Conical screw rotors of twin-screw vacuum pump

A conical screw and vacuum pump technology, which is applied to the components, pumps, and pump elements of the pumping device for elastic fluids, can solve the problems of limited enlargement effect, limited performance improvement effect, incomplete meshing, etc. The effect of reducing the volume of the working chamber, increasing the content ratio, and improving the ultimate vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

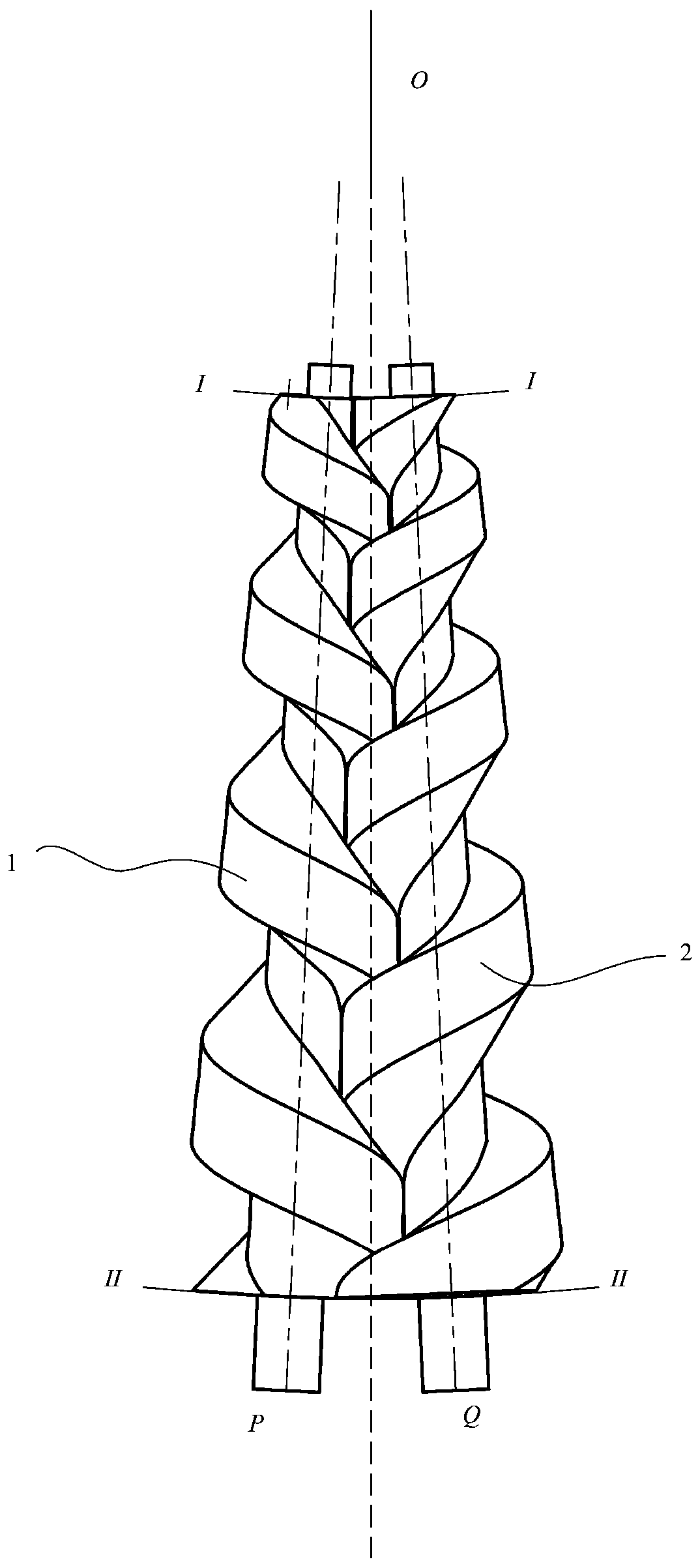

[0057] Such as figure 1 As shown, it is the meshing diagram of two screw rotors, including: left conical screw rotor 1, right conical screw rotor 2, left conical screw rotor 1 and right conical screw rotor 2 are connected from low pressure end II-II to high pressure end Ⅰ-Ⅰ is a linear conical shape, that is, the pitch circle radius, tooth top radius and tooth bottom radius of the left conical screw rotor 1 and the right conical screw rotor 2 are linearly reduced;

[0058] In the working engagement state, the rotation axis OP of the left conical screw rotor 1 and the rotation axis OQ of the right conical screw rotor 2 intersect at one point, the intersection point is O, and the angle between the two rotation axes is ∠POQ=θ, which is taken as The value range is 0°<θ<90°;

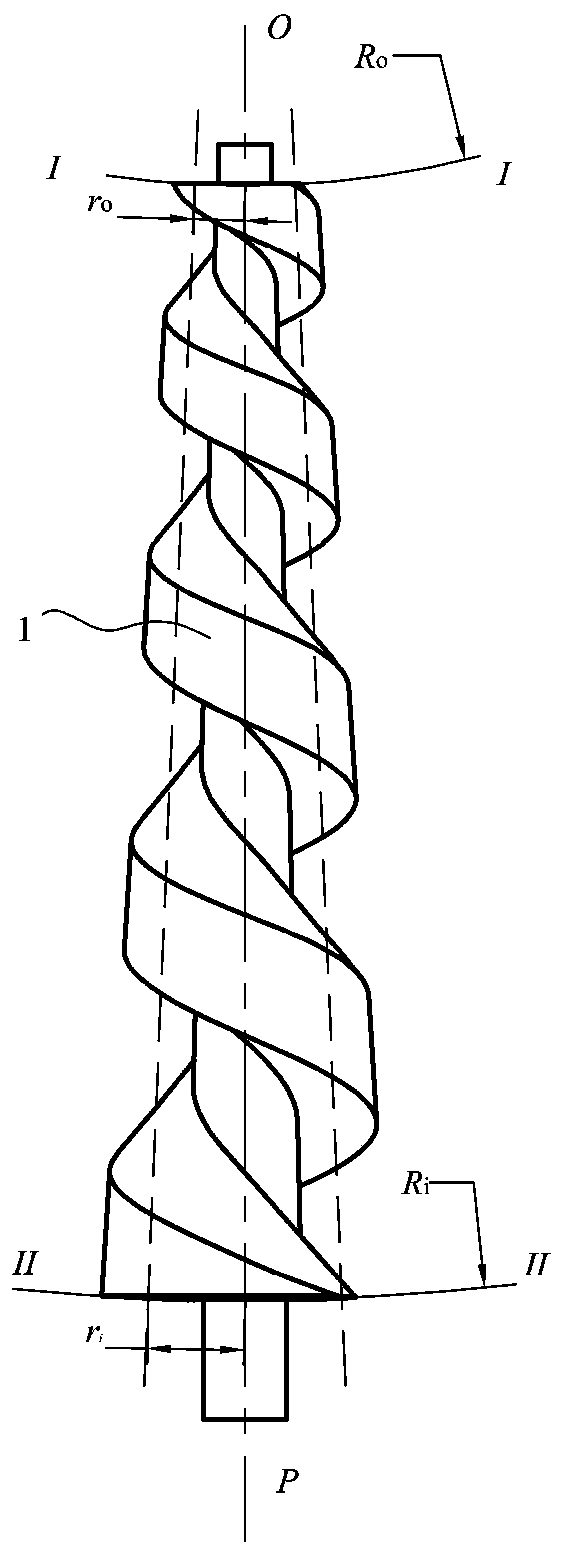

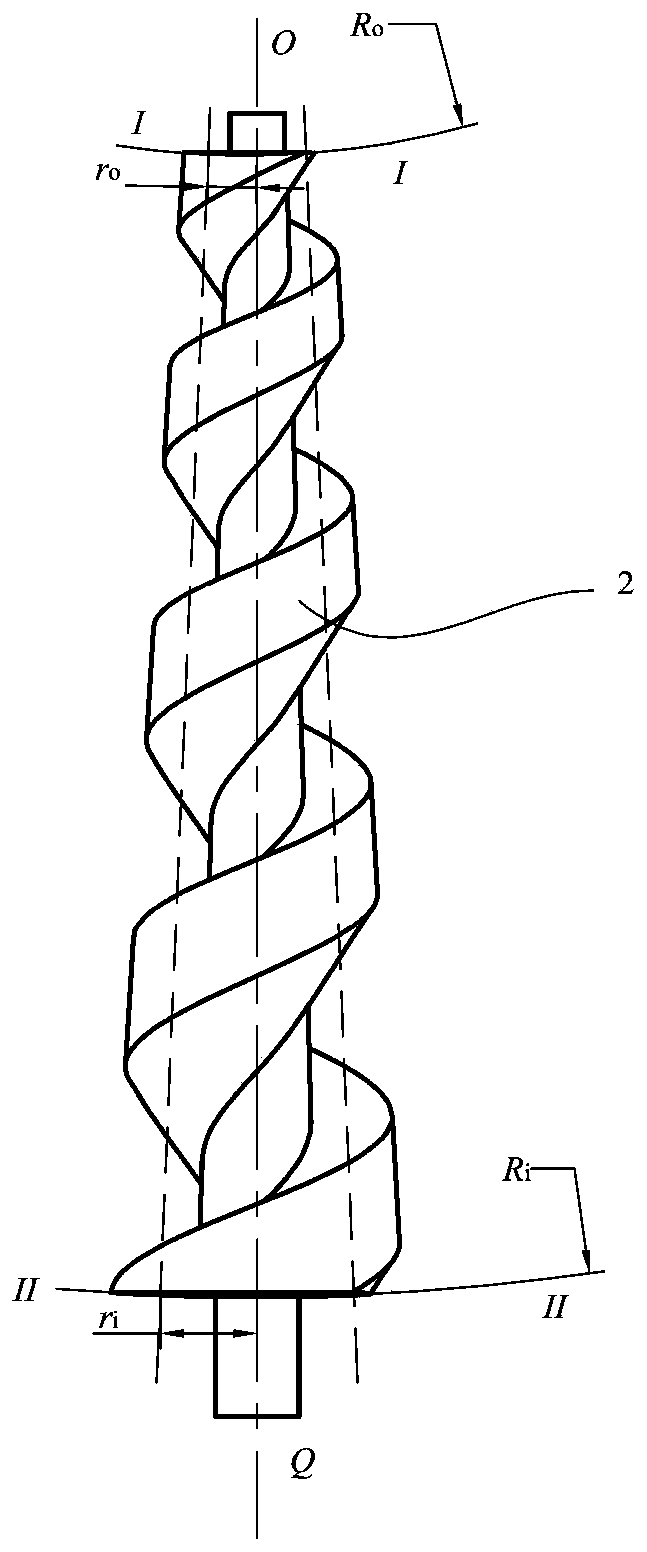

[0059] Such as figure 2 As shown, it is a three-dimensional diagram of the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com