Lifting mechanism and side type lifting garage

A lifting mechanism and garage technology, applied in the field of garages storing multiple vehicles, can solve the problems of unbalanced force and insufficient stability, and achieve the effects of balanced force, less trauma and obvious advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

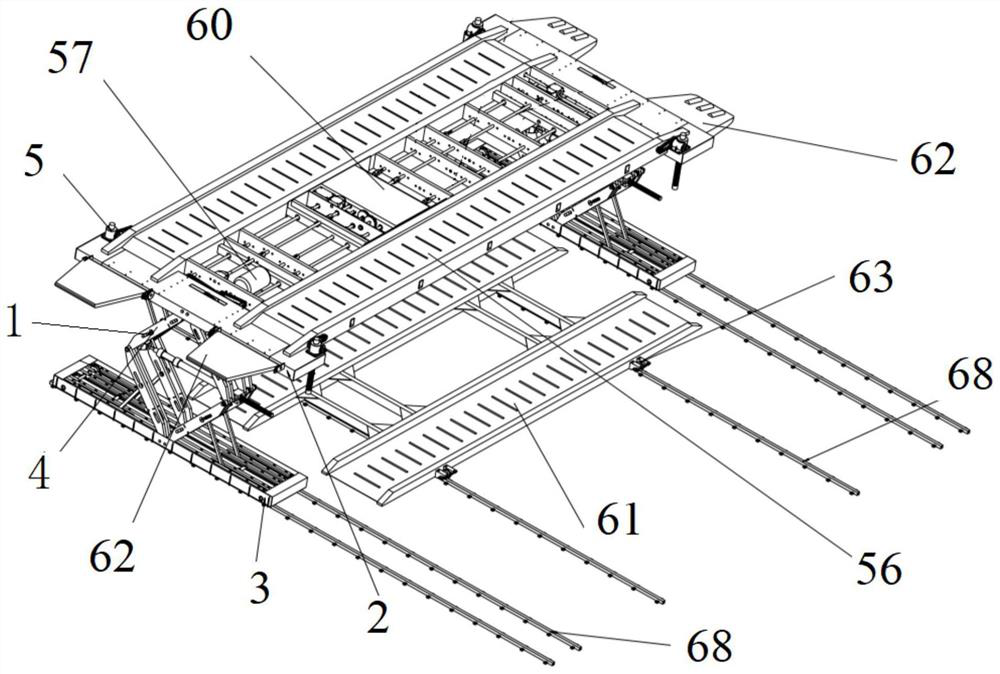

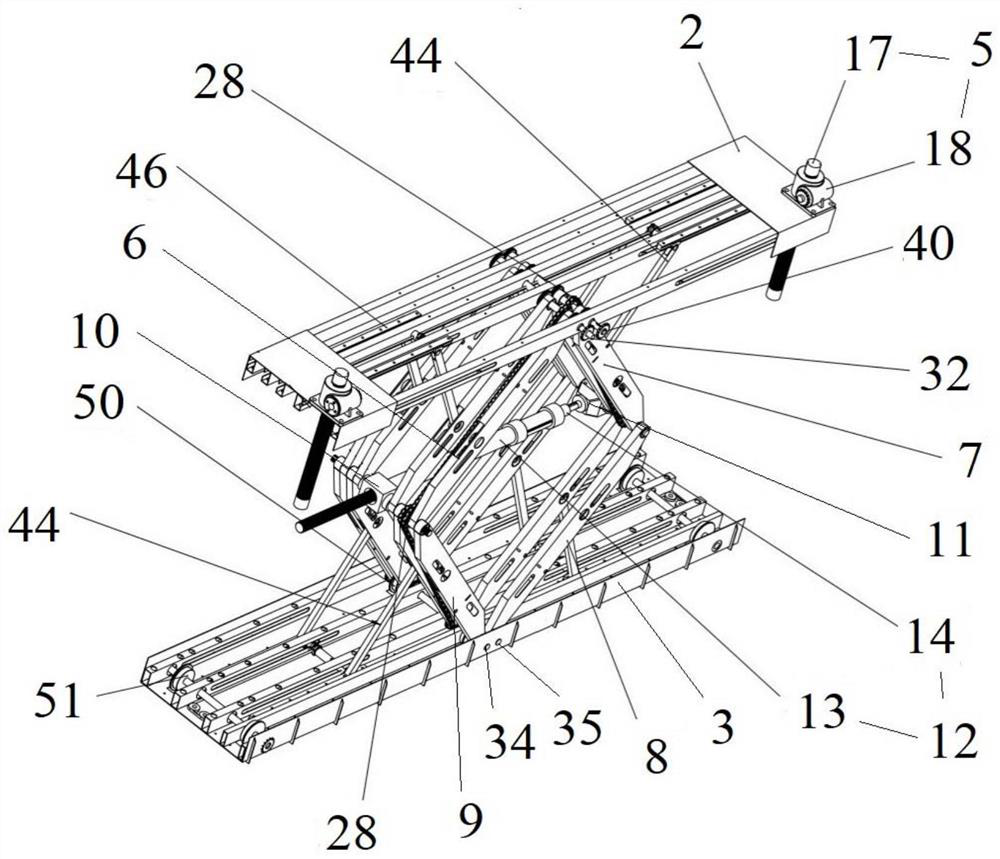

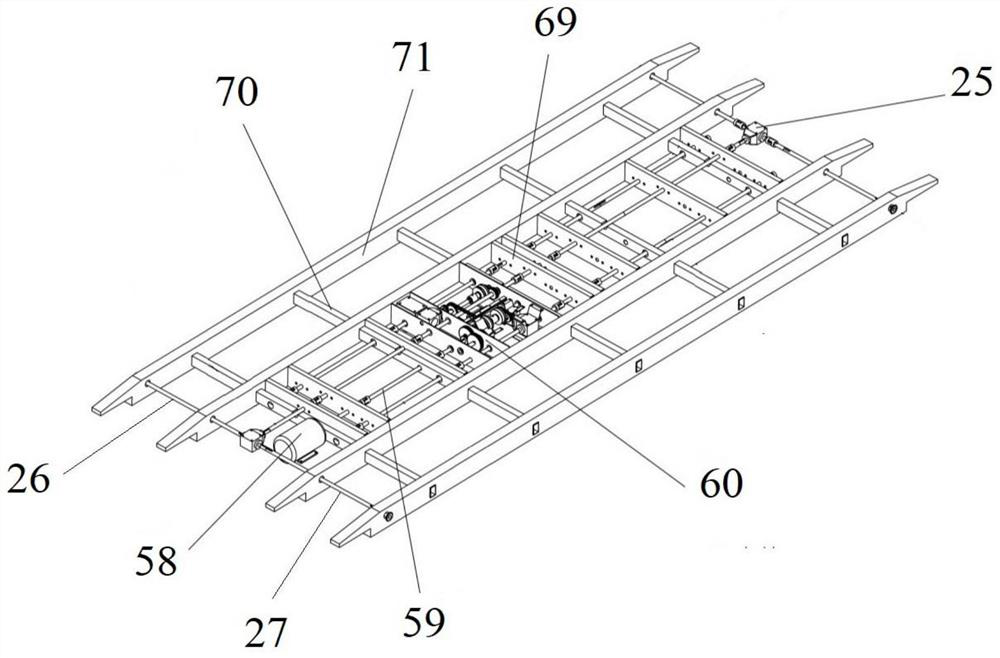

[0056] Comply with the above technical solutions, such as Figure 1 to Figure 13 As shown, the present embodiment provides a lifting mechanism. The lifting mechanism 1 includes an upper beam plate 2 and a lower beam plate 3, and also includes a scissor arm lifting mechanism hinged between the upper beam plate 2 and the lower beam plate 3. The mechanism 4 and the vertical lifting mechanism 5 connected to the upper beam plate 2; the scissor arm lifting mechanism 4 and the vertical lifting mechanism 6 are jointly used for the lifting of the lifting mechanism 1.

[0057] The scissor arm lifting mechanism 4 includes a first upper scissor arm 6, a second upper scissor arm 7, a second lower scissor arm 8 and a first lower scissor arm 9 connected in sequence;

[0058] The first upper scissors arm 6 and the first lower scissors arm 9 are hinged through the first connecting piece 10 , and the second upper scissors arm 7 and the second lower scissors arm 8 are hinged through the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com