Dimethyl formylamine solution three-effect rectification recovery method for wet synthesis of leather

The technology of a dimethylformamide and a recovery method is applied in the field of three-effect rectification and recovery of wet synthetic leather dimethylformamide solution, which can solve the problem of high technical difficulty of the three-effect recovery process, and achieves the promotion of sustainable development and expansion. High productivity and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

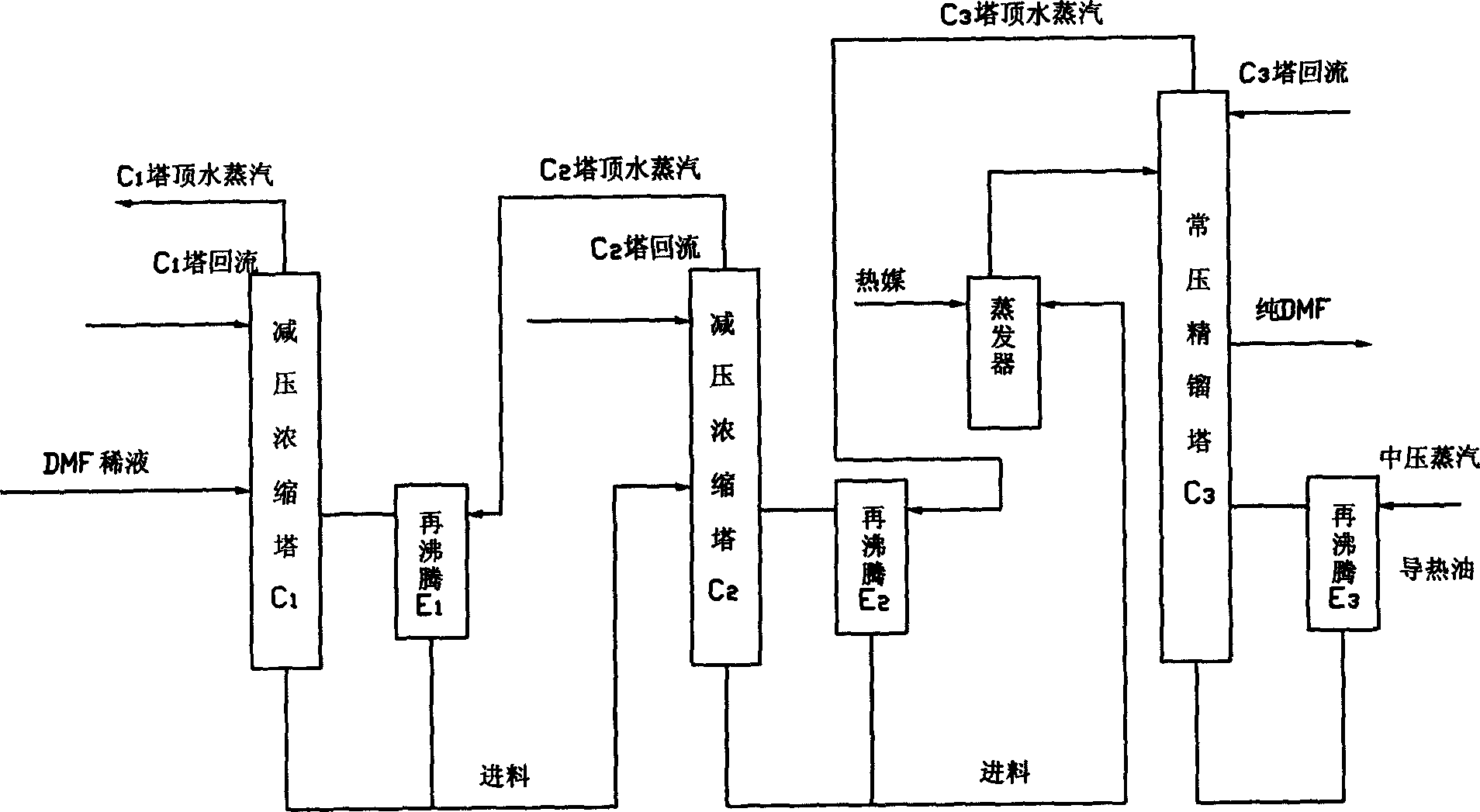

[0013] figure 1 Shown is the schematic diagram of the traditional three-effect DMF recovery process, which includes: feeding, preheating, concentration and separation through the secondary concentration tower and the primary distillation tower, and discharge to form the entire recovery process flow, which uses heat conduction Oil or medium-pressure steam is used as the heat medium, and atmospheric distillation technology is adopted, namely, the first-stage vacuum concentration tower C1, the second-stage vacuum concentration tower C2 and the atmospheric rectification tower C3, and each tower is equipped with a reboiler E1, E2 , E3 carries out reboiling discharge, extracts pure DMF from atmospheric rectification column C3.

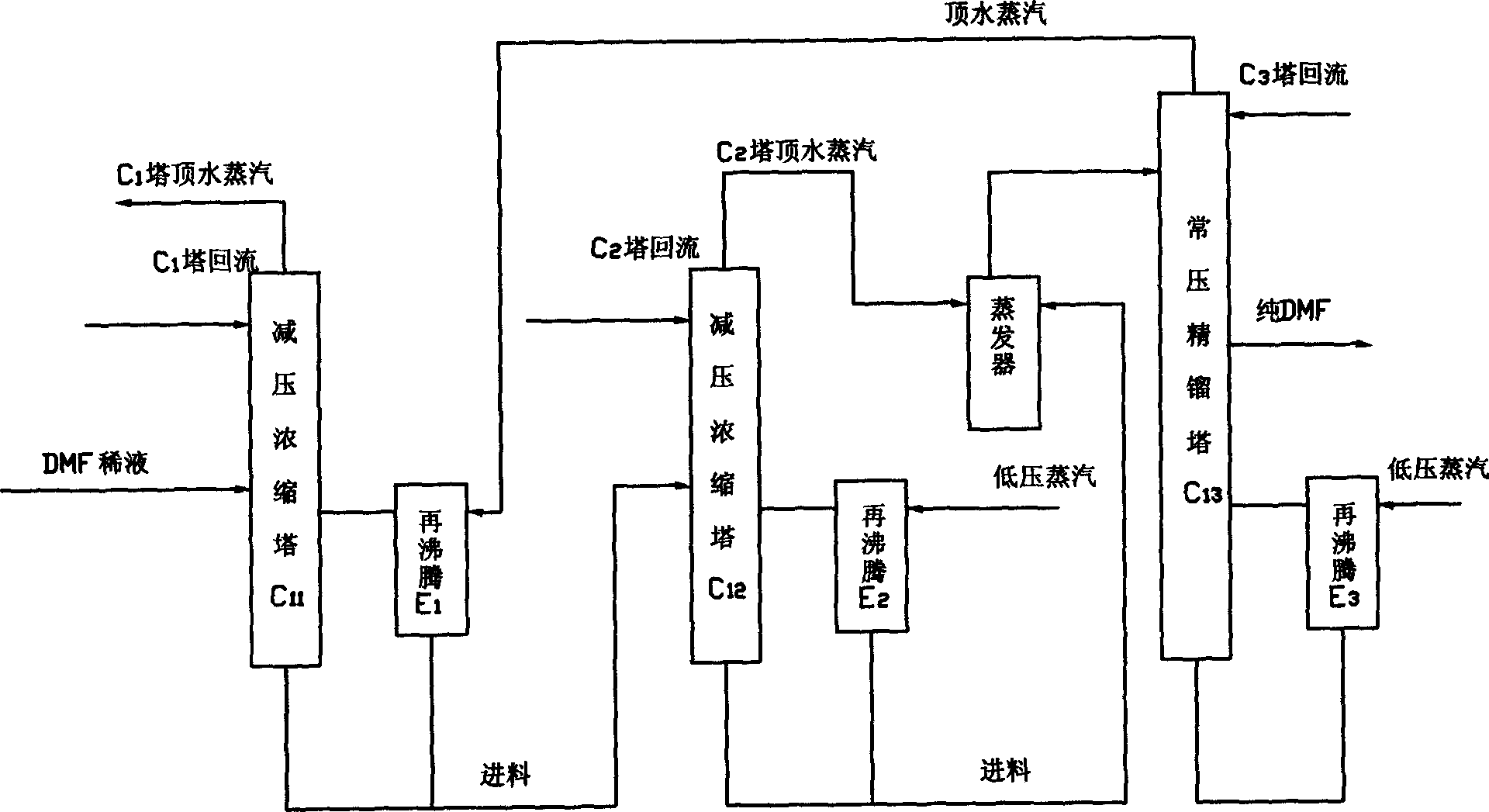

[0014] figure 2 As shown, the process flow of the present invention also includes: feeding, preheating, concentration and separation through the secondary concentration tower and the primary rectification tower, discharging and forming the entire recovery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com