Patents

Literature

61 results about "Conical tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An abnormal conical form of the teeth, that is, a tooth whose sides converge or taper together incisally. [HPO:ibailleulforestier]

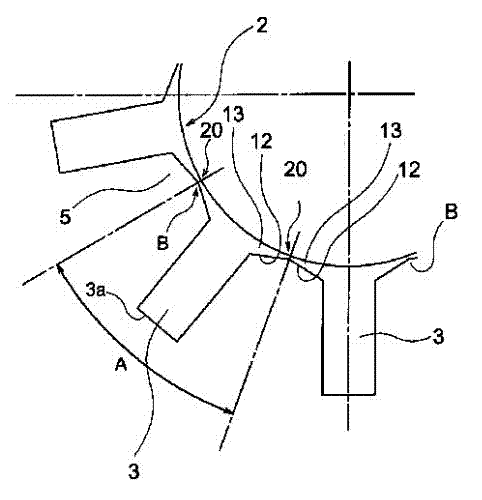

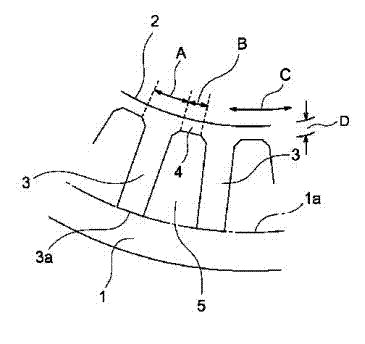

Method of grinding the teeth of spiral-toothed bevel gear wheels

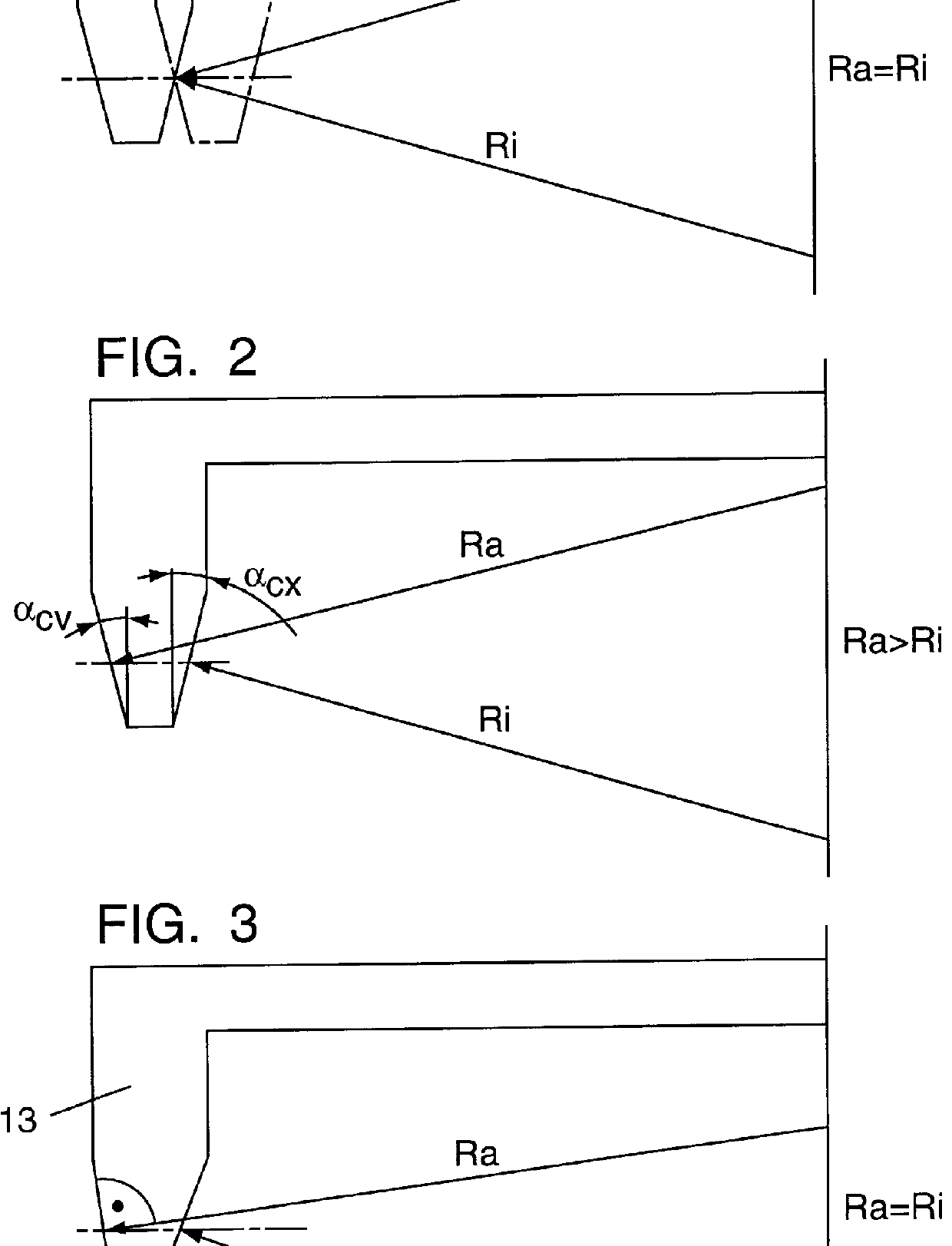

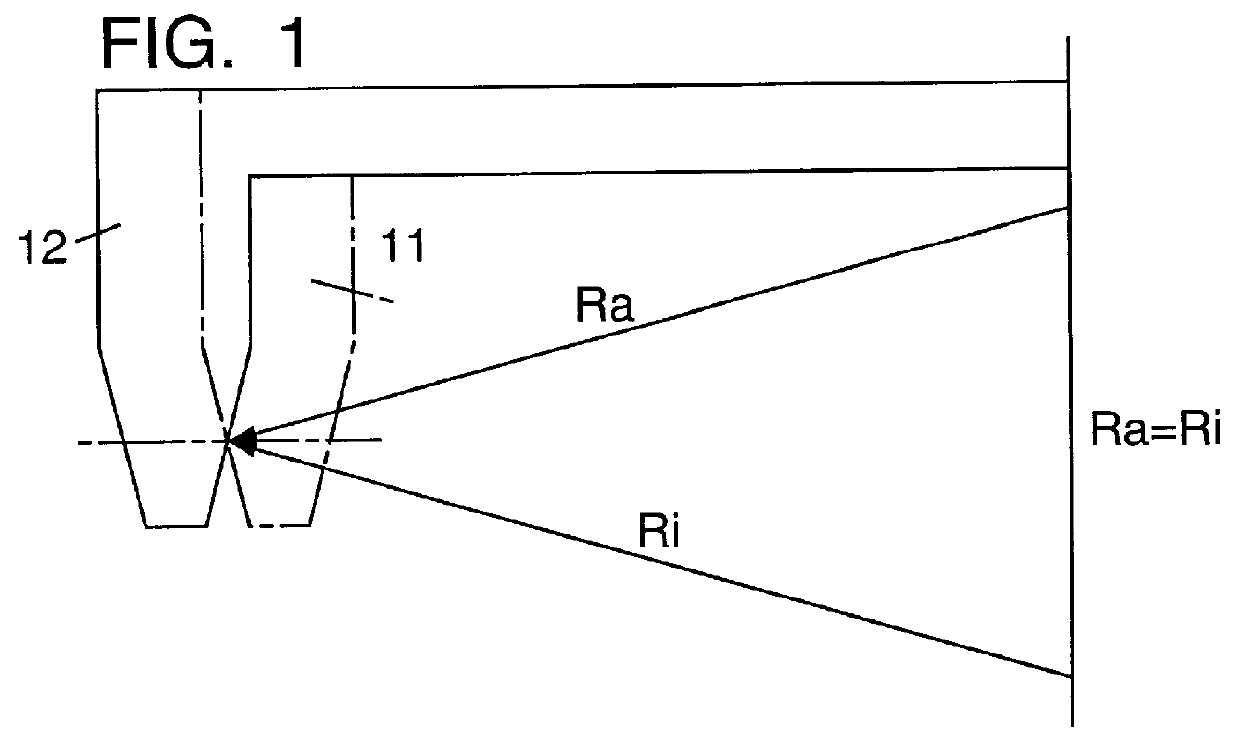

PCT No. PCT / EP96 / 02020 Sec. 371 Date Nov. 5, 1997 Sec. 102(e) Date Nov. 5, 1997 PCT Filed May 10, 1997 PCT Pub. No. WO96 / 35541 PCT Pub. Date Nov. 14, 1996Disclosed is a method of grinding bevel gear teeth in an intermittent indexing process using a single grinding wheel provided with different bevel angles ( alpha ) to produce the desired grinding wheel radii (R): one flank is machined during grinding in downward generation as far as a first turning point, another flank is produced in upward generation as far as a second turning point, and machine settings are so adjusted in the turning points as to ensure a correct pressure angle and correct flank topography during the generating process, irrespective of the different bevel angles ( alpha ). The process combines the advantages of the known completing process, by which both flanks can be ground at the same time at the cost of imposing a particular wheel body geometry with conical teeth, with those of the known two-track process for grinding both flanks with a double grinding head, by which various additional correction factors can be introduced to optimize the flank shape for convex and concave flanks.

Owner:KLINGELNBERG AG

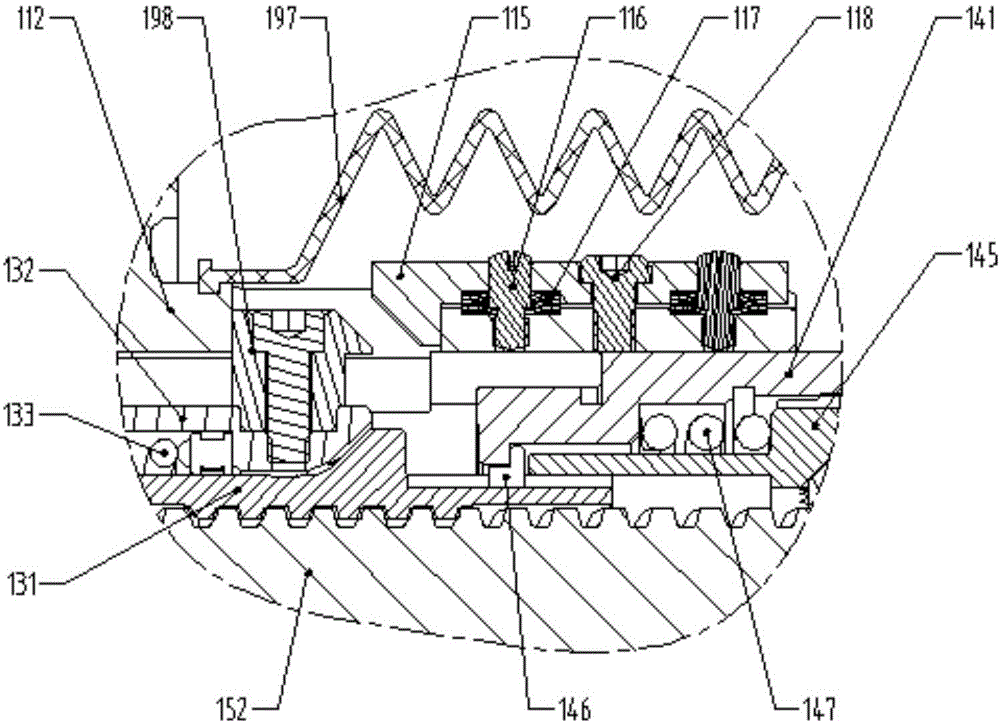

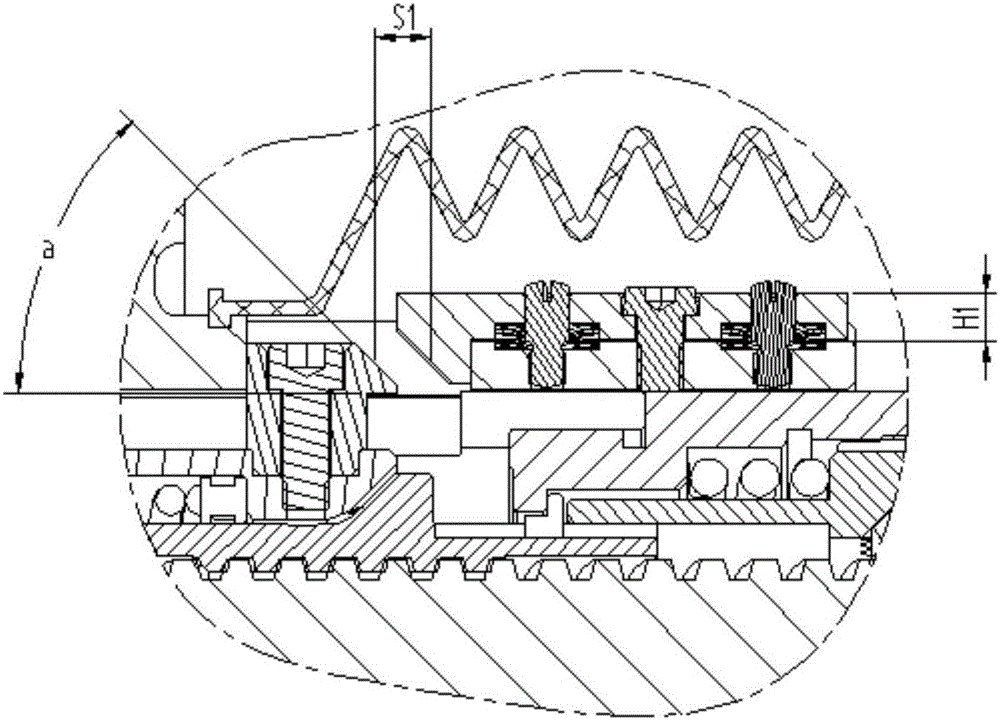

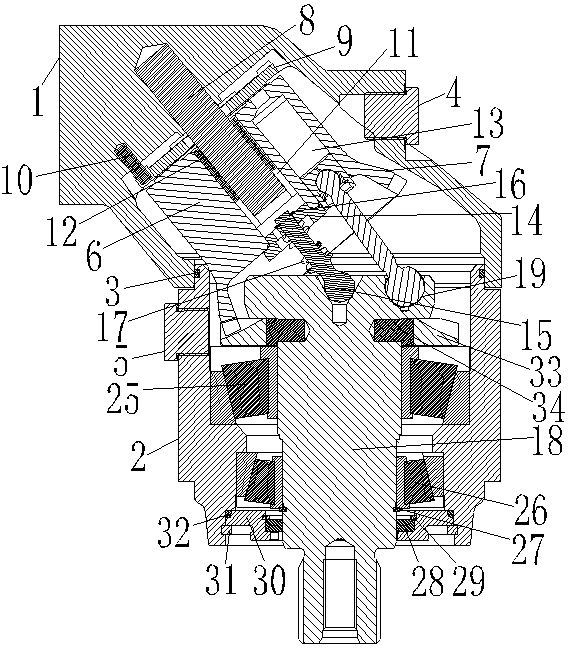

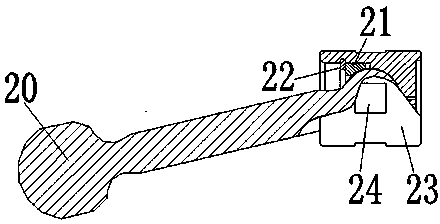

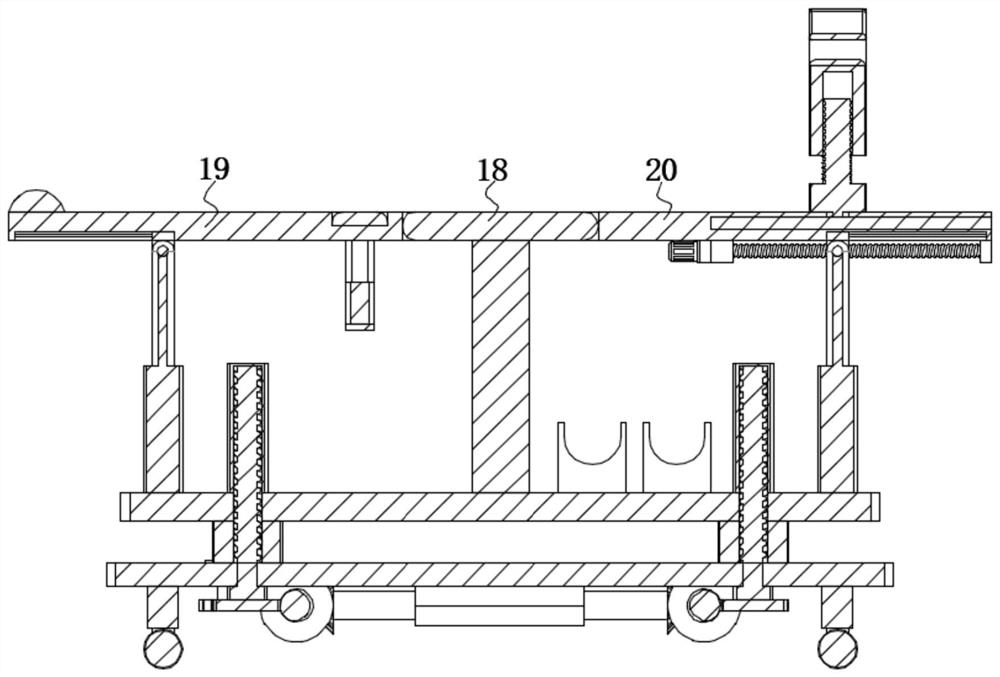

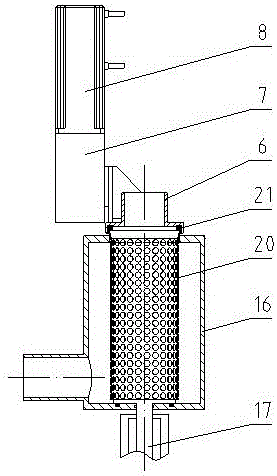

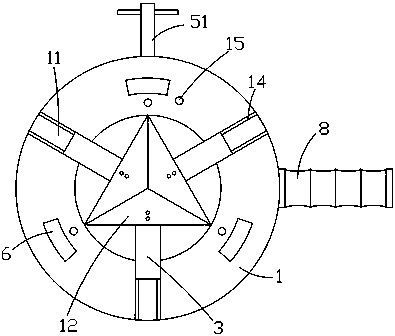

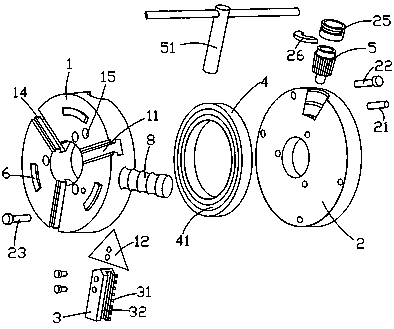

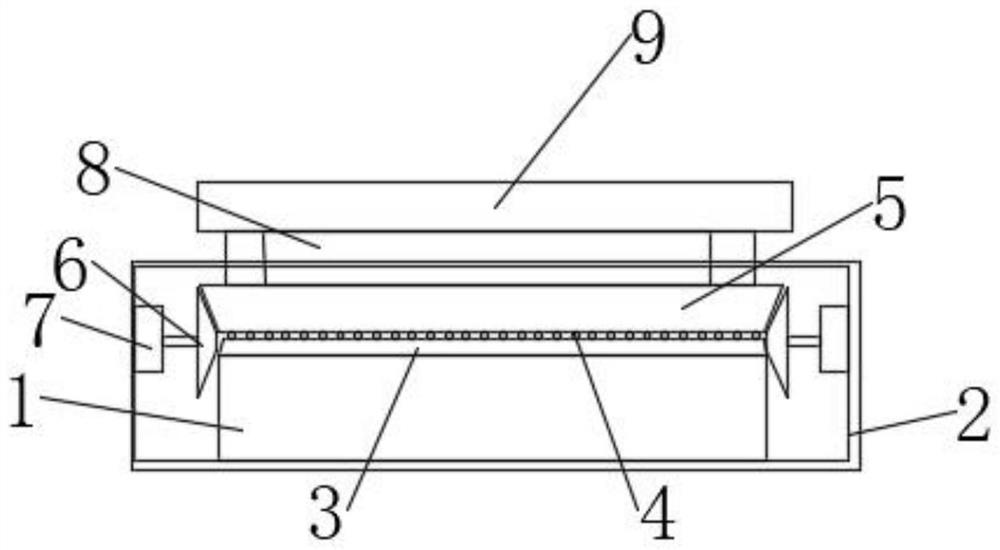

Brake cylinder clearance adjustment mechanism

InactiveCN106195075AAdjustable maximum stroke value without adjustmentRelief Gap Value StabilizationSlack adjustersAxially engaging brake componentsRadial positionEngineering

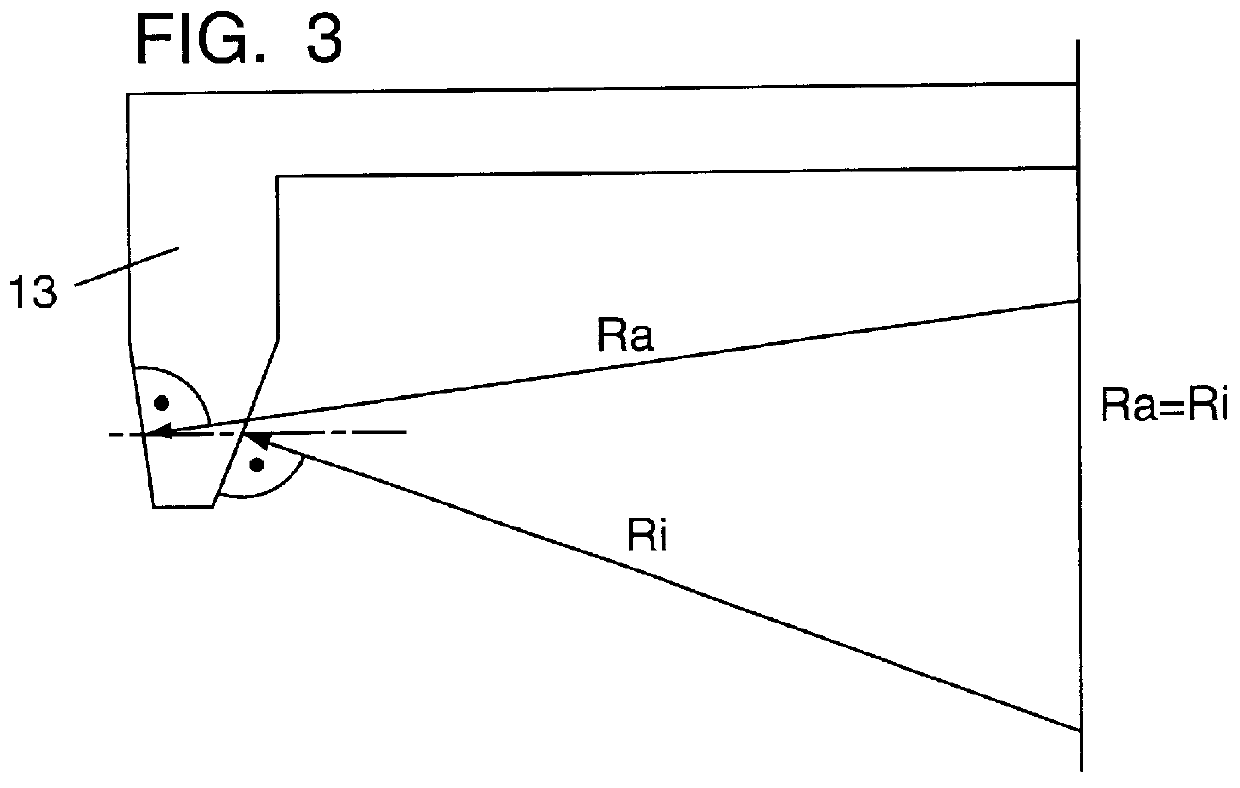

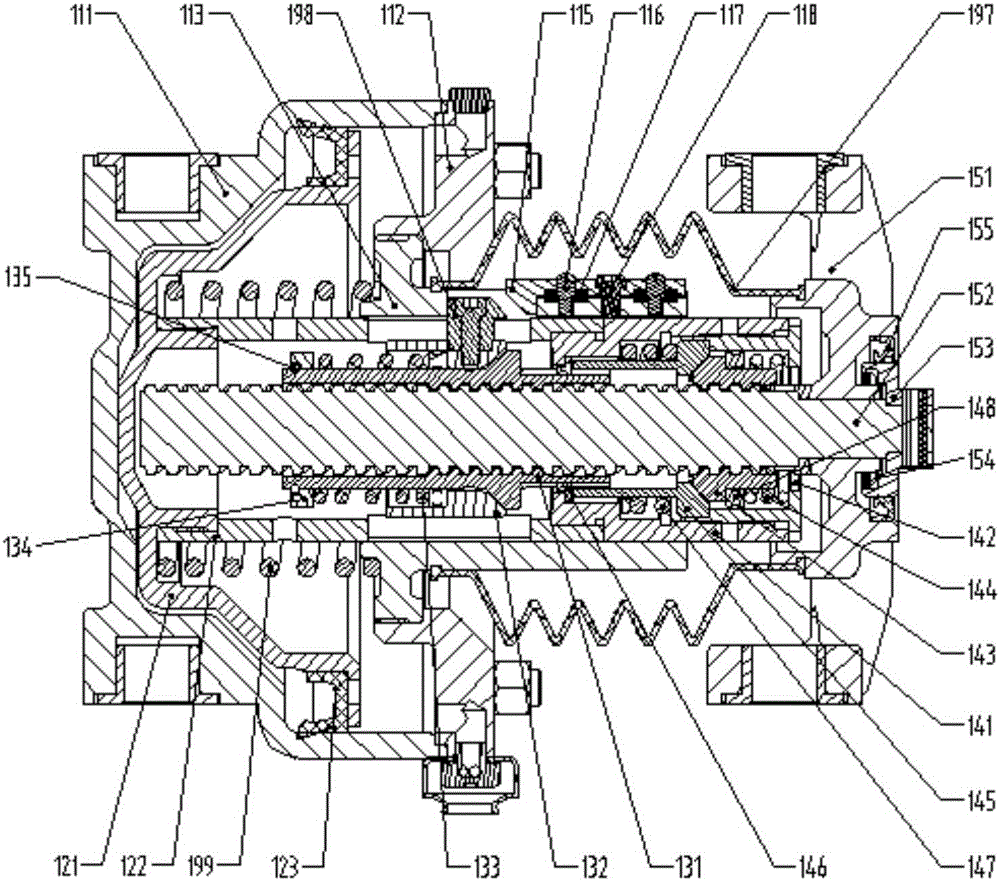

The invention relates to a brake cylinder clearance adjustment mechanism, and belongs to the technical field of vehicle transmission. The inner end of a piston pipe embedded in an inner cavity of a cylinder cover pipe of the mechanism is axially and fixedly connected with a piston, and a buffer spring is arranged between the cylinder cover pipe and the piston; the outer end of the piston pipe is fixedly connected with a guide resistance adjusting device body, and a square key groove and a wedge-shaped adjusting block mounting groove are axially formed in the cylinder cover pipe; a cone sleeve and a guide nut are engaged with the mounting end face in the guide resistance adjusting device body, and one end of the cone sleeve and one end of the guide nut abut against a resistance adjusting spring and a guide spring correspondingly; an adjusting lead screw shaft screwed with an adjusting nut is arranged in an inner hole of the guide nut, and a conical tooth sliding sleeve is arranged outside the adjusting nut; the outer circle of the conical tooth sliding sleeve is fixedly connected with a square key of the square key groove on the cylinder cover pipe, and a wedge-shaped adjusting block with the adjustable radial position is mounted in the wedge-shaped adjusting block mounting groove of the cylinder cover pipe, and the adjacent ends of the square key and the wedge-shaped adjusting block are provided with an outer wedge-shaped face and an inner wedge-shaped face correspondingly; by the adoption of the mechanism, the adjustable maximum adjustable-free stroke value of a brake cylinder is achieved, and the stable clearance adjusting amount is ensured.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

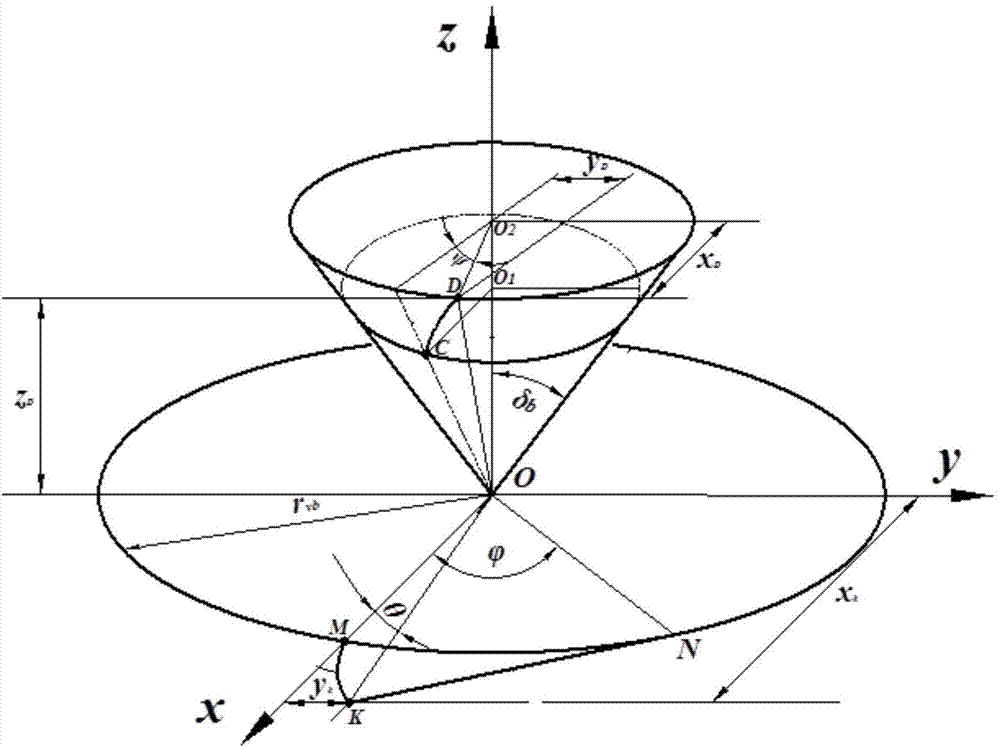

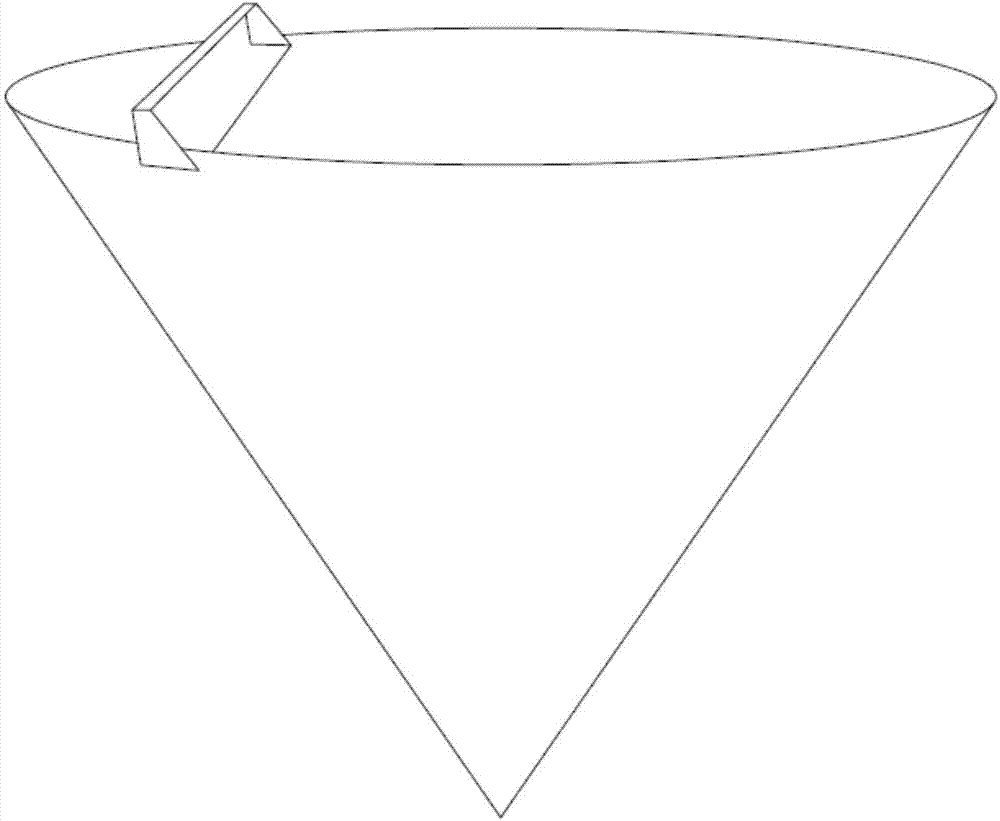

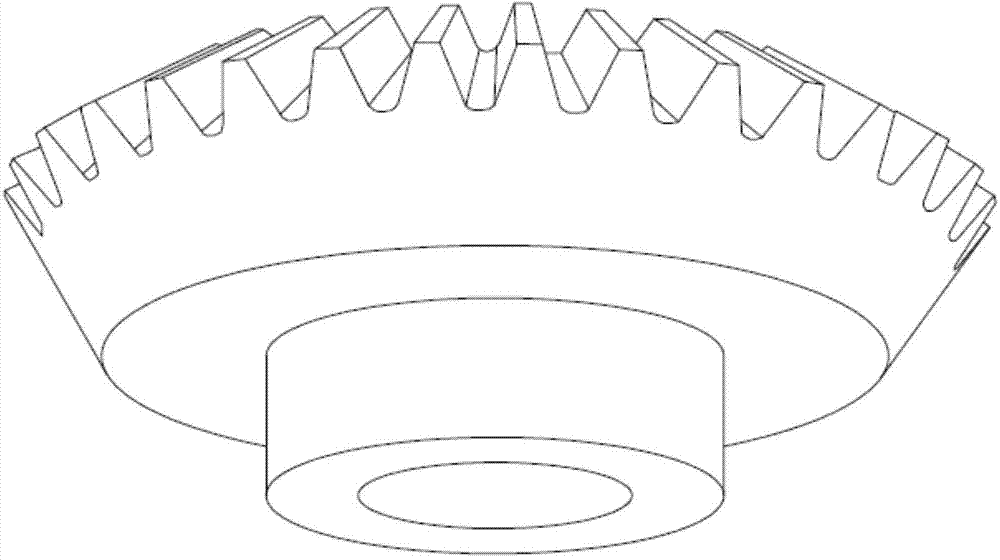

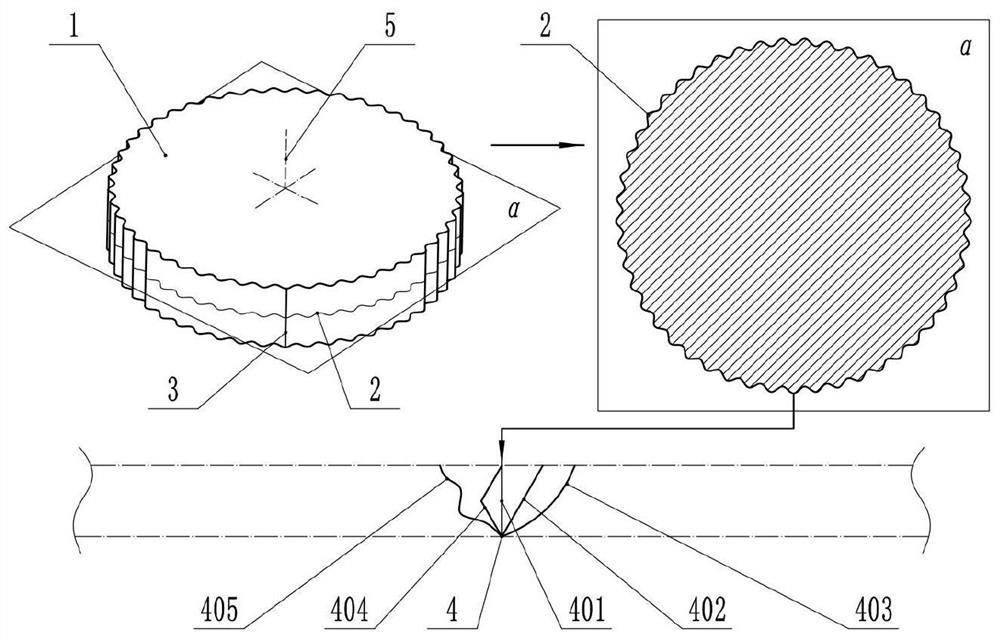

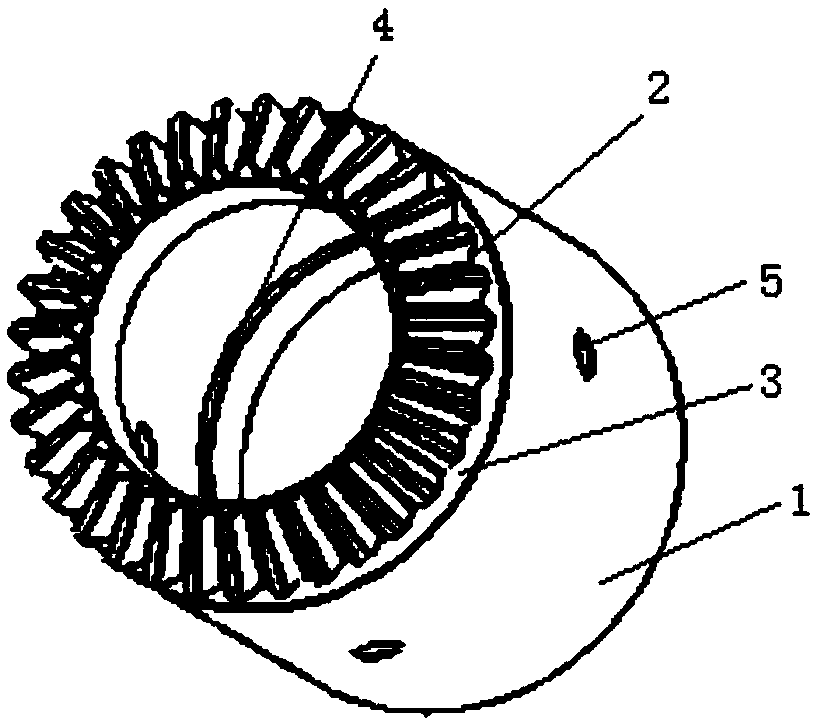

Bevel gear tooth profile design method based on circular conical surface involute

InactiveCN104728390AAvoid difficultiesRelatively small errorPortable liftingGearing elementsState of artGear wheel

The invention discloses a bevel gear tooth profile design method based on a circular conical surface involute. The bevel gear tooth profile design method based on the circular conical surface involute includes the steps of building a coordinate system, unfolding a bevel gear into a fan-shaped cylindrical gear, building a parameter equation for the fan-shaped cylindrical gear, building a parameter equation for the conical surface involute of the bevel gear, carrying out CAD drawing and the like. The bevel gear tooth profile design method based on the circular conical surface involute adopts an inverse unfolding method, builds the conical surface involute equation, is based on the inverse unfolding method, avoids the difficulty of design and manufacturing of a spherical surface involute profile, and also avoids the problem in the prior art that when a planar involute is used for replacing the conical surface involute to design the tooth profile, large errors are generated.

Owner:SHAANXI UNIV OF TECH

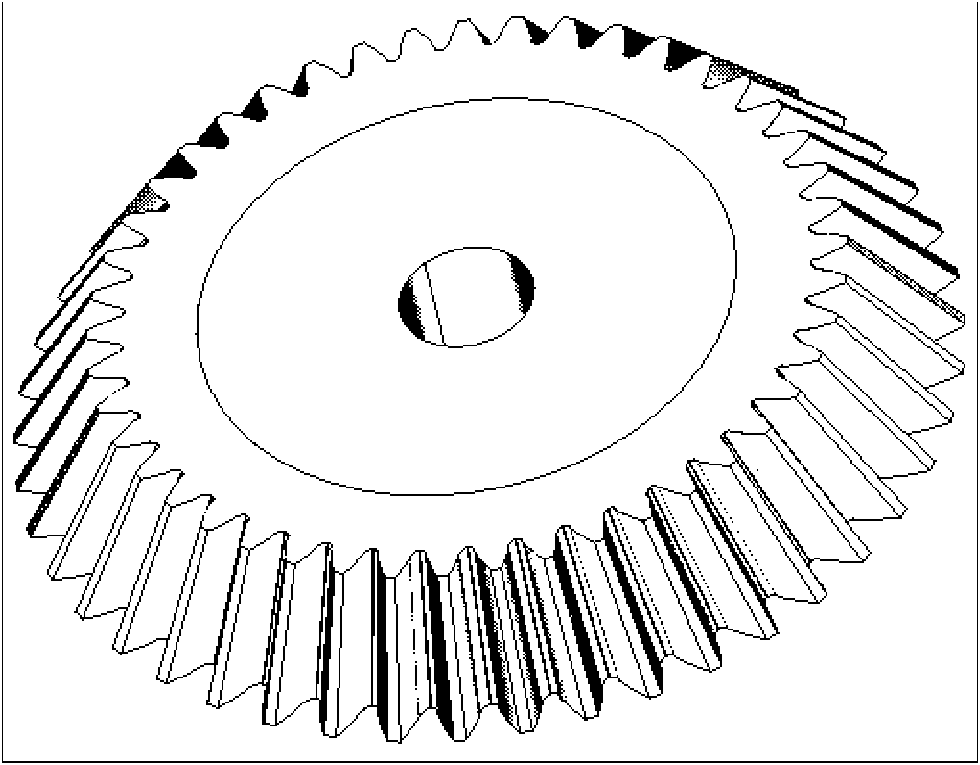

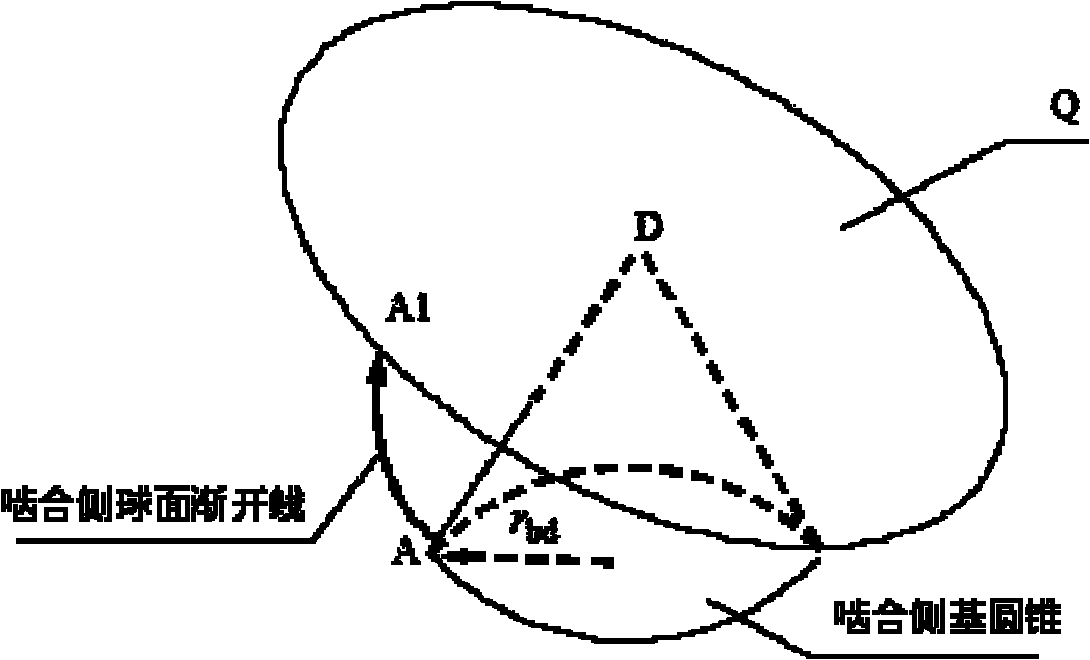

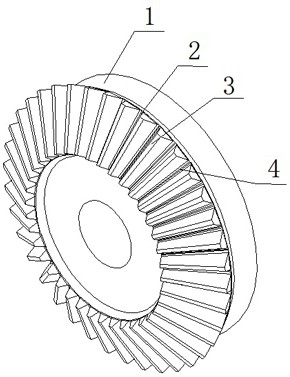

Plastic cone gear

InactiveCN102155528AGood transmission effectReduce volumePortable liftingGearing elementsGear wheelRooted tooth

The invention provides a plastic cone gear which can increase the fatigue resistance strength of a dedendum and basically does not affect the impact resistance performance of the dedendum; the plastic cone gear is characterized in that a meshing pendant group circular conical surface is worked out by taking rbd as a radius, a first occurrence surface is tangent to the meshing side base conical surface, and a line segment AD is a tangent line of the first occurrence surface and the meshing side base conical surface. When the first occurrence surface purely rolls without slipping along the meshing side base conical surface, the locus of a point A is a meshing side tooth profile curved surface of the plastic cone gear. A non-meshing side base conical surface is worked out by taking rbc as a radius, a second occurrence surface is tangent to a non-meshing side base conical surface, and a line segment BC is a tangent line of the second occurrence surface and the non-meshing side base conical surface. When the second occurrence surface purely rolls without slipping along the non-meshing side base conical surface, the locus of a point B is a non-meshing side tooth profile curved surface of the plastic cone gear. The wheel gear reference circle modulus and tooth depth modulus of the plastic cone gear are unequal; and the design method of big tooth addendum coefficients is adopted.

Owner:JIANGSU UNIV OF TECH

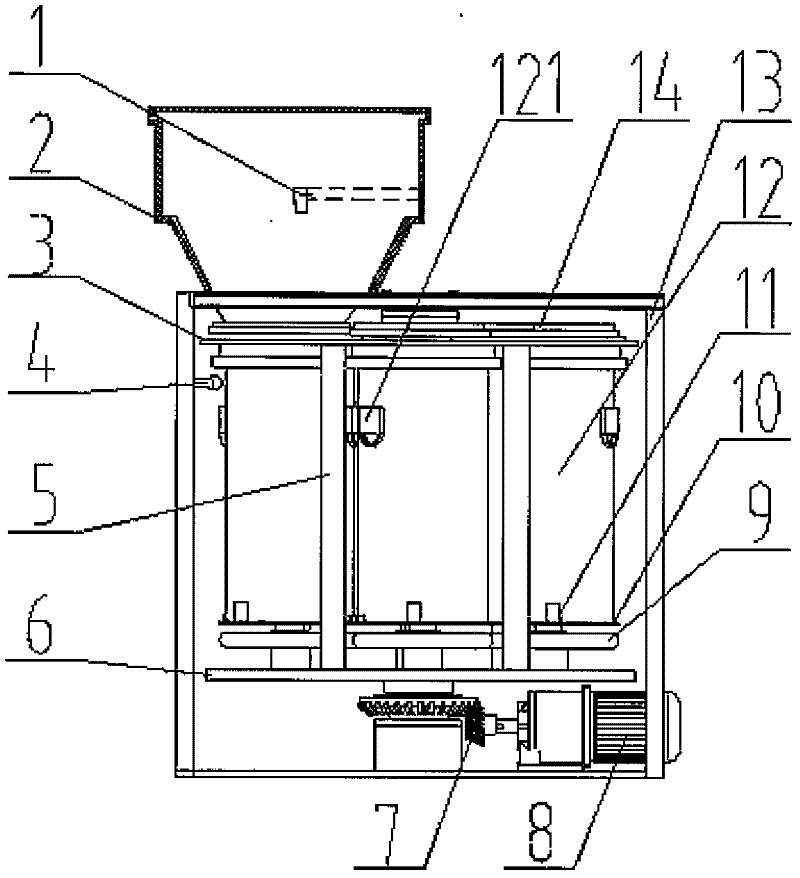

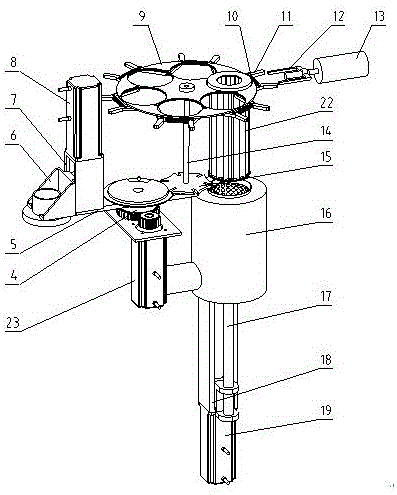

Coal sample gathering device and gathering method

InactiveCN102353800ARealize automatic collectionHigh degree of automationPreparing sample for investigationFixed frameSoftware engineering

The invention provides a coal sample gathering device and a gathering method, so as to solve the present problem of low gathering efficiency when gathering different varieties of coal samples. According to the gathering device, the bottom of a fixing frame is fixed with a motor and a conical tooth transmission device, which is connected with the bottom of a main shaft; the main shaft is fixed with an upper rotating disk and a lower rotating disk; a collecting basket is disposed on the lower rotating disk; the corresponding position on the upper rotating disk is provided with a hole which fits with the collecting basket; a feed hopper is connected to the top of the fixing frame; and a level sensing device is connected inside the feed hopper. According to the invention, the motor can drive the conical tooth transmission device to drive the main shaft to rotate, and the main shaft is fixed with the upper and lower rotating disks, therefore, the rotation of the upper and the lower rotating disks can drive the collecting basket on the lower rotating disk to rotate. When the collecting basket rotates under the feed hole of the feed hopper, automatic gathering of the coal sample can be accomplished, thus raising the automation degree of coal sample gathering and helping improve the efficiency of coal sample detection and examination.

Owner:CHINA SHENHUA ENERGY CO LTD +1

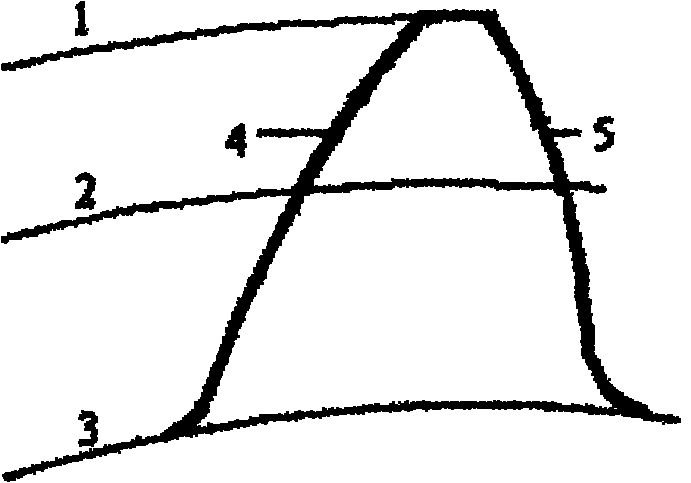

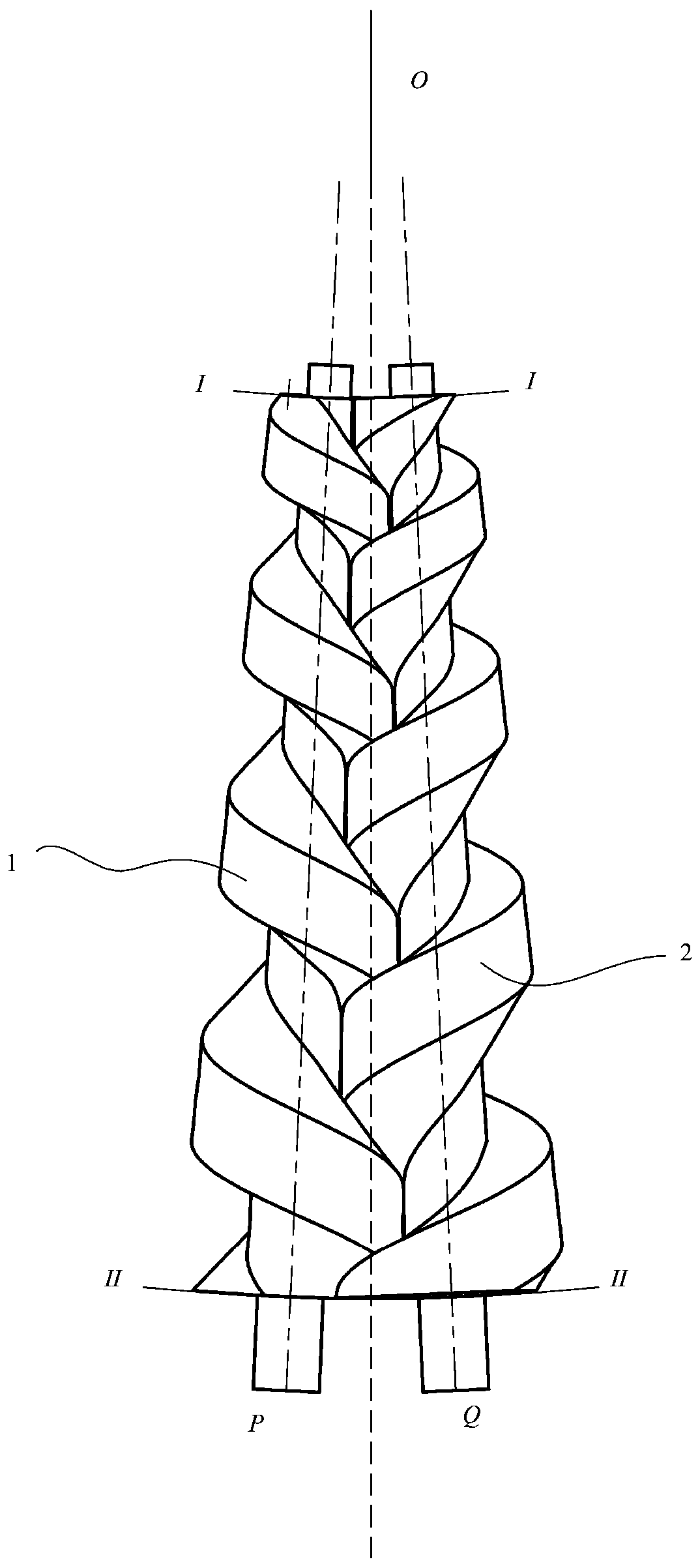

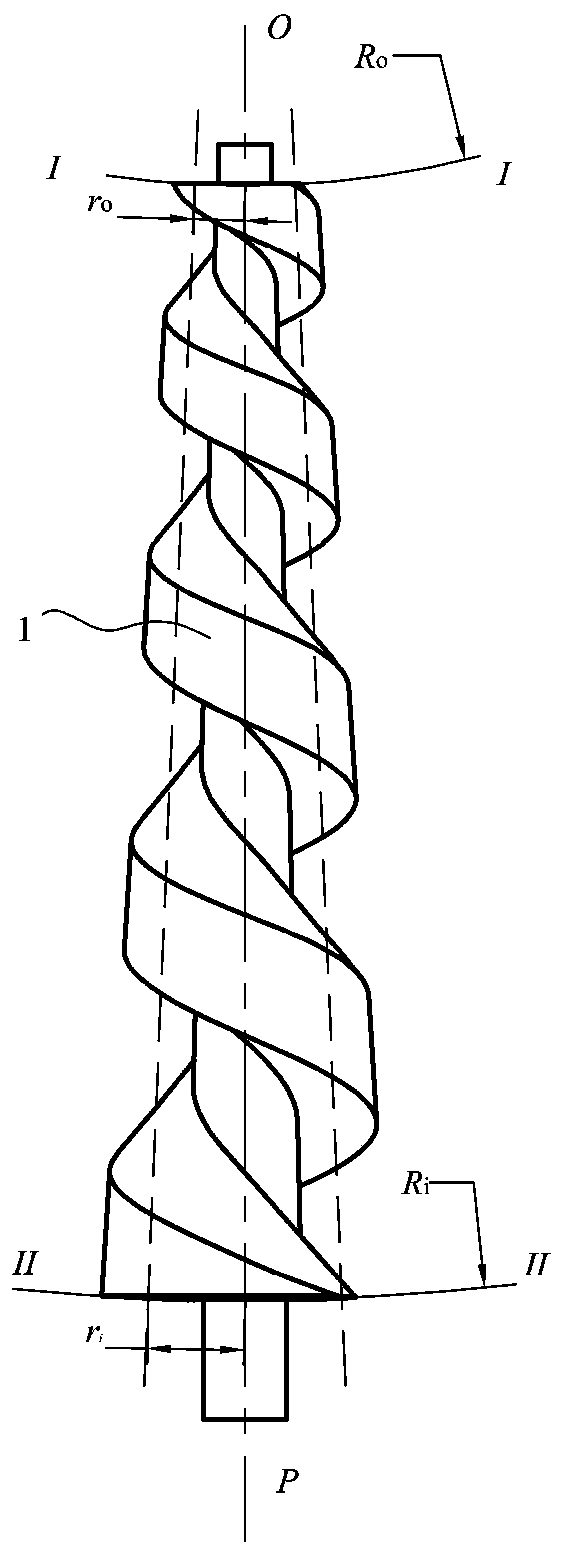

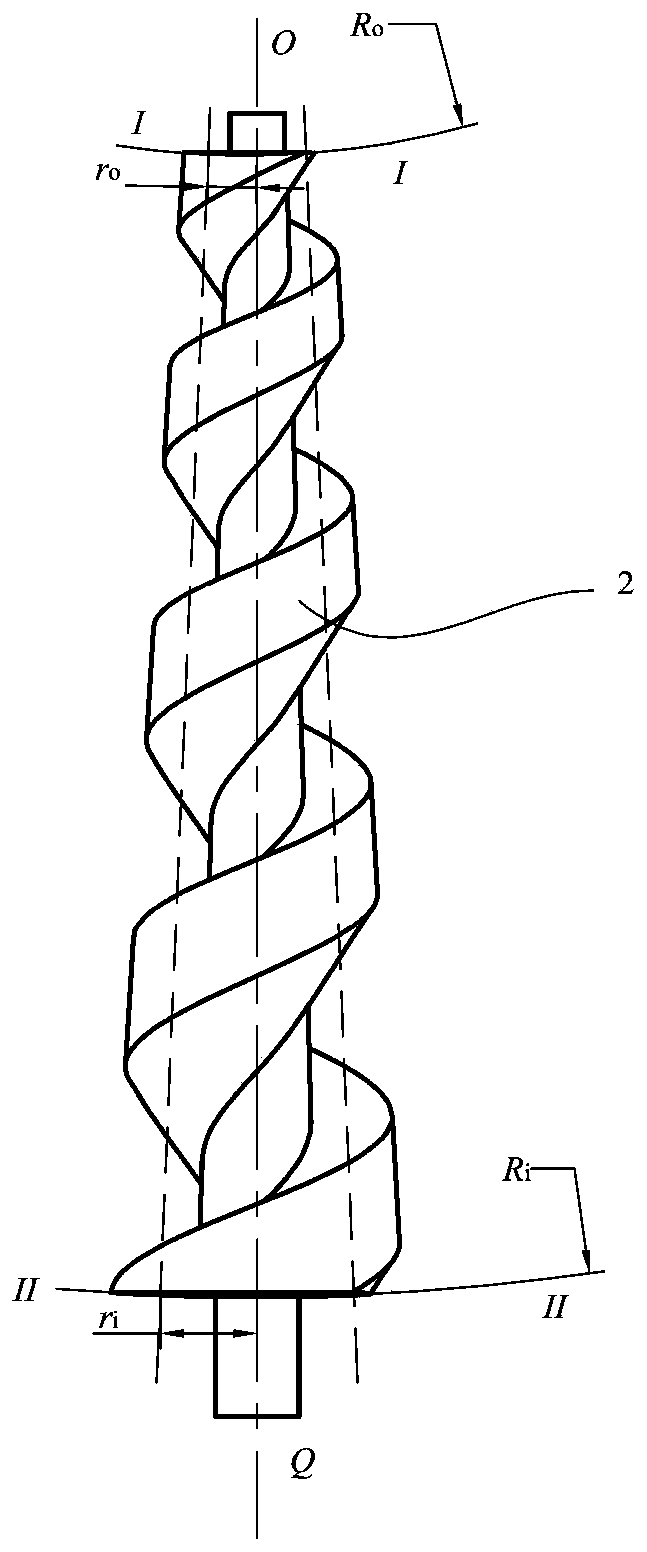

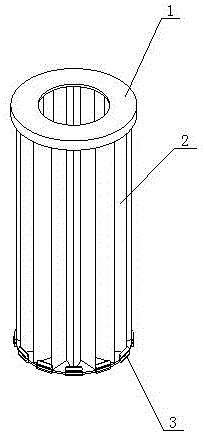

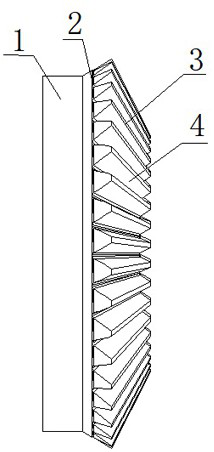

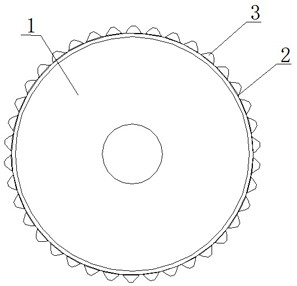

Conical screw rotors of twin-screw vacuum pump

PendingCN110821835AReduce working chamber volumeIncrease ultimate vacuumRotary piston pumpsRotary piston liquid enginesEngineeringVacuum pump

The invention discloses conical screw rotors of a twin-screw vacuum pump. The left conical screw rotor (1) comprises a high-pressure end concave spherical face, a low-pressure end convex spherical face and four tooth faces, and the four tooth faces are a left conical tooth top face (11), a left conical oblique tooth face (12), a left conical tooth root face (13) and a left conical concave tooth face (14). The right conical screw rotor (2) comprises a high-pressure end concave spherical face, a low-pressure end convex spherical face and four tooth faces, and the four tooth faces are a right conical tooth top face (21), a right conical oblique tooth face (22), a right conical tooth root face (23) and a right conical concave tooth face (24). The left conical screw rotor (1) and the right conical screw rotor (2) can achieve cross axial meshing with the transmission ratio of 1:1. a larger air suction volume is achieved under the same structure parameters, a large effective volumetric rate is achieved, the pumping speed of the twin-screw vacuum pump is increased, the volume of a work cavity of the exhaust end is reduced, large content ratio and compression ratio are achieved, and the limit vacuum degree of the vacuum pump can be increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

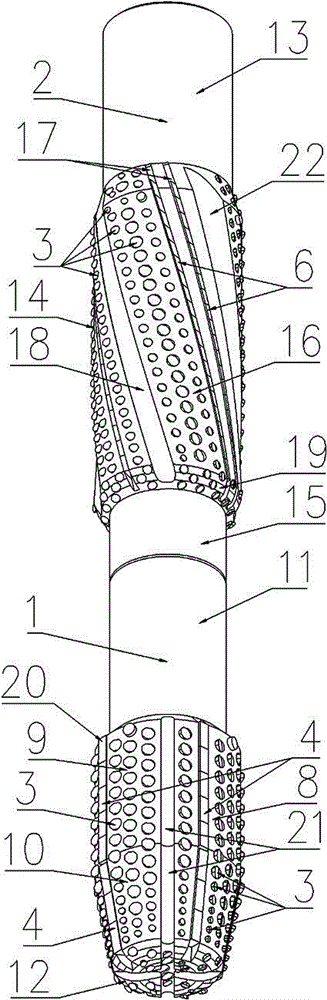

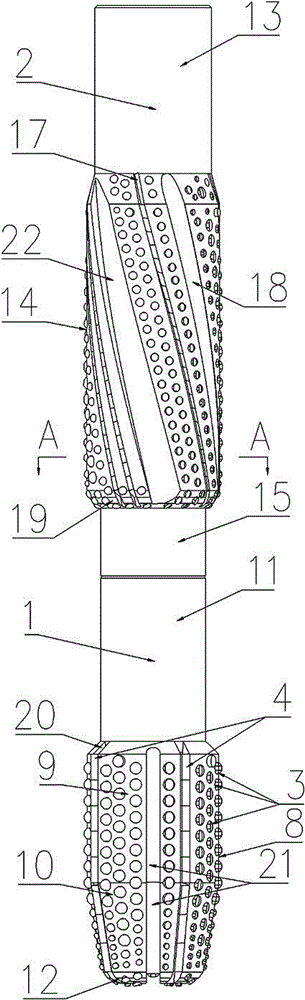

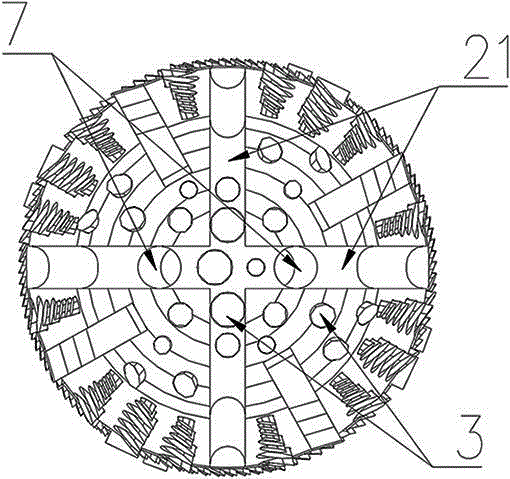

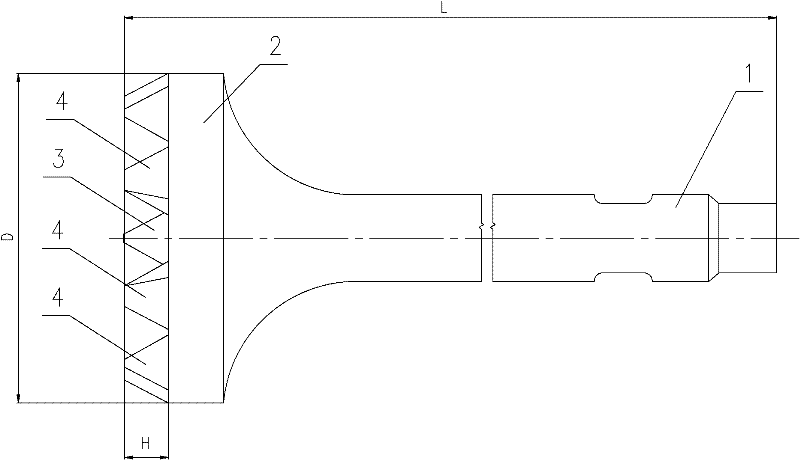

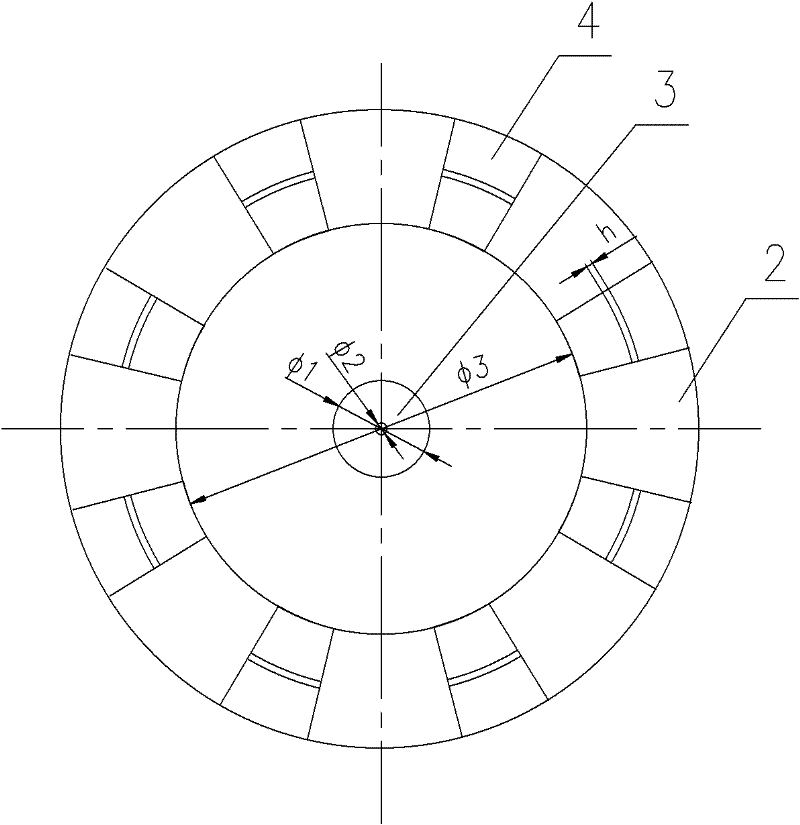

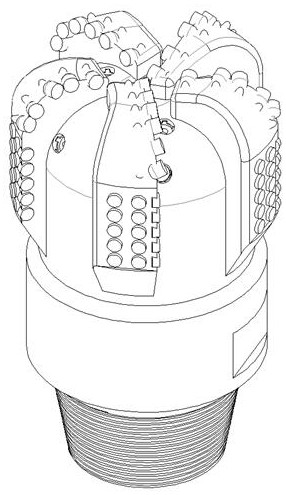

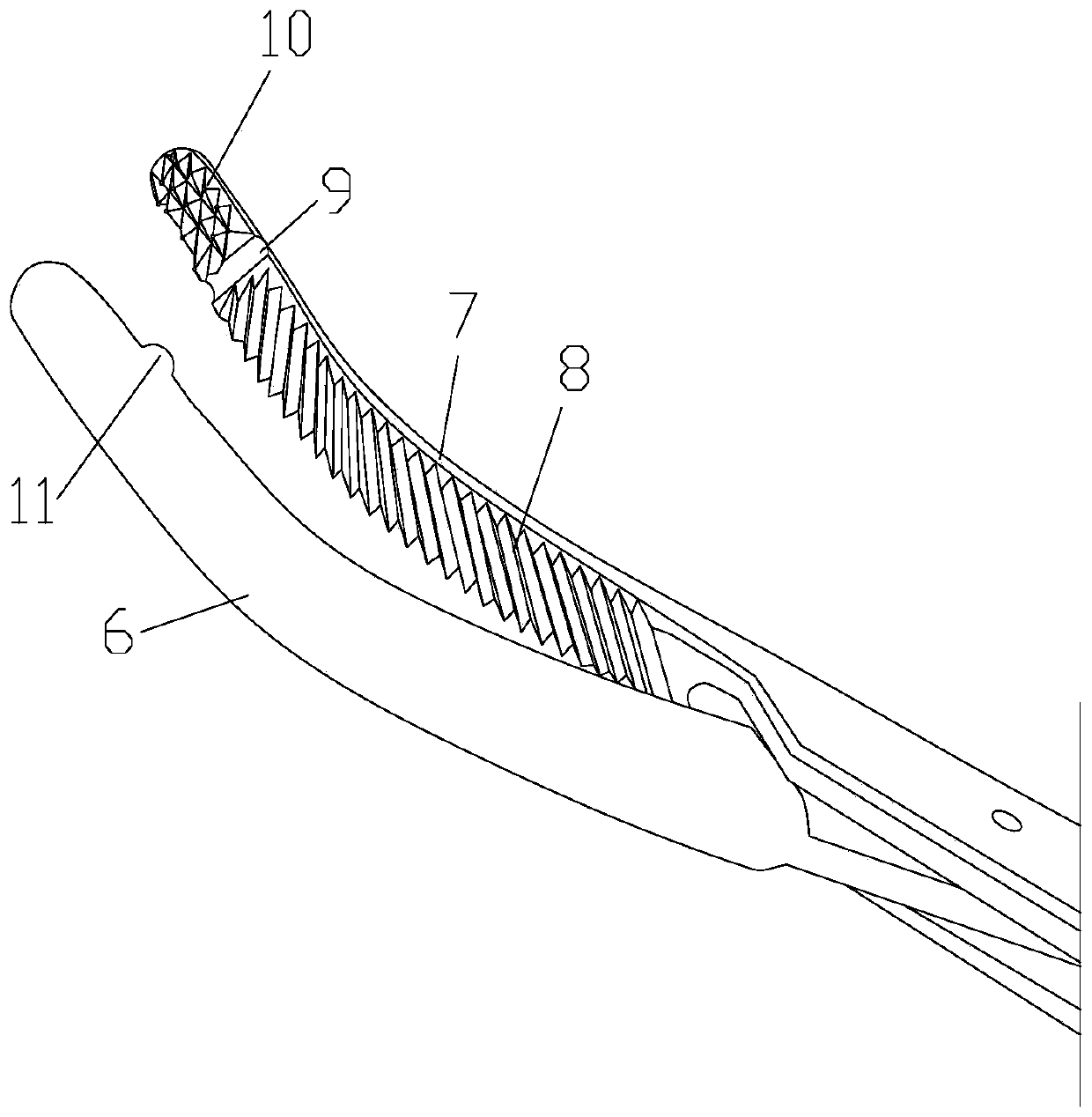

Double-layered casing windowing drillbit

ActiveCN102943628AImprove cutting performanceImprove wear resistanceDrill bitsConstructionsEngineeringAlloy

The invention discloses a double-layered casing windowing drillbit. The drillbit comprises a primary drillbit basic body (1) and a secondary drillbit basic body (2), wherein a columnar tooth distribution surface (9), a conical tooth distribution surface (10), a bottom end face (12), a transition folding surface (19) and a tooth socket (20) are formed on the primary drillbit basic body (1), a spiral columnar tooth distribution surface (16) and a spiral tooth socket (17) are formed on the secondary drillbit basic body (2), and hard alloy teeth (3) and a hard alloy block are respectively formed on different positions of the primary drillbit basic body (1) and the secondary drillbit basic body (2). The drillbit has the beneficial effects that the drillbit has the advantages of combining the cutting of both the hard alloy teeth and the hard alloy block, teeth are reasonably distributed in a staggering mode, so that the drillbit can be better suitable for the continuous cutting working condition of double-layered casing windowing process; and the drillbit has the characteristics of high efficiency, long service life and high success ratio, and the technical problems of low double-layered casing windowing success rate and low efficiency are solved.

Owner:SOUTHWEST PETROLEUM UNIV

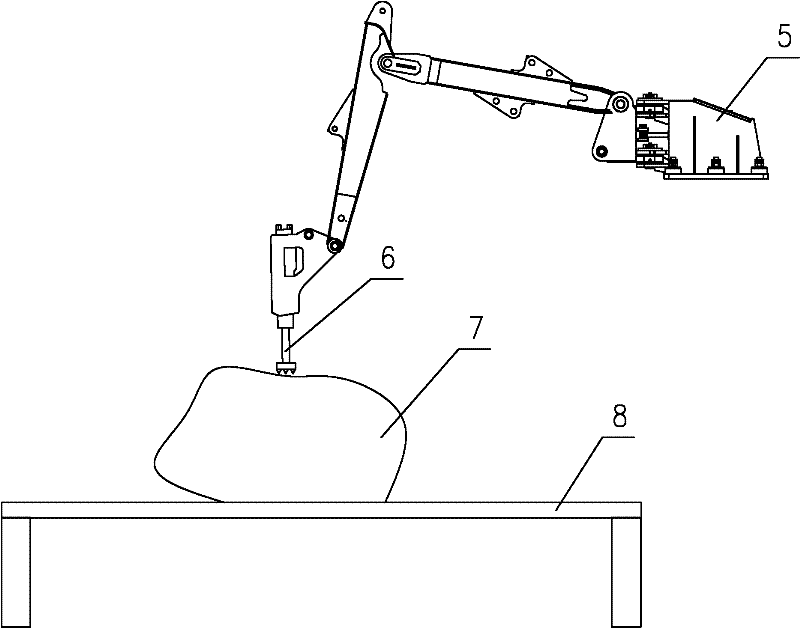

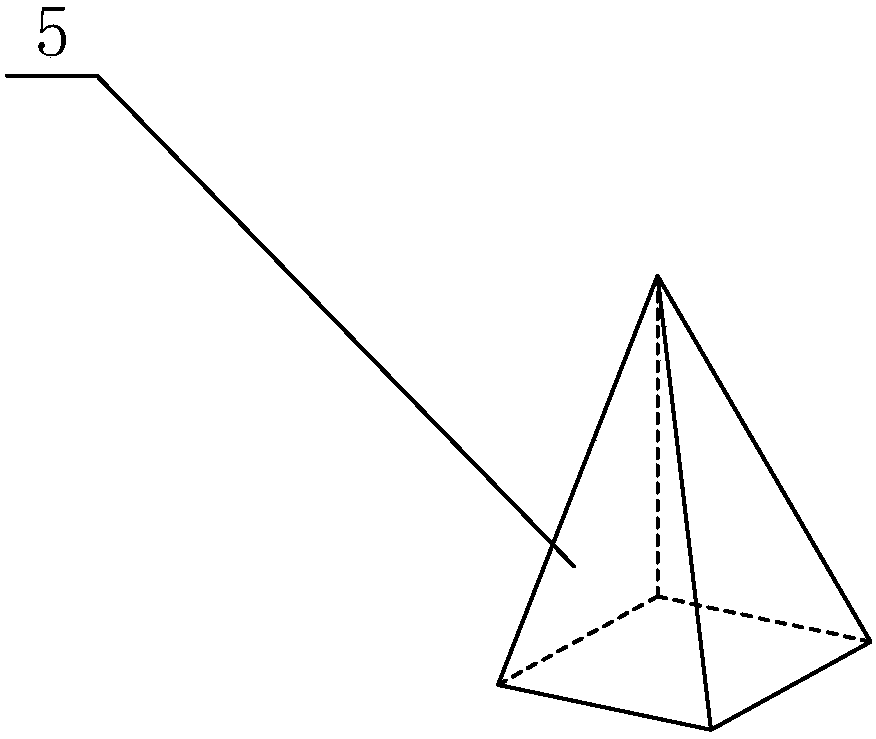

Primary crushing method of coal-series needle coke and device thereof

ActiveCN102600922ALess investmentQuality improvementGrain treatmentsThree-dimensional spaceFree state

The invention relates to the field of primary crushing of needle coke (green coke), and particularly relates to a primary crushing method of coal-series needle coke. The primary crushing method is characterized in that a multi-cone hammer head is driven by a full-station mechanical arm provided with an impaction hammer to impact and crush tower-discharged green coke in a free state. The multi-cone hammer head is in an integrated structure, a drill rod is arranged at one end of the multi-cone hammer head, and a crushing head is arranged at the other end of the multi-cone hammer head and is provided with circular conical teeth and square conical teeth. Compared with the prior art, the primary crushing method of coal-series needle coke and the device adopted by the method, disclosed by the invention, have the following advantages that: (1) the problem of device appearance selection of large or ultralarge crushed material in the coal-series needle coke (the tower-discharged green coke) is solved, and the investment of a crushing device is reduced largely; (2) an impaction crushing manner is suitable for anisotropic structure characteristics of the needle coke, and is also beneficial for improving the quality of the needle coke; (3) high-efficiency transmission of impaction energy is ensured and the crushing work efficiency is improved due to a unique structure of the multi-cone hammer head; and (4) the full-station (in a three-dimensional space and five freedom degrees) mechanical arm meets station requirements during operation and is convenient to capture objects to be hammered.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

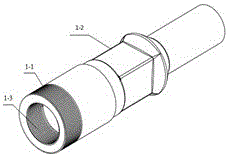

Sucker rod dual-thread anti-disengagement device

InactiveCN106285508AOvercoming the problem of easy shacklesExtended use timeDrilling rodsDrilling casingsEngineeringScrew thread

The invention provides a sucker rod dual-thread anti-disengagement device which comprises a male thread buckle, a female thread buckle, a ring cap with oblique conical teeth, a conical tooth anti-retreat gasket and a spring. A thread in the direction opposite to the detaching direction of the female thread buckle is formed in the outer surface of the female thread buckle and matched with the ring cap. The ring cap is installed at one end of the male thread buckle. The ring cap can move up and down on a screw when not buckled. One end of the spring is fixed to a male screw, and the other end of the spring is fixed to the conical tooth anti-retreat gasket. The conical tooth anti-retreat gasket is matched with the oblique bevel teeth at one end of the ring cap. When a sucker rod works and the transverse torque exists, due to the fact that the direction of the thread of the female thread buckle is opposite to the detaching direction of the thread in the outer surface of the female thread buckle, when one thread has unbuckling tendency, the other thread has buckling tendency, and the two threads act on each other and are prevented from being disengaged; the spring and the conical tooth anti-retreat gasket are used for preventing the ring cap from disengagement. The original weight of the sucker rod can not be changed, and the anti-disengagement aim is achieved when the two threads restrain each other.

Owner:SOUTHWEST PETROLEUM UNIV

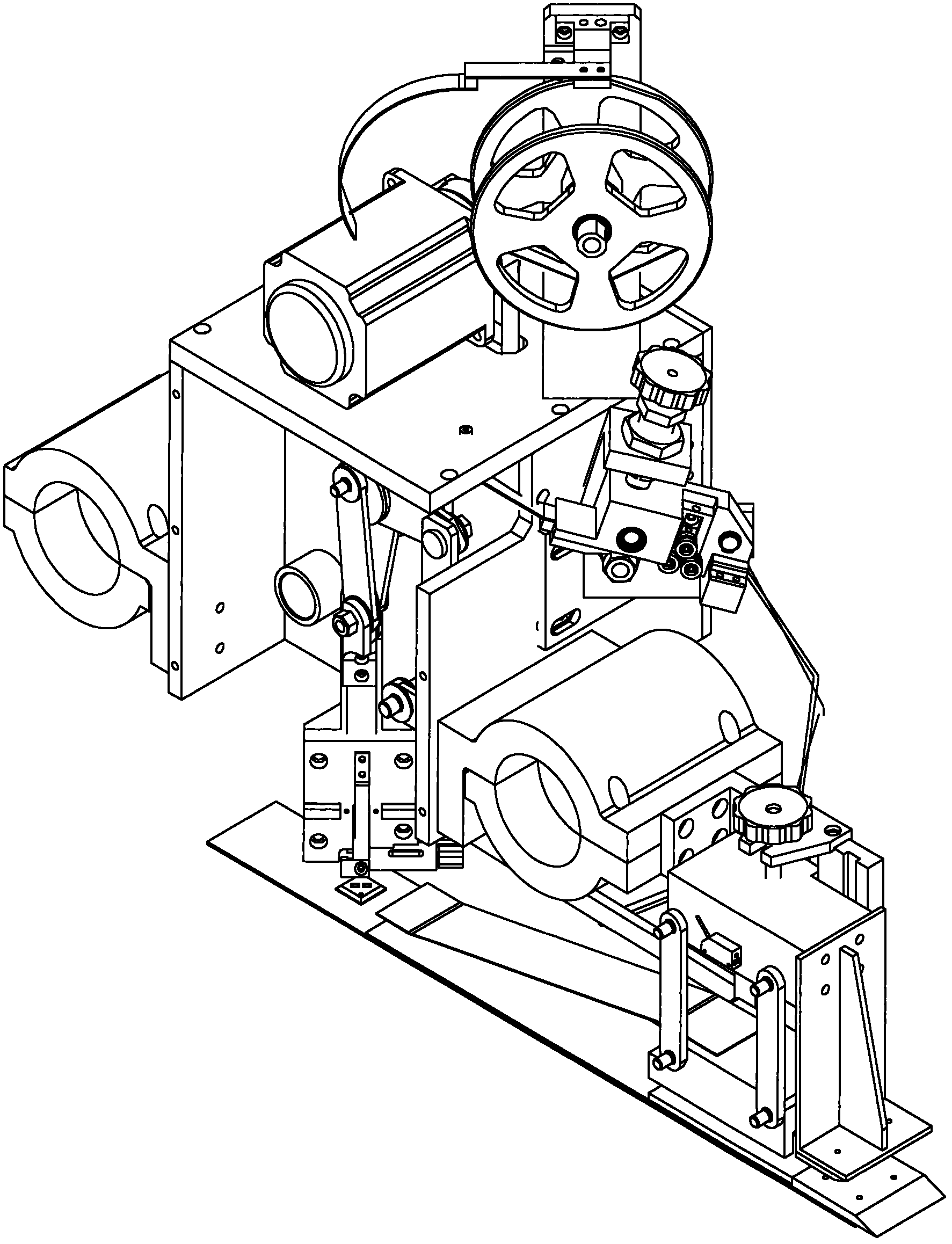

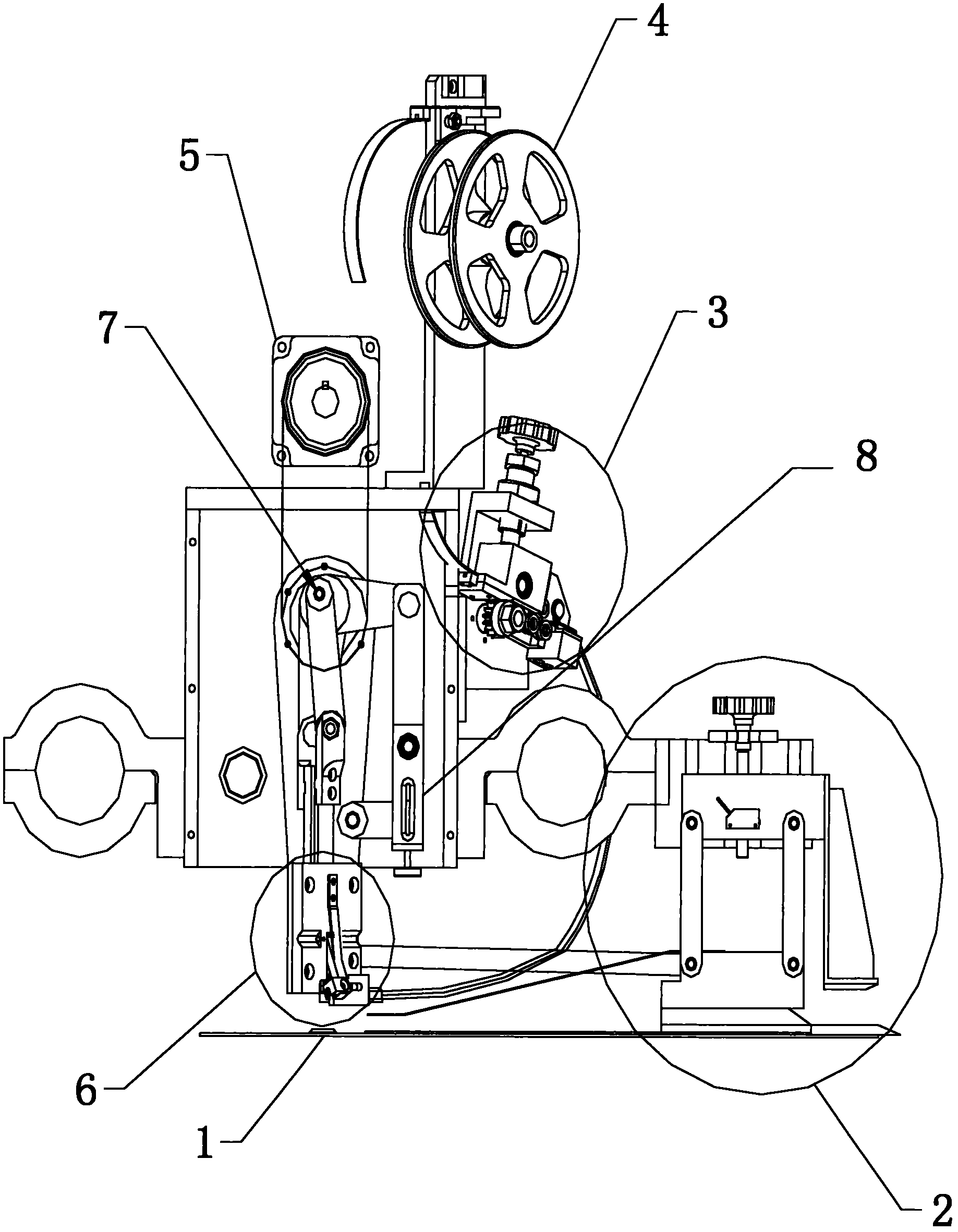

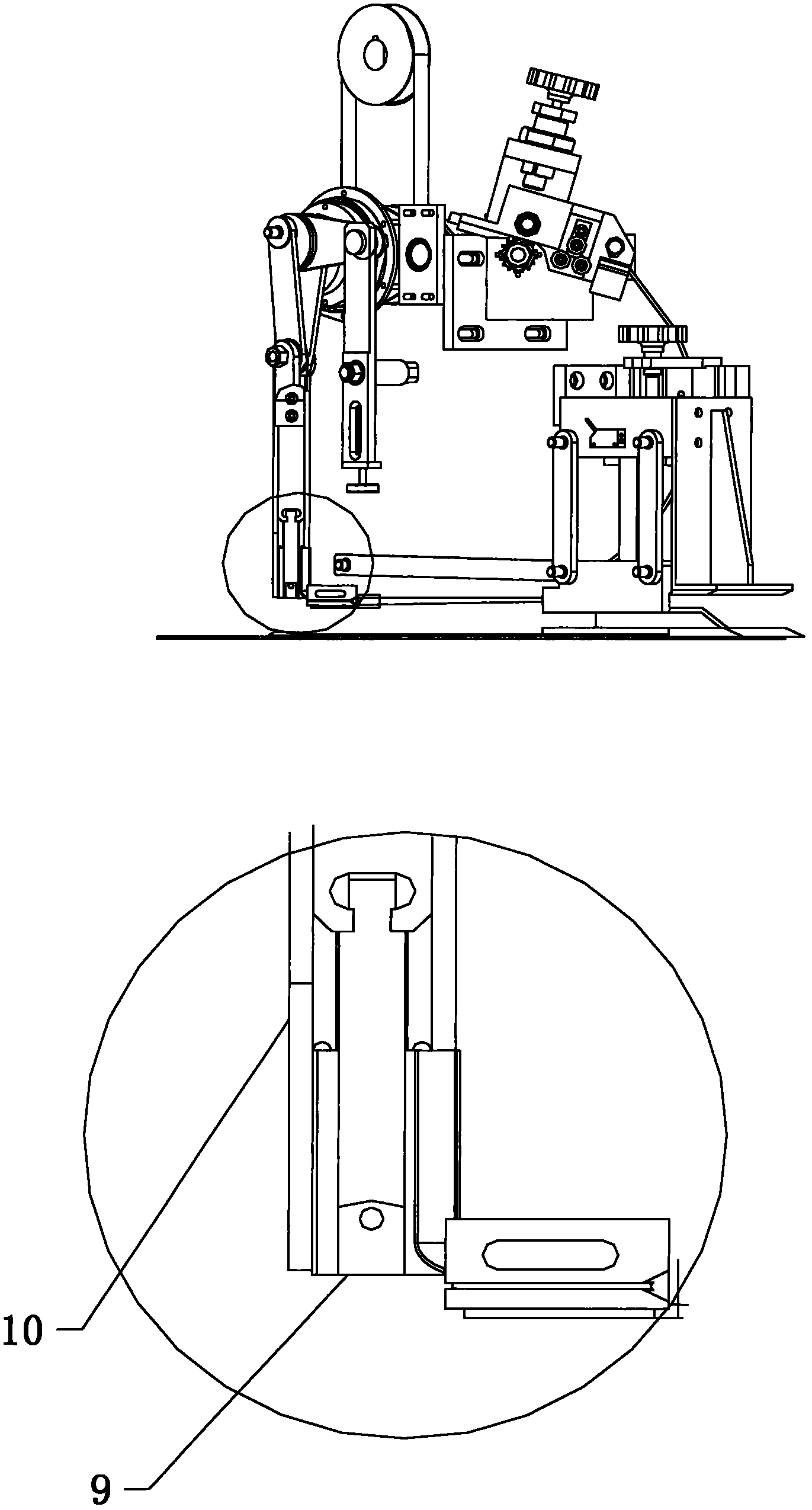

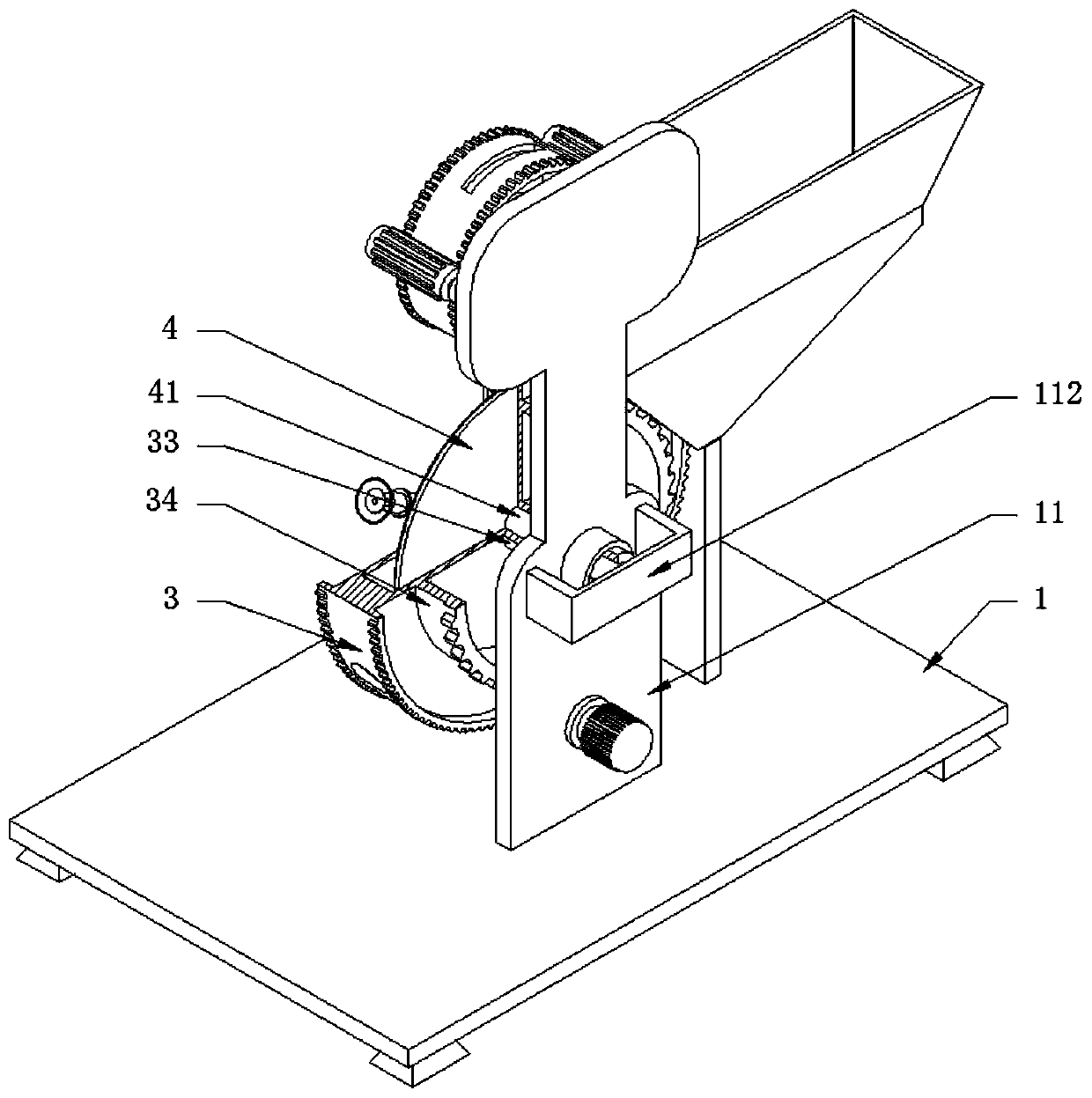

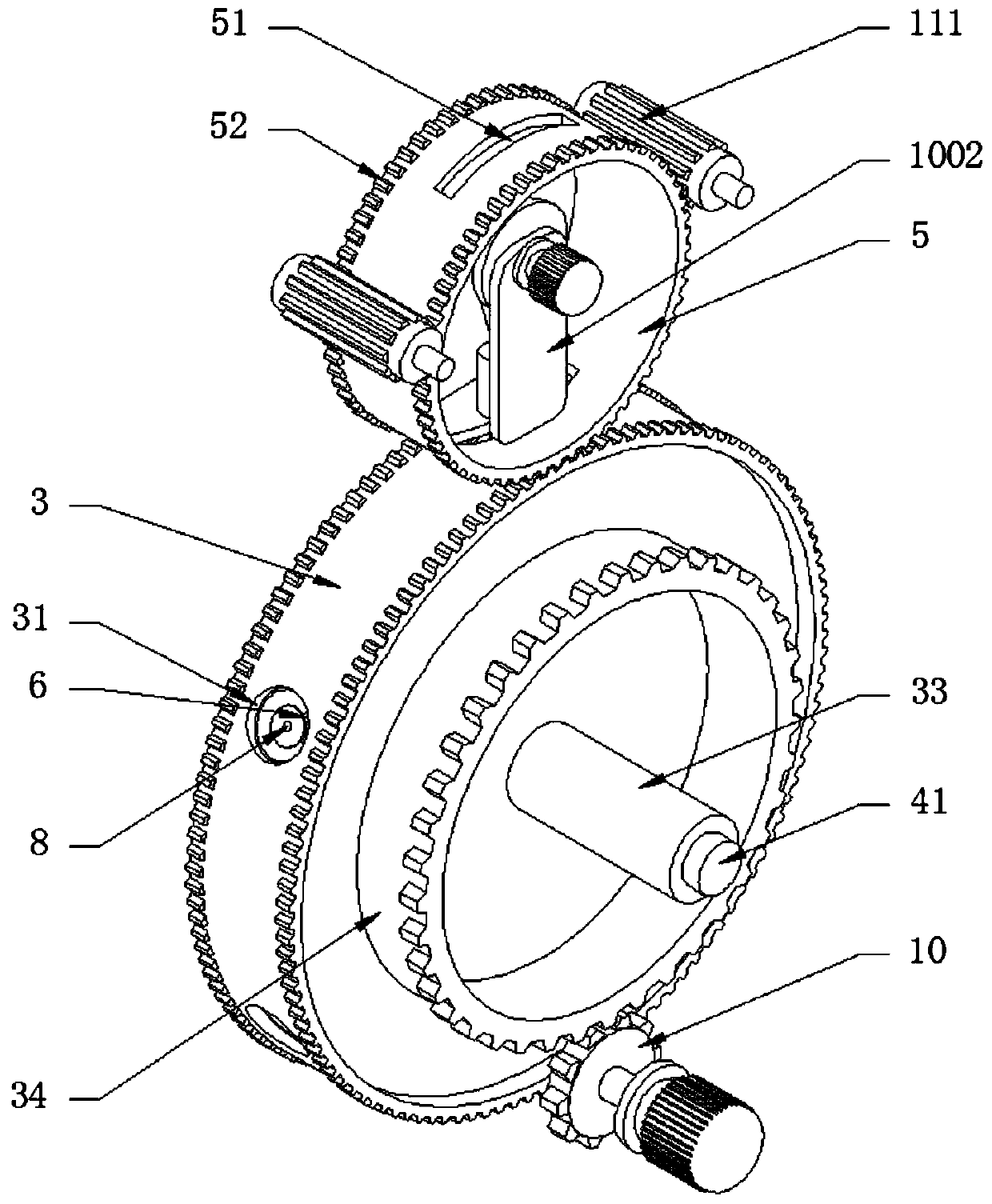

Nailing machine containing swinging type continuous nailing head

InactiveCN102179957AOvercome the disadvantages of complex structureSimple structureBox making operationsPaper-makingEngineeringServomotor

The invention discloses a nailing machine containing a swinging type continuous nailing head. The nailing machine is characterized by comprising a base, a base linking device, a wire feeding mechanism, a wire nailing disc, a servo motor and the nailing head, wherein the wire feeding mechanism is connected with a main shaft by a timing belt and a conical tooth chain; and the nailing head and the base linking device are connected with the main shaft by swinging pull rods. The nailing machine overcomes the defect that the structure of imported equipment is complex is overcome, reduces the use power consumption and cost; the nailing machine has the advantages of simplified structure, low fault rate and higher stability, and is convenient to maintain, easy to manufacture, is safe and reliable and convenient to operate.

Owner:苏州埃伯瑞机械科技有限公司

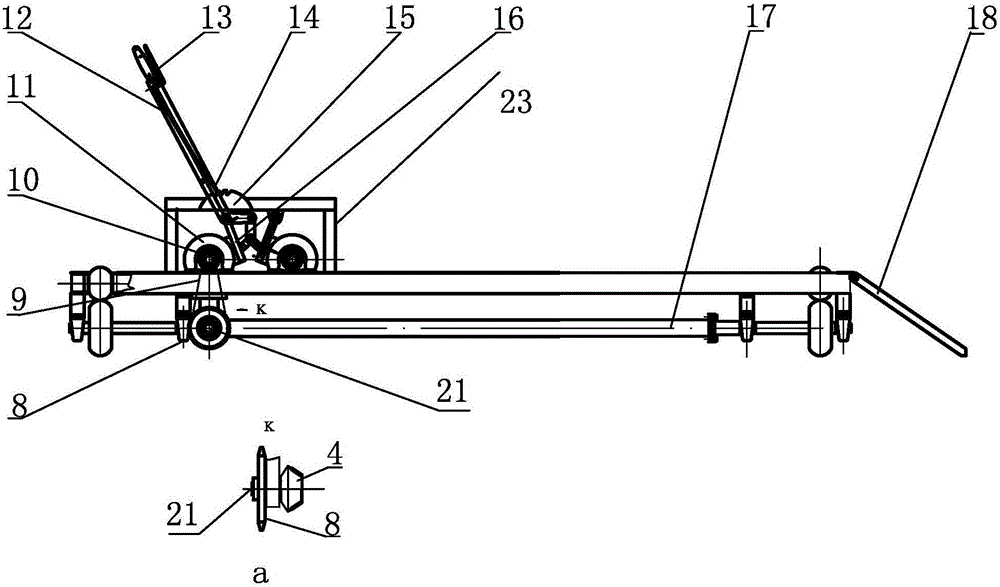

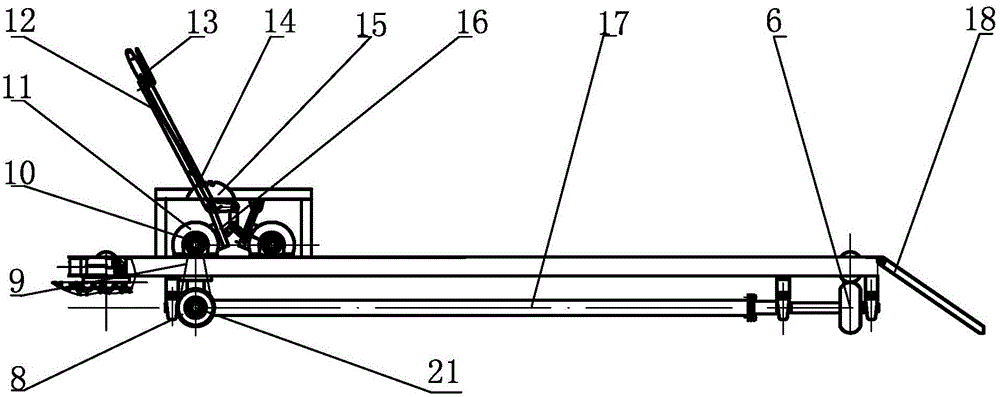

Self-driven roadside-parking aid device

InactiveCN105151017AImprove congestionGuarantee smooth passageVehicle manoeuvring devicesDrive wheelDrive shaft

The invention discloses a self-driven roadside-parking aid device, relates to a roadside-parking aid device, particularly relates to a self-driven roadside-parking aid device and aims to solve the problem of traffic jam caused by difficulty of parking roadside of small vehicles in the prior art. The self-driven roadside-parking aid device comprises a movable platform, two vehicle wheel supporting rollers, two main driving wheels, a conical-tooth driving wheel, a conical-tooth driven wheel, two platform driving wheels, two platform supporting wheels, a large chain wheel, a driving chain, a small chain wheel, a brake mechanism, a driving shaft, a foldable slope plate, a first rotation shaft, a second rotation shaft and a transition rotation shaft, wherein the movable platform is a horizontally-disposed rectangular plate body; the two platform supporting wheels are arranged on one side of the lower surface of the movable platform along the length direction of the movable platform. The self-driven roadside-parking aid device is applied to the field of traffic and transportation.

Owner:肖玉生

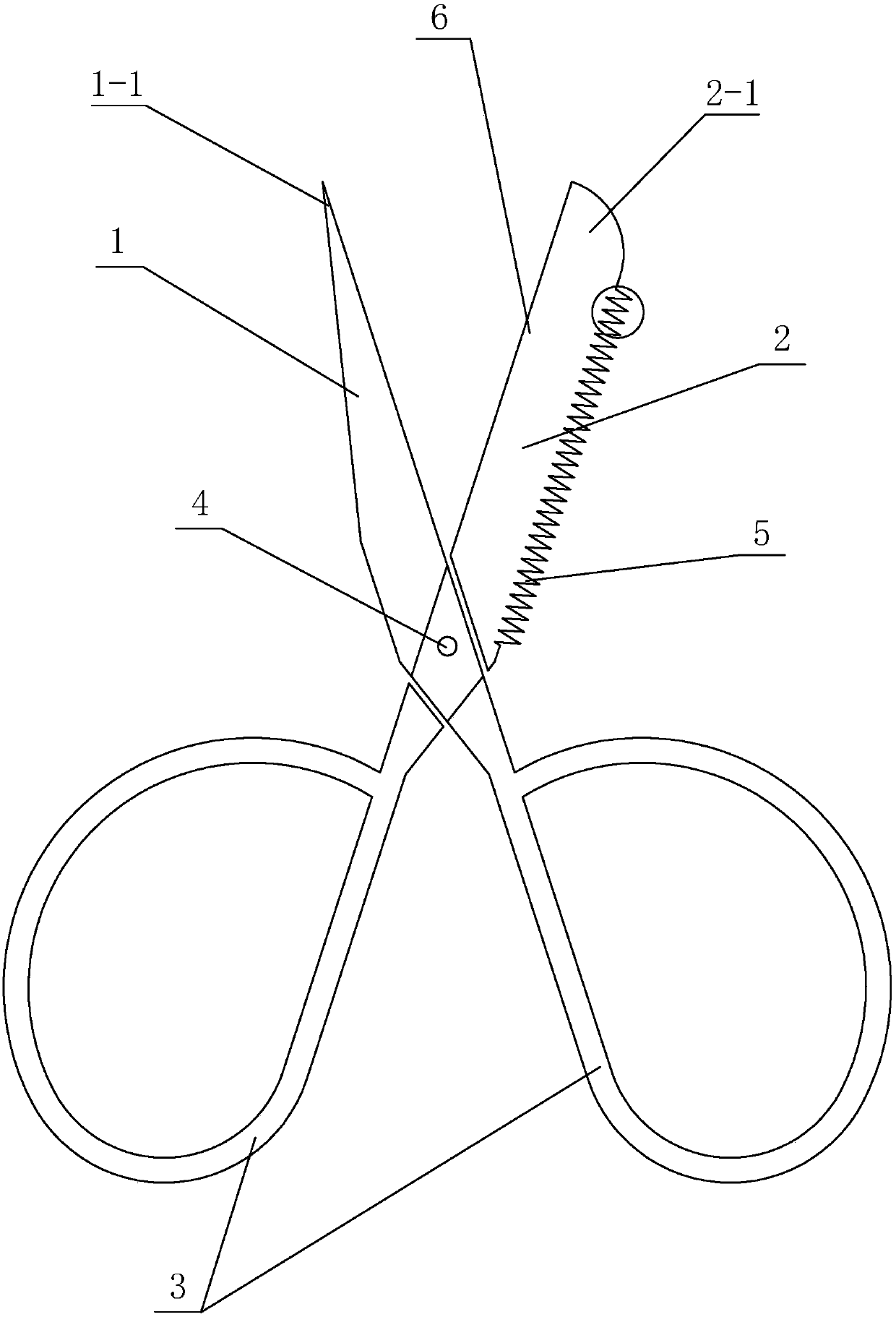

Special fish carving scissors provided with conical teeth

PendingCN108015815AQuick clearImprove processing efficiencyFish washing/descalingPoultry/fish slaughtering/stunningFish processingEngineering

The invention discloses a pair of special fish carving scissors provided with conical teeth. The pair of special fish carving scissors comprises a straight edge blade, a toothed blade and a spindle, wherein one end of the straight edge blade is hinged with the spindle and then is connected with one holding knife handle, a tip is arranged at the end part of the other end of the straight edge blade,one end of the toothed blade is hinged with the spindle and then is connected with one holding knife handle, a blunt nose is arranged at the end part of the other end of the toothed blade, one row ofscraping teeth are arranged outside the toothed blade, and the scraping teeth and the toothed blade are molded integrally. The pair of special fish carving scissors is characterized in that one straight edge blade provided with the tip is used for carving and puncturing a fish belly; one toothed blade provided with the blunt nose is arranged, and one row of scraping teeth are arranged outside thetoothed blade, so that functions of rapidly scraping scales and removing fish viscera can be realized. The pair of special fish carving scissors is applicable to cleaning and processing of live fishes, processing operation is coherent, an operation tool does not need to be changed, fish processing efficiency is greatly improved, and the pair of special fish carving scissors disclosed by the invention has the characteristics of simple structure, easy operation, labor conservation and strong practicability.

Owner:QINZHOU UNIV

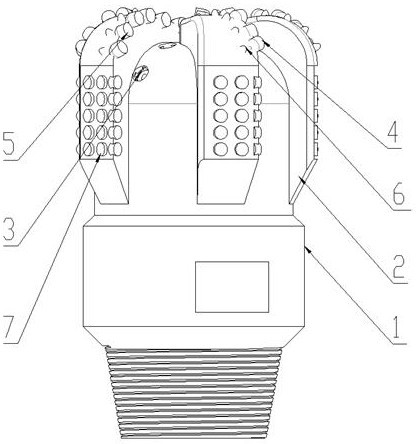

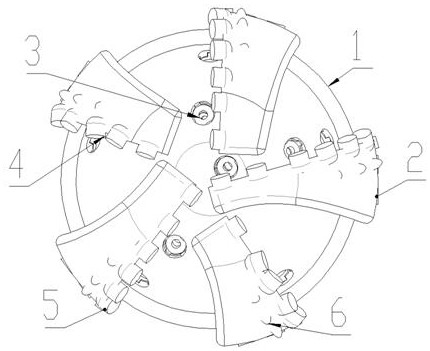

Directional double-tooth self-balancing PDC drill bit suitable for soft and hard interlayers

ActiveCN113404436AReduce impact wearImprove stabilityDrill bitsConstructionsWell drillingDouble teeth

The invention belongs to the technical field of oil field drilling equipment, and particularly relates to a directional double-tooth self-balancing PDC drill bit suitable for soft and hard interlayers. The drill bit comprises a drill bit body, blades and nozzles, and the blades and the nozzles are arranged on the drill bit body; and the number of the blades is five, double-tooth structures, front-row single teeth, rear-row conical teeth and gauge teeth are distributed on the blades, and the rear-row conical teeth are distributed behind the front-row single teeth on the same rail. The nozzles are distributed in the straight line area and the arc area of the crown part of each blade; the crown part of each blade is a straight line-arc crown part, and the cone depth of each crown part is moderate; and the lower part of the drill bit body is a male joint, the lower end is provided with a thread line, and a groove is turned in the middle part and facilitates screwing on a well. Single-tooth impact abrasion is reduced, and the rock breaking efficiency is improved.

Owner:NORTHEAST GASOLINEEUM UNIV

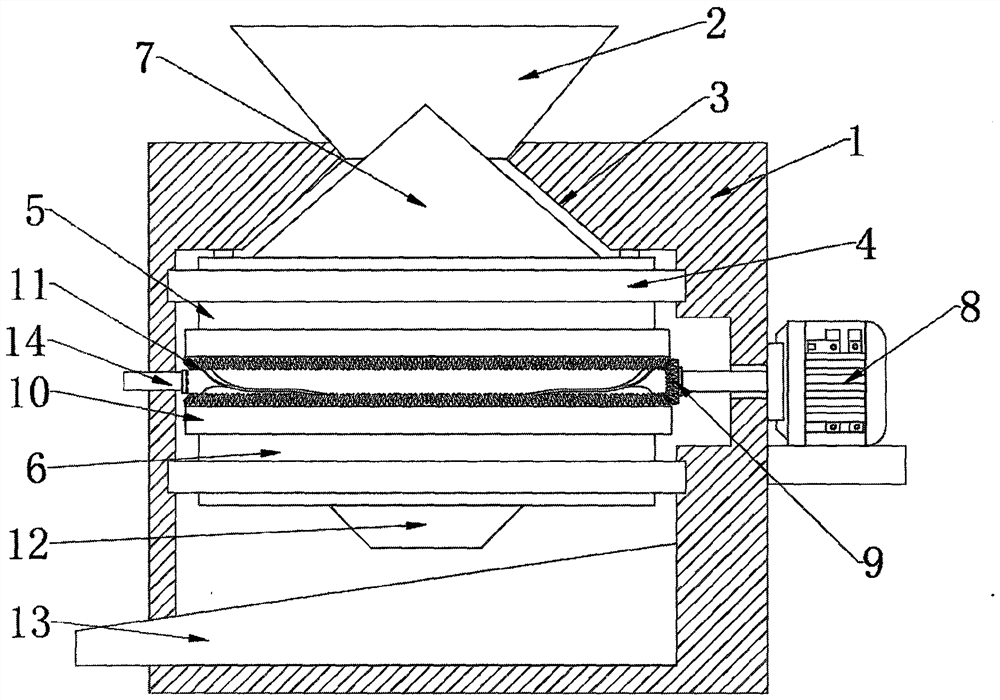

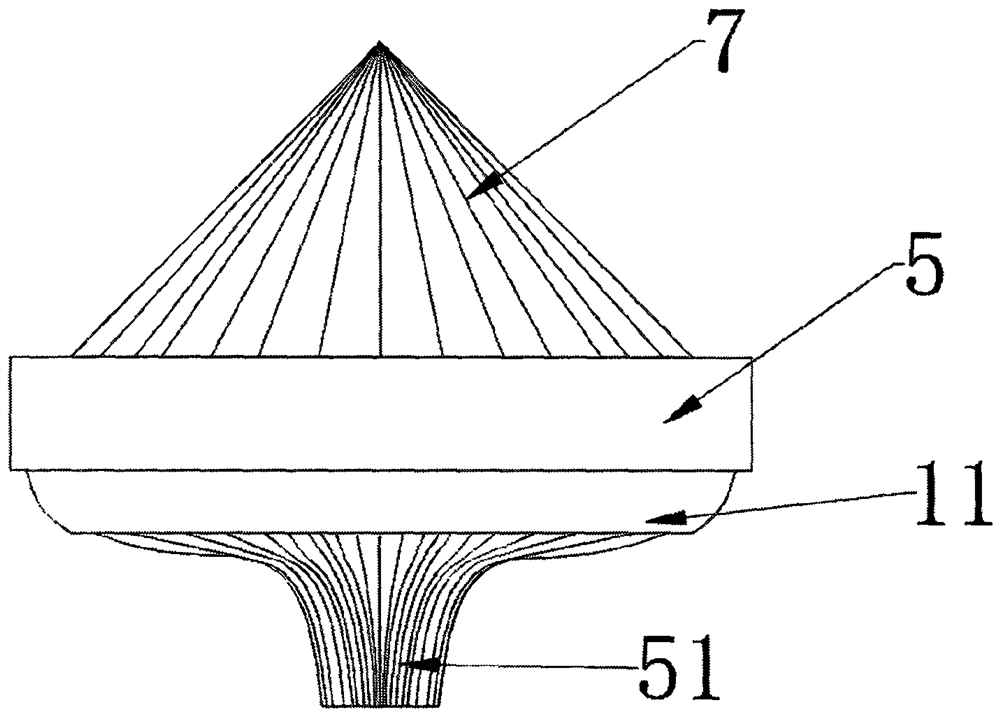

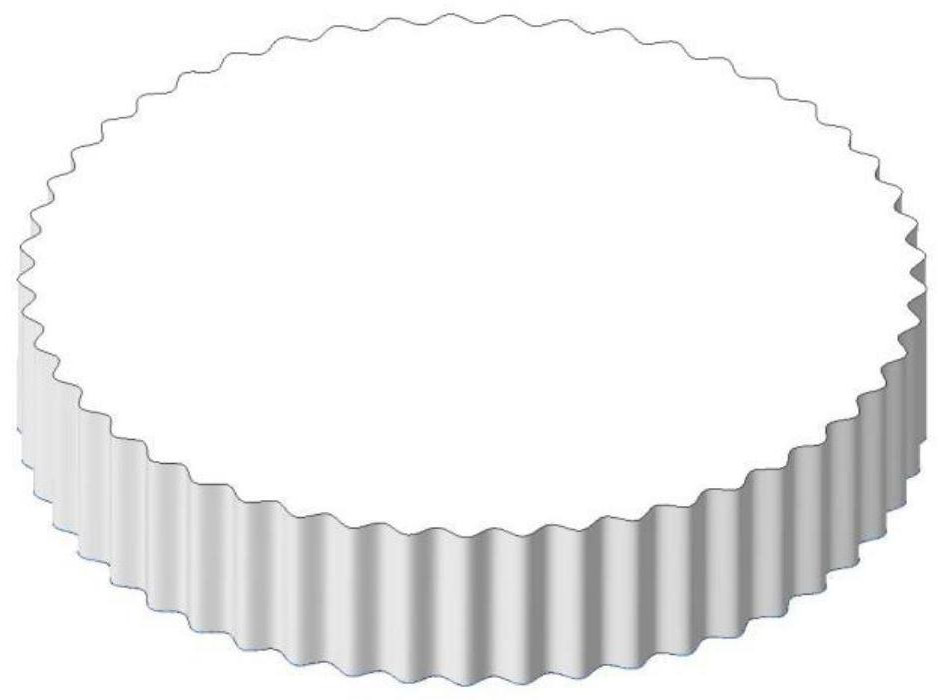

Low-rotation-speed sesame paste production grinding device and grinding method

The invention discloses a low-rotation-speed sesame paste production grinding device in the technical field of sesame paste production. A grinding box is included. A feeding hopper is arranged on thetop of the grinding box. A conical channel is arranged on the top of an inner cavity of the grinding box. The inner cavity of the grinding box is provided with a grinding upper base and a grinding lower base through an upper bearing and a lower bearing respectively. A rough grinding cone is arranged on the top of the grinding upper base. A grinding motor is arranged on the right side end face of the grinding box. A powder guiding shell is arranged at the bottom of the grinding upper base. A discharging hopper is arranged at the middle portion of the bottom end of the grinding lower base. A U-shaped discharging groove is formed in the bottom of the inner cavity of the grinding box. The left end wall of the grinding box is provided with a water injection pipe in a penetration manner. A sprayer of the water injection pipe is located on the left side of the part between an upper conical tooth ring and a lower conical tooth ring. The device conducts grinding two times, grinding is finer, low-speed grinding is adopted, the ground sesame temperature is low, and fragrance and nutrients cannot run off.

Owner:沁水县晋香食品开发有限公司

A kind of full string gear and its gear set

ActiveCN112228529BImproved meshing characteristicsEliminate backlashPortable liftingGearing elementsInvolute gearGear wheel

The present invention provides a full chord gear, comprising: a chordal cylindrical gear and a chordal bevel gear, the addendum lines of all the teeth of the chordal cylindrical gear are on the same cylindrical surface; all of the chordal bevel gears The addendum line of the tooth is on the same conical surface; through any point on the shaft of the chord cylindrical gear or the chord bevel gear, make its axial normal section, and the normal section is the same as the chord line Cylindrical gears or the chord-line bevel gear intersect, and the boundary formed by all the teeth on it is a chord-line tooth profile. The present invention mainly utilizes a new type of chord-line tooth profile, and the chord-line tooth profile is periodically distributed in a plane with multiple The continuous closed curve of the wave, the application of this new type of chordal tooth profile is flexible and varied, covering a wide range, and can replace the entire series of involute gears.

Owner:YANSHAN UNIV

Forging forming method of triple gear and triple gear thereof and application

ActiveCN109454198AImprove general performanceImprove pass rateForging/hammering/pressing machinesWheelsGear wheelSurface roughness

The invention discloses a forging forming method of a triple gear. A pre-treatment process and a forging process are adjusted and a forging mold is optimized, so that the procedure of repeated descaling in a forging process is reduced, and the percent of pass of the tooth surface roughness of the triple gear can be effectively improved; meanwhile, top conical teeth and bottom surface end teeth aresimultaneously forged and formed in the forging process, the stability of the structure of the triple gear is guaranteed, the material utilization rate is improved, and the time and the tool cost ofmilling machining the end teeth are saved, and the anti-fatigue strength of the end teeth is improved. The forging forming method of the triple gear enables the surface of a whole product to be uniform and consistent, the quality stability is improved, the technological steps are optimized, the production time is effectively shortened, the production efficiency is improved, and huge economic benefits are achieved; the triple gear manufactured by the forging forming method is high in quality stability, and the consistency of the surface roughness and the tooth surface precision after the forging are good; and large-scale batch production can be realized.

Owner:HANDE AXLE (ZHUZHOU) GEAR CO LTD

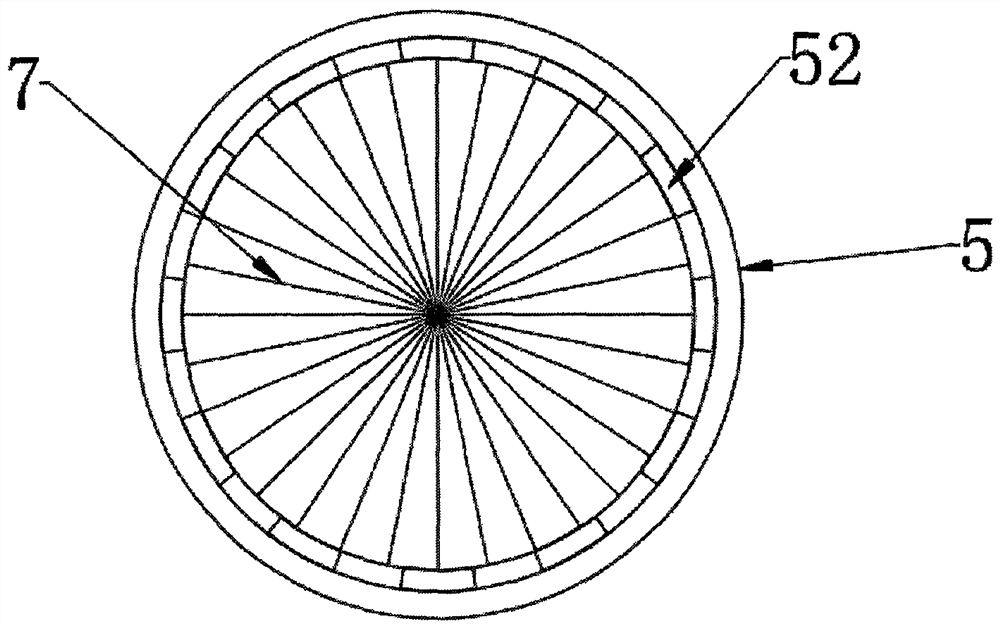

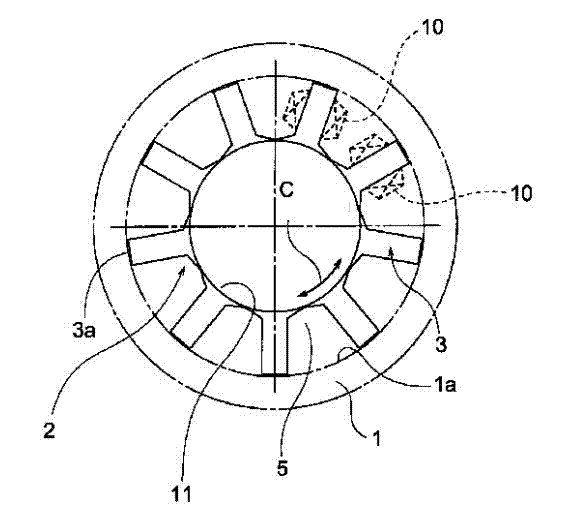

Motor stator structure

InactiveCN102510139APrevention of poor deformation characteristicsStable structureMagnetic circuit stationary partsEngineeringMechanical engineering

The invention aims at preventing a wheel-shaped stator tooth structure from being deformed by eliminating connecting portions between stator tooth portions to form a thinner middle portion and absorbing force caused by interference among iron cores at a fixed portion. A motor stator structure is provided with a pair of conical tooth portions facing to two sides of an inner circumferential position of each stator tooth portion, and the thinner middle portion is formed between the conical tooth portions which are adjacent to each other instead of the connecting portion and used for bearing the force caused by the interference among the iron cores at the fixed portion.

Owner:多摩川精密电机(苏州)有限公司

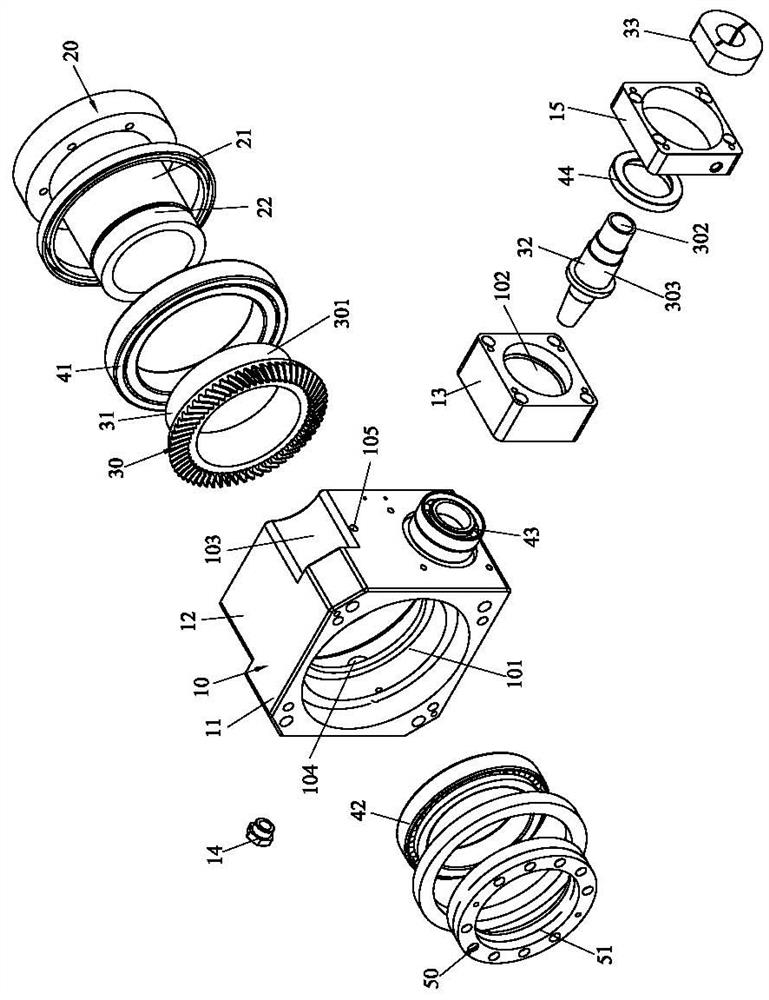

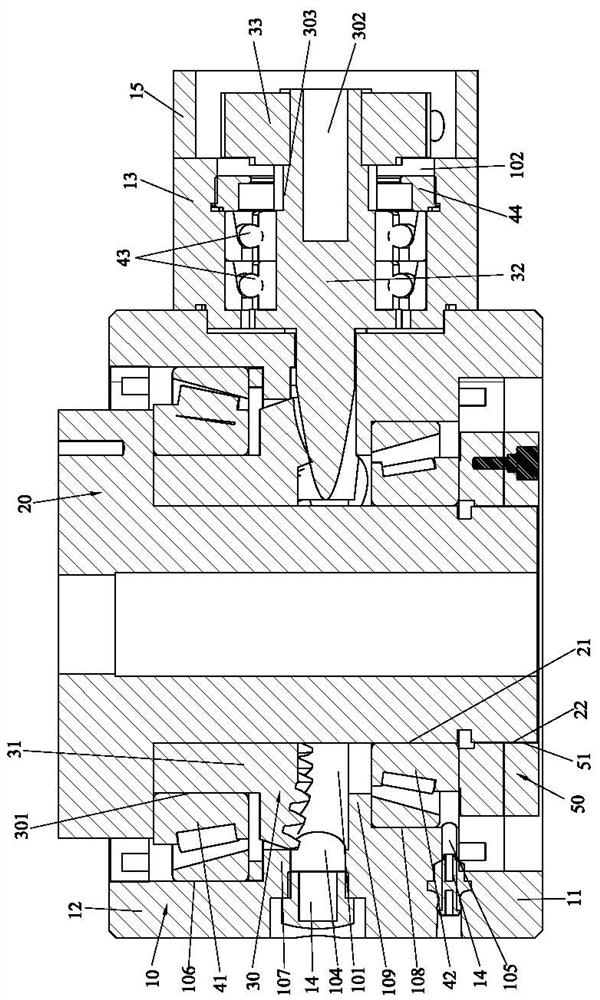

Oblique-axis conical tooth pump

InactiveCN111075678AReasonable structureEasy and flexible installationPositive-displacement liquid enginesMulti-cylinder pumpsNeedle roller bearingEngineering

The invention relates to an oblique-axis conical tooth pump. The oblique-axis conical tooth pump comprises a rotor shell and a bearing shell, the rotor shell and the bearing shell are connected with each other, a sealing ring I is arranged at the joint between the rotor shell and the bearing shell, a plug I is arranged on the rotor shell, a plug II is arranged on the bearing shell, a conical toothcylinder body is arranged in the rotor shell, conical teeth are arranged at one end of the conical tooth cylinder body, the conical tooth cylinder body is connected with the rotor shell through a central pin, an oil distribution disc is arranged at the joint between the conical tooth cylinder body and the rotor shell, the oil distribution disc is connected with the rotor shell through a positioning pin I, the center pin is arranged in a central hole of the conical tooth cylinder body, and needle bearings are arranged in the central hole, and sleeve the central pin. The oblique-axis conical tooth pump has the advantages that the noise is small, the volume is small, the displacement is large, the weight is light, the efficiency is high, the torsion is small, the operation is light and quick, the service life of an accessory is long, and the energy consumption is low.

Owner:江苏可奈力机械制造有限公司

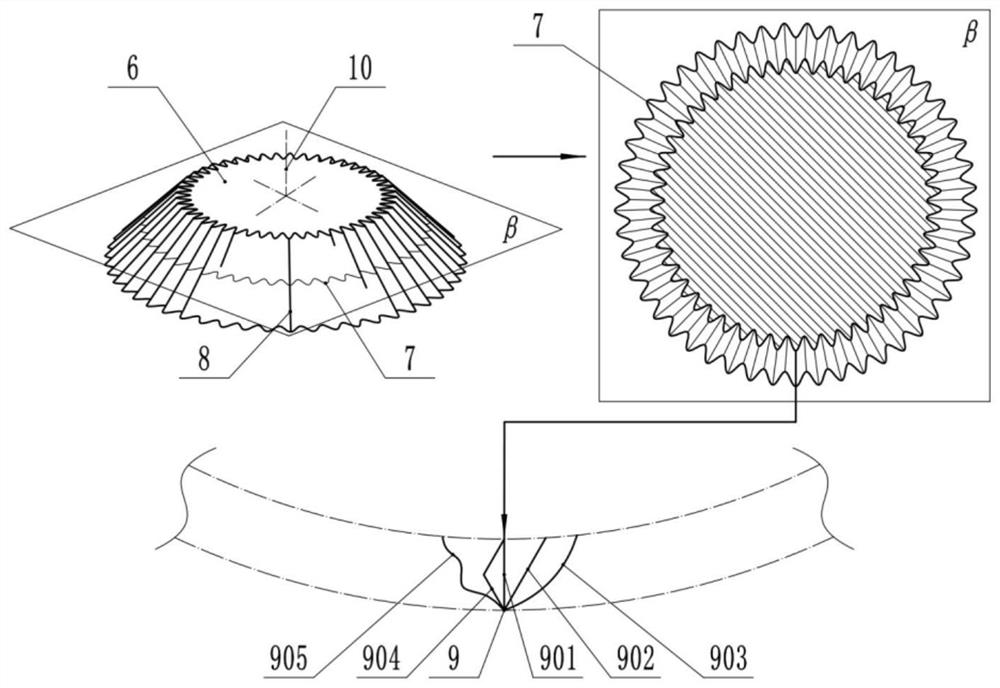

Wave gear type hollow rotating platform

PendingCN112747081ARealize self-locking functionHigh precisionToothed gearingsGearing detailsRotary stageGear drive

The invention discloses a wave gear type hollow rotating platform. The wave gear type hollow rotating platform comprises a shell, an output rotating table and a wave gear set; a first installation cavity is formed in the upper end face of the shell in a penetrating mode, and a second installation cavity communicates with the first installation cavity is formed in the side face of the shell; the output rotating table is of a hollow structure and is rotatably mounted in the first installation cavity; the wave gear set comprises a driven gear and a driving gear. The arc-shaped driven gear and the conical driving gear are adopted in a matched mode to form a wave gear set, transmission of 4-5 conical tooth surfaces meshed with the driven gear can be achieved at the same time, the characteristics of high precision and large bearing torque are achieved due to the fact that the number of the tooth surfaces of the gears meshed at the same time is large, and a hollow device is achieved due to the fact that the diameter of the driven gear is large and a large through hole can be formed in the middle of the driven gear, and due to the fact that the transmission mode is offset 40-degree meshing transmission, a certain self-locking function can be achieved.

Owner:深圳卓创传动科技有限公司

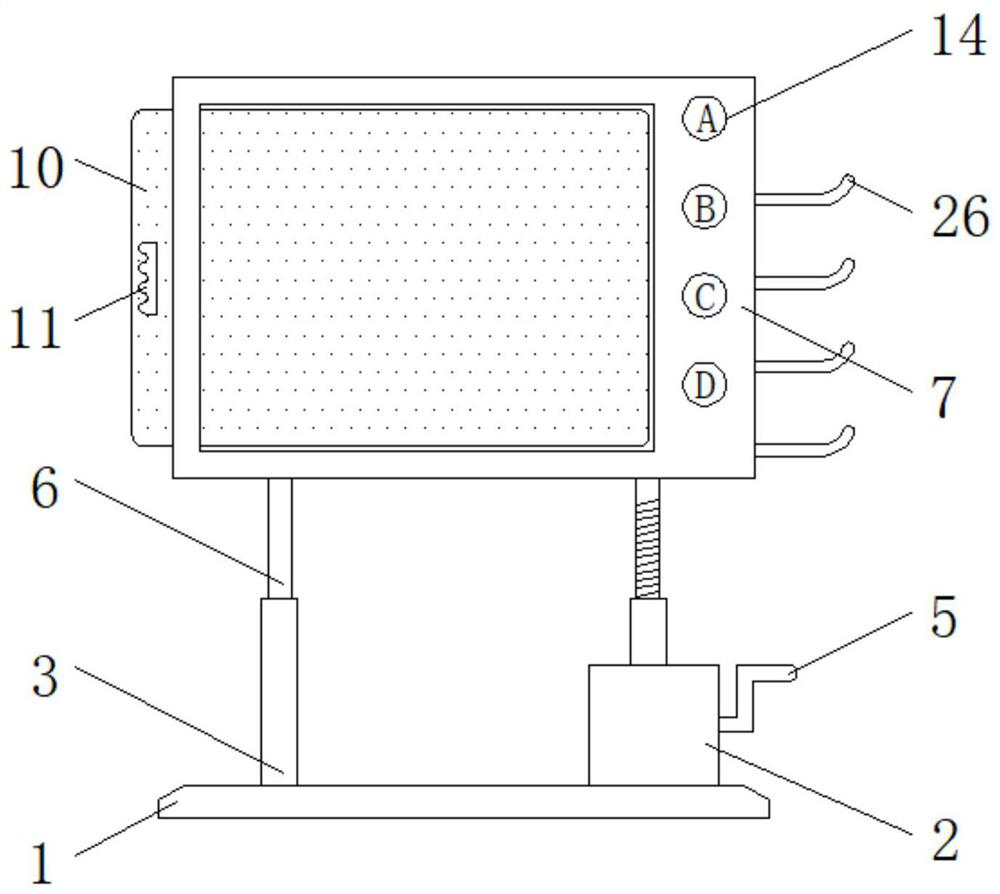

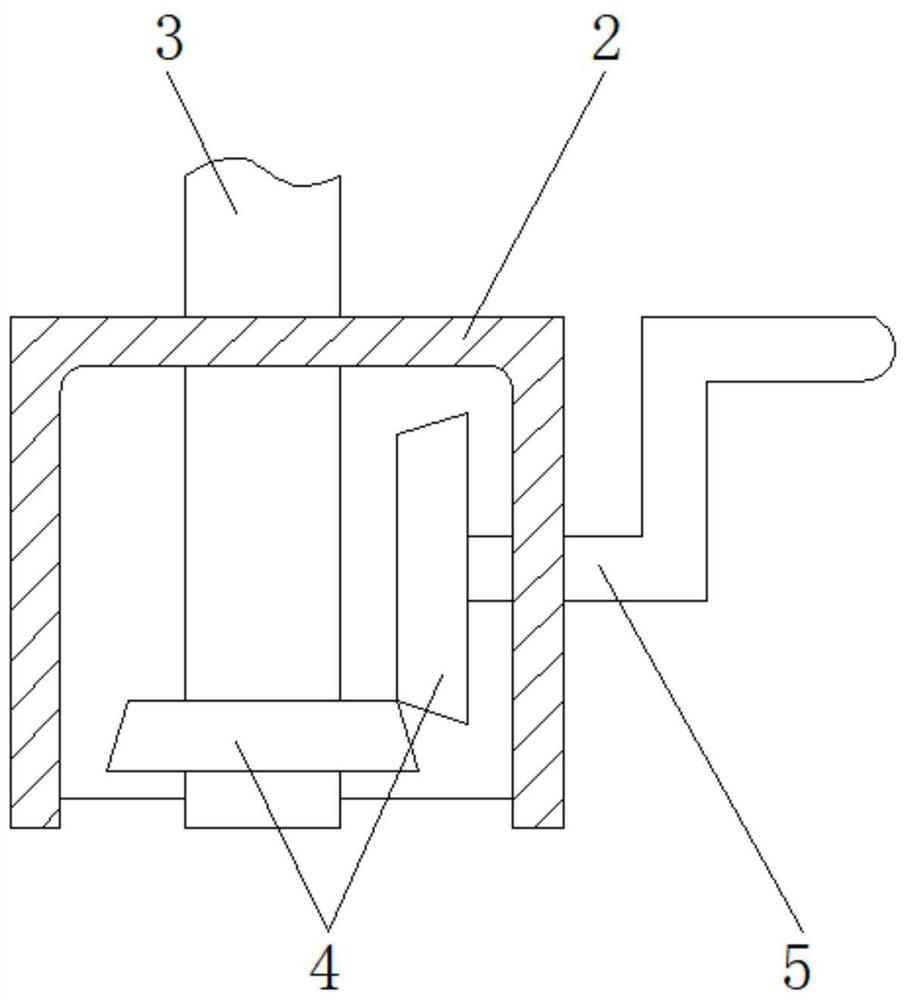

Game type teaching device applied to preschool education

ActiveCN112185182AImprove concentrationEntertainingBoard cleaning devicesWriting boardsEngineeringGame type

The invention discloses a game type teaching device applied to preschool education, which comprises a base plate, an adjusting rod, a teaching device body, a connecting plate and a discharging hole; aprotective box is fixed on the upper end surface of the base plate, conical teeth sleeve the outer side of a sleeve, and the top of the sleeve is connected with one end of a guide rod; a fixing groove is formed in the teaching device body, a writing board is movably installed in the fixing groove, a movable rod movably penetrates through the edge of the teaching device body, the other end of themovable rod is connected with one end of a connecting plate, and a tooth block is welded to the lower end face of the fixing plate. A movable cylinder penetrates through the interior of the gear, anda connecting rod is movably arranged at the other end of the movable cylinder. According to the game type teaching device applied to preschool education, an interaction structure with children is additionally arranged, certain entertainment can be achieved while learning is conducted, the attention of the children to the learning device can be improved, and then the learning effect is improved.

Owner:BINZHOU UNIV

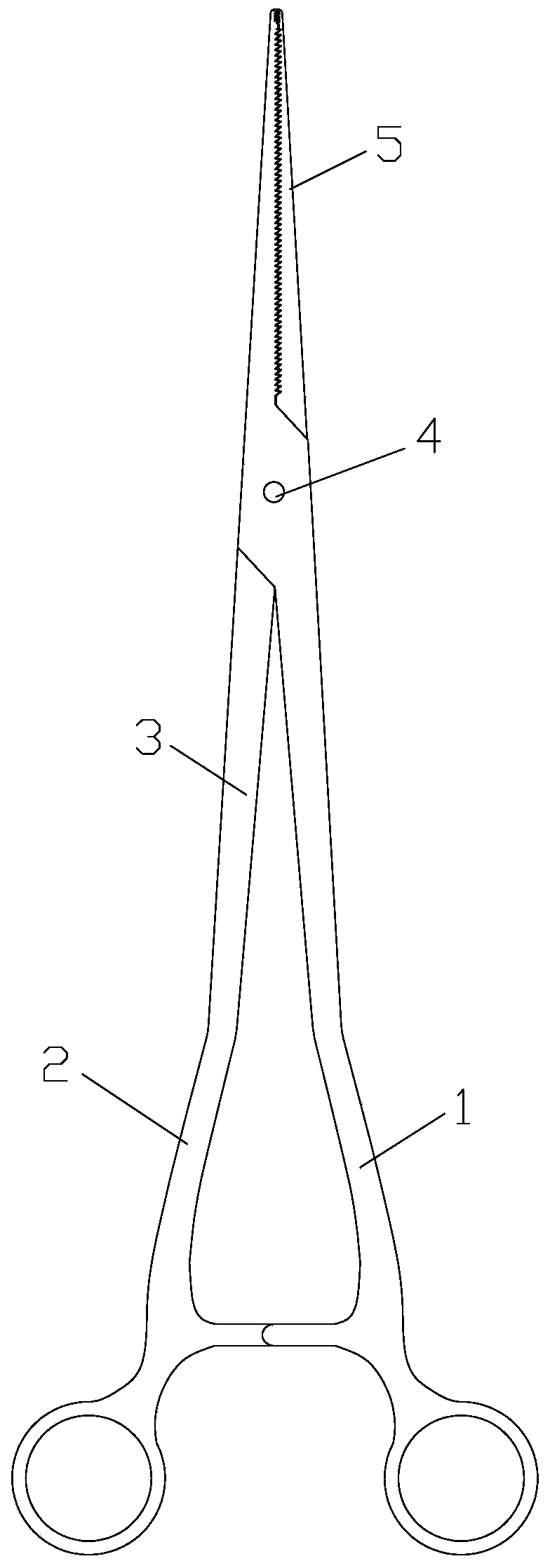

Tissue clamping forceps

The invention discloses tissue clamping forceps, including forceps handles, a pin shaft and forceps heads. The forceps handles comprise a left forceps handle and a right forceps handle, which are bothcomposed of a first forceps handle and a second forceps handle; the slope of the first forceps handle is less than slope of the second forceps handle; the forceps heads comprise a left forceps head and a right forceps head; strip-shaped engaging teeth and strip-shaped engaging grooves which are engaged with each other are formed in the inner wall surfaces of the lower sections of the left forcepshead and the right forceps head; a strip-shaped protrusion is arranged on the left forceps head in its width direction; a strip-shaped arc-shaped groove is formed in the position, corresponding to the strip-shaped protrusion, above the right forceps head; the strip-shaped protrusion and the strip-shaped arc-shaped groove are in an occlusal relationship; and the upper section of the strip-shaped protrusion of the left forceps head and the upper section of the strip-shaped arc-shaped groove of the right forceps head are provided with conical teeth and a tapered groove which are engaged with each other. The tissue clamping forceps are more labor-saving in use. The clamping strength can be guaranteed, and clamping damage to tissues can be prevented.

Owner:FIRST AFFILIATED HOSPITAL OF KUNMING MEDICAL UNIV

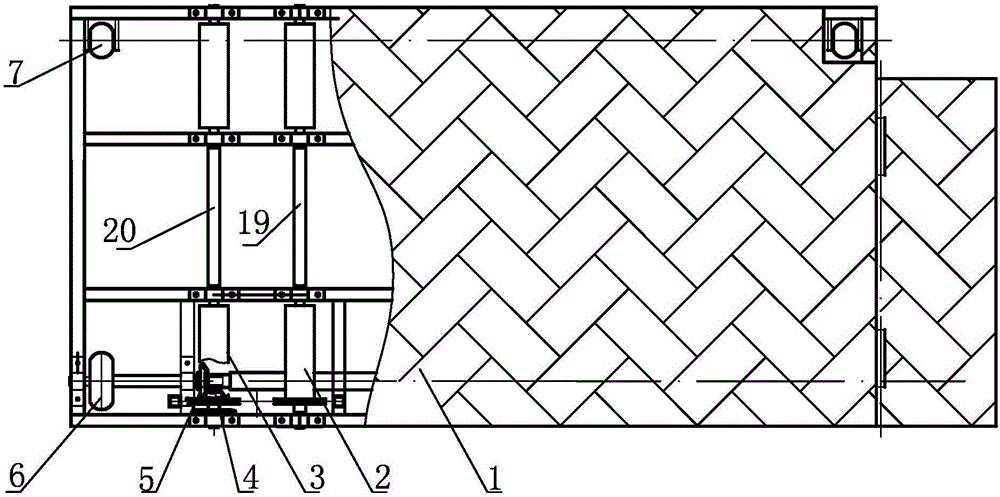

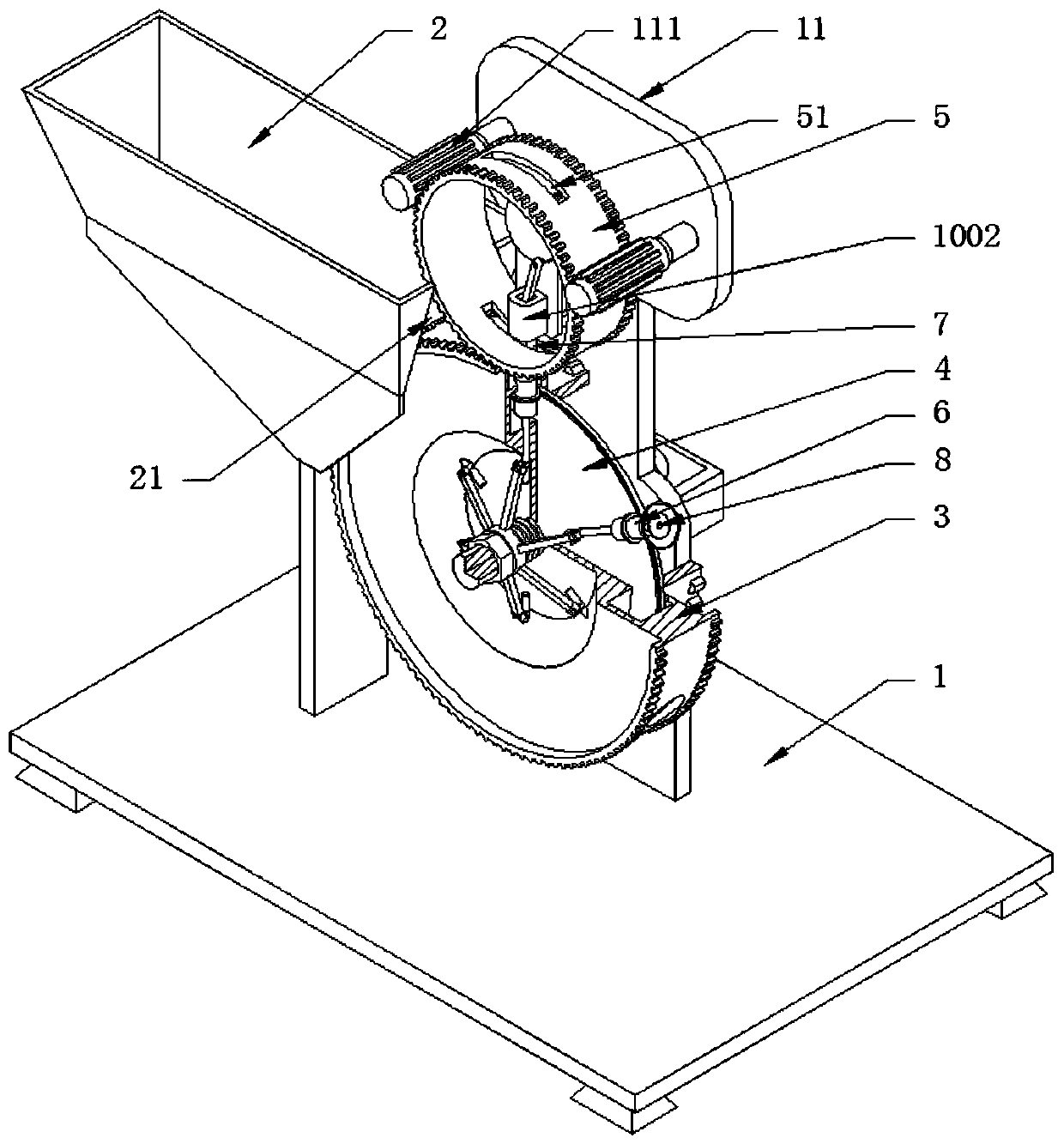

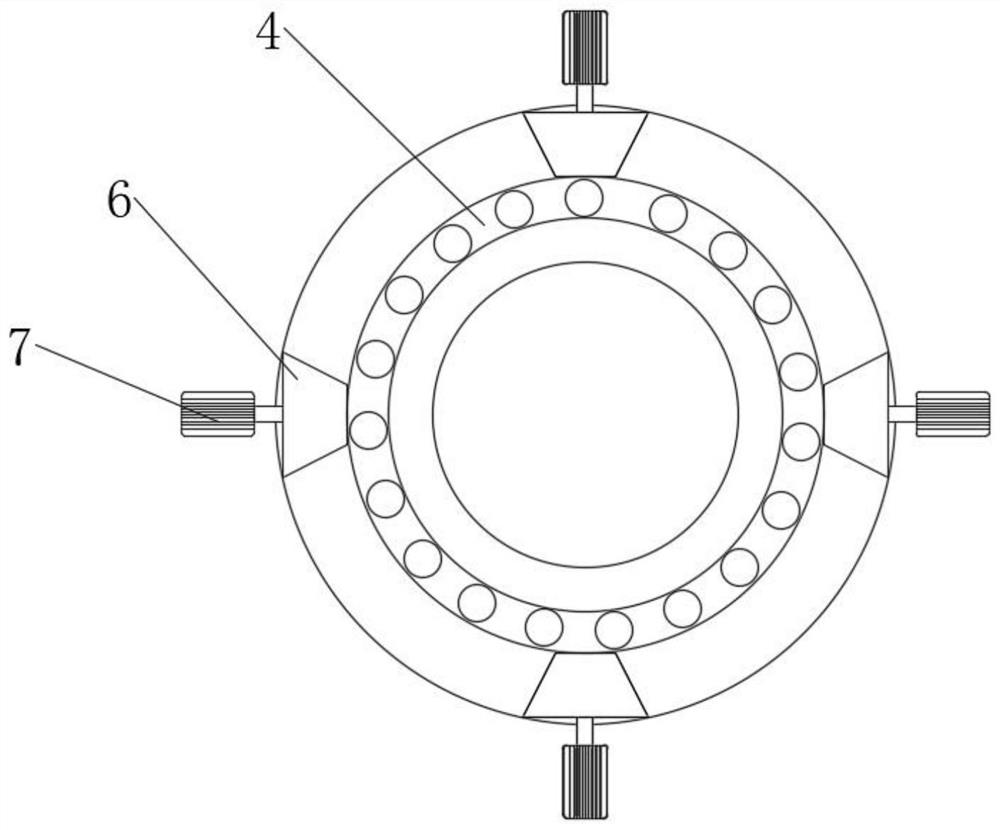

Traditional Chinese medicine decoction piece positioning hole-punching machine

The invention discloses a traditional Chinese medicine decoction piece positioning hole-punching machine. The traditional Chinese medicine decoction piece positioning hole-punching machine comprises abottom plate, a material feeding box, a vertical type hollow disc, a drive conical tooth disc located inside the hollow disc, an annular tooth ring which is located at the top of the hollow disc andis in engaged coordination, a crank piston mechanism located inside the annular tooth ring and a drive gear externally engaged with the hollow disc, and the bottom plate is fixedly provided with a vertical plate. According to the traditional Chinese medicine decoction piece positioning hole-punching machine, by means of the arrangement of the rotating vertical type hollow disc, the hollow disc isinternally provided with the drive conical tooth disc performing relative rotating, the outer circumference of the hollow disc is provided with guide holes, the guide holes are internally provided with rotary sleeves, the tops of the rotary sleeves are provided with shaping sleeves, the rotary sleeves are internally provided with punching sleeves at intervals in a sleeving manner, from this, afterirregularly-arranged or irregular-shaped decoction pieces fall into the shaping sleeves, the rotating shaping sleeves can arrange the irregularly-arranged decoction pieces to be flat to tend to the inner center positions of the shaping sleeves and align with the punching sleeves in coordination with the punching sleeves, and from this, hole-punching processing of an arranged punching head is facilitated.

Owner:JIANGXI GROUNDIONG PHARM CO LTD

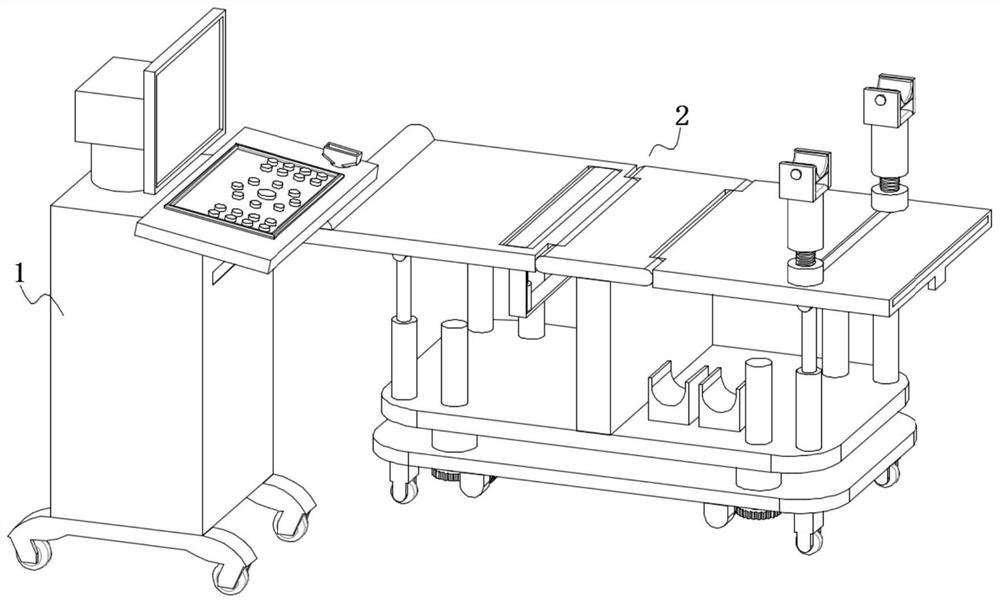

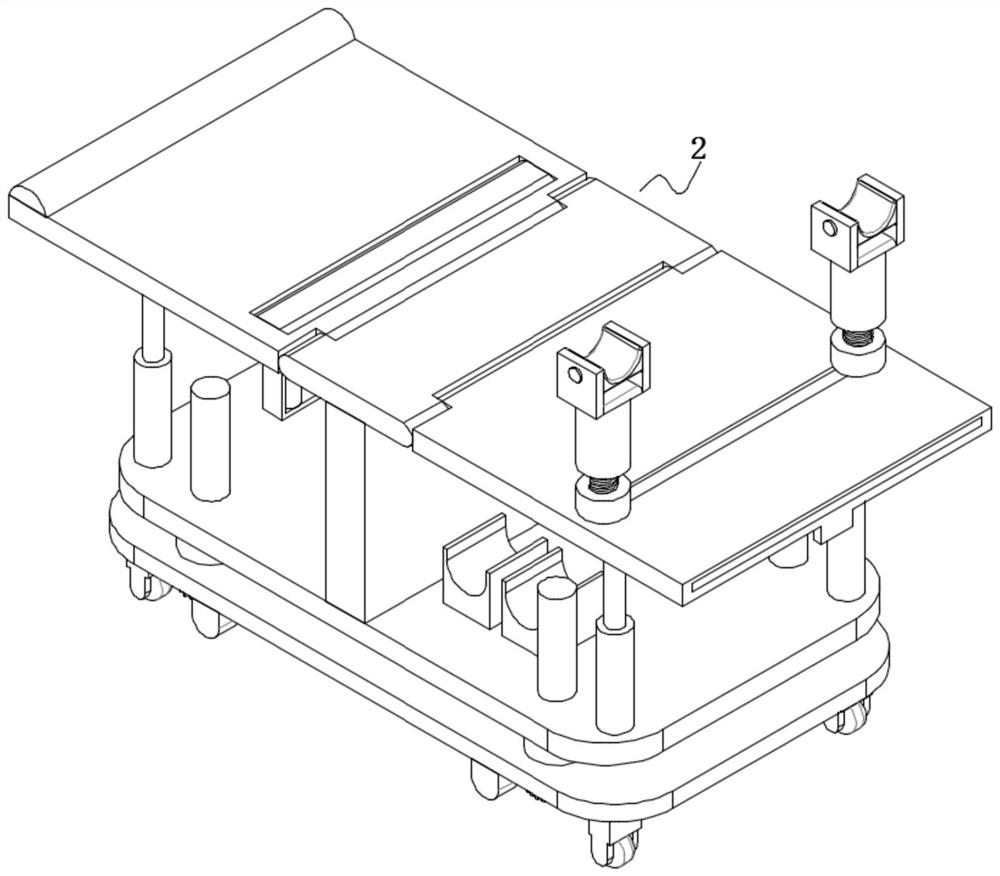

Novel B-ultrasonic examination device and using method thereof

PendingCN111938696AAdjustable inclinationEasy and comfortable inspectionDiagnostic probe attachmentInfrasonic diagnosticsClinical examEngineering

The invention discloses a novel B-ultrasonic examination device and a using method thereof, and relates to the technical field of medical facilities. The novel B-ultrasonic examination device comprises a B-ultrasonic machine, wherein an examination bed assembly is arranged on one side of the B-ultrasonic machine; the examination bed assembly comprises a base, and a group of fixed seats which are distributed in a rectangular array are fixedly connected to the bottom surface of the base; a threaded screw rod is rotationally connected between the opposite surfaces of every two fixed seats; a conical tooth ring is fixedly connected to the peripheral side surface of each of the two threaded screw rods; an annular seat is fixedly connected to the bottom surface of the base; a connecting rod is rotationally connected to the inner wall of the annular seat; and bevel gears are fixedly connected to two ends of the connecting rod. Through the design of the base, a supporting seat, electric telescopic rods, an upper supporting plate and a lower supporting plate, the problems that in the using process of an existing B-ultrasonic examination device, an examination bed cannot meet different clinical examination requirements easily, so that the examination efficiency of the device is low, an examinee feels much uncomfortable in the examination process, and further the practicability of the device is poor can be solved.

Owner:SUZHOU MUNICIPAL HOSPITAL

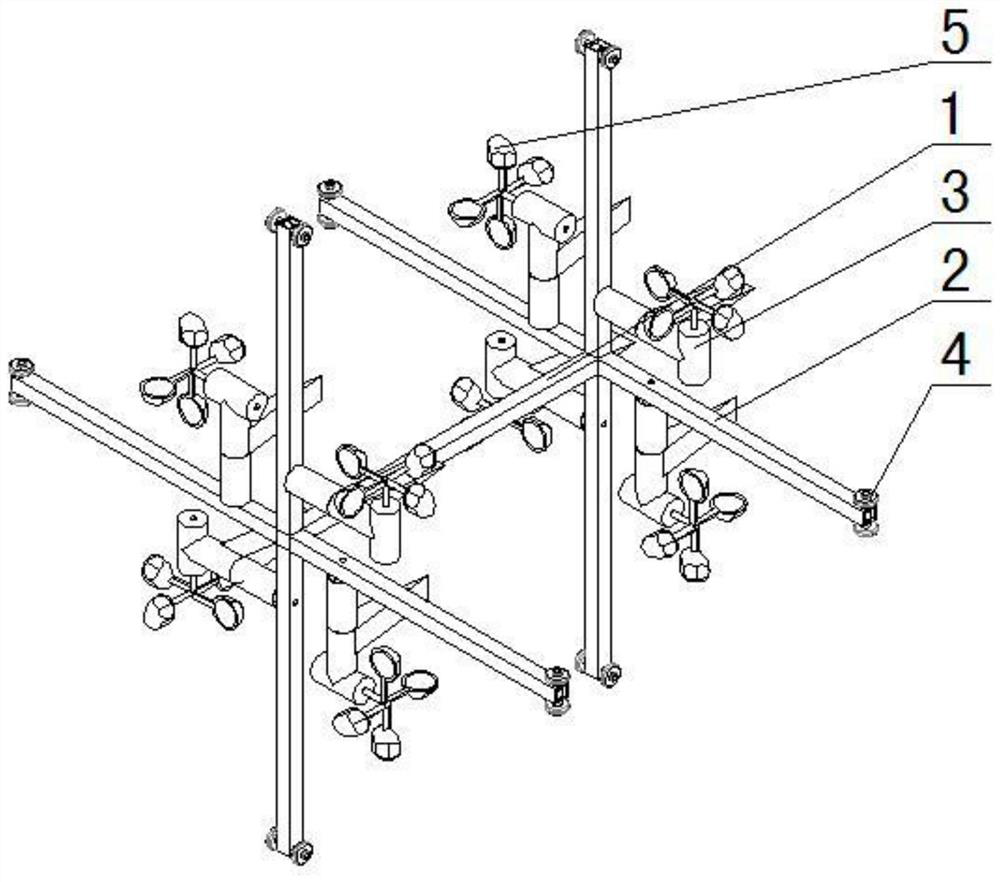

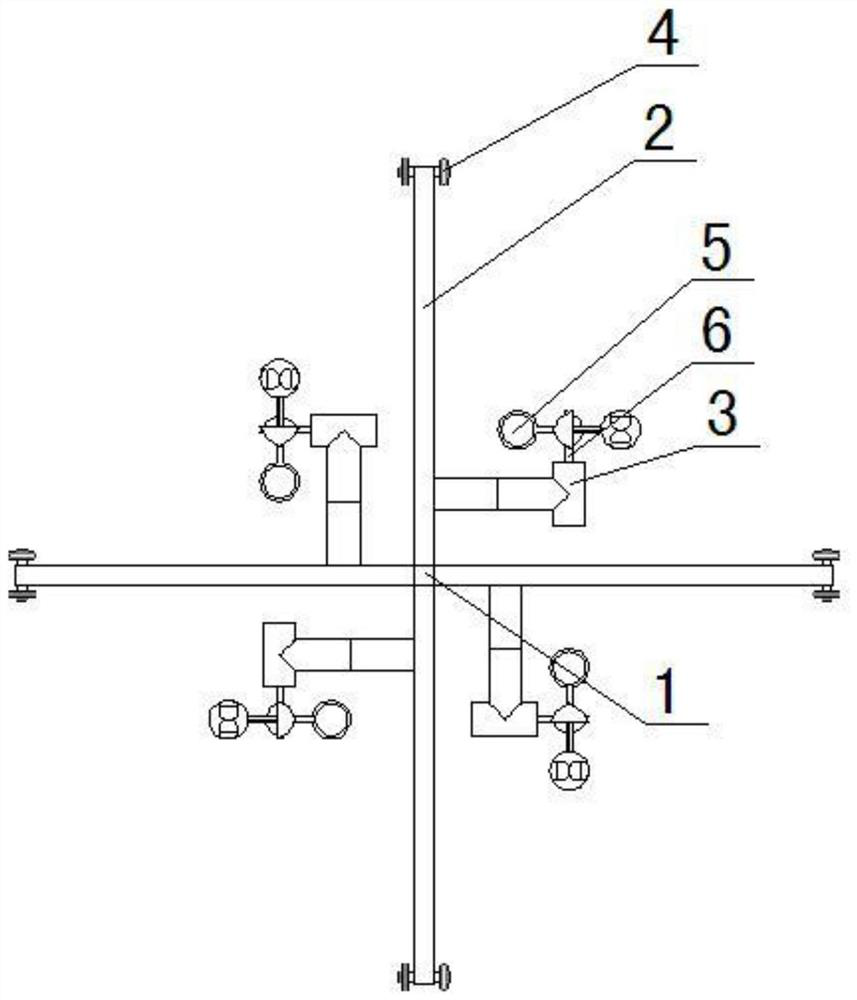

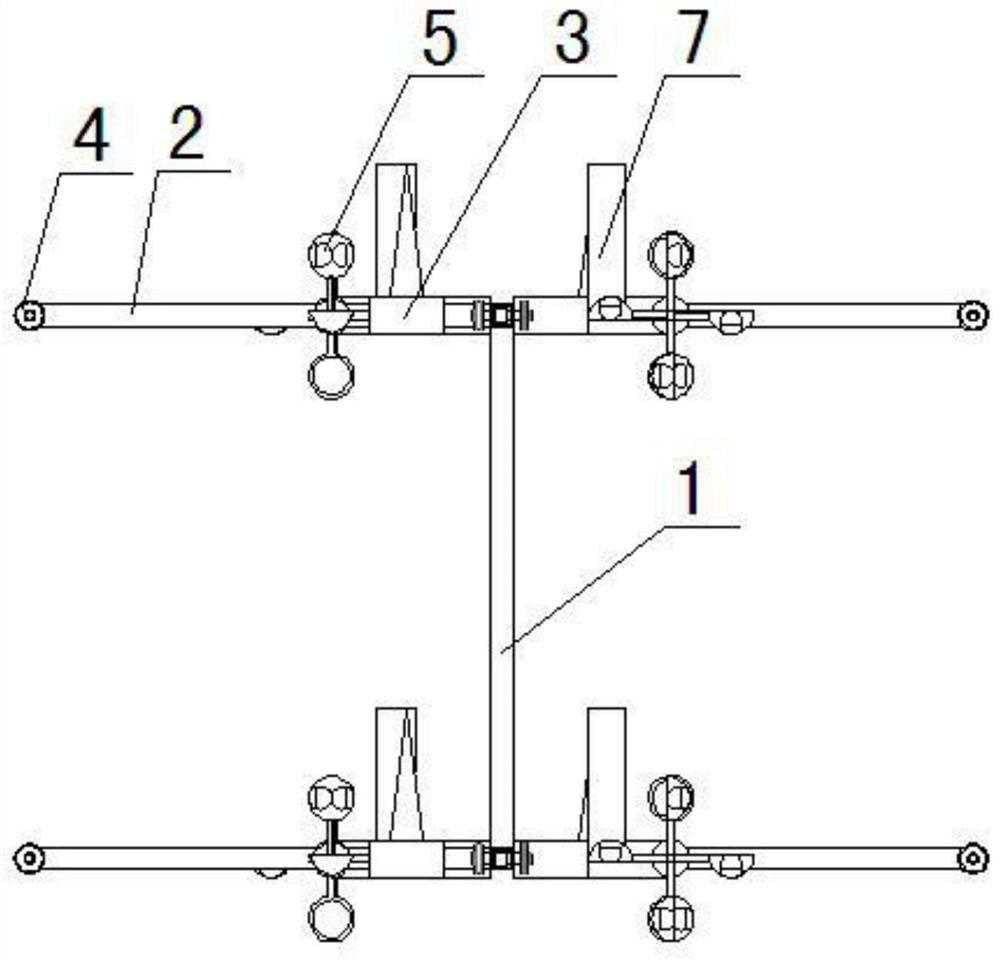

Cross-shaped pipeline robot

The invention discloses a cross-shaped pipeline robot. The cross-shaped pipeline robot comprises two symmetrical cross-shaped supports, wherein the cross-shaped supports are connected through a connecting rod, a damping wheel is installed at the tail end of each support, a driving mechanism is vertically installed on each support, each driving mechanism comprises a driving frame, a conical tooth shaft and a transmission conical tooth shaft are installed in each driving frame, each conical tooth shaft is vertically connected with the corresponding transmission conical tooth shaft in a meshed mode, each spoon rod is connected with the corresponding conical tooth shaft, each transmission conical tooth shaft is connected with a conical tooth telescopic motor, and transmission is carried out and interrupted by controlling the conical tooth telescopic motors; a driving synchronous belt shaft is connected with the conical tooth telescopic motors, and a synchronous belt is connected with the driving synchronous belt shaft and a driven synchronous belt shaft; and the damping wheels are installed on the driven synchronous belt shaft, and four spoon rods and rotating spoons are installed at the tail ends of the conical tooth shafts in the circumferential direction. According to the cross-shaped pipeline robot, the rotation of the conical tooth shafts is realized through the rotation of the rotating spoons, the rotation of the transmission conical tooth shafts is driven, then the transmission conical tooth shafts connected with the transmission conical tooth shafts rotate, and the synchronous belt is connected with the driving synchronous belt shaft and the driven synchronous belt shaft to drive the damping wheels to rotate.

Owner:汪皖豫

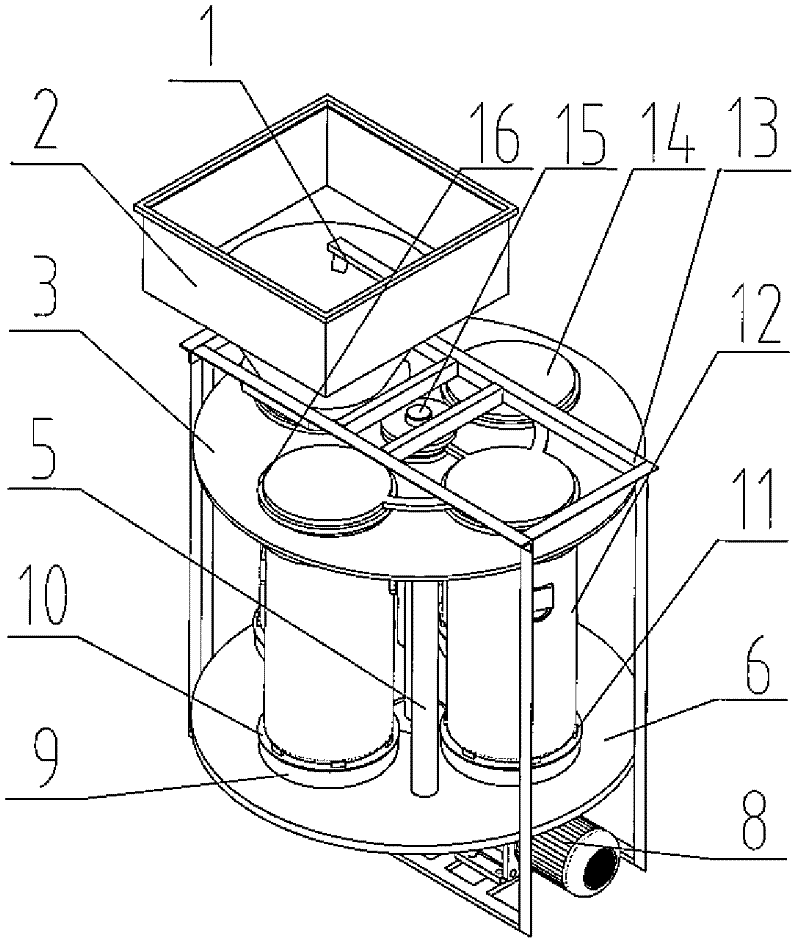

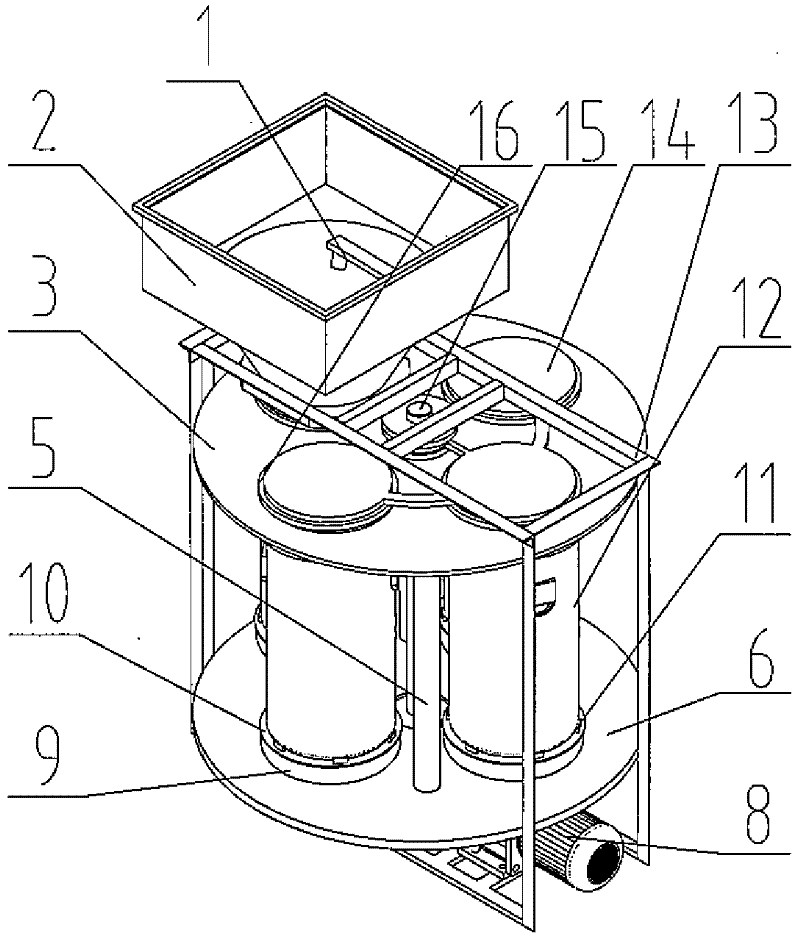

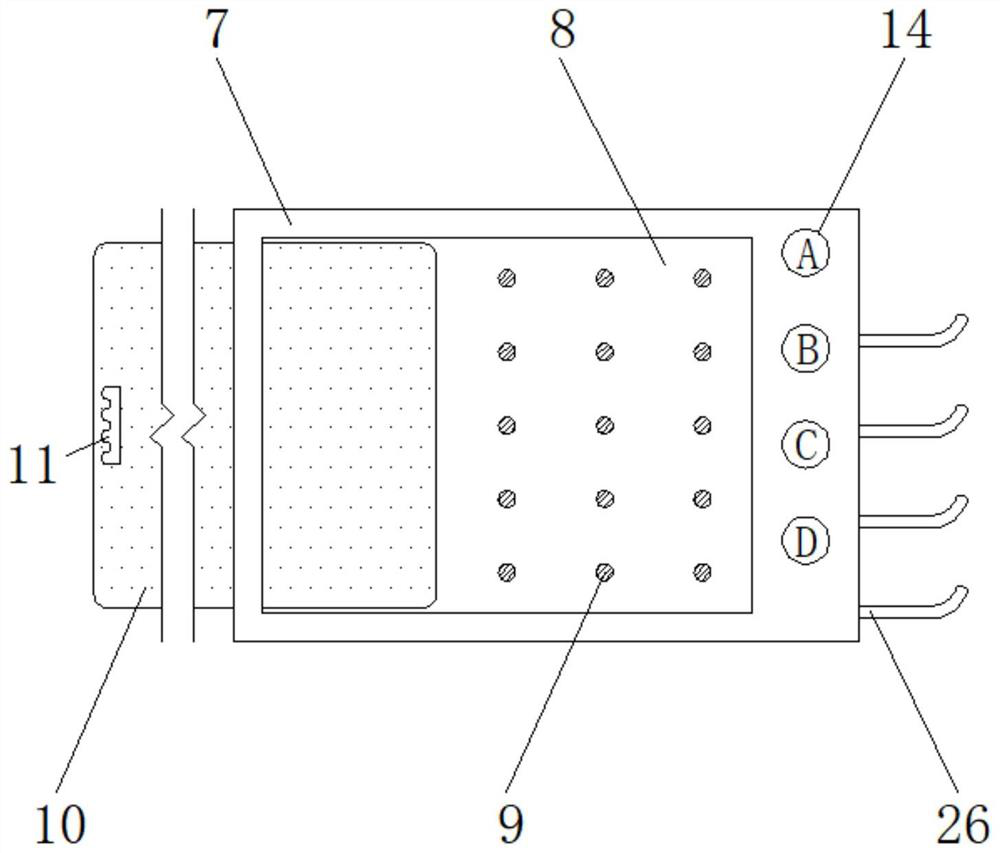

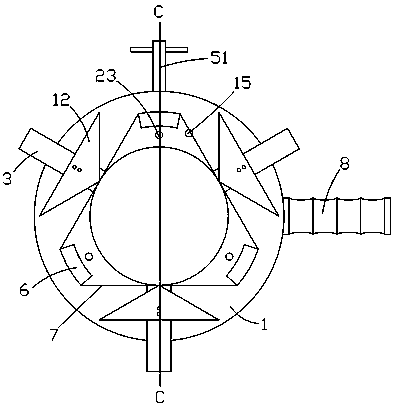

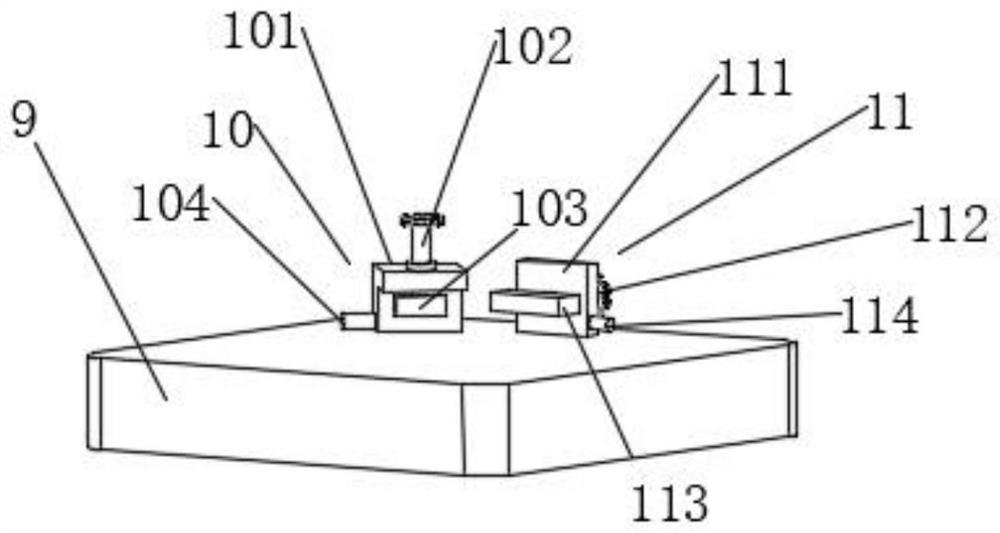

A step-by-step large-flow aerosol sampling device

ActiveCN105466733BSimple structureEasy to operateWithdrawing sample devicesLower limitPulp and paper industry

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Tail cutter for puppy

The invention discloses a tail cutter for a puppy. The tail cutter comprises a ring incision disc, a through hole used for placing the tail of the puppy is formed in the middle of the ring incision disc, and the ring incision disc comprises a front end cover, a rear end cover and three sliding claws; the front end cover is matched with the rear end cover, a cutter is arranged at the end in each sliding claw, and a scroll and a bevel gear are installed between the front end cover and the rear end cover; the scroll is installed in a scroll groove in the right end face of the front end cover, thebevel gear is in meshed transmission with conical teeth on the right end face of the scroll, and a spiral groove is formed in the left end face of the scroll; multiple clamping teeth meshed with thespiral groove are arranged on the sliding claws, a spanner is connected to the outer end of the bevel gear, a supporting structure is arranged on the left end face of the front end cover, and a hemostasis binding belt sleeves the supporting structure; when the ring incision disc works, the spanner is screwed up to make the bevel gear rotate, then the scroll is driven to rotate, and then the spiralgroove in the left end face of the scroll rotates to drive the three sliding claws move radially along a sliding claw track of the front end cover. The operation time for cutting the tail is short, and the removal effect is good.

Owner:临沭县济才人力资源服务有限公司

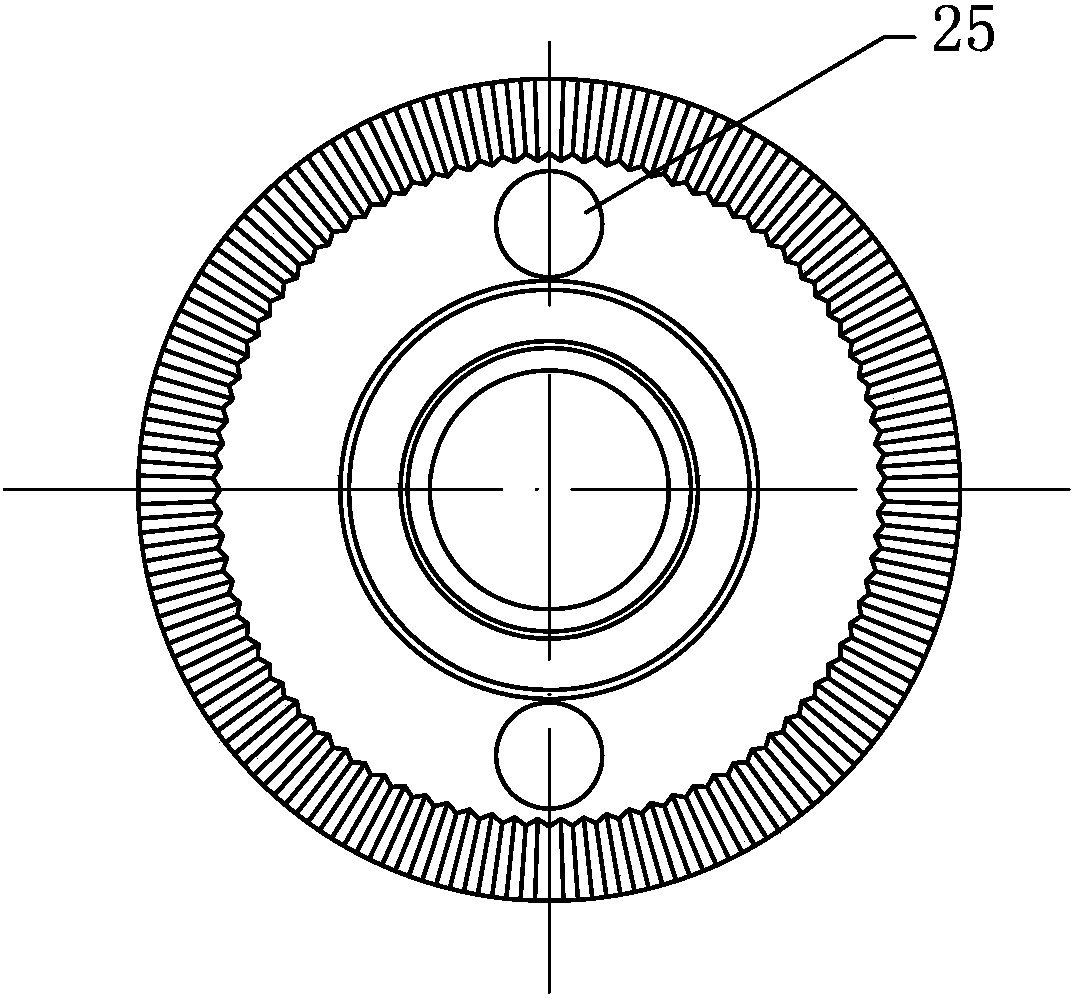

Special gear for optical fiber rotary connector

InactiveCN110701280AReduce the numberSave FixturesPortable liftingCoupling light guidesGear wheelEngineering

Owner:安徽澜轩光电科技有限责任公司

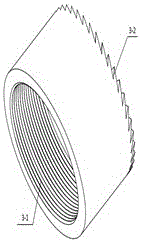

End face driving bevel gear tooth-shaped connecting structure

PendingCN114321322AReduce weightIncrease the bearing surfacePortable liftingGearing elementsGear wheelBevel gear

The invention discloses an end face driving bevel gear tooth-shaped connecting structure which is characterized in that the outer end of the end face of a component I is an externally tangent inclined annular inclined face I, a plurality of inclined bevel gears I are evenly and outwards arranged on the annular inclined face I in a protruding mode, bevel grooves I are formed between the bevel gears I, and bevel gears are formed by the bevel gears I and the bevel grooves I; the outer end part of the end surface of the part II is a concave and inclined ring-shaped inclined surface II; the inclined plane II and the inclined plane I have the same width and inclination angle; conical grooves II which are the same as the conical teeth I in number and are matched with the conical teeth I are uniformly and inwards concavely formed in the inclined surface II, conical teeth II matched with the conical grooves I are arranged among the conical grooves II, and each conical tooth II and each conical groove II form an inwards concave bevel gear; and the component I and the component II are axially compressed, and the bevel gear and the concave bevel gear are completely meshed together. The invention has the advantages of large stress area, good transmission stability, strong wear resistance and long service life; the self-centering function is achieved, jumping generated by rotation is avoided, noise is low, and the self-centering rotary joint is suitable for being used in occasions with higher rotating speed and higher power rotary connection.

Owner:耐世特凌云驱动系统(涿州)有限公司

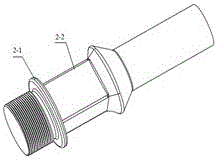

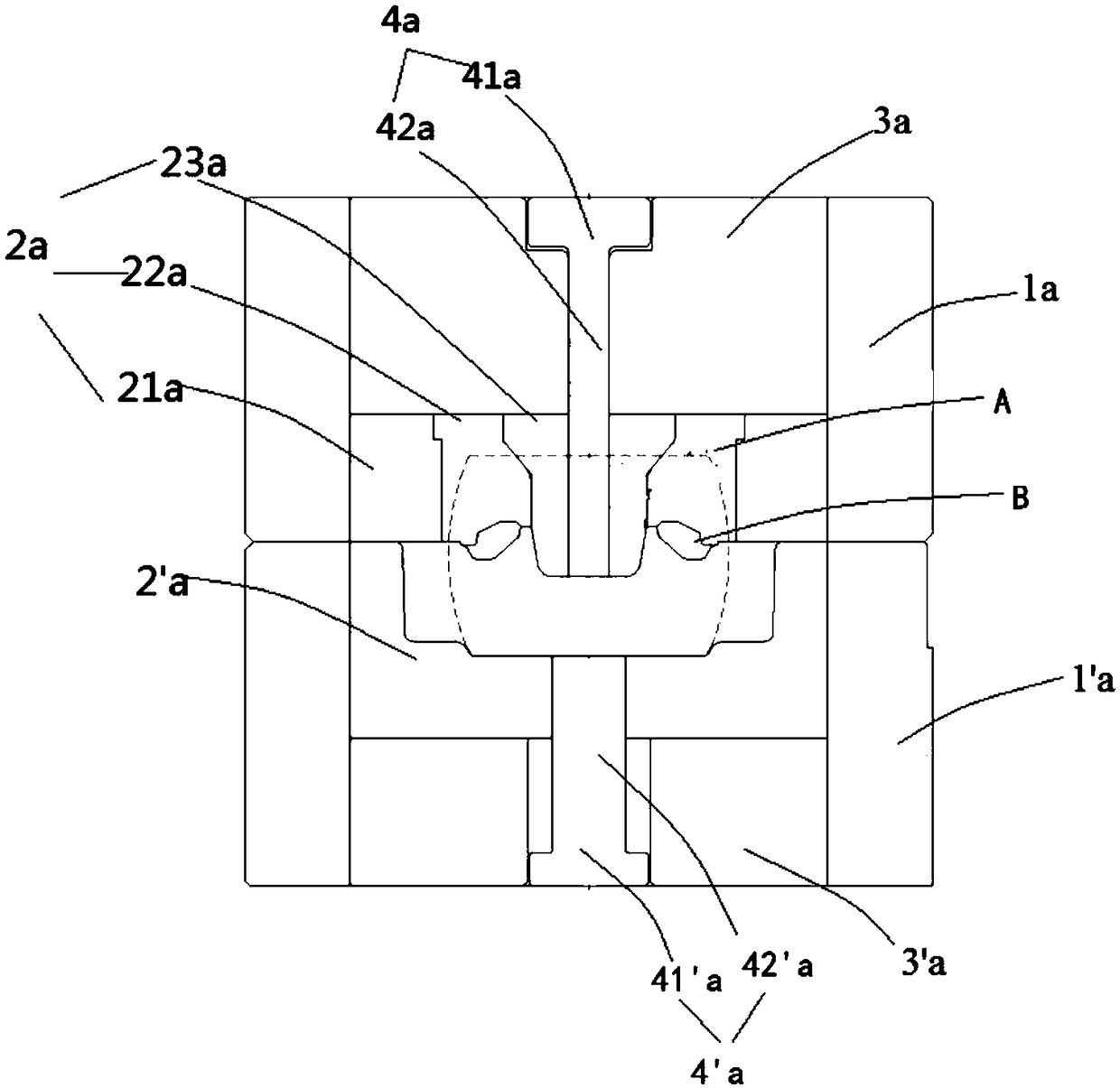

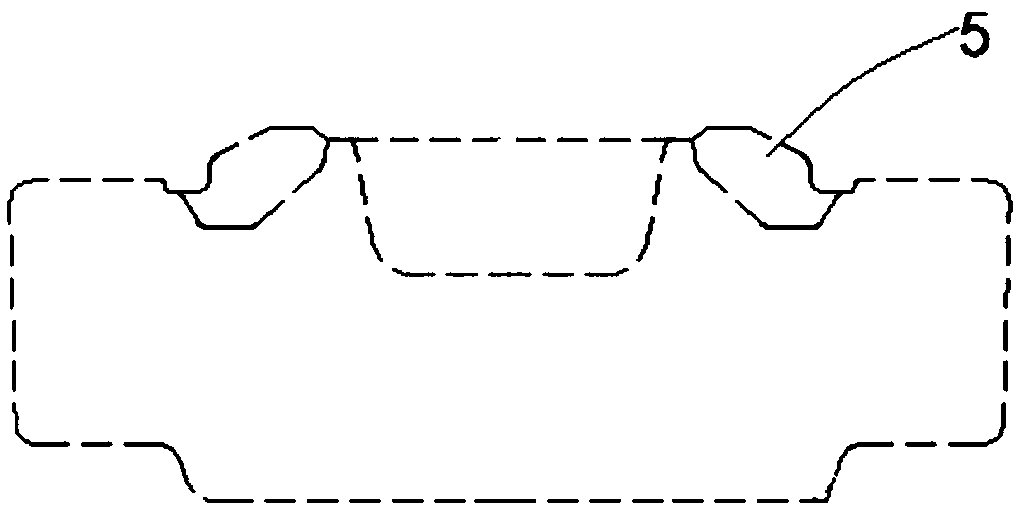

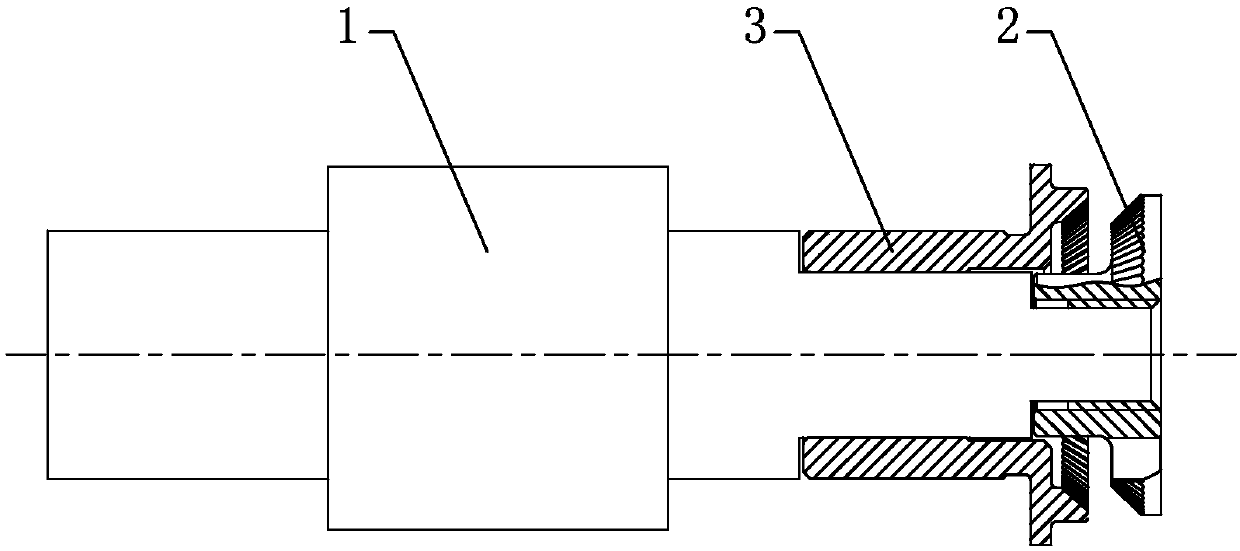

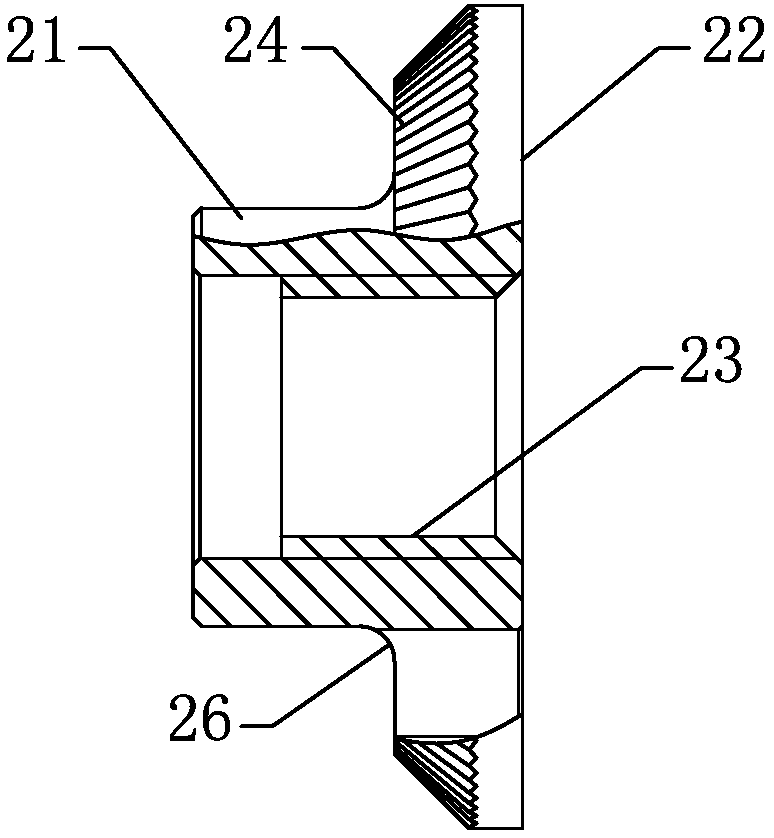

Conical tooth clutch assembly and machining technology thereof

The invention discloses a conical tooth clutch assembly, aims at providing a conical tooth clutch assembly in which a worm shaft and an outer conical tooth clutch are of a separated structure, and machining is easy, and belongs to the technical field of the automobile braking technology. According to the technical scheme, the conical tooth clutch assembly is characterized by comprising the worm shaft and further comprising an inner conical tooth clutch sleeved with the worm shaft, and the outer conical tooth clutch detachably connected with the worm shaft, the inner conical tooth clutch and the worm shaft are movably connected in the axial direction, and the inner conical tooth clutch is matched with the outer conical tooth clutch.

Owner:玉环市润浩机械股份有限公司

Industrial robot connecting base facilitating angle adjustment

PendingCN114654502APrevent rotationRelieve pressureProgramme-controlled manipulatorEngineeringIndustrial robotics

The invention discloses an industrial robot connecting base convenient for angle adjustment, relates to the technical field of industrial robots, and solves the technical problem that the angle of an industrial robot is inconvenient to adjust. Comprising a base and a shell, the base is arranged at the bottom in the shell, a thrust shaft seat is installed at the upper end of the base, and conical teeth are arranged at the upper end of the thrust shaft seat; a circular groove is formed in the center of the conical tooth, a thrust ball journal is installed at the bottom of the conical tooth, and a plurality of driving units are evenly arranged in the circumferential direction of the conical tooth. The upper ends of the conical teeth are fixedly connected with the bottom of a mounting seat; a plurality of first fixing units and a plurality of second fixing units are arranged at the upper end of the mounting base, and the four first fixing units and the four second fixing units are distributed in a staggered mode in the circumferential direction. The structure is reasonable, and angle adjustment of the industrial robot is facilitated.

Owner:迅立达智能装备制造科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com