Patents

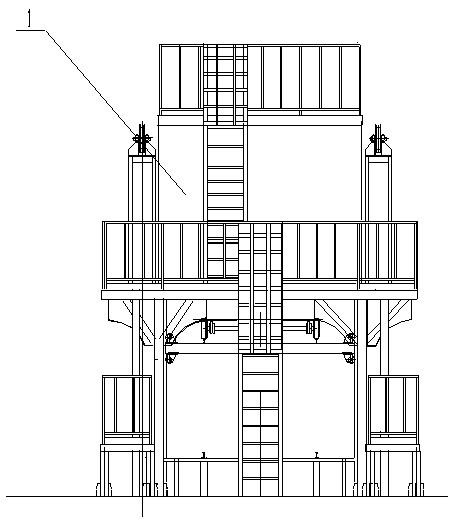

Literature

1820 results about "Cold blast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold blast, in ironmaking, refers to a furnace where air is not preheated before being blown into the furnace. This represents the earliest stage in the development of ironmaking. Until the 1820s, the use of cold air was thought to be preferable to hot air for the production of high-quality iron; this effect was due to the reduced moisture in cool winter air.

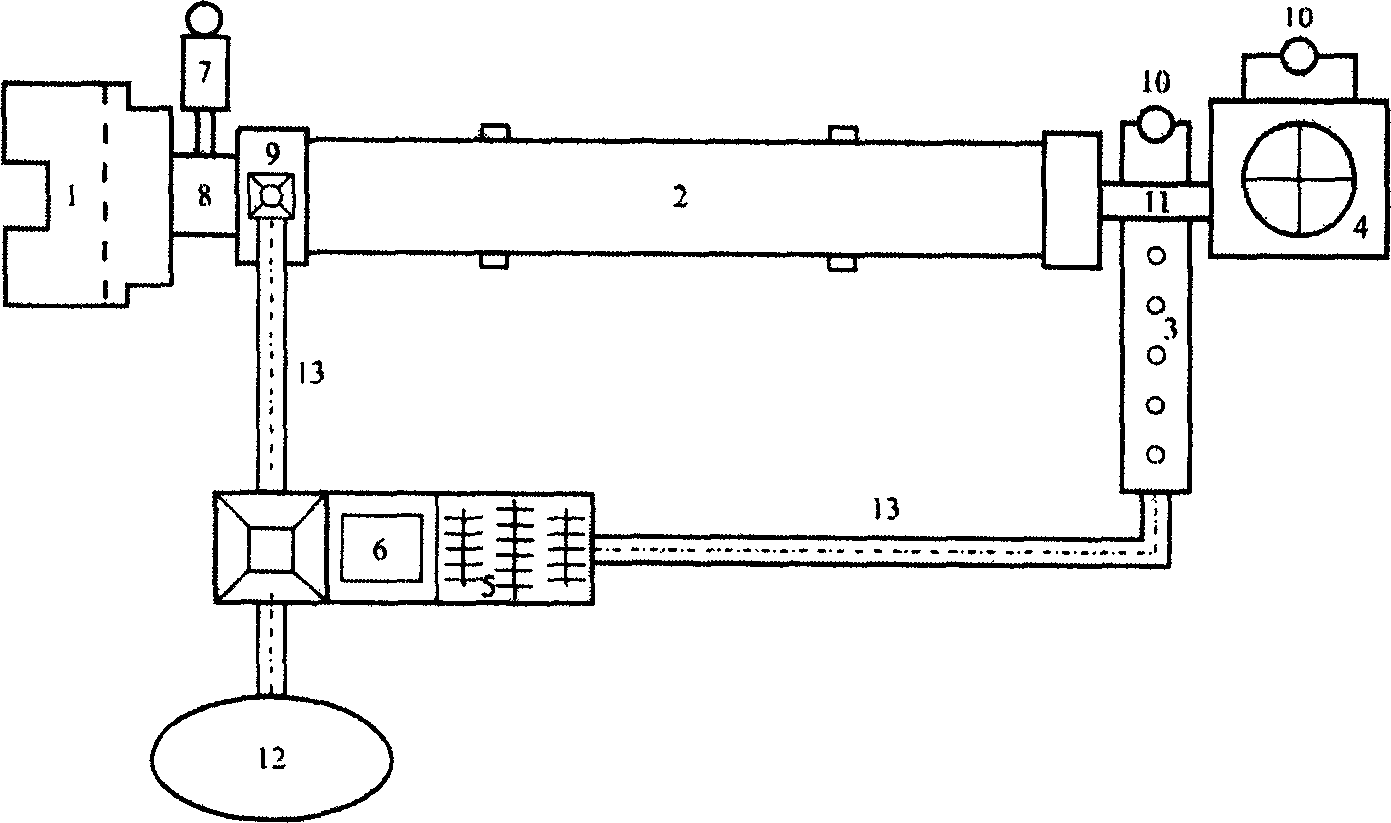

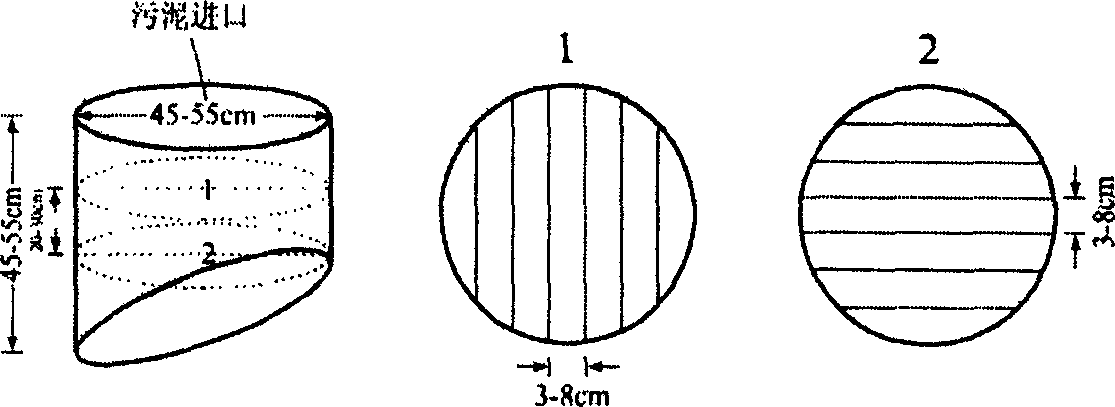

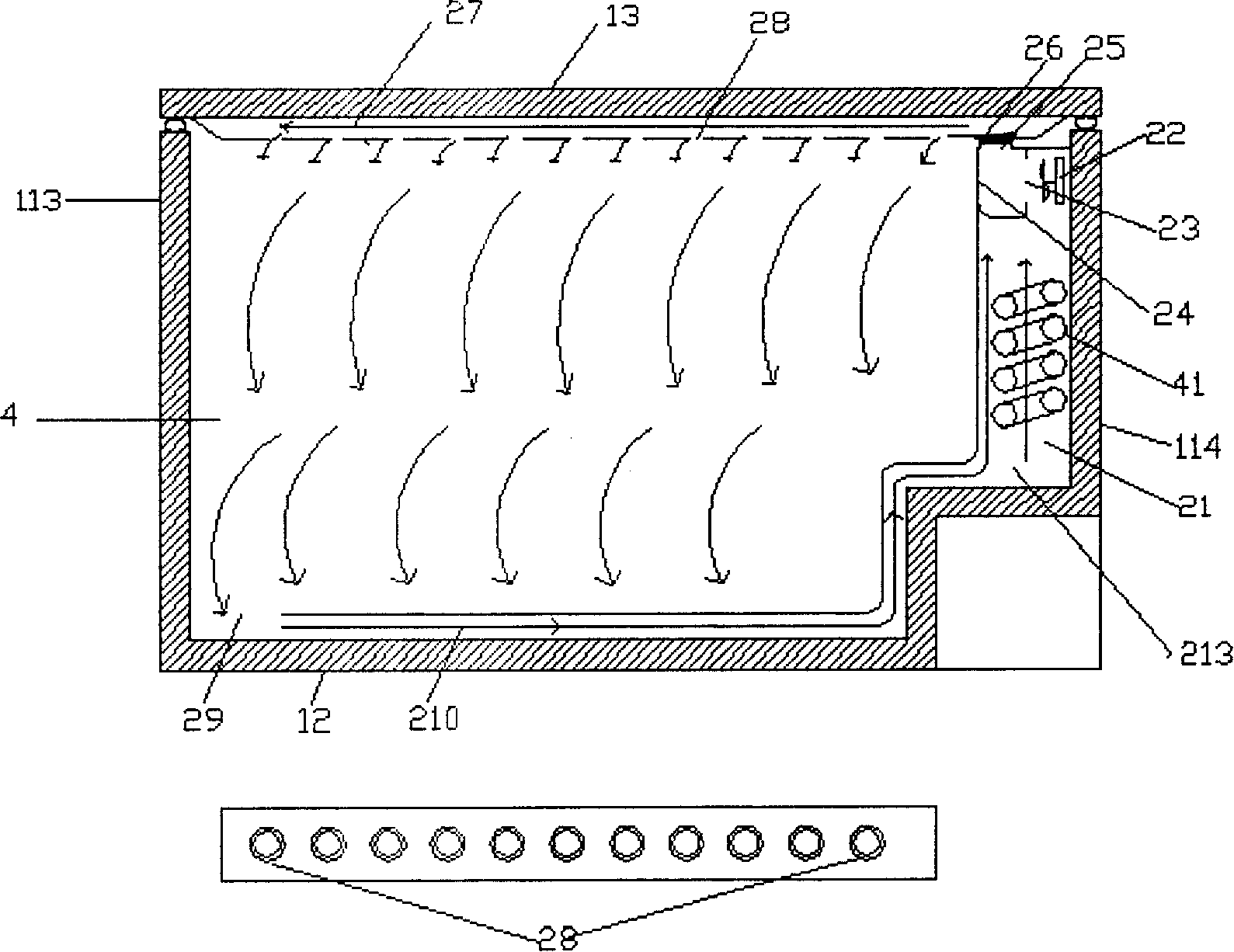

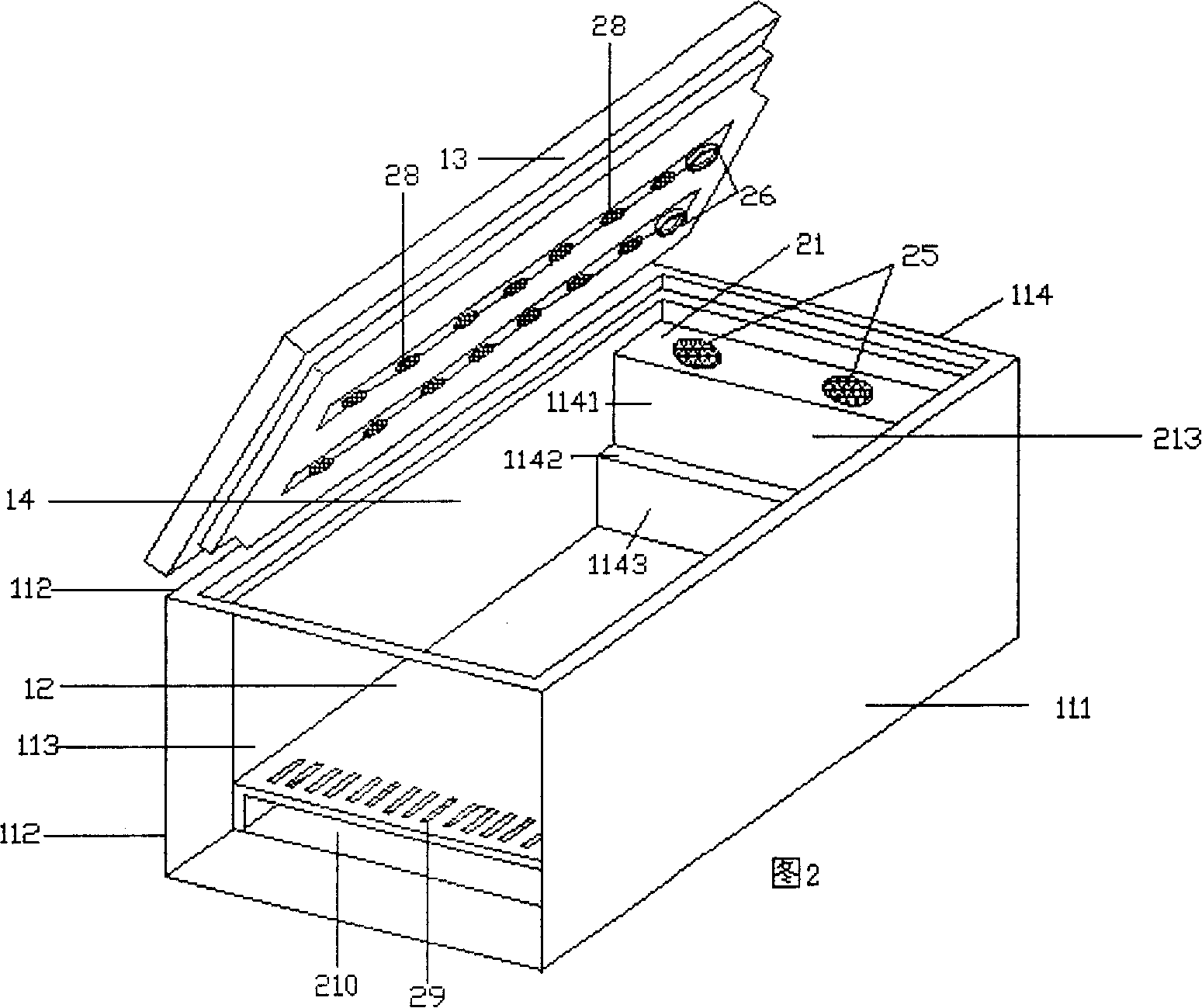

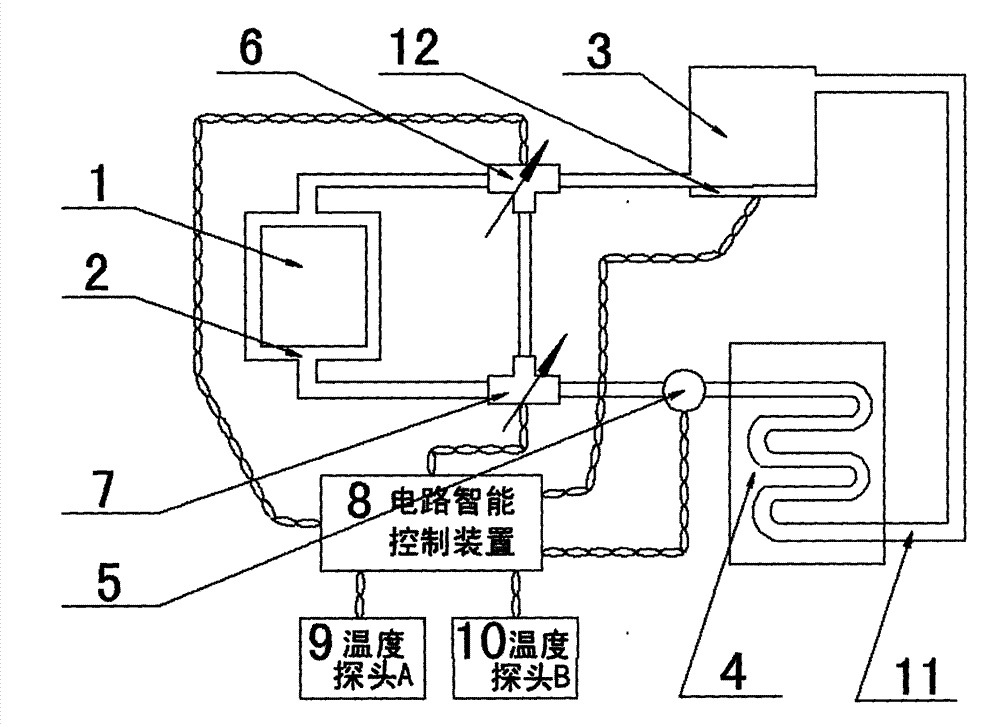

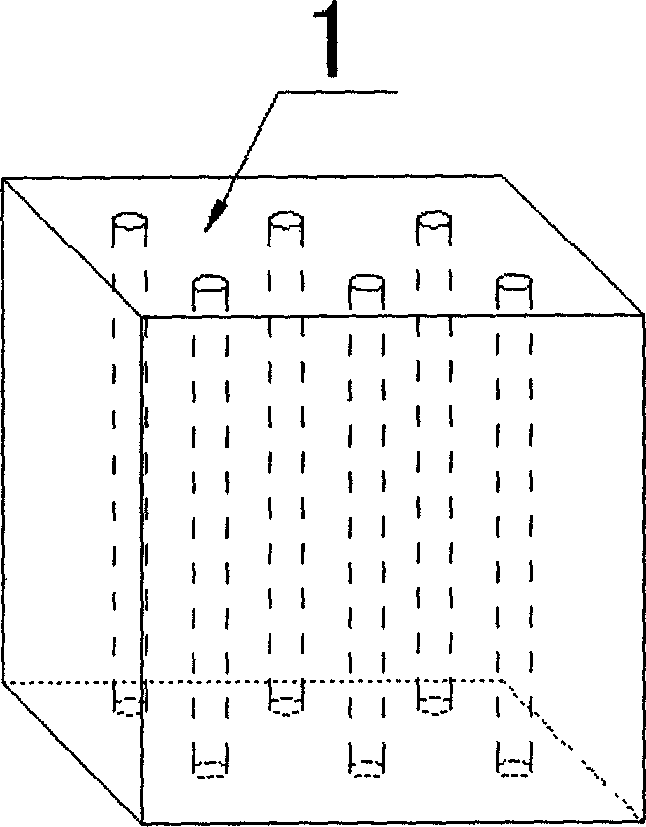

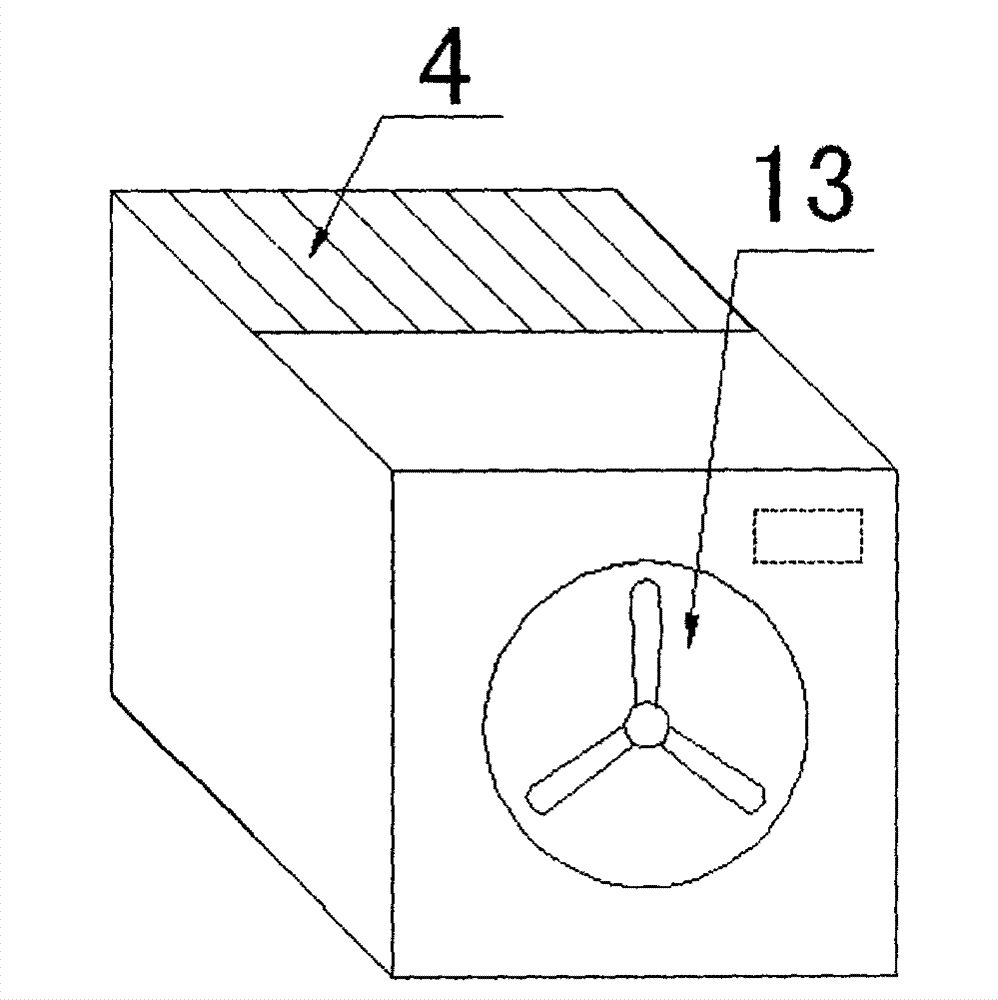

Reflux type temperature controllable sludge drying device and method

InactiveCN1587127AEfficient dryingSludge treatment by de-watering/drying/thickeningTemperature controlReflux

The present invention discloses one kind reflux type temperature controllable sludge drying apparatus and method. Drying sludge in 5-20 % is mixed with wet sludge and through the sludge inlet with two, one transverse and one longitudinal, layers of cutting steel wires, sludge is cut into small blocks before entering into the rotary kiln. Inside the rotary kiln, sludge is thrown and crushed by the throwing plate and chain for fast heating to dry in the temperature controlled with the jetting blower. Hot sludge from the rotary kiln is blown with the cold wind blower to further dry. The dried sludge is crushed and sieved, sludge with size below 4 mm is pelletized for comprehensive utilization and large sized sludge is refluxed. The present invention can reach ideal drying effect while maintaining over 95 % of its organic matter components.

Owner:ZHEJIANG UNIV

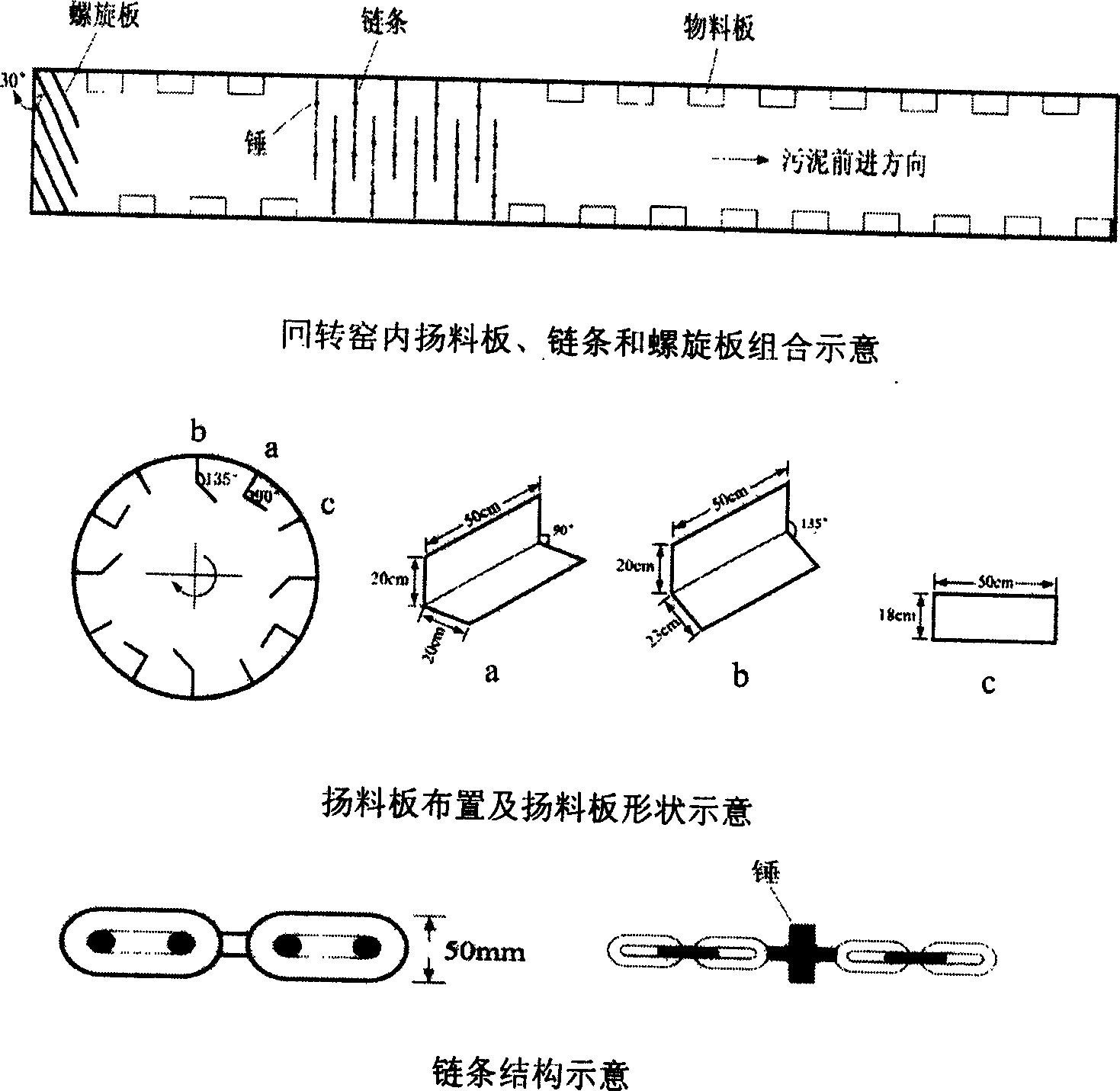

Control method for improving outlet air temperature comfort of air conditioner

ActiveCN101592389AImprove comfortIncrease heating capacitySpace heating and ventilation safety systemsLighting and heating apparatusCold airEngineering

The invention discloses a control method for improving outlet air temperature comfort of an air conditioner. A cold air preventing temperature value is not a fixed parameter value but a function of environmental temperature, namely the cold air preventing temperature value TE is the function of the environmental temperature T1. By setting a maximum limit value and a minimum limit value of the cold air preventing temperature value, and in the range of the maximum limit value and the minimum limit value, when the environmental temperature rises, the cold air preventing temperature value rises synchronously; and when the environmental temperature declines, the cold air preventing temperature value declines synchronously; therefore, the control method can effectively improve the low-temperature heating amount. Under the control of the method, the heating amount at low temperature can be improved, and the blown air which is not over-cold can be ensured.

Owner:MIDEA GRP CO LTD

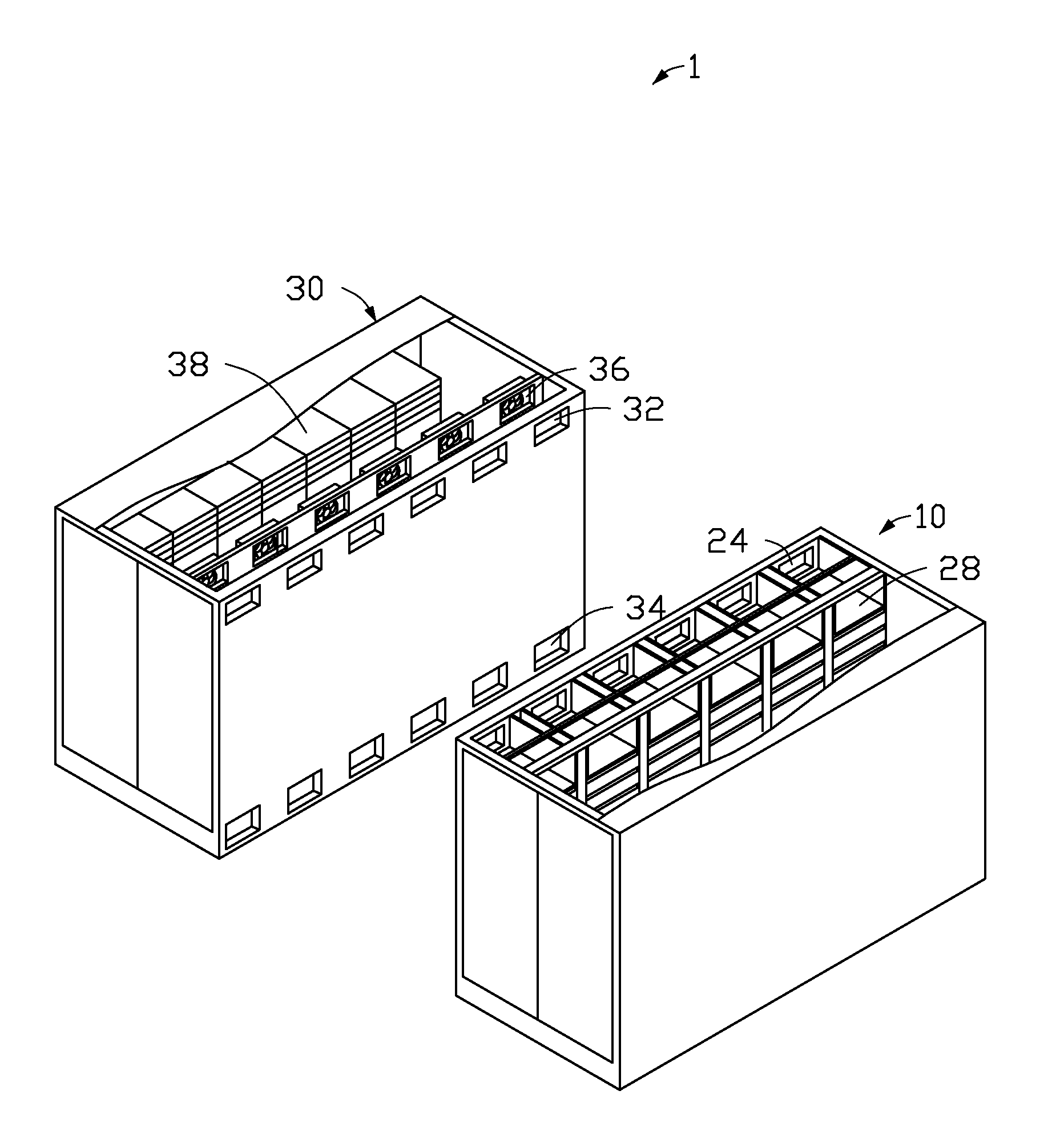

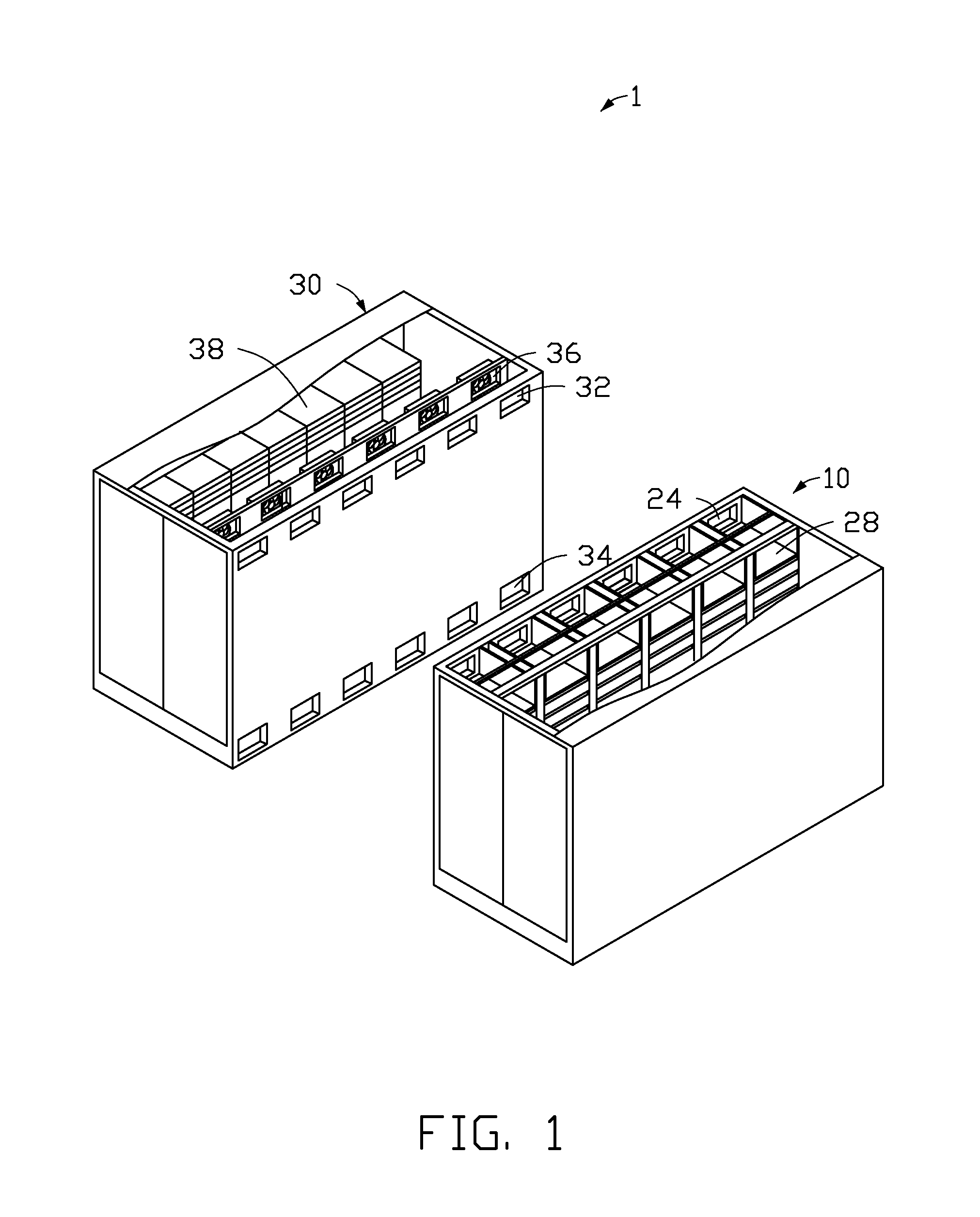

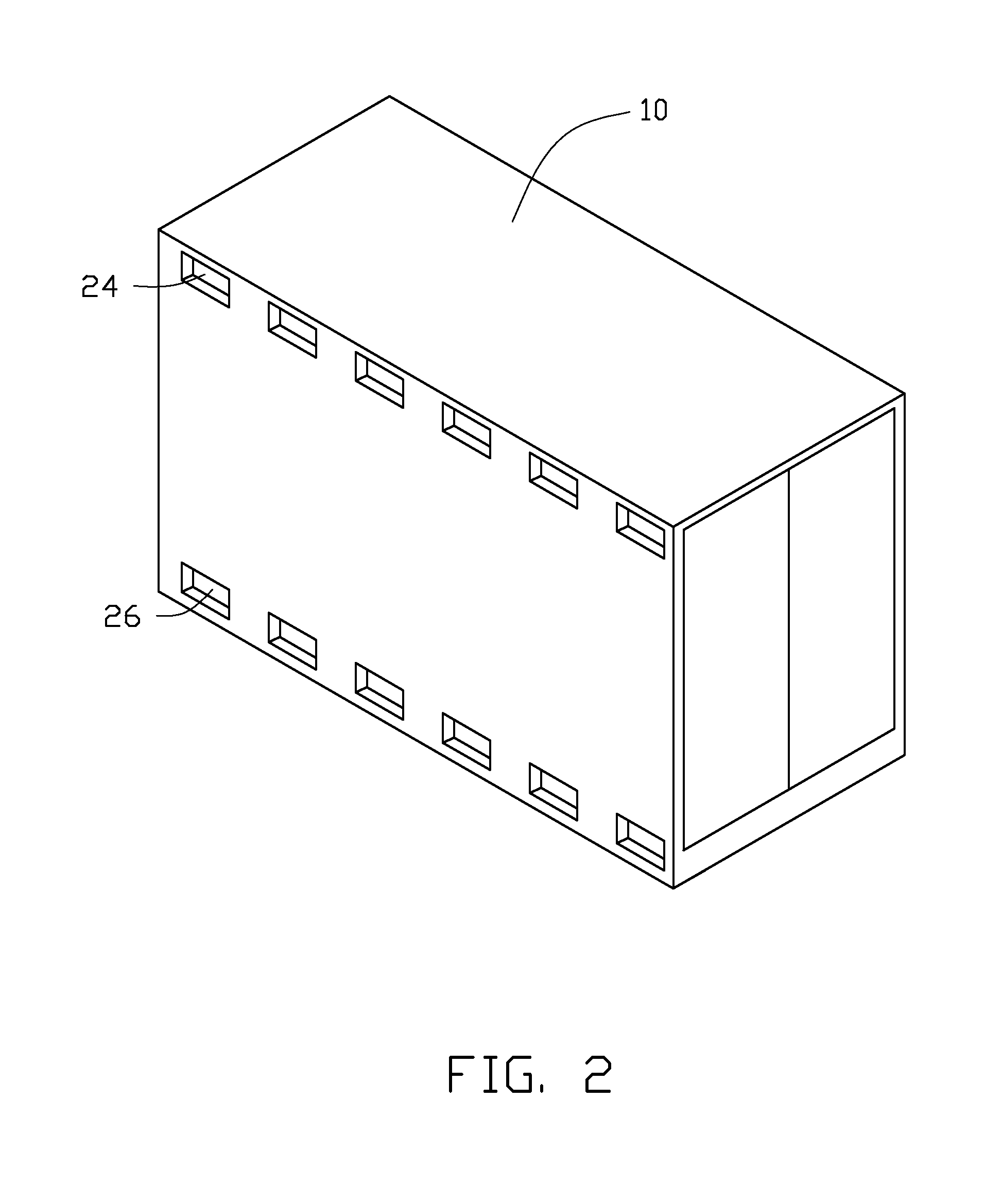

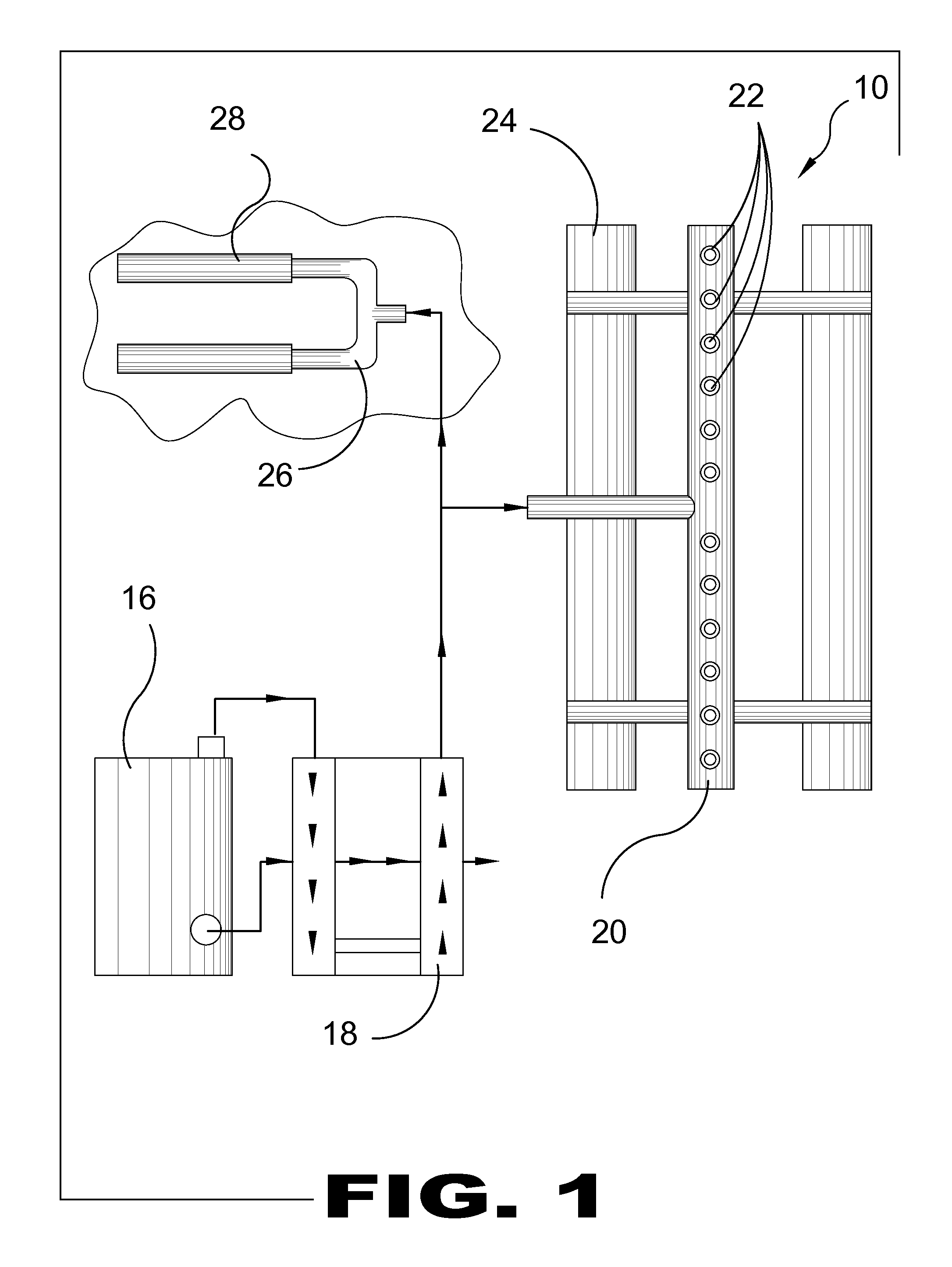

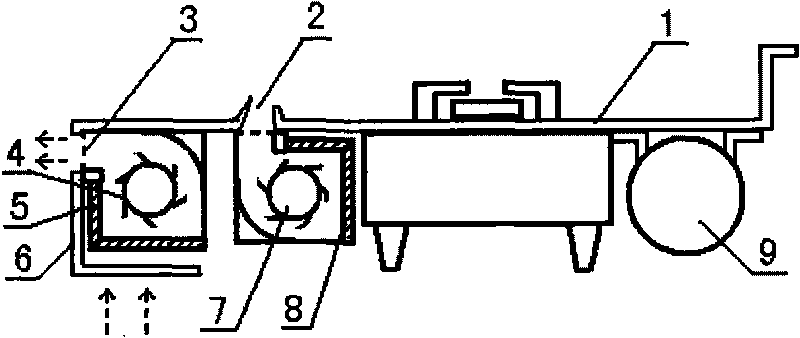

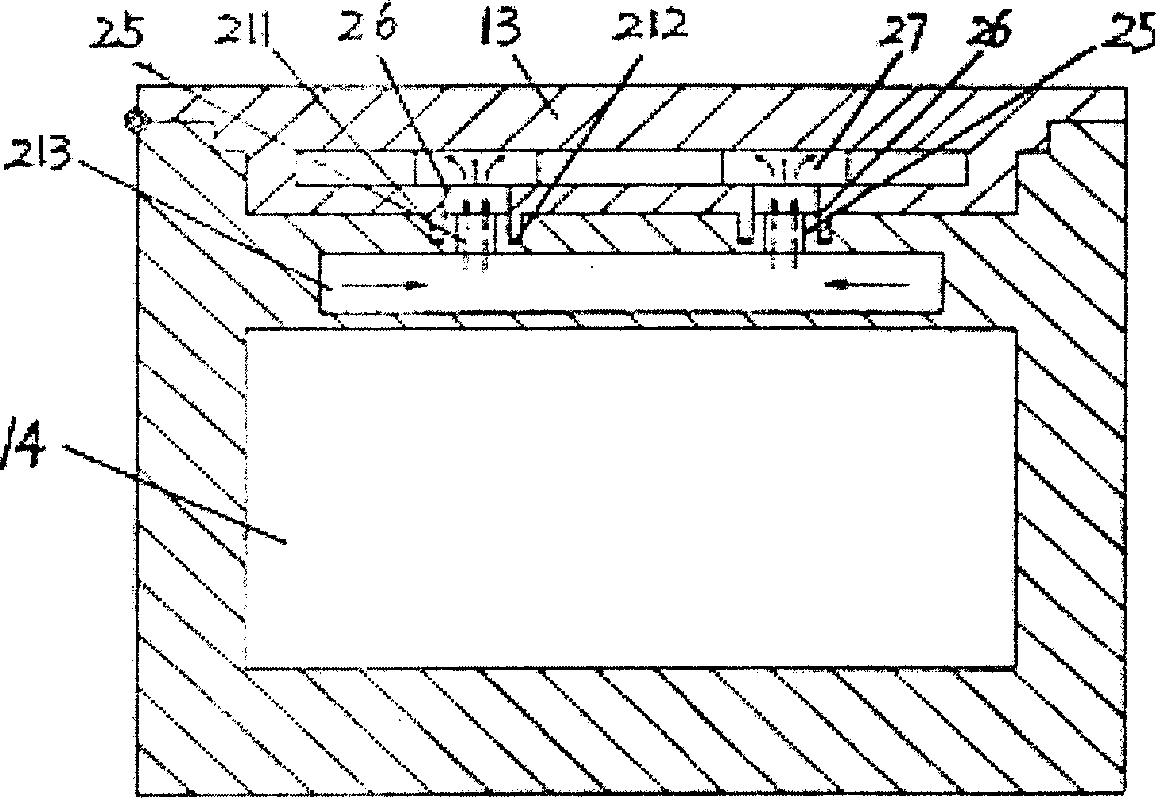

Container data center

A container data center includes a first container installed with a plurality of servers, and at least one cold air inlet and at least one hot air outlet are defined on the first container. The container data center further includes a second container installed with a cooling system, and at least one hot air inlet and at least one cold air outlet are defined on the second container. Cold air flows from the second container to the first container through the cold air outlet and the cold air inlet, and hot air flows from the first container to the second container through the hot air outlet and the hot air inlet. The cold air is generated from the cooling system and becomes the hot air after flowing through the servers and removing heat generated from the servers. The cooling system removes heat of the hot air and generates the cold air.

Owner:HON HAI PRECISION IND CO LTD

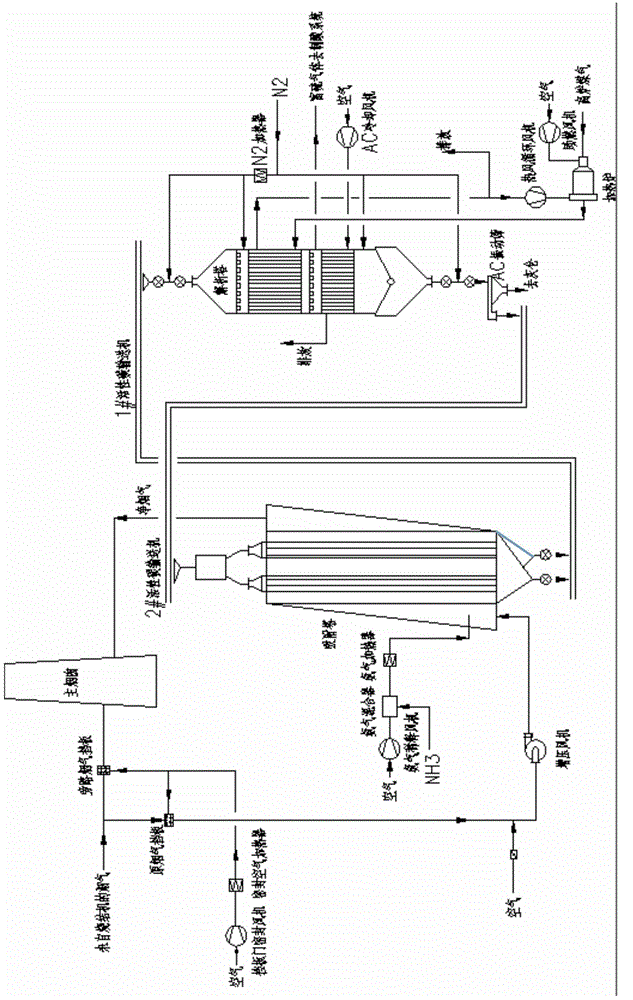

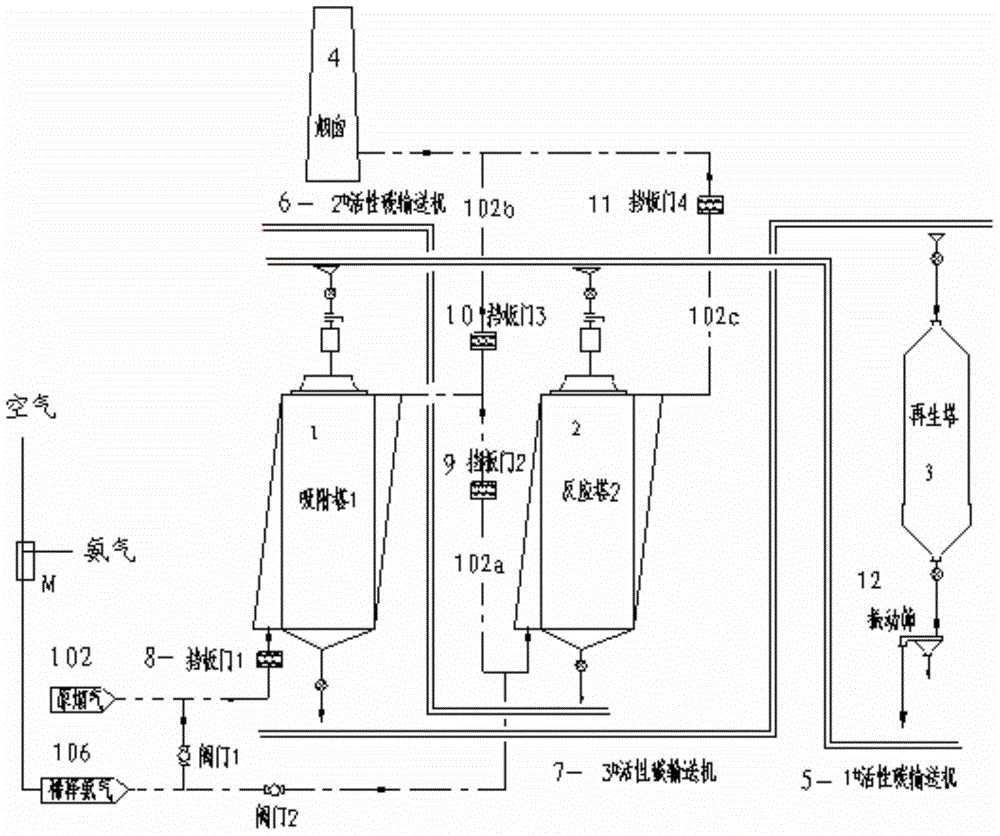

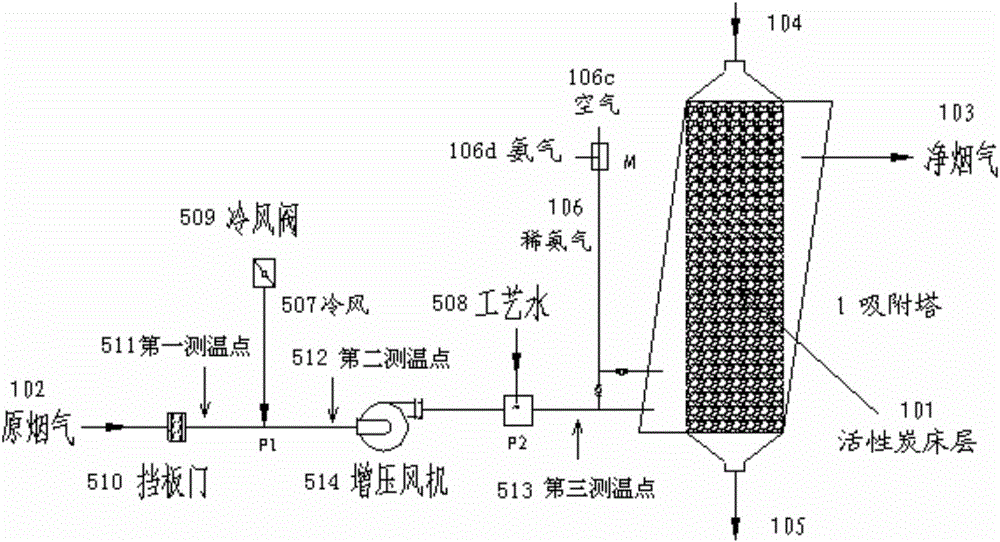

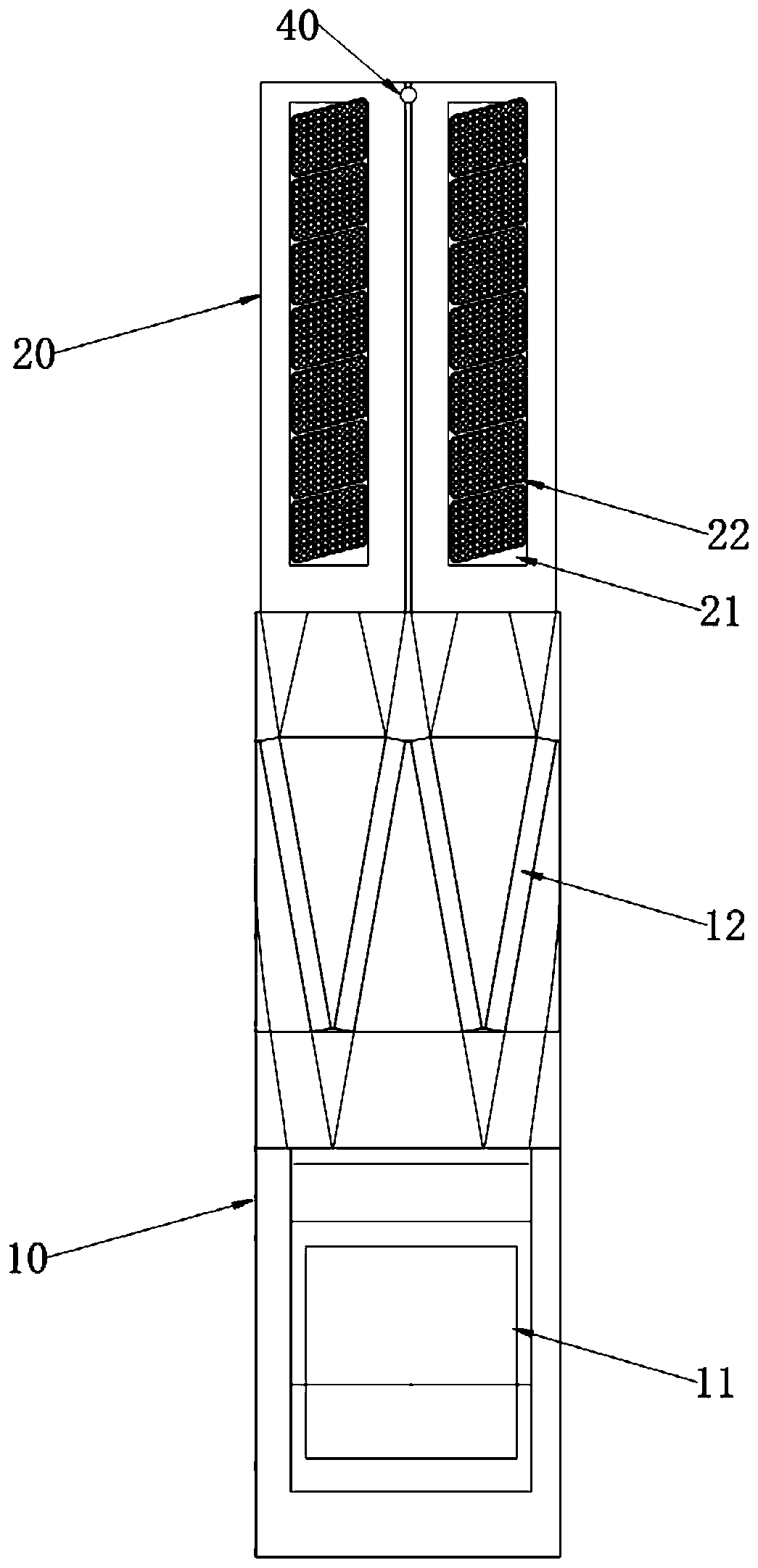

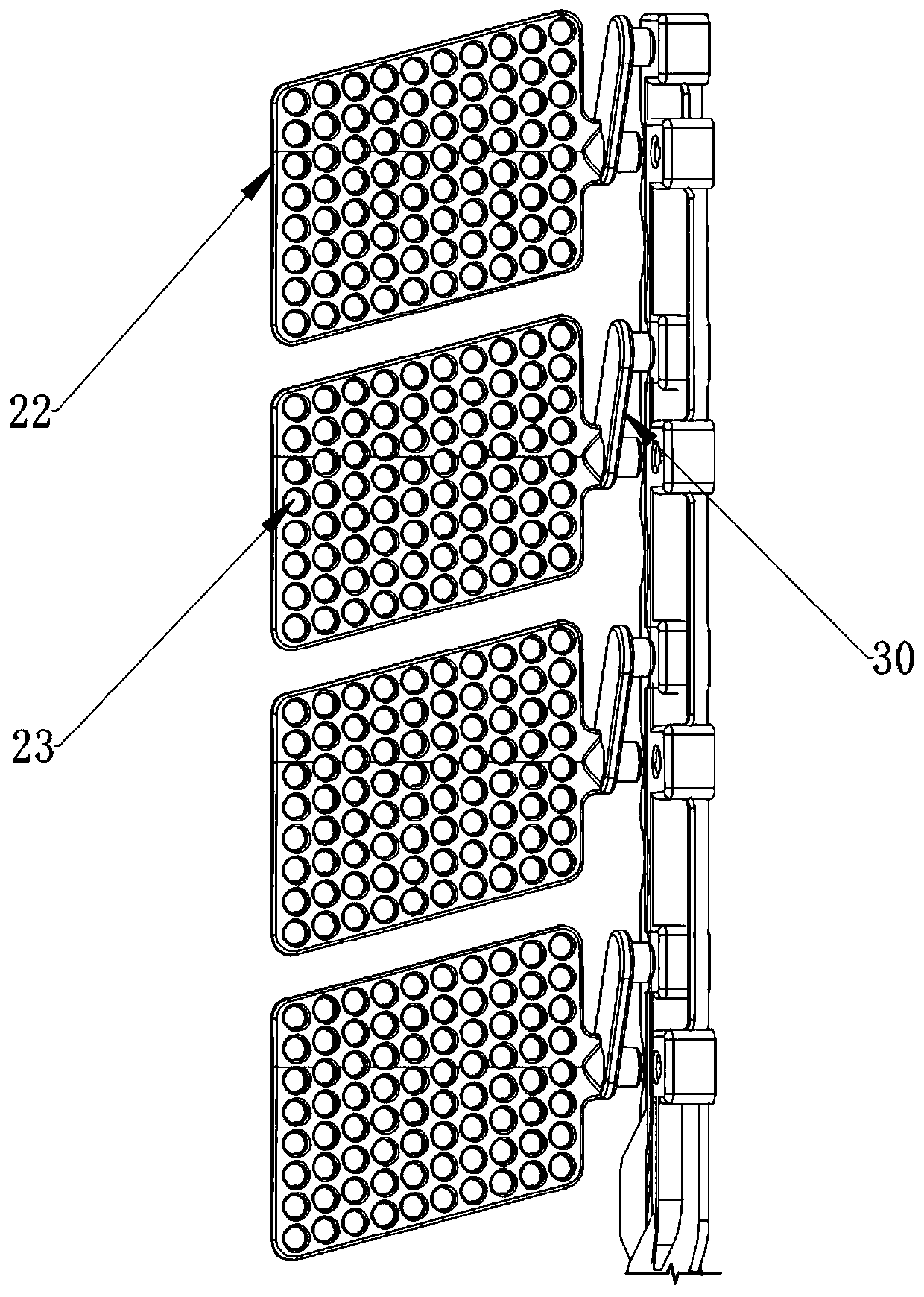

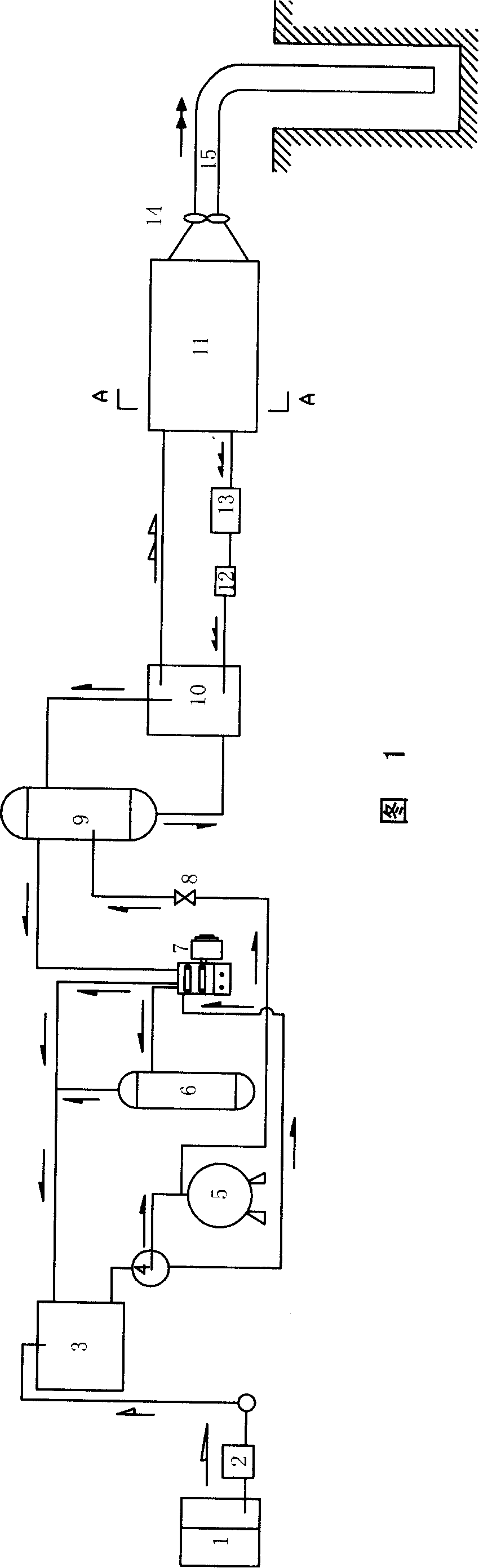

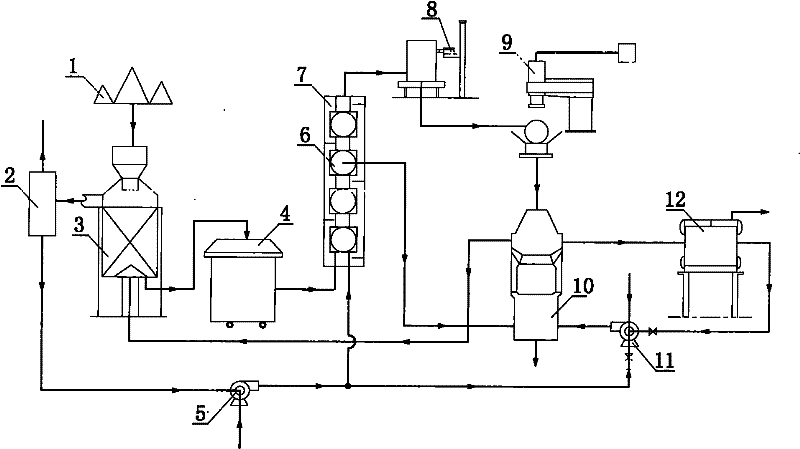

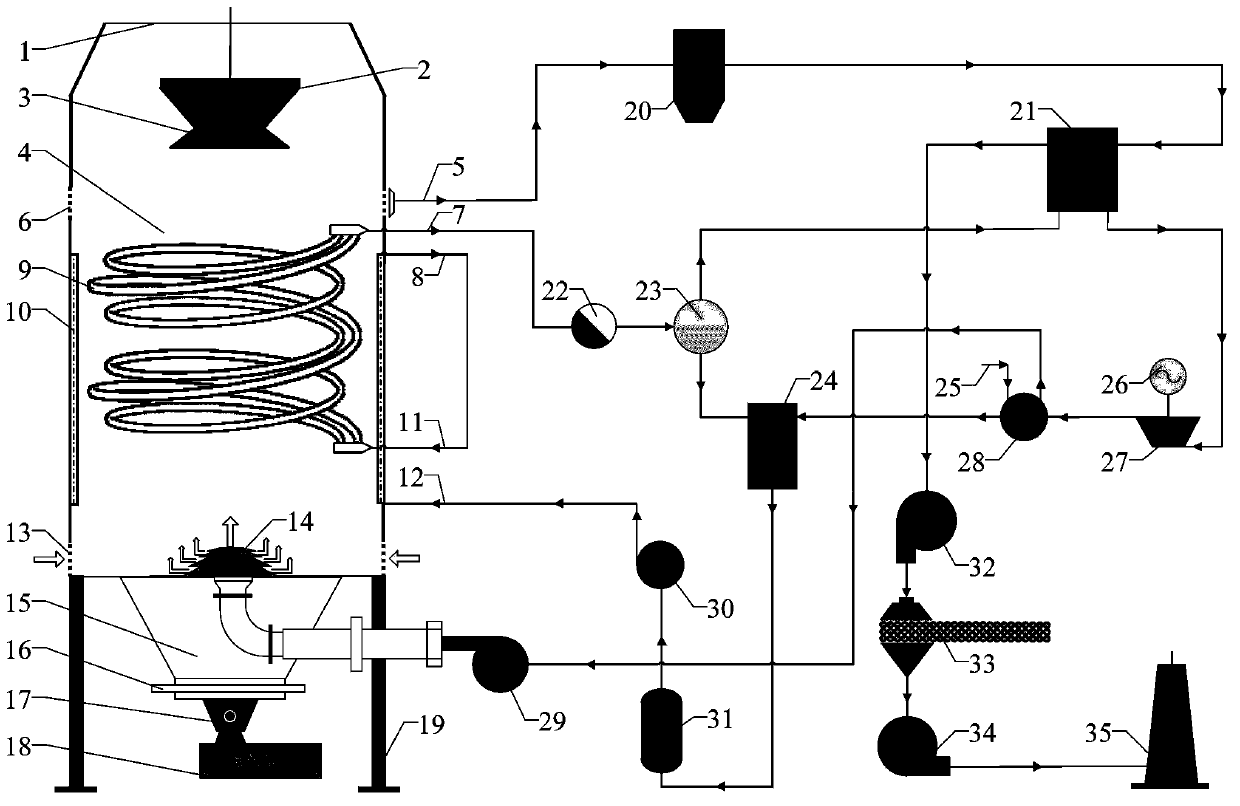

A flue gas desulphurization denitration method adopting two adsorption columns in series connection and a device therefor

ActiveCN105688622AIncrease flexibilityImprove denitrification rateDispersed particle separationSpray coolingEnvironmental geology

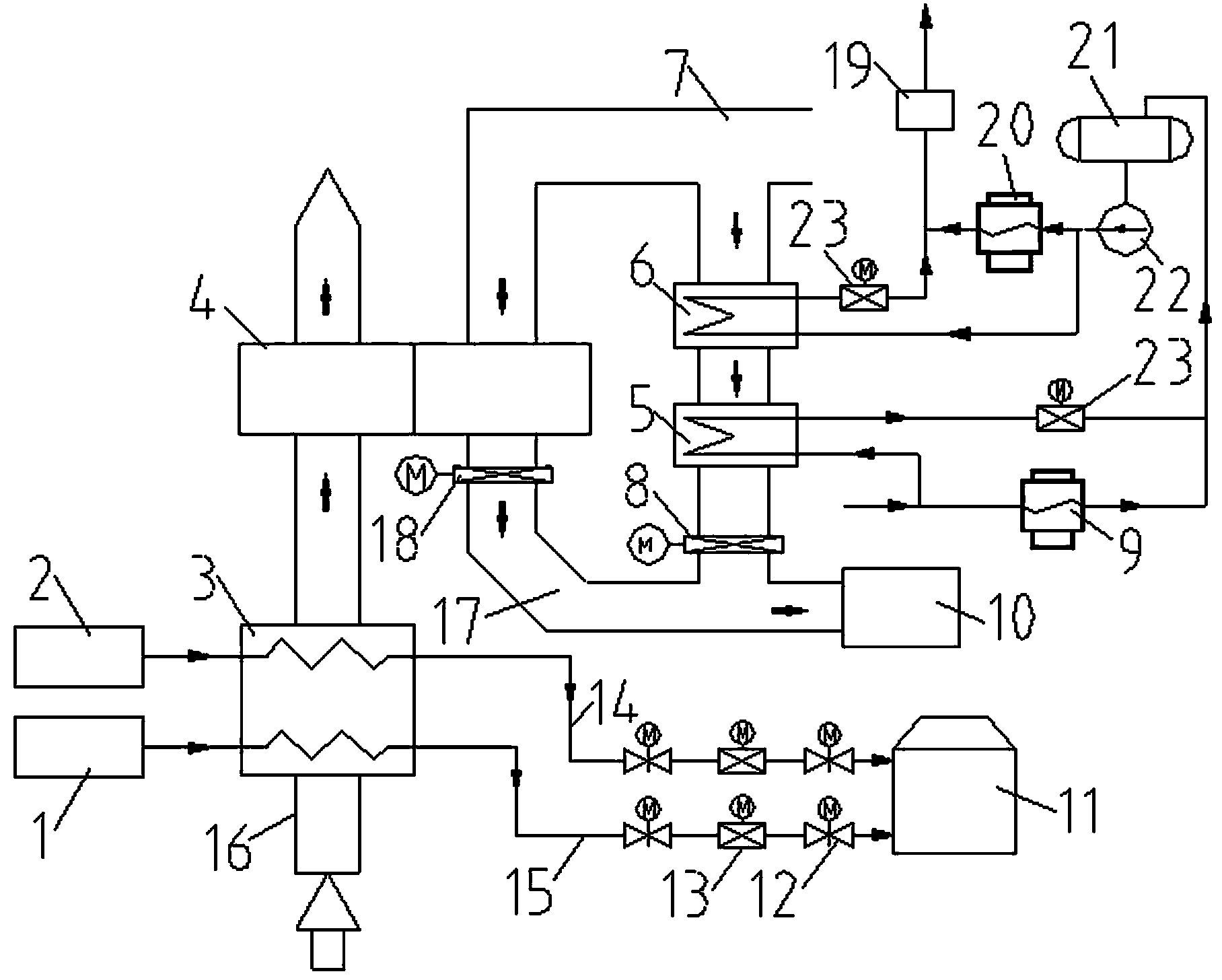

A flue gas desulphurization denitration method adopting two activated-carbon adsorption columns (1, 2) in series connection and comprising a flue gas temperature control apparatus and a device therefor are provided. The method includes I) a step of flue gas temperature control and II) a step of desulphurization and denitration, wherein the step of flue gas temperature control comprises (1) a step of subjecting flue gas to first time of cooling by feeding cold air into a flue conveying high-temperature flue gas to activated-carbon adsorption columns from a cold-air inlet at an upstream position (P1) of the flue, (2) spraying cooling water or cold water mist into the flue gas in the flue from a process water spray nozzle at the downstream position (P2) of the position (P1) from which the cold air is fed, and allowing the flue gas to flow along the flue to the adsorption columns, and (3) feeding diluted ammonia gas into the flue gas in the adsorption columns after the flue gas is fed into gas feeding chambers of the adsorption columns. The temperature of the flue gas fed into the adsorption columns is controlled by mixing with the cold air and spraying water. The two activated-carbon adsorption columns (1, 2) in series connection are adopted to significantly increase the denitration efficiency of the device.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Air conditioner, air-blowing control method and device, and computer readable storage medium

InactiveCN109708201AAvoid blowingImprove organizationMechanical apparatusSpace heating and ventilation safety systemsCold blastControl theory

The invention discloses an air conditioner, an air-blowing control method and device, and a computer readable storage medium. The air conditioner comprises a shell, a draught fan in the shell, and anair outlet drum movably connected with the shell, wherein the cold-blast air in the air conditioner can be blown out of the air outlet drum; in addition, a driving mechanism connected with the air outlet drum, a controller connected with the driving mechanism and a detecting component are further arranged. After detecting a human body position, the detecting component transmits the detected humanbody information to the controller, and the controller controls the driving mechanism to drive the air outlet drum to rotate to a corresponding position. The rotatable air outlet drum can prevent thecold-blast air from continuously and directly blowing to the human body, controls the rotary speed of the draught fan to improve the air distribution indoors, and simulates the blowing-in mode of natural wind to improve the comfort level of a user.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

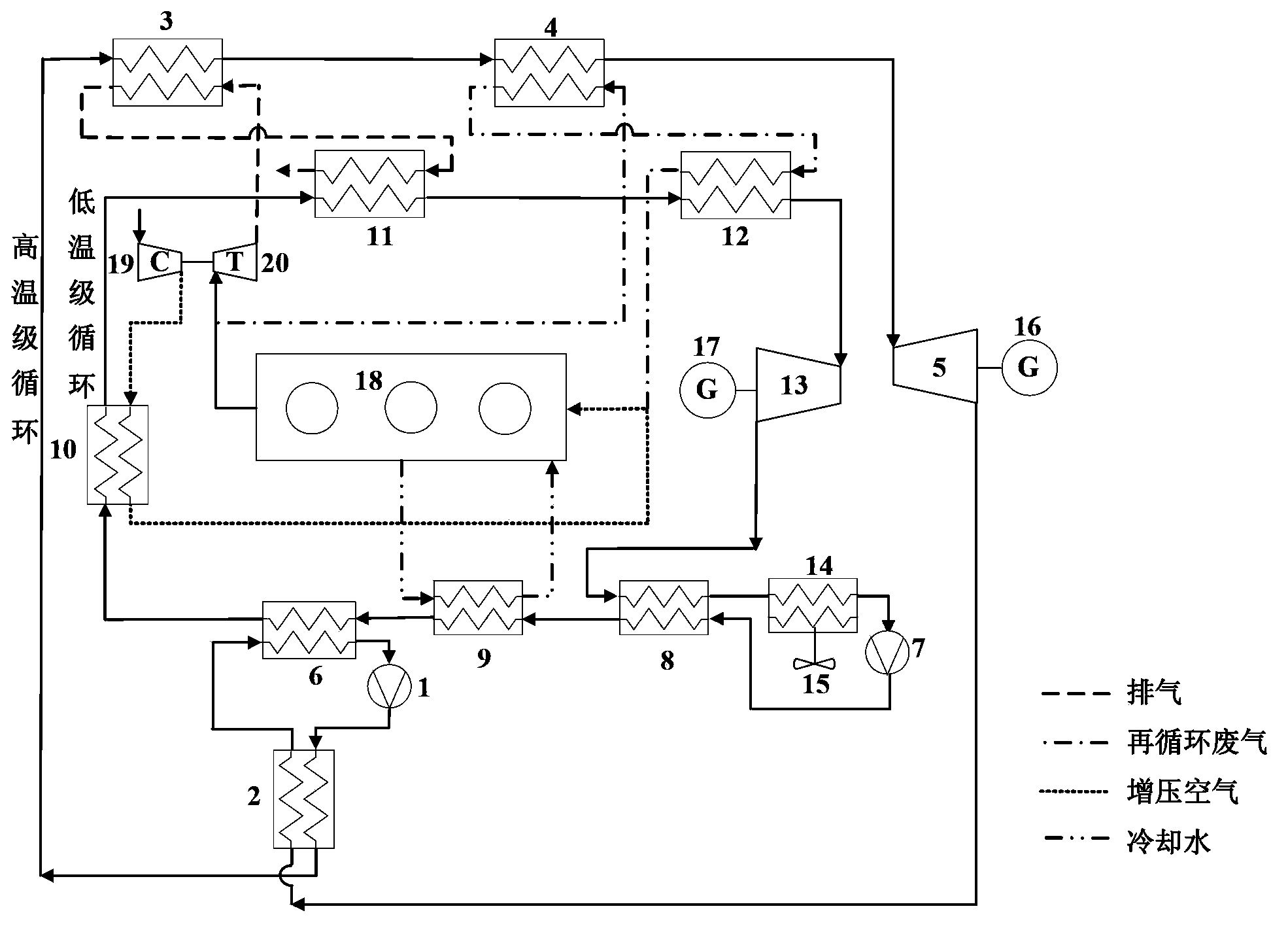

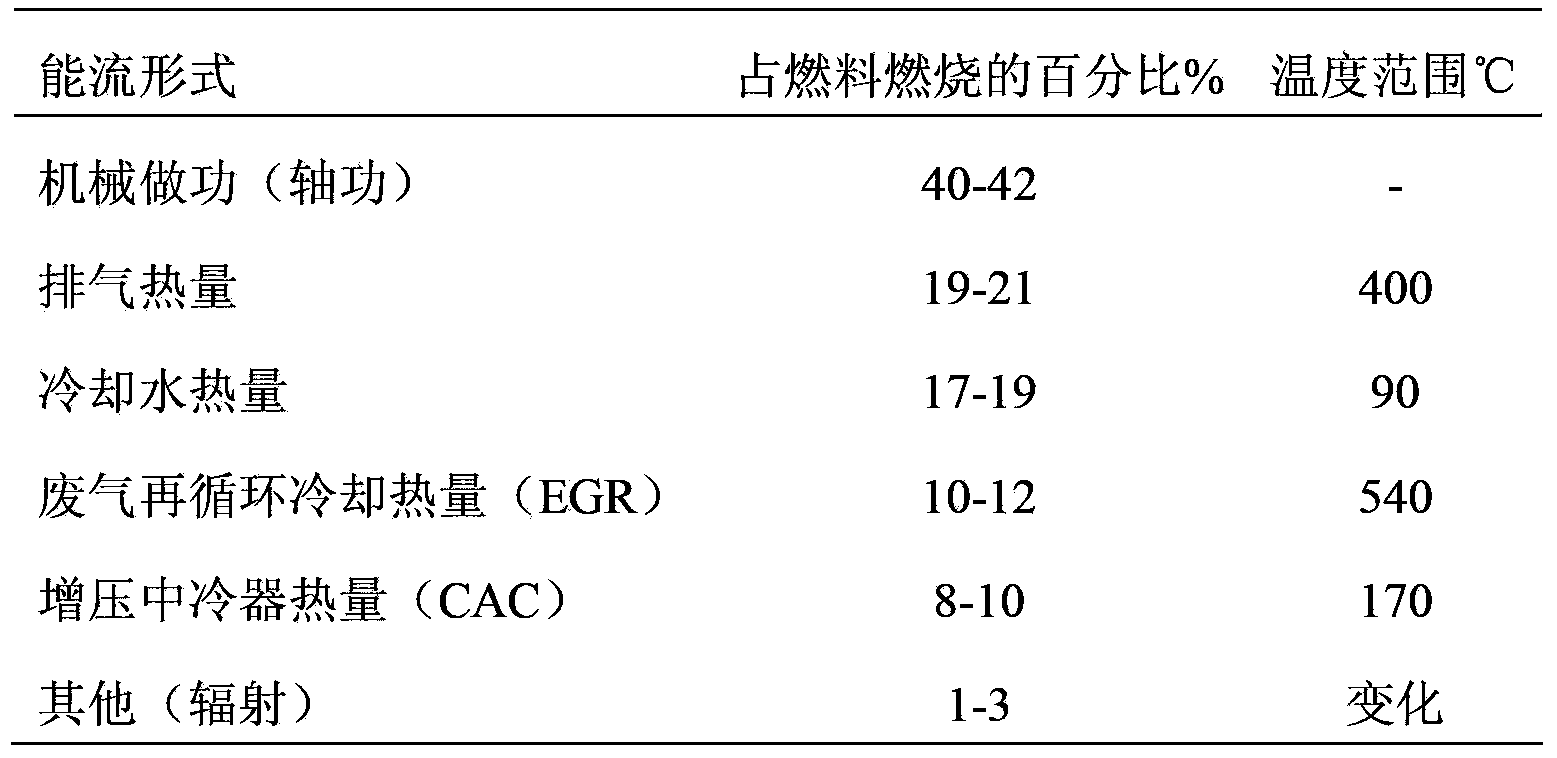

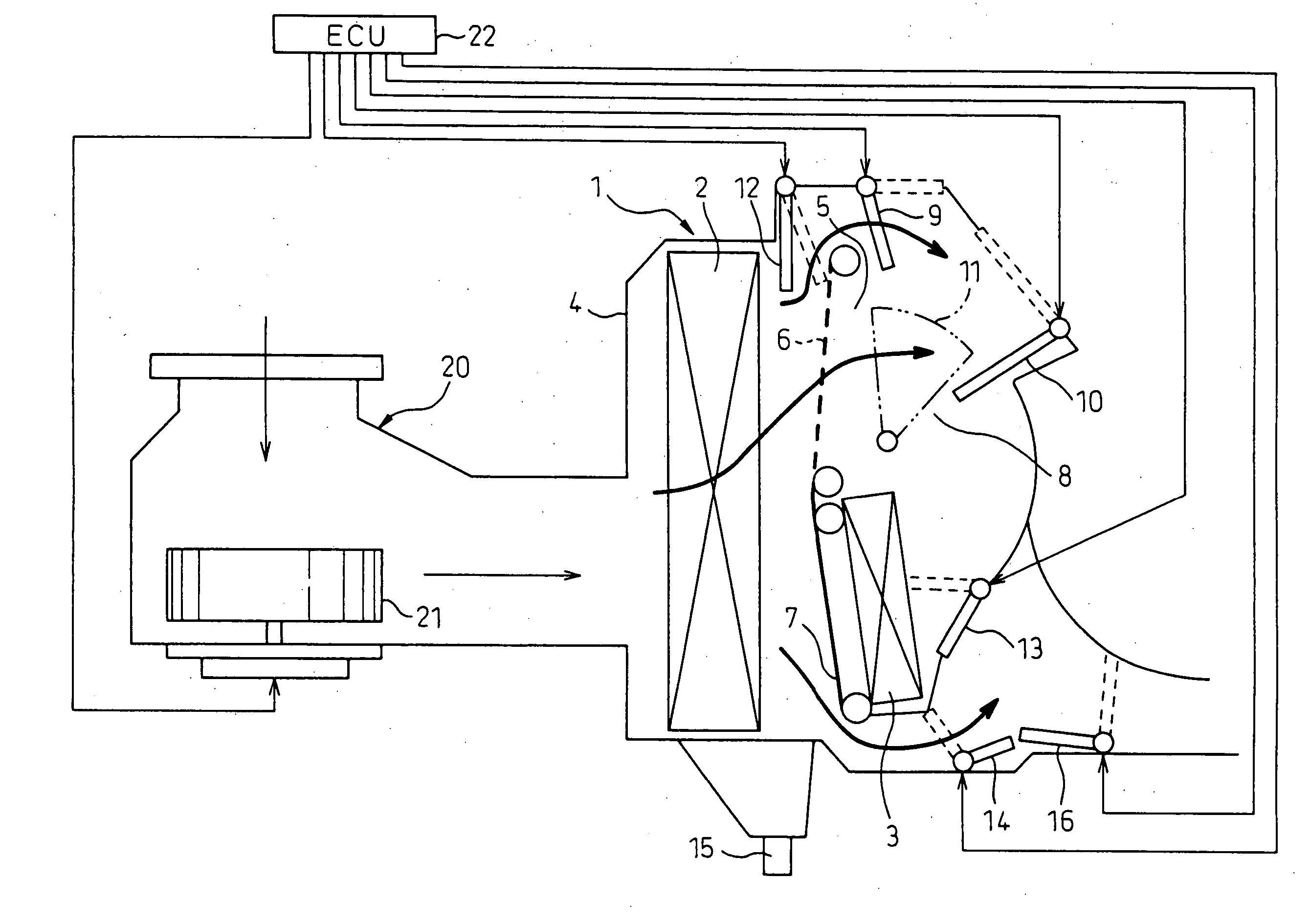

Combined cycle thermoelectric conversion system utilizing multi-grade waste heat of internal combustion engine

ActiveCN103352772ARealize comprehensive utilizationImprove fuel economyInternal combustion piston enginesEngine componentsOrganic Rankine cycleExhaust gas recirculation

The invention provides a combined cycle thermoelectric conversion system utilizing multi-grade waste heat of an internal combustion engine. According to the system, combined organic Rankine cycle is formed by high-temperature grade cycle and low-temperature grade cycle, heat is supplied by exhaust waste heat of the internal combustion engine, supercharged and mid-cooling waste heat, exhaust gas recirculation waste heat and cooling water waste heat, a cooling quantity is provided by cold wind, and the system comprises a high-temperature grade working medium pump, a high-temperature grade heat regenerator, a high-temperature grade exhaust heater, a high-temperature grade EGR (exhaust gas recirculation) heater, a high-temperature grade expansion engine, a high-temperature grade condenser, a low-temperature grade working medium pump, a low-temperature grade heat regenerator, a low-temperature grade cooling water heater, a low-temperature grade supercharged air heater, a low-temperature grade exhaust heater, a low-temperature grade EGR heater, a low-temperature grade expansion engine, a low-temperature grade condenser, a low-temperature grade condenser fan and a power generator. According to the combined cycle thermoelectric conversion system utilizing multi-grade waste heat of the internal combustion engine, comprehensive and efficient utilization of multi-grade waste heat of the internal combustion engine can be achieved, further, irreversible loss is smaller when both the high temperature and the low temperature adopt supercritical expanding cycle, and the integral efficiency of the internal combustion engine can be effectively improved.

Owner:TIANJIN UNIV

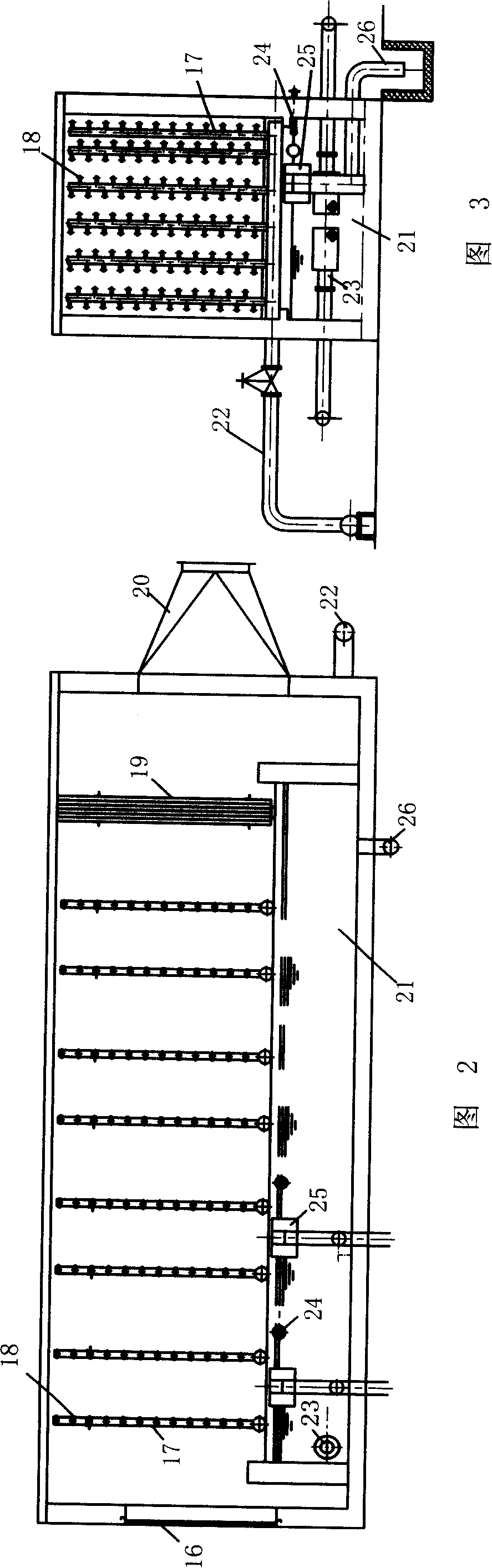

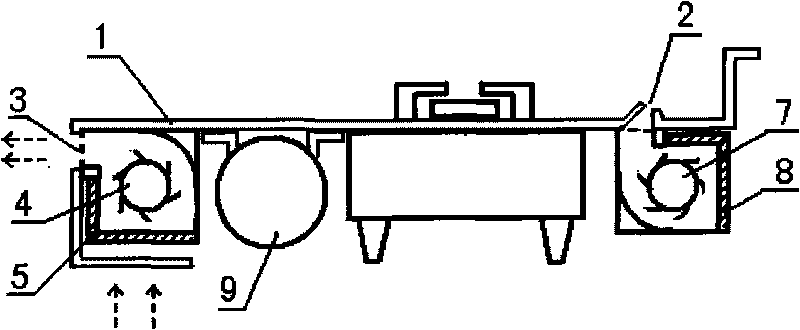

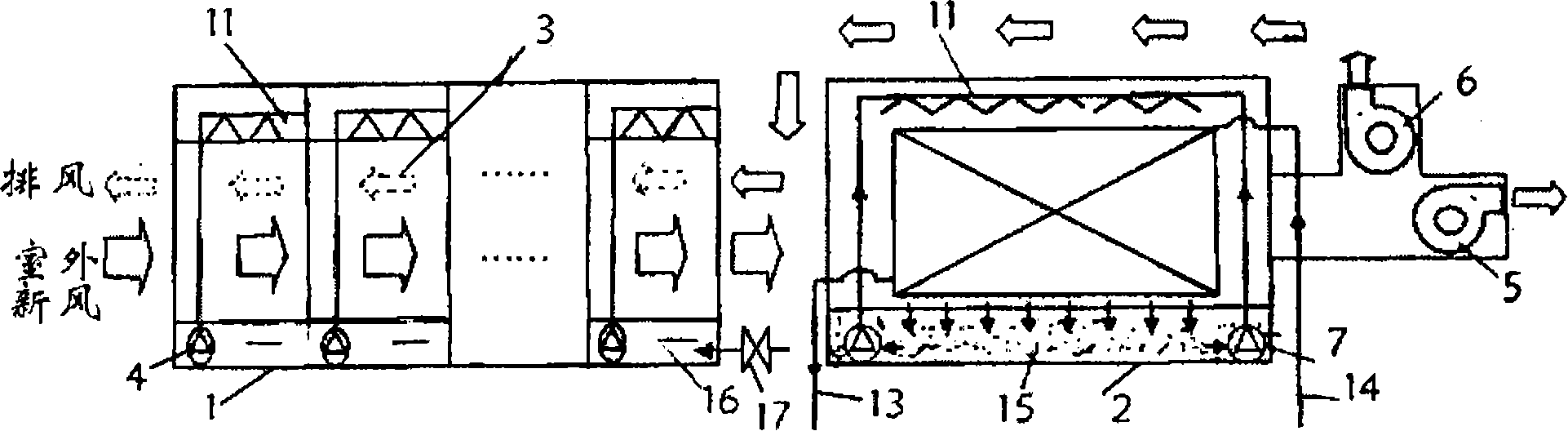

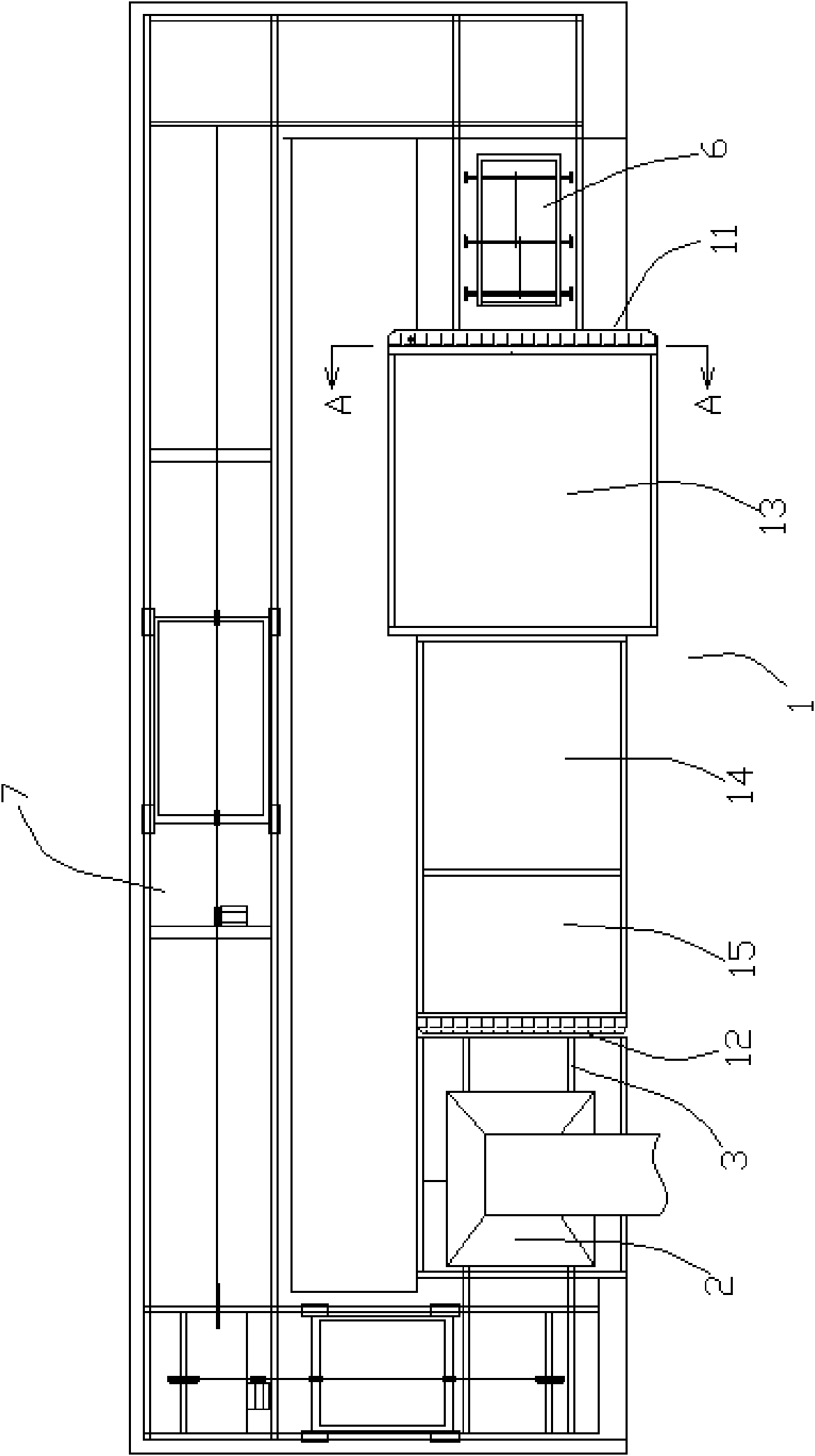

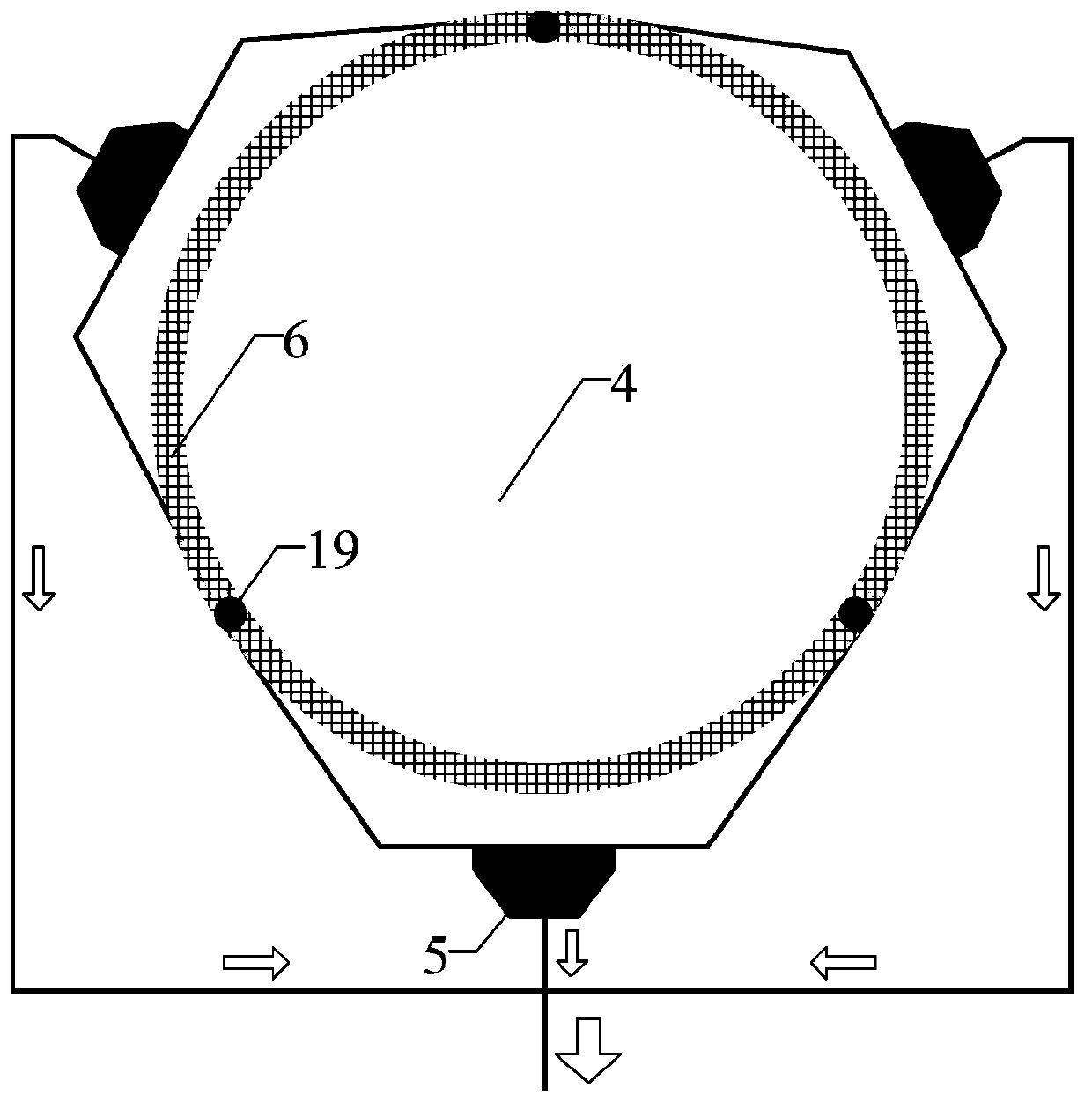

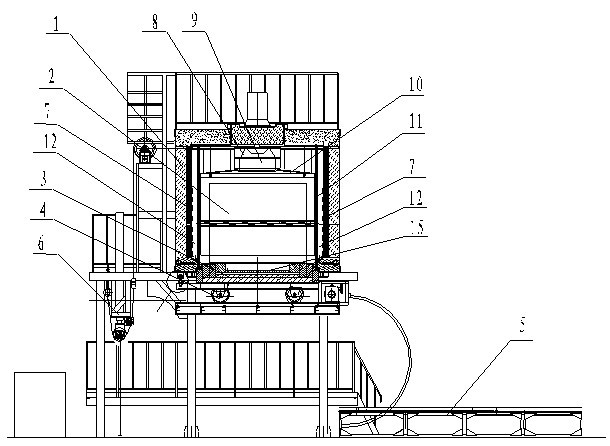

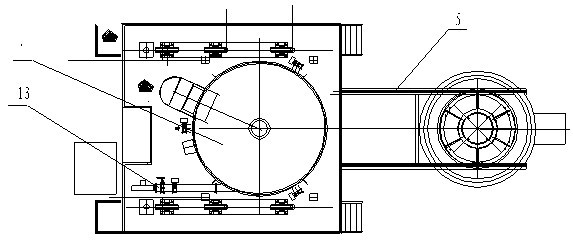

Mine working face cooling system

InactiveCN101169040AReduce the temperatureReduce the number of heat exchange processesDust removalFire preventionAir volumeEngineering

The invention provides a cooling system for the working face of the mine. The invention consists of a ground refrigerating unit, a cooling water recycling device, a cold wind preparing device and a cold wind conveying pipeline. The refrigerating unit and the cooling water recycling device comprise a compressor 7, a condenser 3, a throttle 8, a heat exchanger 10, a cooling water pond 1, and a fresh water pump 2. The cold wind preparing device is a wind spraying chamber 11, and uses the cold media water prepared by the refrigerating unit to spray the wind current, can comprises a wind-inlet grille 16, a wind outlet 20, a water squirting pipe 17, a nozzle 18, a breakwater 19, a wind chamber water falling pond 21, a general water inlet pipe 22, a general water outlet pipe 23 and the like. A plurality of rows of vertical water squirting pipes are arranged between the wind-inlet grille and the wind inlet, nozzles are arranged on the top of the water squirting pipes, and the general water inlet pipe introduces the cold media water of the refrigerating unit. The invention adopts the cold media water spray to process, and prepare the cold wind with the high wind volume, high temperature difference, high enthalpy difference; can reduce the times of the heat exchanging process, lower the heat transferring temperature difference, improve the whole efficiency, and reduce the cold volume waste of the middle course; thereby is applicable for cooling the high-temperature hot and harmful circumstance.

Owner:兖矿新陆建设发展有限公司

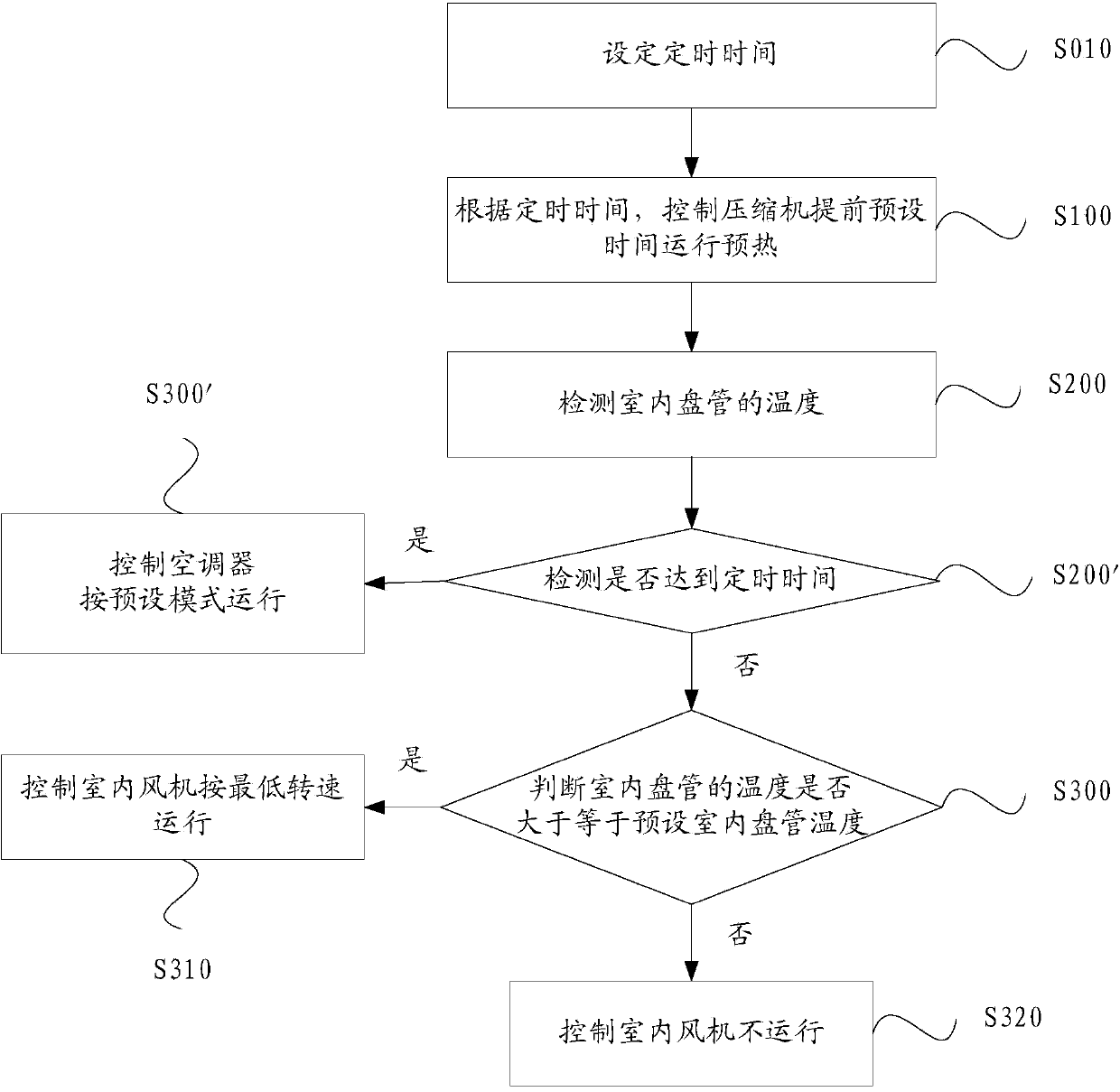

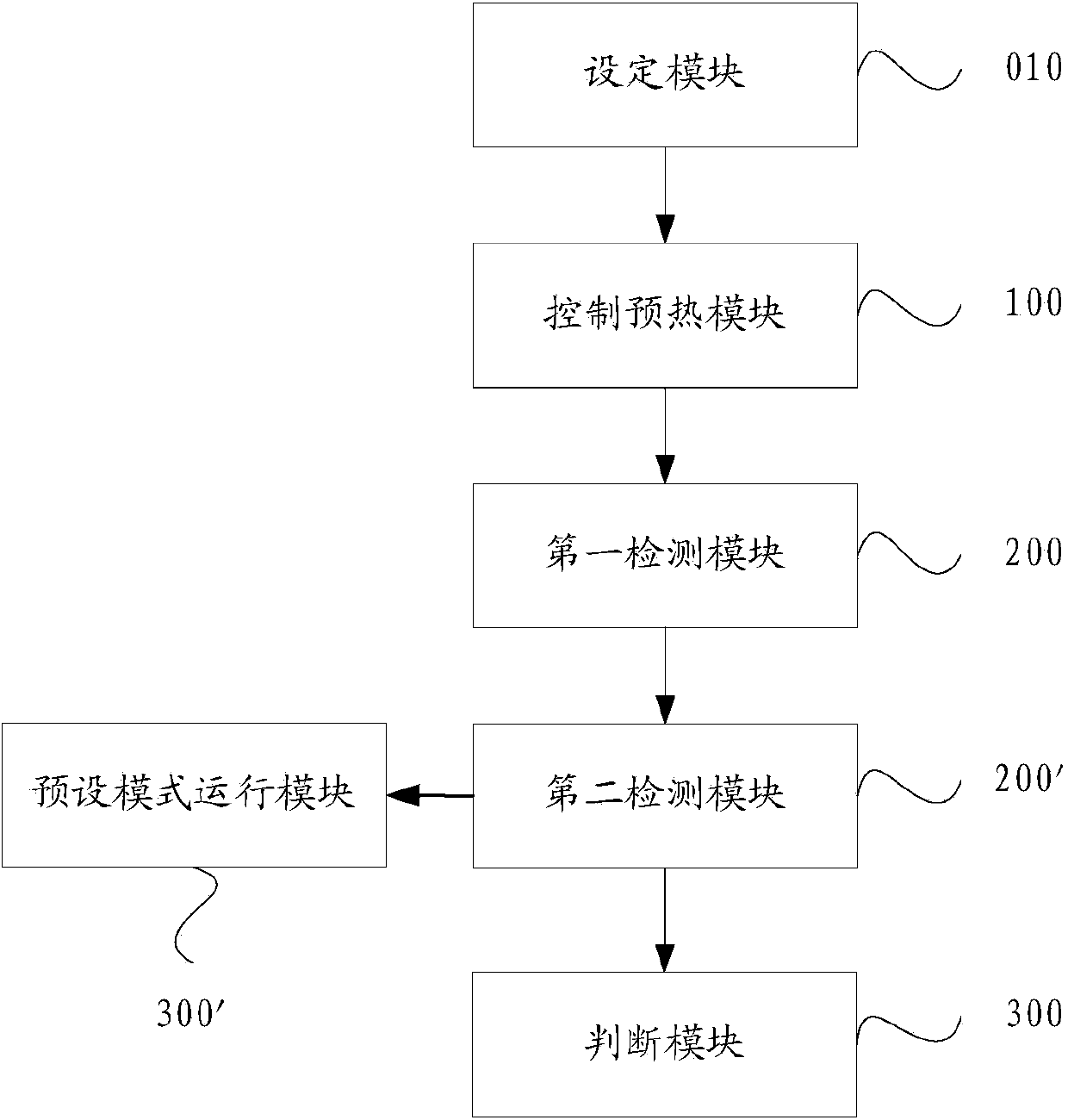

Method and system for controlling heating of air conditioner

InactiveCN104197464AGuaranteed temperatureAvoid blowing people directlySpace heating and ventilation safety systemsLighting and heating apparatusCold airCold blast

The invention provides a method and system for controlling heating of an air conditioner. The method for controlling heating of the air conditioner comprises the following steps that a compressor is controlled to conduct preheating before a preset time according to a set time; the temperature of an indoor coiler is detected; whether the temperature of the indoor coiler is higher than or equal to a preset temperature of the indoor coiler is judged; if yes, an indoor draught fan is controlled to operate at the lowest rotating speed; if not, the indoor draught fan is controlled not to operate. According to the method and system for controlling heating of the air conditioner, preheating is conducted before the preset time, the situation that clod air is directly blown to people can be avoided, the use comfort of users is improved, energy is saved relatively, and energy consumption is reduced; it is guaranteed that hot air is directly blown out by the air conditioner in heating operation when it reaches the set time, cold air is prevented from being blow out directly, user complaints are reduced, and the product competitiveness is improved for companies.

Owner:GREE ELECTRIC APPLIANCES INC

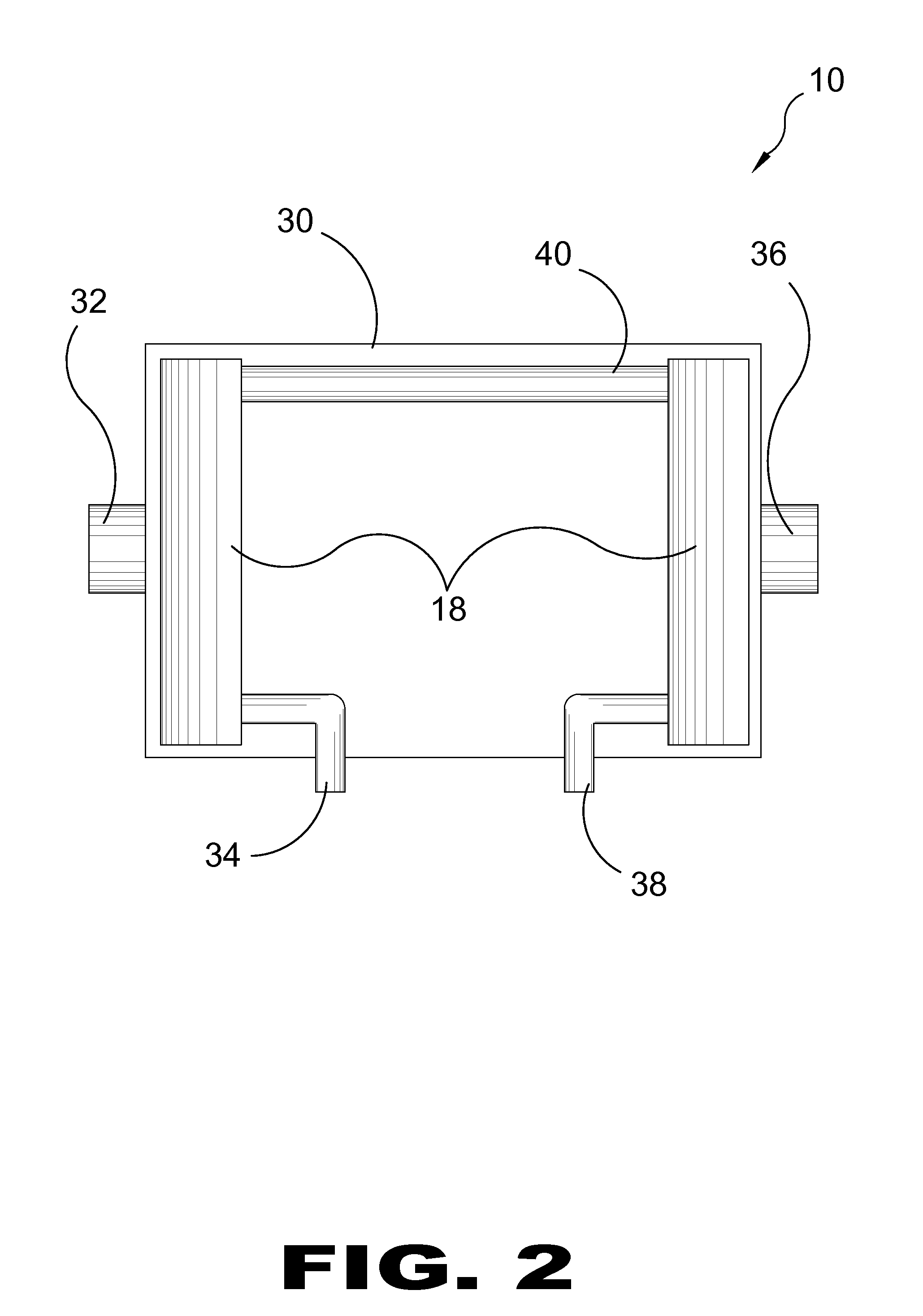

Land Based and Pontoon Based Forced Air Thermal Evaporator

InactiveUS20110168646A1Great evaporation rateImprove efficiencyEvaporators with forced circulationWater/sewage treatment by heatingCold airWater source

A method of evaporating waste water utilizing waste heat employs a forced air thermal evaporator system having an air heat exchanger with: a waste heat inlet, a waste heat outlet, a cold air inlet and a hot air outlet; a compressor connected with the cold air inlet to force air into the cold air inlet; and a distribution header having a hot air inlet connected with the hot air outlet, a waste water inlet connected to a waste water source, and air / water mixing nozzles connected with the hot air inlet and the waste water inlet. Engaging the compressor forces air through the heat exchanger and into the distribution header where the waste water is admixed with the hot air which then exits through spray nozzles as water vapor.

Owner:TAFOYA JAMES

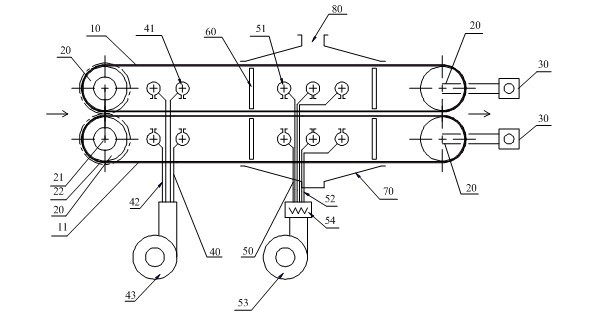

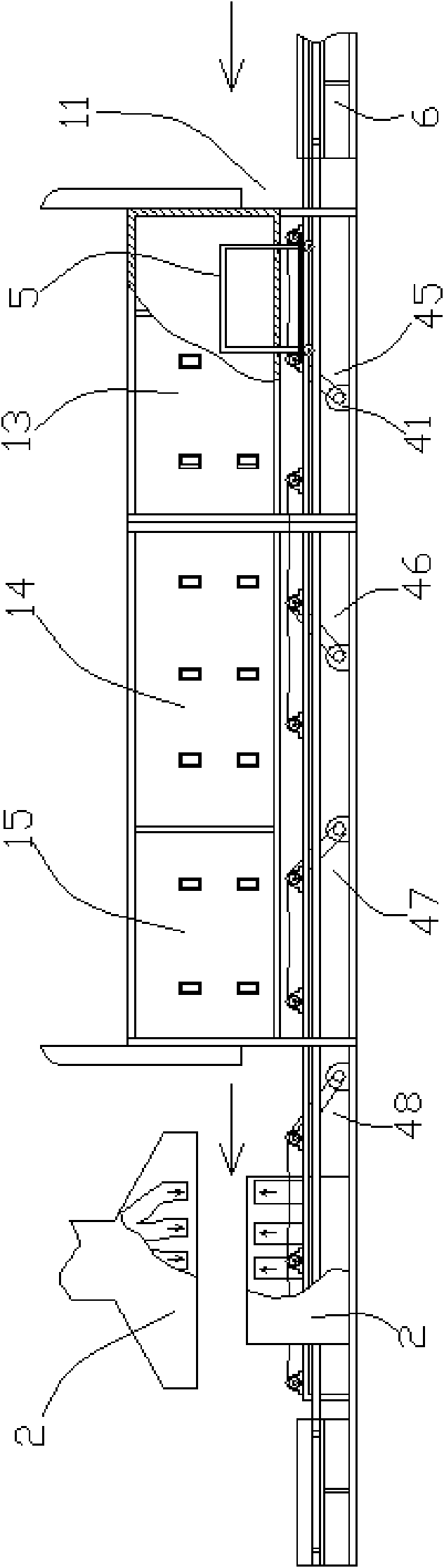

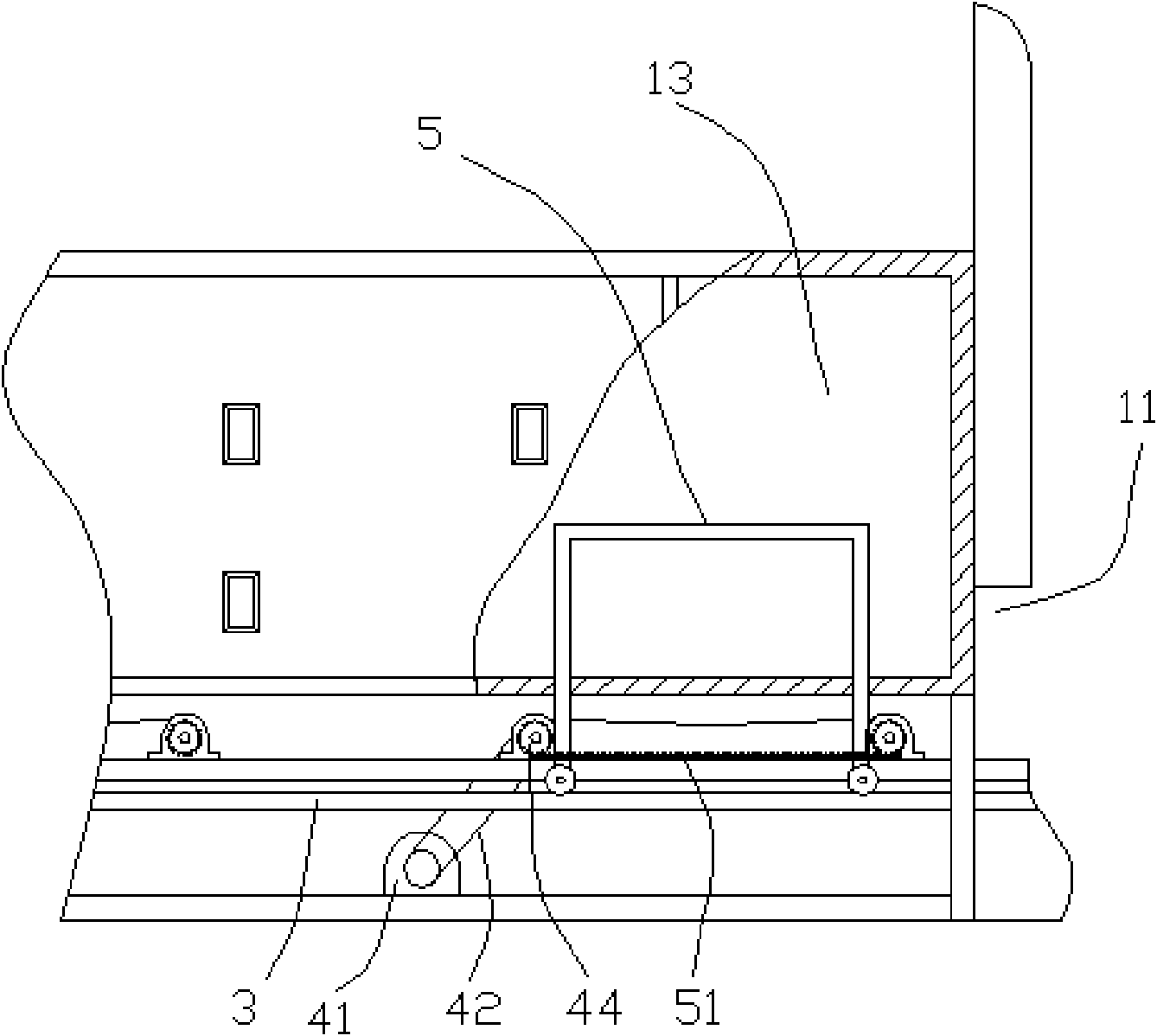

Drying system for flexible circuit board

ActiveCN102384641ADry fastFirmly connectedDrying gas arrangementsDrying machines with progressive movementsCold airFlexible circuits

The invention provides a drying system for a flexible circuit board. The drying system comprises two conveying devices, four rotating shafts, offset mechanisms, a hot air device and a cold air device, wherein the two conveying devices are made of polytetrafluoroethylene materials and comprise an upper conveying belt and a lower conveying belt which are close and parallel to each other; the four rotating shafts are arranged at two ends of one conveying device and two ends of the other conveying device and are used for driving the transmission of the conveying belts; the offset mechanisms are arranged on the rotating shafts and are used for adjusting the tension of the upper conveying belt and the lower conveying belt; the hot air device is used for blowing hot air out and comprises an air heater and a hot air cutter; the air heater is connected with the hot air cutter by an air heater hose; an electric heater for heating is arranged between the air heater hose and the air heater; the cold air device is used for blowing cold air out, and comprises an air cooler and a cold air cutter; the air cooler is connected with the cold air cutter by an air cooler hose; and a heat-insulating plate is arranged between the cold air device and the hot air device and is used for isolating the cold air from the hot air.

Owner:博罗县精汇电子科技有限公司

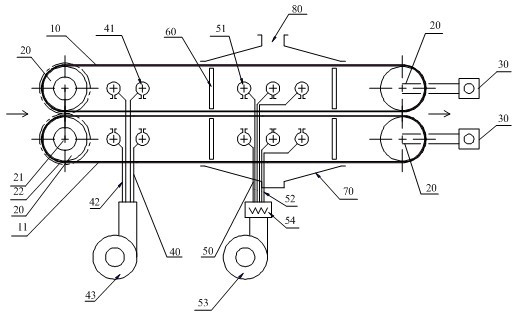

Processing technology of noodles with four-phase variable-temperature drying method

The invention relates to a processing technology of noodles with four-phase variable-temperature drying method. The processing steps are completely finished in a chain and track type drying room. The chain and track type drying room comprises a cold-blast air zone, a drying zone, a main drying zone and a drying finishing zone, and the producing steps comprise (1) cold-blast, (2) rising temperature drying, (3) high-temperature main drying and (4) falling temperature drying. The invention has the characteristics of low temperature, low speed, steady process, easy mastery, and the like, and dried noodles produced by the process has the advantages of flatness, smoothness, good noodle shape, good product quality and no crisp part. By adopting the different speeds and temperatures of air flows in every zone of the drying room, the invention reasonably achieves the goal of fluent drying, realizes the same speed of inward and outward diffusion of noodles, consequently improves the drying effect, effectively prevents noodles from crazing and getting crisp, ensures the noodle quality and saves the energy at the same time.

Owner:陆昌盛

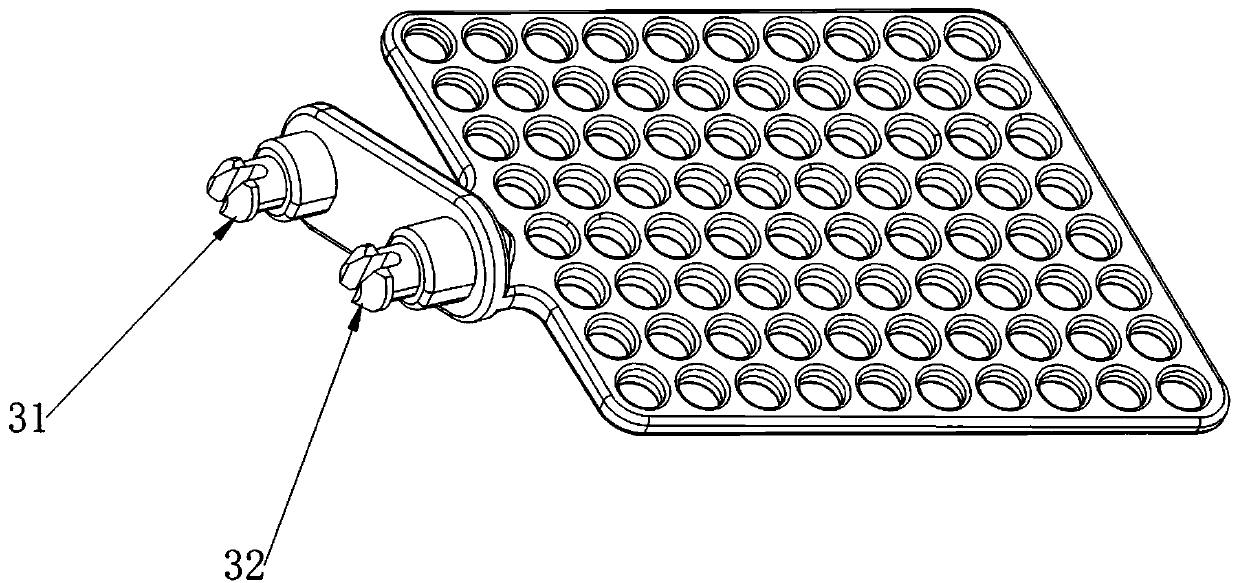

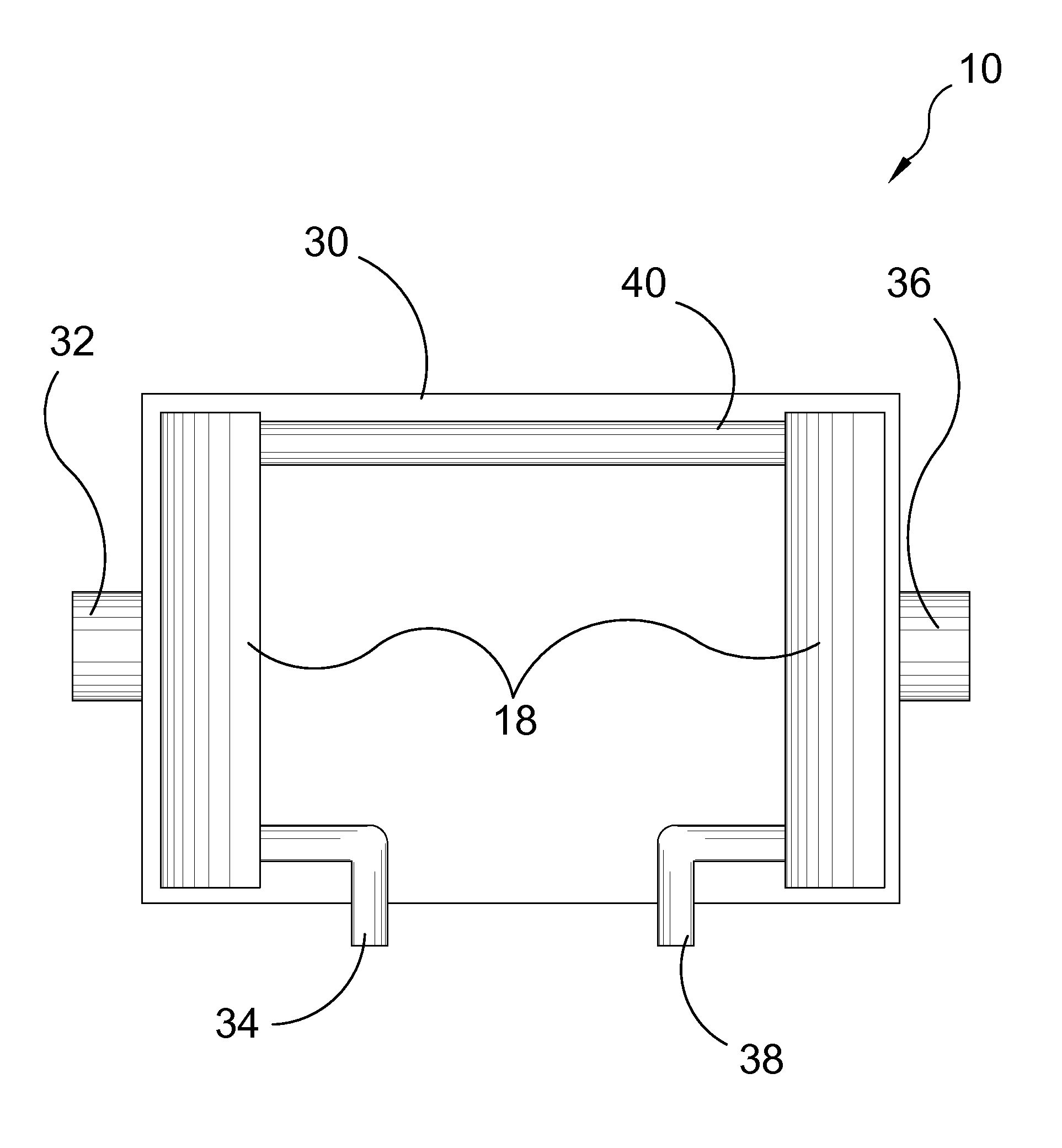

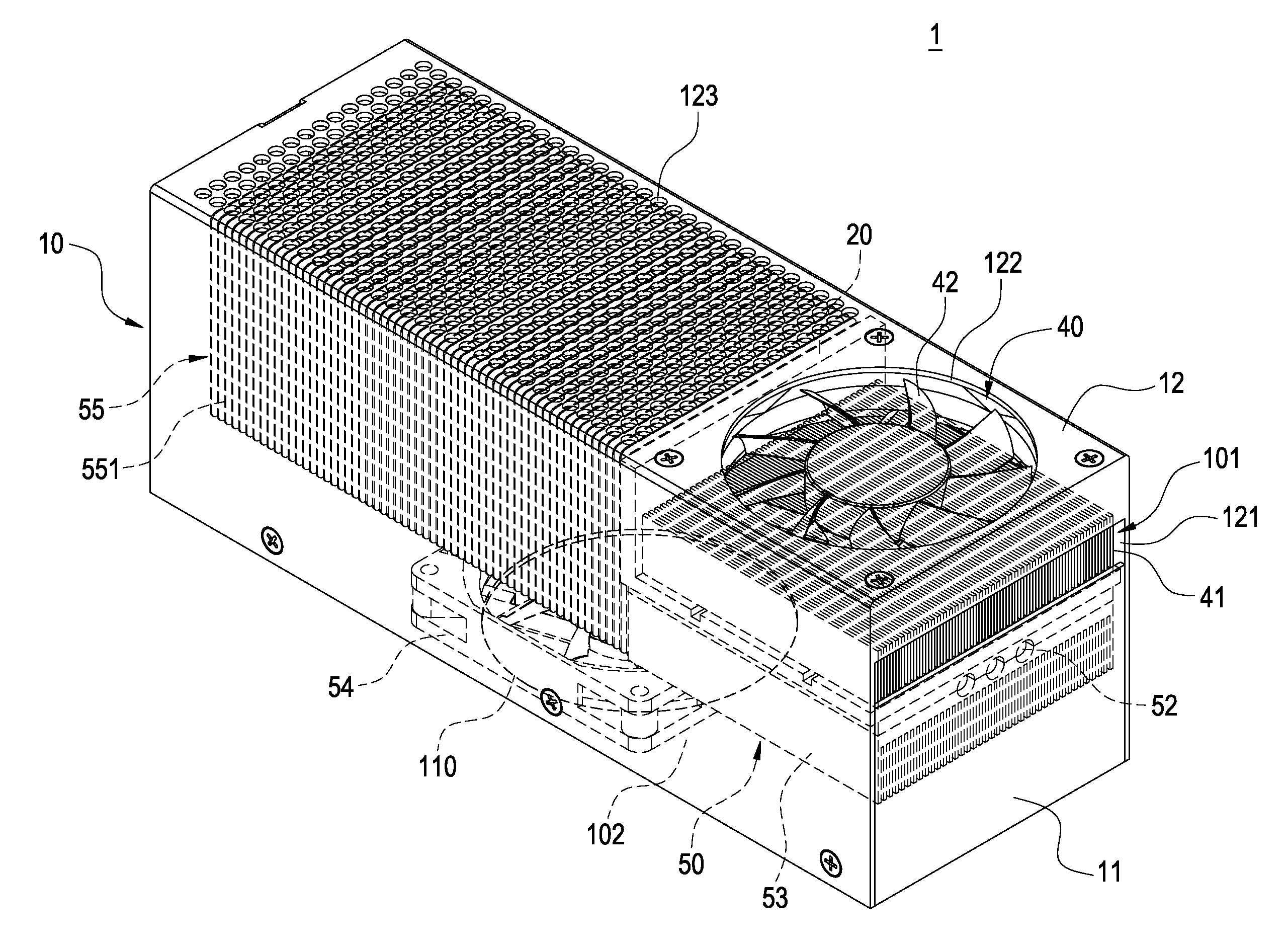

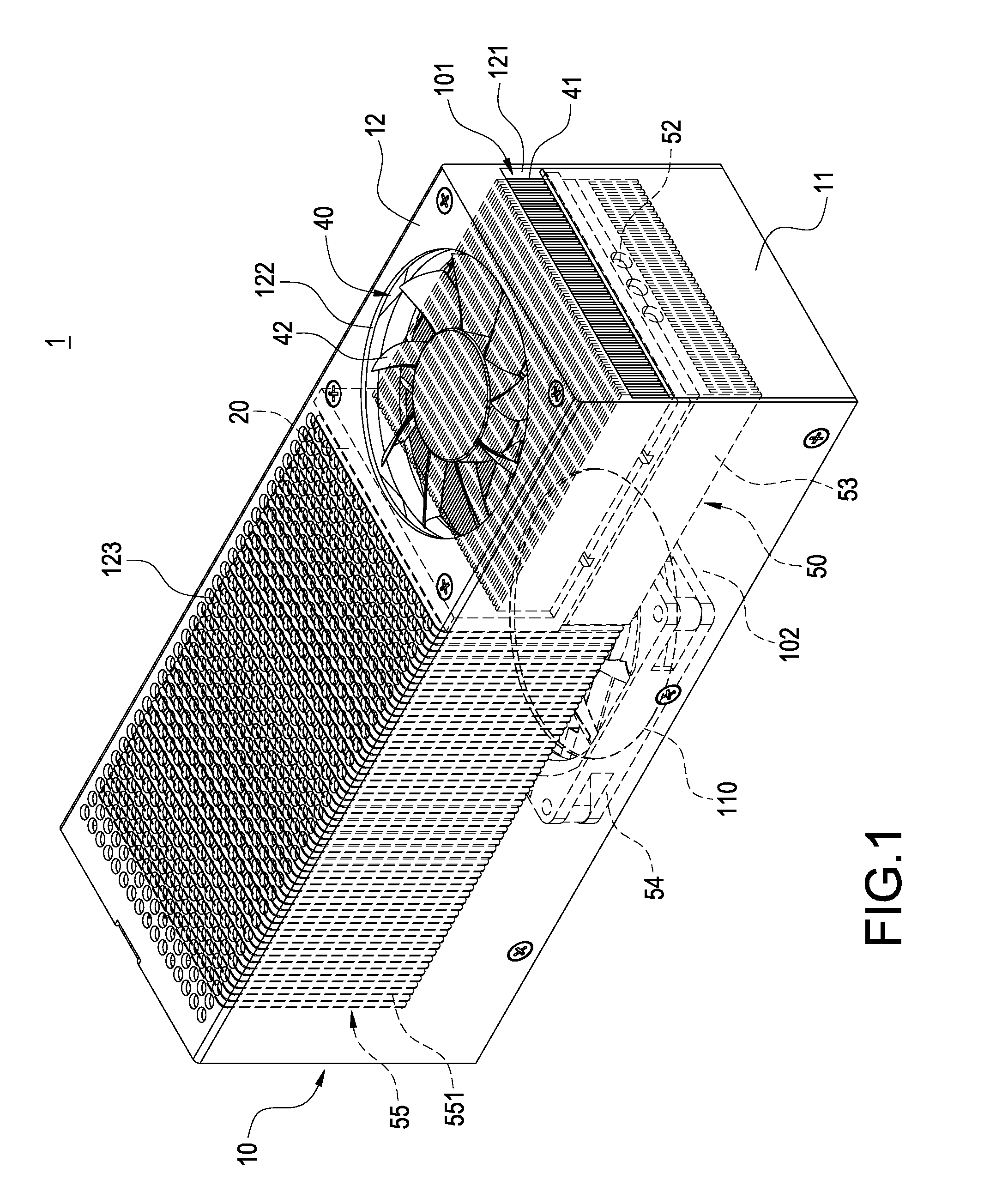

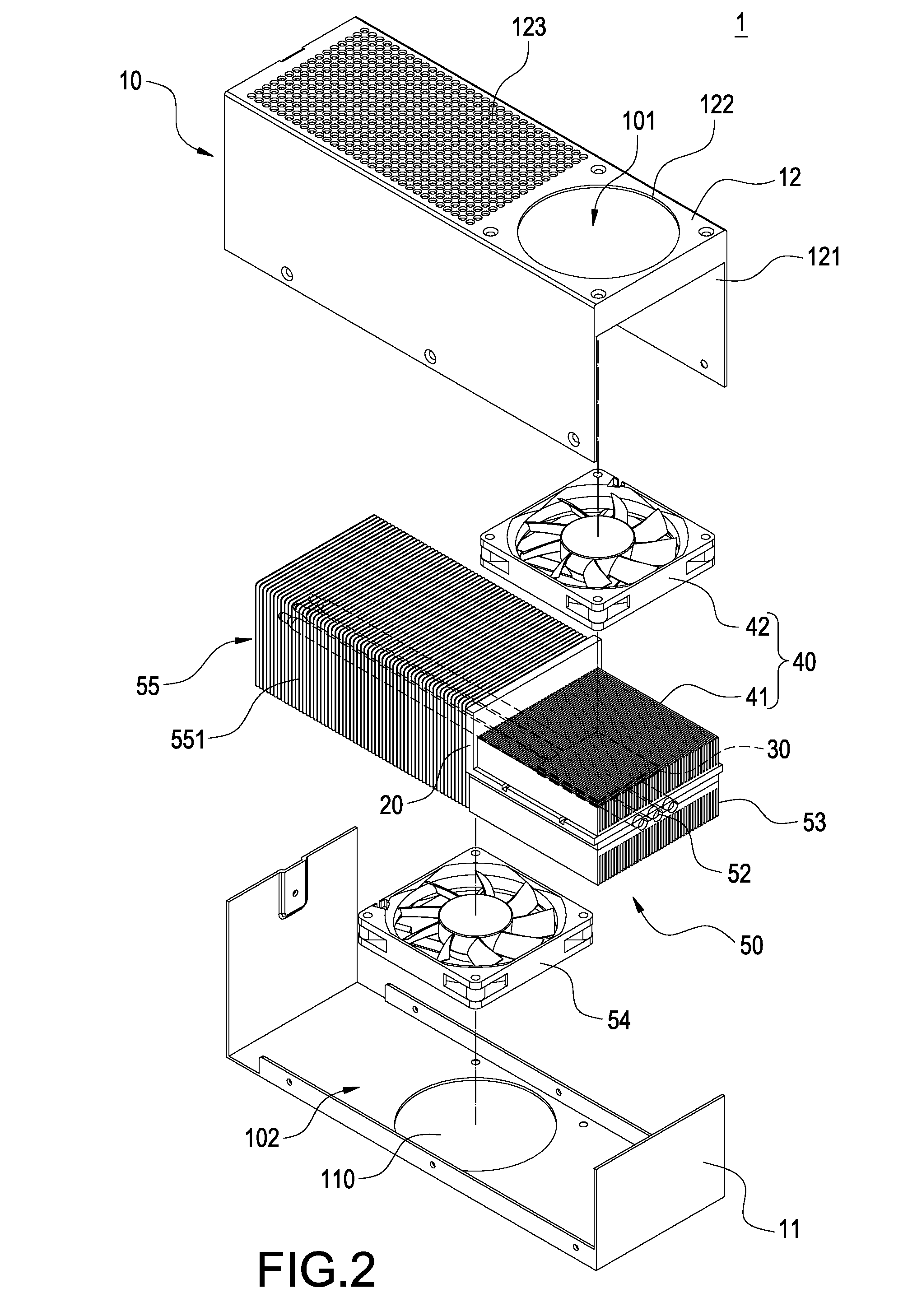

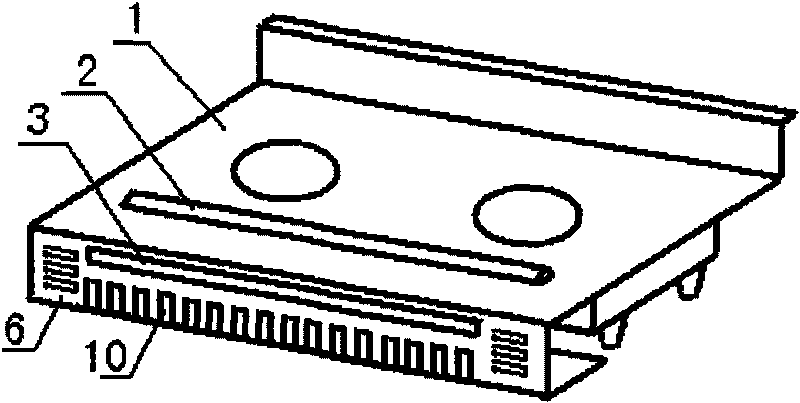

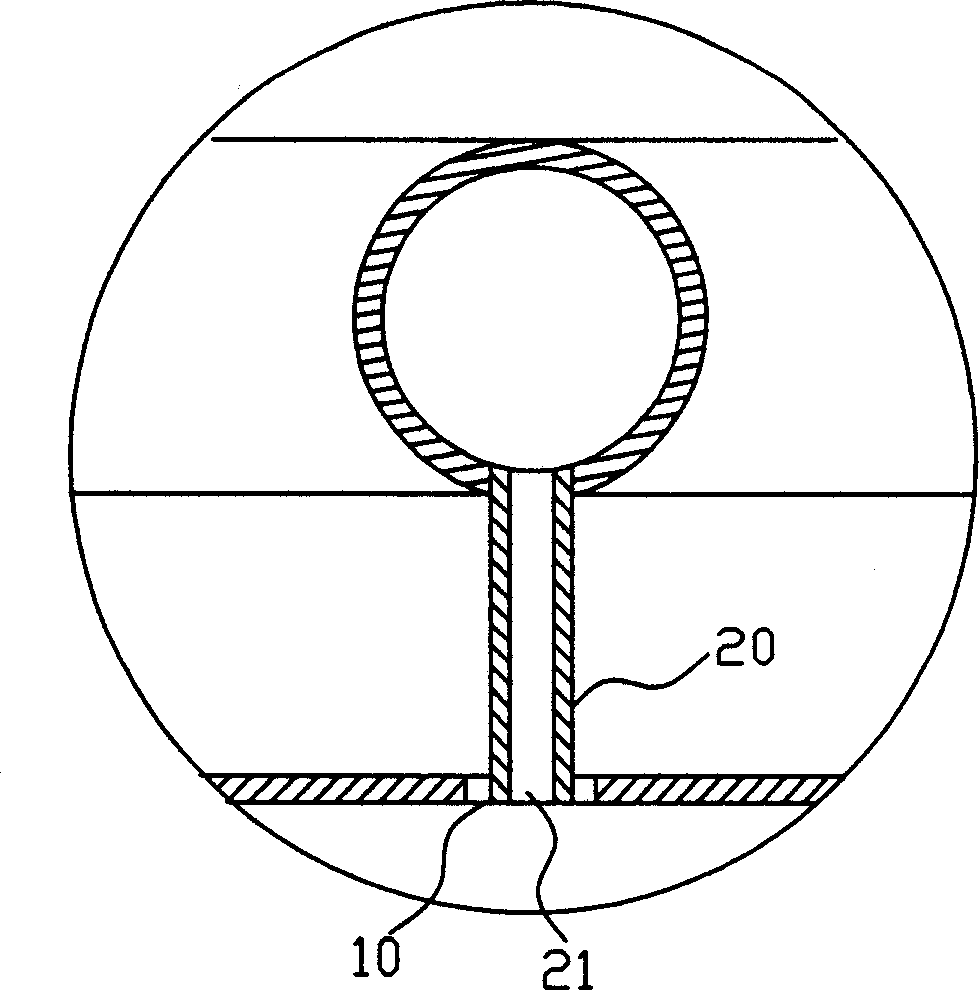

Heat-Dissipating Device For Supplying Cold Airflow

InactiveUS20110197598A1Great practicabilityImprove convenienceSemiconductor/solid-state device detailsSolid-state devicesThermoelectric coolingCold air

A heat-dissipating device (1) includes a casing (10) and a thermal insulation plate (20) provided within the casing (10). The thermal insulating plate (20) divides the interior of the casing (10) into a first accommodating space (101) and a second accommodating space (102). A hot air outlet (121) and a first air inlet (122) of the casing (10) are in communication with the first accommodating space (101). A cold air outlet (110) and a second air inlet (123) of the casing (10) are in communication with the second accommodating space (102). A thermoelectric cooling chip (30) is disposed in a through-hole (200) of the thermal insulation plate (20) and has a hot-end surface (31) facing the first accommodating space (101) and a cold-end surface (32) facing the second accommodating space (102). A heat-dissipating module (40) is received in the first accommodating space (101). A cold-airflow supplying module (50) is received in the second accommodating space (102). The heat generated by the hot-end surface (31) is dissipated to the hot air outlet (121) by the thermal conduction of the heat-dissipating module (40). The cold generated by the cold-end surface (32) is conducted and distributed uniformly by the cold-airflow supplying module (50) to the cold air outlet (110).

Owner:GOLDEN SUN NEWS TECHN +1

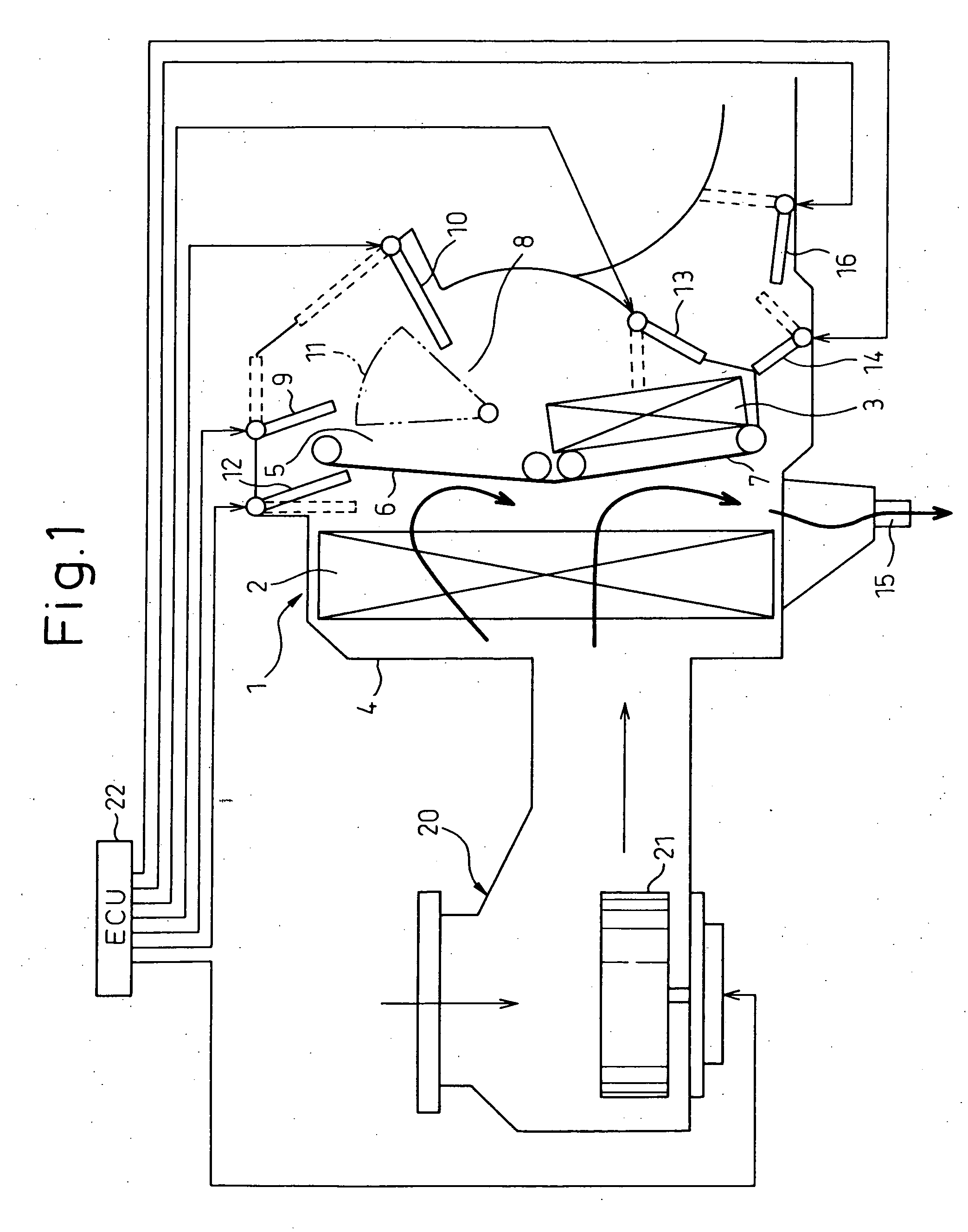

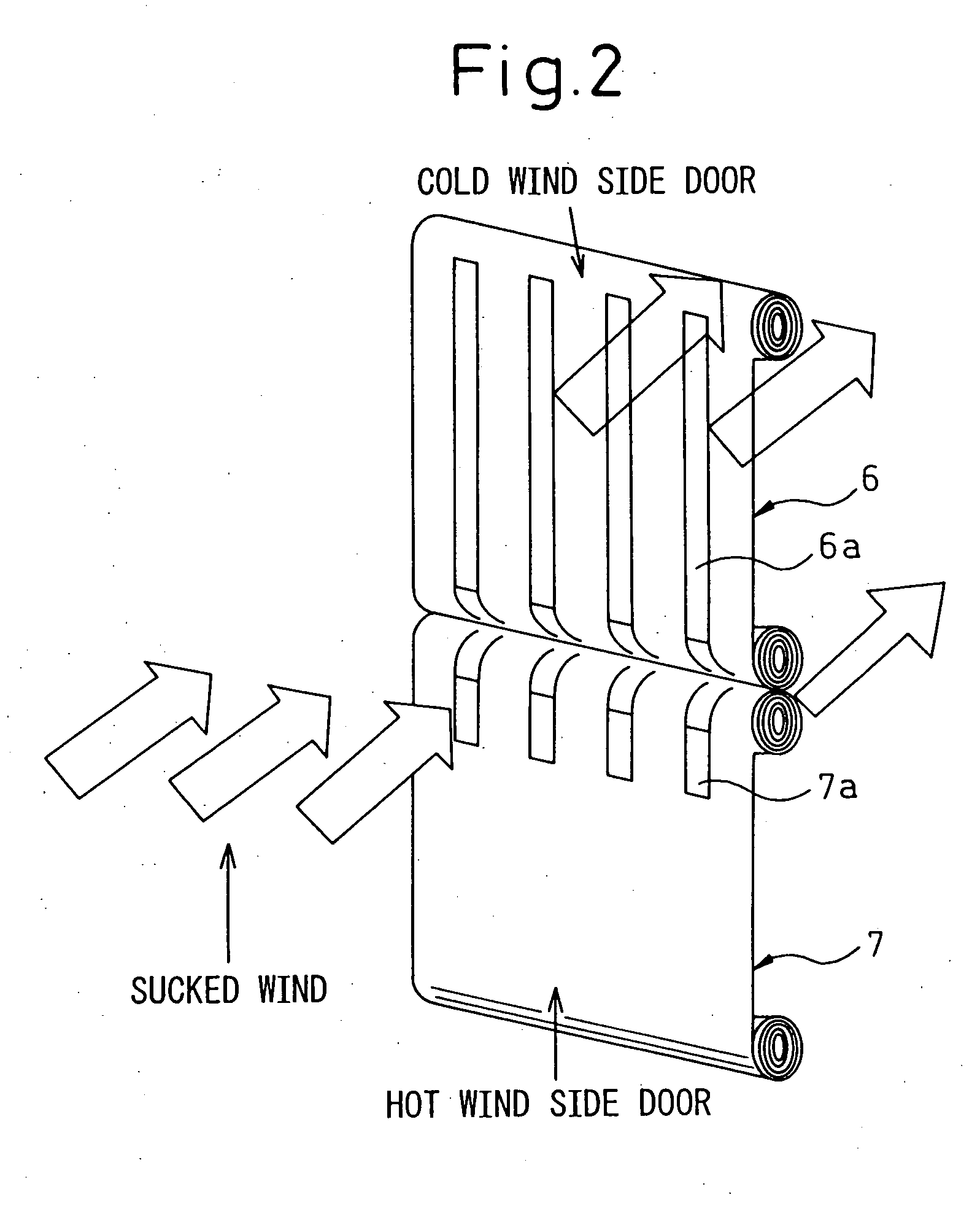

Air conditioner for vehicle use

When it is assumed that a vehicle is stopped or parked after its engine was stopped and a predetermined period of time has passed, a cold wind side air mixing door, hot wind side air mixing door, cold wind door and rear cold wind side air mixing door are totally closed and a blower is operated for a predetermined period of time. Accordingly, while a cooler is being dried, drying air containing much offensive smell components, which has passed through the cooler, is discharged outside the vehicle. Therefore, it is unnecessary to provide an exclusively used air passage and an opening and closing door for opening and closing the air passage used for composing an air blowing passage to dry the cooler. By utilizing the existing equipment, air used for drying, which has passed through the cooler, containing much offensive smell components can be discharged outside the vehicle.

Owner:DENSO CORP

Energy-saving and environment-friendly small air conditioner

InactiveCN101737885AReduce cooling powerLower ambient space temperatureAir-treating devicesCondensate preventionCold airEngineering

The invention provides a small air conditioner which is provided with a cold air outlet positioned above a small space, such as a cooking utensil, a range hood, a kitchen or a washroom, an elevator room and a space in the front end of a header board, and uses an air conditioning system or a semiconductor refrigerating sheet to play a role in cooling human body. The air conditioner is characterized in that: an air conditioner compressor is positioned below the cooking utensil or above the range hood; the air inlet of an air conditioner evaporator is positioned above a cooking utensil panel or the range hood, while the cooling air hole is positioned on a front panel of the cooking utensil or the range hood; and cold air produced by the evaporator is discharged outside from the air outlet to cool the human body cooking in front of the cooking utensil or the range hood, so the severe high temperature environment in front of the cooking utensil in summer is improved in a large scale. The invention has the advantages that: an independent small air conditioning system or a semiconductor refrigerating device is used for partially cooling the environment around the human body within a small range; and the air conditioner has greatly lowered refrigerating power, a greatly lowered ambient temperature, comfort and health, and energy conservation and environment friendliness in comparison to the traditional widely used air conditioning device which performs full cooling in an entire space range.

Owner:HEFEI BOPU HIGH TECH

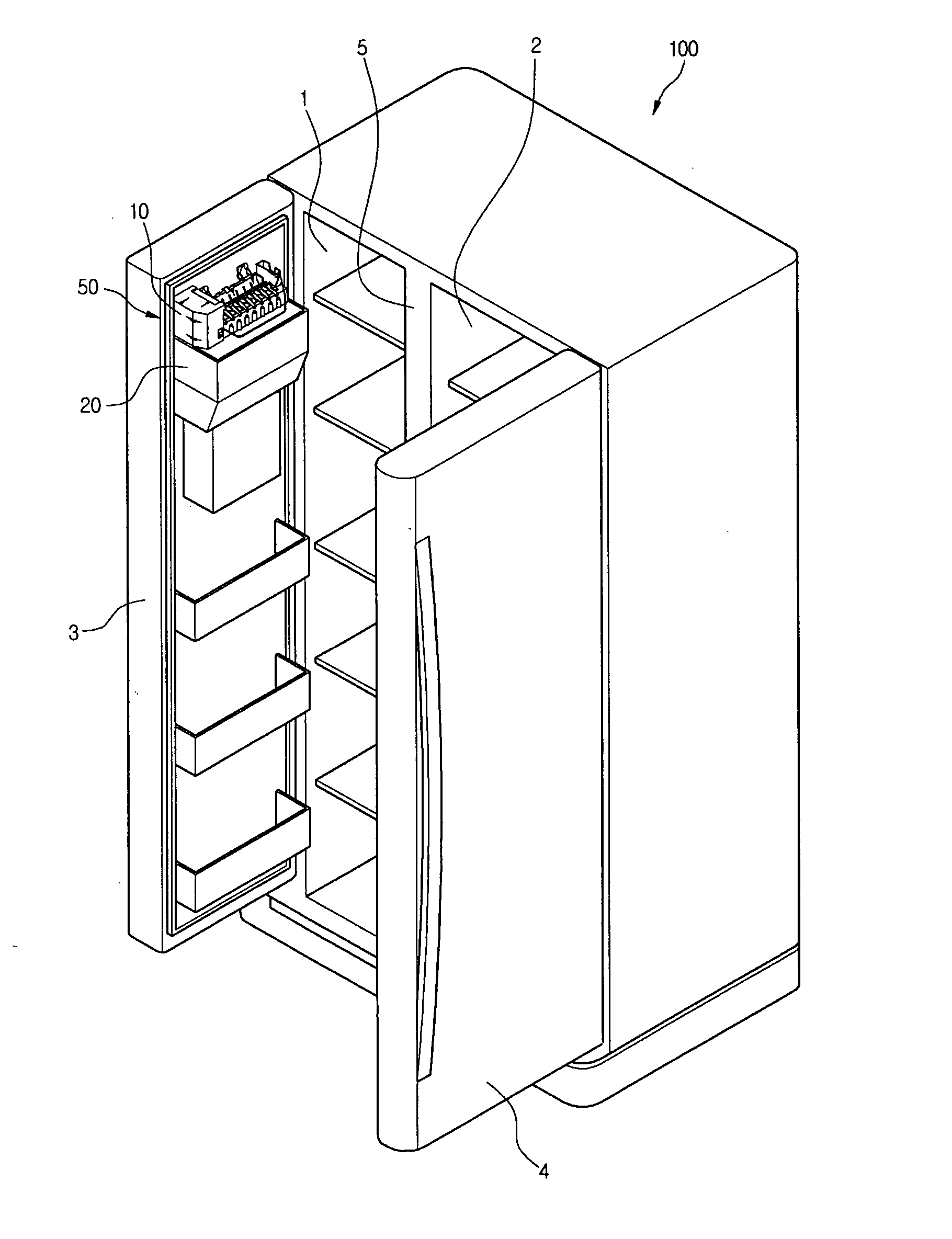

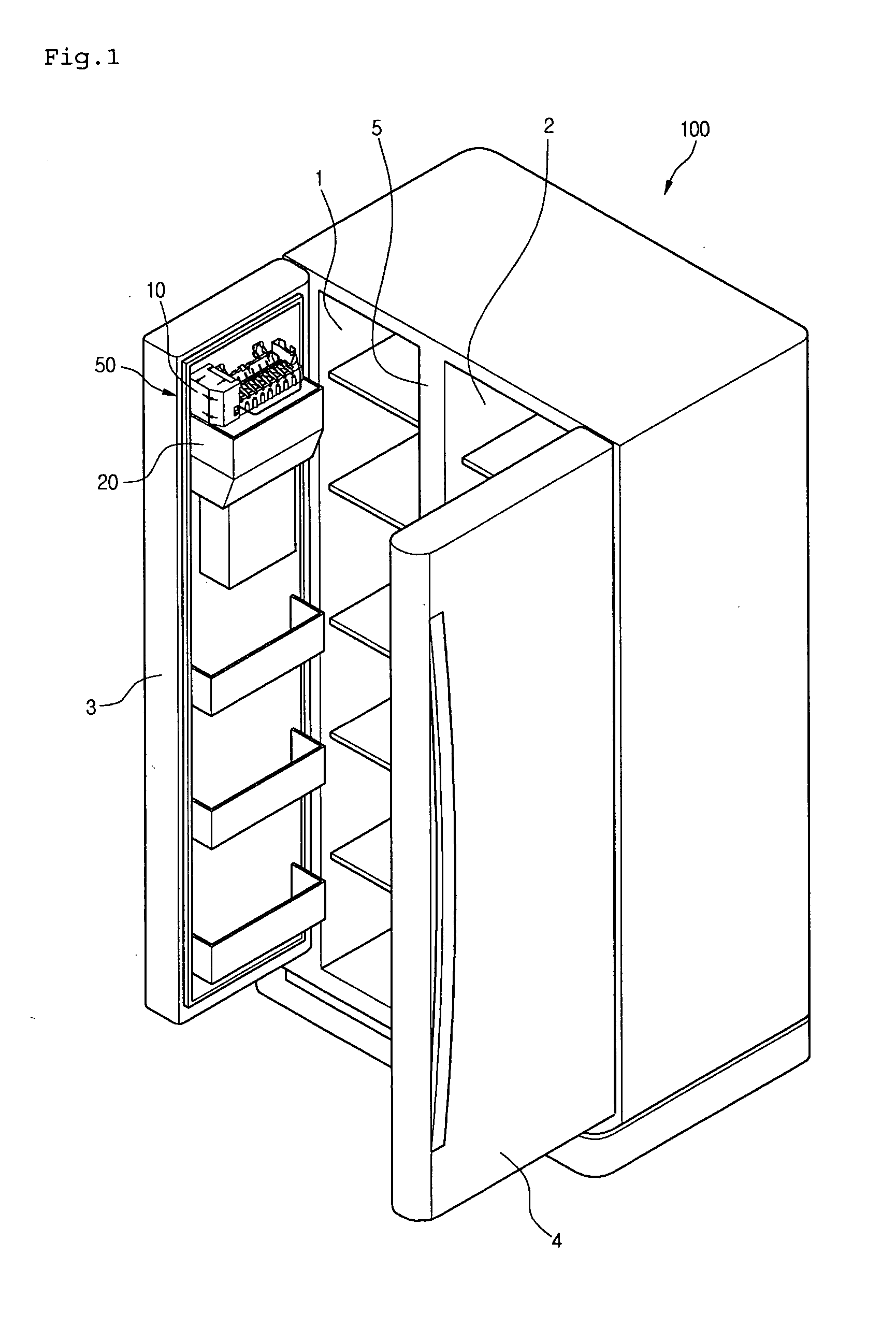

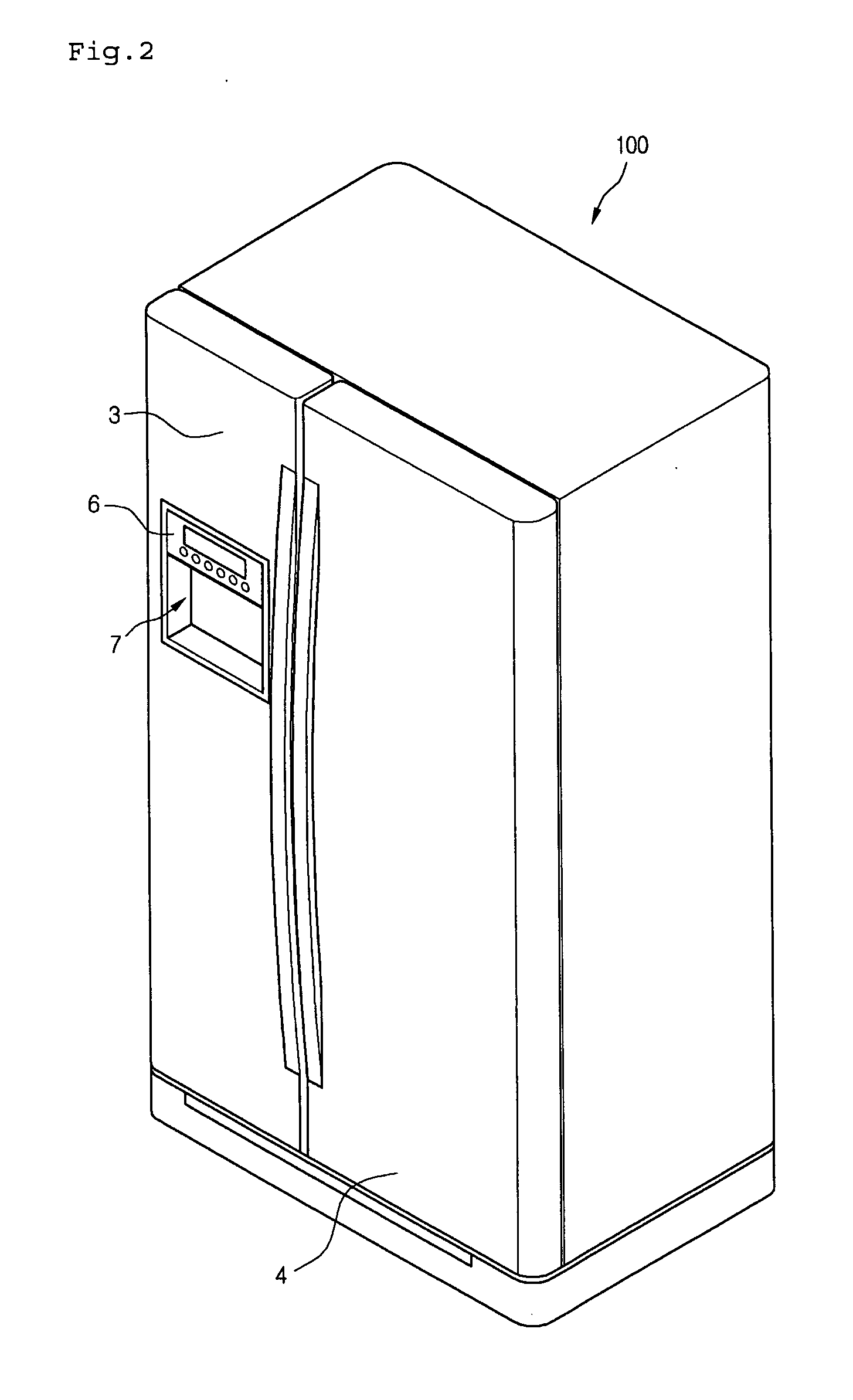

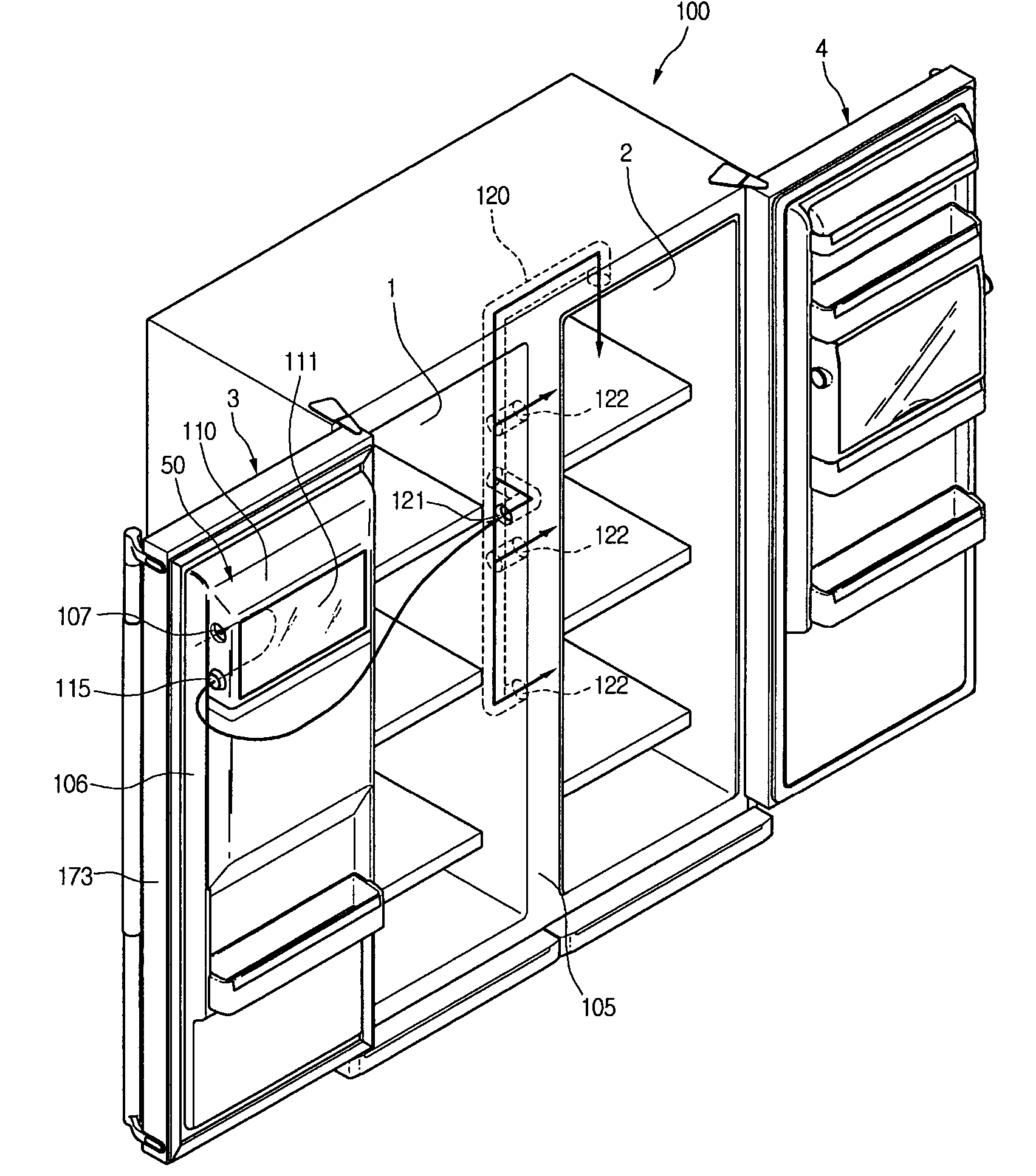

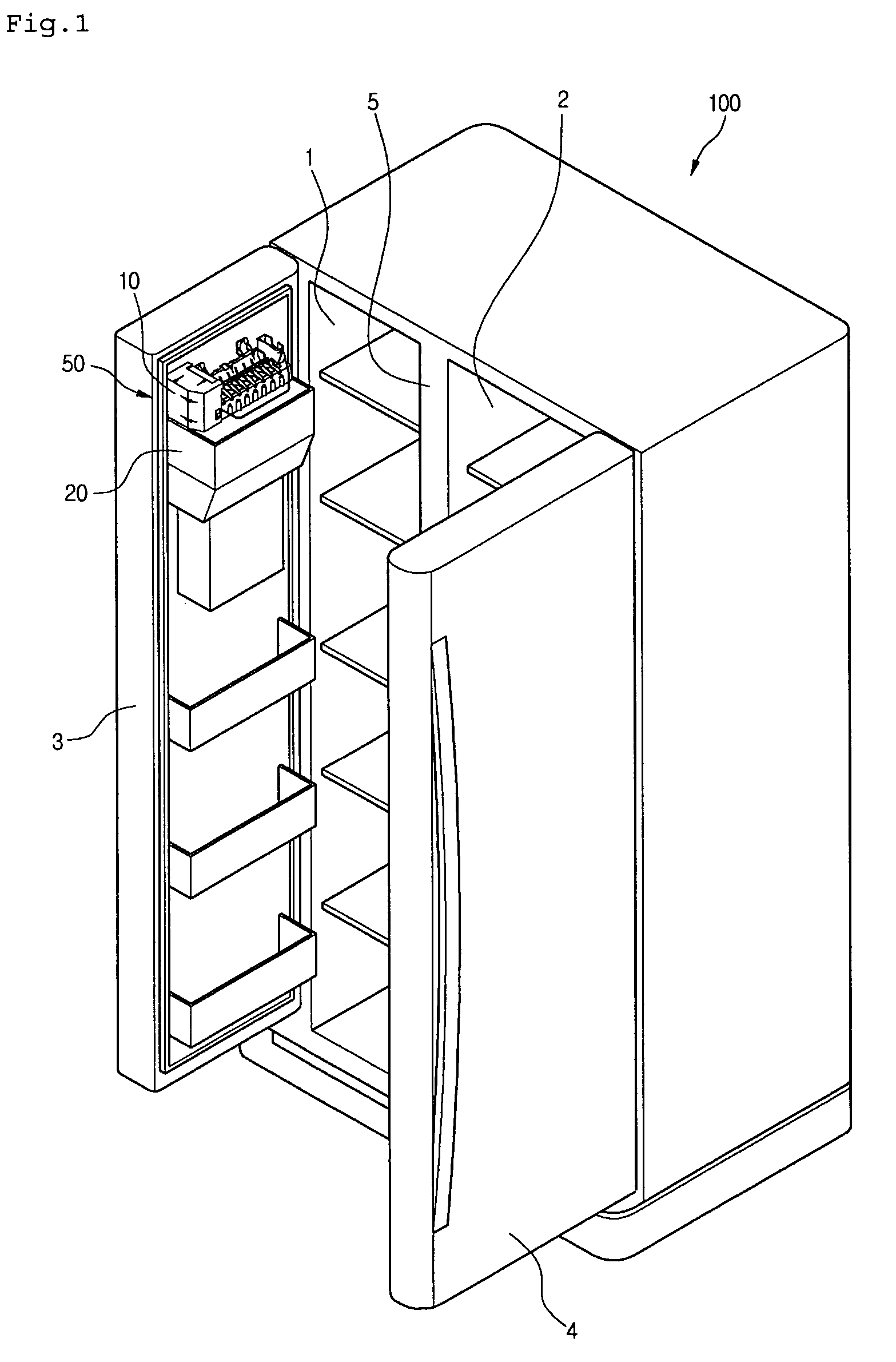

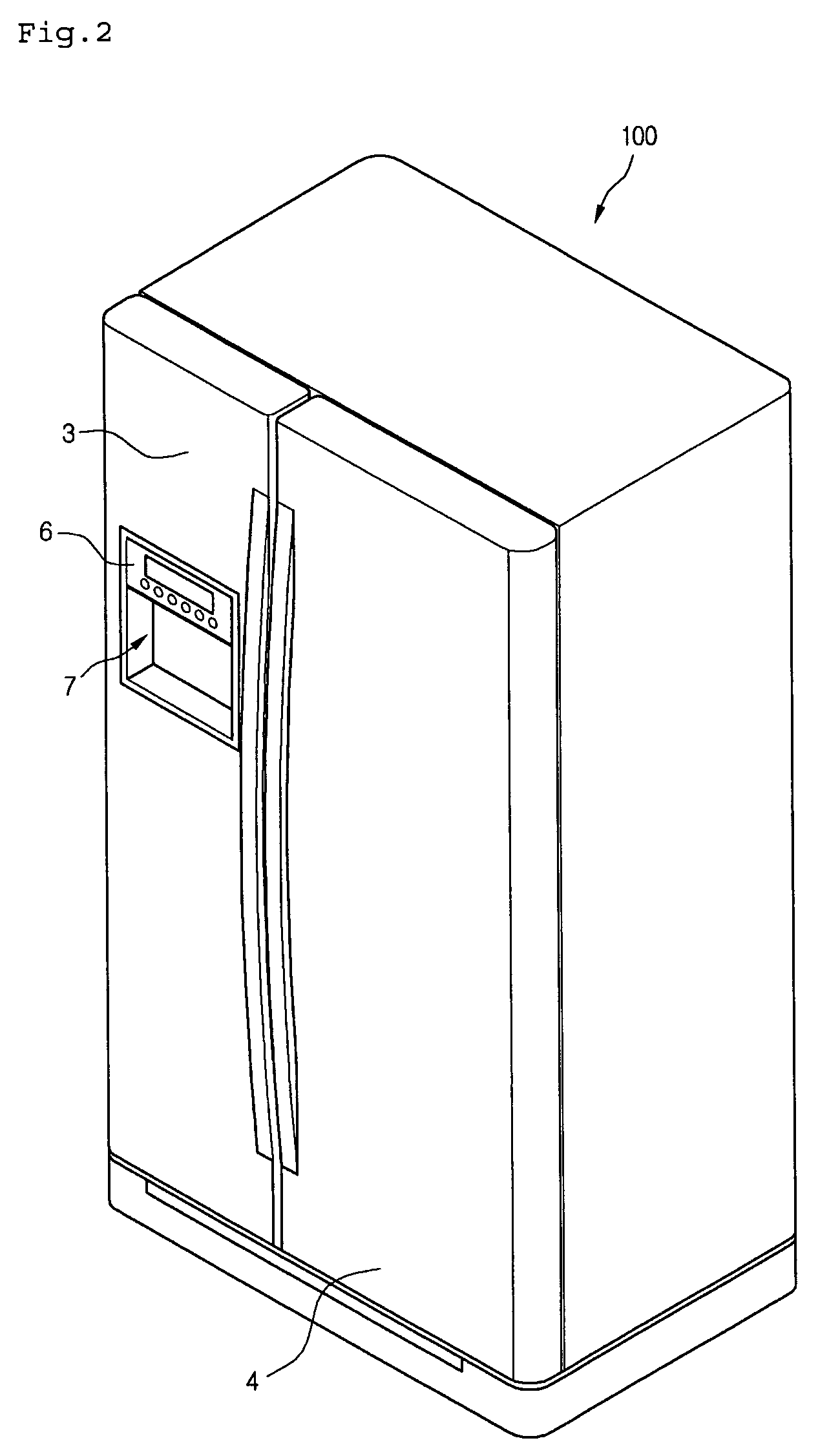

Cold air path structure of refrigerator

ActiveUS20050183441A1Improve efficiencyIncrease available spaceSewerage structuresLighting and heating apparatusCold airEngineering

A cold air path structure of a refrigerator is provided. The cold air path structure defines a passage from an ice machine installed in a freezing chamber to a chilling chamber in order to discharge an cold air used to freeze water of the ice machine to the chilling chamber, such that new cold air can be smoothly supplied to the ice machine, thereby increasing the efficiency of the ice machine. Further, an additional air passage is not required to supply the cold air to the chilling chamber, thereby simplifying the structure of the refrigerator and decreasing power consumption.

Owner:LG ELECTRONICS INC

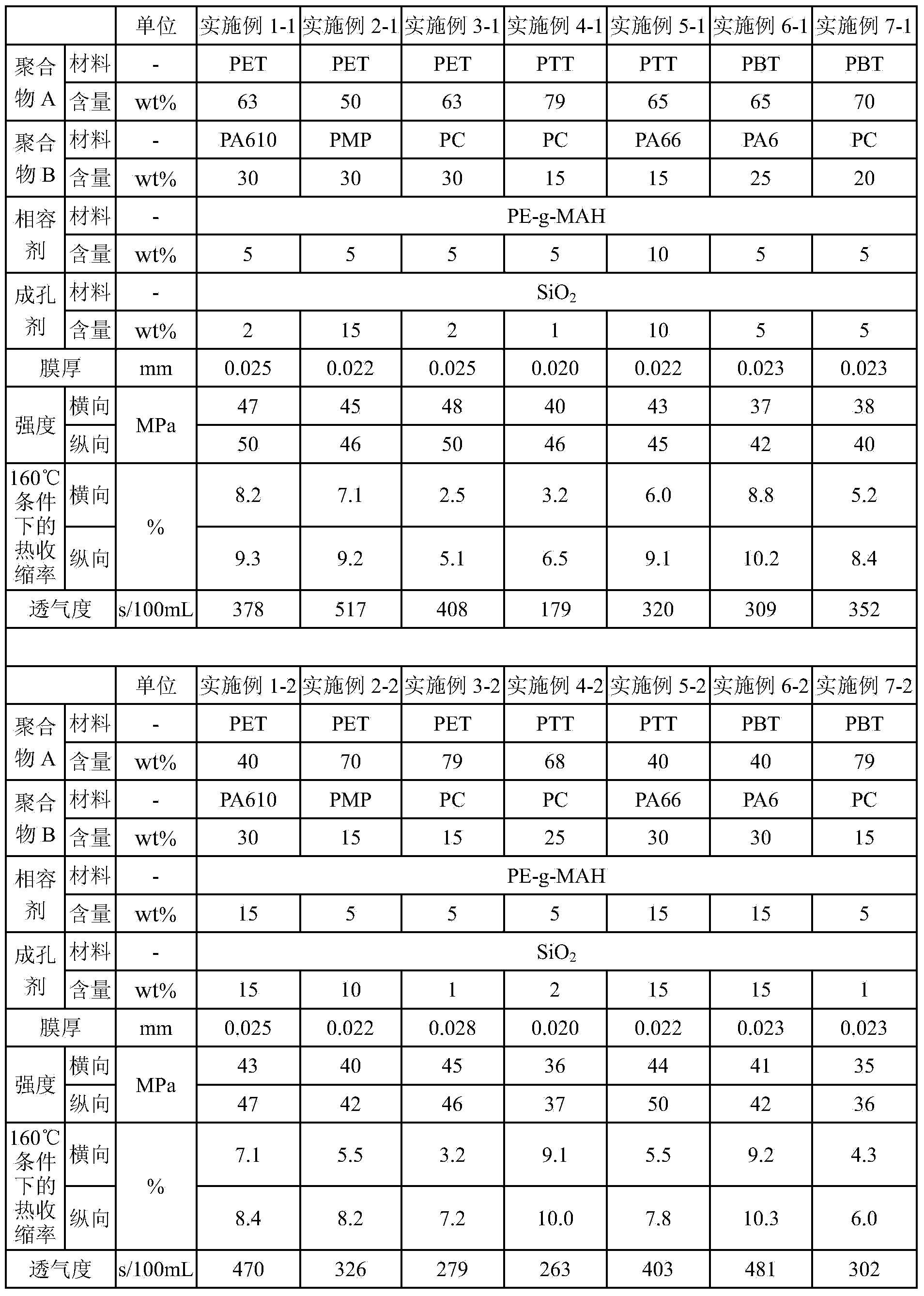

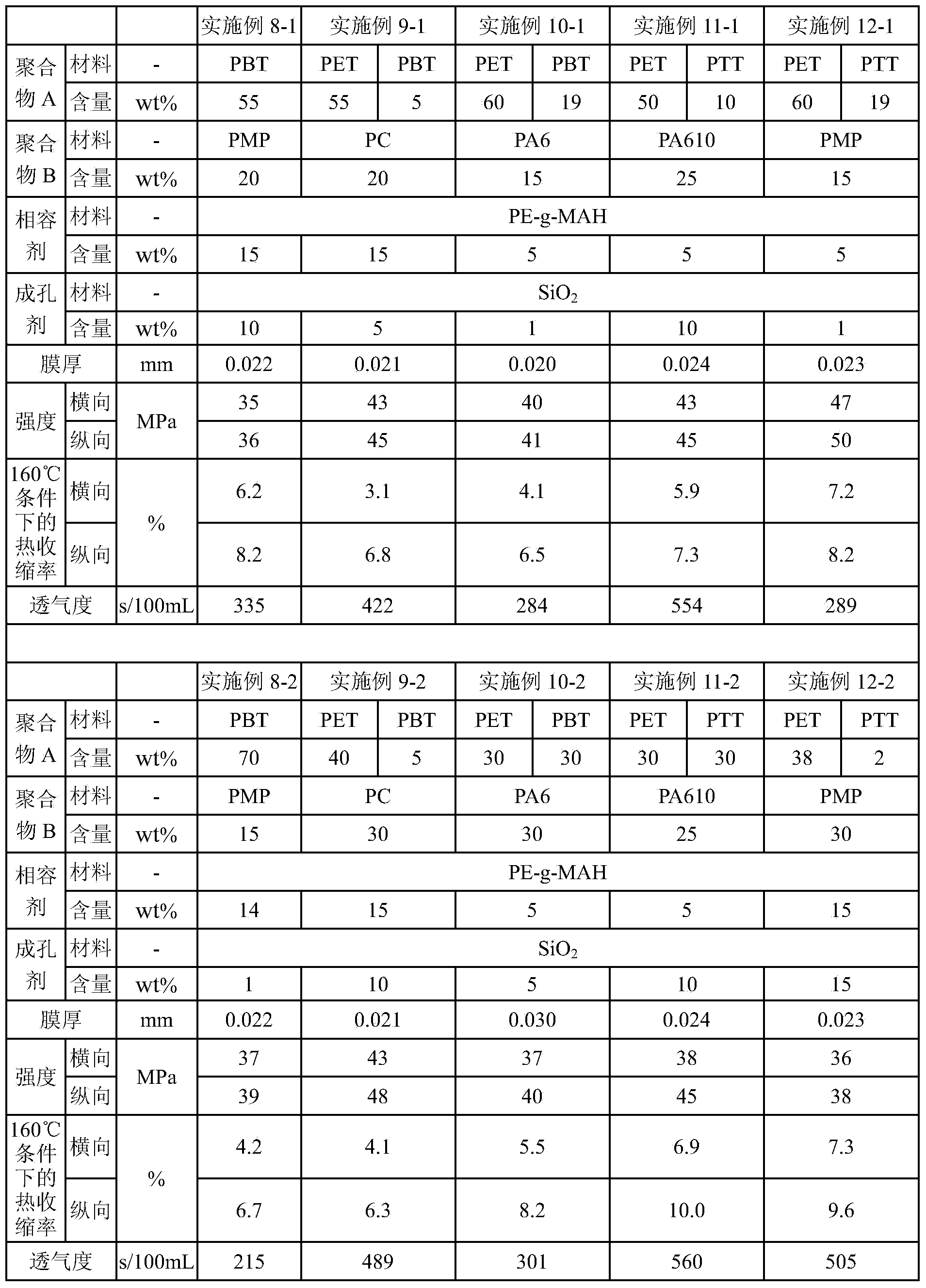

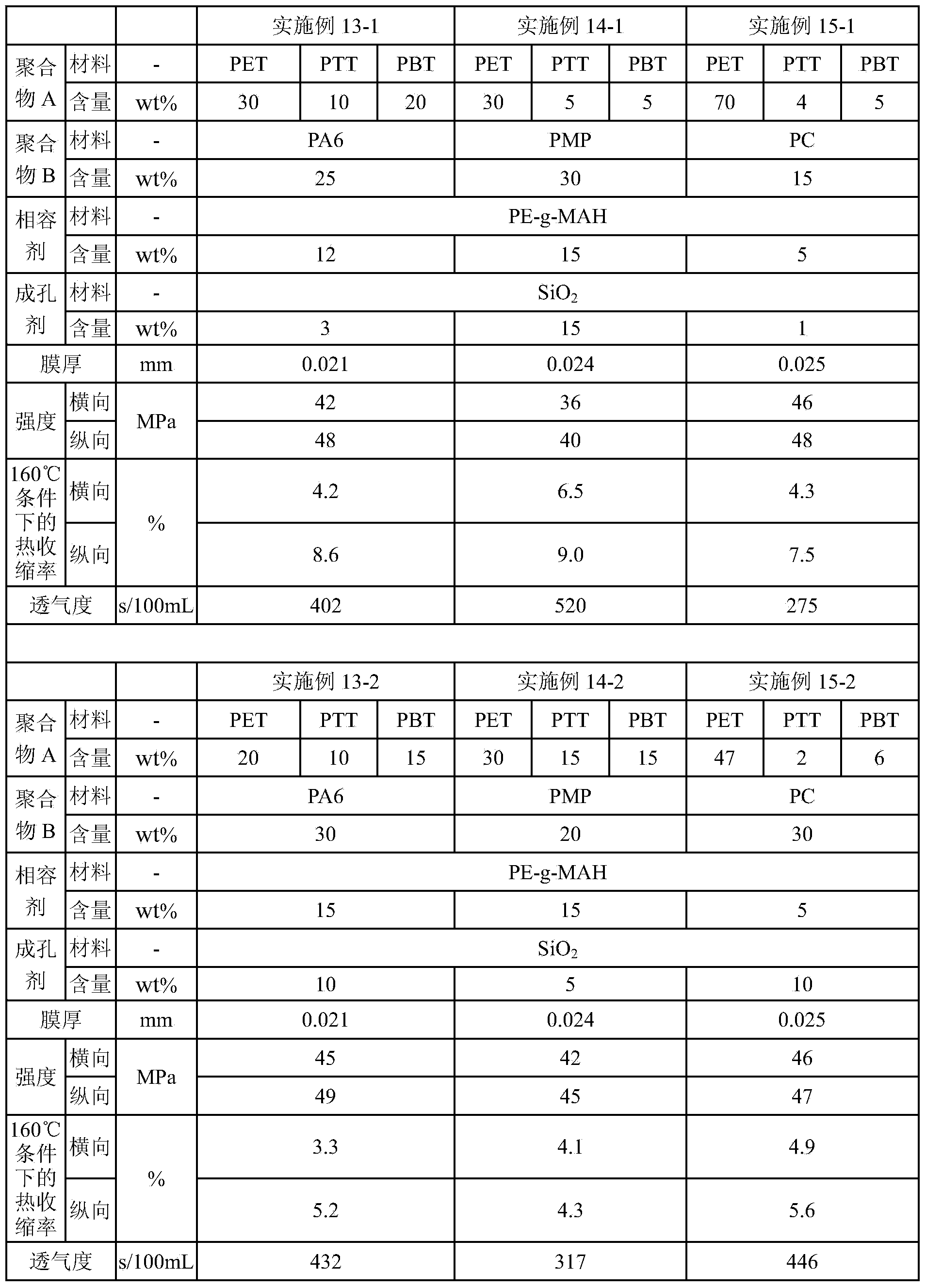

Polyester porous diaphragm for secondary lithium battery and preparation method of polyester porous diaphragm

ActiveCN103724951AHigh mechanical strengthGood heat shrinkabilityCell component detailsPolyesterPolymer science

The invention discloses a polyester porous diaphragm for a secondary lithium battery. The polyester porous diaphragm is characterized by consisting of the following components in percentage by mass: 40-79 percent of polymer A, 15-30 percent of polymer B, 5-15 percent of a compatilizer and 1-15 percent of a pore-forming agent, wherein the thickness of the diaphragm is 0.01-0.05mm. The method for preparing the diaphragm comprises the following steps: uniformly mixing the polymer A, the polymer B, the compatilizer and the pore-forming agent, melting, mixing and granulating through a double-screw extruder, drying, performing melt extrusion through a single screw extruder, performing cold blast casting, longitudinally stretching for 2-8 times at the temperature of 80-150 DEG C, synchronously and longitudinally stretching for 2-6 times and transversely stretching for 1.5-8 times at the temperature of 80-150 DEG C, performing heat setting treatment, and preparing the polyester porous diaphragm. The polyester porous diaphragm has excellent mechanical strength, heat shrinkable property and closure characteristics, can be used for production and manufacture of the secondary lithium battery and is particularly suitable for the secondary lithium battery which works at the temperature of over 160 DEG C.

Owner:四川东方绝缘材料股份有限公司

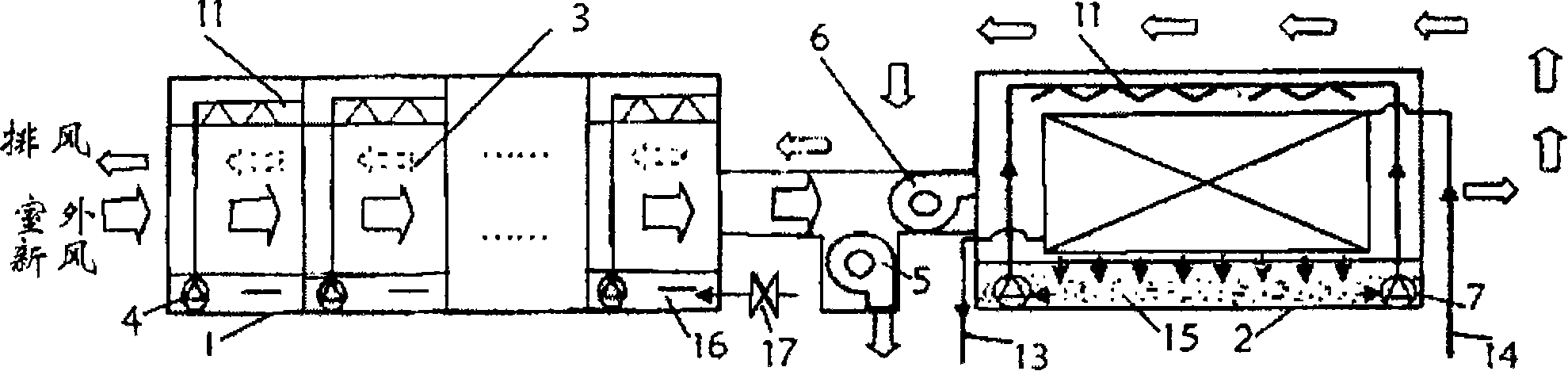

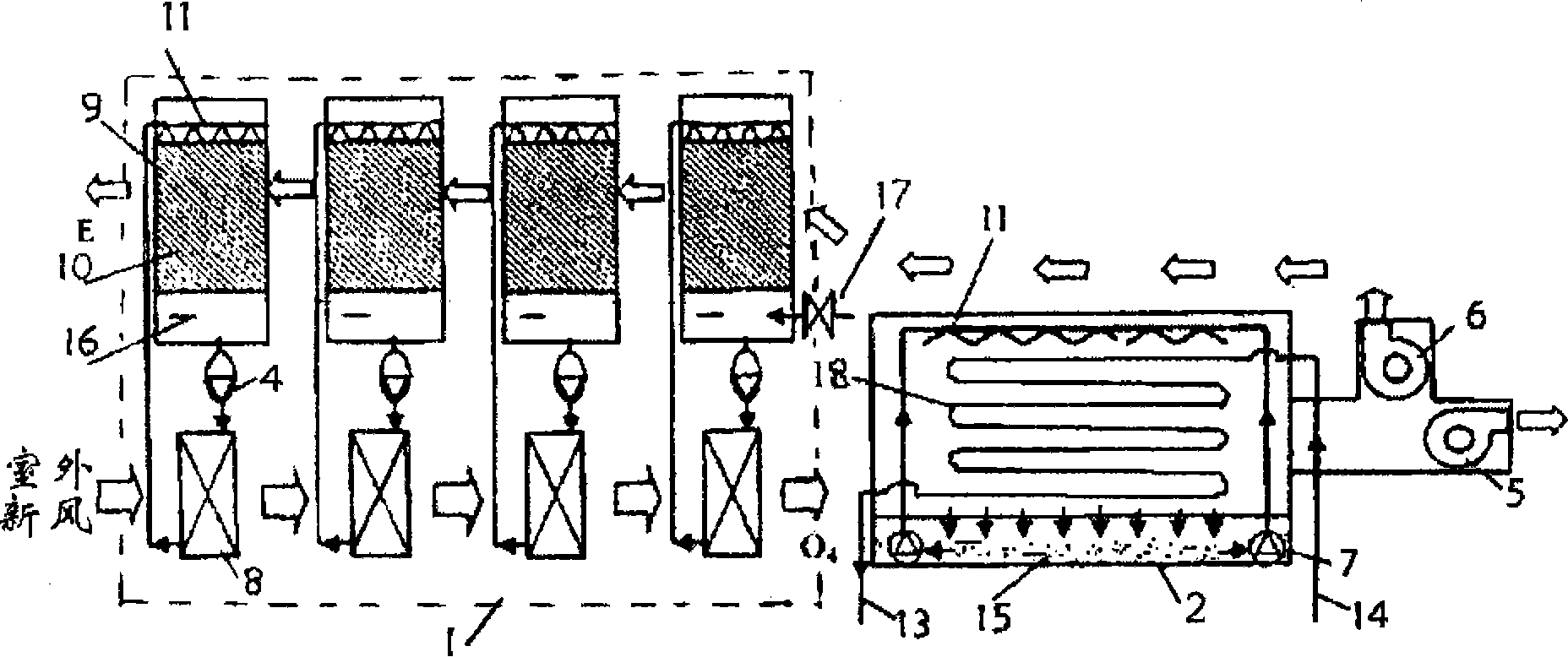

Indirect evaporation refrigerating method and device capable of generating cold water and cold wind meanwhile

ActiveCN101251285ASolve the problem of inconsistent wind and water flow ratioResolving mismatches caused by non-linearityLighting and heating apparatusAir conditioning systemsEvaporative coolerFresh air

The invention discloses an indirect evaporation cooling method of generating cold water and cold wind at the same time and a device, belonging to the energy technical field and relating to an evaporation cooling type cold supply. Fresh air firstly enters a multistage evaporation cooling type heat recoverer, is performed with a wet cooling by an exhaust air evaporation cooling process, etc., then enters an evaporation cooler which generates the cold water and the cold wind at the same time and is performed with a direct evaporation cooling by contacting spray water; part of outlet air of the evaporation cooler is outputted to a user, while another part of the wind is used as exhaust air which is exhausted outdoor via cooling inlet air during multistage evaporation cooling process. In the evaporation cooler, the cold water is outputted after circulated and cold water of the user is cooled by the spray water and an air evaporation cooling process; a temperature of outlet water is lower than a wet bulb temperature of inlet air. The invention outputs the cold water for the user and the fresh air at a lower temperature at the same time, solves a mismatching of a flow ratio of air and water in a sensible heat transferring process and a heat and moisture exchanging process, and solves the mismatching caused by a non linearity of a saturated line through a multistage device; a cold water side for the user can be a closed system, and application situations for a unit can be more widely.

Owner:TSINGHUA UNIV +1

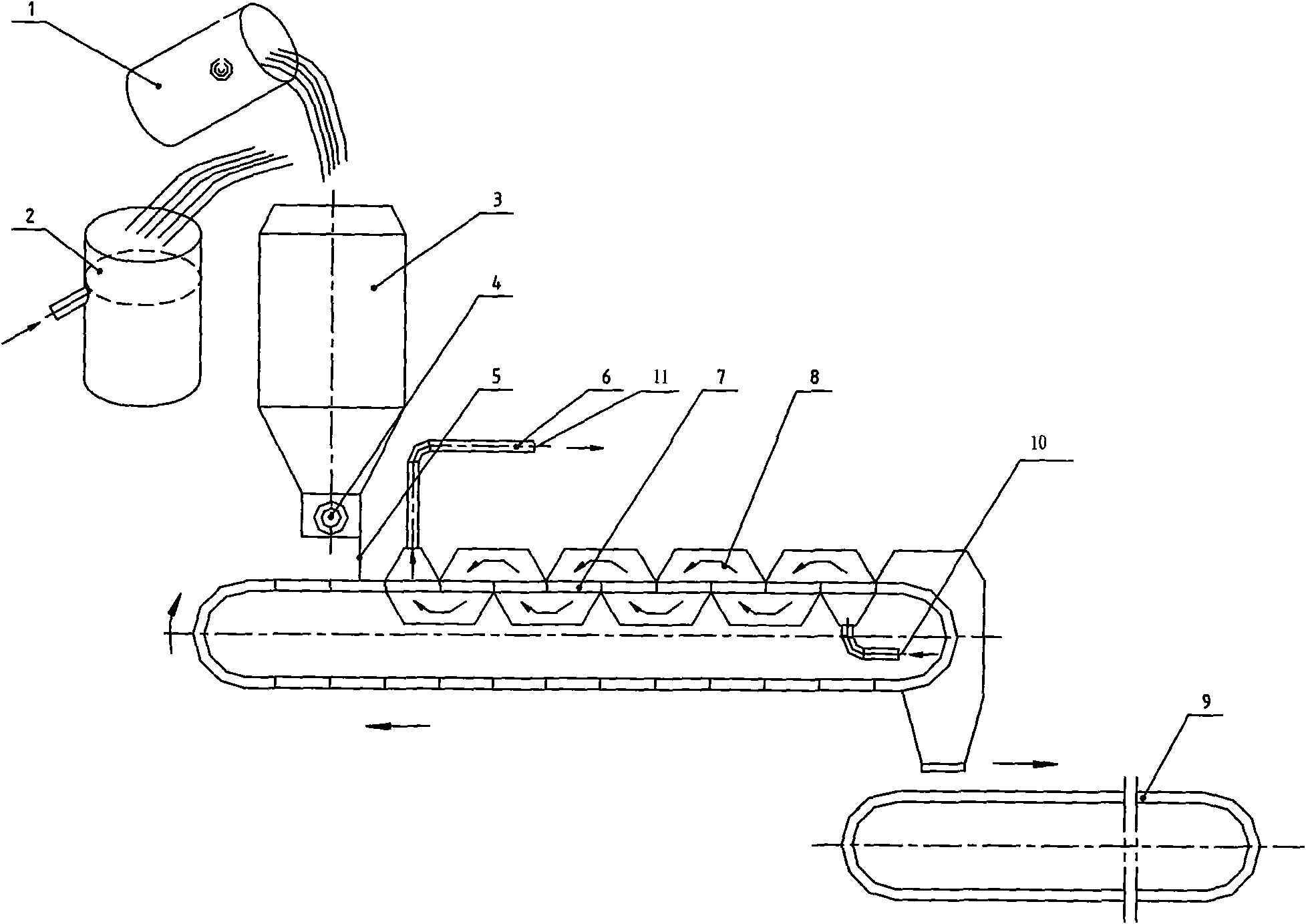

Melting iron and steel slag heat energy recovery method and device

InactiveCN101619367AEfficient use ofEfficient recyclingRecycling and recovery technologiesProcess efficiency improvementThermal energyRecovery method

The invention relates to a melting iron and steel slag heat energy recovery method and a device, which can be applied to enterprises and production technologies relating to slag discharging under high temperature in fields like iron and steel, nonferrous metal metallurgy, etc. The invention comprises the following steps: placing melting iron and steel slags from blast furnace or revolving furnace and a small quantity of cold state iron and steel slags into a heat insulation tank; mixing evenly to ensure that a slag pool is formed in the slag tank; enlarging heat exchange area by the granulation effect of the cold slag on the melting iron and steel slag to ensure that the heat energy of melting slag is effectively recovered; realizing the process of heat energy recovery by blowing in cold wind and introducing hot wind into a waste heat boiler after the cold wind is heated. The invention fully utilizes sensible heat in slag discharging, centralizes the heat slags in a storage tank by granulating cold slags to realize heat energy recovery, therefore, the invention has simple technology, low cost, and can utilize waste heat resources effectively; besides, ferrous recovery and reuse can be carried out on the slags after treated under a low temperature.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

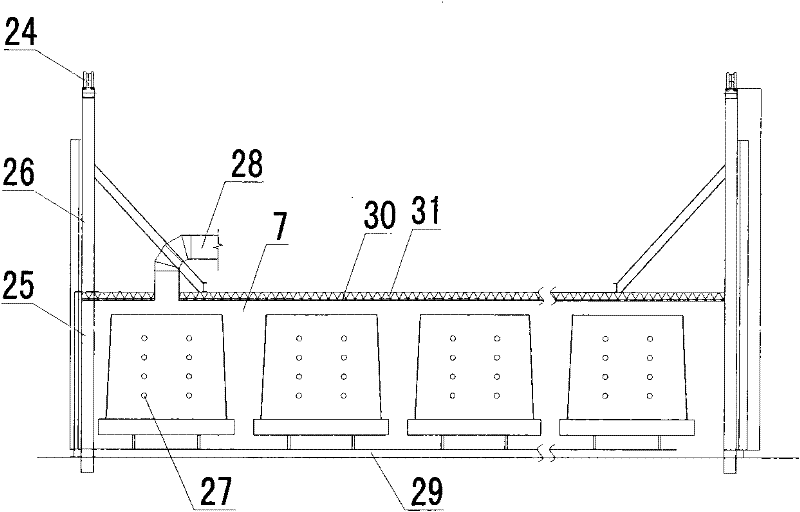

Continuous tempering furnace and processing technique of bent tempered glass

InactiveCN101628783AQuality improvementLower skill requirementsGlass tempering apparatusGlass productionHigh energyHeating furnace

The invention relates to a continuous tempering furnace used for processing bent tempered glass, comprising a heating furnace and a quenching air duct. The front end and the rear end of the heating furnace are respectively provided with a feed port and a discharge port, respectively. The heating furnace consists of a hot forming region, a glass balanced heat-preservation region and a fast heating region which are arranged sequentially. A track and a driving device are arranged at the bottom of the heating furnace and the quenching air duct. A plurality of mobile trolleys running through the heating furnace and the quenching air duct run on the track, and the mobile trolleys are driven to run by the driving device. The invention further discloses a processing technique of bent tempered glass utilizing the tempering furnace. The tempering furnace has reasonable structure, high production efficiency, convenient operation and high energy utilization rate.

Owner:陈永乐

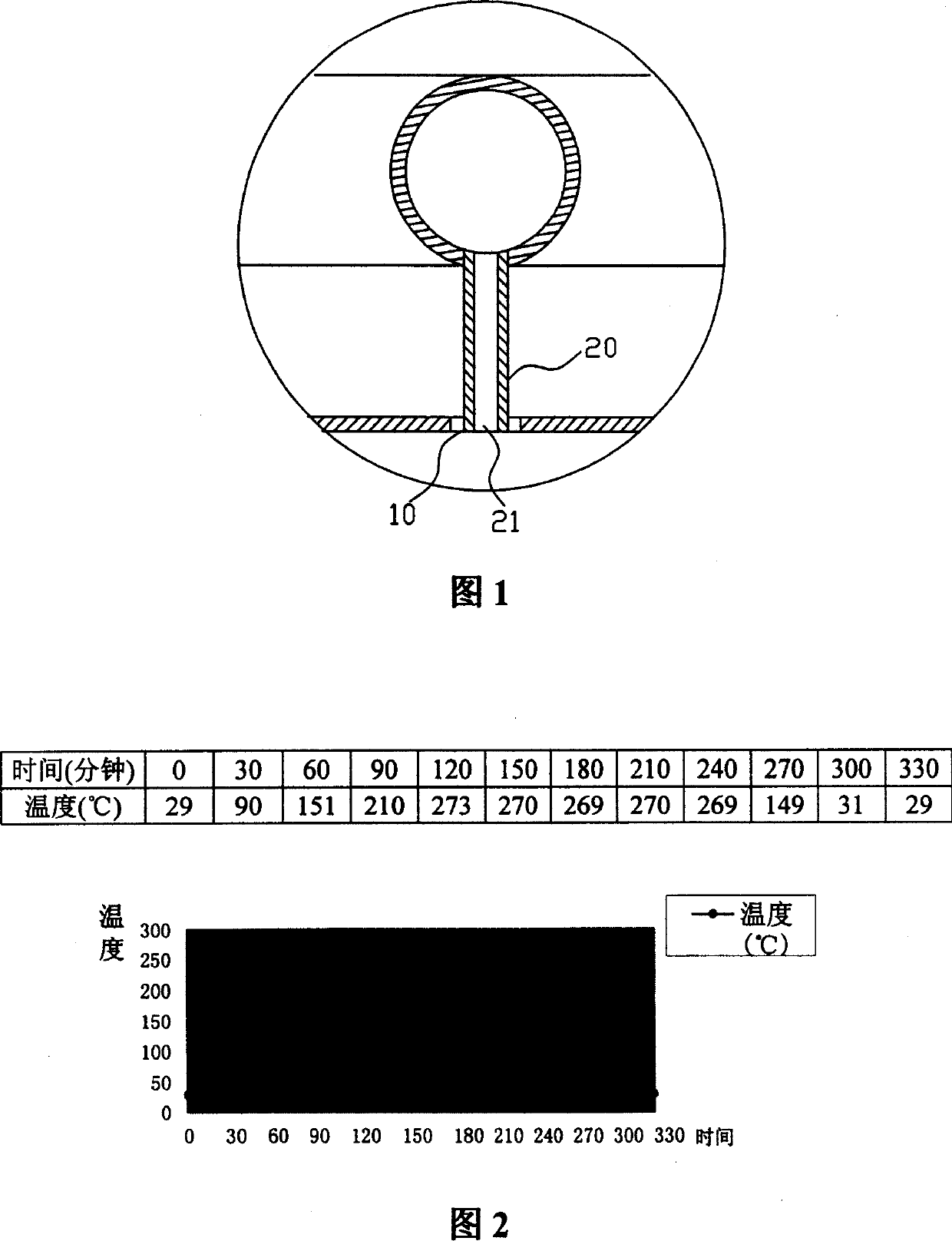

Technology and device for recycling waste heat of electrically fused magnesia smelted block

InactiveCN102345983AAchieve mechanical propertiesAchieve brokenIncreasing energy efficiencyWaste heat treatmentCold airCold blast

The invention relates to a technology and a device for recycling waste heat of an electrically fused magnesia melted block, which are characterized in that after a high-temperature magnesia melted block smelted in an electrically fused magnesia processing technique is entirely cooled in a tunnel heat exchange chamber, magnesia crystal crystallization and solidification are quickly completed, and hot air with medium-low temperature being preheated to be 200-300 DEG C is simultaneously obtained. The solidified magnesia melted block is hulled and cracked at high temperature to produce a high-temperature block. Cold air and the hot air with the medium-low temperature from the tunnel heat exchange chamber are fed into a high-temperature heat exchange tower to carry out heat exchange with the high-temperature block through a circulation air cooling method, hot air with high temperature being more than 1000 DEG C is generated to be fed into a mineral aggregate preheating tower, and magnesite is preheated to be more than 500 DEG C, so that the charging of hot materials is realized.

Owner:SHENYANG DONGDA IND FURNACE +1

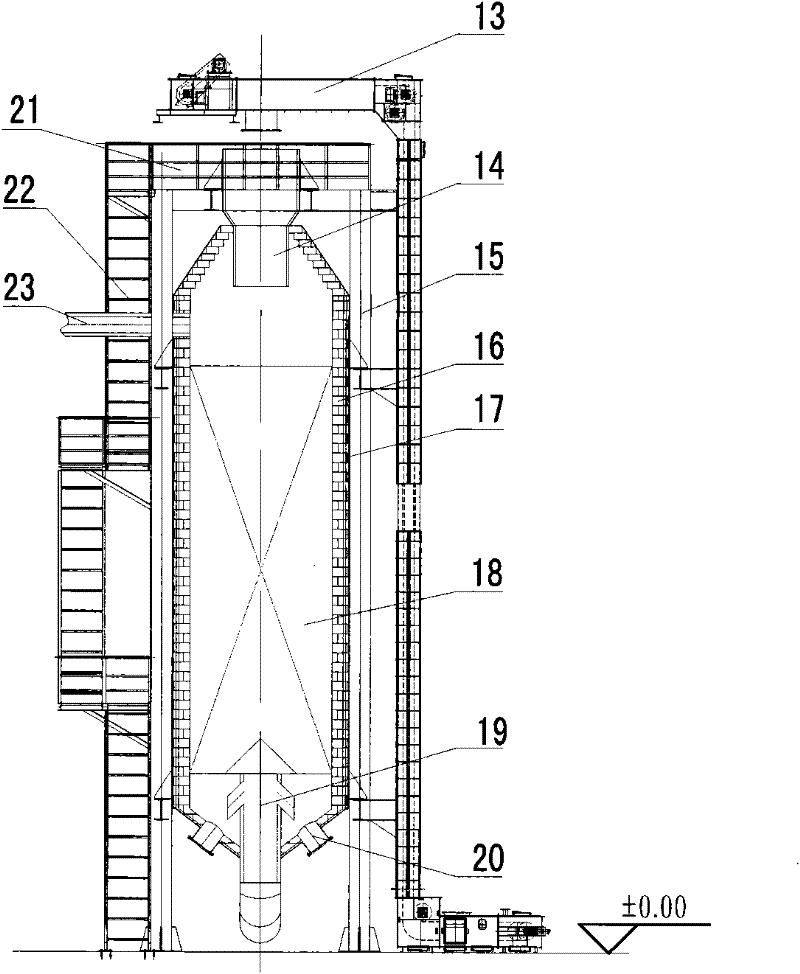

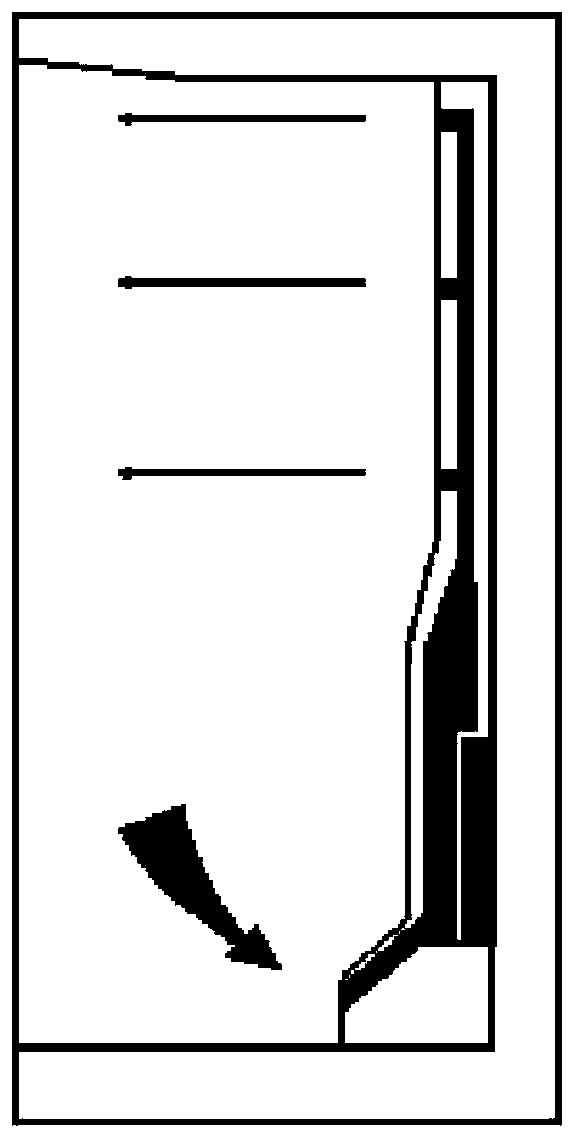

High-temperature material vertical cooler and waste heat using system

ActiveCN103424001AReduce breakageImprove yieldIncreasing energy efficiencyHandling discharged materialSuperheaterEngineering

The invention relates to a high-temperature material vertical cooler and a waste heat using system. The high-temperature material vertical cooler comprises a cylindrical machine body supported by a support, the lower portion of the machine body is a cold air input section, the middle portion of the machine body is a cooling section, and the upper portion of the machine body is a material input section. In the cooling section, materials are cooled by means of combination of air draft and air blowing, heat of the high-temperature materials is obtained by cooling air and a cooling pipe by means of heat conduction and conversion, and preheating is conducted on circulating water through a water cooling wall; the high-temperature cooling air is used for overheating steam generated by the vertical cooler and after the temperature of the cooling air is decreased, the cooling air is led to preheat sintering raw materials in a sintering machine; after air heated by a condenser is mixed with the cold air and the air is led to a central funnel cap; steam generated by the vertical cooler is led to a turbine to drive an electric generator to generate power after passing through a steam super-heater; water output by the condenser and a steam pocket is led to a deoxidizing machine for deoxidization and then is led to a water cooling wall so that circulation can be achieved. The high-temperature material vertical cooler is compact in structure, capable of greatly reducing air leakage of a system, guaranteeing the quality of the materials and effectively recycling the waste heat of the high-temperature materials in a stepped mode.

Owner:XI AN JIAOTONG UNIV

Air supply system of refrigerator, refrigerator and air supply method

ActiveCN103851852AImprove the preservation effectImprove temperature uniformityLighting and heating apparatusCooling fluid circulationProcess engineeringCold blast

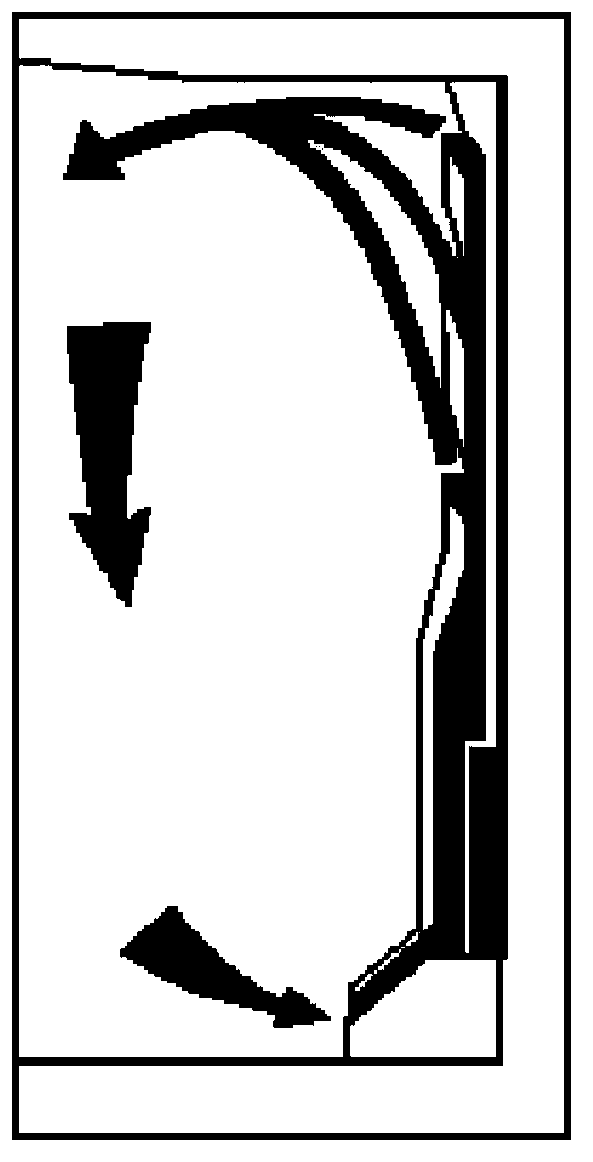

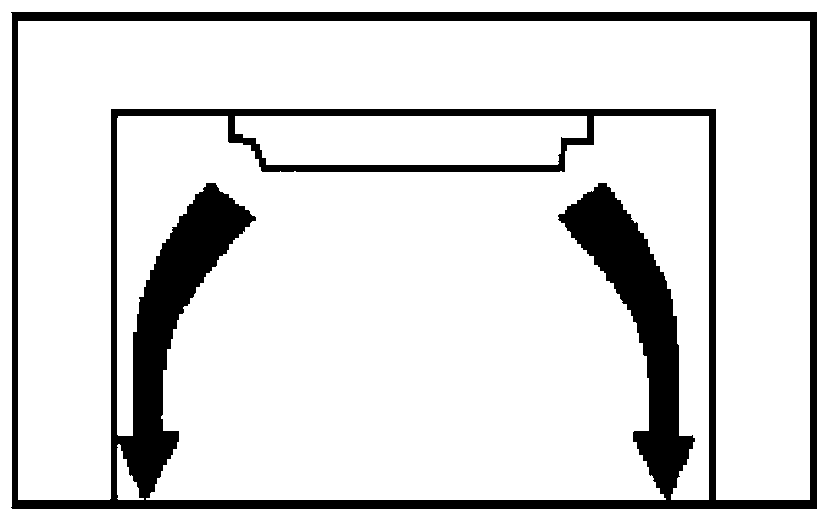

The invention relates to an air supply system of a refrigerator, the refrigerator and an air supply method. The air supply method is characterized in that small separated circulations are formed by respective and independent air supplying in each area separated by laminating frames, elevation-type air supply is adopted in an upper area of a refrigerator body, diving-type air supply is adopted in a middle area of the refrigerator body, thus reverse circulation of the middle area of the refrigerator body is caused, and airflow disturbance is formed by joining downward airflow with reserve airflow. According to the air supply system of the refrigerator, the refrigerator and the air supply method, disclosed by the invention, independent air supply in each area of the refrigerator is realized, thus no dead corner is generated in the refrigerator, the temperature uniformity is good, the refrigerating efficiency is high, food cannot be directly blown by cold air, and the fresh preservation capacity of the food is obviously increased; in addition, the elevation-type air supply is matched with the diving-type air supply, thus the reserve circulation can be formed in local areas, the active airflow disturbance can be caused, the non-uniformity of refrigerating capacity is overcome, the loss of the refrigerating capacity is reduced, and the temperature balancing performance and the refrigerating efficiency are further increased.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

Air blowing method employing top cover to blow air and air-cooling type refrigerator employing the method

InactiveCN1880894AFast coolingImprove cooling effectShow cabinetsLighting and heating apparatusRefluxEngineering

The invention relates to a wind cold refrigerator and a method for feeding wind with top cover, wherein said method comprises: using force wind cycle refrigerating system to flow cold wind in refrigerator to cool food; the invention is characterized in that: the wind open is arranged on the top cover of refrigerator; the reflux open is on the bottom wall to feed the cold wind from down to up to the cold room. The inventive refrigerator is characterized in that: the wind open is on the top cover; the reflux open is on the bottom wall. The invention can force the air cooled by vaporized into the cold room, to be blown into cold room from up to down, to obtain high cooling speed, better cooling effect, and high efficiency.

Owner:HAIER GRP CORP +1

Method for mfg. high strengthening environmental protection fireproof glass

InactiveCN1693246AStrength reachedReach strength stressGlass tempering apparatusGlass productionManufacturing technologyHigh intensity

A high-strength fire-proof glass is prepared from ordinary float glass through cold treating, heating it to its softening point in a special strengthening furnace, and moving it through a special wind wall of compressed air at a speed of 300-500 mm / s for cooling and strengthening it.

Owner:何志强

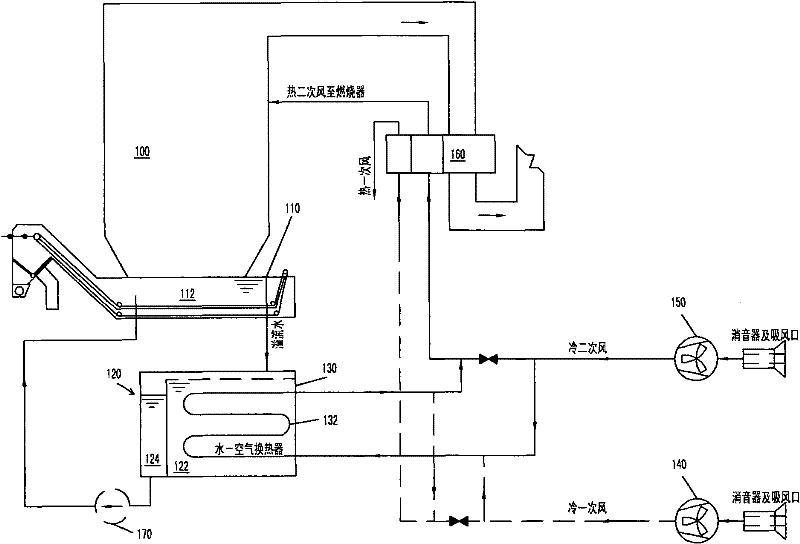

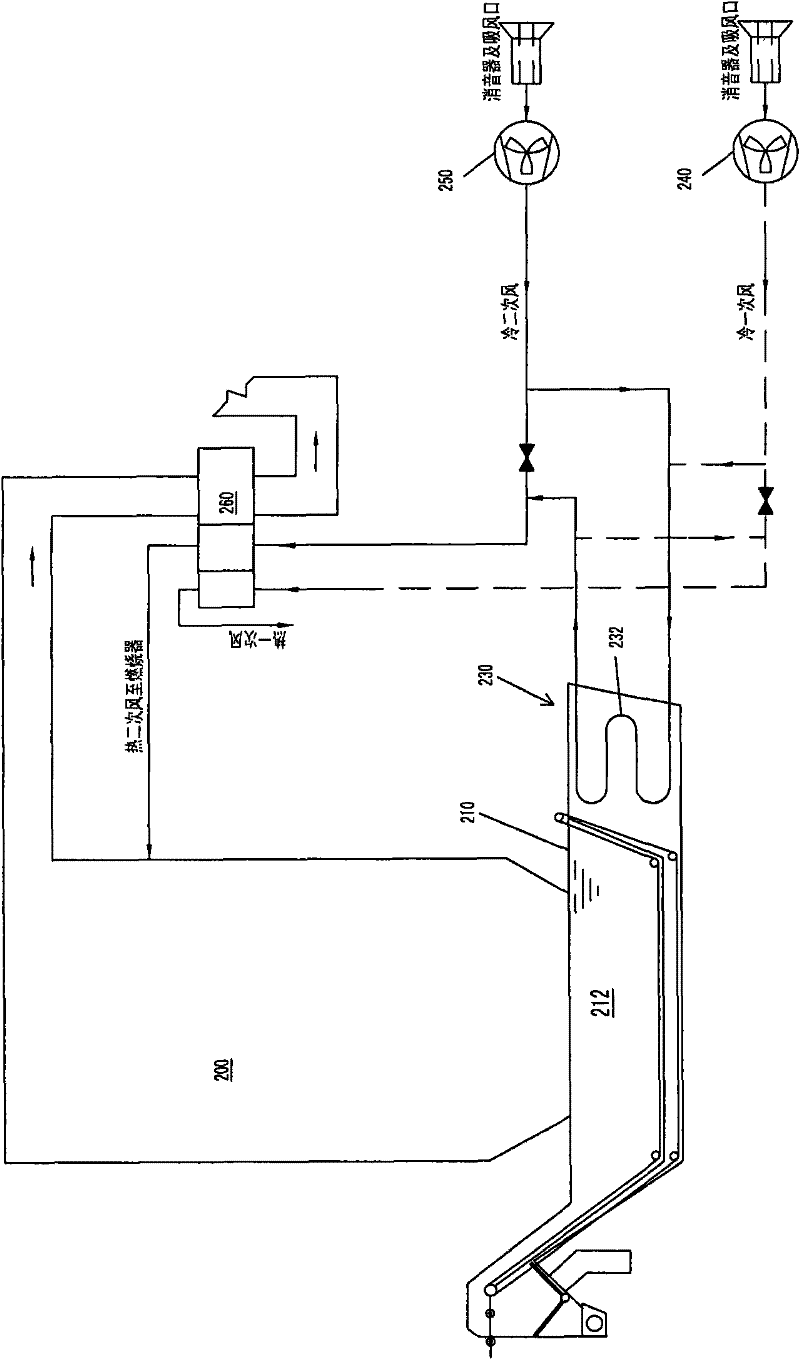

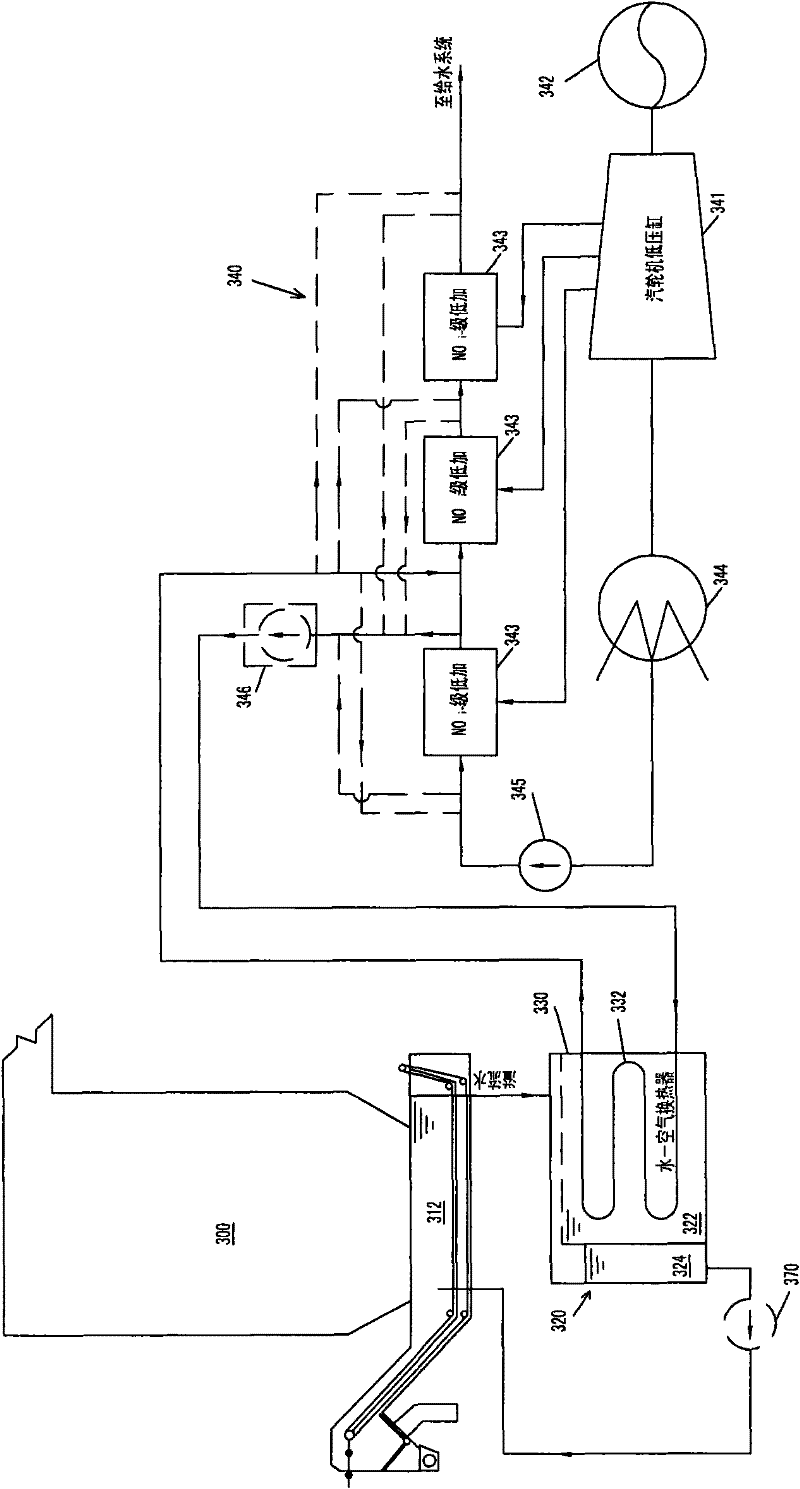

Method and system for comprehensive utilization of tail heat of boiler

InactiveCN103398369AImprove efficiencyReduce lossesLiquid degasificationCombustion processCold airAir preheater

The invention relates to a method and system for comprehensive utilization of tail heat of a boiler. According to the method and system for comprehensive utilization of the tail heat of the boiler, low-level steam extraction is carried out by means of a turbine, in-boiler cold air in a boiler air inlet duct connected with the boiler is heated by extracted steam through a steam air heater, heated cold air in the steam air heater enters an air pre-heater through the boiler air inlet duct, heat exchange is carried out in the air pre-heater between part of smoke from a boiler economizer or a denitration device and the heated cold air, and the other part of smoke is used for heat exchange of part of supplied water through a water supply economizer. According to the method and system for comprehensive utilization of the tail heat of the boiler, the low-pressure steam is extracted to heat the cold air so that the heat of the steam is recovered to reduce cold source loss, part of the high-temperature smoke is saved at the same time, and the saved high-temperature smoke is used for heating part of the supplied water through an outlet flue of the economizer or an outlet flue the denitration device; high-level extraction steam of the turbine is saved due to the fact that the high-level smoke is used for heating part of the supplied water, the saved high-level extraction steam can continue to work in the turbine, and then the efficiency of the turbine is improved and fuel coal is saved.

Owner:吕克庆

Boiler wet slag removal system

InactiveCN102287835AIncrease power generationReduce fuel consumptionCombustion processMachines/enginesAir preheaterBottom ash

The invention relates to a boiler wet slag removal system, which comprises a slag extractor and a heat exchanger. The slag extractor is located under the boiler and has a water tank for receiving boiler bottom slag. The heat exchanger includes a heat exchange surface, one side of the heat exchange surface introduces the water in the water tank as the first heat exchange medium, and the other side of the heat exchange surface is the flowing second heat exchange medium to absorb the water in the water tank energy. In one solution of the present invention, the second heat exchange medium can be air, which is provided by the blower or the primary blower of the boiler, and is sent to the air preheater for the boiler together with the cold air of the blower or the primary blower after being heated . In another solution of the present invention, the second heat exchange medium can be condensed water, which is provided by one or more low-pressure heaters of the steam turbine condensate system, and is heated and delivered to one or more low-pressure heaters . In this way, the waste heat of the slag can be recovered, which simplifies the structure of the wet slag removal system and reduces the water consumption.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

Cold-storing type water-circulation fan air conditioner

ActiveCN102788395AExtended use timeEasy to operateSpace heating and ventilation safety systemsLighting and heating apparatusSolenoid valveEngineering

An air conditioning fan type cold-storing type water-circulation fan air conditioner comprises cold storing tanks, a refrigerating chamber, a water tank, tubular fin type cold-scattering (radiating) sheets, a water pump, a three-way solenoid valve and the like. A plurality of cold storing tanks cooled by a refrigerator and serving as a refrigerating source are placed in the refrigerating chamber in turns and serially connected with the solenoid valve, the water pump, the tubular fin type cold-scattering (radiating) sheets and the water tank with a positive temperature coefficient (PTC) heater serially through a water pipe to form a water-circulation temperature-control system. The temperature-control system can continuously feed cold air in a long time according to the set temperature without any refrigerating device. The cold-storing type water-circulation fan air conditioner adopts water circulation for refrigerating and heating so that the air at the air outlet can achieve the human comfortableness standard, and the cold-storing type water-circulation fan air conditioner is good in temperature control, capable of moving, free of installation, low in cost, saving in electricity, free of noise and small in size, has no heat source in refrigerating, can continuously blow out natural cool air for a long time, is convenient to operate and can be used widely.

Owner:中山市壹比壹节能环保科技有限公司

Cold air path structure of refrigerator

ActiveUS7240511B2Improve efficiencyIncrease available spaceSewerage structuresLighting and heating apparatusCold airEngineering

Owner:LG ELECTRONICS INC

Bottom lifting type resistance heating annealing furnace

InactiveCN102219364AHigh degree of automationImprove furnace temperature uniformityFurnace temperatureCold blast

The invention discloses a bottom lifting type resistance heating annealing furnace comprising a furnace body, a furnace cavity and a control device. A movable furnace bottom cover is arranged on the bottom surface of the furnace body, travelling wheels are arranged below the furnace bottom cover, the furnace bottom can be lifted under the driving of a lifting device, after being lifted, the furnace bottom cover is closely matched wit the furnace body so as to form a work bottom surface of the furnace cavity, and being descended, the furnace bottom cover drops on a matched track, and the travelling wheels can move on the track; a plurality of electric heaters are arranged on the side surface of the furnace cavity; a fan, the top guide plate and a side guide plate are arranged on the top end of the furnace cavity, a certain gaps is arranged between the side guide plate and the electric heater so as to form an air circulation channel, a cooling air channel is arranged on the furnace body, and used for sending cooling air into the furnace cavity. For the annealing furnace, the degree of automation is high; the processes such as loading, travelling, lifting of movable furnace bottom, heating for temperature rising, temperature reducing and the like are conducted under the control of the control device, and the degree of automation is high; and in the heating process, the annealing furnace achieves the demands that the furnace temperature uniformity is higher, the furnace temperature stability is higher, and the temperature reducing rate can meet the thermal treatment process.

Owner:重庆飞达电炉有限公司

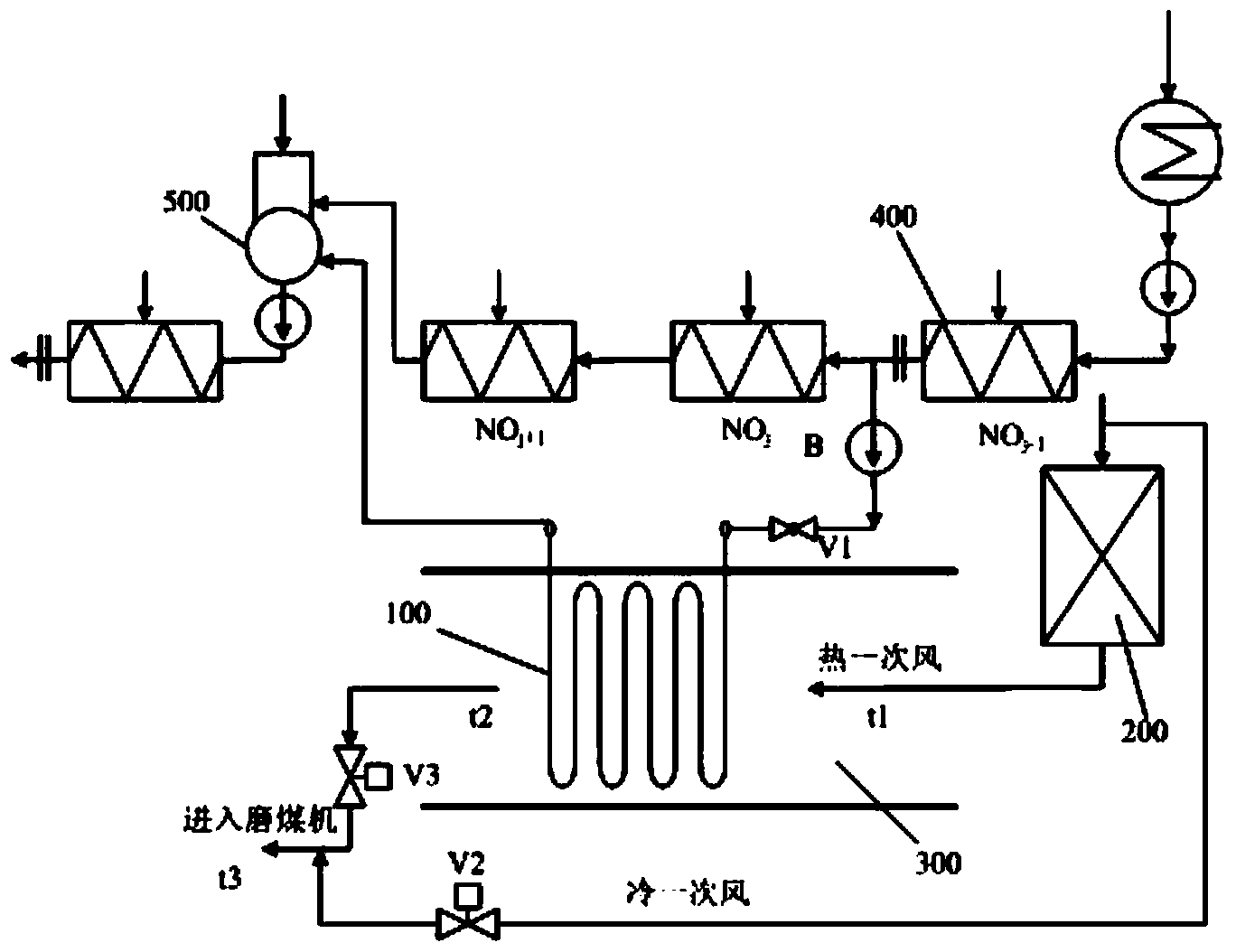

Primary air cooler heat regenerative system and controlling method

ActiveCN103438686AReduce cooling air volumeLower exhaust gas temperatureDrying gas arrangementsGrain treatmentsAir preheaterWater use

The invention discloses a primary air cooler heat regenerative system and a controlling method. According to the primary air cooler heat regenerative system and the controlling method, a primary air cooler is arranged in a primary heat air duct of an outlet of a boiler air heater, low-pressure supplied water used as cooling water is introduced by a coal-fired unit low-pressure water-supply heat regenerative system, heat of primary heat wind is absorbed, the heated supplied water is sent back to a unit deaerator, the flow of the cooling water is adjusted so as to enable the temperature of the primary wind to be reduced to meet the temperature requirement of drying medium at the inlet of a coal mill. By means of the technical scheme, the cold wind amount of a side road of a boiler air preheater can be greatly reduced, the smoke exhausting temperature of the boiler is reduced, the power-supply coal consumption of the unit is reduced, and the stable operation of the unit is not affected.

Owner:SHANGHAI MINGHUA ELECTRIC POWER TECH & ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com