Mass spectrometer leak detection method

A leak detection and mass spectrometry technology, applied in the field of mass spectrometry leak detection, can solve the problems of inaccurate detection of leak rate of sealed box, long detection cycle, too many interference factors, etc., and achieve fast detection efficiency, high accuracy and ultimate vacuum degree high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

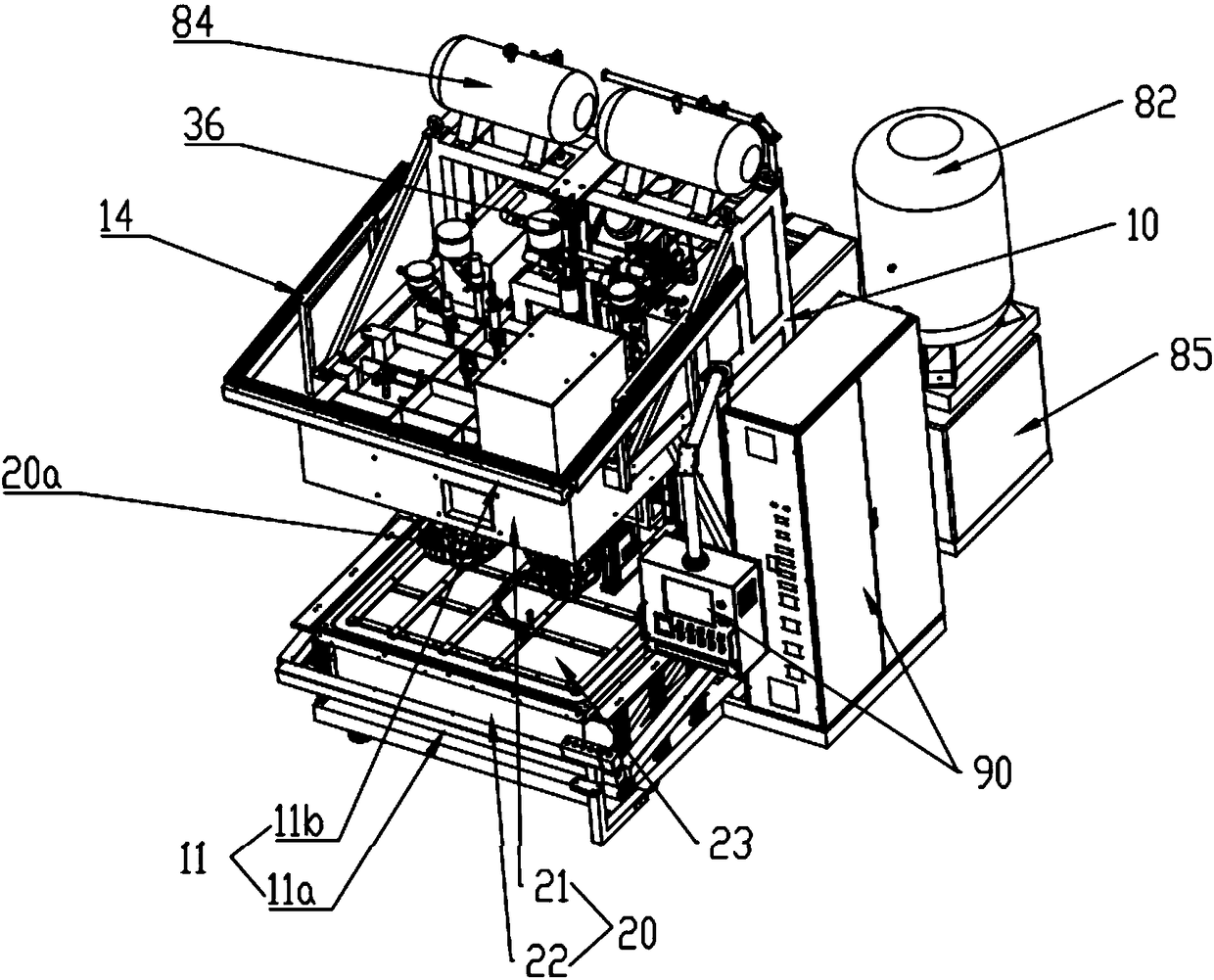

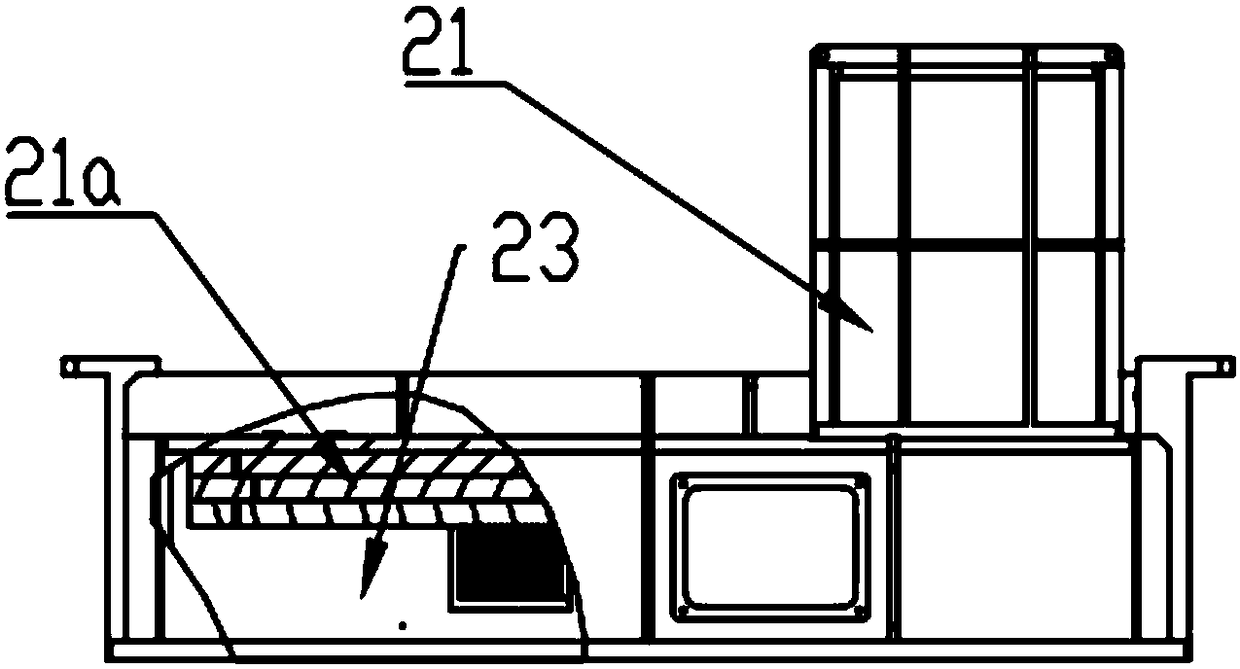

[0028] see figure 1 , Figure 10 and Figure 11 , the present invention provides a mass spectrometer leak detection device for testing the airtightness of the box to be tested 20a, the box to be tested 20a may be a box with airtightness requirements such as a gearbox, a water tank or an oil tank. The mass spectrometry leak detection equipment includes a support frame 10, a grating sensor 11, a vacuum cavity 20, a lifting mechanism 30, a graded air extraction mechanism 40, a tracer gas source 50, an inflation mechanism 60, a mass spectrometry leak detection device 70, and a gas recovery mechanism 80 And the control device 90.

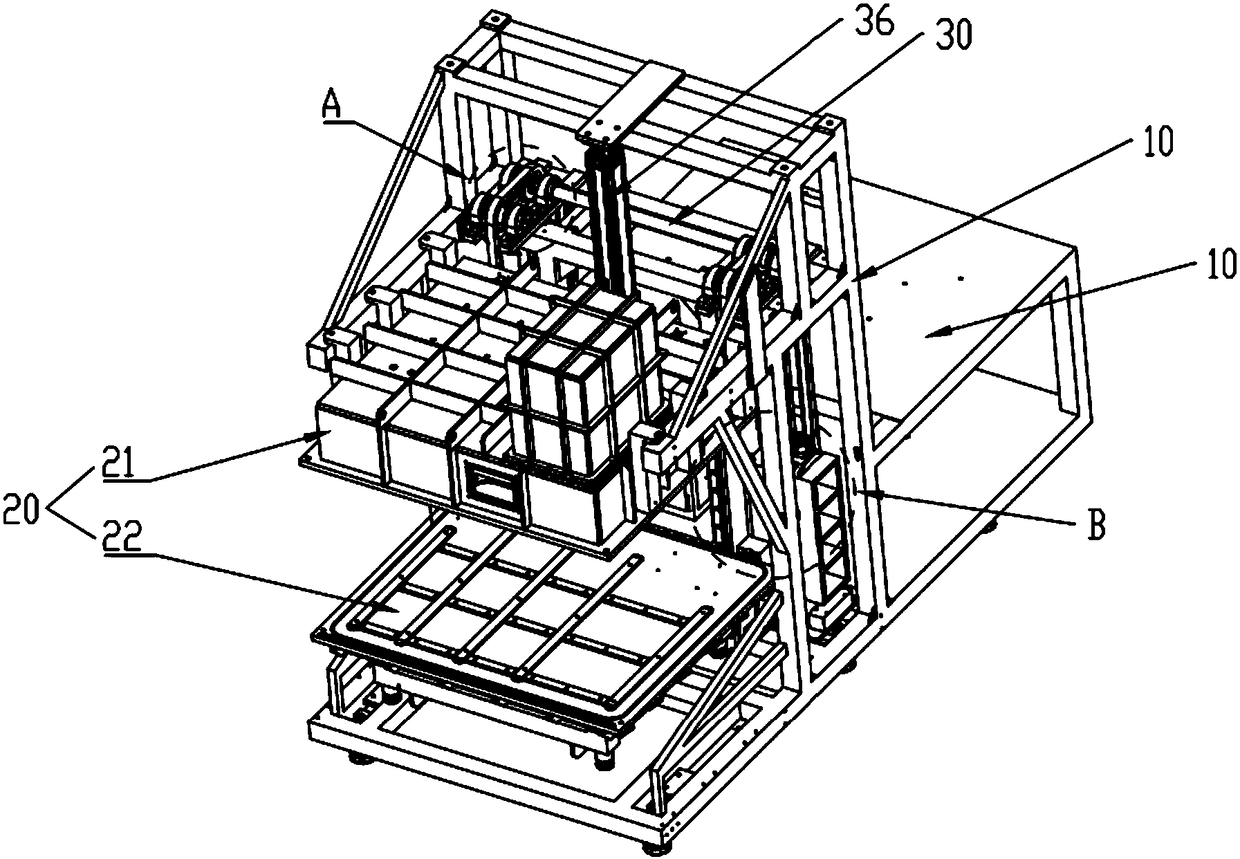

[0029] see figure 1 and Image 6 The support frame 10 is provided with a first guide rail 12 and a second guide rail 13 extending along the longitudinal direction of the support frame 10, and the cross section of the first guide rail 12 is I-shaped. The cross section of the second guide rail 13 is V-shaped, and the first guide rail 12 and the second...

Embodiment 2

[0070] see Figure 12 , the present invention also discloses a mass spectrometry leak detection method for detecting the airtightness of the box body 20a to be tested, comprising the following steps:

[0071] S10, performing an empty box leak detection on the airtight vacuum cavity;

[0072] In this step, after the mass spectrometer leak detection equipment is powered on, it first detects the vacuum chamber, so as to detect whether the internal structure or pipeline of the vacuum chamber is leaking at the first time. The specific detection method may be to inject compressed air into the vacuum cavity, and then detect the change of the air pressure in the vacuum cavity within a preset time through a pressure sensor, so as to know whether there is a leak in the vacuum cavity. Of course, tracer gas can also be used for detection, which is not specifically limited here.

[0073] S101. Correcting the leak rate obtained after the leak detection;

[0074] The tracer gas in the cal...

Embodiment 3

[0092] see Figure 13 , the present invention also discloses another mass spectrometry leak detection method, which is similar to the method in the second embodiment, the difference being that step S14 of the method specifically includes:

[0093] S141, the tracer gas source 50 delivers a first output amount of tracer gas to the box body 20a to be tested through the first inflatable branch 61;

[0094] In this step, a small amount of tracer gas is delivered to the test box 20a through the first inflation branch 61, and if the seal of the test box 20a is poor, a large amount of tracer gas leaks to the The accommodating cavity 23 is inside the body, thus avoiding waste caused by a large amount of transport, and excessive tracer gas leaking into the accommodating cavity 23 , which takes time to clean and thus leads to low detection efficiency.

[0095] Preferably, the tracer gas source 50 includes a high-pressure tracer gas tank 51 and a tracer gas quick-fill valve 52 connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com