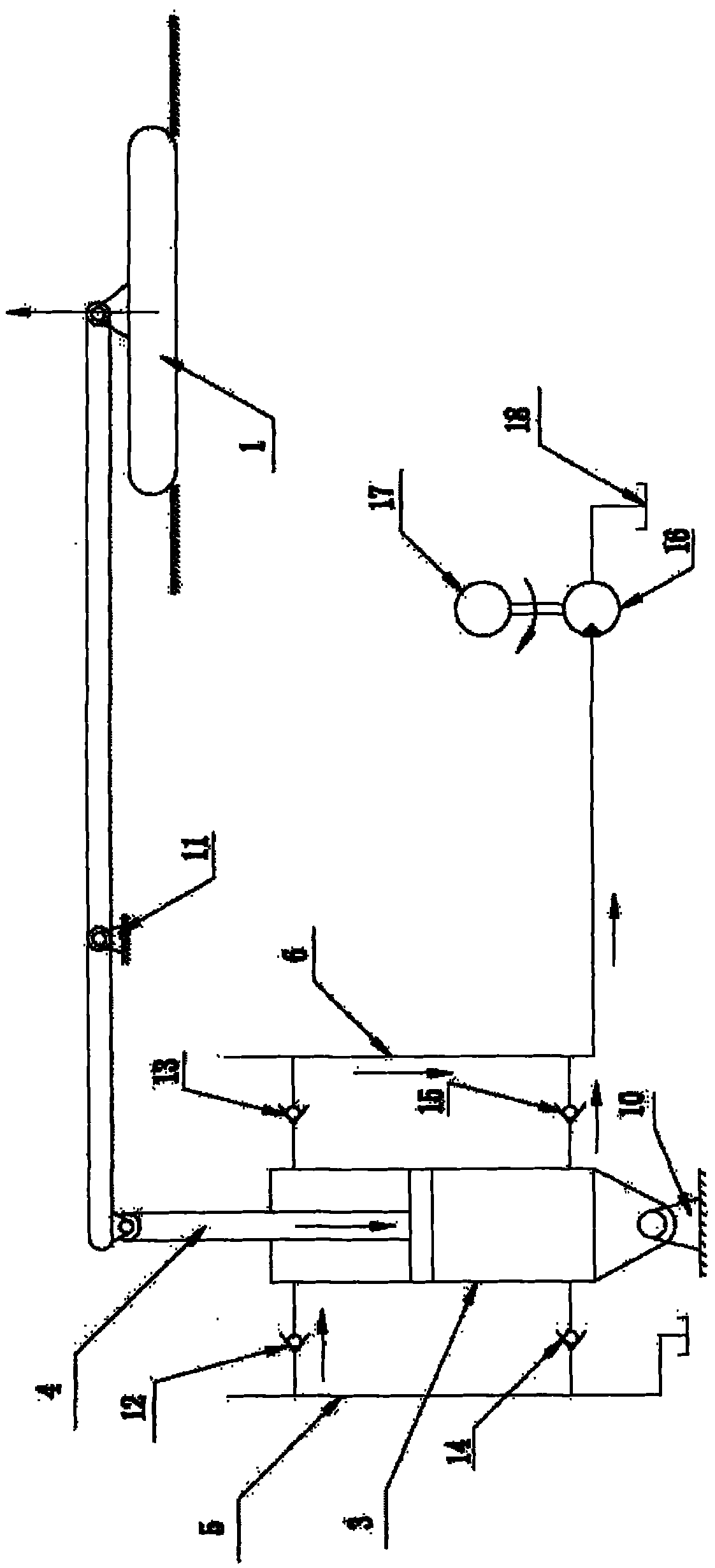

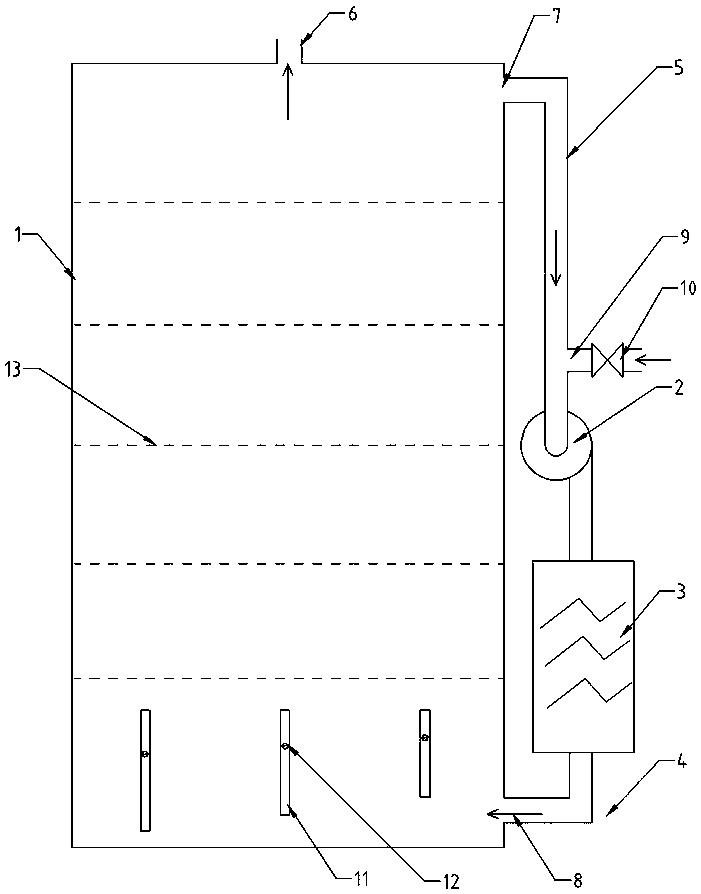

Drying room for deep processing of agricultural and sideline products

ActiveCN105509427AEasy to installLow costDrying gas arrangementsDrying chambers/containersAgricultural engineeringFresh air

The invention relates to a drying room for the deep processing of agricultural and sideline products. The drying room comprises a drying chamber, an air blower, heat source bellows, an air delivery pipe, an air return pipe and moisture removing pipes, wherein an air outlet of the air blower is connected with an air inlet through the heat source bellows and the air delivery pipe; the air suction end of the air blower communicates with an air return opening through the air return pipe; a fresh air opening and a regulating air valve are further arranged on the air return pipe; three to four transverse guide plates are arranged at the lower part, directly facing the air inlet, in the drying chamber from the near to the distant; and each guide plate can rotate or swing around rotating shafts at the two ends of the guide plate. When the drying room carries out drying processing on agricultural and sideline products, hot air in the drying room is enabled to evenly circularly flow up and down. The whole temperature difference of the drying room is reduced, and temperature and humidity distribution is relatively even.

Owner:郴州市芝草农业科技开发有限公司

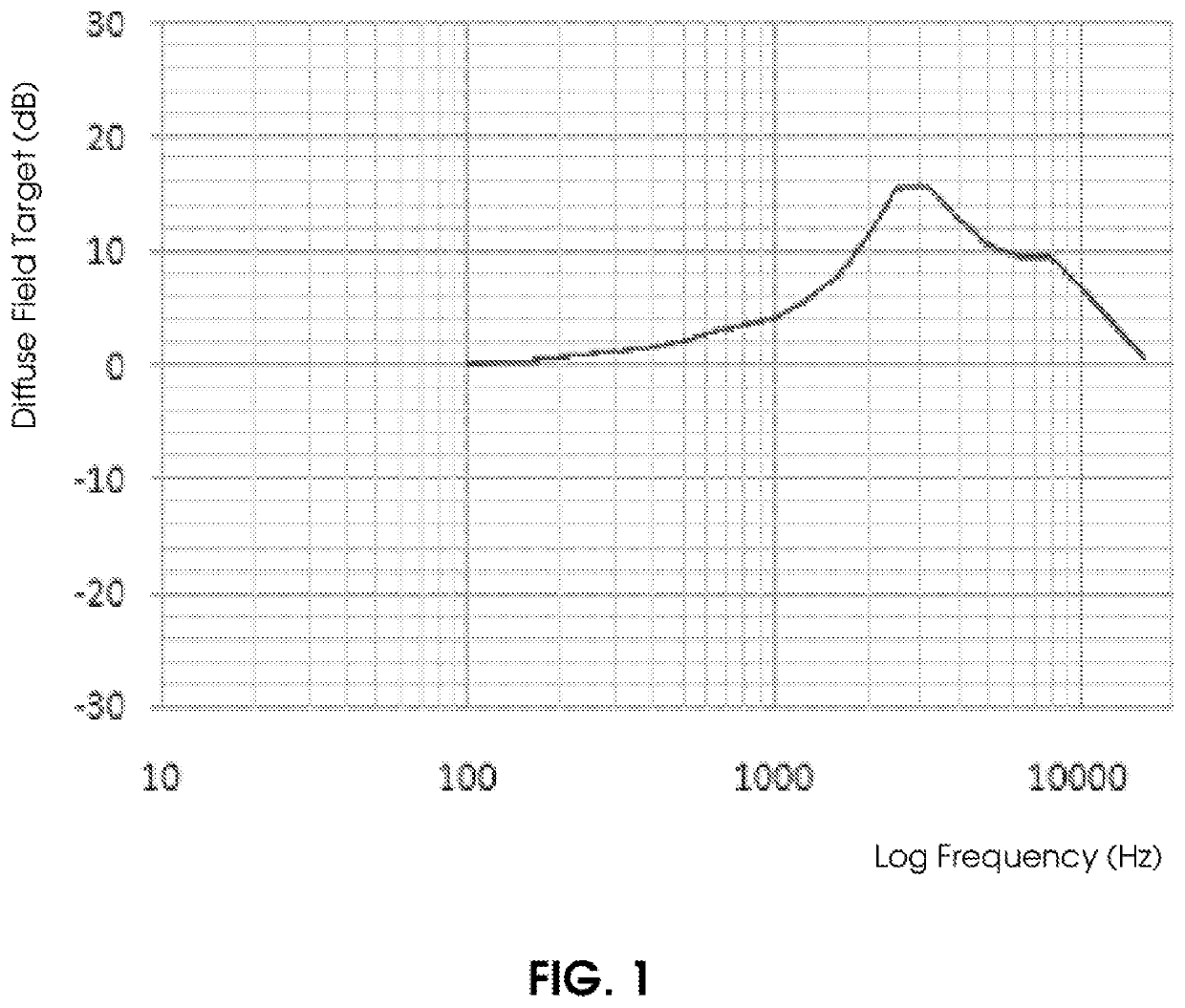

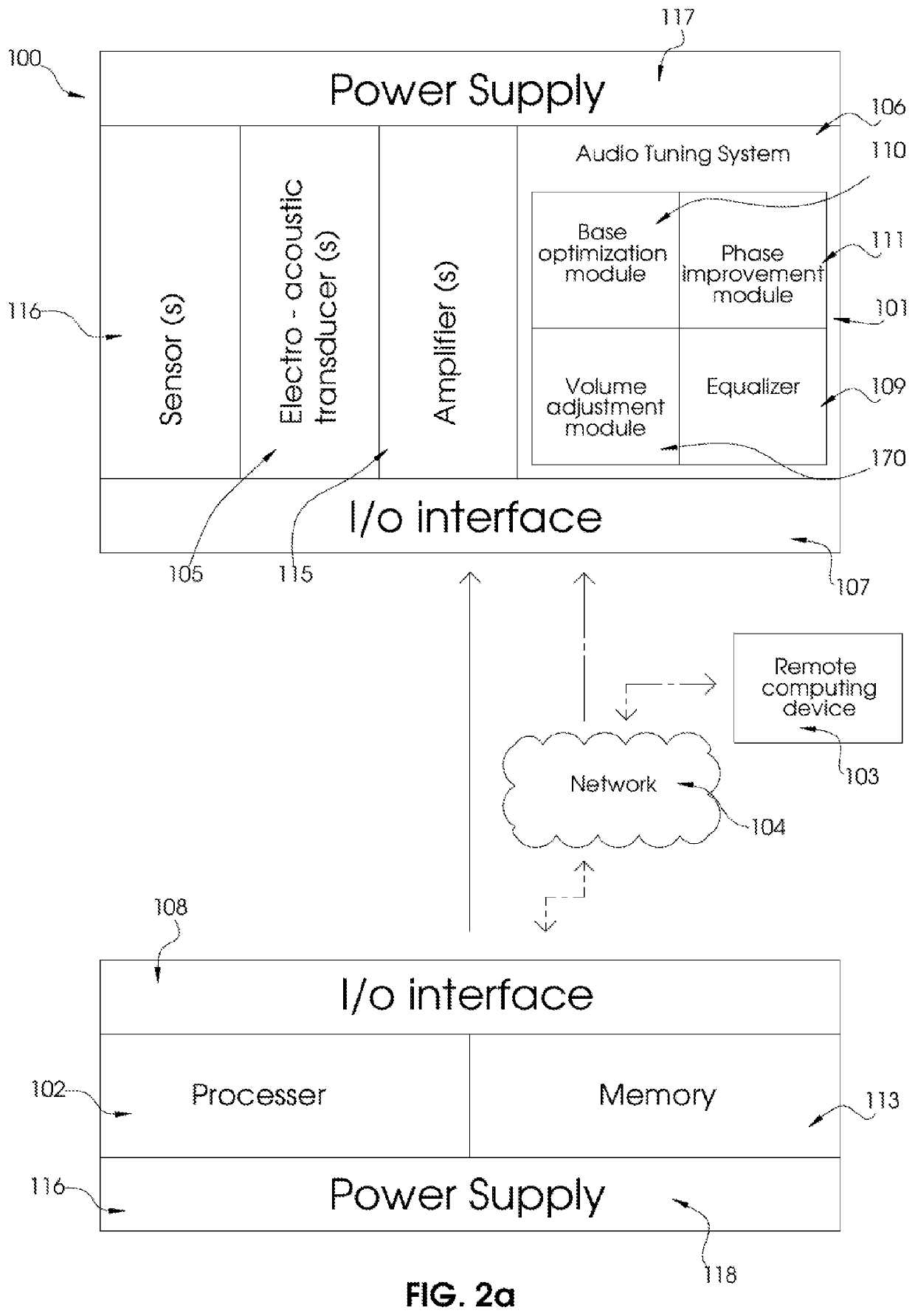

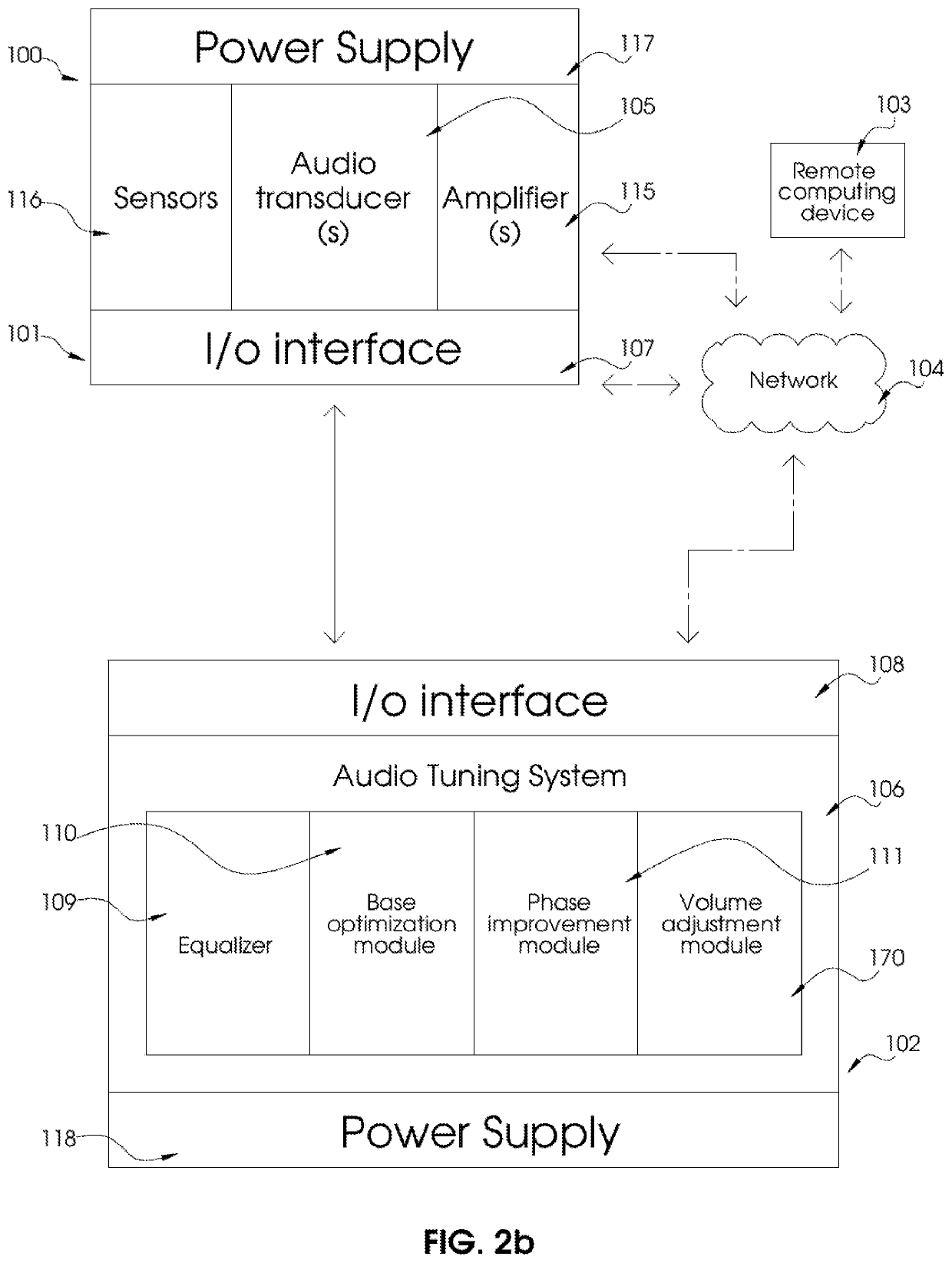

Improvements in or relating to audio systems

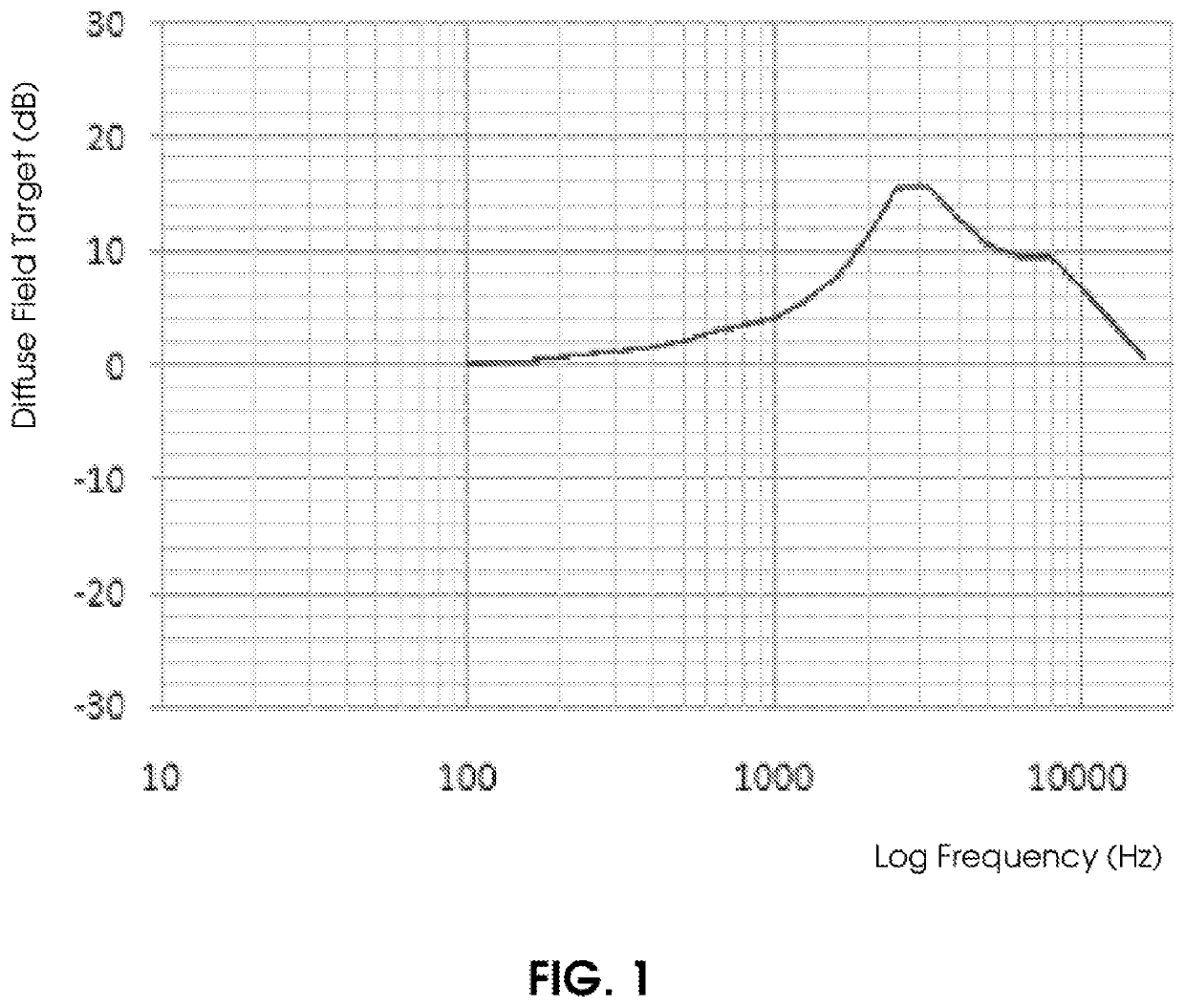

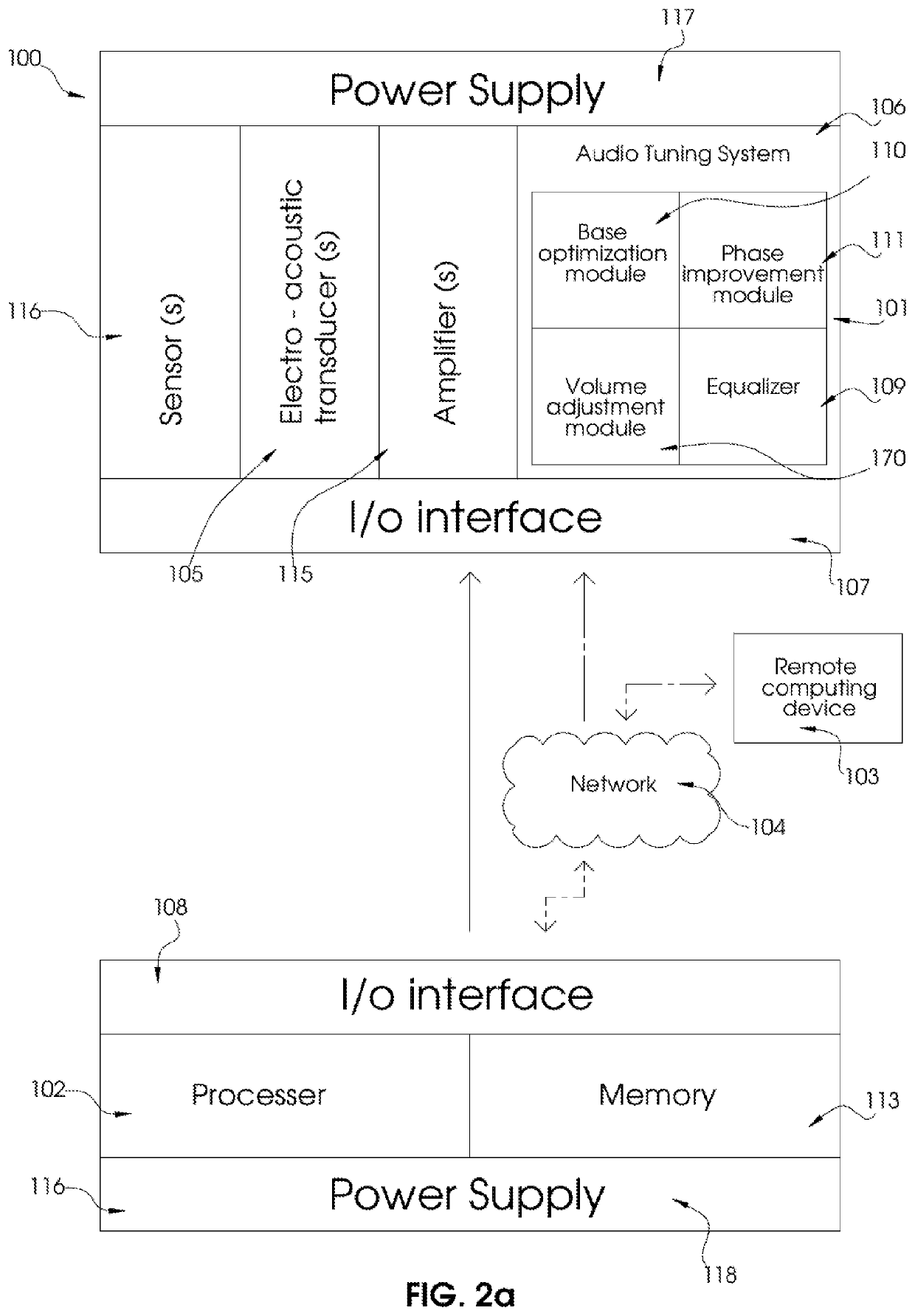

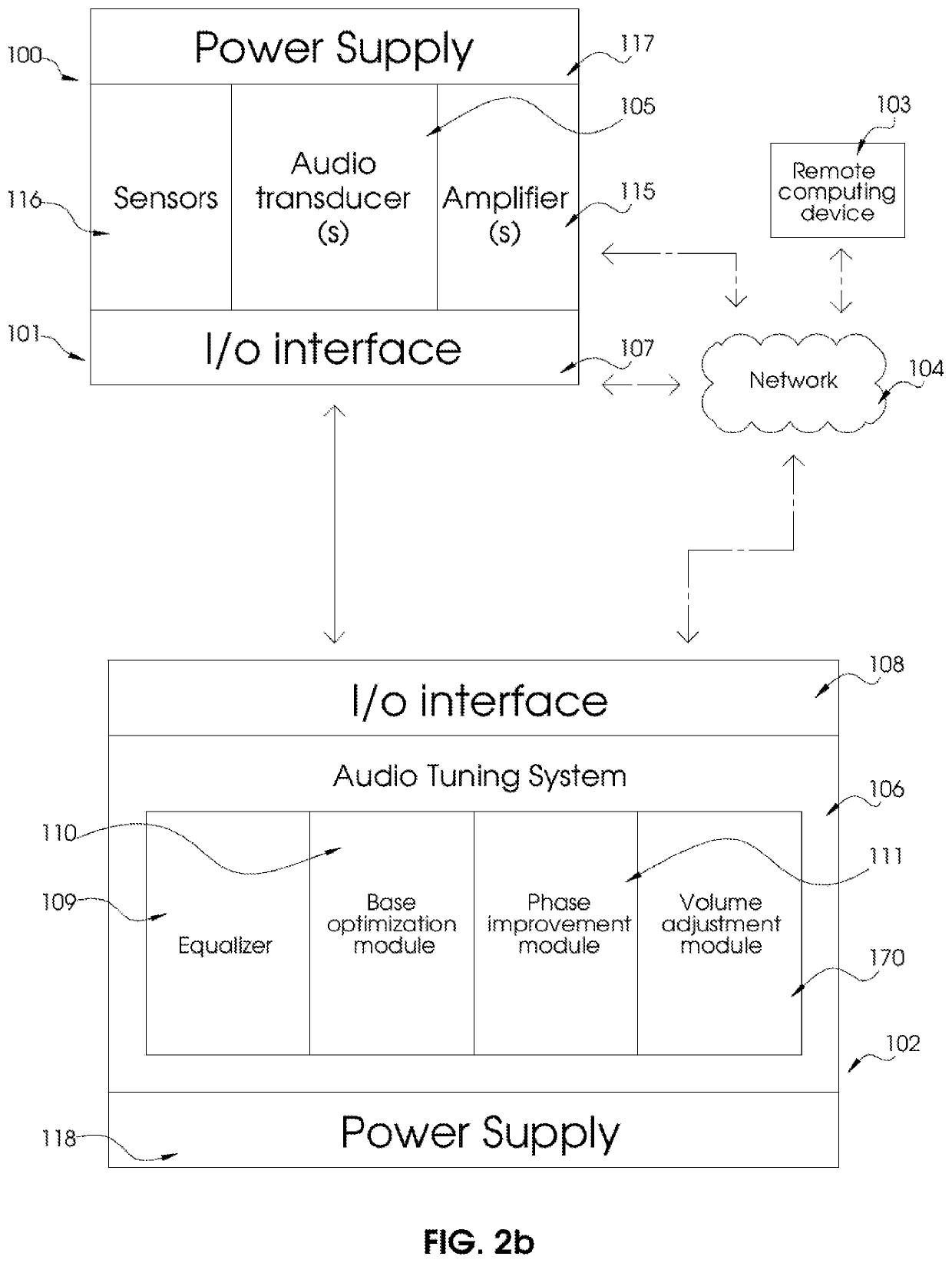

ActiveUS20200092647A1Control flowReduce mechanical transmissionLoudspeaker transducer fixingHeadphones for stereophonic communicationTransducerDiffuse field

The invention relates to audio transducer technology, including audio tuning systems to be utilised in personal audio devices, such as headphone, earphones, mobile phones and the like. The audio tuning system optimises the frequency response of the personal audio device by using Diffuse Field curve characteristics. The audio transducers of the personal audio device incorporate low resonance designs, including low resonance transducer and diaphragm suspensions to further optimise the sound quality of the device. The invention also relates to an audio transducer diaphragm construction that includes a three-dimensional lattice which may be utilised in any audio transducer application.

Owner:WING ACOUSTICS LTD

Fatigue testing machine for rubber diaphragm

PendingCN110579415AExtended service lifeReduce mechanical transmissionWeather/light/corrosion resistanceMaterial strength using repeated/pulsating forcesFatigue damageEngineering

The invention discloses a fatigue testing machine for a rubber diaphragm. The fatigue testing machine comprises a bracket platform, a bottom support, a diaphragm, a pressing block and a booster pump,a bayonet is formed in the surface of the bracket platform, the diaphragm is arranged above the bayonet, the bottom support is connected with the bayonet and located below the diaphragm, the diaphragmis in sealed connection with the bottom support, an air inlet and an air outlet are formed in the bottom support, the booster pump is connected with the air inlet through an air inlet pipe, the air outlet is connected with an air outlet pipe, the air inlet pipe and the air outlet pipe are controlled by a control valve to be connected or disconnected, and the pressure block is placed above the diaphragm. Motion control over the diaphragm is achieved through inflation and deflation, resistance borne by the diaphragm is established through the pressing block, mechanical transmission is reduced,fatigue damage to the whole equipment is reduced, stable operation of the equipment is guaranteed, and the service life of the testing equipment is prolonged.

Owner:中广核高新核材科技(苏州)有限公司 +1

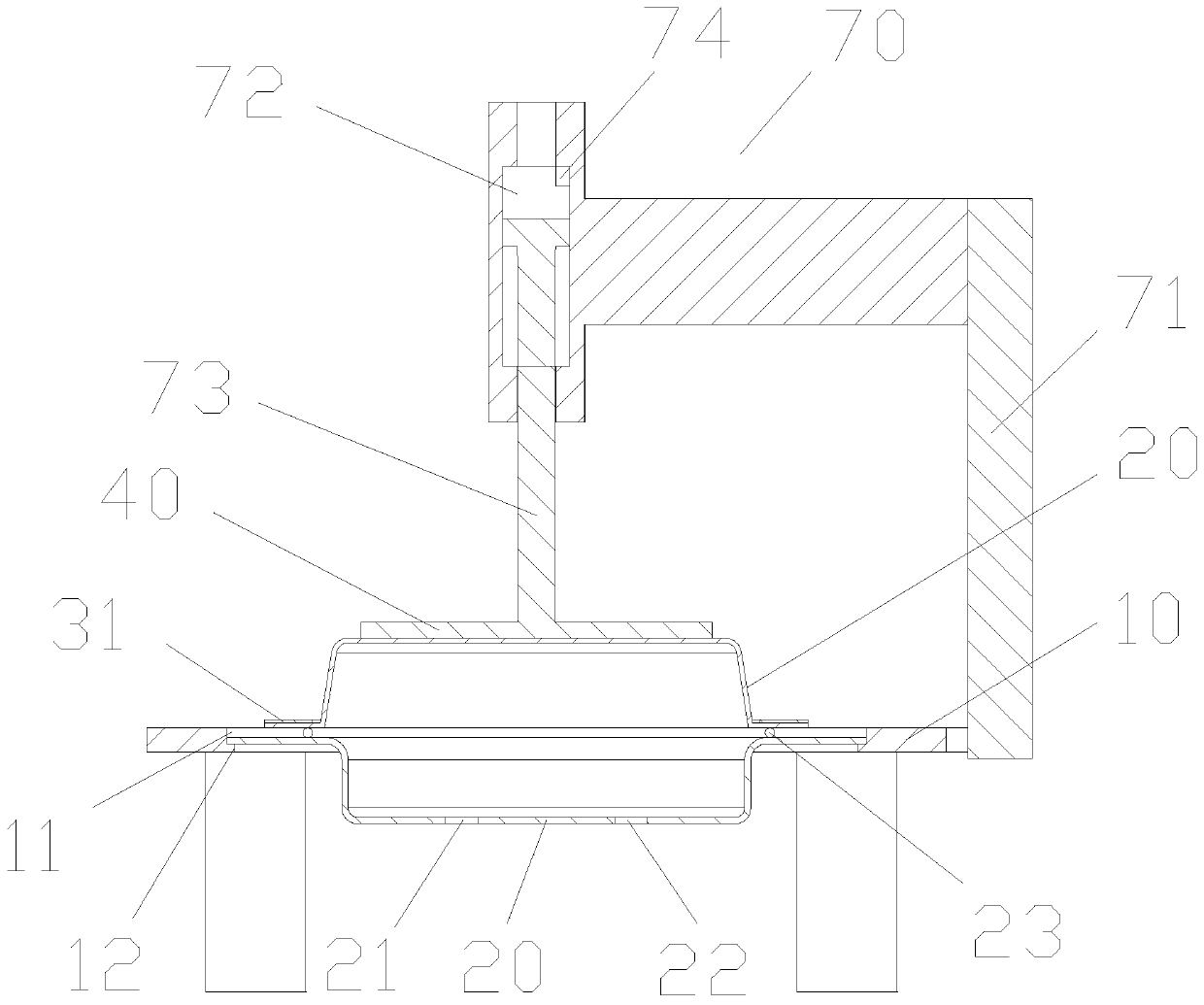

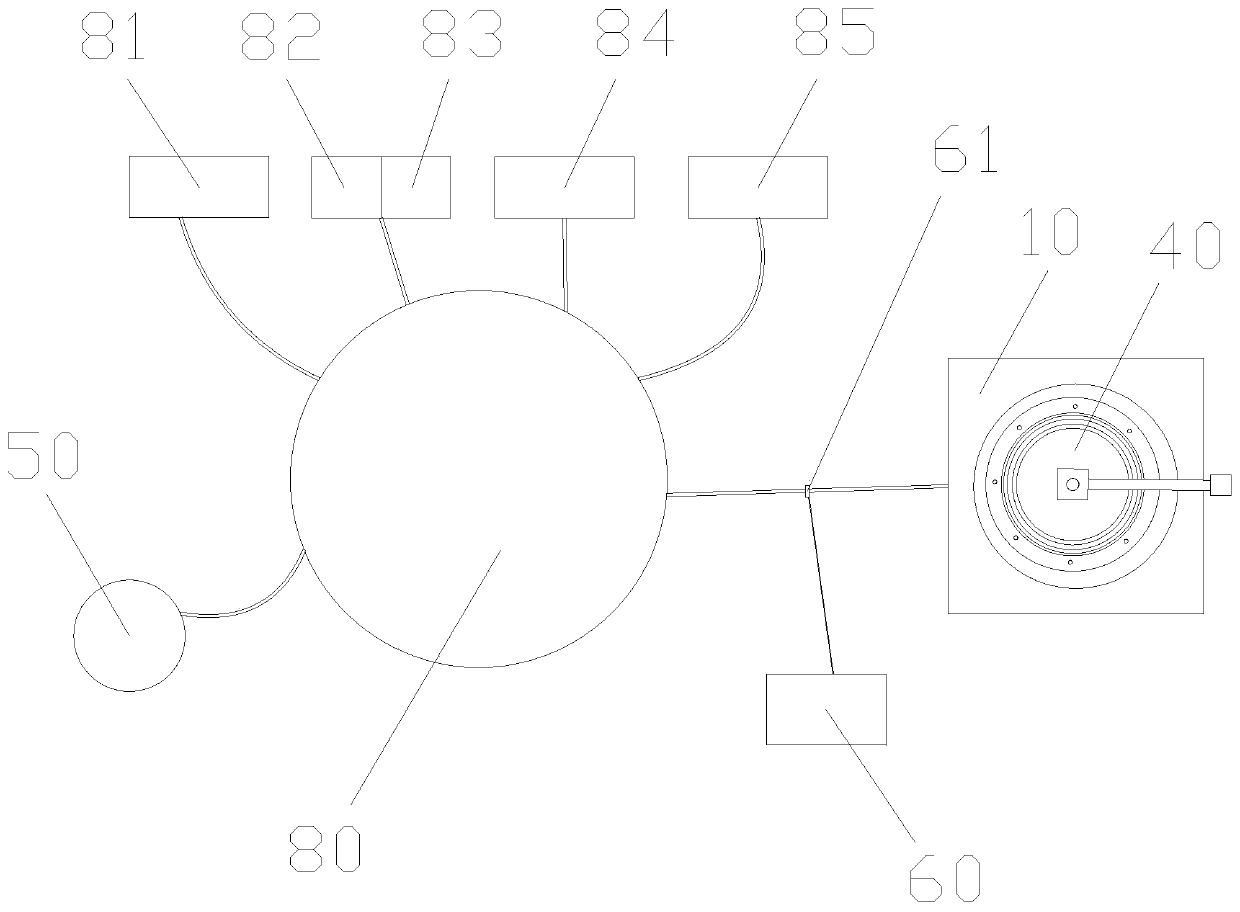

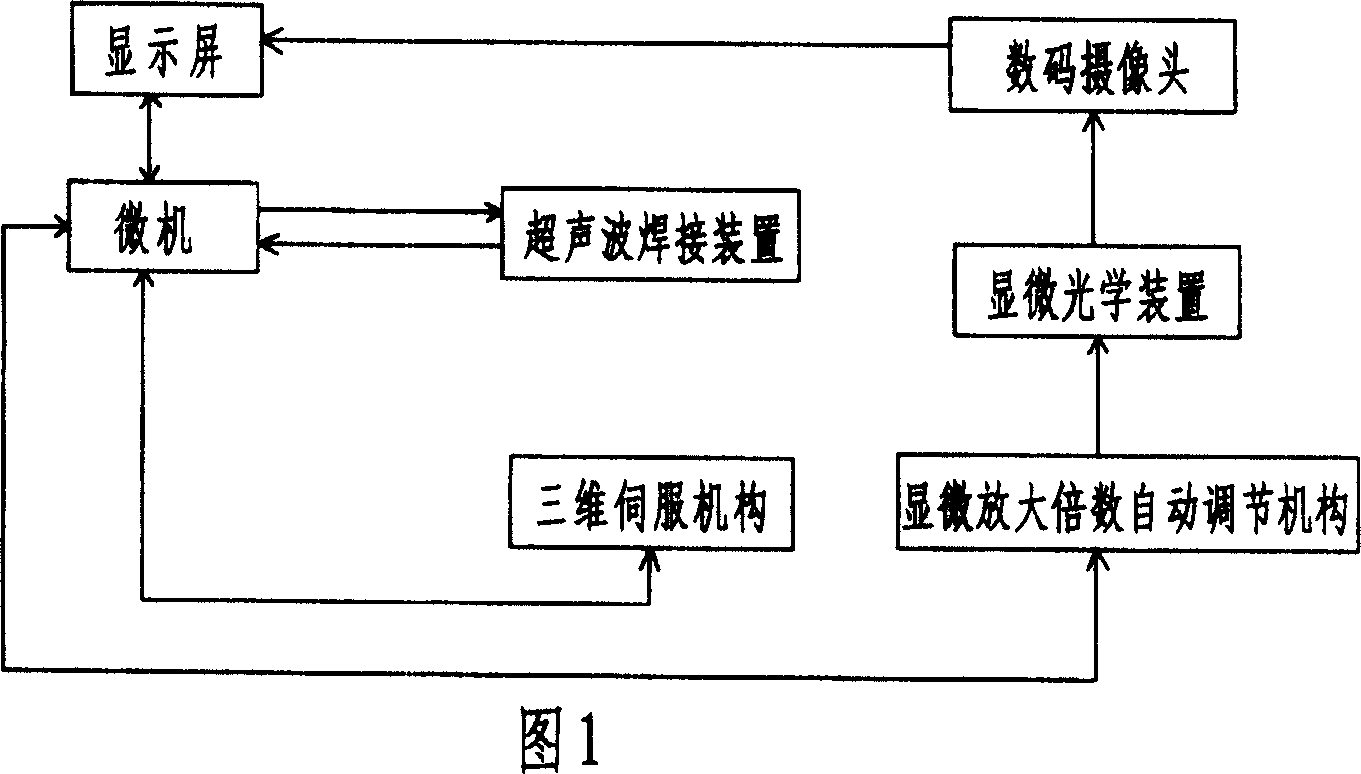

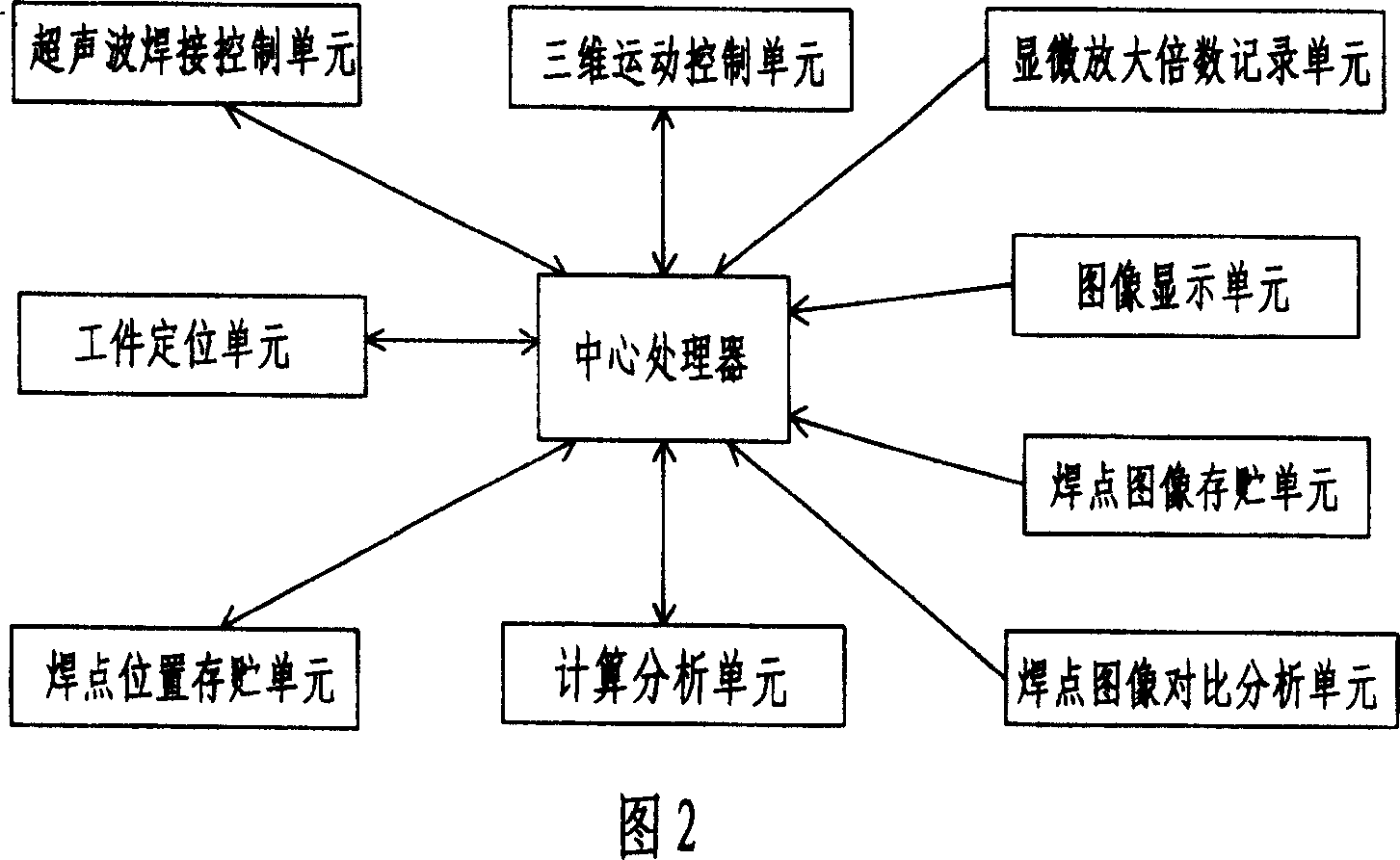

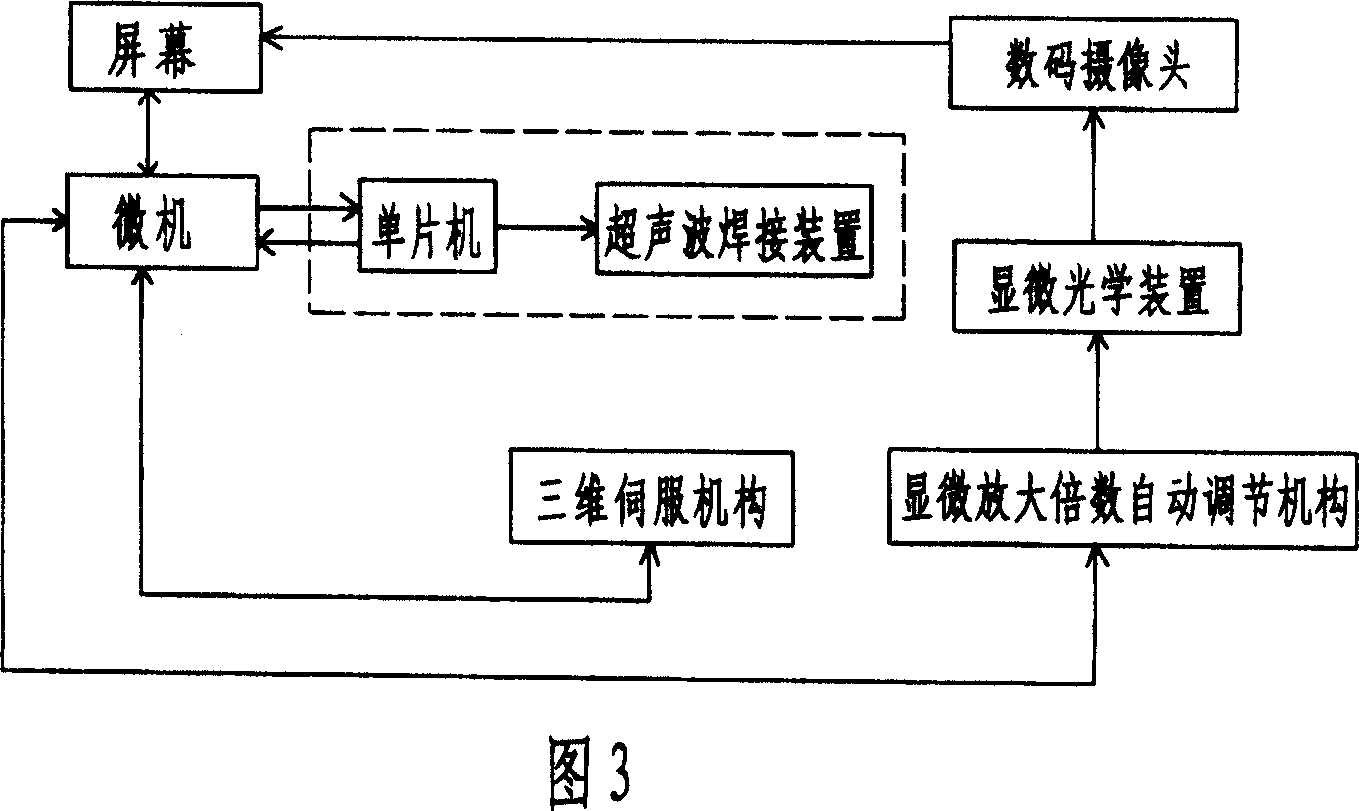

Welding apparatus with micropicture automatic-computing positioning system and operation mode

InactiveCN100351721CHigh precision of mechanical movementReduce mechanical transmissionComputer controlSimulator controlMicrocomputerUltrasonic welding

The disclosed positioning system includes welding set, precision 3D servomechanism composed of 3D servomotor and worktable, micro optical unit, microcomputer, and digital pick-up head. The system possesses functions of automatic image recognition and microposition, and operational functions: determining position of welding spot by mouse click, automatic storing calculation, reaching to the designated position, and completing welding. It is possible to modify manual ultrasonic welding machine to automatic welding machine by using the invention. Comparing with manual welding machine, the system possesses advantages: lowering labors intensity, raised work efficiency to 4-6 times, high positioning precision (+ / -0.005mm), good welding quality, and easy of use etc. Comparing with automatic ultrasonic welding machine, the system uses mouse to replace trackball so as to raise positioning precision, lower cost, and provide intuitive operation.

Owner:李光

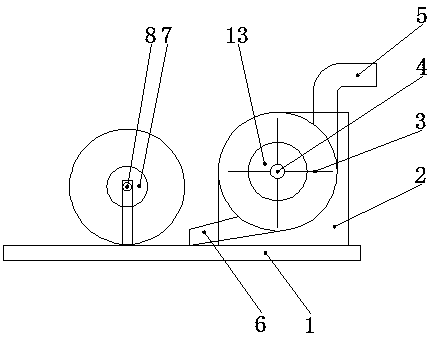

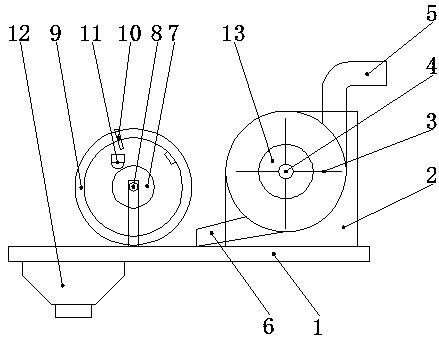

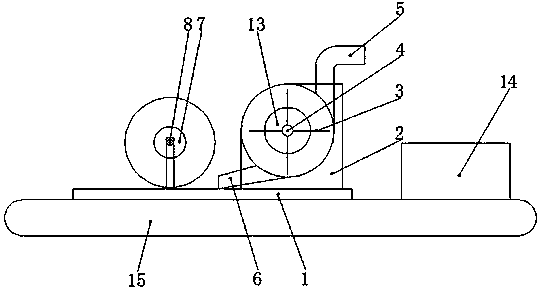

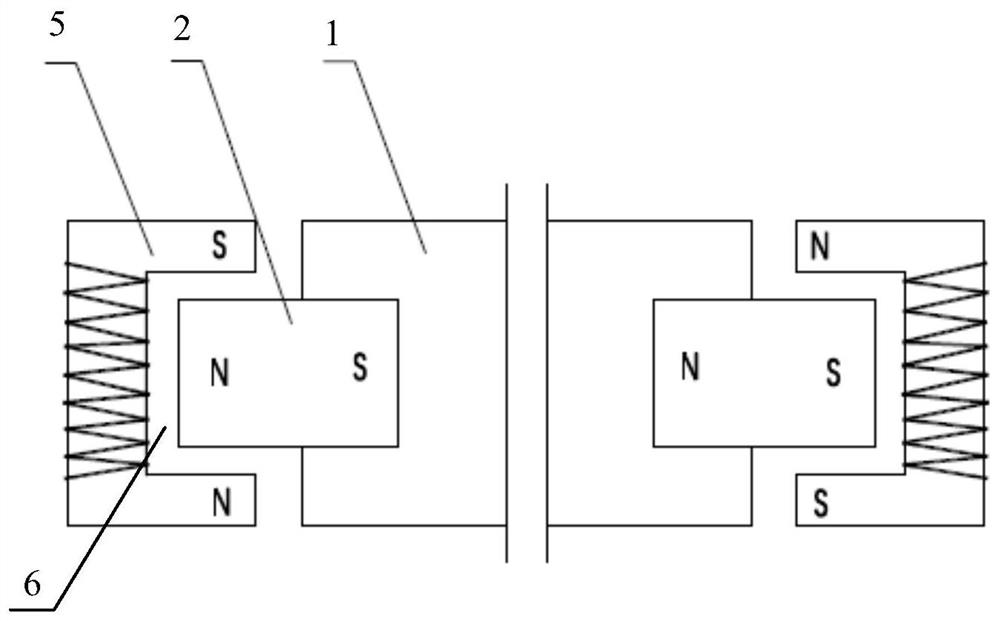

Self-driven river sand magnetic separator

PendingCN108620230AReduce mechanical transmissionOptimize volumeMagnetic separationMagnetic separatorRiver sand

The invention discloses a self-driven river sand magnetic separator. The self-driven river sand magnetic separator comprises a platform, a magnetic separation device and a turbine device, wherein themagnetic separation device and the turbine device are arranged on the platform, the turbine device comprises a shell, a turbine shaft arranged in the shell, and a turbine blade arranged on the turbineshaft, a river sand inlet formed in the upper part of the shell and a river sand outlet formed in the lower part of the shell, the magnetic separation device comprises a driving shaft, the turbine shaft is connected with a generator, the driving shaft is connected with a motor, and the generator is connected with the motor through a wire.

Owner:河南省拾祺机械科技有限公司

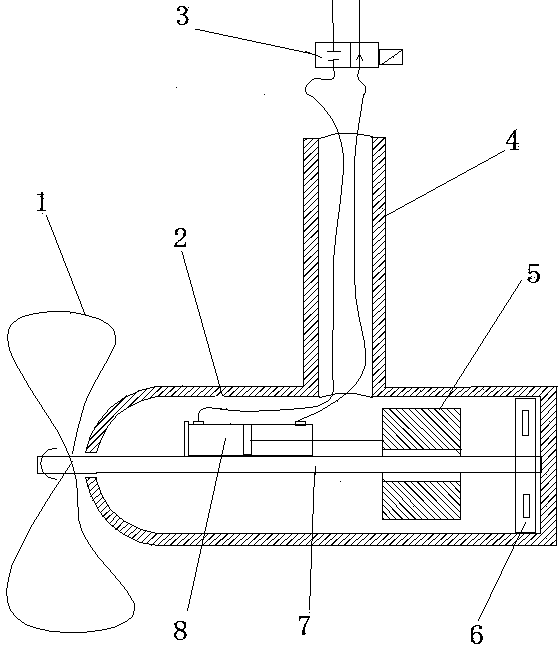

Figuring yarn guiding device of war knitting machine

A patterning finger tricot machine, the needle being integrated with the intermediate by dielectric made of electric materials, and then fixed onto the guide bar. The dielectric has piezoelectric coatings on both sides, which consist of interior electrode, piezoelectric coating covered by exterior electrode. The exterior electrode binds one control circuit which produces electron-positron pair to affect exterior electrode. The structure of this instrument is simple and the cost is low.

Owner:王占洪

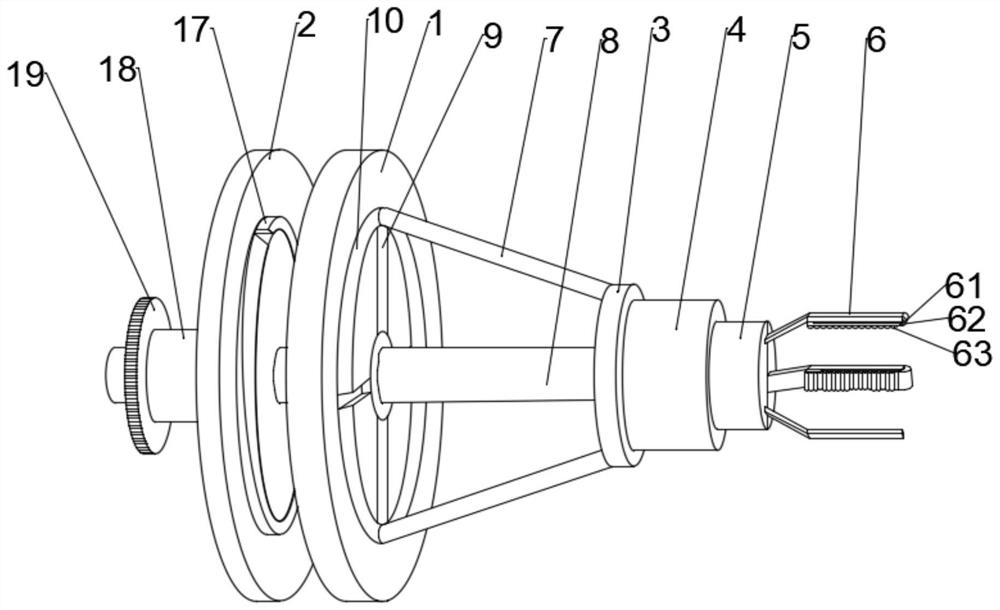

Nacelle type propeller based on gyroscopic precession

InactiveCN103847944ASimple structureEasy to usePropulsion power plantsPropulsive elementsHydraulic cylinderHydraulic motor

The invention provides a nacelle type propeller based on gyroscopic precession, and belongs to the field of ship equipment. The nacelle type propeller based on gyroscopic precession comprises a propeller, a casing, a hydraulic control valve, a nacelle main shaft, a heavy block, a hydraulic motor, a transmission shaft and a hydraulic cylinder, wherein the upper part of the casing is provided with the nacelle main shaft, the rotating shaft is arranged inside the casing, the left end of the rotating shaft is provided with the propeller, the right end of the rotating shaft is provided with the hydraulic motor, the heavy block is sheathed on the rotating shaft, the hydraulic cylinder is fixedly arranged on the rotating shaft, and the hydraulic cylinder and the heavy block are mutually connected. The invention provides the nacelle type propeller utilizing the gyroscopic precession theory for realizing the steering direction change, the steering direction is directly determined through the direction of the heavy block deviating from the main shaft, the structure is greatly simplified, meanwhile, the direct driving through the hydraulic motor is realized, a complicated mechanical structure is omitted, and the nacelle type propeller has the characteristics that the structure is simple, and the use is convenient.

Owner:ZHEJIANG OCEAN UNIV

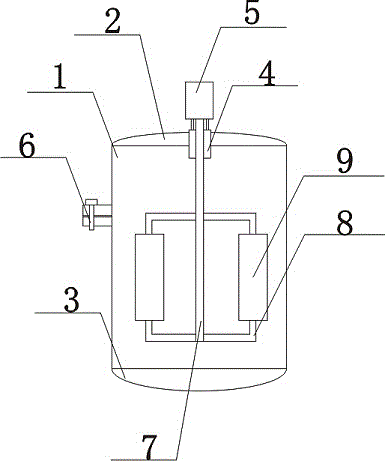

Chemical reaction tank

InactiveCN104941555ACompact structureReduce mechanical transmissionChemical/physical/physico-chemical stationary reactorsChemical reactionReaction rate

The invention discloses a chemical reaction tank. The chemical reaction tank comprises a reaction tank main body, a side of the reaction tank main body is provided with a gas-liquid outlet, the gas-liquid outlet is connected to the reaction tank main body, the top and the bottom of the reaction tank main body are respectively connected to a top cover and a bottom cover, the top cover and the bottom cover are respectively and detachably connected to the reaction tank main body, the part of the reaction tank main body close to the top is provided with a heating jacket, the heating jacket is fixed to the reaction tank main body, a stirring pipe is arranged in the heating jacket, the top of the stirring pipe goes through the heating jacket and is connected to a heater, a heating pipe is arranged in the stirring pipe, and the heating pipe is electrically connected to the heater. The chemical reaction tank has a compact reaction tank structure, less mechanical transmission, a long service life and high safety, is convenient for use and maintenance, prevents reaction solution outflow, realizes full mixing of the reaction solution in flowing, can carry out heating according to cases, improves a reaction rate, realizes a vacuum reaction and further improves reaction solution full-reaction performances.

Owner:CHENGDU JUZHI IND DESIGN

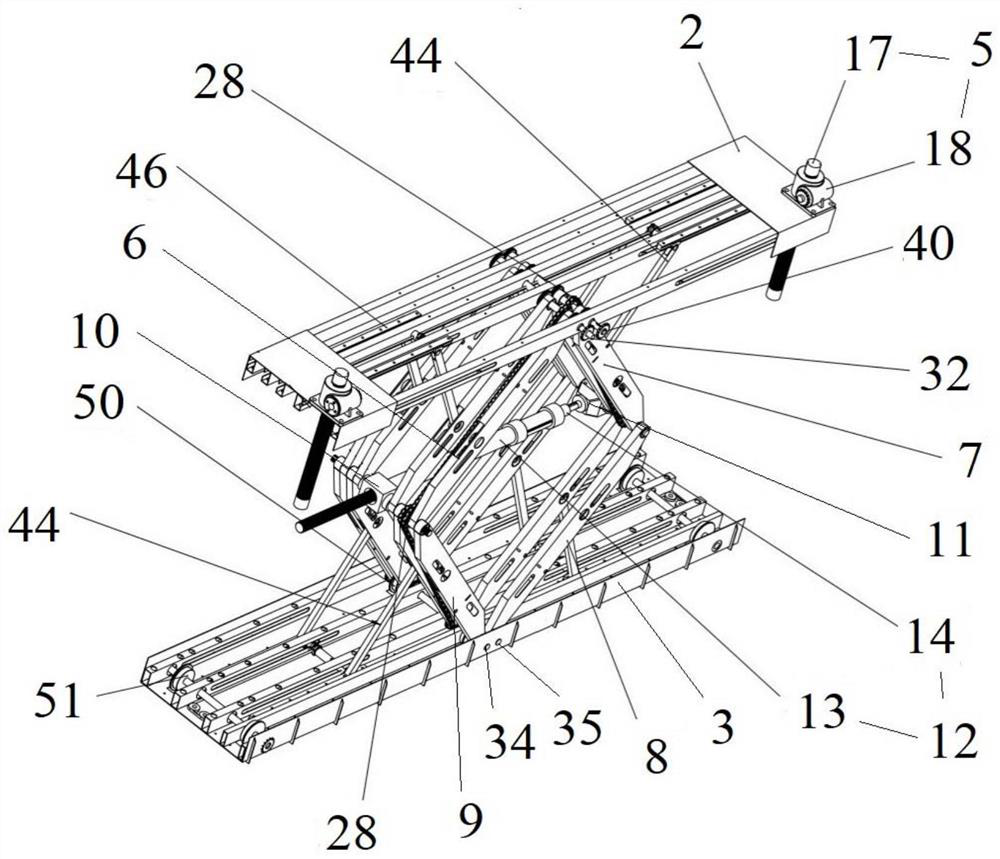

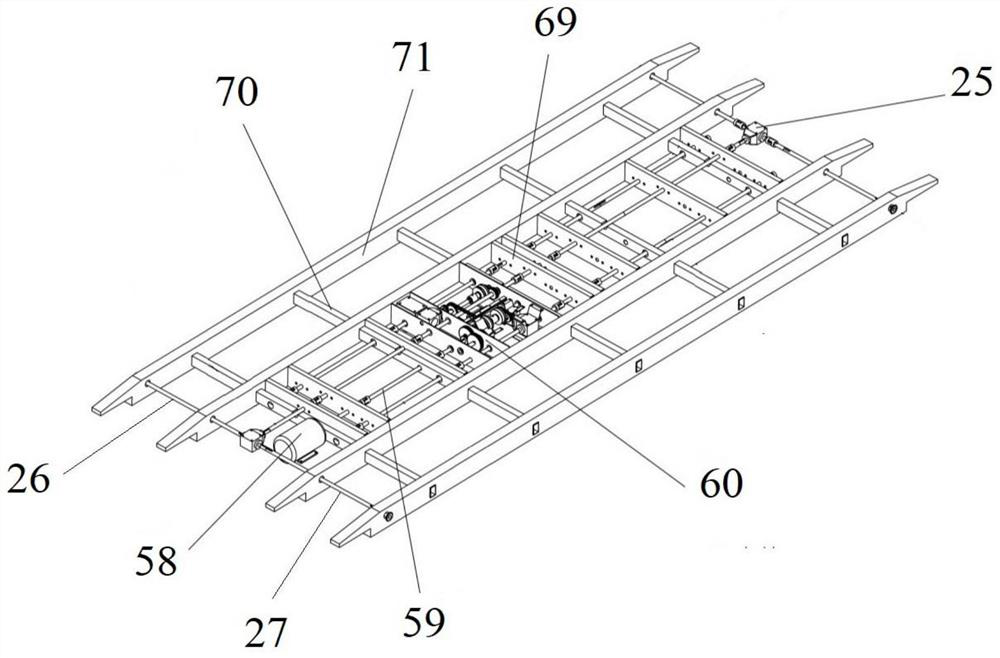

Lifting mechanism and side type lifting garage

PendingCN112065128AReasonable mechanical structureEven by forceParkingsStructural engineeringClassical mechanics

The invention discloses a lifting mechanism. The lifting mechanism comprises an upper beam plate and a lower beam plate, and further comprises a shear fork arm lifting mechanism hinged between the upper beam plate and the lower beam plate and a vertical lifting mechanism connected to the upper beam plate. The lifting mechanism combines a shear fork type lifting device and a lead screw type liftingdevice, in the initial stage, a vertical lifting worm device is used for lifting, after the lifting device is lifted to a certain height, the shear fork type lifting device bears subsequent lifting,the lifting devices are arranged at the two ends of the length direction of an upper vehicle carrying plate, on the premise that the use of the shear fork type lifting device is reduced, mechanical transmission is achieved, the mechanical structure is reasonable, stress is balanced, no deflection torque exists, safety and reliability are achieved, and the failure rate is low.

Owner:张洪源

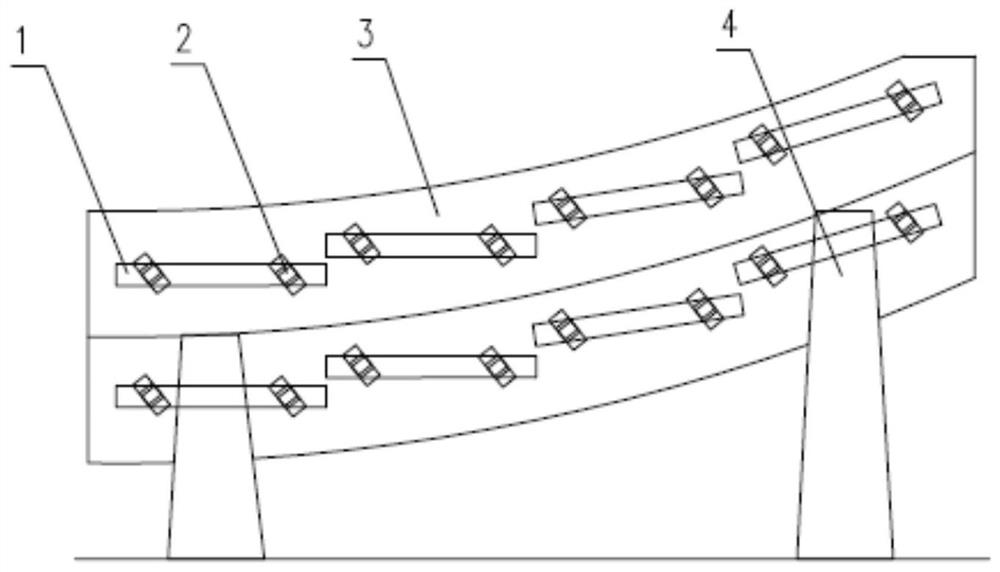

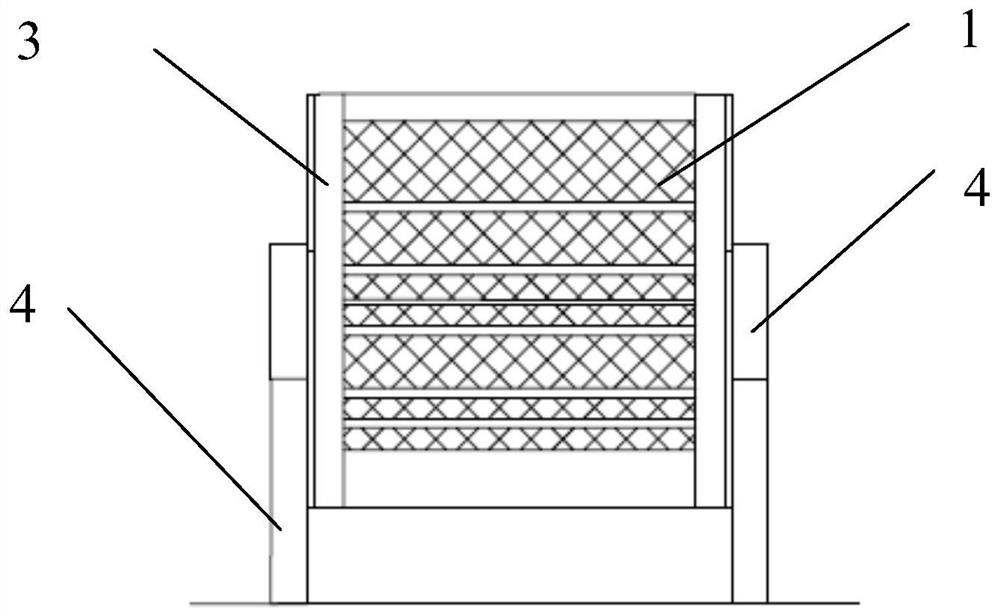

Vibrating screen with vibration exciters

InactiveCN112191508AVibration without contactNo noise pollutionSievingScreeningVibration amplitudeEngineering

The invention discloses a vibrating screen with a vibration exciter, and relates to the field of vibrating screens. The vibrating screen comprises screen meshes, the vibration exciters, a screen frameand supports, at least one layer of screen surface is arranged in the screen frame, and each layer of screen surface is formed by segmentally connecting a plurality of stages of screen meshes from bottom to top in sequence at certain-angle intervals, so that the screen surface gradually tilts upwards and is curve-shaped; the supports are arranged on the left side and the right side of the screenframe and used for supporting the screen frame; and a vibration exciter is arranged on each screen mesh and is used for adjusting the vibration frequency of the screen mesh and conducting stepless amplitude modulation on the vibration amplitude of the screen mesh. The vibrating screen adopts an electromagnetic vibrator, so that non-contact vibration and no noise pollution are realized; the vibration frequency and the vibration amplitude are steplessly adjustable, so that the material applicability and the screening effect are improved; the structural form that the screen surface vibrates and the screen frame does not vibrate is adopted, and compared with a traditional vibrating screen, the whole machine vibration weight is greatly reduced, and more energy is saved; and the vibration frequency and amplitude of each screen surface can be independently adjusted, so that the applicability of different materials and the screening effect of the whole machine are greatly improved.

Owner:日昌升建筑新材料设计研究院有限公司

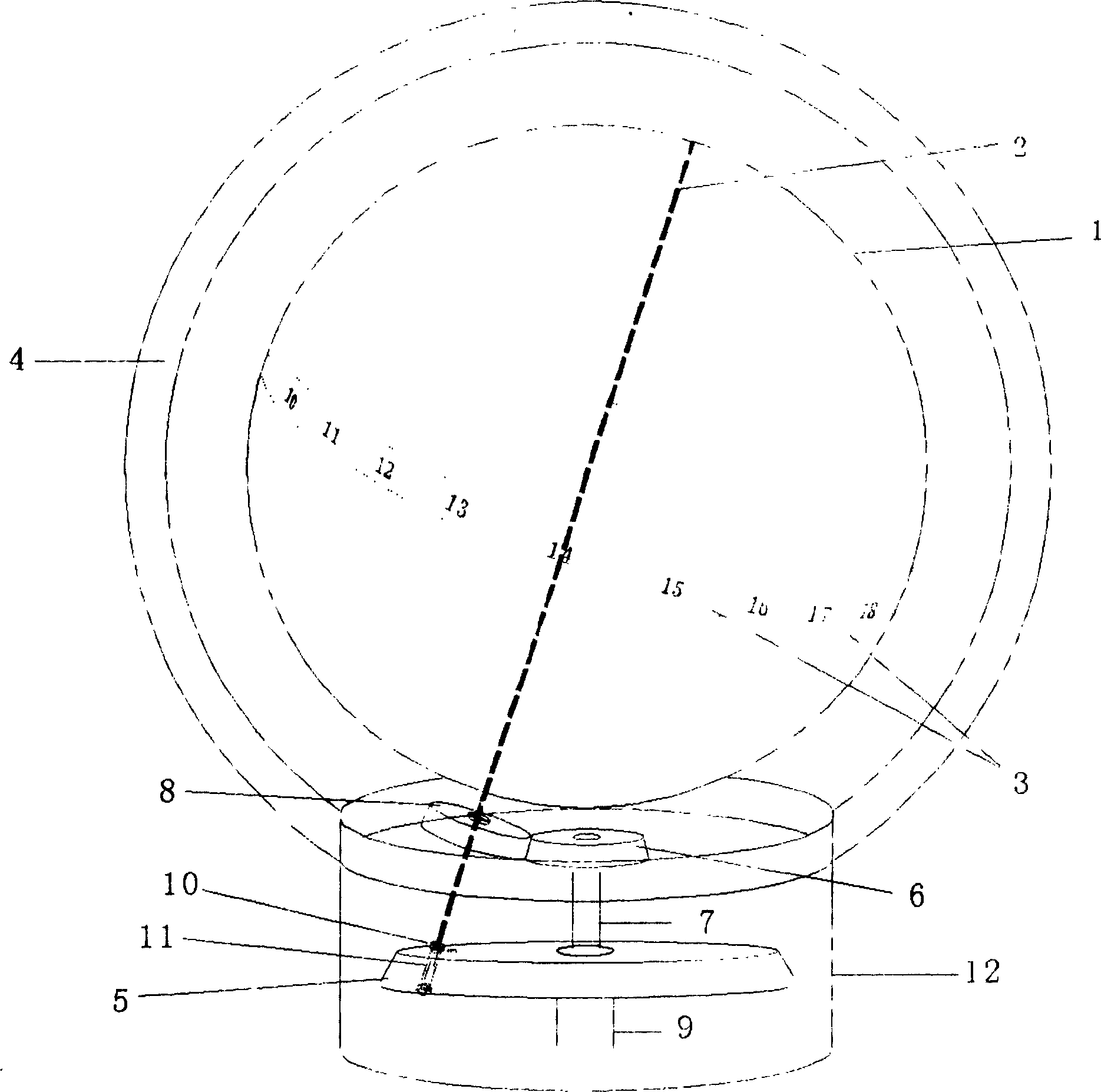

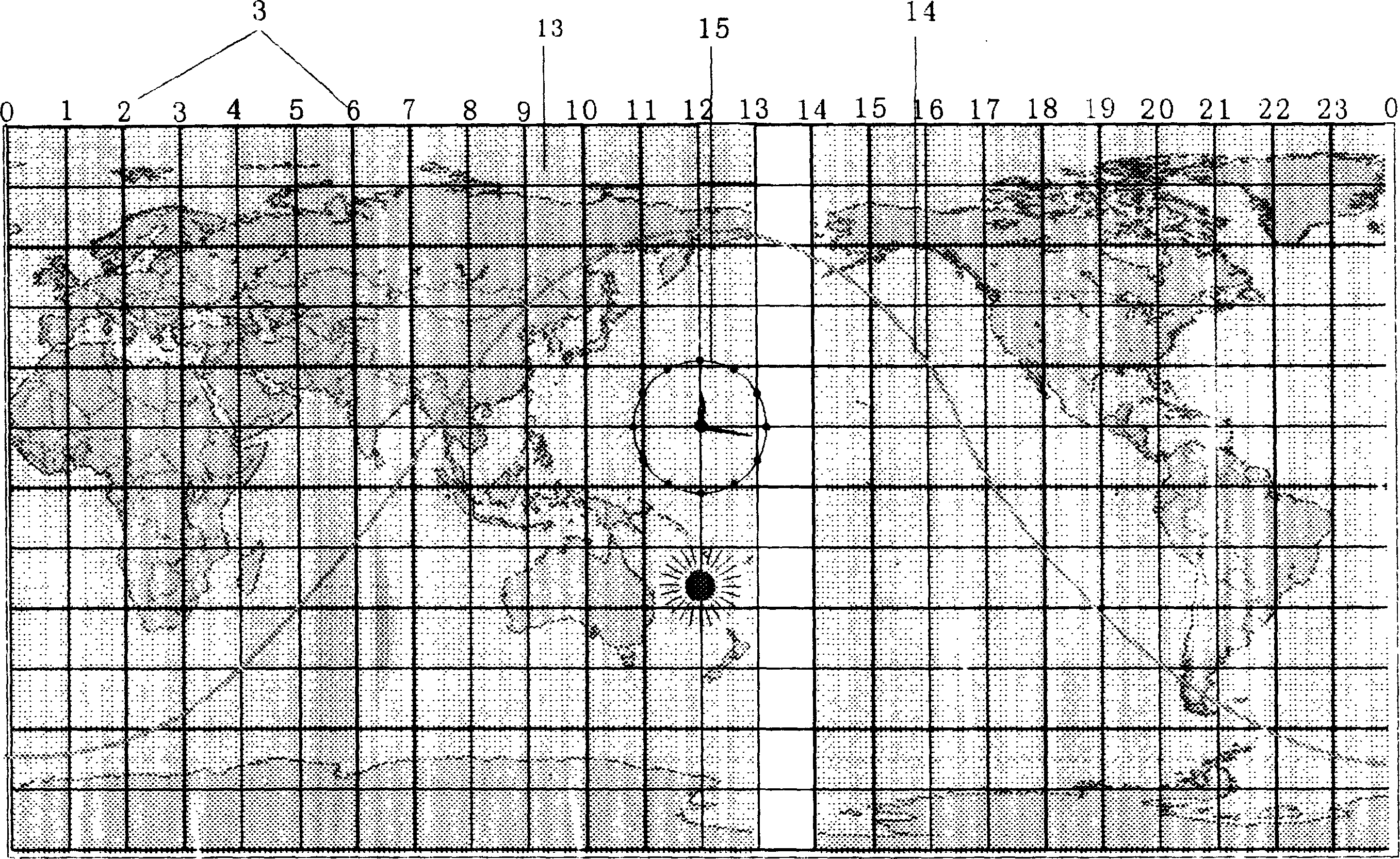

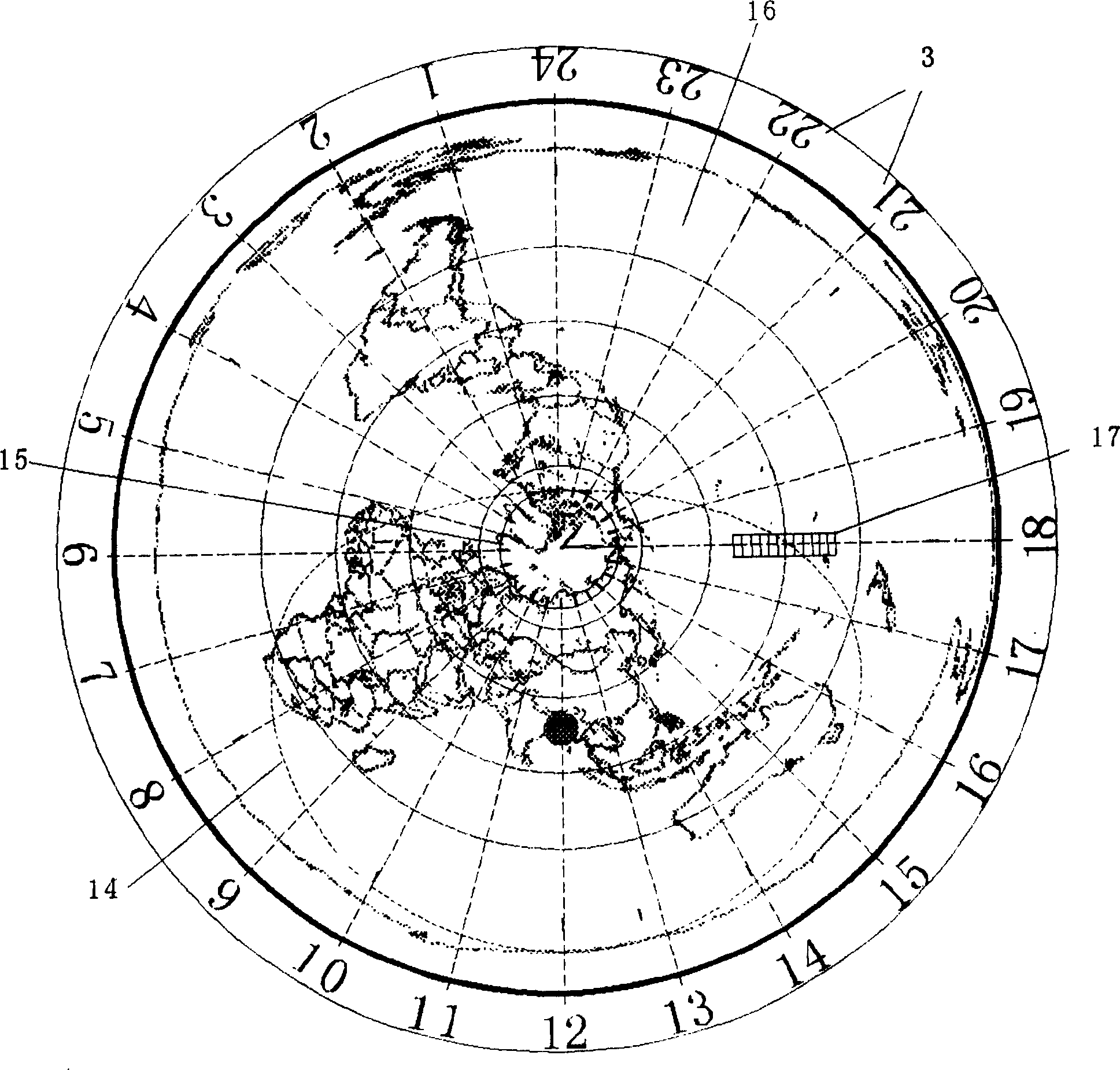

Time-space instrument

InactiveCN1834824AEasy to manufactureWide range of usesVisual indicationPlanetaria/globesLongitudeTime zone

The invention is a space-time apparatus for visually displaying corresponding relation between ground space and time, comprising main body, world map with time zone, main body supporting base, local hour longitude marked on map, 24-hour number circle, terminator, solar terms, and minute-second clock, solving synchronous displaying problem and able to display day and night lengths, morning and night, solar terms and other related messages, having characters of being scientific and real, simple and direct and practical, and beautiful and funny, and able to be widely applied to science and education, handcrafts, space-time indicator and dynamic sculptures for squares and courtyards.

Owner:胡小鹏

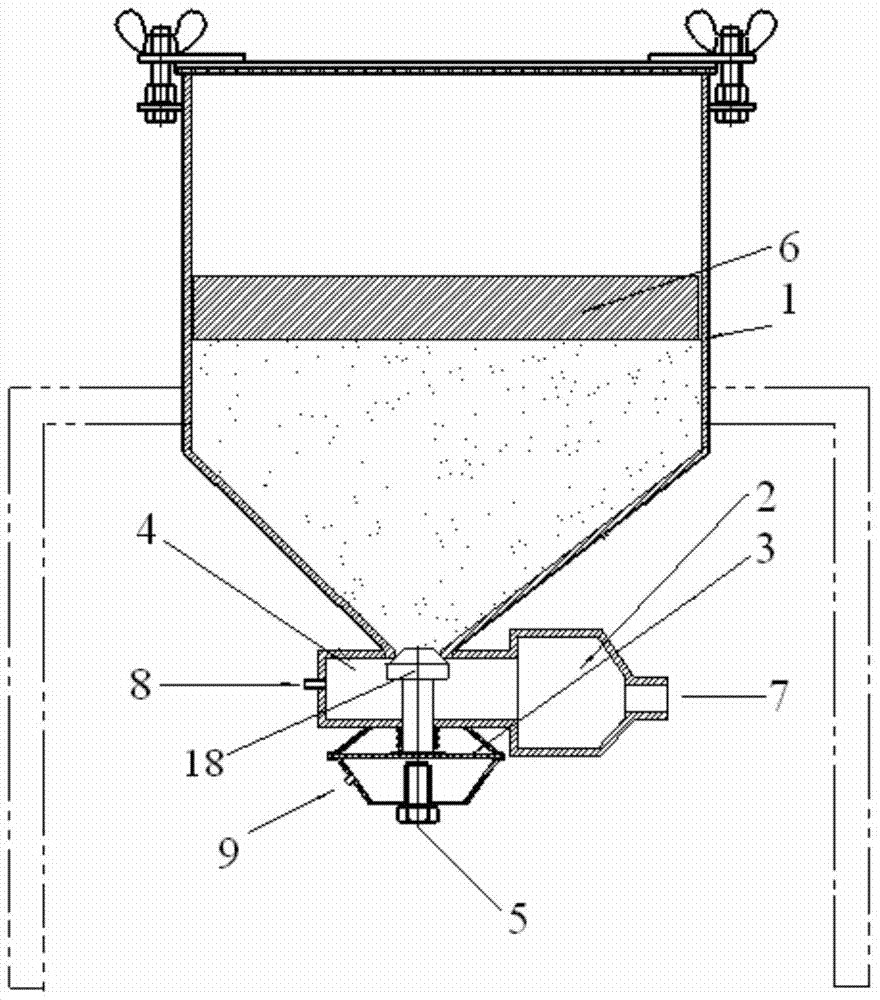

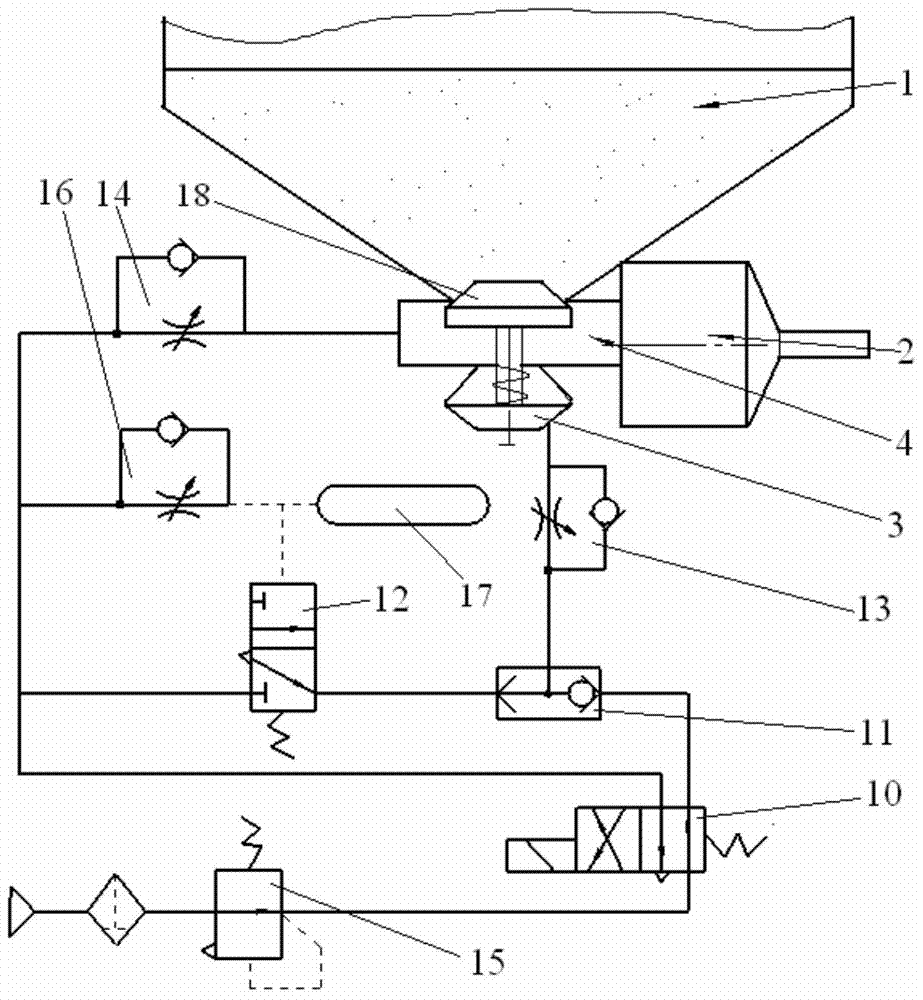

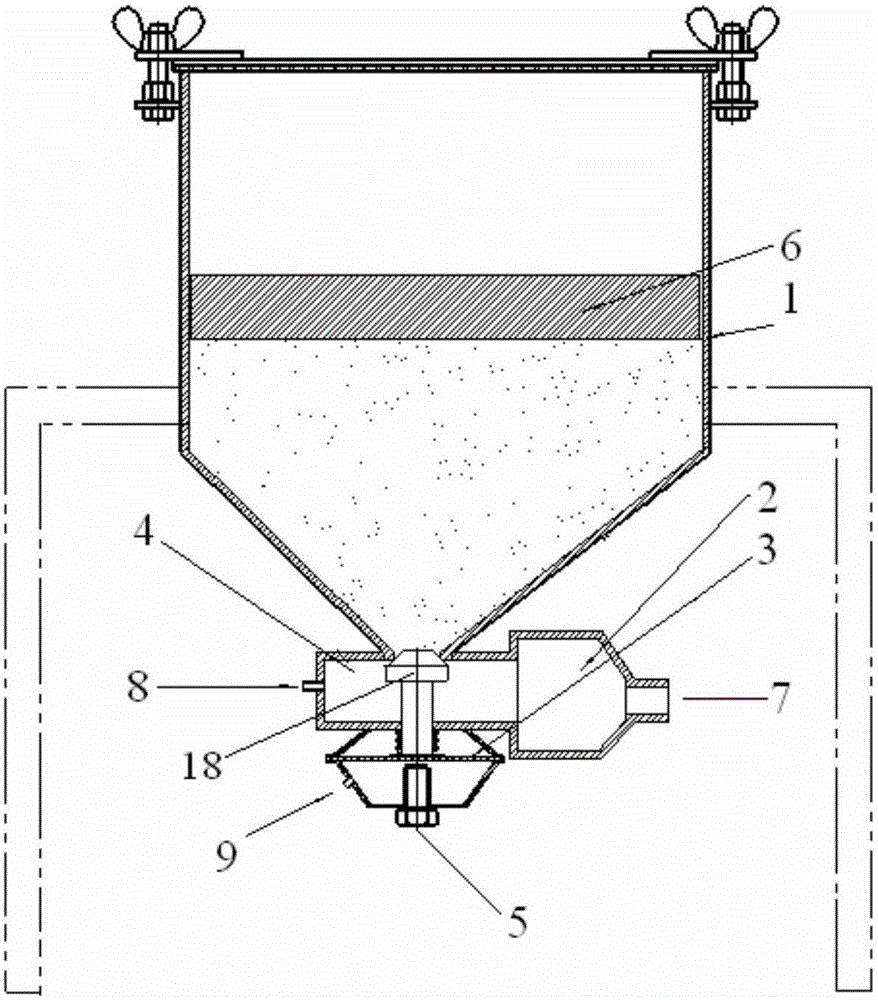

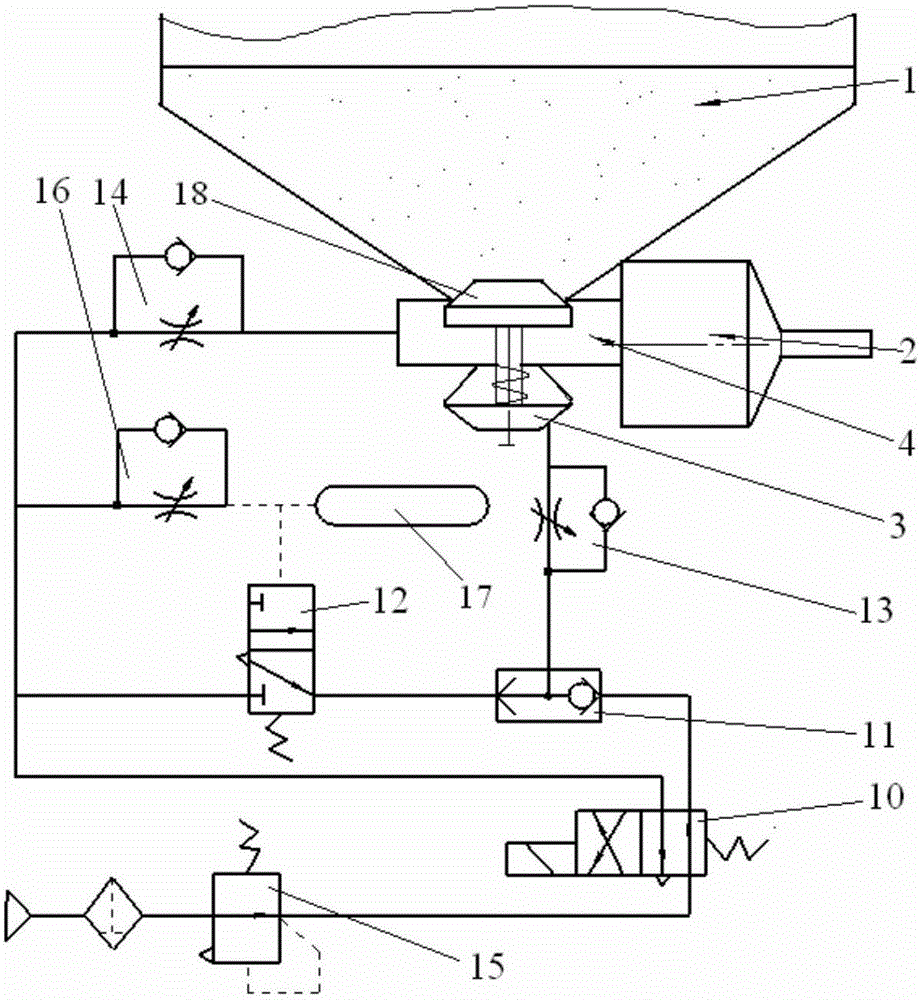

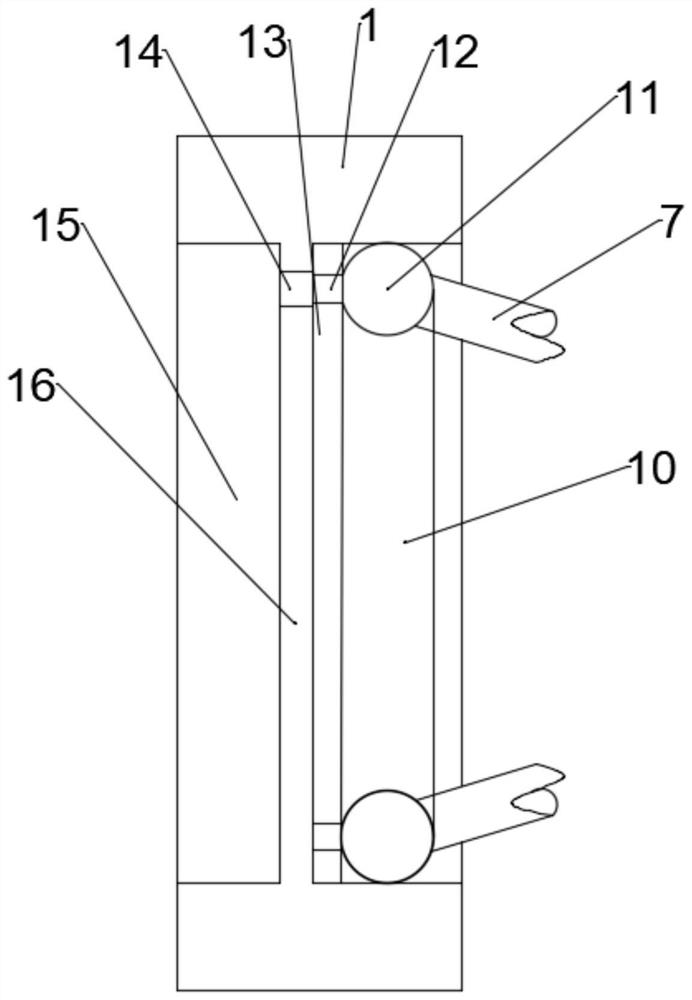

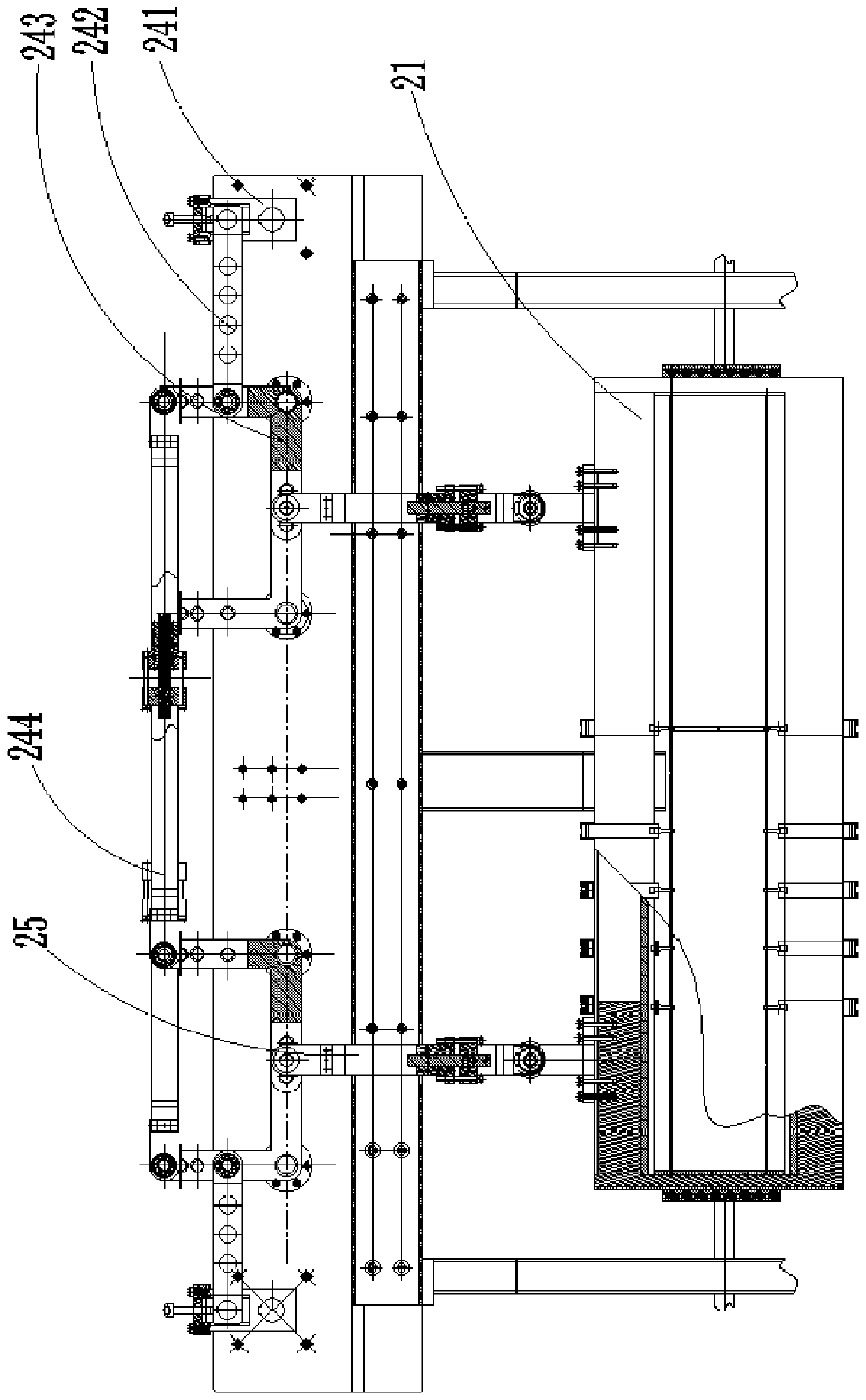

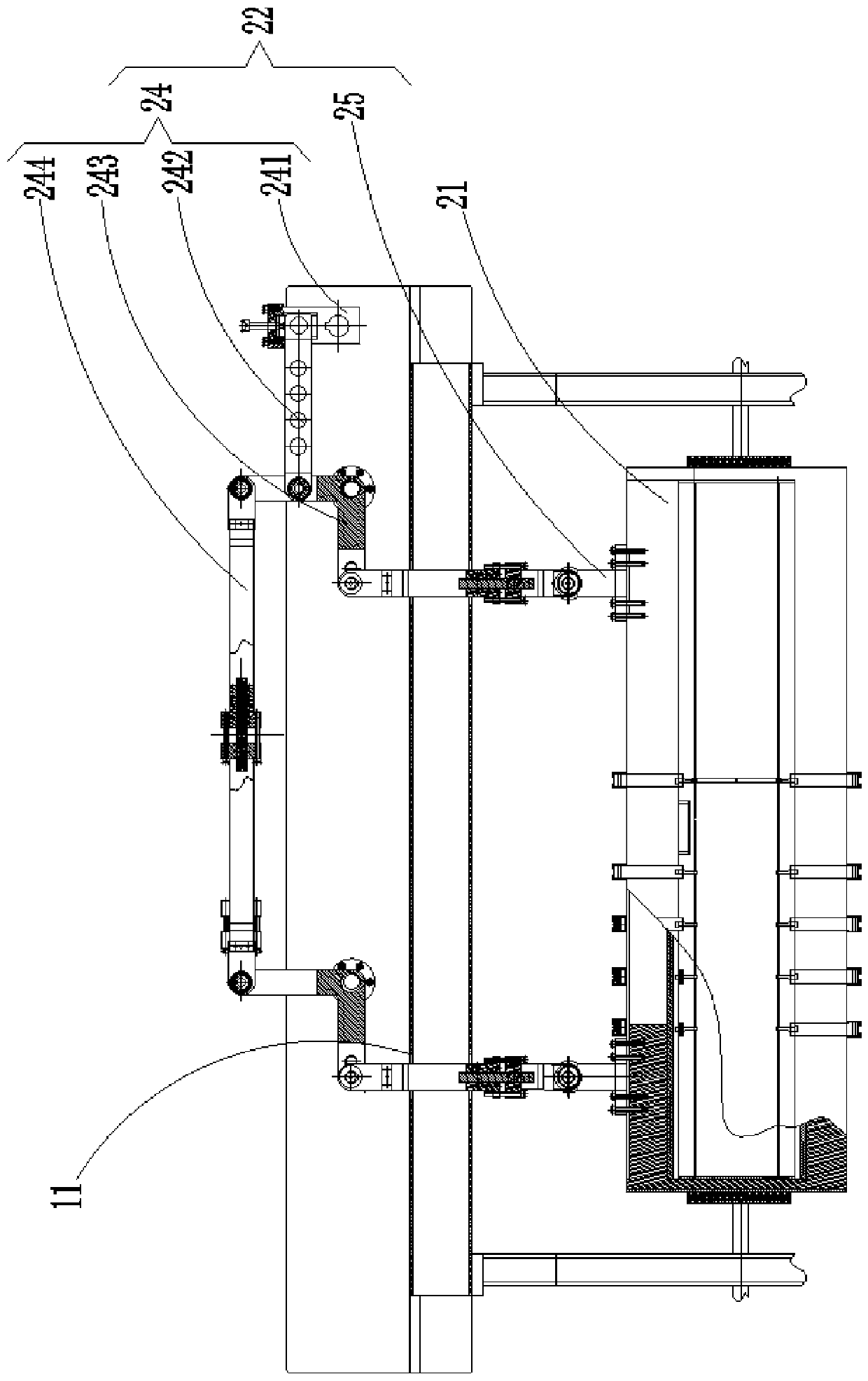

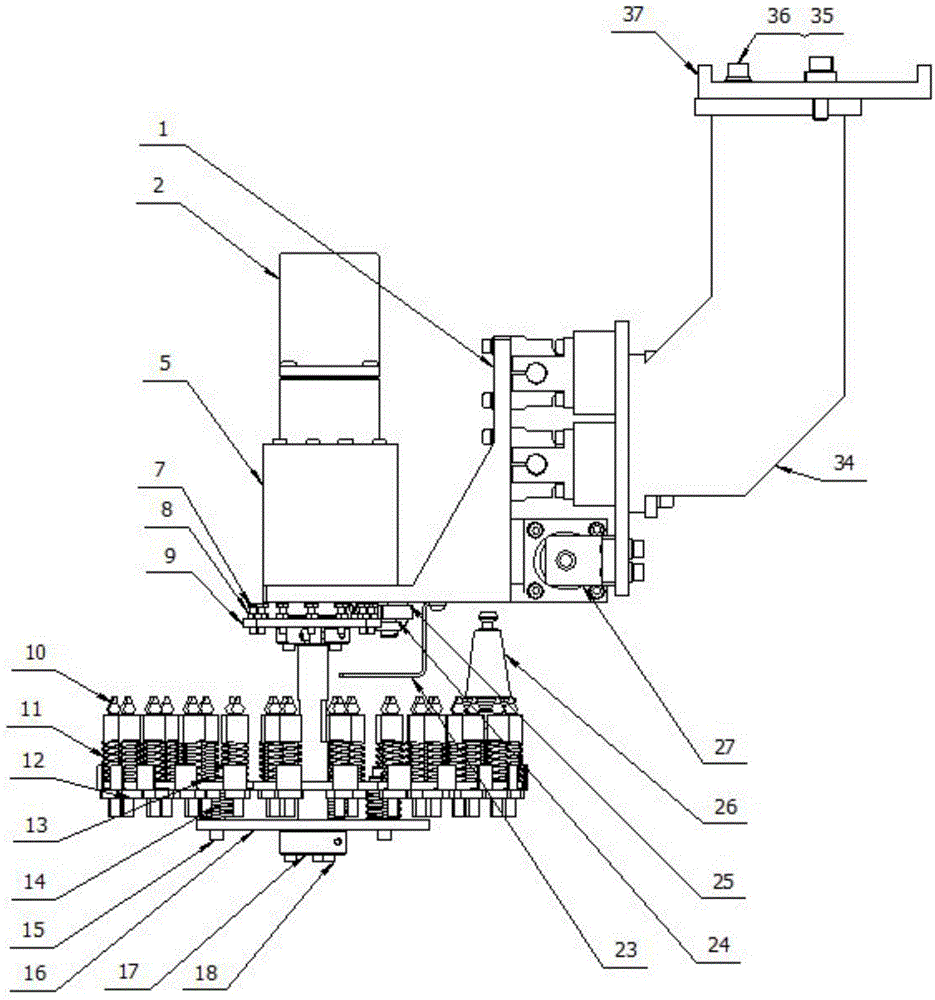

A pipe mold powder spraying machine

ActiveCN105236144BReduce replacement costsReduce mechanical transmissionBulk conveyorsMolding machineSprayer

The invention discloses a pipe mold powder spraying machine, which comprises a large hopper (1) and an air pressure system; The tube mold powder injection gas path connection. Adopting the above-mentioned technical scheme and adopting the air pressure control transmission technology reduces complicated mechanical transmission, reduces the cost of replacement of wearing parts, and improves production efficiency.

Owner:WUHU XINXING DUCTILE IRON PIPES

Spraying machine for pipe mold powder

ActiveCN105236144AReduce replacement costsReduce mechanical transmissionBulk conveyorsEngineeringAtmospheric pressure

The invention discloses a spraying machine for pipe mold powder. The spraying machine comprises a big hopper (1) and a gas pressure system. An injection pipe (4) is arranged under the big hopper (1) and connected with a pipe mold powder injection gas channel of the gas pressure system. According to the technical scheme, the technique of gas pressure control transmission is adopted, so that complex mechanical transmission is reduced, the replacement cost of abrasion parts is reduced, and the production efficiency is improved.

Owner:WUHU XINXING DUCTILE IRON PIPES

Bass optimization for audio systems and devices

ActiveUS11166100B2Reduce mechanical transmissionLoudspeaker transducer fixingHeadphones for stereophonic communicationTransducerDiffuse field

The invention relates to audio transducer technology, including audio tuning systems to be utilised in personal audio devices, such as headphone, earphones, mobile phones and the like. The audio tuning system optimises the frequency response of the personal audio device by using Diffuse Field curve characteristics. The audio transducers of the personal audio device incorporate low resonance designs, including low resonance transducer and diaphragm suspensions to further optimise the sound quality of the device. The invention also relates to an audio transducer diaphragm construction that includes a three-dimensional lattice which may be utilised in any audio transducer application.

Owner:WING ACOUSTICS LTD

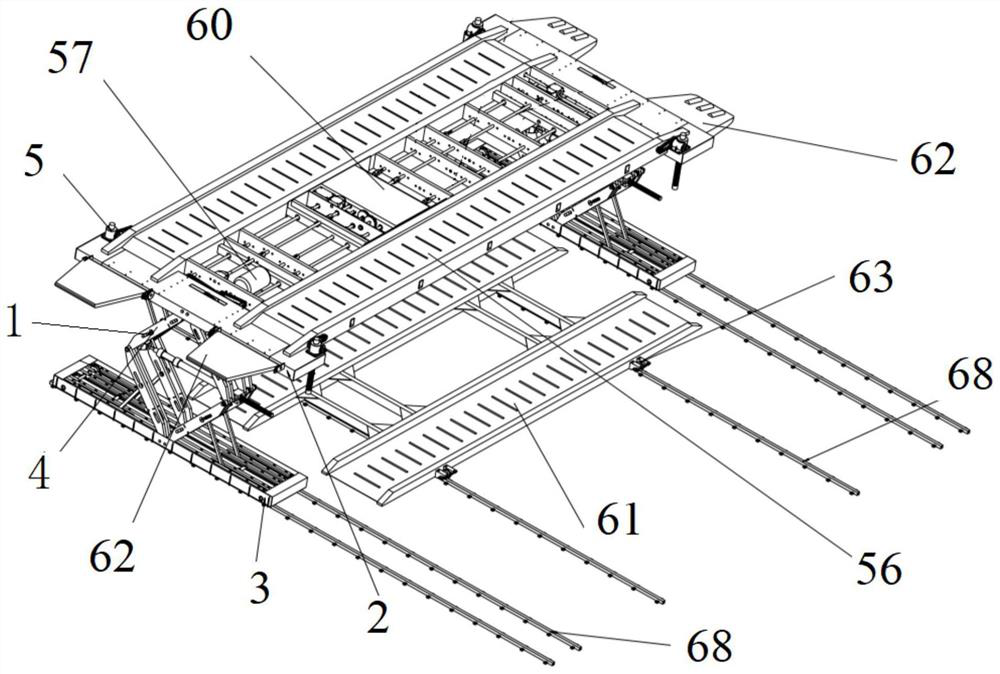

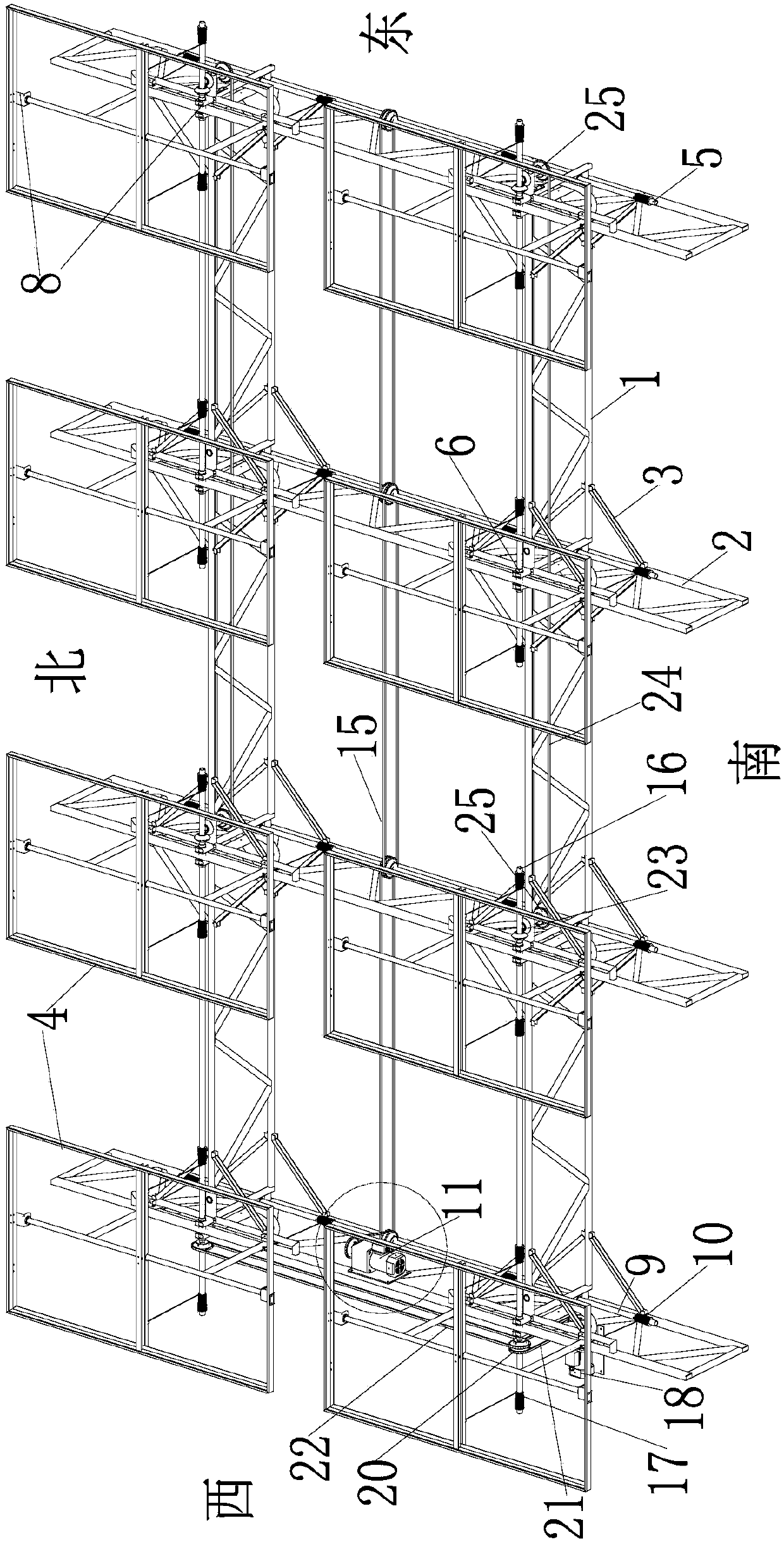

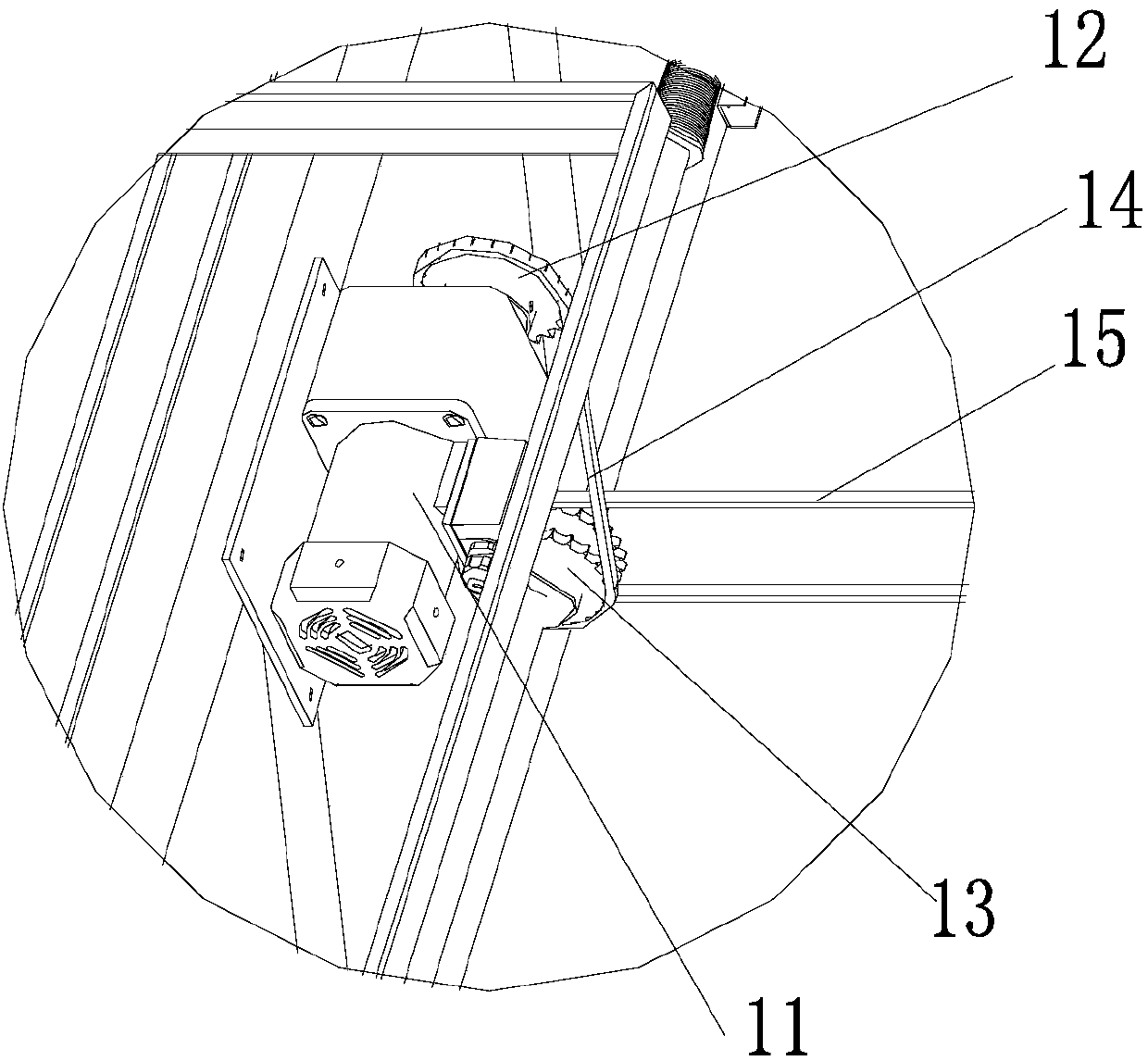

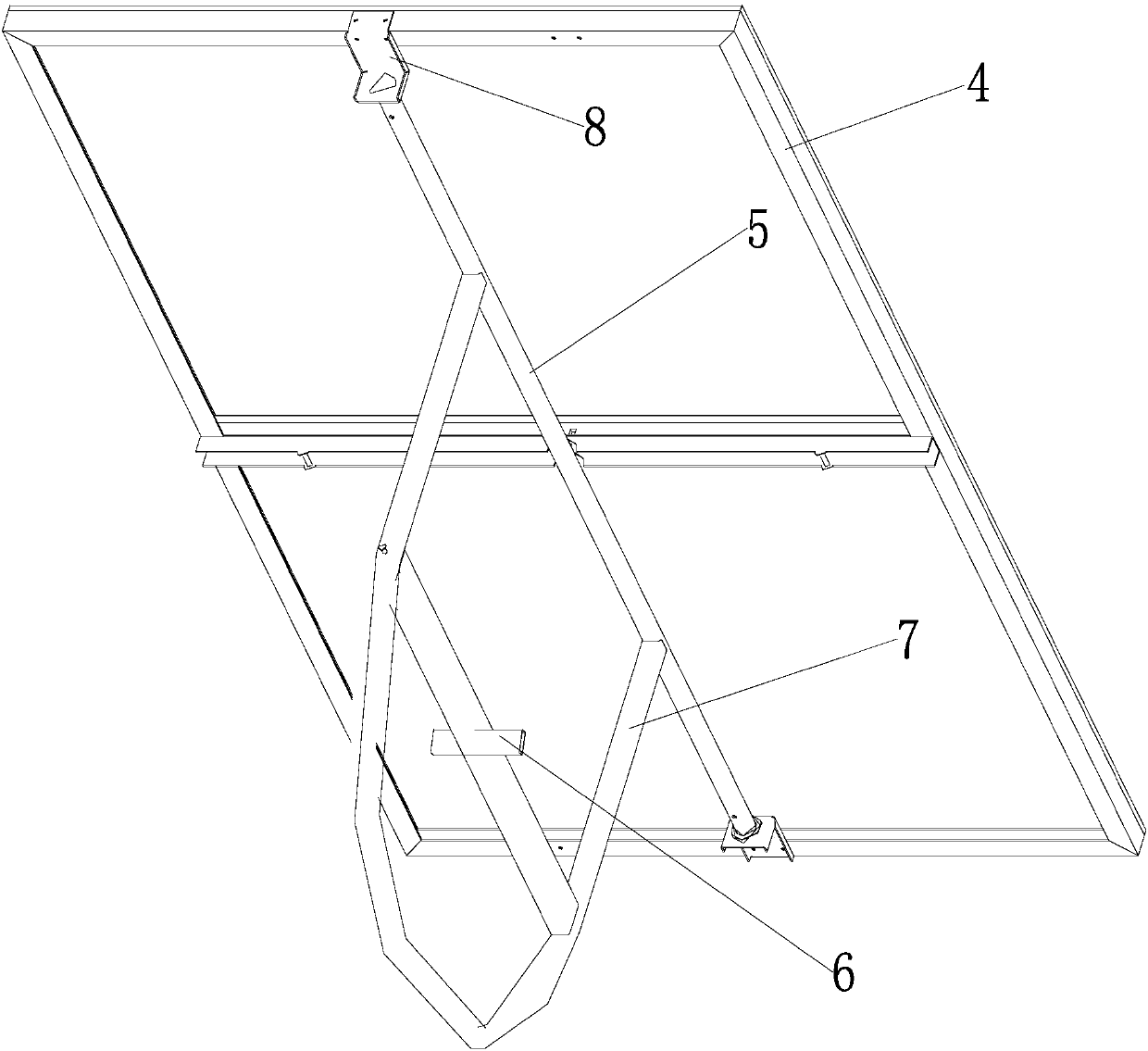

Follow-up device of solar photovoltaic power generation system

PendingCN107911069AImprove power generation efficiencyIncrease power generationPhotovoltaic supportsControl without using feedbackTerrainEngineering

A follow-up device of a solar photovoltaic power generation system comprises the follow-up units which are connected orderly along the east, west, south and north directions, and each follow-up unit comprises a battery panel frame, a south-north turning device and an east-west turning device. The battery panel frame is a rectangular frame, and the south-north turning device and the east-west turning device are arranged under the battery panel frame. The beneficial effects of the present invention are that (1) the follow-up device is formed by assembling the plurality of follow-up units and isconvenient to transport and simple and rapid to assemble, and the mechanical transmission in an overall structure is reduced, thereby reducing the damage, and improving the mechanical service life substantially; (2) the follow-up device can move front and back and left and right, can utilize the sunlight fully, and enables the power generation efficiency to be improved; (3) the follow-up device can select the different coverage areas and assembly modes according to the terrain and topography, is very flexible, and is strong in versatility.

Owner:SHANGHAI WESTHOUSE SWITCHGEAR

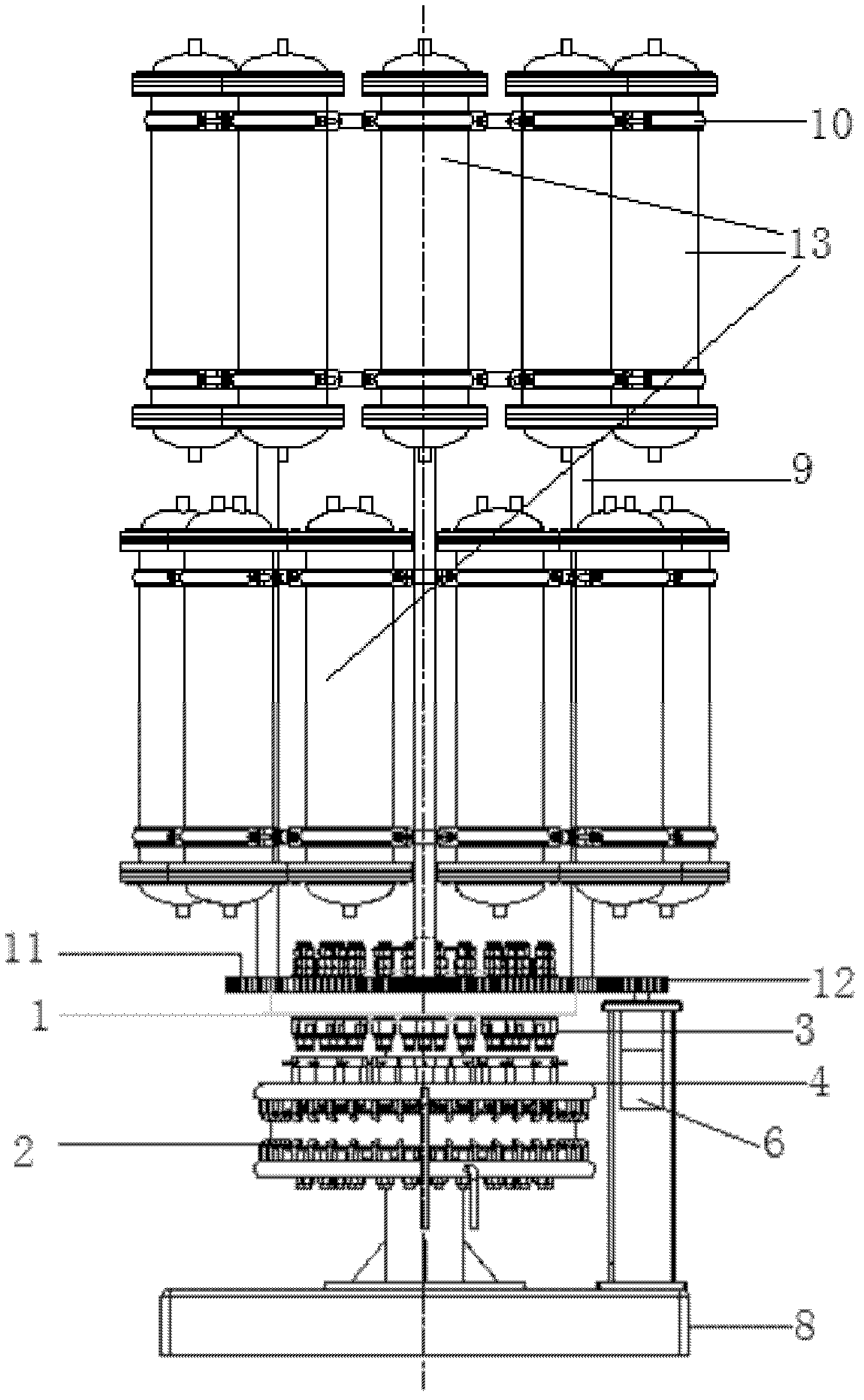

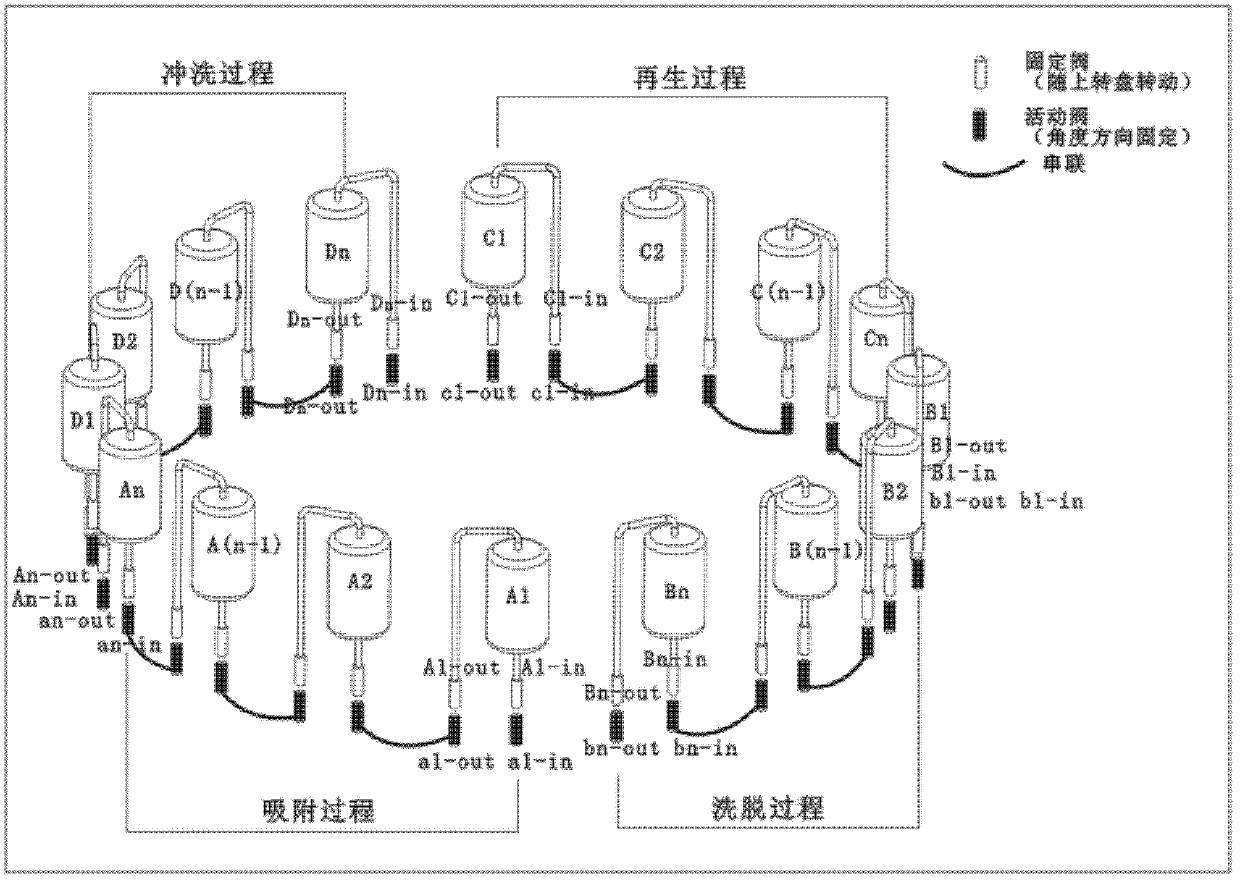

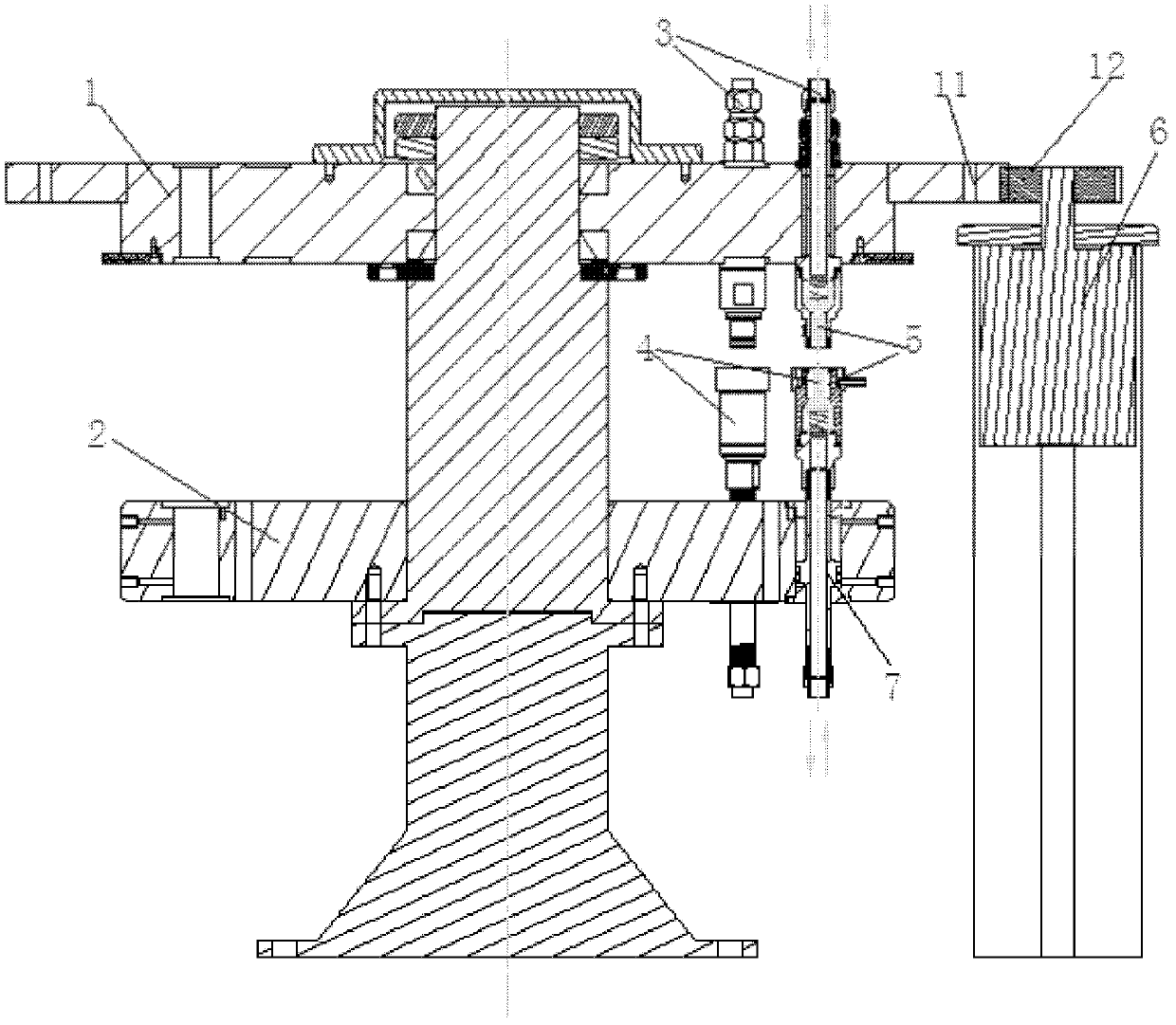

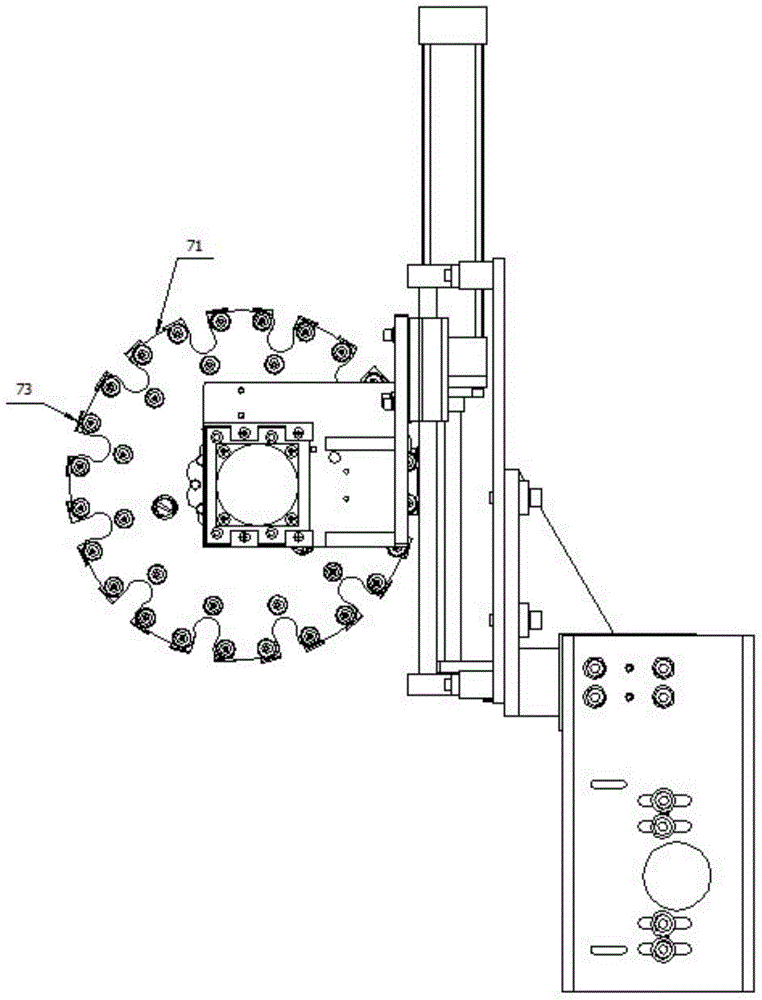

Continuous ionic adsorption and exchange device system

InactiveCN102628102BAvoid vacant wasteLow efficiencyIon-exchange process apparatusIon-exchanger regenerationRegenerative processDesorption

A continuous ionic adsorption and exchange device system comprises resin tanks and a porous distributing valve, wherein the porous distributing valve comprises a fixed valve array and a movable valve array. Each movable valve and each fixed valve are respectively provided with an upper port and a lower port, an inlet of each resin tank is communicated with the upper port of one fixed valve, and an outlet of each resin tank is communicated with the upper port of another fixed valve, the upper ports of the movable valves are in one-to-one butting design with the lower ports of the fixed valves in the working process, and the lower ports of the movable valves are communicated with each other or communicated with the outside. The continuous ionic adsorption and exchange device system is compact in device, simplified in system, reduced in pipeline and small in occupation area, overcomes the shortcomings of bias current phenomena easily occurring in the adsorption process, vacancy and wasteof partial resin, low using efficiency of resin, large using amount and serve waste of chemical agents in the desorption and regenerative process, large discharging amount of effluent, long operationperiod, large quantity of connection pipelines and valves, fussy operation and the like.

Owner:关宏强

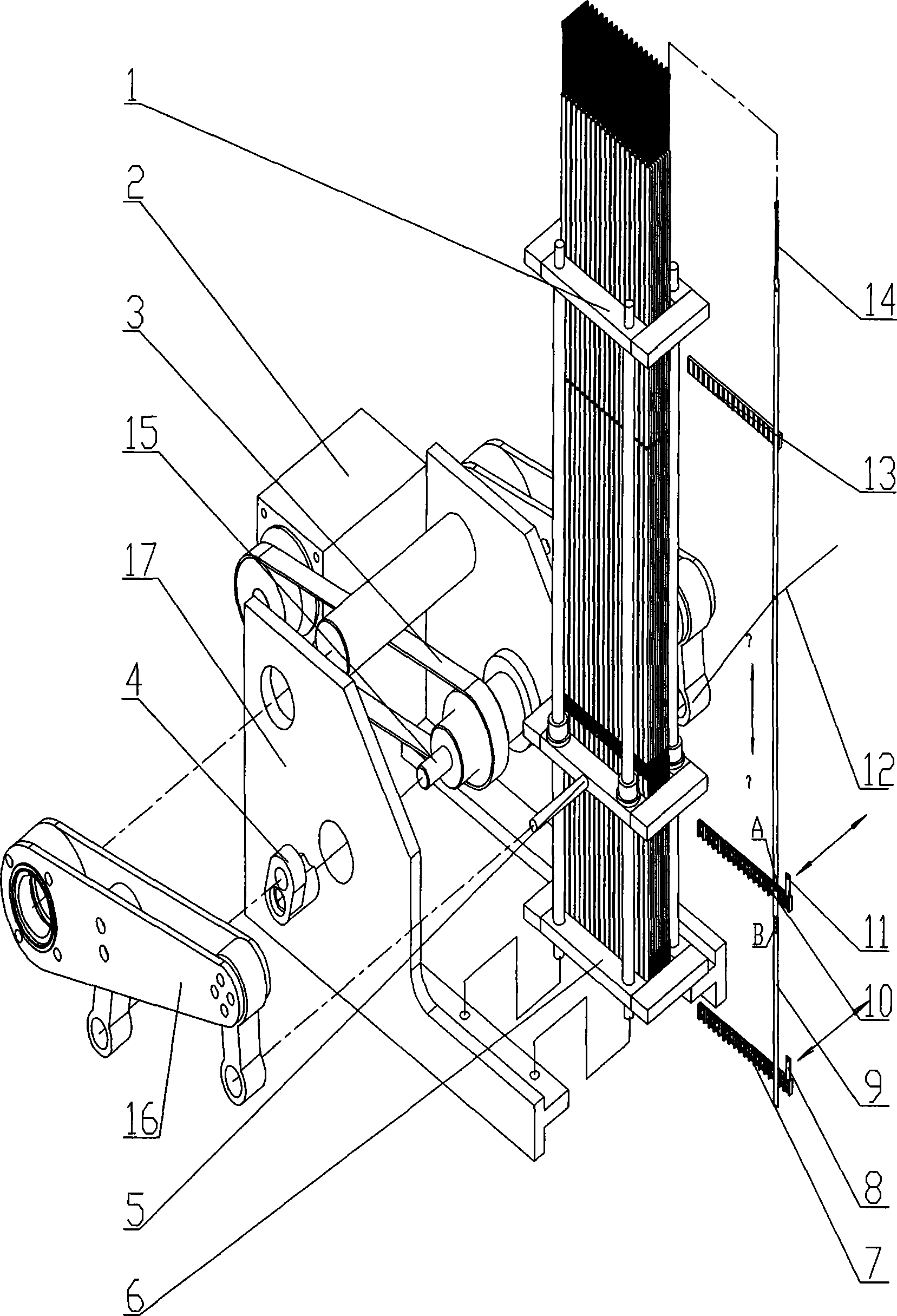

Harness wire-free jacquard head

The invention discloses a harness wire-free jacquard head, belongs to parts for textile machinery, and in particular to the technical field of design and manufacture of the harness wire-free jacquard head. A driving motor is arranged on the front part of a body frame; hook piece slideway linkage mechanisms are arranged on two sides of the body frame; an upper piezoelectric ceramic piece is arranged on a hook piece middle slideway; a lower piezoelectric ceramic piece is arranged on a hook piece lower slideway; during weaving, a toothed belt is driven through the driving motor to rotate an eccentric block, so that a hook piece middle slideway moving frame is driven to reciprocate up and down in a reciprocating way between a hook piece upper slideway fixing frame and a hook piece lower slideway fixing frame, the retention time sequence of the upper and lower positions of the hook piece is controlled by utilizing the deformation of the piezoelectric ceramic piece, and the retention time sequence of the upper and lower positions of the electromagnet-controlled warp yarns is replaced. The piezoelectric ceramic piece is small in size, low in power consumption, stable and reliable, the performance is far superior to that of the electromagnet, the stability of the machine is improved, and the harness wire-free jacquard head is energy-saving and environment-friendly. The harness wire-free jacquard head is mounted on the lowest part of a textile machine, so that the harness wire-free jacquard head is convenient to mount and maintain and does not occupy large space; and moreover, the problems in the conventional products are solved.

Owner:纪美惠

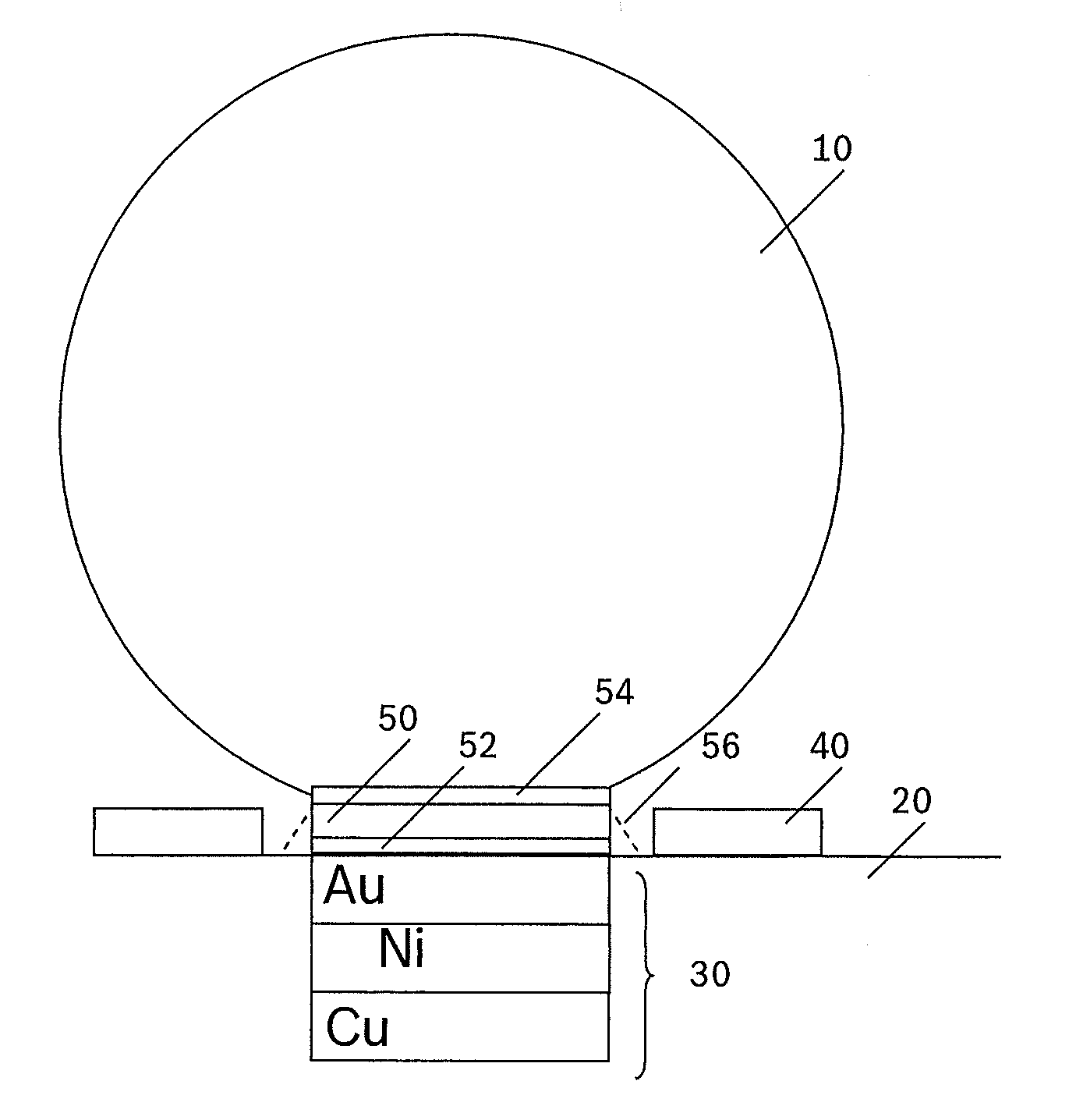

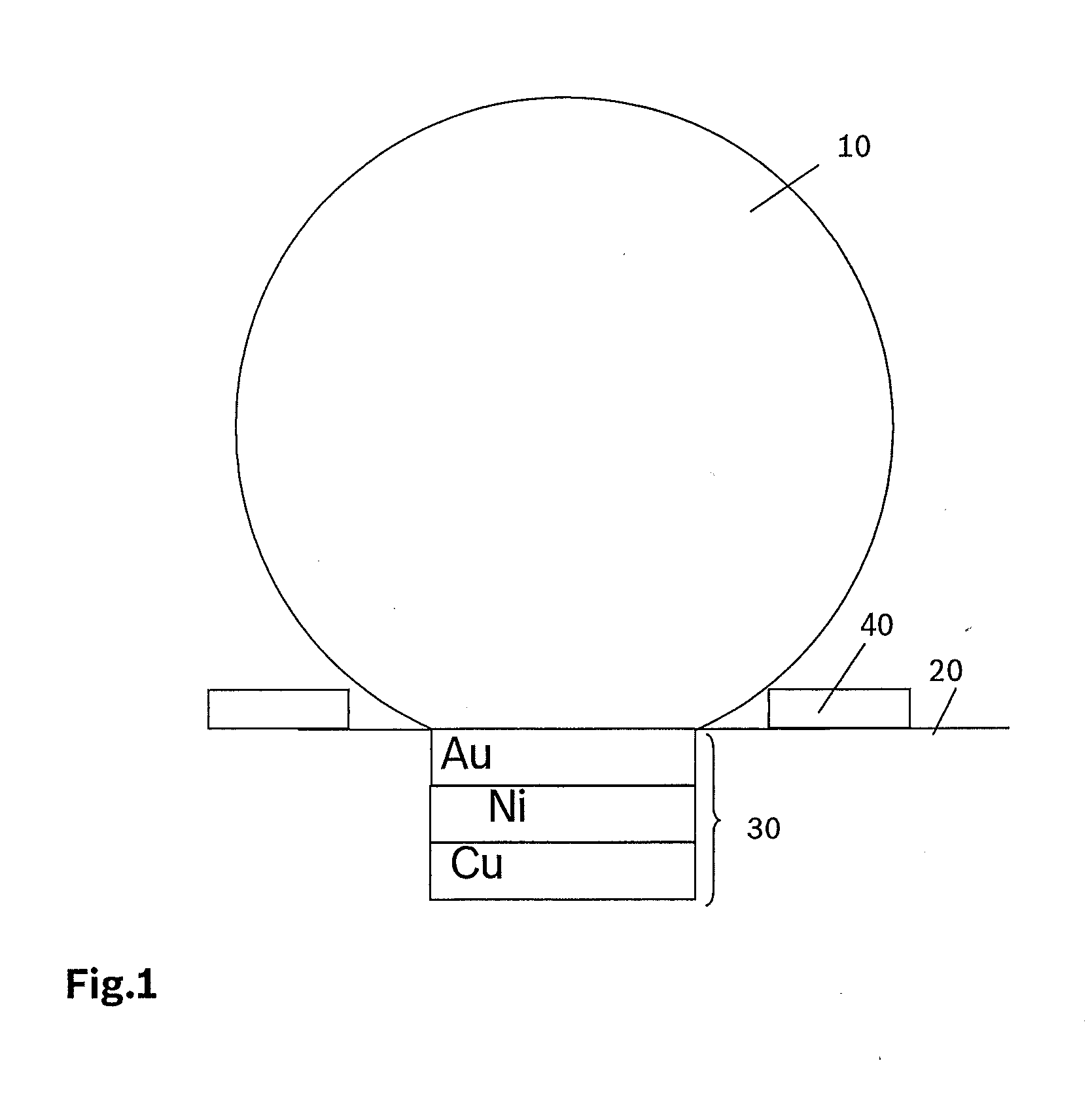

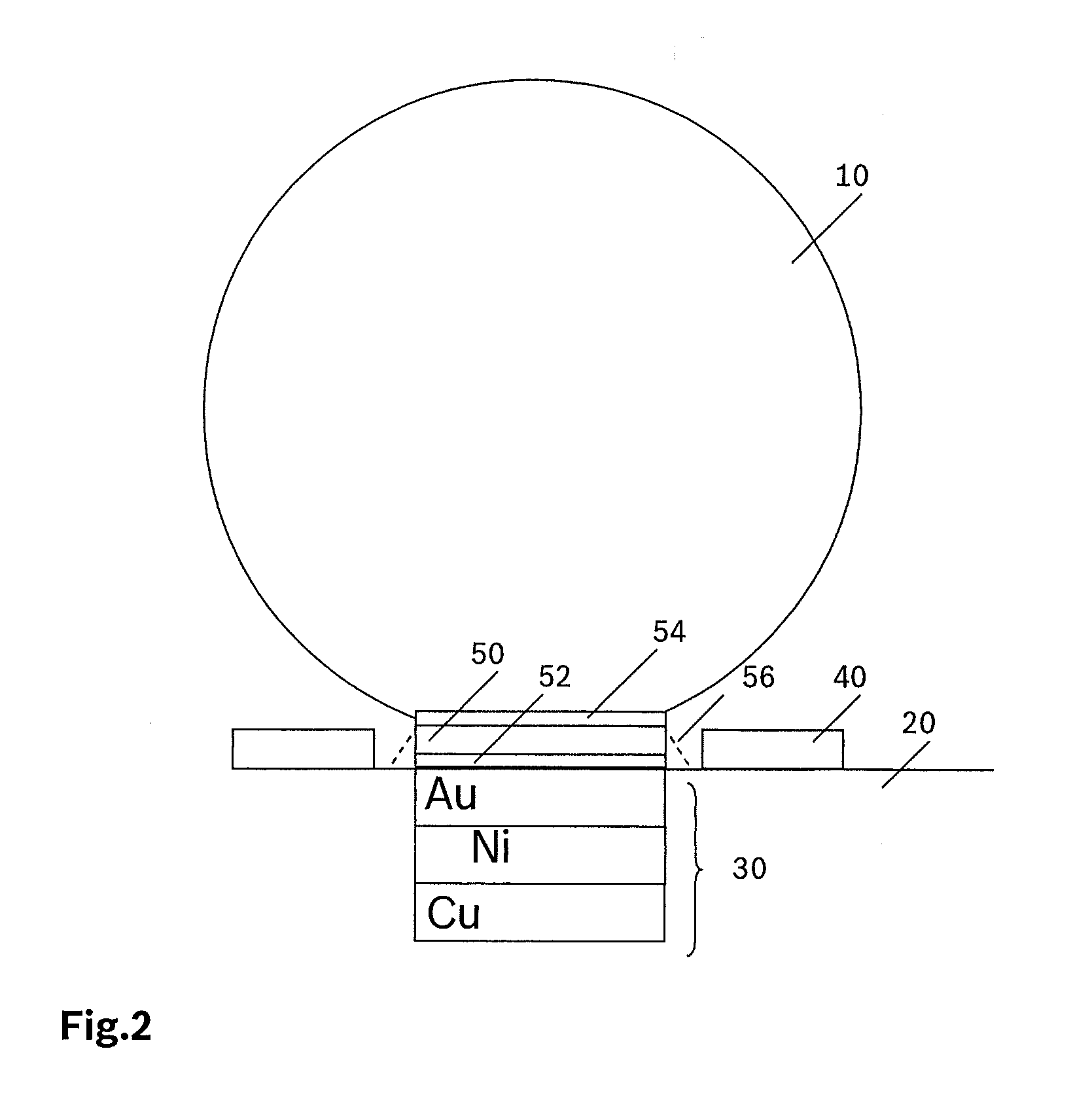

Solder ball device, housing having a solder ball device and production process for a solder ball device

InactiveUS20130161087A1Reduce mechanical stressReduce transmissionNon-insulated conductorsCircuit arrangements on support structuresConductive polymerSolder ball

A solder ball device has a contact surface and a solder ball that is connected electrically conductively to the contact surface. Between the solder ball and the contact surface, a conductive polymer is situated, which is connected to the solder ball and the contact surface.

Owner:ROBERT BOSCH GMBH

A New CNC Milling Machine for Machining Pentahedron with Single Spindle

ActiveCN105108214BReduce manufacturing costReduce processing costsPrecision positioning equipmentMilling machinesNumerical controlAgricultural engineering

The invention discloses a novel single-spindle pentahedron machining CNC milling machine, belongs to the field of numerically-controlled machine tools and relates to pentahedron machining tools. The novel single-spindle pentahedron machining CNC milling machine comprises a lathe bed, a stand column, a horizontal feeding system and a vertical feeding system. The vertical feeding system is connected with a spindle in a 360-degree rotating mode through a spindle indexing device. The horizontal feeding system is connected with a workbench indexing device in a 360-degree rotating mode. According to the novel single-spindle pentahedron machining CNC milling machine, a single-spindle pentahedron can be machined; meanwhile, machining transmission precision and indexing accuracy are improved, the machining range is widened, machining efficiency is improved and the machining cost is lowered.

Owner:邓力凡

Drying room for deep processing of agricultural by-products

ActiveCN105509427BUniform temperature distributionReduce mechanical transmissionDrying gas arrangementsDrying chambers/containersFresh airAgricultural engineering

The invention relates to a drying room for the deep processing of agricultural and sideline products. The drying room comprises a drying chamber, an air blower, heat source bellows, an air delivery pipe, an air return pipe and moisture removing pipes, wherein an air outlet of the air blower is connected with an air inlet through the heat source bellows and the air delivery pipe; the air suction end of the air blower communicates with an air return opening through the air return pipe; a fresh air opening and a regulating air valve are further arranged on the air return pipe; three to four transverse guide plates are arranged at the lower part, directly facing the air inlet, in the drying chamber from the near to the distant; and each guide plate can rotate or swing around rotating shafts at the two ends of the guide plate. When the drying room carries out drying processing on agricultural and sideline products, hot air in the drying room is enabled to evenly circularly flow up and down. The whole temperature difference of the drying room is reduced, and temperature and humidity distribution is relatively even.

Owner:湖南芝草农业科技开发股份有限公司

An automatic rotating clamping device for an industrial robot

ActiveCN107838913BLarge circular torqueImprove applicabilityProgramme-controlled manipulatorGripping headsGear wheelControl engineering

The invention discloses an automatic rotary clamping device for an industrial robot. The automatic rotary clamping device for the industrial robot comprises a rotary displacement base, a transfer disc, a fixed base and a main control shaft; the main control shaft penetrates through the rotary displacement base and the transfer disc; the fixed base is connected with the rotary displacement base through a connecting rod; the main control shaft is fixedly connected to the fixed base; a revolving hydraulic device is mounted on the fixed base, and is connected with a rack mechanical driving device;a jaw arm is mounted on the rack mechanical driving device; an annular rail and a back ring rail are arranged on two side surfaces of the rotary displacement base separately; a cross displacement rail is arranged in the annular rail; the annular rail is provided with a spherical hinge; the spherical hinge is provided with a limiting slide column; the transfer disc is arranged at the left end of the rotary displacement base; an arc transfer pin is arranged on the right side surface of the transfer disc; a rotary sleeve rod is mounted on the left side surface of the transfer disc; a gear pair sleeves the left end of the rotary sleeve rod; and the rotary sleeve rod sleeves the main control shaft. The automatic rotary clamping device for the industrial robot realizes higher annular torque ofthe industrial robot, precisely assists transverse displacement drive, and improves the applicability and the working efficiency.

Owner:ANHUI POLYTECHNIC UNIV

A working method of a pipe mold powder spraying machine

ActiveCN105312509BReduce replacement costsReduce mechanical transmissionMoulding toolsEngineeringAtmospheric pressure

The invention discloses a working method of a pipe powder spraying machine. The pipe powder spraying machine comprises a large hopper (1) and a pneumatic system. A spraying pipe (4) is arranged under the large hopper (1). The spraying pipe (4) is connected with a pipe powder spraying air channel of the pneumatic system. By the adoption of the technical scheme, a pneumatic control transmission technique is adopted, complex mechanical transmission is omitted, the cost for replacing abraded pieces is reduced, and the production efficiency is improved.

Owner:WUHU XINXING DUCTILE IRON PIPES

Variable-interaction mechanism and screen weaving equipment thereof

PendingCN110331492AGuaranteed penetrationStrong penetrating powerLoomsHealdsEngineeringMechanical engineering

The invention provides a variable-interaction mechanism. The mechanism comprises a rack body, at least four heald frames, at least four drive assemblies and a matched controller, wherein the four heald frames are arranged in parallel, and the lower ends of the heald frames draw fed warp; the drive assemblies are mounted on the rack body, connected with the heald frames respectively and used for driving the connected heald frames to perform vertical interactive movement; each drive assembly is electrically connected with the controller. The invention further provides screen weaving equipment provided with the variable-interaction mechanism. The screen weaving equipment comprises a warp let-off mechanism, a rapier transmitting and weft insertion mechanism, a beating-up mechanism and a winding mechanism, and each mechanism is provided with an independent driver. According to the variable-interaction mechanism and the screen weaving equipment thereof, a conventional complicated and tediousmulti-stage transmission relation is changed, the problem of shutdown caused by the fact that warp and weft materials are broken by scraping in a production process can be solved, and therefore, product quality and production efficiency are improved.

Owner:河北英凯模金属网有限公司

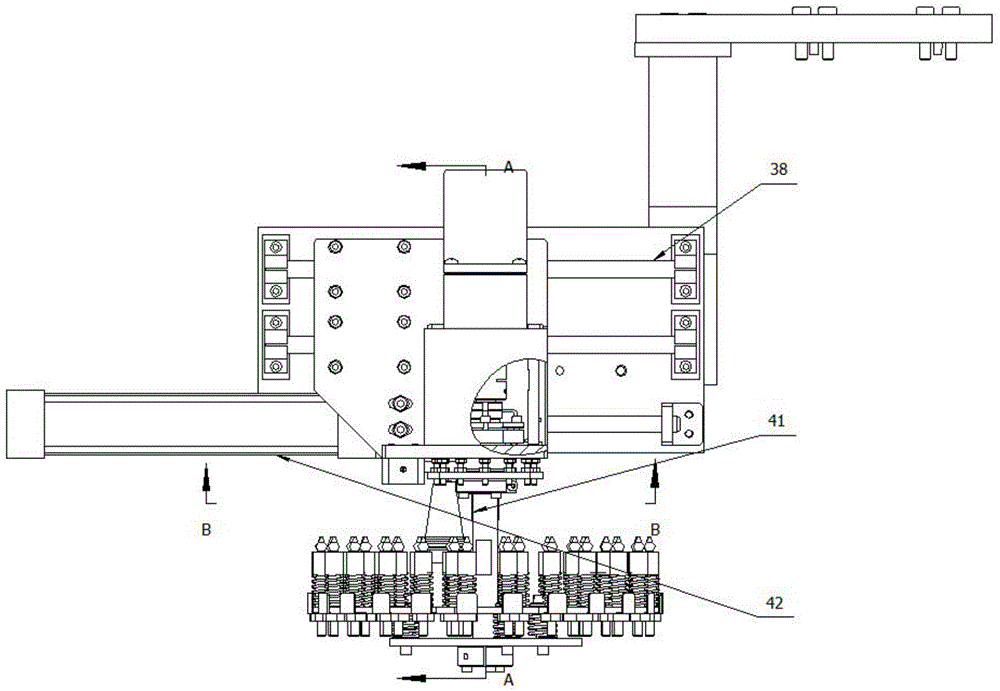

Tool changer assembly

InactiveCN104339206ACompact structureReduce volumePositioning apparatusMetal-working holdersKnife holderControl system

The invention discloses a tool changer assembly. The tool changer assembly comprises a tool changer fixing bracket I, a tool changer fixing plate, a linear guide rail, a tool changer fixing plate I, a rotary shaft, a cutter assembly and a positioning disk, wherein the tool changer fixing plate is mounted on the tool changer fixing bracket; the linear guide rail is mounted on the tool changer fixing plate; the tool changer fixing plate I is mounted on the linear guide rail through a sliding block; an air cylinder assembly, which drives the tool changer fixing plate I to move, is arranged between the tool changer fixing plate and the tool changer fixing plate I; the rotary shaft is rotationally mounted on the tool changer fixing plate I, and the upper part of the rotary shaft is connected to an alternating current motor through a coupler; the cutter assembly is mounted at the lower part of the rotary shaft and is used for assembling a tool; the positioning disk is mounted below the tool changer fixing plate I and is positioned on the rotary shaft; a positioning mechanism matched with the positioning disk is arranged below the fixing plate I; a signal fixing bracket is mounted below the tool changer fixing plate I and is provided with an approach switch which is matched with the positioning disk and is connected to a control system. The tool changer assembly has the benefits of compact overall structure, small size, low cost and convenience in manufacturing.

Owner:SHANGHAI ZHENZHENG NUMERICAL CONTROL MACHINE TOOL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com