Patents

Literature

63results about How to "Increase ultimate vacuum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

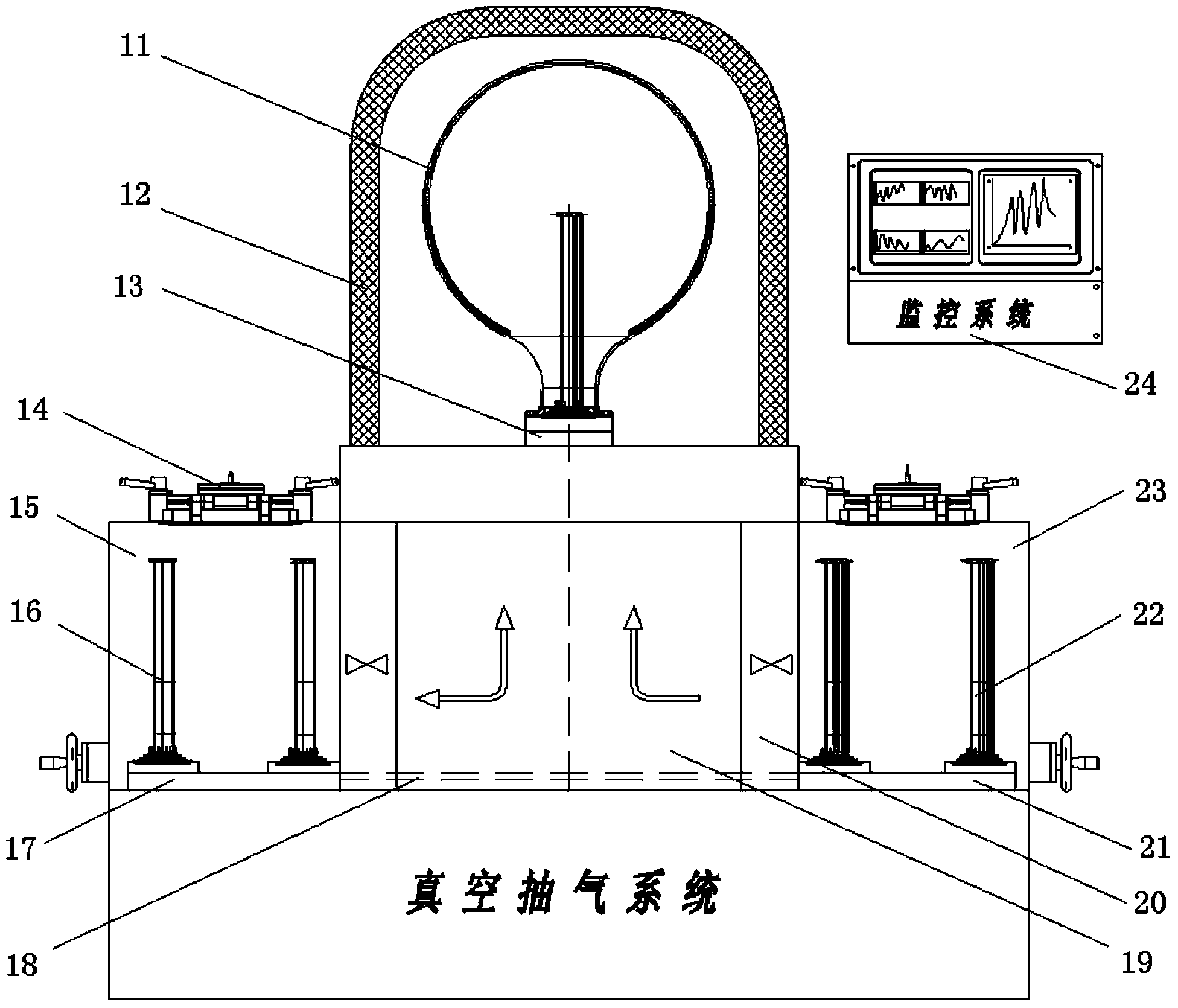

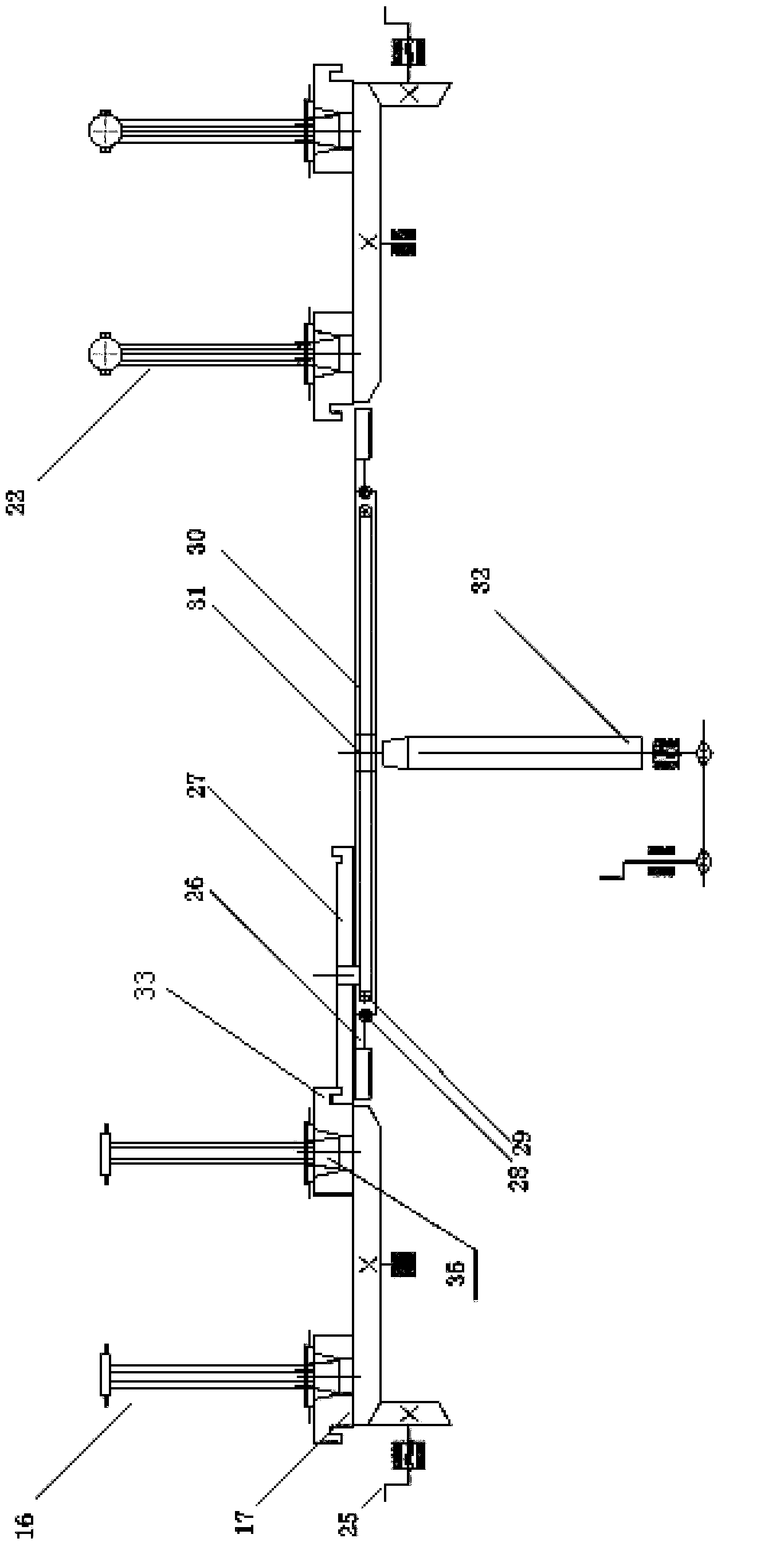

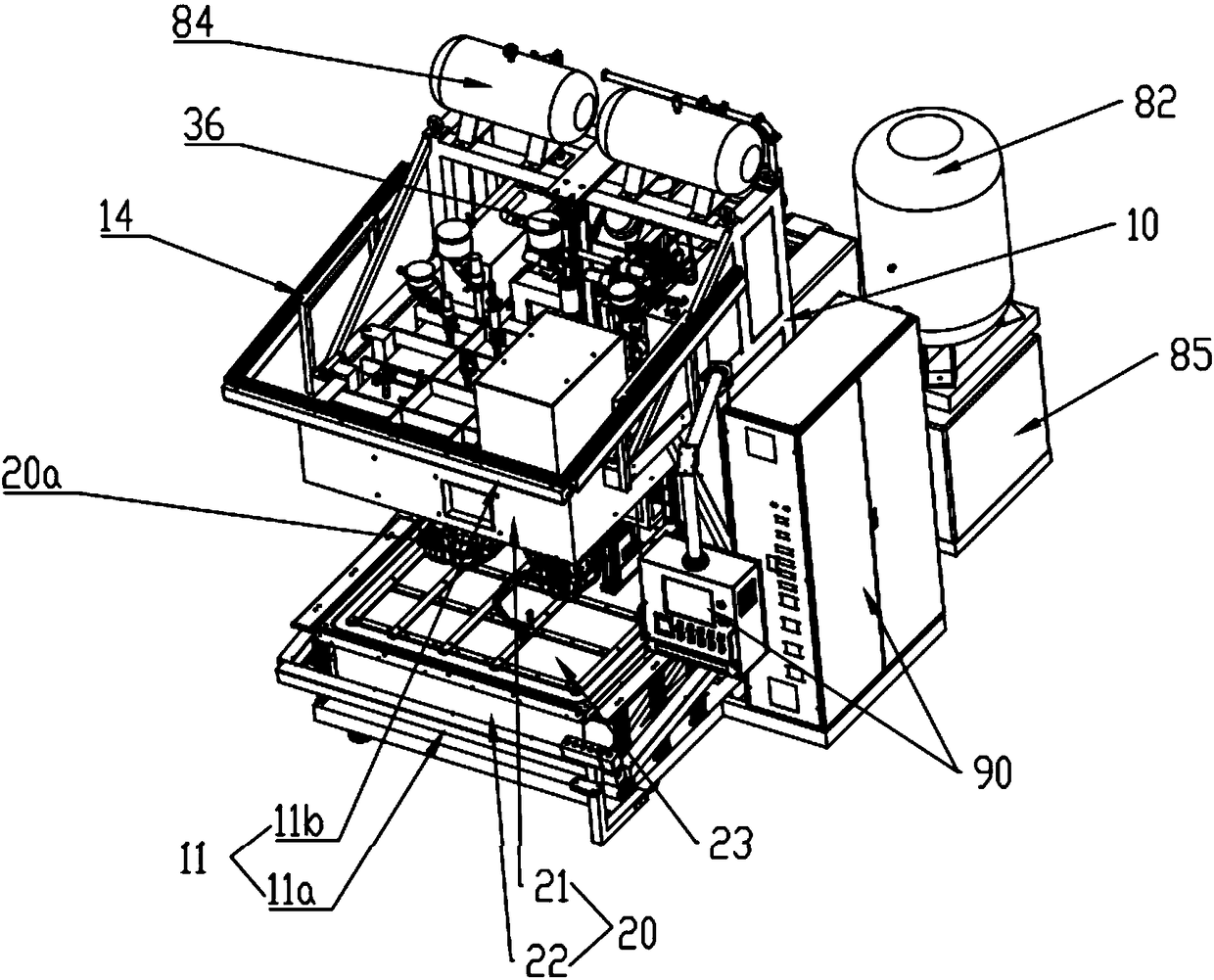

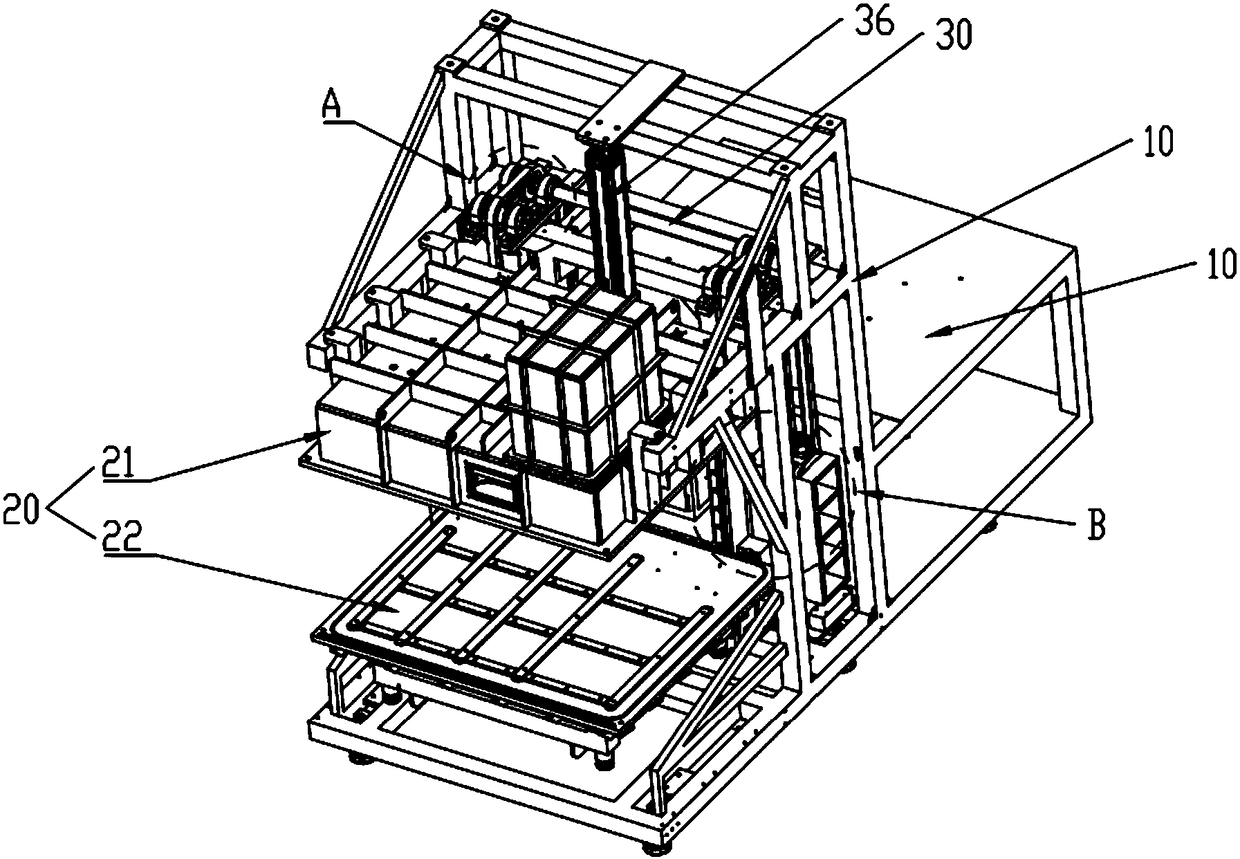

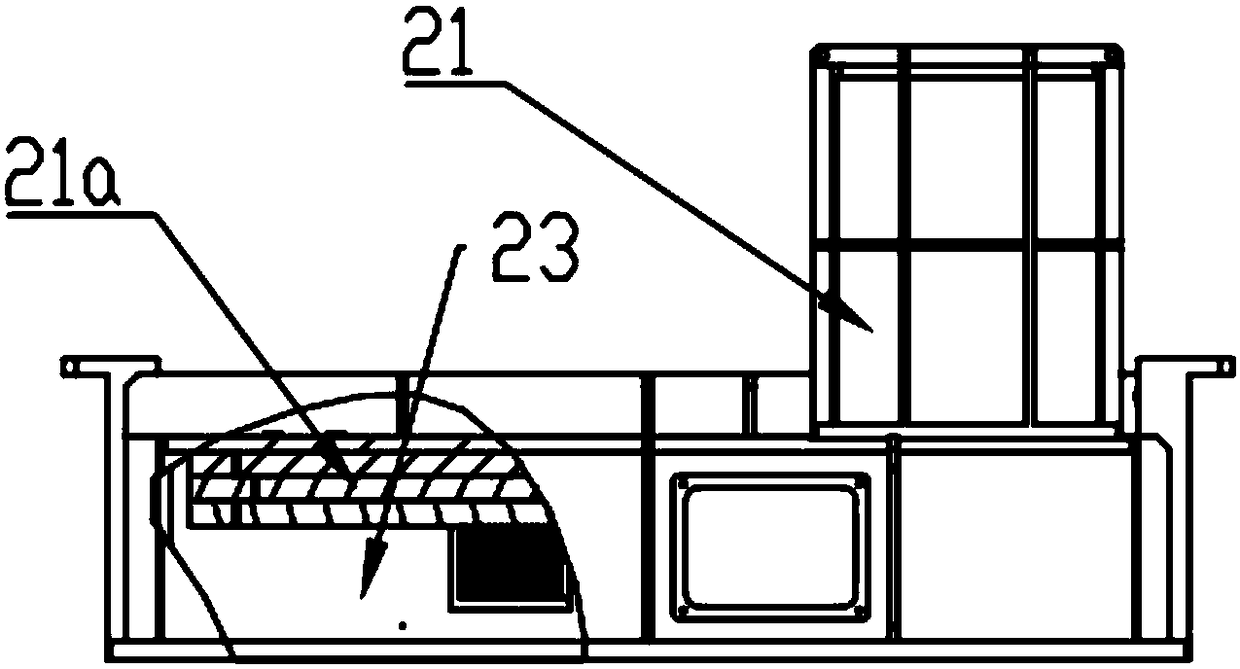

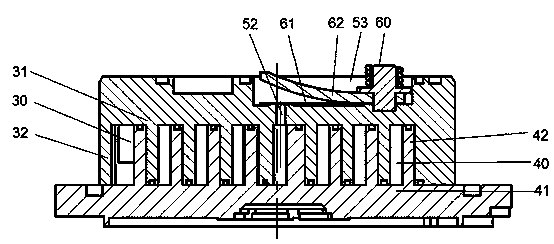

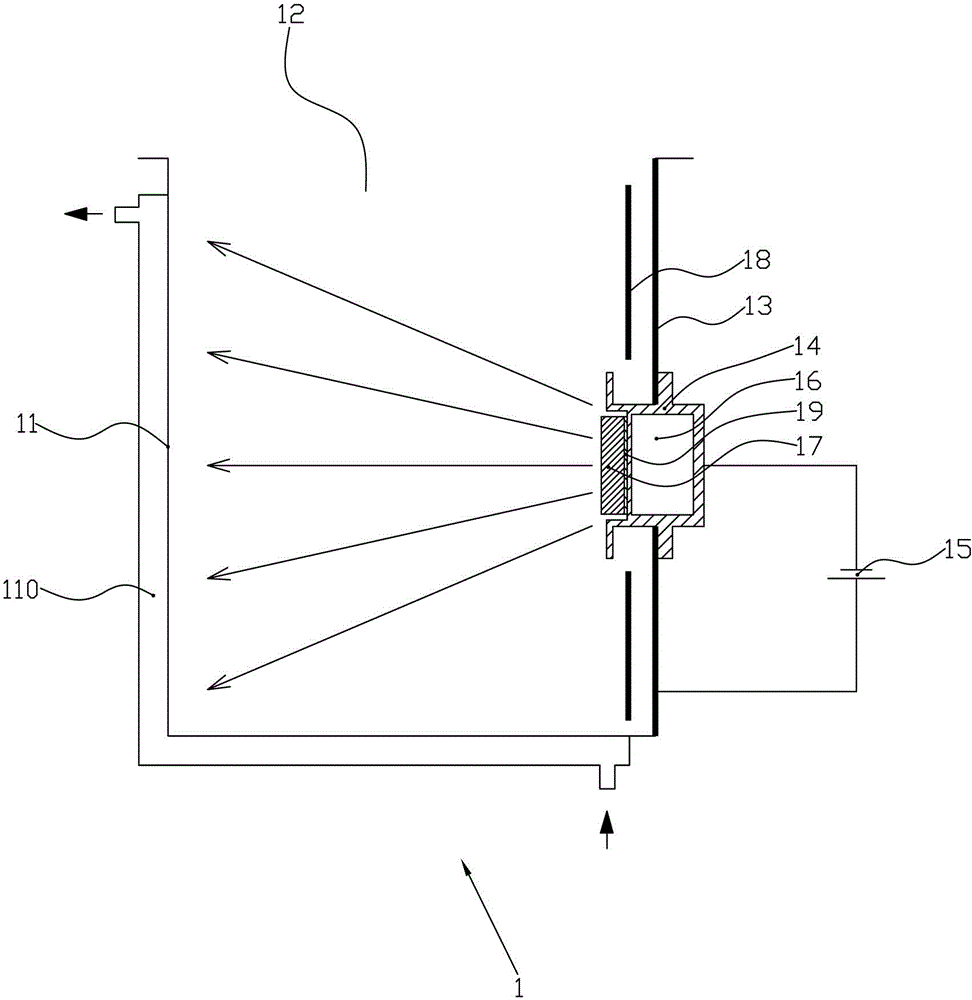

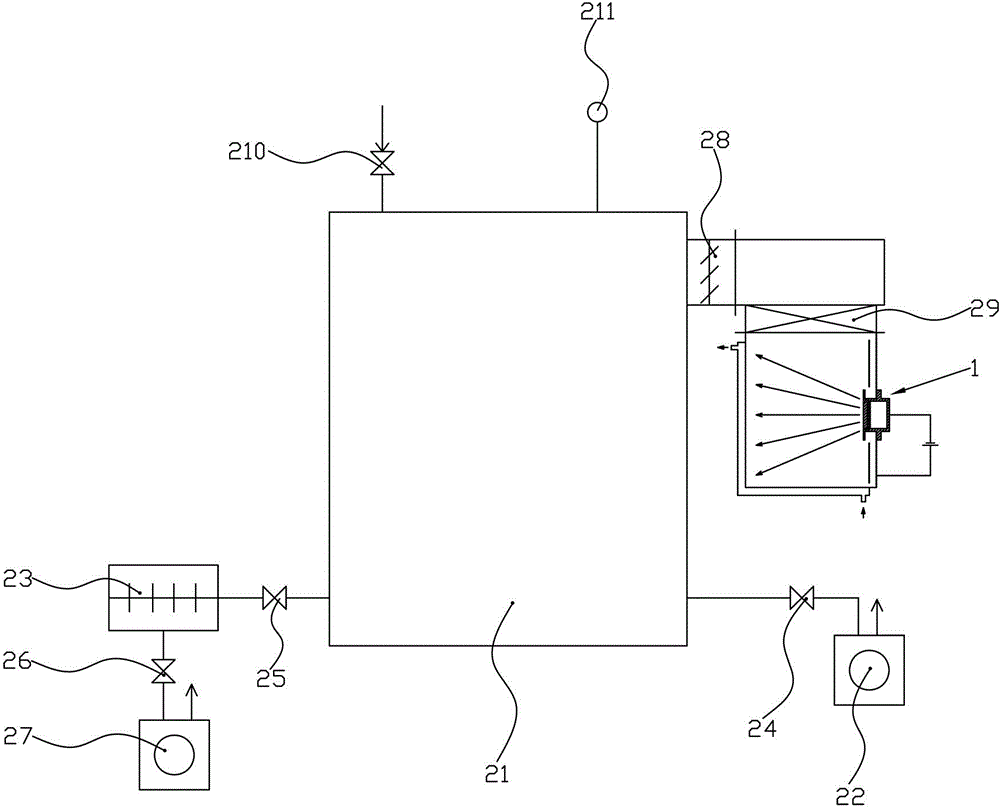

Photoelectric detection device transfer manufacturing system and method

ActiveCN103715034AIncrease ultimate vacuumImprove performanceCold cathode manufactureHorizontal transmissionVacuum pumping

The invention provides a photoelectric detection device transfer manufacturing system and method. The photoelectric detection device transfer manufacturing system comprises a cathode cavity, an anode cavity, a working transmission cavity, a transfer transmission system, a drying oven and a vacuum-pumping system, wherein the cathode cavity, the anode cavity and the working transmission cavity are separated through valves, the cathode cavity and the anode cavity are located on the two sides of the working transmission cavity respectively, the transfer transmission system comprises a horizontal transmission system and a lifting system, and the horizontal transmission system comprises an anode assembly containing device, a cathode assembly containing device and a horizontal transmission device. When a photoelectric detection device is manufactured through the manufacturing system, all other technological processes except the anode assembly assembling process are completed in a clean environment with ultrahigh vacuum, and therefore core devices of an MCP can be prevented from being polluted in the manufacturing process; the MCP anode assembly processing process and the photocathode manufacturing process are independent from each other so that non-cathode parts can be prevented from being polluted by cathode alkali metal and the MCP can be kept in a working state with the optimum performance.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

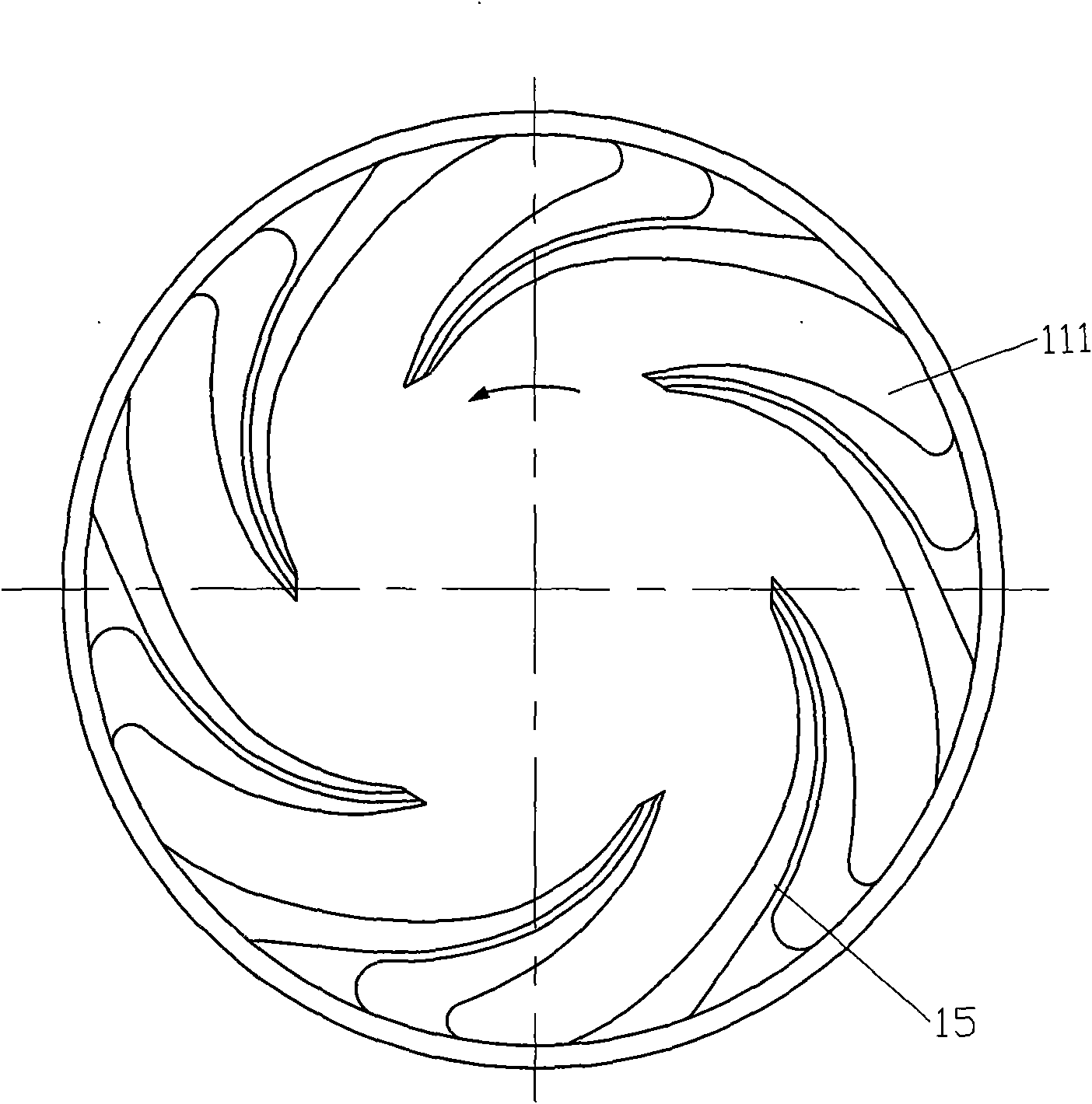

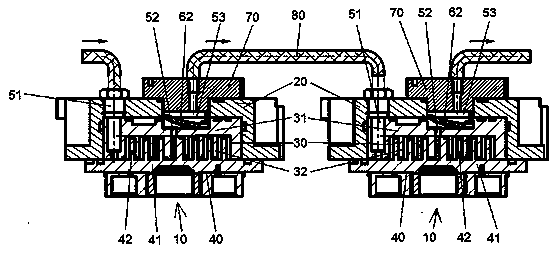

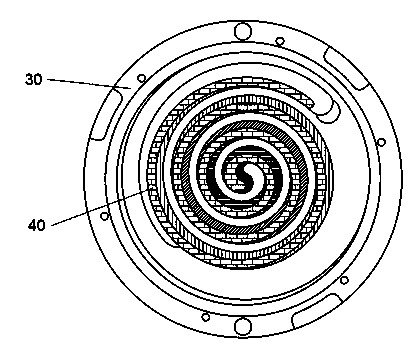

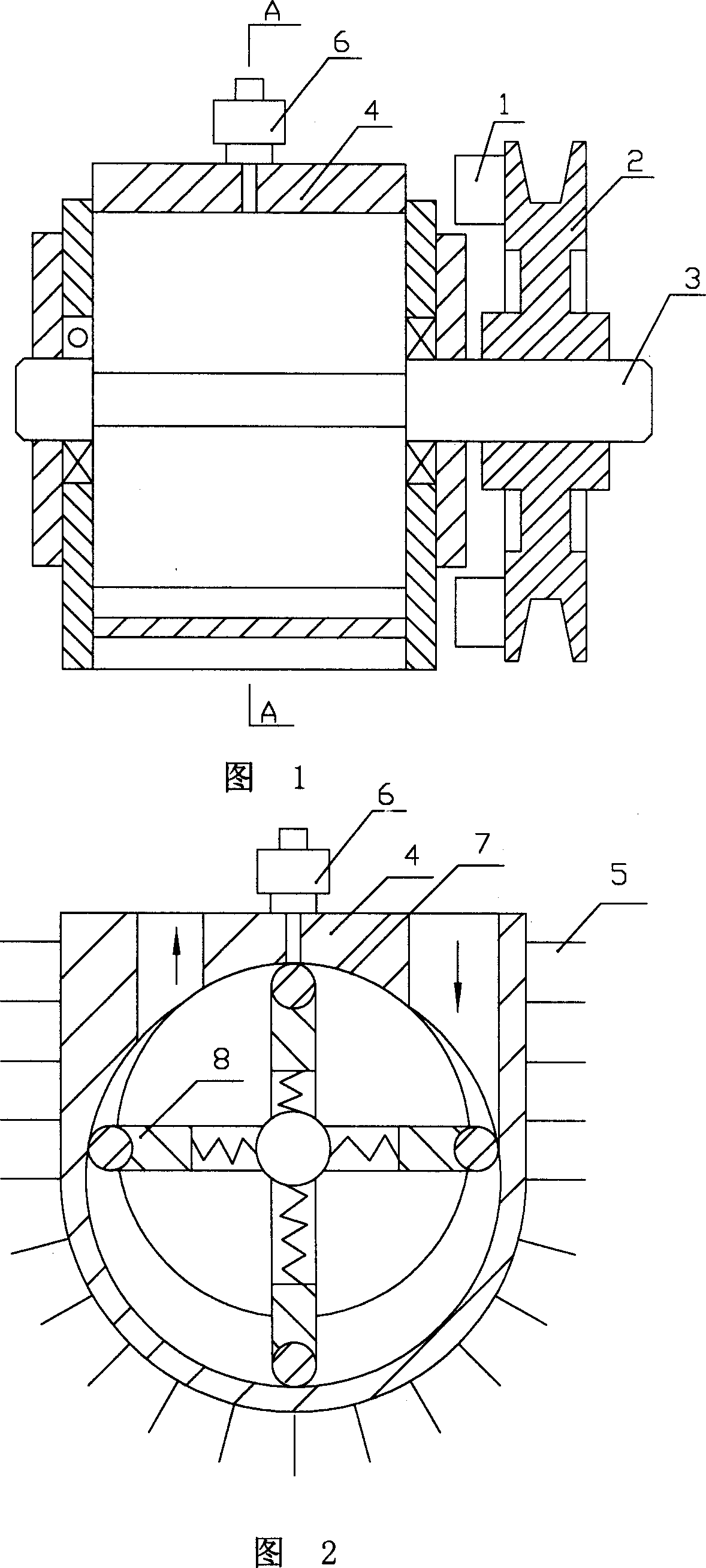

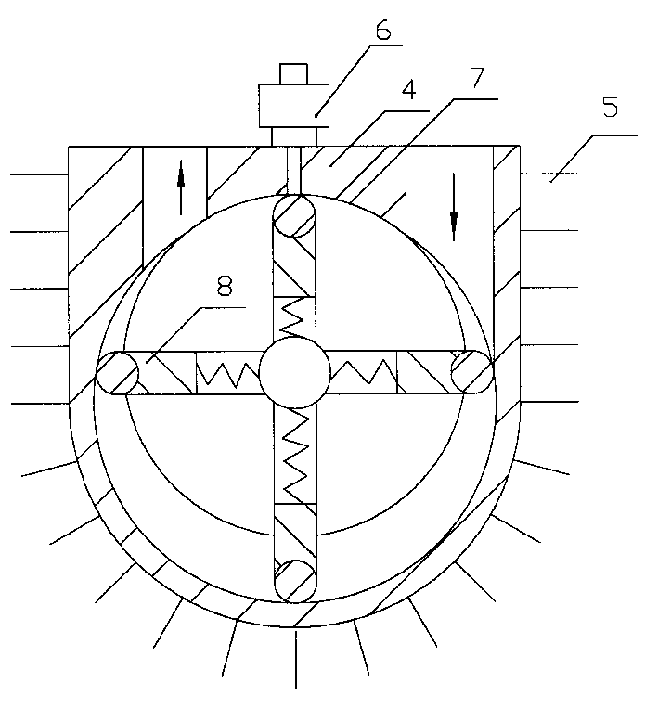

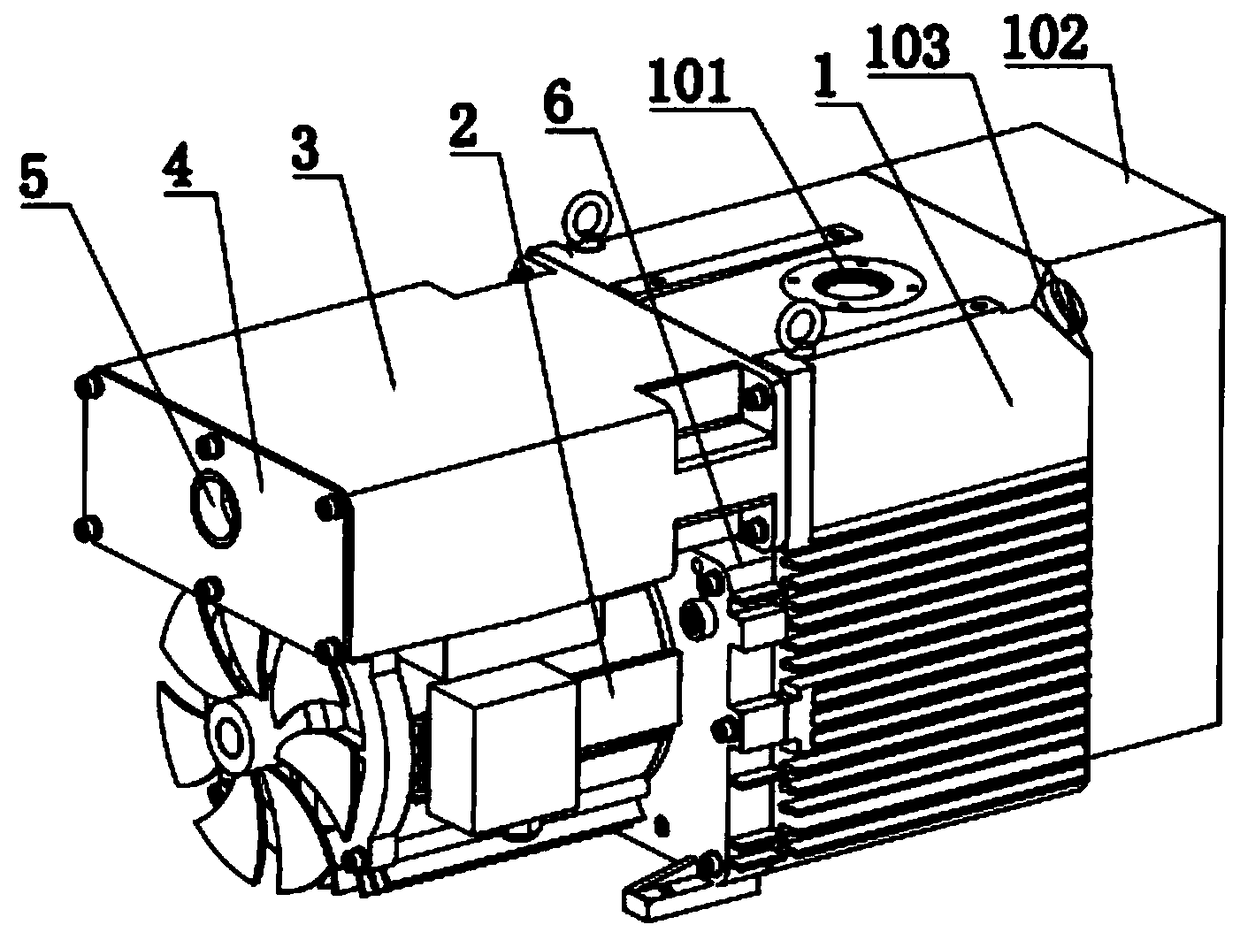

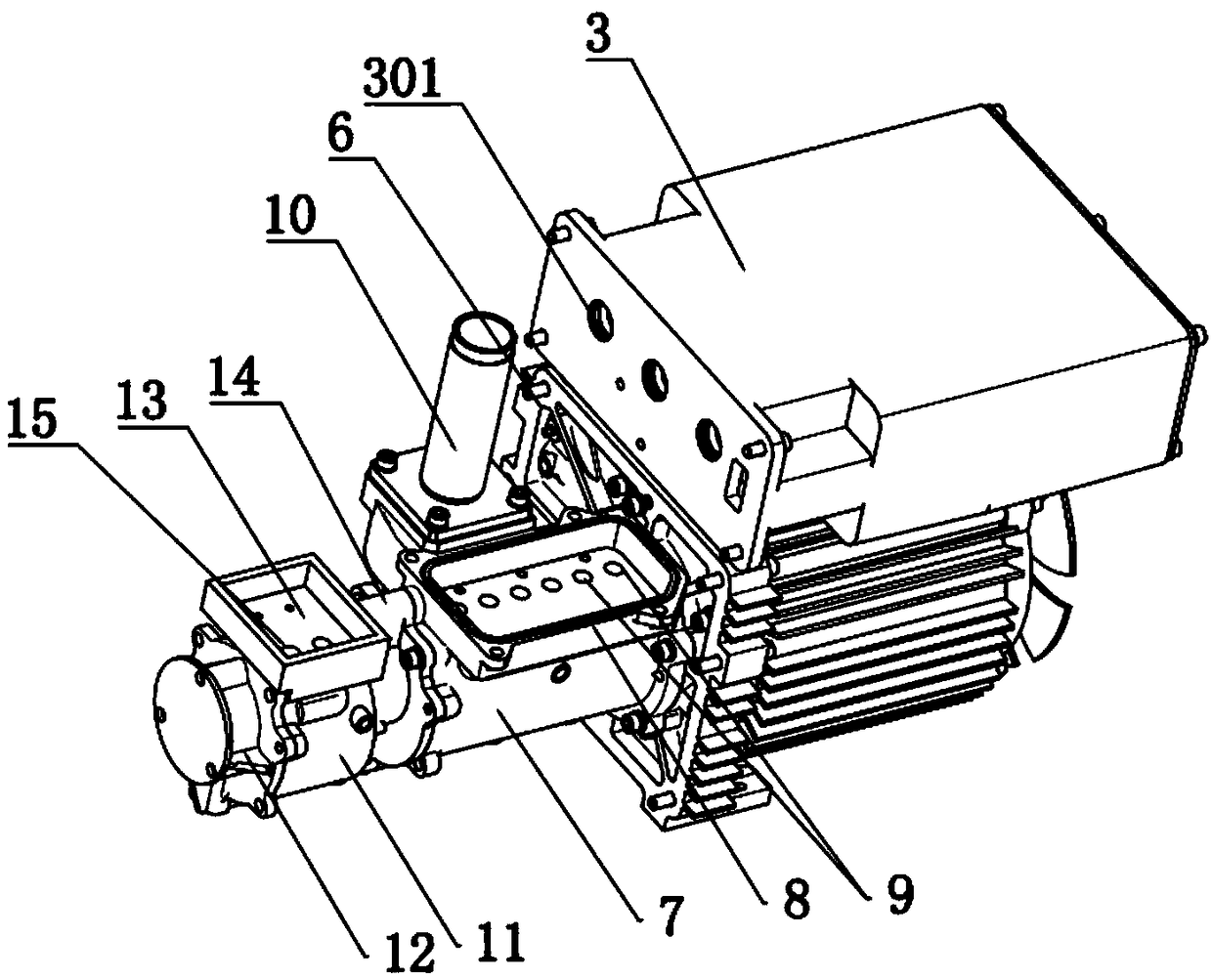

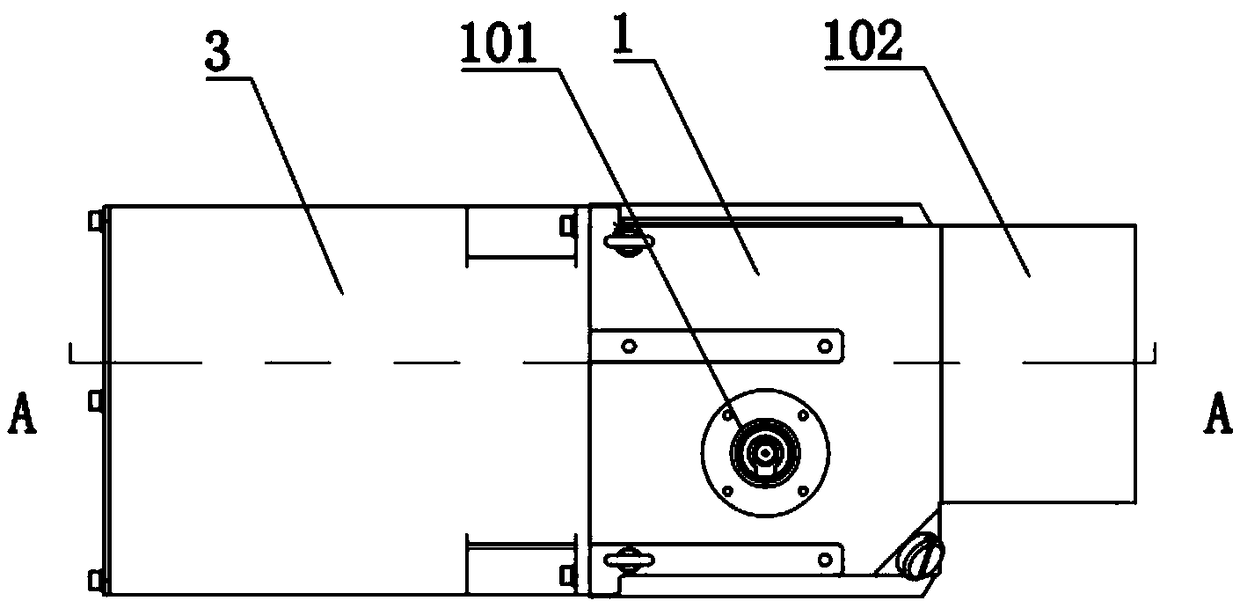

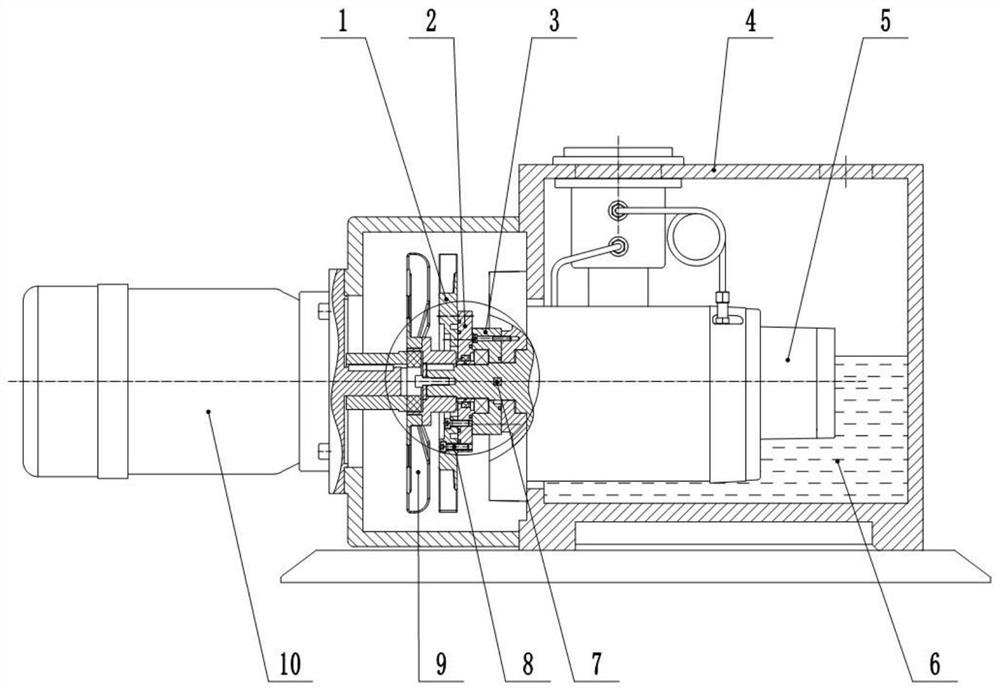

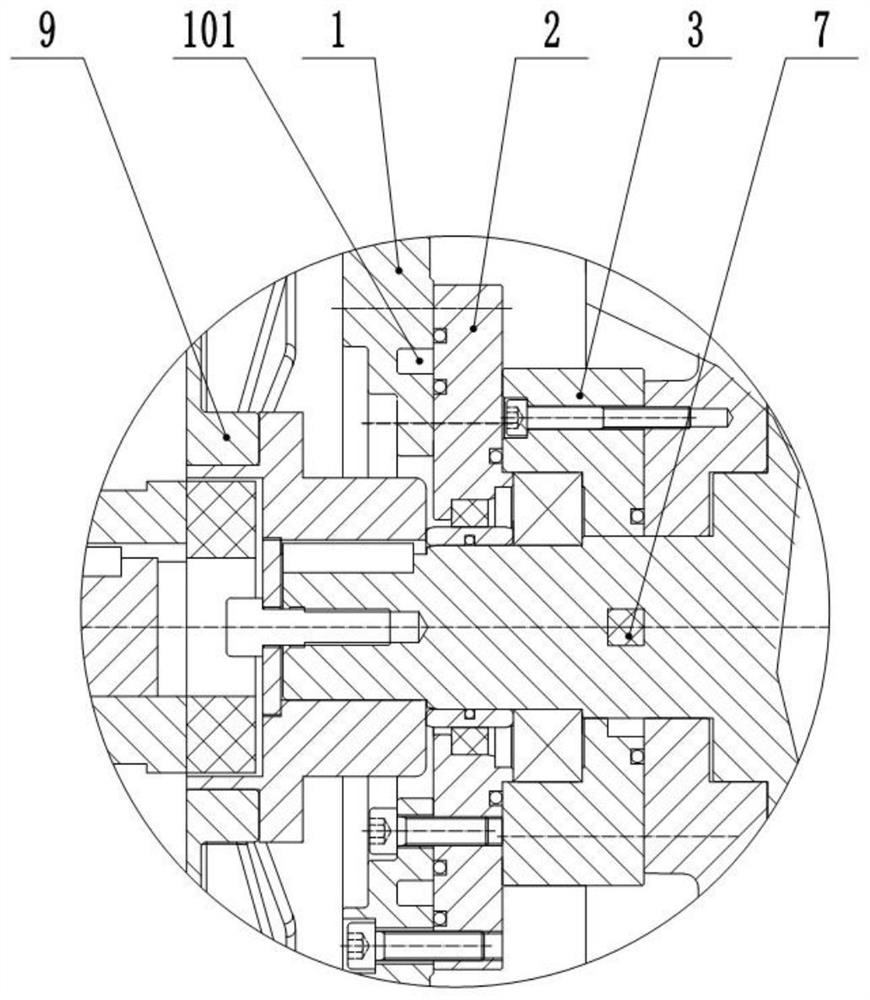

Composite vacuum pump

InactiveCN101852199AIncrease ultimate vacuumReduce energy consumptionRotary piston pumpsRotary piston liquid enginesVacuum pumpingProcess engineering

The invention belongs to the field of vacuum-pumping equipment and provides a composite vacuum pump which comprises a pump shell, a gas inlet and a gas outlet, wherein the gas inlet and the gas outlet are formed on the pump shell; a plurality of levels of molecular drag pumps and Roots pumps, which are installed coaxially, are arranged in the pump shell; the molecular drag pumps are combined in parallel or series and are arranged at the part near the gas inlet; the Roots pumps are combined in series and are arranged at the part near the gas outlet; and the molecular drag pumps and the Roots pumps are combined in series. The composite vacuum pump provided by the invention has the advantages of high pumping speed, high ultimate vacuum, low energy consumption, small size and light weight and can also acquire clean medium vacuum and high vacuum.

Owner:储继国

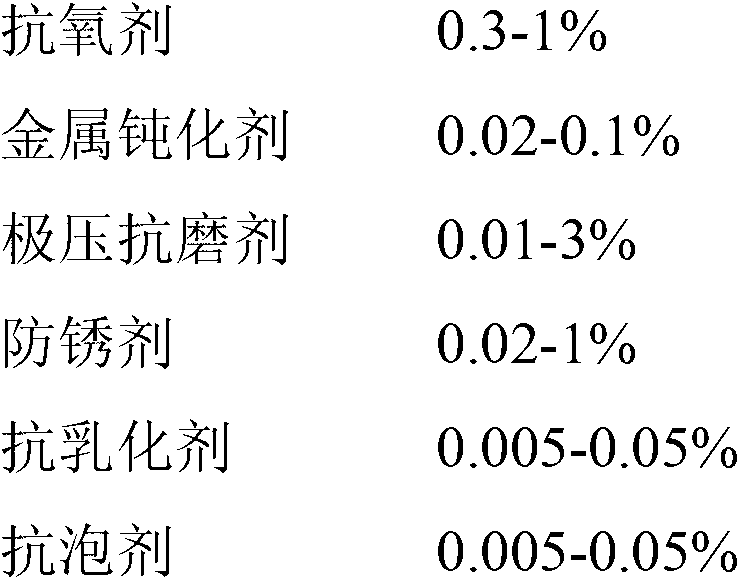

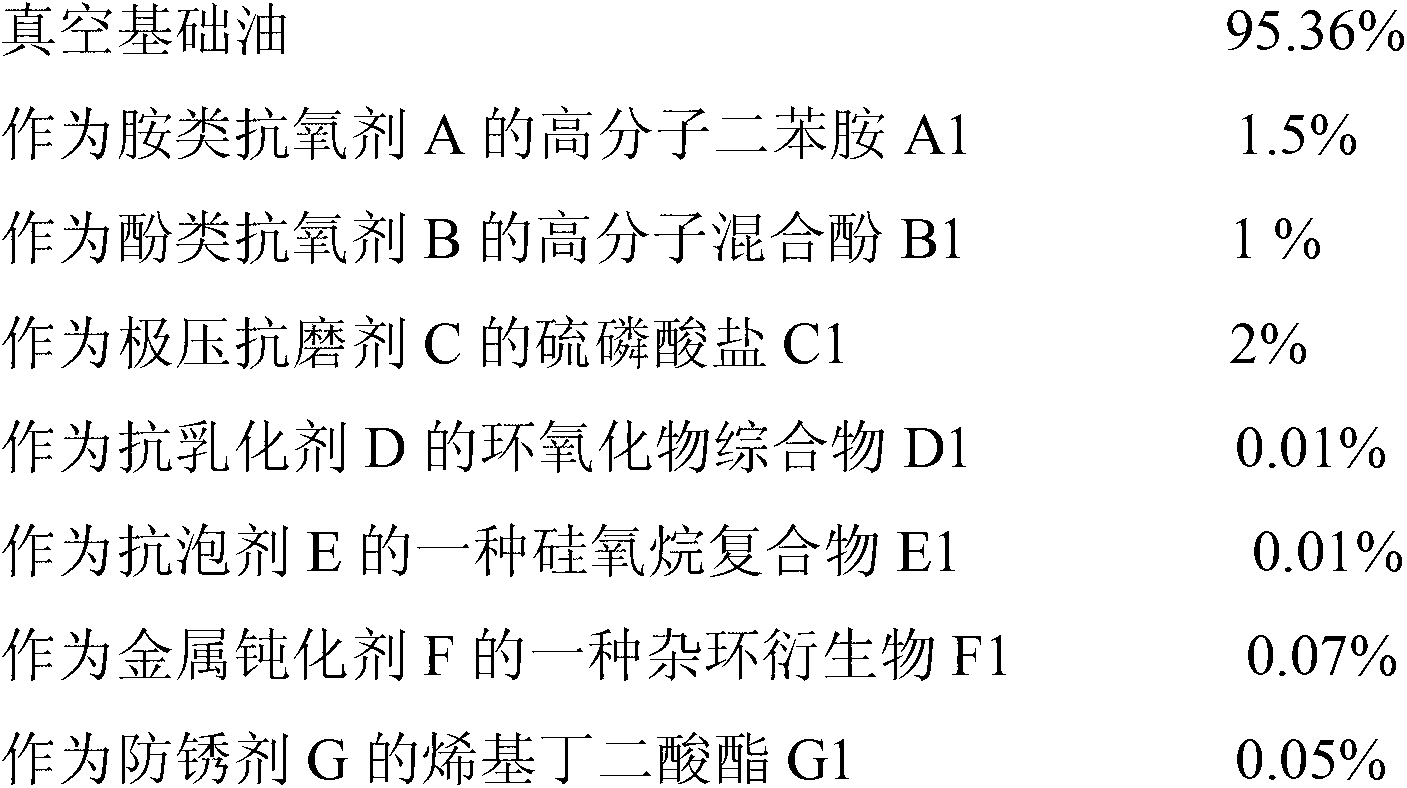

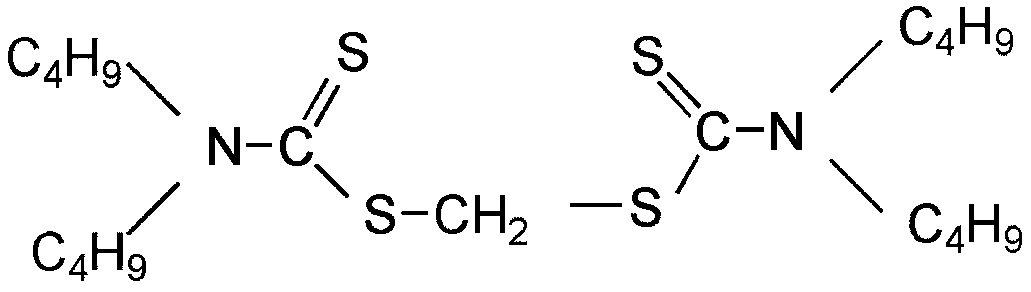

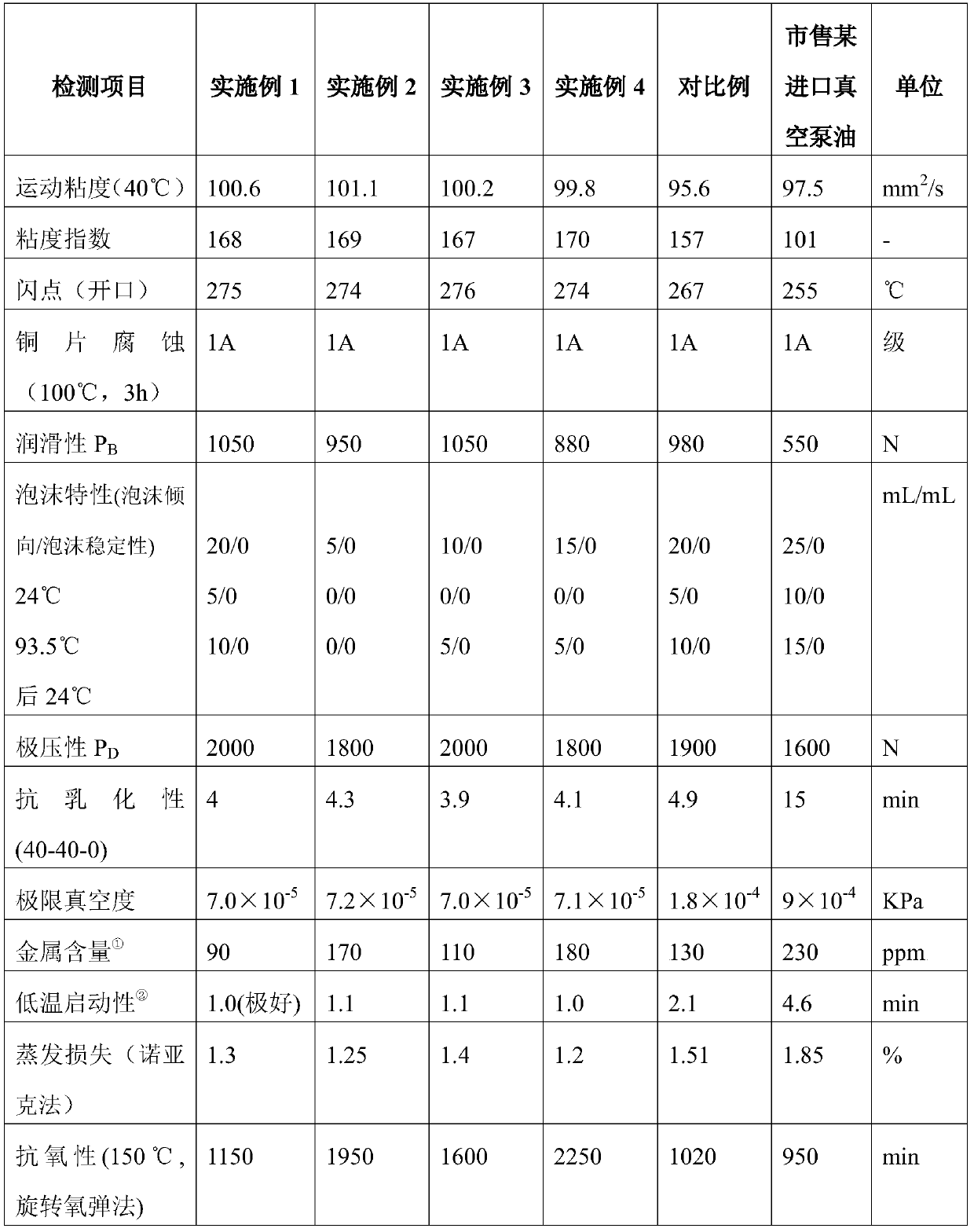

High-vacuum vacuum pump oil

InactiveCN103060065AGood antioxidant propertiesImprove extreme pressure and anti-wear performanceLubricant compositionChemistryPhenols

The invention discloses high-vacuum pump oil which is obtained by adding ash-free additive to compressed and distilled high-vacuum base oil. The high-vacuum pump oil comprises the following components in percentage by weight: 0.3%-1% of antioxidant, 0.02%-0.1% of metal passivator, 0.01%-3% of anti-wear reagent at extreme pressure, 0.02%-1% of antirust agent, 0.005%-0.05% of demulsifying compound and 0.05%-0.05% of anti-foaming agent, wherein the antioxidant comprises amine antioxidant and / or phenolic antioxidant; the amine antioxidant comprises high-polymer diphenylamine; the phenolic antioxidant comprises high-polymer mixed phenol. The high-vacuum pump oil disclosed by the invention has high-limit vacuum degree, and total limit pressure of 1*10<-4>kPa; and moreover, the vacuum oil is further provided with excellent oxidation resistance, high temperature resistance and anti-wear performance at extreme pressure without affecting the vacuum.

Owner:SUZHOU HUIFENG LUBRICANT

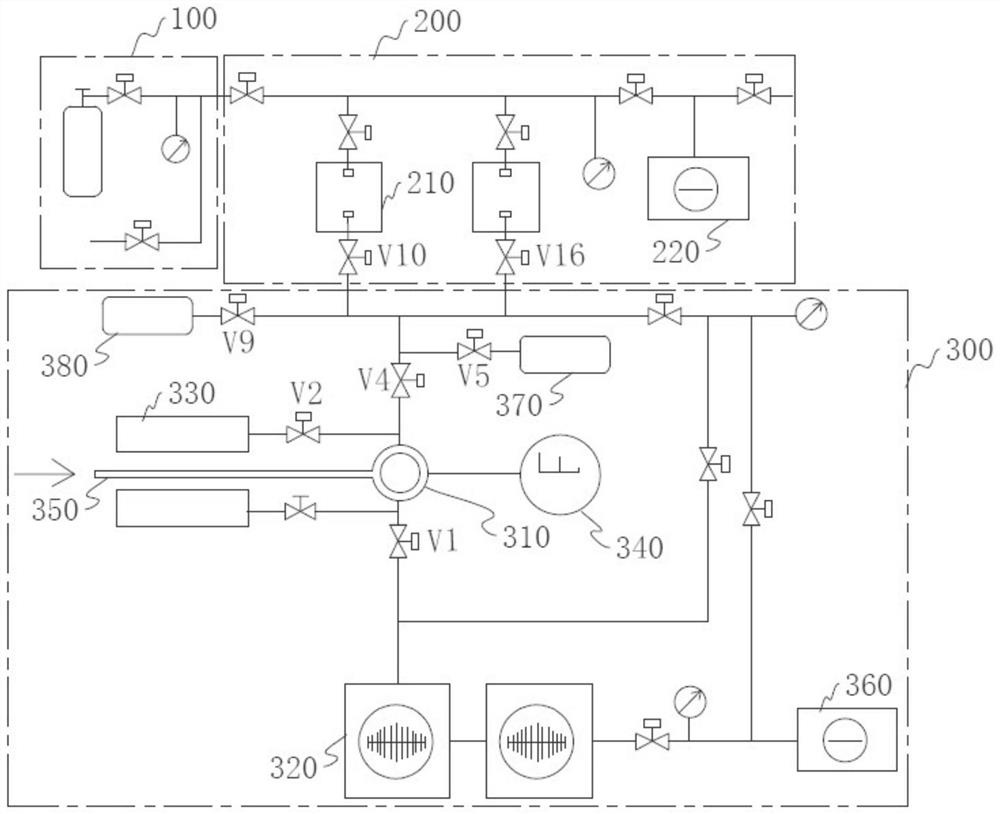

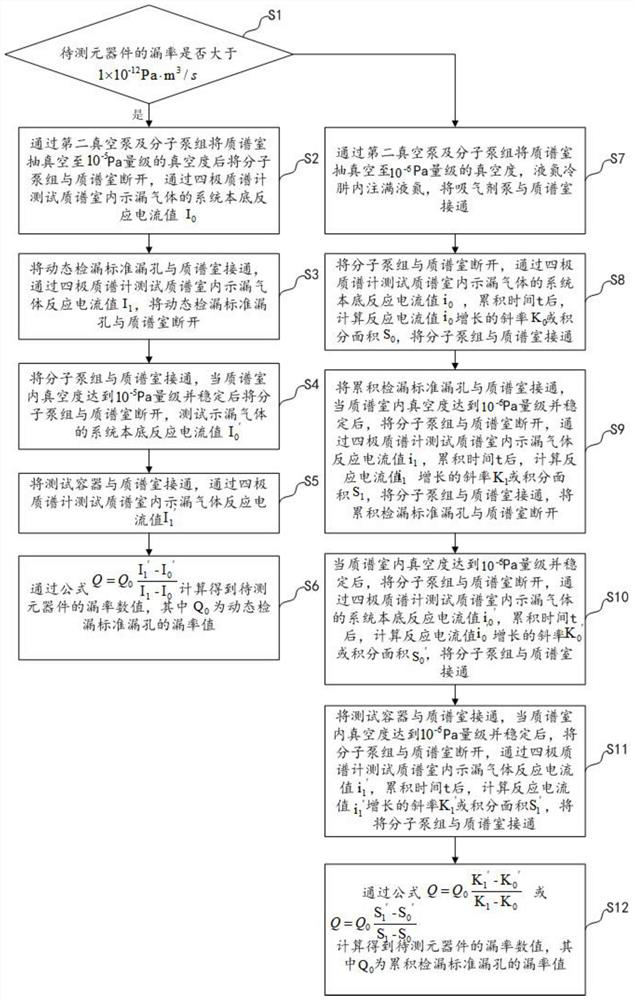

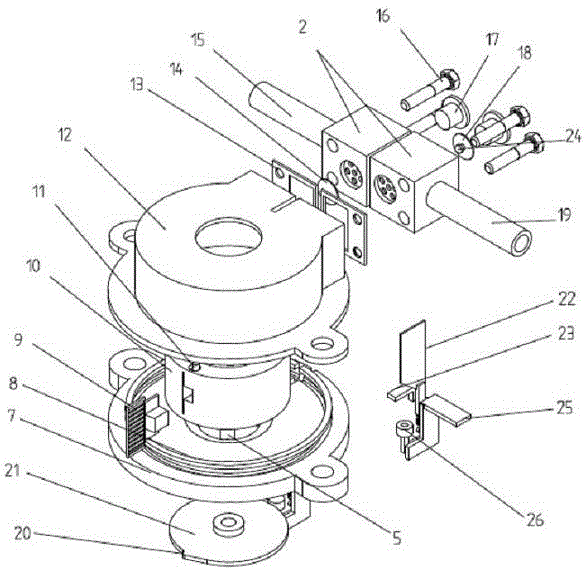

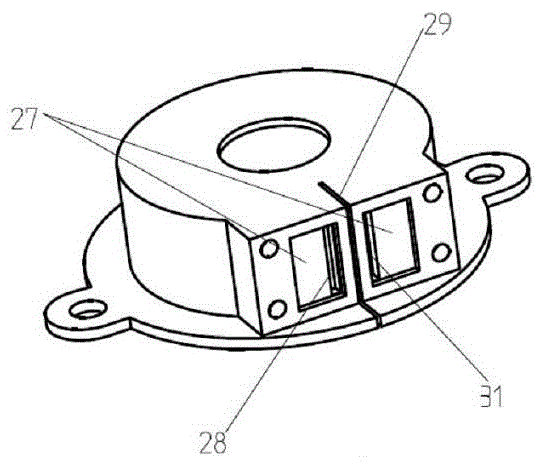

Leak detection device and leak detection method

ActiveCN112197912AReduce indoor temperatureReduce noiseDetection of fluid at leakage pointFluid-tightness measurement using electric meansEngineeringPumping vacuum

The invention provides a leak detection device and a leak detection method. The leak detection device comprises an inflation area, a to-be-detected station area and a test area. The inflation area isused for inflating and deflating the to-be-detected station area. The to-be-detected station area comprises a test container and a first vacuum pump for vacuumizing the test container. The test area comprises a mass spectrum chamber, a molecular pump set, a getter pump, a quadrupole mass spectrometer, liquid nitrogen cold hydrazine, a second vacuum pump, a dynamic leak detection standard leak holeand an accumulated leak detection standard leak hole. The test container is communicated with the mass spectrum chamber through a valve assembly, the quadrupole mass spectrometer is connected with the mass spectrum chamber, the liquid nitrogen cold hydrazine is connected with the mass spectrum chamber, and the molecular pump set, the getter pump, the dynamic leak detection standard leak hole andthe accumulated leak detection standard leak hole are respectively communicated with the mass spectrum chamber through valve assemblies. The beneficial effects are that the vacuum dynamic leakage detection of a to-be-detected component can be realized through the single use of the molecular pump set; and vacuum accumulated leak detection of the to-be-detected component can be realized through cooperation of a getter pump, a molecular pump and the liquid nitrogen cold hydrazine.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

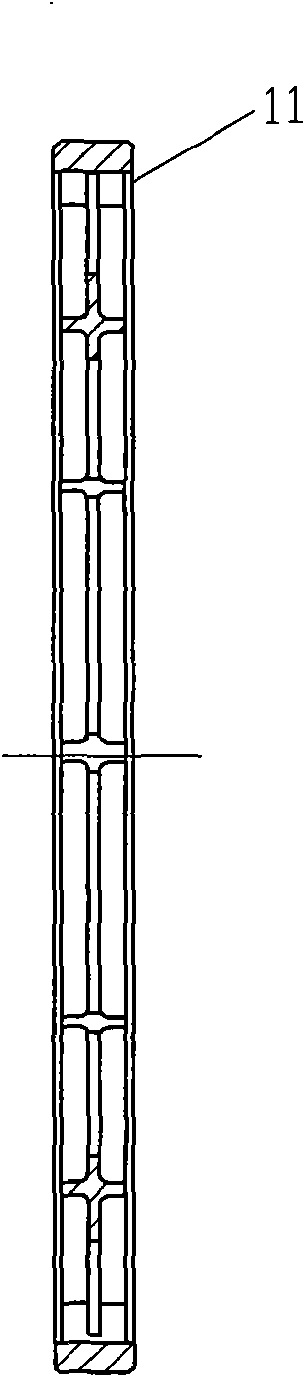

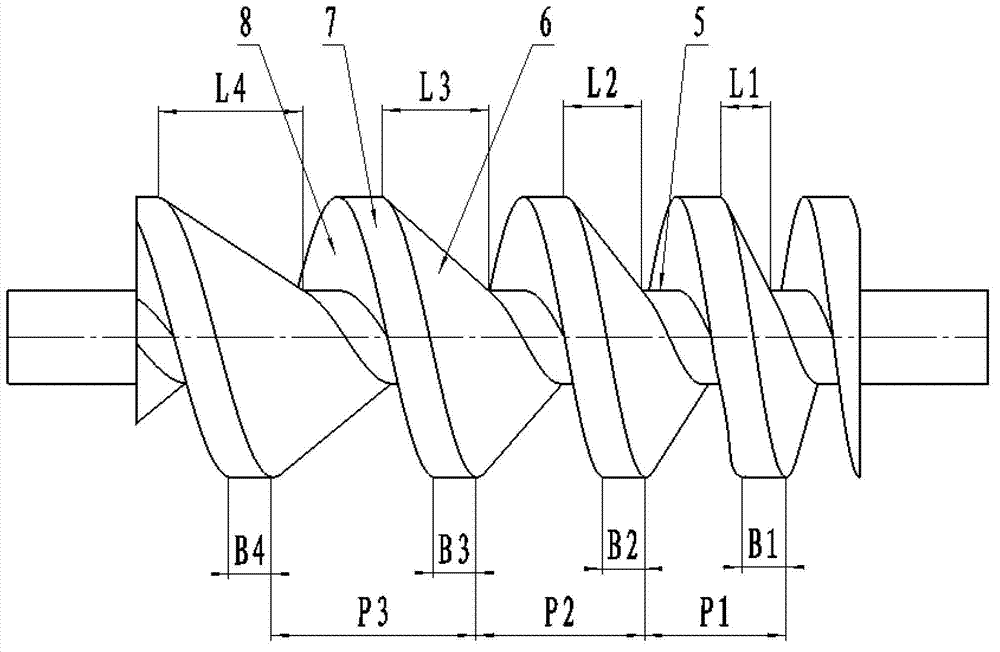

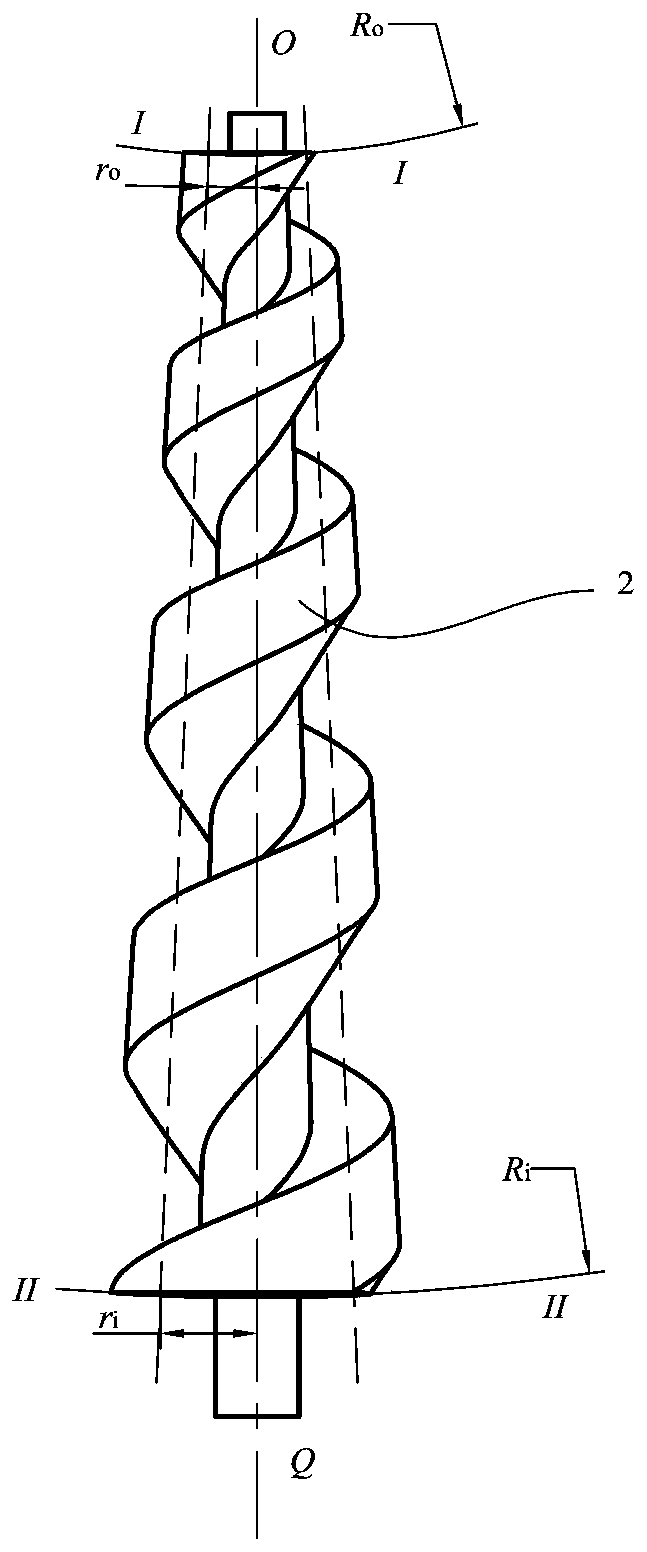

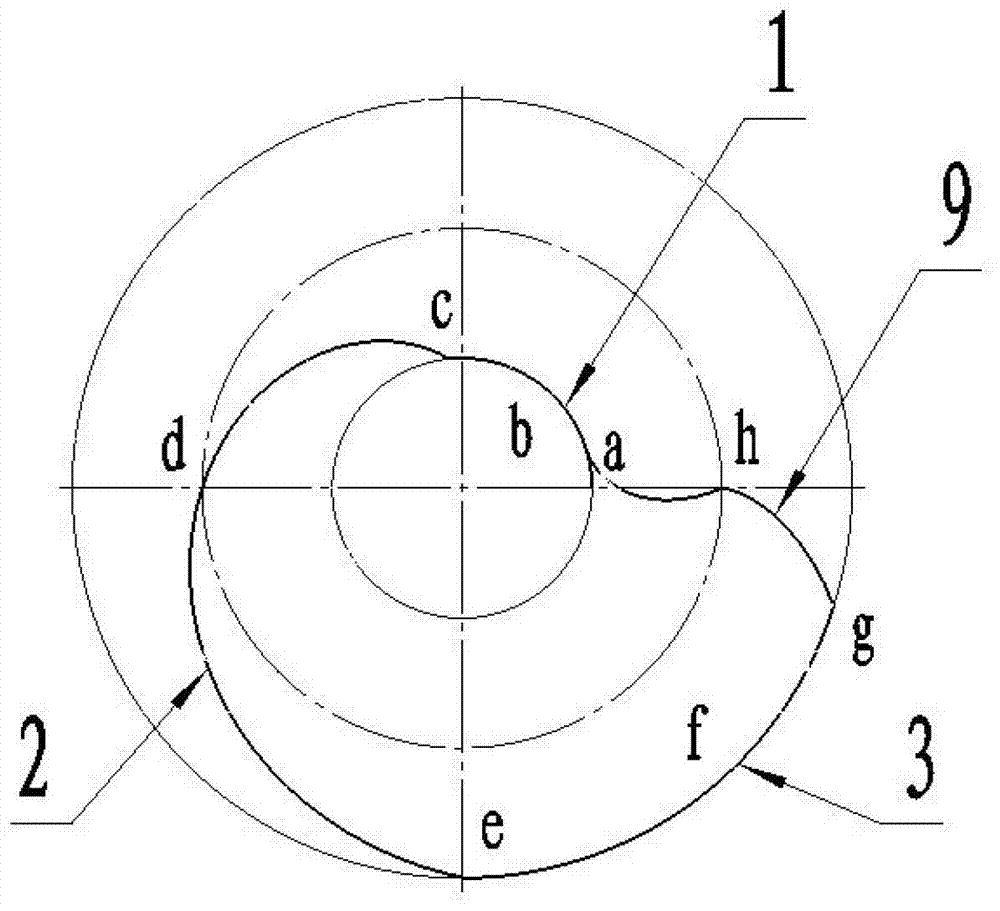

Single-head varying-pitch screw rotor with equal tooth top width

ActiveCN102808771AIncrease ultimate vacuumInspiratory volume between small stagesRotary piston pumpsRotary piston liquid enginesTooth root surfaceEngineering

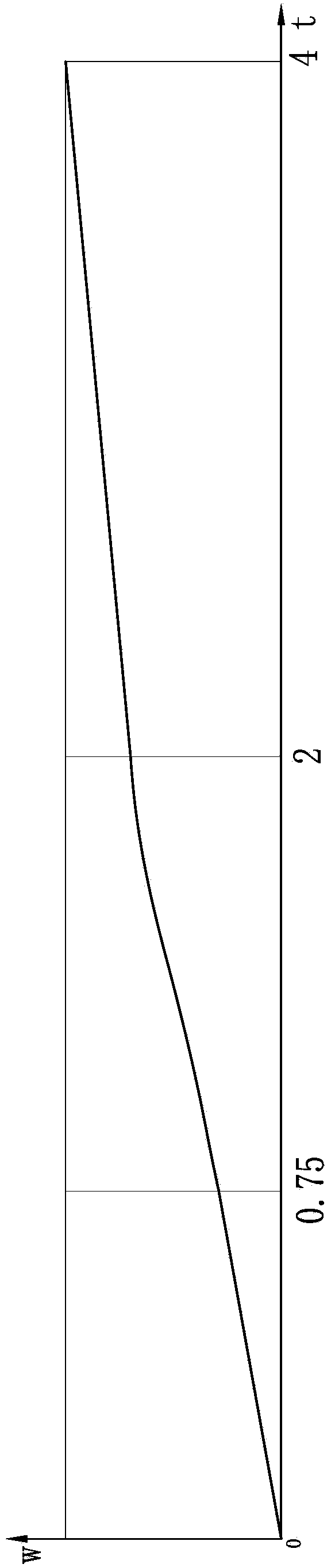

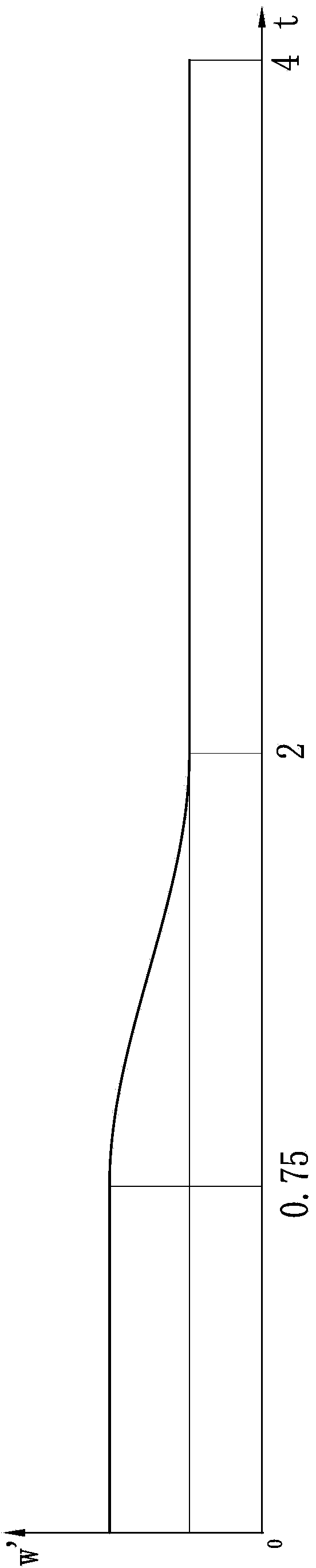

The invention relates to a single-head varying-pitch screw rotor with equal tooth top width. A tooth form surface of the screw rotor is formed in a manner that a tooth root surface, an oblique tooth surface, a tooth top surface and a transition tooth surface are sequentially connected with one another, the screw lead of the rotor is linearly increased from an exhaust end to a suction end along an axial coordinate, the axial width of the oblique tooth surface is gradually increased along the screw lead, but the width of the tooth top surface always remains unchanged. Compared with various existing single-head varying-pitch screw rotors, the tooth top width of the suction end of the molded line rotor is relative narrow, thus, larger inter-stage suction volume is formed, and the molded line rotor has a larger volume utilization factor, so that the molded line rotor has a higher theoretical pumping speed under the condition of the same structural parameters; and on the other hand, the tooth top width of the exhaust end of the molded line rotor is relatively wide, thus, the molded line rotor has stronger inter-stage blocking capacity and is capable of decreasing the inter-stage gas leakage backflow volume, so that the ultimate vacuum degree and the actual effective pumping speed of a vacuum pump are beneficially improved.

Owner:NORTHEASTERN UNIV LIAONING +1

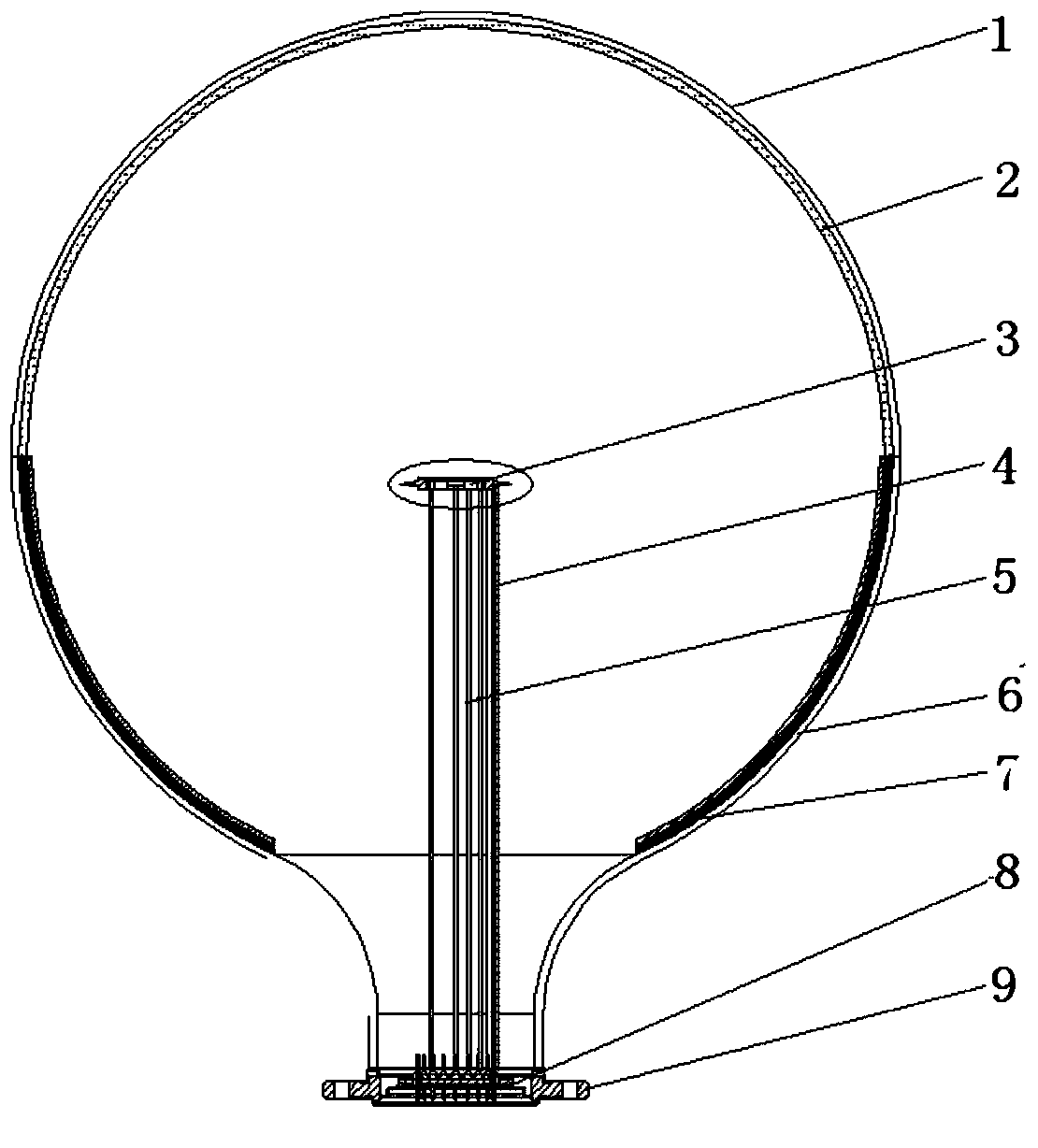

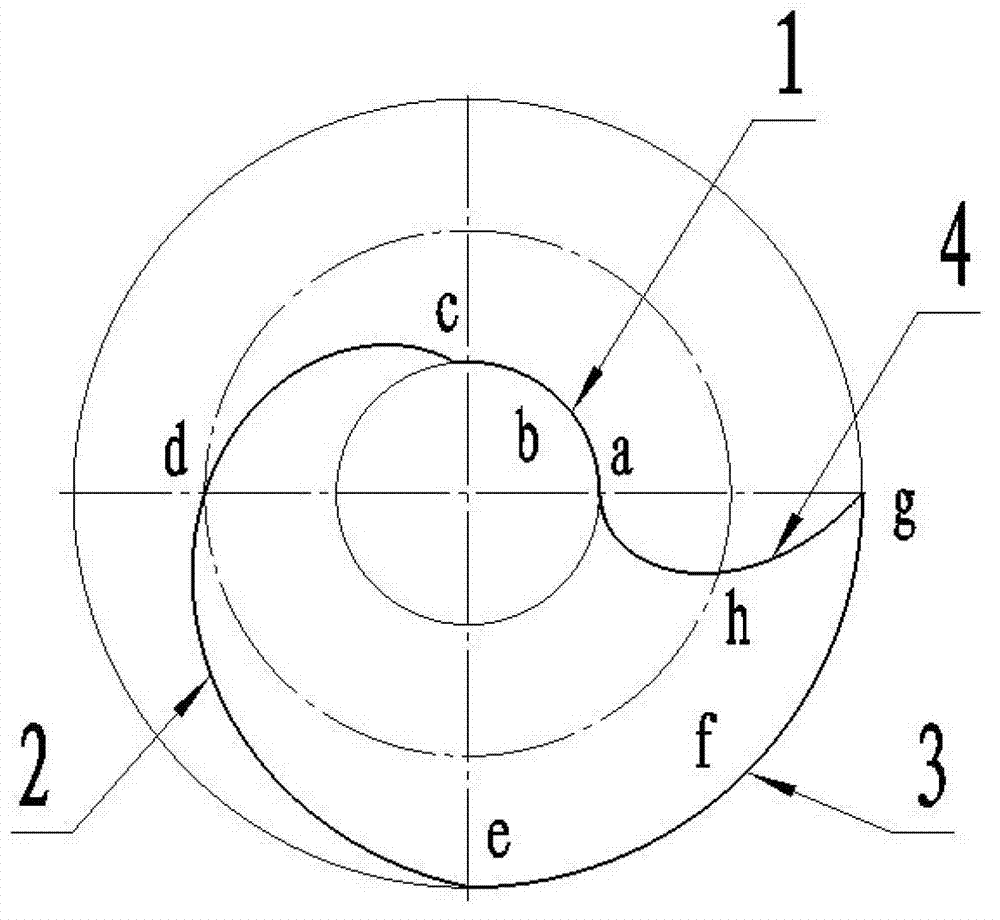

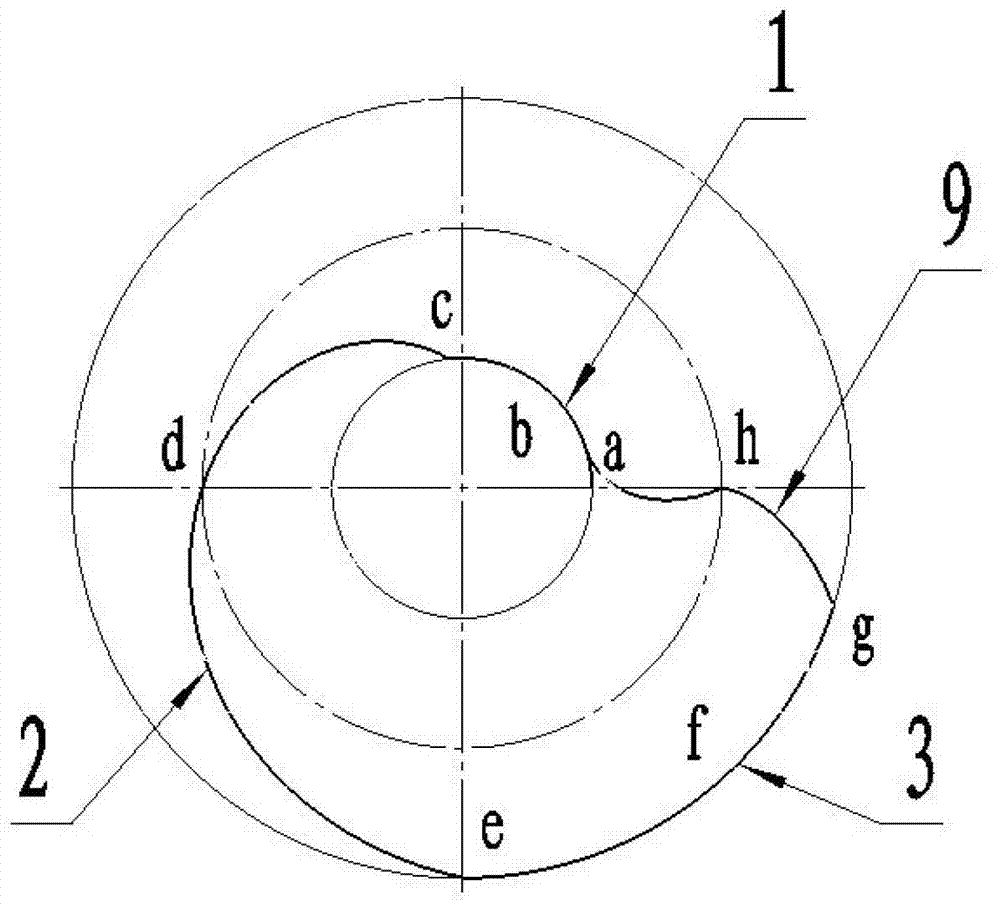

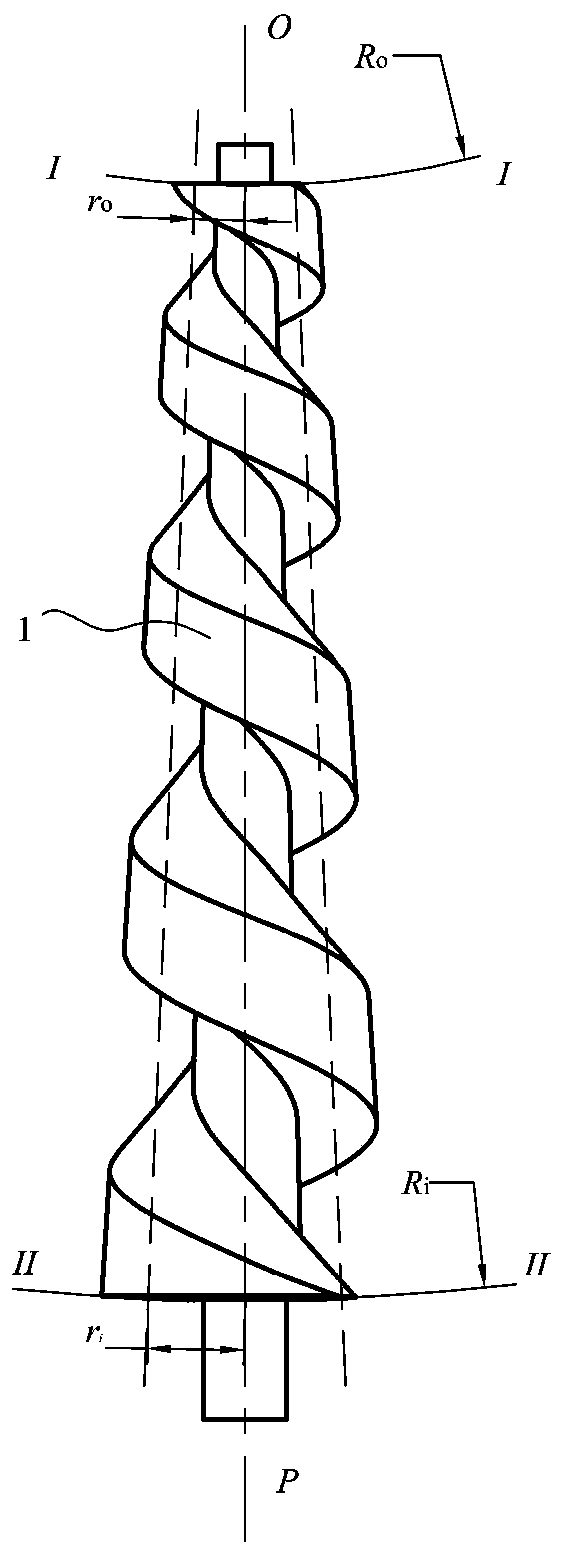

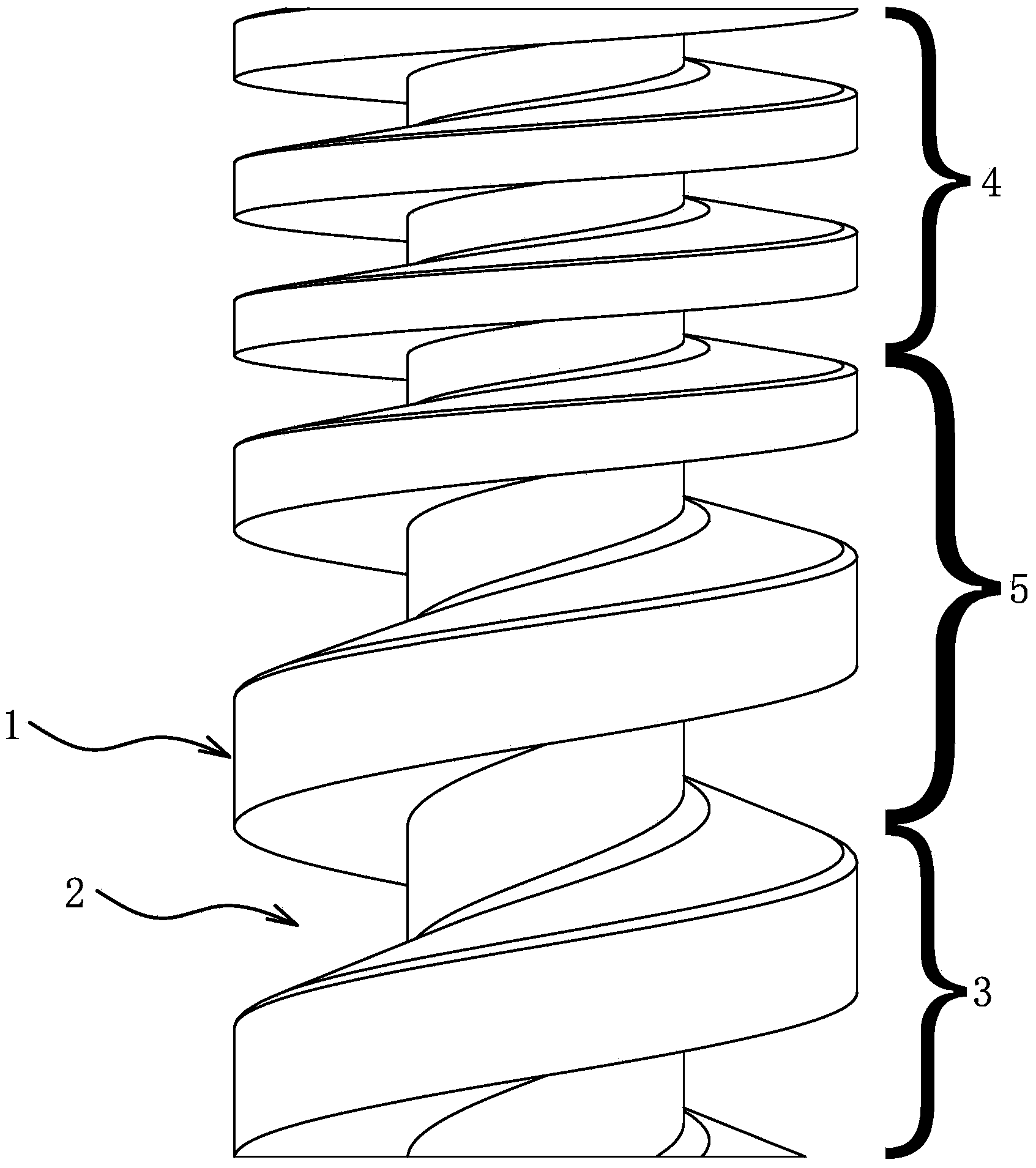

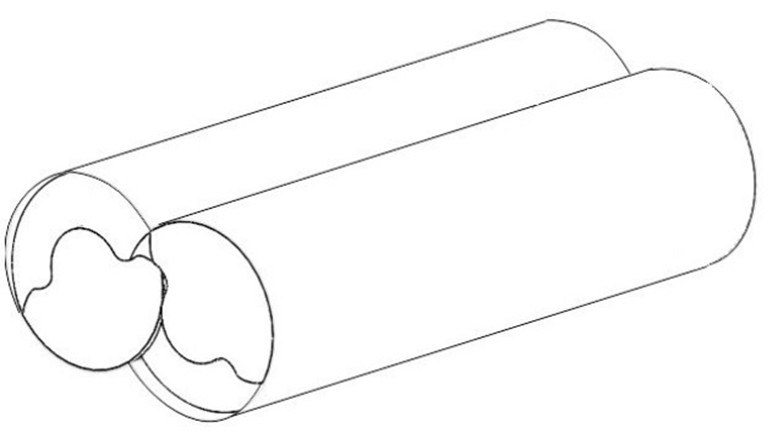

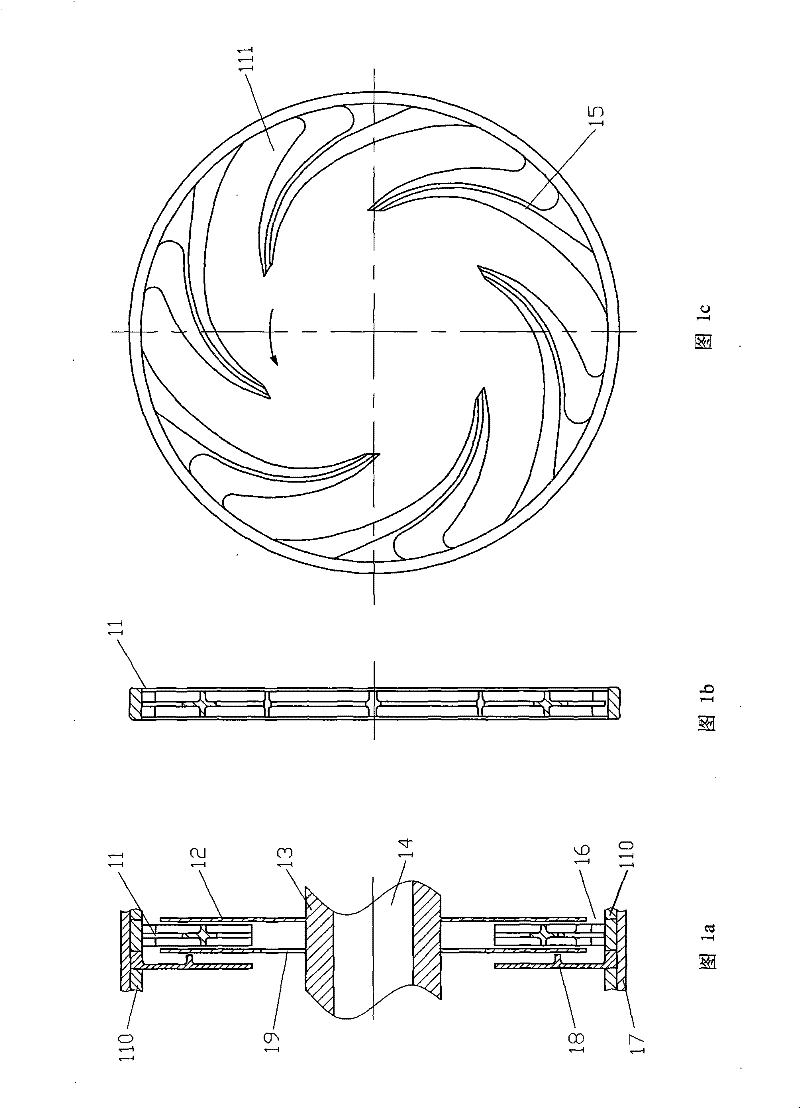

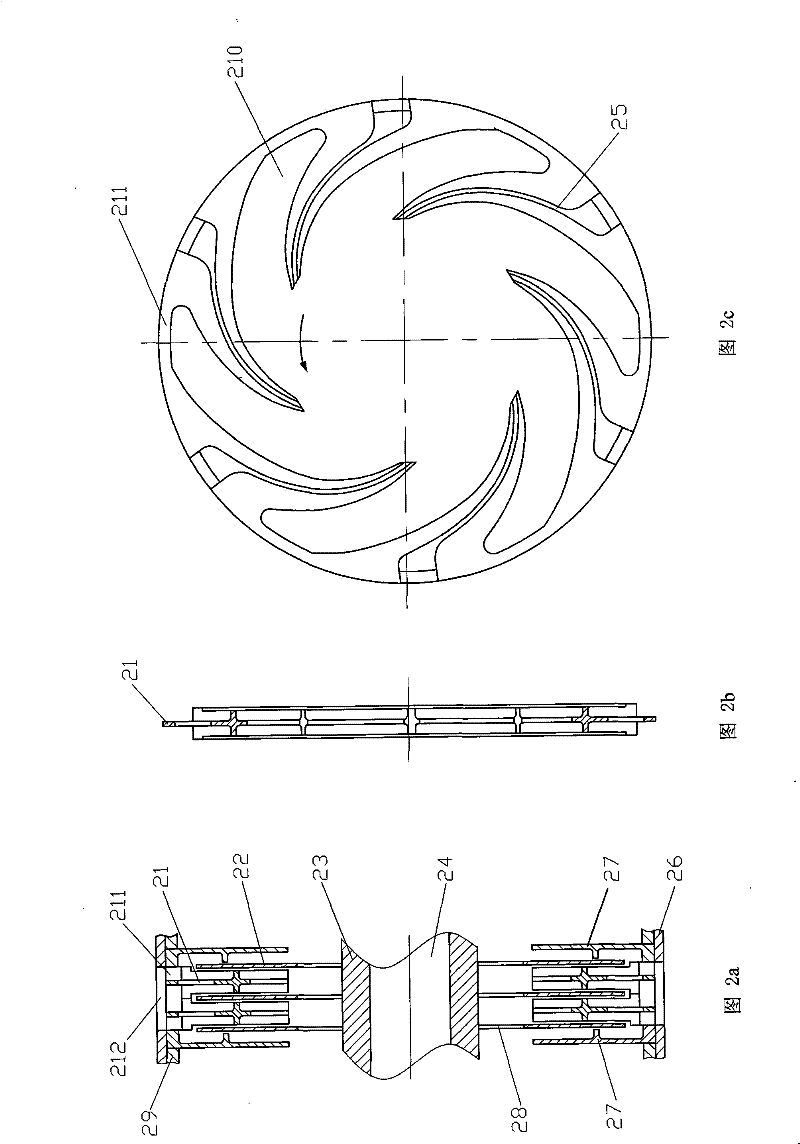

Conical screw rotors of twin-screw vacuum pump

PendingCN110821835AReduce working chamber volumeIncrease ultimate vacuumRotary piston pumpsRotary piston liquid enginesEngineeringVacuum pump

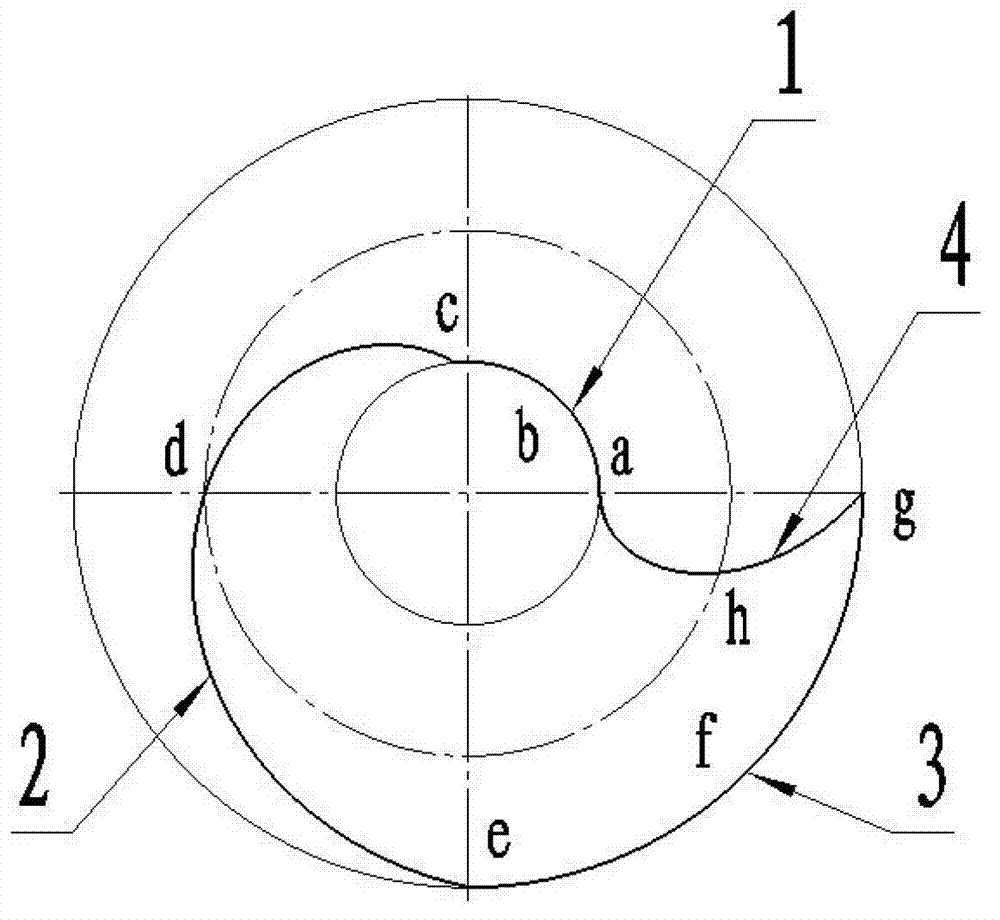

The invention discloses conical screw rotors of a twin-screw vacuum pump. The left conical screw rotor (1) comprises a high-pressure end concave spherical face, a low-pressure end convex spherical face and four tooth faces, and the four tooth faces are a left conical tooth top face (11), a left conical oblique tooth face (12), a left conical tooth root face (13) and a left conical concave tooth face (14). The right conical screw rotor (2) comprises a high-pressure end concave spherical face, a low-pressure end convex spherical face and four tooth faces, and the four tooth faces are a right conical tooth top face (21), a right conical oblique tooth face (22), a right conical tooth root face (23) and a right conical concave tooth face (24). The left conical screw rotor (1) and the right conical screw rotor (2) can achieve cross axial meshing with the transmission ratio of 1:1. a larger air suction volume is achieved under the same structure parameters, a large effective volumetric rate is achieved, the pumping speed of the twin-screw vacuum pump is increased, the volume of a work cavity of the exhaust end is reduced, large content ratio and compression ratio are achieved, and the limit vacuum degree of the vacuum pump can be increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

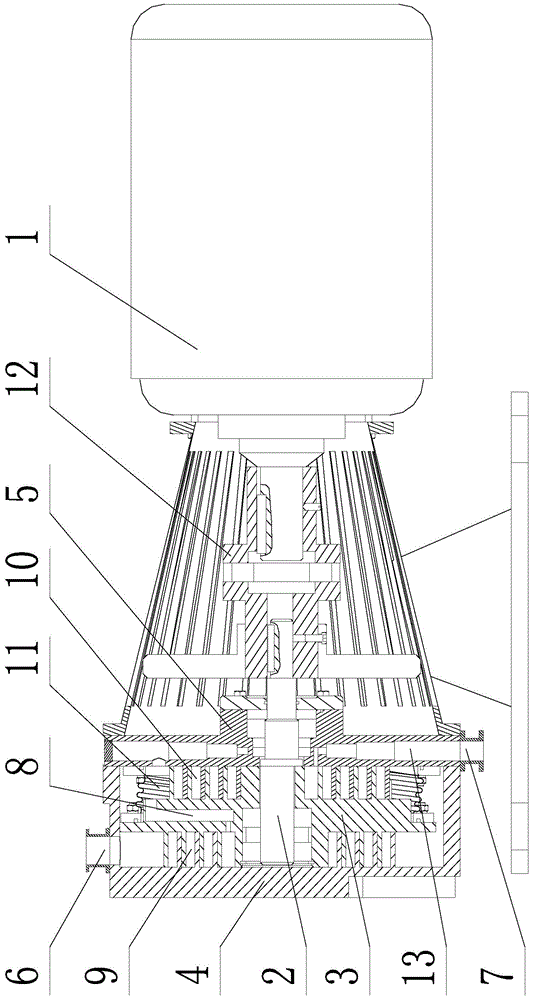

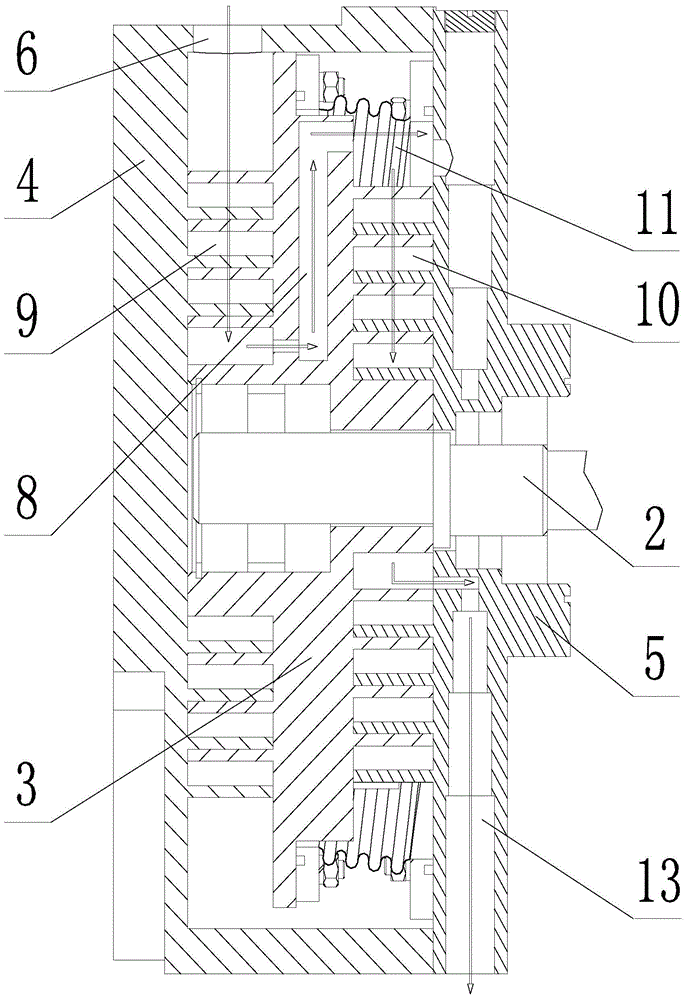

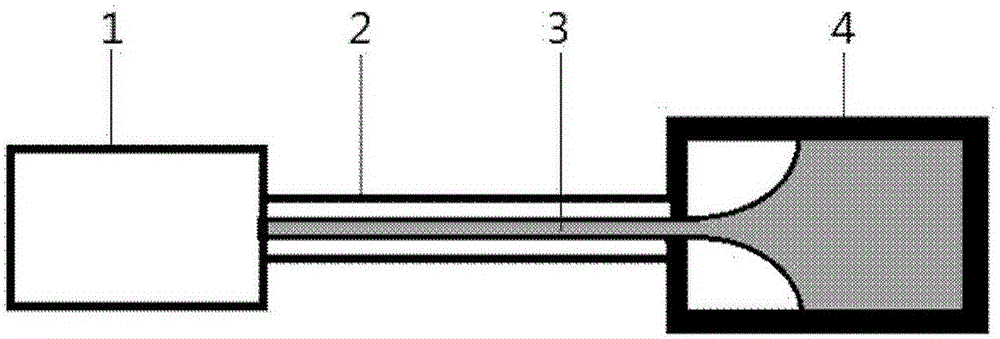

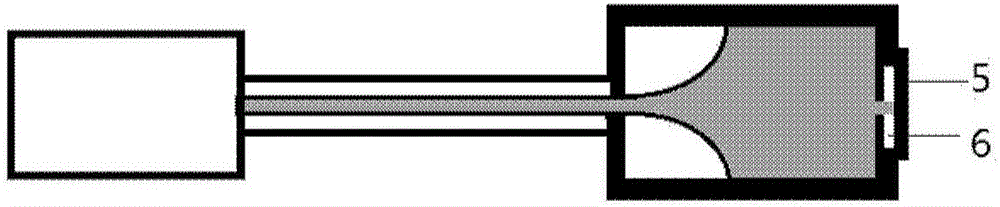

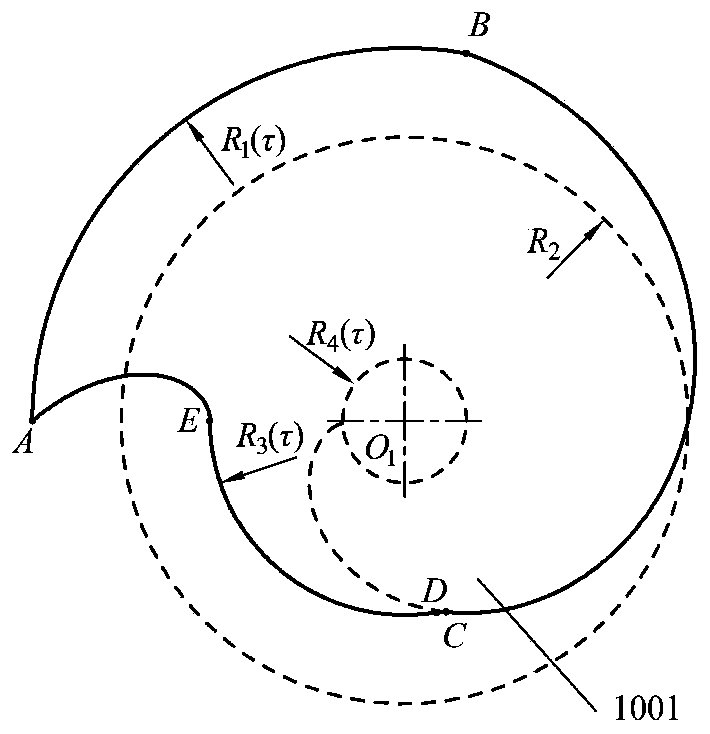

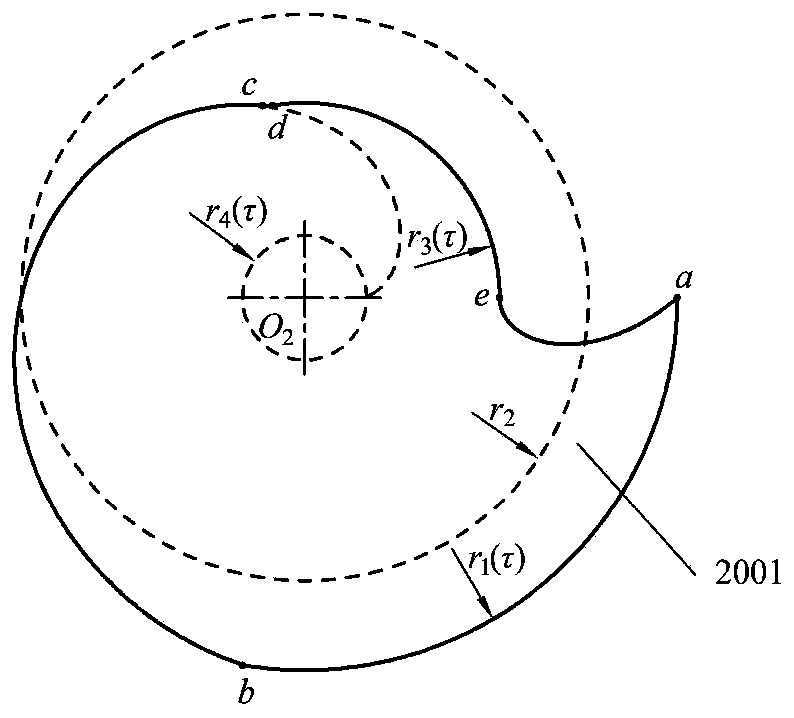

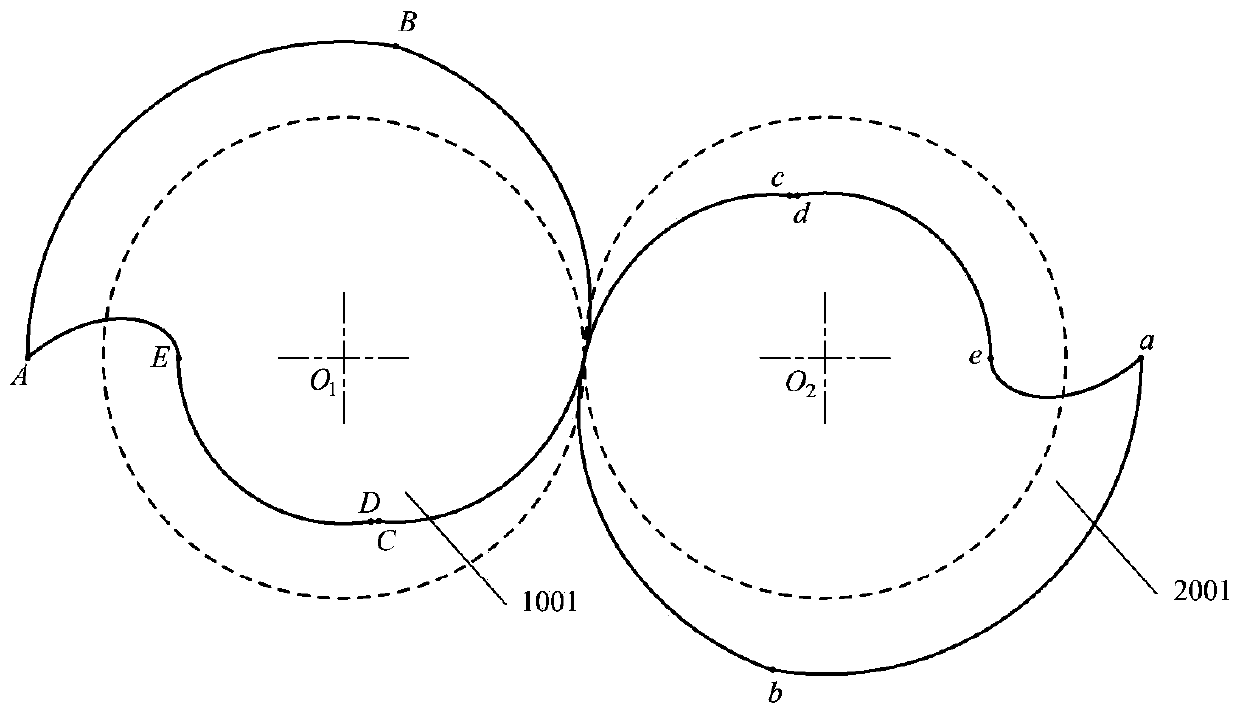

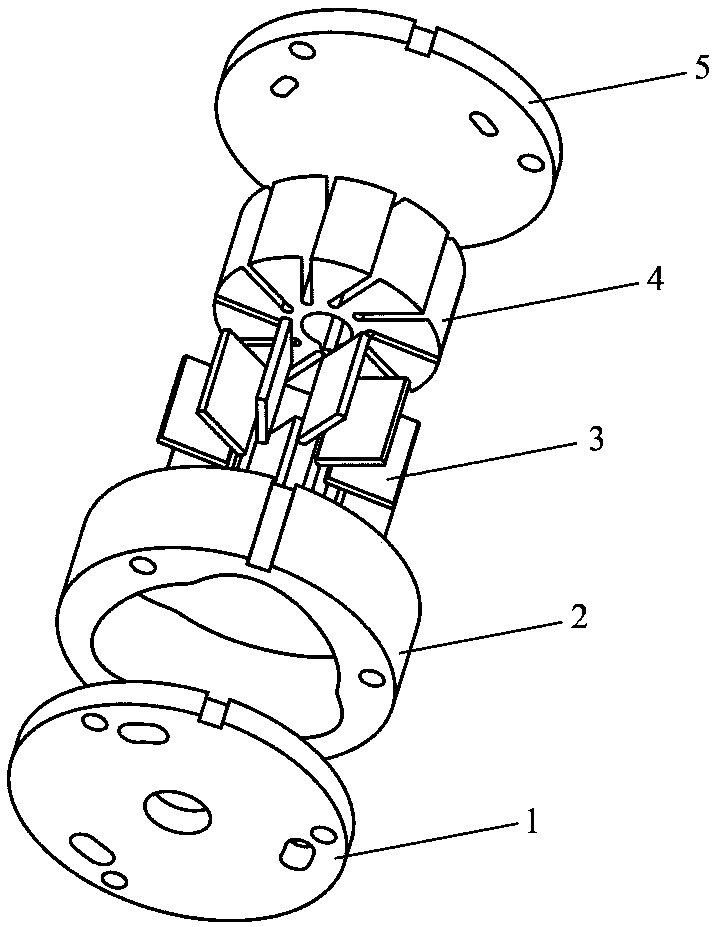

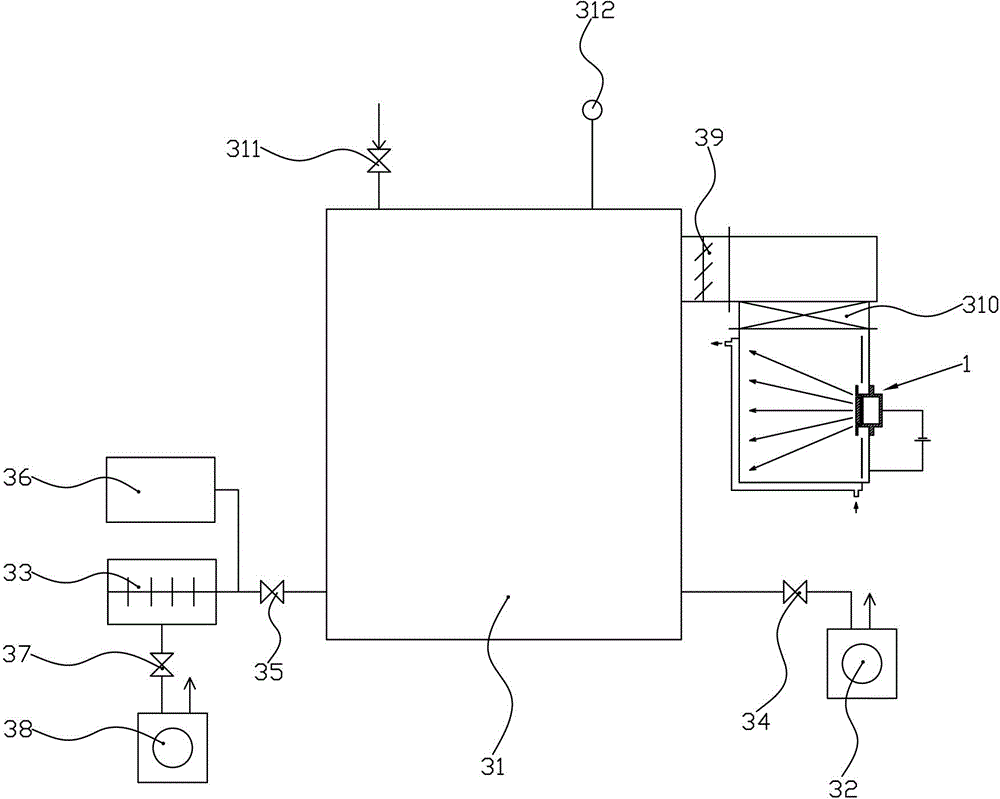

A two-stage vortex dry vacuum pump

ActiveCN104612968AIncrease the compression ratioIncrease ultimate vacuumRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringVacuum pump

A two-stage vortex dry vacuum pump is disclosed. The outer circumferential side of a first vortex working cavity is communicated with an air inlet in a left vortex fixed disc. At least one airflow channel is disposed along the radial direction in a vortex moving disc. One end of each airflow channel is communicated with the center side of the first vortex working cavity, and the other end is communicated with the outer circumferential side of a second vortex working cavity. The center side of the second vortex working cavity is communicated with an air discharging channel and an air discharging port in a right vortex fixed disc. The outer circumferential side of the vortex moving disc and the outer circumferential side of the right vortex fixed disc are hermetically connected through a corrugated pipe. The outer circumferential side of the first vortex working cavity and the outer circumferential side of the second vortex working cavity are sealed and separated by the corrugated pipe. The corrugated pipe, the vortex moving disc and the right vortex fixed disc are connected through flanges or welding. The two-stage vortex dry vacuum pump breaks the limitation on the compression ratio and the final vacuum of two-side vortex dry vacuum pumps at present, and increases the compression ratio and the final vacuum of the vacuum pump by two-stage continuous compression of the two vortex working cavities connected in series.

Owner:NORTHEASTERN UNIV +1

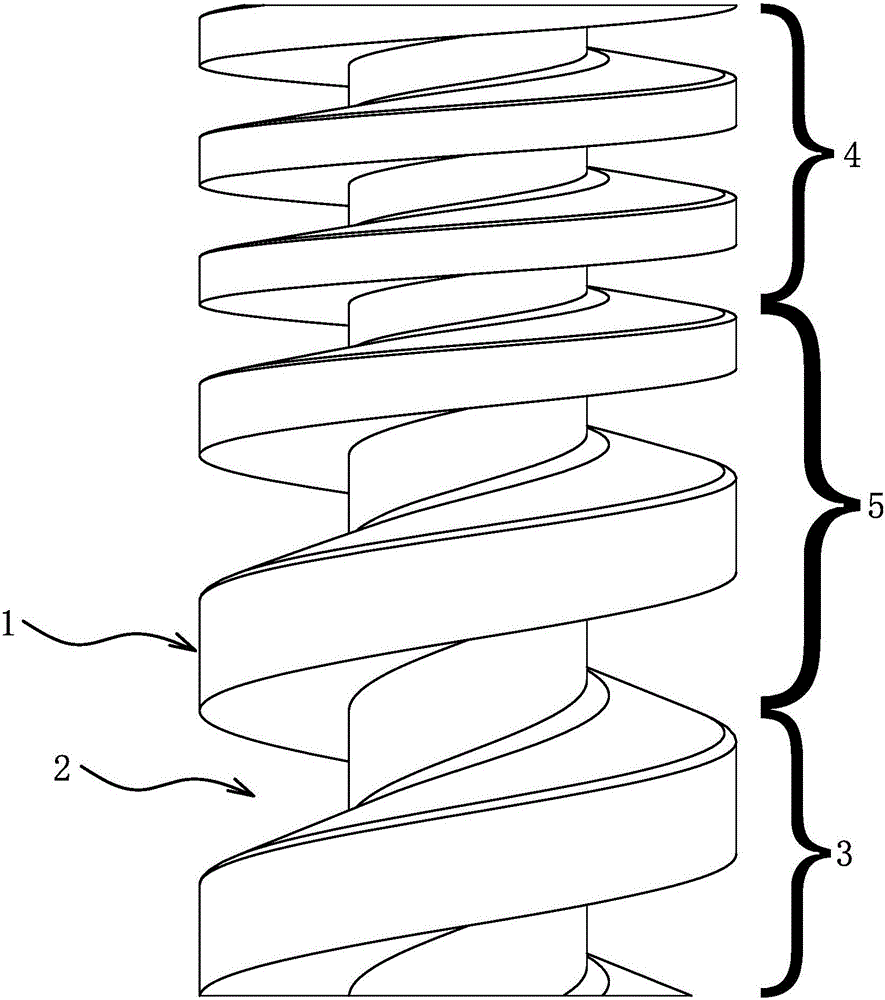

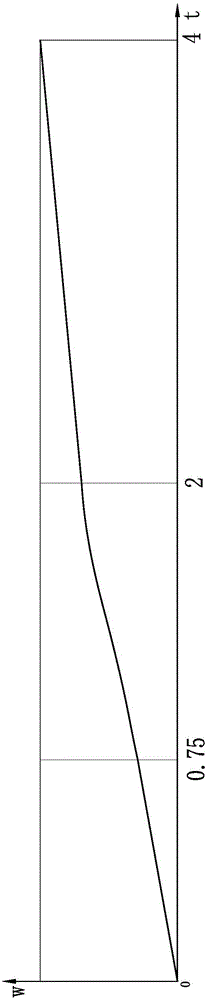

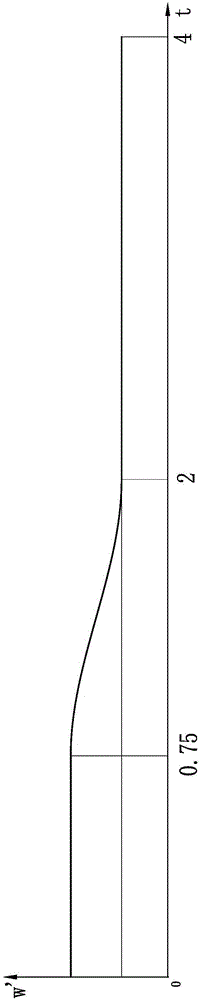

Screw of screw vacuum pump

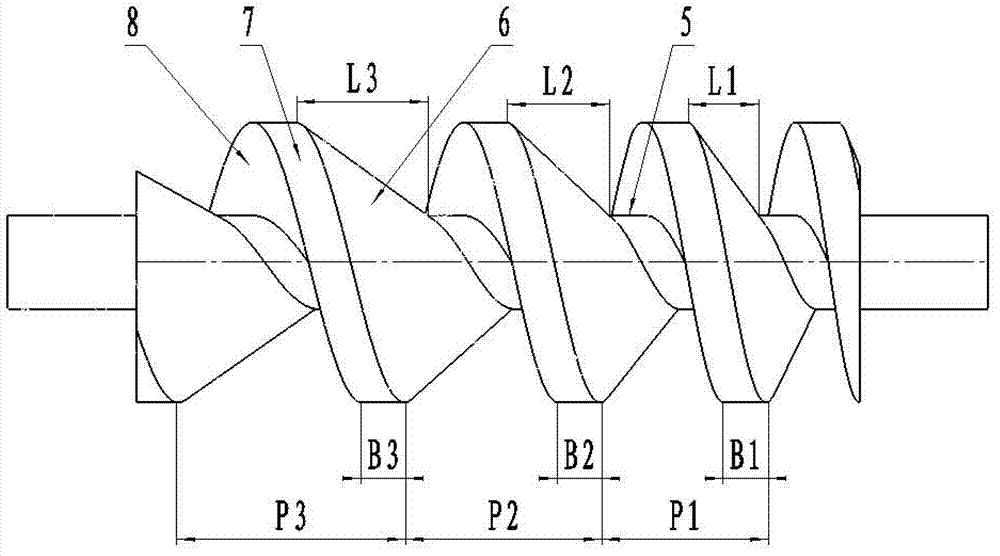

ActiveCN104373347AMany modelsIncrease ultimate vacuumPump componentsRotary piston pumpsEngineeringProcess conditions

The invention provides a screw of a screw vacuum pump, and belongs to the technical field of vacuum pumps. The problem that the screw of the existing screw vacuum pump cannot meet the specific process conditions at present is solved. The number of turns of the upper spiral groove of a suction part, in the screw of the screw vacuum pump, is 0.75-1.25; when the number of turns of the upper spiral groove of a compression transition part is 1, the number of turns of the upper spiral groove of an exhaust part is more than 3; when the number of turns of the upper spiral groove of the compression transition part is more than 1, the number of turns of the upper spiral groove of the exhaust part is 1.75-4. The screw of the screw vacuum pump has the advantages that the vacuum pump is high in ultimate vacuum, is stable in performance while the manufacturing cost is almost not increased, and then more types of screw vacuum pumps are available with a more widespread application domain. In the screw vacuum pump adopting the pitch variable screw provided by the invention, the compression ability is optimized by appropriately increasing the number of turns of the spiral groove as wound, the exhaust efficiency of the exhaust part is improved, the excessive compression phenomenon because the air in the exhaust part cannot be exhausted is alleviated, and then the unit energy consumption is reduced effectively.

Owner:台州市星光真空设备制造有限公司

Single-head varying pitch screw rotor with uniform tooth top width

ActiveCN102808772AIncrease ultimate vacuumInspiratory volume between large stagesRotary piston pumpsRotary piston liquid enginesEngineeringSmall tooth

A single-head varying pitch screw rotor with uniform tooth top width consists of a tooth root face, an oblique tooth face, a tooth top face and a transitional tooth face that are sequentially connected, wherein a rotor helical lead is linearly increased from an exhaust end to a suction end along with a helical angle of spread, so that the axial width of the oblique tooth face is gradually increased correspondingly, and the width of the tooth top face remains unchanged. Compared with the existing single-head varying pitch screw rotors, the molded line rotor has a relatively small tooth top face width at the suction end, so that a bigger interstage suction volume is formed, and the molded line rotor has the relatively big volume utilization rate, so that the bigger theoretic pumping speed is achieved under the same structural parameters; in contrary, the molded line rotor has the relatively bigger tooth top width at the exhaust end, has stronger interstage leakage resistance and can reduce the gas interstage leakage backflow rate, so that the improvement of the limit vacuum degree and the actual effective pumping speed of the vacuum pump are facilitated.

Owner:NORTHEASTERN UNIV +1

Space traveling wave tube, collector thereof and preparation method of the connector

ActiveCN105762047AClever exclusionLow costTravelling-wave tubesCold cathode manufactureEconomic benefitsEngineering

The invention relates to a controller of a space traveling wave tube, wherein a small hole is arranged on the bottom of the collector, and the small hole is hermetically covered by a metal sheet, which is equal to arrange a window. The invention also comprises a preparation of the collector and a space traveling wave tube comprising the collector. The window of the collector can leak gas after electron bombardment for a period of time, the residual gas in the space traveling wave tube enters space with 1*10<-8> Pa vacuum degree through an opened window; so that limiting vacuum of the space traveling wave tube is greatly improved, the service live of parts can be further greatly prolonged, and enormous economic benefits are produced. According to the invention, the tube, collector and method have advantages of simpleness, easy operation, low cost and high economic value.

Owner:山东微波电真空技术有限公司

Power-driven vacuum pump for car braking system

The invention relates to a power-driven vacuum pump for a car braking system, and belongs to the field of car braking. The power-driven vacuum pump comprises a motor, and a lower shell and an upper shell body are internally provided with a pump body assembly, a one-way valve assembly, a cam and a connecting rod assembly; and single blades are adopted for rotating at a high speed in an annular cavity and are matched with the cam, an air blocking sheet and the one-way valve to move to form a vacuum cavity. The inner wall of an annular cavity formed by the blade and a blocking sheet rotor and the inner wall of an annular cavity formed by the blade, an upper cover plate and a lower cover plate are in clearance fit, friction cannot be generated, heat cannot be generated, long-time running can be achieved, the reliability is improved, and noise is reduced; and air pumping and air discharging are carried out at the same time, the vacuumizing rate is high, air leakage is reduced, and the final vacuum degree of the vacuum pump can be improved.

Owner:JILIN DONGGUANG AOWEI AUTOMOBILE BRAKE SYST

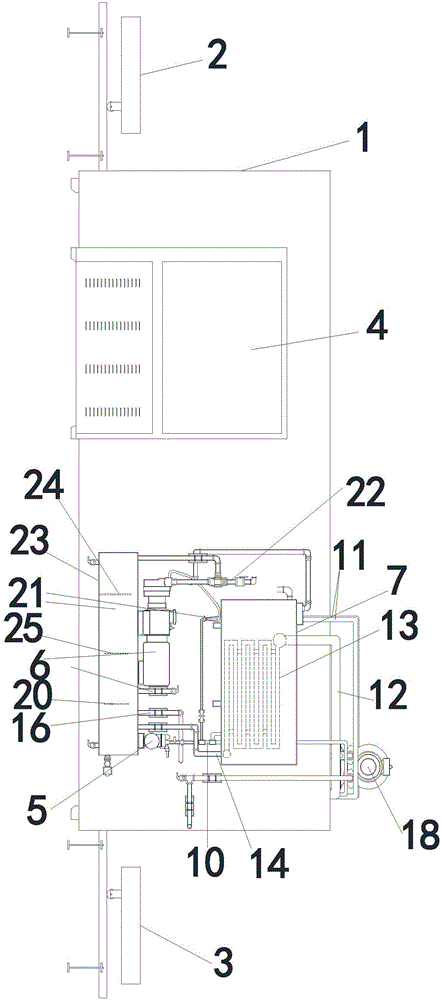

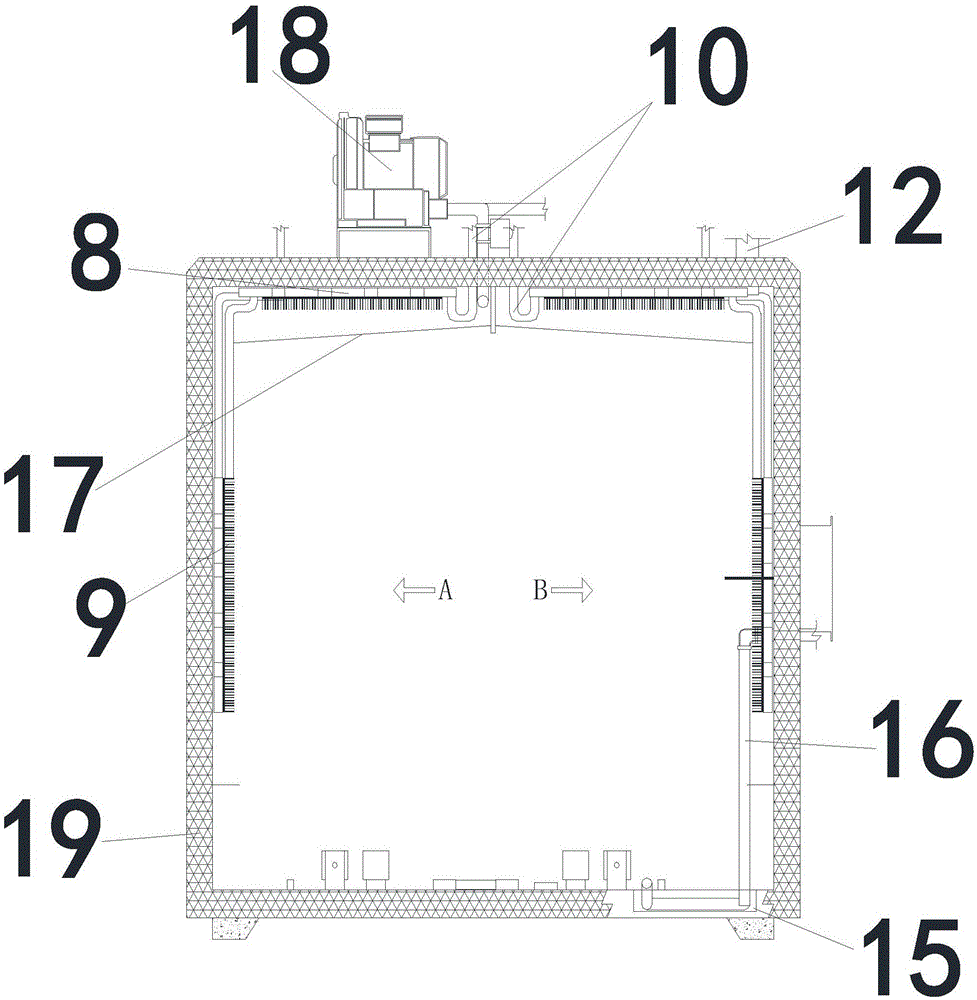

Double-station type high-frequency vacuum dryer and implementation method thereof

ActiveCN105157355AIncrease productivitySimple structureDrying solid materials without heatDrying machines with local agitationEngineeringCirculating pump

The invention discloses a double-station type high-frequency vacuum dryer. The double-station type high-frequency vacuum dryer comprises a box body which is provided with a front opening door and a back opening door, wherein a front material trolley is arranged at the front opening door, and a rear material door is arranged at the back opening door; a high-frequency machine is arranged on the side edge of the outer part of the box body; a water collecting box system is arranged on the side edge of the high-frequency machine; a water circulating pump, which is connected with a vacuum pump through a pipeline, is arranged on the water collecting box system; the vacuum pump is connected to the top part of a water filling box through the pipeline. The double-station type high-frequency vacuum dryer has the characteristics of being simple in structure, low in cost, high in production efficiency, wide in scope of application, and complete in circulating systems, saving energy and reducing emission, and being outstanding in condensing effect and good in use effect.

Owner:东阳市尚德电器机械有限公司

Mass spectrometer leak detection method

InactiveCN109323819AFast pumping speedImprove detection efficiencyDetection of fluid at leakage pointMass spectrometryEngineering

The invention discloses a mass spectrometer leak detection method, comprising the following steps of: S10, performing empty box leak detection on the sealed vacuum cavity; S101, correcting the leak rate obtained after the leak detection; S11, placing a box to be tested in the containing cavity of the vacuum cavity; S12, controlling a fore pump to pump the gas of the containing cavity of the vacuumcavity; S13, controlling the fore pump to drive a cavity vacuum pump to simultaneously pump the gas of the containing cavity; and S14, controlling the tracer gas source to charge the box to be testedwith the tracer gas, and detecting the tracer gas content in the containing cavity by the mass spectrometer leak detection device, and determining whether the box to be tested meets a preset condition according to the tracer gas content. The mass spectrometer leak detection method has the advantages of high detection efficiency and high accuracy.

Owner:深圳市远望工业自动化设备有限公司

Multilevel floating vortex vacuum pumps and usage method thereof

InactiveCN103573627AIncrease ultimate vacuumIncrease vacuumRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringDynamic balance

The invention discloses a multilevel floating vortex vacuum pumps and usage method thereof. The multilevel floating vortex vacuum pumps comprise a plurality of vacuum pumps, each of which comprises a fixed scroll base, a fixed scroll located on the base and an orbiting scroll which do orbiting movement with the fixed scroll, wherein an air inlet is formed in the end plate of a scroll element which is located at the outer ring of the fixed scroll; an air outlet is formed in the end plate of the scroll element which is located at the inner ring of the fixed scroll; the air outlet is provided with a row of vent valve components; the air inlet of every downstream vacuum pump is communicated with the air outlet of the adjacent upstream vacuum pump through a pipe. By adopting the multilevel floating vortex vacuum pump and the usage method, the downstream vacuum pump extracts air from the air outlet of the upstream vacuum pump, thereby reducing the pressure in the volume below the air outlet of the upstream vacuum pump; the dynamic balance between the air inlet and the air outlet is interrupted, the backflow from the air outlet to the air inlet is reduced and the air extracted from the air inlet is increased, thereby reducing the air pressure of the upstream air inlet and increasing the ultimate vacuum degree of the air inlet.

Owner:ADVANCED SCROLL TECH HANGZHOU

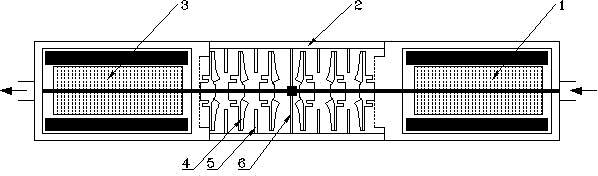

Novel vacuum pump and novel multi-stage vacuum pump

InactiveCN105298869ACompact structureReduce volumePump componentsRadial flow pumpsImpellerElectric machine

The invention discloses a novel vacuum pump which comprises a straight-barrel-shaped pump body. An air inlet and an air outlet are formed in the two ends of the pump body respectively. Two high-speed motors are arranged at the two ends in the pump body respectively. Rotary shafts of the two high-speed motors are opposite, and the two high-speed motors are opposite in the rotating direction. The rotary shafts of the two high-speed motors are each provided with two or more impellers. Guide vanes are arranged between the adjacent impellers. A support used for supporting the rotary shafts of the high-speed motors is arranged in the center of the pump body. According to the novel vacuum pump and a novel multi-stage vacuum pump, the structure is simple and compact, the size is small, no other matched devices are needed, ultimate vacuum is higher, consumed power is lower, and noise is lower.

Owner:XIANGTAN PUMP GRP

Double-screw rotor set and vacuum pump

ActiveCN111734632AExtend your lifeImprove volumetric efficiencyRotary piston pumpsRotary piston liquid enginesWork cycleEngineering

The invention provides a double-screw rotor set. The double-screw rotor set is composed of two screw rotors meshing with each other, and each screw rotor is formed by symmetrically connecting two sections of variable-pitch screws opposite in rotation direction; the screw pitch of each variable-pitch screw meets a formula p = (pe-ps) / L<2> * z<2>, wherein p is the screw pitch of the variable-pitch screw, ps is an initial screw pitch of the variable-pitch screw, pe is an end screw pitch of the variable-pitch screw, L is the length of the variable-pitch screw, and z is an axial position of the variable-pitch screw; the axial position of each variable-pitch screw meets a formula z = p / (2pi) * t, wherein t is a rotation angle of the variable-pitch screw; and the axial position of each variable-pitch screw further meets a formula z =-(L * ((pi<2> * L<2> + (ps<2>-pe * ps) t<2>) <0.5>)-pi * L) / ((pe-ps) * t), wherein pi is the screw pitch of the variable-pitch screw at an axial position z of thevariable-pitch screw, and pi is reduced in a quadratic relation from ps to pe. The displacement of the screw rotor in a working cycle is twice the displacement of a common single screw rotor, so thatthe air exhaust efficiency is improved.

Owner:NINGBO BAOSI ENERGY EQUIP

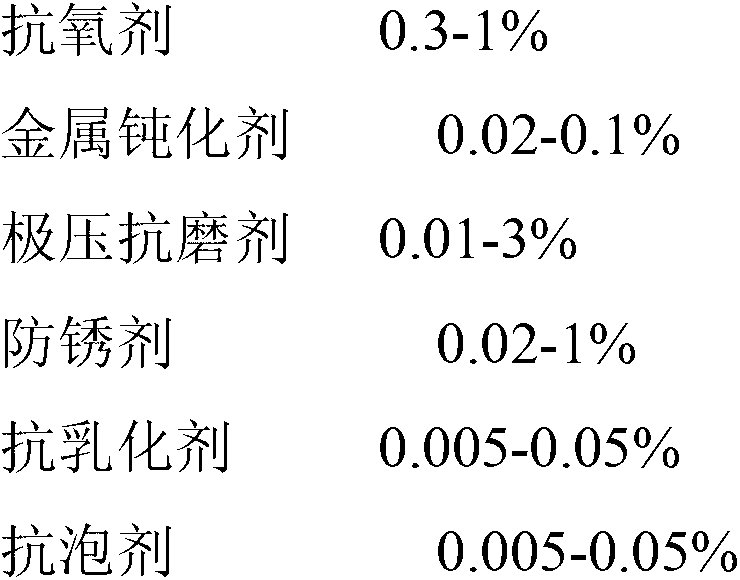

Ashless high-performance vacuum pump oil

InactiveCN109762631AImprove performanceIncrease ultimate vacuumLubricant compositionFault probabilityMetal deactivator

The invention relates to the field of lubricating oil, in particular to ashless high-performance vacuum pump oil. The ashless high-performance vacuum pump oil is prepared from the following componentsin percentage by mass: 0.6-3% of an ashless anti-wear agent, 0.05-1% of an ashless metal passivator, 0.01-0.5% of an ashless antifoaming agent, 0.5-2% of an ashless antioxygen, and the balance of base oil used for supplementing to 100%. The ashless high-performance vacuum pump oil obtained through optimized combination of all optimal additives has excellent comprehensive performance, high limit vacuum degree, and long service life. The antioxygen and the base oil are optimized to establish a long-life cycle use system, and emission of waste oil is significantly reduced; and by optimizing theantifoaming agent, the base oil and the anti-wear agent, operation of a pump body is ensured, and the fault probability of the pump body is decreased.

Owner:广州科卢斯流体科技有限公司

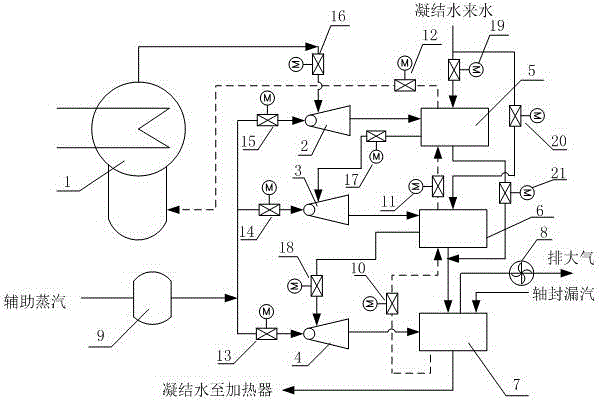

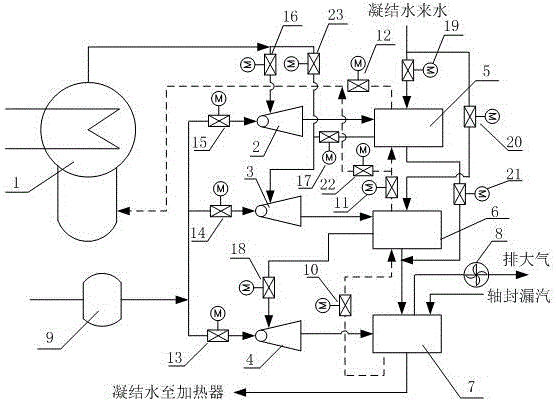

Multi-stage hot-pressing type vacuum pumping system

ActiveCN105865219ASignificant energy saving benefitsEasy maintenanceSteam/vapor condensersCondensed waterEngineering

The invention provides a multi-stage hot-pressing type vacuum pumping system. The system comprises a power steam pressure stabilization tank, a multi-stage hot presser, a steam condensing device, valves and pipe parts, wherein the steam condensing device is matched with the hot presser, and the valves and pipe parts are used for connecting related units. The set of system adopts auxiliary steam as a power source, does not use service power and is simple to maintain; moreover, cooling water of the condensing device adopts condensed water of a main machine; drain water automatically flows to a hot well of a steam condenser stage by stage, so that afterheat of steam and the drain water can be utilized, and energy saving effect is improved; besides, a tail-stage condenser of the device is replaced with a gland heater, so the floor area of the equipment is reduced, and power plant reconstruction is facilitated.

Owner:普瑞森(北京)工程技术有限公司

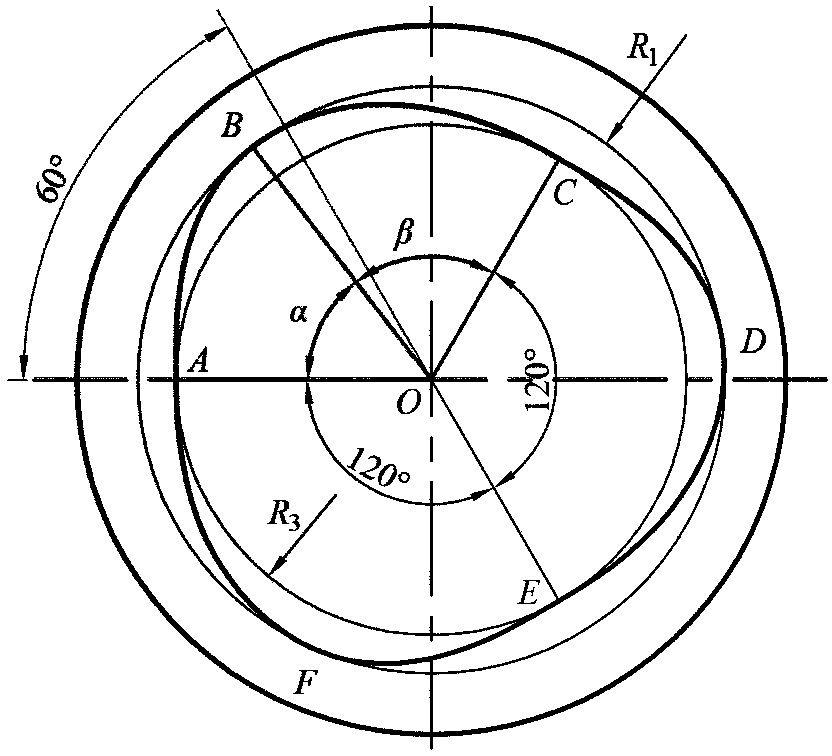

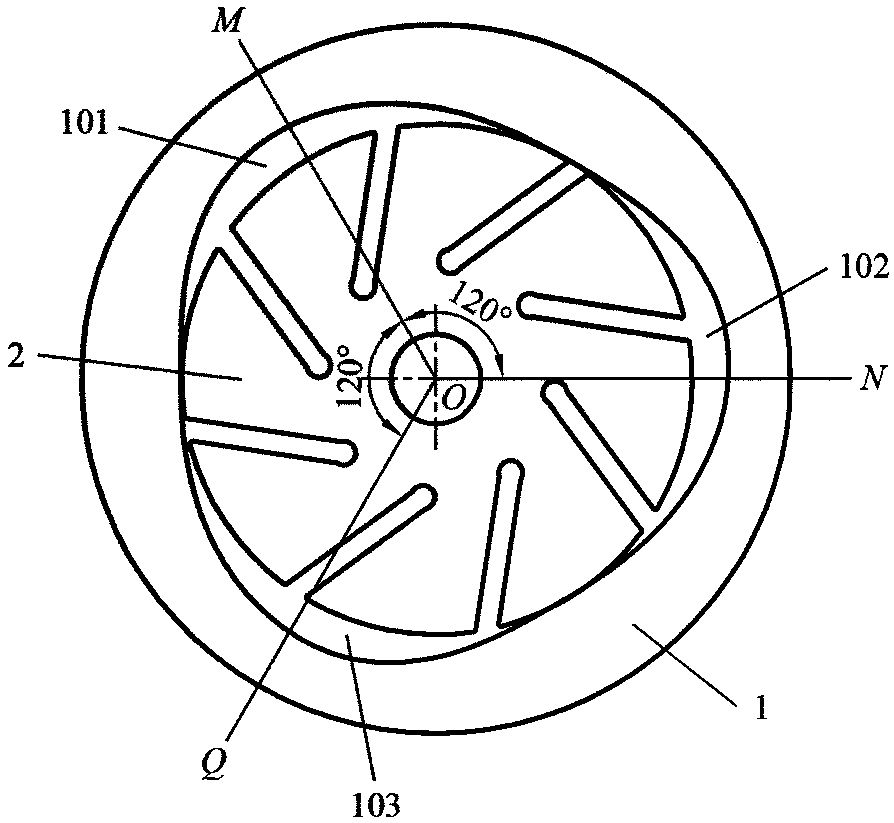

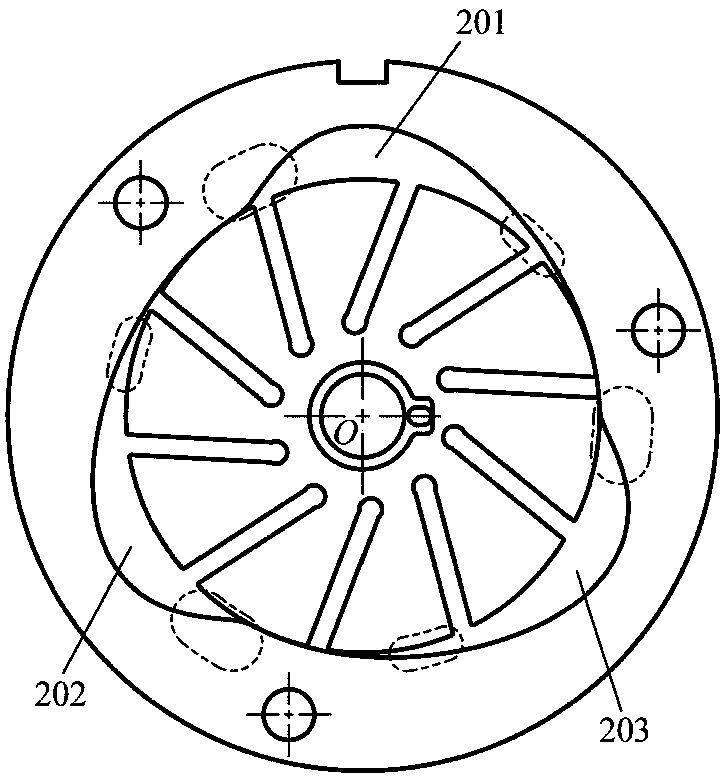

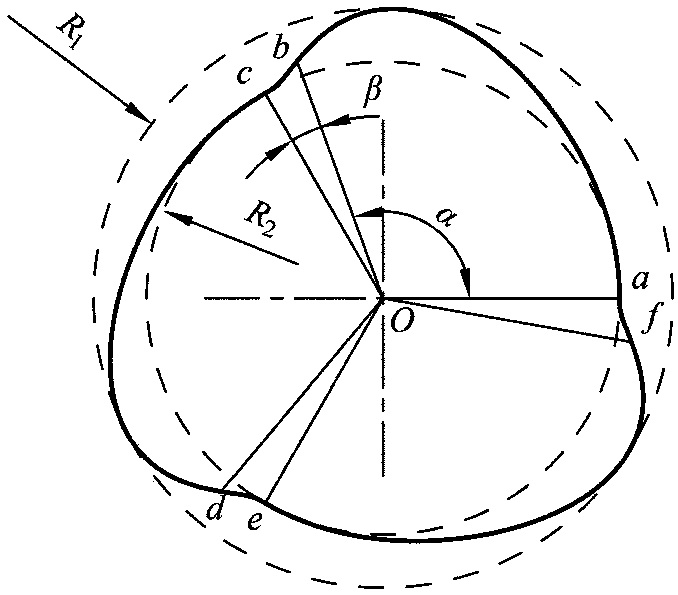

Three-cavity sliding vane vacuum pump cylinder and type line design method thereof

ActiveCN108443156AIncrease the internal volume ratioIncrease ultimate vacuumGeometric CADRotary piston pumpsEngineeringCylinder block

The invention discloses a three-cavity sliding vane vacuum pump cylinder and a type line design method thereof. A sine spiral line is adopted to form a cylinder type line; a first suction section curved line, a second suction section curved line and a third suction section curved line as well as a first discharge section curved line, a second discharge section curved line and a third discharge section curved line rotate around an original point at 120 degrees so as to be symmetrical, so that the formed curved lines are in completely smooth connection and second derivative continuity; the sizeof a central angle corresponding to the first suction section curved line is alpha, the size of a central angle corresponding to the first discharge section curved line is beta, alpha is smaller thanbeta, and alpha plus beta is equal to 120 degrees; and three same unsymmetrical working cavities are formed between the cylinder and a rotor, so that the displacement volume is reduced, and the interior volume specific ratio is effectively increased. According to the three-cavity sliding vane vacuum pump cylinder provided by the invention, on the premise of ensuring that the top ends of sliding vanes slide on an inner wall of the cylinder in a contacting way, rigid impulse and flexible impulse are avoided; and the interior volume specific ratio of a sliding vane vacuum pump can be increased through changing the sizes of the central angles corresponding to the curved lines, so that the slide vane vacuum pump has a higher limiting vacuum degree.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Screw of screw vacuum pump

ActiveCN105673503AMany modelsIncrease ultimate vacuumRotary piston pumpsRotary piston liquid enginesPulp and paper industryEnergy consumption

The invention provides a screw of a screw vacuum pump, and belongs to the technical field of vacuum pumps. The problem that an existing screw of the screw vacuum pump can not meet specific technological conditions is solved. The number of circles of a spiral groove in an air intake part in the screw of the screw vacuum pump is 0.75-1.25. When the number of circles of a spiral groove in a compression transition part is 1, the number of circles of a spiral groove in an exhausting part is larger than 3. When the number of circles of the spiral groove in the compression transition part is larger than 1, the number of circles of the spiral groove in the exhausting part is 1.75-4. By means of the screw of the screw vacuum pump, the final vacuum degree of the vacuum pump is higher, the performance is more stable, the manufacturing cost is hardly increased, the screw vacuum pumps have more models, and the application range is wider. According to the screw vacuum pump adopting the variable-pitch screw, by properly increasing the number of winding circles of the spiral grooves, the compression capacity is optimized, the exhausting efficiency of the exhausting part is improved, the phenomenon that air of the exhausting part can not be exhausted and compression is excessive is relieved, and the unit energy consumption is further effectively lowered.

Owner:巫修海 +1

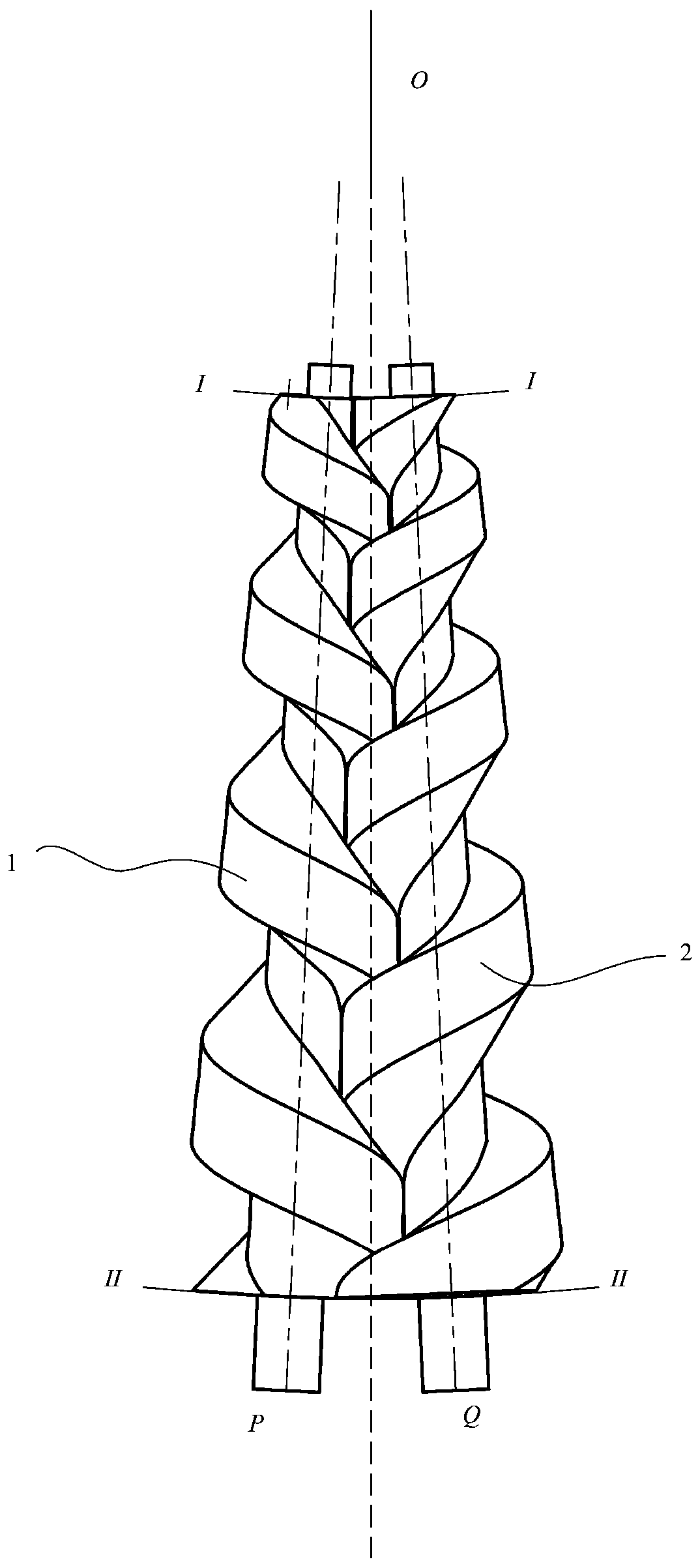

Sectional variable-section screw rotor

PendingCN110230595AIncrease the internal volume ratioIncrease the scope of applicationPump componentsRotary piston pumpsEngineeringCurve line

The invention discloses a sectional variable-section screw rotor. A left rotation screw rotor (100) and a right rotation screw rotor (200) are arranged in sections and can be rightly engaged with eachother; screw pitch of each screw rotor has sectional continuous change; section lines have sectional continuous change; each section line is formed by five curved lines which are connected from end to end; types of the section lines are unchanged; area utilization coefficients of the section lines of two screw rotors are gradually increased from a first axial position I-I to a ninth axial position IX-IX; the volume of a formed operation cavity is gradually increased, and the center distance remains unchanged; tooth widths of the two screw rotors are small on an air absorption side; tooth widths of the two screw rotors are large on an air exhausting side; good inter-stage sealing performance is achieved. The sectional variable-section screw rotor has high pumping speed, ultimate vacuum degree and internal volume ratio under the same axial length; and the application range and the application field of the sectional variable-section screw rotor are more extensive.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

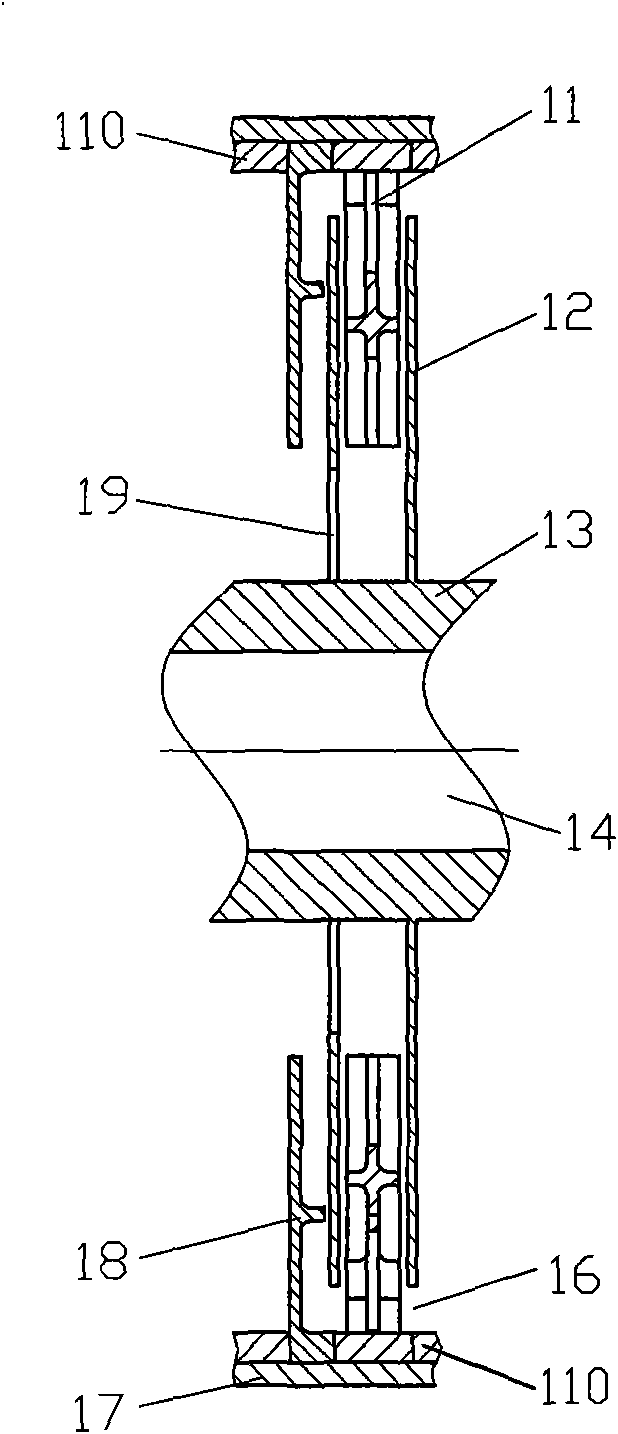

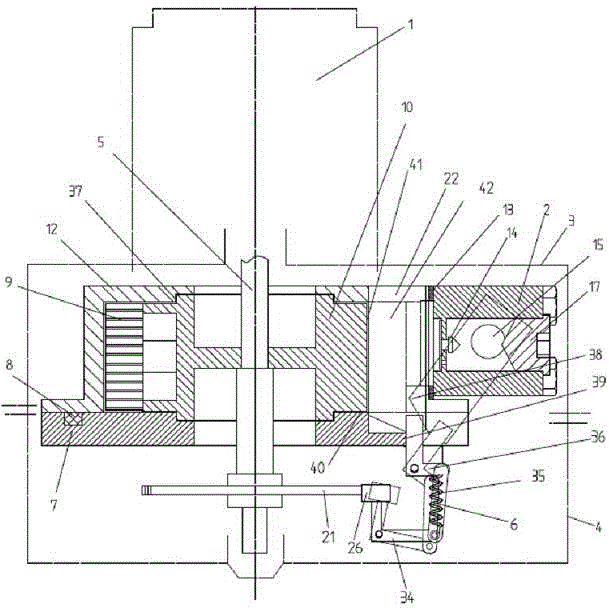

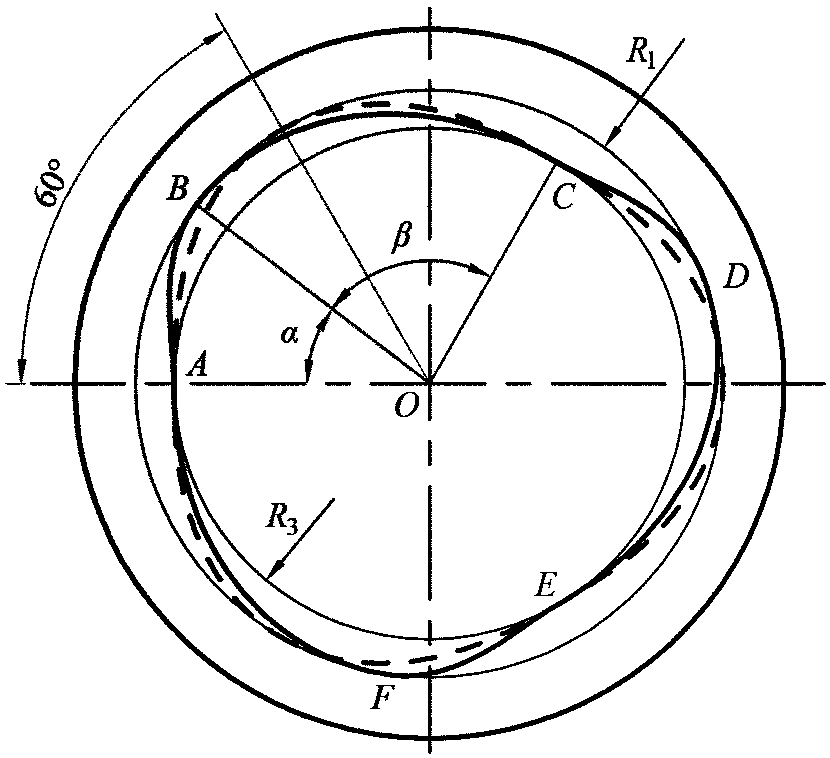

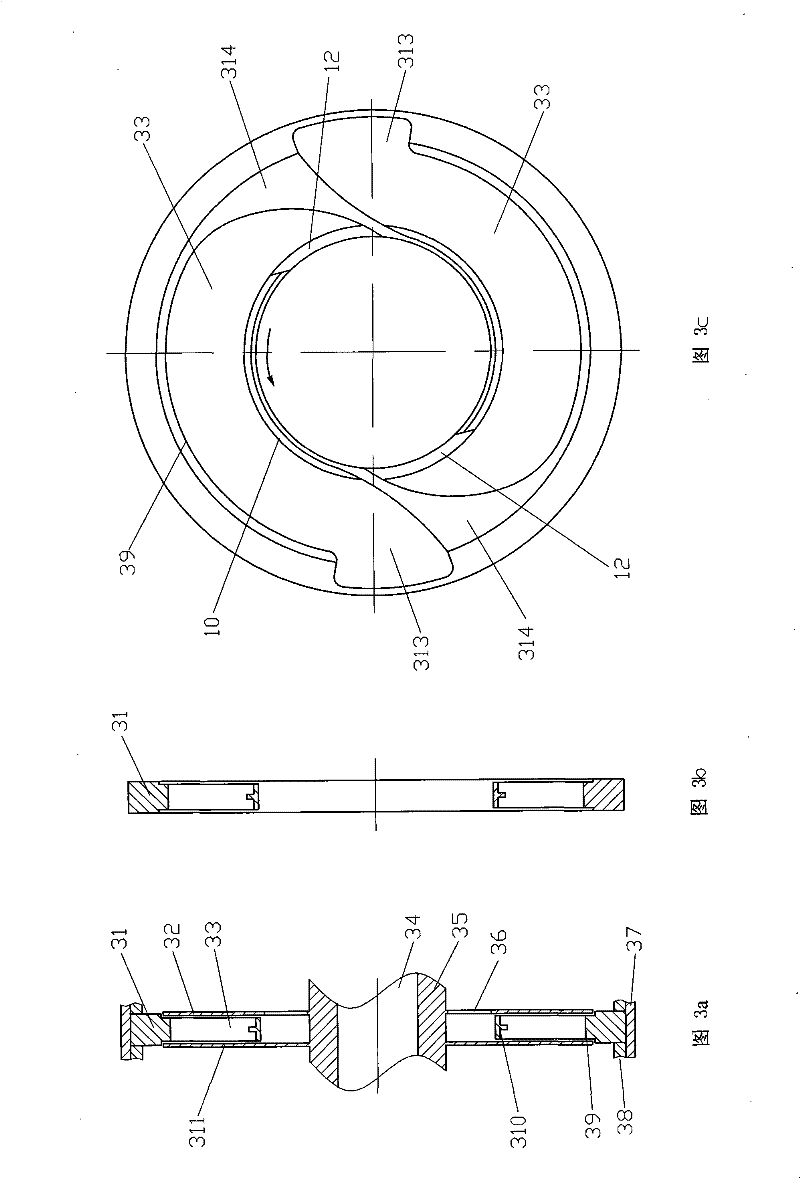

Three-cavity sliding-vane-type vacuum pump

PendingCN108443155AReduced exhaust air pulsationImprove vibrationGeometric CADRotary piston pumpsVacuum pumpAirflow

The invention discloses a three-cavity sliding-vane-type vacuum pump. The vacuum pump comprises an air suction end cover (1), a pump cavity (2), sliding vanes (3), a rotor (4) and an exhaust end cover(5). A three-working-cavity structure is adopted, three identical closed working cavities are formed among the air suction end cover (1), the pump cavity (2), the exhaust end cover (5) and the rotor(4), the formed closed working cavities are asymmetric working cavities, and the volume of the part, near a corresponding exhaust port, of each working cavity is smaller than the volume of the part, near a corresponding air suction port, of each working cavity. In the working process, the relative positions of the sliding vanes in the different working cavities at any moment are different, therefore, the working steps of the working cavities are not consistent, the three working cavities can be prevented from exhausting air at the same time, and the pulsation of the exhaust gas flow can be reduced. According to the vacuum pump, the inner volume ratio of the three-cavity sliding-vane-type vacuum pump is remarkably improved, the limit vacuum degree of the three-cavity sliding-vane-type vacuum pump is effectively improved, and the problems of vibration and noise caused by exhaust flow pulsation are solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

High vacuum arc pump and pumping unit thereof

ActiveCN104100492AGuaranteed uptimeAvoid burn-through accidentsVacuum evaporation coatingSputtering coatingWater jacketMechanical engineering

The invention belongs to the technical field of vacuum obtaining and particularly relates to a high vacuum arc pump and a pumping unit thereof. High vapor pressure material is mixed to a cathode target of a traditional arc pump and is made of magnesium, aluminum, zinc, calcium or mixture of any two of them; the high vapor pressure material accounts for 0.5-80% of the cathode target by weight. High vacuum operating range of the high vacuum arc pump is greatly broadened. A metal retainer plate is disposed between the cathode target of the arc pump and an openable face plate and is insulated from peripheral parts, temperature rise of the face plate is eliminated, the desorption amount of gas adsorbed to the face plate is significantly reduced, and ultimate vacuum of the arc pump is further increased. In addition, consumption precautions are made for the cathode target of the arc pump, burn-through of a cooling water jacket of the arc pump is effectively avoided, and operational reliability of the arc pump is improved.

Owner:苏州摩星真空科技有限公司

Composite vacuum pump

InactiveCN101852199BIncrease ultimate vacuumReduce energy consumptionRotary piston pumpsRotary piston liquid enginesVacuum pumpingProcess engineering

The invention belongs to the field of vacuum-pumping equipment and provides a composite vacuum pump which comprises a pump shell, a gas inlet and a gas outlet, wherein the gas inlet and the gas outlet are formed on the pump shell; a plurality of levels of molecular drag pumps and Roots pumps, which are installed coaxially, are arranged in the pump shell; the molecular drag pumps are combined in parallel or series and are arranged at the part near the gas inlet; the Roots pumps are combined in series and are arranged at the part near the gas outlet; and the molecular drag pumps and the Roots pumps are combined in series. The composite vacuum pump provided by the invention has the advantages of high pumping speed, high ultimate vacuum, low energy consumption, small size and light weight andcan also acquire clean medium vacuum and high vacuum.

Owner:储继国

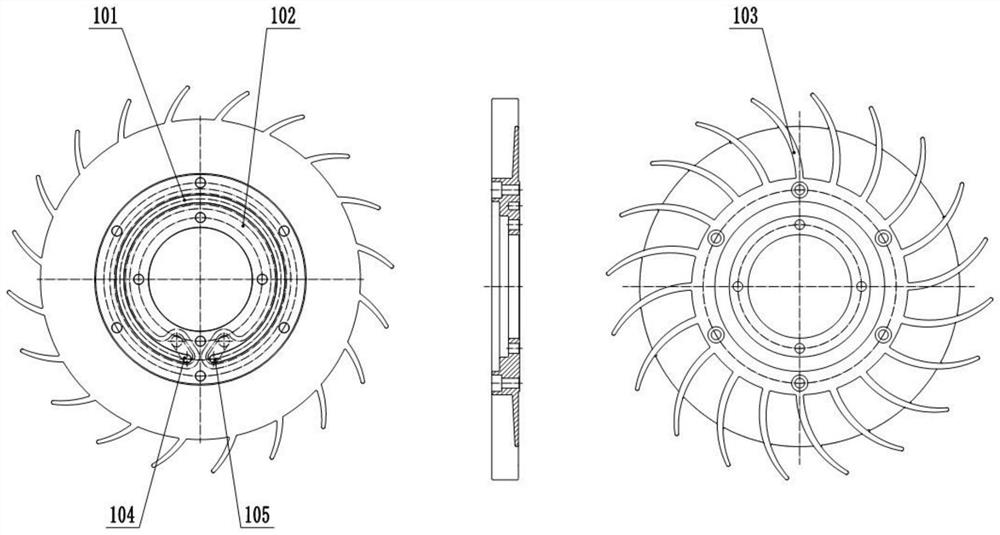

Air blast cooling rotary vane roller pump

InactiveCN1464198AIncrease ultimate vacuumReduce temperature riseRotary piston pumpsRotary piston liquid enginesHeat sinkVacuum pressure

The forced wind cooled rotating sheet roller pump is used as vacuum pump or vacuum-pressure composite air pump. It has cast radiating fins in the outer surface for expanding heat radiating area, fan in the belt pulley for forced cooling of the pump, double-arc inner cavity to eliminate harmful space inside the pump and raise extreme vacuum degree, and needle valve type oil cup to reach boundary lubricating effect. The pump has simple structure, low cost, high energy saving effect and no pollution.

Owner:王安大

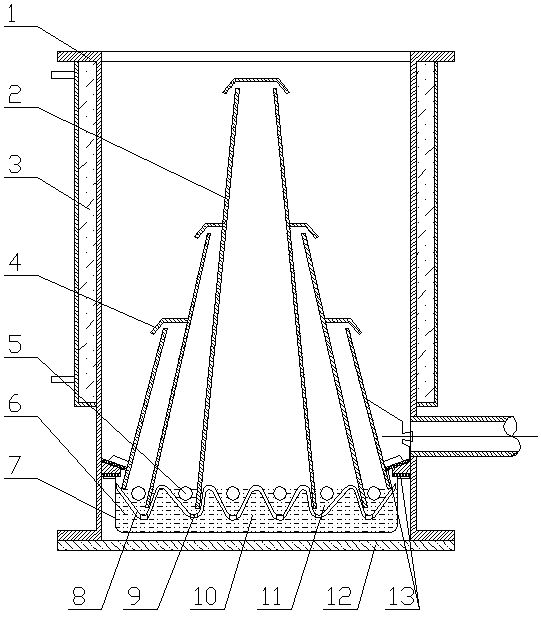

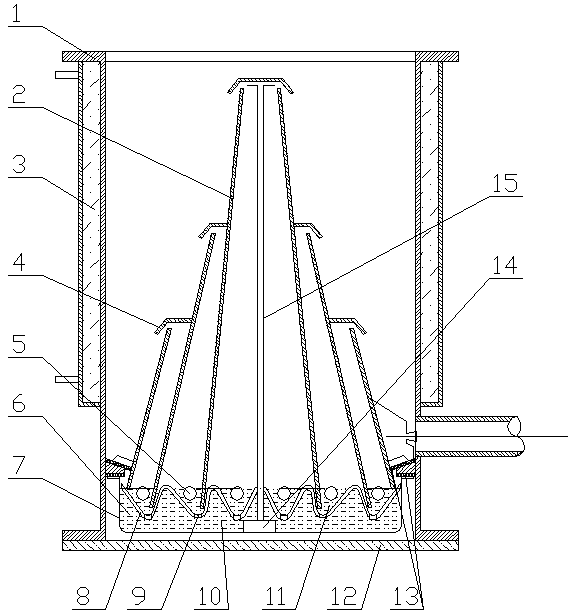

Floating heating type vacuum diffusion pump

InactiveCN108691821AReduce the temperatureTemperature low to highMachines/enginesDiffusion pumpsTemperature controlControl system

The invention discloses a floating heating type vacuum diffusion pump. The pump comprises a pump body, pump oil, a pump core, an evaporation system, a cooling system, an injection system and a controlsystem, the evaporation system of the pump adopts a heating mode of floating heating, the evaporation system comprises an evaporator, a heater and a temperature measuring and temperature control element, the evaporator is provided with a heating area and an oil storage area, the heating area and the oil storage area are separated through a middle partition plate and communicate with each other through an oil hole in the partition plate, the heater is arranged in the heating area, and is used for heating the pump oil in the heating area to enable the pump oil to be instantly evaporated to become steam, the heater is fixed on the middle partition plate, the middle partition plate can float in the pump oil so that the heating area can kept constant and unchanged within the normal pump oil range, the heater is fixed on the middle partition plate, and the middle partition plate can float in the pump oil so that the heating area can kept constant and unchanged in the normal pump oil range.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

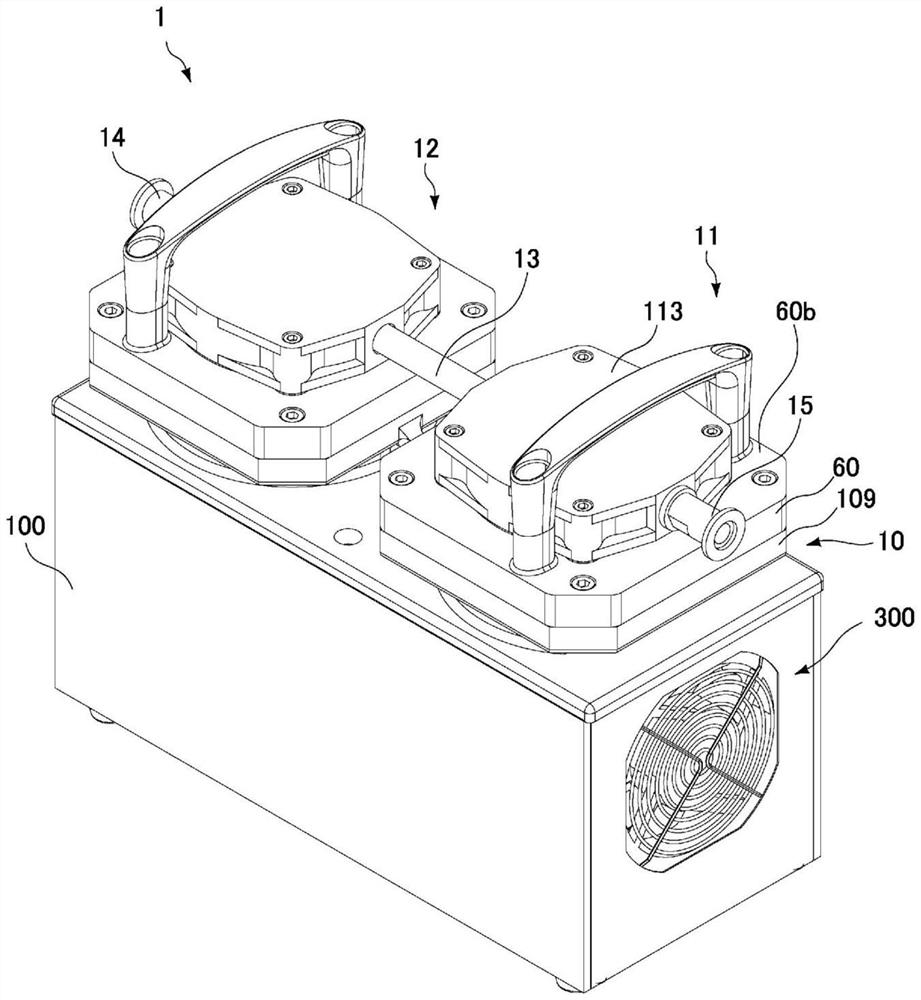

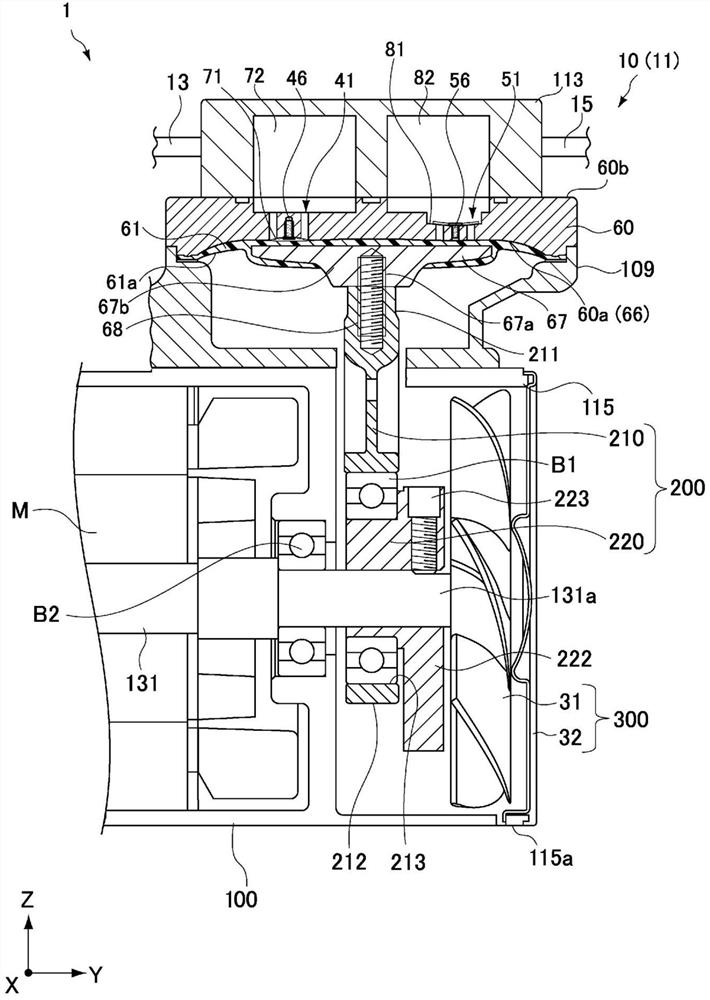

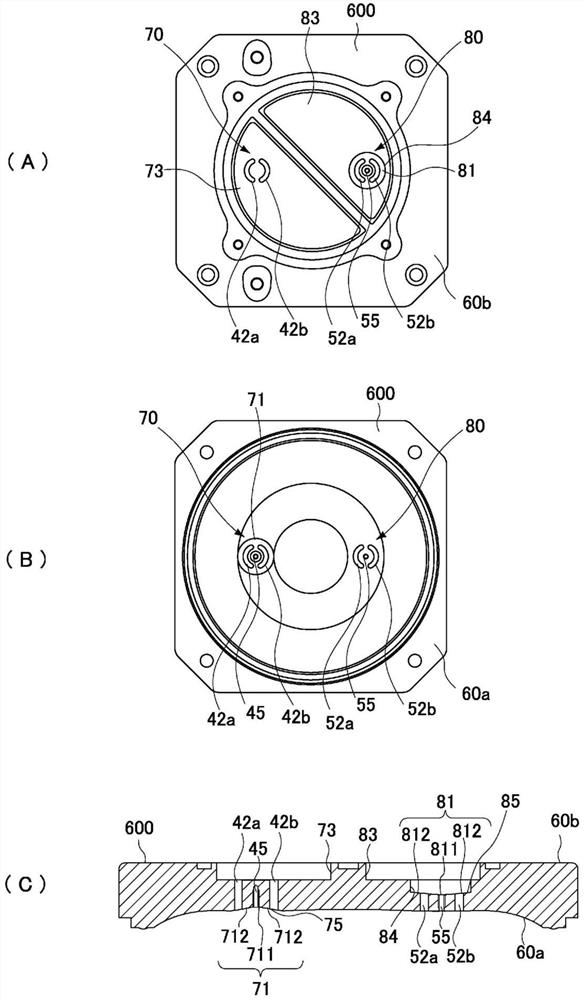

Valve units, pump heads and pump units

ActiveCN111386417BIncrease ultimate vacuumPlug valvesPositive displacement pump componentsEngineeringPump head

A valve device according to one aspect of the present invention includes a valve seat, a valve member, and a fastener. The valve seat is formed by a conical concave surface having a bottom formed with a connection hole and a plurality of ventilation holes formed around the connection hole. The valve member has a supporting portion and a plurality of valve portions, the supporting portion faces the bottom; the plurality of valve portions has a plurality of slits extending radially from the outer side of the supporting portion, and the plurality of The valve portion faces the plurality of vent holes and is elastically deformable. The fastener is connected with the connection hole and fixes the supporting part on the valve seat.

Owner:爱发科机工株式会社

Single-stage and double-stage switching rotary vane vacuum pump

InactiveCN108869294AIncrease the compression ratioIncrease vacuumMachines/enginesPumpsExhaust valveSingle stage

The invention relates to a single-stage and double-stage switching rotary vane vacuum pump. The pump comprises a first pump body, a front end cover, a rear end cover, a first rotor and a motor, wherein the first rotor is eccentrically arranged in the first pump body, and the motor drives the first rotor to rotate, a first exhaust groove is formed in the upper end of the first pump body, first exhaust ports are formed in the bottom of the first exhaust groove, the first exhaust ports are internally provided with first exhaust valves, a second pump body is arranged between the first pump body and the front end cover in an oil tank, a second rotor which synchronously rotates with the first rotor is eccentrically arranged in the second pump body, the top of the second rotor is provided with asecond air suction port and second exhaust ports, second exhaust valves are arranged in the second exhaust ports, and one end, far away from the second pump body, of the second air suction port communicates with the bottom of the side wall of the first air exhaust groove. According to the pump, the purchasing cost can be reduced, the limit vacuum degree can be improved, and the space utilization efficiency can be improved.

Owner:ULVAC NINGBO

Oil leading-out cooling structure of large-pumping-speed rotary vane pump

PendingCN114294230AIncrease ultimate vacuumReduce the temperatureSealing arrangement for pumpsPumpsCooling effectElectric machinery

The invention relates to an oil leading-out cooling structure of a high-pumping-speed rotary vane pump, the high-pumping-speed rotary vane pump comprises a motor, an oil tank and a pump core, and the pump core comprises a rotor and an oil pump rotary vane; the extending end of the rotor is installed on a bearing seat through a bearing, and an oil pump groove is formed in the center of the pump core side of the bearing seat and can allow an oil pump rotary vane to rotate. The other side of the bearing seat is hermetically connected with a bearing gland, and the other side of the bearing gland is hermetically connected with an oil cooling radiating fin; a C-shaped oil groove is formed in one side, connected with the bearing gland, of the oil-cooling radiating fin; and a fan is mounted on the other side of the oil cooling radiating fin. On the basis of air cooling heat dissipation, after pump oil is cooled through the oil tank, the oil cooling heat dissipation fins are introduced for reinforced cooling firstly, then the pump oil enters the pump core for circulation, the cooling effect is good, a cooling water circulation system does not need to be additionally arranged, cost is saved, and simplicity and convenience are achieved.

Owner:BEIJING BEIYI WOOSUNG VACUUM TECH

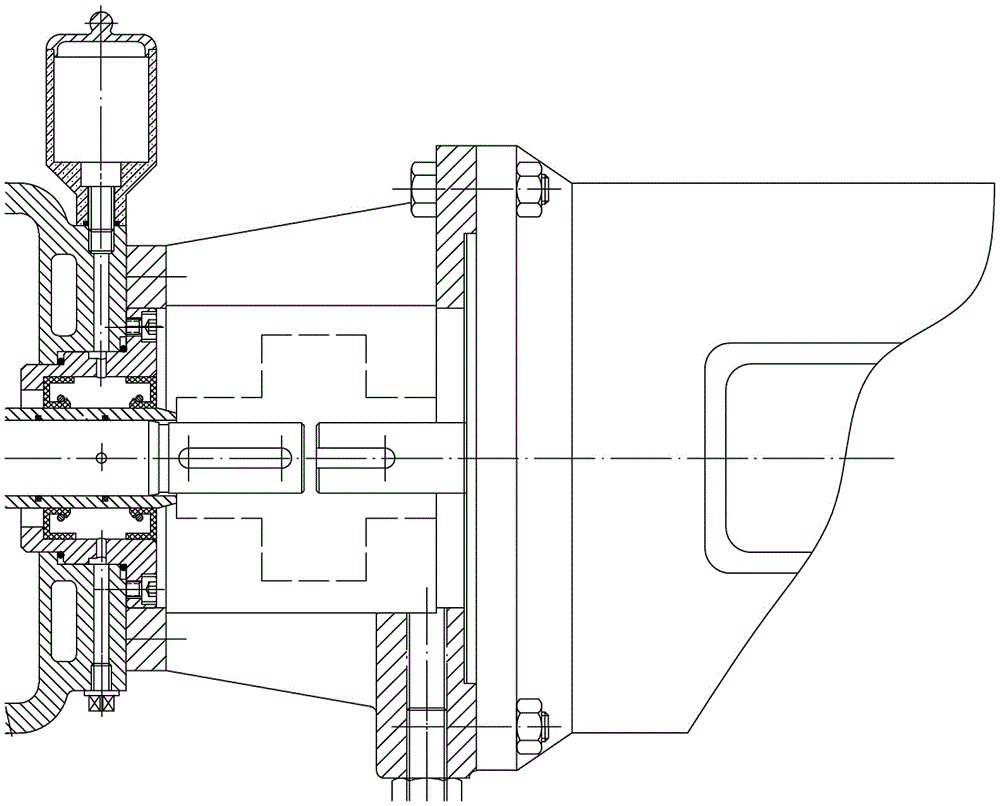

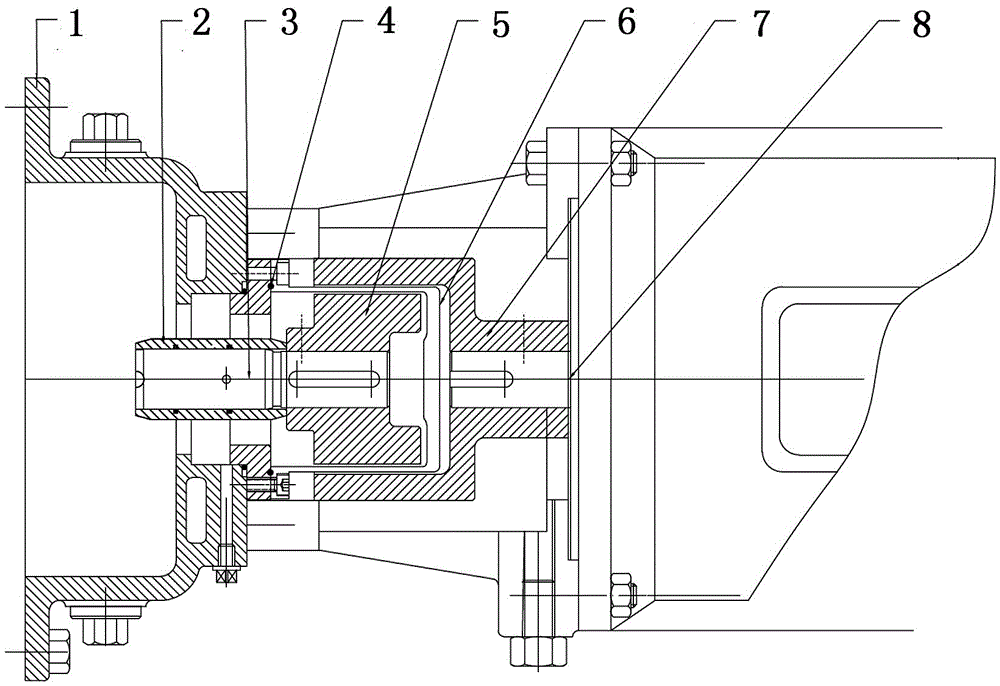

Magnetic sealing structure for drive end of roots pump

InactiveCN105485010AIncrease ultimate vacuumBoth economical and practicalSealing arrangement for pumpsMachines/enginesLubricationMotor shaft

The invention discloses a magnetic sealing structure for a drive end of a roots pump. The magnetic sealing structure comprises a magnetic transmission device, and is characterized in that the magnetic transmission device comprises an inner magnetic rotor and an outer magnetic rotor; the inner magnetic rotor is connected with a drive shaft; the outer magnetic rotor is connected with a motor shaft; and a static sealing structure is arranged between the outer magnetic rotor and the inner magnetic rotor. According to the invention, a magnetic transmission technology is utilized, and dynamic sealing for the drive end is changed into static sealing, thus oil leakage and wear of the outer side of the drive end of the roots pump are solved; meanwhile, due to no friction, lubrication is not needed, and heat is avoided, and independent oil cup and cooling water are cancelled; and complete static sealing is achieved, thus the limit vacuum degree of the roots pump is further increased. The magnetic sealing structure is more economic compared with motor sealing in case of meeting the needs of customers, achieves the effect of motor sealing, and has both economical efficiency and practicability.

Owner:ELIVAC COMPANY +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com