Automatic brake gap regulating arm for automobile

A technology of automatic arm adjustment and automobile braking, applied in the direction of slack adjusters, etc., can solve problems such as short service life, adjustment failure, and large force on internal parts, so as to improve reliability and stability, prolong service life, and mechanical well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

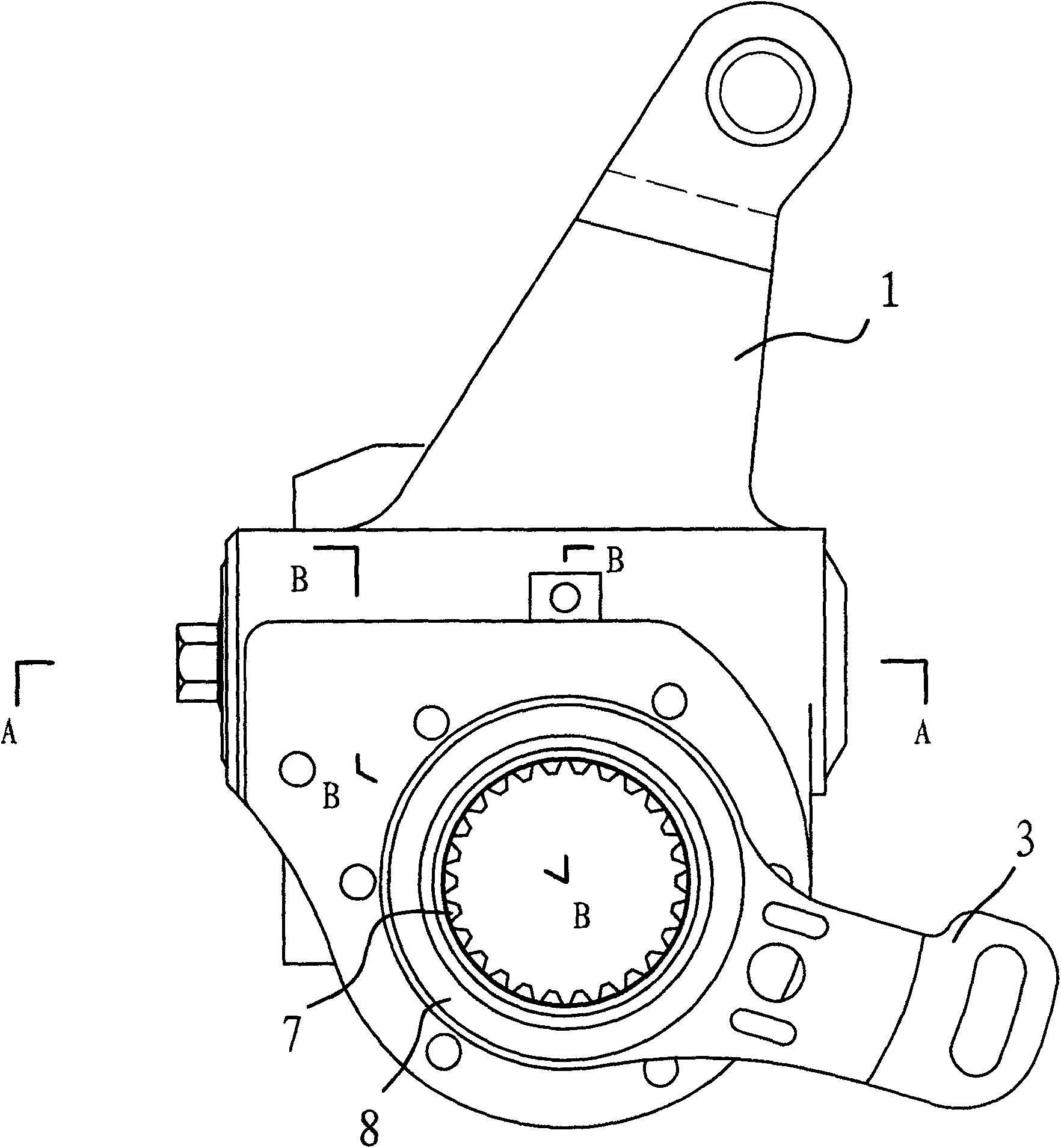

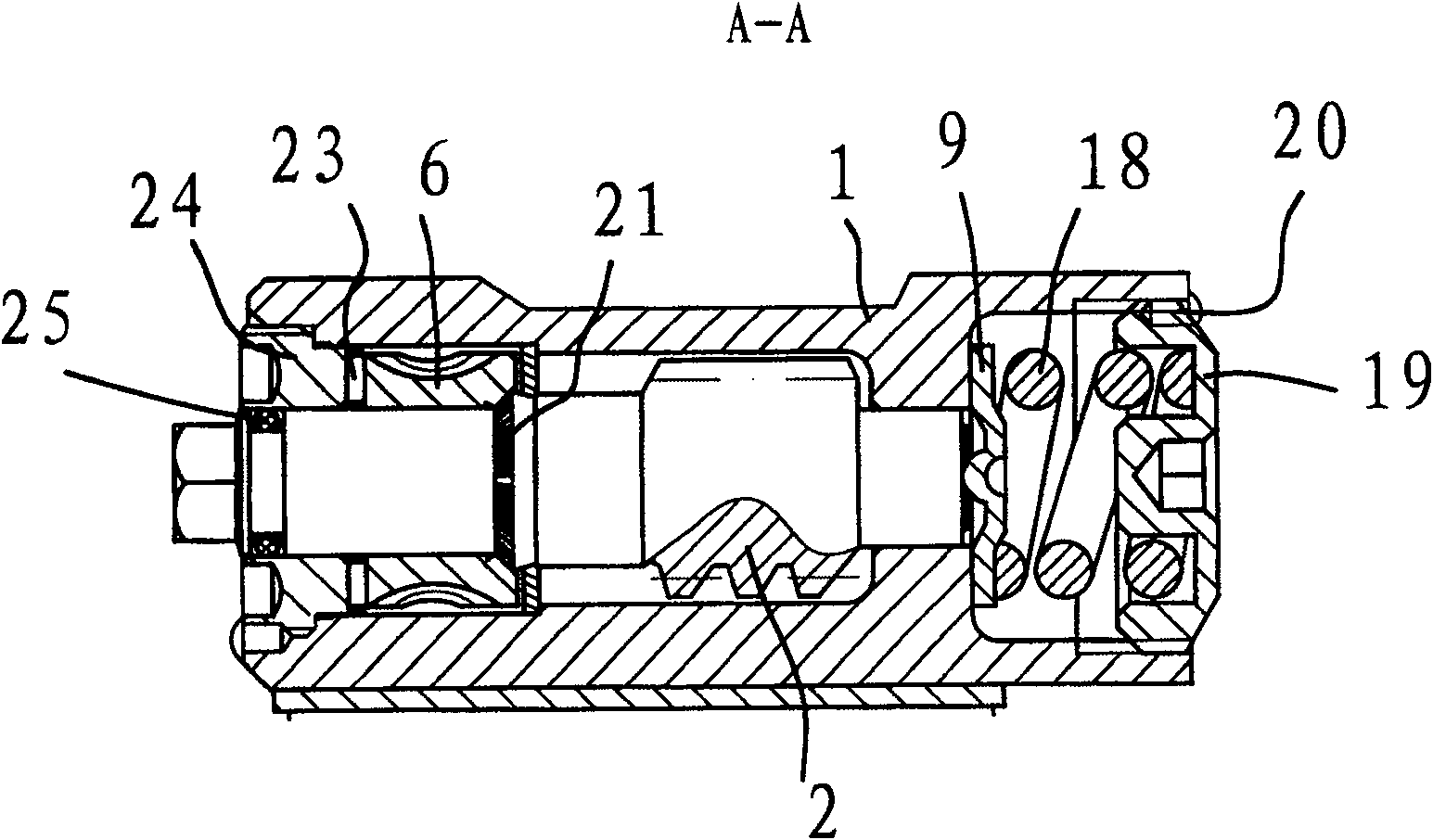

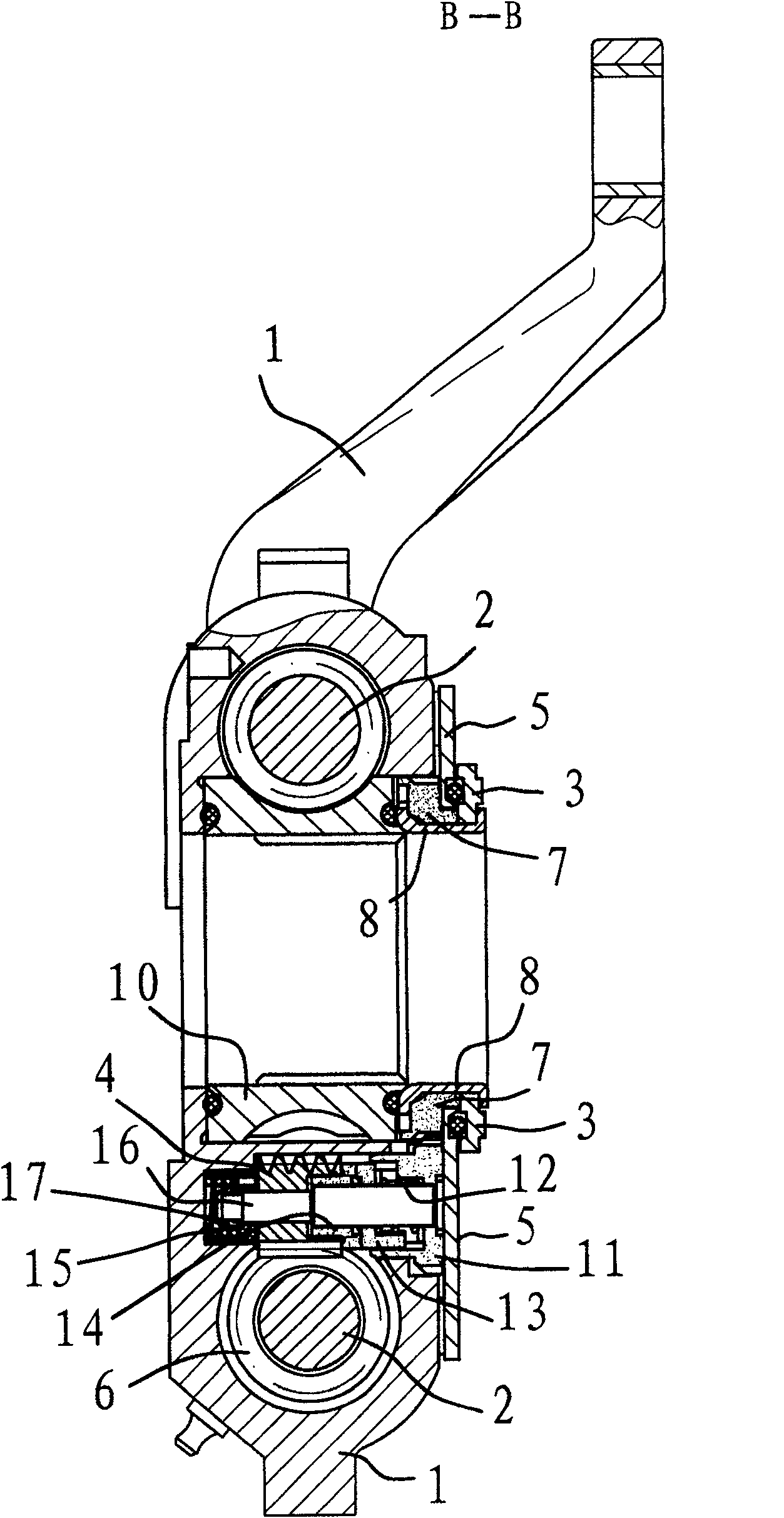

[0028] Such as figure 1 , figure 2 and image 3 Shown, this automobile braking gap automatic adjustment arm is made up of housing 1, large worm wheel 10, large worm screw 2, worm screw spring seat 9, worm screw spring 18, spring screw cap 19, small worm wheel 6, one-way clutch device and control arm Composed of parts such as components. The large worm wheel 10 meshes with the large worm 2 and is contained in the housing 1 .

[0029] Such as figure 2 As shown, one end of the large worm 2 is successively provided with a worm spring seat 9, a worm spring 18 and a spring screw cover 19. The worm spring 18 acts on the large worm 2 through the worm spring seat 9, so that the conical teeth 21 on the sides of the large worm 2 are pushed against the conical teeth 21 on the end of the small worm wheel 6 .

[0030] The worm teeth on the side of the large worm 2 are unidirectional teeth. Along the large worm gear 10 such as figure 1 When the direction shown turns counterclockwise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com