Patents

Literature

835 results about "Reduced energy expenditure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

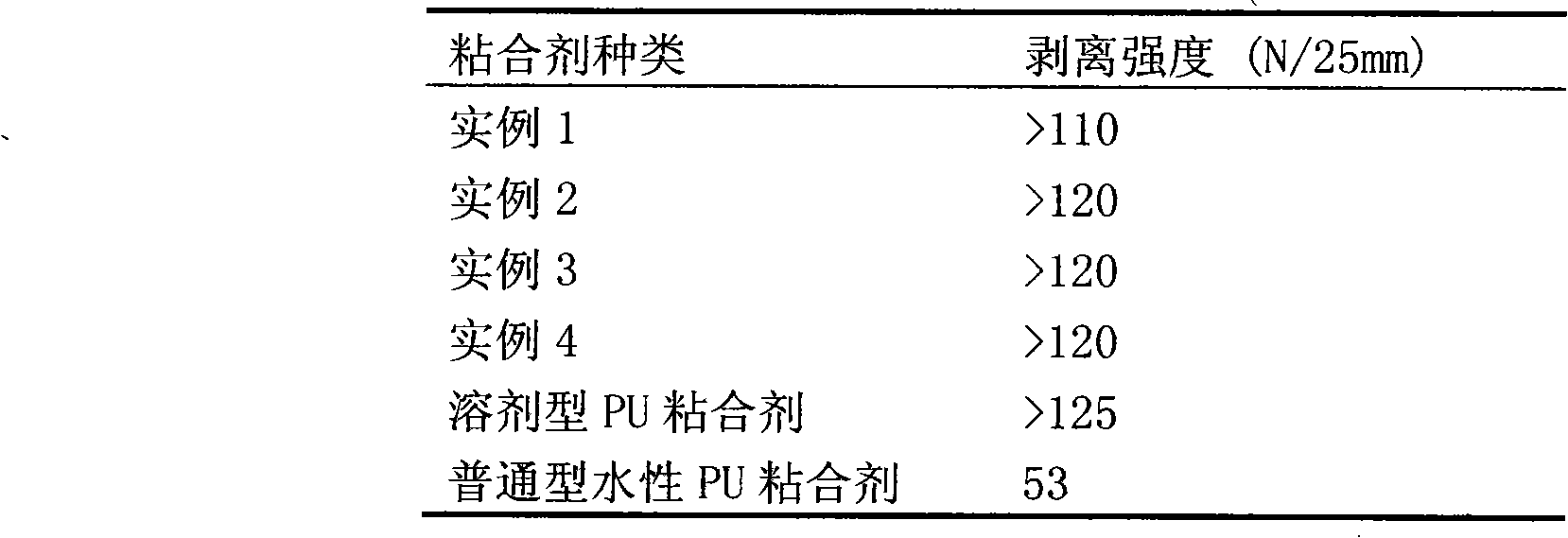

Method for preparing aqueous polyurethane adhesive and superfine fiber synthetic leather

ActiveCN101665675AHigh peel strengthIncrease elasticityPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterFolding endurance

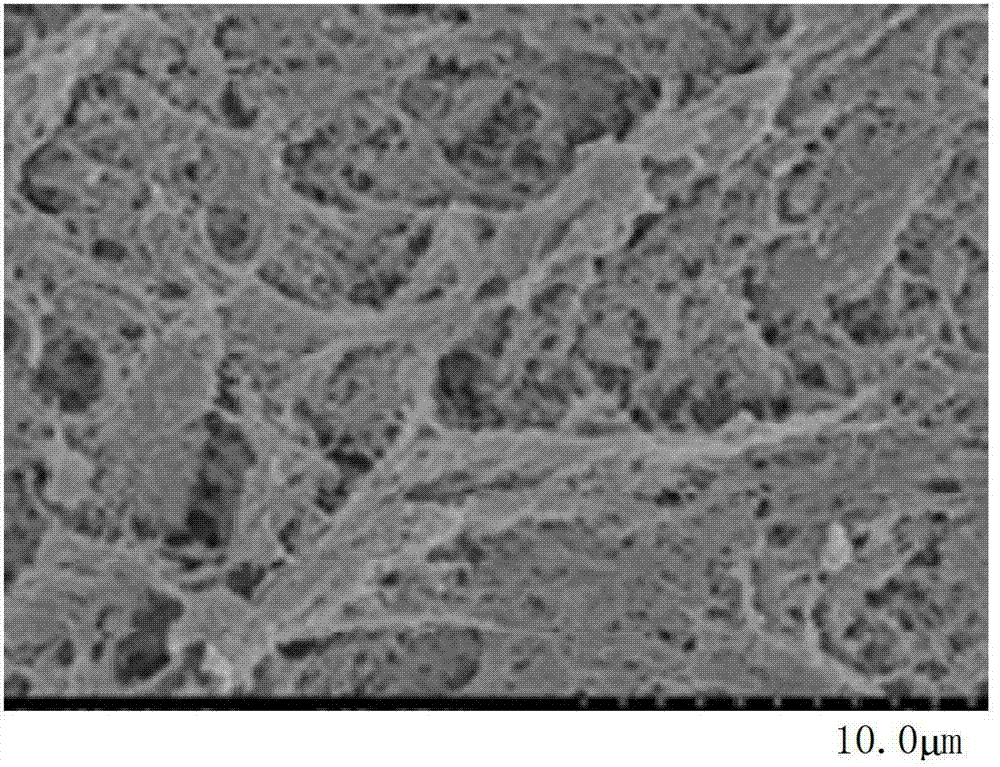

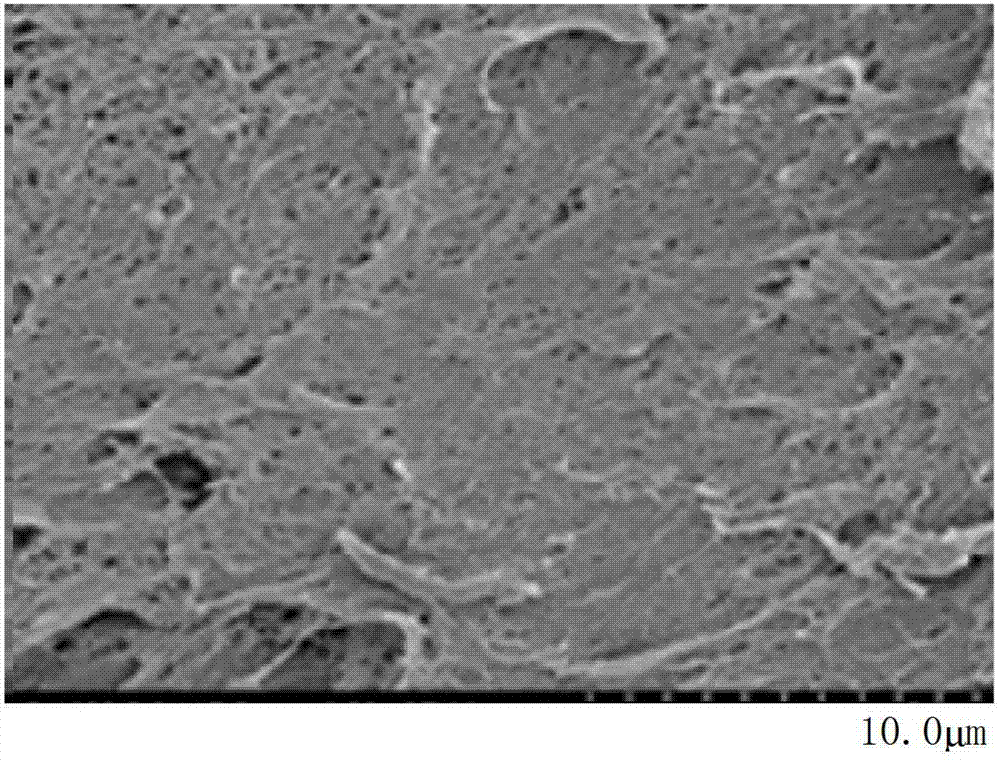

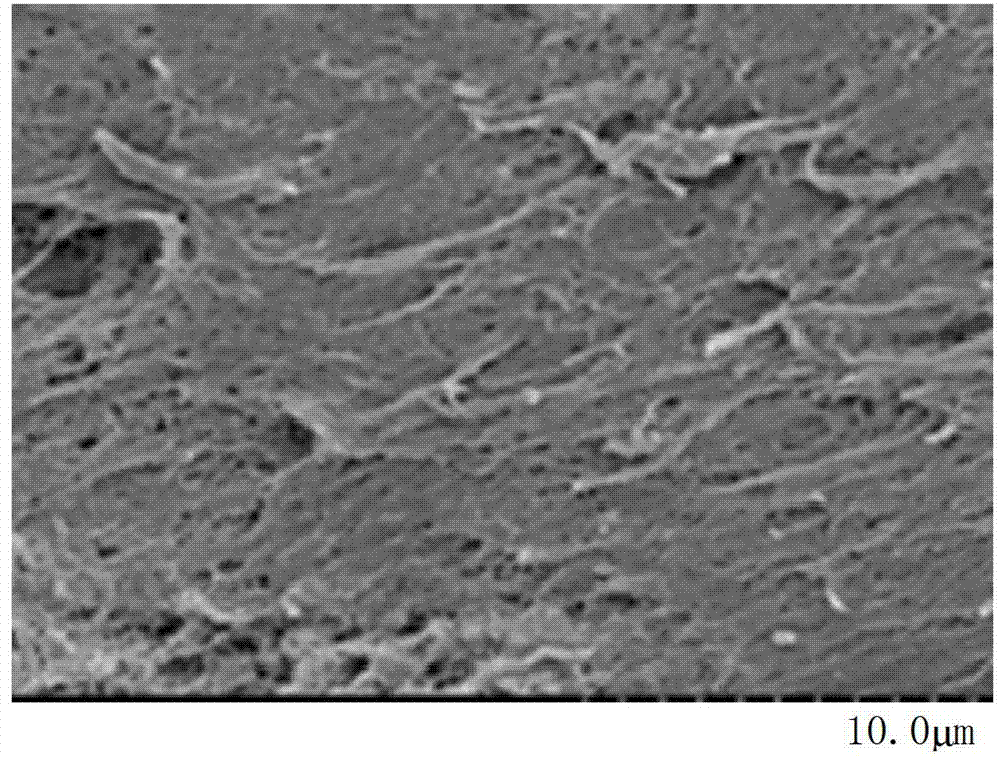

The invention relates to a method for preparing an aqueous polyurethane adhesive and superfine fiber synthetic leather, which belongs to the technical field of chemical products and preparation methods thereof. The method is characterized by comprising the following steps: mixing polyester polyol, isocyanate, a hydrophilic chain extending agent, a micromolecule chain extending agent and an amine environment friendly catalyst to obtain a hydrophilic aqueous polyurethane prepolymer; adding a neutralizing agent to the aqueous polyurethane prepolymer to obtain an aqueous polyurethane latex; then adding an amine chain expanding agent, a thickening agent, a defoaming agent and a flatting agent to the aqueous polyurethane latex to obtain the aqueous polyurethane adhesive; coating the aqueous polyurethane latex on release paper; drying the release paper; then coating the aqueous polyurethane adhesive on the dried release paper; and pressing the release paper and base cloth together to obtain the superfine fiber synthetic leather. The high solid content aqueous polyurethane adhesive prepared by the method has better initial tack and rebound resilience and higher final strength, and the prepared superfine fiber synthetic leather has higher peel strength and low-temperature folding endurance. The preparing process of the method greatly reduces the use and the discharge of organic solvents, reduces the energy consumption and furthest reduce the environmental pollution.

Owner:HUADA CHEM GRP CO LTD

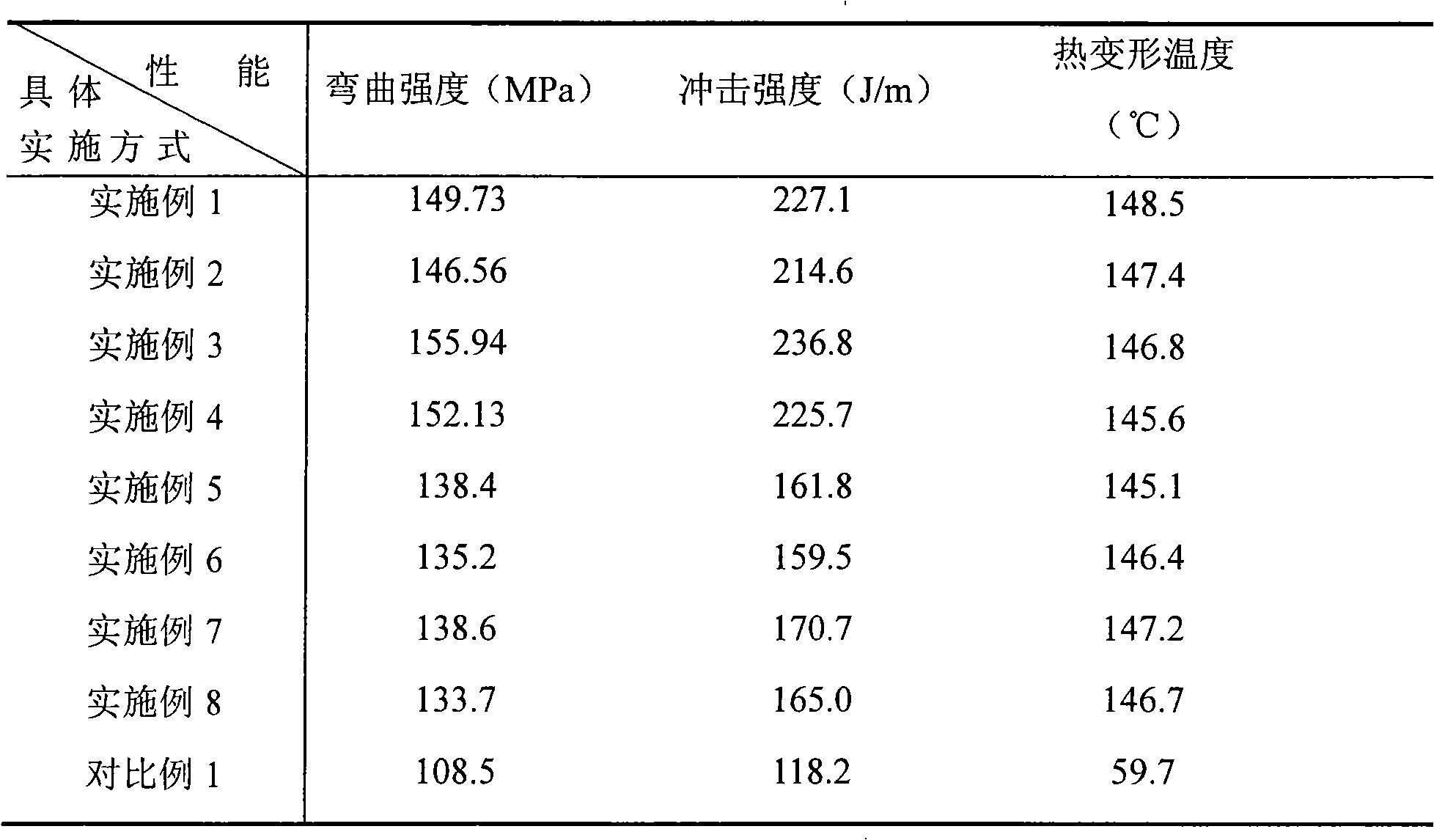

High strength and high heat resistance polylactic acid composite material and preparation method thereof

The invention relates to a high performance polylactic acid composite material and a preparation method. The high performance polylactic acid composite material comprises the following components in parts by mass: 40-85 parts of polylactic acid, 10-40 parts of modified inorganic or natural fibres; 1-10 parts of organic modified natural minerals, 0.8-5 parts of sensitizing agents, 0.1-2 parts of heat stabilizers, 0.1-1 part of antioxygen and 0.1-1 part of lubricating agent. The inorganic or natural fibre reinforced polylactic acid is selected to improve the mechanics performance, silane coupling agents are adopted to carry out surface processing to improve the compatibility with the polylactic acid matrix; and organic modified natural minerals are selected to improve the crystallization rate of the polylactic acid, also improve the material performance, reduce energy source consumption, and reduce the cost of products. After heat processing is carried out, the heat resistance and the mechanics performance of the composite material are further improved through the radiation crosslinking of crystallized polylactic acid. The prepared polylactic acid composite material has excellent mechanical property and heat resistance, and can avoid the problem of property reduction caused by a single modification method. The method is simple. The composite material can be prepared through the traditional plastic processing methods. The invention is suitable for industrial production.

Owner:SHANGHAI UNIV

Organic silicon transparent wear-proof hardened coating and mfg. process thereof

A transparent antiwear and hardening organosilicon paint for the resin lens is prepared from tetraalkoxysilane, trialkoxysilane and dialkoxysilane through mixing, acid catalytic hydrolyzing in solvent, polymerizing, adding coupling agent, ageing, and adding solidifying agent and solidifying promoter. Its advantages are high hardness and antiwear nature and long storage time.

Owner:厦门威亮光学涂层技术有限公司

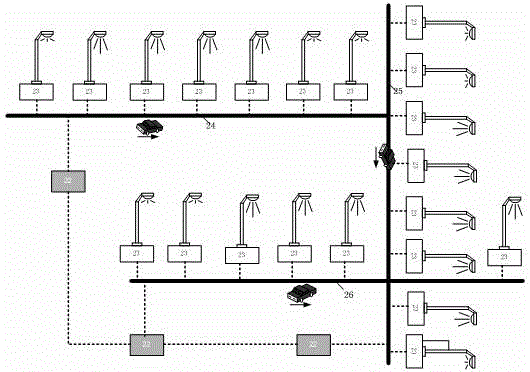

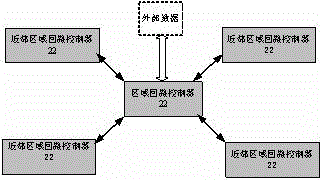

Intelligent road-perceiving LED (Light-Emitting Diode) illuminating controller

InactiveCN102752922AElectric light circuit arrangementEnergy saving control techniquesIlluminanceVehicle driving

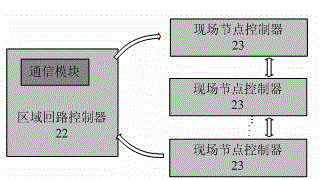

The invention relates to an intelligent road-perceiving LED (Light-Emitting Diode) illuminating controller. The intelligent road-perceiving LED illuminating controller comprises a zone loop controller and a site node controller, wherein the zone loop controller comprises a power module, a control core, a clock module, a human-computer interaction module, a control module selector, a system setting module, a diagnosis interface, a communication module, a traffic information acquisition module, an external information acquisition module and a display module interface; the site node controller comprises a power module, a control core, a clock module, an LED light adjusting module, a human-computer interaction module, a control interface, a system setting module, a diagnosis interface, a communication module and a display module interface; the site node controller is in two-way wireless connection with the zone loop controller; and each site node controller is connected with a corresponding LED illuminator. The intelligent road-perceiving LED illuminating controller has the advantages that the brightness of streetlamps at the road sections related to vehicle driving is controlled according to the positions of vehicles without influence on the streetlamps at the other road sections, so that the energy consumption can be greatly reduced; and the specific illumination values of the LED streetlamps and the illumination switching among the LED streetlamps are related to the current speeds of the vehicles in real time.

Owner:TONGJI UNIV

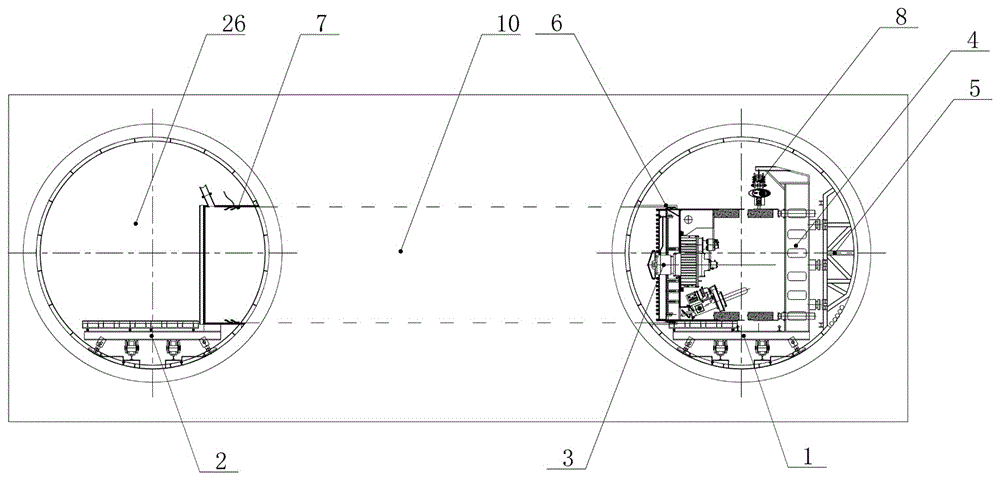

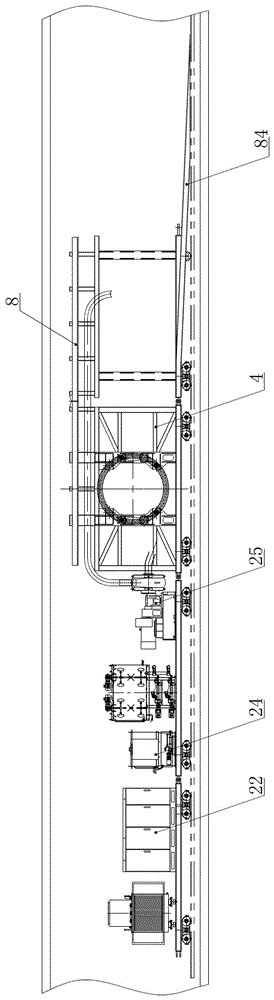

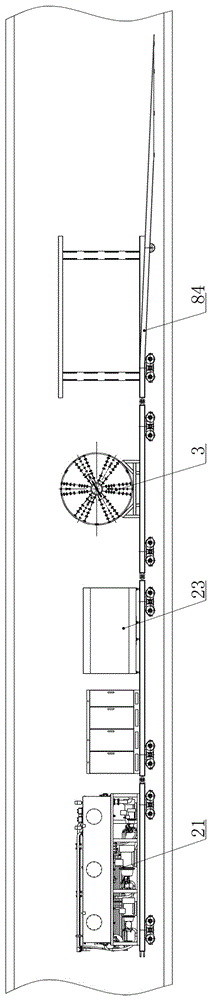

Shield tunneling machine for tunnel connecting passageway and connecting passageway tunneling method of shield tunneling machine

ActiveCN106437735AReaction support enoughCompact and reasonable structure designTunnelsShield tunnelingUltimate tensile strength

The invention belongs to the technical field of tunnel construction equipment, and relates to a shield tunneling machine for a tunnel connecting passageway and a connecting passageway tunneling method of the shield tunneling machine. The shield tunneling machine comprises a start end supporting walking platform and a receiving end supporting walking platform which are respectively arranged on material transportation rails in two main tunnels, a shield tunneling machine main unit, a counterforce supporting frame and a main tunnel supporting assembly which are respectively arranged on the start end supporting walking platform and a corresponding main tunnel duct piece, and a start end socket sealing assembly and a receiving end socket sealing assembly which are respectively arranged at the start end and the receiving end of the connecting passageway, wherein a duct piece hanging assembly is arranged on the start end supporting walking platform; a jacking tunneling assembly is arranged between the counterforce supporting frame and the shield tunneling machine main unit. The shield tunneling machine can realize automatically mechanical excavation; the labor intensity is greatly reduced, the energy consumption is reduced, and the cost is reduced; meanwhile, equipment construction is stable, and the efficiency is high; settling of the ground is effectively controlled, and the construction risk is reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

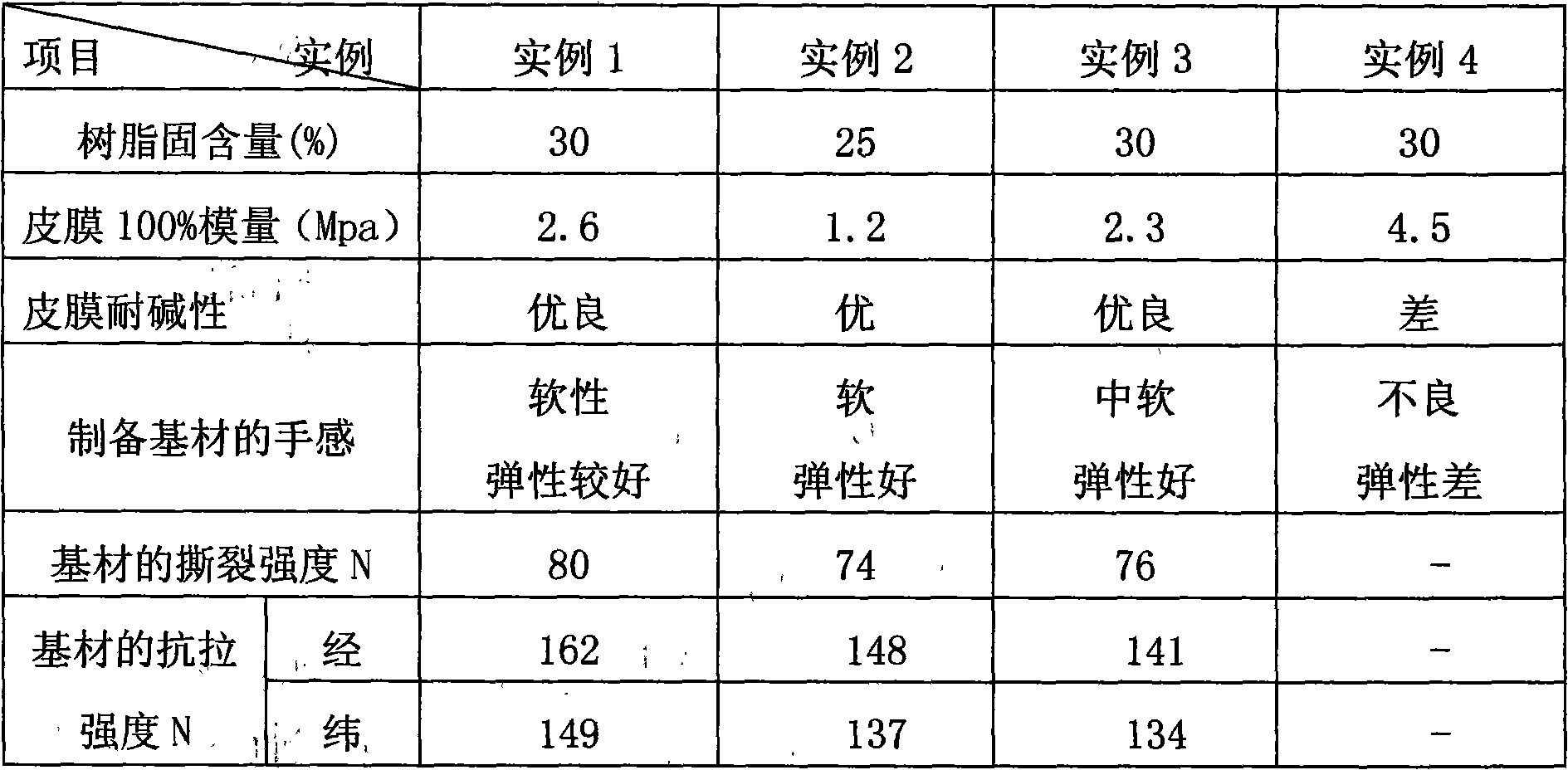

Waterborne polyurethane resin and preparation method of dipping sizing agent for synthetic leather base material

The invention relates to a preparation method of waterborne polyurethane dipping sizing agent for synthetic leather base material, belonging to the technical field of chemical products and a preparation method thereof. The preparation method is characterized in that diisocyanate, polyester polyol, polyether polyol and hydrophilic chain-extending agent carry out polymerization to generate prepolymer; the prepolymer is reacted with a neutralizer to carry out water dispersion emulsification to generate a waterborne polyurethane resin; and the waterborne polyurethane resin, wetting agent, thickener and stabilizer are reacted to generate synthetic leather base material dipping sizing agent. In the preparation method for synthesizing the leather base material dipping sizing agent by the waterborne polyurethane, synthetic leather and artificial leather base material manufactured after an ultrafine non-woven fabric is dipped in the dipping sizing agent have favorable performance, soft handle, favorable elasticity and stronger tear strength and tensile strength. In addition, the use and the discharge of organic solvent in a manufacture process is greatly reduced, the energy consumption and the environmental pollution is reduced to the maximum extent, and the invention has a wide popularization and application prospect.

Owner:烟台道成化学有限公司

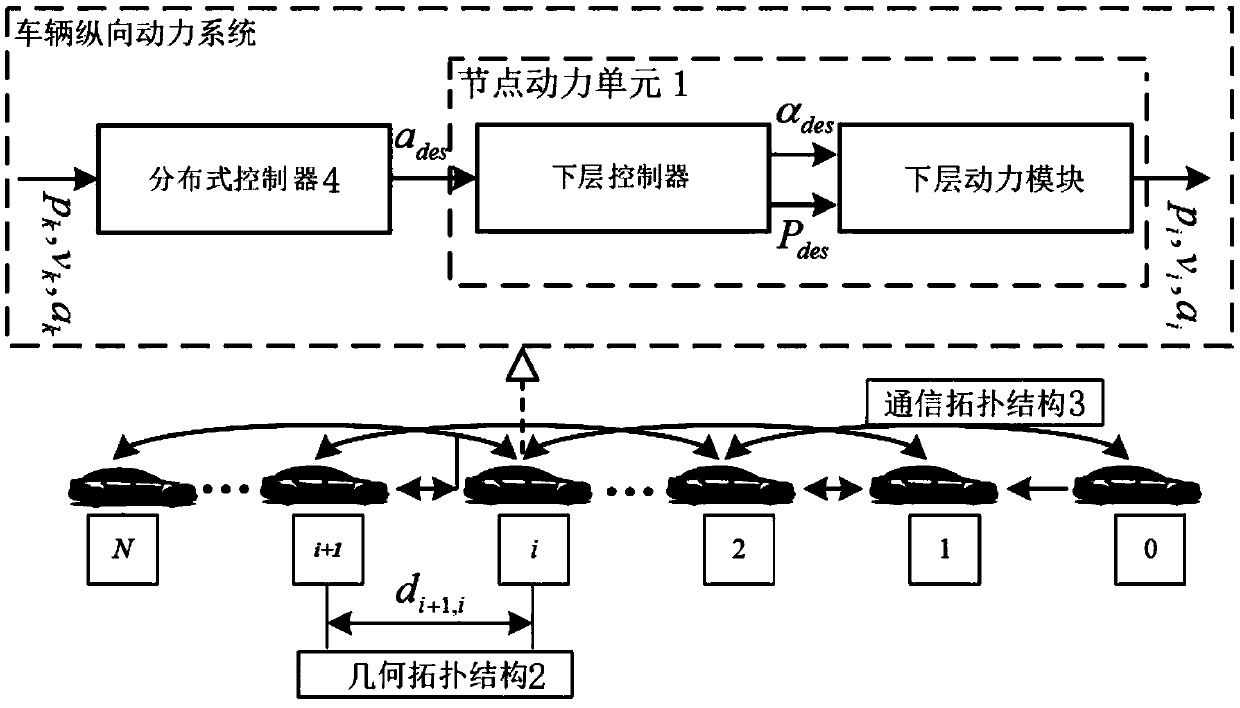

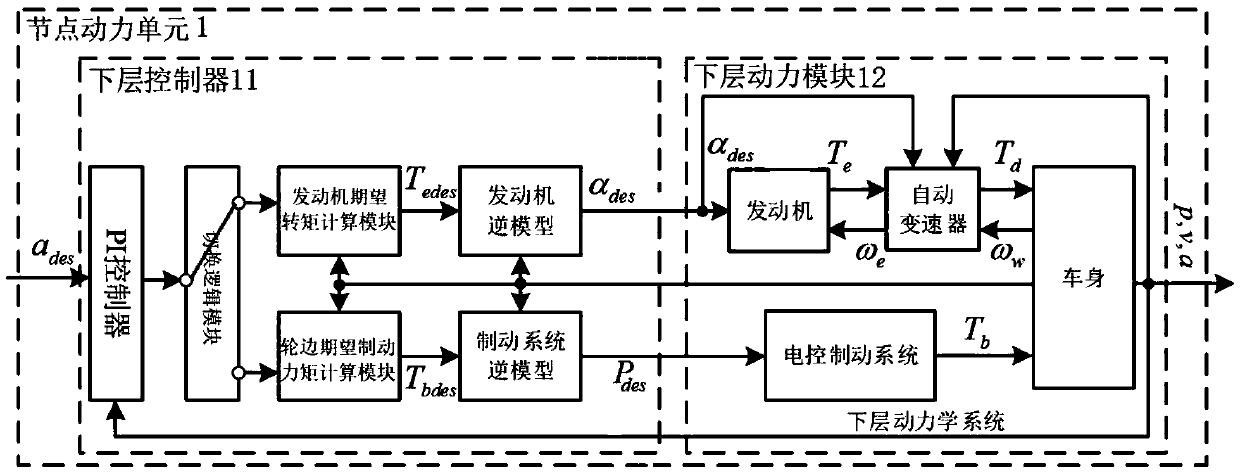

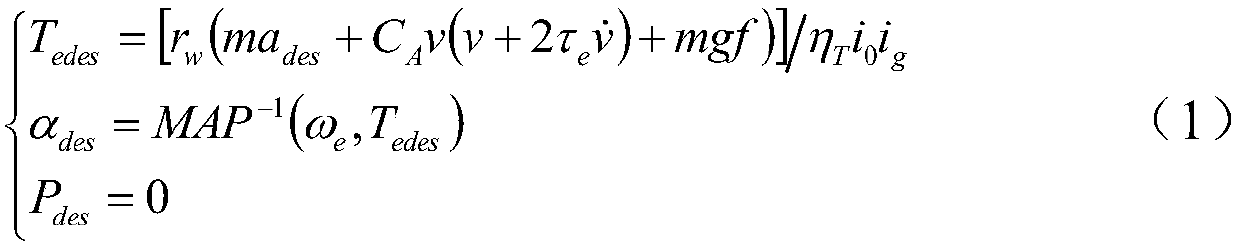

Vehicle queue stability control method considering communication delay

InactiveCN109591804AReduce operational burdenReduce energy consumptionExternal condition input parametersMathematical modelClosed loop

The invention discloses a vehicle queue stability control method considering communication delay. The method comprises the steps that 1, a vehicle queue following mathematical model is established; 2,a nonlinear lower layer control gain is constructed by a feedback linearization strategy, and a node power unit is described as a node linear model; 3, a high-dimensional closed-loop state equation of a vehicle queue following control system under dynamic parameter uncertainty is established; 4, sufficient conditions are used for giving sufficient conditions that a vehicle queue with communication delay has a stabilization controller under the symmetric communication topology; and 5, the stabilization controller is constructed to obtain a controller gain so as to control static feedback control of a distributed controller, and the stability of the vehicle queue following control system is ensured. The method can ensure the stability of the vehicle queue following control system, reduces the vehicle queue following interval, increases the traffic flow, and reduces the energy consumption.

Owner:HUNAN UNIV

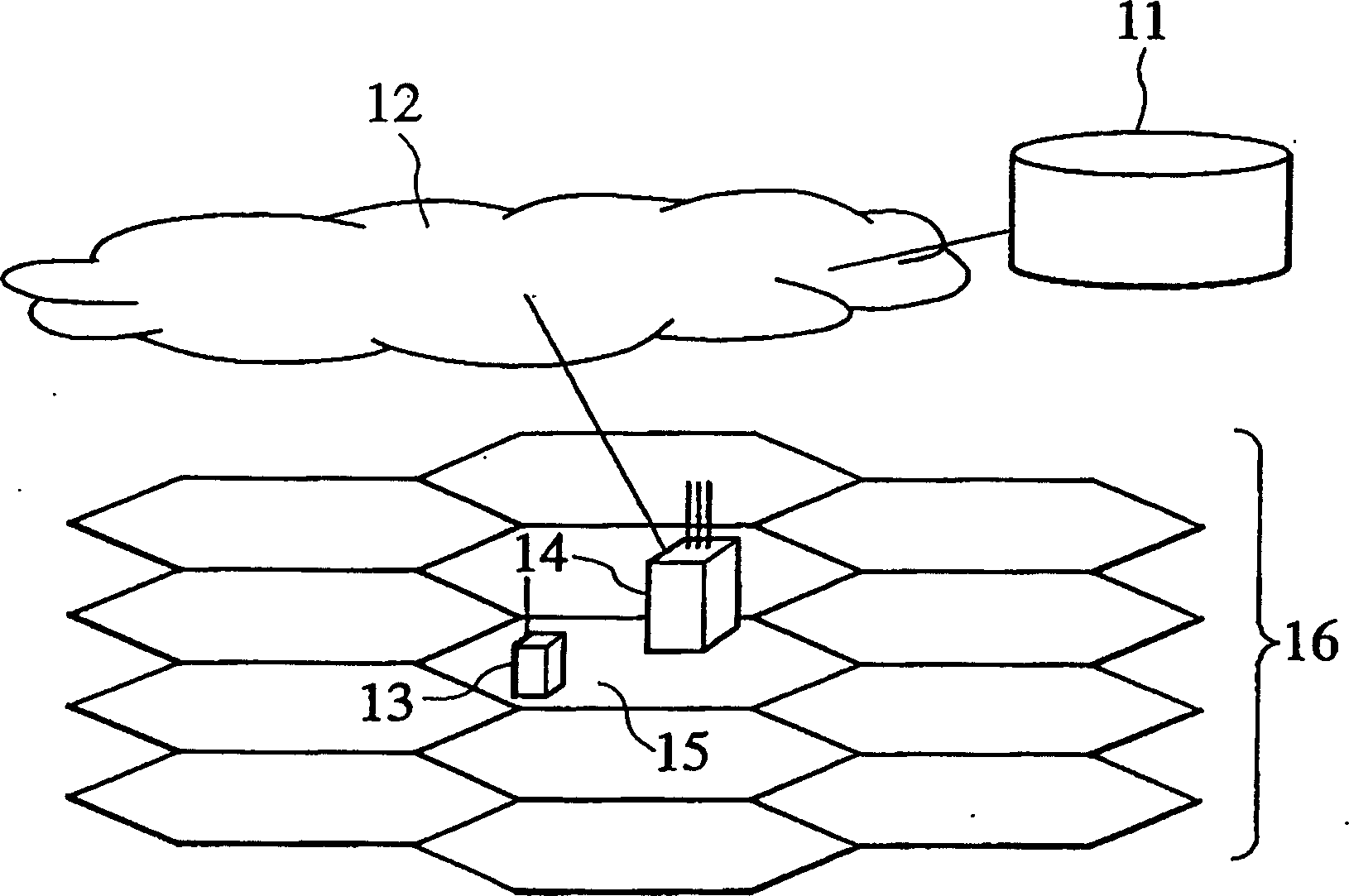

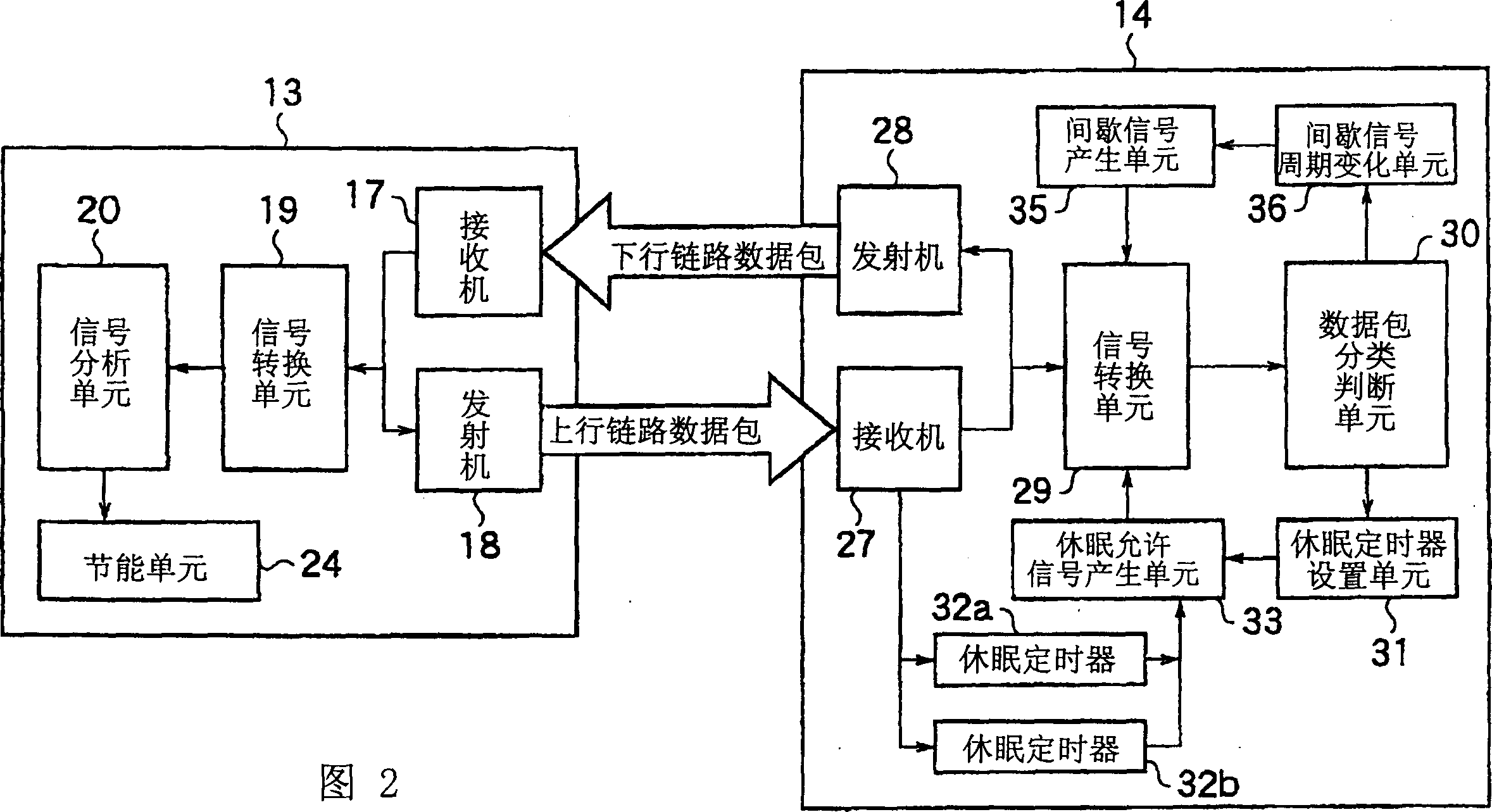

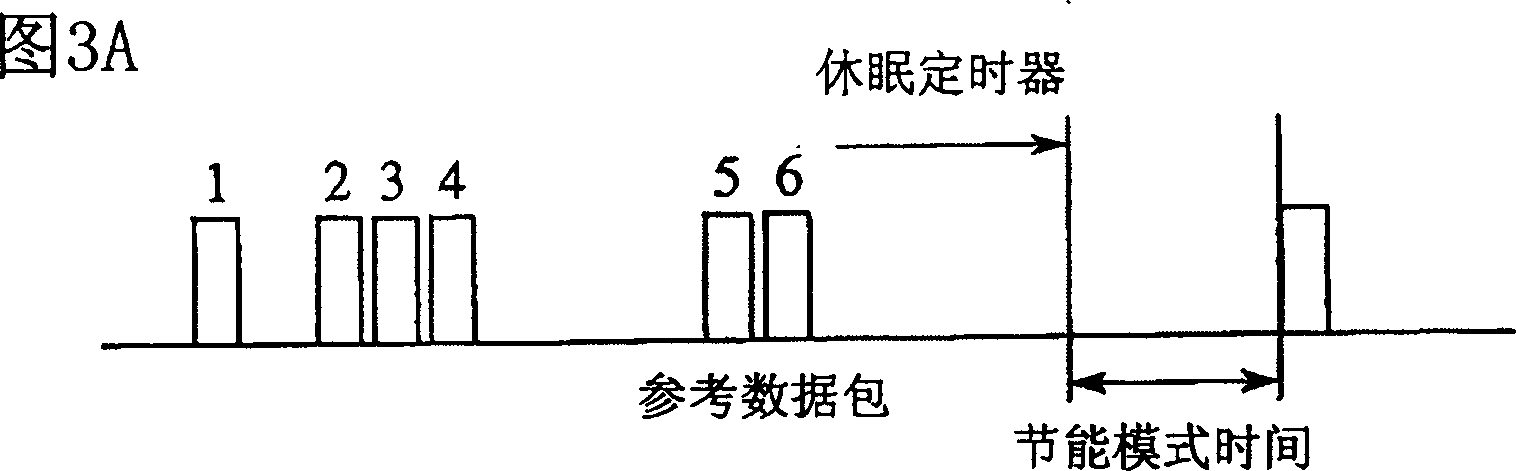

Mobile communication system, method, mobile terminals and base stations

InactiveCN1424859APower managementEnergy efficient ICTMobile communication systemsRadio Base Station

In a mobile communication system for carrying out packet transmission / reception between a mobile terminal (13) having a power saving mode to reduce a power consumption and a radio base station (14), a packet type of a packet is judged, and a sleep timer value indicating a time duration since a last packet is transmitted / received until the power saving mode starts is set according to a judgement result. Then, at least one sleep timer (32a, 32b) for measuring an elapsed time since the packet is transmitted / received is activated, and the mobile terminal is controlled to execute the power saving mode at a timing at which the elapsed time measured by the at least one sleep timer exceeded the sleep timer value.

Owner:NTT DOCOMO INC

Infrared reflective wall paint

ActiveUS20050215685A1Reduce energy consumptionReduce absorptionLiquid surface applicatorsElectrostatic spraying apparatusInfraredLacquer

Presented are methods for reducing energy consumption by coating external vertical walls of a building with a wall paint comprising reflective metal oxide pigments. Methods for painting external vertical walls as well as compositions comprising base paint combined with reflective metal oxide pigments are also presented.

Owner:TEXTURED COATINGS OF AMERICA

Thermal insulative coating and preparing method thereof

InactiveCN1583895AIsolated conductionGood weather resistanceFireproof paintsPetrochemicalMaterials science

The sun-proof coating of a kind of heat insulation and method of preparing, are suitable for various kinds of vehicles, shipping, all kinds of pots in the petrochemical industry, the trough, the appearance of the pipeline, and the outer walls of all kinds of buildings, the covering, the appearance of the tarpaulin insulates against heat, decorate and scribble to decorate using; Insulate against heat sun-proof coating join 1-30% of the hollow ceramic thermal insulator in invention this, form one pre -pressing vacuum layer things surface put to paint, a very ettective one isolate the sun ray radiation hot and heat radiation of air conduct, differ by with temperature not external inside not painting by object that put 4-8deg.C, great reduction energy very consume, the heat insulation coating of this invention has the good one and is able to bear the waiting, wearability is waterproof, since clean.

Owner:吕艺

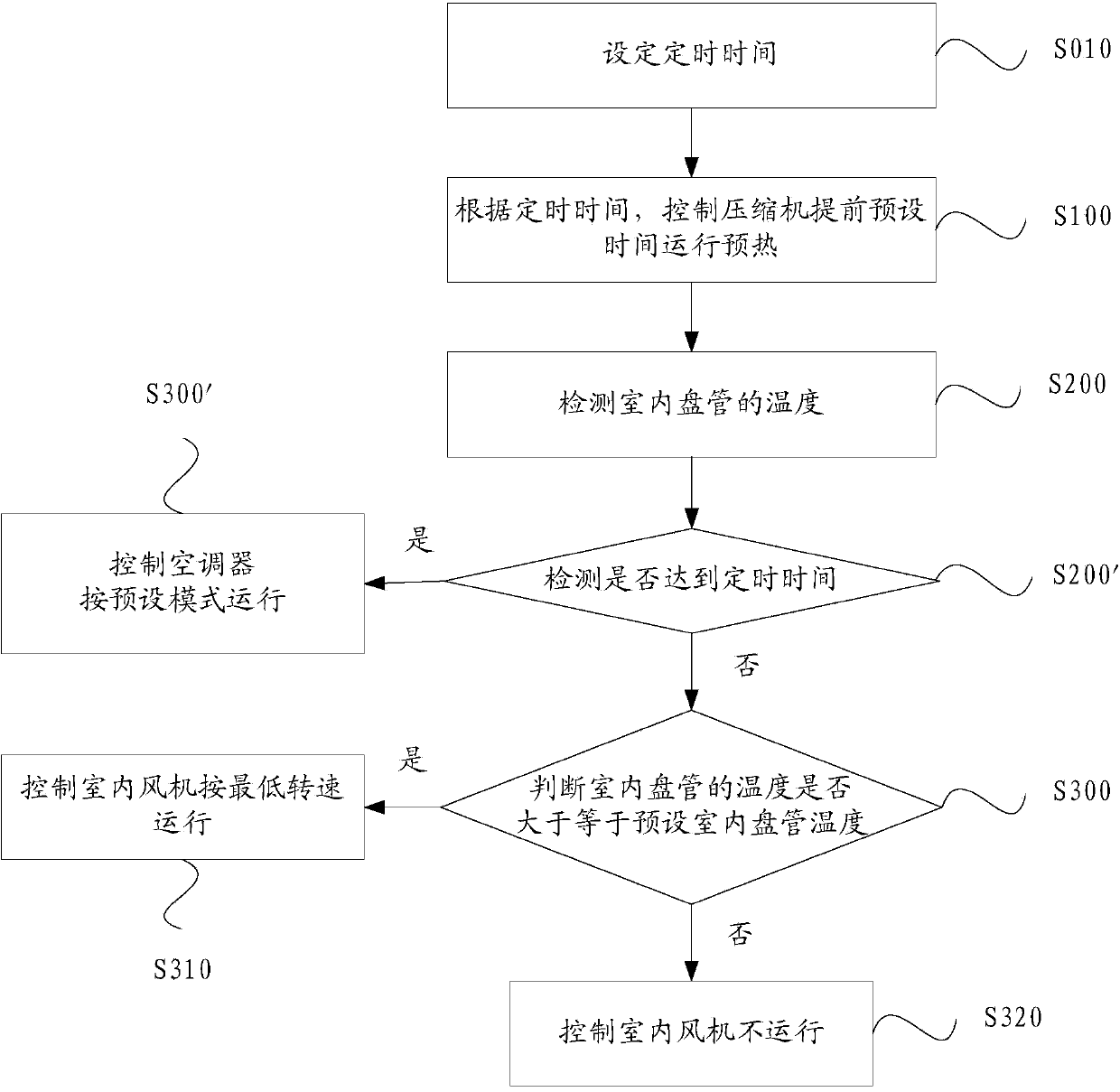

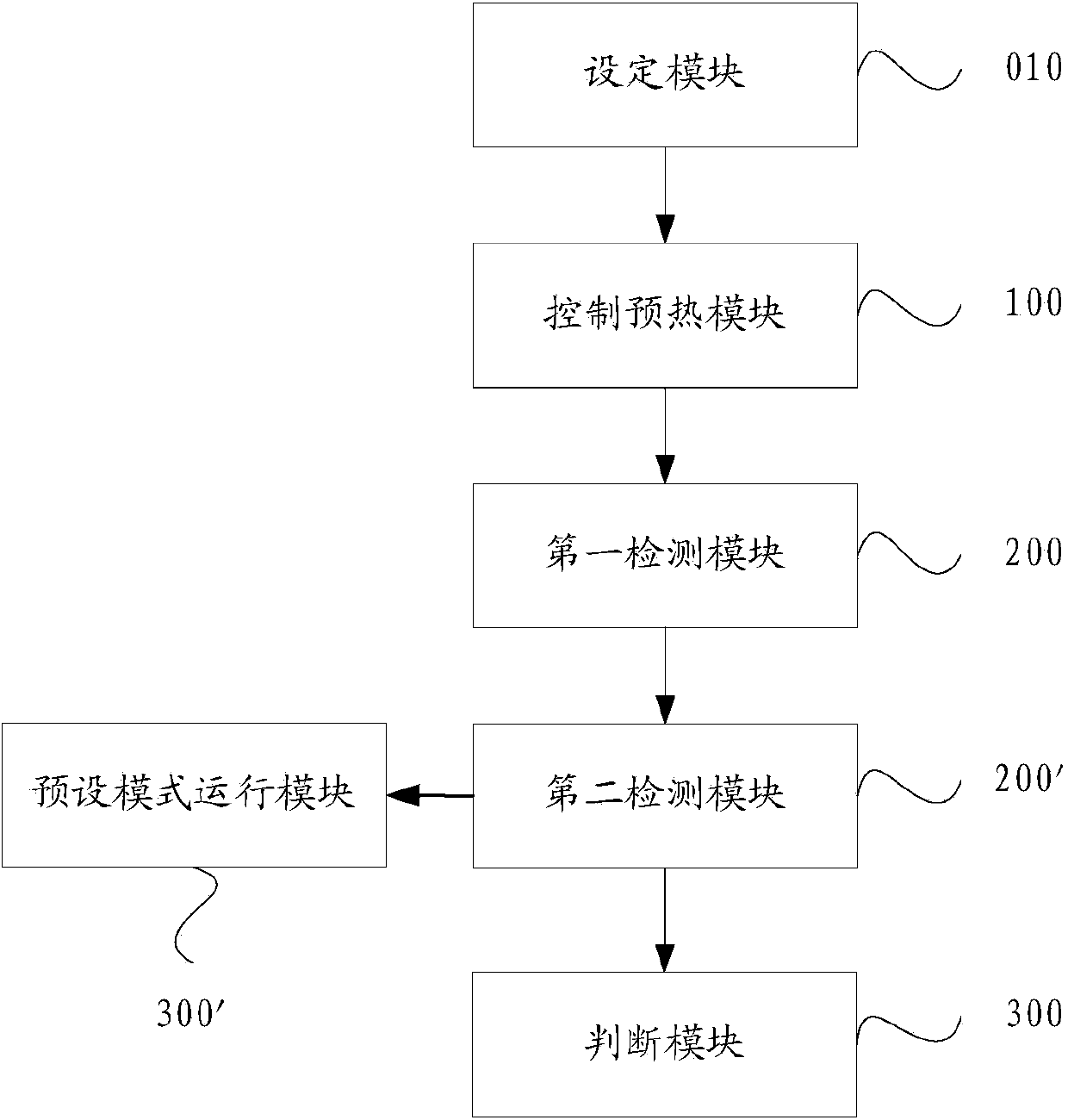

Method and system for controlling heating of air conditioner

InactiveCN104197464AGuaranteed temperatureAvoid blowing people directlySpace heating and ventilation safety systemsLighting and heating apparatusCold airCold blast

The invention provides a method and system for controlling heating of an air conditioner. The method for controlling heating of the air conditioner comprises the following steps that a compressor is controlled to conduct preheating before a preset time according to a set time; the temperature of an indoor coiler is detected; whether the temperature of the indoor coiler is higher than or equal to a preset temperature of the indoor coiler is judged; if yes, an indoor draught fan is controlled to operate at the lowest rotating speed; if not, the indoor draught fan is controlled not to operate. According to the method and system for controlling heating of the air conditioner, preheating is conducted before the preset time, the situation that clod air is directly blown to people can be avoided, the use comfort of users is improved, energy is saved relatively, and energy consumption is reduced; it is guaranteed that hot air is directly blown out by the air conditioner in heating operation when it reaches the set time, cold air is prevented from being blow out directly, user complaints are reduced, and the product competitiveness is improved for companies.

Owner:GREE ELECTRIC APPLIANCES INC

Ceramic product prepared from waste ceramic and preparation method thereof

The invention relates to a ceramic product prepared from waste ceramic and a preparation method thereof. The blank formula of the ceramic product comprises the following components in part by weight: 32-36 parts of waste ceramic powder, 25-28 parts of kaolin, 15-22 parts of plastic clay and 17-25 parts of feldspar. The basic glaze formula of the ceramic product comprises the following components in part by weight: 30-35 parts of miniumite, 8-12 parts of limestone, 20-30 parts of feldspar, 8-14 parts of clay and 20-25 parts of quartz. A right amount of coloring metal compounds and / or coloring materials are added into the basic glaze. Compared with the prior art, a large amount of waste ceramic powder is used for replacing the traditional ceramic raw material for the basic glaze formula, and the technological difficulties of waste ceramic powder compounding, grain composition, sintering, decoration and the like are overcome. Not only is the waste changed into the valuable and a large amount of waste ceramic products are fully utilized, but also the sintering temperature of the ceramic product can be lowered, the energy consumption is reduced, the production cost of ceramic manufacturers is lowered, and the market competitiveness of the product is increased.

Owner:FUJIAN DEHUA NINGCHANG CERAMIC

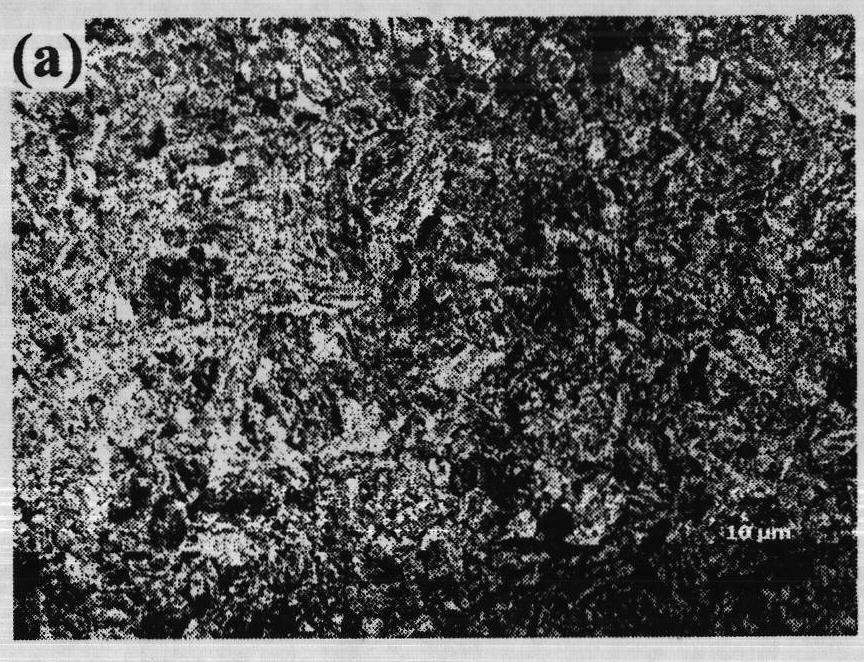

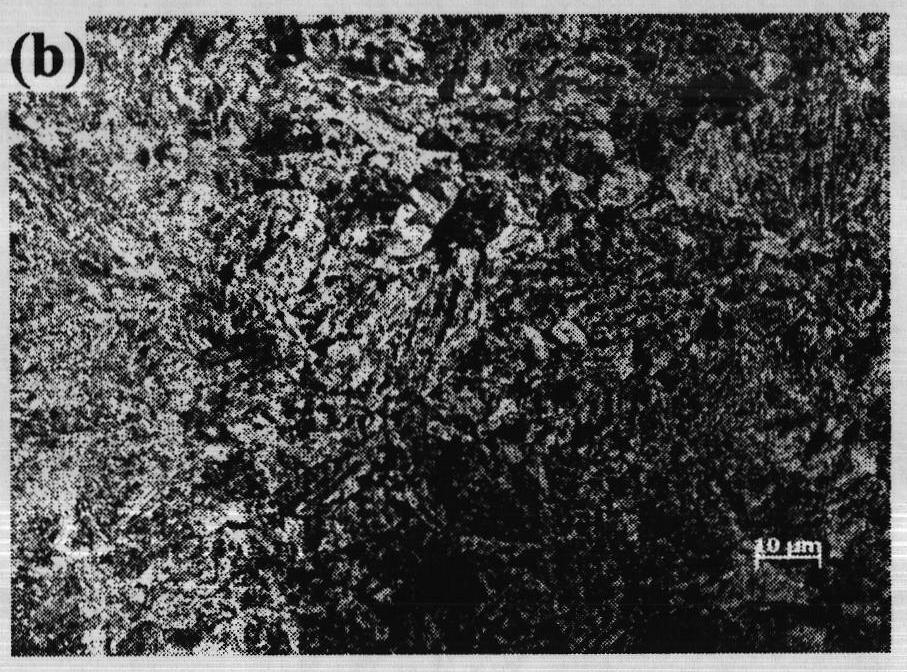

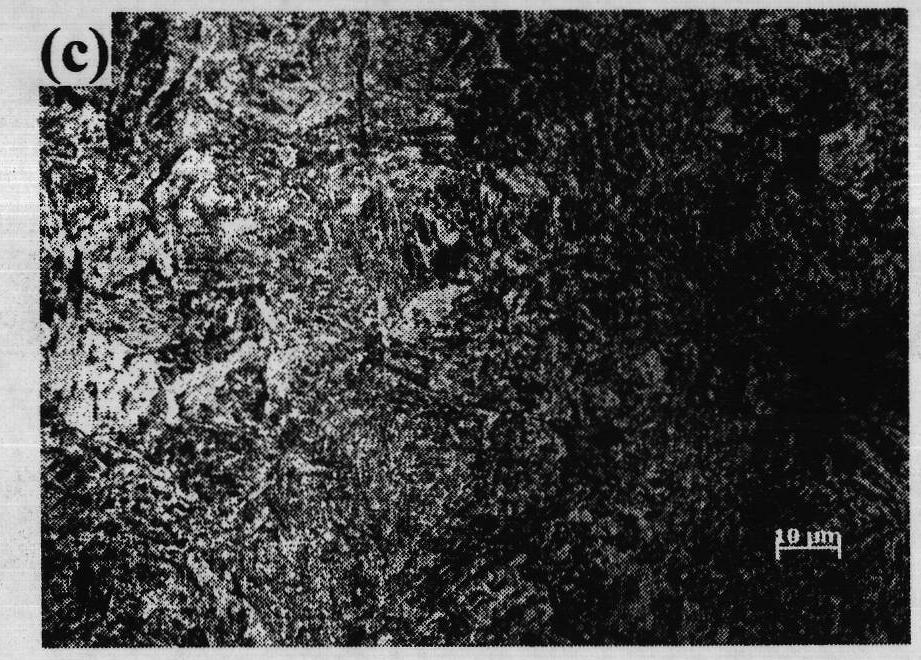

Process for producing plastic mould steel thick plate with uniform section rigidity

InactiveCN102002638ANo tension correctionFast crystallizationTemperature control deviceFurnace typesSheet steelThick plate

The invention discloses a process for producing a plastic mould steel thick plate with uniform section rigidity, which is used for properly regulating components of the traditional plastic mould steel. The plastic mould steel thick plate is obtained through rolled medium temperature tempering treatment by adopting the casting of an openable water cooling die casting machine and a reasonable heating cycle and a controlled rolling and cooling process. The process realizes on-line pre-hardening by using a water cooling die casing blank thick slab through controlled rolling, rolled residual heat and controlled cooling, then realizes steel pre-hardening treatment through medium temperature tempering. The invention not only can reduce energy consumption and pollution, but also can improve the uniformity of tissues and hardness and the stability of the pre-hardening tempering process. A steel plate with 60-120mm in thickness is obtained through rolling of a casting blank with 300-400mm in thickness, the section hardness is uniform, the hardness difference is small, and the comprehensive property is good.

Owner:NANJING IRON & STEEL CO LTD

Non-ironing post-finishing technique for cotton fabric

The invention relates to weaving cotton fabric no ironing post collating technology. It includes the following steps: face fabric preparation; padding resin; framing drying; baking; pre-shrinking; winding. The face fabric preparation includes gray cloth seaming, singeing, de-sizing, alkali mercerization, dying, framing forming, liquid ammonia collating. The padding resin includes two times. The above technology can make the cotton fabric have good feeling, gas permeability, moisture absorption, and increase wrinkle resistance, greatly reduce formaldehyde residual, energy resource consumption, sewage discharge.

Owner:上海白玉兰染整有限公司

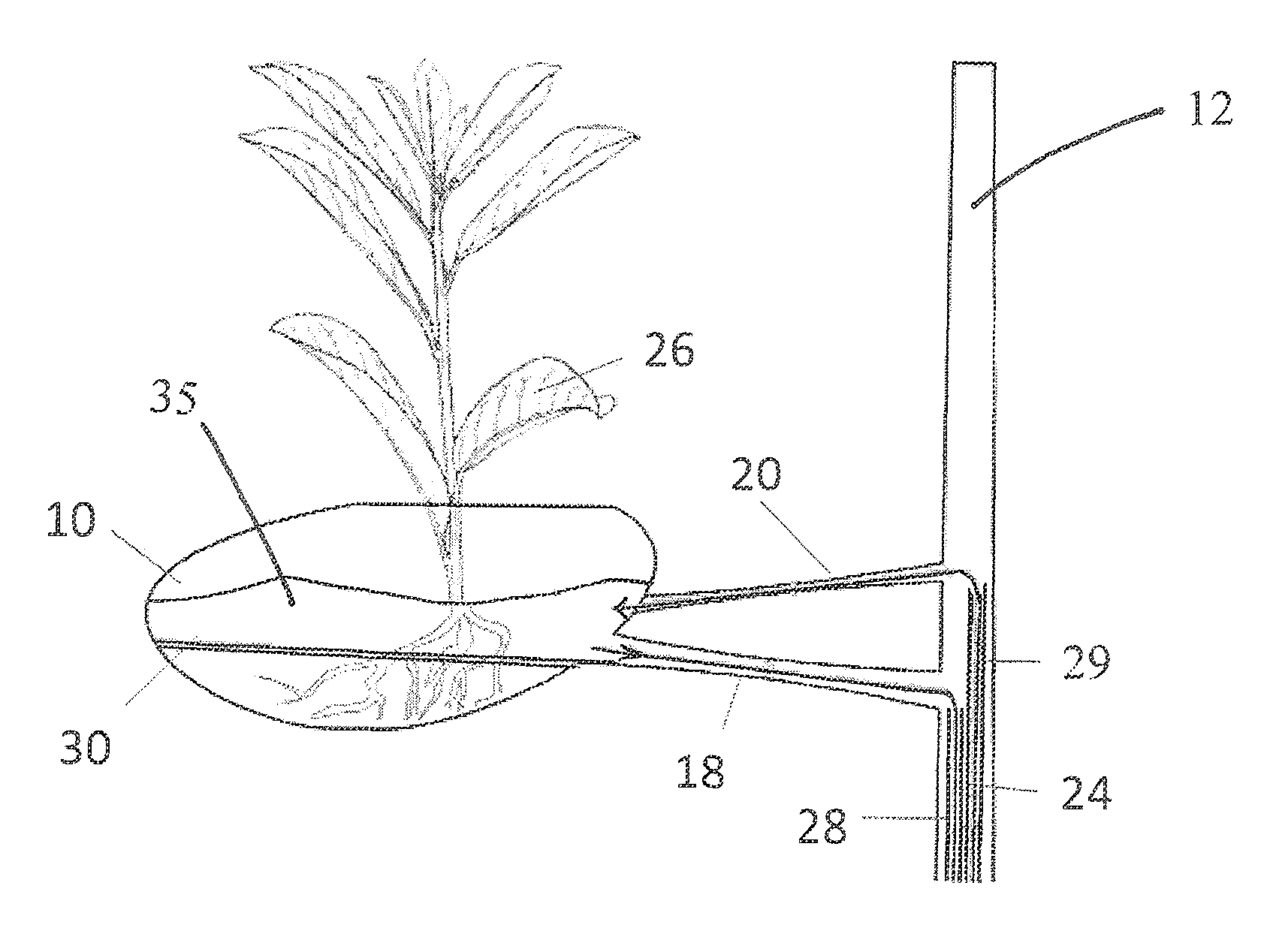

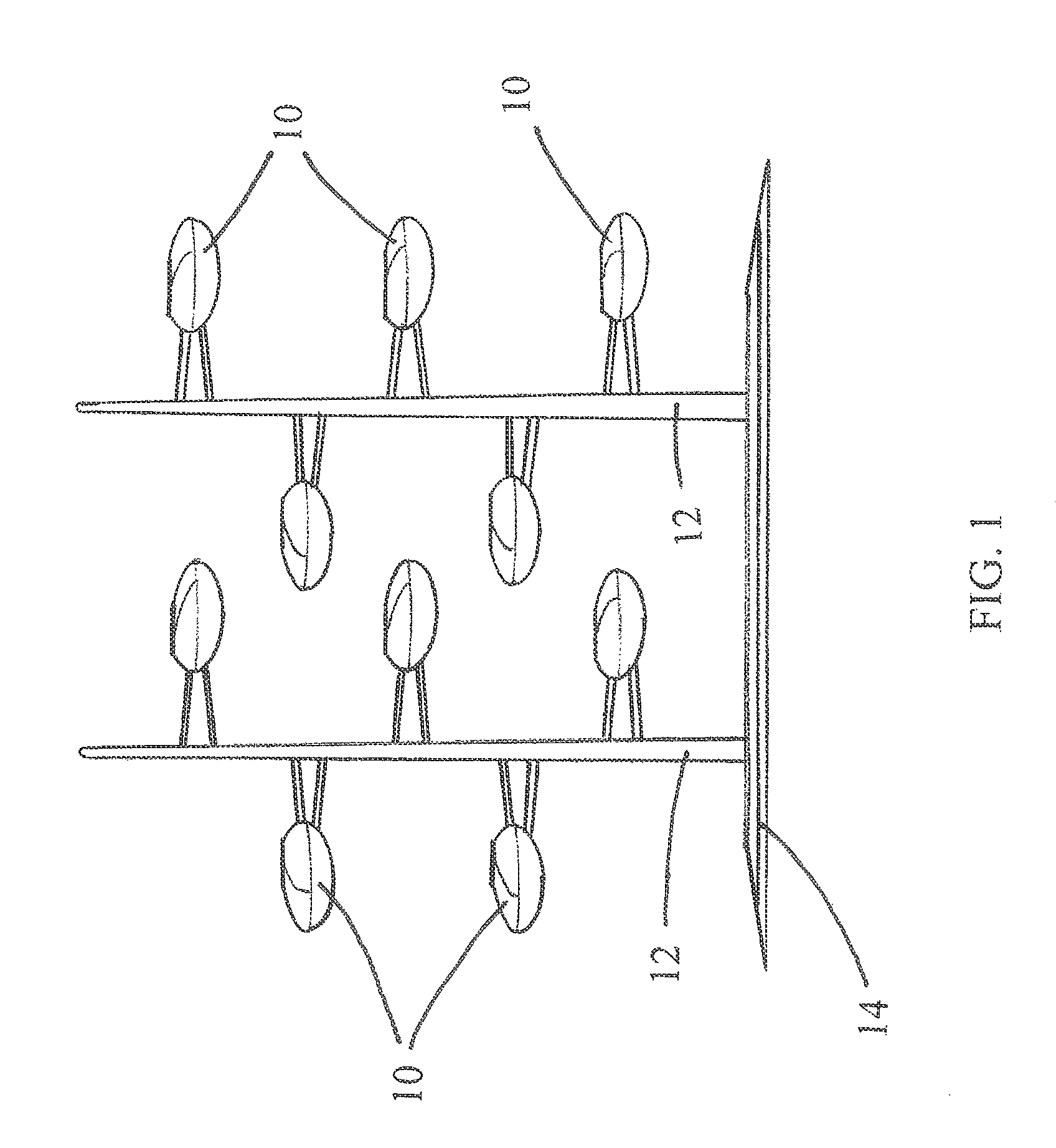

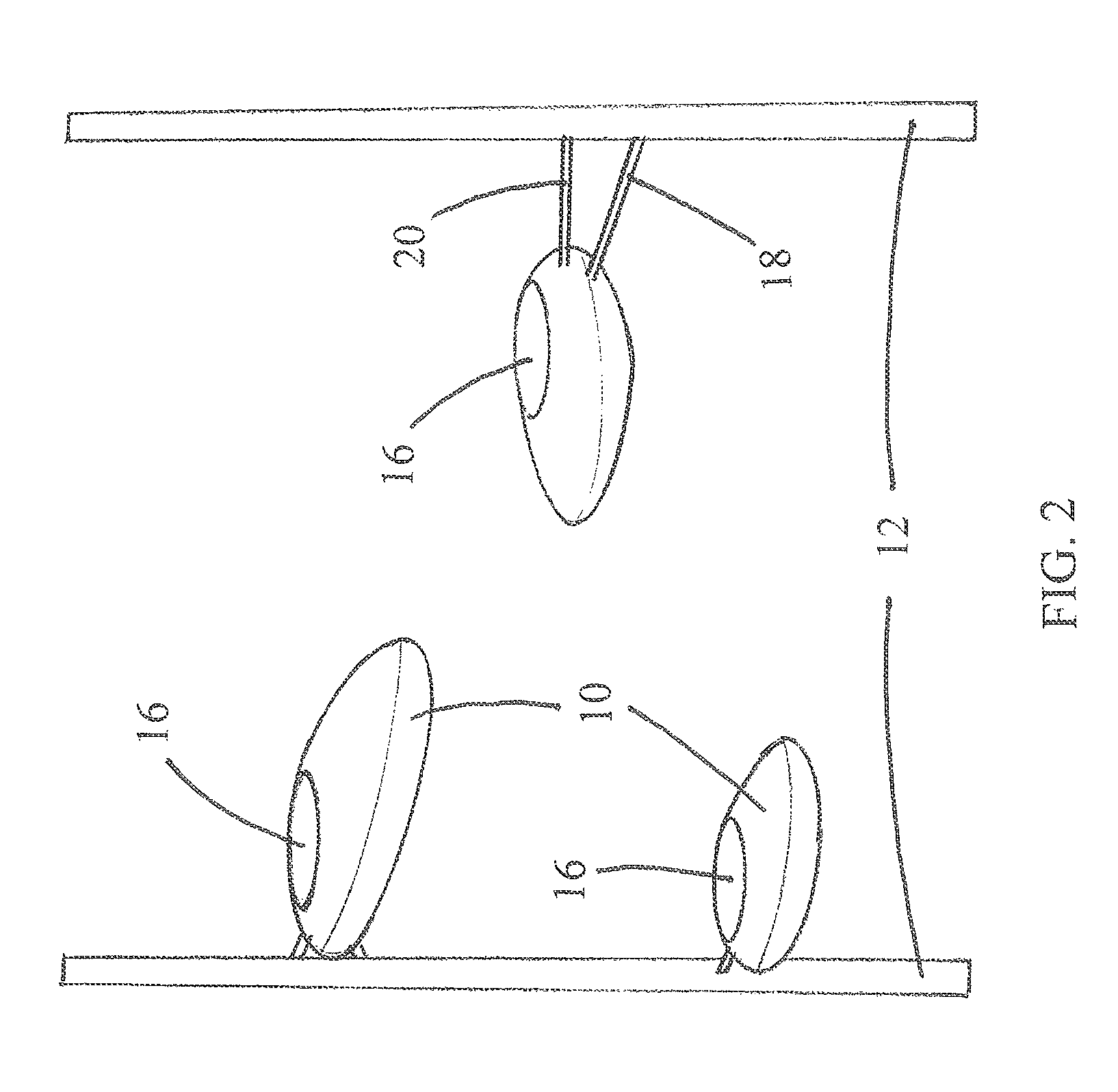

Modular self-sustaining planter system

A self-irrigating planter system that waters vegetation on a regular schedule using hollow upright supports to convey the water from a pump and reservoir to multiple organic-shaped pods that are attached to the upright supports in a tiered manner, and which uses gravity to deliver water so as to provide sustained plant growth and a healthier living environment with reduced energy usage.

Owner:DANIELLE TROFE DESIGN

Minced fillet product producing method

ActiveCN103027317AReduce consumptionReduce manufacturing costFood preparationAquatic productFresh fish

A minced fillet product producing method relates to aquatic product processing and comprises the following steps: grinding without any addictive: adding a protease inhibitor and an acid seasoning aqueous solution into semi-thawed minced fillet, and chopping, blending, grinding and mixing uniformly at 4-10 DEG C; grinding with salt: adding salt and glucolactone into the ground minced fillet, grinding at 4-10 DEG C; gelating: shaping and heating the ground minced fillet, and gelating the minced fillet; and refrigerating: packaging in a sealing way, and refrigerating at 4-10 DEG C to obtain a minced fillet product. Only medium-temperature heating is required, so that the energy consumption is reduced and the production cost is reduced; the minced fillet product producing method is simple in process, low in requirement on equipment, short in production period and high in production efficiency; and the produced minced fillet product is faintly acid, low in fishy taste, strong in fresh fish meat taste, more compact in internal structure and macroscopically dedicate in mouth feel, and is superior in gel strength to he conventional minced fillet product heated at a high temperature.

Owner:SHISHI ZHENGYUAN AQUATIC TECH DEV

Compound natural preservative for meat products

InactiveCN102265921AGood spectral antibacterial propertiesGood inhibitory effectMeat/fish preservation using chemicalsBiotechnologyAdditive ingredient

The present invention relates to a special compound natural preservative for meat products, which comprises the following components: nisin, tea polyphenol, chitosan, forsythia extract, mannan, perilla leaf extract, and the added percentage is : 0.02-0.05% nisin, 0.02-0.05% tea polyphenols, 0.01-0.6% chitosan, 0.01-0.6% forsythia extract, 0.01-0.6% mannan, 0.01-0.06 perilla leaf extract. The preservative can effectively reduce the sterilization temperature of meat products, prolong the shelf life, and maintain the original nutritional content, flavor and color of meat products. At the same time, it can also effectively reduce operating procedures and energy consumption. The preservative is easy to use, safe and efficient, can significantly prolong the shelf life of meat products, and has an outstanding fresh-keeping effect.

Owner:HEILONGJIANG BAODI MEAT FOOD

Dimethyl formylamine solution three-effect rectification recovery method for wet synthesis of leather

ActiveCN1891685AReduce consumptionAchieve consumptionCarboxylic acid amide separation/purificationThermal energyRecovery method

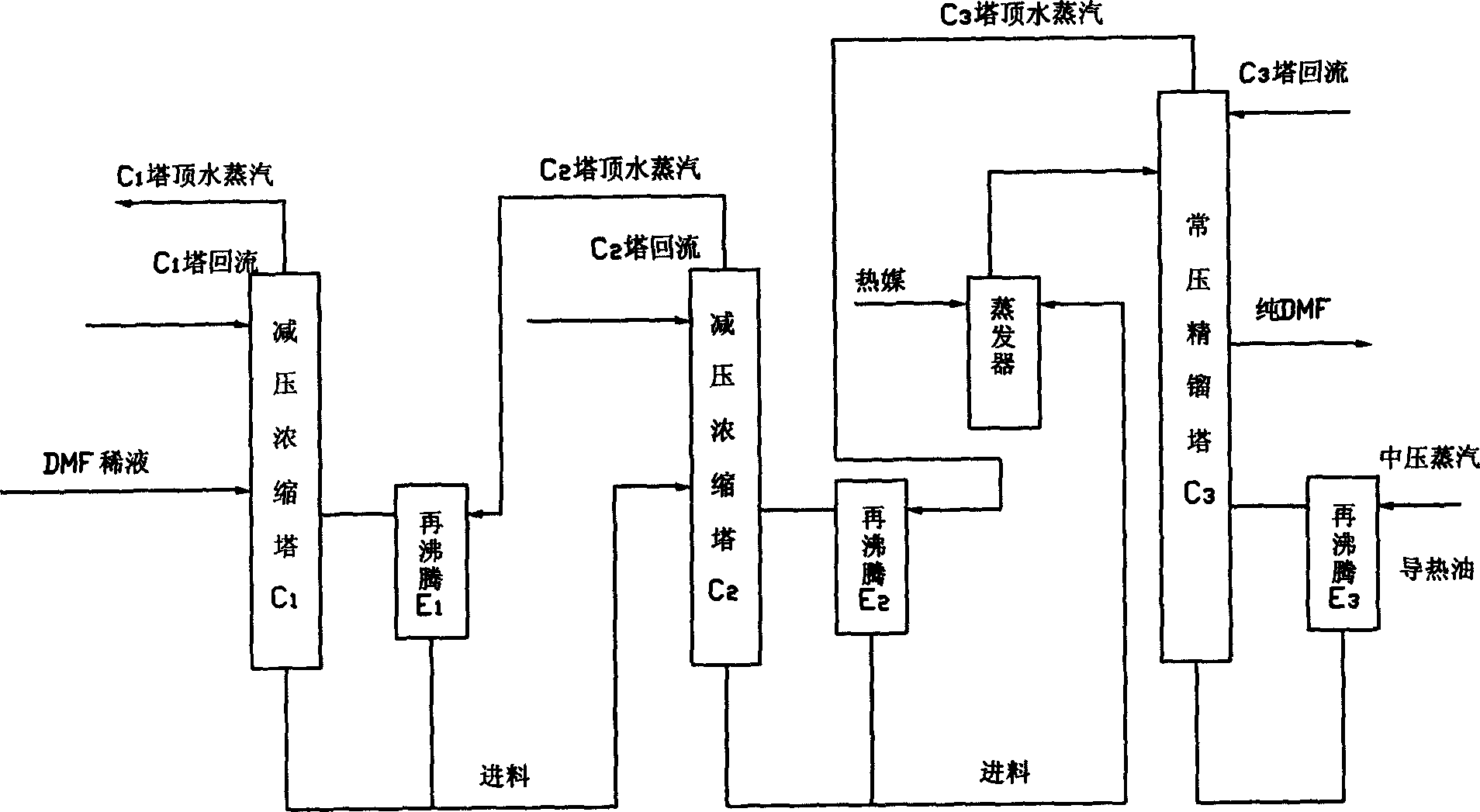

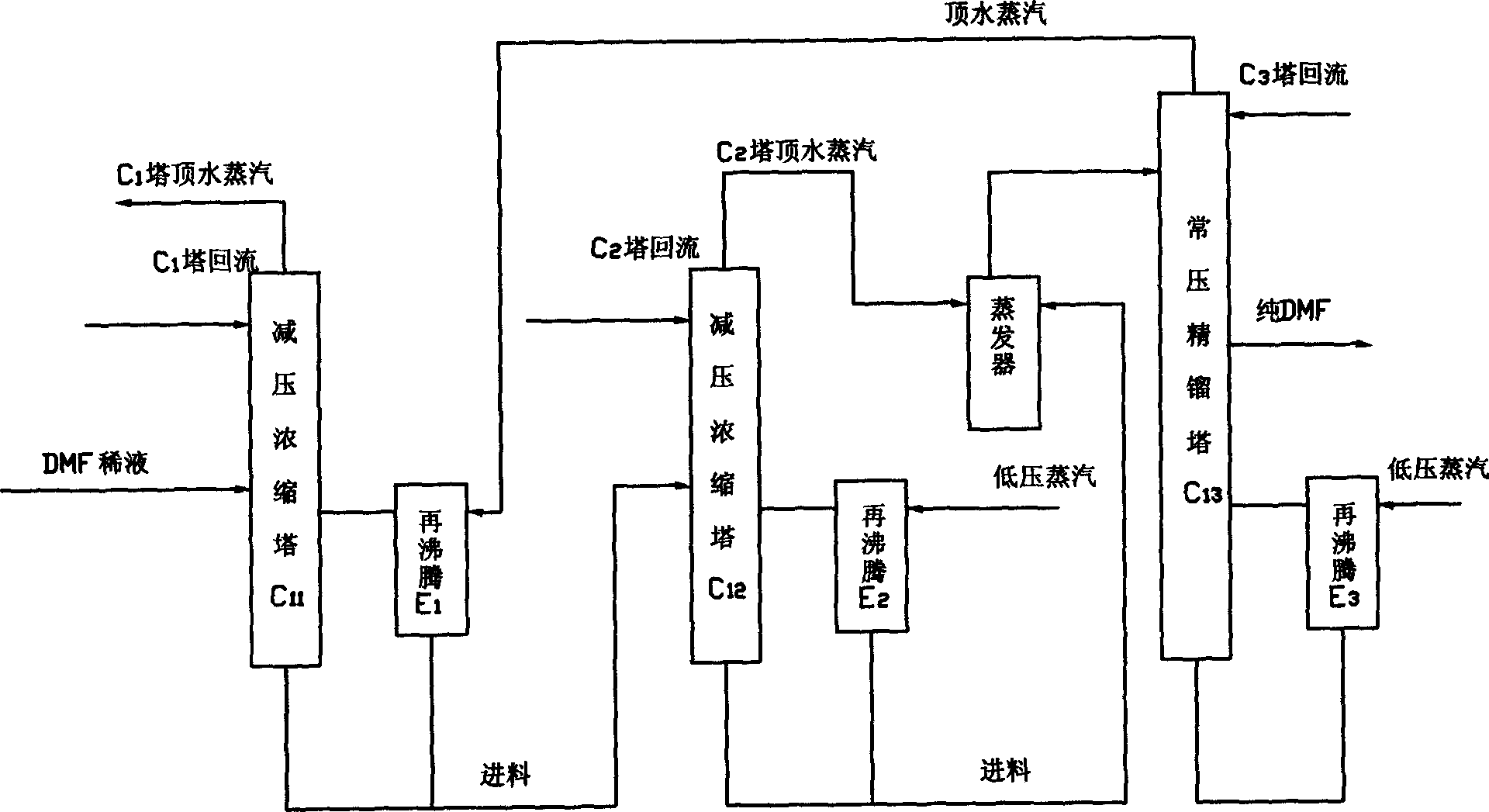

A triple-effect distillation and recovery method for wet synthetic leather dimethylformamide(DMF) solution includes: feeding, preheating, condensing and separating it by a concentration tower and a distillation tower to output it to complete the recovery process, in which, low-pressured steam is the heating media, using decompressed concentration for step I, atmospheric concentration for level II and vacuum distillation, the decompressed concentration processes in the packing tower, atmospheric concentration processes in the plate column, decompressed concentration processes in the combined packing and plate column. In the described cycle process, energy can be recycled between the steam in the top, heating at the bottom, feed preheating, preheating of finished condensation, distillation, reboilling processes.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

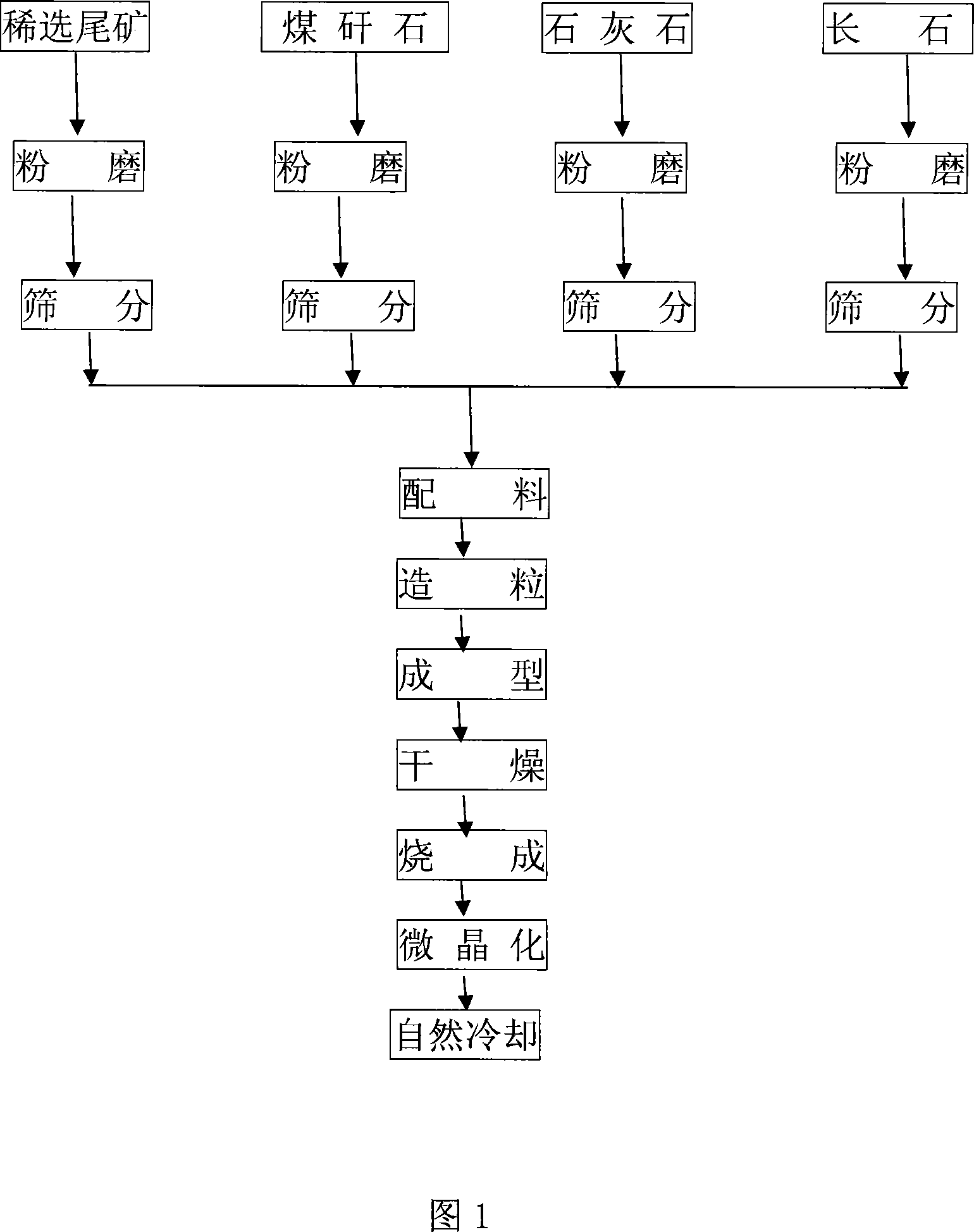

Method for manufacturing glass-ceramics

The invention relates to a microcrystalline glass preparation method, which belongs to the comprehensive utilization of industrial wastes. The invention is characterized in that rare earth tailing powder, feldspar and coal gangue are respectively filled in a ball mill tank in weight proportion of 100 to 8.5-25 to 9.5-17 to 8-22. Through the screening, the proportioning, the material mixing, the granulation, the molding, the drying, the sintering and the micro-crystallization, a main demanded crystal phase is fully precipitated from the sintered material. The powder obtained from the granulation is ball shaped. The molding pressure is 30-100MPa. When the micro-crystallization thermal treatment is finished, the sintered green body lowers to be at the room temperature with the furnace. The invention changes wastes into valuables, solves the secondary pollutions, improves the utilization ratio of industrial wastes, shortens the processing time, improves the working efficiency and reduces the energy consumption. The technology is simple, and the production cost is low. The nucleation activation energy is lowered, the nucleation and the crystallization of glass are promoted, and the micro-glass is finer. Therefore, the mechanical performance of the microcrystalline glass is improved and the cost for producing the tailings microcrystalline glass is greatly lowered.

Owner:内蒙古科韵环保材料股份公司

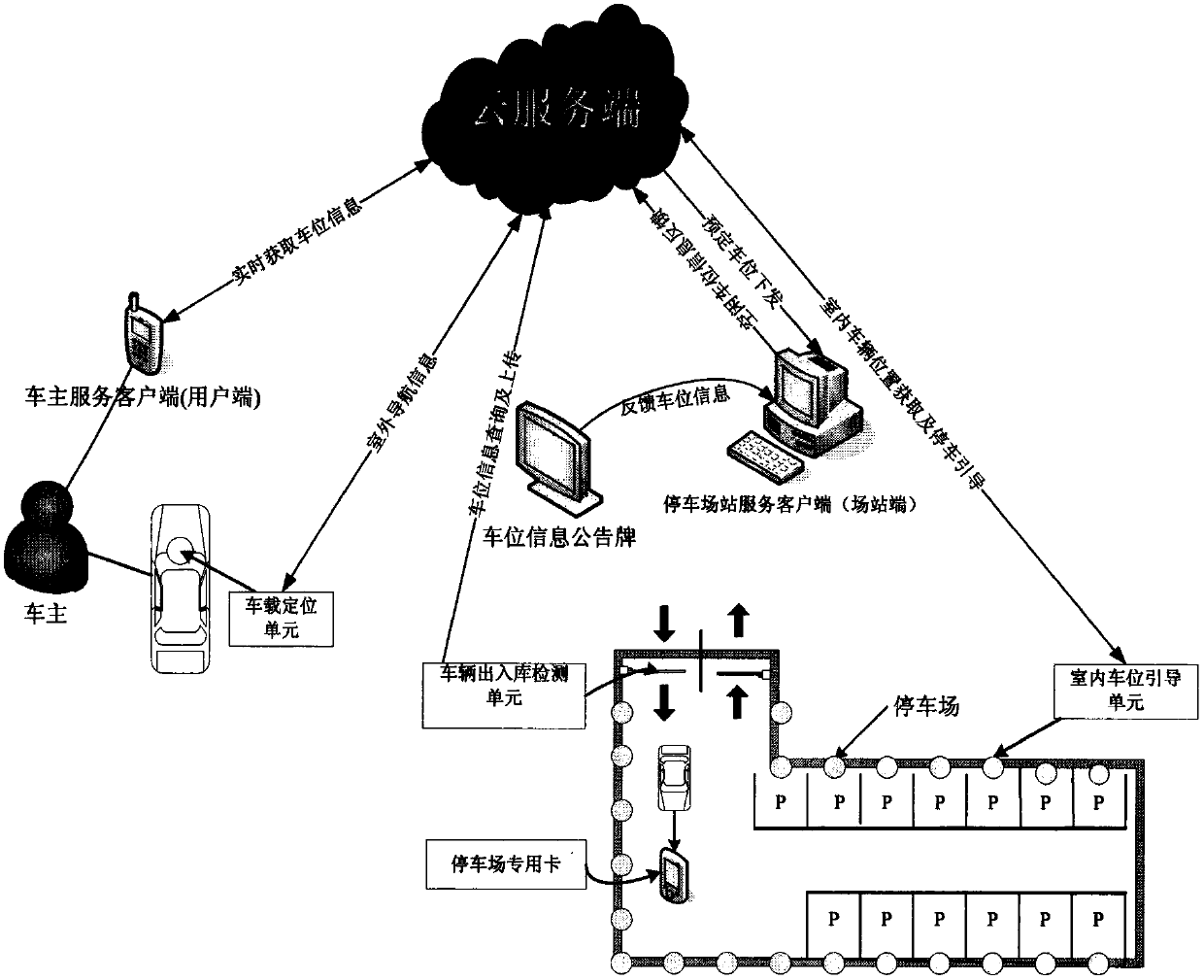

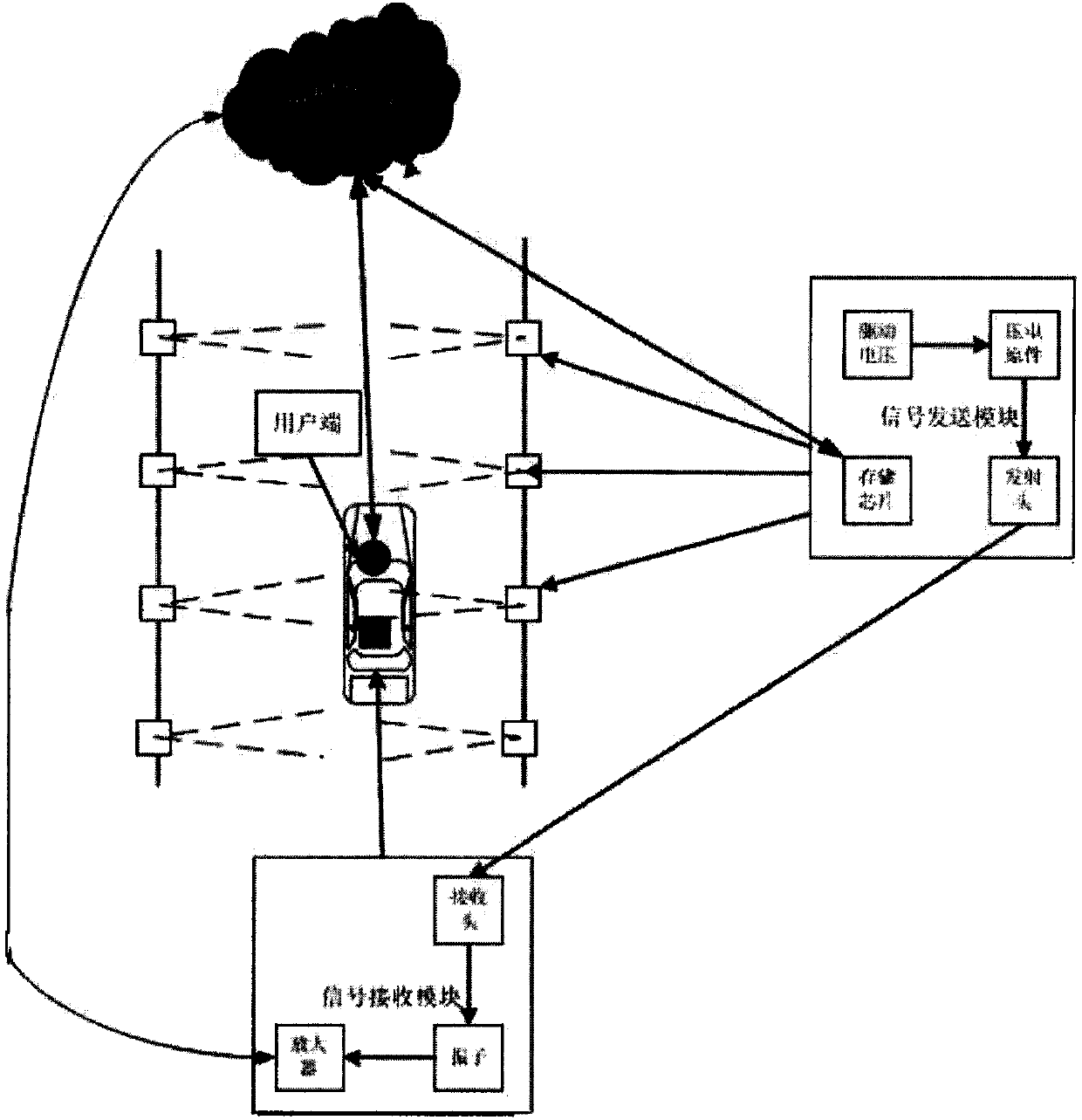

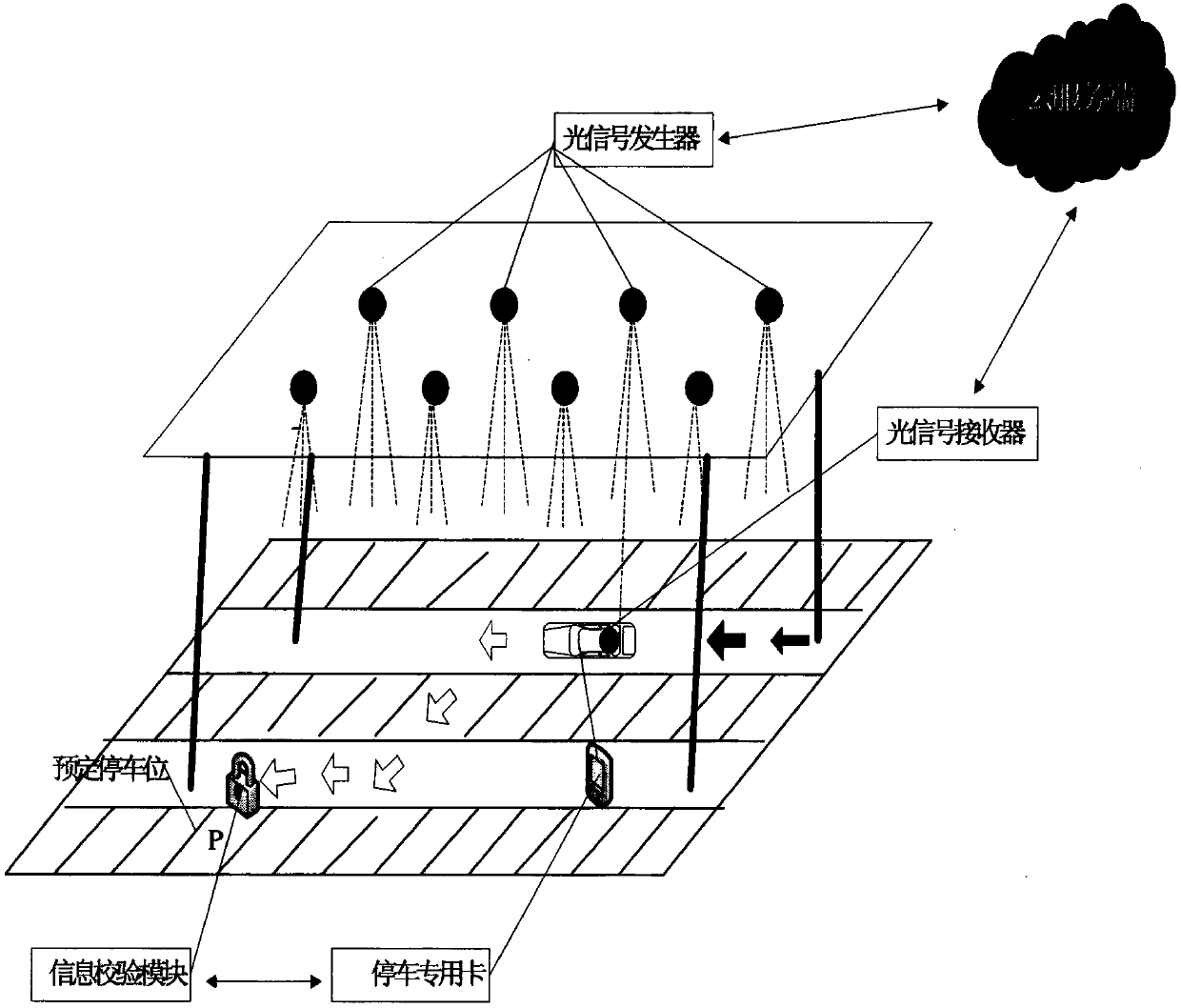

Vehicle service system

InactiveCN104700650AImprove travel efficiencyReduce consumptionIndication of parksing free spacesNetwork communicationEnergy consumption

The invention discloses a vehicle service system comprising a cloud server, a vehicle owner service client, a parking lot station service client, a vehicle-borne positioning unit, a vehicle incoming and outgoing detection unit, a parking card, a parking spot information bulletin board, and an indoor parking spot guidance unit. The cloud server is connected with a user, a parking lot station, the vehicle-borne positioning unit and the indoor parking spot guidance unit in a two-way mode, and connected with the vehicle-borne positioning unit in a one-way mode. The system can provide real-time idle parking spot query, parking spot reservation, vehicle guidance and other services for vehicle owners. The additionally-arranged indoor parking spot guidance unit of the system can provide accurate indoor guidance service for vehicles under the condition that the GPS and other satellite positioning signals are poor or the network communication signals are unstable, so as to provide more user-friendly intelligent vehicle services for vehicle owners, improve the travel efficiency of vehicle owners, and reduce energy consumption.

Owner:何金锦

Coal gas anhydrous dust collecting equipment of revolving furnace and technique thereof

ActiveCN101195766AReduce consumptionHigh calorific value utilizationEnergy inputGas dust removalThermal energyTemperature control

The invention relates to a converter coal gas non-water dust removing equipment, which comprises a converter, a radiant type waste-heat boiler, an adjusting valve, a cyclone dust remover, a bag-type dust remover, a coal gas temperature controlling device, a flow meter, a main induced draft fan, a three-way valve, an emission chimney, a rotary water seal, a U-shaped water seal, and a coal gas tank. The invention is characterized in that a convection type waste-heat boiler is connected between the outlet position of the radiant type waste-heat boiler and the adjusting valve, and the convection type waste-heat boiler is composed of a settling chamber, a heat exchange component, a baffle plate, a box body, and an ash discharging opening. A process method comprises the steps that converter coal gas comes into the convection type waste-heat boiler via radiant type waste-heat boiler after recovery waste heat, the gravitational settling is performed to come into the adjusting valve, and the bag-type dust remover, etc to perform dust fining removal after the recovery waste heat, the emission is performed through the three-way valve or the converter coal gas comes into the coal gas tank to perform coal gas recovery, and the invention has the advantage that the energy consumption is reduced through recovering heat energy.

Owner:北京中冶设备研究设计总院有限公司

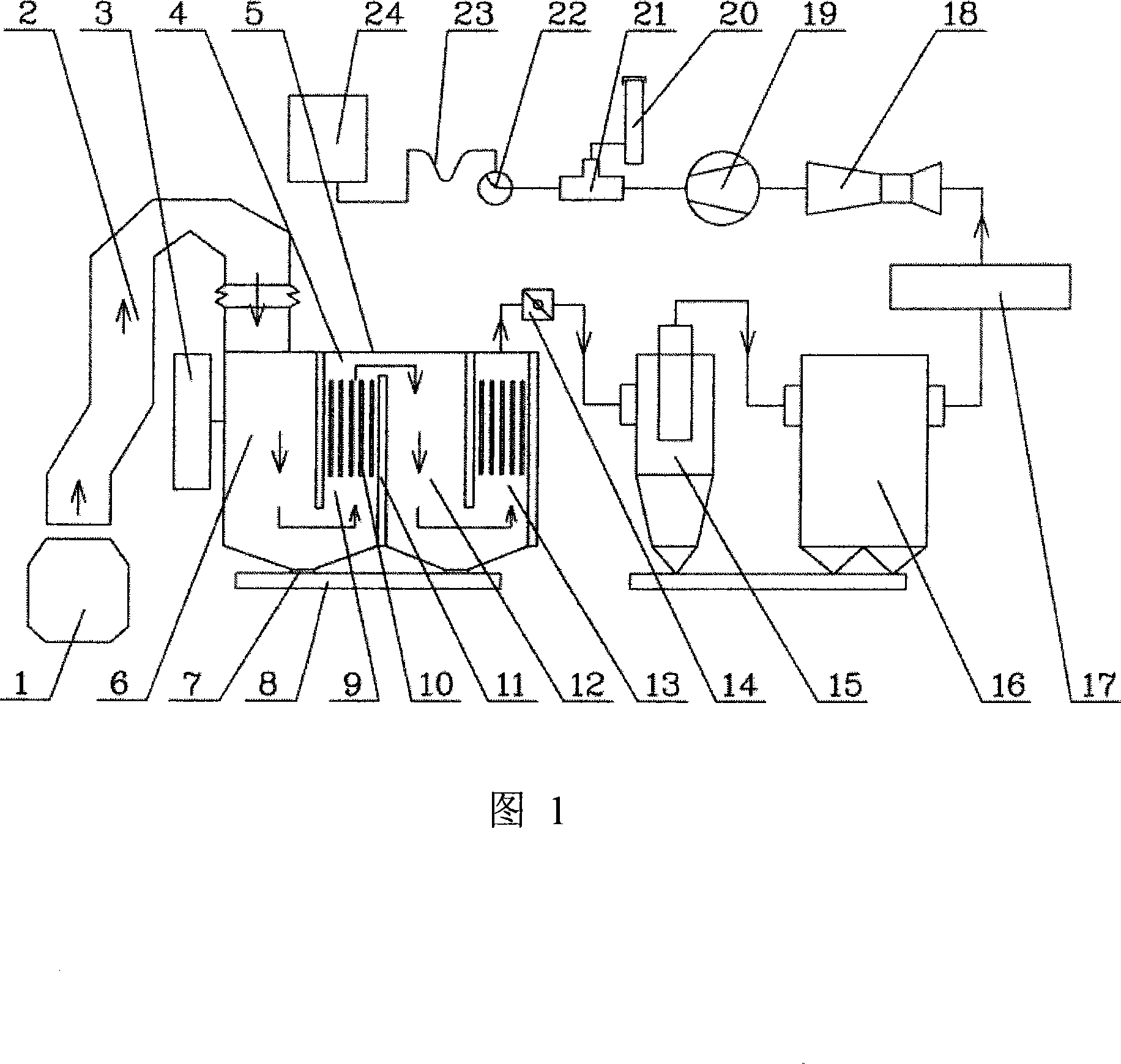

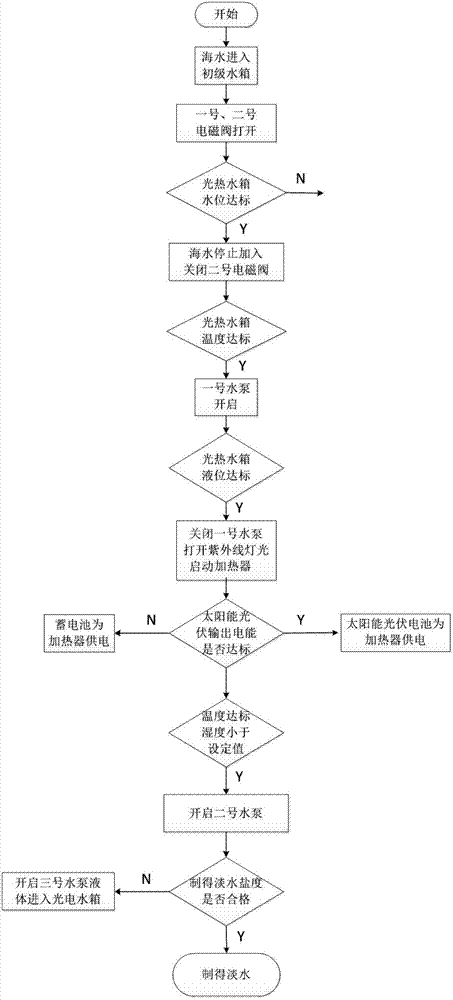

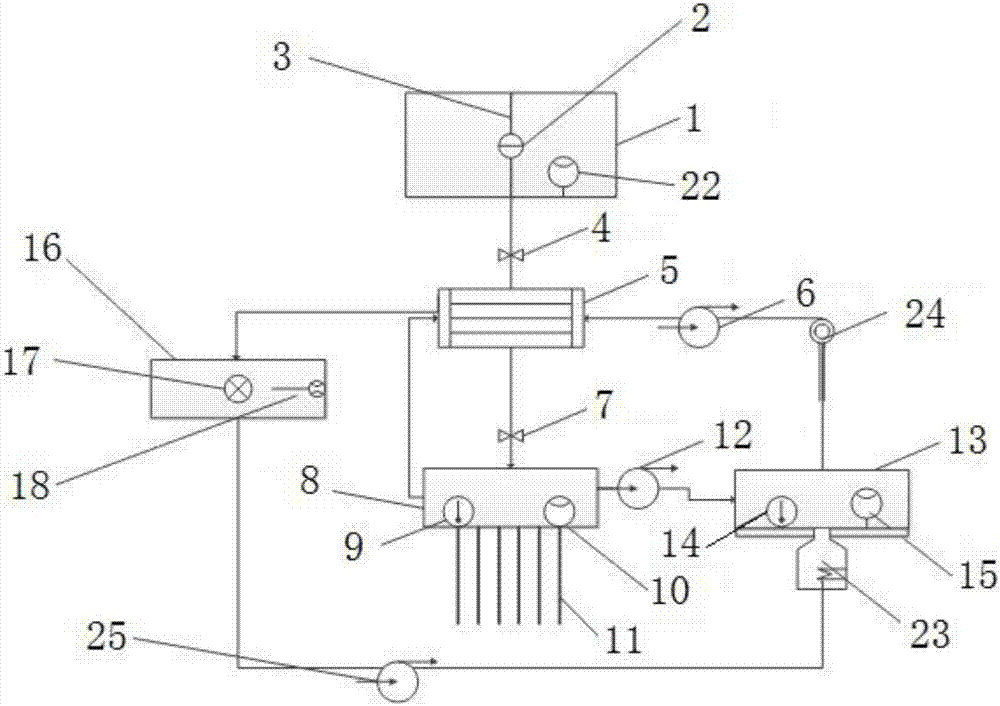

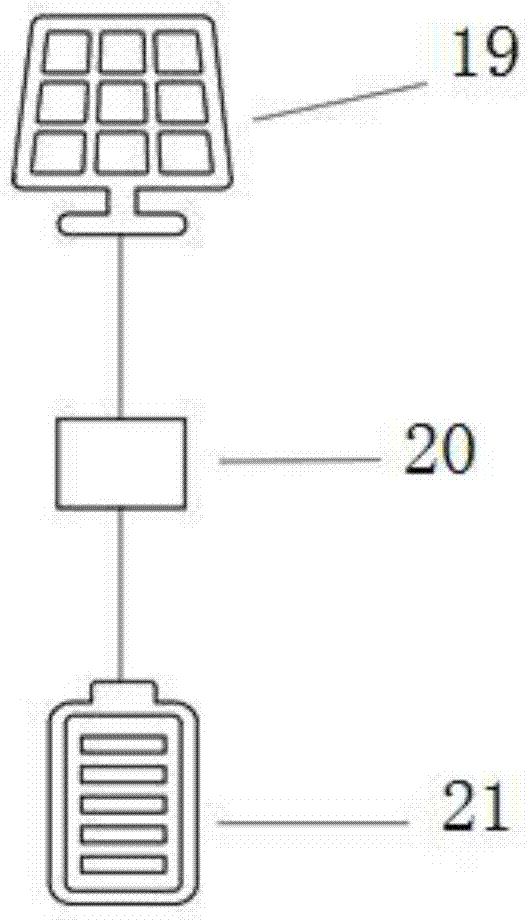

Double-stage solar seawater desalination device and desalination method

ActiveCN107311377AImprove efficiencySustainable operationWater treatment parameter controlSeawater treatmentSolar generatorEngineering

The invention discloses a double-stage solar seawater desalination device. The double-stage solar seawater desalination device includes a primary water tank, the primary water tank is connected to a condenser through a first electromagnetic valve, the condenser is connected to a photothermal water tank through a second electromagnetic valve, the photothermal water tank is connected to a photoelectric water tank through a first water pump, the photoelectric water tank is connected to a condenser through a second water pump, the condenser is connected to a fresh water tank, and the fresh water tank is connected to the photoelectric water tank through a third water pump. A heater is disposed below the photoelectric water tank, the first electromagnetic valve, the second electromagnetic valve, the first water pump, the second water pump, the third water pump and the heater are connected to the controller. The controller, the first electromagnetic valve, the second electromagnetic valve, the first water pump, the second water pump, the third water pump, the heater and an ultraviolet lamp are connected to a solar power generation mechanism. The photothermal water tank is also connected to a solar heat collection pipe. The invention also provides a double-stage solar seawater desalination method. The device and the method provided by the invention can reduce energy consumption and provide high quality fresh water.

Owner:WUHAN UNIV OF TECH

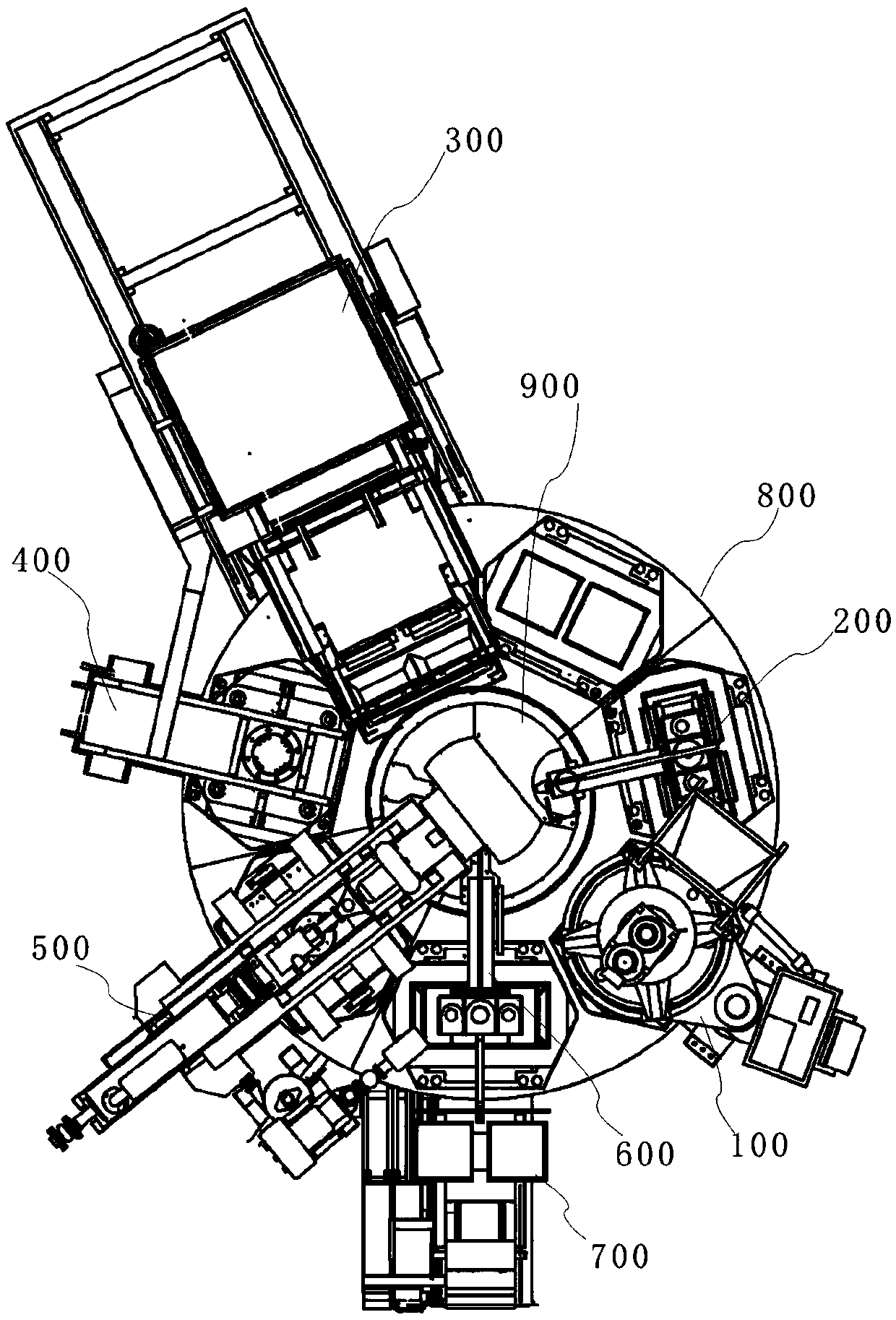

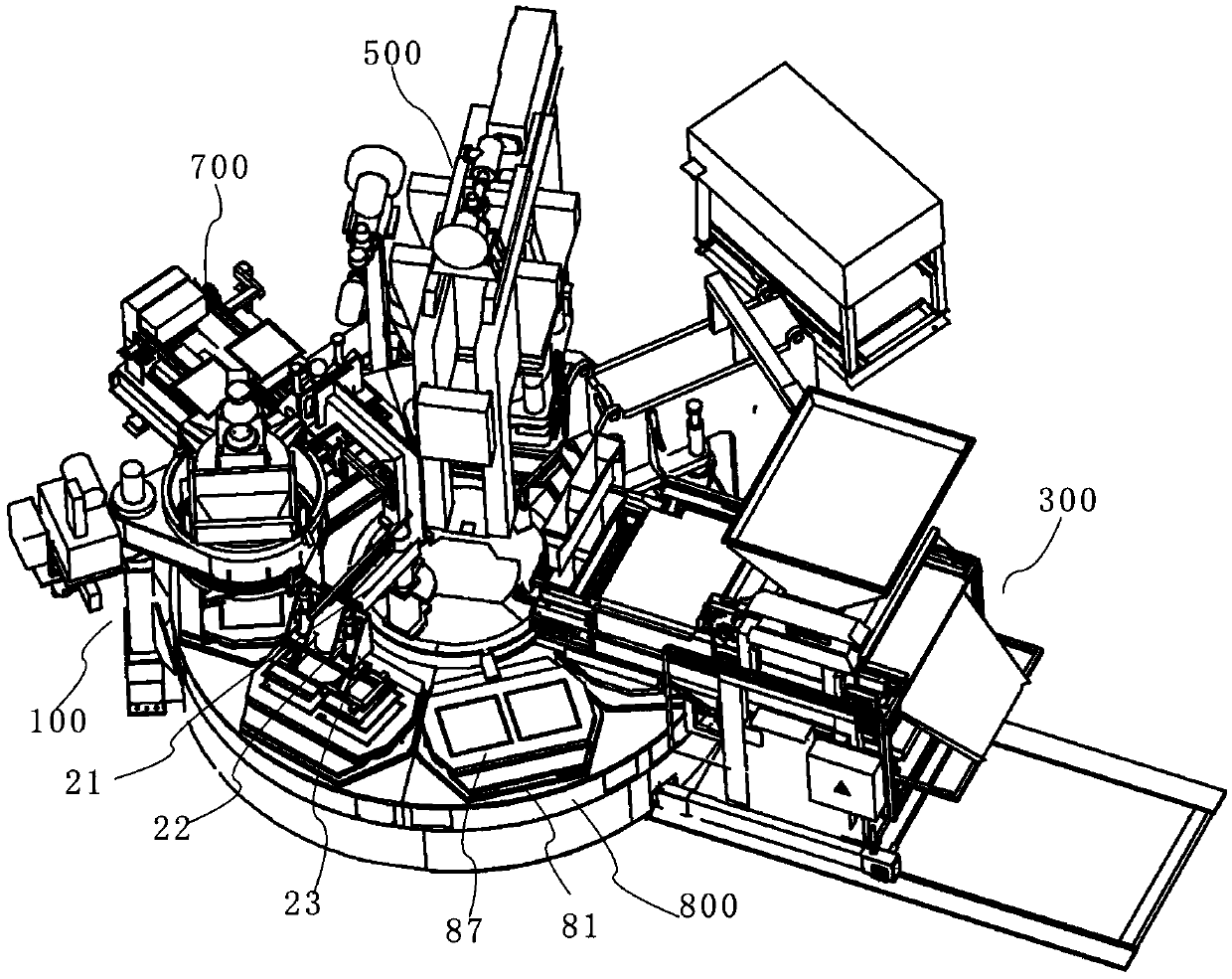

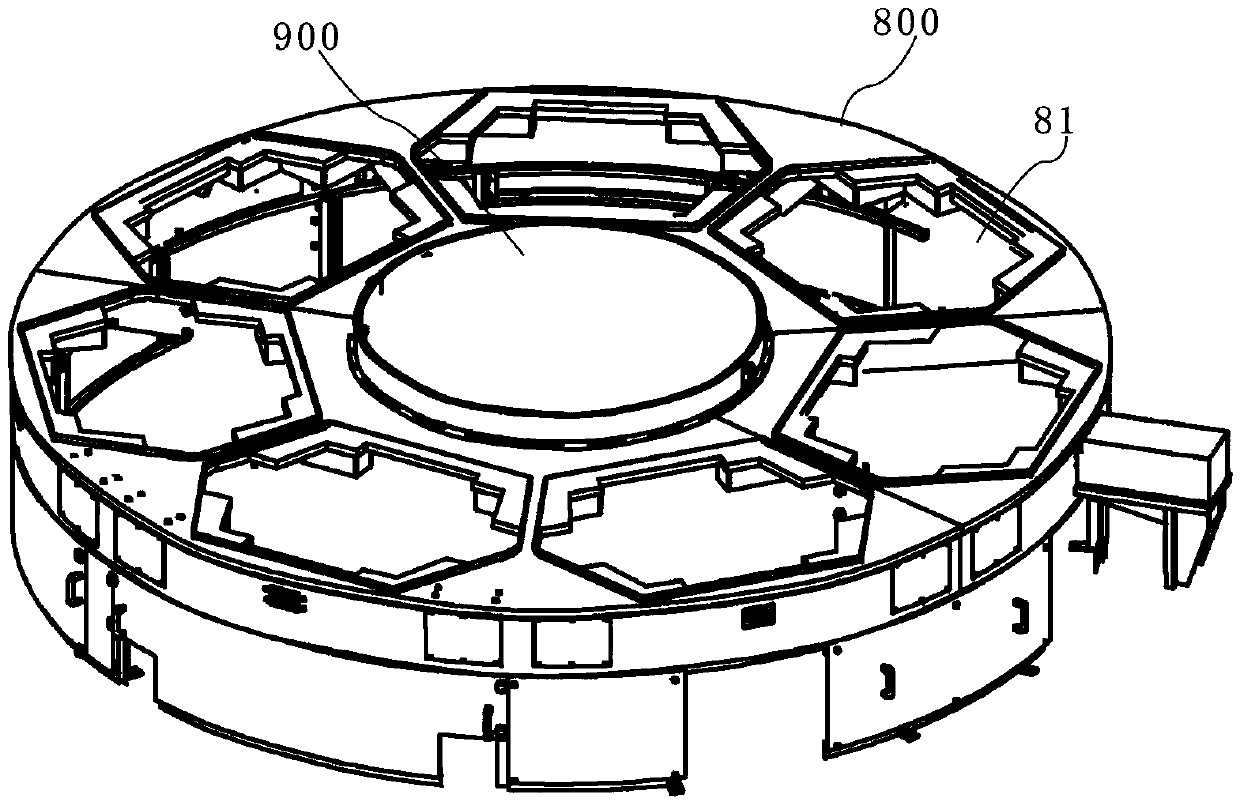

Full-automatic stone-like brick making machine and brick making method

PendingCN109676750ALower requirementReduce consumptionDischarging arrangementFeeding arrangmentsBrickSurface layer

The invention relates to a full-automatic stone-like brick making machine and a brick making method. The stone-like brick making machine comprises a center seat and a rotary disc, a plurality of moldpositions are uniformly distributed on the rotary disc in the circumferential direction, a vibration box body is fixedly mounted at each mold position through a rubber cushion block, a vibration motoris mounted on the bottom of each vibration box body and is hidden in the vibration box body, lifting oil cylinders are respectively mounted on two symmetrical sides of each vibration box body, and apiston rod of each lifting oil cylinder is connected with a connecting block; and a fabric distributing machine, a vibrating press, a prepressing machine, a main press unit and a demolding and brick discharging unit are sequentially arranged at each mold position correspondingly in the rotating direction of the rotary disc, and 0-2 transition positions are reserved between the vibrating press andthe prepressing machine. According to the invention, brick making processes are innovatively separated and arranged into an annular layout, the occupied area is small, the various processes can act simultaneously, the production period is shortened, the surface of a surface layer is compact, the requirement on raw materials is reduced, produced bricks can be maintained in a maintenance kiln or ina manner of standing and drying in the shade, the production period can be greatly shortened, and the energy consumption is reduced.

Owner:QUANGONG MACHINERY

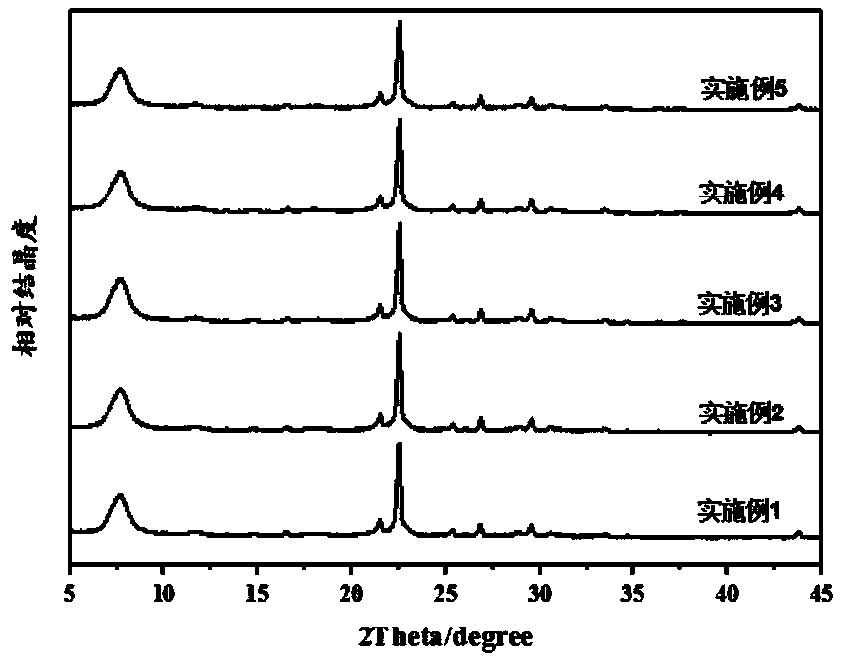

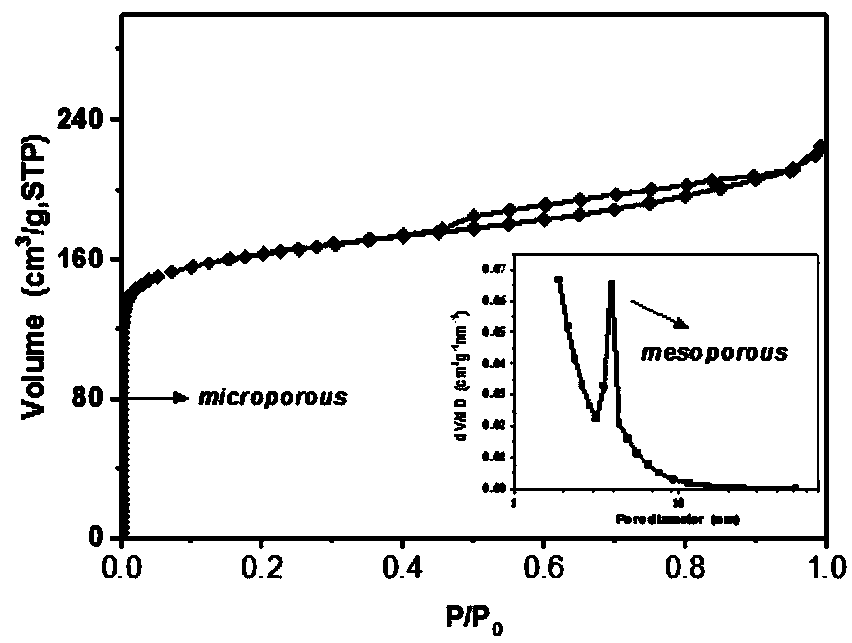

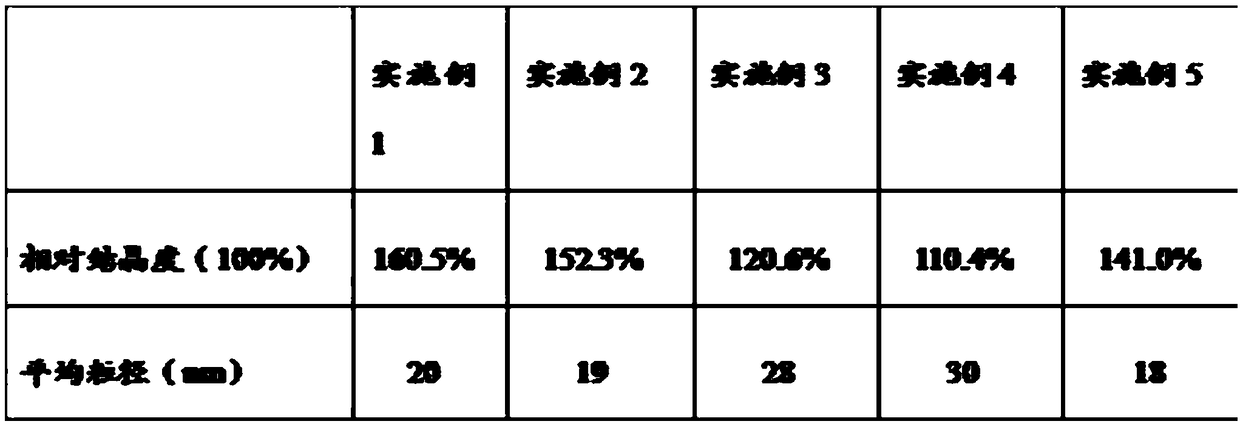

Preparation method of nanoscale pure silicon hierarchically porous Beta zeolite

The invention provides a preparation method of nanoscale pure silicon hierarchically porous Beta zeolite. Compared with the existing synthesis method, the method breaks through limits of traditional hydrothermal synthesis of pure silicon Beta zeolite on the basis of fluoride, and the pure silicon Beta zeolite is obtained with a steam assisting method under the condition of fluorine absence for thefirst time. According to the method, a little crystallization liquid is needed, and emission of a large amount of crystallization waste liquid is avoided effectively; fluoride is not needed for synthesis, use quantity of a template agent is small, an inorganic silicon source is taken as a silicon source, and synthesis cost is low; utilization rates of a device and raw materials are high, and almost 100% of product yield can be realized; only 36 h is needed for synthesis, steps are simple, and energy consumption can be reduced effectively. A synthesized pure silicon Beta zeolite sample has theadvantages of being high in crystallinity degree and specific surface area, rich in hierarchically porous structure, nanoscale, good in hydrothermal stability and the like.

Owner:FUZHOU UNIV

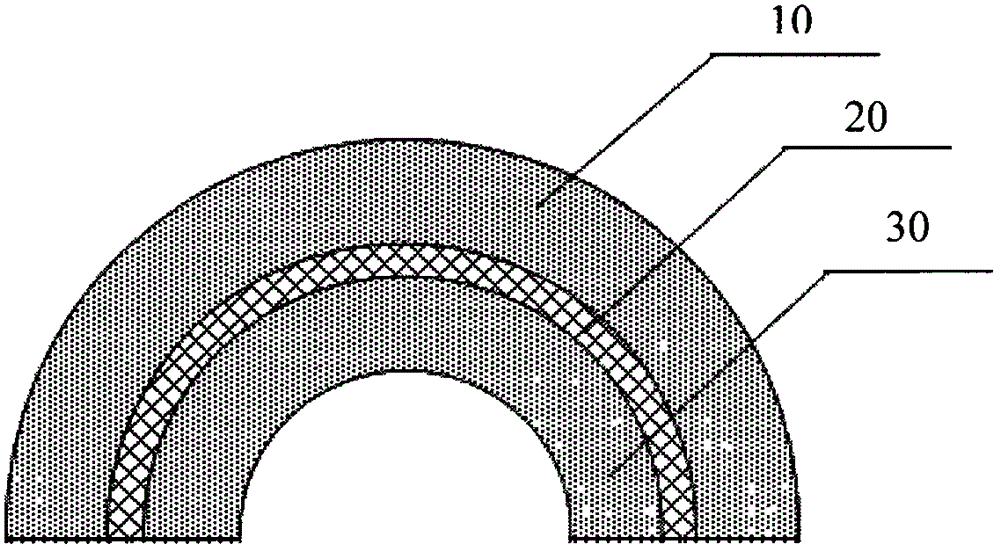

Arced vacuum heat insulation composite plate and manufacturing method thereof

InactiveCN102748558AStay flexibleIncrease elasticityThermal insulationPipe protection by thermal insulationHeat conservationComposite plate

The invention discloses an arced vacuum heat insulation composite plate and a manufacturing method thereof. The arced vacuum heat insulation composite plate is characterized by comprising three layers, wherein the middle layer is a vacuum heat insulation plate, and two sides are heat-conservation organic foam; the organic foam is polyurethane foam and polypropylene foam; the polyurethane foam is composed of single-component polyurethane and double-component polyurethane; wherein the single-component polyurethane is used for wrapping the vacuum heat insulation plate to obtain a soft composite plate; and the double-component polyurethane is used for wrapping the vacuum heat insulation plate to obtain a hard composite plate. The arced vacuum heat insulation composite plate has the advantages that the heat conduction coefficient of a heat conservation layer material is relatively lower than the conventional heat conservation material, so that the thickness of the heat conservation layer is reduced greatly, the increase of the pipeline load caused by the pipeline temperature unevenness is avoided, and the service life of a pipeline is prolonged; meanwhile, the procedure that raw petroleum in a seabed petroleum transmission pipeline of which the heat conservation layer is made of the conventional heat conservation material can be heated at each certain distance so as to keep the flowability is omitted; the energy consumption is reduced; and working procedures are simplified.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

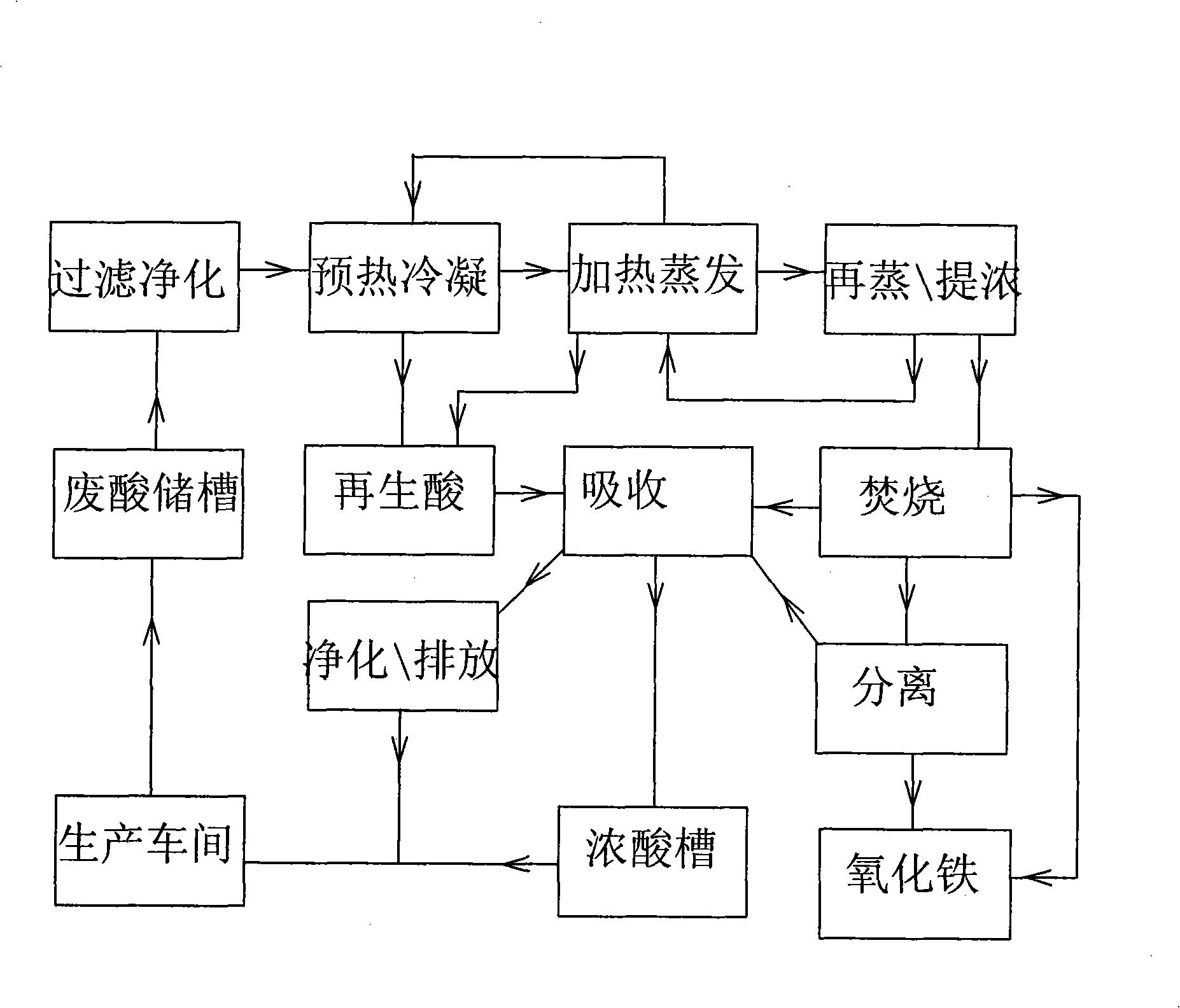

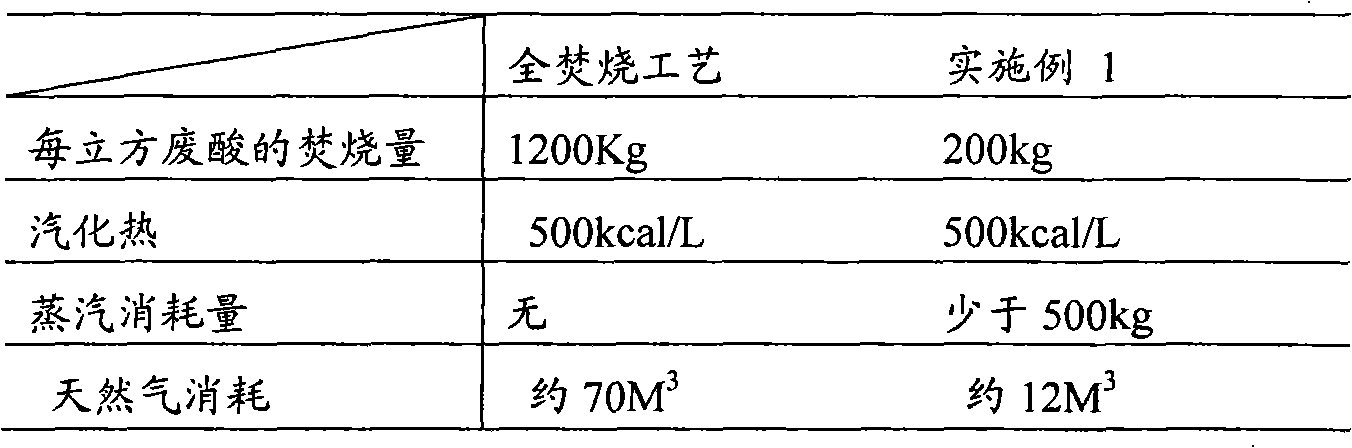

Pickling waste acid regeneration process

The invention relates to a method for recycling acid washing waste acid. The invention provides a method for regenerating the acid washing waste acid which contains hydrochloric acid and ferrous chloride. The method comprises the following steps of filtration, preheating, multi-effect evaporation, combustion and separation of the acid washing waste acid. The method has the advantages of obvious reduction of the cost of a recovery system, reduction of the operating cost, simplification of system equipment, reduction of the energy consumption and achievement of regeneration and recycle of resources.

Owner:NANTONG CHENGGUANG GRAPHITE EQUIP

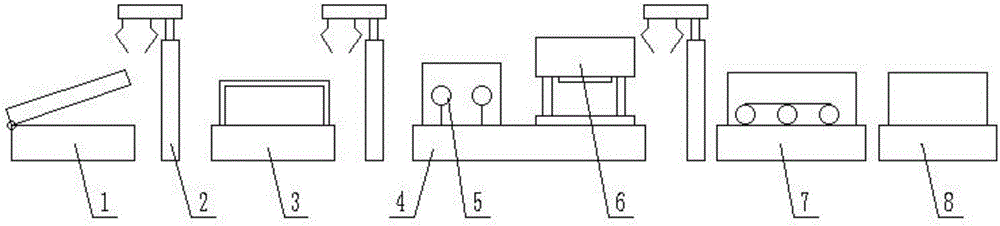

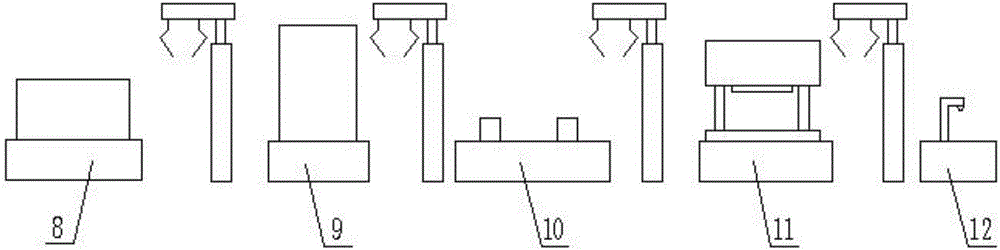

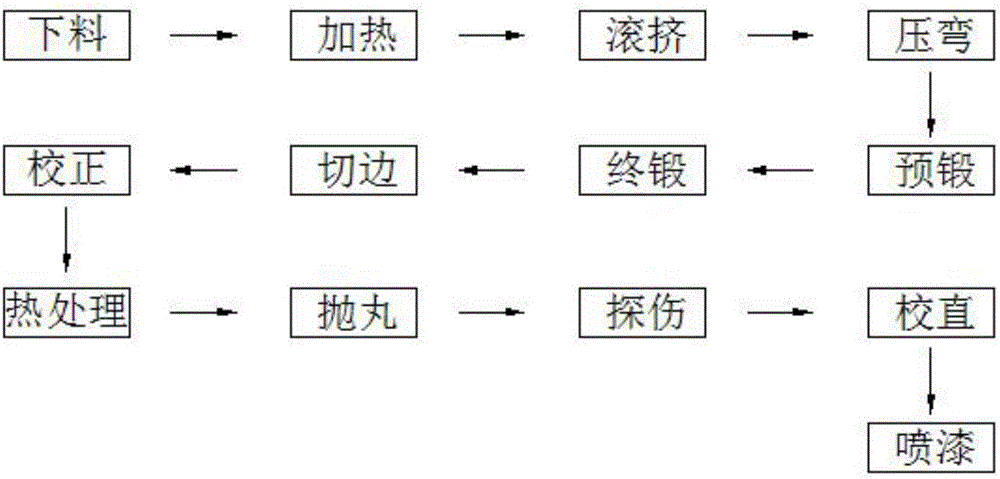

Automobile front axle production line and processing method

InactiveCN106141693AEliminate the effects ofImprove internal tissue uniformityOther manufacturing equipments/toolsClosed loopPerformance index

The invention discloses an automobile front axle production line. An automatic sawing machine, an intelligent medium-frequency induction heating device, a forging and shaping device, a heat treatment intelligent automatic conveying device and a closed-loop heat preservation and heating heat treatment device are sequentially arranged; wherein the workpirces among the automatic sawing machine, the intelligent medium-frequency induction heating device and the forging and shaping device are conveyed by intelligent robot arms. The invention further discloses a processing method of the automobile front axle. The processing method comprises the following steps: blanking, heating, roll-extruding, press-bending, pre-forging, finish-forging, trimming, correcting and heat treatment. According to the invention, the blank workpiece is heated once and quickly molded, the processing steps are simplified, the internal structure uniformity, the performance index and the machining forming rate of the workpiece are improved, the energy consumption and the waste gas emission are reduced, the manual physical labor is reduced, and the processing cost is reduced.

Owner:SHAANXI AOBANG FORGING

Surface modification method of hollow glass beads

InactiveCN102604439AReduce consumptionImprove adhesionPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsEpoxyBound property

The invention discloses a surface modification method of hollow glass beads. The method comprises the following steps: firstly, removing surface impurities of the hollow glass beads with absolute ethanol or acetone, and then drying the hollow glass beads for 3 to 5 hours; secondly, adding the dried hollow glass beads into an agitator to be continuously heated after the agitator is preheated, and adding a coupling reagent 0.2-1.5% of the mass of the glass beads after the surface temperature of the hollow glass beads is increased to 95 to 135 DEG C; and thirdly, continuously stirring the hollow glass beads for 10-30min at 95 to 135 DEG C, and then discharging the hollow glass beads to obtain the hollow glass beads with modified surfaces. According to the method, the agitator is adopted to perform dry modification, the technology is simple, the operation is easy, the modification time is short, the cost is low, subsequent drying is not required, and the energy consumption is reduced. The hollow glass beads treated through the method can be better dispersed in epoxy resin, the binding property between the resin and fillers is improved, the material strength is improved, and the mechanical property of the composite material is obviously improved.

Owner:BENGBU HUAYANG POWDER TECH +2

Method for extracting active constituent from Tibetan capillary

ActiveCN101053589ANo pollutionReduce consumptionDigestive systemPlant ingredientsSide effectTherapeutic effect

The invention discloses a method for extracting anagallidium effective components with a producing steps of extracting, removing the impurity, primary separation, absorbing separation, concentrating, drying, smashing, secondary refining and etc. The extracting method extracts by solvent water and ethanol which can be recovered and has no pollution. The ultrasonic accessory extraction can shorten the extraction period, improves the efficiency, reduces energy consumption. The centrifugation and large-hole resin absorption treatments can keep the effective components, remove the impurity in a high limit, refine the Chinese traditional medicine, reduce dosage and facilitate to dispose a plurality of preparation formulation containing injection (intravenous injection ), oral reagent, external use regent, and also can be the material of the compound preparation. Meanwhile, it can reduce the side effects and bad reaction incidence rate because the impurity is removed throughly.

Owner:TIBENTAN RIKEZE ZANGNUO PHARMA CO LTD

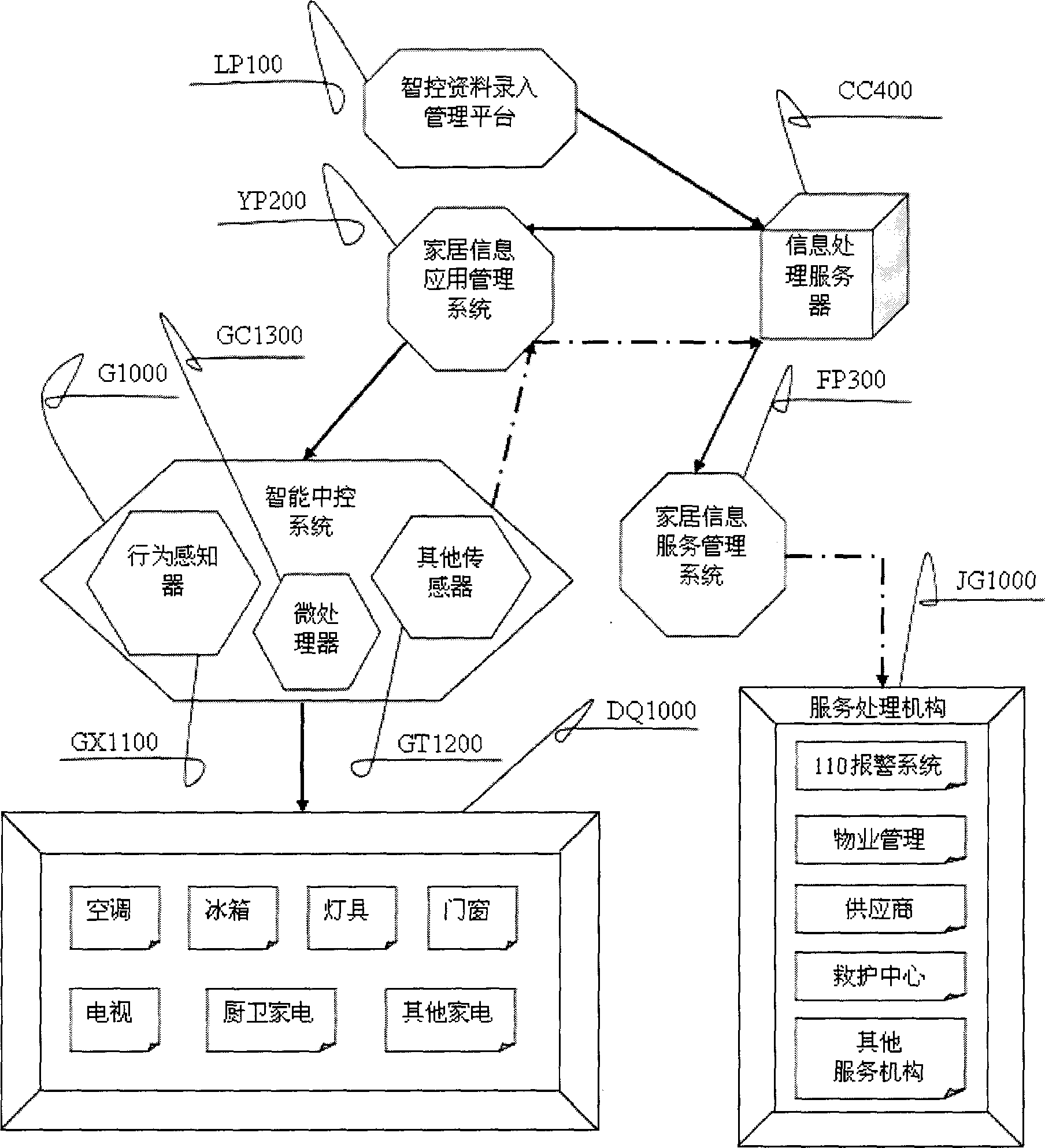

Smart home environment system and smart control method

InactiveCN104181893AComputer controlProgramme total factory controlHome environmentMaterial resources

The invention discloses a smart home environment system and a smart control method. The smart home environment system and the smart control method import user information through a smart data entering and management platform, meet different demands of multiple users and achieve actualized, reliable and healthy household product functions according to health agencies, occupations, hobbies and interests and personal habits. In addition, the upstream demands and downstream demands of the users are combined, supply and demand needs are simplified, a service chain is shortened, the user efficiency and user experience are improved, manpower and material resources can be saved in the downstream service process, energy consumption is reduced, food loss is reduced, a reliable data basis is provided for planting and cultivation of agricultural products, market regulation is assisted, and convenient and fast service is provided for the users to the greatest extent.

Owner:河南富业智能建设有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com