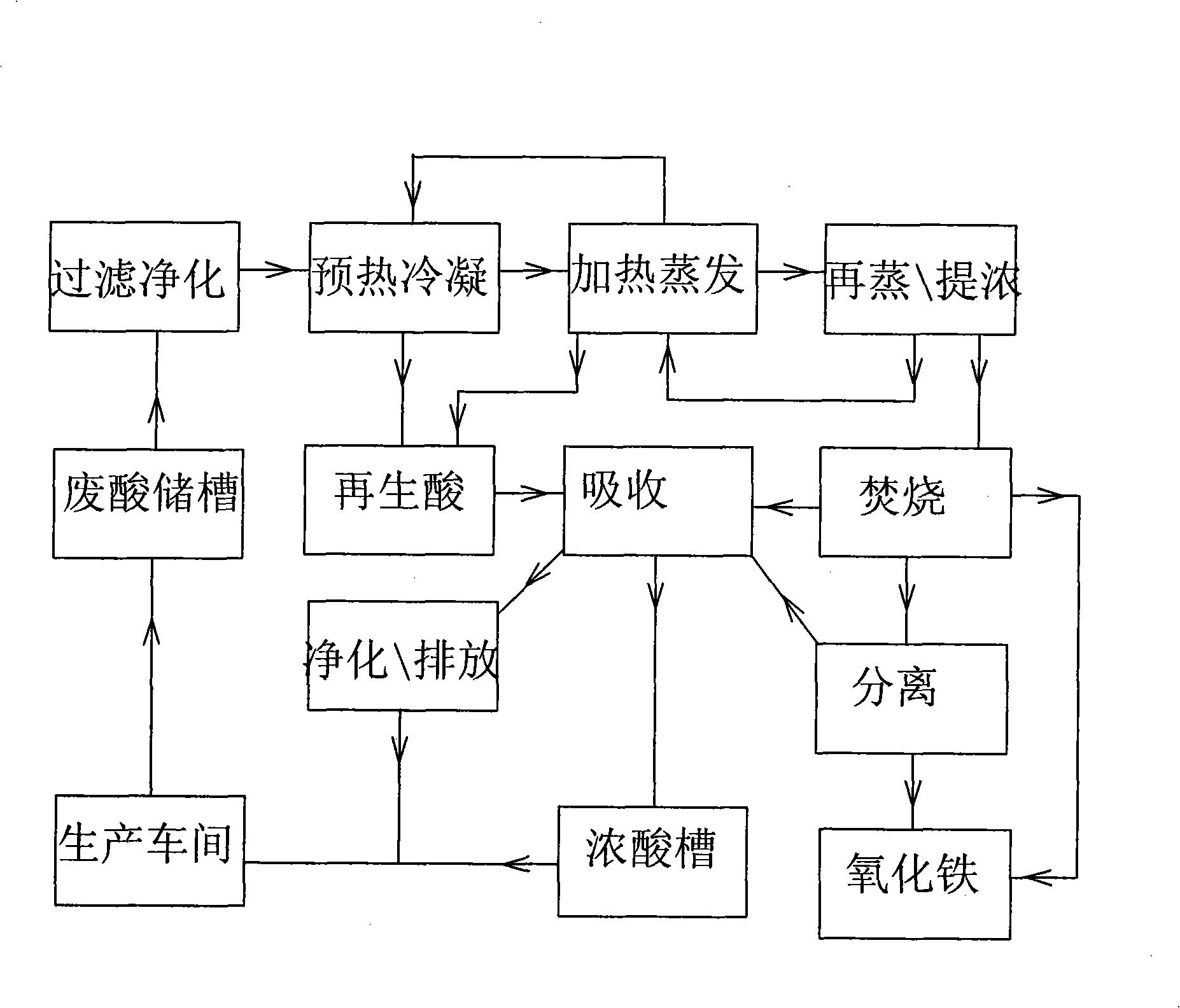

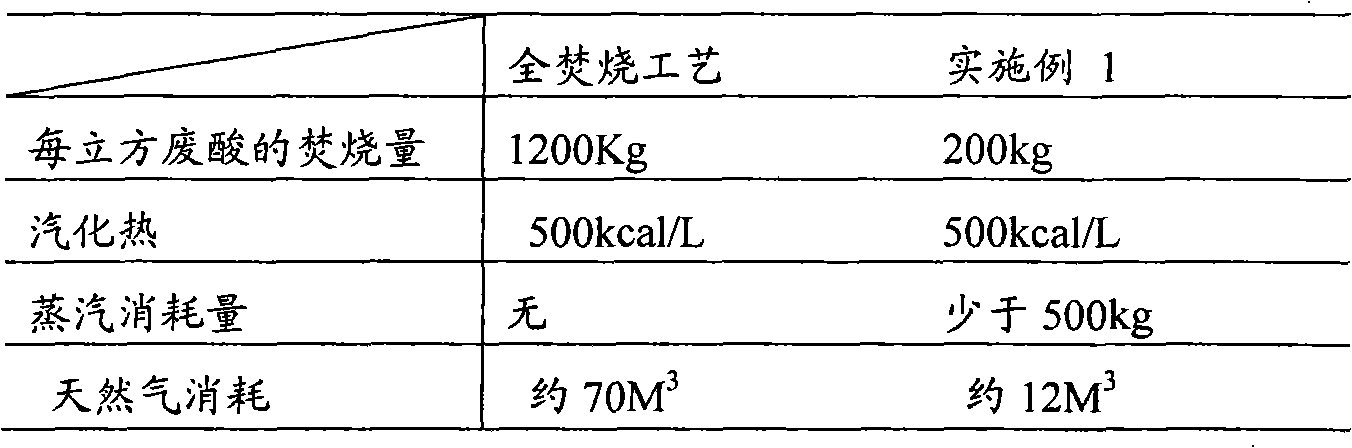

Pickling waste acid regeneration process

A technology for pickling waste acid and hydrochloric acid, applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of difficulty in cost recovery and large investment, and achieve the effects of reducing investment, small footprint and significant environmental protection significance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following examples illustrate the method for regenerating waste pickling acid of the present invention without limitation in conjunction with the accompanying drawings. Those of ordinary skill in the art can also make various changes and modifications to the present invention without departing from the spirit and scope of the present invention, but all equivalent technical solutions belong to the category of the present invention, and the protection of the present invention The scope is defined by the claims of the present application.

[0036] The pickling waste acid sent from the production workshop of pickling waste acid mainly contains hydrochloric acid, ferrous chloride and waste residue. After being stored in the waste acid storage tank, pumping and filtering are used to filter out dirt and impurities, and the pickling waste acid after filtration and purification (mainly containing the waste hydrochloric acid mixture of ferrous chloride, the content of ferrous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com