Preparation method of nanoscale pure silicon hierarchically porous Beta zeolite

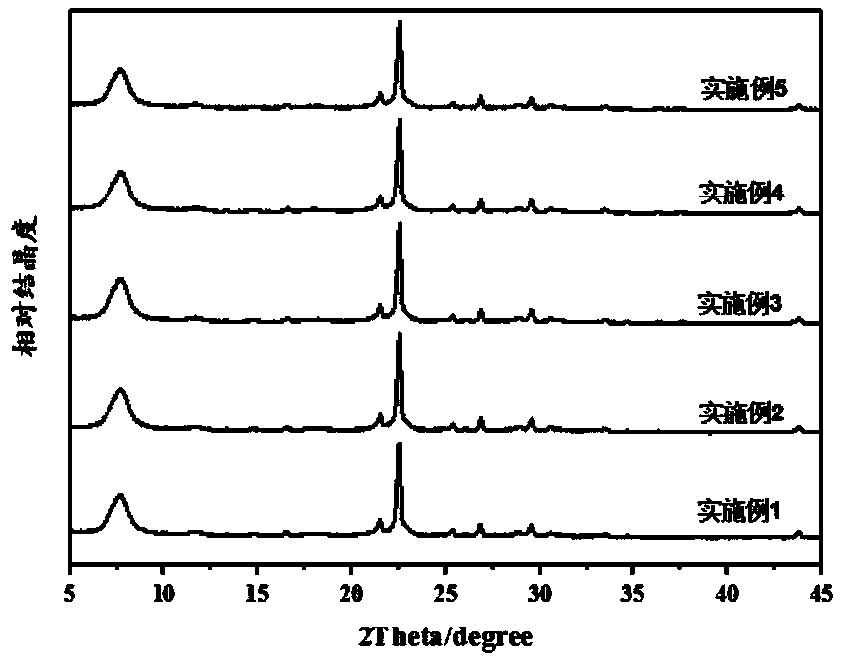

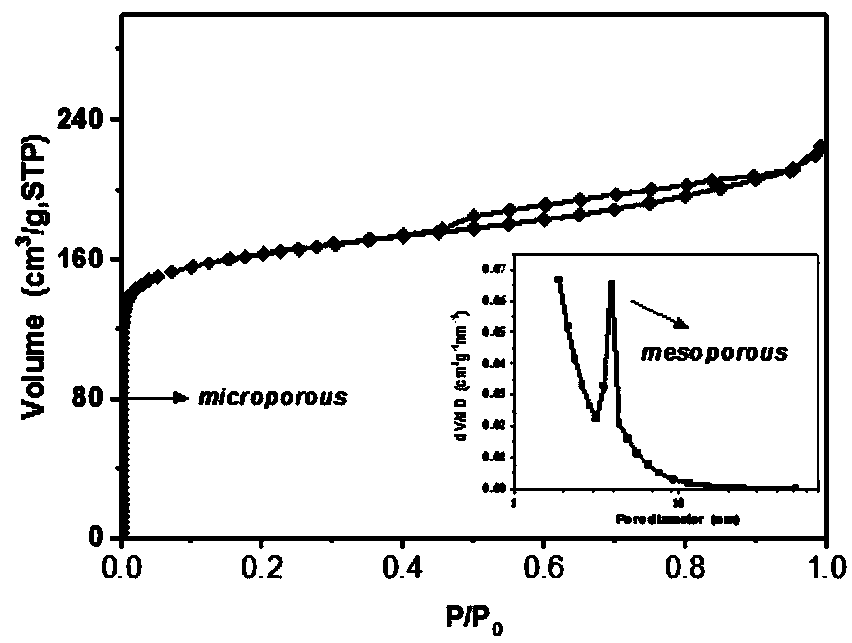

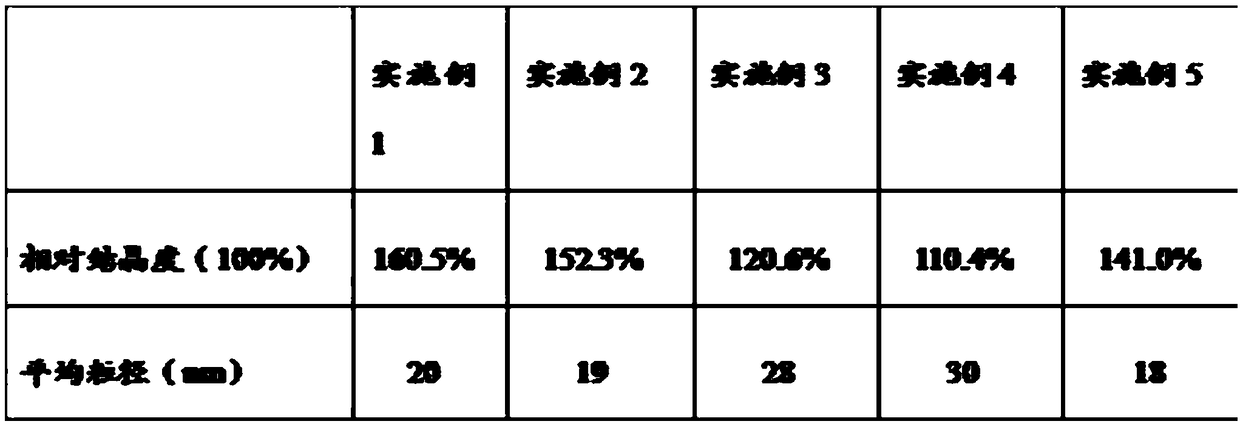

A molecular sieve and stepped hole technology, applied in the field of preparation of nano-scale pure silicon beta molecular sieve, can solve the problems of long crystallization cycle, high pollution, large particle size of beta molecular sieve, etc., and achieve high product yield, high specific surface area, high The effect of crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention provides a kind of preparation method of nanoscale pure silicon step hole Beta molecular sieve, it is characterized in that, the method comprises the following steps:

[0030] 1) Silicon source is SiO 2 Calculate, fully mix with alkali source, template agent and water according to the molar ratio of silicon source: alkali source: template agent: water = 1:0.11~0.245:0.01~0.1:20~80, and then add 0.001% of the mass of silicon source ~10% of the seed crystals are aged at a temperature of 30-80° C. for 0.5-2 hours. Evaporating the aged hydrogel in an oil bath at 30-90° C. for 12-48 hours to obtain a templated and seeded xerogel.

[0031] 2) Grind the xerogel obtained in step 1), place it in the kettle and the small lining respectively according to the water:dry powder mass ratio of 0.1-1, crystallize at 130-160°C for 20-40 hours, and wash the obtained product After being neutralized and dried, it is calcined at 550° C. for 6 hours to obtain a pure si...

Embodiment 1

[0050] This example is used to illustrate a preparation method of a nano-scale pure silicon step-pore Beta molecular sieve.

[0051] First, white carbon black (as SiO 2 According to silicon source: NaOH: TEAOH: H 2 The molar ratio of O=1:0.16:0.05:50 is fully mixed, and then a seed crystal equivalent to 1% of the mass of the silicon source is added, and aged at a temperature of 30° C. for 0.5 hour. The aged hydrogel was evaporated in an oil bath at 60°C for 24 hours to obtain a templated and seeded xerogel. Grind the obtained xerogel until there is no grain feeling, take 10g and put it in a small inner liner, then put it into a crystallization kettle filled with 2.5g of water, seal the kettle, and crystallize at 145°C for 36 hours, the obtained The product was washed with deionized water until neutral and dried, then calcined at 550° C. for 6 hours to obtain product S1.

Embodiment 2

[0053] This example is used to illustrate a preparation method of a nano-scale pure silicon step-pore Beta molecular sieve.

[0054] First, the silica sol (as SiO 2 According to silicon source: NaOH: TEAOH: H 2 The molar ratio of O=1:0.23:0.08:30 is fully mixed, then a seed crystal equivalent to 0.5% of the mass of the silicon source is added, and aged at a temperature of 70° C. for 1 hour. The aged hydrogel was evaporated in an oil bath at 70°C for 24 hours to obtain a templated and seeded xerogel. Grind the obtained xerogel until there is no grain feeling, take 10g and put it in a small inner liner, then put it into a crystallization kettle filled with 6g of water, seal the kettle, and crystallize at 140°C for 28 hours, the obtained product After washing with deionized water to neutrality and drying, it was calcined at 550°C for 6 hours to obtain product S2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com