Patents

Literature

328 results about "Conical teeth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conical teeth. Introduction: Conical teeth. Description of Conical teeth. Conical teeth (medical condition): Abnormally shaped permanent front teeth (incisors). The defect is...more ». See also: Hutchinson incisors:

Method of grinding the teeth of spiral-toothed bevel gear wheels

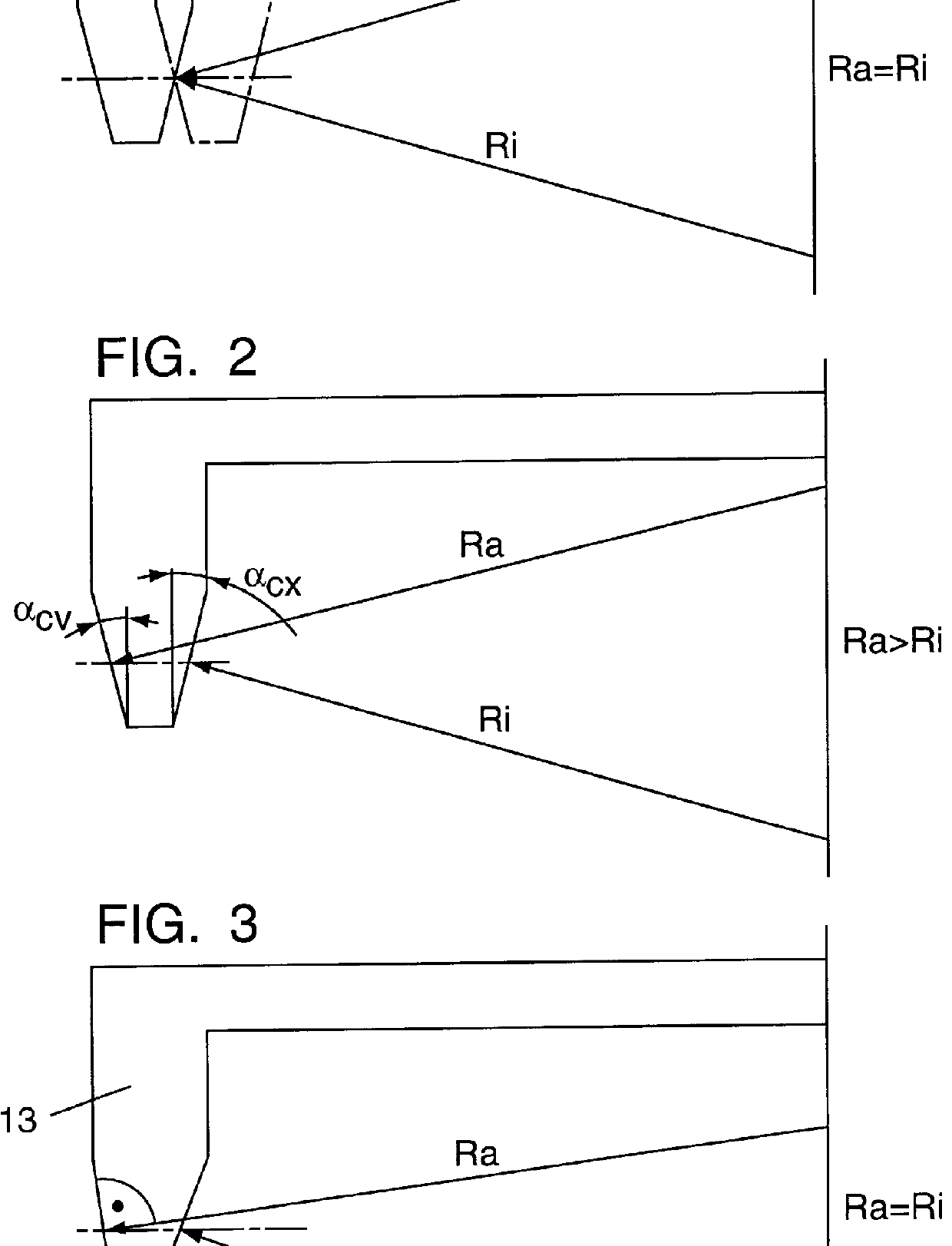

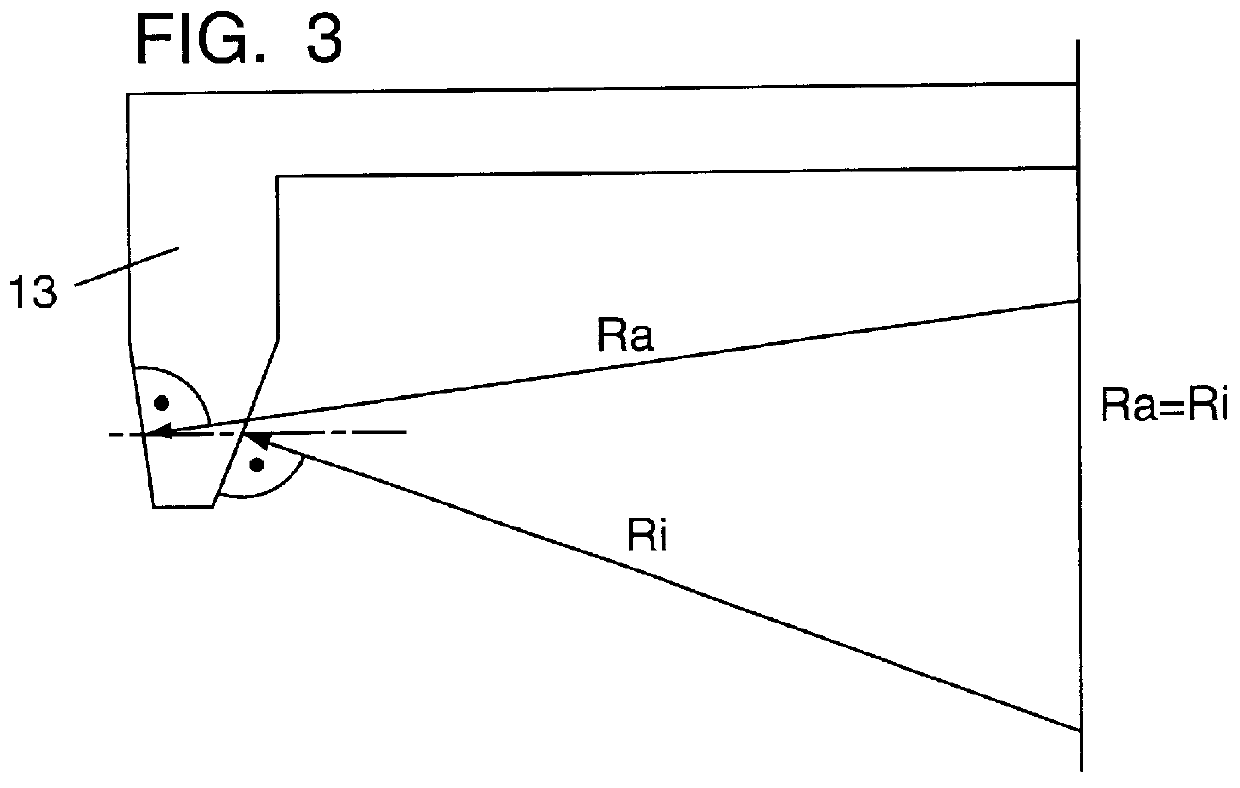

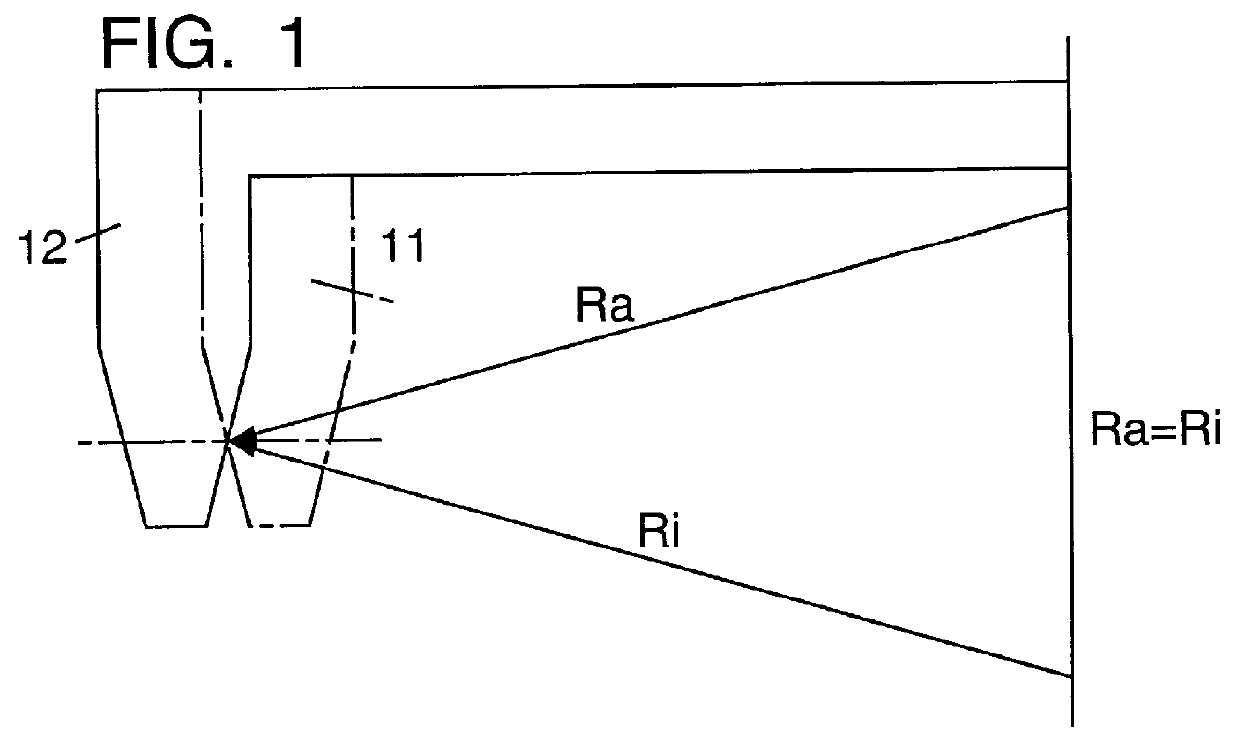

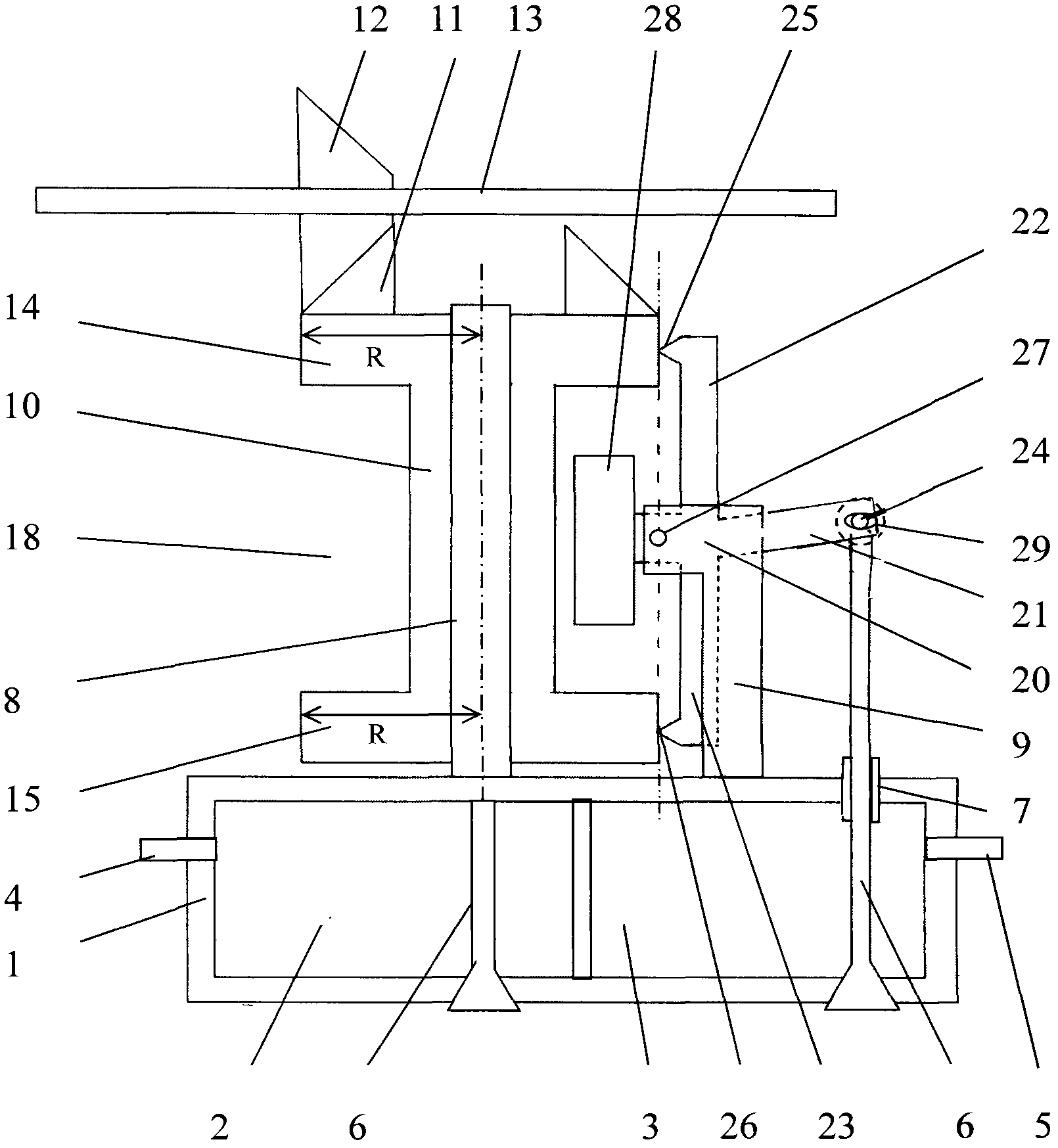

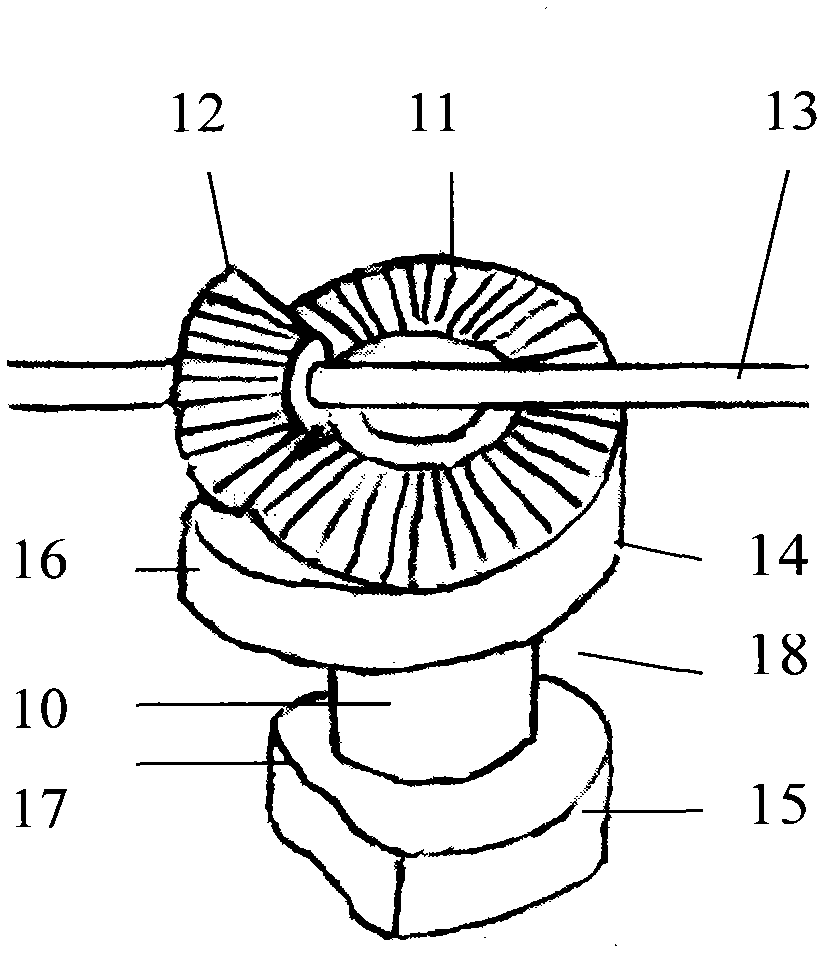

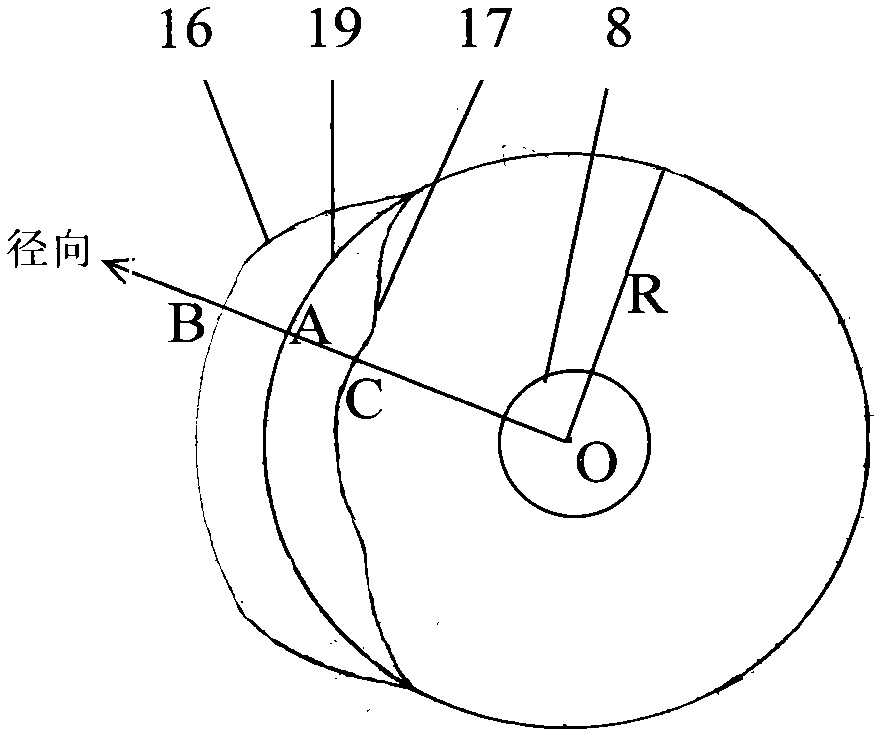

PCT No. PCT / EP96 / 02020 Sec. 371 Date Nov. 5, 1997 Sec. 102(e) Date Nov. 5, 1997 PCT Filed May 10, 1997 PCT Pub. No. WO96 / 35541 PCT Pub. Date Nov. 14, 1996Disclosed is a method of grinding bevel gear teeth in an intermittent indexing process using a single grinding wheel provided with different bevel angles ( alpha ) to produce the desired grinding wheel radii (R): one flank is machined during grinding in downward generation as far as a first turning point, another flank is produced in upward generation as far as a second turning point, and machine settings are so adjusted in the turning points as to ensure a correct pressure angle and correct flank topography during the generating process, irrespective of the different bevel angles ( alpha ). The process combines the advantages of the known completing process, by which both flanks can be ground at the same time at the cost of imposing a particular wheel body geometry with conical teeth, with those of the known two-track process for grinding both flanks with a double grinding head, by which various additional correction factors can be introduced to optimize the flank shape for convex and concave flanks.

Owner:KLINGELNBERG AG

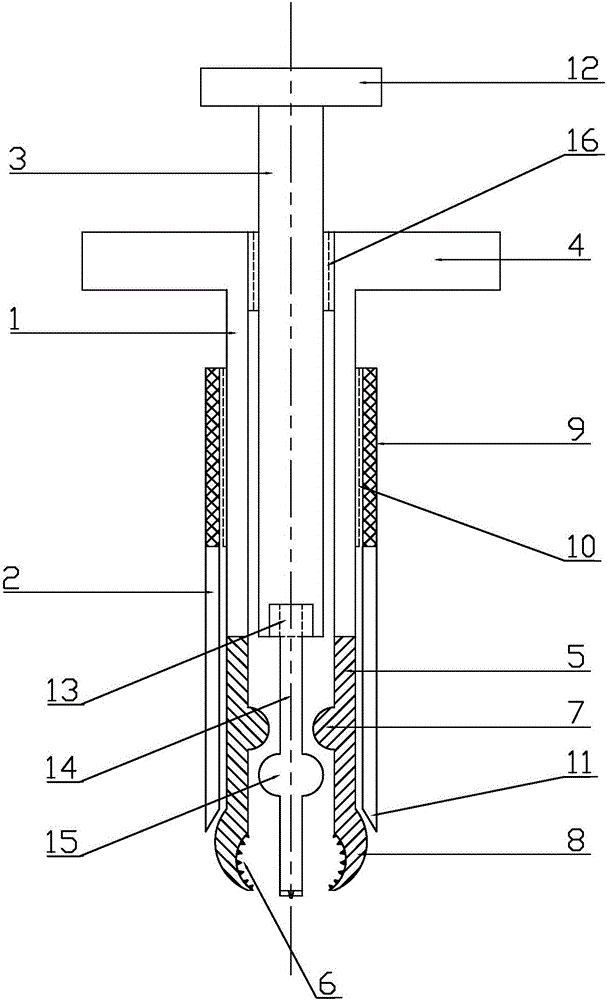

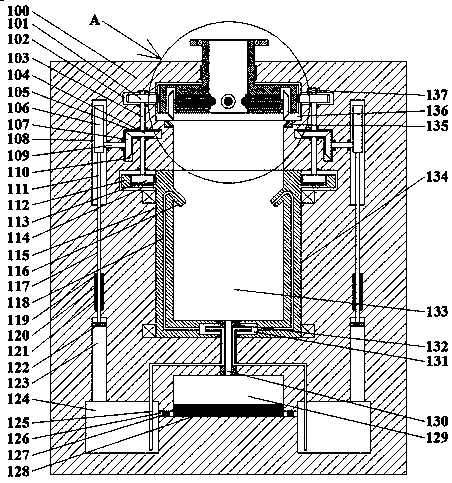

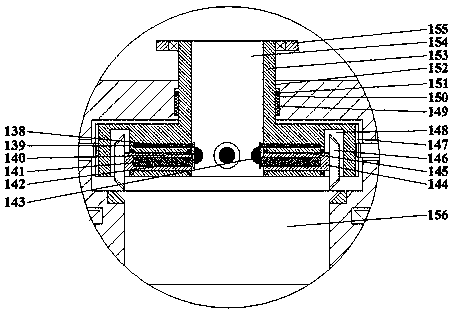

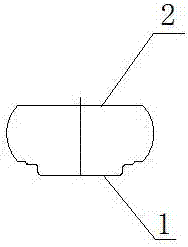

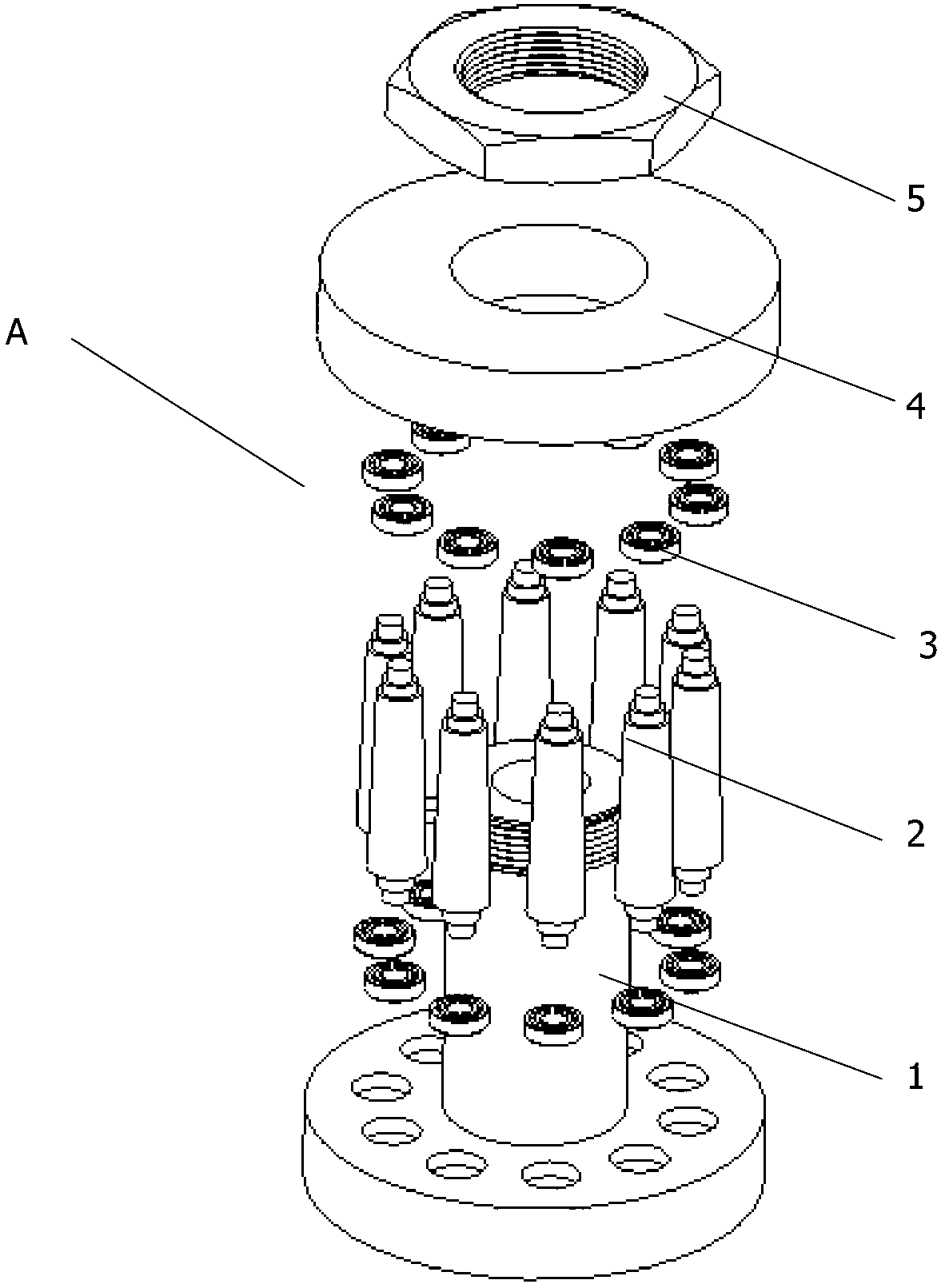

Screw extractor for orthopedic surgery

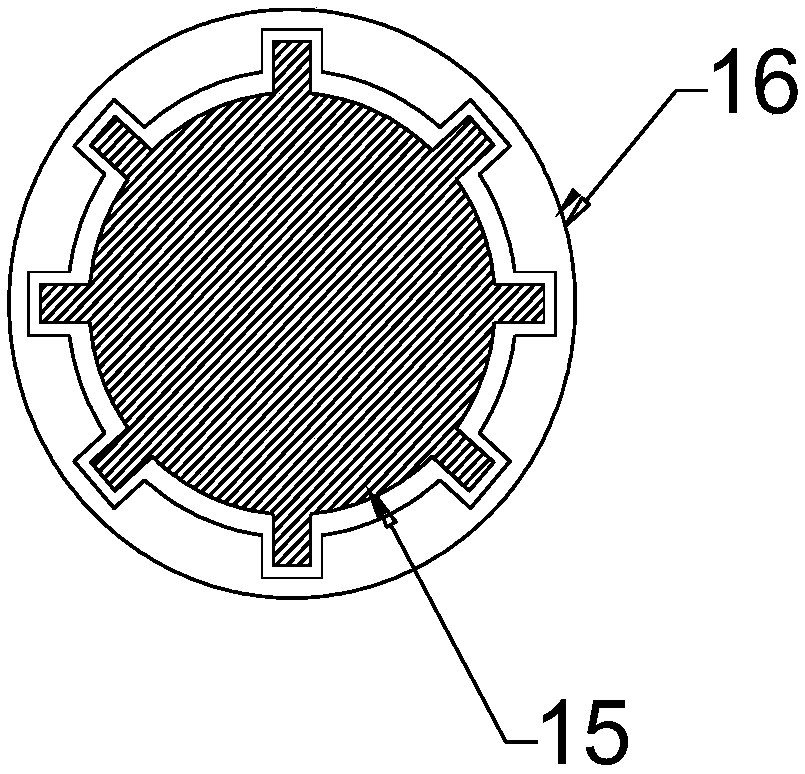

The invention discloses a screw extractor for an orthopedic surgery. The screw extractor comprises a screw extracting tube, holding tubes, a dilator, holding clamps, conical teeth, tooth clamp convex sections, arc-shaped chucks, a driver bar and a dilating ball joint, wherein the dilator is arranged in the screw extracting tube through limit threads in a screwing manner; the holding tubes are arranged at the outer part of the screw extracting tube through fastening threads; handles are arranged at the outer sides of the upper end of the screw extracting tube, and the limit threads are arranged at the inner side of the upper end of the screw extracting tube; a plurality of holding clamps and holding clamp grooves are arranged at and formed in the lower end of the screw extracting tube; the arc-shaped chucks and the conical teeth are arranged at the lower ends of the corresponding holding clamps; one tooth clamp convex section is arranged at the inner side of each holding clamp; the driver bar is arranged at the lower end of the dilator; the dilating ball joint is arranged in the middle of the dilator; the dilating ball joint is moved by the dilator through the limit threads; the dilating ball joint pushes away the tooth clamp convex sections and drives the holding clamps to dilate; a bone screw cap is clamped and fixed by the plurality of arc-shaped chucks. According to the screw extractor disclosed by the invention, the screw cap is fixed by the arc-shaped chucks and the conical teeth; screws can be quickly and conveniently taken out and are prevented from sliding out of the groove, so that pains of a patient are relieved, and the efficiency of the surgery is improved.

Owner:SUZHOU SUNAN ZIMMERED MEDICAL INSTR

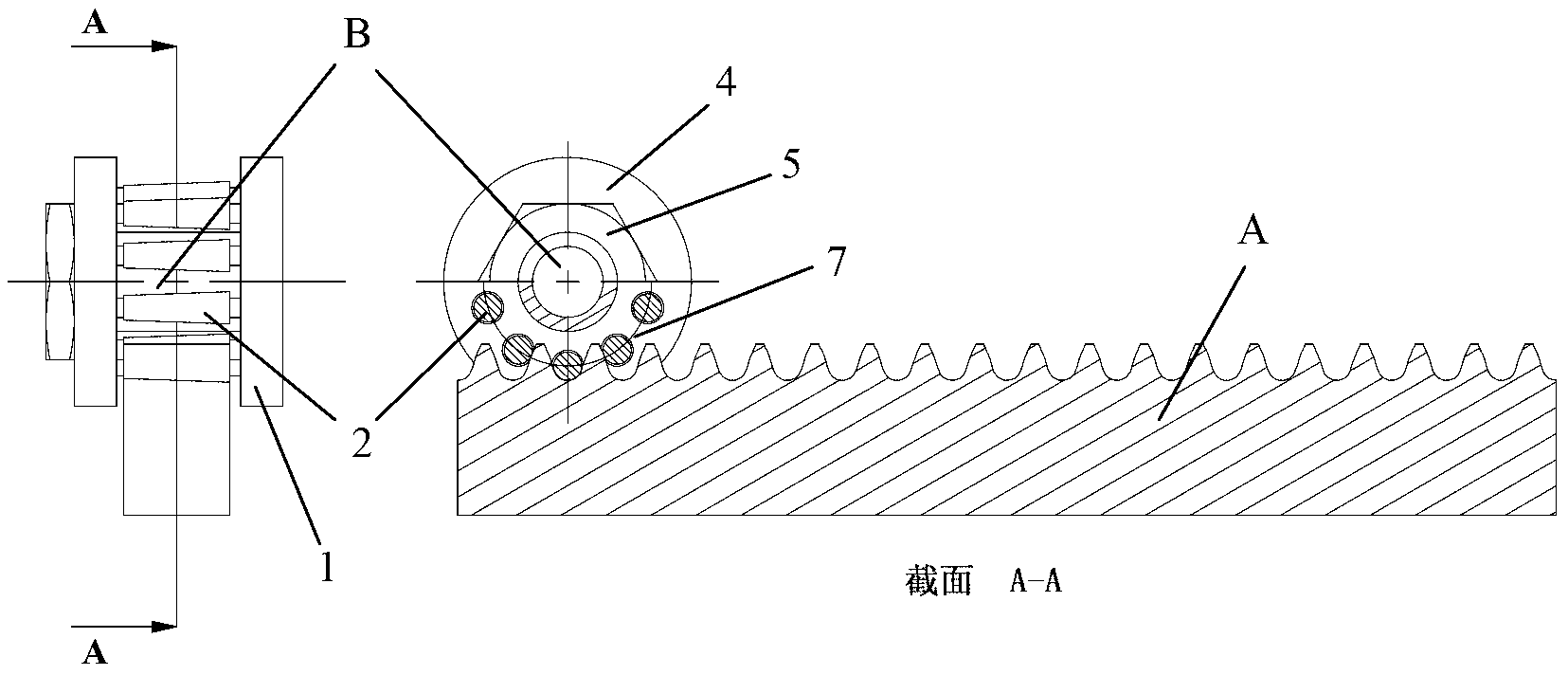

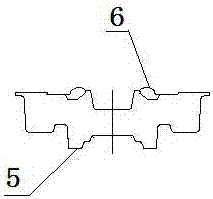

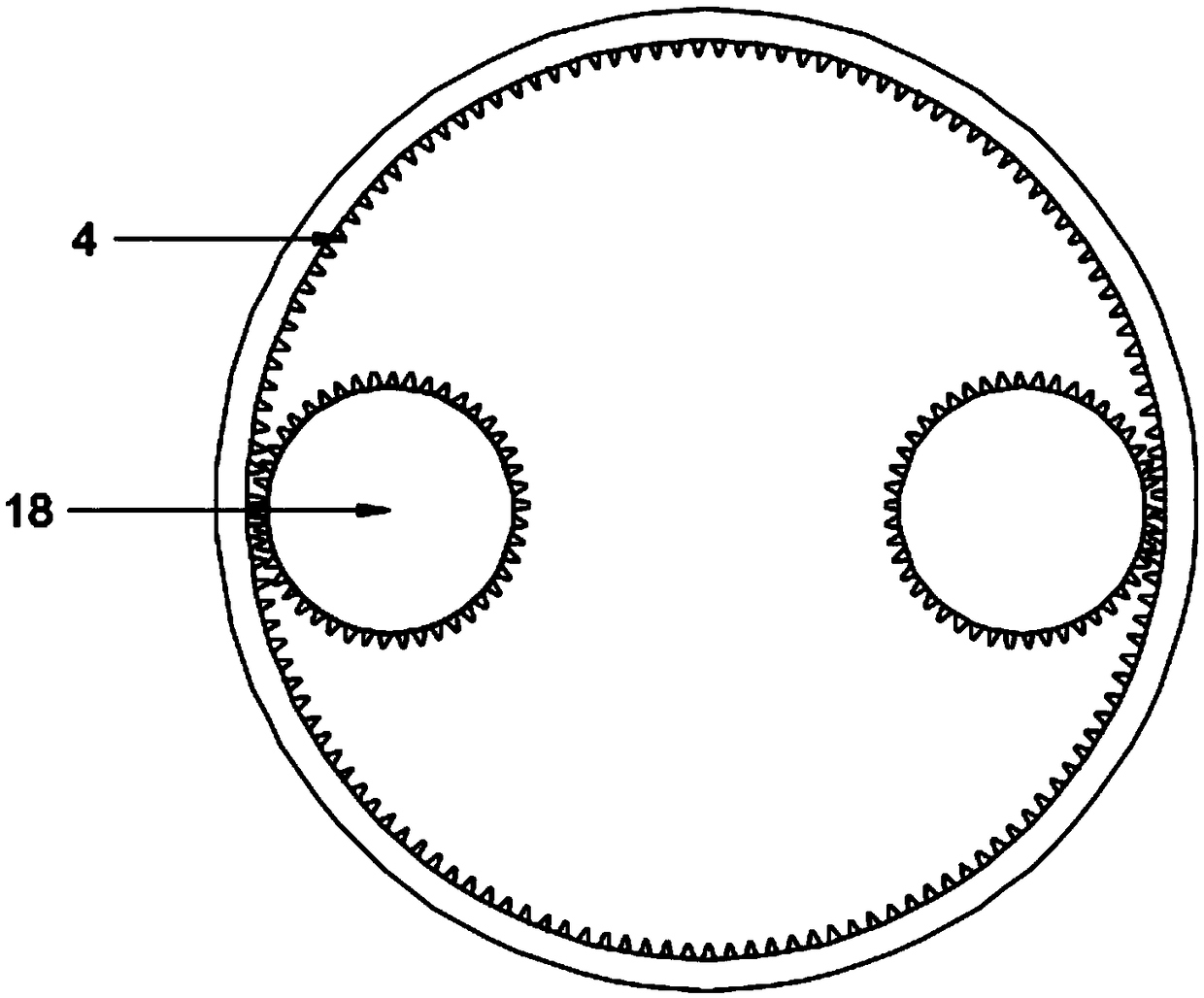

Anti-backlash transmission comprising trochoid gears and roll pins with conical teeth

InactiveCN103062348AImprove interchangeabilityExtended service lifePortable liftingFriction gearingsGear wheelEngineering

The invention relates to an anti-backlash transmission comprising trochoid gears and roll pins with conical teeth, and belongs to the technical field of mechanical transmission. The anti-backlash transmission mainly comprises a pin gear and a trochoid rack, and a rack pair consisting of the pin gear and the trochoid rack realizes movement transmission. Working tooth profiles of teeth of the trochoid rack are flat trochoid internal equidistant lines, and each tooth has a certain conical degree along the tooth width direction. The pin gear meshed with the trochoid rack is provided with a plurality of roll pins, and conical degrees of the roll pins are identical to a conical degree of the rack. The anti-backlash transmission has the advantages that the anti-backlash transmission is good in interchangeability, low in maintenance cost, high in transmission precision and long in service life, backlash is prevented in a meshing procedure, tooth gaps caused by abrasion in a transmission procedure can be compensated, smooth transition between clockwise rotation and anticlockwise rotation can be realized, and the like.

Owner:BEIJING UNIV OF TECH

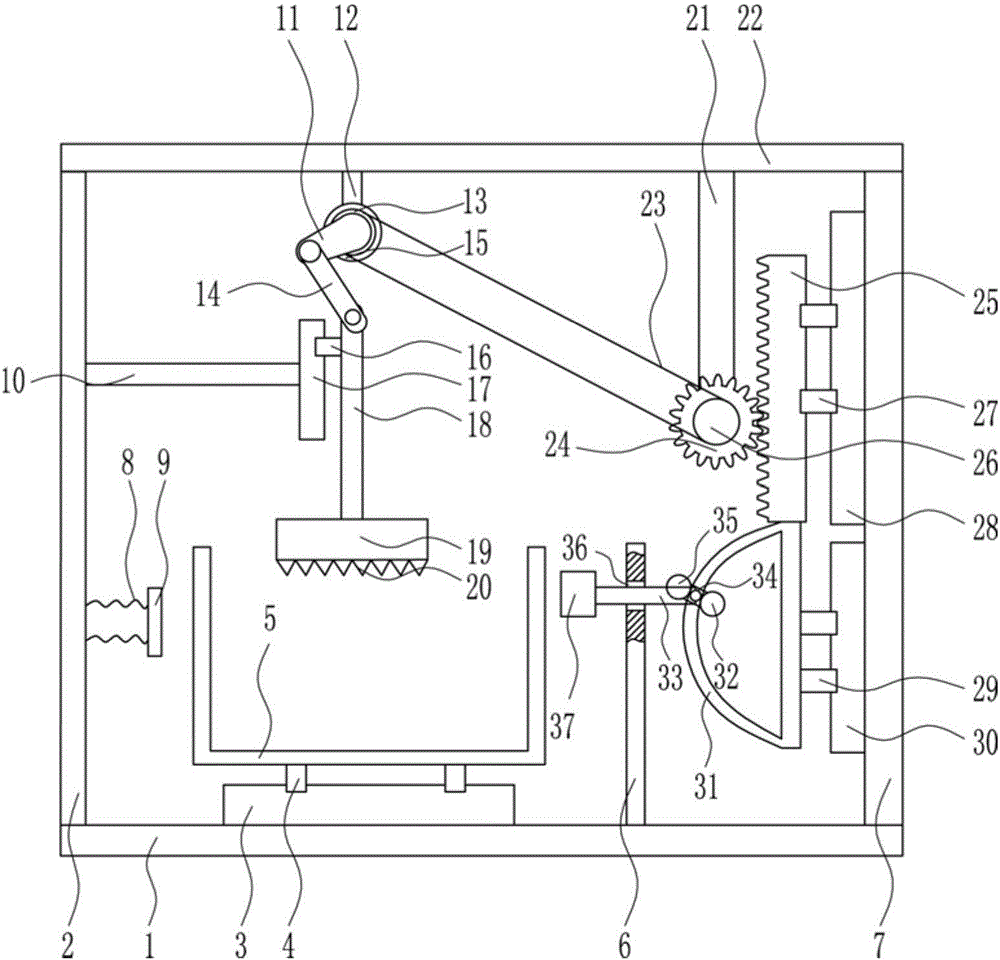

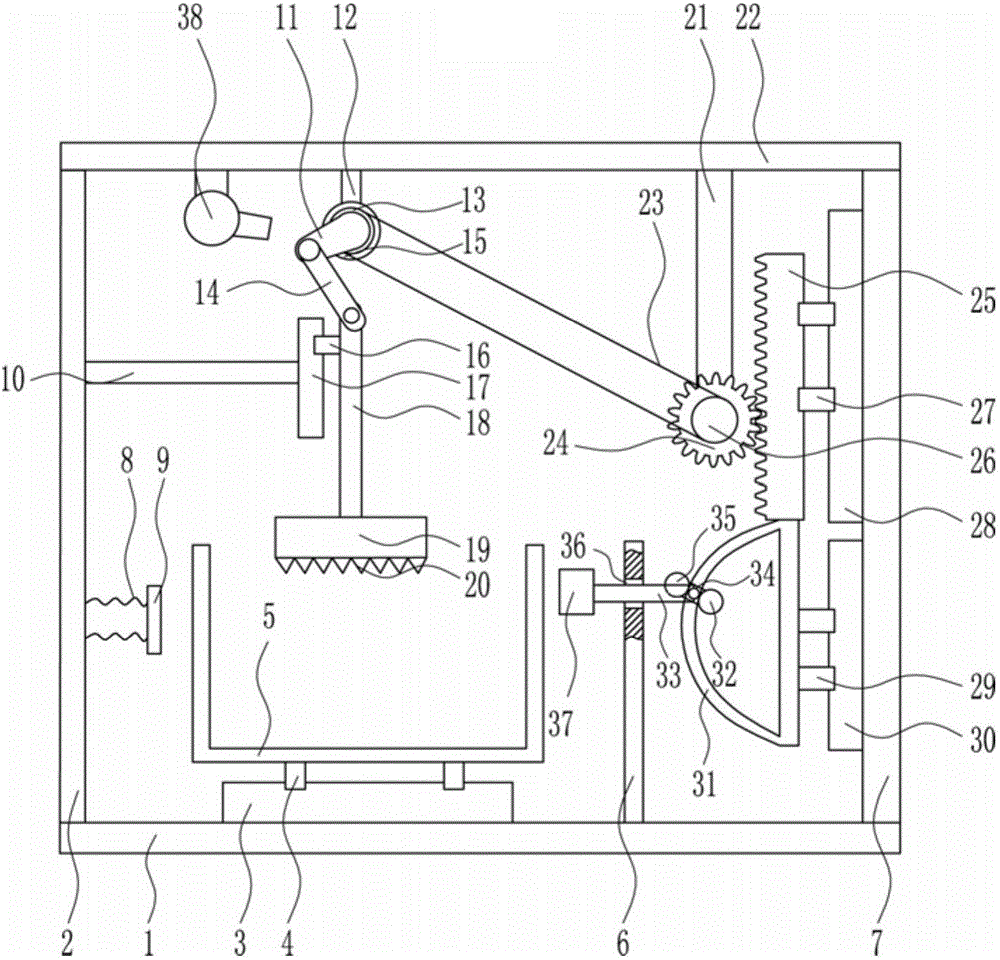

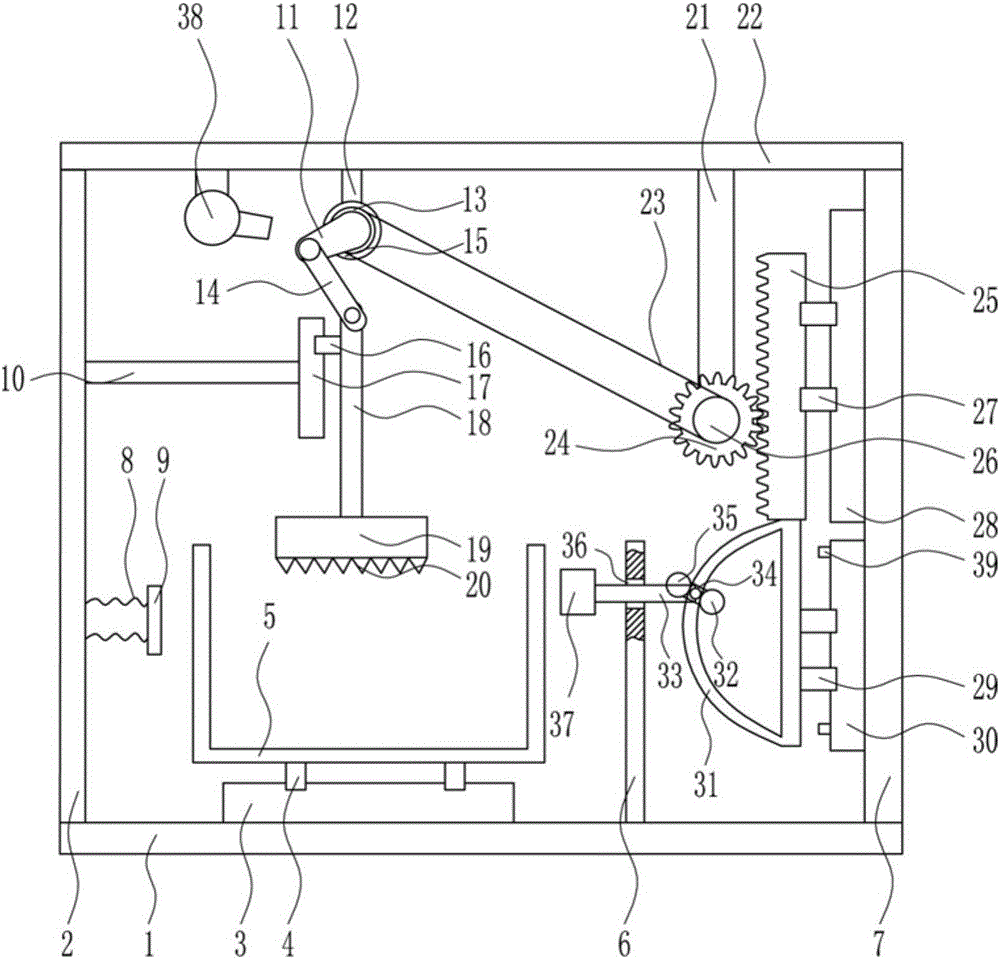

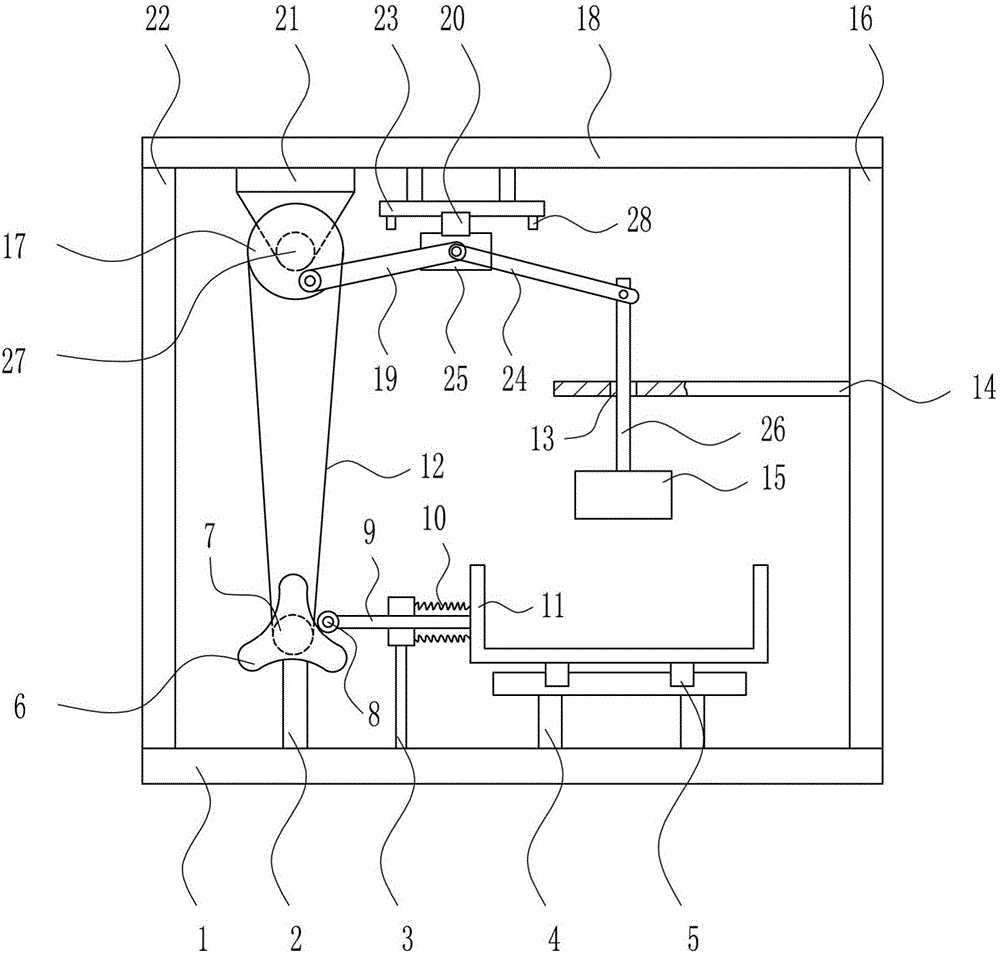

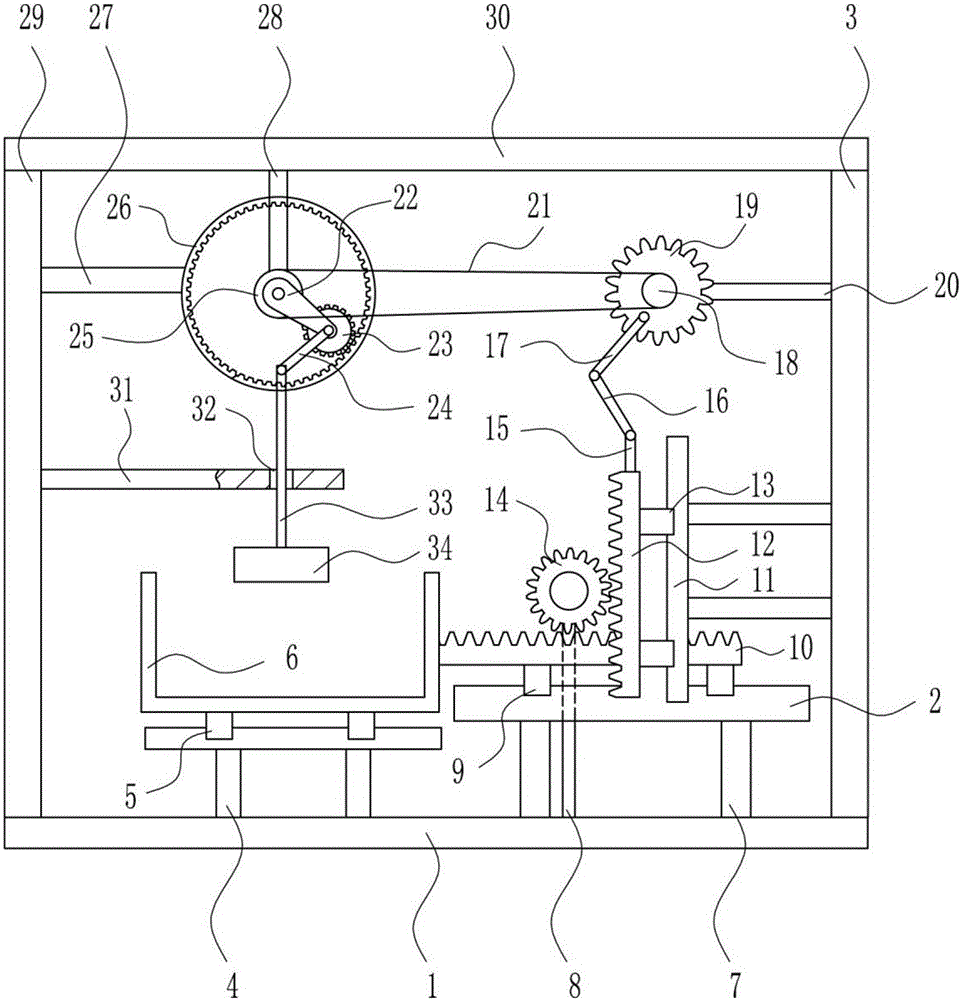

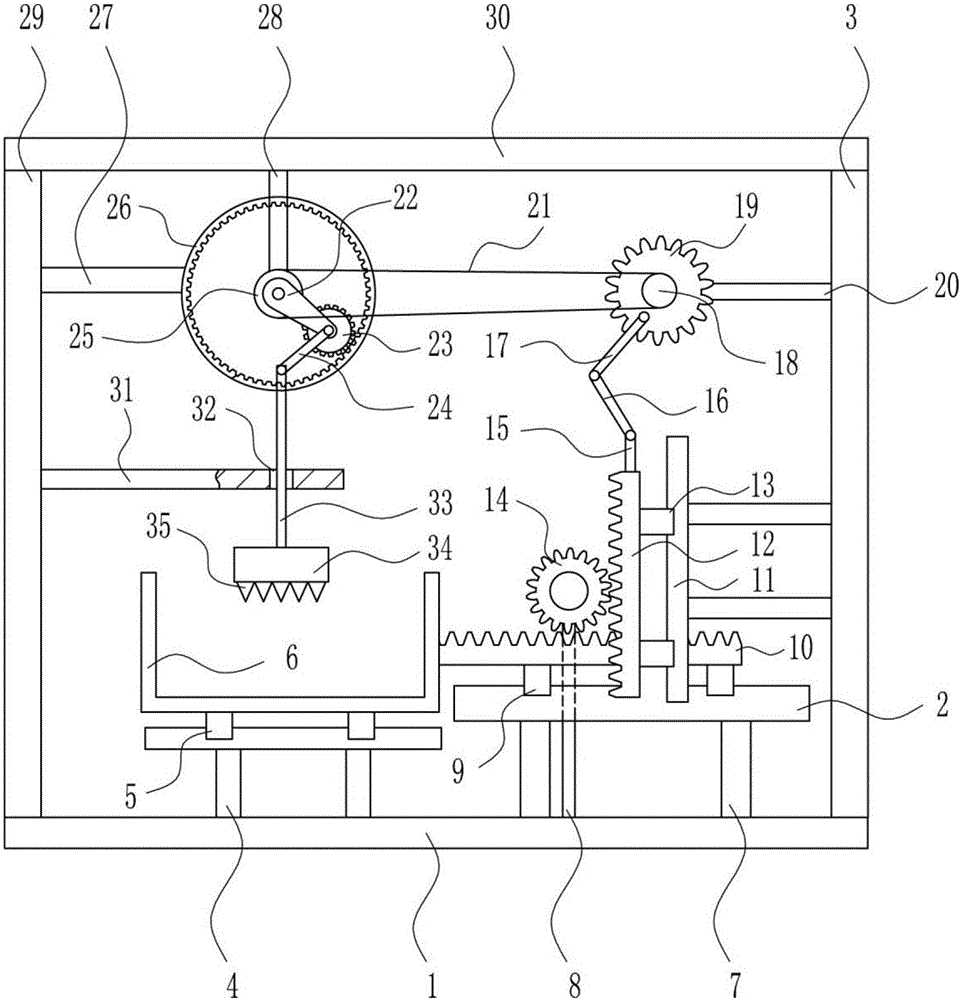

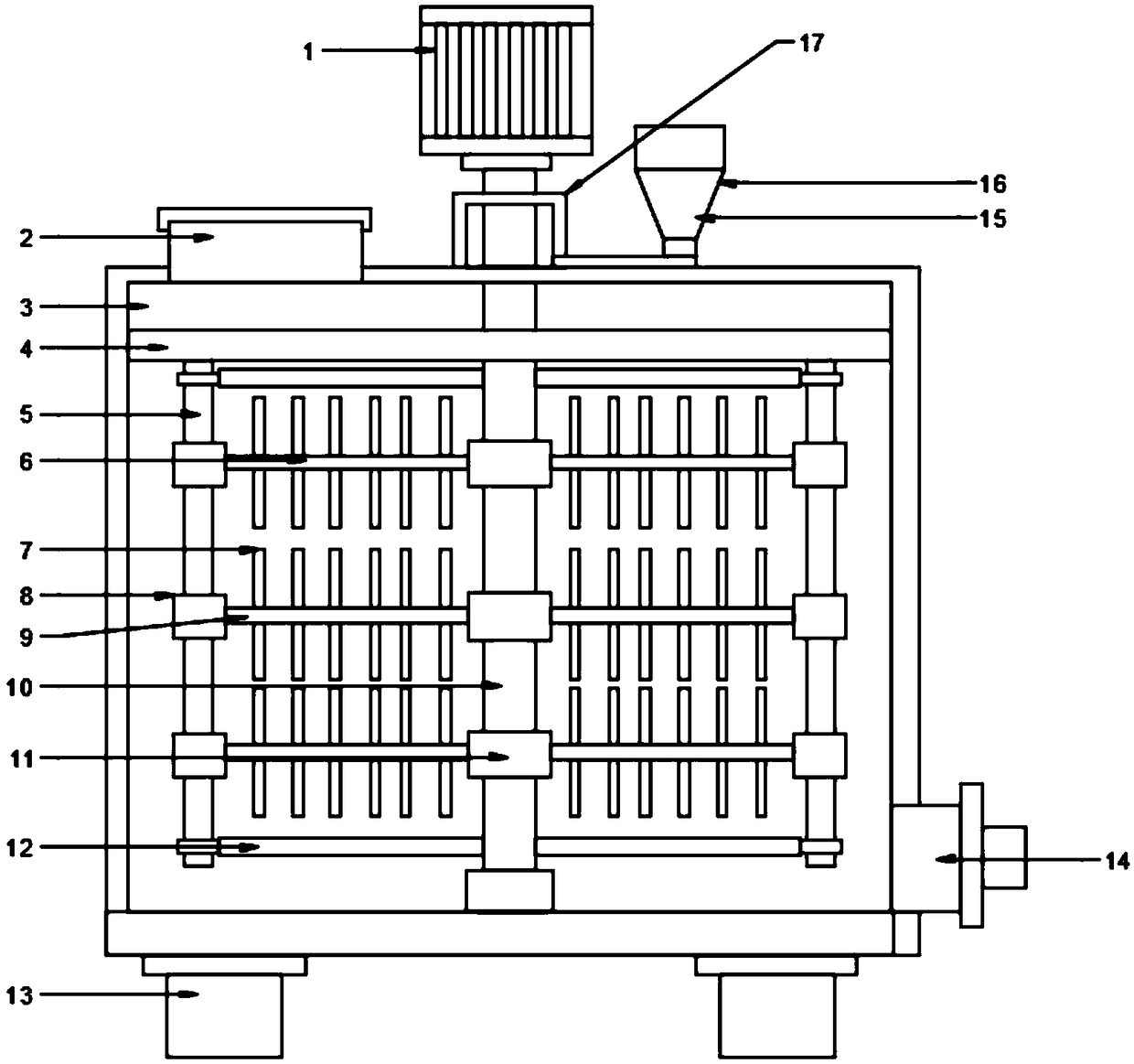

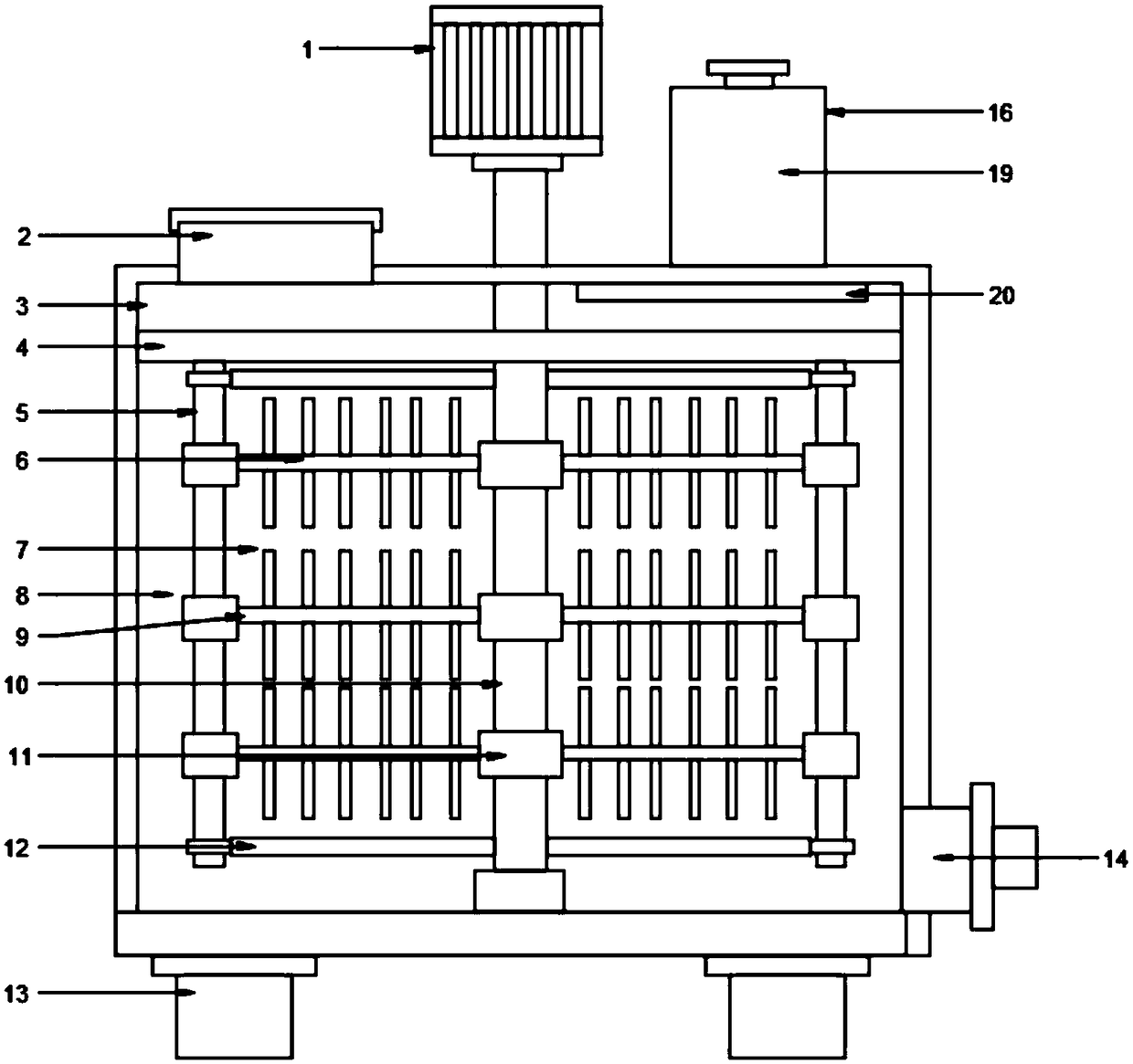

Efficient garbage crushing device for buildings

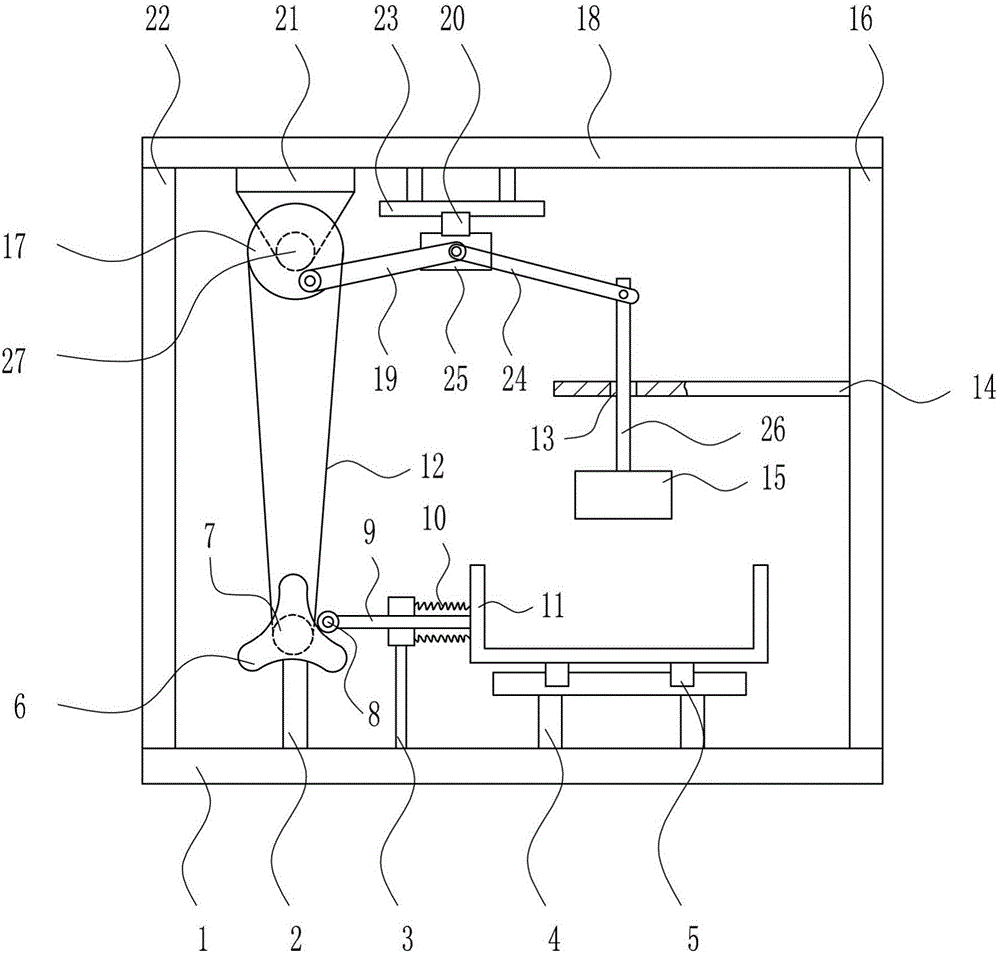

The invention relates to a building garbage crushing device, particularly to an efficient garbage crushing device for buildings, and provides the good-crushing effect, high-crushing speed and high-automation degree efficient garbage crushing device for buildings aimed at solving the technical problem. The efficient garbage crushing device for buildings provided by the invention comprises a bottom plate, a left rack, a first slide rail, first sliding blocks, a crushing box, a guide plate, a right rack, springs, a pressing plate, a first supporting rod, a cam, a second supporting rod, a first belt pulley, a first connecting rod, a motor, a second sliding block, a second slide rail, a first moving rod, a pressing block, conical teeth, a third supporting rod, a top plate, a flat belt, a gear, a rack, an arc-shaped slide, a first pin roller, a second pin roller, a knocking block, and the like, wherein the left rack, the first slide rail, the guide plate and the right rack are sequentially arranged at the top of the bottom plate front left to right. According to the efficient garbage crushing device, the effects of good crushing effect, high crushing speed and high automation degree are achieved.

Owner:刘鹏 +2

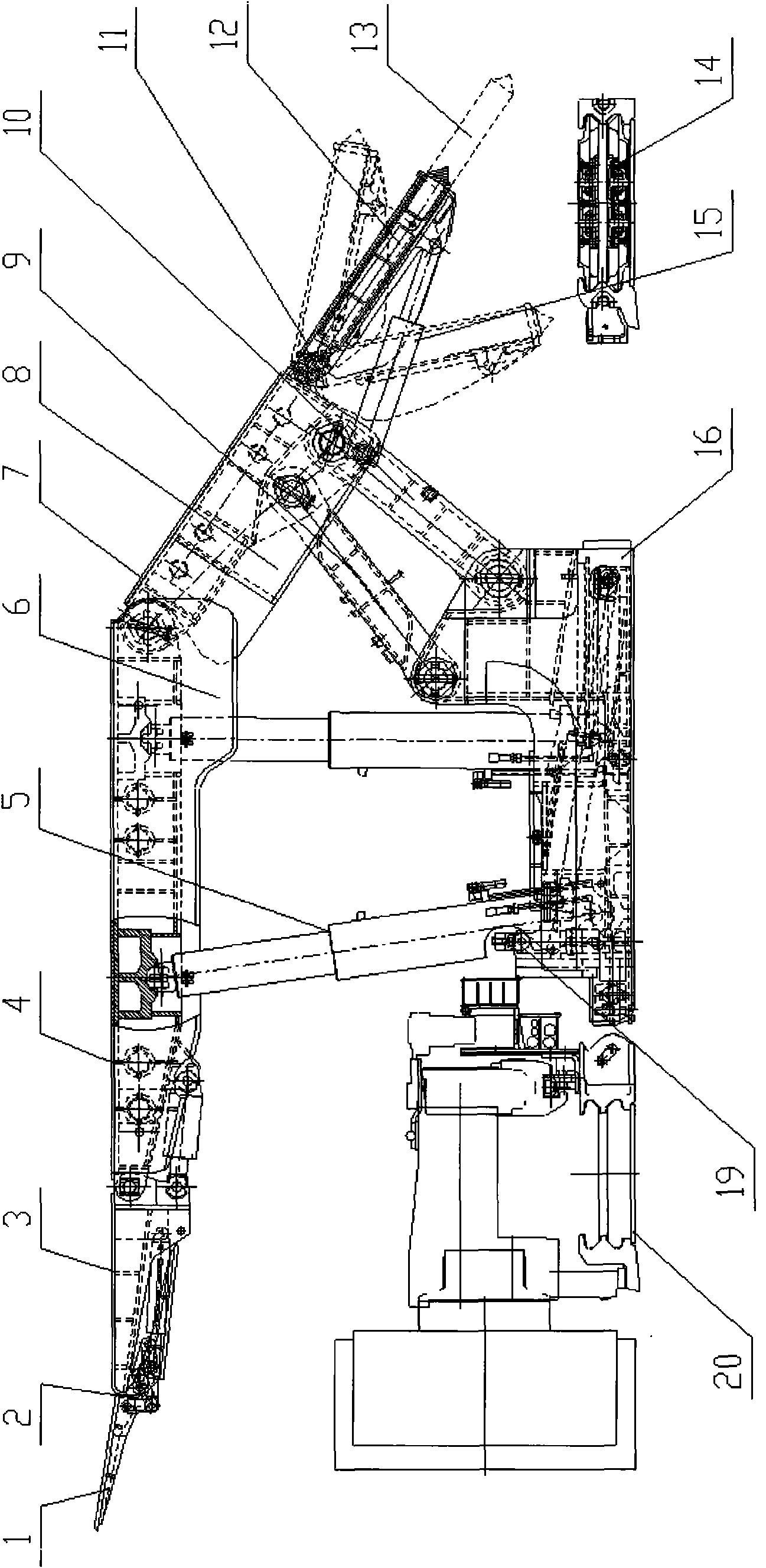

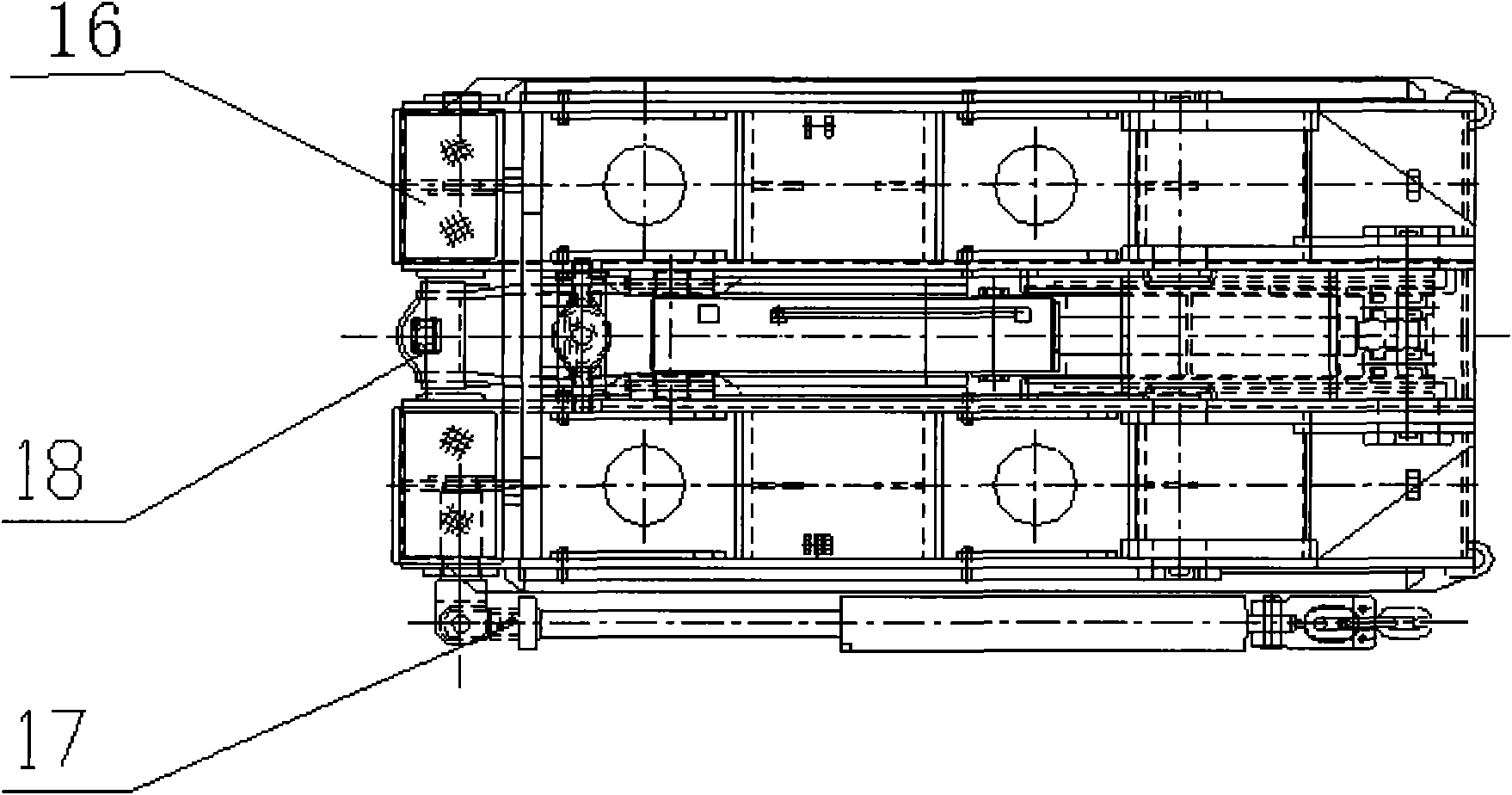

Large mining height shield type low caving coal hydraulic support

The invention discloses a large mining height shield type low caving coal hydraulic support. The support comprises a base, a top beam and a shielding beam, wherein an upright post is arranged between the top beam and the base; the upright post is a double telescopic upright post; the inner diameter of the large cylinder body of the upright post is more than or equal to 500mm; and the expanded height of the upright post is more than or equal to 4m. A push device is arranged in the middle of the base, the front end of the push device is connected with a front scraper conveyor; a pull back sliding device is arranged outside the base; and the rear end of the pull back sliding device is connected with a back scraper conveyor. A coal feed mechanism comprises a tail beam and a tail beam jack; a flashboard and a flashboard jack are arranged in the tail beam, and the end part of the flashboard is provided with a conical tooth for crushing range coal; and the upper oscillation angle of the tail beam is between 10 and 15 degrees, while the lower oscillation angle is between 40 and 45 degrees. The support can be applied to primary top-coal caving mining for super high coal seam with support height of over 4 meters, thickness of a coal placement layer of over 16 meters and good top-coal caving performance, and improve the production efficiency of a sub-level caving working face and the resource recovery rate.

Owner:CHINA COAL BEIJING COAL MINING MACHINERY

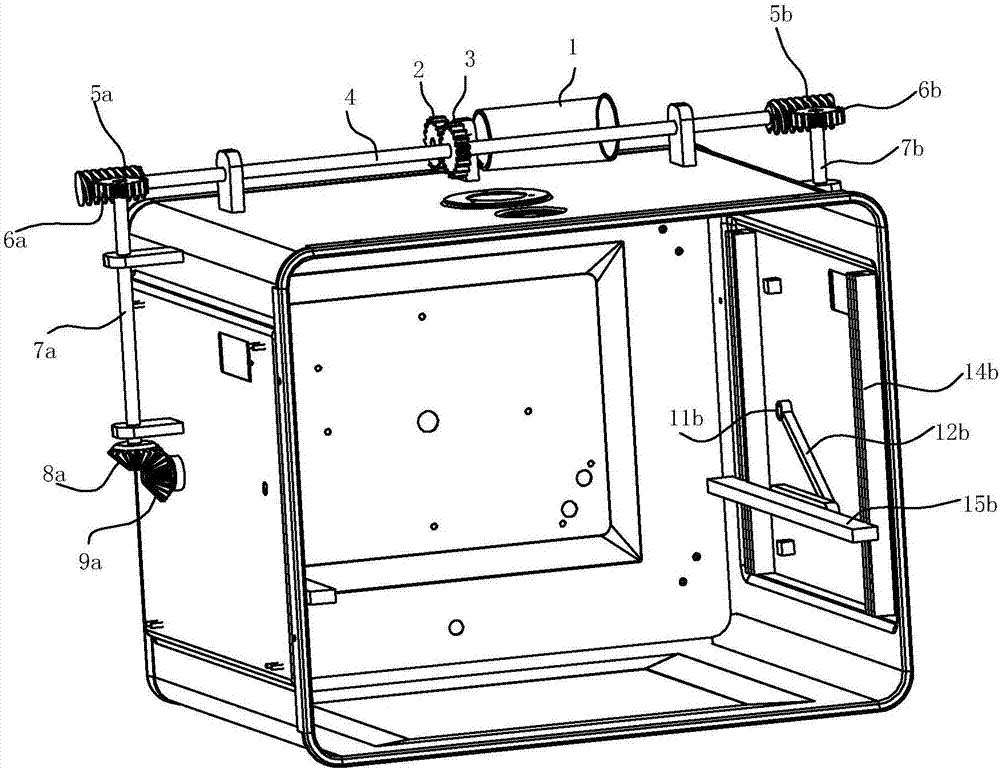

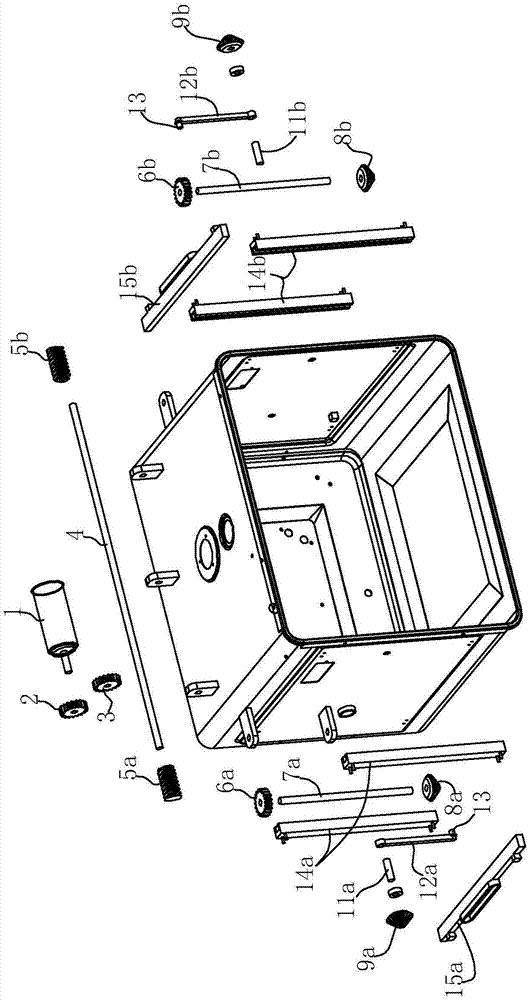

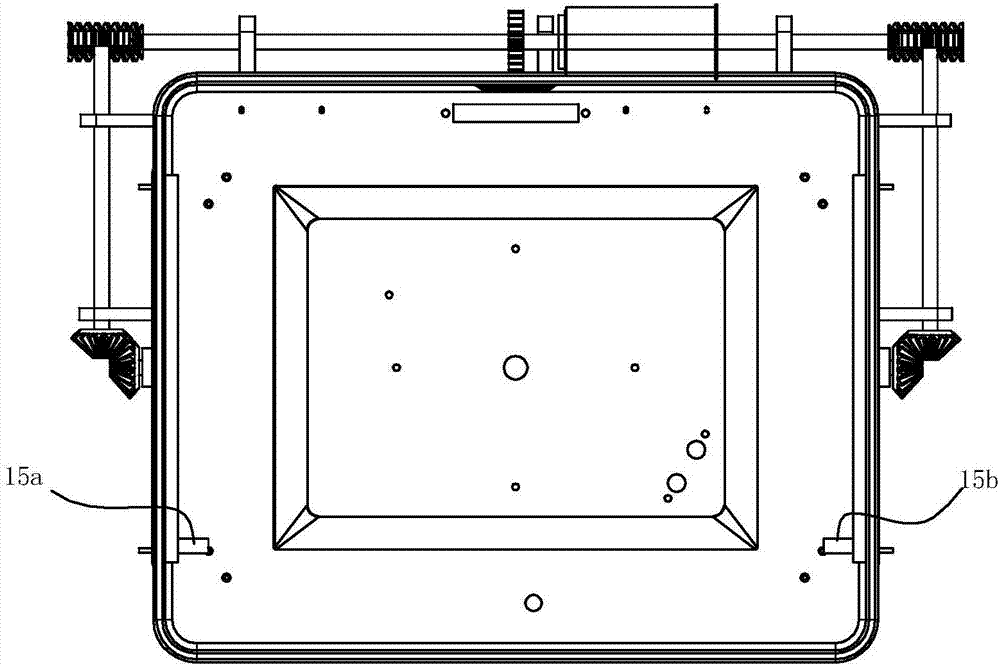

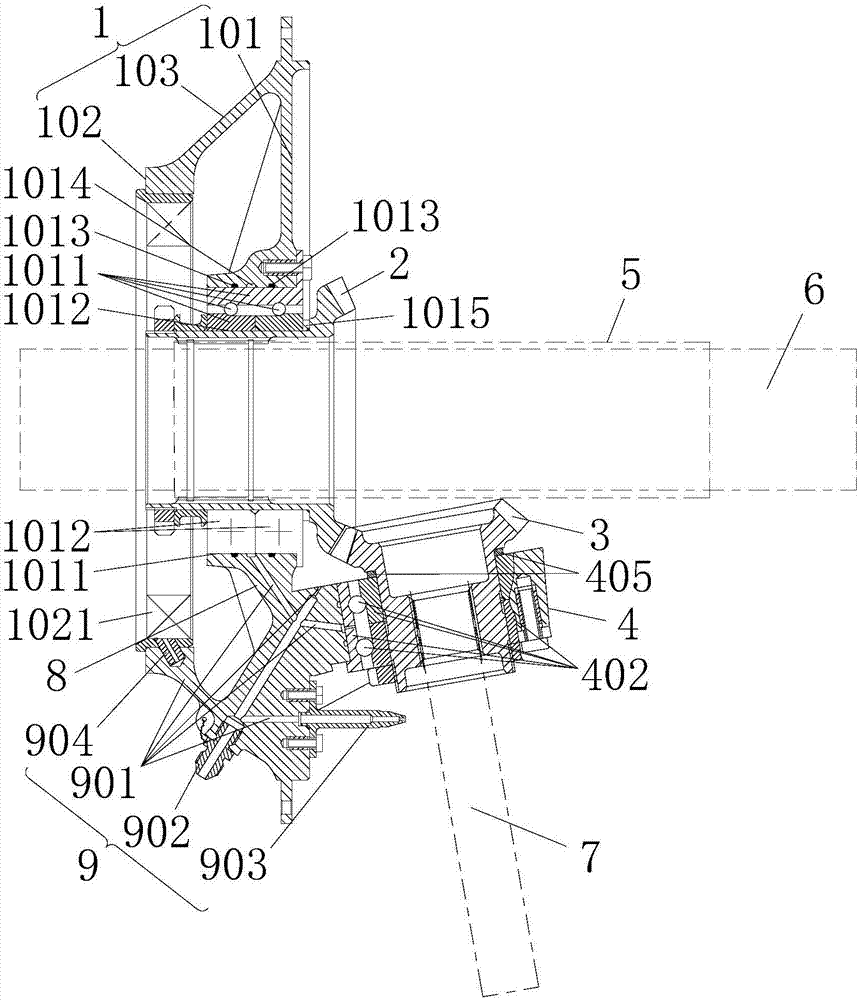

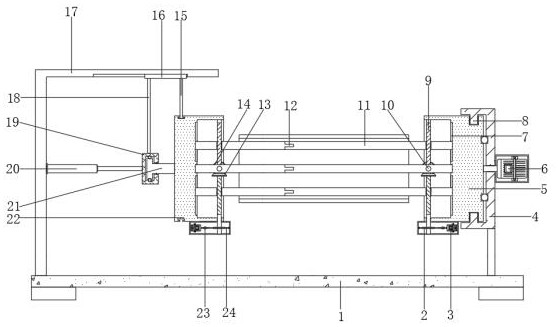

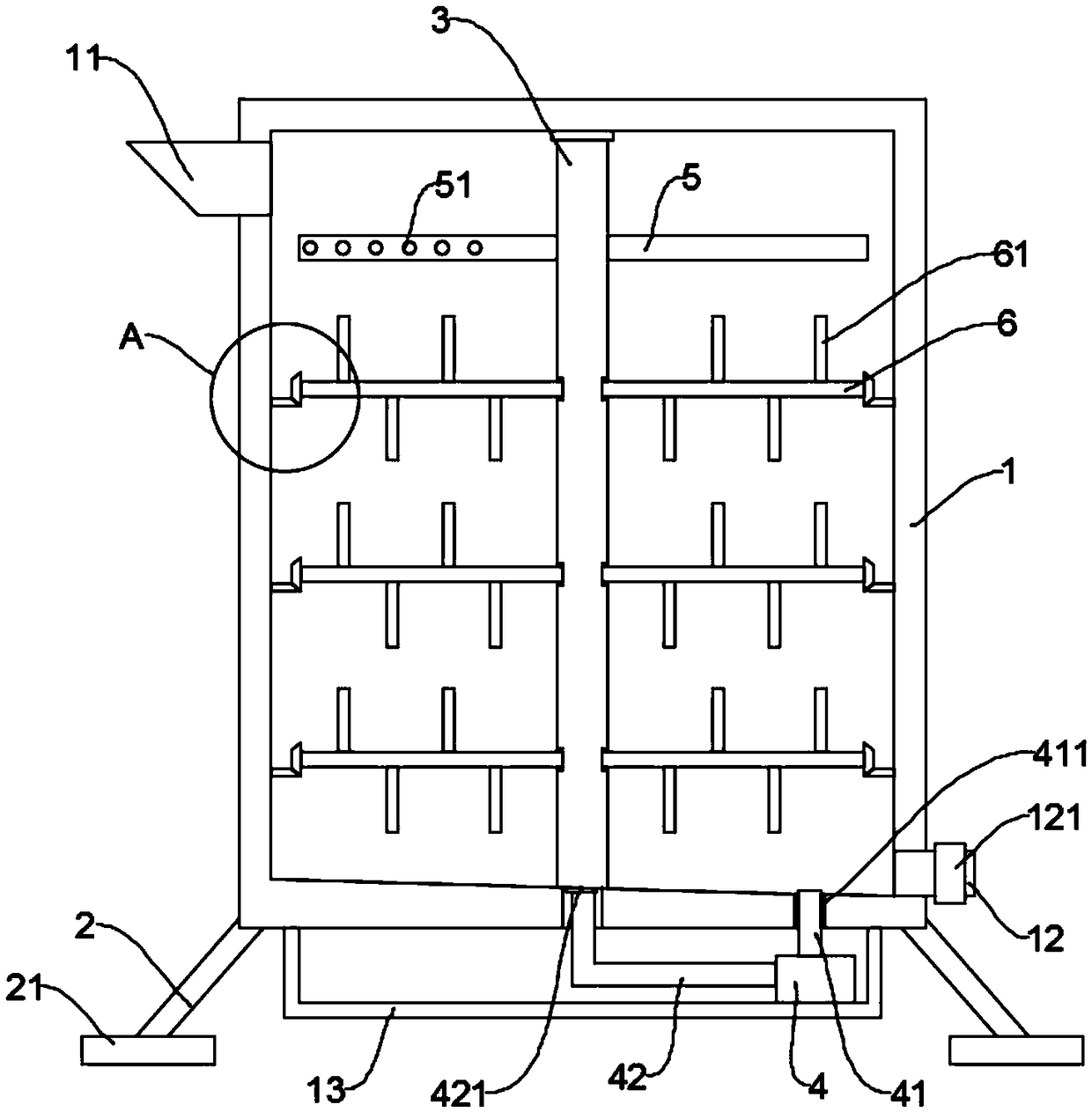

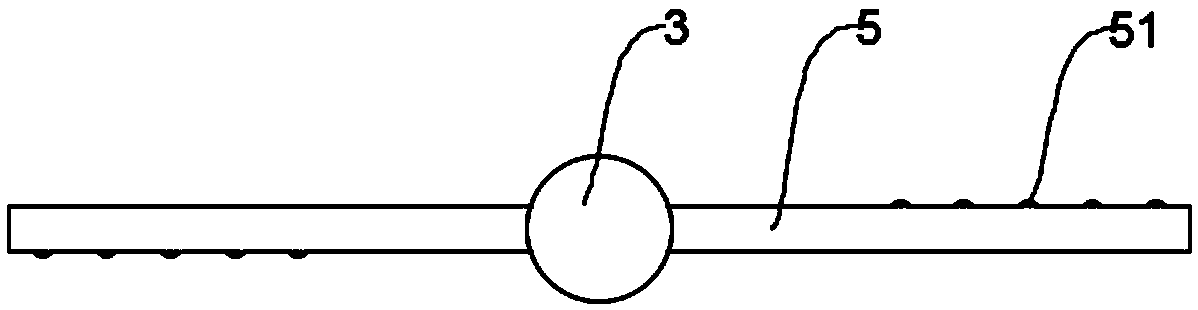

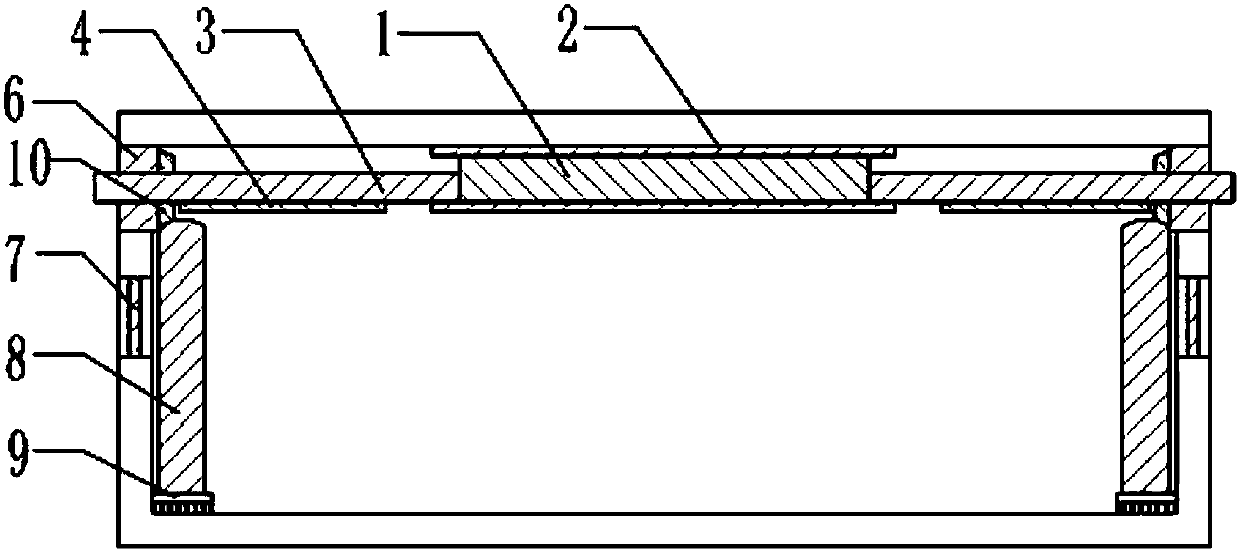

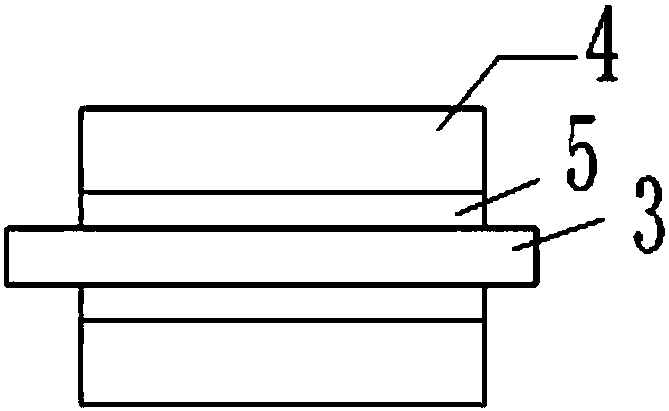

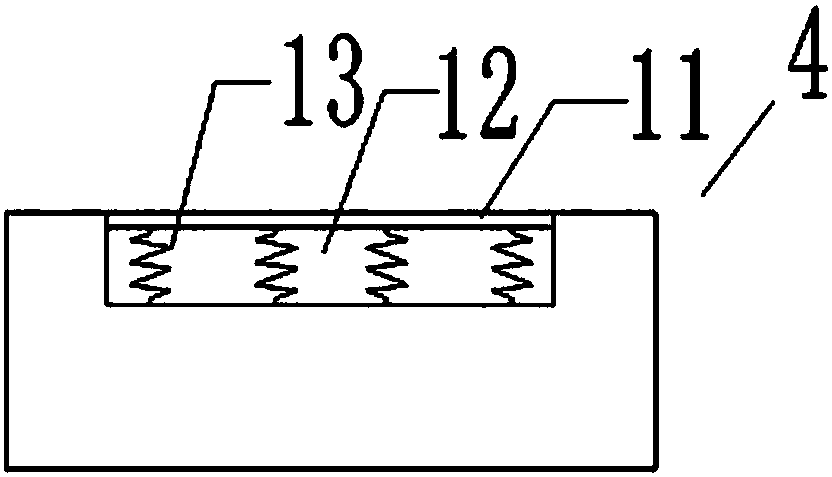

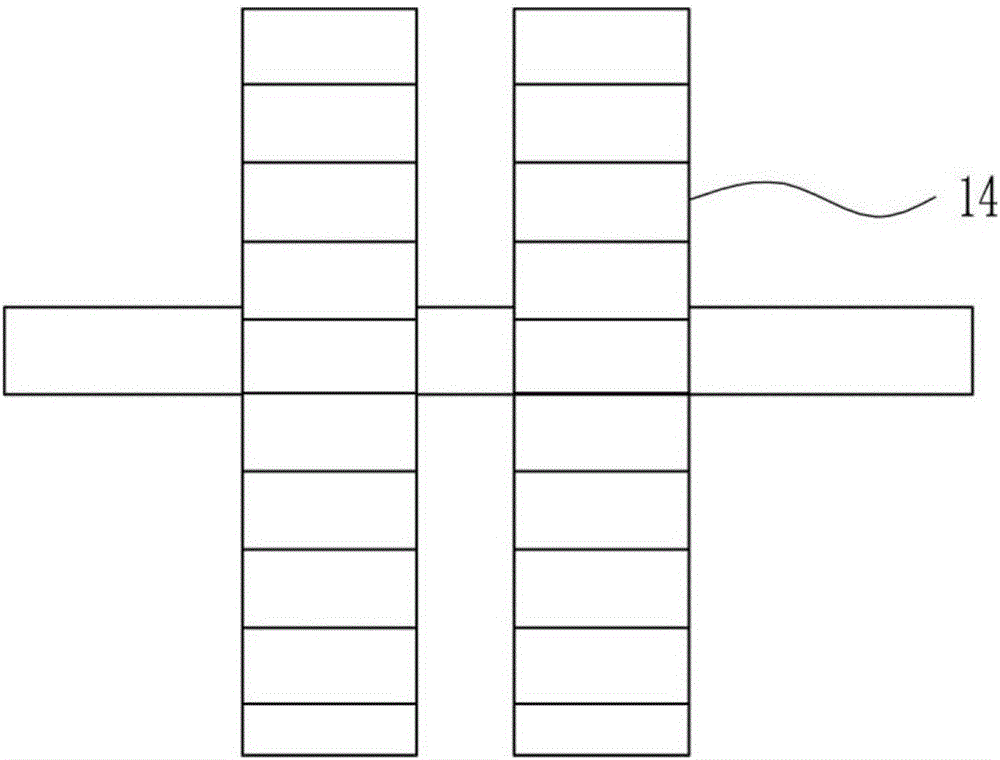

Baking tray support lifting mechanism for oven

PendingCN107997614AImprove reliabilitySimple structureStoves/ranges shelves or racksRoasting apparatusGear wheelDrive shaft

The invention relates to a baking tray support lifting mechanism for an oven. The mechanism is connected with a left baking tray support and the right baking tray support which are arranged on the left side and the right side of an inner container of the oven and used for supporting baking trays, and used for driving the left baking tray support and the right baking tray support to move up and down in the inner container of the oven; the mechanism is characterized by comprising a driving motor, a first gear, a second gear, a first worm, a second worm, a left transmission shaft, a third gear, first left conical teeth, second conical teeth, a left crank, a right transmission shaft, a fourth gear, first right conical teeth, second right conical teeth and a right crank. Compared with the priorart, the mechanism has the advantages that the lifting mechanism is realized through a crank sliding block principle, static self-locking can be achieved for oven side support at different heights inthe inner container of the oven; the oven support can rise and fall according to a trigonometric function uninterruptedly, an unexpected effect is brought for cooking, the structure is simple, and the reliability is high.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

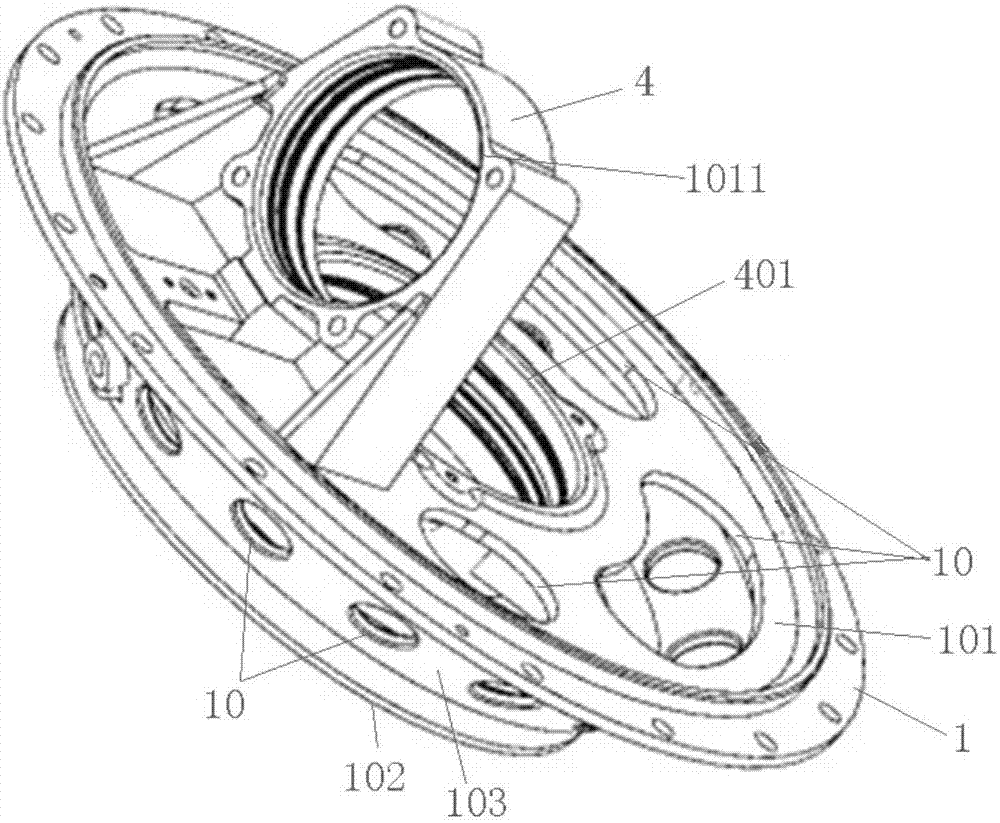

Oblique central transmission frame assembly used for aircraft engine and aircraft engine

ActiveCN107218355AStable deliveryIncrease independenceToothed gearingsGear lubrication/coolingAviationCantilever

The invention discloses an oblique central transmission frame assembly used for an aircraft engine and the aircraft engine. The oblique central transmission frame assembly used for the aircraft engine comprises a conical basin-shaped support. The conical basin-shaped support comprises a large end surface, a small end surface and an oblique side surface. A hollow inner cavity is formed in the conical basin-shaped support. A first bearing pedestal hole used for assembling a drive bevel gear along the conical basin-shaped support is formed in the axial center of the large end surface of the conical basin-shaped support. The large end surface of the conical basin-shaped support is provided with a cantilever bearing pedestal used for assembling a driven circular-arc bevel gear in conical tooth engagement with the drive bevel gear. The cantilever bearing pedestal inclines towards the central axis of the conical basin-shaped support and overhangs on the large end surface of the conical basin-shaped support. The cantilever bearing pedestal is provided with a second bearing pedestal hole used for assembling the driven circular-arc bevel gear. The bearing hole in the cantilever bearing pedestal is small in stress, and stress of all components of the oblique central transmission frame assembly should meet strength requirements. By adoption of the form of the oblique transmission assembly, the output power of the oblique central transmission frame assembly approximately triples that of up-down vertical transmission.

Owner:CHINA HANGFA SOUTH IND CO LTD

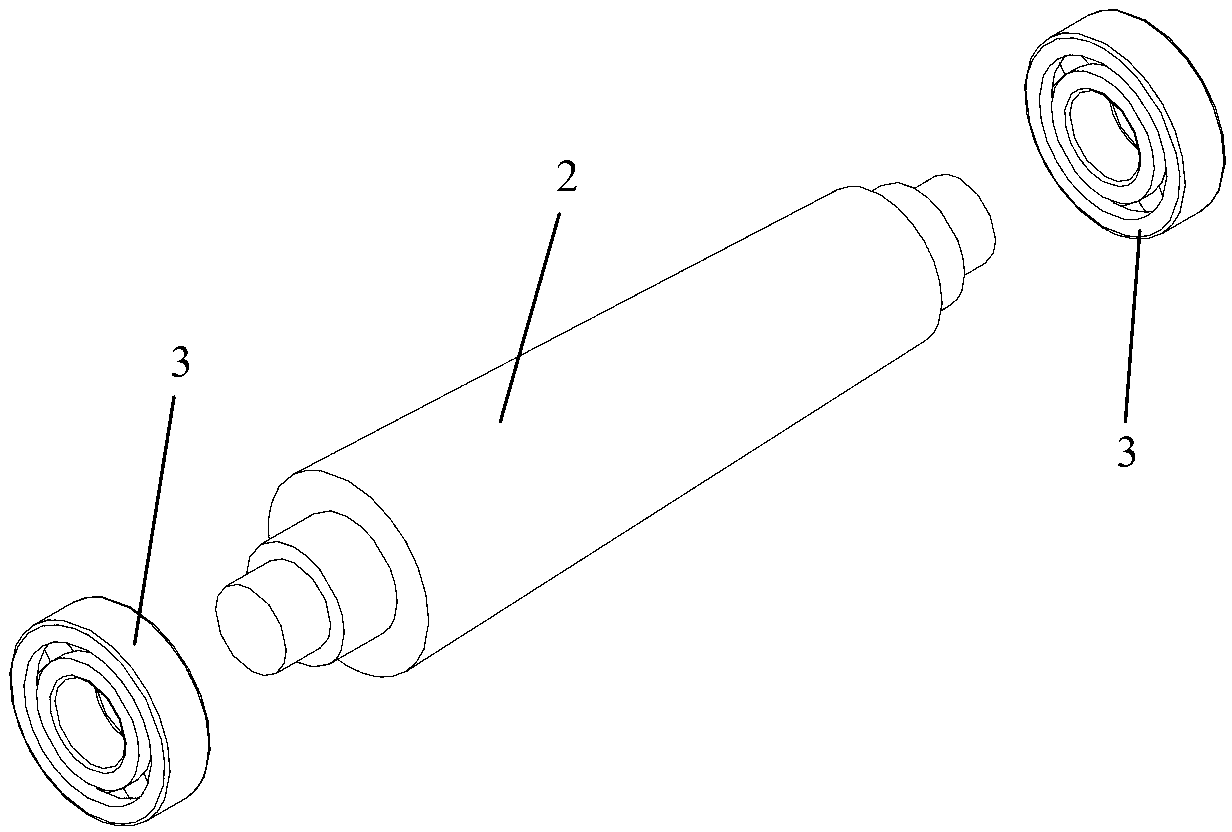

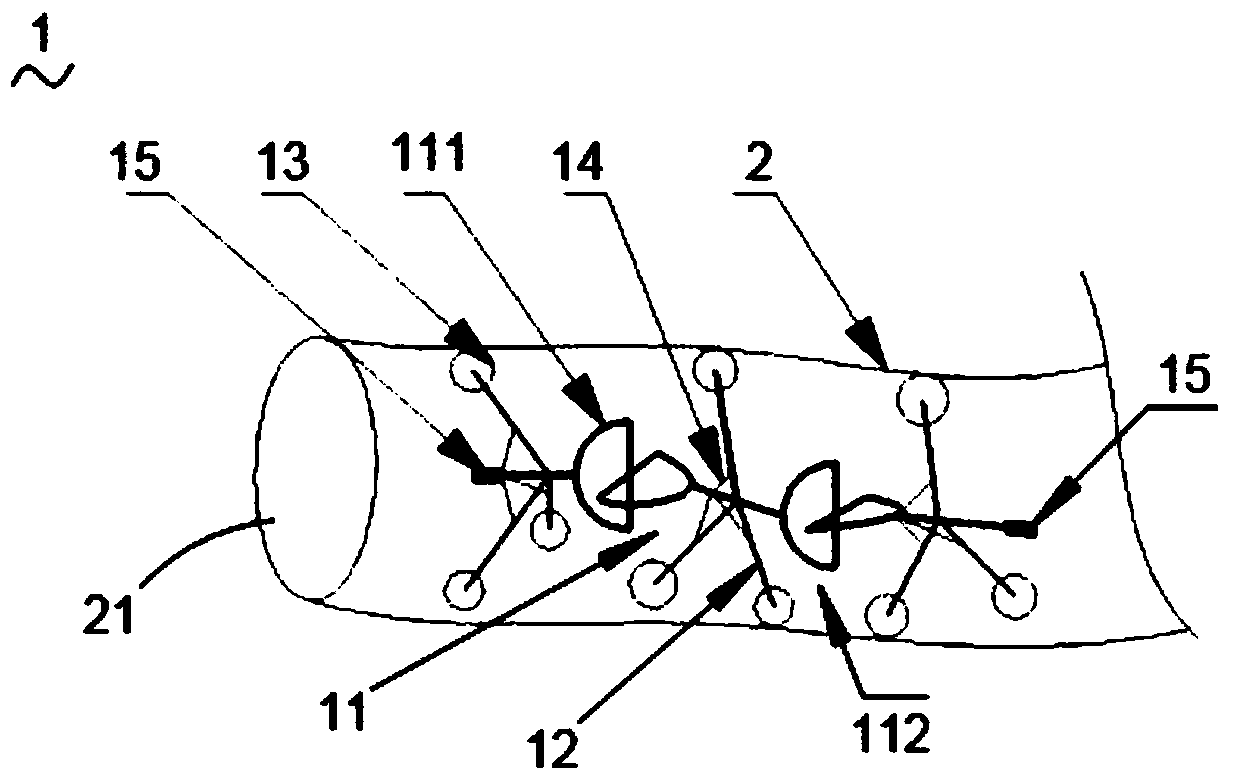

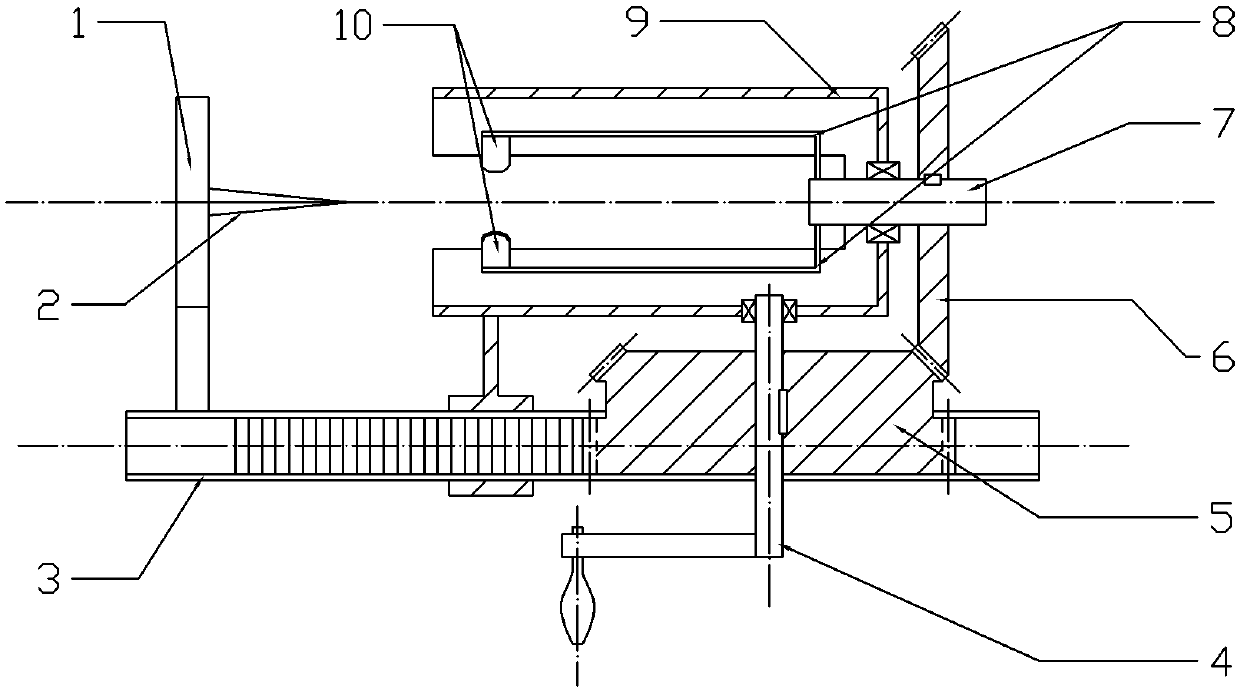

Pipeline robot

A pipeline robot comprises a robot framework, supporting rods, transmission wheels, sensors, a wireless signal transceiver and a control unit. The robot framework is formed by connecting first universal joint pin universal hinges and second universal joint pin universal hinges in series. One end of each supporting rod is connected to the robot framework in a hinged through a hinge, one transmission wheel is arranged at the other end of each supporting rod, and the opening angles of the supporting rods are adjusted by the ends, connected with the robot framework, of the supporting rods through elastic elements. Each transmission wheel is arranged at one end of the corresponding supporting rod, and the transmission wheels are electrically connected with a driving motor through conical teeth and universal couplings. The sensors are arranged at the two ends of the robot framework respectively. The wireless signal transceiver is arranged on the pipeline robot. The control unit controls the pipeline robot to work according to signals of the sensor and instructions of an external computer. The pipeline robot is compact in structure by adopting the robot framework formed by connecting the first universal joint pin universal hinges and the second universal joint pin universal hinges in series, the effect that the pipeline robot can turn freely in bent pipelines can be ensured, and meanwhile remote control can be achieved through the wireless signal transceiver.

Owner:SHANGHAI DIANJI UNIV

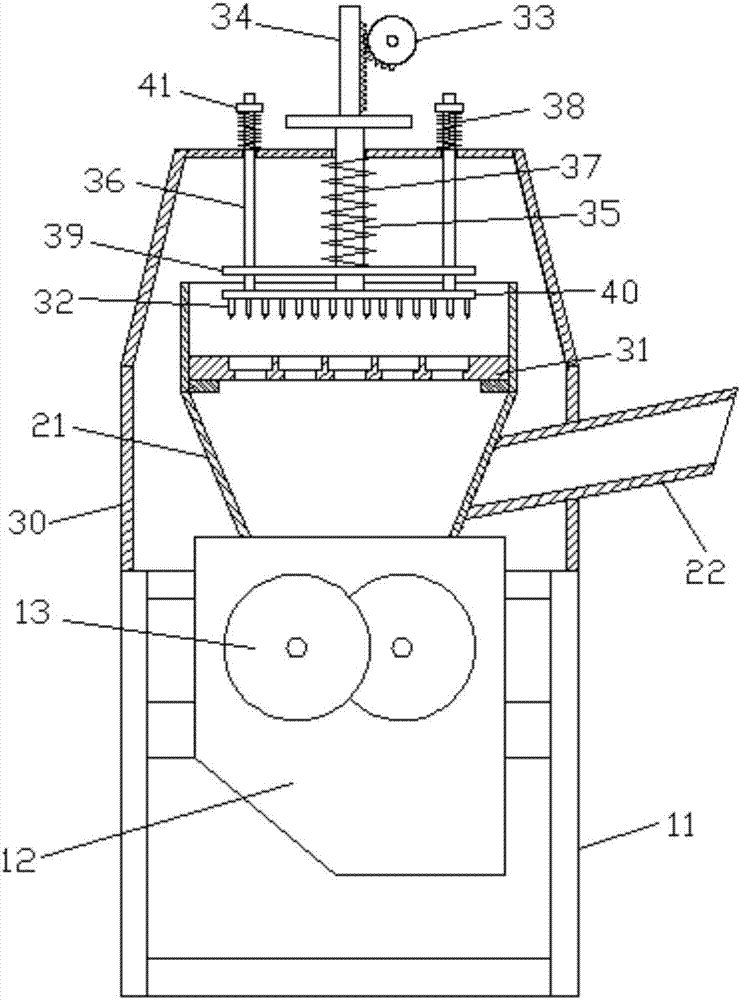

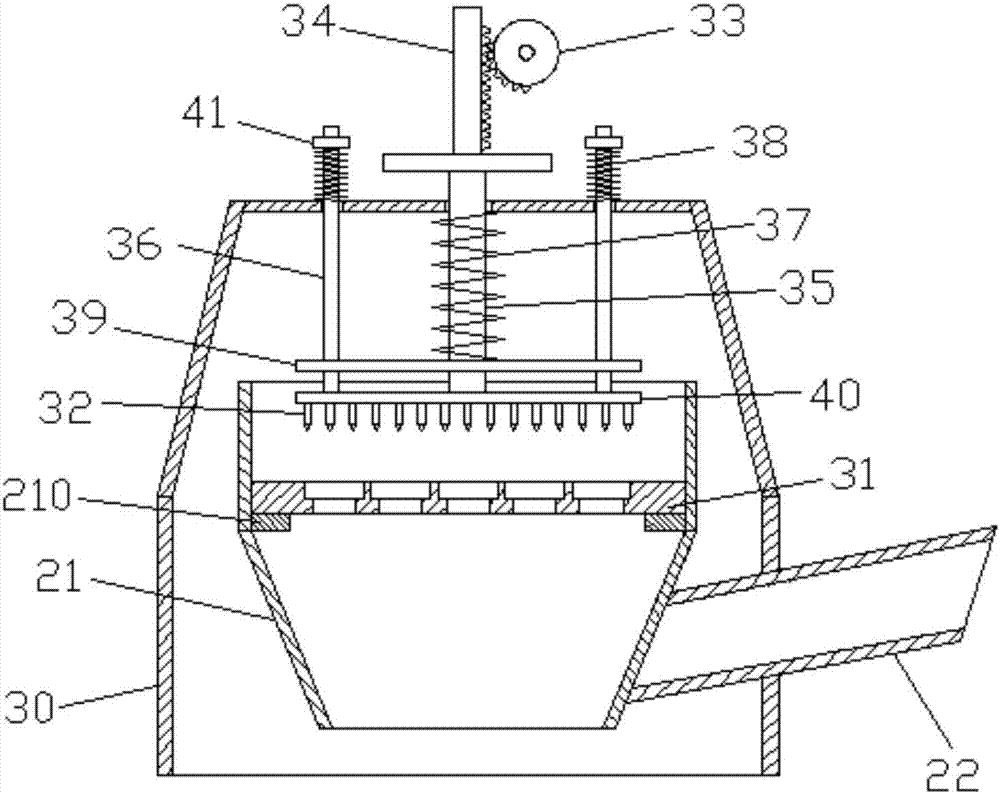

Glass crushing device

The invention discloses a glass crushing device. In the invention, the crushing box and the installation frame are both fixed on the frame, two crushing rotors are rotated and installed in the crushing box, the feeding box is fixed on the frame, the first guide rod and the second The two guide rods are plugged on the mounting frame, the push plate and the mounting plate are fixed on the first and second guide rods in layers, the first spring is sleeved on the first guide rod, and the upper and lower ends of the first spring are respectively Butt against the mounting frame and the push plate, the positioning nut is threadedly connected to the top of the second guide rod, the second spring is sleeved on the second guide rod, and the upper and lower ends of the second spring respectively abut against the positioning nut and the mounting frame Above, a number of crushing cone teeth are fixed on the lower end surface of the mounting plate, the crushing plate is arranged in the feeding box, the rack is fixedly connected with the first guide rod, and the incomplete gear is meshed with the rack. The invention avoids manual breaking of large glass pieces, reduces potential safety hazards, and directly enters between broken rotors after the large pieces of glass are broken, thereby improving efficiency.

Owner:NANJING CHAOYANG GLASS CO LTD

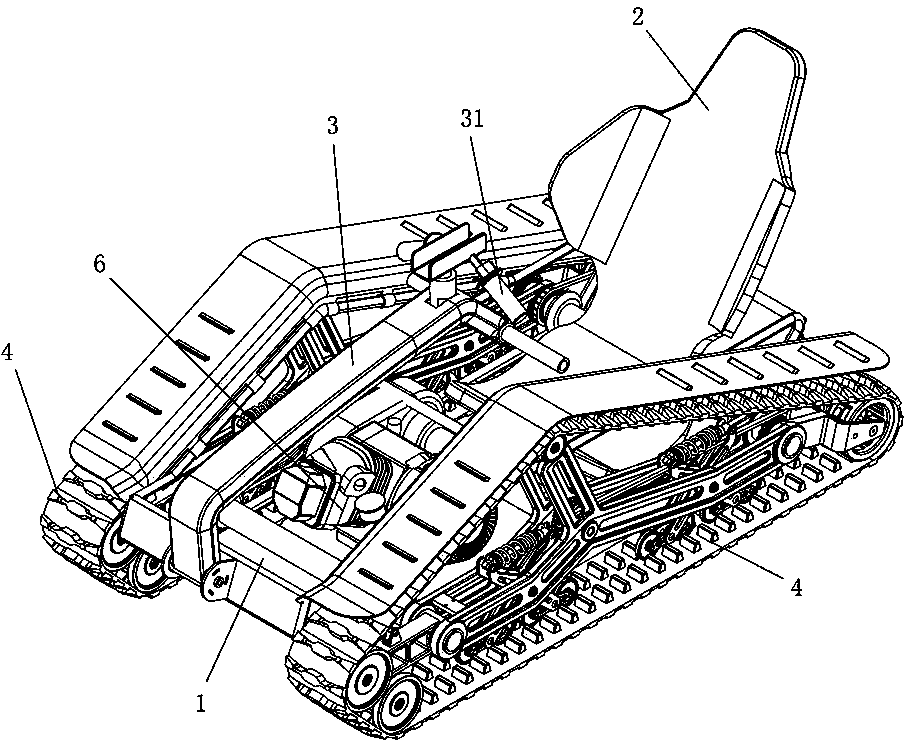

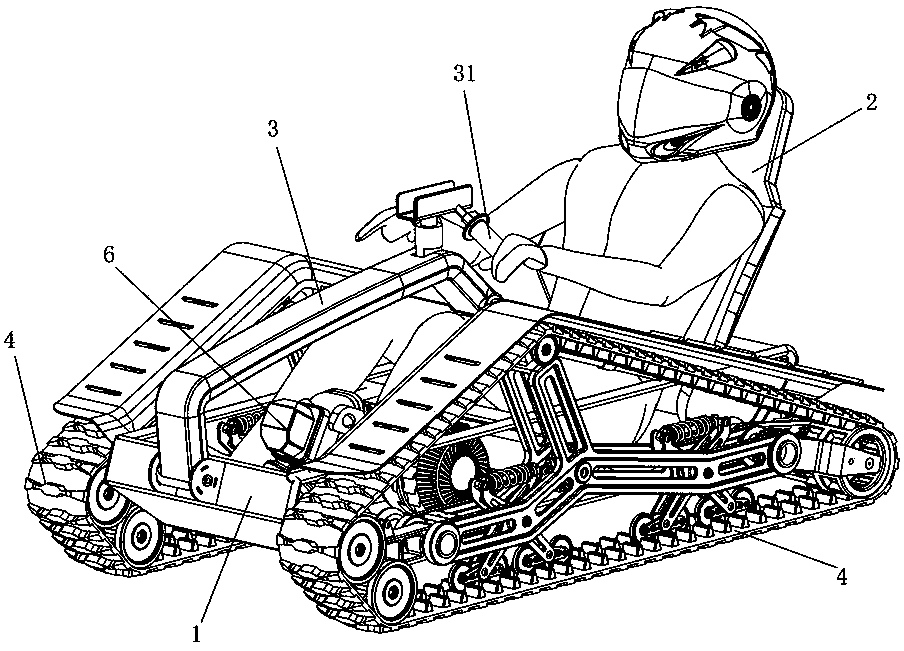

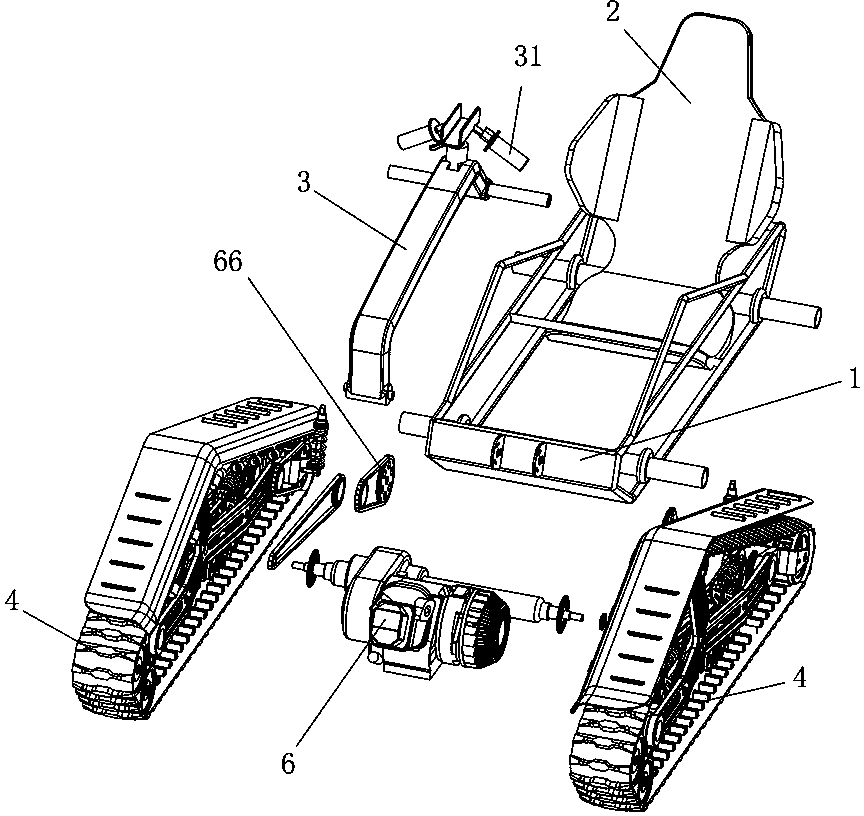

Single-person all-terrain crawler-type moving carrier

ActiveCN103770634ACompact structureReduce sizeVehicle seatsFoot actuated initiationsTerrainLeft half

The invention discloses a single-person all-terrain crawler-type moving carrier. The single-person all-terrain crawler-type moving carrier comprises a chassis, crawler wheel sets, a driving seat and a power transmission system, wherein the crawler wheel sets are arranged on both sides of the chassis respectively; the driving seat and the power transmission system are arranged on the chassis; a suspension damping system is arranged in each crawler wheel set; the power transmission system comprises an engine; a belt type continuously variable transmission is connected to an output shaft of the engine; a helical conical tooth differential mechanism is embedded into a driven disk of the belt type continuously variable transmission; the two output ends of the helical conical tooth differential mechanism are connected with a rear axle left half shaft and a rear axle right half shaft respectively; the rear axle left half shaft and the rear axle right half shaft are used for driving the crawler wheel sets on corresponding sides respectively. The single-person all-terrain crawler-type moving carrier has the advantages of simple and compact structure, convenience in operation and small size, and can be moved conveniently and rapidly on special terrains such as sand, mud, marsh, ice and snow by a single person.

Owner:NAT UNIV OF DEFENSE TECH

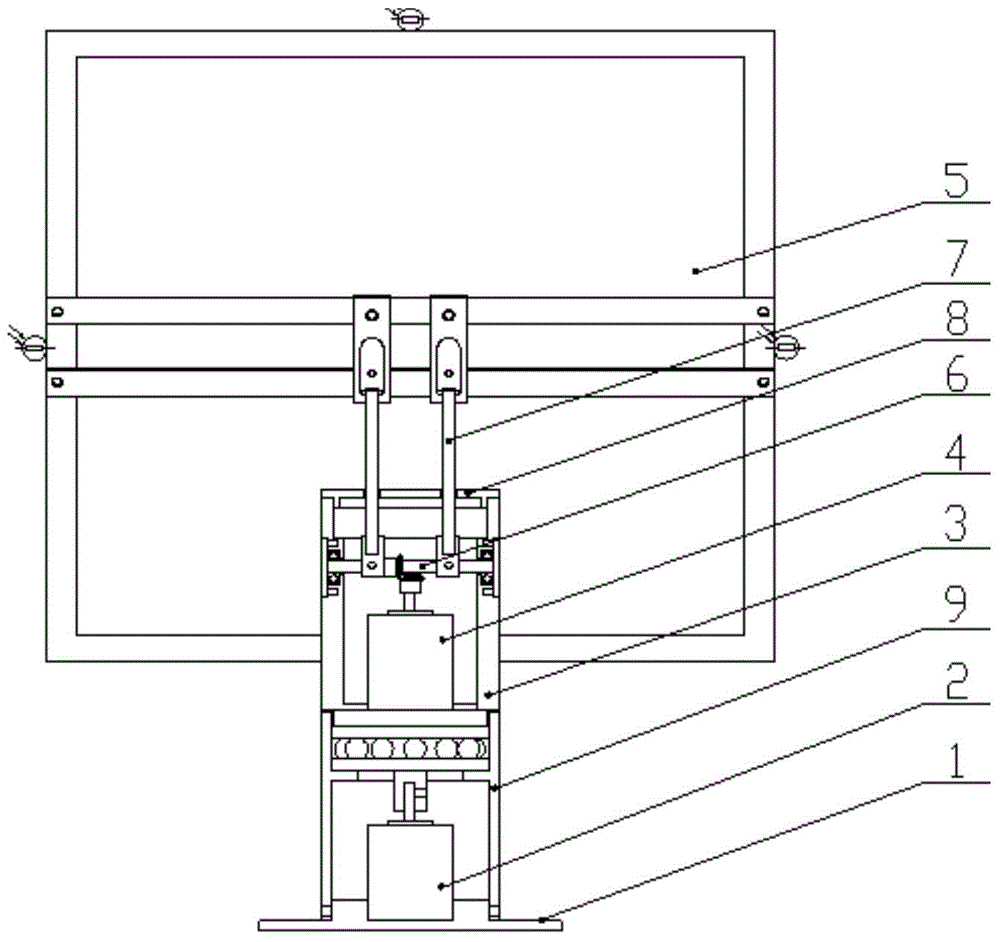

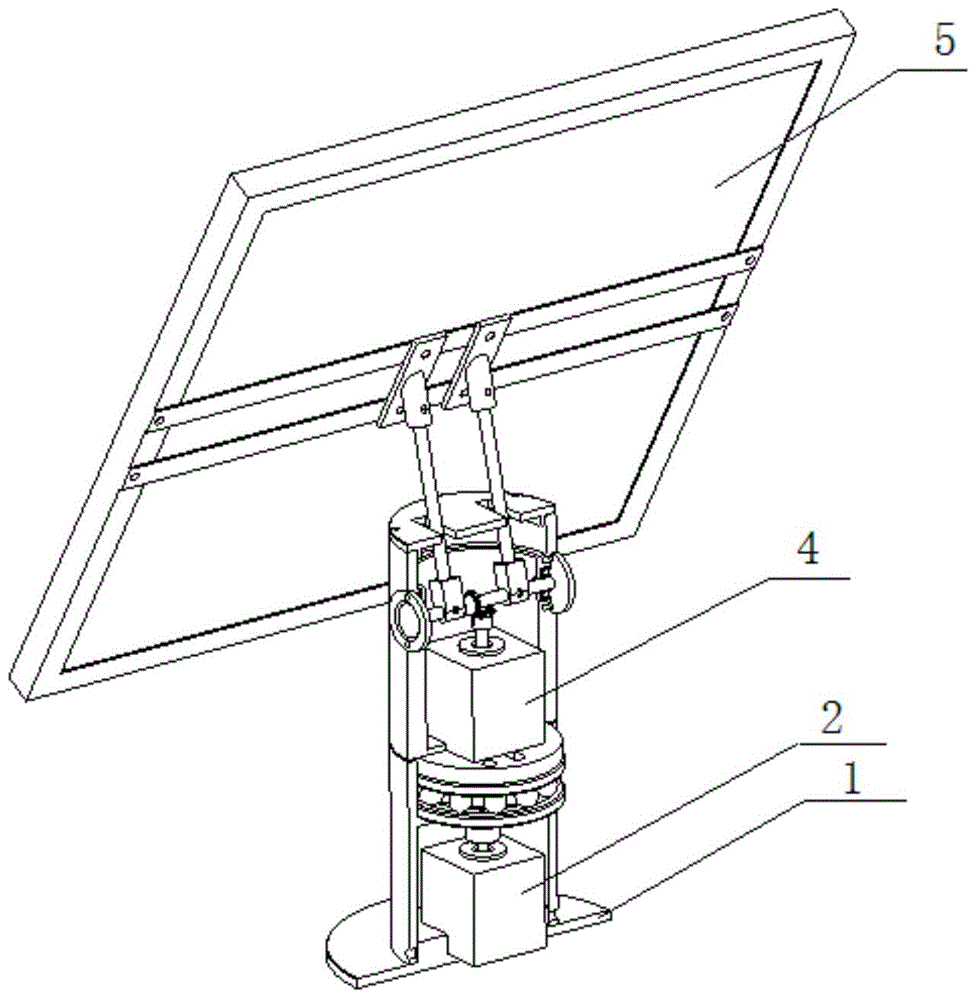

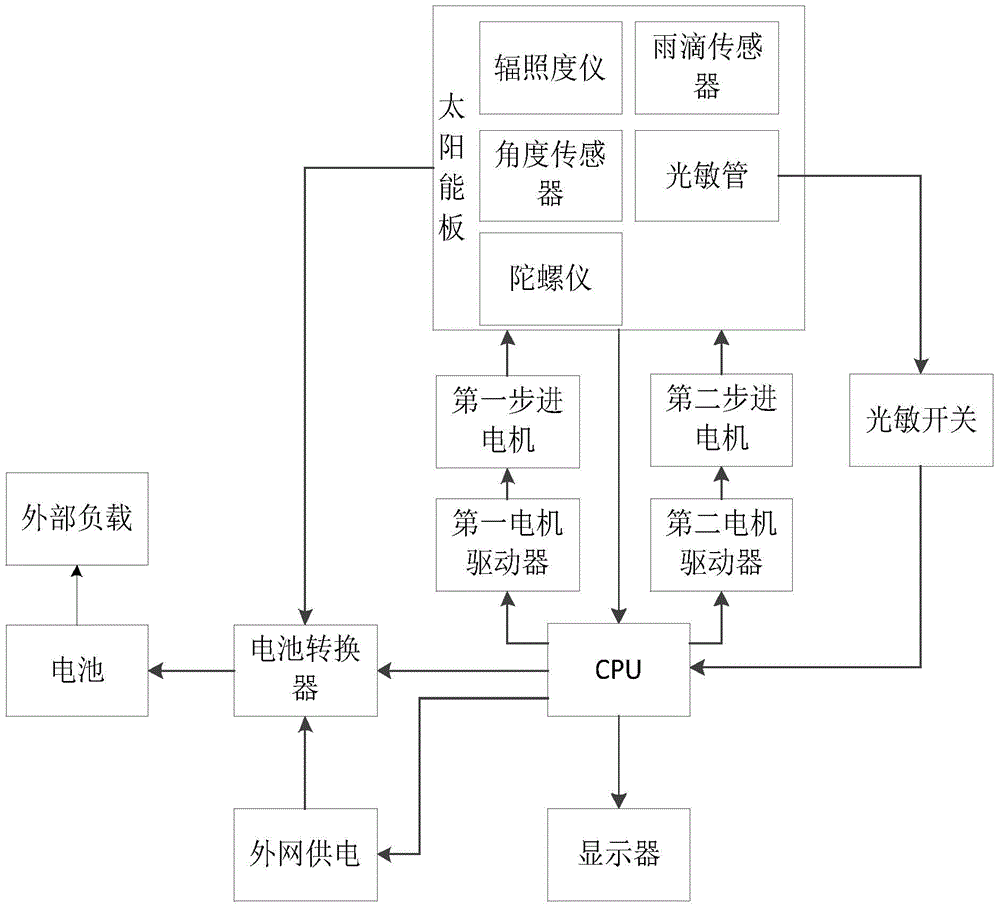

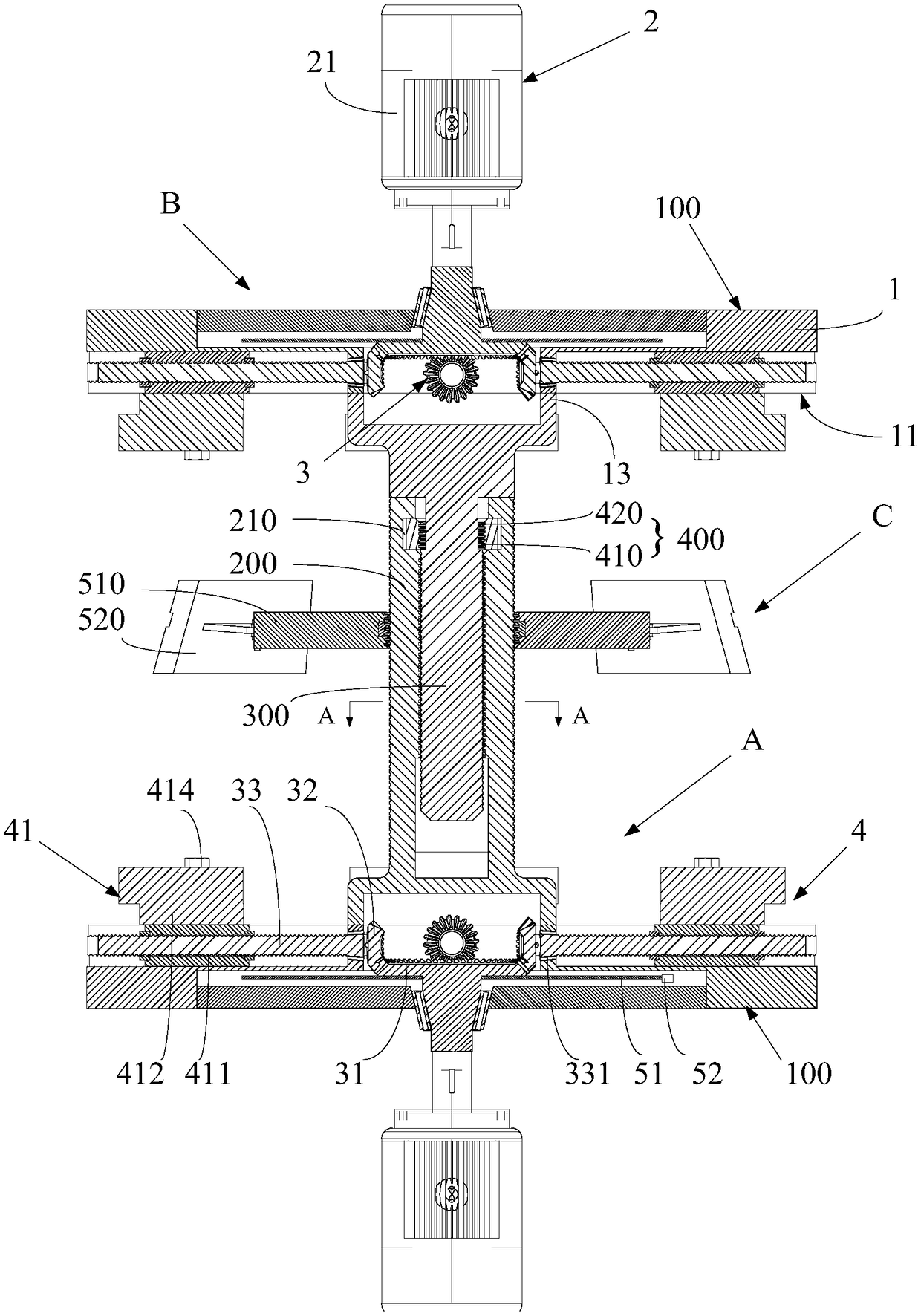

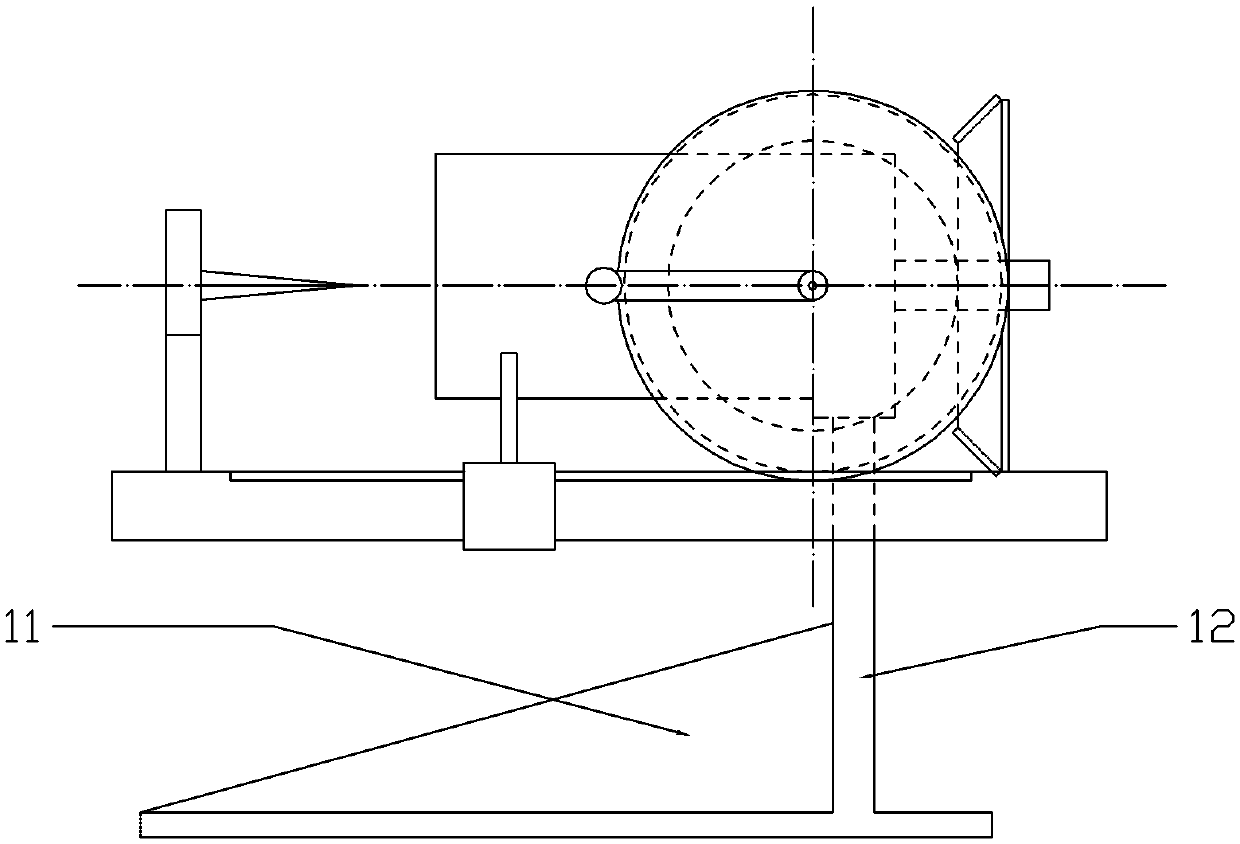

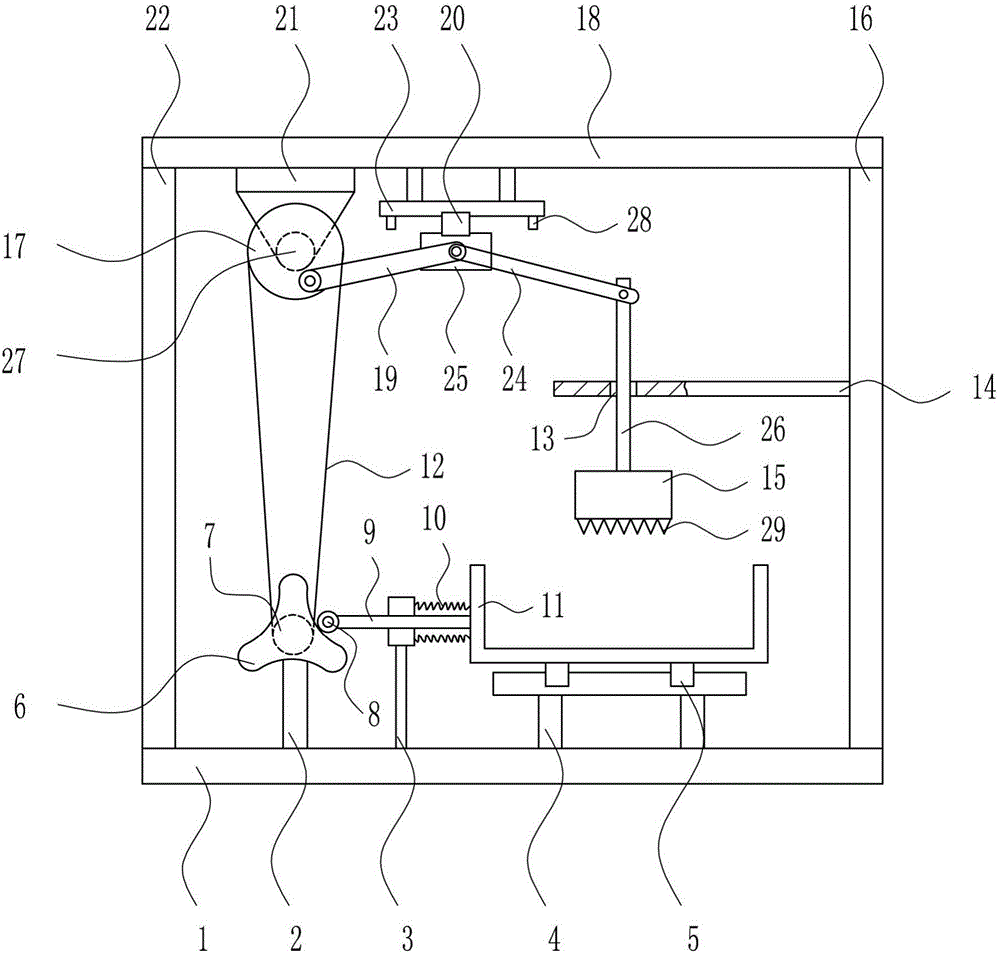

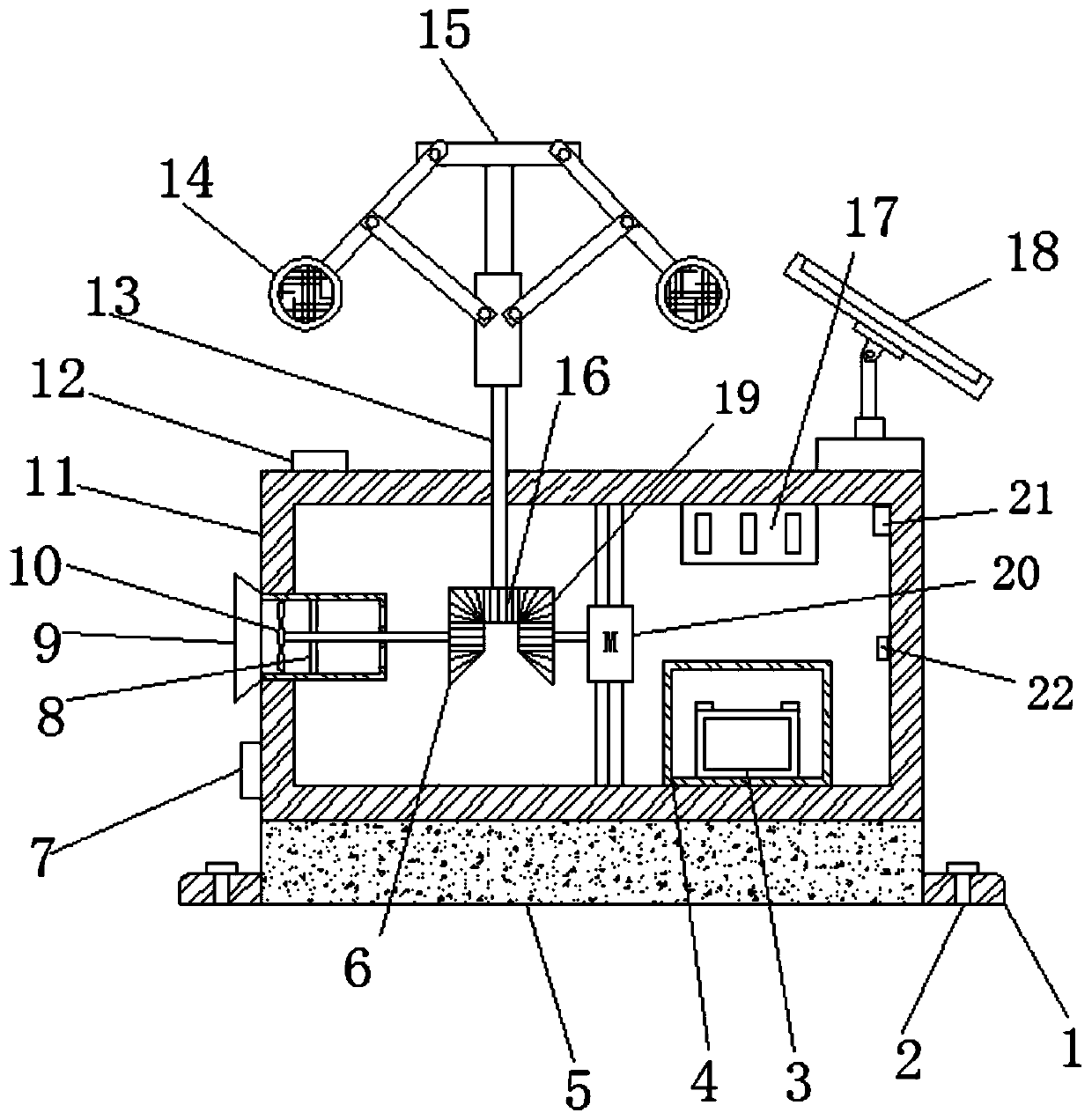

Cup-type distribution photovoltaic power generation self-tracking system and control method

InactiveCN105094156AStrong dockingSimple cup structureControl using feedbackElectrical batteryType distribution

The present invention discloses a cup-type distribution photovoltaic power generation self-tracking system and a control method. The system comprises a cup-type structure and a control unit. The cup-type structure comprises a first stepping motor arranged on a base. The first stepping motor drives an upper cylinder to rotate. A second stepping motor is arranged in the upper cylinder. Through a conical-tooth rotating mechanism, a solar panel is driven by the second stepping motor to conduct the pitching movement via a support rod. The four edges of the solar panel are provided with photosensitive transistors. The control unit comprises a CPU. The photosensitive transistors are connected with the CPU. The differential analysis and calculation is conducted on the switching values of the four photosensitive transistors by the CPU. The CPU respectively controls the first stepping motor and the second stepping motor via a motor driver, namely drives an azimuth-angle stepping motor and an elevating-angle stepping motor to drive a mechanical mechanism to rotate. In this way, the solar panel is enabled to track the sunlight in an orientation highest in illumination intensity all the time. The electric energy generated by the solar panel is delivered to a battery via a battery converter, and then the electric energy is used for powering up the control unit, the stepping motors and external loads by the battery. According to the technical scheme of the invention, the power generation efficiency of solar photovoltaic panels is effectively improved.

Owner:XIAN UNVERSITY OF ARTS & SCI

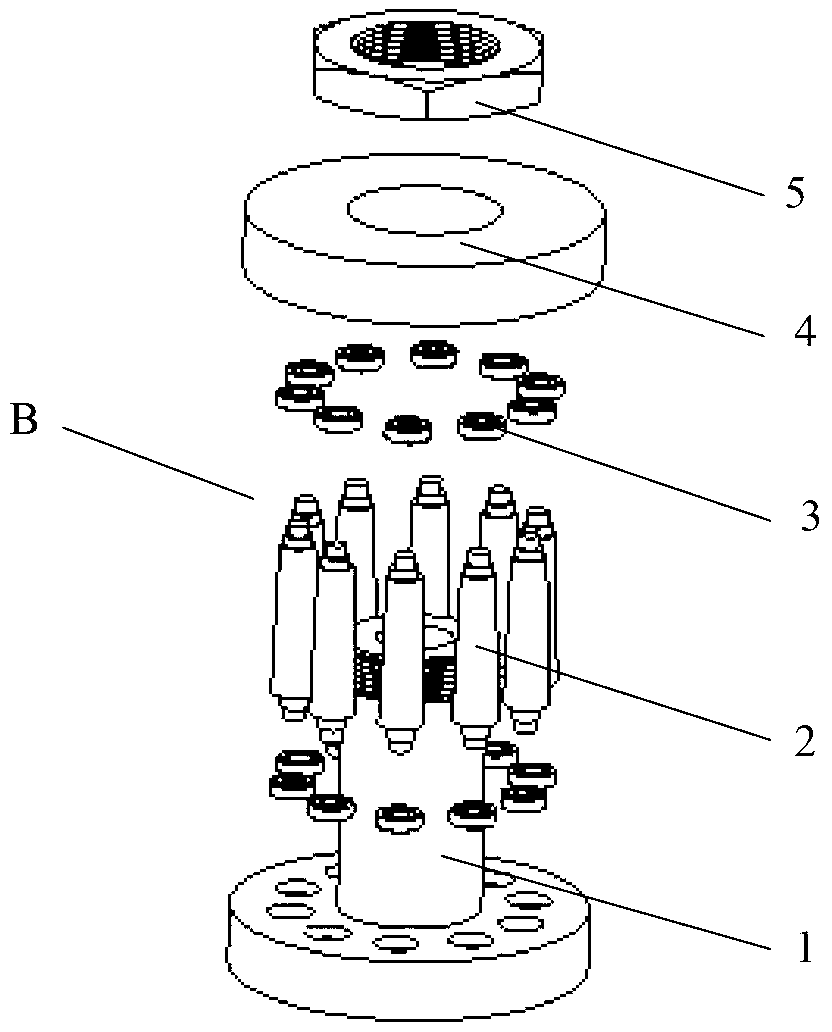

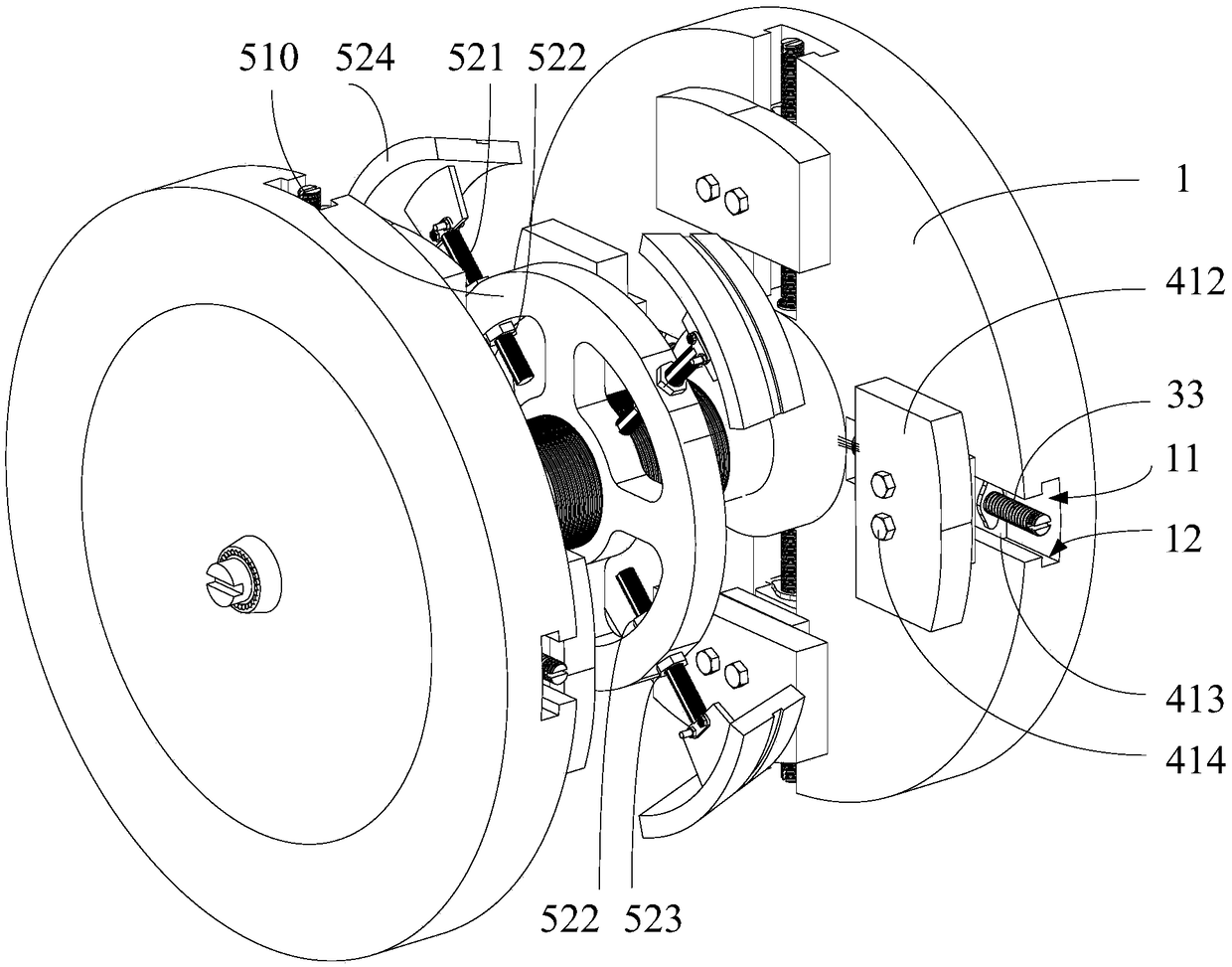

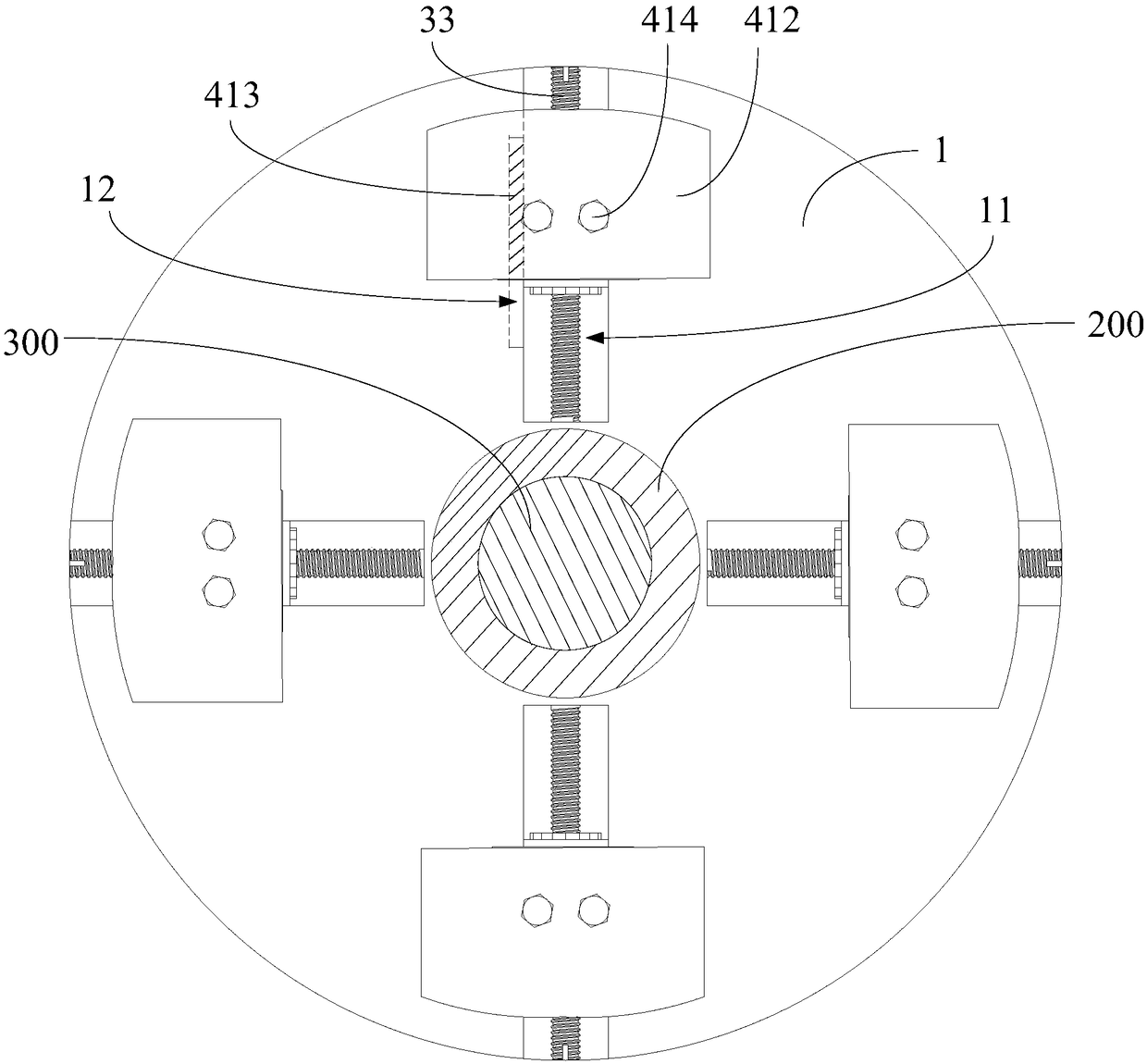

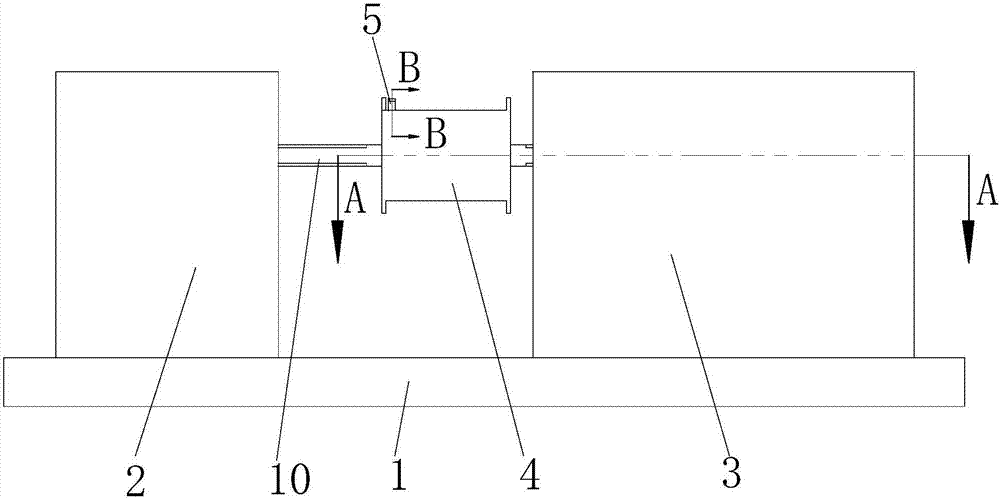

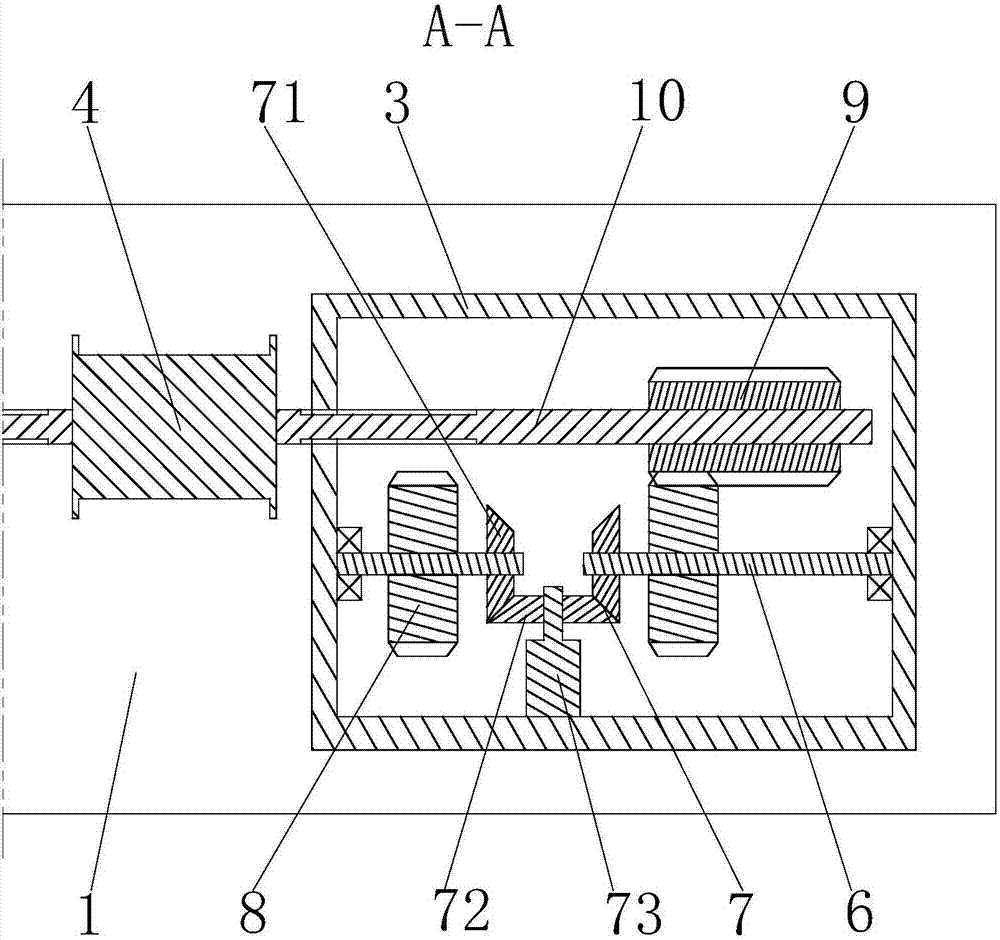

Flexible tool for annular part welding

ActiveCN109304567ARealize clamping and fixingRealize locking positionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringScrew thread

The invention discloses a flexible tool for annular part welding, and belongs to the field of mechanical tooling. The flexible tool comprises a first tool and a second tool, wherein the first tool comprises a clamping part and a sleeve; the second tool comprises a clamping part and a double-screw bolt; the two clamping parts comprise shells, drive mechanisms, transmission mechanisms and fixing assemblies; the drive mechanisms are fixedly arranged on the shells; the transmission mechanisms comprise conical tooth plates, bevel gears and screw rods; the drive mechanisms are in transmission connection with the conical tooth plates; the bevel gears are coaxially arranged at one ends of the corresponding screw rods and mesh with the conical tooth plates; the fixing assemblies comprise fixing blocks; the fixing blocks are in screw-thread fit with the corresponding screw rods; sliding chutes in one-to-one correspondence to the screw rods are formed in the shell; each sliding chute extends along the axial direction of the corresponding screw rod; the fixing blocks are slidably arranged in the corresponding sliding chutes; and the double-screw bolt is coaxially inserted into the sleeve. Theflexible tool for annular part welding provided by the invention can be applicable to welding annular parts with multiple specifications.

Owner:WUHAN MARINE MACHINERY PLANT

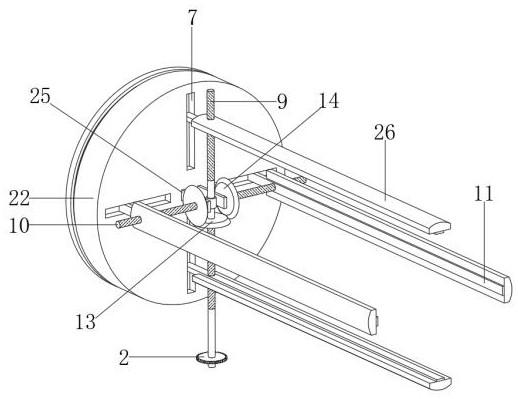

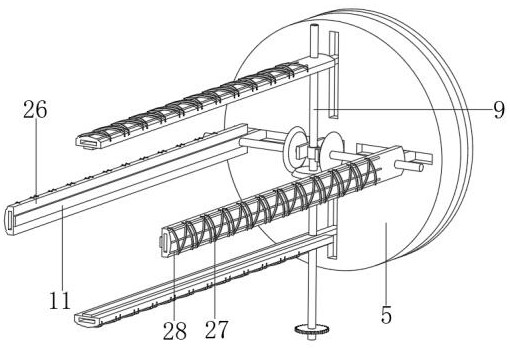

Helical coating type welding wire weaving machine

InactiveCN106892305ARealize the effect of automatic collectionNice appearanceFilament handlingWelding/cutting media/materialsEngineeringHelix

The invention relates to a helical coating type welding wire weaving machine which comprises a rack, wherein a left case and a right case are fixedly arranged on the rack; a long weaving wheel is arranged between the left case and the right case; a start fixing device is arranged on the long weaving wheel; rotating shafts are connected to the left side and the right side of the long weaving wheel; the two rotating shafts are in threaded connection with the left case and the right case; two branch shafts are mounted inside the right case; a conical tooth direction changing device is arranged between the two branch shafts; a straight gear is mounted on each branch shaft; an outer spline is mounted on the rotating shaft, which is located on the right side, of the two rotating shafts. The helical coating type welding wire weaving machine can drive a welding wire to realize coating type winding on the long weaving wheel from the inner circle to the outer circle in a clockwise cylindrical screwing manner and an anticlockwise cylindrical screwing manner, so that the effect of automatically weaving the welding wire in a simple control way is achieved; and meanwhile, the welding wire woven by the helical coating type welding wire weaving machine is attractive in appearance and coated tightly, and has the advantage of saving materials and cost.

Owner:ANHUI REMFG ENG DESIGN CENT

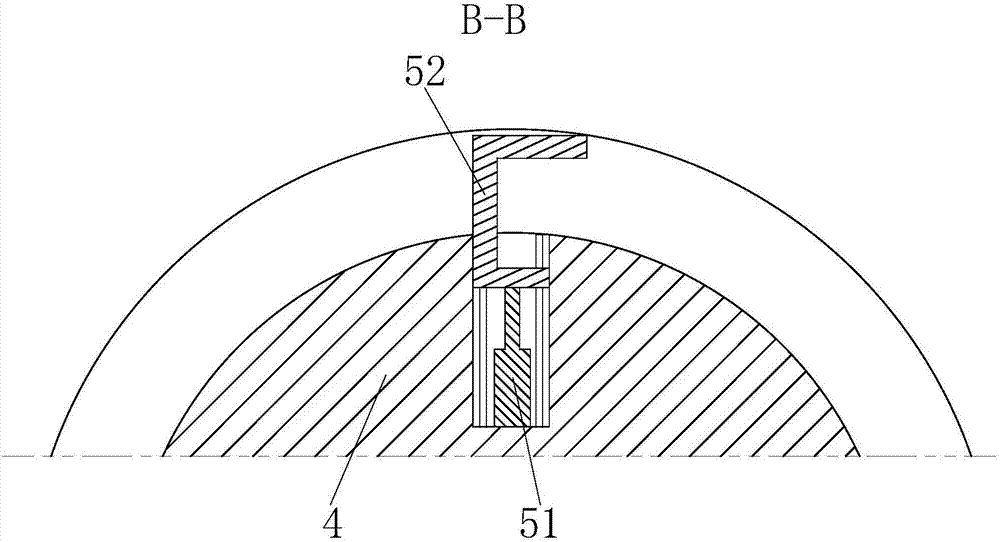

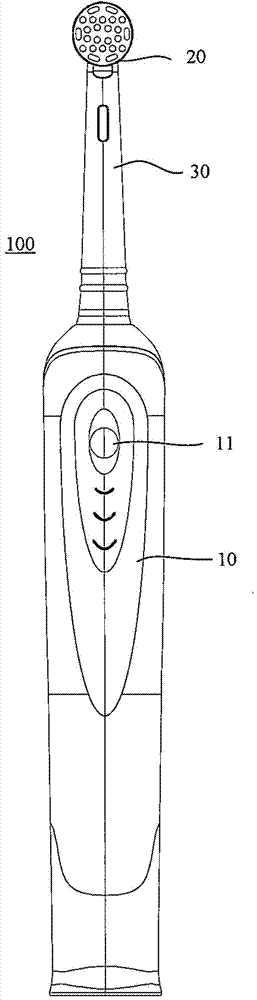

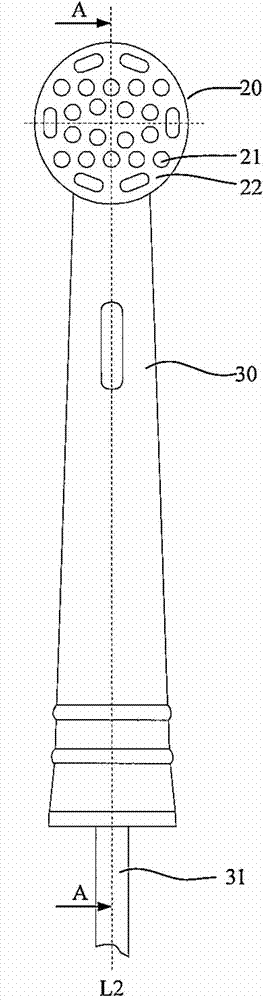

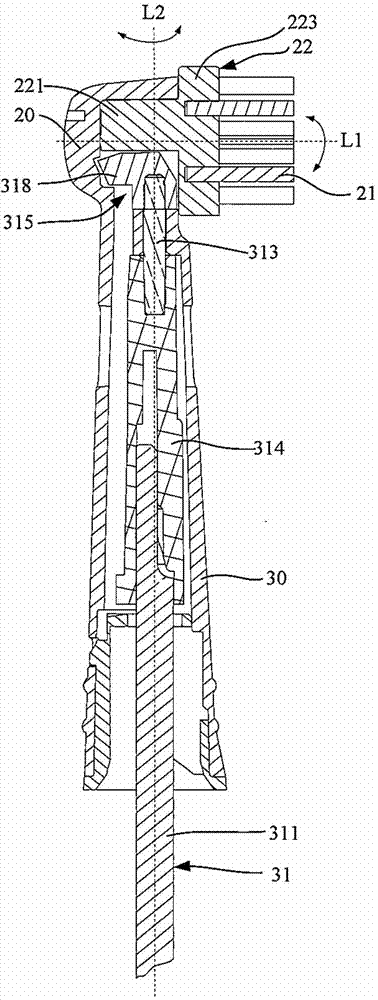

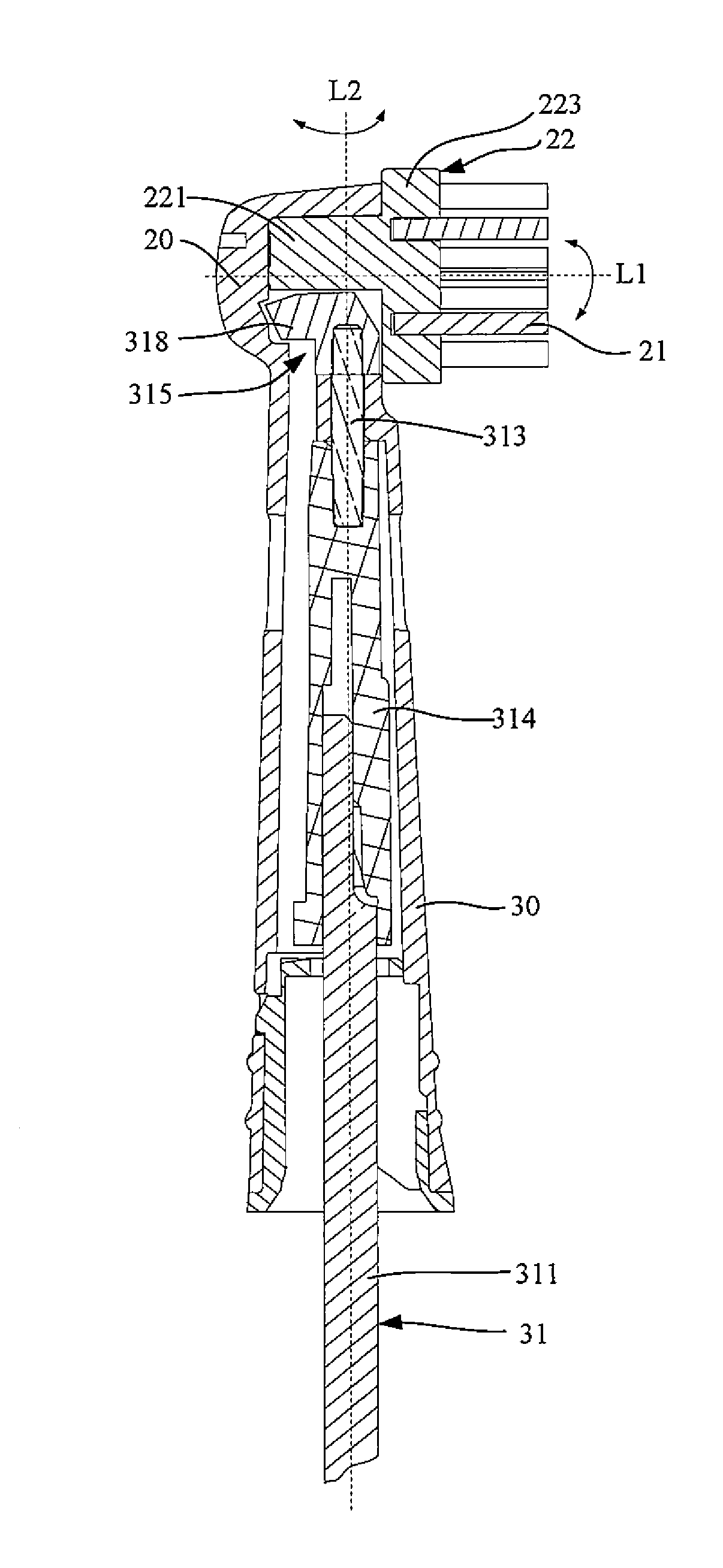

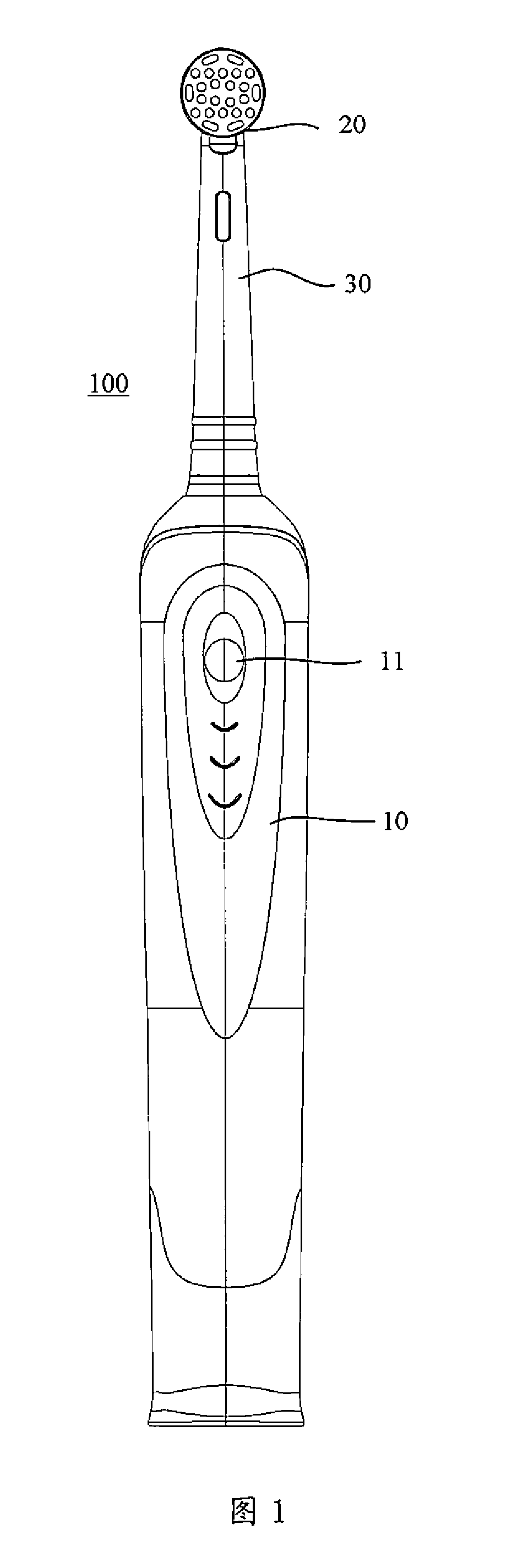

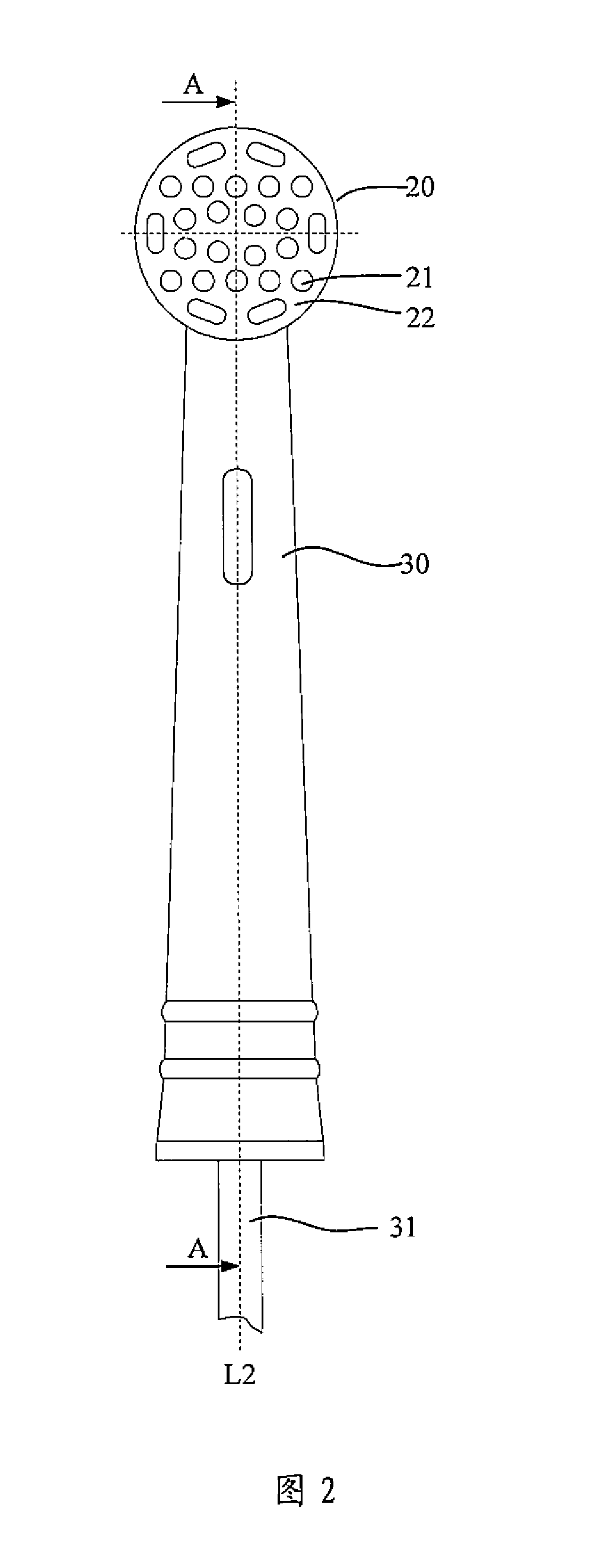

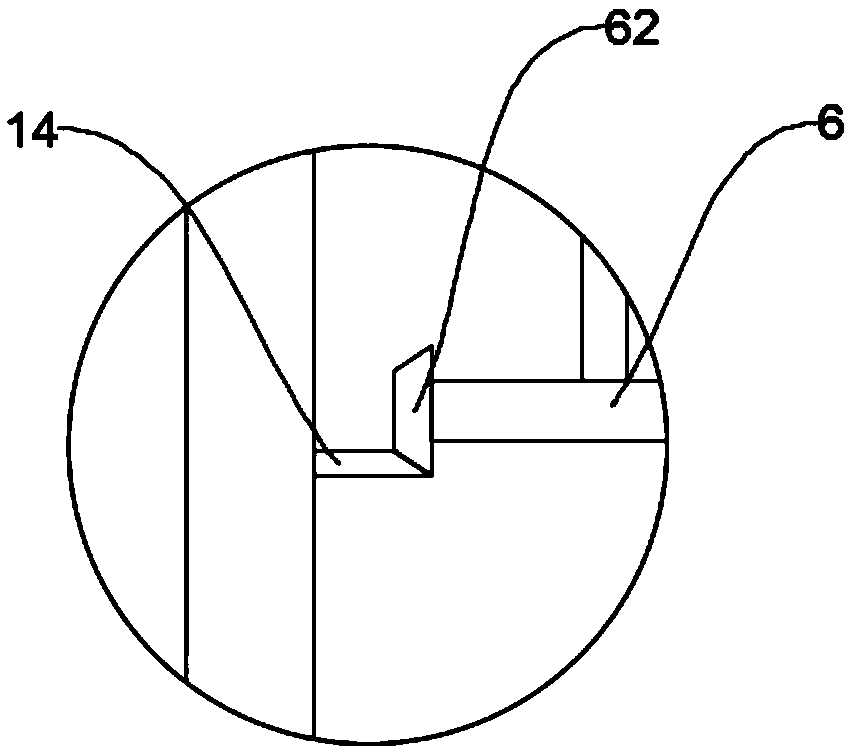

Personal electric cleaning tool

A personal electric cleaning tool comprises a handle part accommodating a driven element and a head part connected with a supporting body for supporting a cleaning element, wherein the supporting body limits a first joint shape; and a transmission rod with the end far away from the head operably connected to the drive element and the end close to the head part fixed with a drive wheel which limits a second joint shape matched with the first joint shape; when the transmission rod is driven by the driven element, the supporting body conducts reciprocating rotation with the drive wheel, wherein one of the first joint shape and the second joint shape is a shape limited by two opposite conical tooth surfaces on a cone gear, and the other of the first joint shape and the second joint shape is a shape limited by a conical tooth engaged with the two conical tooth surfaces. Through the personal electric cleaning tool, the volume of the head part of the personal electric cleaning tool is designed to be smaller, so that a user can more comfortably use.

Owner:SHANGHAI SHIFT ELECTRIC CO LTD

Writing brush cleaning device

The invention discloses a writing brush cleaning device comprising a device body, a first cavity formed in the device body and a second cavity formed in the device body. A first communicating hole isformed between the first cavity and the second cavity in a communicating mode. An inner conical tooth ring is fixedly mounted at an opening in the top of the first communicating hole. A second communicating hole communicating with the exterior is formed in the top wall of the second cavity. A first rotating block is rotatably arranged in the second communicating hole. A first gear is fixedly mounted at the bottom of the first rotating block. The writing brush cleaning device is simple in structure and convenient to operate, clamping and rotating of a writing brush are driven by the same powersource, meanwhile, reverse rotation of a cleaning container and jetting of cleaning liquid are driven while the writing brush rotates, and thus the cleaning efficiency and quality are improved; and meanwhile, the cleaned liquid is purified through a filtering device, recycling of the cleaning liquid is achieved, all the processes are mutually matched and not affected, and the practical performanceof the writing brush cleaning device is improved.

Owner:刘文明

Personal electric cleaning tool

A personal electric cleaning tool comprises: a handle accommodating a driving element therein; a head connected with a supporting body supporting a cleaning element, the supporting body defining a first engaging shape; and a transmission rod, one end thereof far away from the head being operably connected to the driving element and the other end thereof near the head being fixedly provided with a driving wheel defining a second engaging shape matched with the first engaging shape, so that the supporting body rotates in a reciprocating manner along with the driving wheel as the transmission rod is driven by the driving element, wherein one of the first engaging shape and the second engaging shape is a shape defined by two conical tooth surfaces facing each other on one bevel gear, while the other one is a shape defined by one conical tooth engaged with the two conical tooth surfaces.

Owner:SHANGHAI SHIFT ELECTRIC CO LTD

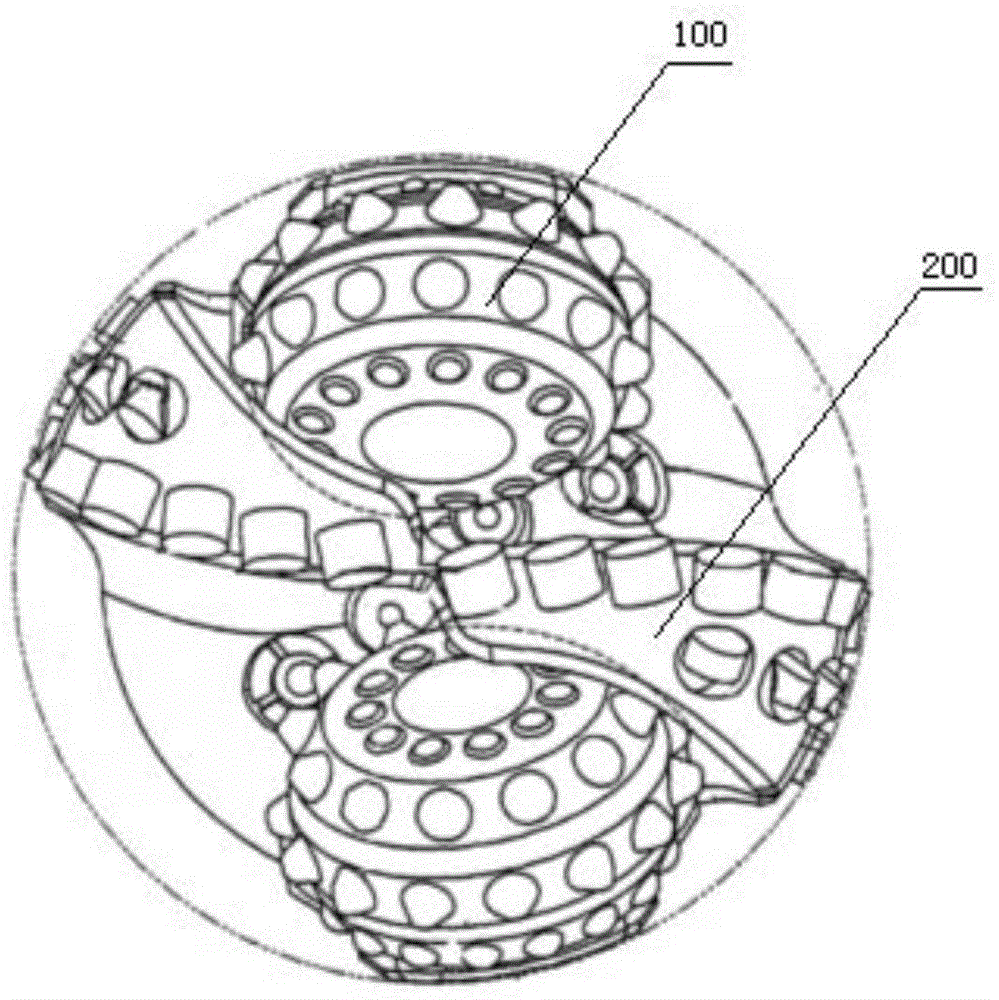

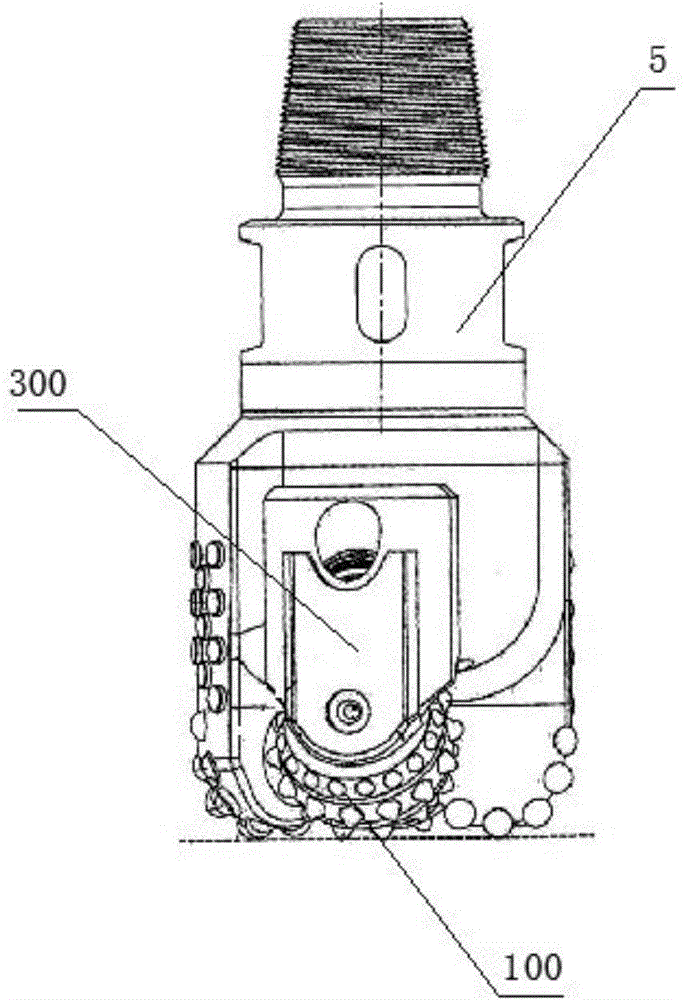

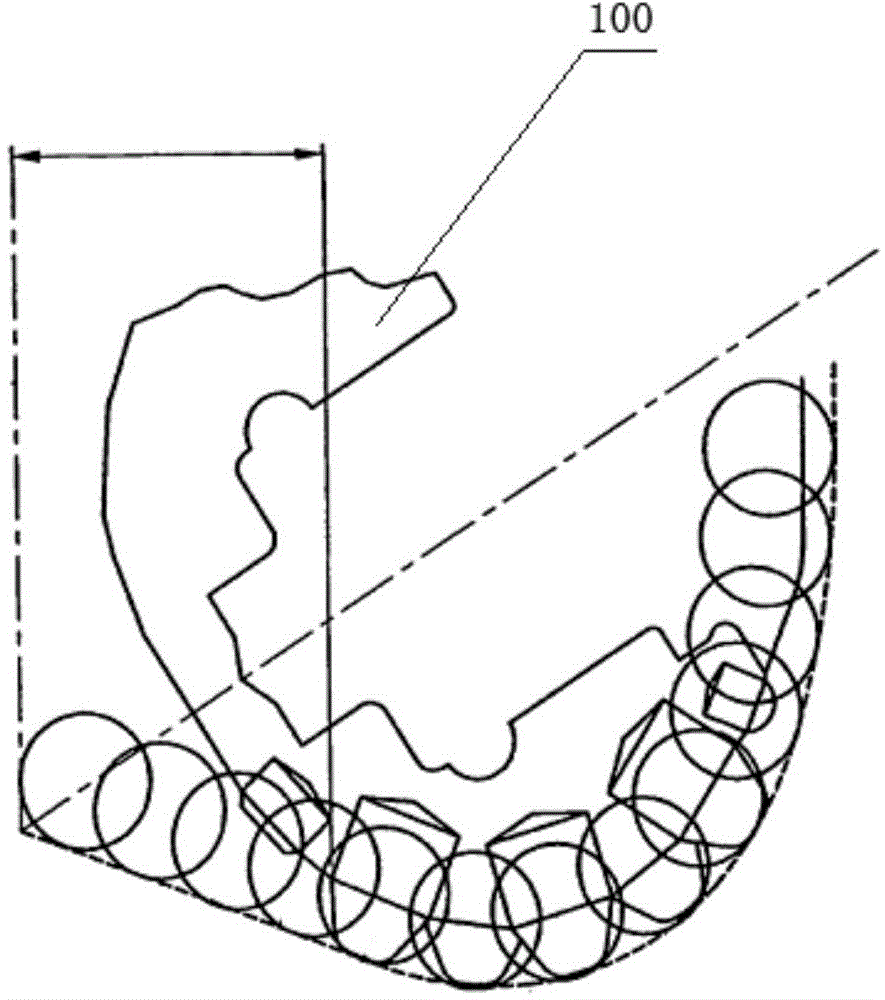

Mixed type downhole drilling bit

InactiveCN106194033AImprove cutting efficiencyImprove mechanical propertiesDrill bitsWell drillingStick-slip phenomenon

The invention discloses a mixed type downhole drilling bit. The mixed type downhole drilling bit comprises a drilling bit body, blades, heads and cones, wherein the blades and the heads are fixedly connected with the upper end of the drilling bit body; the lower ends of the heads are fixedly connected with the side wall of the drilling bit body; the cones are rotationally connected with the upper ends of the heads through shaft journals; an included angle is formed between a central axis of each cone and a central axis of the drilling bit body; multiple conical teeth or / and wafer cutting teeth are arranged on the blades; multiple chisel-point teeth and flat teeth are arranged on the cones. By the combination of impact crushing of a cone drilling bit and ploughing motion and shearing motion of a blade structure drilling bit capable of realizing mixed tooth distribution, downhole primary crushing is realized, fixed cutting teeth are effectively drilled into rock, the stick-slip phenomenon of the drilling bit in some specific strata is eliminated, impact load of the fixed cutting teeth is reduced, the probability of impact damage of the fixed cutting teeth is reduced, and the cutting efficiency and the mechanical drilling rate are increased.

Owner:CHENGDU BEST DIAMOND BIT

Manufacturing method for triple gear

The invention relates to a manufacturing method for a triple gear. The method comprises the steps that a metal rod is selected, the length of the rod is worked out according to the weight of the triple gear, the rod is put into a medium-frequency induction heating furnace and heated, the heating temperature ranges from 1,100 DEG C to 1,180 DEG C, then upsetting, pre-forging and final forging are conducted for forming, and descaling and oxidation prevention are included in the forming process; then shot blasting cleaning is conducted, and the surface of a workblank is coated with a lubricant; and the lubricated triple gear workblank is put into a finishing die, the cold reshaping process is conducted, normal-temperature reshaping is conducted on a conical tooth part of the triple gear, and the triple gear is formed. By the adoption of the manufacturing method, the operation is convenient, the quality of products is stable, the degree of finish of the tooth surface reaches over 1.6, the tooth portion accuracy reaches over the level 6 specified in the DIN standard through reshaping, no machining is needed for the conical tooth part, only one-time heating is needed, the production cycle is short, the efficiency is high, energy and materials are saved, the operation is convenient, and the product accuracy is high; and an existing manufacturing method of machining or multi-fire forging of the triple gear is changed thoroughly.

Owner:HANDE AXLE (ZHUZHOU) GEAR CO LTD

Anti-deformation pipe fitting fixing device for machining

InactiveCN111716124AUniform supportImprove fixation stabilityWork holdersPositioning apparatusPipe fittingEngineering

The invention belongs to the technical field of machining, and particularly relates to an anti-deformation pipe fitting fixing device for machining. Aiming at the problem that most traditional fixingdesigns for pipe fitting machining are simple, generally, fixing is conducted by adopting the mode of extruding the exteriors of two sides, and thin-wall pipe fittings are prone to being deformed, thefollowing scheme is provided, the anti-deformation pipe fitting fixing device comprises a base, and a bracket and an L-shaped fixing vertical plate are welded to the two sides of the outer wall of the top of the base correspondingly; and a hydraulic rod is fixed to one side of the L-shaped fixing vertical plate through a bolt, and a clamping mechanism is installed at the top end of the base. According to the anti-deformation pipe fitting fixing device, driving bi-directional screws can be driven to rotate by arranging a driving mechanism, in the meantime, corresponding driven screws are driven to rotate oppositely through driving conical teeth and driven conical teeth which are the same in specification, accordingly, moving rods on limiting slide groove operate away from each other at thesame time and expand outwards, and uniform supporting and fixing treatment on the inner wall of a pipe fitting are achieved through arc-shaped abutting plates.

Owner:高彦科

Circulation type pesticide mixing device with spontaneous stirring function

InactiveCN108889225AWell mixedImprove uniformityFlow mixersRotary stirring mixersWater flowWater spray

The invention discloses a circulation type pesticide mixing device with a spontaneous stirring function. The circulation type pesticide mixing device comprises a tank, a hollow rotary shaft and a pumpmachine. The hollow rotary shaft is vertically arranged in an inner cavity of the tank and is rotationally connected with the walls of the inner cavity of the tank, backflow pipes are symmetrically connected with two sides of the top of the hollow rotary shaft, and water spray orifices which face reverse directions are formed in the backflow pipes on the two sides of the top of the hollow rotaryshaft; the hollow rotary shaft is equidistantly provided with a plurality of groups of stirring blades along the length direction of the hollow rotary shaft, one end of each stirring blade is rotationally connected onto the hollow rotary shaft, a bevel gear is connected with the other end of each stirring blade, annular conical tooth surfaces which mesh with the bevel gears are arranged on the walls of the inner cavity of the tank, and a plurality of auxiliary stirring blades are connected with the upper side and the lower side of each stirring blade and are perpendicular to the stirring blade; the pump machine is mounted on a U-shaped frame fixed to the bottom of the tank. The circulation type pesticide mixing device has the advantages that the circulation type pesticide mixing device isin a circulation flow type design, and accordingly liquid can be uniformly mixed by the circulation type pesticide mixing device; the liquid can be spontaneously stirred by the aid of water flow, accordingly, energy can be saved, and environments can be protected.

Owner:宁波暄妍日化科技有限公司

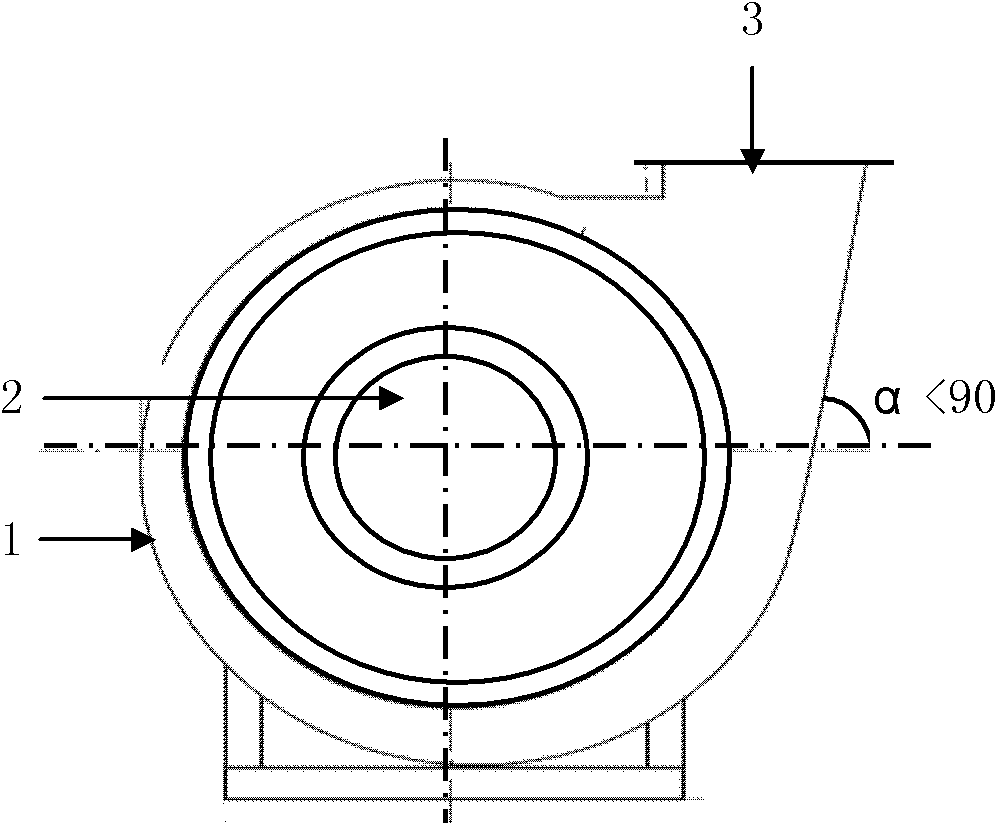

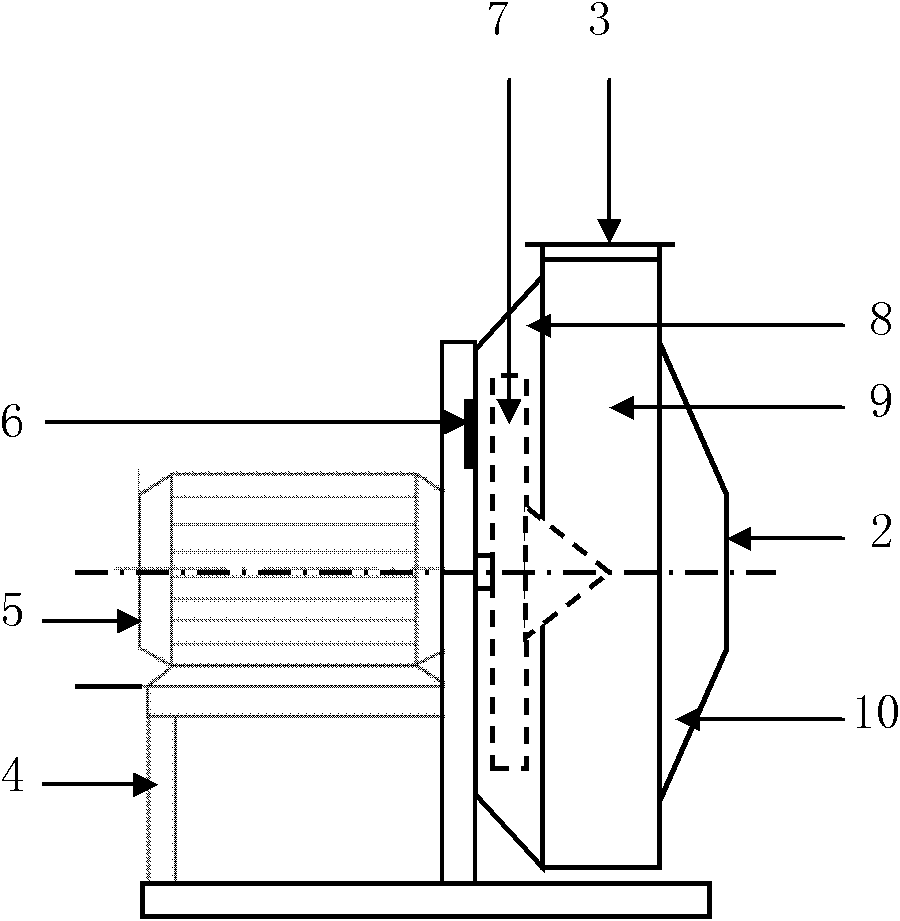

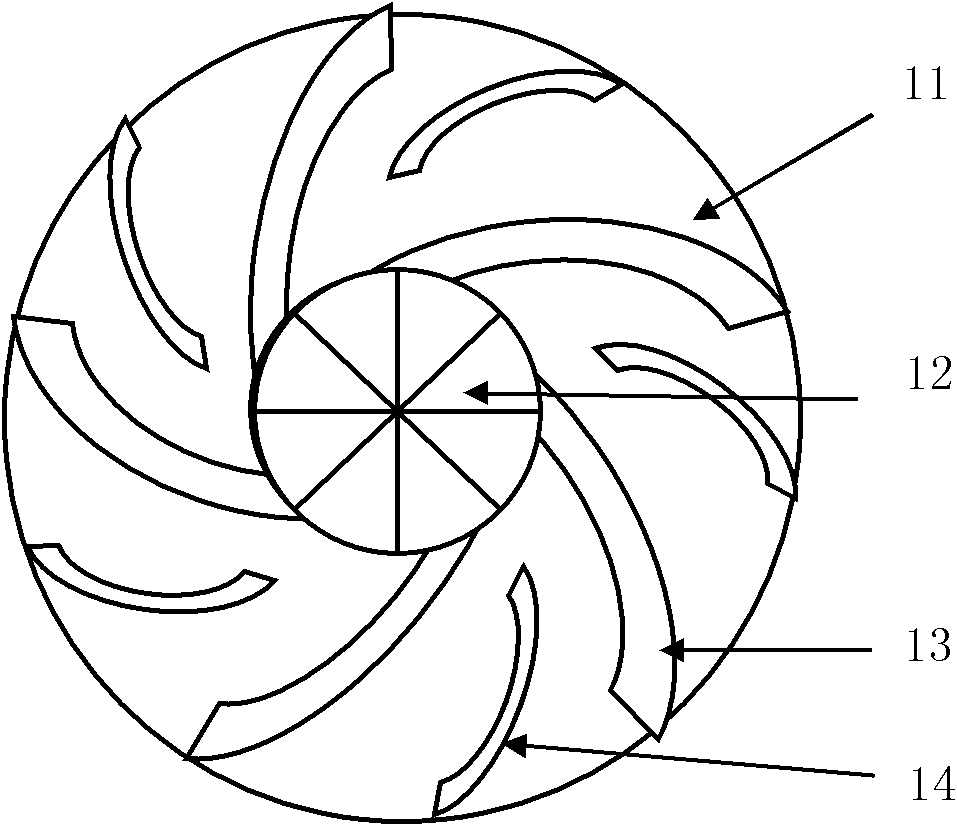

Spiral-flow type blockage-free energy-efficient centrifugal fan

InactiveCN102128174AReduce consumptionLess consumablesPump componentsPump installationsLow noiseCircular disc

The invention relates to a spiral-flow type blockage-free energy-efficient centrifugal fan which comprises a rack, an enclosure, an impeller and a motor, wherein the enclosure is composed of a frustum-shaped flow inducing chamber, a round or volute-shaped spiral-flow chamber and an umbrella-type flow expanding chamber, wherein the impeller is of a dual-wheel structure which is composed of a blade-type circular disk impeller opened axially and unilaterally and a conical tooth-form impeller; the blade-type circular disk impeller is provided with two groups of long blades and short blades, and the long blades and the short blades are same in number and are distributed alternatively and uniformly, or the impeller disk provided with two groups of high blades and low blades, and the high blades and the low blades are same in number and are distributed alternatively and uniformly; the long blades and the short blades or the high blades and the low blades are vertically linked with the impeller disk in an circular arc shape which expand axially and radially; and the frustum-shaped impeller is a conical body the tooth surface of which is of an involute profile. The working principle of the fan of the structure is that gas (or a material) is delivered by a gas spiral flow field in a 'gas driven by gas' mode, but not delivered by the rotary impeller or blades; the fan has the characteristics of high efficiency, less energy consumption, low noise, no blockage, long service life, less material consumption, multiple functions and the like, and is easy to manufacture, and the comprehensive economic and technical norms of the fan reach the domestic and international leading level; and the fan has various functions such as air ventilation, air delivery, air induction, smoke exhaustion, dust absorption, material suction and exhaustion, and the like, and has the advantages of obvious energy conservation and emission reduction effects and remarkable economic and social benefits.

Owner:SHANDONG UNIV

Method used for automatic heat dissipation and dust removal of transformer box

ActiveCN107768990ATemperature stability rangeExpand the blowing rangeSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsVertical planeTransformer

The invention relates to a method used for automatic heat dissipation and dust removal of a transformer box, and belongs to the field of closed type transformer substations. According to such problemsas additional energy consumption and external dew invasion and small ash removal range in the prior art, the following scheme is provided. According to the scheme, the method includes the following steps that 1, when the temperature is increased, an expansion air bag extend toward the two ends under the limiting effects of limiting pipes respectively, and thus threaded rods fixedly connected withthe two ends of the air bag are driven to extend outward on support plates; 2, the horizontal positions of propeller fans are fixed, and the moving threaded rods push the propeller fans with inner threads matched with outer threads of the threaded rods to rotate; 3, rotating bars of a rotating-bar type blind window are fixedly connected with rotating ropes, and the other ends of the rotating ropes are fixedly connected with the threaded rods; 4, the moving threaded rods pull the rotating ropes, the rotating bars are driven to rotate, and thus the angle between a blade surface of the blind window and a vertical plane is thus controlled; 5, second conical teeth on tapered pipes fixedly and coaxially connected with the propeller fans are meshed with first conical teeth on the top of transmission rods, the propeller fans drive the transmission rods to rotate, and thus cleaning disks are driven to rotate.

Owner:宁波南顿电力科技有限公司

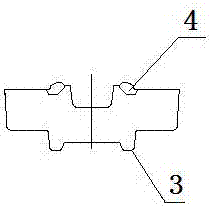

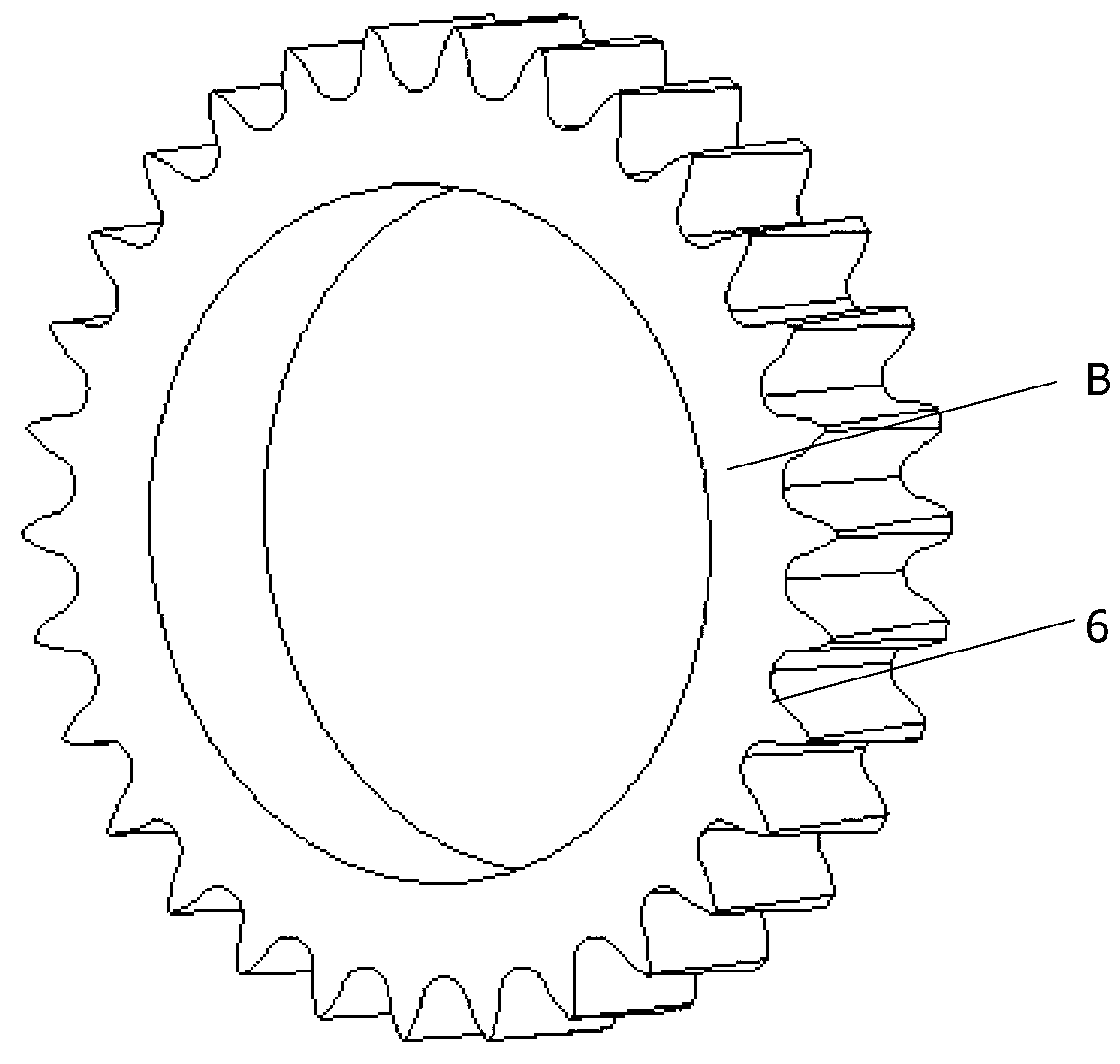

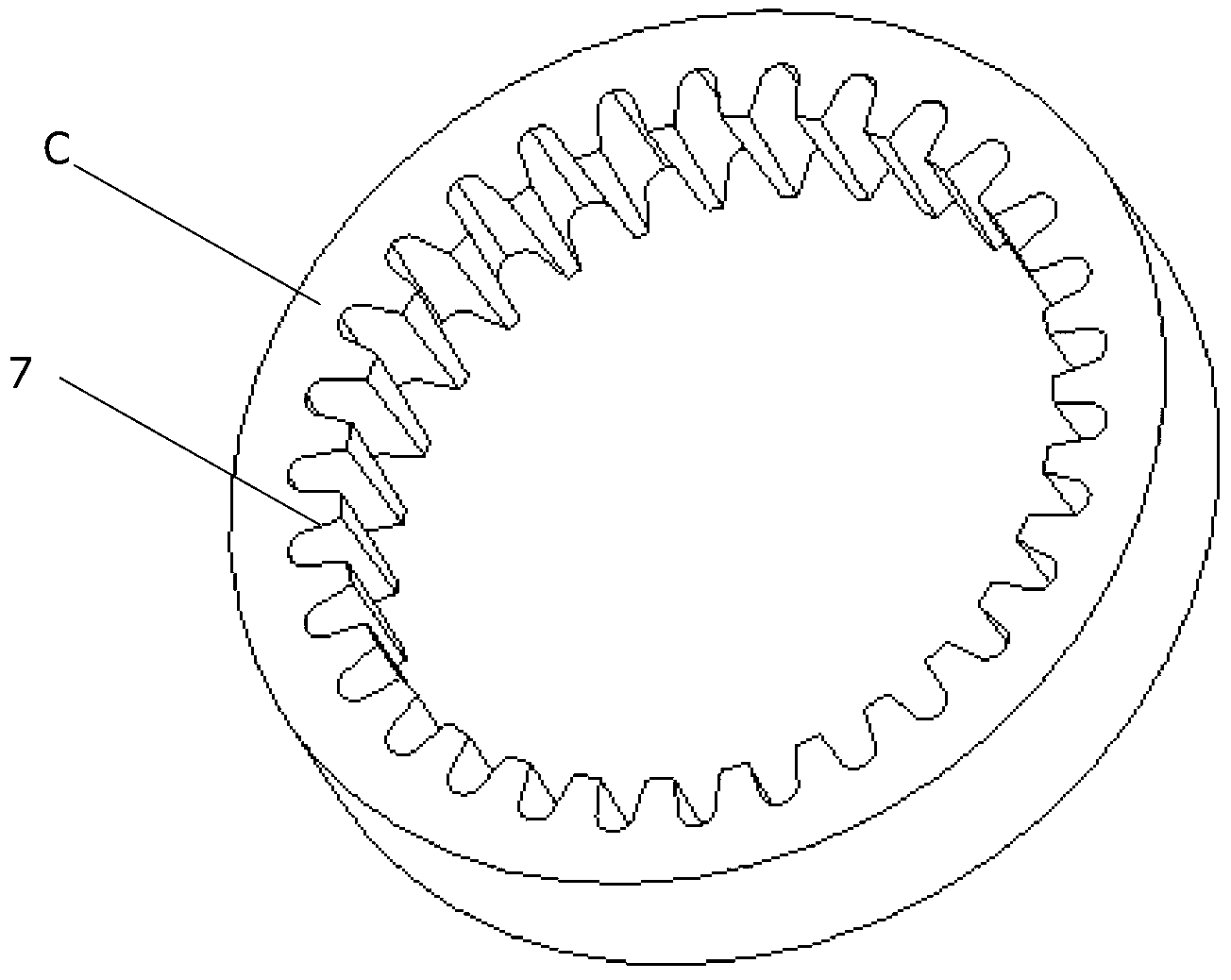

Anti-backlash transmission comprising trochoid gears and roll pins with conical teeth

InactiveCN103062334AImprove interchangeabilityIncrease profitPortable liftingToothed gearingsGear wheelEngineering

The invention relates to an anti-backlash transmission comprising trochoid gears and roll pins with conical teeth. The transmission has two transmission modes, and a pin gear is respectively externally meshed and internally meshed with the corresponding trochoid gears to implement the two transmission modes. The pin gear is provided with a plurality of conical roll pins, and tooth gaps are eliminated by axially pushing the pin gear along the end, which is provided with a small diameter, in a transmission procedure; and the trochoid gears are conical trochoid gears, and the trochoid gears and the pins are meshed to realize zero-backlash power transmission. The pin gear or the trochoid gears is driven by a servo motor to continuously relate, and accordingly a deceleration function or an acceleration function is realized. The anti-backlash transmission is simple in structure, requirements on high-speed and high-precision transmission are met, the tooth gaps generated by abrasion during transmission can be eliminated, the meshing accuracy is guaranteed, and the utilization rate of the roll pins is increased.

Owner:BEIJING UNIV OF TECH

Corn threshing mechanism

The invention discloses a corn threshing mechanism which comprises a rocker and a threshing cylinder. The threshing cylinder is in a hollow cylinder shape, one end of the threshing cylinder is an open part, the rocker is in an L shape, one arm of the rocker is a rotary shaft part, and the other arm of the rocker is a drive arm. The mechanism comprises a rack, a push plate, a fixed cone, a duplicate gear, a bevel gear, a milling cutter, an L-shaped support and a rotary shaft. The rack is connected with the threshing cylinder in a sliding mode, and the rack and the threshing cylinder are axially parallel. The fixed cone is fixed to the rack, points to the open part and is coaxial with the threshing cylinder. A straight tooth part of the duplicate gear is meshed with the rack, and a conical tooth part of the duplicate gear is meshed with the bevel gear. The rotary shaft part of the rocker is fixedly connected into a gear hole of the duplicate gear and is fixed to the threshing cylinder through a bearing. The rotary shaft is fixedly connected with the bevel gear and is fixed to the end face of the threshing cylinder through a bearing. The L-shaped support is located in the threshing cylinder, the short arm end of the L-shaped support is fixedly connected to the peripheral wall of the rotary shaft, the long arm end of the L-shaped support points to the open part, and the milling cutter is fixed to the front end of the long arm end. The corn threshing mechanism has the advantages of reducing labor intensity and improving efficiency.

Owner:CHONGQING CANHONG MACHINERY MFG

Concave-convex wheel rocker arm type valve distribution mechanism and matched internal combustion engine

ActiveCN102619583ASimple structureEasy to manufactureValve drivesMachines/enginesExternal combustion engineRadial position

The invention discloses a concave-convex wheel rocker arm type valve distribution mechanism. The concave-convex wheel rocker arm type valve distribution mechanism comprises a cylinder cover, wherein a vertical shaft and two rocker arm frames are arranged on the cylinder cover; a concave-convex wheel is arranged on the vertical shaft; conical teeth are arranged at the top of the concave-convex wheel; conical gears are arranged on the conical teeth and are located on a horizontal shaft; the gear ratio of the conical teeth to the conical gears is 2 to 1; the two rocker arm frames are respectively arranged on two radial positions of the concave-convex wheel; the inclined angle between the two radial positions is 90 DEG; and T-shaped rocker arms are arranged on the rocker arm frames. An internal combustion engine matched with the concave-convex wheel rocker arm type valve distribution mechanism is provided with concave-convex wheel rocker arm type valve distribution mechanisms with the same number as cylinders; the horizontal shafts of the valve distribution mechanisms are integrally connected, are located on shaft frames and are connected with crankshafts through driven chain wheels, chains and drive chain wheels; and the driven chain wheels have the same tooth number as the drive chain wheels. The concave-convex wheel rocker arm type valve distribution mechanism is simple in structure and convenient to manufacture, is reliable in performance and can tightly close and easily open the valve, is less in internal consumption, high in efficiency and more oil-saving, and can fully open the valve for conveniently sucking and exhausting air.

Owner:广西东兴市富佳五金皮具有限公司

Fast crushing device for waste mold for 3D printing

The invention relates to a fast crushing device for a waste mold for 3D printing. The invention needs to achieve the technical purpose of providing a fast crushing device for a waste mold for 3D printing, and the fast crushing device for the waste mold for 3D printing is thorough and uniform in crushing and complex in structure. In order to achieve the technical purpose, the invention provides the fast crushing device for the waste mold for 3D printing, and the fast crushing device for the waste mold for 3D printing comprises a bottom plate, a supporting rod, a guiding sleeve, a first slide rail, a first slider, a disk-shaped cam, a small belt pulley, a roller, a guiding rod, a first spring, a crushing frame, a flat belt and the like; a left frame, the supporting rod, the guiding sleeve, the first slide rail and a right frame are sequentially arranged on the top of the bottom plate from left to right; and a top plate is arranged on each of the tops of the left frame and the right frame. The fast crushing device for the waste mold for 3D printing achieves the effects of being thorough and uniform in crushing and complex in structure; and besides, because of the effect of conical teeth, the conical teeth can perform thorough crushing on the waste mold in the crushing frame again.

Owner:枣庄市鹏展木制品有限公司

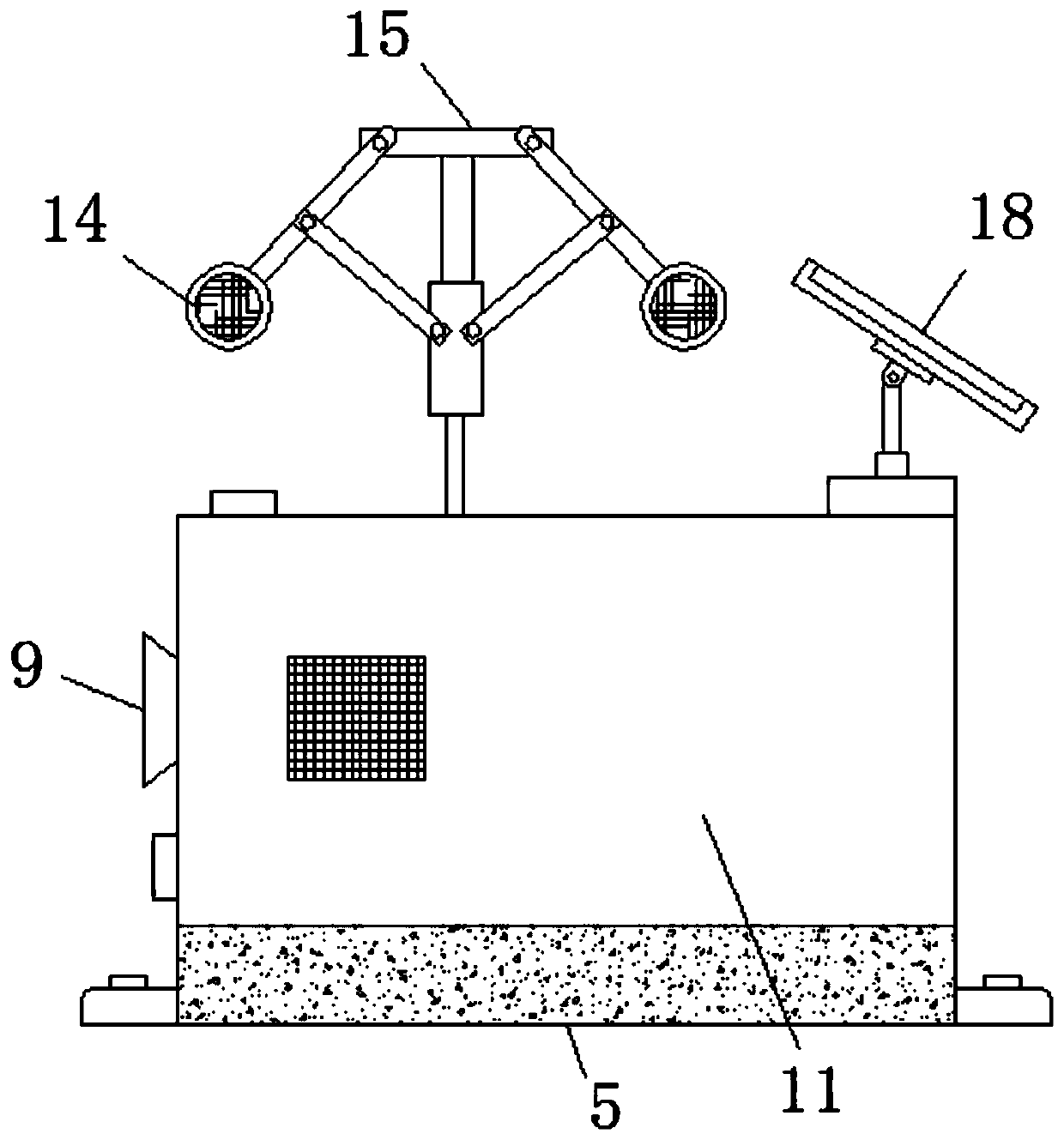

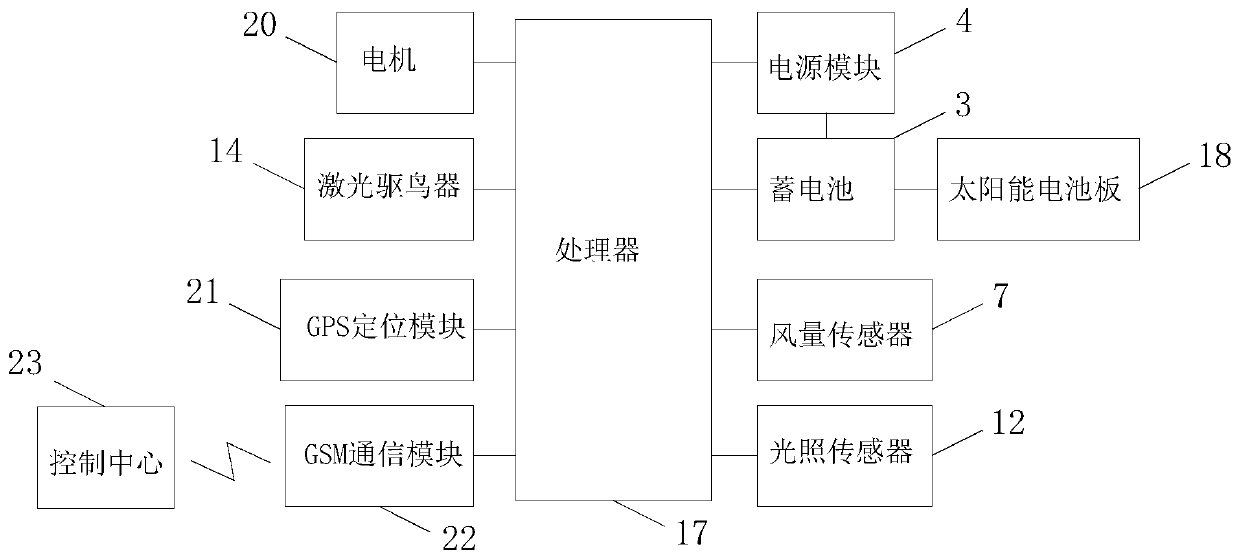

Bird repelling device for power transmission tower

InactiveCN109997833AOperation impactGuarantee the safety of useOverhead installationBatteries circuit arrangementsComputer moduleEngineering

The invention provides a bird repelling device for a power transmission tower, and relates to the technical field of bird repelling for transmission lines. A box body is fixed on the outer wall of thetop of a base through screws, a through hole is formed in the outer wall of the top of the box body, the inner wall of the through hole is connected with a rotating rod through a bearing, a second conical tooth is in sleeve connection to the bottom end of the rotating rod, a mounting frame is fixed on the outer wall of the top of the rotating rod through screws, and laser bird repellers are fixedon two sides of the outer wall of the bottom of the mounting frame through screws; fan blades or motors rotate to drive the rotating rod to rotate, and then the laser bird repellers rotate to achievea purpose of repelling birds. The bird repelling device for the power transmission tower can achieve a good bird repelling effect, can prevent birds from affecting the operation of the power transmission tower, and ensures the use safety of the power transmission tower. Meanwhile, through a positioning module and a communication module, a worker of a control center can find the positions of different bird repelling devices, monitoring state information transmitted by the communication module can be received, and control instructions and the like can also be sent to a processor.

Owner:TRAINING CENT OF ANHUI ELECTRIC POWER +2

Medical planetary gear type waste blood collection pipe crushing device

The invention relates to a medical waste blood collection pipe crushing device, in particular to a medical planetary gear type waste blood collection pipe crushing device. In order to achieve the technical aims, the medical planetary gear type waste blood collection pipe crushing device is uniform and thorough in crushing and simple in structure. To achieve the above technical aims, the medical planetary gear type waste blood collection pipe crushing device comprises a bottom plate, a second sliding rail, a right rack, first sliding rails, first sliding blocks, a crushing frame, third supporting rods, a first supporting rod, second sliding blocks, a first gear rack, a third sliding rail and the like. A left rack and the first sliding rails are arranged on the left side of the top of the bottom plate, and the first sliding rails are located on the right side of the left rack. The medical planetary gear type waste blood collection pipe crushing device achieves the effects of being uniform and thorough in crushing and simple in structure; and due to the function of conical teeth, a waste blood collection pipe in the crushing frame is crushed by a press block more uniformly.

Owner:刘义东

Chemical settlement reaction apparatus for production wastewater of thiophanate-methyl

PendingCN108928901AMix well and evenlyImprove adsorption capacityTransportation and packagingRotary stirring mixersThiophanate-methylWastewater

The invention discloses a chemical settlement reaction apparatus for production wastewater of thiophanate-methyl. The apparatus includes a reaction tank and an auto-rotating framework. An inner teethring is formed in the reaction tank. The auto-rotating framework is installed inside the reaction tank and is composed of a rotary shaft and stirring rods that are distributed on the rotary shaft in array. The rotary shaft is connected to a transmission rotary shaft through a transmission box. Second conical teeth, in the transmission box, are formed on the rotary shaft and are engaged with firstconical teeth which are fixed on the transmission rotary shaft. The upper end of the transmission rotary shaft is engaged with the inner teeth ring through a gear. In the apparatus, the auto-rotatingframework achieves rotation during revolution process, so that wastewater and a PAC flocculating agent are uniformly mixed, which is beneficial to adsorption on the impurities in wastewater.

Owner:江苏泰仓农化有限公司

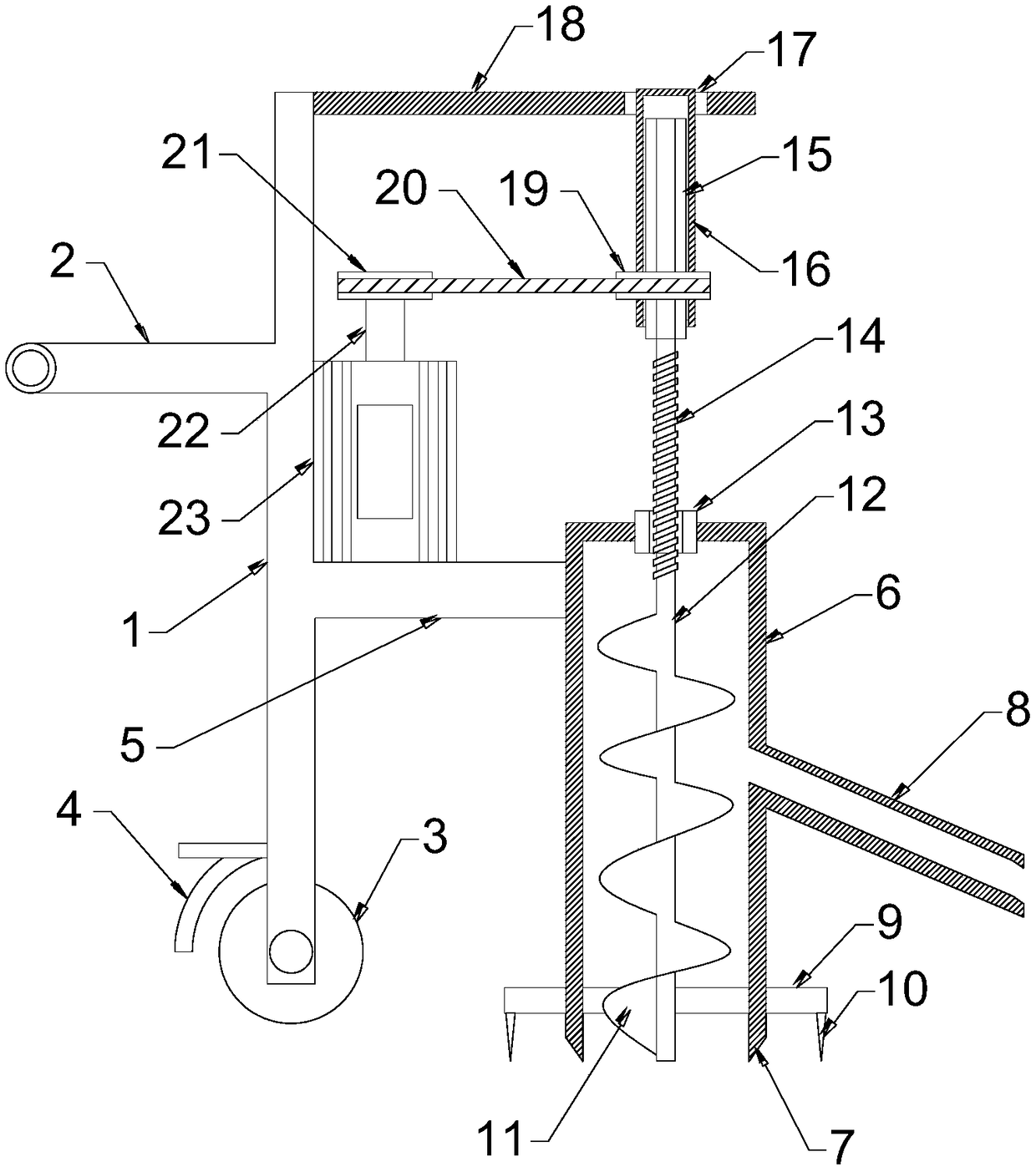

Pit-digging apparatus convenient for moving

InactiveCN108156889APrevent splashPrevent proliferationPlantingFurrow making/coveringVehicle frameSpiral blade

The invention discloses a pit-digging apparatus convenient for moving. The pit-digging apparatus comprises a vehicle frame and a driving motor, a transverse slat is arranged at the vehicle frame, thetransverse slat is fixedly connected with a soil sampling barrel, a spiral blade is arranged in the soil sampling barrel, a rotation roller is fixedly connected with the spiral blade, a threaded rod is fixedly connected with the rotation roller, the threaded rod passes through the soil sampling barrel, and a screw sleeve is fixedly connected with at center position of the top of the soil samplingbarrel. An internal spline shaft and an external spline sleeve are arranged, cooperation of the internal spline shaft and the external spline sleeve drives the spiral blade to downwardly rotate, soilcan be dug, the structure is simple, dissipating energy is less, the soil sampling barrel and a soil-discharge pipe are arranged, the soil is dug and then raised, the accumulated soil is discharged, splash and diffusion of the soil can be avoided, anaphase refilling is convenient, and plantation efficiency is increased. The vehicle frame and a fixed plate having conical tooth are provided, and themobility and stability of the pit-digging apparatus are increased.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com