Self-balancing conical screw rotor

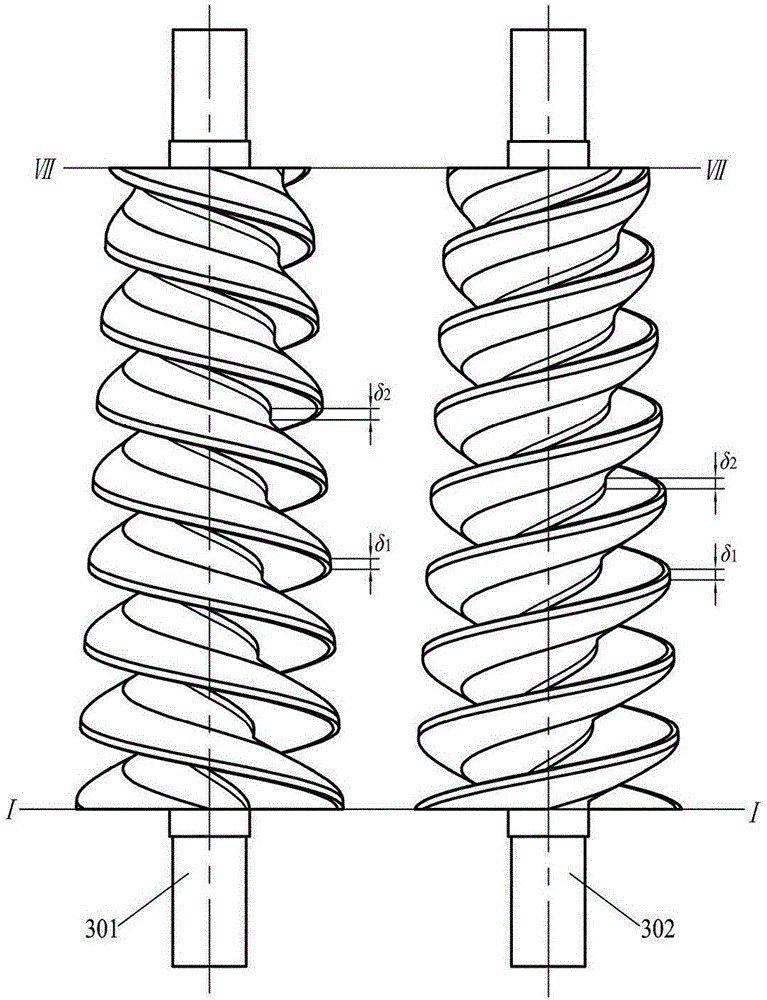

A conical screw, self-balancing technology, used in rotary piston pumps, rotary piston machines, components of pumping devices for elastic fluids, etc., can solve the problem of occupying suction volume, reducing deformation, and increasing strength and other problems, to achieve the effect of increasing the volume of the working chamber, reducing the deformation, and ensuring the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

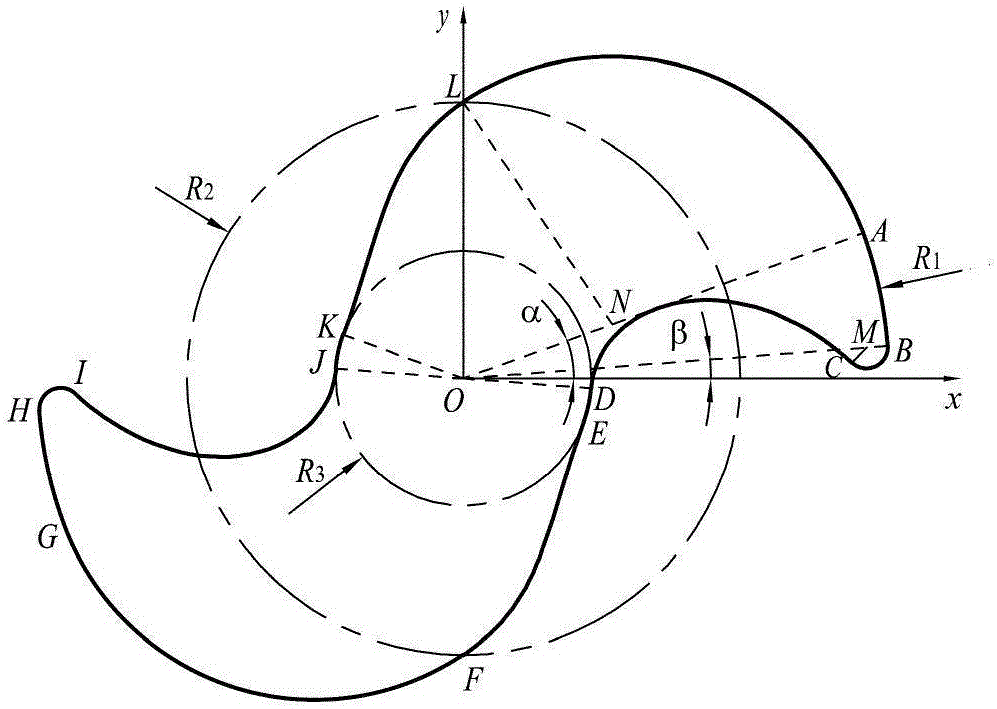

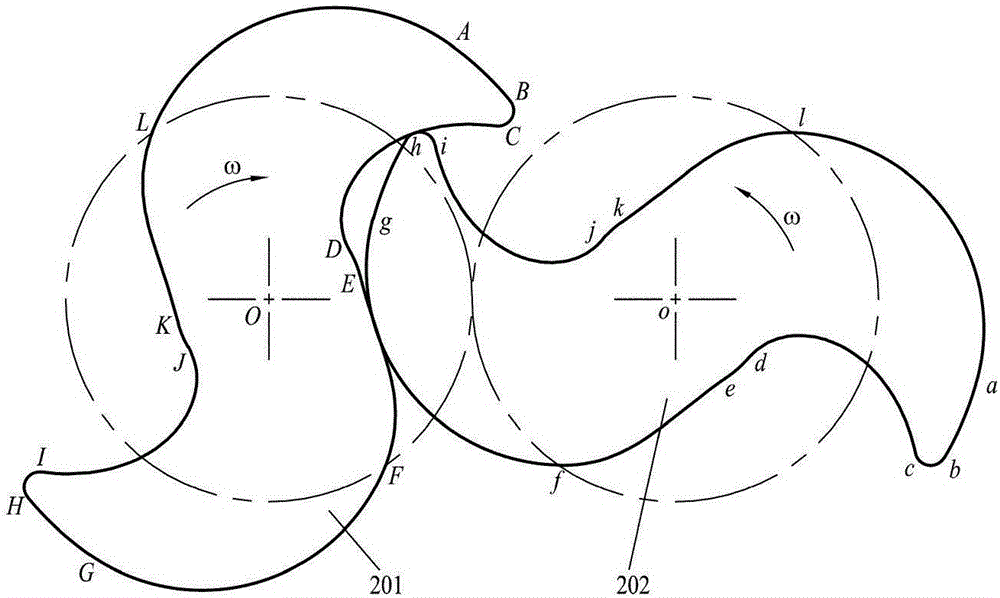

[0054] Such as figure 1 Shown is the cross-sectional line diagram of the self-balancing conical screw rotor; the cross-sectional line of the screw rotor refers to: using a plane perpendicular to the centerline of the screw rotor rotation, the screw rotor is cut off from any axial position, and the cross-section The contour curve obtained; the cross-sectional profile of the screw rotor is surrounded by 12 curves, clockwise as follows: the first addendum arc AB, the first addendum arc BC, the equidistant curve CD of the first cycloid, the first A dedendum arc DE, the envelope EF of the first connecting arc, the first connecting arc FG, the second addendum arc GH, the second tooth tip arc HI, and the equidistant curve IJ of the second cycloid , the second dedendum arc JK, the envelope KL of the second connecting arc, and the second connecting arc LA; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com