Multi-stage type vacuum pumping device and vacuum pumping method thereof

A vacuum device, multi-stage technology, applied in the direction of liquid displacement machinery, machine/engine, mechanical equipment, etc., can solve the problems of energy consumption, energy consumption, waste gas pollution, etc., achieve fast pumping speed, reduce manufacturing cost, security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Before the present invention is described in detail, it is noted that in the following description, similar elements are denoted by the same numerals.

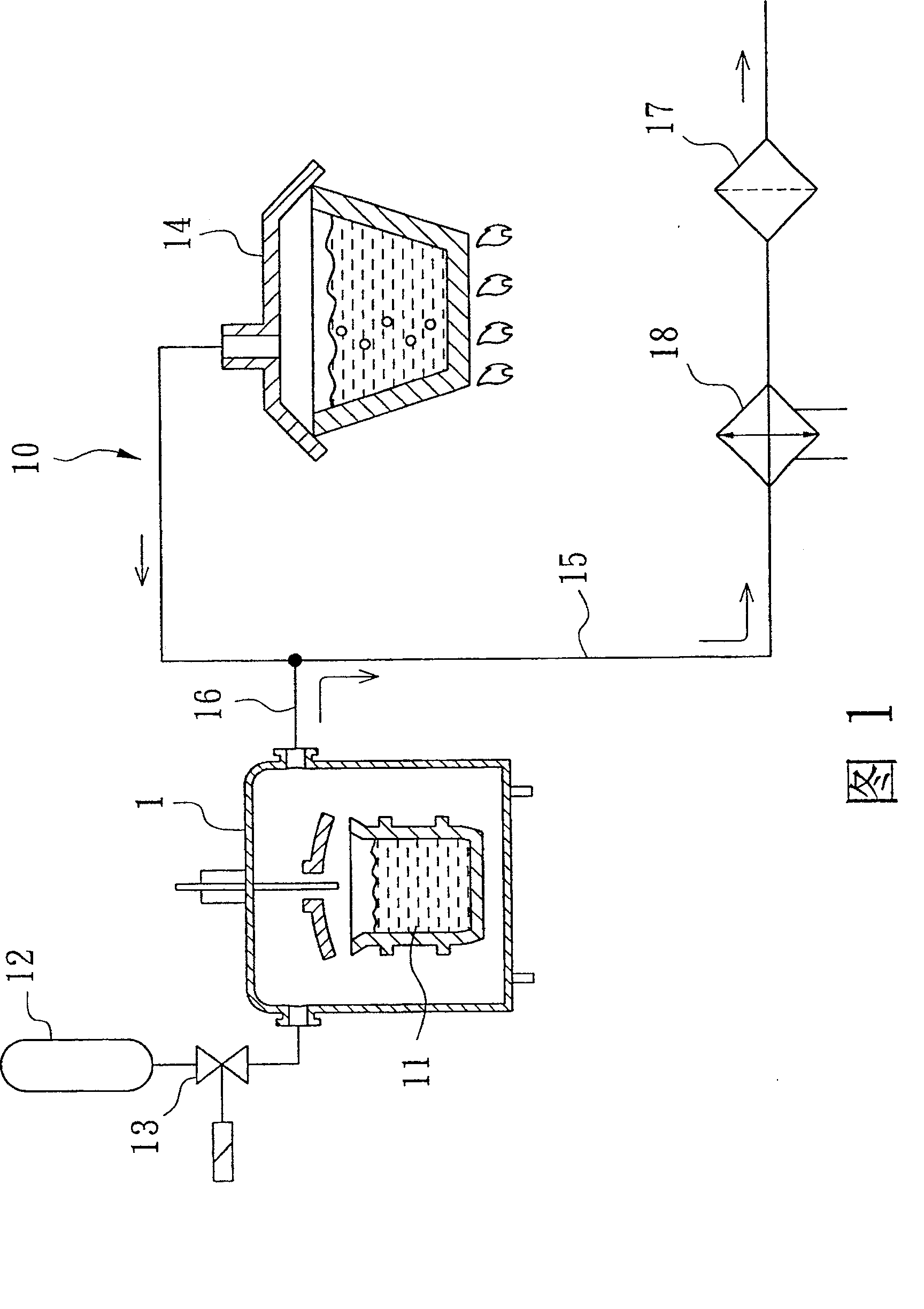

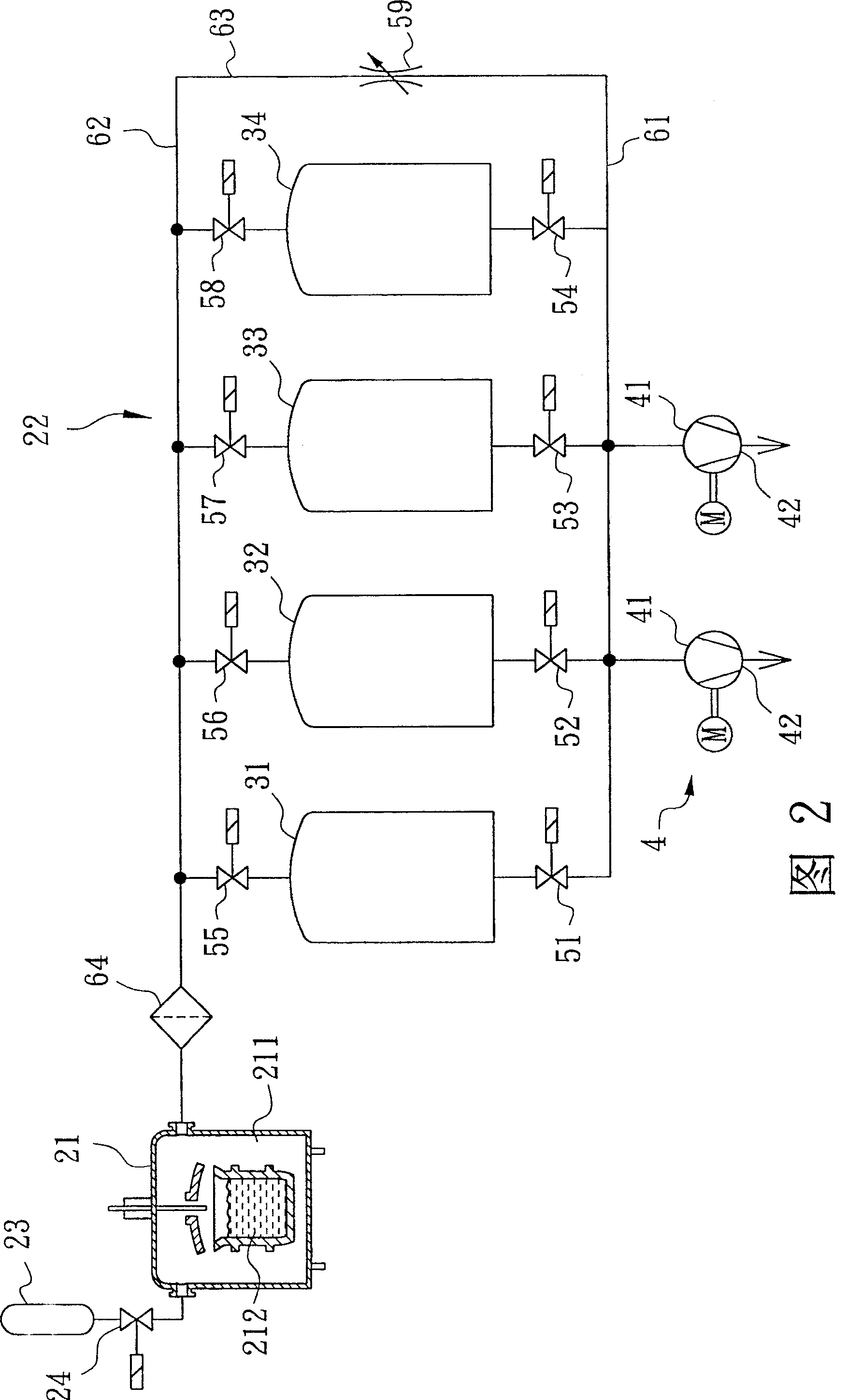

[0046] As shown in Figure 2, a first preferred embodiment of the multistage vacuum pumping device of the present invention can be applied on the VOD refining equipment, and this refining equipment comprises a melting furnace 21, a vacuum device 22 connected to the melting furnace 21, a Connect the gas storage cylinder 23 of the melting furnace 21, and a valve unit 24 for controlling the output gas of the gas storage cylinder 23, wherein the melting furnace 21 has a chamber 211 and is used to store a container filled with molten steel 212 .

[0047] The vacuum device 22 is used to extract the gas in the chamber 211 of the furnace 21 and includes several cavities 31-34, an air extraction unit 4, several first control valves 51-54, and several second control valves 55 ˜58 , a bypass restrictor valve 59 , a first pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com