Minced fillet product producing method

The technology of a surimi product and a production method, which is applied in the field of aquatic product processing, can solve the problems of high energy consumption, dissolution of water-soluble protein, single variety, etc., and achieve the effects of simple production process, low fishy smell and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 (control group)

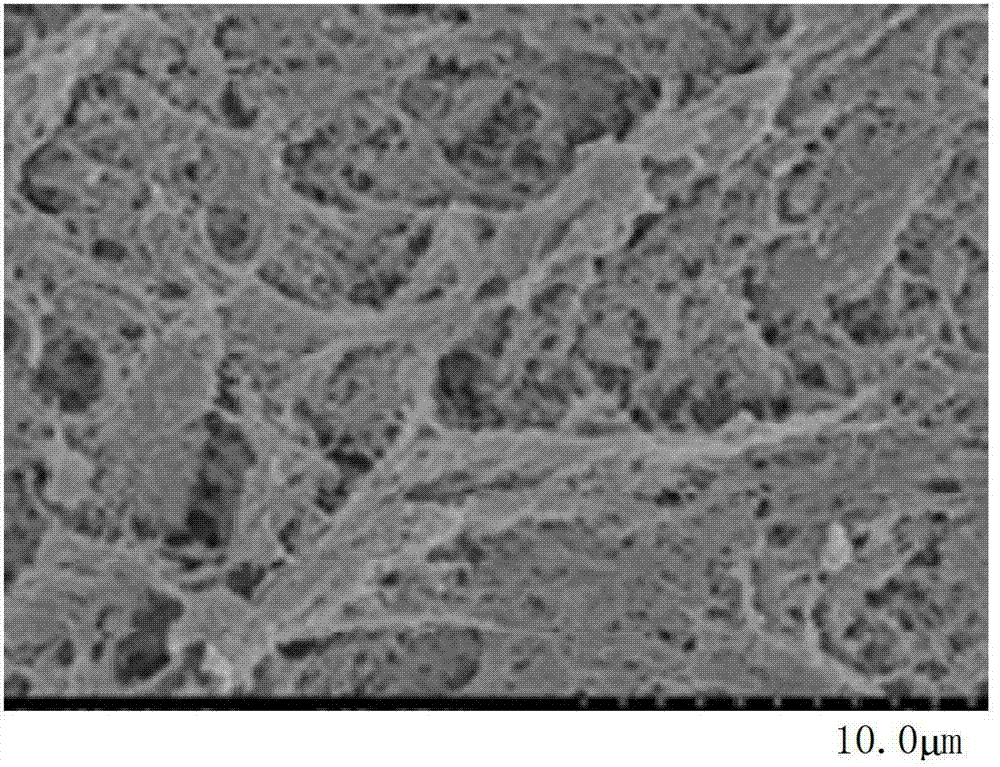

[0030] Add 1g of egg white protein to 1kg of semi-thawed silver carp surimi, beat at 4°C and mix evenly, then add 20g of salt and 200ml of distilled water at 10°C, beat at 4°C for 10min, after mechanical molding, at 30°C ℃ for 120 minutes, and then heated at 90 ℃ for 15 minutes. After the prepared surimi products were cooled rapidly with crushed ice, the prepared surimi products were sealed in plastic bags and stored at 4 ℃ for 24 hours. Place it at 25°C for 1 hour to return the temperature of the sample to normal temperature, measure the gel strength of the sample with a texture analyzer (see Table 1), and measure the internal structure of the sample with a scanning electron microscope (see Table 1). figure 1 ), and the samples were sensory evaluated (see Table 2).

Embodiment 2

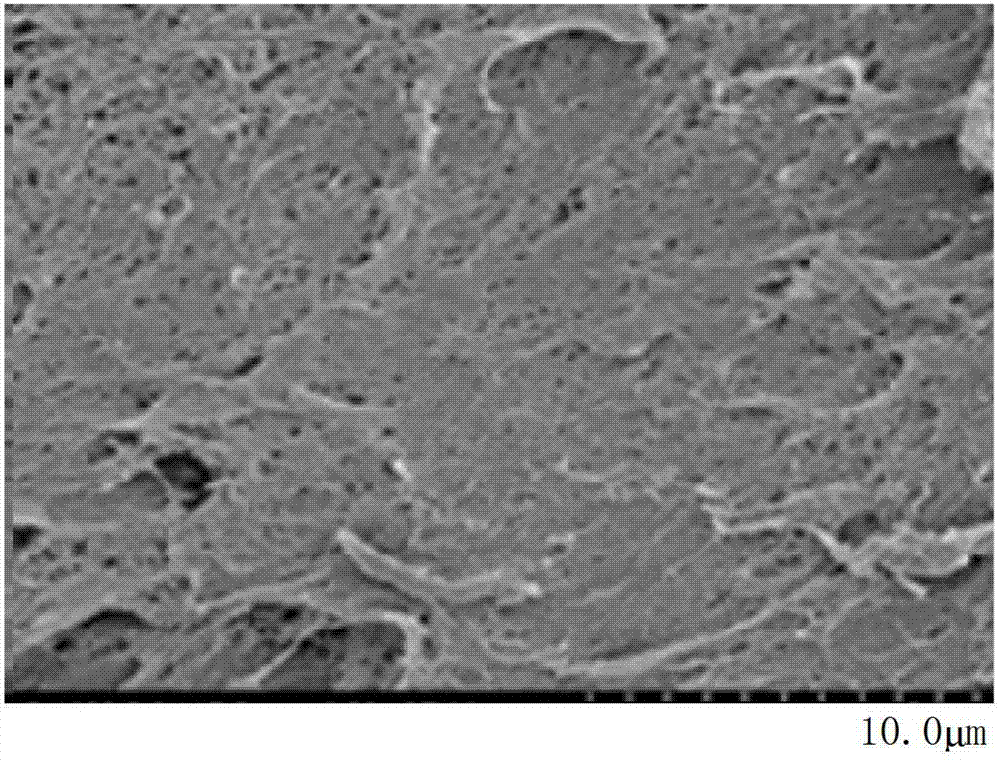

[0032] Add 1g of egg white protein to 1kg of semi-thawed silver carp surimi, and an acidic seasoning aqueous solution at a temperature of 10°C [monosodium glutamate 8% (w / v), rice wine 30% (v / v), white pepper 5% (w / v), cardamom 1% (w / v), vinegar 0.15% (v / v)] 200ml, beat at 4°C and mix evenly, then add 20g of salt and 10g of gluconolactone, beat at 4°C Squeeze for 10 minutes, after mechanical molding, gelatinize at 30°C for 120min, then seal the gelatinized surimi products with plastic bags, store at 4°C for 24h, place the sample at 25°C for 1h to make the sample The temperature of the sample is returned to normal temperature, the gel strength of the sample is measured with a texture analyzer (see Table 1), and the internal structure of the sample is measured with a scanning electron microscope (see Table 1). figure 2 ), and the samples were sensory evaluated (see Table 2).

Embodiment 3

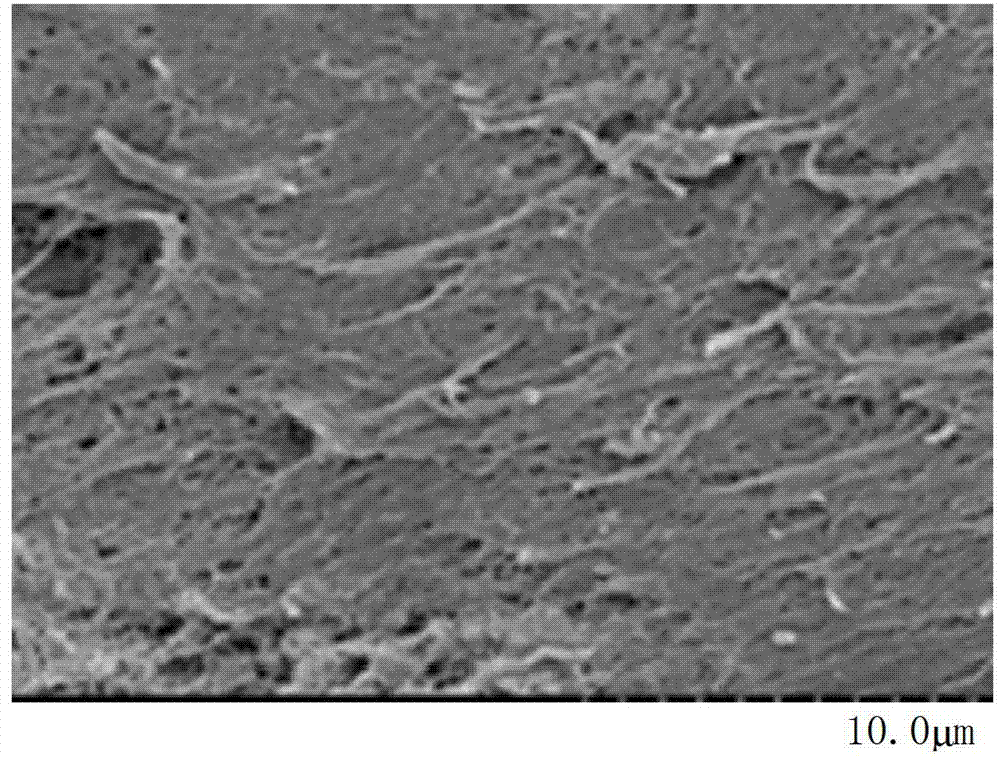

[0034] Add 2g of porcine blood protein to 1kg of half-thawed tilapia surimi, and an acidic seasoning aqueous solution at a temperature of 8°C [monosodium glutamate 7% (w / v), rice wine 35% (v / v), white pepper 4% (w / v), cardamom 2% (w / v), malic acid 0.1% (v / v)] 250ml, beat at 4 ℃ and mix well, then add 30g salt and 20g gluconolactone, at 4 ℃ Knock down for 10 minutes, after mechanical molding, gelatinize at 40°C for 60min, then pack the gelatinized surimi products in a plastic bag, store at 4°C for 12h, and place the sample at 25°C for 1h The temperature of the sample was returned to normal temperature, the gel strength of the sample was measured with a texture analyzer (see Table 1), and the internal structure of the sample was measured with a scanning electron microscope (see Table 1). image 3 ), and the samples were sensory evaluated (see Table 2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com