Arced vacuum heat insulation composite plate and manufacturing method thereof

A vacuum heat insulation board and vacuum heat insulation technology, applied in heat exchange equipment, pipeline protection through heat insulation, heat preservation, etc., can solve problems such as increased pipeline load, insulation layer thickness, closed cell rate less than 100%, and avoid Energy consumption, thermal insulation performance avoidance, effect of improving thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Apply a layer of release agent evenly on the inner wall of the mold. Put the 7mm-thick circular tube-shaped vacuum insulation panel vertically into the inner tube of the mold, 5mm away from the outer wall of the inner tube, and embed it in the prefabricated round polyurethane foam support block coated with adhesive to fix it. Close the mold, fill the molded polyurethane foam and cure for 0.5 to 1 hour. After demoulding, removing the board and deburring, a 17mm thick two-component polyurethane-coated rigid sandwich cylinder of vacuum insulation board was obtained.

Embodiment 2

[0031] Apply a layer of release agent evenly on the inner wall of the mold. Put the 8mm thick circular tube-shaped vacuum insulation board vertically into the inner tube of the mold, 3mm away from the outer wall of the inner tube, close the mold, fill with one-component polyurethane adhesive, heat and cure for 24-72 hours. After demoulding, removing the board and trimming the corners, a 14mm thick single-component polyurethane-coated soft sandwich cylinder of vacuum insulation board was obtained.

Embodiment 3

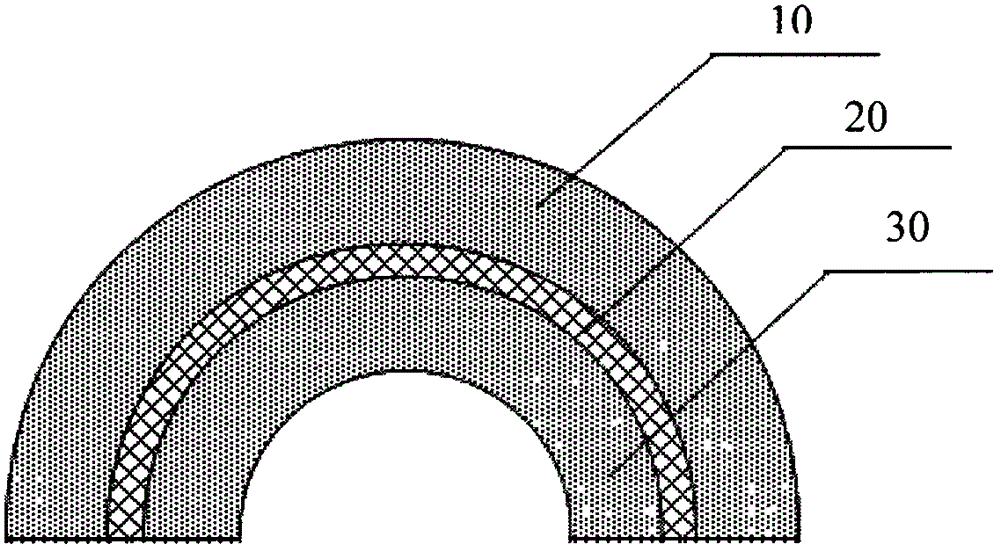

[0033] Apply a layer of release agent evenly on the inner wall of the mold. A 7 mm thick semicircular vacuum insulation panel was placed vertically in the center of the mold cavity. And embedded in the prefabricated semicircular polypropylene foam support block coated with adhesive to fix. Close the mold, and fill with 4mm thick polypropylene foam material on both sides and solidify for a period of time. Afterwards, a 15mm-thick semicircular polypropylene-coated rigid sandwich panel with a vacuum insulation panel was obtained after demoulding, board removal and deburring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com