Patents

Literature

62results about How to "Improve furnace temperature uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum alloy heating furnace and heat treatment furnace

InactiveCN101619427AMeet the requirements of different processing techniquesWide Temperature Operating RangeFurnace typesHeat treatment furnacesFurnace temperatureHearth

The invention provides an aluminum alloy heating furnace and a heat treatment furnace. The heating furnace comprises heaters, circulating fans and fan motors, wherein the heaters are arranged at both sides of the top of the heating furnace, and are used for heating a furnace hearth of the heating furnace with different temperatures; the circulating fans are symmetrically arranged at both sides of the center line of the furnace top along the length direction of the heating furnace, and each circulating fan is provided with a fan motor; and each fan motor adopts a frequency converter to regulate speed, is used for driving each circulating fan to work, and enables each circulating fan to carry out wind circulation on the furnace hearth with different wind speeds. The heat treatment furnace comprises the heating furnace and a quenching device. The aluminum alloy heating furnace has wider temperature work range and favorable uniformity of furnace temperature, and satisfies the technical requirements of heating, annealing, quenching and aging treatment of aluminum alloy. Therefore, the heating furnace has multiple functions without separation manufacture of the aluminum alloy heating furnace and the heat treatment furnace, and saves the investment cost and the occupied area of huge equipment.

Owner:SOUTHWEST ALUMINUM GRP

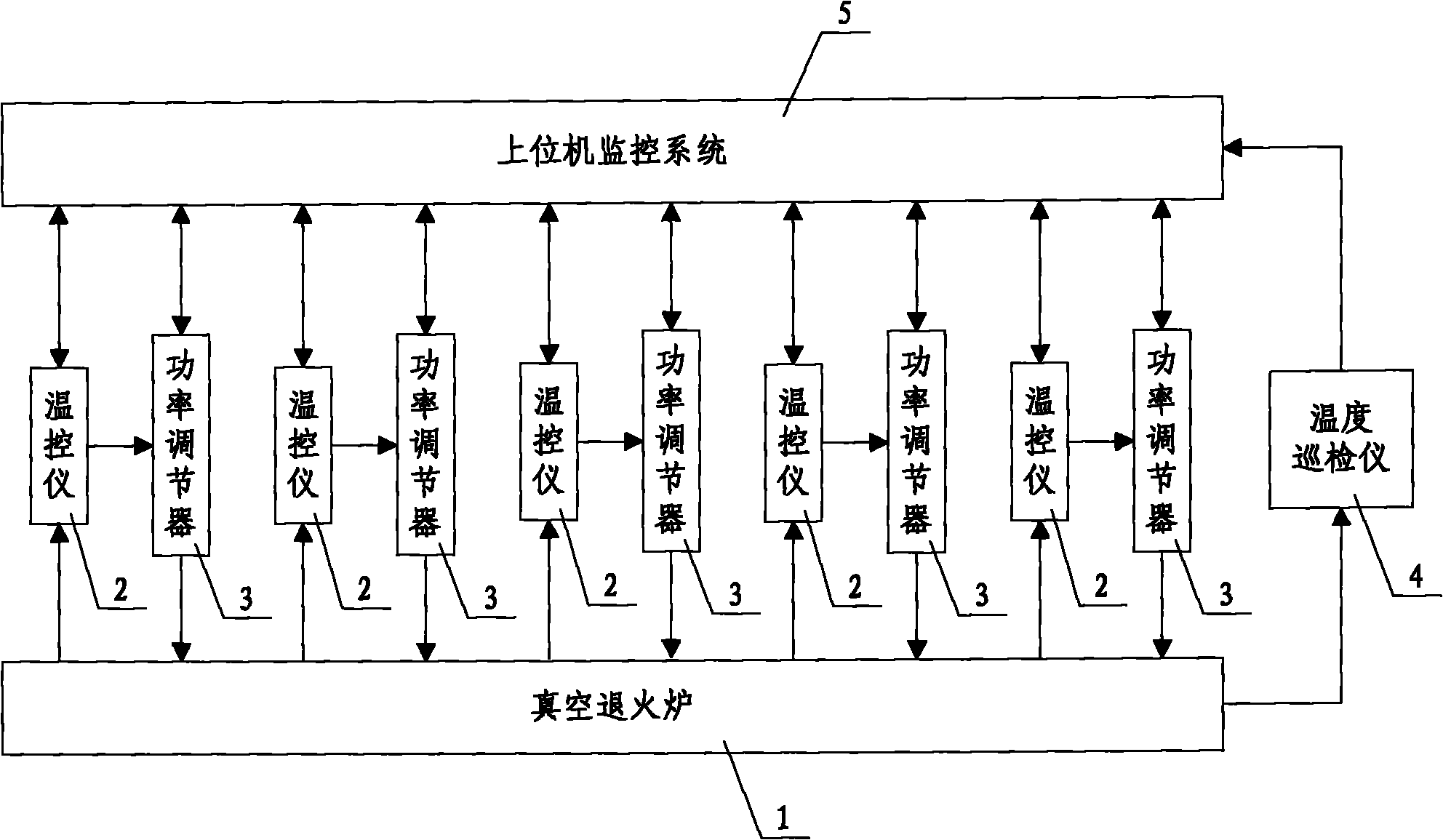

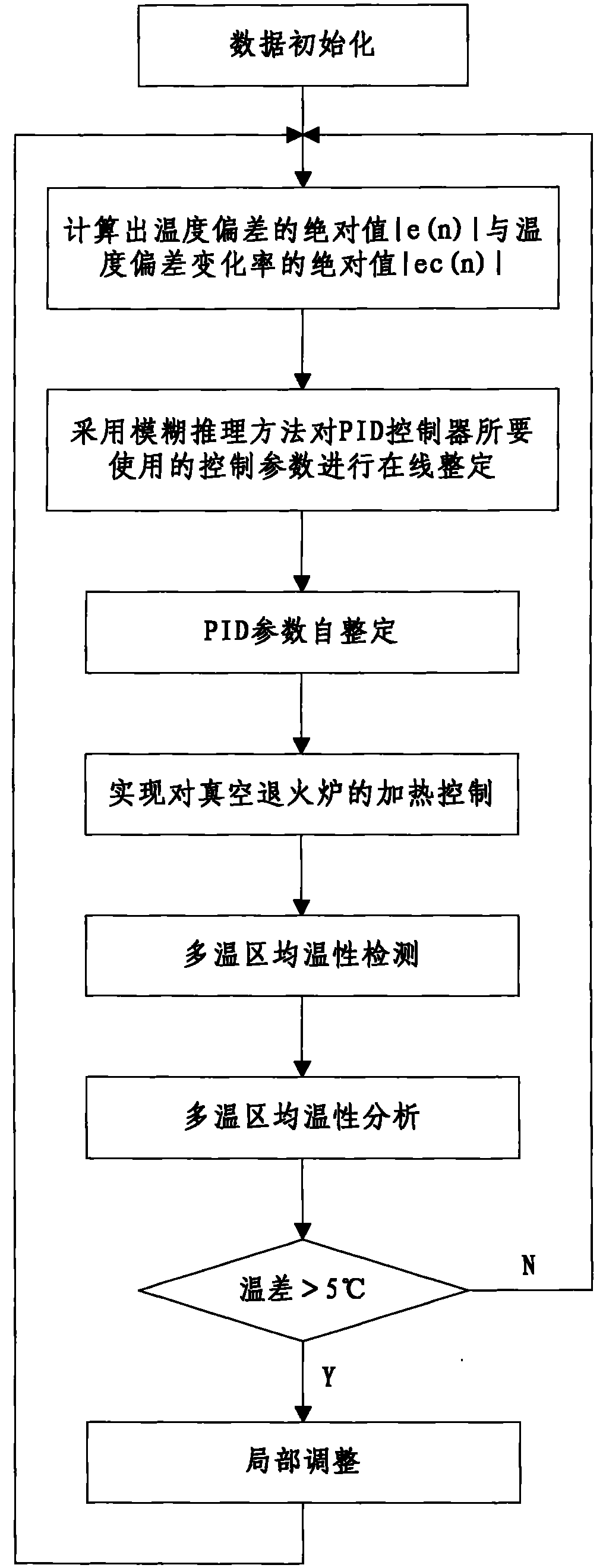

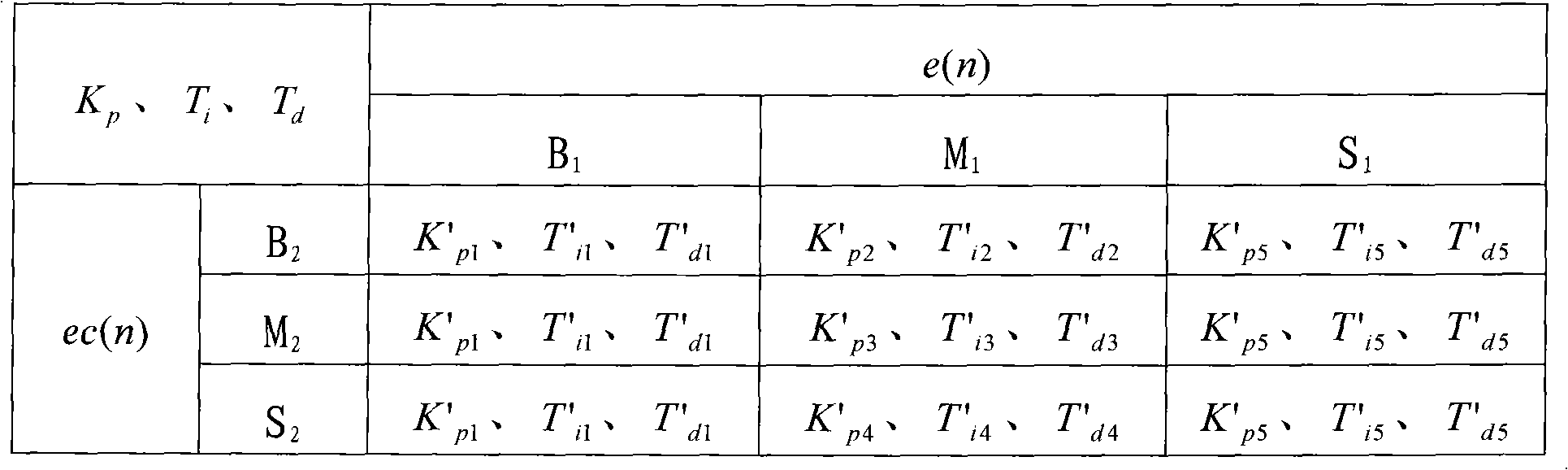

Temperature uniformity control system for multi-temperature zone of large plate vacuum annealing furnace and control method thereof

InactiveCN101962708AHigh degree of intelligenceEasy to useFurnace typesHeat treatment process controlTemperature controlProportion integration differentiation

The invention discloses a temperature uniformity control system for a multi-temperature zone of a large-plate vacuum annealing furnace and a control method thereof. The control system comprises a plurality of temperature controllers, a plurality of power regulators, a uniform temperature data logging device and an upper computer monitoring system, wherein the upper computer monitoring system is used for analyzing detection signals of the uniform temperature data logging device and monitoring the working process of each temperature controller and each power regulator. The control method comprises the following steps of: (1) initiating data; (2) working out the absolute value of the temperature difference e(n) and the absolute value of the temperature difference change rate ec(n); (3) setting control parameters required to be used by a PID (Proportion Integration Differentiation) controller on line by using a fuzzy reasoning method; (4) automatically setting the PID parameters; (5) controlling the heating of the vacuum annealing furnace; (6) detecting the temperature uniformity of the multi-temperature zone; and (7) analyzing and locally adjusting the temperature uniformity of the multi-temperature zone. The control system has the advantages of high temperature control accuracy, good temperature uniformity, high reliability and good adaptivity and robustness, the production process requirements of the rare metal vacuum annealing furnace can be well satisfied, and the control system is convenient for popularization and application.

Owner:XI'AN PETROLEUM UNIVERSITY

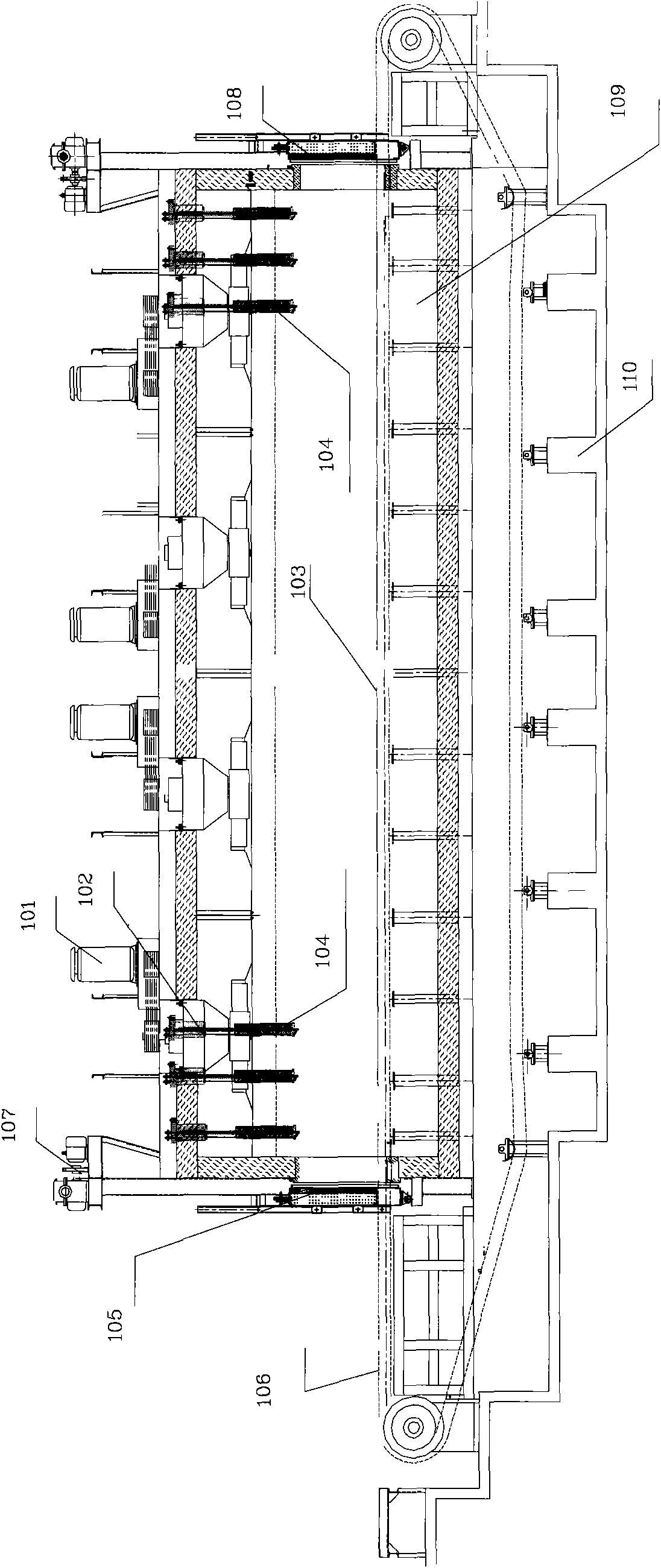

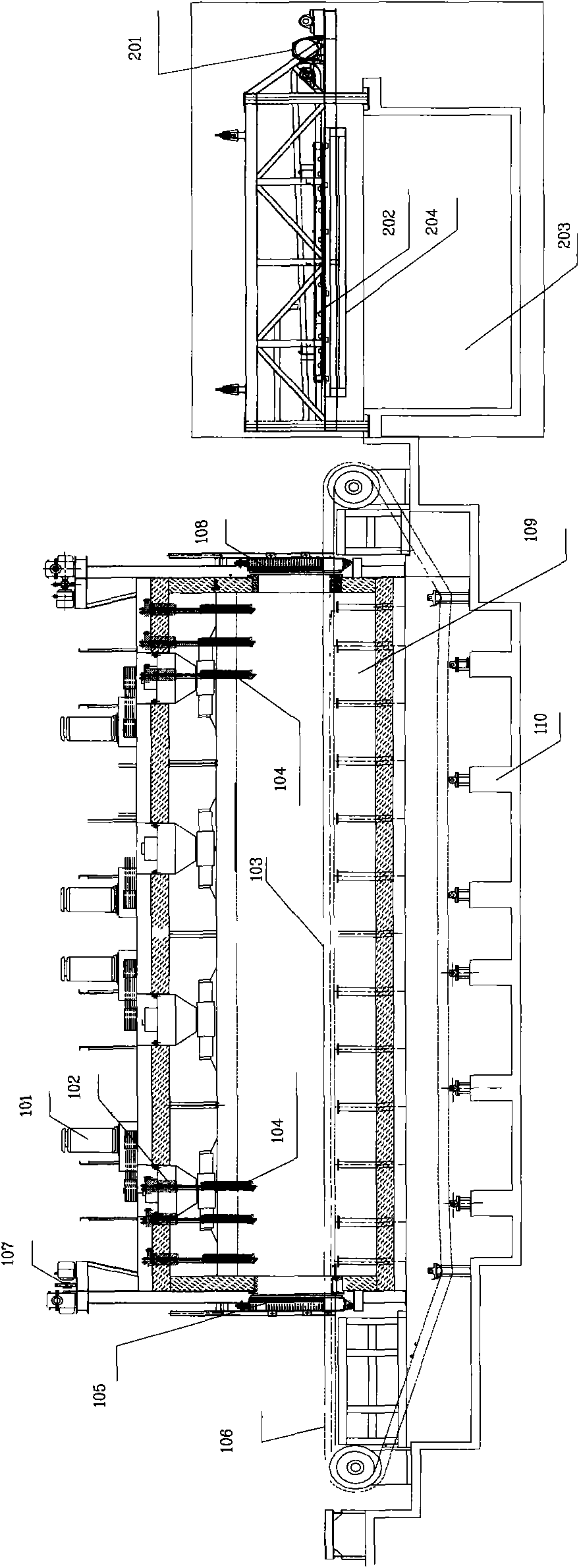

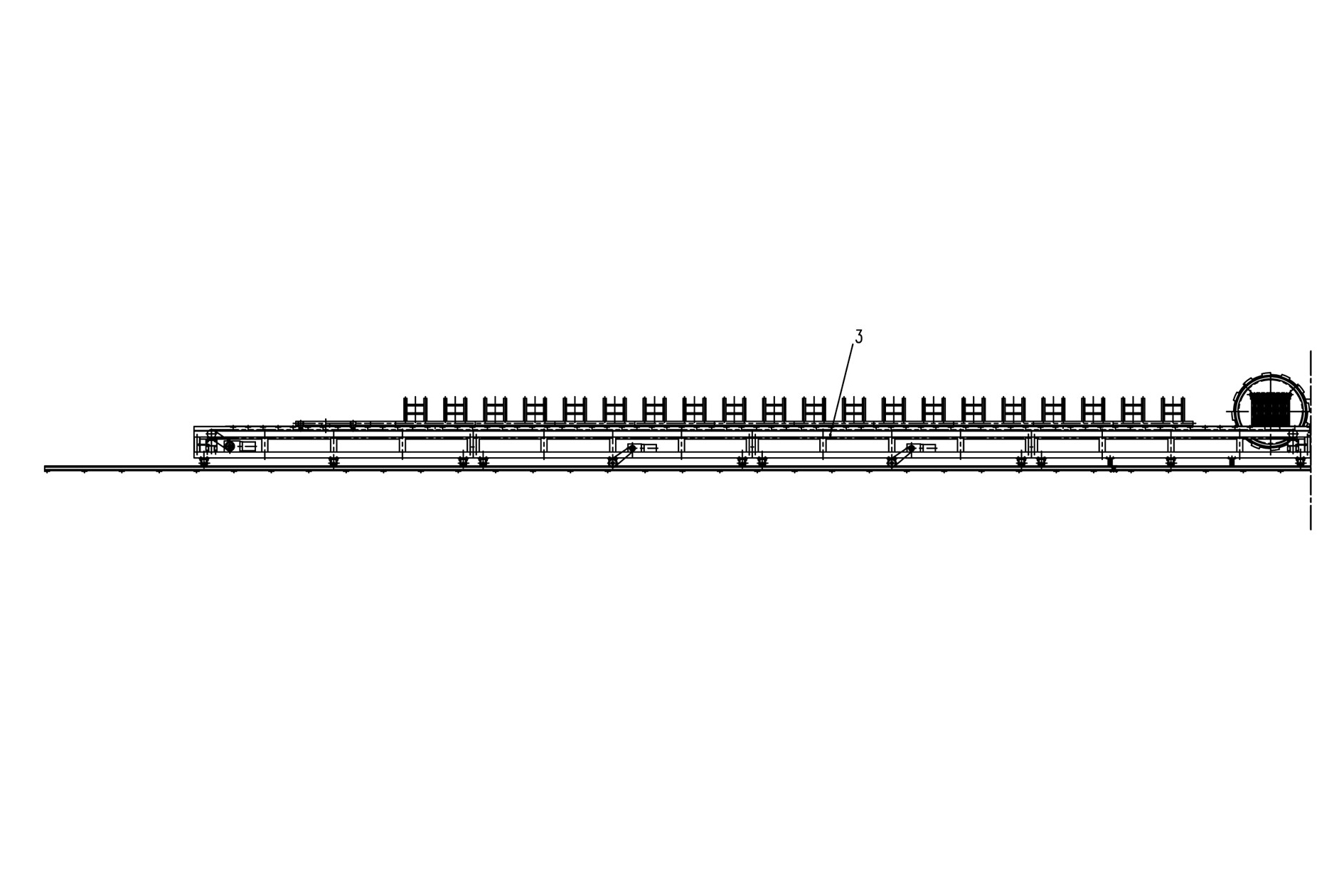

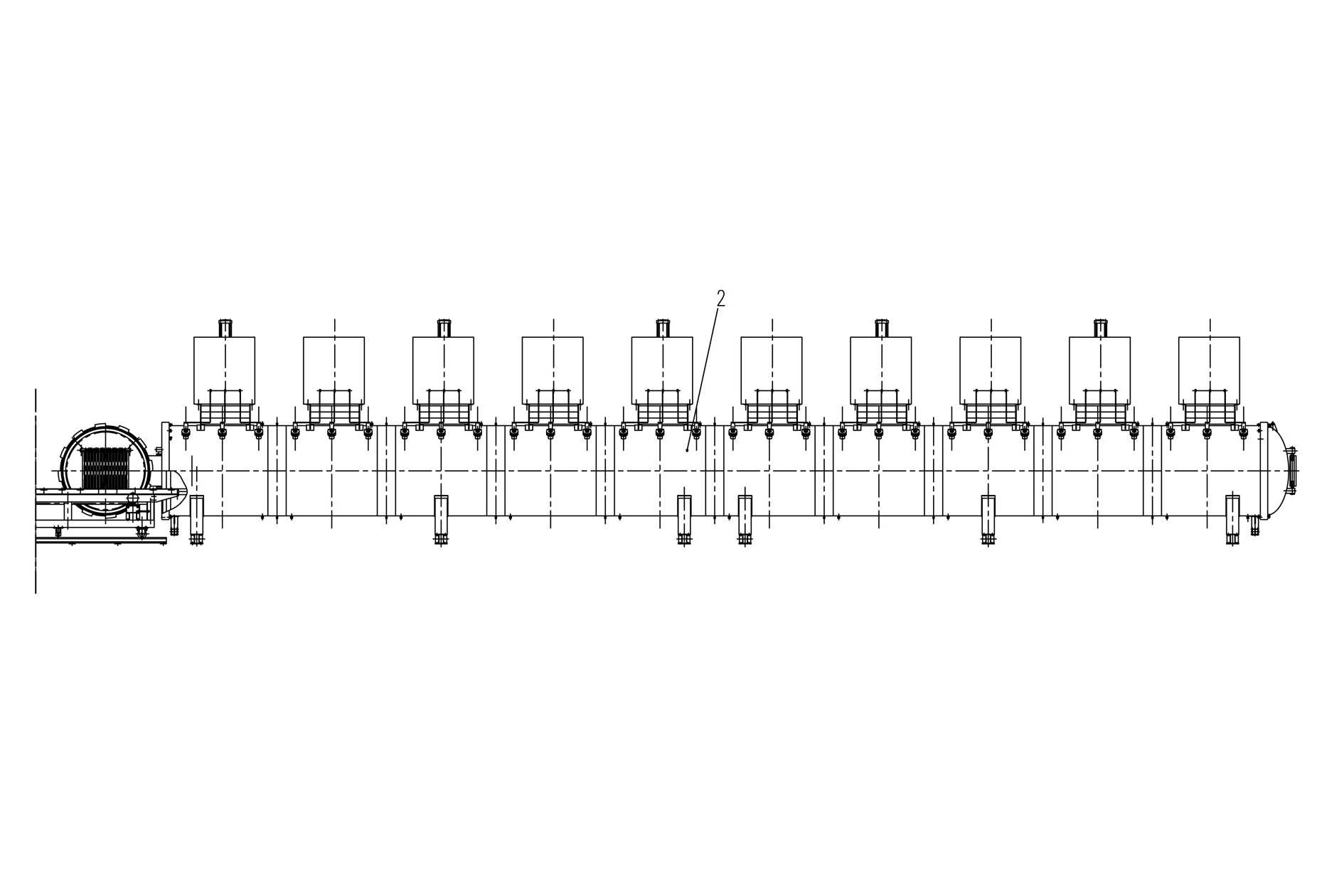

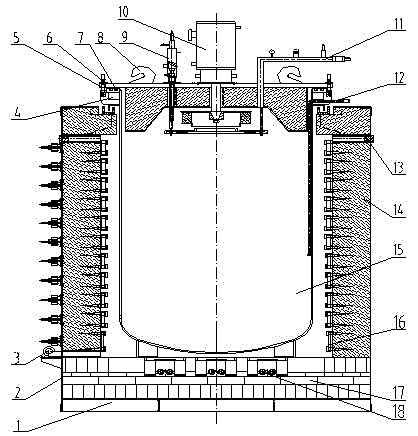

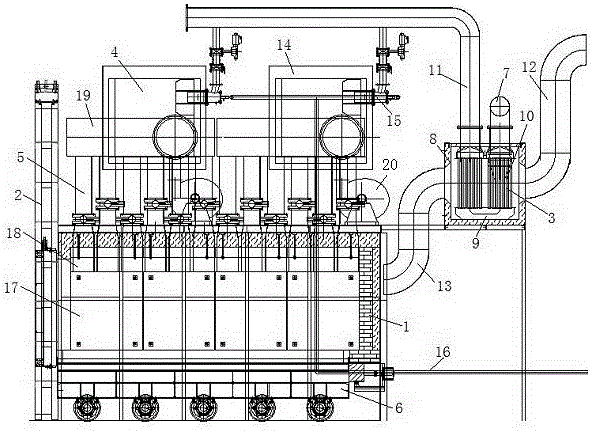

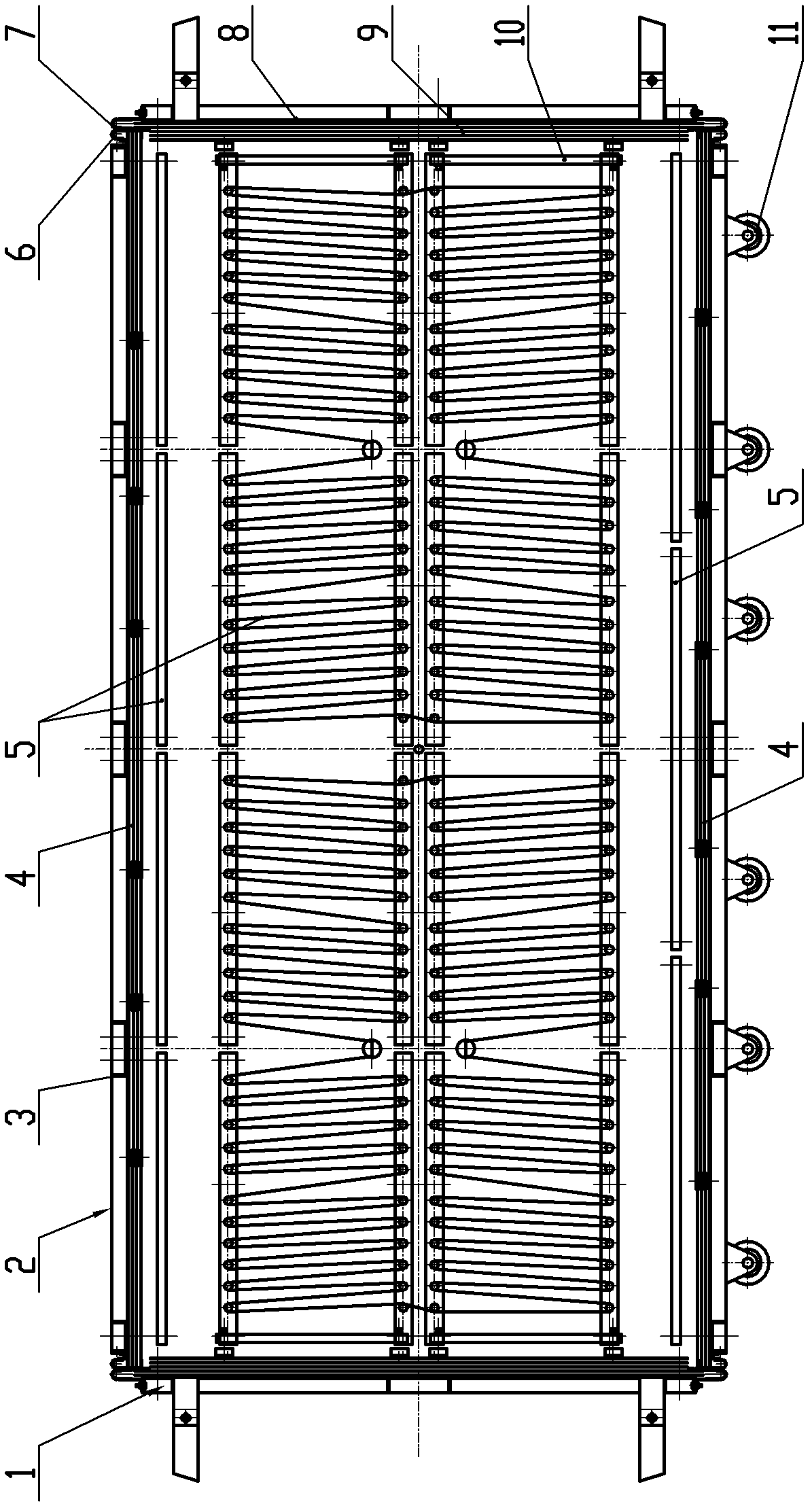

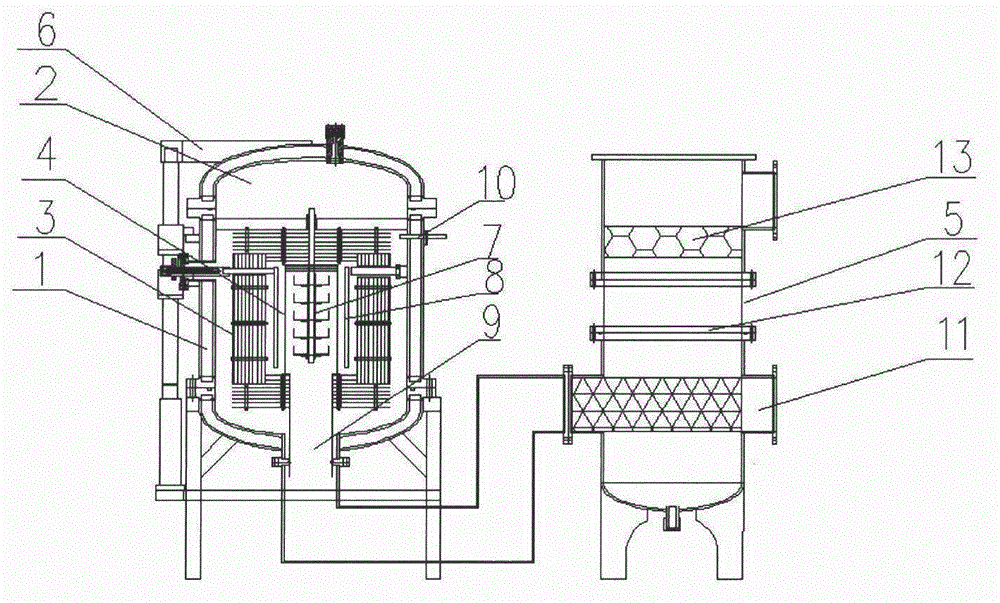

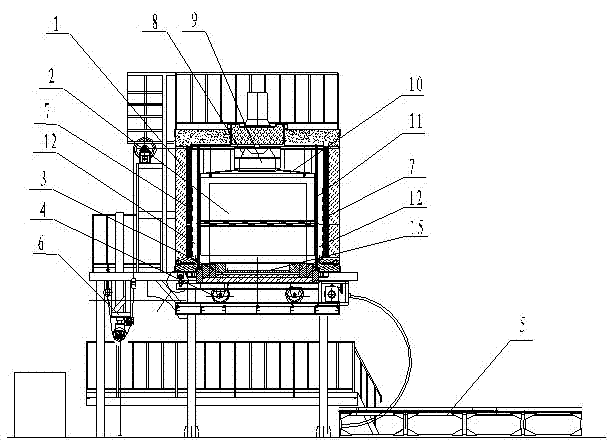

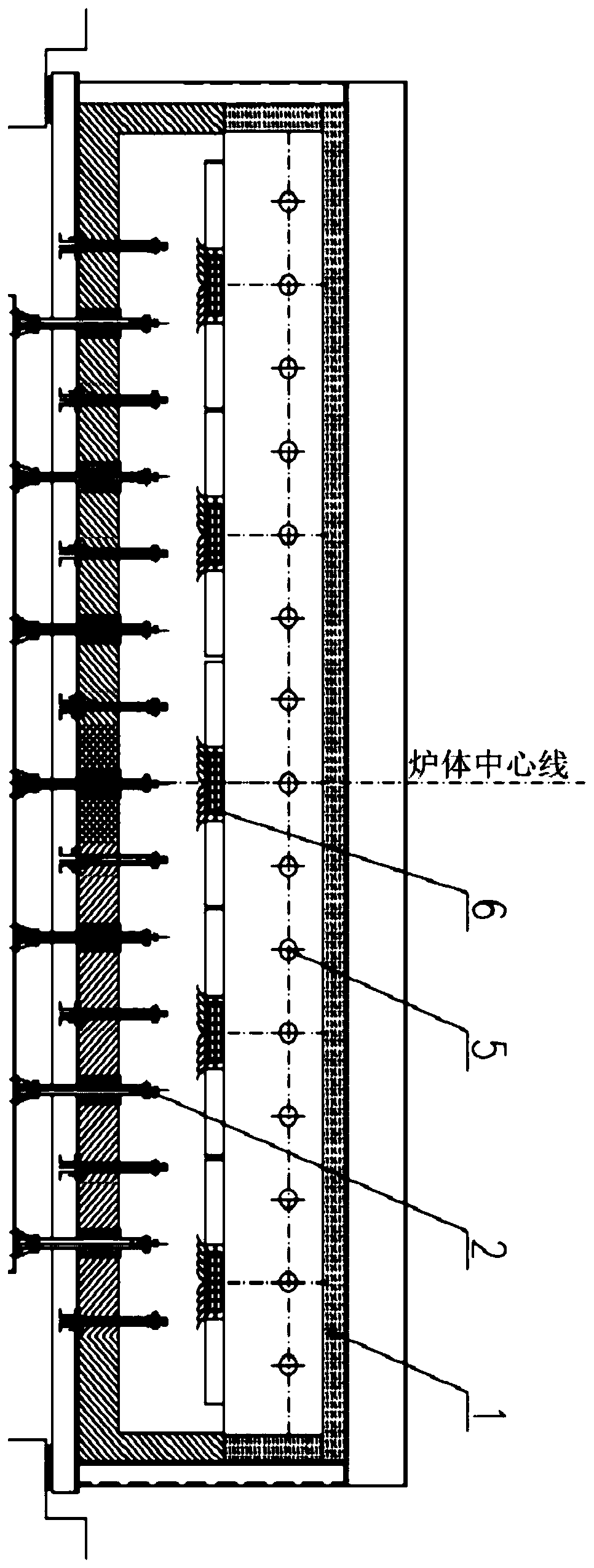

Large vacuum annealing furnace

ActiveCN101956047AHigh precision vacuum and temperature controlGood furnace temperature uniformityFurnace typesEngineeringMultiple layer

The invention discloses a large vacuum annealing furnace which is composed of a furnace body, a heating device, a feeding system, a vacuum system, a cooling system and an electric control system, wherein the heating device is arranged in a furnace pipe; the feeding mechanism comprises a feeding trolley, a trailer wagon, a rack and a guide rail along which the rack moves back and forth; the feeding trolley moves back and forth along a steel rail laid in front of a furnace door under the action of a travelling mechanism; the rack travels on the guide rail by a roller row which is composed of a plurality of parallel rollers, and each roller is connected with a roller row frame by a shaft; the vacuum system is used for maintaining the vacuum degree of each annealing stage in the furnace body; the cooling system at least comprises a cooling water system for cooling each group of heaters; the heating device is composed of a plurality of heaters which are mutually and movably connected, and the heaters are installed in the furnace pipe in order; multiple layers of heat shields are arranged between each group of heaters and the inner wall of the furnace pipe; and the a guide rail along which a feeding rack moves back and forth is provided with a group of dismountable sectioned racks which are movably connected.

Owner:GRIMAT ENG INST CO LTD

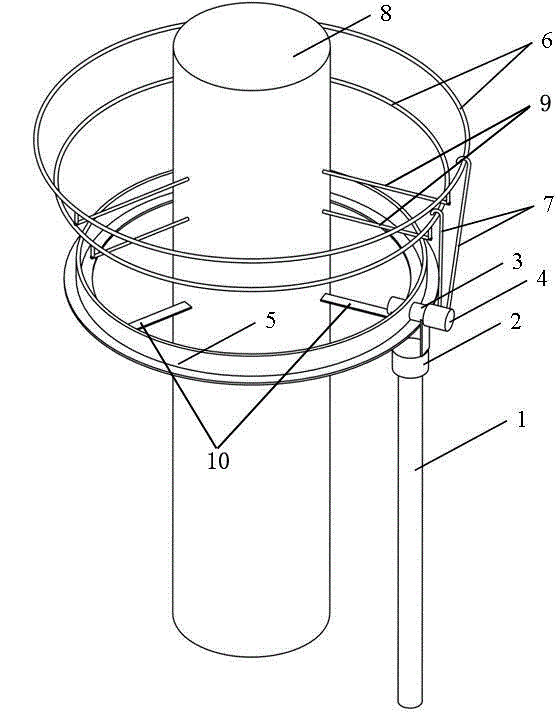

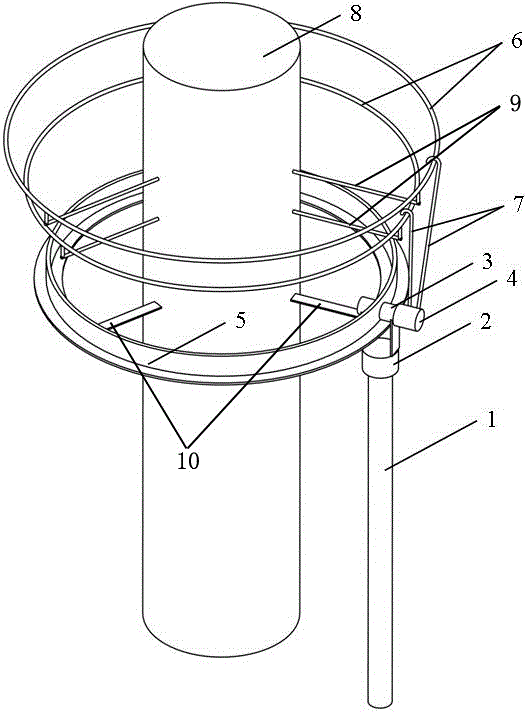

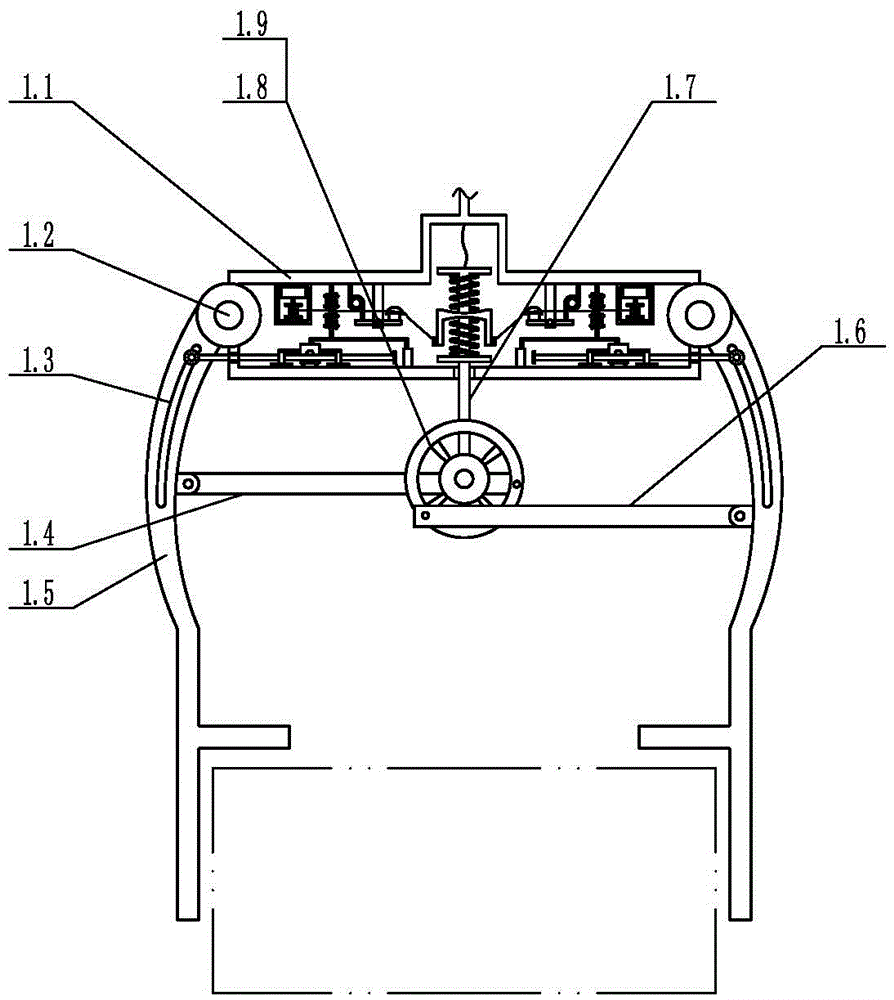

Stirring apparatus for rare earth metal electrolysis furnace

InactiveCN103952727AImprove furnace temperature uniformityImprove performance and stabilityElectrolysis componentsStirring devicesMischmetalFurnace temperature

The present invention discloses a stirring apparatus for a rare earth metal electrolysis furnace. The stirring apparatus comprises a vertical column capable of providing a power supply, wherein an circular track is arranged on the vertical column body and is provided with a track car, the lower portion of the track car is connected with a stirring graphite rod, the vertical car is further provided with two electric cable rings, and the electric cable rings are connected with both poles of a track car micro motor, and further connected with both poles of the vertical column. According to the present invention, the graphite rod stirs the electrolyte in the furnace at a certain frequency so as to increase the uniformity of the temperature of the electrolysis furnace, avoid the excessive carbon content in the product due to the too high or too low furnace temperature and increase the performance stability of the product, and characteristics of strong practicality and easy promotion are provided.

Owner:GANZHOU SANYOU RARE EARTH NEW MATERIAL

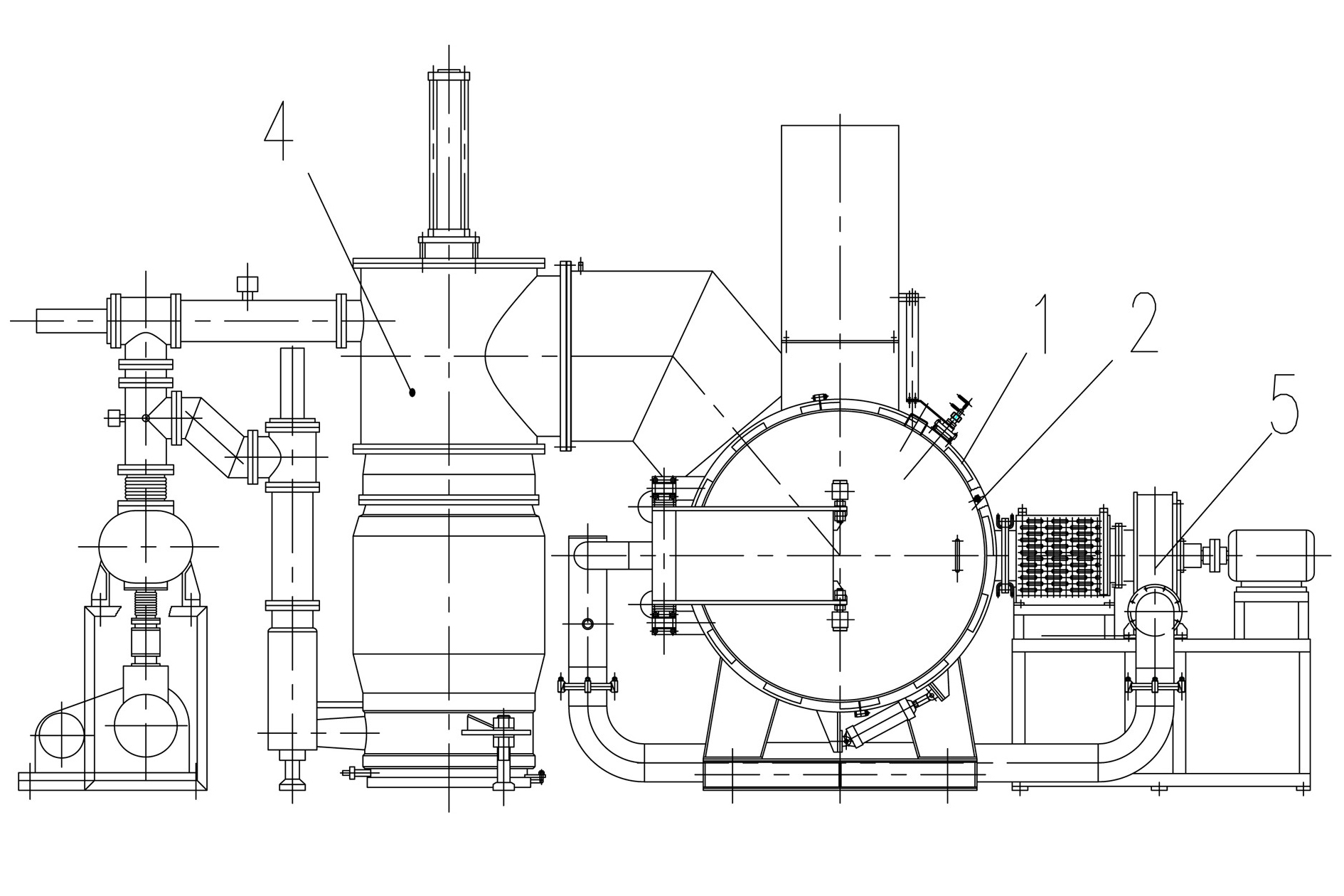

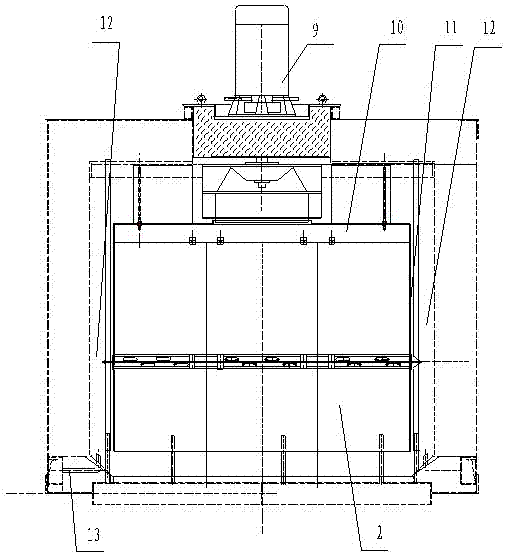

Non-oxidation well vacuum furnace

InactiveCN104018102ANovel ideaReasonable designFurnace typesHeat treatment furnacesShielding gasThermocouple

The invention discloses a non-oxidation well vacuum furnace which comprises a furnace body, a liner (15) and a cover body, wherein the furnace body comprises a furnace frame (1), a furnace shell (2) and a furnace lining (14); the furnace shell (2) is fixed on the furnace frame (1); a screw rod lifting mechanism (6) mounted on the furnace body and the cover body is used for opening and closing the furnace cover (5) and the furnace body; a sealing ring (7) is arranged between the furnace cover (5) and the liner (15); the furnace cover (5) is provided with a vacuumizing pipe (11), a protective gas filling pipe (12) and a fan (10). The non-oxidation well vacuum furnace is characterized in that the furnace cover (5) is also provided with a thermocouple (9) which passes through the furnace cover (5) and enters the hearth to measure the temperature in the furnace and feeds the temperature back to a user. The non-oxidation well vacuum furnace disclosed by the invention is novel in conception and reasonable in design; in non-oxidation annealing treatment, the temperature of the whole furnace has good uniformity, and the scale of the annealed workpiece is avoided; quick cooling can be performed after heating, the production efficiency is greatly improved, and the service life is long.

Owner:江苏华烨炉业有限公司

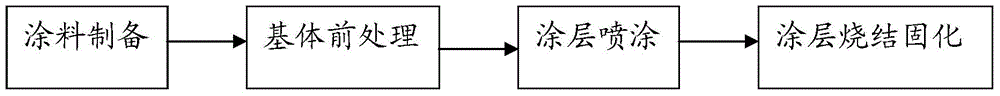

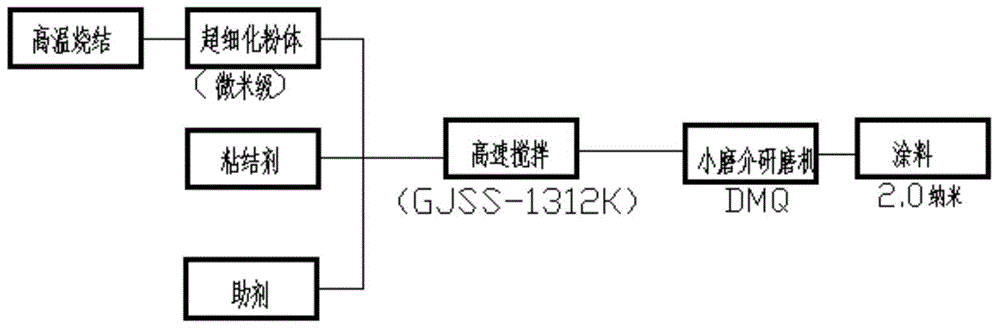

Preparation method of high-emissivity energy-saving infrared radiation coating

ActiveCN104098936AEnhanced radiation heat transferIncrease surface temperatureChemical industryCoatingsEmissivityCeramic coating

The invention discloses a preparation method of a high-emissivity energy-saving infrared radiation coating. The preparation method comprises steps as follows: step one, preparation of coating materials; step two, pretreatment of a base body; step three, spraying of the coating; and step four, sintering and curing of the coating. The coating is stable in structure under high-temperature sintering, performance is comprehensively promoted, the emissivity of the coating cannot be attenuated and aged during use, and the service life of the coating is longer than six years; glazing ceramic coating with a compact structure is formed on the furnace lining surface, the service life of a furnace is prolonged by more than two times, and maintenance and overhaul workload of a furnace lining, consumption of raw materials and maintenance cost are reduced.

Owner:北京恩吉赛威节能科技有限公司

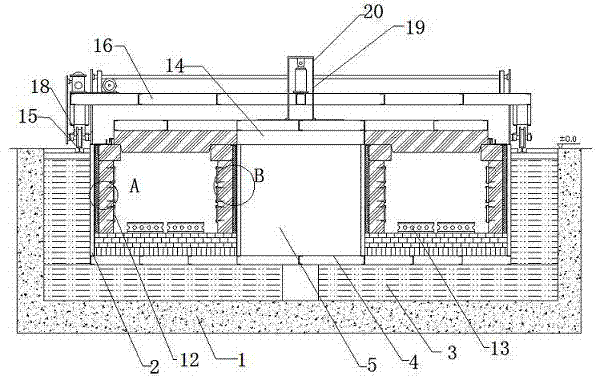

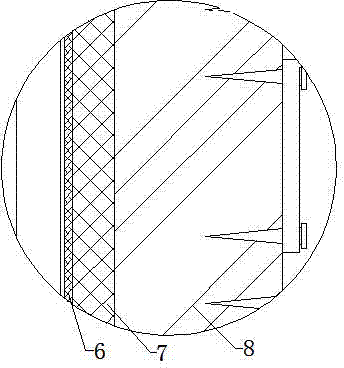

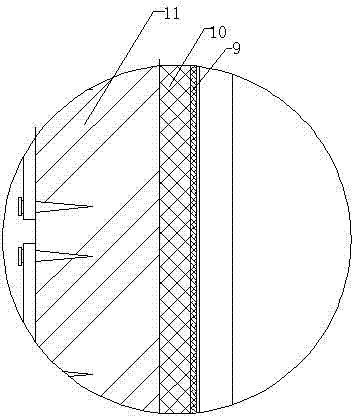

Well type thermal treatment furnace for ring piece

ActiveCN104513894AImprove stabilityIncreased thermal insulation and high temperature resistanceFurnace typesHeat treatment furnacesHeating elementHorizon line

The invention discloses a well type thermal treatment furnace for a ring piece. The thermal treatment furnace is arranged in a laid foundation below a horizon line of a workshop. A furnace bottom channel which can facilitate maintenance of the thermal treatment furnace is arranged between a furnace body of the treatment furnace and the foundation; a middle barrel is arranged in the furnace body; furnace linings are arranged on both the inner wall of the furnace body and the outer wall of the middle barrel and are respectively tightened and fixed through stainless steel and round steel; a plurality of heating elements positioned by high-aluminum porcelain nails are hung on the furnace linings; a furnace cover with heat insulation property and sealing property is also arranged at the top end of the furnace body; and a lifting mechanism and a moving mechanism are arranged on the furnace cover. The well type thermal treatment furnace is simple in structure and convenient to manufacture, is generally used for performing thermal treatment such as hardening, normalization, quenching, annealing and tempering on medium and large size metal ring pieces and is relatively professional periodic thermal treatment equipment which is more energy-saving.

Owner:南通洋口港劳务服务有限公司

A stirring device for rare earth metal electrolytic furnace

InactiveCN103952727BImprove furnace temperature uniformityImprove performance and stabilityElectrolysis componentsStirring devicesFurnace temperatureRare earth

The present invention discloses a stirring apparatus for a rare earth metal electrolysis furnace. The stirring apparatus comprises a vertical column capable of providing a power supply, wherein an circular track is arranged on the vertical column body and is provided with a track car, the lower portion of the track car is connected with a stirring graphite rod, the vertical car is further provided with two electric cable rings, and the electric cable rings are connected with both poles of a track car micro motor, and further connected with both poles of the vertical column. According to the present invention, the graphite rod stirs the electrolyte in the furnace at a certain frequency so as to increase the uniformity of the temperature of the electrolysis furnace, avoid the excessive carbon content in the product due to the too high or too low furnace temperature and increase the performance stability of the product, and characteristics of strong practicality and easy promotion are provided.

Owner:GANZHOU SANYOU RARE EARTH NEW MATERIAL

Strong convection structure box type furnace

InactiveCN101876509AImprove furnace temperature uniformitySimple structureMaintainance of heating chambersFurnace typesElectric arc furnaceControl system

An air cooling experiment electric furnace comprises an electric furnace body installed in a convection chamber box body; a furnace body convection chamber is arranged between the electric furnace body and the convection chamber box body; the bottom of the convection chamber box body is provided with a bottom box body; the side of the bottom box body is provided with a fan; an air inlet chamber in the bottom box body is communicated with the furnace body convection chamber of the convection chamber box body; the electric furnace body is provided with a furnace door installed in a furnace door convection chamber housing; a furnace door convection chamber is arranged between the furnace door convection chamber housing and the furnace door; and the furnace door is connected with the furnace body convection chamber. A convection environment is formed around the electric furnace body to perform air blowing cooling for control system, thereby guaranteeing cold end accuracy and sensitivity of sensor. The air convection on the outer periphery of the furnace body can timely take away most heat; compared with natural cooling, the cooling time of the electric furnace is largely shortened.

Owner:李锦桥

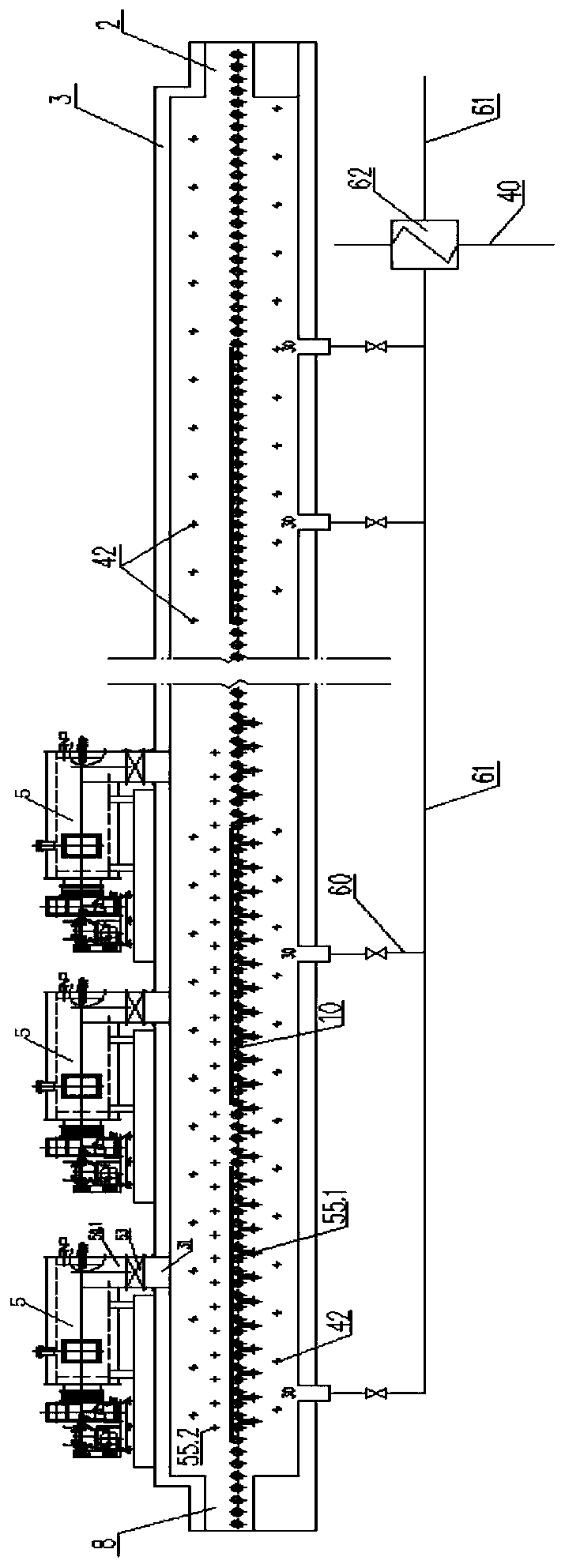

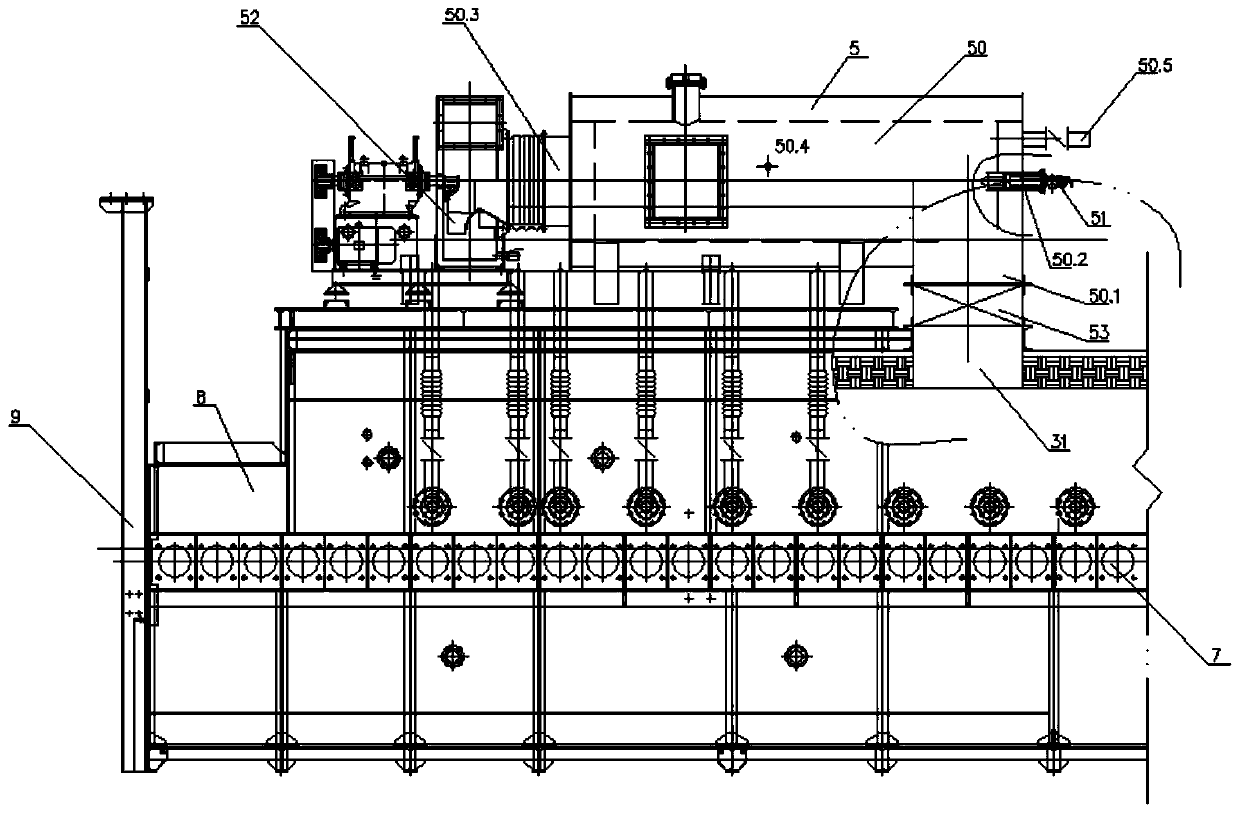

Large-scale average-temperature table type low-temperature annealing furnace

InactiveCN106048199AHeating evenlyEasy to makeFurnace typesHeat treatment furnacesFurnace temperatureTemperature Unit

The invention discloses a large-scale average-temperature table type low-temperature annealing furnace, and belongs to the technical field of gas heating furnaces. Key points of the technical scheme provided by the invention are as follows: the large-scale average-temperature table type low-temperature annealing furnace comprises a furnace body, a furnace door, an air preheating unit, gas heat supply devices, an average-temperature unit and a hot air circulation device, wherein the air preheating unit consists of an air inlet pipe, a preheating cavity, a U-shaped communicating pipe, heat exchange pipes and an air supply pipe; each gas heat supply device consists of a gas chamber and a gas burner, and the gas burner is fixed on the side wall of the gas chamber; the average-temperature unit consists of average-temperature plates, rectangular nozzles and a hot air main; and the hot air circulation device consists of a circular blower, an air inlet pipe and an air outlet pipe. The large-scale average-temperature table type low-temperature annealing furnace has the advantages that the manufacturing is precise, practicable and safe, the operation is reliable, the pollution is small, the working efficiency is high, and workpieces in the furnace can be uniformly heated, so that relatively high furnace temperature uniformity is obtained.

Owner:HENAN TIANLI THERMOTECHNICAL EQUIP CO LTD

Vacuum brazing furnace heating chamber

The invention relates to a vacuum brazing furnace heating chamber, which comprises a hollow horizontal barrel and end covers fixed on two ends of the barrel, wherein one ring of barrel reflecting screen is fixed in a barrel frame; a barrel heating assembly is arranged in the barrel reflecting screen; two ends of the barrel are respectively fixed with one ring of barrel sealing belt; the inner wall of an end cover frame is successively fixed with an end cover reflecting screen and an end cover heating assembly; one ring of end cover sealing belt is fixed on the junction of the end cover and the barrel; the barrel reflecting screen and the end cover reflecting screen are respectively made of multiple layers of stainless steel; and the barrel heating assembly and the heating element of the end cover heating assembly are respectively coiled by a broad-belt nickel-chromium belt. The barrel reflecting screen and the end cover reflecting screen are respectively made of multiple layers of stainless steel, which is favorable for reducing the possibility for heat to outwards diffusing, and furnace temperature evenness is good. The barrel heating assembly and the heating element of the end cover heating assembly are respectively coiled by a broad-belt nickel-chromium belt, heating is even, and heat loss is small.

Owner:无锡四方集团真空炉业有限公司

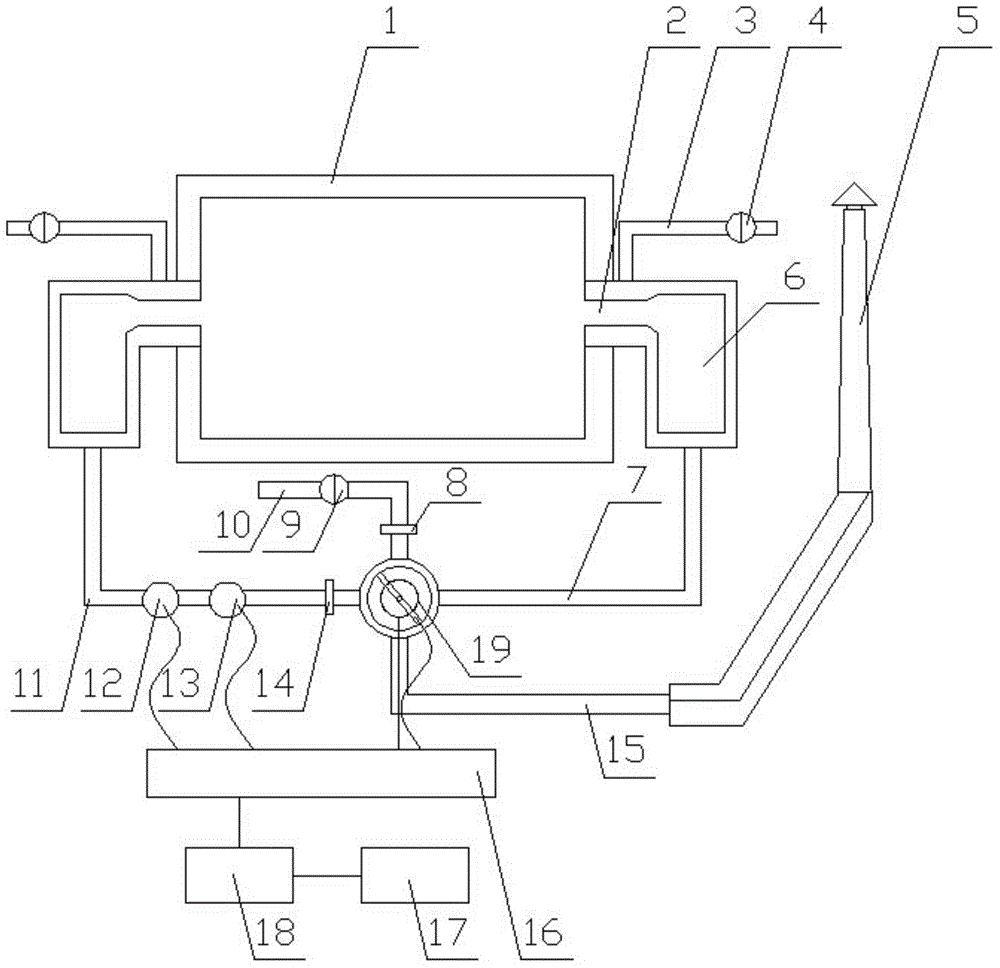

Thermal storage type combustion furnace and working method

InactiveCN105782979AEnergy savingImprove furnace temperature uniformityIndirect carbon-dioxide mitigationGaseous fuel burnerHeat transfer efficiencySmoke

The invention belongs to the technical field of combustion furnaces and provides a thermal storage type combustion furnace and a working method. The thermal storage type combustion furnace comprises a combustion furnace body and two symmetrical thermal storage chambers. Each thermal storage chamber is provided with a fuel gas pipe with a switch valve. The thermal storage chambers are connected with the combustion furnace body through burners. One thermal storage chamber is connected with a gas inlet pipe B, and the other end of the gas inlet pipe B is connected with a reversing valve. The other thermal storage chamber is connected with a smoke exhaust pipe A, and the other end of the smoke exhaust pipe A is connected with the reversing valve. The reversing valve is further connected with a gas inlet pipe A and a smoke exhaust pipe B. A video collector is arranged in the reversing valve. A hearth pressure detector and a smoke temperature detector are further arranged on the smoke exhaust pipe A. The hearth pressure detector, the smoke temperature detector and the video collector are all connected with a signal processor. The signal processor is connected with a programmable logic controller (PLC). The PLC is connected with a thick film transistor (TFT) and an alarm device, and meanwhile the PLC controls reversing of the reversing valve. The thermal storage type combustion furnace and the working method have the following beneficial effects that 1, energy is saved; 2, the furnace temperature uniformity is improved; 3, the heat transfer efficiency is improved; 4, the concentration of NOx is reduced; and 5, the structural design is reasonable, and the conception is ingenious and novel.

Owner:TIANJIN RANDYS IND EQUIP

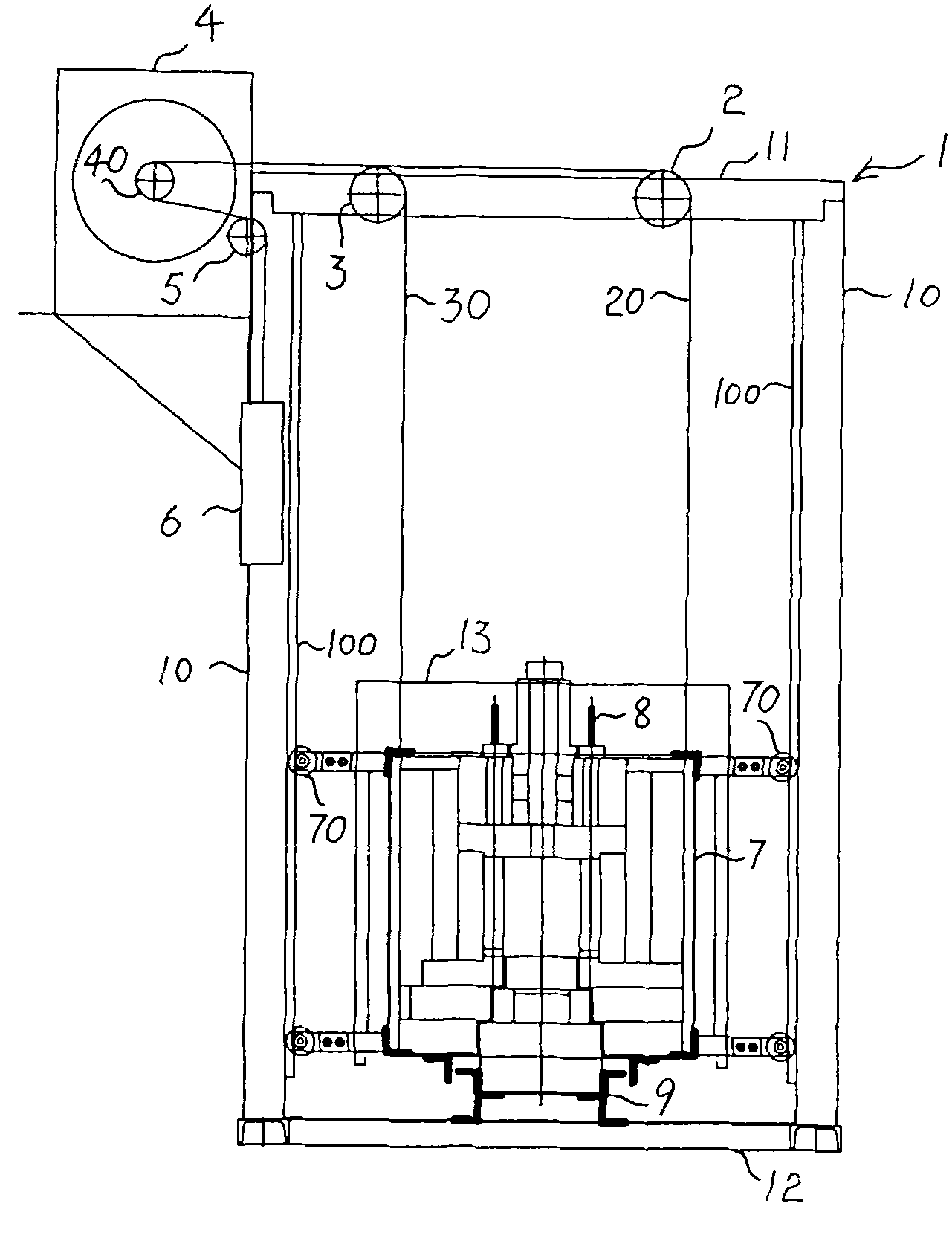

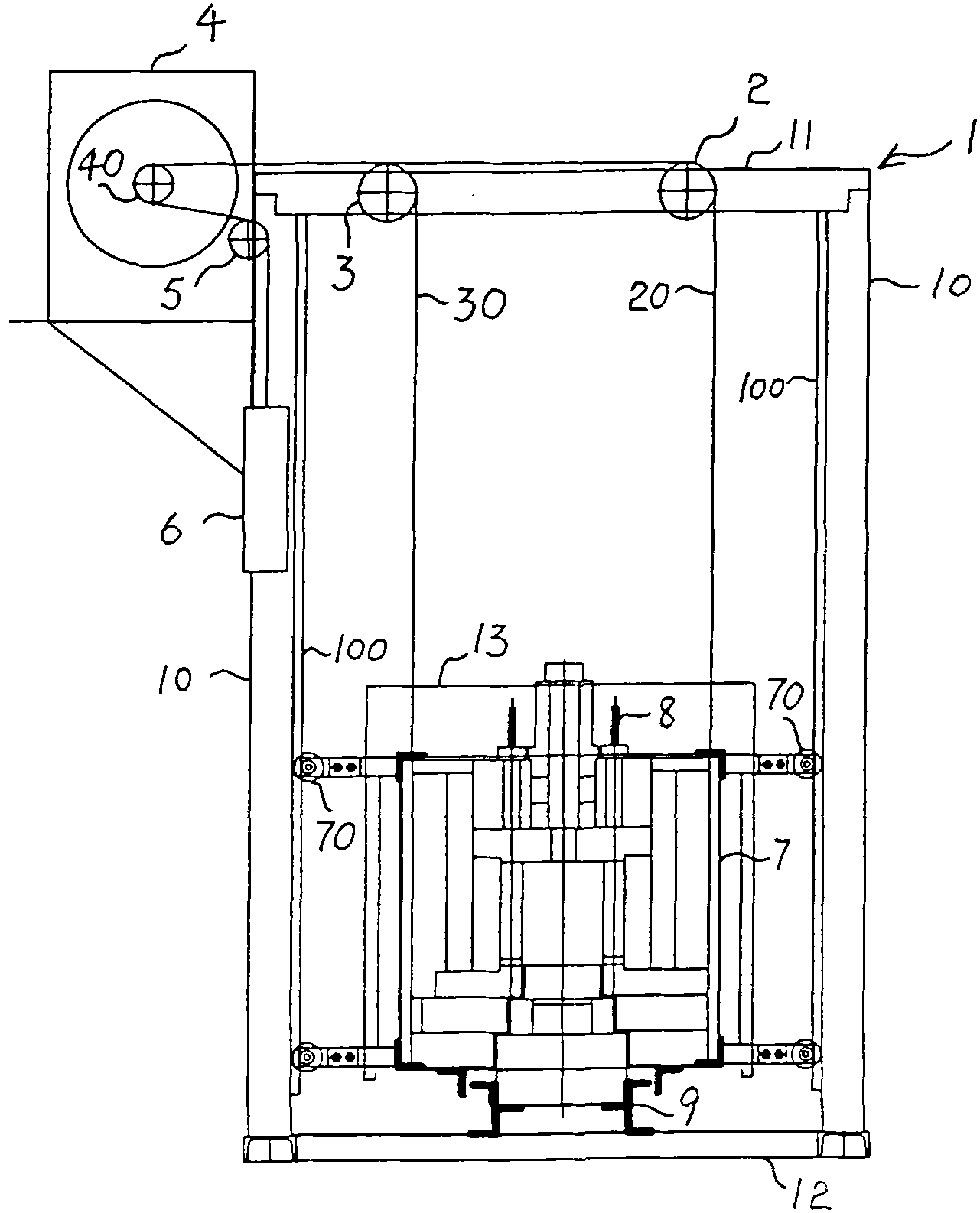

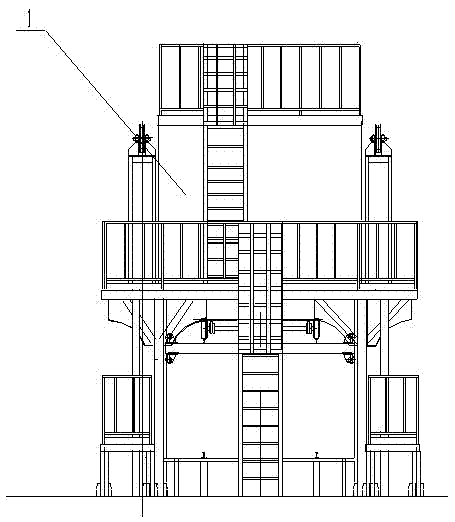

Bell-type electric elevator furnace

InactiveCN101876507AImprove furnace temperature uniformityEasy to save energyFurnace typesEngineeringTrial Site

The invention discloses a bell-type electric elevator furnace, which comprises a heating furnace body (7), wherein a heating body (8) is arranged in the heating furnace body (7). The bell-type electric elevator furnace is characterized in that: a door frame (1) is arranged above the heating furnace body (7); the door frame is provided with a chain elevator mechanism; guide mechanisms are arranged on the two sides of the heating furnace body (7); and thus, an electric furnace elevating system of which the upper part is elevated is formed. The bell-type electric elevator furnace of the invention adopts the chain elevator mechanism to elevate and descend the whole electric furnace through two chains, realizes the precise control over the elevation together with the guide mechanisms, and is provided with a travel switch and an auxiliary positioning device to ensure that the electric furnace is descended to a designated position and further improve the safety coefficient. The bell-type electric elevator furnace of the invention is small in size, simple in structure and low in cost and can be used in trial sites such as colleagues and universities, research institutions and laboratories.

Owner:李锦桥

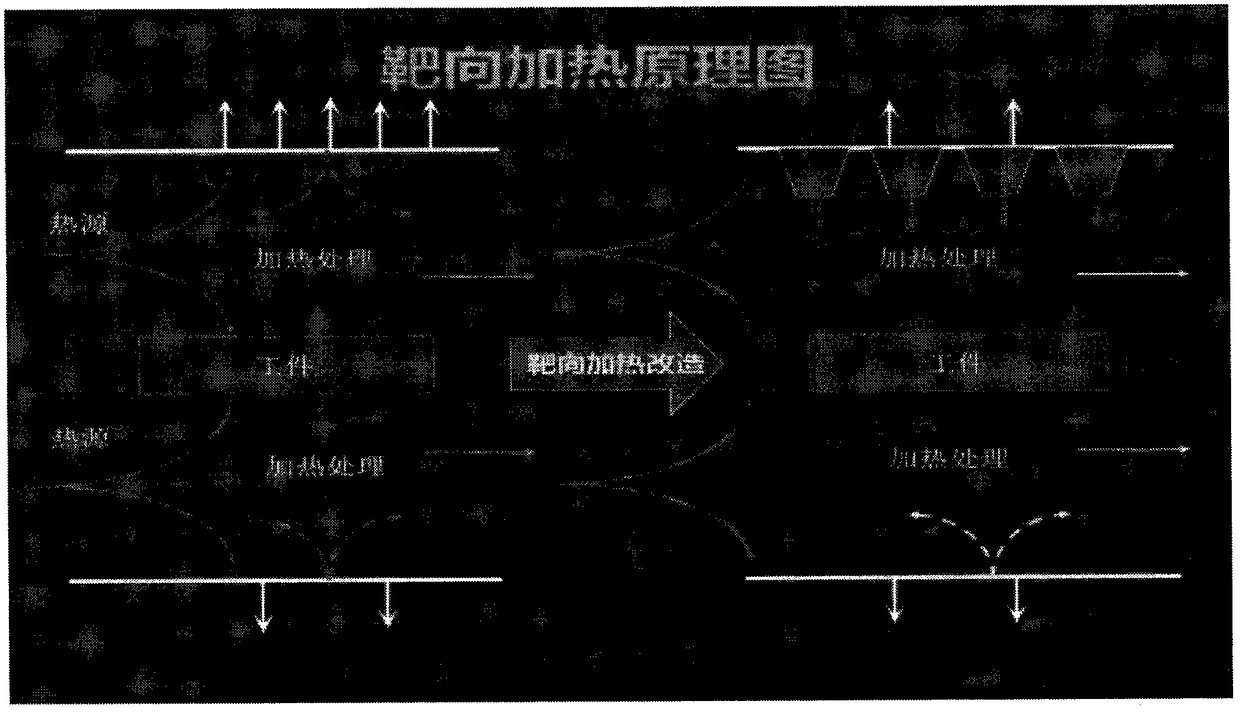

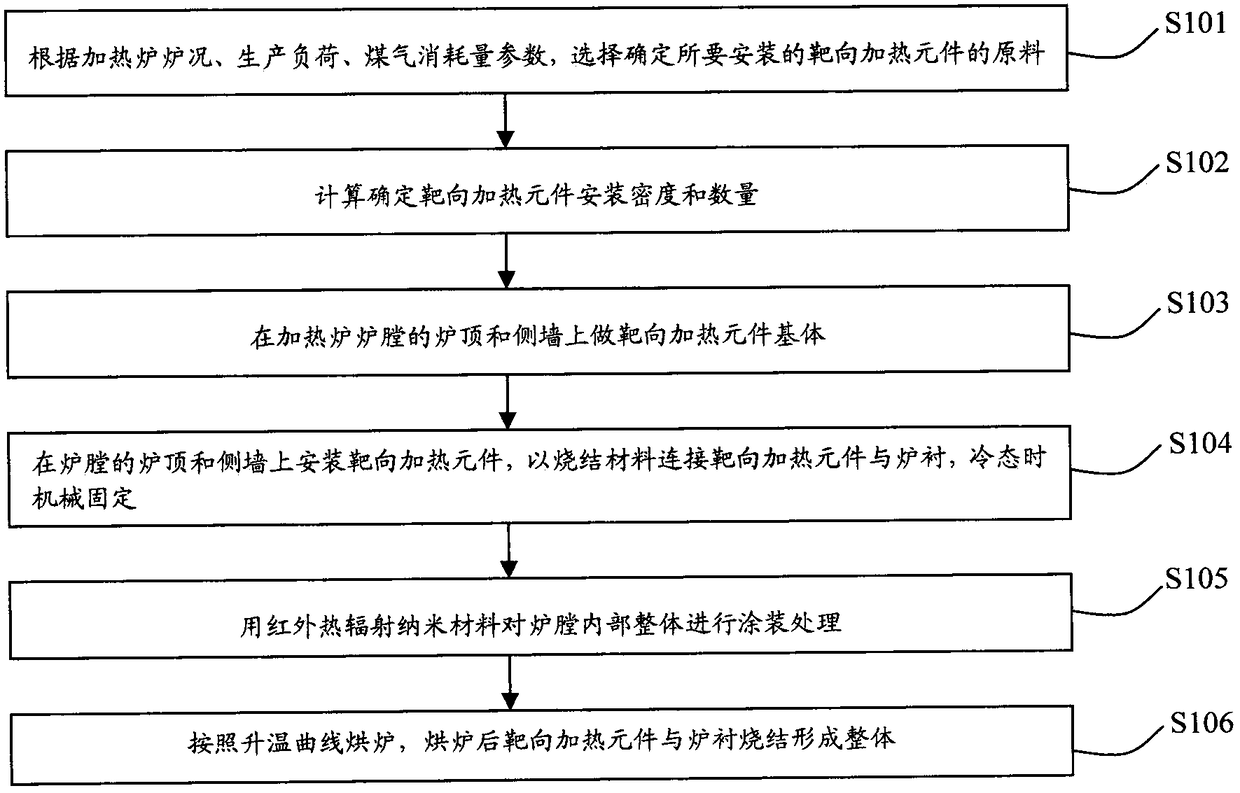

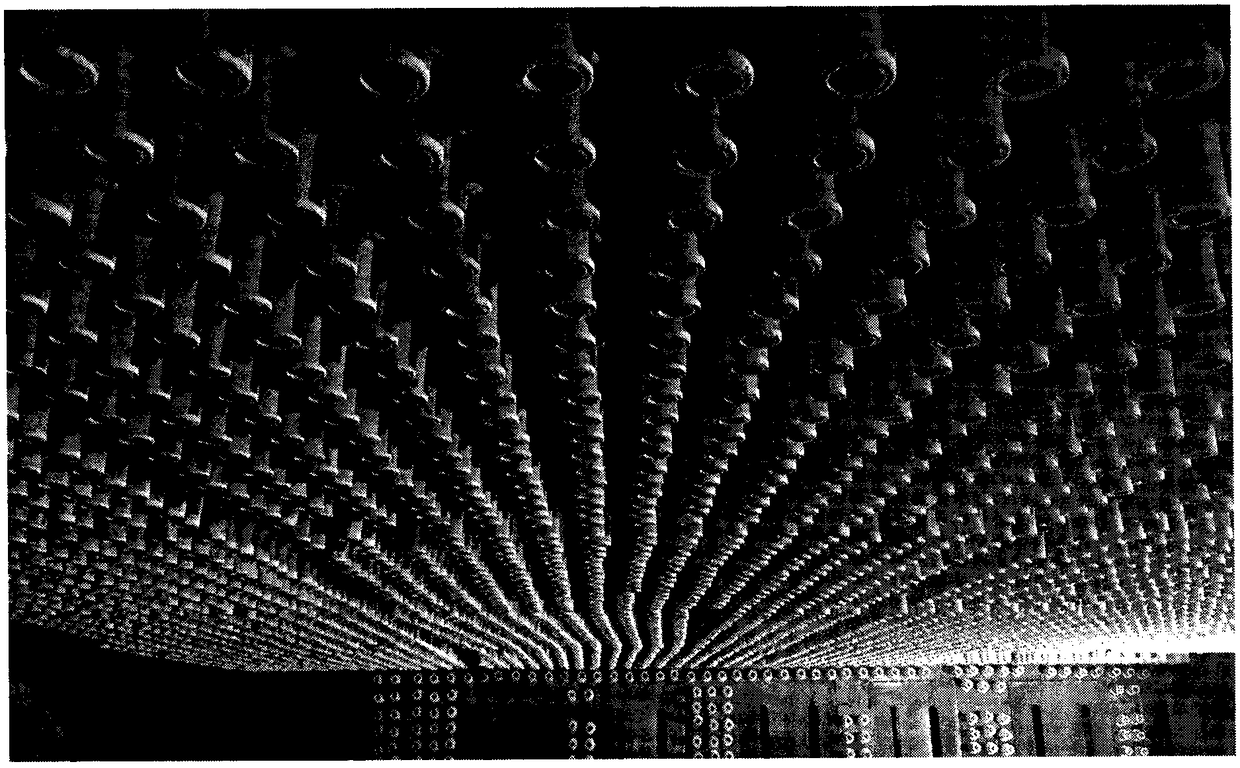

Method for reforming heating furnace with targeted heating elements

PendingCN108088256AGood energy saving effectImprove energy savingLinings repairThermal radiationHearth

The invention relates to a method for reforming a heating furnace with targeted heating elements. The method for reforming the heating furnace with the targeted heating elements comprises the steps that (1) the raw material texture of the targeted heating elements to be installed is determined; (2) the installation density and number of the targeted heating elements to be installed are calculatedand determined; (3) targeted heating element matrixes are made on the furnace top and the side wall of a hearth of the heating furnace; (4) the targeted heating elements are installed on the furnace top and the side wall of the hearth, the targeted heating elements are connected with a furnace lining through sintering materials, and mechanical fixation is conducted in the cold state; (5) coating treatment is conducted on the whole inner portion of the hearth with infrared thermal radiation nanometer materials; and (6) baking is conducted according to a heating curve, and after baking, the targeted heating elements and the furnace lining are sintered into a whole. By the adoption of the method for reforming the heating furnace with the targeted heating elements, radiation heat transfer in the hearth can be greatly enhanced, the service life of the furnace lining is prolonged, energy is saved, and the consumption is lowered.

Owner:HENAN SANSONG CERAMICS IND

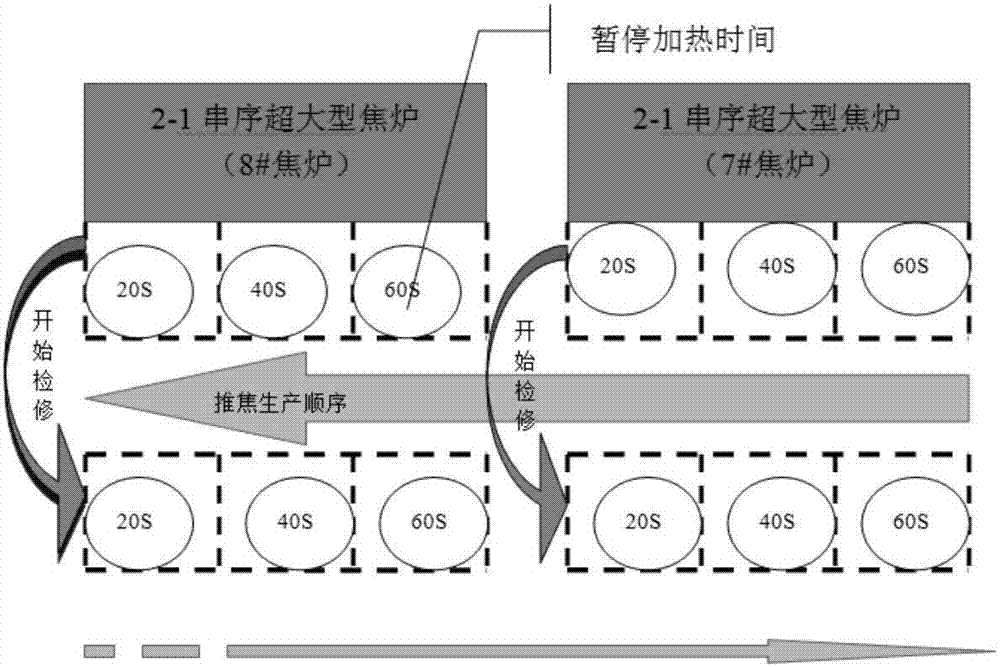

Coke oven temperature adjustment method

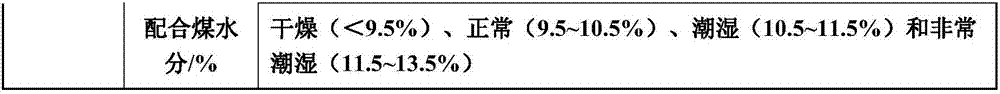

ActiveCN107992130AAchieve consistencyAvoid Furnace Temperature FluctuationsCombustible gas coke oven heatingAuxillary controllers with auxillary heating devicesEngineeringMoisture

The invention discloses a coke oven temperature adjustment method. The coke oven temperature adjustment method includes the step of determining the set values of thermal parameters of coke ovens according to the ambient temperature and the moisture content of mixed coal. The coke oven temperature adjustment method can achieve the consistency in the temperature regulation of the coke ovens, avoid the temperature fluctuation of the coke ovens, ensure controlled straight-line temperature of the coke ovens, effectively control the temperature difference between coke oven groups, ensure the stability of the temperature of the whole coke ovens and achieve the accuracy of the temperature regulation of the coke ovens.

Owner:MAANSHAN IRON & STEEL CO LTD

Vacuum annealing furnace for steel

The invention discloses a vacuum annealing furnace for steel. The vacuum annealing furnace for steel comprises a heat preserving furnace body, a vacuum furnace body and a furnace cover. The vacuum furnace body is arranged in the heat preserving furnace body. The opening end of the heat preserving furnace body and the opening end of the vacuum furnace body are covered with the furnace cover. A heating layer is arranged between the heat preserving furnace body and the vacuum furnace body. An electric heating element is arranged on the portion, where the heating layer is arranged, of the heat preserving furnace body. A heat insulation layer is arranged in the vacuum furnace body and located under the furnace cover. A sealing motor is arranged on the furnace cover. The lower portion of the sealing motor is connected with a fan. The furnace cover is further provided with a vacuum pumping port. The vacuum annealing furnace for steel is rapid in cooling speed and capable of saving time and improving the labor productivity; a vacuum unit is high in pumping rate, and the uniformity of furnace temperature and the using effect are good.

Owner:XINXIELI PRESS PLATE

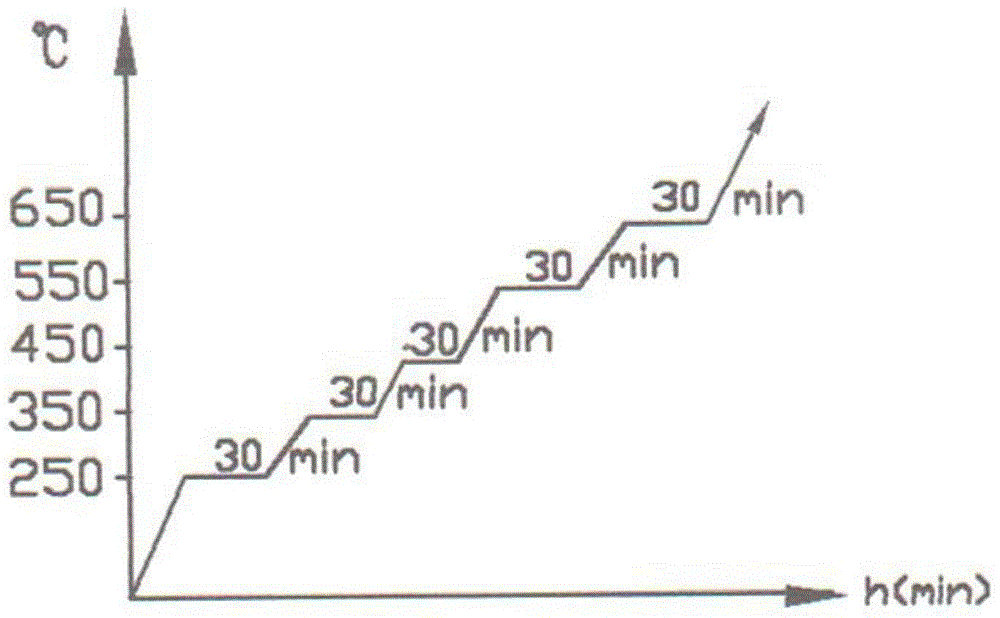

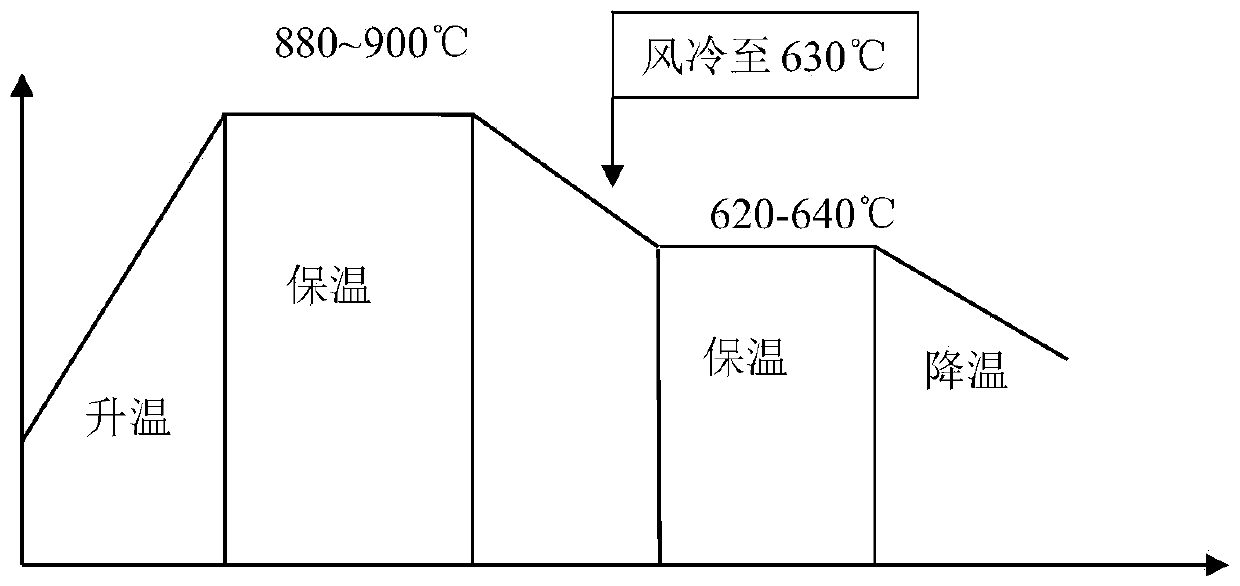

Heat treatment method for 18CrNiMo7-6 steel

PendingCN111518996APrevent annealingImprove plasticityFurnace typesHeat treatment furnacesIsothermal annealingIngot

The invention discloses a heat treatment method for 18CrNiMo7-6 steel. The method is used for carrying out annealing treatment on a round bar forged by an 18CrNiMo7-6 steel ingot; and in the annealingtreatment, the temperature of the round bar is increased to a first heat preservation temperature and heat preservation is carried out at the first heat preservation temperature, then air cooling iscarried out until a second heat preservation temperature is achieved and heat preservation is carried out at the second heat preservation temperature, and finally cooling is carried out, wherein the first heat preservation temperature is larger than or equal to 800 DEG C, and the second heat preservation temperature is 620-650 DEG C. According to the method, the cooling speed and the heat preservation temperature in isothermal annealing are controlled, so that the 18CrNiMo7-6 steel with ferrite and flaky pearlite structures is obtained, the steel has moderate hardness, the steel is convenientto machine, be subjected to blanking and saw, the cutter sticking phenomenon is avoided, and the yield is increased.

Owner:DAYE SPECIAL STEEL CO LTD

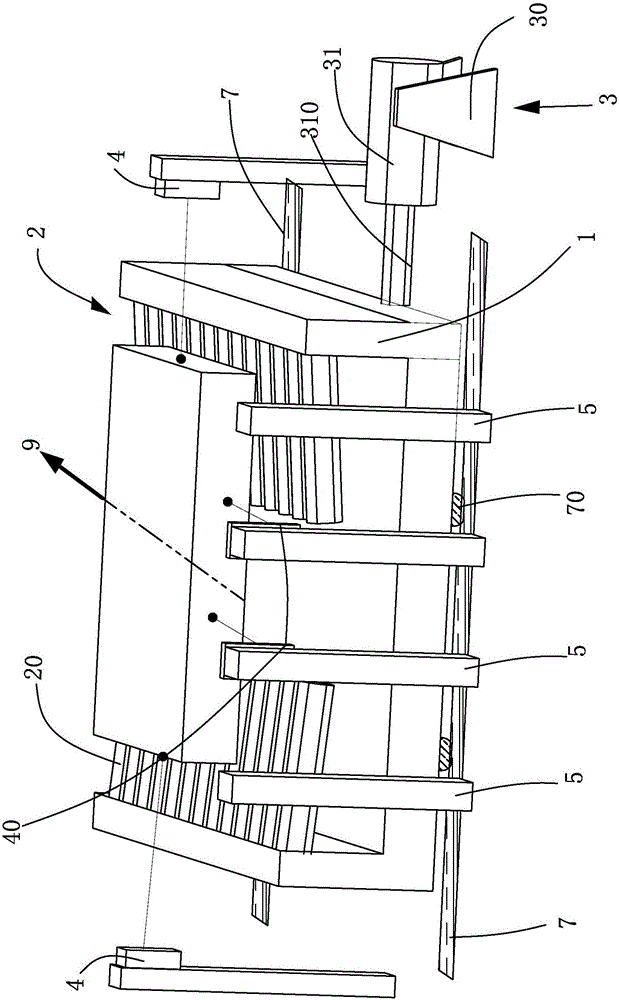

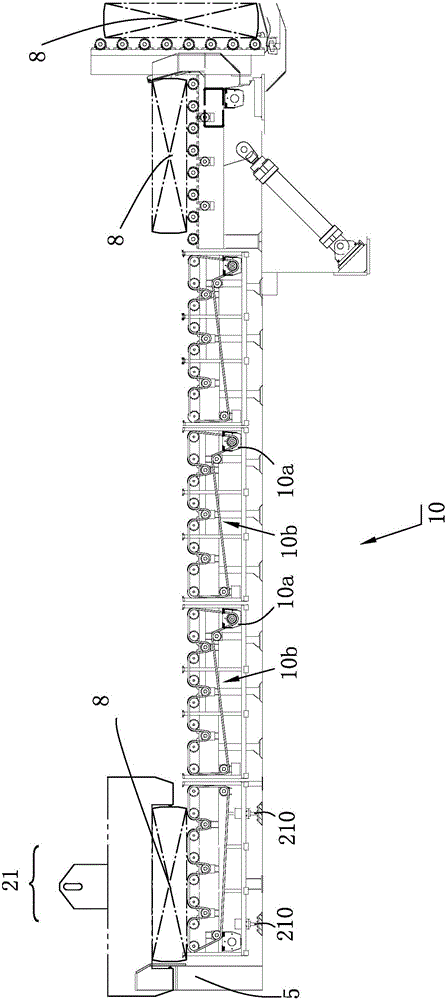

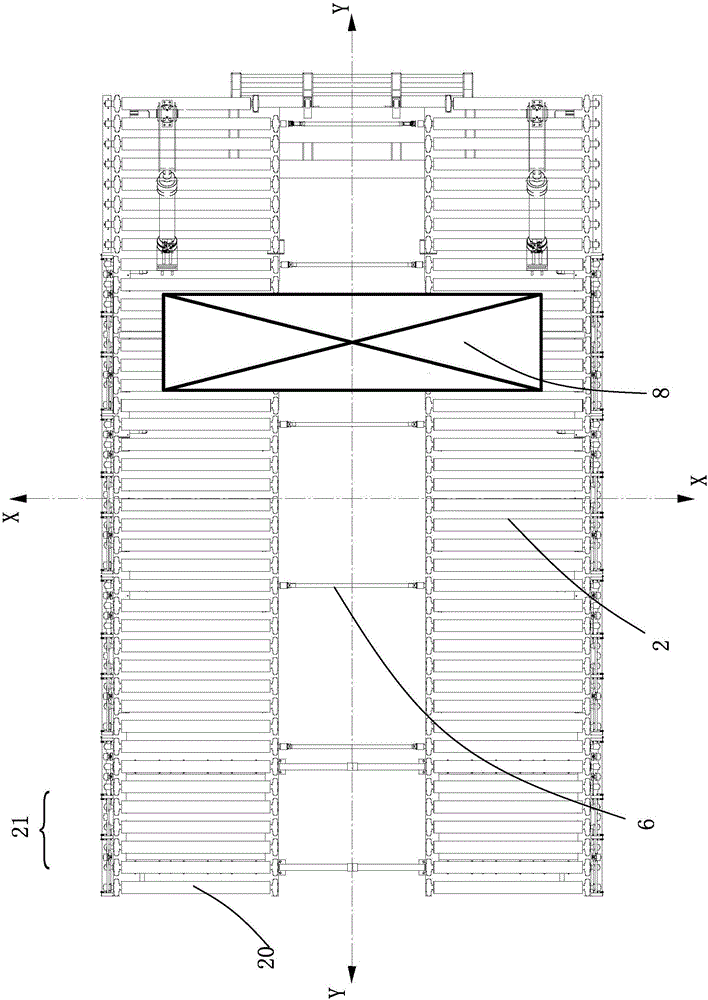

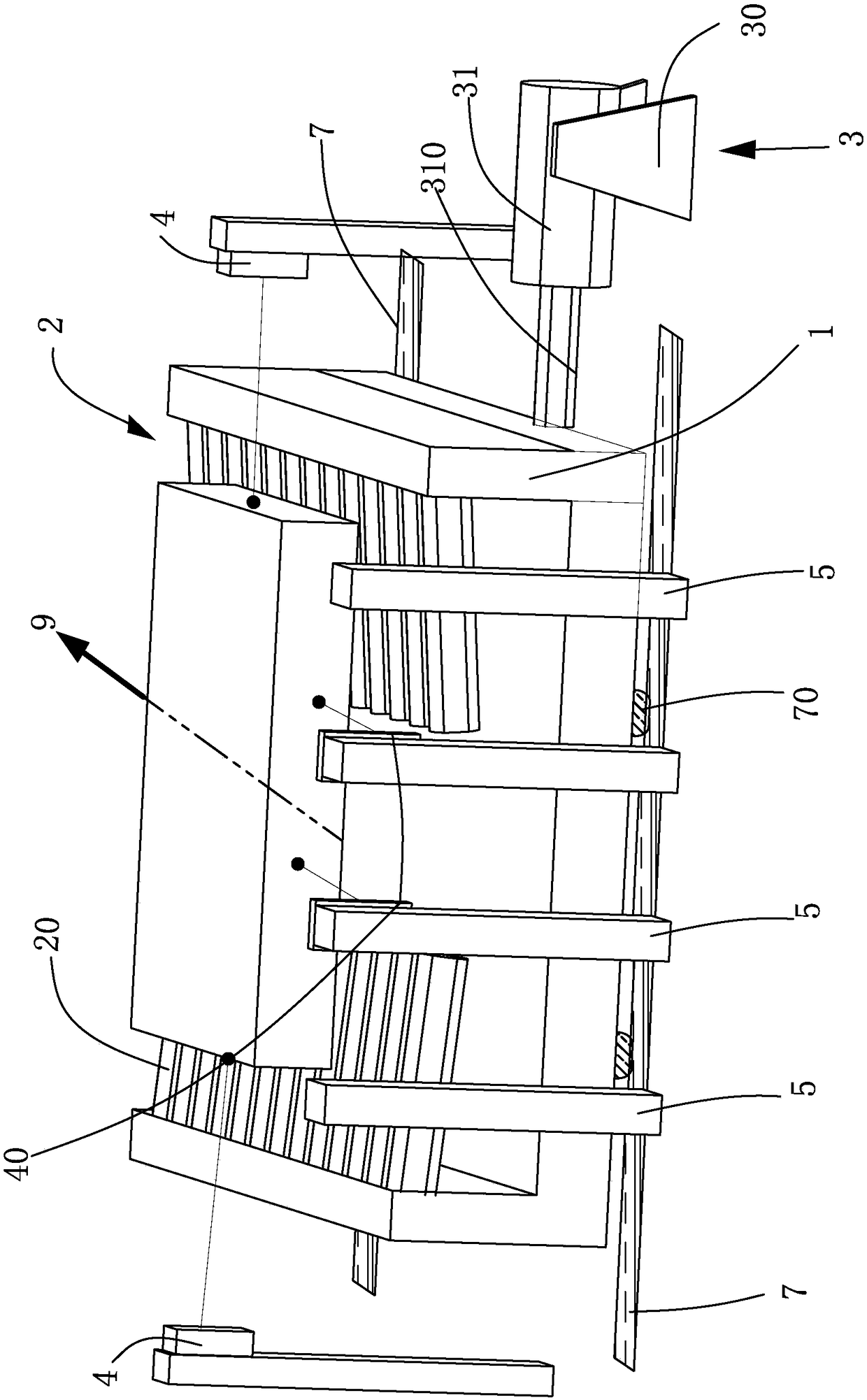

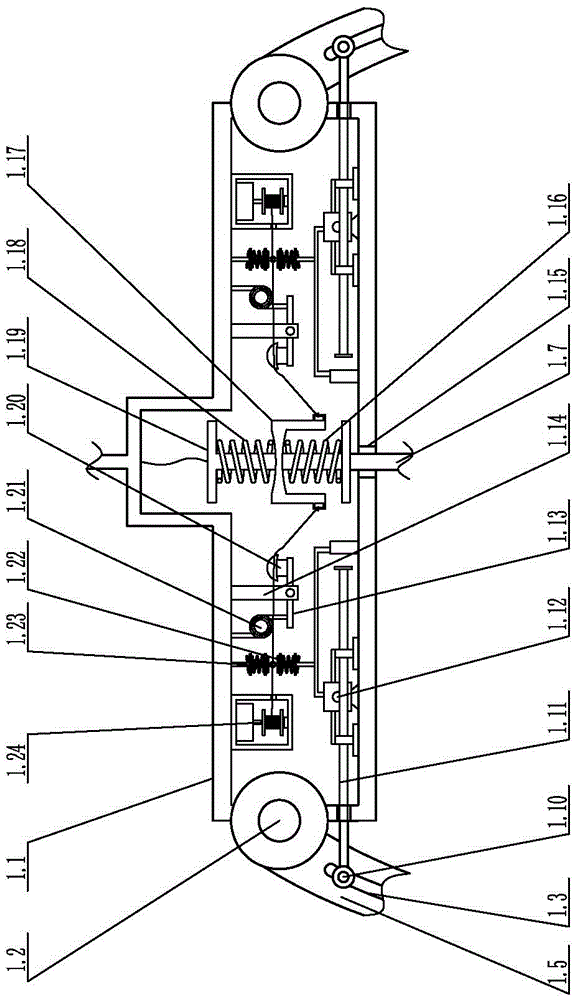

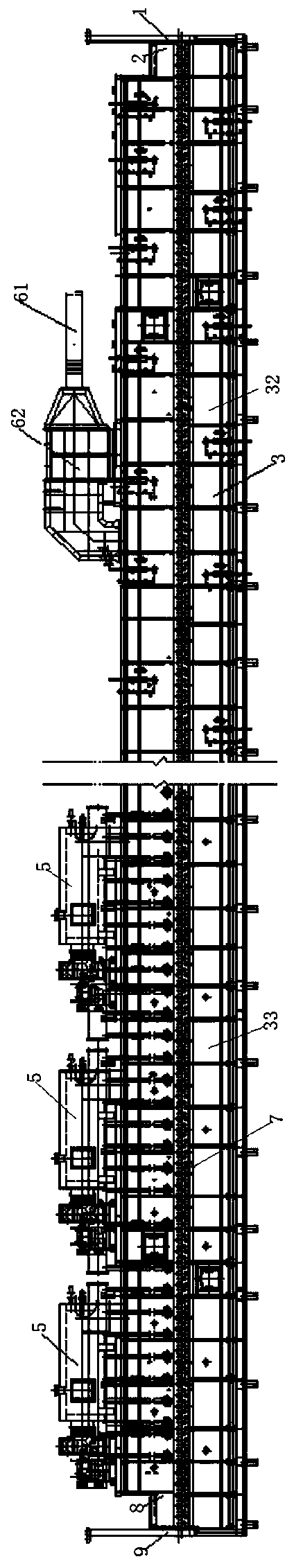

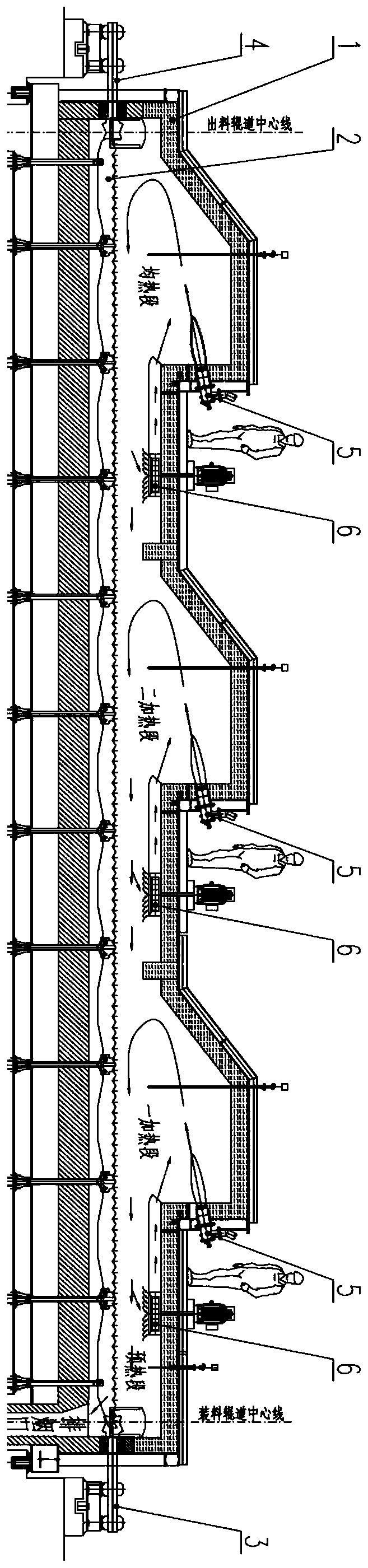

Push-type heating furnace feed mechanism

ActiveCN106500511AEasy to moveOrderly and evenCharge composition/stateCharge manipulationIngot castingHeat stability

The invention relates to a push-type heating furnace feed mechanism used for conveying ingot castings into a heating furnace. The feed mechanism has a transverse direction and a longitudinal direction which are perpendicular to each other. The longitudinal direction is consistent with the conveying direction of the ingot castings towards the heating furnace. The feed mechanism comprises a rack, a roller table which is arranged on the rack and used for conveying the ingot castings and a first driving device. The rack and the roller table located on the rack are provided with two end portions in the longitudinal direction and are provided with two side portions in the transverse direction. The roller table comprises a plurality of rollers which are driven by the first driving device to rotate around the axes of the rollers to be arranged on the rack. The feed mechanism further comprises sliding wheels arranged on the lower portion of the rack and a second driving device which can drive the rack and the roller table on the rack to make transverse movement. When the feed mechanism disclosed by the invention is used for conveying the ingot castings, the phenomenon that the width center line of the ingot castings aligns the center line of the furnace and the phenomenon that all the ingot castings can be located on the same center line after being transported by a roller way to enter the furnace can be guaranteed, and the heat stability of the inside of the whole furnace in the follow-up heat treatment process is ensured.

Owner:艾伯纳工业炉(太仓)有限公司

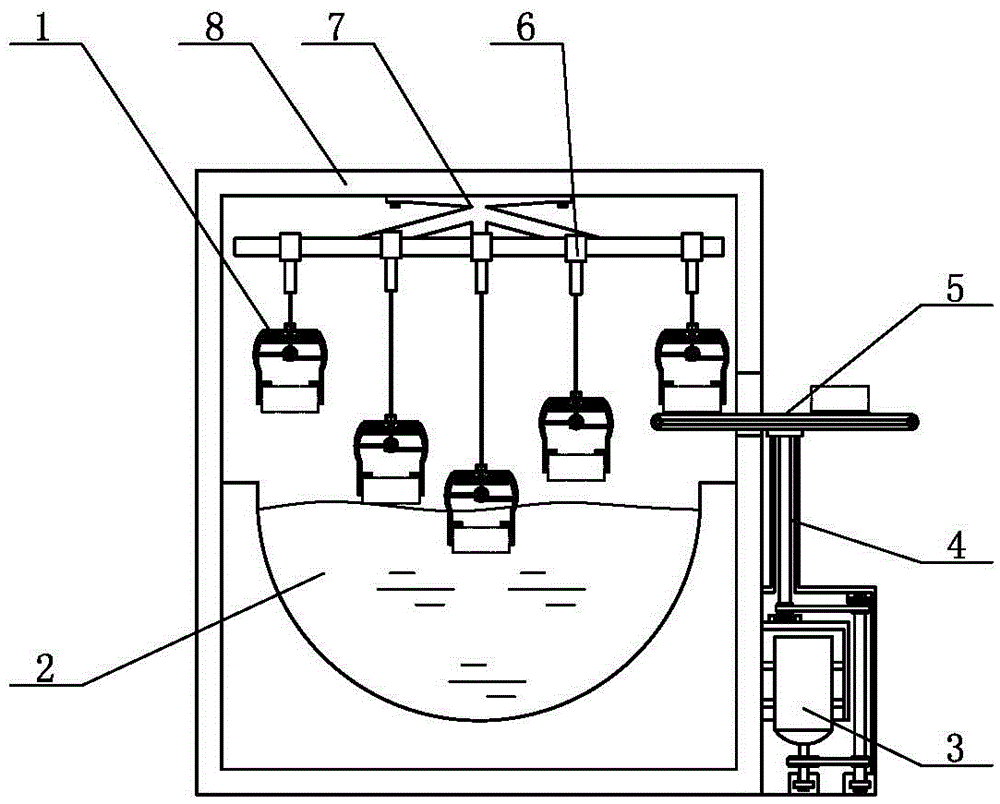

Tantalum capacitor vacuum sintering dewaxing furnace

InactiveCN102980390AReduce cleaning frequencyThere will be no contaminationMuffle furnacesRetort furnacesTantalum capacitorMetallurgy

The invention discloses a tantalum capacitor vacuum sintering dewaxing furnace. The tantalum capacitor vacuum sintering dewaxing furnace mainly comprises a furnace body, a furnace cover, a furnace pipe and a degreasing trapping system, and is characterized in that the furnace cover is connected with the furnace body through a furnace cover lifting mechanism and arranged right above the furnace body; the furnace pipe is arranged in the furnace body; a heater and a workpiece lifting basket are arranged in the furnace pipe; the degreasing trapping system is connected with the furnace body through a pipeline; a muffle tank is arranged in the furnace pipe; the workpiece lifting basket is positioned in the muffle tank; an air suction hole is formed in the bottom of the muffle tank and connected with the pipeline; and an air filling hole is formed in the side wall at the upper part of the furnace body and filled with inert gas. According to the tantalum capacitor vacuum sintering dewaxing furnace, the gas filled in the furnace and the gas generated by dewaxing are sucked away along the bottom of the muffle tank when the temperature in the furnace is increased in the dewaxing process, so that a bonder generated under a high temperature is not volatilized onto a heating chamber in the furnace or a furnace wall, the pollution is prevented being formed, the cleaning frequency of the dewaxing furnace is reduced, and the product quality is effectively improved.

Owner:SUZHOU INDAL PARK JIESHITONG VACUUM TECH

Pusher heating furnace feeding mechanism

ActiveCN106500511BOrderly and evenEvenly placedCharge composition/stateCharge manipulationIngot castingHeat stability

The invention relates to a push-type heating furnace feed mechanism used for conveying ingot castings into a heating furnace. The feed mechanism has a transverse direction and a longitudinal direction which are perpendicular to each other. The longitudinal direction is consistent with the conveying direction of the ingot castings towards the heating furnace. The feed mechanism comprises a rack, a roller table which is arranged on the rack and used for conveying the ingot castings and a first driving device. The rack and the roller table located on the rack are provided with two end portions in the longitudinal direction and are provided with two side portions in the transverse direction. The roller table comprises a plurality of rollers which are driven by the first driving device to rotate around the axes of the rollers to be arranged on the rack. The feed mechanism further comprises sliding wheels arranged on the lower portion of the rack and a second driving device which can drive the rack and the roller table on the rack to make transverse movement. When the feed mechanism disclosed by the invention is used for conveying the ingot castings, the phenomenon that the width center line of the ingot castings aligns the center line of the furnace and the phenomenon that all the ingot castings can be located on the same center line after being transported by a roller way to enter the furnace can be guaranteed, and the heat stability of the inside of the whole furnace in the follow-up heat treatment process is ensured.

Owner:艾伯纳工业炉(太仓)有限公司

Dedicated quenching device of steel plate spring

ActiveCN106119482AIdeal organizationIdeal performanceFurnace typesHeat treatment process controlCooling curveQuenching

The invention discloses a dedicated quenching device of a steel plate spring, and belongs to the field of heat treatment quenching cooling equipment of steel plate springs. According to a whole quenching and cooling dedicated device designed by an inventor, quenching cooling temperature is controlled through a numeric terminal, the cooling curve approaching to the design technology is achieved, the ideal material structure and the ideal performance can be obtained, and the finished product quality of the steel plate spring is greatly improved. The dedicated quenching device can be suitable for small-batch multispecies steel plate spring heat treatment, the production rhythm is rapid, the device is compact in rhythm, and energy consumption losses are small.

Owner:陕西雷帕得悬架系统有限公司

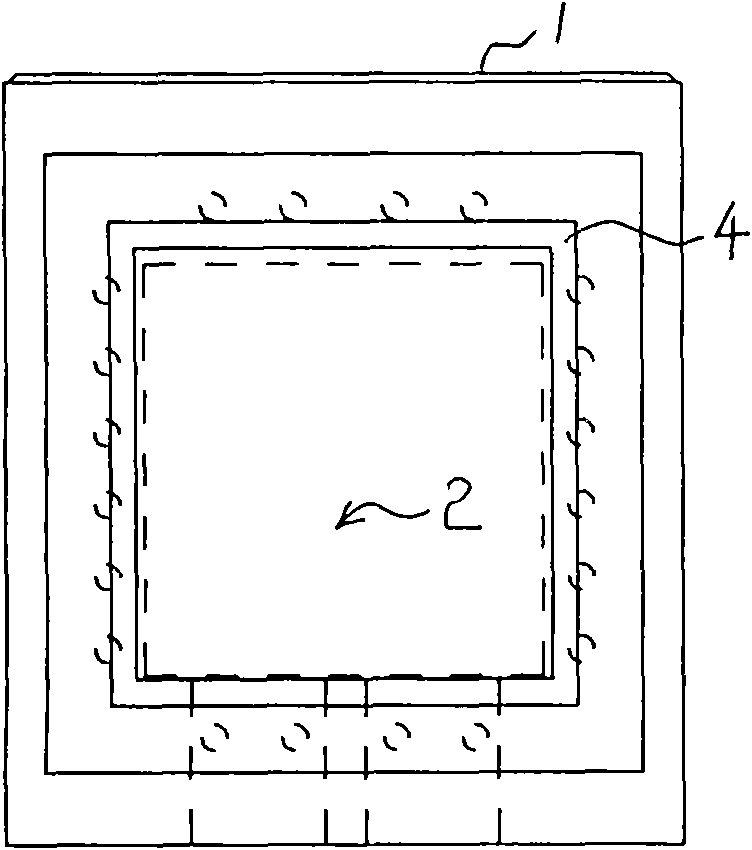

Bottom lifting type resistance heating annealing furnace

InactiveCN102219364BHigh degree of automationImprove furnace temperature uniformityElectricityFurnace temperature

The invention discloses a bottom lifting type resistance heating annealing furnace comprising a furnace body, a furnace cavity and a control device. A movable furnace bottom cover is arranged on the bottom surface of the furnace body, travelling wheels are arranged below the furnace bottom cover, the furnace bottom can be lifted under the driving of a lifting device, after being lifted, the furnace bottom cover is closely matched wit the furnace body so as to form a work bottom surface of the furnace cavity, and being descended, the furnace bottom cover drops on a matched track, and the travelling wheels can move on the track; a plurality of electric heaters are arranged on the side surface of the furnace cavity; a fan, the top guide plate and a side guide plate are arranged on the top end of the furnace cavity, a certain gaps is arranged between the side guide plate and the electric heater so as to form an air circulation channel, a cooling air channel is arranged on the furnace body, and used for sending cooling air into the furnace cavity. For the annealing furnace, the degree of automation is high; the processes such as loading, travelling, lifting of movable furnace bottom, heating for temperature rising, temperature reducing and the like are conducted under the control of the control device, and the degree of automation is high; and in the heating process, the annealing furnace achieves the demands that the furnace temperature uniformity is higher, the furnace temperature stability is higher, and the temperature reducing rate can meet the thermal treatment process.

Owner:重庆飞达电炉有限公司

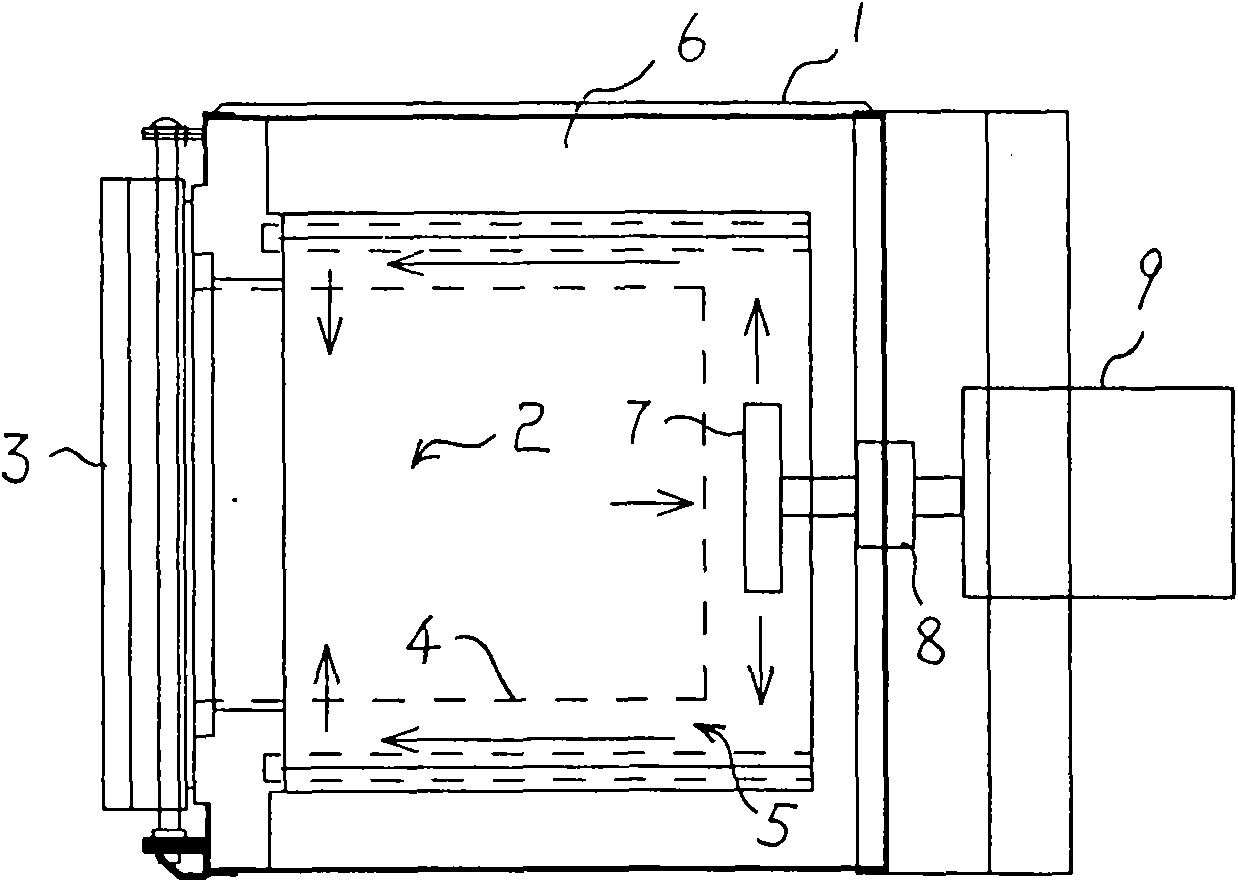

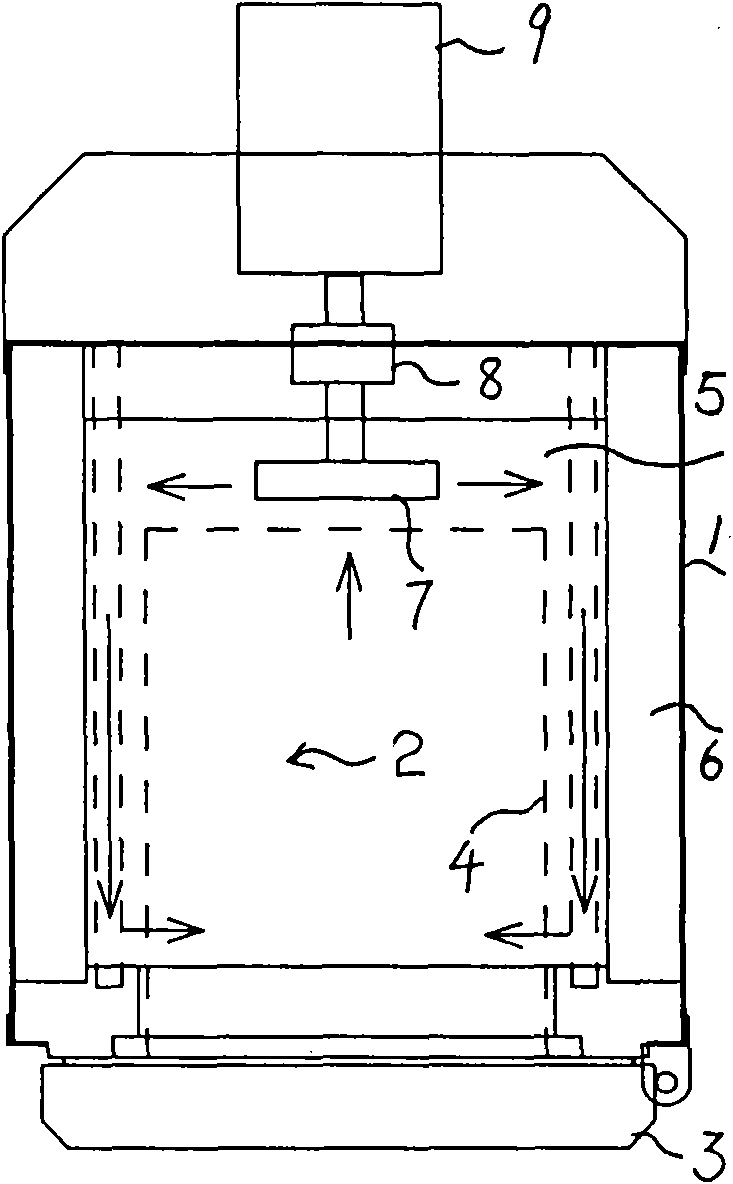

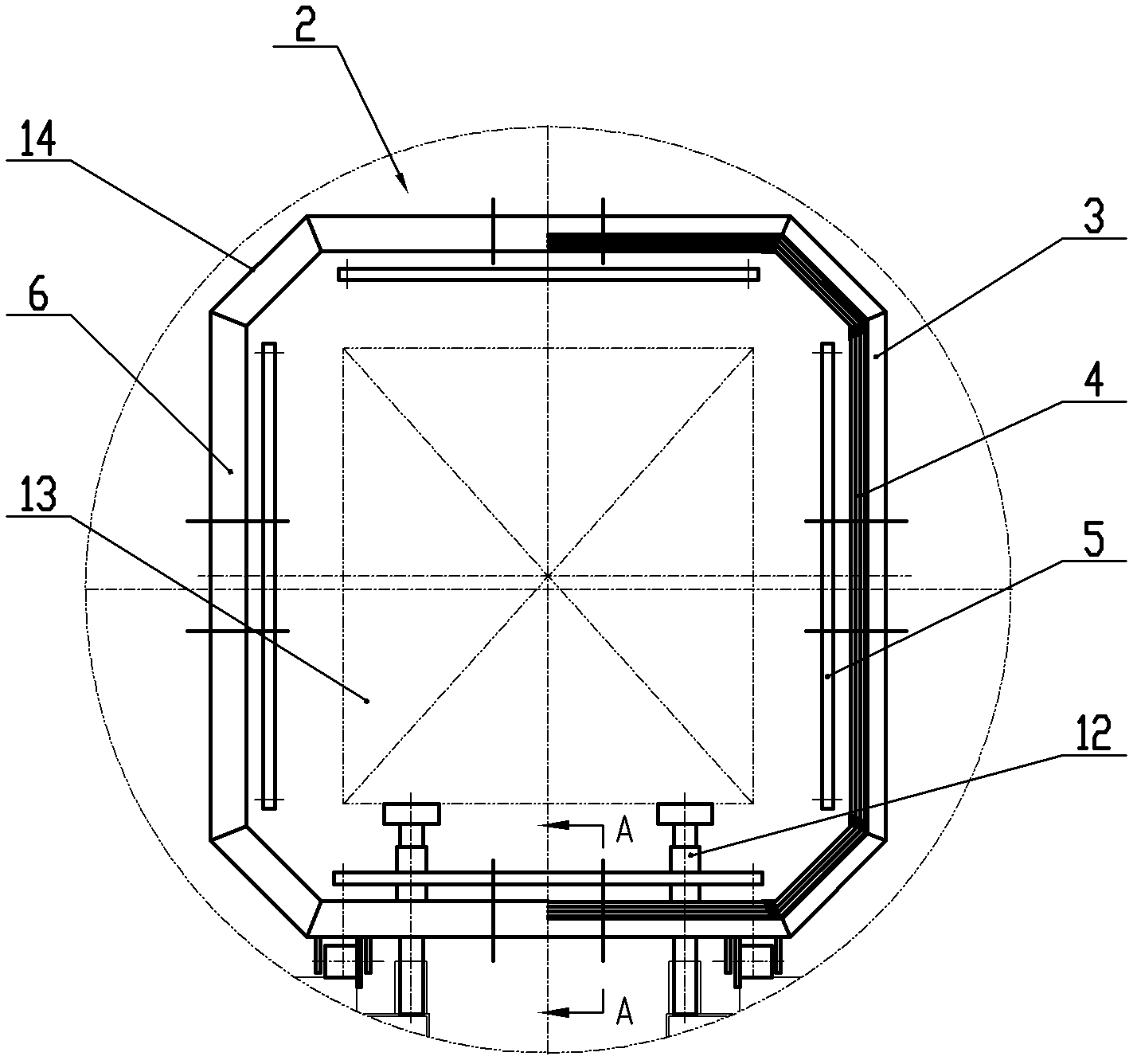

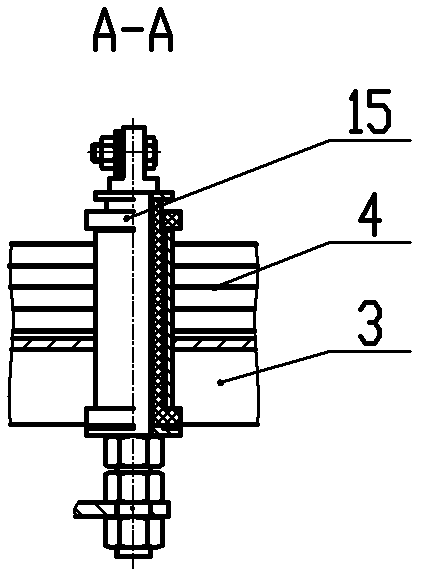

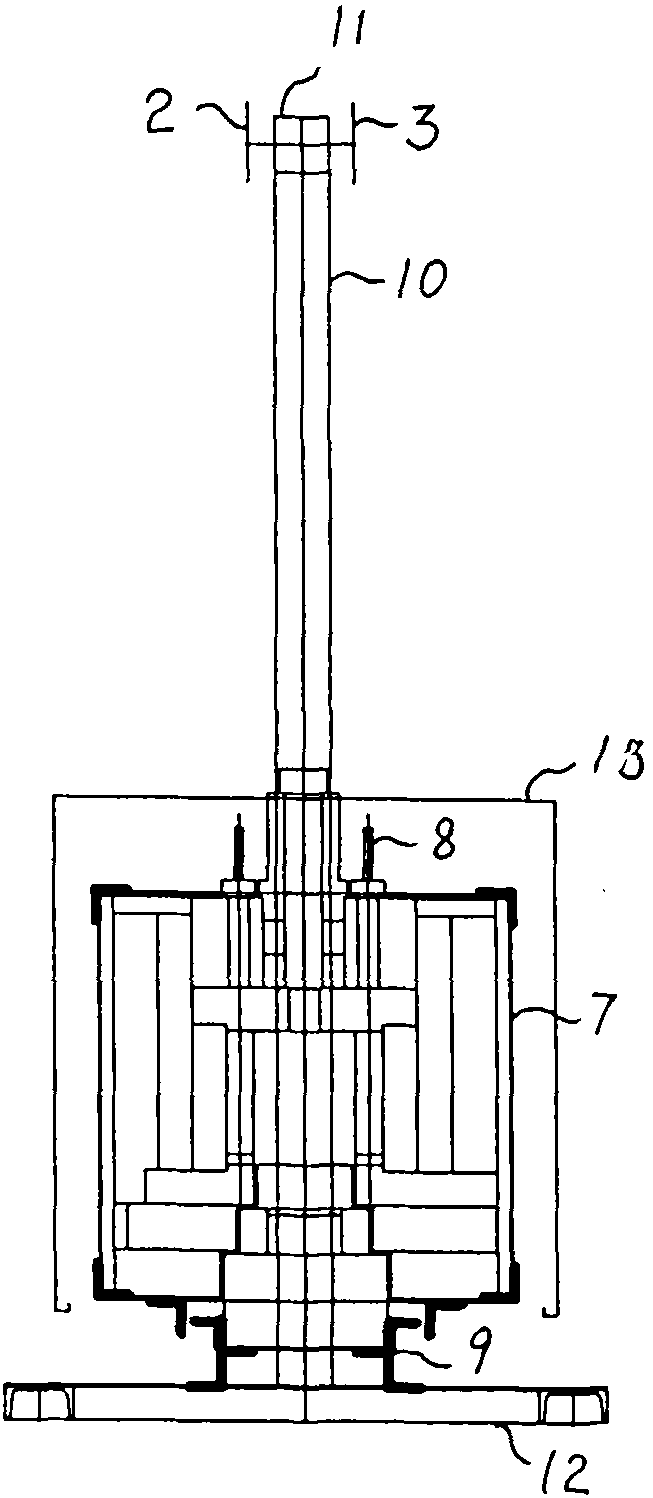

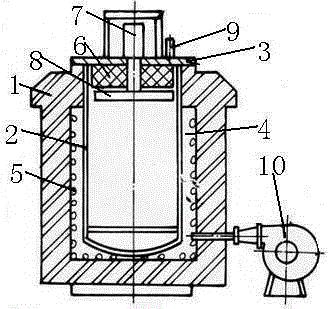

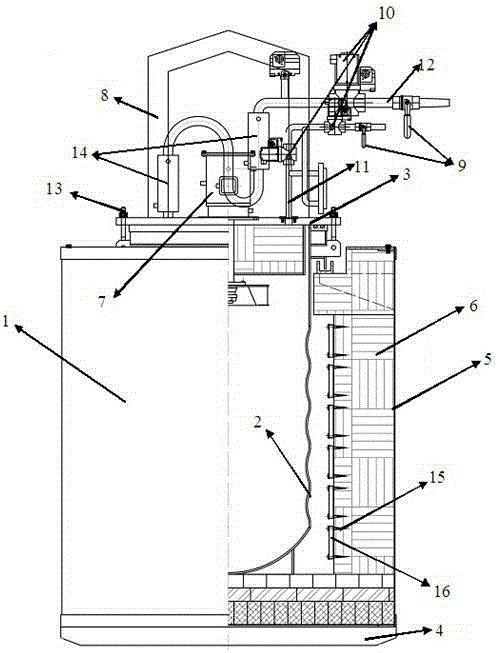

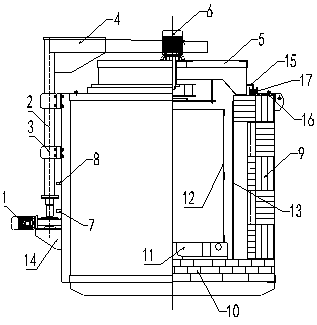

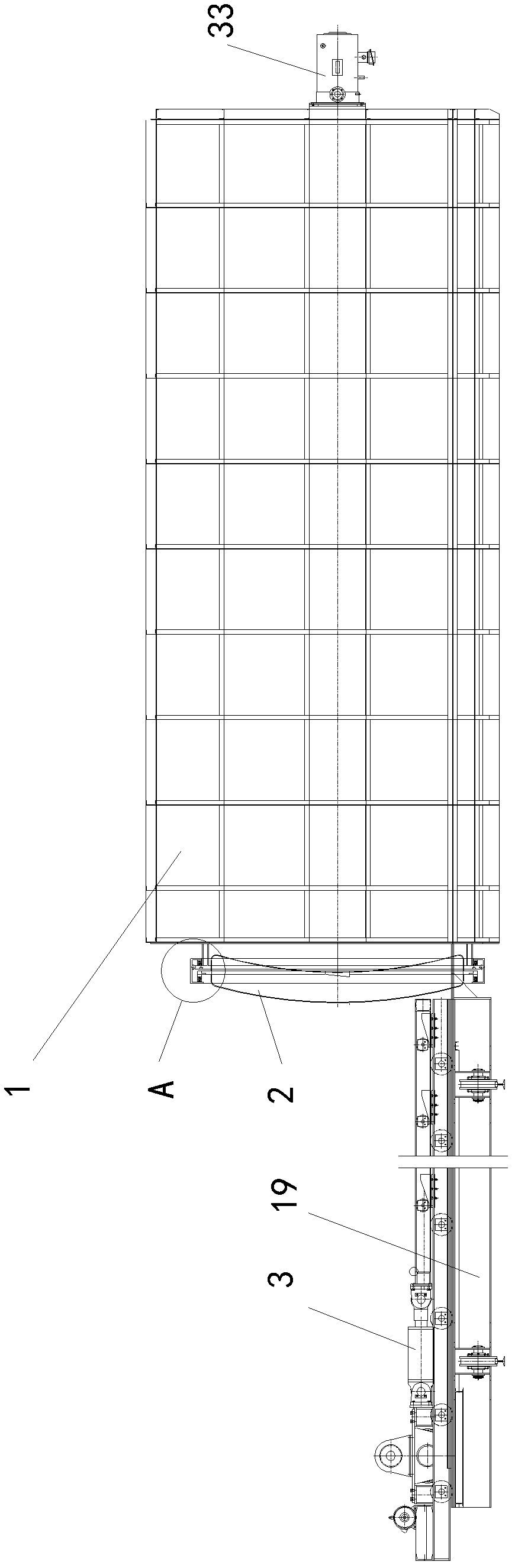

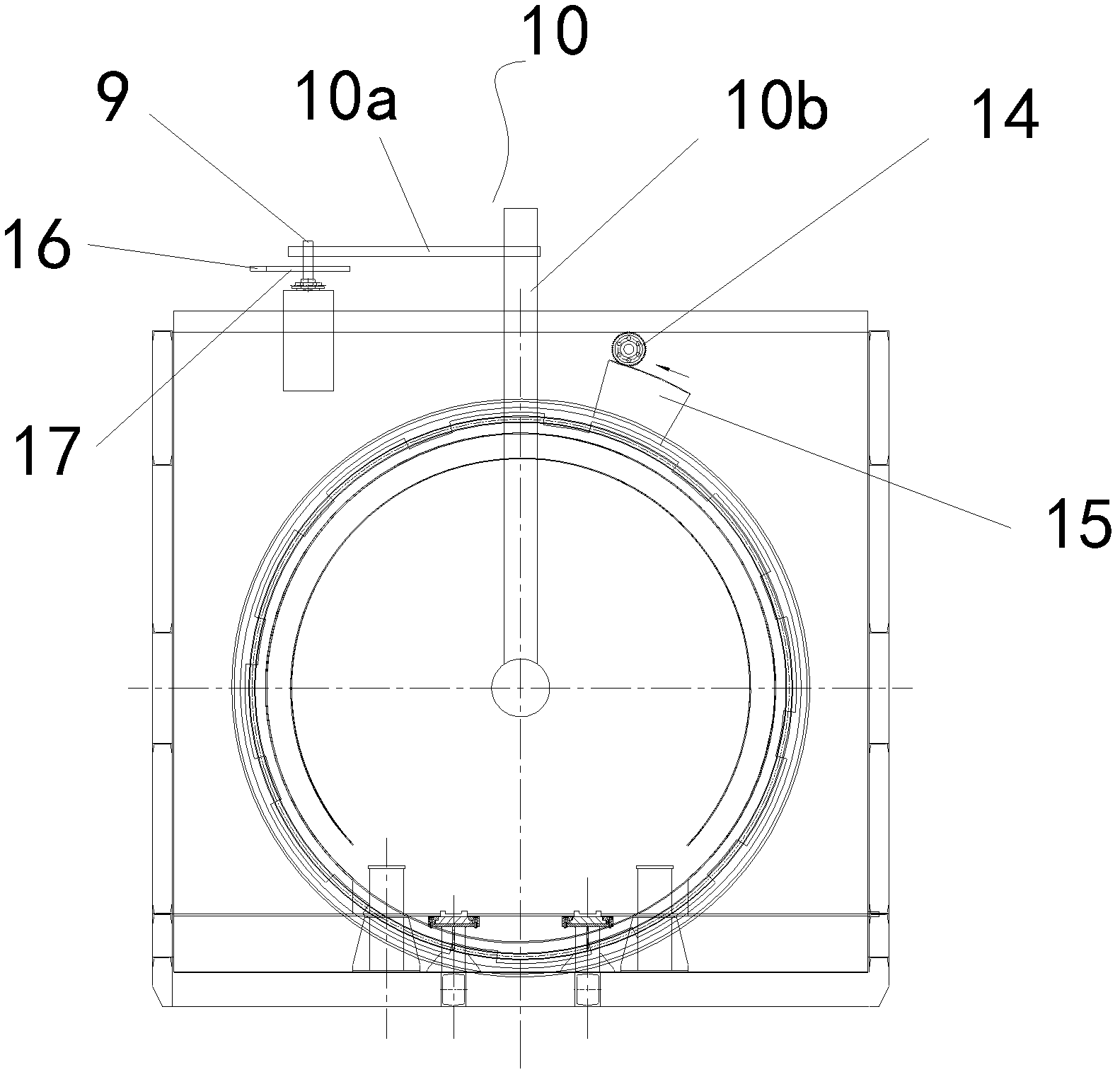

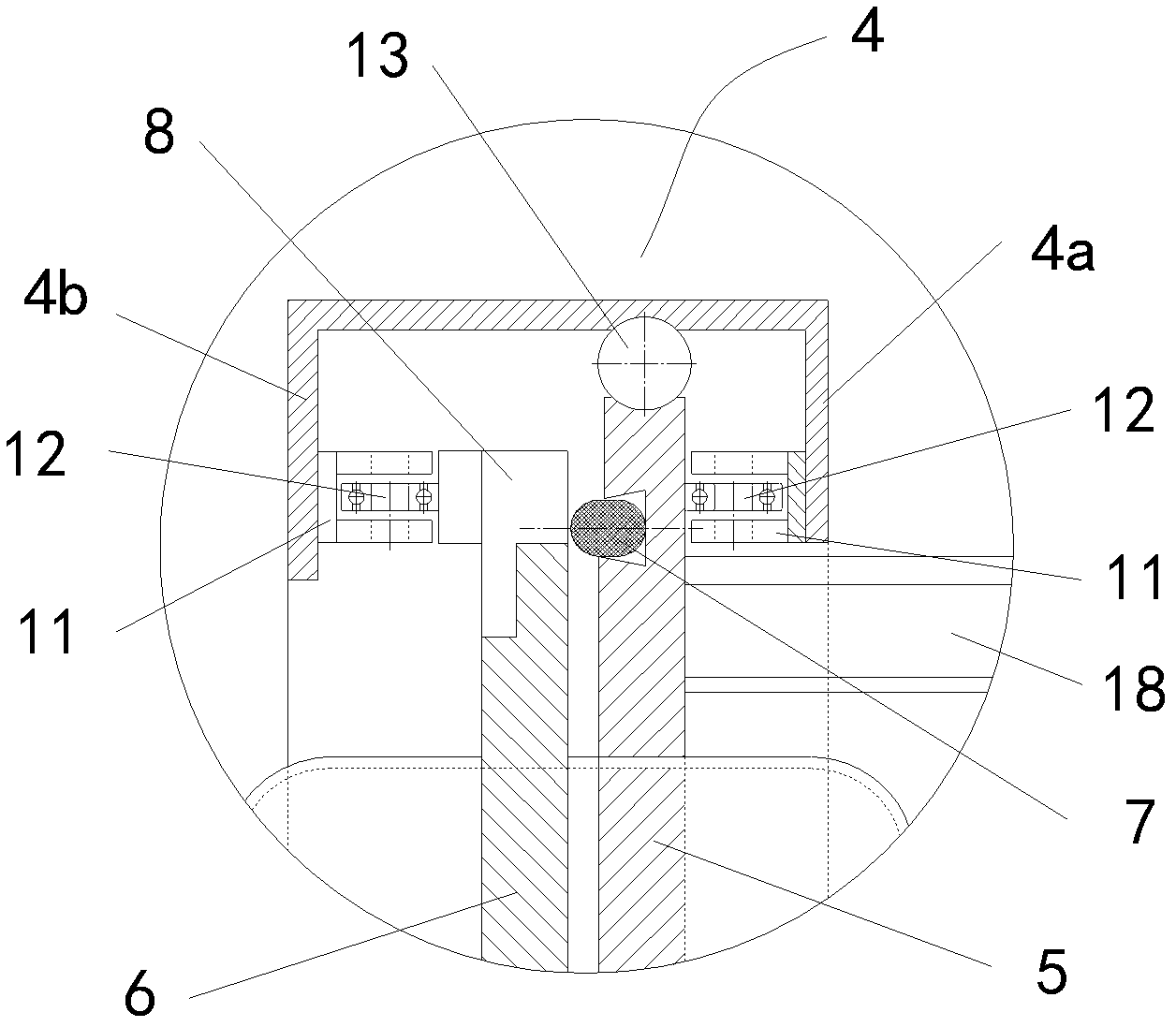

Well-type vacuum furnace

A well-type vacuum furnace comprises a furnace body (1), an inner container (2) and a furnace lid (3), wherein the furnace body (1) comprises a furnace base (4), a furnace shell (5) and a furnace lining (6); the furnace shell (5) is fixed on the furnace base (4); a hearth surrounded by the furnace lining (6) is formed in the furnace shell (5); the inner container (2) is arranged in the hearth; a blower device (7), a lifting frame (8), a hand-operated valve (9), a protective gas inflation pipe (11) and a vacuumizing pipe (12) are fixed on the furnace lid (3). The well-type vacuum furnace is characterized in that a water protecting system (14) is connected onto the vacuumizing pipe (12) on the furnace lid (3); the hand-operated valve (9) is switched on to perform high-temperature vacuumizing; a vacuum pump connected with the vacuumizing pipe (12) is protected by the water protecting system (14). The well-type vacuum furnace is lighter, better in sealing effect, and higher in equipment use efficiency, and has the advantage that no oxide skin is generated on an annealed workpiece.

Owner:江苏邦泰炉业有限公司

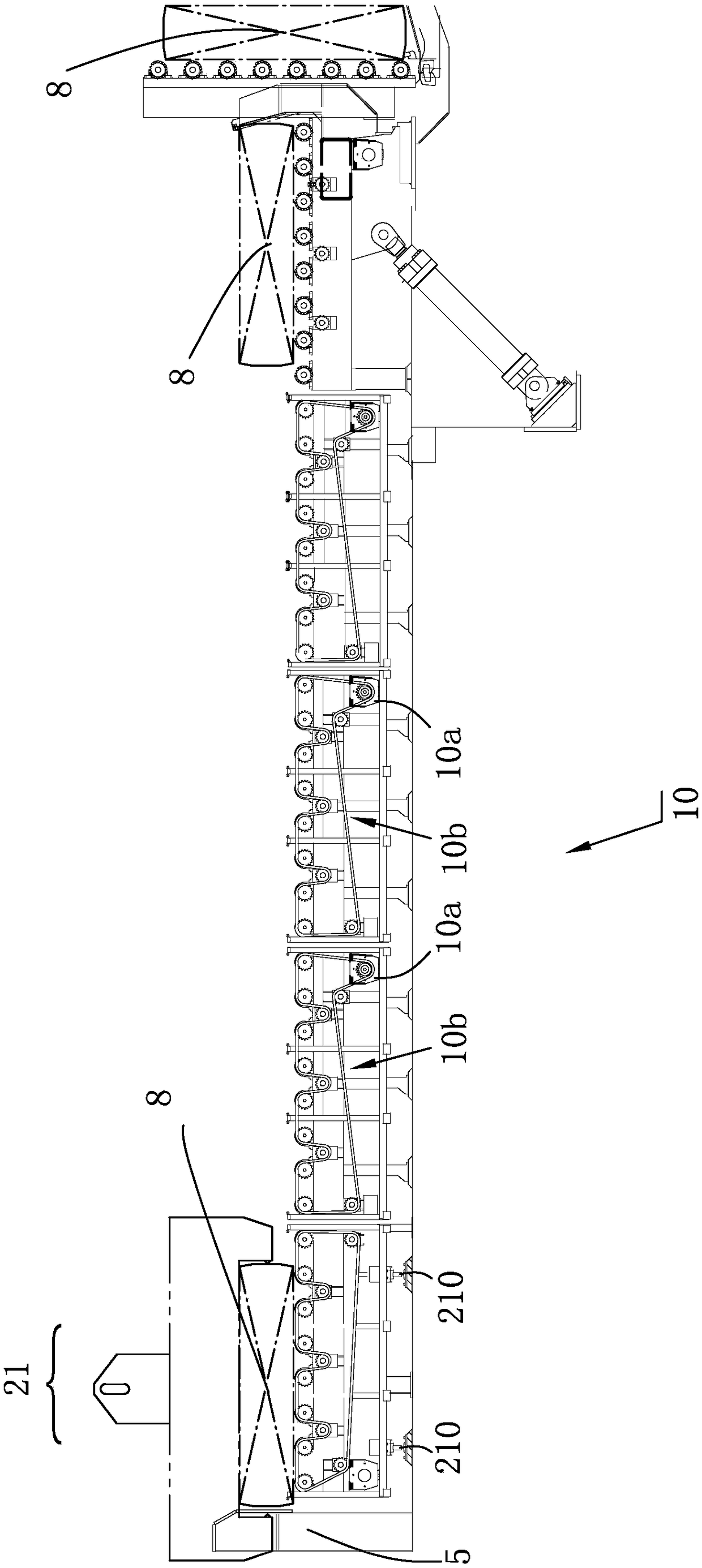

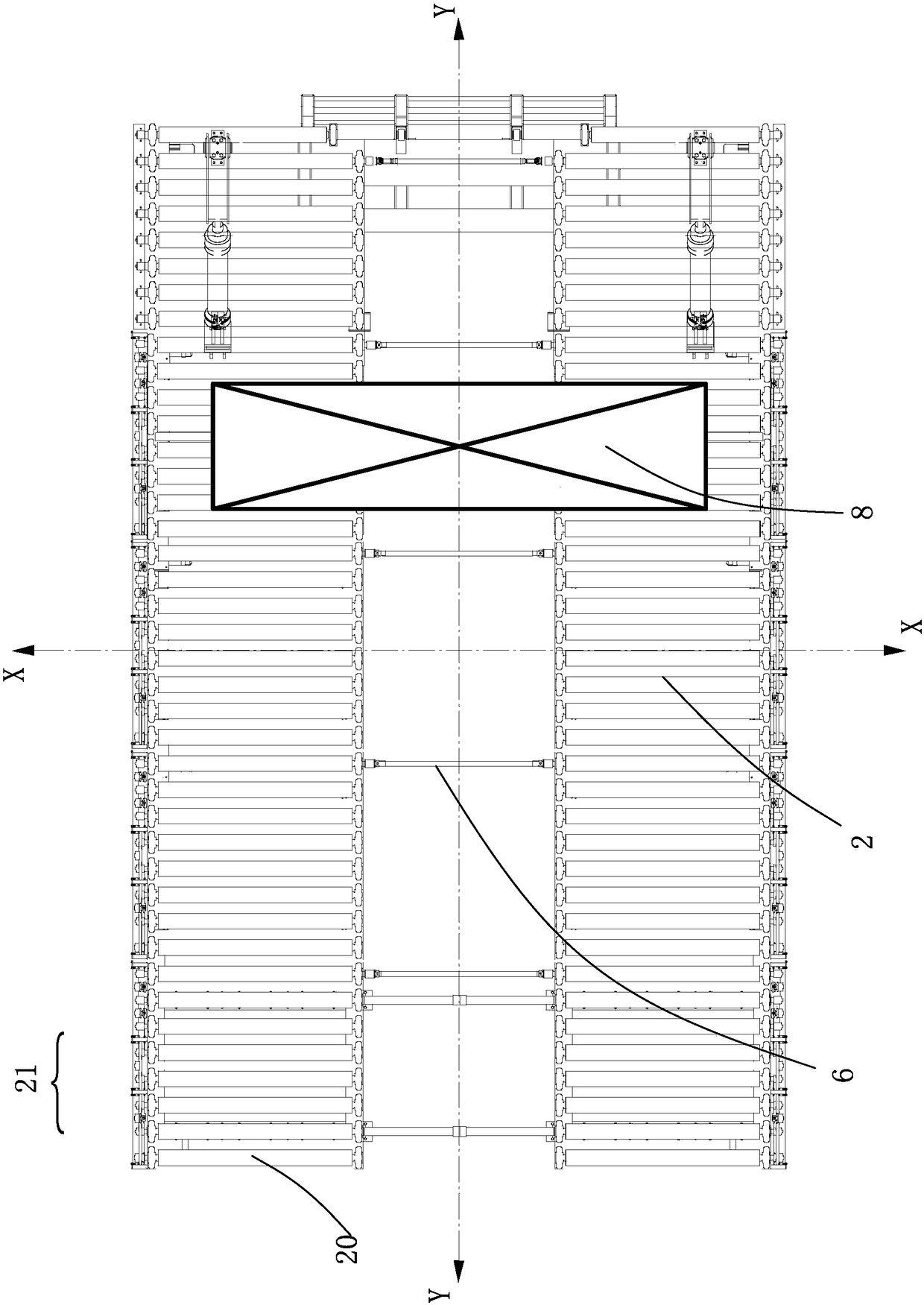

Roller hearth type plate continuous furnace and tempering method thereof

ActiveCN110607429AReduce heat radiationReduce the effect of heating uniformityFurnace typesHeat treatment furnacesCold airFurnace temperature

The invention discloses a roller hearth type plate continuous furnace and a tempering method thereof. An external circulation concurrent heating system is arranged on the rear part of a furnace body.The external circulation concurrent heating system comprises a hot blast stove, an after-burning device, a circulating fan, a main valve, a hot air pipeline and jetting heating devices. The hot blaststove is provided a furnace gas inlet, an after-burning device installation port, a furnace gas outlet, a temperature measurement installation port and a cold air inlet, the furnace gas inlet is connected with a furnace gas outlet of the furnace body through the main valve, the after-burning device installation port is used for installing the after-burning device, the furnace gas outlet is connected with an inlet of the circulating fan, and the temperature measurement installation port is used for installing a temperature sensor. An outlet of the circulating fan is connected with the jetting heating devices through the hot air pipeline, and one branch valve is arranged corresponding to each jetting heating device. The jetting heating devices extend into the furnace body and are distributedon the upper surface and the lower surface of a steel plate needing processing, and are provided with a plurality of nozzles on the sides facing the surfaces of the steel plate, and the lower jettingheating devices are located between hearth rollers. According to the roller hearth type plate continuous furnace, during high-temperature tempering, the adverse impact caused by an open fire heatingdevice to the uniformity of the furnace temperature and the heating uniformity of steel plates is reduced.

Owner:WISDRI WUHAN WIS IND FURNACE

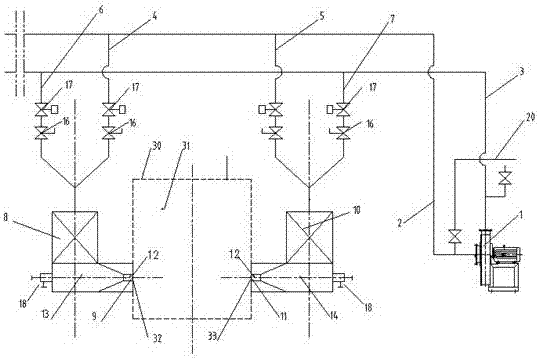

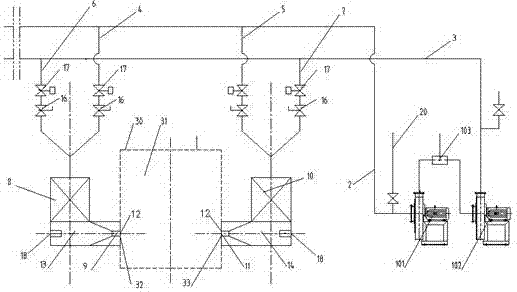

Heat accumulating type furnace gas forced circulation device of industrial furnace

ActiveCN106959014AMeet processing needsImprove furnace temperature uniformityHeat storage plantsMaintainance of heating chambersFurnace temperatureForce convection

The invention discloses a heat accumulating type furnace gas forced circulation device of an industrial furnace. The furnace gas forced circulation device is arranged on an industrial furnace body and comprises a gas treatment unit. A first gas extracting branch pipeline body and a second gas extracting branch pipeline body are arranged on a gas extracting pipeline, and a first gas blowing branch pipeline body and a second gas blowing branch pipeline body are arranged on a gas blowing pipeline; and the first gas extracting branch pipeline body and the first gas blowing branch pipeline body as well as the second gas extracting branch pipeline body and the second gas blowing branch pipeline body communicate with a first heat accumulator and a second heat accumulator correspondingly under a controlled state, pipelines behind the first heat accumulator and the second heat accumulator are arranged to be matched with a first opening and a second opening of a hearth correspondingly, and gas in the hearth is extracted out or blown into by turns. In the heat accumulating type furnace gas forced circulation device of the industrial furnace, according to the principle of heat accumulator heat accumulating and releasing, furnace gas of an electric furnace and a fuel-fired furnace is subjected to forced furnace gas circulation and forced convection through a draught fan outside the furnace, homogeneity of the furnace temperature is greatly improved and reaches + / -3 DEG C or + / -5 DEG C, and the requirements for special material treatment are met; and forced furnace gas circulation, forced convection and forced agitation are conducted, furnace gas circulation is smooth, and homogeneity of the furnace temperature is remarkably improved.

Owner:项玮

Tempering furnace achieving vacuum gas quenching

A vacuum air-quenched tempering furnace, including a furnace body, an inner tank and a furnace cover, the furnace body includes a furnace base, a furnace shell and a furnace lining, the furnace shell is fixed on the furnace base, and the furnace shell is surrounded by a furnace lining The finished furnace, the liner is set in the furnace, the furnace is fixed around the bracket, the electric heating element is fixed on the bracket; the fan device, the hanger, the manual valve, the filling and protective gas pipe, the pump are fixed on the furnace cover. The vacuum tube is characterized in that: the vacuum tube is provided with a solenoid valve. The invention has the advantages of simple structure, reasonable design, good temperature uniformity of the whole furnace, no oxide skin on the annealed workpiece, rapid cooling after heating, greatly improved production efficiency and long service life.

Owner:JIANGSU RUIZHI MEDICAL INSTR TECH CO LTD

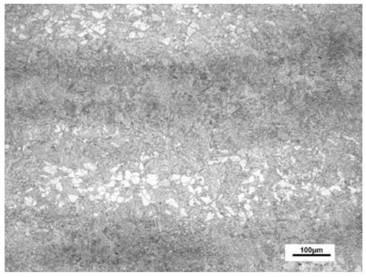

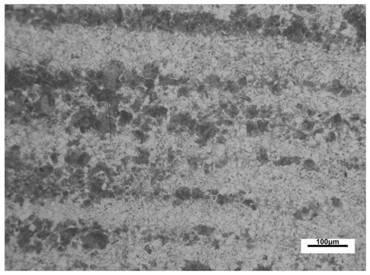

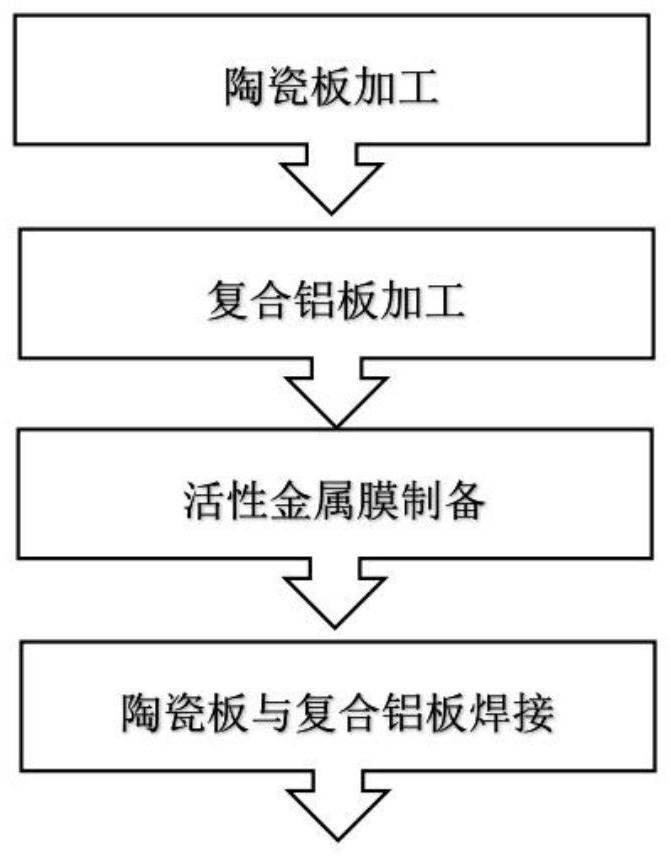

Ceramic aluminum-coated plate for IGBT (Insulated Gate Bipolar Translator) packaging and preparation method thereof

ActiveCN114349471AHigh densityHigh compressive strengthClaywaresCarbide siliconCompressive resistance

The invention discloses a ceramic aluminum-coated plate for IGBT packaging and a preparation method thereof, and relates to the technical field of ceramic metallization, the ceramic aluminum-coated plate comprises a ceramic bottom plate, an active metal liquid film and a composite aluminum plate, the outer surface of the ceramic bottom plate is uniformly covered with the active metal liquid film, and the ceramic bottom plate is connected with the composite aluminum plate through the active metal liquid film. According to the invention, a certain proportion of silicon carbide is added into the production raw materials of clay, quartz and feldspar of the ceramic bottom plate, so that the density, compressive strength, thermal conductivity and other properties of the composite ceramic containing silicon carbide are obviously improved, and the single component of a single ceramic bottom plate is avoided; and when the outer side of the ceramic bottom plate is covered with an aluminum plate, a composite aluminum plate composed of aluminum-magnesium alloy, industrial pure aluminum and aluminum-copper alloy is adopted, so that the corrosion resistance and the pressure resistance of the workpiece are enhanced, and meanwhile, the heat-conducting property of the workpiece is also enhanced.

Owner:深圳思睿辰新材料有限公司

Medium-low temperature heat treatment furnace

PendingCN111394562AGuaranteed uniformityImprove balanceMaintainance of heating chambersFurnace typesFurnace temperatureFlue gas

The invention belongs to the field of industrial furnaces, and relates to a medium-low temperature heat treatment furnace. The medium-low temperature heat treatment furnace comprises a furnace body, wherein a workpiece conveying mechanism arranged in the extending direction of the furnace body is arranged in the furnace body, at least one heat supply section is arranged in the furnace body in theconveying direction of the workpiece conveying mechanism, each heat supply section comprises at least one burner arranged at the top of the furnace body and at least one in-furnace flue gas self-circulation system, and a smoke outlet is formed in the furnace body. According to the medium-low temperature heat treatment furnace, the transverse heat supply balance of a hearth can be guaranteed; the convection heat transfer effect in the furnace is enhanced; the furnace temperature uniformity, especially the temperature uniformity at medium and low temperatures, can be improved; when a in-furnaceflue gas circulation system fails, normal production can still be achieved; the furnace discharges smoke from the tail of the preheating section, the smoke discharge temperature is low, and the heat efficiency is high; and the in-furnace circulation system cannot increase the height of the hearth, and the furnace profile structure is simple and reliable.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD

High-speed steel cutter annealing process

InactiveCN105714037AImprove furnace temperature uniformityUniform and stable tissueFurnace typesHeat treatment furnacesFurnace temperatureTissue material

The present invention discloses a high-speed steel cutter annealing process, a material is W12Cr4V4Mo, the high-speed steel cutter annealing process is characterized by comprising the following steps: in the heating rate of 60-80 DEG C / h, heating to the temperature of 860-880 DEG C, performing thermal insulation for 3-4h, opening a door of a furnace, cooling to 730-750 DEG C in the furnace, performing thermal insulation for 5-6h, then cooling to 500-540 DEG C in the furnace, then taking out of the furnace for cooling, and annealing to obtain tissue materials of sorbite and carbides. The high-speed steel cutter annealing process uses rapid heating, so that the high-speed steel cutter annealing process is energy and time saving, the high-speed steel cutter annealing process uses isothermal annealing, so that furnace temperature uniformity is good, tissues are uniform and stable, the annealing cycle is shortened, and the overall performance of wear resistance and toughness and the like can be improved.

Owner:CHONGQING YEGAO FURNITURE CO LTD

Box-type protective atmosphere heat treatment furnace

InactiveCN102538439BAchieve closurePrevent looseningMuffle furnacesMaintainance of heating chambersEngineeringBlock match

The invention discloses a box-type protective atmosphere heat treatment furnace which comprises a furnace body, a furnace door and a charging device. A furnace door sealing device and a furnace door opening device are arranged between the furnace body and the furnace door. The furnace door sealing device comprises a compressing ring, a driving device, a furnace door flange, a sealing flange and asealing ring, wherein the furnace door flange and the sealing flange are respectively and correspondingly arranged on the furnace body and the furnace door; and the sealing ring is arranged between the furnace door flange and the sealing flange. The compressing ring is sleeved on the furnace door flange. An inner flange and a compressing flange are arranged on the compressing ring. A compressing wedge block matched with the compressing flange is arranged on the sealing flange. A compressing inclined plane is arranged on the compressing wedge block. The furnace door opening device comprises a furnace door supporting rod, a rotary lever and a transmission mechanism, wherein the furnace door supporting rod is rotationally arranged on the furnace body; the rotary lever is respectively connected with the furnace door supporting rod and the furnace door; and the transmission mechanism is used for driving the rotary lever to rotate and hoisting the furnace door to one side of the furnace body. Not only does the box-type protective atmosphere heat treatment furnace have better sealing performance and the protective atmosphere with higher class can be used in the furnace, but also the furnace door is convenient to open and close and the box-type protective atmosphere heat treatment furnace is convenient to implement.

Owner:海盐华辰工业炉有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com