Oblique central transmission frame assembly used for aircraft engine and aircraft engine

A technology for aero-engines and transmission frames, which is applied to transmission parts, transmissions, gear transmissions, etc., can solve problems such as the inability to guarantee the reliability of connection transmissions, improve independence and reliability, meet assembly requirements, reduce The effect of structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

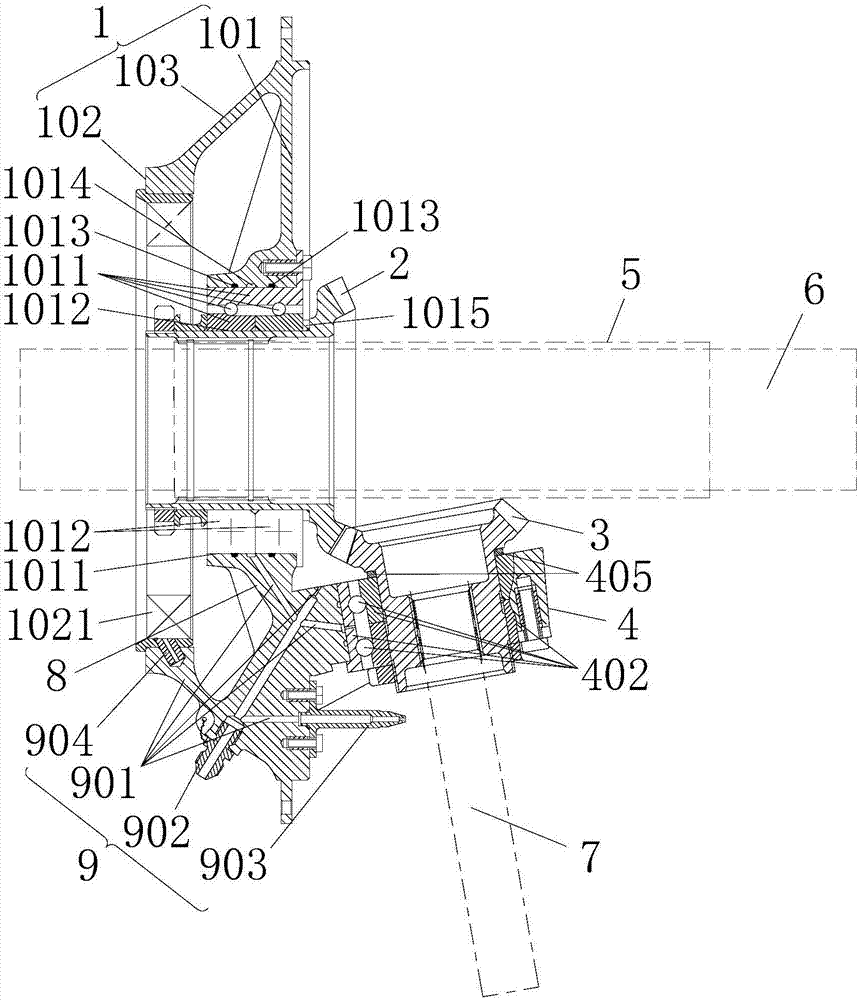

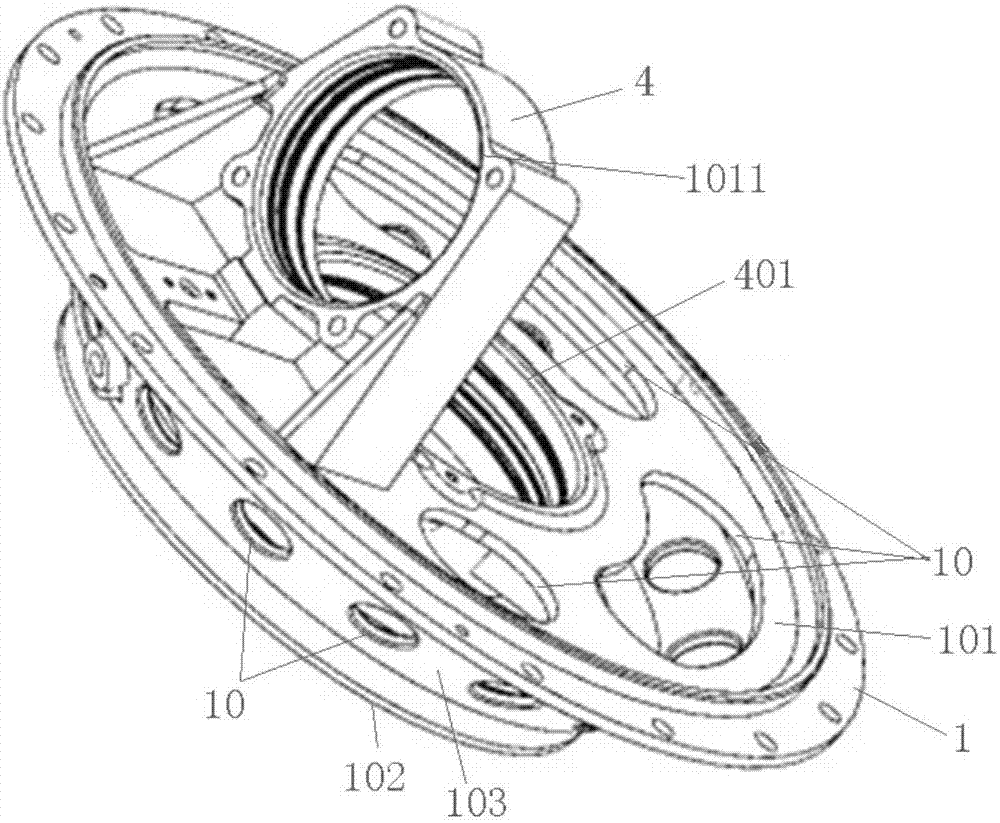

[0023] Such as figure 1 with figure 2 As shown, the slanted drive frame assembly for aero-engines in this embodiment includes a cone-shaped basin-shaped bracket 1. The cone-shaped basin-shaped bracket 1 includes a large end surface 101, a small end surface 102, and an inclined side surface 103. The cone-shaped basin-shaped The inside of the bracket 1 is a hollow cavity, and the large end surface 101 of the tapered basin-shaped bracket 1 is provided with a first bearing seat hole 1011 for assembling the driving bevel gear 2 along the tapered basin-shaped bracket 1 at the axial center position, and the tapered basin-shaped bracket 1 The large end surface 101 of 1 is provided with a cantilever bearing seat 4 for assembling the passive arc bevel gear 3 meshing with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com